Patents

Literature

104results about How to "Increased nickel content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrodeposited copper foil with carrier foil

ActiveUS7691487B2Improve adhesion strengthGood chemical resistanceInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentInterface layerCopper foil

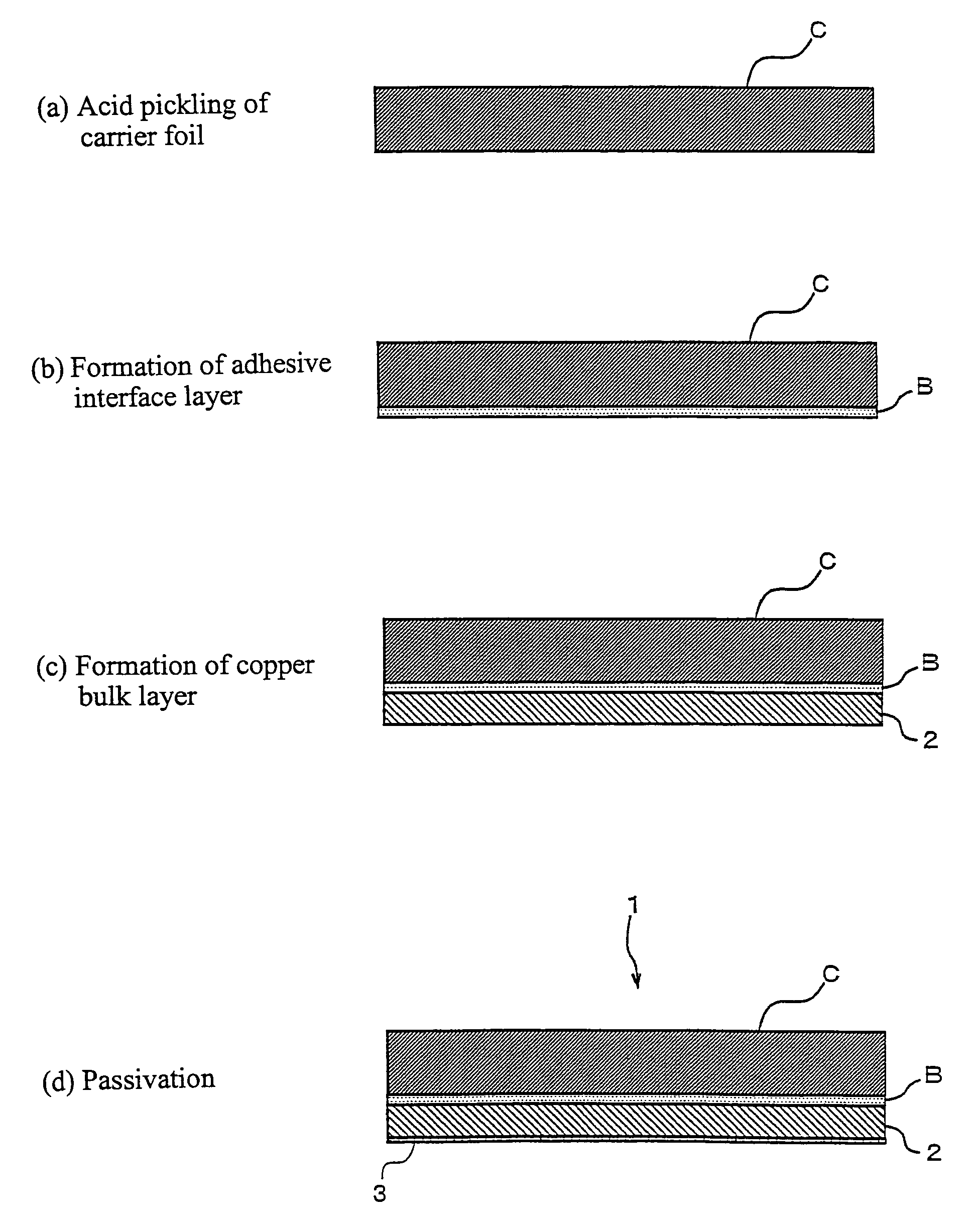

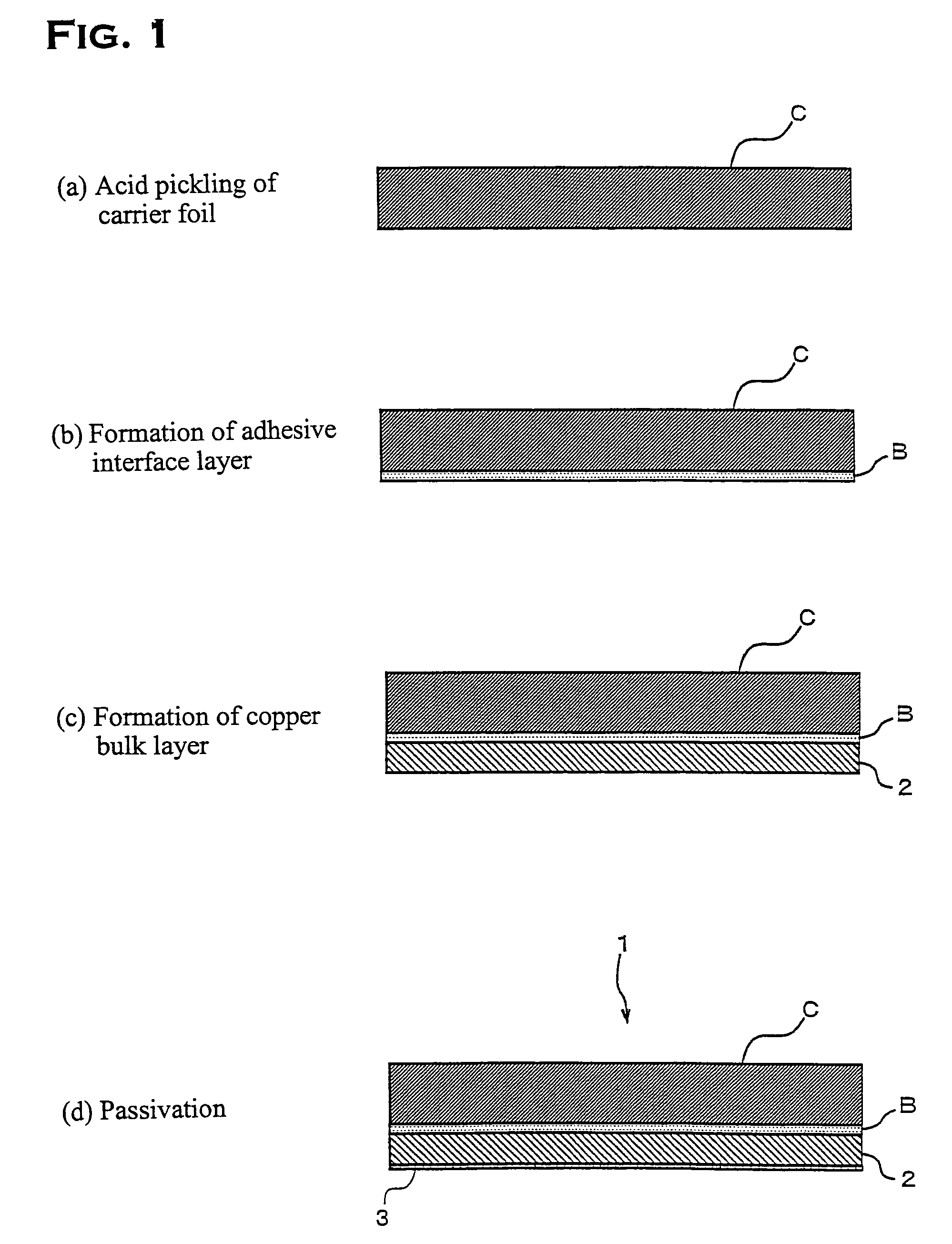

The present invention provides electrodeposited copper foil with a carrier foil which permits the formation of finer-pitch circuits and also enables the multilayer process to be easily performed to meet the requirements for recent printed wiring boards. According to the invention, there is provided electrodeposited copper foil with a carrier foil in which an adhesive interface layer is formed on a surface of the carrier foil and an electrodeposited copper foil layer is formed on the adhesive interface layer, which is characterized in that the electrodeposited copper foil layer is provided with a passivated layer formed without performing roughening treatment as nodular treatment and that a nickel-zinc alloy consisting essentially of 50 to 99% nickel by weight and 50 to 1% zinc by weight is adopted as the passivated layer.

Owner:MITSUI MINING & SMELTING CO LTD

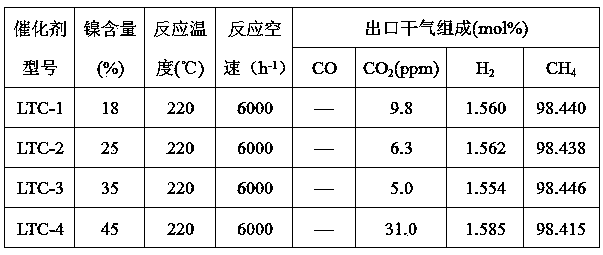

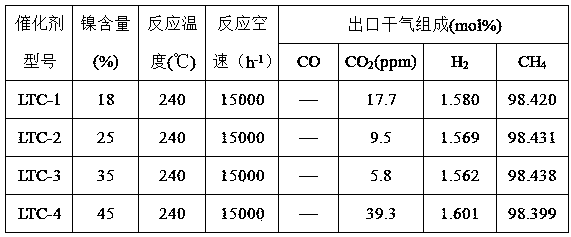

Low-temperature high-activity methanation catalyst and preparation method thereof

ActiveCN103706373AGood dispersionReduce interactionGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMethanation

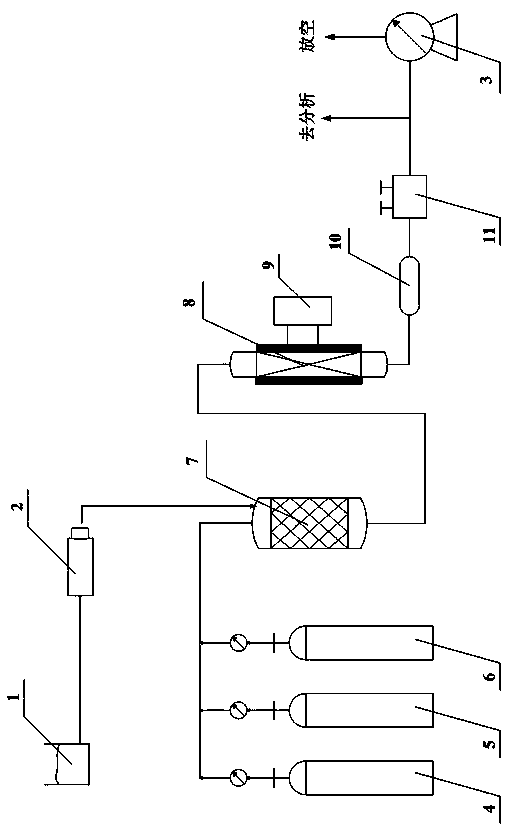

The invention discloses a low-temperature high-activity methanation catalyst and a preparation method thereof. The catalyst comprises metallic nickel as an active component, AL2O3 as a carrier and MgO as a structure auxiliary agent, and an appropriate amount of lanthanum oxide and manganese oxide are added as active auxiliary agents. The catalyst comprises the following main components in percentage by mass: 18-45% of NiO, 40-70% of Al2O3, 5-30% of MgO, 0.4-5% of La2O3 and 0.1-5% of MnO2. The catalyst disclosed by the invention has the advantages of large specific area, uniform nickel dispersity, good heat stability, strong oxidation resistance, low active temperature, adaptability to low hydrogen-carbon ratio and the like. The catalyst is applicable to preparation of LNG (liquefied natural gas) through methanation of industrial gases including coke oven gas, coal synthesis gas, semi coke exhaust gas and the like rich in CO, CO2 and H2, is particularly applicable to a methanation reaction in a low-temperature section, and can effectively improve the quality of synthetic natural gas. Meanwhile, the invention also provides the preparation method of the catalyst, and the preparation method is simple in process flow and can realize industrial production easily.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

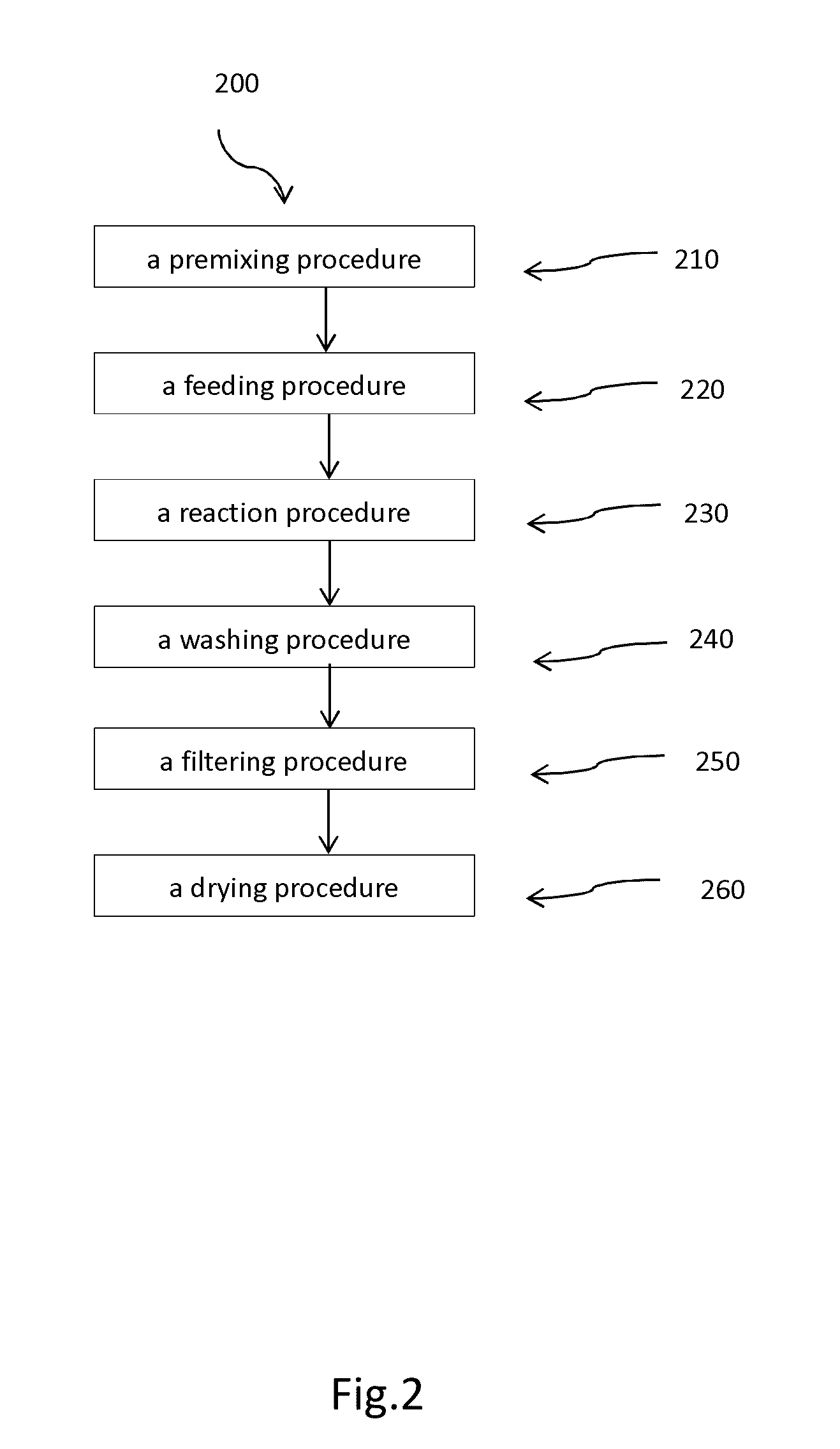

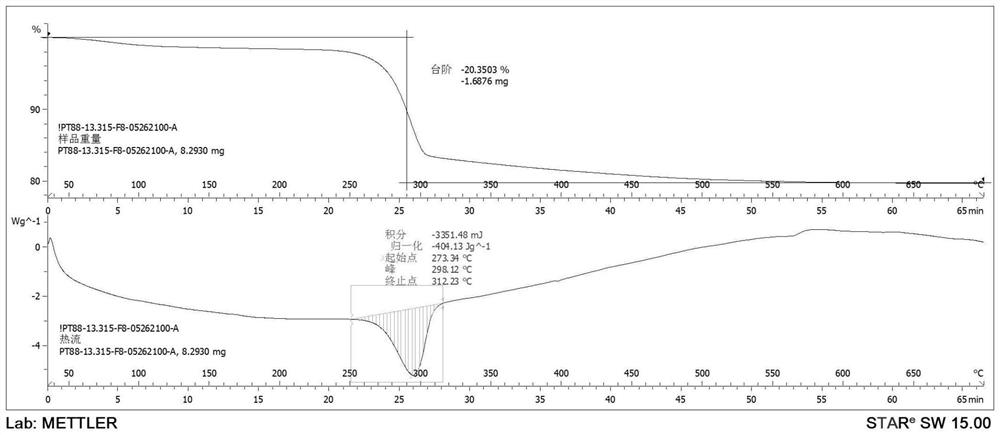

Method for forming Basic Nickel Carbonate

ActiveUS20160090311A1Alleviate volume expansionImprove conversion rateChemical/physical/physico-chemical processesNickel oxides/hydroxidesParticulatesPotential market

The present disclosure provides a novel method to fabricate the basic nickel carbonate particulates. The nickel content in the basic nickel carbonate particulates fabricated by this invention (51-53 mass %) is higher than the present commercialized products (44-46 mass %). Basic nickel carbonate is an important intermediate to prepare NiO and pure Ni particles, and NiO and pure Ni particles are important materials in electronic industrial. Therefore, basic nickel carbonate has its potential market.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

