Patents

Literature

420results about How to "High low temperature activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

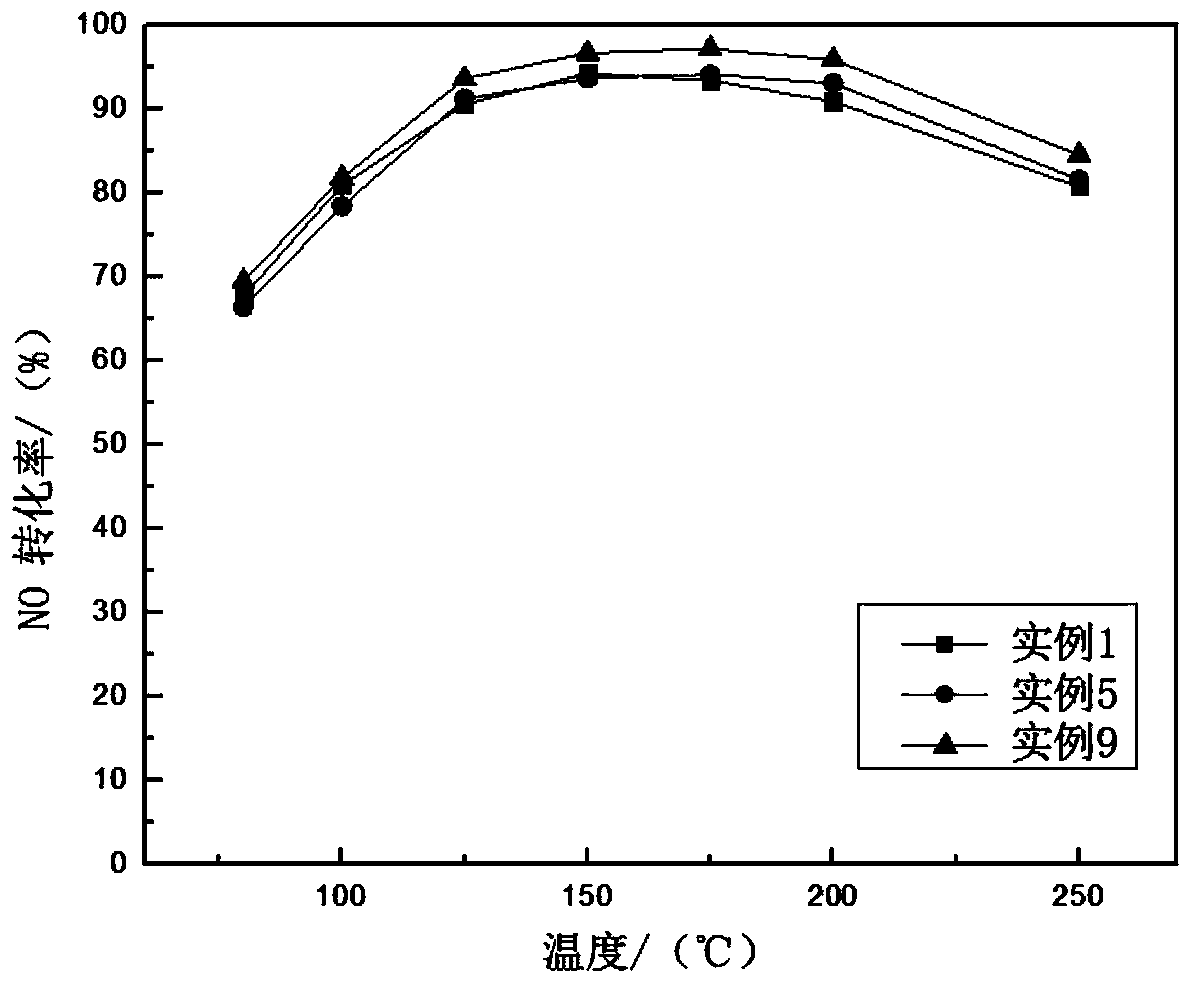

SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of cement kiln and preparation method thereof

ActiveCN103638942AHigh low temperature activityImprove anti-poisoning performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNiobiumManganese

The invention provides an SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of a cement kiln and a preparation method thereof. The SCR catalyst is characterized in that by adjusting the technological conditions such as proportions of active components, mass ratio of carriers and active components, calcining temperature and the like, a composite metal oxide which is formed by one or more metal elements out of manganese (Mn), ferrum (Fe), copper (Cu), cerium (Ce), lanthanum (La), bismuth (Bi), niobium (Nb), tantalum (Ta) and the like is loaded on a carrier by adopting an impregnation method, and tungsten and molybdate are used as active assistants. The active components in the SCR catalyst are uniformly distributed on the surface of the carrier in an unformed shape, the low-temperature activity of the catalyst is improved by utilizing the synergistic effect of multiple metals, the SCR catalyst is particularly suitable for the denitration of the smoke which is discharged from a dust collector on the tail of the cement kiln, the denitration rate can reach higher than 70 percent at the temperature of 80 DEG C, the denitration rate is higher than 90 percent in the temperature range of 125 DEG C to 200 DEG C, and the toxicity resistance is strong.

Owner:CHINA BUILDING MATERIALS ACAD

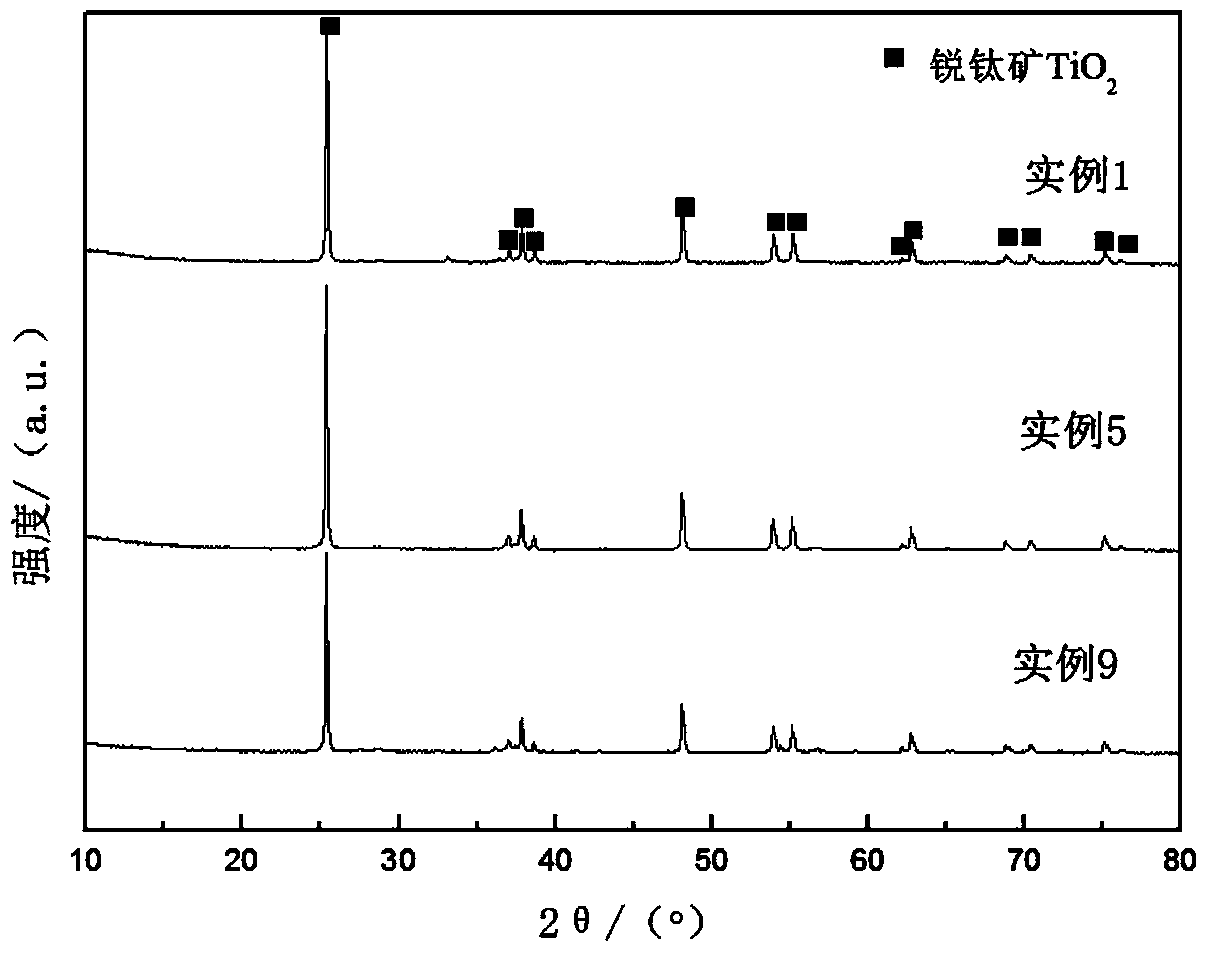

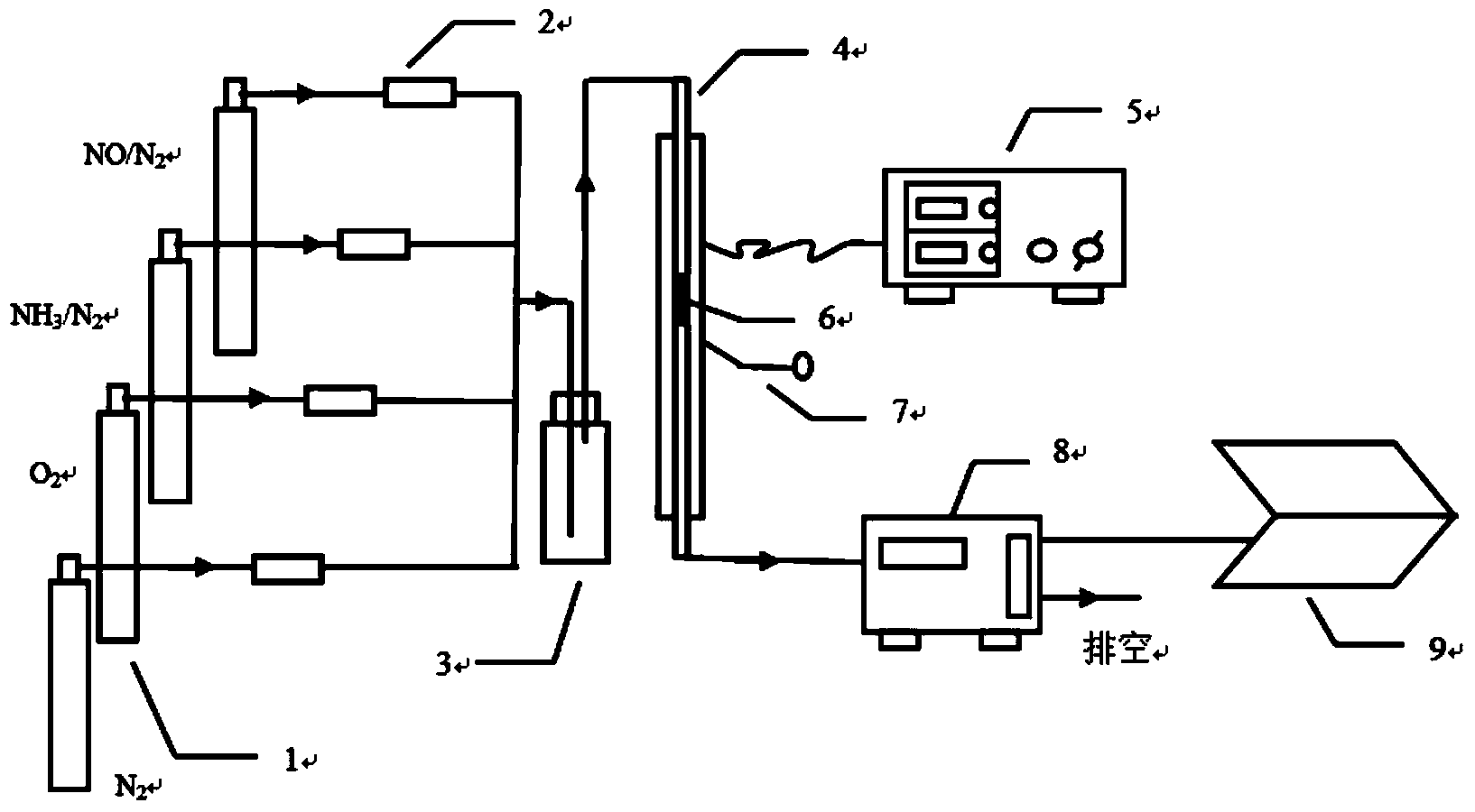

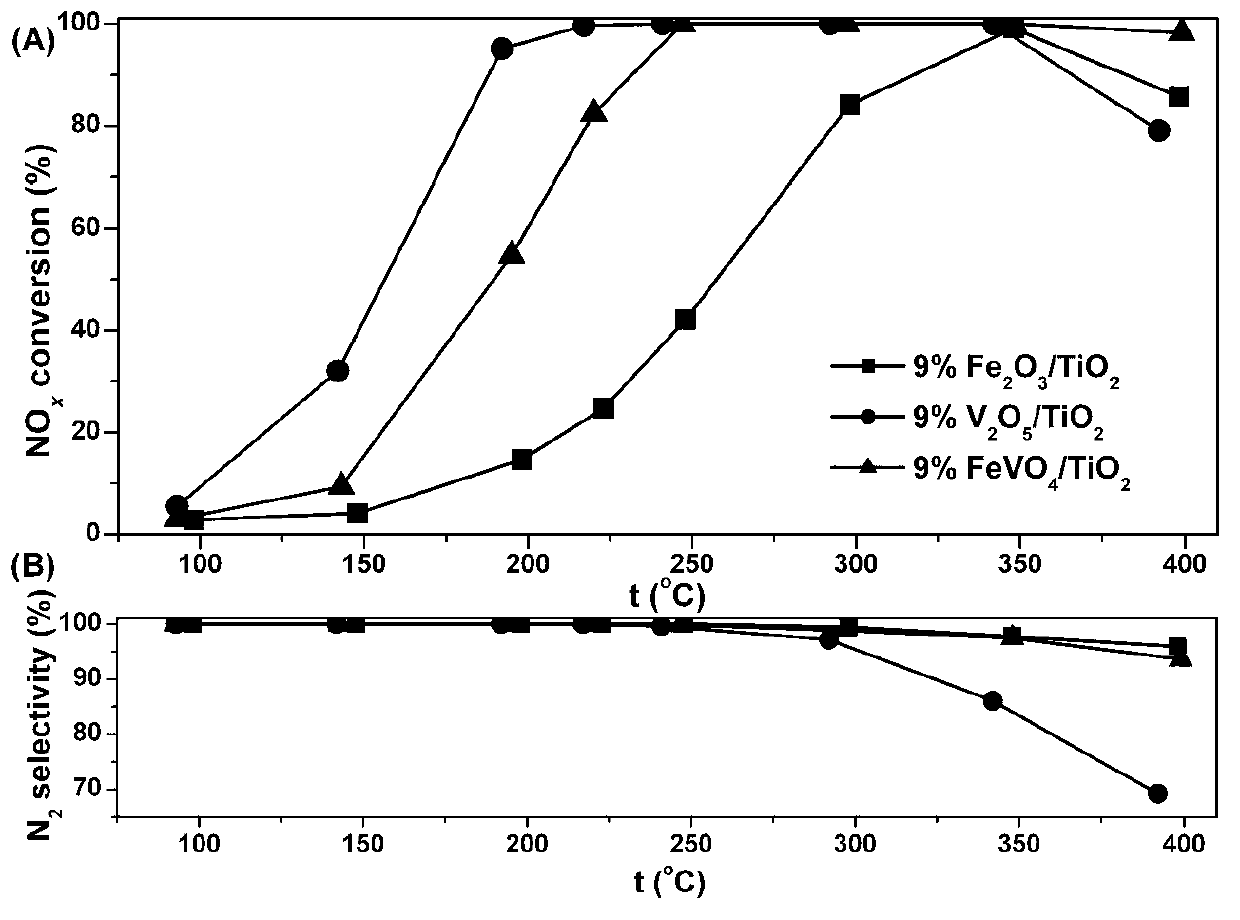

Titanium oxide supported ferric vanadate catalyst, as well as preparation method and use thereof

ActiveCN102989467AEvenly dispersedReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen oxideNitric oxide

The invention relates to a titanium oxide supported ferric vanadate catalyst. The catalyst is composed of a TiO2 carrier, and a FeVO4 active constituent supported on the TiO2 carrier. In term of the mass of the catalyst as 100wt%, FeVO4 is 1.5-15 wt%, preferably 2.5-13.5 wt%, further preferably 8-10 wt%, and most preferably 9 wt%. According to the invention, the TiO2 supported FeVO4 catalyst is used for purifying fixed-source and movable-source nitric oxides in NH3-SCR (selective catalytic reduction) reaction for the first time; and moreover, the preparation method for the catalyst is simple and practicable, and easily realizes industrialized production. The FeVO4 / TiO2 catalyst disclosed by the invention is extremely excellent in anti-H2O-poisoning and anti-SO2-poisoning performances in the NH3-SCR reaction, and very suitable for practical application.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

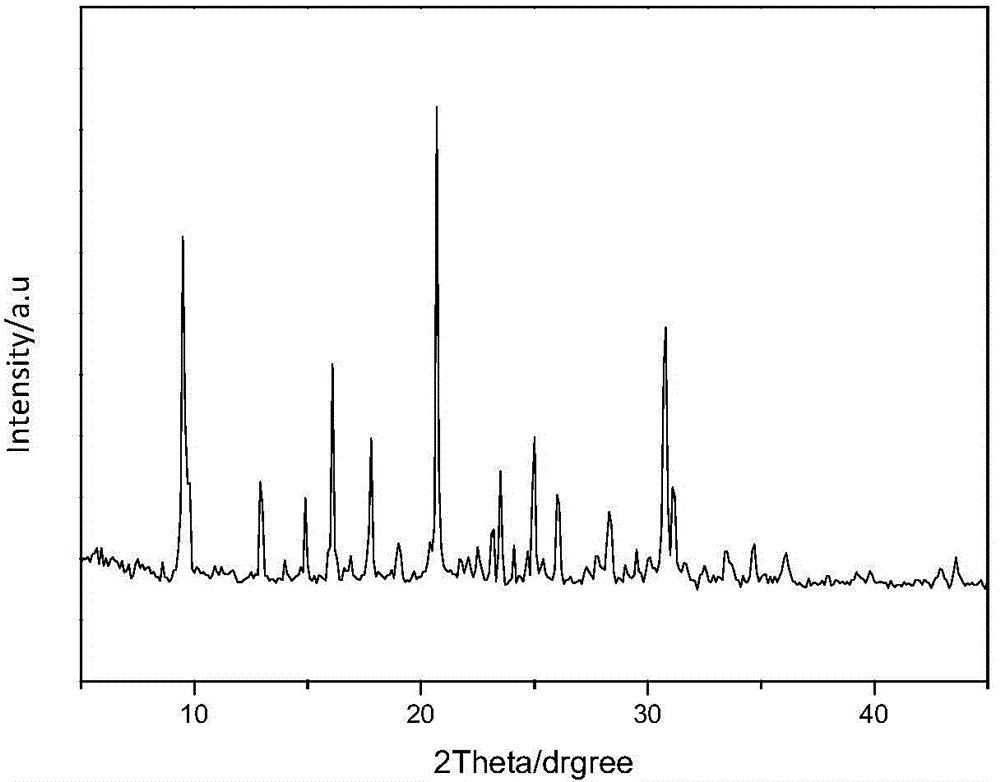

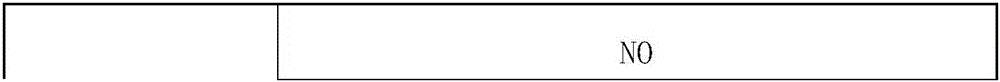

Molecular sieve based catalyst used for low-temperature SCR denitration and its preparation method

InactiveCN103599813AHigh low temperature activityGood choiceMolecular sieve catalystsDispersed particle separationSulfurNitrogen oxide

The invention relates to a low-temperature denitration SCR (selective catalytic reduction) catalyst, which includes a Cu modified molecular sieve carrier and one or more oxides of Ce, Zr, and Mn. The employed carrier is a Cu-SSZ-13 molecular sieve that is synthesized by a cheap template route and then undergoes modification. The catalyst provided by the invention has a nitrogen oxide removal rate up to 62-100% in the range of 100-250DEG C, and the low-temperature catalyst involved in the invention has good sulfur-resisting capacity.

