Patents

Literature

169 results about "Leaf base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recognizing image of plant leaf

InactiveCN101916382AIncrease credibilityImprove recognition rateCharacter and pattern recognitionNeural learning methodsGraphicsFeature extraction

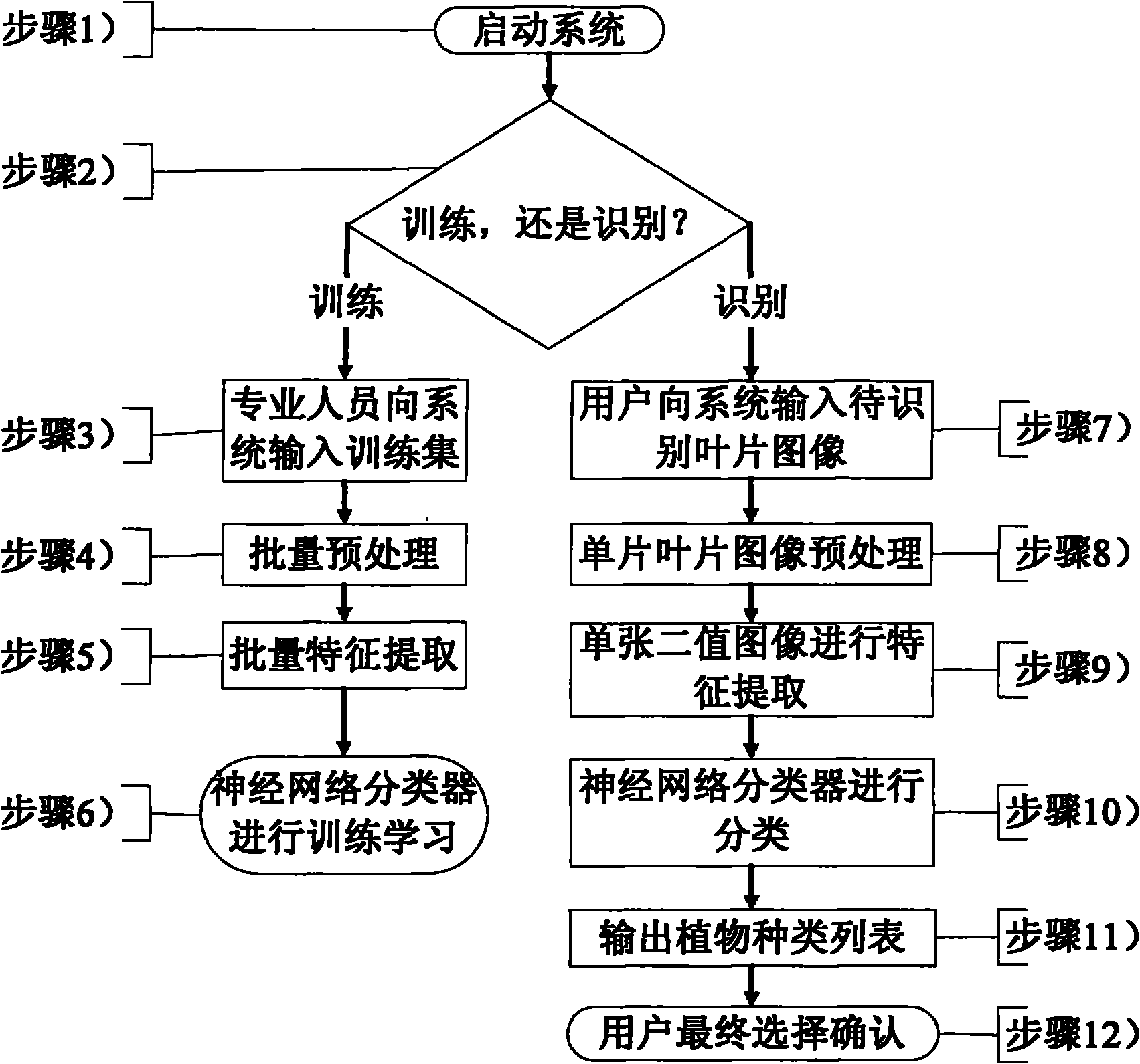

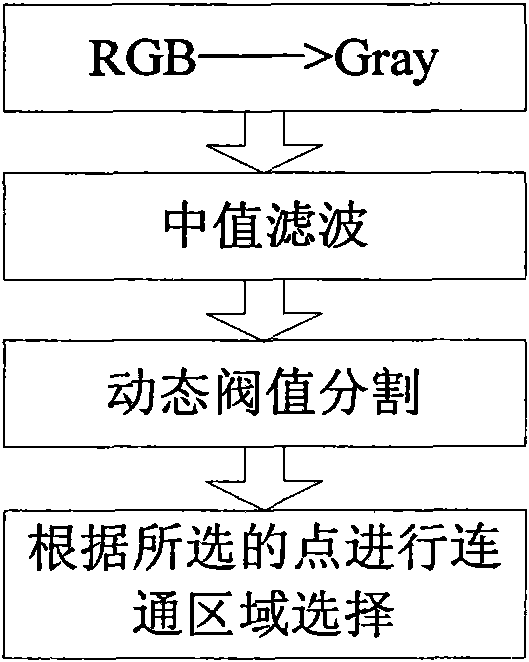

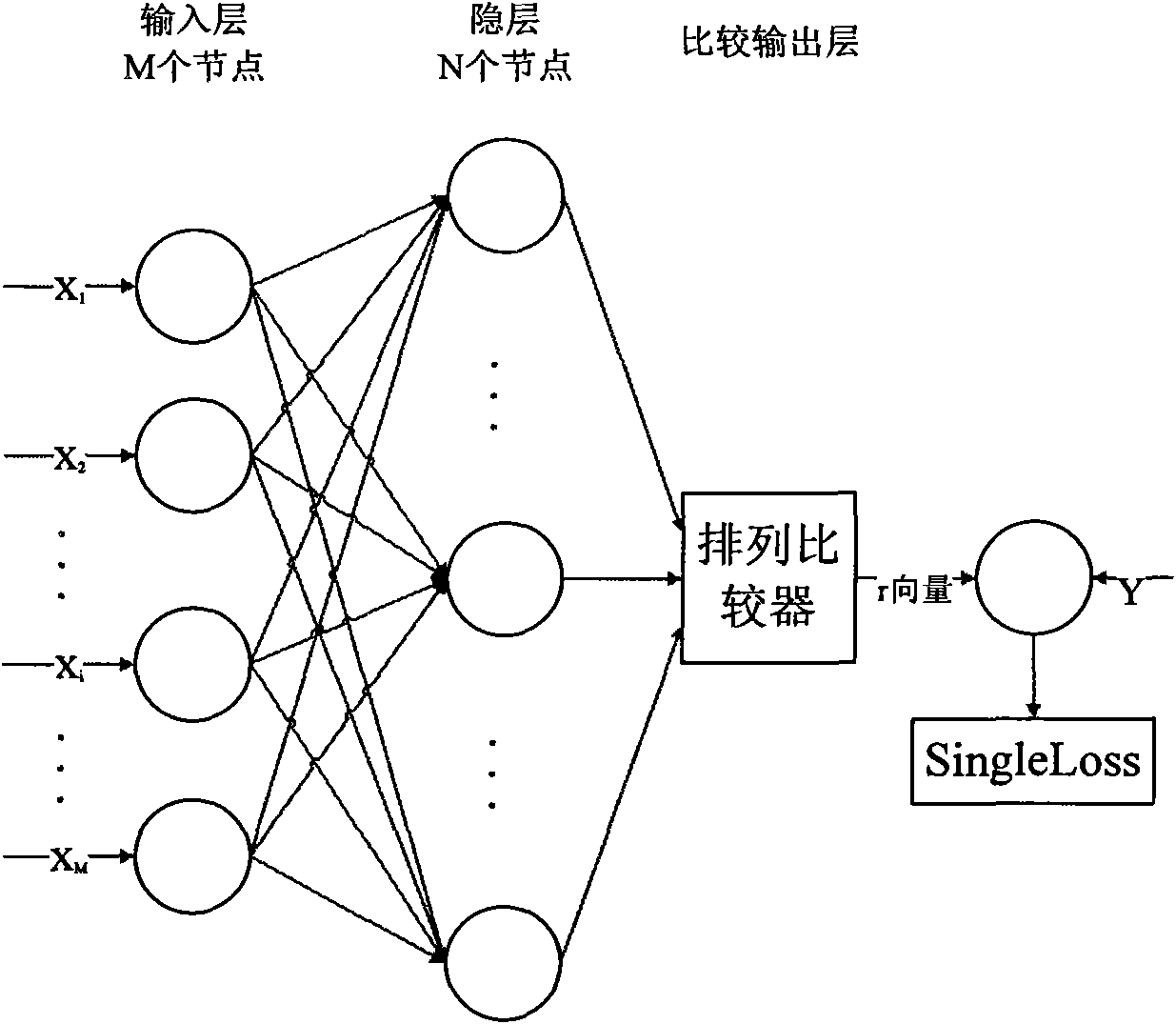

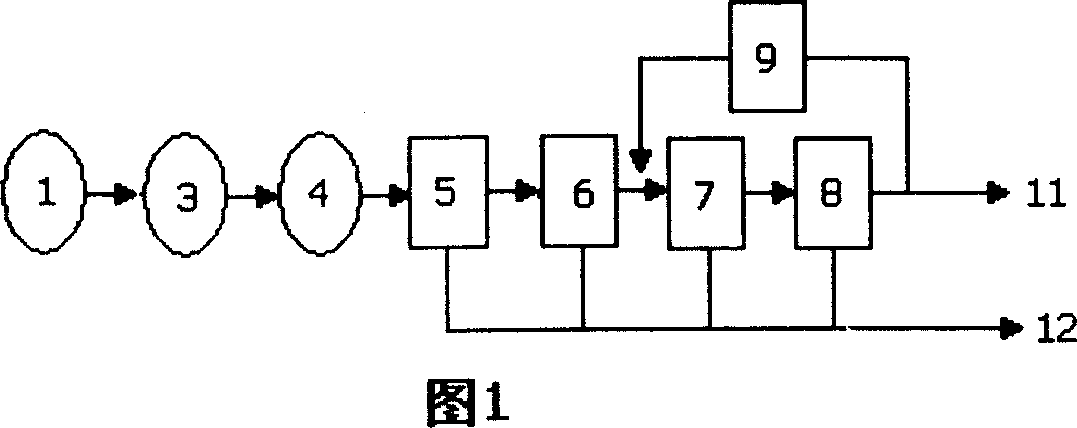

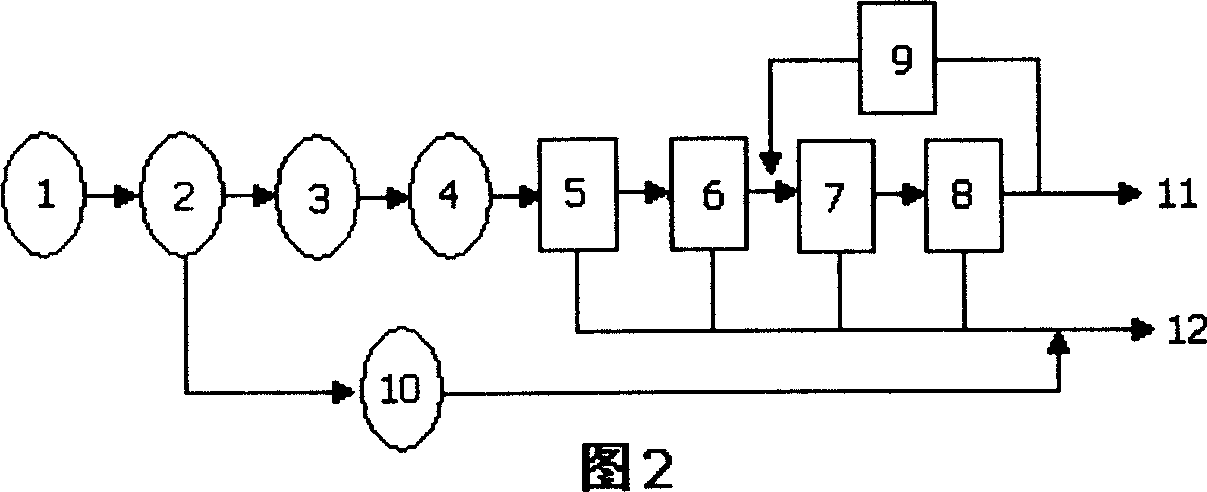

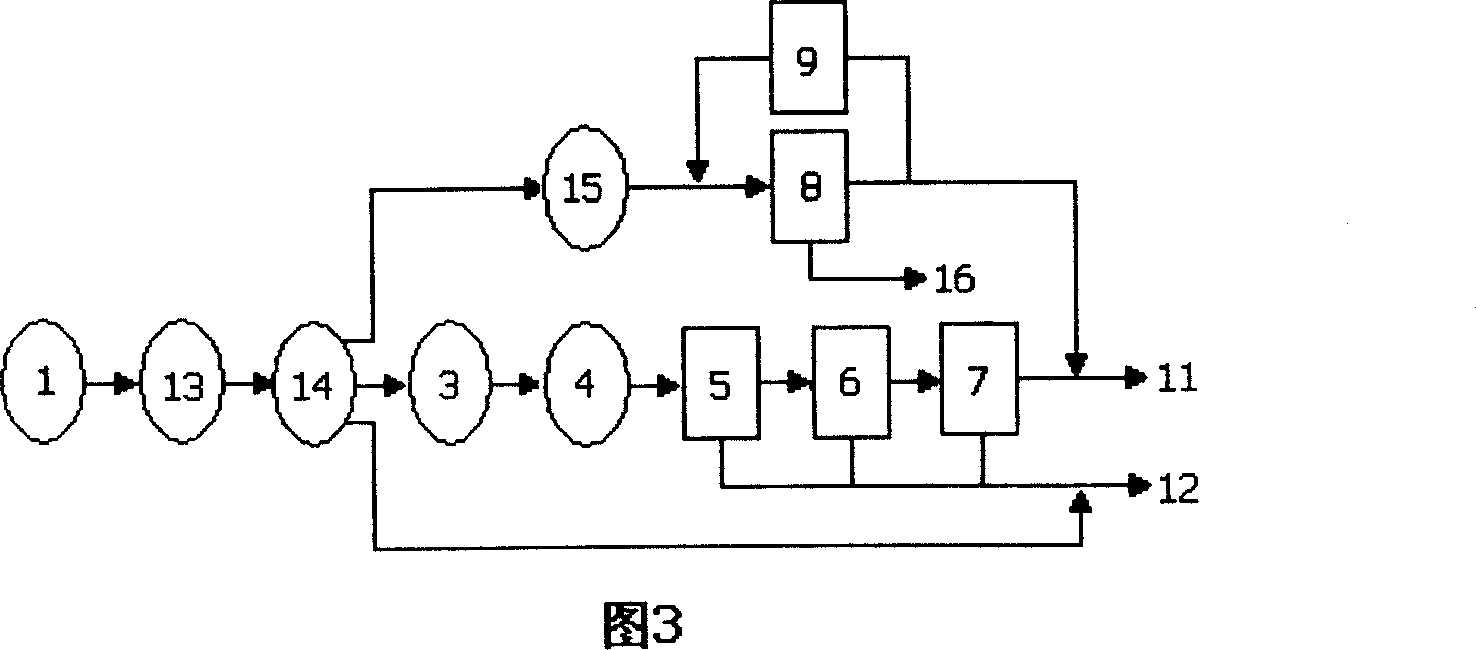

The invention discloses a method for recognizing an image of a plant leaf. The method comprises a training stage and a recognition stage. The training stage comprises the following steps of: inputting an image training set of the plant leaf; and storing a training result after performing batch preprocessing, batch feature extraction and neural network classifier training by using a system. The recognition stage comprises the following steps of: allowing a user to input a single image of the plant leaf of which the variety is unknown to the system and mark the leaf base point coordinate and leaf apex point coordinate of the leaf; performing preprocessing and feature extraction on the single image by using the system; and classifying by using the neural network classifier, outputting a plant variety list and attaching detailed graphics and text information to each item of the list. The method has the advantages of outputting a plurality of high-accuracy candidate results, greatly enhancing recognition credibility, supporting a scalar quantity of leaf features as well as leaf features in complex forms (such as a matrix form) and increasing the recognition rate of the plant leaf.

Owner:GUANGZHOU UNIVERSITY OF CHINESE MEDICINE

Method for processing green tea

InactiveCN101427714AReduced quality impactImprove integrityPre-extraction tea treatmentFlavorDrying time

The invention discloses a green-tea processing method, comprising: fresh leaves withering; de-enzyming, rolling, early drying, uniformly drying, fully drying at 80-100 degree for 10-15 min; the leaves image being changed from tender green to greenish black and the hand being not punctured with dehydration ratio of 30-35%; fully sweating the tea leaves after cooling' shaping in a double-pan roasting machine at 80-100degree and the early-drying temperature being from low to high when the leaf-feeding amount is major pan and the early-drying time being 40-45 minutes; instant scattering and cooling after early shaping and then continuously shaping the cooled leaves in the double-pan roasting machine for 50-60minitue at 60-80degree; cooling when the tea leaves are smooth and 75% dry; drying; sieving and classifying. The green-tea processing method can increase the tea leaves color, aroma, liquor color, flavor and integrity degree of leaf-base and produce high-grade tea leaves using common material.

