Patents

Literature

36 results about "Atomic layer epitaxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atomic layer epitaxy (ALE), more generally known as atomic layer deposition (ALD), is a specialized form of thin film growth (epitaxy) that typically deposit alternating monolayers of two elements onto a substrate. The crystal lattice structure achieved is thin, uniform, and aligned with the structure of the substrate. The reactants are brought to the substrate as alternating pulses with "dead" times in between. ALE makes use of the fact that the incoming material is bound strongly until all sites available for chemisorption are occupied. The dead times are used to flush the excess material. It is mostly used in semiconductor fabrication to grow thin films of thickness in the nanometer scale.

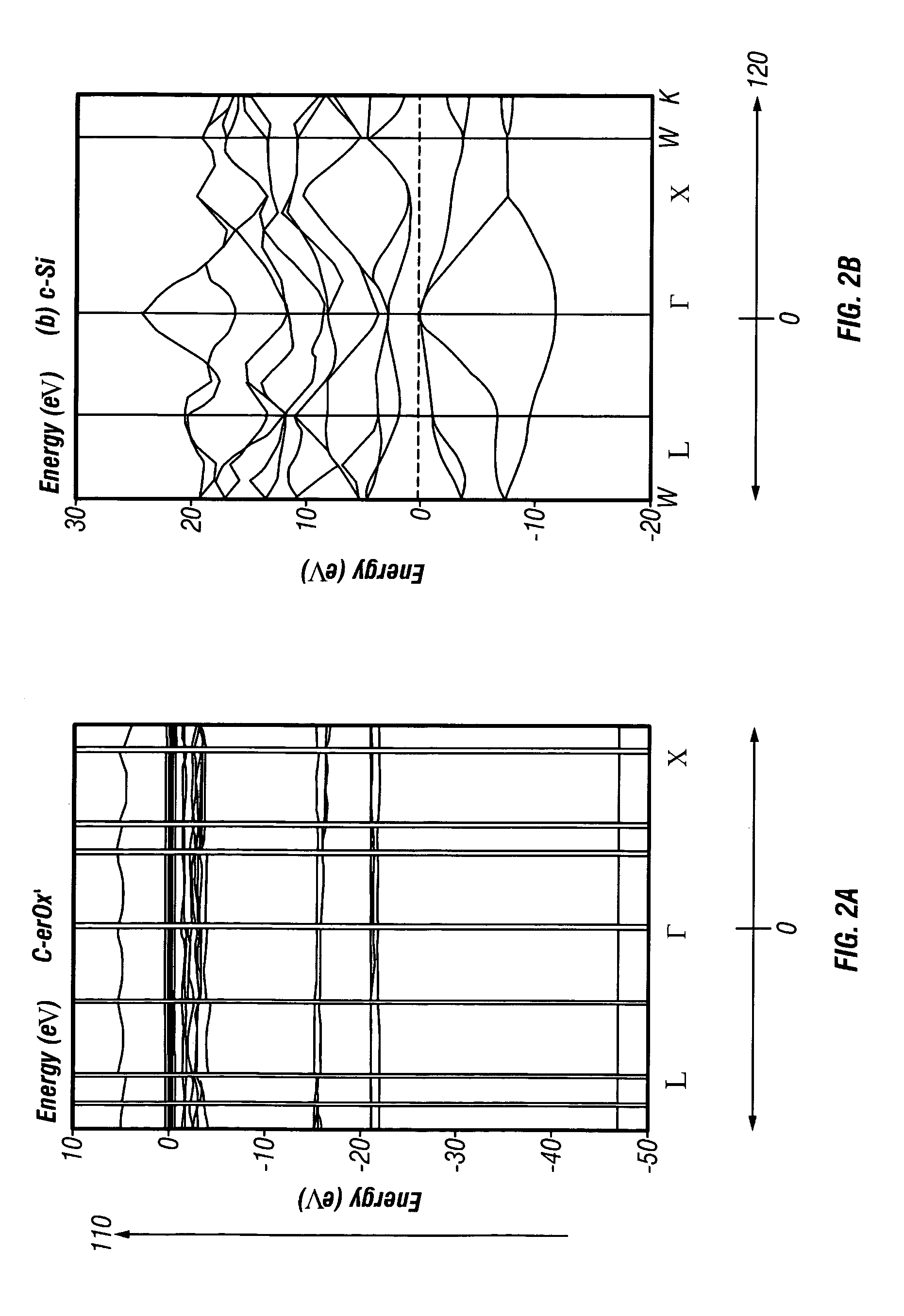

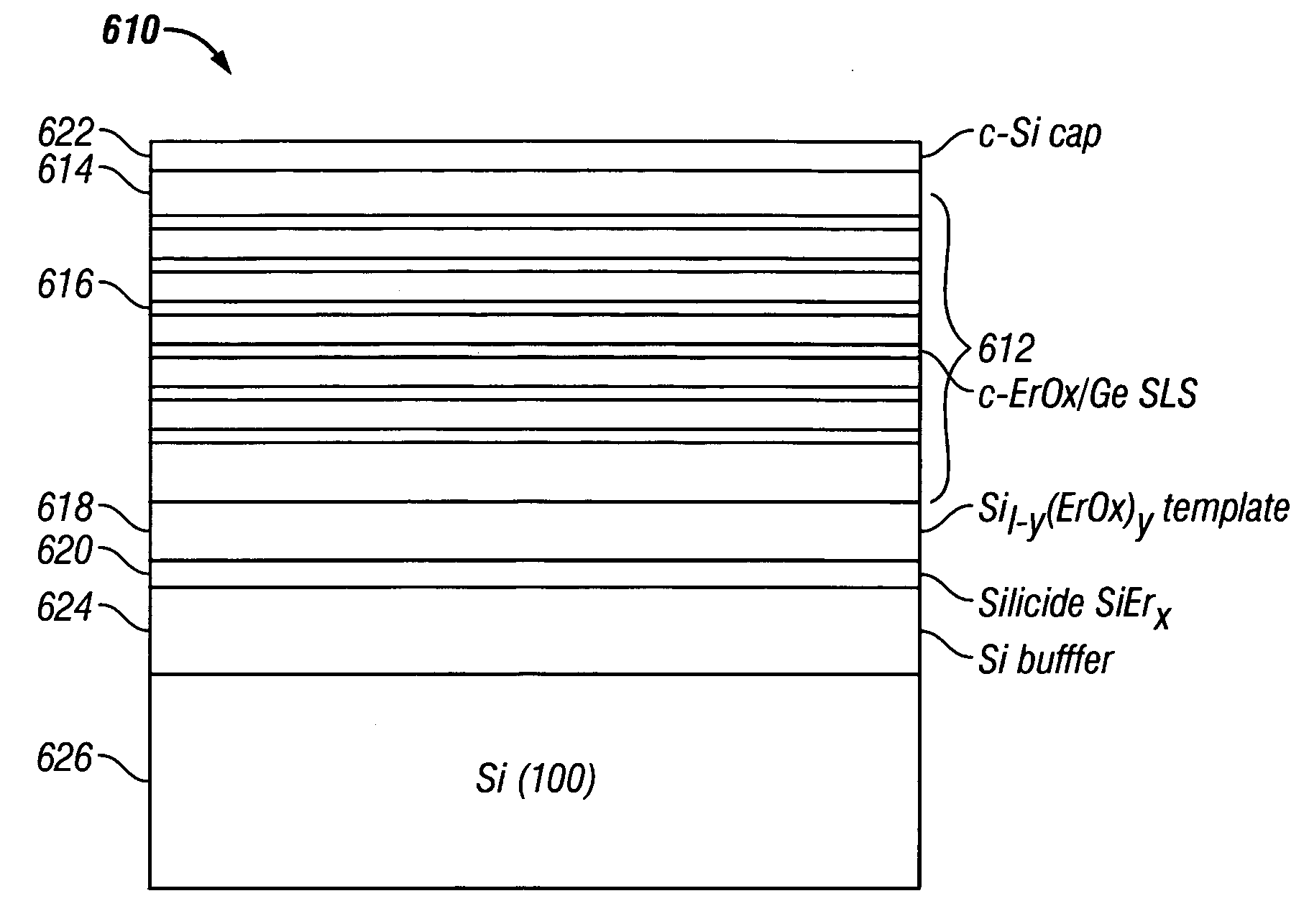

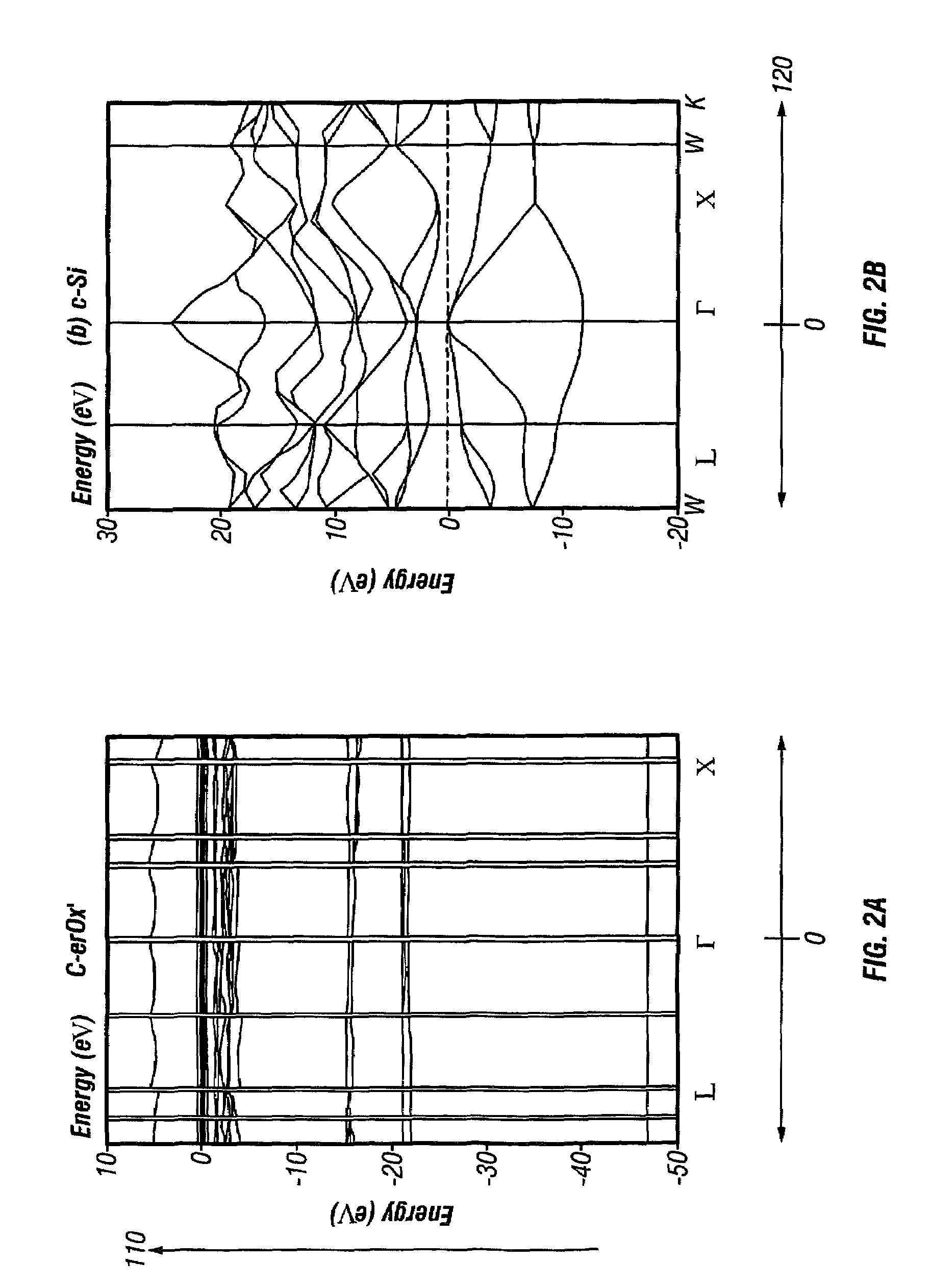

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

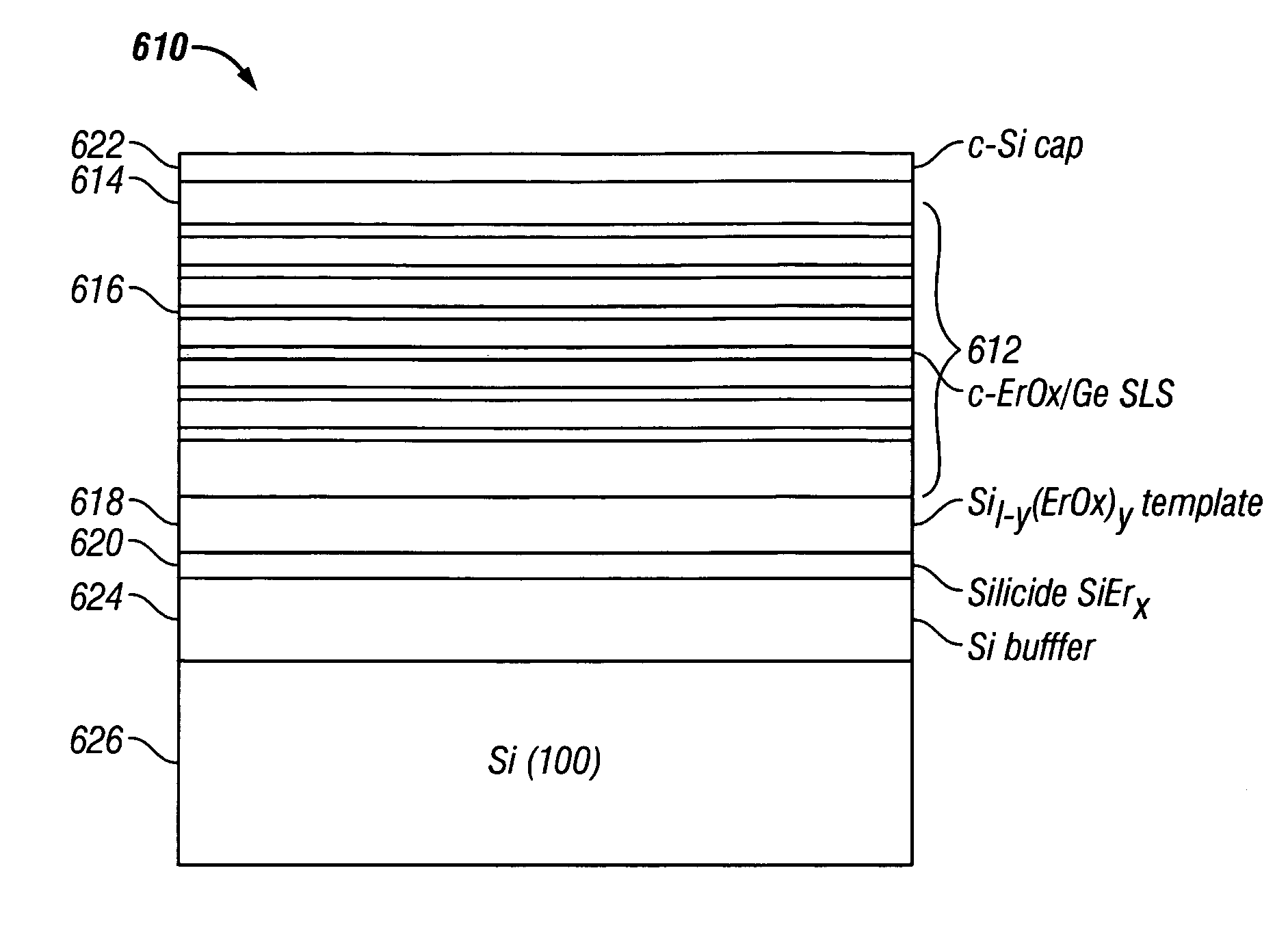

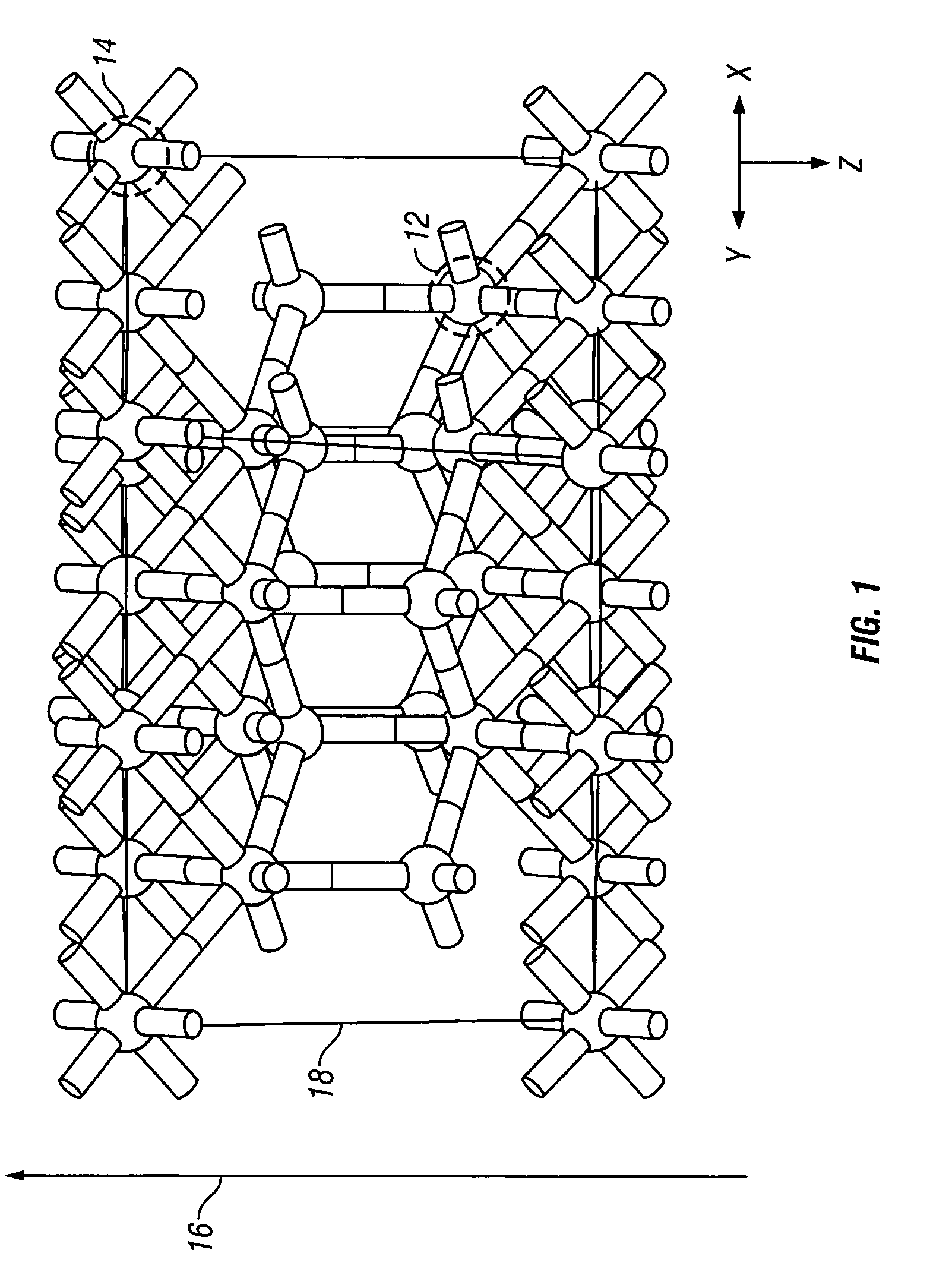

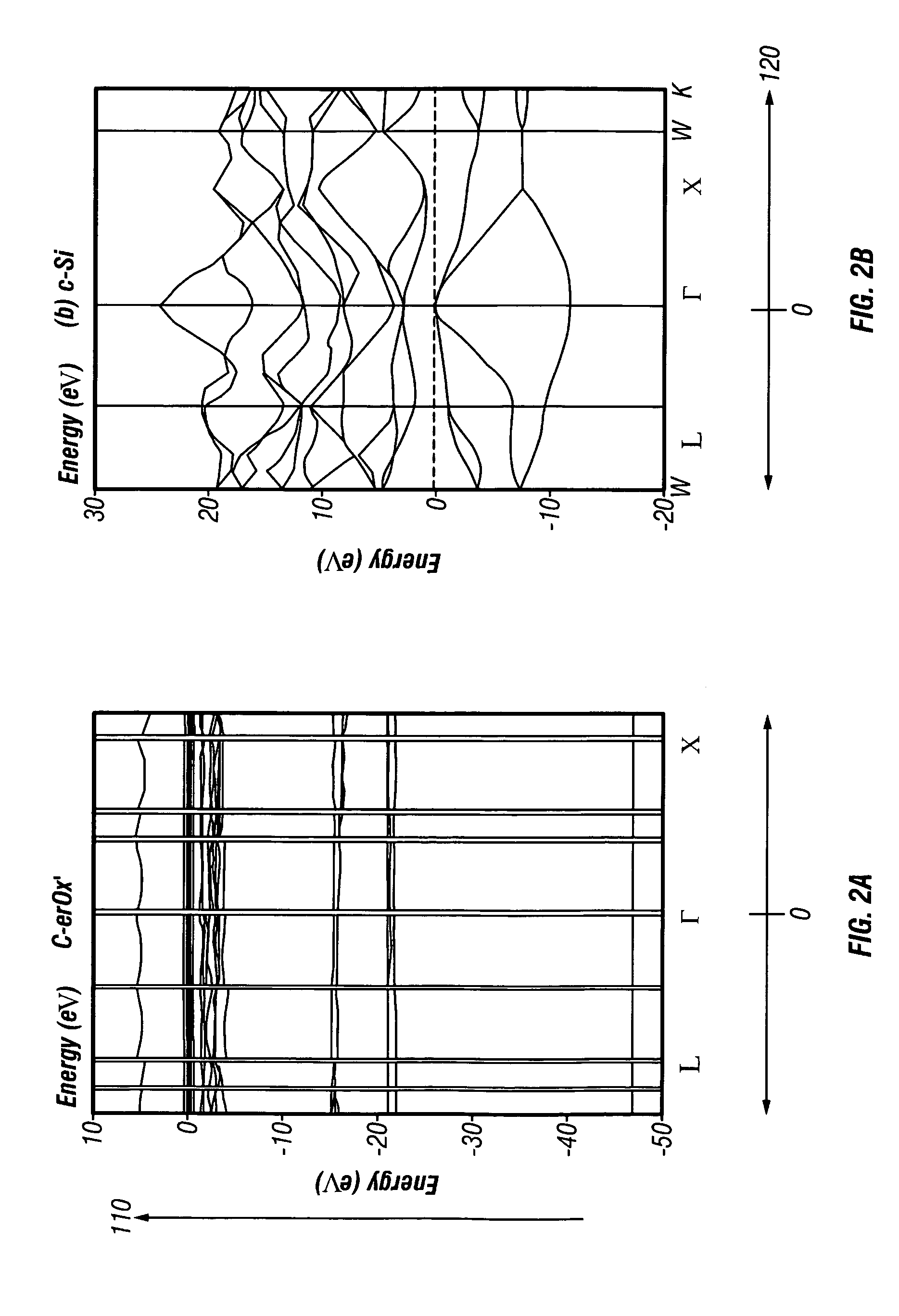

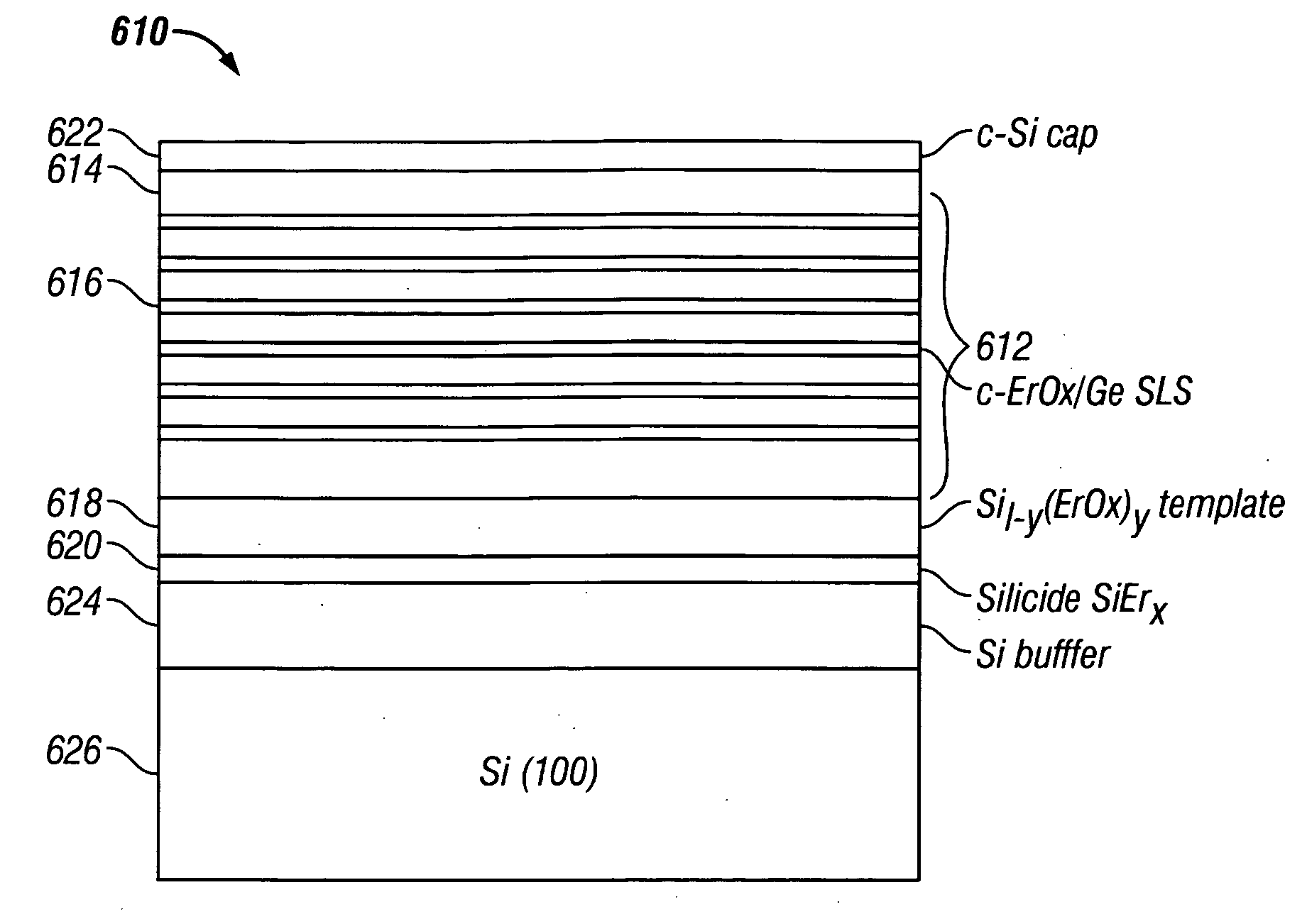

