Patents

Literature

223results about How to "Overcome Corrosivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

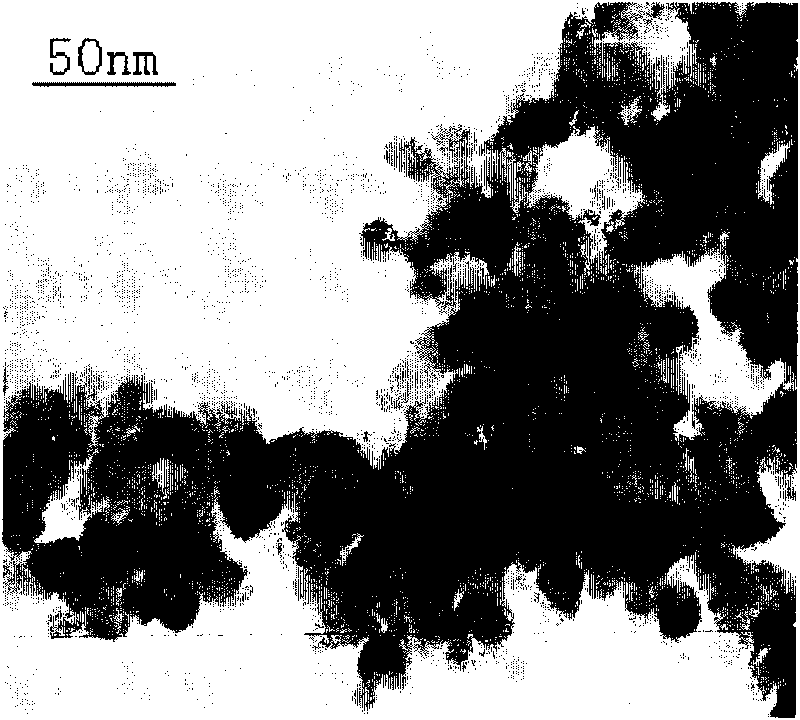

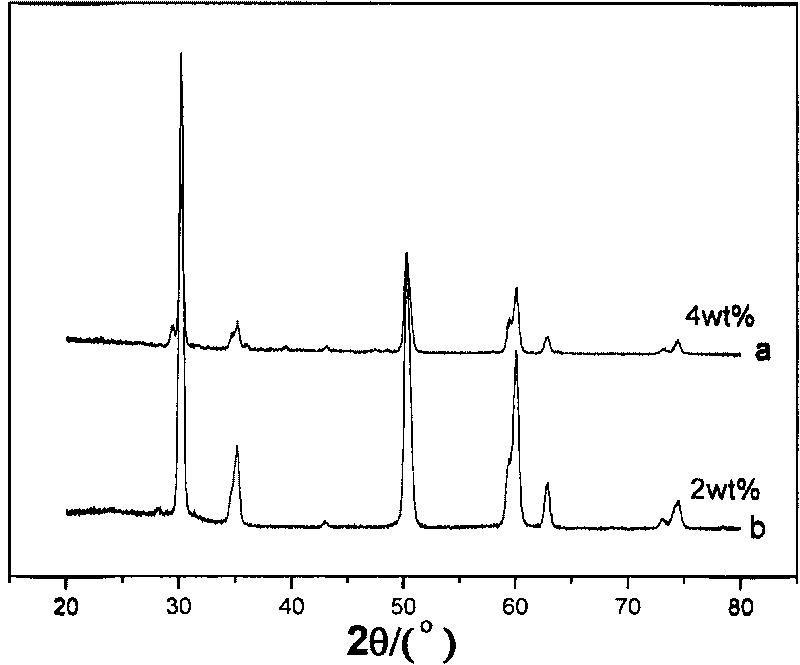

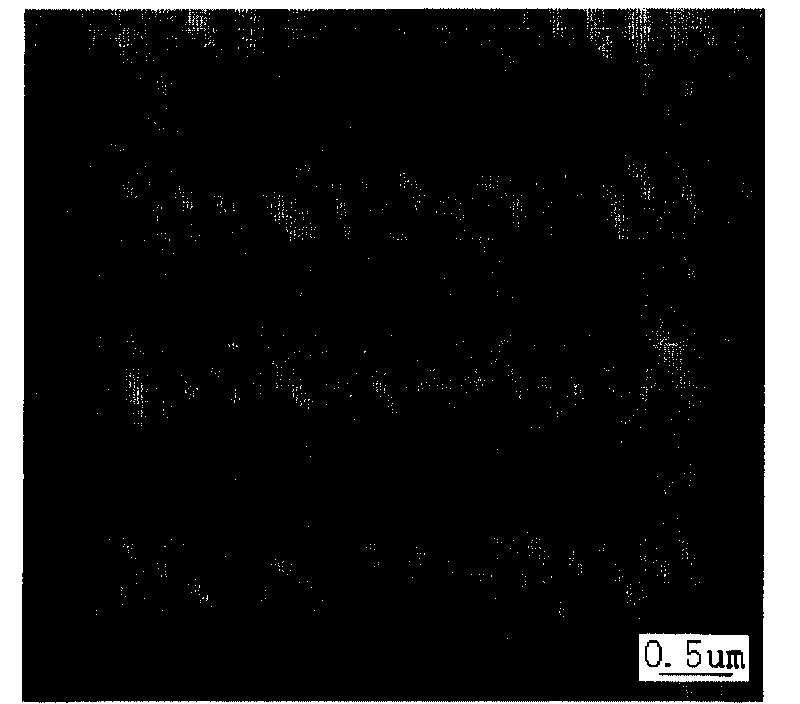

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

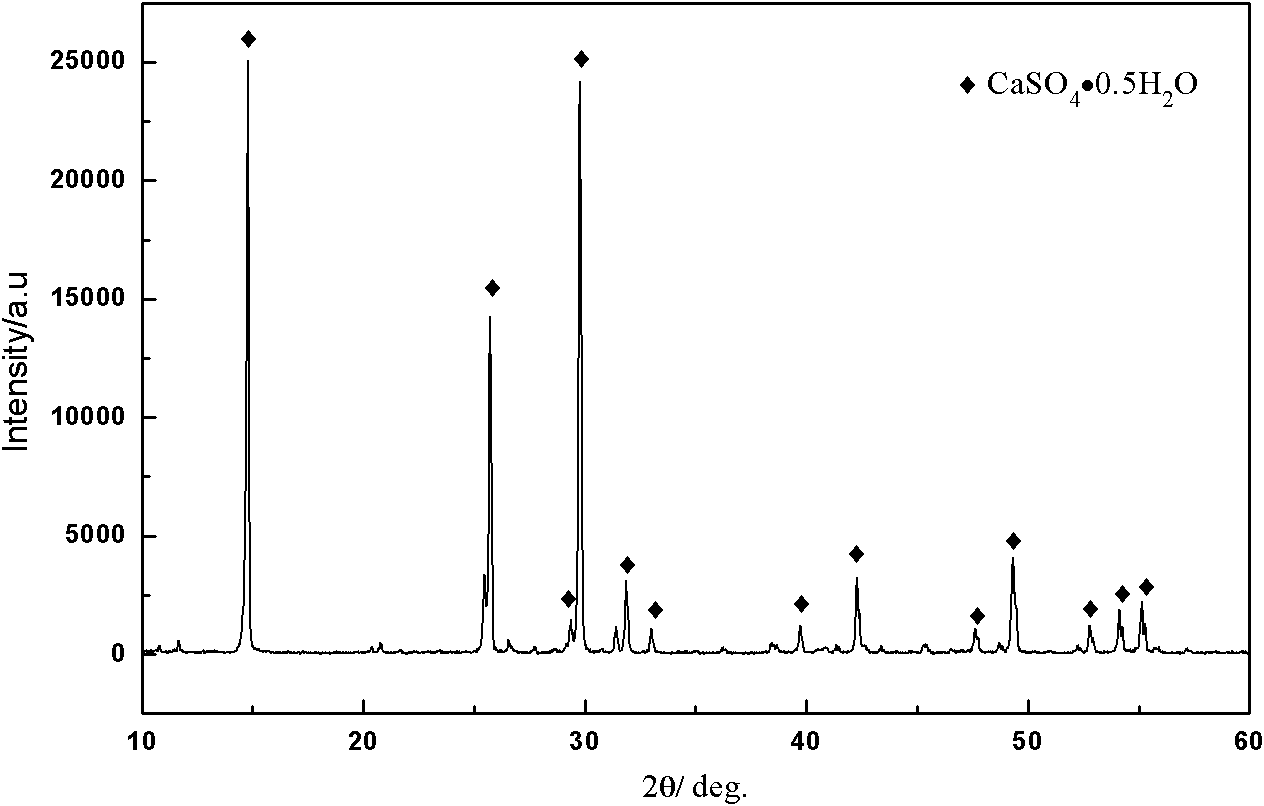

Method for extracting tungsten from scheelite and producing high-quality calcined gypsum

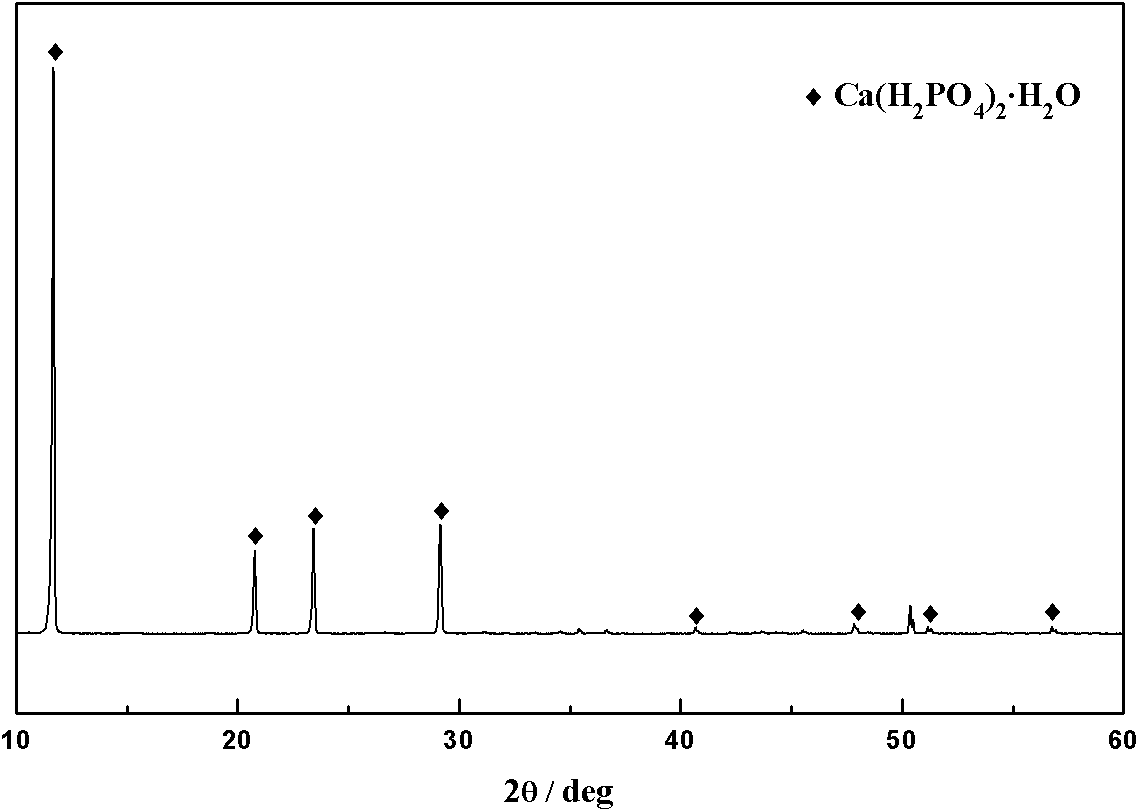

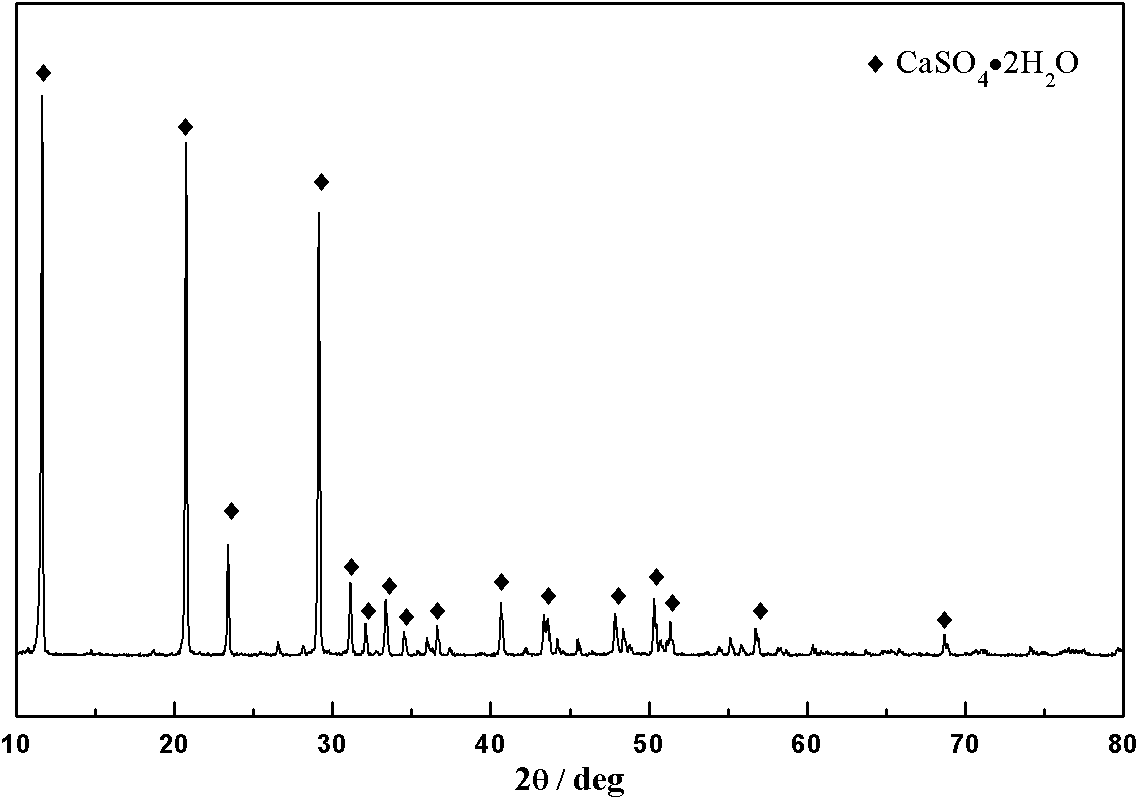

ActiveCN102021329AReduce lossesLow costCalcium/strontium/barium sulfatesProcess efficiency improvementPhosphoric acidSeed crystal

The invention provides a method for extracting tungsten from scheelite and producing high-quality calcined gypsum, comprising the following steps: adding a mixed acid of phosphoric acid and sulphuric acid to decompose scheelite; and after decomposition, adding hydrated gypsum seed crystals to finish the dewatering conversion process of dihydrate gypsum to obtain hydrated gypsum with good properties. The invention has the following advantages: the efficient atmospheric pressure leaching of scheelite is realized, the resource and energy consumption is saved, and the decomposition rate of scheelite can reach over 98%; the serious problems of Cl<-> corrosion and HCl volatilization in the traditional acid decomposition process can be overcome; the recycling of phosphoric acid is basically realized, and the leaching cost and the wastewater discharge are greatly reduced; the leaching device is simple, the operation is convenient and industrialization is easy to realize; the obtained byproduct gypsum has pure quality and can be used to produce gypsum boards, and can be used in retarder, plaster and the like produced by using cement; and due to the recrystallization process, the P2O5 content in gypsum is further reduced to below 0.5%.

Owner:CENT SOUTH UNIV

Method for decomposing scheelite by using phosphoric acid

The invention discloses a method for decomposing scheelite by using phosphoric acid, and the specific operation is as follows: adding the scheelite and phosphoric acid solution into a reaction tank for reaction according to a certain proportion, extracting tungsten from filtrate obtained by filtering after the reaction is finished, further supplementing the phosphoric acid into mother liquor after extracting the tungsten to the initial level, returning for leaching, decomposing filter residue obtained by filtering after the reaction by adopting sulfuric acid so as to recover the phosphoric acid or return the phosphoric acid for recycling. The method has the advantages of having no strict requirement on phosphorus content in the scheelite and eliminating the cost of dephosphorization process step during the ore dressing process; the post-treatment way of extracting the tungsten after the reaction is simple, the remaining solution can be recycled basically, and the pollution can be avoided; the problems of corrosion of Cl- and serious volatilization of HCl (hydrochloric acid) in the traditional acid decomposition process can be overcome; and the normal-pressure leaching of the scheelite can be realized, the energy consumption can be saved, and the decomposition rate can be more than 98%.

