In-situ-generated layered composite negative-temperature-coefficient thermal-sensitive ceramic material, preparation method and application

A technology of negative temperature coefficient, heat-sensitive ceramics, applied in the field of in-situ generation of layered composite negative temperature coefficient heat-sensitive ceramic materials and preparation, can solve the problems of high B value, low resistance value, difficult to obtain, etc. Small, low resistance, highly controllable layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

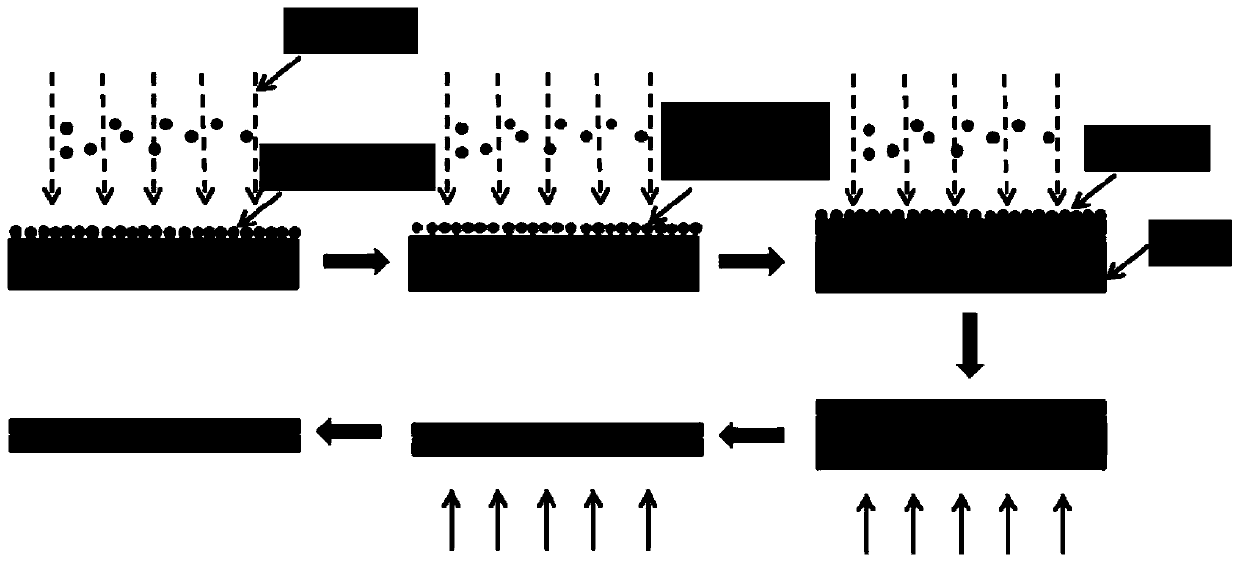

[0056] A method for in-situ generation of layered composite negative temperature coefficient thermal ceramic material includes the following steps:

[0057] (1) Powder preparation:

[0058] To analyze pure La 2 O 3 , Cr 2 O 3 As raw material, press LaCrO 3 The molar ratio of middle atoms, weighing La 2 O 3 , Cr 2 O 3 、Placed in an agate ball milling tank, using agate balls as the ball milling medium and deionized water as the dispersion medium to control the mass ratio of each substance in the ball milling tank as follows: agate ball: raw material: deionized water = 3:1:1, ball milling is smooth Wet-grind alternately counterclockwise for 36h, clockwise for 1h, then dry at 80℃ for 24h, after grinding for 3.5h, get the first powder for use;

[0059] To analyze pure MgO, Al 2 O 3 As raw material, press MgAl 2 O 4 The molar ratio of middle atoms, weighing MgO, Al 2 O 3 , Placed in an agate ball milling tank, using agate balls as the ball milling medium and deionized water as the dispersi...

Embodiment 2

[0070] A method for in-situ generation of layered composite negative temperature coefficient thermal ceramic material includes the following steps:

[0071] (1) Powder preparation:

[0072] To analyze pure La 2 O 3 , MnO 2 , Fe 2 O 3 As raw material, press LaMn 0.5 Fe 0.5 O 3 The molar ratio of middle atoms, weighing La 2 O 3 , MnO 2 , Fe 2 O 3 Placed in an agate ball milling tank, using agate balls as the ball milling medium and deionized water as the dispersing medium to control the mass ratio of each substance in the ball milling tank as follows: agate ball: raw material: deionized water = 3:1:1, ball milling is forward and backward Wet-grind alternately in the clockwise direction for 24 hours, clockwise for an interval of 1 hour, then dry at 80°C for 24 hours, and grind for 3.5 hours after completion to obtain the first powder for use;

[0073] To analyze pure MnO 2 , Ni 2 O 3 , Fe 2 O 3 As raw material, press NiMn 1.8 Fe 0.2 O 4 The molar ratio of the middle atom, weighing MnO 2...

Embodiment 3

[0083] A method for in-situ generation of layered composite negative temperature coefficient thermal ceramic material includes the following steps:

[0084] (1) Powder preparation:

[0085] To analyze pure La 2 O 3 , MnO 2 , CaO as raw material, according to LaMn 0.8 Ca 0.2 O 3 The molar ratio of middle atoms, weighing La 2 O 3 , MnO 2 , Placed in an agate ball milling tank, using agate balls as the ball milling medium and deionized water as the dispersion medium to control the mass ratio of each substance in the ball milling tank as follows: agate ball: raw material: deionized water = 3:1:1, and the ball mill is smooth Wet-grind alternately counterclockwise for 30h, clockwise for 1h, then dry at 70°C for 24h, and grind for 3.5h after completion to obtain the first powder for use;

[0086] To analyze pure MnO 2 , Ni 2 O 3 As raw material, press Ni 0.4 Mn 2.6 O 4 The molar ratio of the middle atom, weighing MnO 2 , Ni 2 O 3 , Placed in an agate ball milling tank, using agate balls as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com