Patents

Literature

2941results about How to "Stress relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing carbon/carbon composite material antioxidation coating layer

InactiveCN101565328AIncreased anti-oxidation timeStress reliefCarbon compositesMaterials preparation

The invention discloses a method for preparing a carbon / carbon composite material antioxidation coating layer. The processed C / C composite material packet is buried in powder lot and put in a graphite crucible and processed for 1 to 3 hours at a temperature of between 1,800 and 2,200 DEG C; MoSi2 powder is sprayed on the surface of the C / C composite material with a SiC transition layer through supersonic plasma spraying equipment; the C / C composite material prepared with the SiC / MoSi2 coating layer is put to a high-temperature furnace and is subjected to heat treatment for 2 to 6 hours at a temperature of between 1,200 and 1,400 DEG C to remove the residual heat stress in the MoSi2 coating layer. The SiC transition coating layer prepared by an embedding method relieves thermal expansion coefficients of a C / C composite material matrix and the MoSi2 coating layer of the outer layer; and subsequently, a C / C composite material preparation piece is subjected to heat treatment to remove the stress of the coating layer so that the antioxidation time of the C / C composite material in static air at a temperature of more than 1,650 DEG C is improved from 200 to 300 to 400 hours compared with the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

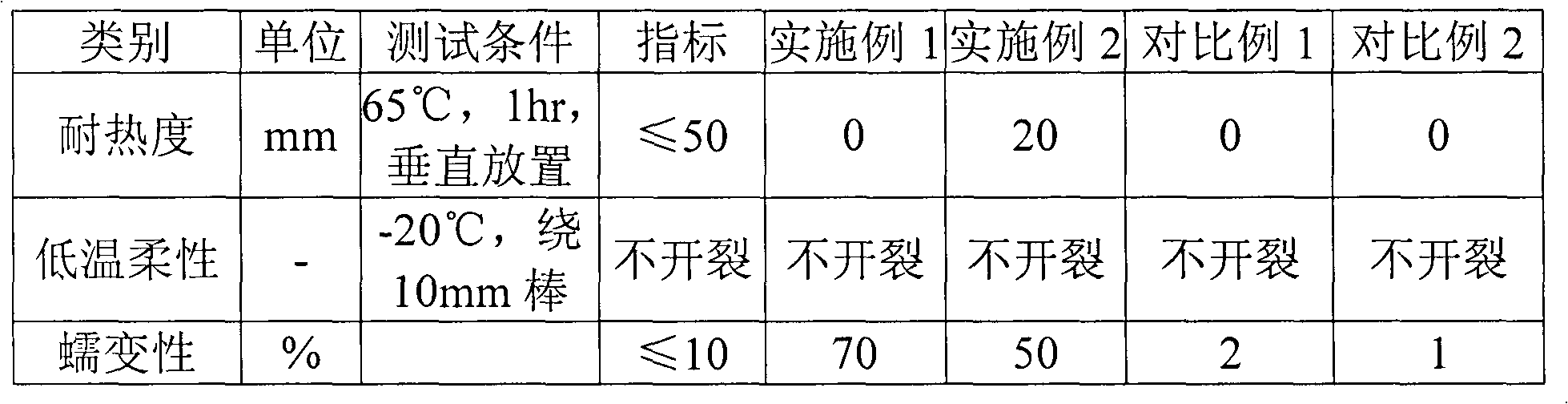

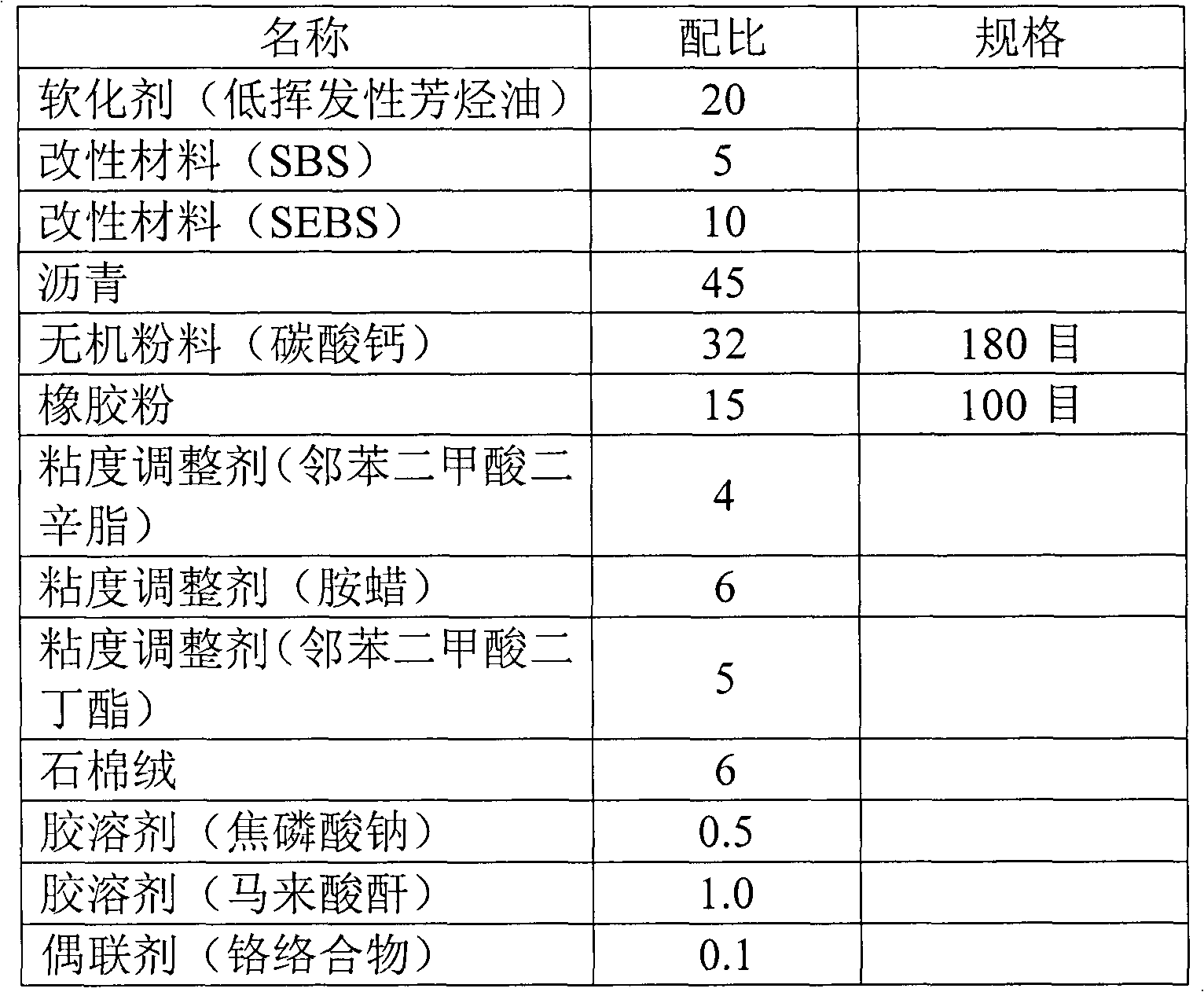

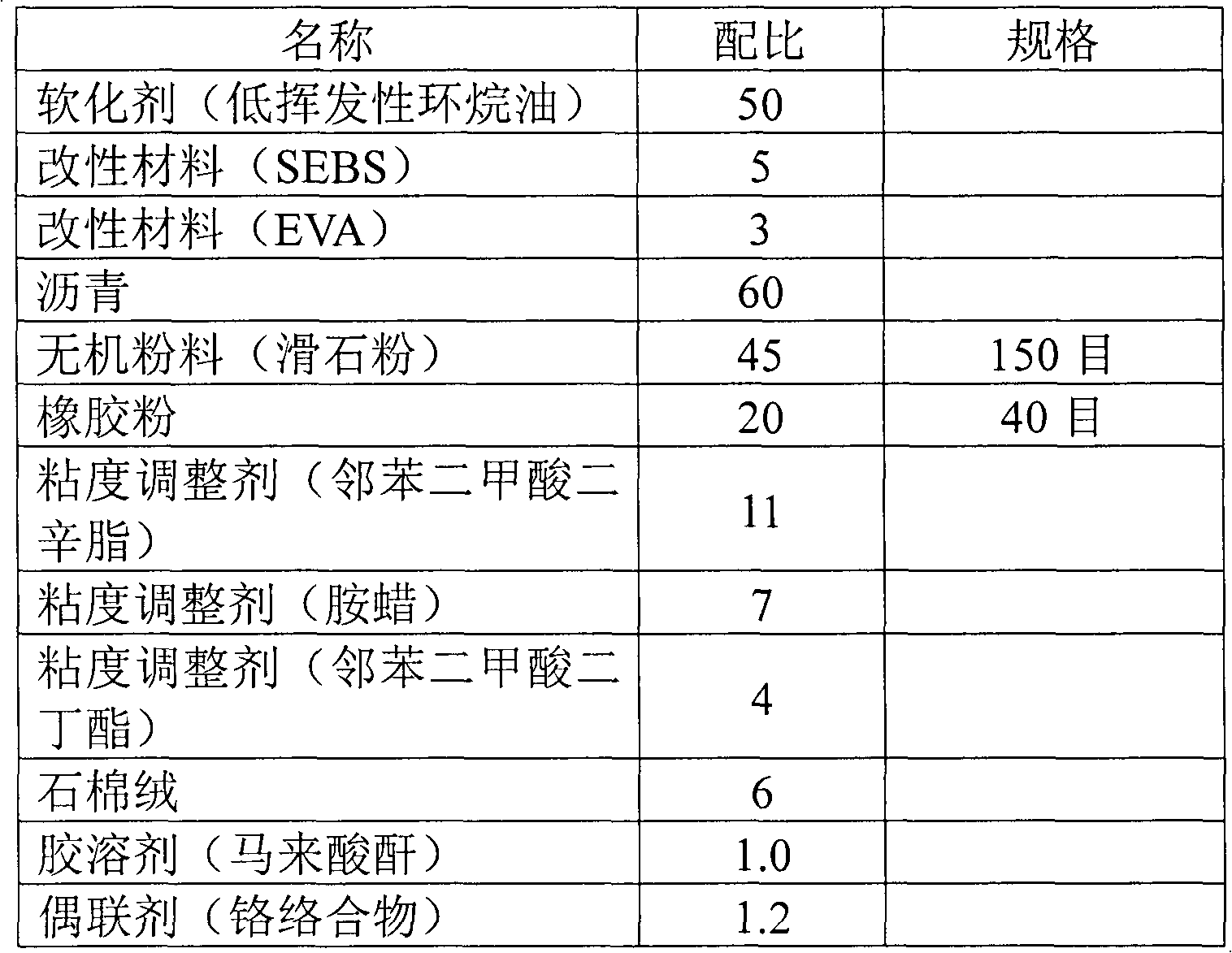

Modified asphalt composition with creeping characteristic and preparation method thereof

InactiveCN102020859AAvoid rapid agingExtended service lifeBuilding insulationsBituminous waterproofingMaterials science

The invention provides a modified asphalt composition with a creeping characteristic, which comprises the following components in parts by weight: 15-60 parts of asphalt, 3-15 parts of modifying material, 5-30 parts of rubber powder, 15-60 parts of softening agent, 15-60 parts of inorganic powder, 3-25 parts of viscosity regulating agent, 0.3-1.5 parts of peptizing agent and 0.1-2 parts of coupling agent. A preparation method of the modified asphalt composition comprises the following steps of: adding the softening agent into a reaction kettle, heating to 170 to 200 DEG C, adding the modifying material, agitating, adding the asphalt and the rubber powder, and agitating for 1-2 h to obtain an intermediate raw material; levigating the intermediate raw material to 150-250 meshes, and putting back to the reaction kettle; and finally, adding the inorganic powder, the viscosity regulating agent, the peptizing agent and the coupling agent into the reaction kettle, agitating and dispersing uniformly. The modified asphalt composition has the characteristics of excellent water-proof performance, strong binding capability and continuous binding capability, large elongation percentage and good low-temperature flexibility.

Owner:ZHEJIANG WOPUMAN HIGH NEW MATERIALS

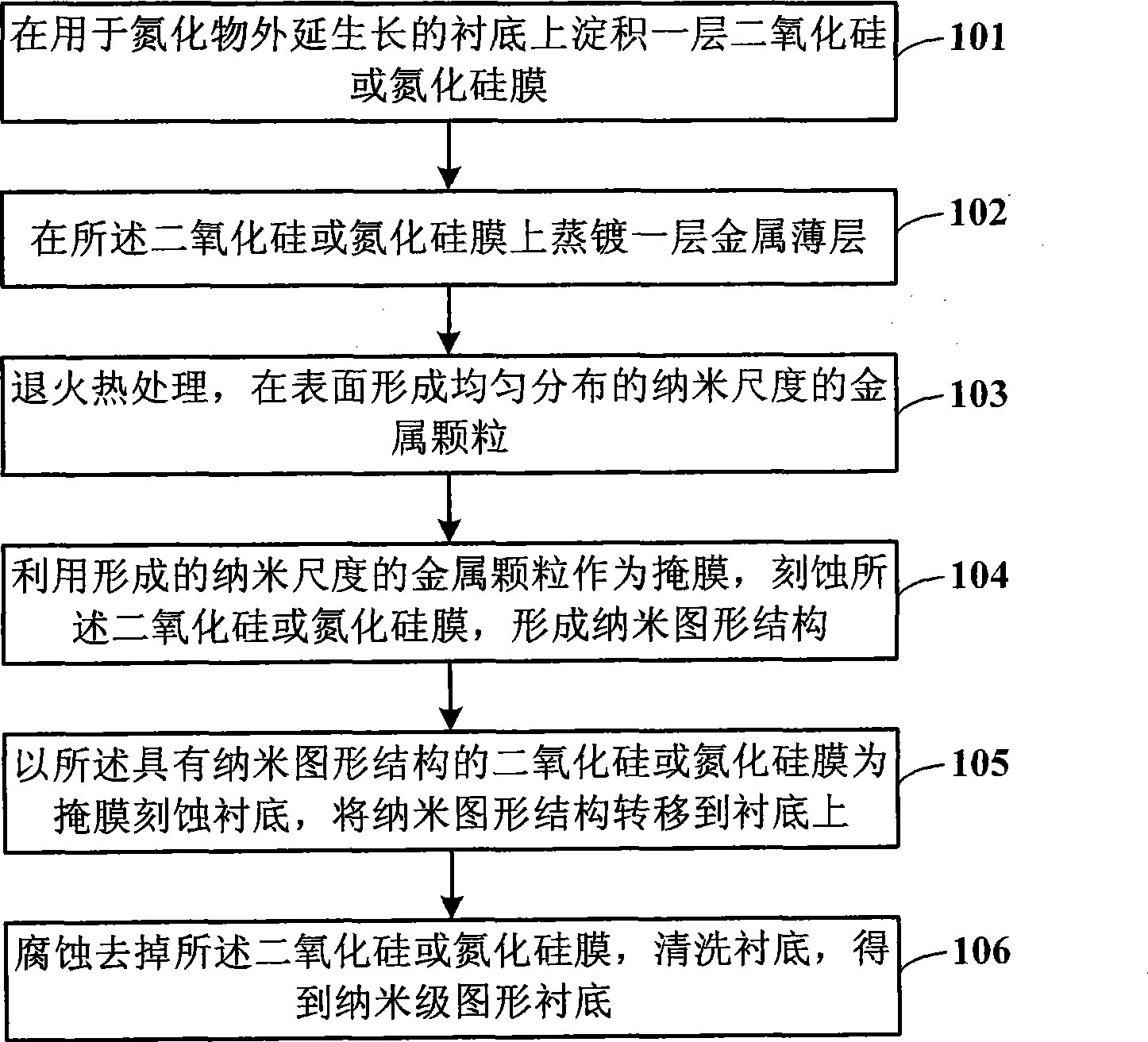

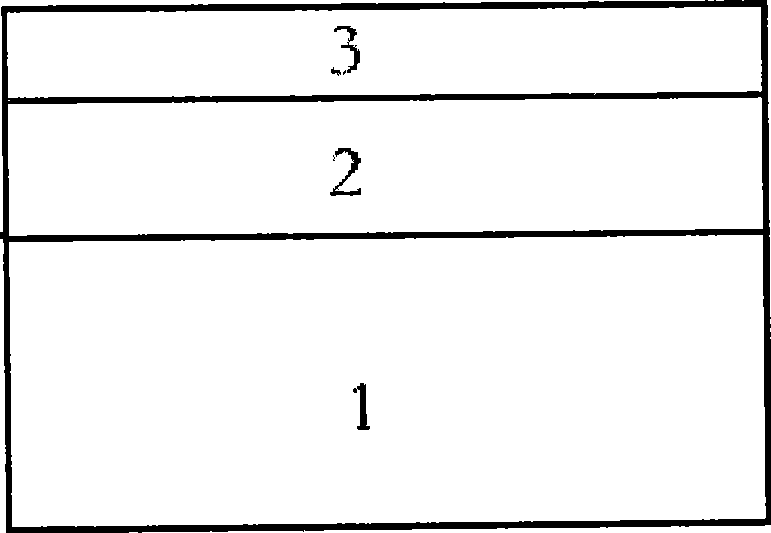

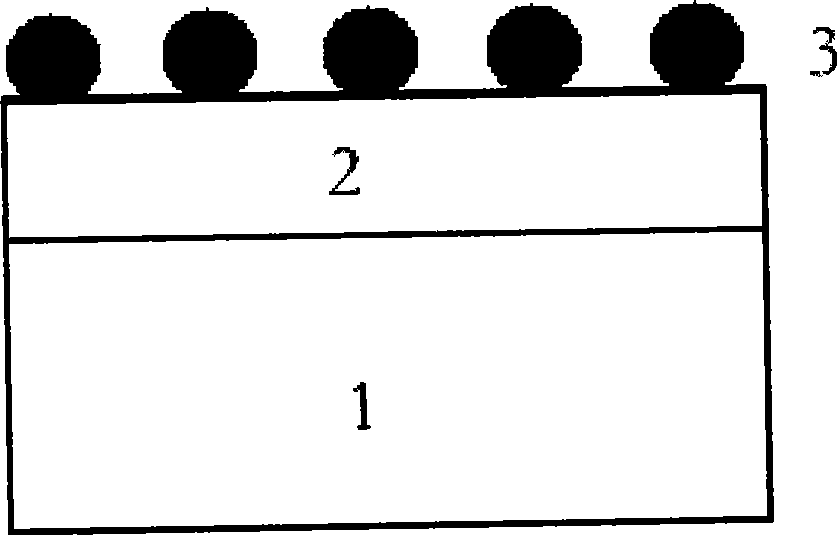

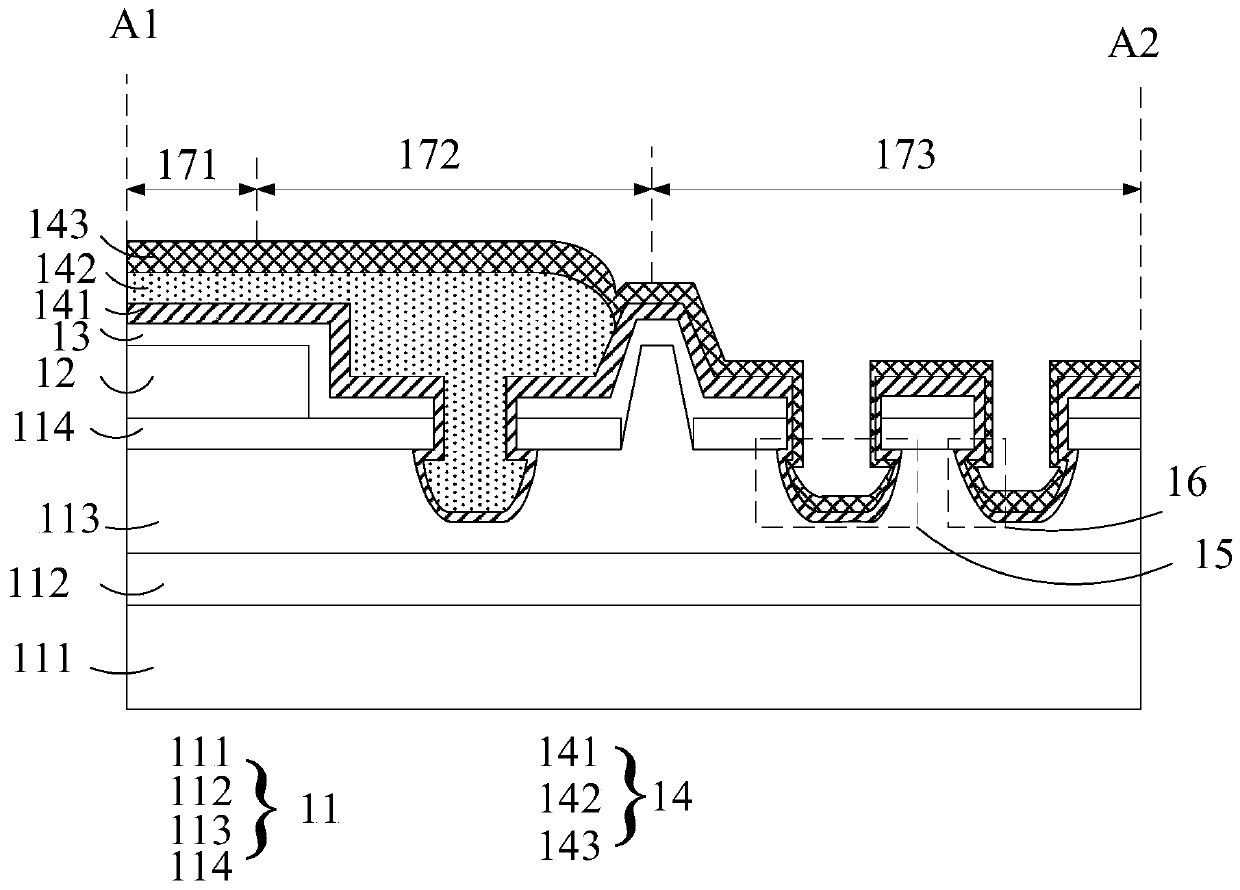

Method for preparing nano-scale pattern substrate for nitride epitaxial growth

InactiveCN101373714AReduce dislocation densityImprove crystal qualitySemiconductor/solid-state device manufacturingThin metalEpitaxial material

The invention relates to the semiconductor technical field and discloses a method for manufacturing a nanometer pattern substrate used for the epitaxial growth of a nitride. The method comprises the followings steps: settling a layer of silicon dioxide or silicon nitride film on a substrate used for the epitaxial growth of the nitride; the silicon dioxide or silicon nitride film is coated with a layer of thin metal layer through vapor deposition; conducting the annealing heat treatment, and forming uniformly distributed nano-scaled metal particles; utilizing the formed nano-scaled metal particles as masks to etch the silicon dioxide or silicon nitride film so as to form a nanometer pattern structure; using the silicon dioxide or silicon nitride film with the nanometer pattern structure as a mask etching substrate to transfer the nanometer pattern structure of the substrate; and etching to remove the silicon dioxide or silicon nitride film, cleaning the substrate, and obtaining the nanometer pattern substrate. The invention can reduce the dislocation density in the epitaxial layer of the nitride, improve the crystal quality of epitaxial materials, improve the performance of devices and help to realize the scaled and large area manufacture.

