Phosphorus-doped lithium battery high-nickel positive electrode material and preparation process thereof

A positive electrode material and preparation process technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of reduced material cycle stability, reduced battery life, and battery capacity attenuation, so as to improve the rate performance and improve stability , conducive to the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1) Weigh 10.5mmol of lithium acetate, 8mmol of nickel acetate and 2mmol of manganese acetate, and add them together to 87ml of N’N-dimethylformamide, and stir until all raw materials are completely dissolved.

[0067] 2) Weigh 4.3 g of polyacrylonitrile, add it into the solution described in step 1, and stir overnight until the polymer is completely dissolved, and the resulting liquid is the spinning solution.

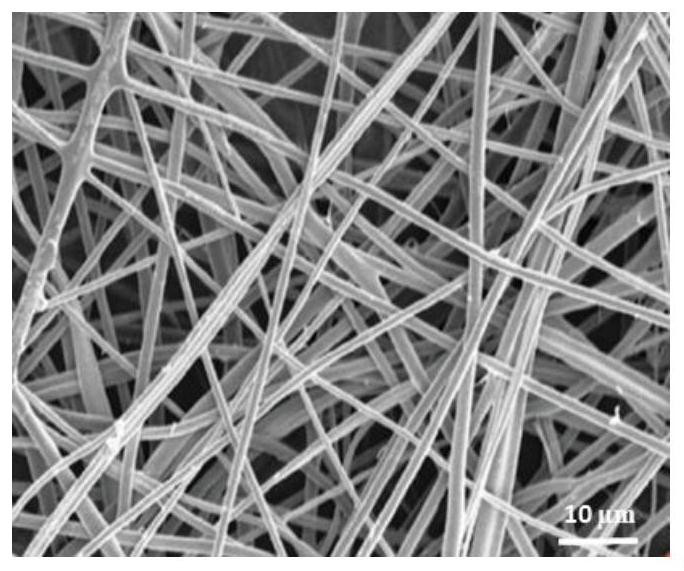

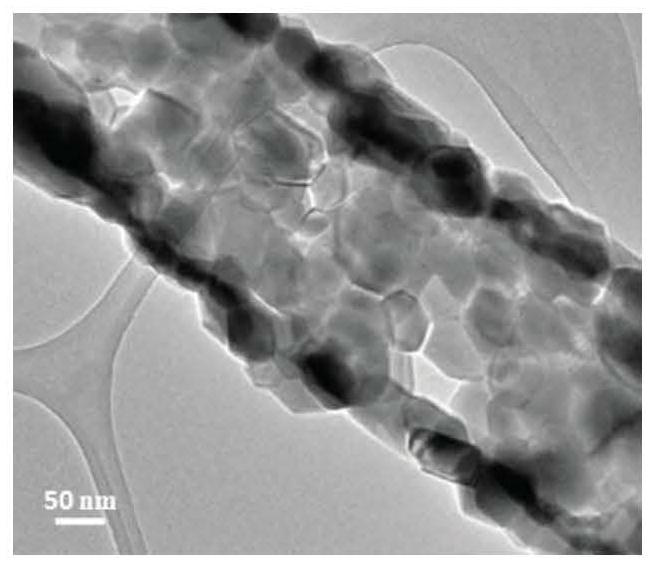

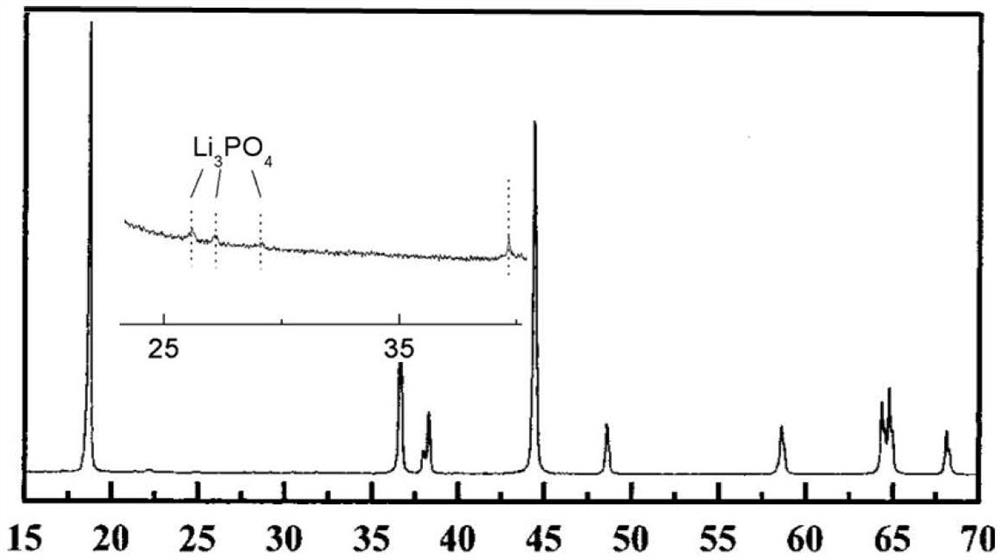

[0068] 3) Transfer the above spinning solution into a 10ml syringe, and take another 21G needle (0.51mm inner diameter) as the spinning needle. Under the condition that the forward voltage is 13KV, the negative voltage is -2.0KV, the distance between the spinning port and the receiver is 15cm, and the injection speed of the spinning solution is 0.3mm / min, the LiNi 0.8 mn 0.2 o 2 Precursor nanofibers (such as figure 1 shown).

[0069] 4) Place the precursor nanofibers obtained in step 3 in a muffle furnace and raise the temperature to 270°C at a rate of 3°C / m...

Embodiment 2

[0073] 1) Weigh 10.5mmol of lithium acetate, 8mmol of nickel acetate and 2mmol of manganese acetate, and add them together to 87ml of N’N-dimethylformamide, and stir until all raw materials are completely dissolved.

[0074] 2) Weigh 8g of polyacrylonitrile, add it into the solution described in step 1, and stir overnight until the polymer is completely dissolved, and the resulting liquid is the spinning solution.

[0075] 3) Transfer the above spinning solution into a 10ml syringe, and take another 21G needle (0.51mm inner diameter) as the spinning needle. Under the condition that the forward voltage is 13.5KV, the negative voltage is -2.0KV, the distance between the spinning port and the receiver is 15cm, and the injection speed of the spinning solution is 0.3mm / min, the LiNi 0.8 mn 0.2 o 2 Precursor nanofibers.

[0076] 4) Place the precursor nanofibers obtained in step 3 in a muffle furnace and raise the temperature to 220°C at a rate of 3°C / min to 5°C / min, keep at this...

Embodiment 3

[0080] 1) Weigh 10.5mmol of lithium acetate, 8mmol of nickel acetate and 2mmol of manganese acetate, and add them together to 87ml of N’N-dimethylformamide, and stir until all raw materials are completely dissolved.

[0081] 2) Weigh 12 g of polyacrylonitrile, add it into the solution described in step 1, and stir overnight until the polymer is completely dissolved, and the resulting liquid is the spinning solution.

[0082] 3) Transfer the above spinning solution into a 10ml syringe, and take another 21G needle (0.51mm inner diameter) as the spinning needle. Under the condition that the forward voltage is 13.5KV, the negative voltage is -2.0KV, the distance between the spinning port and the receiver is 15cm, and the injection speed of the spinning solution is 0.3mm / min, the LiNi 0.8 mn 0.2 o 2 Precursor nanofibers.

[0083] 4) Place the precursor nanofibers obtained in step 3 in a muffle furnace and raise the temperature to 220°C at a rate of 3°C / min to 5°C / min, keep at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com