Owner:BEIJING UNIV OF CHEM TECH

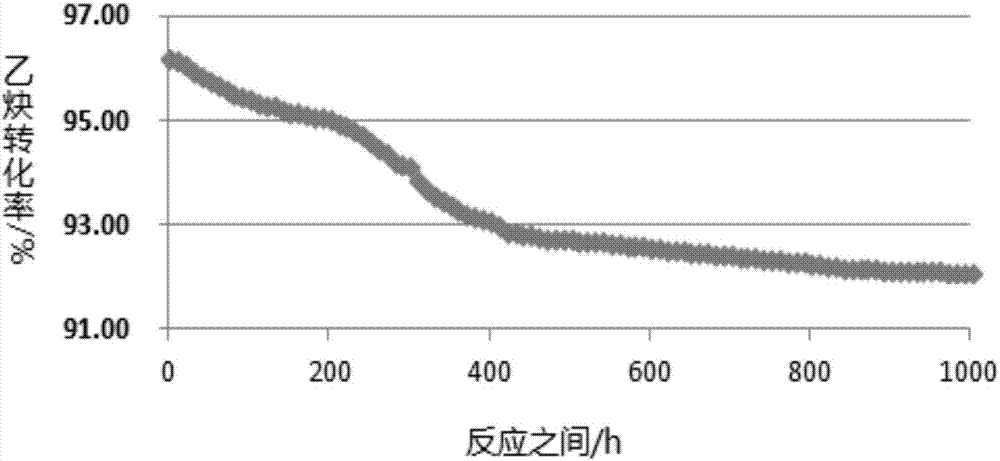

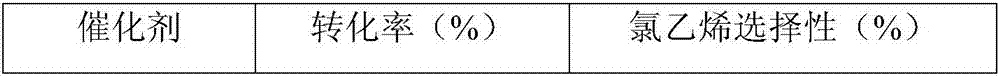

Mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and preparation method and application thereof

ActiveCN106944151AEasy to prepareLow costPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsSolventActive carbon

The invention relates to a mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, dissolving alkali metal salt and an amide solvent in water to prepare a mixed solution; 2, adding active carbon into the mixed solution obtained in step 1, and dipping the active carbon; and 3, filtering the active carbon obtained in step 2, draining the filtered active carbon, and heating and drying the drained active carbon to obtain the catalyst. The concentration of raw gas on the surface of the catalyst is increased through using the synergism of the alkali metal salt and the amide solvent and the adsorbing and dissolving ability of the amide solvent to raw materials comprising acetylene and hydrogen chloride, and the amide solvent is a high-polarity aprotic polar solvent, and has a polarization effect on reactants, so the reaction efficiency is further improved, the low temperature activity of the catalyst is high, and the selectivity and the stability are good.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

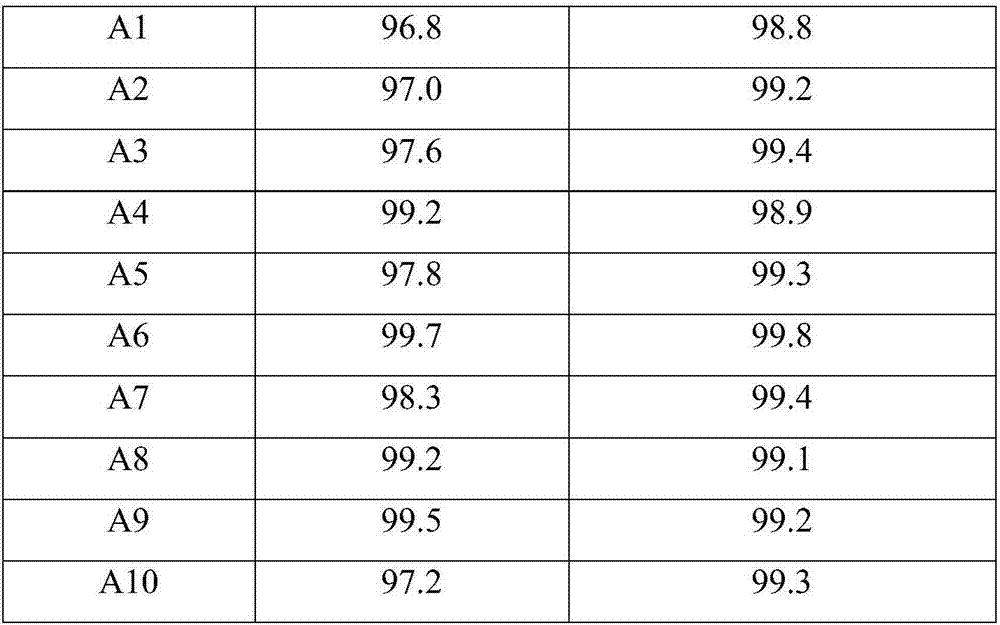

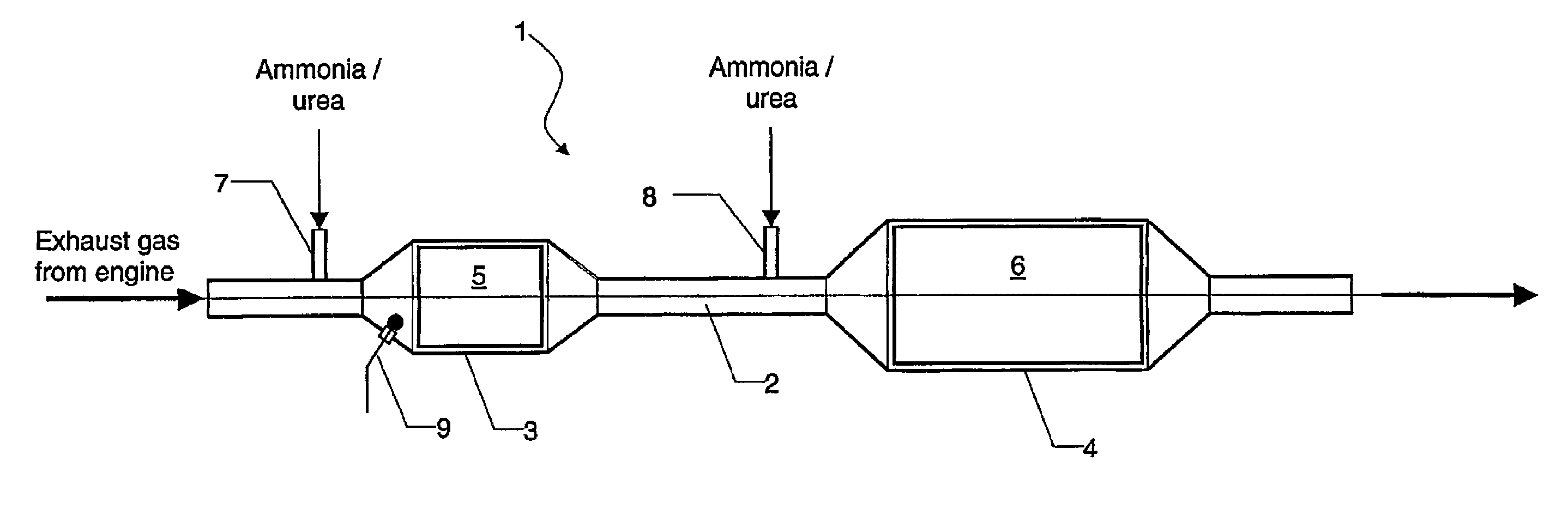

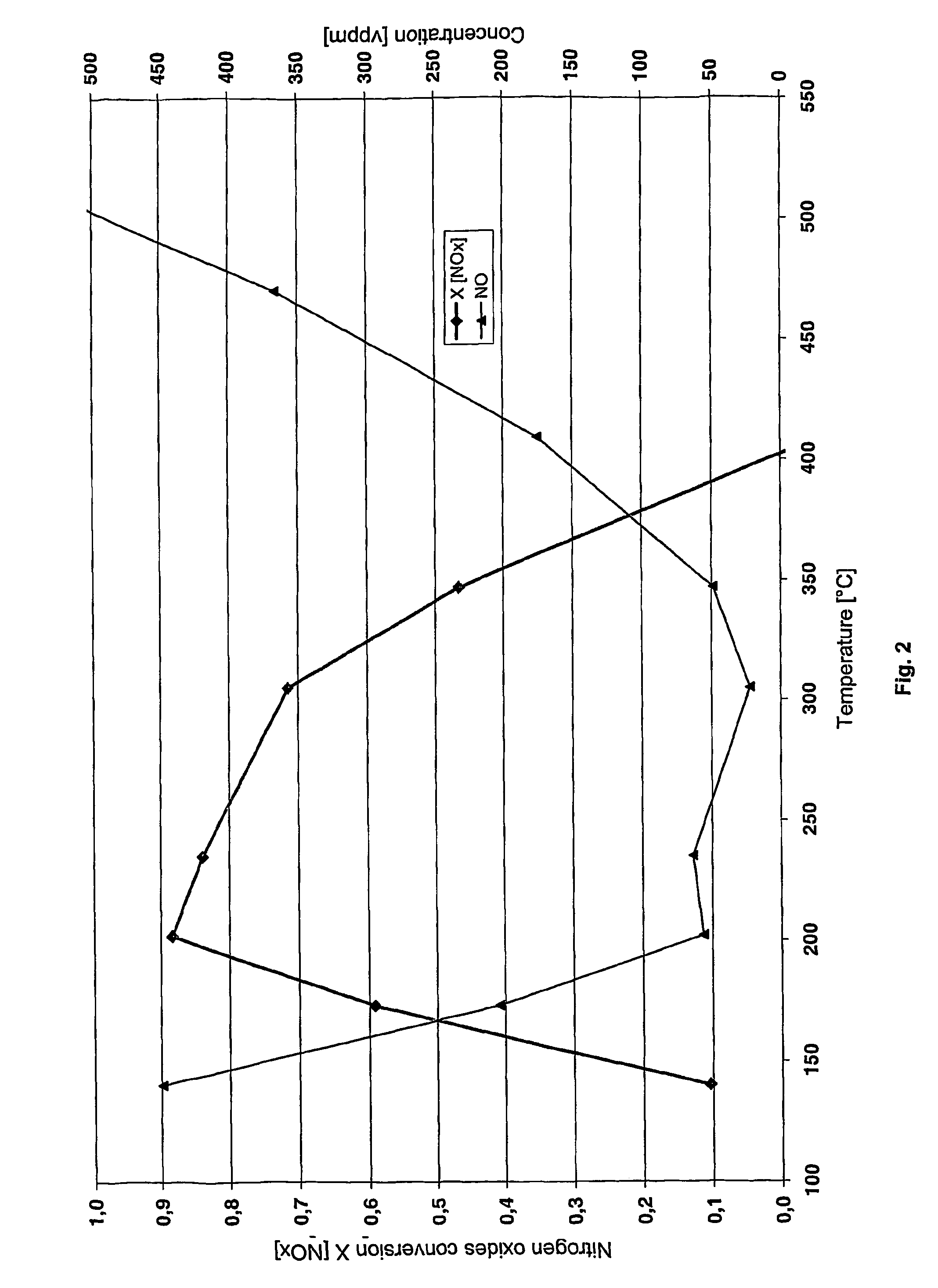

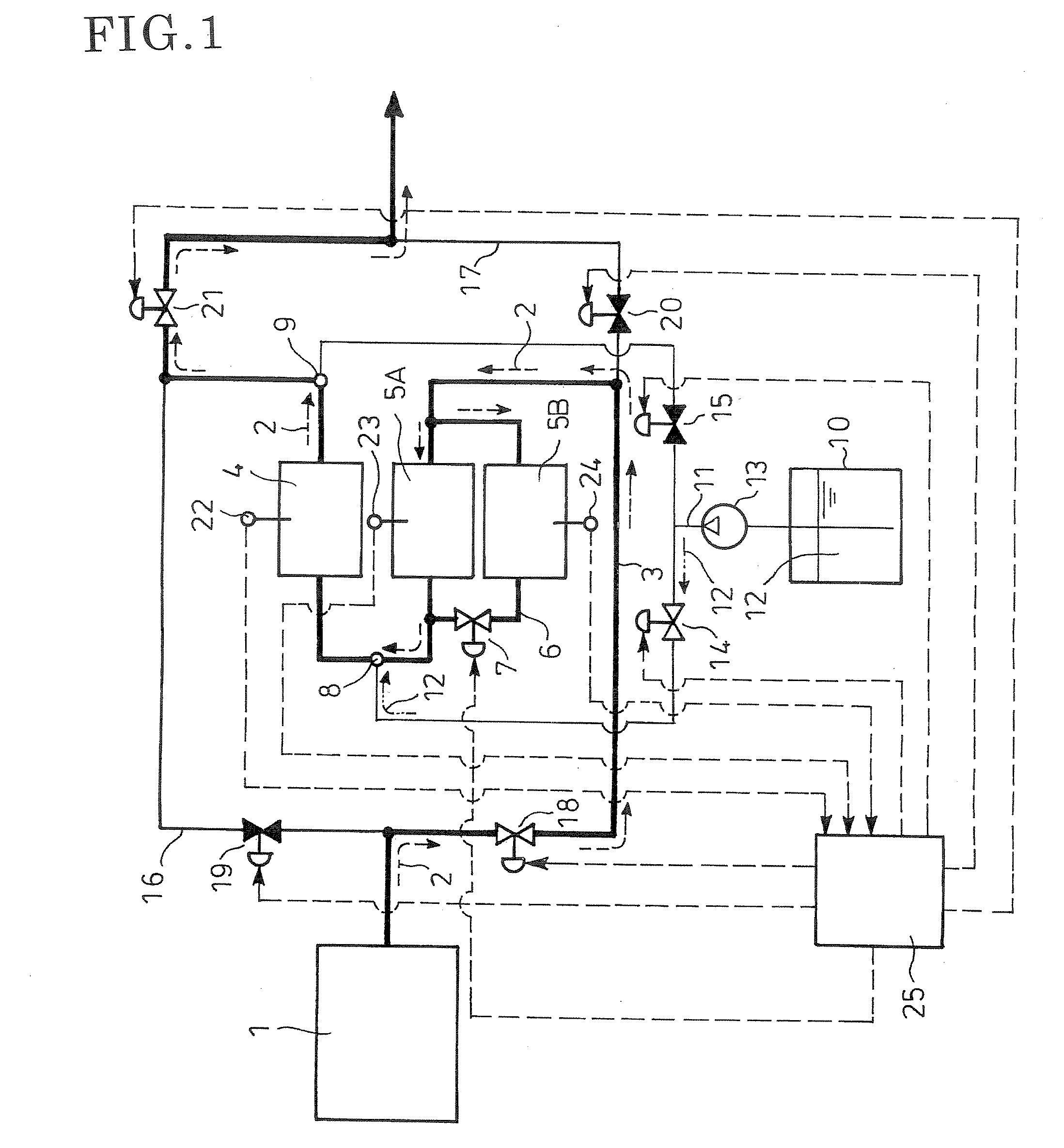

Method of removing nitrogen oxides from the exhaust gas of a lean-burn internal combustion engine and exhaust-gas purification system therefor

ActiveUS7313911B2Promote regenerationPrevent scalingInternal combustion piston enginesExhaust apparatusPlatinumNitrogen

The present invention relates to a method of removing nitrogen oxides from the exhaust gas of a lean-burn internal combustion engine by selective catalytic reduction (SCR) using ammonia. The exhaust gas is routed first over a platinum-containing pre-catalyst and then over an SCR catalyst. The ammonia needed for the selective catalytic reduction is added to the exhaust gas upstream of the pre-catalyst at an exhaust-gas temperature below 250° C., while it is supplied to the exhaust gas between the pre-catalyst and the SCR catalyst at an exhaust gas temperature above 150° C. By adopting this procedure, a very large temperature range for the selective catalytic reduction with high nitrogen conversion rates is obtained.

Owner:UMICORE AG & CO KG

Catalyst for selective catalytic reduction of nitric oxide and preparation method of catalyst

InactiveCN106111183AReduce dosageHigh low temperature activityMolecular sieve catalystsDispersed particle separationMolecular sieveEffective surface

The invention belongs to the technical field of environmental protection and catalysts, and particularly relates to a catalyst for selective catalytic reduction of nitric oxide and a preparation method of the catalyst. The catalyst comprises a molecular sieve and transition metal supported on the molecular sieve and is prepared from the molecular sieve and a transition metal precursor, and the molecular sieve is dried to remove adsorbed water; then the metal precursor is mixed with water, stirring is carried out for dissolving, and a solution is prepared; the prepared solution and the prepared molecular sieve are stirred and mixed, standing, drying and calcining are carried out, the product is cooled to normal temperature, and the catalyst for selective catalytic reduction of nitric oxide is obtained. The molecular sieve is used as a carrier, an effective surface is provided for adsorption and reacting of nitric oxide, high dispersion of active components can be kept, and the use amount of the active components can be reduced. By means of the characteristics of the carrier and the synergetic effect among different kinds of metals, the low temperature activity of the catalyst is improved, and the active window temperature range of the catalyst is widened. The preparation method of the catalyst is simple, easy to carry out and free of pollution.

