Patents

Literature

91results about How to "Good water and sulfur resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

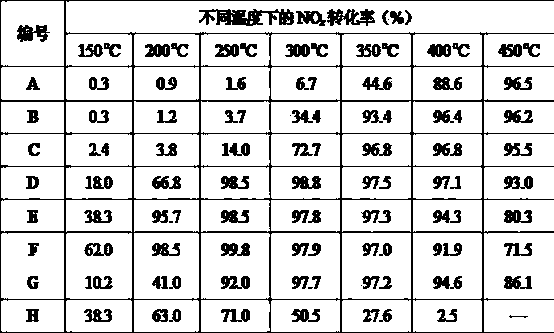

Method for preparing low-temperature SCR (selective catalytic reduction) denitration catalyst

InactiveCN102716752AGood activity at low temperatureHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideAmmonium metavanadate

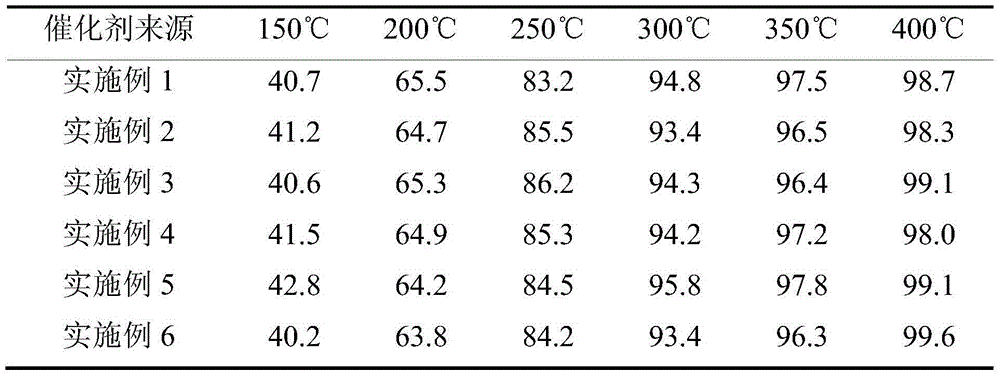

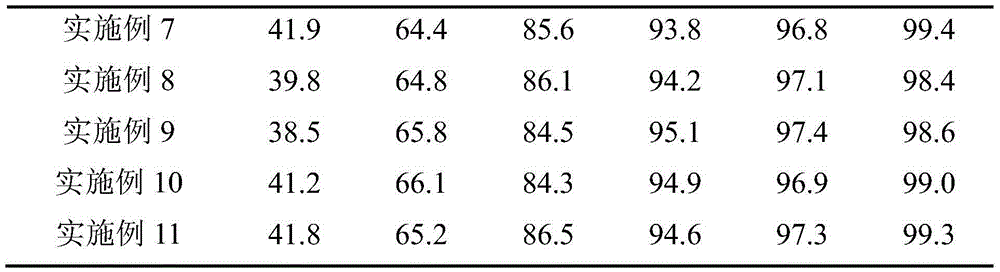

The invention relates to a method for preparing a low-temperature SCR (selective catalytic reduction) denitration catalyst, and belongs to the technical field of catalysis. The denitration catalyst has a good nitric oxide removal rate, water resistance and sulfur resistance when the temperature of flue gas ranges from 150 DEG C to 250 DEG C. The method includes dissolving ammonium metavanadate, transition metal salts and titanium and tungsten powder in water; and drying and calcining the mixed liquor to prepare the low-temperature SCR denitration catalyst. The prepared catalyst is good in low-temperature activity, and can keep the good nitric oxide removal rate, the water resistance and the sulfur resistance at the temperature ranging from 150 DEG C to 250 DEG C. In addition, owing to the high activity and poison resistance at the temperature ranging from 150 DEG C to 250 DEG C, the catalyst can be applied to the field of flue gas after the flue gas flows via dust catchers of thermal power plants and flue gas, with the temperature ranging from 150 DEG C to 250 DEG C, of industrial furnaces and the like, and denitration catalyst technology and application breakthrough is realized.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

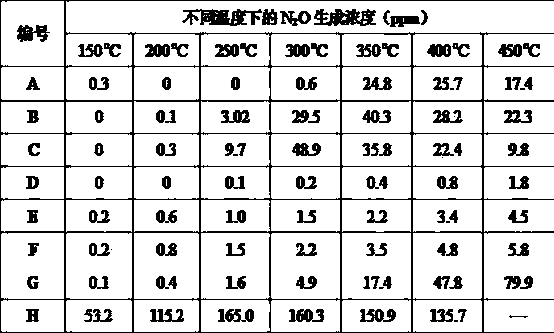

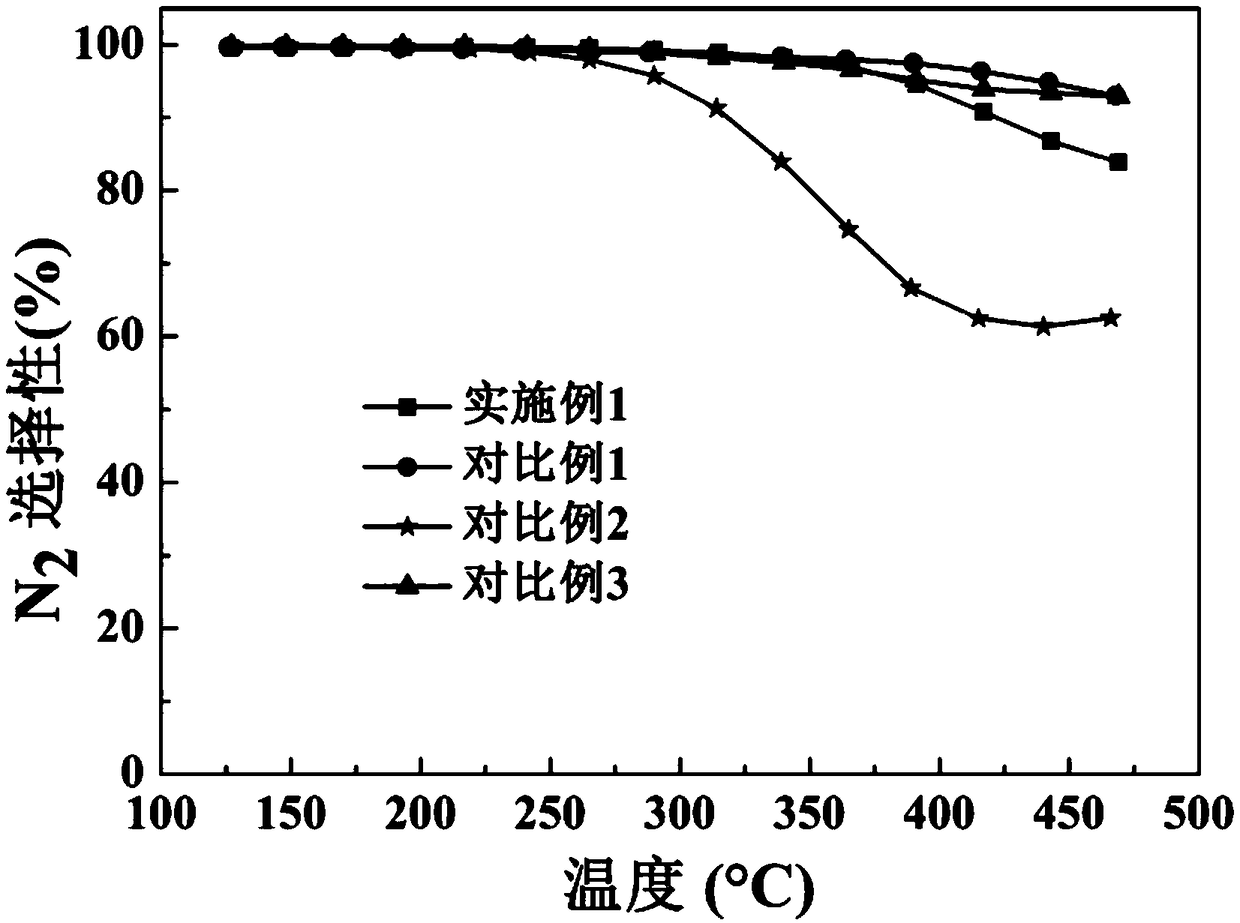

Cerium-zirconium-tungsten composite oxide catalyst as well as preparation method and usage thereof

ActiveCN103240079AWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumNitric oxide

The invention relates to a cerium-zirconium-tungsten composite oxide catalyst used for carrying out selective catalytic reduction on nitric oxide by ammonia, as well as a preparation method and usage thereof. The catalyst is a composite metal oxide formed by three types of metal including cerium, zirconium and tungsten. The catalyst adopts non-toxic and harmless raw materials; the cerium-zirconium-tungsten composite oxide catalyst which can adapt to high space velocity reaction condition and has the characteristics of being excellent in catalytic activity, high in N2 generation selectivity, wide in operating temperature window and the like can be prepared by using a simple and practicable method; and the cerium-zirconium-tungsten composite oxide catalyst is suitable for a nitric oxide catalytic purification device used for a moving source represented by diesel exhaust and a fixed source represented by flue gas of a coal-fired power plant.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Water-resistant sulfur-resistant flue gas denitrification powder catalyst, preparation method and application of flue gas denitrification powder catalyst

ActiveCN105214679AGood denitrification activityGood water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCobalt oxideChemistry

The invention relates to a water-resistant sulfur-resistant flue gas denitrification powder catalyst, a preparation method and an application of the flue gas denitrification powder catalyst. The catalyst comprises main components including titanium dioxide, manganese oxide and auxiliaries, wherein the auxiliaries are two of or a combination of more than two of zirconium oxide, copper oxide, molybdenum oxide, cerium oxide, iron oxide, nickel oxide, cobalt oxide, niobium oxide and tungsten oxide; the mole ratio of Mn to Ti is 0.01-1.0, and the mole ratio of metal in the auxiliaries to titanium metal elements is 0.01-1.0. The catalyst is covered with one silicon dioxide coating or more silicon dioxide coatings. The catalyst is prepared with a coprecipitation method, can be used for an NH3-SCR (selective catalytic reduction) purification process of nitric oxide in flue gas in a fixed source or a moving source, adopts non-toxic and harmless raw materials and has the advantages that the preparation method is simple and convenient, the catalytic activity is high, the active window is wide, the water-resistant and sulfur-resistant stability is good, environment protection is realized and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Application of metal oxide modified CePO4 catalyst to collaborative denitration and demercuration

InactiveCN104888602AEasy to operateRaw materials are readily availablePhysical/chemical process catalystsDispersed particle separationCerium phosphateManganese

The invention discloses application of a metal oxide modified CePO4 catalyst to collaborative denitration and demercuration. The application includes introducing medium-high temperature flue gas containing elemental mercury and nitrogen oxide into a catalyst loaded catalytic apparatus. Specifically, the main component of the catalyst is cerium phosphate, and the modification component is at least one of cobalt, manganese, copper, iron, vanadium, cerium, molybdenum and tin metal oxides. The temperature of the medium-high temperature flue gas is 250-420DEG C. According to the application of the metal oxide modified CePO4 catalyst to collaborative denitration and demercuration, the oxidation efficiency to null valence mercury in high temperature flue gas is high, the NO is the flue gas can promote and enhance the catalytic efficiency of the catalyst, and the practicability is strong. In addition, the catalyst has good medium-high temperature SCR activity and anti-sulfur and waterproof performance.

