Patents

Literature

3865results about How to "Uniform shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

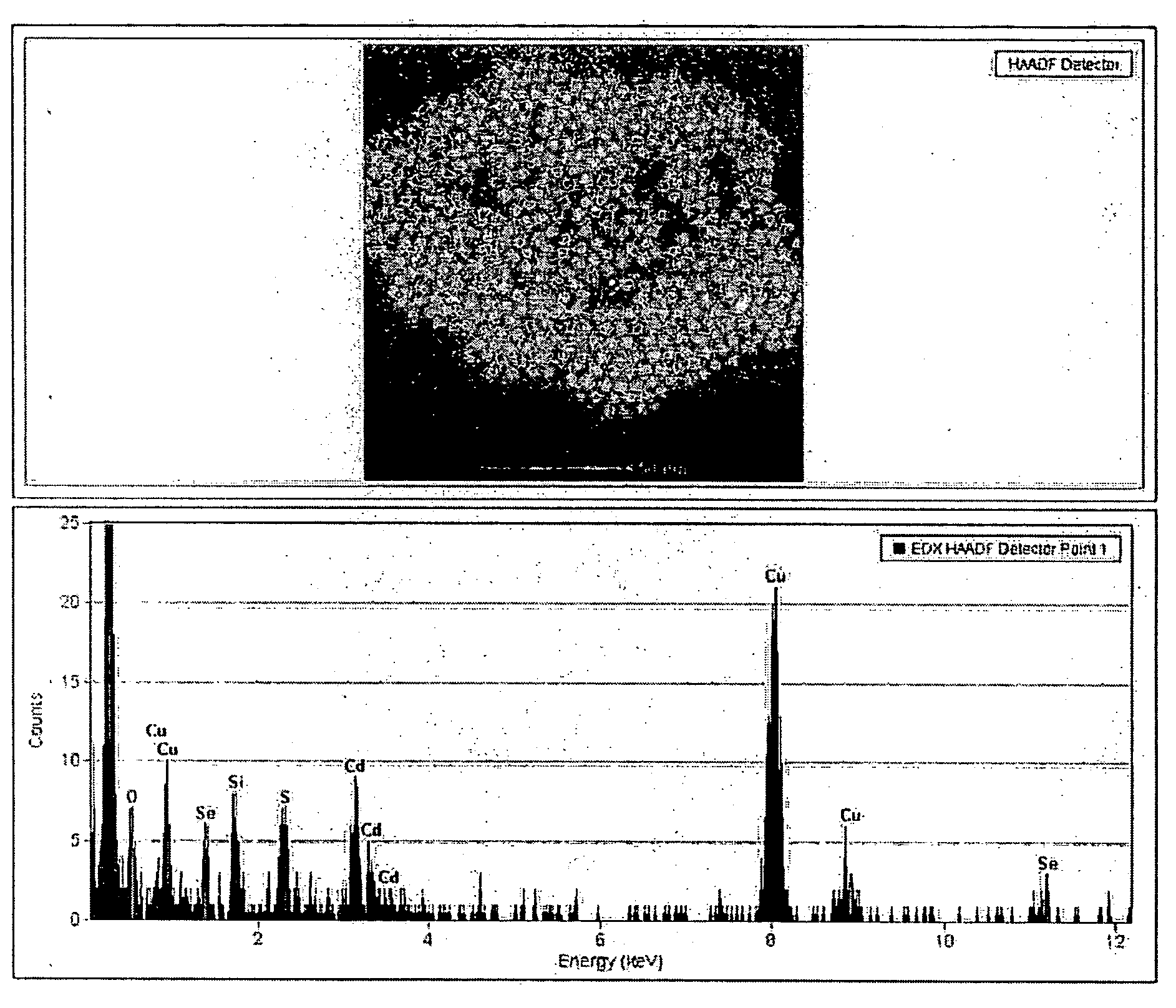

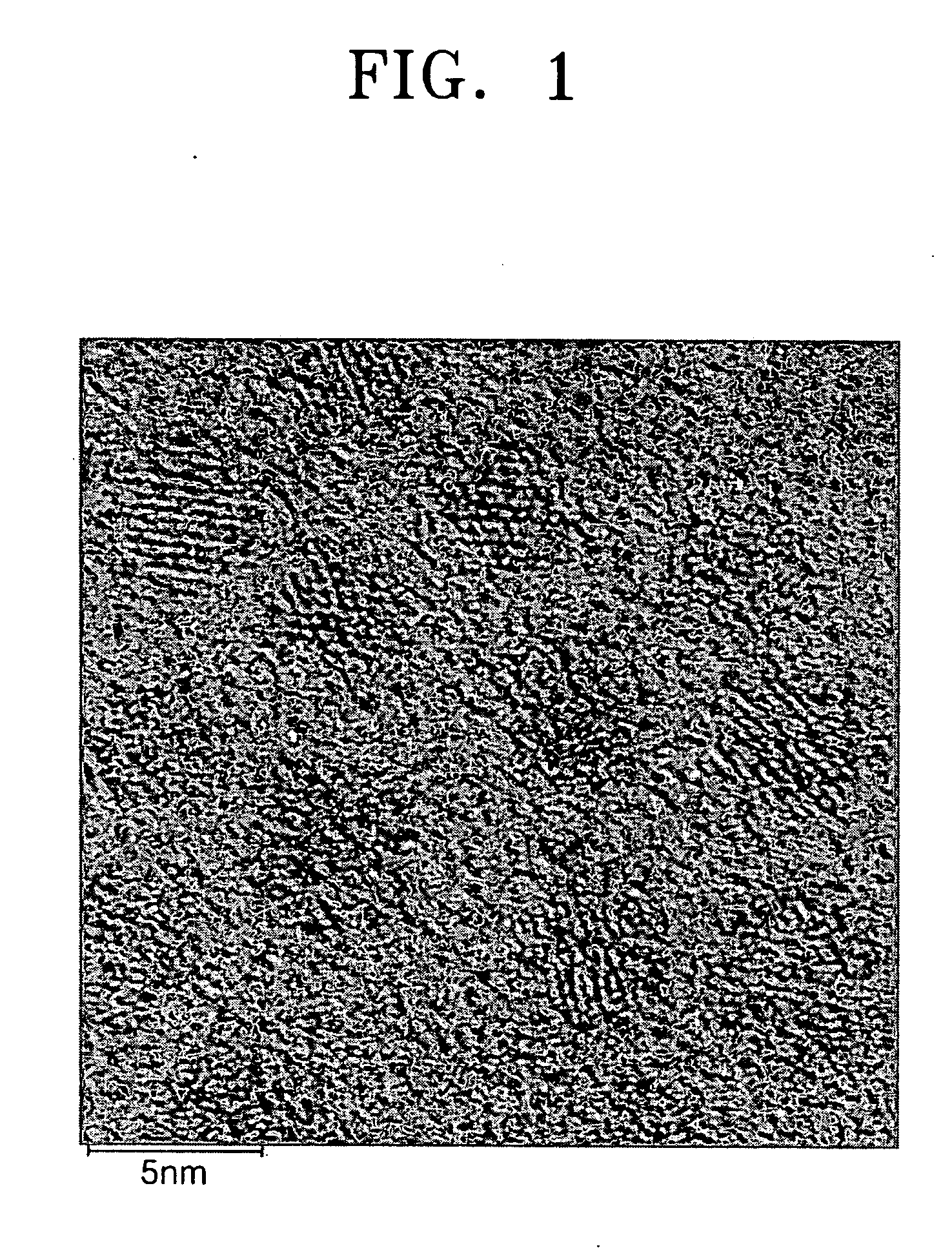

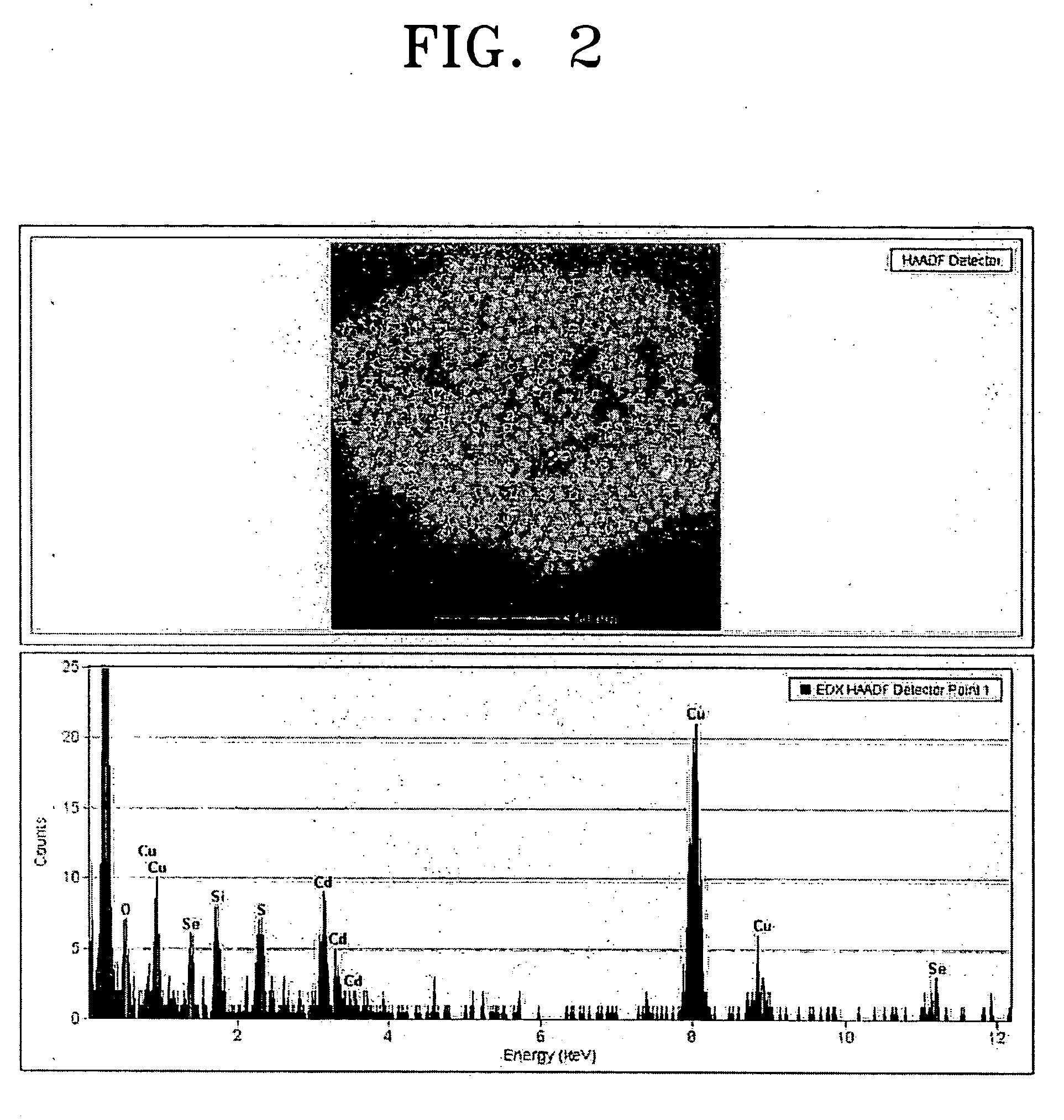

Alloy type semiconductor nanocrystals and method for preparing the same

ActiveUS20050012182A1Improve quantum efficiencyUniform shapeMaterial nanotechnologyFrom normal temperature solutionsSemiconductor nanocrystalsCompound semiconductor

Provided is a chemical wet preparation method for Group 12-16 compound semiconductor nanocrystals. The method includes mixing one or more Group 12 metals or Group 12 precursors with a dispersing agent and a solvent followed by heating to obtain a Group 12 metal precursor solution; dissolving one or more Group 16 elements or Group 16 precursors in a coordinating solvent to obtain a Group 16 element precursor solution; and mixing the Group 12 metal precursors solution and the Group 16 element precursors solution to form a mixture, and then reacting the mixture to grow the semiconductor nanocrystals. The Group 12-16 compound semiconductor nanocrystals are stable and have high quantum efficiency and uniform sizes and shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

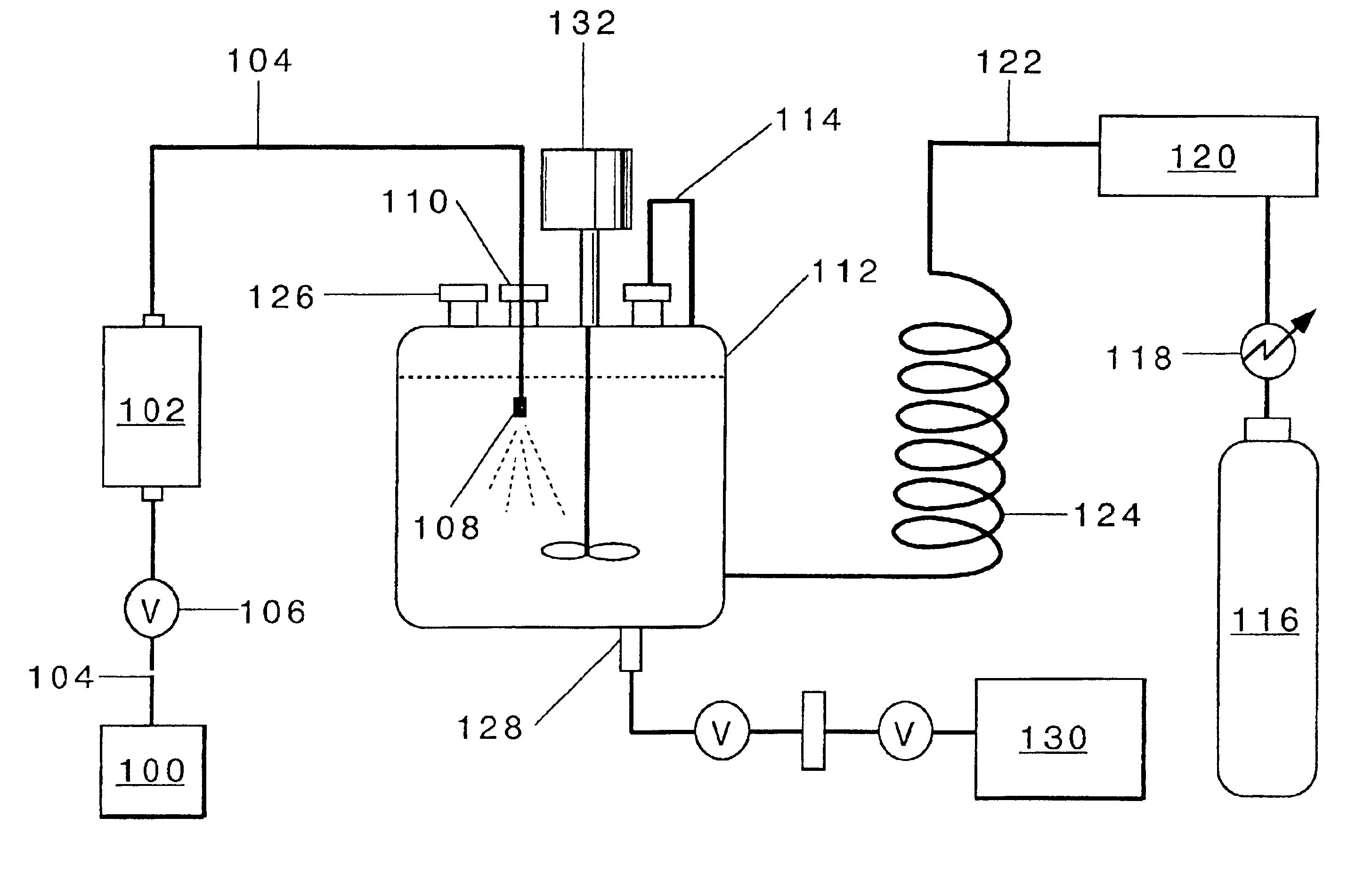

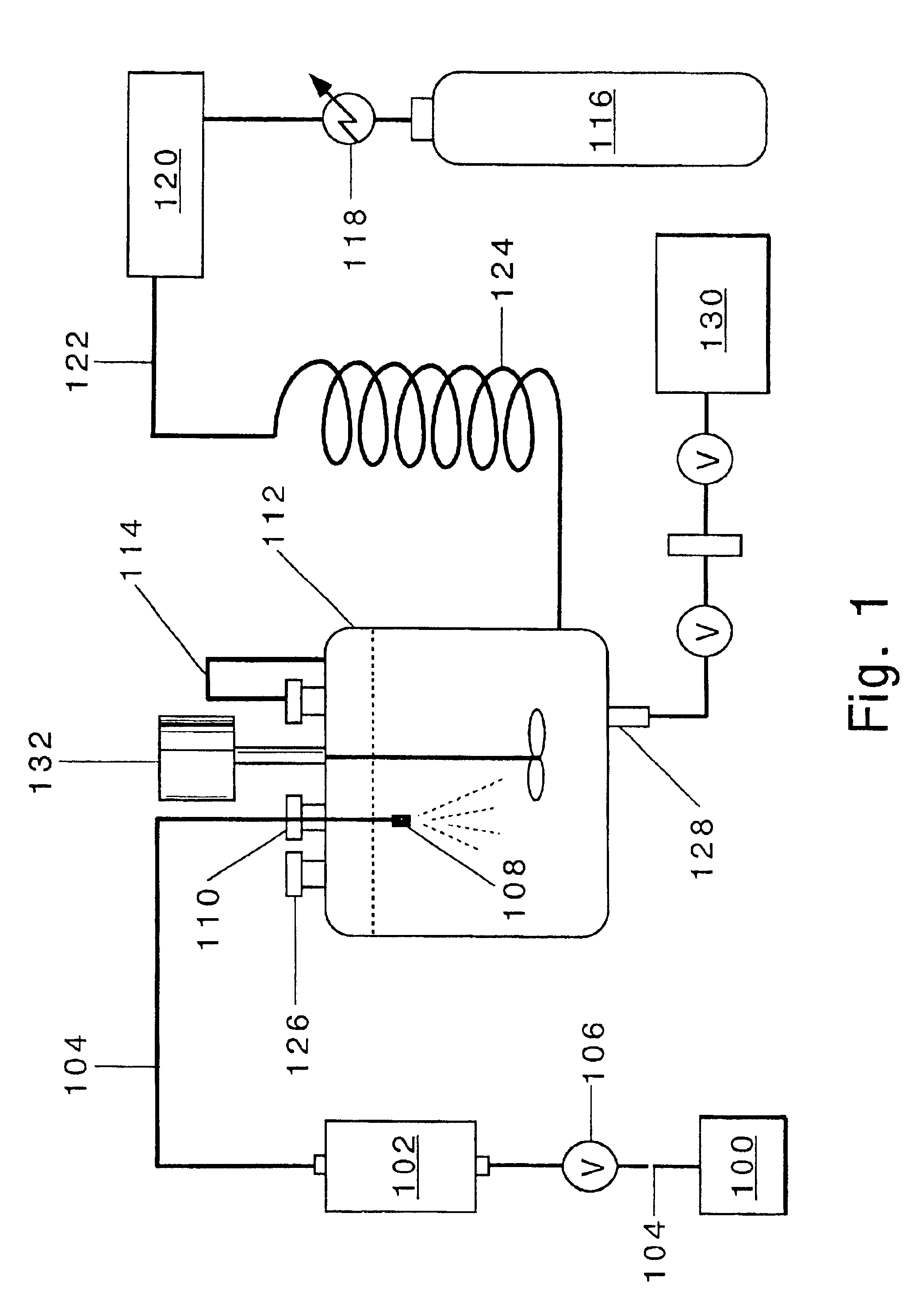

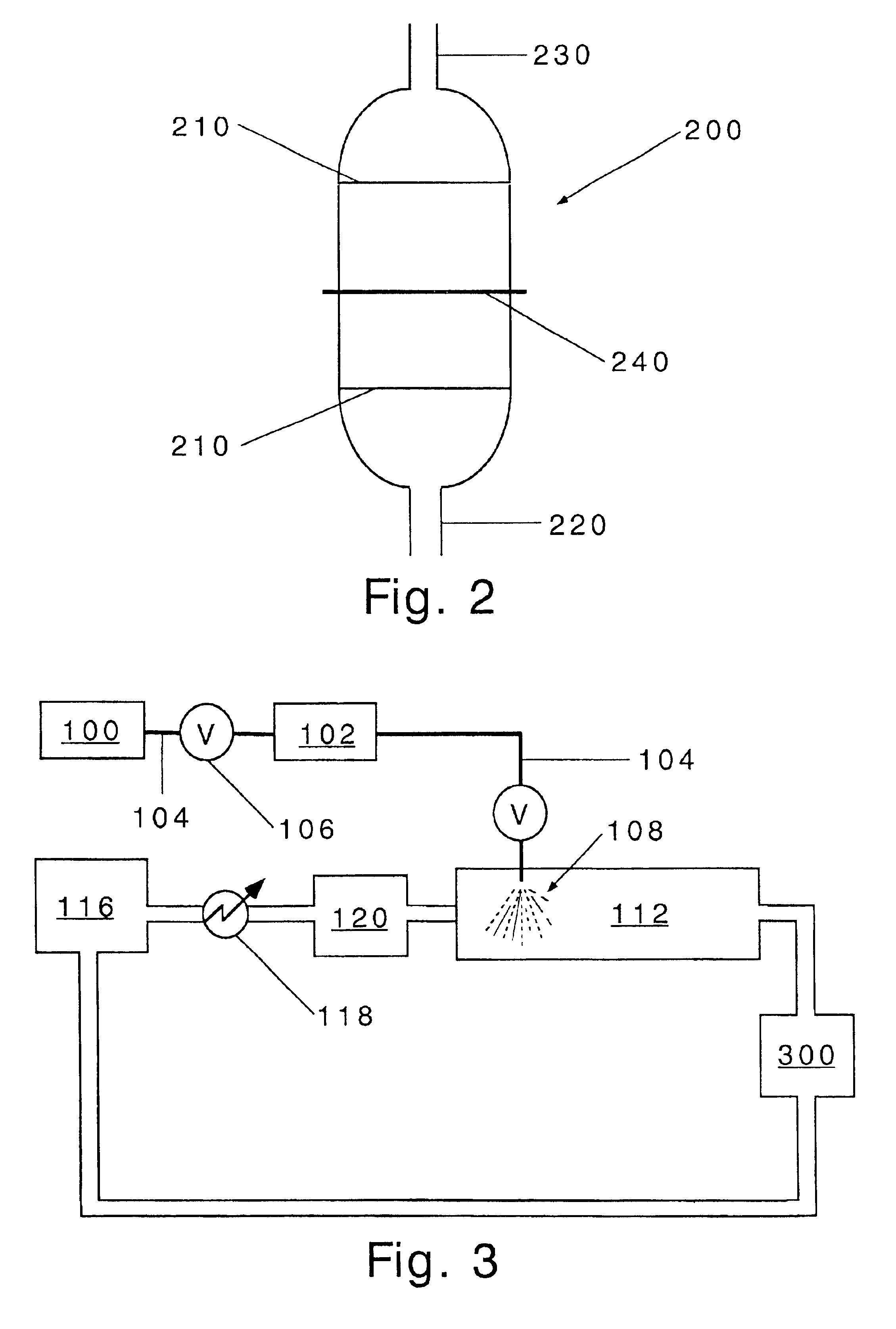

Process for production of nanoparticles and microparticles by spray freezing into liquid

InactiveUS6862890B2Improve efficiencyImprove efficacyPowder deliveryNervous disorderPorosityNanoparticle

The present invention provides a system and a method for the production of microparticles and nanoparticles of materials that can be dissolved. The system and method of the present invention provide quicker freezing times, which in turn produces a more uniform distribution of particle sizes, smaller particles, particles with increased porosity and a more intimate mixing of the particle components. The system and method of the present invention also produce particles with greater surface area than conventional methods. One form of the present invention provides a method for the preparation of particles. An effective ingredient is mixed with water, one or more solvents, or a combination thereof, and the resulting mixture is sprayed through an insulating nozzle located at or below the level of a cryogenic liquid. The spray generates frozen particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