Owner:碗海鹰

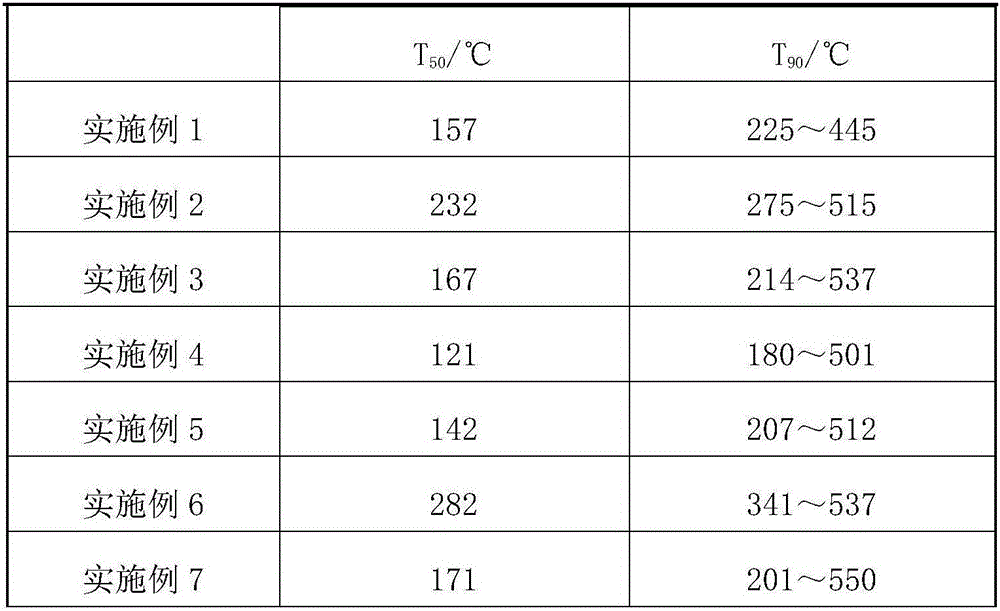

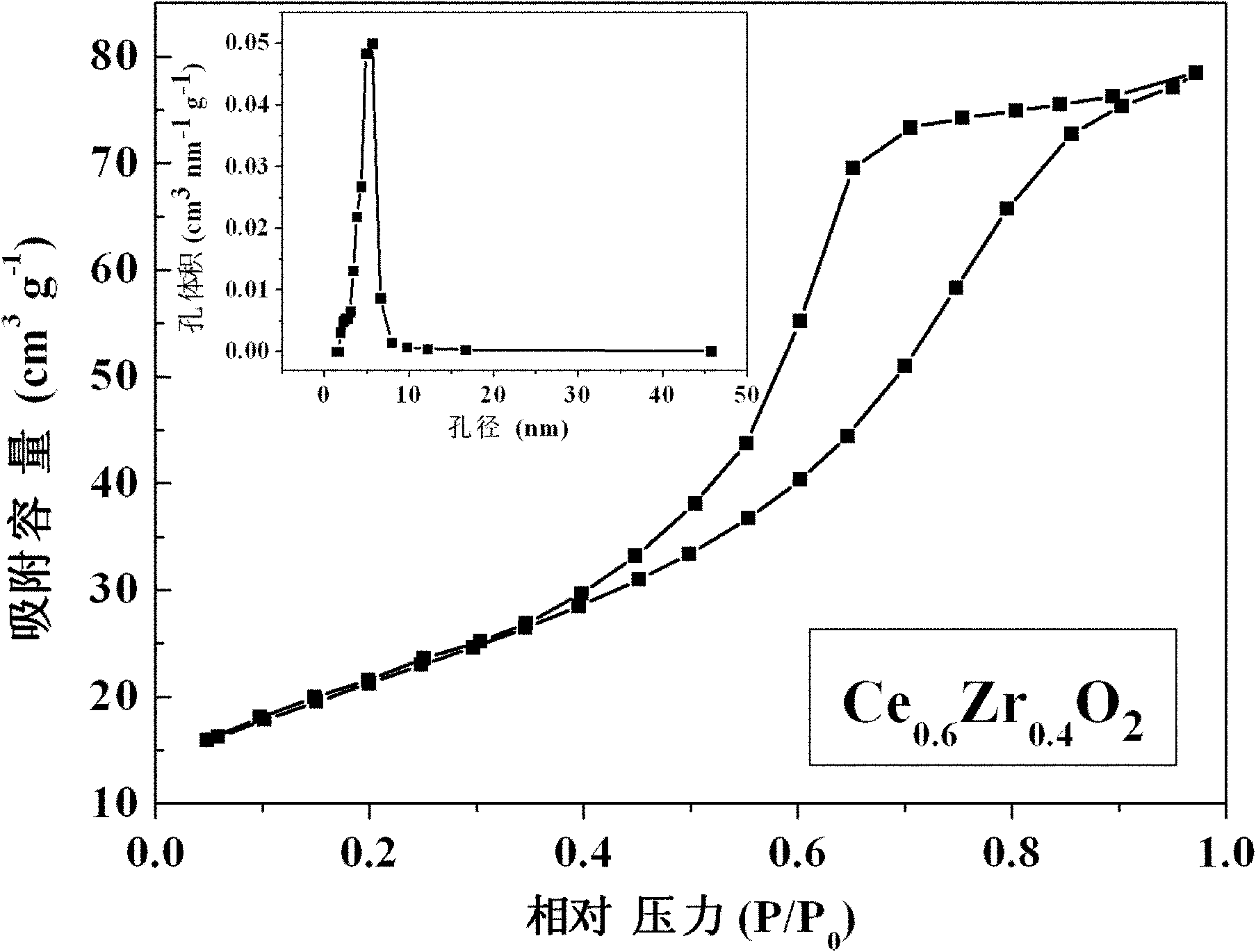

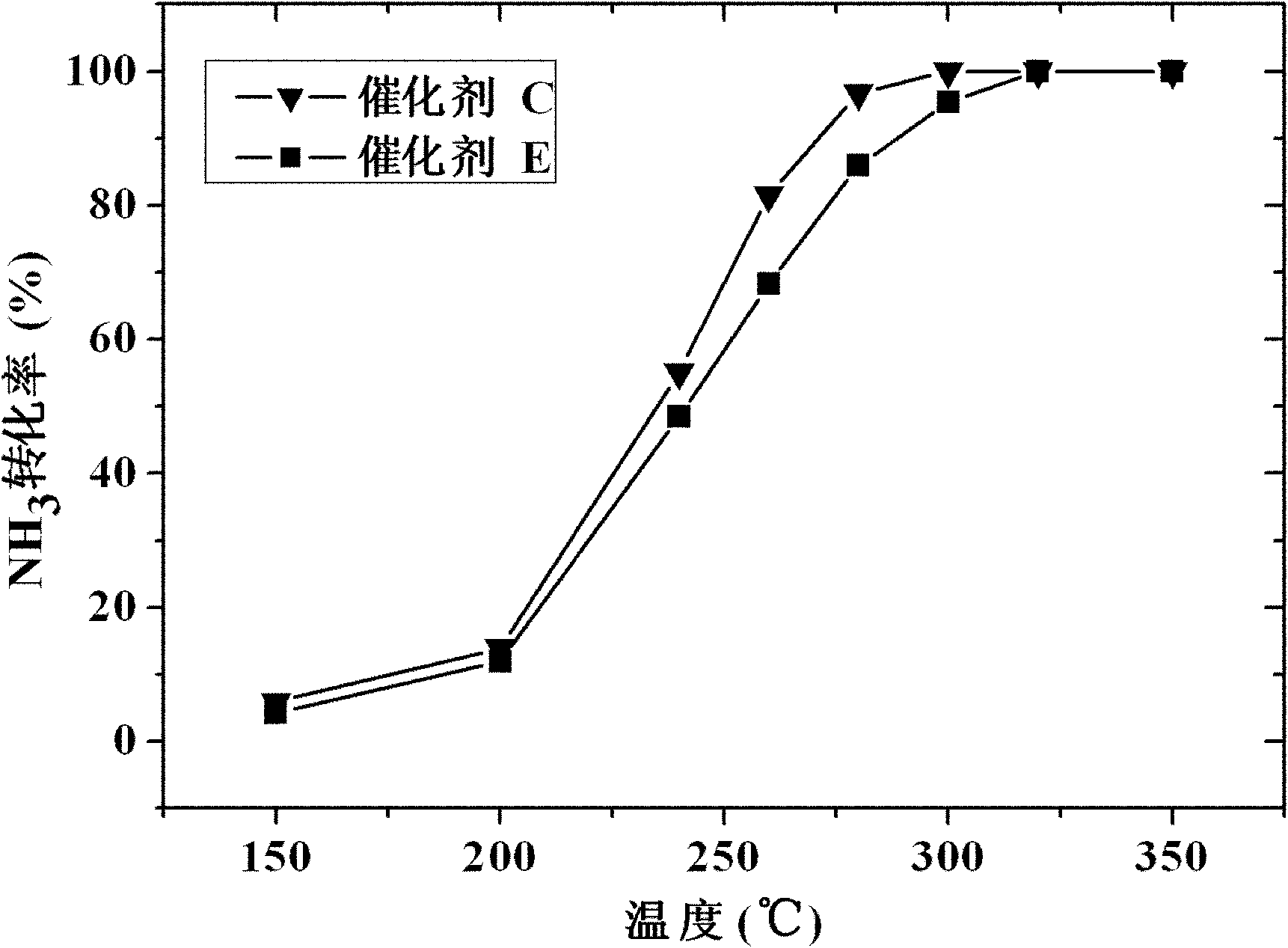

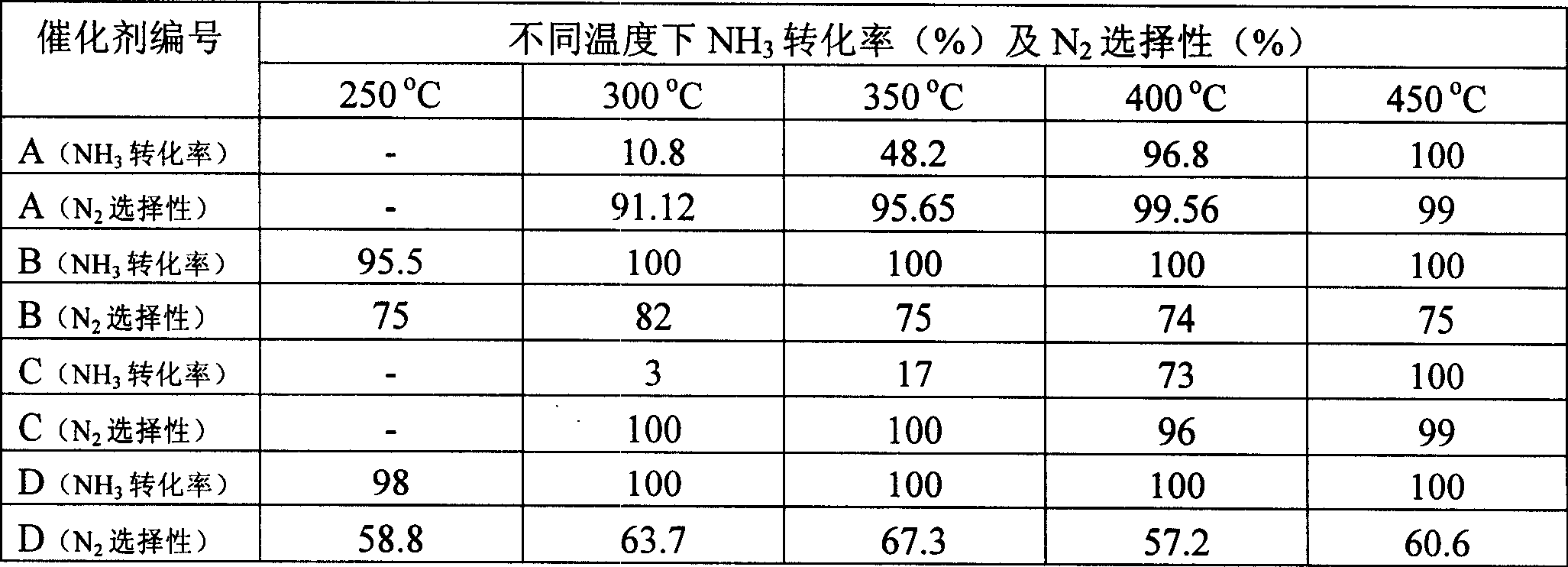

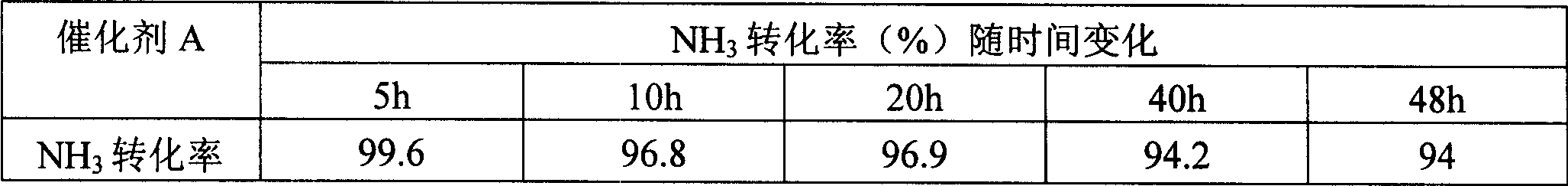

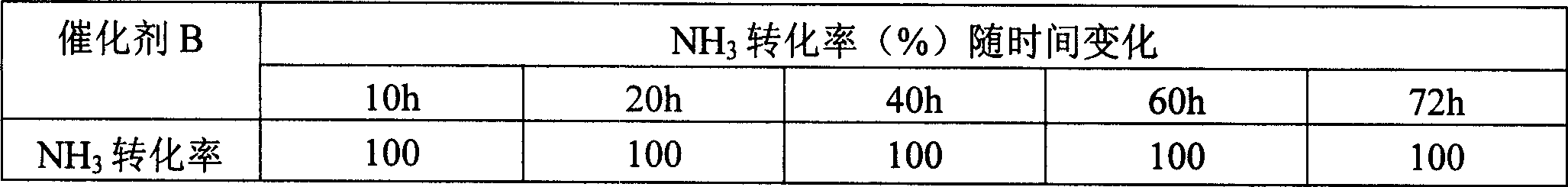

Preparation method and application of nanometer ceria-zirconia solid solution-based catalyst for selectively catalytically oxidizing ammonia

InactiveCN101966451ALow priceHigh low temperature activityDispersed particle separationCatalyst activation/preparationManganeseBULK ACTIVE INGREDIENT

The invention relates to a preparation method and application of a nanometer ceria-zirconia solid solution-based catalyst for selectively catalytically oxidizing ammonia. The preparation method is characterized in that: a carrier of the prepared catalyst is ceria-zirconia solid solution, and the active ingredients are copper, silver, manganese, iron and the like; and the carrier is prepared by an anionic surfactant method, and the active ingredients are loaded on the ceria-zirconia solid solution by a deposit-precipitation method or impregnation method. The raw material used in the method is not toxic or harmful, and the prepared catalyst has the characteristics of large specific area, mesoporous structure and the like. The catalyst prepared by the method has the advantages of high low-temperature activity, 100 percent of conversion rate when NH3 is at 280 DEG C, good N2 selectivity, wide temperature window, high stability, catalysates of N2 and H2O and no secondary pollution. If the prepared catalyst is pulped and loaded to a honey-comb shaped metal wire mesh or a honey-comb ceramic, the catalyst can be applied to ammonia pollution treatment in tail gas of the practical industry and has wide application prospect.

Owner:DALIAN UNIV OF TECH

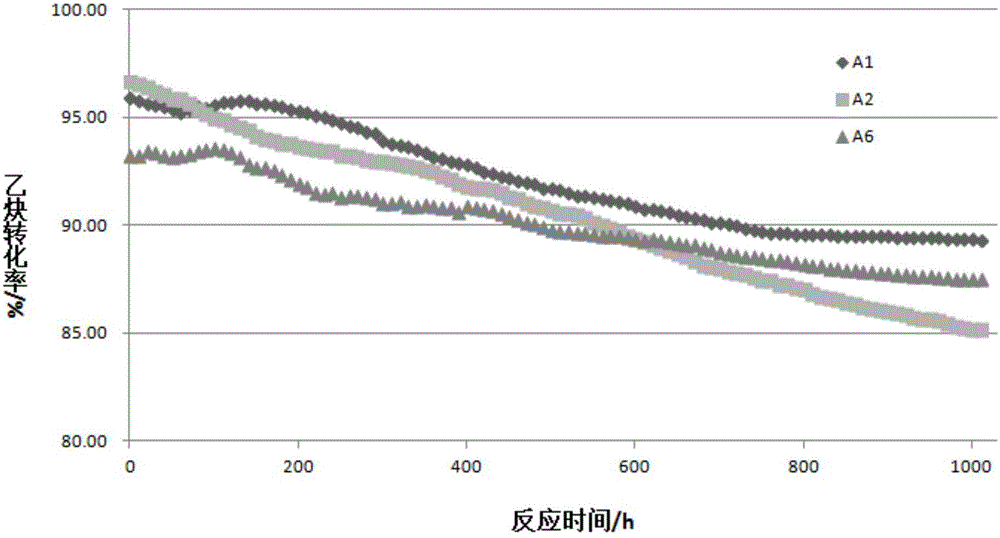

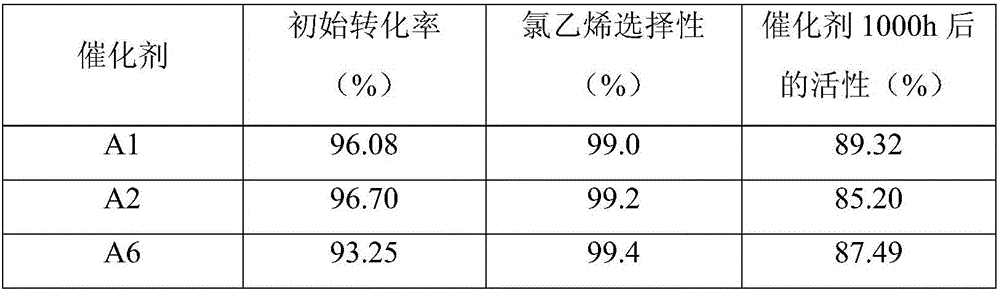

Non-noble metal mercury-free catalyst for acetylene hydrochlorination reaction, preparation method and application thereof

ActiveCN106492869AEmission reductionImprove catalytic stabilityPreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsPhosphateReaction temperature

The invention relates to a non-noble metal mercury-free catalyst for acetylene hydrochlorination reaction, a preparation method and application thereof. The preparation method comprises the steps of: 1) preparing a mixed solution of a copper salt, an ammonium salt and phosphoric acid, or a mixed solution of a copper salt, an ammonium salt and phosphate; 2) adding activated carbon into the mixed solution obtained in step 1 for soaking; 3) spin-drying the soaked activated carbon, and conducting heating and drying to obtain the catalyst. Through the synergistic effect of multiple components, the catalyst prepared by the method provided by the invention acquires good catalytic stability and high low-temperature activity, and under a reaction temperature of 130DEG C and the existing mercury catalyst running pressure condition and feeding intensity, more than 96% of conversion per pass and more than 99% of vinyl chloride selectivity can be obtained. As the technical conditions of the catalyst for acetylene hydrochlorination reaction are similar to those of the existing mercury catalyst, renovation of existing equipment is unnecessary, and the mercury catalyst can be replaced easily on the existing equipment.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

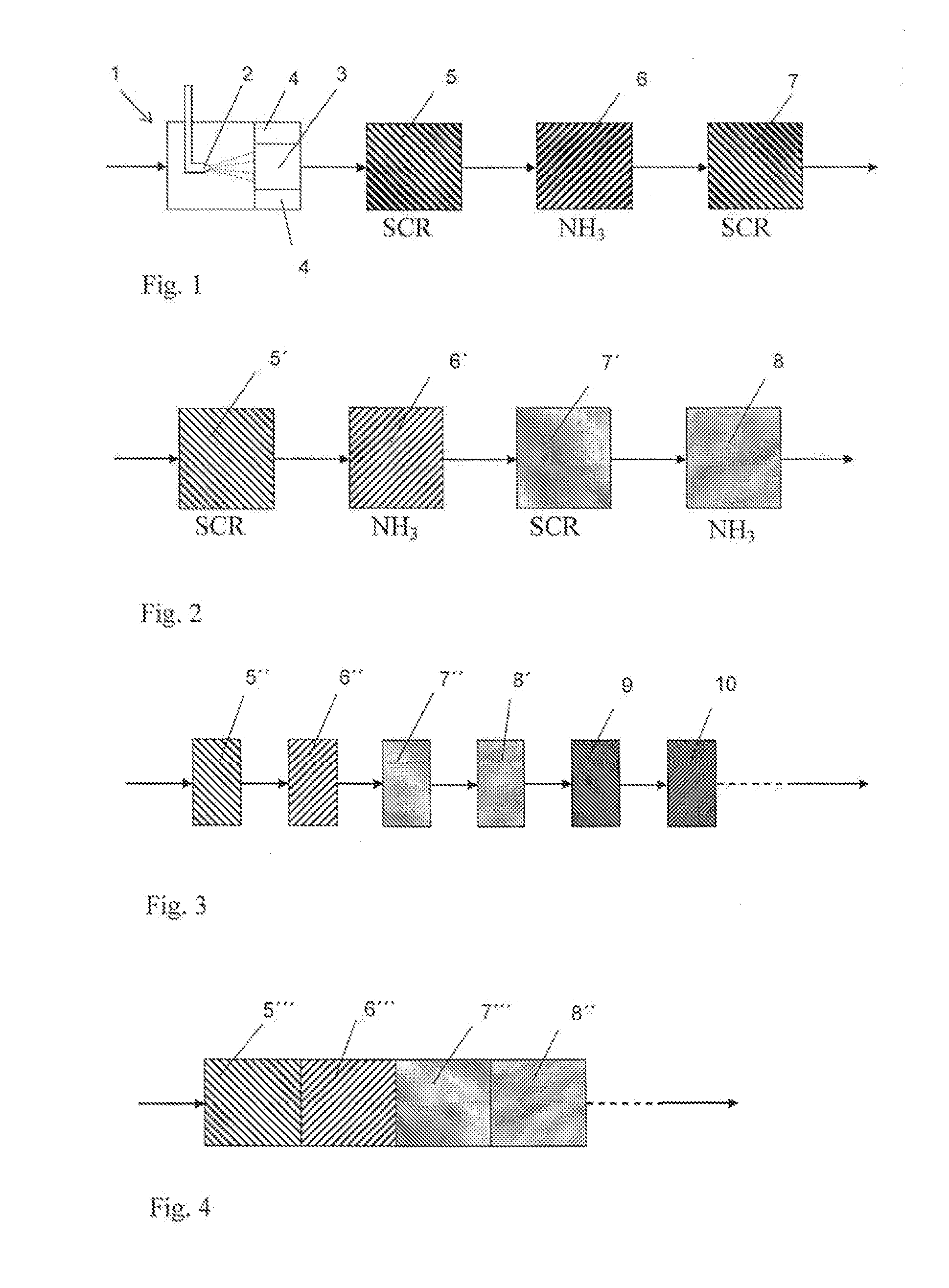

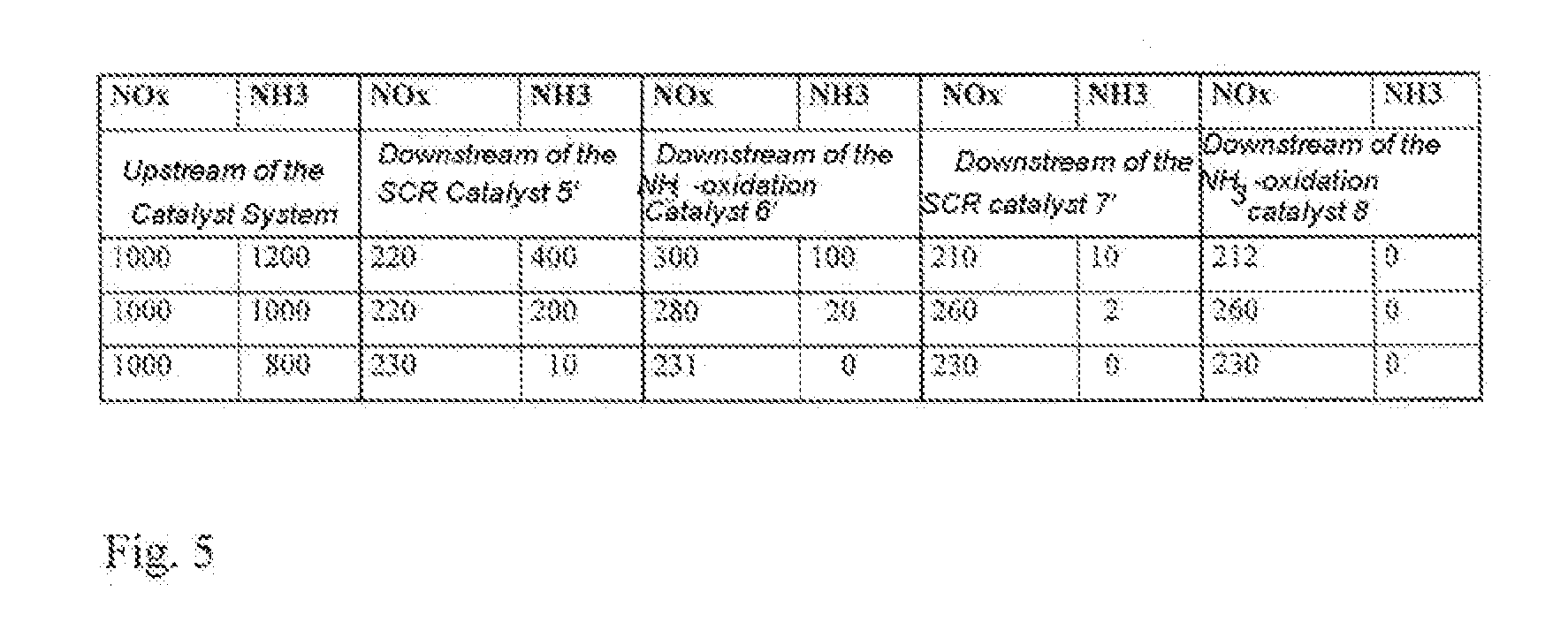

Arrangement for Reducing Nitrogen Oxides in Exhaust Gases

InactiveUS20080008629A1Improve responseHigh low temperature activityCombination devicesAuxillary pretreatmentExhaust fumesNitrogen oxide

An arrangement and method for reducing the nitrogen oxide content in the exhaust gas of an internal combustion engine with the aid of ammonia and / or ammonia-releasing reduction agents, whereby ammonia and / or ammonia-containing reduction agent is added to the exhaust gas stream upstream of a catalyst combination composed of an SCR catalyst and a subsequent NH3-oxidation catalyst in such a way that a homogeneous mixture of exhaust gas and ammonia is present upstream of the SCR catalyst. To optimize the reaction or conversion of nitrogen oxides, disposed downstream of the combination of a first SCR catalyst and a first NH3-oxidation catalyst is at least one second catalyst having SCR activity in order in this way to reduce the nitrogen oxides formed at the first NH3-oxidation catalyst due to insufficient selectivity of the catalyst to nitrogen with not yet oxidized NH3.