Owner:贵州贵茶(集团)有限公司

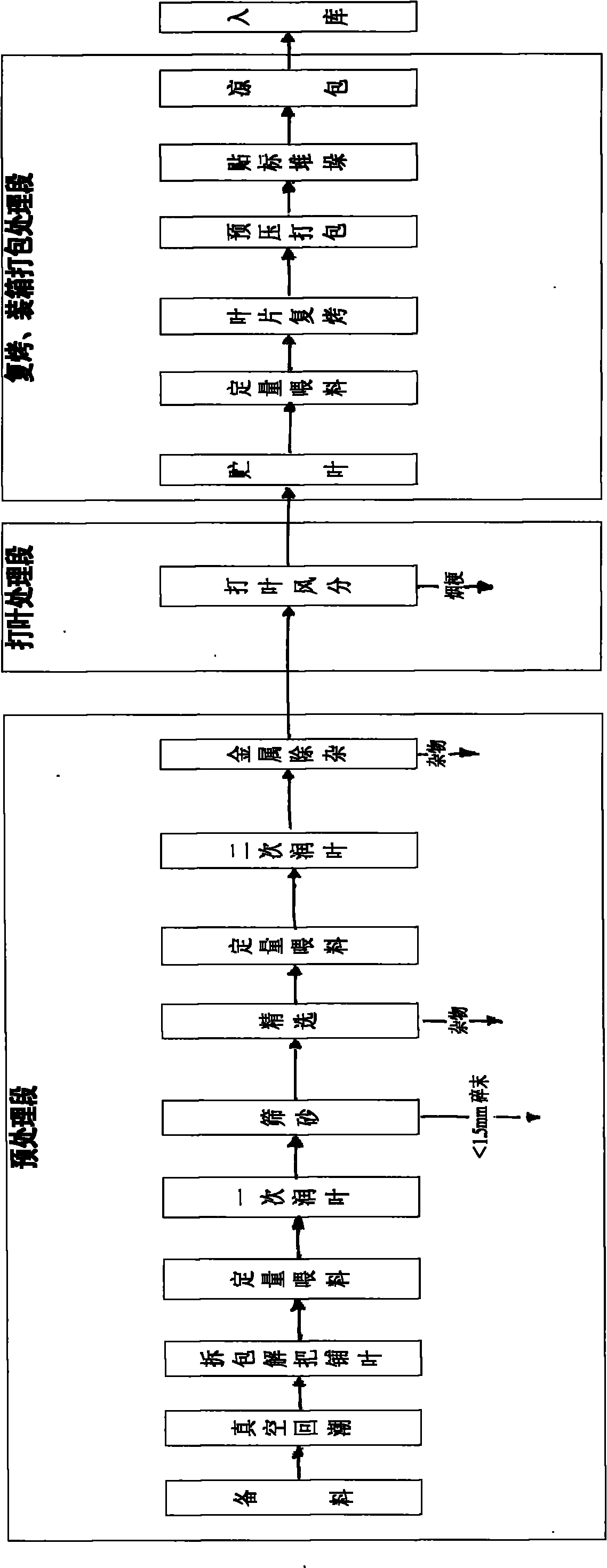

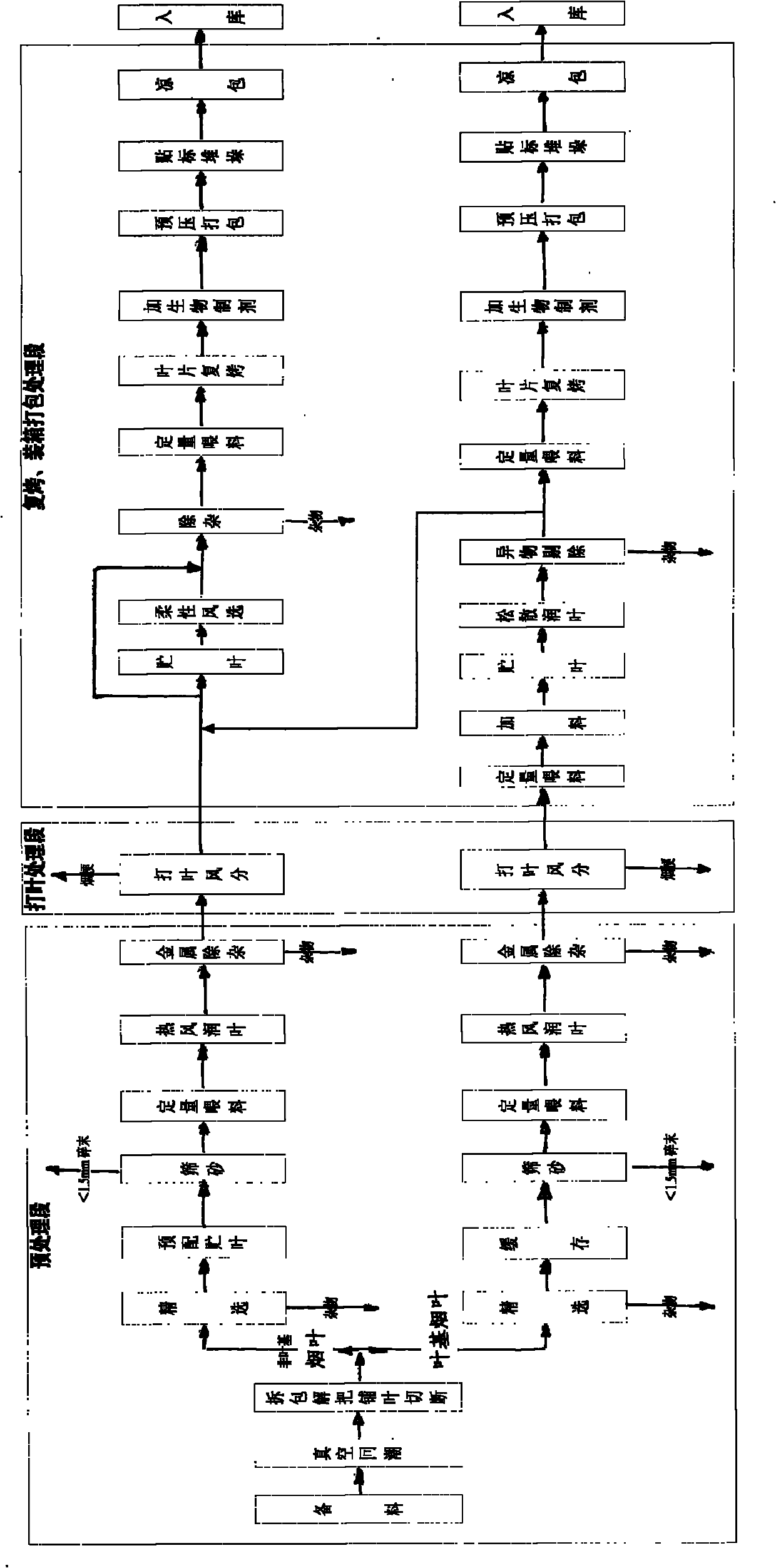

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

Tobacco leaf subsection threshing and redrying method

ActiveCN101214084AReduce Fragmentation RateMeet quality control needsTobacco preparationTobacco treatmentLeaf baseBiology

The invention discloses a tobacco leaf segmentation threshing and redrying method, in the invention, tobacco leaves in different positions and ranks are threshed into three parts which are respectively leaf apex, leaf base and leaf middle. Then, the corresponding threshing and redrying schemes are relatively made according to the quality state of every part or the processing character. The method leads the quality of the perfect tobacco leaves to be more perfect. The tobacco leaves with poorer quality are improved. The use value and the comprehensive utilization benefit of the tobacco leaves are improved. And the application of the method is beneficial to the fragment rate of the tobacco leaves. The bottleneck of the shortage of high-rank tobacco raw material is overcome. And the invention plays a significant role in promoting the development of high-rank brand tobacco and the successive structure adjustment of brand tobacco.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

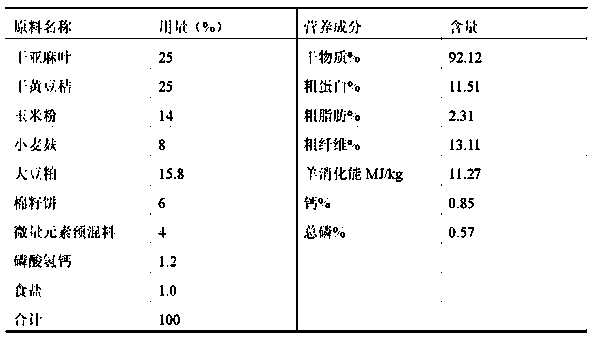

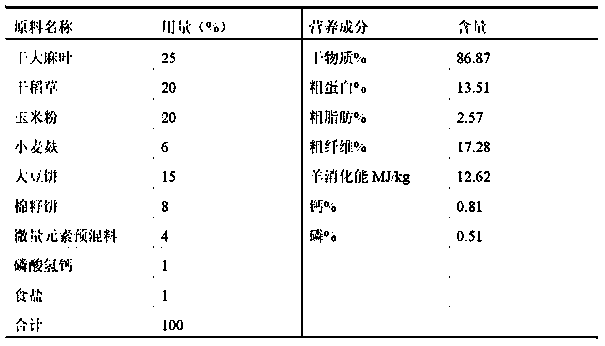

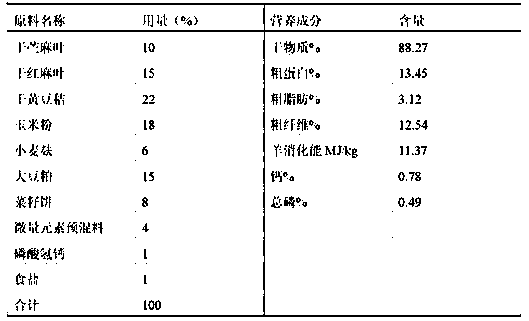

Hemp fimble leaf-based total mixed ration granulated feed for sheep

ActiveCN103431243ARich in nutritional valueLow costFood processingAnimal feeding stuffDry weightAnimal science

The invention discloses hemp fimble leaf-based total mixed ration granulated feed for sheep. The hemp fimble leaf-based total mixed ration granulated feed is prepared from the following raw materials by mass percentage in parts by dry weight: 40-55 parts of dry hemp fimble leaves, 40-55 parts of dry straw, 12-20 parts of corn, 10-15 parts of soybean meal, 10-15 parts of bran, 4-6 parts of trace element premix, 0.8-1.5 parts of calcium hydrogen phosphate and 0.5-1.2 parts of salt which are processed into the total mixed ration granulated feed for sheep through processes such as triturating, grinding, weighing, mixing, tempering and granulating. Animal feeding tests show that in the test period, the average daily feed intake of lambs in a group fed by the total mixed ration granulated feed is higher than that of a control group by 70g, the daily gain is increased by 17.25g compared with the control group, and the net income per sheep is increased compared with the control group on average.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE ANHUI ACAD OF AGRI SCI

Moxa leaf rice paste and its making method

The name of the invention is an artemisia leaf glutinous rice cake and aprepration method, belonging to the glutinous rice cake food technical field. The invention mainly solves the problem that artemisia leaf is not capable of being added directly to glutinous rice cake to be eaten. The invention has the main characteristics that: the manufacturing materials contain sticky rice and artemisia leaf; the sticky rice is 56 to 66 and the artemisia leaf is 37 to 41. the preparation method for artemisia leaf glutinous rice cake is that: {1}the clean-washed tender green artemisia leaf is put into boiling water containing dietary alkali, with a viscosity of 4 percent to 6 percent, and is stewed for five to eight minutes and then the leaf base is removed after being cooled to 40 DEG C to 48 DEG C; {2}the sticky rice is grinded into powder after being soaked in the water for five to eight hours;{3}the dietary alkali water, with a viscosity of 2 percent, is added into the sticky water and the artemisia leaf and is mixed evenly, cut into pieces and grained completely, and then becomes a paste;{4}the paste is changed into an oblate shape or stuffings are wrapped into the paste in an oblate shape;{5}the oblate-shaped paste is covered with big bamboo leaves and tender tug oil tree leaves and is steamed in a steam box. The invention mainly provides the artemisia leaf glutinous rice cake and the preparation method. The taste of the artemisia leaf glutinous rice cake is soft and smooth. Besides, the artemisia leaf glutinous rice cake has the health care function.