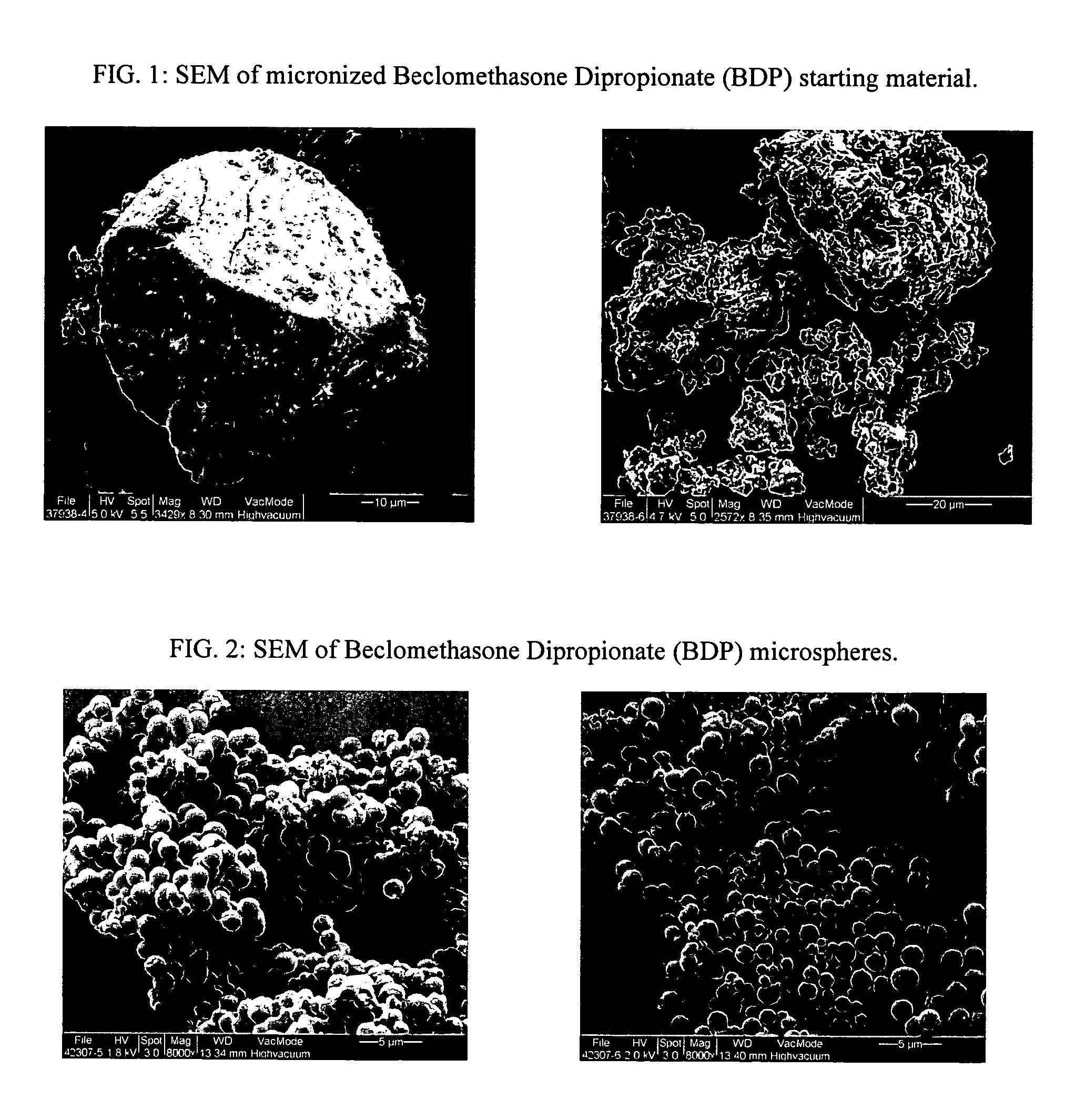

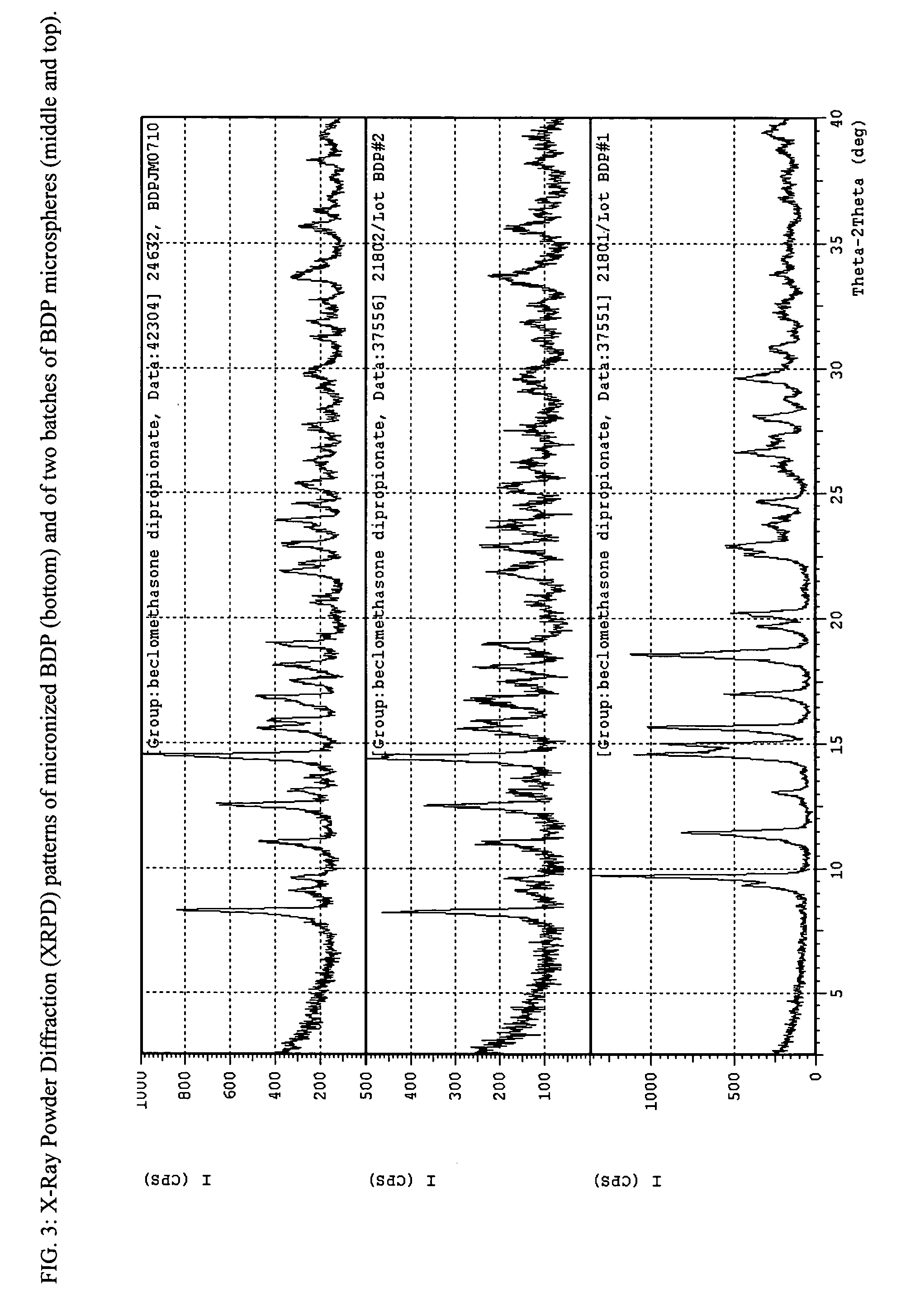

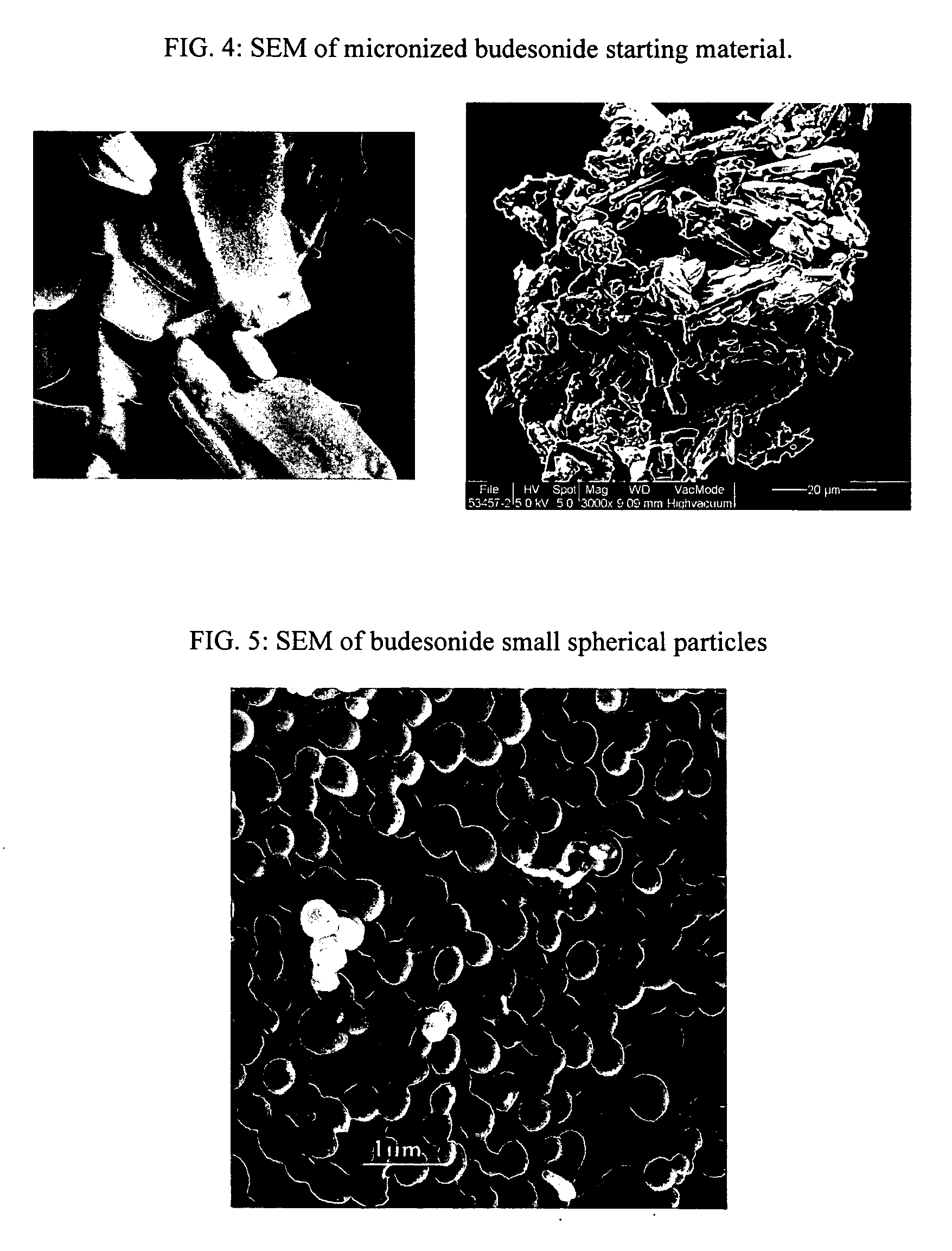

Small spherical particles of low molecular weight organic molecules and methods of preparation and use thereof

InactiveUS20050048127A1Uniform sizeHigh ratio of surface areaPowder deliveryChemical physicsNanosized particle

The invention provides homogeneous small spherical particles of low molecular weight organic molecules, said small spherical particles having a uniform shape, a narrow size distribution and average diameter of 0.01-200 μm. The invention further provides methods of preparation and methods of use of the small spherical particles. These small spherical particles are suitable for applications that require delivery of micron-size or nanosized particles with uniform size and good aerodynamic or flow characteristics. Pulmonary, intravenous, and other means of administration are among the delivery routes that may benefit from these small spherical particles.

Owner:BAXTER INT INC +1

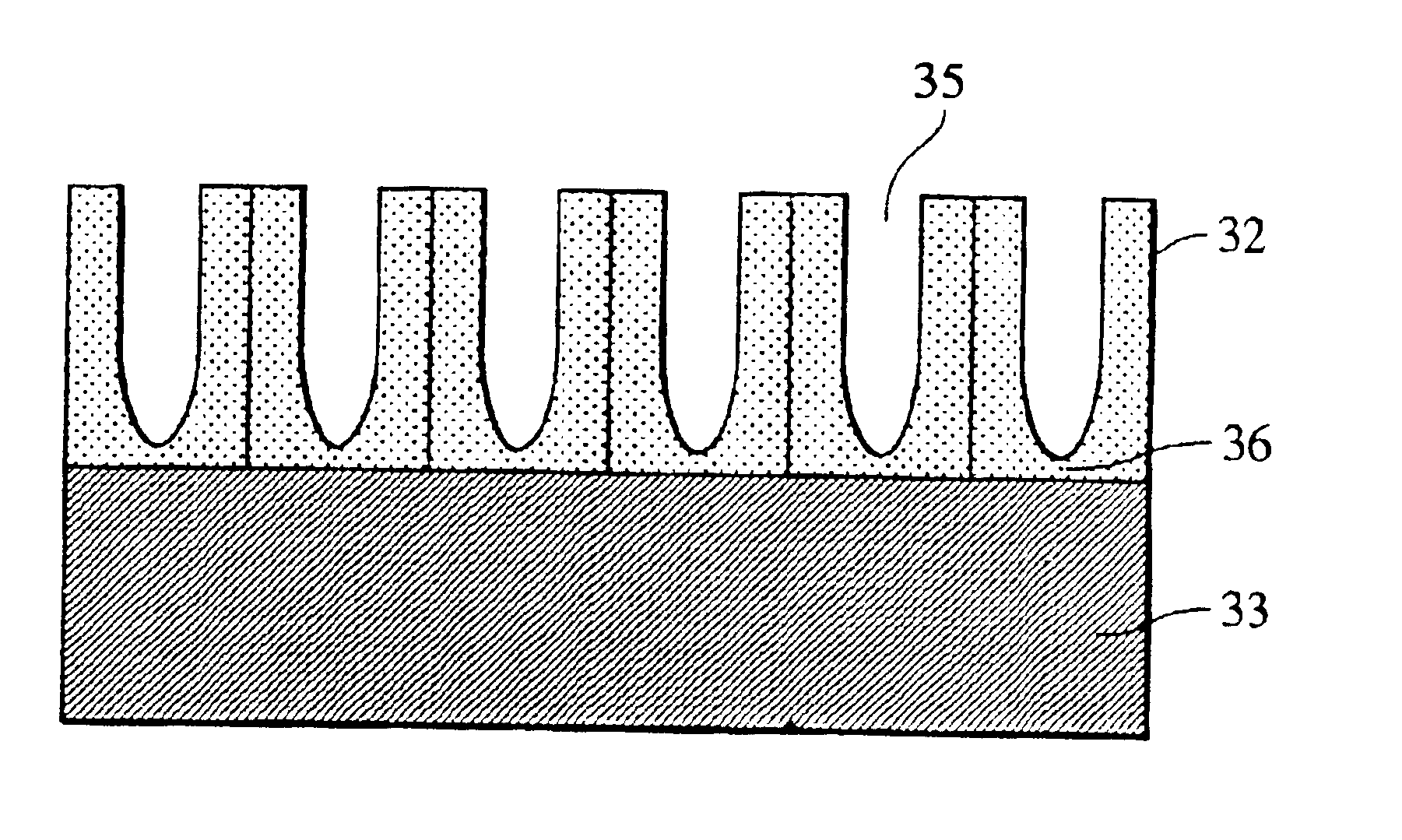

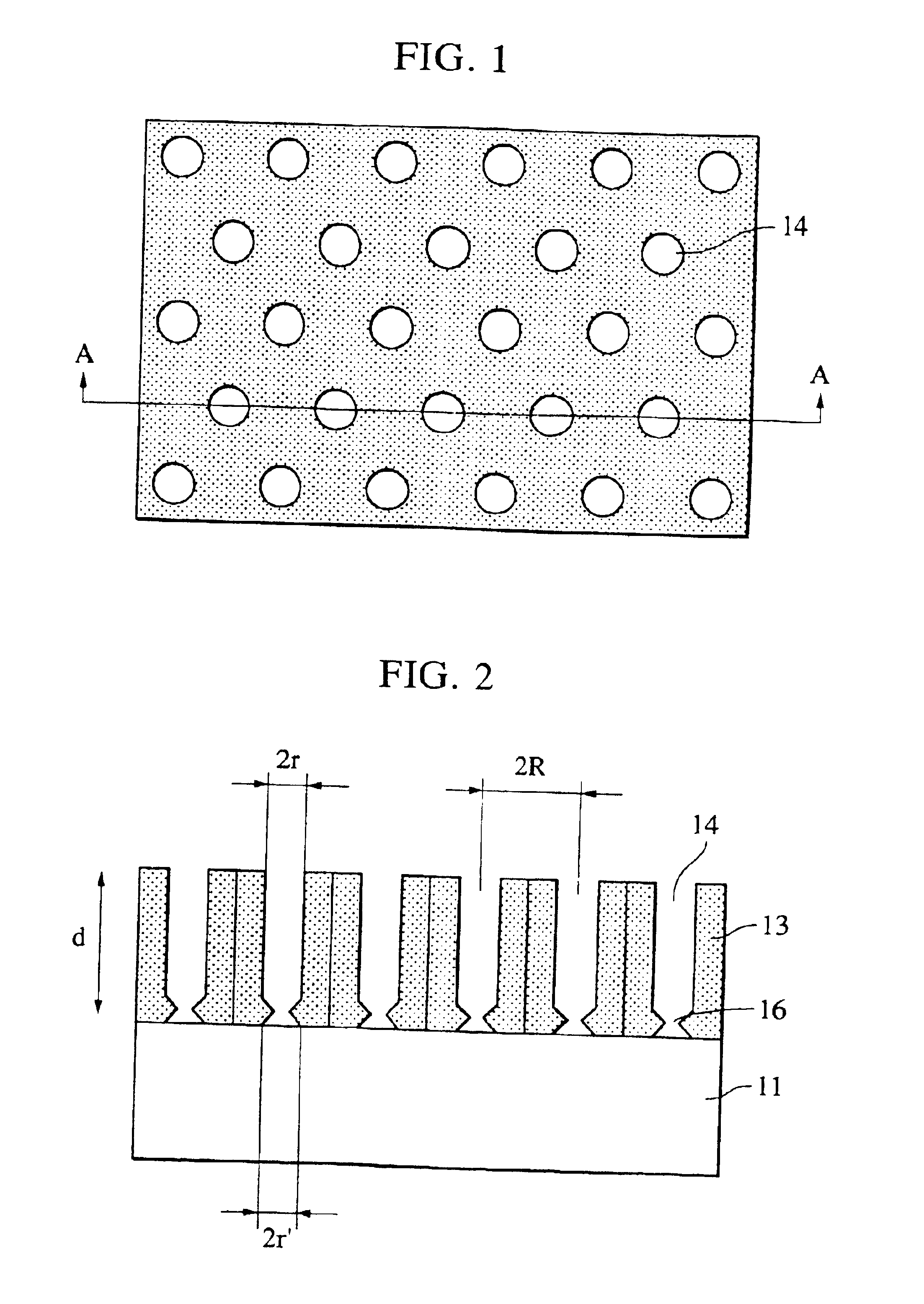

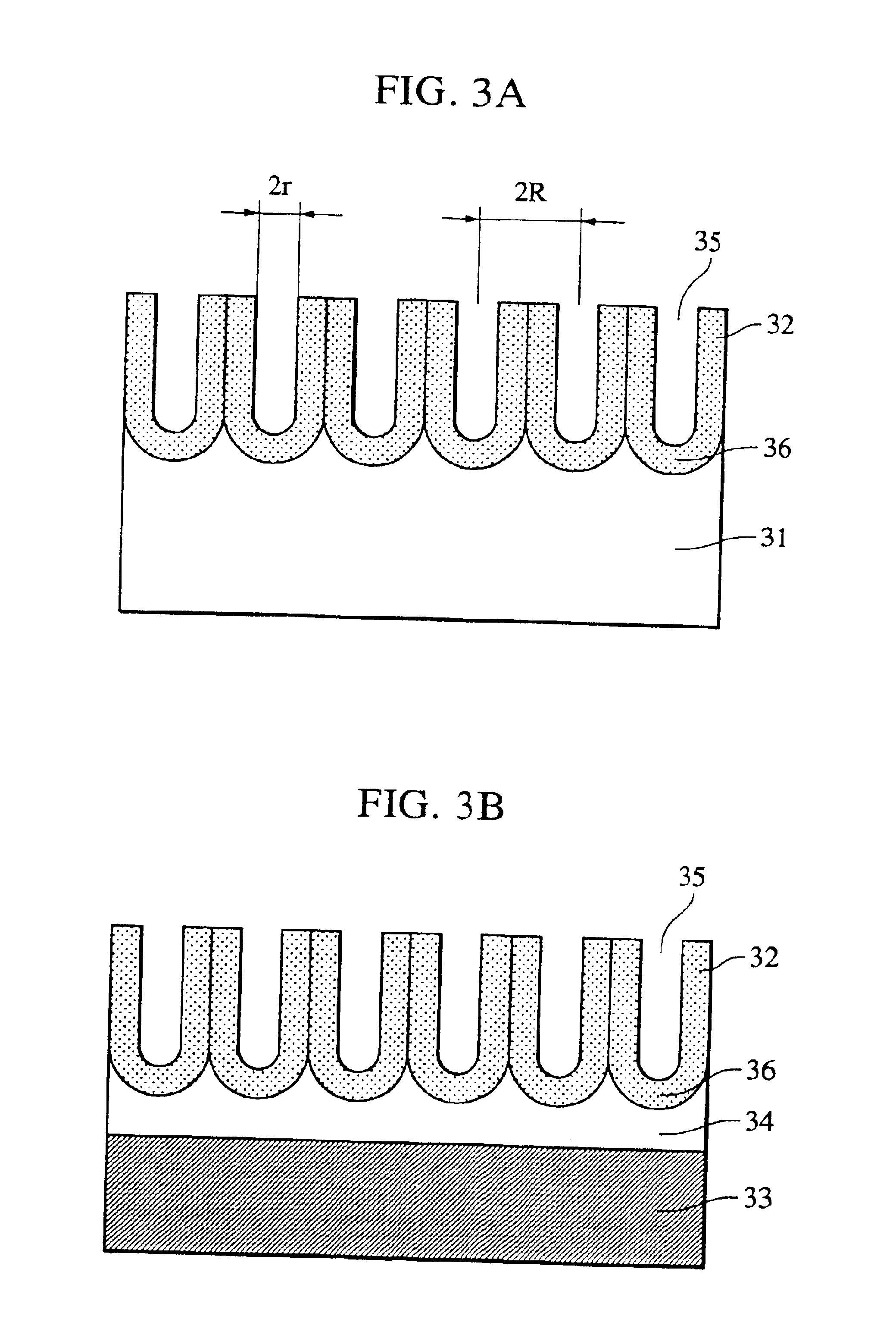

Nanostructure, electron emitting device, carbon nanotube device, and method of producing the same

InactiveUS6838297B2Good shape uniformityReliably producedNanostructure manufactureNanomagnetismNanoholeCarbon nanotube

Owner:CANON KK

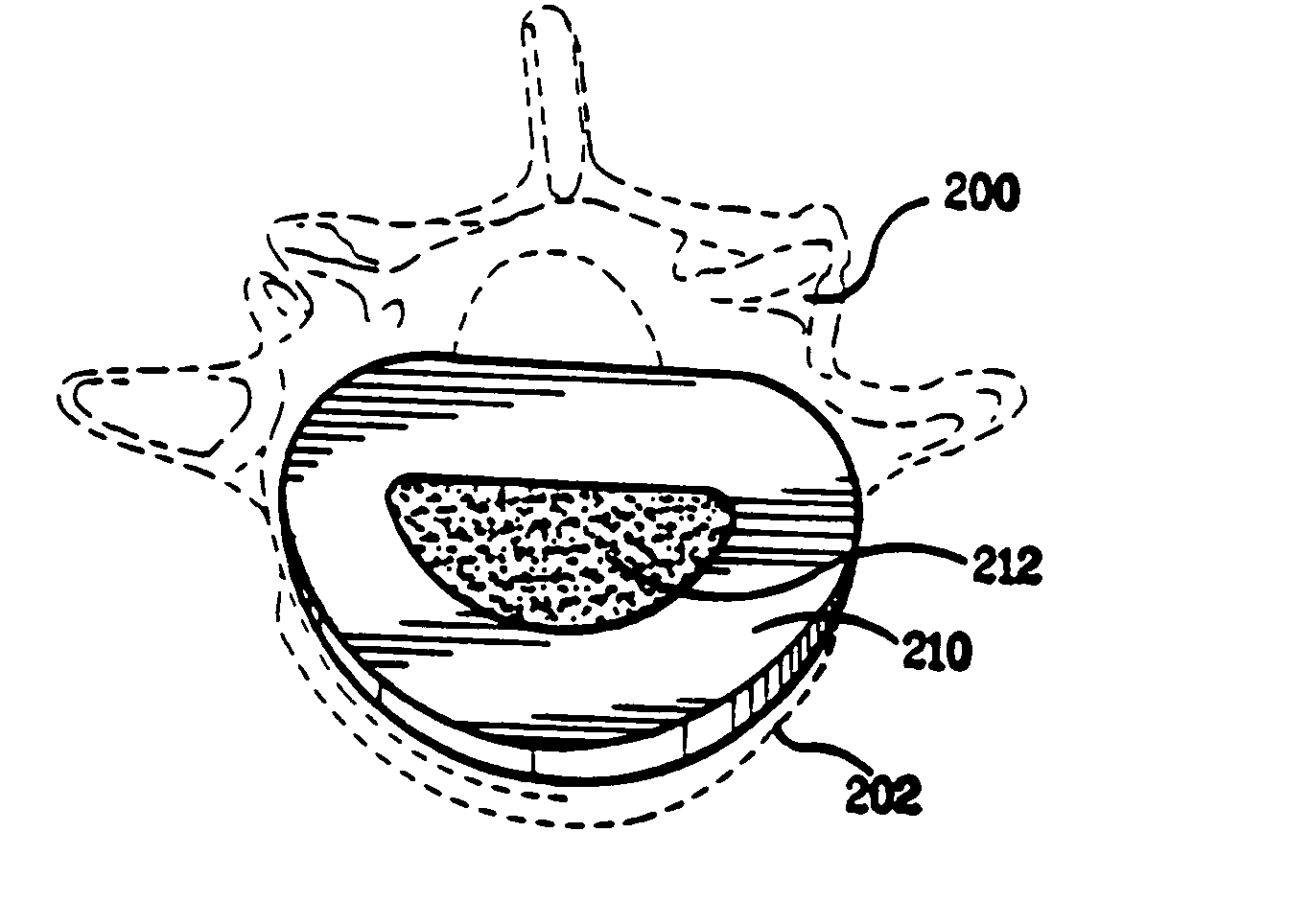

Composite shaped bodies and methods for their production and use

InactiveUS20050042288A1Increase productionLow process temperatureDental implantsPowder deliveryCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

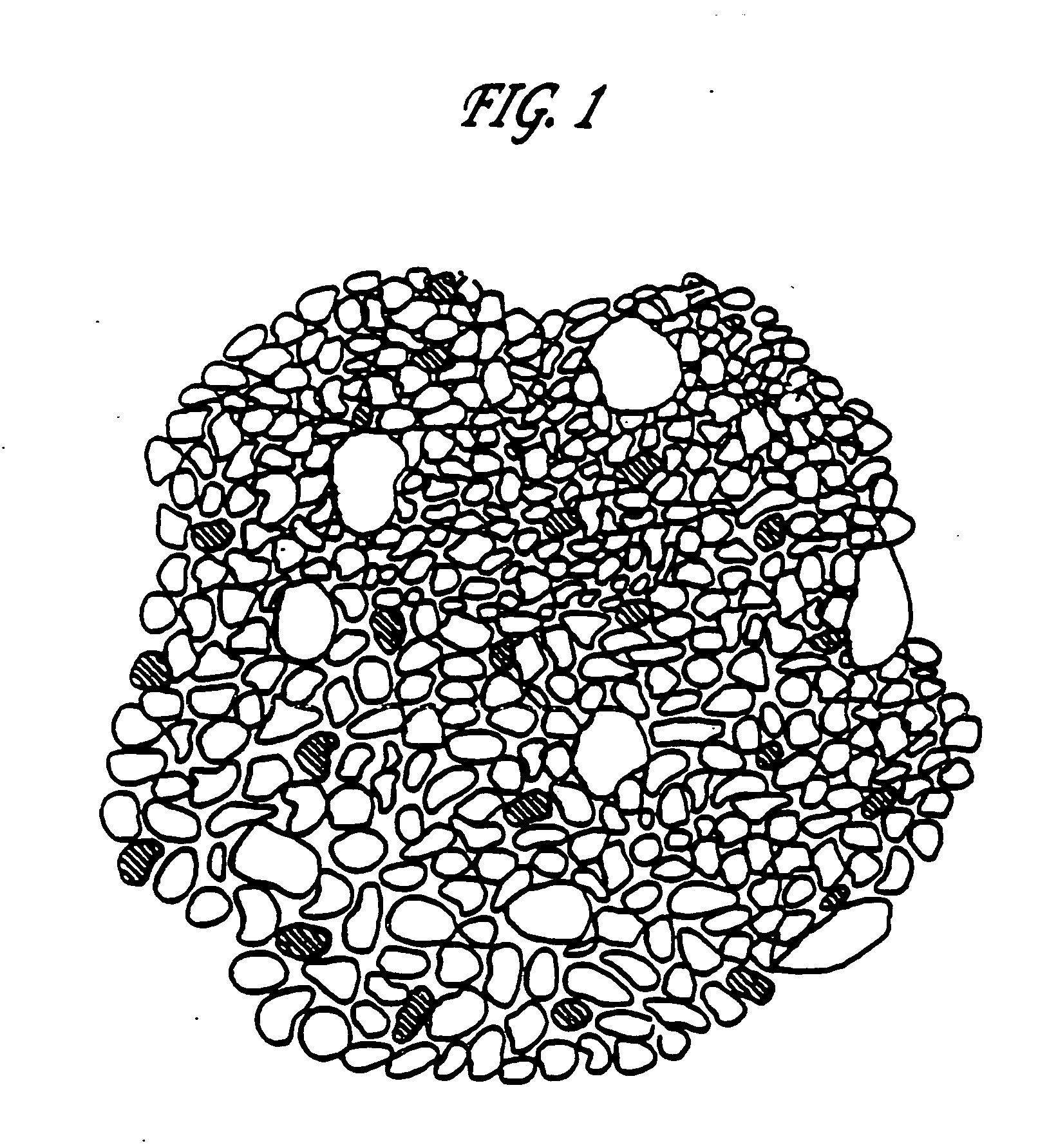

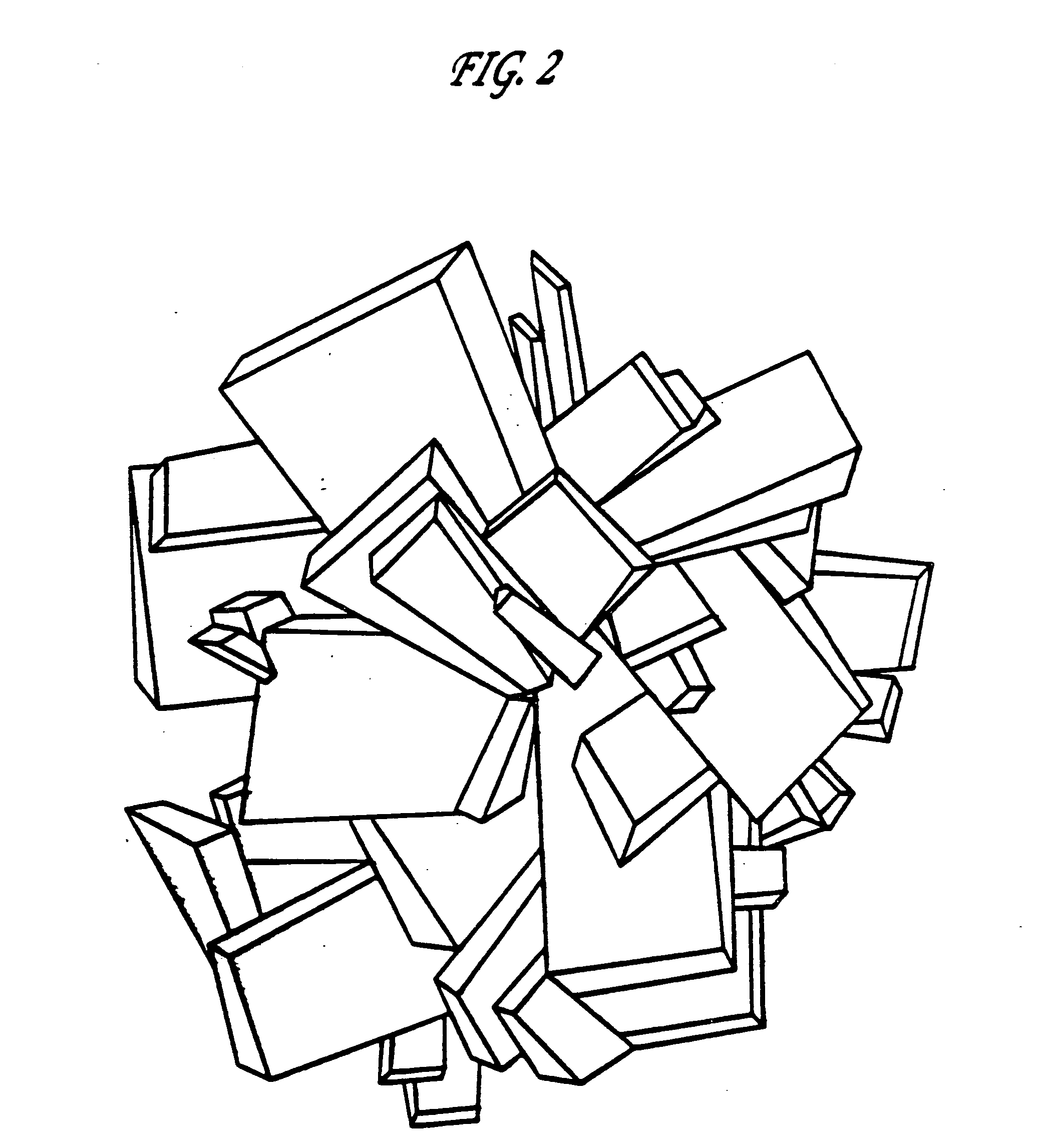

Low density proppant particles and use thereof

InactiveUS20070144736A1Uniform size and shapeDiffer in size , shapeSurveyFluid removalMicrobubblesMaterials science

Composite proppant particles each of which comprises a plurality of microbubbles and a resin binder are disclosed. Also disclosed are a method of using such composite proppant particles to prop fractures in wells formed in underground formations.

