Preparation method of titanium nitride/titanium dioxide nano-composite anti-corrosion coating

A titanium dioxide and nanocomposite technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problem of polluted environment, thin film porosity, uniform thickness of corrosion-resistant layer, poor control accuracy of components, etc. problems, to achieve the effect of good process repeatability, improved metal corrosion resistance, and accurate film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

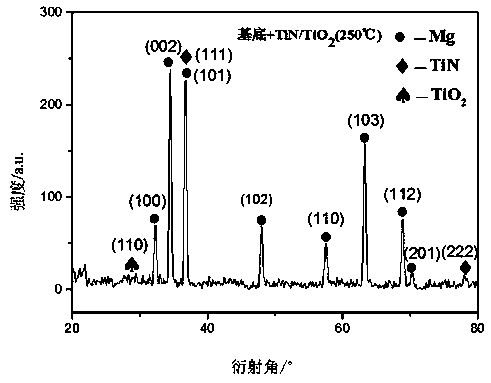

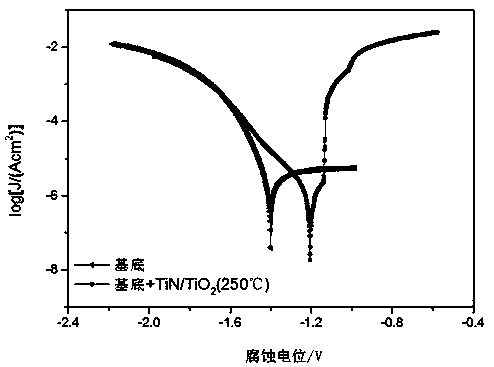

[0024] A magnesium alloy with a size of 50mm×50mm×0.5mm is used as the substrate, and the surface is coated with titanium nitride / titanium dioxide nanocomposite corrosion-resistant coating. As described in the summary of the invention, the preparation of the ALD working chamber, the preparation of the titanium nitride / titanium dioxide nano-composite anti-corrosion coating, the reduction step of the ALD working chamber and other steps are carried out, wherein oxygen is used to convert part of the titanium nitride into titanium dioxide by autoxidation. When the temperature is 250°C, the oxidation process is saturated after 20 minutes of oxygen passing time, and the total weight of the nanocomposite coating no longer increases at this time. After the preparation was completed, the thickness of the corrosion-resistant layer was measured by X-ray reflectivity measurement (XRR) and atomic force microscope (AFM), and the thickness of the corrosion-resistant layer was measured to be 20...

Embodiment 2

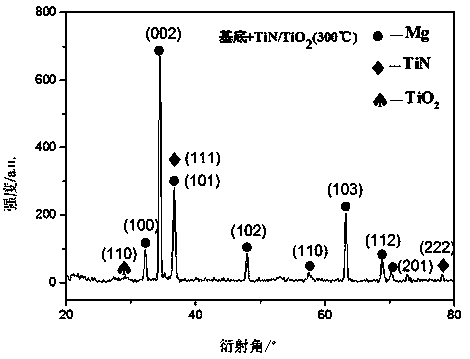

[0027] A magnesium alloy with a size of 50mm×50mm×0.5mm is used as the substrate, and the surface is coated with a 20nm titanium nitride / titanium dioxide nanocomposite corrosion-resistant coating. As described in the summary of the invention, the preparation of the ALD working chamber, the preparation of the titanium nitride / titanium dioxide nano-composite anti-corrosion coating, the reduction step of the ALD working chamber and other steps are carried out, wherein oxygen is used to convert part of the titanium nitride into titanium dioxide by autoxidation. The temperature is 300°C, and the oxidation process is saturated after the oxygen passing time is 10min, at which point the total weight of the nanocomposite coating no longer increases. After the preparation was completed, the thickness of the corrosion-resistant layer was measured by X-ray reflectivity measurement (XRR) and atomic force microscope (AFM), and the thickness of the corrosion-resistant layer was measured to be...

Embodiment 3

[0030]A magnesium alloy with a size of 50mm×50mm×0.5mm is used as the substrate, and the surface is coated with titanium nitride / titanium dioxide nanocomposite corrosion-resistant coating. As described in the summary of the invention, the preparation of the ALD working chamber, the preparation of the titanium nitride / titanium dioxide nano-composite anti-corrosion coating, the reduction step of the ALD working chamber and other steps are carried out, wherein oxygen is used to convert part of the titanium nitride into titanium dioxide by autoxidation. When the temperature is 150°C, the oxidation process is saturated after the oxygen passing time is 60 minutes, and the total weight of the nanocomposite coating no longer increases at this time. After the preparation was completed, the thickness of the corrosion-resistant layer was measured by X-ray reflectivity measurement (XRR) and atomic force microscope (AFM), and the thickness of the corrosion-resistant layer was measured to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com