Patents

Literature

34results about How to "Avoid toxic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

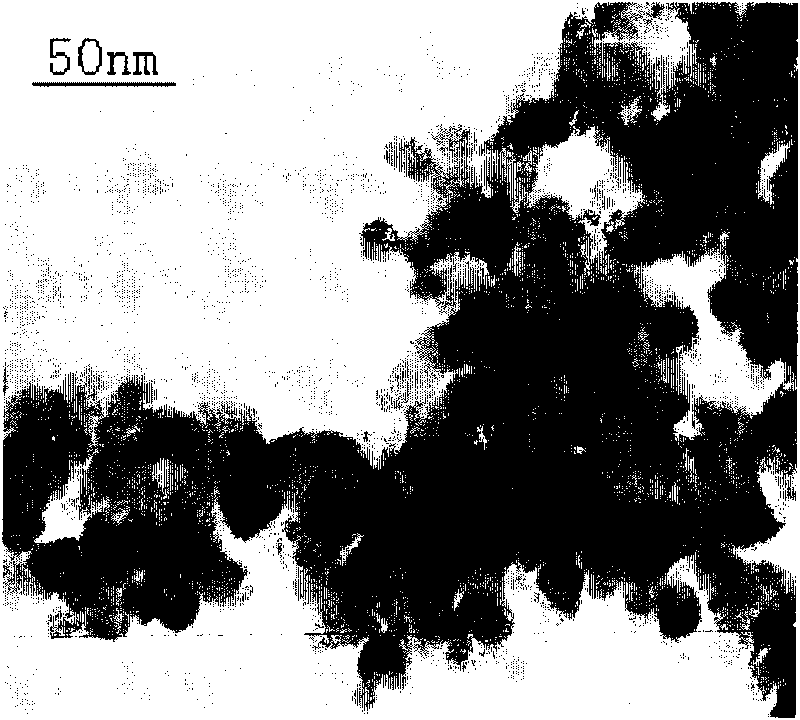

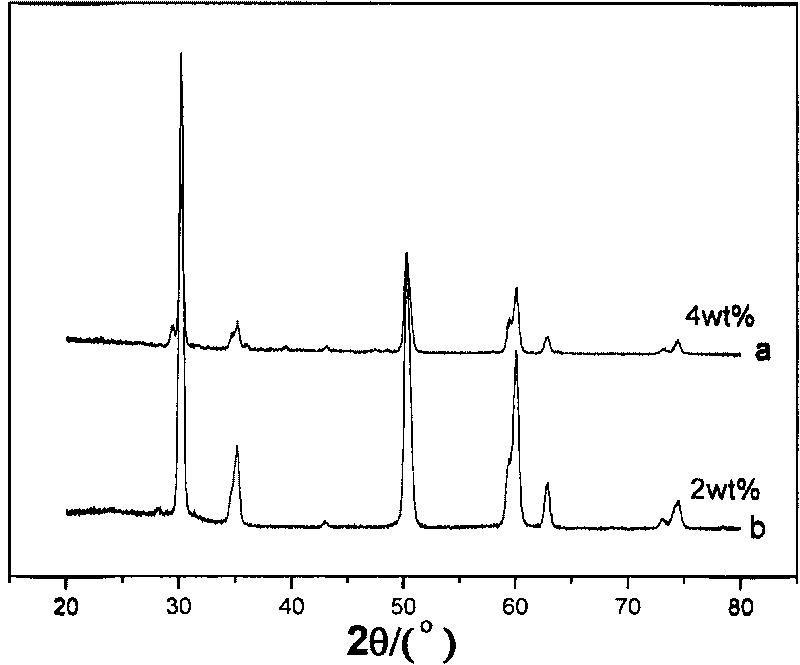

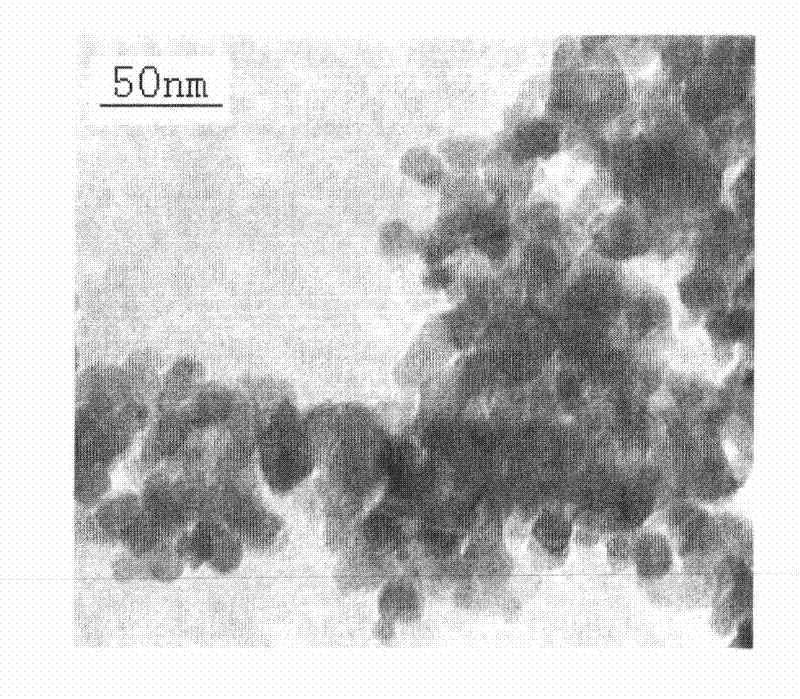

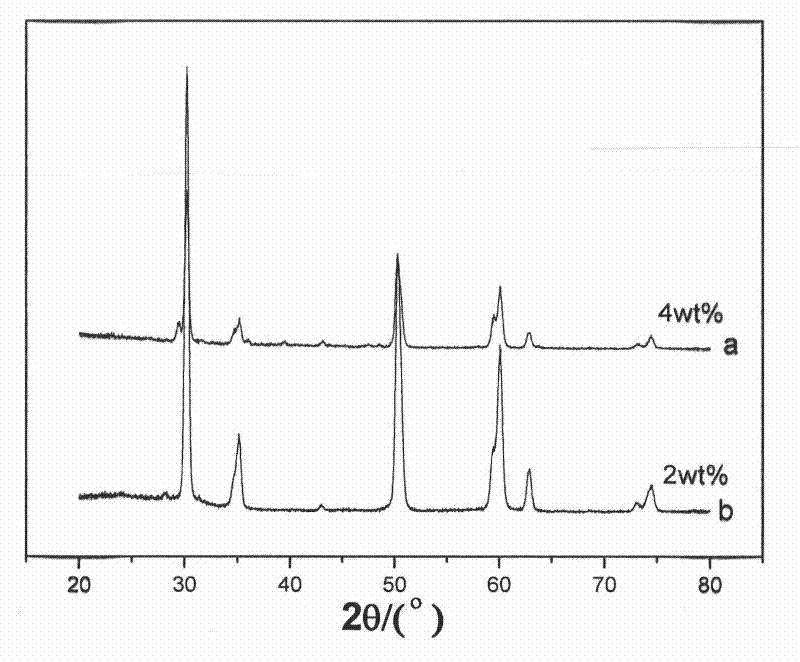

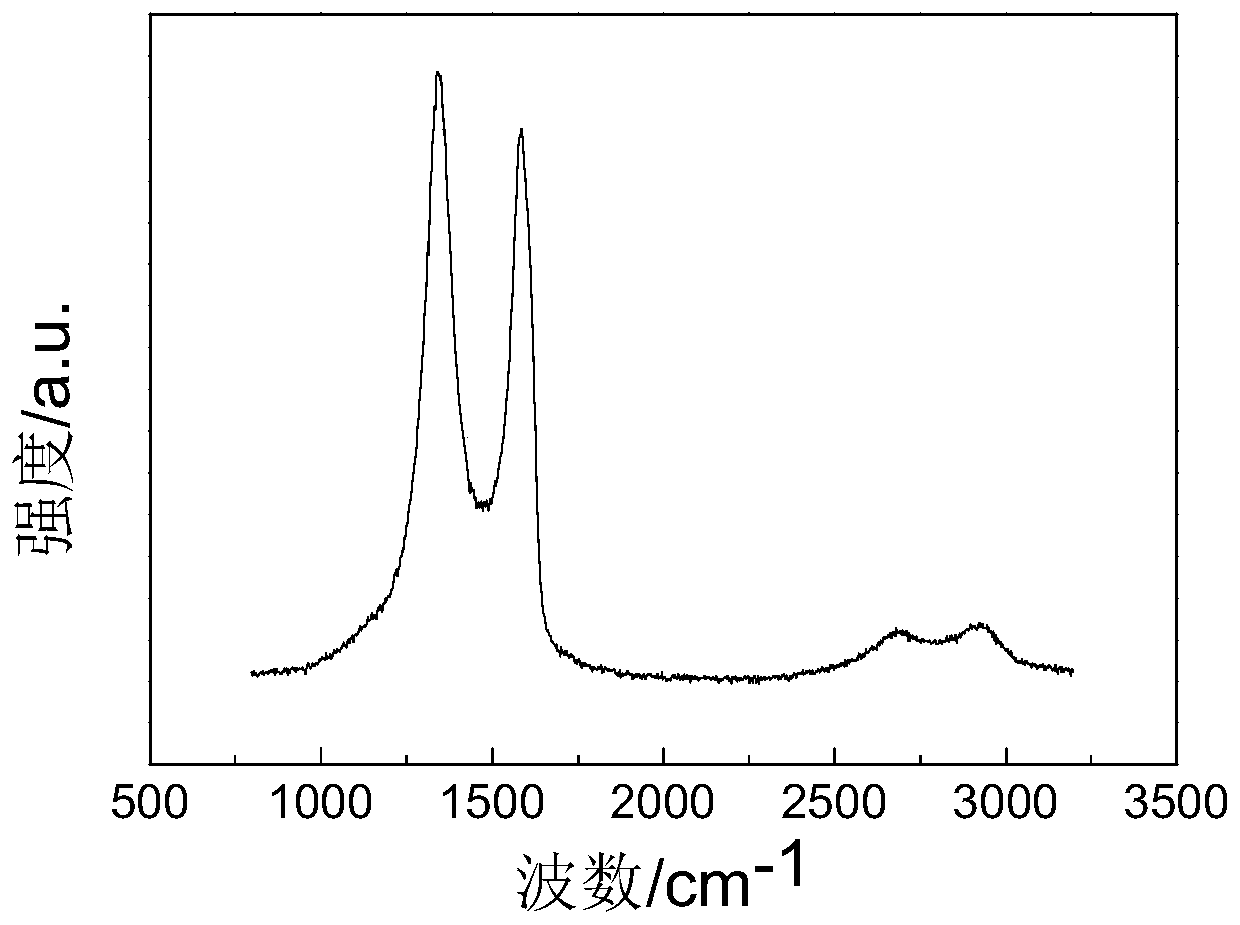

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

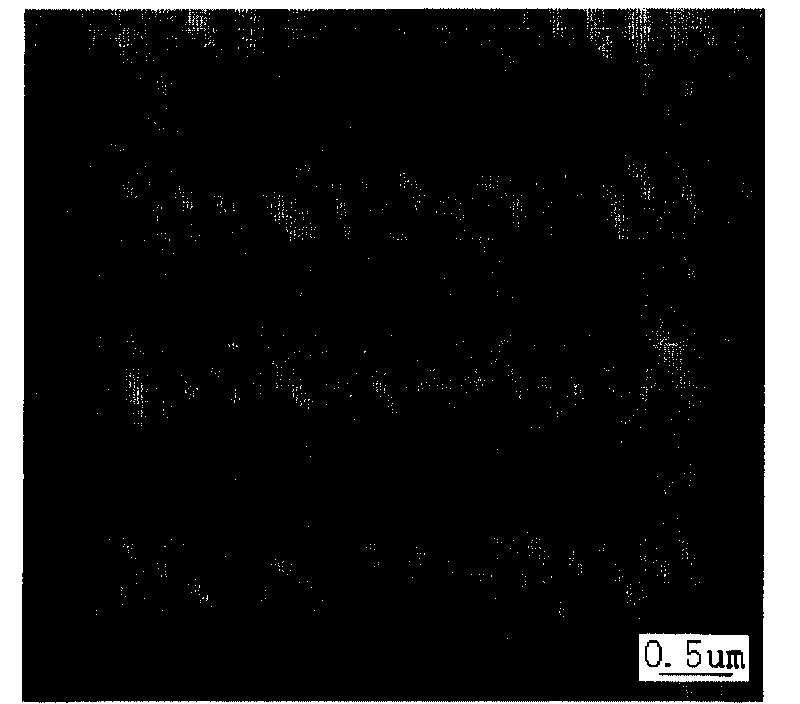

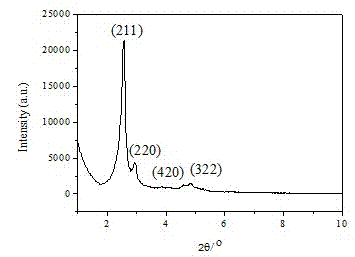

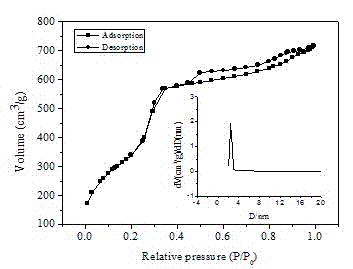

Method for preparing mesoporous molecular sieve

InactiveCN103172080ALower synthesis costAvoid toxicSolid waste disposalCrystalline aluminosilicate zeolitesChemistryMolecular sieve

The invention discloses a method for preparing a mesoporous molecular sieve MCM-48. The method comprises the steps of extracting effective ingredients in coal ash as silicon sources by adopting a single template agent cetyl trimethyl ammonium bromide (CTAB); and synthetizing MCM-48 under alkaline medium by a hydrothermal method. The synthetized mesoporous material is regular in ducts, single in aperture distribution, high in order degree, and large in specific surface area. The method is simple and feasible in actual operation, economic and environment-friendly, and can provide a new path for 'recycling' utilization of the coal ash; and the synthetized sample has practical application value.

Owner:NANJING UNIV OF SCI & TECH

High-efficiency environment-friendly nickel stripper and preparation method thereof

The invention discloses a high-efficiency environment-friendly nickel stripper and a preparation method thereof, which solve the problems of low stripping speed and high stripping temperature of a nickel layer and hostile operating environment. Based on 100 parts by weight, the high-efficiency environment-friendly nickel stripper comprises the following substances: 5.19 to 12.82 parts of ethanediamine, 5.19 to 12.82 parts of sodium metanitrobenzene sulfonate, 0.74 to 1.71 parts of citric acid, 1.48 to 2.56 parts of an organic amine additive and 70.09 to 87.40 parts of pure water. The invention also discloses the preparation method of the high-efficiency environment-friendly nickel stripper. According to the high-efficiency environment-friendly nickel stripper and the preparation method thereof, quick stripping of the nickel layer is promoted; in particular, after the organic amine additive is used, the stripping speed of the nickel layer is greatly increased, the stripping temperature is reduced, and a great deal of smoke generated during stripping is reduced.

