Carburizing alloy steel, and preparation method and application thereof

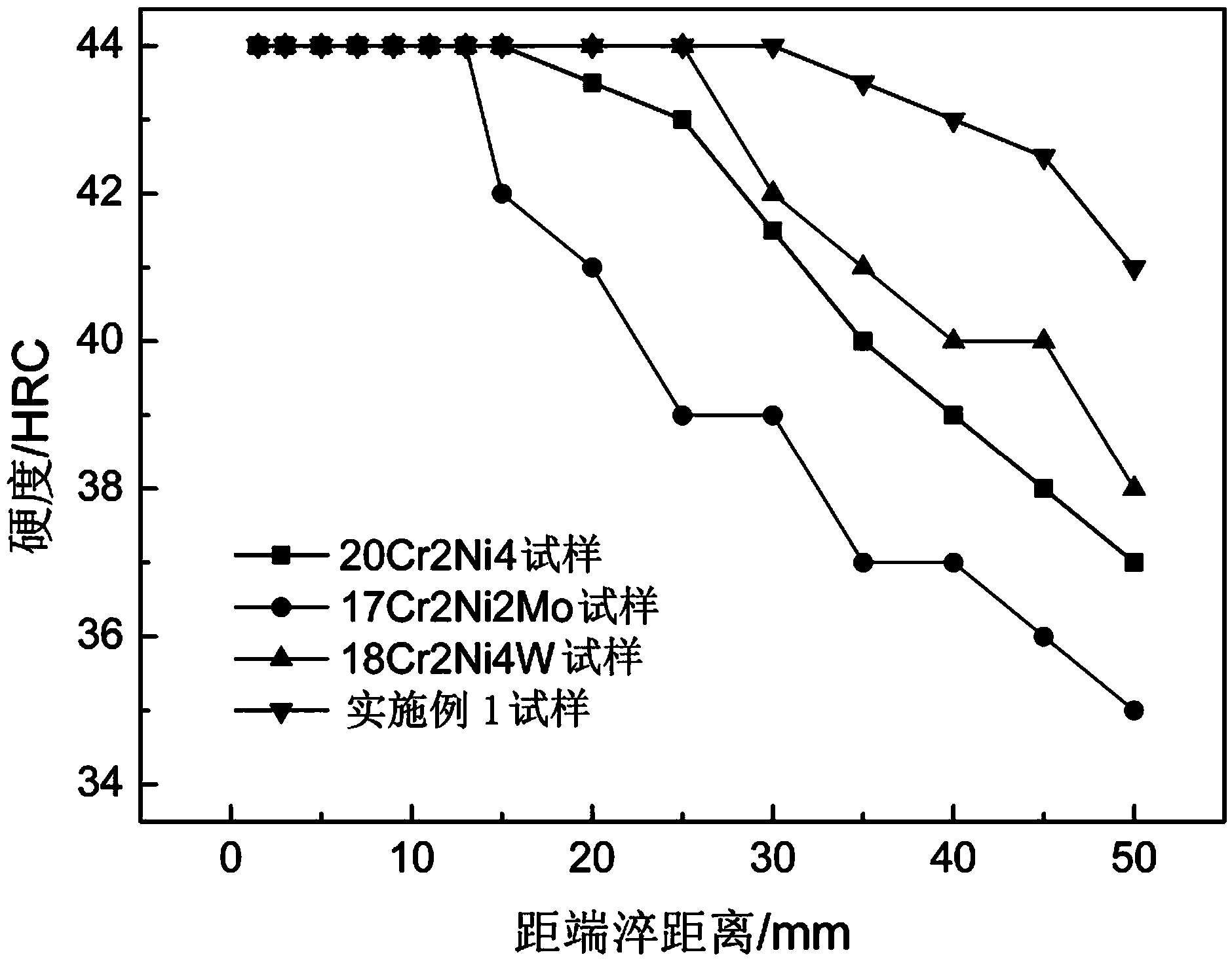

An alloy steel and carburizing technology, applied in the field of iron-based alloys, can solve the problems of inability to meet the requirements of heavy-duty gears and poor comprehensive mechanical properties, and achieve excellent grain growth resistance, low production costs, and high yield strength than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

