Patents

Literature

592results about How to "Reduce Fragmentation Rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

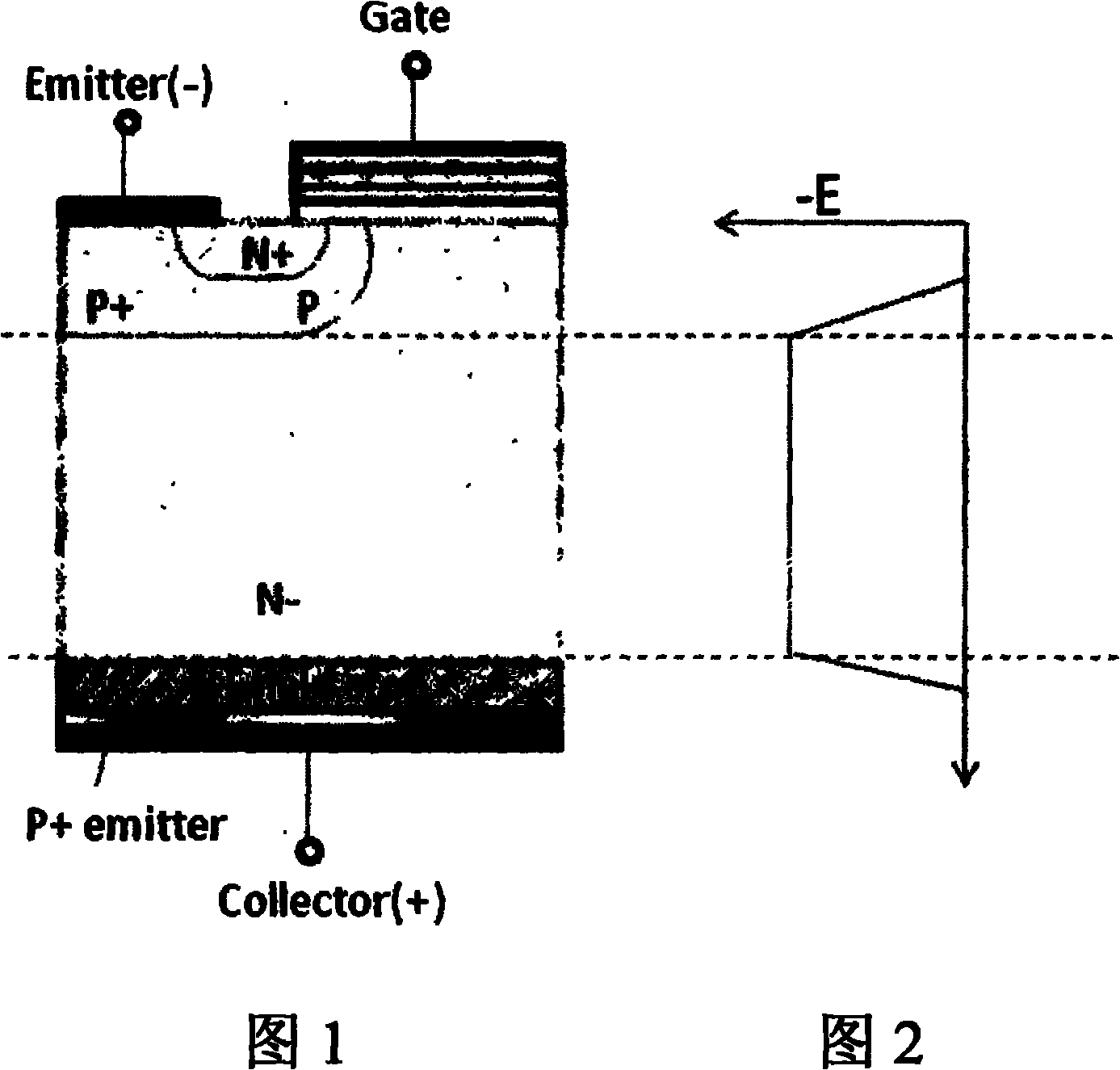

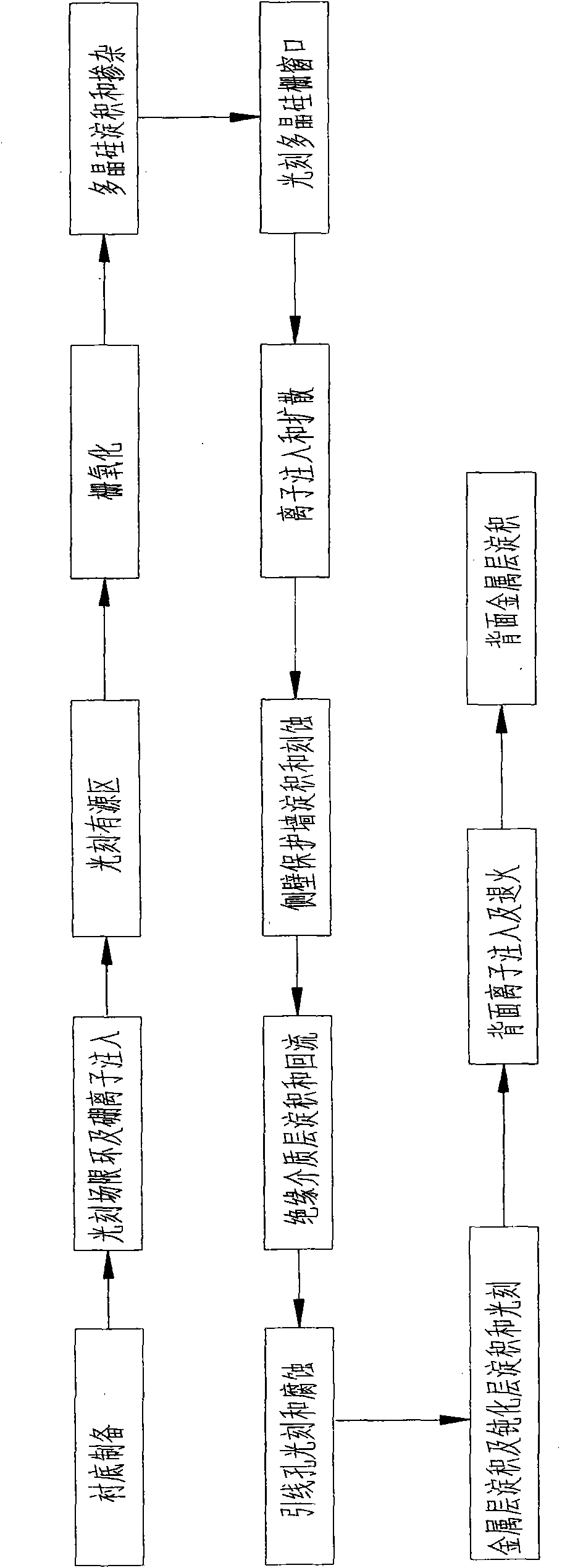

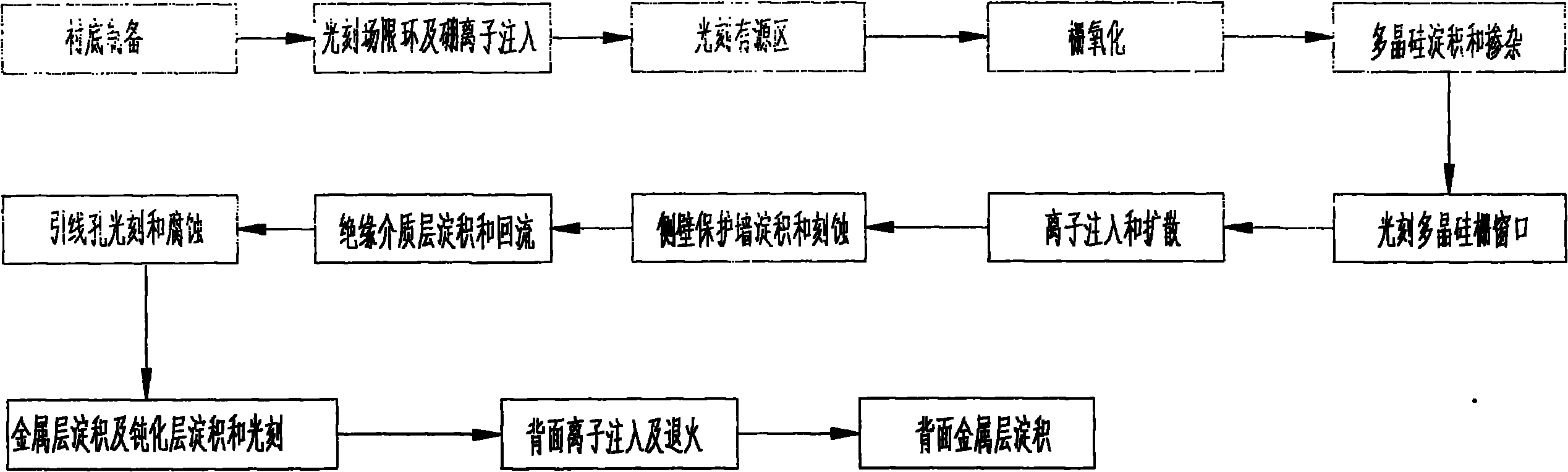

Preparation method of field blocking type bipolar transistor of insulated gate

ActiveCN102142372ASimple processReduce Fragmentation RateSemiconductor/solid-state device manufacturingSemiconductor devicesBoronPolysilicon gate

The invention relates to a preparation method of a field blocking type bipolar transistor of an insulated gate, which comprises the following steps of: pre-diffusing N+ type semiconductor impurities on a positive surface and a negative surface of an N-type single wafer after the N-type single wafer is cleaned; forming N+ impurity regions through main diffusion and knotting; removing one N+ impurity region as a front surface of a silicon wafer through grinding; polishing the front surface of the silicon wafer to obtain a substrate material; photoetching a field-limiting ring to form a P+ window of the field-limiting ring; performing boron ion injection; forming a window of a source region through photoetching; performing polysilicon deposition and doping after a silicon wafer gate is oxidized; injecting ions in the window of the silicon wafer gate, and forming a P impurity region and an N+ impurity region through diffusion; depositing and refluxing an insulated dielectric layer, photoetching a lead hole and depositing a metal layer to form an emitting electrode and a grid electrode; thinning the N+ impurity region at the back of the silicon wafer through grinding; annealing the N+ impurity region to form a P+ impurity region after the boron ions are injected in the N+ impurity region; and depositing a metal layer to form a collecting electrode. The method has the characteristics of having simplified process flow, achieving low production cost, and being beneficial for realizing the soft turn-off of an IGBT (Insulated Gate Bipolar Translator).

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

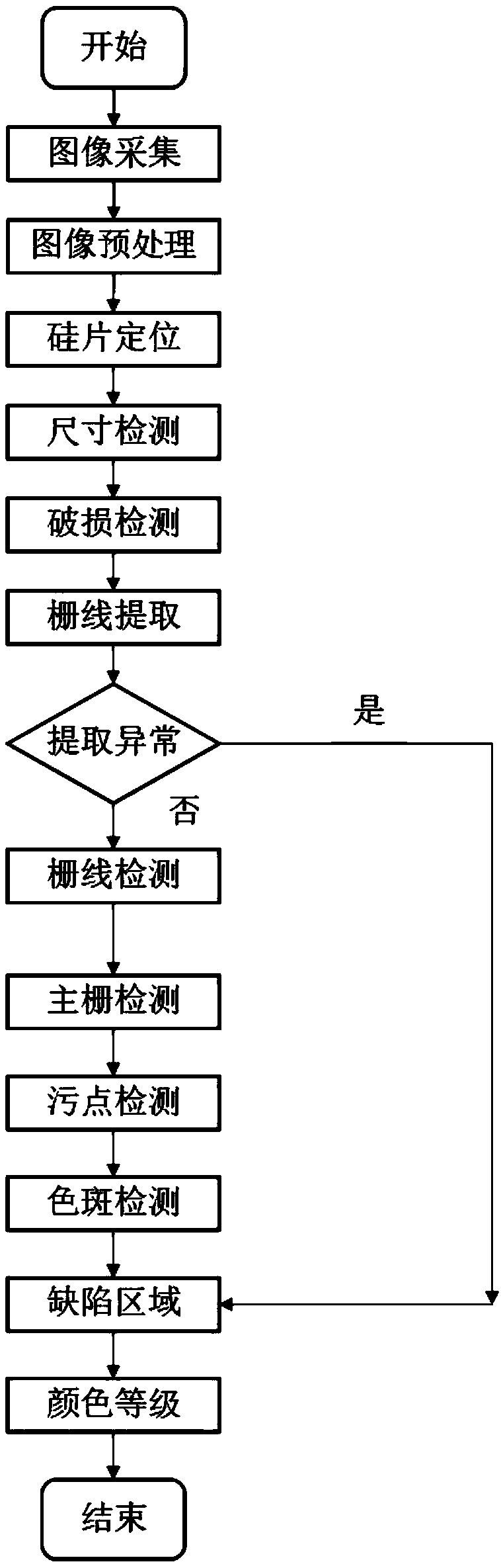

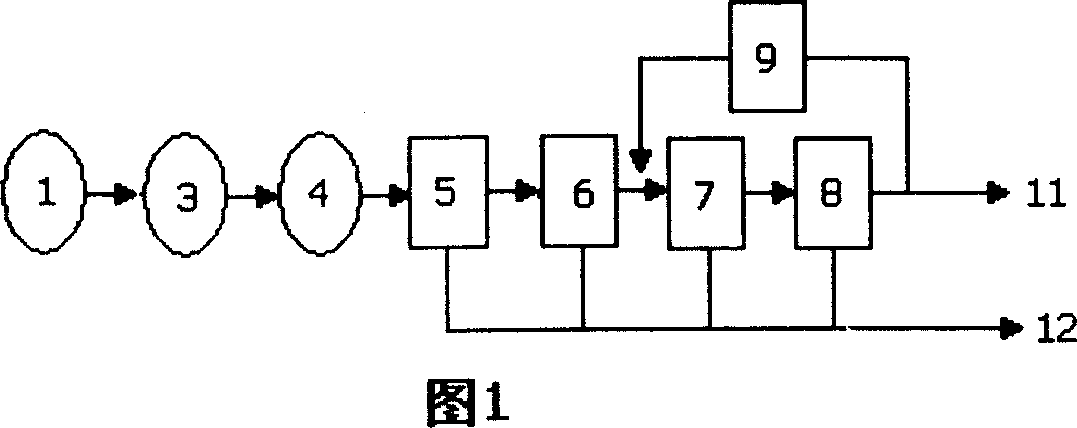

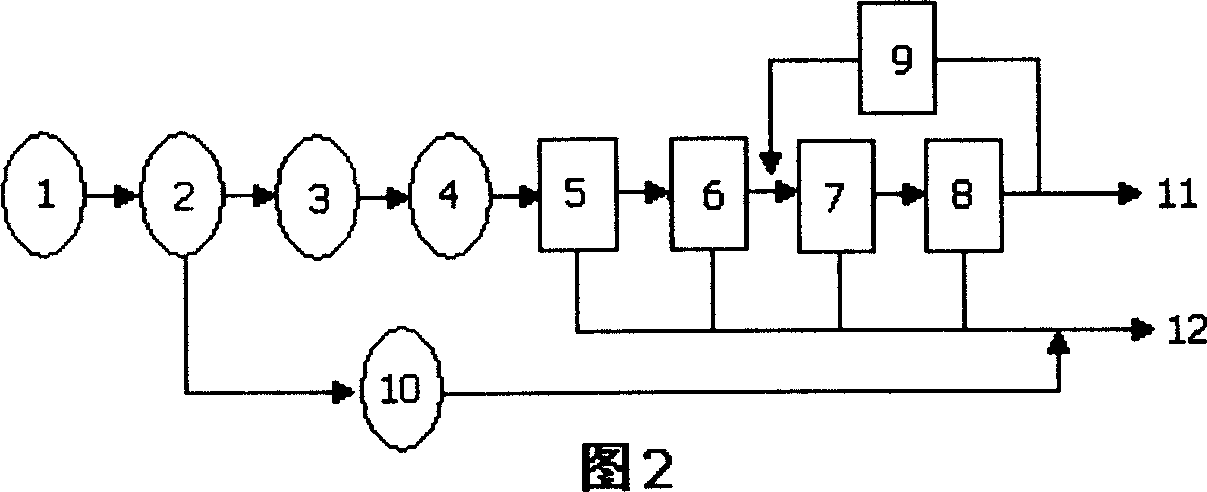

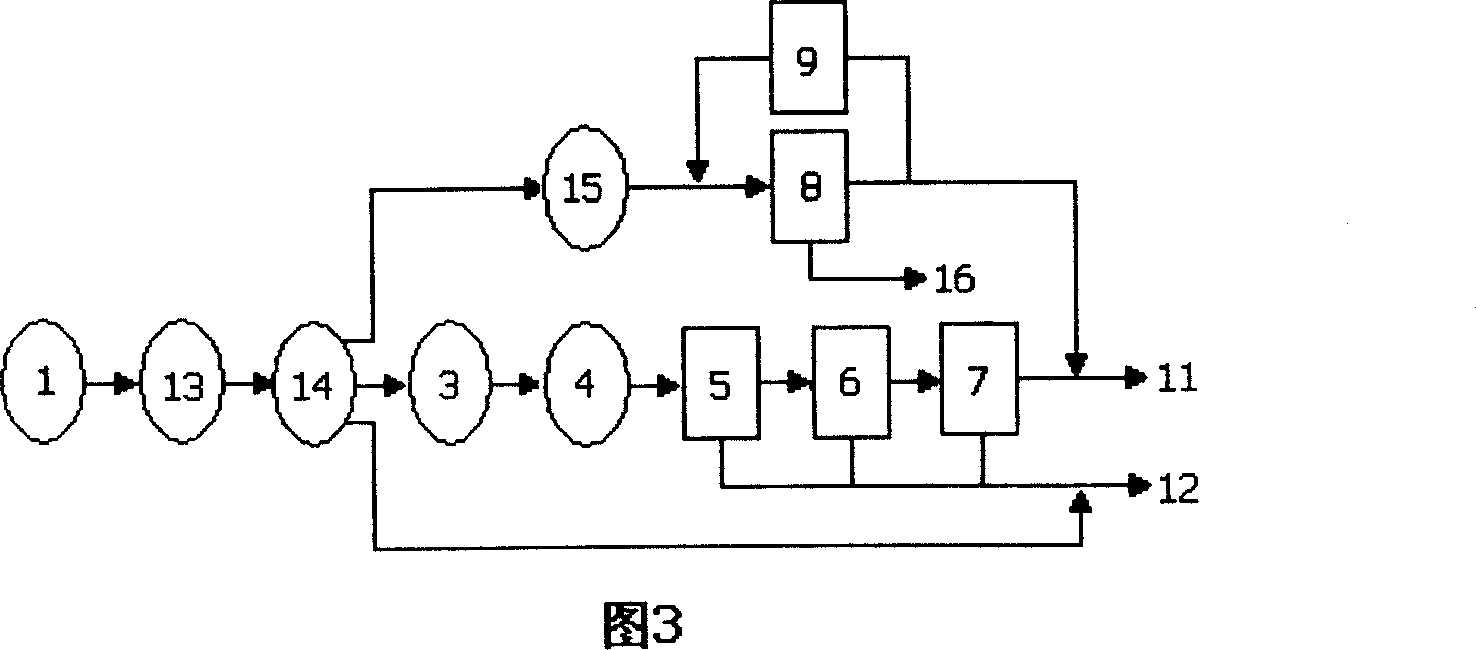

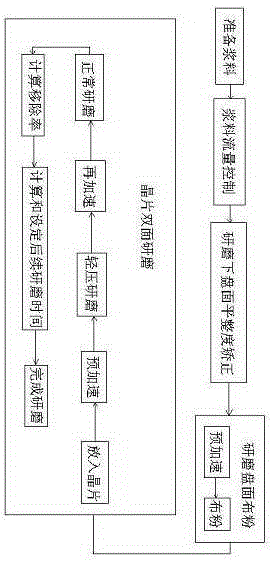

Defect detection and color sorting method of photovoltaic solar crystalline silicon cell, and system thereof

PendingCN109084957AReduce Fragmentation RateReduce manufacturing costOptically investigating flaws/contaminationOptical apparatus testingPhotovoltaic solar energyColor calibration

The invention discloses a defect detection and color sorting method of a photovoltaic solar crystalline silicon cell. The method comprises the following steps: firstly collecting a silicon wafer image, and preprocessing the image to achieve a color calibration aim; and then performing silicon wafer positioning to obtain an interested silicon wafer region; and then performing various detections onthe silicon wafer region, wherein the detections comprise size detection, breakage detection, grid line extraction, grid line detection, main grid detection, stain detection, and color spot detection,thereby detecting a defect region on a product surface; and finally performing classification on different color shades of the silicon wafers. The invention further discloses a defect detection and color sorting system of the photovoltaic solar crystalline silicon cell. The Defect detection and color sorting method of photovoltaic solar crystalline silicon cell and the system thereof are used fordetecting the front appearance defect and the front color grading produced after the photovoltaic solar crystalline silicon cell printing, the non-contact detection is realized, the detection precision is high, and the stability is good.