Owner:ZHEJIANG UNIV

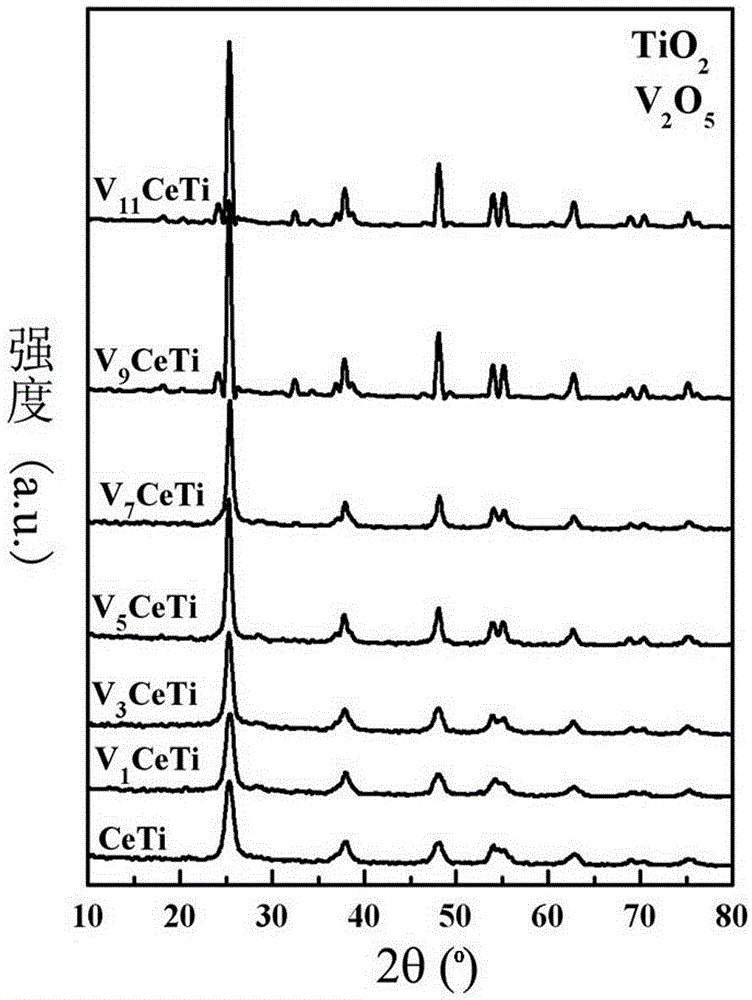

Zirconium-doped vanadium-based oxide catalyst, and preparation method and application thereof

ActiveCN103252232AWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoal plantNitrogen

The invention relates to a zirconium-doped vanadium-based oxide catalyst for selectively catalyzing and reducing the nitrogen oxide through ammonia, and a preparation method thereof. The catalyst is a metal oxide catalyst which is formed by loading zirconium and vanadium oxide onto the surface of titanium tungsten powder. Through the zirconium doping method, the catalytic properties such as high-temperature stability of the traditional vanadium-based catalyst and the N2 (nitrogen) generation selectivity can be greatly improved, the prepared zirconium-doped vanadium-based oxide catalyst is suitable for a nitrogen oxide catalytic purifying device adopting the diesel exhaust as a representative movable resource and the smoke of a coal plant as a representative fixed source.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

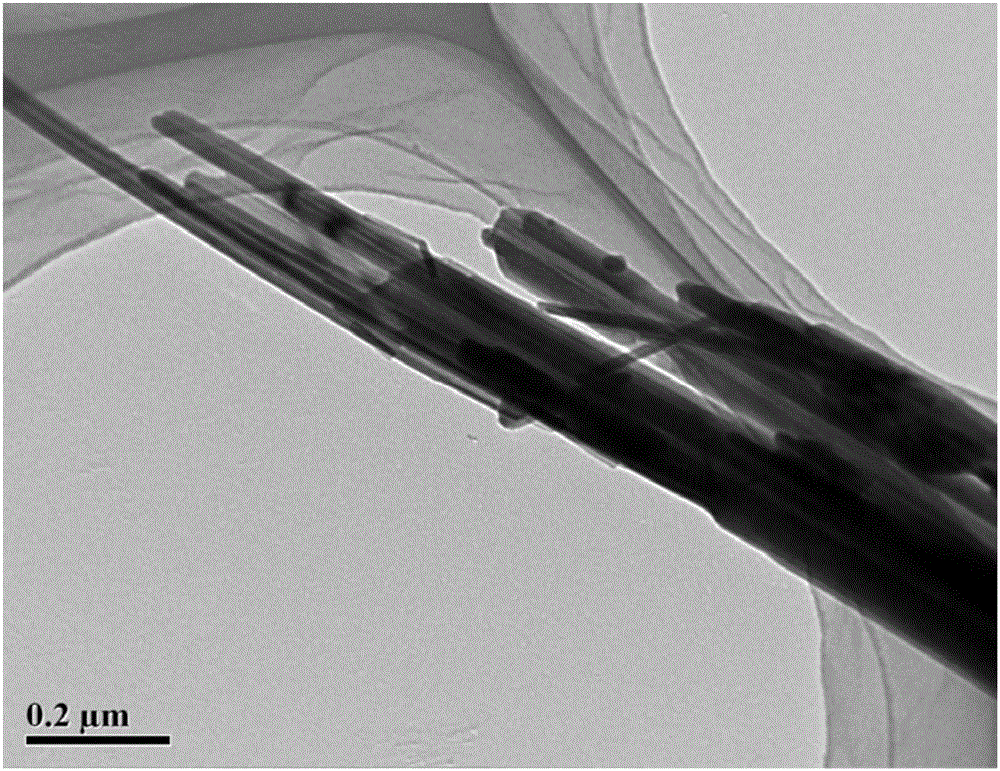

Vanadium oxide nanotube denitration catalyst with anti-poisoning performance and preparation method of catalyst

ActiveCN106140146AExtended service lifeExcellent catalytic reduction performanceGas treatmentHeterogenous catalyst chemical elementsAlkaline earth metalNiobium

The invention discloses a vanadium oxide nanotube denitration catalyst with anti-poisoning performance and a preparation method of the catalyst. The catalyst is prepared from a carrier as well as an active substance and a catalysis aid which are supported on the carrier, wherein the carrier is a vanadium oxide nanotube, the active substance is at least one of oxides of cerium, niobium, iron, copper, chromium, cobalt and manganese, and the catalysis aid is oxide of molybdenum or tungsten. The catalyst has a good inhibition function on poisoning effects of phosphate, heavy metals, alkali metals and alkaline-earth metals.

Owner:ZHEJIANG UNIV

Low-temperature SCR (selective catalytic reduction) smoke gas efficient denitration catalyst and preparation method thereof

InactiveCN106861674ALow denitrification efficiencyGood activity at low temperatureGas treatmentHeterogenous catalyst chemical elementsRare earthWater resistant

The invention relates to a low-temperature SCR (selective catalytic reduction) smoke gas efficient denitration catalyst and a preparation method thereof, and belongs to the technical field of catalyst manufacturing. The catalyst uses titanium dioxide as carriers, and contains tungsten oxide, vanadium oxide and antimony oxides or contains rare earth metal cerium oxide; the catalyst without rare earth metal cerium oxide has a little lower denitration efficiency than the catalyst containing rare earth metal cerium oxide. The denitration efficiency of the catalyst reaches 85 percent or more at the low temperature of 130 degrees; the value is much higher than the current condition of the denitration efficiency of being less than 50 percent in the prior art. The low-temperature activity of the catalyst is good; a good oxynitride removal rate and water-resistant and sulphur-resistant performance can be realized within the temperature range of 130 to 250 DEG C; the catalyst has high activity and toxicity resistance at 130 to 250 DEG C, so that the catalyst can be installed behind a coal-fired boiler dust remover; the defects of the existing smoke gas denitration technology are overcome; the catalyst can also be applied to the smoke gas denitration of industrial kilns and the like.

Owner:大连瑞克科技股份有限公司

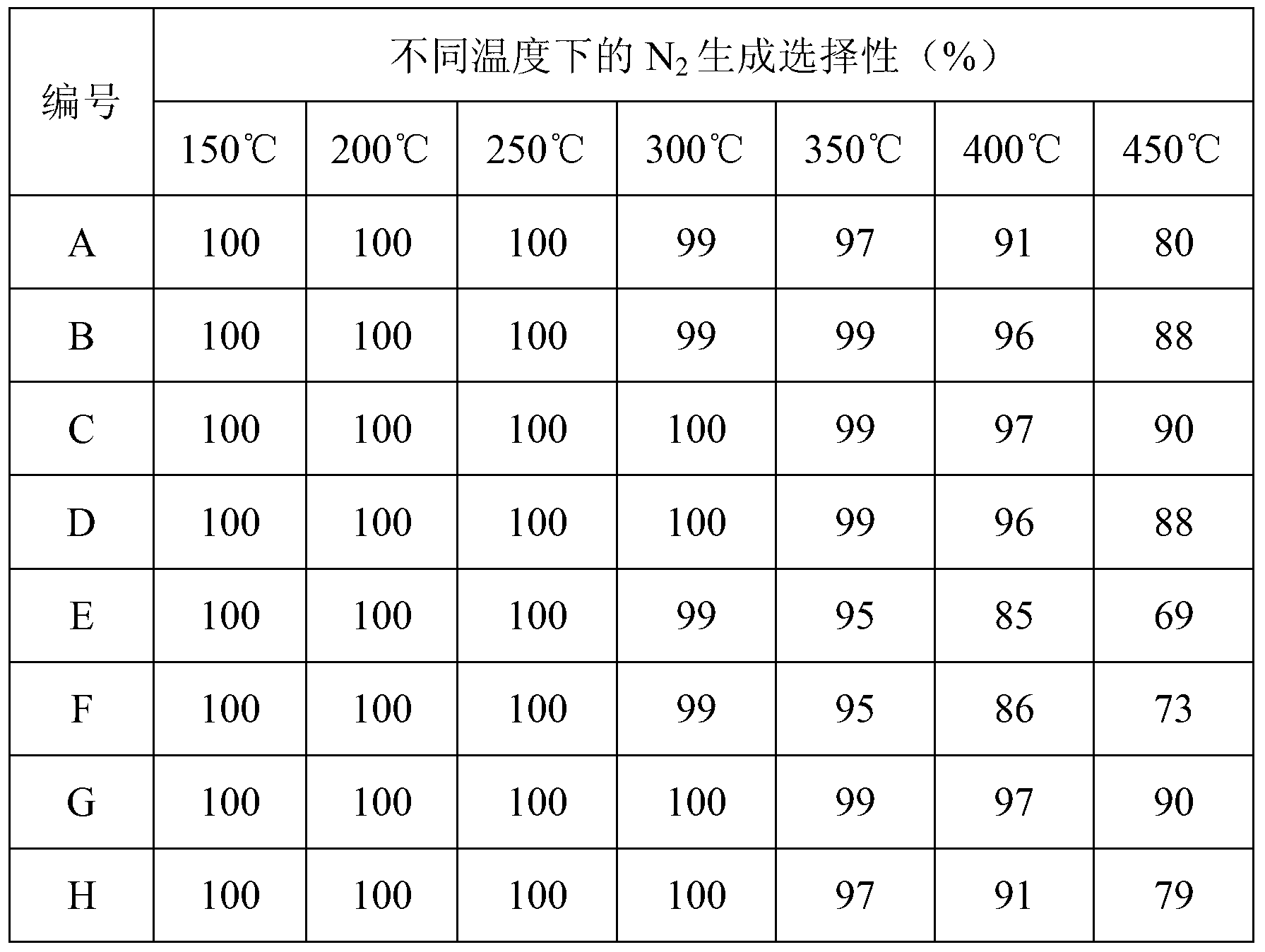

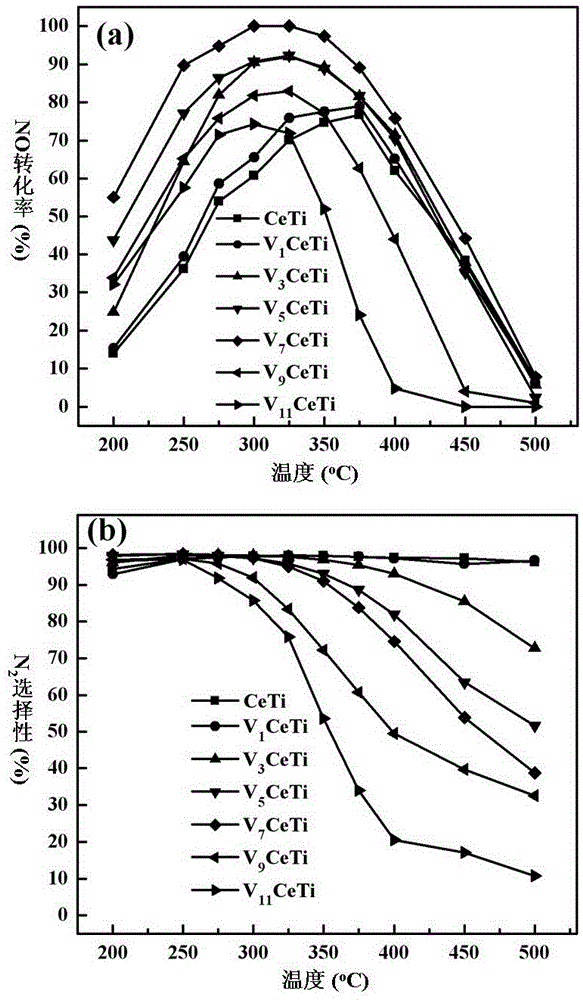

High-performance vanadium, cerium and titanium composite oxide catalyst for flue gas denitration and preparation method thereof

InactiveCN105688888ARaw materials are cheap and easy to getEasy to prepareHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystCerium

The invention discloses a vanadium, cerium and titanium composite oxide catalyst and a preparation method thereof.The main component of a carrier of the vanadium cerium and titanium composite oxide catalyst is a cerium and titanium solid solution, vanadium pentoxide is loaded to the surface of the cerium and titanium solution mainly in a high-dispersion mode, and the specific surface area is 10-105 m<2>.g<-1>.The vanadium, cerium and titanium composite oxide catalyst has the advantages of being large in specific surface area, high in thermal stability and the like.The vanadium, cerium and titanium composite oxide catalyst has high activity and selectivity in NH3 selective catalytic reduction NO reaction, is superior in water resisting and sulphur resisting performance, and has potential application value in the field of denitration.