Owner:CENT SOUTH UNIV

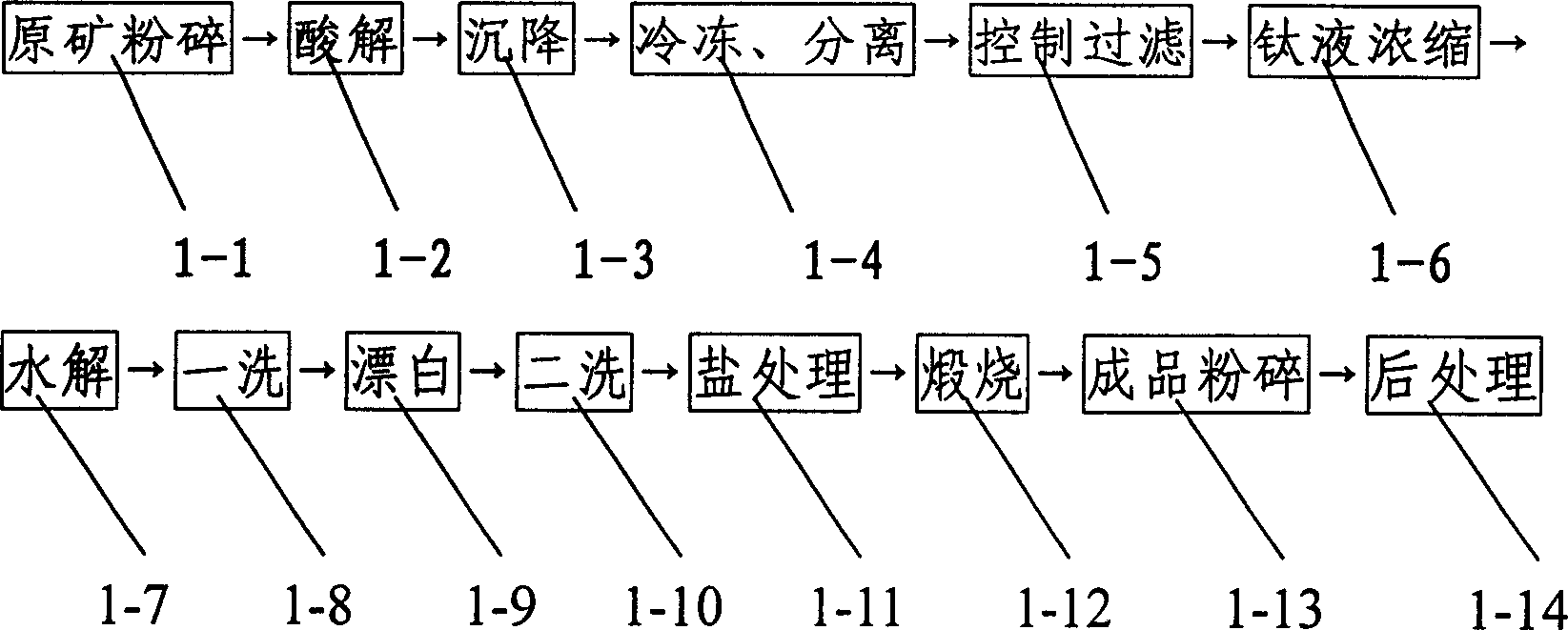

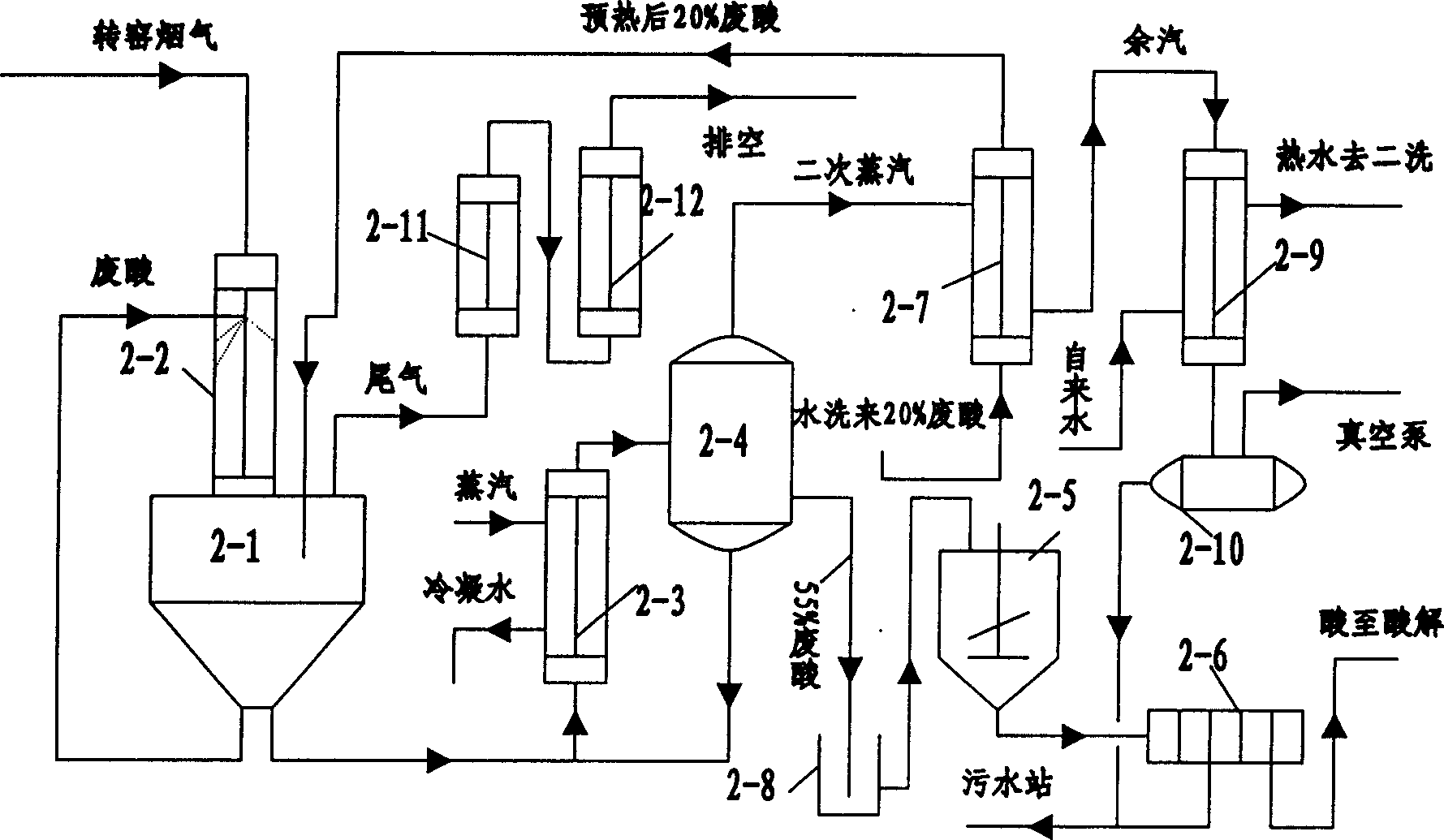

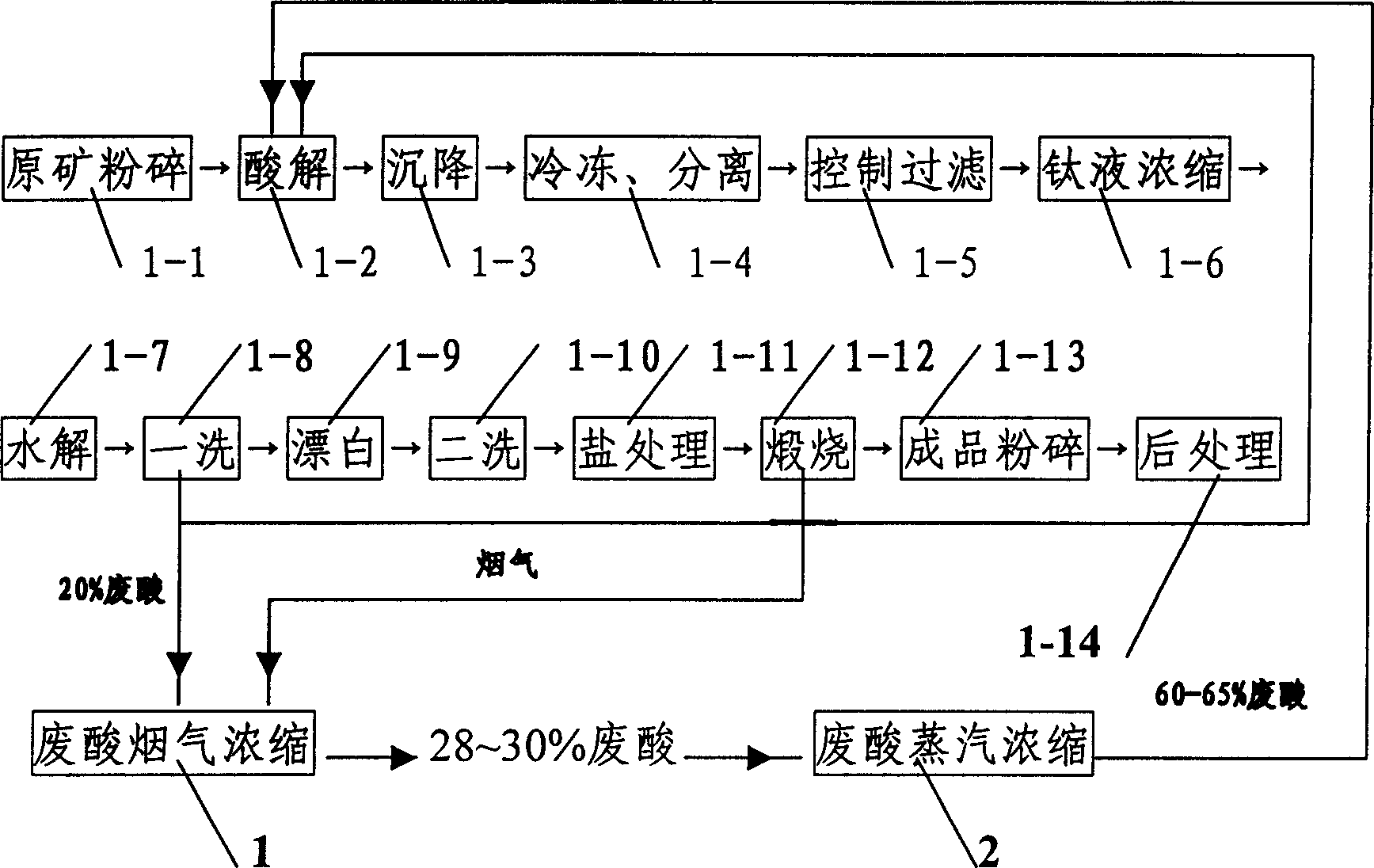

Process of industrialize for waste acid concentrition recovering used in titanium white production by sulfuric acid method

ActiveCN1724339AReduce energy consumptionReduce dosageSulfur-trioxide/sulfuric-acidTitanium dioxideWhite powderTitanium

An industrial process for reclaiming the waste acid in the production of titanium white powder by sulfuric acid method features that the waste acid is concentrated by fume and then by steam. Its advantages are high efficiency, low cost, and no environmental pollution.

Owner:潜江方圆钛白有限公司

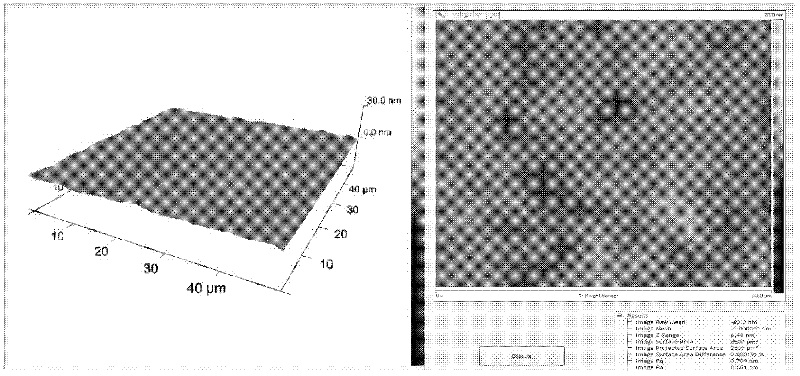

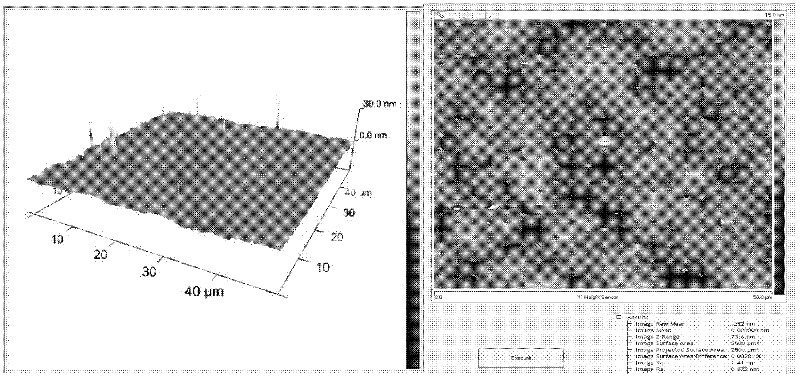

Polishing composition capable of improving silicon wafer polishing accuracy and preparation method thereof

InactiveCN102408837AOvercome precisionOvercome CorrosivityPolishing compositions with abrasivesPhysical chemistrySilicon dioxide

The invention discloses a polishing composition capable of improving silicon wafer polishing accuracy and a preparation method thereof, and belongs to the technical field of chemical and mechanical polishing. The polishing composition consists of the following components in percentage by weight: 0.05-50 percent of functionalized silicon dioxide sol, 0.001-1 percent of oxidant, 0.001-5 percent of chelating agent, 0.001-10 percent of alkaline compound, 0.001-1 percent of surfactant and the balance of de-ionized water, wherein the functionalized silicon dioxide sol is aminated silicon dioxide sol. After a silicon wafer is polished by the polishing component, the surface accuracy of the wafer is higher, the surface corrosion is less, the polishing speed is high, and the flatness is high.

Owner:TSINGHUA UNIV +2

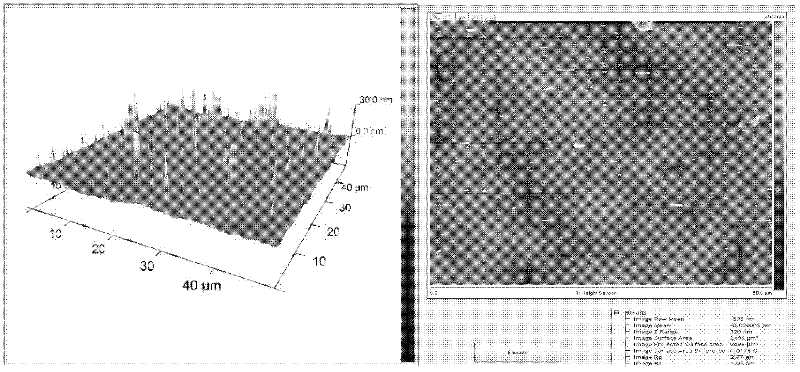

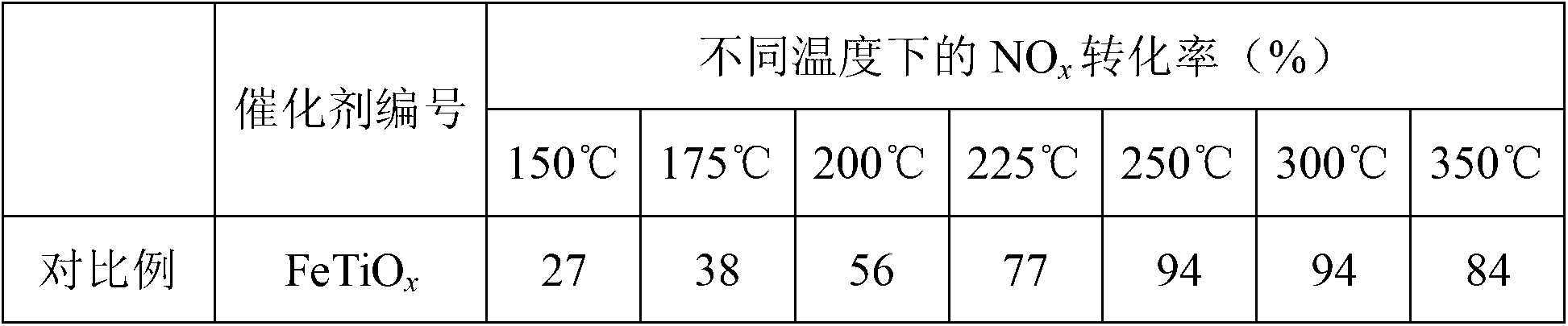

Ferrum-cerium-titanium composite oxide catalyst, preparation method and application of ferrum-cerium-titanium composite oxide catalyst

InactiveCN103071506AImprove purification efficiencyWith water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationCerium

The invention relates to a ferrum-cerium-titanium composite oxide catalyst. A chemical formula of the catalyst is FeCeaTiOx, wherein a is greater than 0 but less than or equal to 1.6. The invention further discloses a preparation method of the catalyst. The method comprises the following steps of (1) preparing and uniformly mixing an Fe source solution, a Ce source solution, and a Ti source solution to obtain a mixed solution, and (2) adding excessive urea precipitant in the mixed solution, precipitating Fe, Ce and Ti ions, conducting suction filtration on an obtained precipitation product, washing, drying, roasting, and obtaining the ferrum-cerium-titanium composite oxide catalyst. The low-temperature activity of the catalyst is improved obviously, the preparation method is simple and practicable, and the catalyst is used for a purification process of selective catalyctic reduction of nitric oxide (NH3-SCR).

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

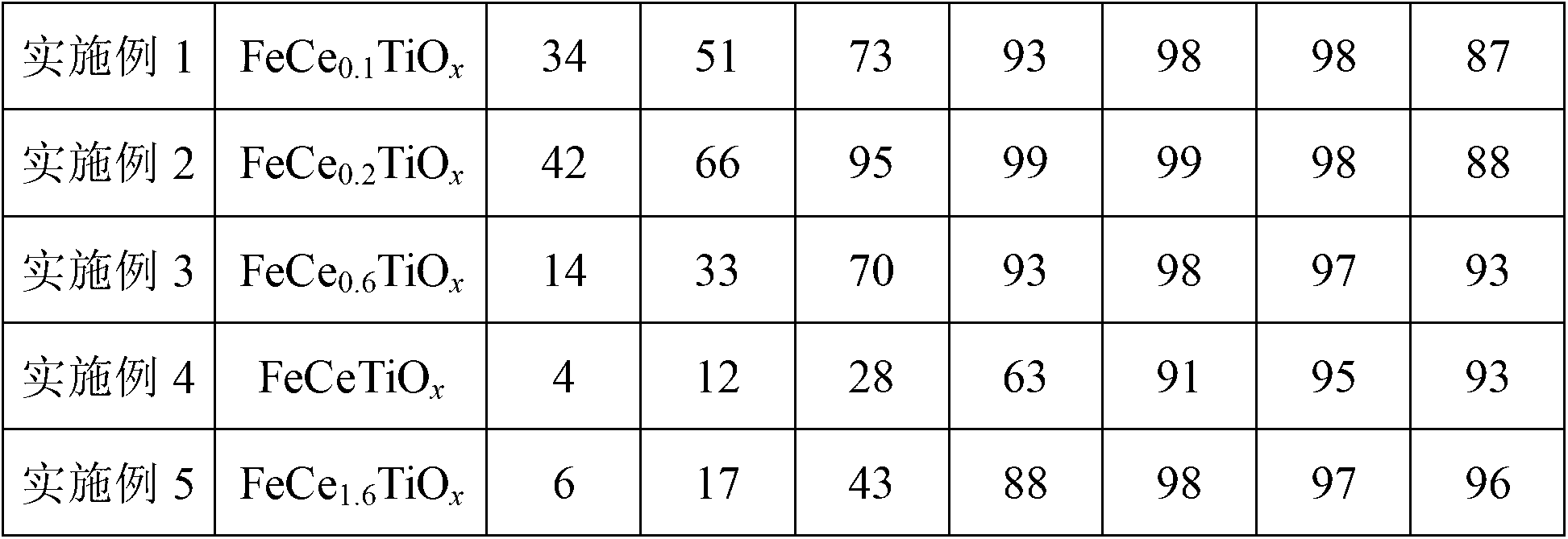

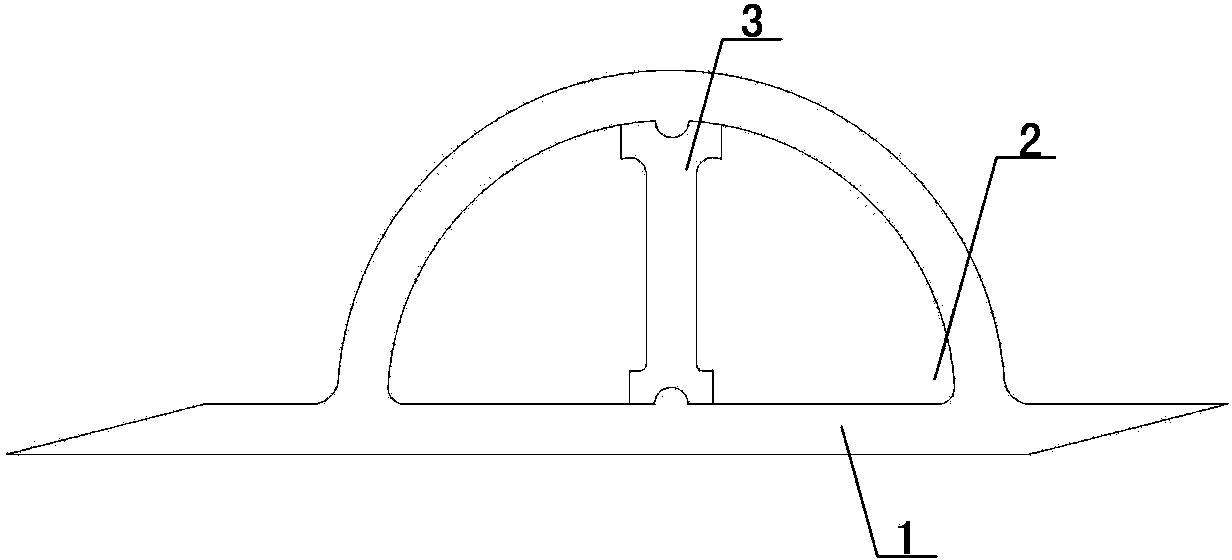

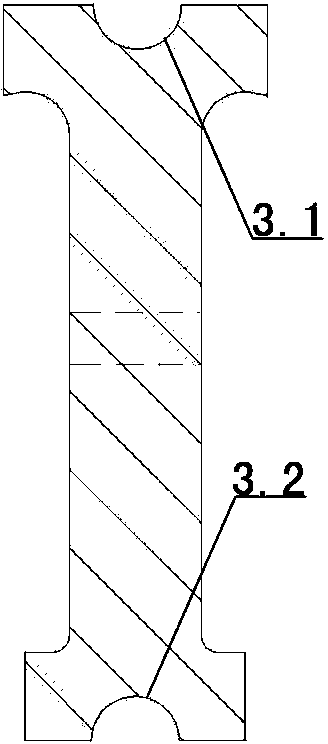

Double-plastics finned wound corrugated pipe and method for manufacturing same

InactiveCN103453240AGuaranteed Ring RigiditySecure connectionPipe connection arrangementsRigid pipesCorrosionEngineering