Owner:3M INNOVATIVE PROPERTIES CO

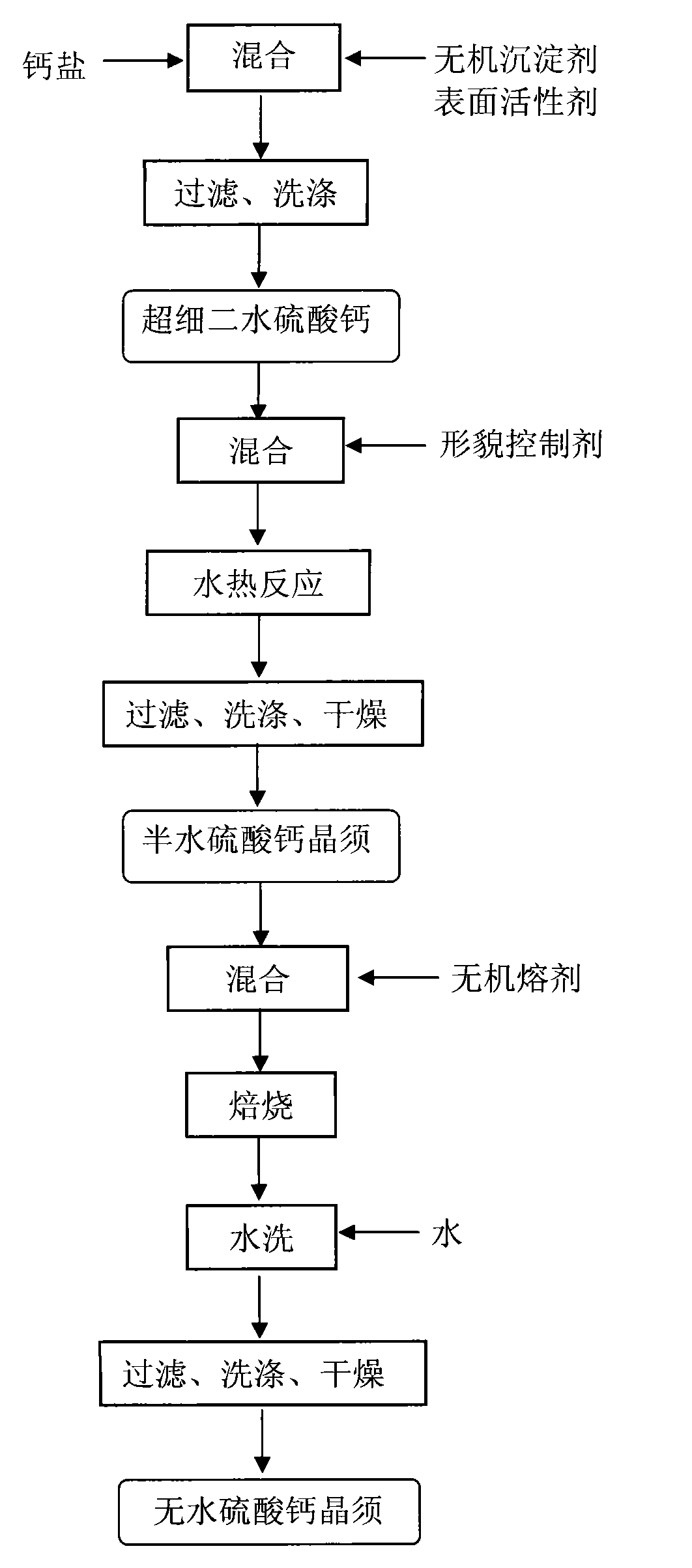

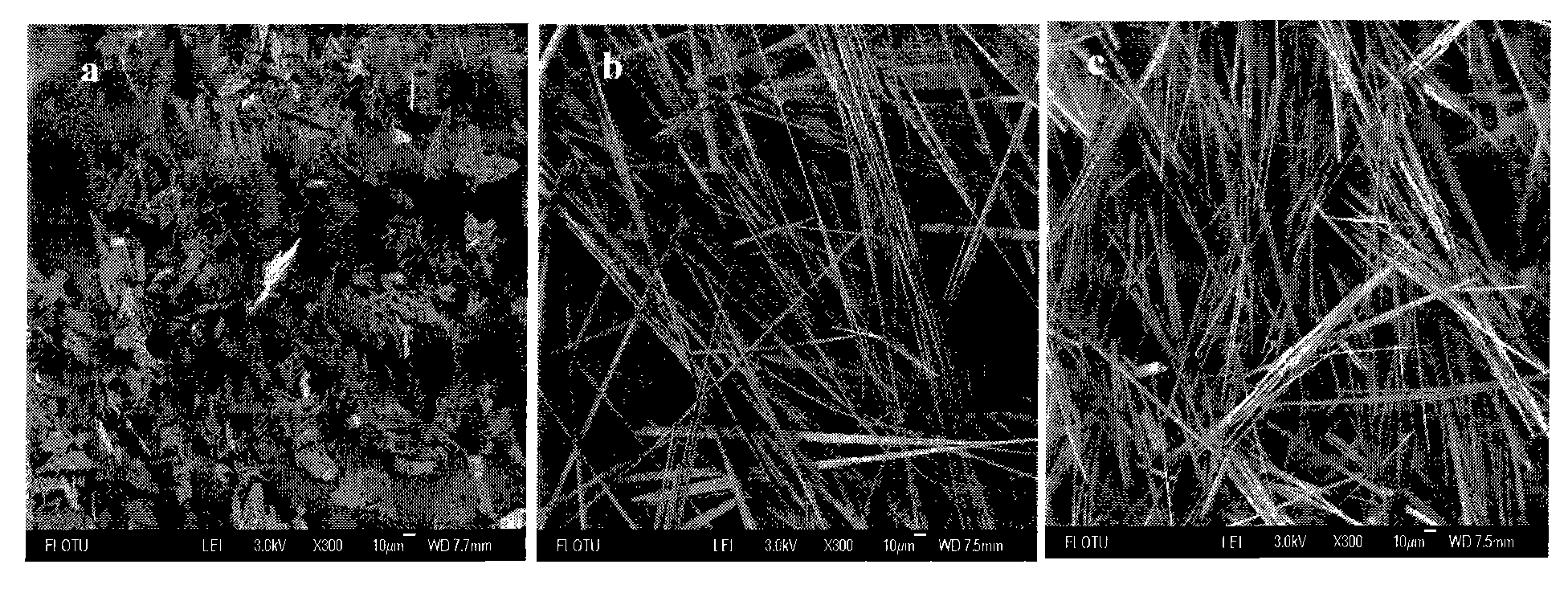

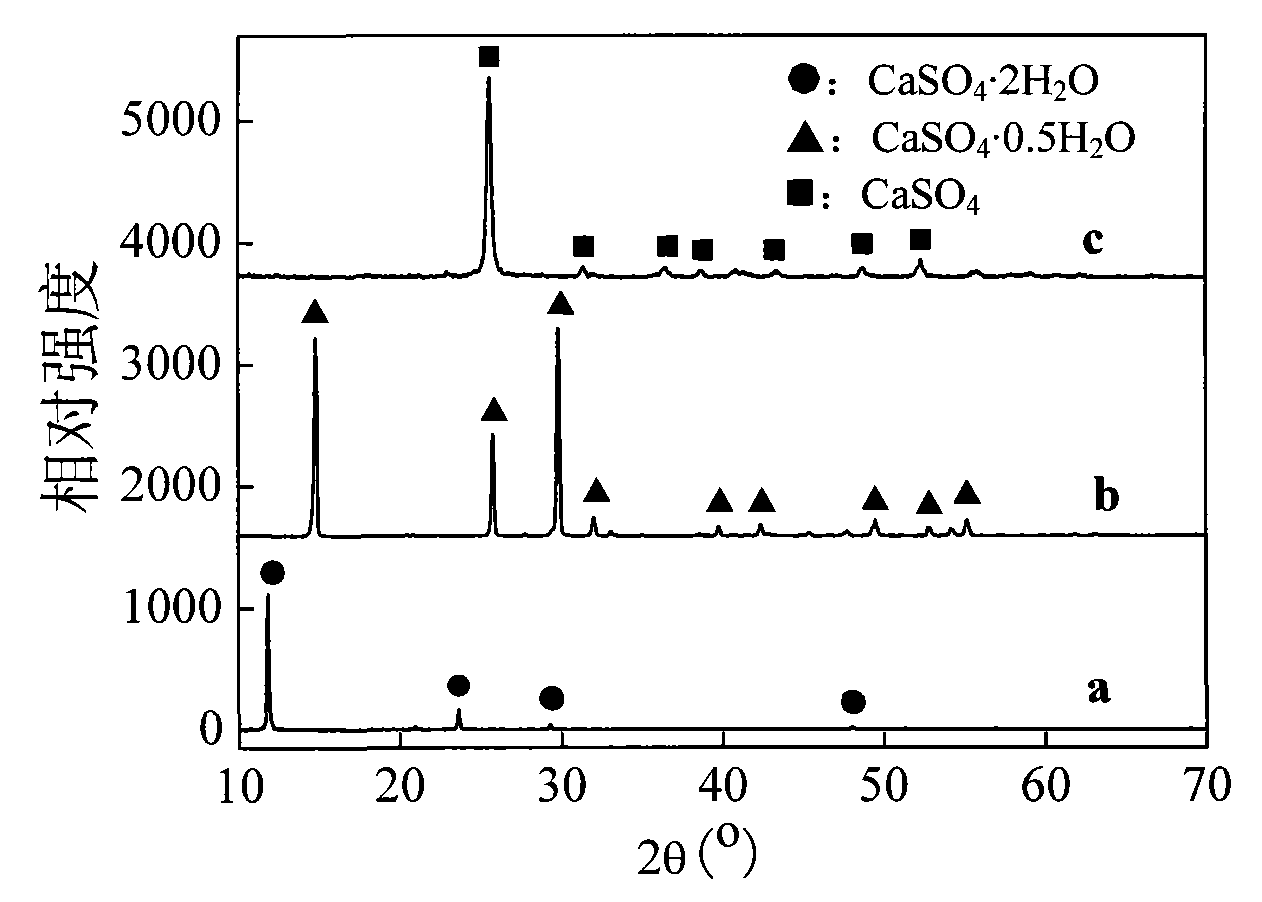

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

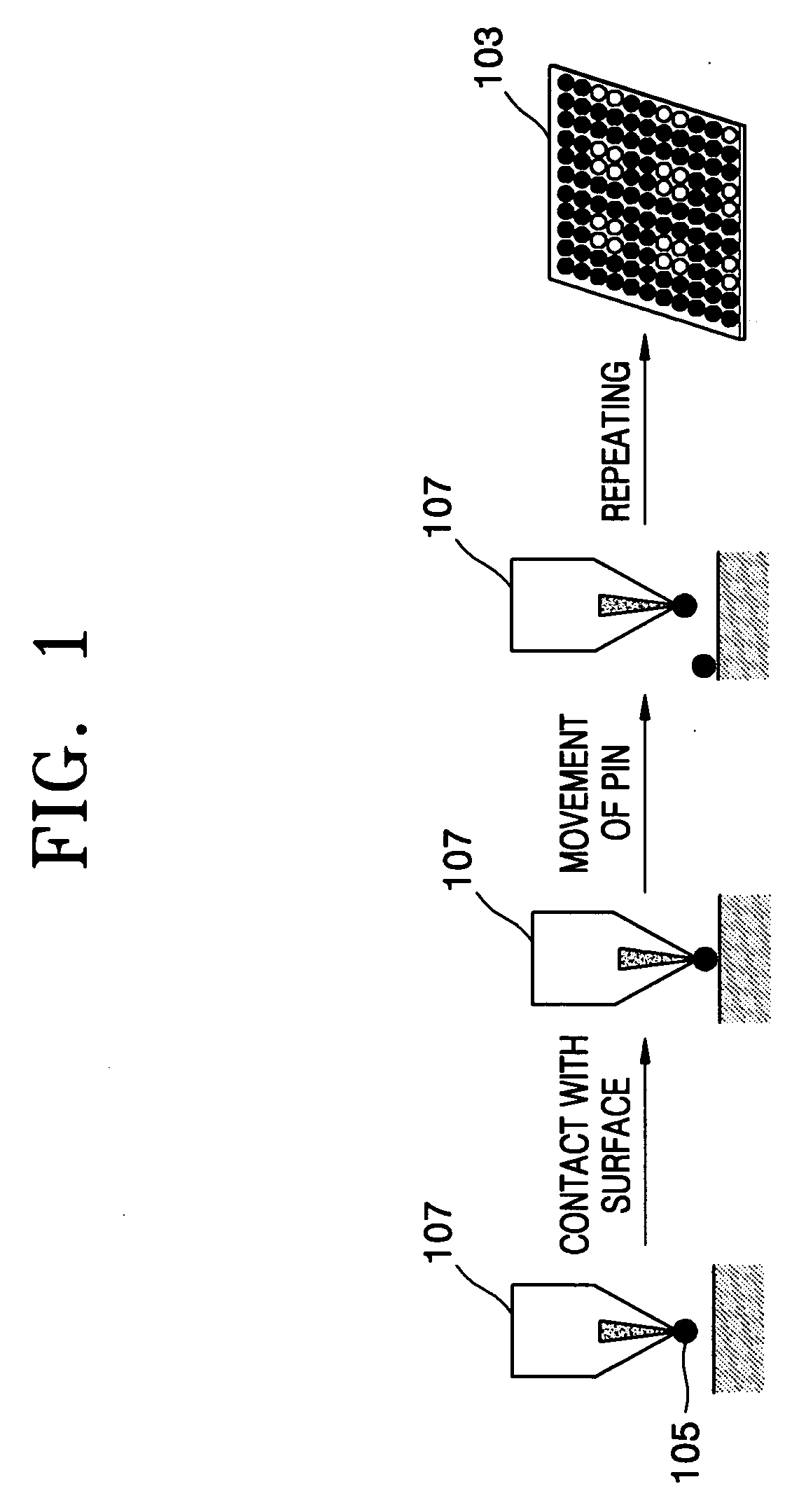

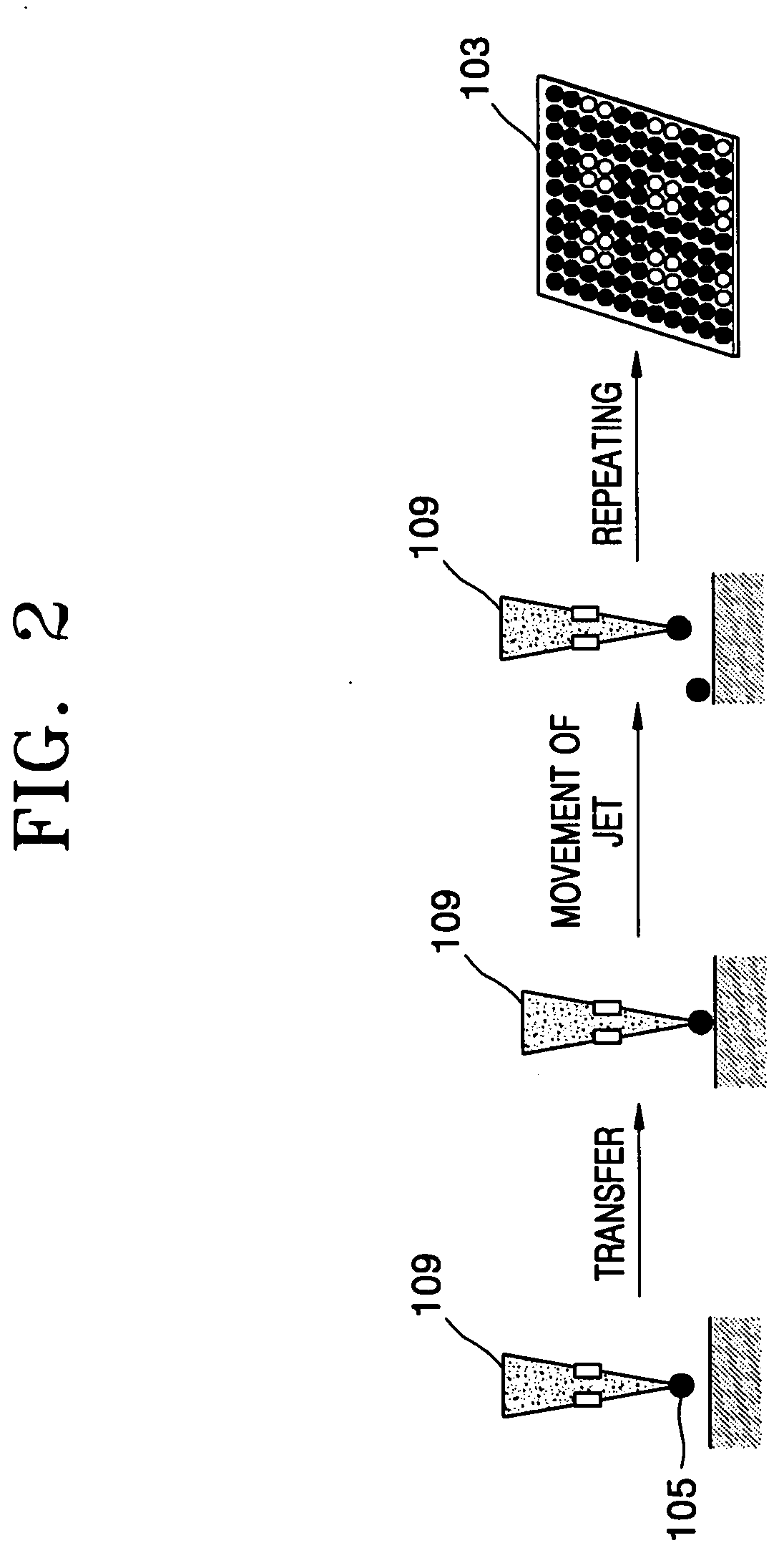

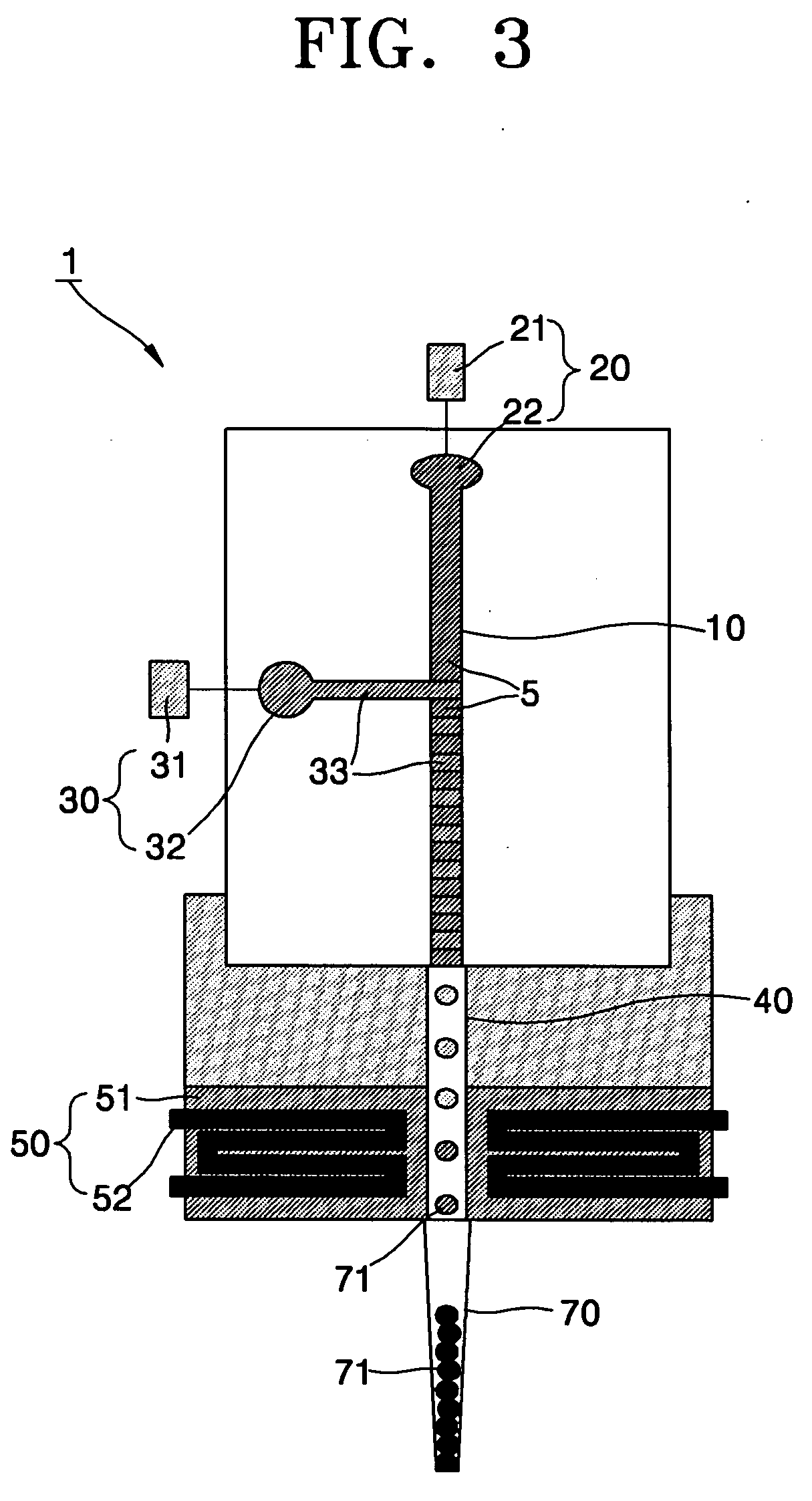

Spotting device for manufacturing DNA microarray and spotting method using the same

InactiveUS20050158755A1Shorten production timeUniform shapeBioreactor/fermenter combinationsMaterial nanotechnologyCross-linkDNA microarray

A spotting device for manufacturing a DNA microarray and a spotting method using the same are provided. The spotting device for dropping and immobilizing a solution of biomolecules, for example nucleic acids such as probe DNA, mRNA, and peptide nucleic acid (PNA), and proteins on a DNA microarray surface to manufacture a DNA microarray, includes a first microchannel with a tube shape; a supplying unit supplying the solution of biomolecules to the first microchannel; a biomolecule solution droplet forming unit cross-linked to the first microchannel and forming biomolecule solution droplets with a predetermined size by periodically jetting a gas toward the biomolecule solution flowing in the first microchannel; a second microchannel linked to the first microchannel and having a greater diameter than the first microchannel; a cooling unit surrounding at least a part of the second microchannel to freeze the biomolecule solution droplets which pass through the second microchannel; and a spotting unit thawing the frozen biomolecule solution droplets and dropping the thawed biomolecule solution droplets on a surface of the DNA microarray. The spotting device can form spots with uniform shape, minimize an effect of temperature on biomolecules, and easily manipulate biomolecules when manufacturing a DNA microarray.

Owner:SAMSUNG ELECTRONICS CO LTD

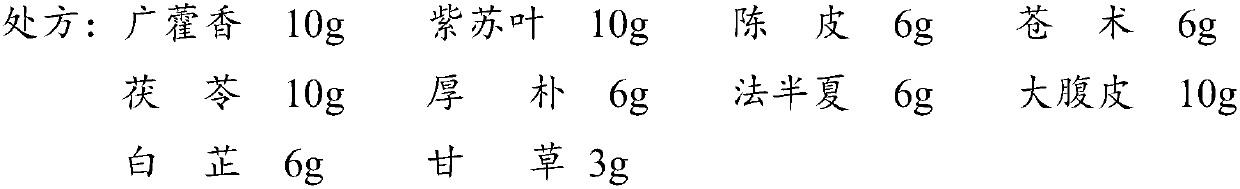

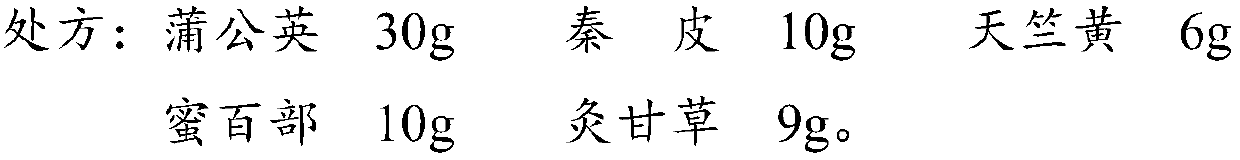

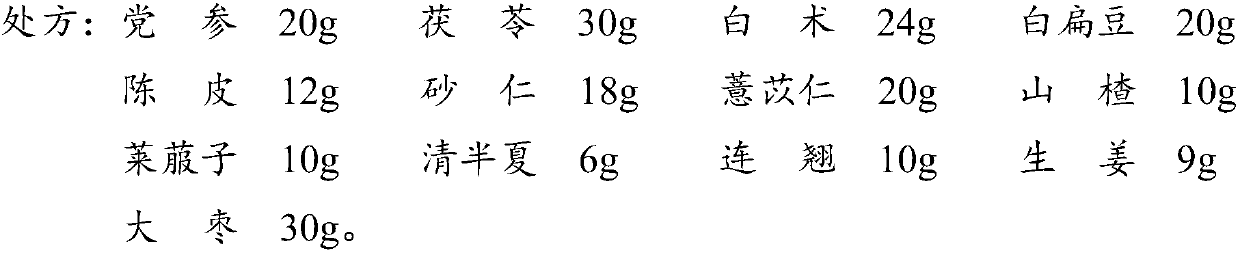

Preparation method of pellet-type formula granules

InactiveCN107744510ASimple preparation processImprove compliancePharmaceutical product form changeCoatingsMedicineMoisture absorption

The invention discloses a preparation method of pellet-type formula granules. The method comprises the following steps: (1) selecting at least one of the traditional Chinese medicinal materials; (2) respectively extracting the medicinal materials selected in step (1) for obtaining extracts, or respectively grinding the medicinal materials, or respectively carrying out partial extraction and partial grinding, thus obtaining pretreated materials; and (3) preparing the pretreated materials obtained in step (2) into pellets, thus obtaining the pellet-type formula granules. According to the preparation method provided by the invention, on the basis of the prior art, the preparation process of the formula granules is innovated, the formula granules are innovated into pellets, the fluidity and moisture absorption resistance are good, the friability is small, the shape is round and uniform as well as regular, the content uniformity is small, and the divided dose is accurate.