Owner:XIANGYANG JINHENG ELECTRIC CO LTD

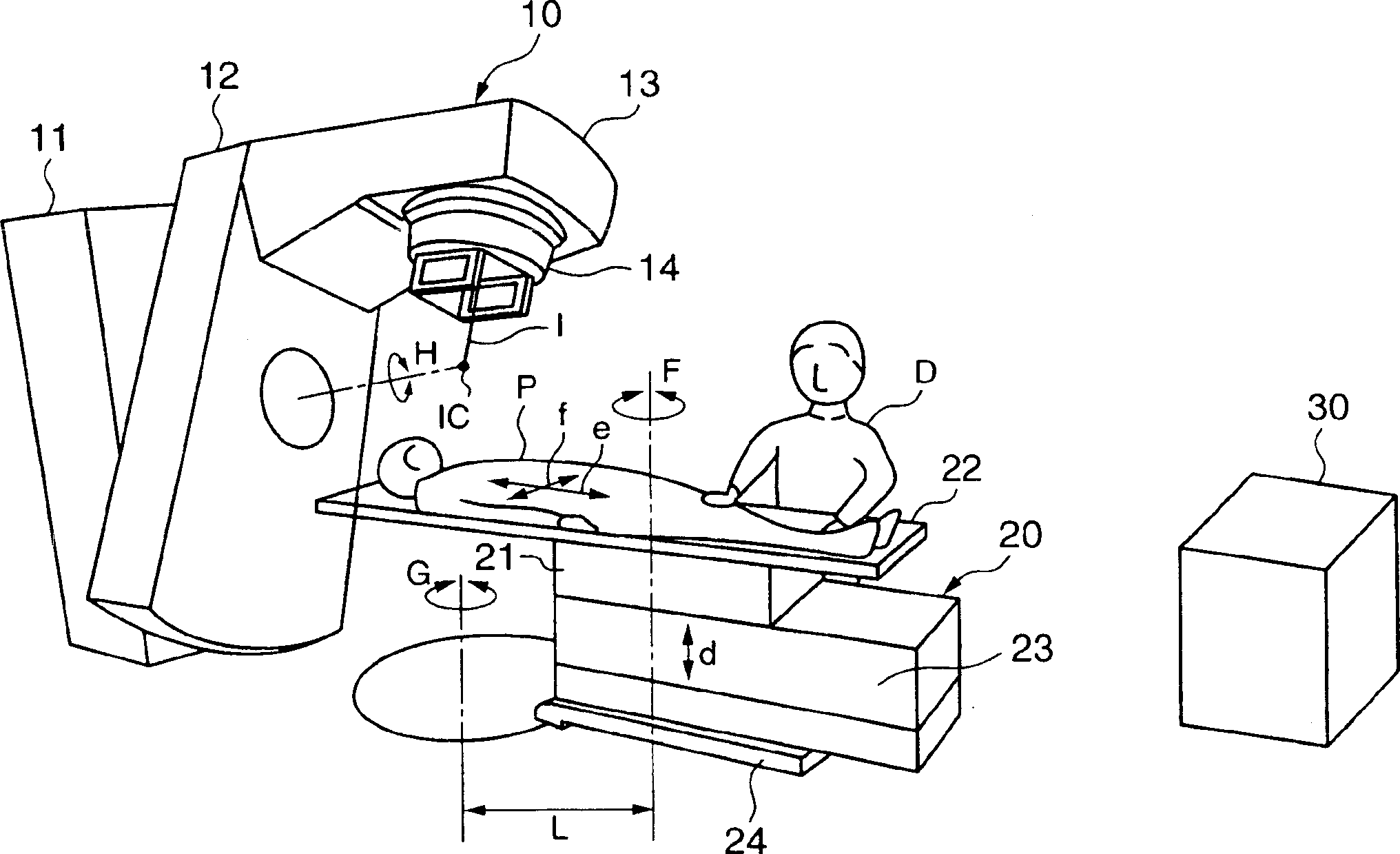

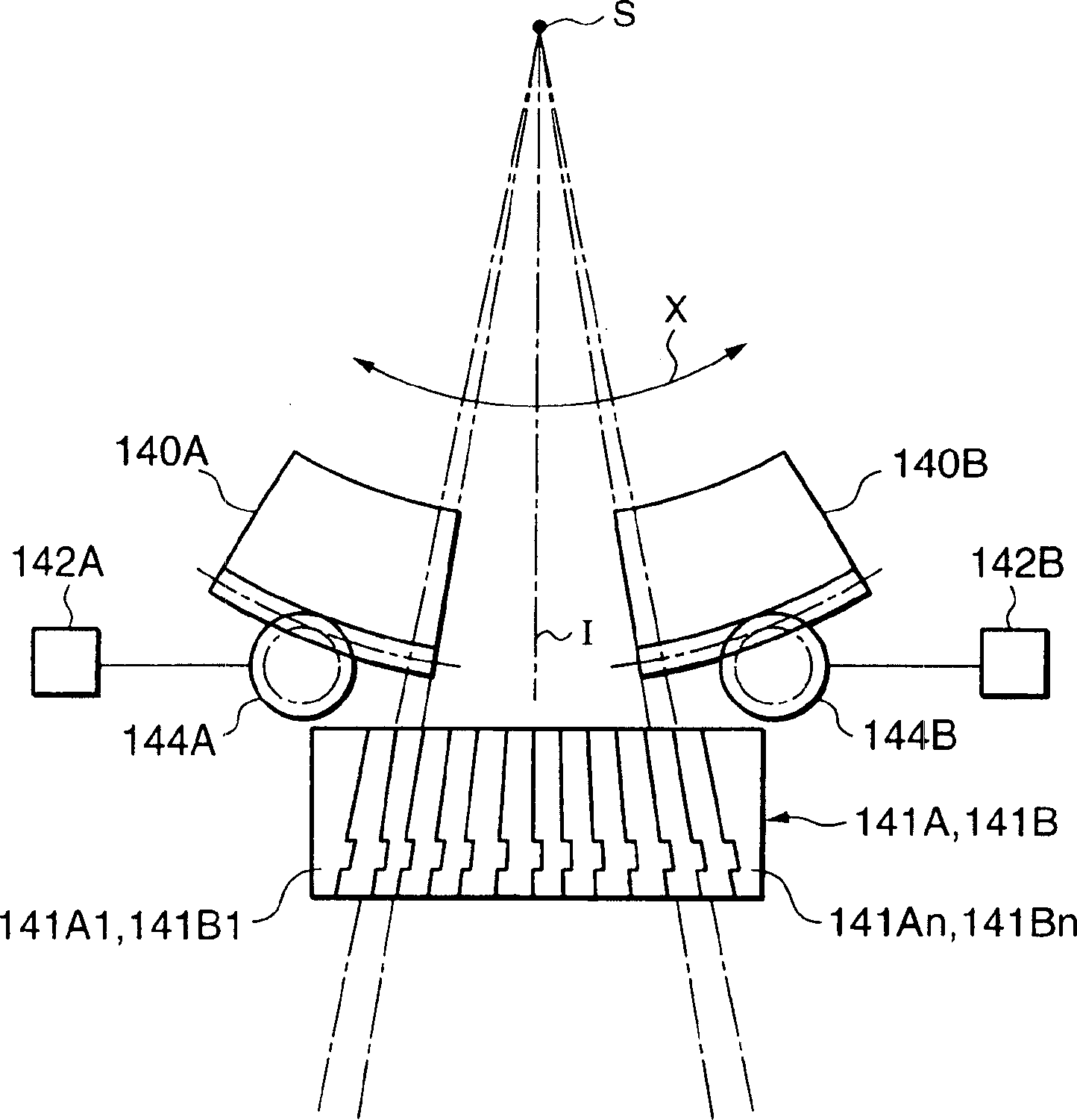

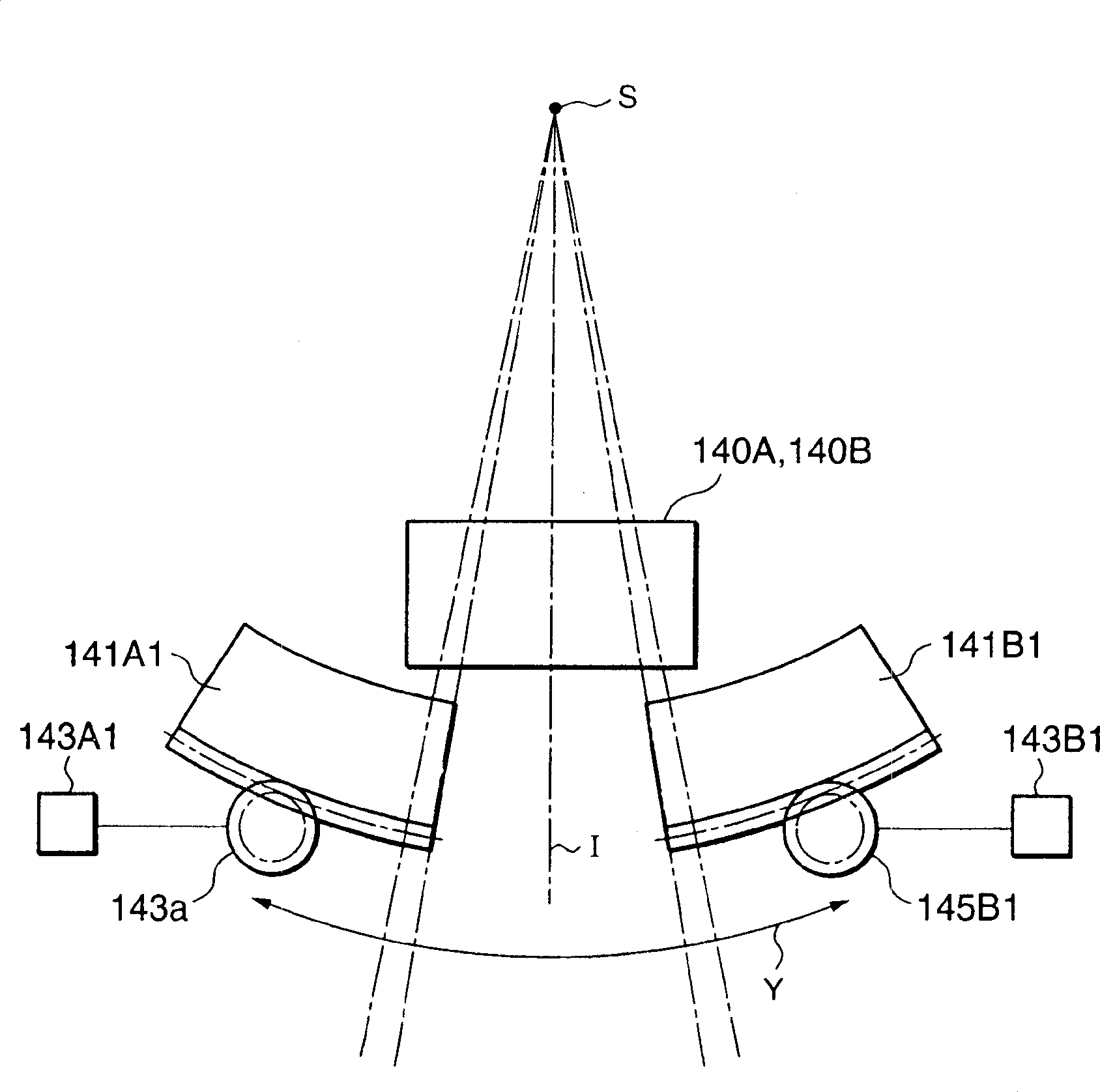

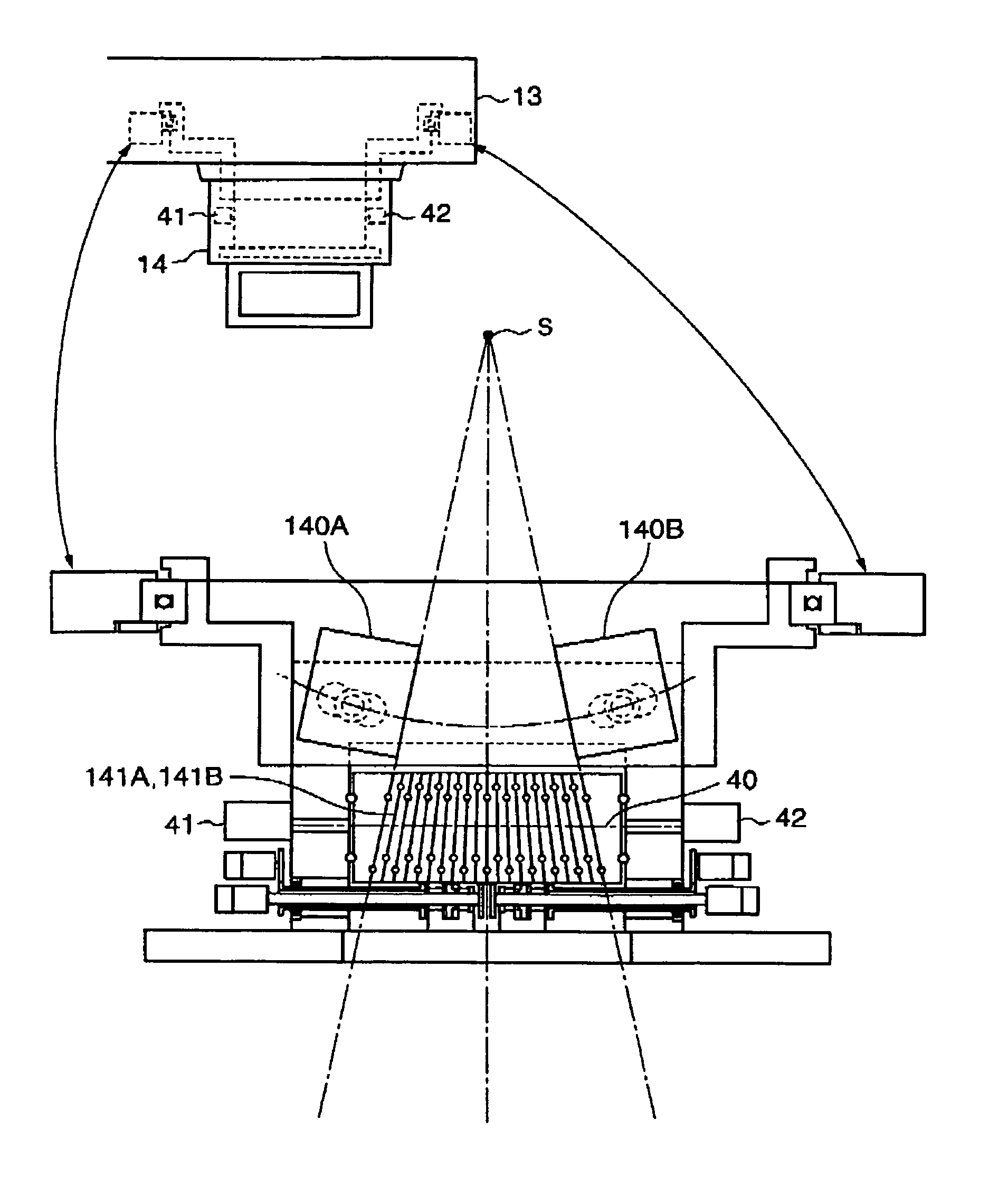

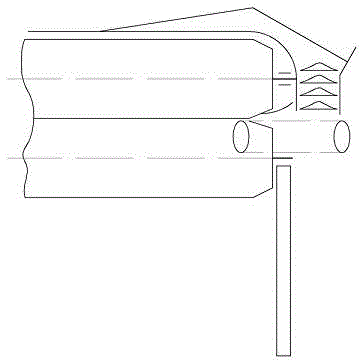

Multiblade collimator

InactiveCN1530151AHandling using diaphragms/collimetersX-ray/gamma-ray/particle-irradiation therapyX-rayRadiation field

A collimating device for controlling a radiation field of an X-ray radiated from an X-ray radiator. The device includes a plurality of first collimating leaves, a plurality of second collimating leaves, a beam generator, a detector, a memory, and a controller. The plurality of second collimating leaves oppose the first collimating leaves. The beam generator is configured to generate a beam. The beam emanates between the first collimating leaves and the second collimating leaves. The detector is configured to detect the beam. The memory is configured to store position information of each leaf of the first and second collimating leaves when the each leaf is determined to intersect the beam based on the detection. The controller is configured to position the each leaf based on the position information so as to control the radiation field.

Owner:TOSHIBA MEDICAL SYST CORP

Pretreatment process for tobacco threshing and redrying

InactiveCN101077213AHigh purityStrong targetingTobacco preparationTobacco treatmentEngineeringPre treatment

The present invention relates to tobacco pre-treatment, and is especially sectional tobacco thrashing and redrying pre-treatment process. The tobacco pre-treatment process includes the following steps: spreading the vacuum dampened tobacco leaf; cutting tobacco leaf into three sections including leaf stem, leaf base and leaf tip; moistening the leaf stem and separating in a leaf stem returning device into tobacco leaf stem and inferior tobacco leaf; and sieving leaf base to eliminate sand, moistening and multi-stage separating to obtain tobacco leaf stem and tobacco leaf. The tobacco pre-treatment process has high product quality.

Owner:CHINA TOBACCO HUNAN INDAL CORP

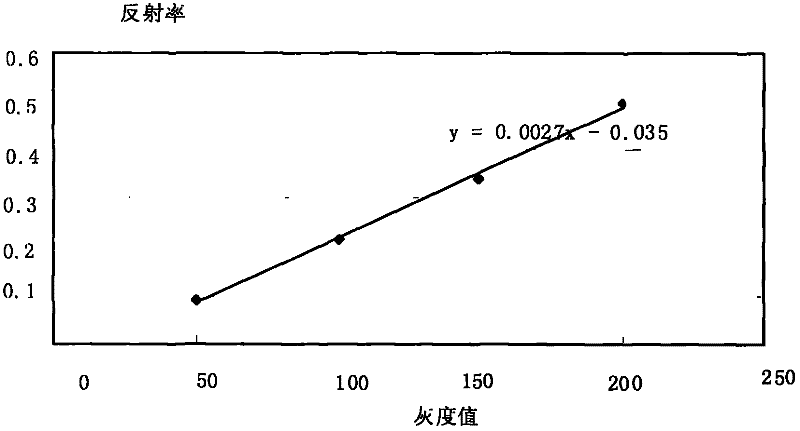

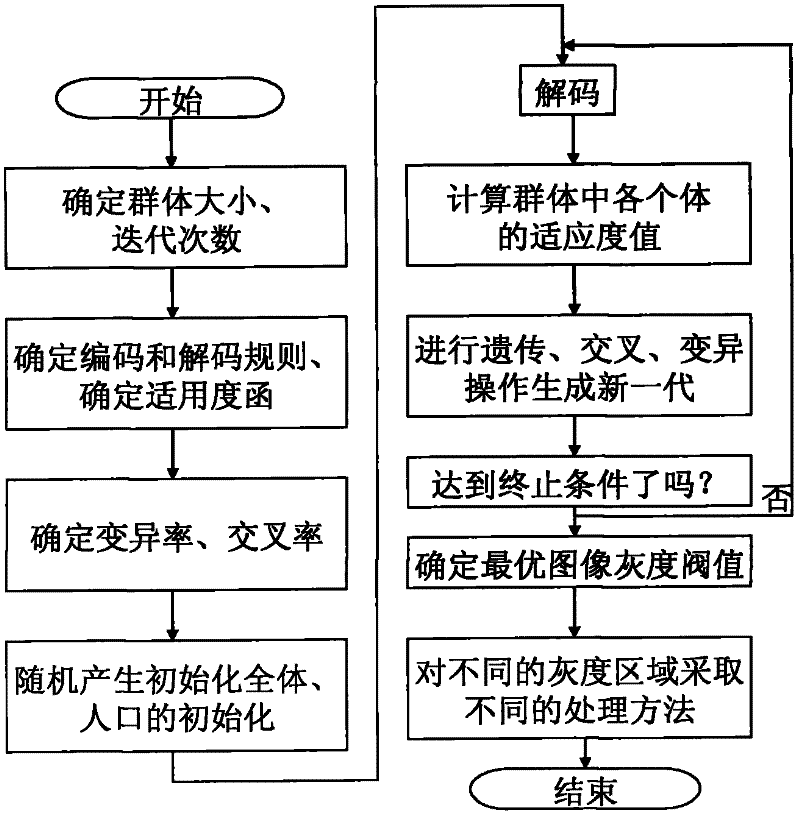

Method for predicting nitrogen content of cucumber leaf based on spectral image analysis

InactiveCN102175626AEasy to operateLow costColor/spectral properties measurementsWavelengthNormalized Difference Vegetation Index

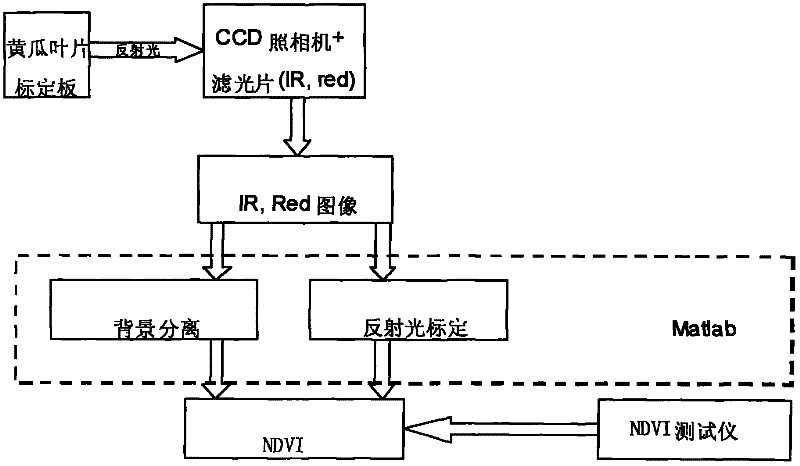

The invention discloses a method for predicting nitrogen content of cucumber leaf based on spectral image analysis. The method is characterized by comprising the following steps of: adding an infrared and red light filter with a characteristic wave length in front of the lens of a CCD (charge coupled device) camera, and firstly collecting a near-infrared and red light image of the cucumber leaf to obtain the gray value of the cucumber leaf; measuring the vegetation reflection range RIR at the characteristic wave length of the infrared light and the reflection rate RR of the cucumber leaf at the infrared characteristic wave length through an empirical formula; obtaining a normalized difference vegetation index (NDVI) according to the reflection rate values RIR and RR of the cucumber leaf at the infrared characteristic wave length and a red light wave segment; and judging the nitrogen content level of the cucumber leaf according to the NDVI so as to realize the prediction on the nitrogen content of the cucumber leaf. By the method, the nutrient state of crops can be obtained visually and effectively, and the nitrogen content of cucumber leaf can be predicted quickly and visually.

Owner:BEIJING KINGPENG INT HI TECH CORP

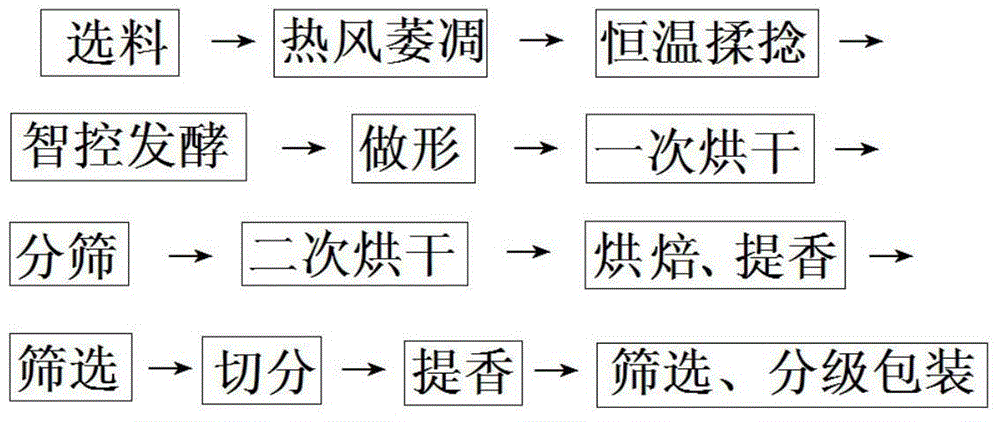

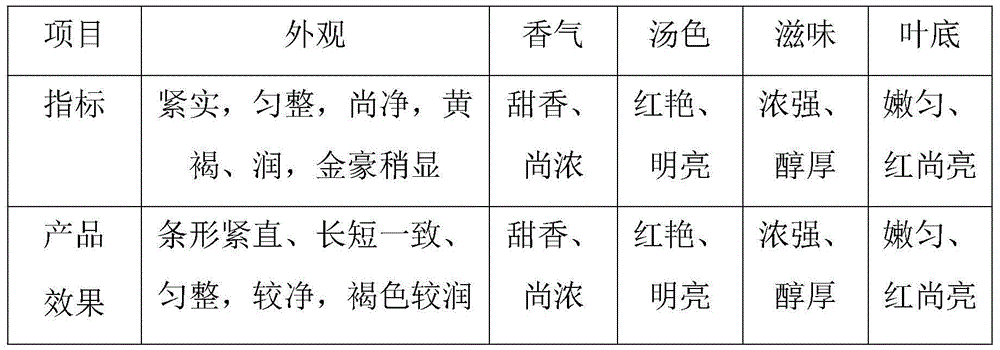

Processing method of congou black tea

ActiveCN103815066AStraight appearanceSame lengthPre-extraction tea treatmentFragrance extractionCooking & baking

The invention provides a processing method of congou black tea. The method comprises the steps of material selection, hot air withering, constant temperature rolling, intelligent controlled fermentation, shaping, primary drying, screening, secondary drying, baking, fragrance extraction, screening, cutting, fragrance extraction, screening, classification and packaging. The method adopts late spring and early summer one-sprout and two or three-leaf green, a constant temperature rolling, intelligent control fermentation, baking, fragrance extraction, optimization, striping and fragrance extraction technique and a standardized precise classification technique, so that 40-50% of energy consumption can be reduced effectively; the yield is increased; the prepared congou black tea is striped, tight and straight in appearance, consistent, even and orderly in length, sweet and thick in fragrance, red and bright in soup, thick and mellow in taste, tender, uniform, red and bright in leaf base, excellent in interior quality, and relatively clear; a safety control index reaches an export standard; the quality reaches the standard; and the method has a good economic benefit.

Owner:贵州省湄潭县芸香茶业有限公司

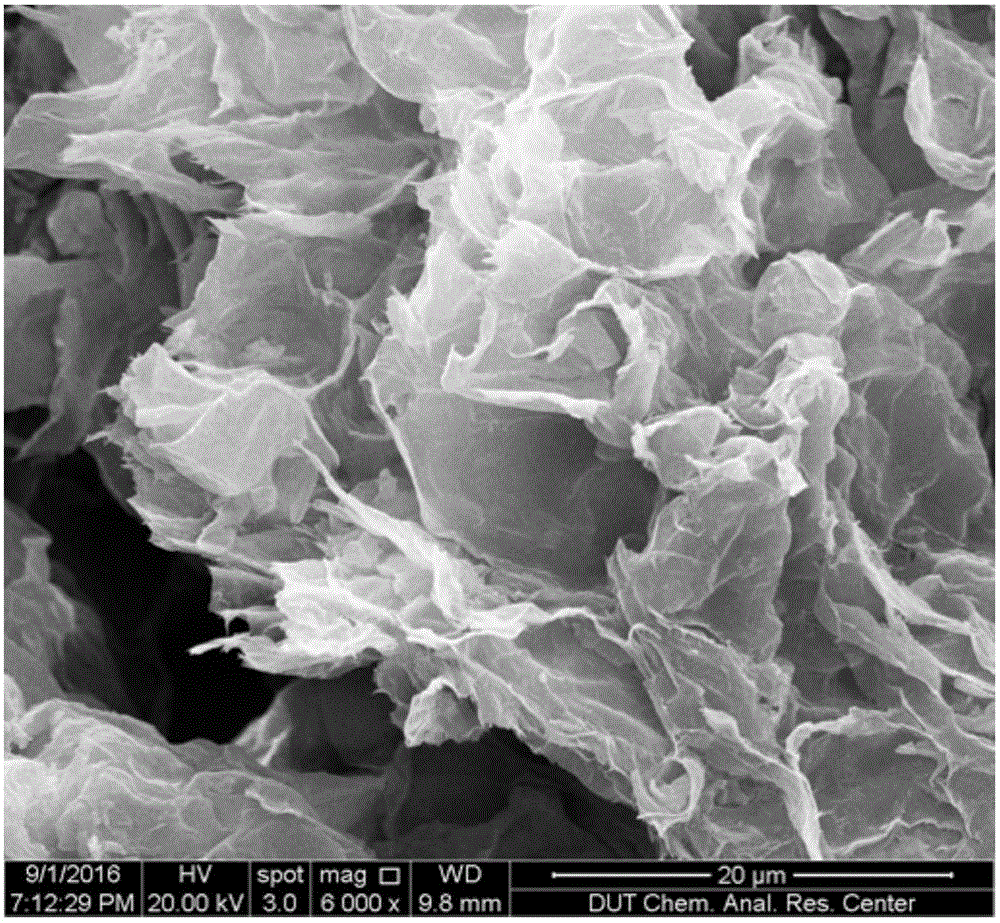

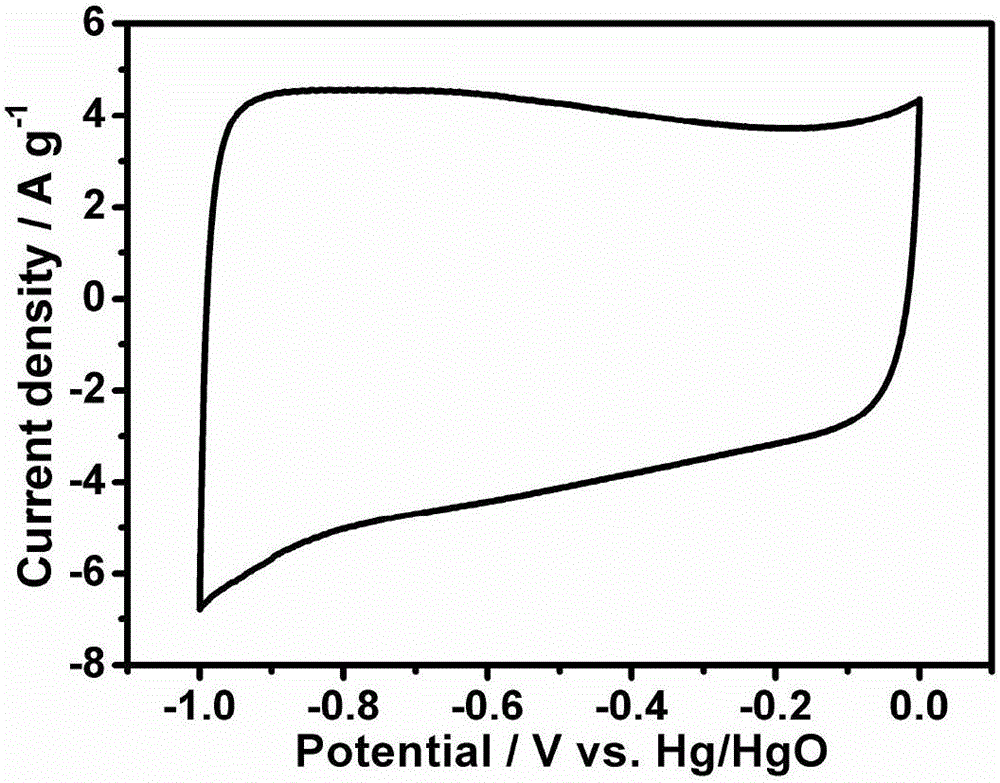

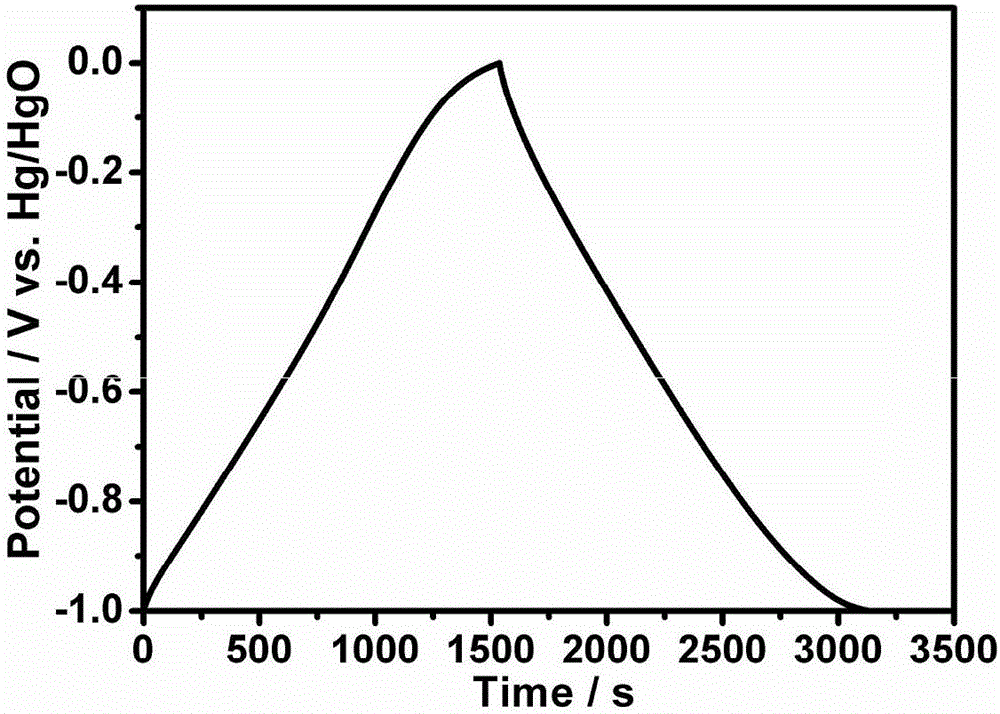

Preparation method and application of sweet potato leaf based active carbon

ActiveCN106430186AHigh specific surface areaHigh specific capacityCarbon compoundsHybrid capacitor electrodesCapacitanceSource material

The invention relates to the technical field of preparation of new energy source materials and provides a preparation method and application of sweet potato leaf based active carbon. The preparation method comprises the following steps: 1, washing sweet potato leaves with de-ionized water and then drying and crushing; carrying out pre-carbonization treatment under the protection of inert gas to obtain a pre-carbonized product; 2, mixing the obtained pre-carbonized product with potassium hydroxide; after drying, carrying out high-temperature activation treatment under the protection of the inert gas to obtain an activated product; and 3, carrying out acid washing and water washing on the obtained activated product, and then freezing and drying to obtain the sweet potato leaf based active carbon. The preparation method provided by the invention is simple in process and low in equipment cost; the raw materials are easy to obtain; and the sweet potato leaf based active carbon prepared by the method is of a sheet-shaped structure and has a series of advantages of high specific capacitance, good rate performance, long circulating long service life and the like when being used as an electrode material of a super-capacitor.

