Method for enhancing luminous efficiency of multiquantum well of semiconductor diode

A technology of multiple quantum wells and luminous efficiency, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of reducing the luminous efficiency of quantum wells, and achieve the effect of improving the probability of crossing, uniform distribution, and preventing the decline of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

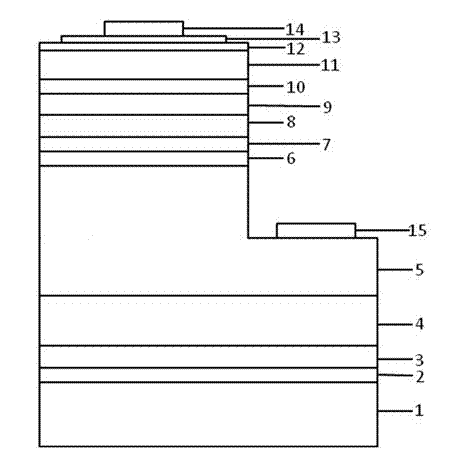

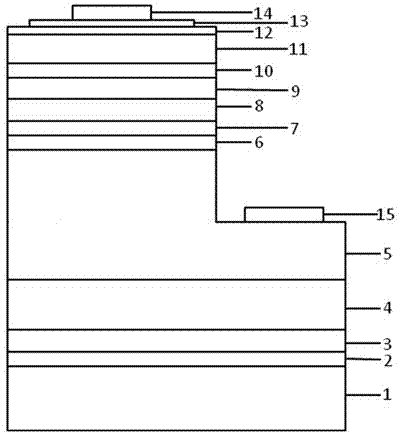

[0034] Such as figure 1 Shown:

[0035] (1) Substrate 1: First, anneal the sapphire substrate at a temperature of 1200°C in a pure hydrogen atmosphere, and then lower the temperature to 600°C for nitriding treatment;

[0036] (2) Low-temperature buffer layer 2: grow a 20nm-thick low-temperature GaN nucleation layer at 600°C. During this growth process, the growth pressure is 420Torr, and the V / III molar ratio is 900;

[0037] (3) High-temperature buffer layer 3: After the growth of low-temperature buffer layer 2 is completed, stop feeding TMGa, raise the substrate temperature by 1220°C, and anneal the low-temperature buffer layer 2 in situ, and the annealing time is 8 minutes; after annealing , adjust the temperature to 1220°C, and epitaxially grow high-temperature undoped GaN with a thickness of 1.2 μm under the lower V / III molar ratio. During this growth process, the growth pressure is 200 Torr, and the V / III molar ratio is 1500 ;

[0038] (4) N-type layer 4: After the...

Embodiment 2

[0053] In Example 2, the growth methods of the epitaxial layers 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, and 12 are the same as those in Example 1. The difference lies in the growth method of the multi-quantum well layer 8: the growth temperature of the well region in MQW (8) is 880°C, 860°C, 840°C, 820°C, and 800°C in sequence, and the In Composition, the flow rate of In during the growth process remains unchanged, and the composition of In is 0.04, 0.08, 0.12, 0.16, 0.20;

[0054] After the chip manufacturing process and testing under the same conditions, the optical output power of a 10×8mil single small chip is 5.4mW, the working voltage is 3.18V, and it can be antistatic: the human body model is 5000V.

Embodiment 3

[0056] In Example 3, the growth methods of the epitaxial layers 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, and 12 are the same as those in Example 1. The difference lies in the growth method of the multi-quantum well layer 8: the growth temperature of the barrier region in the MQW (8) is 950°C, 940°C, 930°C, 920°C, and 910°C in sequence, and the flow rate of In in the well region is kept constant. The change of the temperature of the barrier region changes the In composition of the well region, and the composition of In is 0.06, 0.12, 0.18, 0.24, 0.3 in turn;

[0057] After the chip manufacturing process and testing under the same conditions, the optical output power of a 10×8mil single small chip is 5.5mW, the working voltage is 3.23V, and it can be antistatic: the human body model is 5000V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com