Owner:英洛华科技股份有限公司

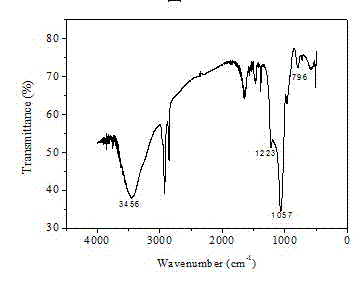

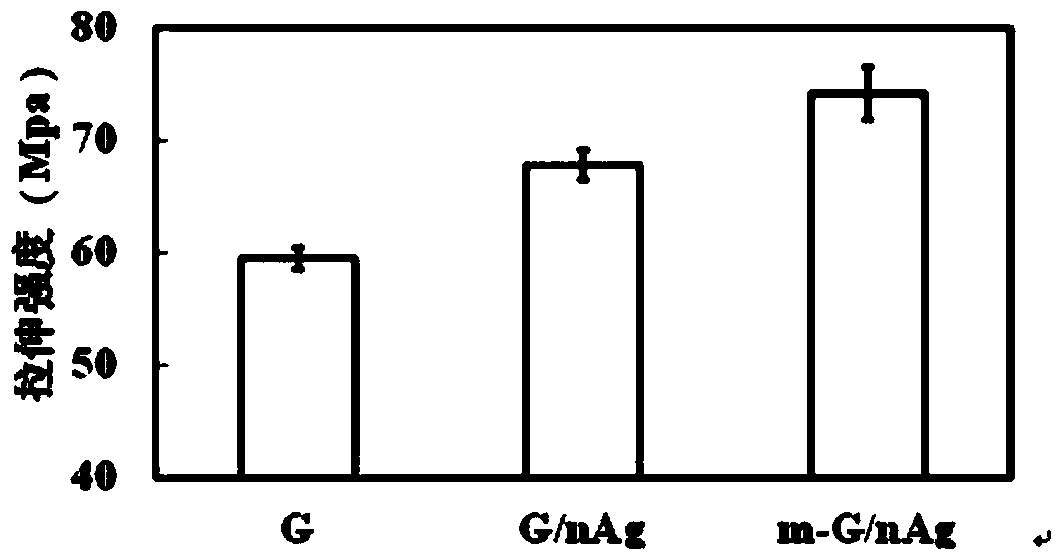

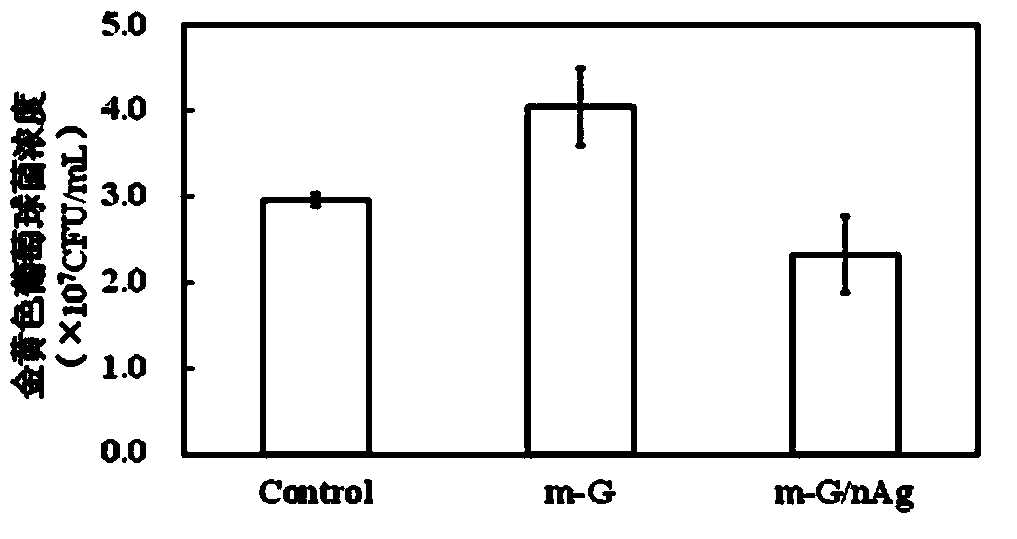

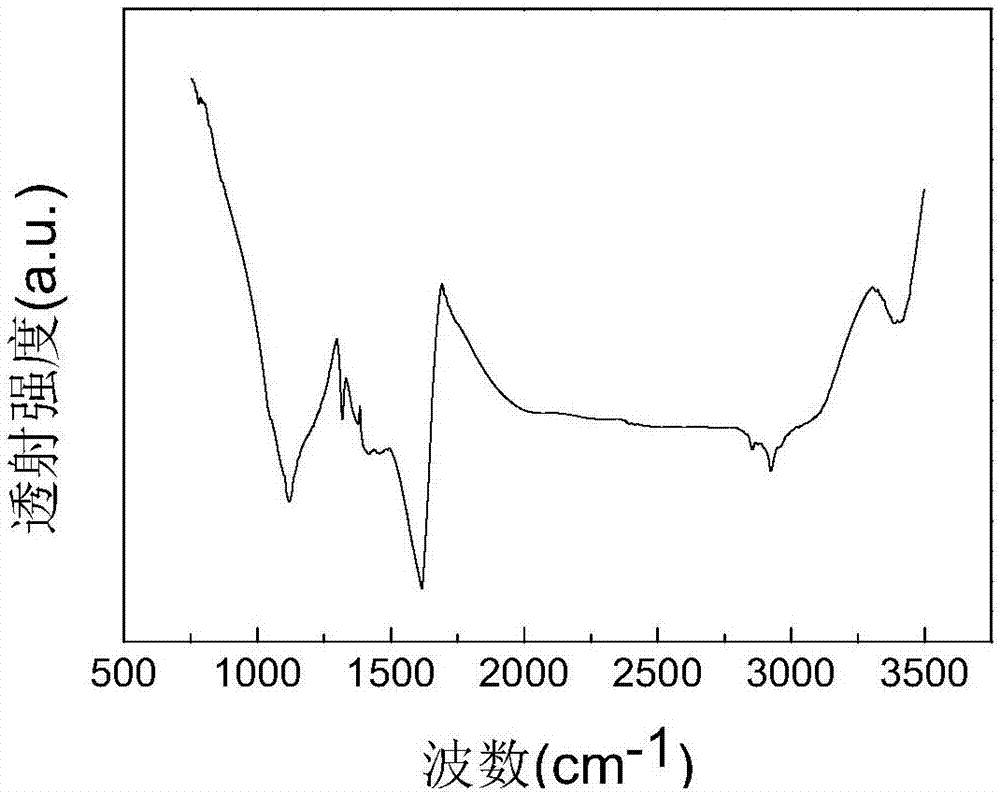

Gelatin/nano silver composite material decorated by microbial transglutaminase as well as preparation method and application thereof

InactiveCN103360613AImprove mechanical propertiesImprove stabilityAbsorbent padsProsthesisNon toxicityBiocompatibility Testing

The invention belongs to the field of biological materials and interdiscipline of polymer chemistry and biochemistry and discloses a gelatin / nano silver composite material decorated by microbial transglutaminase and a preparation method and an application thereof. The gelatin / nano silver composite material decorated by microbial transglutaminase is prepared by utilizing a gelatin / nano silver composite material as main material and utilizing the microbial transglutaminase as a modifier, the material has good biocompatibility, non-toxicity and strong antibacterial activity, the mechanical properties and water stability of the material are good, and meanwhile, the material is simple in preparation process, mild in reaction conditions, easy to control and low in production cost, thereby having good application prospect and very extensive usage in biomedical materials and biomedicine field, such as antibacterial and biodegradable skin dressing capable of reducing infection and inflammation and protecting wound, wound healing agent and artificial skin, and the like.

Owner:WUHAN UNIV OF TECH

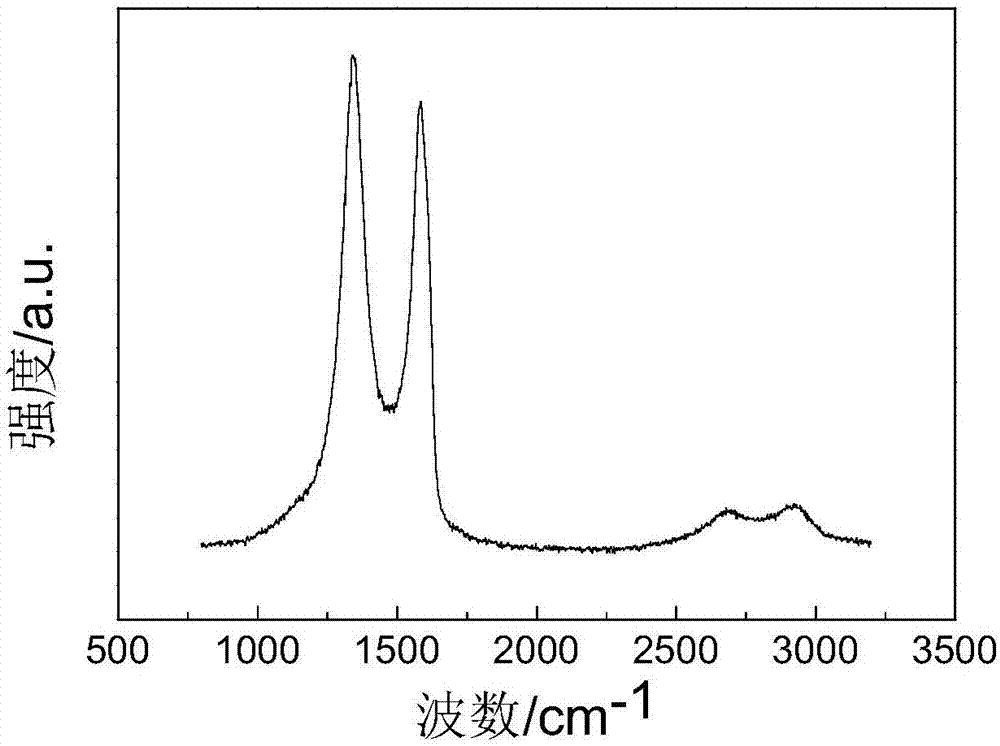

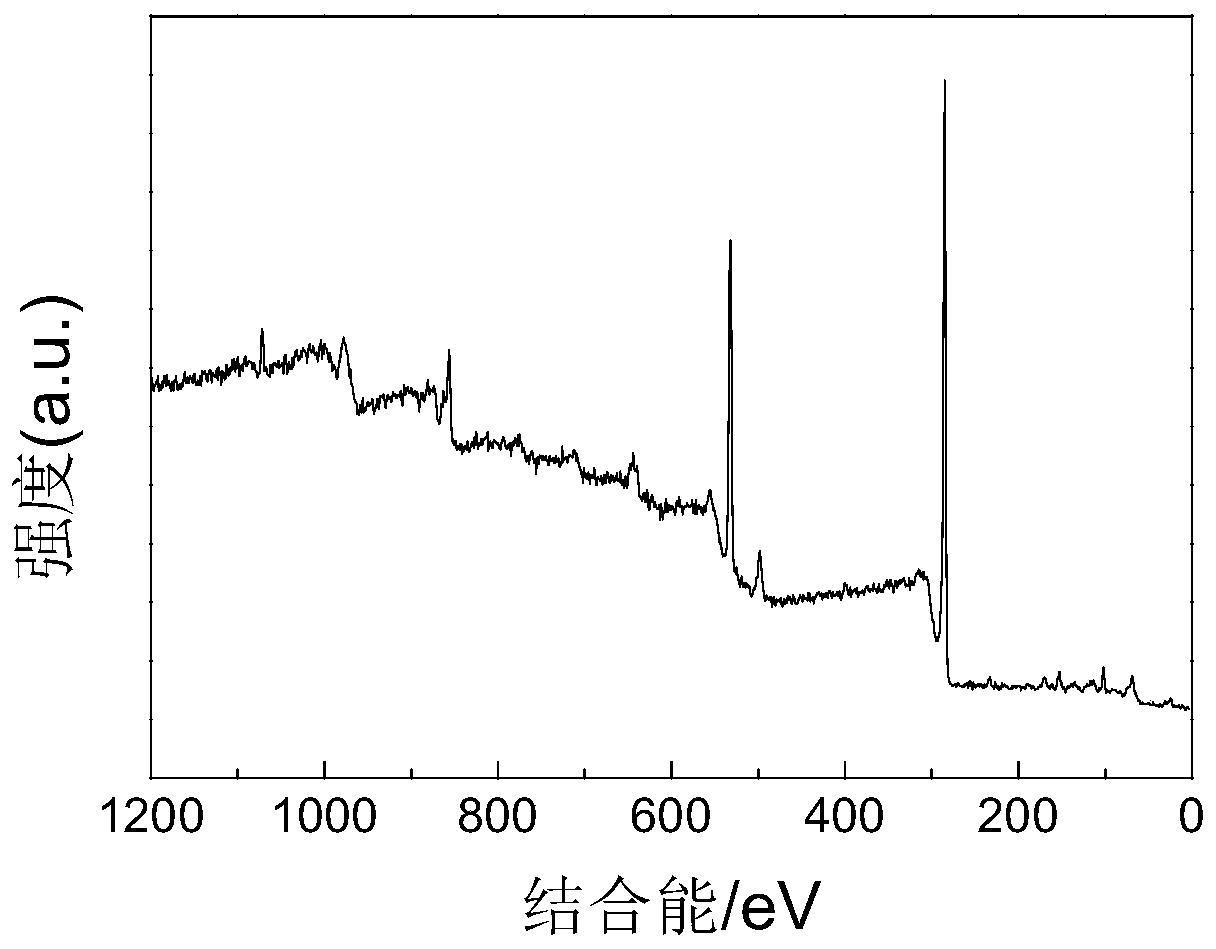

Preparation method of graphene nickel foam electrode

ActiveCN107967998ASave raw materialsEasy to operateHybrid capacitor electrodesCell electrodesCvd grapheneGraphene electrode

The invention relates to a preparation method and application of a graphene nickel foam electrode. The preparation method comprises the steps of cleaning and drying nickel foam as a working electrode,carrying out scanning in a graphene oxide dispersion liquid by using a cyclic voltammetry to prepare a graphene oxide nickel foam electrode; and drying and then carrying out constant-potential reduction in a glycine-hydrochloric acid buffer solution to obtain the graphene nickel foam electrode. Compared with the preparation methods of other graphene electrodes, the preparation method of the graphene nickel foam electrode has the advantages of being cheap in raw materials, free of pollution, green and environment-friendly, and mass production is facilitated. The graphene nickel foam electrodesupported through the nickel foam has good capacitive performance in a neutral electrolyte and can be applied to the field of energy storage.

