Deep-UV light-emitting diode and preparation method thereof

A light-emitting diode, deep ultraviolet technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem that it is difficult to obtain a smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

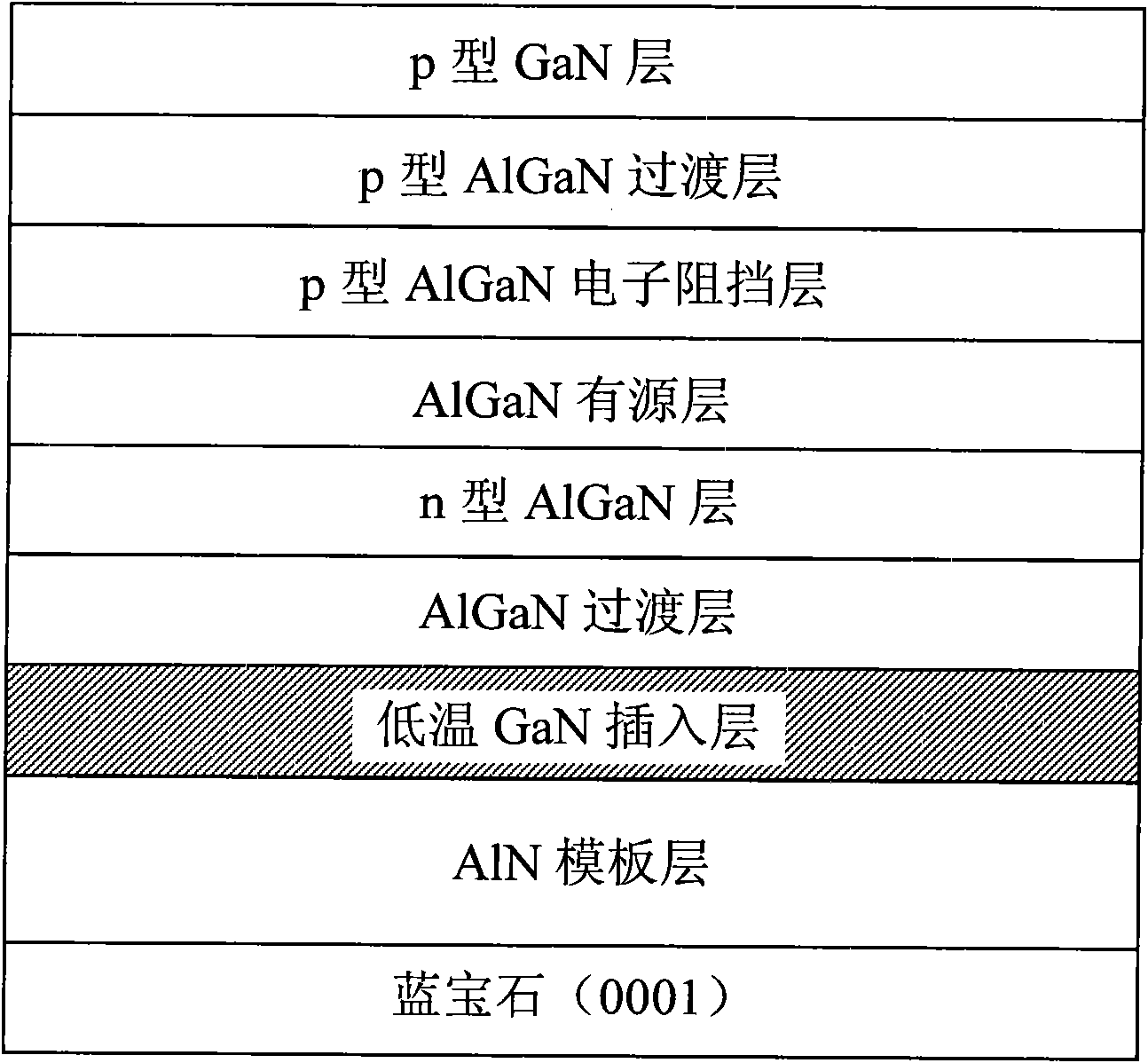

[0036] Deep-UV LEDs were fabricated by metal-organic chemical vapor deposition (MOCVD) according to the following steps:

[0037] 1) Raise the temperature of the reaction chamber to 1060°C, and heat and bake the sapphire substrate in a hydrogen atmosphere for 15 minutes;

[0038] 2) Raise the temperature to 1200°C to grow a 320nm AlN template layer, growth conditions: pressure 50torr, V / III 600;

[0039] 3) Lower the temperature to 500°C, and grow a 20nm low-temperature GaN insertion layer on the basis of step 2), growth conditions: temperature 500°C, pressure 75torr, V / III 1500;

[0040] 4) Raise the temperature to 1150°C at a rate of 1°C per second, and grow 70nm Al on the basis of step 3) 0.7 Ga 0.3 The N layer is used as a transition layer, the growth pressure is 75torr, V / III 1500;

[0041] 5) keep the temperature constant, and grow 1 μm n-type Al on the basis of step 4) 0.6 Ga 0.4 The N layer is used as the n-type contact layer, the growth pressure is 75 torr, V / III...

Embodiment 2

[0050] Deep-UV LEDs were fabricated by metal-organic chemical vapor deposition (MOCVD) according to the following steps:

[0051] 1) Raise the temperature of the reaction chamber to 1060°C, and heat and bake the sapphire substrate in a hydrogen atmosphere for 15 minutes;

[0052] 2) Raise the temperature of the reaction chamber to 1200°C, using TMAl and NH 3 A pulsed AlN buffer layer with a thickness of 100nm was grown for 100 cycles by the pulsed atomic layer epitaxy method alternately fed into the reaction chamber, the specific growth pressure was 150 torr, V / III was 600, and each cycle was 5s TMAl / 3s hydrogen gas / 5s NH 3 / 3s hydrogen;

[0053] 3) Increase the temperature to 1200°C, and grow a 320nm AlN template layer on the basis of step 2), with a growth pressure of 50torr and V / III 600;

[0054] 4) Lower the temperature to 500°C, grow a 20nm low-temperature GaN insertion layer on the basis of step 3), growth pressure 75torr, V / III 1500;

[0055] 5) Raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com