Polishing composition capable of improving silicon wafer polishing accuracy and preparation method thereof

A polishing composition and a technology for silicon wafers, which are applied to polishing compositions containing abrasives and other directions, can solve the problems of low surface precision and corrosion of silicon wafers, and achieve the effects of high flatness, fast polishing rate and high surface precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

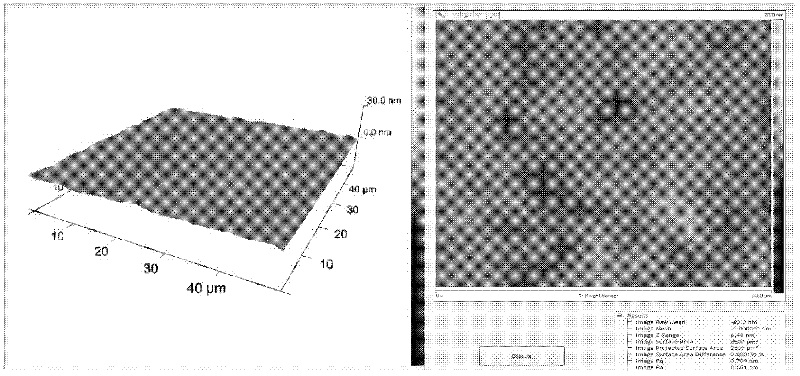

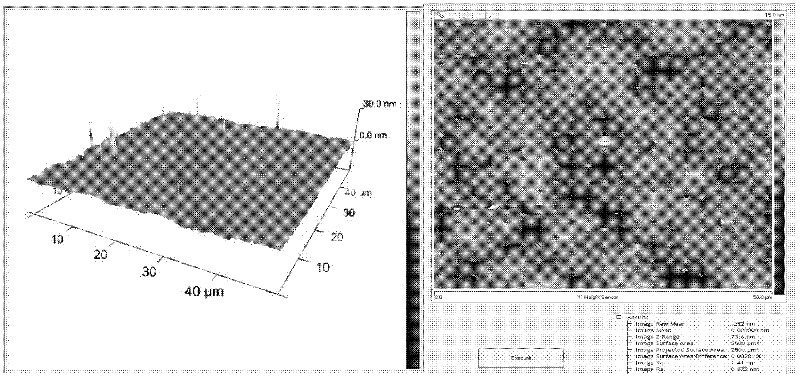

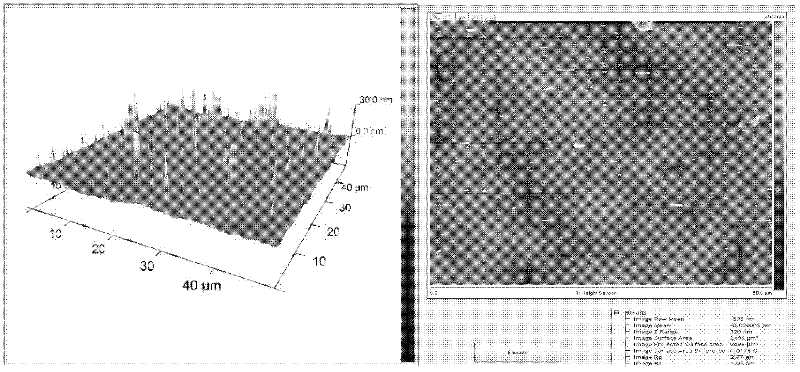

Image

Examples

Embodiment 1~7

[0036] The polishing composition was prepared. According to the specific polishing implementation requirements, 6000g of polishing composition was configured for each example for polishing experiments, as shown in Table 1.

[0037] Among them, the preparation method of the aminated silica sol used in Examples 1 to 3 is as follows: the particle size of the silica sol used in the examples is 40nm, the reaction kettle is heated to 95°C, and KH550 aminosilane is added to couple agent, the mass ratio of colloidal silica to aminosilane coupling agent was 200, and stirred at constant temperature for 3 hours to obtain aminated silica sol.

[0038] The preparation method of the aminated silica sol used in Examples 4 to 6 is as follows: the particle size of the silica sol used in the examples is 25nm, the reaction kettle is heated to 25°C, and A-1110 aminosilane is added to couple agent, the mass ratio of colloidal silica to aminosilane coupling agent is 400, and stirred at constant tem...

Embodiment 7

[0039] The preparation method of the aminated silica sol used in Example 7 is as follows: the particle size of the silica sol used in the example is 75nm, the reaction kettle is heated to 45°C, and A-1120 aminosilane coupling agent is added, The mass ratio of colloidal silica to aminosilane coupling agent was 600, and stirred at constant temperature for 3 hours to obtain aminated silica sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com