Owner:MAN TRUCK & BUS AG

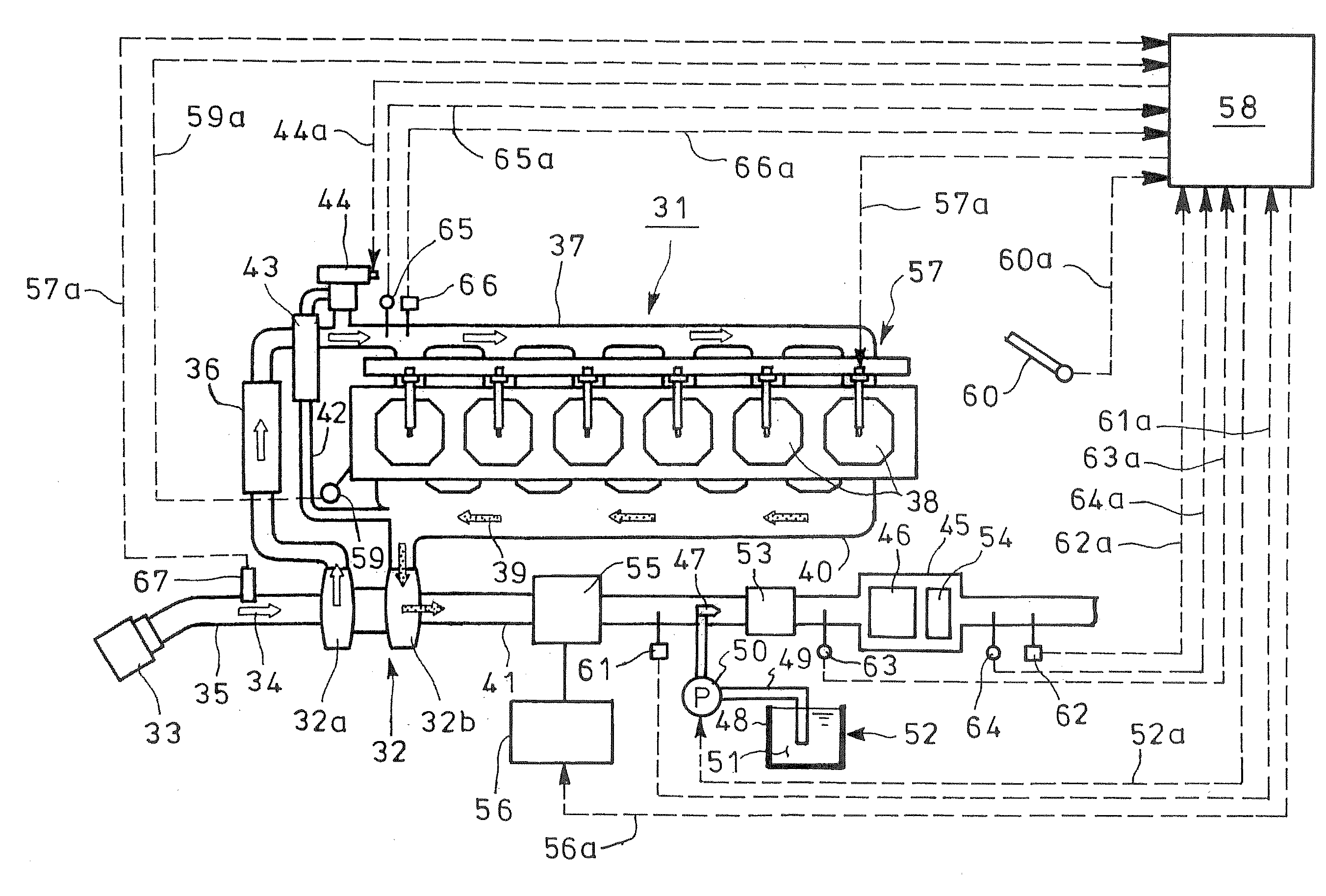

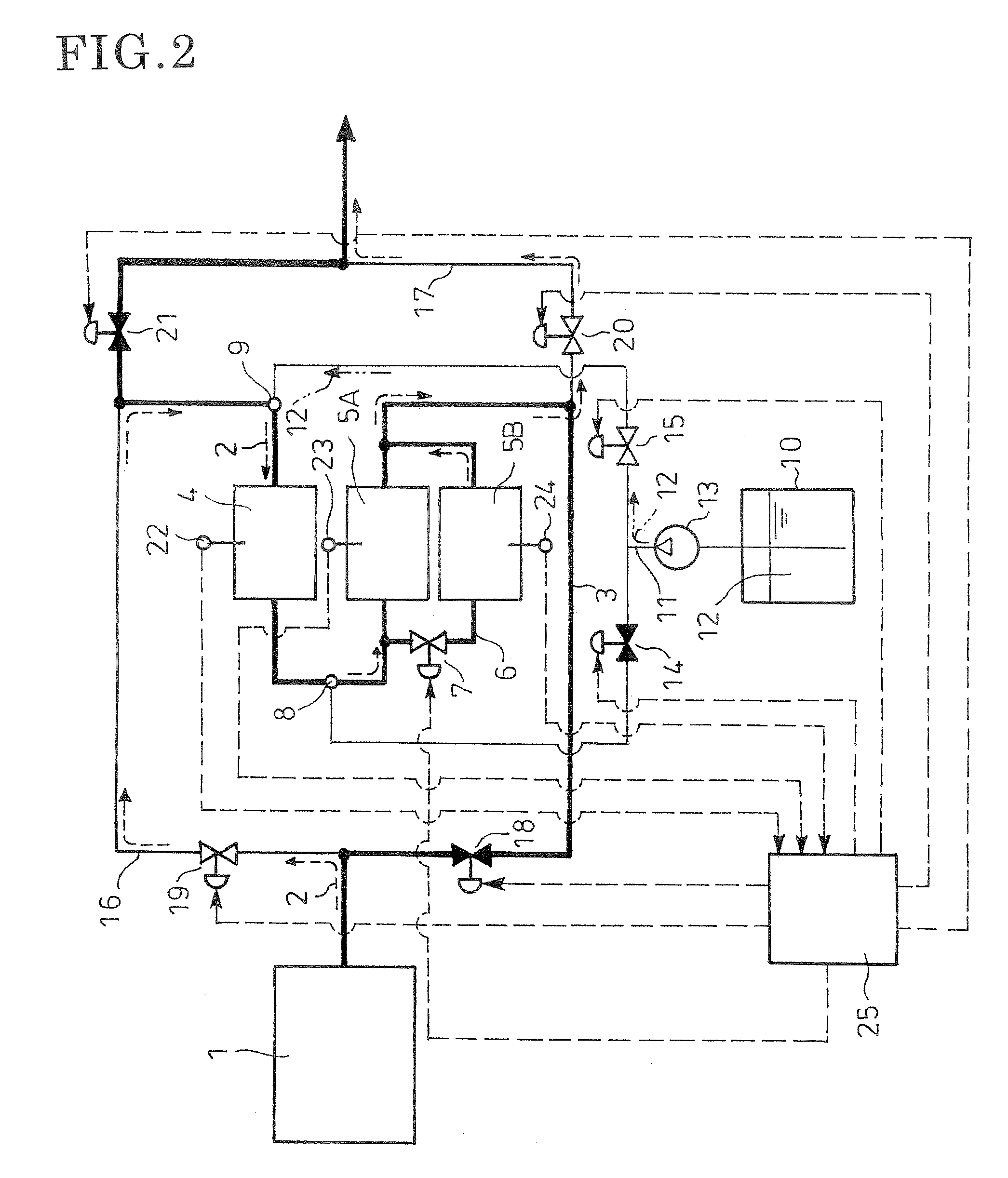

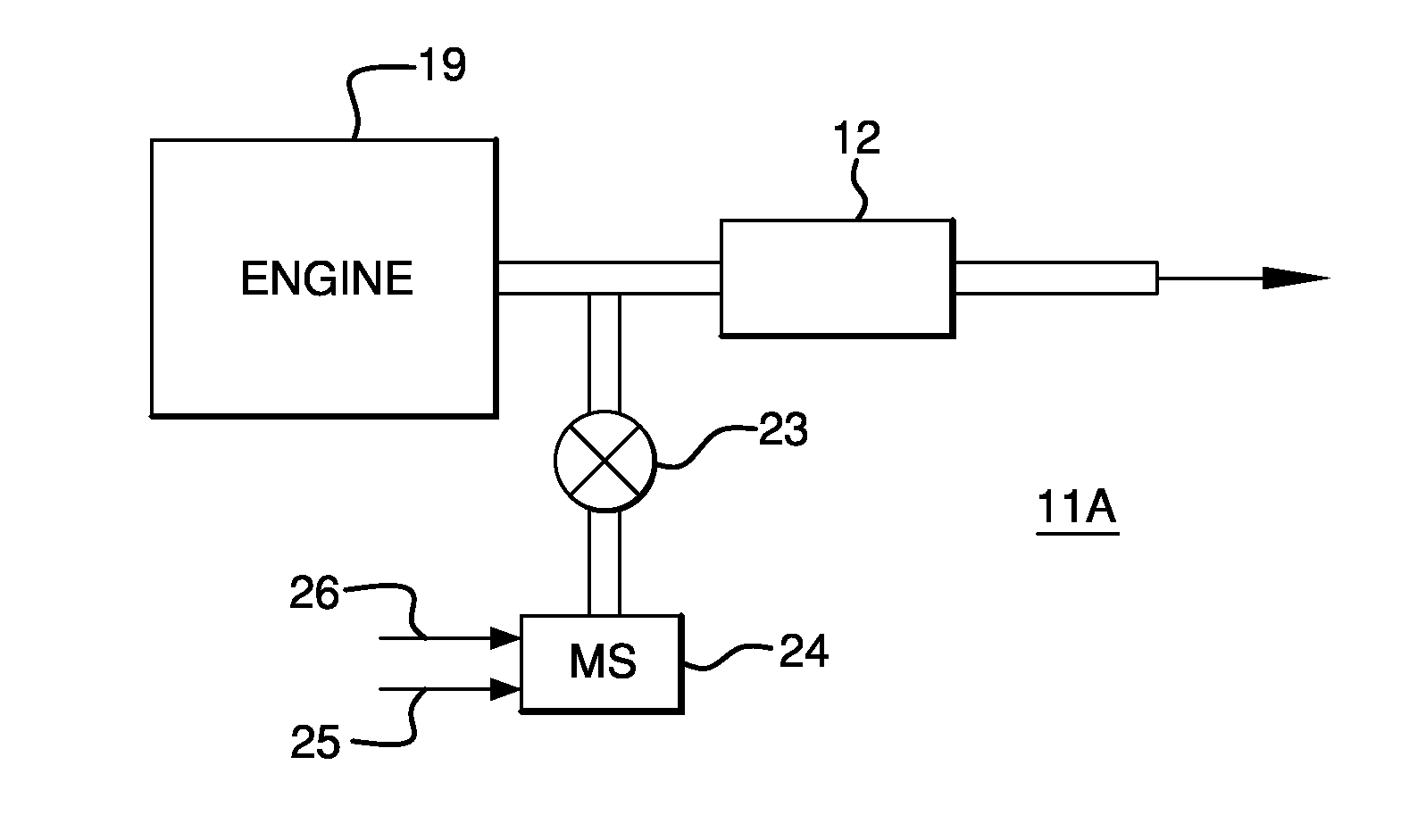

Exhaust Gas Purification Apparatus

InactiveUS20070243115A1High low temperature activityCombination devicesGas treatmentReduction rateExhaust fumes

Excessive generation NO2 by oxidation catalyst arrangement upstream of a selective reduction catalyst is suppressed to prevent falling of NOx reduction rate. A selective reduction catalyst 4 capable of selectively reacting NOx with ammonia even in the presence of oxygen is incorporated in an exhaust pipe 3 from an engine 1. A pair of oxidation catalysts 5A and 5B are arranged in parallel with each other and upstream of the selective reduction catalyst. In an operation condition with low exhaust temperature, amounts of the exhaust gas 2 distributed to the oxidation catalysts 5A and 5B are adjusted so as to make NO / NO2 ratio in the exhaust gas 2 to about 1-1.5. In an operation condition with higher exhaust temperature where the NOx reduction rate is less affected by the NO / NO2 ratio, as a countermeasure against increasing, leaking ammonia, passage changeover is conducted to pass the exhaust gas 2 in backflow through the selective reduction catalyst 4 and the oxidation catalysts 5A and 5B, so that ammonia passing through the selective reduction catalyst 4 without reacted is oxidized in the oxidation catalysts 5A and 5B.

Owner:HINO MOTORS LTD

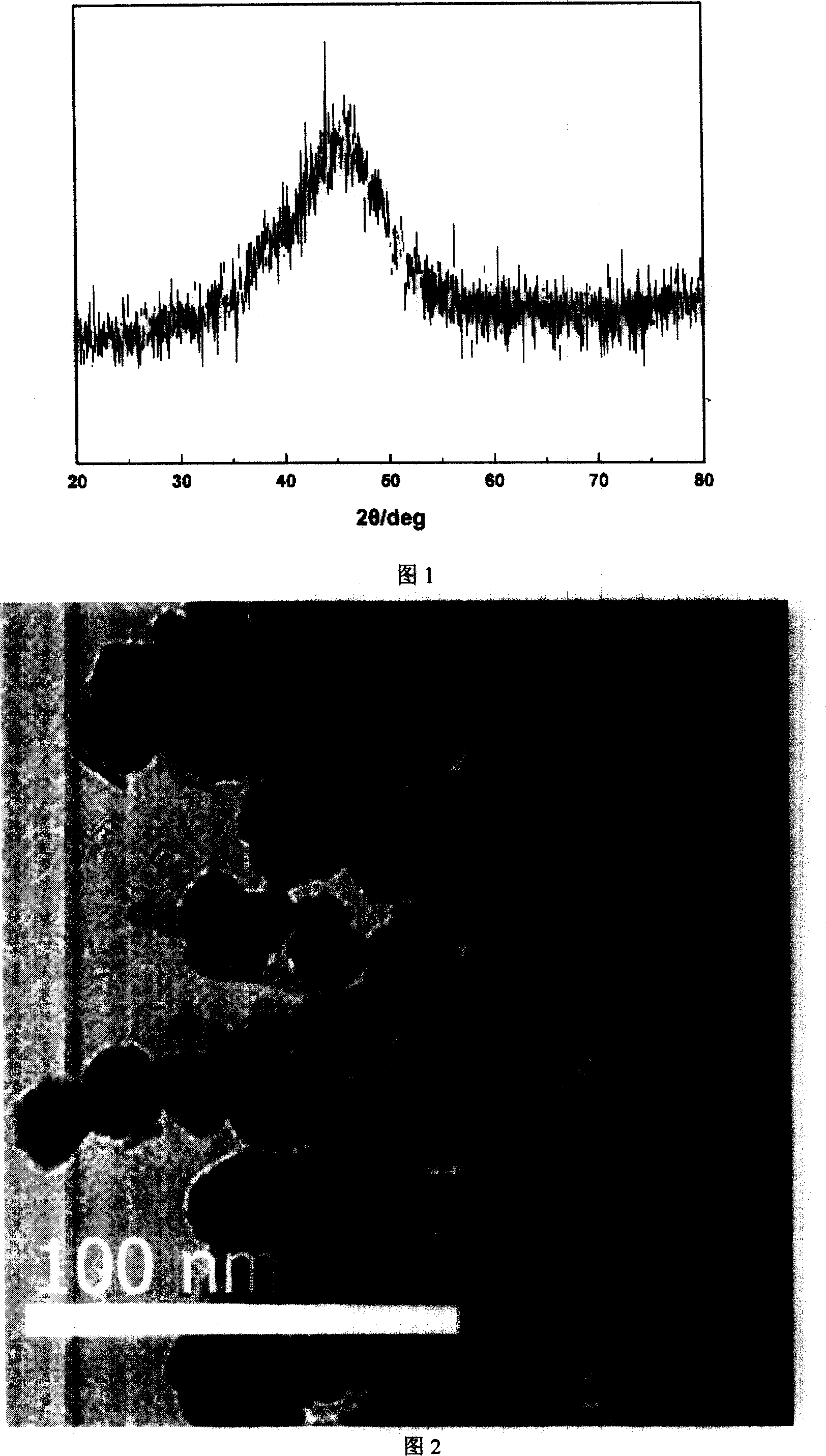

Novel preparation method of amorphous alloy catalyst

InactiveCN101007281AHigh yieldEasy to useOrganic decompositionHydrocarbon from halogen organic compoundsMolecular sieveOxide

The invention involves a new preparation method for amorphous alloy catalyst, it uses KBH4 as reductant, mixes one or two of nickel sulfate, nickel acetate, nickel nitrate, nickel chloride, cobalt sulfate or cobalt chloride into main salt and dissolves them into solution of ethylenediamine, tartaric acid or tartrate, prepares non-load or load amorphous alloy catalyst using oxidant, molecular sieve and high polymer as the carrier. The amorphous alloy catalyst prepared through the invention has characteristics of small dimension of active components, good dispersion degree, high yield of catalyst and high catalyst activity, and it applies to catalyzing hydrogenation and hydrogenation dechlorination reaction.