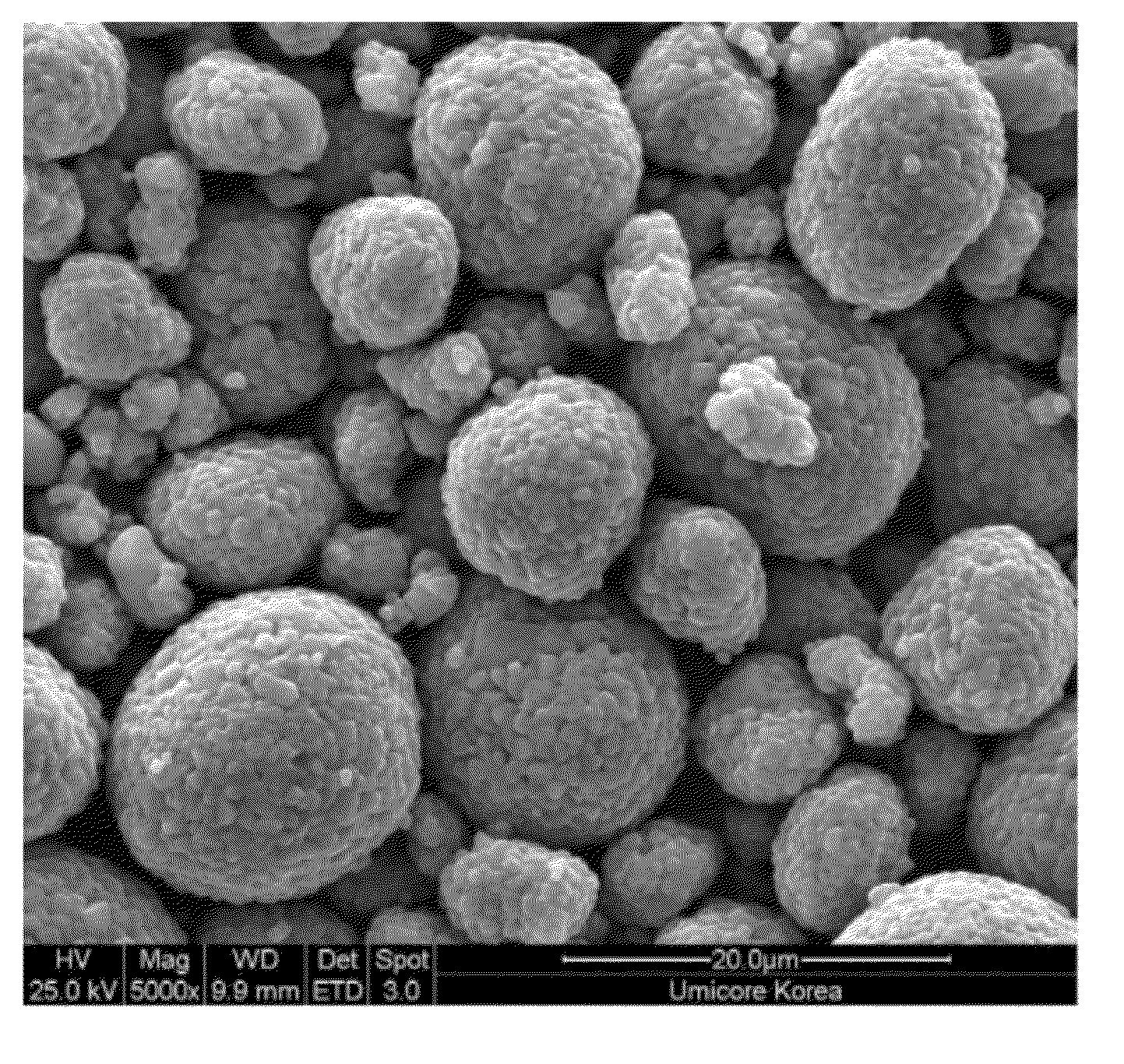

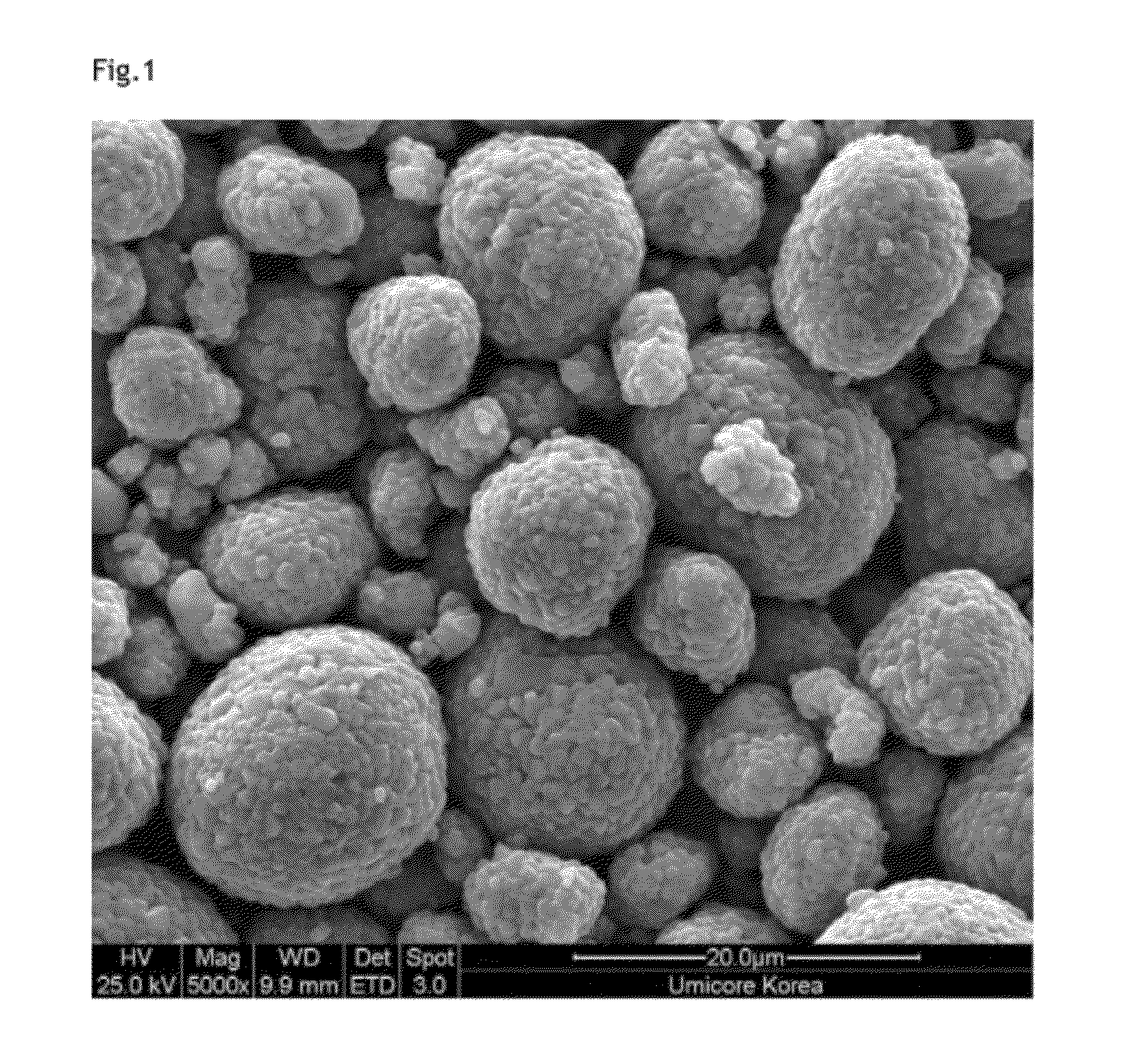

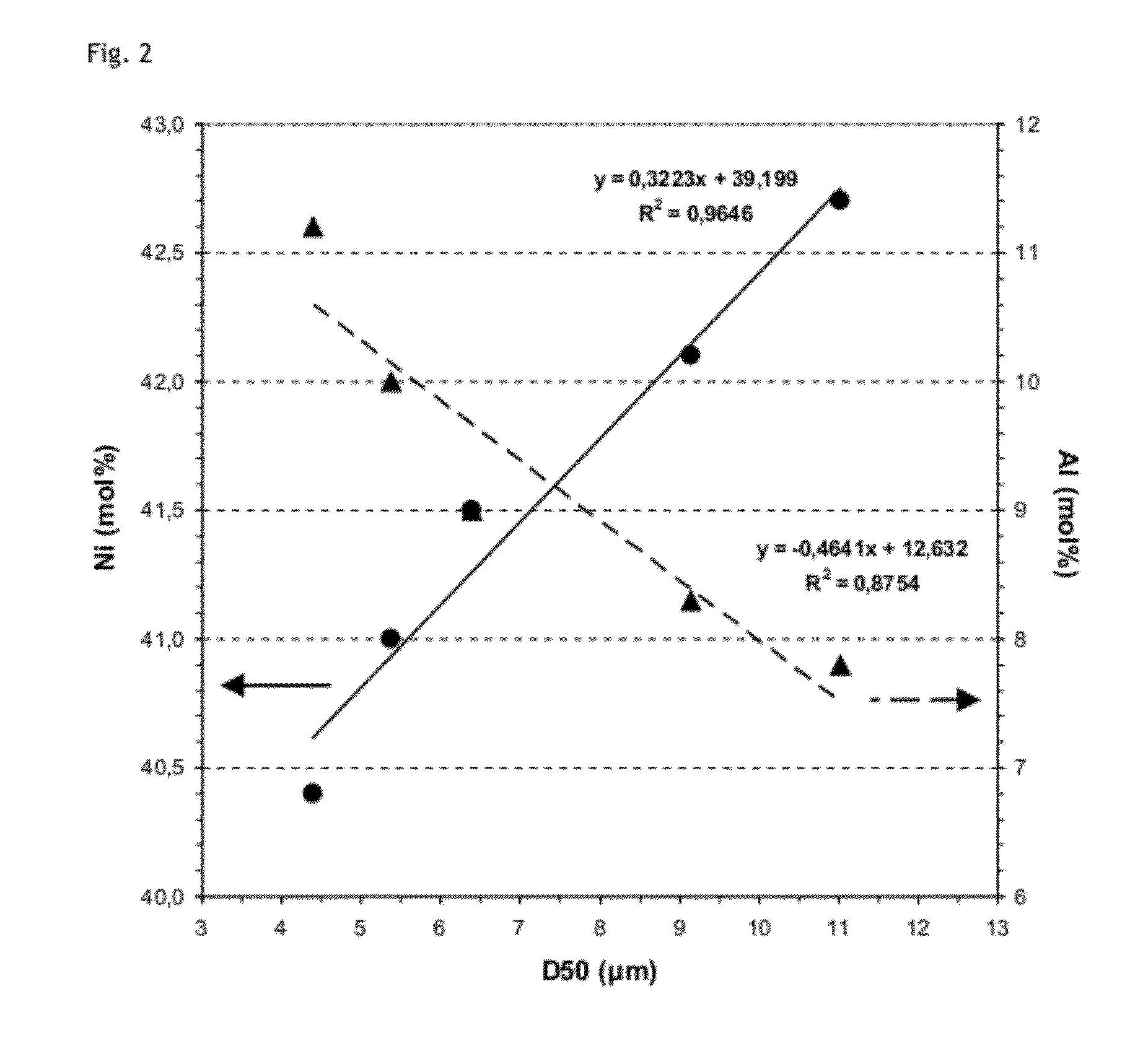

Positive Electrode Materials Combining High Safety and High Power in a Li Rechargeable Battery

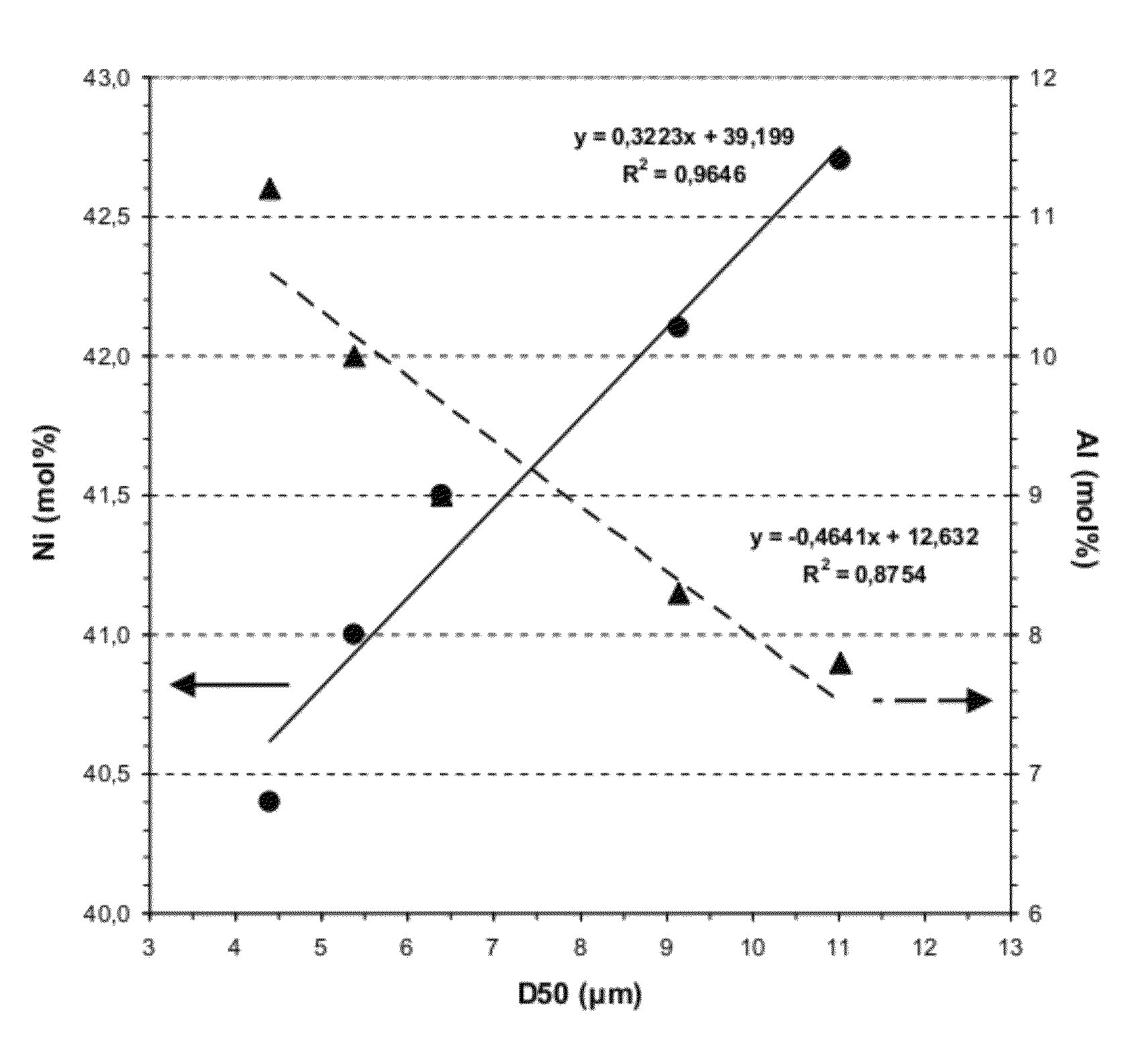

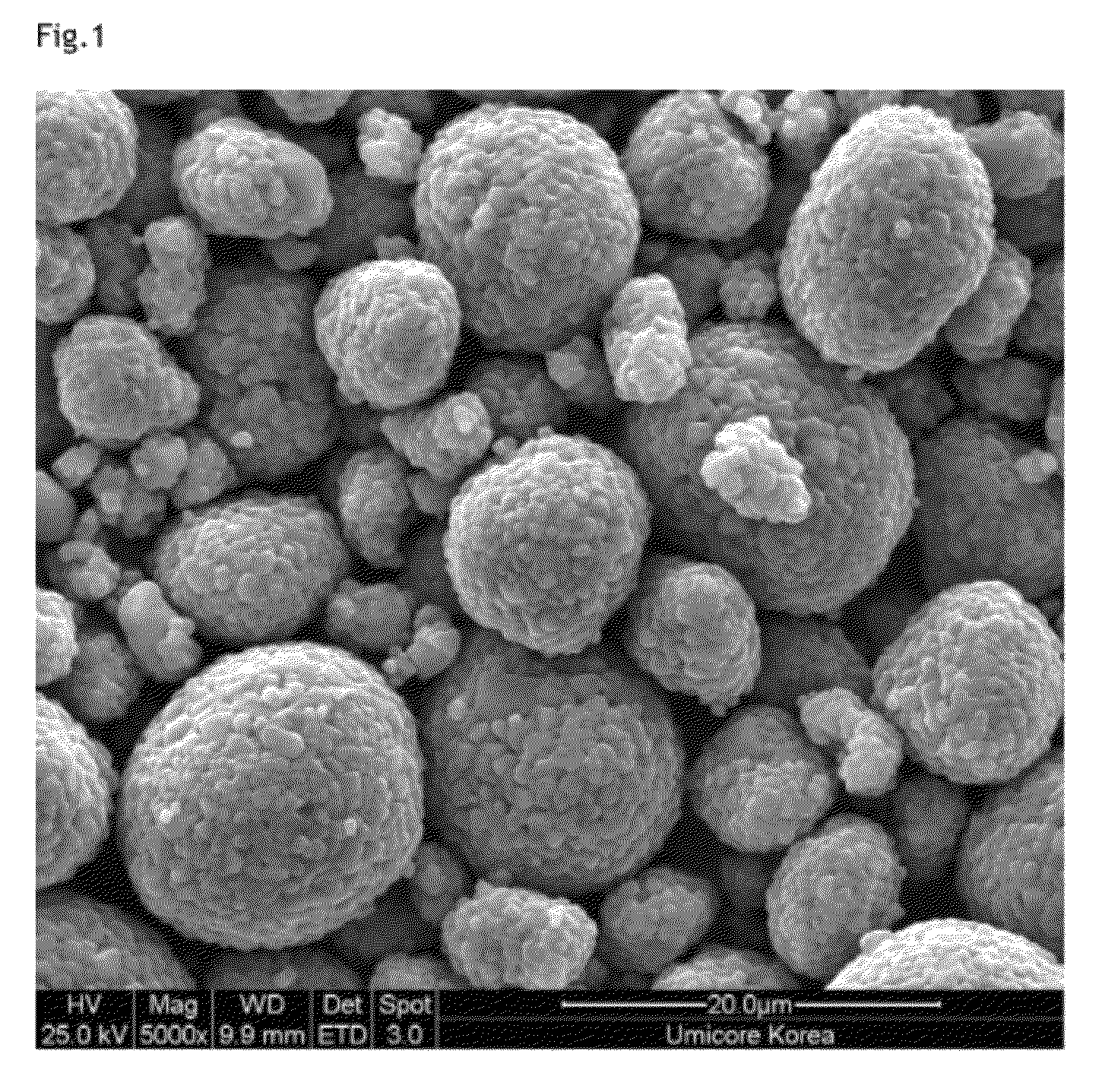

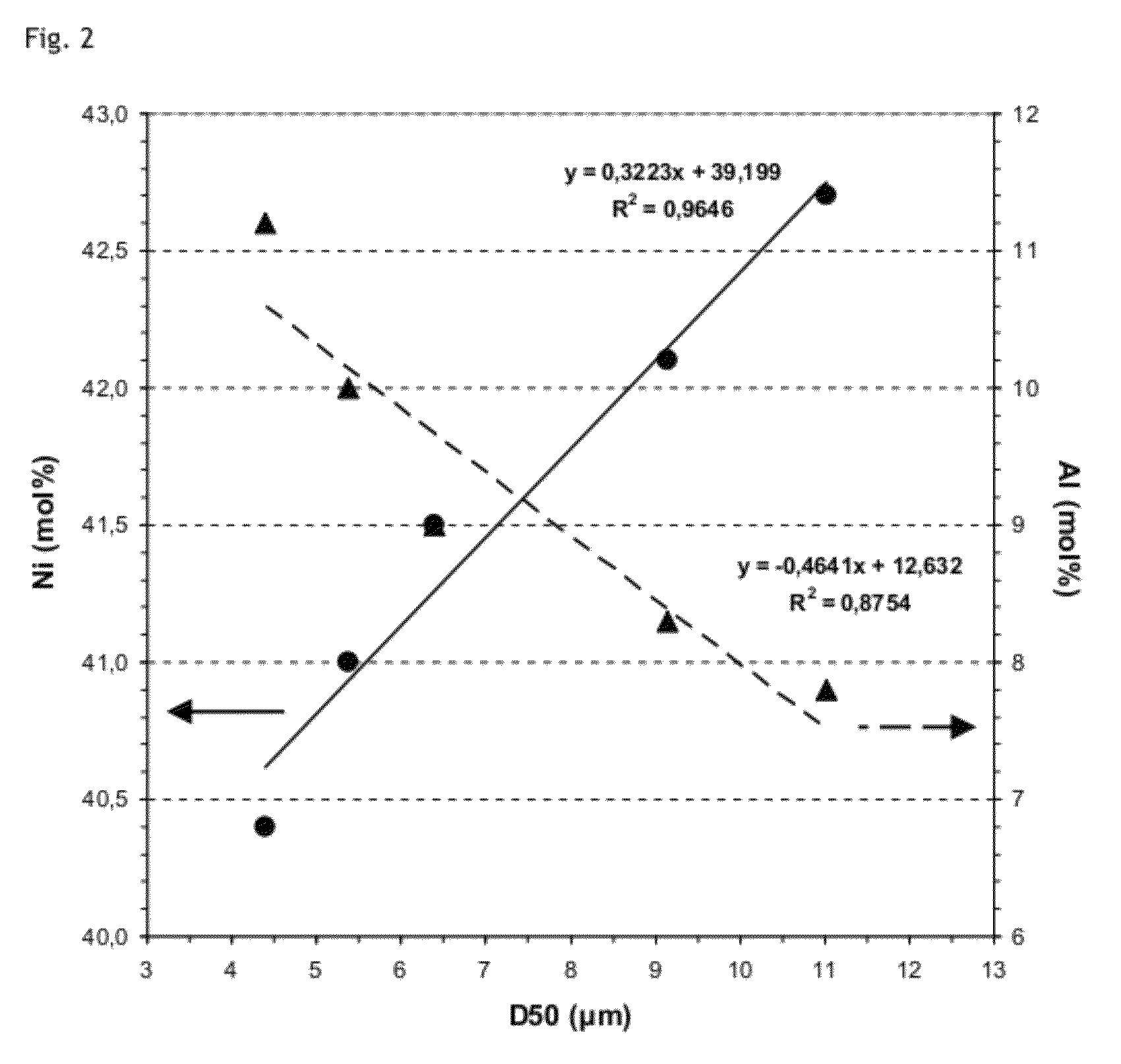

ActiveUS20120074351A1Large particle sizeIncrease contentFinal product manufactureCell electrodesRechargeable cellComposite oxide

The invention relates to a LiaNixCoyMny′M′zO2 composite oxide for use as a cathode material in a rechargeable battery, with a non-homogenous Ni / M′ ratio in the particles, allowing excellent power and safety properties when used as positive electrode material in Li battery. More particularly, in the formula 0.9<a<1.1, 0.3≦x≦0.9, 0<y≦0.4, 0<y′≦0.4, 0<z≦0.35, e<0.02, 0≦f≦0.05 and 0.9<(x+y+y′+z+f)<1.1;M′ consists of either one or more elements from the group Al, Mg, Ti, Cr, V, Fe, Mn and Ga; N consists of either one or more elements from the group F, Cl, S, Zr, Ba, Y, Ca, B, Sn, Sb, Na and Zn. The powder has a particle size distribution defining a D10, D50 and D90; and the x and z parameters varying with the particles size of the powder, and is characterized in that either one or both of:x1−x2≧0.005andz2−z1≧0.005;x1 and z1 being the parameters corresponding to particles having a particle size D90; and x2 and z2 being the parameters corresponding to particles having a particle size D10.