Owner:DALIAN UNIV OF TECH

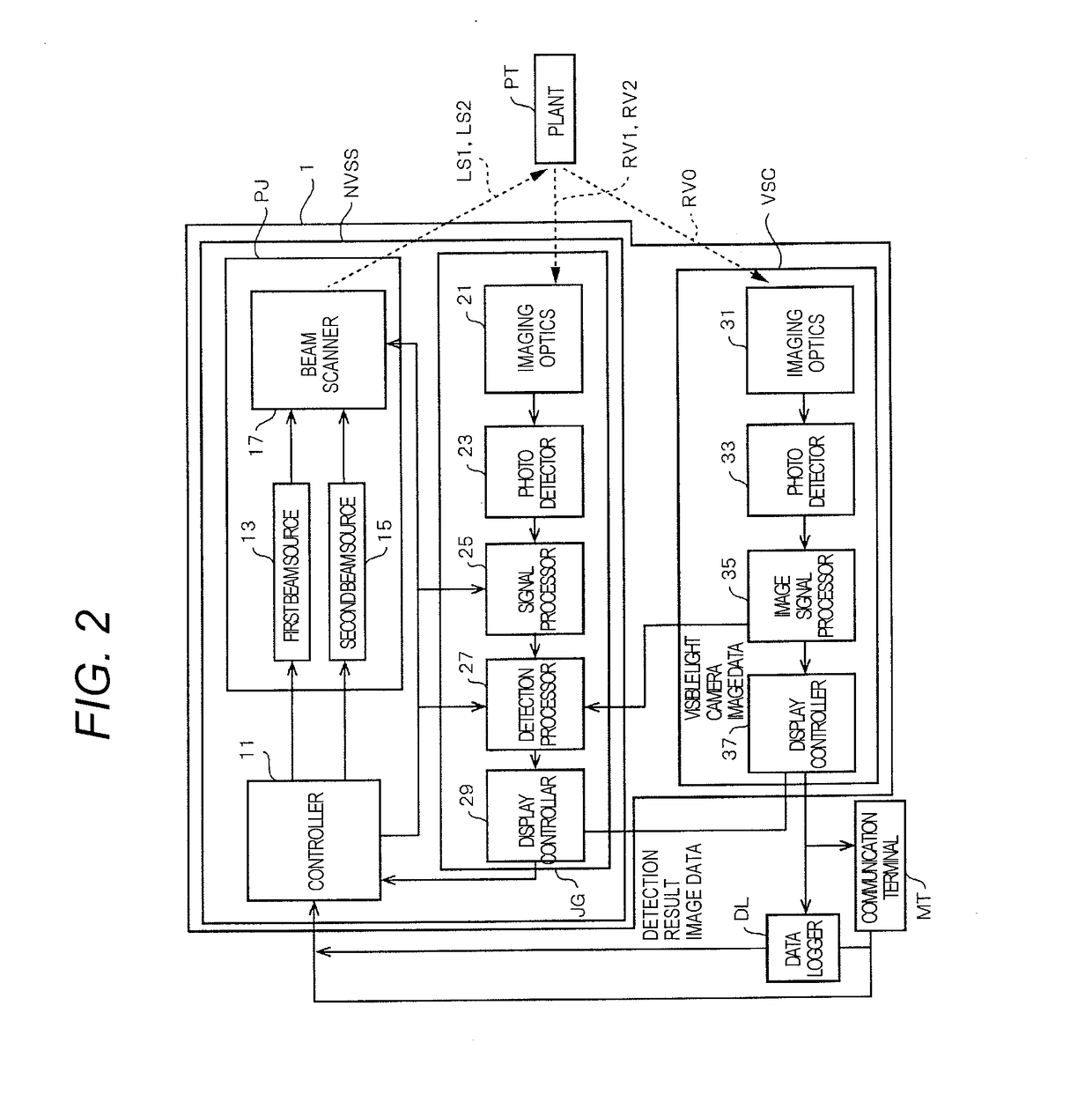

Multileaf collimator

A collimating device for controlling a radiation field of an X-ray radiated from an X-ray radiator. The device includes a plurality of first collimating leaves, a plurality of second collimating leaves, a beam generator, a detector, a memory, and a controller. The plurality of second collimating leaves oppose the first collimating leaves. The beam generator is configured to generate a beam. The beam emanates between the first collimating leaves and the second collimating leaves. The detector is configured to detect the beam. The memory is configured to store position information of each leaf of the first and second collimating leaves when the each leaf is determined to intersect the beam based on the detection. The controller is configured to position the each leaf based on the position information so as to control the radiation field.

Owner:TOSHIBA MEDICAL SYST CORP

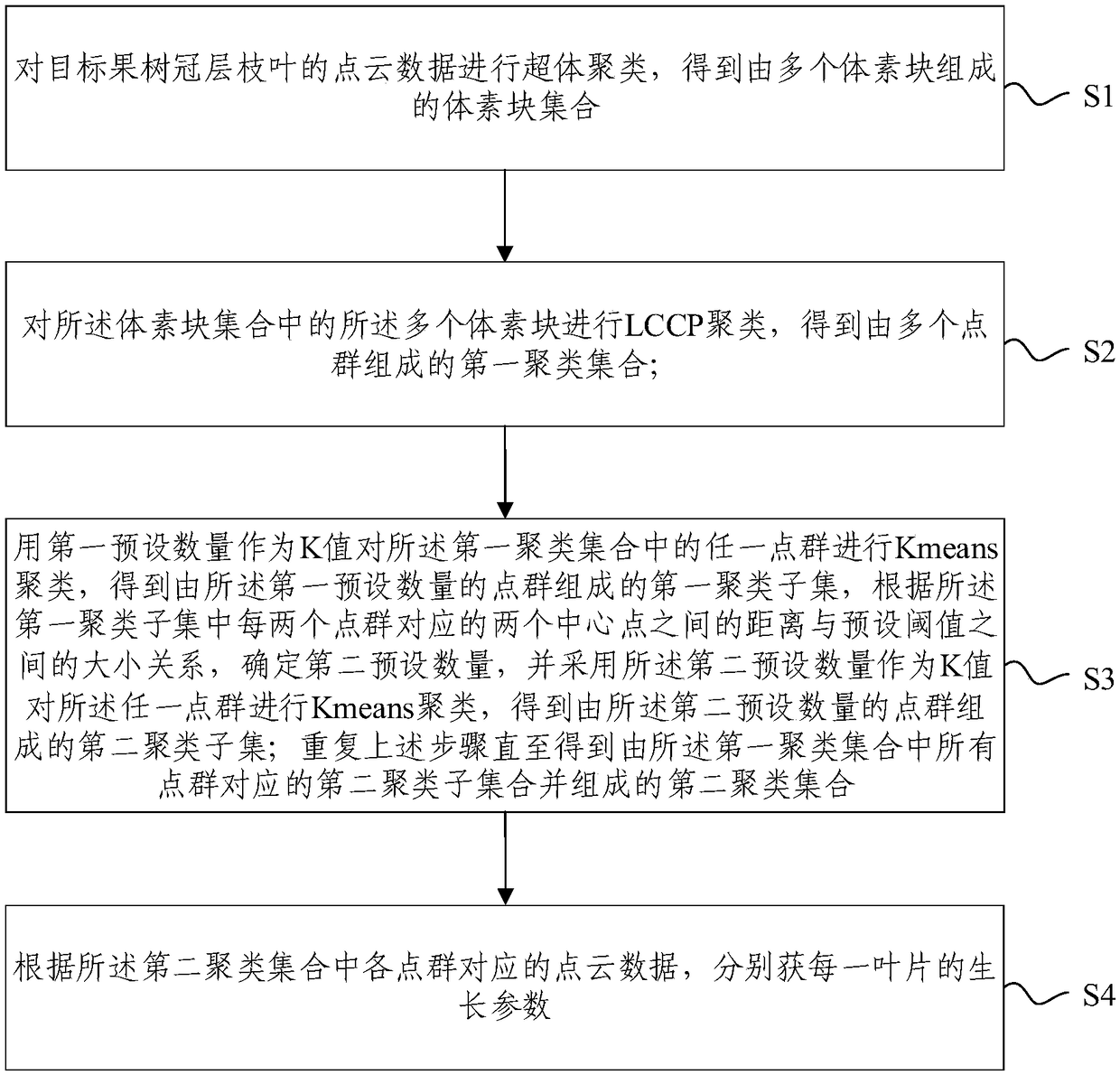

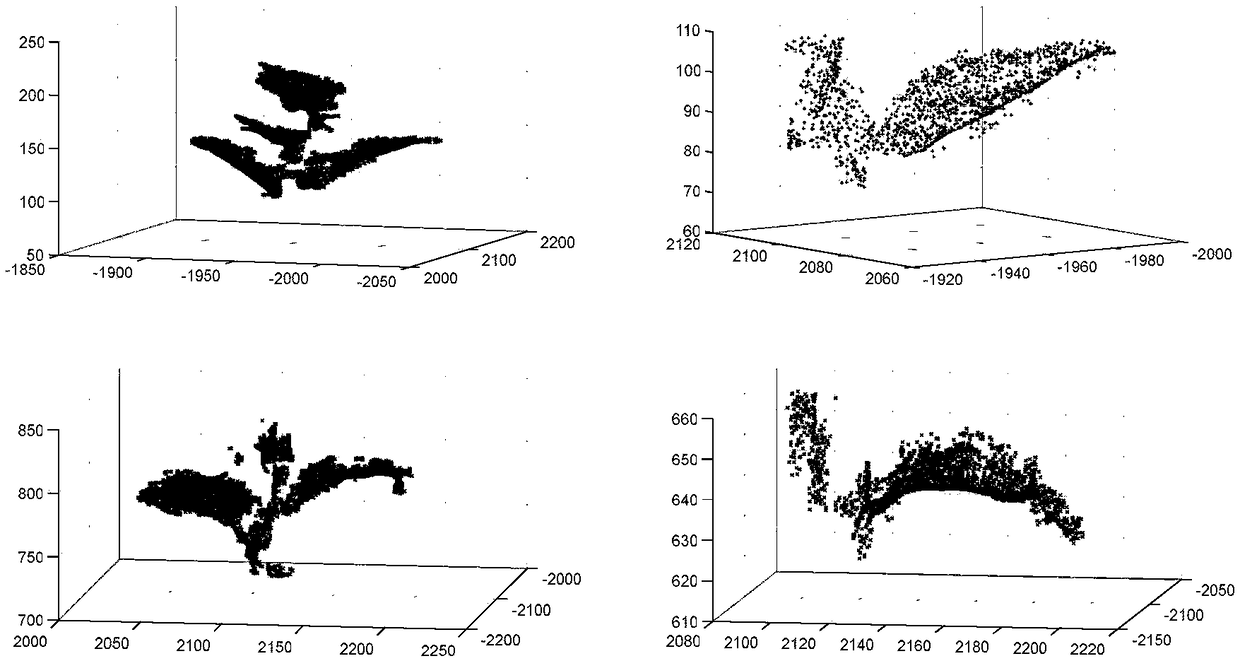

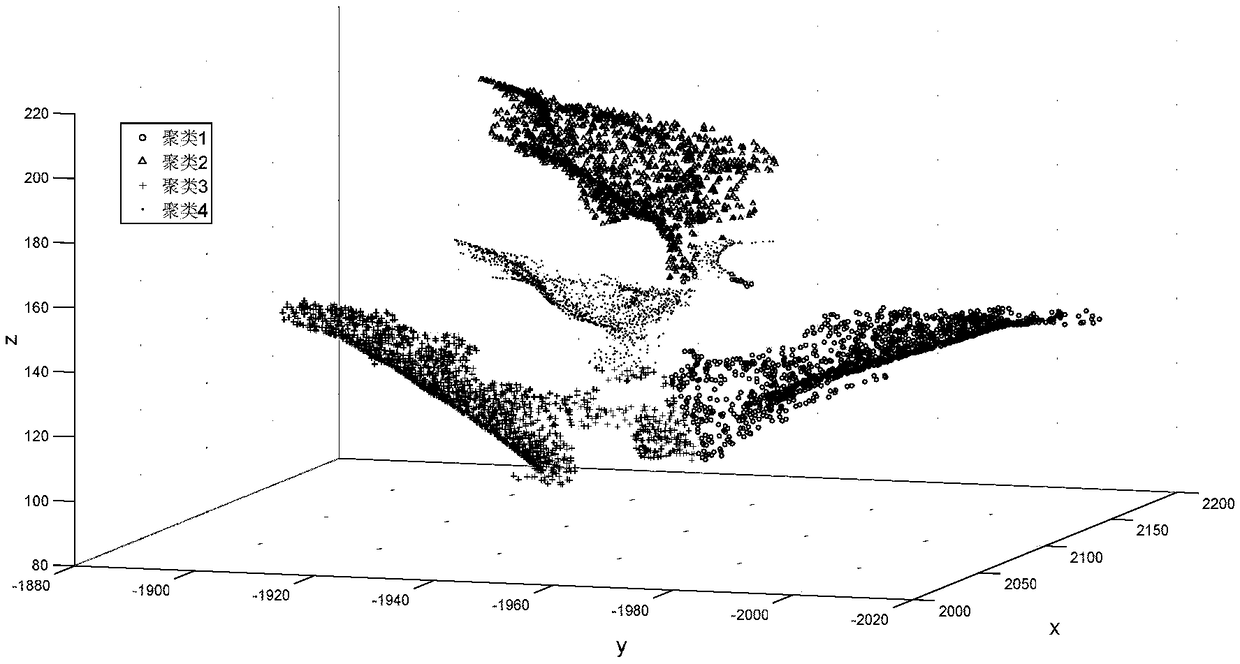

A method and a system for extracting leaf growth parameters of fruit trees based on clustering segmentation

ActiveCN109166145AAccurate growth parametersAccurate extraction of growth parametersImage enhancementImage analysisFruit treeCluster algorithm

The invention provides a method and a system for extracting leaf growth parameters of fruit trees based on clustering segmentation, the method comprising the following steps: superclustering the pointcloud data of the canopy branches and leaves of a target fruit tree, and performing LCCP clustering on a plurality of adjacent voxel blocks in the obtained voxel block set to obtain a first clustering set; applying Kmeans clustering to any point group in the first clustering set to obtain the second clustering set; according to the point cloud data corresponding to each point group in the secondclustering set, obtaining the growth parameters of each leaf based on boundary extraction. After LCCP clustering is used to segment the point group obtained by superbody clustering, and the Kmeans clustering algorithm based on dynamic K-value is further adopted. The improved clustering Kmeans algorithm can automatically obtain the K value, the shortcoming of manual setting the K value in the traditional algorithm is overcome, the point cloud data segmentation of the canopy branches and leaves of the target fruit trees becomes more complete and more thorough, and then extracted leaf growth parameters are more accurately.

Owner:CHINA AGRI UNIV

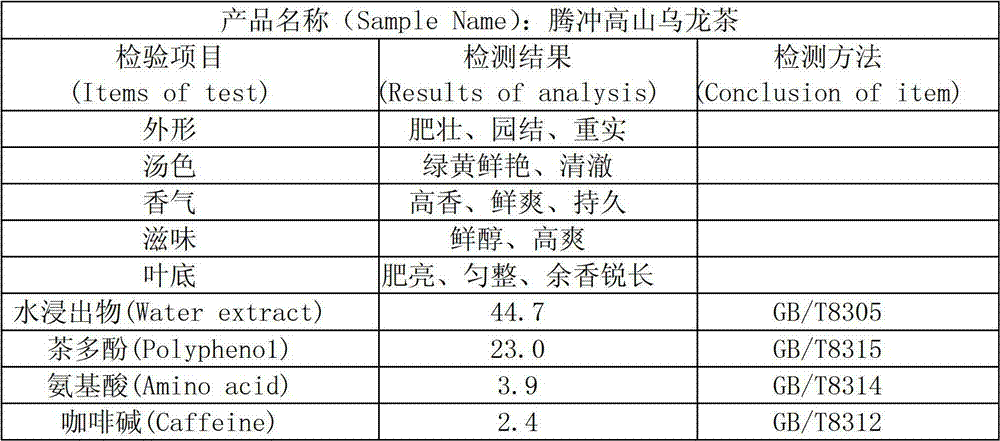

Manufacturing method of organic high-mountain oolong tea

ActiveCN102948501AAppearance cord fatEmerald green colorPre-extraction tea treatmentGreen yellowEmerald

The invention provides a manufacturing method of organic high-mountain oolong tea. Raw materials are qingxin oolong good fresh leaves at the elevation of 1900 to 2600 meters, and standard fresh leaves with buds or small open faces are one bud with two leaves or one tender bud with three leaves. The manufacturing method comprises the following steps of sunning, tedding, rocking of green leaves, standing, killing at high temperature, rolling, samming, balling, drying, cooling and the like. The high-mountain oolong tea has the advantages of strong, round and plump cord, emerald green color, obvious sand green, strong, fresh and permanent aroma, fresh, mellow and brisk taste, green-yellow, bright and clear liquid color, strong, bright and uniform leaf base and fragrance for a long time.

Owner:YUNNAN TAICHA TEA

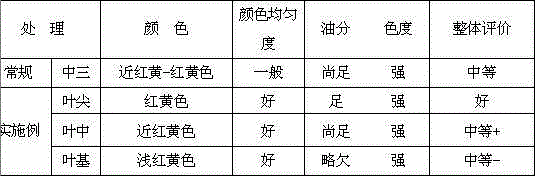

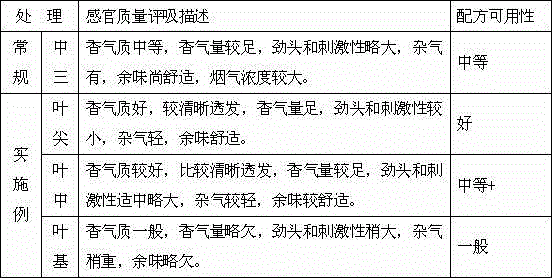

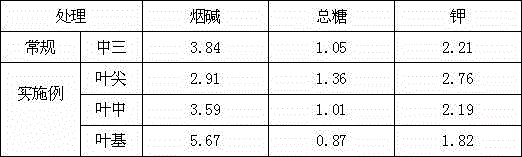

Grouping use method of different slitting areas of tobacco leaves in blend threshing

ActiveCN105768168AImprove use valueImprove effective utilizationTobacco preparationThreshingLeaf base

The invention belongs to a grouping use method of different slitting areas of tobacco leaves in blend threshing.The grouping use method includes following steps: 1, transversely slitting the tobacco leaves into a leaf tip slitting area, a leaf middle slitting area and a leaf base slitting area sequentially; evaluating and scoring appearance quality, physical index, chemical ingredient coordination index, sensory quality and danger index of each slitting area; 3, calculating a comprehensive quality score of each slitting area according to a formula: W=0.1A+0.2B+0.2C+0.3D-0.2E, W refers to the comprehensive quality score of each slitting area, A refers to an appearance quality score, B refers to a physical index score, C refers to a chemical ingredient coordination index score, D refers to a sensory quality score, and E refers to a danger index score.The different slitting areas are utilized to group tobacco leaf raw materials, so that using value of the raw materials is increased, unnecessary waste is reduced, and the bottleneck that raw materials of high-grade cigarettes are in short supply.