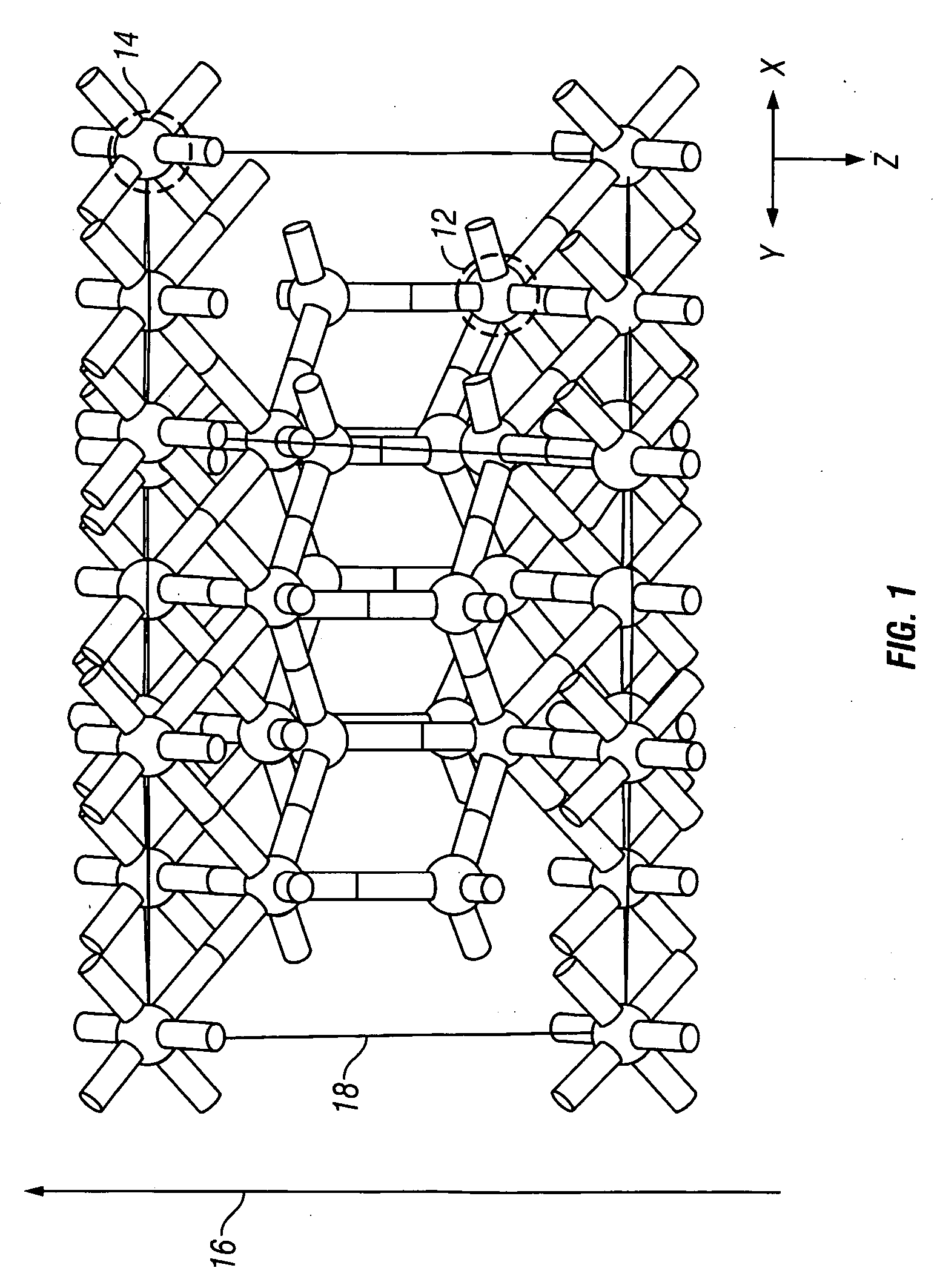

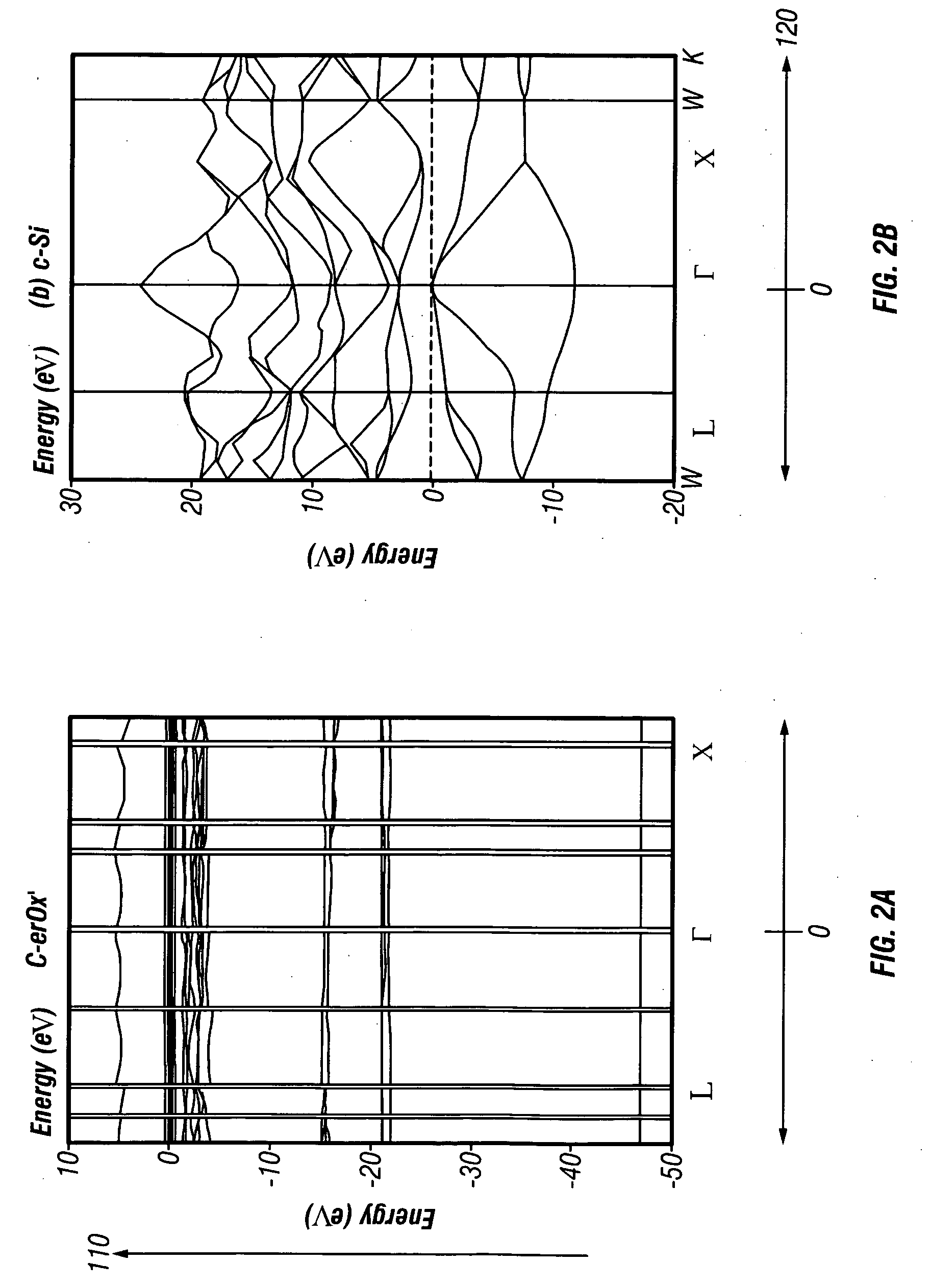

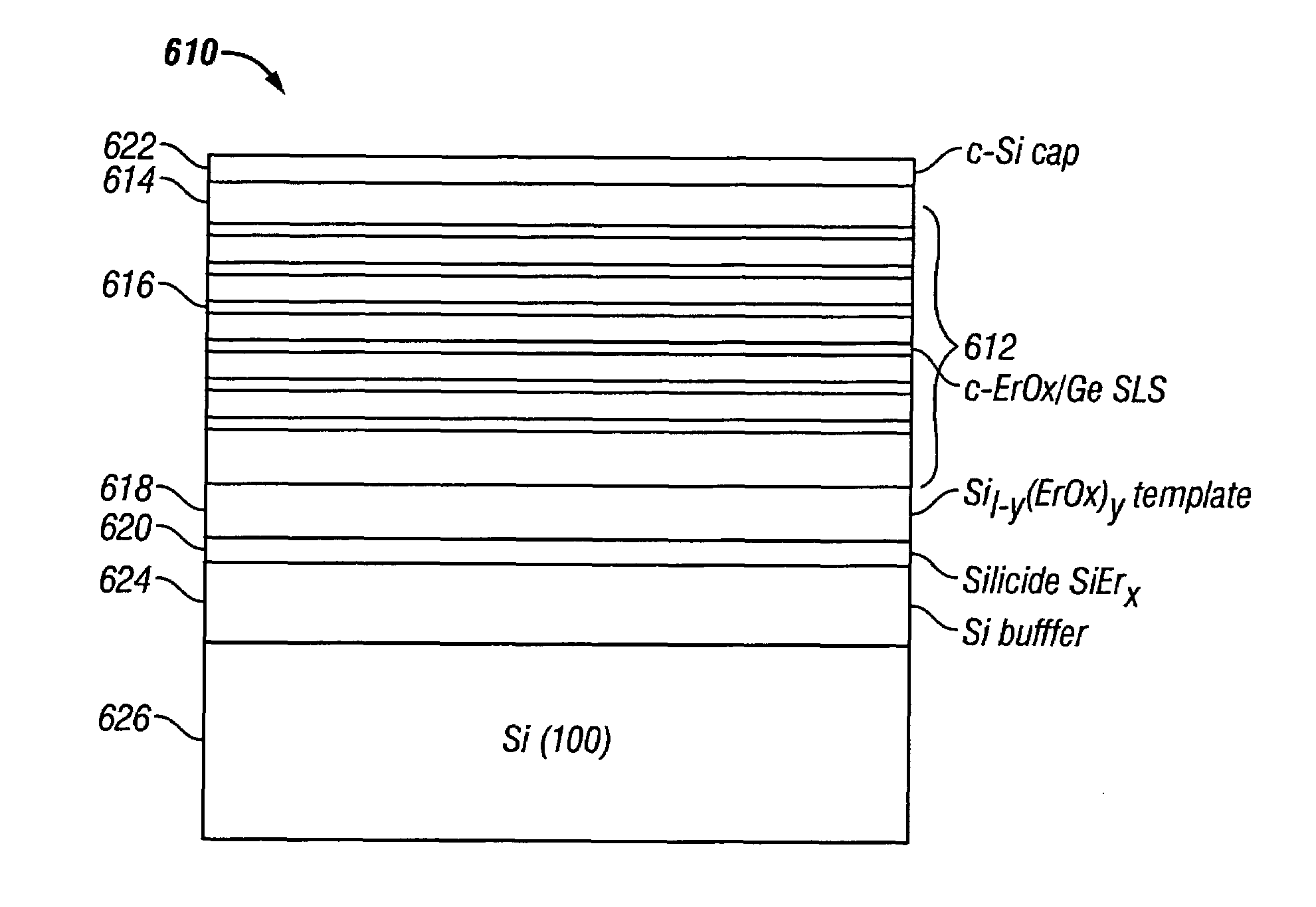

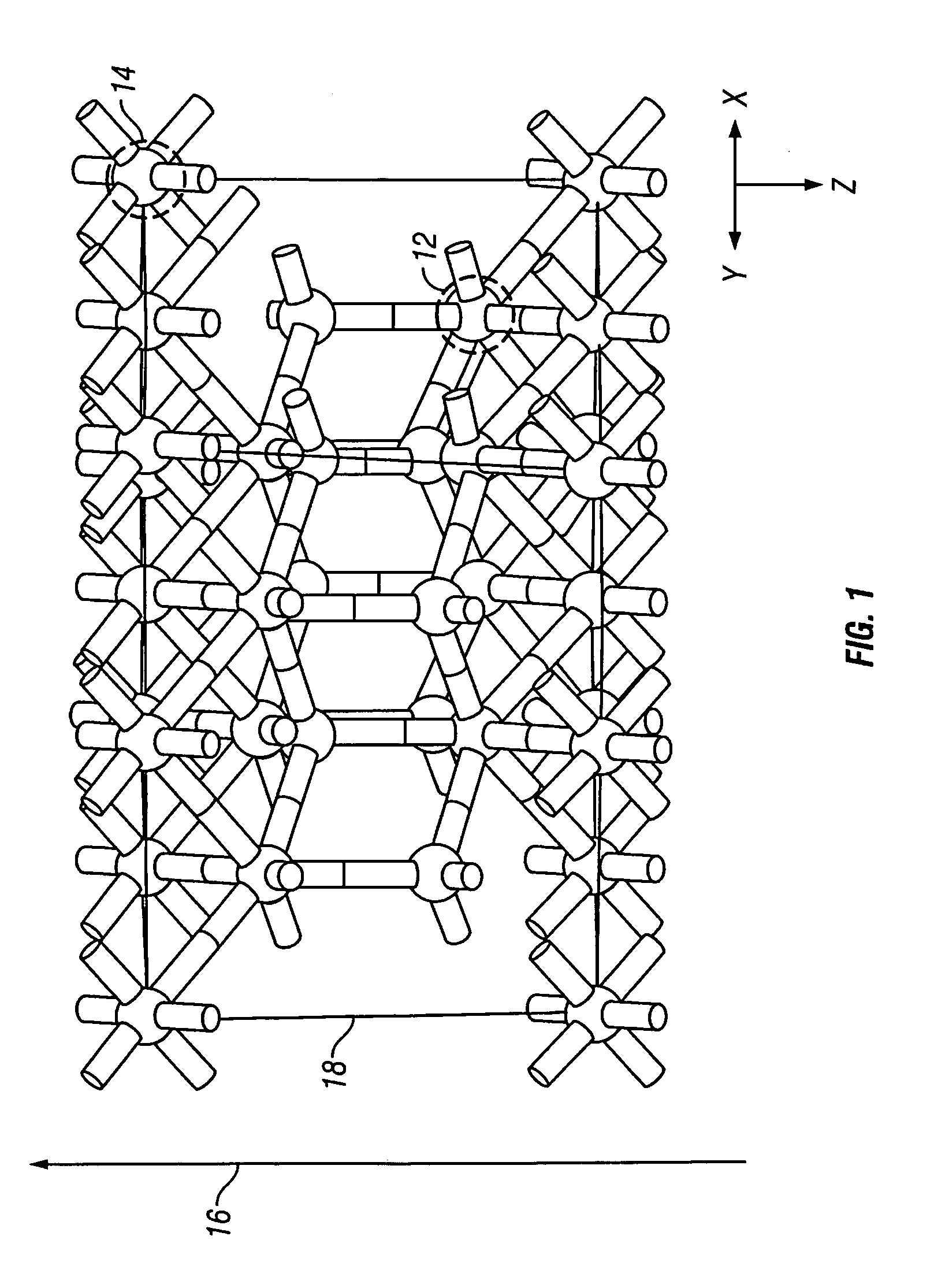

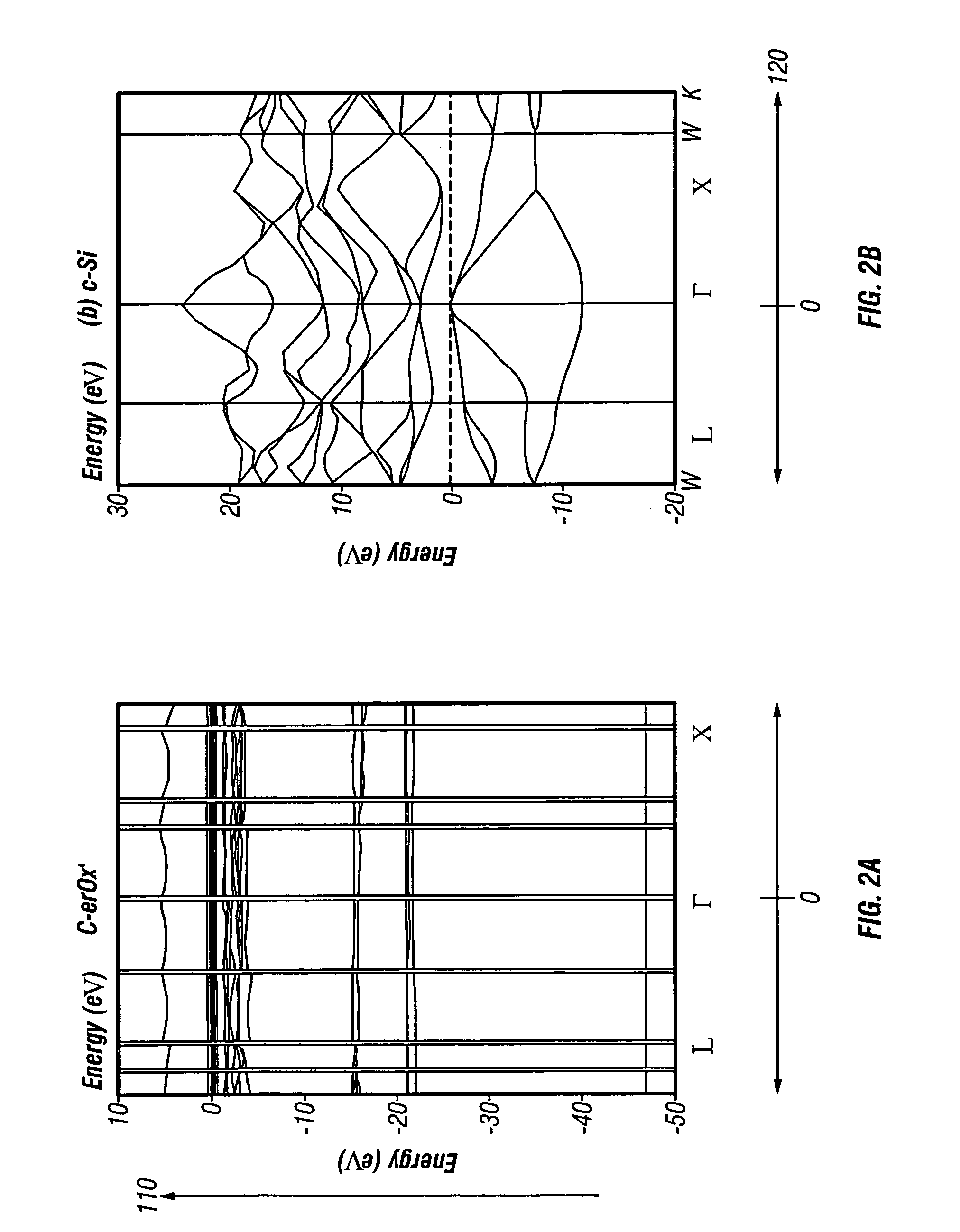

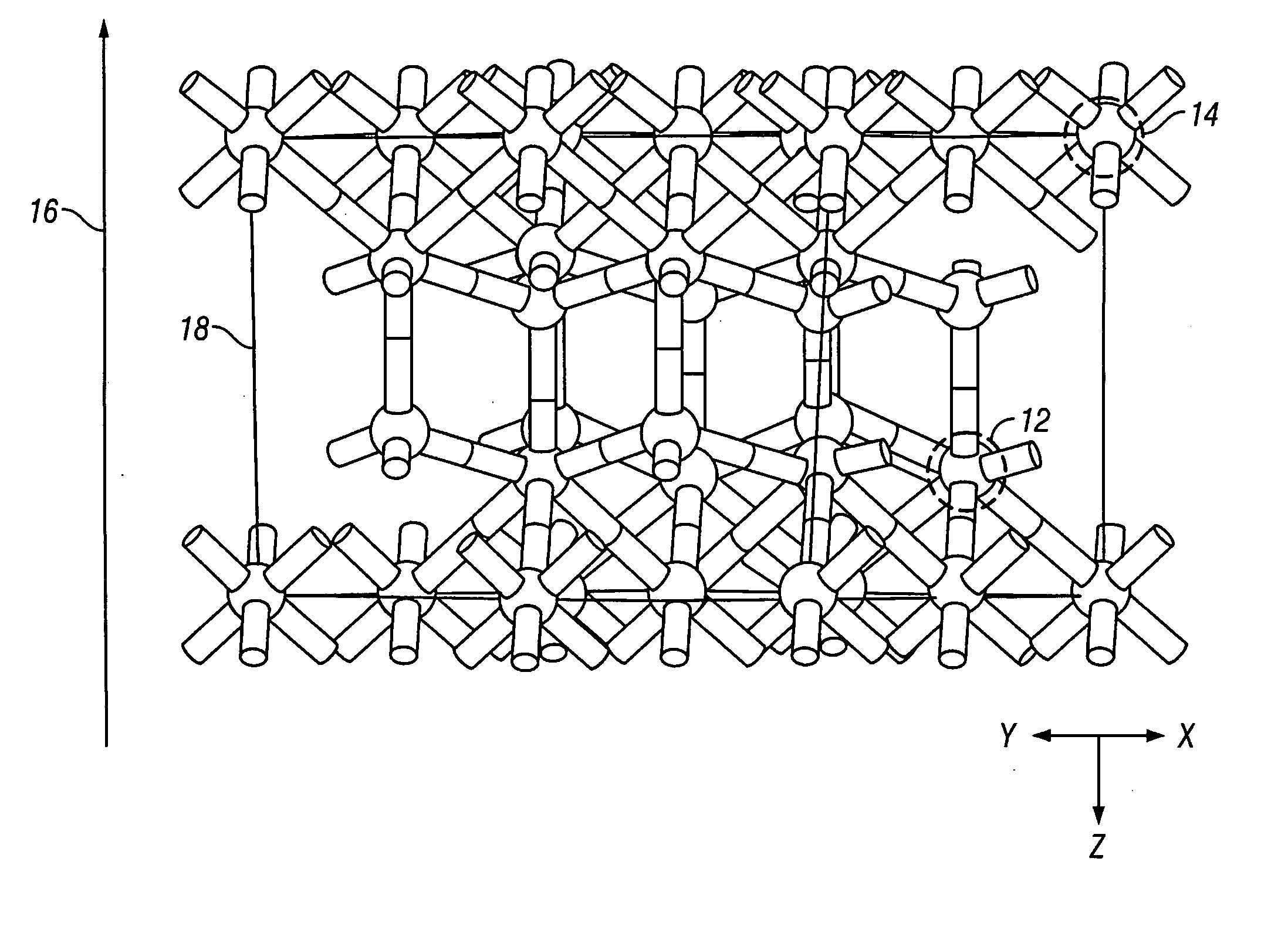

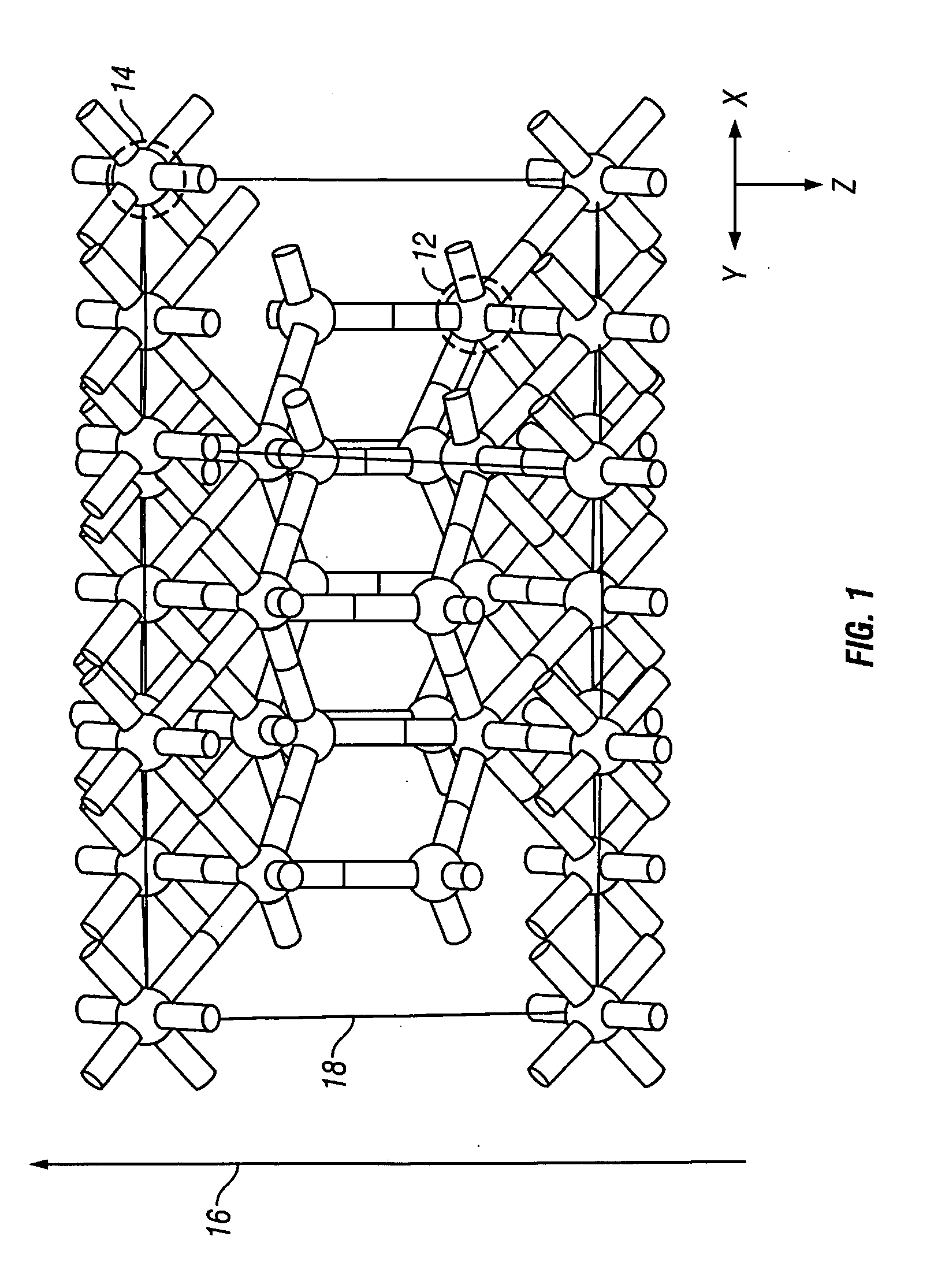

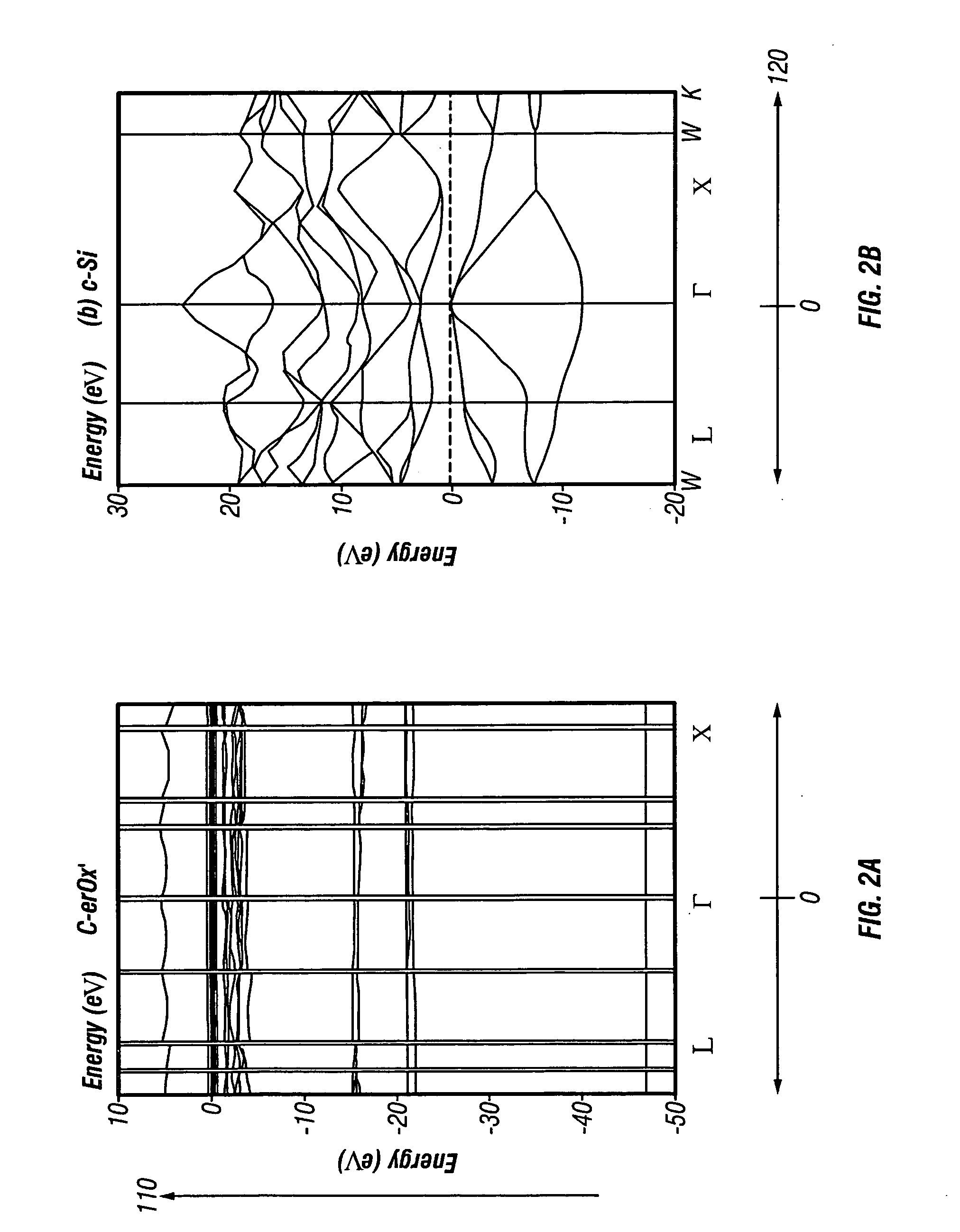

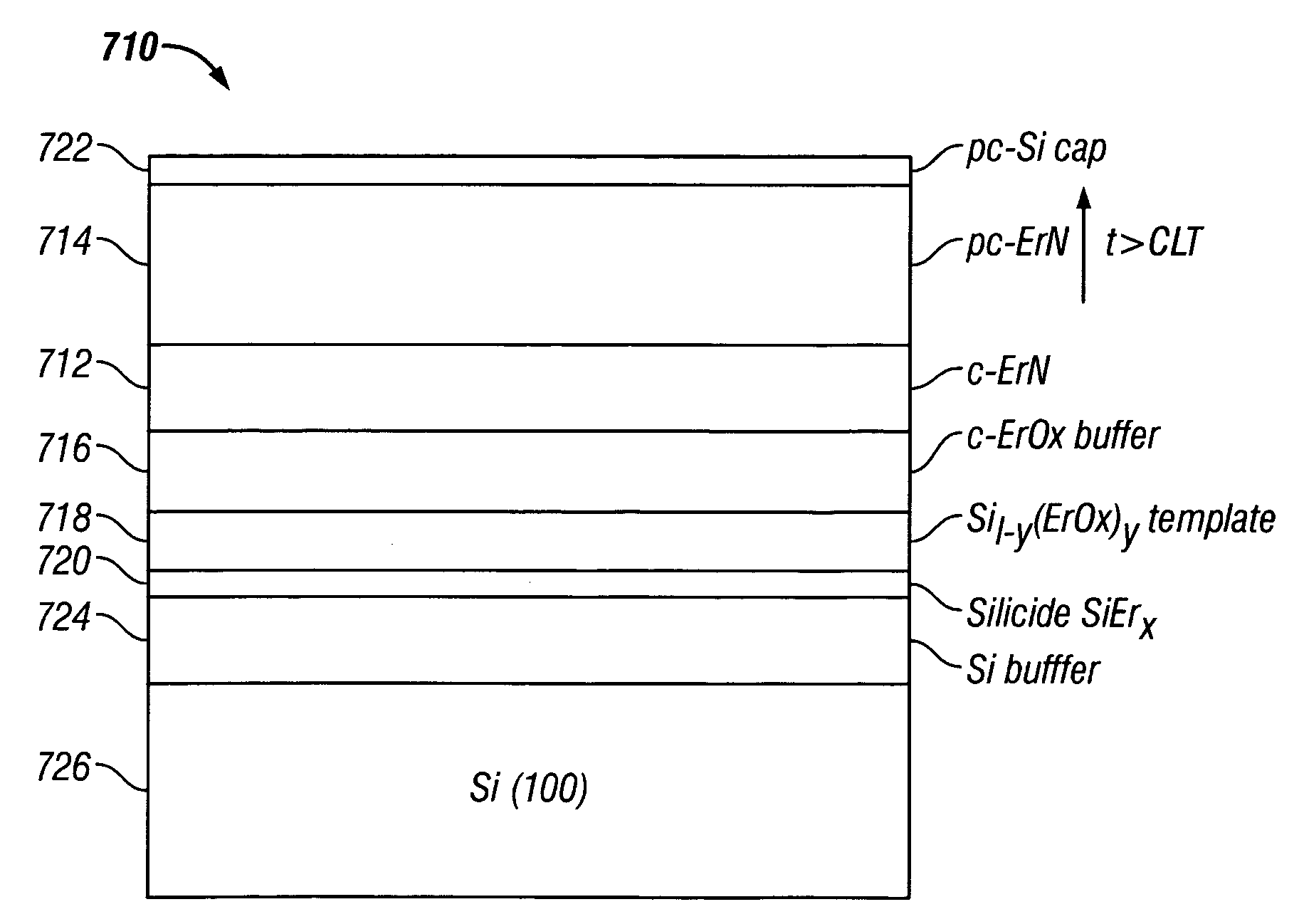

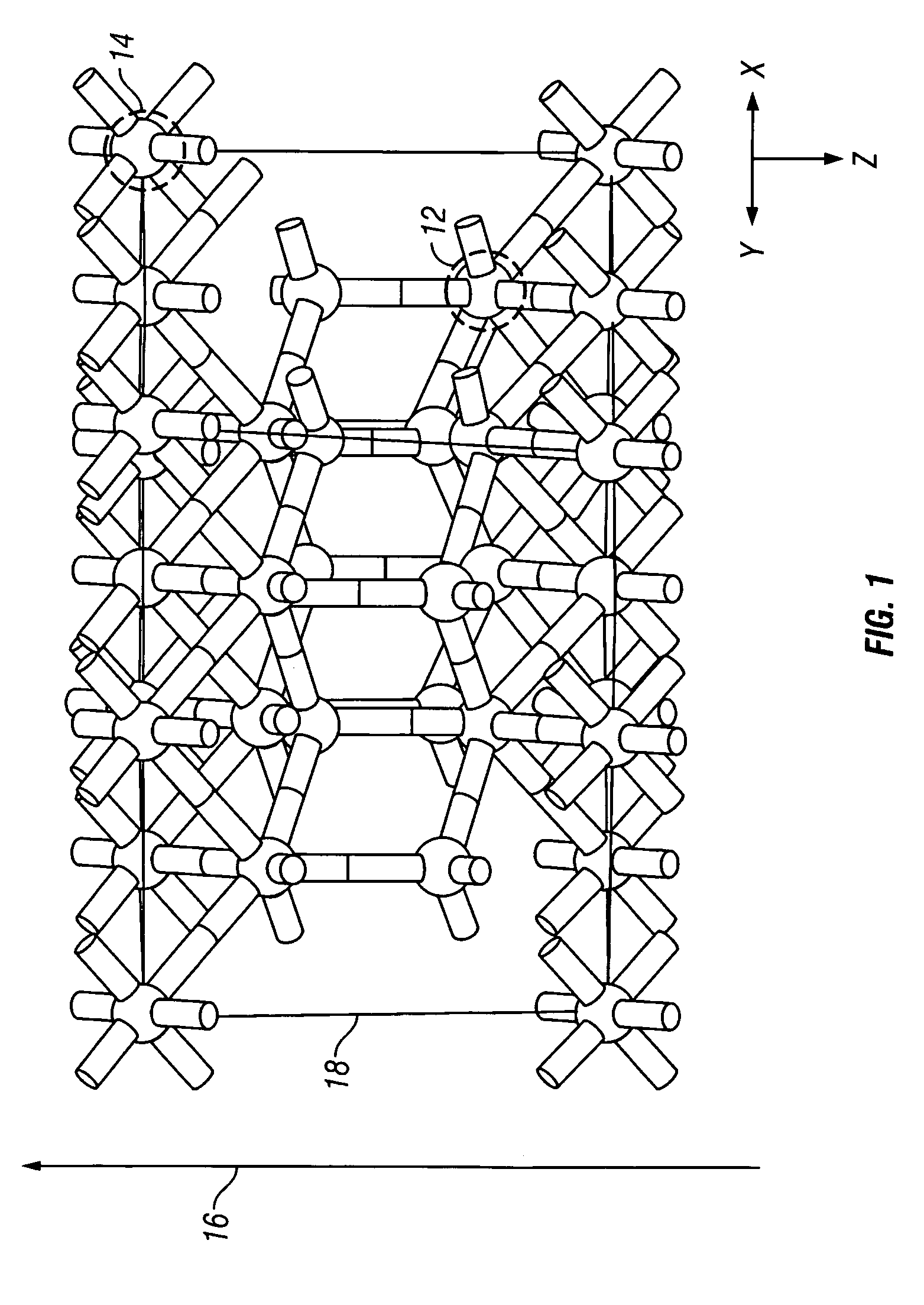

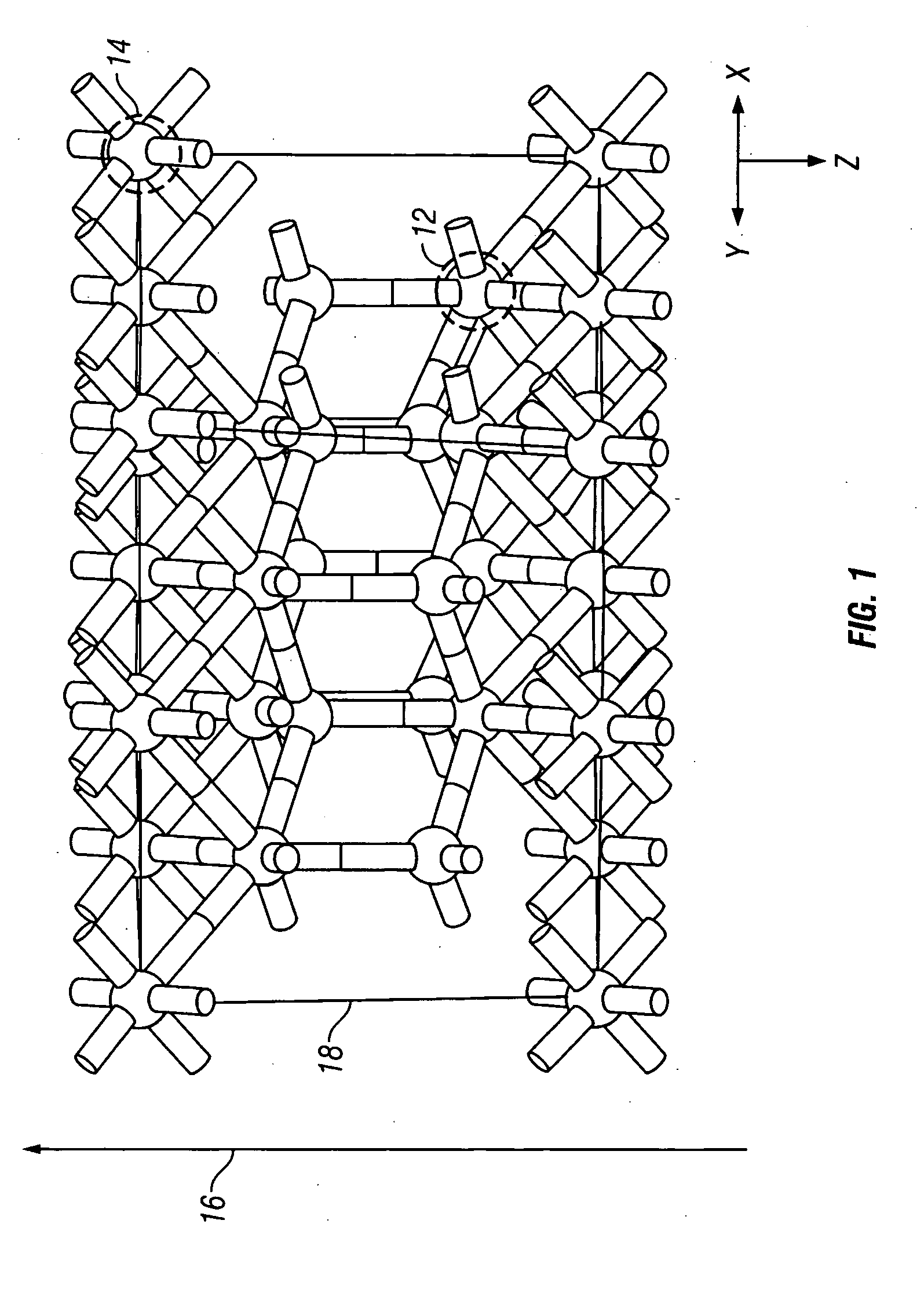

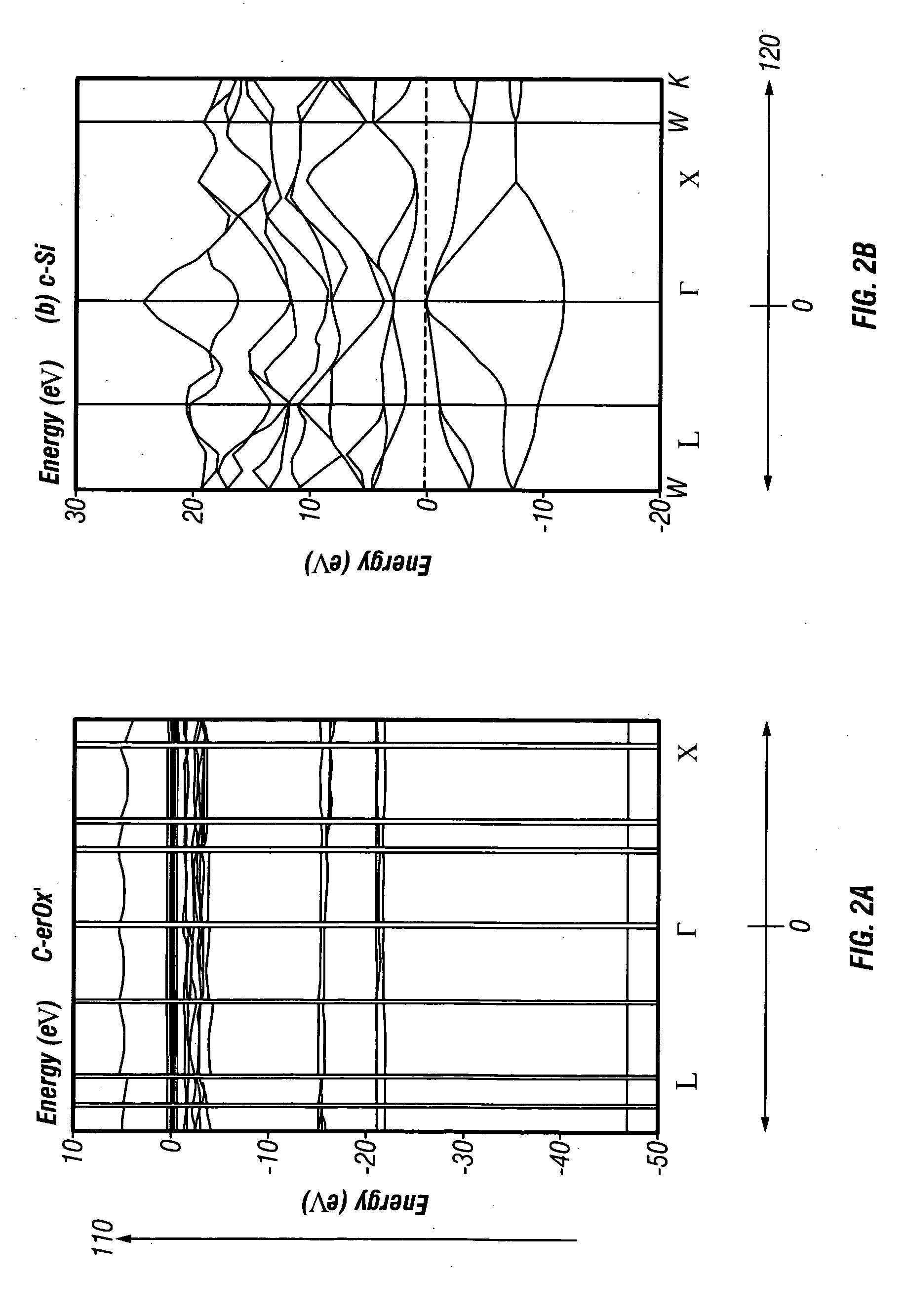

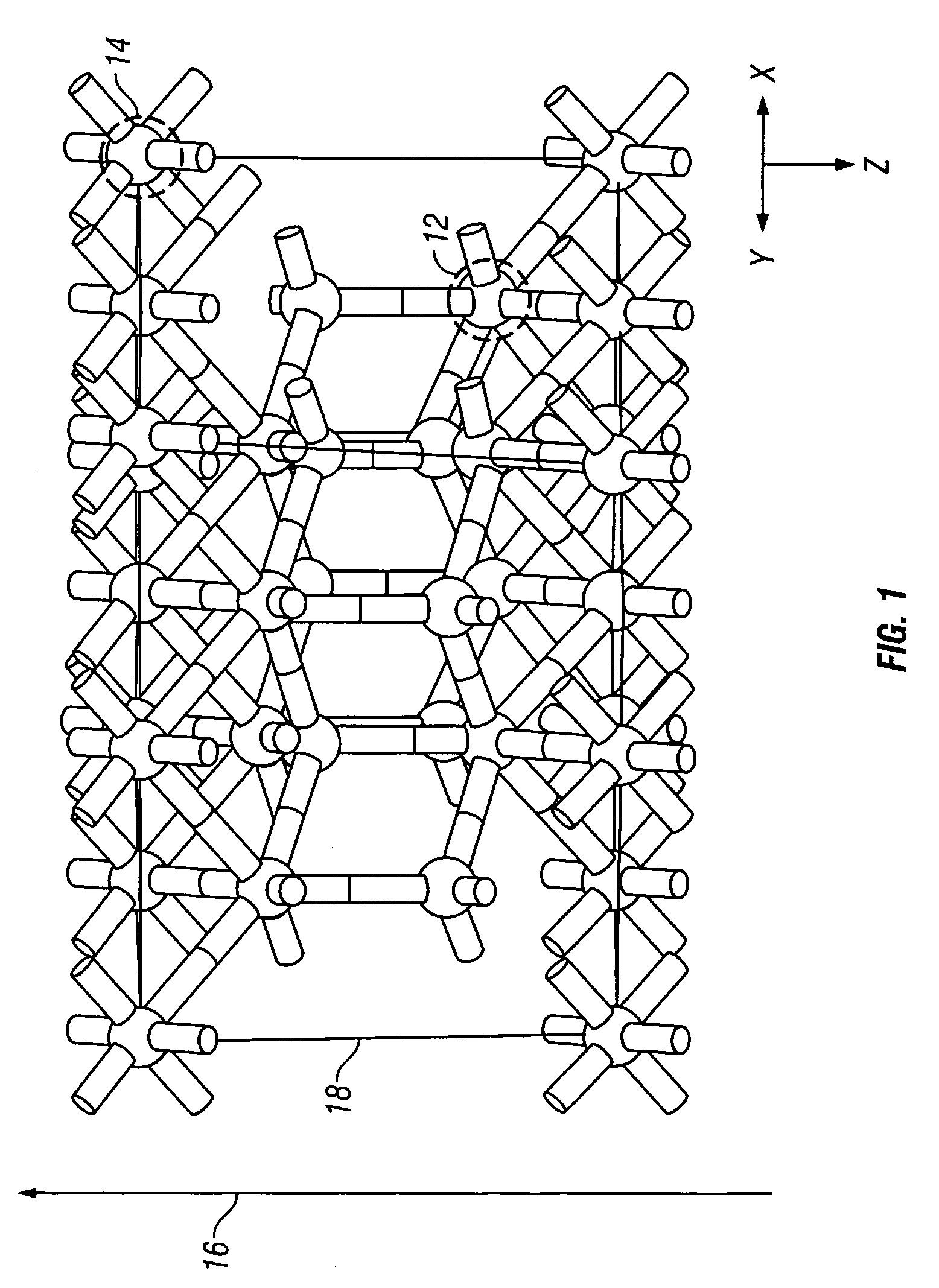

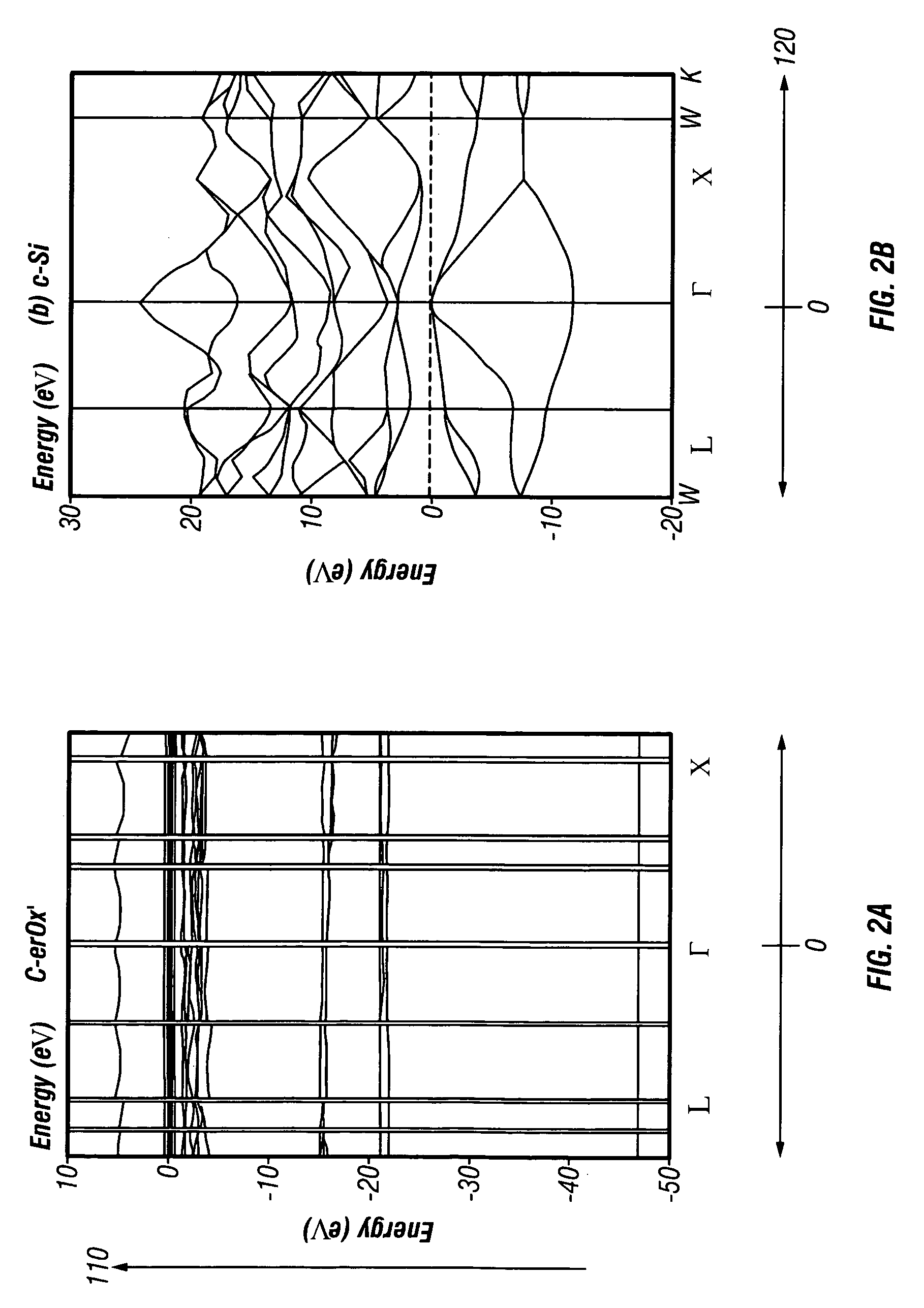

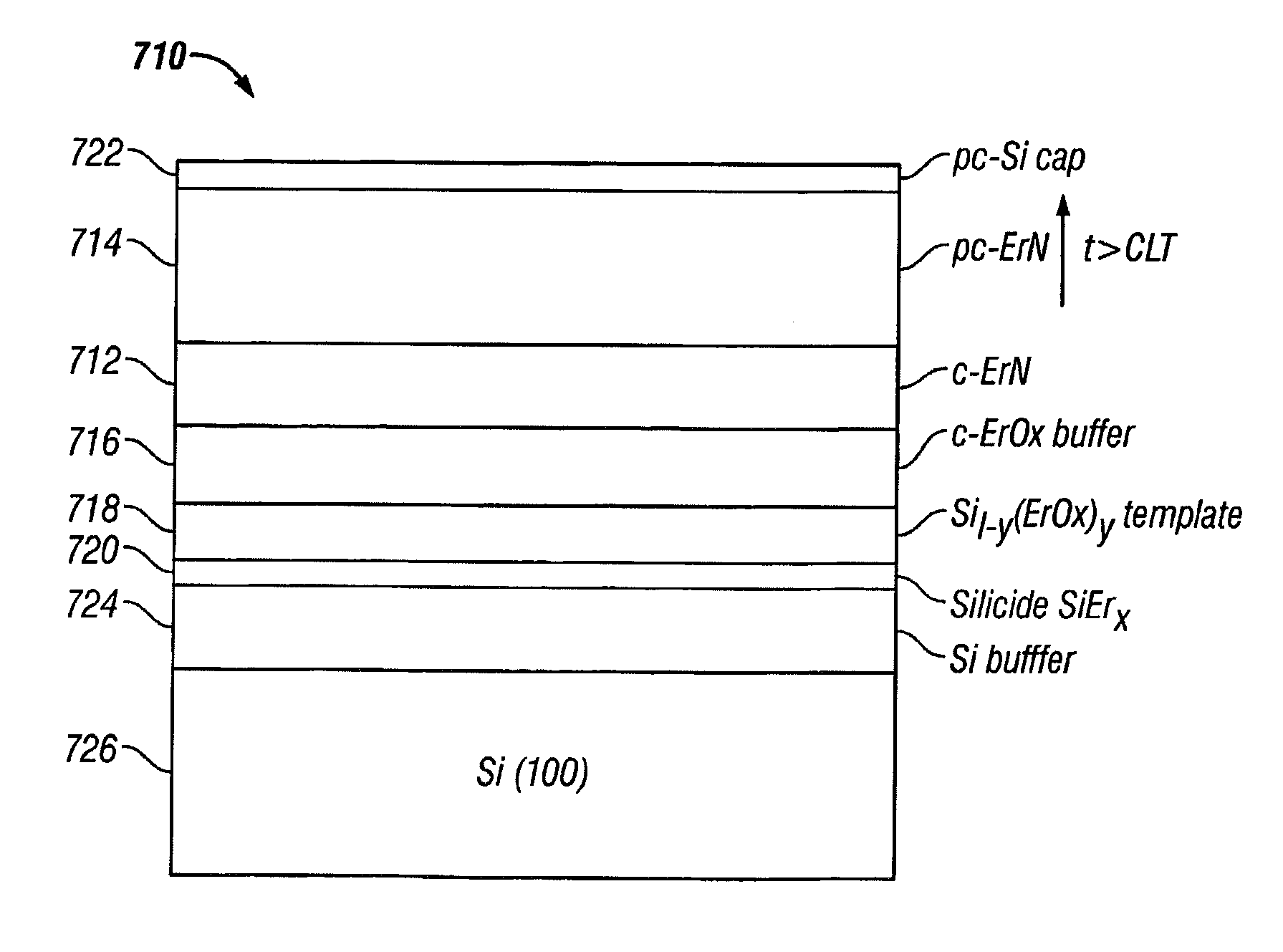

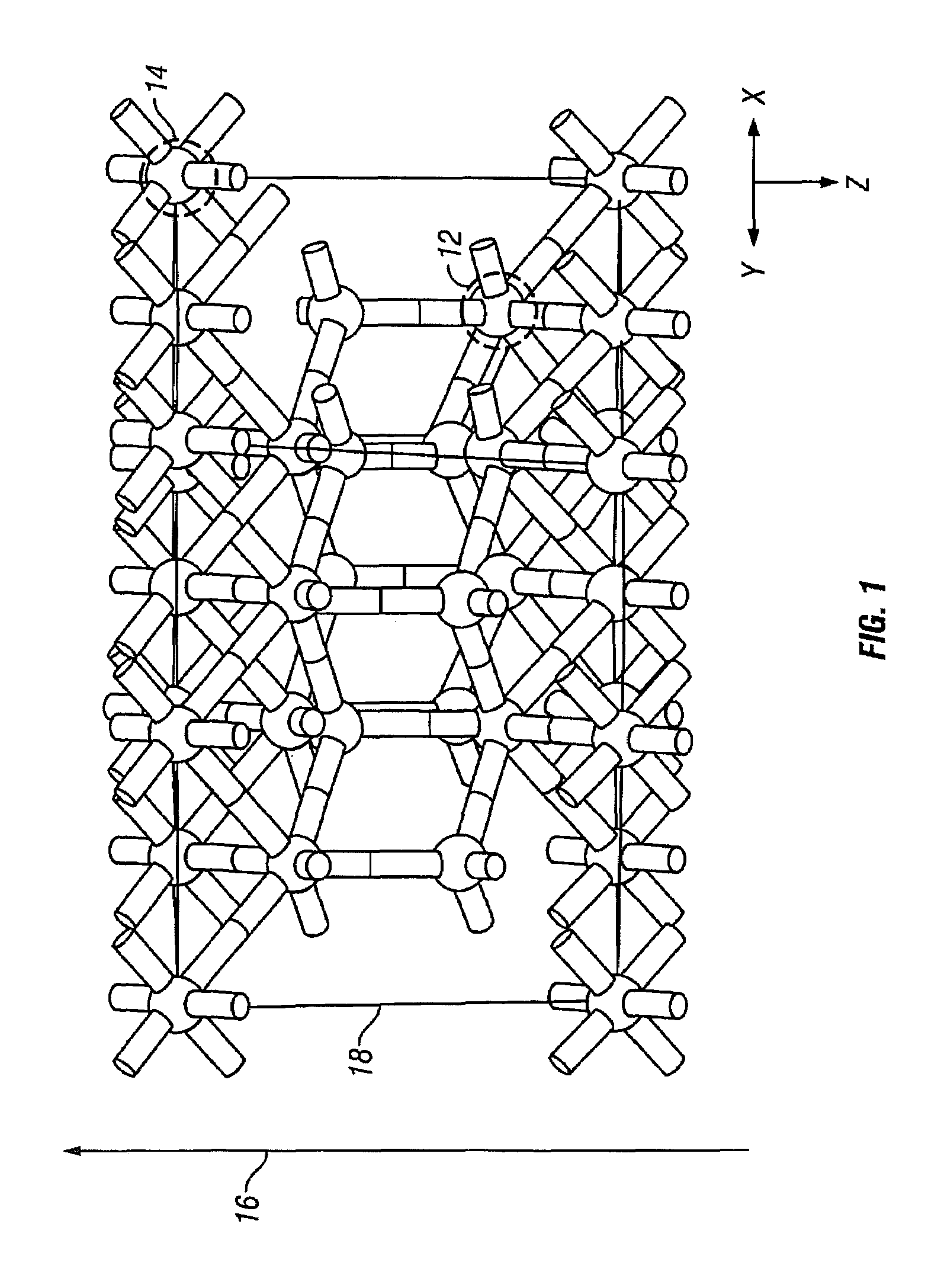

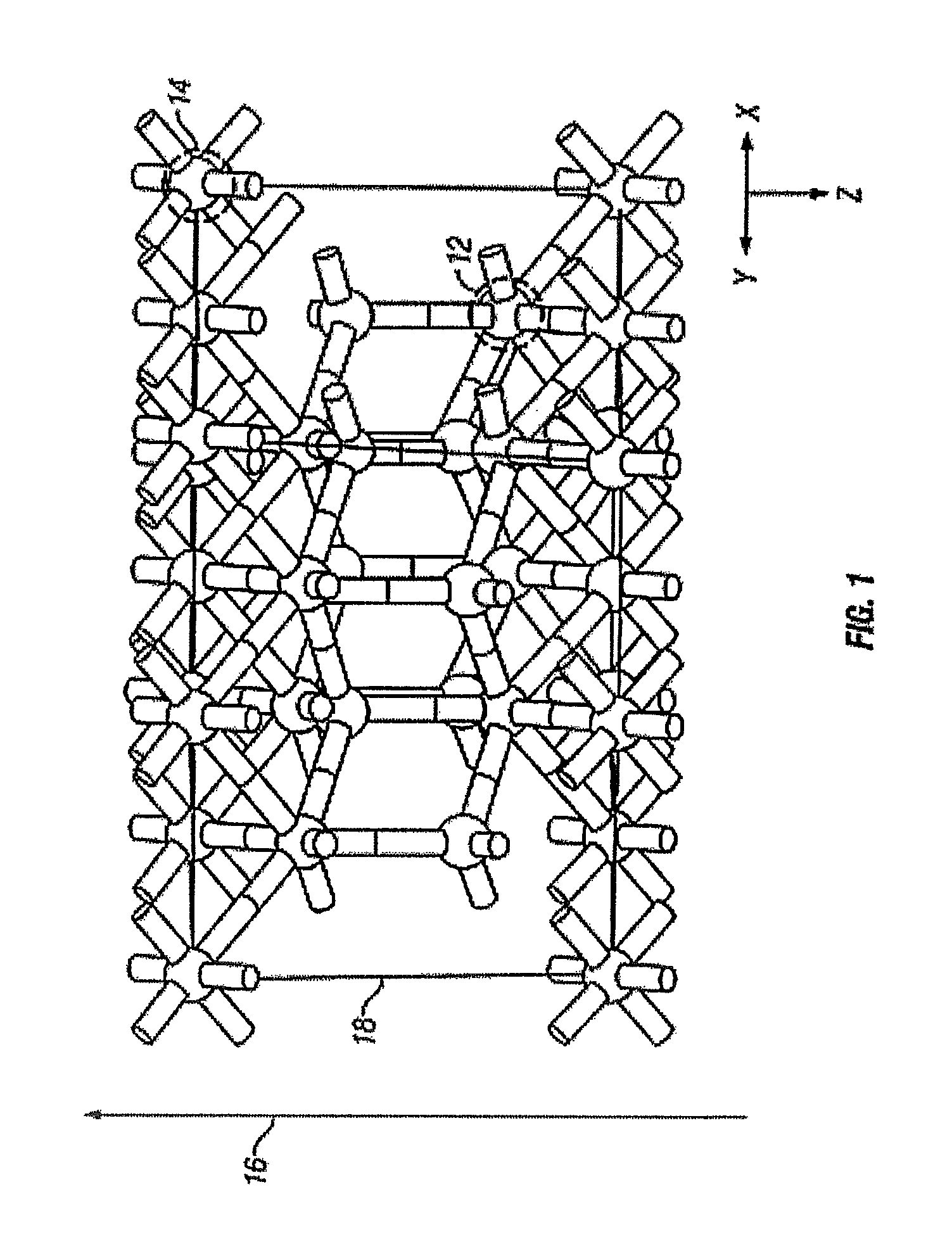

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

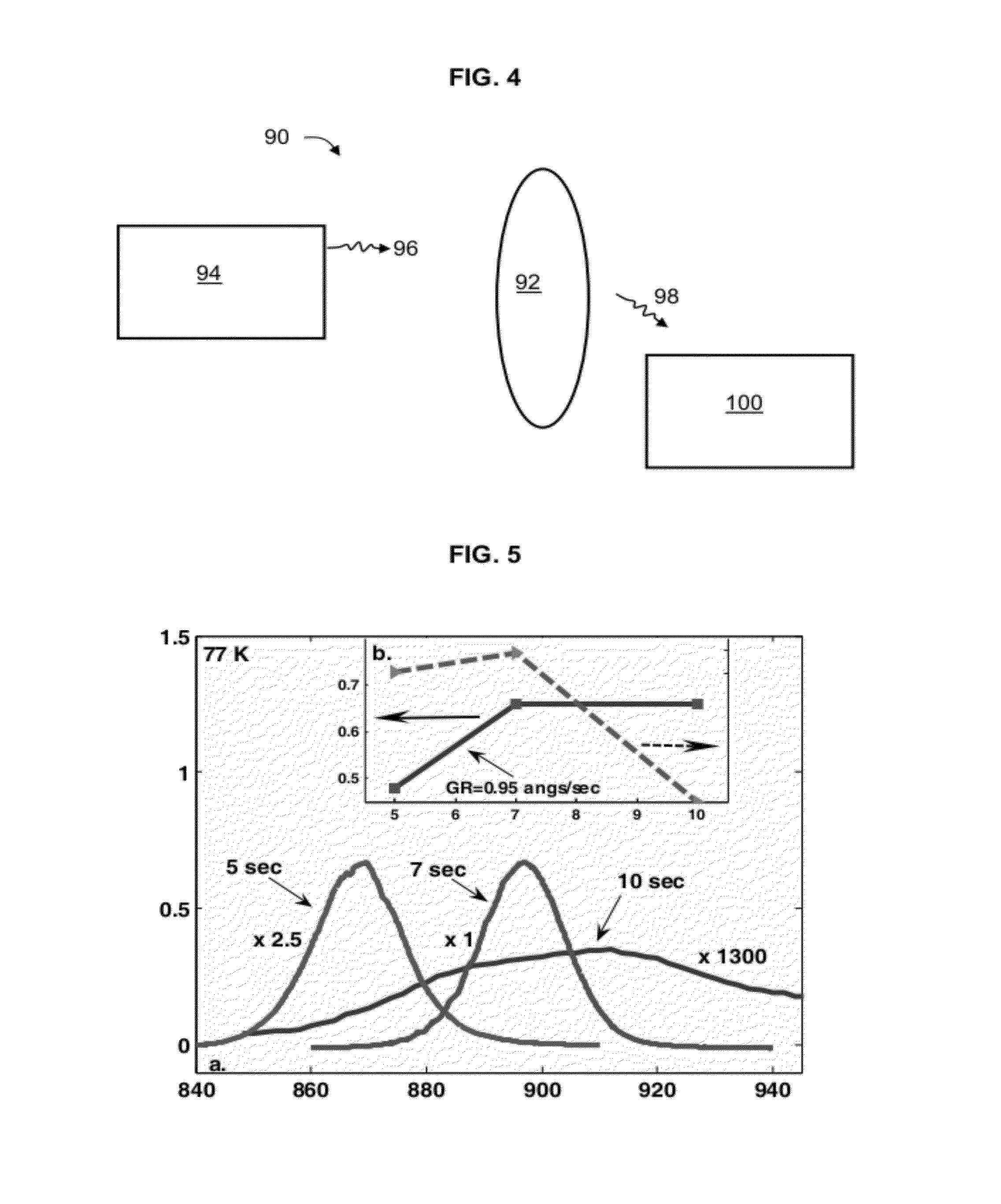

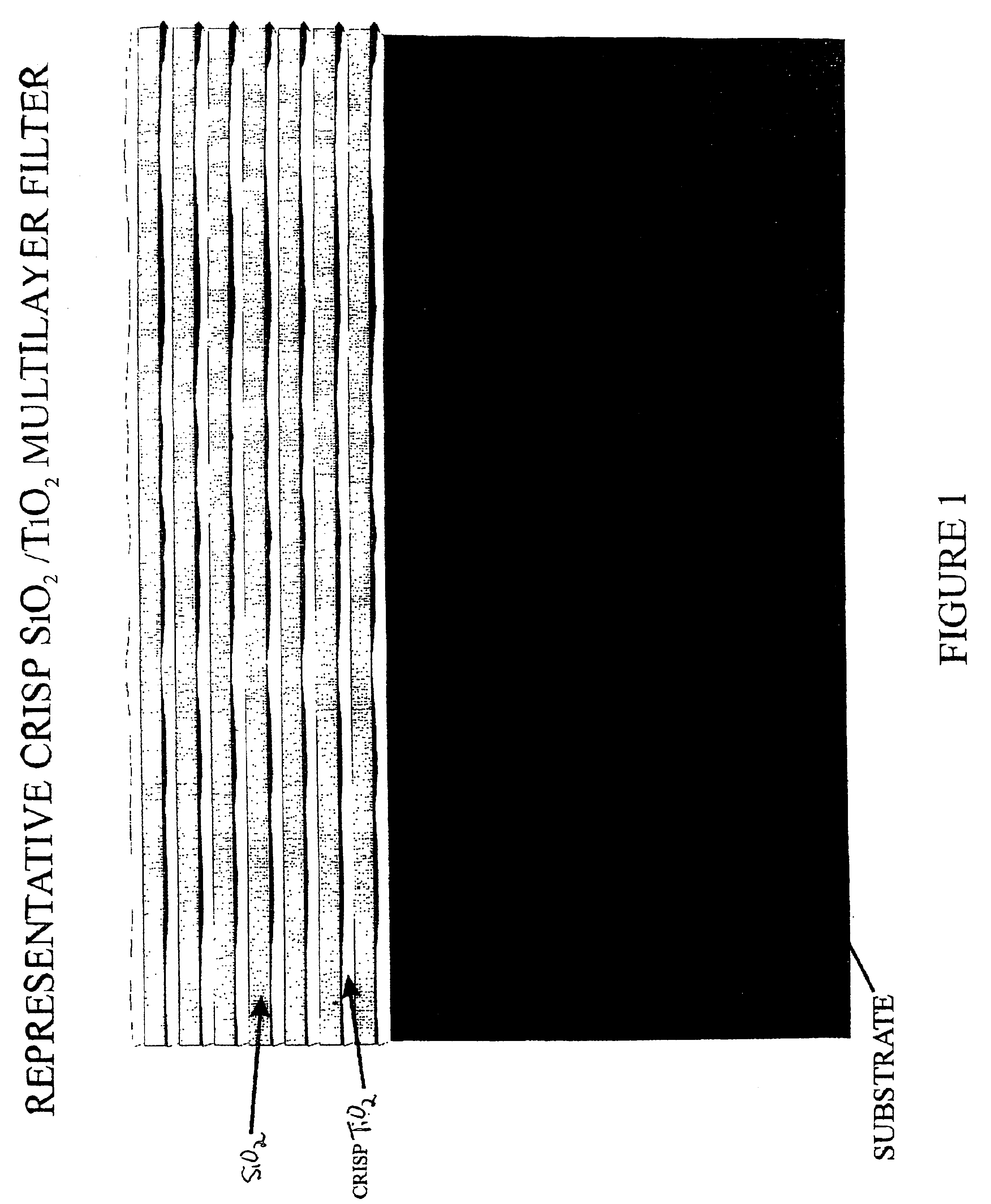

Optical filter construction by atomic layer control for next generation dense wavelength division multiplexer

InactiveUS20020003664A1Polycrystalline material growthVacuum evaporation coatingChemical beam epitaxyChemical reaction

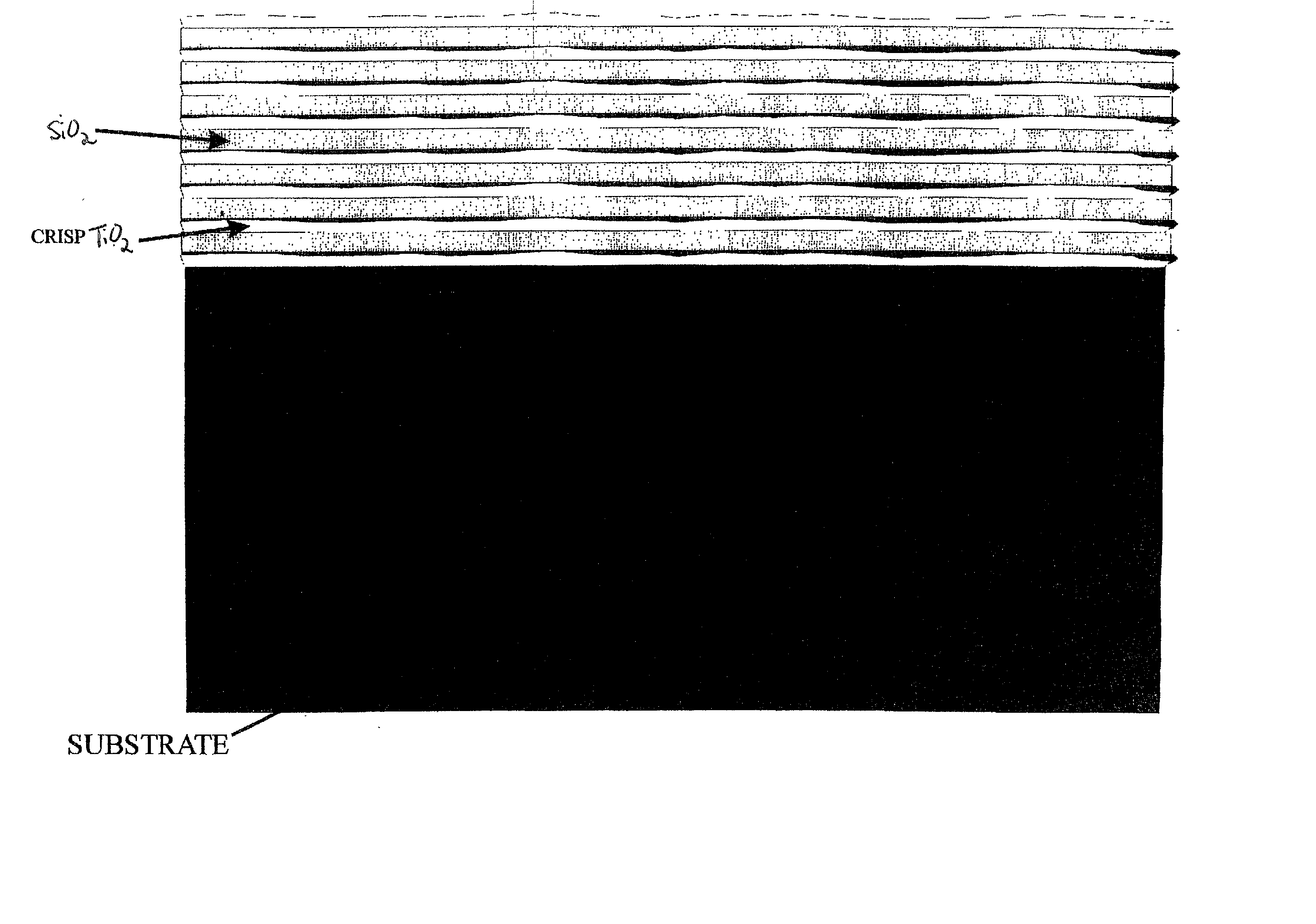

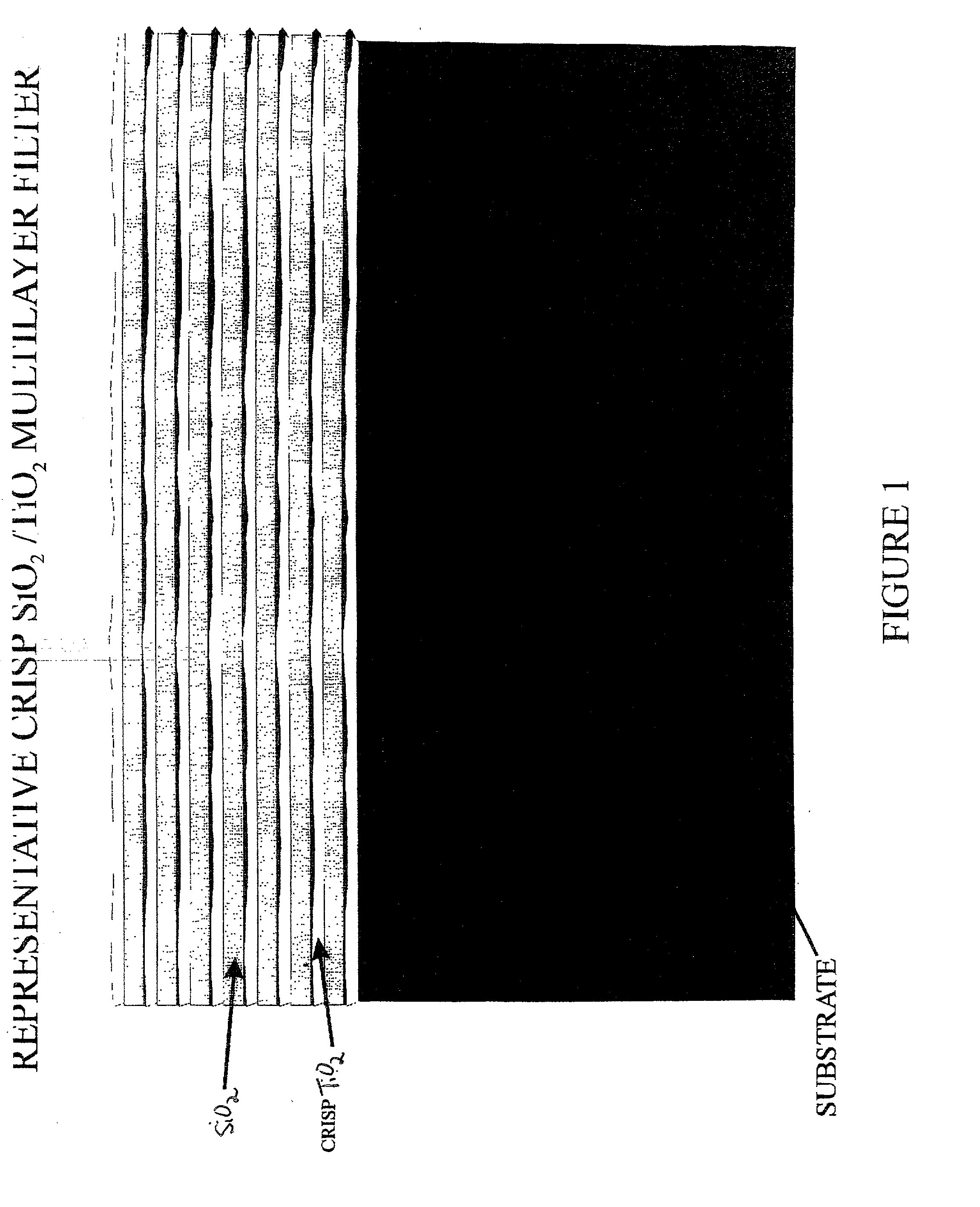

An optical filter using alternating layers of materials with "low" and "high" indices of refraction and deposited with atomic layer control has been developed. The multilayered thin film filter uses, but is not limited to, alternating layers of single crystal, polycrystalline or amorphous materials grown with self-limiting epitaxial deposition processes well known to the semiconductor industry. The deposition process, such as atomic layer epitaxy (ALE), pulsed chemical beam epitaxy (PCBE), molecular layer epitaxy (MLE) or laser molecular beam epitaxy (laser MBE) can result in epitaxial layer by layer growth and thickness control to within one atomic layer. The alternating layers are made atomically smooth using the patent pending Chemical Reactive-Ion Surface Planarization (CRISP) process. Intrinsic stress is monitored using an in-situ cantilever-based intrinsic stress optical monitor and adjusted during filter fabrication by deposition parameter modification. The resulting filter has sufficient individual layer thickness control and surface roughness to enable ~12.5 GHz filters for next generation multiplexers and demultiplexers with more than 1000 channels in the wavelength range 1.31-1.62 mum.