Owner:UNIV OF JINAN

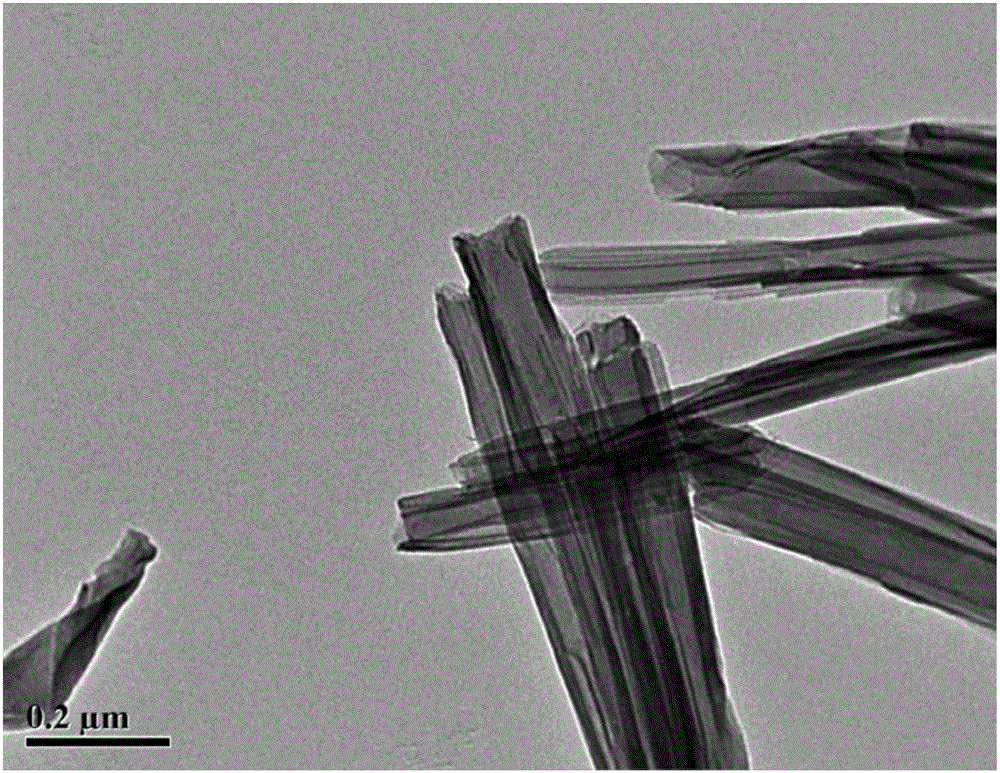

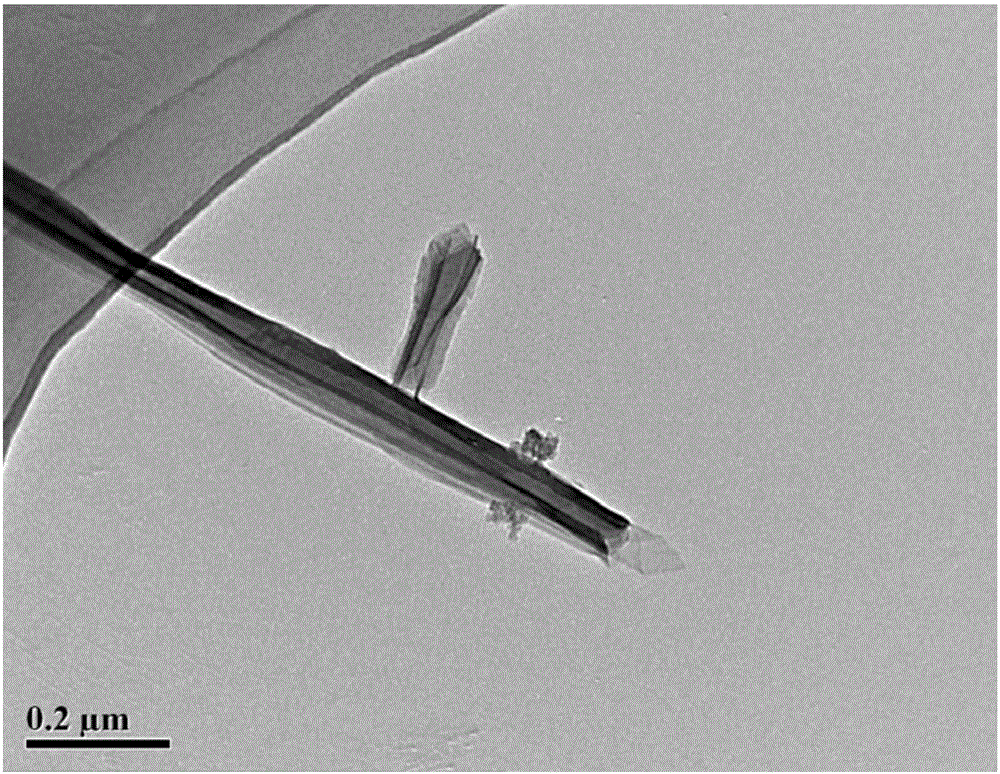

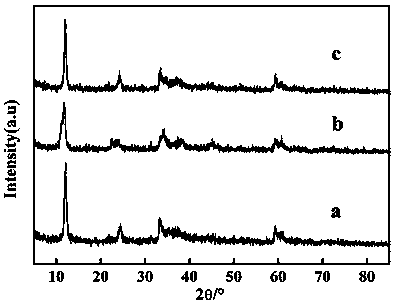

Tungsten titanium composite oxide supported cerium oxide catalyst, preparation method as well as application of catalyst

InactiveCN103846083AWide operating temperature windowGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystComposite oxide

The invention discloses a cerium based oxide catalyst for ammonia selective catalytic reduction nitric oxide, a preparation method as well as application of the catalyst. The catalyst is prepared by the following steps: carrying out controllable regulation on the pH value in the preparation process; forming a metal oxide catalyst CeO(i)x( / i) / WO(i)y( / i)-TiO2 and cerium oxide CeO(i)x( / i) by fractional precipitation, and uniformly dispersing on the surface of a tungsten titanium composite oxide WO(i)y( / i)-TiO2. The cerium based oxide catalyst which has the characteristics of excellent low-temperature catalytic activity, high N2 generation selectivity, wide operation temperature window, capability of being adaptive to high-airspeed reaction conditions and the like is prepared from nontoxic and harmless raw materials by a simple and feasible method, and is suitable for nitric oxide catalytic purification devices with mobile sources represented by tail gas of a diesel vehicle and fixed sources represented by flue of coal burned power plants.

Owner:NANJING UNIV OF SCI & TECH

Metallic monolithic structuring core-shell structured denitration catalyst and preparation method thereof

ActiveCN108212146ANot easy to fall offEasy to makeGas treatmentDispersed particle separationSulfurActive component

The invention discloses a metallic monolithic structuring core-shell structured denitration catalyst and a preparation method thereof. The denitration catalyst is a metallic monolithic structuring core-shell structured catalyst obtained through in situ growth of hydroxide on a metallic monolithic carrier and one-step self-assembling by means of the bidirectional bridging effect of a coupling agent, wherein a main active component and an assistant are used as the core, and metal oxide is used as the shell. The catalyst comprises 0.01-30 wt% of the main active component, 0-30 wt% of the assistant, 0-50 wt% of the metal oxide, and the balance of the metallic monolithic material. The catalyst has the advantages of good low-temperature activity, excellent resistance to sulfur and water, simplepreparation method, no molding, and good heat conduction property, and is suitable for treating nitrogen oxides in tail gas discharged from a coal-fired power plant, a garbage incinerator and a steelmill.

Owner:SHANGHAI UNIV

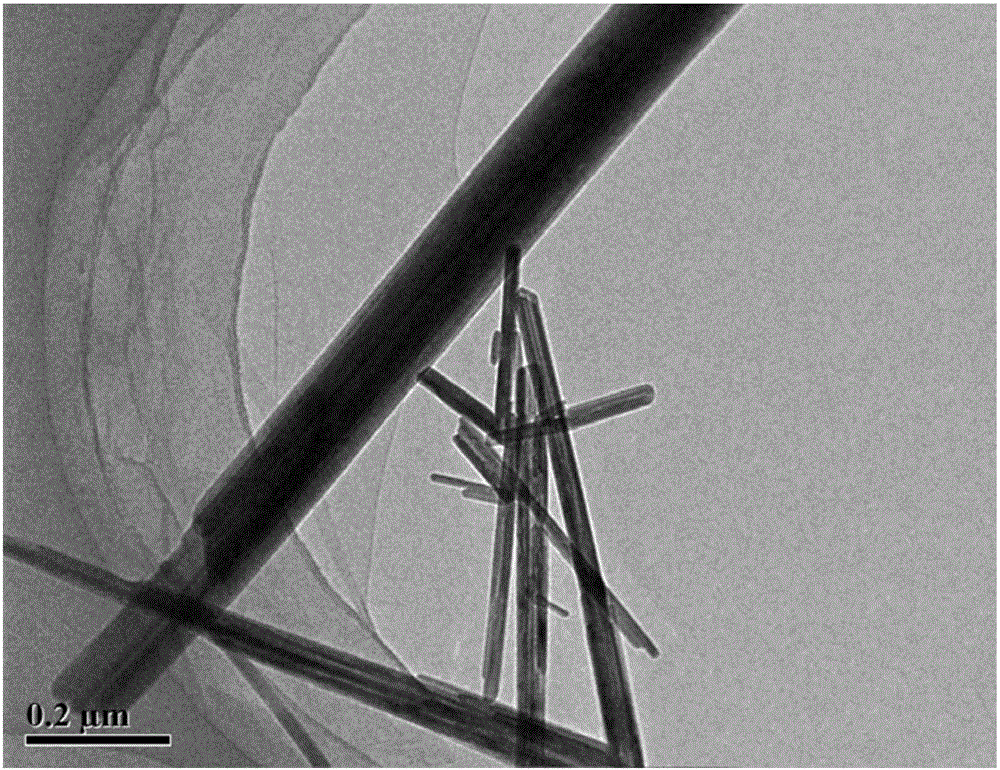

Manganese oxide nanotube loading type denitration catalyst and preparation method therefor

ActiveCN106179326AImprove denitrification activityLow SO2 Oxidation RateHeterogenous catalyst chemical elementsDispersed particle separationAlkaline earth metalToxicant

The invention discloses a manganese oxide nanotube loading type denitration catalyst and a preparation method therefor. The catalyst is prepared from a carrier, an active substance and a catalysis assistant, wherein the active substance and the catalysis assistant are loaded to the carrier; the carrier is manganese oxide nanotubes; and the active substance is an oxide of cerium, vanadium, niobium, chromium, iron or copper, and the catalysis assistant is an oxide of molybdenum or tungsten. According to the denitration catalyst disclosed by the invention, superior denitration activity can be obtained; and meanwhile, the denitration catalyst has good capacity for resisting the simultaneous poisoning of a variety of toxicants (phosphate, heavy metals and alkalis / alkaline-earth metals), a powerful guarantee is provided for the long-term effective use of SCR denitration catalysts in glass kilns, cement kilns, garbage incinerators and biomass fuel boilers, and the service life of the denitration catalyst used in the traditional industrial boiler can be greatly prolonged.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