Owner:CHINA TOBACCO HENAN IND

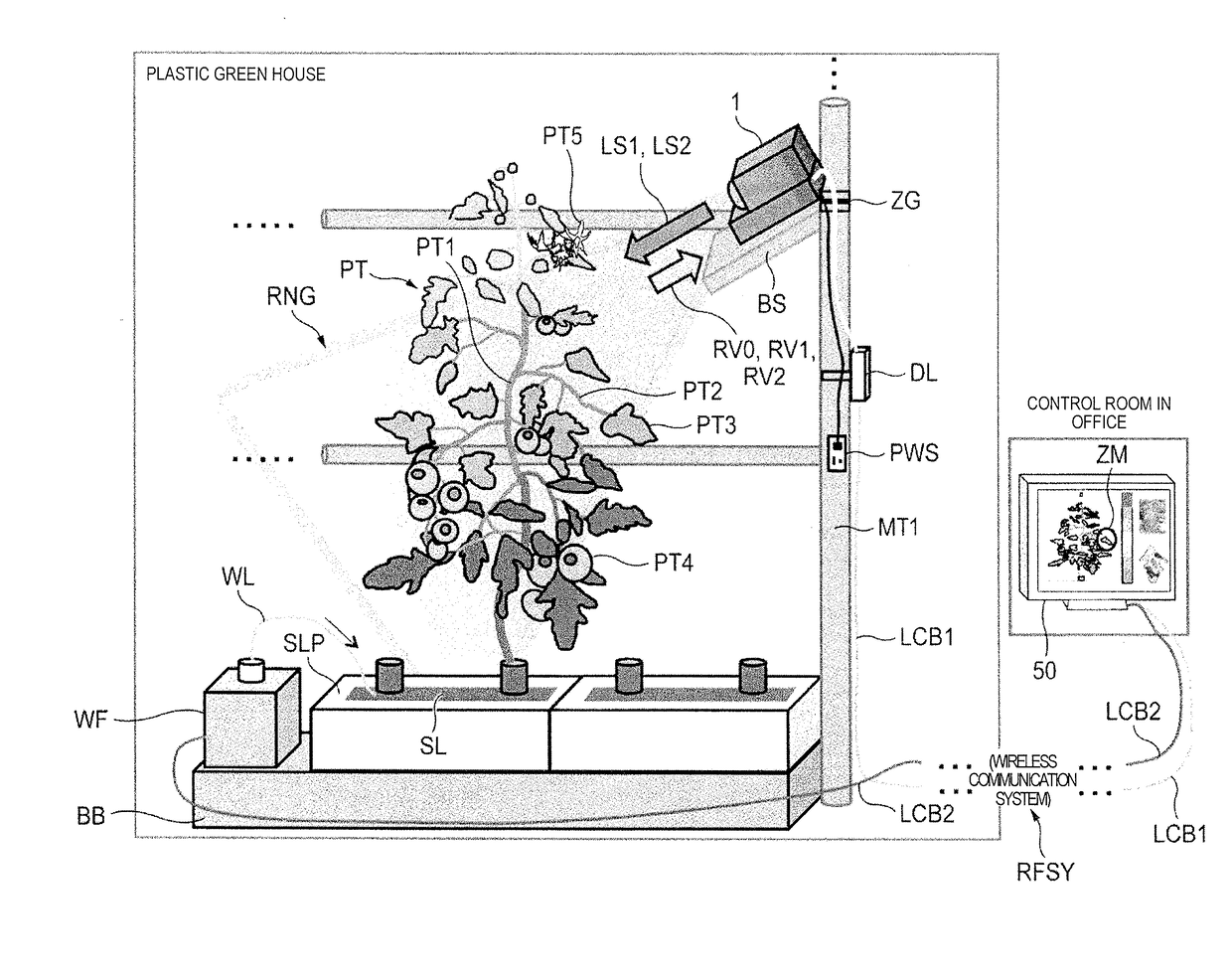

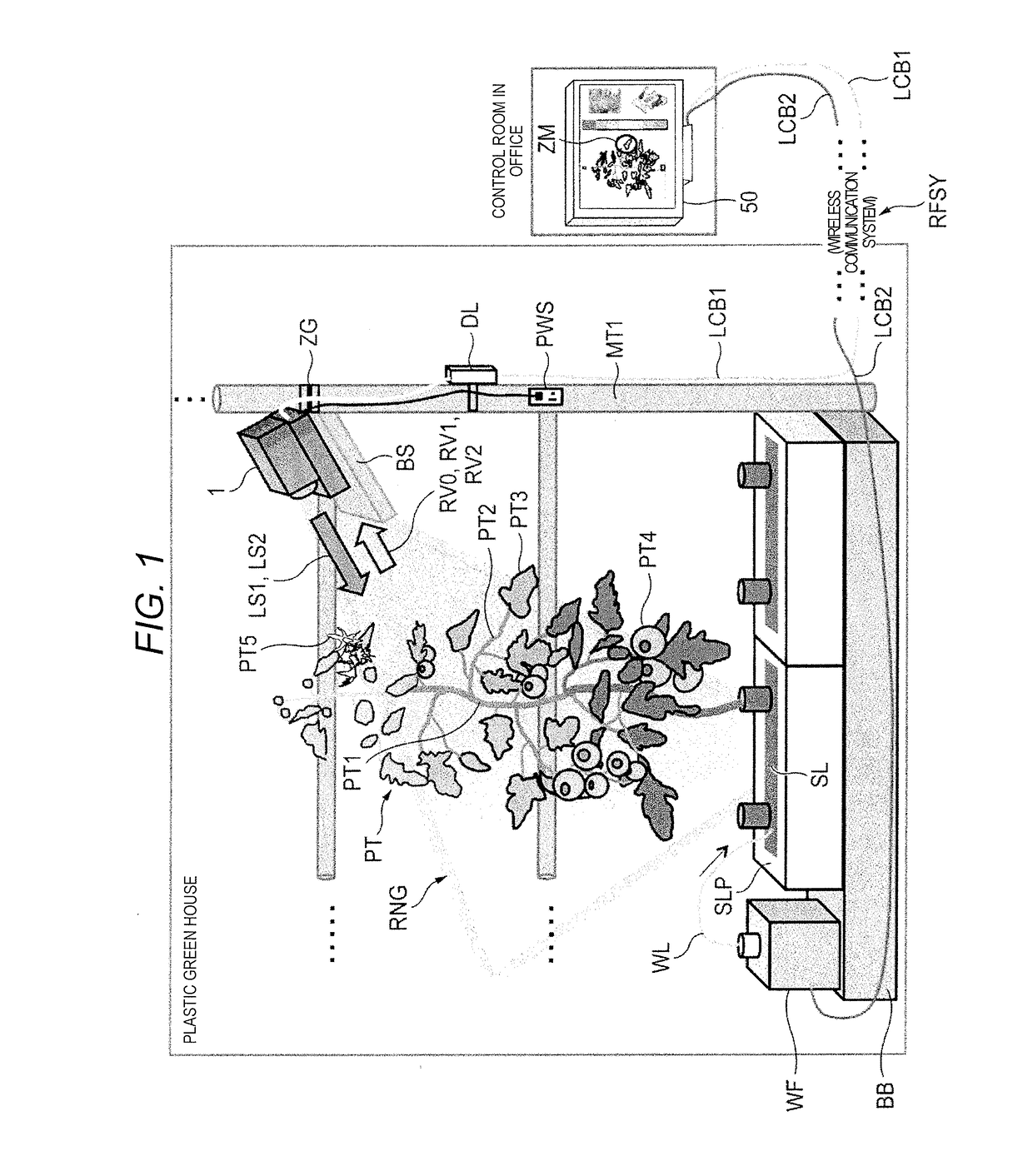

Water content of a part of plant evaluation method and water content of a part of plant evaluation apparatus

ActiveUS20170115210A1Accurate measurementExclude influenceInvestigation of vegetal materialBeam sourceLight beam

In a water content evaluation method, when water content of a part of a plant is evaluated, a white reference substrate (background material) is disposed so as to cover a back surface of a leaf of plant. A first beam source radiates a near infrared beam (reference beam) with a wavelength of 905 nm that has a characteristic of tending not to be absorbed in water toward leaf. A second beam source radiates a near infrared beam (measuring beam) with a wavelength of 1550 nm that has a characteristic of tending to be absorbed in water toward the leaf. Threshold level setter / water content index detector calculates a water content index of one leaf that is total sum Σ Ln (I905 / I1550) of the reflection intensity rate at all irradiation positions of the leaf based on a reflection light of a reference beam and a reflection light of a measuring beam that are reflected on all irradiation positions of the leaf.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Burley tobacco strip fuming processing method

InactiveCN104432473AReduce manufacturing costExpand the scope of useTobacco preparationTobacco treatmentProduction lineEngineering

The invention discloses a burley tobacco strip fuming processing method. The burley tobacco strip fuming processing method comprises the following steps that (1) main veins are removed, and concoction is conducted, wherein the main vein of each burley tobacco leaf collected in a mature state is removed, two half tobacco leaf pieces are obtained, then normal weaving stringing and airing are conducted after folding is conducted, the half tobacco leaf pieces are taken out after a brown changing period is ended, and the main veins are aired independently; (2) segmentation processing is conducted, wherein the burley tobacco half tobacco leaf pieces obtained in the step (1) are stacked neatly, segmentation processing is conducted with 20-30 pieces as a pile, the burley tobacco half tobacco leaf pieces are segmented two times into three pieces which are the leaf tip parts, the leaf middle parts and the leaf base parts; (3) redrying is conducted on the leaves, wherein the segmented tobacco leaf pieces obtained in the step (2) are directly redried, leaf moistening, drying, cooling moisture regaining and packaging are conducted in sequence, and the main veins are redried and packaged independently. The burley tobacco strip processing method is simple in operation technology, easy to implement and capable of being easily transformed into a production line; the technological process is greatly simplified, and the energy loss is obviously lowered; a rib drying period is omitted in the burley tobacco drying stage, the process of cutting for unbinding, picking, leaf beating for stalk removing and the like are omitted in the redrying link, and the production cost of the burley tobacco is lowered.

Owner:HUBEI TOBACCO SCI RES INST

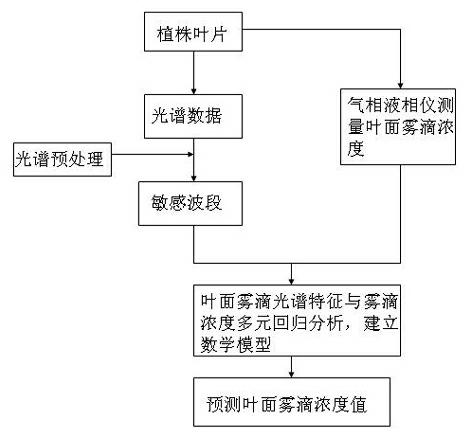

Method for quickly detecting concentration of droplet on crop leaf

ActiveCN102128807ASolve the problem of not being able to obtain information on the amount of medicine contained in the mist dropletsProduce disturbanceColor/spectral properties measurementsInfraredOptical spectrometer

The invention provides a method for detecting the concentration of a droplet on a crop leaf based on a near infrared spectrum technology, which can achieve the purposes of non-contact, quick and accurate detection. The method comprises the following steps: 1) choosing upper-layer leaves of more than 10 plants as samples, and selecting one leaf from the upper-layer leaves of each plant as an object to be detected; 2) utilizing a spectrometer to acquire diffuse reflection near infrared spectrum data of the samples; 3) using a gas-liquid phase meter to measure the concentration value of a liquidmedicine droplet on each leaf; 4) pre-treating the spectrum data; 5) choosing a characteristic wavelength of the spectrum data; 6) building a leaf droplet concentration mathematical model based on multiple regression; and 7) forecasting the concentration value of the droplet on the leaf. By using the method for quickly detecting the concentration of a droplet on a crop leaf, the concentration value of the droplet on the leaf can be acquired in real time, thereby providing a new reference method for judging the occurrence degree of plant diseases and insect pests in the field.

Owner:JIANGSU UNIV

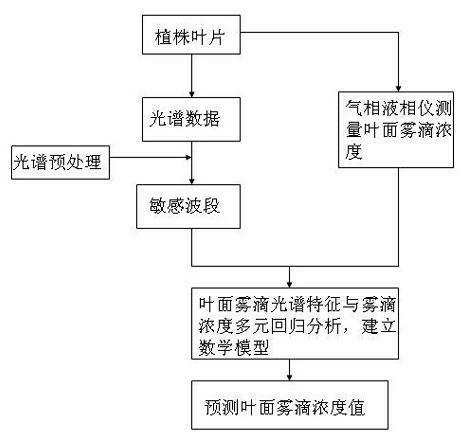

Making method of Xinyang white tea and making method of white tea cakes

InactiveCN106615255ADecreased green energyNice appearancePre-extraction tea treatmentEconomic benefitsPress cake

The invention relates to a making method of Xinyang white tea, and a making method of white tea cakes, and belongs to the technical field of processing of white tea. The making method comprises the following steps of performing picking, performing withering, performing rolling, performing primary drying, performing picking for removal, pressing cakes, and performing redrying so as to obtain finished products. The raw materials of the Xinyang white tea are one or more of Fuding dabaicha, Xinyang species, C.sinensis cv.Baihaozao, Fuyun No.6, C.sinensis cv.Bixiangzao, Wuniuzao, Pingyangtezao, and Xinyang No.10. The processing technology is unique, the made white tea is good in quality, plump and hard in shape, much in tea leaf grading, grayish green and bright in color, and fragrant in flesh flowers and rich in honey fragrance, orange and bright in soup, mellow, fresh, and sweet in taste, and tender in leaf base. Loose and crispy white tea is pressed to obtain tea cakes, so that the size is reduced the shape is beautiful, and the made white tea is convenient to store and carry. In a storage process, a slight enzymatic reaction is also generated, so that the made white tea is thick, mellow and rich in fragrance, and sweet in aftertaste, and the made white tea is well loved by consumers. The making method disclosed by the invention has remarkable economic benefits.