Owner:ATOMIC TELECOM

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

InactiveUS7273657B2Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Owner:IQE

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

InactiveUS20050156155A1Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

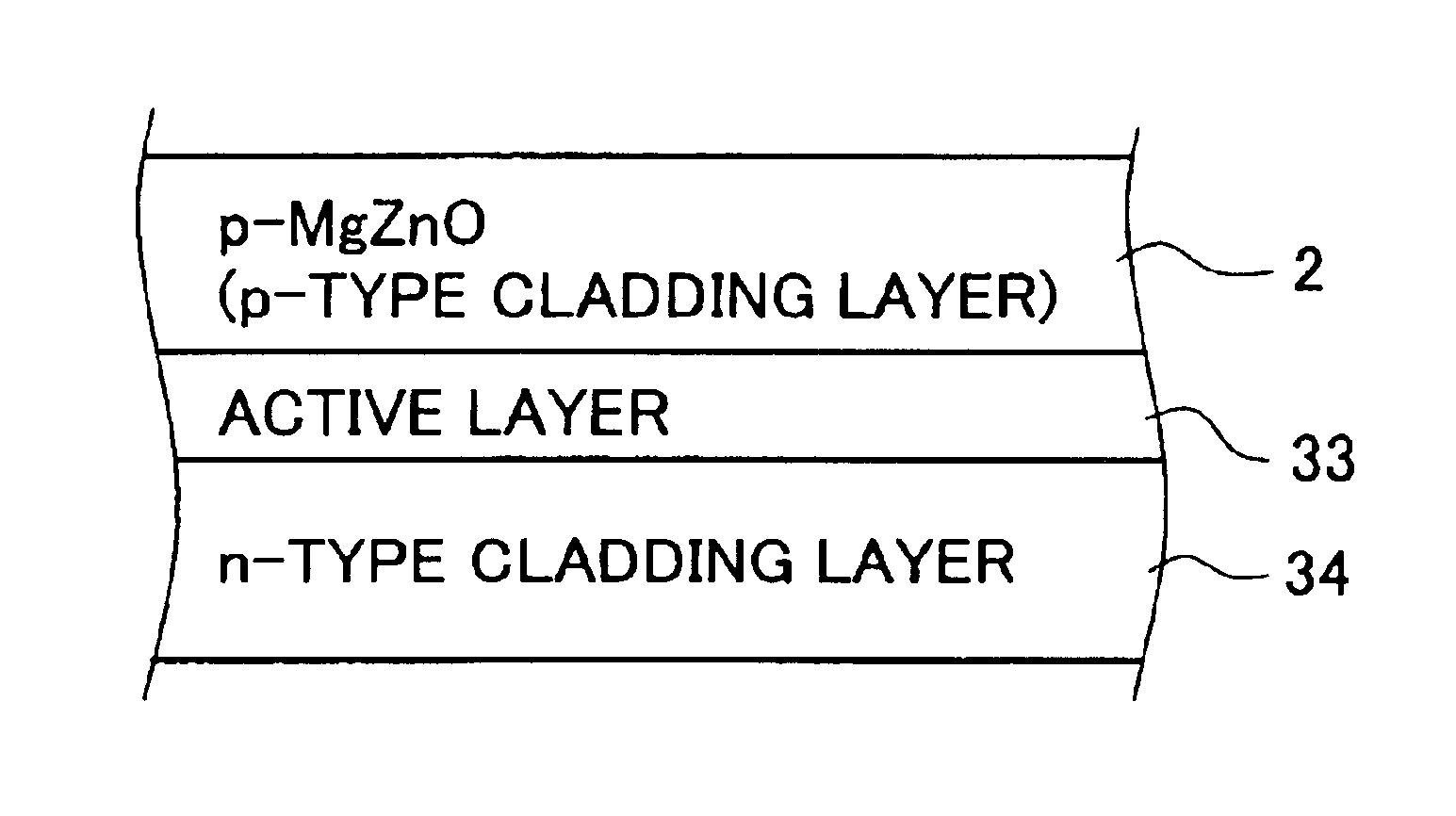

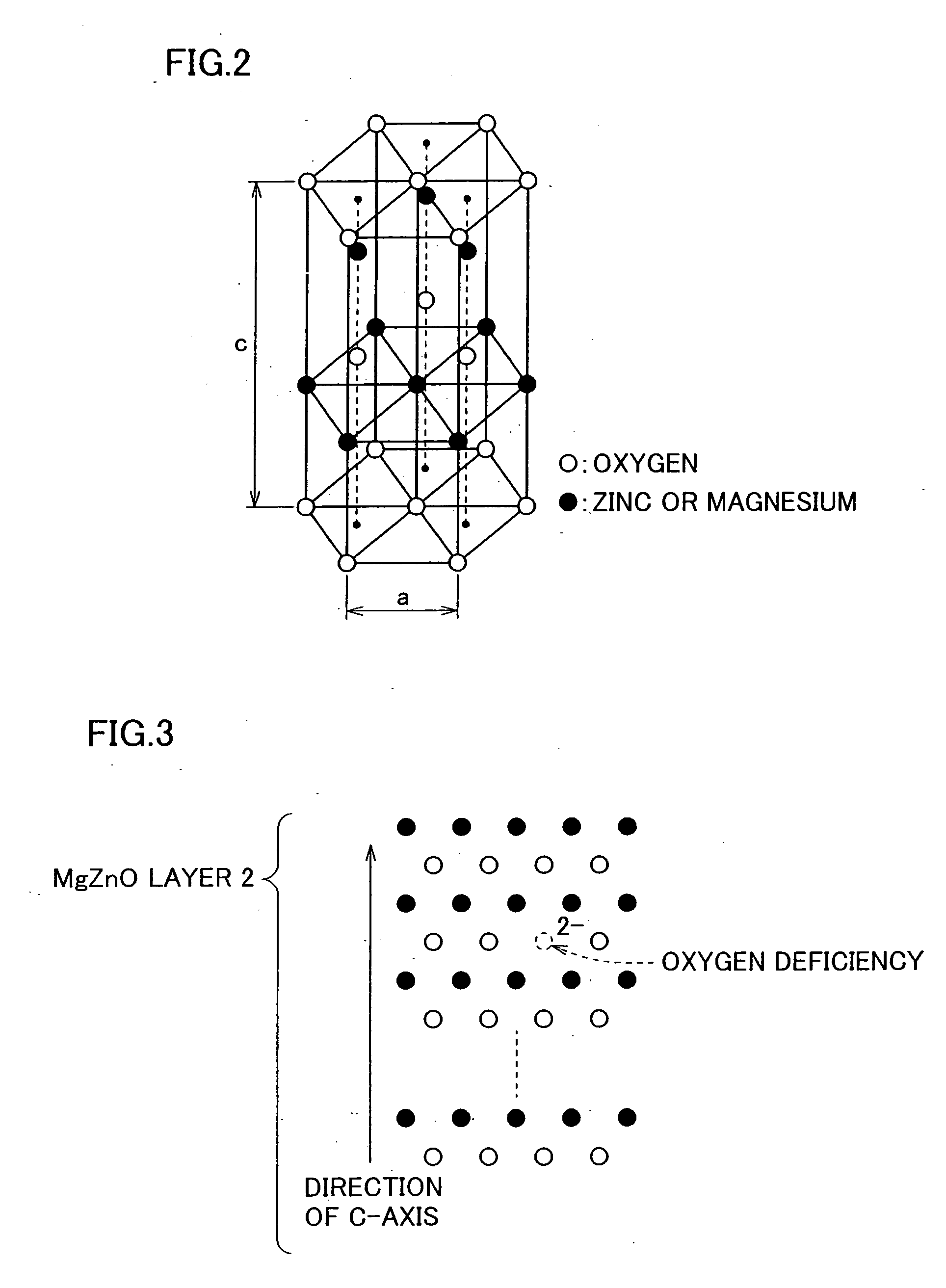

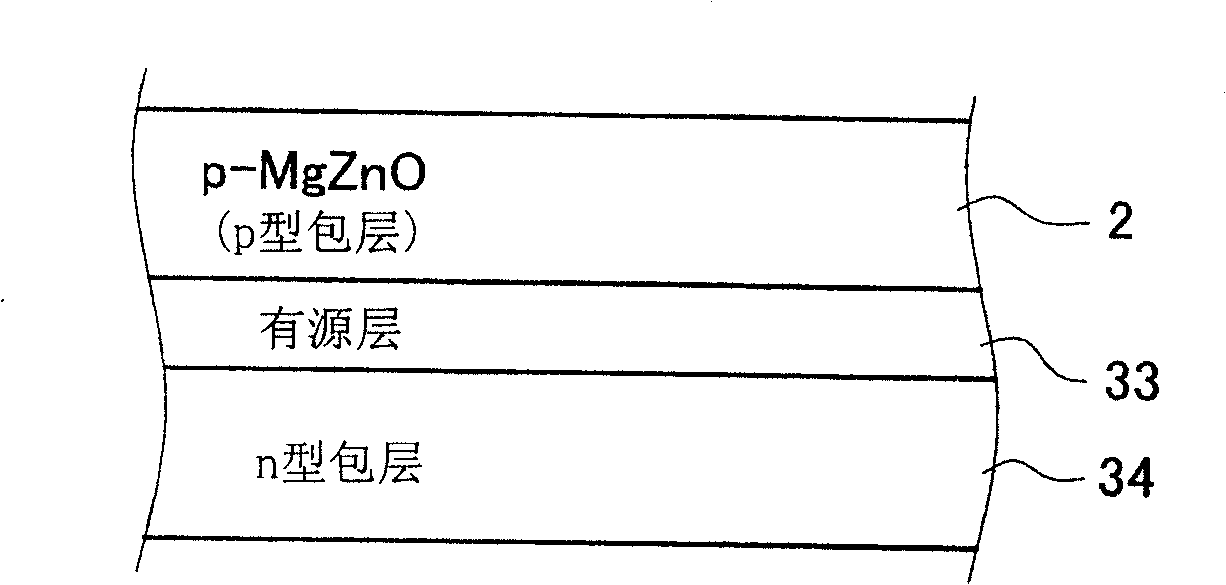

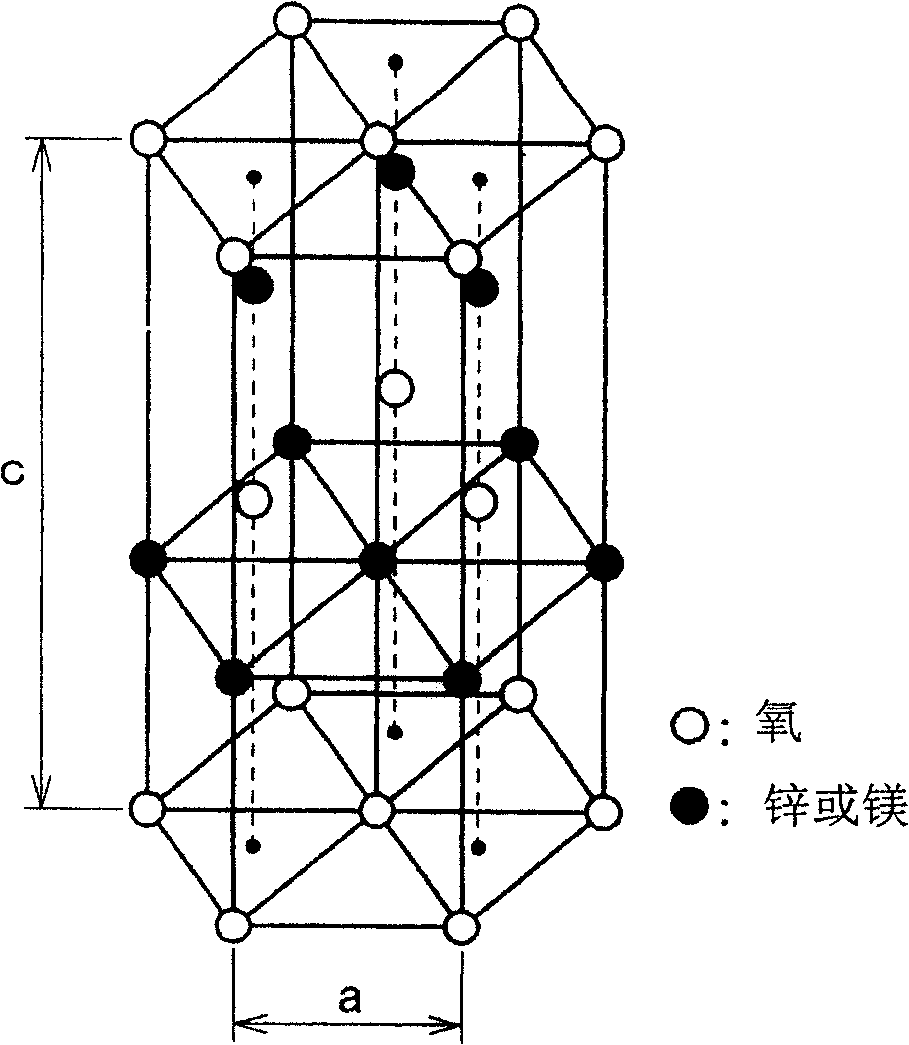

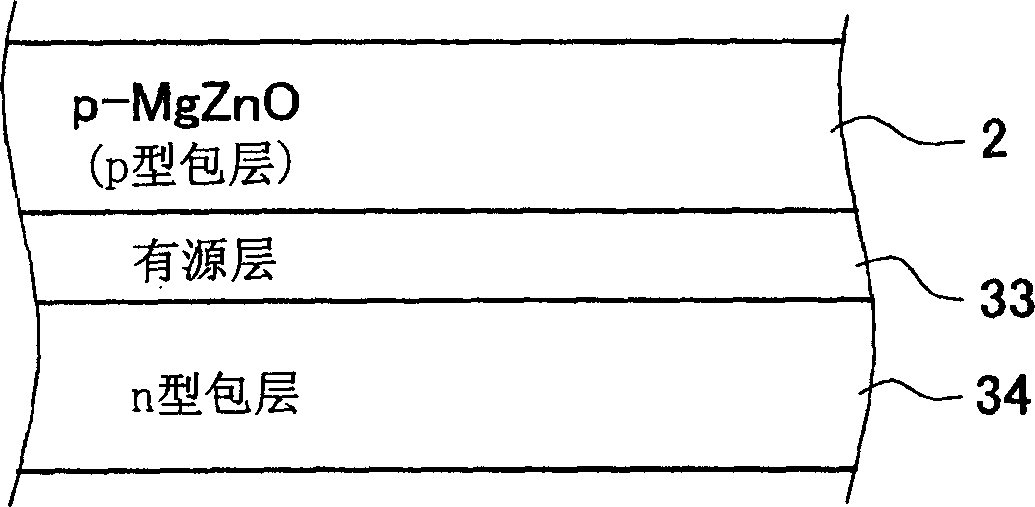

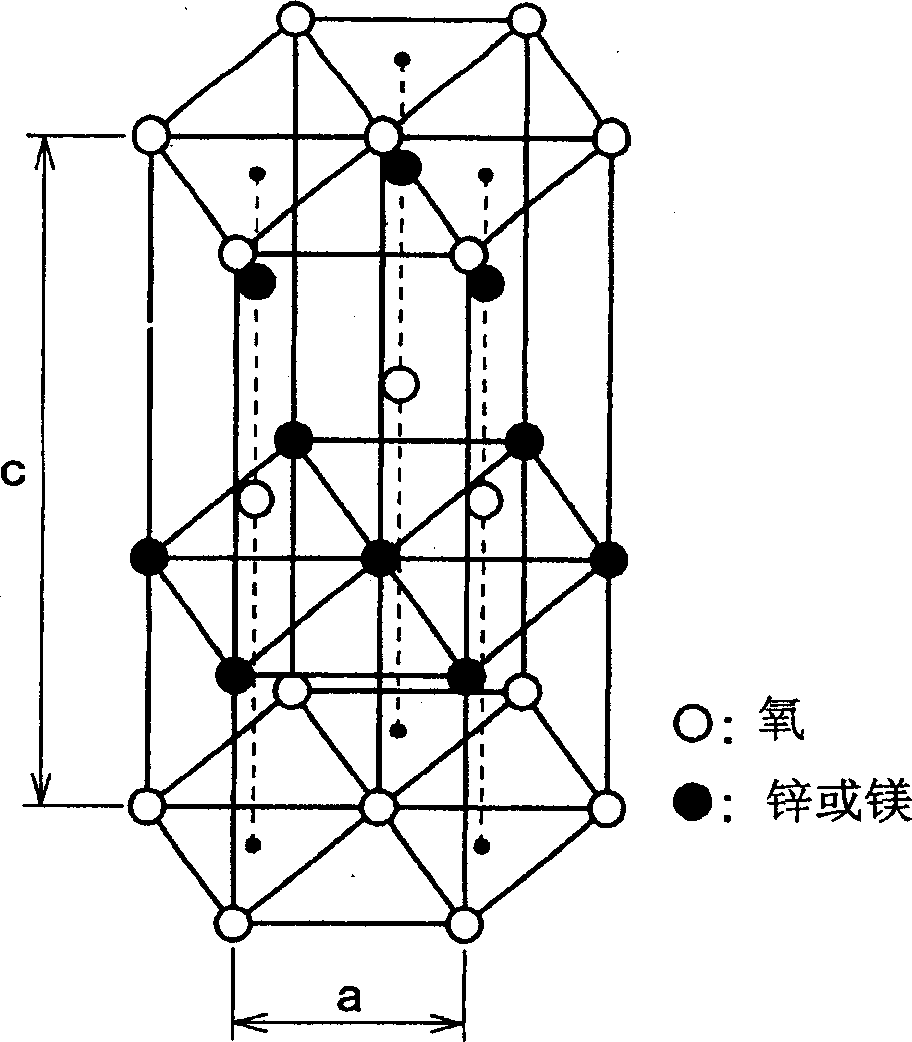

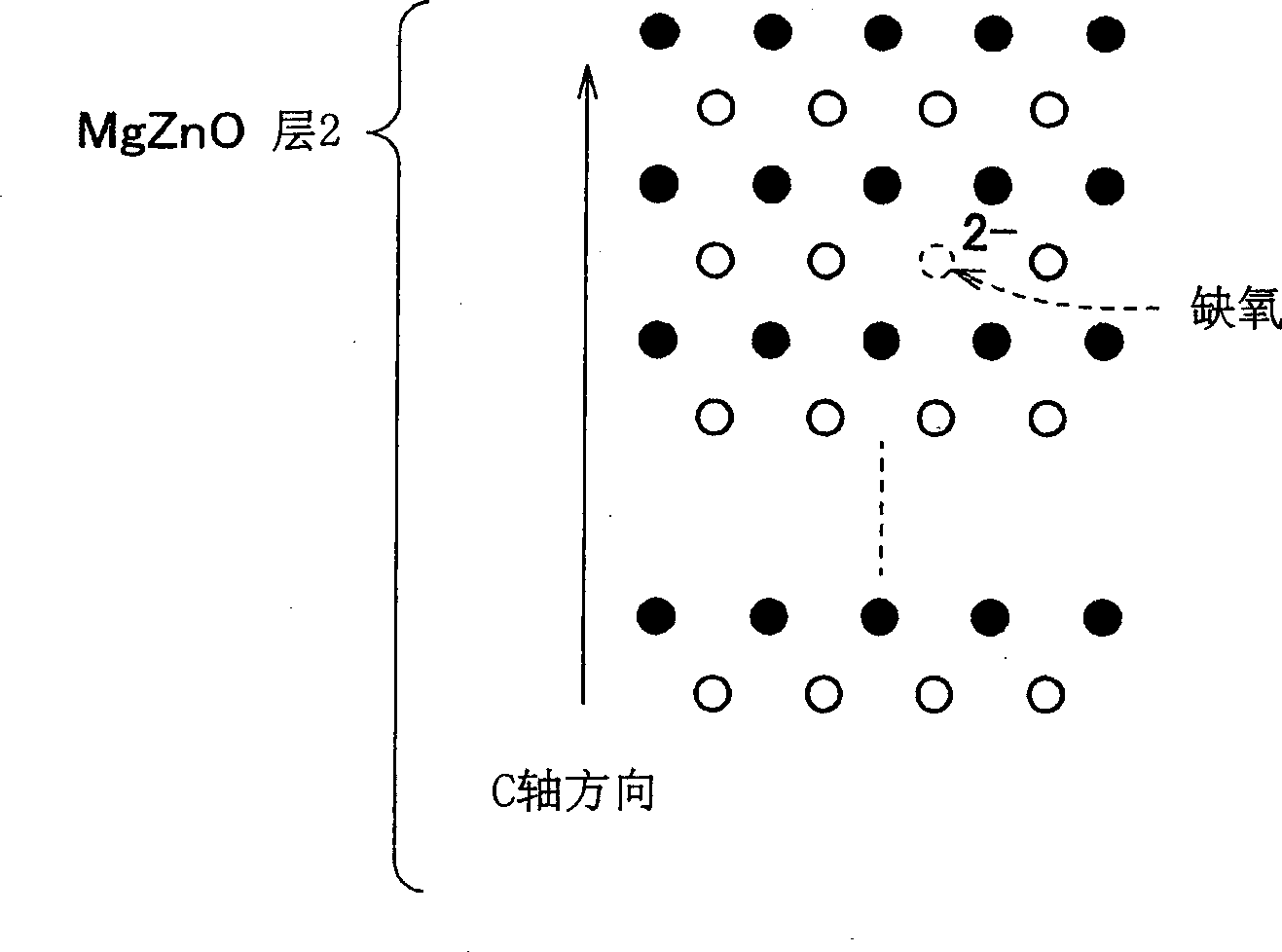

Production method for light emitting element

InactiveUS6939731B2Efficiently planarizedQuality improvementPolycrystalline material growthSolid-state devicesSemiconductor materialsGas phase