The invention discloses a double-plastics finned wound corrugated pipe and a method for manufacturing the same. A pipe wall of the double-plastics finned wound corrugated pipe is in the shape of a corrugated pipe which is squeezed and inflated and is integrated by means of spirally winding and hot melting, a bell socket and a spigot socket are respectively formed in two ends of the double-plastics finned wound corrugated pipe, cavities are arranged in corrugations of the pipe wall, strip-shaped plastic reinforcing ribs are arranged in the cavities and are perpendicular to the pipe wall, the outer edge of each plastic reinforcing rib is connected with a crest ring surface of the corresponding cavity by means of hot melting, and the inner edge of each plastic reinforcing rib is annularly connected with the other surface of the corresponding cavity by means of hot melting. The double-plastics finned wound corrugated pipe and the method have the advantages that the double-plastics finned wound corrugated pipe is good in ring stiffness and corrosion resistance and long in service life, and future maintenance investment is nearly zero; the bell socket and the spigot socket are connected with each other by means of electric hot melting, so that a system is good in airtight property, and forming machines implemented in a manufacturing procedure are simple and are low in investment and cost; the double-plastics finned wound corrugated pipe and the method can be widely applied to wall pipes with large and super-large apertures for drain and blowdown structures.

Owner:黄楠伟

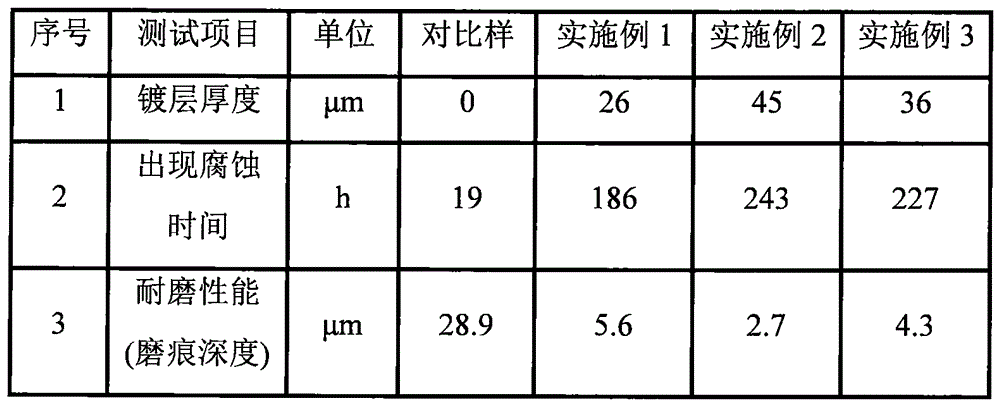

Corrosion-resistant multi-coating neodymium iron boron and preparation process

ActiveCN106710767AAccelerated corrosionImprove wear resistanceMagnetic materialsSuperimposed coating processSingle processDysprosium

The invention provides corrosion-resistant multi-coating neodymium iron boron and a preparation process. The corrosion-resistant multi-coating neodymium iron boron is composed of a neodymium iron boron permanent magnet and multiple coatings arranged on the outer surface of the neodymium iron boron permanent magnet, the multiple coatings sequentially include a nickel-plated layer, a dysprosium-plated aluminum alloy thin film layer and a nickel-chromium composite coating, thickness of the nickel-plated layer is 10-15um, thickness of the dysprosium-plated aluminum alloy thin film layer is 10-20um, and thickness of the nickel-chromium composite coating is 6-10um; modification of the multiple coatings can be realized on the surface of the permanent magnet, binding strength between the coatings and a permanent magnet base is guaranteed, the defect that the coatings are thin and poor in corrosion resistance and wear resistance caused by single process is overcome, and the corrosion-resistant multi-coating neodymium iron boron prepared by the process has high corrosion resistance and wear resistance.