Owner:UNILUMIN GRP

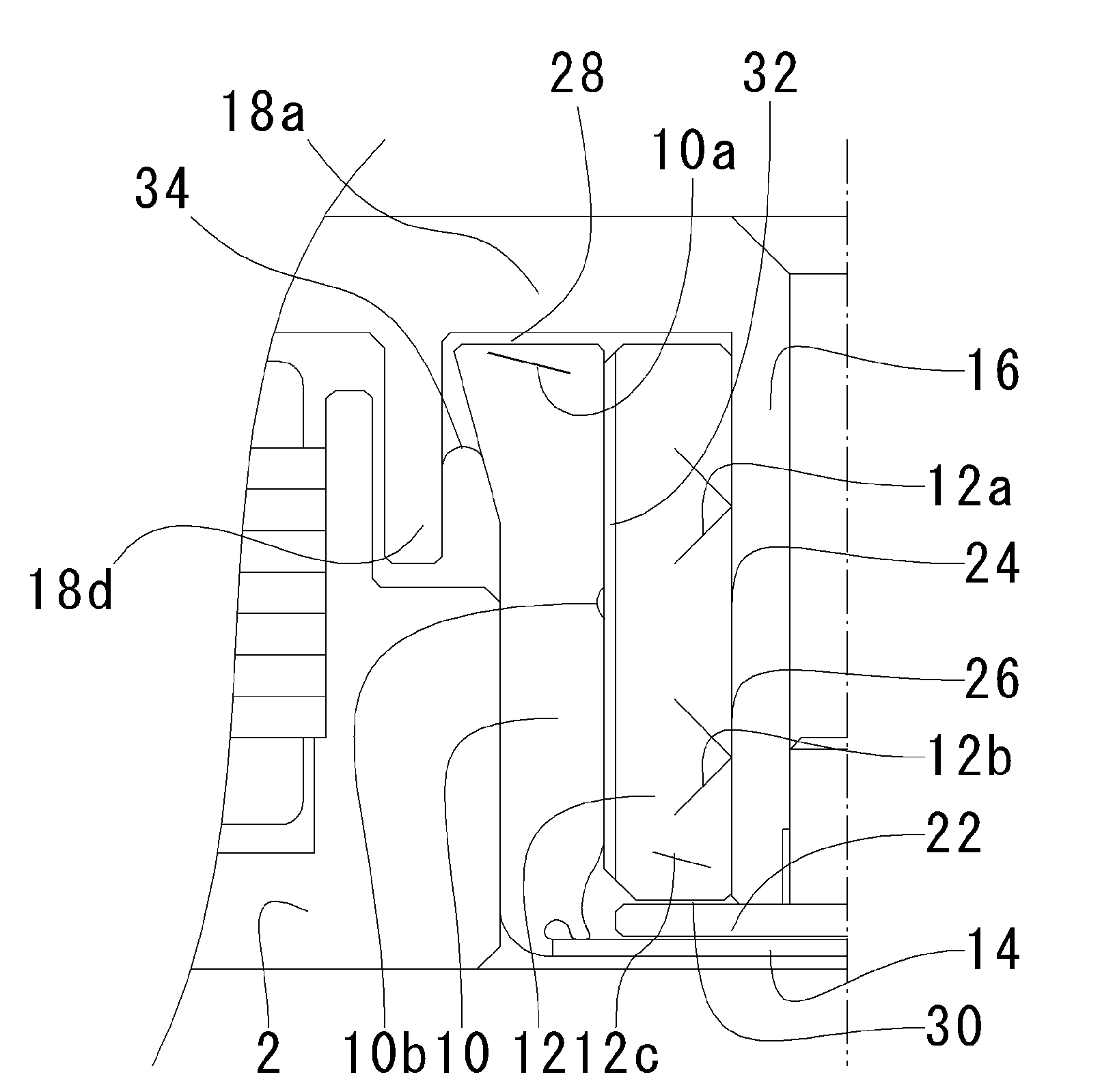

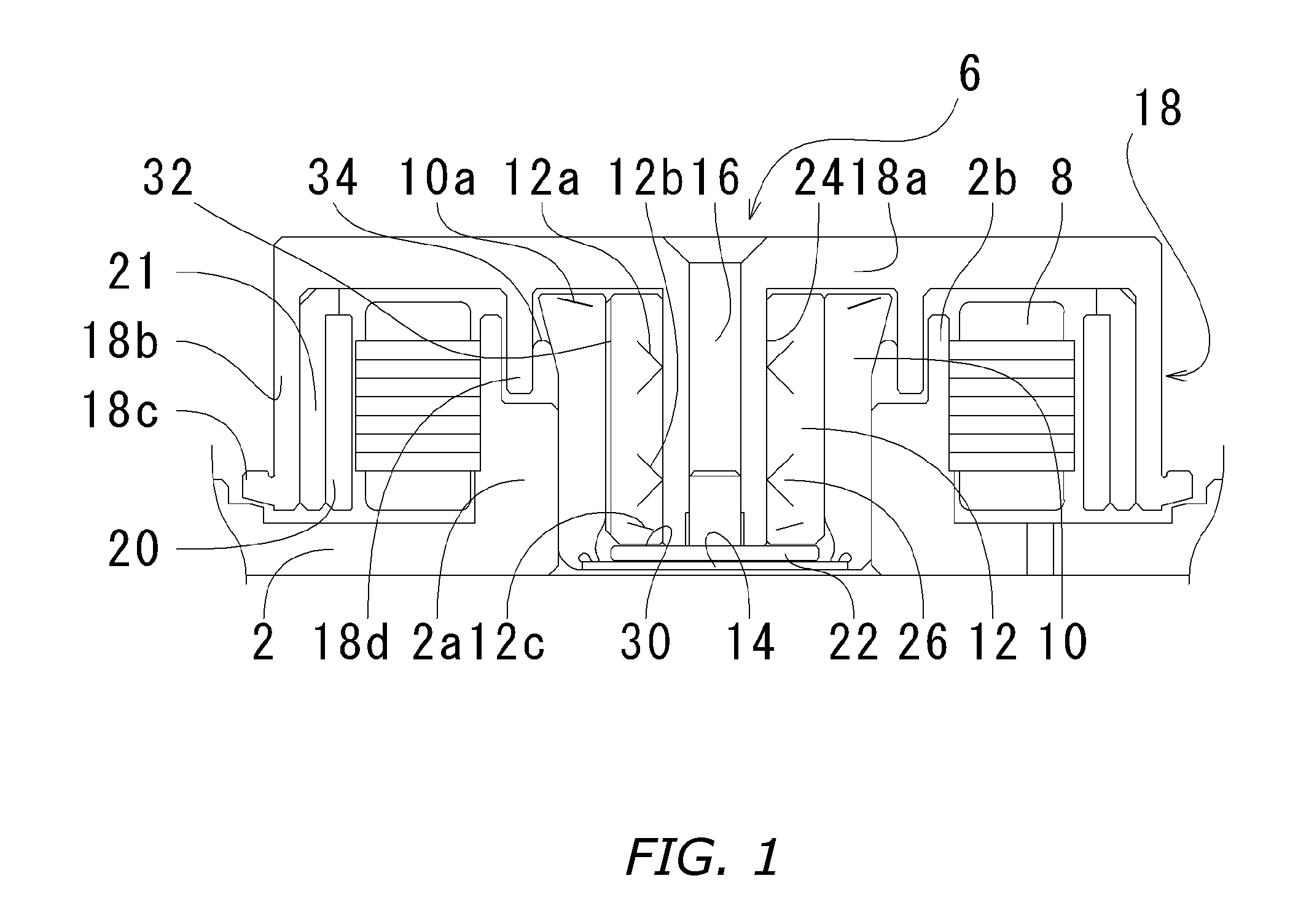

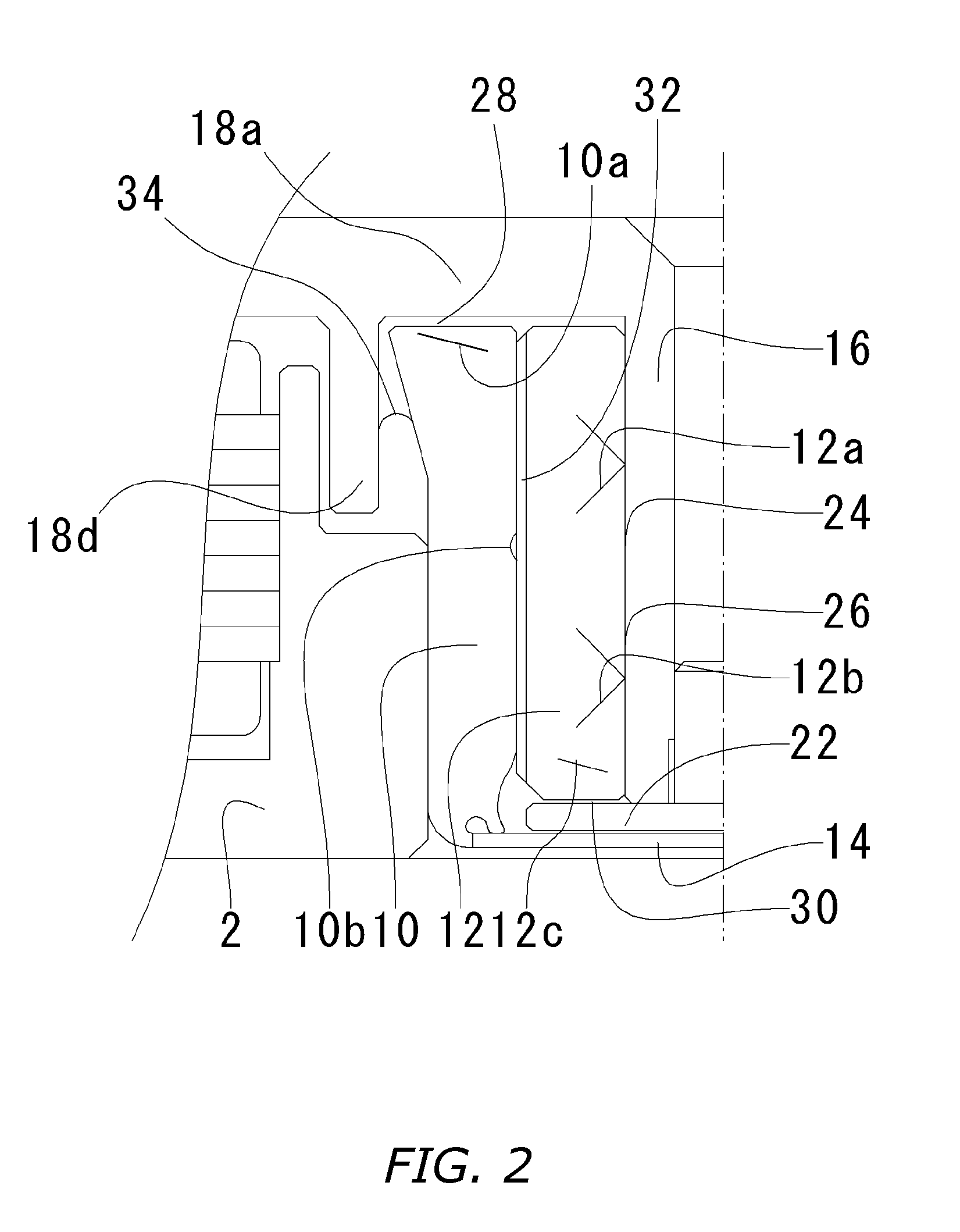

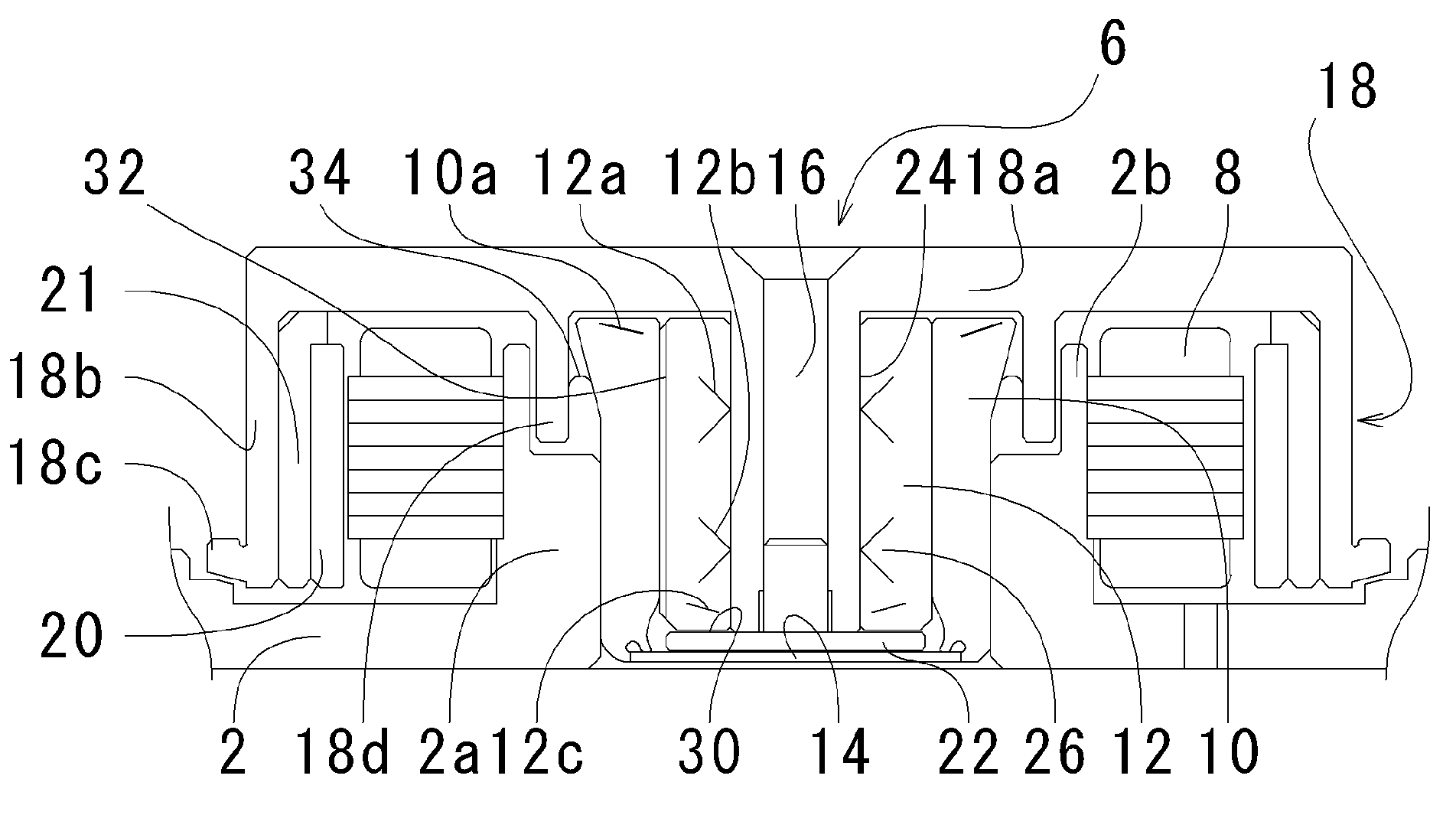

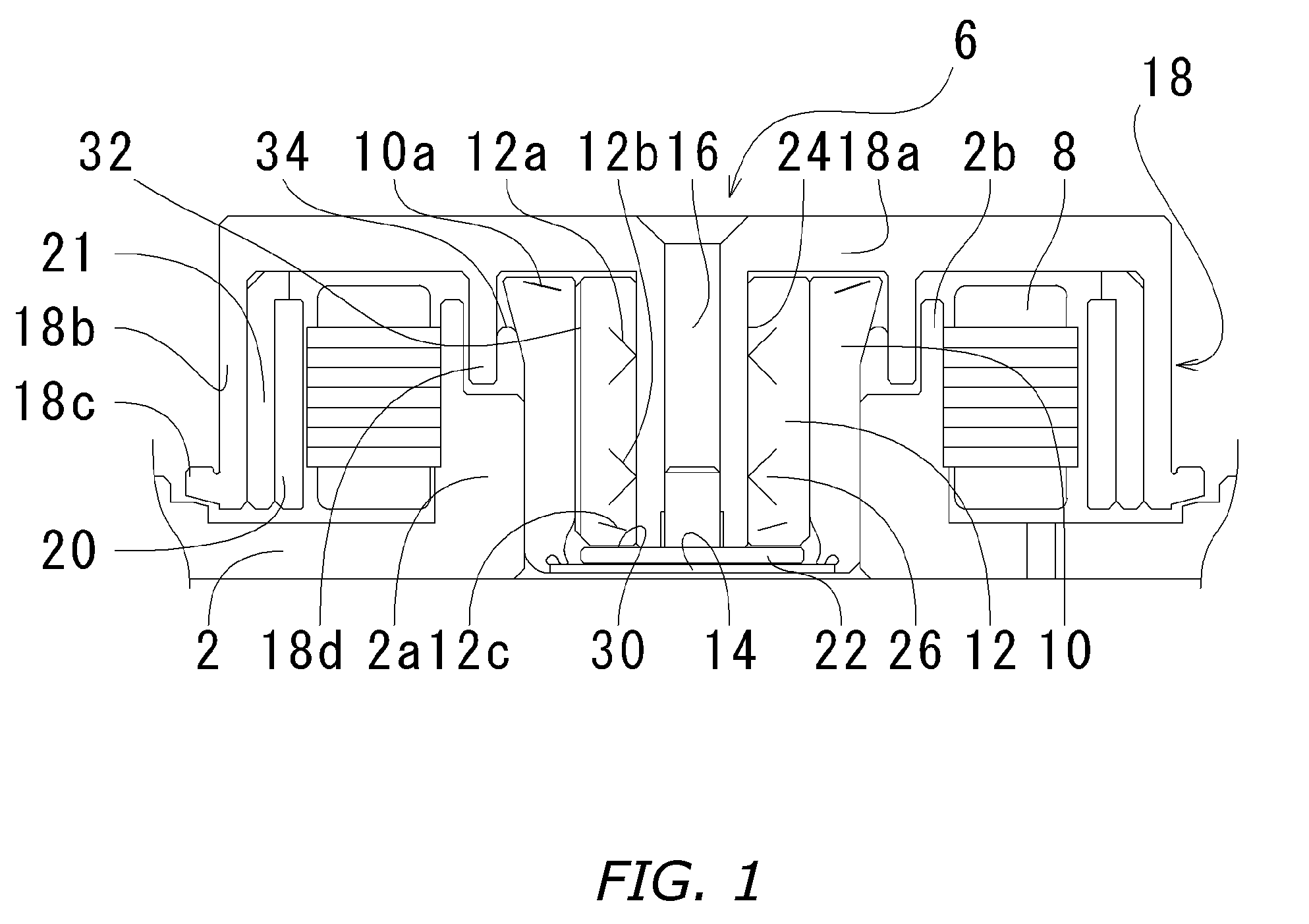

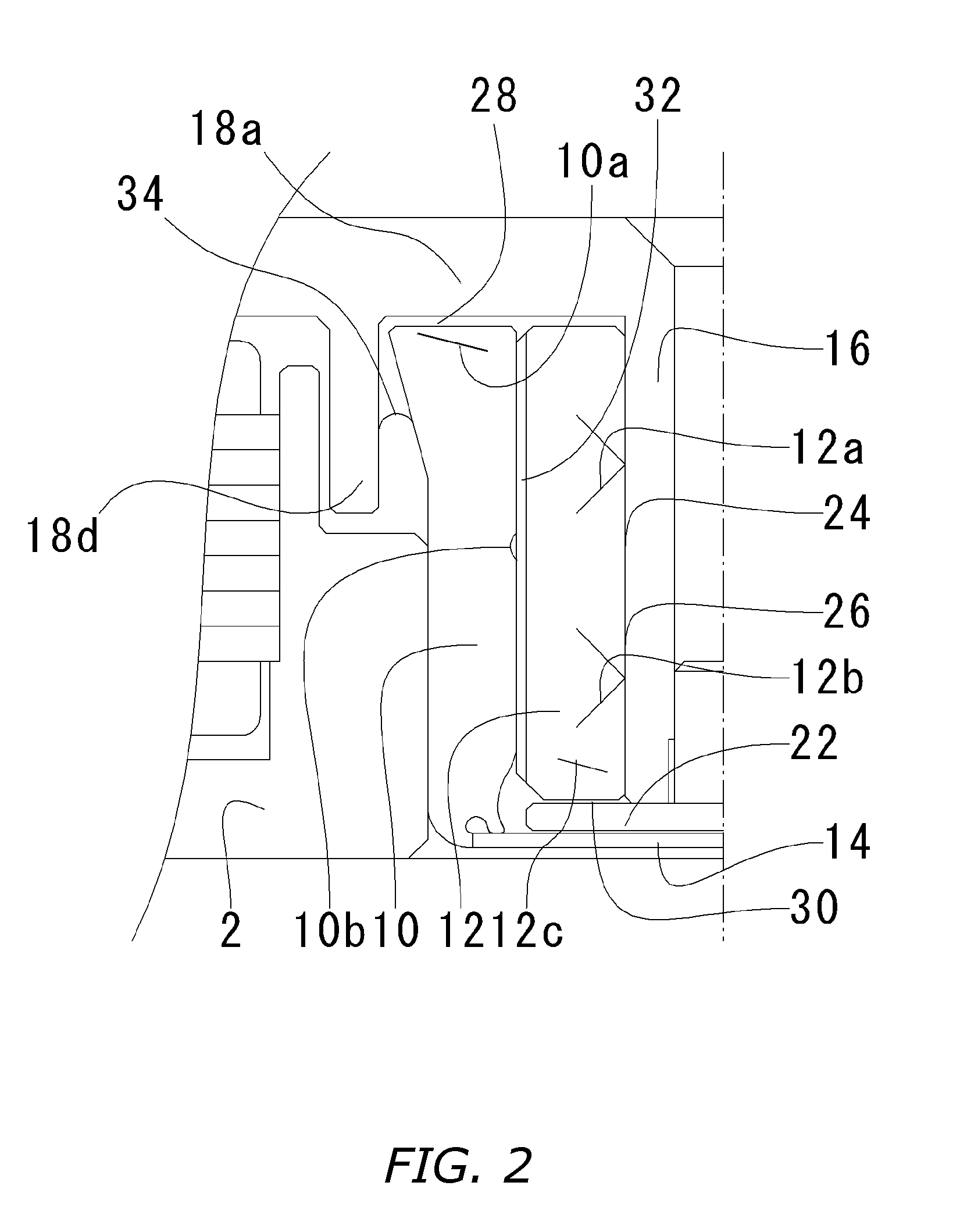

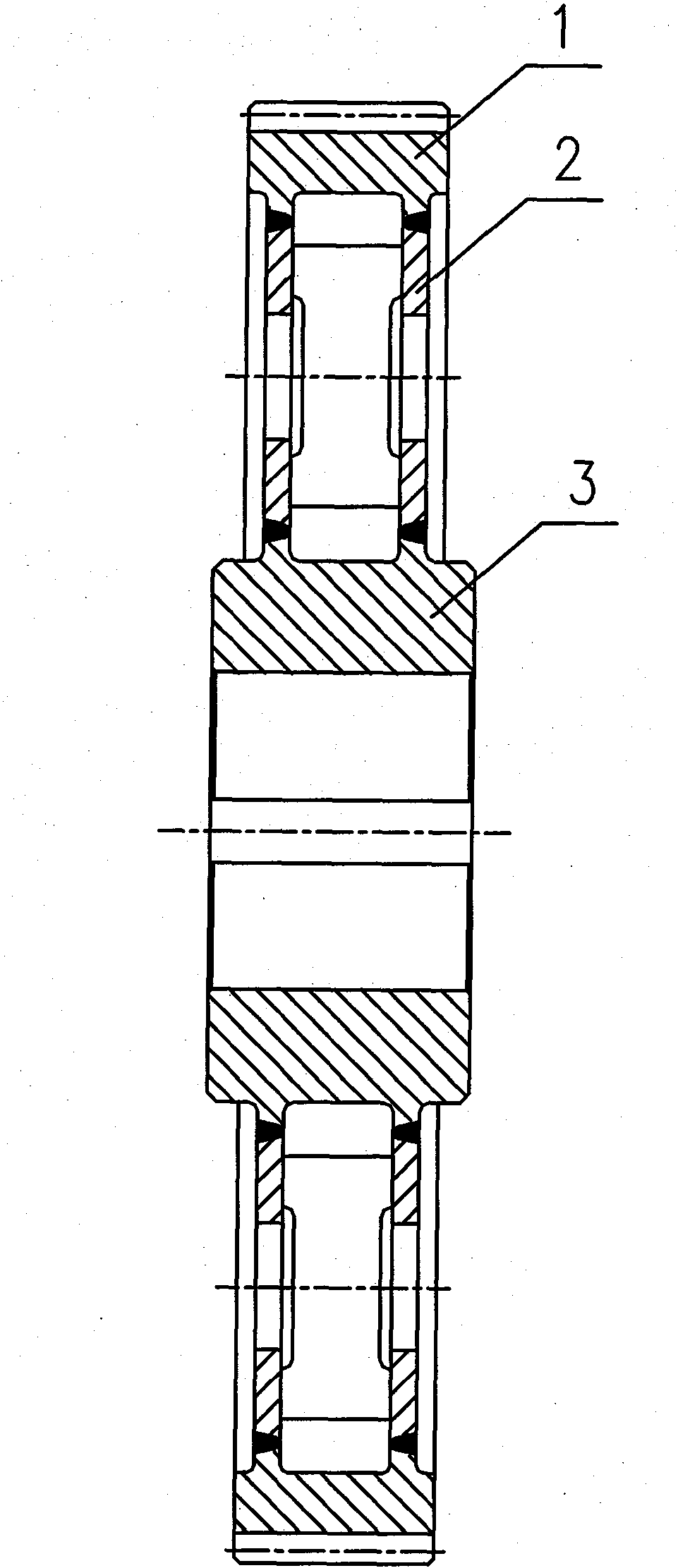

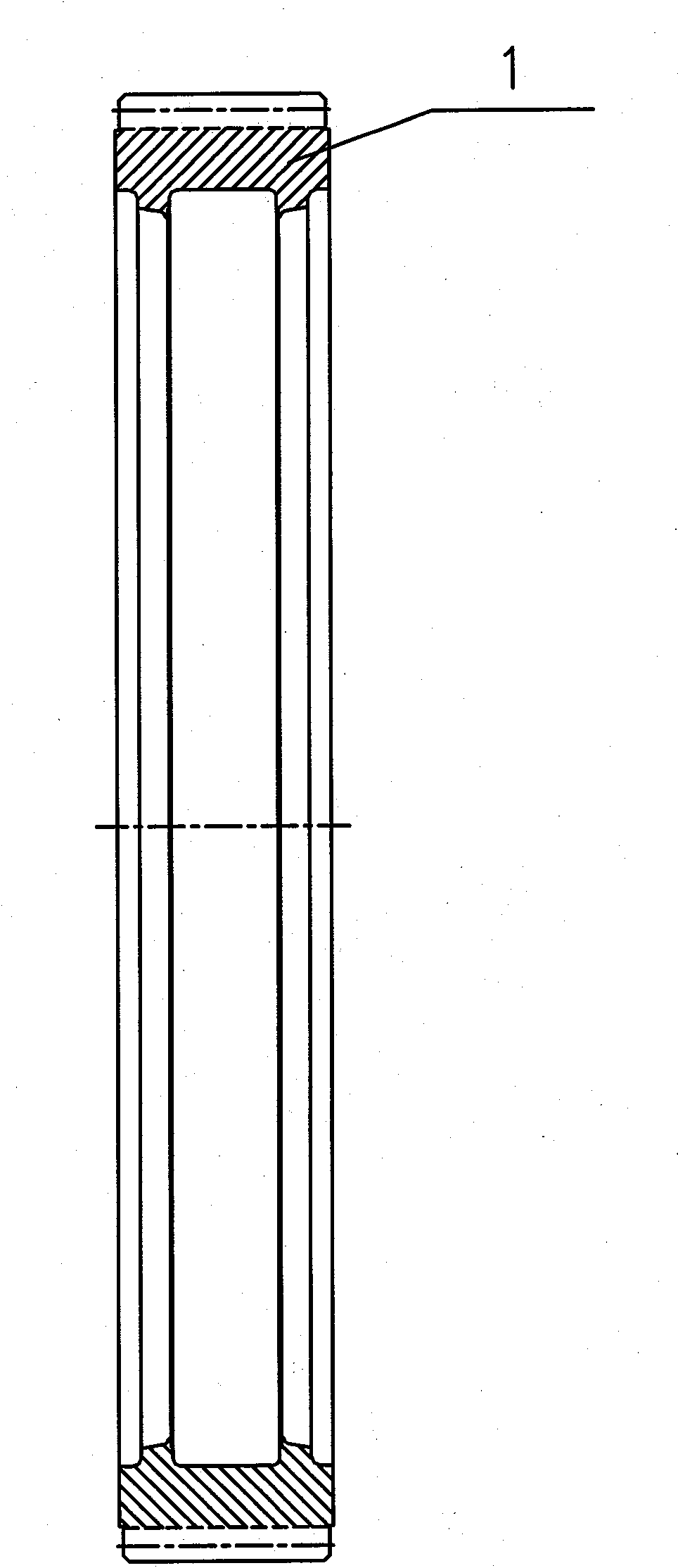

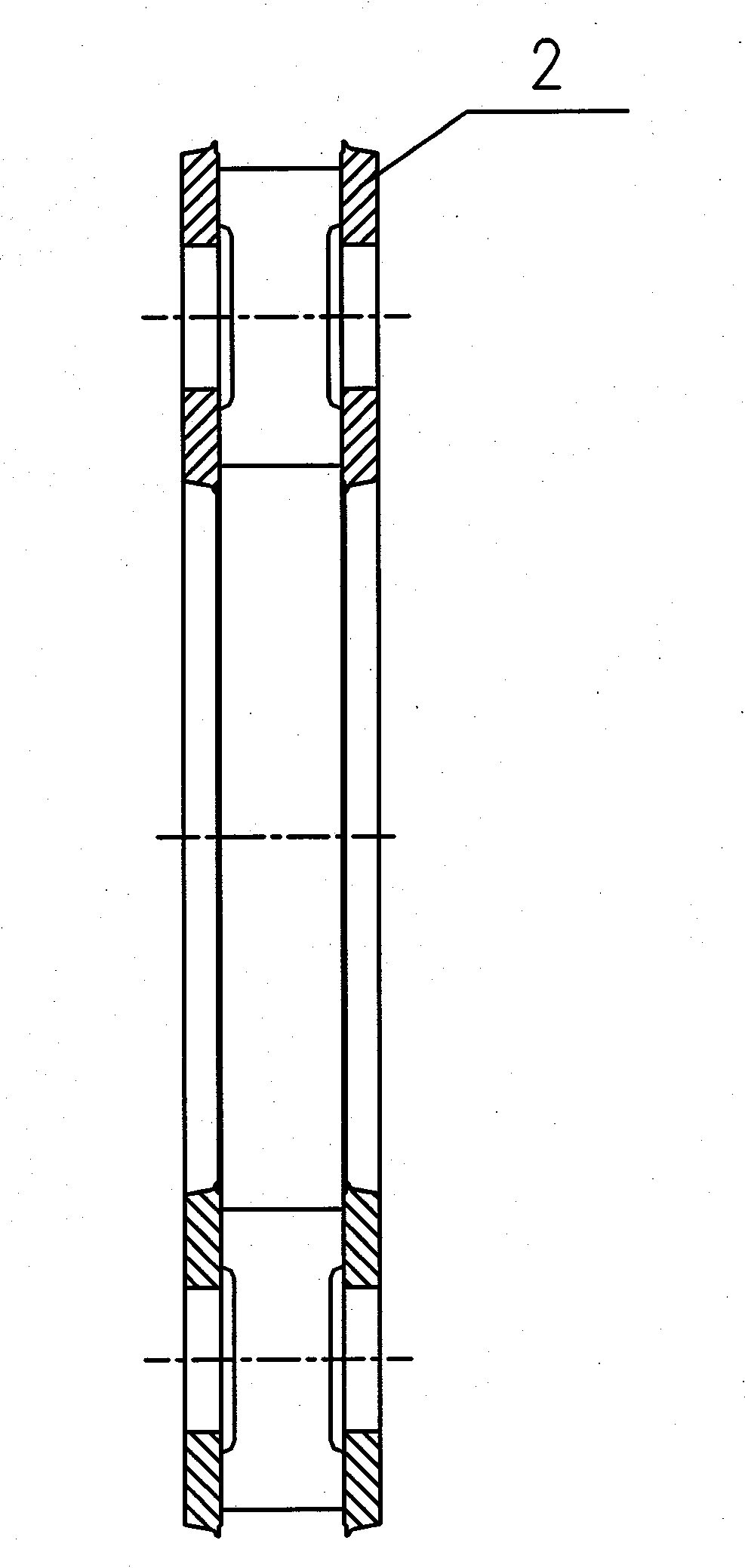

Fluid-Dynamic-Pressure Bearing, Spindle Motor Furnished with the Fluid-Dynamic-Pressure Bearing, Method of Manufacturing Rotor Assembly Applied in the Spindle Motor, and Recording-Disk Drive Furnished with the Spindle Motor

ActiveUS20050025405A1Reduced dimensionStress reliefShaftsRecord information storageMicro gapDynamic pressure

Fluid-dynamic-pressure bearing furnished with a shaft, a top plate fixed to an upper portion of the shaft, a thrust plate fixed to a lower portion of the shaft, a sleeve, and a cuplike bearing housing that along its inner periphery retains the sleeve. A lubricating-fluid-filled continuous micro-gap is formed in between the shaft and the sleeve and the top plate and the sleeve. Radial bearing sections are formed in between the shaft cylindrical outer surface and the sleeve cylindrical inner surface. An upper thrust bearing section is formed in between the undersurface of the top plate and the top-edge face of the bearing housing. A lower thrust bearing section formed in between the bottom margin of the sleeve and the top margin of the thrust plate. The bearing sections are each provided with dynamic-pressure-generating grooves for inducing dynamic pressure in the lubricating fluid when the shaft or sleeve spins.

Owner:NIDEC CORP

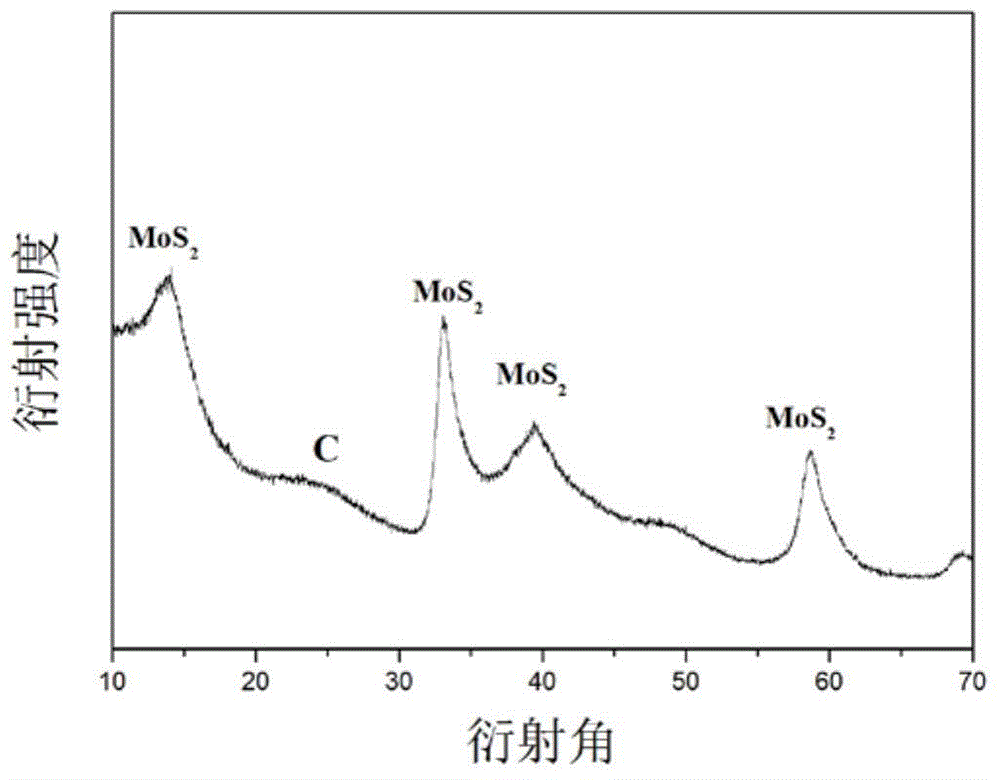

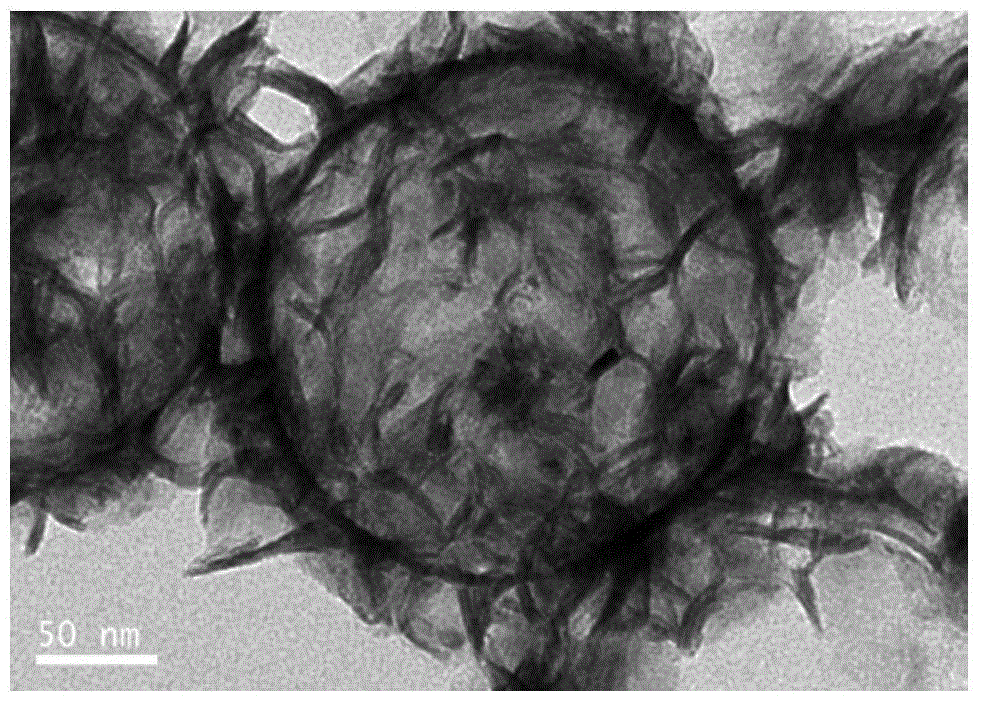

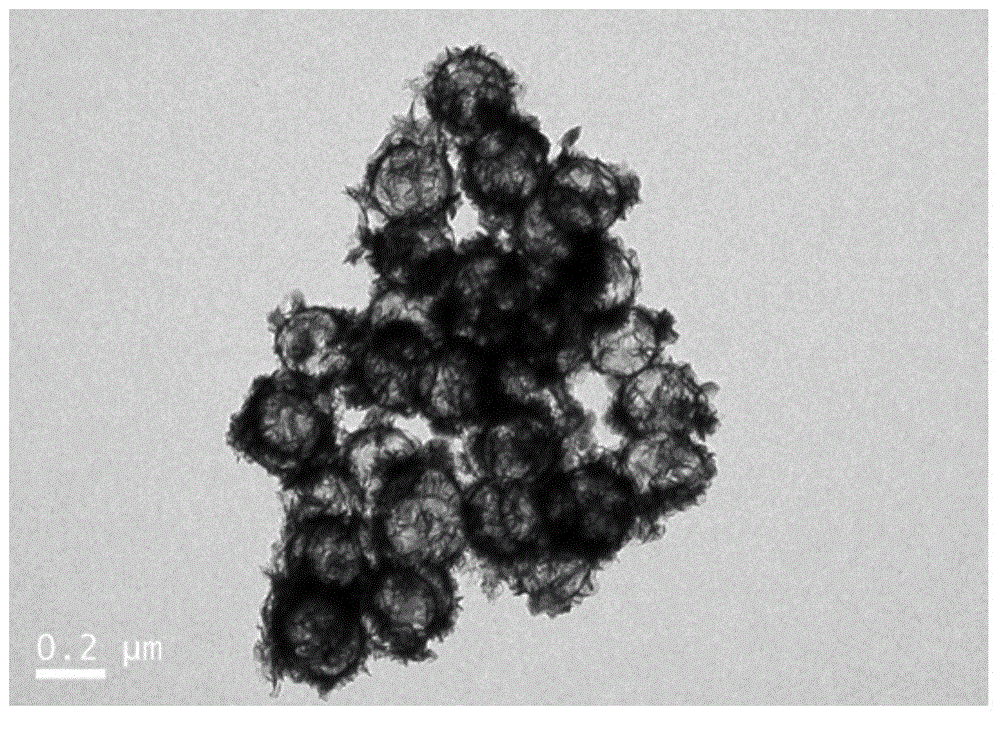

Molybdenum disulfide/carbon composite material and preparation method thereof

InactiveCN104934602AImprove poor conductivityNot easy to reuniteCell electrodesSecondary cellsCarbon compositesCarbonization