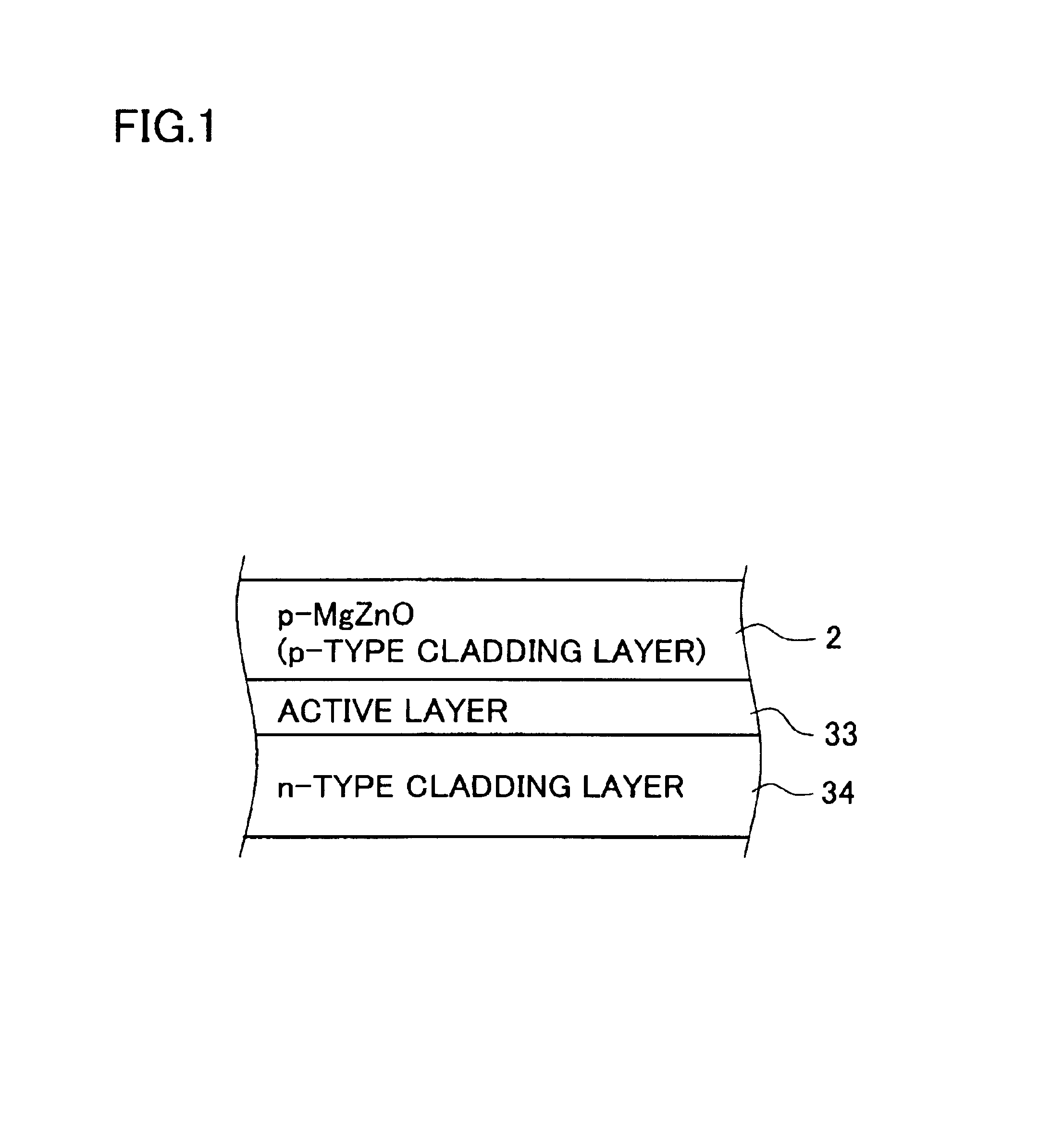

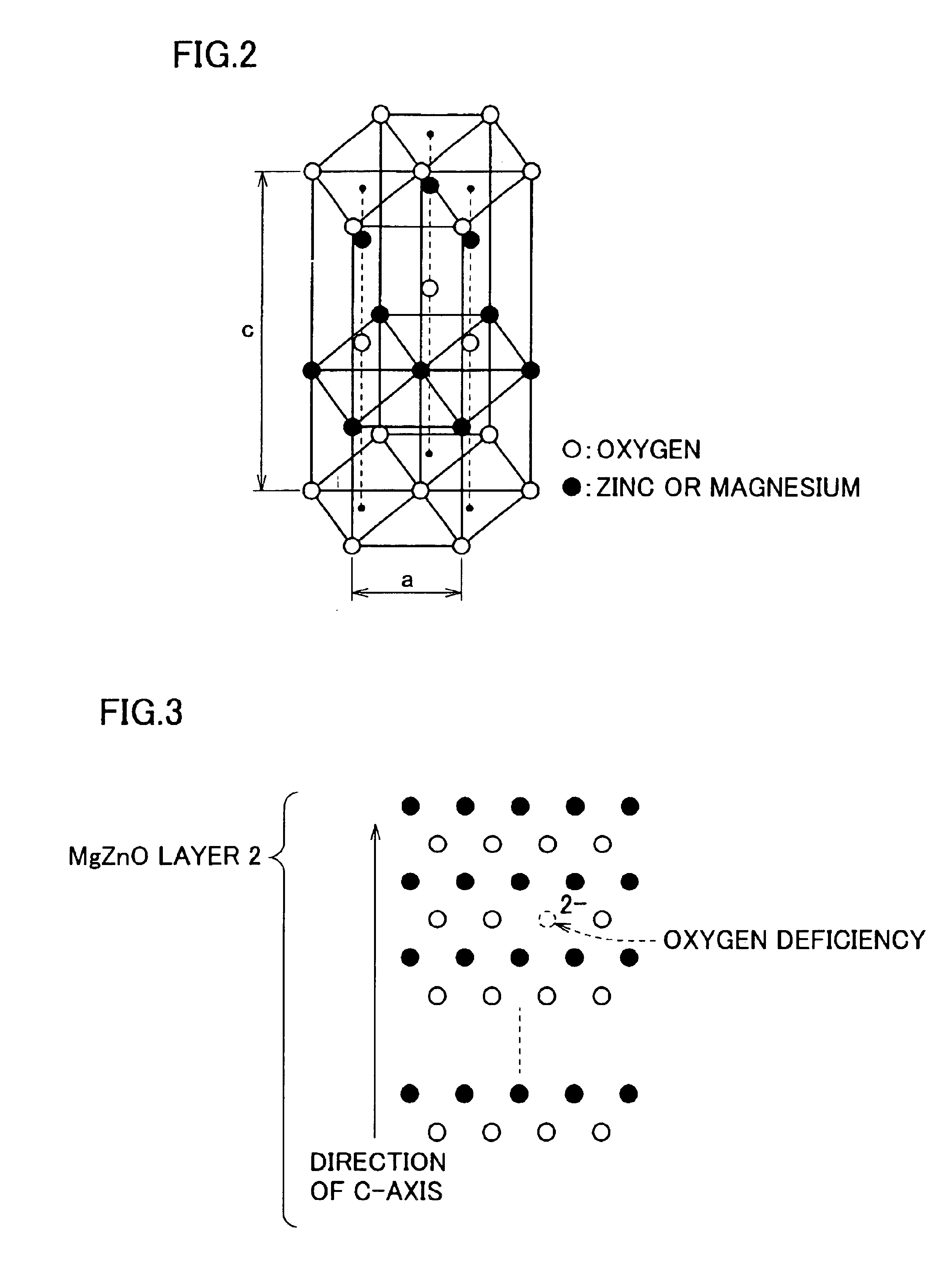

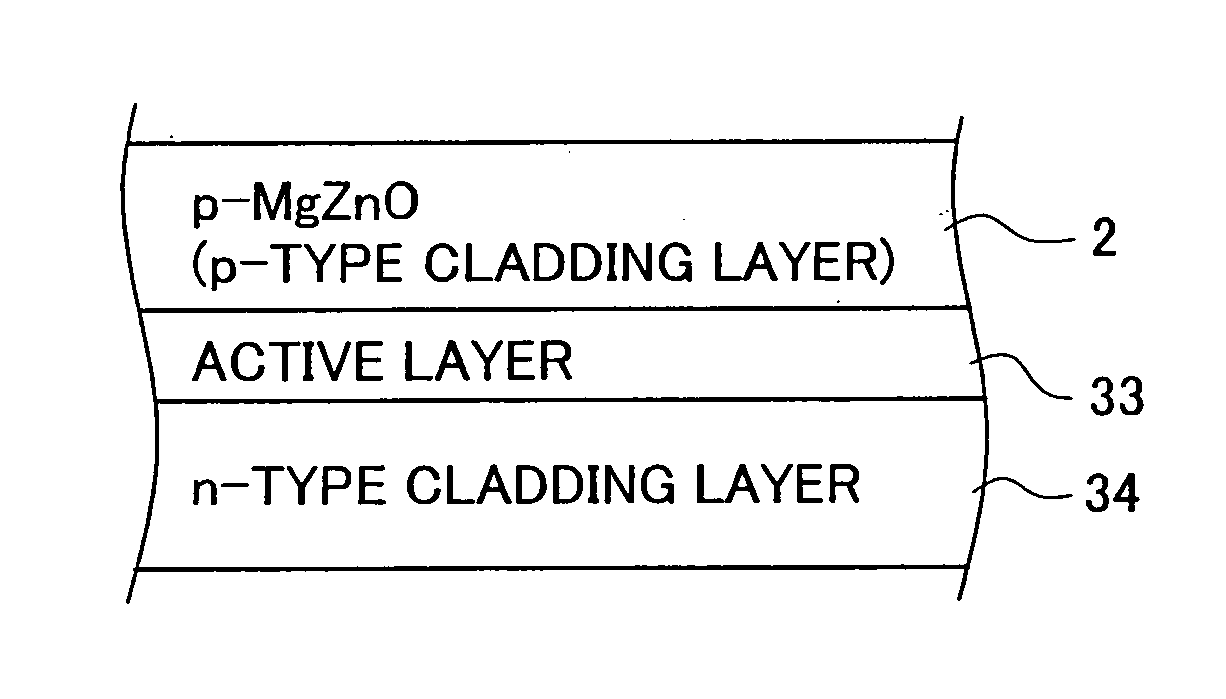

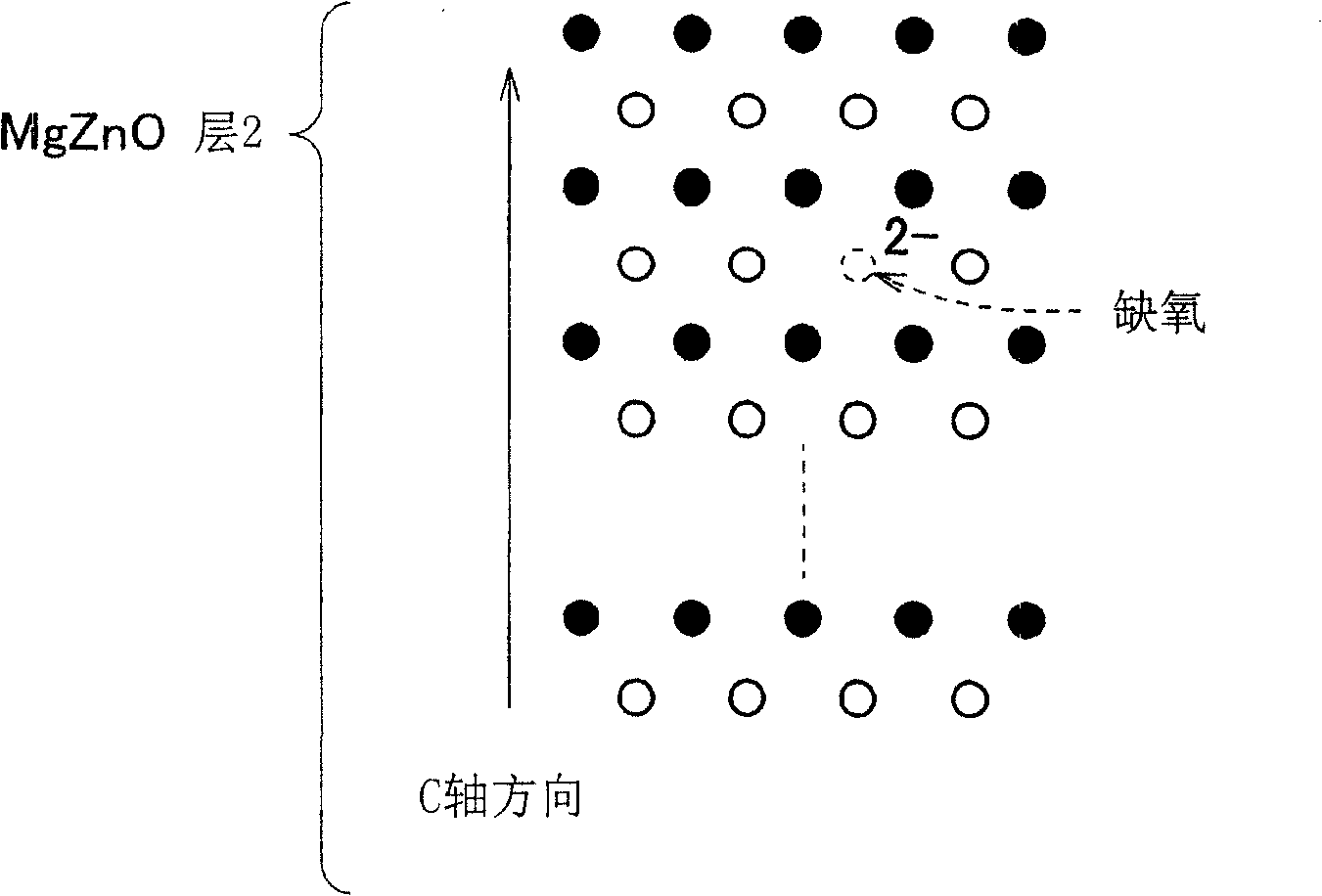

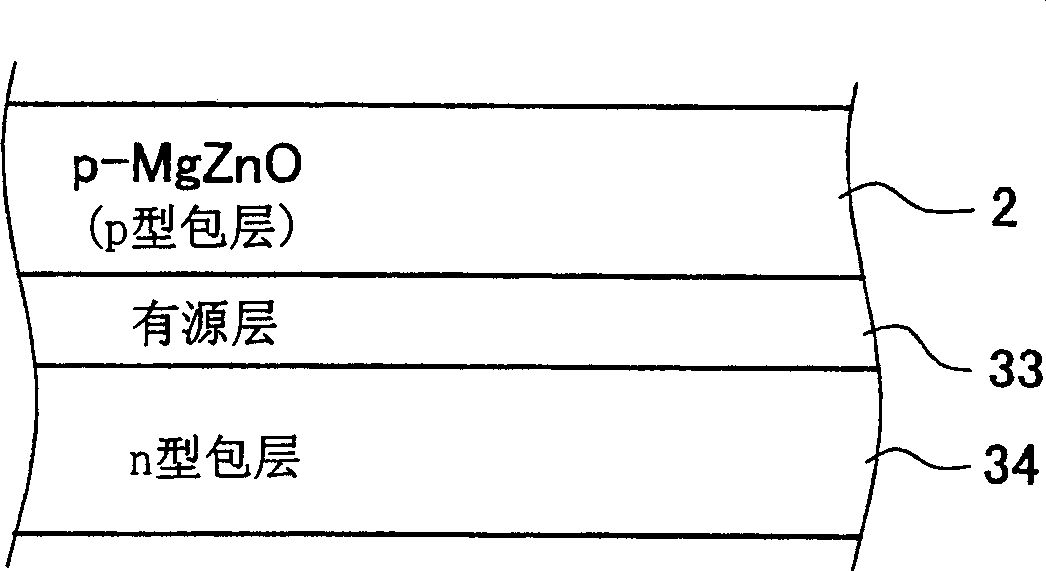

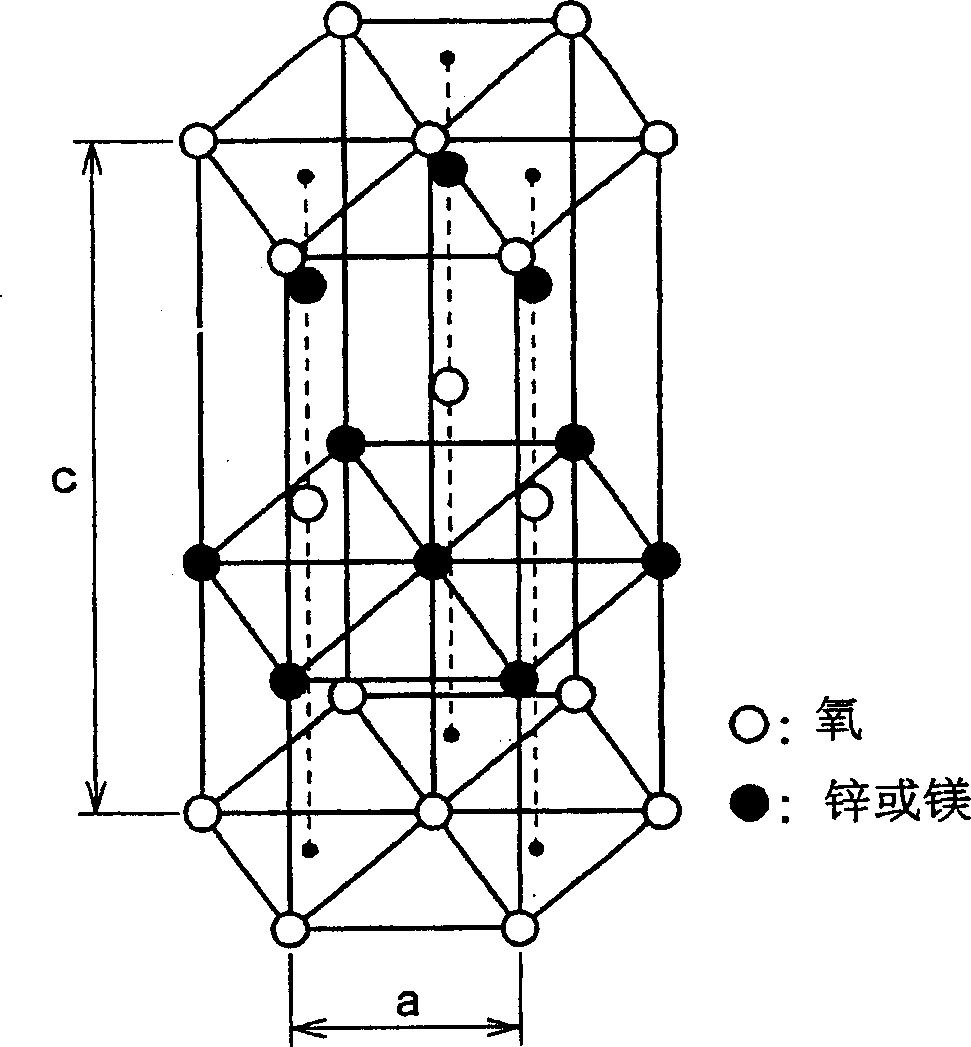

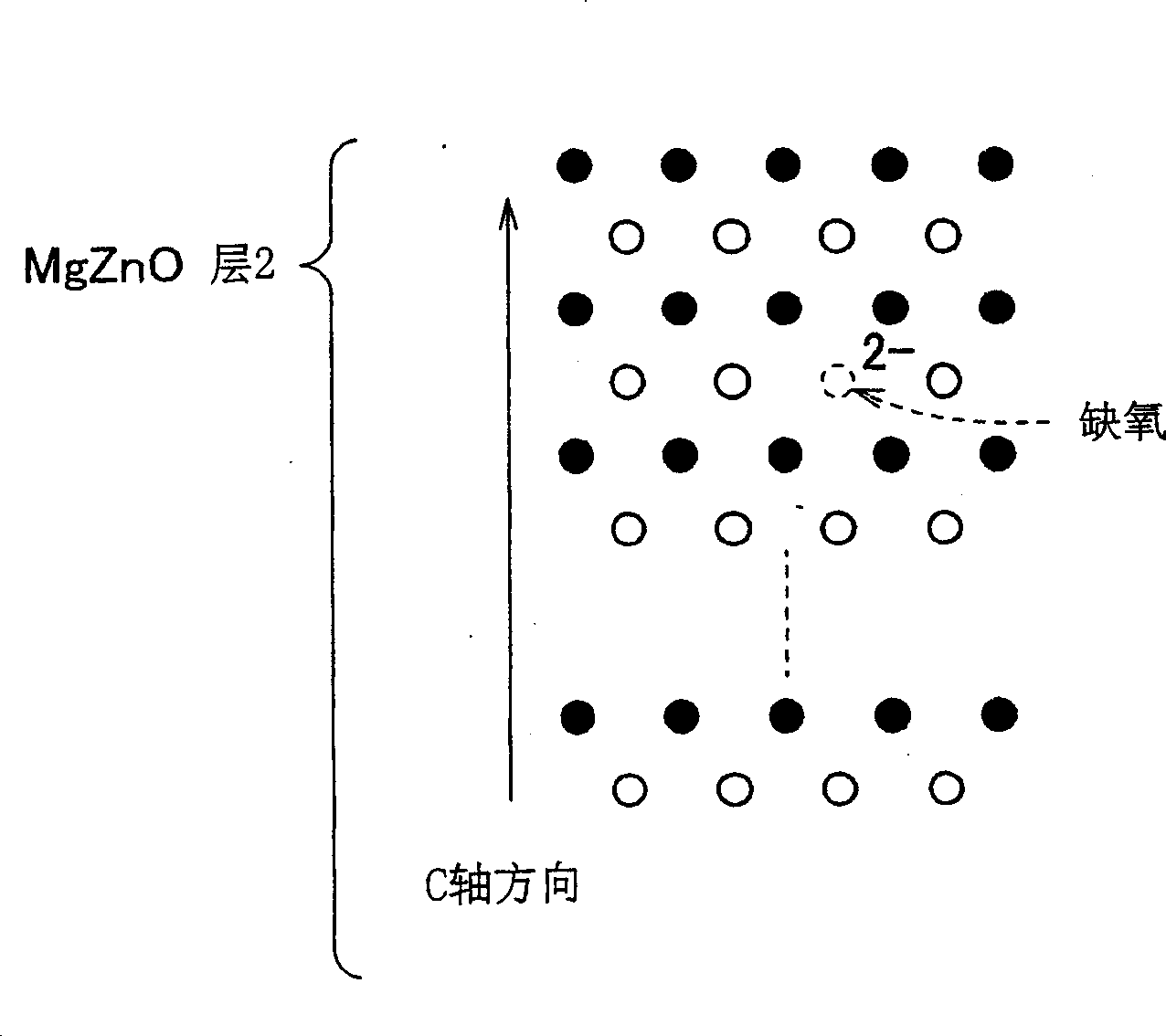

When a p-type MgxZn1-xO-type layer is grown based on a metal organic vapor-phase epitaxy process, the p-type MgxZn1-xO-type layer is annealed in an oxygen-containing atmosphere during and / or after completion of the growth of the p-type MgxZn1-xO-type layer. In addition, a vapor-phase epitaxy process of a semiconductor layer is proceed while irradiating ultraviolet light to the surface of a substrate to be grown and source gasses. In addition, when a MgxZn1-xO-type buffer layer that is oriented so as to align the c-axis thereof to a thickness-wise direction is formed by an atomic layer epitaxy process, a metal monoatomic layer is grown at first. In addition, a ZnO-base semiconductor active layer is formed by using a semiconductor material mainly composed of ZnO containing Se or Te. A light emitting device is formed by using these techniques.

Owner:SHIN-ETSU HANDOTAI CO LTD

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Rare earth-oxides, rare earth nitrides, rare earth phosphides and ternary alloys with silicon

InactiveUS20050161773A1Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Production method for light emitting element

InactiveUS20050224825A1Improve stabilityGood reproducibilityPolycrystalline material growthSemiconductor/solid-state device manufacturingChemical reactionSemiconductor materials

In a first invention, a p-type MgxZn1-xO-type layer is grown based on a metal organic vapor-phase epitaxy process by supplying organometallic gases which serves as a metal source, an oxygen component source gas and a p-type dopant gas into a reaction vessel. During and / or after completion of the growth of the p-type MgxZn1-xO-type layer, the MgxZn1-xO-type thereof is annealed in an oxygen-containing atmosphere. This is successful in forming the layer of p-type oxide in a highly reproducible and stable manner for use in light emitting device having the layer of p-type oxide of Zn and Mg. In a second invention, a semiconductor layer which composes the light emitting layer portion is grown by introducing source gases in a reaction vessel having the substrate housed therein, and by depositing a semiconductor material produced by chemical reactions of the source gas on the main surface of the substrate. A vapor-phase epitaxy process of the semiconductor layer is proceed while irradiating ultraviolet light to the main surface of the substrate and the source gases. This is successful in sharply enhancing reaction efficiency of the source gases when the semiconductor layer for composing the light emitting layer portion is formed by a vapor-phase epitaxy process, and in readily obtaining the semiconductor layer having only a less amount of crystal defects. In a third invention, a buffer layer having at least an MgaZn1-aO-type oxide layer on the contact side with the light emitting layer portion is grown on the substrate, and the light emitting layer portion is grown on the buffer layer. The buffer layer is oriented so as to align the c-axis thereof to the thickness-wise direction, and is obtained by forming a metal monoatomic layer on the substrate based on the atomic layer epitaxy, and then by growing residual oxygen atom layers and the metal atom layers. This is successful in obtaining the light emitting portion with an excellent quality. In a fourth invention, a ZnO-base semiconductor active layer included in a double heterostructured, light emitting layer portion is formed using a ZnO-base semiconductor mainly composed of ZnO containing Se or Te, so as to introduce Se or Te, the elements in the same Group with oxygen, into oxygen deficiency sites in the ZnO crystal possibly produced during the formation process of the active layer, to thereby improve crystallinity of the active layer. Introduction of Se or Te shifts the emission wavelength obtainable from the active layer towards longer wavelength regions as compared with the active layer composed of ZnO having a band gap energy causative of shorter wavelength light than blue light. This is contributive to realization of blue-light emitting devices.

Owner:SHIN-ETSU HANDOTAI CO LTD

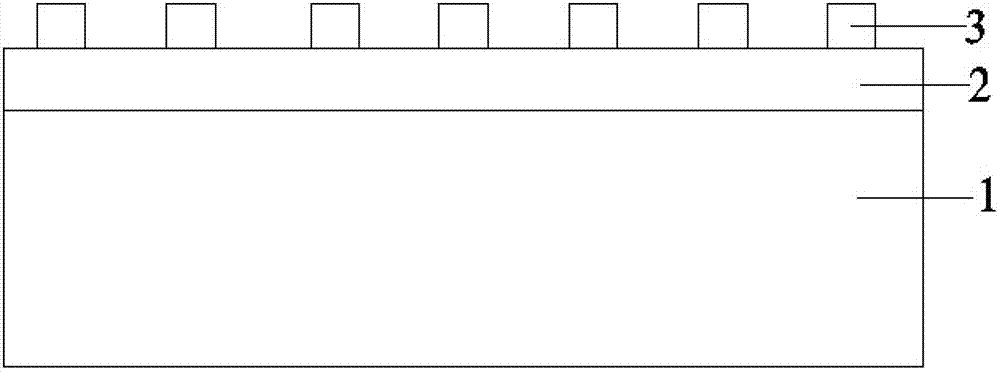

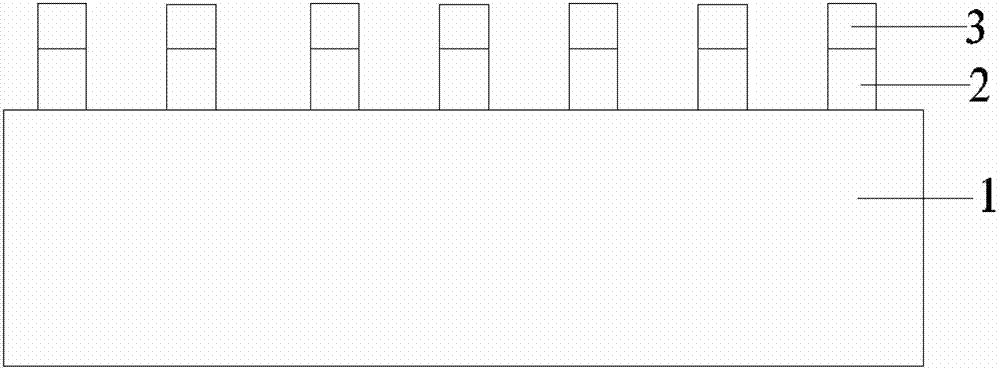

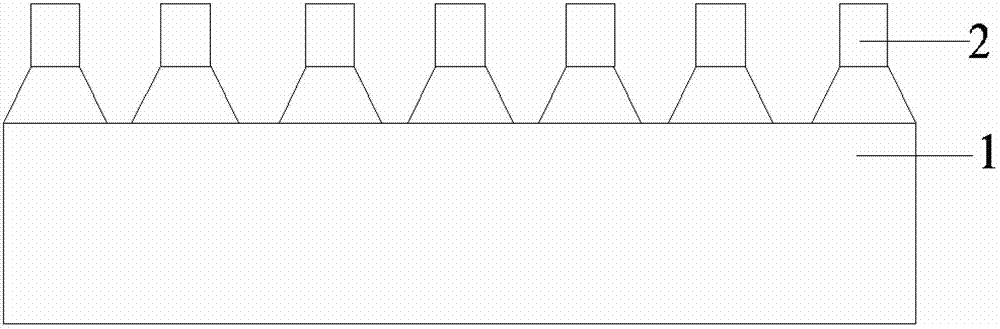

Method for improving luminous efficiency of AlGaN-based ultraviolet LED (Light-Emitting Diode)

The invention belongs to the technical field of semiconductors, and in particular relates to a method for improving luminous efficiency of an AlGaN-based ultraviolet LED (Light-Emitting Diode). According to the method, the crystal quality of an AlNBuffer layer is improved by etching a triangularly prism-shaped graph on the surface of a C-side sapphire along the direction of [10-10], and the surface topography of an AlN layer is improved by a high-temperature pulse type atomic layer epitaxy. The traditional AlGaN-based LED with a flipchip structure can improve the light extraction rate by adopting a plated bragg grating, and the method not only is limited by the refractive index of materials and high in cost, but also is easy to wear and fall off. The method disclosed by the invention and adopting etching of a subwavelength grating not only is simple in design and process, but also is not easy to wear and fall, and is beneficial to heat dissipation, so that the luminous efficiency of the device can be improved.

Owner:ZHEJIANG EUVILEDS TECH

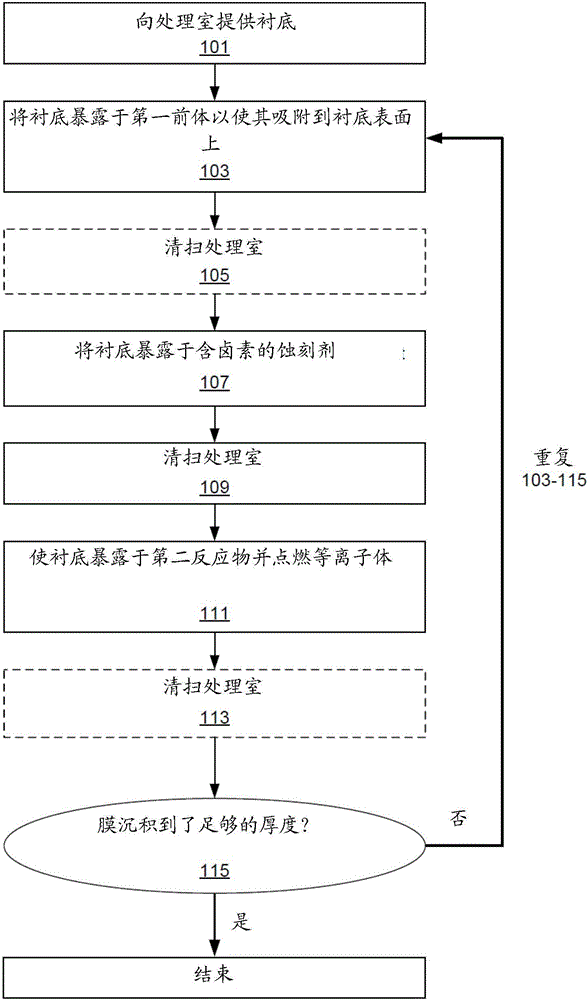

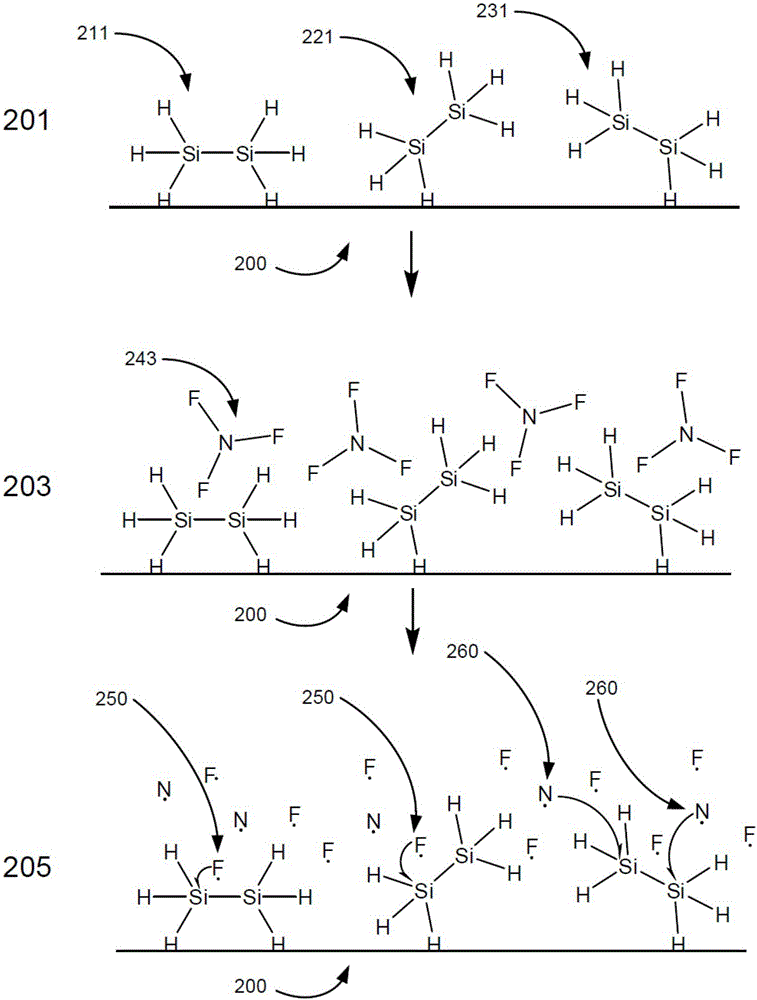

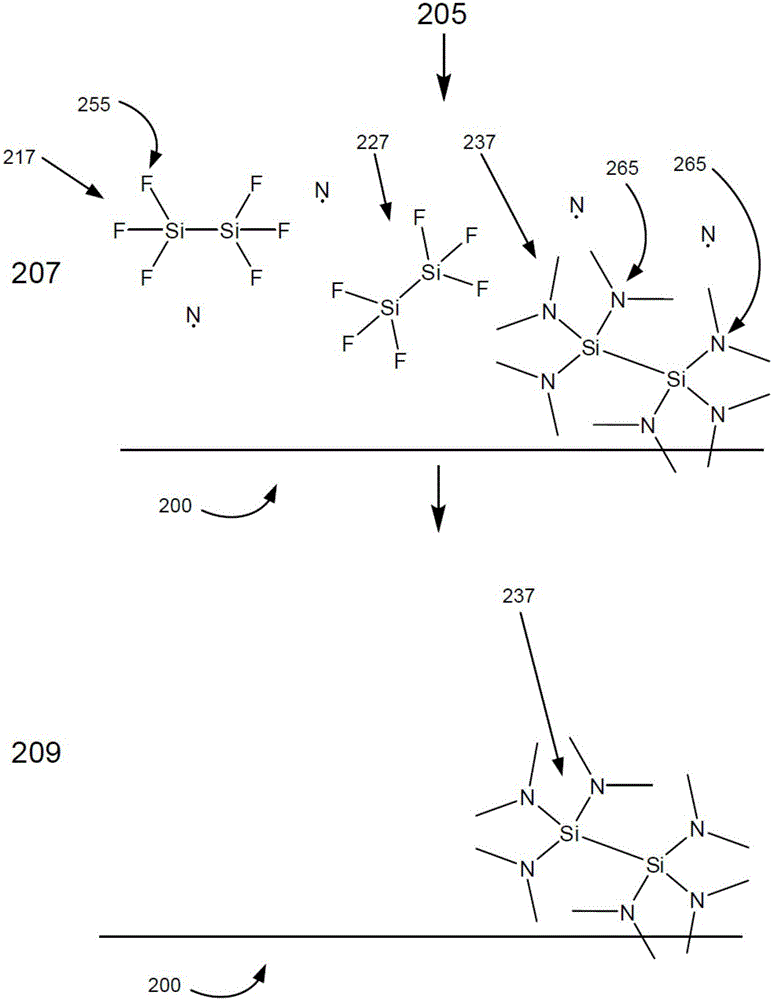

Deposition of conformal films by atomic layer deposition and atomic layer etch

ActiveCN106057637AElectric discharge tubesSemiconductor/solid-state device manufacturingHalogenAtomic layer epitaxy

The invention relates to deposition of conformal films by atomic layer deposition and atomic layer etch. Methods for depositing conformal films using a halogen-containing etchant during atomic layer deposition are provided. Methods involve exposing a substrate to a halogen-containing etchant such as nitrogen trifluoride between exposing the substrate to a first precursor and exposing the substrate to a second plasma-activated reactant. Examples of conformal films that may be deposited include silicon-containing films and metal-containing films. Related apparatuses are also provided.

Owner:LAM RES CORP

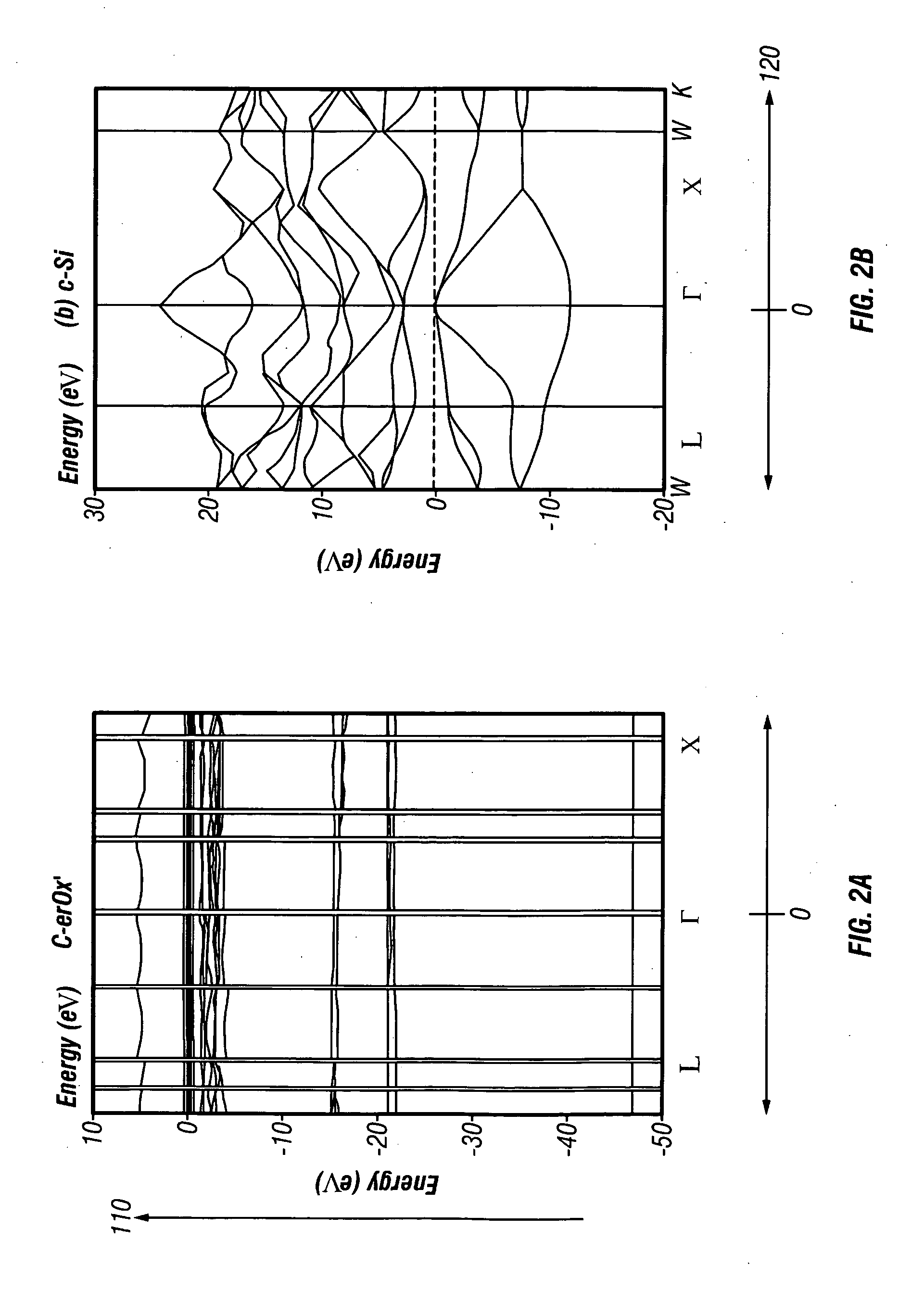

Rare earth-oxides, rare earth nitrides, rare earth phosphides and ternary alloys with silicon

InactiveUS7645517B2Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOxygen

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE—(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Rare earth-oxides, rare earth-nitrides, rare earth-phosphies, and ternary alloys with silicon

InactiveUS7709826B2Quality improvementTransistorPolycrystalline material growthAtomic layer epitaxyNitride