Owner:GUANGDONG LUOFUSHAN SINOPHARM

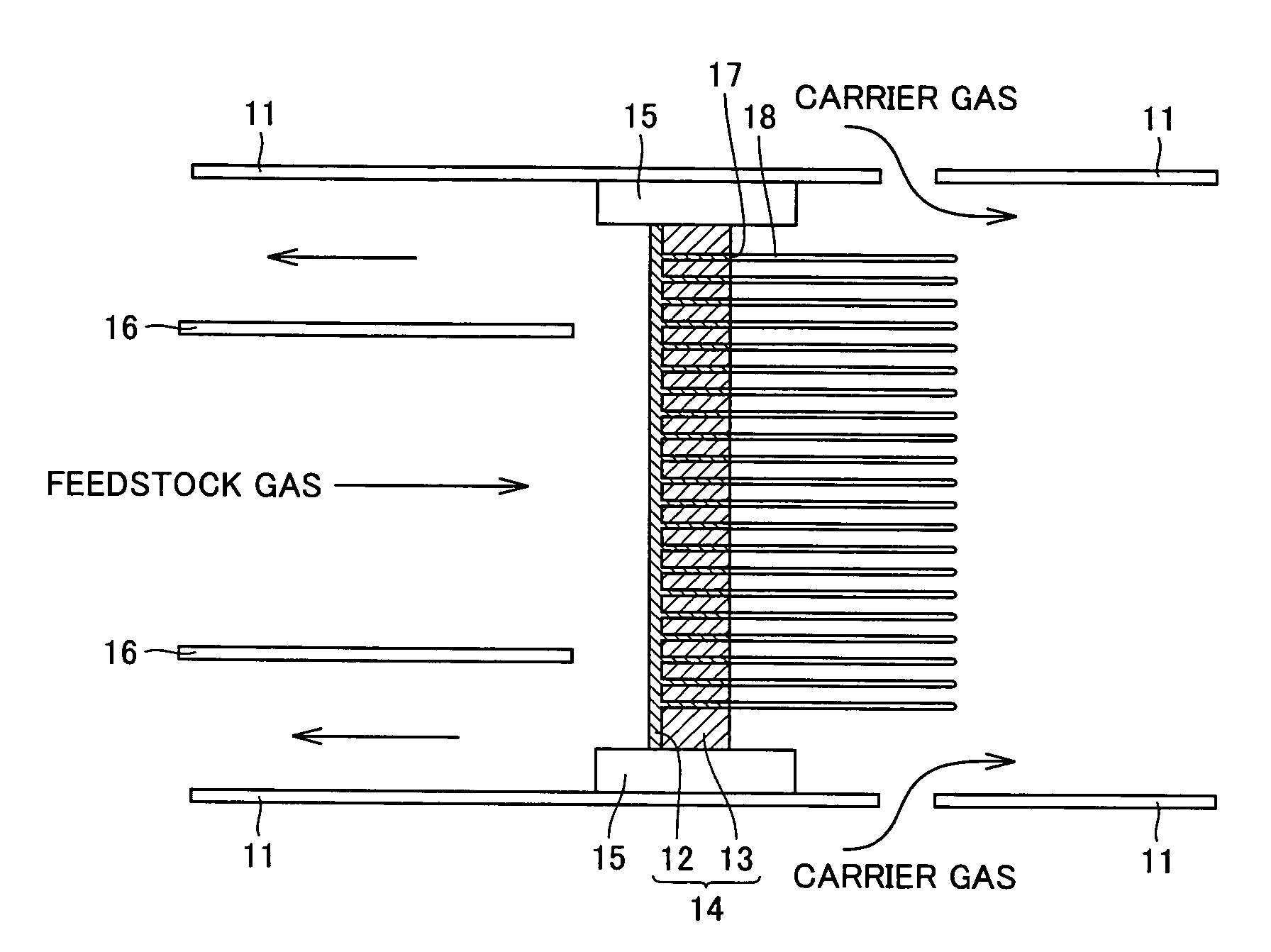

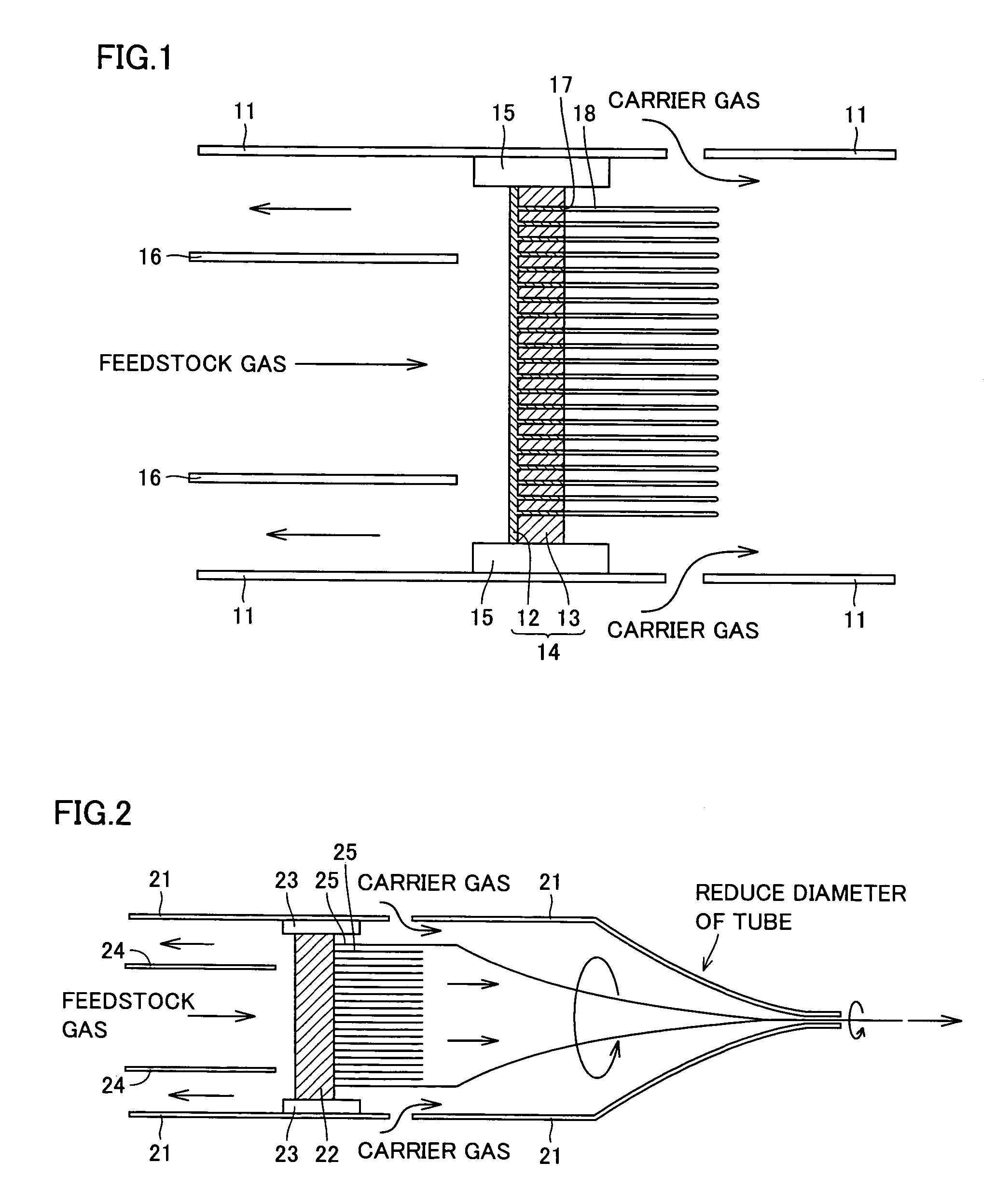

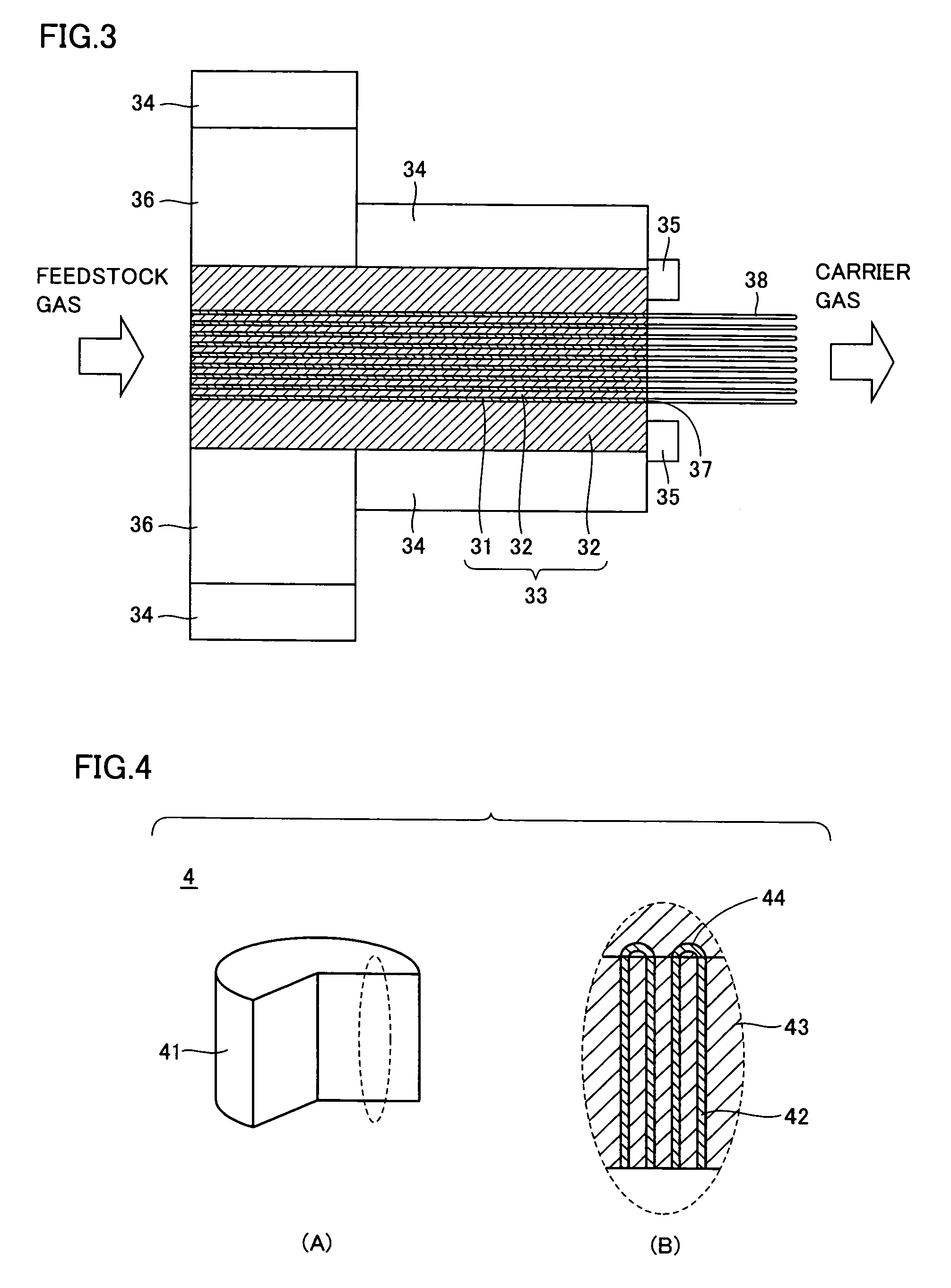

Method of manufacturing carbon nanostructure

ActiveUS7785558B2Uniform shapeHigh purityMaterial nanotechnologyPigmenting treatmentCarbon ionGas phase

The present invention relates to a method of manufacturing a carbon nanostructure for growing crystalline carbon by vapor deposition from a crystal growth surface of a catalytic base including a catalytic material, and in particular, to a method of manufacturing a carbon nanostructure where at least two gases including a feedstock gas are brought into contact with the catalytic base simultaneously. Preferably, the at least two gases are constituted by at least one feedstock gas and at least one carrier gas. Preferably, the carrier gas is brought into contact with the crystal growth surface, and the feedstock gas is brought into contact with at least a part of a region except for the crystal growth surface with which the carrier gas has been brought into contact. Preferably, the material gas contains an ion, and further preferably, it contains a carbon ion.

Owner:SUMITOMO ELECTRIC IND LTD

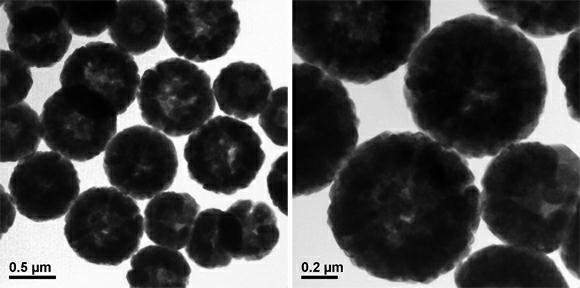

Magnetic inorganic nano-particle/ordered meso-porous silica core-shell microspheres and preparation thereof

InactiveCN101205420AGood magnetic responseUniform shapePigmenting treatmentChemical synthesisSol-gel

The invention belongs to the nano-composite material technology field, in particular to a magnetic inorganic nano-particle / ordered mesoporous silica core-shell microsphere and a preparation method thereof. The invention first utilizes sol-gel chemical synthesis method, coats a layer of amorphous silica on the surface of a plurality of magnetic inorganic nano-particles, then utilizes self-assembly of an organic surfactant as structure-directing agent and inorganic species in the solution, coats a layer of ordered meso-structured silica / surfactant composite material on the surface of the magnetic inorganic nano-particle / silica composite microsphere, removes the surfactant through solvent extraction, and obtains the ordered mesoporous magnetic inorganic nano-particle / silica core-shell structure composite microsphere material. The composite microsphere has high specific surface area, strong magnetic responsiveness, and wide application prospect in bioseparation and bioabsorption. The invention is simple in method, easy in obtaining raw materials, and suitable for large scale production.

Owner:FUDAN UNIV

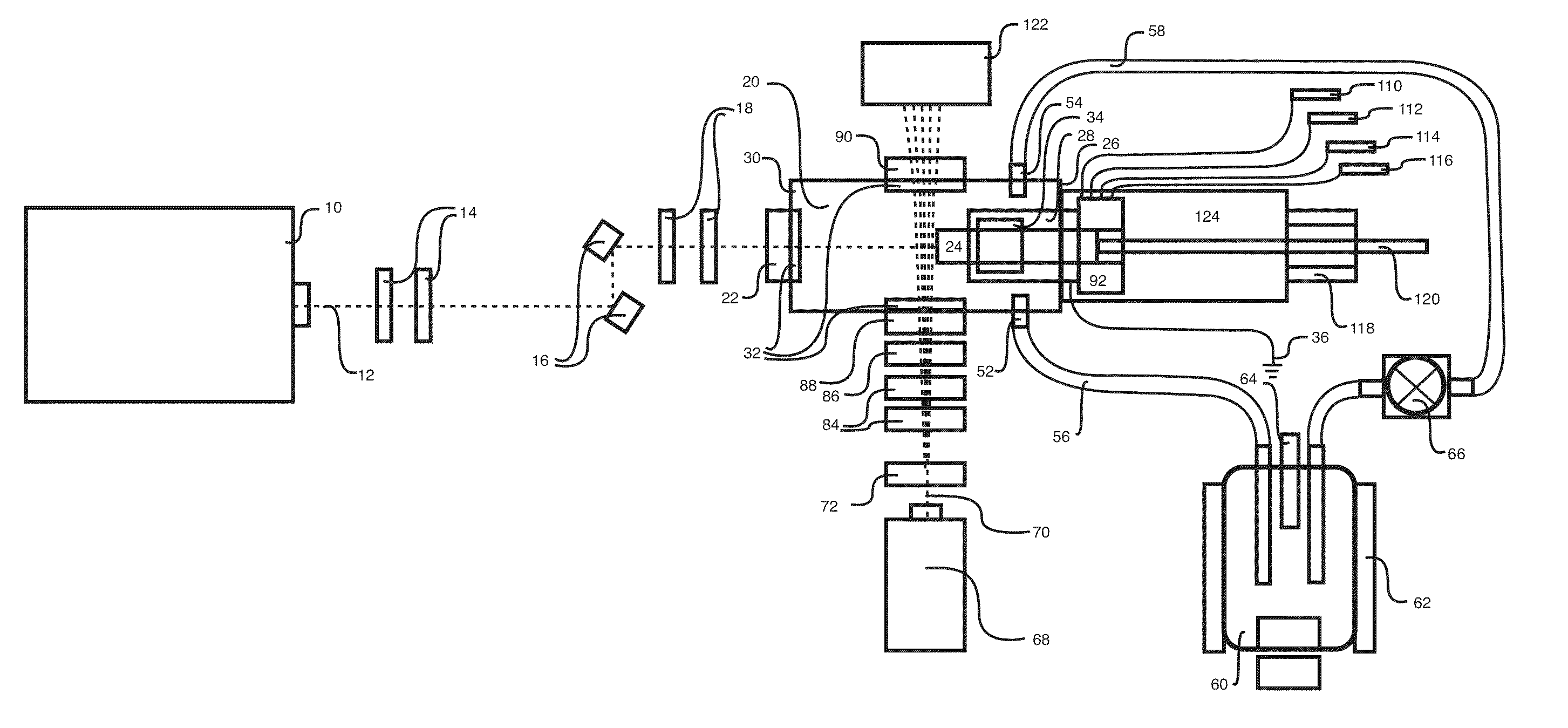

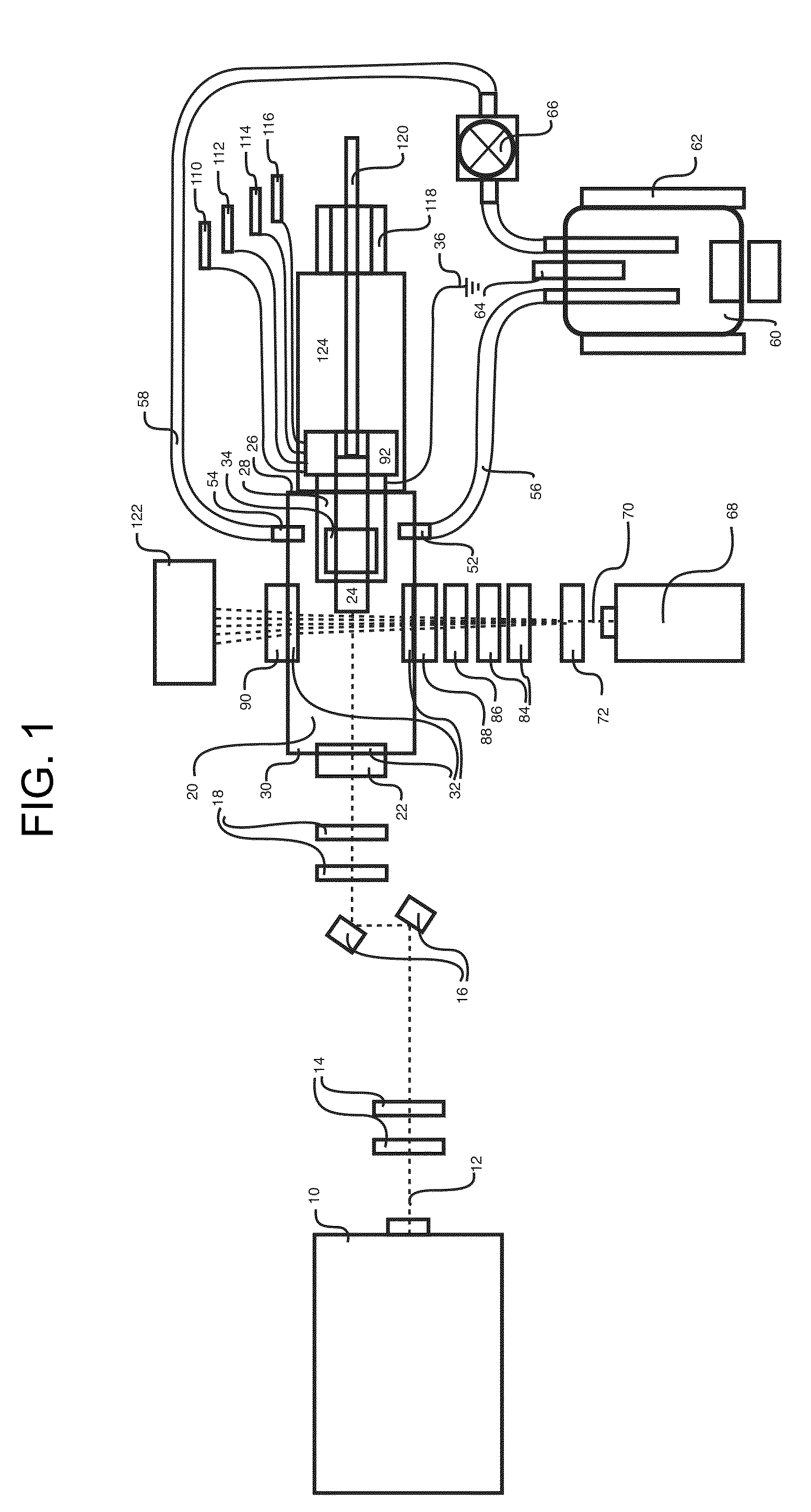

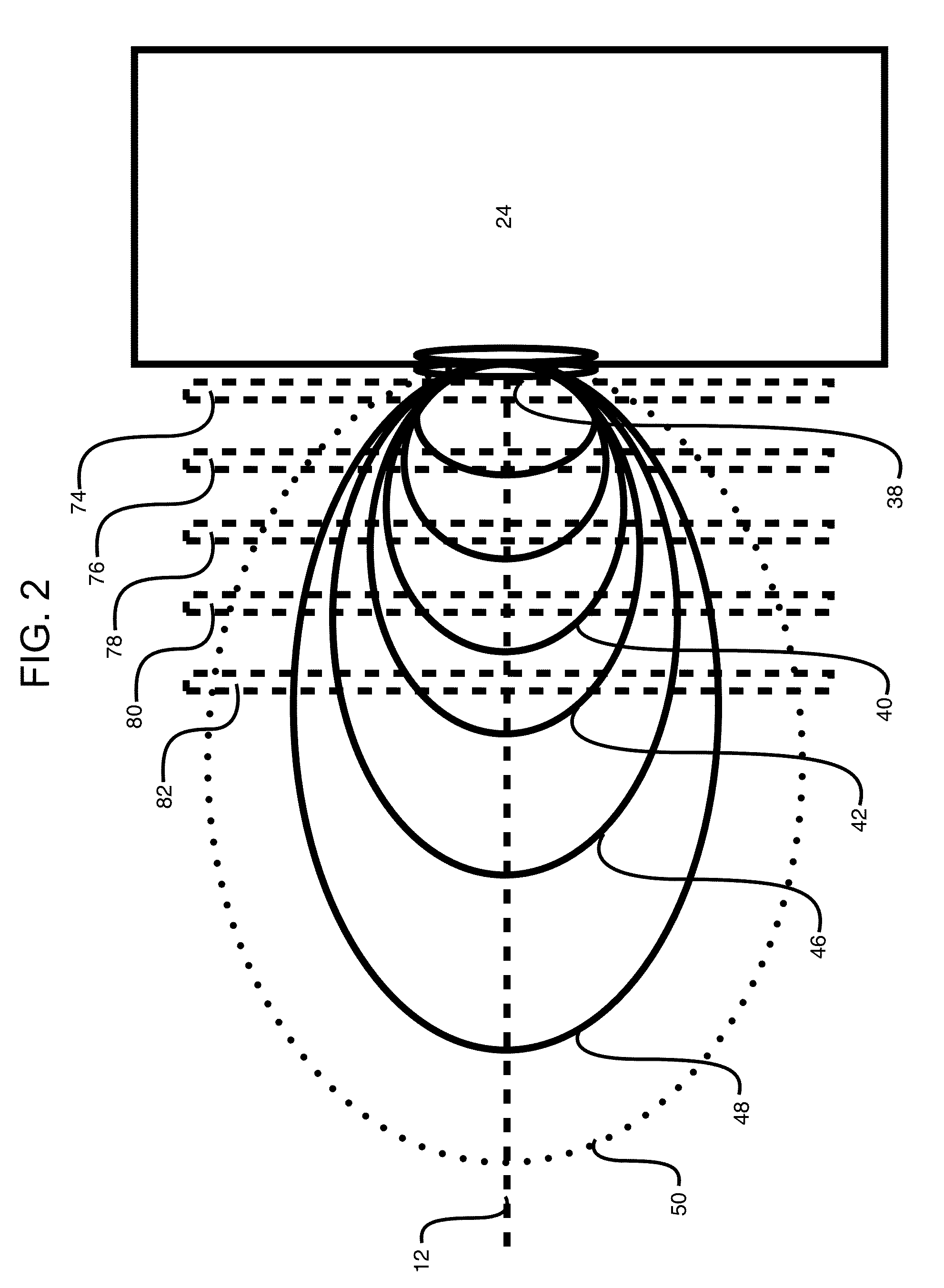

Method and apparatus for production of uniformly sized nanoparticles

ActiveUS20130001833A1Reduce in quantityLightweight productionMetal-working apparatusNanotechnologyTarget surfaceNanoparticle

An apparatus and process for creating uniformly sized, spherical nanoparticles from a solid target. The solid target surface is ablated to create an ejecta event containing nanoparticles moving away from the surface. Ablation may be caused by laser or electrostatic discharge. At least one electromagnetic field is placed in front of the solid target surface being ablated. The electromagnetic field manipulates at least a portion of the nanoparticles as they move away from the target surface through the electromagnetic field to increase size and spherical shape uniformity of the nanoparticles. The manipulated nanoparticles are collected.

