Flange forge piece made of dual-phase steel and production technique of flange forge piece

A flange forging and production process technology, applied in the field of metal forging, can solve problems such as inability to meet requirements, and achieve the effect of improving low-temperature impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

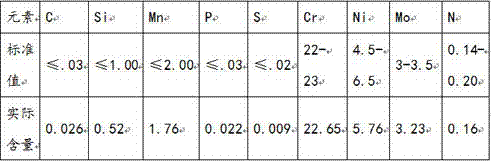

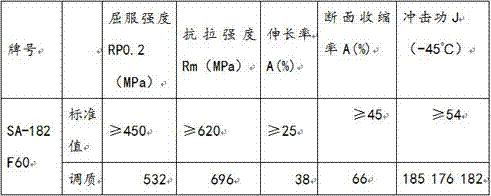

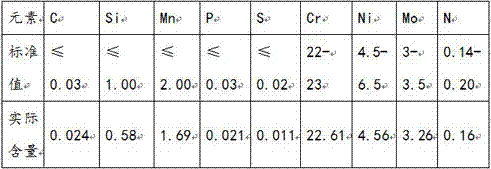

[0015] Selected the F60 material of two smelting furnace numbers, wherein table 1 is the chemical composition specific gravity situation of the flange forgings of low-temperature dual-phase steel material provided by the present invention, and table 2 is the chemical composition specific gravity situation of common material;

[0016] Table 1 Chemical composition of SA-182 F60 (melting furnace number: 2536220) %

[0017]

[0018] Table 2 Chemical composition of SA-182 F60 (melting furnace number: 2536266) %

[0019]

[0020] The production process of the flange forging made of the dual-phase steel material provided by the present invention includes the following steps: Step 1: smelting;

[0021] Step 2: Forging, each of the two materials is 25Kg, and forged into a forging with a size of φ200×100mm, the initial forging temperature is 1180°C ± 20°C, the final forging temperature is greater than 900°C, the total forging ratio is greater than 3, and air cooling after forging;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com