Owner:NORTHEASTERN UNIV

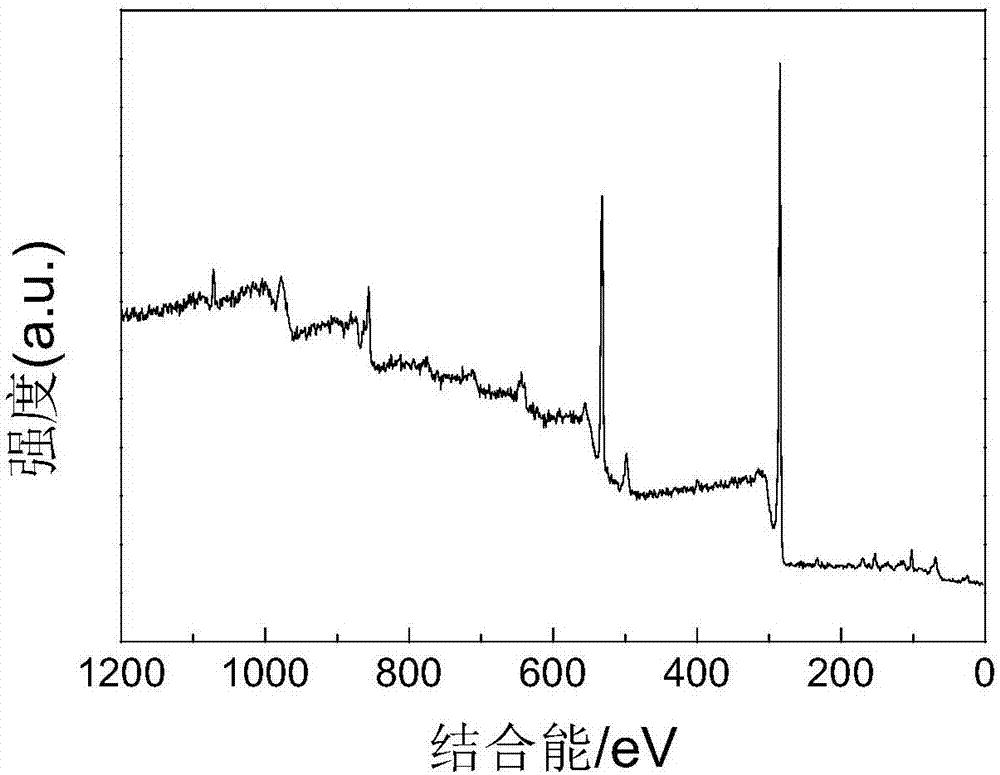

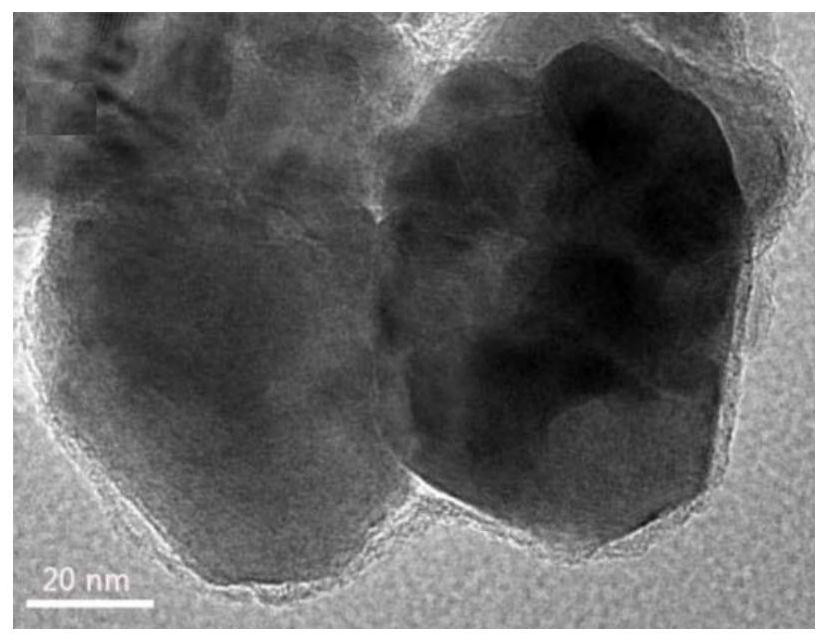

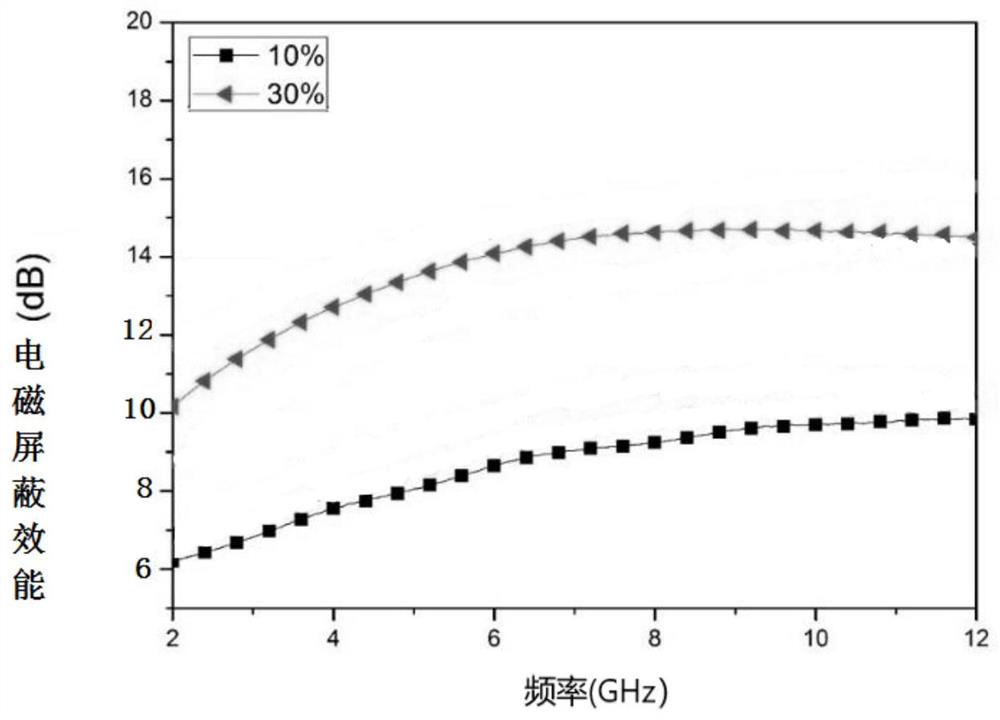

Two-dimensional graphene-coated copper composite material with core-shell structure and preparation method and application thereof

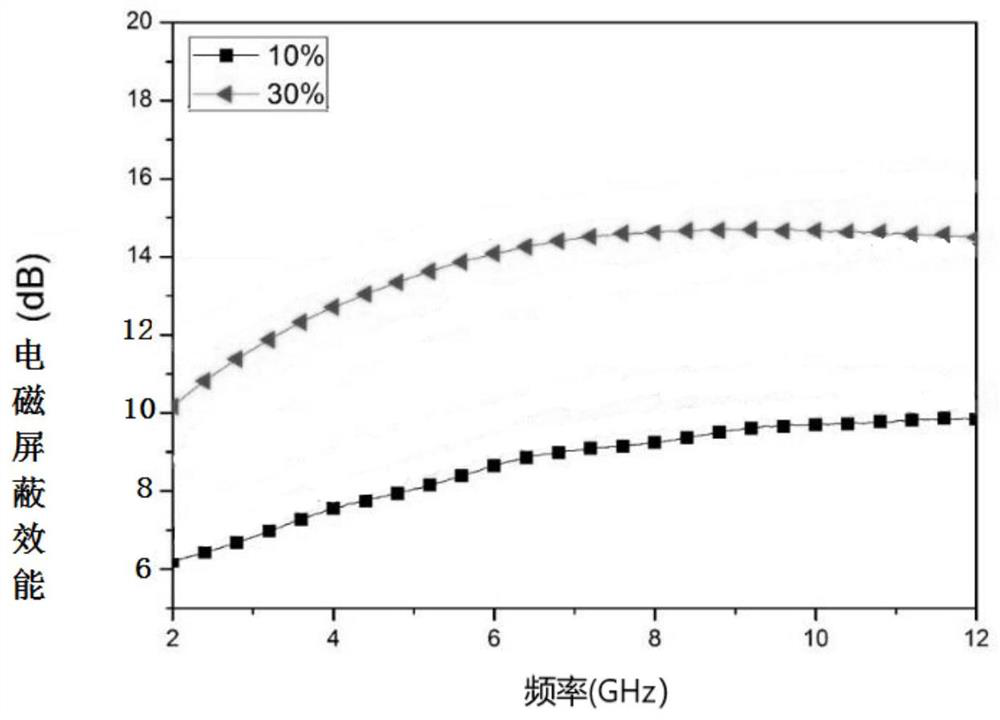

ActiveCN111757657APrevent oxidationGuaranteed catalytic effectMagnetic/electric field screeningMetal particleNano copper

The invention discloses a two-dimensional graphene-coated copper composite material with a core-shell structure and a preparation method and application thereof. The structure of the graphene-coated copper composite material is a core-shell structure formed by coating nano-copper particles with outer-layer graphene, the graphene-coated copper composite material is constructed through an electrostatic adsorption self-assembly method, after graphene is coated with copper, copper particles can be prevented from being oxidized, the intrinsic catalytic capacity and conductivity of the composite material are guaranteed, expansion / compression of metal particles can be controlled, the synergistic effect between the two materials is promoted, and therefore the integrity of the composite material isremarkably improved. The two-dimensional graphene coated copper composite material with the core-shell structure has excellent electromagnetic shielding performances.

Owner:TIANJIN UNIV

Organic paint removing agent, preparation method and application in removing paint layer at surface of special equipment

The invention discloses an organic paint removing agent and a preparation method. The paint removing agent is prepared by dichloromethane, formic acid, phenol, Span 80, lauryl sodium sulfate, organic glass powder and a surface modifying agent in percentage by weight. The preparation method comprises the following steps: mixing the dichloromethane and the formic acid; after the phenol is heated to 45-55 DEG C till being melted, adding mixing liquid; then adding the Span 80 and the lauryl sodium sulfate into the mixed liquid to stir; adding the organic glass powder and dissolving the organic glass powder to the mixed liquid; adding the surface modifying agent into one second of mixed liquid and then heating the mixture to 35-65 DEG C together till the mixture is completely melted; then adding one second of residual mixed liquid. The organic paint removing agent has the characteristics of low poison, no corrosion, rapid paint removal and less environmental pollution and can be widely applied to remove the paint layer at the surface of special equipment.

Owner:NANJING BOILER & PRESSURE VESSEL SUPERVISION & INSPECTION INST

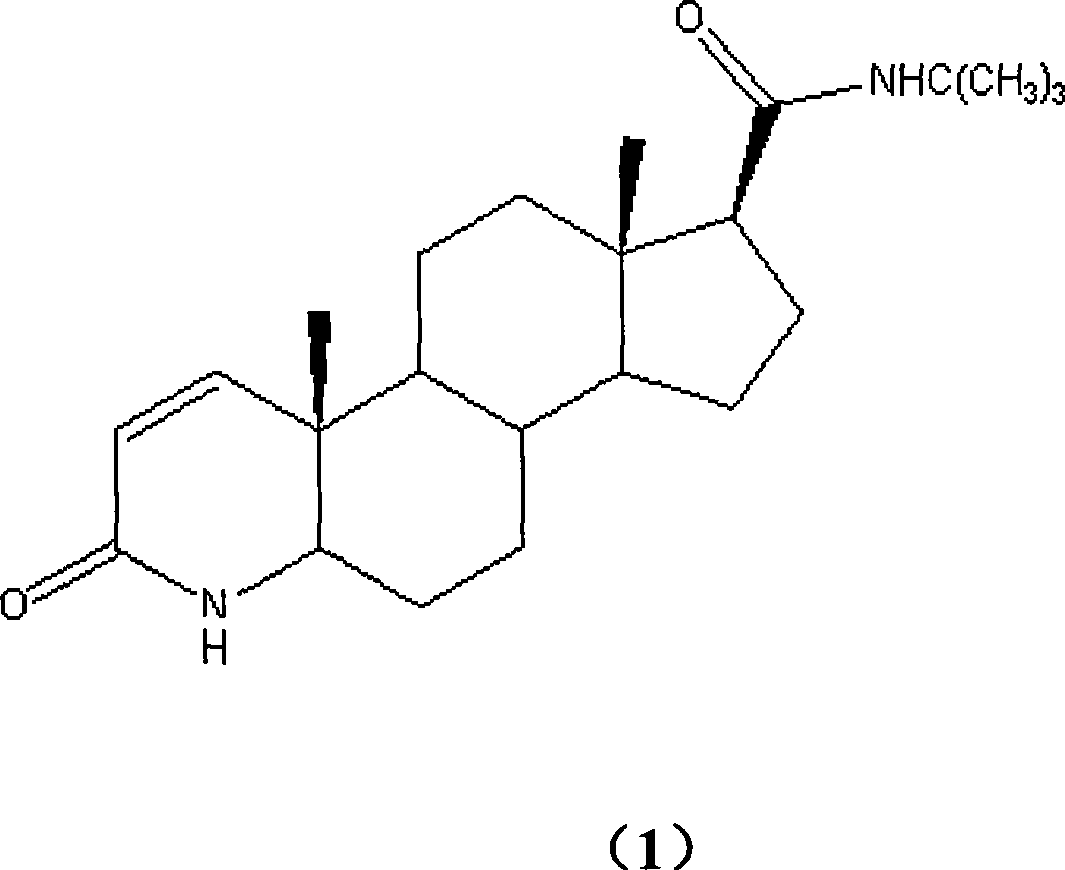

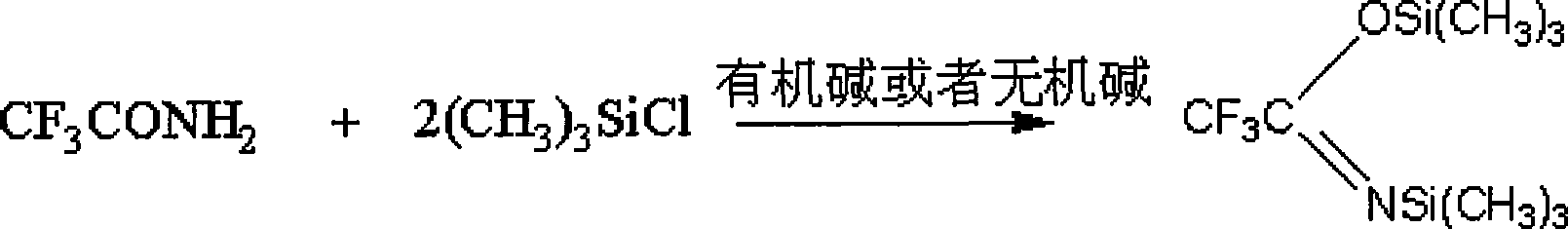

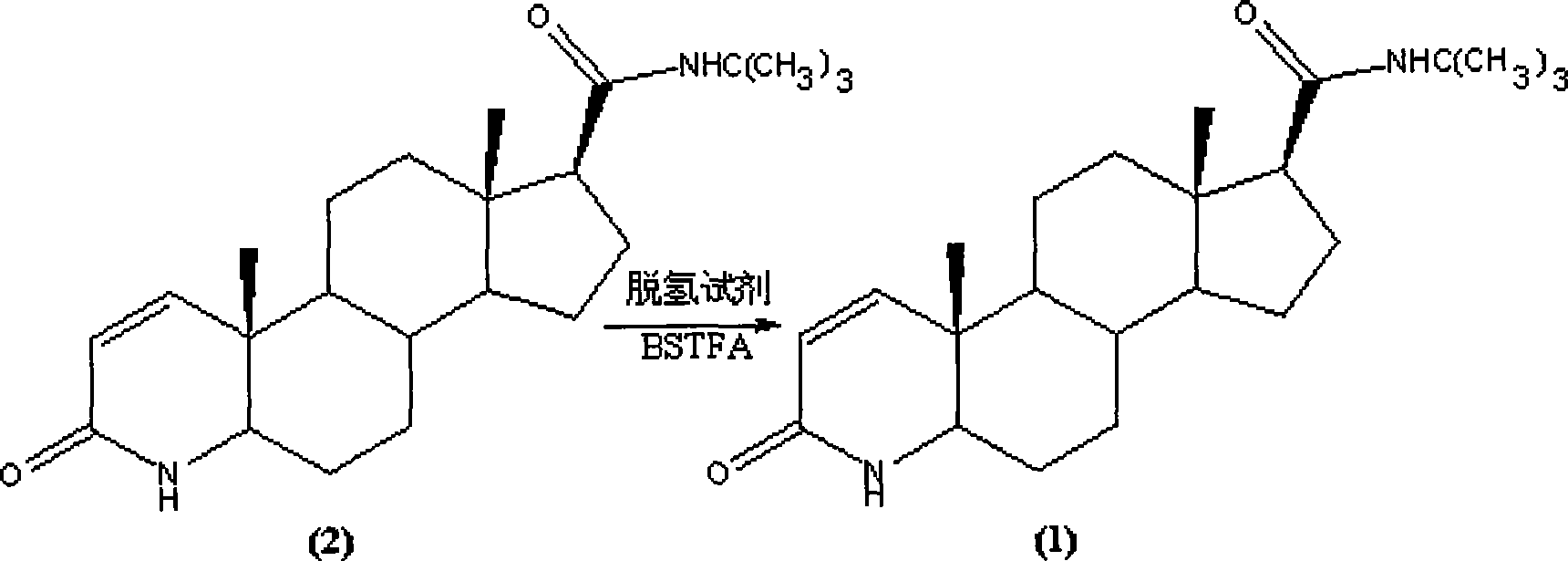

Method for synthesizing finasteride

InactiveCN101418033AAvoid purification difficultiesAvoid Yield ProblemsSteroidsUrinary disorderTrimethylsilyl chlorideDehydrogenation

The invention provides a method for synthesizing finasteride. The method comprises the following steps: (1) dissolving trifluoroacetamide in solvent, reacting the solvent with trimethylchlorosilane in the presence of organic alkali or inorganic alkali, filtering out solid from reaction products, and collecting filtrate; and (2) dissolving the filtrate obtained in step (1) in the solvent, adding 3-carbonyl-4-aza-5 alpha-androstane-17 belta-tert-butylformamide and dehydrogenation agent into the solvent for reaction, and collecting target products from reaction products. The method has the advantages that the method has higher yield, high selectivity, and is simple and safe; after simple purification, the purity of the finasteride can reach more than 99 percent; moreover, the method has easily obtained reagents used in the whole reaction, simultaneously having high reaction yield and mild reaction conditions, reclaiming the solvent and facilitating the industrialized production.