Owner:宁波元辰新材料有限公司

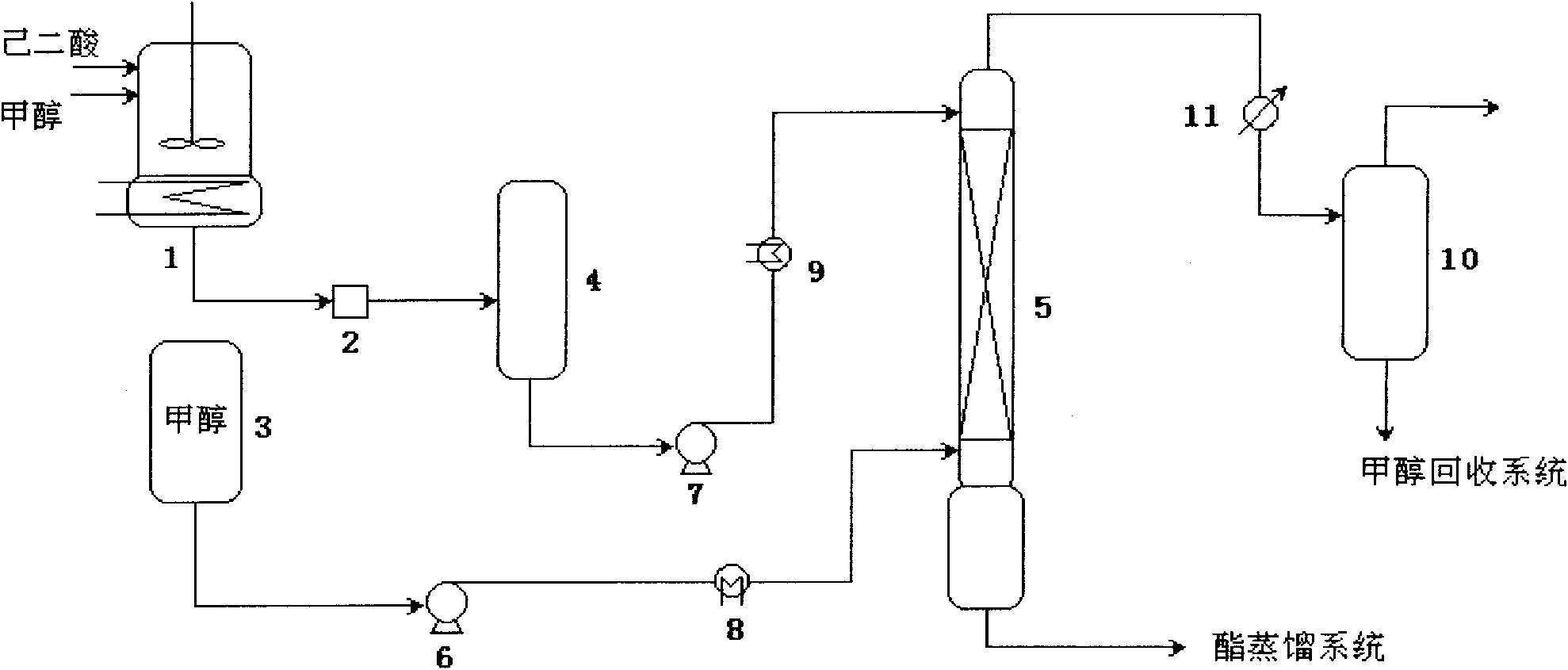

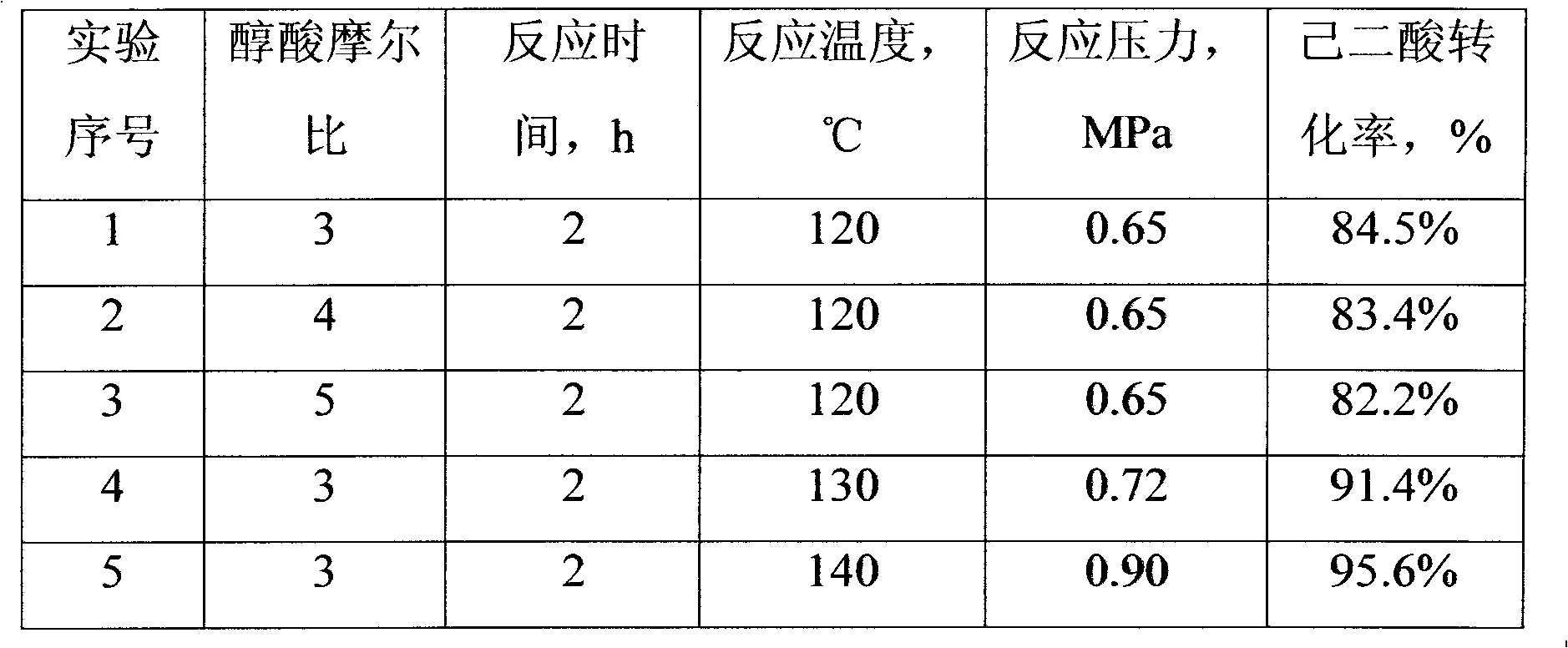

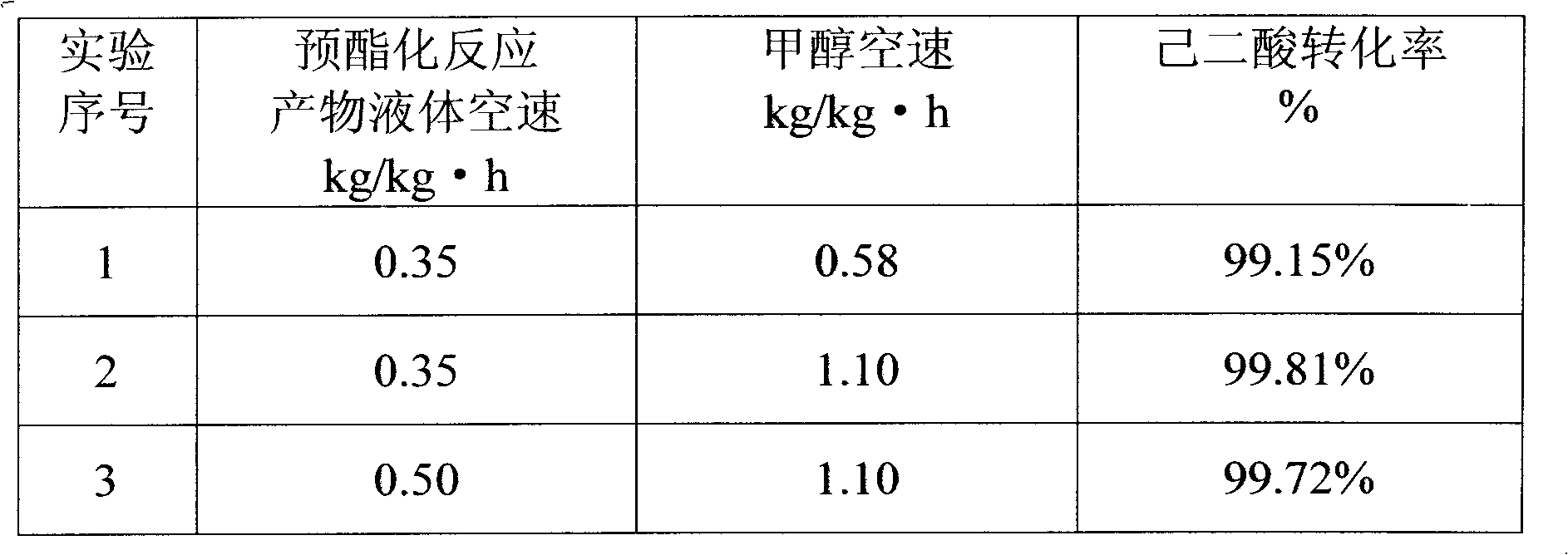

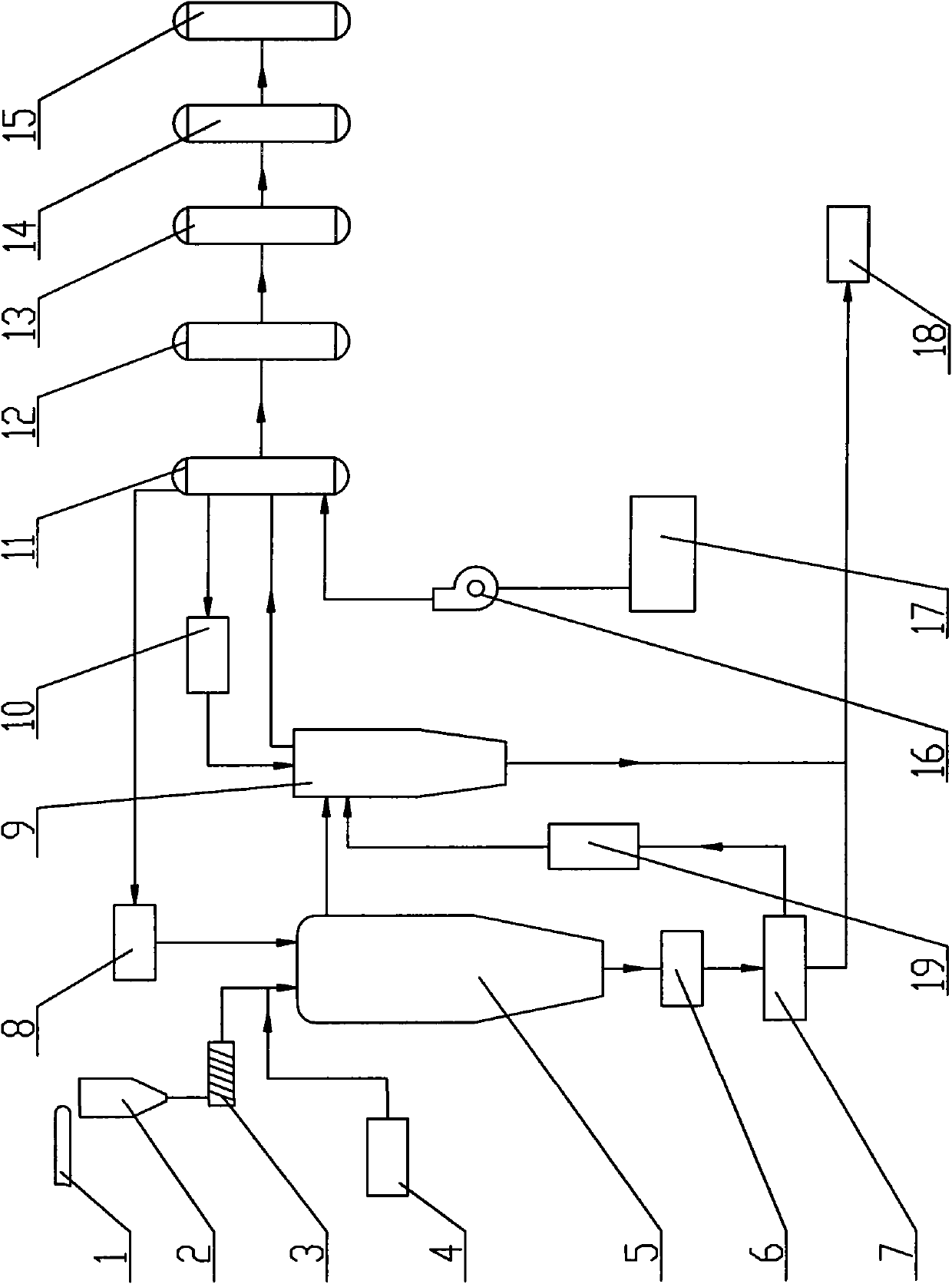

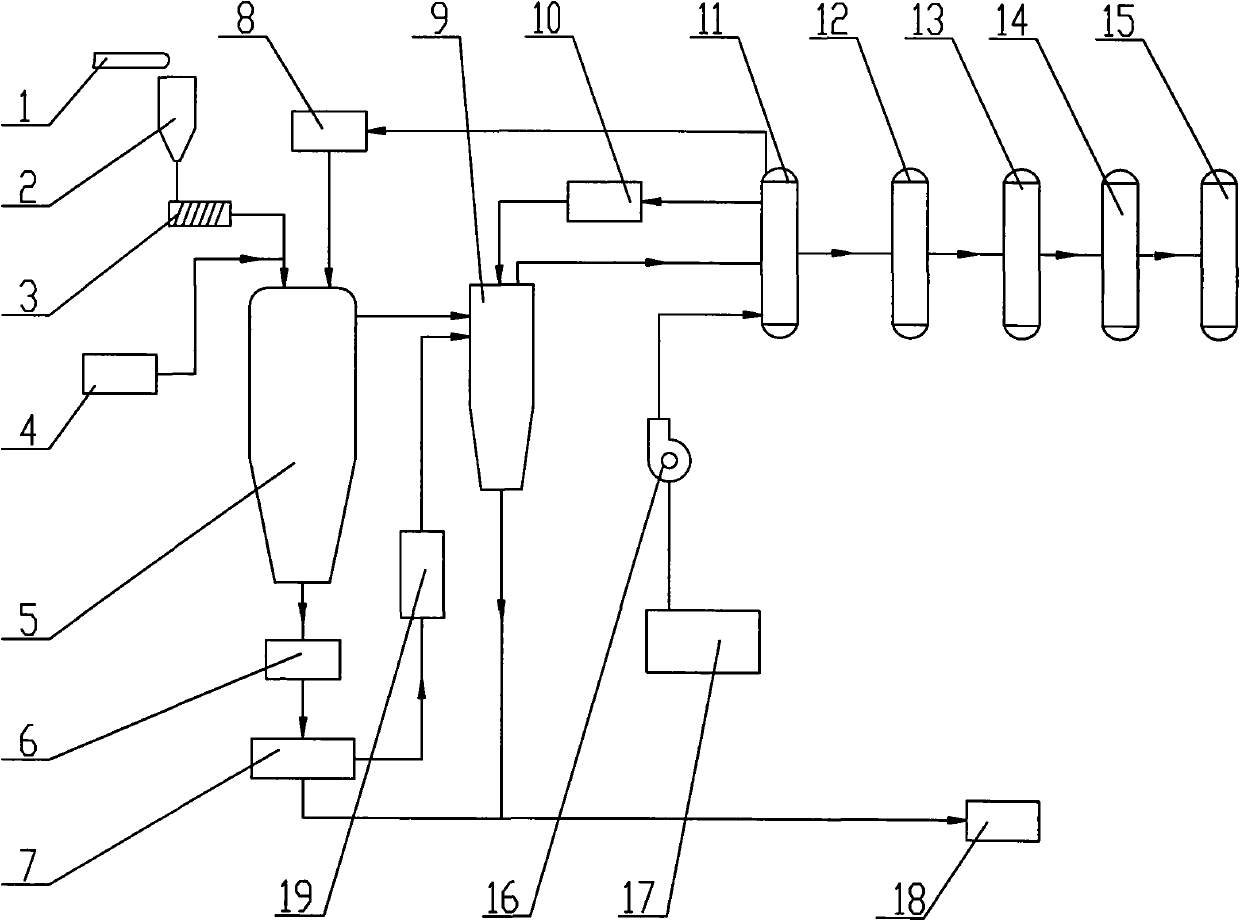

Method for producing 1,6-dimethyl adipate

ActiveCN102311342AOvercome CorrosivityOvercoming pollutionOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterEsterification reaction

The invention discloses a method for producing 1,6-dimethyl adipate. The method comprises the following steps of: (1) mixing adipic acid and methanol without adding a catalyst, and performing pre-esterification reaction at the temperature of 80 and 200 DEG C under the gage pressure of between 0.05 and 3 MPa; and (2) conveying materials which are subjected to the pre-esterification reaction to the upper part of a continuous catalytic rectifying tower, and gasifying the dried methanol, conveying to the lower part of the catalytic rectifying tower, allowing the materials which are subjected to the pre-esterification reaction to contact methanol steam in a reverse flow mode in the catalytic rectifying tower and performing esterification reaction further. By the method, the problems of equipment corrosion and pollution which are caused by the utilization of a sulfuric acid catalyst in the conventional process are solved, and the defects of complex processes, large consumption level of the catalyst and the like which are caused by the adoption of two-step or multi-step catalytic esterification are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for manufacturing compressed carbonized poplar board

InactiveCN101733805AReduce stressGood dimensional stabilityWood compressionWood charring/burningCarbonizationHardness

The invention relates to a method for manufacturing fast-growing wood sheet, in particular to a manufacturing method for modifying a fast-growing poplar board, belonging to the technical field of sheet manufacture. The invention has the advantages of small internal stress of a compressed carbonized poplar board manufactured by the method and good stability of the size of the board, thereby ensuring the quality of a compressed carbonized wood. The invention overcomes the defects of a fast-growing poplar sheet, such as low density, low hardness, low strength, easy corrosion, difficult direct use and the like, improves the density of the sheet by carrying out compression and densification for the poplar sheet, carries out carbonization on the compressed poplar sheet on the condition of pressurization, and eliminates the compression stress inside the sheet so as to prevent springback of the sheet and improve the size stability, density and strength. The poplar board manufactured by the method can be directly used as a sheet. The compressed carbonized poplar board can be partially or entirely used to replace high-quality precious wood, thereby relieving the contradiction between continuously reduced precious wood resources and increasing demand for wood.

Owner:NANJING FORESTRY UNIV

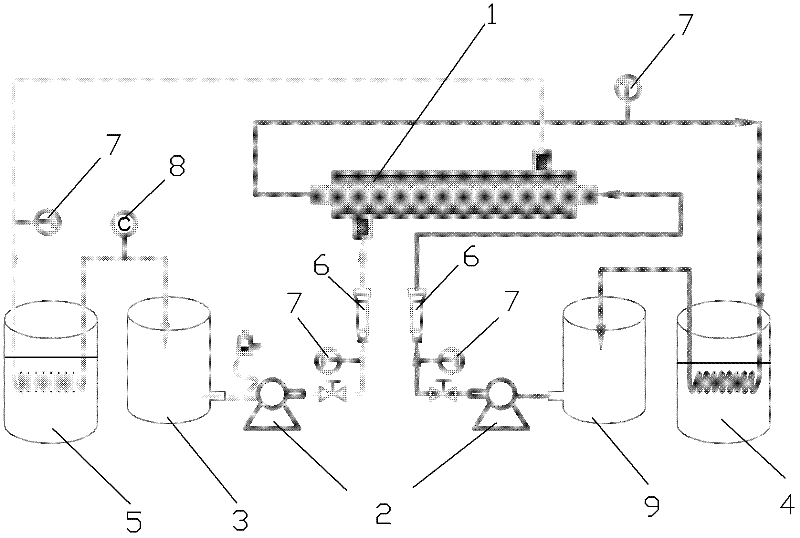

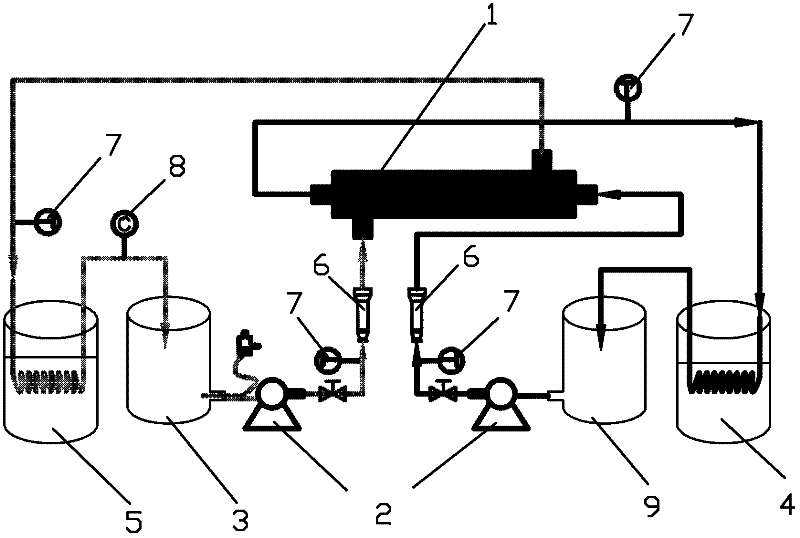

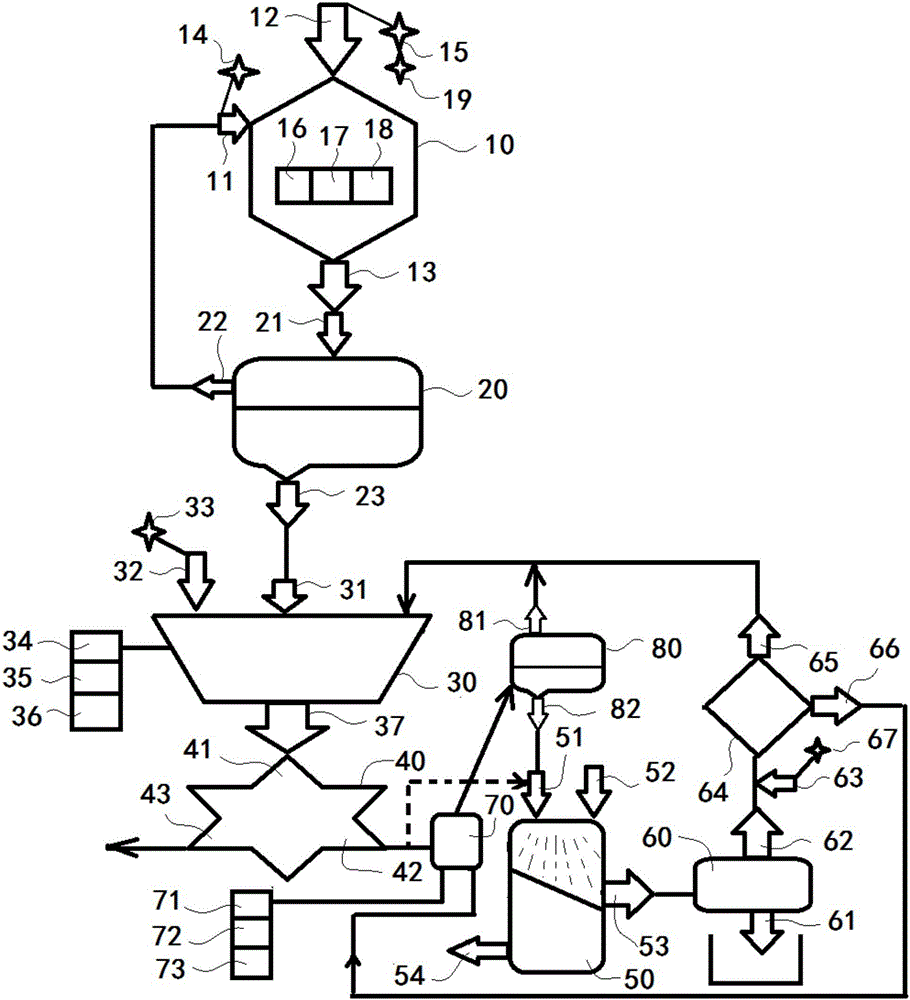

Process and apparatus thereof for low-temperature cracking and high-temperature gasification of biomass

ActiveCN101906325AReduce energy consumptionReduce the total project investmentProductsReagentsAlkali metal oxideWater storage tank

The invention discloses a process and an apparatus thereof for low-temperature cracking and high-temperature gasification of biomass. By adopting superheated vapor steam as oxidizing agent and an energy carrier, the process comprises the following steps of: firstly, carrying out the low-temperature cracking on the biomass fuel in the temperature region of 500-800 DEG C and obtaining the crude synthetic gas and the coke without containing alkali metal oxides; secondly, carrying out the high-temperature gasification on the crude synthetic gas and the coke in the temperature region of 1200-1600 DEG C to obtain the initial synthetic gas without containing tar component; finally, cooling, dust-removing, deacidifying and drying the generated initial synthetic gas, i.e., acquiring the pure synthetic gas of high quality. The apparatus mainly consists of a cracking furnace, a gasifying furnace, a low-temperature plasma torch heater, a high-temperature plasma torch heater, a water storage tank,a water delivery pump and a heat exchanger and the like. The process of the invention has the advantages of easy control, low energy consumption and investment cost and high efficiency of cooled coalgas; the generated synthetic gas has high calorific value and does not contain tar and alkali metal compounds. The invention is suitable for not only biomass gasification combined cyclic power generation, but also preparation of biomass liquid fuel.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

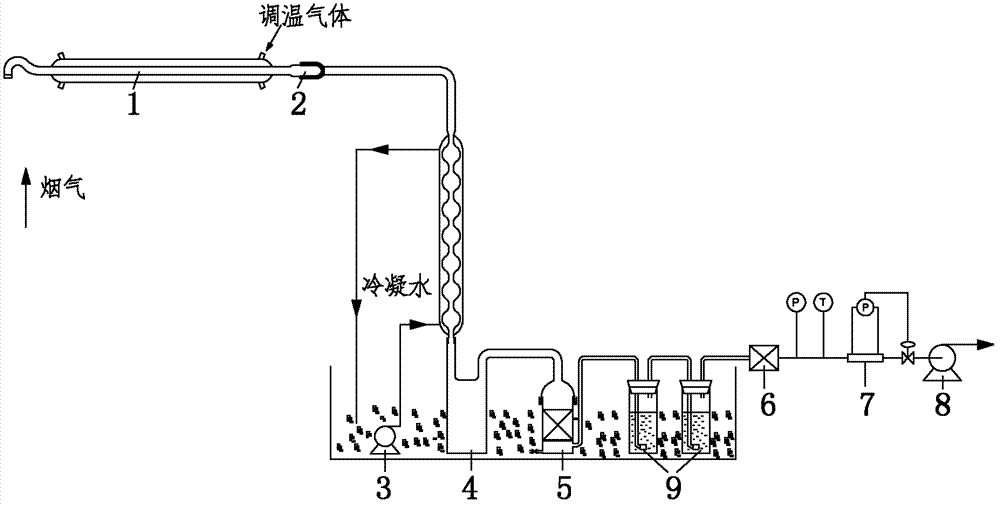

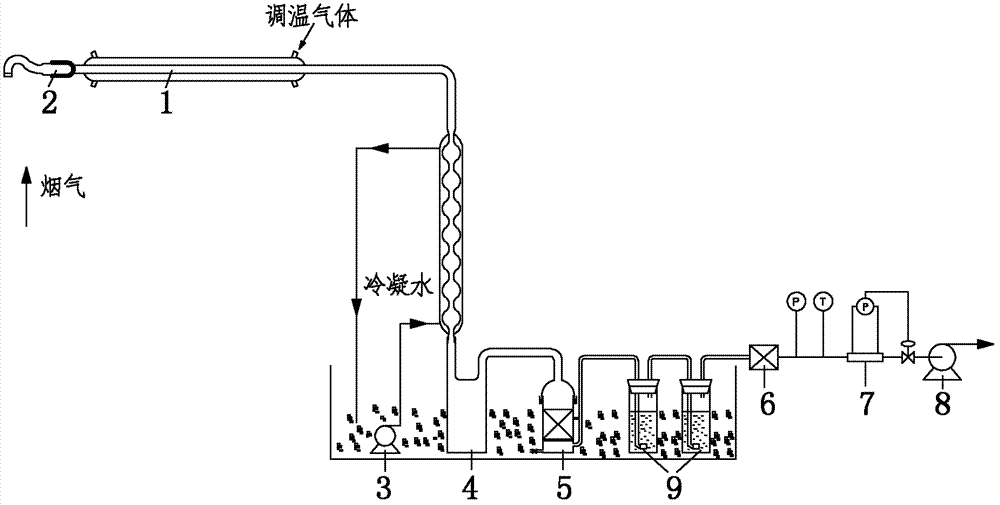

Method for sampling special organic gas in flue gas

The invention relates to a method for sampling a special organic gas in a flue gas. The method comprises the following steps: allowing the flue gas to enter through the inner tube of a sleeve from the inlet of a sampling gun, adjusting the temperature, intercepting particles by a filter cylinder, condensing the flue gas by a condensation device, allowing the obtained condensate liquid into a cooling and liquid removing bottle, trapping the cooled and dried gas by a trapping bottle to remove dioxin substances, further collecting by a washing bottle, and allowing the gas to go through a dryer, a gas flow meter, a thermometer and a sampling pump to complete the whole sampling process. A whole flue gas sampling pipeline adopting a full glass structure has the advantages of corrosion resistance, no chemical reaction, convenient cleaning, and prevention of the loss caused by the adsorption or contamination of the acquired sample by the wall surface of a tube wall utensil; the jacket glass sampling gun can heat or cool the acquired flue gas by hot or cold air entering through an external layer; the condensate liquid collection bottle having scales can rapidly judge whether there is severe gas leakage in the sampling process or not; and the flue gas is cooled, condensed, and dehydrated, and then adsorbs a sampling agent to guarantee a high sampling efficiency.