The invention discloses a molybdenum disulfide / carbon composite material. The molybdenum disulfide / carbon composite material comprises a molybdenum disulfide layer and a carbon hollow ball, wherein the molybdenum disulfide layer is positioned outside the carbon hollow ball; and the carbon hollow ball has a hollow structure. The invention also discloses a preparation method of the molybdenum disulfide / carbon composite material. The preparation method comprises the following steps of using amino modified silica spheres as a template; wrapping the template by pyrolyzation of an organic carbon source; performing thermal reaction on the template and ammonium tetrathiomolybdate through solvent; performing high-temperature carbonization in an inert atmosphere; and removing the silicon oxide template to obtain the molybdenum disulfide / carbon composite material. The lithium-intercalation capacity of the molybdenum disulfide / carbon composite material is 1467mAh / g for the first time, and the specific capacity of the molybdenum disulfide / carbon composite material can be kept at 733mAh / g after 30 times of repeated charging and discharging cycles.

Owner:SHANGHAI JIAO TONG UNIV

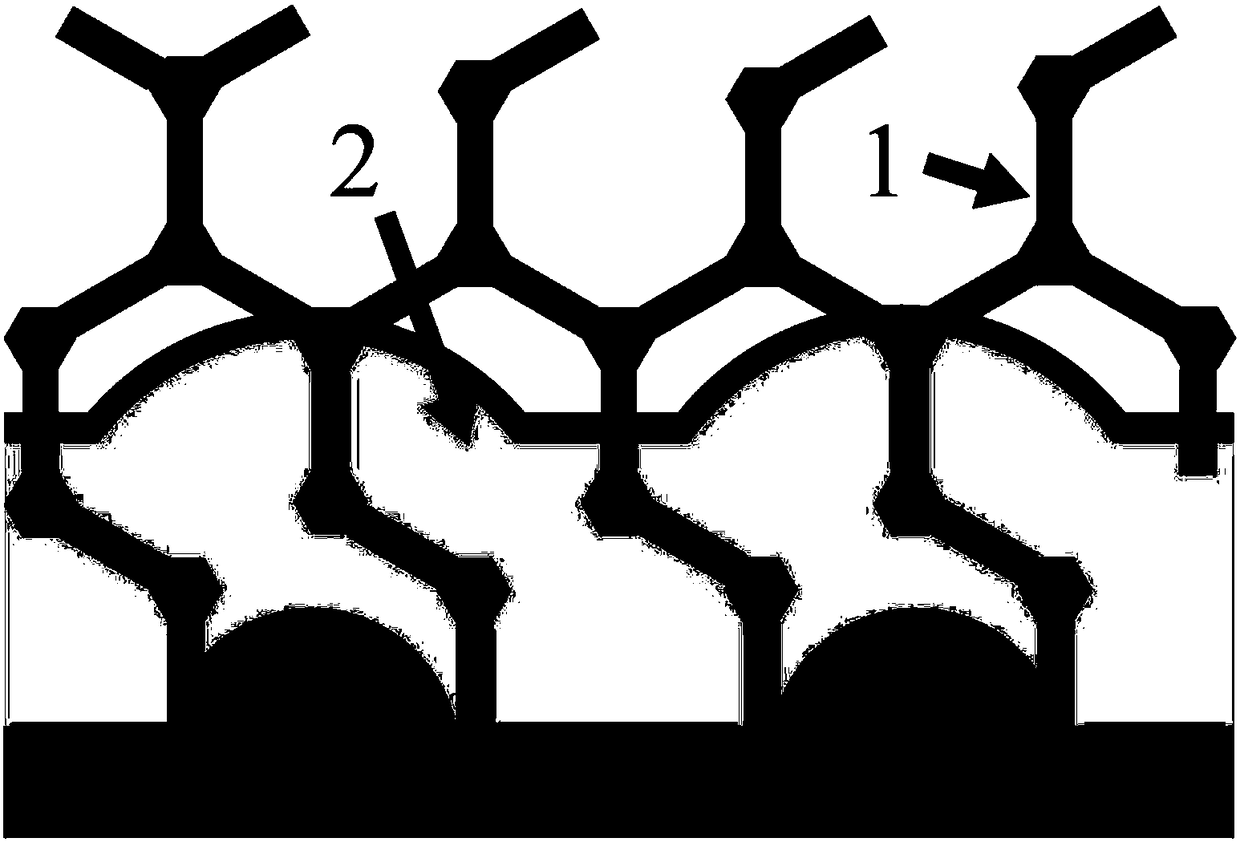

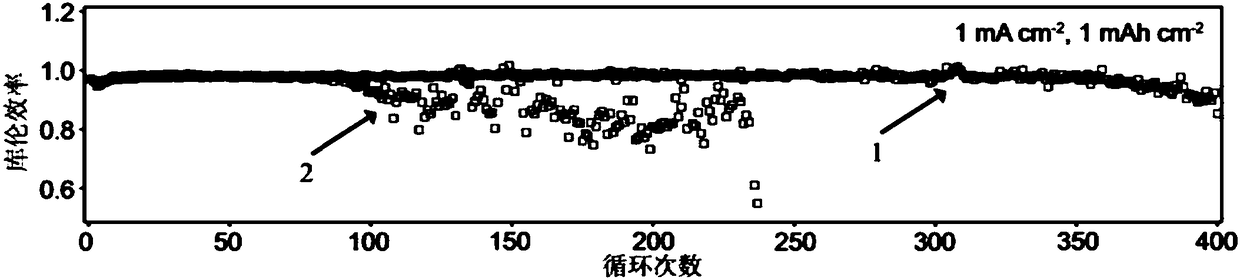

Anode material for lithium metal battery as well as preparation method and application of anode material

PendingCN108232117AImprove Coulombic efficiencyImprove securityCell electrodesLi-accumulatorsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses an anode material for a lithium metal battery. The anode material comprises a current collector and a carrier which is in tight fit with the current collector, wherein the carrier has a three-dimensional framework structure; a gap of the three-dimensional framework structure is filled with lithium metal; the carrier is selected from at least one of polymelamine, polyacrylonitrile, polyaniline, polyimide, polyvinylidene fluoride and polytetrafluoroethylene. The anode material disclosed by the invention has the advantages that a nonconductive polymer with the three-dimensional framework structure is used as the carrier, and stable deposition of lithium ions is realized by using interaction of functional groups contained in the carrier and the lithium ions; meanwhile,volumetric expansion is inhibited, internal stress of the battery is relieved, and thereby the aim of inhibiting growth of lithium dendrites is achieved. The coulombic efficiency, the safety of the lithium ion battery obtained by assembling the anode material prepared disclosed by the invention is remarkably improved and cycle life is obviously prolonged.

