Molecular sieve based catalyst used for low-temperature SCR denitration and its preparation method

A molecular sieve base and catalyst technology, applied in the field of molecular sieves, can solve the problems of poor sulfur resistance, insufficient mechanical strength, poor water resistance, etc., and achieve the effects of rich micropore structure, good selectivity, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Dissolve 0.492 g of sodium metaaluminate (aluminum source) and 3.6 g of sodium hydroxide in 15.8 g of deionized water and stir to dissolve them completely. 2.3 g of choline chloride were added to the mixture and stirred for 15 minutes to completely dissolve it. Slowly add 18 g of LUDOX-AS-40 silica sol (silicon source) dropwise under rapid stirring.

[0066] After stirring at room temperature for one hour, the final colloid was divided into two parts (A and B), and A and B were respectively transferred to a stainless steel autoclave lined with Teflon, placed in an oven at 140 °C and kept for 4 days ( for A) and 6 days (for B).

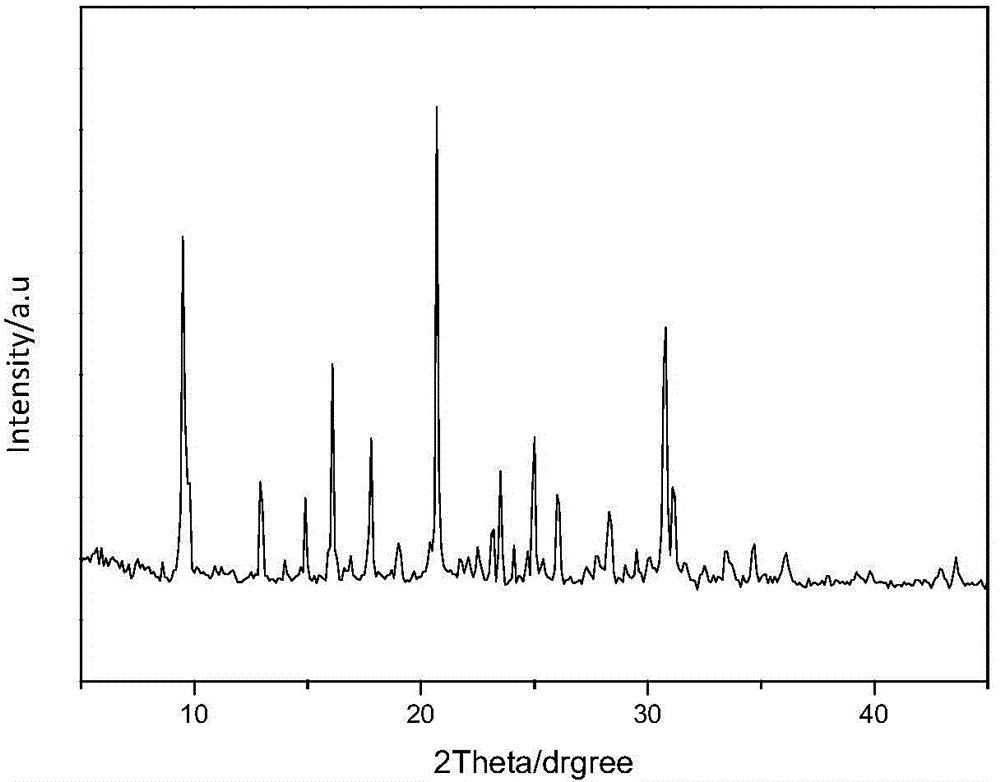

[0067] The product was washed with deionized water, collected by filtration, dried in a vacuum oven at 100°C for 12 hours, and then calcined in a muffle furnace at 550°C for 8 hours to remove the structure-directing agent to obtain SSZ-13 molecular sieves, in which A and B were two The XRD spectrum of the SSZ-13 molecular sieve prepared by the...

Embodiment 2

[0070] Dissolve 0.853 g of sodium metaaluminate (aluminum source) and 3.0 g of sodium hydroxide in 15.8 g of deionized water and stir to dissolve completely. 1.8 g of choline chloride was added to the mixture and stirred for 15 minutes to completely dissolve it. Slowly add 17.25 g of LUDOX-AS-40 colloidal silica (silicon source) dropwise under rapid stirring.

[0071] After stirring for one hour at room temperature, the final colloid was divided into two parts (A and B), and A and B were transferred to a stainless steel autoclave lined with Teflon, respectively, and placed in an oven at 130 °C (for A) and 150°C (for B) and hold for 6 days.