Owner:周开启

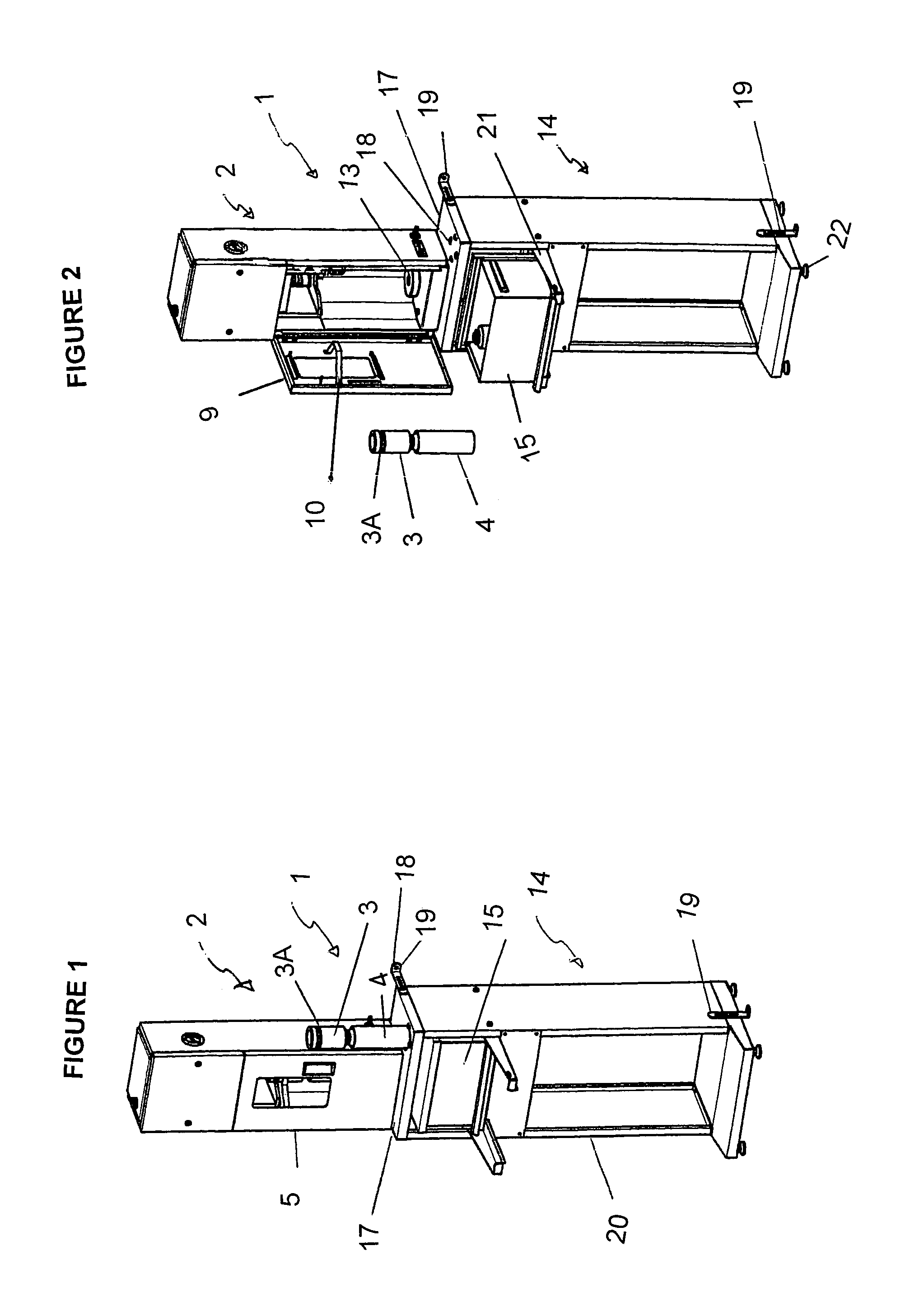

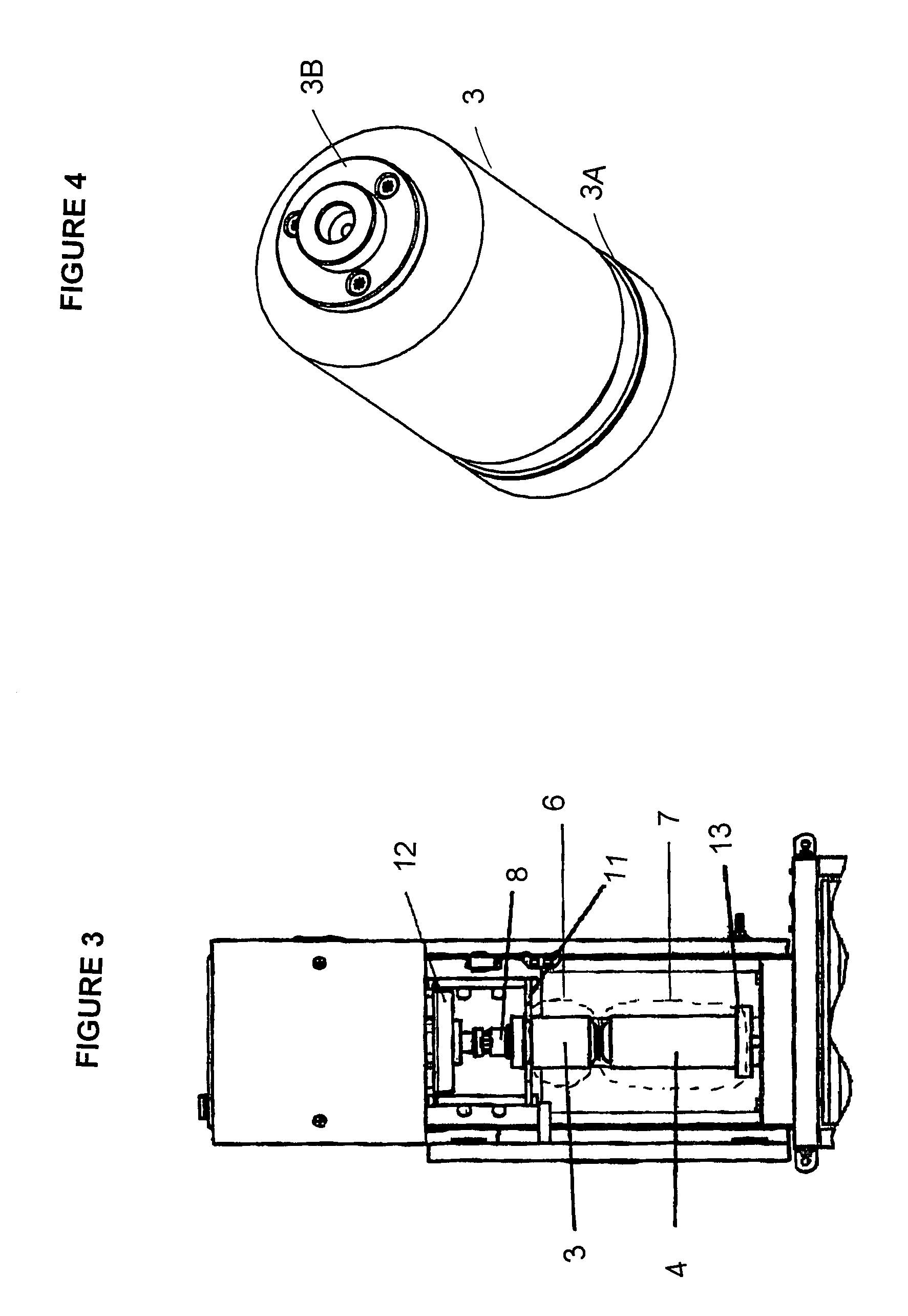

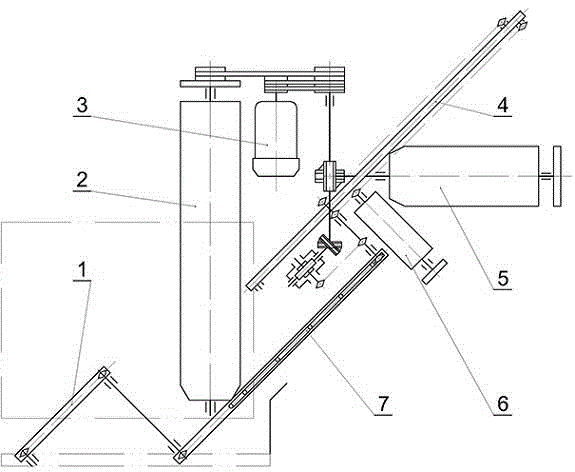

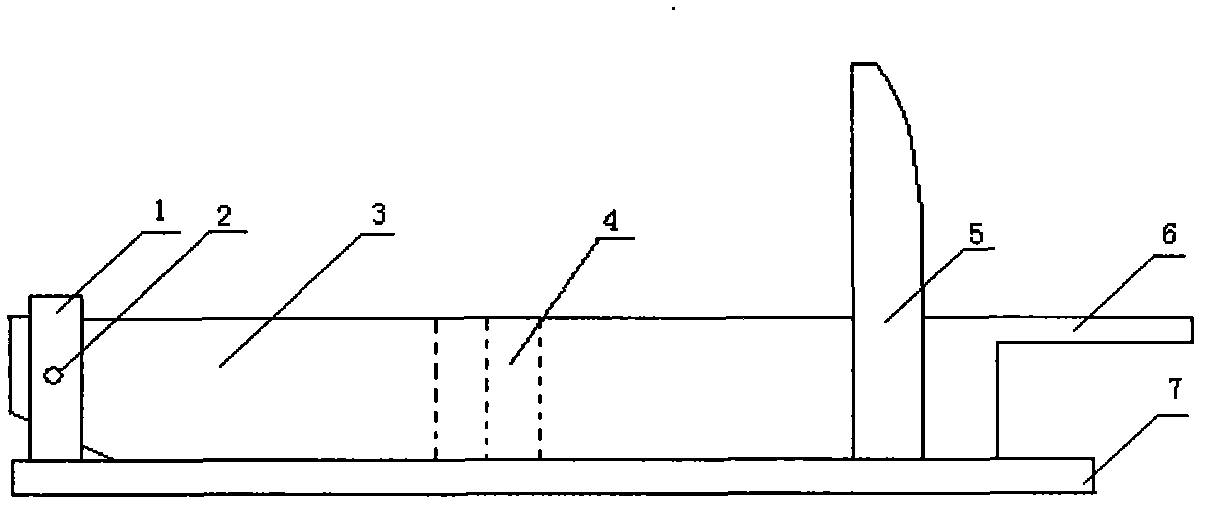

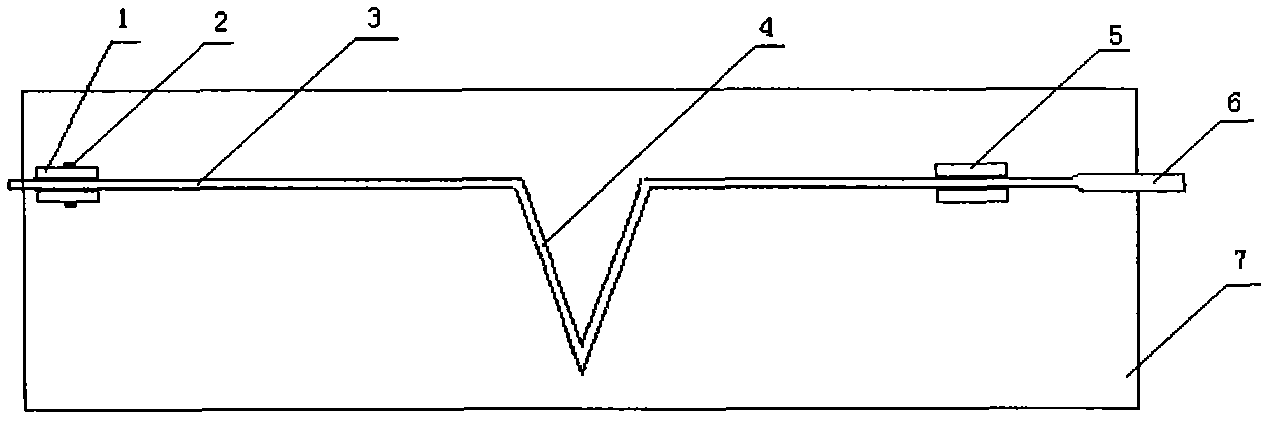

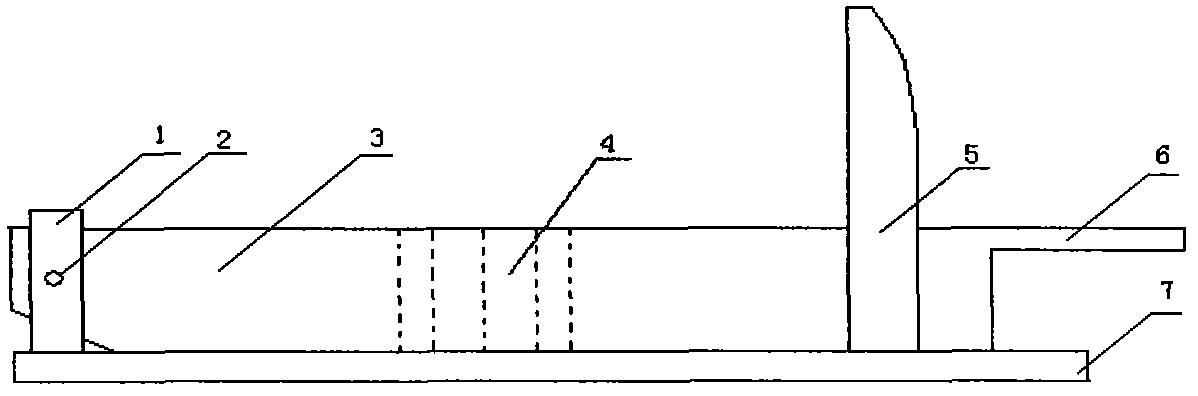

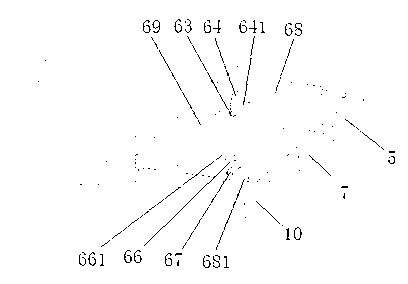

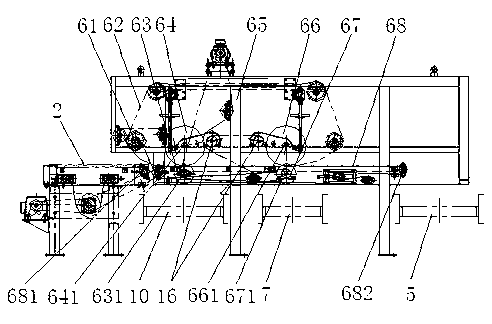

Novel sisal fiber extraction method and device

The invention provides a novel sisal fiber extraction method and device. The method comprises the steps that sisal leaves are crosswise fed into one hemp peeling mechanism from the middle of the sisal leaves, and fibers are obtained through direct reverse drawing. The device comprises a feeding mechanism, a sisal leaf clamping and delivery mechanism, a fiber clamping and delivery mechanism, a left hemp peeling mechanism and a right hemp peeling mechanism, sisal leaf base crushing mechanism, and a power and transmission device, wherein the sisal leaves and the fiber clamping and delivery mechanism are arranged in an inclined mode toward the hemp peeling mechanisms and perpendicular to the crushing mechanism, a chain and a belt are arranged in parallel and the delivery speeds are the same, and the linear speed of a crushing roller is 1.4 times those of the chain and the belt. Double-vane rolling cylinders with two vanes rotating in opposite directions serve as the hemp peeling mechanisms. The sisal leaves are crosswise fed into the left hemp peeling mechanism by the feeding mechanism, fibers are drawn out by the sisal leaf clamping chain and enter the fiber clamping belt, tip fibers are further drawn out, bases enter the right hemp peeling mechanism after winding around the shaft end of the crushing roller, and base fibers are reversely drawn out. By the adoption of the method and device in sisal fiber extraction, the per capita productivity of an existing device is improved by 2 to 3 times, and the productivity per kilowatt hour is improved by 1 to 2 times.

Owner:XIANNING AGRI ACADEMY OF SCI

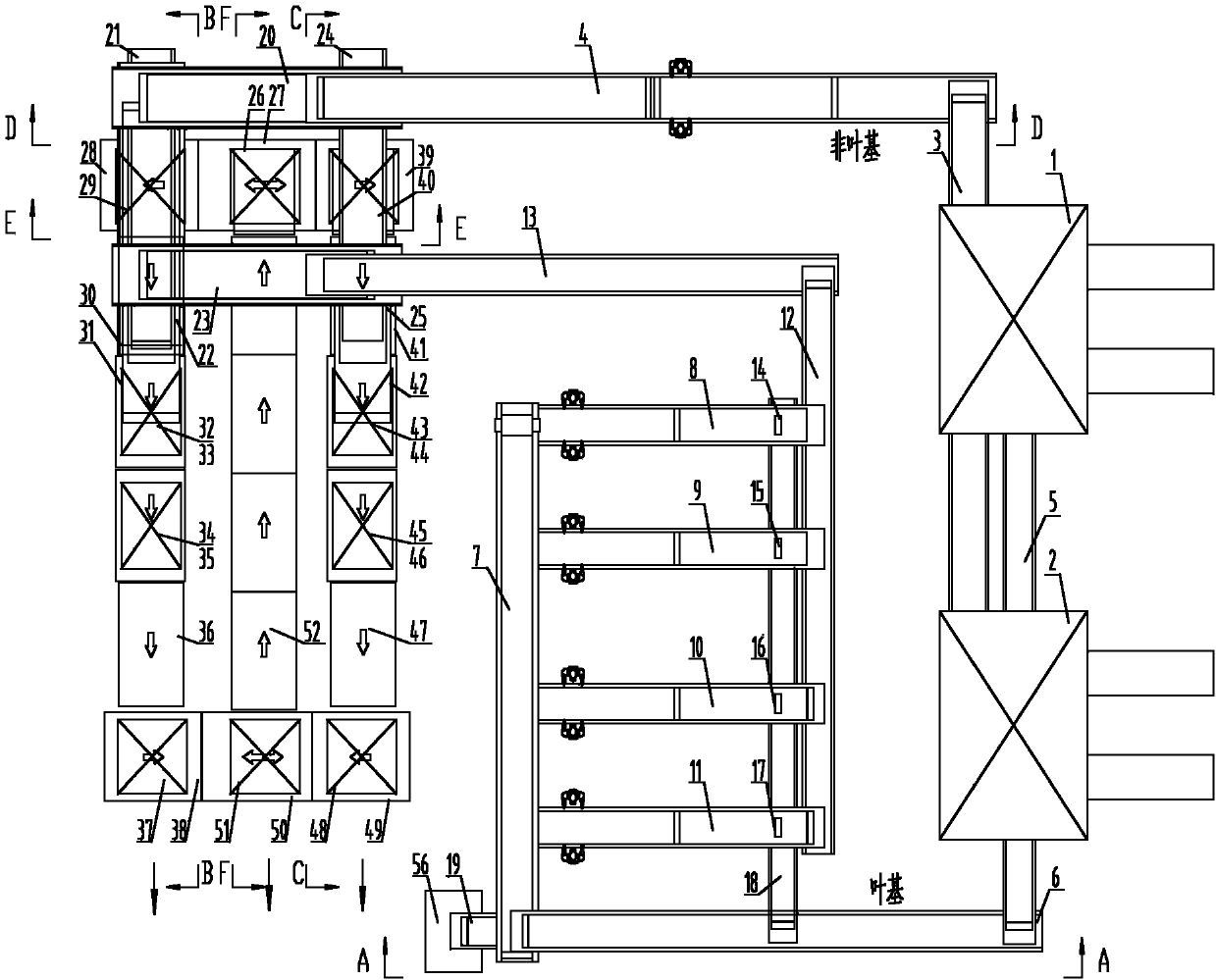

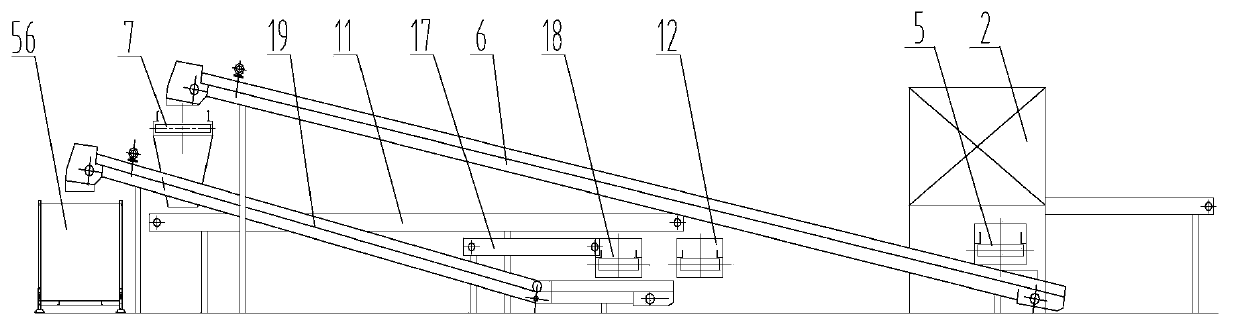

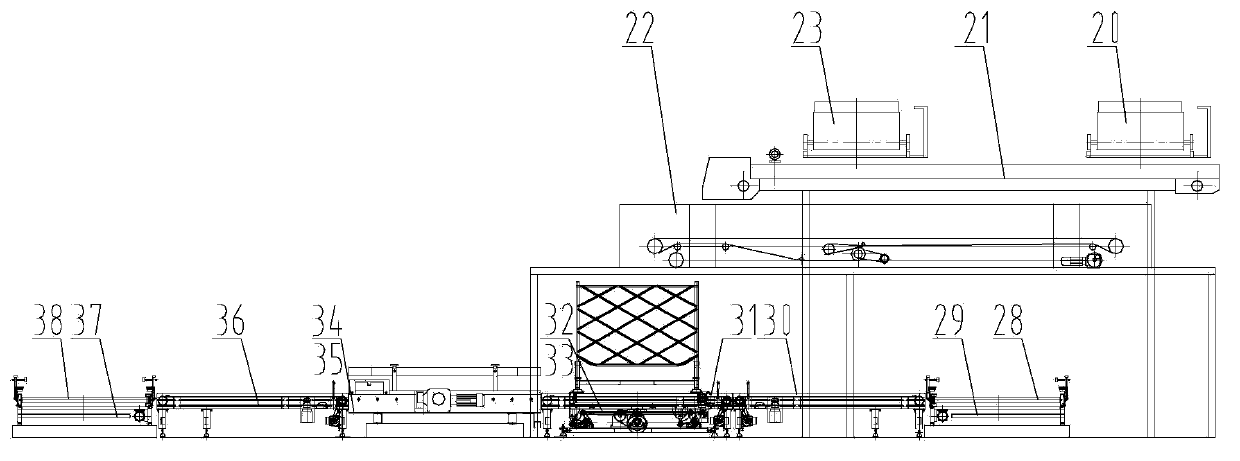

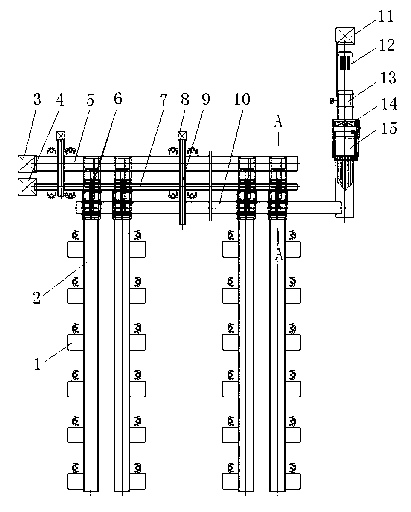

Quantitative classification frame system of crude tobacco and frame technology of crude tobacco

ActiveCN103395635AGuaranteed accuracyEfficient tracking managementTobacco preparationLoading/unloadingEngineeringLeaf base

Disclosed are a quantitative classification frame system of original cigarettes and a frame technology of the crude tobacco. The quantitative classification frame system comprises a double-line leaf distributing, cutting and releasing machine, a first leaf base conveyor and a first non-leaf base conveyor, wherein the double-line leaf distributing, cutting and releasing machine is used for cutting off the original cigarettes and classifying the same into leaf bases and non-leaf bases, and the first leaf base conveyor and the first non-leaf base conveyor are contrary in conveying direction. By the quantitative classification frame system, both quantitative classification frame and quantitative mixed frame can be performed upon leaf base parts and non-leaf base parts.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE +1

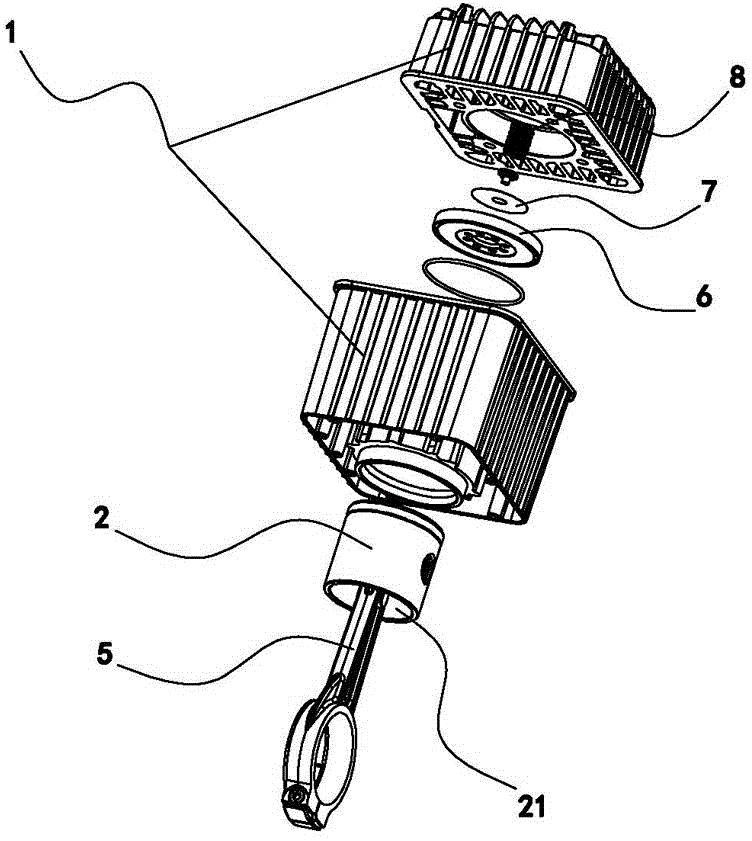

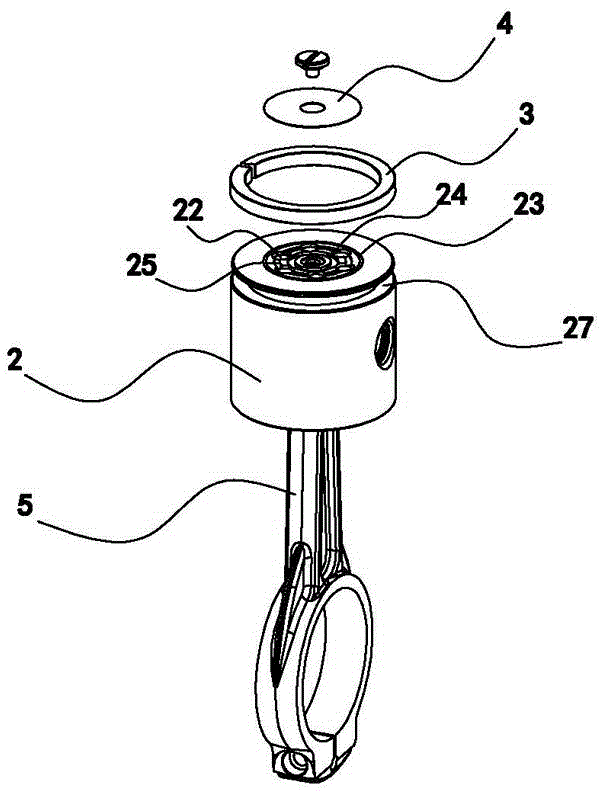

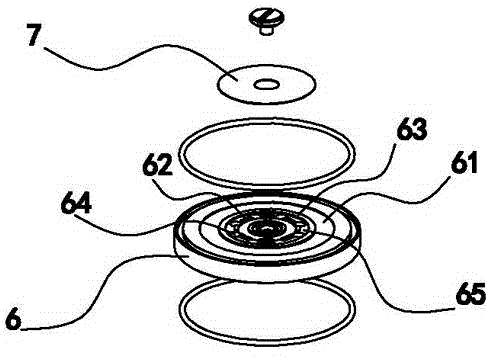

Air compression device and air compressor

ActiveCN104912773AGood sealImprove sealingPositive displacement pump componentsPump installationsAir compressionGas compressor

The invention provides an air compression device and an air compressor, pertaining to the technical field of air compression with the purpose of solving the problem that a conventional air compressor has poor compression effect. The air compression device comprises an air cylinder, a piston and a piston rod. The piston and the piston rod are arranged in the air cylinder. The air cylinder is provided with an air inlet and an air outlet. The piston has an inner cavity, in which a connecting rod is arranged. One end of the piston rod is arranged onto the connecting rod in a sleeving mode. The lower end of the piston is provided with an opening, in which multiple air inlet holes are formed. The air inlet holes are communicated with the air inlet by means of the inner cavity and the opening at the lower end. A diaphragm leaf base is arranged in the air cylinder. The upper end of the piston is provided with an air inlet diaphragm leaf enabling the air inlet holes to be sealed with or communicated with an above compression cavity. The upper end of the diaphragm leaf base is provided with multiple air outlet holes enabling the above compression cavity to be communicated with the air outlet of the air cylinder. The upper end of the diaphragm leaf base is provided with an air outlet diaphragm leaf. The air compression device is advantaged by being fine in air compression effect, high in efficiency and long in service lifetime.