Owner:UMICORE AG & CO KG

Positive electrode materials combining high safety and high power in a Li rechargeable battery

ActiveUS8753532B2Increased nickel contentIncrease powerFinal product manufactureNon-aqueous electrolyte accumulator electrodesRechargeable cellComposite oxide

The invention relates to a LiaNixCoyMny′M′zO2 composite oxide for use as a cathode material in a rechargeable battery, with a non-homogenous Ni / M′ ratio in the particles, allowing excellent power and safety properties when used as positive electrode material in Li battery. More particularly, in the formula 0.9<a<1.1, 0.3≦̸x≦̸0.9, 0<y≦̸0.4, 0<y′≦̸0.4, 0<z≦̸0.35, e<0.02, 0≦̸f≦̸0.05 and 0.9<(x+y+y′+z+f)<1.1; M′ consists of either one or more elements from the group Al, Mg, Ti, Cr, V, Fe, Mn and Ga; N consists of either one or more elements from the group F, Cl, S, Zr, Ba, Y, Ca, B, Sn, Sb, Na and Zn. The powder has a particle size distribution defining a D10, D50 and D90; and the x and z parameters varying with the particles size of the powder, and is characterized in that either one or both of: x1−x2≧0.005 and z2−z1≧0.005; x1 and z1 being the parameters corresponding to particles having a particle size D90; and x2 and z2 being the parameters corresponding to particles having a particle size D10.

Owner:UMICORE AG & CO KG

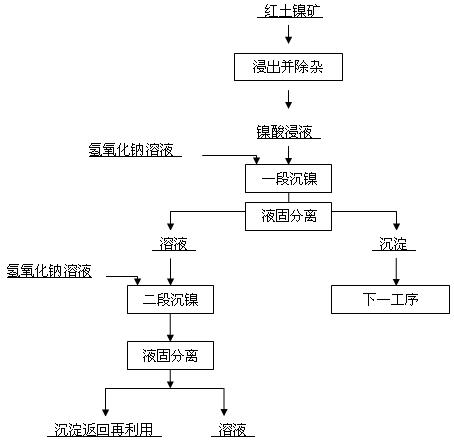

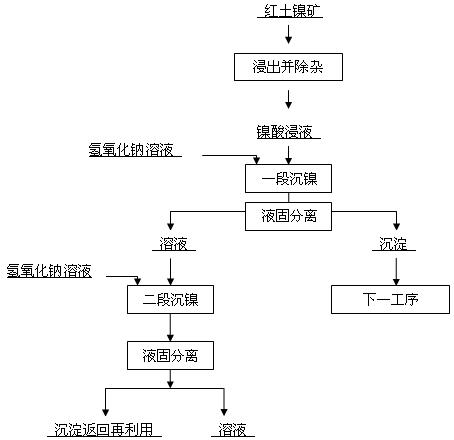

Two-stage type nickel precipitation method

InactiveCN102061387AIncreased nickel contentPrecipitate low in magnesiumProcess efficiency improvementEnvironmental chemistryNickel hydroxide (II)

The invention discloses a two-stage type nickel precipitation method. The method comprises the following steps of: (1) primary nickel precipitation: adding a NaOH solution to a nickel sulfate solution containing magnesium, regulating a pH value to be 7.5-8.5 and reacting at a temperature of 20-80 DEG C for 0.5-3 h; (2) separating precipitates obtained in the step (1) from a nickel precipitation mother liquid; (3) secondary nickel precipitation: adding a NaOH solution to the nickel precipitation mother liquid obtained in the step (2), regulating the pH value to 9-10 and reacting at a temperature of 20-80 DEG C for 0.5-3 h; (4) separating precipitates obtained in the step (3) from the nickel precipitation mother liquid and returning precipitates obtained in the step (4) by separation to a system of an agitation and leaching procedure to be cycled. Nickel hydroxide products containing more than 45% of nickel can be precipitated with the two-stage type nickel precipitation method, and the nickel precipitation rate can reach more than 99%.

Owner:广西银亿新材料有限公司

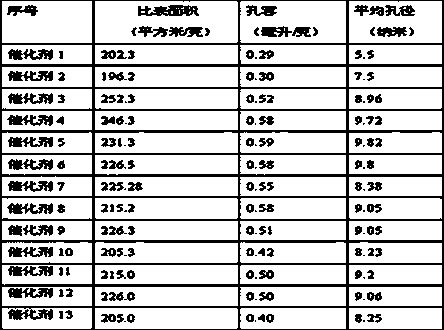

Nickel base catalyst

ActiveCN103418384AReduce nickel contentIncreased nickel contentHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsComposite oxideOxide

The present invention relates to a nickel base catalyst, wherein problems of low nickel content and low active specific surface in the prior art are mainly solved with the present invention. The technical scheme comprises that the catalyst comprises the following components, by weight: a) 20-75 parts of metal nickel, and b) 25-80 parts of a composite oxide carrier comprising 20-40 parts by weight of aluminum oxide and 5-40% by weight of silicon oxide, wherein a specific surface area of the catalyst is 150-400 m<2> / g, a pore volume is 0.3-0.8 ml / g, and an average pore size is 5-15 nm. With the technical scheme, the problems in the prior art are well solved, and the catalyst can be widely used for industrial production of hydrotreating of light oil fractions, heavy oil fractions, unsaturated greases, cracking gasoline, and especially cracking C9 and hydrocarbons with a carbon atom number of more than 9.

Owner:CHINA PETROLEUM & CHEM CORP +1

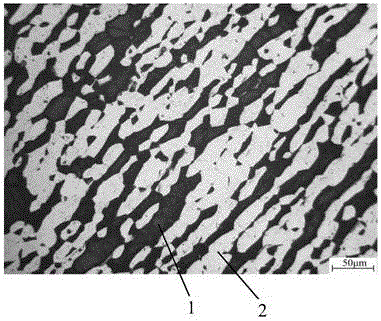

Steel for large power locomotive traction gear

This invention discloses steel, in particular to steel for large power locomotive traction gear. The steel comprises the following components in mass percent: 0.16 to 0.21 percent of carbon, 1.50 to 1.80 percent of chromium, 1.50 to 1.70 percent of nickel, less than 0.40 percent of silicon, 0.50 to 0.90 percent of manganese, less than 0.020 percent of sulfur, less than 0.020 percent of phosphor, 0.25 to 0.35 percent of molybdenum, and balance of iron, wherein hydrogen content is not more than 2 ppm; and oxygen content is not more than 20 ppm. Compared with the prior art, the steel for large power locomotive traction gear has the advantages that chemical components are adjusted, carbon content and nickel content are increased, the strength is ensured and simultaneously the plasticity is improved, sulfur content and phosphor content are adjusted simultaneously, the processing property is ensured, a novel material which has high strength and good plasticity and can be processed easily is formed, and the special requirement for the steel for large power locomotive traction gear is satisfied.

Owner:CRRC DALIAN CO LTD

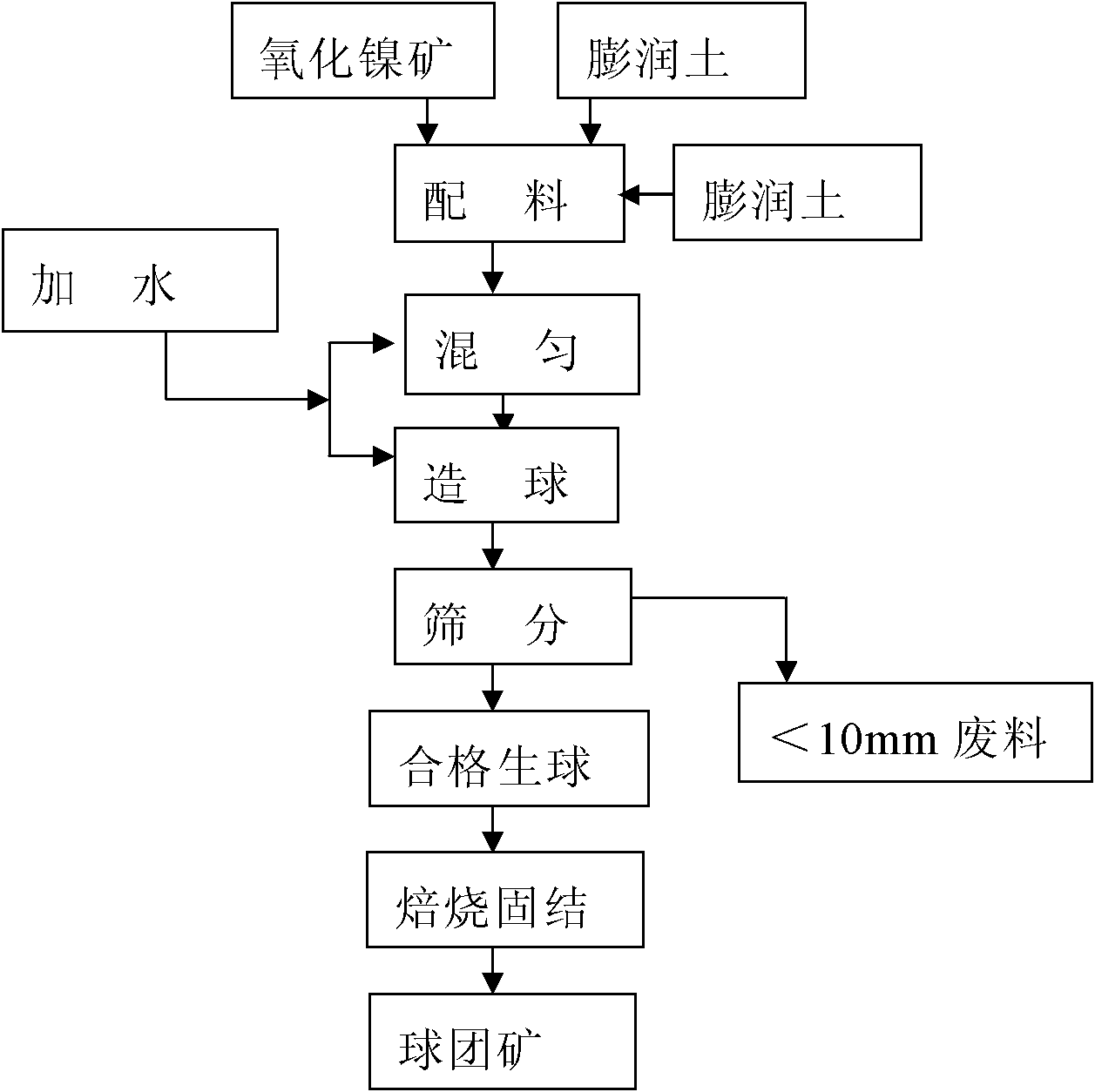

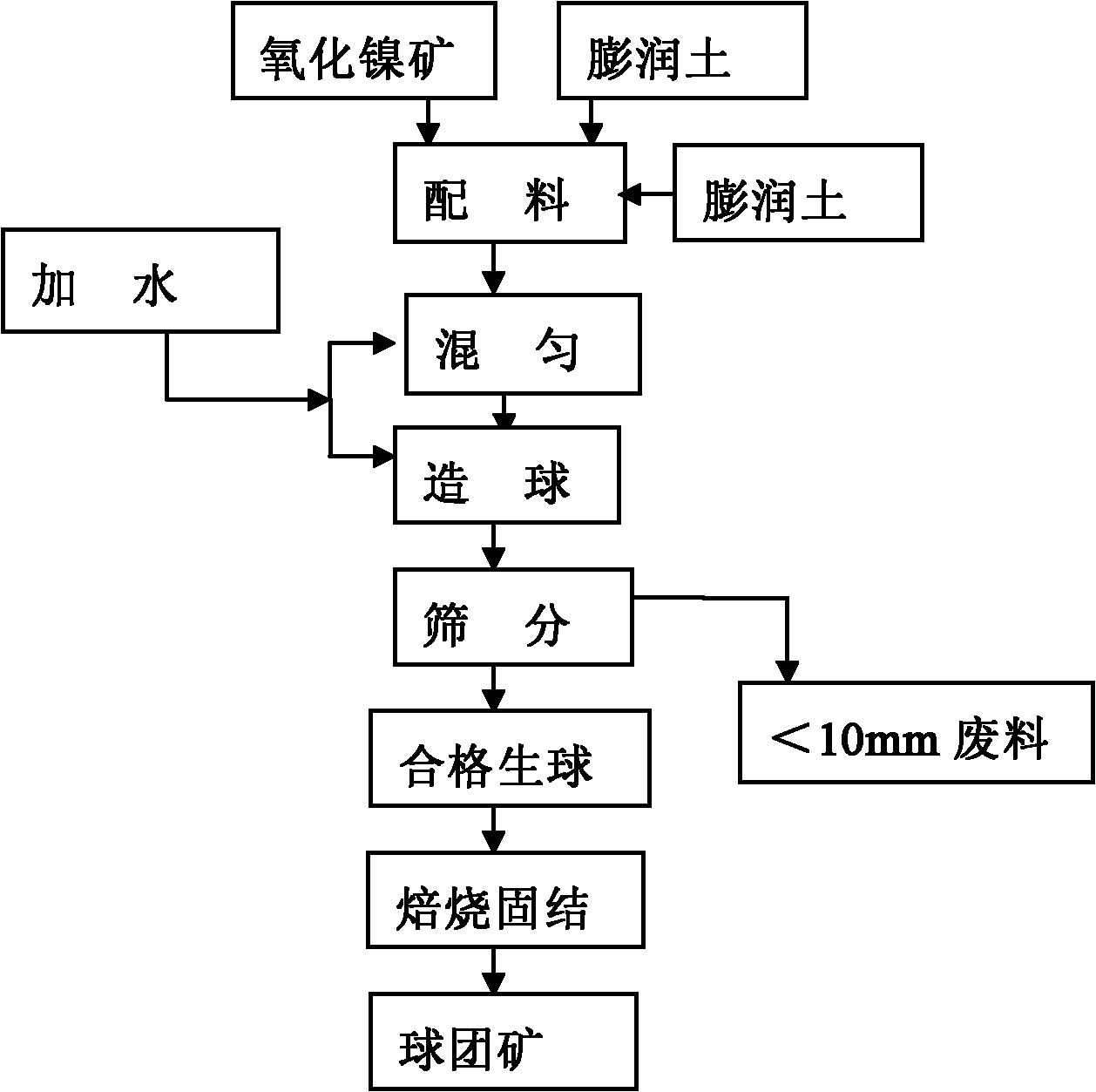

Method for producing pellets from laterite-nickel ore

The invention belongs to production techniques of ferronickel, and particularly relates to a method for producing pellets from laterite-nickel ore, which comprises the following steps: proportioning: evenly mixing 1-4 wt% of bentonite, 1-8 wt% of quicklime and the balance of nickel oxide; pelletizing: adding water to the uniform mixture until the water content reaches 10-15%, and pelletizing by using a pelletizer; screening to remove raw materials of which the particle sizes are smaller than 10mm, thereby obtaining qualified raw pellets; and roasting to solidify, and cooling to obtain the nickel pellets. In the invention, the pellets are made into alkaline ore with a certain alkalinity, and the amount of coke is reduced in the blast-furnace smelting, thereby improving the physical properties of the blast-furnace smelted ferronickel; and in the ferronickel smelting process, the coke ratio is low, the yield is high, and the content of nickel in the smelted ferronickel is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

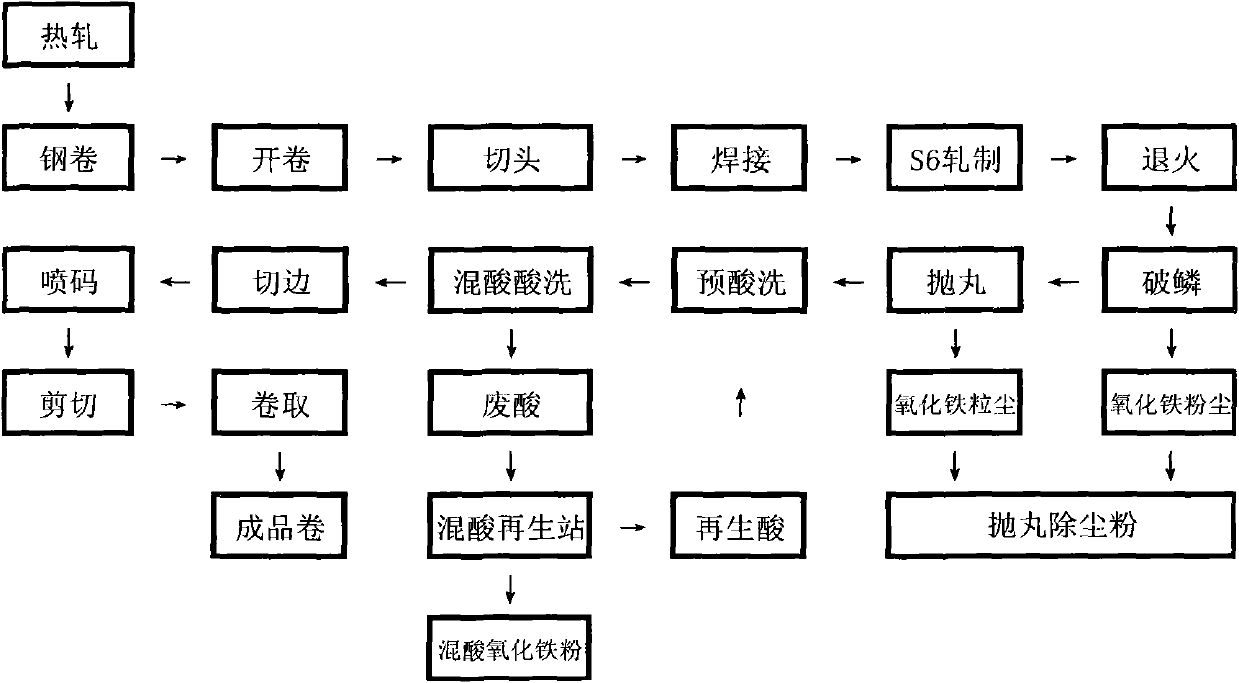

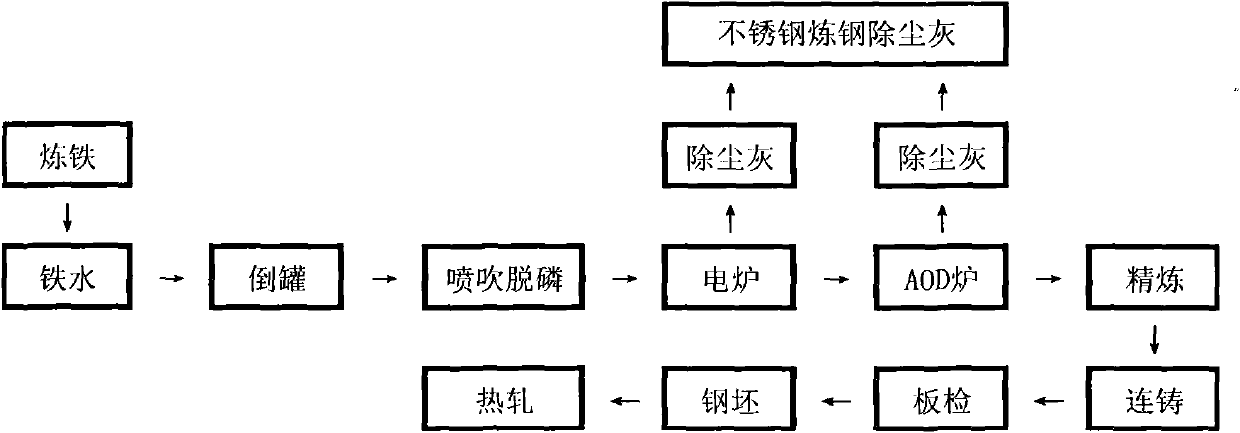

Molten iron dephosphorization agent, and dephosphorization and desilication method for molten iron

InactiveCN102199686AImprove reactive oxidizing atmosphereEmission reductionProcess efficiency improvementSteelmakingSmelting process

