Sheet steel product, a steel component produced from such a sheet steel product, and body for a motor vehicle

A technology of products and flat steel, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve problems such as limitations, and achieve the effects of high energy absorption, delaying fracture formation, and delaying fracture induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

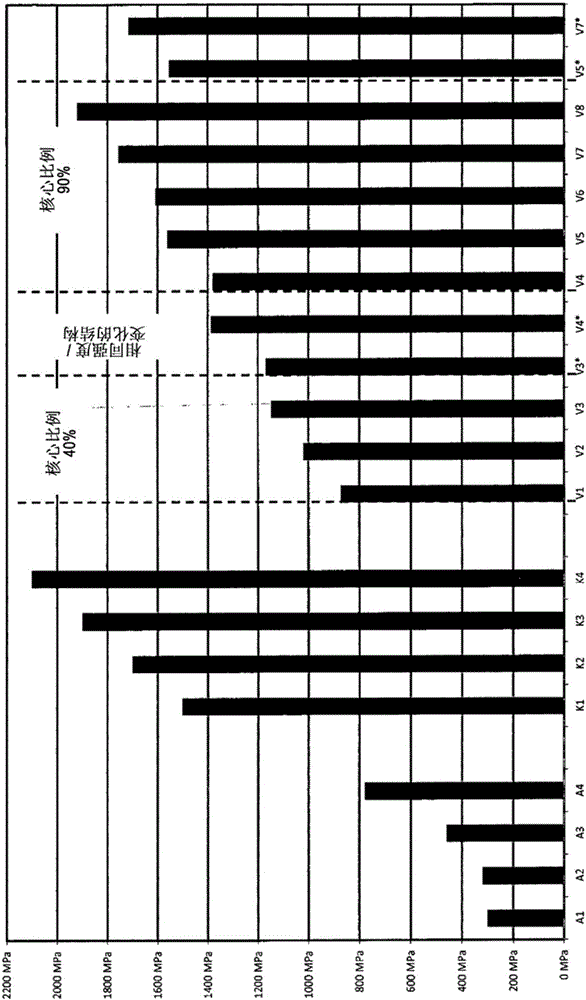

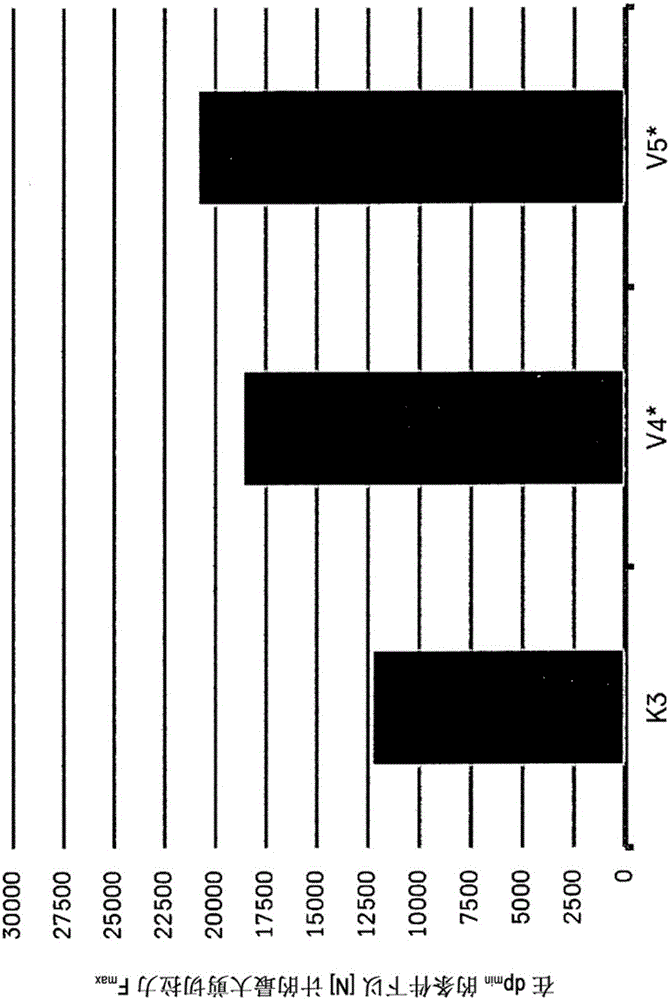

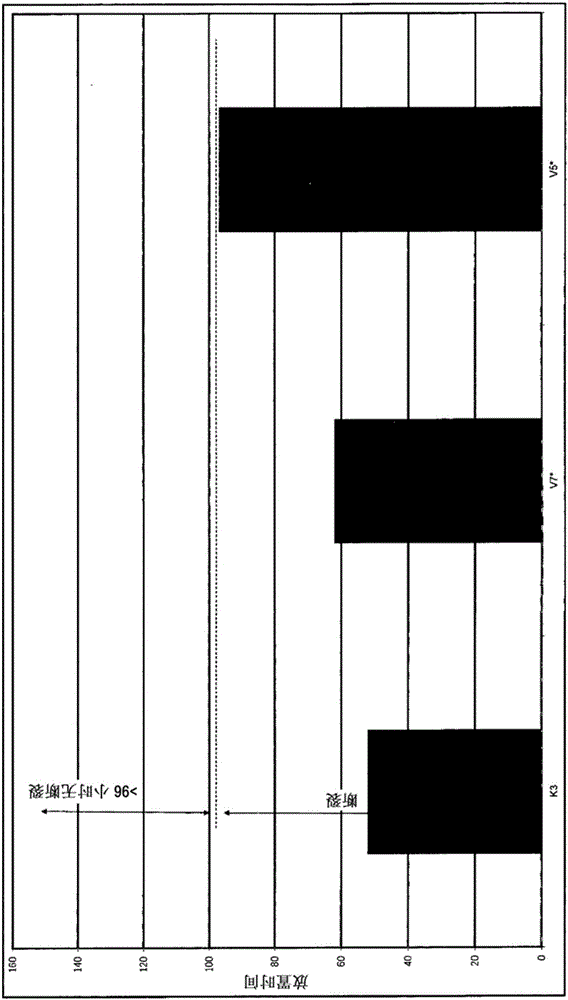

[0067] Flat steel products V1, V2, V3, V3 constructed in composite material are produced by the roll cladding method from commercially available flat steel products A1-A4 and K1-K4 produced in a conventional manner * , V4 * , V4, V5, V5 * , V6, V7, V7 * and V8. The corresponding composition of the flat steel products A1-A4 consisting of mild steel and the composition of the flat steel products K1-K4 consisting of high-strength steel is specified in Table 1.

[0068] It can be seen in Table 2 which flat steel products A1-K4 constitute the corresponding core layer KL; which products constitute the corresponding outer layer AL; and the thickness of the core layer KL in each composite material-flat steel product V1-V8 What is the ratio of A-KL on it. The ranges of the tensile strength Rm determined for the respective press-hardened components of the composite material flat steel products V1-V8 are additionally given in Table 2.

[0069] For rolling the cladding, the metal sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com