Metallic monolithic structuring core-shell structured denitration catalyst and preparation method thereof

A denitration catalyst and a core-shell structure technology, applied in the field of nitrogen oxide control and purification in environmental protection, can solve the problems of high treatment cost, cumbersome steps, uneven coating, etc., and achieve excellent sulfur and water resistance and environmental toxicity. Small, low temperature activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

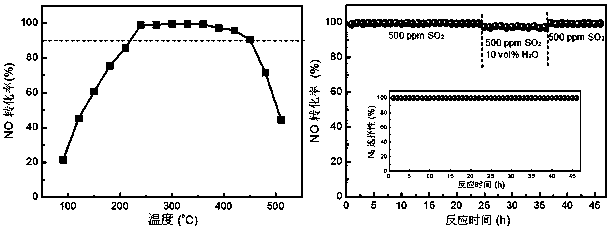

Embodiment 1

[0029] Embodiment one: 1 g aluminum wire mesh is placed in the hydrothermal reactor containing deionized water, 100 o C water heat for 12 h. Washed three times with deionized water, 100 o C drying for 12 h, the aluminum wire mesh structured pseudo-boehmite composite material was prepared. Weigh iron nitrate containing 0.1 g Fe and cerium nitrate containing 0.03 g Ce and dissolve it in 0.8 g methanol, add 0.416 g bis-triethanolamine diisopropyl titanate, and sonicate for 10 minutes. Then, the incipient wetness of pseudo-boehmite structured with aluminum mesh was impregnated in the above mixed solution, and after standing for 2 hours, 0.08 g of deionized water was added dropwise, and stood for 4 hours to make the coupling agent and the pseudo-boehmite on the monolithic carrier Boehmite is fully hydrolyzed. The resulting material 100 o C drying 12 h, 500 oC Calcined for 3 h to prepare Al mesh-structured titanium dioxide-wrapped iron-cerium catalyst.

[0030] To test the cat...

Embodiment 2

[0031] Embodiment two: 1 g aluminum wire mesh is placed in the hydrothermal reaction kettle containing deionized water, 100 o C water heat for 12 h. Washed three times with deionized water, 100 o C drying for 12 h, the aluminum wire mesh structured pseudo-boehmite composite material was obtained. Weigh iron nitrate containing 0.1 g Fe and zirconium nitrate 0.03 g Zr and dissolve in 0.8 g methanol, add 0.416 g bis-triethanolamine diisopropyl titanate, and sonicate for 10 minutes. Then, the incipient wetness of pseudo-boehmite structured with aluminum mesh was impregnated in the above mixed solution, and after standing for 2 hours, 0.08 g of deionized water was added dropwise, and stood for 4 hours to make the coupling agent and the pseudo-boehmite on the monolithic carrier Boehmite is fully hydrolyzed. The resulting material 100 o C drying 12 h, 500 oC Calcined for 3 h to prepare the Fe-Zr catalyst wrapped in TiO2 with Al mesh structure.

[0032] To test the catalytic act...

Embodiment 3

[0033] Embodiment three: 1 g aluminum wire mesh is placed in the hydrothermal reactor containing deionized water, 100 o C water heat for 12 h. Washed three times with deionized water, 100 o C drying for 12 h, the aluminum wire mesh structured pseudo-boehmite composite material was obtained. Weigh ferric nitrate containing 0.1 g Fe and 0.03 g La lanthanum nitrate and dissolve in 0.8 g methanol, add 0.416 g bis-triethanolamine diisopropyl titanate, and sonicate for 10 minutes. Then, the incipient wetness of pseudo-boehmite structured with aluminum mesh was impregnated in the above mixed solution, and after standing for 2 hours, 0.08 g of deionized water was added dropwise, and stood for 4 hours to make the coupling agent and the pseudo-boehmite on the monolithic carrier Boehmite is fully hydrolyzed. The resulting material 100 o C drying 12 h, 500 oC Calcined for 3 h to prepare aluminum mesh structured titania-wrapped iron lanthanum catalyst.

[0034] To test the catalytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com