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

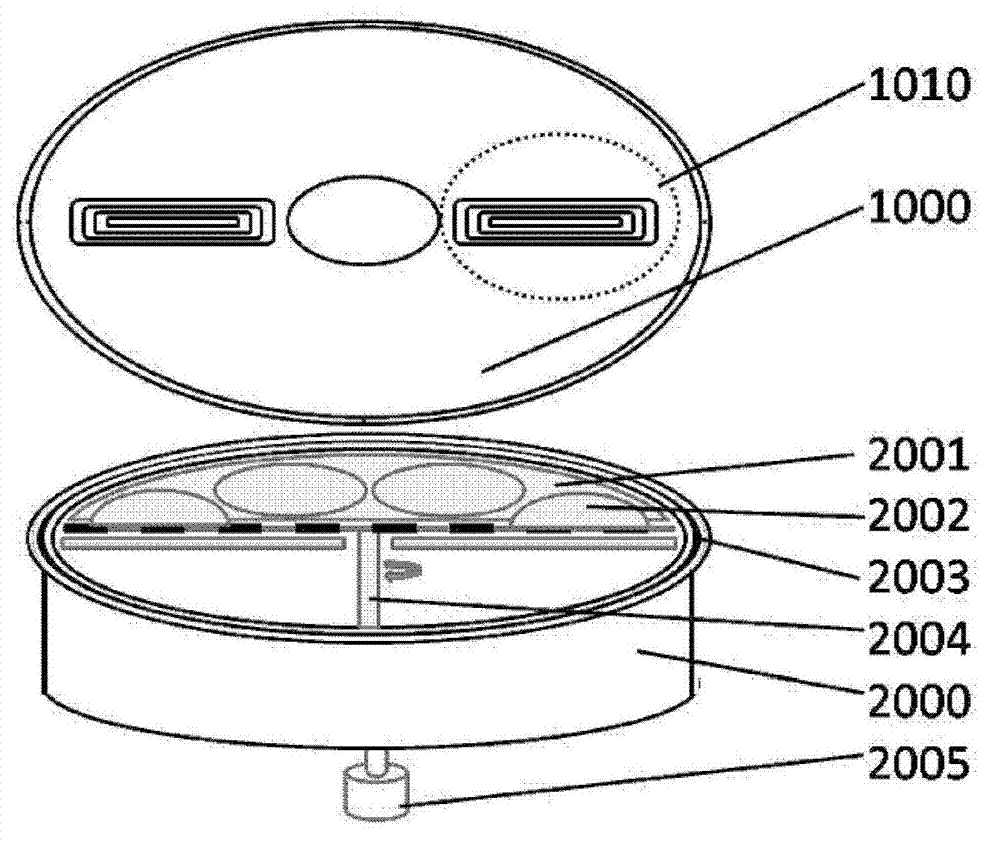

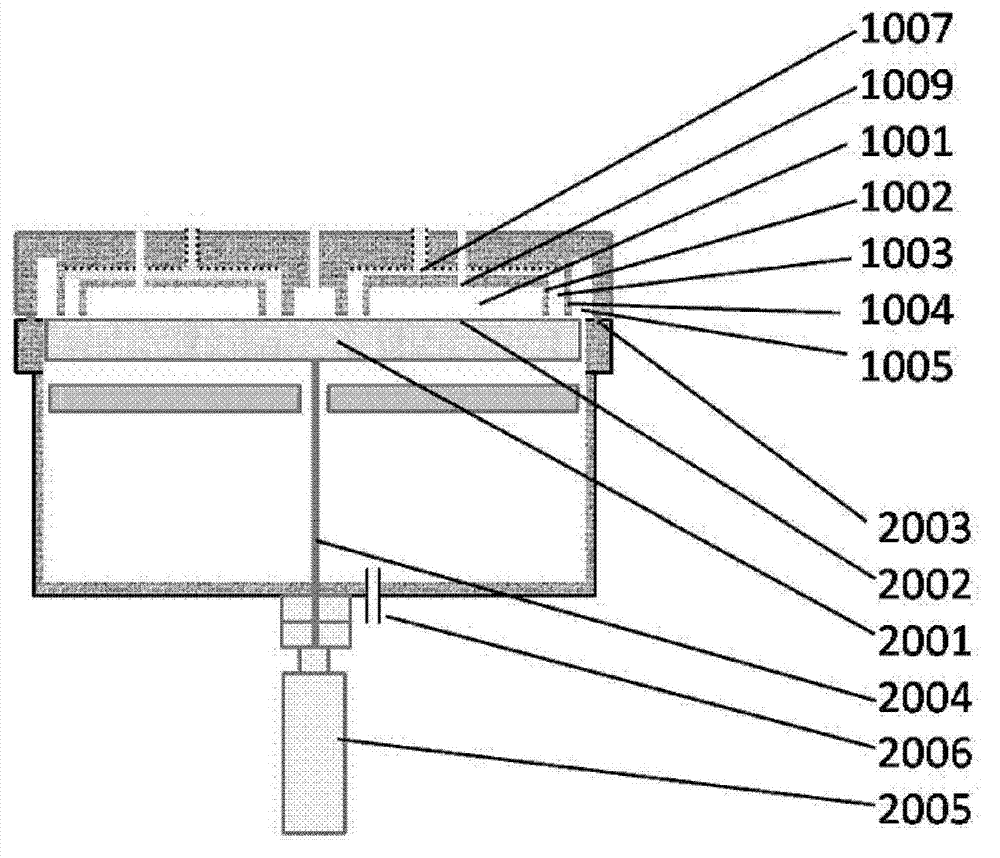

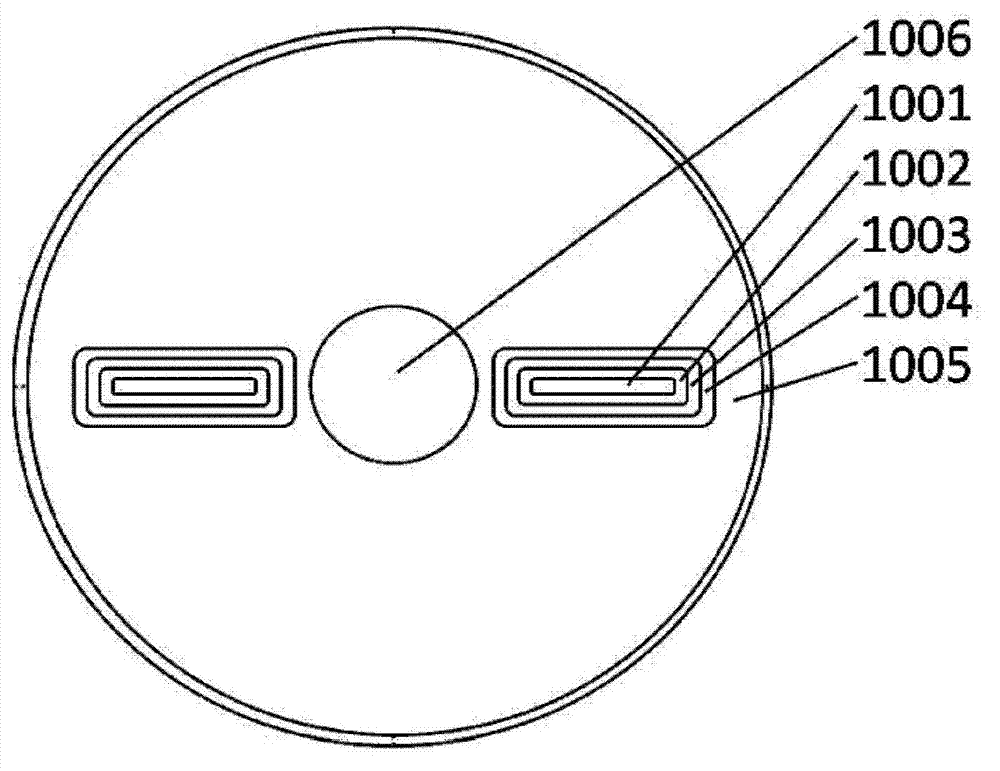

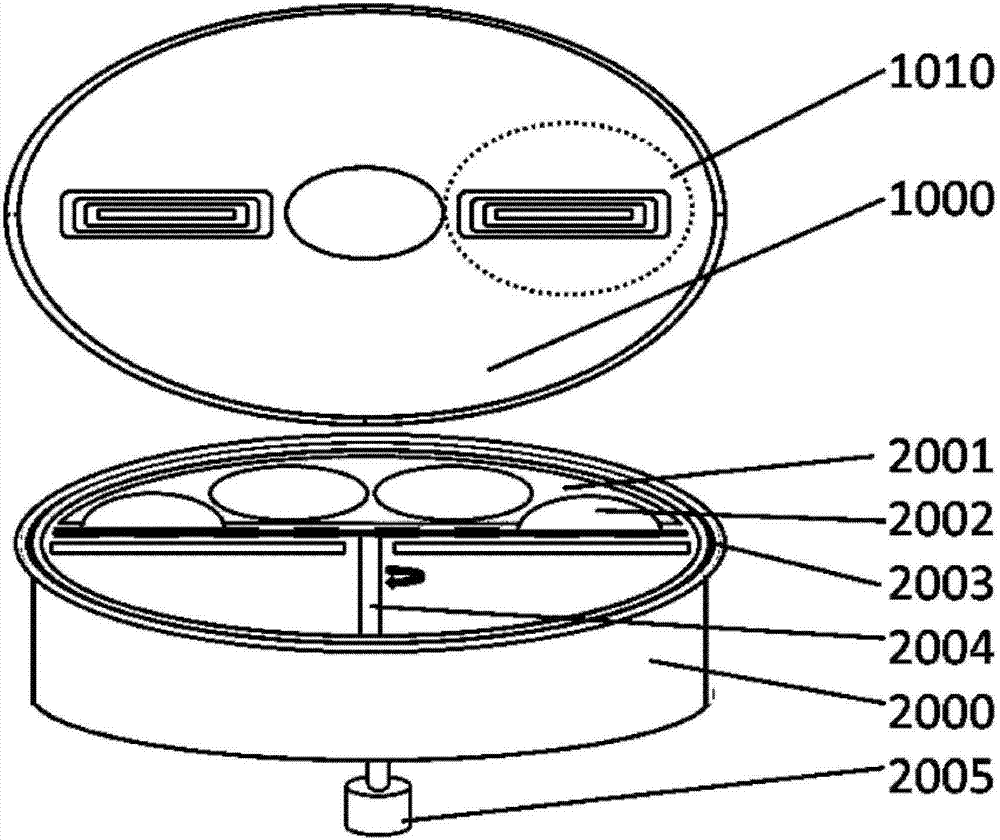

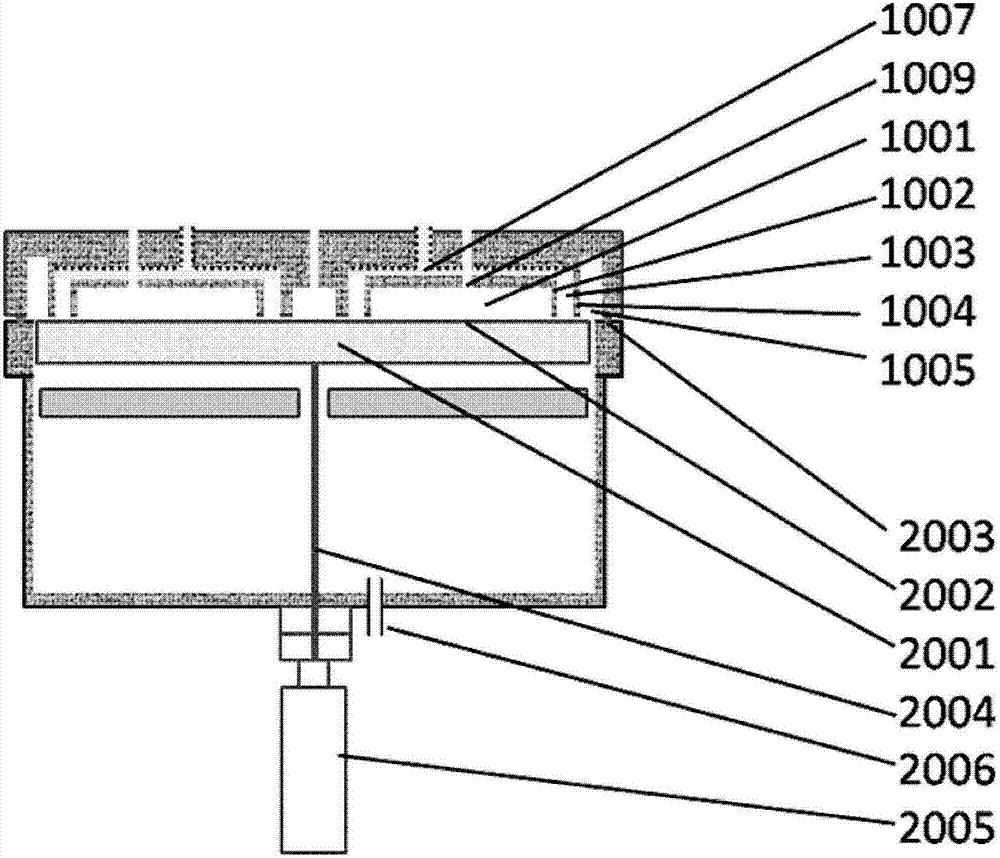

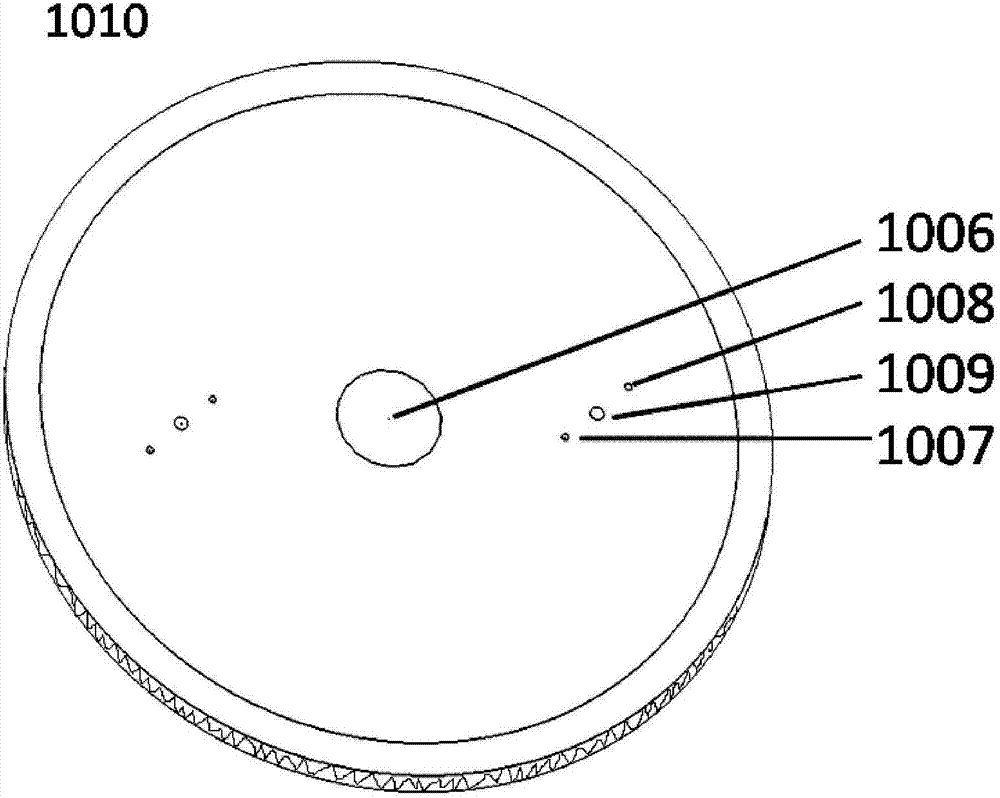

Atomic layer deposition equipment

InactiveCN103114277ANo stacking effectTo achieve the purpose of cleaningChemical vapor deposition coatingSingle processEngineering

The invention discloses atomic layer deposition equipment which is an openable and closable closed cavity comprising a cover plate and a main cavity, wherein the inner surface of the cover plate is provided with an air path unit; the air path unit comprises a plurality of airflow channels; the plurality of airflow channels are spaced through spacing layers, and each airflow channel is communicated with a plurality of air holes arranged on the outer surface of the cover plate; the main cavity comprises a rotatable loading disc and a transmission system; the transmission system drives the rotatable loading disc to rotate; the rotatable loading disc is provided with a groove used for placing a wafer; the plurality of airflow channels at least include a first airflow channel and a second airflow channel; the first airflow channel is used for accessing a reaction source gas; and the second airflow channel is used for exhausting the unreacted reaction source gas. The atomic layer deposition equipment disclosed by the invention can increase the speed of atomic layer epitaxy, save the single process time and enhance the growth rate of the atomic layer epitaxy by increasing the rotation speed of the loading disc.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

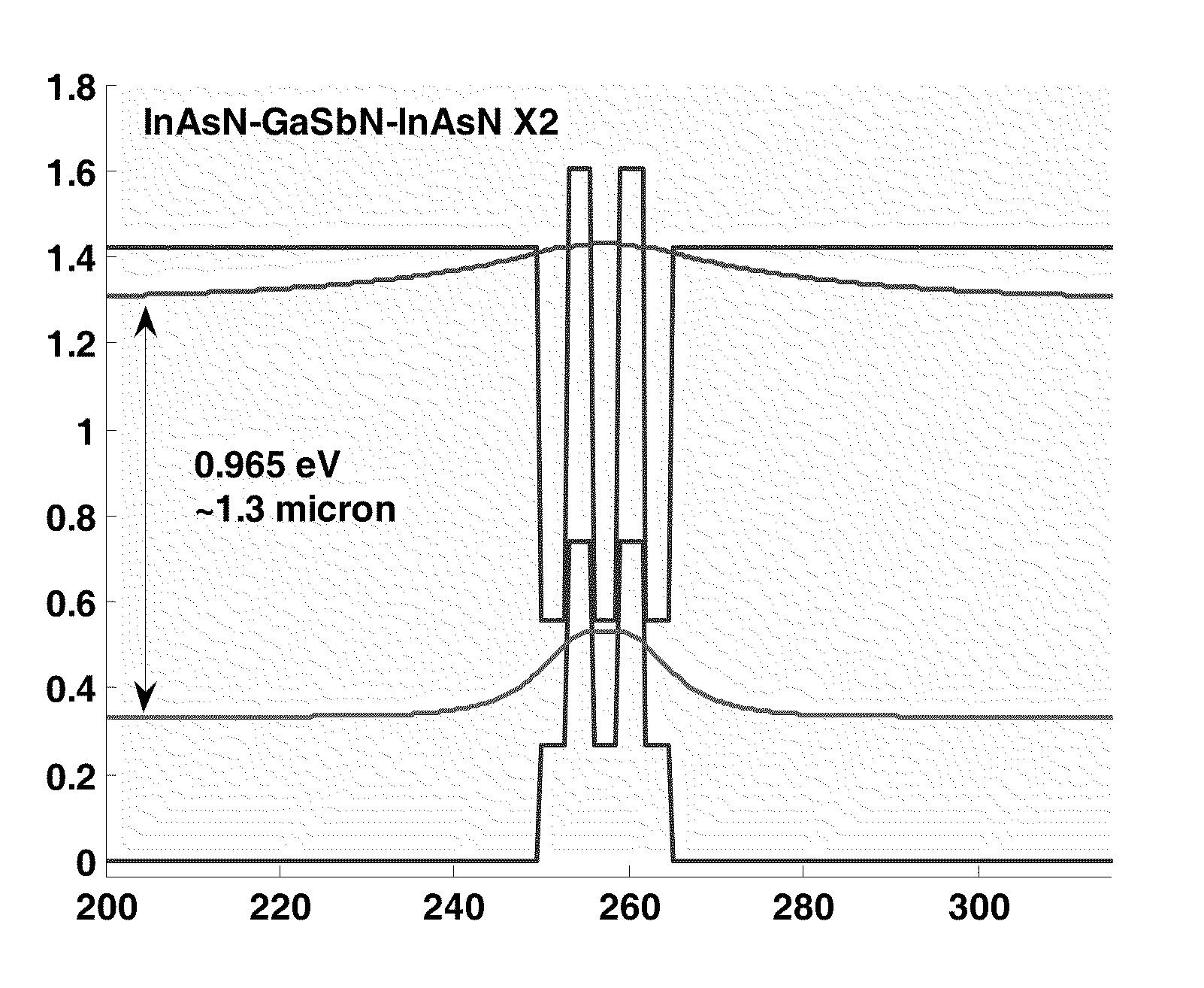

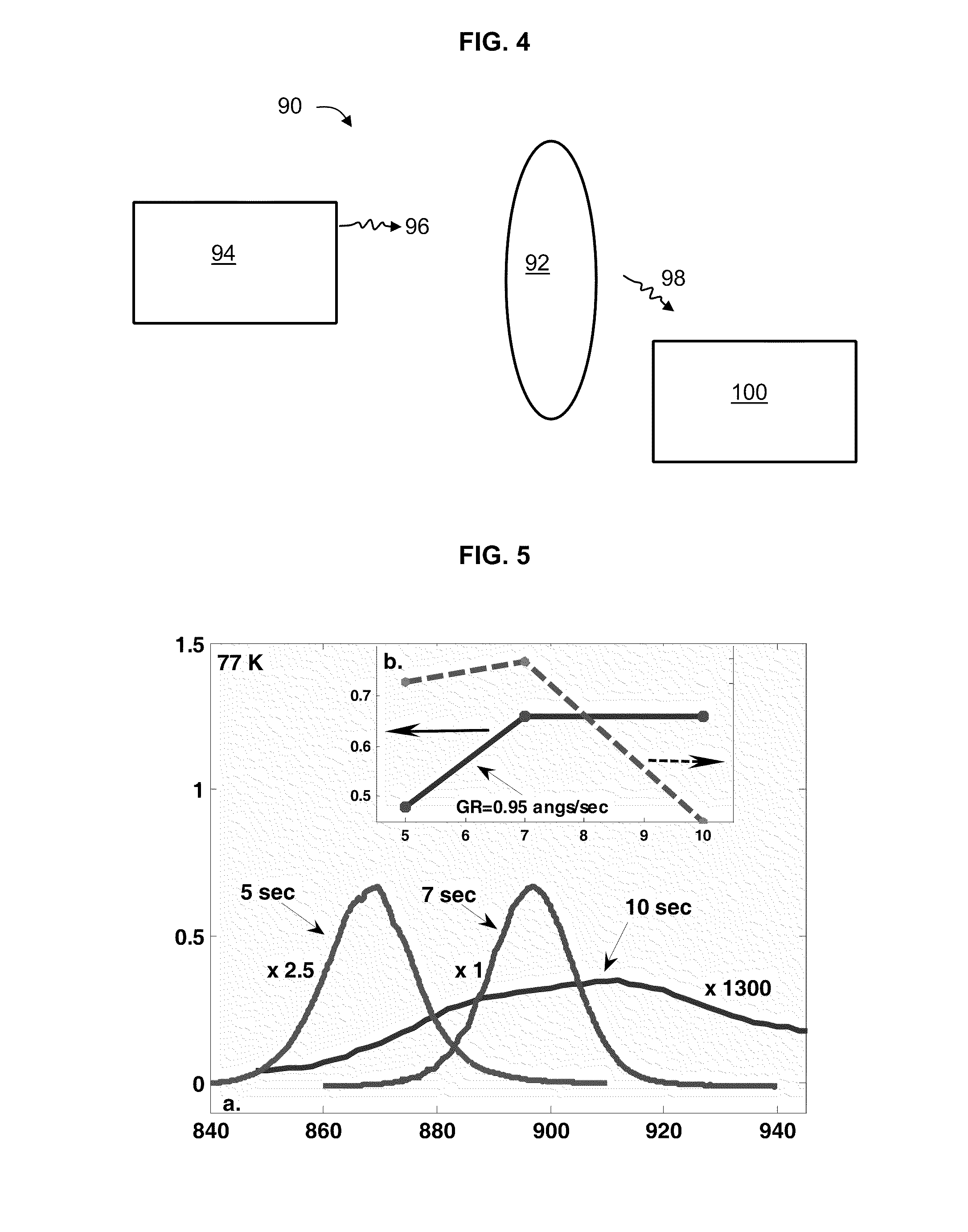

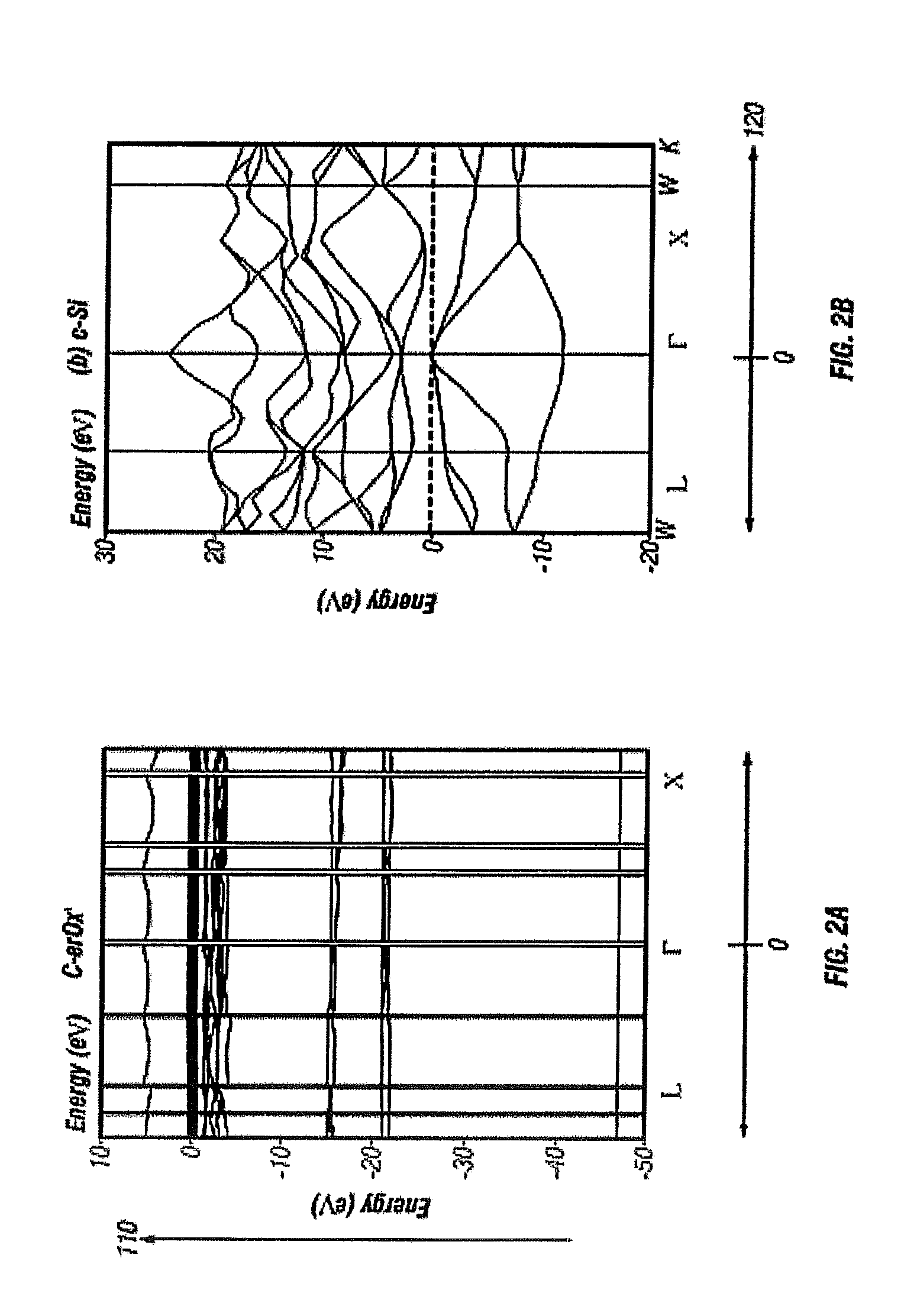

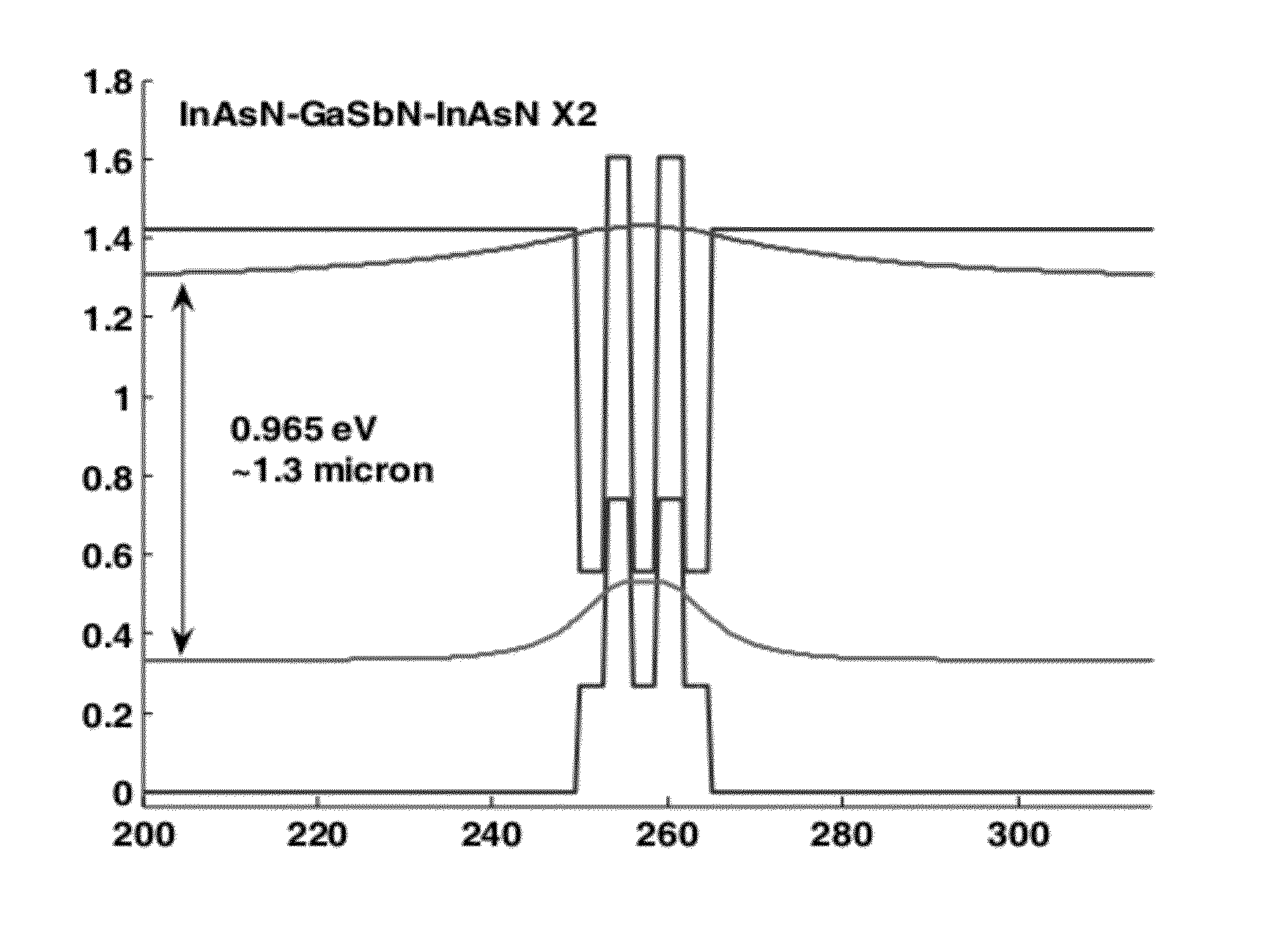

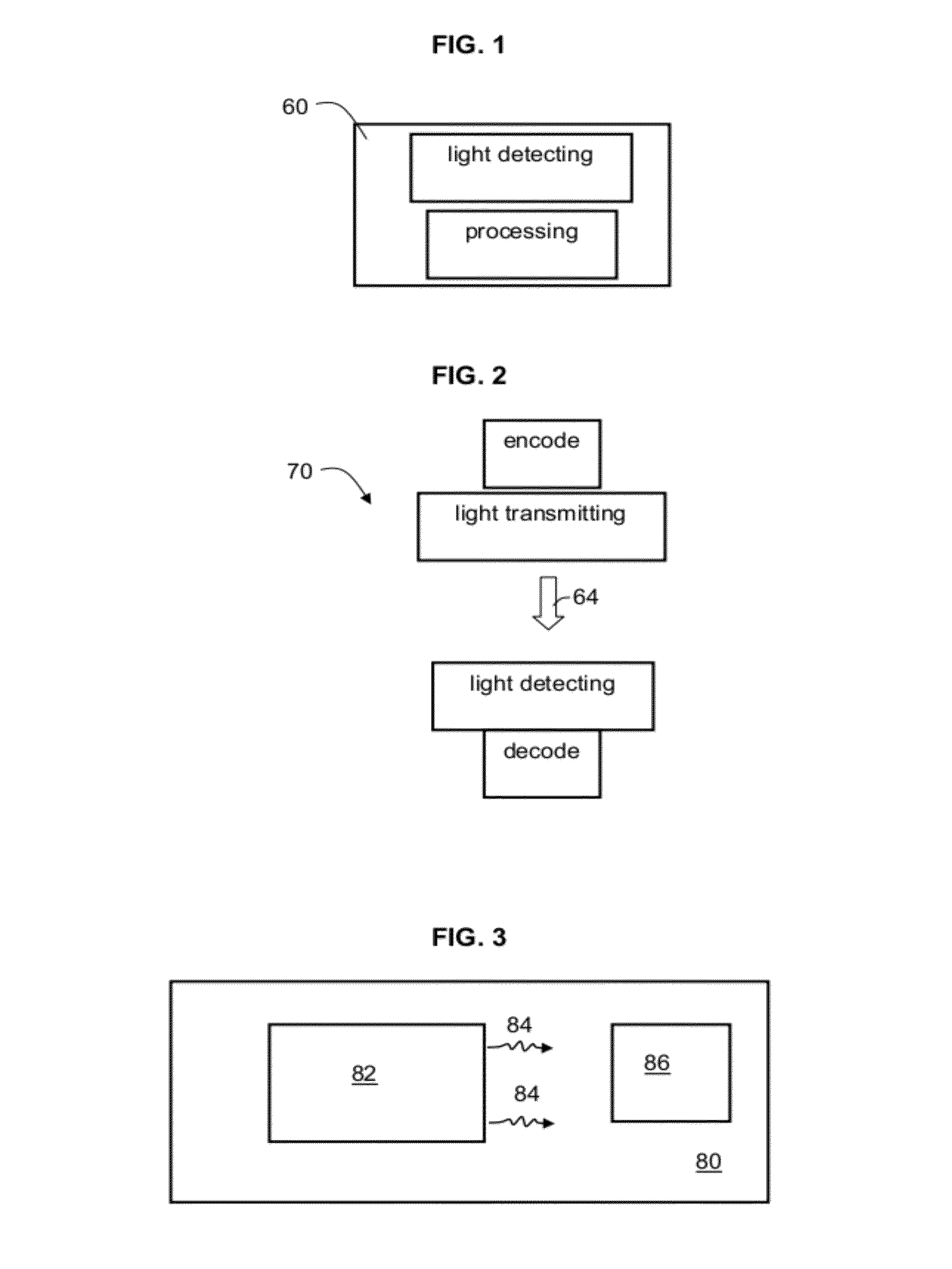

Strain-controlled atomic layer epitaxy, quantum wells and superlattices prepared thereby and uses thereof

ActiveUS20100301306A1Polycrystalline material growthSolid-state devicesQuantum wellOptical communication

Processes for forming quantum well structures which are characterized by controllable nitride content are provided, as well as superlattice structures, optical devices and optical communication systems based thereon.

Owner:TECHNION RES & DEV FOUND LTD

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

InactiveUS7902546B2Improve thermal conductivityLaser detailsNitrogen compoundsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Strain-controlled atomic layer epitaxy, quantum wells and superlattices prepared thereby and uses thereof

ActiveUS8293628B2Polycrystalline material growthSolid-state devicesCommunications systemQuantum well

Processes for forming quantum well structures which are characterized by controllable nitride content are provided, as well as superlattice structures, optical devices and optical communication systems based thereon.

Owner:TECHNION RES & DEV FOUND LTD

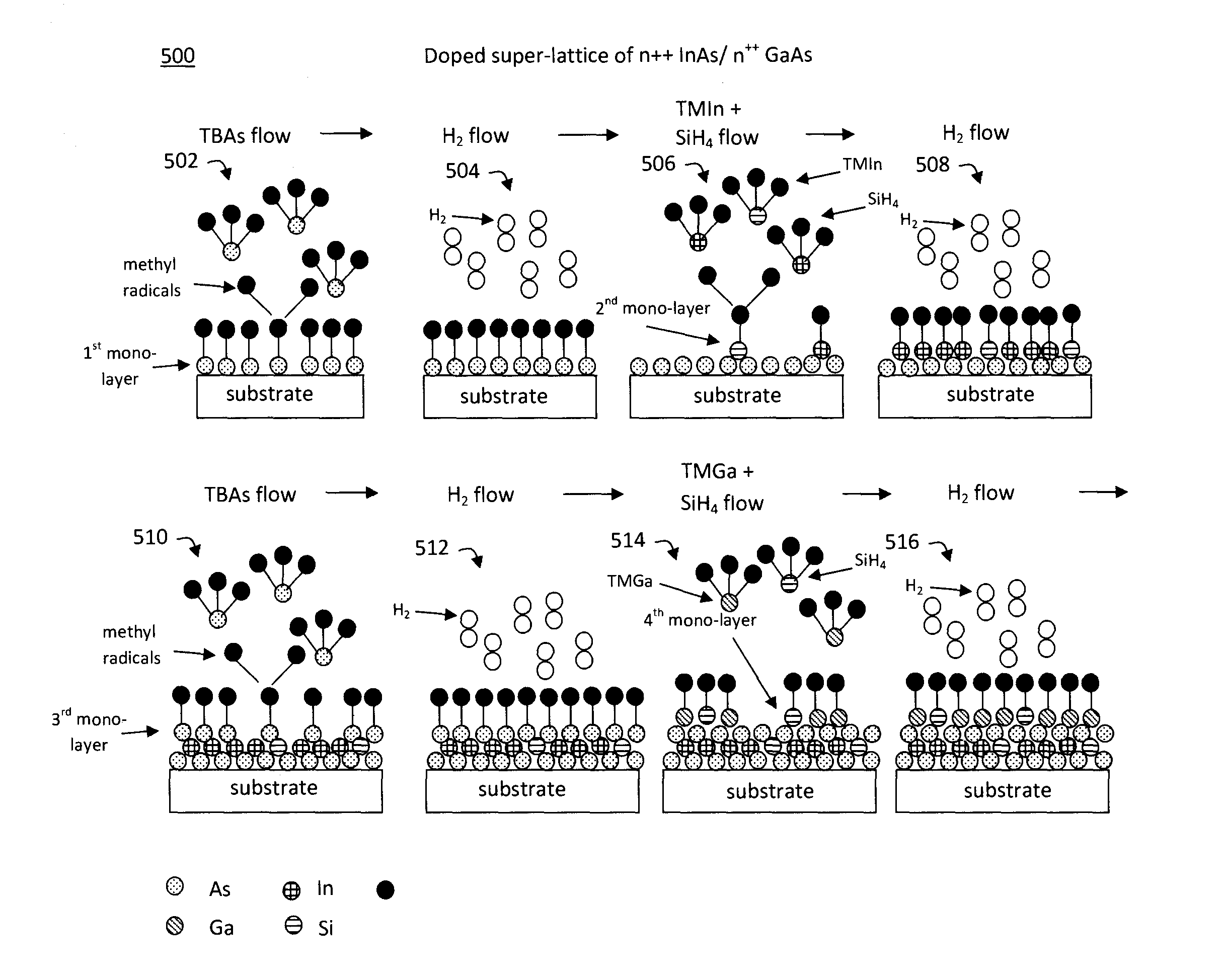

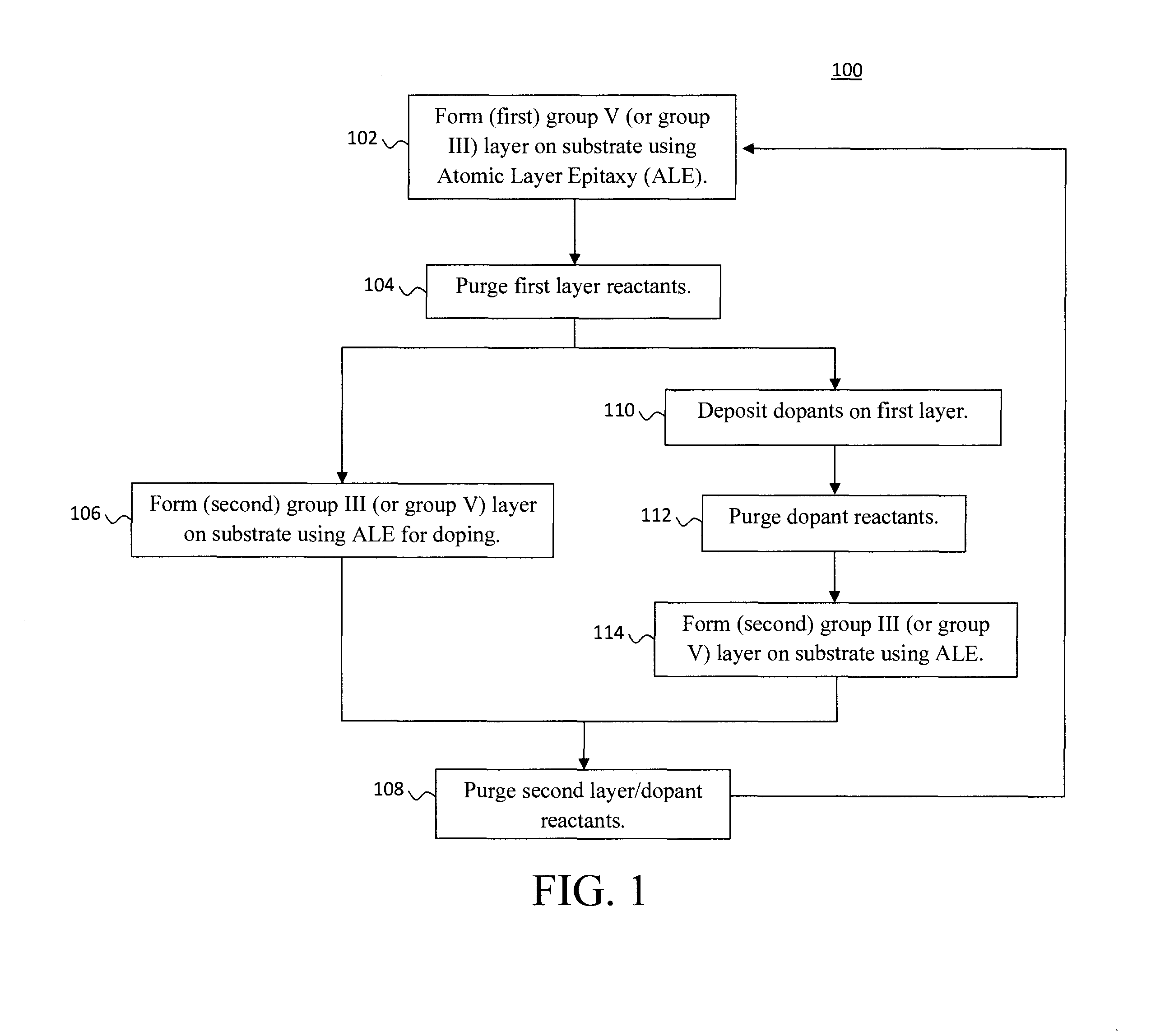

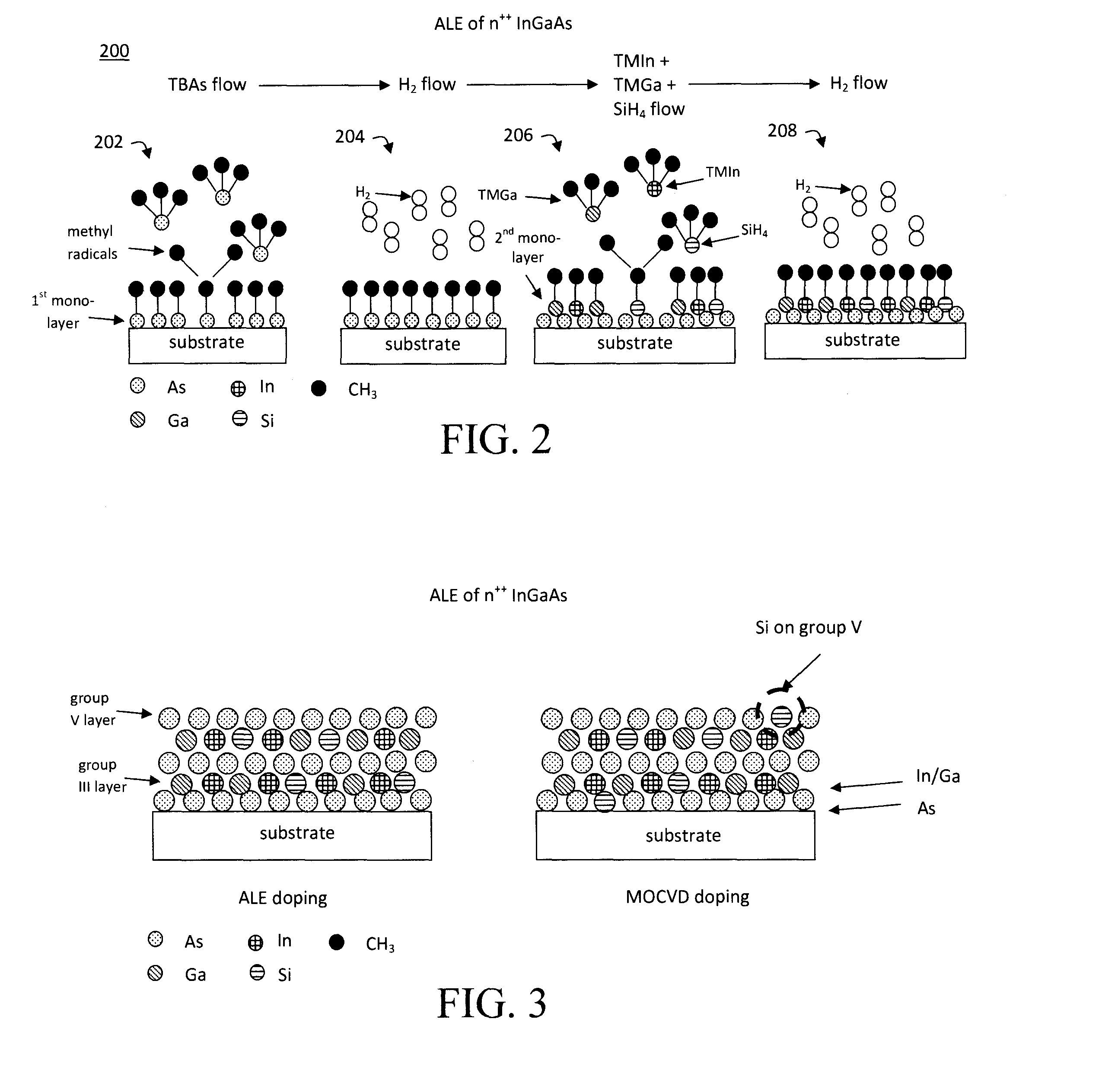

Reducing Autodoping of III-V Semiconductors By Atomic Layer Epitaxy (ALE)