Owner:SOUTH CHINA UNIV OF TECH

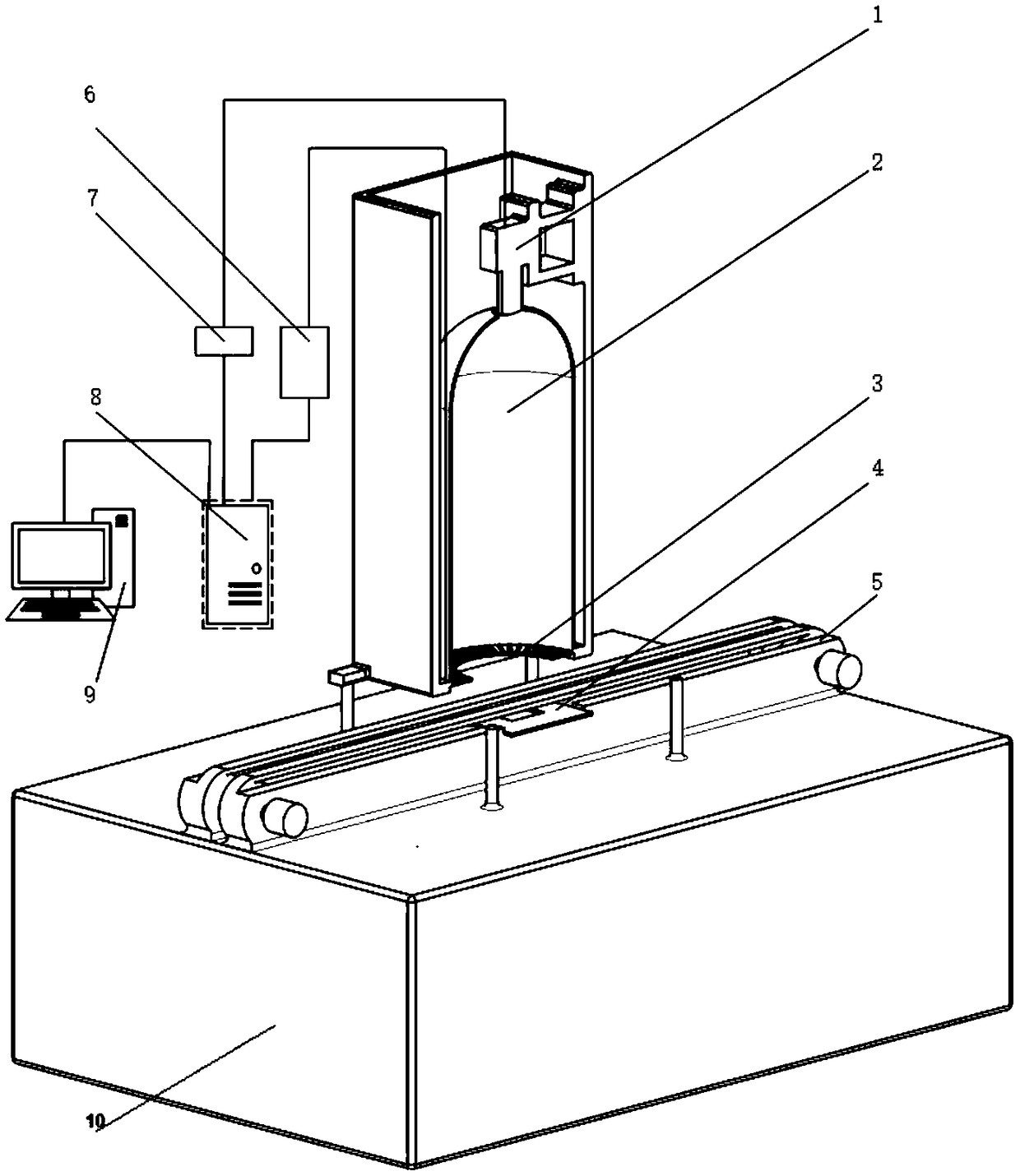

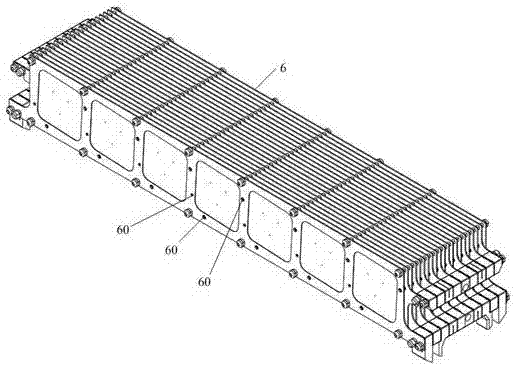

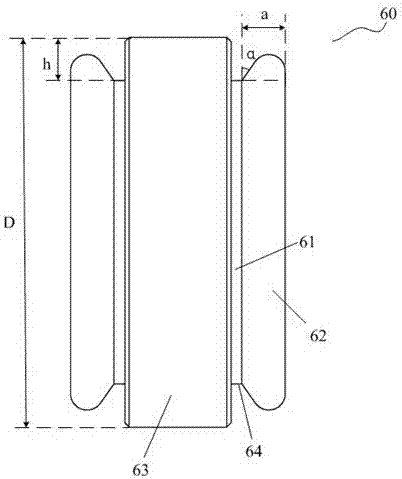

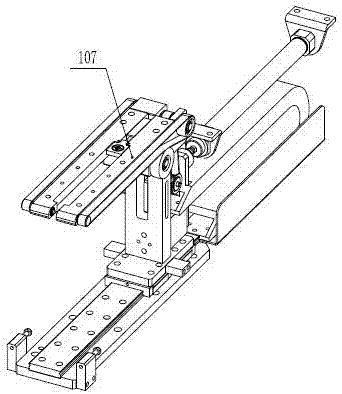

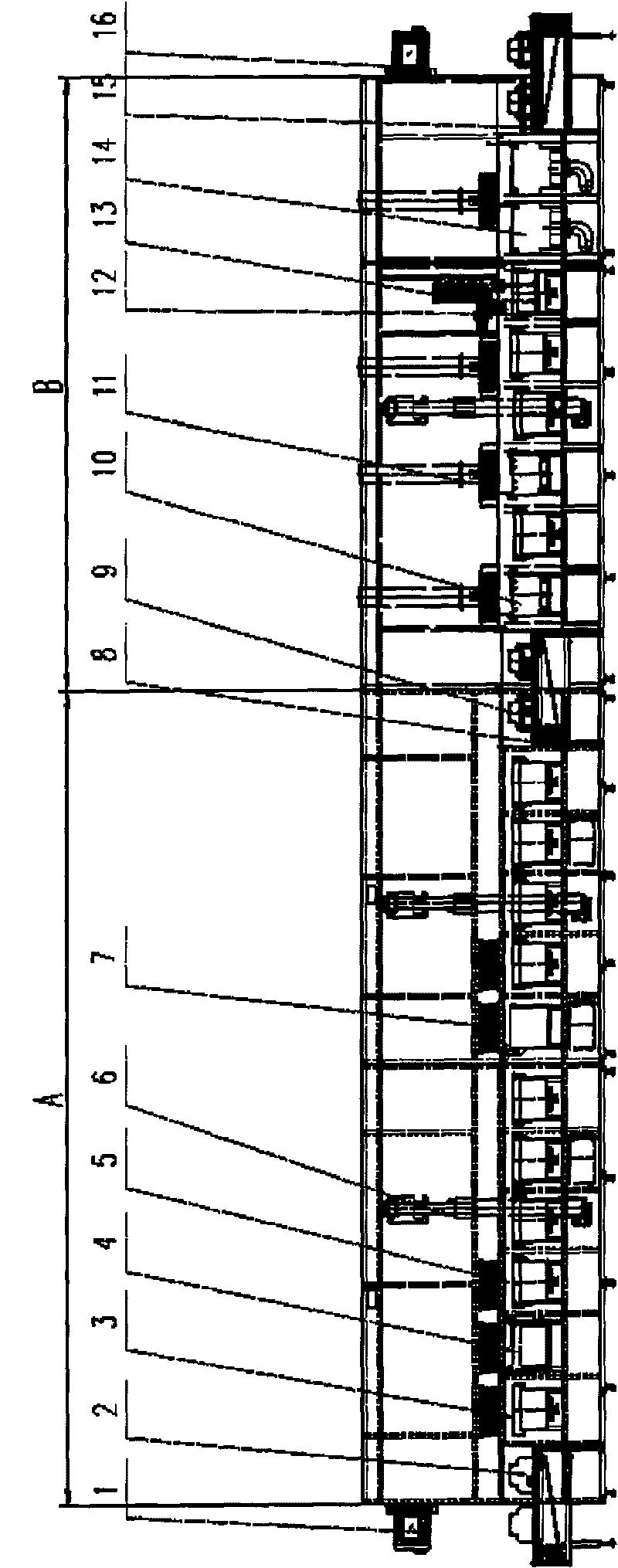

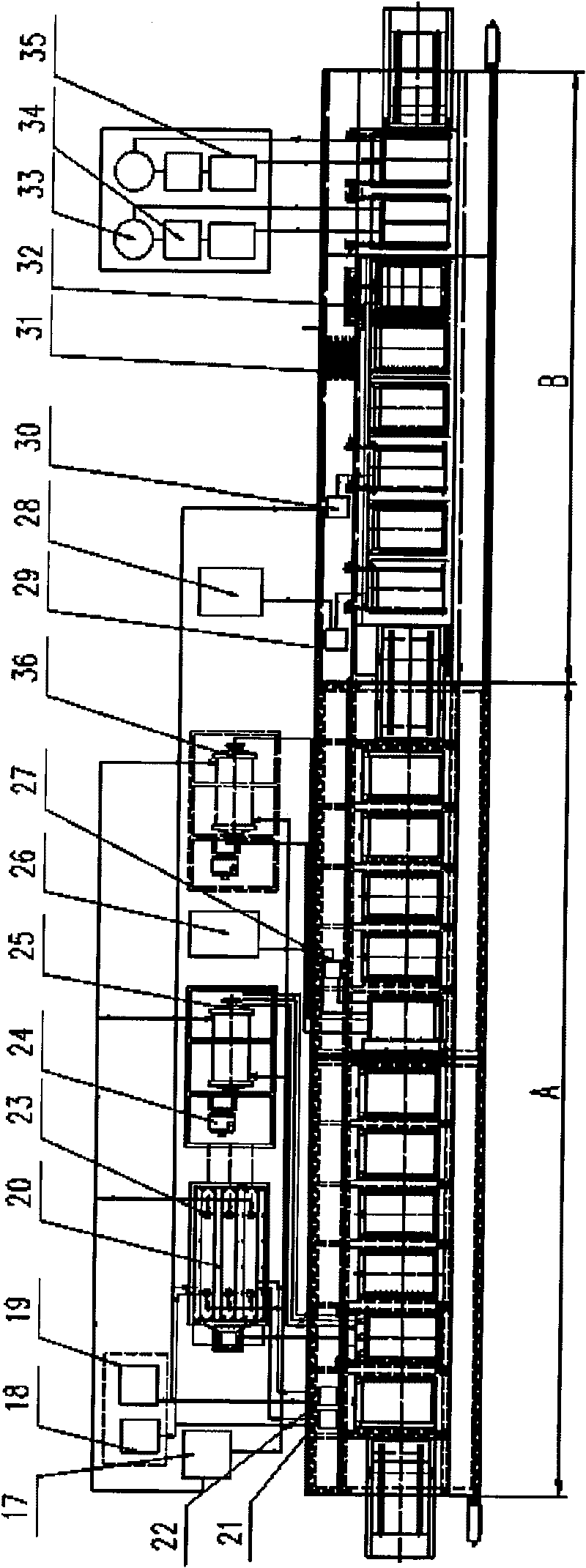

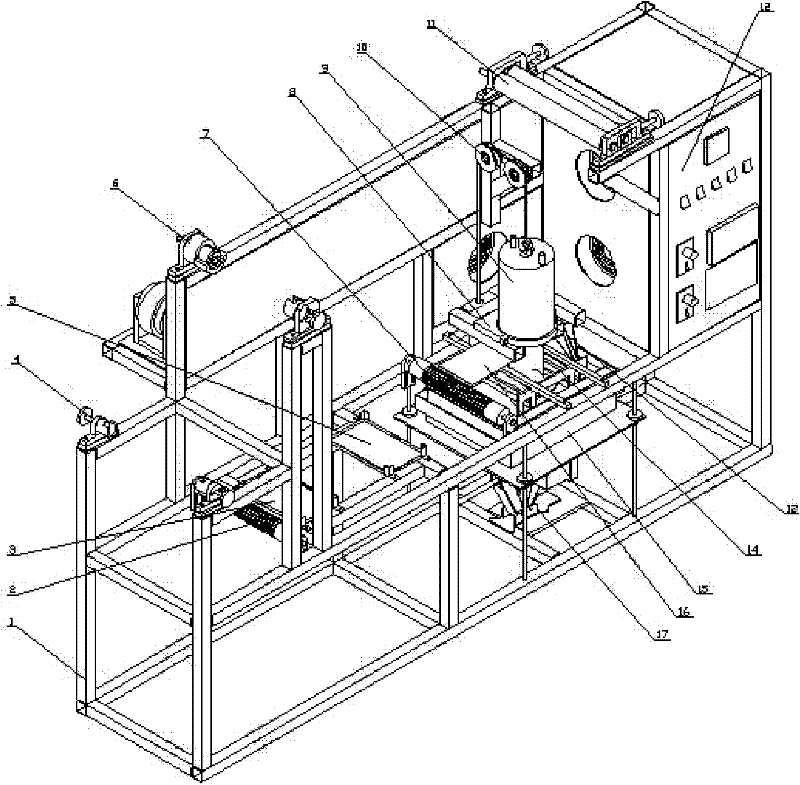

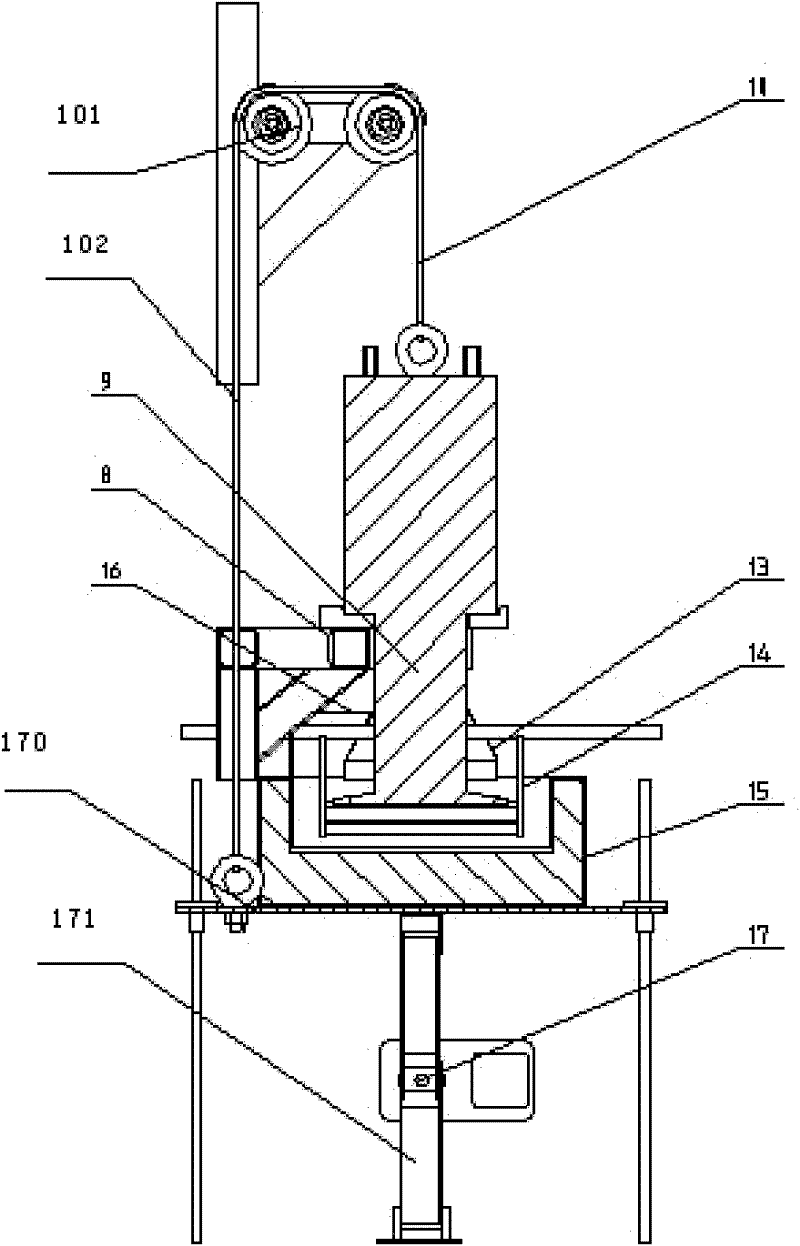

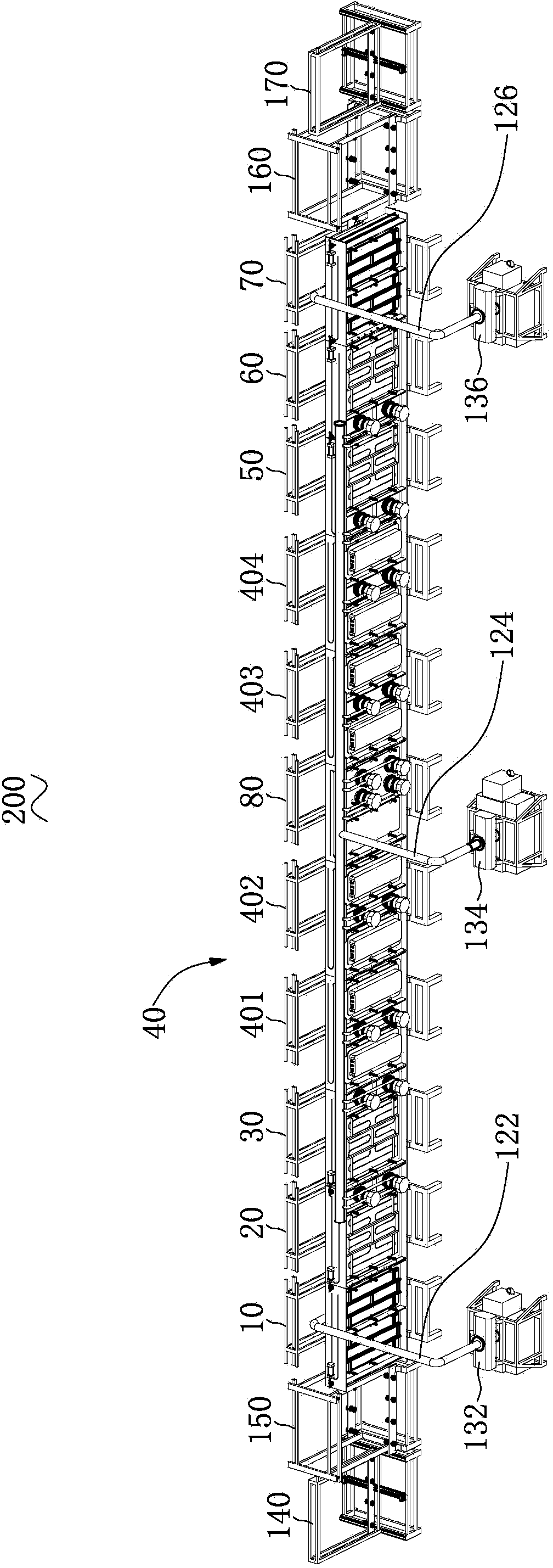

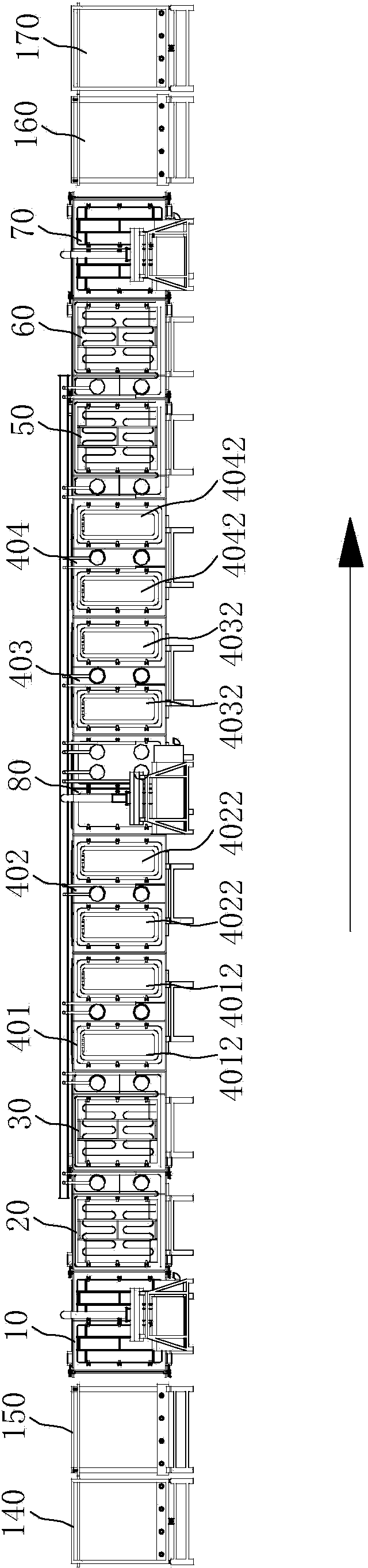

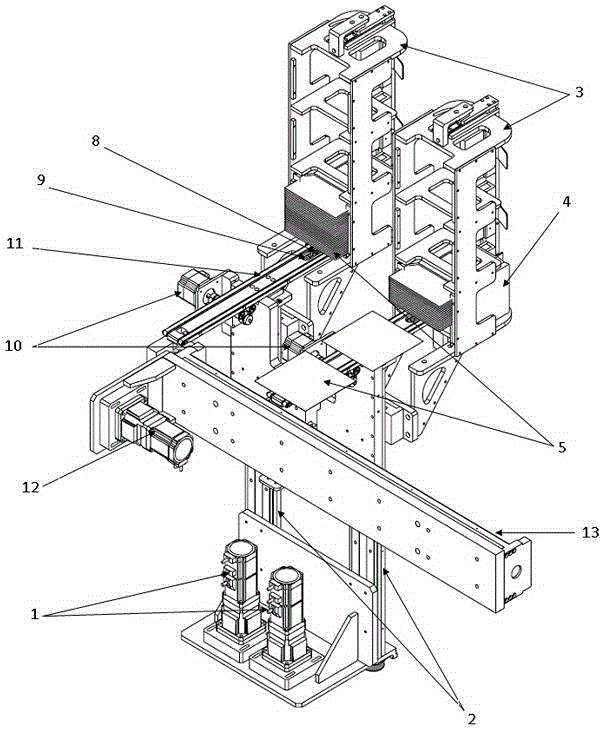

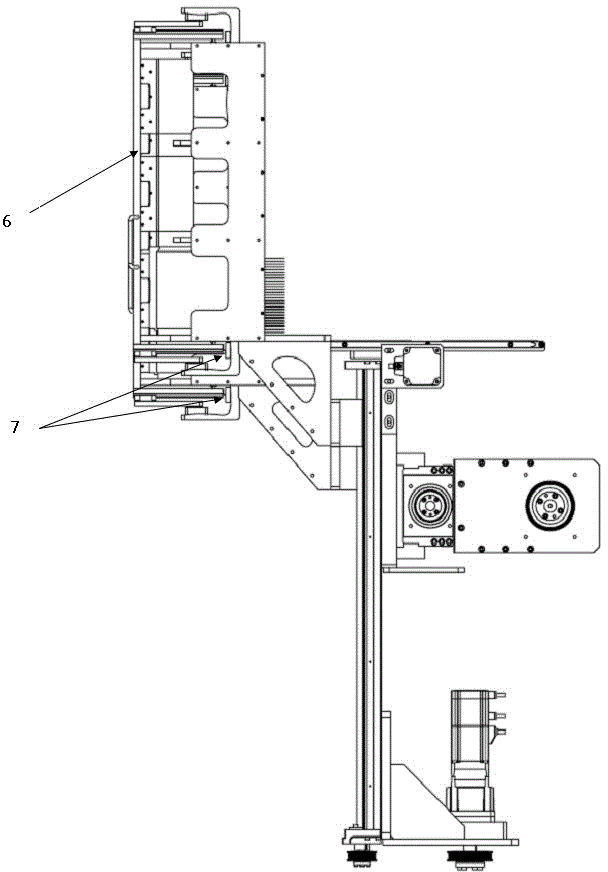

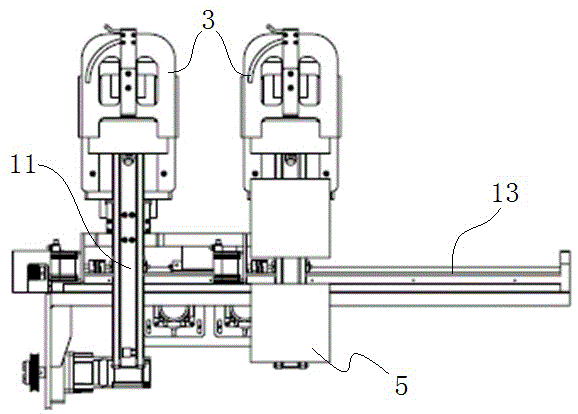

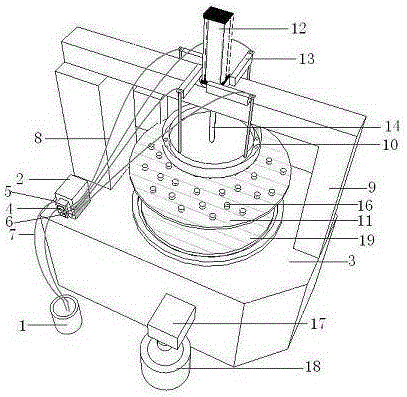

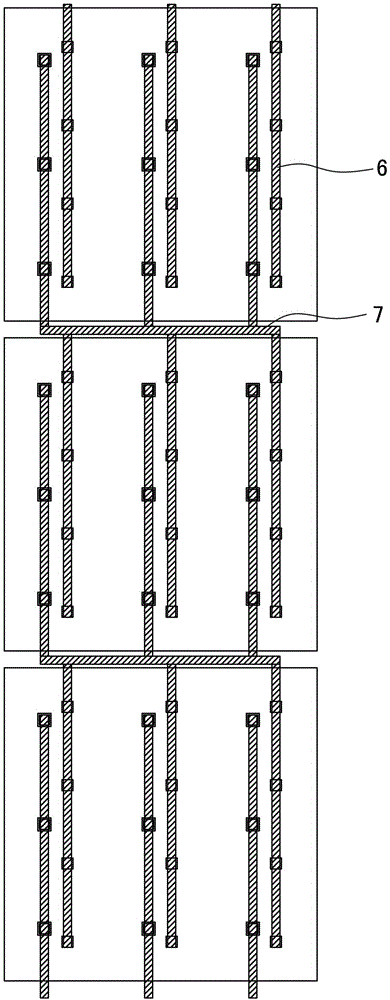

Automatic series welding machine for photovoltaic crystalline silicon cell pieces with radians

ActiveCN104139272AIncrease productivityReduce Fragmentation RateWelding/cutting auxillary devicesAuxillary welding devicesControl systemMicrometer

An automatic series welding machine capable for photovoltaic crystalline silicon cell pieces with radians is composed of a welding strip supply system, a loading system, a conveying system, a discharging system and a control system; the welding strip supply system comprises a welding strip feeding mechanism, a welding strip processing mechanism, a welding strip traction mechanism and a welding strip pressing mechanism; the loading system comprises a rotary loading mechanism, a jacking mechanism, a high-speed robot and a CCD detection system; the conveying system comprises a conveying mechanism, a tensioning mechanism and a welding mechanism; the discharging system comprises a cell string turnover mechanism, a cell string transferring mechanism and a drawer type discharging mechanism; the control system comprises a cantilever type touch screen computer, a Mitsubishi PLC, a circuit system and a gas path system. According to the actual measurement, the machine can weld the cell pieces with the length of 120 micrometers to 200 micrometers, the highest production efficiency can reach 800 pieces / hour, the breakage rate is smaller than 0.3 percent, and the length precision of a cell string can reach + / - 1 mm.

Owner:WUXI AUTOWELL TECH

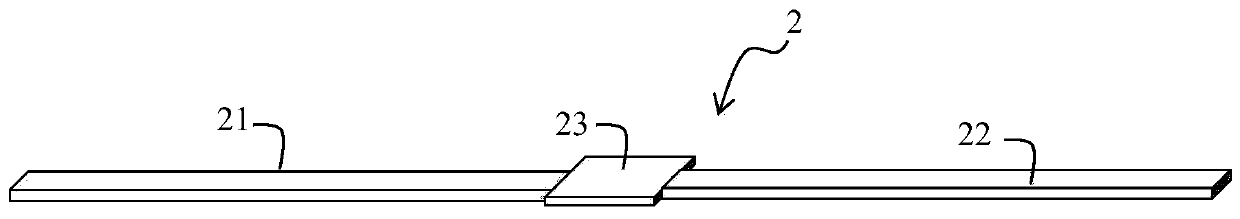

Single welding and series welding integrity device of solar cell slices

ActiveCN102699587AReduce wasteLow costFinal product manufactureWelding/cutting auxillary devicesFailure rateTemperature control