Owner:ZHEJIANG UNIV

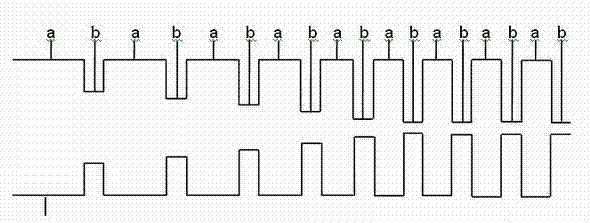

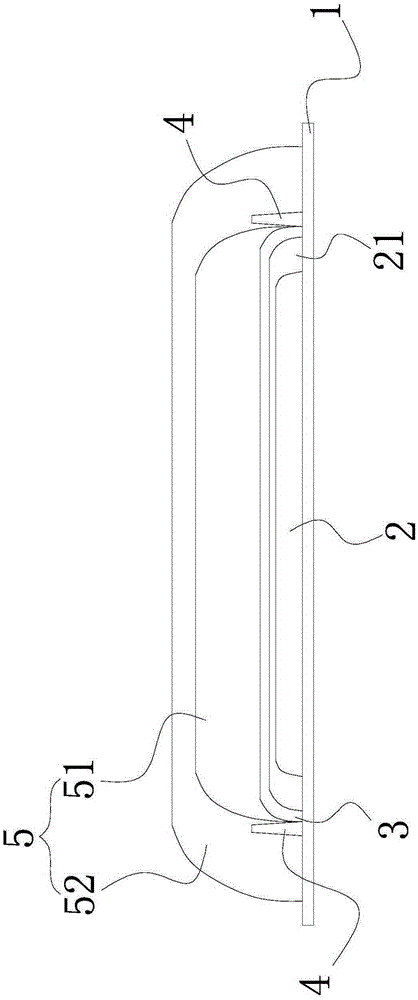

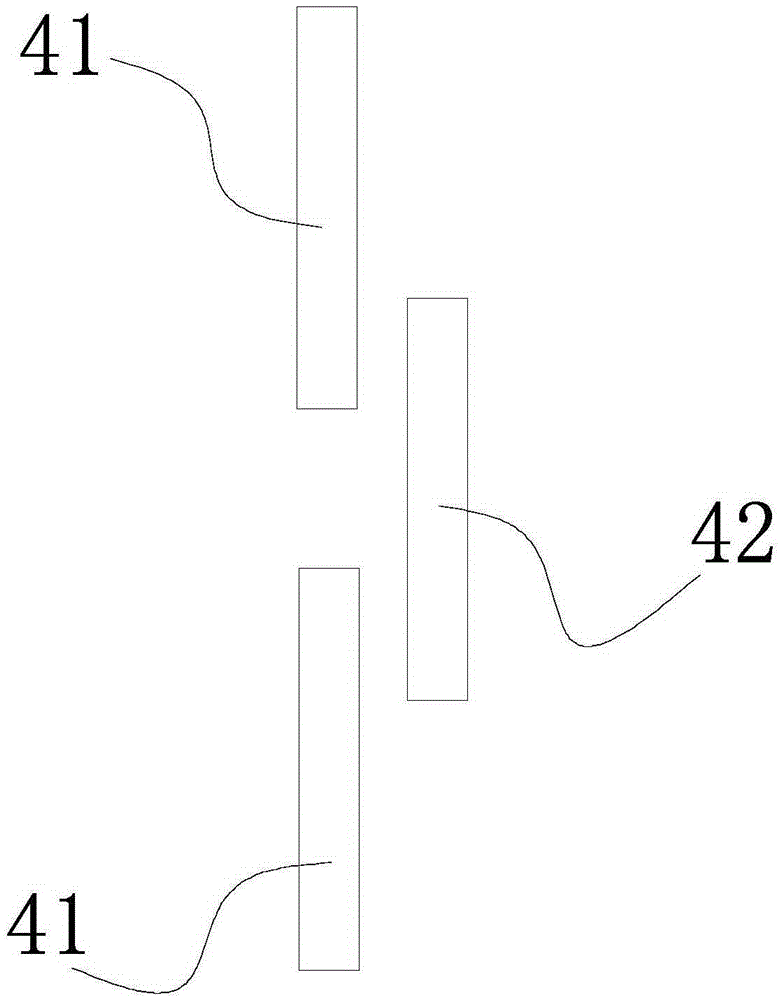

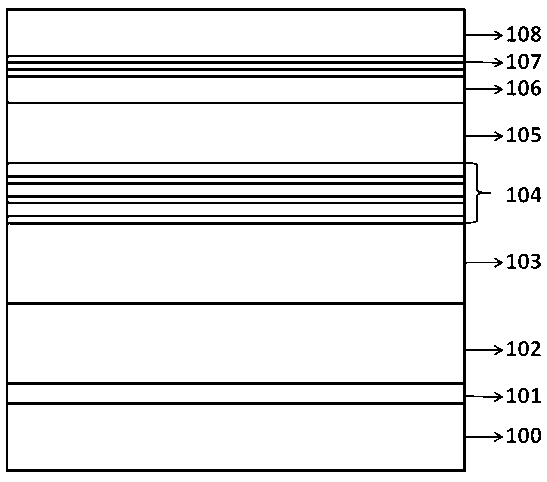

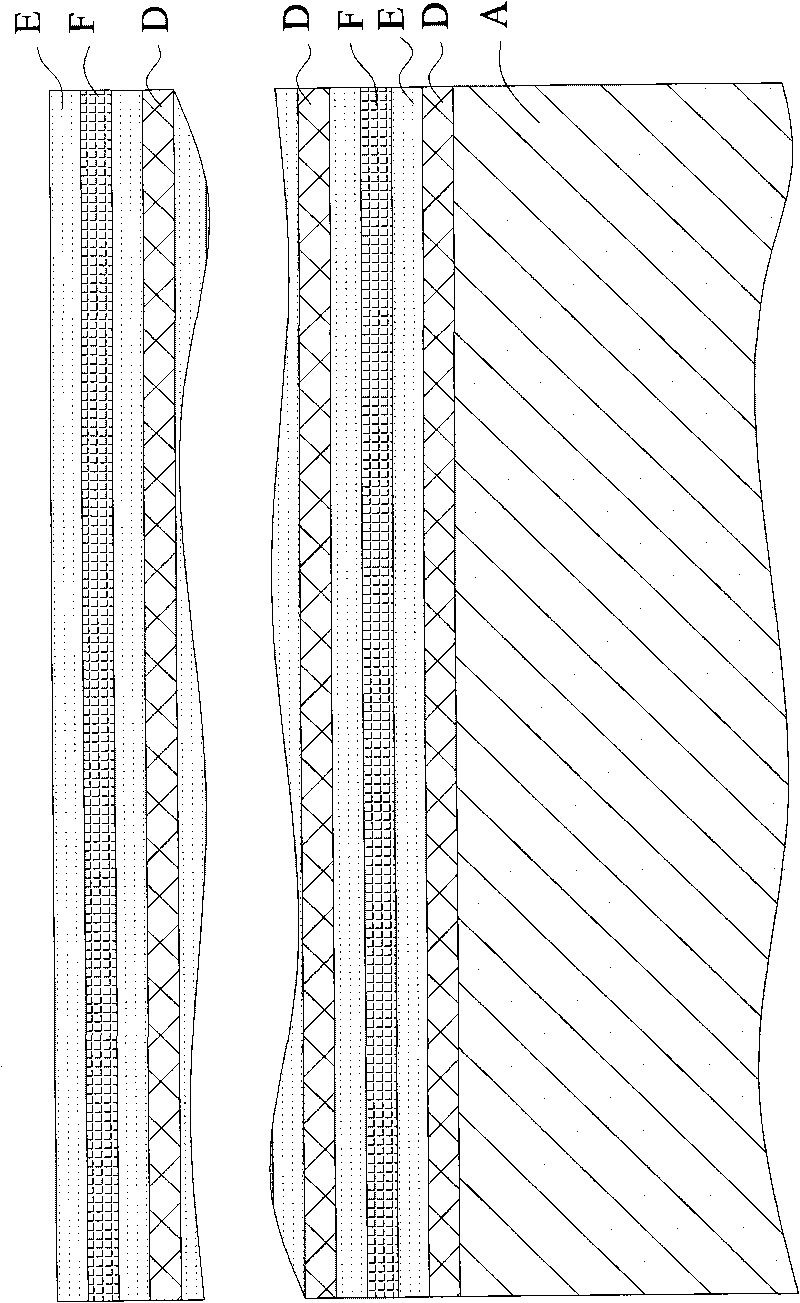

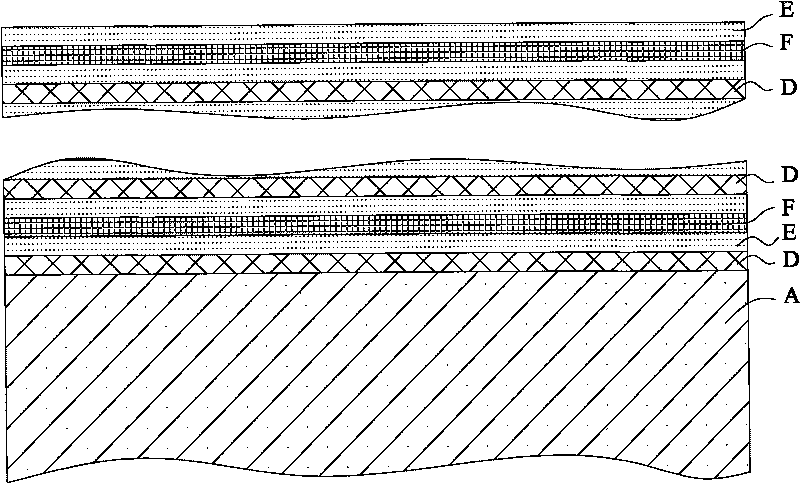

Epitaxial structure and growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency

InactiveCN103066174AImprove crystal qualityStress reliefSemiconductor devicesPotential wellEffect light

The invention discloses an epitaxial structure and a growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency. The order of the epitaxial structure from bottom to up is that a substrate, a low-temperature GaN buffer layer, a GaN non-doping layer, a N-shaped GaN layer, a multiple quantum well (MQW) structure, a multiple quantum well active layer, a low-temperature P-shaped GaN layer, a P-shaped aluminum (AL) GaN layer, a high-temperature P-shaped GaN layer and a P-shaped contact layer, wherein the order of the multiple quantum well active layer from bottom to up comprises a InyGa1-yN potential well layer, a InN layer and a barrier layer in sequence. The growing method of the multiple quantum well active layer structure is that by inserting the InN layer and a low-temperature annealing step in the growing process of a InyGa1 potential well layer and a GaN barrier layer, so that the composition of In quantum dot in the barrier layer is advanced and crystalline quality of the quantum well is improved, therefore, gallium nitride based LED lighting efficiency is improved.

Owner:合肥彩虹蓝光科技有限公司

Fluid-dynamic-pressure bearing, spindle motor furnished with the fluid-dynamic-pressure bearing, method of manufacturing rotor assembly applied in the spindle motor, and recording-disk drive furnished with the spindle motor

ActiveUS7021829B2Reduced dimensionStress reliefShaftsMetal-working apparatusEdge surfaceThrust bearing

Fluid-dynamic-pressure bearing furnished with a shaft, a top plate fixed to an upper portion of the shaft, a thrust plate fixed to a lower portion of the shaft, a sleeve, and a cuplike bearing housing that along its inner periphery retains the sleeve. A lubricating-fluid-filled continuous micro-gap is formed in between the shaft and the sleeve and the top plate and the sleeve. Radial bearing sections are formed in between the shaft cylindrical outer surface and the sleeve cylindrical inner surface. An upper thrust bearing section is formed in between the undersurface of the top plate and the top-edge face of the bearing housing. A lower thrust bearing section formed in between the bottom margin of the sleeve and the top margin of the thrust plate. The bearing sections are each provided with dynamic-pressure-generating grooves for inducing dynamic pressure in the lubricating fluid when the shaft or sleeve spins.

Owner:NIDEC CORP

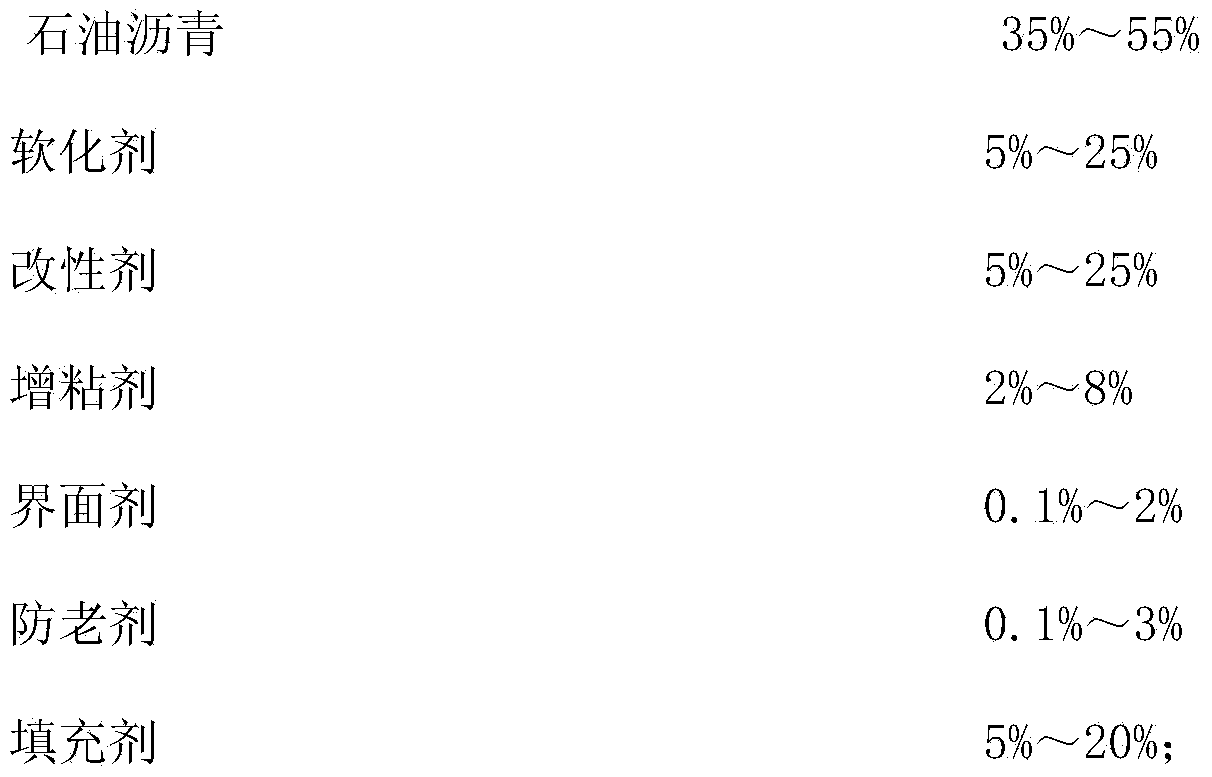

Creeping self-adhesive asphalt water-proof coiled material and preparation method thereof

InactiveCN104194719ASolve the leakExtended service lifeNon-macromolecular adhesive additivesBituminous material adhesivesAsphaltAnti ageing

The invention relates to a creeping self-adhesive asphalt water-proof coiled material and a preparation method thereof. An asphalt sizing material used for the creeping self-adhesive asphalt water-proof coiled material has good adhesive property and creeping property, and the asphalt sizing material is prepared from the following raw materials in percentage by weight: 35%-55% of petroleum asphalt, 5%-25% of softening agent, 5%-25% of modifying agent, 2%-8% of tackifying agent, 0.1%-2% of interface agent, 0.1%-3% of anti-aging agent and 5%-20% of filling agent. The self-adhesive asphalt water-proof coiled material disclosed by the invention has very good initial adhesion, can be well adhered with a base layer under the conditions of the wet base layer and lower temperature even if a little dust is positioned on the surface of the base layer, is difficult to strip after being adhered, and can ensure that a complete sizing material can be retained on the base layer after being stripped, thus meeting the requirement for water-proof property.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

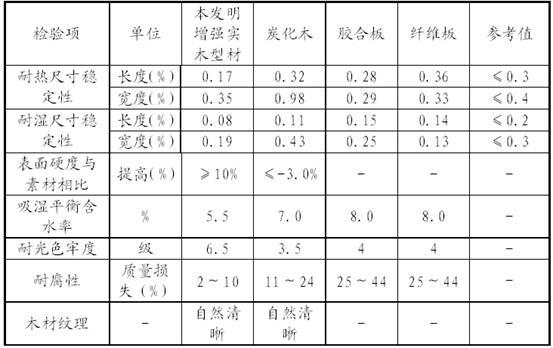

Stable enhanced type solid wood profile and production method thereof

ActiveCN101879736AReduce surface hardnessReduce surface strengthWood impregnation detailsSolid woodWeather resistance

The invention provides a production method of a stable enhanced type solid wood profile improved by a wood carbonization and acetylation process, which belongs woodwork production technique. The production method comprises the following steps of: a, drying treatment, wherein the wood moisture content is reduced to be as low as 5.0 to 8.0 percent, the moisture content deviation in the wood thickness is less than 2.0 percent, and the wood internal residual stress is less than 2.0 percent; b, carbonizing treatment; c, acetylation treatment; and d, equalization treatment. The invention also discloses a stable enhanced type solid wood profile prepared by the production method. The solid wood profile prepared by the method is stable, has high corrosion resistance and weathering resistance, high output, long product service life and wide utilization ways, is favorable for realizing flow line production, and is convenient for industrialization.

Owner:ZHEJIANG SHIYOU TIMBER

Method for enhancing luminous efficiency of multiquantum well of semiconductor diode

ActiveCN102368519AImprove crystal qualityBlock pass chanceSemiconductor devicesElectron holeQuantum well

The invention discloses a method for enhancing the luminous efficiency of a multiquantum well of a semiconductor diode. A novel gradient growth method is adopted as a multiquantum well growth manner of an epitaxial wafer structure of a light emitting diode; in the multiquantum well structure, InGaN components in the first several periods are gradually increased, so that the stress generated in the growth process of suddenly transferring GaN to InGaN with high In components is eased, and thus the polarization effect is reduced, the crystal quality of the quantum well is improved, and the compounding possibility is increased. In addition, the thicknesses of barrier layers in the first several periods are gradually reduced, the speed of electrons and the traversing possibility of electrons can be reduced by the barrier layers with larger thickness, the traversing possibility of electron holes can be increased by the barrier layers with smaller thickness, so that the electrons and the electron holes are distributed more uniformly and the problem of the reduced efficiency under high current injection is avoided, and therefore the luminous efficiency of the multiquantum well is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