Owner:TONGJI UNIV

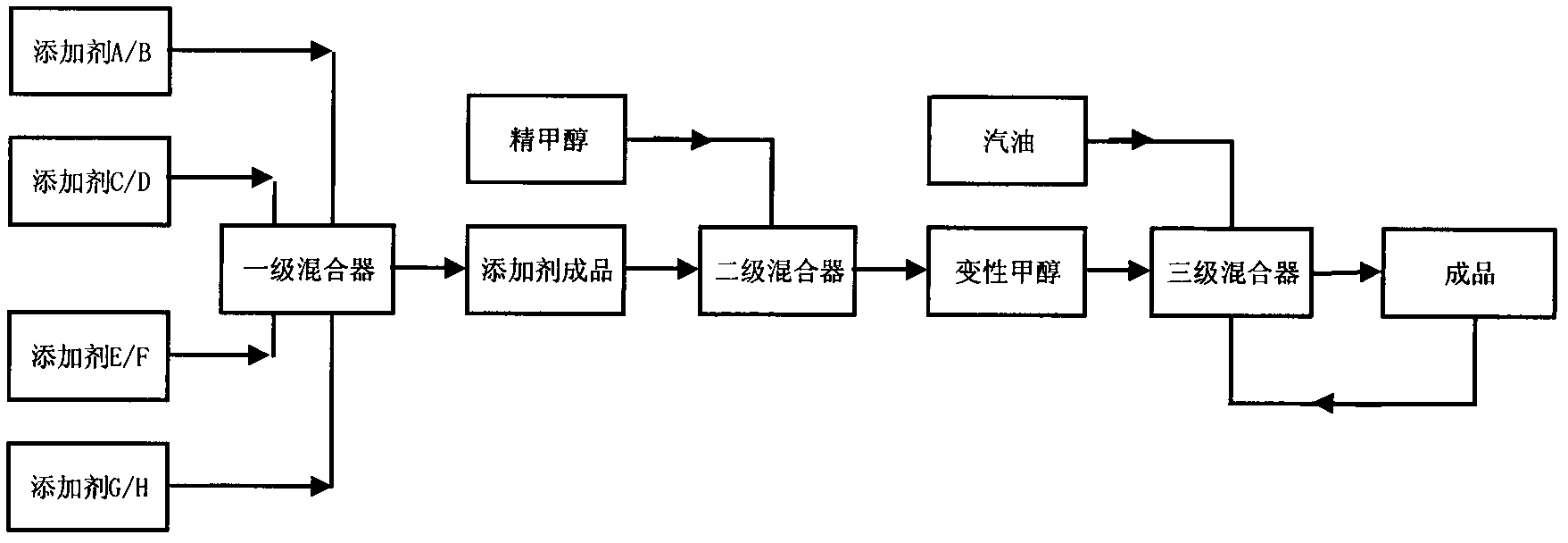

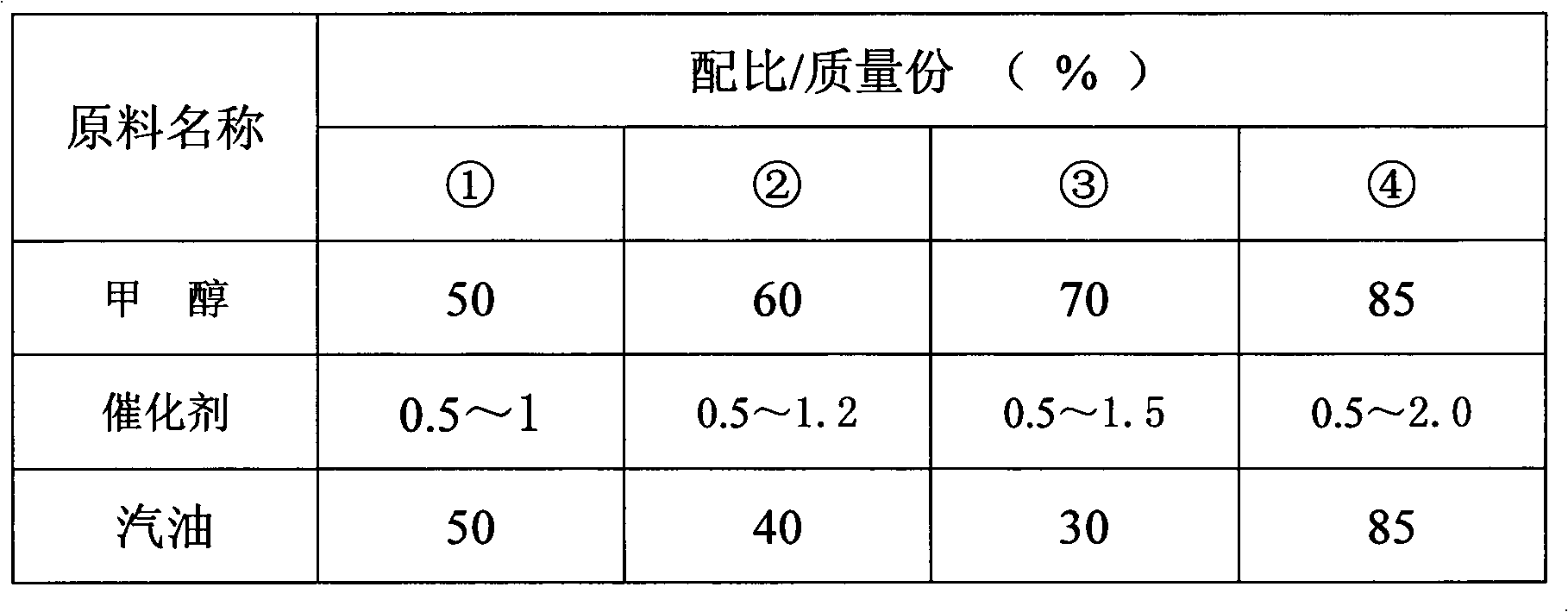

Large-proportion methanol gasoline catalyst and preparation method

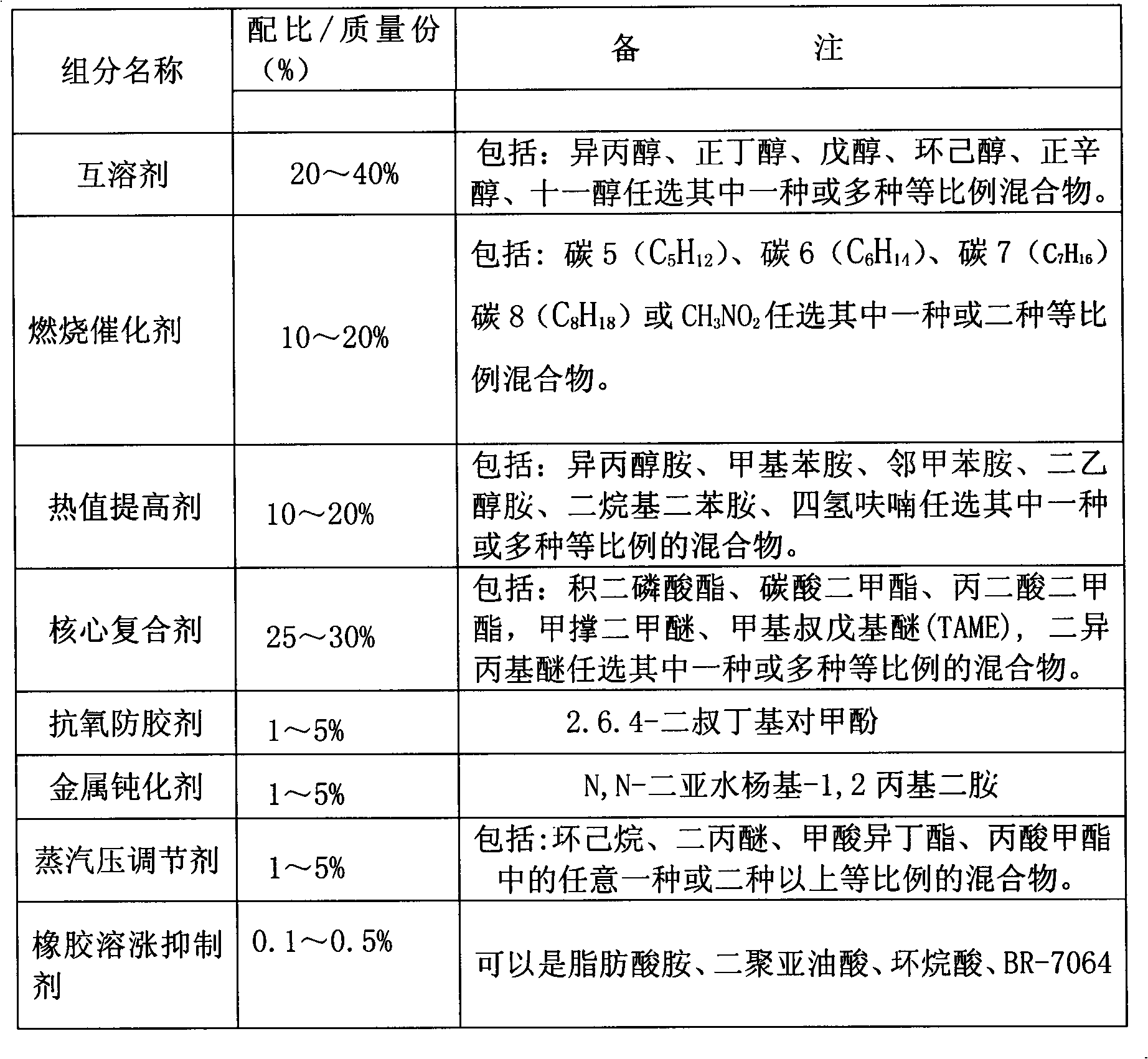

InactiveCN103160344AGood miscibilityImprove water resistanceLiquid carbonaceous fuelsFuel additivesAlkaneNaphtha

The invention provides a large-proportion methanol gasoline catalyst and a preparation method thereof. A product mark of the large-proportion methanol gasoline can be expressed by M50 and M85, wherein M represents a first letter of methanol; 50 and 85 respectively represent 50% of methanol and 85% of methanol are added in the gasoline The large-proportion methanol gasoline catalyst is obtained by mixing refined methanol with a purity of 99.9% and national standard gasoline or naphtha and component oil in presence of a special catalyst. A preparation method of the special catalyst is composed of high alcohols (C3-C11), alkanes (C5(C5H12), C6(C6H14), C7(C7H16), C8(C8H18) or CH3NO2), an organic amine, a plurality of esters and auxiliary inhibitors. The large-proportion methanol gasoline produced by the invention passes through a road test longer than 10,000 KM, without changing an engine structure. The large-proportion methanol gasoline is powerful, can be easily started at a low temperature, has no gas block at a high temperature, is not stratified when being contacted with water, can resist rubber swelling, and is low in production cost and flexible in operations. Besides, all project technical indicators are superior to those of national standard gasoline for vehicles. Practice proves that the large-proportion methanol gasoline catalyst has the advantages in a plurality of aspects such as technology, economy, feasibility for large-scale application, and the like, and has obvious competitive advantages as alternative energy.

Owner:杨军

Process for synthesizing p-aminophenol by nitrobenzene catalytic hydrogenation

InactiveCN101157622AReduce usageWeak corrosiveOrganic compound preparationAmino-hyroxy compound preparationDevice materialReaction temperature

The invention relates to a technique of synthesizing paraaminophenol by catalyzing and dydrogenating nitrobenzene, and belongs to the technical field of aminophenol. The invention is the technique of producing the paraaminophenol from the nitrobenzene catalyzing dydrogenating device in the metal salt liquors, wherein, the quality compounding rate of the material has a mass distribution ratio that Lewis acid metal salt: load metal Pt activator: nitrobenzene: hexadecyl trimethyl ammonium bromide: water is equal to 0.5 to 5 : 0.1 to 0.3 : 1 to 5 : 0.01 : 50. The invention has the reacting conditions that: a branch pressure of the hydrogen is 0.1 to 1.0 M Pa, a reacting temperature is 80 to 200 DEG C, and a reacting time is 1 to 10 hours. The reaction which is proceed in the neutral or acidulous metal salt liquors has not high requirements to the device material, thereby preventing using abundant ammonia during the managing process, simplifying the production craftworks and overcoming the problems of the canker of the device and the serious environmental pollution; the metal salt and the activators can be separated from the reaction system for being reused repeatedly; therefore, the invention reduces the production cost, also prevents the discharging of the waste liquids and makes the yield of PAP highly reach to 25 to 73 percents.

Owner:HEBEI UNIV OF TECH

Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and preparation method thereof

The invention discloses Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and a preparation method thereof. The alloy contains main alloying elements of Al-Zn-Mg or Al-Zn-Mg-Cu and microalloying elements of Zr, Ta, Fe and Si; moreover, a mass ratio of the microalloying elements satisfies the conditions that Ta is larger than or equal to 0.1Zr and less than or equal to 0.5Zr, Si is larger than or equal to 0.1Zr and less than or equal to 0.3Zr, and Fe / Si is larger than or equal to 0.7 and less than or equal to 1.5; according to the preparation method of the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy, after an ingot metallurgy method is adopted for preparing the alloy, the alloy is subjected to homogenizing treatment, deformation treatment and solid solution waterquenching, and then artificial ageing is conducted. According to the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and the preparation method thereof, a multielement microalloying methodis adopted, cooperation of the multielement microalloying elements is strictly controlled to form a multielement coherent dispersed phase, recrystallization is completely inhibited, the microalloyingelements are used for improving the corrosion resistance effect of aluminium alloy passive film, high strength and good corrosion resistance performance are combined, and the problem that the strength and the corrosion resistance of existing Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy cannot be achieved at the same time is solved; the preparation method of the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy is simple in technology, and the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy is suitable for industrialized production.

Owner:CENT SOUTH UNIV

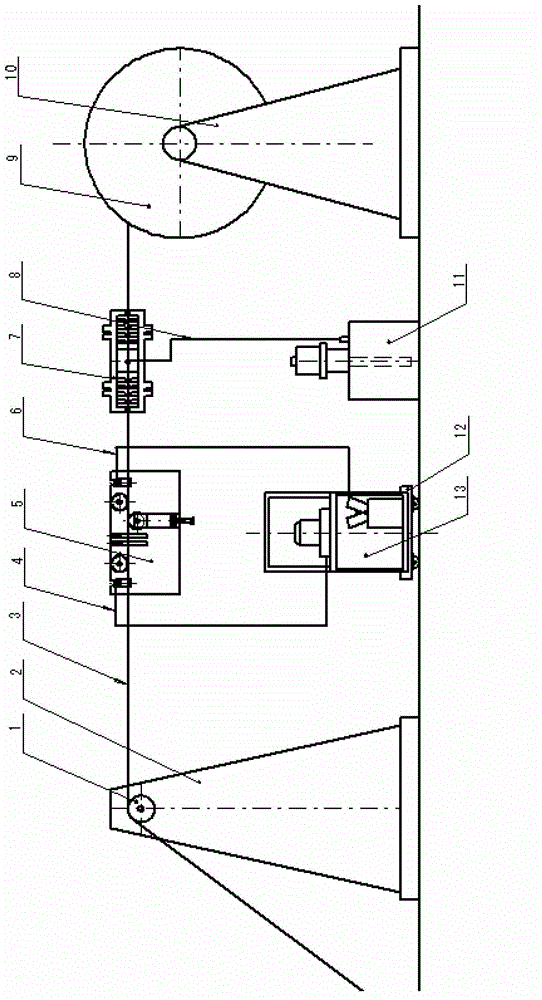

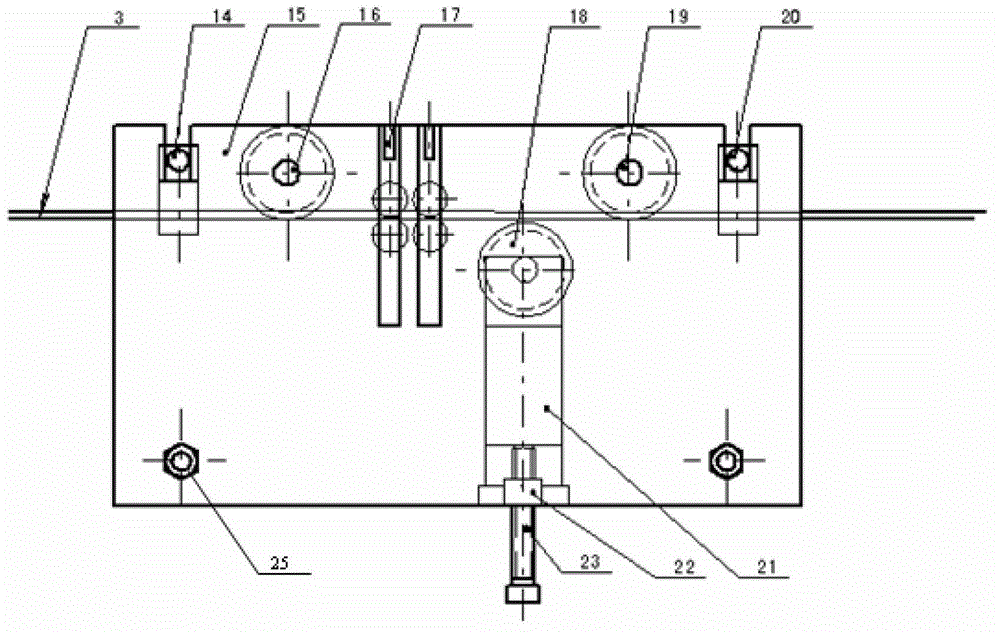

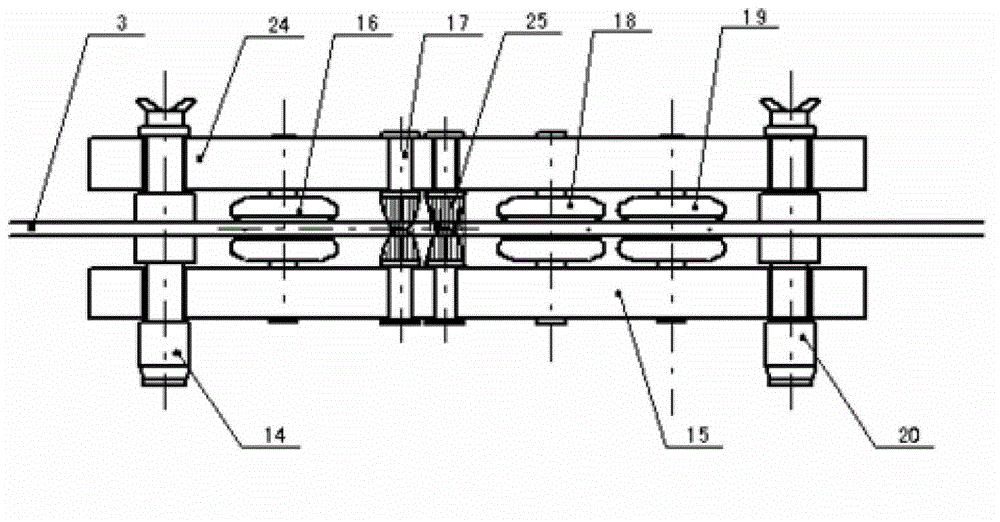

Steel cable comprehensive maintenance, cleaning and maintaining system of winch for boat

ActiveCN103144749AEfficient integrationCompact structureVessel cleaningHullsFresh waterAir compressor

The invention relates to a steel cable comprehensive maintenance, cleaning and maintaining system of a winch for a boat. A guide wheel support frame is coaxially and fixedly arranged on a deck in front of the winch, a guide wheel is arranged on the guide wheel support frame, a steel cable is wound on a groove wheel arranged in the winch, a cleaner is coaxially sheathed on the steel cable arranged between the guide wheel and the winch, an oil coater is coaxially sheathed on the steel cable arranged between the cleaner and the winch, the cleaner is respectively communicated with a compressed air pipe of an air compressor and a pressure fresh water pipe of a pressure boosting water pump, and the oil coater is communicated with a pressure oil pipe of a small-size grease pump. The system has the advantages that the cleaner and the oil coater are sequentially arranged on the steel cable in front of the winch, the cleaner comprises the steps of pressure fresh water cleaning and compressed air blow-drying, and the goal of steel cable cleaning is reached; and pressure lubricating grease is uniformly smeared on the oil coater through the cleaned steel cable, moisture in the steel cable is squeezed out through the pressure lubricating grease, the fresh lubricating grease is fully filled inside the steel cable, the corrosion of the steel cable is effectively lightened, and the service life of the steel cable is prolonged.