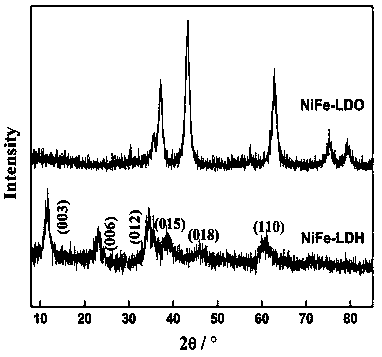

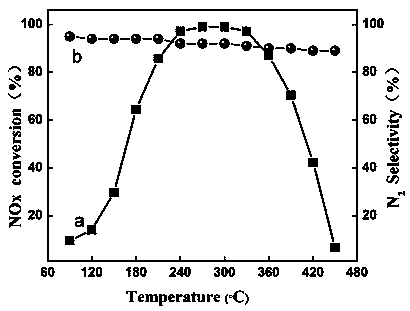

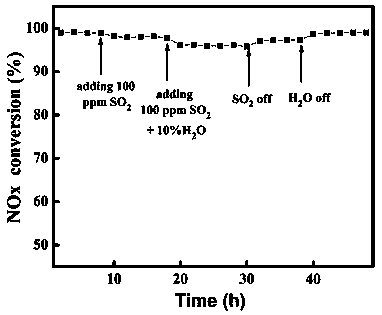

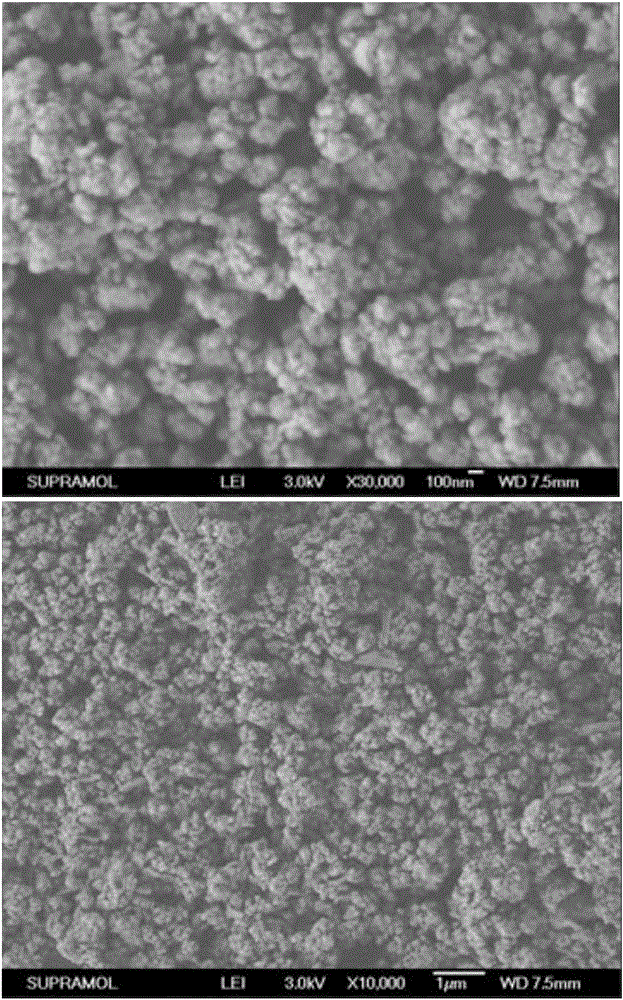

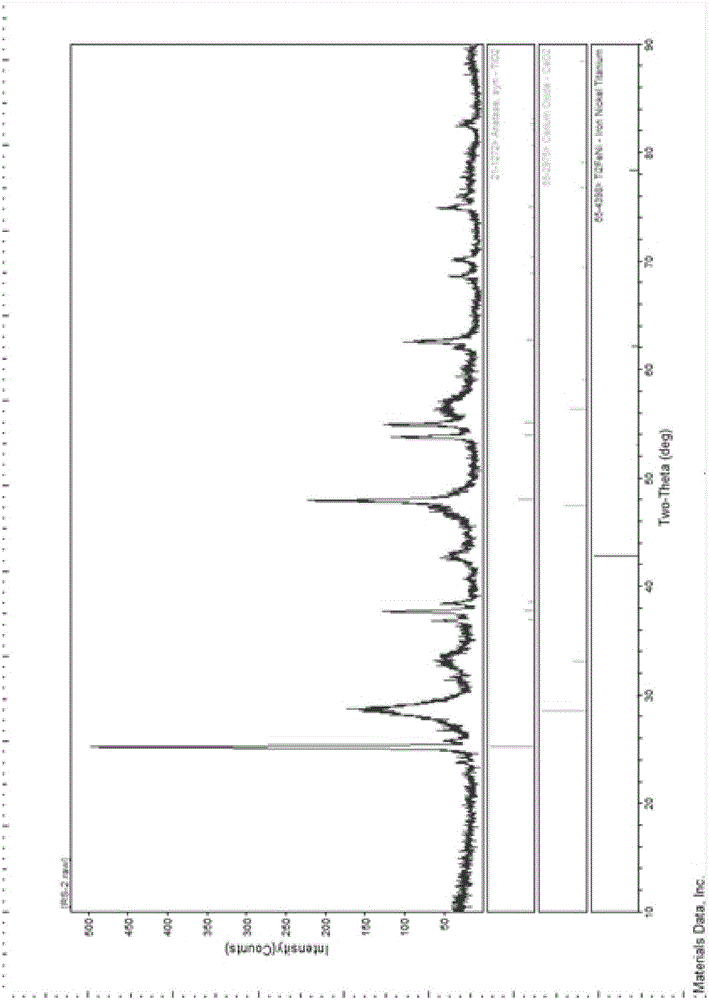

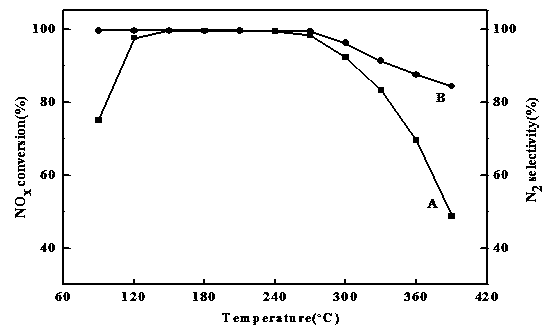

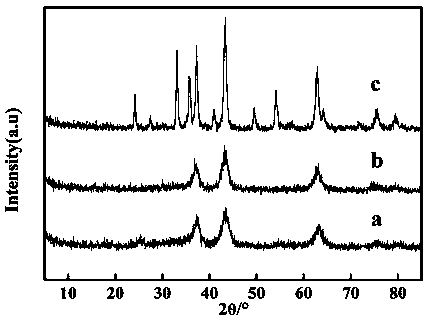

Ferronickel compound oxide catalyst and preparation method and application thereof

InactiveCN108940289AHigh selectivityGood water and sulfur resistanceHeterogenous catalyst chemical elementsDispersed particle separationSolventAtmospheric pollution

The invention discloses a ferronickel compound oxide catalyst and a preparation method and an application thereof and belongs to the technical field of atmospheric pollution control. The preparation method comprises the following steps: by taking nickel nitrate hexahydrate and iron nitrate nonahydrate as raw materials, urea as a precipitant, sodium citrate as a complexing agent, deionized water asa solvent and a detergent, carrying out solution preparation, hydro-thermal treatment, sample washing, drying and the like to prepare a NiFe-LDH precursor; and roasting NiFe-LDH to obtain a ferronickel compound oxide (NiFe-LDO) catalyst. By applying the catalyst to an ammonia gas selective catalytic reduction (NH3-SCR) denitration experiment, a result verifies that the prepared NiFe-LDO catalysthas catalytic activity over 85% at a window of 210-360 DEG C, N2 selectivity close to 95% and water resistance and sulfur resistance.

Owner:TAIYUAN UNIV OF TECH

Composite carrier type SCR denitration catalyst capable of simultaneously removing nitrate and mercury, and preparation method thereof

InactiveCN105597732ALarge specific surface areaGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention discloses a composite carrier type SCR denitration catalyst capable of simultaneously removing nitrate and mercury, and a preparation method thereof. The catalyst comprises, by mass, 0.2 to 1.2% of V2O5 and 1.0 to 10% of WO3, with the balance being a TiO2-Ce2 composite oxide carrier. The nanometer TiO2-Ce2 composite oxide carrier has a higher specific surface area, enables active components to be better dispersed and has good water resistance and sulfur resistance; through interaction between the active components and the carrier, activity of the catalyst is further improved, and the catalyst has strong HgO oxidation activity in absence of HCl or under the condition of low HCl; and the catalyst simultaneously completes catalytic reduction of NOx and catalytic oxidation of HgO without additional installation of flue gas purifying facilities of a coal-fired power plant, thereby realizeing simultaneous controlling of NOx and HgO.

Owner:HUNAN UNIV

Transition metal oxide composite catalyst, preparation method thereof and application of catalyst

InactiveCN109351358AWide operating temperature windowImprove denitrification efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOxide compositeComposite oxide

The invention provides a transition metal oxide composite catalyst, a preparation method thereof and an application of the catalyst. The catalyst comprises a transition metal oxide active component and a carrier, and the transition metal oxide comprises an iron and vanadium composite oxide. According to the catalyst, iron is led in a vanadium and titanium denitration catalyst, the operating temperature of the catalyst can be widened to 200-450 DEG C by the aid of interaction between the iron and the vanadium and combination between an active site and an acid site of the carrier, denitration efficiency is improved, the conversion rate of NOx within the temperature range reaches 80% or more, generating selectivity of N2 is good, stability, sulfur resistance and water resistance of the catalyst can be enhanced, and the catalyst is low in cost, simple and easy in preparation process and wide in application range.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

Fume oxidation denitration catalyst prepared by sol-gel method and preparation process thereof

ActiveCN106732543AGood dispersionSimple preparation processGas treatmentHeterogenous catalyst chemical elementsPtru catalystNitrogen oxides

The invention relates to a fume oxidation denitration catalyst prepared by a sol-gel method and a preparation process thereof. The catalyst is prepared from the following components in percentage by weight: 19-70 wt% of manganic oxide, 10-40 wt% of transition metal oxide and 10-60 wt% of cerium oxide. The preparation process comprises the steps: under the effect of polyethylene glycol and citric acid, performing sol-gel reaction of the soluble salt of manganese, the soluble salt of transition metal and the soluble salt of cerium; through aging, drying and calcining to obtain the fume oxidation denitration catalyst. The catalyst has the advantages that a required instrument for preparation is simple; the raw materials can be easily obtained; the cost is low; the activity under low temperature is good; the good nitrogen oxide removal rate and anti-water and anti-sulfur performances at 150-207 DEG C are maintained; the catalyst can be applied to the fume oxidation denitration of thermal power plants and industrial furnaces and the like.

Owner:SHANDONG UNIV

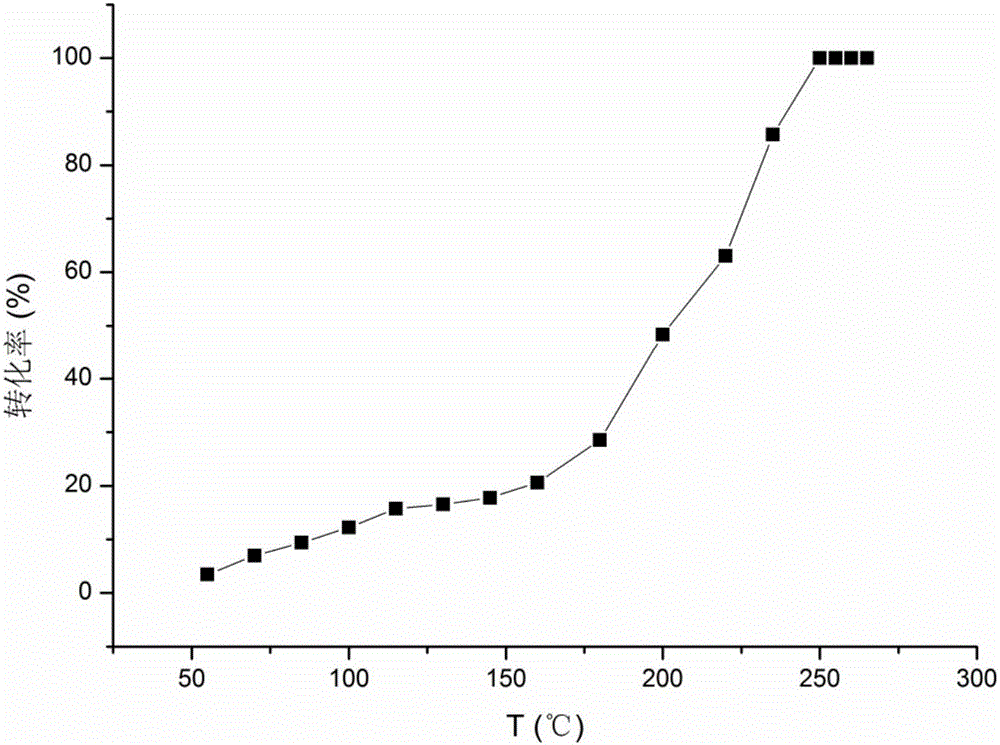

Monolithic catalyst for catalytic oxidation of CO at normal temperature and preparation method thereof

ActiveCN107376935AEfficient removalImprove water resistanceGas treatmentHeterogenous catalyst chemical elementsAir volumeCatalytic oxidation

The present invention belongs to the technical field of environmental protection, and in particular relates to a monolithic catalyst for catalytic oxidation of CO at normal temperature and a preparation method thereof. The monolithic catalyst comprises precious metal Pt as an active component, a composite metal oxide as an auxiliary agent coating, and honeycomb ceramic as a carrier; the mass ratio of the precious metal Pt, the composite metal oxide coating and the honeycomb ceramic carrier is 0.01-2:5-20:80-90. The composite metal oxide coating is a mixture of a cobalt-based composite metal oxide, pseudoboehmite and gamma-Al2O3 in a mass ratio of 10-15: 1-5: 1-5. The catalyst prepared by the method has high activity at normal temperature, lowers the energy consumption of CO removal process, has good water and sulfur resistance and stability, can achieve CO effective removal under the conditions of high space velocity, CO concentration and air volume change, and is applicable to normal temperature elimination of CO in all types of combustion tail gases and closed and semi-enclosed places.