Owner:NANKAI UNIV

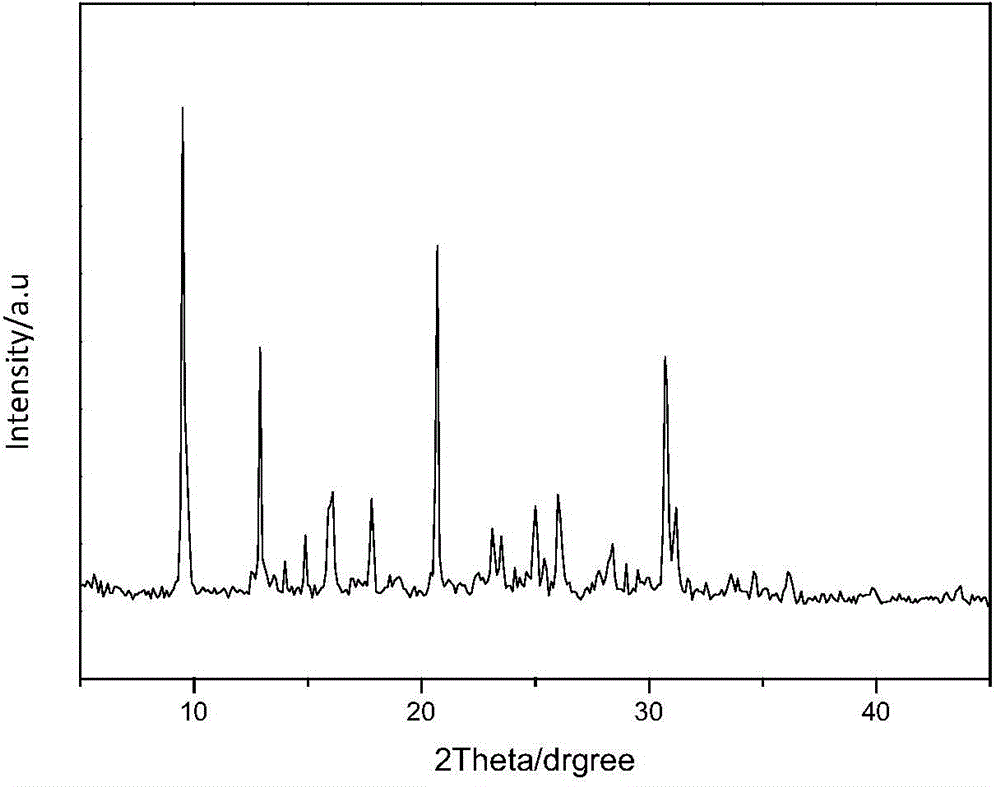

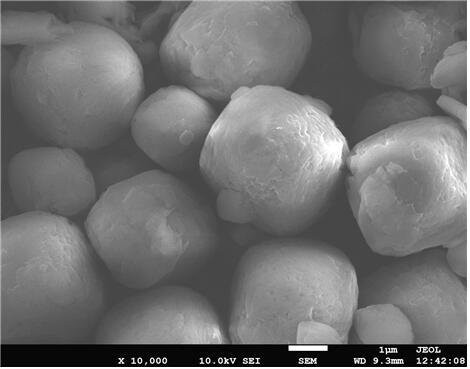

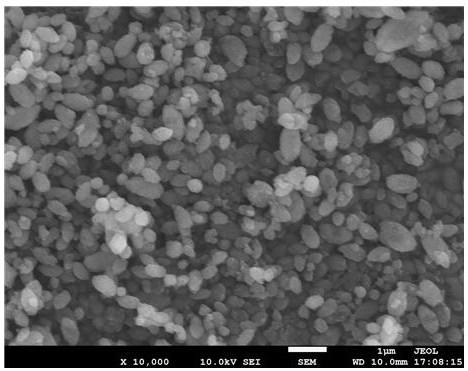

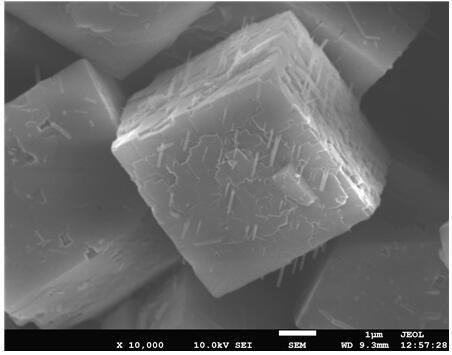

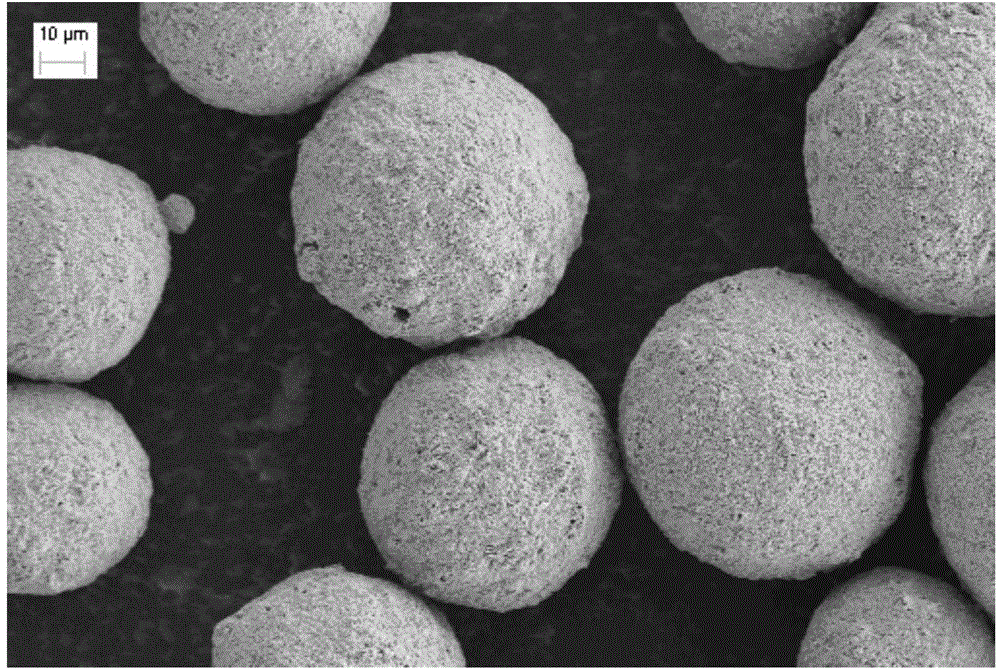

Modified Cu-SSZ-13 molecular sieves as well as preparation method and application thereof

ActiveCN110078090AImprove low temperature catalytic activityHigh crystallinityNitrous oxide captureDispersed particle separationMolecular sievePhysical chemistry

The invention discloses modified Cu-SSZ-13 molecular sieves as well as a preparation method and the application thereof. The preparation method comprises the following steps: mixing an aluminum source, alkali metal hydroxides, a template agent, a silicon source and water to obtain initial sol; performing hydrothermal crystallization on the initial sol and then roasting to obtain M-SSZ-13 molecularsieves; performing ion exchange reaction between the M-SSZ-13 molecular sieves and ammonium salt and then roasting to obtain H-SSZ-13 molecular sieves; and performing ion exchange reaction with divalent copper salt and then roasting to obtain the modified Cu-SSZ-13 molecular sieves. The molecular sieves with different morphologies are synthesized in situ through adding the different alkali metalhydroxides. The modified Cu-SSZ-13 molecular sieves as well as the preparation method and the application thereof disclosed by the invention have the benefits that the different alkali metal hydroxides are directly added in the synthesis process, and the morphologies and the grain sizes of the molecular sieves are changed while alkali metal ions are introduced; each of the obtained modified Cu-SSZ-13 molecular sieves is high in degree of crystallinity and high in pure phase, and shows higher low temperature activity and nitrogen selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

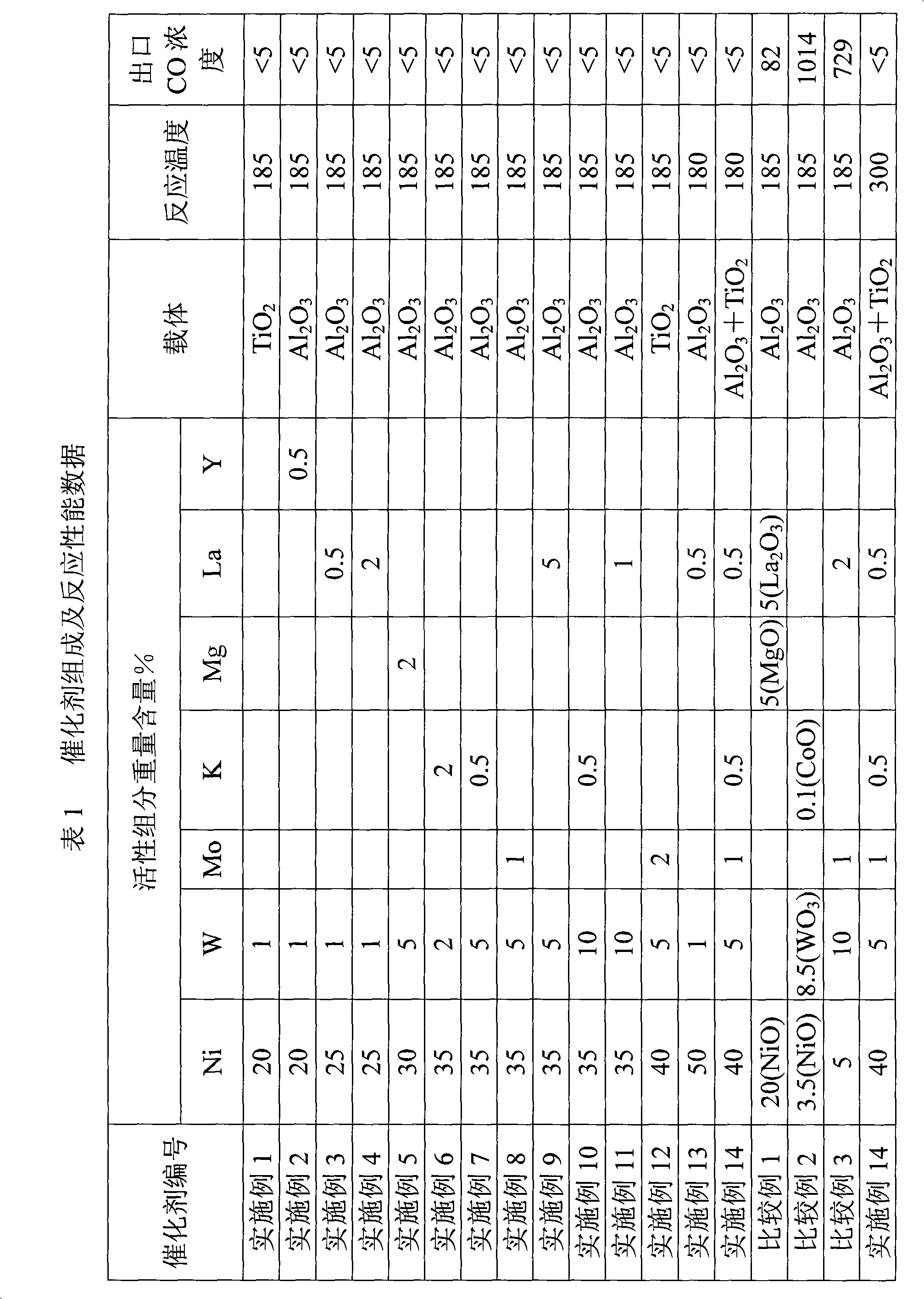

Reformed oil olefine saturation hydrogenation method

InactiveCN1394937AHigh low temperature activityReduce metal contentRefining by selective hydrogenationChemistryNickel oxides

The reformate olefine saturation hydrogenation method includes the following steps: in the presence of one kind of catalyst making the reformate contact with hydrogen gas, its contact temp. is 200-320 deg.C, contact pressure is not less than 0.7 MPa, liquid hourly space velocity is 1-8 hr (-1), and volume ratio of hydrogen and oil is not less than 30. The described catalyst contains tungsten oxide and / or molybdenum oxide, nickel oxide and cobaltous oxide loaded on the alumina, the catalyst is used as reference, the content of the described tungsten oxide and / or molybdenum oxide is 4 wt% to less than 10 wt%, the content is nickel oxide is 1-5 wt%, the content of cobaltous oxide is 0.01-1 wt% and the ratio of total atomicity of nickel and cobalt and total atomicity of nickel, cobalt, tungsten and / or molybdenum is 0.3-0.9.

Owner:CHINA PETROLEUM & CHEM CORP +1

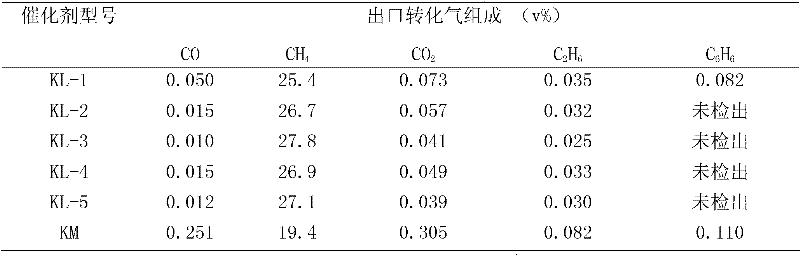

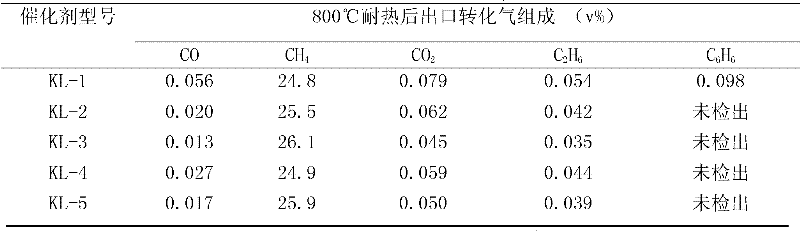

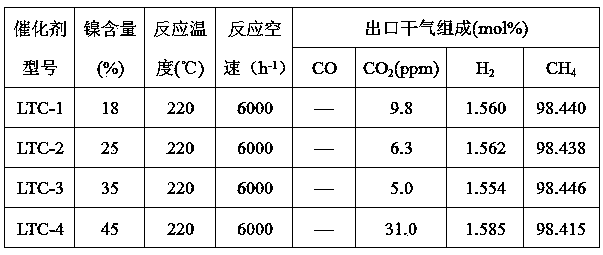

A coke oven gas methanation catalyst and preparation method thereof

ActiveCN102259003AHigh low temperature activityHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMethanation

The invention provides a coke-oven gas methanation catalyst and a preparation method thereof. The coke-oven gas methanation catalyst is prepared by loading a certain amount of active ingredients Ni on composite oxide TiO2-ZrO2-SiO2 serving as a carrier, and using rare-earth elements RE and metal M as aids. The catalyst has the advantages which cannot be achieved by other methanation catalysts. The catalyst has the characteristics of high low-temperature activity, sulfur resistance capacity, good high temperature resistance performance and the like, and the function of hydrocarbon cracking andgood antioxidation performance and the like and is easy to prepare.

Owner:WUHAN KELIN FINE CHEM

Polynary metal oxide catalyst and preparing process thereof

ActiveCN101199933AHigh activityHigh low temperature activityCatalyst carriersCombined combustion mitigationCerium(IV) oxideManganese

The invention discloses a multi-complex-metal-oxides catalyst and the preparation method. The catalyst carrier is multi-complex-metal-oxides solid alkali or surface solid alkali or the precursors of the solid alkali or surface solid alkali. The multi-complex-metal-oxides is complex oxides by combining two or more than two selections from alumina, titania, zirconium dioxide and ceria with one or more than one selections from magnesia, calcium oxide, baryta, potassium oxide and sodium oxide. Active ingredient is composed of cobalt oxides or / and nickel oxide and molybdenum trioxide or / and tungsten trioxide. The additive added to carriers or active components is the oxide of at least one of the following elements: cerium, lanthanum, zinc, zirconium, nickel or manganese. The invention has the advantages of high activity, high activity at low-temperature, high activity stability and wide temperature range of activity; high intensity, high intensity stability and high anti-hydration and anti-pulverization ability, wide water / gas ratio adaptability and wide range for impurity content. The catalyst of the invention is applied to the promotion of dirty water gas shift reaction.

Owner:汤海溶 +2

PtX-Fe-ZSM-5 molecular sieve catalyst for ammine selective catalytic oxidation

InactiveCN101417237ASimple preparation processEasy to operateMolecular sieve catalystsDispersed particle separationIonIon exchange

The invention provides a NH3 selective oxidation catalyst; the NH3 is selectively catalytically oxidated as N2 and H2O without pollution. The catalyst mainly solves the problems that the oxidation catalyst which is applied to elimination industries and traffic and the like and generates the NH3 pollution has bad low-temperature activity, low selectivity and poor anti-sulfur performance. The catalyst firstly prepares Fe-ZSM-5 molecular sieve catalyst with large specific area by a secondary ion exchanging method; subsequently, trace noble metal Pt is loaded on the Fe-ZSM-5 so as to prepare the Ptx-Fe-ZSM-5 catalyst; and the oxidation catalyst has high activity, N2 selectivity, good stability and anti-SO2 poisoning performance, and excellently solving the technical problem of the prior art. If the catalyst is prepared into slurry and loaded on honeycomb ceramics, the NH3 pollution in the practical industrial tailings can be expected to be removed; furthermore, the catalyst can be used as postpositive oxidation catalyst in the tailings disposal system of diesel engine so as to prevent the pollution caused by the leakage of NH3 in the NH3-SCR catalytic system.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

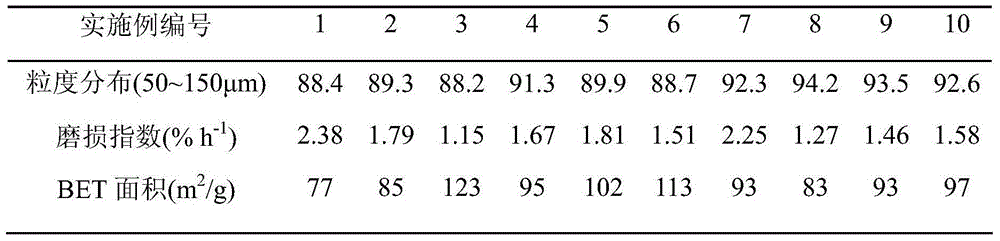

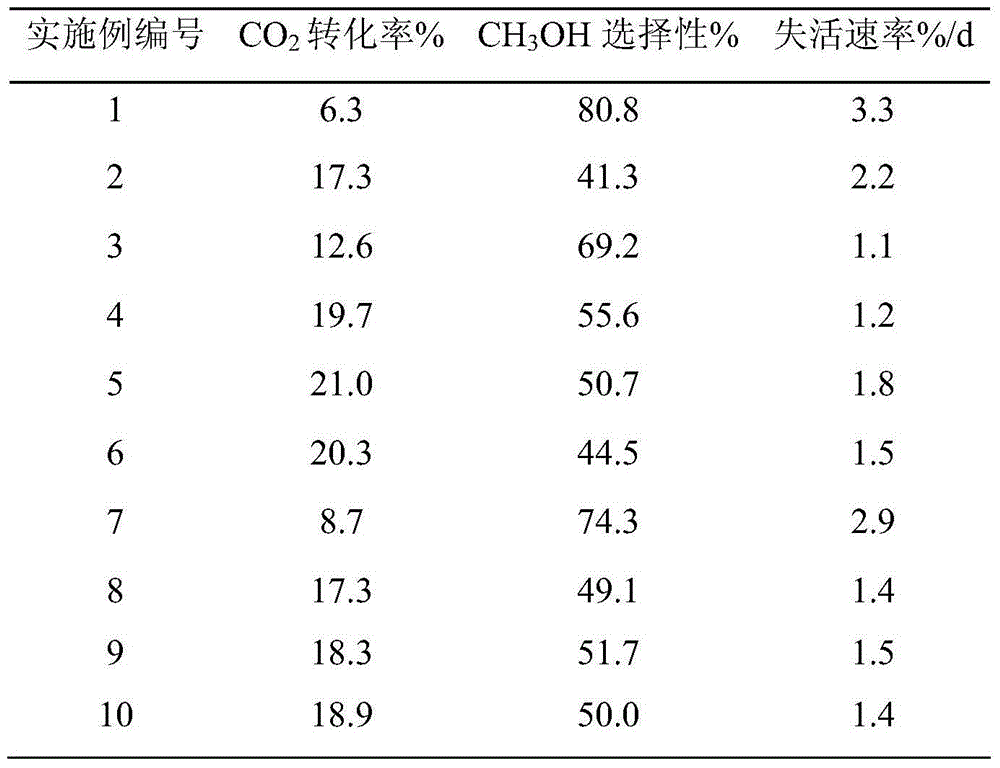

Catalyst for methanol synthesis via CO2 hydrogenation on slurry bed reactor, preparation method and application

InactiveCN104959143AUniform particle size distributionLarge specific surface areaOrganic compound preparationHydroxy compound preparationHydrogenation reactionSlurry

The invention provides a catalyst for methanol synthesis via CO2 hydrogenation on a slurry bed reaction. The catalyst comprises the following components in percentage by weight: 30%-50% of CuO, 15%-30% of ZnO, 10%-25% of Al2O3, 2%-10% of transition metal oxides and 5%-40% of structural promoters. The catalyst has the advantages that the degree of sphericity of particles is high, the particles are distributed uniformly, the specific surface area is large, the wear resistance is high, the service life is long, the performance of the catalyst is stable in CO2 hydrogenation reaction, low-temperature activity, transformation activity and selectivity are high, the catalyst can be operated at low temperature ranging from 180-220 DEG C, the cost is low, and the catalyst is easy and convenient to prepare and can be industrially amplified easily. The CO2 single-pass conversion rate of the catalyst can be high at the temperature of 220 DEG C, and the wear resistance of the catalyst is quite high.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