Owner:QINGDAO CHENMING MARINE EQUIP TECH CO LTD

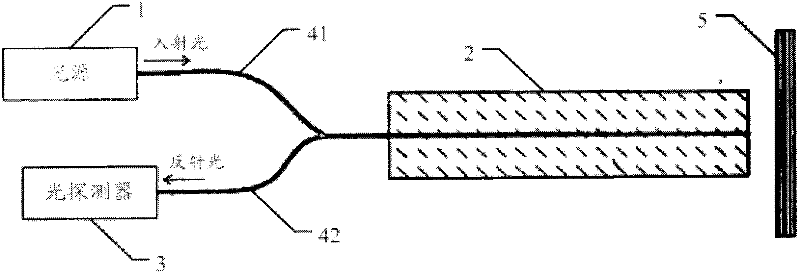

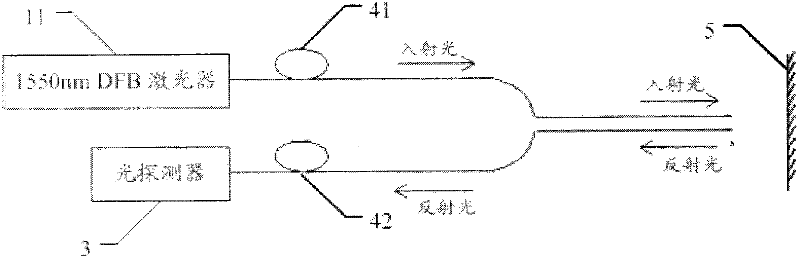

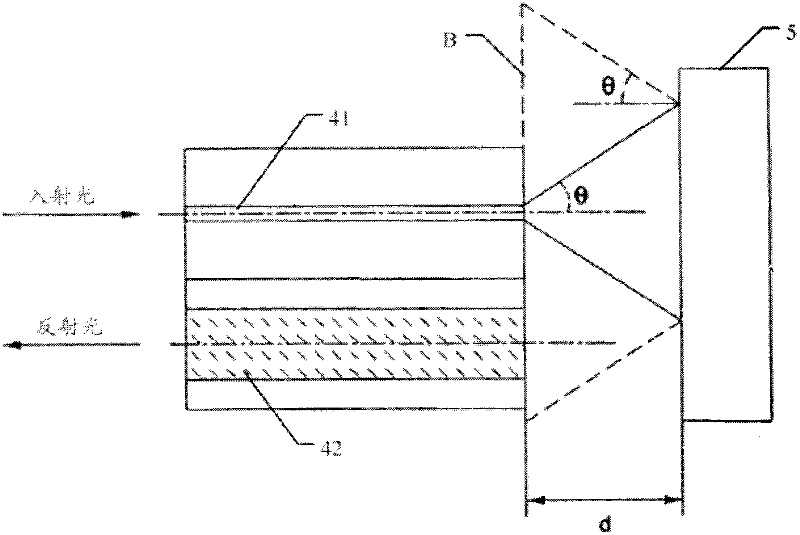

Reflective optical fiber sensor device

InactiveCN102410850AStructure has no effectExtended service lifeWeather/light/corrosion resistanceForce measurement by measuring optical property variationElectromagnetic interferenceOptical detector

The invention discloses a reflective optical fiber sensor device, which comprises a light source, an optical detector and a sensor probe, wherein the sensor probe is used for receiving and processing the incident light emitted by the light source and sending the obtained reflected light to the optical detector. The reflective optical fiber sensor device can overcome the defects that the sensor in the prior art has large volume, cannot be used in an environment with electromagnetic interference and has short service life and poor corrosion resistance, and has the advantages of small volume, wide application range, long service life and good corrosion resistance.

Owner:王建伟 +3

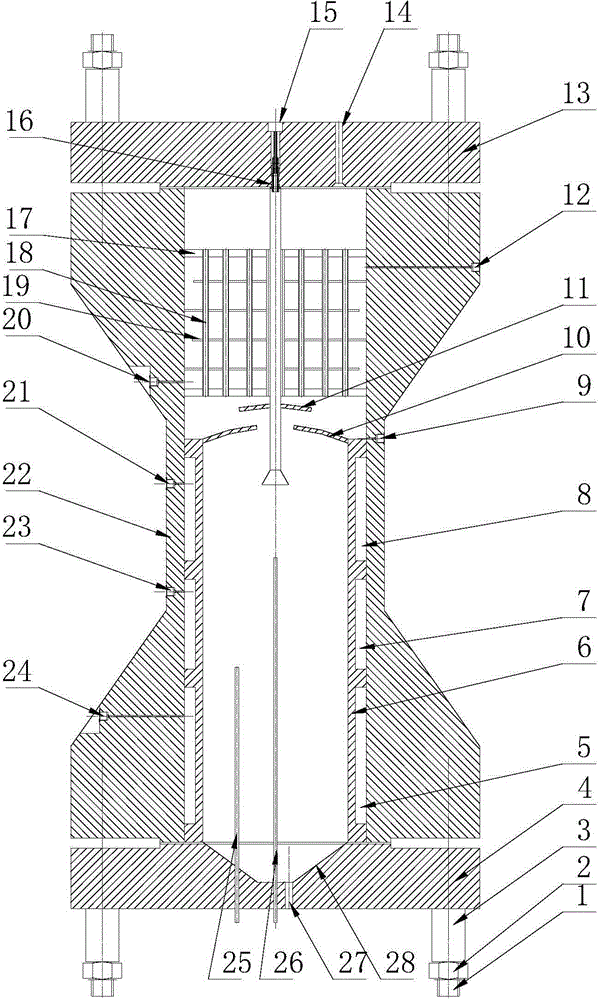

Evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water

ActiveCN104478064AReduce material selectionAchieve separationWater/sewage treatment by oxidationWater useSaline water

The invention relates to an evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water. The cylinder is fixed with an upper end cover and a lower end cover; the middle part of the upper end cover is provided with a burner component which extends to the inside of the cylinder; the upper end cover is provided with a gas-phase outlet and a sewage secondary inlet; the upper part in the cylinder is fixedly provided with a shell-and-tube heat exchanger; the upper part of the cylinder is provided with a sewage primary inlet and a normal temperature sewage outlet; the cylinder is provided with a subcritical water outlet; the lower part in the cylinder is fixedly provided with a multilayer evaporation wall; a plurality of annular spaces are formed between the multilayer evaporation wall and the cylinder from top to bottom; the cylinder is sequentially provided with a plurality of evaporation wall water inlets; the upper edge of the multilayer evaporation wall is provided with an evaporation wall spherical baffle; the lower end of the burner component is fixedly provided with a burner spherical baffle; and the bottom of the lower end cover is provided with a brine outlet. The oxidation reactor effectively prevents the preheater, reactor and pipelines from blockage and corrosion, reduces the quantity of pure water used by the evaporation wall, and can reduce the reactor volume and lower the noble alloy consumption.

Owner:碧流天能(北京)科技股份有限公司

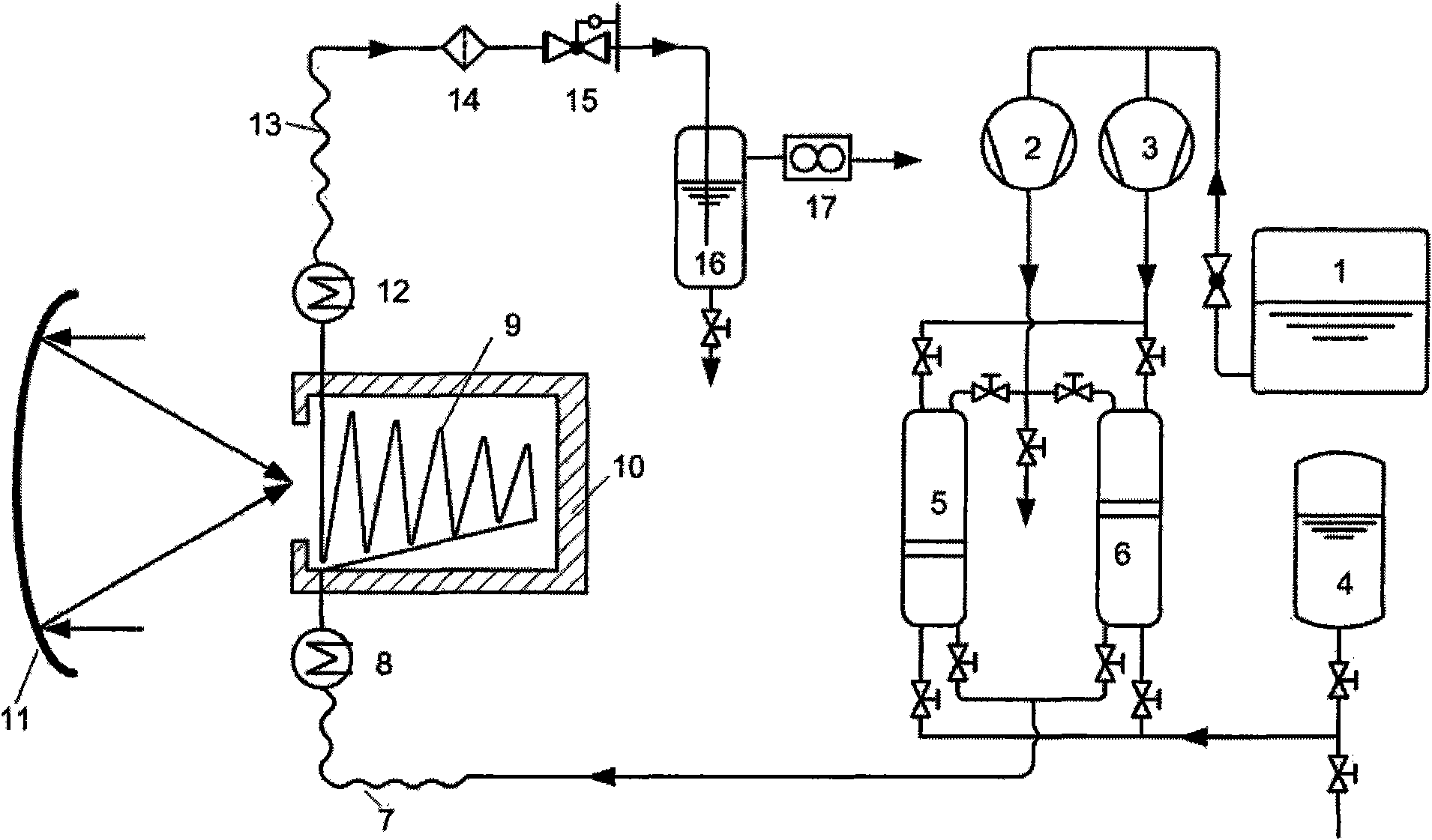

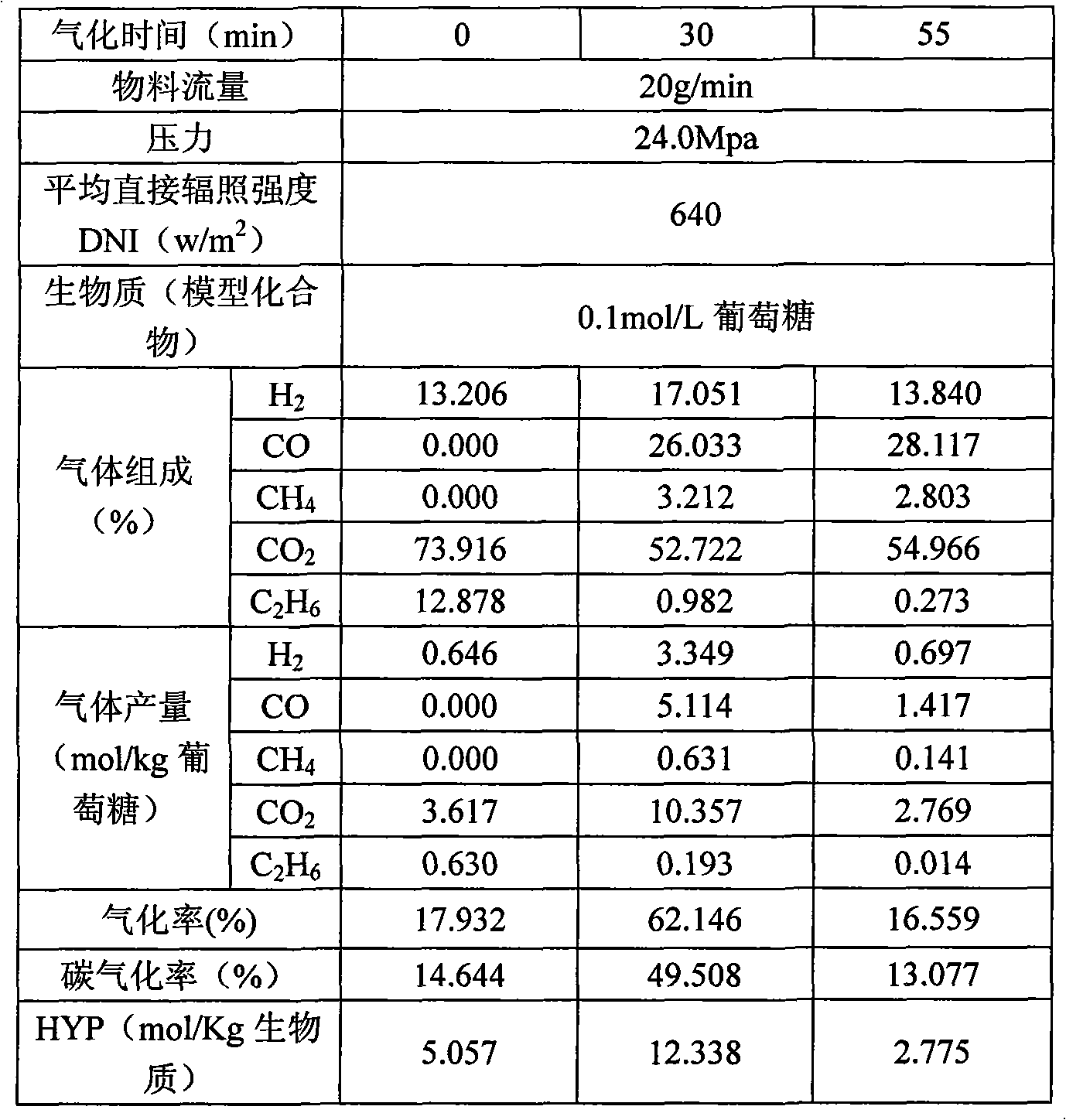

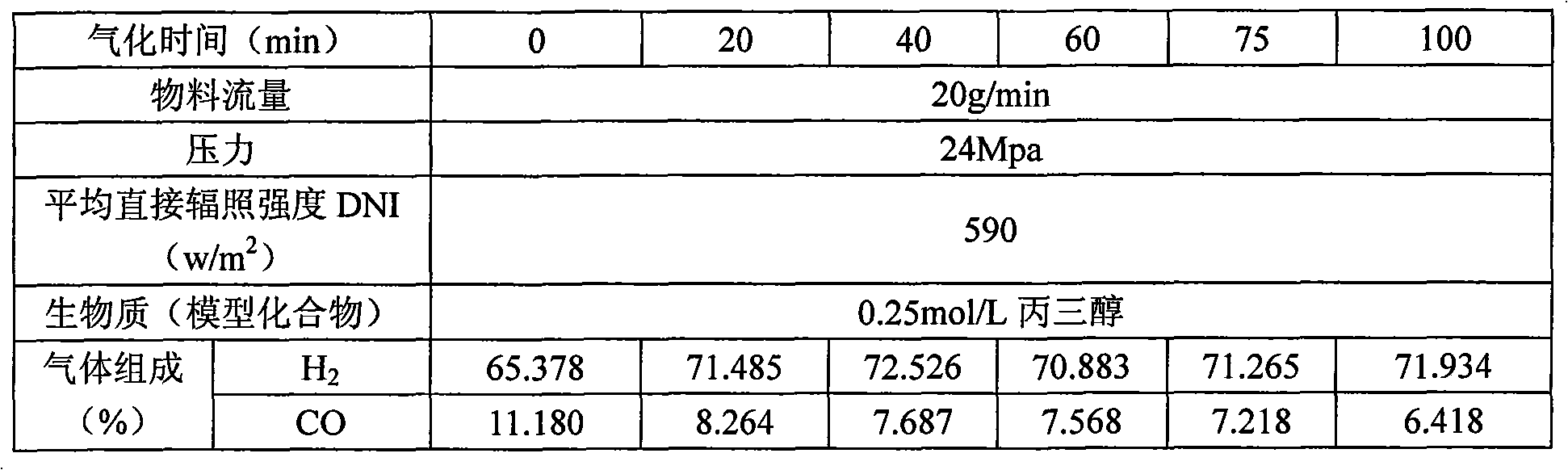

Biomass supercritical water gasification and multi-plate focusing heat supply coupling hydrogen production device and method

ActiveCN101597027AIncrease independenceOvercome CorrosivitySolar heating energyHydrogenSolubilityHigh energy

The invention discloses a biomass supercritical water gasification and multi-plate focusing heat supply coupling hydrogen production device and a method; wherein the device adopts a cavity absorber to realize efficient absorption of solar energy, adopts a coil type distribution to cause the structure of a reactor to be compact and strengthen heat transmitter in the reactor, and adopts a multi-plate solar energy condenser to realize high-accuracy automatic tracking of the sun and provide a solar energy source with high focusing ratio and high energy current density for biomass supercritical water gasification hydrogen production, thus realizing direct solar thermolysis supercritical water and biomass hydrogen production. The hydrogen production method provided by the invention utilizes the characteristics of water of high solubility, high diffusivity and the like in supercritical state to realize complete efficient gasification of biomass, so as to generate hydrogen rich gas; and meanwhile, reaction temperature required by solar energy thermochemistry circulation hydrogen production is reduced to be lower than 600 DEG C from more than 1500 DEG C, thus greatly reducing direct solar hydrogen production cost and realizing a renewable energy source hydrogen production system.