Owner:SHANGHAI RES INST OF CHEM IND

Low-temperature denitration catalyst and preparation method thereof

InactiveCN106732758AHigh low temperature activityImprove sulfur resistanceMolecular sieve catalystsMolecular sieveHigh concentration

The invention discloses a low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: by taking honeycombed ceramic as a substrate, firstly, coating the substrate with an Al2O3 coating in a soaking manner, secondly, coating the substrate with a TiO2-molecular sieve coating in the soaking manner, and finally loading active components of Mn, Cu, Ce and Sn in the soaking manner. According to the low-temperature denitration catalyst disclosed by the invention, based on the honeycombed ceramic substrate, the percentage of the Al2O3 coating is 1-10wt%, the percentage of the TiO2-molecular sieve coating is 1-10wt%, and the mass ratio of TiO2 to a molecular sieve ranges from (10:1) to (1:1); the percentage of the active component Mn is 1-10wt%, the percentage of Cu is 0.5-5wt%, the percentage of Sn is 0.1-1wt%, and the percentage of Ce is 1-10wt%. The preparation method disclosed by the invention is simple in preparation process, and the prepared catalyst contains fume of SO2 and H2O of high concentration, and is good in low-temperature denitration activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for flue gas denitrification and preparation method of catalyst

InactiveCN106732624AReduce the cost of denitrificationImprove catalytic performanceGas treatmentHeterogenous catalyst chemical elementsHigh resistanceFlue gas

The invention provides a catalyst for flue gas denitrification. The catalyst is multi-component metal oxide comprising Fe2O3, CeO2, NiO and TiO2. The Fe2O3-CeO2-NiO / TiO2 multi-component metal oxide serving as an SCR (selective catalytic reduction) flue gas denitrification catalyst has the advantages of high resistance to H2O and SO2 poisoning, low denitrification cost and the like and also has higher thermal stability, wider temperature window and better low-temperature denitrification activity.

Owner:JILIN ELECTRIC POWER RES INST LTD

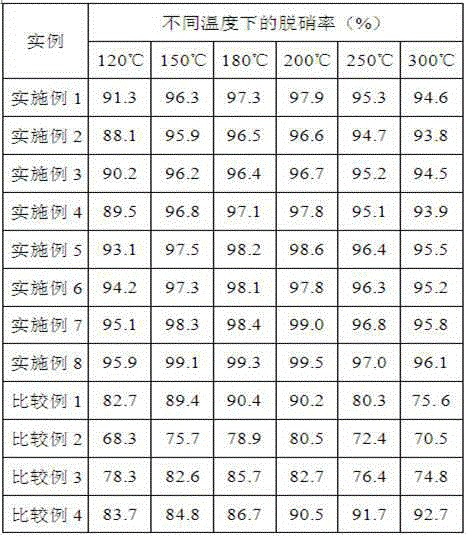

Preparation method of manganese series low-temperature SCR denitration catalyst

InactiveCN105817233AGood activity at low temperatureGood removal rateGas treatmentHeterogenous catalyst chemical elementsRare earthManganese

The invention discloses a preparation method of a manganese-based low-temperature SCR denitrification catalyst, which comprises: first preparing a manganese salt solution, adding transition metal salts or rare earth metal salts to the prepared manganese salt solution to obtain a metal salt mixed solution, and ultrasonically treating Mix the solution evenly, prepare the ammonium salt solution, add the metal salt mixed solution to a certain weight of titanium dioxide, stir evenly to obtain a solid, slowly add the pre-prepared ammonium salt solution to the obtained solid, stir evenly, and wash , dried, and calcined to obtain a manganese-based low-temperature SCR denitration catalyst. Beneficial effects of the present invention: the obtained catalyst has good low-temperature activity, and can maintain a good nitrogen oxide removal rate and water and sulfur resistance at 120-250 ° C. This catalyst can be applied to thermal power plant dust collectors and after desulfurization As well as low-temperature fields such as industrial kilns where the flue gas temperature is between 120-250 ° C, a breakthrough in denitrification catalyst technology and application has been achieved.

Owner:北京科林佰德环保有限公司

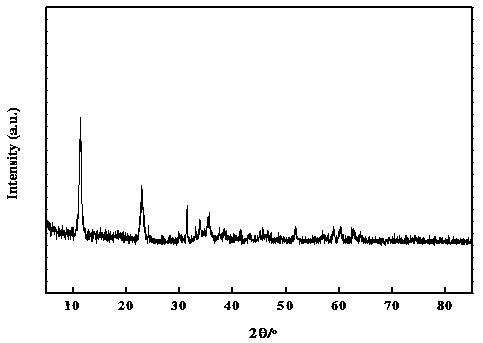

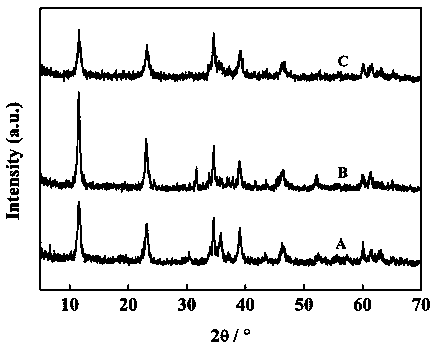

Preparation method and application of hydrotalcite-based CoMnFe composite metal oxide denitration catalyst

ActiveCN108927169AImprove performanceEfficient co-assemblyGas treatmentHeterogenous catalyst chemical elementsFiltrationManganese

The invention discloses a preparation method and application of a hydrotalcite-based CoMnFe composite metal oxide denitration catalyst and belongs to the field of pollution prevention and control. Thepreparation method comprises the steps: carrying out the steps including solution preparation, titration coprecipitation, hydrothermal treatment, suction filtration, washing and drying by taking cobalt nitrate hexahydrate, iron nitrate nonahydrate and manganese nitrate as raw materials, sodium hydroxide as a precipitator, sodium citrate as a complexing agent and deionized water as a solvent and adetergent to prepare a CoMnFe hydrotalcite (CoMnFe-LDHs) precursor; and roasting CoMnFe-LDHs at a certain temperature to obtain the CoMnFe composite metal oxide (CoMnFe-LDO) denitration catalyst. When being applied to ammonia selective catalytic reduction reaction (NH3-SCR), the obtained composite oxide shows excellent denitration activity (the temperature is 120-270 DEG C, the conversion rate ofNOx reaches 90% or above), high N2 selectivity and good water resistance and sulfur resistance.

Owner:TAIYUAN UNIV OF TECH

Preparation method and application of hydrotalcite-like NiMnFe low temperature denitration catalyst

InactiveCN109012688AHarmless to healthEcologically harmlessHeterogenous catalyst chemical elementsDispersed particle separationFiltrationManganese

The invention discloses a preparation method and an application of a hydrotalcite-like NiMnFe low temperature denitration catalyst, and belongs to the field of preparation of gas purification denitration catalysts. The method comprises the following steps: a NiMnFe hydrotalcite-like precursor is prepared through solution preparation, uniform stirring, hydrothermal treatment, suction filtration, washing and drying steps by using a nickel nitrate and manganese nitrate hexahydrate solution (having a mass fraction of 50%), iron nitrate nonahydrate as a raw material, urea as a precipitant, sodium citrate as a complexing agent and deionized water as a solvent and a washing agent; and the NiMnFe hydrotalcite-like precursor is calcined at a certain temperature to obtain the NiMnFe composite oxidedenitration catalyst. The NiMnFe composite oxide catalyst prepared by the method has good catalytic activity (NOx conversion rate of 90% or above at 150-330 DEG C), high N2 selectivity, excellent H2Oresistance and excellent anti-SO2 poisoning performance when applied to a low-temperature NH3-SCR reaction.