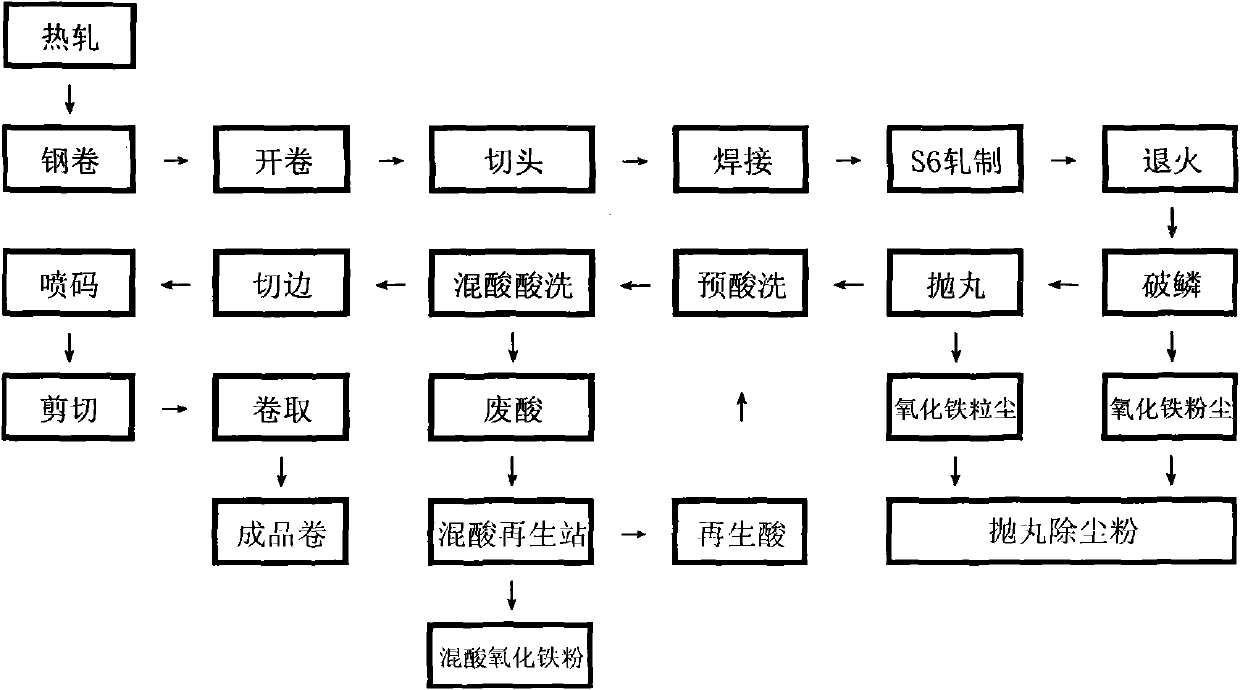

The invention discloses a molten iron dephosphorization agent, and a dephosphorization and desilication method for molten iron. The molten iron dephosphorization agent is composed of the following components in parts by weight: 20-35 parts of acid-mixed iron oxide powder, 50-60 parts of dust-removed shot-blasting powder and 14-25 parts of dust-removed stainless steel smelting ash. The molten irondephosphorization agent provided by the invention can be applied in all molten iron pretreatment processes, and has a strong dephosphorization function; simultaneously the molten iron dephosphorization agent contains solid oxides containing Cr and Ni, can slightly increase the Ni content in molten iron at a dephosphorization terminal by 5-8%, compared with original Ni content, and can reduce Ni addition amount during sequent smelting processes and lower production cost when used for smelting stainless steel; and all the raw materials for the molten iron dephosphorization agent are solid wastes containing Ni and Cr generated during stainless steel production processes of steel enterprises, and the wastes are recycled for molten iron dephosphorization, thus saving cost and reducing the emission of wastes.

Owner:BAOSHAN IRON & STEEL CO LTD

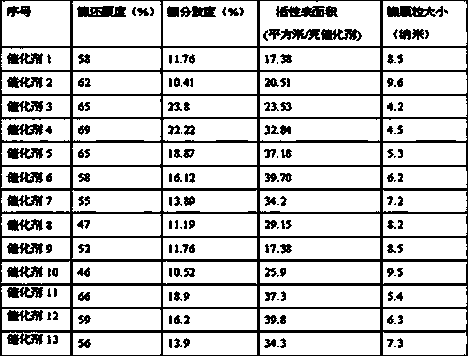

Mineral spirit platreating catalyzer and preparation method thereof

ActiveCN101172233AIncreased nickel contentGuaranteed anti-sinteringCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel oxidesGel method

The invention discloses solvent oil hydrogenation catalyst and a preparation method thereof. The preparation method of the catalyst comprises the following steps: firstly, nickel oxide and aluminium oxide (or the precursor thereof) are mixed and pinched, squeezed into strips for molding, dried and roasted to obtain a carrier, and then a metallic solution including the nickel is soaked, dried and roasted to obtain the catalyst. The amount of the nickel oxide added to the process of the mixing and pinching occupies 50 wt percent to 70wt percent of the total content of the nickel oxide, and the nickel oxide is made through roasting the nickel carbonate obtained by sol through the gel method. The preparation method of the invention has only one mixing and pinching step and one soaking step, therefore, the process is simple, the material loss is less, and the cost is reduced; and the prepared catalyst has high hydrogenation activity, good anti-sintering performance and high operation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

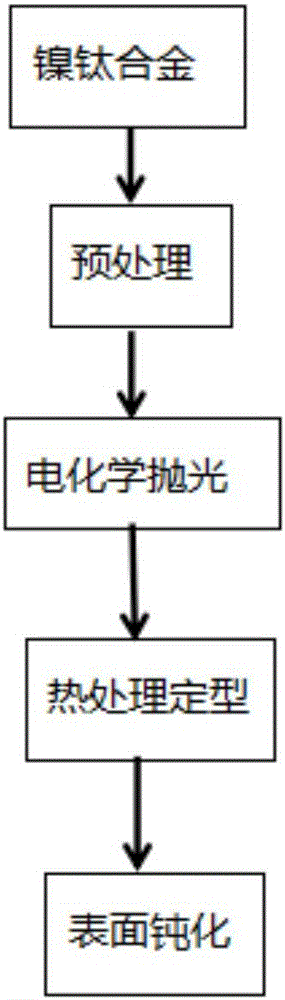

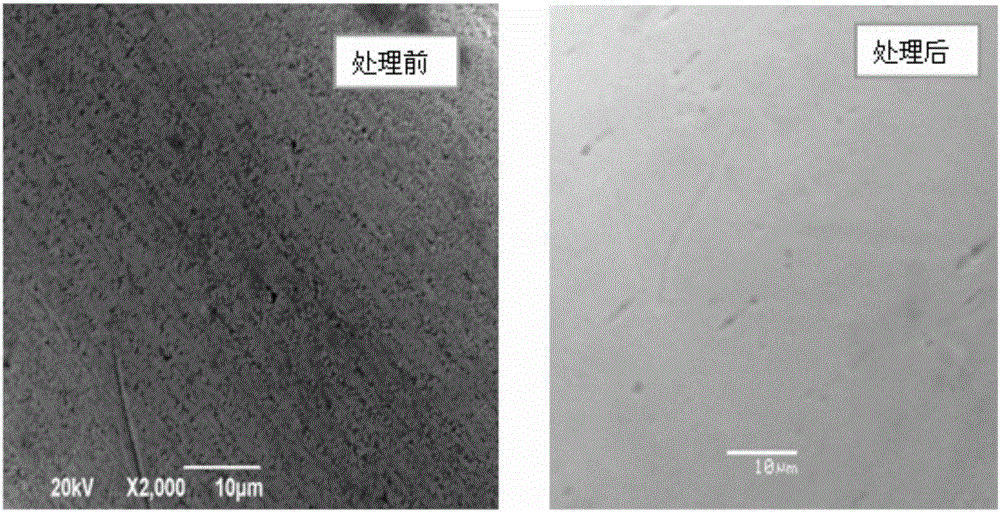

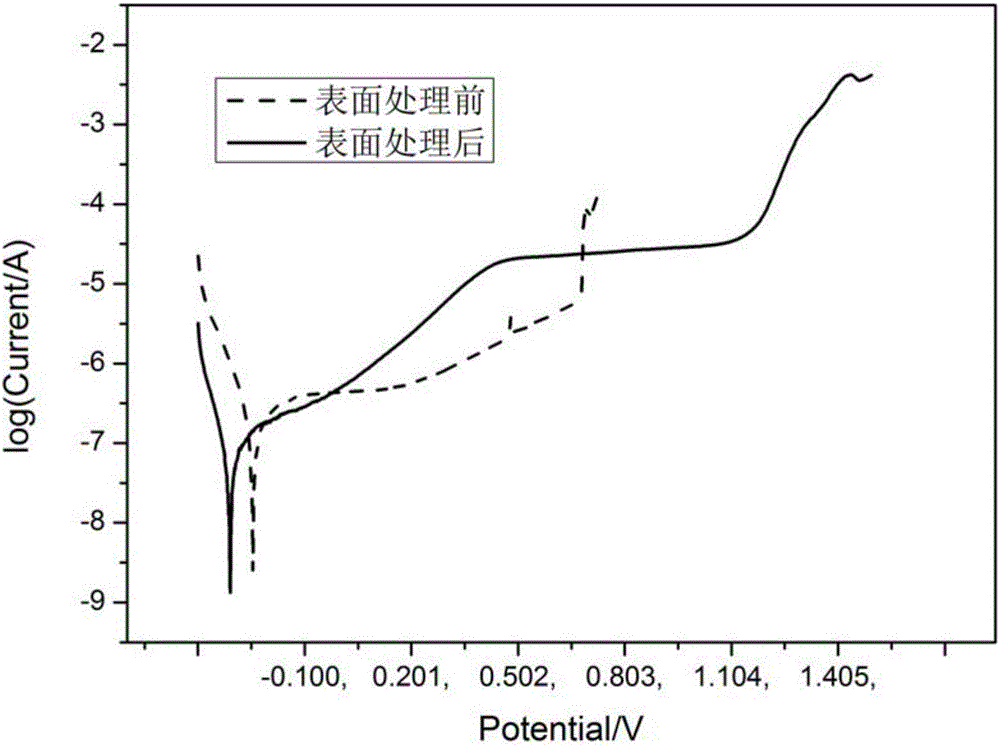

Surface treatment method for material nickel-titanium alloy for left aurcle plugging device

InactiveCN106811753AReduce surface roughnessEasy to useSurgeryPharmaceutical delivery mechanismTitaniumPre treatment

The invention discloses a method for surface treatment of a nickel-titanium alloy, a material used for a left atrial appendage occlusion device, and belongs to the technical field of medical metal surface treatment; the invention relates to a method for surface treatment of a biomedical nickel-titanium alloy, comprising the following steps and process conditions: (1) Substrate pretreatment; (2) Electrochemical polishing; (3) Product heat treatment setting; (4) Surface passivation process. Compared with the prior art, the process can significantly improve the surface treatment quality, improve the corrosion resistance of the nickel-titanium plug, and can expand the scope of the process treatment, especially suitable for the surface treatment of small pieces and complex-structured nickel-titanium products, with low cost and low cost. Simple and convenient for factory production and use of nickel-titanium products.

Owner:XIANGTAN UNIV

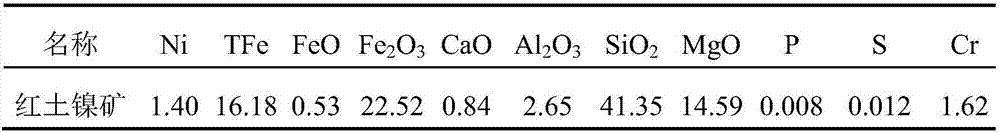

Method for improving laterite-nickel ore carbothermic reduction selectivity

The invention discloses a method for improving laterite-nickel ore carbothermic reduction selectivity. A sulfur-containing assistant is added in laterite-nickel ore and the mixture is subjected to carbothermic reduction-sorting process so that a nickel-iron product is obtained. Through action of the sulfur-containing assistant, based on an appropriate carbothermic reduction process, nickel oxide in the laterite-nickel ore is reduced into metallic nickel, iron oxide is reduced into metallic iron and other parts are bonded to sulfur in the assistant so that ferrous sulfide is obtained. The method realizes nickel and iron selective reduction / sulfuration in laterite-nickel ore carbothermic reduction, greatly improves a nickel grade of the reduced product nickel-iron, produces a high-quality nickel-iron product, satisfies requirements on stainless steel smelting raw materials, has the characteristics of strong raw material adaptability, simple processes, good product quality, low treatment cost and good nickel recovery effects, and provides a novel direction for future high-efficiency and low-cost treatment on laterite-nickel ore.

Owner:CENT SOUTH UNIV

Molten iron desiliconizing reagent and molten iron desiliconizing method

InactiveCN102199685AImprove reactive oxidizing atmosphereEmission reductionSteelmakingSmelting process

The invention discloses a molten iron desiliconizing reagent and a molten iron desiliconizing method. The molten iron desiliconizing reagent comprises the following components in part by weight: 10 to 20 parts of mixed acid ferric oxide powder, 15 to 25 parts of shot blasting dedusting powder, 10 to 20 parts of stainless steel making dedusting ash and 40 to 60 parts of hot rolling ferric oxide scale. The molten iron desiliconizing reagent can be used all molten iron pretreatment processes and has high desiliconizing capacity; meanwhile, chrome- and nickel-containing solid oxides are used in the formula, the nickel content in the molten iron at the end of desiliconization is slightly improved by 5 to 8 percent on the basis of the original nickel content, so that for smelting stainless steel, the added amount of nickel during smelting in a subsequence process can be reduced correspondingly and the production cost can be lowered; and all raw materials in the formula are from chrome- and nickel-containing solid waste from production in stainless steel production processes of stainless steel enterprises, and by recovering and processing the waste and using the processed product for molten iron desiliconizing, cost is saved and the discharge of the waste is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

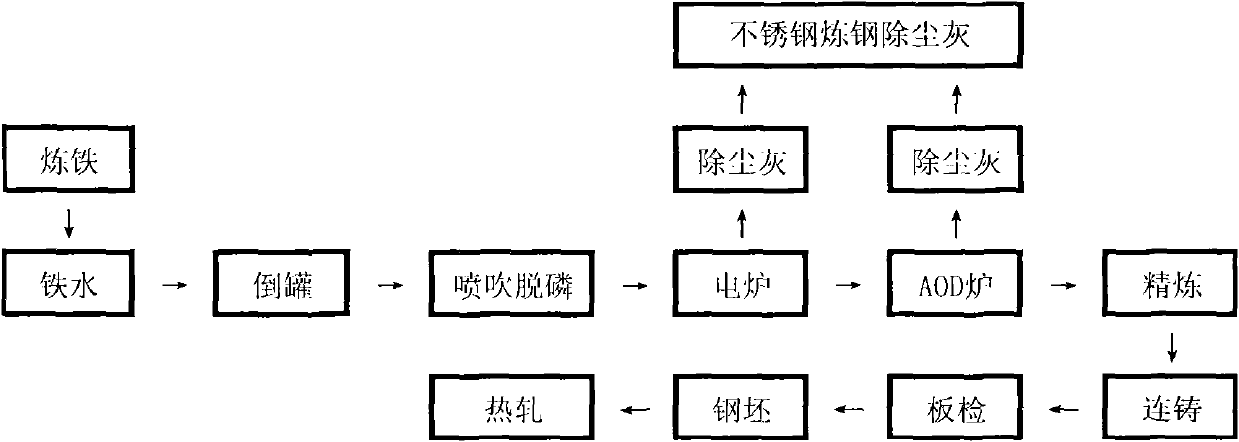

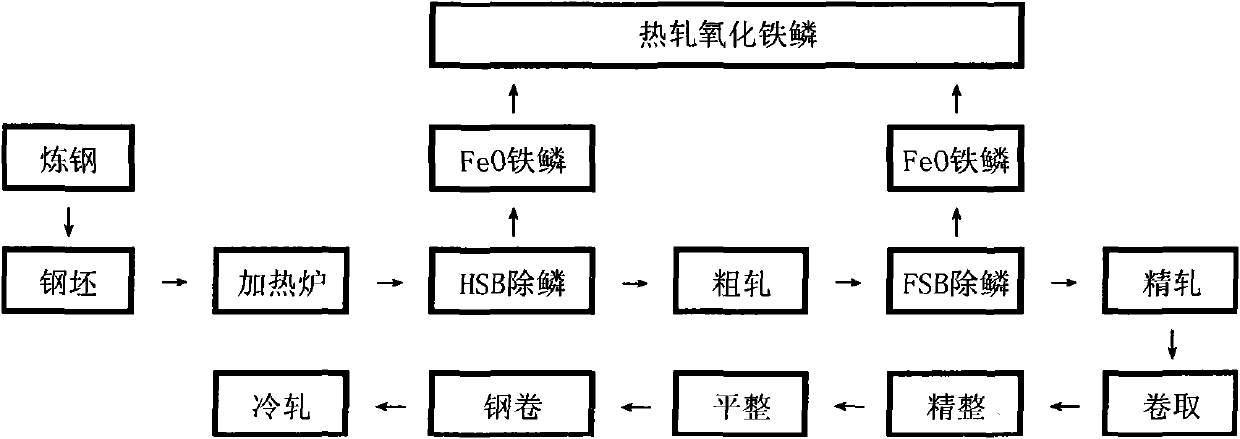

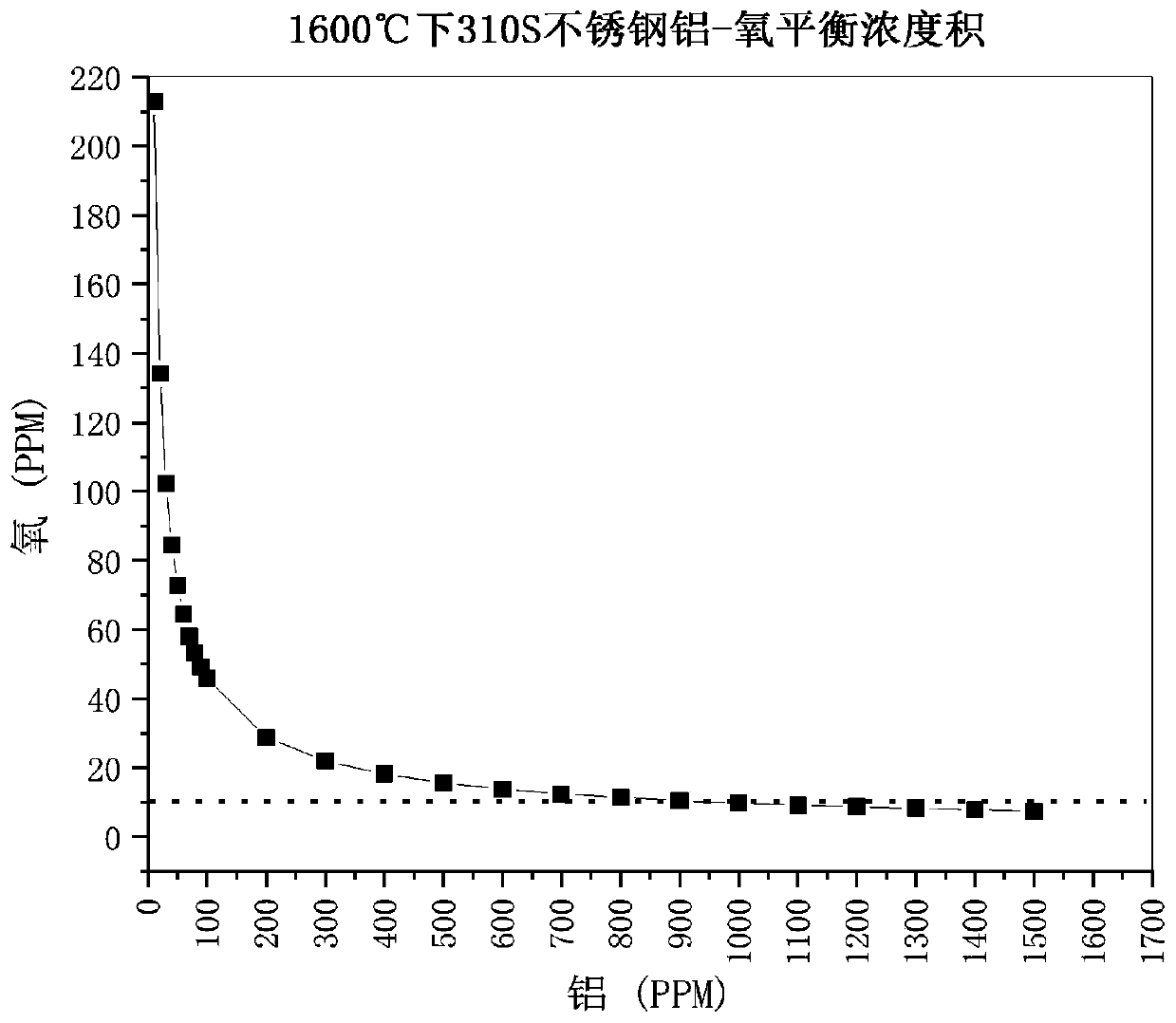

Preparation method of 310S stainless steel and 310S stainless steel

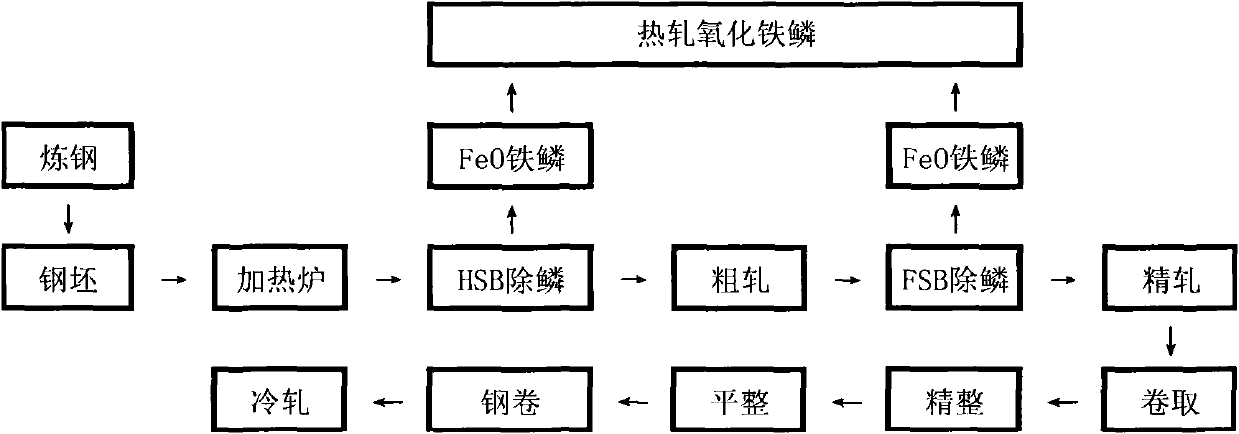

ActiveCN110669986AReduce oxygen contentImprove product surface qualityFurnace typesProcess efficiency improvementMill scaleMaterials science