Owner:陕西中核交大超洁能源技术有限公司

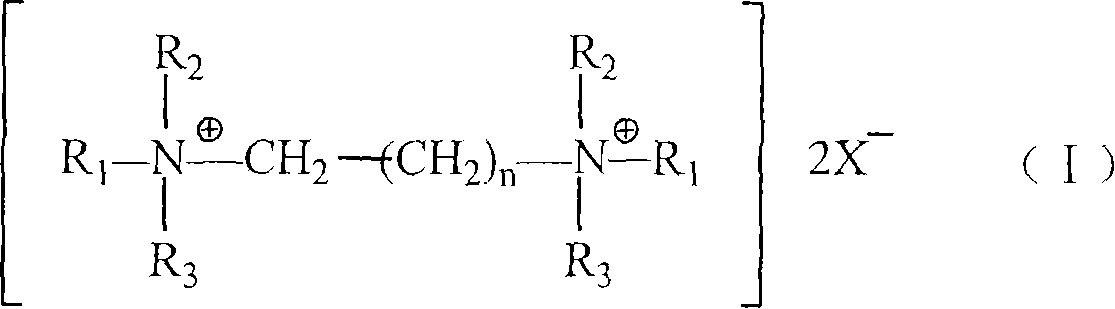

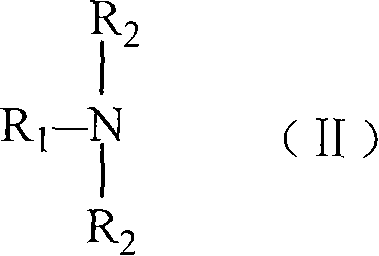

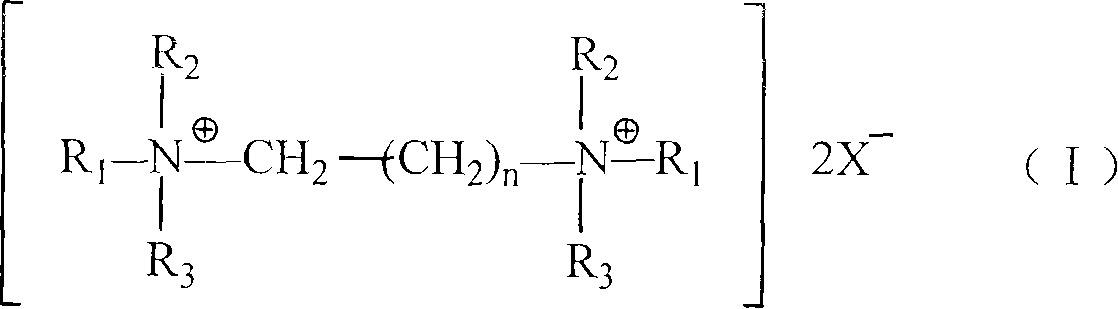

Disinfectant

InactiveCN101066054AStabilized virus killing effectEfficient bactericidalBiocideFungicidesAquaculture industryDisinfectant

The disinfectant is one kind of complex containing quaternary ammonium salt cationic surfactant and iodine. It is produced through mixing the quaternary ammonium salt compound and iodine and reacting for 1-2 hr. It is used mainly for disinfection in animal raising and aquiculture, and has high sterilizing and algae-killing efficiency and high safety.

Owner:孙保兴

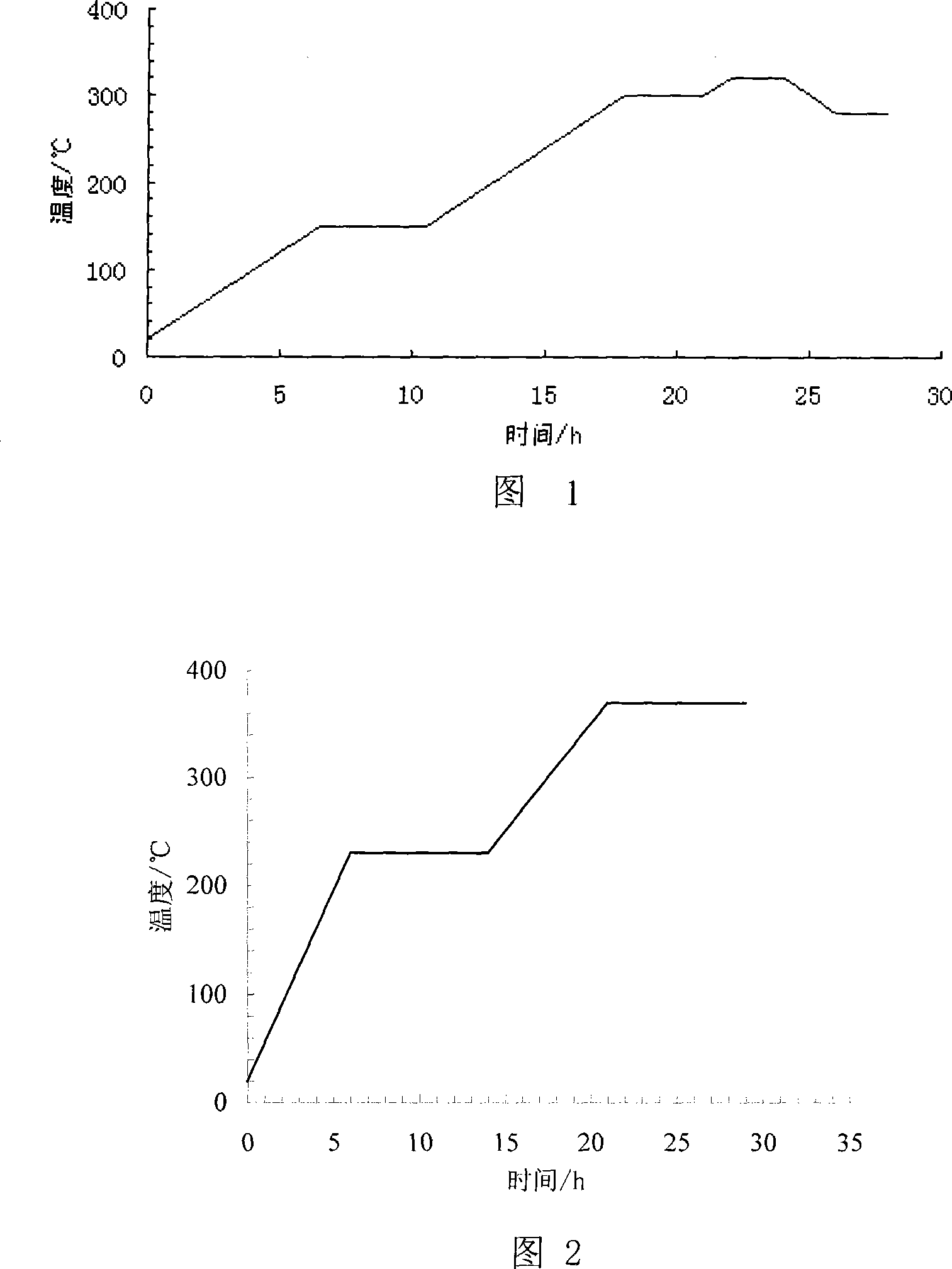

Hydrogenation catalyst presulfurizing method

InactiveCN101024204AOvercome lossOvercome CorrosivityCatalyst activation/preparationOil processingVulcanization

This invention discloses a hydrogenation catalyst pre-curing method. The method used the by-products of the oil and gas industry processing acidic gas as medium sulfide, pretreatment the hydrogenation catalyst, the main component of acid gas is hydrogen sulfide and carbon dioxide, the invention can be used inside or outside of pre-vulcanization mode, put the oxidation states catalyst into vulcanization reactor, heated to200-500degree centigrade in an inert atmosphere, and then conducted hydrogen and acid gas to sulphate under 0.1-10MPa pressure, the reaction time is 0.5 to 30 hours, of which an acid gas occupy 1-40%. The invention method not only overcome the presence of sulfide wet curing agent losses, metal tube surface corrosion defects, also have fast curing process, even curing, can greatly improve the activity and stability of catalysts, extended catalyst life and other advantages, and wide sulfide-media sources, easy to get, significantly lower sulfide cost.

Owner:DAQING GASOLINEEUM INST

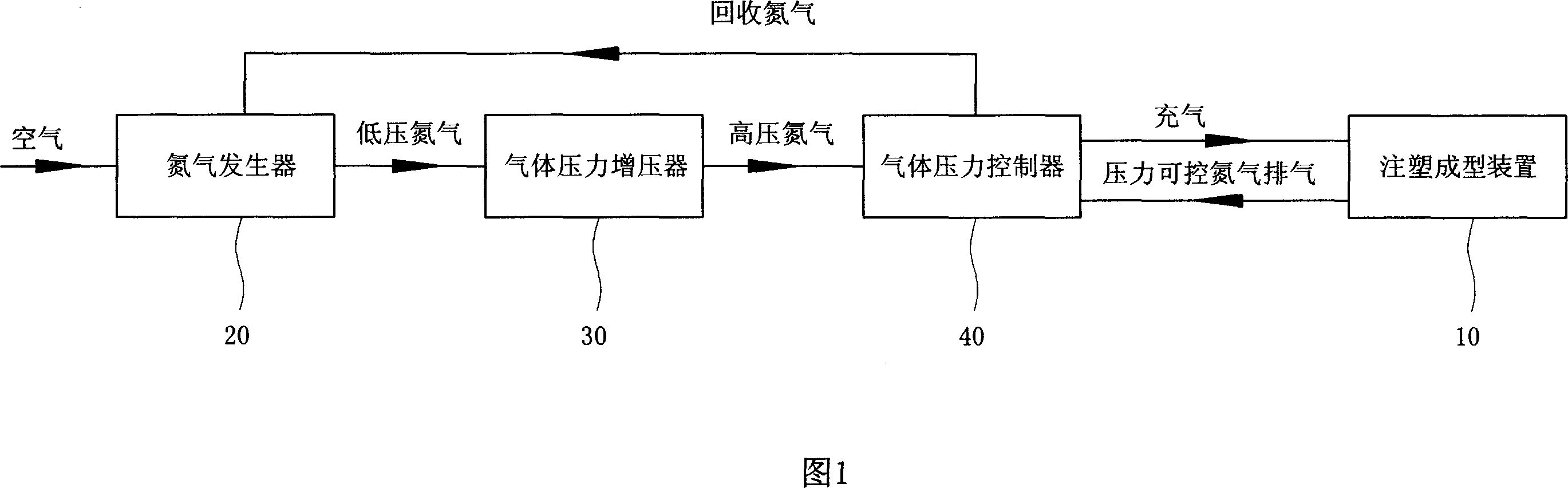

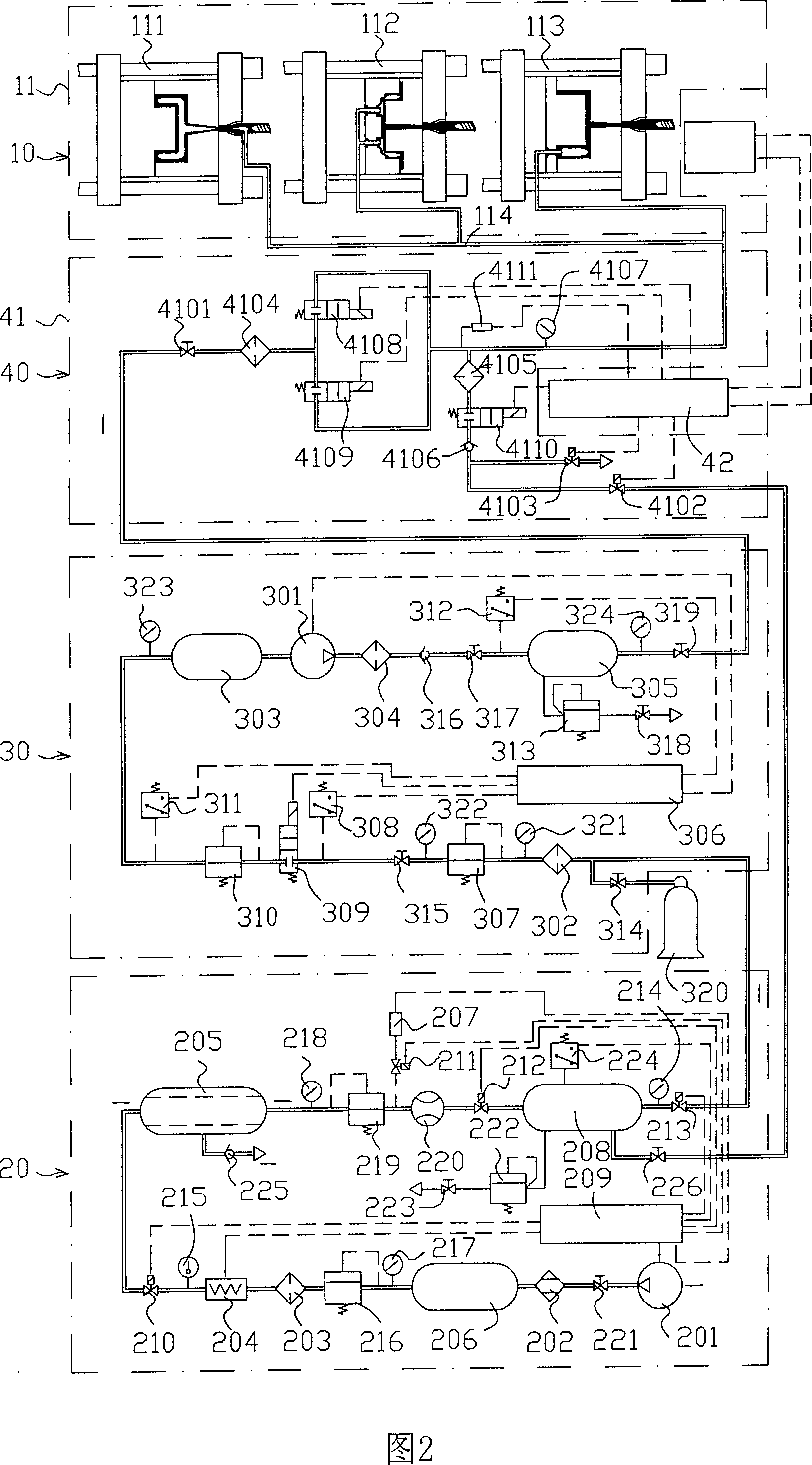

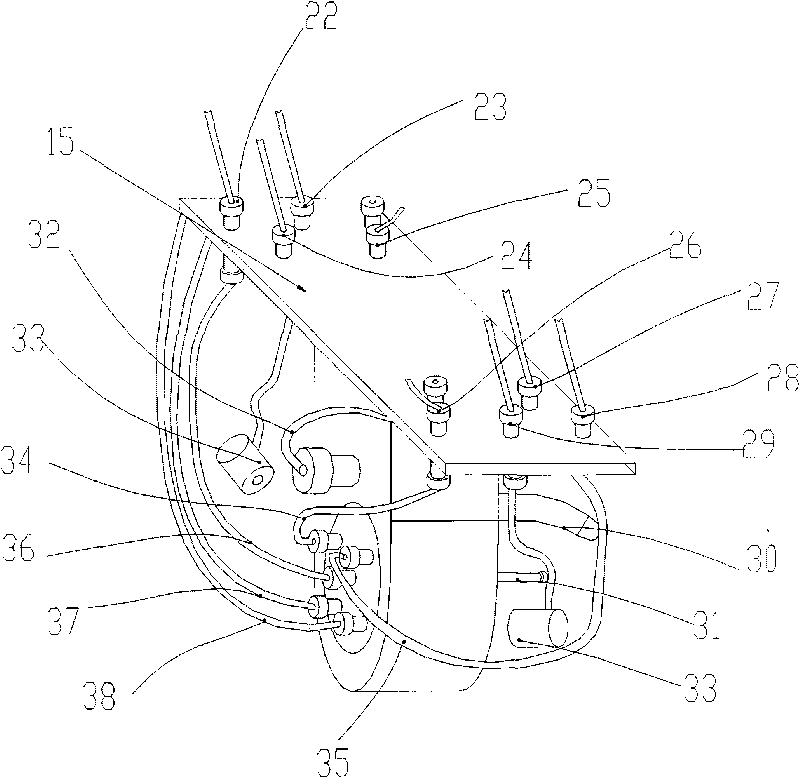

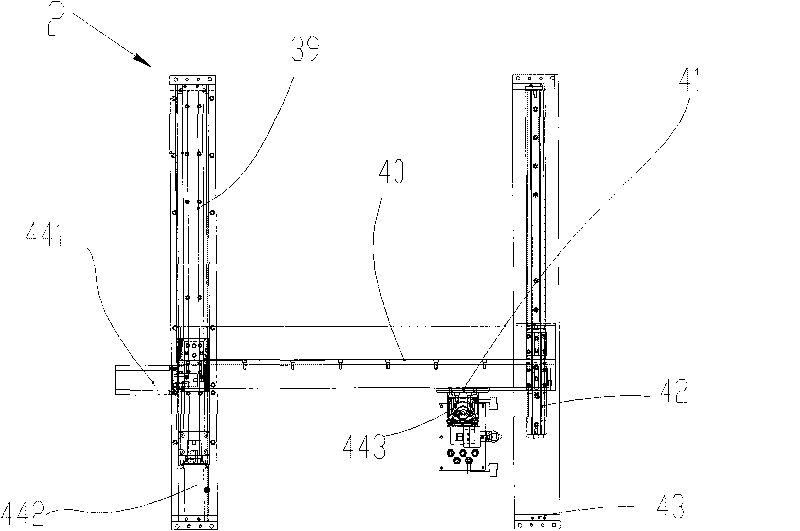

Pressure-sustaining gas assistant injection molding system

InactiveCN1990212AQuality improvementSmooth gas injectionNitrogen purification/separationNitrogen generatorAutomatic control

The invention discloses an auxiliary injection molding system of constant pressure gas, which comprises the following parts: injection molding device (10), nitrogen generator (20), gas pressure booster (30) and gas pressure controller (40), wherein the gas pressure controller (40) connects injection molding device (10) and gas pressure booster (30); the gas pressure booster connects nitrogen generator (20).

