Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and preparation method thereof

A stress corrosion resistance, a1-zn-mg technology, applied in the field of metal material preparation, can solve problems such as restricting the development and application of super-strength aluminum alloys, overcome the inability to balance strength and corrosion resistance, improve stress corrosion resistance, The effect of easy content control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

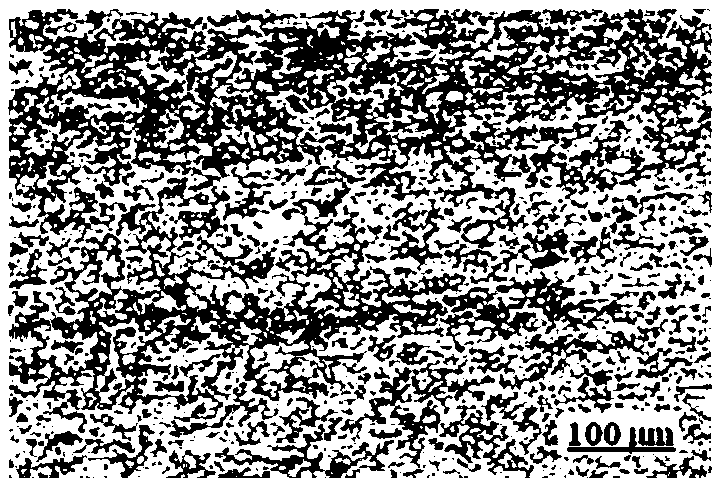

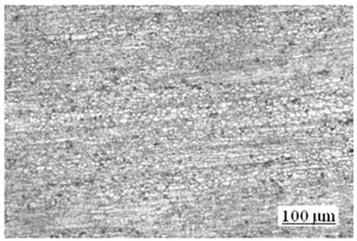

Image

Examples

Embodiment Construction

[0048] Embodiments 1-12 of the present invention and comparative examples 1-7 are prepared by the following scheme:

[0049] The alloy compositions of Examples 1-12 and Comparative Examples 1-7 were determined according to the data recorded in Table 1.

[0050] The ingredients are prepared according to the mass fractions of alloying elements in Table 1; Zr, Si, and Ta are prepared with Al-Zr alloy, Al-Si alloy and Al-Ta alloy respectively, and Al, Zn, Mg, and Cu are prepared with high-purity alloys. The materials are prepared in the form of aluminum (99.99%), industrially pure zinc (99.9%), industrially pure magnesium (99.9%), and industrially pure copper (99.9%).

[0051] For smelting, first coat the inner wall of the crucible with boron nitride refractory material. After air-drying, put the prepared aluminum ingot into the crucible. The resistance furnace is heated to 800 ° C. After the aluminum ingot is completely melted, the prepared industrial pure copper is added. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com