InactiveUS20170004969A1Polycrystalline material growthSemiconductor/solid-state device manufacturingDopantSemiconductor materials

In one aspect, a method for forming a doped III-V semiconductor material on a substrate includes the steps of: (a) forming a first monolayer on the substrate, wherein the first monolayer comprises at least one group III or at least one group V element; and (b) forming a doped second monolayer on a side of the first monolayer opposite the substrate, wherein the second monolayer comprises either i) at least one group V element if the first monolayer comprises at least one group III element, or ii) at least one group III element if the first monolayer comprises at least one group V element, wherein a dopant is selectively introduced only during formation of the second monolayer, and wherein steps (a) and (b) are performed using atomic layer epitaxy. Doped III-V semiconductor materials are also provided.

Owner:ELPIS TECH INC

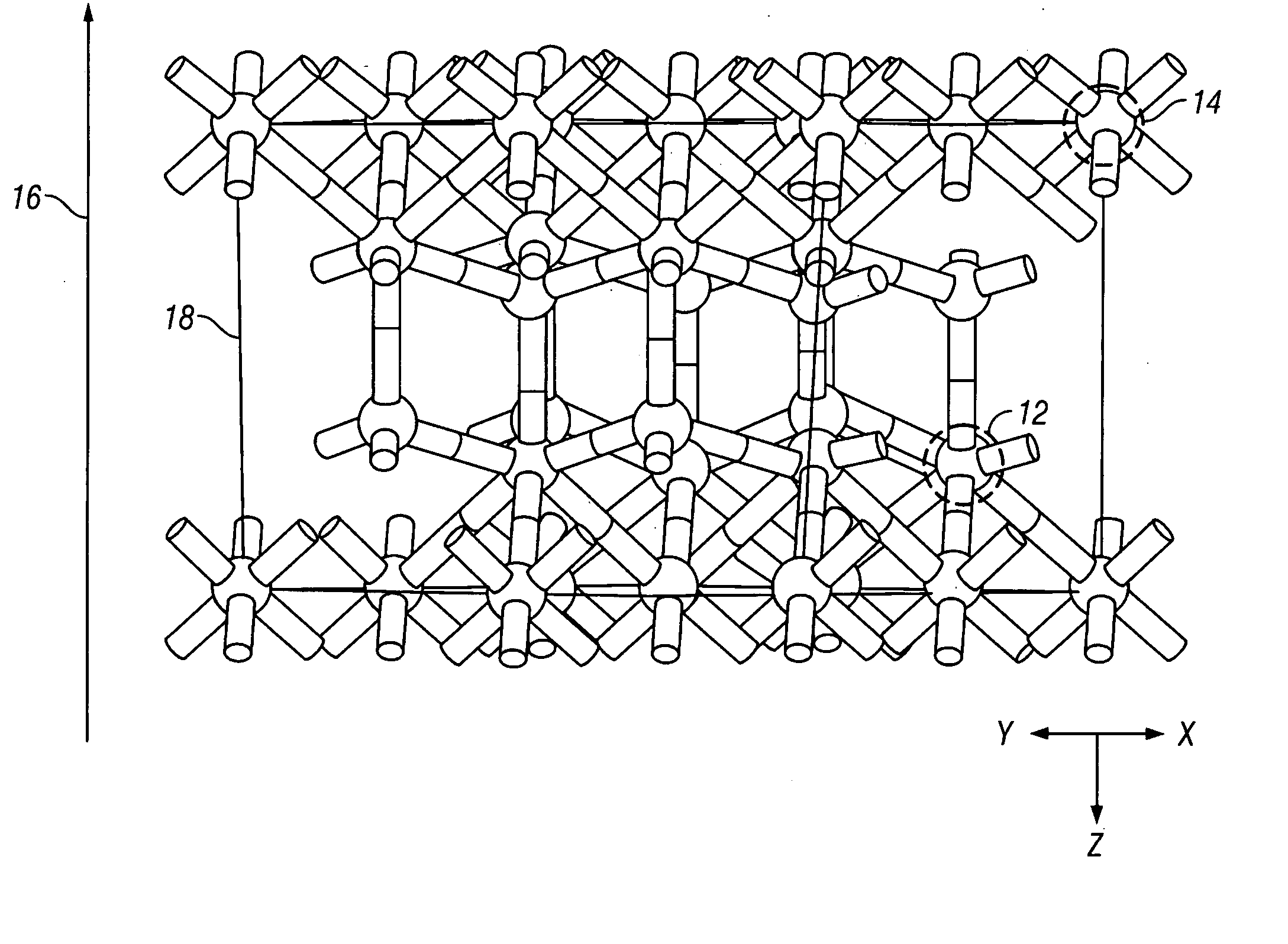

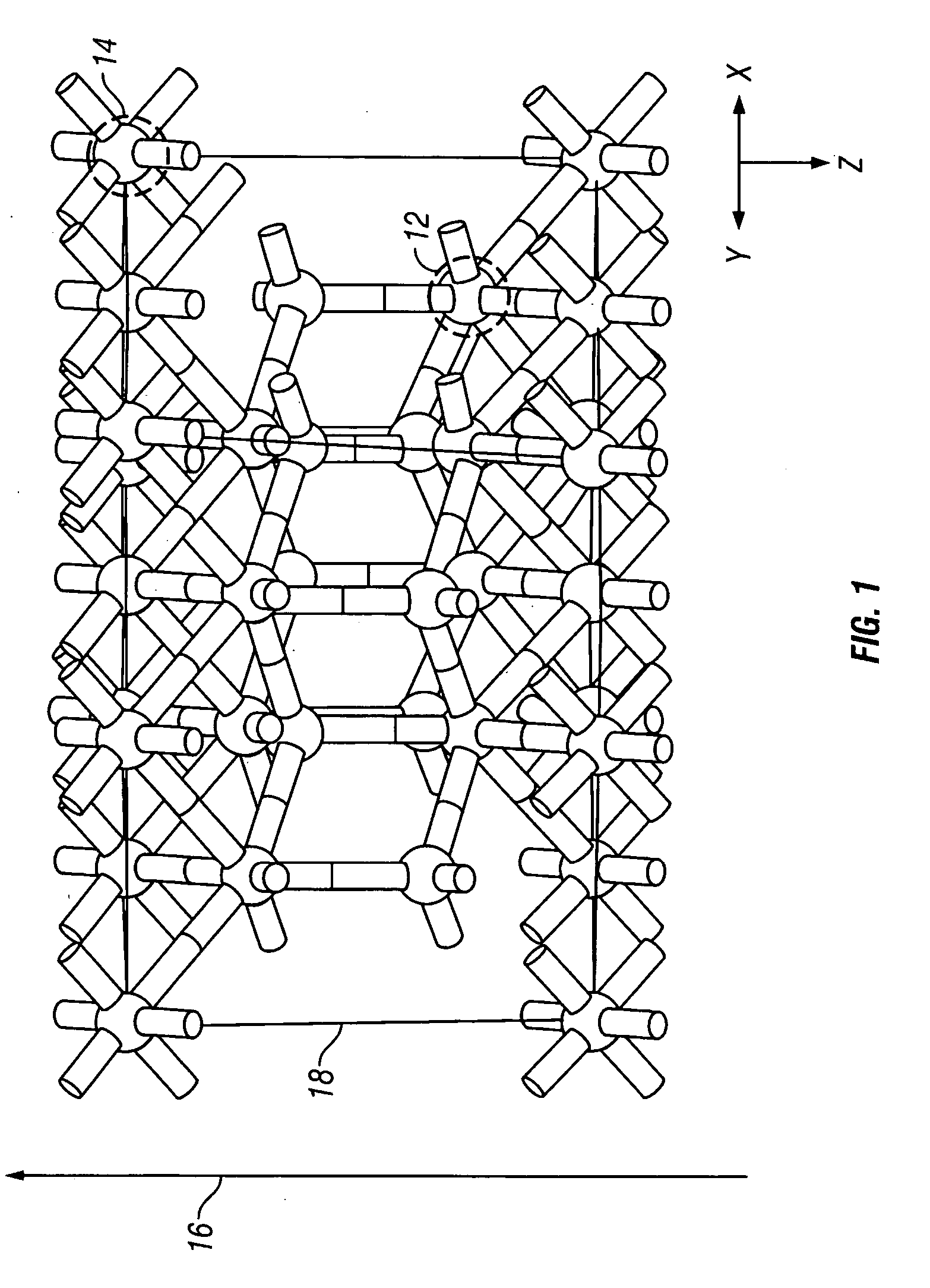

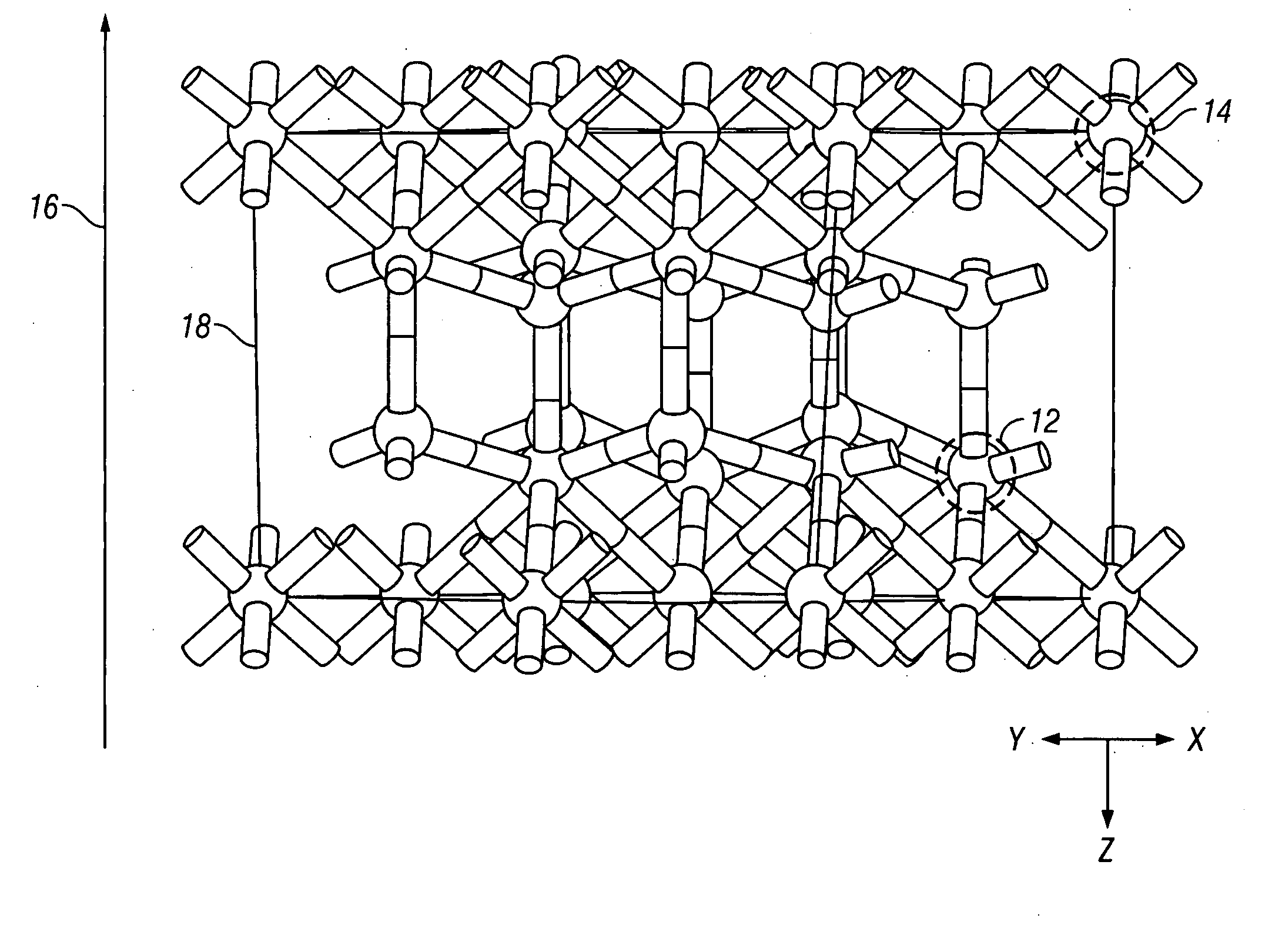

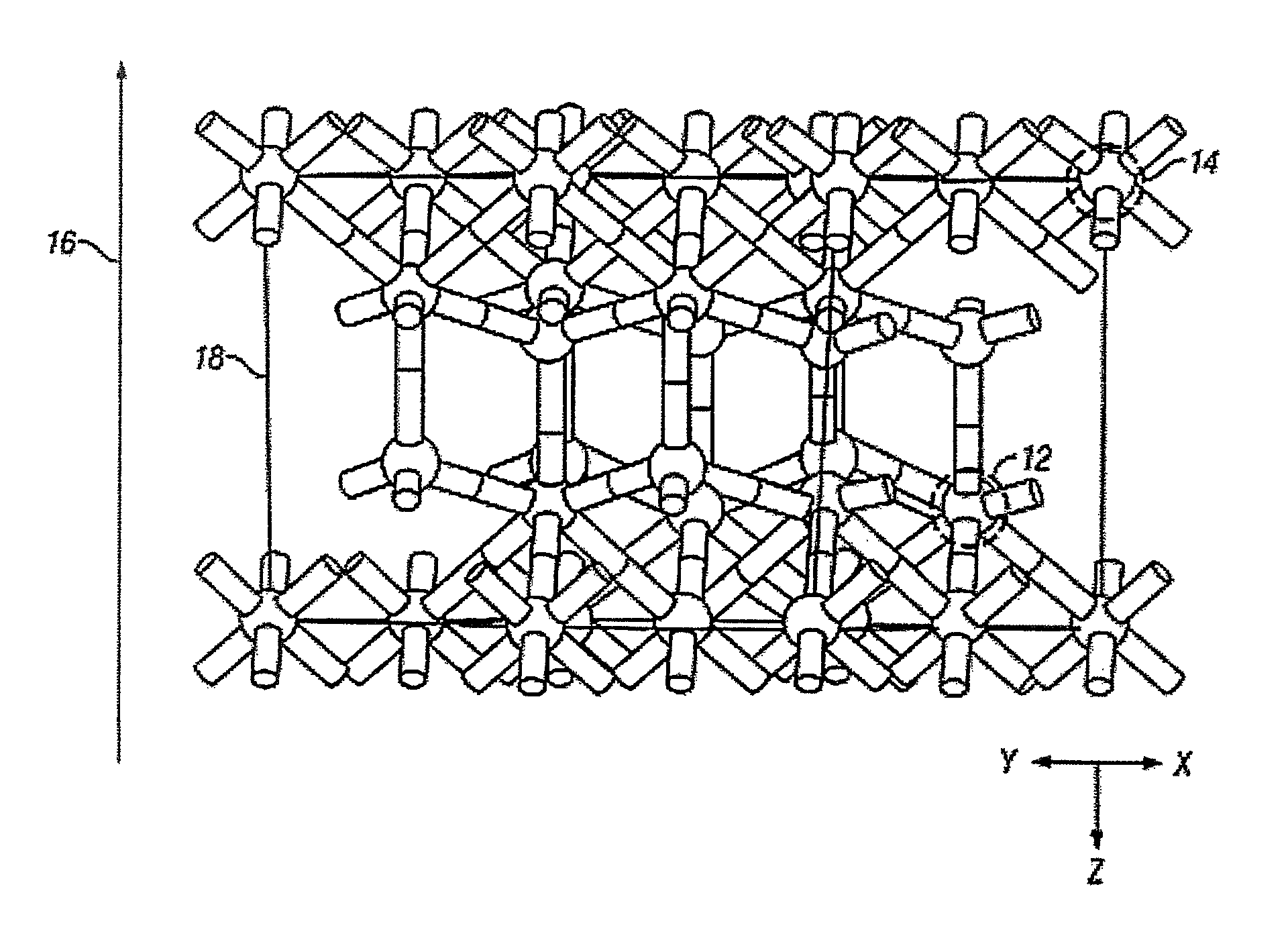

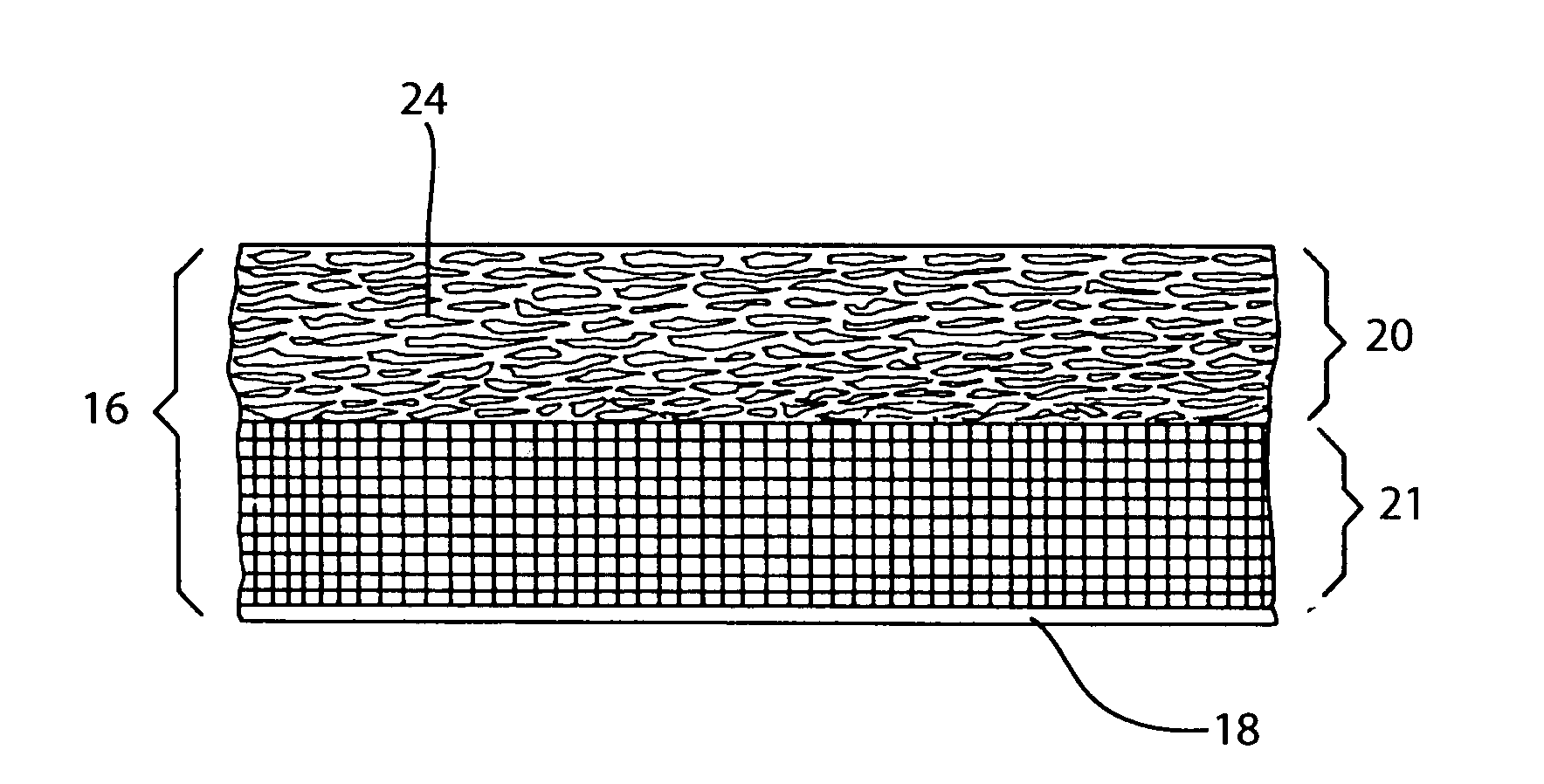

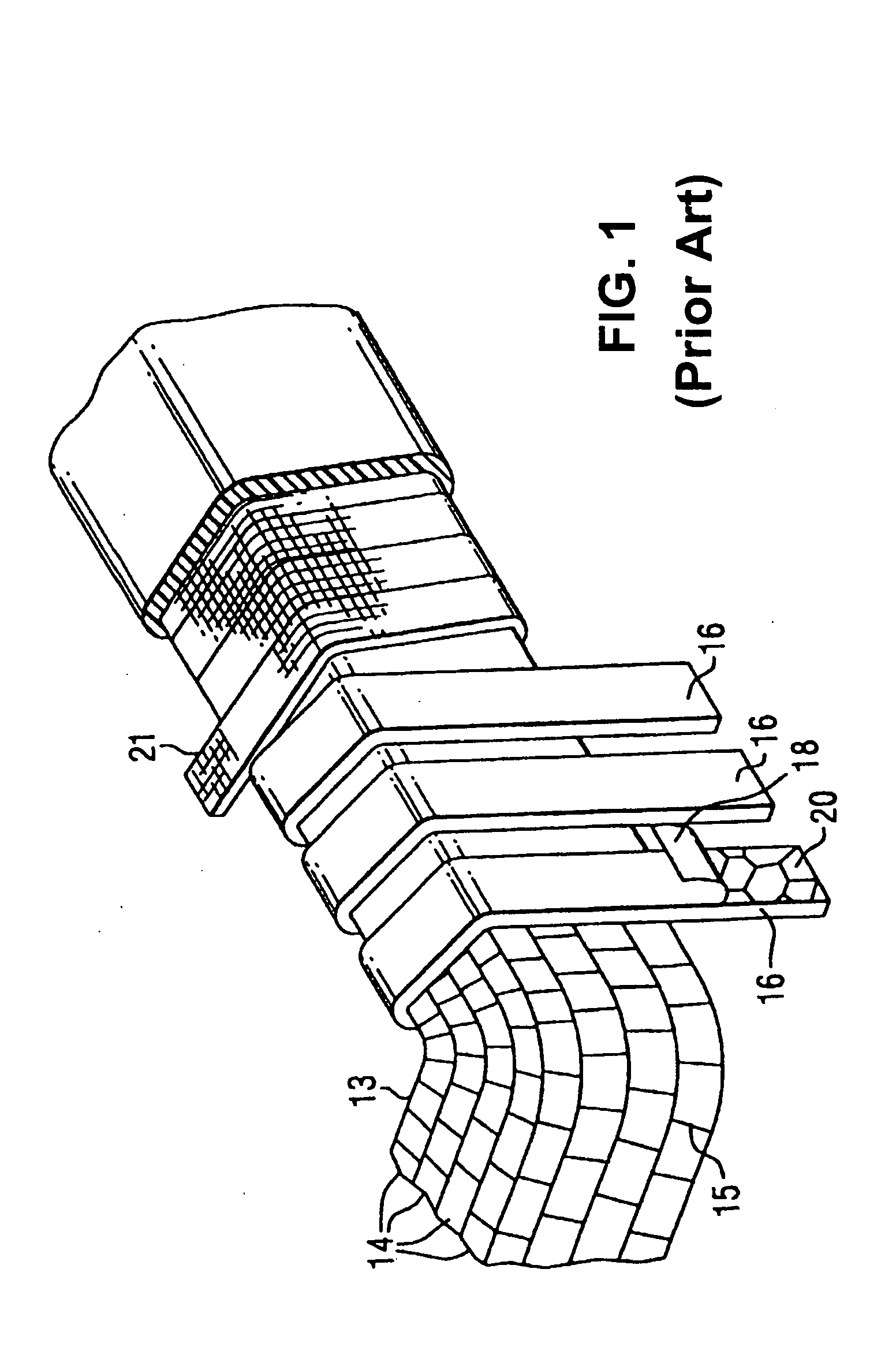

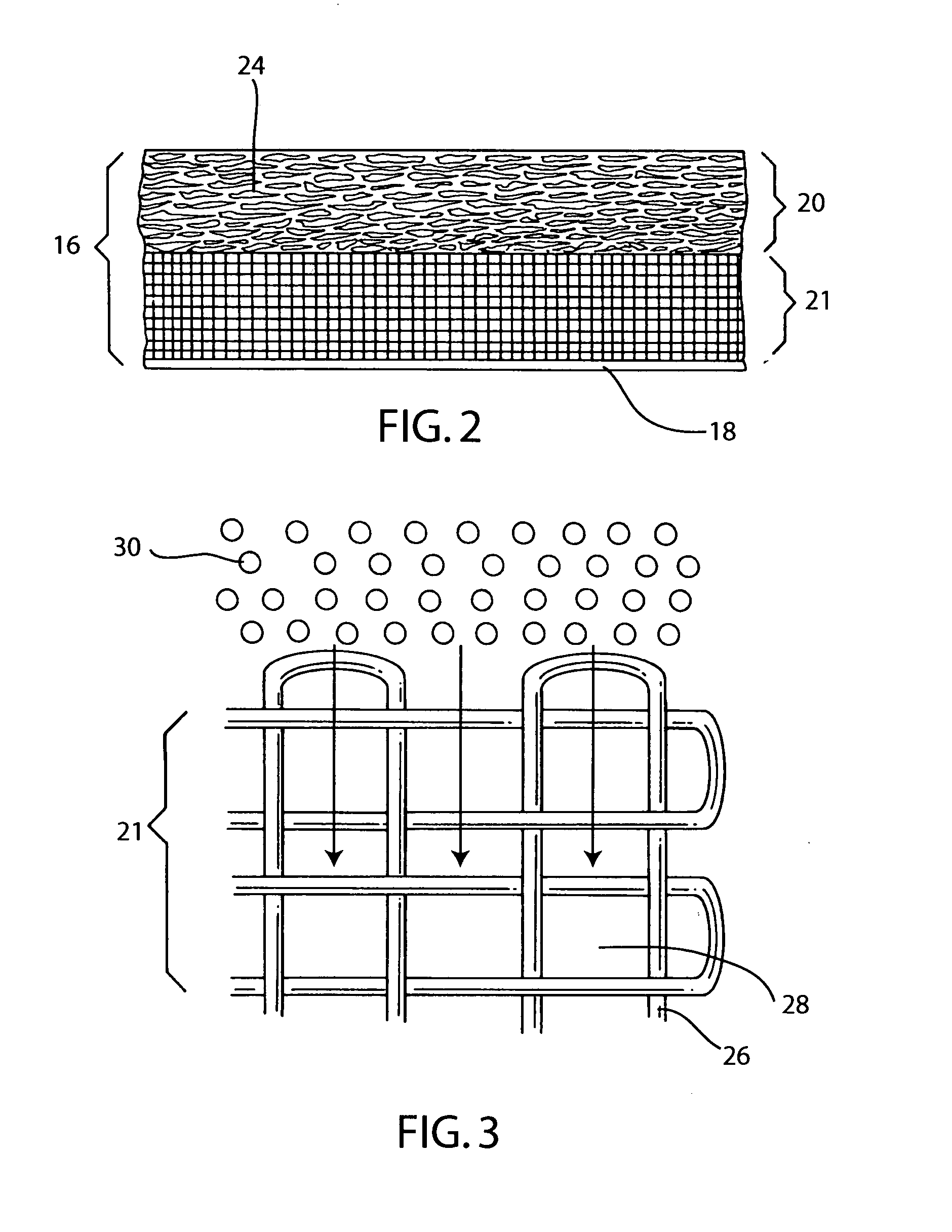

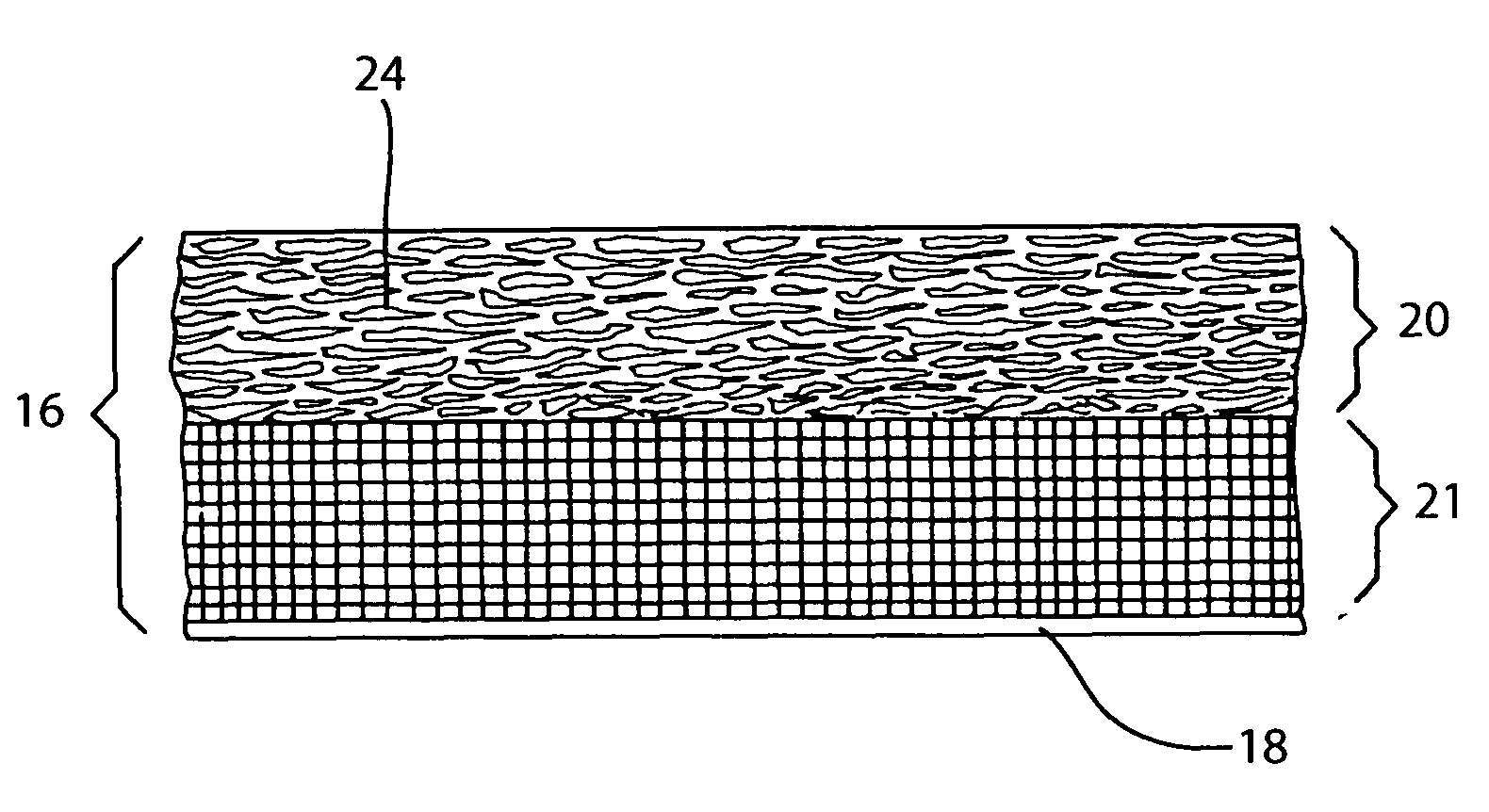

Atomic layer epitaxy processed insulation

InactiveUS20090000541A1Easy to addLow selectivityPolycrystalline material growthFrom chemically reactive gasesOptoelectronicsAtomic layer epitaxy