Owner:EVOQ NANO INC

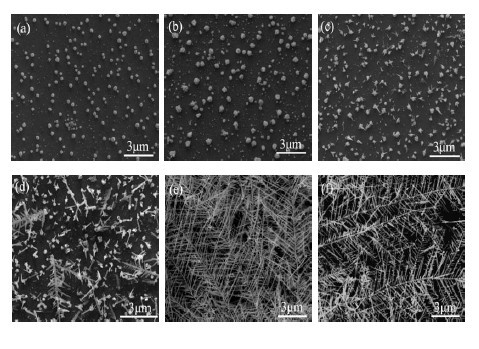

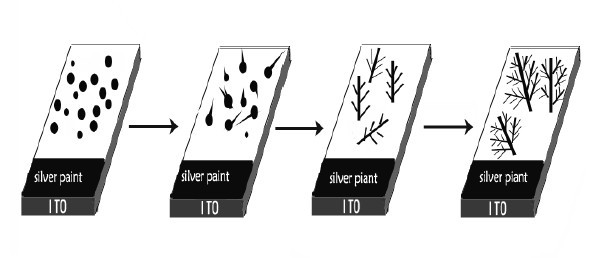

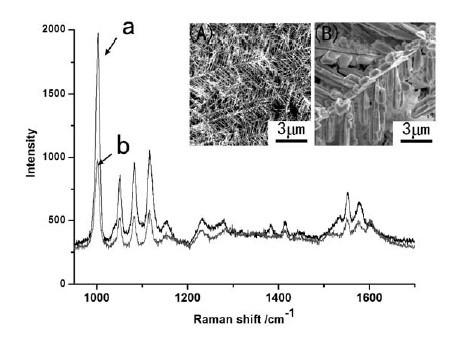

Silver nanodendrite surface enhanced Raman scattering (SERS) substrate, and preparation method and application thereof

InactiveCN102181891AUniform shapeSize is easy to controlRaman scatteringNanotechnologyThree Dimensional SizeRaman scattering

The invention discloses a silver nanodendrite surface enhanced Raman scattering (SERS) substrate, and a preparation method and application thereof, relating to the technical field of nanomaterial science and Raman detection. The SERS active substrate is of silver dendrites which are distributed evenly, and the three-dimensional sizes of dendrites are adjustable. The preparation method of the invention is characterized in that the silver nanodendrites are electrically deposited on commercially available ITO (Indium-doped Tin Oxide) conductive glass by adopting a constant current deposition method and using a silver nitrate solution as electrolyte without adding any other auxiliary. The preparation method of the invention has the advantages of simple, convenient fast (30s) preparation process, low cost, small current and low voltage, and the silver dendrites can be transferred to any substrate (paper, other metal sheets or plastic sheets). The substrate obtained by the method disclosed by the invention has high stability and ordered and controllable structure, and exhibits quite high sensitivity in Raman spectrum detection.

Owner:WENZHOU UNIVERSITY

Process for preparing hydrated sodium titanate and nano titanate tube series

InactiveCN1378977AWith ion exchangeLarge specific surface areaTitanium compoundsSodium titanateThermal stability

A process for preparing the nanometre tubes of hydrated sodium titanate and titanate series includes such steps as hydrothermal reaction of TiO2 or metatitanic acid to obtain the nanometre tubes of hydrated sodium titanate, mixing them with the solution containing one or two kinds of metal ions to convert them to the nanometre tubes of hydrated titanate or composite hydrated titanates of the saidmetal ions, and thermal dewatering to obtain the nanometre tubes of corresponding titanate or composite titanates. Its advantages are uniform shape, large specific surface area, high thermal stability and regulatable catalytic performance.

Owner:TSINGHUA UNIV

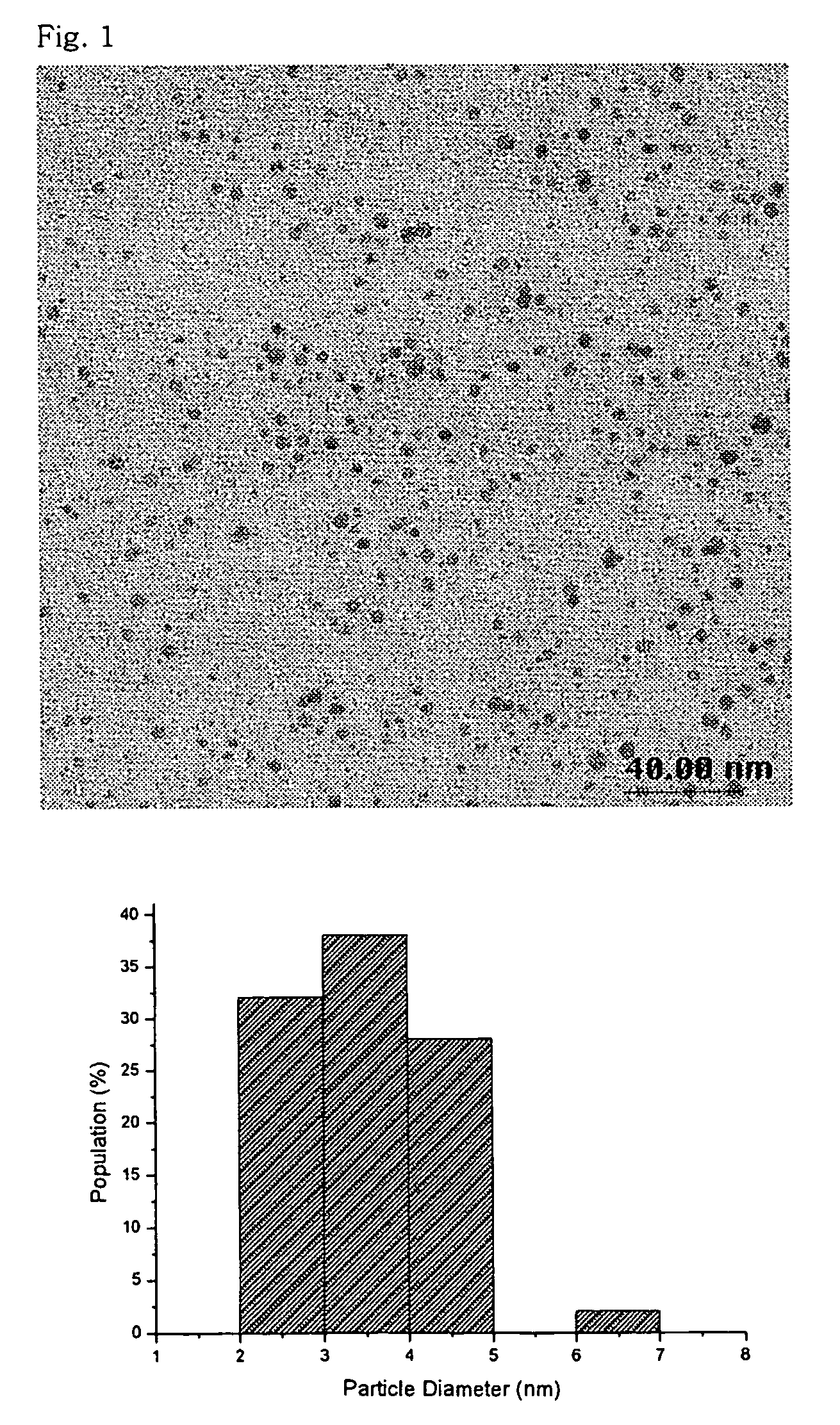

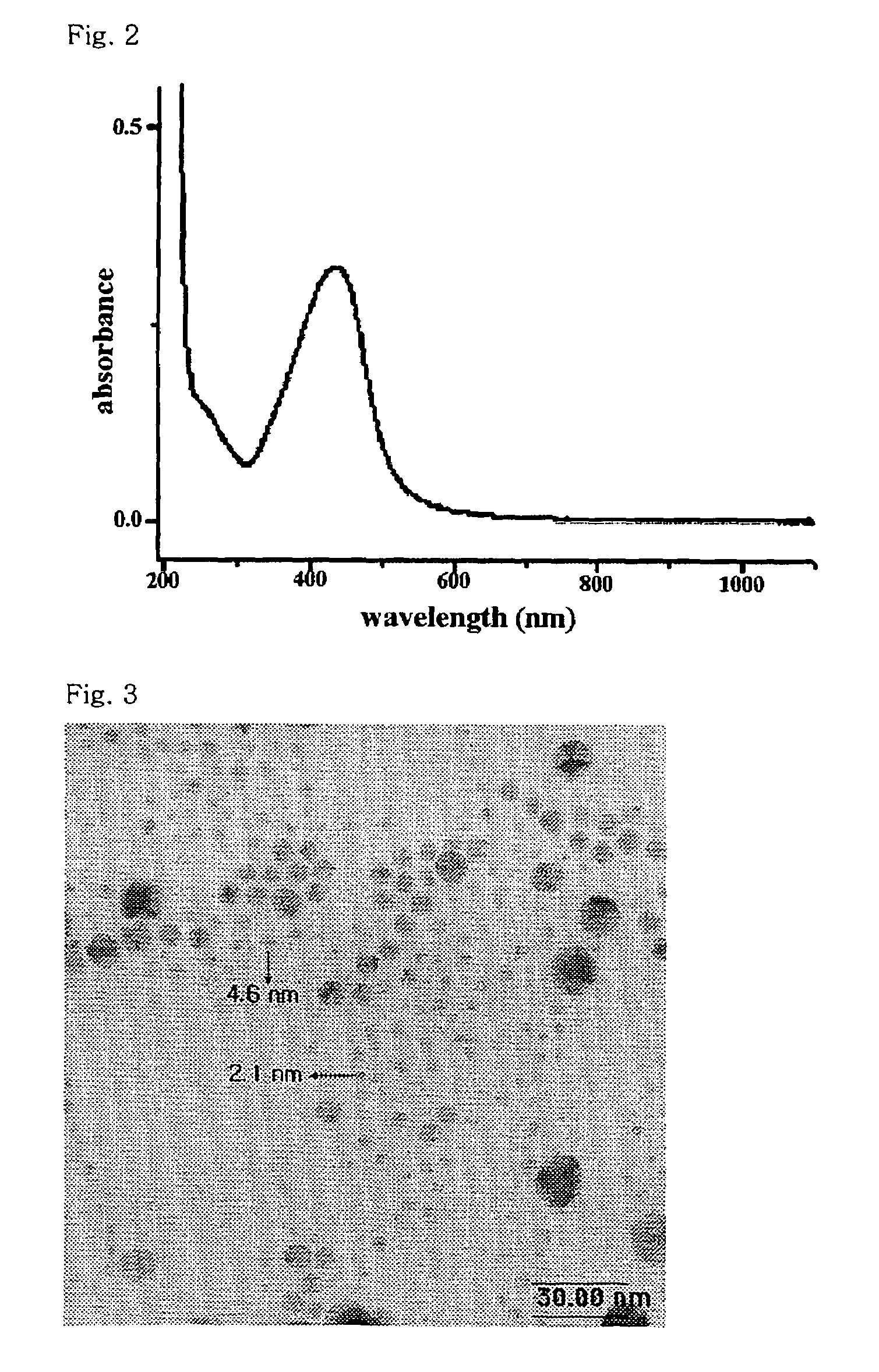

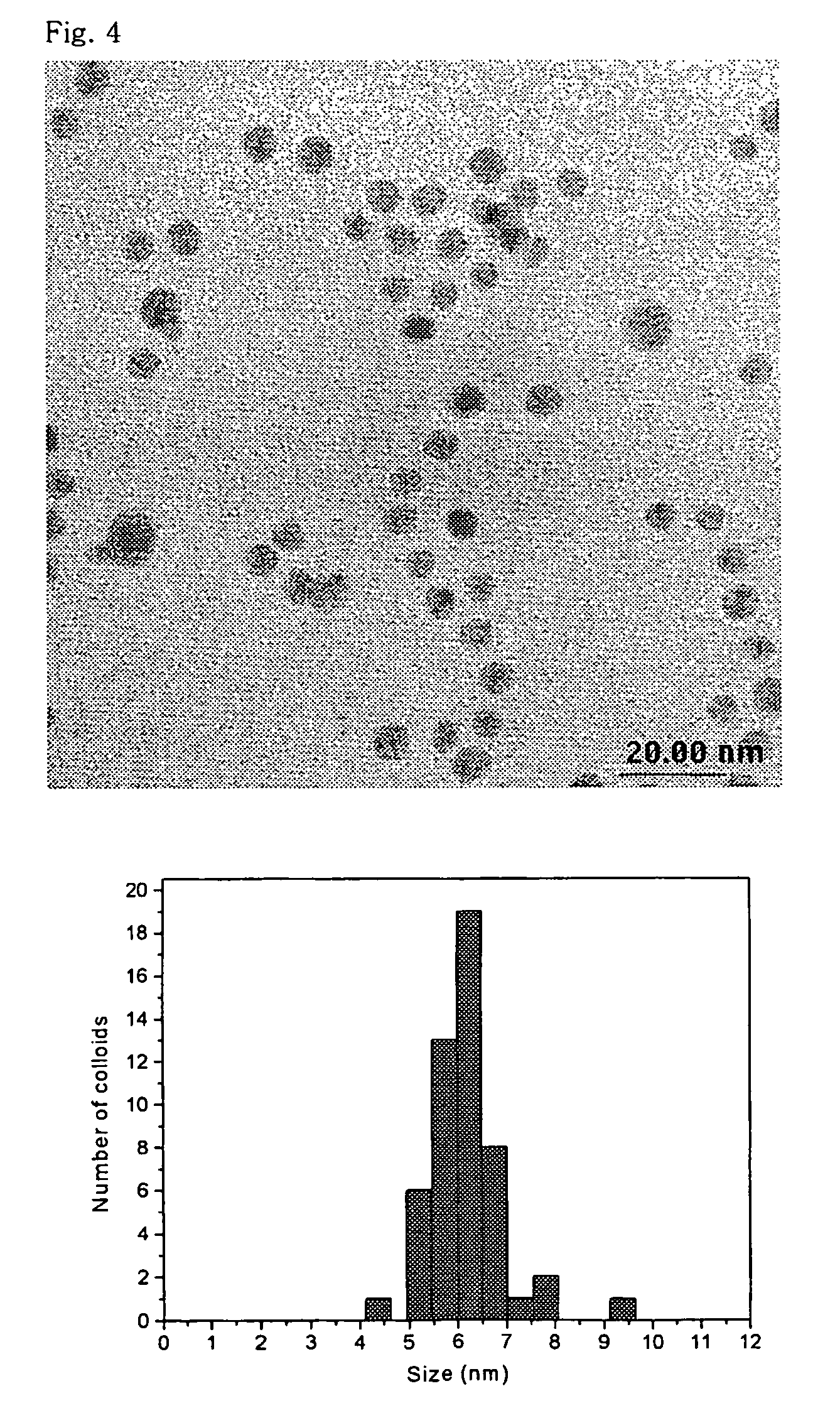

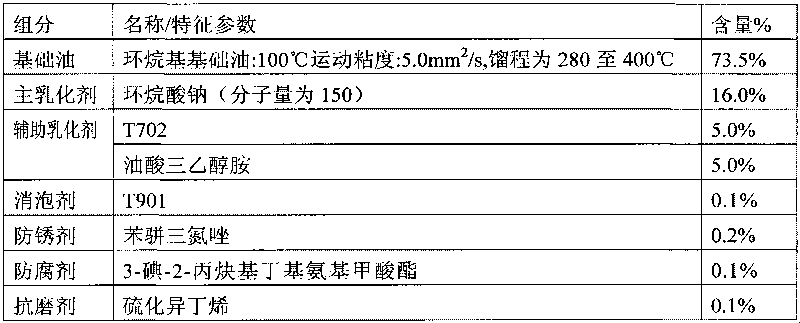

Colloid solution of metal nanoparticles, metal-polymer nanocomposites and methods for preparation thereof

InactiveUS7348365B2Easy to controlGood effectOther chemical processesTransportation and packagingStabilizer for polymersNanometre

A metal nanoparticle colloid solution, metal-polymer nanocomposites, and methods for preparing the same are provided. The metal nanoparticle colloid solution and the metal-polymer nanocomposites can be prepared with a variety of polymeric stabilizers and have uniform particle diameter and shape. The metal nanoparticle colloid solution and the metal-polymer nanocomposites have wide applications, for example, as an antibacterial agent, a sterilizer, a conductive adhesiv, conductive ink or an electromagnetic wave shielder for an image display.

Owner:POSTECH ACAD IND FOUND +1

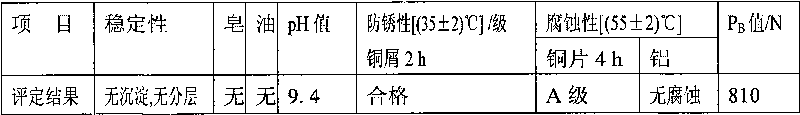

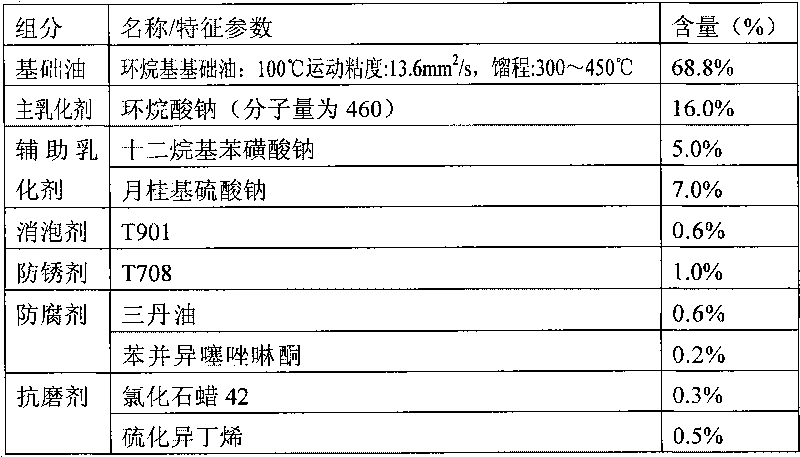

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

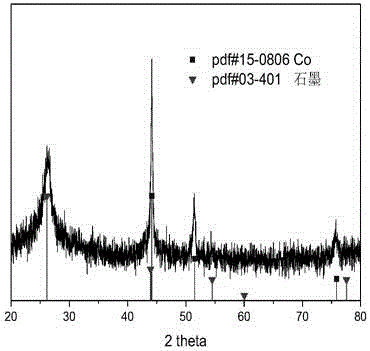

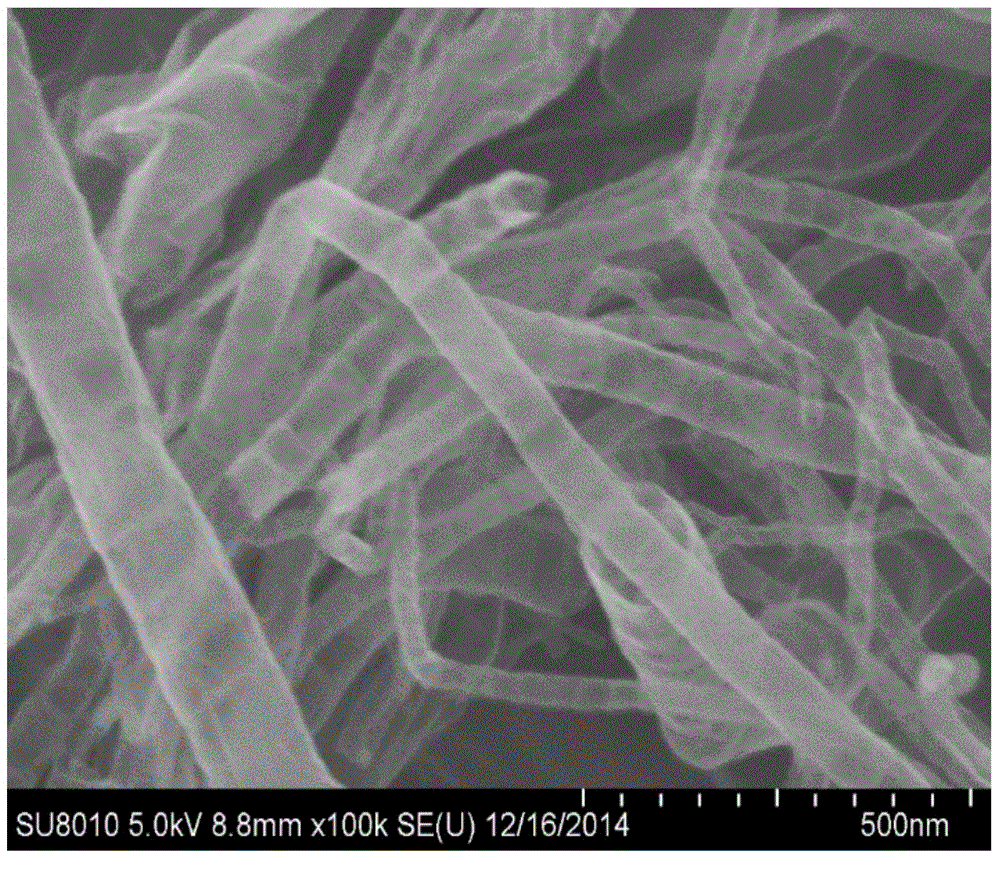

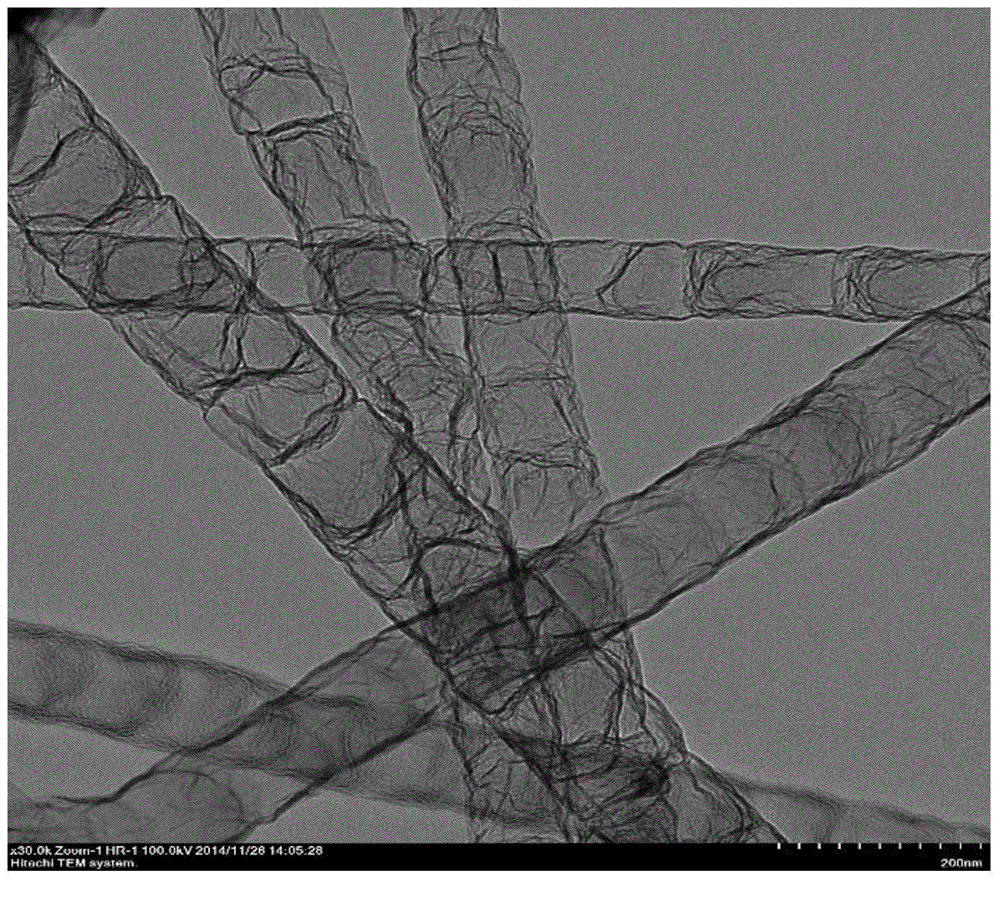

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Controllable synthesis method for nitrogen and phosphorus co-doped graphitized carbon ball with hollow structure

InactiveCN103183330AHigh purityUniform shapeMaterial nanotechnologyCarbon preparation/purificationSolventCarbon source

The invention relates to a controllable synthesis method for a nitrogen and phosphorus co-doped graphitized carbon ball with a hollow structure. The method comprises the following preparation steps: (1) a carbon source, soluble metal salt and a catalyst are dissolved in a solvent according to a molar ratio, the mixture is transferred to a hydrothermal reaction kettle for hydrothermal synthesis after stirred to be dissolved completely, and an obtained precipitate is cleaned, filtered and dried to obtain a primary product; (2) the obtained primary product is subjected to high-temperature reduction under the protection of gas in a high-temperature reaction furnace; and (3) the product obtained by high-temperature reduction is placed in an acid solution to be soaked, and then cleaned, filtered and dried to obtain the nitrogen and phosphorus co-doped graphitized carbon ball with the hollow structure. The nitrogen and phosphorus co-doped graphitized carbon ball with the hollow structure prepared with the method has the advantages that the appearance is uniform, a carbon shell has a cellular structure, the interior of the carbon ball has a mesoporous carbon support structure, the graphitization degree is good, and the like; and the carbon ball can be used in various fields of efficient catalytic conversion, energy storage and conversion, medicine release and control, substance adsorption and separation and the like. A template-free hydrothermal synthesis technique is simple and controllable, and can be used for mass production.

