Patents

Literature

248 results about "Homogeneous precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese-based composite oxide catalyst for catalytically decomposing ozone, and preparation method of manganese-based composite oxide catalyst

ActiveCN102600861AAchieve decentralizationAchieve catalytic effectDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureAir treatmentHydrothermal synthesis

The invention relates to a manganese-based composite oxide catalyst for catalytically decomposing ozone, and a preparation method of the catalyst. The catalyst comprises manganese oxide and at least one transition metal oxide. The preparation method is a homogeneous precipitation method or a hydrothermal synthesis method. The manganese-based composite oxide catalyst adopts innocuous and non-poisonous materials, prepares a manganese-based composite oxide catalyst with high catalytic activity, good wet resistance and high catalytic deposition content by the simple and easy method, so that the catalyst is suitable for catalytically decomposing ozone produced in water or air treatment and modern industry and home appliance.

Owner:上海棕晟企业管理合伙企业(有限合伙)

Low-concentration methane catalytic combustion catalyst and preparation method of the same

InactiveCN103131488ASolve the problem of poor hydrothermal stabilityEasy to prepareGaseous fuelsFuel additivesIridiumPtru catalyst

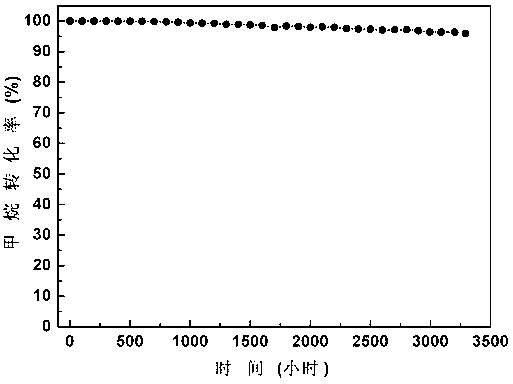

The invention provides a low-concentration methane catalytic combustion catalyst and a preparation method of the low-concentration methane catalytic combustion catalyst. The low-concentration methane catalytic combustion catalyst comprises a catalytic activity component, a catalyst carrier of Al2O3 and a metal oxide co-carrier. One kind or several kinds of the combination of platinum family precious metal of palladium (Pd), platinum (Pt), ruthenium (Ru), iridium (Ir) and rhodium (Rh) are used as the catalytic activity component; at least one kind in metal oxide of magnesium (Mg), lanthanum (La), ferrum (Fe), manganese (Mn), nickel (Ni), cobalt (Co), chromium (Cr) and calcium (Ca) is used as the metal oxide co-carrier. Arbitrary one kind of the methods of an impregnation method, a homogeneous precipitation method, a co-precipitation method and a pyrolytic method is used for preparing a catalyst precursor. Then the catalyst is formed after being filtered, washed, dried, roasted, formed, roasted again and restored. The low-concentration methane catalytic combustion catalyst and the preparation method of the low-concentration methane catalytic combustion catalyst have the advantages of being capable of stably combusting under the lean-burn, oxygen-enriched and high-water-vapor conditions, high in activity, long in service life and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

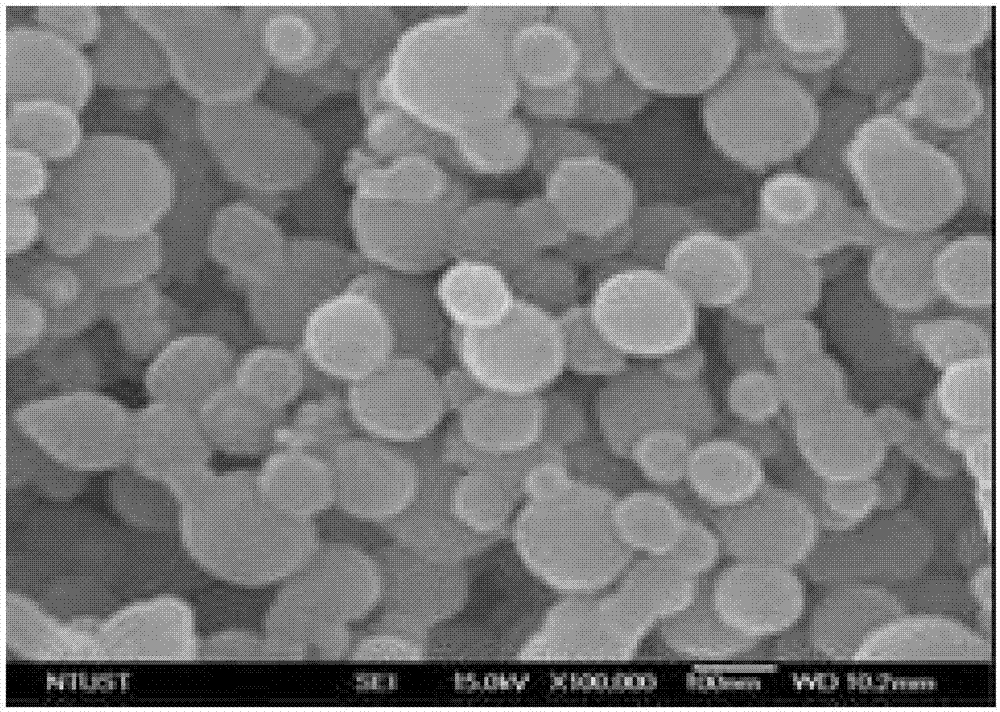

Process for producing homodisperse spherical iron lithium phosphate

InactiveCN101508431ALow costSimple process controlCell electrodesPhosphorus compoundsLithium iron phosphateRoom temperature

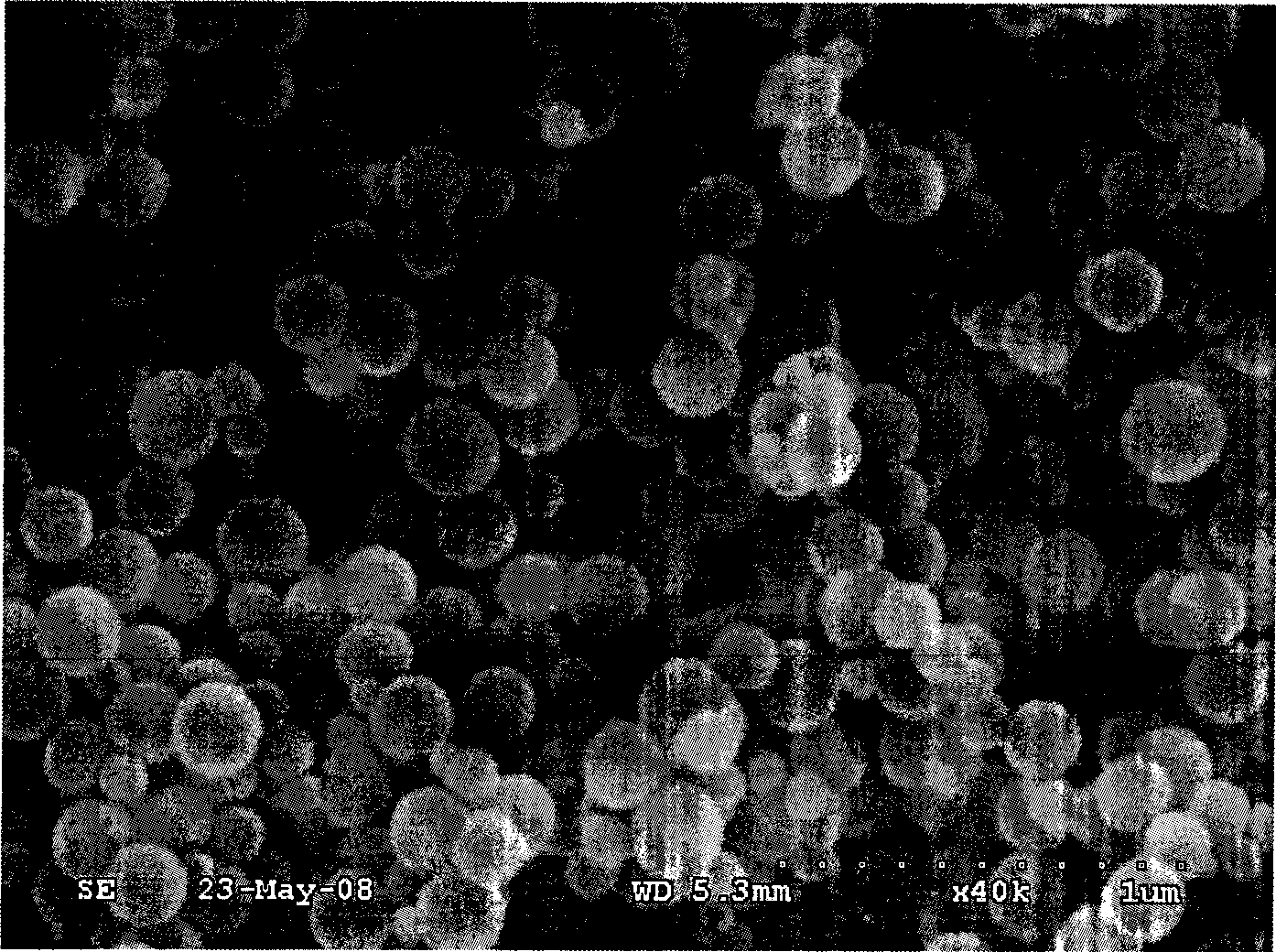

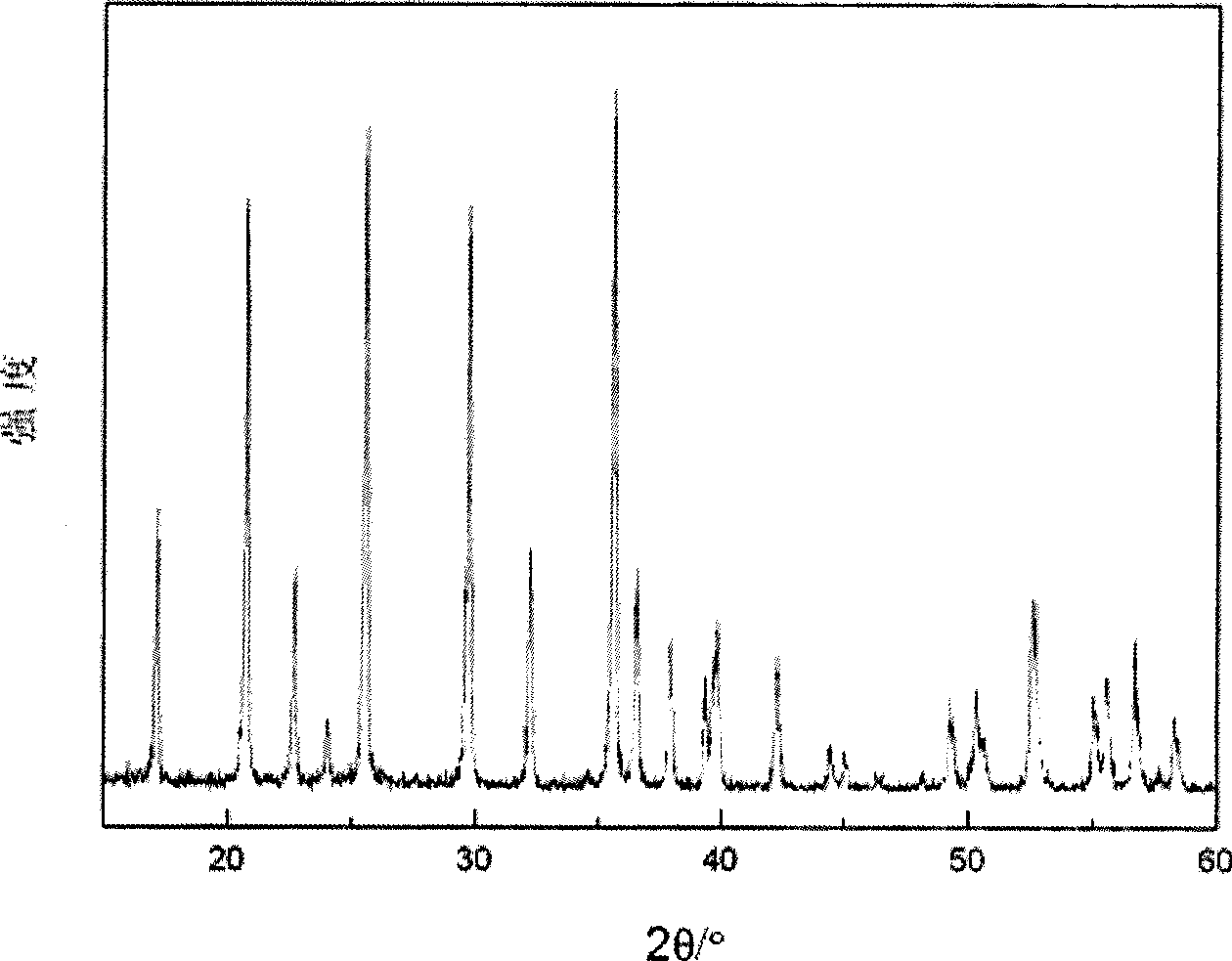

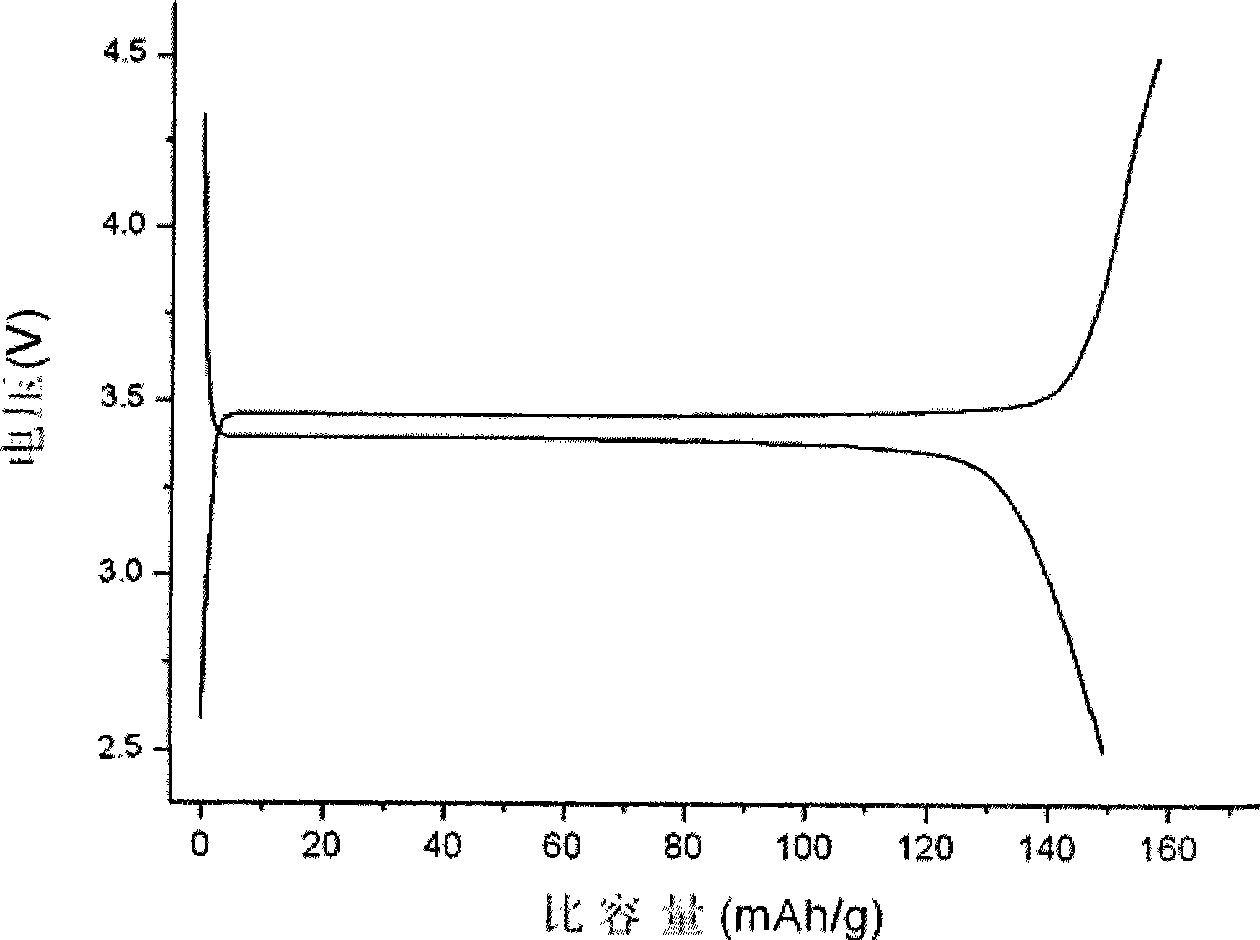

The invention relates to a method for preparing uniformly dispersed spherical lithium iron phosphate-an anode material for a lithium ion battery, and belongs to the field of green energy materials. The method comprises the following steps: firstly, preparing a spherical iron phosphate precursor through liquid-phase homogeneous precipitation; secondly, performing predecomposition on the spherical iron phosphate precursor at a temperature of between 350 and 450 DEG C for 2 to 8 hours under the protection of inert gas; and thirdly, performing reaction at the temperature of between 550 and 800 DEG C for 2 to 24 hours to obtain the uniformly dispersed spherical lithium iron phosphate. The particle diameter of the product is between 100 and 200 nanometers, the tap density is between 1.6 and 2.0 g / cm, and the specific capacity of initial discharge at the room temperature reaches 140 to 160 mAh / g. The method utilizes a liquid-phase spheroidization process to prepare the uniformly dispersed spherical lithium iron phosphate, has simple process, and is easy to realize industrialized production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