The invention discloses a single welding and series welding integrity device of solar cell slices. The provided single welding and series welding integrity device of the solar cell slices is good in positioning accuracy and compatible in the solar cell slices with different specifications, and can improve the single welding and series welding production efficiency of the solar cell slices. The device comprises a device rack, the device rack is provided with a feed mechanism, a transmission and positioning mechanism, a welding and temperature control mechanism, a blanking mechanism, a control mechanism and a power supply and control mechanism. According to the single welding and series welding integrity device of the solar cell slices, a full manual welding mode is replaced by a full automatic mechanical welding mode, the production efficiency is remarkably increased, the cell slice failure rate during a welding process is reduced, and the device is suitable for cell slice welding of the solar cells.

Owner:沈园众

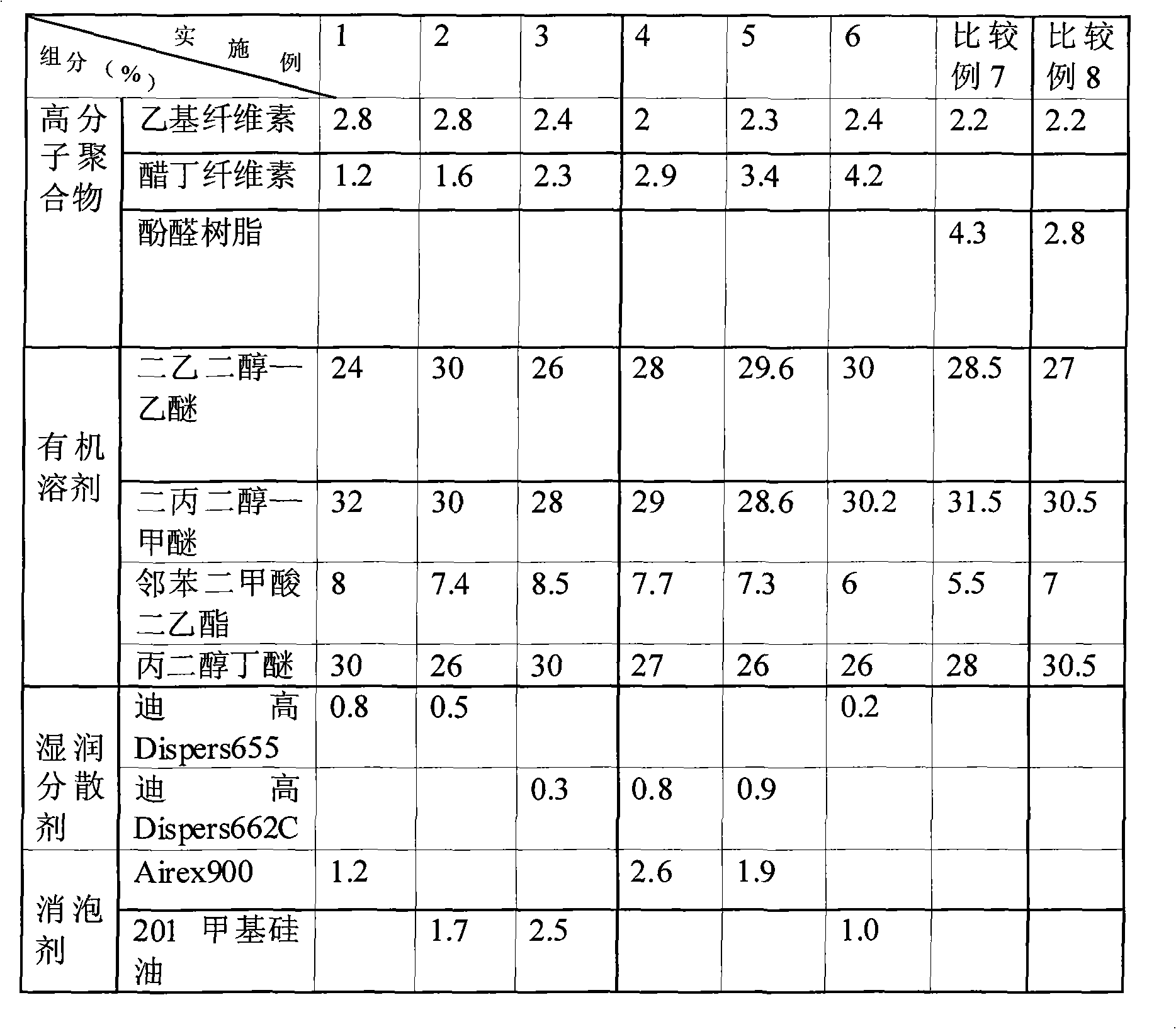

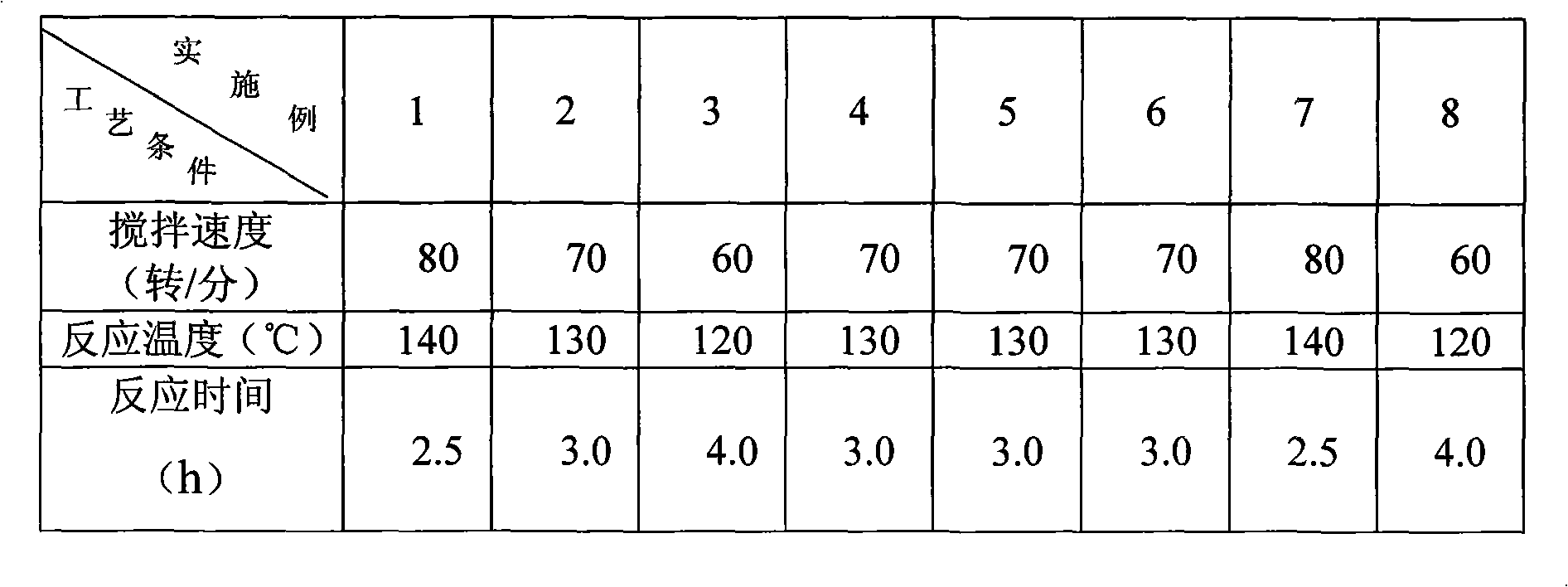

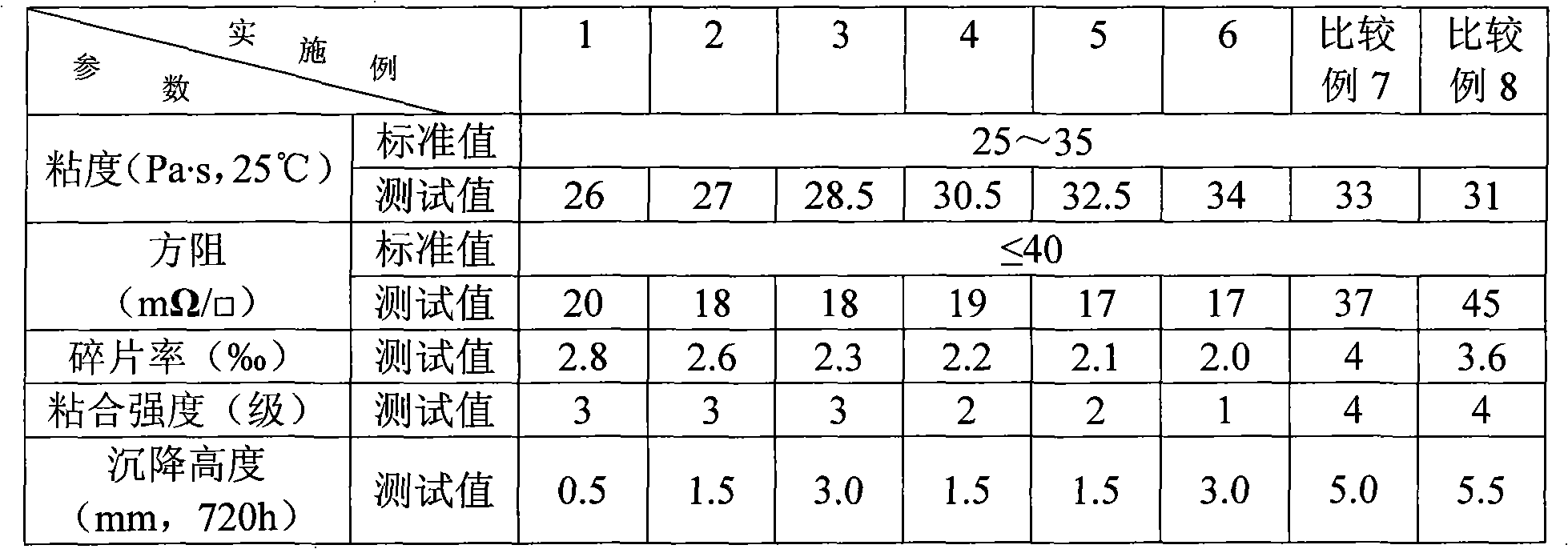

Organic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555394AReduce stressReduce Fragmentation RateFinal product manufactureCellulose adhesivesAluminum Oxide PasteChemistry

The invention provides organic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The organic adhesive comprises the following components by the weight part: 23% of ethyl cellulose, 1% to 5% of cellulose acetate butyrate, 88% to 94% of organic solvent, 0.2% to 1% of wetting dispersant and 1% to 3% of defoamer with the total amount being 100%. The preparation method comprises the following steps: putting the components into a reaction kettle; heating the components up to the temperature of 120 to 140 DEG C while stirring at the speed of 60 to 80 RPM and holding at a constant temperature for 2 to 4 hours to ensure that the components in the reaction kettle can be evenly stirred and subjected to complete reaction; and cooling the reactant and filtering the reactant with mesh to obtain the final product of the organic adhesive. The aluminum paste prepared from the organic adhesive has the advantages that the dispersibility or the suspensibility thereof is high, the aluminum paste does not laminate or precipitate after long-time storage and the aluminum paste can be uniformly coated so that the solid powder in the dried aluminum powder has the advantages of high adhesive strength and low stress generated on silicon chips.