The invention discloses a preparation method of 310S stainless steel and the 310S stainless steel. The 310S stainless steel is prepared from the following components in percent by mass: 0.03-0.06% ofC, 0.40-0.70% of Si, 1.30-1.60% of Mn, less than or equal to 0.025% of P, less than or equal to 0.0010% of S, 25.30-25.90% of Cr, 19.00-19.80% of Ni, 0-0.5% of Mo, 0.02-0.05% of N, 0-0.5% of Cu, 0-0.1200% of Al and the balance Fe. The preparation method comprises the following steps: smelting; continuous casting; hot rolling; annealing and pickling. The preparation method has the beneficial effects that the oxygen content of plain steel is reduced effectively by controlling the oxygen content precisely, so that the surface quality of a product is enhanced; surface scales are easy to clean, andthe 310S stainless steel has excellent heat resistance and is suitable for a severe high-temperature environment.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Nickel-containing industrial wastewater treatment device and process

InactiveCN107759006AProlong settling timeEasy to handleTreatment using aerobic processesWater contaminantsConstructed wetlandElectroless nickel

The invention discloses a device and a process for treating nickel-containing industrial wastewater. The device comprises a set of combined reactors, chemical nickel wastewater and electronickelling wastewater are respectively treated with a chemical precipitation method, the precipitation time is prolonged, and the natural precipitation and water discharge is realized. Ammonia nitrogen is treatedby an ammonia nitrogen blowing and lifting device, and finally, the COD (chemical oxygen demand) is efficiently treated in a classified manner with an anaerobic-aerobiotic-artificial wetland system combination method. The actual nickel-containing industrial wastewater is inflow water, nickel is removed and recovered in the form of a chemical precipitate by controlling the material addition amountand the reaction time, meanwhile, the COD and the ammonia nitrogen are efficiently removed with a physical-biological combination method, and finally, effluent reaches the national discharge standard. On the basis that the wastewater is effectively treated, the recovery of the nickel is improved, and the device and the process have the advantages of simple process method, low operating cost and the like.

Owner:HUNAN UNIV

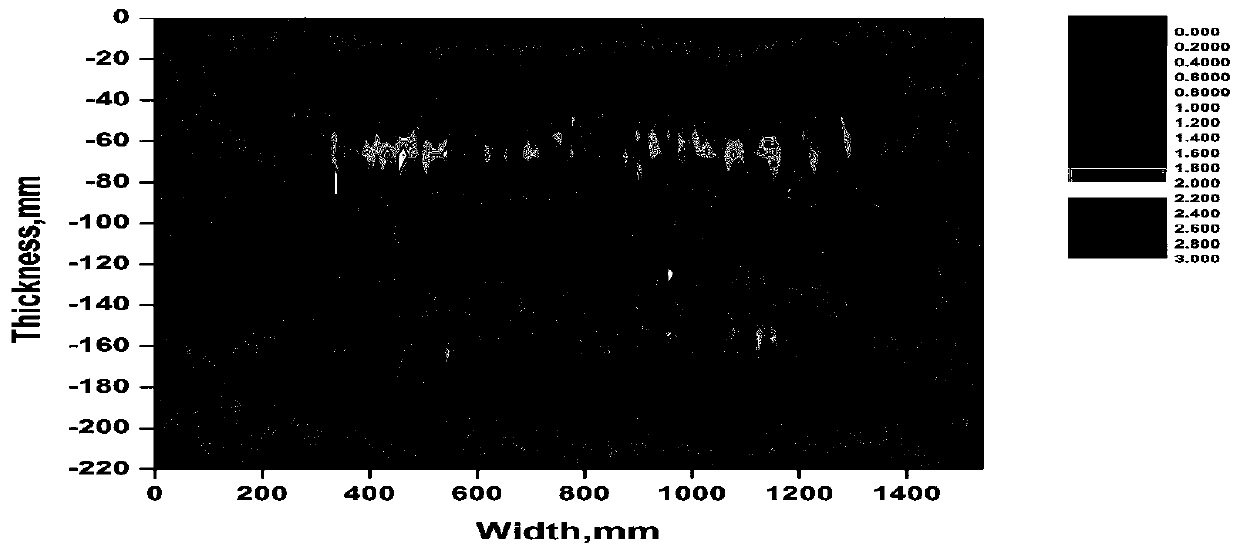

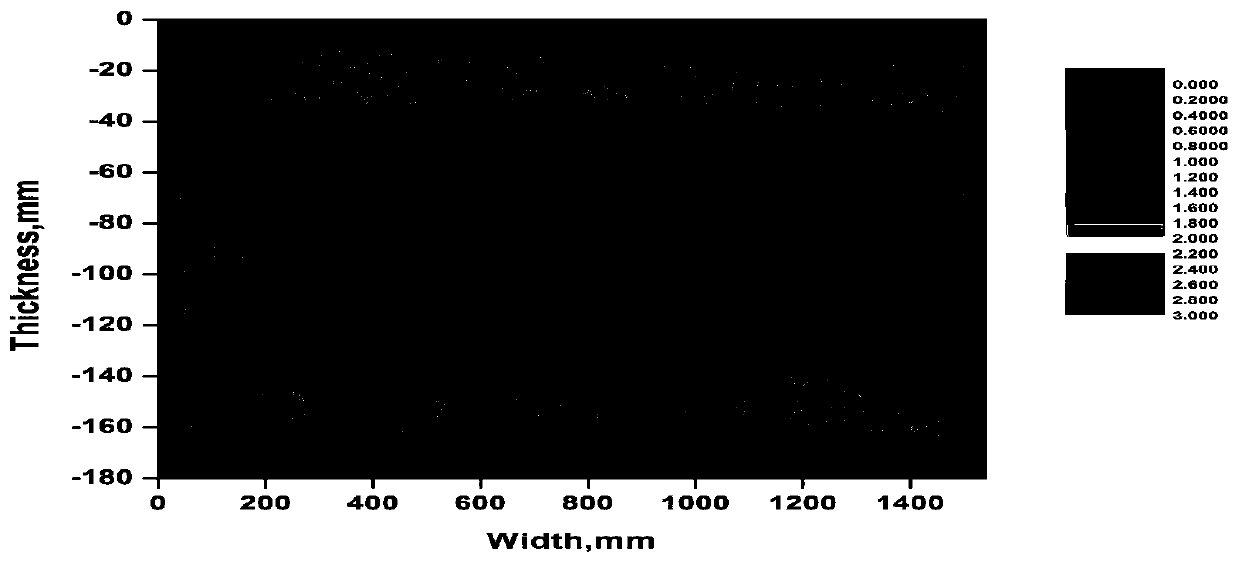

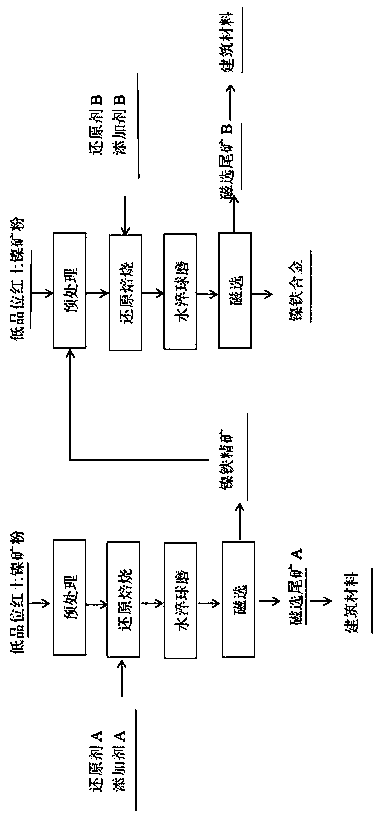

Method for preparing ferronickel alloy utilizing low-grade laterite nickel ore

The invention discloses a method for preparing ferronickel alloy utilizing low-grade laterite nickel ore and belongs to the technical field of laterite nickel ore resource utilization. The method comprises the steps that the low-grade laterite nickel ore is dried and crushed till the low-grade laterite nickel ore with the particle size being -0.074 mm accounts for 75% or above, and low-grade laterite nickel ore powder is obtained after screening; the low-grade laterite nickel ore powder, a reducing agent A and an annexing agent A are mixed evenly to be prepared into a pellet A, under the condition of the temperature being 1150-1300 DEG C, the pellet A is subjected to high-temperature reduction roasting to obtain roasted ore, the roasted ore is subjected to water quenching ball milling to obtain ore pulp A, and the ore pulp A is placed in the condition of the magnetic field strength being 120-180 mT to be subjected to magnetic separation to obtain magnetic separation tail ore A and ferronickel concentrate; and the ferronickel concentrate is added in the low-grade laterite nickel ore powder to be mixed evenly, then a reducing agent B and an annexing agent B are added in to be mixed evenly and prepared into a pellet B, under the condition of the temperature being 1150-1300 DEG C, the pellet B is subjected to high-temperature reduction roasting to obtain the roasted ore, the roasted ore is subjected to water quenching ball milling to obtain ore pulp B, and the ore pulp B is placed in the condition of the magnetic field strength being 120-180 mT to be subjected to magnetic separation to obtain magnetic separation tail ore B and the ferronickel alloy.

Owner:KUNMING UNIV OF SCI & TECH

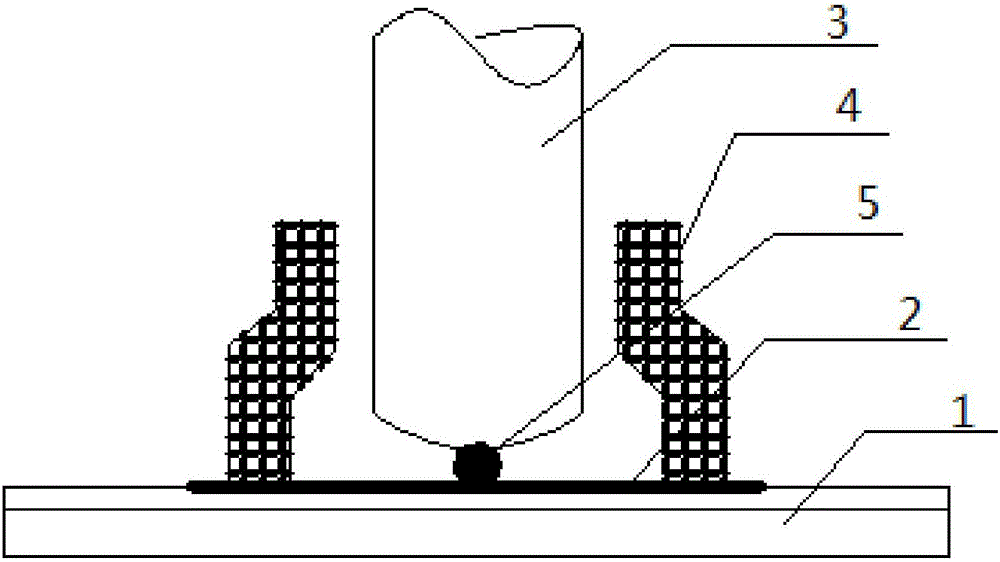

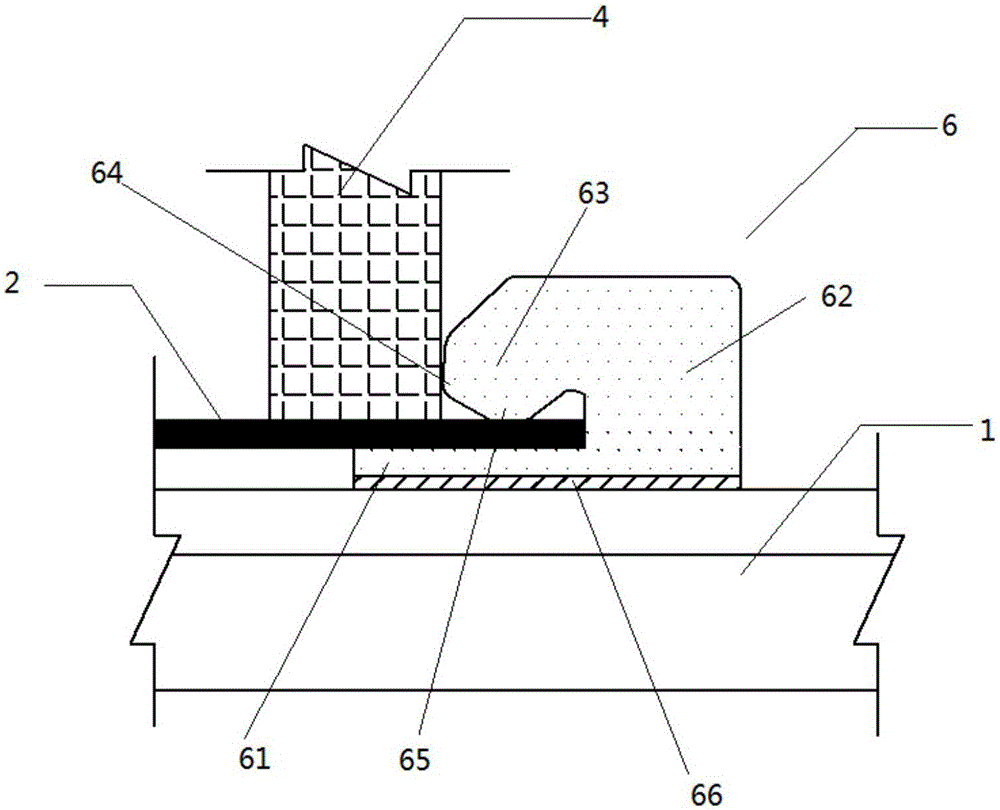

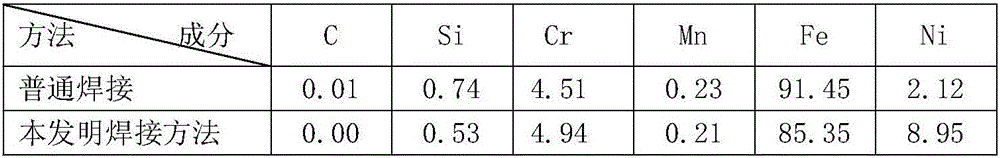

Method capable of improving corrosion resistance of stainless steel composite plate welded through carbon steel stud welding

ActiveCN106112226AImprove corrosion resistanceIncreased nickel contentArc welding apparatusStud weldingComposite plate

The invention discloses a method capable of improving corrosion resistance of a stainless steel composite plate welded through carbon steel stud welding. The method comprises following steps: firstly, a nickel strip (2) with the nickel content larger than 99% is placed on a stainless steel composite plate base material (1); secondly, a welding nail (3) is placed in a clamping device of a welding gun, protection ceramic rings (4) are placed on the stainless steel composite plate base material (1) laid with the nickel strip (2), and the welding nail (3) is inserted into the protection ceramic rings (4) and makes contact with the nickel strip (2); thirdly, a power switch is pressed, the welding nail (3) is automatically lifted, an electric arc is excited, the end of the welding nail (3) and the local surface of the stainless steel composite plate base material (1) are molten, and after the set time reaches, the welding nail (3) is automatically pressed into the stainless steel composite plate base material (1); and after a welding line is cooled, the protection ceramic rings (4) are broken to pieces and cleared way, and welding is completed. According to the method, corrosion resistance and tensile strength of a welding joint are improved, and welding safety is improved.