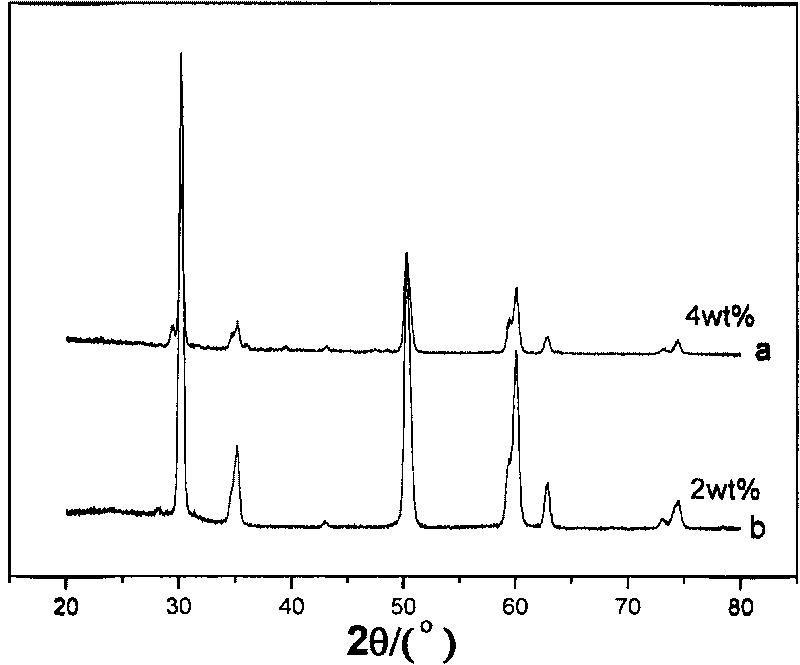

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

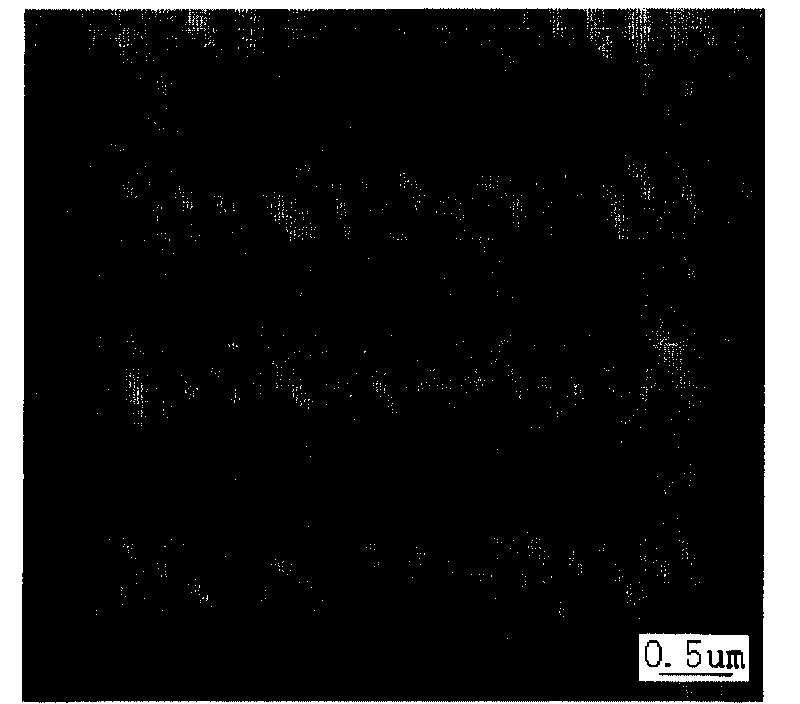

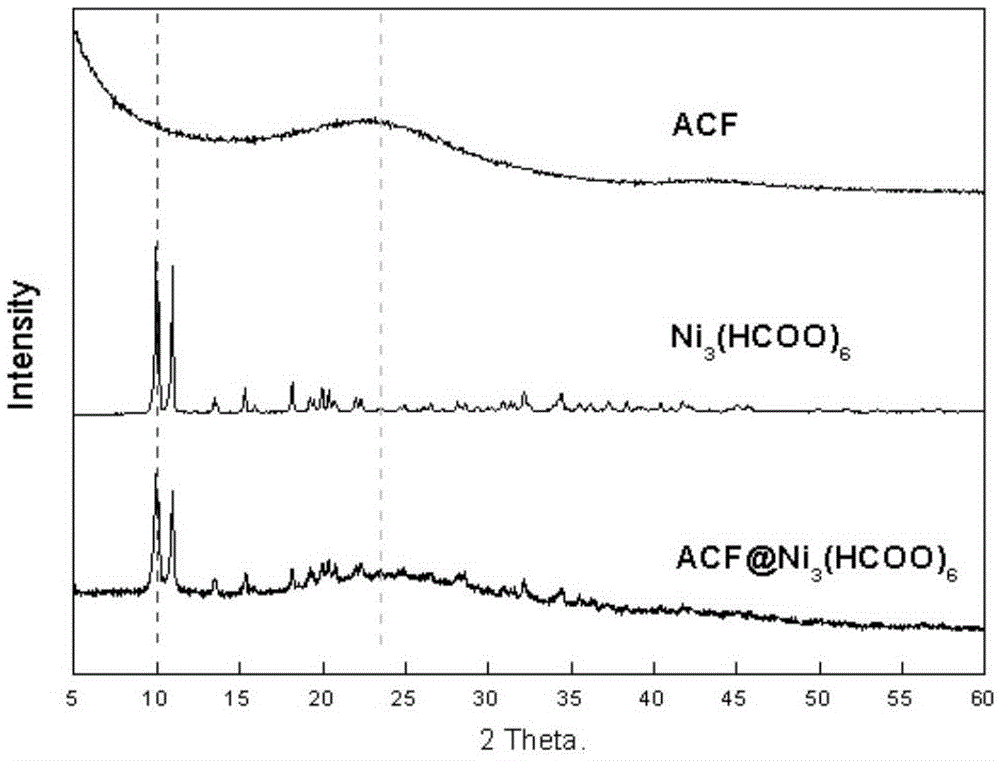

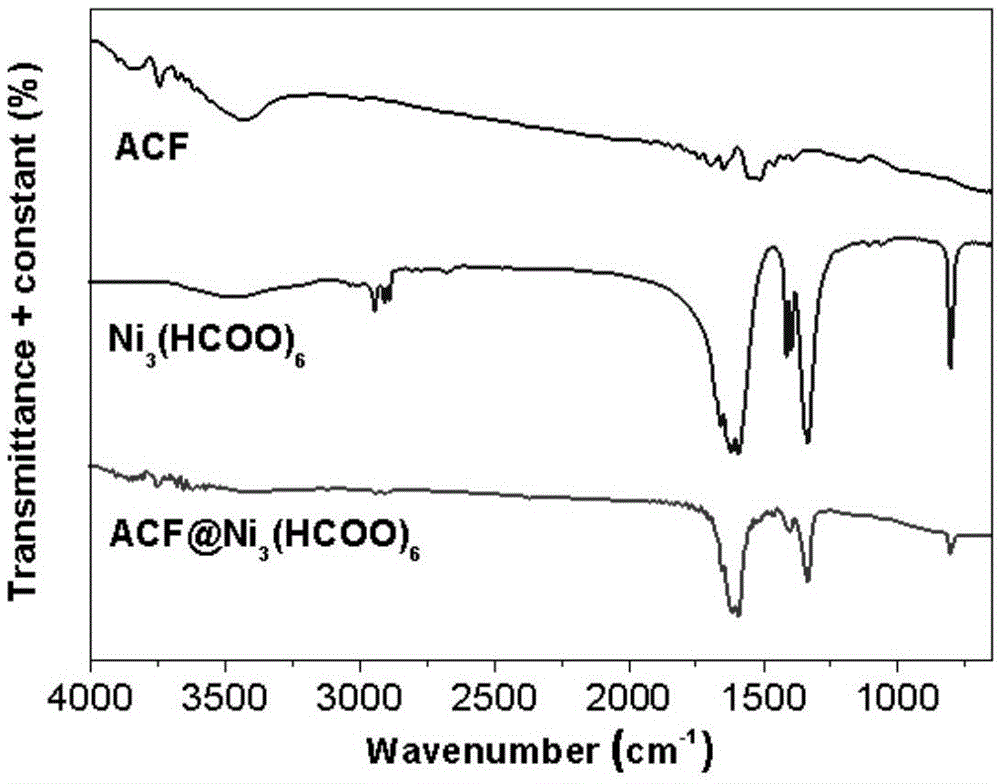

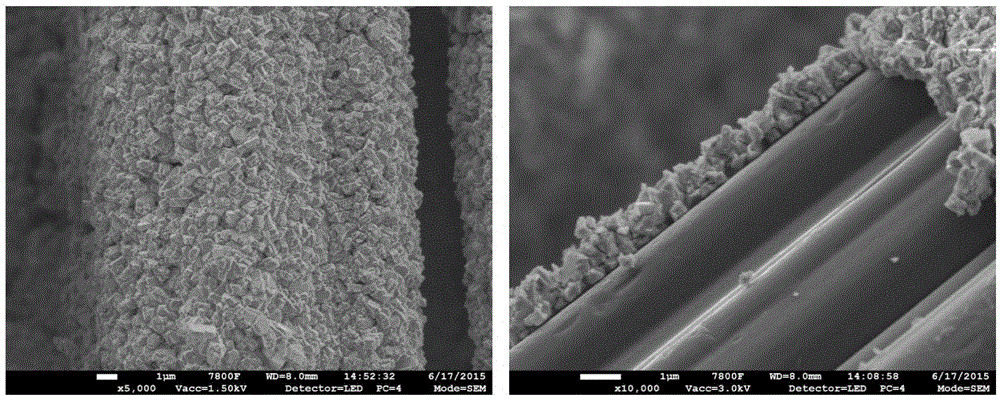

Preparation of active carbon fiber-metal organic framework composite material, and composite material and application

InactiveCN106807329AIncrease surface areaLarge hole volumeProductsGas treatmentFiberHigh concentration

The invention relates to a preparation of an active carbon fiber-metal organic framework composite material for adsorbing and separating gases. The preparation comprises the following steps: covering surfaces of active carbon fibers with a metal precursor by utilizing a homogeneous precipitation method, coordinating and complexing the metal precursor and an organic ligand at the surface of the surfaces of the active carbon fibers under a water or solvent thermal condition to form a metal organic framework structure, so that the compounding of the active carbon fibers and the metal organic framework material is finally realized. The preparation process of the active carbon fiber-metal organic framework composite material is simple, the reaction condition is moderate, the material property is stable, and the active carbon fiber-metal organic framework composite material has a porous structure. The composite material has apparent selectively adsorption performance for CH4 and CO2 in the adsorption and separation process of the gases such as CH4 / N2, CO2 / CH4, CO2 / N2, CO2 / CH4 / N2 and the like, and is particularly suitable for separating low-quality methane gas, purifying high-concentration methane and capturing CO2.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

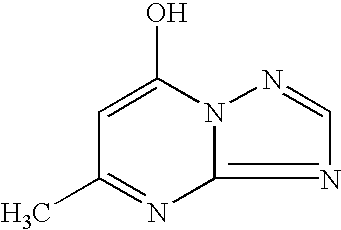

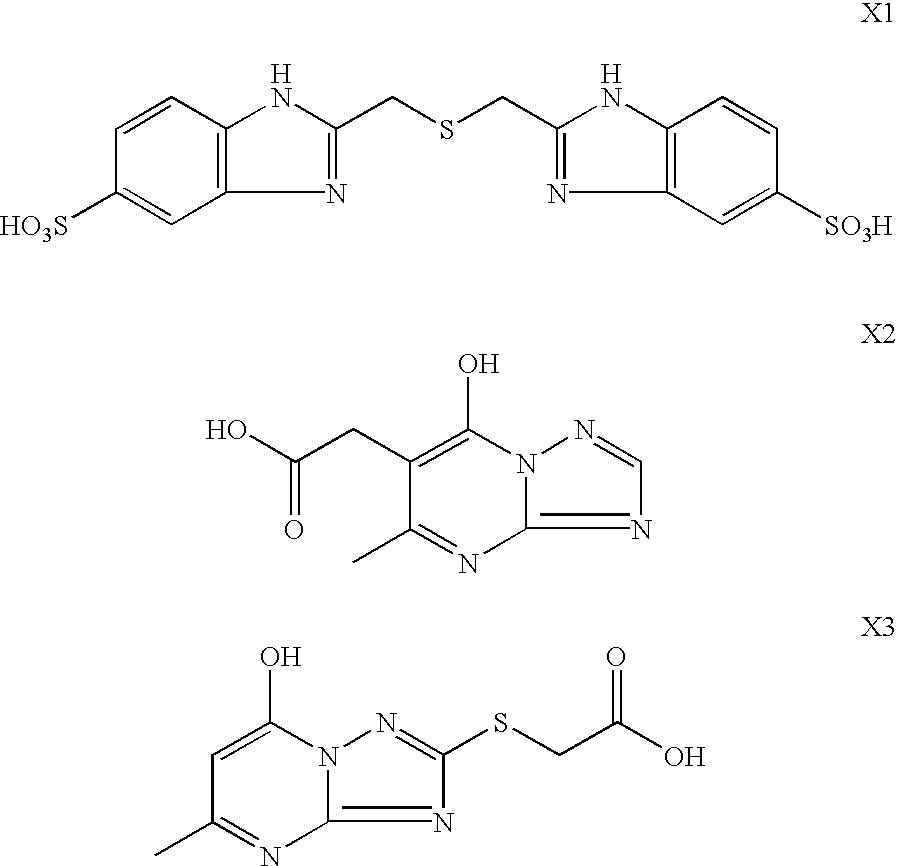

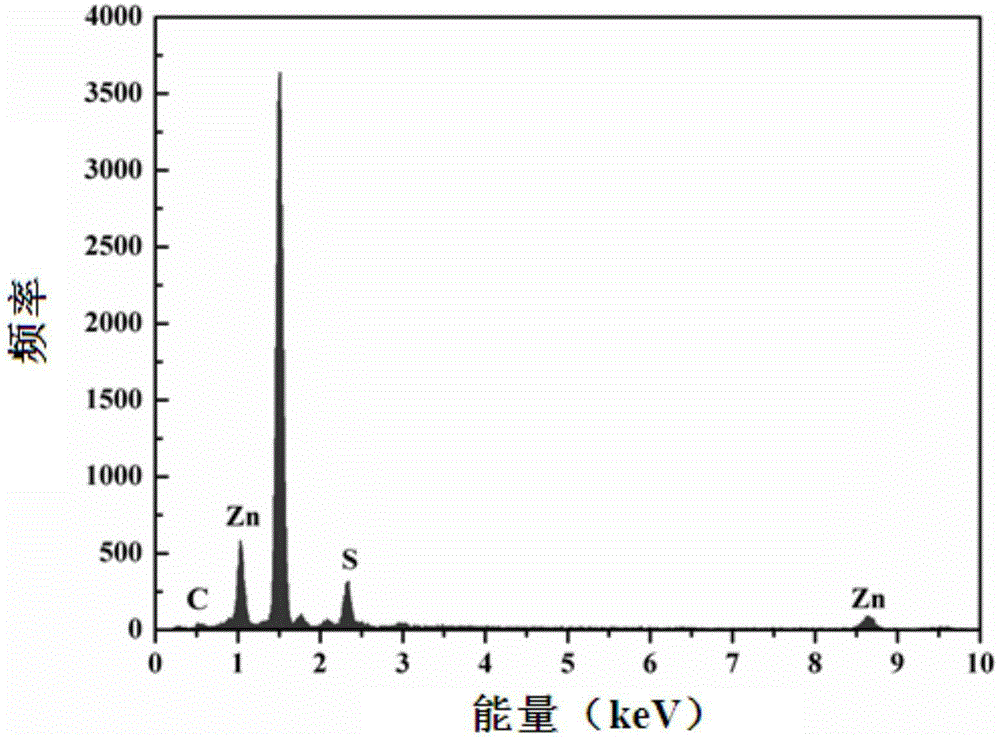

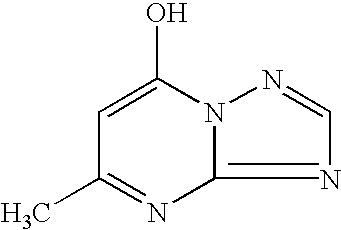

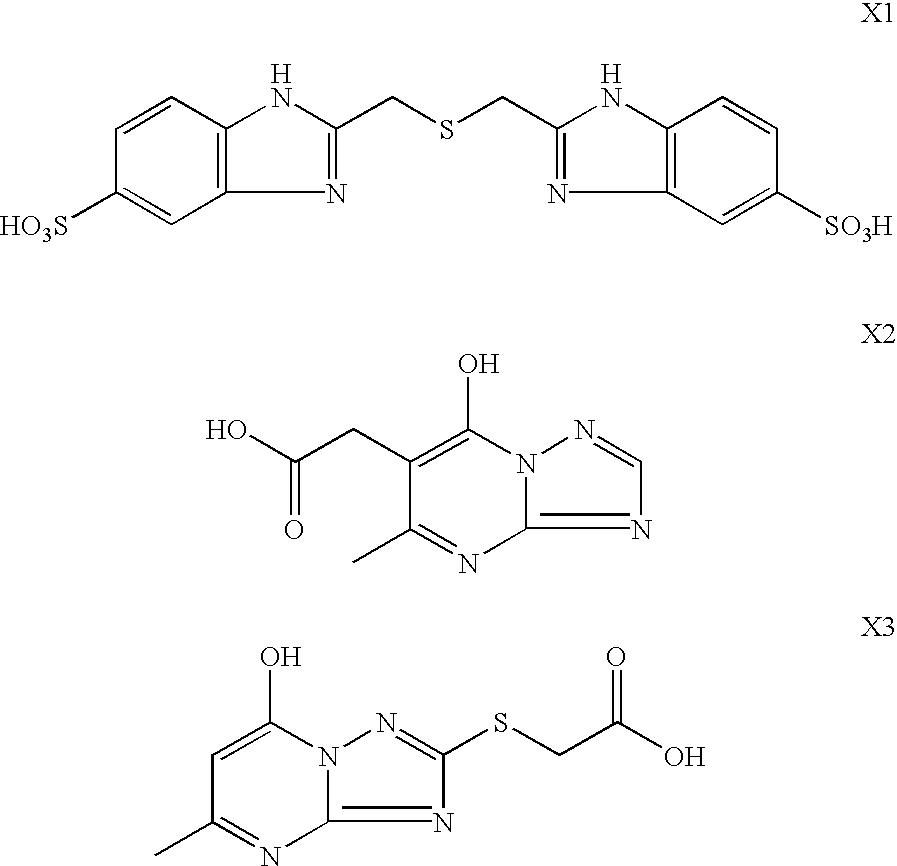

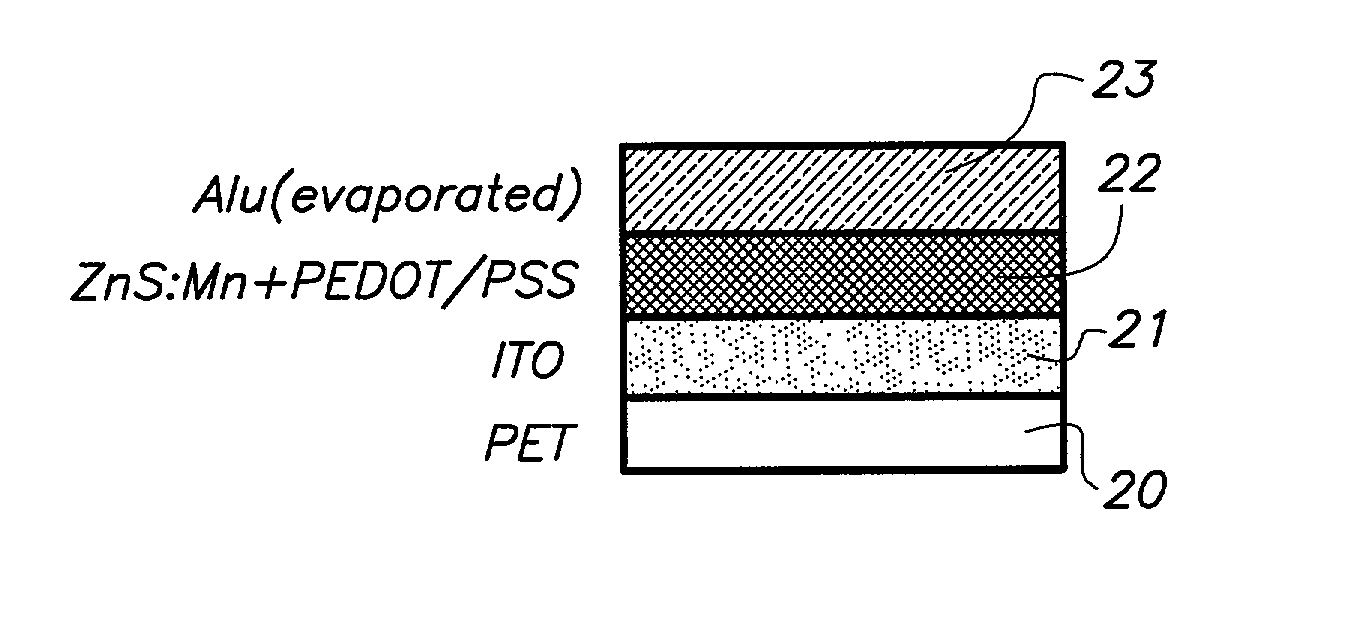

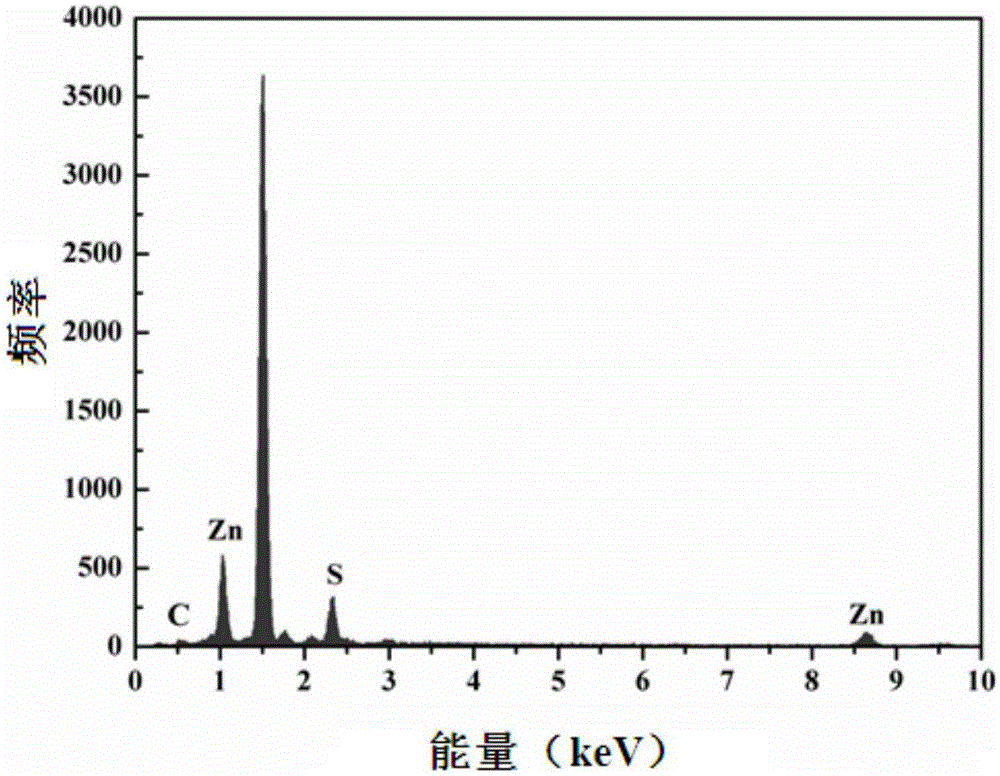

Perparation of improved ZnS:Mn phosphors

InactiveUS6558575B2Economical and simpleImprove stabilityDischarge tube luminescnet screensLamp detailsPhosphorHomogeneous precipitation

Highly efficient ZnS:Mn phosphors can be obtained by using triazole or diazole compounds during homogeneous precipitation in aqueous medium. Coated layers containing such phosphors can be incorporated in Thin Film Inorganic Light Emitting Diodes.