Owner:WUXI RUXING TECH DEV +1

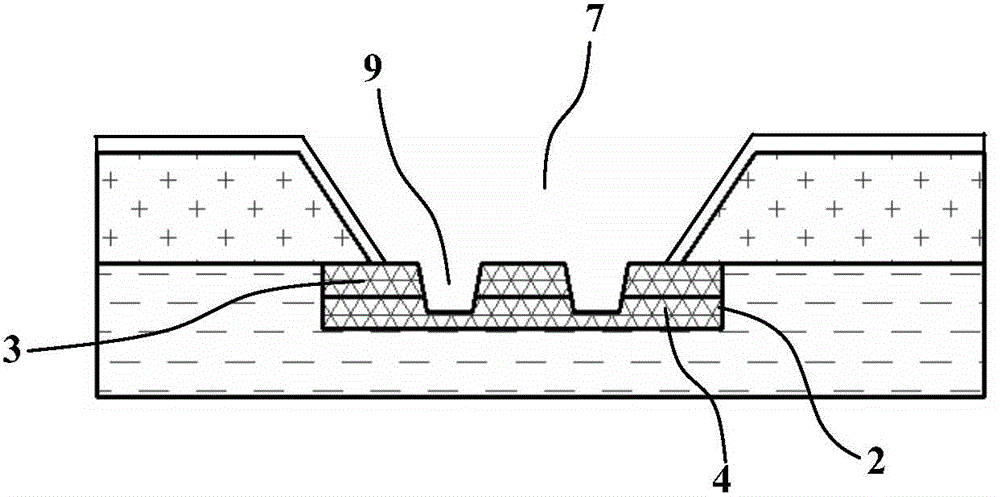

Coating equipment and method for tube-type PERC solar cells

ActiveCN107287579AReduce depthReduce gap sizeFinal product manufactureChemical vapor deposition coatingSilanesSolar cell

The invention discloses coating equipment for tube-type PERC solar cells. The coating equipment comprises a wafer loading region, a furnace body, a gas cabinet, a vacuum system, a heating system, a control system and a graphite boat; the gas cabinet is provided with a first gas pipeline for introducing silane, a second gas pipeline for introducing ammonia, a third gas pipeline for introducing trimethylaluminum, a fourth gas pipeline for introducing laughing gas and a fifth gas pipeline for introducing methane; the graphite boat is used for loading or unloading a silicon wafer; before being used or after being coated many times, the graphite boat needs to be subjected to pretreatment comprising the steps: drying the graphite boat; and coating at least one layer of silicon carbide film on the surface of the dried graphite boat. Correspondingly, the invention further discloses a coating method for tube-type PERC solar cells. By using the coating equipment and method, the pretreatment step of the graphite boat is simplified, the consumption of the silicon wafer is reduced, the silicon wafer is prevented from being scratched, and the EL yield of the cells is increased.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

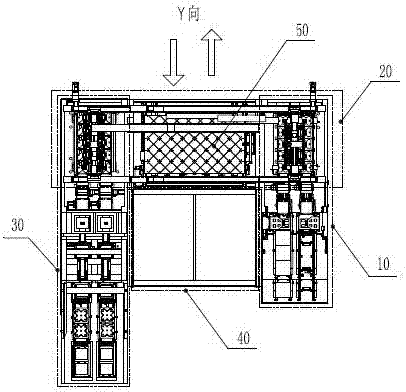

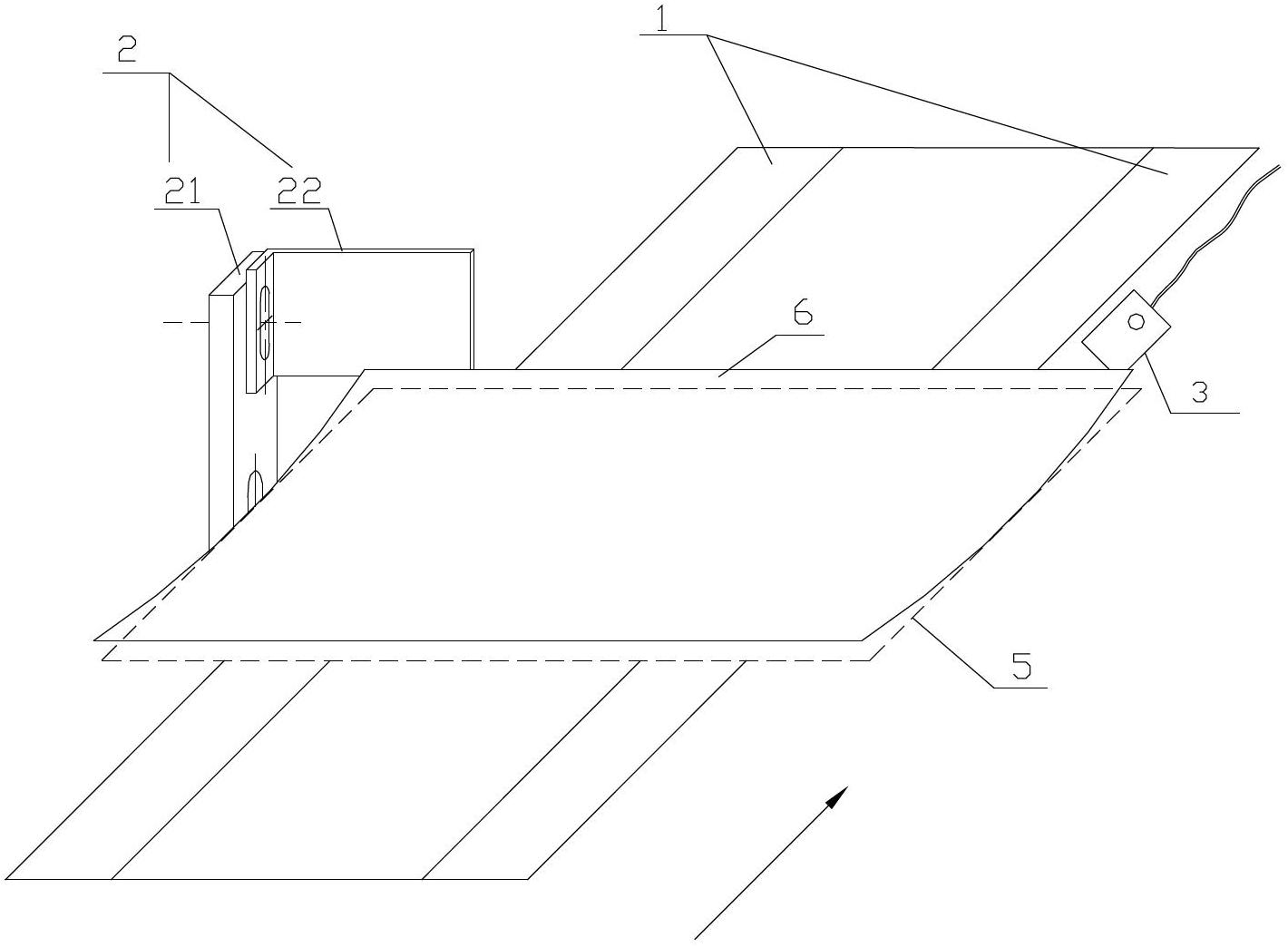

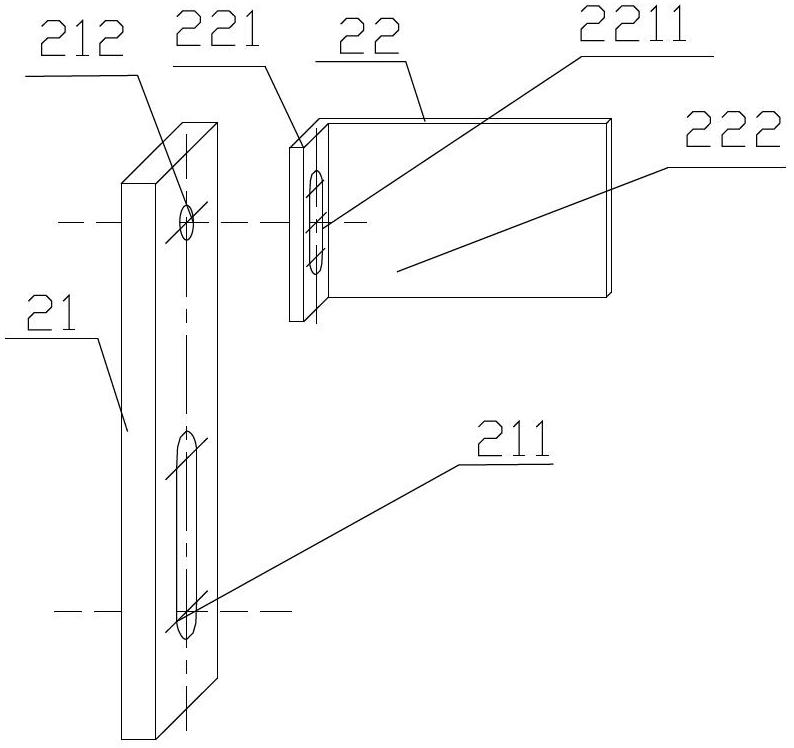

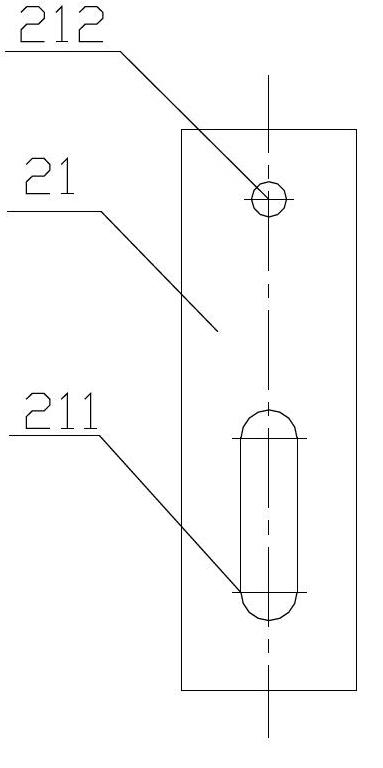

Solar silicon wafer two-in-one automatic loading and unloading equipment

PendingCN107093651AImprove work efficiencyShorten the feeding and discharging cycleSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringMechanical engineering

The invention discloses solar silicon wafer two-in-one automatic loading and unloading equipment, which is characterized in that a loading module and an unloading module are respectively located at two sides of a lifting platform, a transferring module is arranged above a discharging port of the loading module and a feeding port of the unloading module, the lifting platform is butted with a feeding and discharging end of main equipment along a Y moving direction of a carrier plate, the discharging port of the loading module and the feeding port of the unloading module respectively correspond to two sides in the X-direction of the feeding and discharging end of the main equipment; the lifting platform comprises an upper discharging station and a lower feeding station, the upper discharging station is butted with the discharging port above the feeding and discharging end of the main equipment in the Y-direction, and the lower feeding station is butted with the feeding port below the feeding and discharging end of the main equipment in the Y-direction; the unloading module comprises CCD detection module, an eliminating device and a lamination structure; and the lamination structure enables dropped silicon wafers to be neatly stacked by using a principle of automatic positioning of an oblique plane, thereby enabling the silicon wafer to be directly stacked into a block shape so as to be convenient for being directly packaged and transported, and greatly improving the product packaging efficiency.

Owner:江西比太科技有限公司 +1

Pretreatment process for tobacco threshing and redrying

InactiveCN101077213AHigh purityStrong targetingTobacco preparationTobacco treatmentEngineeringPre treatment

The present invention relates to tobacco pre-treatment, and is especially sectional tobacco thrashing and redrying pre-treatment process. The tobacco pre-treatment process includes the following steps: spreading the vacuum dampened tobacco leaf; cutting tobacco leaf into three sections including leaf stem, leaf base and leaf tip; moistening the leaf stem and separating in a leaf stem returning device into tobacco leaf stem and inferior tobacco leaf; and sieving leaf base to eliminate sand, moistening and multi-stage separating to obtain tobacco leaf stem and tobacco leaf. The tobacco pre-treatment process has high product quality.

Owner:CHINA TOBACCO HUNAN INDAL CORP

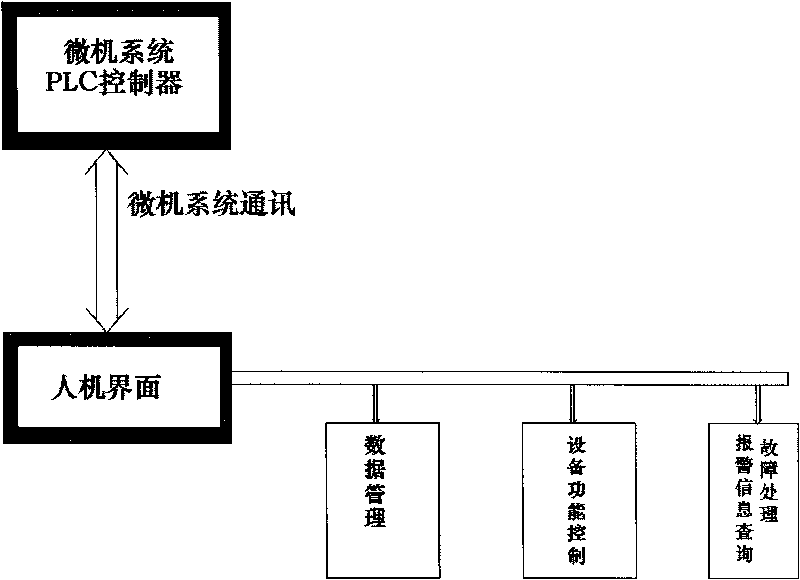

Polysilicon solar battery slice etching device

InactiveCN101719530AReduce consumptionGuaranteed constancyFinal product manufactureSemiconductor devicesControl systemForeign technology

The invention discloses a polysilicon solar battery slice etching device which comprises a polysilicon solar battery slice etching part, a polysilicon solar battery slice acid-cleaning part and a microcomputer control system, wherein the polysilicon solar battery slice etching part and the polysilicon solar battery slice acid-cleaning part are both connected to the microcomputer control system, and the microcomputer control system carries out independent control or coordinated control on the polysilicon solar battery slice etching part and the polysilicon solar battery slice acid-cleaning part. The invention can reduce the secondary pollution, improves the working environment and the production efficiency, breaks down the monopoly of foreign technologies and provides conditions for the application of domestic equipment.

Owner:上海科伟达超声波科技有限公司

Texture etching method for single crystalline silicon solar cell

InactiveCN101431124AImprove conversion efficiencyIncrease short circuit currentFinal product manufactureSemiconductor devicesHydrofluoric acidEtching

The invention discloses a preparation method of a monocrystalline silicon solar cell texture, the process is as follows: a monocrystalline silicon wafer which is rinsed cleanly by pure water after the chemical pre-cleaning in the former step is put in an ultrasonic tank of an ultrasonic cleaning machine with the power of 1,800-2,400w and the frequency of 25-40kHz, mixed water solution with 1 percent-2 percent NaOH and 3 percent-6 percent isopropyl alcohol according to the weight percentage is prepared in the ultrasonic tank, the temperature of the mixed water solution is set to be 75-85 DEG C, the ultrasound time is 30-35min, then the monocrystalline silicon wafer is taken out and put in hydrochloric acid water solution with the volume percentage of 10 percent for soaking for 4-6min, hydrofluoric acid water solution with the volume percentage of 10 percent is further used for soaking for 4-6min after the rinsing, then deionized water is used for cleaning, and drying is finally carried out. The silicon wafer texture prepared by the preparation method is even and low in reflection rate; furthermore, the preparation method reduces the fragmentation rate and improves the production efficiency and the production capacity.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

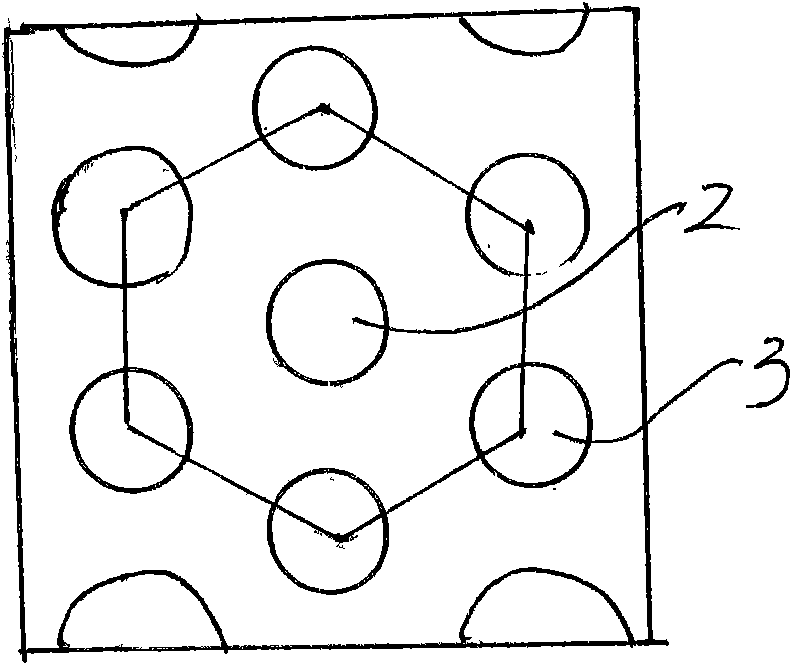

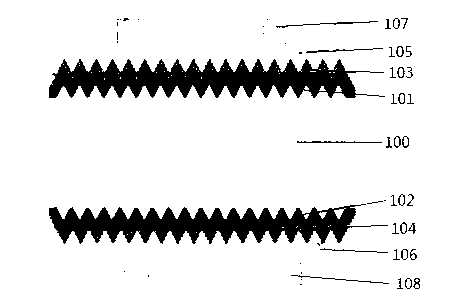

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848AStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of the conductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

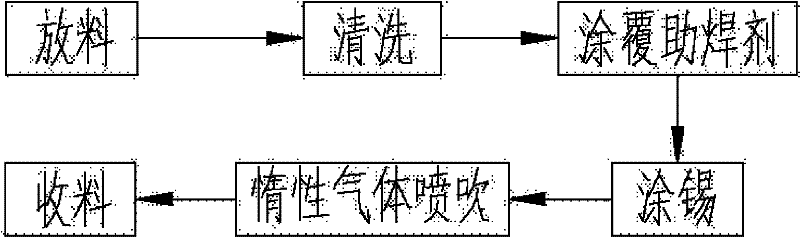

Manufacturing method of photovoltaic welding strip and tin coating machine thereof

ActiveCN102226259AAvoid pinholesQuality improvementHot-dipping/immersion processesFinal product manufactureSlagTransducer

The invention provides a manufacturing method of a photovoltaic welding strip and a tin coating machine thereof. The method comprises the following steps: A, carrying out a simple pretreatment on a copper strip; B, sending the pretreated copper strip into a plating solution of a tin furnace for tin coating, when tin coating, carrying out an ultrasonication to the copper strip with ultrasonic waveemitted by an ultrasonic wave transducer arranged above the tin furnace; C, blowing tin with inert gases, and D, receiving materials. According to the invention, by adding ultrasonic wave in the tin coating process, tin liquor can rapidly form an alloy layer of copper and tin on the surface of the copper strip by the sound pressure effect of the ultrasonic wave, the production efficiency of the photovoltaic welding strip is increased, the transporting speed of the copper strip reaches to 10-80m / min; by removing grease and oxide layer on the copper strip surface, reducing the usage of chemicalreagents, simplifying the pretreatment before coating, and utilizing the ultrasonic wave to crush clusters of tin oxide, the defects of pinhole and tin slag of the welding strip is prevented, the quality of the welding strip is improved, and the production efficiency is raised greatly.