Owner:山东济钢鲍德金属复合板科技有限公司

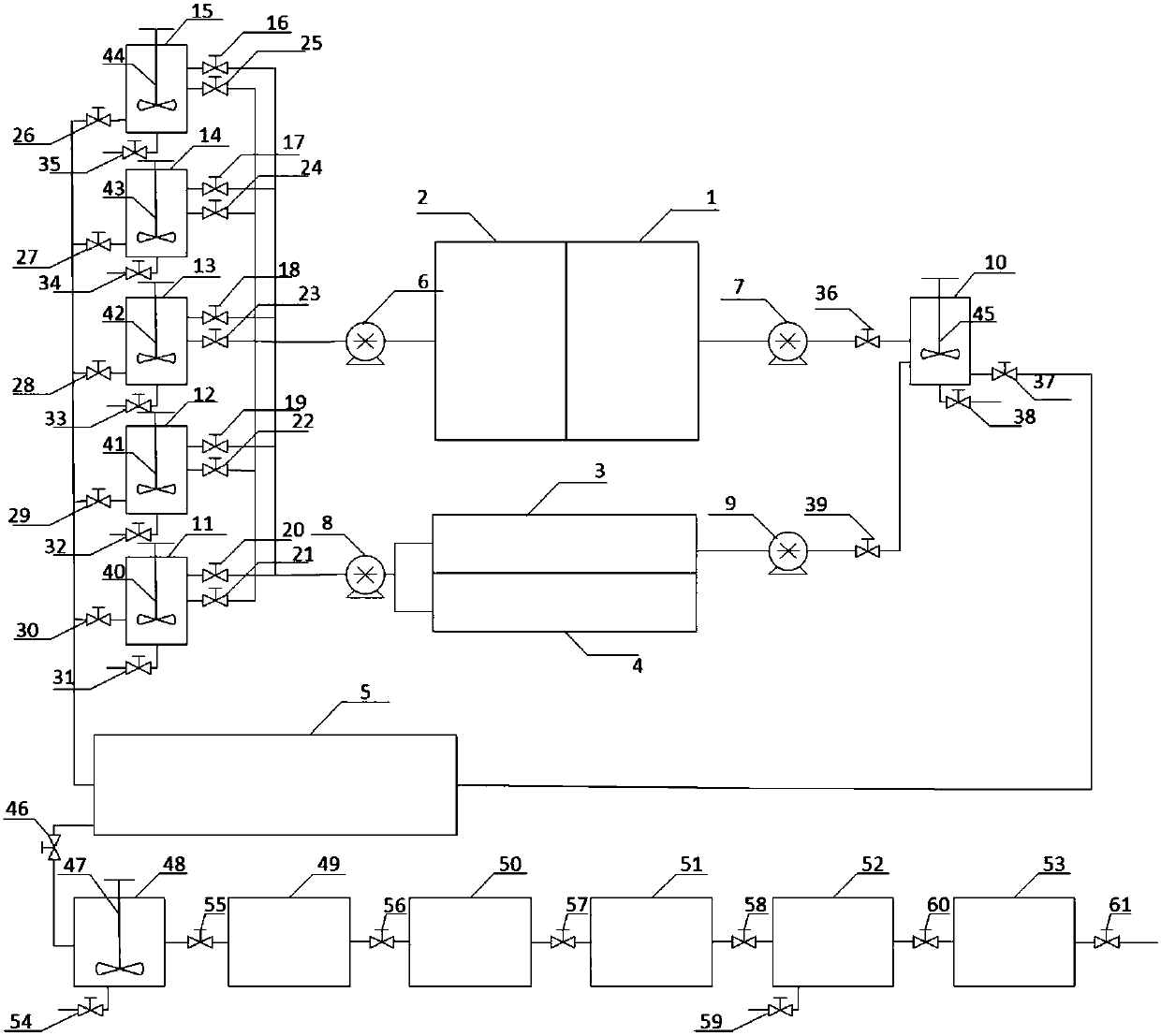

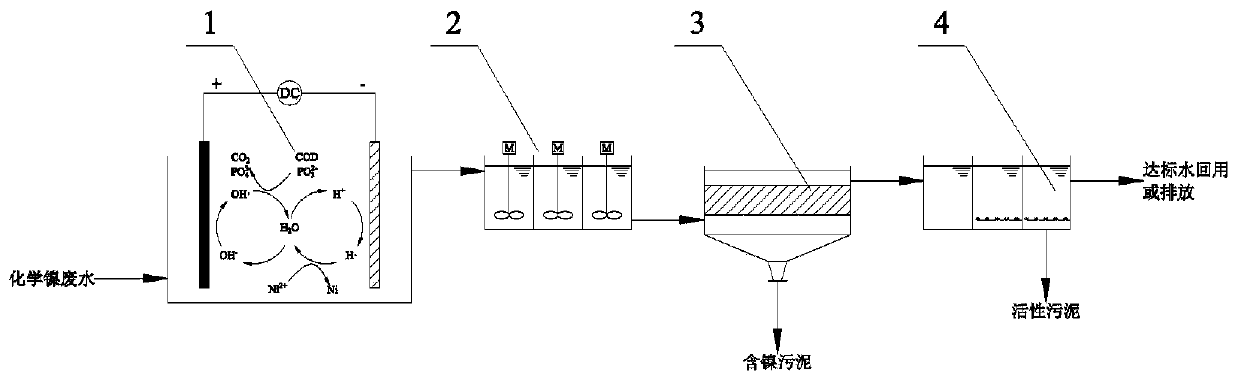

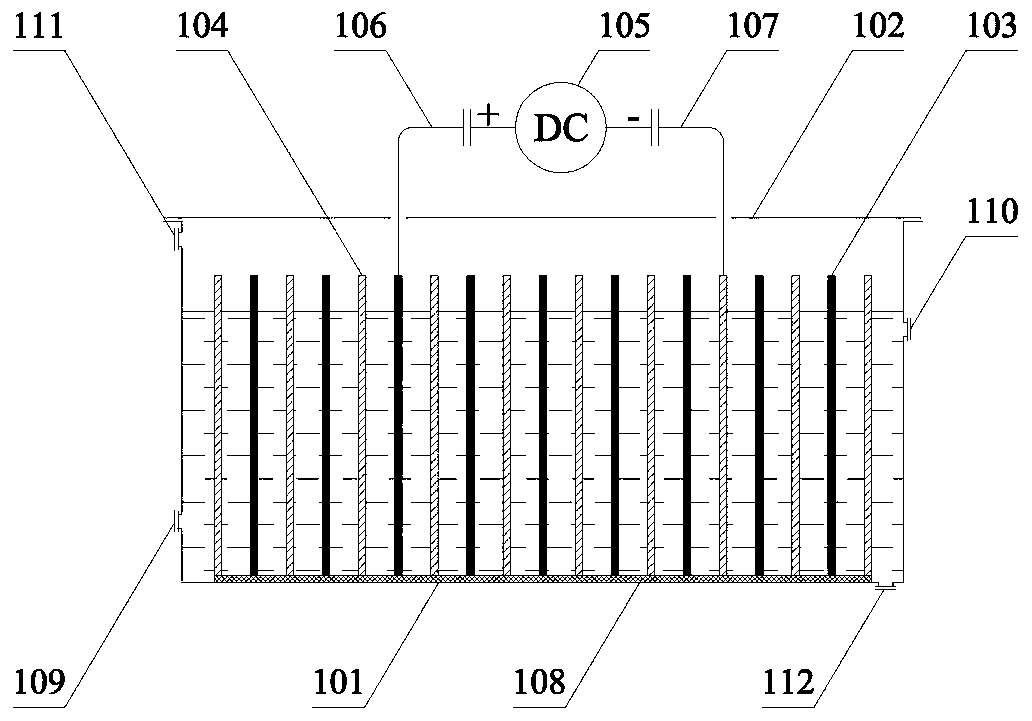

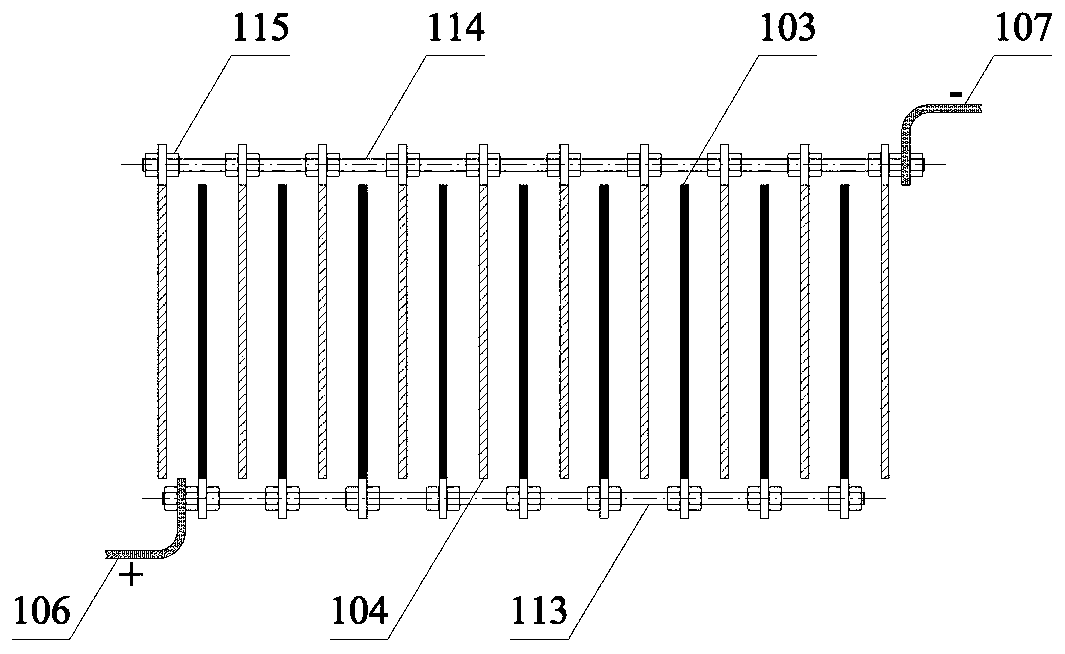

Method and system for carrying out electrocatalytic oxidation treatment on chemical nickel wastewater

PendingCN109809652AMild reaction conditionsReduce dependenceWaste water treatment from metallurgical processMultistage water/sewage treatmentChemistryCarbon dioxide

The invention discloses a technology for carrying out electrocatalytic oxidation treatment on chemical nickel wastewater. The technology is characterized by taking an inactive metal oxide compound electrode as an electrode, forming intermediate products such as hydroxyl radicals with strong oxidizing properties through catalysis under the action of an electric field, enabling the intermediate products to react with an inorganic or organic ligand of nickel, and oxidizing the inorganic or organic ligand into micromolecules such as carbon dioxide and water or oxidizing the inorganic or organic ligand into orthophosphate radicals, thus achieving the purpose of 'decomplexation'. The technology disclosed by the invention has the characteristics that an oxidizing agent requires not to be added, reaction conditions are gentle, the decomplexation effect is good, the running cost is low, the system is simple, stable and reliable, the automation degree is high, and the like.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

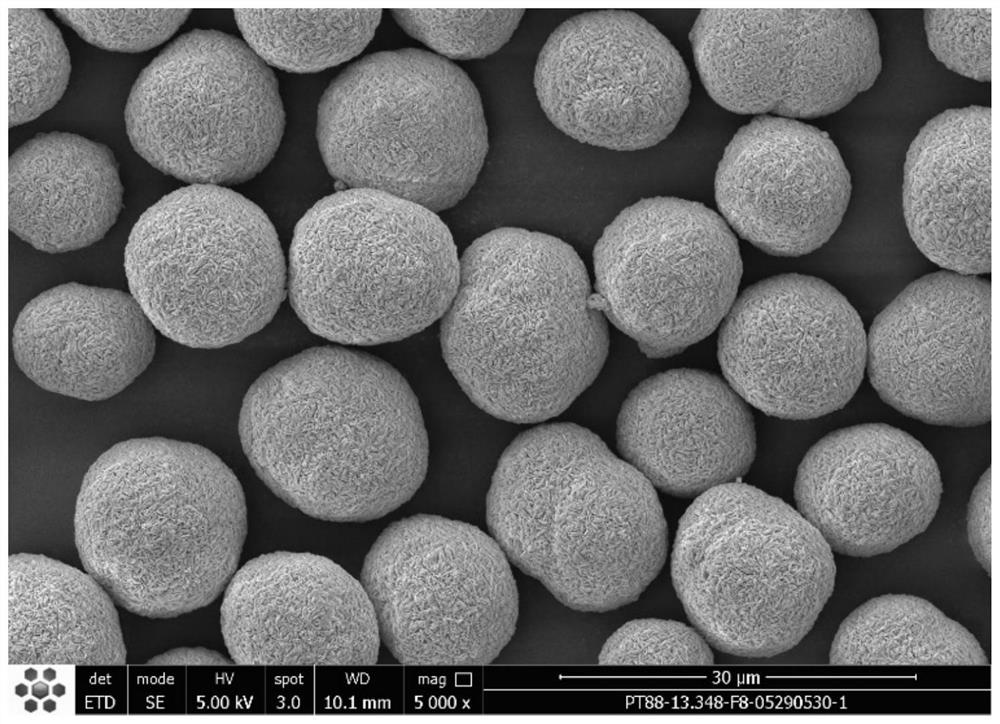

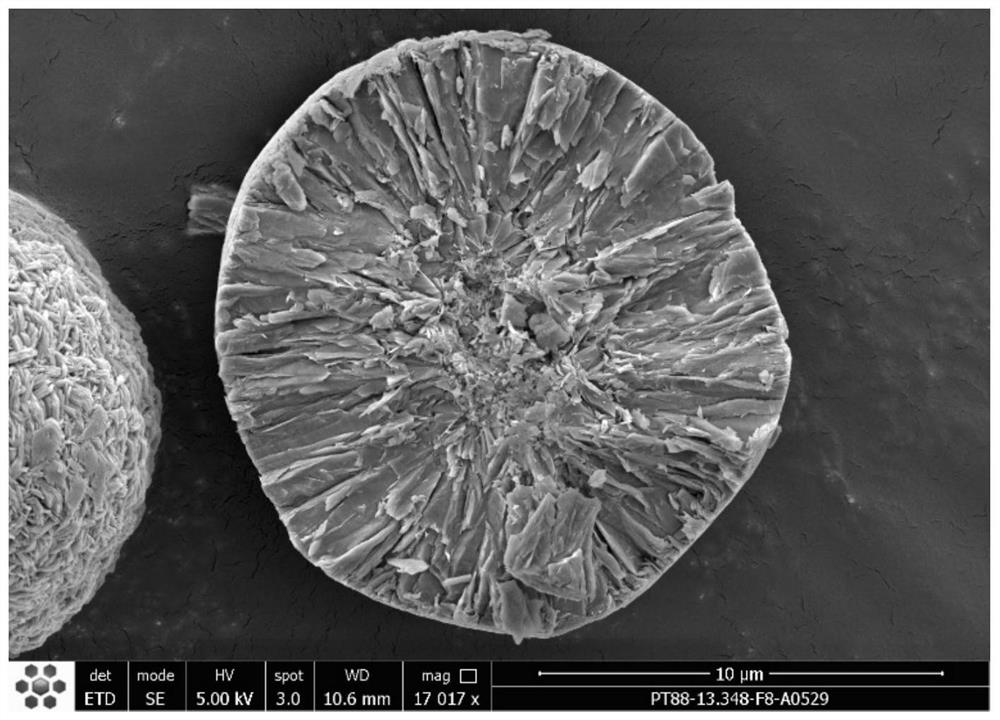

Multi-layer aluminum-doped nickel-cobalt-manganese precursor and preparation method thereof

PendingCN113603159AImprove thermal stabilityImprove structural stabilityNickel compoundsPhysical chemistrySodium aluminate

The invention provides a multi-layer aluminum-doped nickel-cobalt-manganese precursor which is of a core-shell structure, an aluminum-undoped nickel-cobalt-manganese hydroxide serves as an inner core, the surface of the inner core is sequentially coated with an aluminum-doped nickel-cobalt-manganese hydroxide layer and an aluminum-undoped nickel-cobalt-manganese hydroxide layer which are of an alternating structure, and the aluminum-doped nickel-cobalt-manganese hydroxide layer is arranged on the outermost layer of the nickel-cobalt-manganese precursor. The preparation method comprises the following steps: adding ammonia water as a reaction base solution into a reaction kettle, introducing nitrogen, starting stirring, adding a metal salt mixed solution, a precipitator and a complexing agent into the reaction kettle in a parallel flow manner, and reacting until the particle size of generated particles reaches the particle size of the inner core; introducing a sodium metaaluminate solution, and generating the aluminum-doped nickel-cobalt-manganese hydroxide layer on the surface of the inner core; stopping introducing the sodium metaaluminate solution, and generating the aluminum-undoped nickel-cobalt-manganese hydroxide layer on the surface of the aluminum-doped nickel-cobalt-manganese hydroxide layer; and repeating the steps until the multi-layer aluminum-doped nickel-cobalt-manganese precursor with the designed structure is generated. The nickel-cobalt-manganese precursor has relatively good thermal stability and structural stability.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

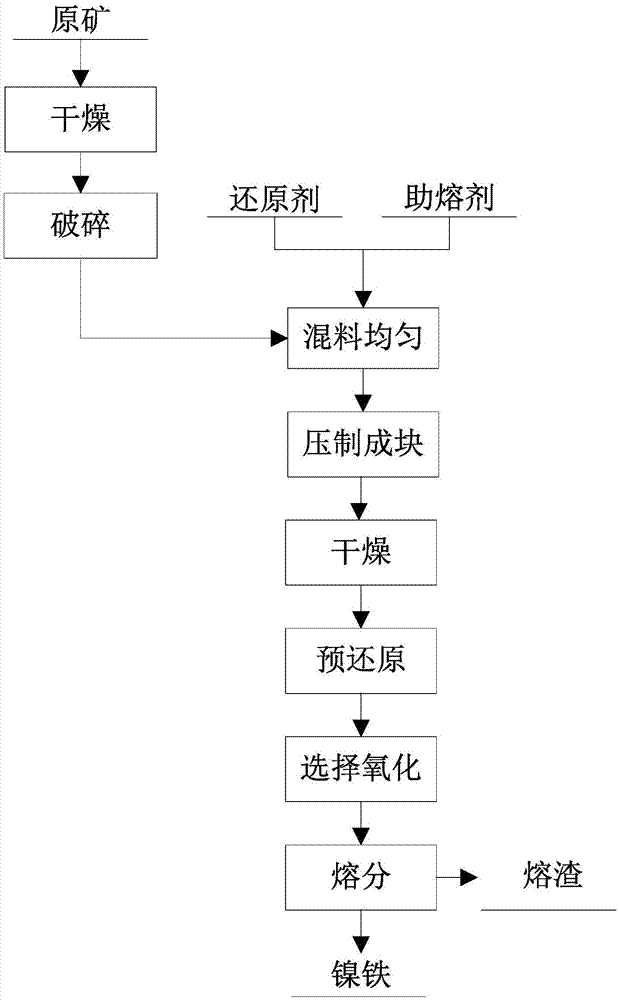

Method for preparing ferronickel by enriching nickel in laterite-nickel ore

ActiveCN107574278ABreak through habitual thinkingAvoid pollutionFluidised-bed furnacesMixed materialsOperability

The invention discloses a method for preparing ferronickel by enriching nickel in laterite-nickel ore. The method comprises the following steps that 1, crushed laterite-nickel ore powder is uniformlymixed with a reducing agent and a fluxing agent, and the mixed materials are pressed into blocks; and 2, heating and pre-reducing in a high-temperature kiln, selective oxidation and melting separationare carried out sequentially to obtain the ferronickel with high content of nickel. According to the method, selective oxidation of iron and nickel in a pre-reduced product is realized, the content of nickel in the ferronickel can be greatly improved, meanwhile, the high recovery rate of nickel is realized, and the obtained high-quality ferronickel is beneficial to smelting of stainless steel. The method has the advantages of being high in raw material adaptability, simple in technological process, high in operability, high in product quality, good in recovery effect of nickel, low in energyconsumption, low in processing cost, and capable of providing a new direction for the enrichment of nickel in the laterite-nickel ore.