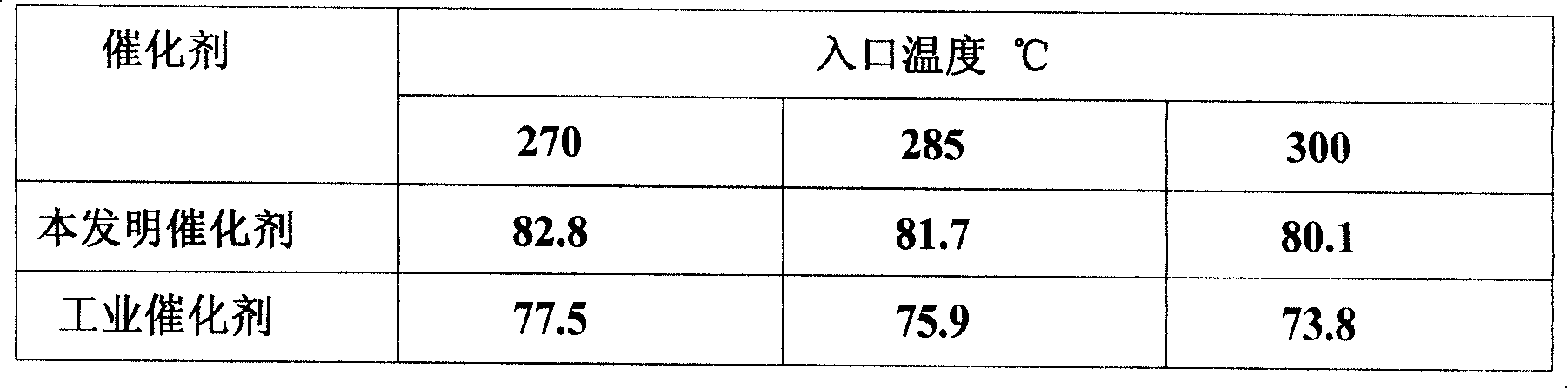

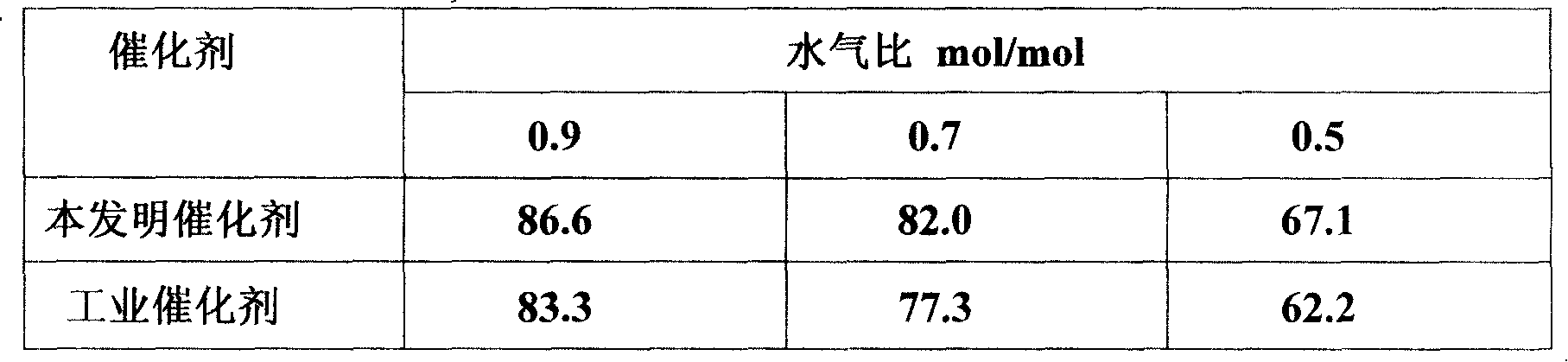

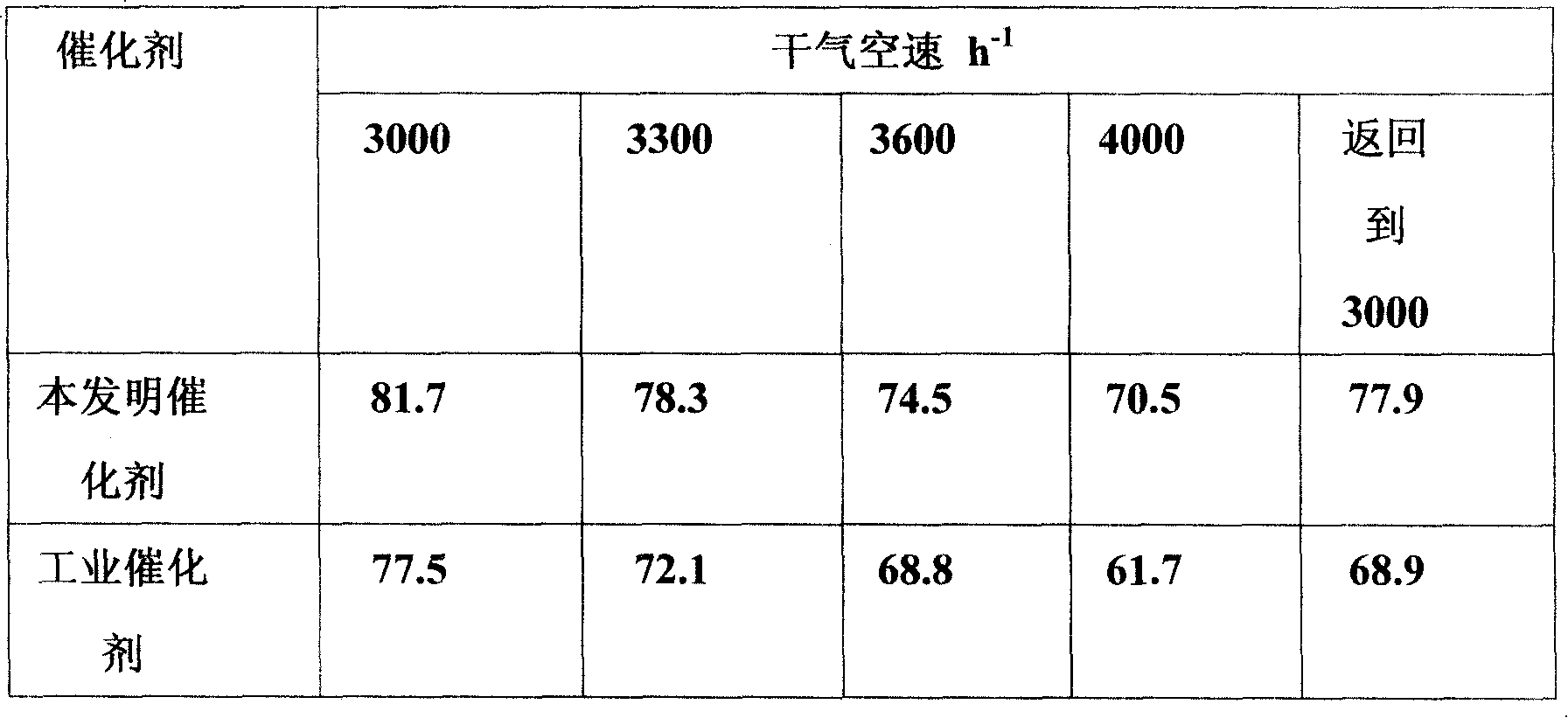

Low-temperature low-SO2-oxidation-rate honeycomb denitration catalyst and preparation method thereof

InactiveCN106807393AReduce oxidation rateLow temperature denitrification efficiency is highDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberHoneycomb

The invention discloses a low-temperature low-SO2-oxidation-rate honeycomb denitration catalyst and a preparation method thereof. The catalyst is prepared from, by mass, 1-5% of V2O5, 0.01-6% of WO3, 0.01-10% of MoO3, 0.01-0.5% of MgO, 3-6% of glass fibers, 66.5-95.96% of TiO2 and one or more of 0.01-1% of B2O3, 0.01-1% of F, 0.01-2% of P2O5, 0.01-1% of SnO2 and 0.01-1% of Sb2O3. Anatase type titanium dioxide serves as a carrier, V2O5 serves as an active center, and auxiliary agents including MgO, B2O3, F, SnO2, P2O5, Sb2O3 and the like are added to enhance synergistic effects among the active center, the auxiliary agents and the carrier to realize preparation of the low-temperature low-SO2-oxidation-rate honeycomb denitration catalyst. Compared with existing industrial V2O5-WO3-TiO2 catalysts, the denitration catalyst prepared according to the method has advantages of wide operating temperature window, high denitration efficiency, low SO2 oxidation rate, high water resistance, less proneness to hole blockage, long service life and the like and is especially suitable for low-temperature conditions (200-300 DEG C).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

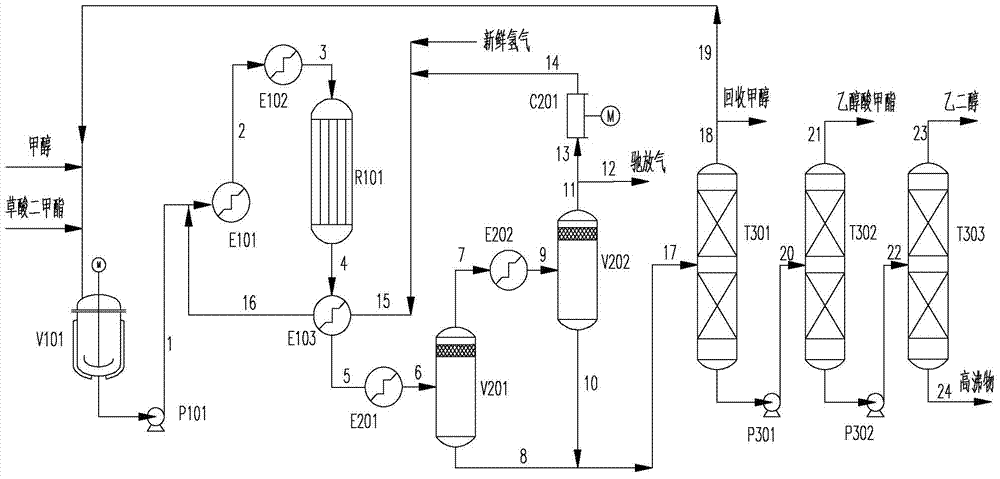

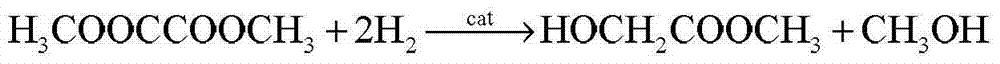

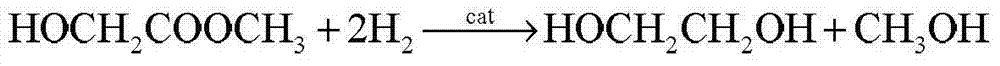

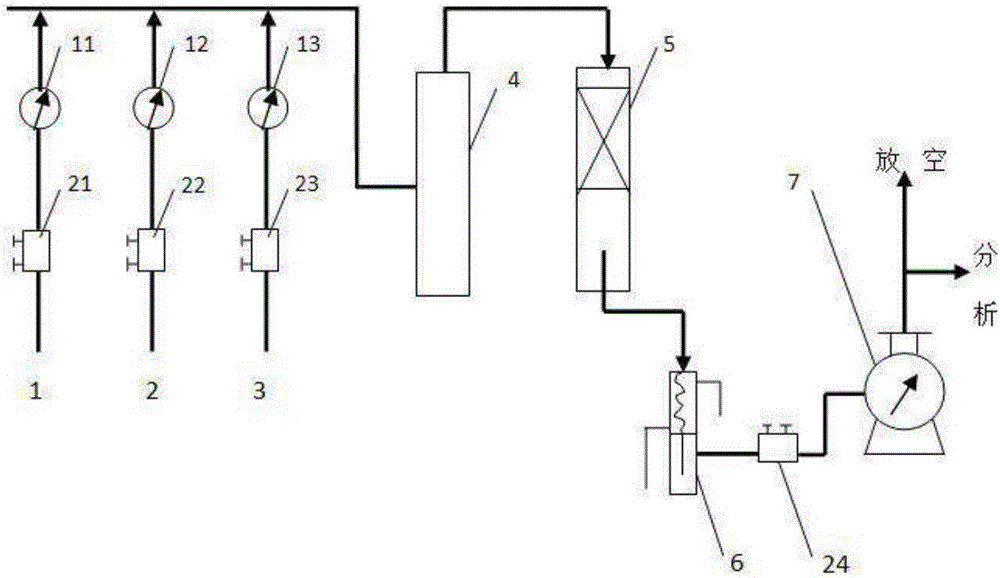

Production method of methyl glycolate

InactiveCN104262152AHigh selectivityReduce partial pressureOrganic compound preparationCarboxylic acid esters preparationDistillationMixed materials

The invention relates to a production method of methyl glycolate, aiming to mainly solve the problems of low conversion rate of dimethyl oxalate and low selectivity of methyl glycolate in the prior art. The production method of methyl glycolate comprises the following steps of (1) enabling a mixed material composed of a methanol solution of dimethyl oxalate and feed gas containing hydrogen to be in contact with a silver-containing catalyst in a reactor to react to obtain a mixture flow containing methyl glycolate, carrying out heat exchange, and then, enabling the mixture flow to enter a gas-liquid separation system; (2) sequentially carrying out condensation, primary gas-liquid separation, condensation and secondary low-temperature gas-liquid separation on the mixture flow subjected to heat exchange to obtain crude methyl glycolate; and (3) carrying out reduced-pressure distillation separation on crude methyl glycolate to obtain the methyl glycolate product. According to the technical scheme, the conversion rate of dimethyl oxalate can be higher than 99%, the selectivity of methyl glycolate can be higher than 80%, and the production method can be applied to industrial production of methyl glycolate.

Owner:SHANGHAI HUAYI GRP CO

Medium and low temperature denitration catalyst and preparation method thereof

ActiveCN106492791AReduce oxidation activityHigh activityHeterogenous catalyst chemical elementsDispersed particle separationCeriumStearic acid

The invention provides a medium and low temperature denitration catalyst, and belongs to the technical field of denitration catalysts. The catalyst is prepared from ultrafine titanium dioxide, strontium-doped cerium manganese calcium titanium ore type composite oxides, vanadium pentoxide, tungsten trioxide, molybdenum trioxide and stannic oxide; glass fiber is used as an enhancing agent; carboxymethylcellulose and polyoxyethylene are used as bonding agents; stearic acid is used as a lubricating agent. The invention also relates to a preparation method of the medium and low temperature denitration catalyst. The concrete preparation method comprises the steps of preparation of the strontium-doped cerium manganese calcium titanium ore type composite oxides, preparation of carrier materials, preparation of powder catalysts, extrusion forming of honeycomb-shaped catalysts and post treatment of honeycomb-shaped denitration catalysts. The denitration catalyst prepared by the method has the advantages of high denitration efficiency, good sulfur-resistant and waterproof performance, reliable production process and the like in the wide temperature range from 180 DEG C to 350 DEG C; the requirements of oxynitride removal from industrial smoke gas in industries of coking, petrifaction, furnaces and the like can be met; wide application prospects are realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

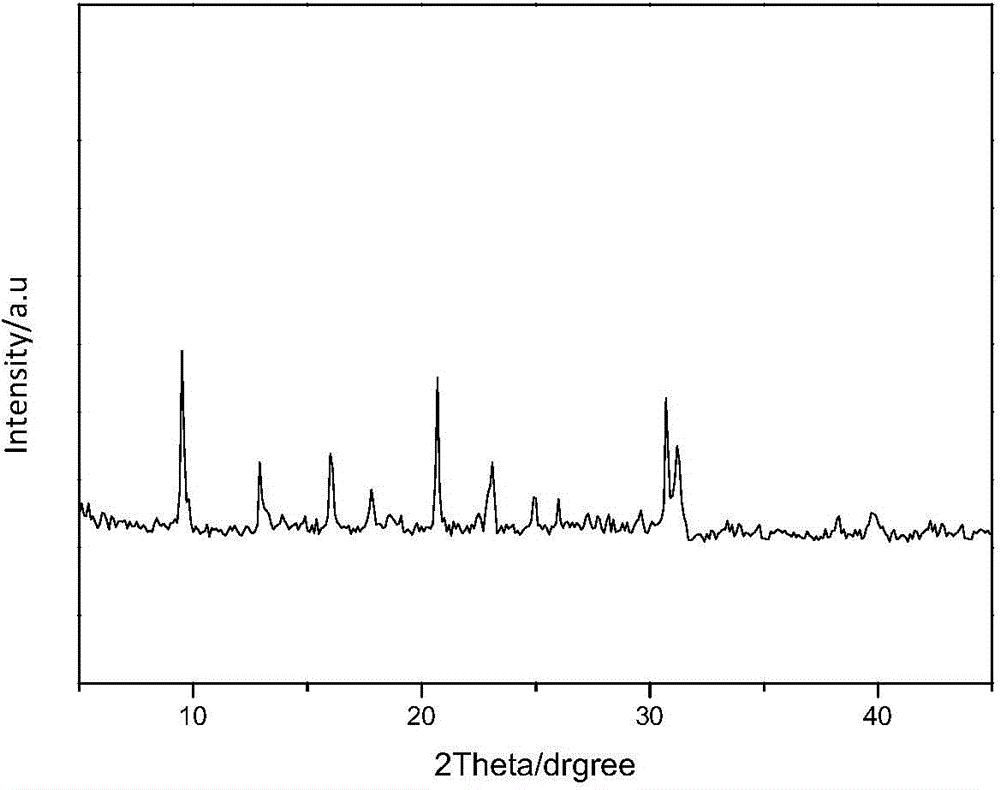

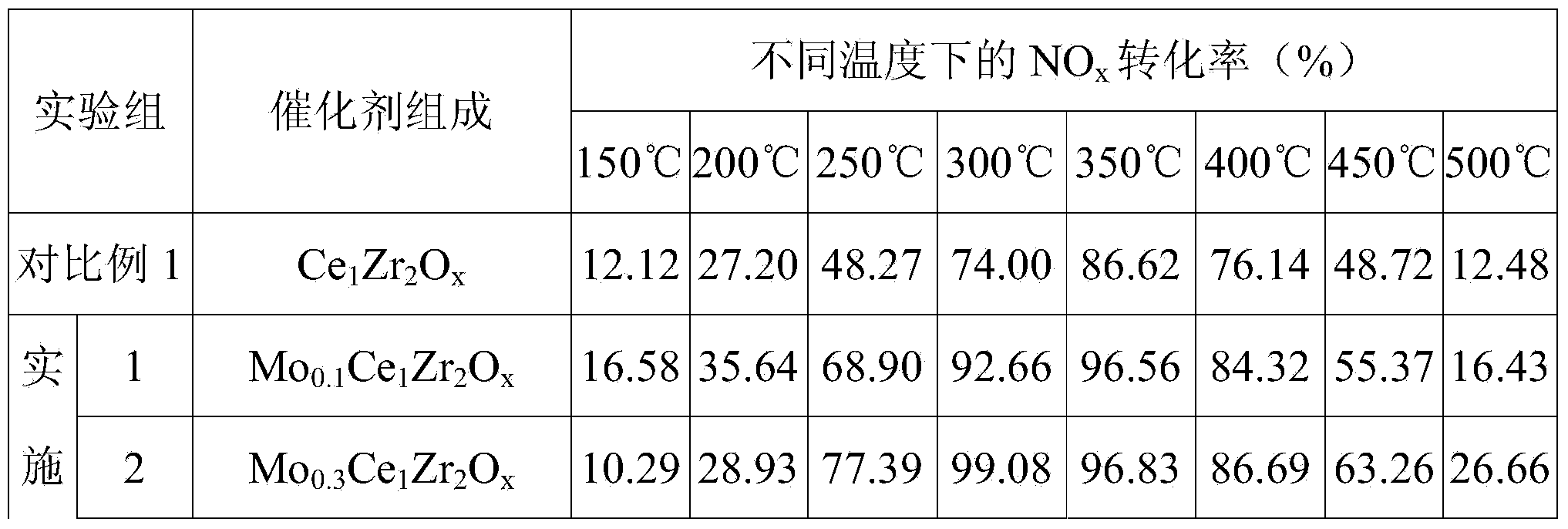

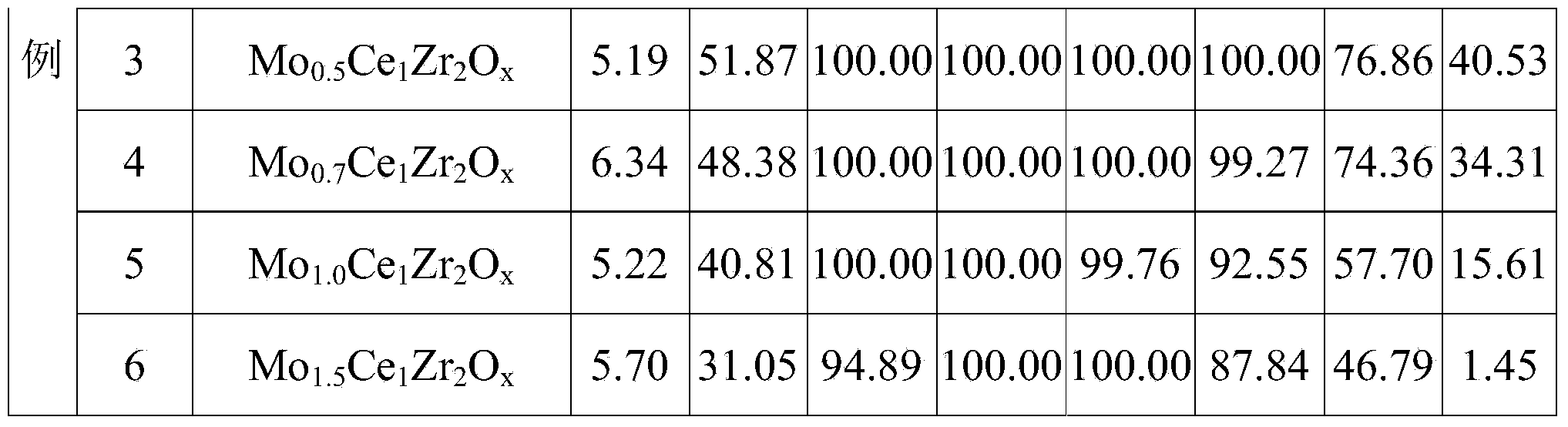

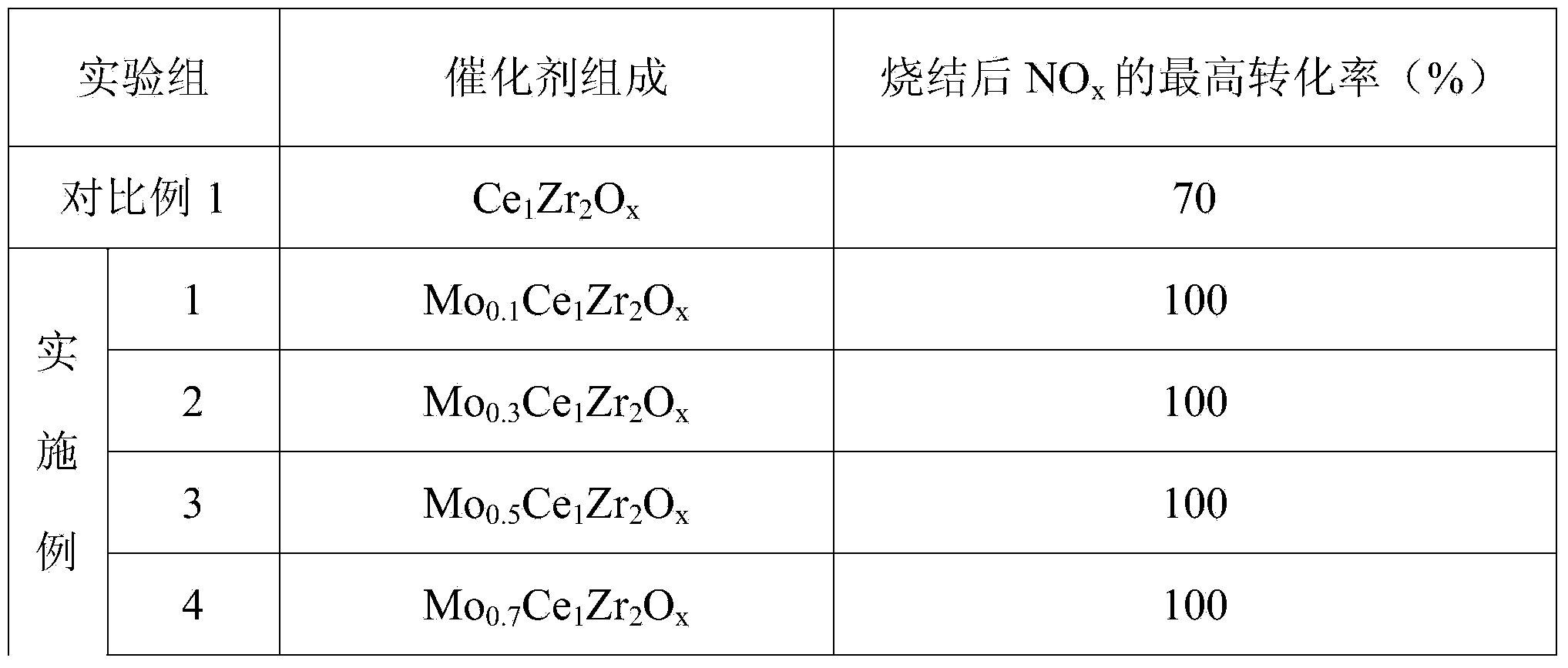

Cerium-molybdenum-zirconium composite oxide catalyst, and preparation method and application thereof