Owner:AGFA GEVAERT AG

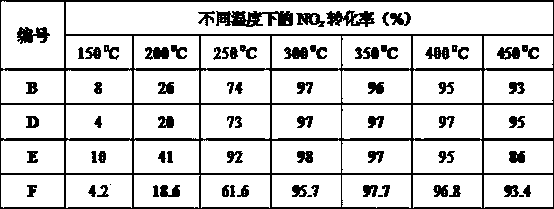

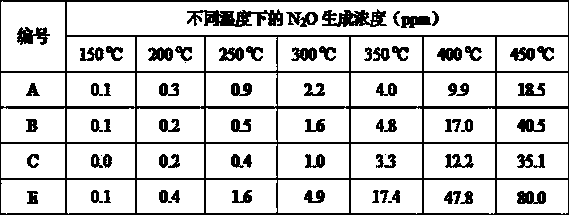

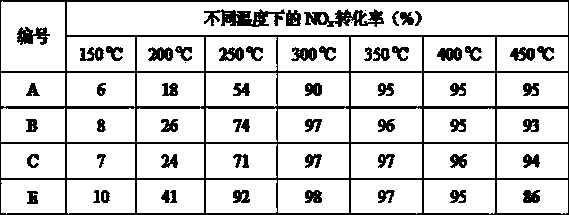

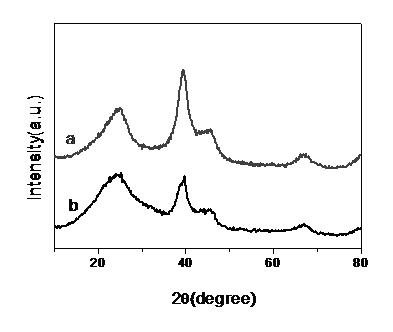

Nanocrystalline Ce-Ti composite oxide catalyst used for selective catalytic reduction of nitric oxide by utilizing ammonia

InactiveCN101785994AExtended service lifeReduce usageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumNitric oxide

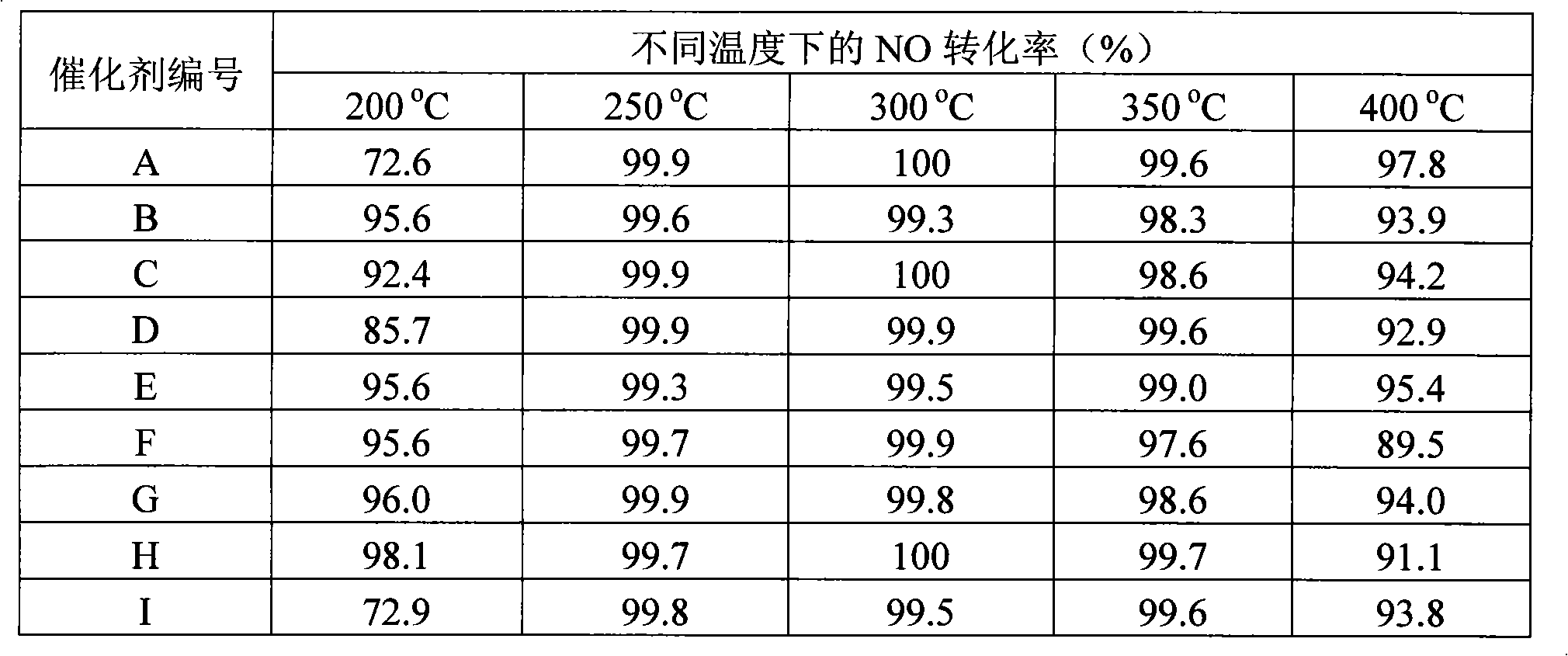

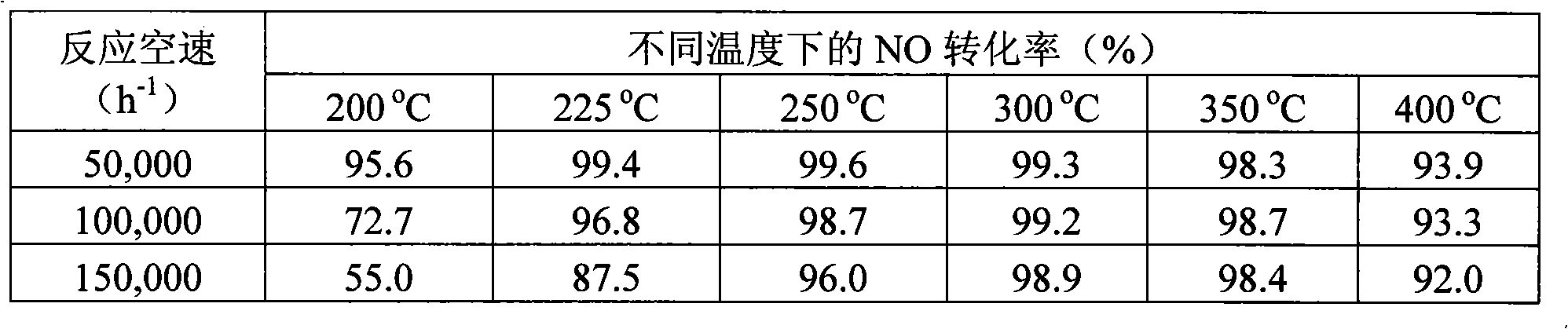

The invention relates to a preparation method of a nanocrystalline Ce-Ti composite oxide catalyst used for the selective catalytic reduction of nitric oxide by utilizing ammonia and an application thereof. The preparation method of the catalyst is the homogeneous precipitation method, namely, the required cerium salt and titanium salt are prepared to mixed solution, and the molar ratio of cerium and titanium is 0.1-1.0; the solution is continuously stirred for 6-10h at the temperature of 90-95 DEG C by taking excessive urea as the precipitator and then is pumped, filtered, washed and dried; and finally, the catalyst is obtained by roasting the processed solution for 4-6h in the air at the temperature of 400-500 DEG C. In the invention, the nanocrystalline Ce-Ti composite oxide catalyst is prepared by taking non-toxic and harmless raw materials and adopting the simple and easy method, which has the characteristics of high catalytic activity, good N2 selection, wide temperature window, good adaptability of high airspeed condition, good SO2 intoxication resistance and the like. The catalyst is applicable to various tail gas sources including fixed combustion devices in an engine of a diesel vehicle, a coal-fired power plant and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

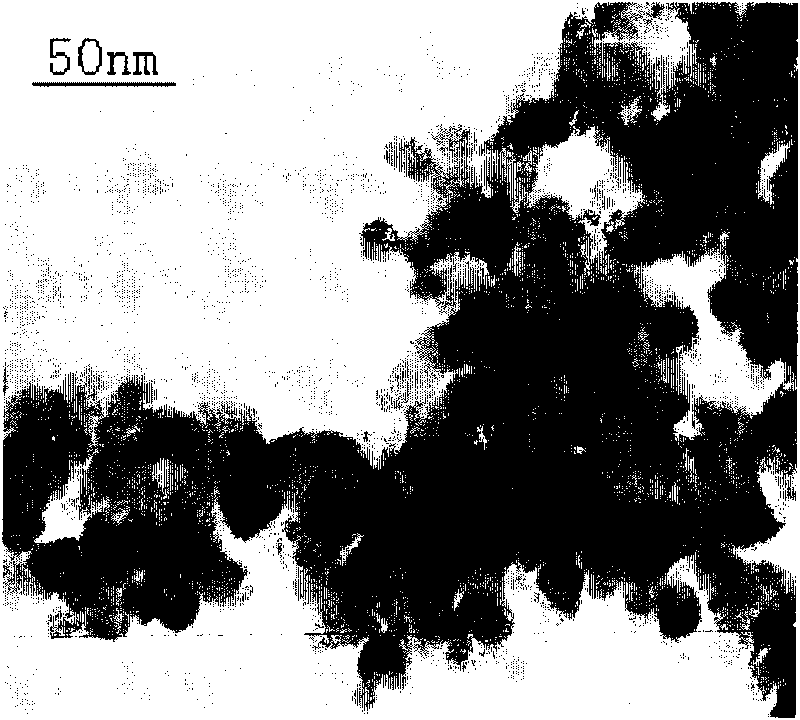

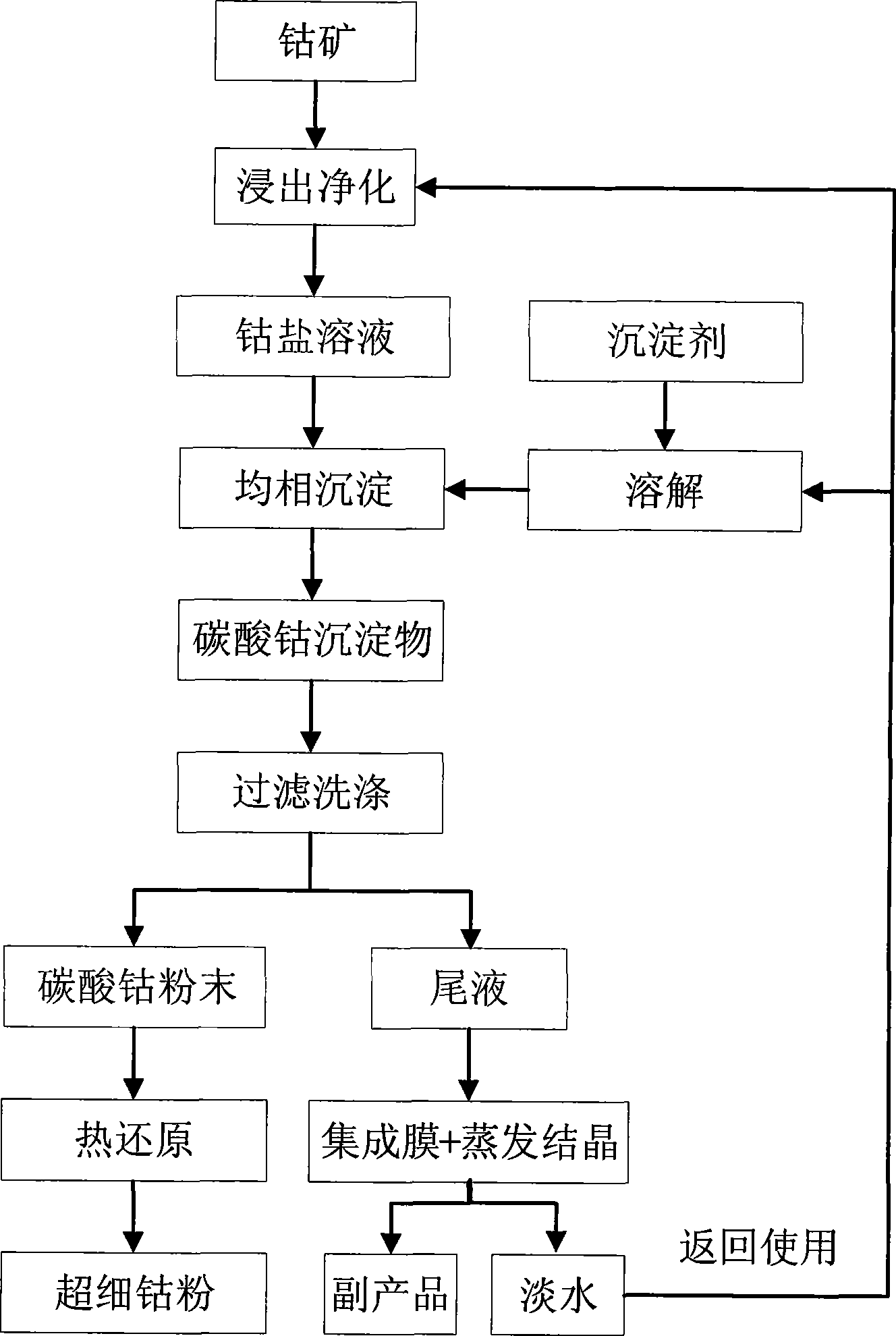

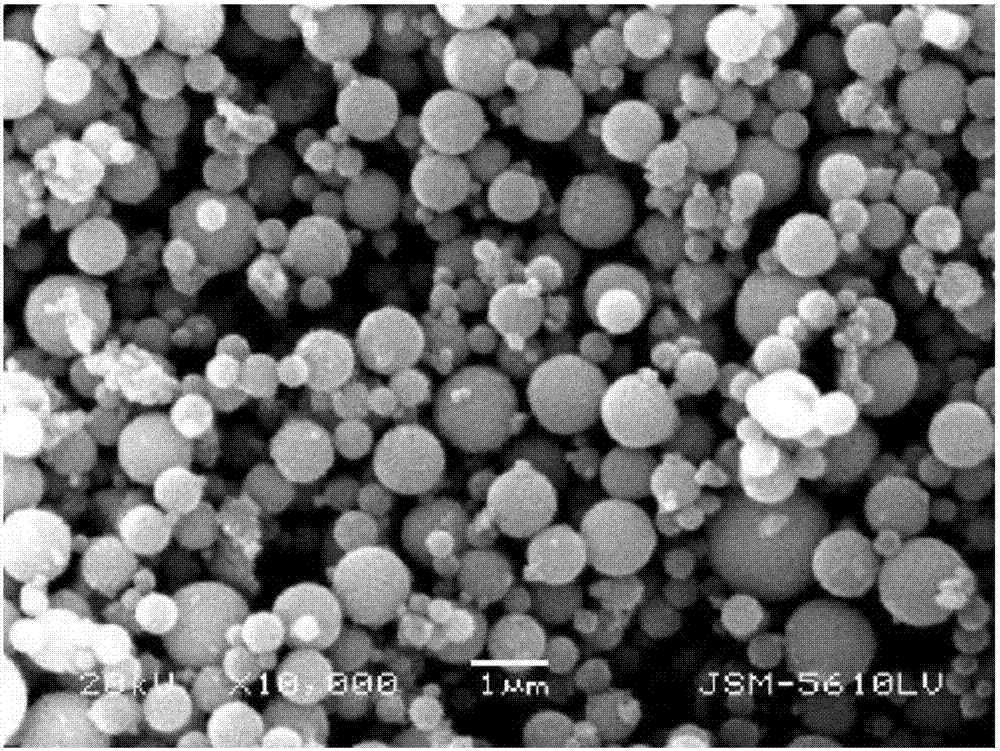

Method for preparing superfine spherical cobalt powder

The invention relates to a method for preparing ultrafine spherical cobalt powder. The method adopts the cobalt ore as the raw material and the homogeneous precipitation-thermal reduction method to continuously prepare the mono-disperse ultra-fine spherical cobalt powder, processes the tail liquid generated during the synthesis process, and returns the tail liquid to the production system for recycling, thereby reducing the wastewater discharge, saving the production water supply and realizing the environment-friendly industrialized mass production of the ultrafine spherical cobalt powder. The prepared product of the ultrafine cobalt powder is in the shape of spherical particle with uniform particle size and intensive distribution. The method has the advantages of simple process, low production cost, high production efficiency, no environmental pollution and suitability for industrialized mass production.

Owner:ZHEJIANG HUAYOU COBALT

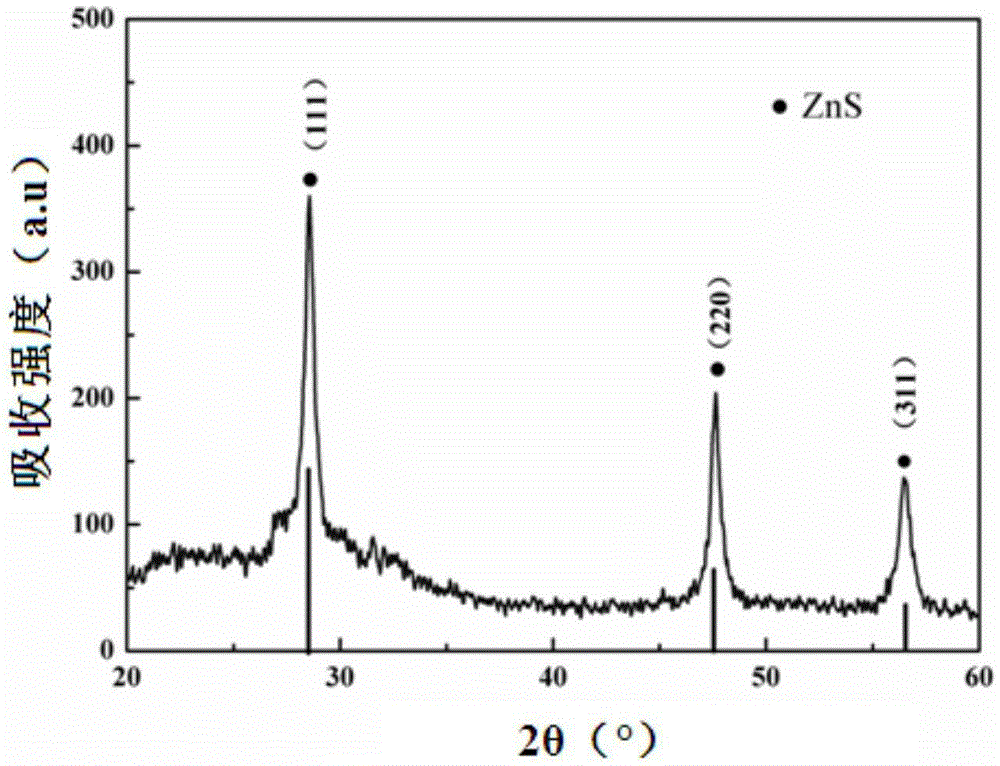

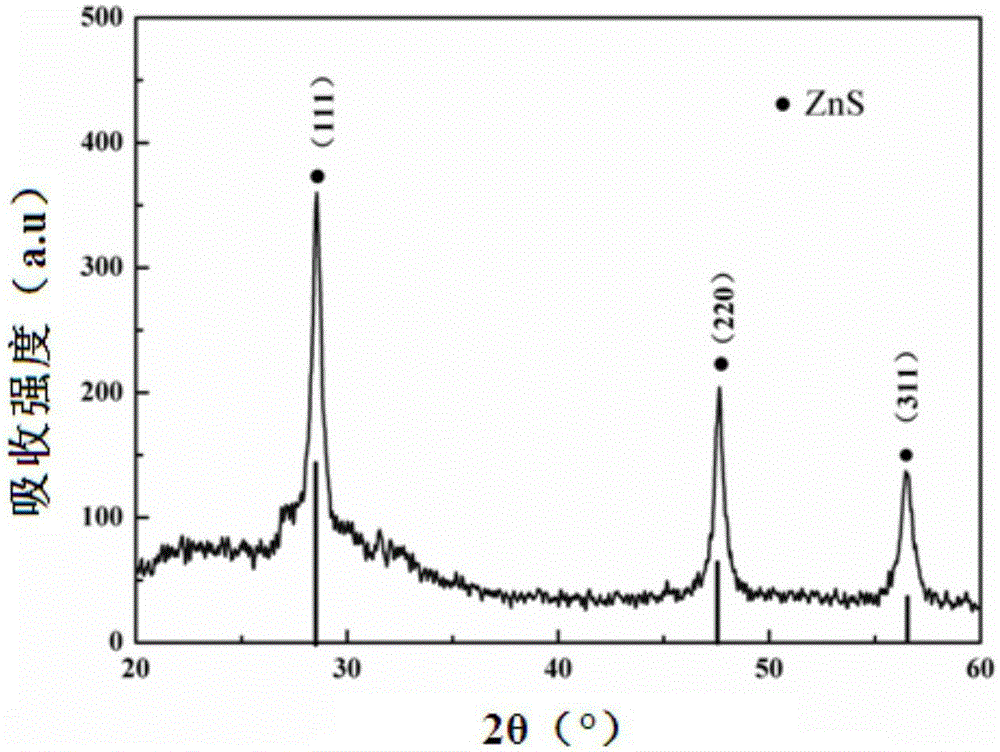

Low angle dependence blue ZnS structural color film and preparation method thereof

The present invention discloses a low angle dependence blue ZnS structural color film and a preparation method thereof, and belongs to the technical field of the preparation of the structural color material. The method is as follows: first, chemical homogeneous precipitation method is used to prepare uniform size ZnS microsphere nanoparticles, a film is produced on glass or ceramic substrate surface, and the film is calcined in a reducing atmosphere for protection, so that trace organics are carbonized to obtain the blue structural color film with uniform distributed carbon black. The method is simple, and highly repetitive, solves the technical problems that organic chemical paint is easy to fade and harmful to human body, meanwhile overcomes problems of high substrate requirements, harsh coating conditions and the like of opal structure photonic crystal, is suitable for construction of angle-dependent color-variable structural color pigments on surface of a variety of materials, and has broad application prospects. The prepared blue ZnS structural color film has uniform distributed carbon black, no angle dependence, good sphericity, and uniform particle size.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of high temperature resistant vanadium tungsten titanium oxide catalyst

InactiveCN104162421AHigh selectivityGood water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideTemperature resistance

Owner:NANJING UNIV OF SCI & TECH

Perparation of improved ZnS: Mn phosphors

InactiveUS20020149025A1Improve stabilityStructuredDischarge tube luminescnet screensLamp detailsPhosphorHomogeneous precipitation

Highly efficient ZnS:Mn phosphors can be obtained by using triazole or diazole compounds during homogeneous precipitation in aqueous medium. Coated layers containing such phosphors can be incorporated in Thin Film Inorganic Light Emitting Diodes.