Owner:韩国海 +1

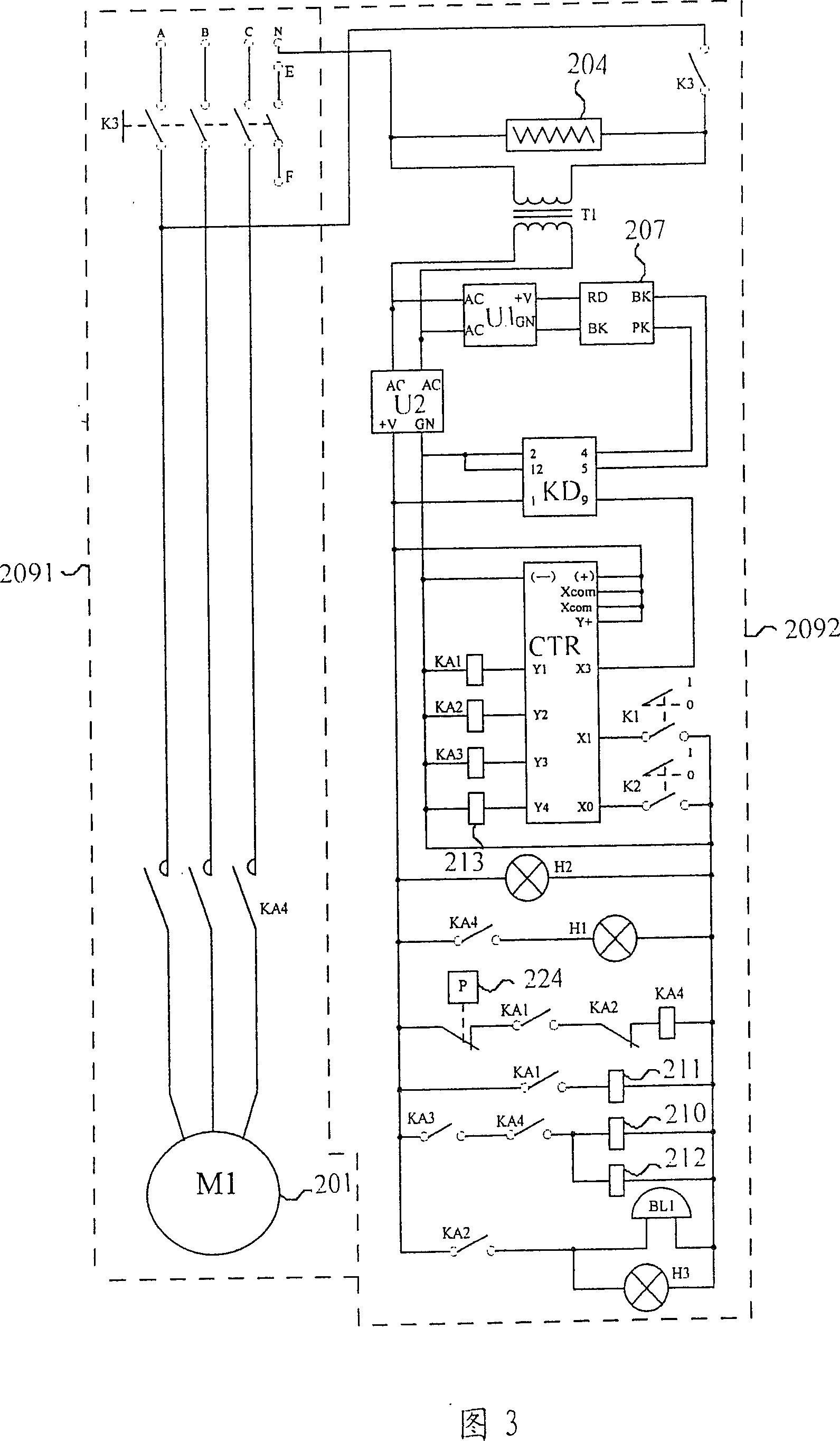

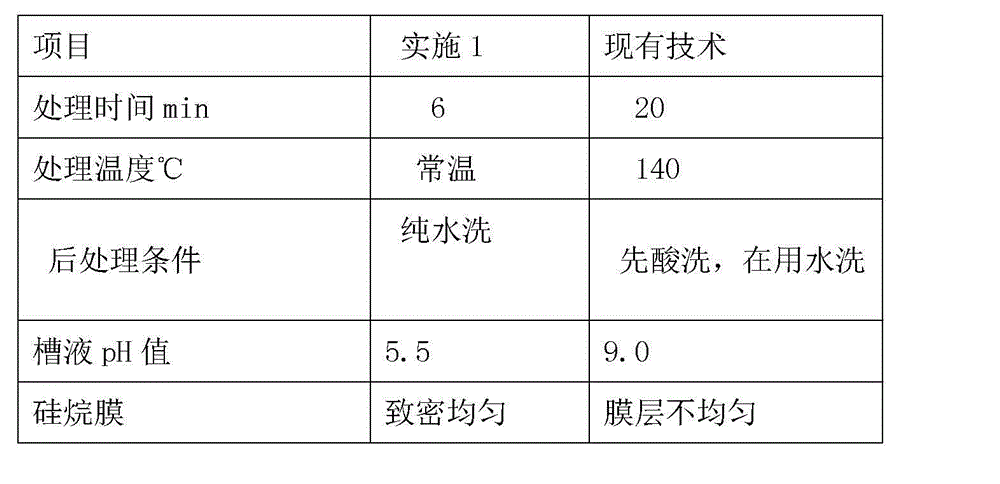

Modified silane surface pretreating agent containing polyoxyethylene octadecanol ether and preparation method of modified silane surface pretreating agent

ActiveCN102977774AOvercome CorrosivityOvercome uniformity issuesAnti-corrosive paintsPerfluorooctanoic acidChemistry

The invention discloses a modified silane surface pretreating agent containing polyoxyethylene octadecanol ether. The modified silane surface pretreating agent is prepared from the following raw material components in parts by weight: 100 parts of deionized water, 10-15 parts of modified coupling agent, 10-15 parts of ethanol, 30-40 parts of silane coupling agent 702, 20-30 parts of silane coupling agent KH-550, 1-2 parts of dicumyl peroxide, 0.002-0.003 part of sodium perfluorooctanoate, 0.3-0.5 part of tree ash, 4-6 parts of polyacrylic emulsion, 0.8-1.2 parts of polyoxyethylene octadecanol ether, 0.05-0.1 part of lanthanum triacetate and 0.2-0.3 part of phytic acid. The final product is obtained through modifying by using the coupling agent, compounding, adding additives, distributing, mixing and reacting. The modified silane surface pretreating agent provided by the invention has the characteristics of no toxicity, environment friendliness, convenience in use, compact and uniform silane membrane, strong adhesion and high corrosion resistance property.

Owner:蚌埠尚维知识产权运营有限公司

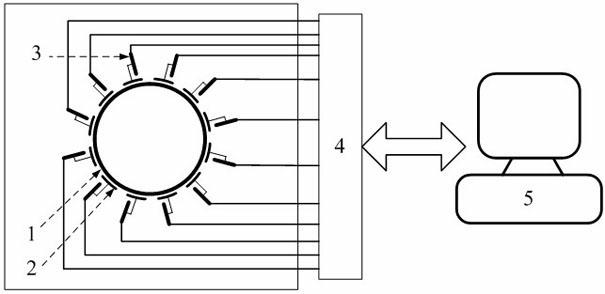

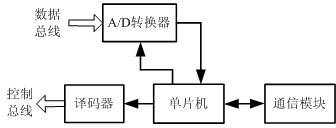

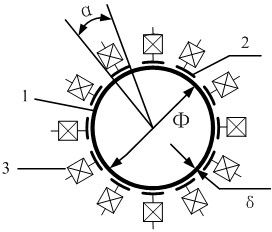

Contactless electrical resistance tomography (ERT) measurement device and method

InactiveCN102183550AOvercoming electrode polarizationOvercome CorrosivityMaterial resistanceTomographyMeasurement device

The invention discloses a contactless electrical resistance tomography (ERT) measurement device and a contactless ERT measurement method. The device consists of a resistance sensor, a data acquisition module and a computer, wherein the resistance sensor is connected with the data acquisition module; and the data acquisition module is connected with the computer. The resistance sensor comprises an insulated pipeline, rectangular metal electrodes and excitation / detection modules, wherein the metal electrodes are arranged on the outer wall of the insulated pipeline in equal distance; respective excitation / detection module is fixed on each metal electrode; and all the excitation / detection modules are connected with the data acquisition module through flat cables. The device effectively solves the problems of electrode polarization, corrosion and the like of contact ERT, simultaneously has advantages of convenience in installation, simple structure, non intrusion, no influence on the flow of the fluid in the pipeline and the like, and provides useful reference for the contactless ERT of the two-phase fluid.

Owner:ZHEJIANG UNIV

Sulfur magnesium cement building material processing method

InactiveCN104817311AImprove technical issues that are difficult to controlLow apparent densityCeramic shaping apparatusMagnesium phosphateMagnesium orthophosphate

The invention discloses a sulfur magnesium cement building material processing method which includes the steps: preparing and diluting sulfur magnesium mixing liquid; mixing magnesium oxide, coal ash and modifiers to prepare magnesium oxysulfate cement gel materials; injecting discharged materials into a building material mould, curing building materials for 8-12 hours within the environmental temperature range of 15-40 DEG C, demoulding the building materials and continuing curing the demoulded building materials for 25-28 days under the condition of environmental temperature reaching 15-40 DEG C and relative air humidity reaching 30-65%. The modifiers include any of phosphate, boric acid or citric acid, and the phosphate includes any of monopotassium phosphate, ammonium dihydrogen phosphate, sodium dihydrogen phosphate and magnesium phosphate. A glass fiber woven mesh fabric is laid at the bottom of the building material mould. The sulfur magnesium mixing liquid replaces magnesium chloride water solution in the prior art, magnesium chloride with strong activity and poor stability is removed, the technical problem of difficulty in controlling the magnesium cement building materials is fundamentally solved, and long-term difficultly solved problems of scumming, buckling deformation and corrosion of metal components caused by chloride ions are solved.

Owner:张禹 +1

Device and method for radioactive waste water concentration treatment

ActiveCN102351359ALow operating pressureIncrease the concentration factorMultistage water/sewage treatmentDifferential pressureWater concentration

The invention discloses a device and a method for radioactive waste water concentration treatment, which belongs to the technical field of environment protection. A high-polymer hollow fiber type membrane assembly of hydrophobic materials is used as a main body, and the separation between radioactive nuclide and water is realized through controlling the temperature of solution at both sides of a membrane by using water vapor differential pressure as the pushing force, so the goal of concentrating the waste water is reached. The method has the advantages that the flow process is simple, the operation is easy, the decontamination factor is high, the concentration factor is high, the adaptability is high, and the combination with other processes is easy. The water outlet quality of the wastewater can reach the discharge standard only through one-step membrane distillation.

Owner:TSINGHUA UNIV

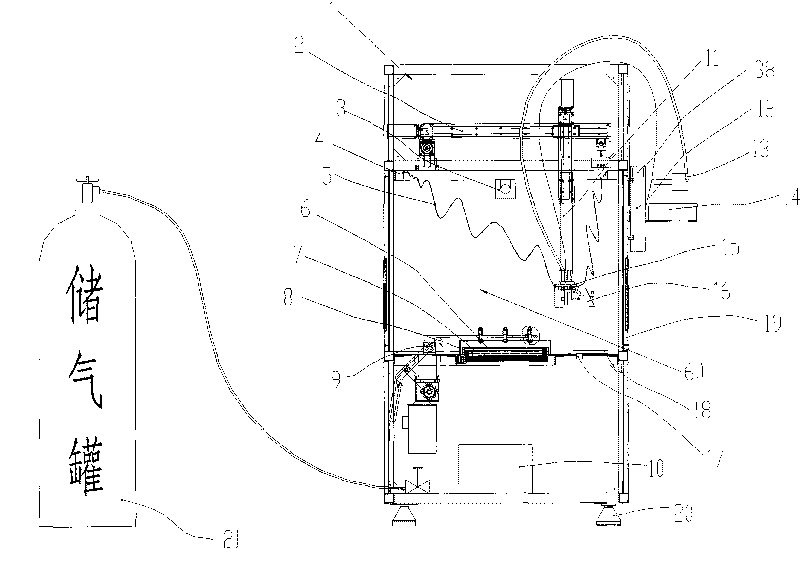

Integrative ultrasonic spray pyrolysis large-area wide-temperature zone coating device

InactiveCN101759372AOvercome the problem of usingOvercoming frequencyLiquid/solution decomposition chemical coatingSpray nozzleEngineering

The invention discloses an integrative ultrasonic spray pyrolysis large-area wide-temperature zone coating device, comprising a frame, an air tank and an infusion pump arranged on the frame. A three-dimensional motion mechanism and a control module for controlling the three-dimensional motion mechanism to do three-dimensional motion are arranged above the frame. A temperature-controllable heating platform is arranged in the frame and under the three-dimensional motion mechanism. An integrative ultrasonic spray nozzle system capable of high-temperature coating is arranged between the heating platform and the three-dimensional motion mechanism and is toward the heating platform, and the infusion pump is communicated with the integrative ultrasonic spray nozzle system which is glidingly connected with the three-dimensional motion mechanism. Utilizing an integrative ultrasonic spray nozzle, the coating device solves the problems of high ultrasonic frequency, uneven gas spray and complex organization existing in the traditional ultrasonic spray mode. Utilizing a peripheral cooling gas nozzle, the coating device solves the problem that the integrative ultrasonic spray nozzle is usually used in low temperature and realizes high-temperature film formation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

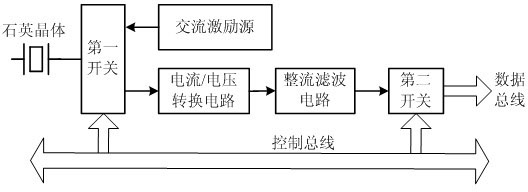

Non-contact electrical resistance tomography data acquisition device and method

InactiveCN102323302AOvercoming electrode polarizationOvercome CorrosivityMaterial resistanceElectrical resistance and conductanceData acquisition

The invention discloses a non-contact electrical resistance tomography data acquisition device and a method. The device comprises a sensor, a data acquisition module, and an image reconstruction computer; the sensor is connected to the data acquisition module; and the data acquisition module is connected to the image reconstruction computer. The sensor comprises an insulating pipeline, rectangular metal electrodes, phase-sensitive demodulation modules, and a direct digital frequency synthesizer module. The metal electrodes are mounted at the periphery of the insulating pipeline with an equal interval; respective phase-sensitive demodulation module is fixed on each metal electrode; the phase-sensitive demodulation modules are parallelly connected by arranging wires and are connected to thedirect digital frequency synthesizer module; all the phase-sensitive demodulation modules are connected to the data acquisition module by arranging wires. The device of the invention effectively overcomes the problems of electrode polarization and chemical corrosion of contact electrical resistance tomography (ERT), and has the advantages of simple structure, non contact, strong adaptability, andthe like. The invention provides beneficial reference for the non-contact electrical resistance tomography of two-phase fluid.

Owner:ZHEJIANG UNIV

Method for processing scheelite concentrate through sulfuric acid to prepare tungstate solution

InactiveCN105925823AEase of mass productionEasy to produceProcess efficiency improvementTungsten compoundsTungstateSlag

The invention discloses a preparation method of tungstate solution. The preparation method is characterized by comprising the following steps: a traditional hydrochloric acid decomposition process is discarded to prevent bad Cl- corrosion and the HCl volatilization problem; sulfuric acid is adopted to treat scheelite, so that WO3 and Ca are separated in a precipitation form; the scheelite is transformed to obtain transformed filtrate and a transformed material; after the transformed filtrate is replenished with the sulfuric acid, the transformed filtrate is returned into the scheelite transformation process; the transformed material is dissolved out, and is mixed with a common accessory easy to get for reaction under normal temperature or high temperature and normal pressure or high pressure; a liquid phase generated in the dissolving process is comprehensively used in a no-pollutant discharge manner; and a solid phase is separated and washed to obtain dissolved slag and tungstate solution. The method prepares the tungstate solution by treating the scheelite with sulfuric acid, and is high in resolution ratio, low in energy consumption, free of pollution, low in cost, convenient for operation and environmentally friendly.

Owner:江钨高技术开发应用有限公司 +1

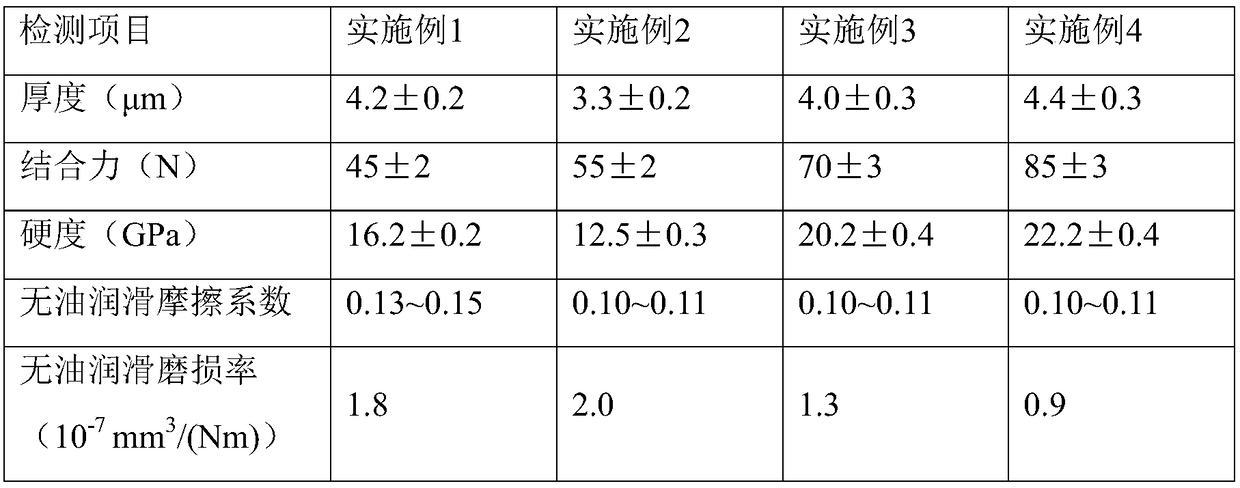

Surface anti-impact abrasion-resisting lubricating composite coating for hydraulic valve rod and preparation method thereof

ActiveCN109023362AExtended service lifeIt has the treatment effect of impact resistance, wear resistance and lubrication integrationVacuum evaporation coatingSputtering coatingFriction reductionComposite function

The invention discloses a surface anti-impact abrasion-resisting lubricating composite coating for a hydraulic valve rod. The coating is composed of a gradient transition layer, a composite multifunctional layer and an amorphous carbon top layer which are sequentially arranged on the surface of a substrate in a stacked mode front bottom to top, and the total thickness is controlled to be 3.0-5.0 microns. The invention further provides a preparation method of the composite coating, the gradient transition layer is prepared through the magnetron sputtering technology or the arc ion plating technology, the composite multifunctional layer is prepared through the magnetron sputtering technology, and the amorphous carbon top layer is prepared through the magnetron sputtering technology or the plasma chemical vapor deposition technology. The surface hardness of the surface anti-impact abrasion-resisting lubricating composite coating for the hydraulic valve rod is larger than or equal to 12 GPa, the friction coefficient is lower than 0.15, high hardness, high toughness, abrasion resistance and friction reduction are integrated, the coating can be better applied to severe working conditions, high-reliability and long-life operation of the hydraulic valve rod is achieved, the coating-plating process is simple, and application value is large.

Owner:中国人民解放军空军勤务学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com