Owner:WUHAN UNIV OF SCI & TECH

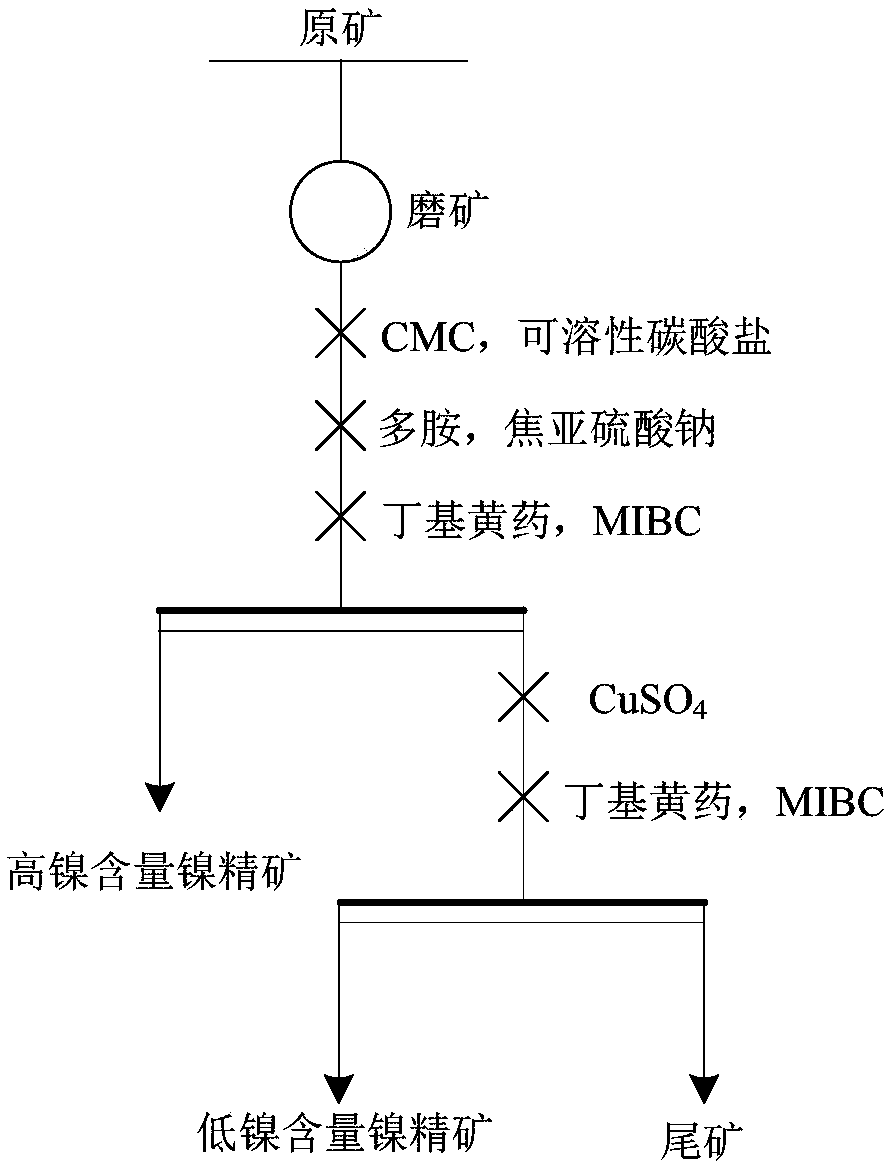

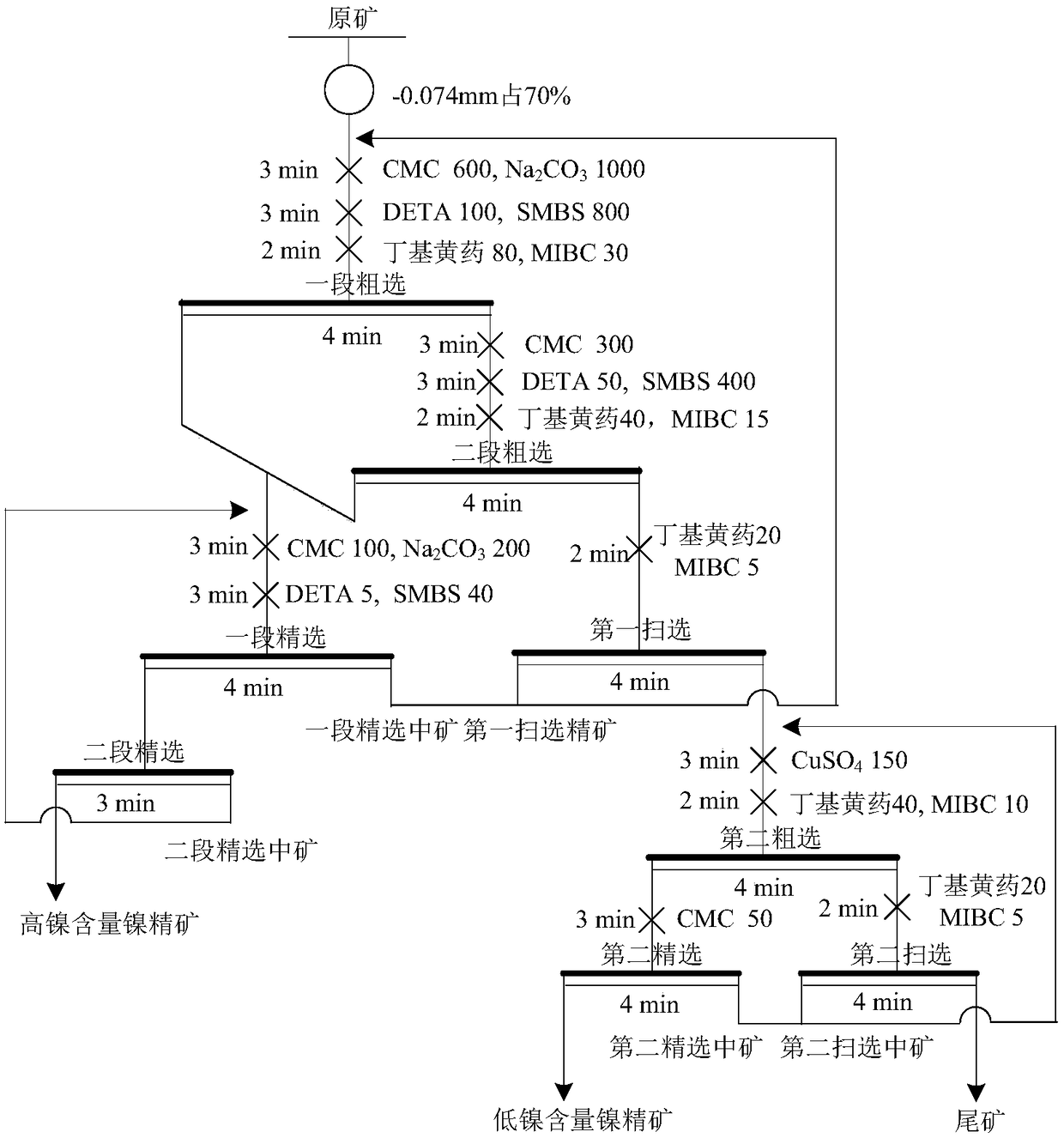

Pyrrhotite flotation depressant and application thereof

InactiveCN109107772AIncreased nickel contentReduce nickel contentFlotationCarboxymethyl celluloseSodium metabisulfite

The invention provides a pyrrhotite flotation depressant. The pyrrhotite flotation depressant comprises sodium carboxymethyl cellulose, soluble carbonate, sodium metabisulfite and polyamine. The invention further provides an ore separating method using the flotation depressant. The depressant can effectively depress gangue minerals and pyrrhotite, so that high-nickel-content nickel concentrates can be separated. According to the ore separating method, the gangue minerals and the pyrrhotite are depressed through the depressant, high-nickel-content products, such as pentlandite, in ores are first separated through flotation, and accordingly, the high-nickel-content nickel concentrates are obtained. Then, copper sulphate is added for activation, and the depressed pyrrhotite is recycled, so that low-nickel-content nickel concentrates are obtained.

Owner:CHINA ENFI ENGINEERING CORPORATION

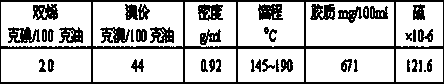

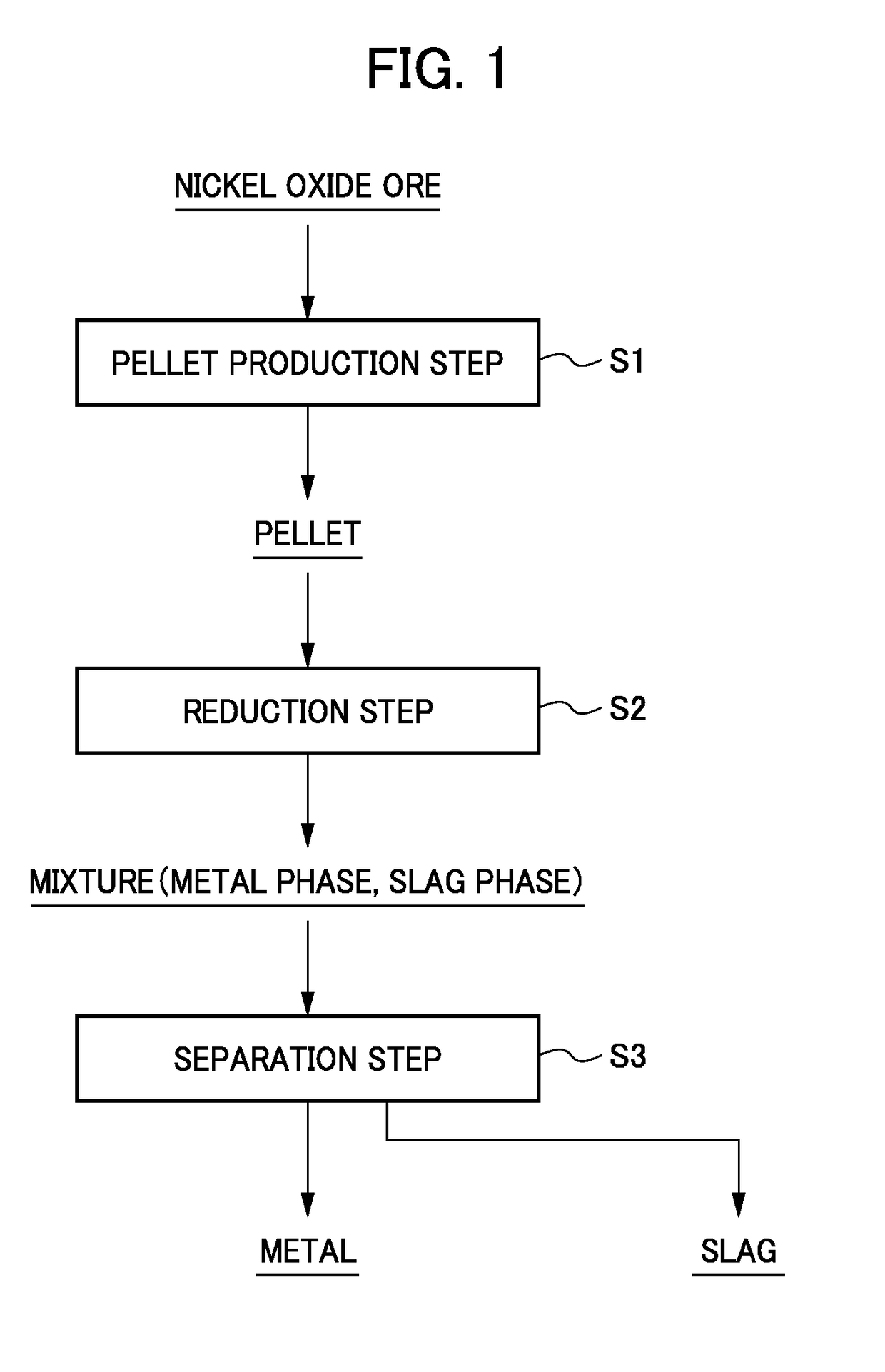

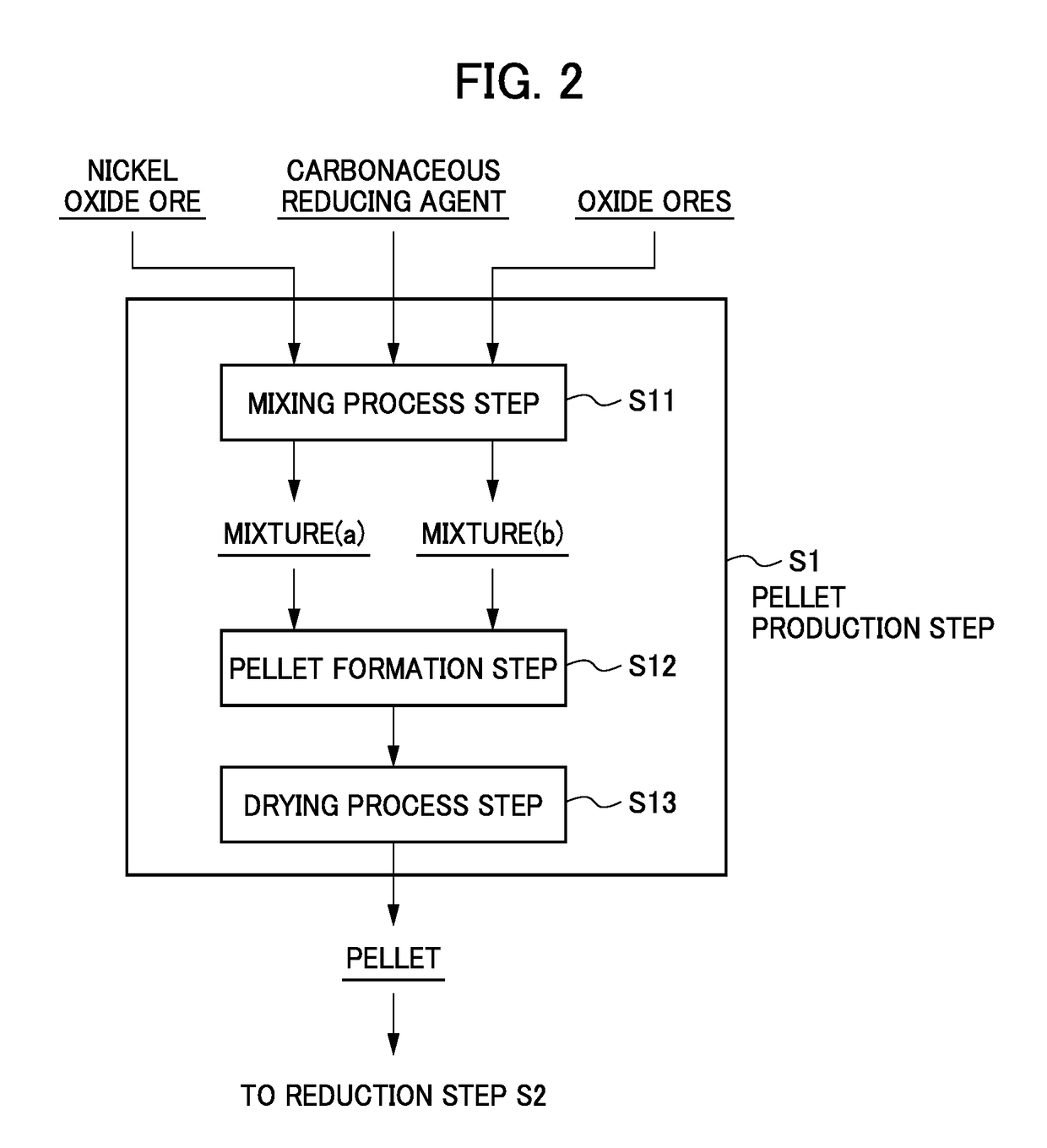

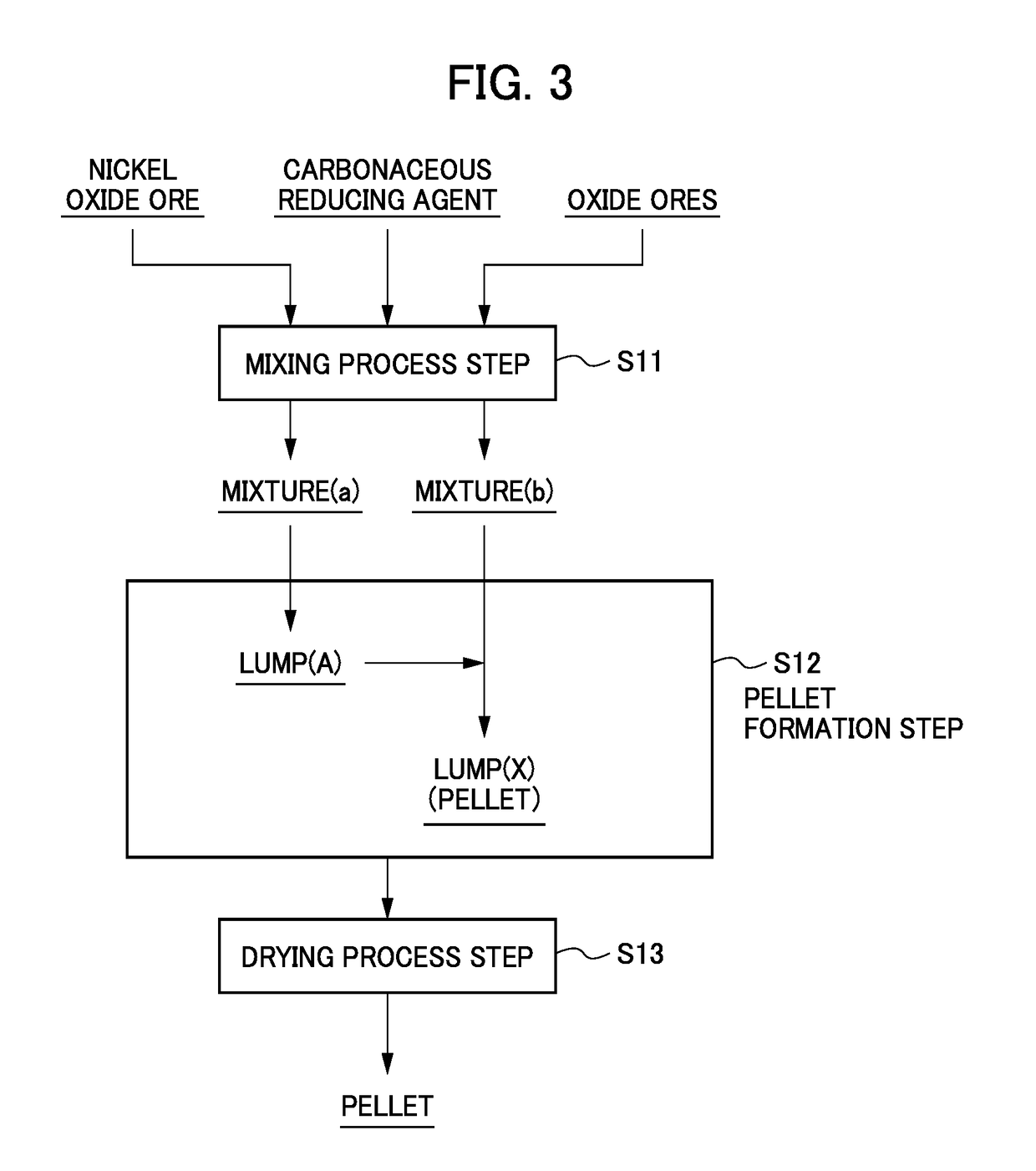

Method for producing pellets and method for producing iron-nickel alloy

Provided is a production method for producing pellets that are used for producing an iron-nickel alloy and that are produced by mixing at least a nickel oxide ore, a carbonaceous reducing agent, and an iron oxide and agglomerating the obtained mixtures, the method comprising: a step S11 for producing at least two types of mixtures having different mixing ratios of said nickel oxide ore, said carbonaceous reducing agent, and said iron oxide; and a step S12 for forming pellets, which are agglomerates having a layered structure, by using said two or more types of mixtures such that the mixture with the highest content ratio of said iron oxide, among said two or more types of mixtures that have been obtained, forms the outermost layer.

Owner:SUMITOMO METAL MINING CO LTD

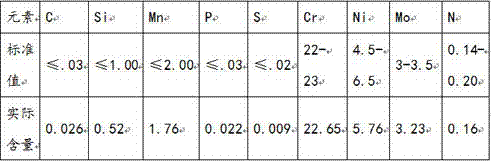

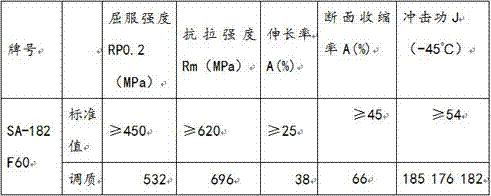

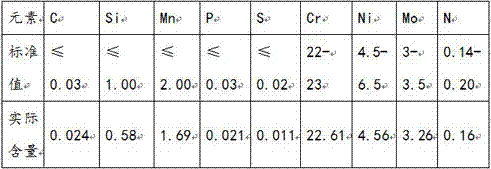

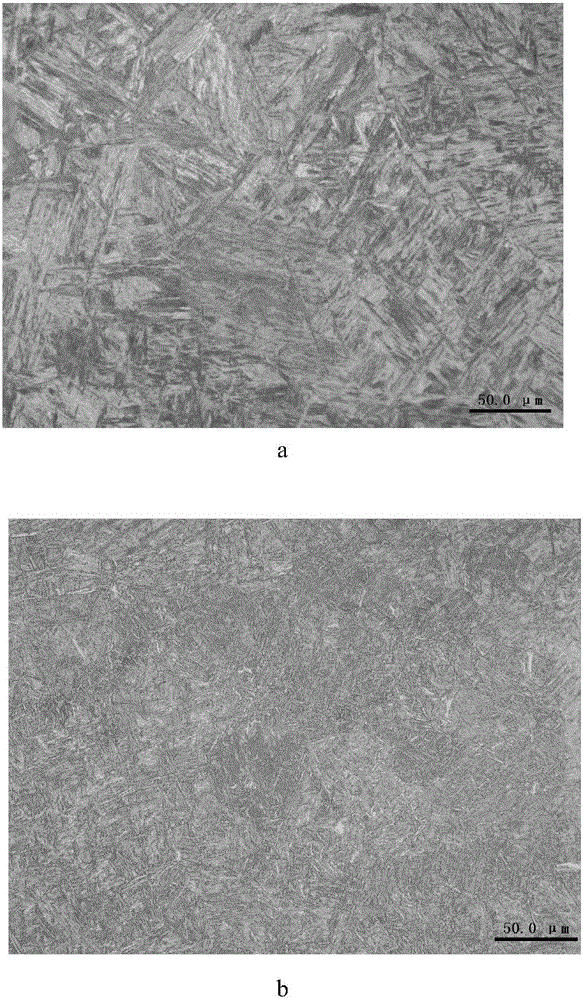

Flange forge piece made of dual-phase steel and production technique of flange forge piece

InactiveCN106957998AIncreased nickel contentHigh impact energy at low temperatureChemical compositionDual-phase steel

The invention provides a flange forge piece made of dual-phase steel and a production technique of the flange forge piece. The dual-phase steel comprises 0-0.03% of C, 0-1.00% of Si, 0-2.00% of Mn, 0-0.03% of P, 0-0.02% of S, 22-23% of Cr, 4.5-6.5% of Ni, 3-3.5% of Mo and 0.14-0.20% of N. Production machining is conducted through smelting, forging and heat treatment. In the forging process, the initial forging temperature is 1180+ / -20 DEG C, the final forging temperature is higher than 900 DEG C, and air cooling is conducted after forging. According to the flange forge piece made of the dual-phase steel, the content of nickel in the chemical composition is increased, and accordingly the low-temperature impact work is substantially improved.