Owner:TAIYUAN UNIV OF TECH

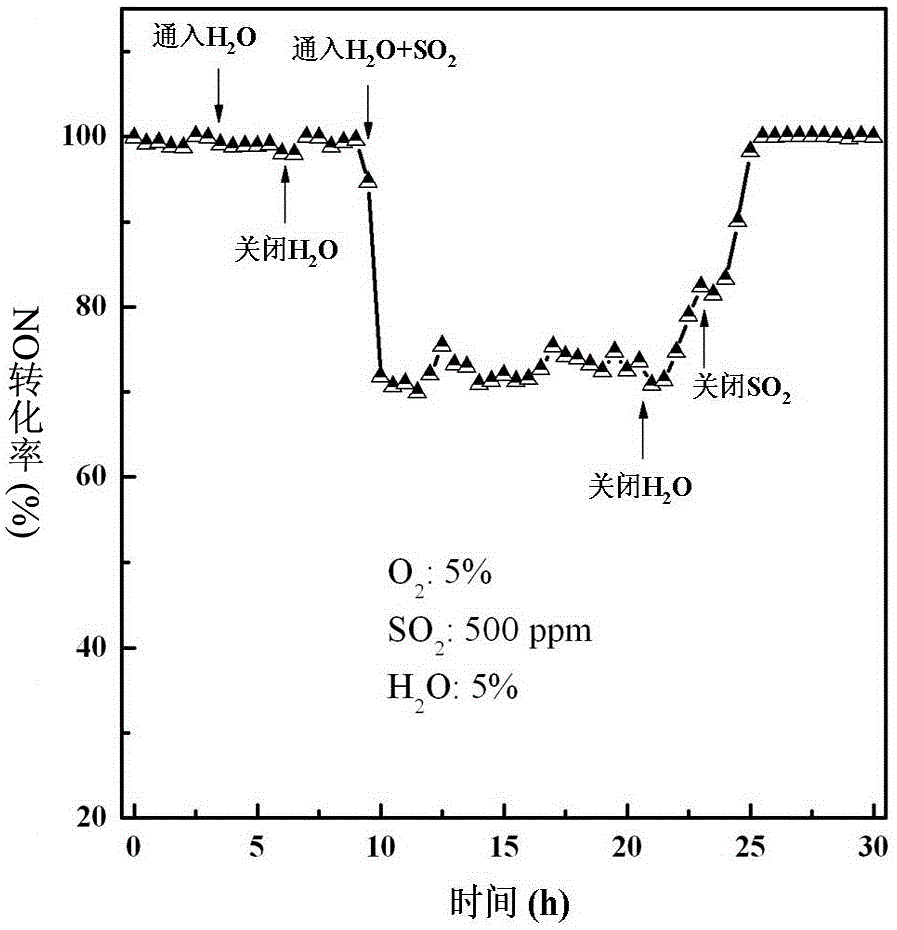

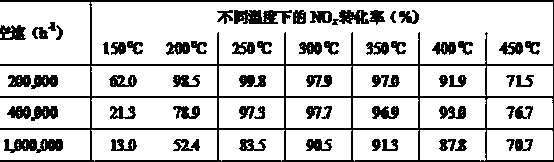

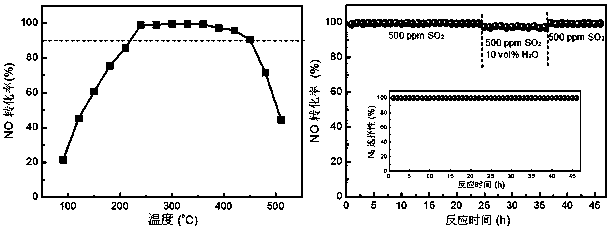

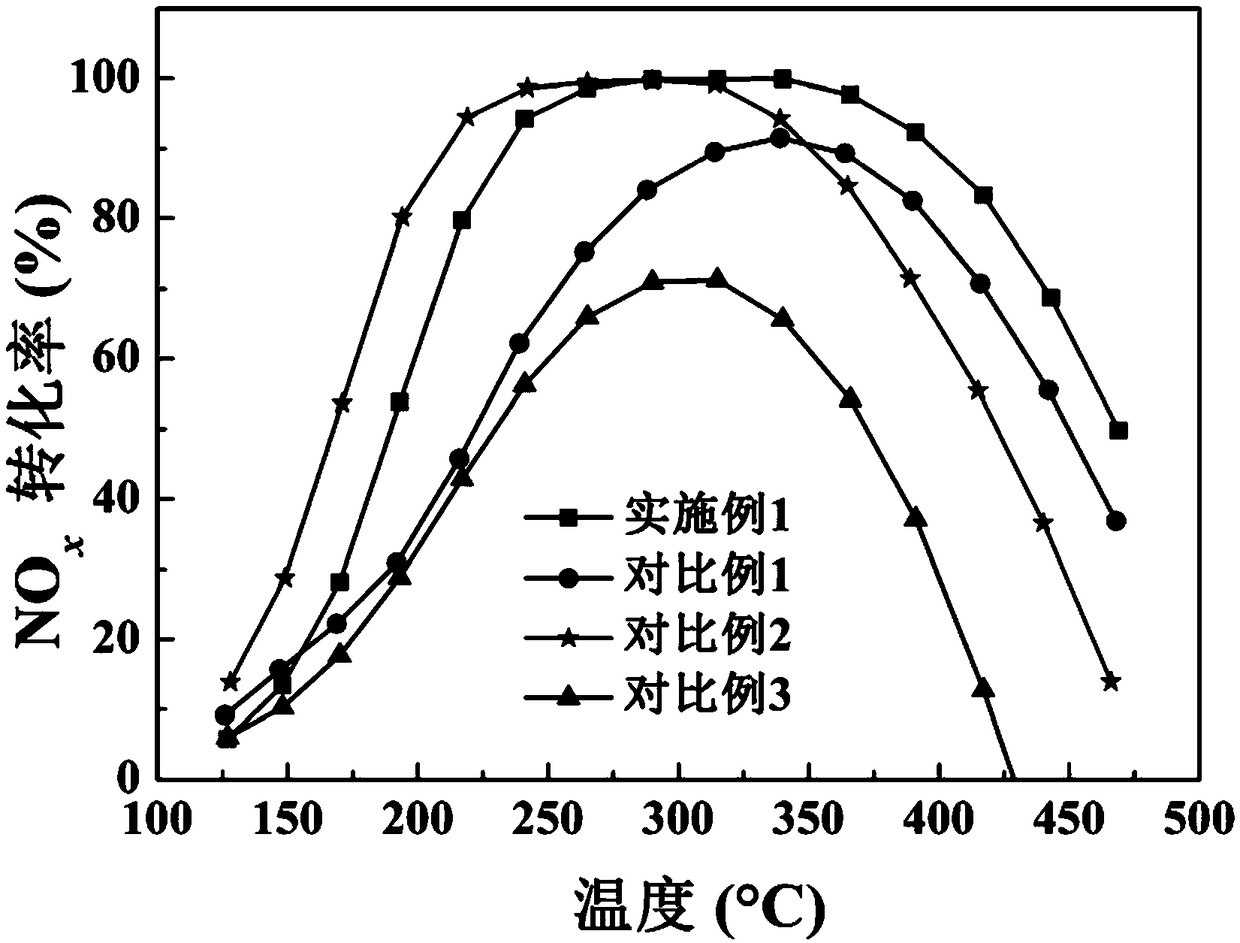

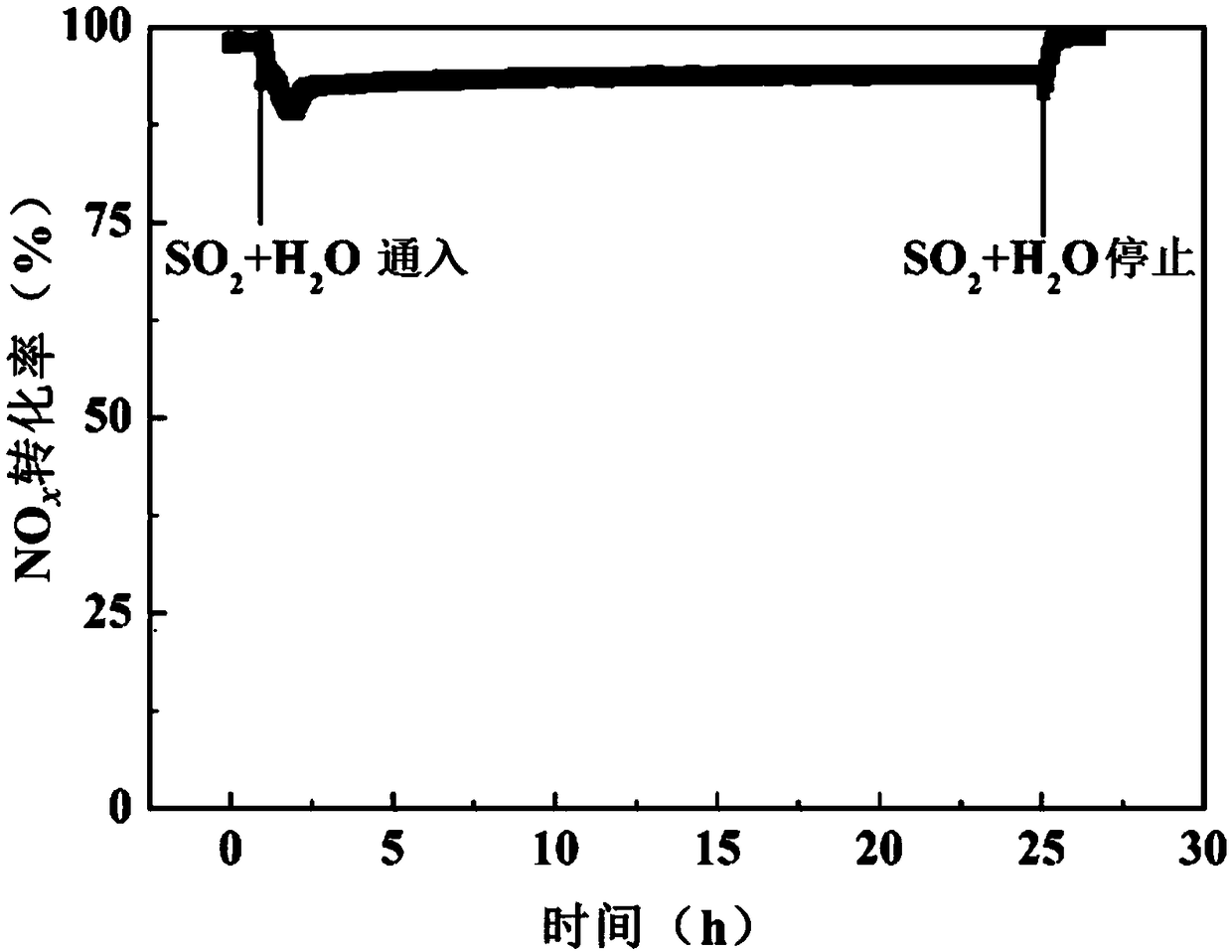

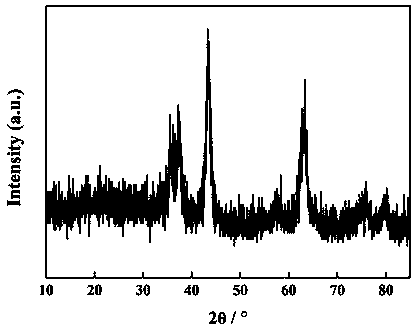

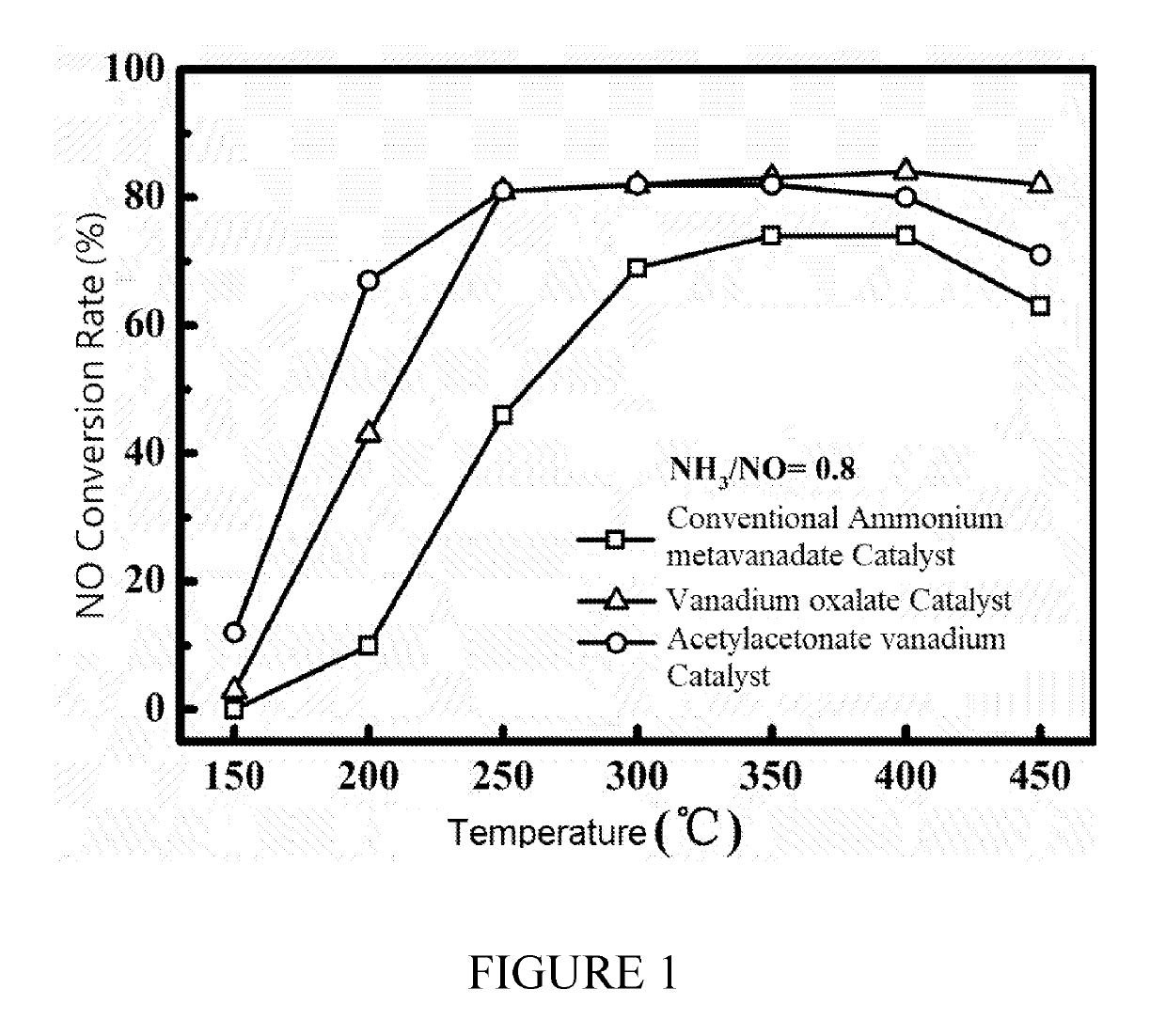

Preparation Method of Denitration Catalyst with Wide Operating Temperature Range for Flue Gas

ActiveUS20190224663A1Excellent resistance to sulfurExcellent to water poisoningGas treatmentHeterogenous catalyst chemical elementsOperating temperature rangeVanadium oxide