Owner:AGFA GEVAERT AG

Preparation method for normal-temperature iron series hydrogen sulfide removal agent

The invention relates to a preparation method for a normal-temperature iron series hydrogen sulfide removal agent. The preparation method is characterized by including the steps of (1) alkaline activation of carrier clay and (2) homogeneous precipitation of load iron and copper. Compared with the prior art, the preparation method has the advantages that the method is high in controllability of preparation conditions and convenient to operate, the defect of poor reproducibility of grain products can be overcome, metal salt is converted completely, activity of the hydrogen sulfide removal agent is improved, and the hydrogen sulfide removal agent can be used for removal of hydrogen sulfide at the high air speed.

Owner:CHANGZHOU UNIV

Method for prepn. of electrode catalyst with function of anti-CD and contg. platinum and ruthenium series carried on carbon nanometer tube

InactiveCN1418725AHas the ability to resist COGood dispersionCell electrodesCatalyst activation/preparationPorosityIn situ chemical reduction

The preparation method of Pt-Ru series CO resistant electrode catalyst is characterized by that it uses carbon nano tube as carrier, utilizes the in-situ chemical reduction homogeneous precipitation method and makes the ions of Pt, Ru and Sn into compounding ion respectively (called complex ion for short), then it uses two kinds of three kinds of complex ions and mixes them together to obtain metastable colloid, them adopts cheap reduction agent formaldehyde (or sodium borohydride or ethyl alcohol or hydrogen gas) to make the metastable colloid be reduced and deposited on the activated carbonnano tube so as to obtain the invented electrode catalyst for proton-exchange membrane fuel cell. It possesses good electric catalytic activity and resistance to Co, and features large specific area,high porosity, good dispersion property and low ptatinum use level.

Owner:BEIJING JIAOTONG UNIV +1

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952AReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingCrystal systemInorganic salts

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

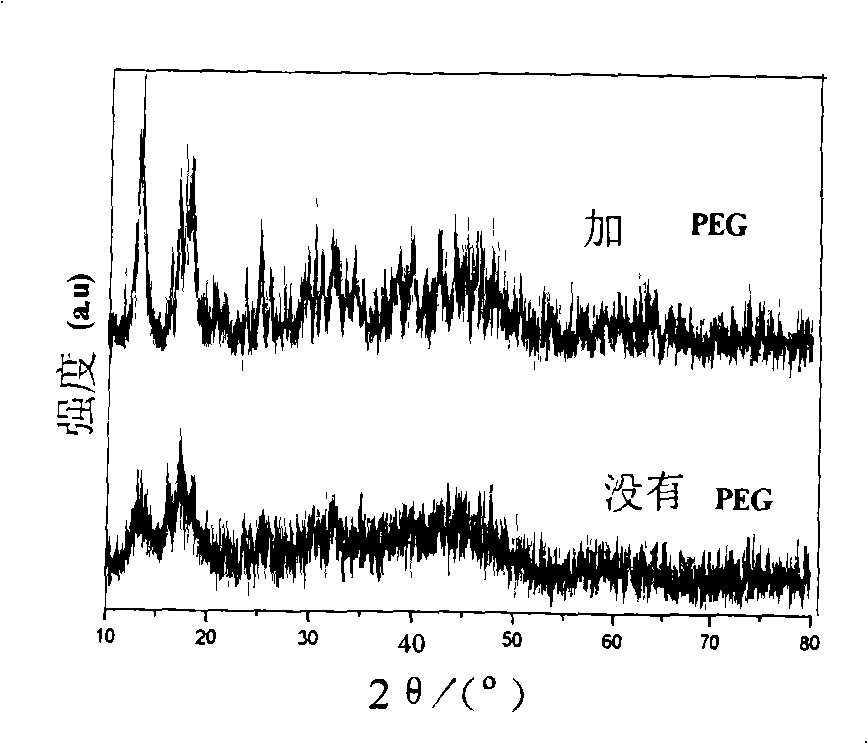

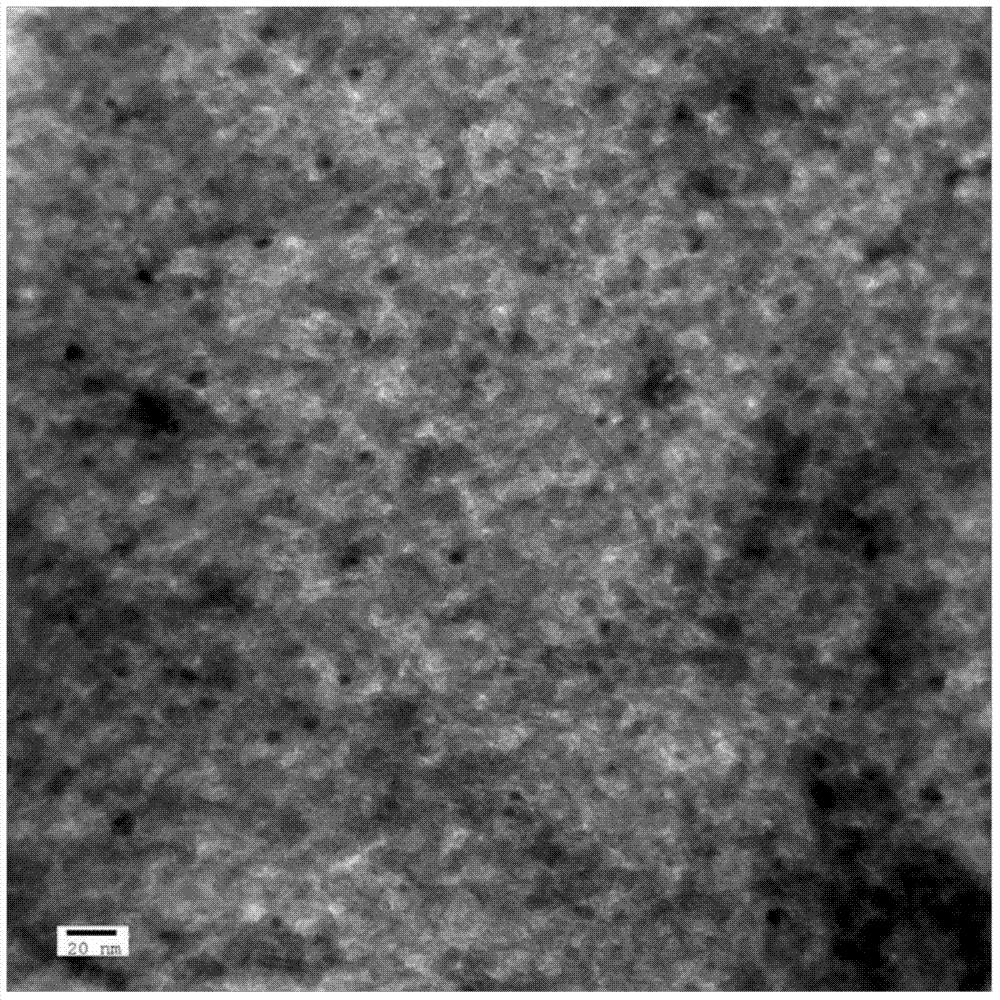

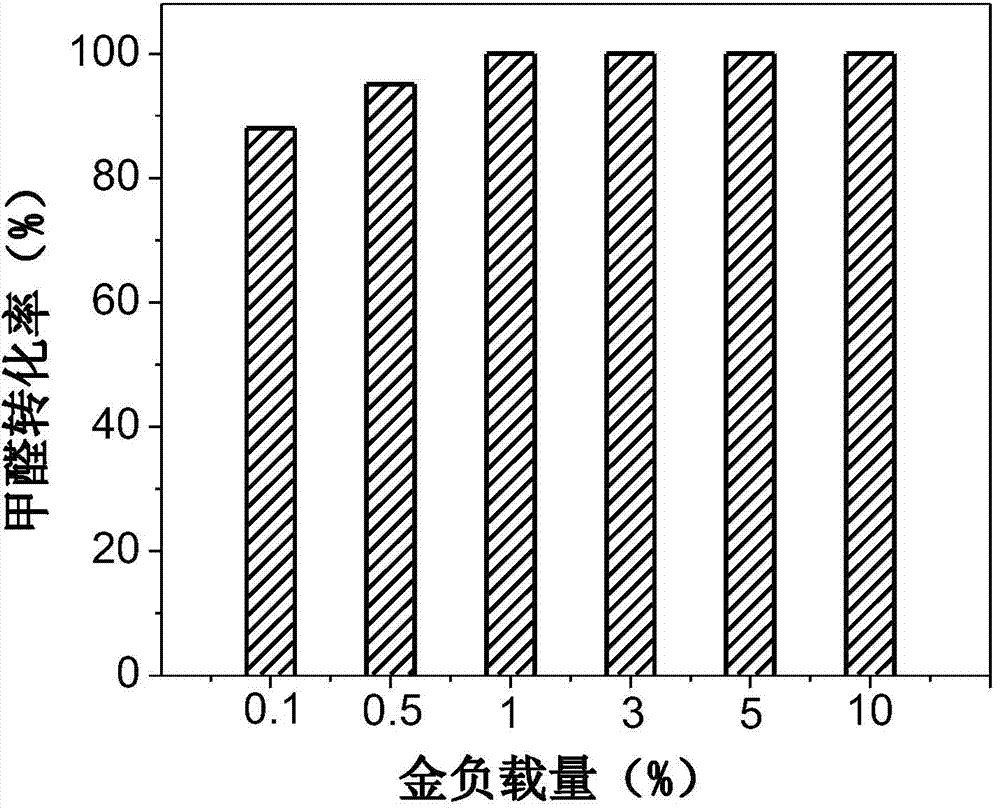

Method for applying gold hydroxyapatite loaded catalyst to catalytic oxidation reaction of formaldehyde at room temperature

InactiveCN103691461AMeet the actual use requirementsMeet the use requirementsPhysical/chemical process catalystsDispersed particle separationReaction temperatureCatalytic oxidation

The invention relates to a method for applying a gold hydroxyapatite loaded catalyst to catalytic oxidation reaction of formaldehyde at room temperature, belonging to the technical field of indoor air purification. The method is characterized by comprising the following steps: by taking calcium nitrate and diammonium hydrogen phosphate as precursors, obtaining hydroxyapatite by a liquid deposition method; by taking chloroauric acid as a precursor and the hydroxyapatite as a carrier, preparing the gold hydroxyapatite loaded catalyst by an urea homogeneous precipitation method, wherein the percentage by weight of Au is 0.1%-10%; and carrying out the reaction of removing formaldehyde by catalytic oxidation in a reactor, and passing formaldehyde gas through a gold hydroxyapatite loaded catalyst bed layer, wherein the reaction temperature is ranged from -15 DEG C to 25 DEG C. The method provided by the invention has the beneficial effects that formaldehyde pollutants are oxidized to CO2 and H2O at room temperature without complex operations such as temperature rising and heating. The method satisfies the actual using demands on indoor air purification, and has a wide application prospect in the field of indoor air pollutant purification.

Owner:DALIAN UNIV OF TECH

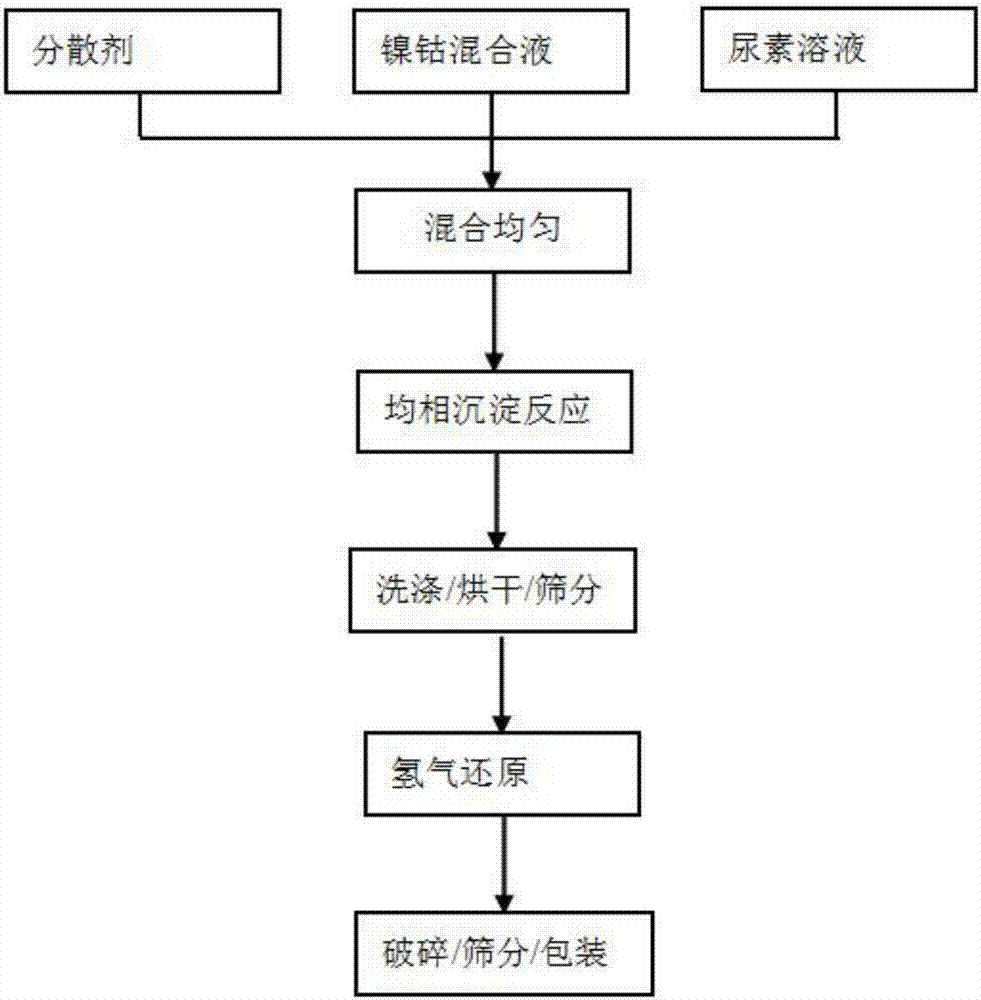

Preparation method of superfine nickel-cobalt alloy powder

PendingCN107088660AShort processLow costTransportation and packagingMetal-working apparatusHydrogenMicrometer

The invention relates to a preparation process of functional powder materials, and in particular to a preparation method of superfine nickel-cobalt alloy powder. The preparation method of the superfine nickel-cobalt alloy powder comprises the following steps that (1) mixing nickel-cobalt solution, a dispersing agent and urea according to a certain ration; (2) preparing a nickel-cobalt precursor precipitate by homogeneous precipitation reaction; (3) washing, drying and screening the nickel-cobalt precursor precipitate; (4) carrying out hydrogen reduction on the nickel-cobalt precursor precipitate to obtain the nickel-cobalt alloy powder; and (5) crushing, screening and packaging the nickel-cobalt alloy powder to carrying out post-treatment. Compared with an existing method, the preparation method adopts the homogeneous coprecipitation to prepare the nickel-cobalt precursor, then the hydrogen reduction is carried out to obtain the superfine nickel-cobalt alloy powder, and the obtained product is uniform in particle size distribution and low in impurity (carbon, sulfur and the like) content, the powder is spherical, products with the particle size ranging from 0.2 micrometers to 10 micrometers can be prepared, and the nickel-cobalt alloy powder can be widely applied to various industries.