Owner:江苏威腾新材料科技有限公司

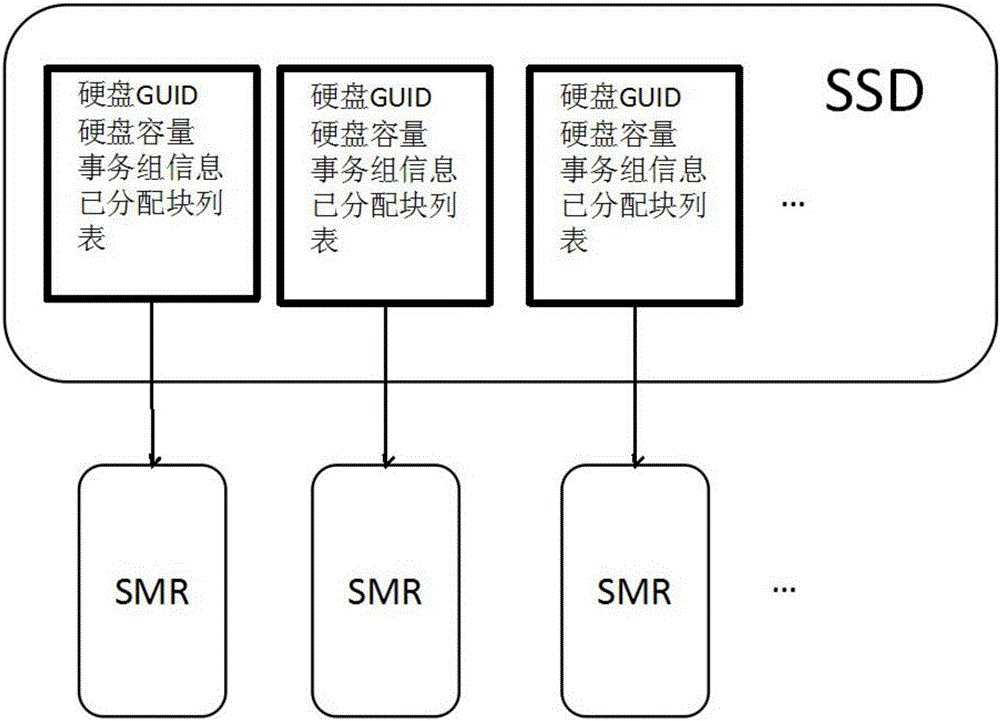

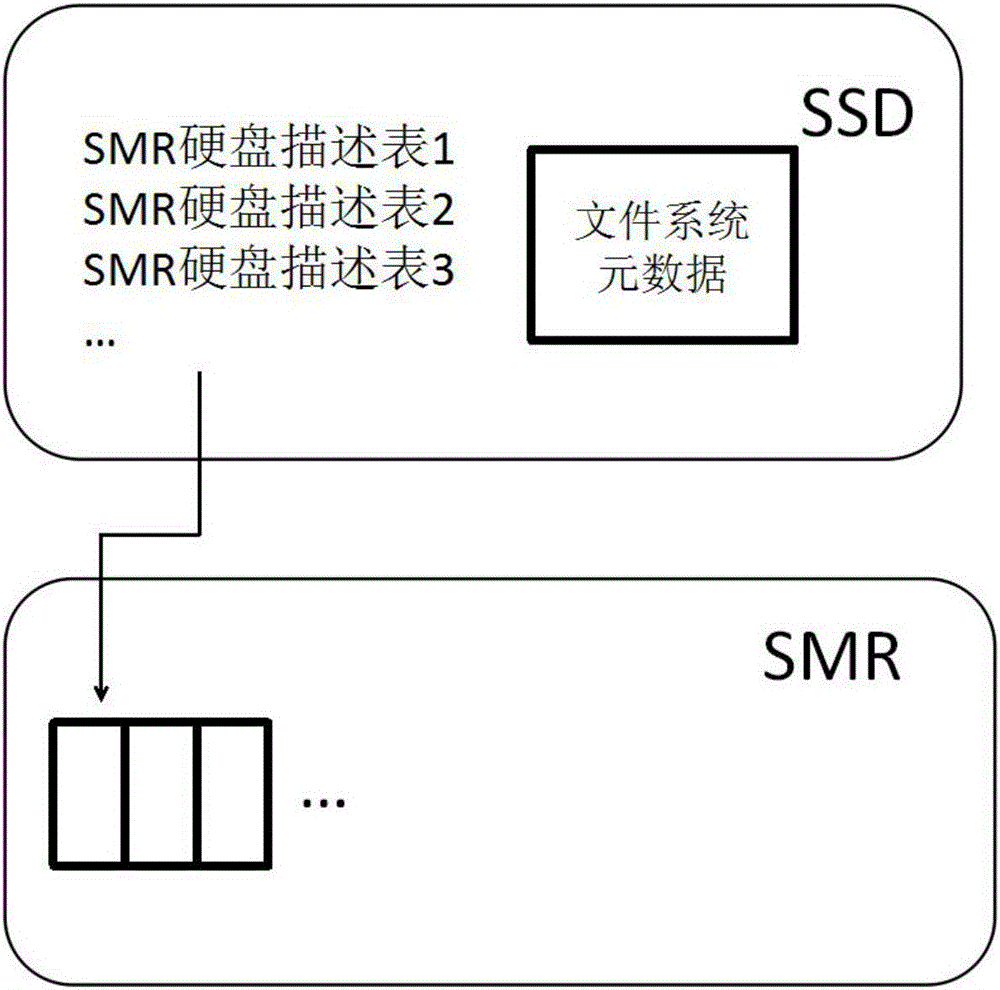

Method for mixed utilization of SSD and SMR hard disks in disk file system

InactiveCN105138286AEnsure consistencyImprove efficiencyInput/output to record carriersMemory adressing/allocation/relocationStorage efficiencySolid-state

The invention relates to a method for mixed utilization of a solid state disk (SSD) and a shingled magnetic recording (SMR) hard disk in a disk file system. The method is characterized by comprising the following steps of: establishing an SMR hard disk description list in the SSD hard disk so as to form a mapping relationship between the SSD hard disk and the SMR hard disk; allocating data blocks to to-be-written data by the file system; writing the allocated data into the SSD hard disk and the SMR hard disk separately by the file system according to a data block allocation result; and updating affair group information of the SMR hard disk description list, thereby finishing a data writing cycle. According to the method, the data of the file system are divided into a part that frequently needs to be modified and a data part, the SSD hard disk is used for storing the frequently-changed part, such as metadata, so as to improve the access efficiency; and the SMR hard disk is used for storing the data blocks of a file, and because the SSD hard disk stores most random modifications, the fragment rate of the system is greatly reduced and the storage efficiency and performance are improved.

Owner:ICLOUD INNOVATION BEIJING TECH CO LTD

Solar cell sheet electric sheet-splitting device

ActiveCN103337554AImplement the shard functionEliminate randomnessFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringCam

Owner:TRINASOLAR CO LTD

Monocrystalline silicon wafer precleaning liquid and cleaning method thereof

ActiveCN103087850AReduce concentrationReduce Fragmentation RateInorganic non-surface-active detergent compositionsCleaning using liquidsHydrogenWater rinsing

The invention relates to monocrystalline silicon wafer precleaning liquid and a cleaning method thereof. The invention is characterized in that the precleaning liquid comprises the following compositions: hydrogen peroxide, sodium hydroxide or potassium hydroxide, and water. The cleaning method of the monocrystalline silicon wafer precleaning liquid as in claim 1 is characterized in that the method comprises the following steps: putting a silicon wafer inserted into a flower basket into a uniformly mixed monocrystalline silicon wafer precleaning liquid at a temperature of 55-80 DEG C, performing ultrasonic cleaning for 60-600 seconds, after ultrasonic cleaning, rinsing with deionized water at 60 DEG C for 1 min, after deionized water rinsing, taking the silicon wafer out, and drying. The advantages of the invention are that with the hydrogen peroxide process, the alkali concentration is reduced; the hydrogen generation amount is low; no bubble trace is generated on the silicon wafer surface; no basket rinsing is caused; no obvious boundary is generated. Since the alkali concentration is reduced, the thickness reduction amount is effectively decreased, which facilitates the reduction of the fragment rate of battery pieces in subsequent procedures.

Owner:徐州鑫宇光伏科技有限公司 +1

Frosting liquid used in production line of frosted glass

A frosting liquid used in a production line of frosted glass includes following components, by weight, 5-10 parts of ammonium fluoride, 5-10 parts of inorganic acid, 5-10 parts of organic acid, 5-10 parts of inorganic salt, 3-5 parts of solid dispersed particles, 0.2-0.3 parts of a surfactant, 0.2-0.3 parts of a dispersing agent and 76.6-80 parts of water. The frosting liquid can enhance the strength of frosted glass and reduce fragment rate.

Owner:HUBEI HCT

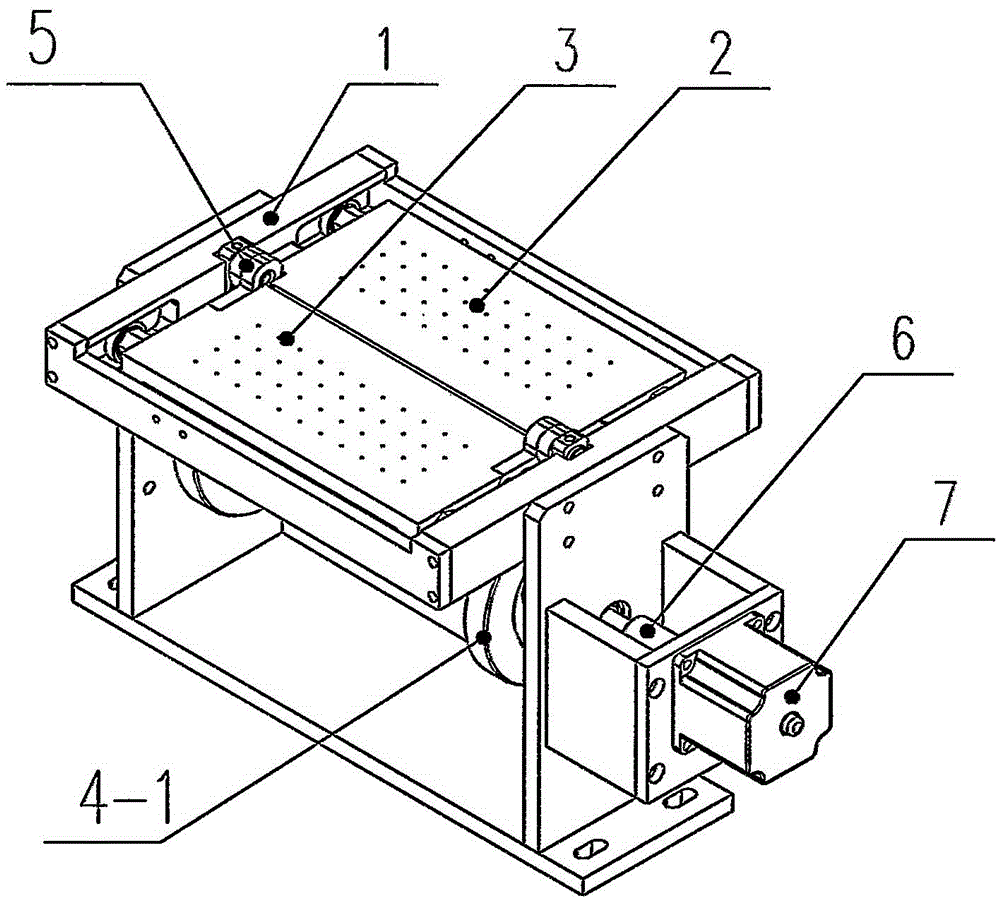

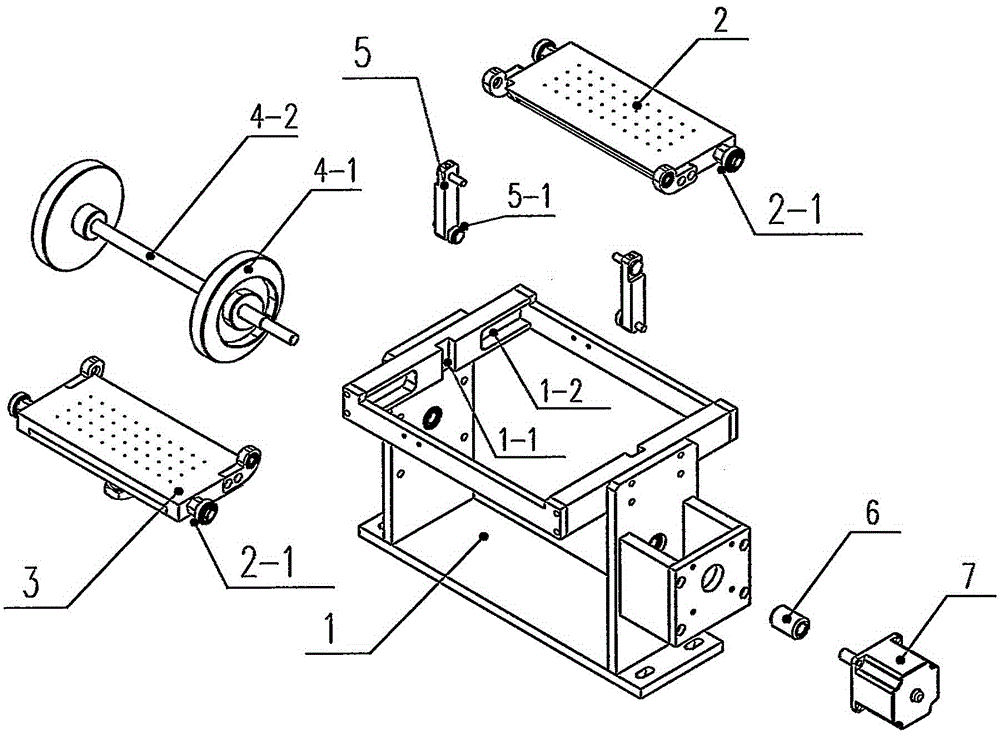

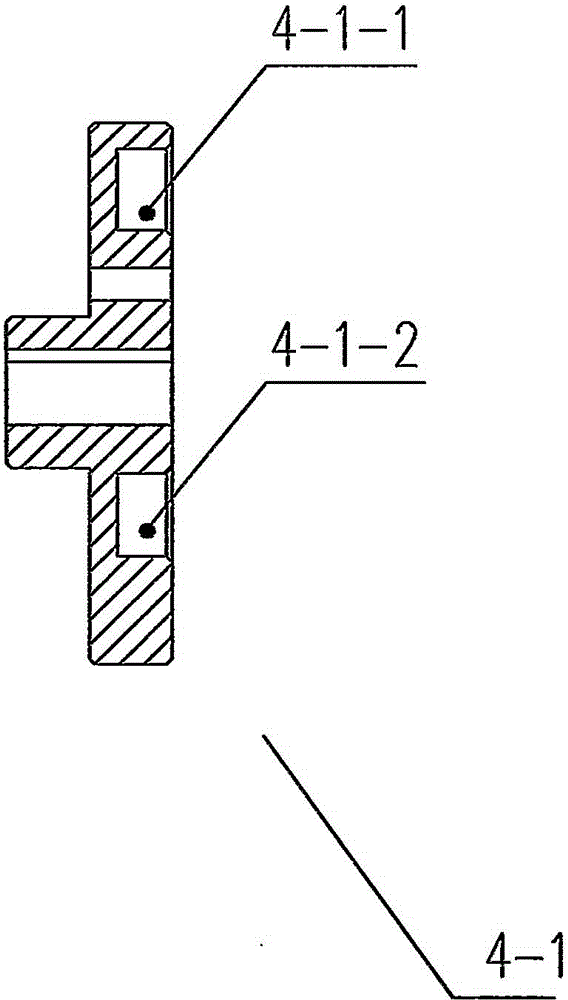

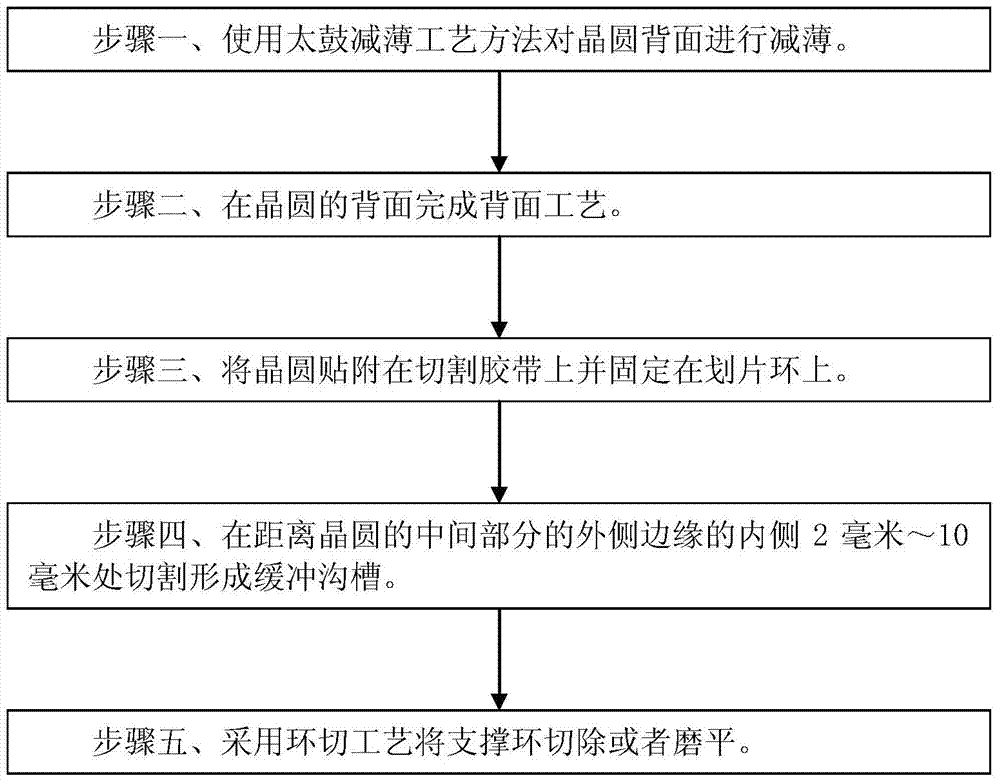

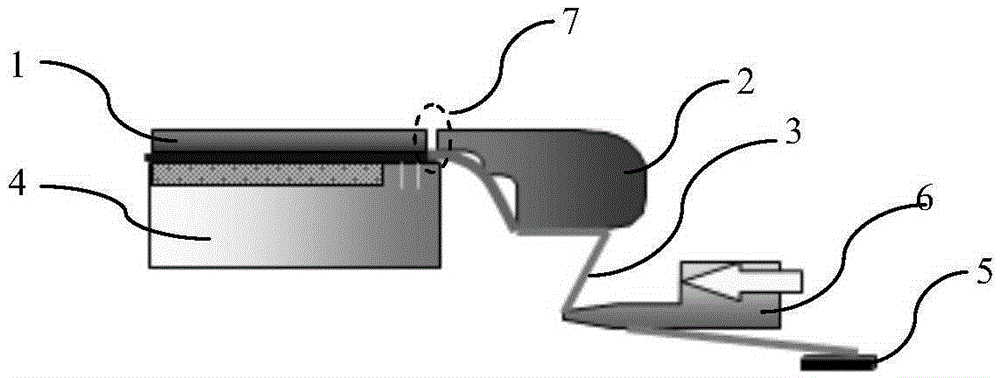

Ring removing method of Taiko thinning process

ActiveCN104517804AWon't breakReduce Fragmentation RateSemiconductor/solid-state device manufacturingThinningEngineering