Owner:湖南玉新药业有限公司

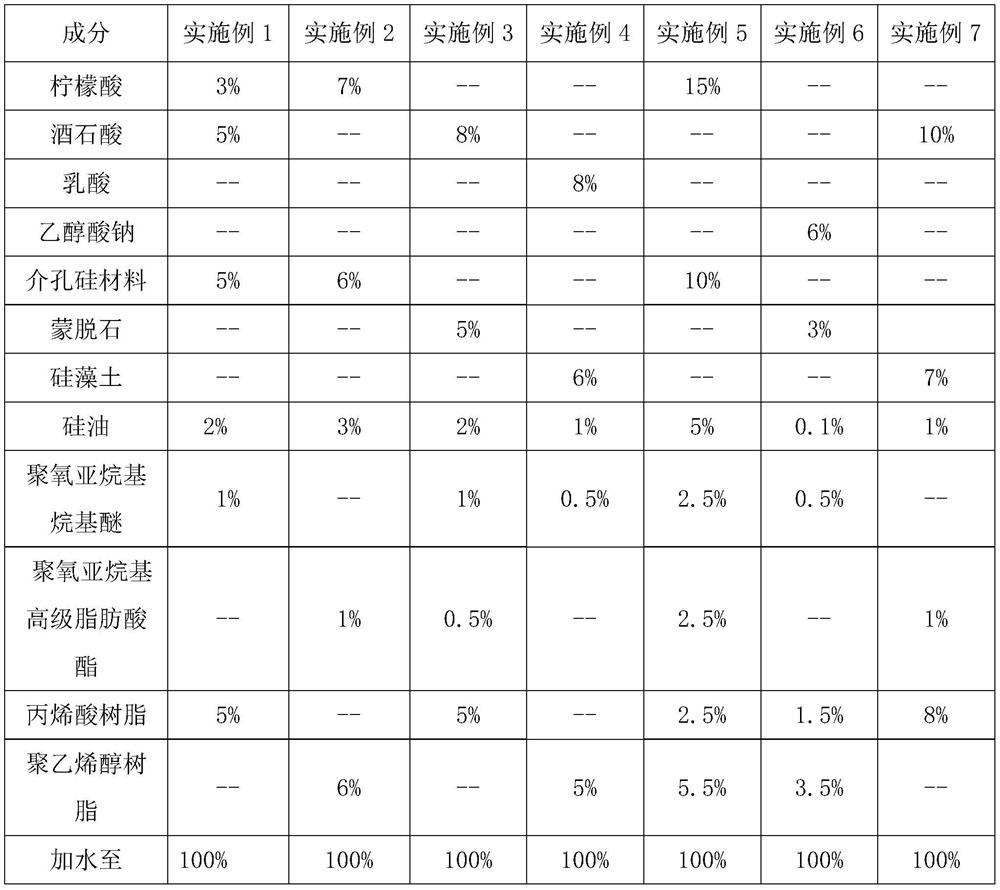

Air filter screen, preparation method and application thereof

ActiveCN112191024AInhibit sheddingFacilitated releaseFiltration separationAir quality improvementAir filtrationActive agent

The embodiment of the invention relates to an air filter screen, a filter material attached antibacterial composition. The antibacterial composition is prepared from the following components by mass:1-15 parts of an antibacterial agent, 1-10 parts of a porous carrier, 0.1-5 parts of a stabilizer, 0.5-5 parts of a surfactant and 1-15 parts of an adhesive; wherein the antibacterial composition is added into the filter material according to an addition amount of 2-70g / m<2>. The air filter screen has the effects of resisting bacteria, mildew and viruses and reducing peculiar smell.

Owner:SHUNDE APOLLO AIR CLEANER

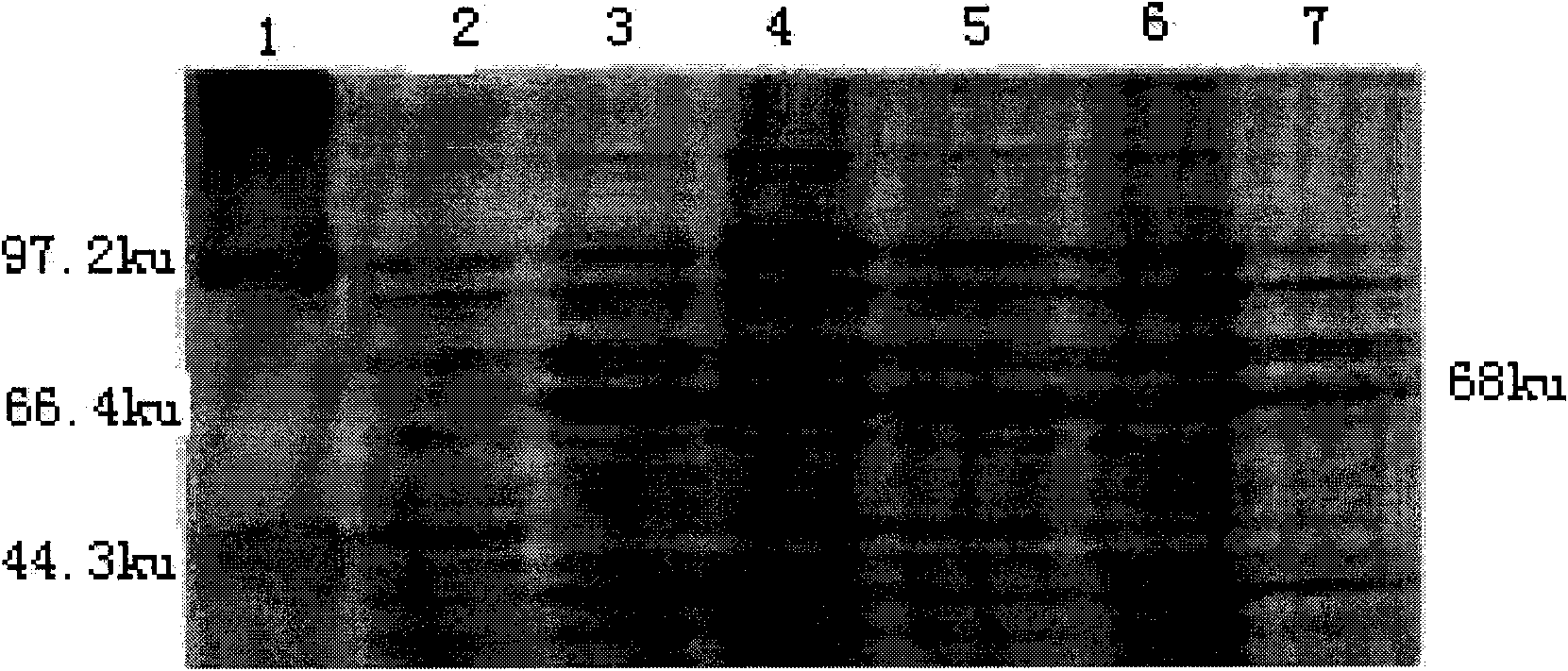

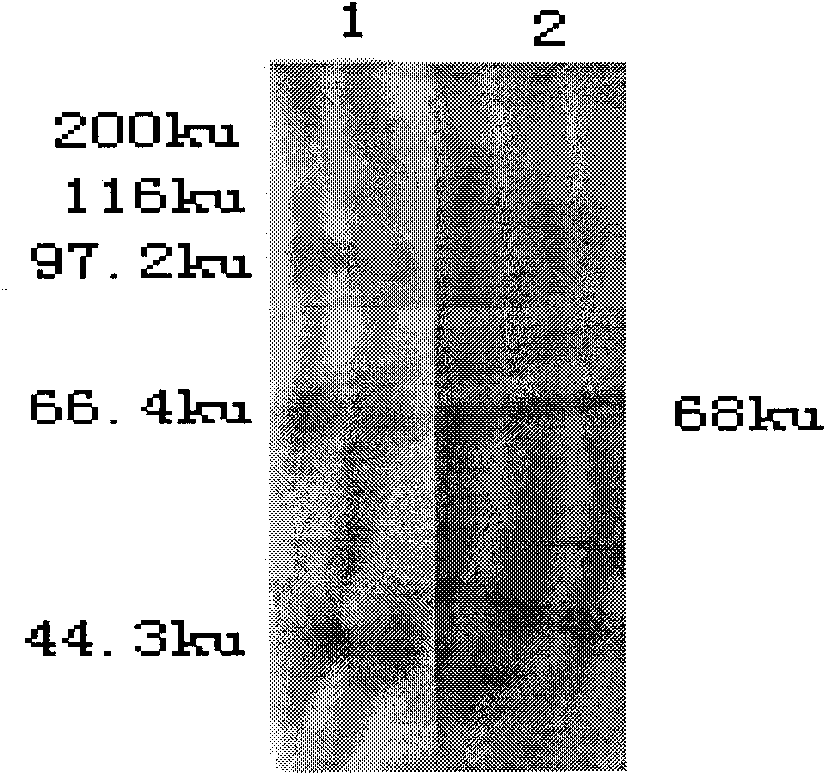

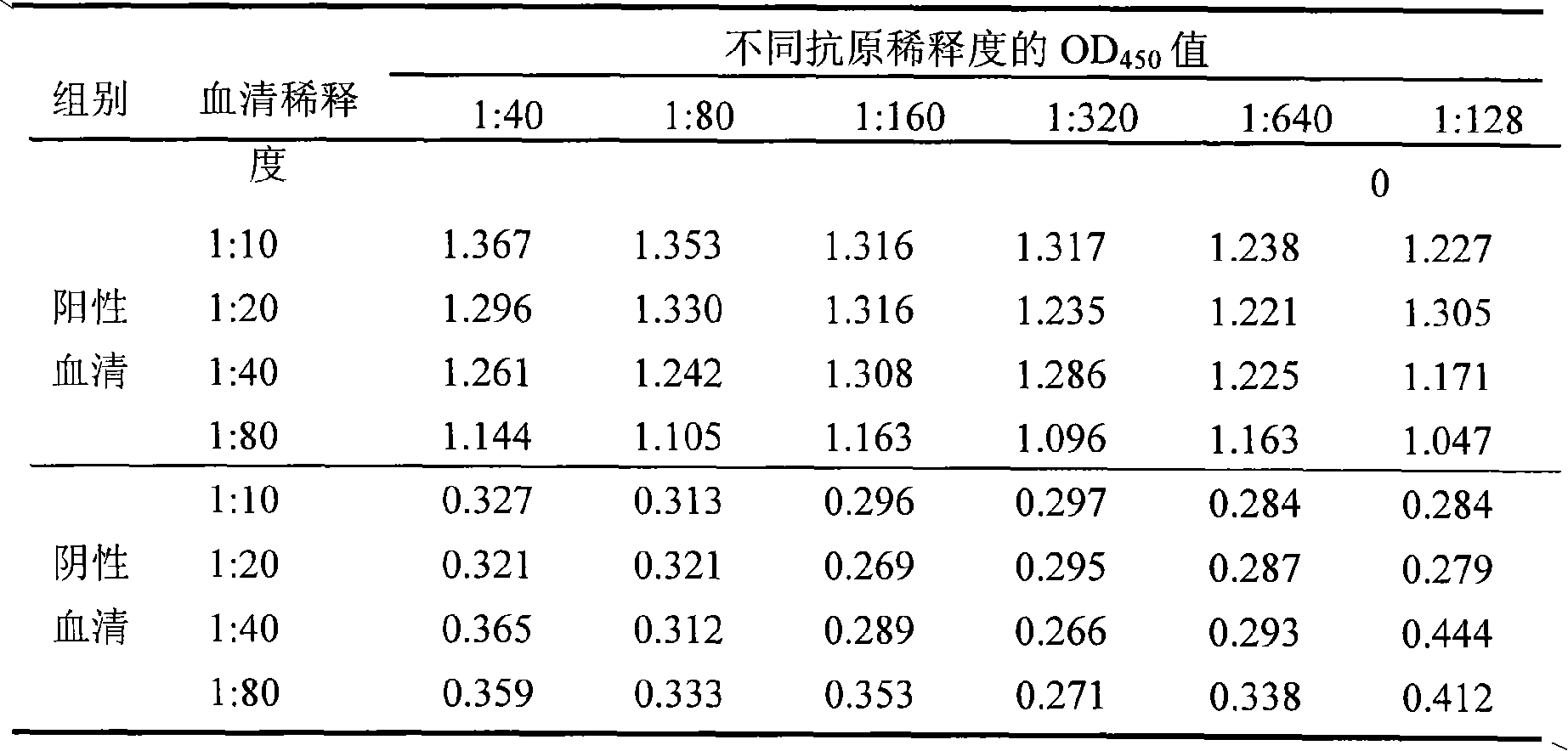

Kit used for detecting bovine abortus Chlamydia psittaci antibody and preparation method thereof

InactiveCN101581723AQuick checkAvoid toxicPreparing sample for investigationMicroorganism based processesChlamydia psittaci antigenElisa kit

The invention discloses an ELISA kit used for detecting a bovine abortus Chlamydia psittaci antibody and a preparation method thereof. The ELISA kit comprises a horizontally coated abortus Chlamydia psittaci, an ELIAS plate longitudinally coated with rabbit anti-bovine IgG-HRP as a second antibody, a washing liquid, a confining liquid, a substrate buffer solution A, a substrate buffer solution B and a stop solution, wherein the coated abortus Chlamydia psittaci antigen is abortus Chlamydia psittaci outer membrane protein OmpA, especially the recombinant protein of the abortus Chlamydia psittaci outer membrane protein OmpA.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

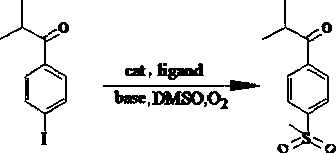

Preparation method of Firocoxib intermediate

ActiveCN107778204AAvoid harmEnvironmental protection of productionOrganic chemistryOrganic compound preparationChemical synthesisKetone

The invention discloses a preparation method of a Firocoxib intermediate. The preparation method belongs to the technical field of chemical synthesis. The preparation method comprises the steps: adding isobutyryl-containing aryl halide, a catalyst, a ligand and thin alkali into an organic solvent at an air or oxygen atmosphere, raising the temperature to carry out a reaction for 10-20h, and then,carrying out aftertreatment to prepare 2-methyl-1-[4-(methylsulfonyl)phenyl]propane-1-ketone. According to the preparation method, isobutyryl-containing aryl halide is used as a reaction raw material,so that a high-yield target product can be obtained; in addition, compound raw materials such as thioether or sulfoxide capable of generating great environmental hazards are avoided from being adopted, so that the production is environment-friendly, meanwhile, few reaction steps are required, few side reactions are generated, and the purity and yield of a product are high.