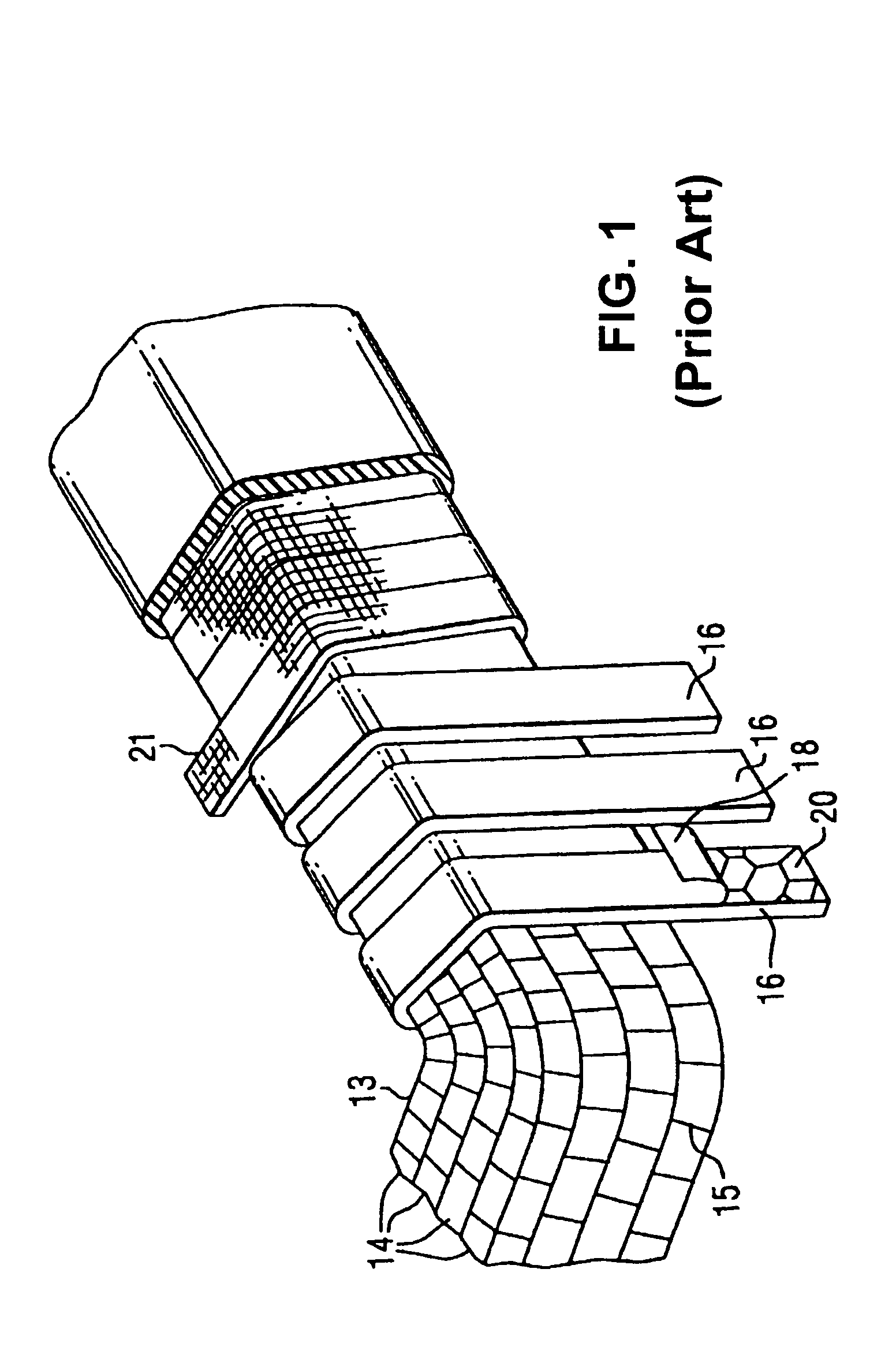

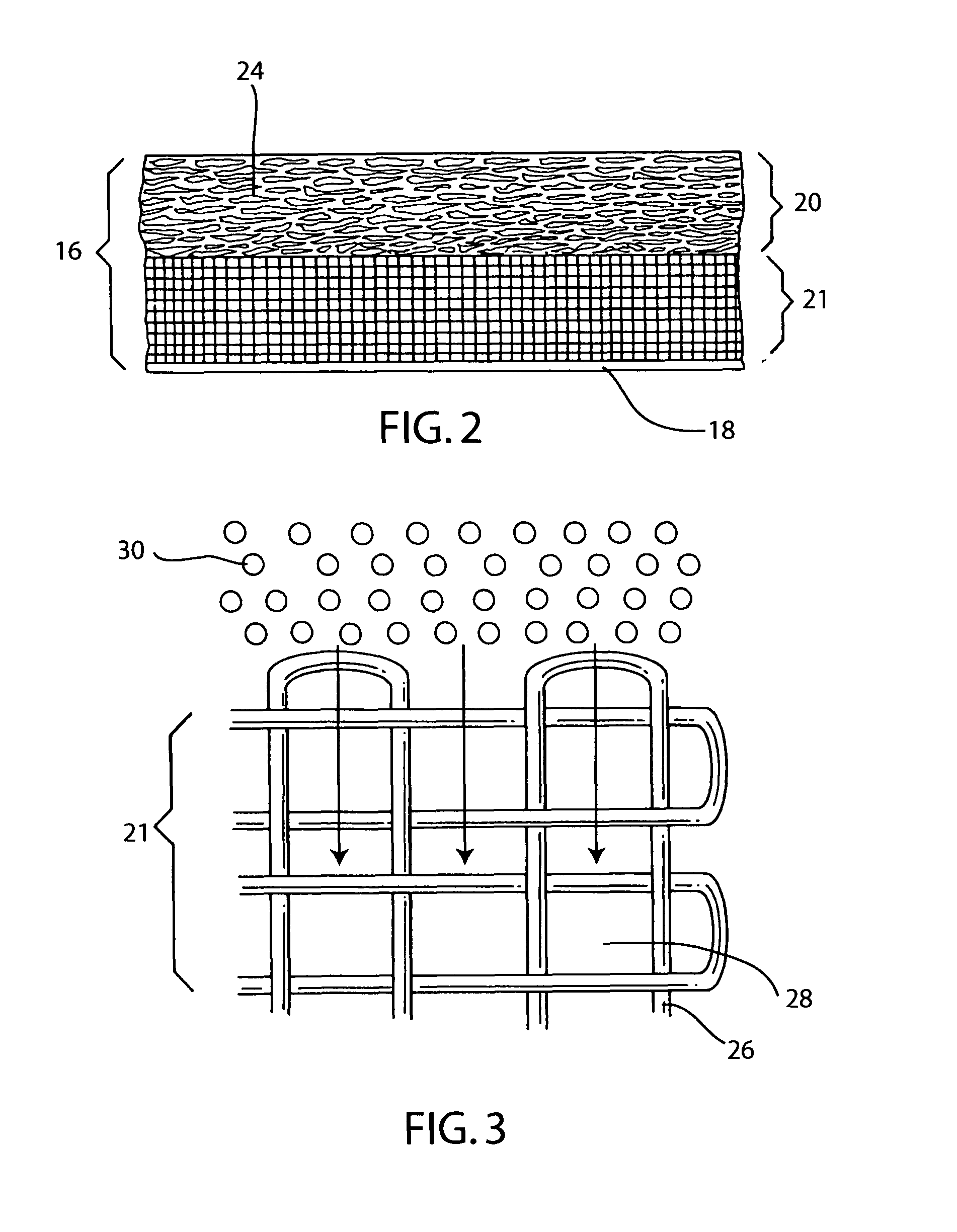

In one embodiment the present invention proved for a method for depositing a thin film layer onto a composite tape 16, that comprises depositing at least one thin film layer of physically enhancing material 30 onto at least one portion of the composite tape. The depositing is accomplished by atomic layer epitaxy and the thin film layer is approximately 1-10 molecules thick.

Owner:SIEMENS ENERGY INC

Atomic layer epitaxy processed insulation

InactiveUS7947128B2Polycrystalline material growthFrom chemically reactive gasesOptoelectronicsAtomic layer epitaxy

In one embodiment the present invention provides for a method for depositing a thin film layer onto a composite tape 16, that comprises depositing at least one thin film layer of physically enhancing material 30 onto at least one portion of the composite tape. The depositing is accomplished by atomic layer epitaxy and the thin film layer is approximately 1-10 molecules thick.

Owner:SIEMENS ENERGY INC

Method of constructing optical filters by atomic layer control for next generation dense wavelength division multiplexer

InactiveUS6893500B2Polycrystalline material growthVacuum evaporation coatingChemical beam epitaxyChemical reaction

A method of constructing optical filters using alternating layers of materials with “low” and “high” indices of refraction and deposited with atomic layer control. The multilayered thin film filter uses, but is not limited to, alternating layers of single crystal, polycrystalline or amorphous materials grown with self-limiting epitaxial deposition processes well known to the semiconductor industry. The deposition process, such as atomic layer epitaxy (ALE), pulsed chemical beam epitaxy (PCB E), molecular layer epitaxy (MLE) or laser molecular beam epitaxy (laser MBE) can result in epitaxial layer by layer growth and thickness control to within one atomic layer. The alternating layers are made atomically smooth using a Chemical Reactive-Ion Surface Planarization (CRISP) process. Intrinsic stress is monitored using an in-situ cantilever based intrinsic stress optical monitor and adjusted during filter fabrication by deposition parameter modification. The resulting filter has sufficient individual layer thickness control and surface roughness to enable ˜12.5 GHz filters for next generation multiplexers and demultiplexers with more than 1000 channels in the wavelength range 1.31-1.62 μm.

Owner:ATOMIC TELECOM

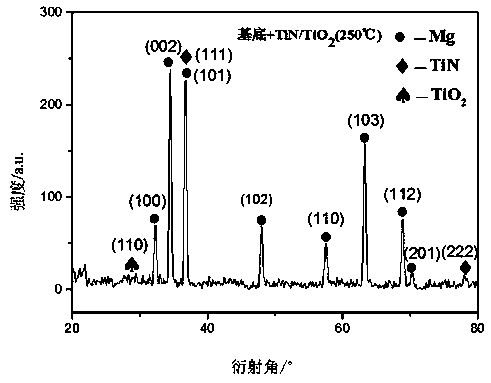

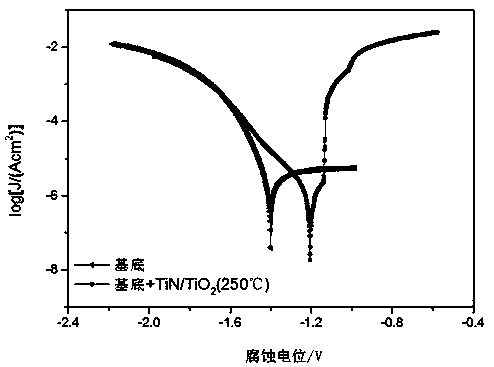

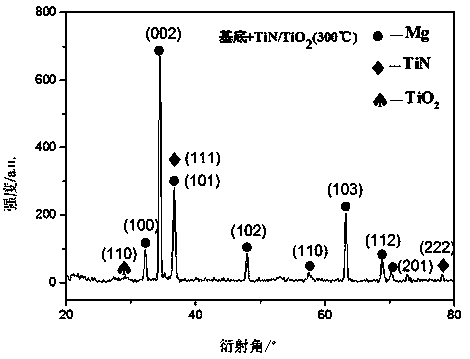

Preparation method of titanium nitride/titanium dioxide nano-composite anti-corrosion coating

InactiveCN108823552AStoichiometric ratio is accurateIncrease coverageChemical vapor deposition coatingTitanium nitrideAtomic layer epitaxy

The invention discloses a preparation method of a titanium nitride / titanium dioxide nano-composite anti-corrosion coating. The preparation method comprises the following steps of (1) ALD working cavity preparing; (2) titanium nitride / titanium dioxide nano-composite anti-corrosion coating preparing, specifically, a titanium nitride film is prepared, part of titanium nitride is converted into titanium dioxide through self-oxidation, and finally the titanium nitride / titanium dioxide nano-composite coating is obtained; and (3) ALD working cavity reducing. According to the titanium nitride / titaniumdioxide nano-composite anti-corrosion coating prepared through an atomic layer epitaxy technology, a nano coating with the precise stoichiometric ratio, the good covering property and the precise film thickness can be formed on the surfaces of any shapes (two-dimensional or three-dimensional), and the repeatable stability of the technology is good. Coating materials are poisonless and harmless toa human body and can improve the corrosion resistance of metals, especially active metals such as magnesium and zinc.

Owner:NANCHANG UNIV

Method for producing light-emitting device

InactiveCN100438088CEasy to flattenProne to irregularitiesPolycrystalline material growthSemiconductor/solid-state device manufacturingChemical reactionSemiconductor materials

In a first invention, a p-type MgxZn1-xO-type layer is grown based on a metal organic vapor-phase epitaxy process by supplying organometallic gases which serves as a metal source, an oxygen component source gas and a p-type dopant gas into a reaction vessel. During and / or after completion of the growth of the p-type MgxZn1-xO-type layer, the MgxZn1-xO-type thereof is annealed in an oxygen-containing atmosphere. This is successful in forming the layer of p-type oxide in a highly reproducible and stable manner for use in light emitting device having the layer of p-type oxide of Zn and Mg. In a second invention, a semiconductor layer which composes the light emitting layer portion is grown by introducing source gases in a reaction vessel having the substrate housed therein, and by depositing a semiconductor material produced by chemical reactions of the source gas on the main surface of the substrate. A vapor-phase epitaxy process of the semiconductor layer is proceed while irradiating ultraviolet light to the main surface of the substrate and the source gases. This is successful in sharply enhancing reaction efficiency of the source gases when the semiconductor layer for composing the light emitting layer portion is formed by a vapor-phase epitaxy process, and in readily obtaining the semiconductor layer having only a less amount of crystal defects. In a third invention, a buffer layer having at least an MgaZn1-aO-type oxide layer on the contact side with the light emitting layer portion is grown on the substrate, and the light emitting layer portion is grown on the buffer layer. The buffer layer is oriented so as to align the c-axis thereof to the thickness-wise direction, and is obtained by forming a metal monoatomic layer on the substrate based on the atomic layer epitaxy, and then by growing residual oxygen atom layers and the metal atom layers. This is successful in obtaining the light emitting portion with an excellent quality. In a fourth invention, a ZnO-base semiconductor active layer included in a double heterostructured, light emitting layer portion is formed using a ZnO-base semiconductor mainly composed of ZnO containing Se or Te, so as to introduce Se or Te, the elements in the same Group with oxygen, into oxygen deficiency sites in the ZnO crystal possibly produced during the formation process of the active layer, to thereby improve crystallinity of the active layer. Introduction of Se or Te shifts the emission wavelength obtainable from the active layer towards longer wavelength regions as compared with the active layer composed of ZnO having a band gap energy causative of shorter wavelength light than blue light. This is contributive to realization of blue-light emitting devices.

Owner:SHIN-ETSU HANDOTAI CO LTD

Production method for light emitting element

InactiveCN1835254AEasy to flattenProne to irregularitiesPolycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsUltraviolet

When p-type MgxZn1-xO is grown by an organometallic vapor growth method, a MgxZn1-xO layer is heat treated in an oxygen atmosphere during the growth and / or after the growth completion. In addition, the surface of a substrate to be grown and a material gas are irradiated with a ultraviolet ray when a semiconductor layer is vapor-grown. In addition, when a MgxZn1-xO buffer layer having its c-axis oriented in a layer thickness direction is formed by an atomic layer exitaxy method, a metal mono-atomic layer is grown at first. In addition, a ZnO-based semiconductor active layer is formed by a semiconductor material mainly consisting of ZnO containing Se or Te. A light emitting element is formed by using these techniques.

Owner:SHIN-ETSU HANDOTAI CO LTD

Magnesium alloy surface corrosion-resistant coating preparation method

InactiveCN107164744AUniform stoichiometric ratioStoichiometric ratio is accurateChemical vapor deposition coatingSelf limitingHydrogen

The invention discloses a magnesium alloy surface corrosion-resistant coating preparation method. The magnesium alloy surface corrosion-resistant coating preparation method comprises the following steps: (1) removing hydrogen from a magnesium alloy; (2) preparing an ALD (Atomic Layer Deposition) working cavity; (3) preparing a corrosion-resistant by adopting ALD; (4) reducing in the ALD working cavity. According to the magnesium alloy surface corrosion-resistant coating preparation method, an Atomic Layer Deposition technology is adopted; the self-limiting properties (adsorption self-limiting property and reaction self-limiting property) of a preparation process are utilized, various types of oxides, nitrides and composite corrosion-resistant coatings which are good in thickness uniformity, precise in component control and high in compactness and have strong combining property with a magnesium alloy substrate are prepared on the surface of the magnesium alloy. In the preparation, the coating can be prepared on a surface of any shape, and the temperature is the only process parameter; the controllability and the process stability are high.

Owner:NANCHANG UNIV

Production method for light emitting element

InactiveCN1835255AEasy to flattenProne to irregularitiesPolycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsUltraviolet

When p-type MgxZn1-xO is grown by an organometallic vapor growth method, a MgxZn1-xO layer is heat treated in an oxygen atmosphere during the growth and / or after the growth completion. In addition, the surface of a substrate to be grown and a material gas are irradiated with a ultraviolet ray when a semiconductor layer is vapor-grown. In addition, when a MgxZn1-xO buffer layer having its c-axis oriented in a layer thickness direction is formed by an atomic layer exitaxy method, a metal mono-atomic layer is grown at first. In addition, a ZnO-based semiconductor active layer is formed by a semiconductor material mainly consisting of ZnO containing Se or Te. A light emitting element is formed by using these techniques.

Owner:SHIN-ETSU HANDOTAI CO LTD

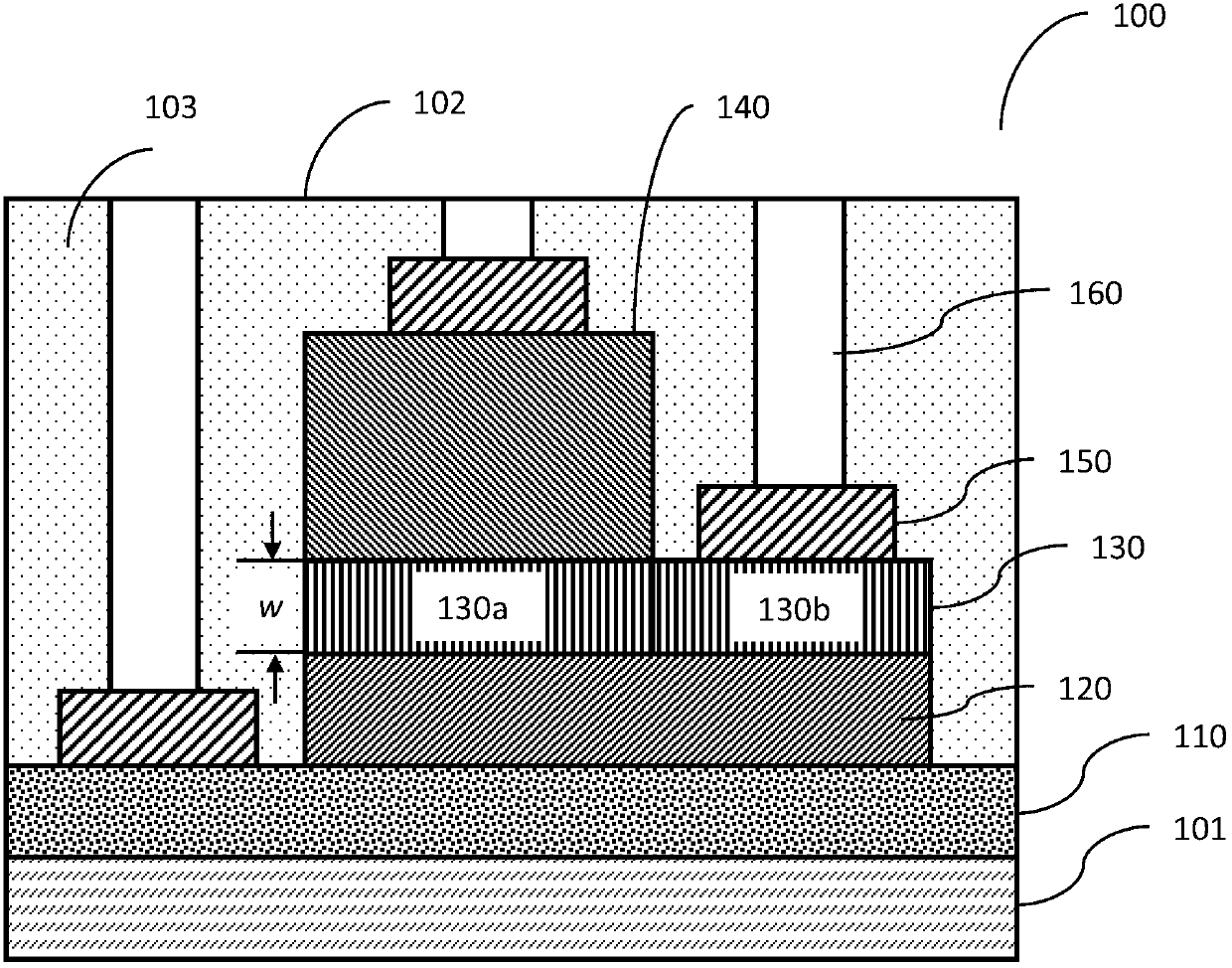

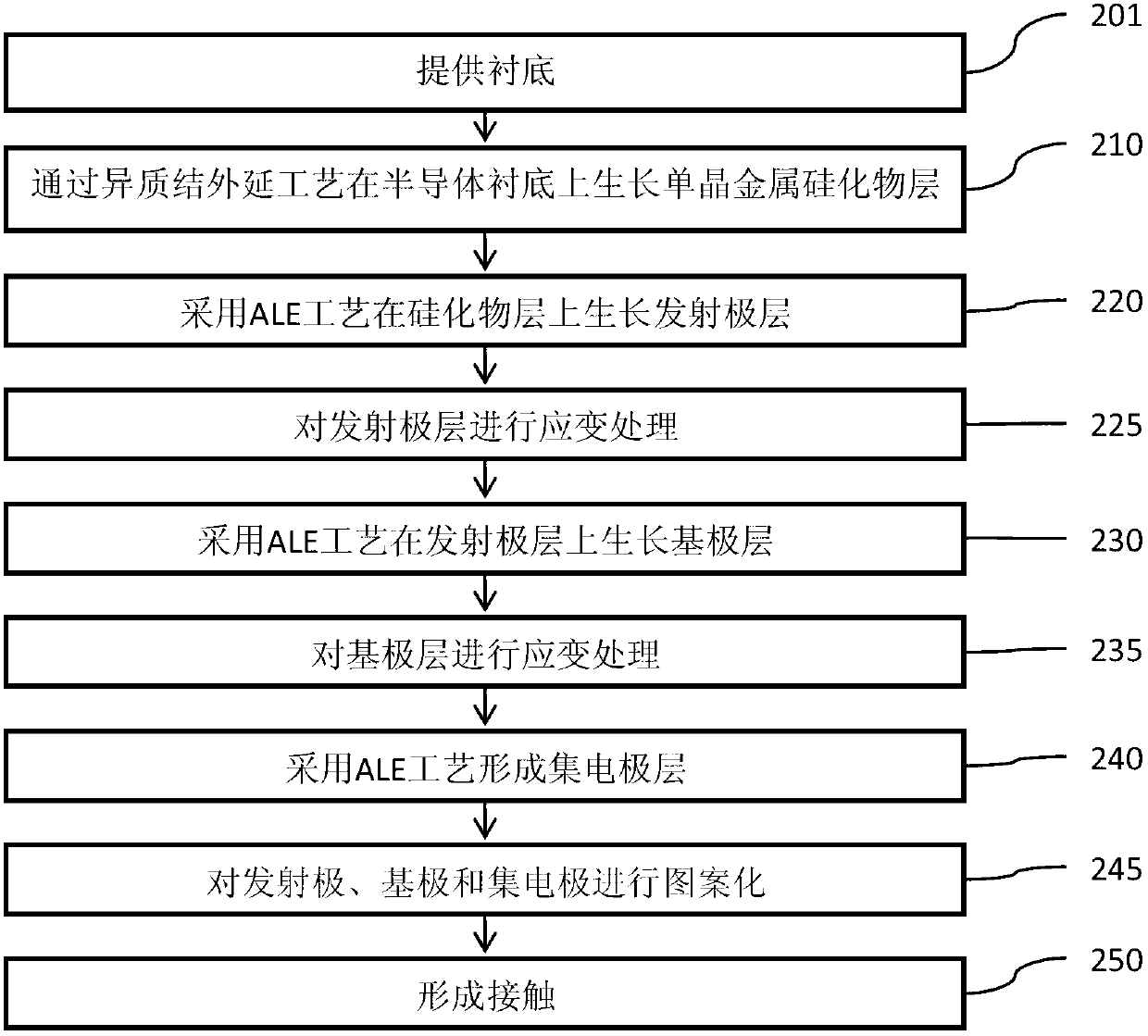

Transistor and manufacturing method thereof

A transistor is in an inverted heterojunction structure, wherein an emitting electrode layer is formed before forming of a base layer and a collector layer. Good thermal budgets are provided for the critical base region morphology and the doping distribution control, so that a high cut-off frequency (fT) can be obtained; and the contact area of a collector region and a base region is minimized, so that the stray capacitance can be greatly reduced, and the highest oscillation frequency (fmax) can be increased. Thus, frequency characteristics of the transistor can be greatly improved. An atomic layer epitaxy (ALE) process can be used for forming the emitting electrode layer on an epitaxial monocrystalline metal silicide which is formed in advance, the base layer is formed on the emitting electrode layer, and the collector layer is formed on the base layer, so that the inverted heterojunction structure can be obtained.

Owner:FUDAN UNIV

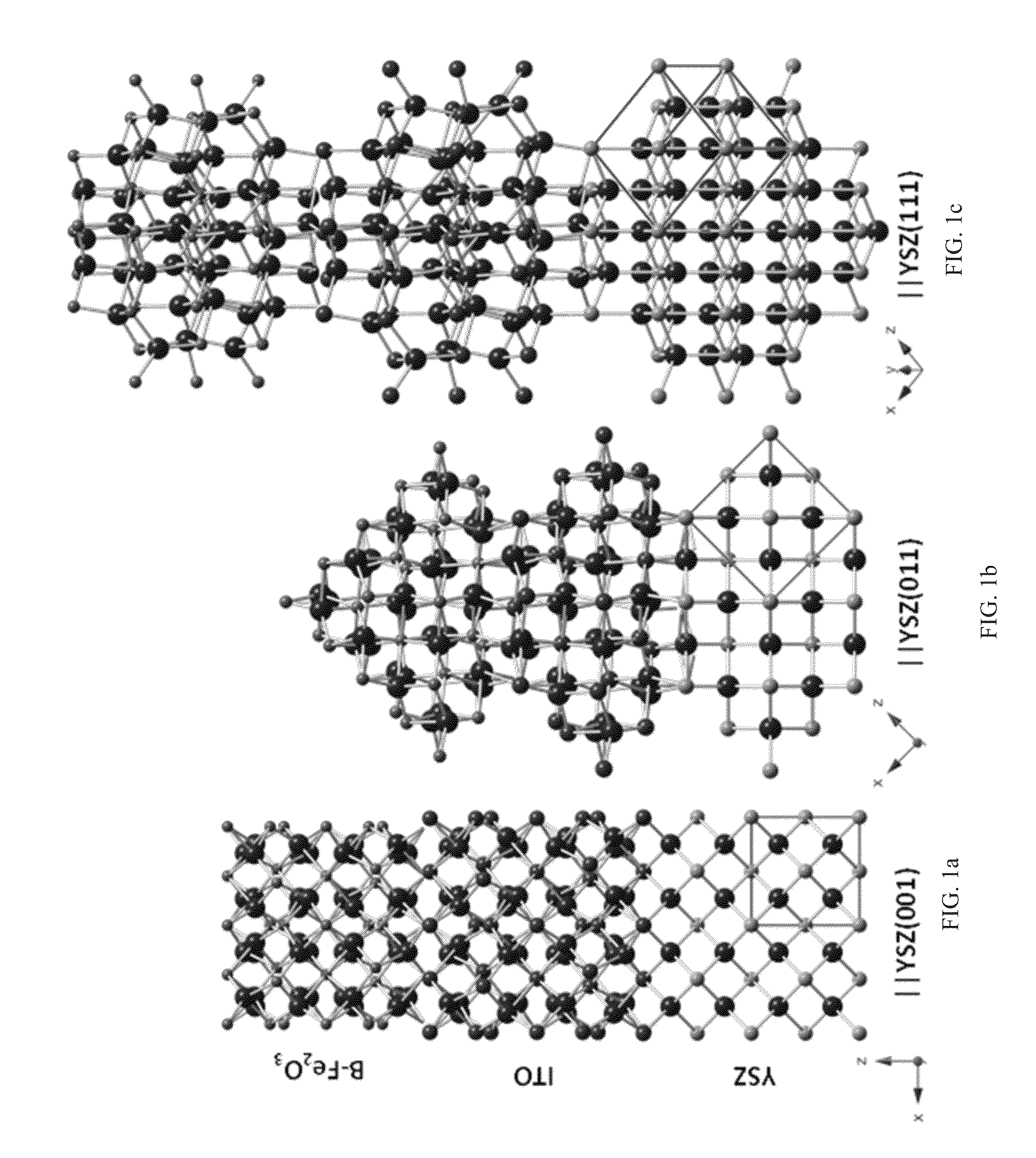

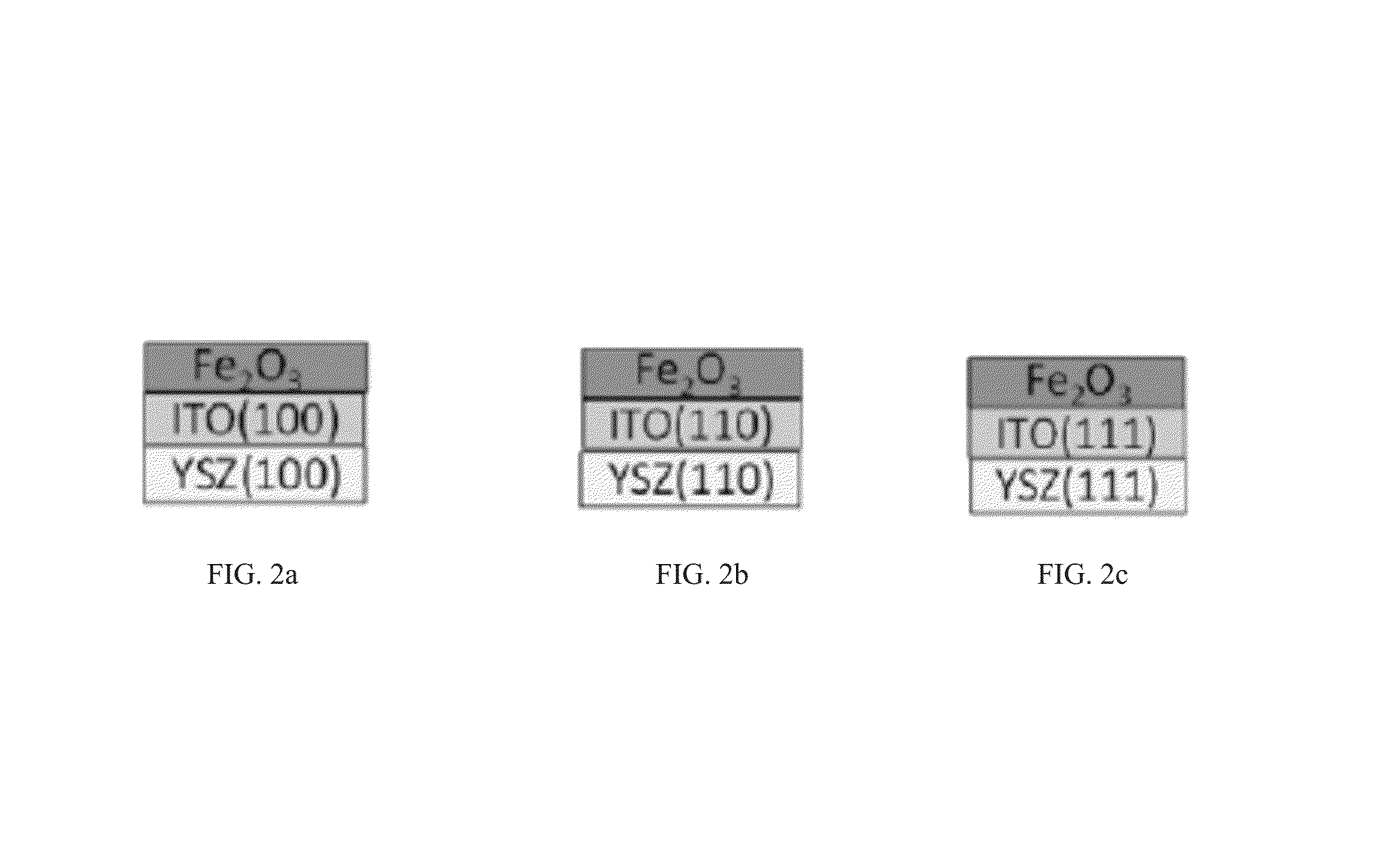

Atomic layer epitaxy of hematite on indium tin oxide for application in solar energy conversion

ActiveUS9388499B2High densityPolycrystalline material growthLight-sensitive devicesIndium zinc oxideAtomic layer epitaxy

A method to provide an article of manufacture of iron oxide on indium tin oxide for solar energy conversion. An atomic layer epitaxy method is used to deposit an uncommon bixbytite-phase iron (III) oxide (β-Fe2O3) which is deposited at low temperatures to provide 99% phase pure β-Fe2O3 thin films on indium tin oxide. Subsequent annealing produces pure α-Fe2O3 with well-defined epitaxy via a topotactic transition. These highly crystalline films in the ultra thin film limit enable high efficiency photoelectrochemical chemical water splitting.

Owner:UCHICAGO ARGONNE LLC

ALD (atomic layer deposition) equipment and reaction source diffusion distribution and control method applied to ALD equipment

ActiveCN103882410AHigh speedRegulate growth rateChemical vapor deposition coatingDiffusionEngineering

The invention discloses ALD (atomic layer deposition) equipment and a reaction source diffusion distribution and control method applied to the ALD equipment. The ALD equipment comprises a cover plate and a main body chamber matched with the cover plate, at least two gas circuit unit groups are arranged on the inner surface of the cover plate, each gas circuit unit group comprises at least one gas circuit unit, at least two gas circuit unit groups are used for introducing different reaction source gases; each gas circuit unit comprises a first gas flow channel, a first spacer layer, a second gas flow channel and a second spacer layer; the first gas flow channel is used for introducing the reaction source gas; the second gas flow channel is used for pumping out unreacted reaction source gas; the first spacer layer is arranged between the first gas flow channel and the second gas flow channel, the second spacer layer is arranged between the second gas flow channel and a third gas flow channel. The ALD equipment can increase speed of atomic layer epitaxy, save time of a single technology and adjust growth velocity of the atomic layer epitaxy.

Owner:厦门紫硅半导体科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com