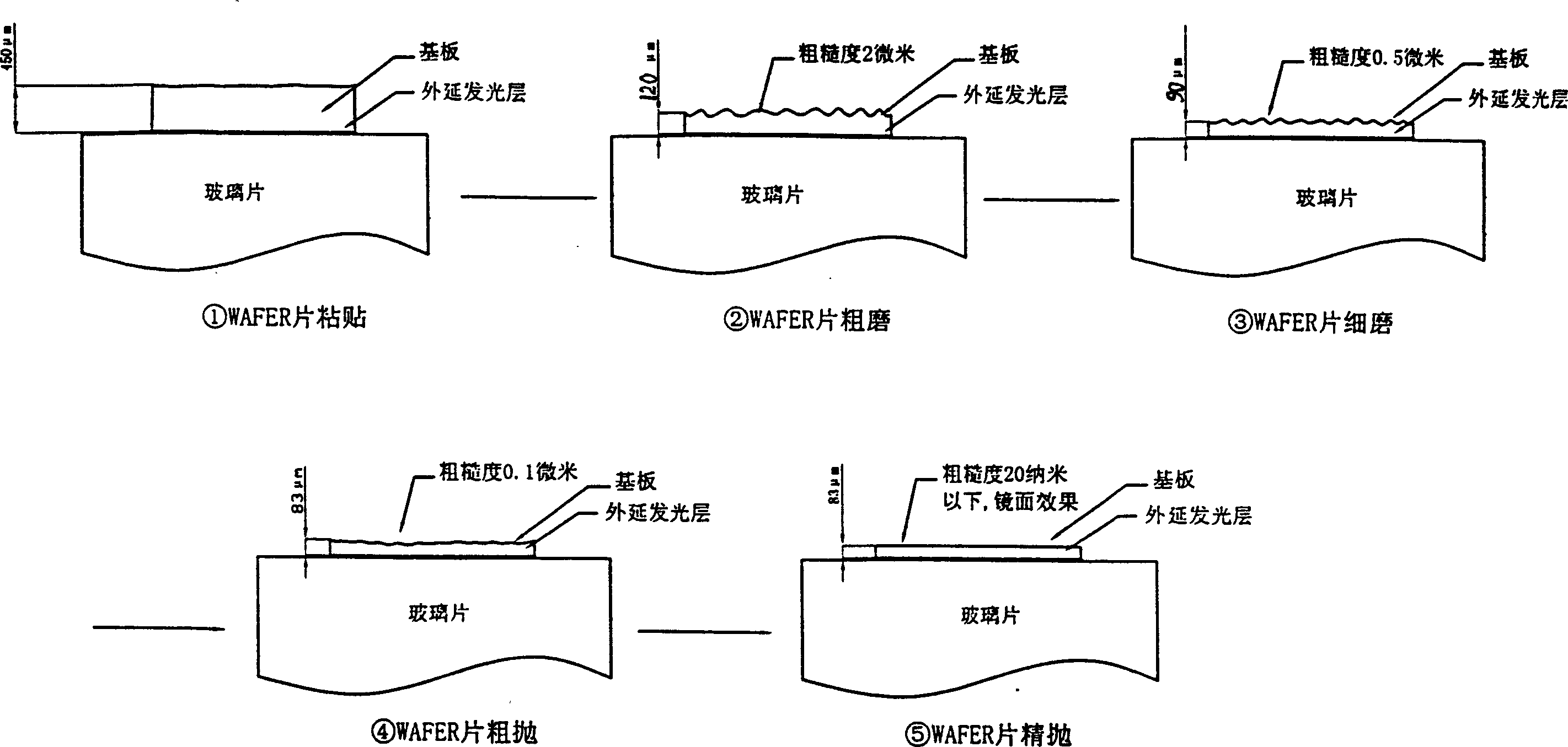

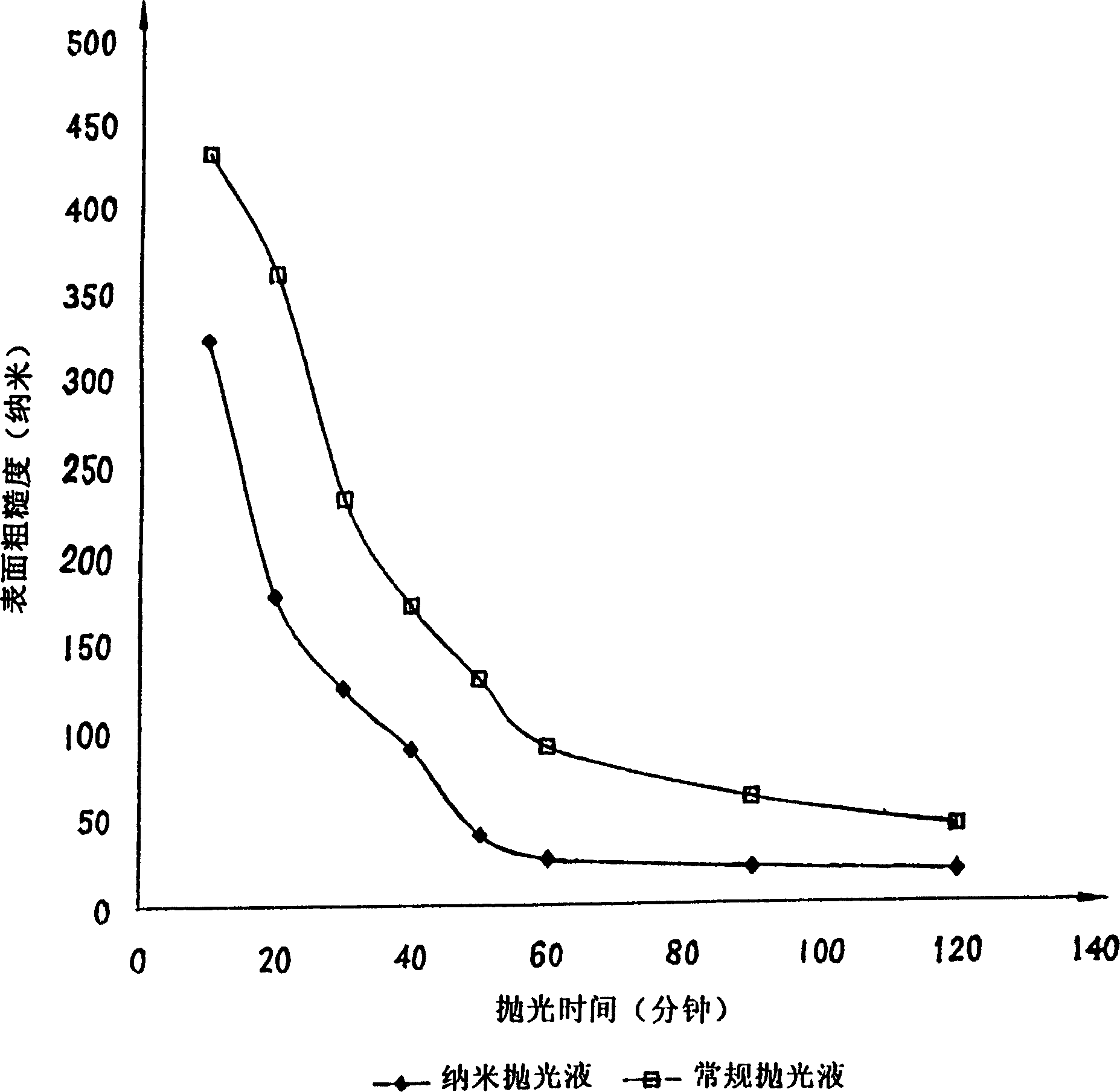

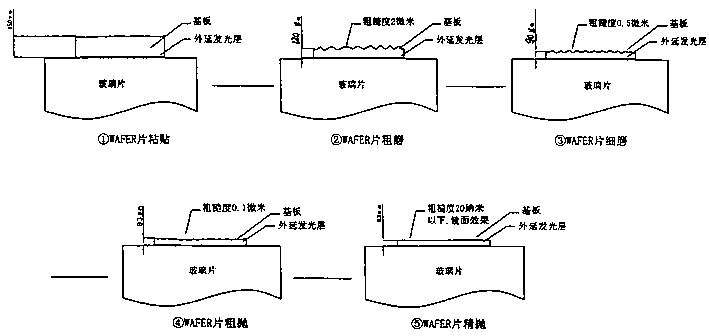

Processing method of nano level saphire substrate and its special polishing liquid

InactiveCN1469459AHigh surface finishExtended service lifeOther chemical processesSemiconductor/solid-state device manufacturingSurface finishNano silicon

The present invention relates to the processing technology of semiconductor device and is especially the processing method of sapphire substrate for HB-LED tube core and special polishing liquid. The processing method includes the steps of adhering, coarse grinding, fine grinding, coarse polishing and fine polishing. The nano polishing liquid consists of nano silicon powder, glycol, glycerine, ethanolamine and deionized water. The present invention can raise surface smoothness to obtain the mirror polishing effect, eliminate stress, lower loss of cutting tool, raise product quality and lower production cost. In addition, the polishing liquid can shorten polishing period greatly compared with micron level polishing liquid.

Owner:东莞市福地电子材料有限公司

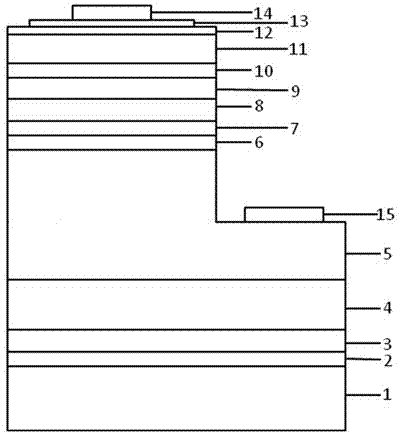

Flexible OLED display panel

ActiveCN105261712AAvoid scratchesPrevent crushingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWater block

The invention discloses a flexible OLED display panel, which comprises a flexible substrate, an OELD device, a first encapsulation layer, a barrier layer and a second encapsulation layer, wherein the OLED device is arranged on the flexible substrate; the first encapsulation layer is arranged on the flexile substrate and covers the OLED device; the barrier layer is arranged on the flexible substrate, surrounds the periphery of the first encapsulation layer, and comprises a plurality of discontinuous barrier units; the plurality of barrier units are arranged in a chain form; and the second encapsulation layer is arranged on the flexible substrate and covers the first encapsulation material and the barrier layer. The flexible OLED display panel is capable of effectively blocking the diffusion effect of atomic deposition coating and enhancing the water blocking capacity of a thin-film encapsulation on the periphery of the flexible OLED display panel; meanwhile, the reelability of the barrier layer is increased; the development requirement of the flexible OLED display panel is relatively well met; and an important idea is also provided for development of the flexible OLED display panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

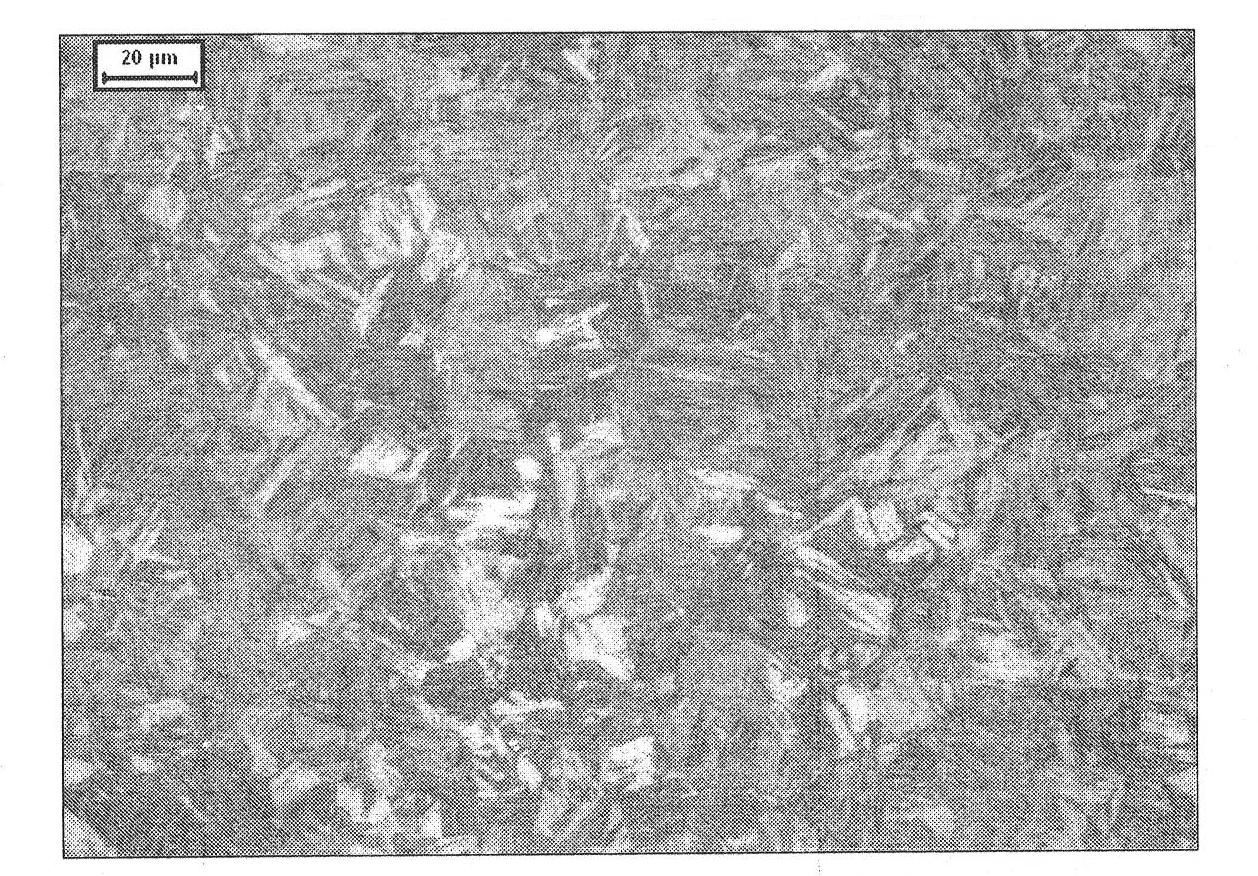

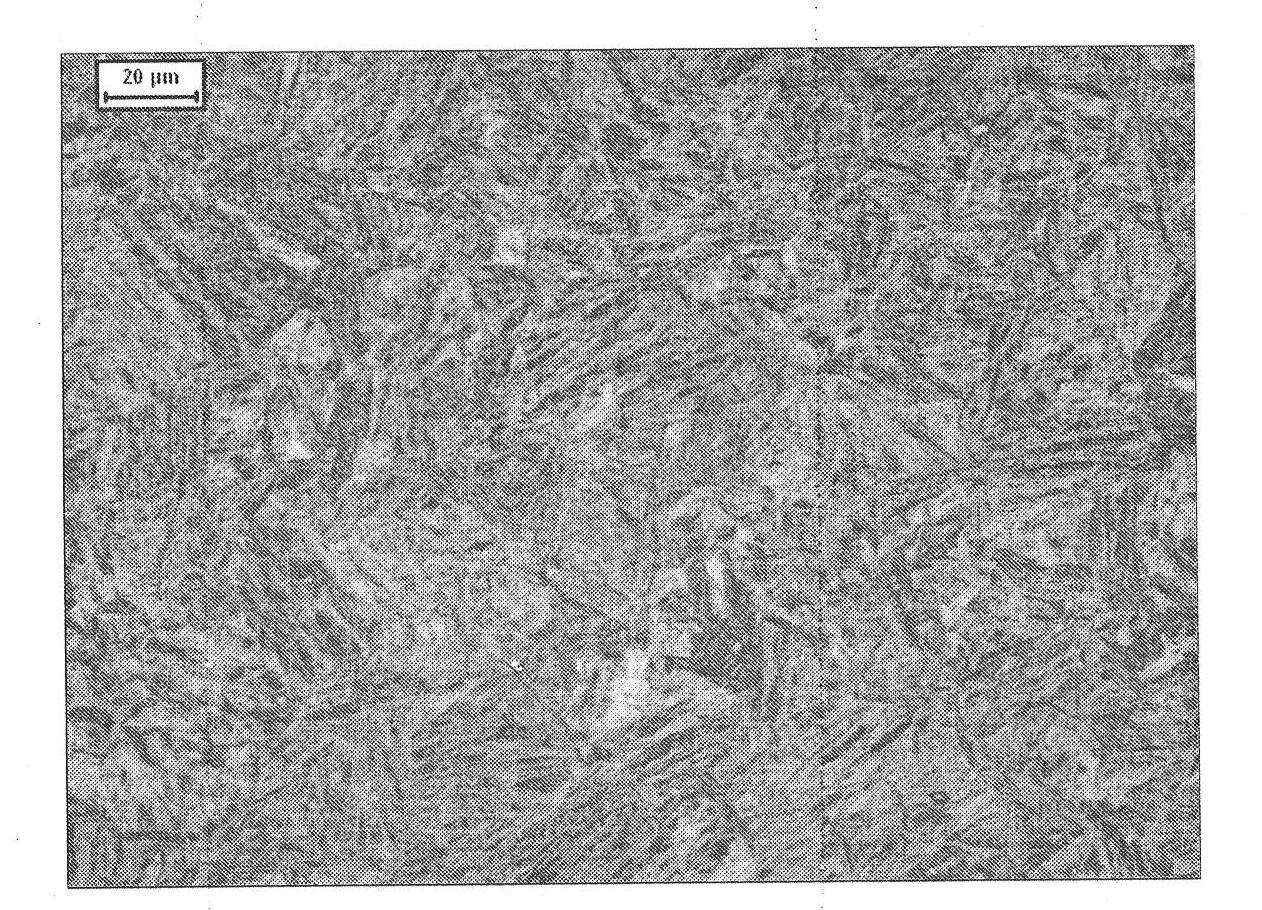

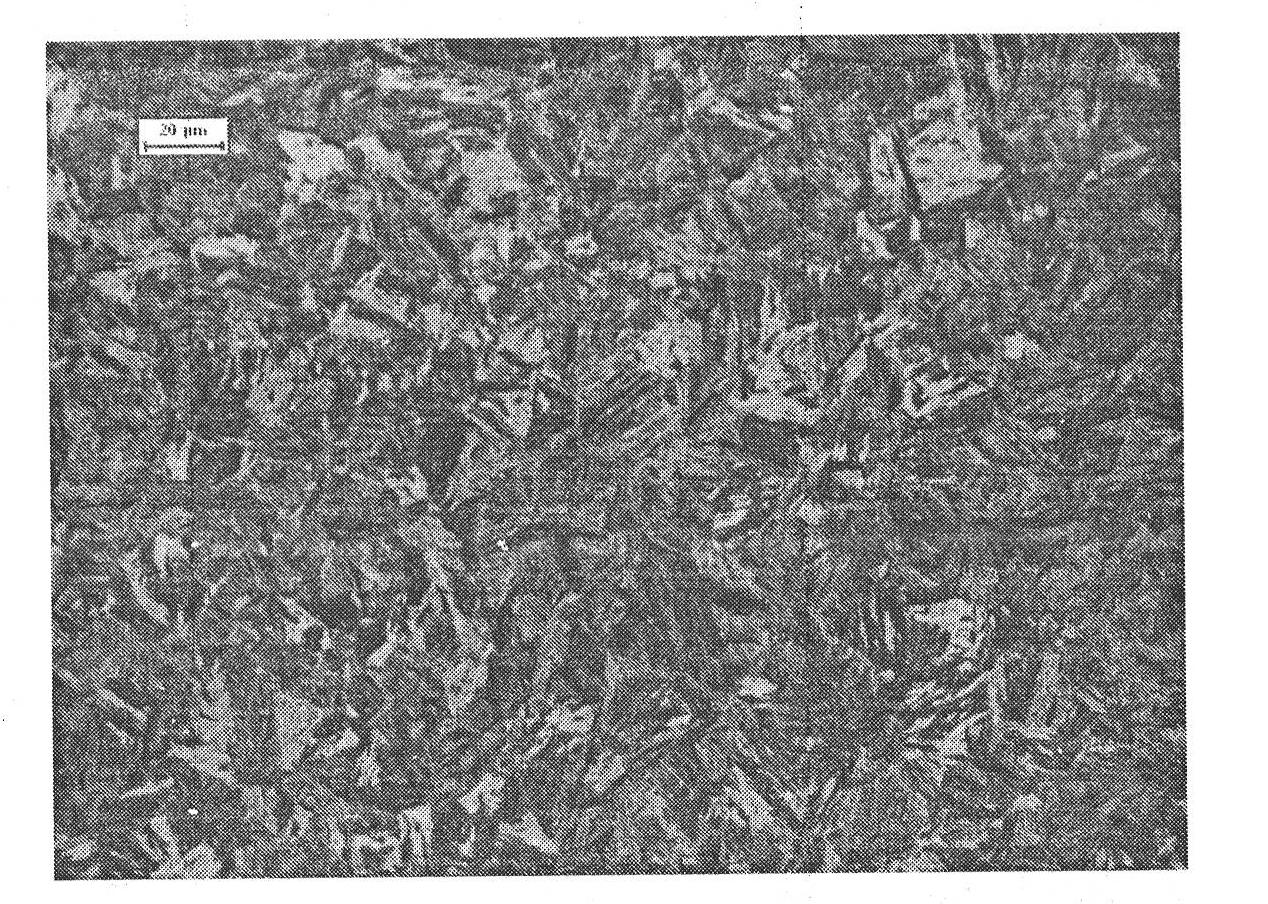

High-strength-and-toughness low alloy wear resistant steel and manufacturing method thereof

The invention relates to high-strength-and-toughness low alloy wear resistant steel and a manufacturing method thereof, belonging to the technical filed of metallurgy. The high-strength-and-toughness low alloy wear resistant steel comprises the following components by weight percent: 0.15-0.20% of C, 0.1-0.5% of Si, 1.2-1.6% of Mn, less than or equal to 0.015% of P, less than or equal of 0.005% S, 0.02-0.04% of Al, 0.016-0.022% of Ti, 0.16-0.20% of Cr, 0.16-0.22% of Mo, 0.001-0.0015% of B and the balance of Fe, and simultaneously the carbon equivalent Ceq (%) is less than or equal to 0.55. The manufacturing method comprises the following steps: smelting molten steel and pouring into a slab, and carrying out rough rolling after heating and heat insulation; and then carrying out complete quenching treatment, or sub-temperature quenching treatment, or carrying out the complete quenching treatment and then carrying out the sub-temperature quenching treatment, and adopting low temperature tempering to eliminate stress after the quenching. The method of the invention ensures higher hardness, simultaneously can obviously improve the impact toughness of steel plates, increase the impact resistance of the steel plates, and prolong the service life of mechanical equipment, and can obtain wear resistant steel plates with different strength and toughness grades by using the steel with same components and different quenching processing methods.

Owner:NORTHEASTERN UNIV +1

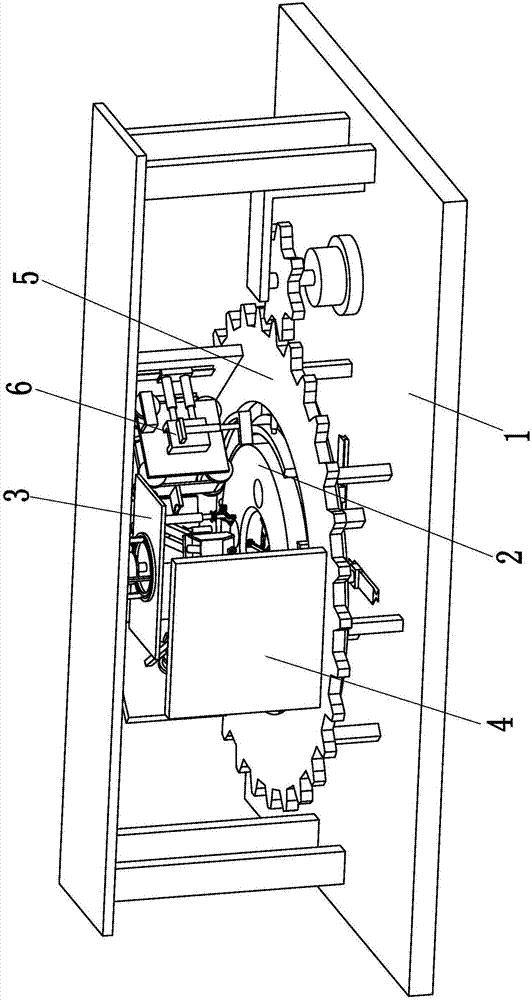

Automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints

InactiveCN107877075AImprove grinding effectEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesAfter treatmentEngineering

The invention relates to an automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints. The automatic welding treatment integrated machine comprisesa supporting base plate, a fixing device, a polishing device, a welding device, a rotating device and a post-weld treatment device, wherein the fixing device is arranged in the middle of the supporting base plate, the polishing device is located above the fixing device and is arranged on the supporting base plate, the rotating device is located on the outer side of the fixing device and is connected to the supporting base plate, the welding device and the post-weld treatment device are arranged on the rotating device, and the welding device is located on the front side of the post-weld treatment device. The automatic welding treatment integrated machine has the advantage that the existing problems that when flanges are welded to steel tubes, multiple fixation cannot be carried out on the flanges, the flanges are not fixed firmly and need to be polished manually before welding, the polishing effect on the flanges before welding is not good, the welding operation cannot be performed automatically, the flanges and the steel tubes need to be subjected to post-weld treatment manually, and the manual post-weld treatment is not thorough can be solved.