Owner:YANGZHOU TIANHE PHARM CO LTD

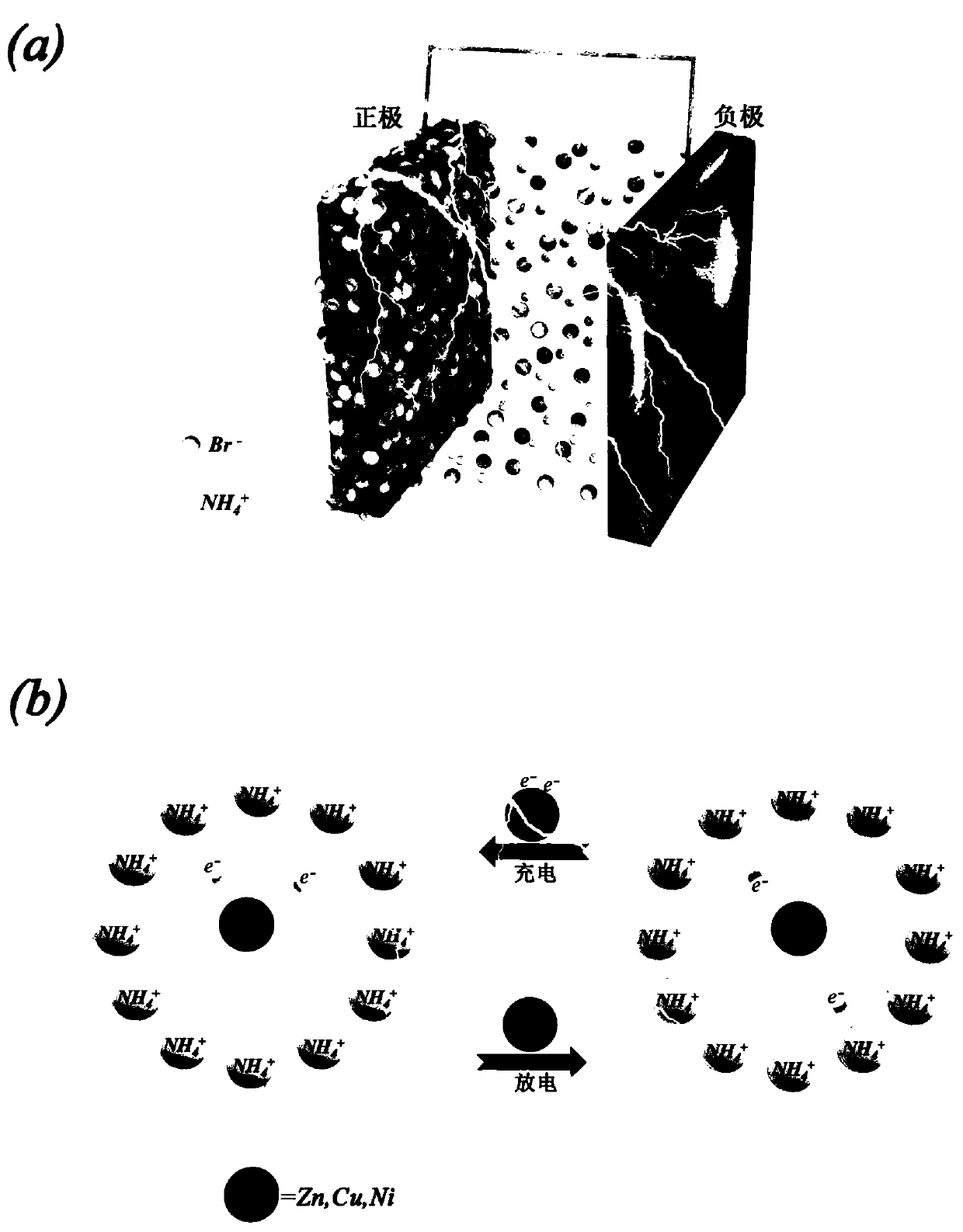

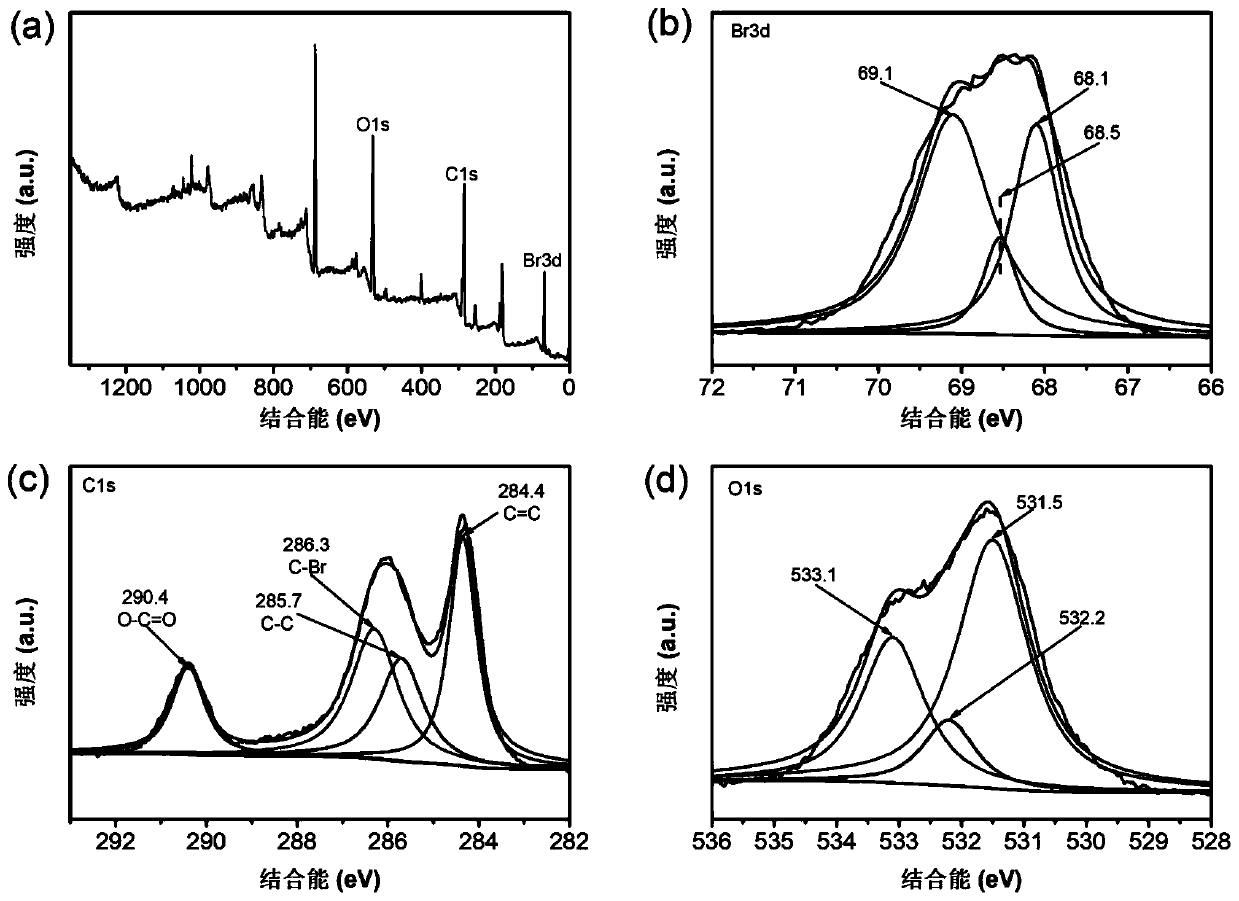

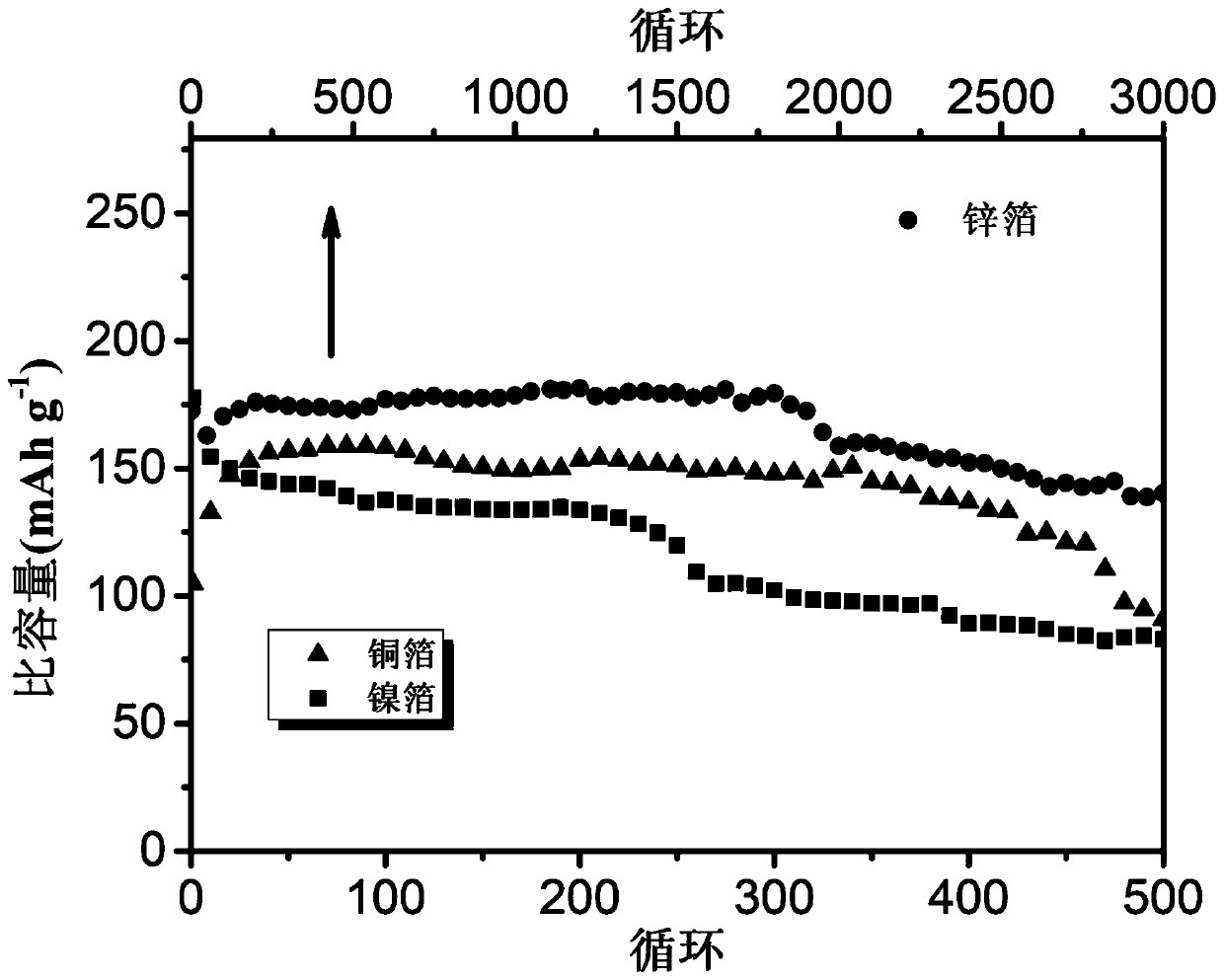

Bromine ion battery

ActiveCN110957467AImprove securityLow costNon-aqueous electrolyte accumulatorsNegative electrodesElectrolytic agentPhysical chemistry

The invention provides a bromine ion battery, and belongs to the field of batteries. According to the battery, carbon black is adopted as an intercalation material of bromide ions, ammonium bromide with the concentration of 1-2 mol / L in an ethylene glycol non-aqueous system is adopted as an electrolyte, three coordination metals of zinc, copper or nickel are adopted as the negative electrode material of the bromide ion battery, and a soft package battery is assembled. According to the invention, the bromide ion battery is provided based on the intercalation principle of bromide ions in a carbon material, the bromide ions avoid the defects of toxicity, volatility and the like of elemental bromine, and the safety of the battery is improved. Meanwhile, the carbon black is low in price, so that the cost of the bromine ion battery is reduced, and large-scale popularization is facilitated. The ethylene glycol ammonium bromide electrolyte of a non-aqueous system avoids hydrogen evolution andoxygen evolution reaction, so that the bromine ion battery is stable in circulation, and the characteristic of high theoretical specific capacity of bromine ions is fully exerted. The zinc, the copperand the nickel are used as the negative electrode materials of the bromine ion battery, so that the theoretical basis is provided for the negative electrode research of the non-metal ion battery while the battery cost is reduced.

Owner:DALIAN UNIV OF TECH

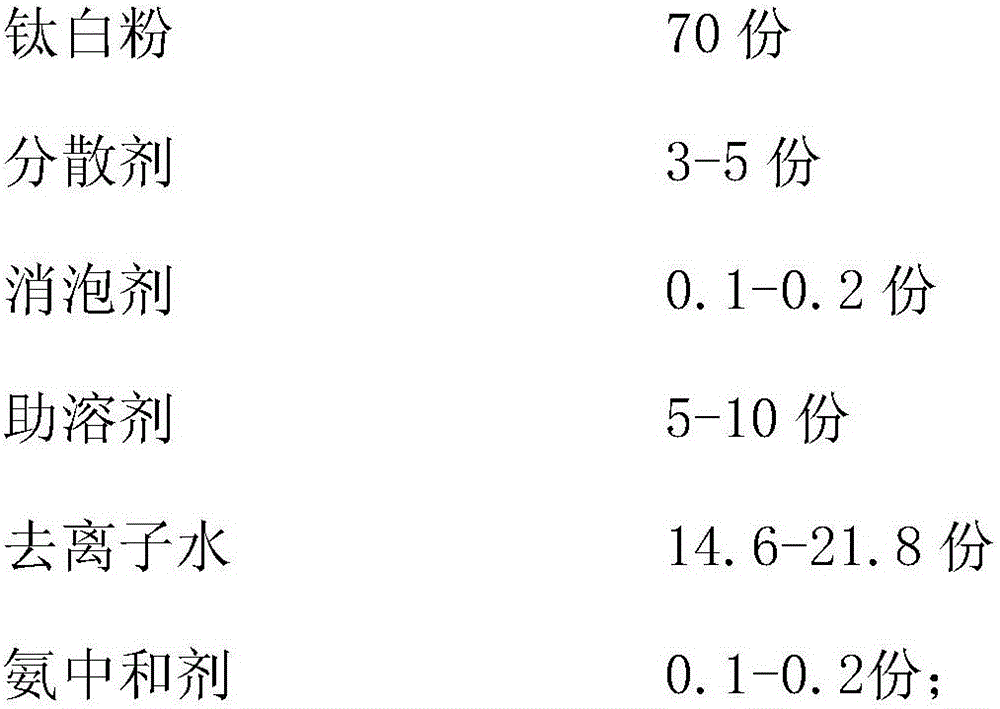

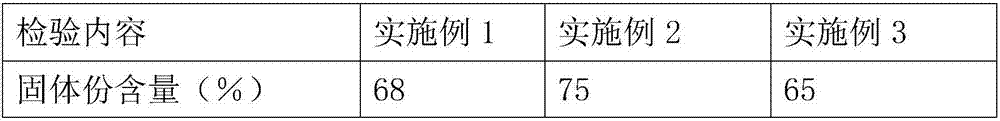

Safety helmet protection paint and preparation method thereof

The invention discloses safety helmet protection paint and a preparation method thereof, and relates to the technical field of paint. The safety helmet protection paint is prepared from waterborne saturated polyester resin, ammonia neutralizers, white emulsion adhesives, beewax, defoaming agents, thickening agents, petroleum coke powder, waterborne white paste and deionized water, wherein the thickening agents comprise, by weight, hydroxymethyl fibers, bentonite, apatite, sea-foam stone powder and corn starch. The preparation method includes the steps: 1) adding 24-25 parts of waterborne saturated polyester resin into a container, stirring the waterborne saturated polyester resin by a high-speed disperser and gradually dripping the ammonia neutralizers while stirring; 2) completely grinding solid raw materials, adding all the solid raw materials into the container, and sufficiently mixing and emulsifying the solid raw materials; 3) adding the waterborne white paste and the white emulsion adhesives into the container, finally, adding the deionized water, continuing dispersion for 10-15 minutes and enabling a test pH (potential of hydrogen) value to range from 7.5 to 8.5 to obtain the paint. The paint is environmentally friendly, safe, free from pollution, high in hardness, not easy to scratch, convenient to produce and long in service life.