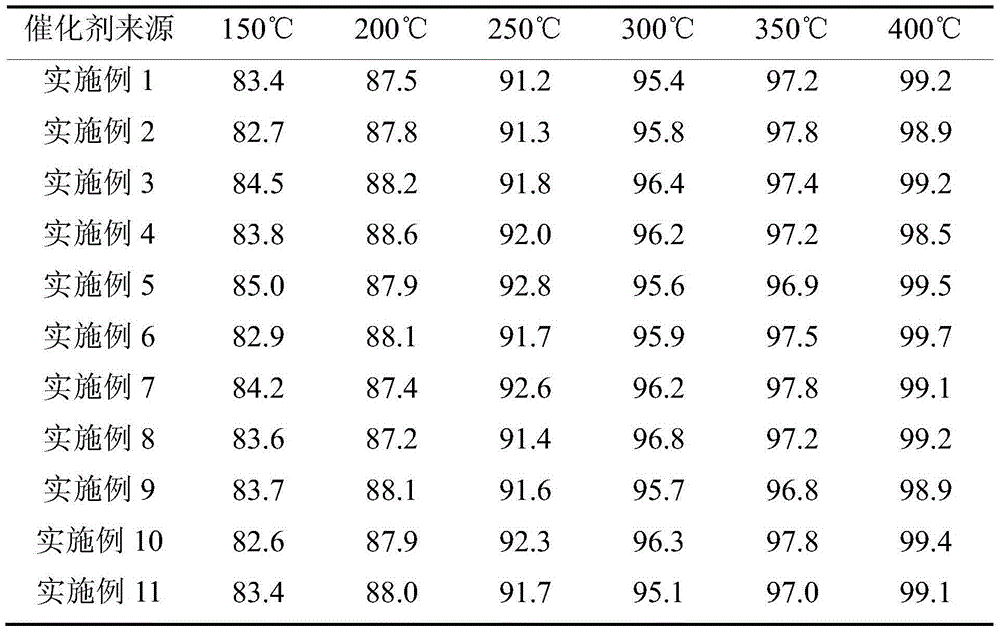

The invention discloses a preparation method and application of a denitration catalyst with wide operating temperature for flue gas, which utilizes an organic vanadium compound as a vanadium precursor, and titanium dioxide powder or titanium tungsten powder as a carrier, and is prepared by mechanical ball milling method and heat treatment to obtain a catalyst, which denitration of fixed source flue gas under wide temperature range. Compared with the existing arts, the present invention includes minor modifications to the traditional vanadium tungsten titanium catalyst system and adopts the mechanical ball milling method, the activity and resistance to sulfur and water poisoning are improved significantly, thus providing a preparation technology of SCR denitration powder catalyst which is green, highly efficient, low cost and simple in operation. Through the interaction of the organic vanadium precursor with the carrier, the vanadium surface atom concentration of the catalyst is higher, the species of polymeric vanadium is more, and the vanadium oxide is more easily reduced, thereby obtaining higher denitrification activity at low temperature. The denitration catalyst of the present invention has relatively higher activity at 200-450° C. while having good resistance to sulfur and water poisoning.

Owner:TSINGHUA UNIV

Manganese-based oxide catalyst with wide temperature window and preparation method thereof

InactiveCN106492788AWide operating temperature windowGood water and sulfur resistanceGas treatmentHeterogenous catalyst chemical elementsNitrogen oxidesSulfur

The invention discloses a manganese-based oxide catalyst for catalytic purification of nitrogen oxide and a preparation method thereof. The preparation method comprises the following steps: preparing a Mn3CeW0.3Ox composite oxide by using a uniform precipitation method and then carrying out roasting so as to obtain the (MnOx)3-CeO2-(WO3)0.3 oxide catalyst. According to the invention, the manganese-based oxide catalyst with the characteristics of a wide temperature window, excellent resistance to water and sulfur, high N2 generation selectivity, high-temperature resistance, heat stability and the like is prepared from nontoxic and harmless raw materials by using the simple and easily practicable method; and the prepared manganese-based oxide catalyst is applicable to a nitrogen oxide catalytic purification apparatus with flue gas of a coal-fired power plant as a representative fixed source and tail gas of a diesel car as a representative movable source.

Owner:NANJING UNIV OF SCI & TECH

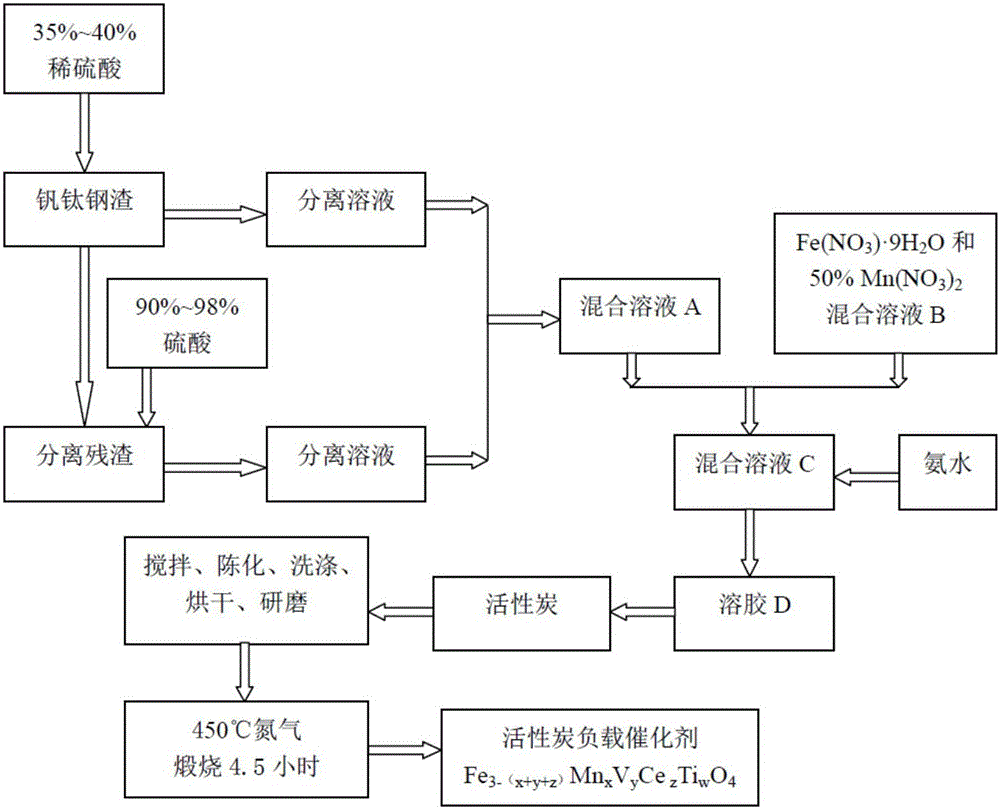

Method for extracting nanometer multi-metal oxide loaded activated carbon fibers

InactiveCN105817234AGood water and sulfur resistanceImproved sulfur and water resistance propertiesHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsFiberManganese

The invention discloses a method for extracting nanometer multi-metal oxide loaded activated carbon fibers. Waste vanadium-titanium slags are taken as raw materials, rare earth metals and transition metals of Ce (Cerium), V (Vanadium), Ti (Titanium), Fe (iron), Co (Cobalt), W (Tungsten) and Mn (Manganese) in the vanadium-titanium slags are fully utilized and loaded on activated carbon for preparing a catalyst, so that vanadium-titanium slag wastes are comprehensively utilized to lower the treatment cost of volatile organic compounds.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Preparation method and application of hydrotalcite-based NiMnTi catalyst

ActiveCN108993530ASingle crystal phaseHigh crystallinityHeterogenous catalyst chemical elementsDispersed particle separationFiltrationComposite oxide

The invention discloses a preparation method and application of a hydrotalcite-based NiMnTi catalyst. The preparation method adopts nickel nitrate hexahydrate, a butyl titanate solution and a manganese nitrate solution with a mass fraction of 50% as raw materials and urea as a precipitant, synergistically exerts the advantages of Ni, Mn and Ti as the cut-in point and utilizes the preparation of NiMnTi-like hydrotalcite to effectively assemble Ni, Mn and Ti in situ. The preparation method comprises: dissolving the raw materials and a precipitant in distilled water, adding ethanol into the solution to obtain a mixed solution, carrying out reflux condensation on the mixed solution in an oil bath, carrying out cooling, suction filtration, washing, drying and grinding to obtain a NiMnTi-like hydrotalcite precursor, and calcining the NiMnTi-like hydrotalcite precursor to obtain the NiMnTi composite oxide catalyst. The NiMnTi composite oxide catalyst has good catalytic activity in the NH3-SCRreaction (with an NOx removal rate of 90% or more at 150-360 DEG C), high N2 selectivity and excellent water and sulfur resistance.