Owner:CHINA UNIV OF MINING & TECH +1

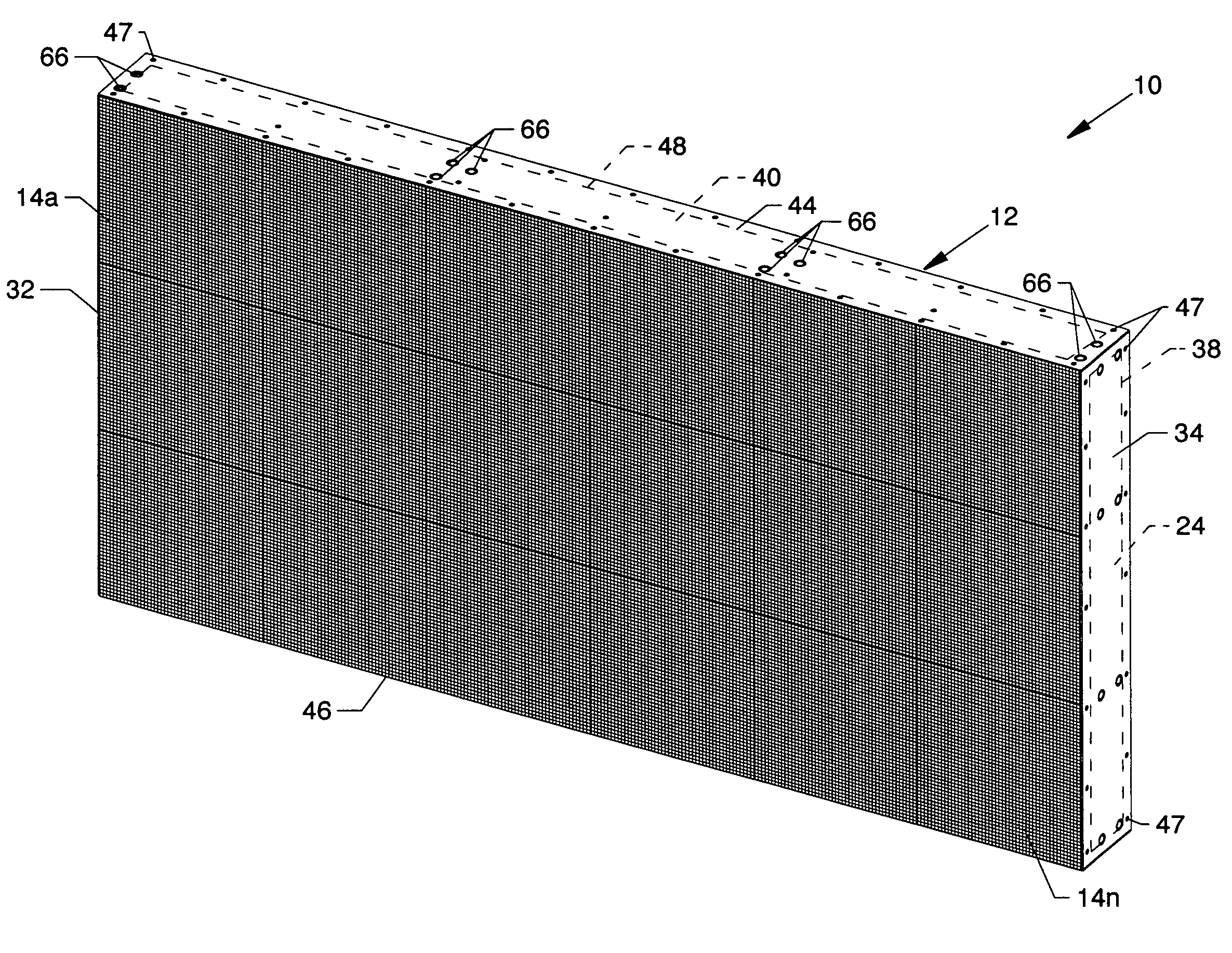

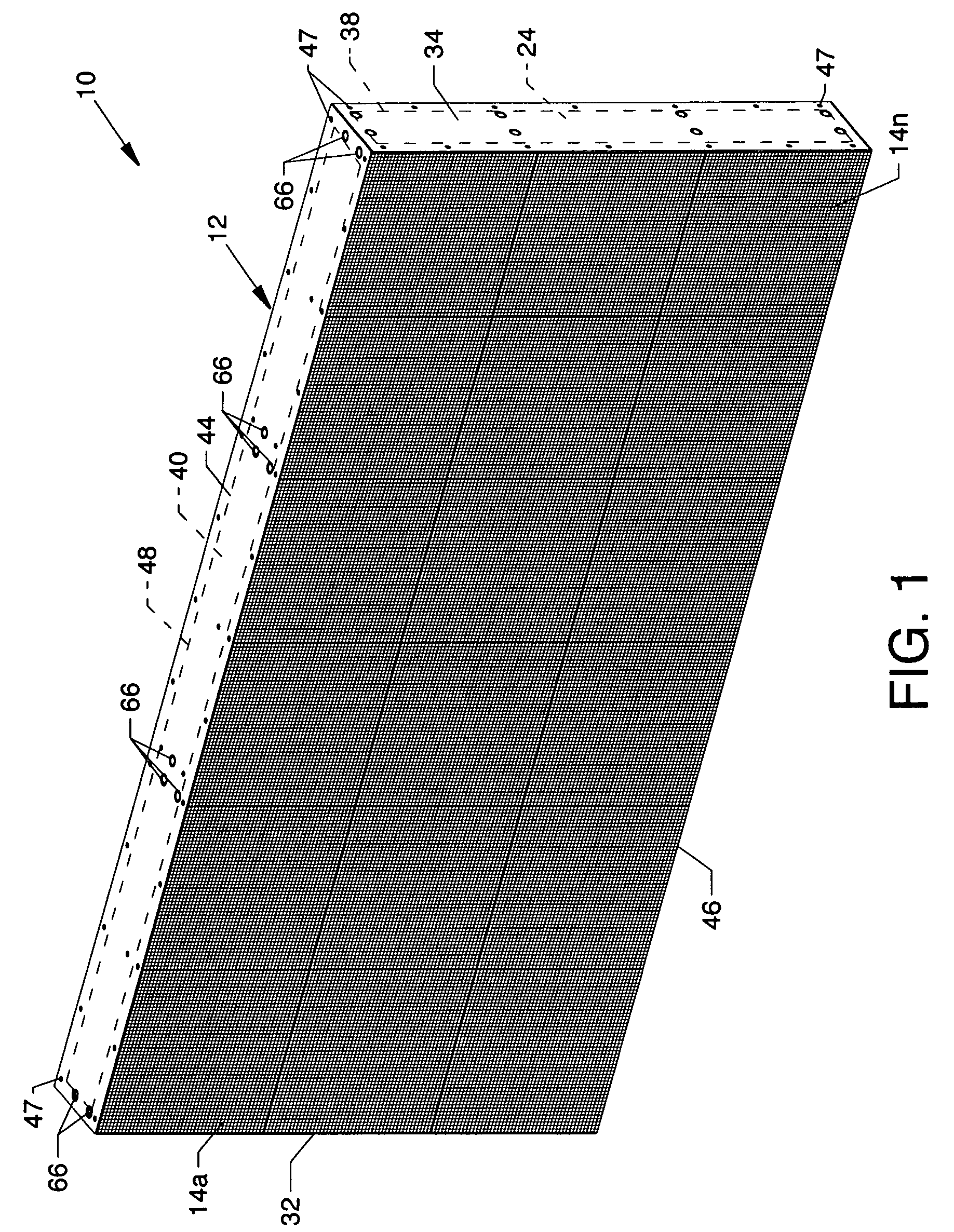

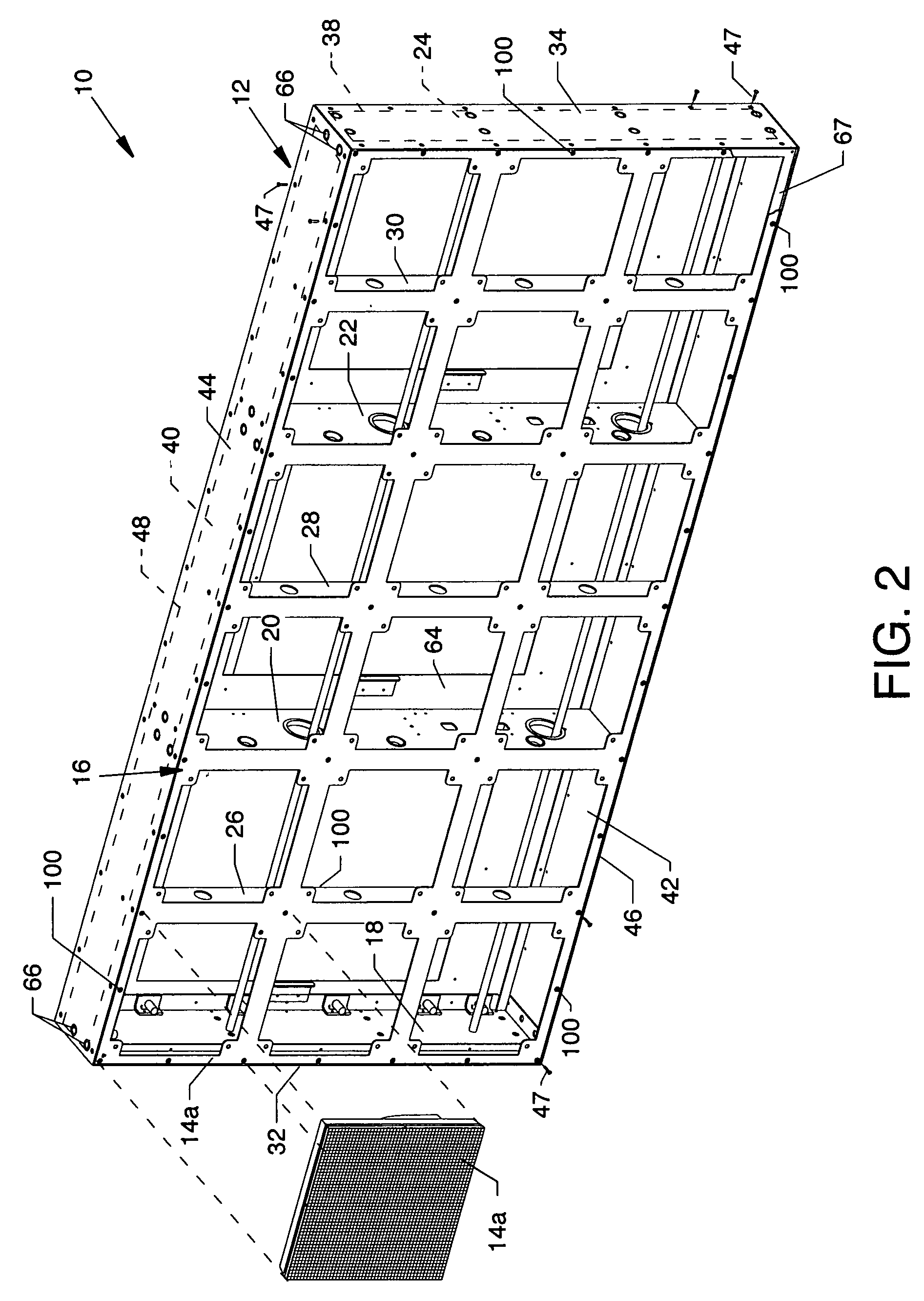

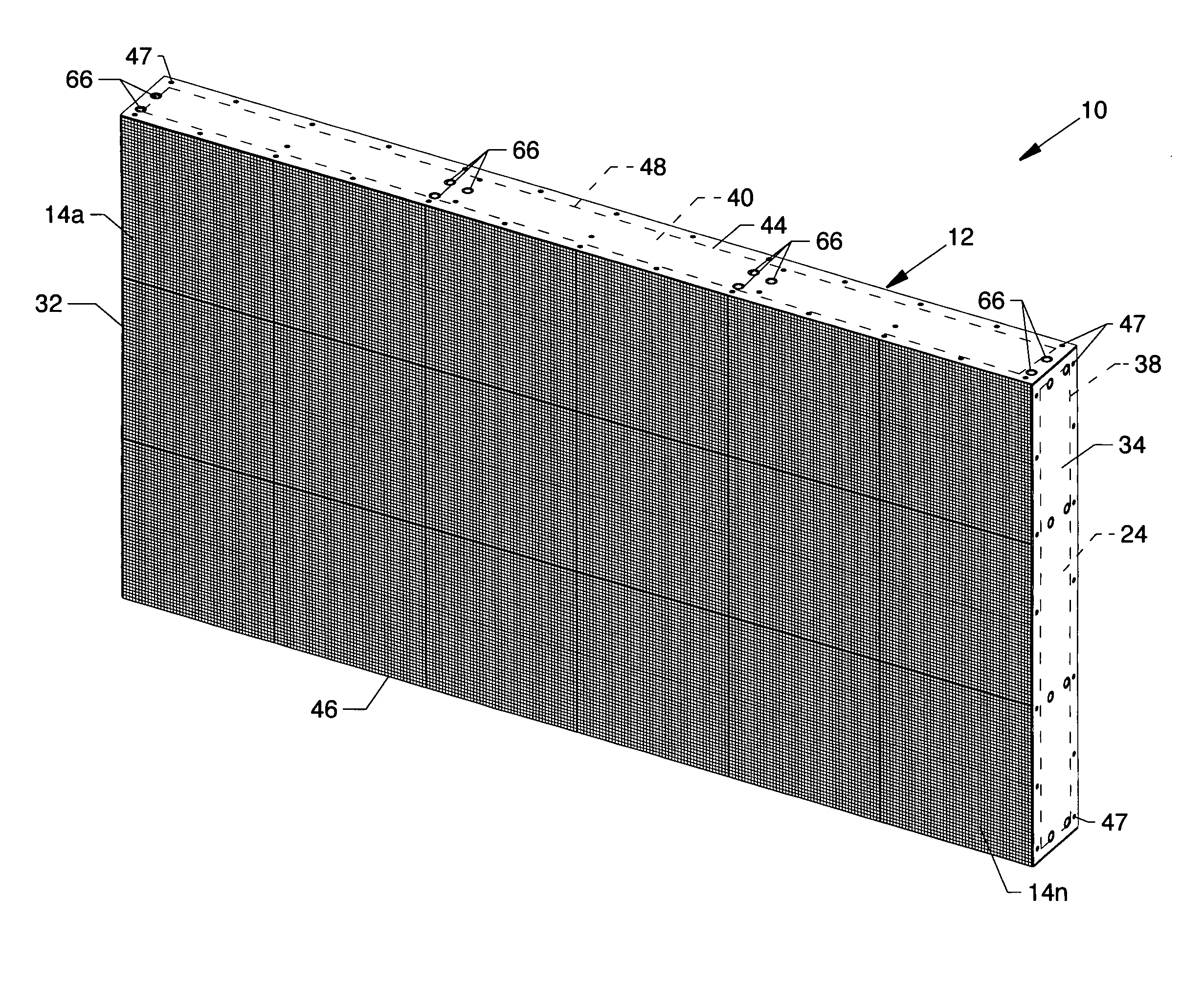

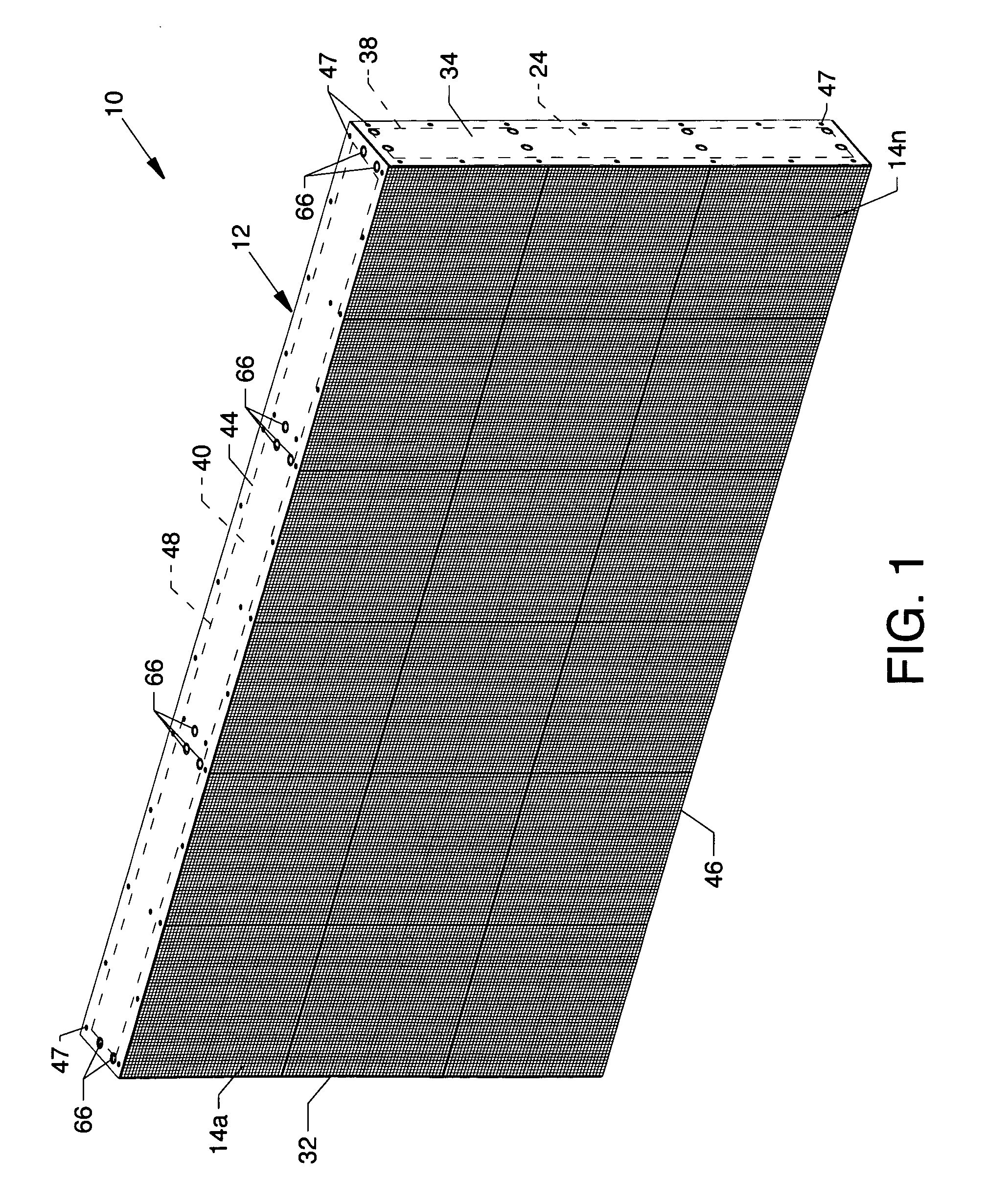

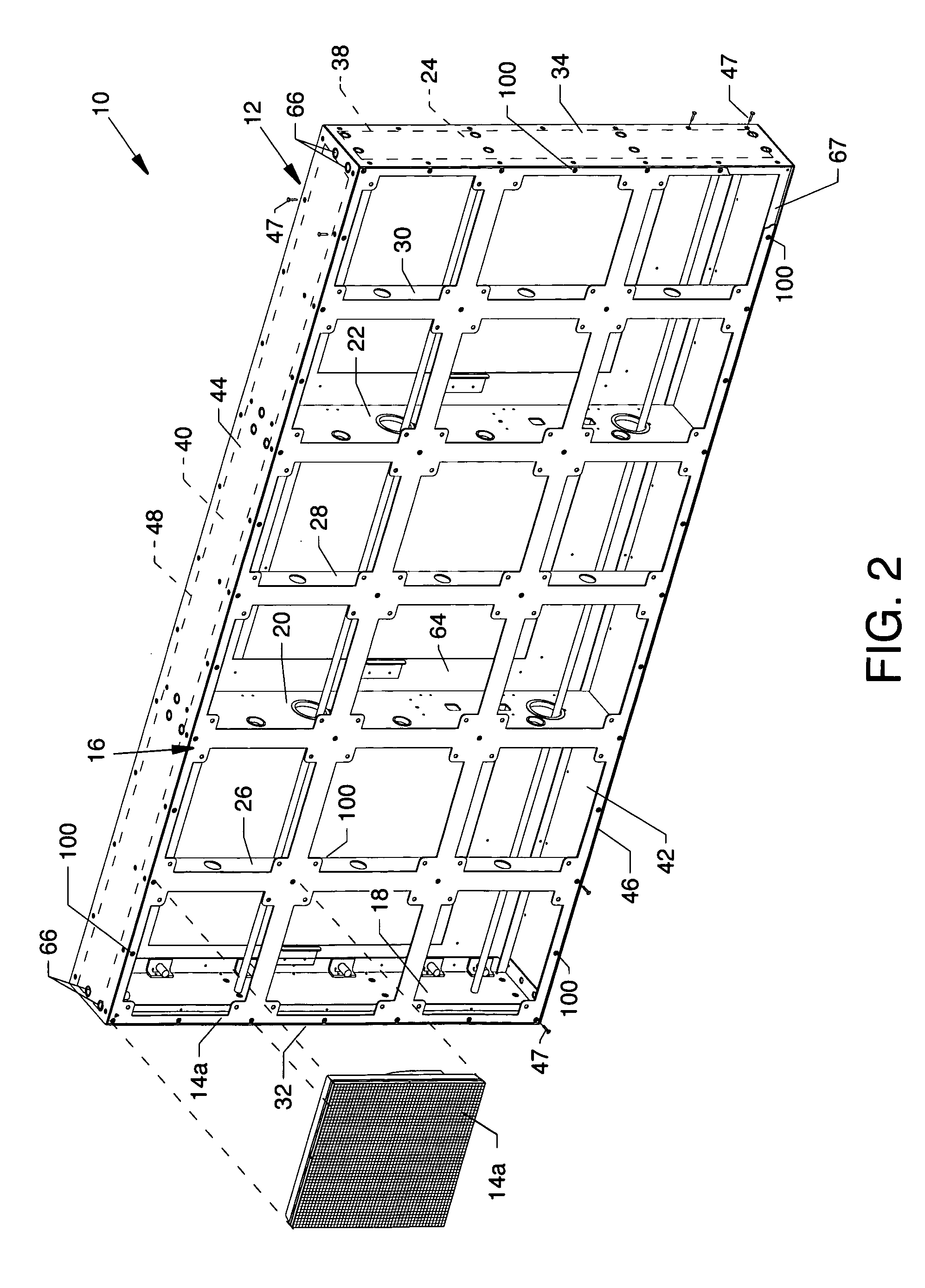

Electronic sign having a formed metal cabinet

ActiveUS7823308B1Quick assemblyUniform shapeStampsMetal casingsElectronic signageElectrical and Electronics engineering

Owner:DAKTRONICS

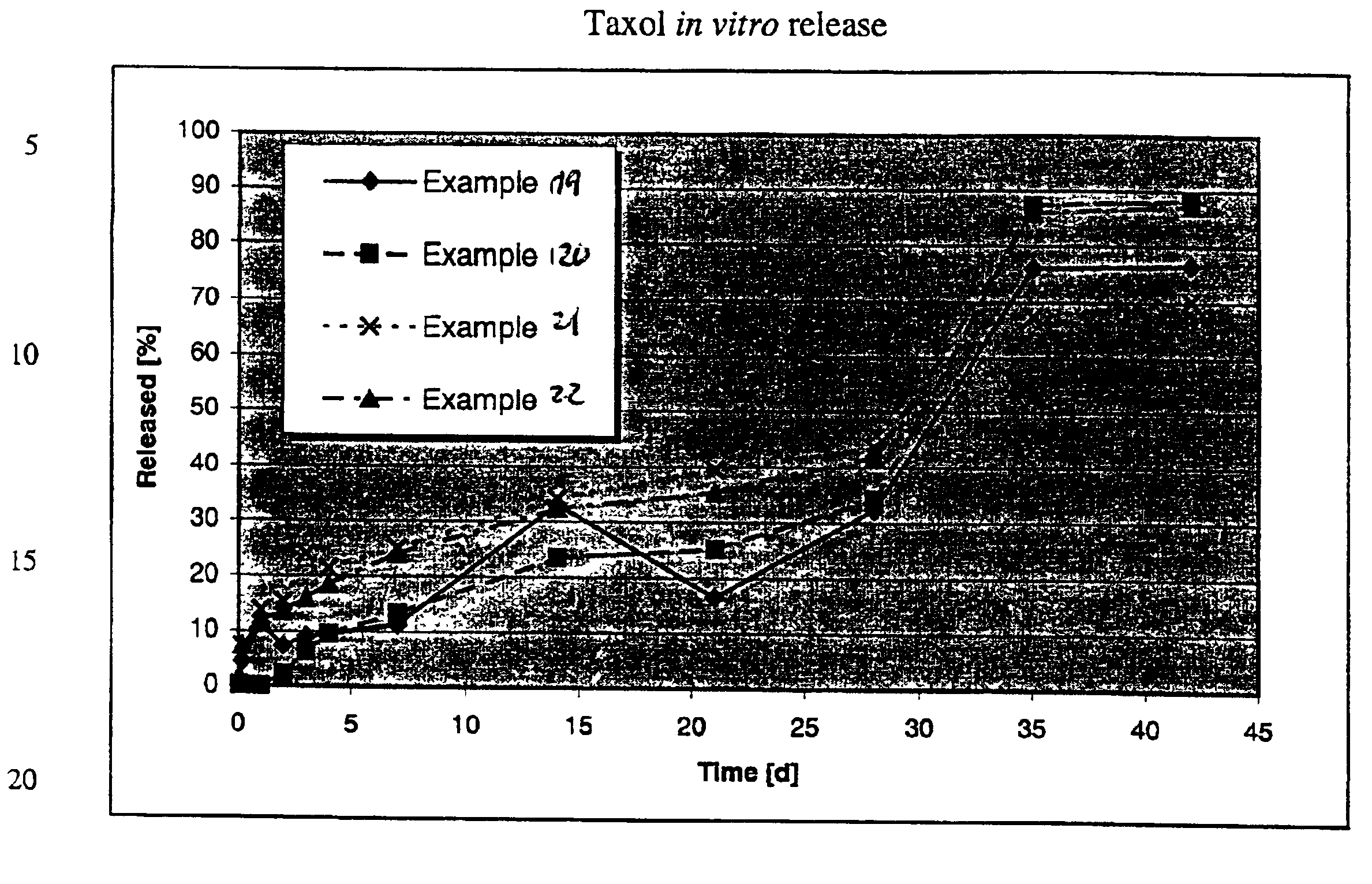

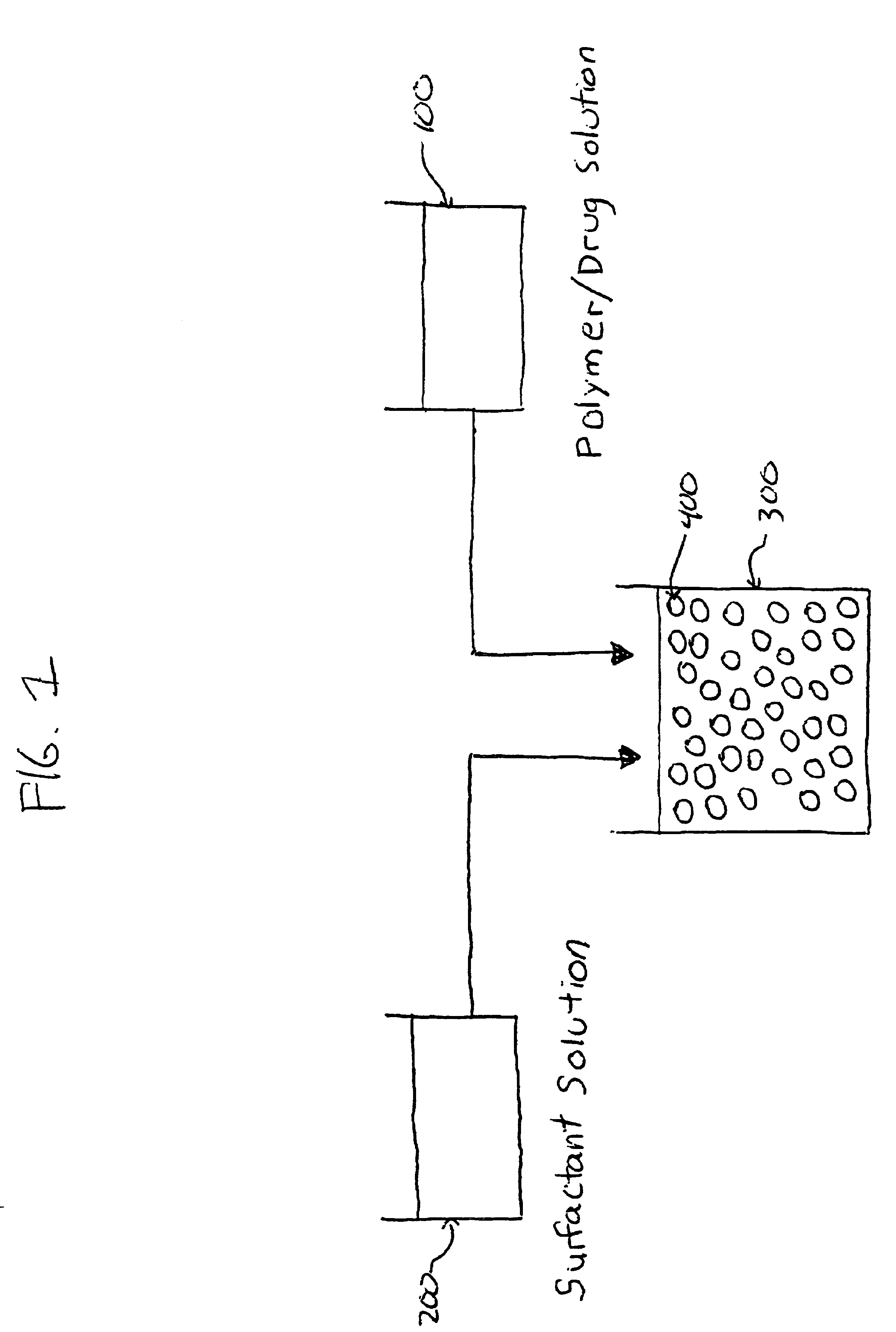

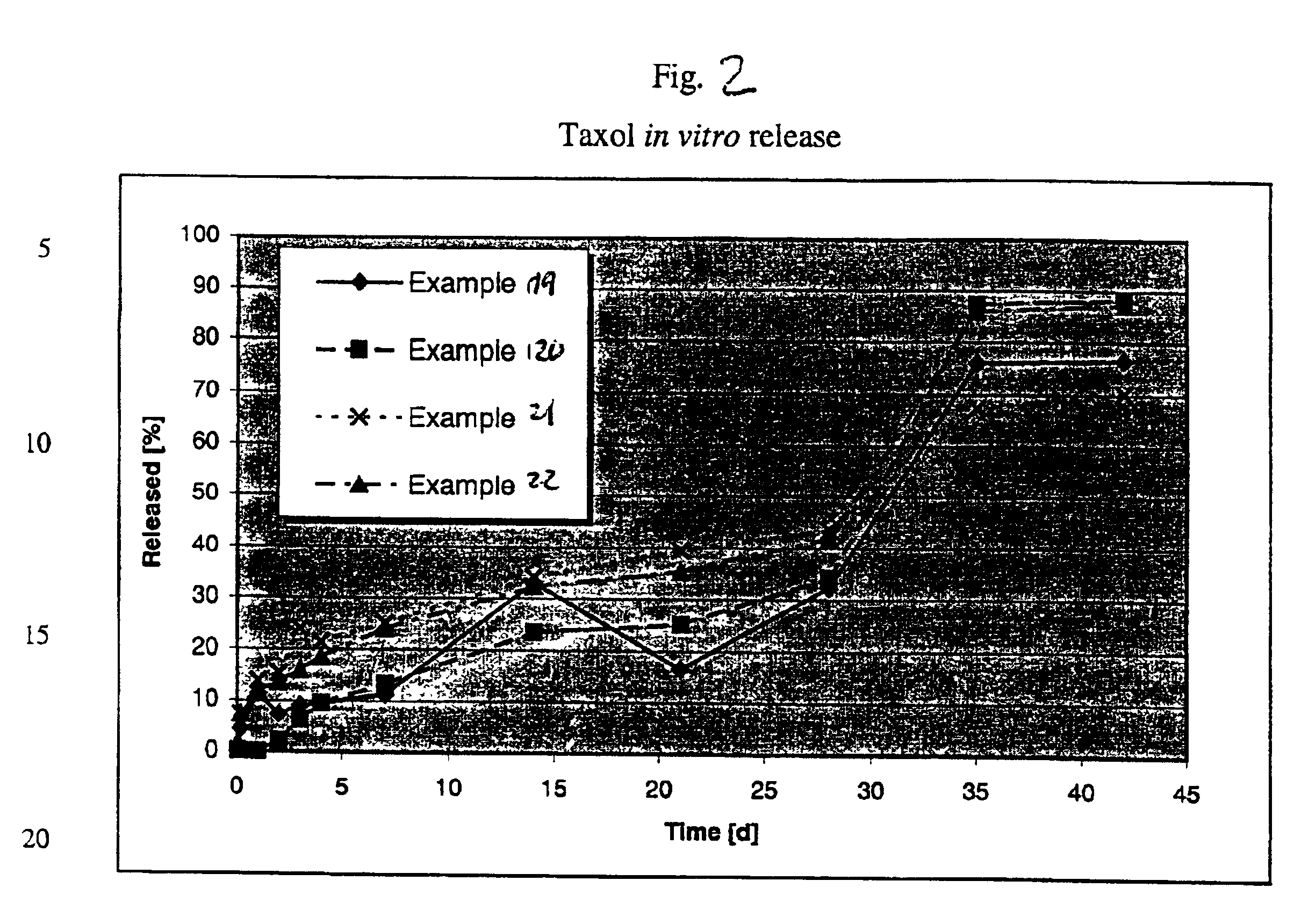

Induced phase transition method for the production of microparticles containing hydrophobic active agents

InactiveUS6899898B2Shorten production timeDisadvantage is reduced and avoidedPowder deliveryOrganic active ingredientsActive agentWater soluble

Microparticles and a method for their production is described. The process of the present invention provides a simple, quick, and efficient one-pot process for the production of microparticles containing a non-water soluble active agent. The microparticles are preferably used for pharmaceutical applications and comprise at least 80 wt % microspheres.