Owner:阜南县邰氏宇崴运动器材有限公司

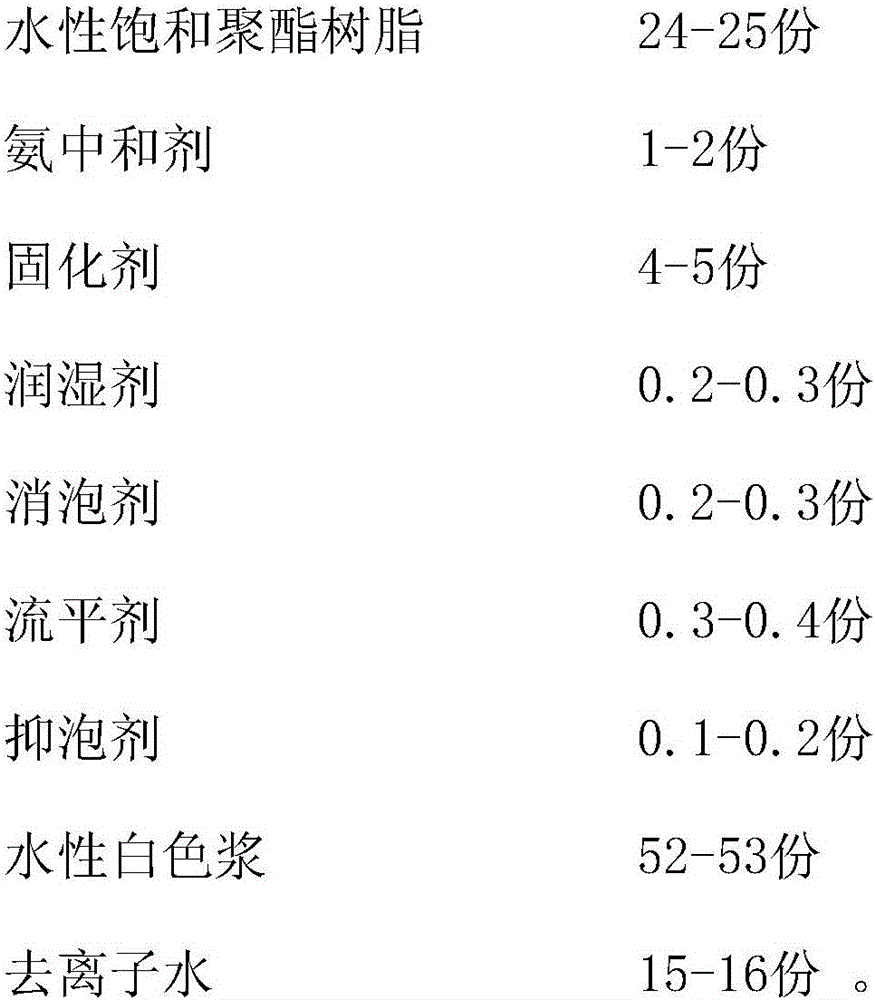

Water-based coating for sports equipment and preparation method thereof

The invention discloses a water-based coating for sports equipment. The water-based coating is prepared from the following components in parts by weight: 24-25 parts of water-based saturated polyester resin, 1-2 parts of ammonia neutralizing agent, 4-5 parts of curing agent, 0.2-0.3 part of wetting agent, 0.2-0.3 part of antifoaming agent, 0.3-0.4 part of leveling agent, 0.1-0.2 part of foam inhibitor, 52-53 parts of water-based white paste and 15-16 parts of deionized water. The water-based coating is environment-friendly, economical and durable; and a paint film has the advantages of high hardness, good flexibility, impact resistance, ultraviolet resistance and the like. The invention also provides a preparation method of the water-based coating for sports equipment.

Owner:广州产协高分子有限公司

Method for producing biological fertilizer by using marijuana degumming waste liquid

InactiveCN107056431AAvoid toxicBioloigcal waste fertilisersLayered/coated fertilisersChemical treatmentLiquid waste

The invention provides a method for producing biological fertilizer by using marijuana degumming waste liquid. The method comprises the following steps: (1) adding the marijuana degumming waste liquid and starch which serve as indicators into a reaction container, and under an alkaline condition, dropwise adding an iodine-potassium iodide solution, and stopping adding the iodine-potassium iodide solution till reaction liquid turns into light blue; (2) adding activated carbon for adsorption, standing for 30 to 60 minutes, performing filtering, thus obtaining filtrate A, adding glucan for stirring for 1 to 2 hours, performing filtering, and removing filter residues, thus obtaining filtrate B; (3) adding the filtrate B into a fermentation tank, and then adding a microbial agent for fermentation, thus obtaining biofertilizer stoste; (4) adding beta-cyclodextrin into the biofertilizer stoste, and stirring for 2 to 4 hours, thus obtaining required biological fertilizer. According to the method, harmful substances can be removed from the degumming waste liquid, which is produced by electrochemical-enzymolysis united degumming, through chemical treatment, and gum in the degumming waste liquid is turned into the biological fertilizer easily absorbed by plants through biological fermentation.

Owner:WENZHOU RENHE EDUCATION TECH CO LTD

A method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at low temperature, and belongs to the technical field of high-temperature structural material preparation. Said method uses homogeneous precipitation method to synthesize nanometer coloring agent and co-precipitation method to synthesize nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as colorant. Do not add any sintering aids to the zirconia powder, only add a small amount of coloring agent, and sinter at 1150-1350°C to obtain black zirconia ceramics with excellent performance and bright color. Because the invention adopts the homogeneous precipitation colorant powder, monodisperse nano particles with uniform particle size, narrow size distribution and high purity are obtained, so that the colorant is easy to color. Co-precipitation is used to synthesize zirconia powder to obtain nanoparticles with small particle size, large surface area and high activity, which can reduce the temperature of solid-phase reaction, greatly reduce the sintering temperature, and solve the problem of high-temperature decomposition and volatilization of black colorant oxides. At the same time, the present invention adopts Fe-Co-Ni-Mn as the coloring agent, which avoids the toxic effect of Cr on the human body.

Owner:TSINGHUA UNIV

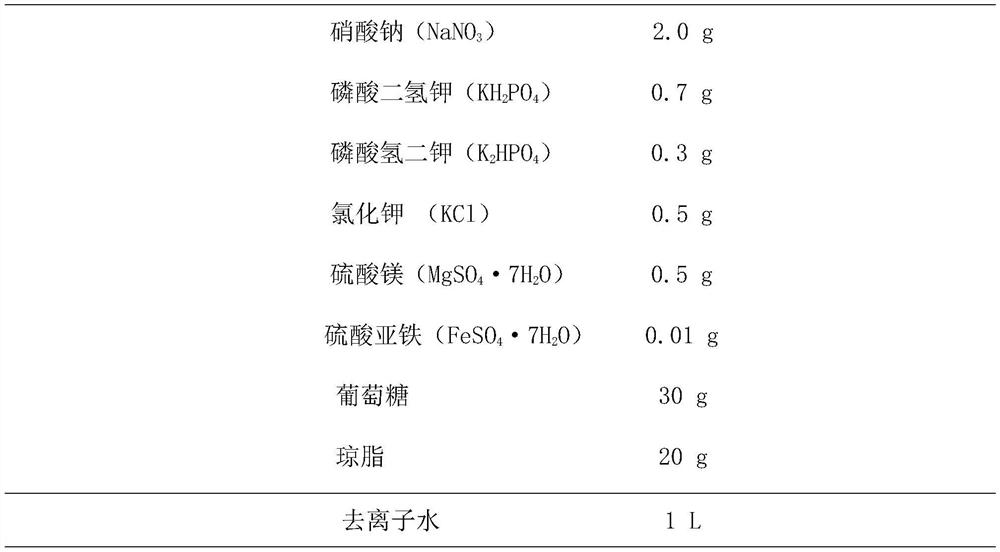

Organic selenium-rich pleurotus eryngii cultivation method

InactiveCN106105770AIncrease profitImprove conversion rateCalcareous fertilisersFungiMicrobiologyBacterial strain

The invention provides a method for cultivating Pleurotus eryngii rich in organic selenium. The method for cultivating Pleurotus eryngii rich in organic selenium comprises: step 1, screening the first-grade strains; step 2, screening the second-grade strains; step 3, screening the third-grade strains; and step 4, screening the selected strains The above-mentioned three-level strains were inoculated into the compost of Pleurotus eryngii for cultivation. The method for cultivating Pleurotus eryngii rich in organic selenium provided by the present invention has put an end to the situation of spraying inorganic selenium on the artificial foliage in the past and externally forcibly increasing the content of selenium element; High utilization rate and conversion rate, strong selenium tolerance and stability; high quality and high yield of cultivated products.

Owner:湖南极硒生物科技有限公司

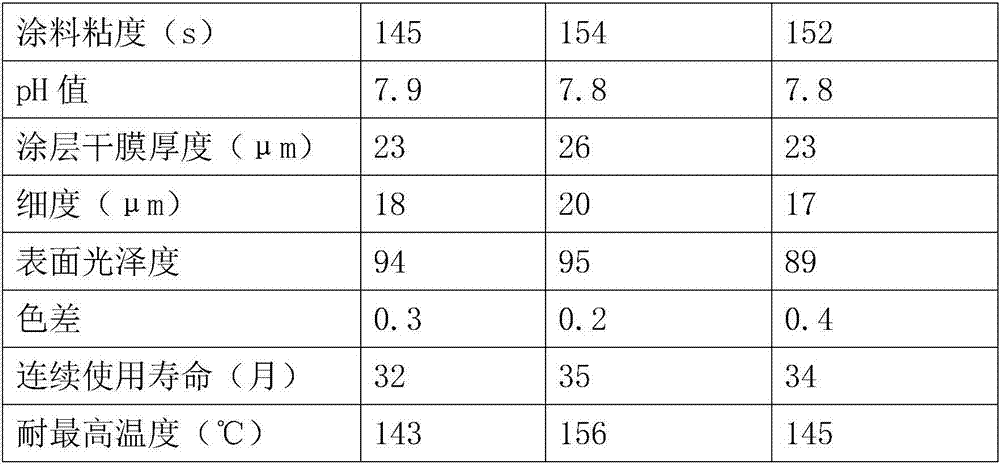

Water pump external layer protection coating and preparation method thereof

InactiveCN107163757AHigh strengthImprove uniformityFireproof paintsMulticolor effect coatingsSodium PyrithioneAcrylic resin

The invention relates to a water pump external layer protection coating and a preparation method thereof, and relates to the technical field of pump productions. The coating is prepared from acrylic resin, mica powder, cupric gold powder, polypropylene adipate, dimethicone, isocyanate, phthalic anhydride, zinc pyrithione, ethyl palmitate, an antioxidant, diethylene glycol butyl ether, a VAE emulsion, white latex, beeswax, an antifoaming agent, a thickener, petroleum coke powder, aqueous stock white and deionized water. The preparation method comprises the following steps: 1, fully mixing all above materials except liquid materials, and stirring and dispersing the mixed materials; 2, milling all solid raw materials, adding all the solid raw materials into a container, adding the above liquids, and fully mixing the solid raw materials with the liquids to carry out emulsifying treatment; 3, cooing a material obtained in step 2 to 50-60 DEG C, and keeping the temperature for 20-30 min; and 4, cooing the stirred material to normal temperature, and continuously grinding the cooled material to form gel. The coating has the advantages of difficulty in scratch, convenience in production, long service life, good resistance to water and a high temperature, and long service life.

Owner:张黎明

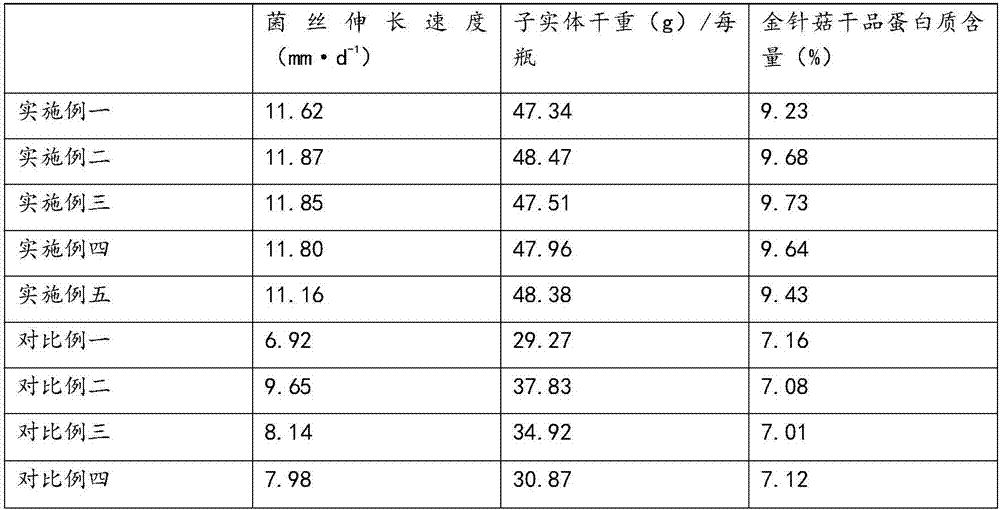

Rare-earth-containing enoki mushroom culture medium and planting method

InactiveCN107473790APromote growthHigh in proteinCalcareous fertilisersBioloigcal waste fertilisersBiotechnologyCorn flour

The invention discloses a rare earth containing enoki mushroom culture medium. According to the technical scheme, the culture medium comprises the raw materials as follows: 20-24 parts of rice bran, 28-30 parts of corn cob, 4-6 parts of corn flour, 4-6 parts of soybean meal, 10-14 parts of bran, 2-4 parts of beet pulp, 3-5 parts of cotton seed hulls, 1 part of calcium carbonate, 0.4-0.6 parts of a trace element supplement and 0.1-0.15 parts of a rare earth accelerator. Quality of enoki mushrooms is improved, and finally, the technical effects of promoting growth of the enoki mushrooms and increase of the protein content synchronously and improving the product competitiveness of production enterprises are achieved.

Owner:天津有茂食用菌开发有限公司

Poplar pencil coating and preparation method thereof

Owner:安徽杰可森木业科技有限公司

Coating process for protective paint of sports equipment

InactiveCN107099224AHigh strengthImprove uniformityStarch coatingsPolyether coatingsWater basedLacquer

The invention provides a coating process for protective paint of sports equipment, and relates to the technical field of paint. The coating process comprises: (1) stirring the protective paint fully, wherein the protective paint is prepared from the following components in parts by weight: 30-40 parts of waterborne saturated polyester resin, 1-2 parts of an ammonium neutralizing agent, 4-5 parts of white latex, 0.2-0.4 part of beeswax, 0.2-0.3 part of a defoaming agent, 0.3-0.4 part of a thickener, 0.1-0.2 part of petroleum coke powder, 40-50 parts of a water-based white paste, and 18-25 parts of deionized water; (2) heating the liquid after stirring to ensure that the temperature of the liquid reaches 20-30 DEG C; (3) spraying the protective paint onto the sports equipment, and controlling the spraying thickness of the protective paint to be 10-100 microns; (4) taking out the sports equipment, and spraying a coagulant solution for 2-5 minutes; (5) performing furnace drying or air drying on the sports equipment after the step (4). The coating process provided by the invention is environment-friendly, safe, and pollution-free, and the protective paint is high in hardness, cannot be scratched easily, is convenient to produce and has a long service life.