ActiveCN103816891AImprove thermal stabilityImprove conversion rateGas treatmentHeterogenous catalyst chemical elementsCeriumNitrogen oxide

The invention relates to a cerium-molybdenum-zirconium (Ce-Mo-Zr) composite oxide catalyst. The molar ratio of Zr to Ce in the catalyst is 1:2, and the molar ratio value of Mo to Ce is 0.1-1.5. By the adjustment of the ratio of the three elements, namely cerium, molybdenum and zirconium, the catalyst which is wide in temperature window, high in conversion rate and excellent in temperature resistance and sintering resistance, and is used for converting nitrogen oxides is obtained; the preparation process is simple, the cost is low, and the realization of the industrialization is facilitated.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

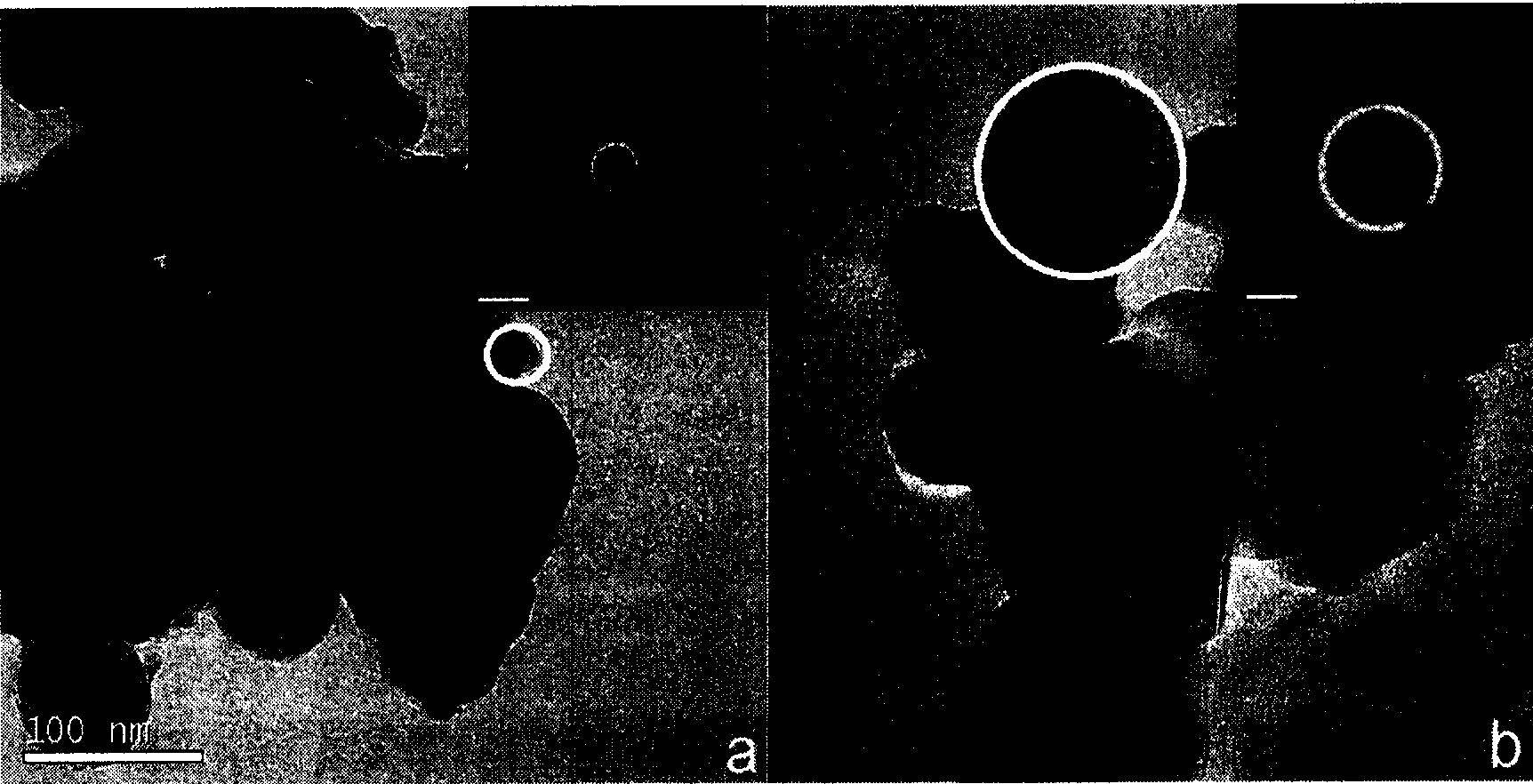

Method for preparing NiB non-crystalline alloy catalyst with the aid of microwave

InactiveCN1792440ACluster size controllableGood dispersionCatalyst carriersHydrocarbon by hydrogenationChemical platingIron(II) chloride

A microwave aided process for preparing the catalyst of non-crystalline NiB alloy suitable for catalytic hydro-reaction with high catalytic active features that the chemical reduction and chemical plating in microwave field is used, KBH4 is used as reducer, its primary salt is chosen from nickel sulfate, nickel acetate, etc, its secondary salt is chosen from cobalt chloride, iron chloride, etc, its carrier is chosen from oxide, molecular sieve, etc, its solvent is chosen from water, tetrahydrofuran, etc and the complex agent, stabilizer and additive is used.

Owner:NANKAI UNIV

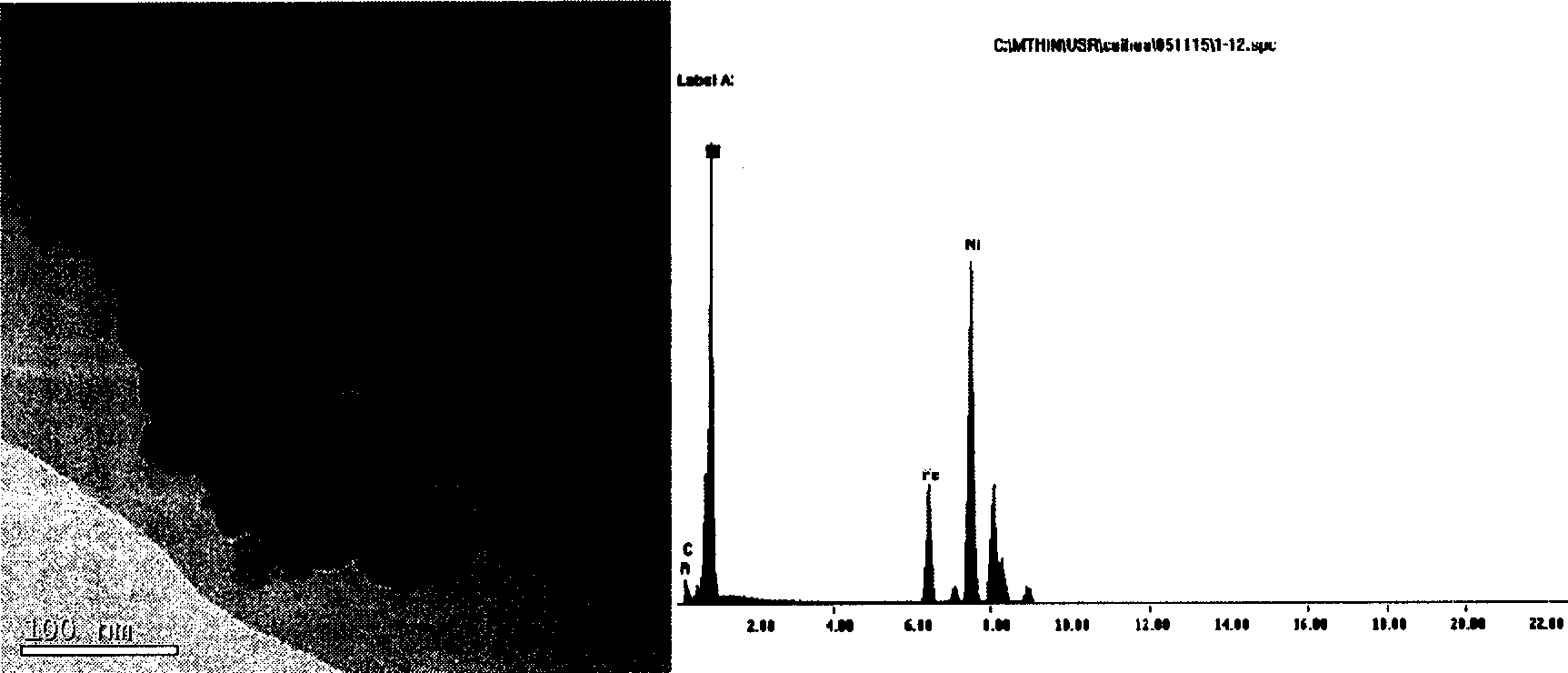

Methanation catalyst for removing trace amounts of oxycarbide

ActiveCN101347735AImprove anti-toxic performanceImprove thermal stabilityHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationAlkali metal oxide

The invention discloses a methanation catalyst of carbon oxides containing nickel, the methanation catalyst contains active components of a) nickel oxide, b) tungsten oxide and / or molybdenum oxide, and c) at least one active component which is selected from alkali metal oxides, alkaline earth metal oxides and rare earth metal oxides which are loaded on a carrier of the oxides, and the carrier of the oxides is aluminium oxide, silicon oxide, titanium oxide, zirconium oxide or the mixture thereof. The catalyst of the invention has very high activity at low temperature, high anti-poisoning capacity and thermal stability and broad application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-potential gradient zinc oxide piezoresistive material by low-temperature sintering

InactiveCN1801409AHigh nonlinear indexRaise the potential gradientResistor manufactureVaristor coresManufacturing technologyHigh energy

The preparation method for high-potential gradient ZnO piezoresistor material comprises: with high-energy ball grinding technology, adding rare earth oxides included Bi2O3, Sb2O3, Cr2O3, Co2O3, MnO2, and Y2O3; sintering at 800Deg, and obtaining the product. The advantages of this invention comprises: simple process technology, low sintering temperature, fit to traditional device, well properties of the product, 5.50~5.64g / cm3 density, 1845.66~2233.33V / mm voltage-sensitive potential gradient, 21.3~25.8 nonlinear index, and 1.55~10.2ª–A drain current (given 0.75V1mA).

Owner:EAST CHINA NORMAL UNIV

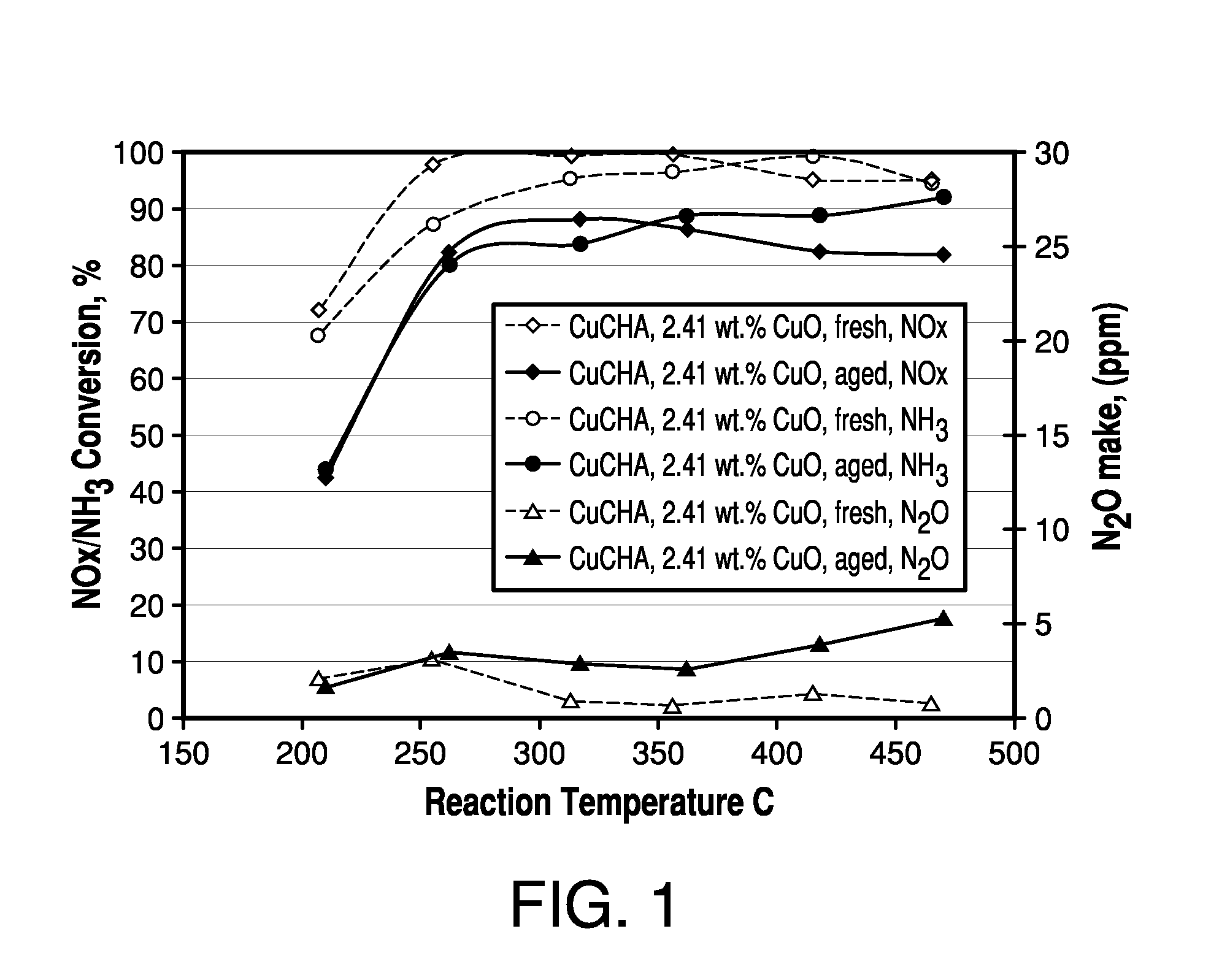

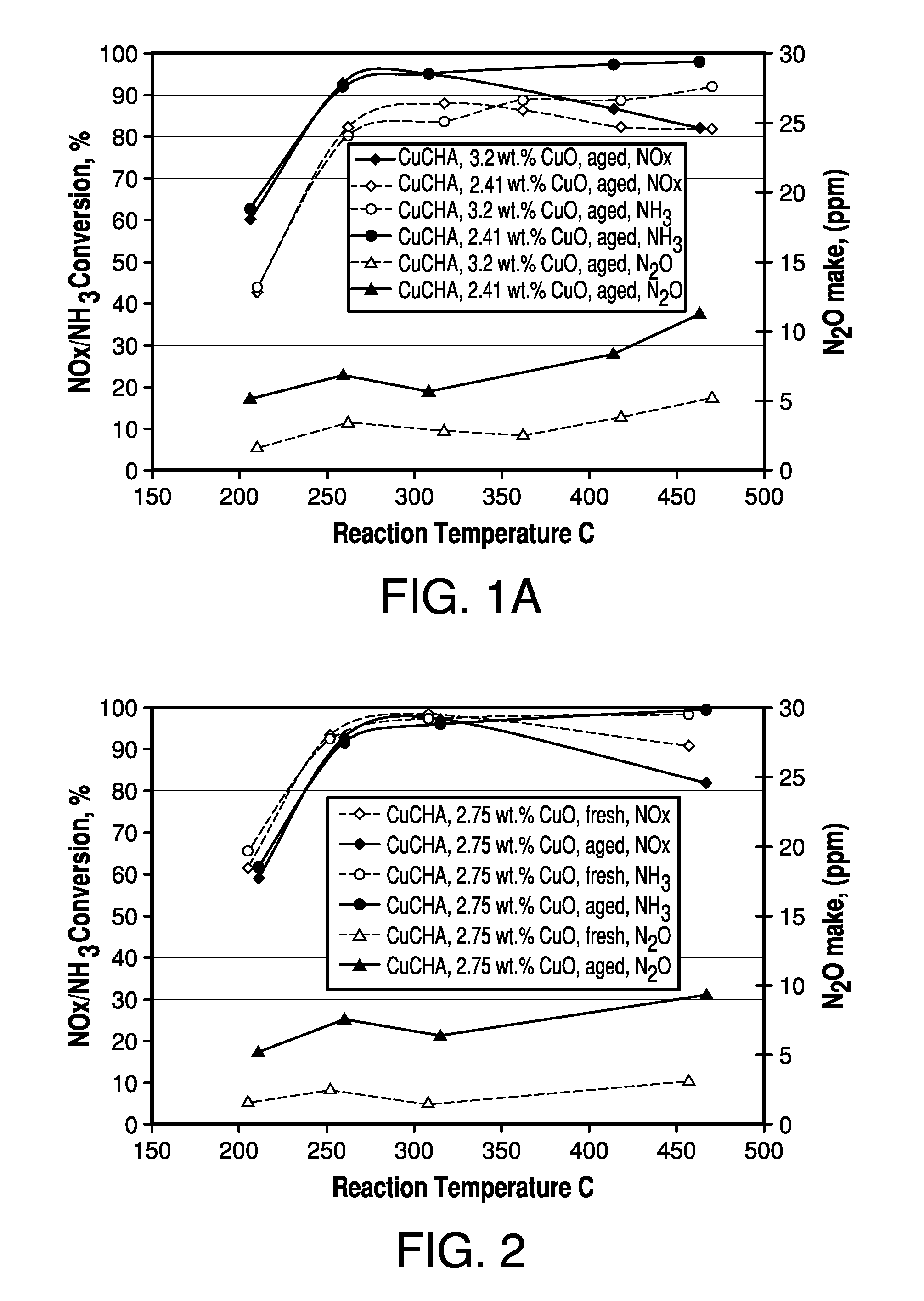

Copper CHA Zeolite Catalysts

ActiveUS20130195731A1Reduce decreaseImproved NH SCRNitrous oxide captureCombination devicesCrystal structureReaction temperature

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25: 1 to about 1:1.