Owner:TAIYUAN UNIV OF TECH

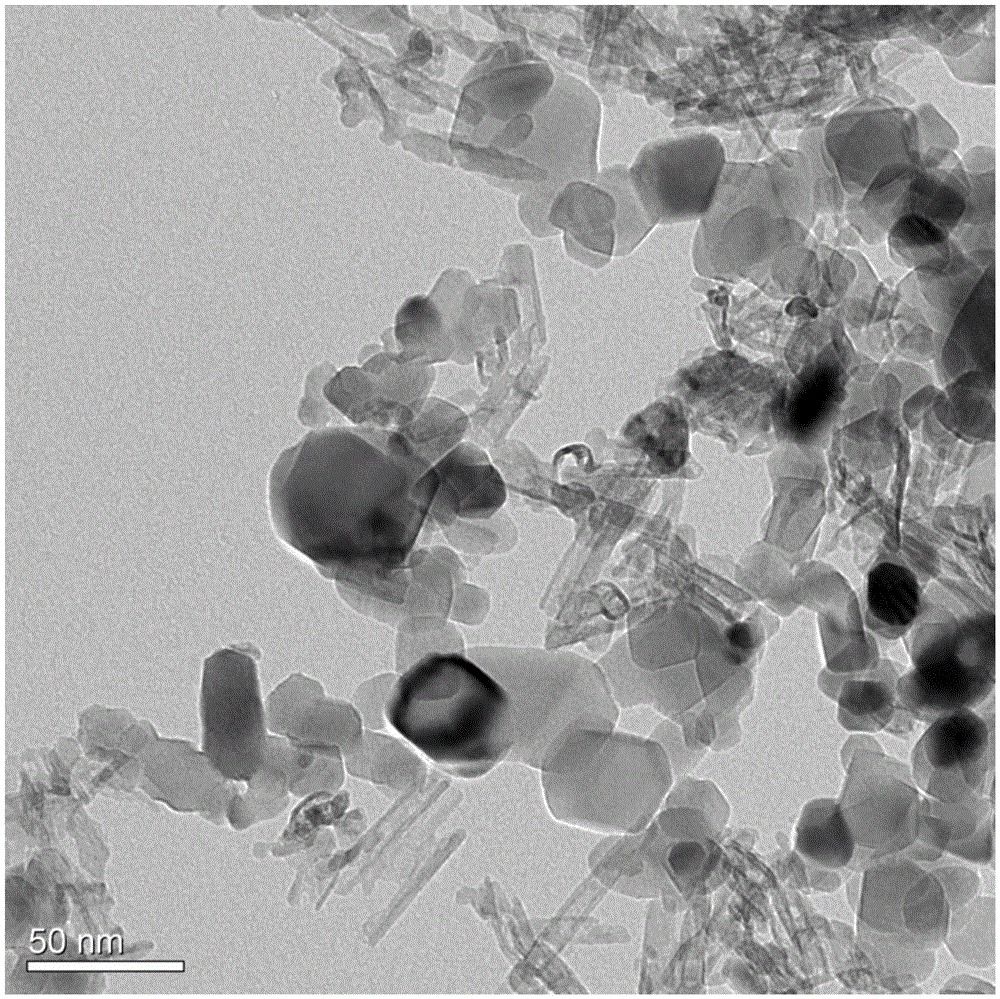

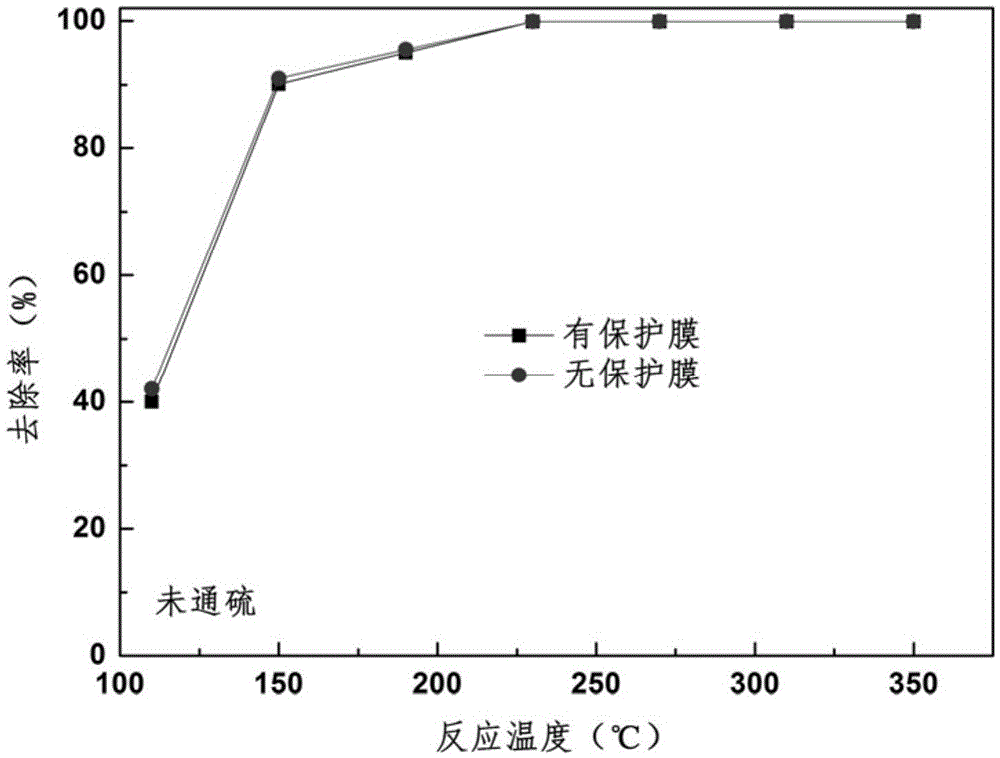

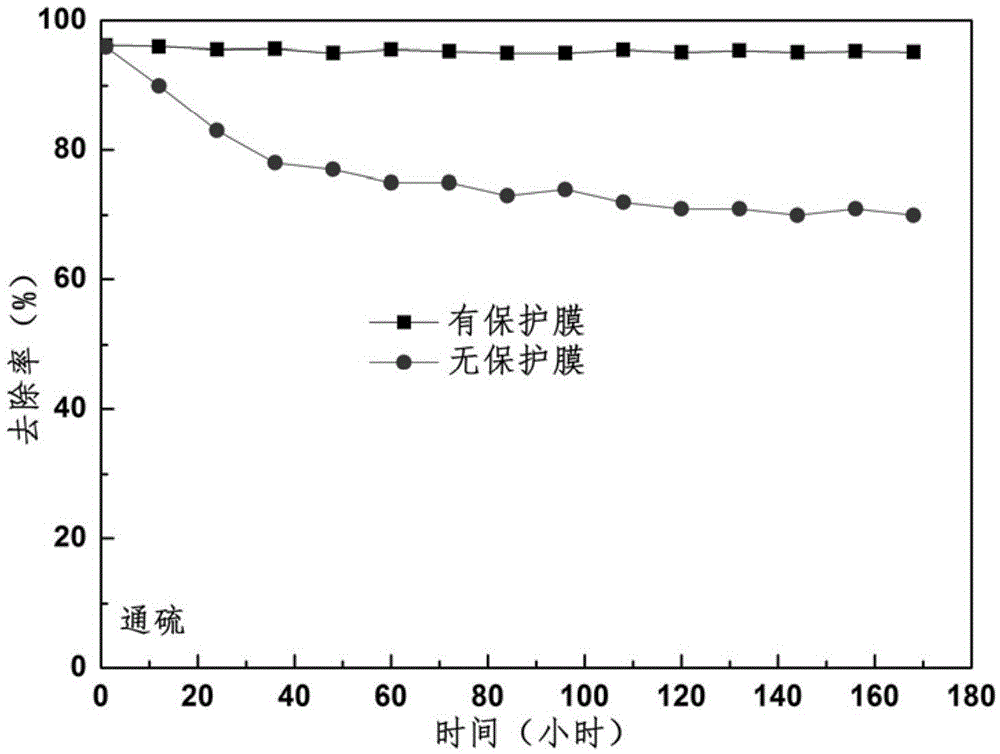

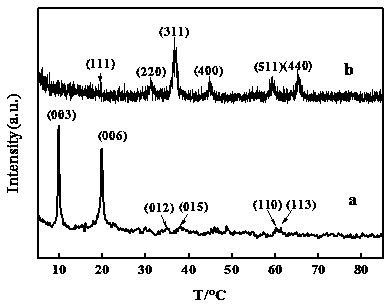

Medium and low temperature denitration catalyst with protective layer and preparation method thereof

ActiveCN105457646AGood water and sulfur resistanceExtended service lifeGas treatmentHeterogenous catalyst chemical elementsTectorial membraneSulfur

The invention discloses a medium and low temperature denitration catalyst with a protective layer and a preparation method thereof. The catalyst is composed of an outer layer protective film and an inner layer catalyst body; the outer layer protective film takes a mixture of titanium dioxide nanoparticles and titanium nanotubes as a substrate material, and V, Ce and Cu composite oxide is doped; the inner layer catalyst body takes the titanium dioxide nanoparticles as carriers, takes V and Ce composite oxide as a main active component and takes trace precious metal as an additive. The catalyst is provided with the protective film with a special structure, the protective film has good medium and low temperature denitration activity by itself, sulfur ammonium salt particles can not enter pore passages of the titanium nanotubes, reaction gas can reach the inner layer catalyst body through the pore passages of the titanium nanotubes, the catalyst shows excellent water-resistant and sulfur-resistant properties, and the service life is effectively prolonged.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

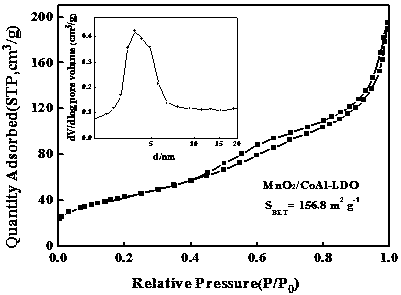

Preparation method and application of MnO2/CoAl-LDO low temperature flue gas denitration catalyst

ActiveCN109012687AEfficient assemblyLarge specific surface areaGas treatmentDispersed particle separationFiltrationHexamethylenetetramine

The invention discloses a preparation method and an application of a MnO2 / CoAl-LDO low temperature flue gas denitration catalyst. A nitrate-intercalated CoAl hydrotalcite-like precursor (CoAl-NO3-LDH)is prepared by using cobalt nitrate nonahydrate and aluminum nitrate nonahydrate as raw materials and using hexamethylenetetramine (HMT) as a precipitant through the steps of preparation of a solution, hydrothermal treatment, suction filtration, washing and drying; a MnO2-intercalated CoAl hydrotalcite-like (CoAl-MnO2-LDH) is prepared by using permanganate ions as target anions and an oxidant through the steps of an ion exchange and redox reaction, suction filtration, washing and drying; and the CoAl-MnO2-LDH is calcined to obtain the MnO2 / CoAl-LDO low temperature flue gas denitration catalyst. The catalyst has good catalytic activity, high N2 selectivity and good water and sulfur resistance when applied to a low temperature (90-300 DEG C) ammonia selective catalytic reduction (NH3-SCR) denitration reaction.

Owner:TAIYUAN UNIV OF TECH

Preparation method of iron-manganese catalyst

InactiveCN111068709AGood water and sulfur resistanceSimple methodDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNanoparticle

The invention discloses a preparation method of an iron-manganese catalyst. The method comprises the following steps: adding manganese oxide nanoparticles into deionized water, ultrasonic dispersion for 40-50 min, adding a ferric nitrate solution, dropwise adding ammonia water under a magnetic stirring condition until the pH value is 2.4-2.6, transferring the mixed solution into a hydrothermal reaction kettle, putting the hydrothermal reaction kettle into a drying oven for hydrothermal reaction at 165-175 DEG C for 4-5 hours, separating and washing, drying the obtained solid at 65-75 DEG C for23-25 hours, finally calcining the solid at 380-390 DEG C in an oxygen atmosphere for 4-5 hours, and cooling. The method is simple, convenient, rapid and easy to operate, the prepared iron-manganesecatalyst has high NOx catalytic activity, and meanwhile, the catalyst shows excellent water resistance and sulfur resistance and can be prepared on a large scale.

Owner:HAIMEN YUANMEI MEISHU TUAN SHEJI CO LTD

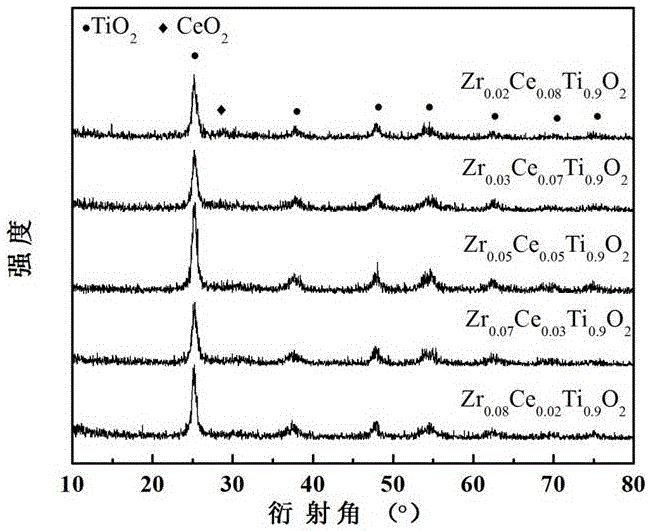

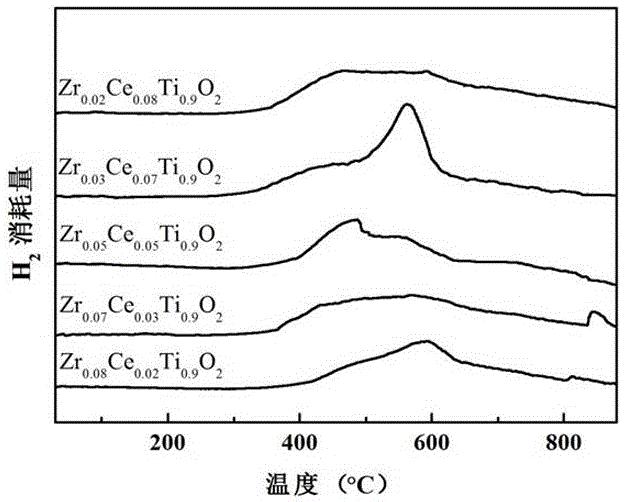

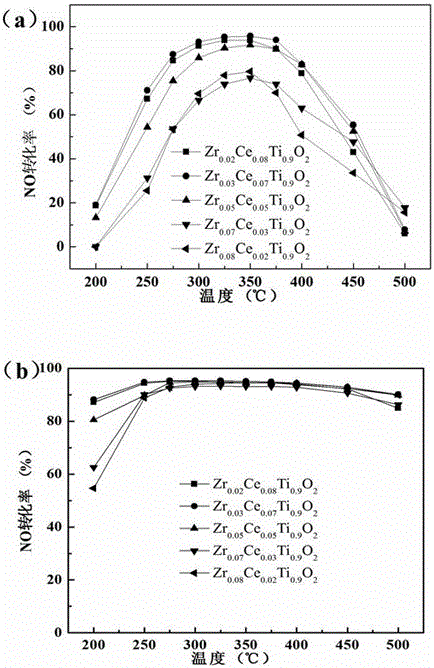

High-performance zirconium cerium titanium solid-solution catalyst for flue gas denitration and preparation method thereof

InactiveCN105688883ARaw materials are cheap and easy to getEasy to prepareGas treatmentHeterogenous catalyst chemical elementsPtru catalystTitanium zirconium

The invention provides a zirconium cerium titanium solid-solution catalyst. The main component of the zirconium cerium titanium solid-solution catalyst is an anatase type titanium zirconium cerium titanium solid solution. The zirconium cerium titanium solid-solution catalyst has the advantages of high heat stability, excellent reduction performance and the like, has higher activity and selectivity in NH3 selective catalytic NO-reducing reaction, excellent water and sulfur resistance properties and has a potential application value in the field of denitration. The invention discloses a preparation method of the zirconium cerium titanium solid-solution catalyst.

Owner:UNIV OF JINAN

Catalyst of reaction for removing oxynitrides by methane and preparation method thereof

InactiveCN101406847AImprove catalytic performanceGood water and sulfur resistanceMolecular sieve catalystsDispersed particle separationMolecular sieveCobalt acetate

The invention provides a catalyst for oxynitride removing reaction by using methane, as well as a preparation method thereof. The catalyst is characterized in that a carrier of the catalyst is an H-Beta / Mordenite double-micropore molecular sieve; an active ingredient is cobalt; the weight percentage of the cobalt is between 0.5 and 10 percent; and the weight percentage of H-Beta / Mordenite is between 90 and 99.5 percent. The preparation method for the catalyst adopts an ion exchange method, which is to put H-Beta / Mordenite double-micropore molecular sieve powder into cobalt acetate solution with the concentration of between 0.005 and 0.03mol / L to react for 24 hours at 90 DEG C, wash, filter, dry and roast the powder to obtain the catalyst. The catalyst can allow the conversion rate of oxynitride to reach over 90 percent, has no inactivation phenomenon after maintaining activity for 72 hours, is wide in the operation interval (between 400 and 650 DEG C) of reaction temperature, and shows good performances of resisting water and sulfur at the same time.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com