The invention discloses a ring removing method of a Taiko thinning process. The method includes: using the Taiko thinning process to thin the back of a wafer; completing a back process at the back of the wafer; attaching the wafer to a cutting rubber belt and fixing the same on a wafer ring; cutting at a position 2-10mm away from the inner side of the outer edge of the middle part of the wafer to form a buffer groove; using a ring cutting process to remove or flatly grind a support ring. By the method, wafer breaking rate during ring cutting can be lowered or wafer breaking during ring cutting can be prevented completely.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

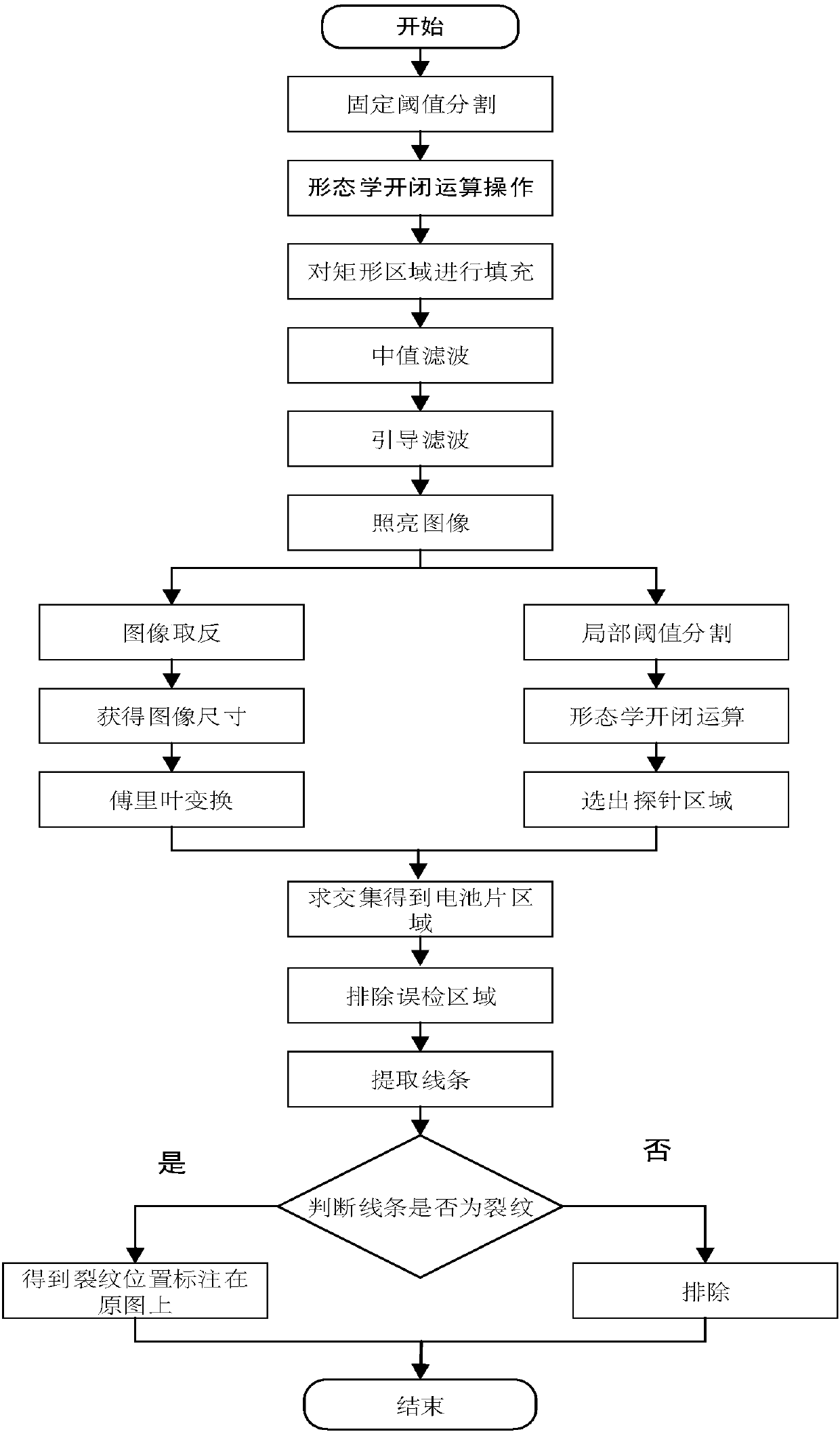

Crack defect detection method of EL test of polycrystalline silicon solar cell

InactiveCN107742286ARealize non-contact detectionRealize online automationImage enhancementPhotovoltaic monitoringFeature extractionEngineering

The invention discloses a crack defect detection method of an EL test of a polycrystalline silicon solar cell. The detection method is applicable to industrial production solar cell sites. The detection method comprises the steps that collected images are preprocessed, global threshold segmentation and opening operation and closing operation of morphology are conducted to suppress interference ofa non-processing area; then median filtering and guide filtering are conducted to remove image noise; a probe area is extracted through threshold differentiation and feature extraction, the probe areaand an area formed after threshold segmentation are subjected to complementary operation, the probe area is eliminated, and the area to be detected is remained; the smoothed images are subjected to Fourier transformation; the probe area and the area subjected to Fourier transformation are eliminated, intersection is conducted to obtain the area to be detected, lines of the area to be detected areextracted, and then whether or not the lines are cracks is judged according to the attribute of the lines. The crack defect detection method achieves non-contact detection, improves the detection quality and efficiency, effectively lowers the debris rate of the detection process, and can effectively achieve on-line automation of detection.

Owner:HEBEI UNIV OF TECH +1

Black heterogeneous crystalline cell and manufacture method thereof

InactiveCN103000741AReduce thermal stressLess prone to warpingFinal product manufacturePhotovoltaic energy generationScreen printingTrapping

The invention discloses a black heterogeneous crystalline cell which sequentially comprises a first metal electrode, a first conductive film, a P-shaped amorphous silicon layer, a first intrinsic amorphous silicon layer, a silicon wafer, a second intrinsic amorphous silicon layer, an N-shaped amorphous silicon layer, a second conductive film and a second metal electrode. The first conductive film and the second conductive film are polycrystalline boron-doped ZnO films. The manufacture method comprises the steps of preprocessing the surface of the silicon wafer; depositing intrinsic amorphous silicon layer plating in a double-faced mode; depositing the P-shaped amorphous silicon layer from the front side, and depositing the N-shaped amorphous silicon layer from the back side; and growing the ZnO films on the front side and the back side of a cell piece and screen printing metal grid lines on the front sides and the back sides of the conductive films. The polished silicon wafer with the smooth surface is adopted, and light trapping is achieved through pyramid structures of the ZnO films, so that a light trapping structure and surface passivation of the cell can be achieved maximally and respectively, and photoelectric converting efficiency of the cell is improved.

Owner:GD SOLAR

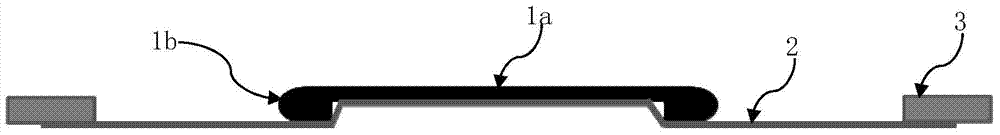

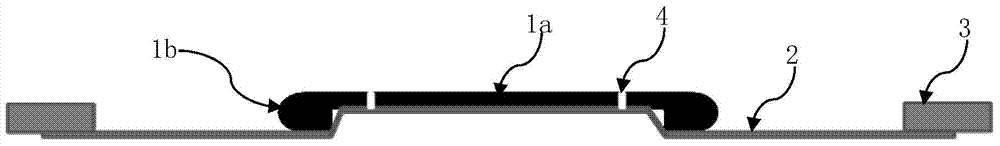

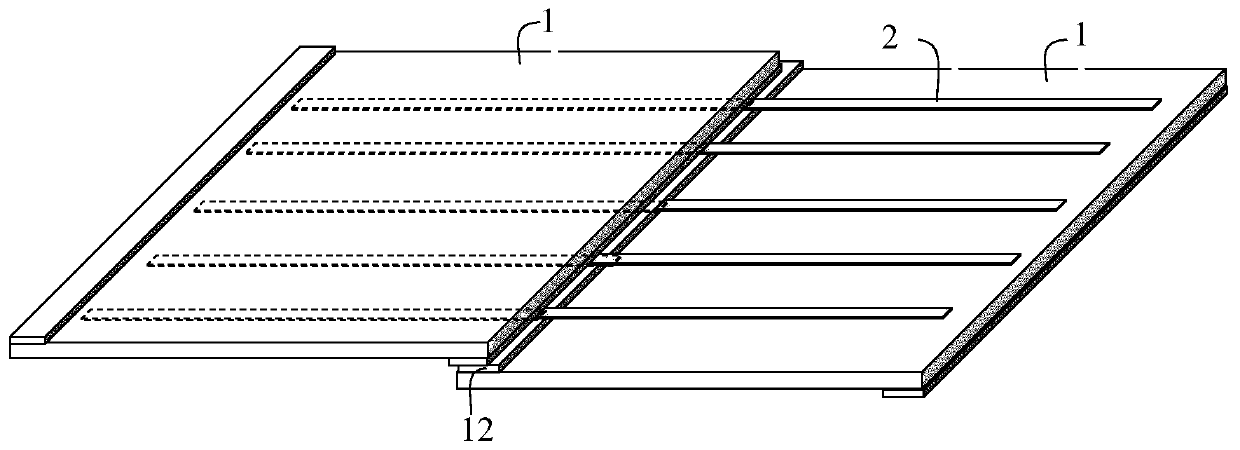

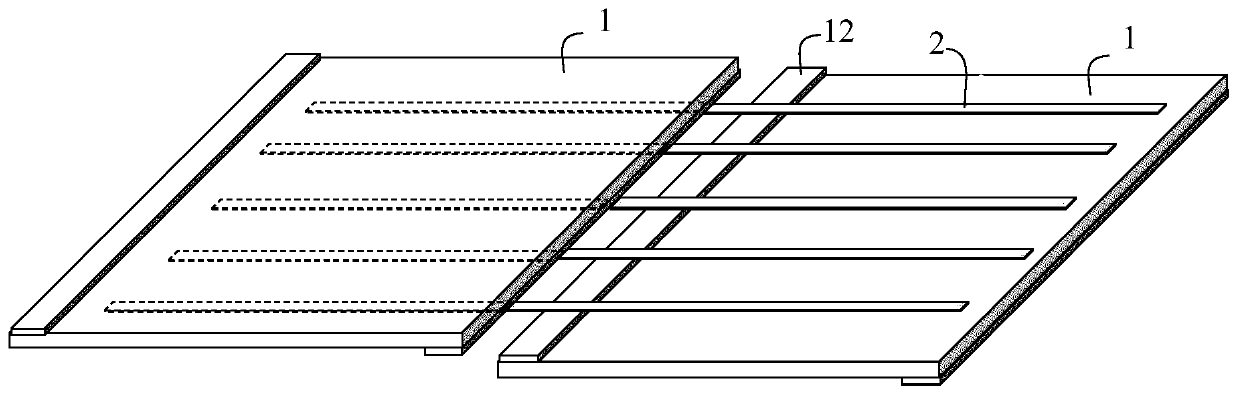

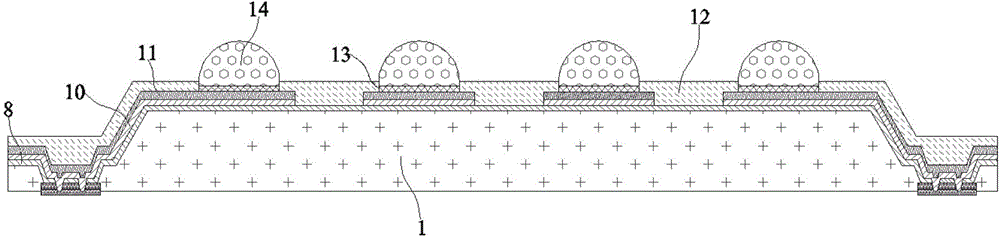

Photovoltaic module and manufacturing method thereof

PendingCN109786492AHard Touch ReliefReduce Fragmentation RateFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The embodiment of the invention provides a photovoltaic module and a manufacturing method thereof, wherein the photovoltaic module comprises several battery strings; the battery string comprises several solar batteries, a solder strip and a buffer layer; the solder strip is used for connecting adjacent two solar batteries, so that the several solar batteries are connected into a string; and the buffer layer can be arranged at the edge of the solar battery crossed with the solder strip, and positioned between the surface of the solar battery with an electrode and the solder strip.

Owner:CSI CELLS CO LTD +2

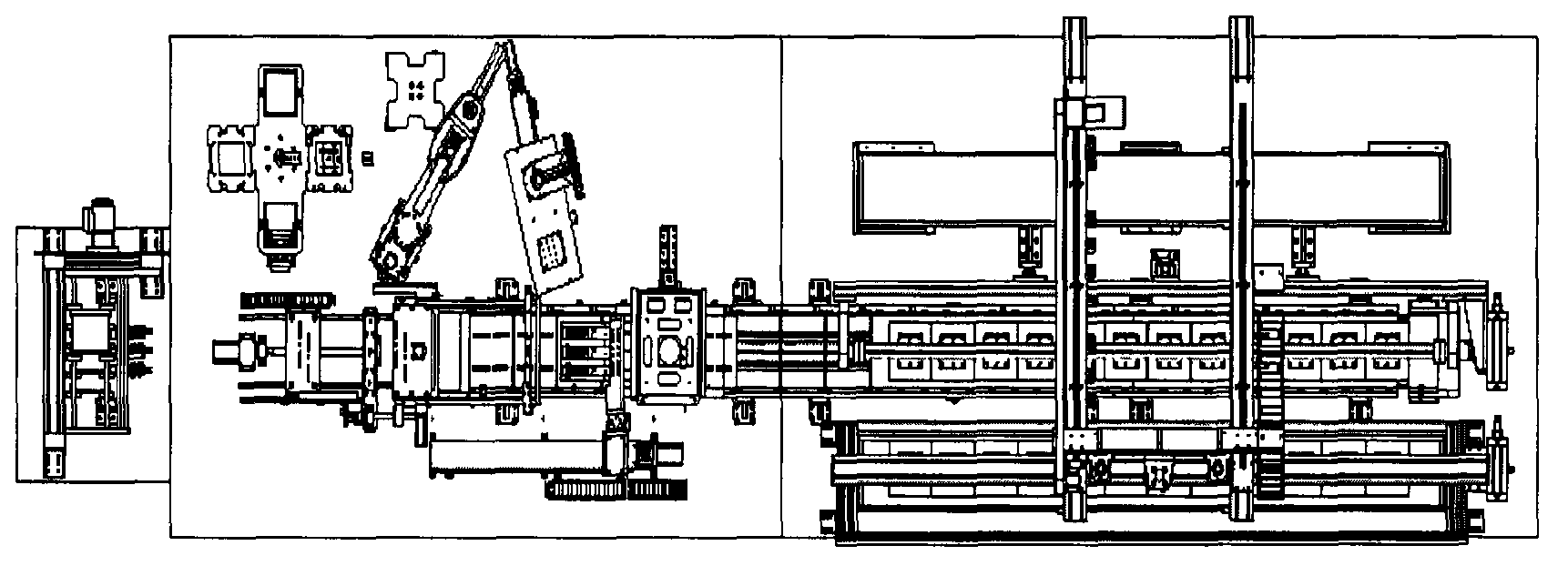

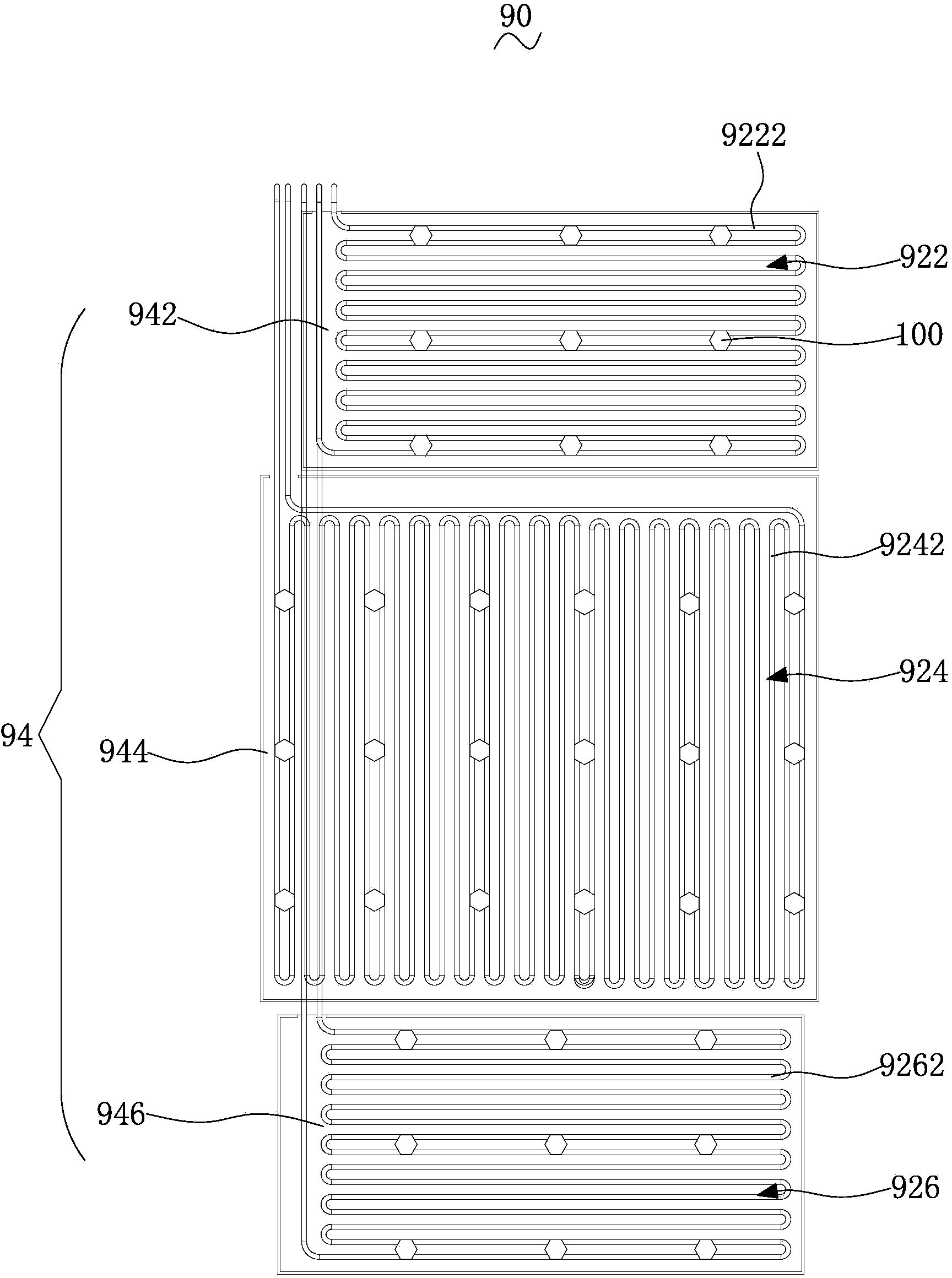

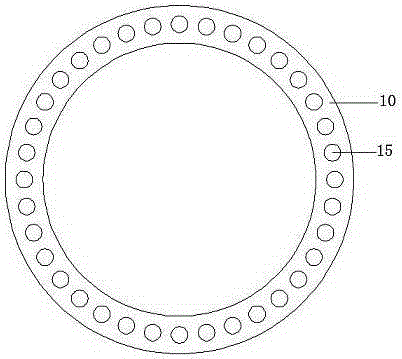

Magnetron sputtering coating system

ActiveCN103820762ALow plating resistanceMeet the coating process requirementsVacuum evaporation coatingSputtering coatingCoating systemOn cells

The invention relates to a magnetron sputtering coating system, comprising a linearly arranged slice entering chamber, a first buffer chamber, a first transition chamber, a sputtering coating chamber, a second transition chamber, a second buffer chamber and a slice discharging chamber, wherein the sputtering coating chamber comprises a first direct current sputtering chamber, a second direct current sputtering chamber, a third direct current sputtering chamber and a fourth direct current sputtering chamber which are connected successively. The first direct current sputtering chamber is connected to the first transition chamber; the fourth direct current sputtering chamber is connected to the second transition chamber; the first direct current sputtering chamber is provided with two first cathode targets; the second direct current sputtering chamber is provided with two second cathode targets; the third direct current sputtering chamber is provided with two third cathode targets; and the fourth direct current sputtering chamber is provided with two fourth cathode targets. By using the magnetron sputtering coating system for coating, fragment rate can be effectively reduced; coating of the film with relatively low sheet resistance can be facilitated; process requirements of on-cell coating are met; and production yield is increased.