Owner:阜南县邰氏宇崴运动器材有限公司

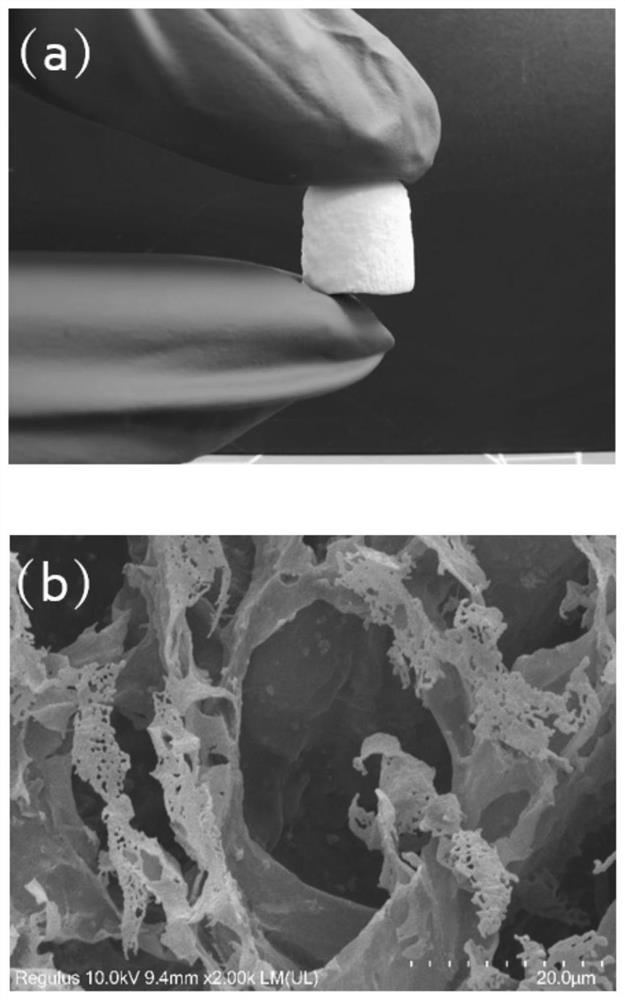

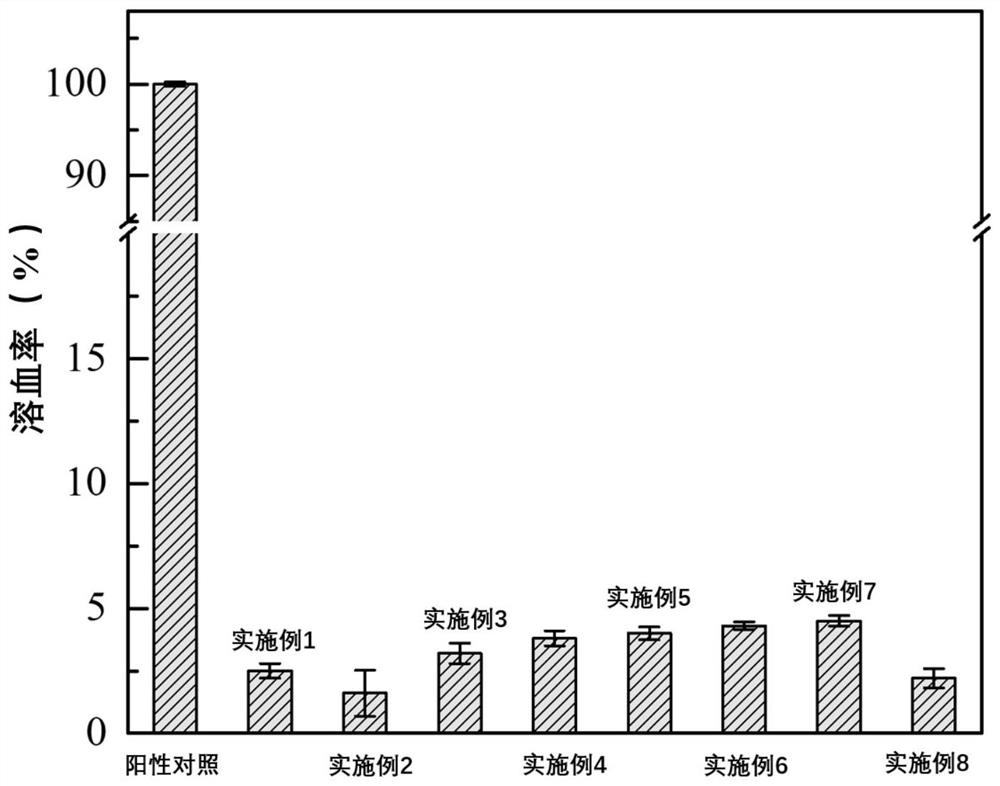

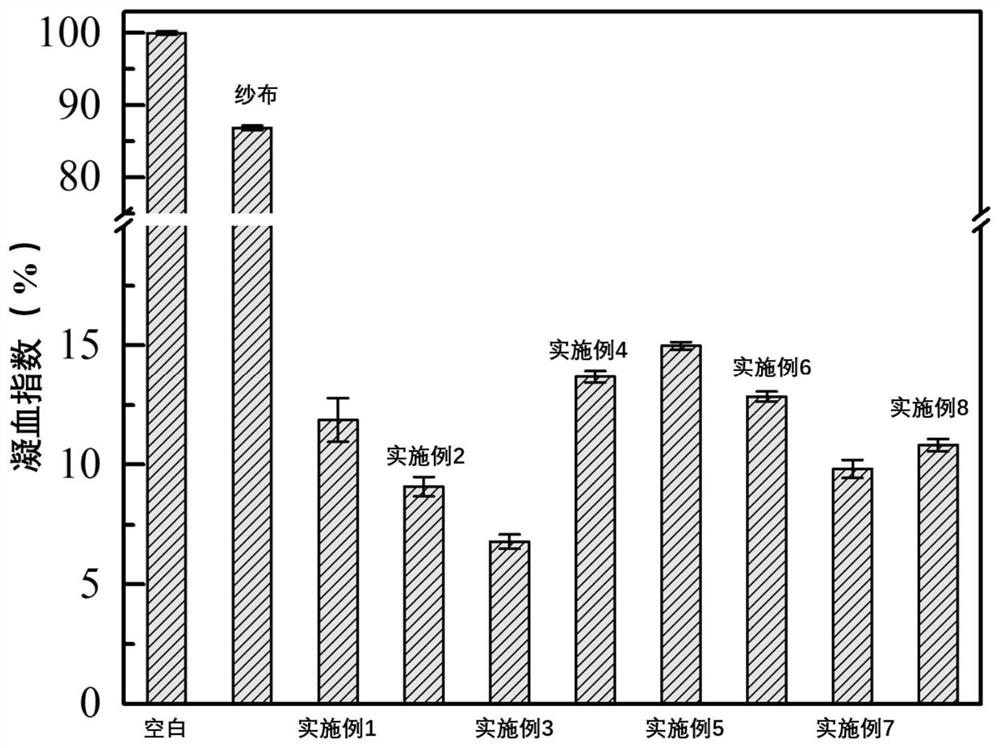

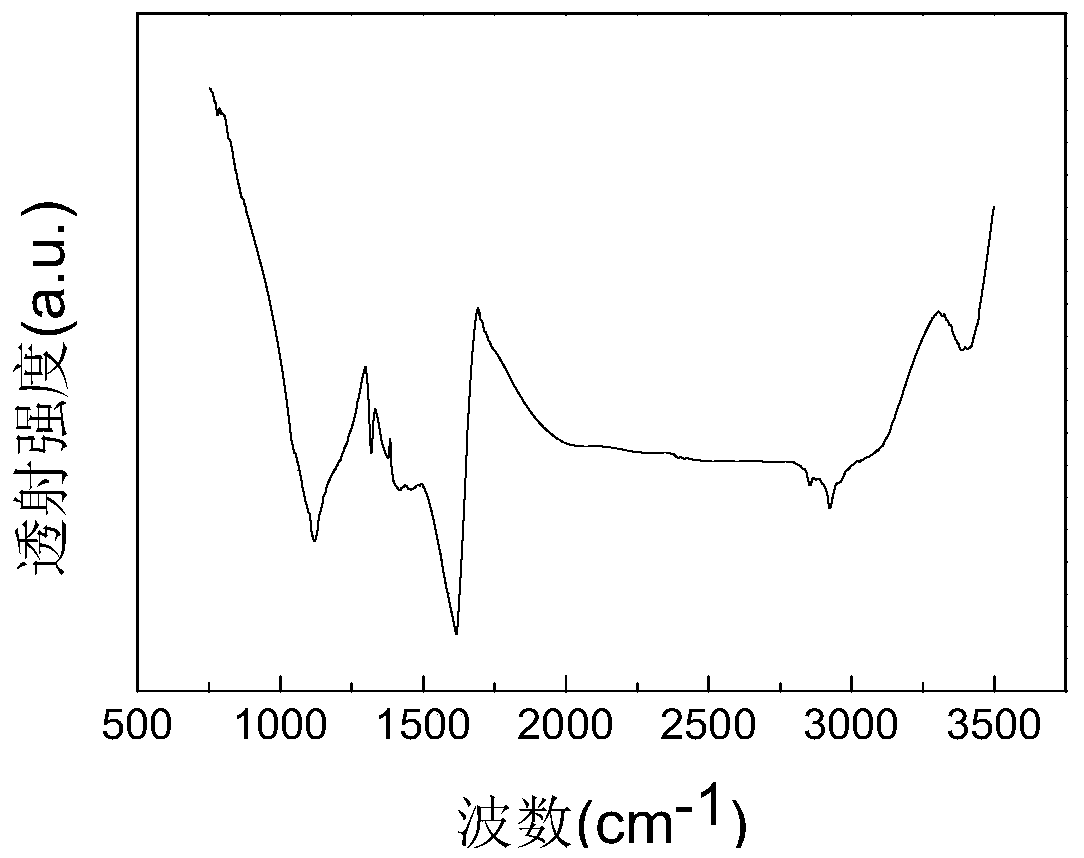

Natural polysaccharide sponge and preparation method and application thereof

InactiveCN113952499AGood biocompatibilityGood for uniform dispersionSurgical adhesivesPharmaceutical delivery mechanismChemistryInorganic chemical compound

The invention discloses a natural polysaccharide sponge and a preparation method and application thereof, and belongs to the field of biomedical polymer materials. The preparation method of the natural polysaccharide sponge comprises the following steps: (1) preparing a solution A containing polysaccharide I with amino and an inorganic compound; (2) preparing a solution B containing polysaccharide II with aldehyde; (3) mixing the solution A and the solution B, and carrying out a cross-linking reaction to obtain hydrogel; and (4) freezing the hydrogel at -80 DEG C to -196 DEG C for 12-72 hours, and then performing freeze drying treatment to obtain the natural polysaccharide sponge. The natural polysaccharide sponge provided by the invention has the advantages of good hemostatic effect, light weight, strong liquid absorption and lower hemolysis rate, and the hemolysis rate of the natural polysaccharide sponge is less than 5%, meeting the biological safety requirements on biological materials in the national standard.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Aspen wood pencil protective paint and preparation method thereof

The invention relates to aspen wood pencil protective paint and a preparation method thereof and relates to the technical field of paint materials. The aspen wood pencil protective paint is prepared from an aqueous saturated polyester resin, an ammonia neutralizer, a white emulsion adhesive, beeswax, a defoamer, a thickener, shell powder, water-based white color paste and deionized water. The thickener comprises, by weight, hydroxymethyl fibers, bentonite, apatite, sepiolite powder and gypsum powder. The preparation method comprises 1) adding 24-25 parts of the aqueous saturated polyester resin into a container, carrying out stirring through a high-speed disperser along with gradual dropwise addition of the ammonia neutralizer, 2) grinding all the solid raw materials, adding all the solid raw materials into the container and carrying out full mixing emulsification, and 3) adding the water-based white color paste and white emulsion adhesive into the container, adding deionized water into the container, carrying out dispersion for 10-15min and testing pH of 7.5-8.5 to obtain the paint. The aspen wood pencil protective paint is safe and environmentally friendly, has no pollution, has high hardness, is not easy to scratch, is easy to produce and has a long service life.

Owner:安徽杰可森木业科技有限公司

Preparation method of graphene foamed nickel electrode

ActiveCN107967998BImprove Capacitive PerformanceCapacitive increaseHybrid capacitor electrodesCell electrodesElectrolytic agentCapacitance

The invention relates to a preparation method and application of a graphene nickel foam electrode. The preparation method is to wash and dry the nickel foam and use it as a working electrode. In the graphene oxide dispersion, use cyclic voltammetry to scan to prepare the graphene oxide nickel foam electrode. After drying, it is maintained in a glycine-hydrochloric acid buffer solution. Potential reduction was performed to obtain a graphene nickel foam electrode. Compared with other graphene electrode preparation methods, the preparation method of the graphene foam nickel electrode of the present invention has cheap raw materials, no pollution, is green and environmentally friendly, and is convenient for mass production. Graphene nickel foam electrodes supported by nickel foam show good capacitive properties in neutral electrolytes and can be used in the field of energy storage.

Owner:NORTHEASTERN UNIV LIAONING

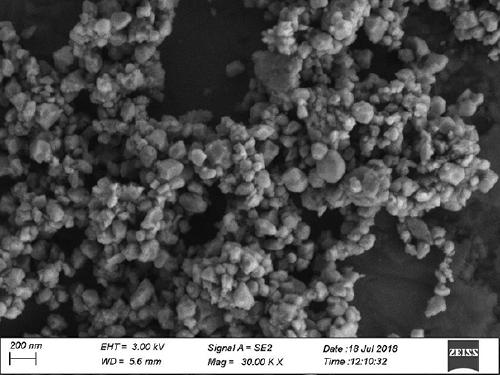

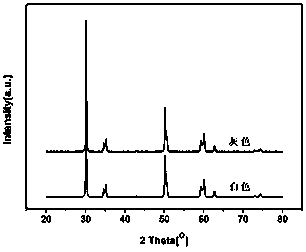

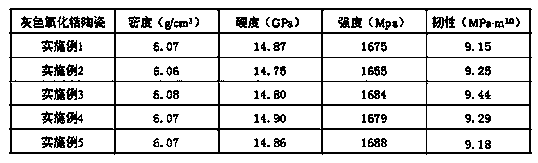

A high -intensity gray oxidant ceramic and its preparation method

The invention discloses a high strength grey zirconia ceramic and a preparation method thereof. The method includes: conducting high energy ball milling treatment on a mixed slurry containing zirconia, yttrium oxide, a dispersant and deionized water; then performing drying treatment on the slurry subjected to high energy ball milling to obtain zirconia nano-powder; then molding the zirconia nano-powder and conducting high temperature sintering to obtain white zirconia ceramic; and finally, placing the white zirconia ceramic under a hydrogen reduction atmosphere in an atmosphere furnace for high temperature sintering, thus obtaining the grey zirconia ceramic. The preparation process is simple and convenient, and the energy consumption and cost are low. At the same time, the preparation process of the grey zirconia ceramic has no need for introducing volatile Cr, Co, Mn and other transition metal colorants, solves the problem of uneven color distribution of ceramics caused by easy high temperature decomposition and volatilization of colorants, and avoids the toxic effect of parts of coloring ions on the human body and the defect that the doping of parts of transitional metal colorants can reduce the mechanical properties of ceramics.