Owner:ALRISE BIOSYST

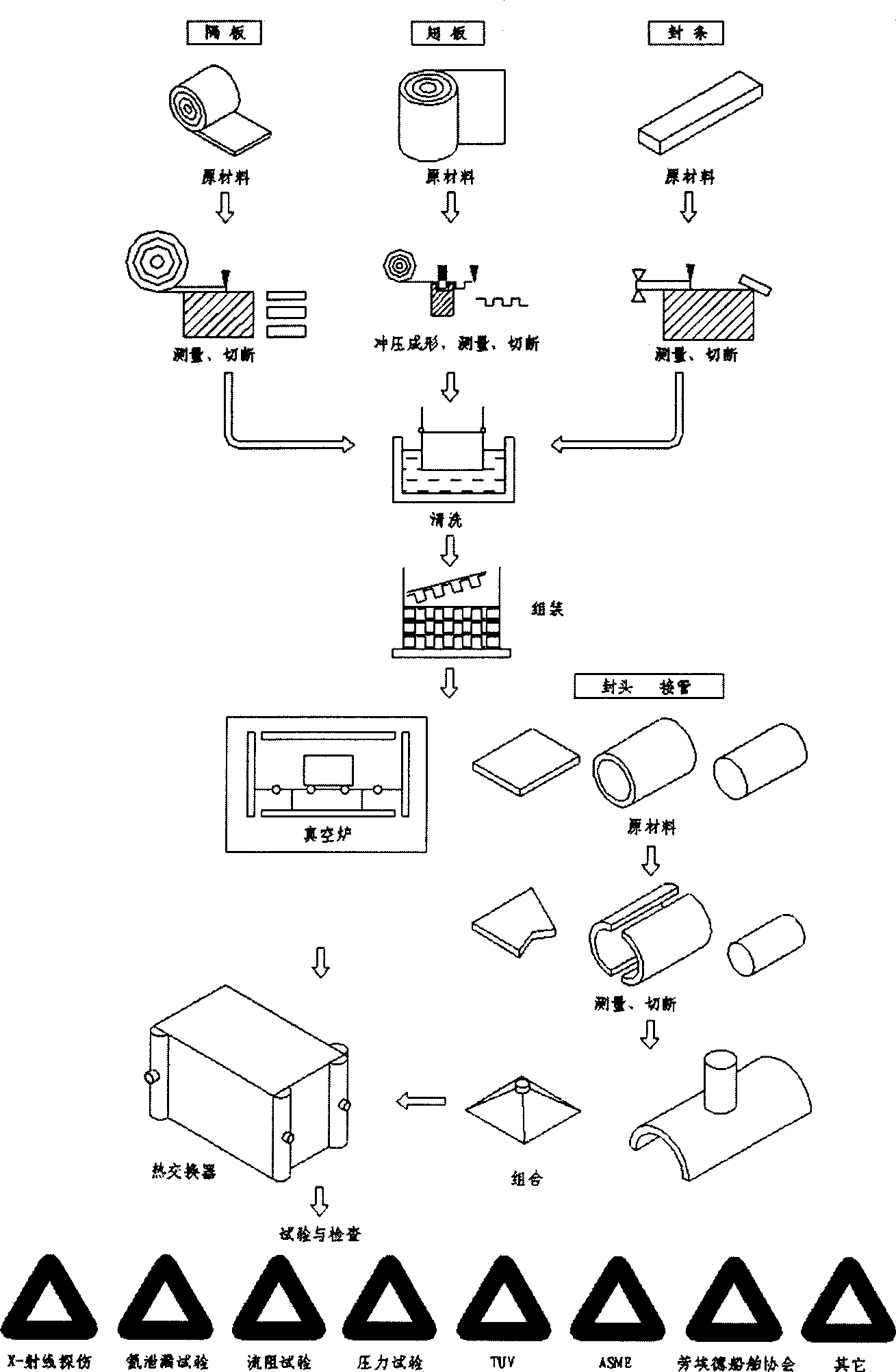

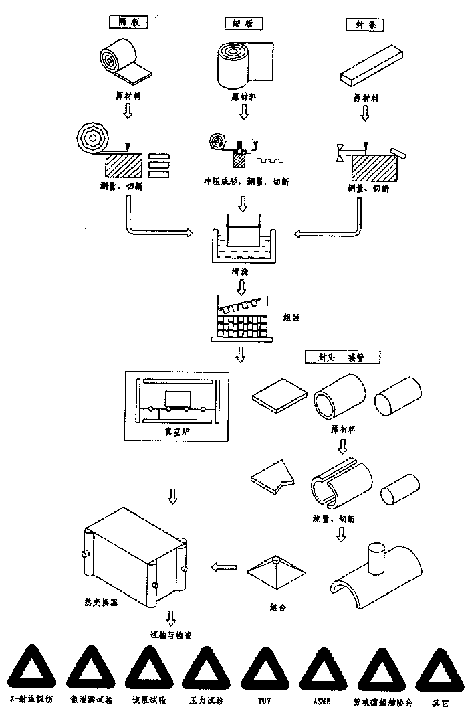

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

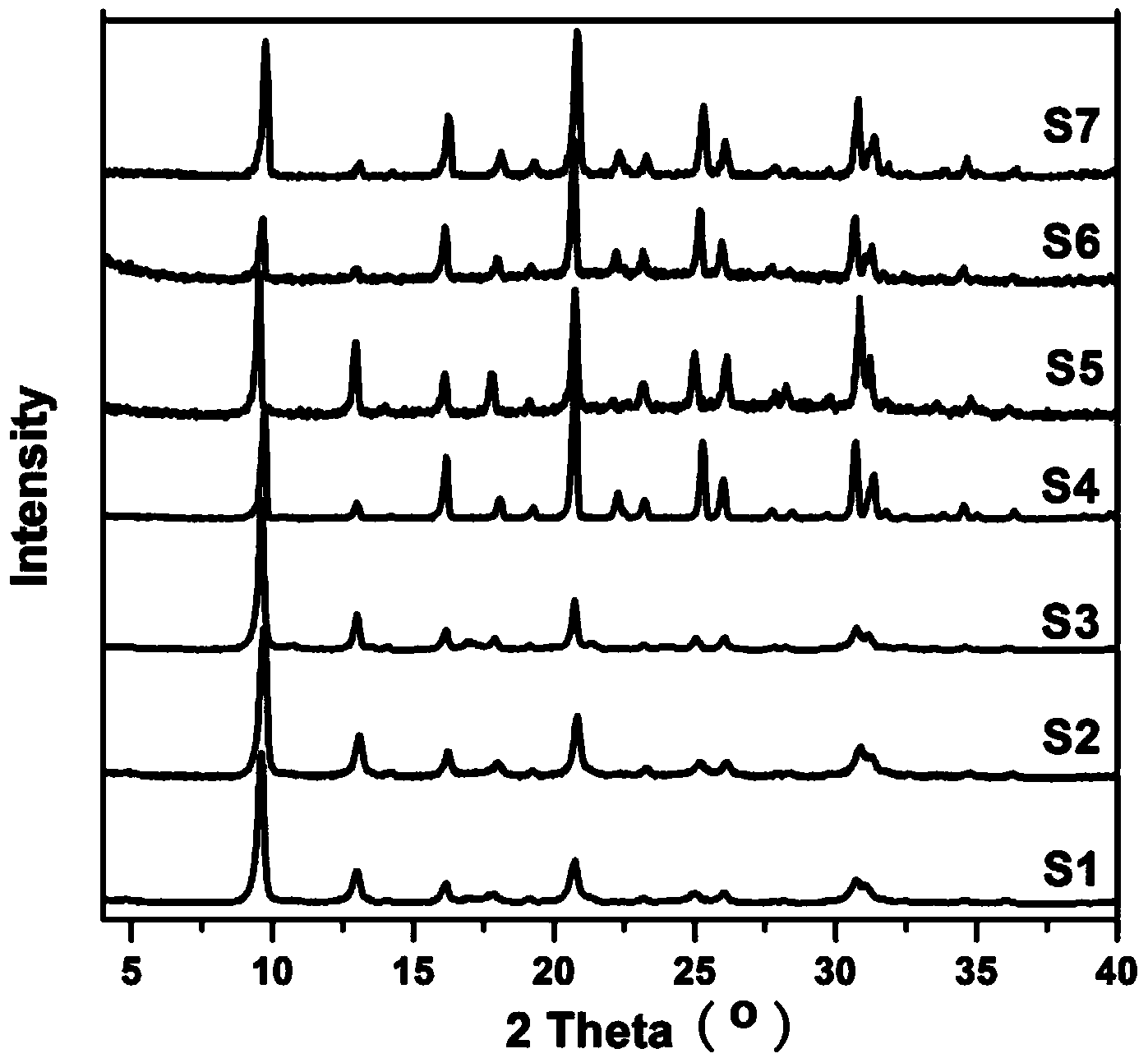

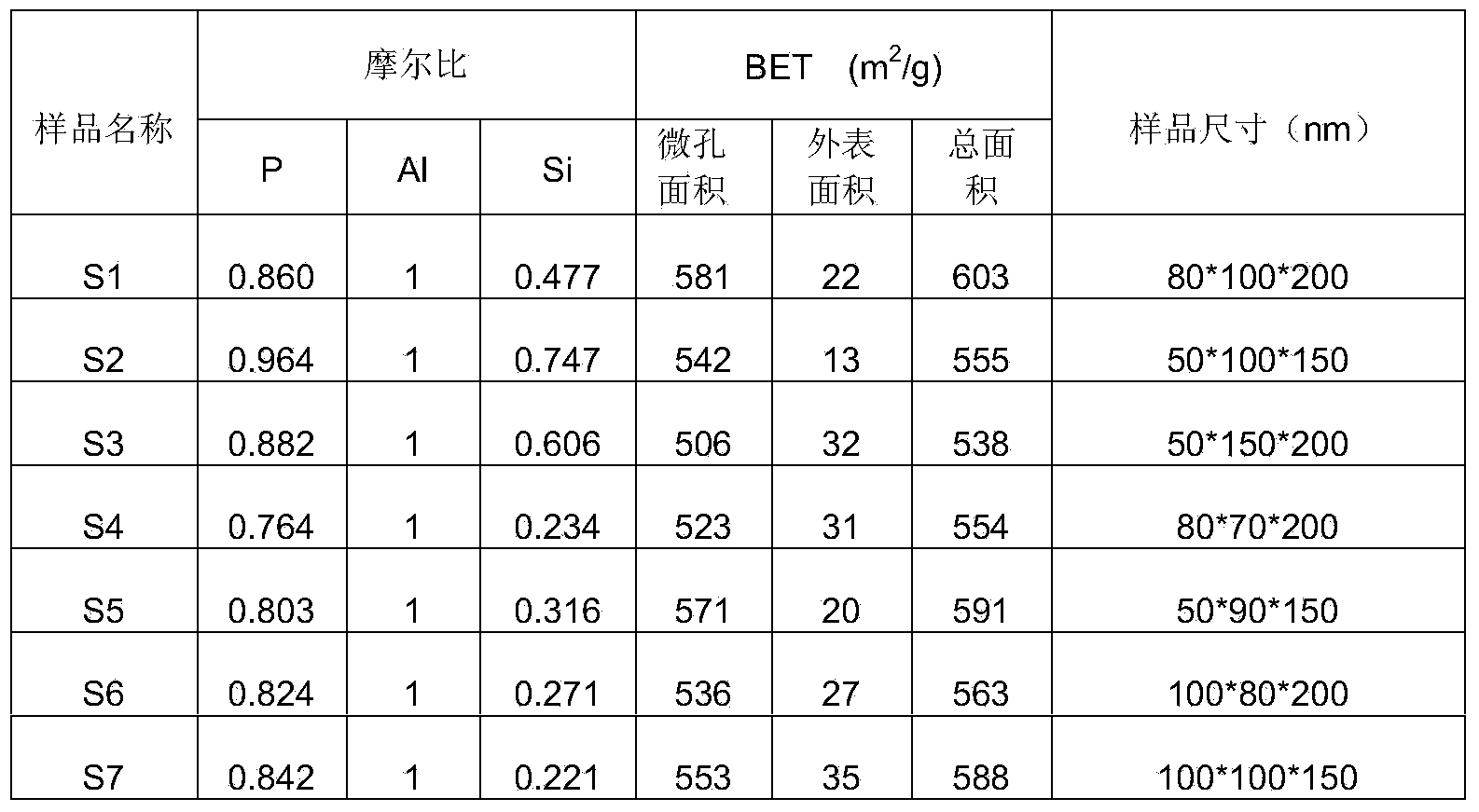

Slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, preparation method and application thereof

ActiveCN103641131ALong catalyst lifeIncreased diffusion rateMaterial nanotechnologyMolecular sieve catalystsGranularitySolvent

The invention discloses a slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, a preparation method and an application thereof, and belongs to the technical field of molecular sieves. Tetraethylammonium hydroxide is used as a template, the slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content is synthesized by using the traditional hydrothermal method or a solvothermal synthesis method. The synthesized nanometer SAPO-34 sample is a slice-shaped feature, of which the average crystal granularity size is 50-250nm and the thickness is 50-100nm. The synthetic method is simple and efficient; the solvent consumption is low; the yield of the synthesized nanometer SAPO-34 sample is extremely high and can be up to 85-90 percent; the synthesized nanometer SAPO-34 sample is high in low carbon olefin selectivity during reaction of methanol to olefin (MTO), particularly, the total yield of ethylene and propylene can be up to more than 83 percent, and the molecular sieve is very suitable for industrial amplification application.

Owner:JILIN UNIV

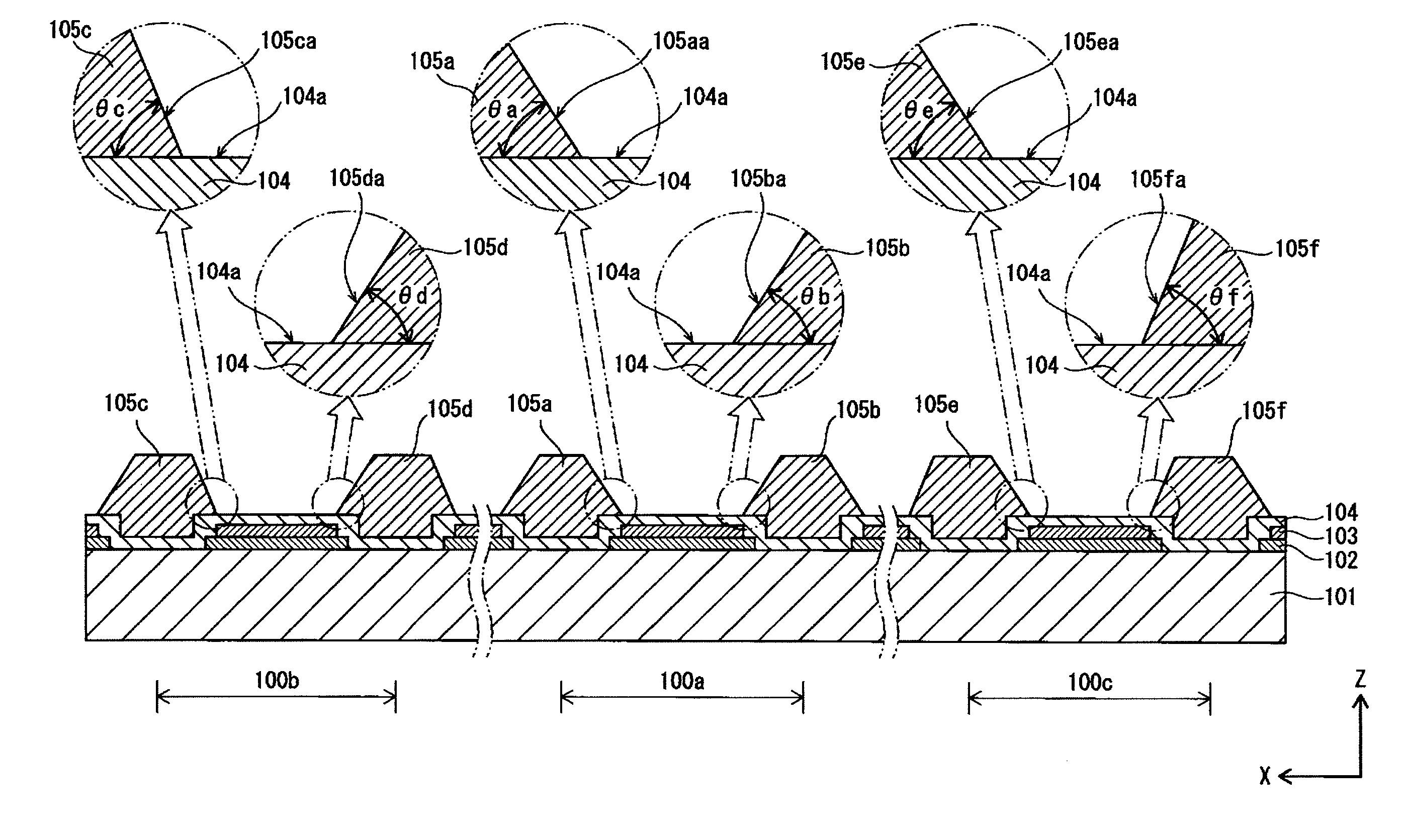

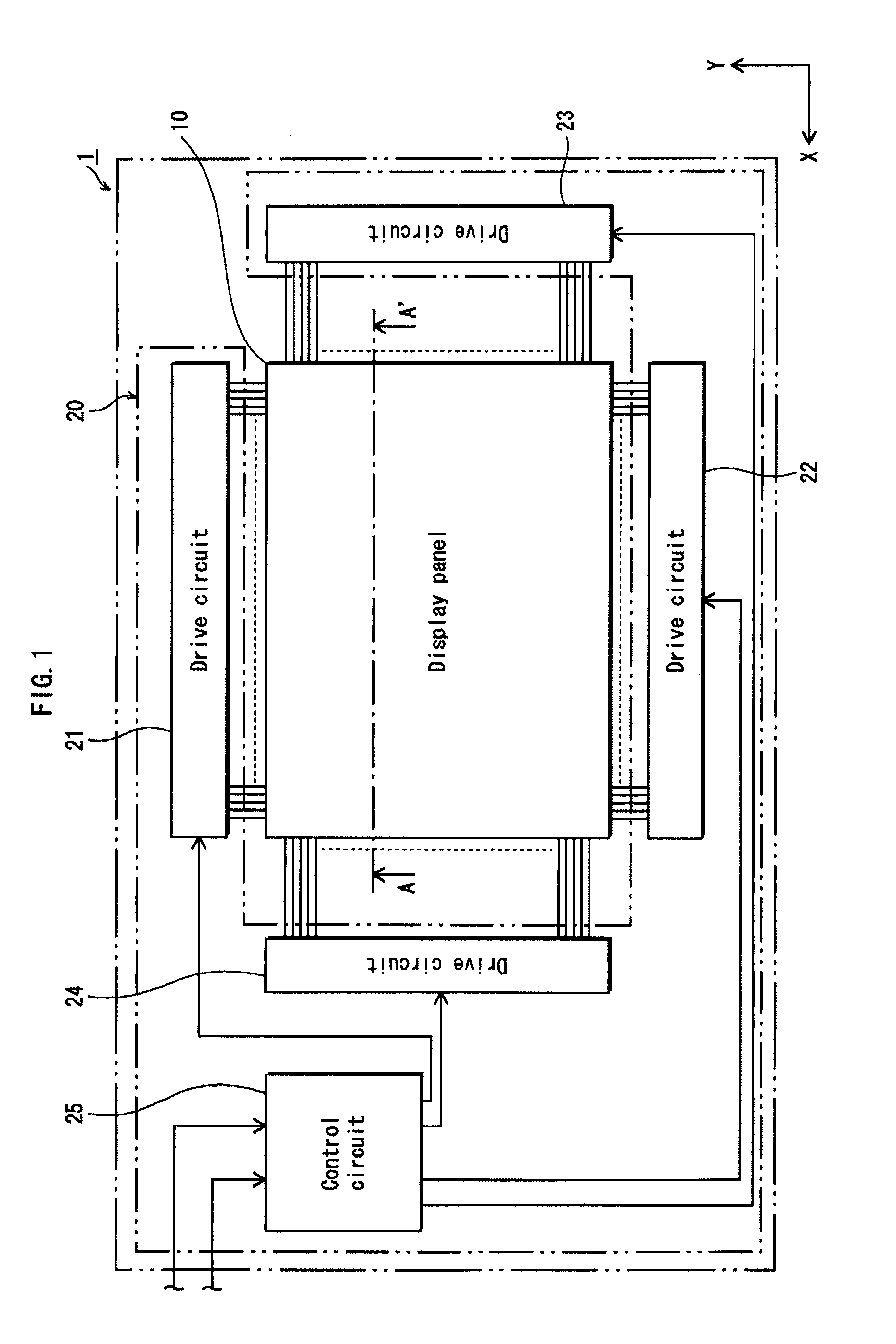

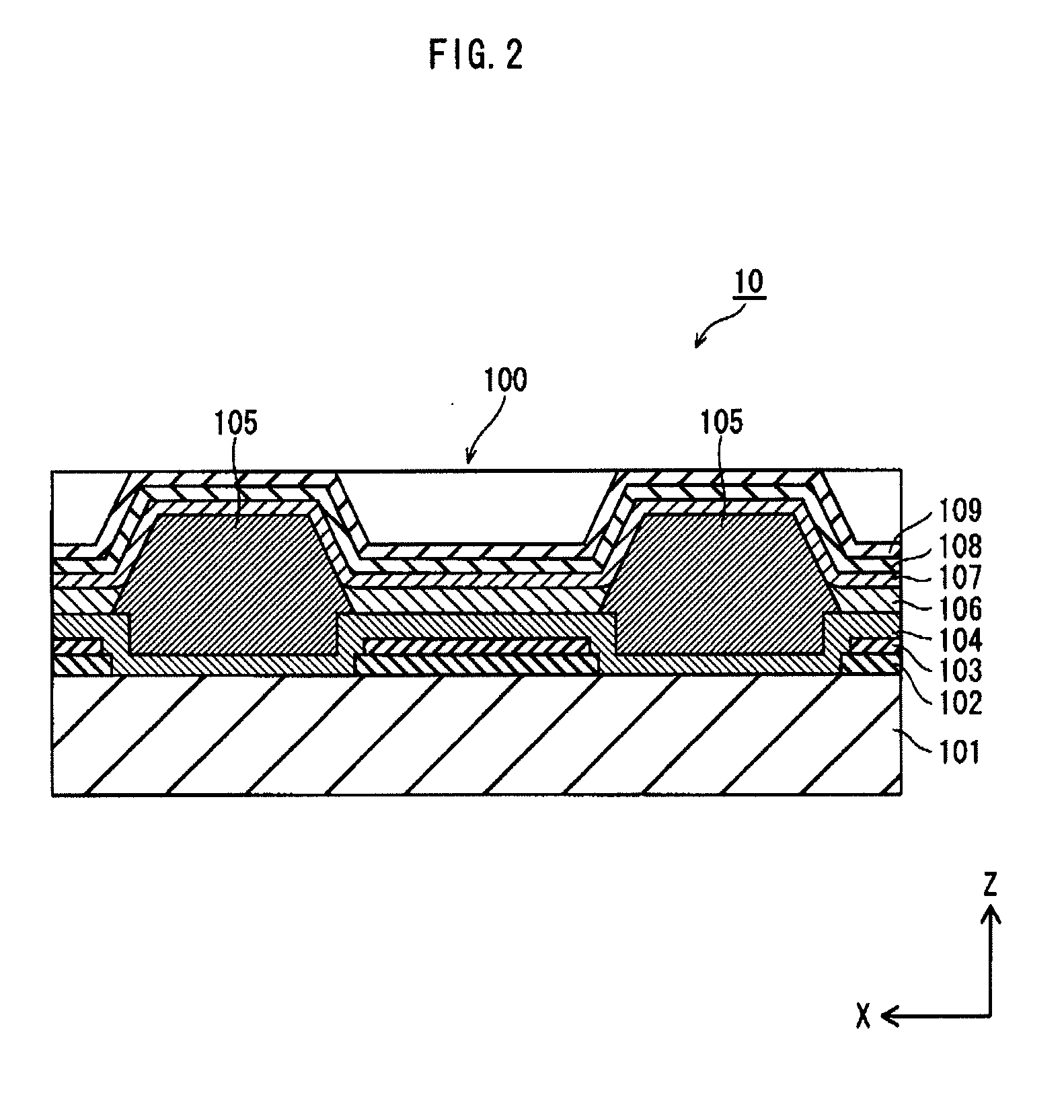

Display device and manufacturing method thereof

ActiveUS20110180821A1Uniform film shapeAvoid thickness thinningSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

