A method for preparing black zirconia ceramics at low temperature

A technology of black zirconia and ceramics, which is applied in the field of preparation of low-temperature sintered black zirconia ceramic materials, which can solve the problems of material strength, hardness and corrosion resistance reduction, and achieve the effects of avoiding toxic effects, narrow size distribution and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Black ZrO 2 Preparation of ceramics:

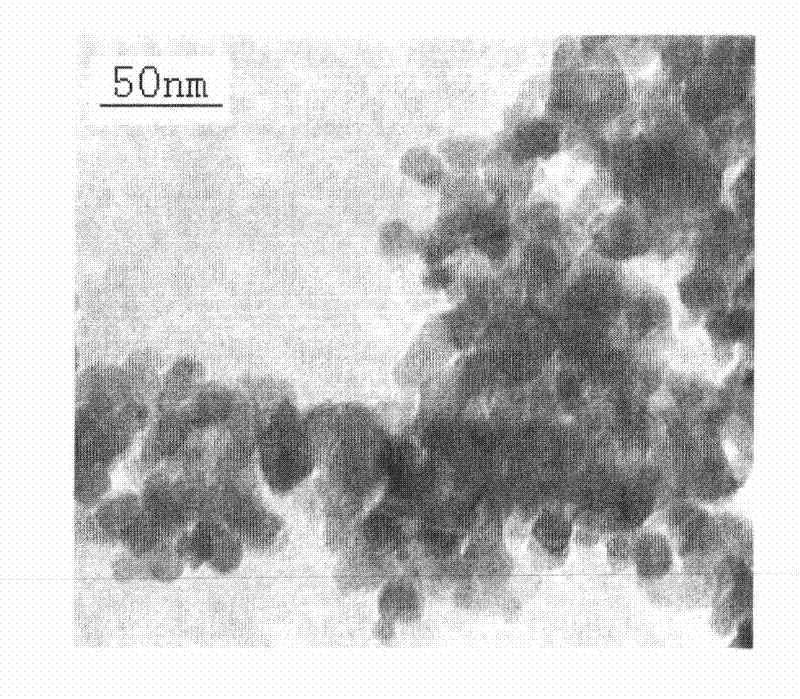

[0036] (1) Raw material preparation: zirconium oxychloride ZrOCl 2 ·8H 2 O and Y (NO 3 ) 3 ·6H 2 O is the raw material, and ZrOCl with a concentration of 0.2mol / L is prepared with secondary deionized water 2 -Y(NO 3 ) 3 solution and a 10% ammonia solution. ZrOCl 2 -Y(NO 3 ) 3 Solution according to n(ZrO 2 ) / n(Y 2 o 3 )=97 / 3. A certain amount of deionized water, ammonia water, dispersant polyethylene glycol and 6-10% solution weight hydrogen peroxide are taken as the reaction base liquid, and the pH value of the reaction base liquid is adjusted to 10. Stir the reaction base solution continuously at room temperature, and drop the two solutions prepared above (ZrOCl 2 -Y(NO 3 ) 3 solution and ammonia solution), after the dropwise addition, the stirring was continued for 1 hour, and a white sol precipitate was obtained. Stand and age at room temperature for 10 hours, use a centrifuge to separate the solid from the li...

Embodiment 2

[0052] Black ZrO 2 Preparation of ceramics:

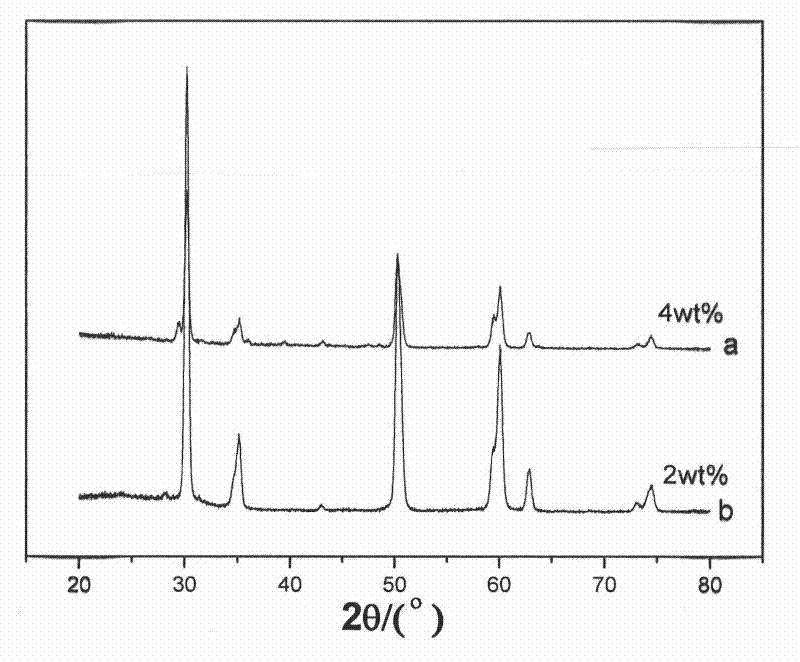

[0053] Raw material ZrO 2 , coloring agent and green body preparation method are basically the same as embodiment one. The difference: the added amount of the coloring agent is 2wt% and 0wt%.

[0054] Characterization method:

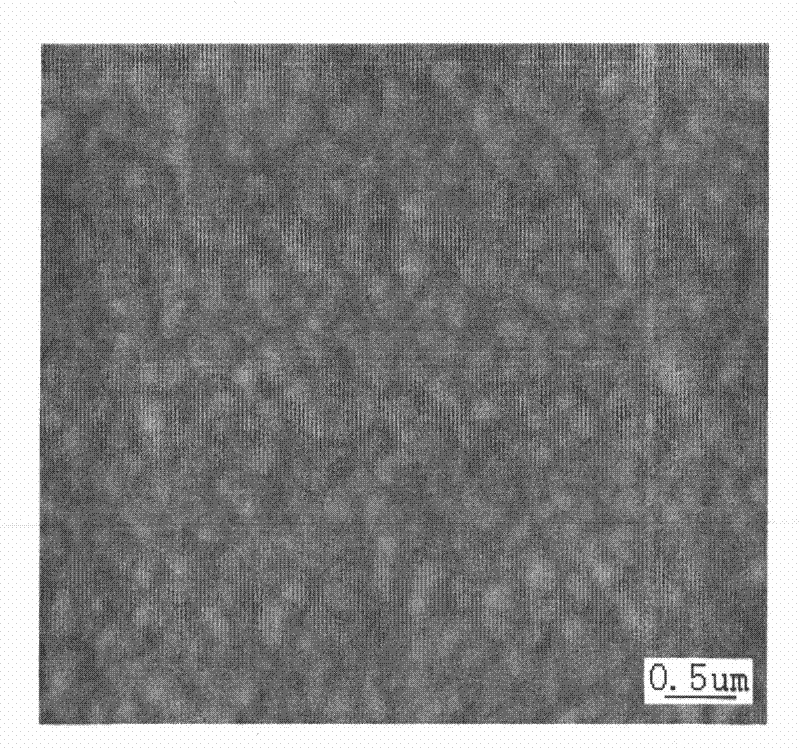

[0055] The phase analysis of the material was carried out with a Japan Rigaku D / max X-ray diffractometer (CuKα line); the microstructure of the sample was observed with a SSX-550 scanning electron microscope; the AG-1C type of the Shimadzu universal material testing machine was used to measure the material Bending strength; test the Vickers hardness of the sample with the HV-50 Vickers hardness tester; test the bulk density of the sample with the Archimedes drainage method; soak the sample in 20% hydrochloric acid and sodium hydroxide solution for 48 hours, wash and observe Changes in surface color and gloss to evaluate its corrosion resistance.

[0056] result:

[0057] 1. Black ZrO 2 ceramic structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com