Low-temperature high-activity methanation catalyst and preparation method thereof

A methanation catalyst, high activity technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Expensive, no data and other problems, to achieve the effect of increasing surface utilization, improving low-temperature activity, and increasing nickel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

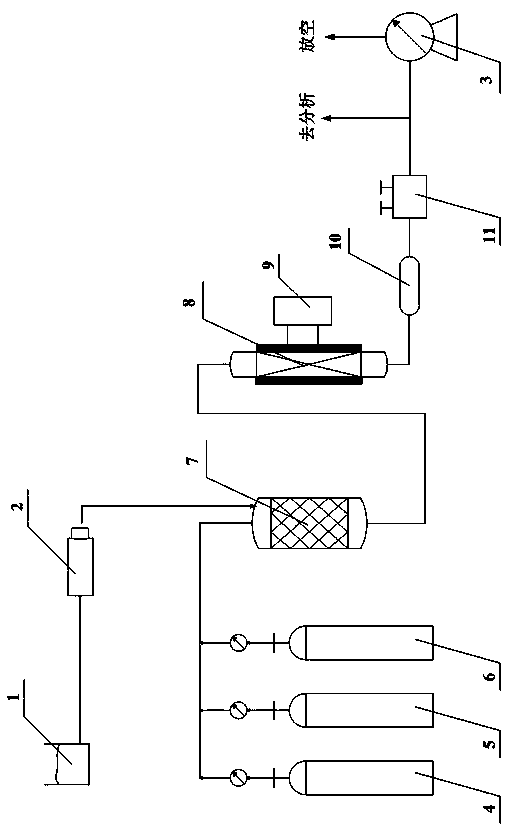

Method used

Image

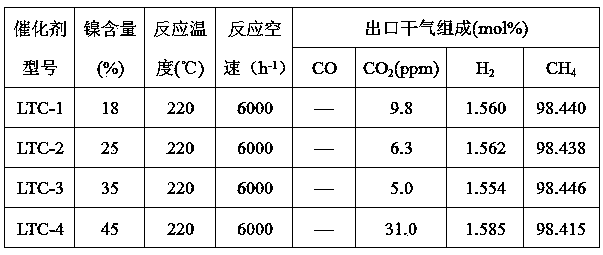

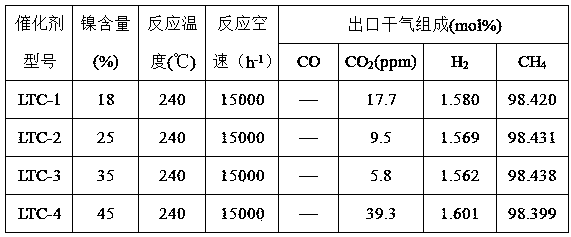

Examples

Embodiment 1

[0049] In the present embodiment, the component mass percent of the low-temperature high-activity methanation catalyst is required to be:

[0050] NiO: 18%, Al 2 o 3 : 70%, MgO: 11.5%, La 2 o 3 : 0.4%, MnO 2 : 0.1%.

[0051] The specific preparation process is as follows.

[0052] a) Auxiliary precipitation: Weigh 214.33g of porous Al(OH) passing through a 300-mesh sieve 3 , and add 147.21g Mg(NO 3 ) 2 ·6H 2 O is poured into the first constant temperature reactor. Then add 3000ml of deionized water into the first constant temperature reaction kettle to form a turbid solution. When the turbid liquid in the first constant temperature reaction kettle was uniformly heated to 70°C, slowly add 9% Na 2 CO 3 The solution was stirred continuously, keeping the temperature constant, and reacted for 2 hours. When the pH value of the cloudy solution was 7.0, the carrier mixture was obtained. Then the carrier mixture was filtered, and the filtered slurry was poured into a polyt...

Embodiment 2

[0056] In the present embodiment, the component mass percent of the low-temperature high-activity methanation catalyst is required to be:

[0057] NiO: 25%, Al 2 o 3 : 40%, MgO: 30%, La 2 o 3 : 2%, MnO 2 : 3%.

[0058] The specific preparation process is as follows.

[0059] a) Precipitation of additives: Weigh 122.48g of porous Al(OH) passing through a 300-mesh sieve 3 , and add 384.05g Mg(NO 3 ) 2 ·6H 2 O, poured into the first constant temperature reactor. Then add 3000ml of deionized water into the first constant temperature reaction kettle to form a turbid solution. When the turbid liquid in the first constant temperature reaction kettle was evenly heated to 65°C, slowly add 9% Na 2 CO 3 The solution was stirred continuously, keeping the temperature constant, and reacted for 3 hours. When the pH value of the cloudy solution was 6.5, the carrier mixture was obtained. Then the carrier mixture was filtered, and the filtered slurry was poured into a polytetrafluo...

Embodiment 3

[0063] In the present embodiment, the component mass percent of the low-temperature high-activity methanation catalyst is required to be:

[0064] NiO: 35%, Al 2 o 3 : 45%, MgO: 15%, La 2 o 3 : 2%, MnO 2 : 3%.

[0065] The specific preparation process is as follows.

[0066] a) Precipitation of additives: Weigh 137.78g of porous Al(OH) passing through a 300-mesh sieve 3 , and add 192.00g Mg(NO 3 ) 2 ·6H 2 O, poured into the first constant temperature reactor. Then add 3000ml of deionized water into the first constant temperature reaction kettle to form a turbid solution. When the turbid liquid in the first constant temperature reaction kettle was evenly heated to 70°C, slowly add 9% Na 2 CO 3 The solution was stirred continuously, keeping the temperature constant, and reacted for 2 hours. When the pH value of the cloudy solution was 7.5, the carrier mixture was obtained. Then the carrier mixture was filtered, and the filtered slurry was poured into a polytetrafluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com