Owner:ZHEJIANG SHENYUAN ELECTRO MACHINERY

Tobacco leaf modulating and stalk-removing method and cutter

InactiveCN103564640ASlow dehydrationModulation consumes a lot of energyTobacco treatmentEconomic benefitsEngineering

The invention provides a tobacco leaf modulating and stalk-removing method and a cutter. Before or in a tobacco leaf modulating process, a common cutter, a special cutter or a professional machine isused for removing a part of the stalk of each tobacco leaf, wherein a leaf base or the tobacco stalk with 1 / 5 to 1 / 2 of the length of each tobacco leaf is cut off. The cutter comprises a cutter holder, a cutter head fixing frame, a cutter shaft, a cutter body, a stabilizing frame and a cutter handle, wherein the cutter body is hinged to the cutter shaft through the cutter head fixing frame and then is arranged on the cutter holder; the middle part of the cutter body is bent in a V or M shape, and a cutter slot matched with the cutter body is formed in the cutter holder. The tobacco leaf modulating and stalk-removing method disclosed by the invention is applied to a flue-cured tobacco leaf piece dense baking process; the temperature of a stalk drying period can be reduced, the baking time is shortened, and 30-50% of energy is saved; the operation is simple and convenient, the efficiency is high, the disadvantages of a manual stalk removing process are overcome, and the popularization inproduction is easy; the quality of modulated tobacco leaves is improved, the stalk-removing and modulation of tobacco leaves can be realized in large scale, and excellent energy saving, environment-friendliness and economic benefits are achieved.

Owner:朱大恒

Method and system for separating and classifying different parts of tobacco leaves

InactiveCN103005662AImprove qualityImprove production environmentTobacco preparationProduction lineChemical composition

The invention provides a method and a system for separating and classifying different parts of tobacco leaves. The system comprises a butt putting and leaf laying conveyor, a slitting and separating machine, a stem end tobacco conveyor, a leaf tip tobacco conveyor and a leaf base conveyor. Different parts of the same grade of tobacco can be slit, classified and collected, and then are quantitatively packed, so that when the following tobacco leave-beating and re-drying are carried out, according to chemical compositions of different parts of tobacco, a formula is accurately made, thereby effectively improving the quality of cigarette products. In addition, the leaf laying, butt putting and slitting procedures before tobacco leave-beating and re-drying are adjusted to a sorting workshop, so that the process flow is shortened, materials are quantitatively and accurately prepared, the production environment of a main production line is improved, the breakage rate is effectively reduced, and the production cost is reduced.

Owner:云南同云科贸有限公司

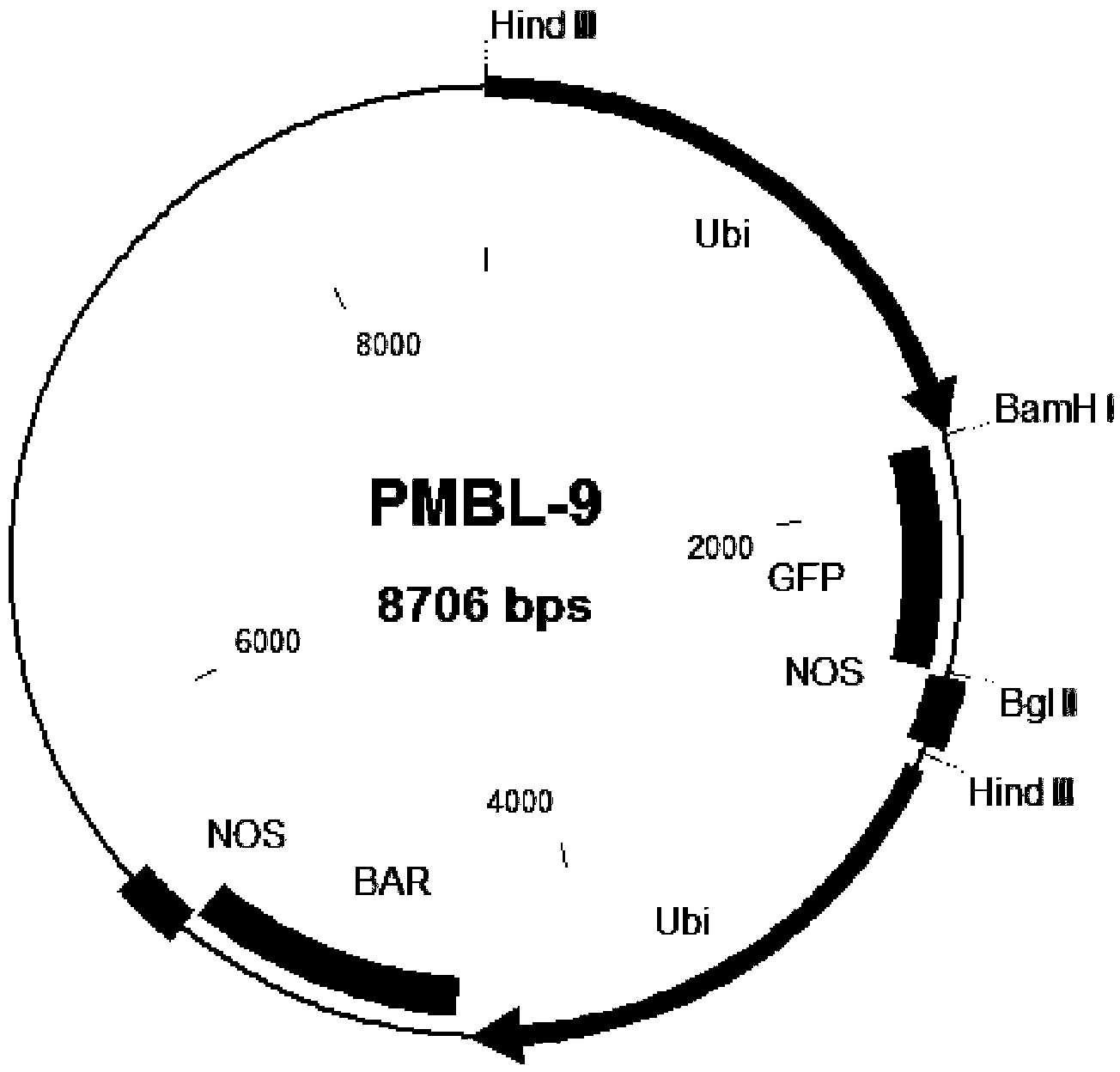

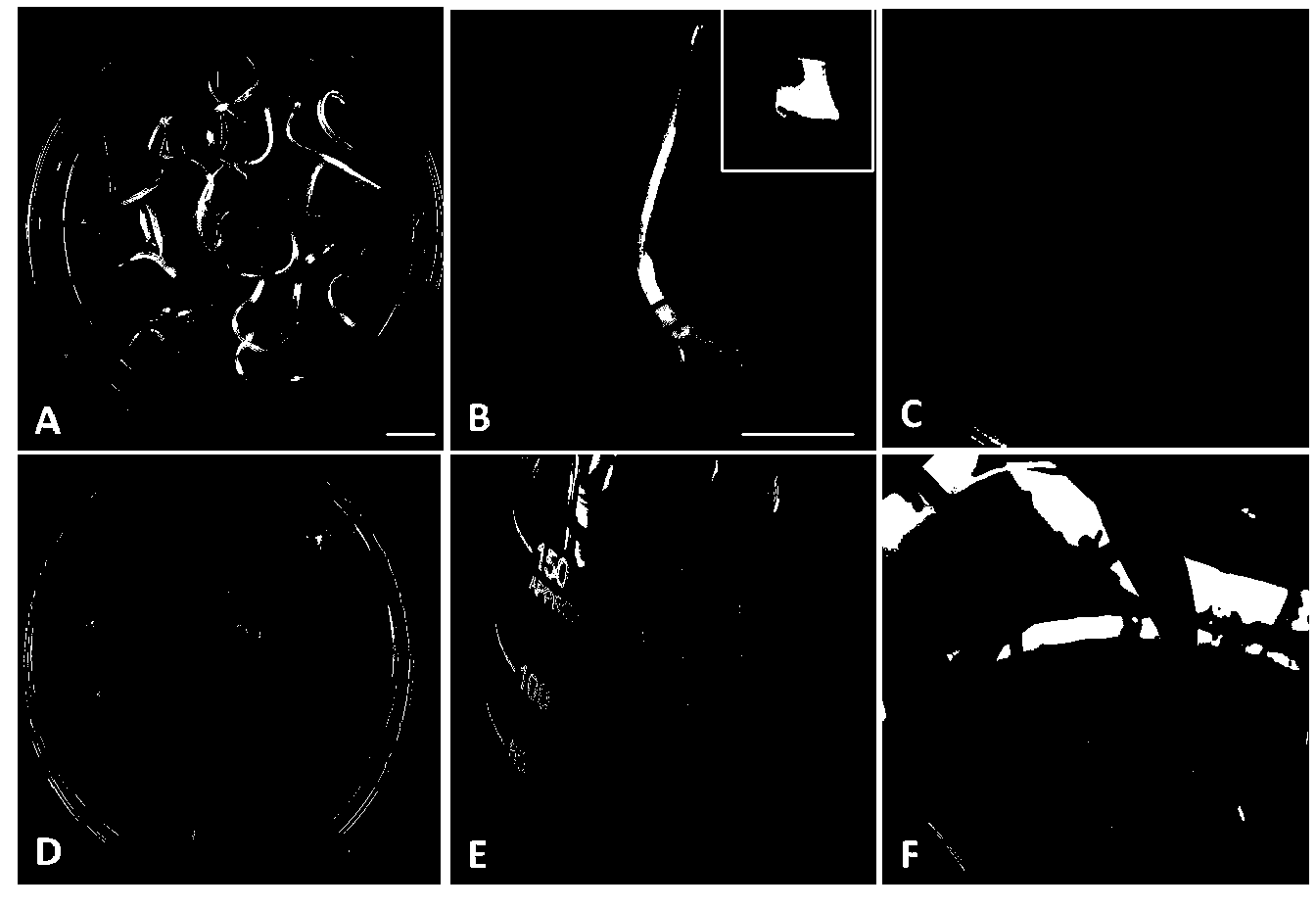

Agrobacterium tumefaciens-mediated barley leaf base transformation method

InactiveCN103421837AIncrease planting costsShorten the timeFermentationGenetic engineeringHordeum vulgareTime limit

The invention belongs to the technical field of plant transgenosis, and particularly relates to an agrobacterium tumefaciens-mediated method for obtaining a transgenic plant by adopting a barley seedling leaf base to induct a callus. The agrobacterium tumefaciens-mediated method has the key points as follow: a barley leaf base serves as an explant to induct the callus; an agrobacterium tumefaciens-mediated genetic transformation method is adopted, a Bar gene is used as a screening gene, and a herbicide of glufosinate ammonium is used as a selective agent; the transformed callus and differentiated plants are screened; a foreign gene is confirmed to be integrated into a barley genome through PCR and Southern hybridization analysis; a transgenic barley plant is obtained. Compared with the prior art, the invention has the advantage that the explant (callus) of the transgenic plant can be supplied all the year round; compared with a classic transformation method in which a young embryo is taken as an acceptor, the agrobacterium tumefaciens-mediated method has the advantage that the acceptor obtaining time is shortened to be 3 days form 150 days, and the time limit of young embryo sampling is eliminated; compared with a stem tip transformation method, the agrobacterium tumefaciens-mediated method is lower in technical requirement and simpler to operate.

Owner:HUAZHONG AGRI UNIV

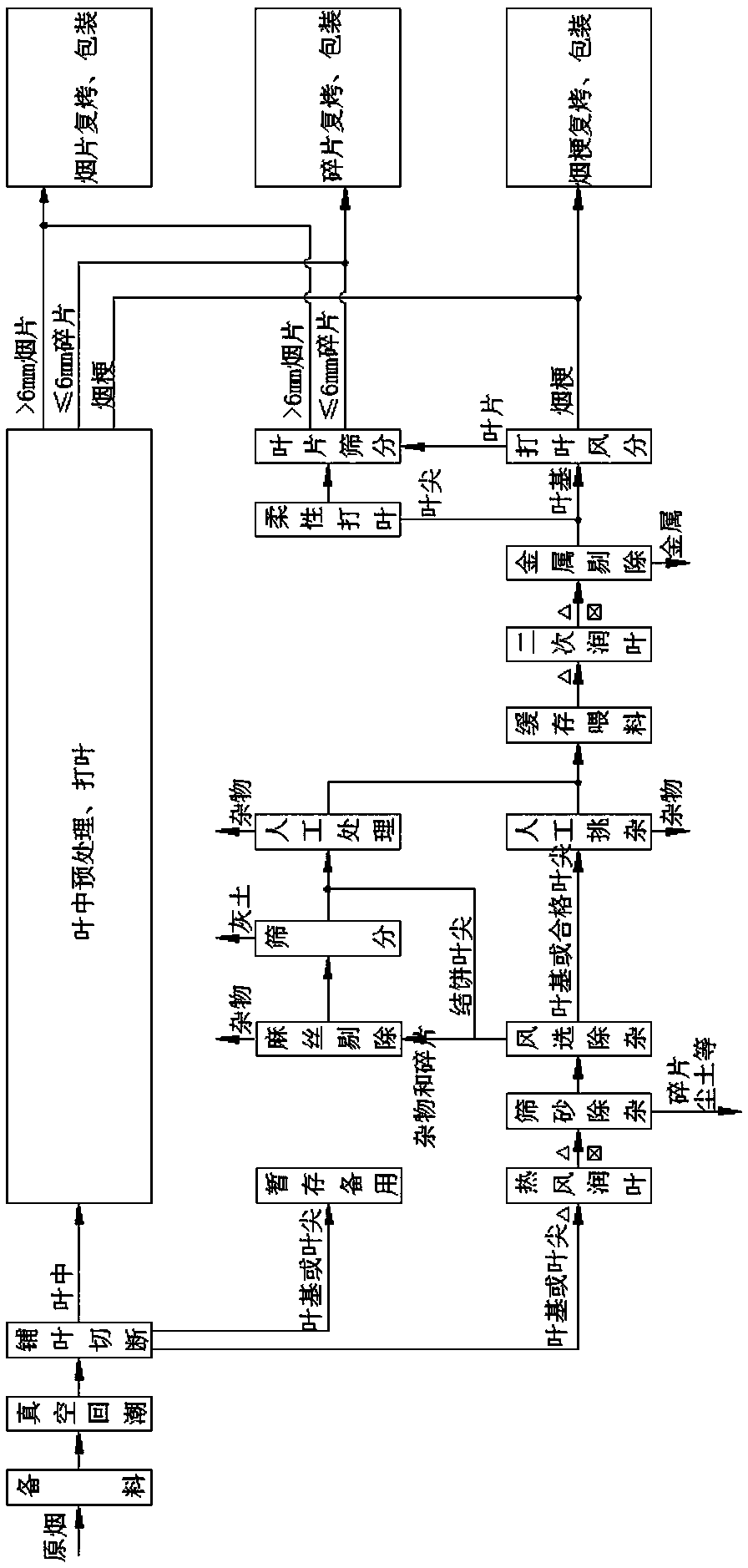

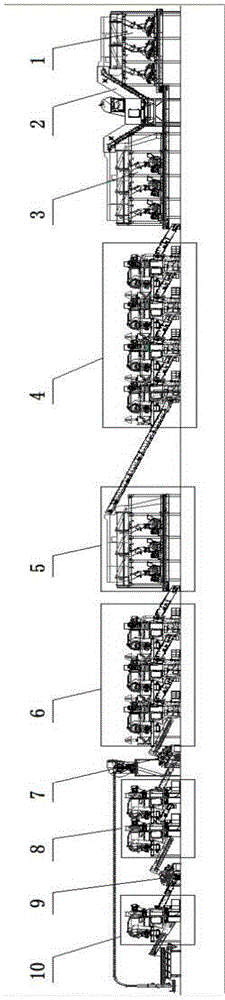

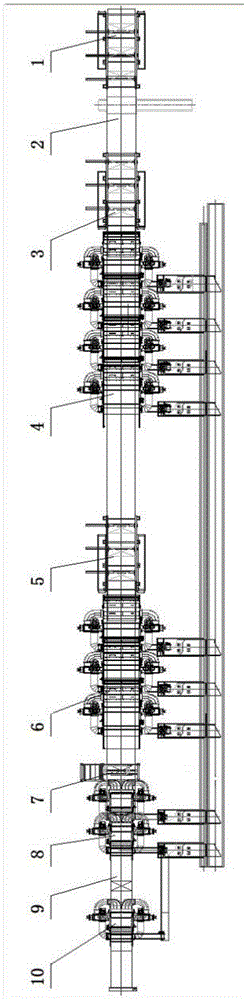

Multifunctional threshing and redrying production line processing technology for leaf bases and leaf tips of tobacco leaves

ActiveCN108523202AMeet processing requirementsAdjustable widthTobacco preparationProduction lineEngineering

The invention relates to a multifunctional threshing and redrying production line processing technology for leaf bases and leaf tips of tobacco leaves. A traditional leaf middle pre-processing threshing processing unit (1), a leaf base or leaf tip processing unit (2), a leaf base or leaf tip temporary storage unit (3) which are arranged in a parallel connection mode; the leaf base or leaf tip processing unit (2) sequentially carries out the technical processes of primary hot air leaf moistening, impurity removal through sand sieving, impurity removal through wind selection, manual impurity picking, slow feeding, secondary leaf moistening, metal removal, leaf base threshing and separation or leaf tip flexible threshing and leaf screening; leaves, debris and tobacco stems generated by the unit (2) are combined with leaves, debris and tobacco stems generated by the unit (1) for processing. The multifunctional threshing and redrying production line processing technology for the leaf basesand the leaf tips is provided for solving the problems that the segmented processing flow for tobacco leaves is complicated, a lot of devices are needed, and the investment is huge; the production line achieves multiple purposes, the technical requirements of tobacco leaf tip cutting processing, leaf base cutting process, three-segment processing and the like can be met, the number of devices andthe investment are reduced, the utilization rate of the devices is increased, and the processing requirements of different customers are met.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