Owner:内蒙古晶陶锆业有限公司 +1

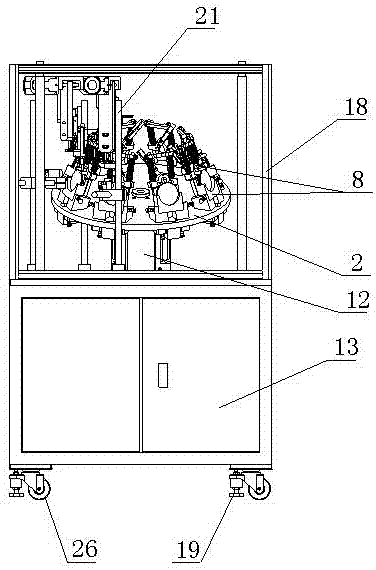

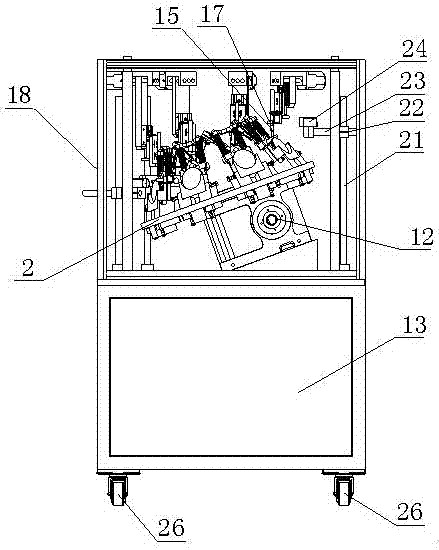

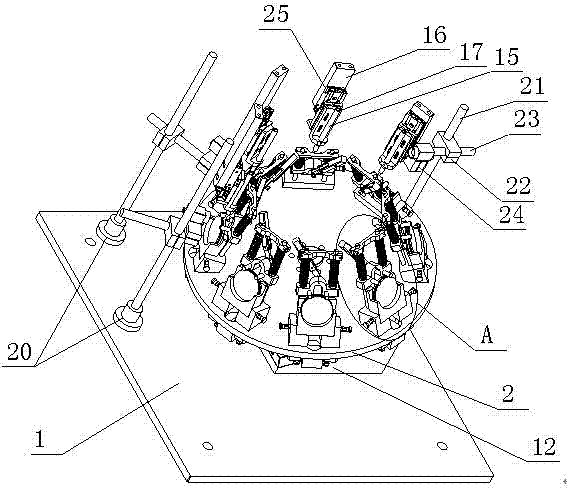

Full-automatic rotary inclined plane filling machine for resin lens

InactiveCN107351430AImprove filling efficiencySimple structureOptical articlesLens plateFully automatic

The invention relates to the technical field of equipment, in particular to a full-automatic rotary inclined plane filling machine for a resin lens. The full-automatic rotary inclined surface filling machine for the resin lens comprises an inclined rotating disc, a control cabinet, a protective cabinet, a vertical supporting rod and an air cylinder fixing plate. The full-automatic rotary inclined surface filling machine for the resin lens can achieve unmanned production in the whole process of filling, avoids the harm to workers caused by toxicity, carcinogenicity and flammability of the lens, reduces the labor intensity of employees, provides the employees with the physical and mental health, and optimizes the factory environment. Per person beat of the manual operation is about 8-12 seconds, the per person beat of the automatic inclined plane filling machine is within 3 seconds, the filling efficiency of the resin lens is greatly improved, and the quality of the produced lens is more complete and uniform. The fully-automatic rotary inclined plane filling machine for the resin lens is simple in structure, convenient to use, and convenient to repair and clean, reduces the labor intensity of the workers, and is suitable for being used and popularized.

Owner:黄新龙

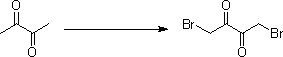

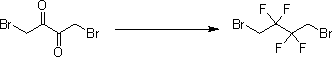

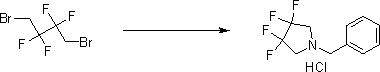

Synthesis method of 3,3,4,4-tetrafluoropyrrolidine

The invention discloses a synthesis method of 3,3,4,4-tetrafluoropyrrolidine and mainly solves the technical problems of poisonous introduced fluorine, relatively long steps and relatively low yield in the existing synthesis process. The synthesis method disclosed by the invention comprises four steps: firstly, mixing butanedione with chloroform, then, carrying out addition on the mixture and bromine to form 1,4-dibromo-2,3-butanedione; secondly, introducing sulfur tetrafluoride into the obtained 1,4-dibromo-2,3-butanedione, and carrying out a reaction to obtain 1,4-dibromo-2,2,3,3-tetrafluorobutane; thirdly, carrying out a high-temperature reaction on 1,4-dibromo-2,2,3,3-tetrafluorobutane and benzylamine to obtain 1-benzyl-3,3,4,4-tetrafluoropyrrolidine hydrochloride; and fourthly, carrying out catalytic hydrogenation debenzylation on 1-benzyl-3,3,4,4-tetrafluoropyrrolidine hydrochloride to obtain 3,3,4,4-tetrafluoropyrrolidine. The invention provides the synthesis method of 3,3,4,4-tetrafluoropyrrolidine which is relatively low in toxicity, low in raw material price, simple in operation and high in yield.

Owner:武汉药明康德新药开发有限公司

Two-dimensional graphene-wrapped copper composite material with core-shell structure and preparation method and application thereof

ActiveCN111757657BPrevent oxidationGuaranteed catalytic effectMagnetic/electric field screeningNano copperMetal particle

The invention discloses a two-dimensional graphene-wrapped copper composite material with a core-shell structure and its preparation method and application. The structure of the graphene-wrapped copper composite material is a core formed by wrapping nano-copper particles with outer graphene Shell structure, the graphene-coated copper composite material is constructed by electrostatic adsorption self-assembly method, graphene-coated copper can not only avoid the oxidation of copper particles, ensure the intrinsic catalytic ability and electrical conductivity of the composite material, but also control the The expansion / compression of the two materials promotes the synergy between the two materials to significantly improve the composite integrity. Two-dimensional graphene-wrapped copper composites with core-shell structure have excellent electromagnetic shielding properties.

Owner:TIANJIN UNIV

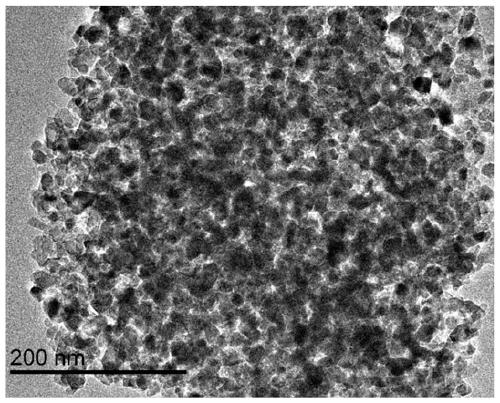

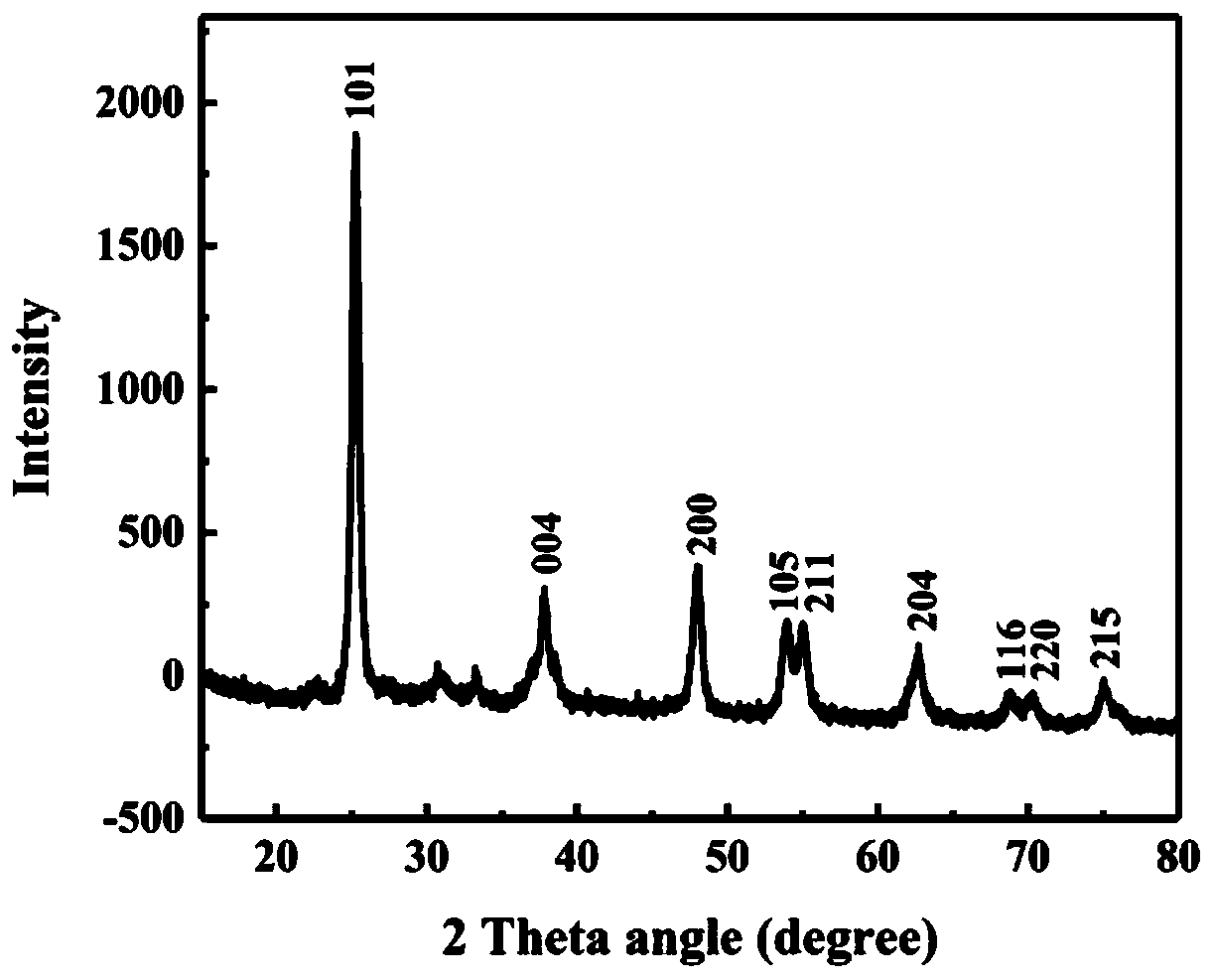

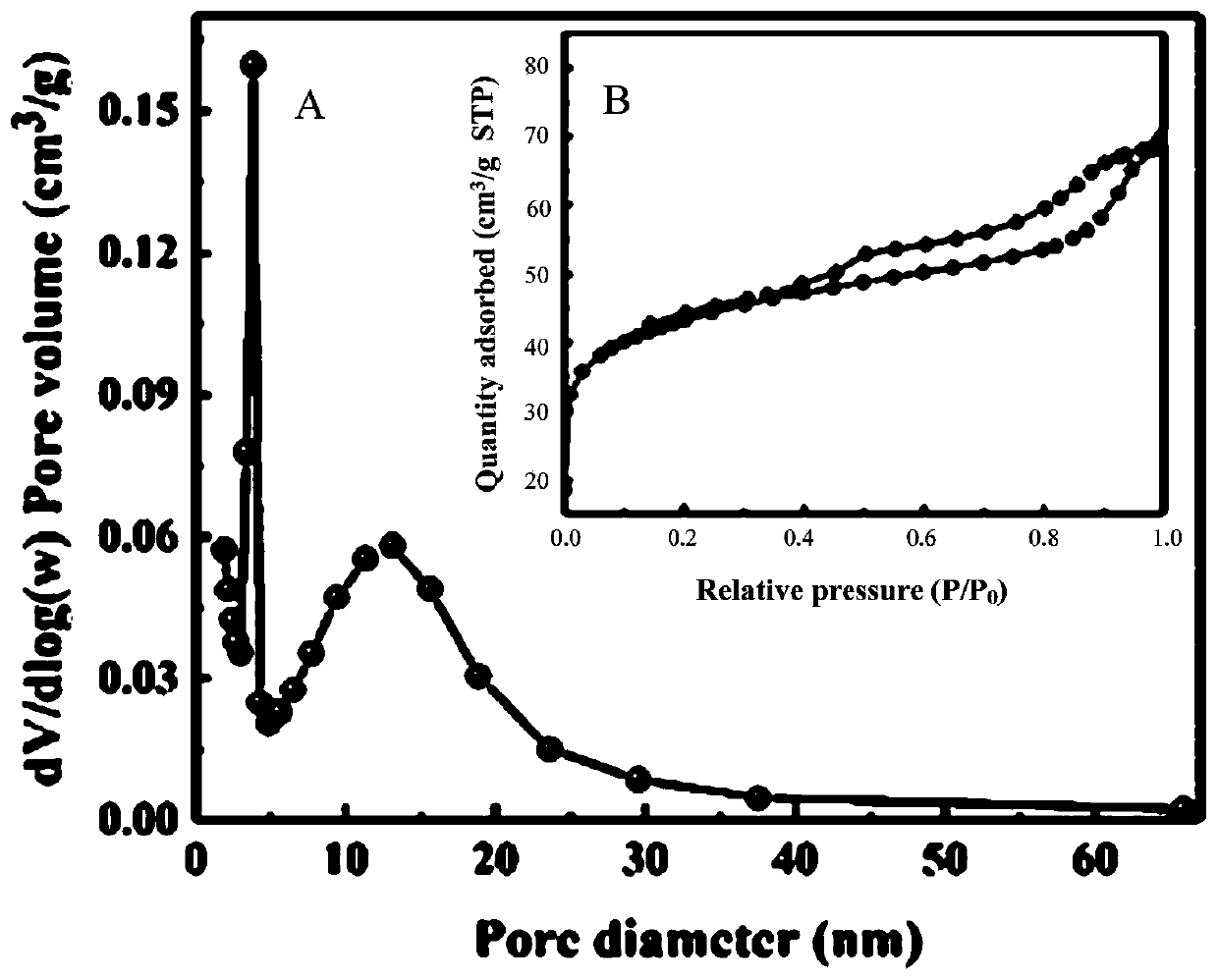

Hierarchically porous TiO2 material and preparation method thereof, and application of hierarchically porous TiO2 material in protein adsorption

ActiveCN110465259AAvoid priceAvoid toxicIon-exchange process apparatusOther chemical processesBiological macromoleculeAdsorption effect

The invention specifically relates to a hierarchically porous TiO2 material and a preparation method thereof, and application of the hierarchically porous TiO2 material in protein adsorption, belonging to the field of hierarchically porous metal oxide materials. According to the invention, a triblock copolymer and a biomass material, i.e., a vegetable tanning agent, are used as double templates; non-toxic and low-valence soluble inorganic metal salt of titanium is used as a metal source; self-assembling is carried out mildly without high-temperature hydrothermal conditions so as to promote crystal form conversion; and finally, calcining is performed so as to form the hierarchically porous TiO2 material with a specific surface area of 32-142 m<2> / g and a pore size range of 1.8-94 nm. The invention provides a low-cost easily-operable synthetic route for preparation of the hierarchically porous TiO2 material; and the prepared hierarchically porous TiO2 material can effectively adsorb protein biomacromolecules in virtue of its large specific surface area and rich pore structures, and has good adsorption effect on protein substances in softening wastewater produced in tanning.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of microencapsulated fast curing agent for epoxy resin

InactiveCN110790901AAvoid premature decompositionPrevent volatilizationMicroballoon preparationMicrocapsule preparationPolymer scienceFirming agent

The invention discloses a preparation method of a microencapsulated fast curing agent for epoxy resin, and belongs to the field of curing agent preparation. According to the preparation method, the problems that a microencapsulated curing agent prepared by an existing method is complex in preparation process, and the wall material of the microencapsulated curing agent is prone to cracking in advance are solved. The preparation method comprises the steps that an active curing agent, PS and dichloromethane are prepared into an oil phase solution; a water phase solution is prepared; an oil-in-water emulsion is prepared; and a microcapsule precipitate is prepared, and the microencapsulated fast curing agent is obtained after filtering and drying. According to the preparation method, the evaporation of a microencapsulated solvent is achieved through a physical method, and operation is simple; the PS with good affinity with the epoxy resin is used for preparing a microcapsule, the decomposition or volatilization of the active curing agent in advance in the storage process of the epoxy resin can be effectively avoided, thus the room temperature storage period of an epoxy resin-typed pregreg is greatly prolonged, fast curing is achieved, the mechanical properties of epoxy resin products cannot be reduced, the vitrification transformation temperature of the PS is 100 DEG C, and the storage property of the microcapsule is good at room temperature. The preparation method is suitable for the fast curing agent of the epoxy resin.

Owner:肇庆市海特复合材料技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com