Owner:张成亮

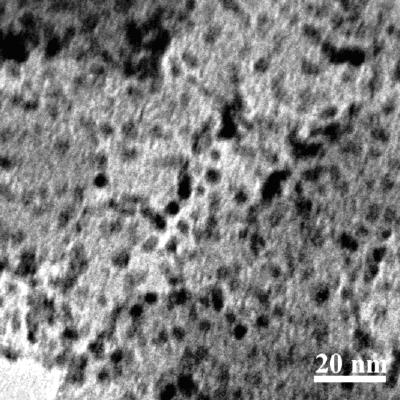

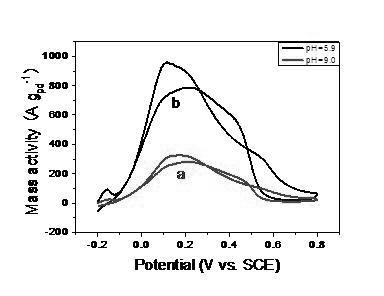

Method for preparing carbon loading Pd nanometer particle catalyst by using homogeneous precipitation-reduction in situ method

InactiveCN102078811AHigh catalytic activityImprove catalytic stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsDose ReducedHomogeneous precipitation

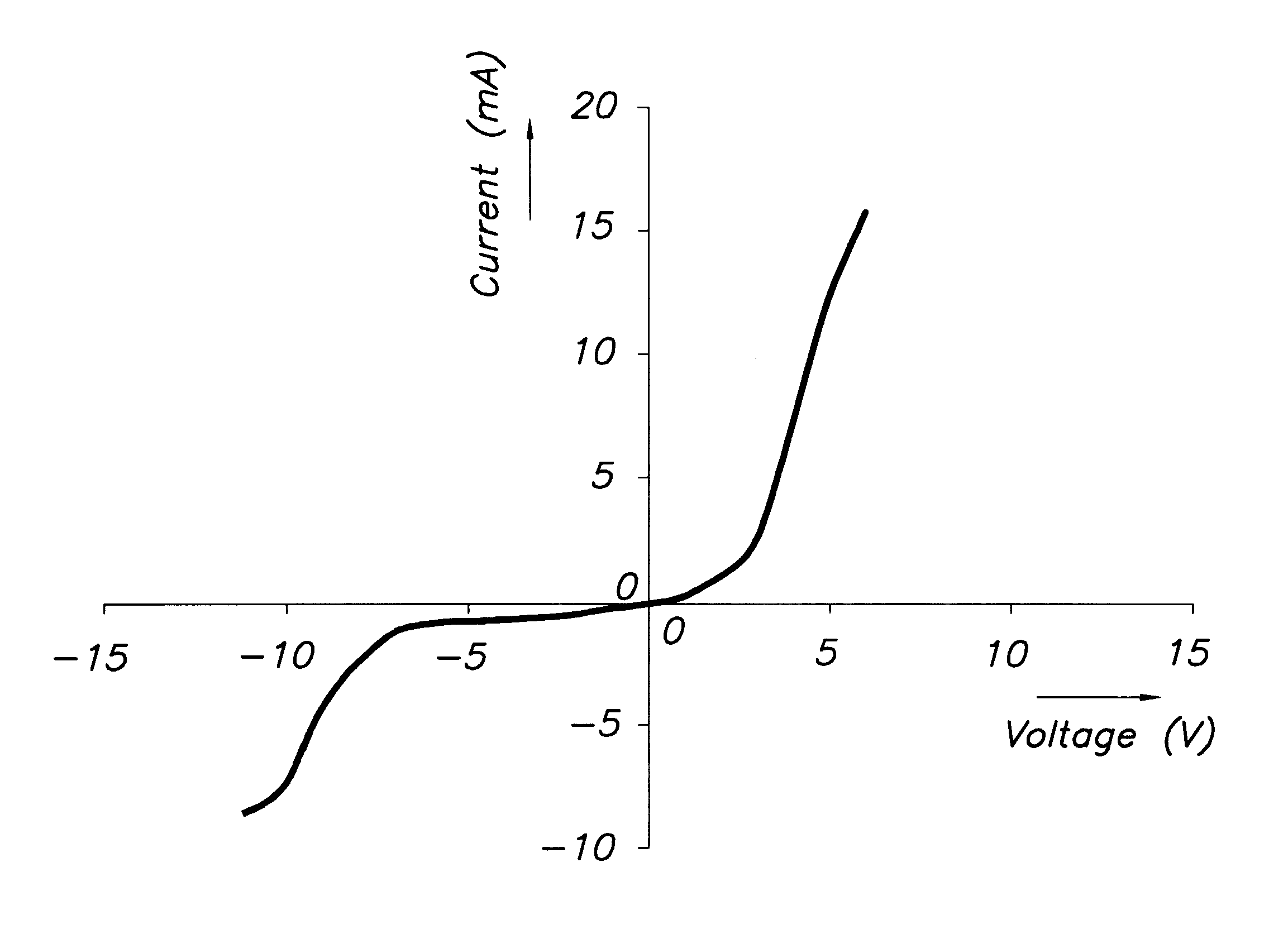

The invention discloses a method for preparing a Pd nanometer particle catalyst by using a homogeneous precipitation-reduction in situ method, which comprises the following steps of: adding a soluble PdII salt solution into a certain quantity of carbon carrier suspending solution; regulating pH of a mixture solution to be between 5.6 and 7.4; heating the solution at 30-100 DEG C; heating and hydrolyzing the soluble PdII salt solution to obtain a component A, i.e. carbon loading PdO.H2O nanometer particles; adding over-dose reducing agents into the component A and fully stirring so that the carbon loading PdO.H2O nanometer particles are fully reacted with the reducing agents; carrying out the reduction in-situ to obtain a component B; washing the component B; and drying the component B under the protection of vacuum or inert gases to obtain the carbon loading Pd nanometer particle (Pd / c) catalyst. The catalyst obviously improves the electro-catalysis performance of formic acid and shows excellent electro-catalysis activity and stability. The preparation method of the invention is simple and economic, and is suitable for industrial large-scale production.

Owner:JIANGSU DAOBO CHEM

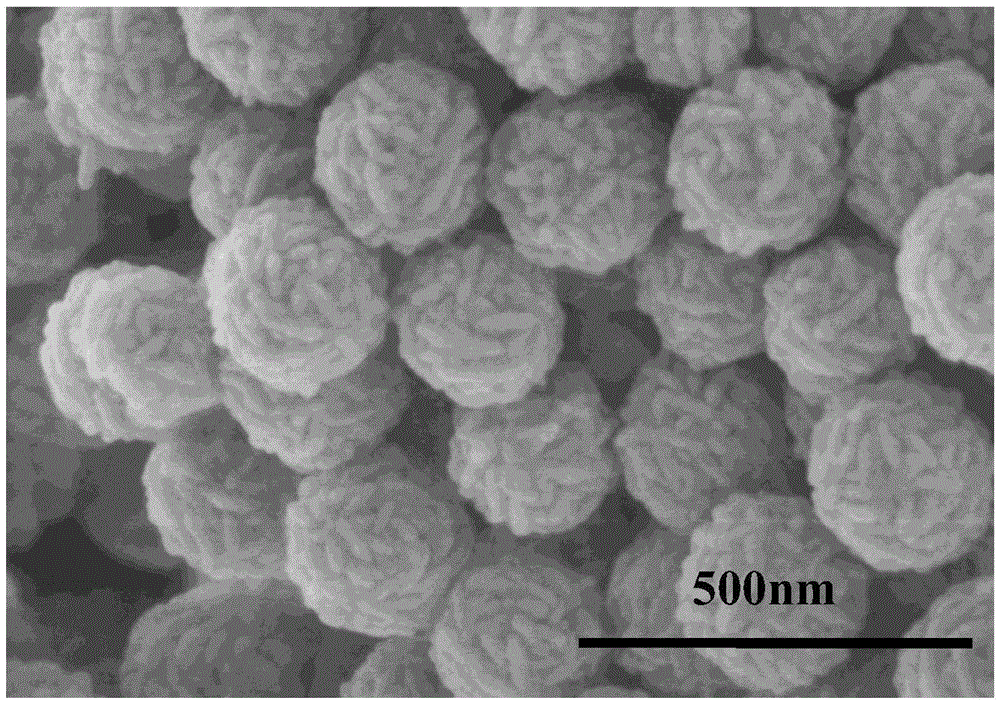

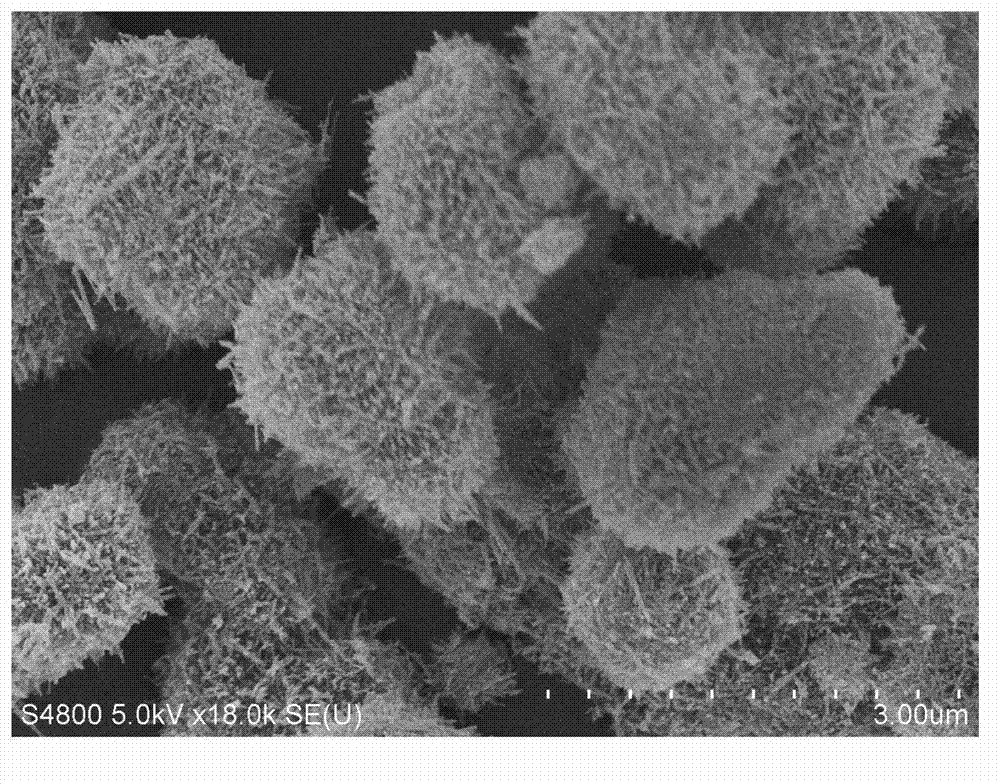

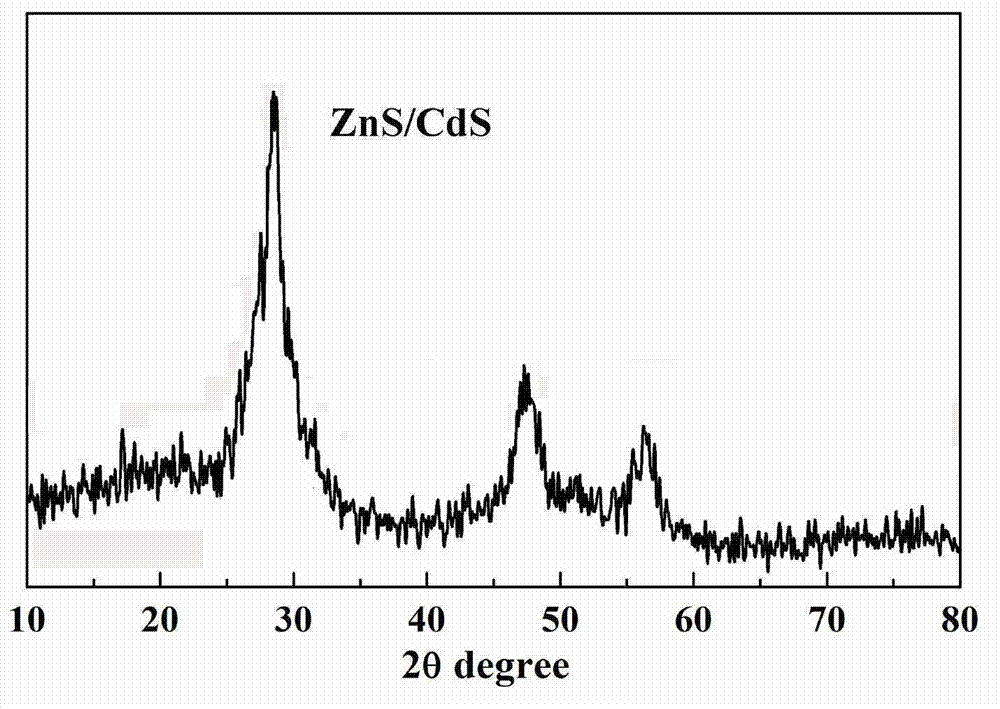

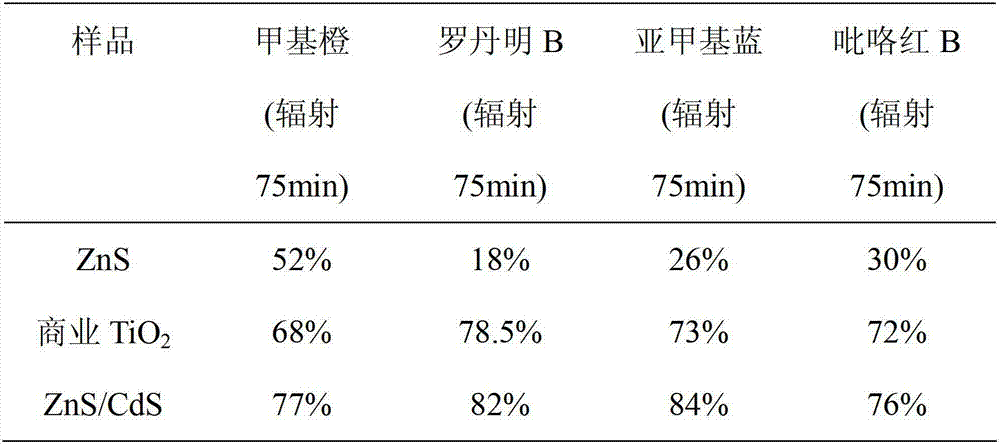

Preparation method of three-dimensional echinoid ZnS/CdS composite semiconductor photocatalytic nano material

InactiveCN103111309AUnique three-dimensional sea urchin-like structureHigh catalytic activityPhysical/chemical process catalystsNanoparticleHomogeneous precipitation

The invention relates to a preparation method of a three-dimensional echinoid ZnS / CdS composite semiconductor photocatalytic nano material, which comprises the following steps: preparing uniform-size echinoid ZnS, and carrying out functional assembly on CdS nanoparticles; and by combining the advantages of ZnS and CdS, preparing the three-dimensional ZnS / CdS echinoid nano composite catalyst by a solvothermal and homogeneous precipitation process. The invention aims to solve the problem of low efficiency in the ZnS photocatalysis. The ZnS / CdS composite semiconductor photocatalytic nano material provided by the invention has a unique three-dimensional echinoid structure, and is composed of hexagonal crystal echinoid ZnS and hexagonal structure CdS nanoparticles. The invention has the advantages of high catalytic activity, low cost, accessible raw materials, simple preparation technique and favorable repetitiveness, and has favorable application prospects.

Owner:SHAANXI UNIV OF SCI & TECH

Methods for producing monodispersed particles of barium titanate

InactiveUS6264912B1Energy efficiencyAlkaline earth titanatesZirconium compoundsMicrosphereBarium titanate