Owner:范满香

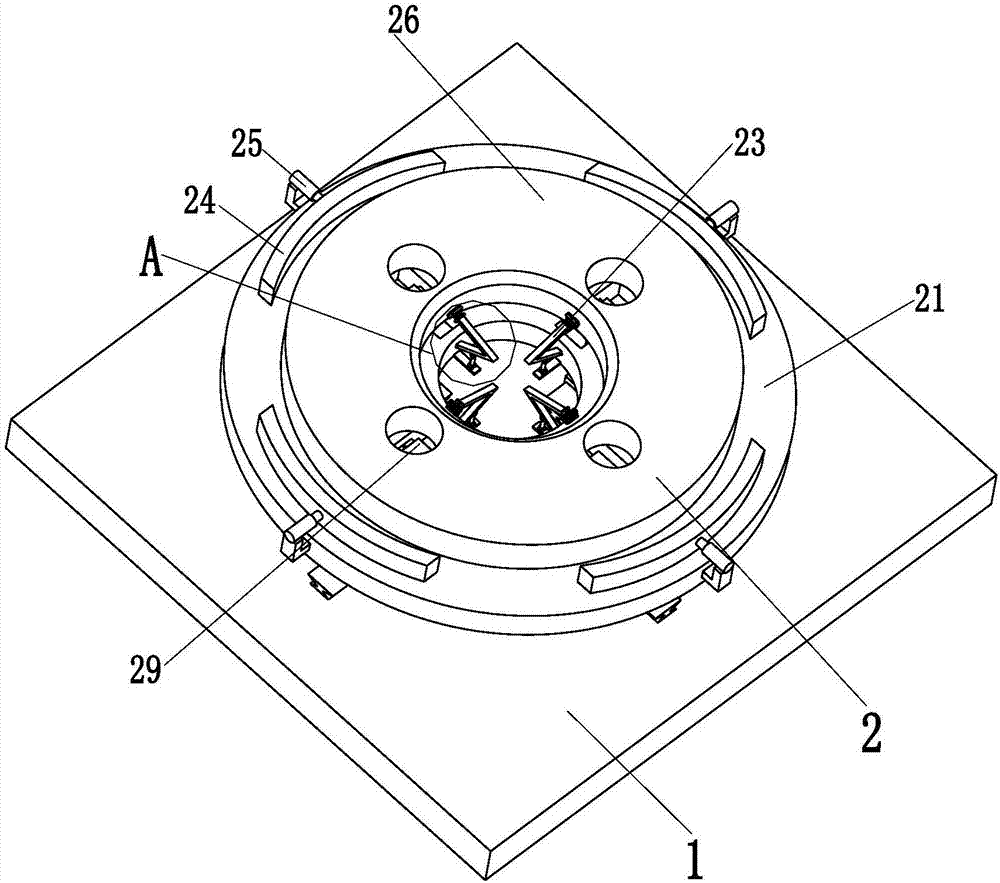

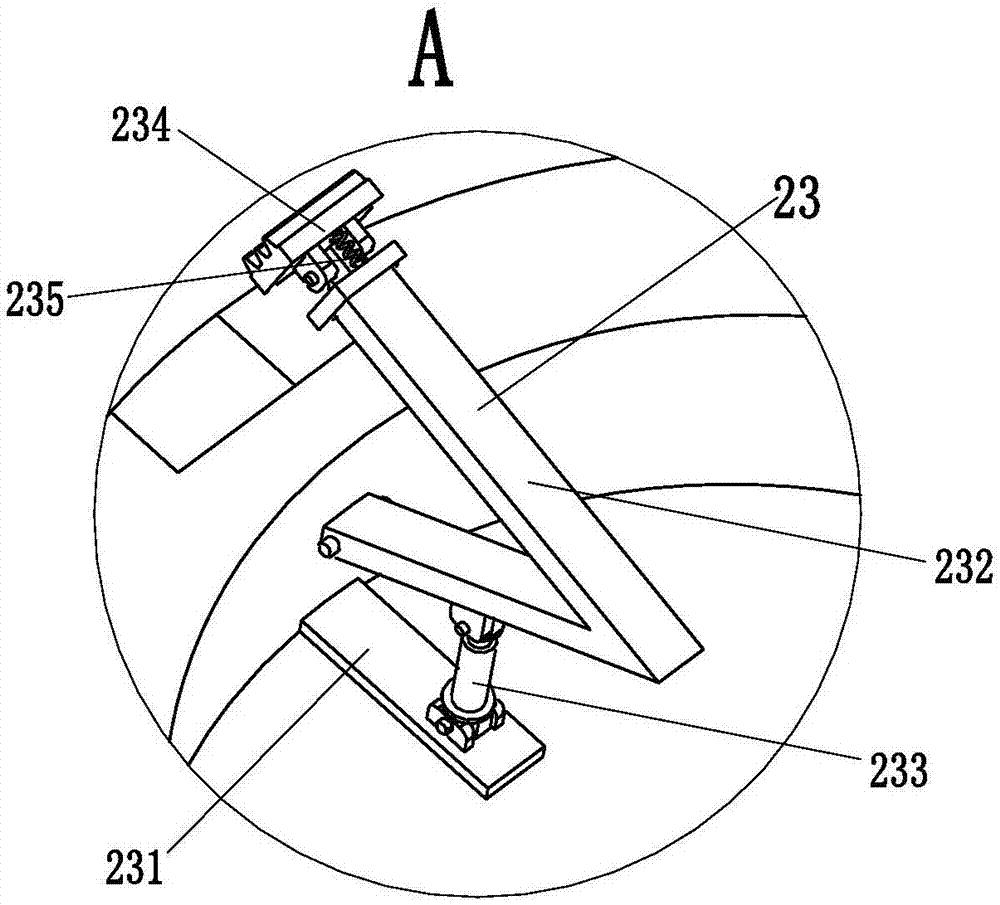

Manufacturing method of large-size welding type carburizing and quenching gear

The invention discloses a manufacturing method of a large-size welding type carburizing and quenching gear, comprising the following steps of: selecting gear material; determining the basic process routes when processing a gear ring, a subplate and a hub, and processing sperately; and integrally processing the gear. The manufacturing method has the advantages of reducing welding lobar intensity, improving production efficiency and ensuring the stability of welding quality.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

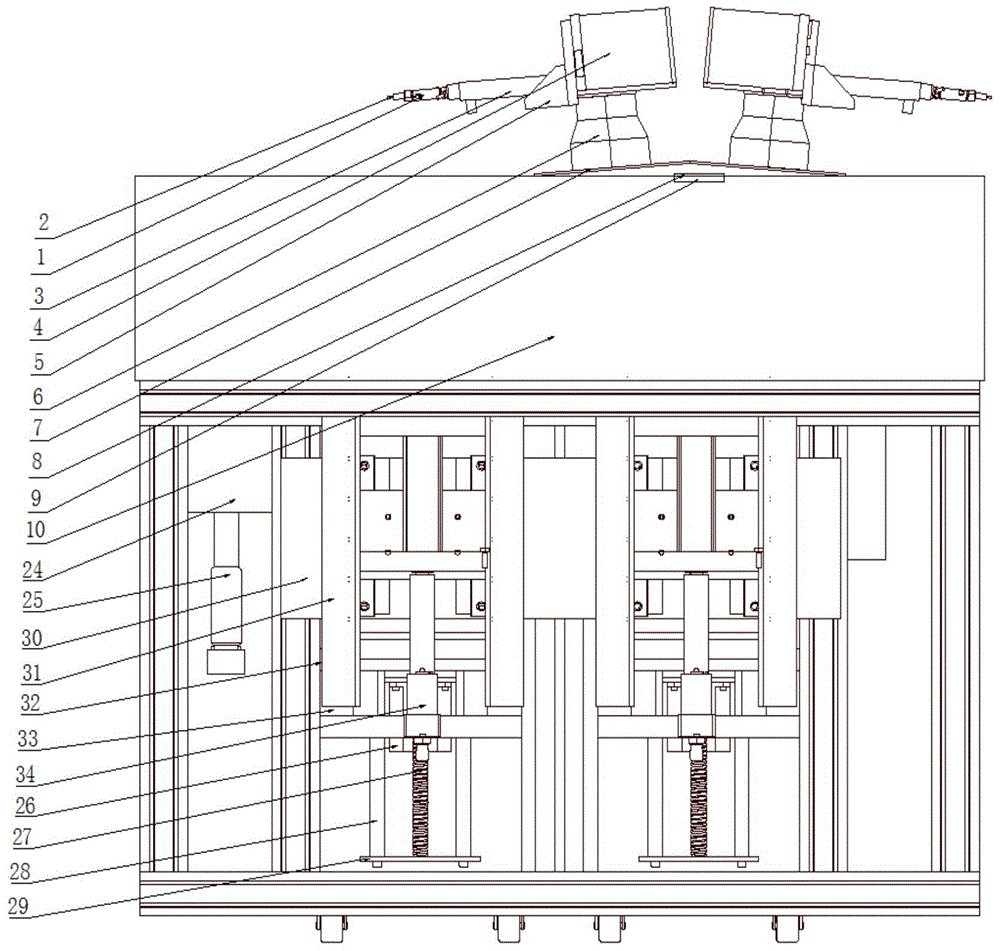

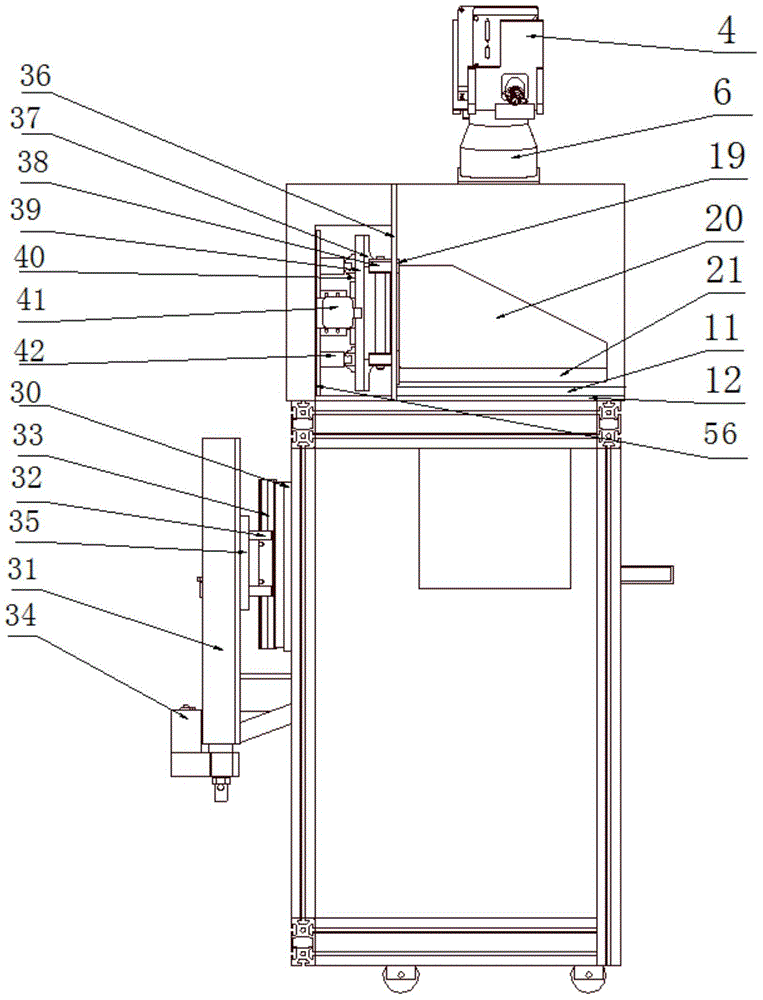

Dual-beam laser selective melting and moulding equipment with exchangeable powder cylinder

ActiveCN105039970AEasy to replaceImprove absorption rateMetallic material coating processesDual beamLight beam

The invention discloses dual-beam laser selective melting and moulding equipment with an exchangeable powder cylinder. The equipment comprises two optical systems, a frame, a workbench plate, a powder feeding cylinder, a powder storage cylinder, a moulding cylinder, a powder returning cylinder, a moulding cavity, and two first driving mechanisms, which are used to respectively drive the moulding cylinder and powder feeding cylinder to move up and down. The workbench plate is fixed on the frame, the moulding cavity is fixed on the upper surface of the workbench plate, and the powder returning cylinder, the moulding cylinder, the powder feeding cylinder, and powder storage cylinder are fixed on the lower surface of the workbench plate from left to right in sequence. A scraper is arranged in the moulding cavity, and a second driving mechanism is arranged on the frame. A substrate is arranged in the powder feeding cylinder, a substrate is arranged in the moulding cylinder, the lower ends of the powder feeding cylinder and the moulding cylinder are both provided with a cylinder end cover, and the substrates are connected to a first piston system. A second piston system is arranged in the powder storage cylinder. The provided equipment has a high moulding efficiency and is capable of effectively reducing the deformation and cracking of members.

Owner:XI AN JIAOTONG UNIV

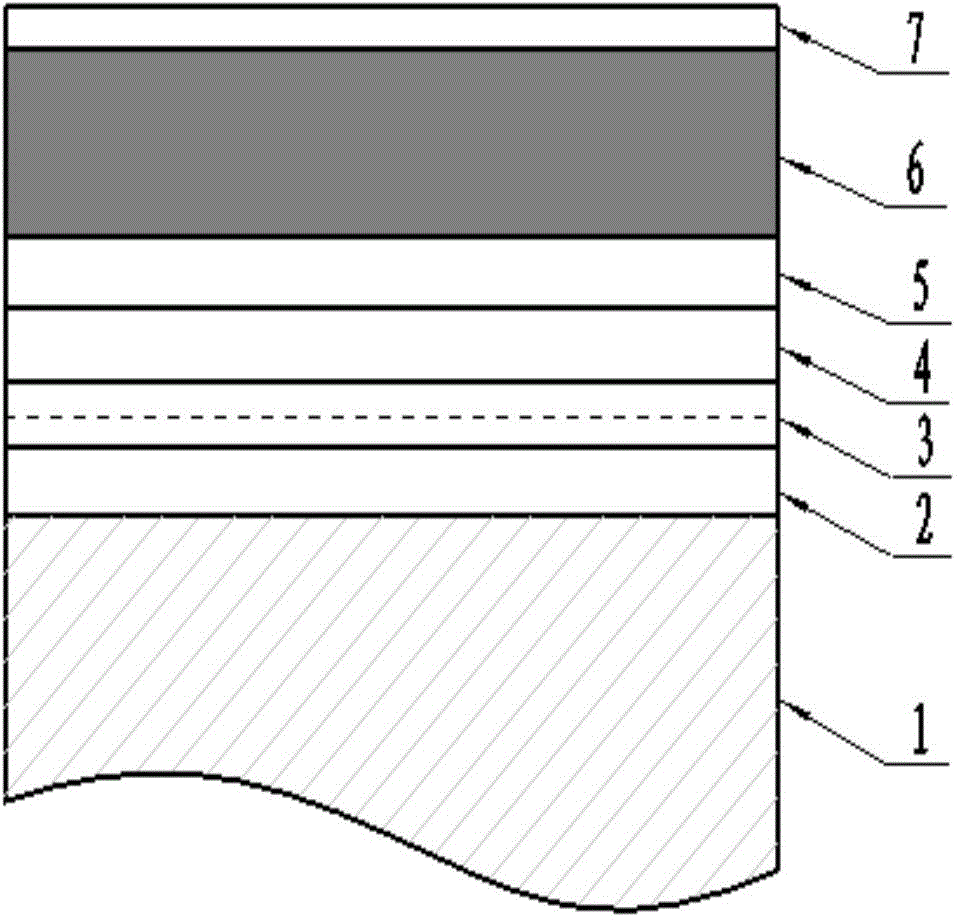

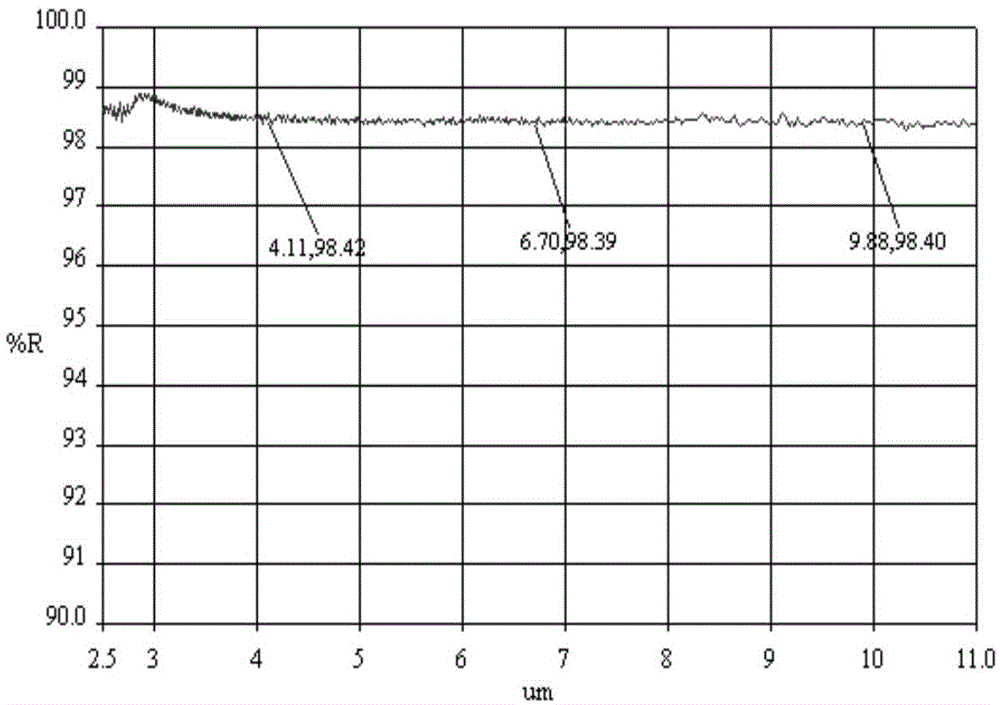

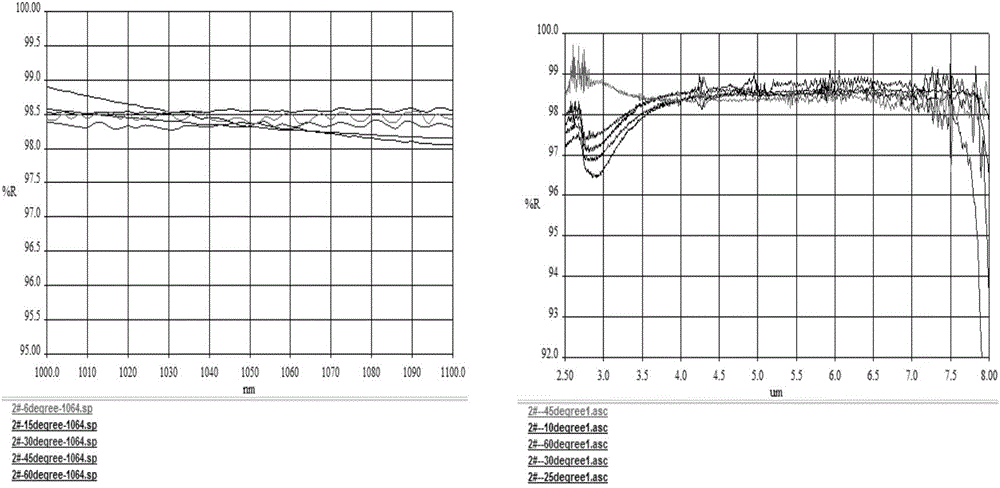

Infrared metal reflecting film with high adhesive force and manufacturing method thereof

ActiveCN104090312AGood physical occlusionImprove adhesionVacuum evaporation coatingSputtering coatingAdhesiveWear resistant

The invention provides an infrared metal reflecting film with high adhesive force and a manufacturing method thereof, wherein the infrared metal reflecting film with high adhesive force is plated on substrates of optical components such as glass, metal and silicon crystals. The infrared metal reflecting film with high adhesive force comprises a substrate, and is characterized in that a first transition layer, a holding-on bonding layer, a metal layer, a stress matching layer, a dielectric enhancement protecting layer and a hard wear-resistant layer are sequentially arranged on the substrate in an evaporation mode. The infrared metal reflecting film has the advantages of being good in film adhesive force, high in reflectivity, resistant to wear and high in environmental suitability, has a high laser damage resistance threshold value level, and can be widely applied to military and civilian photoelectron technical fields such as infrared lasers, refraction-reflection type optical systems and laser / infrared universal photoelectric equipment.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

Infrared energy-saving coating with anti-corrosion and anti-coking functions and preparation method thereof

InactiveCN102585571AStress reliefLow shrinkageAnti-corrosive paintsInorganic adhesivesBoron nitrideManganese(III) oxide

The invention relates to an infrared energy-saving coating with anti-corrosion and anti-coking functions, which is prepared from a component A and a component B according to the weight ratio of 1: 1-2. The particle size of powder materials in the component A is not less than 280 meshes and the component A is prepared from the following powder materials according to the weight ratio: 40-60 parts of spinel structure infrared composite darkening agent, 10-30 parts of corundum powder and 3-10 parts of high-temperature binding agent. The component A further comprises an anti-coking agent, and the anti-coking agent is prepared from the following powder materials according to the weight ratio: 3-10 parts of graphite, 0-10 parts of boron nitride and 1-5 parts of manganese sesquioxide. The component B is of a film-forming substance and prepared from the following raw materials according to the weight ratio: 60-80 parts of water glass, 10-30 parts of silica sol and 0-20 parts of water-borne resin solution. The invention further discloses a preparation method of the coating. The coating provided by the invention has the advantages: corrosion prevention, capability of reducing coking, high temperature resistance and excellent infrared radiation performance.