Owner:WGTECH JIANGXI

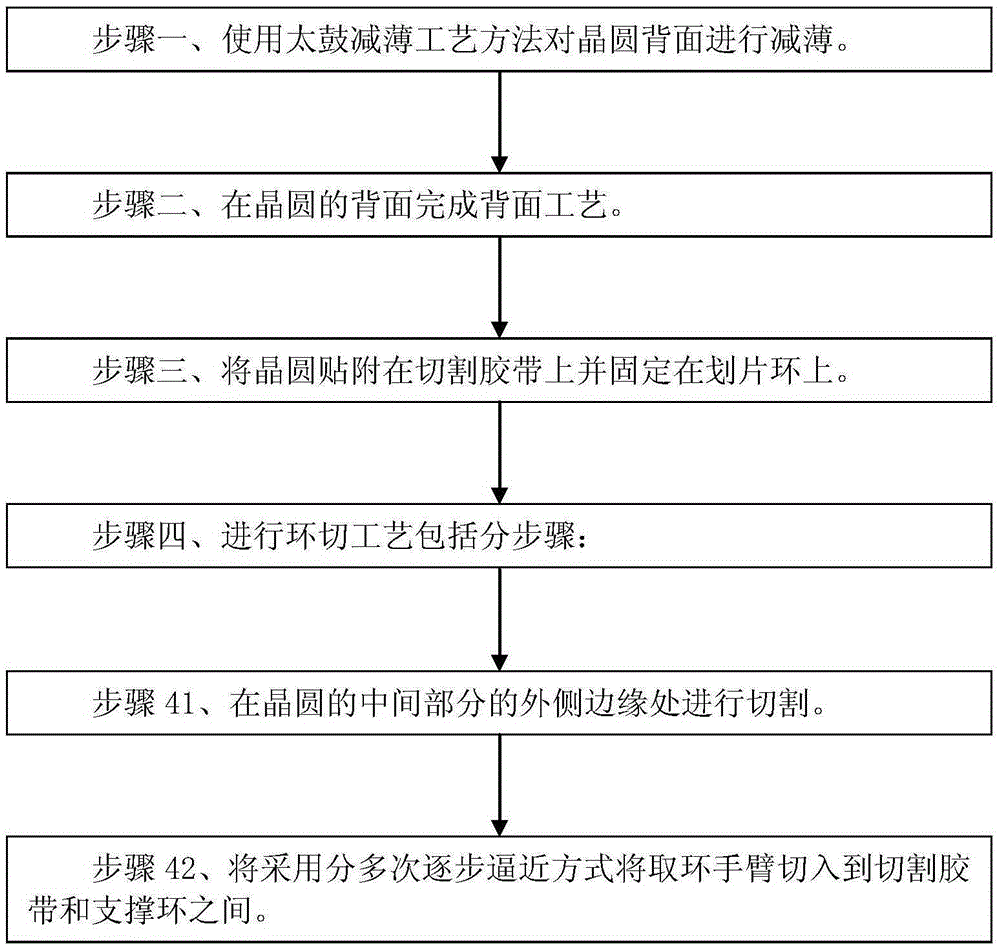

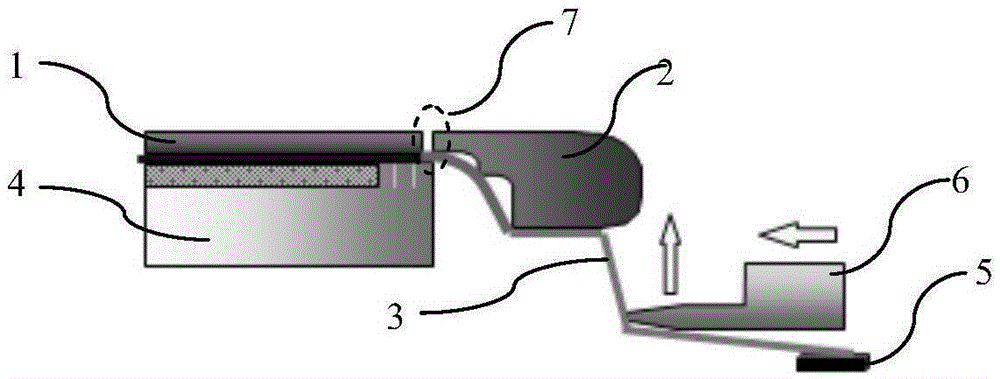

Annular cutting process method of Taiko thinning process

ActiveCN105428220AStable separationForce and torque controlSemiconductor/solid-state device manufacturingEngineeringThinning

The invention discloses an annular cutting process method of a Taiko thinning process. The annular cutting process method comprises the following steps of thinning the back surface of a wafer by the Taiko thinning process method; completing a back surface process on the back surface of the wafer; and attaching the wafer onto a cutting adhesive tape and fixing the wafer on a scribing ring. The annular cutting process comprises the following steps of cutting an edge of an outer side at the middle part of the wafer; and cutting a ring taking arm to be between the cutting adhesive tape and a support ring by a successive approximation mode in multiple times. By the annular cutting process, the debris rate in the annular cutting step can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

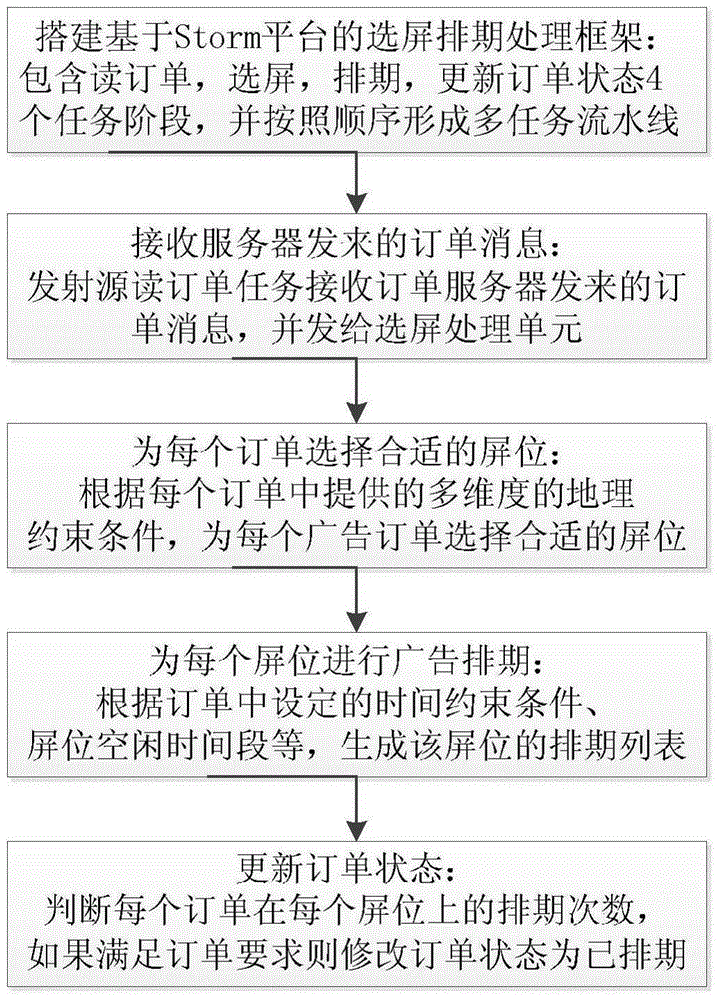

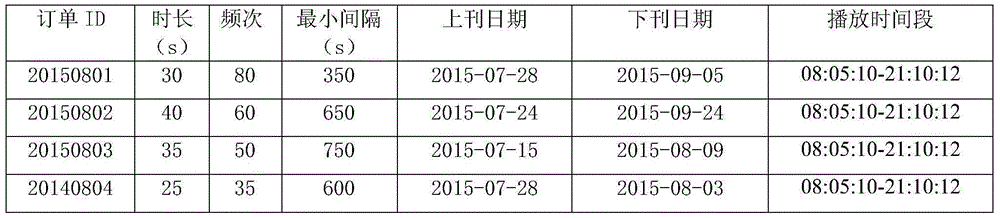

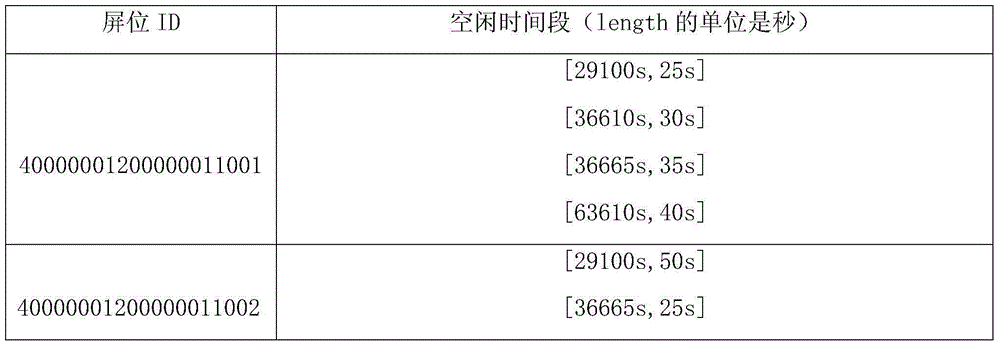

Distributed digital signage advertisement delivery method based on Storm platform

ActiveCN105184614AImprove resource utilizationAvoid scheduling conflictsSpecific program execution arrangementsMarketingStormReal-time computing

The invention discloses a distributed digital signage advertisement delivery method based on a Storm platform. The advertisement delivery method comprises the steps that: 1) a processing framework based on the Storm platform is established, wherein the processing framework includes order reading, screen selecting, scheduling and order state updating; 2) an emission source receives order messages and sends the order messages to a screen selection processing unit; 3) the screen selection processing unit selects a screen position for each order according to constraint conditions such as order geographical location; 4) a scheduling processing unit generates a scheduling list of the screen position according to a time constraint condition in the order and screen position idle time periods; 5) and a state processing unit updates the order state according to the scheduling results. The distributed digital signage advertisement delivery method can achieve instant and precise delivery of mass order advertisements efficiently, can increase screen position utilization rate of the digital signage, reduces time fragments, and has very high commercial value as well as application and popularization value.

Owner:广州冠众电子科技股份有限公司

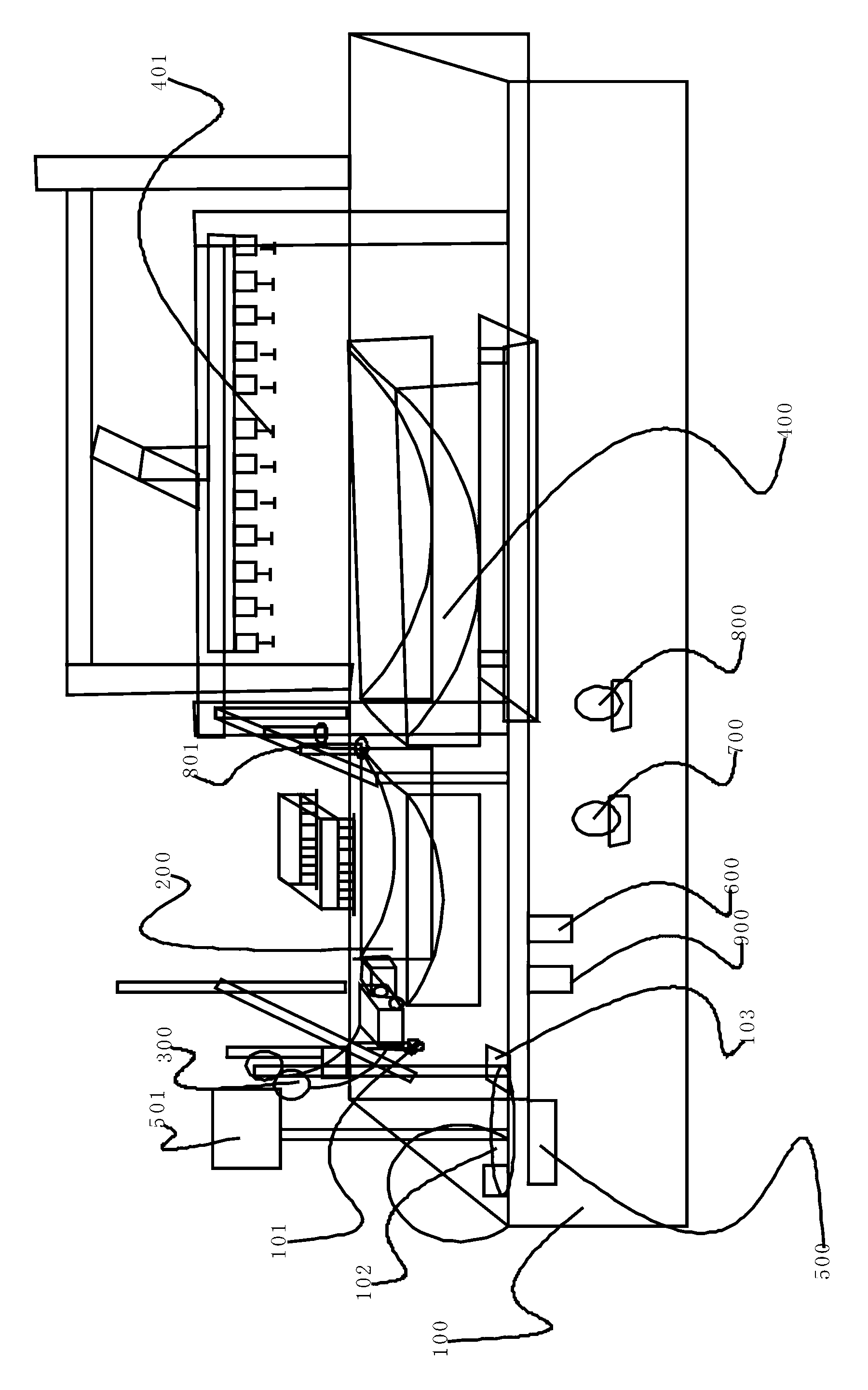

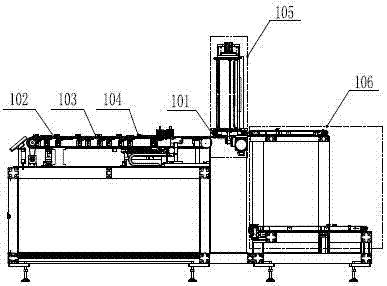

Feeding system and feeding method for silicon chip quality sorting equipment

ActiveCN104307759ARealize uninterrupted feedingIncrease the feeding speedSortingButt jointEngineering

The invention discloses a feeding system for silicon chip quality sorting equipment. The feeding system mainly comprises multiple feeding units with the same structure. Each one of the feeding units comprises a vertical guide rail, the vertical guide rail is provided with a feeding box, a basket case is installed in the feeding box, a side of the vertical guide rail is provided with a horizontal transmission mechanism, the horizontal transmission mechanism is used for transmitting silicon chips in the basket case to a downstream station, an output end of the horizontal transmission mechanism is provided with a horizontal guide rail, and the multiple horizontal transmission mechanisms can horizontally move reciprocatingly so that butt joint of the corresponding horizontal transmission mechanism and the downstream station is switched and thus when the feeding box in the multiple feeding units carries out feeding, the rest of the feeding boxes carry out loading. The multiple feeding units are installed on the horizontal guide rail capable of horizontally moving so that left-to-right switching of the multiple feeding units is realized. When one of the feeding units carries out a feeding process, the rest of the feeding units carry out basket case loading so that uninterrupted feeding is realized.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Bending piece detection device for battery piece

The invention provides a bending piece detection device for a battery piece testing procedure. By the device, a fragmentation ratio of the testing procedure can be obviously reduced, and automatic degree of detecting the bending piece can be improved. The bending piece detection device comprises a photoelectric sensor and an indicator, wherein the photoelectric sensor is arranged at the side of a transmission belt and is used for detecting bending pieces existing on the transmission belt; and the indicator is in signal connection with the photoelectric sensor and can send an indication signal indicating that the bending pieces exist on the transmission belt to an operator. The photoelectric sensor detects whether the bending pieces exist on the transmission belt through a photoelectric path; and if the bending pieces are detected, a detection signal is transmitted to the indicator, and the indicator sends the indication signal indicating that the bending pieces exist on the transmission belt so as to alarm the operator to take out the bending pieces, so that the bending pieces are automatically detected. The operator only needs to take out the bending pieces; the fussy processes of manually picking up the bending pieces in the prior art are avoided; the detection precision is improved; and the labor cost is saved.