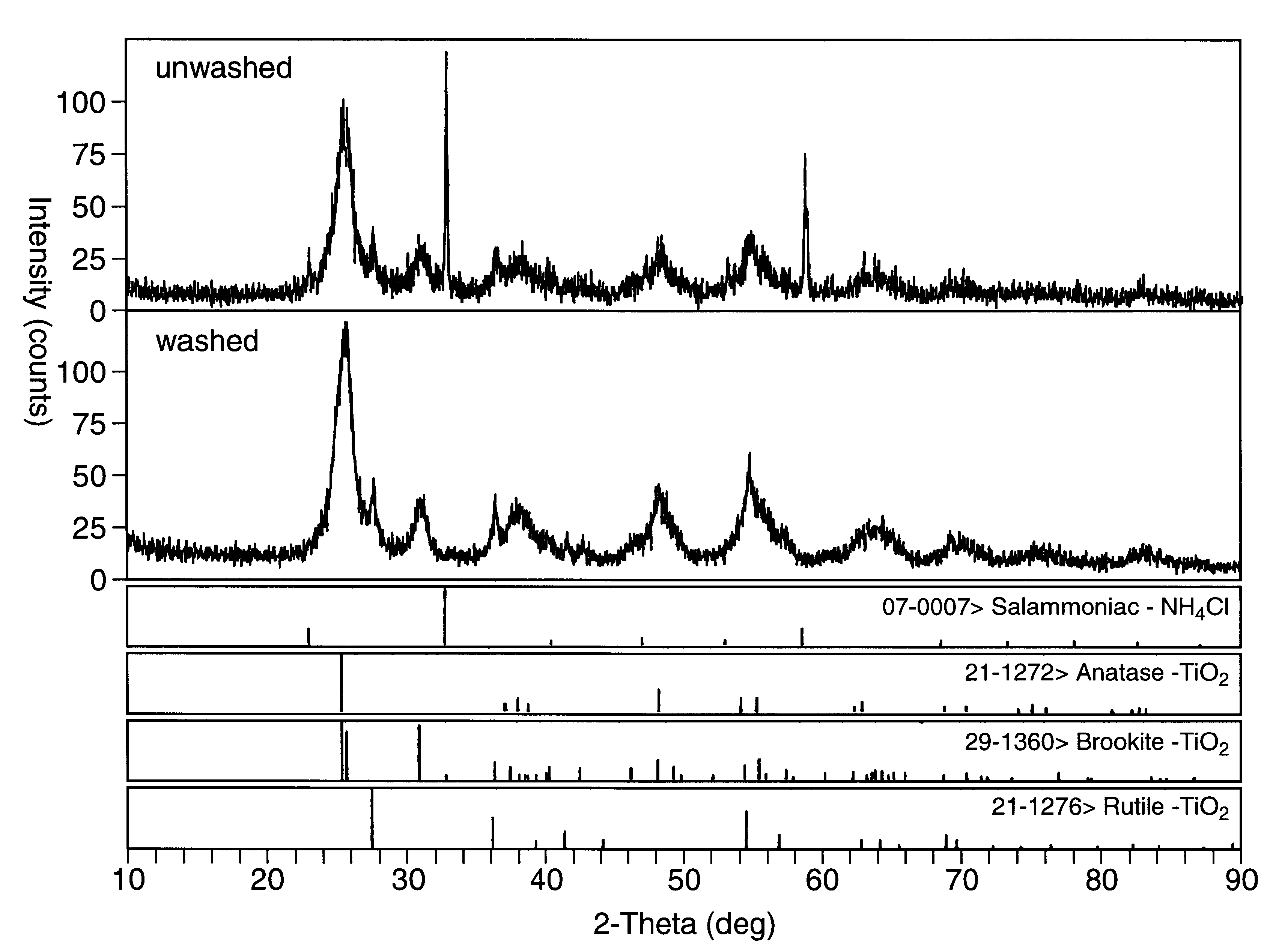

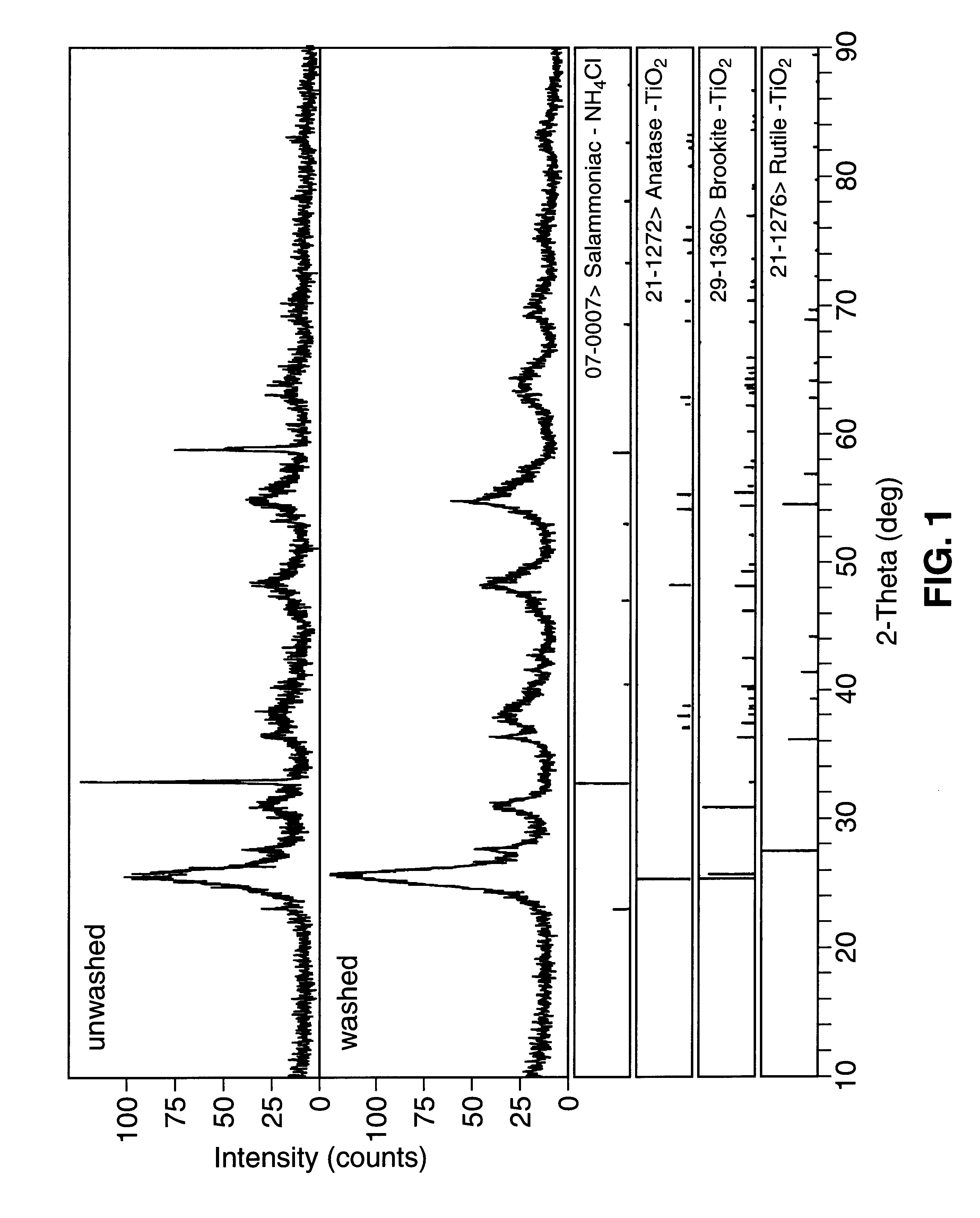

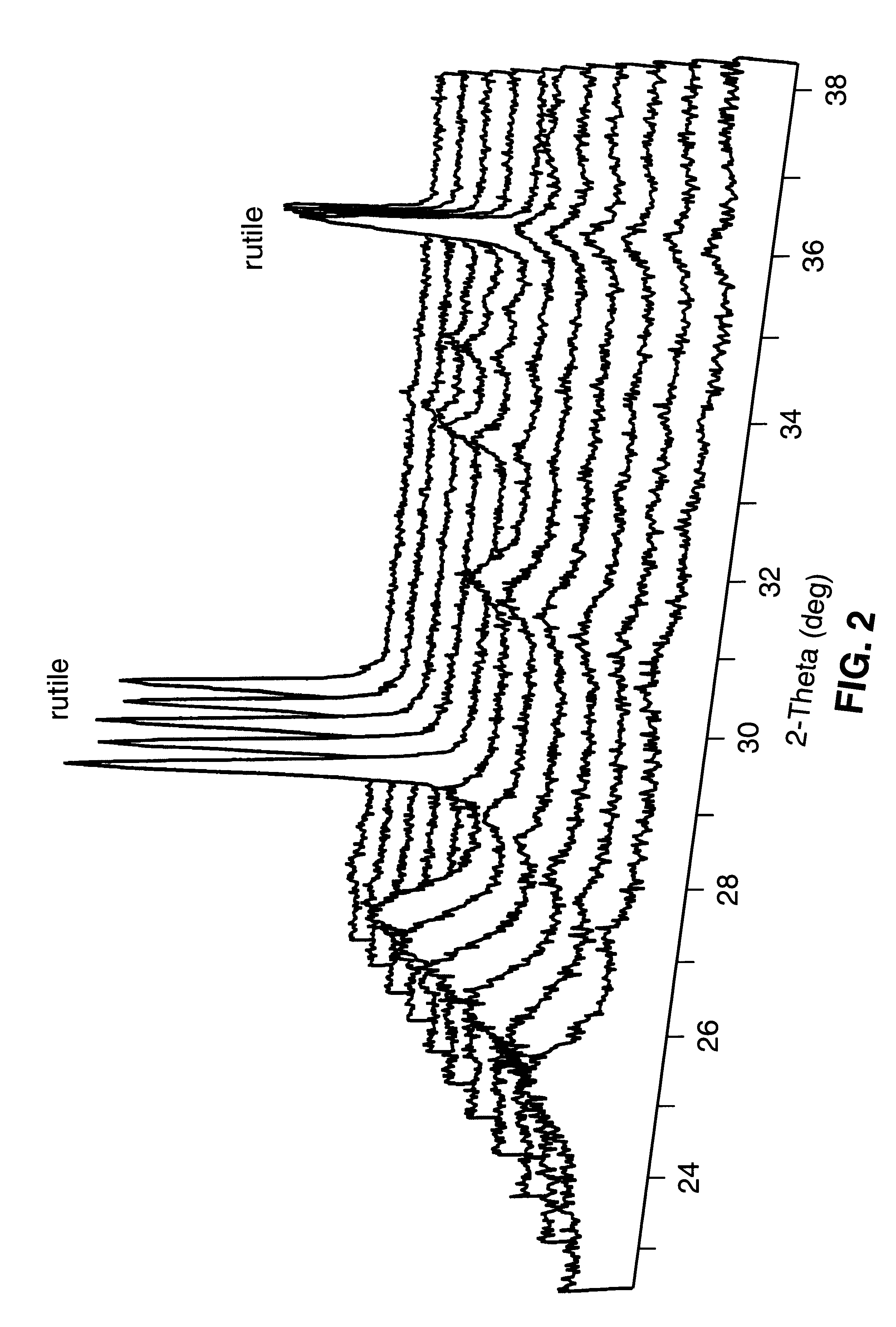

The present invention is a low-temperature controlled method for producing high-quality, ultrafine monodispersed nanocrystalline microsphere powders of barium titanate and other pure or composite oxide materials having particles ranging from nanosized to micronsized particles. The method of the subject invention comprises a two-stage process. The first stage produces high quality monodispersed hydrous titania microsphere particles prepared by homogeneous precipitation via dielectric tuning in alcohol-water mixed solutions of inorganic salts. Titanium tetrachloride is used as an inorganic salt precursor material. The second stage converts the pure hydrous titania microsphere particles into crystalline barium titanate microsphere powders via low-temperature, hydrothermal reactions.

Owner:LOCKHEED MARTIN ENERGY SYST INC

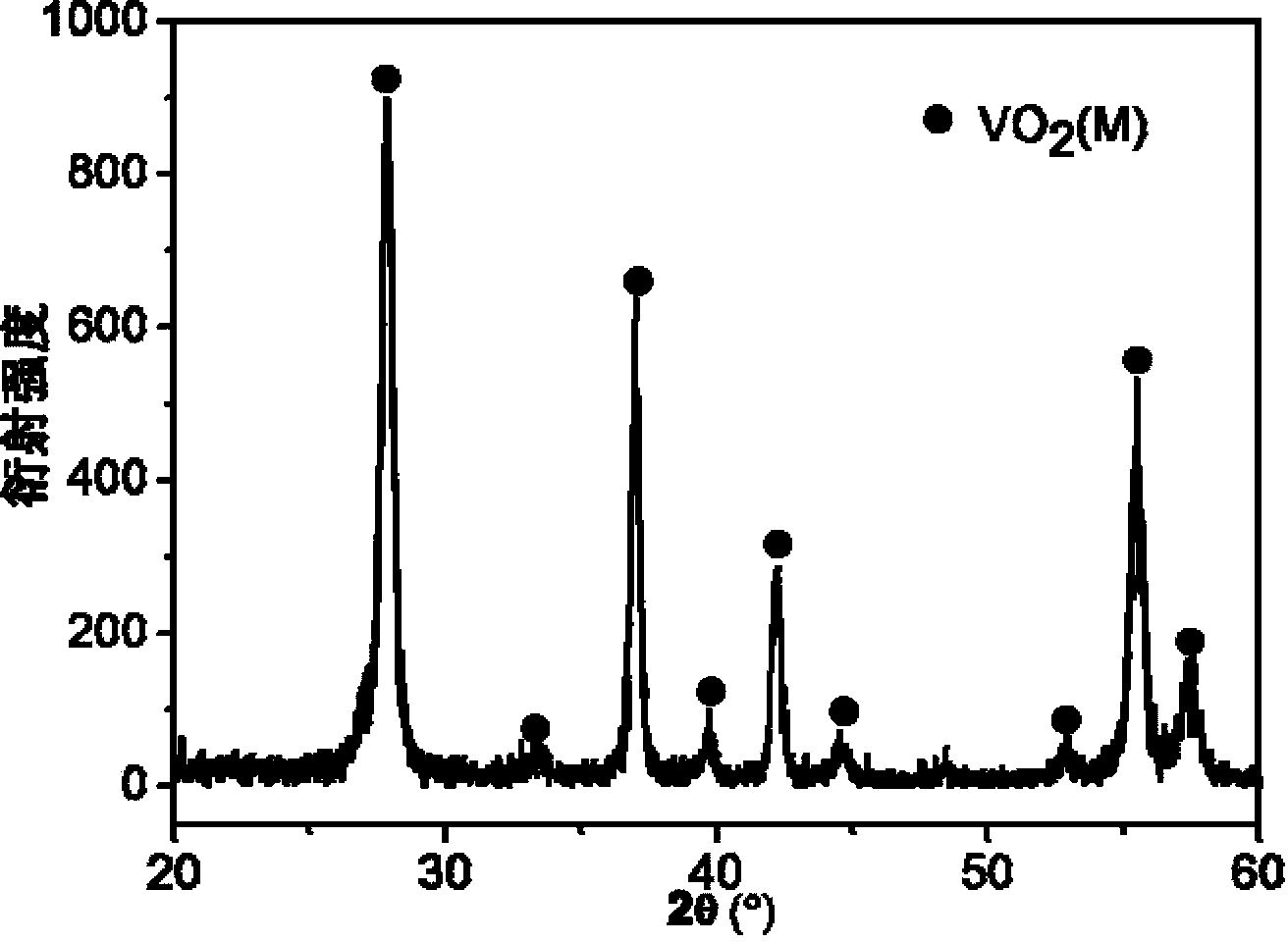

Method for preparing vanadium dioxide powder through hydrothermal auxiliary homogeneous precipitation method

InactiveCN103880080AUniform particle size distributionHigh purityNanotechnologyVanadium oxidesVanadium dioxideAmmonium hydroxide

The invention relates to a method for preparing vanadium dioxide powder through a hydrothermal auxiliary homogeneous precipitation method. The method disclosed by the invention comprises the following steps of (1), adding a homogeneous precipitation agent into aqueous solution containing tetravalent vanadium ion, and uniformly stirring to form mixed solution; and (2), transferring the obtained mixed solution into a hydrothermal kettle, preserving heat at 200-350 DEG C for 1-120 h, carrying out hydrothermal reaction, cooling, centrifuging, washing, and drying, thereby obtaining vanadium dioxide powder, wherein the homogeneous precipitation agent is a substance capable of being slowly hydrolysed to generate precipitation ion in hydrothermal reaction in the step (2), the precipitation ion is hydroxyl ion, and the mol ratio of tetravalent vanadium ion to the homogeneous precipitation agent is 1:5 to 2:1. By means of the homogeneous precipitation agent, on the one hand, the yield can be increased, and on the other hand, the phenomenon of being non-uniform in local concentration of solution caused by using direct precipitators (such as ammonium hydroxide and sodium hydroxide solution) is avoided, and therefore, monodispersed high-purity nano powder can be obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of activated carbon fiber loaded titanium dioxide photocatalyst

InactiveCN103100378AAvoid uneven loadSimple processPhysical/chemical process catalystsFiberCarbon fibers

The invention relates to a preparation method of an activated carbon fiber loaded titanium dioxide photocatalyst. Characterized by employing an oxidation modification and homogeneous precipitation combined technology to prepare a titanium dioxide / activated carbon fiber photocatalyst, the method mainly comprises the steps of: soaking activated carbon fiber inhydrogen peroxide for 1 hour, then taking it out and conducting washing with deionized water, performing drying in an oven for 4 hours, and taking the activated carbon fiber out for stand-by use; preparing a mixed solution of a titanium salt and urea according to certain mole ratio, stirring the solution evenly for 3 hours for stand-by use; placing the treated activated carbon fiber in the mixed solution of the titanium salt and urea, conducting stirring for 5 hours under 80DEG C, after complete reaction, taking the activated carbon fiber out, and drying it in the oven at 100DEG C; and roasting the dried activated carbon fiber for 2 hours under nitrogen protection, thus obtaining the titanium dioxide / activated carbon fiber photocatalyst. The method provided in the invention has the characteristics of simple preparation process, uniform load, and high photocatalytic efficiency, etc.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A kind of production method of polyaluminum chloride

InactiveCN102295305AReduce manufacturing costReduced settling timeAluminium chloridesWater/sewage treatment by flocculation/precipitationLiquid productAluminium chlorohydrate

The invention relates to a production method of polyaluminium chloride, the main features of which are: adding industrial hydrochloric acid into a reaction kettle, adding aluminum ash while stirring, then adding a catalyst, passing steam to raise the temperature for reaction, and the reaction temperature is controlled at 85-95 ℃, reaction time 1-1.5 hours; stop the steam, add calcium aluminate powder into the reaction kettle, control the temperature at 95-115 ℃, react for 1-1.5 hours, control the basicity of the product through the addition of calcium aluminate powder . At the end of the reaction, add a precipitation accelerator, stir and precipitate evenly for 12-14 hours, and then transfer the upper liquid to the finished product tank to obtain a liquid polyaluminum chloride product. The present invention adds a catalyst before the reaction, and adds a precipitation accelerator to accelerate the precipitation at the end of the reaction, which can effectively reduce the water-insoluble matter of the product from more than 1.0% to less than 0.3%, and reduce the precipitation time of the product from the original 5-7 The world is reduced to 12-14 hours, which greatly shortens the settling time, improves production efficiency and reduces production costs.