Owner:KING STRONG MATERIAL ENG LTD

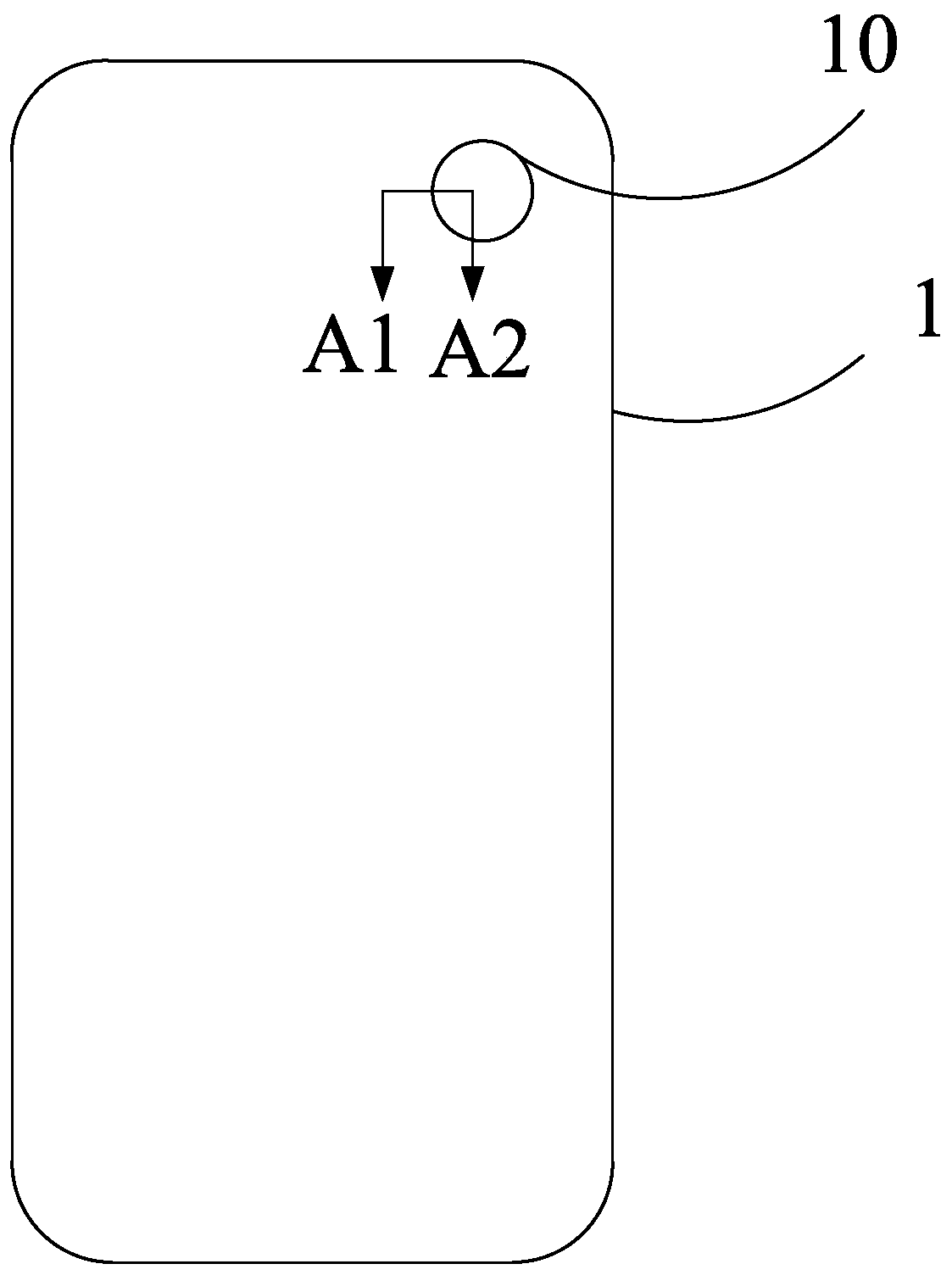

OLED display panel, preparation method thereof and OLED display device

InactiveCN111403621ASolve failed technical issuesStress reliefSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention provides an OLED display panel, a preparation method thereof and an OLED display device. The OLED display panel comprises a special-shaped cutting area and a display area, the display area is arranged around the special-shaped cutting area, and the display area comprises an effective display area, a first packaging area and a second packaging area, and the first packaging area and the second packaging area are located between the effective display area and the special-shaped cutting area; wherein a stress buffer component is arranged in a concave corner at the undercut in the second packaging area; through arranging the stress buffer components in the concave corners at the undercut positions, stress in the concave corners is eliminated, breakage in the undercut positions is avoided, and the technical problem that an existing OLED display panel fails due to the fact that the concave corners at the undercut positions are prone to breakage is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Preparation method for mu75 magnetic powder core of ferrosilicon aluminum

ActiveCN102360671AIncrease heat treatment temperaturePromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingFerrosilicon

The invention belongs to the field of preparation of metallic soft magnetic materials, and particularly relates to a preparation method for a mu75 magnetic powder core of soft magnetic ferrosilicon aluminum, which includes steps of smelting, rough smashing, heat treatment, fine smashing, annealing treatment, powder grading, powder insulating, compression molding, secondary heat treatment and coating treatment and requires components, by weight, 9.10% of silicon, 5.95% of aluminum and the rest iron. The preparation is performed with the smelting temperature of 1600 DGE C, the compression molding pressure ranging from 1700MPa to 2000Mpa, magnetic powder core pressing temperature ranging from 600 DEG C to 800 DEG C, and one hour for warm keeping in a nitrogen-oxygen mixed atmosphere. The magnetic powder core mu=75+-6 at 100kHz, the magnetic conductivity mu is smaller than 1% in variation under 1000kHz, the magnetic powder core loss is accordant to Pcv (powder loss) 50kHZ / 50mT<=100Mw / cm3, and the direct-current bias magnetic field is not lower than 70Oe when the magnetic conductivity is reduced to 50%. The preparation method for the mu75 magnetic powder core of soft magnetic ferrosilicon aluminum has the advantages that added binder is solid organic binder, the heat treatment after molding includes keeping warm for one hour in the nitrogen-oxygen mixed atmosphere, and the prepared magnetic powder core is free of pulverization, high in strength and stable in performance and has fine direct current bias characteristics, frequency stability and low loss.

Owner:TDG HLDG CO LTD

Stainless steel compound welding steel pipe and manufacturing method thereof

ActiveCN102889434AImprove corrosion resistanceImprove structural strengthRigid pipesStainless steel electrodeUltimate tensile strength

The invention discloses a stainless steel compound welding steel pipe and a manufacturing method thereof. The stainless steel compound welding steel pipe is formed by welding stainless steel compound hotly-rolled rolling plates through a welding line, wherein the welding line is formed by a stainless steel compound welding line and a carbon steel welding line. The manufacturing method comprises the following steps of: milling an edge and arranging a groove; when putting a stainless steel compound layer on the inner layer, firstly utilizing gas shield welding to weld a middle layer; then, utilizing a stainless steel welding strip to weld a stainless steel compound layer welding line in an argon arc welding manner; then, utilizing a carbon steel welding strip to weld the carbon steel welding line by a submerged-arc welding manner; when the stainless steel layer is less than 0.9 mm, directly welding a stainless steel welding line by submerged-arc welding; and when the stainless steel compound layer is located at the outer layer, firstly welding the carbon steel welding line by adopting the carbon steel welding strip and the submerged-arc welding, and adopting the stainless steel welding strip and the argon arc welding manner to weld the stainless steel compound layer welding line. According to the stainless steel compound welding steel pipe and the manufacturing method thereof, the manufactured stainless steel compound welding steel pipe has high structural strength and strong corrosion resistance; and the bonding strength of an inner pipe and an outer pipe is not less than 200 MPa.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

Laser repairing process for automobile mold

ActiveCN102732831ADoes not affect mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingHardnessAlloy

The invention relates to a laser repairing process for an automobile mold. The repairing process comprises the following steps of: (A) processing the surface of the mold, and carrying out detection and analysis on the mold; (B) heating the mold at a low temperature; (C) programming a cavity of a worn part of the mold according to a detection and analysis result of the mold, setting process parameters, and sequentially carrying out laser cladding on edges and corners of the mold and plane parts and step parts on the mold; and (D) detecting, wherein alloy powder adopted by the process comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 2.5-15% of TiO and the balance of Fe. The laser repairing process for the automobile mold can be used for carrying out laser cladding on the worn parts and enabling the surface hardness and the sizes of the worn parts to meet a using requirement.

Owner:中科恩吉瑞特(烟台)科技发展有限公司

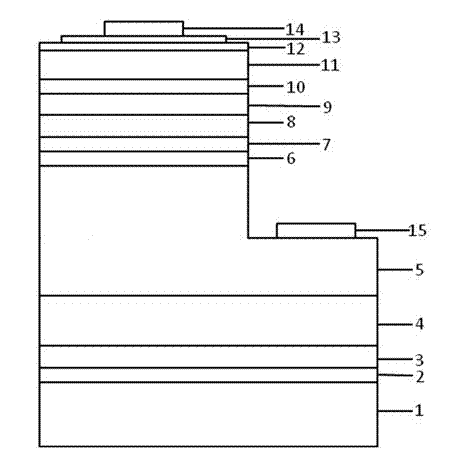

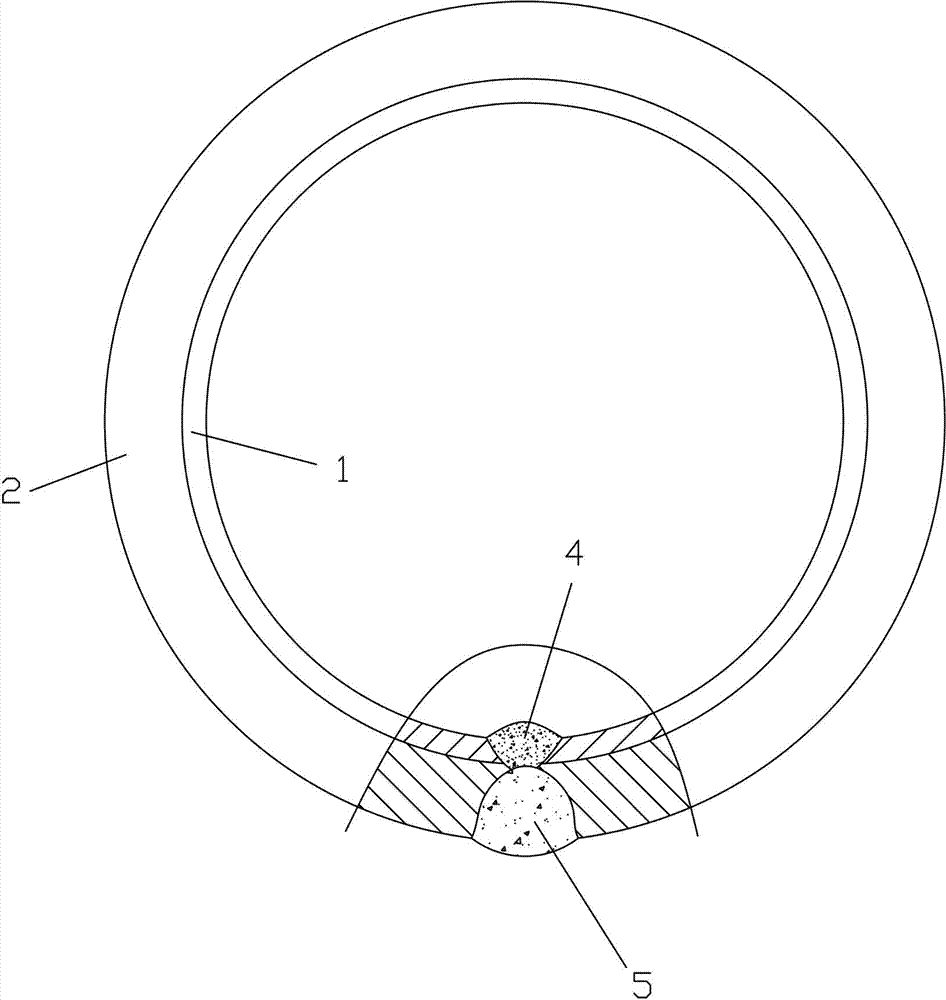

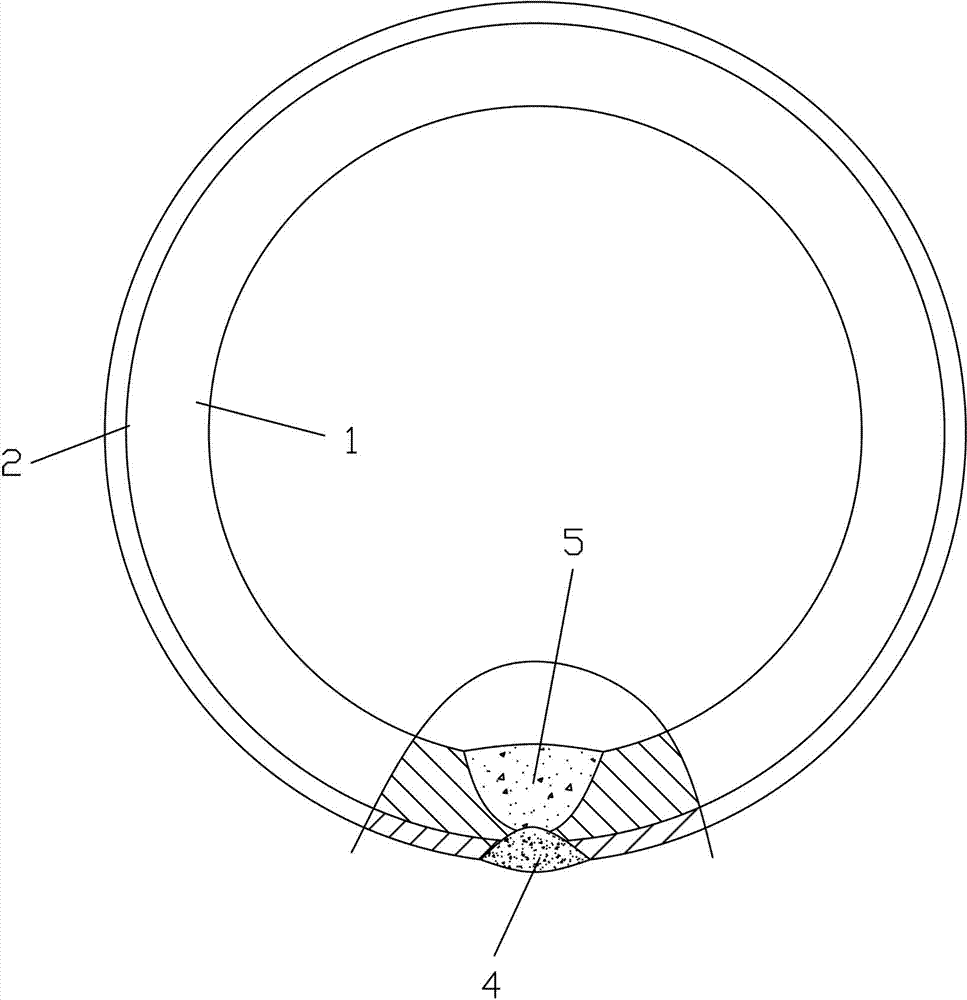

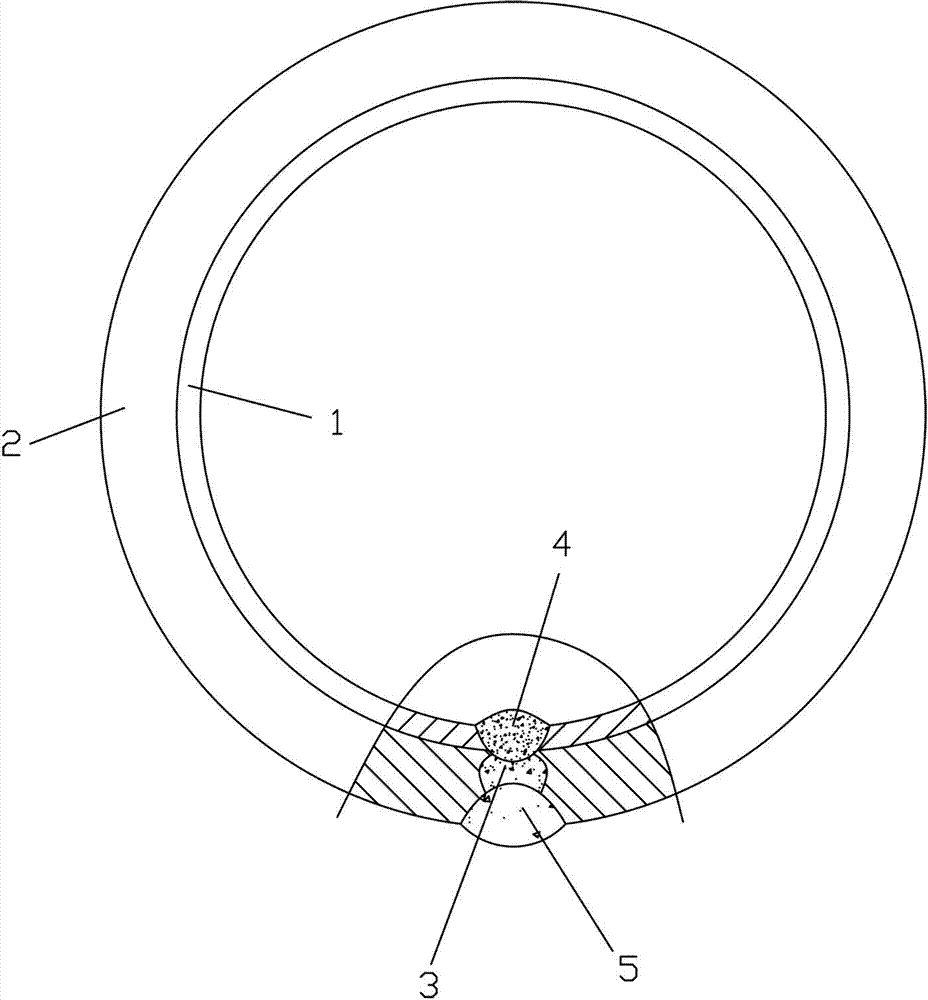

Nitride light-emitting diode (LED) epitaxial wafer and growing method thereof

InactiveCN102969416AStress reliefReduced polarizing electric fieldSemiconductor devicesPower flowHole injection layer

The invention provides a nitride light-emitting diode (LED) epitaxial wafer and a growing method thereof and relates to the technical field of semiconductor optoelectronics. The nitride LED epitaxial wafer structurally and sequentially comprises a substrate, a low-temperature buffer layer, an unintentionally doped GaN, an N-shaped electron-injection layer, an InGaN / GaN inserting layer, an active area, an electron blocking layer, a u-GaN / p-GaN superlattice and a p-GaN hole-injection layer from bottom to top. The InGaN / GaN inserting layer is grown between the N-shaped electron-injection layer and the active area so as to effective relieve stress of the active area, lower polarization electric fields, reduce limitation of stark effect through a quantum well, and improve luminance and anti-static properties. The u-GaN / p-GaN superlattice is inserted between the electron blocking layer and the P-shaped hole-injection layer so as to improve current expansion capacity and lower chip operating voltage.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