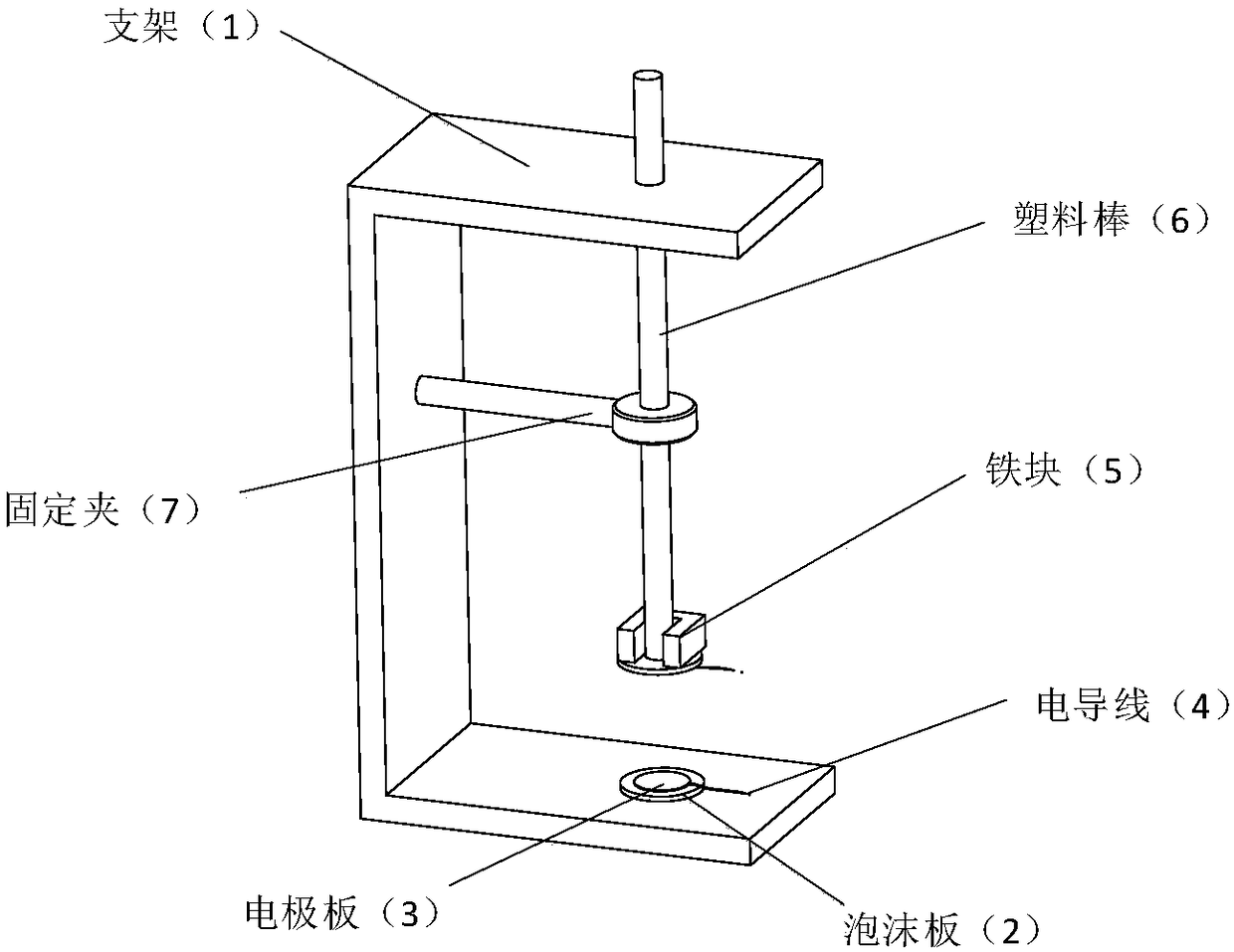

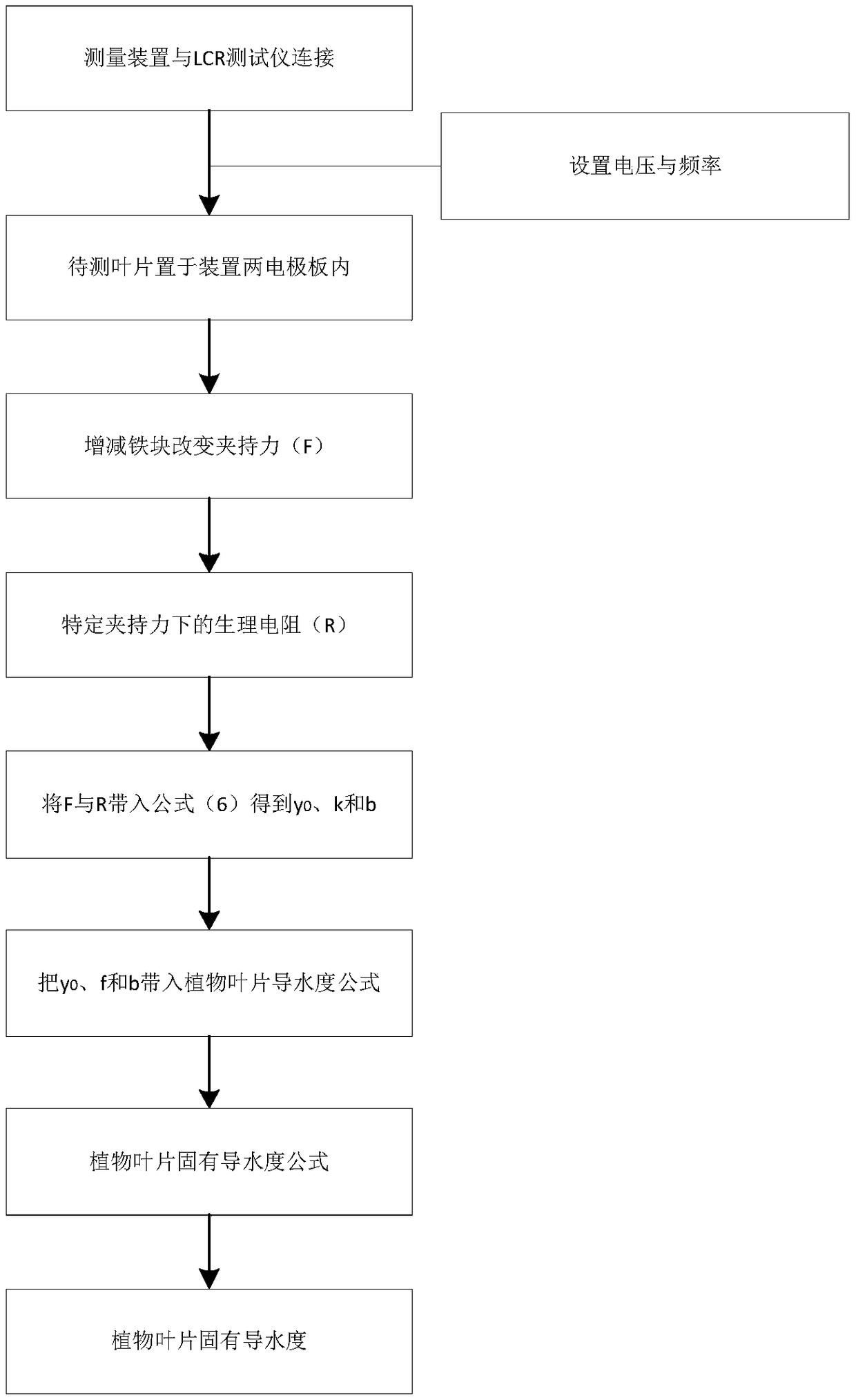

Measuring method and device for hydraulic conductivity and inherent hydraulic conductivity of plant leaves based on physiological resistance

InactiveCN108572194ASo as not to damageReduce edge effectsTesting plants/treesMaterial resistanceElectrical resistance and conductanceEngineering

The invention discloses a measuring method and device for hydraulic conductivity and inherent hydraulic conductivity of plant leaves based on physiological resistance. The measuring device comprises asupport, foam plates, plate electrodes, wires, iron blocks and a plastic bar, wherein the foam plates embedded with the plate electrodes separately adhere to the bottom end of the support and the plastic bar; the plastic bar is added with the iron blocks in different weights to change the pressure of the device so as to adjust clamping force; when the device is used, the plate electrodes are connected with an LCR testing instrument through the wires; the two plate electrodes clamp a plant leaf to be measured; different clamping forces are set to measure the physiological resistance of the plant leaf; a coupling model of the physiological resistance of the plant leaf under different clamping forces is established on the basis of a Nernst equation, and a model equation is derived to obtainhydraulic conductivity and inherent hydraulic conductivity of the plant leaf based on the physiological resistance; and then the economy of water for plants is judged. The hydraulic conductivity and inherent hydraulic conductivity of plant leaves can be detected conveniently, rapidly and quantitatively, economy of water conduction of plants is judged quantitatively, and a measuring result has comparability.

Owner:JIANGSU UNIV

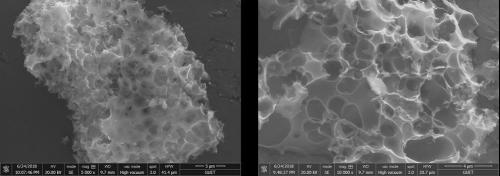

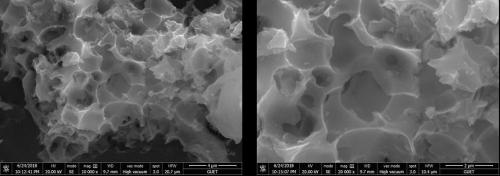

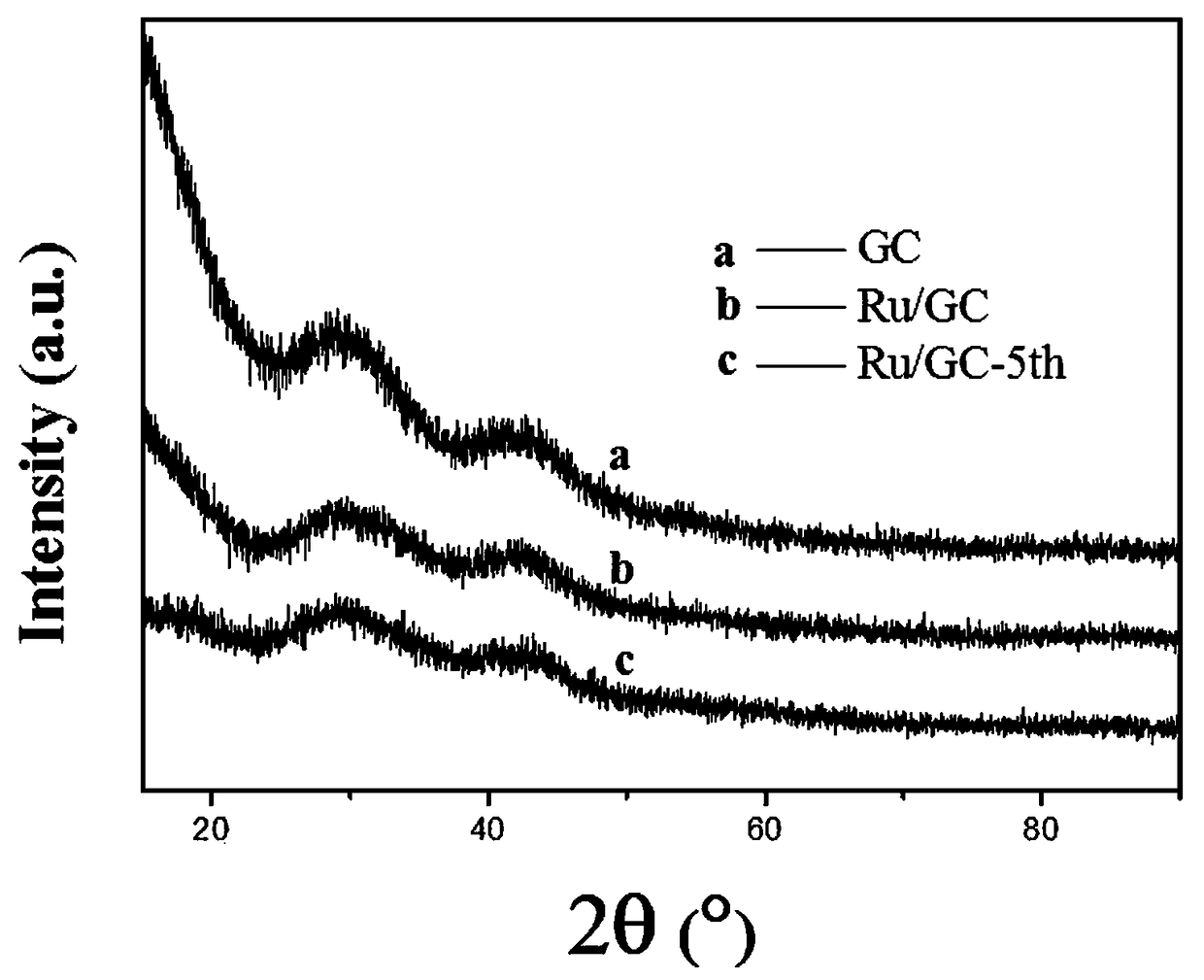

Ginkgo leaf-based porous carbon material loaded with ruthenium and preparation method and application thereof

InactiveCN109046419ALow costConducive to the realization of standardized productionPhysical/chemical process catalystsHydrogen productionPorous carbonGinkgo biloba

The invention discloses a ginkgo leaf-based porous carbon material loaded with ruthenium. Ginkgo leaves serve as a carbon source, after low-temperature carbonization, a nitrogen-containing compound and alkaline inorganic matter are added, calcination and activation are performed to obtain the ginkgo leaf-based porous carbon material, and then metal ruthenium is loaded onto the porous carbon material through an in-situ reduction method to obtain the ginkgo leaf-based porous carbon material loaded with the ruthenium. A preparation method of the porous carbon material comprises the following steps: (1) the low-temperature carbonization of the ginkgo leaves; (2) the activation and post-treatment of the ginkgo leaf-based porous carbon material; and (3) loading of the metal ruthenium. The ginkgoleaf-based porous carbon material loaded with the ruthenium serves as an ammonia borane hydrolysis hydrogen production catalyst, hydrogen release is completed for 40s at room temperature, the hydrogen release quantity is 92% of a theoretical value, and the hydrogen release rate is up to 3,718 ml s<-1> g<-1>. The ginkgo leaf-based porous carbon material can be recycled, after cycling for five times, the hydrogen release is completed for 60s, the hydrogen release rate is 2,158ml s<-1> g<-1>, and 58% of first-time hydrogen release rate is maintained. By catalyzing ammonia borane at different temperatures for hydrolysis tests, relatively low activation energy Ea=23.86 kJ mol<-1> is shown. The ginkgo leaf-based porous carbon material has a broad application prospect in the fields of manufacturing hydrogen materials, fuel cells and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

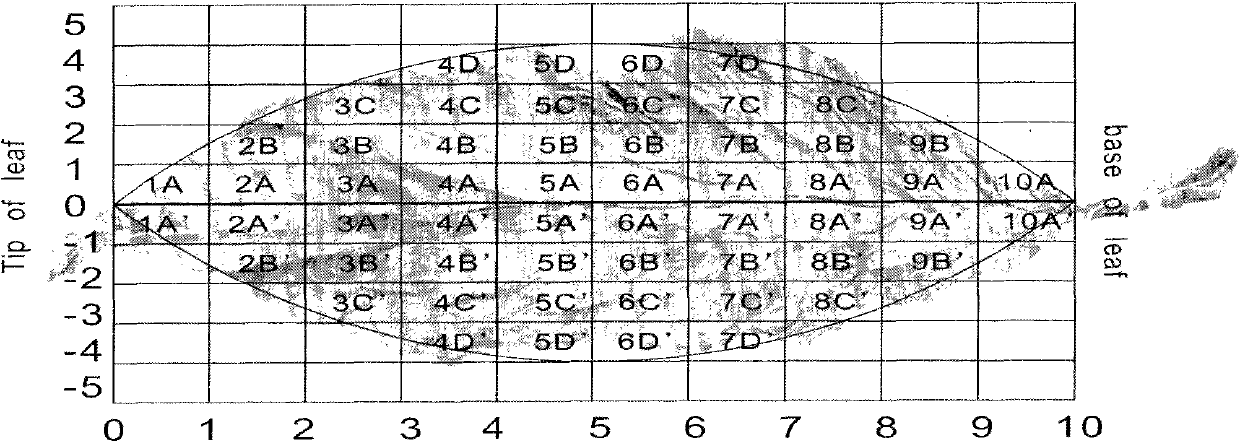

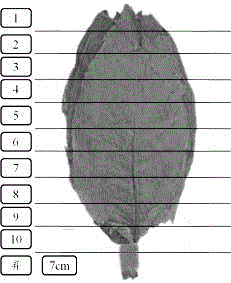

Using method for tobacco leaf slitting

InactiveCN105935150AImprove use valueOvercome the bottleneck of scarcityTobacco treatmentLeaf baseBiology

The invention belongs to a using method for tobacco leaf slitting. The using method comprises the following steps that 1, the base part of a tobacco leaf is transversely cut off for 7 cm, the residual part of the tobacco leaf is transversely slit into 10 slit zones, and the 10 slit zones are equal in width and are sequentially numbered as 1th to 10th slit zones in the direction from a leaf apex to a leaf base; 2, the tobacco leaves of the 1th to 4th slit zones are combined to form a first group, the tobacco leaves of the 5th and 6th slit zones are combined to form a second group, and the tobacco leaves of the 7th to 10th slit zones are combined to form a third group. Uniform slitting of nine-time cutting for ten sections is performed by transversely slitting the tobacco leaf. The tobacco leaves of the different slit zones are grouped according to the nicotine contents of different zones of a variety of highly flavored tobacco leaves in different tobacco planting regions, the using value of raw materials is improved, unnecessary waste is reduced, the bottleneck of top-grade cigarette raw material shortage is overcome, and accordingly the using method has a good popularization and application value.

Owner:CHINA TOBACCO HENAN IND +1

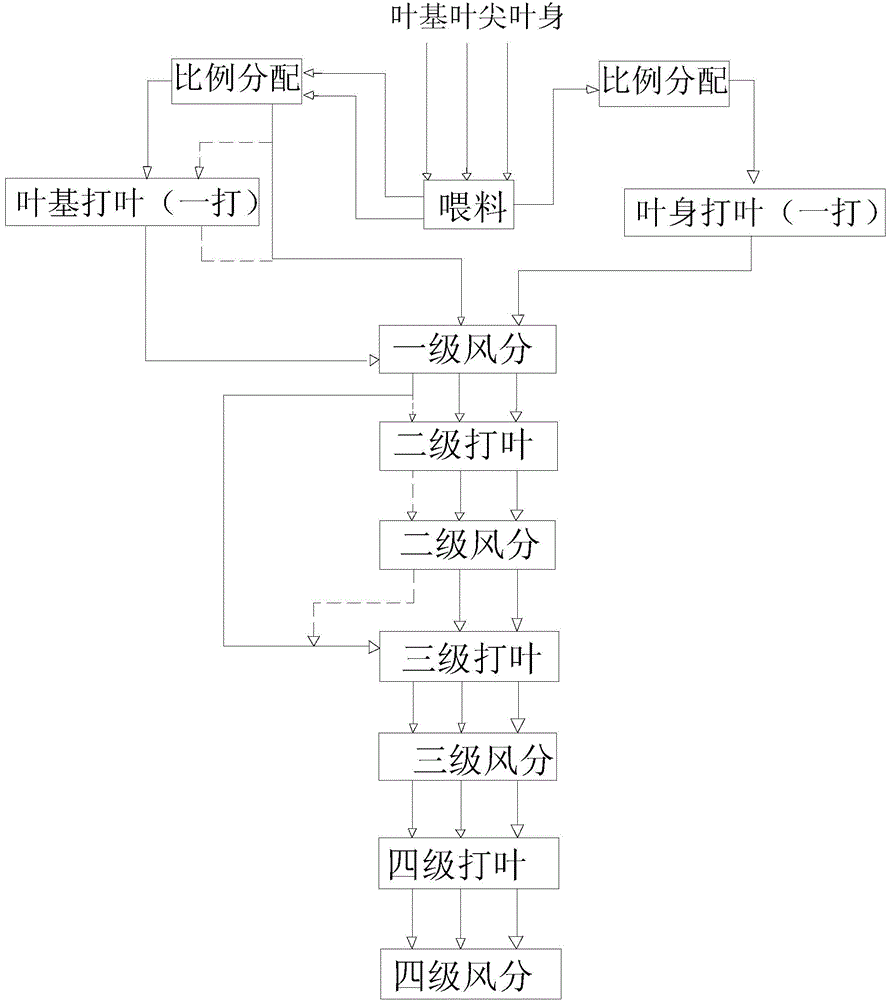

Flexible threshing and pneumatic separating process

InactiveCN104957759ARealize production flexibilityLess investmentTobacco treatmentGas current separationThreshingLeaf base

The invention discloses a flexible threshing and pneumatic separating process. The flexible threshing and pneumatic separating process comprises the working procedures of feeding, leaf base threshing, leaf body threshing, primary pneumatic separating, secondary threshing, secondary pneumatic separating, tertiary threshing, tertiary pneumatic separating, quaternary threshing and quaternary pneumatic separating, wherein a dozen leaf base threshing mode is adopted for the leaf base threshing, a dozen leaf body threshing mode is adopted for the leaf body threshing, the working procedure of feeding is preferably feeding for the working procedure of leaf base threshing or leaf body threshing and can also be direct pneumatic separating leaf apex feeding for the working procedure of pneumatic separating, and the working procedures of primary pneumatic separating, secondary threshing, secondary pneumatic separating, tertiary threshing, tertiary pneumatic separating, quaternary threshing and quaternary pneumatic separating are performed in sequence. By means of the flexible threshing and pneumatic separating process, slit leaves can be threshed and pneumatically separated in a targeted mode, production organization can be also simplified, device investment can be reduced, a process route is flexible, and devices are simple.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com