Owner:BASF CORP

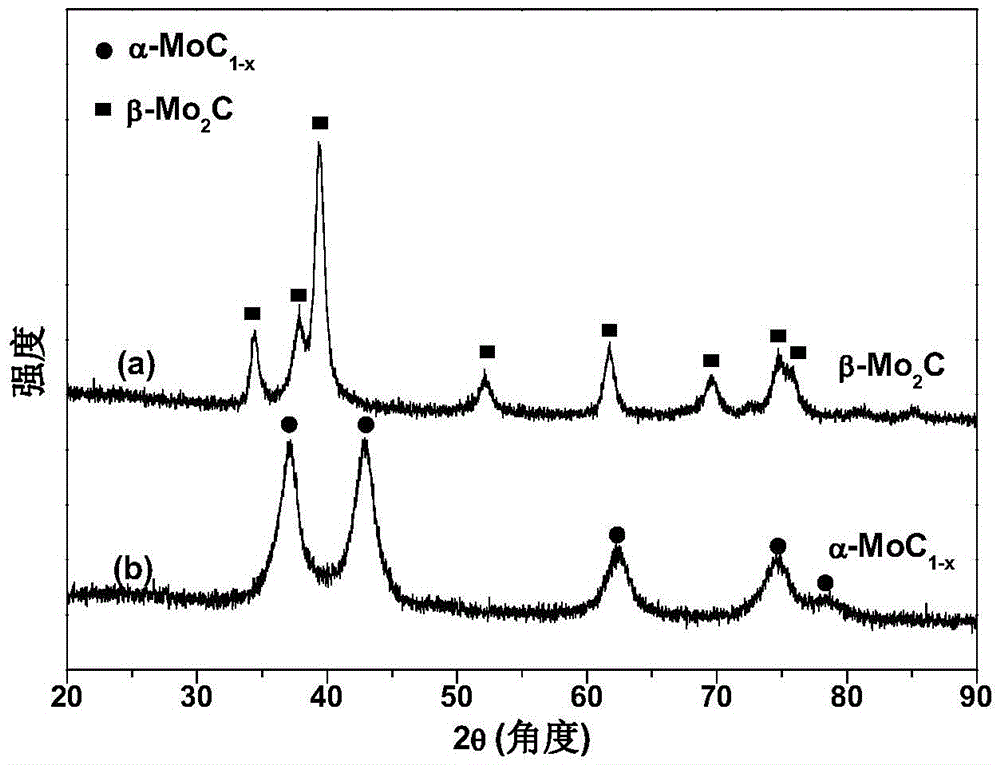

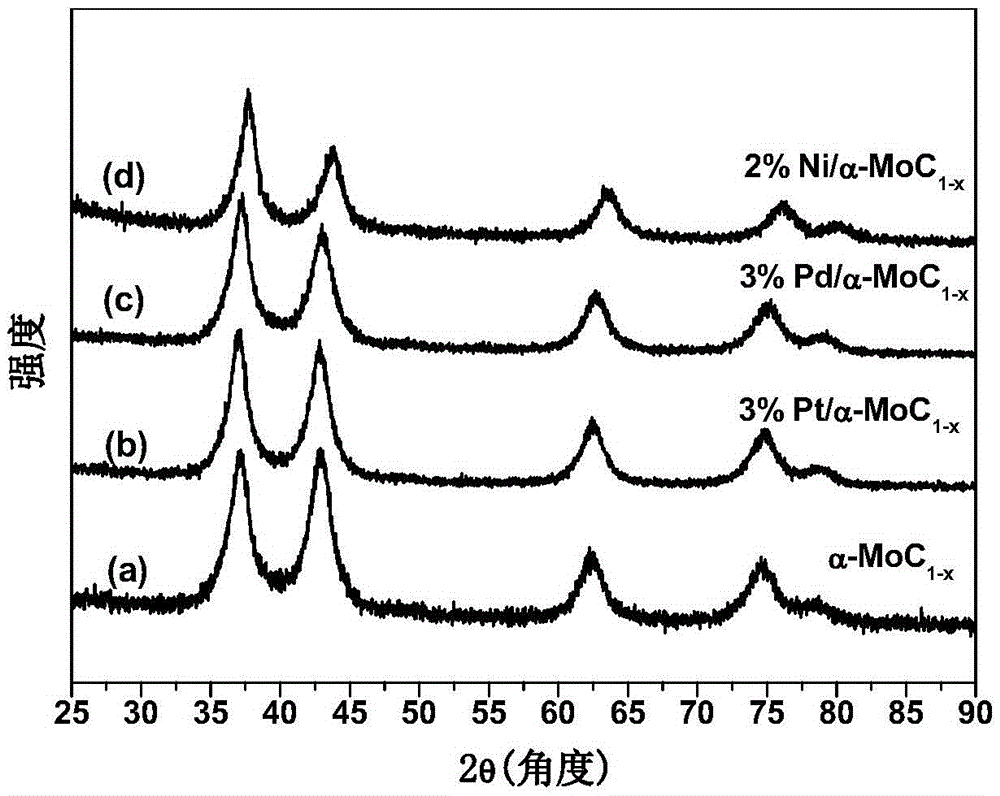

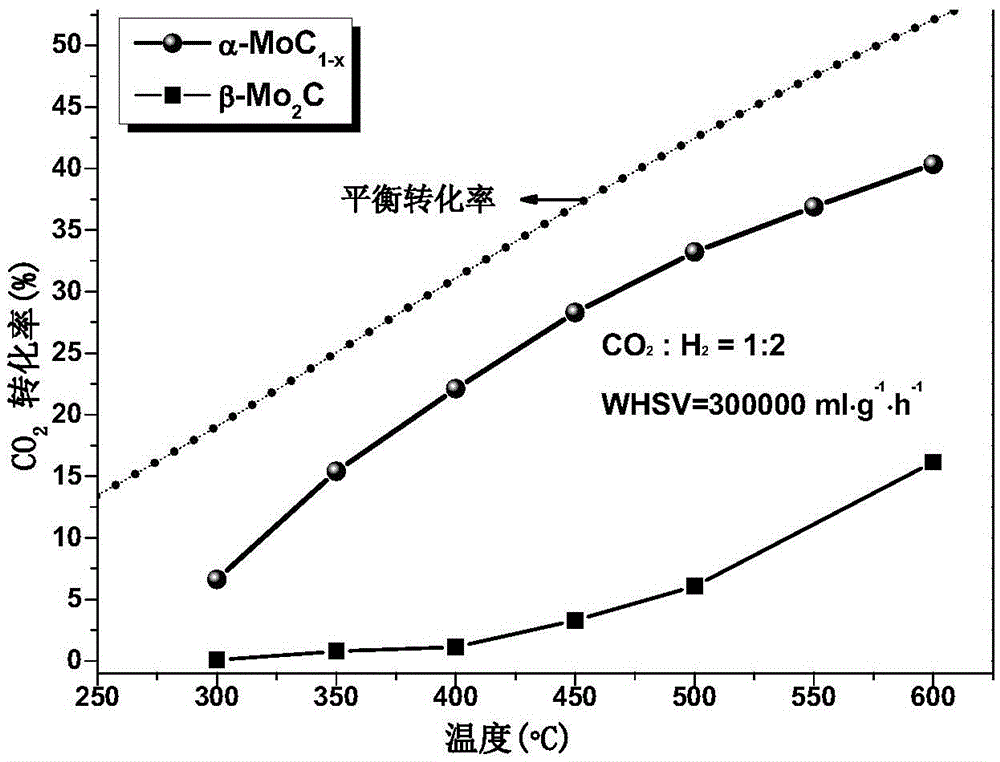

Application of alpha-molybdenum carbide and metal-modified alpha-molybdenum carbide catalyst to reaction for preparing carbon monoxide through hydrogenation of carbon dioxide

ActiveCN105540588AHigh low temperature activityEasy to makePhysical/chemical process catalystsCarbon monoxideReaction temperatureThermal stability

The invention discloses an application of alpha-molybdenum carbide or metal-modified alpha-molybdenum carbide as a catalyst to a reaction for preparing carbon monoxide through hydrogenation of carbon dioxide. In the reaction for preparing carbon monoxide through hydrogenation of carbon dioxide, the reaction atmosphere is a mixed gas of CO2 and H2, the reaction pressure is normal pressure, and the reaction temperature is 300-600 DEG C. The alpha-molybdenum carbide and metal-modified alpha-molybdenum carbide catalysts are low in cost and easy to prepare, and have relatively high low-temperature activity and CO selectivity and excellent thermal stability when applied to the reaction for preparing carbon monoxide through hydrogenation of carbon dioxide. The catalyst can meet the operating requirements of reaction situations of high temperature and strong reduction in the reaction for preparing carbon monoxide through hydrogenation of carbon dioxide, and therefore, has bright application prospects in the field of CO2 catalytic conversion and utilization.

Owner:DALIAN UNIV OF TECH

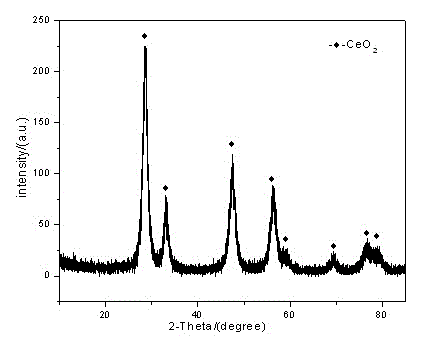

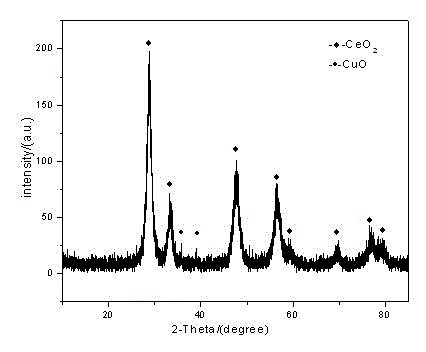

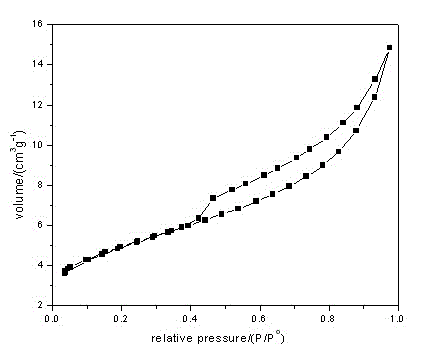

Preparation method of catalytic material mixed by copper and cerium oxide

InactiveCN103055875ALow priceNo pollution in the processMetal/metal-oxides/metal-hydroxide catalystsCerium(IV) oxideThermal stability

The invention provides a preparation method of a catalytic material mixed by copper and cerium oxide. The preparation method comprises the following steps of: (a) dissolving copper salt in a solvent, and continuously mixing the copper salt for 0.5-1 hour, wherein the concentration of Cu ions is 0.00872-0.17492 mol / mL; (b) adding mesoporous cerium oxide powder into a copper salt solution obtained by the step (a) according to the liquid-to-solid ratio of 10:1 to 6:1, stilling the copper salt solution for 24-48 hours after the mesoporous cerium oxide powder is dissolved, and meanwhile, aperiodically stirring the copper salt solution; (c) drying the mixed solution obtained by the step (b) at 110-120 DEG C for 10-12 hours, grinding the dried resultant, and calcining the resultant at 200-300 DEG C for 2-3 hours, thus obtaining the catalytic material mixed by the copper and the cerium oxide. The preparation method has the advantages of simplicity in operation and experimental procedure, low cost of raw materials, and no environmental pollution, and the prepared catalytic material has the advantages of large specific surface area and pore volume, high low-temperature activity and favorable thermal stability. The prepared catalytic material can be widely applied to optical CO oxidation sensors, motor vehicle exhaust gas cleaning and purification systems and the like, and is prone to industrial production.

Owner:KUNMING UNIV OF SCI & TECH

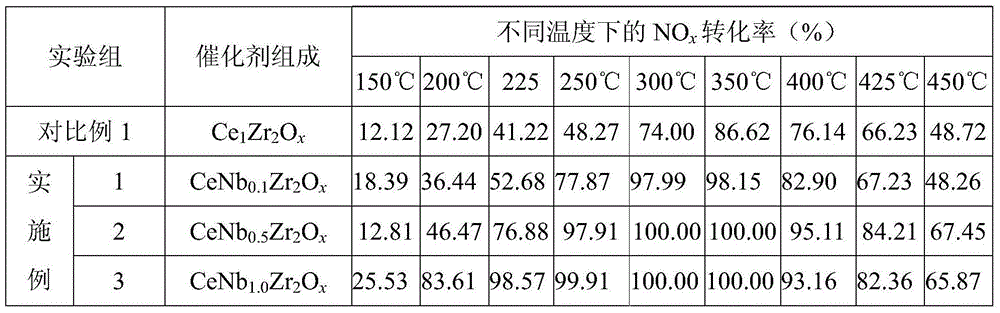

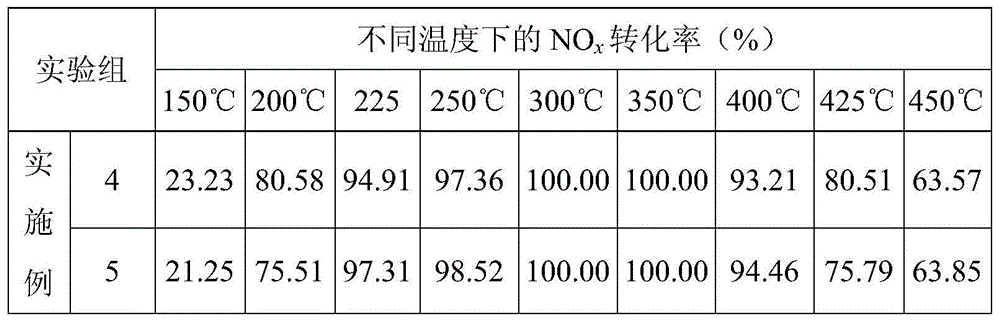

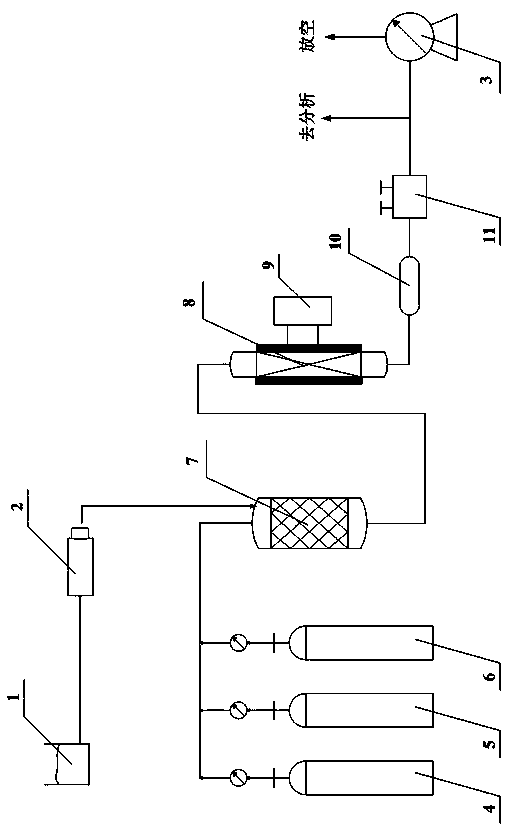

Cerium-niobium-zirconium composite oxide catalyst, preparation method and uses thereof

ActiveCN104368329AHigh low temperature activityWide temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemical compositionNiobium

The present invention relates to a cerium-niobium-zirconium composite oxide catalyst, a preparation method and uses thereof. The catalyst has the following chemical composition: CeNbaZr2Ox, wherein a is 0-1.0 and does not include 0. The method comprises: (1) preparing a mixed aqueous solution comprising a cerium source and a zirconium source; (2) adding a niobium source aqueous solution and an excess urea precipitation agent to the mixed solution in the step (1) to completely precipitate cerium, niobium and zirconium; (3) carrying out suction filtration and washing on the obtained precipitated product to obtain the filter cake; and (4) drying and calcining the filter cake to obtain the cerium-niobium-zirconium composite oxide catalyst, wherein the catalyst has characteristics of excellent low-temperature activity, wide operation temperature window, high N2 selectivity and high NOx conversion rate, and can be used for the NH3-SCR reaction.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

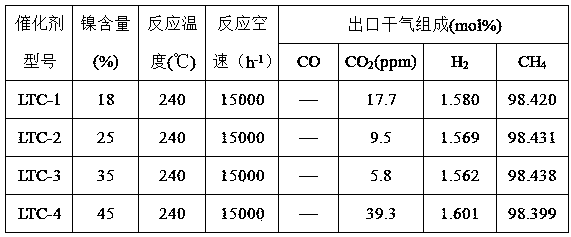

Low-temperature high-activity methanation catalyst and preparation method thereof

ActiveCN103706373AGood dispersionReduce interactionGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMethanation

The invention discloses a low-temperature high-activity methanation catalyst and a preparation method thereof. The catalyst comprises metallic nickel as an active component, AL2O3 as a carrier and MgO as a structure auxiliary agent, and an appropriate amount of lanthanum oxide and manganese oxide are added as active auxiliary agents. The catalyst comprises the following main components in percentage by mass: 18-45% of NiO, 40-70% of Al2O3, 5-30% of MgO, 0.4-5% of La2O3 and 0.1-5% of MnO2. The catalyst disclosed by the invention has the advantages of large specific area, uniform nickel dispersity, good heat stability, strong oxidation resistance, low active temperature, adaptability to low hydrogen-carbon ratio and the like. The catalyst is applicable to preparation of LNG (liquefied natural gas) through methanation of industrial gases including coke oven gas, coal synthesis gas, semi coke exhaust gas and the like rich in CO, CO2 and H2, is particularly applicable to a methanation reaction in a low-temperature section, and can effectively improve the quality of synthetic natural gas. Meanwhile, the invention also provides the preparation method of the catalyst, and the preparation method is simple in process flow and can realize industrial production easily.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

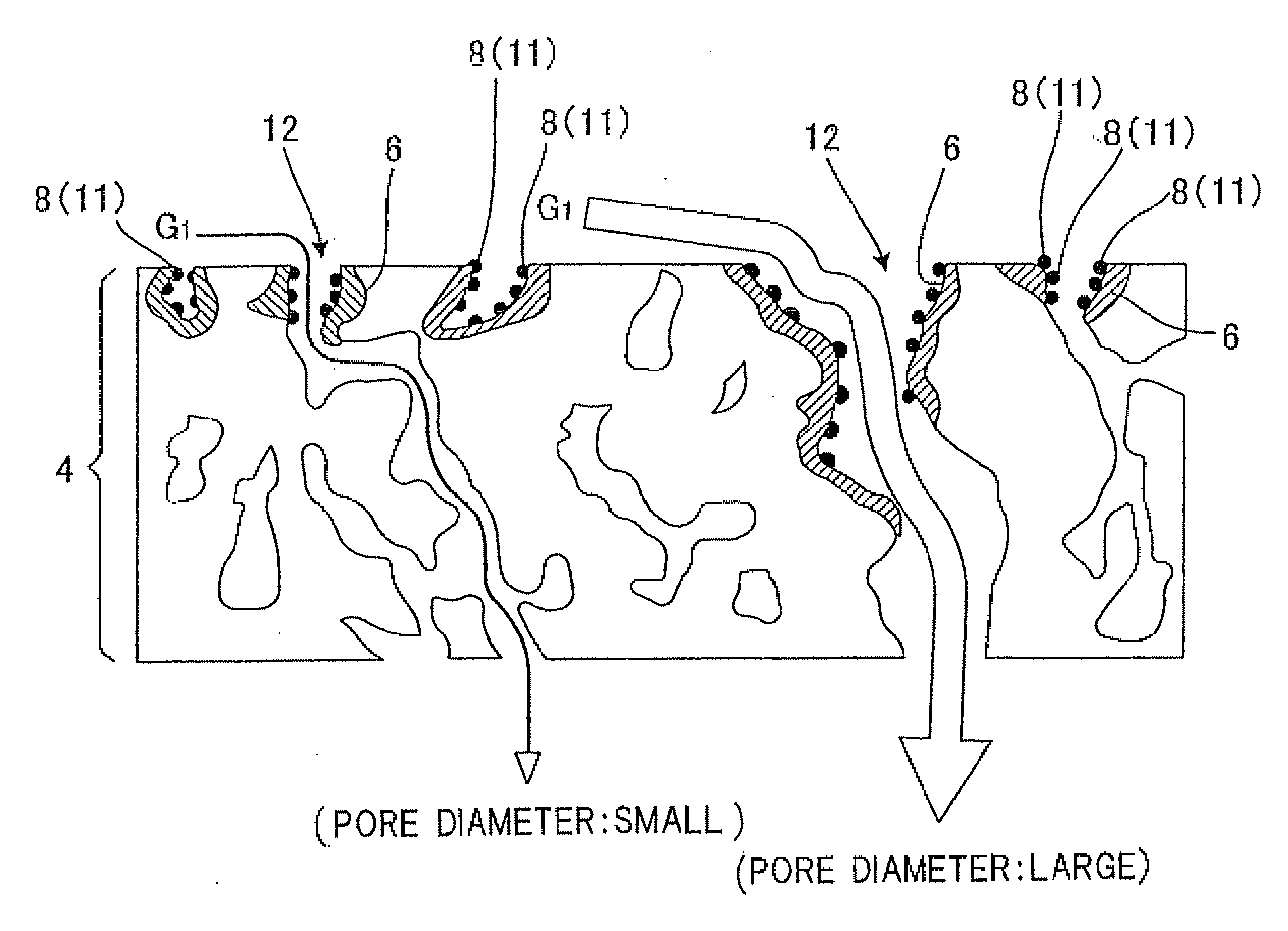

Catalytic diesel particulate filter and manufacturing method thereof

InactiveUS20090247399A1High low temperature activityEasy to carryGas treatmentHeterogenous catalyst chemical elementsEngineeringDiesel particulate filter

There are provided a catalytic diesel particulate filter that is arranged in an exhaust system of a diesel engine and includes a catalyst that burns a particulate matter contained in an exhaust gas from the diesel engine, wherein the catalyst is configured in such a manner that a ceria based catalyst coat layer 6 containing no noble metal and a noble metal based catalyst coat layer 11 containing a noble metal are separately provided on a substrate constituted of a honeycomb structure, and a method for producing the same.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com