Owner:无锡市法兰锻造有限公司

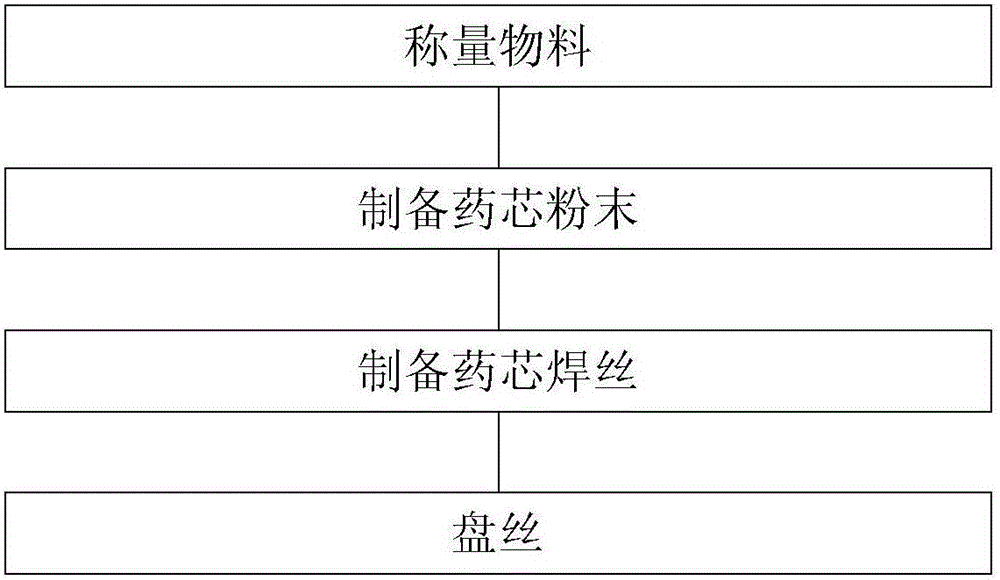

Iron-based flux-cored wire and preparation method thereof

InactiveCN104999193AHigh strengthImprove heat strengthWelding/cutting media/materialsSoldering mediaHeat-affected zoneSlag

The invention discloses an iron-based flux-cored wire and a preparation method thereof. The flux core comprises the following components in percentage by mass: 2.5%-5% of silicon iron, 5%-7% of manganese powder, 0.8%-2% of chromium powder, 5%-15% of nickel powder, 0.5%-1.2% of molybdenum powder and the balance of iron powder. The iron-based flux-cored wire can reduce brittleness and martensite structure specific gravity of a heat-affected zone of a steel welding joint, can increase welding seam toughness storage, is used for 31Si2MnCrMoVE steel welding, and avoids welding cold cracks. The iron-based flux-cored wire has good welding processing property, and is free of a slag inclusion problem in a welding process; and a welding seam surface is smooth and flat, is not required to clear after being welded, and is high in deposition rate; and in comparison with a solid-cored welding wire, the production efficiency is improved by 1.2-1.5 times. The preparation method for the iron-based flux-cored wire is simple, convenient to operate, and suitable for batched production.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

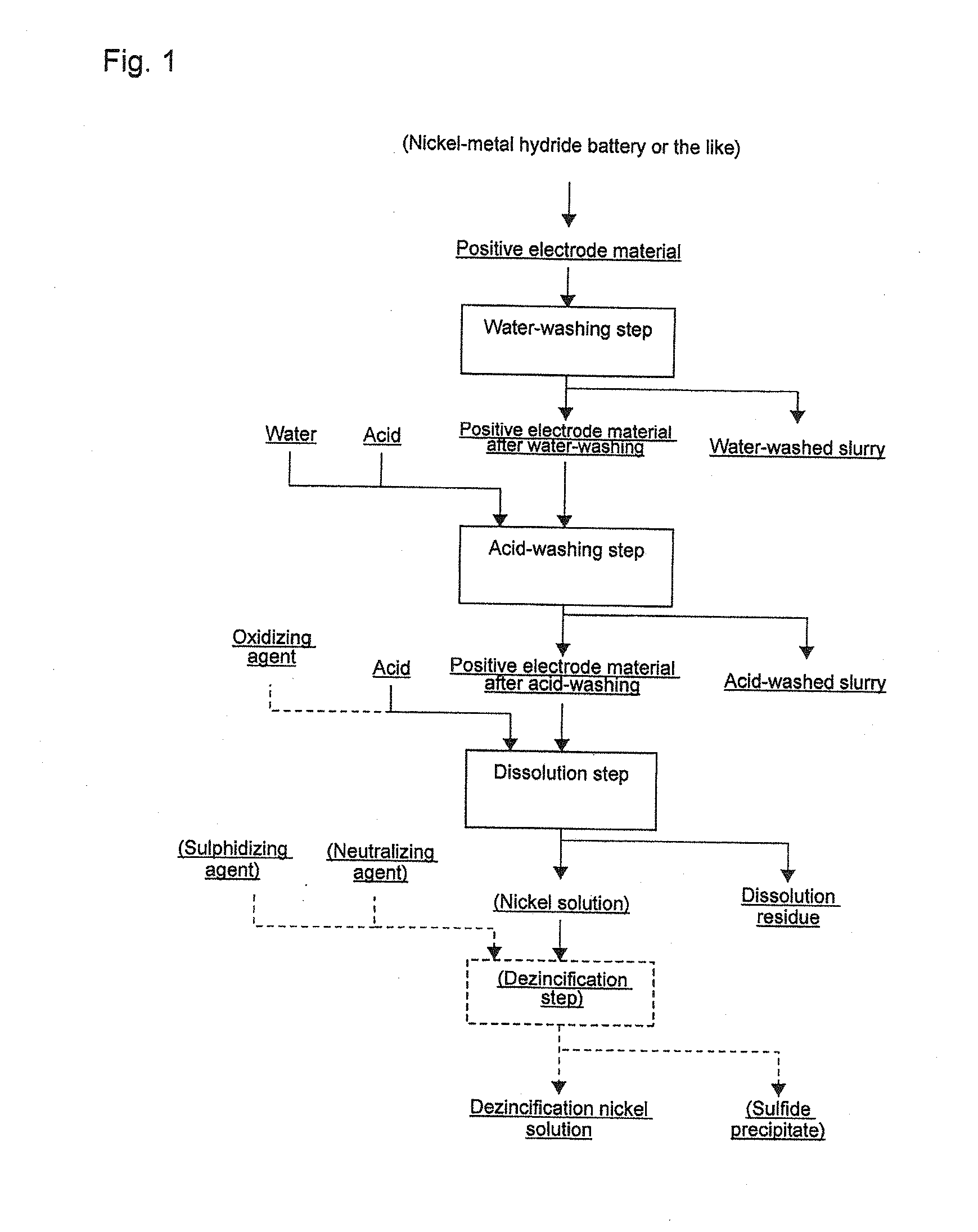

Method for producing nickel-containing acid solution

ActiveUS20140308183A1Low costRemarkable effectSolvent extractionAlkaline accumulator electrodesChemistryMaterial Separation

The method for obtaining an acid solution containing nickel is obtained by treating a positive electrode material of a nickel-metal hydride battery. The method includes a water-washing step, wherein a positive electrode material of a nickel-metal hydride battery is water-washed by adding water, and then separated to form a positive electrode material after water-washing and a water-washed slurry. An acid-washing step then is performed, wherein an acid is added and mixed into the positive electrode material obtained after water-washing in the water-washing step, and, separation is performed to form a positive electrode material after acid-washing and an acid-washed slurry. A dissolution step is performed wherein the positive electrode material obtained in the acid-washing step is separated into a nickel solution and a dissolution residue by adding any one of an acid and an oxidizing agent.

Owner:SUMITOMO METAL MINING CO LTD

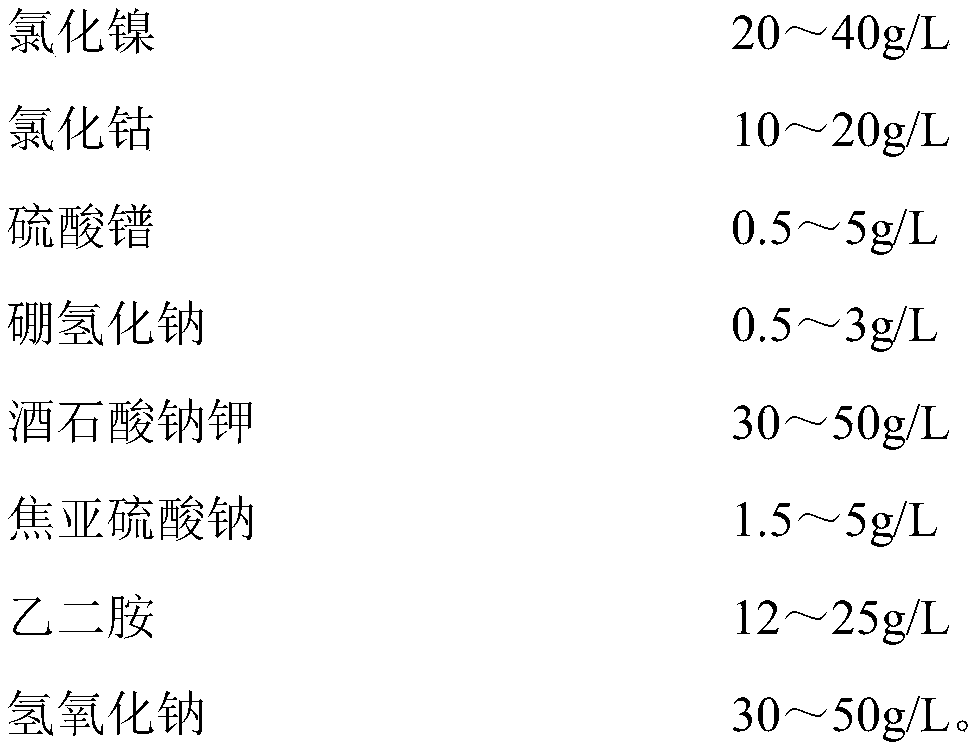

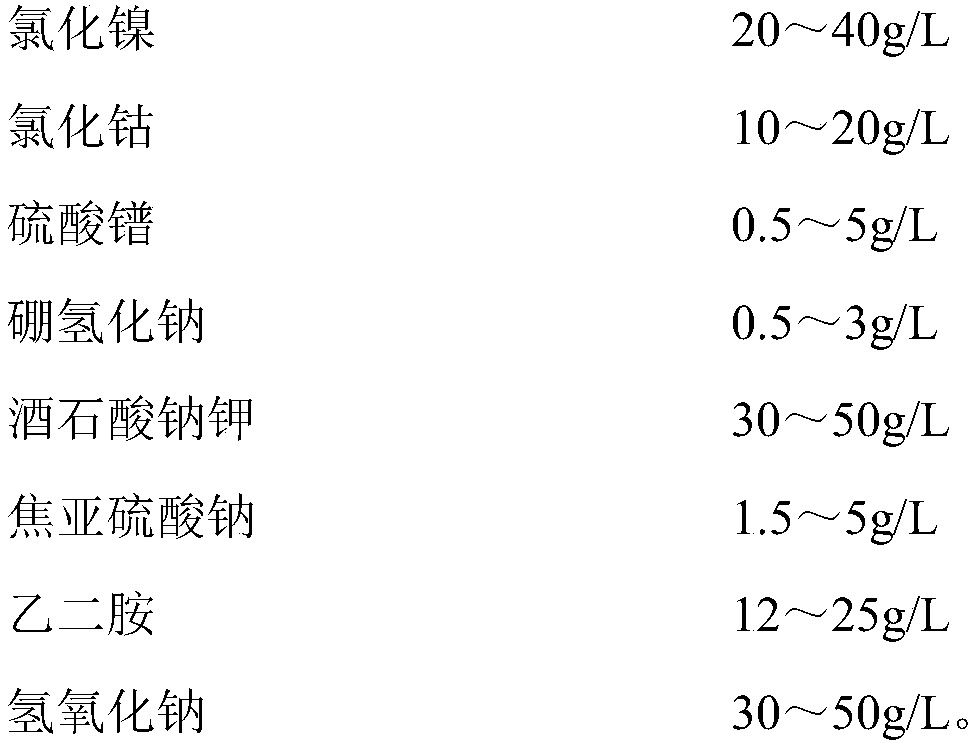

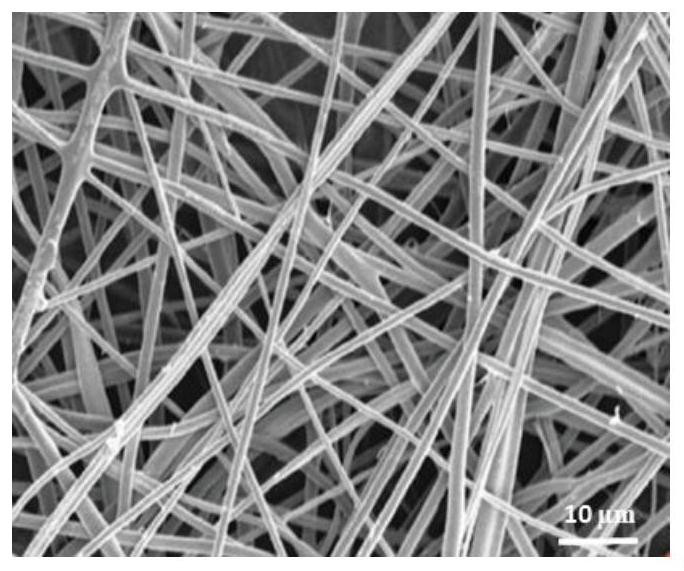

Glass fiber surface chemical plating Ni-Co-Pr-B quarternary alloy plating solution and preparation method thereof

InactiveCN108342721AHigh nickel contentImprove bindingLiquid/solution decomposition chemical coatingEthylenediamineChemical plating

The invention discloses glass fiber surface chemical plating Ni-Co-Pr-B quarternary alloy plating solution and a preparation method thereof. The preparation method comprises the following operating steps: 1, pretreating glass fiber; 2, dissolving nickel chloride, cobalt chloride, praseodymium sulfate, sodium borohydride, potassium sodium tartrate, sodium metabisulfite and ethylenediamine in distilled water separately; 3, uniformly mixing the nickel chloride solution, cobalt chloride solution, praseodymium sulfate solution, sodium metabisulfite solution and ethylenediamine solution completely dissolved in step 2 to obtain a mixed solution, adding the mixed solution in the potassium sodium tartrate solution and uniformly stirring; 4, slowly adding sodium borohydride solution in the solutionprepared in step 2, diluting and adopting sodium hydroxide to adjust the pH value to 11-14; 5, adding the glass fiber pretreated in step 1 in the plating solution prepared in step 3 for chemical plating of tin and nickel, wherein the plating temperature is 55-90 DEG C; and 6, drying the plated Ni-Co-Pr-B glass fiber prepared in step 5. The Ni-Co-Pr-B glass fiber plating layer prepared and obtainedby adopting the technical scheme is high in nickel content, plating layer binding force, electrical conductivity and stability.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

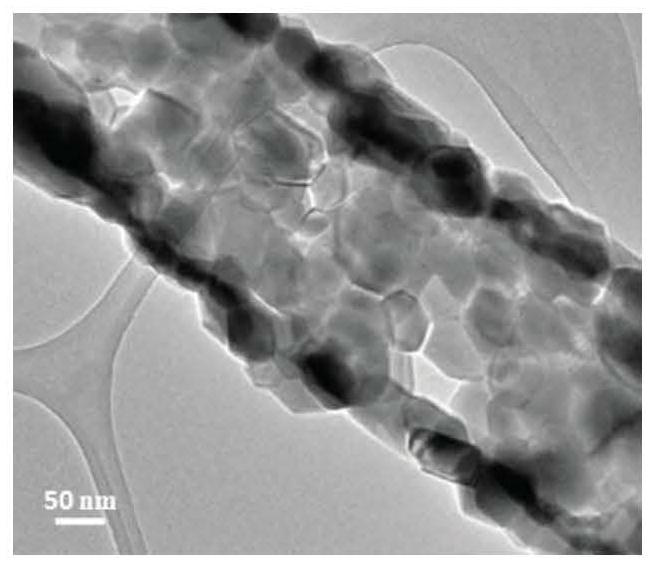

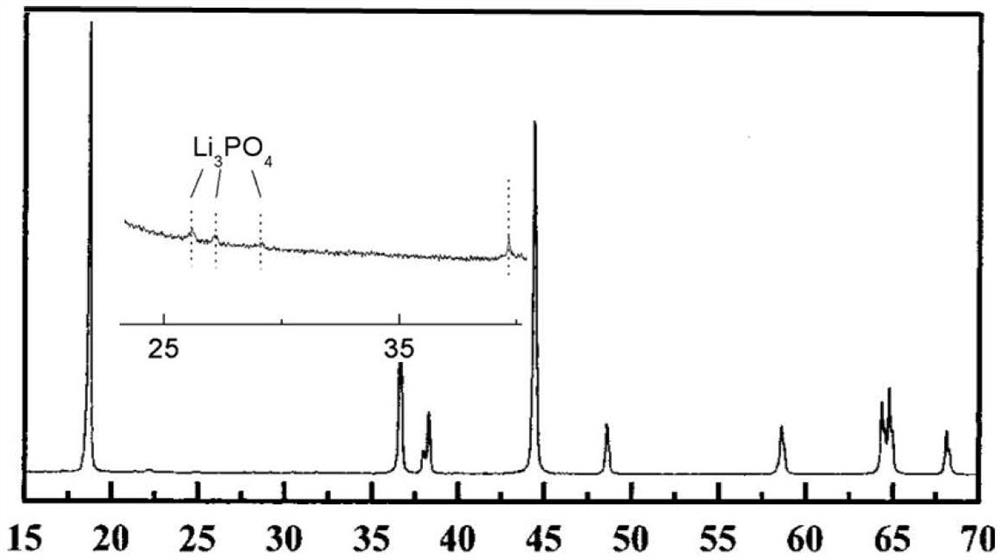

Phosphorus-doped lithium battery high-nickel positive electrode material and preparation process thereof

ActiveCN111916725AImprove stabilityIncreased nickel contentMaterial nanotechnologyInorganic material artificial filamentsPhysical chemistryLithium-ion battery

The invention discloses a phosphorus-doped lithium battery high-nickel positive electrode material, a preparation process and a lithium ion battery based on the positive electrode material. The positive electrode material comprises phosphorus, LiNixMn1xO2 nanofibers or LiNixCoyMn1xyO2 nanofibers, and has the characteristics of low residual lithium content on the surface, high length-diameter ratio, high specific surface area, high specific capacity, long cycle life, simple and convenient preparation process and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel iron smelting technique by laterite nickel ore

The invention relates to a technology for smelting ferronickel from lateritic nickel ore by an electric furnace. The technology comprises the steps as follows: (1) raw material is pretreated: the lateritic nickel is counted as one ton, coal powder with the weight of 8-12 percent of the weight of the lateritic nickel or coke powder with the weight of 6-10 percent of the weight of the lateritic nickel is added into the lateritic nickel to be mixed uniformly and returned to a rotary kiln to be sintered at the temperature of 600 DEG C to 1000 DEG C for 3 to 6 hours, wherein, the pre-reduction of 20-30 percent of NiO is achieved; (2) the raw material is put into a submerged arc furnace to be smelted: an electric furnace magnesia and carbon mixture furnace lining is arranged; adjustable electric furnace voltage is set with the high voltage of 280-300V and the low voltage of 200-220V, and that is the high voltage starts arc, and after 30 minutes, the electric furnace is changed to low voltage for smelting and calcining an electrode; the charge of smelting furnace charging material consists of one ton of sintered nickel and 90-120kg of fusing agent lime; coke or coal is added as a reducer; the raw material and the auxiliary material are put into the electric furnace to be smelted; and (3) crude ferronickel is refined: liquid molten iron is put into a finery, and a refining agent is added for refining by oxygen blast. A product contains more than 13 percent of nickel, thereby satisfying the requirement of producing high-quality steel material product; and the recovery rate of nickel element is more than 95 percent. The technology has simple technology, saves energy and has high efficiency.

Owner:TAONAN JINSHENG METALLURGY PRODS

High-carbon high-chromium duplex stainless steel

The invention relates to duplex stainless steel, and particularly relates to duplex stainless steel containing high-carbon and high-chromium elements and a production process thereof. The stainless steel provided by the invention comprises the following chemical components in percentage by weight: 0.20-0.35% of C, 22-26% of Cr, 10-14% of Ni, 2-5% of Mo, 1-5% of Cu, 0.5-4% of V, 0.5-5% of W, less than or equal to 0.015% of S, less than or equal to 0.015% of P, less than or equal to 1% of other impurity elements and the balance of Fe. In the duplex stainless steel provided by the invention, the carbon content of the stainless steel is increased, the alloy strength and hardness are improved, and the wear resistance is enhanced; apart from the commonly used elements Cr, Ni and Mo, the alloy is also added with the elements Cu, W and V, thus the tensile strength and hardness of the alloy are greatly improved under the condition of guaranteeing enough corrosion resistance of the duplex stainless steel.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com