Owner:YUEYANG ANTAI IND CO LTD

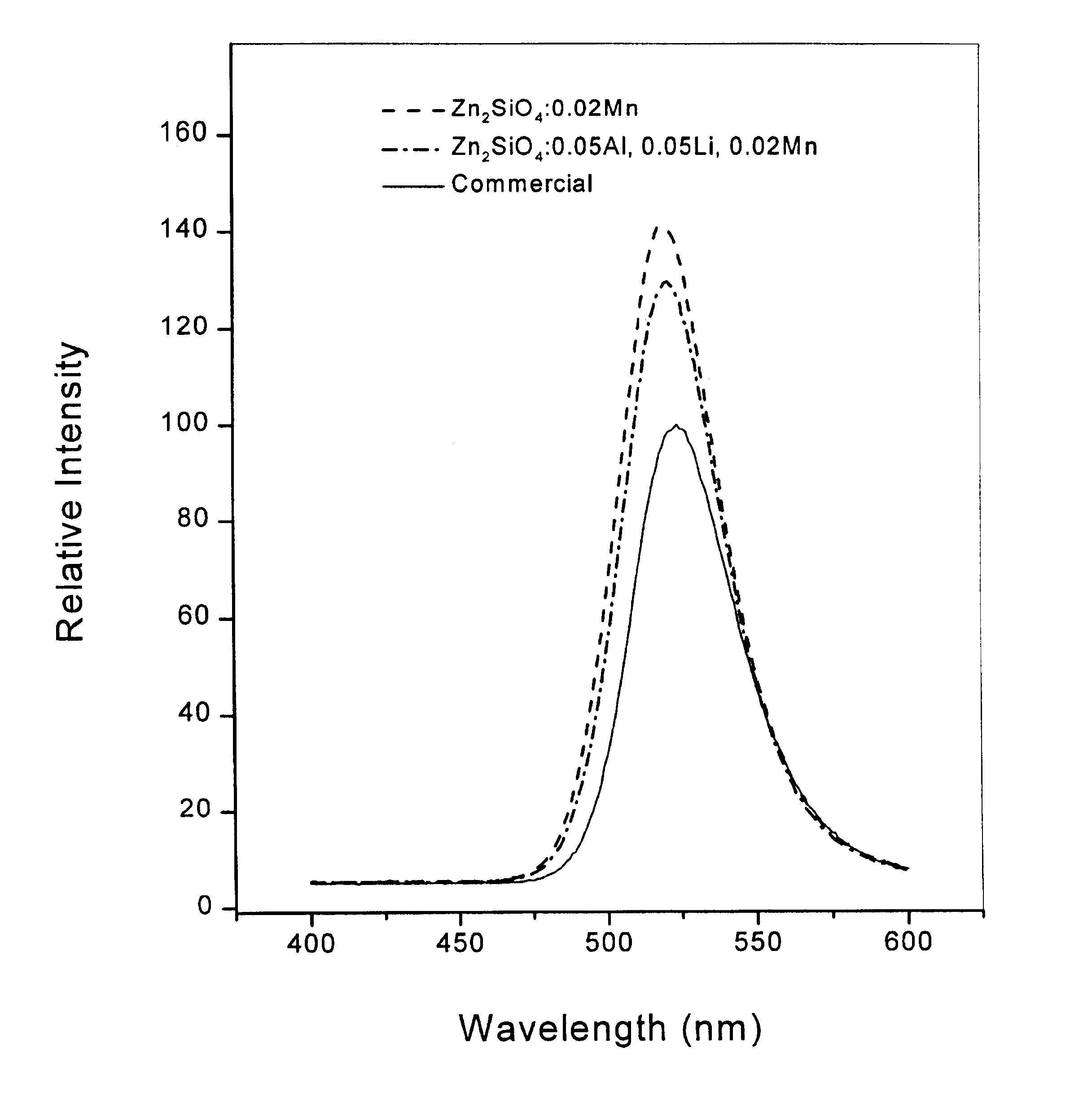

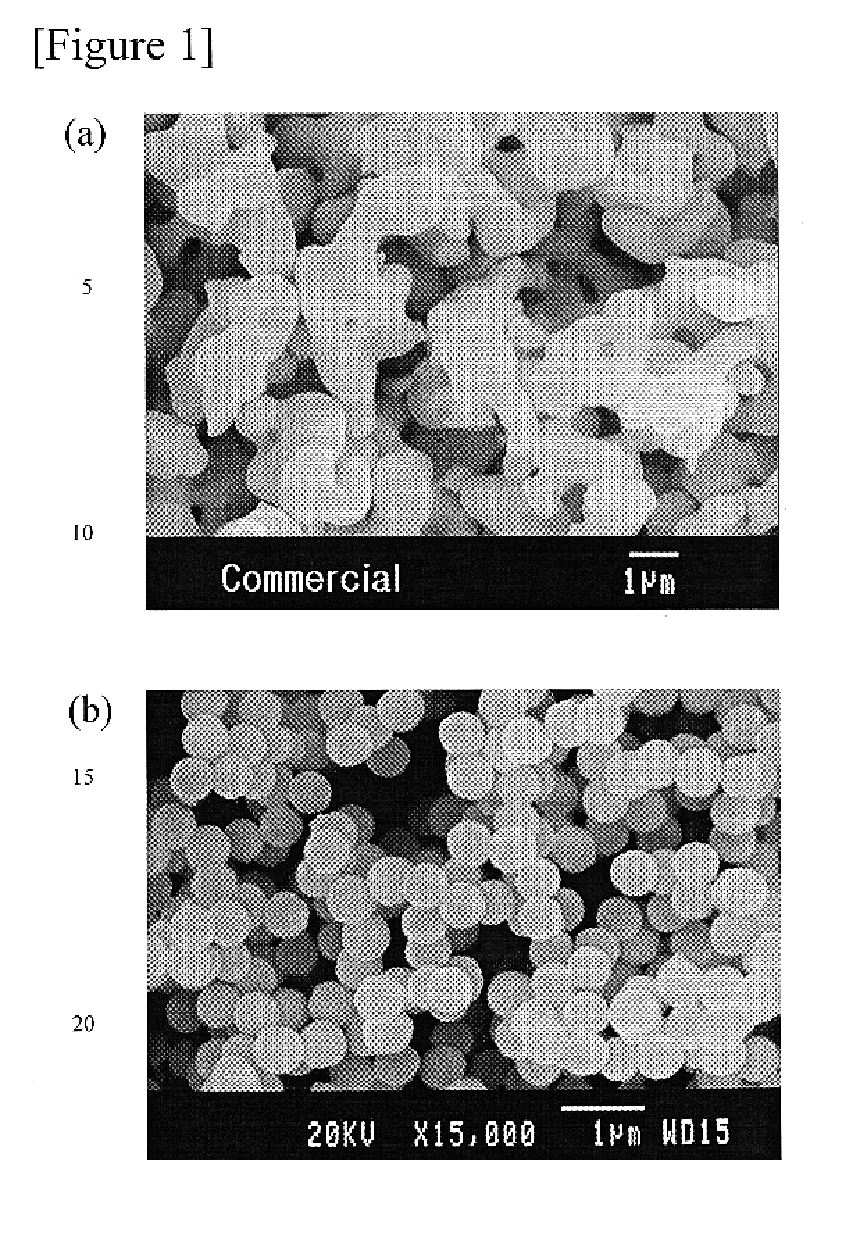

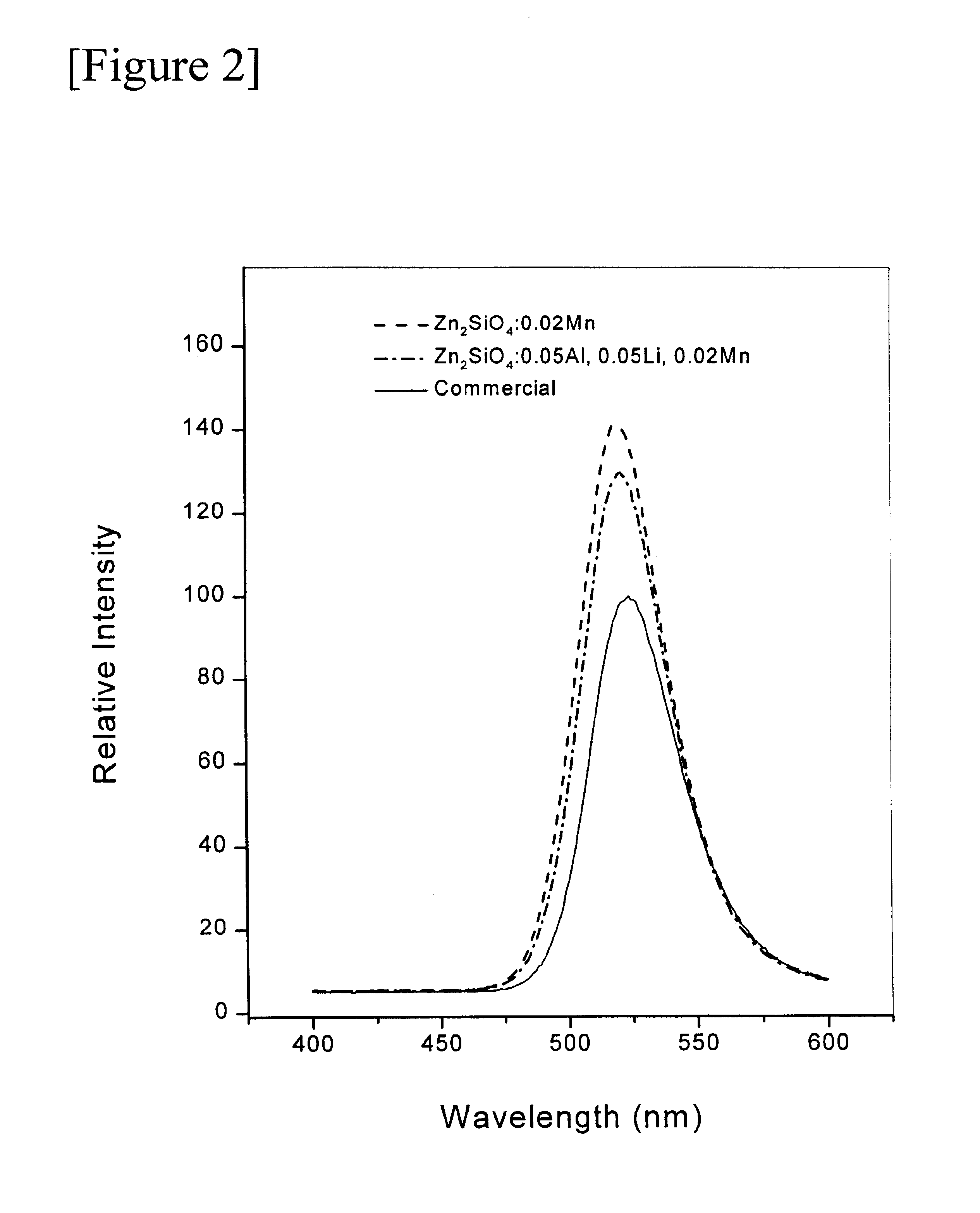

Preparing green phosphor based on zinc orthosilicate

This invention relates to a process for preparing a spherical green-emitting phosphor based on zinc orthosilicate and more particularly, to the process for a zinc orthosilicate-based green-emitting phosphor demonstrating an emission spectrum at visible regions, when excited by electron beam, via a new application of 'the homogeneous precipitation method' comprising the following steps such as i) a solution of tetraethylorthosilicate (TEOS) diluted in ethanol is hydrolyzed to obtain a hydrated silica, ii) said hydrated silica is dispersed together with the solution containing zinc and manganese components, iii) a precipitant selected from oxalic acid and oxalates is added to said dispersed solution together with a basic solution, while precipitating zinc and manganese components, iv) said admixture precipitate, so filtered off and dried, is calcined in the air and reheated under the reducing atmosphere to generate a phosphor powder; hence, the above-described phosphor particle is quite effective in a variety of display fields of industry including PDP, since it has a spherical shape with less agglomeration and homogeneous distribution of manganese, an activator, thus proving superior to the conventional phosphor prepared by the solid state reaction method in terms of brightness.

Owner:KOREA RES INST OF CHEM TECH

Preparation method of Al2O3-SiO3 solid acid catalyst in nuclear shell structure

InactiveCN101850244ARaw materials are cheap and easy to getHigh activityPhysical/chemical process catalystsEther preparation by compound dehydrationSolid acidSilica gel

The invention relates to a preparation method of an Al2O3-SiO3 solid acid catalyst in a nuclear shell structure. The Al2O3-SiO3 solid acid catalyst in the nuclear shell structure contains 10-80 wt% of Al2O3,is made from raw material of silica gel and an aluminum source of aluminum nitrate by adopting a homogeneous precipitation method. The preparation method is simple, the raw materials are low-cost and easily obtainable, and the prepared catalyst is used in a methanol dehydration reaction for generating dimethyl ether and has higher activity and stability at a lower temperature of 250-310 DEG C.

Owner:ZHEJIANG UNIV

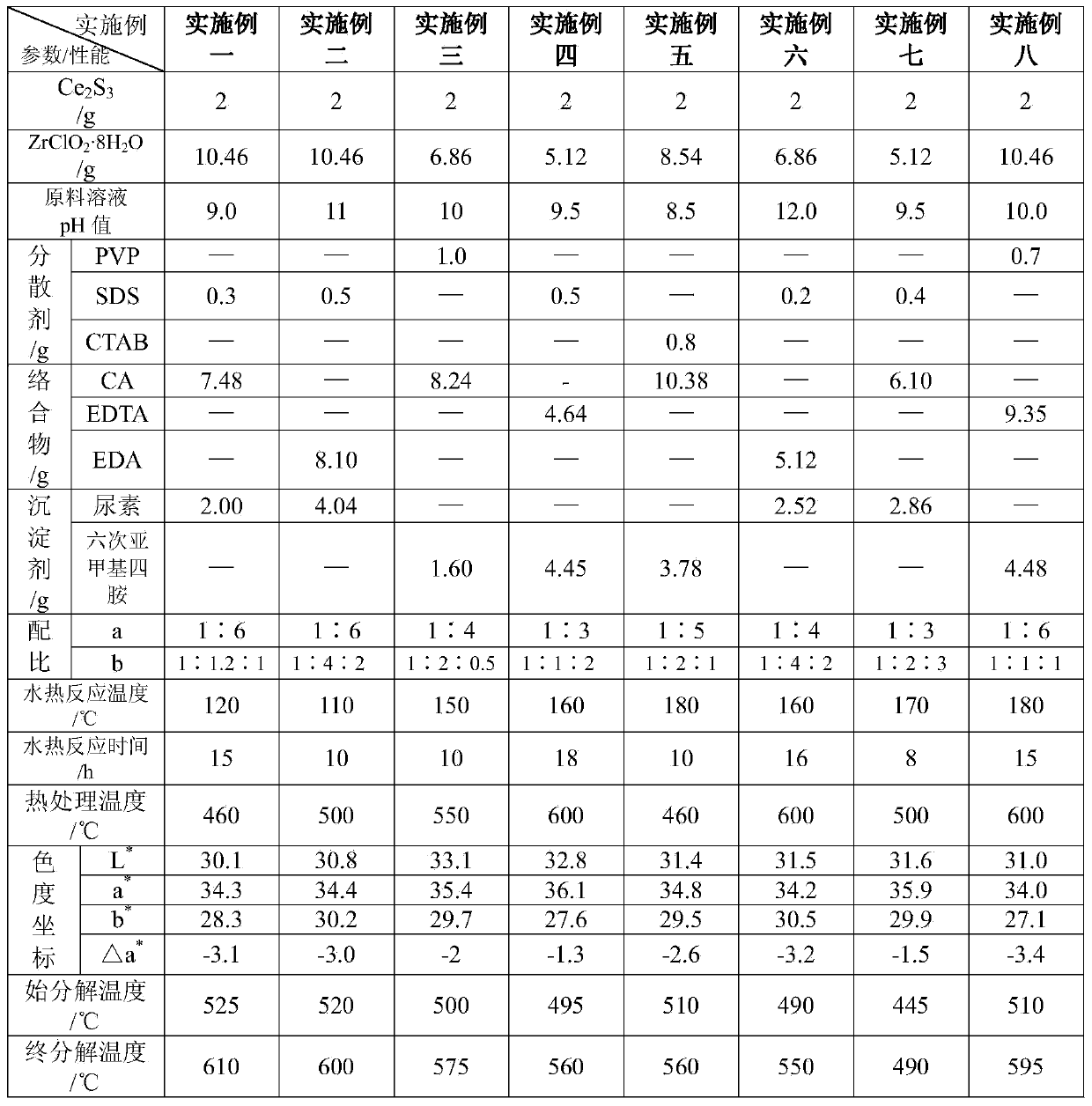

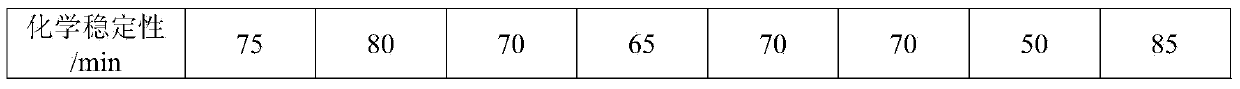

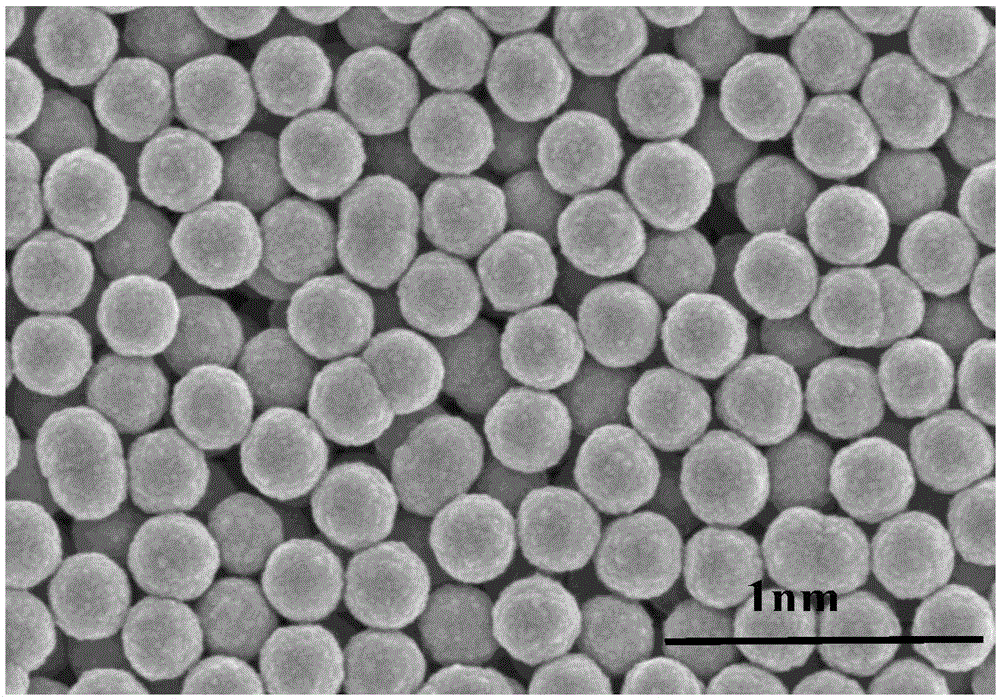

Red ZrO2-coated gamma-Ce2S3 pigment and preparation method thereof

ActiveCN103992660ARealize comprehensive applicationImprove product qualityPigment physical treatmentHomogeneous precipitationChemical stability

The invention discloses a red ZrO2-coated gamma-Ce2S3 pigment comprising a gamma-Ce2S3 chromogen core and a ZrO2 shell coated outside the chromogen core. In addition, the invention also discloses a preparation method of the red ZrO2-coated gamma-Ce2S3 pigment. According to the invention, the red ZrO2-coated gamma-Ce2S3 pigment is firstly prepared by using a homogeneous precipitation method, the breakthrough of a preparation technology of the red coated gamma-Ce2S3 pigment is realized, and the red ZrO2-coated gamma-Ce2S3 pigment is remarkably improved on oxidation resistance and chemical stability, favorable in dispersing performance, widened in application field and beneficial to popularization and development of a production technology.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Low-angle-dependence violet zinc-sulfide structural color film and preparing method thereof

InactiveCN105175015ALow roughness requirementsHigh color saturationAngle dependenceShort range order

The invention discloses a violet zinc-sulfide photonic crystal structural color film and a preparing method thereof, and belongs to the technical field of photonic crystal material preparing. The preparing method includes the steps that zinc sulfide microsphere nano-particles with uniform particle sizes are firstly prepared with a chemical homogeneous precipitation method, a short-range order film is prepared and then roasted in protection atmosphere to enable a trace of organic substances to be carbonized, and therefore the violet structural color film with evenly-distributed carbon black is obtained. The preparing method is simple, repeatability is high, the technical problems that chemical organic pigment is prone to fading and is harmful to the human body are solved, and meanwhile the problems that the requirements of opal structure photonic crystals for a substrate are high, and film coating conditions are strict are solved. The operating process is simple and practicable, large-scale industrial production can be achieved, the preparing method is suitable for building optically-variable-free structural color pigment on the surfaces of various materials, and the broad application prospects are achieved. The prepared violet zinc-sulfide photonic crystal structural color film is even in carbon black distribution, free of angle dependence, good in sphericity degree and uniform in particle size.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing inorganic crystal whisker with SiO2-coated surface

InactiveCN1569746AThickness is easy to controlGood surface modificationPolycrystalline material growthAfter-treatment detailsAcetic acidCoated surface

Disclosed is a method for preparing inorganic crystal whisker with SiO2-coated surface which comprises, subjecting the inorganic crystal whisker to decentralized processing in precursor solution, carrying out inorganic coating by employing homogeneous precipitation method, thermal insulating and ageing, filtering, scouring, and drying to obtain the inorganic crystal whisker with SiO2-coated surface.

Owner:SHANGHAI JIAO TONG UNIV

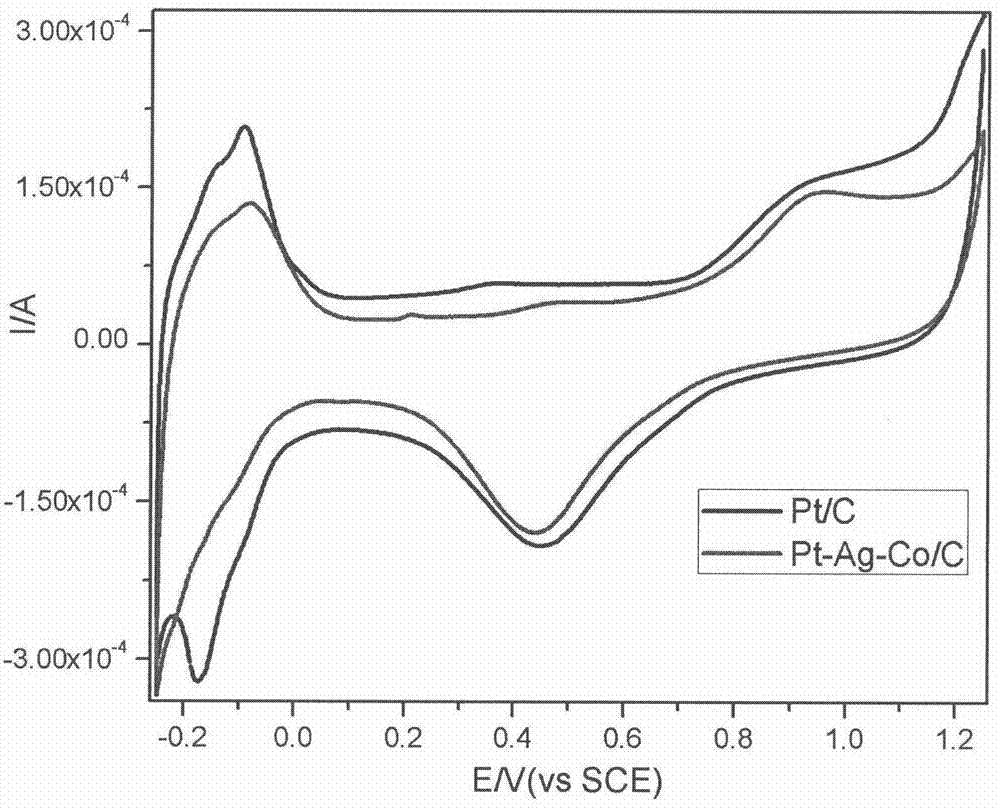

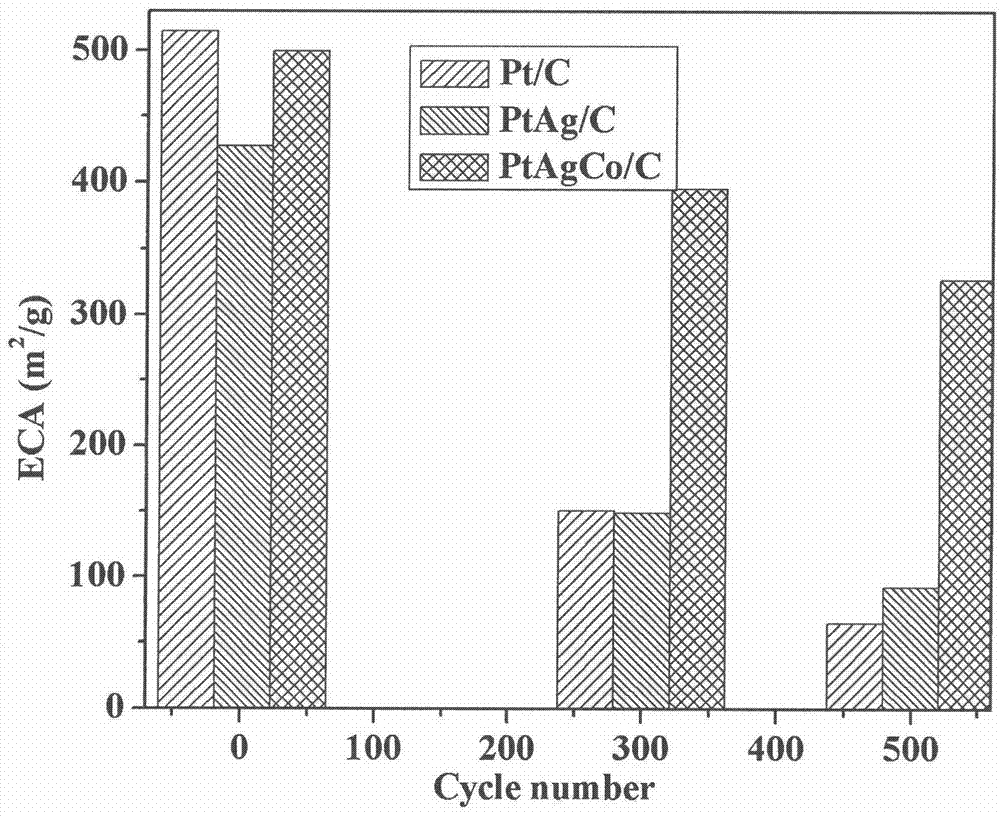

Preparation method of Pt-Ag-Co/C catalyst

InactiveCN104707625ASimple preparation processLow costCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystIn situ chemical reduction

The invention relates to a preparation method of a proton exchange membrane fuel cell carbon-supported metal electrocatalyst. The active component of the electrocatalyst is Pt-Ag-Co, an atom ratio of Pt:Ag:Co is 20:1:0.01-1:20:0.01, and the mass percentage content of the active component is 10-50%. The preparation method comprises the following steps: 1, dissolving processed carbon powder in an alcohol solvent, carrying out ultrasonic treatment to obtain a uniform slurry, adding an Ag and Co precursor solution to the slurry, and mixing; 2, reducing a mixed solution obtained in step 1 by sodium borohydride for 10-24h, washing, and drying to obtain Ag-Co / C; 3, dissolving the Ag-Co / C by alcohol, and carrying out ultrasonic treatment to obtain a slurry; and 4, processing a Pt precursor through an in situ chemical reduction homogeneous precipitation process to prepare complexing ions, processing to prepare a colloid, and carrying out reduction deposition on the colloid in the slurry obtained in step 3 by using a reducing agent formaldehyde in order to prepare the Pt-Ag-Co / C catalyst. The method has the advantages of simple process, low cost and easy enlarged production, and the catalyst has good catalysis activity, and has better durability than commercial Pt / C electrocatalysts and binary Pt-Ag / C electrocatalysts.