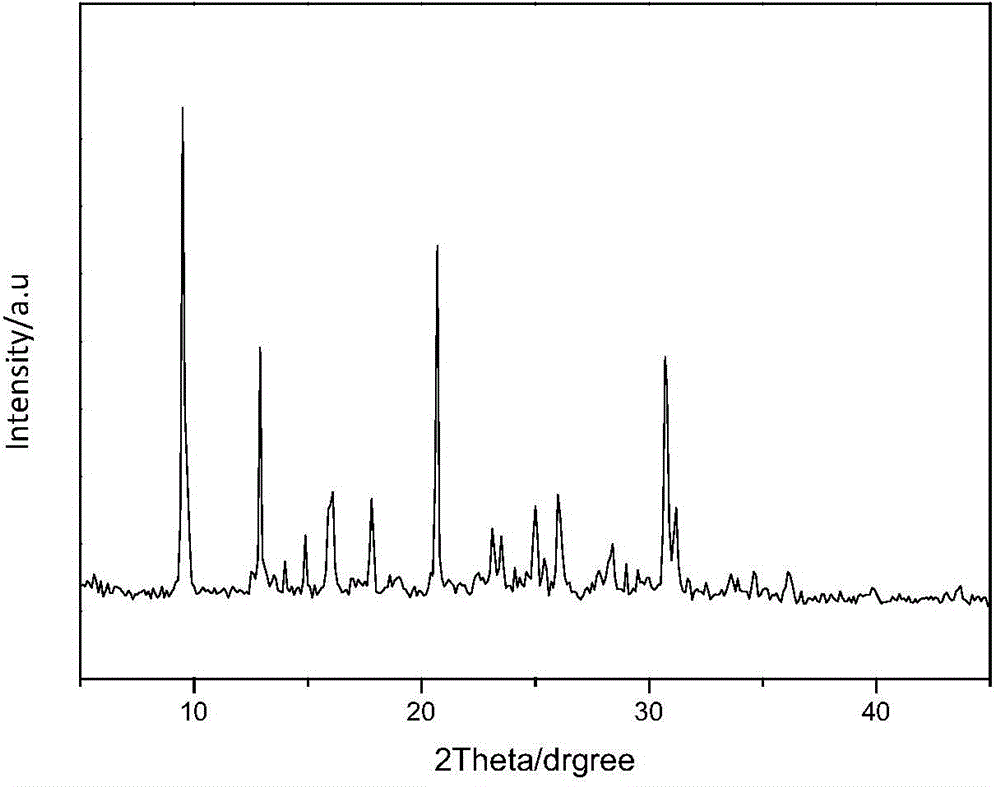

[0072] The product was washed with deionized water, collected by filtration, dried in a vacuum oven at 100°C for 12 hours, and then calcined in a muffle furnace at 550°C for 8 hours to remove the structure-directing agent to obtain SSZ-13 molecular sieves, in which A and B were two The XRD spectrum of the SSZ-13 molecular sieve prepared ...

Embodiment 3

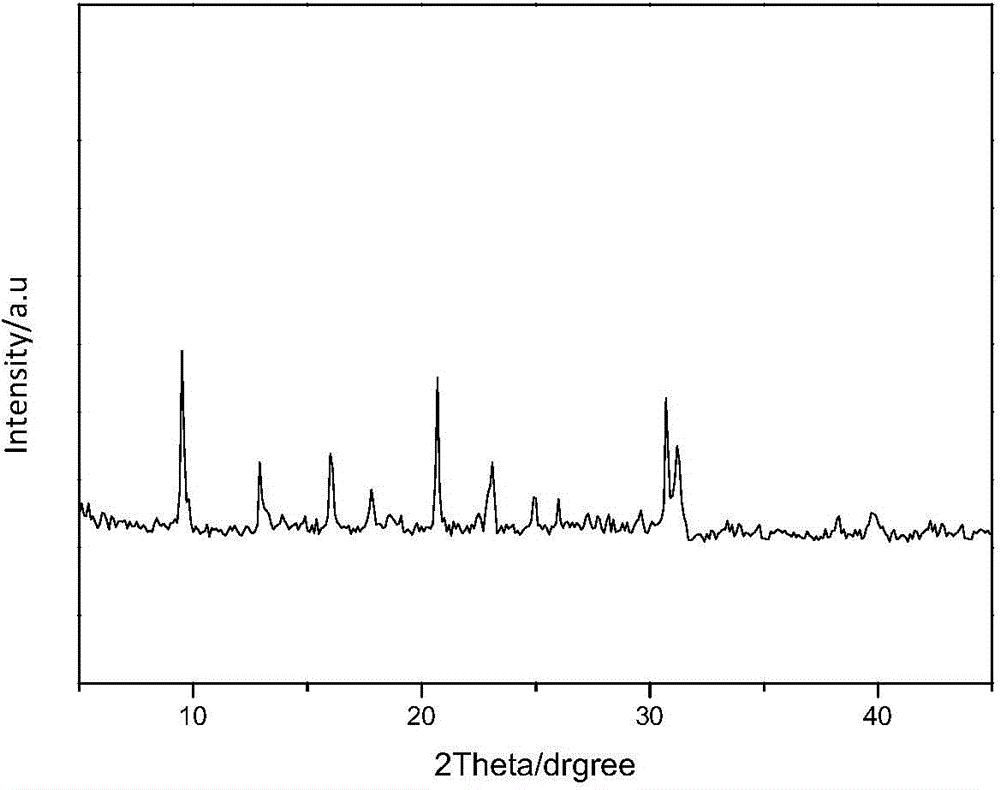

[0075] Compared with Example 1, the only difference is that the specific selection and molar dosage ratio of the molecular sieve crystal materials in this example are different, specifically:

[0076]

[0077] In this embodiment, the tetravalent silicon source is sodium silicate, the trivalent aluminum source is pseudoboehmite, the alkali metal compound is sodium hydroxide, and the hydroxide ion is provided in the form of sodium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com