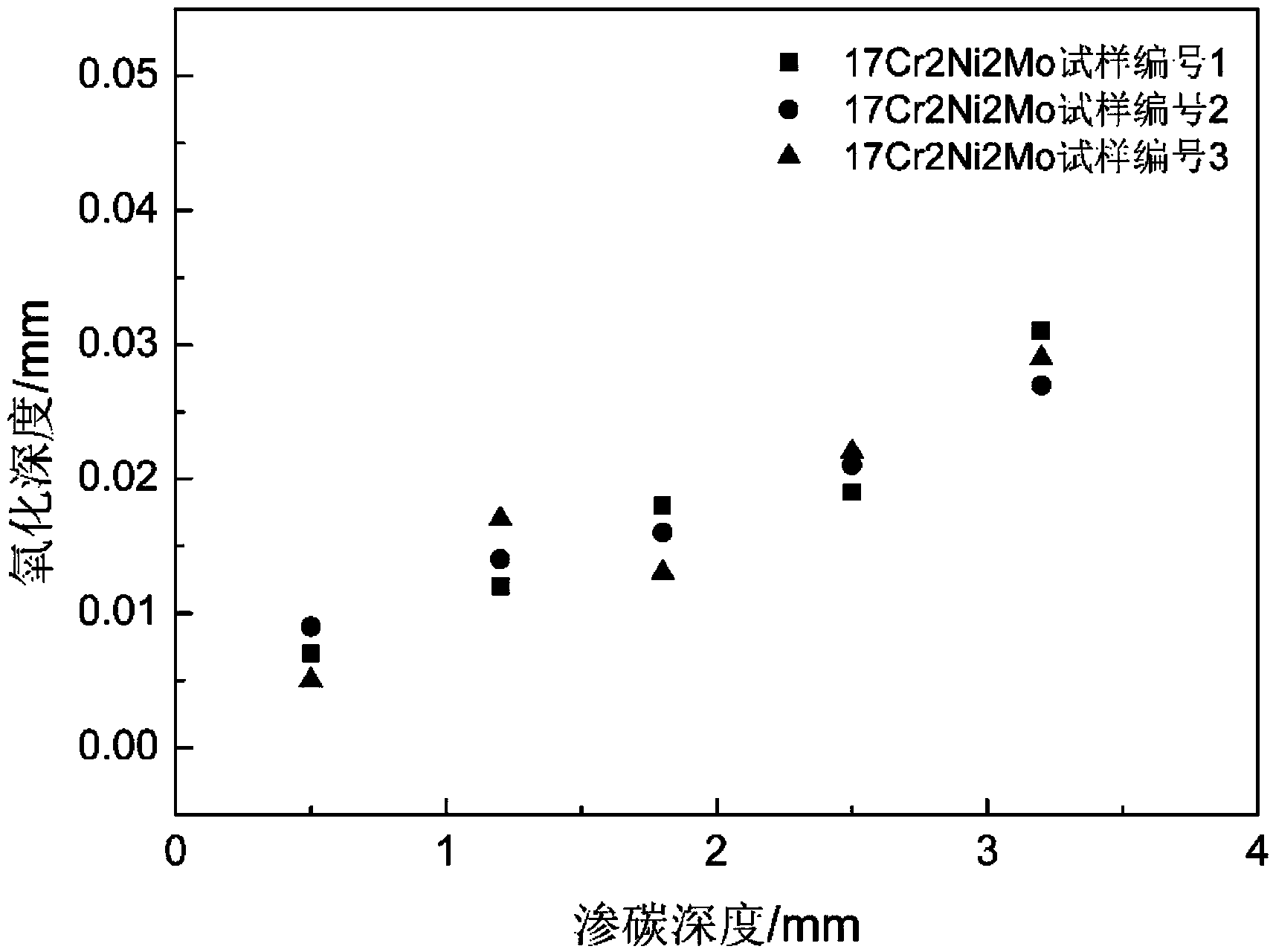

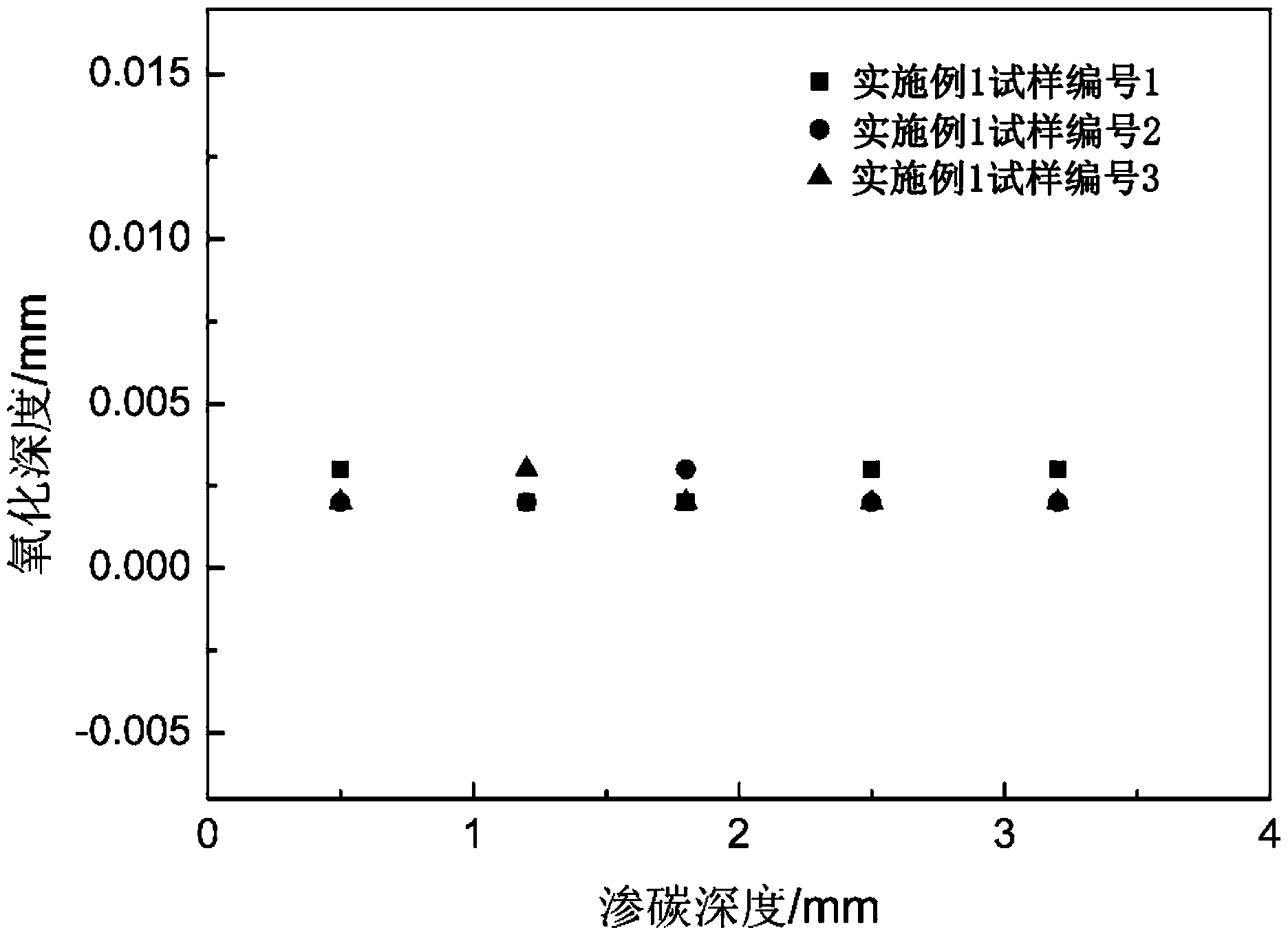

Method used

Image

Examples

Embodiment 1

[0049] The components and mass percentages of the carburizing alloy steel in this embodiment are: C: 0.18%, Si: 0.16%, Mn: 0.69%, P: 0.009%, S: 0.005%, Cr: 1.00%, Ni: 3.55 %, Mo: 0.62%, Al: 0.04%, V: 0.05%, Nb: 0.03%, N: 0.0092%, O: 0.0019%, H: 0.00015%, and the balance is iron and unavoidable impurities.

[0050] The preparation method of the carburized alloy steel of the present embodiment comprises the following specific steps:

[0051] A. According to the composition and content of the alloy steel, the ingredients are prepared, and the steelmaking and refining process of electric furnace + ladle refining furnace (LF) + vacuum degassing furnace in the prior art is used for alloy melting.

[0052] B. Cast steel ingots, roll the steel ingots into round steel, and take sample blanks on the round steel according to the national standard GB / T2975-1998 "Sampling Position and Sample Preparation for Mechanical Properties Test of Steel and Steel Products".

[0053] C. Normalize and...

Embodiment 2

[0056] The components and mass percentages of the carburized alloy steel in this embodiment are: C: 0.15%, Si: 0.20%, Mn: 0.95%, P: 0.008%, S: 0.006%, Cr: 1.20%, Ni: 3.75 %, Mo: 0.41%, Al: 0.08%, V: 0.12%, N: 0.0080%, O: 0.0016%, H: 0.00016%, and the balance is iron and unavoidable impurities.

[0057] The preparation method of the carburized alloy steel of the present embodiment comprises the following specific steps:

[0058] A. According to the composition and content of the alloy steel, the ingredients are prepared, and the steelmaking and refining process of electric furnace + ladle refining furnace (LF) + vacuum degassing furnace in the prior art is used for alloy melting.

[0059] B. Cast steel ingots, roll the steel ingots into round steel, and take sample blanks on the round steel according to the national standard GB / T2975-1998.

[0060] C. Normalize and temper the sample blank. First raise the temperature of the blank to 900°C, keep it warm for 1 hour, and cool it...

Embodiment 3

[0063] The components and mass percentages of the carburizing alloy steel in this embodiment are: C: 0.23%, Si: 0.14%, Mn: 0.45%, P: 0.008%, S: 0.004%, Cr: 0.45%, Ni: 3.05 %, Mo: 0.79%, Al: 0.02%, Nb: 0.09%, N: 0.0078%, O: 0.0012%, H: 0.00013%, and the balance is iron and unavoidable impurities.

[0064] The preparation method of the carburized alloy steel of the present embodiment comprises the following specific steps:

[0065] A. According to the composition and content of the alloy steel, the ingredients are prepared, and the steelmaking and refining process of electric furnace + ladle refining furnace (LF) + vacuum degassing furnace in the prior art is used for alloy melting.

[0066] B. Cast steel ingots, roll the steel ingots into round steel, and take sample blanks on the round steel according to the national standard GB / T2975-1998.

[0067] C. Normalize and temper the sample blank. First raise the blank to 920°C, keep it warm for 1 hour, and cool it to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com