Owner:NANJING UNIV OF TECH

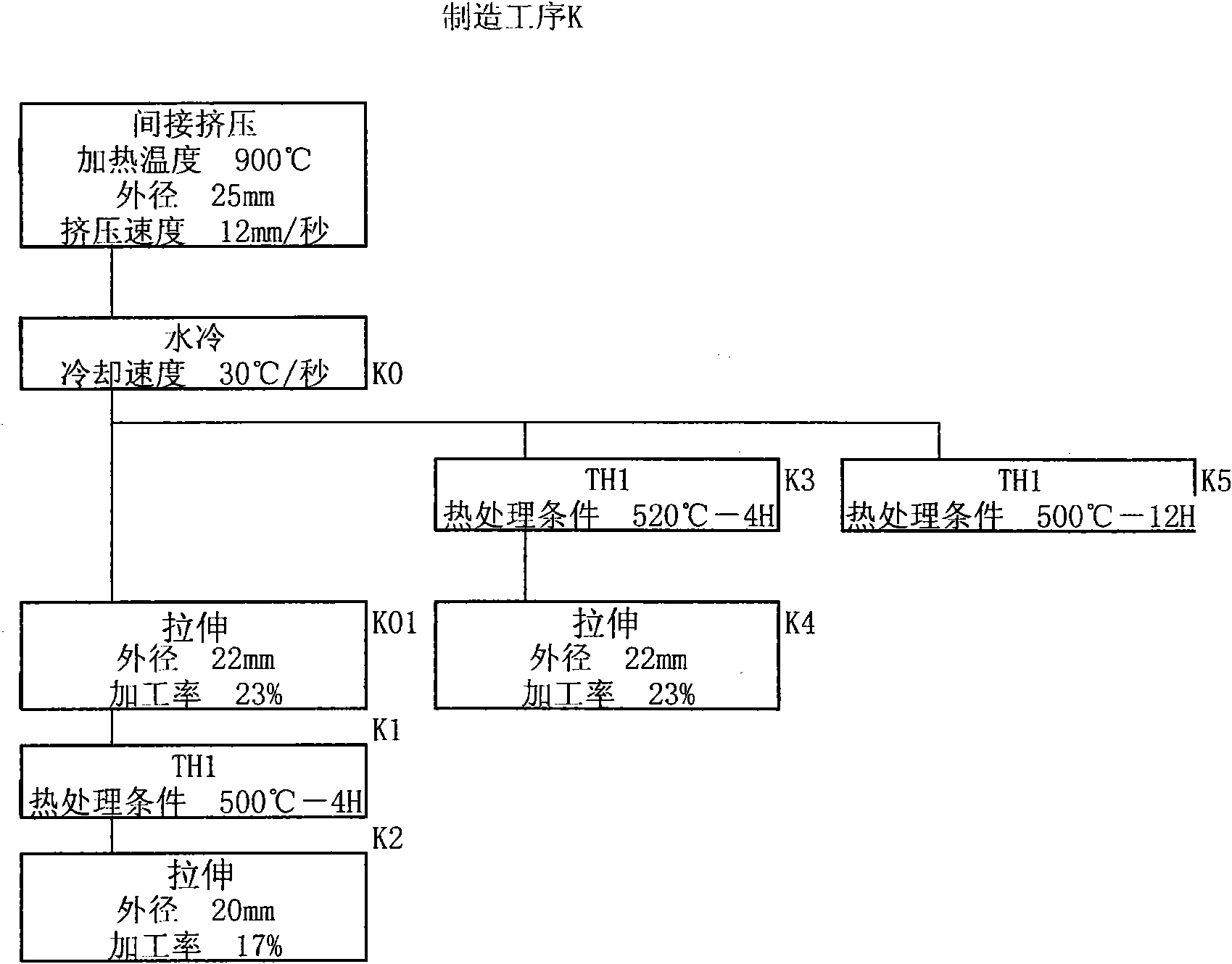

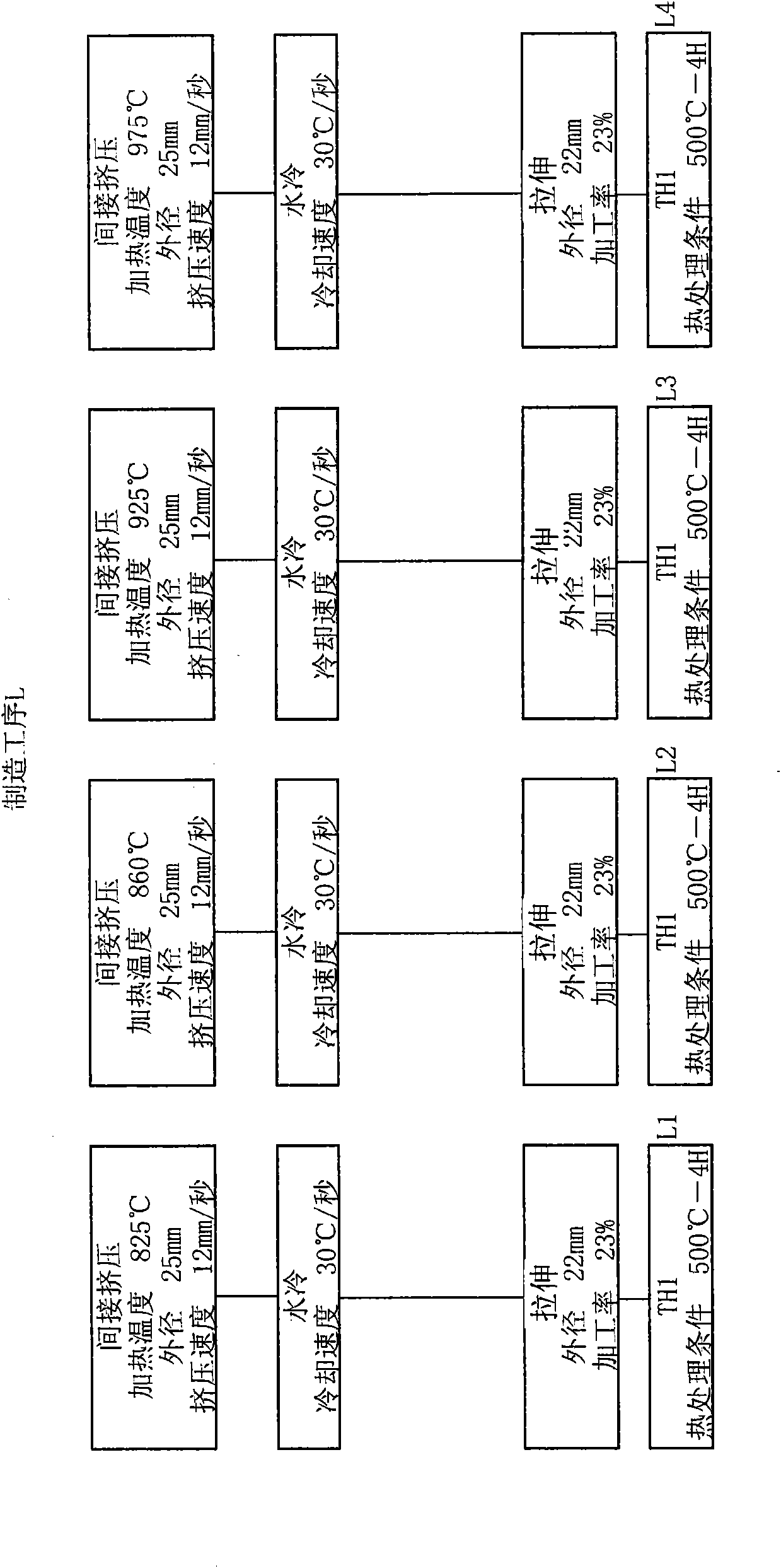

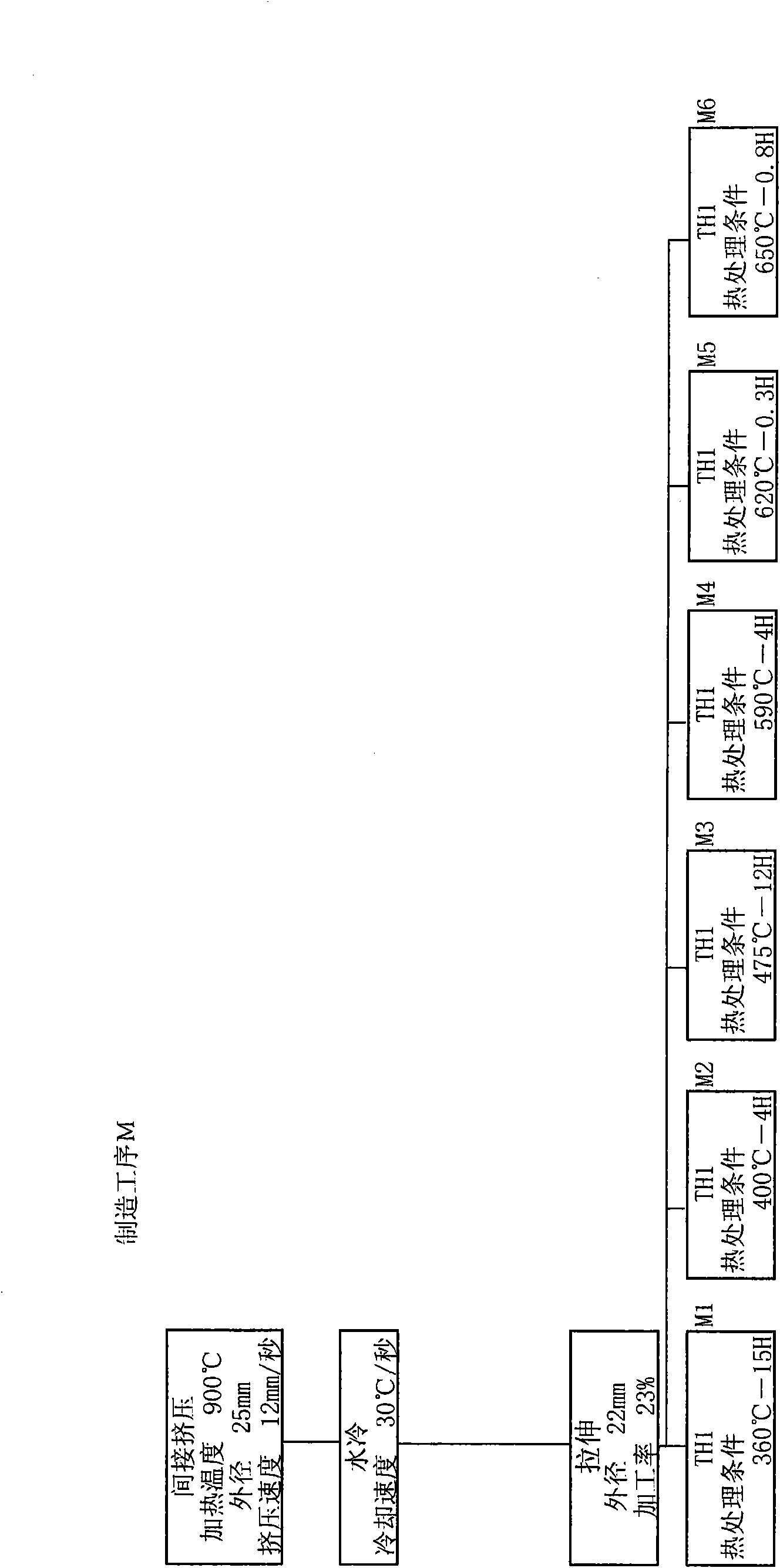

High-strength and high-electroconductivity copper alloy pipe, bar, and wire rod

ActiveCN101960028AHigh strengthImprove conductivitySingle bars/rods/wires/strips conductorsSingle tube conductorsWire rodDissolution

Disclosed are high-strength and high-electroconductivity copper alloy pipe, bar, and wire rod. The high-strength and high-electroconductivity copper alloy pipe, bar, and wire rod are produced by a process comprising providing an alloy comprising 0.13 to 0.33% by mass of Co, 0.044 to 0.097% by mass of P, 0.005 to 0.80% by mass of Sn, and 0.00005 to 0.0050% by mass of O with the balance consisting of Cu and unavoidable impurities, Co and P satisfying a requirement of 2.9 <= ([Co] - 0.007) / ([P] - 0.008) <= 6.1, wherein [Co] represents the content of Co, mass%; and [P] represents the content of P, mass%, and hot extruding the alloy. Homogeneous precipitation of Co and P compounds and dissolution of Sn as a solid solution can improve the strength and electroconductivity of the high-strength and high-electroconductivity copper alloy pipe, bar, and wire rod. Further, since the high-strength and high-electroconductivity copper alloy pipe, bar, and wire rod are produced by hot extrusion, a reduction in cost can be realized.

Owner:MITSUBISHI SHINDOH CO LTD

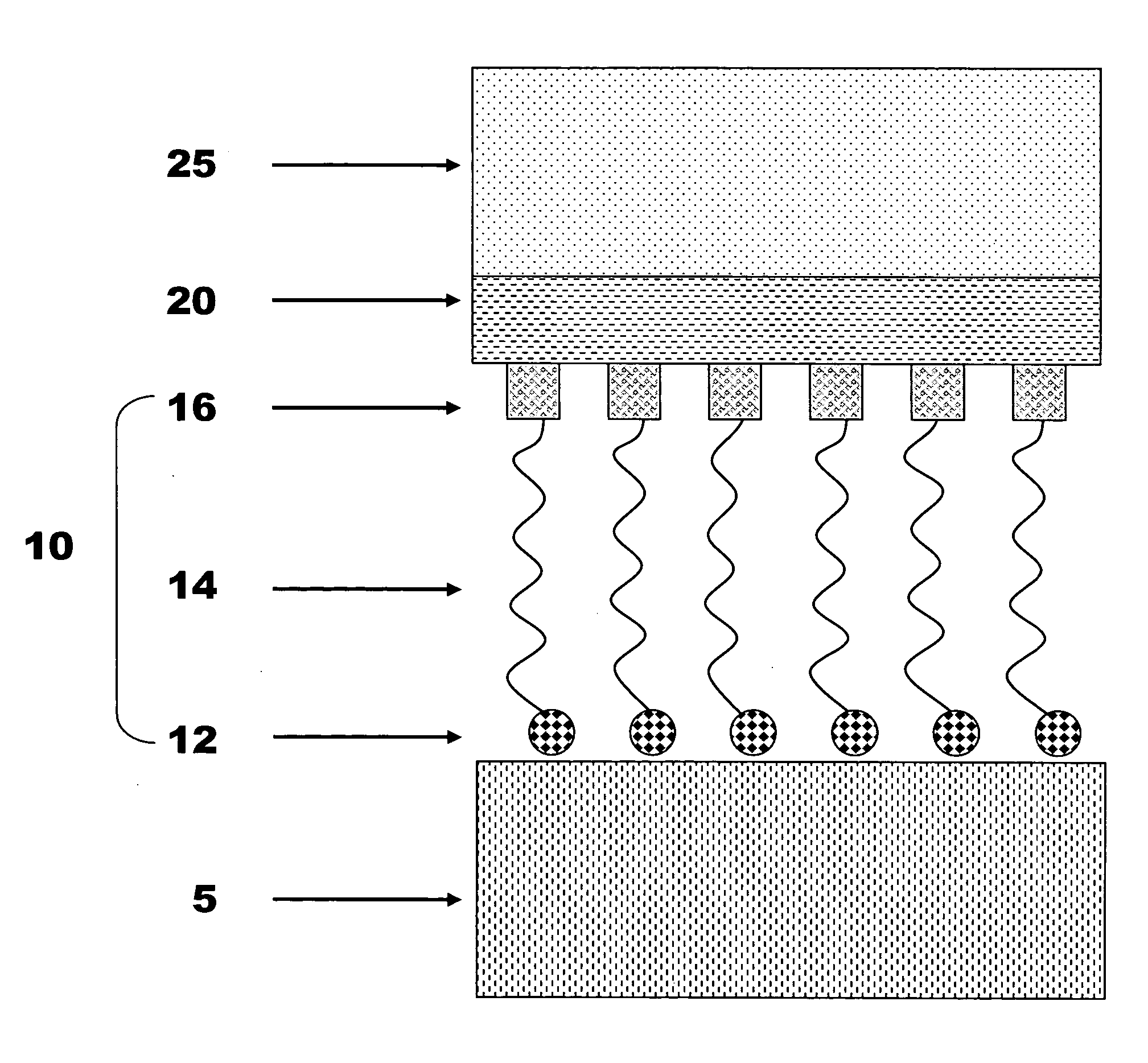

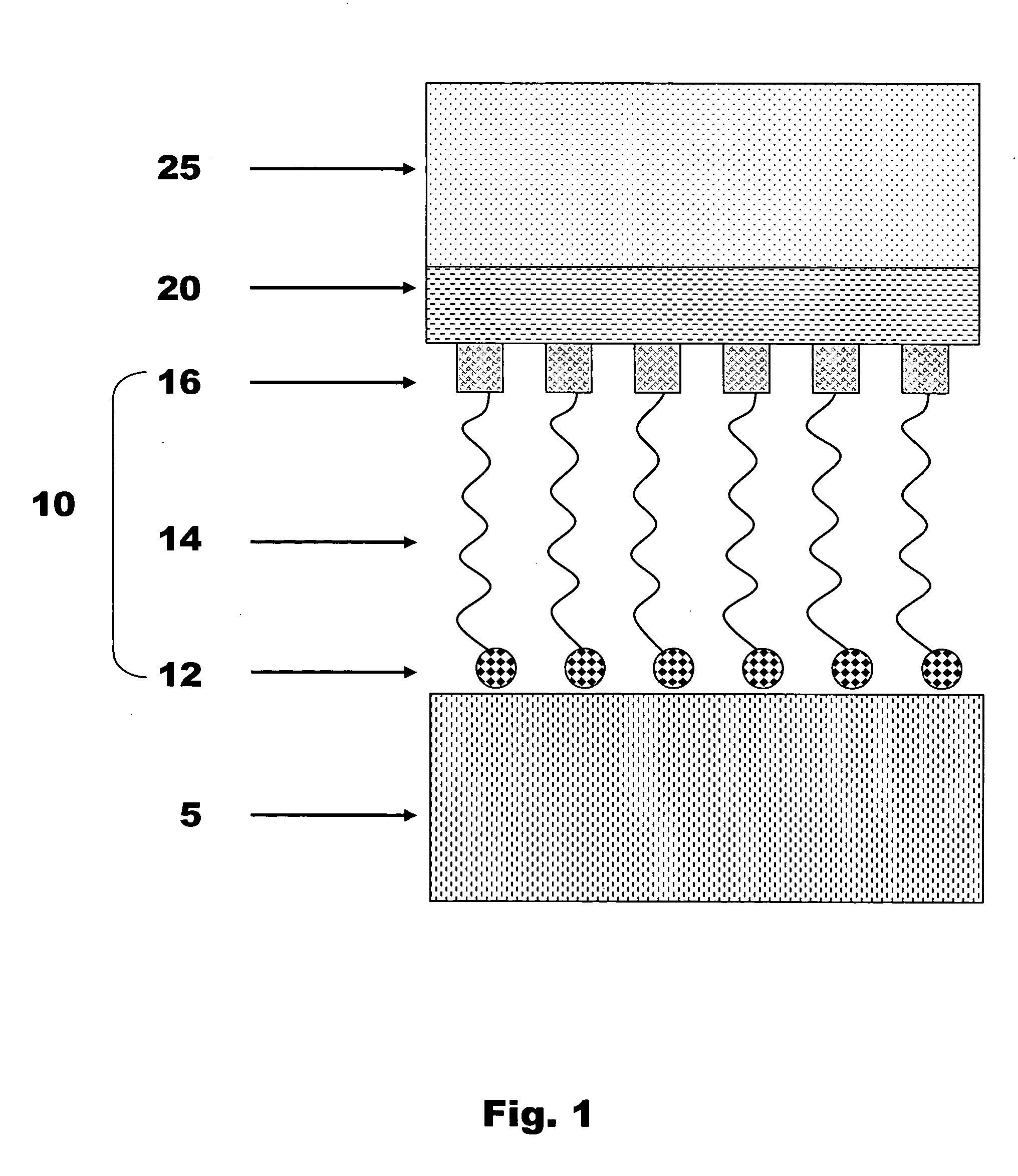

Method for fabricating hafnia films

InactiveUS20060030135A1Quality improvementMaterial nanotechnologyLiquid surface applicatorsCross-linkSelf-assembled monolayer

The present invention comprises a method for fabricating hafnia film comprising the steps of providing a substrate having a surface that allows formation of a self-assembled monolayer thereon via covalent bonding; providing an aqueous solution that provides homogeneous hafnium ionic complexes and hafnium nanoclusters wherein the aqueous solution is capable of undergoing homogeneous precipitation under controlled conditions for a desired period of time at a controlled temperature and controlled solution acidity for desired nanocluster nucleation and growth kinetics, desired nanocluster size, desired growth rate of film thickness and desired film surface characteristics. The method further comprising forming the self-assembled monolayer on the surface of the substrate wherein the self-assembled monolayer comprises a plurality of hydrocarbon chains cross-linked together along the surface of the substrate, the hydrocarbon chains being uniformly spaced from one another and wherein each of the hydrocarbon chains having a functional anchoring group at a first end of the chain covalently bonded with the surface of the substrate and each of the hydrocarbon chains having a functional terminating group projected away from the surface wherein the functional terminating group provides a bonding site for the hafnium film to grow; and exposing the substrate to the aqueous solution for a desired period of time at a controlled temperature wherein the hafnium ionic complexes and the hafnium nanoclusters are deposited on the bonding site of the functional terminating group thereby forming the hafnia film wherein the hafnium bonded to the hydrocarbons and to one another provide a uniform ordered arrangement defined by the uniform arrangement of the hydrocarbons.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com