Owner:BAODING TIANWEI YINGLI NEW ENERGY RESOURCES

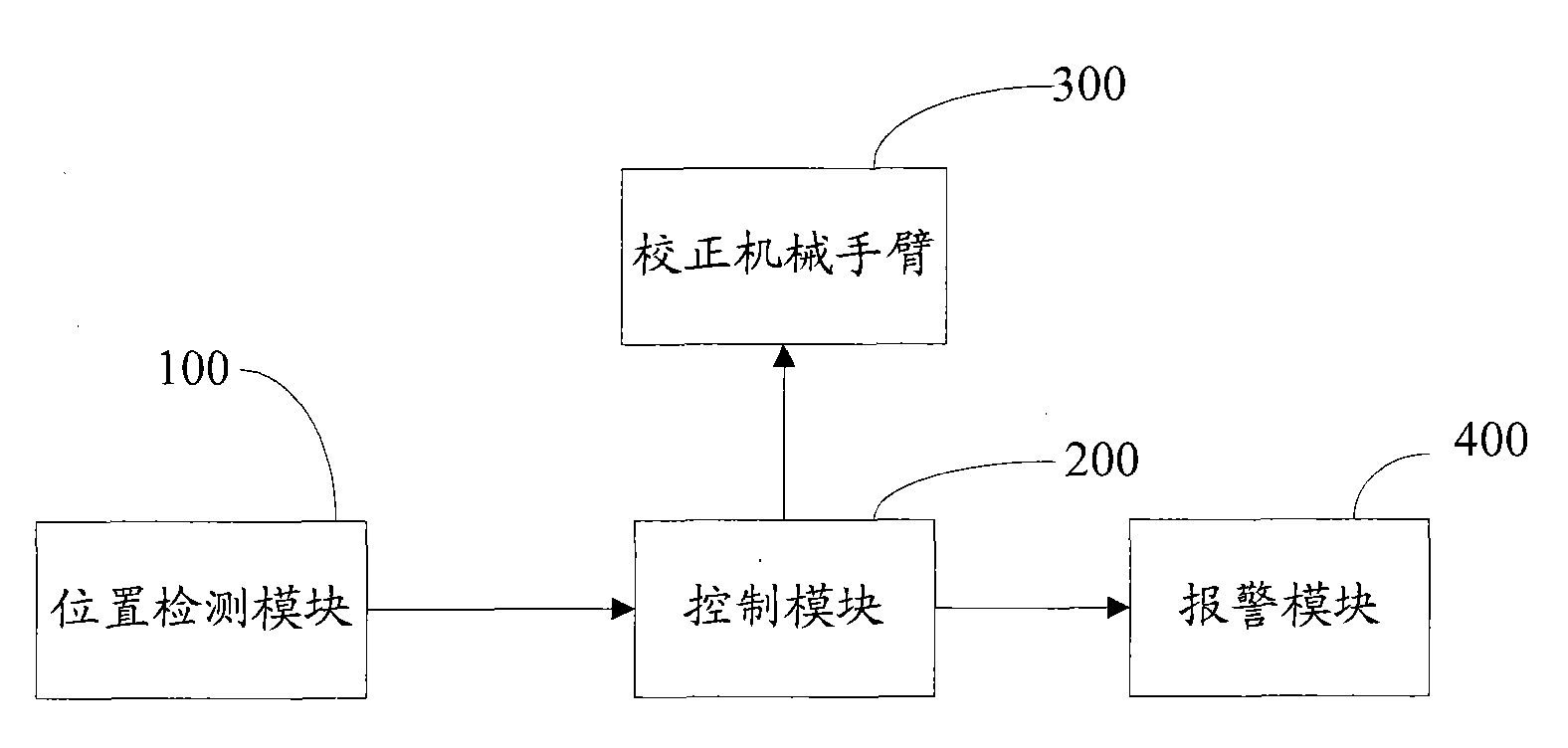

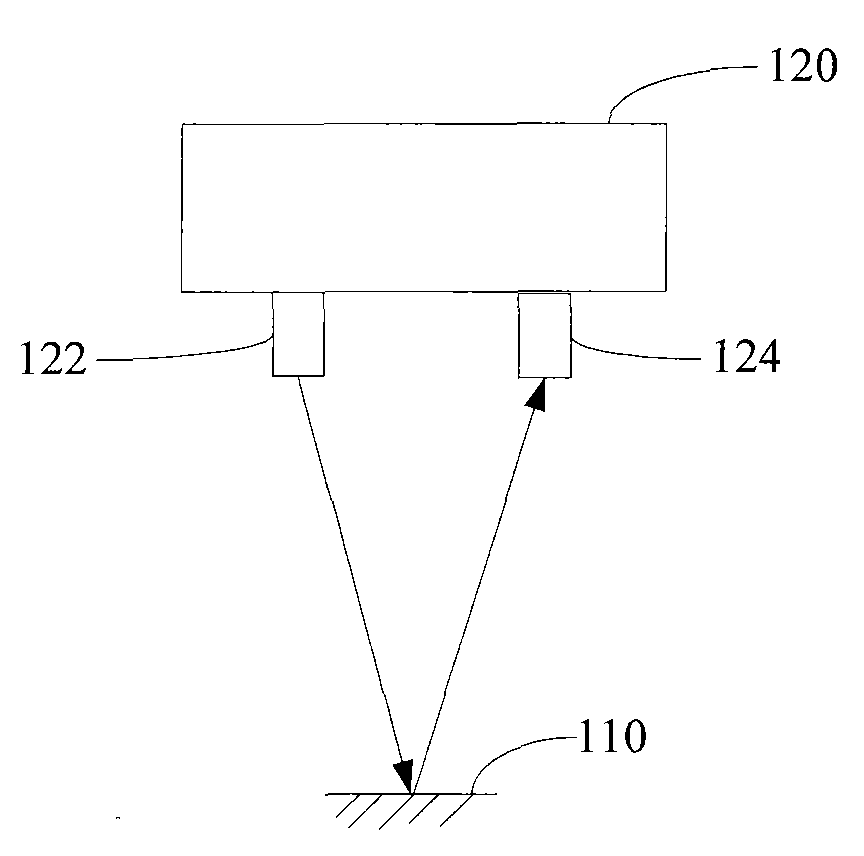

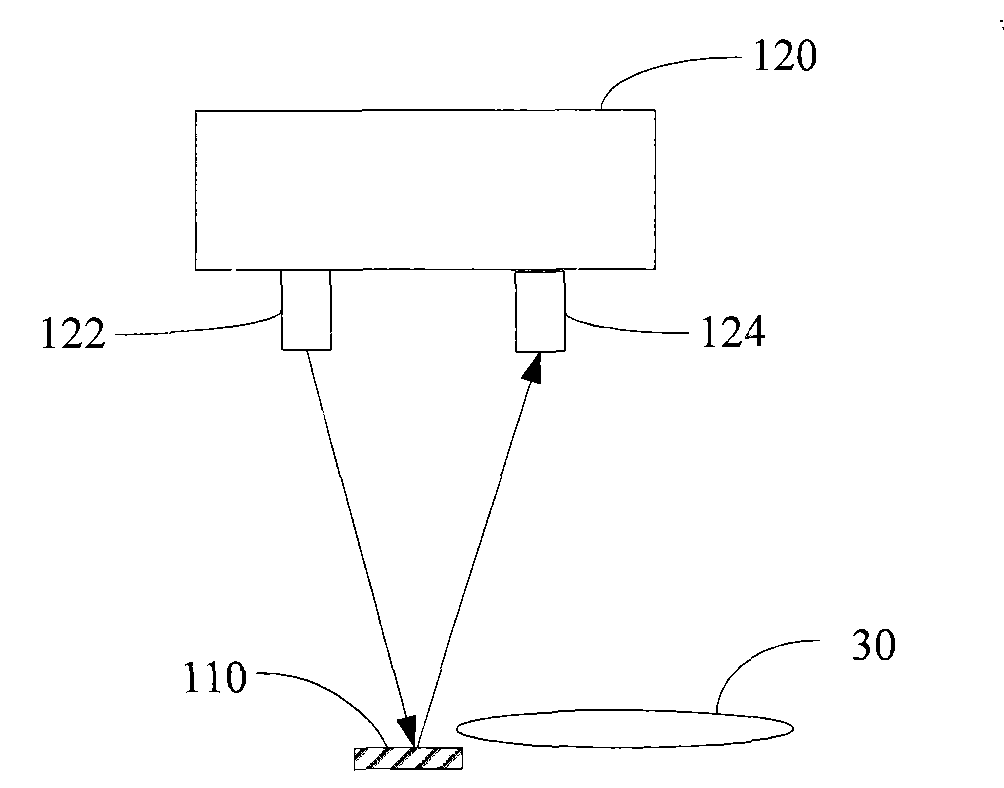

Wafer transfer method and device

InactiveCN102376608AAvoid FragmentsImprove stabilityConveyor partsEngineeringElectrical and Electronics engineering

The invention relates to a wafer transfer method and device. The method comprises the following steps of: detecting whether a wafer deviates from a designated position; and stopping transferring the wafer when the wafer deviates from the designated position. According to the invention, before the wafer is transferred, whether the wafer deviates from the designated position is detected, and when the wafer deviates from the designated position, a wafer storing and lifting device is stopped transferring the wafer, thereby avoiding the problem of wafer fragment because the wafer deviating from the designated position is continued to be transferred, further improving the stability and safety of wafer transfer, reducing the fragment percent and greatly saving cost.

Owner:CSMC TECH FAB1 +1

Grinding device for sapphire wafers and grinding method thereof

ActiveCN105215838AStir wellGood suspensionLapping machinesGrinding/polishing apparatusPeristaltic pumpPulp and paper industry

The invention discloses a grinding device for sapphire wafers. The grinding device for sapphire wafers comprises a pulp stock barrel, a peristaltic pump and a grinder, wherein a pulp stock trough is arranged on the grinder, and pulp stock enters into the grinder through the peristaltic pump and the pulp stock trough. The grinding method for the sapphire wafers comprises the following steps: 1, preparing the pulp stock: putting in raw materials by levels and layers; 2, controlling pulp stock flows: putting pulp stock accurately; 3, correcting the flatness of the surface of a grinding lower plate: repeatedly measuring by using a long gauge, a short gauge and a dial gauge, and correcting; 4, distributing powder on the surface of a grinding plate; and 5, grinding both sides of each wafer: firstly carrying out light pressing grinding. The grinding method provided by the invention is characterized in that raw material ratio of the pulp stock is optimized, the pulp stock supplying flow is more accurate, the conveying is more even, before normal grinding, light pressing grinding is performed firstly, the problem of wafer breakage during a grinding process can be prevented for the greatest possible, the wafer breakage rate is lowered, the merit factor of grinding is improved, the removing rate during grinding is stable, the problems of over grinding and low removing rate cannot be caused, and the efficiency is relatively high.

Owner:TUNGHSU GRP

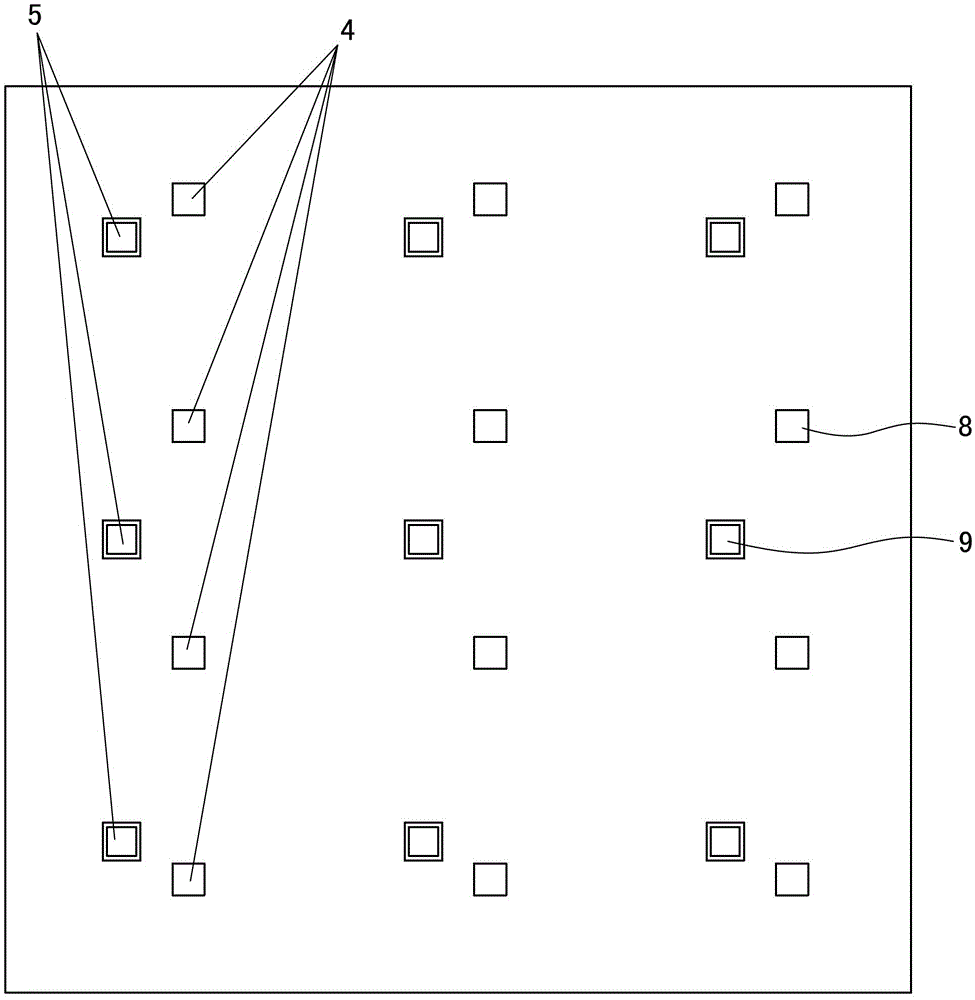

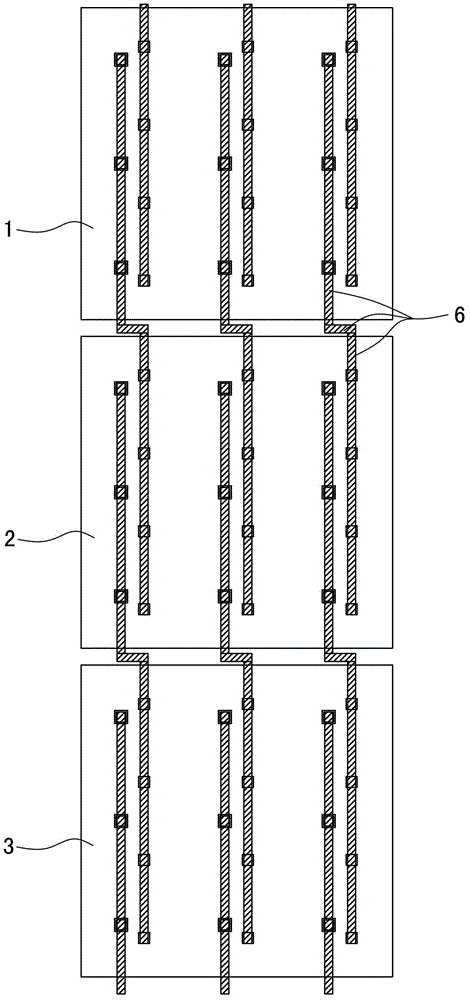

Back-contact solar cell module

InactiveCN102723380AImprove electrical performanceIncrease electric powerPhotovoltaic energy generationSemiconductor devicesElectricityInterconnection

The invention discloses a back-contact solar cell module. The back-contact solar cell module comprises a first cell, a second cell and a third cell which are connected in series and are adjacent, the back surface of each cell is provided with at least one group of back electrode array and at least one group of hole metal electrode array, the number of the back electrode array on each cell is equal to that of the hole metal electrode array, the electrode distribution structures of adjacent cells are the same, the hole metal electrode array of the first cell is directly connected with the back electrode array on the second cell which is adjacent to the first cell through a flow guidance piece in a broken line or curve way, and the hole metal electrode array of the second cell is directly connected with the back electrode array on the third cell which is adjacent to the second cell through the flow guidance piece in the broken line or curve way. According to the back-contact solar cell module disclosed by the invention, a confluence piece adopted by the traditional back-contact cell in interconnection is omitted, not only is a series welding step omitted and is the welding work amount greatly reduced, but also the electric performance and the total power of the back-contact solar cell module are increased, and the back-contact solar cell module has unexpected technical effect.

Owner:CSI CELLS CO LTD +1

Packaging technology for novel fingerprint lock device

ActiveCN104681454AEliminate the wiring stepsReduce thicknessSemiconductor/solid-state device manufacturingTotal thicknessThrough-hole technology

The invention discloses a packaging technology for a novel fingerprint lock device. The novel fingerprint lock device comprises a fingerprint recognition chip, a ceramic cover plate, a flexible PCB and a data processing chip. The packaging technology comprises the following steps: filling the surfaces of aluminum welding pads in blind holes of the fingerprint recognition chip with nickel metal layers to extend out of the upper surface and form bulges so as to form bonding pad thickening parts; coating the upper surface, having the bonding pad thickening parts, of the fingerprint recognition chip with a temporary bonding adhesive layer; bonding a glass supporting plate with the surface, having the bonding pad thickening parts, of the fingerprint recognition chip through the temporary bonding adhesive layer; thinning the lower surface opposite to the upper surface of the fingerprint recognition chip so as to reduce the thickness of the fingerprint recognition chip to about 150-300 microns; sequentially forming a first tapered blind hole, a second tapered blind hole and third tapered blind holes in the lower surface of the fingerprint recognition chip by etching gradually. After wafer-level chip packaging technology and a silicon through hole technology are integrated, a set of novel process is formed, so that the thickness is reduced, the total thickness of a product is greatly reduced and the reliability of the product is greatly improved.

Owner:苏州科阳半导体有限公司

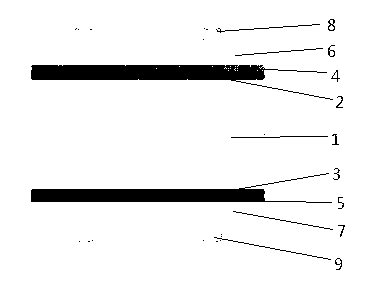

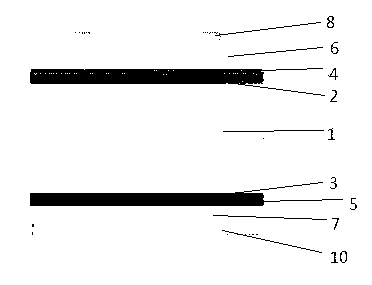

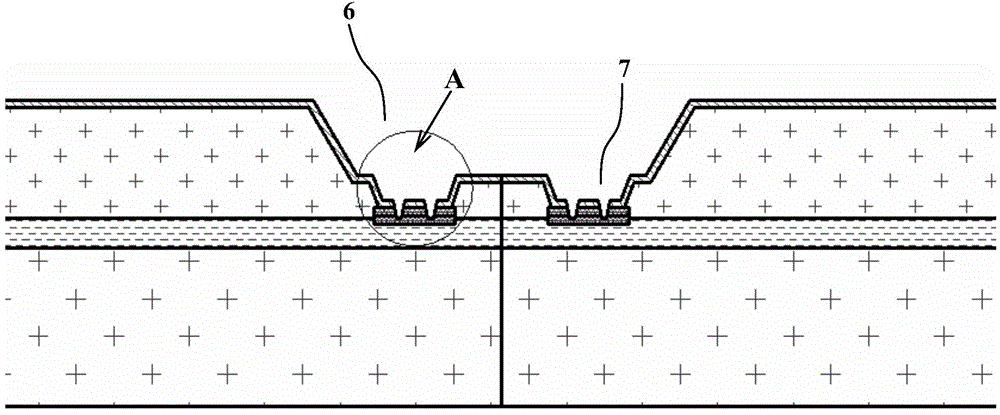

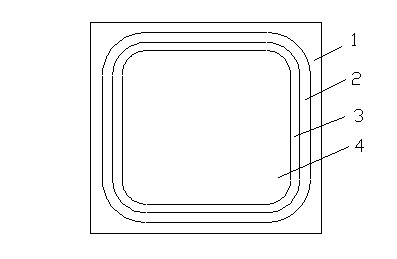

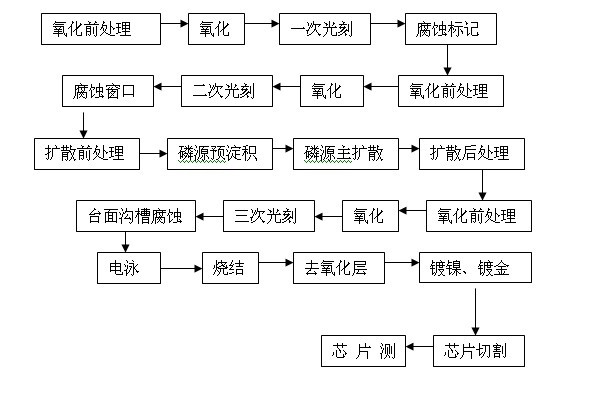

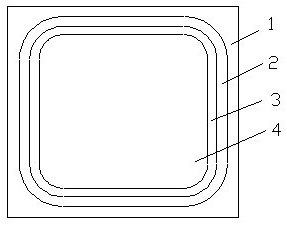

Chip for two-way voltage regulator diode DB3 and manufacturing technique thereof

ActiveCN102082093AImprove trigger abilityImproved pressure stabilityPhotomechanical apparatusSemiconductor/solid-state device manufacturingEtchingFragmentation rate

The invention relates to a manufacturing technique of a chip for a two-way voltage regulator diode DB3, wherein the two-way voltage regulator diode DB3 is a symmetrical diode with the structure of N<+> PN<+>. The resilience voltage is increased due to the adoption of a triple photolithographic process, the trigger capacity of the two-way voltage regulator diode is improved; due to the application of shallow mesa or trench etching, the fragmentation rate is reduced; and glass is passivated due to the adoption of an electrophoretic process, the withstand voltage stability and reliability of the two-way voltage regulator diode are improved. The manufacture technique of the chip for the two-way voltage regulator diode has the advantages of improving the breakdown voltage stability of the two-way voltage regulator diode DB3, enhancing the trigger capacity of the diode, reducing the high-temperature power consumption, prolonging the service life of the diode, and simultaneously improving the qualification rate.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com