Owner:JOLED INC

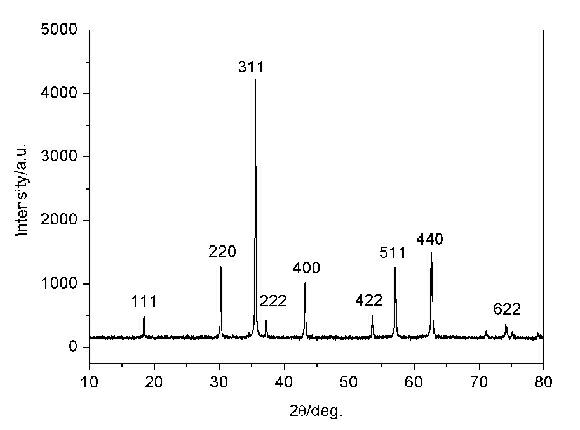

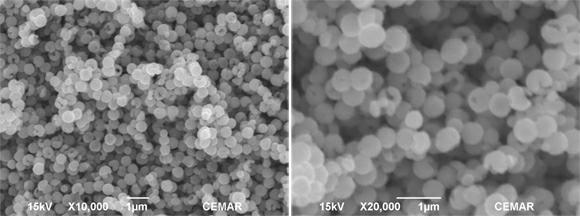

Method for synthesizing Fe3O4/C lithium ion battery cathode material with hollow sphere structure by one-step process

The invention discloses a preparation method of a lithium-stored composite material Fe3O4 / C with a hollow sphere structure and an application of the lithium-stored composite material Fe3O4 / C with a hollow sphere structure in a lithium ion battery, belonging to the technical fields of material synthesis and high-energy lithium-ion storage batteries. The preparation method is characterized in that a solvothermal method or hydrothermal method is utilized to prepare the Fe3O4 / C composite material with a hollow sphere and narrower particle size distribution, wherein the Fe3O4 / C composite material is high in purity; and the mean particle size of the Fe3O4 / C composite material is 750 nanometers and the wall thickness of the Fe3O4 / C composite material is 250 nanometers. An electrochemical test proves that the first discharging specific capacity of the Fe3O4 / C composite material prepared by the method can be 1157mAh / g, and the discharging specific capacity of the Fe3O4 / C composite material can be 900mAh / g after being circulated for 65 times, thus showing the perfect cyclical stability. The Fe3O4 / C composite material has good rate performance; and the charging specific capacity of the Fe3O4 / C composite material is 620mAh / g and 460mAh / g respectively under 2C and 5C charge-discharge rates, thus the rate performance is superior to that of an existing commonly-used carbon cathode material (theoretical specific capacity is 372mAh / g). The Fe3O4 / C lithium ion battery cathode material is low in cost, simple in process and easy to industrialize, and has wide application prospects in the high-energy lithium ion battery field.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

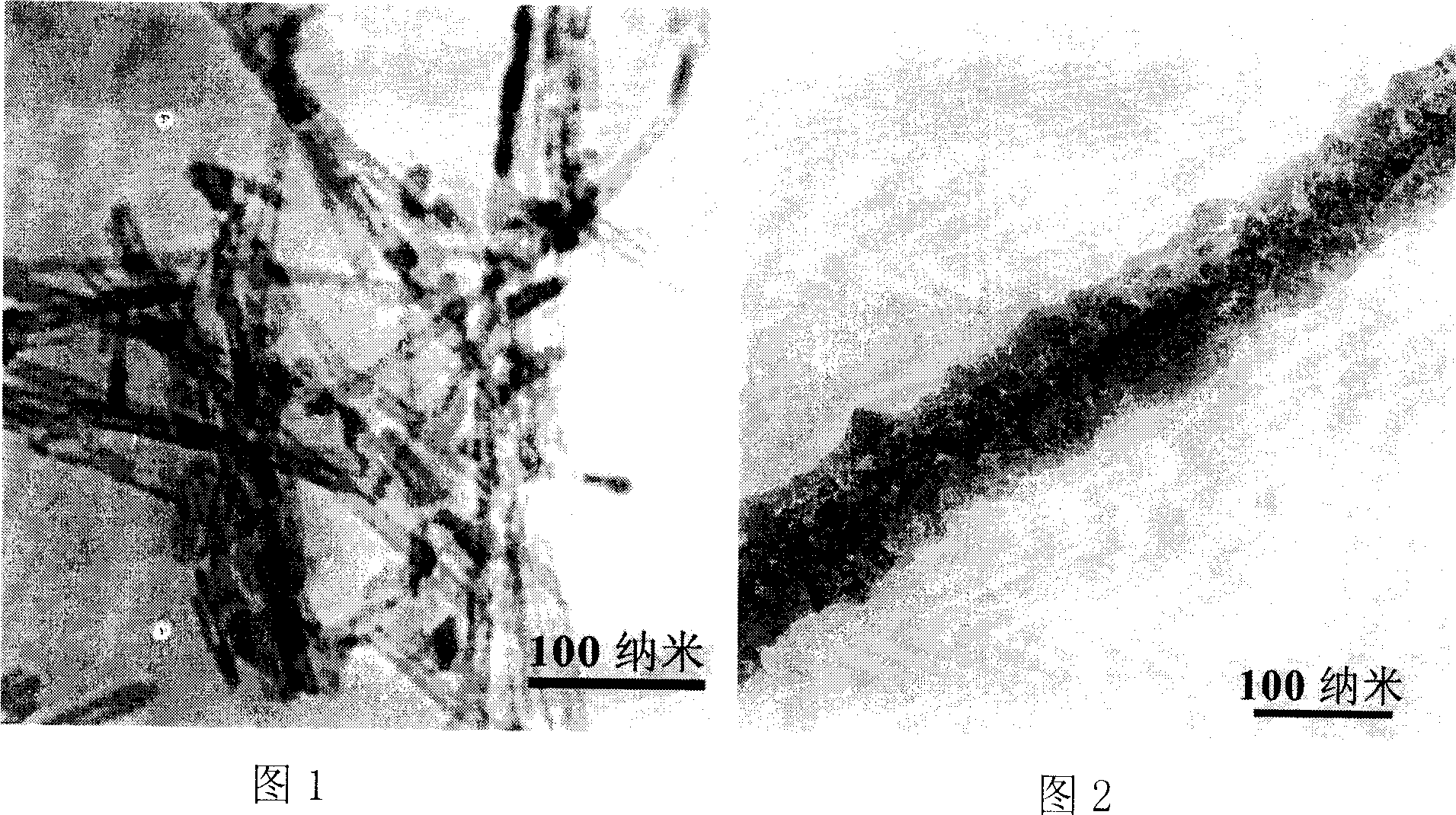

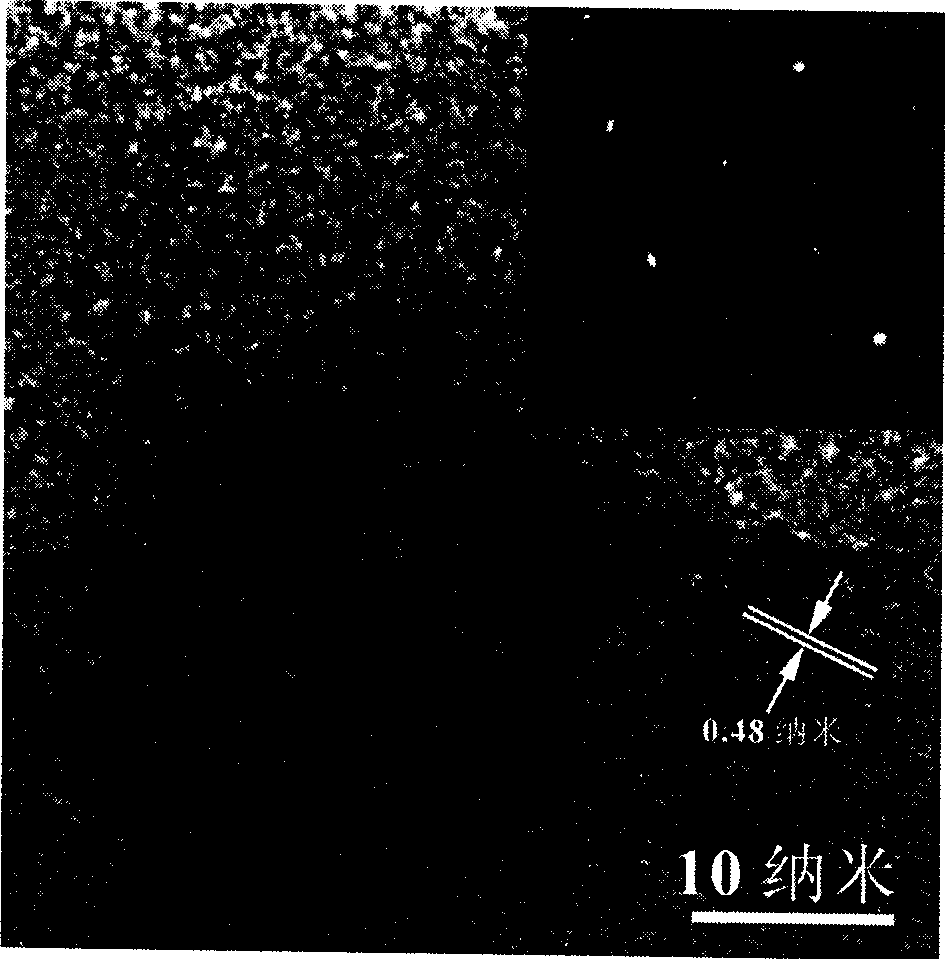

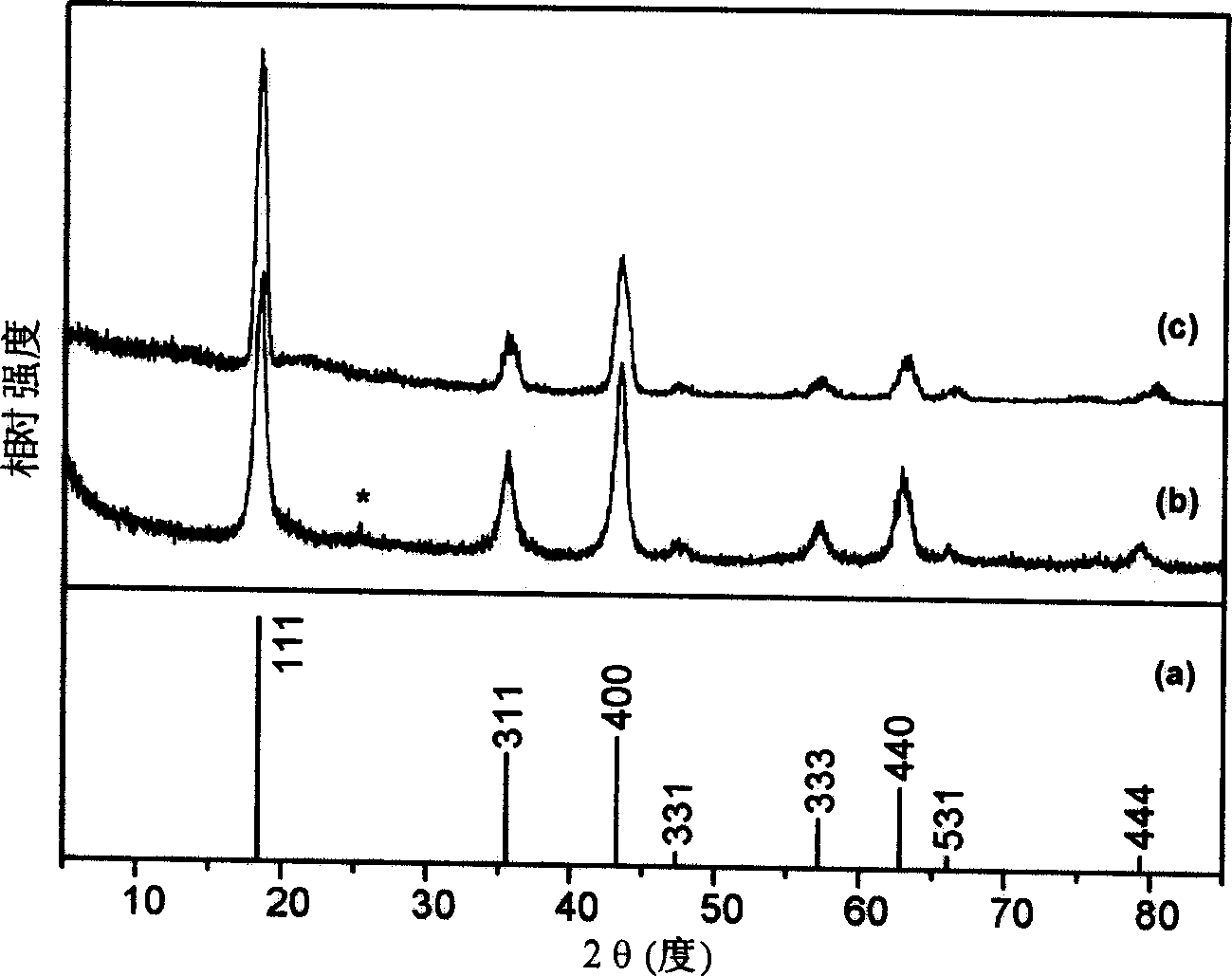

Preparation method of spinel lithium titanate nano tube/wire for lithium battery and capacitor

InactiveCN1725530AReduce energy consumptionUniform shapeNanostructure manufactureElectrode manufacturing processesNanowireIon exchange

This invention discloses a preparation method for spinel lithium titanate nm pipes / nm lines used in Li batteries and capacitors, which applies cheap industrial TiO2 as the raw material and supersonic chemical method to prepare said nm pipes / lines then takes them as the raw materials to be mixed with a certain quantity of soluble Li salt solution to be baked in air and by low-temperature hydrothermal ion exchange method to manufacture spinel lithium titanate nm pipes / lines with uniform shape, uniform diameter and even larger major diameter ratio and big ratio surface area.

Owner:TSINGHUA UNIV

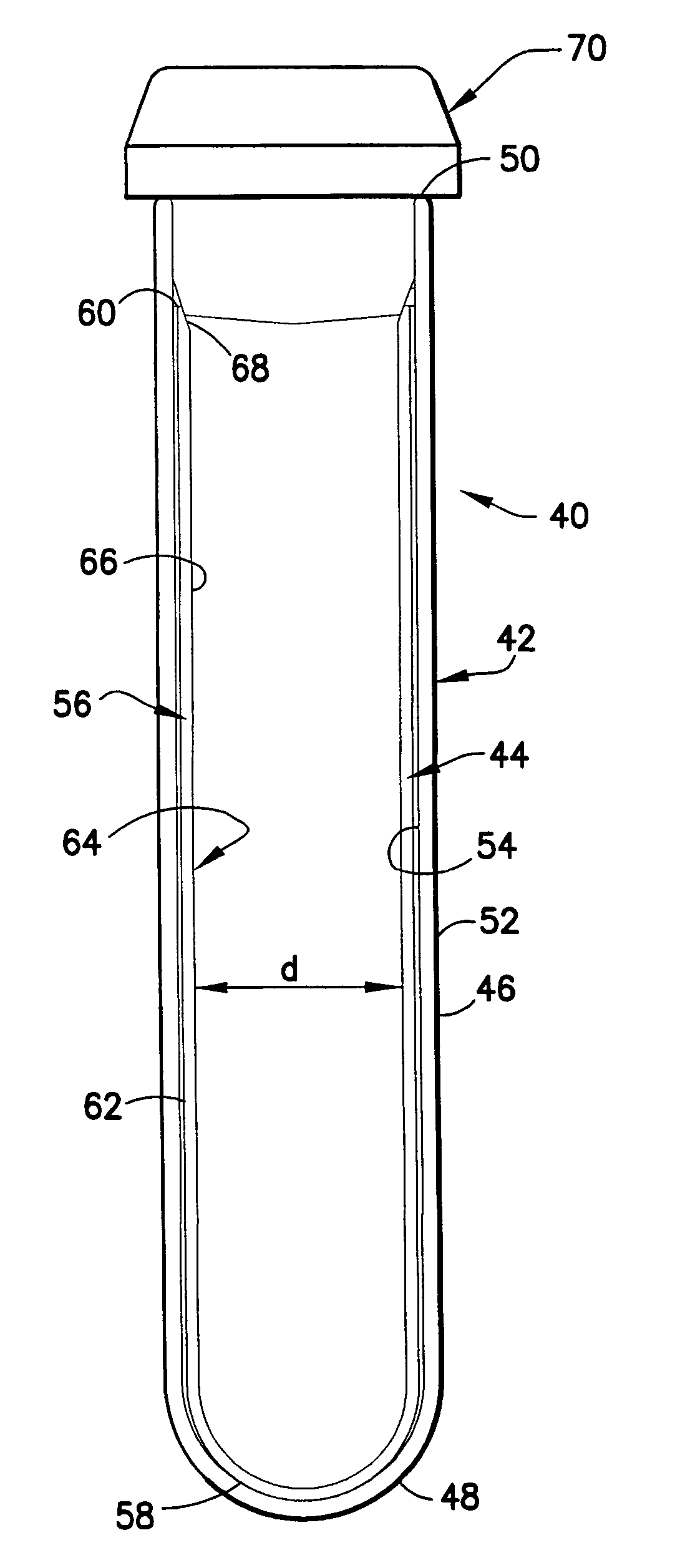

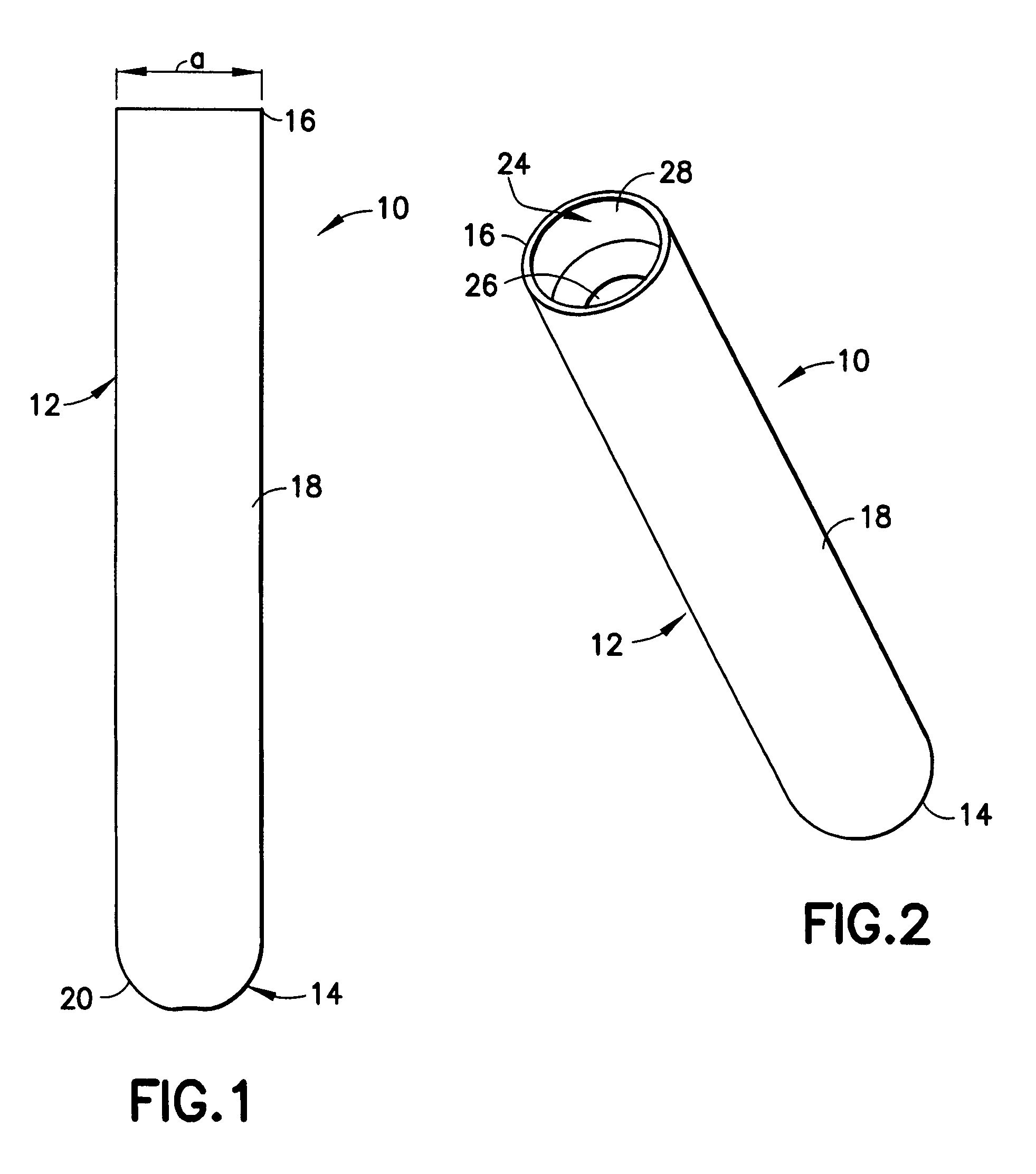

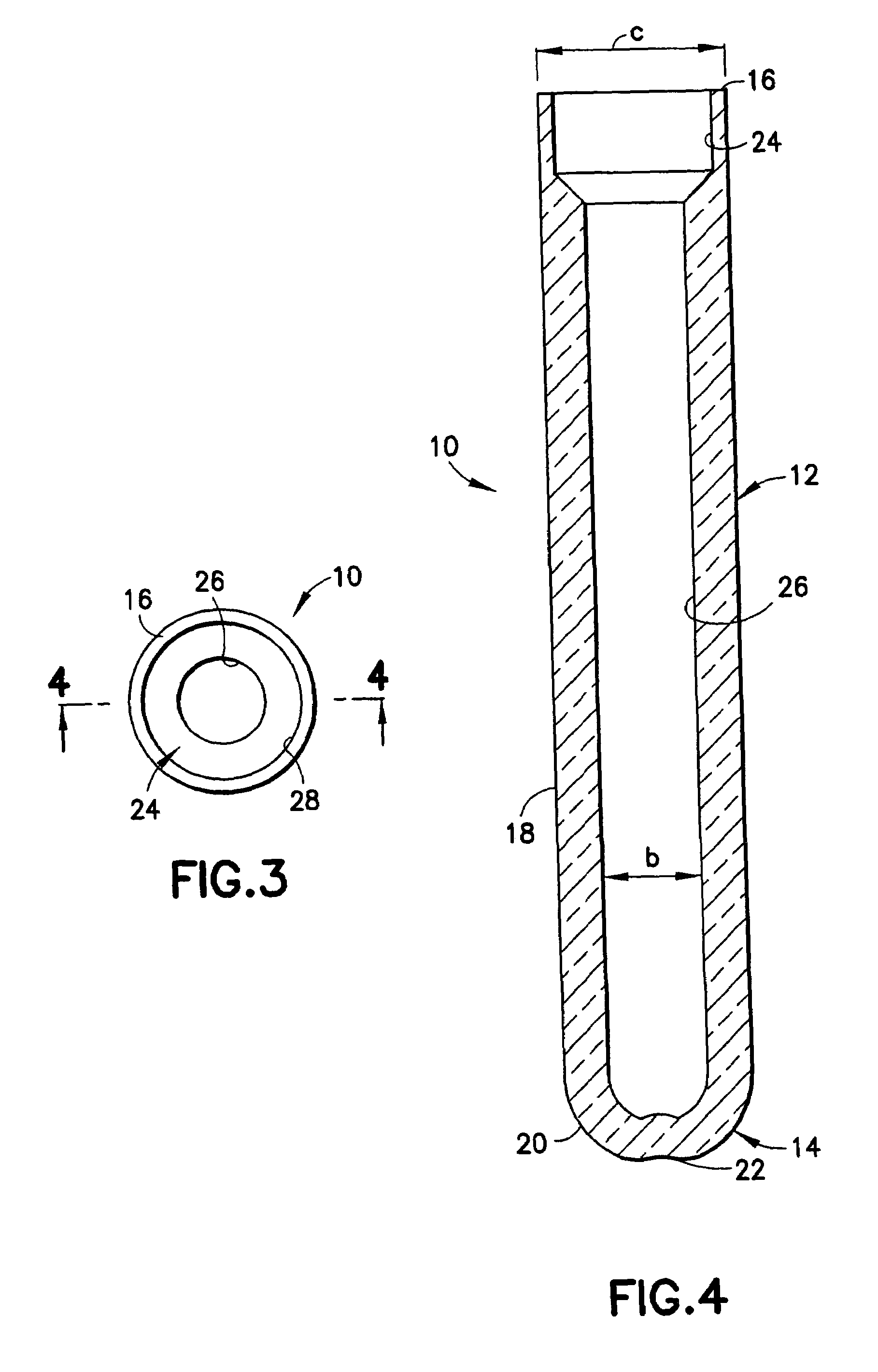

Collection assembly

ActiveUS7507378B2Small and substantially uniform head spaceLower the volumeCombination devicesWithdrawing sample devicesEngineeringExterior dimension

A plurality of container assemblies are provided. Each container assembly has substantially identical external dimensions. However, the internal volumes of certain container assemblies differ from the internal volumes of other container assemblies. The container assemblies are configured in accordance with the required volume of material to be collected or maintained in the respective container assemblies and to enable uniform head spaces despite the different volumes of materials in the respective container assemblies. Each container assembly may have an inner container and an outer container. The inner and outer containers may be assembled together or formed integrally by molding.

Owner:BECTON DICKINSON & CO

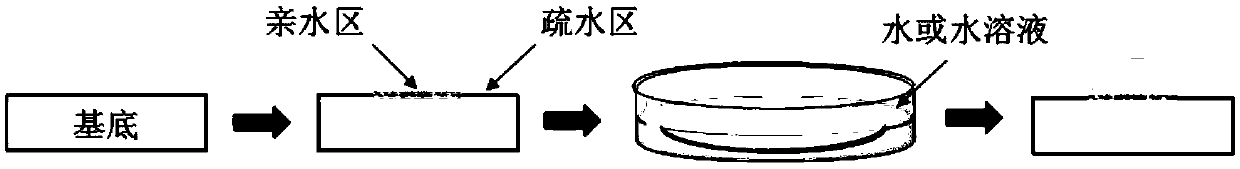

Drop array chip and preparation method thereof

InactiveCN105505742AEfficient and accurate generationLow costBioreactor/fermenter combinationsBiological substance pretreatmentsDrop structureHydrophilic hydrophobic

The invention discloses a drop array chip which comprises a substrate. The substrate is provided with hydrophilic areas and hydrophobic areas, and the hydrophilic areas and the hydrophobic areas are alternately arranged to form a hydrophilic-hydrophobic array. The invention further discloses a preparation method of the drop array chip. According to the drop array chip, a large number of array type drop structures with uniform and controllable morphologies can be precisely and efficiently generated through the hydrophilic-hydrophobic property of the surface of the drop array chip, a foundation is provided for complex biochemical application based on drops, and meanwhile the advantages of being low in cost and capable of being reused are achieved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Dark tea processing method

InactiveCN103109940AImprove fresh leaf qualityExpand the scale of leaf sourcePre-extraction tea treatmentWater contentChemistry

The invention discloses a dark tea processing method. The dark tea processing method is characterized by comprising the following steps of: (1) picking fresh leaves; (2) withering the fresh leaves; (3) then removing water; (4) then twisting for 20-25 minutes; (5) heating tea bases to increase temperature to 50-60 DEG C, then blanking the tea bases and slightly spreading, and reducing the temperature of the tea bases to 35-40 DEG C, wherein the water content of the tea bases is 60%-65%; (6) lining the tea bases by using reed leaves, cladding, and then covering by using a wet cloth for pile fermentation; and (7) drying by using a drying machine for the first time, drying by using a roasting machine for the second time, drying by using the drying machine for the third time, and spreading for airing after drying every time. The dark tea processed by the dark tea processing method disclosed by the invention has the advantages of uniform and strip-shaped outline, jet-black and lubricating color and luster, golden and bright soup color similar to amber, mellow and sweet flavor, rich fragrance, fruit honey aroma, yellow brown and uniform leaf base, stable quality and drinking safety and is a high-quality loose dark tea with unique style.

Owner:刘超建

Low density proppant particles and use thereof

Composite proppant particles each of which comprises a plurality of microbubbles and a resin binder are disclosed. Also disclosed are a method of using such composite proppant particles to prop fractures in wells formed in underground formations.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com