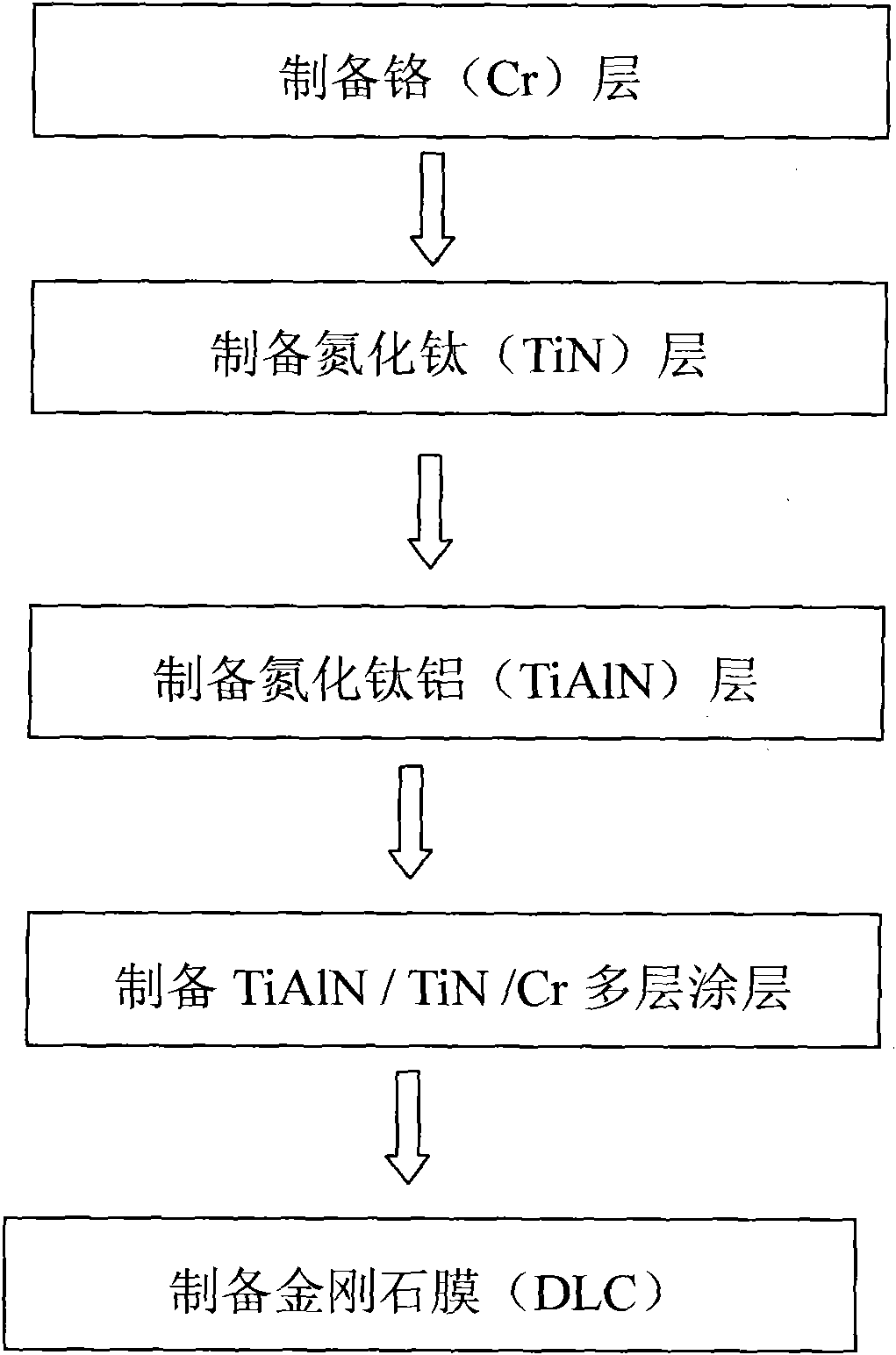

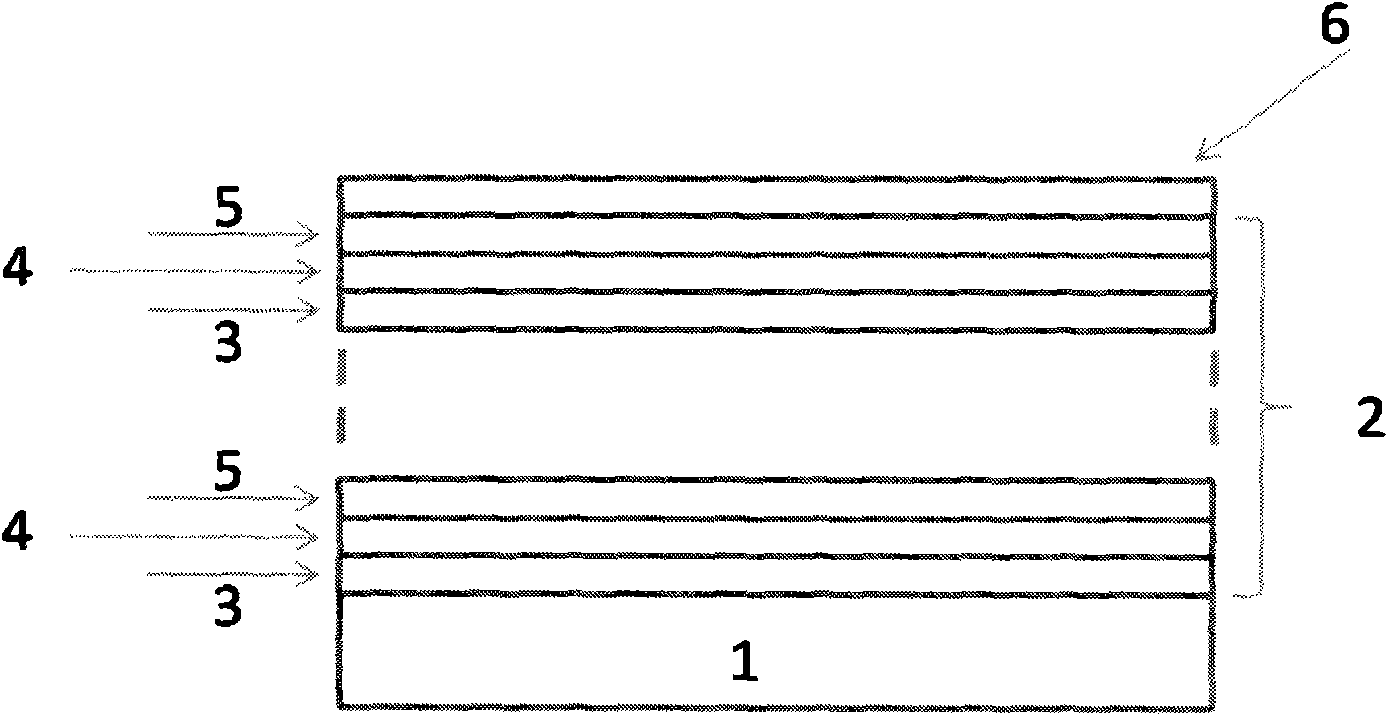

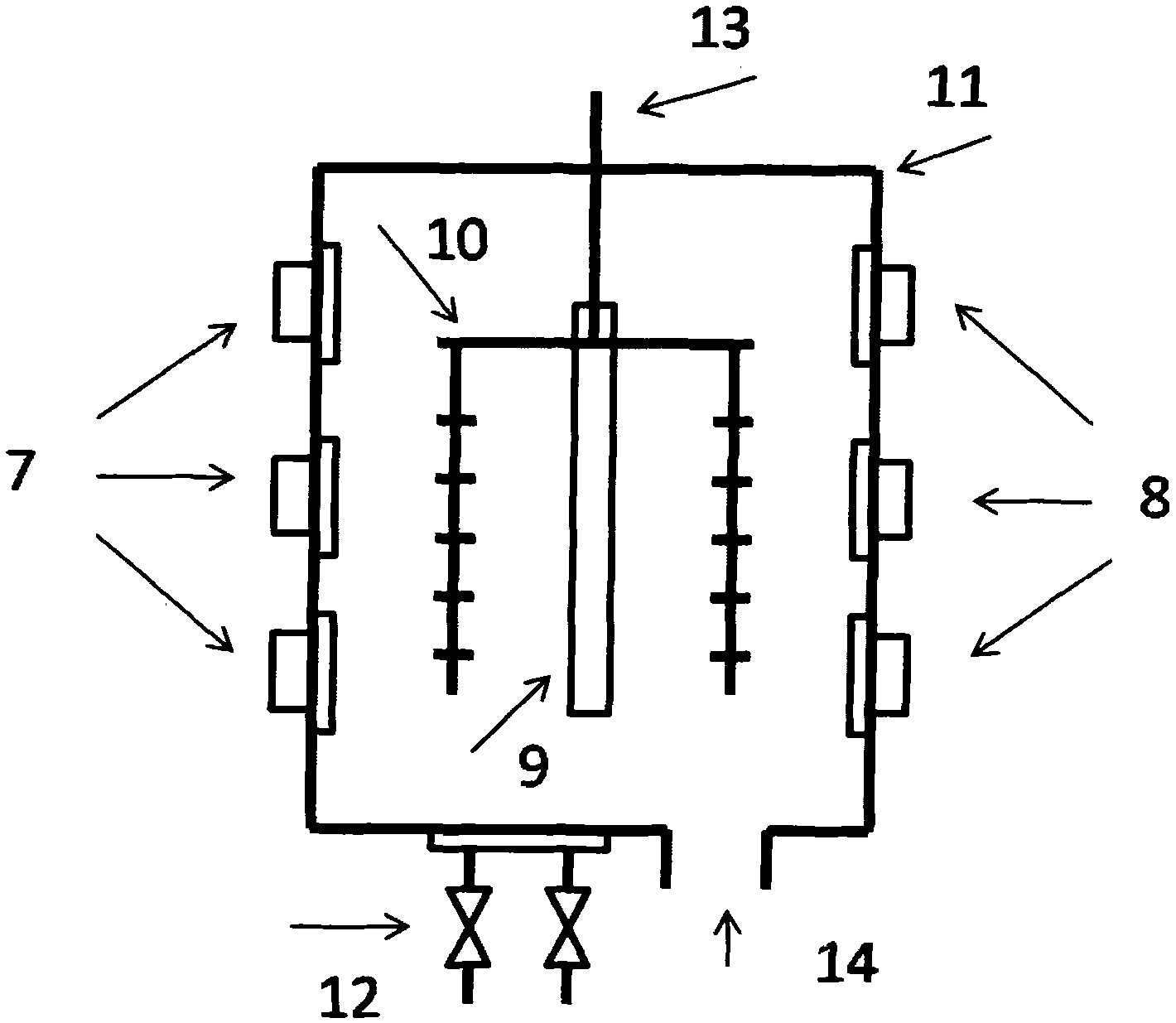

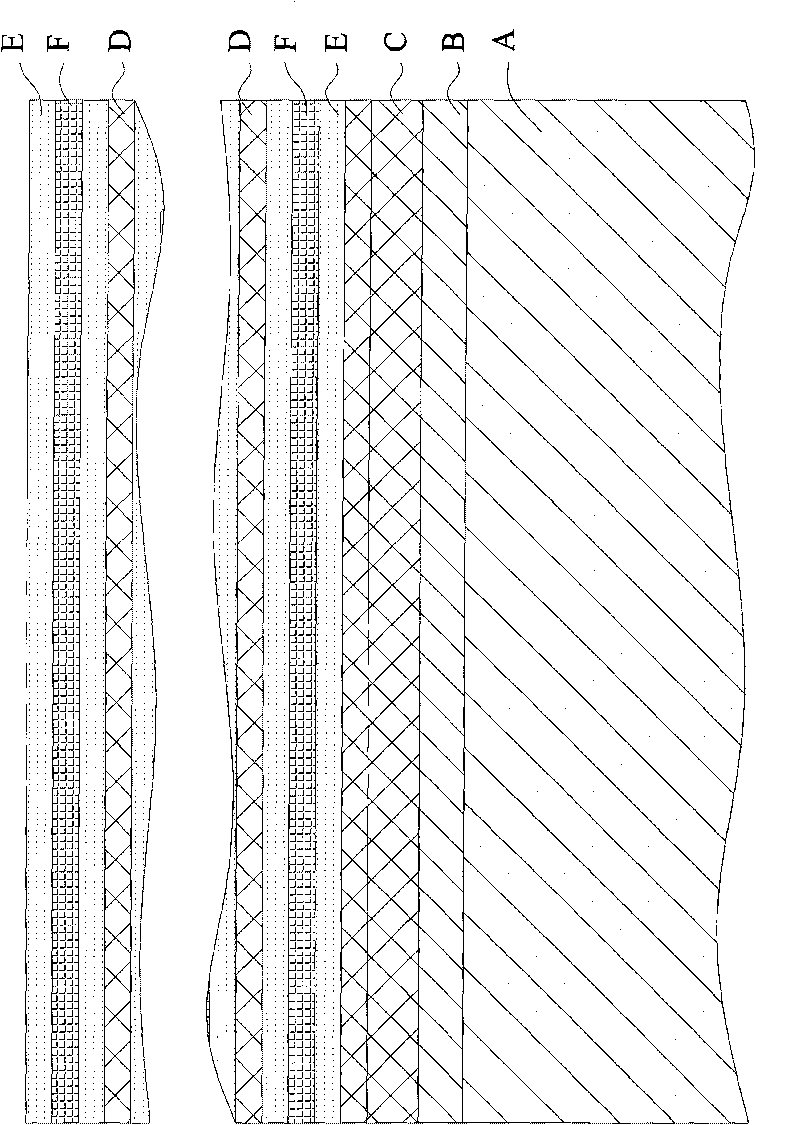

DLC (diamond-like carbon)/TiAlN (titanium aluminium nitride)/CrN (chromium nitride)/Cr (chromium) multilayer superhard film coating and preparation method thereof

InactiveCN102080207AImprove bindingImprove performanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideDiamond-like carbon

The invention discloses a DLC (diamond-like carbon) / TiAlN (titanium aluminium nitride) / CrN (chromium nitride) / Cr (chromium) multilayer superhard film coating for the surface treatment of piston rings of automobile engines, and the multilayer superhard film coating is prepared by adopting a multi-arc ion plating technology and a magnetron sputtering technology. The thickness of the prepared multilayer superhard film coating is between 5 mu m and 20 mu m (micrometer), and the hardness of the coating is greater than 40GPa.

Owner:SHENZHEN GUANGDA NANO ENG

Method for manufacturing aluminum alloy hollow section for sedan bumper

The invention discloses a method for manufacturing an aluminum alloy hollow section for a sedan bumper, relates to a method for manufacturing an aluminum alloy hollow section, and aims to solve the problem that domestic limousine bumpers are low in tensile strength and non-proportional extension strength and dependent on import. The method comprises the following steps of: 1, preparing alloy melt; 2, casting an alloy cast rod; 3, cutting the cast rod off; 4, turning the cast rod to remove oxide; 5, performing homogenizing annealing; 6, heating a cast ingot; 7, extruding; 8, pre-straightening;9, quenching; 10, straightening; 11, aging; and 12, cutting according to length to obtain the aluminum alloy hollow section for an automobile bumper. The straightness and size of the hollow section prepared by the method completely meet the standards of imported bumpers, and the hollow section has high comprehensive mechanical properties. The method can be used for processing and manufacturing sections for limousine bumpers.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Multi-coating cutting tool deposited in periodicity and preparation method thereof

ActiveCN101690978AAntioxidantHigh temperature stabilityLayered productsTurning toolsOxidation resistantHardness

The invention discloses a multi-coating cutting tool deposited in periodicity and a preparation method thereof. The multi-coating cutting tool comprises a cutting tool matrix and a coating deposited on the cutting tool matrix; the coating comprises a composite coating which is a multiple periodic coating taking TiN layer to TiSiN layer to TiAlSiN layer to TiSiN layer as one period. The multi-coating cutting tool prepared through simple process, conventional equipment and low manufacturing cost has high rigidity, high strength, excellent high-temperature oxidation resistance and high-temperature stability; and the coating and matrix have favorable bonding strength.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

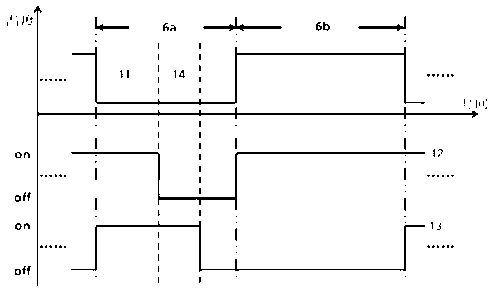

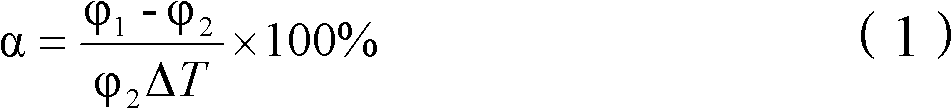

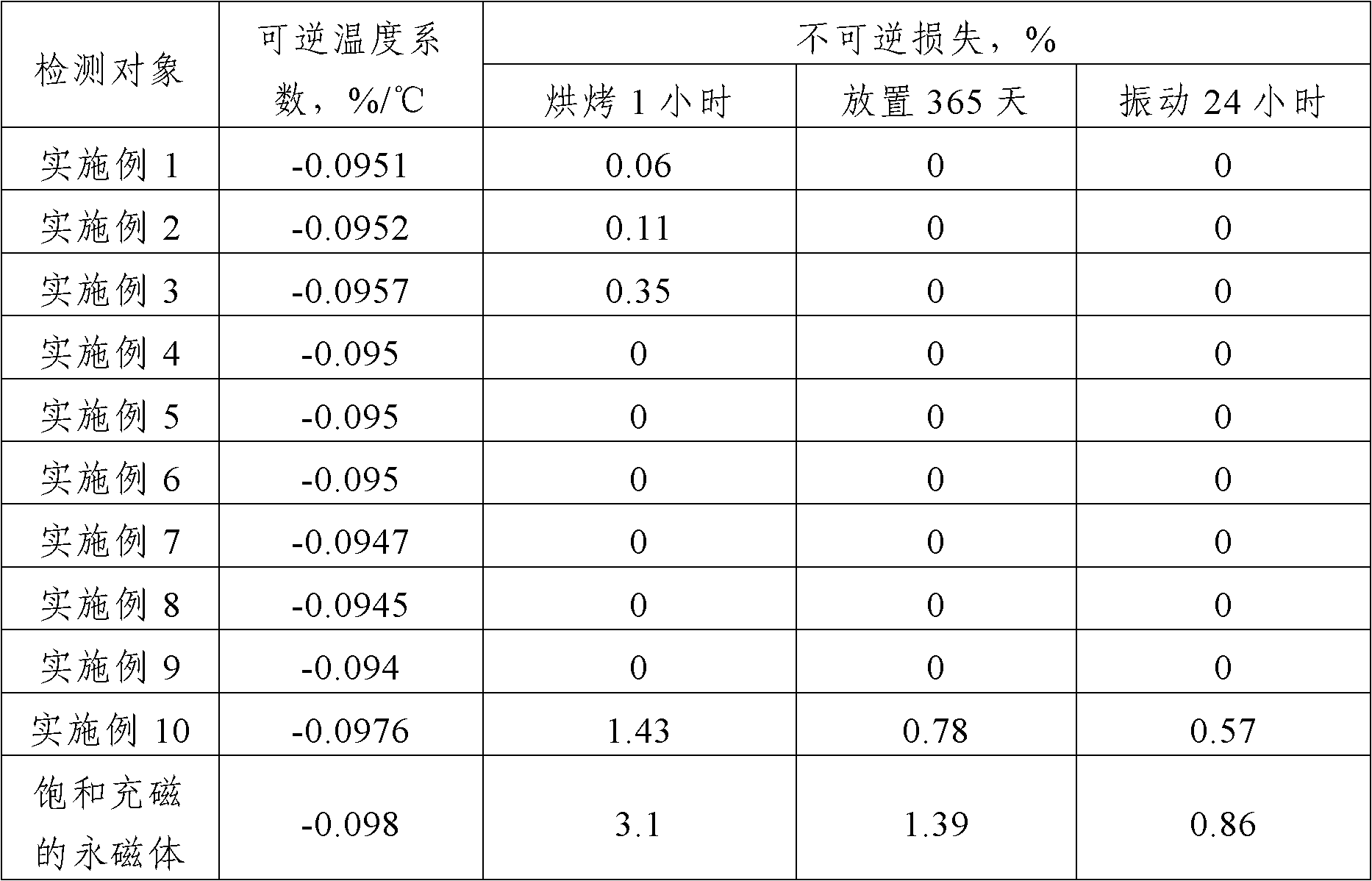

Cold-heat circulation aging treatment method for increasing magnetic stability of permanent magnets

ActiveCN102568808ASimple processEasy to operatePermanent magnetsInductances/transformers/magnets manufactureMagnetic stabilityRadiation resistant

The invention discloses a cold-heat circulation aging treatment method for increasing magnetic stability of permanent magnets. The method comprises the following steps of: putting one or more permanent magnets magnetized in a saturated manner on a non-magnetic bottom plate; then putting in a high-low temperature chamber, and freezing at minus 70 DEG C to minus 20 DEG C for 30-120 min; then, heating the high-low temperature chamber to 60-250 DEG C at the temperature increasing rate of 1-10 DEG C / min, and keeping the temperature for 30-240 min; and finally, naturally cooling to room temperature, and completing cold-heat circulation aging treatment. By adopting the method disclosed by the invention, total loss, irreversible loss, reversible loss and reversible temperature coefficients when temperature of the permanent magnets is changed can be effectively eliminated or reduced; and heat stability, time stability, magnetic stability and radiation-resistant magnetic stability of the permanent magnets under a vibration condition can be increased.

Owner:西安西工大思强科技股份有限公司

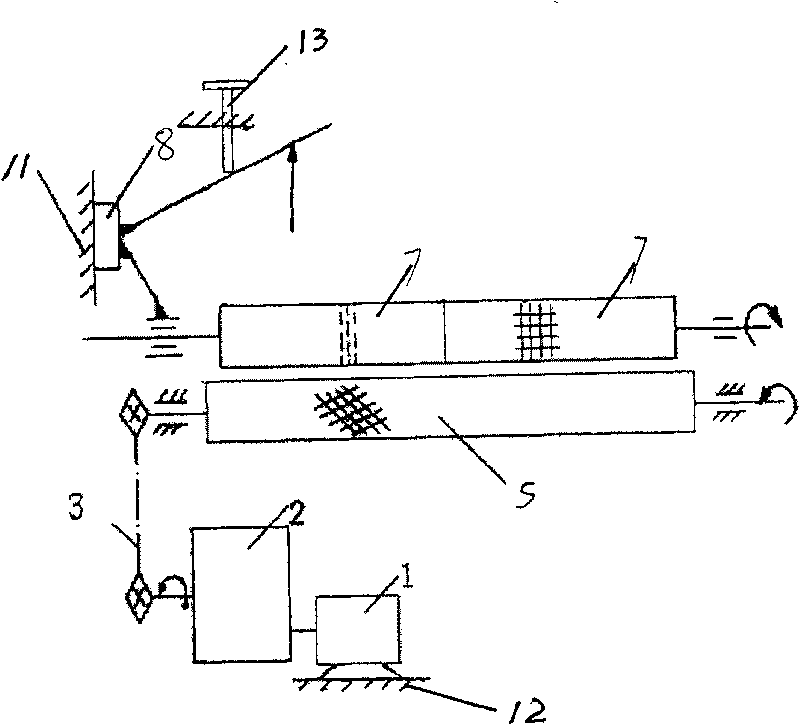

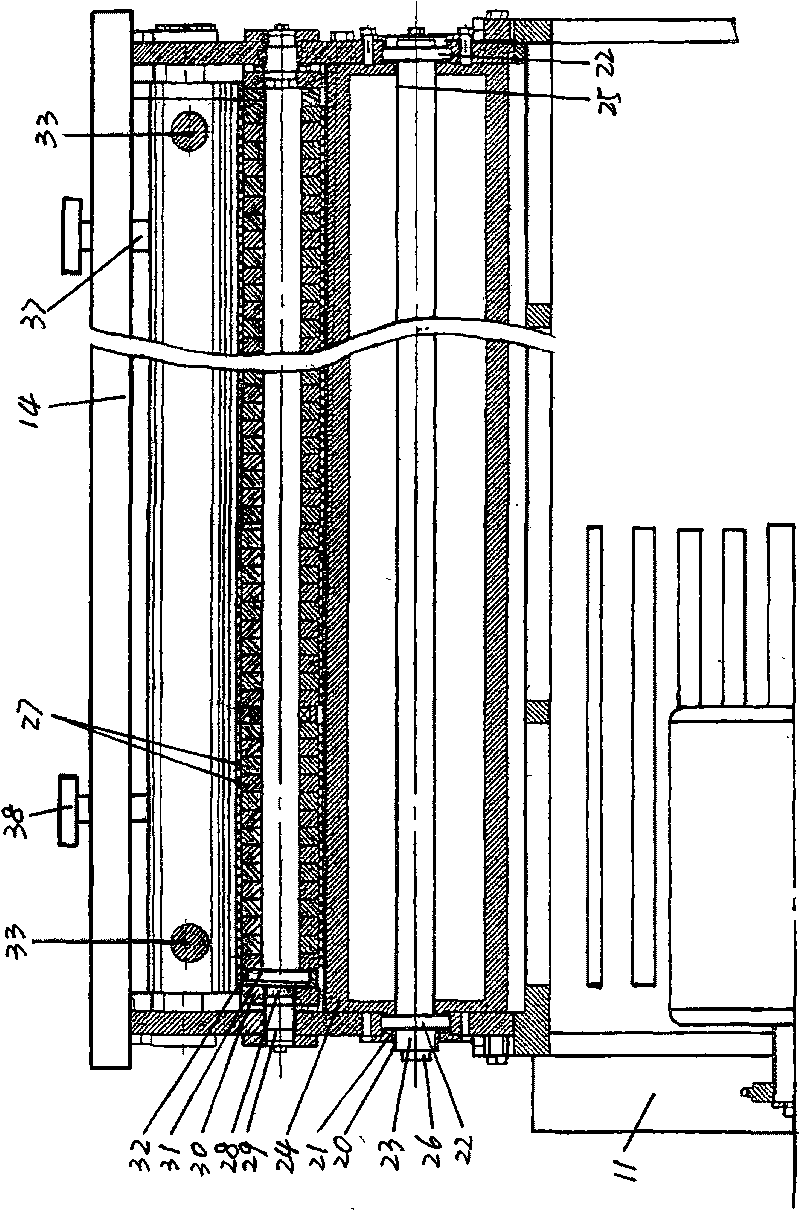

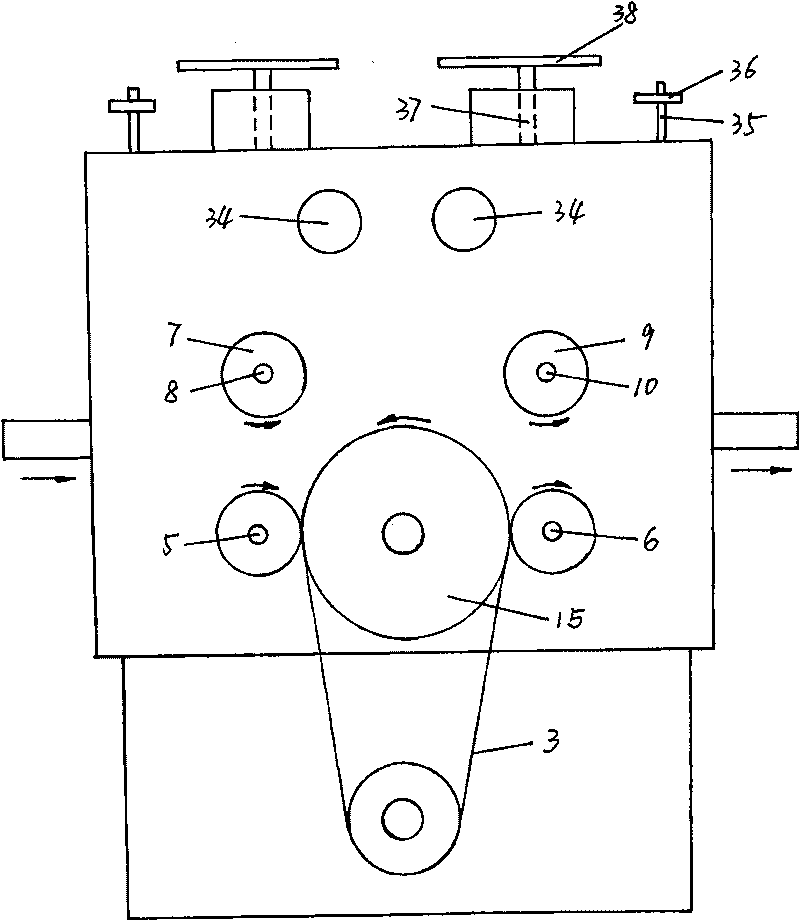

Green-removing and yellow-removing fluffer for bamboo

The invention relates to a green-removing and yellow-removing fluffer for bamboo. The device is provided with a pedestal, a main motor arranged on the pedestal, a main speed reducer and a case body. The improvement is that: the case body is also provided with two friction roller shaft systems, two fluffer shaft systems and a transmission gear shaft; each fluffer shaft system is formed by combining a shaft of which the two ends are provided with locking screw rods, a bearing and a plurality of deformed laminated untwining rotary blades fixed on the shaft by keys; each friction roller shaft system is formed by combining a roller shaft of which the two ends are provided with locking screw rods, the bearing, a gear and a textured friction roller body fixed on the roller shaft by a key; and an output shaft of the main motor is connected with the transmission gear shaft through a chain transmission device. The device can effectively remove wax green and yellow membrane and untwine bamboo fiber. The bamboo is processed into a meshed bamboo chip curtain which is not broken in the longitudinal direction and is transversely loose and connected in a staggered way, so the arrangement direction of bamboo fiber is kept. The bamboo curtain can produce restructured bamboo through an ordinary plate-making process, so the utilization rate of the bamboo reaches over 90 percent.

Owner:廊坊市双安结构胶合板研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com