Patents

Literature

77results about How to "Small degree of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

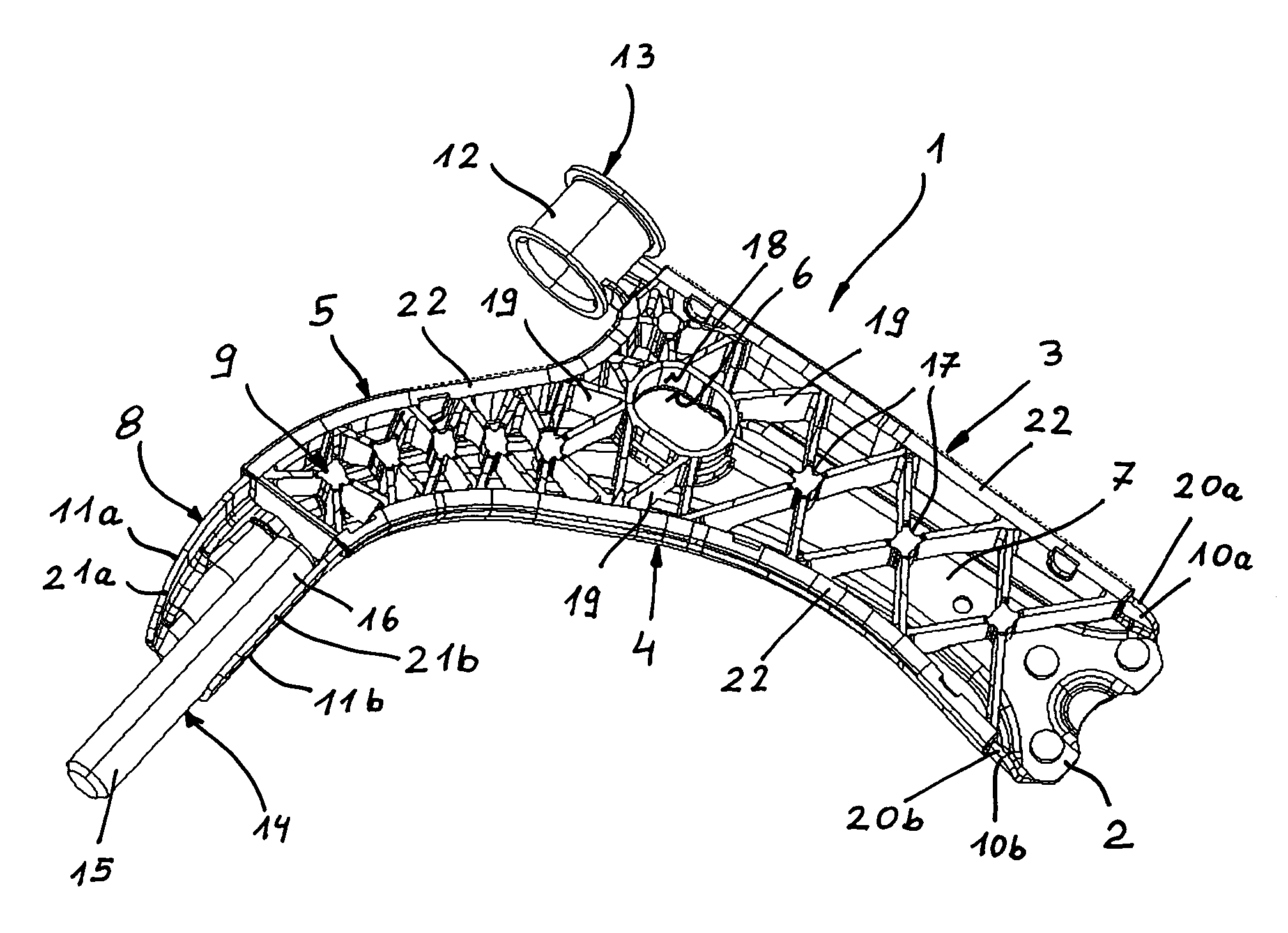

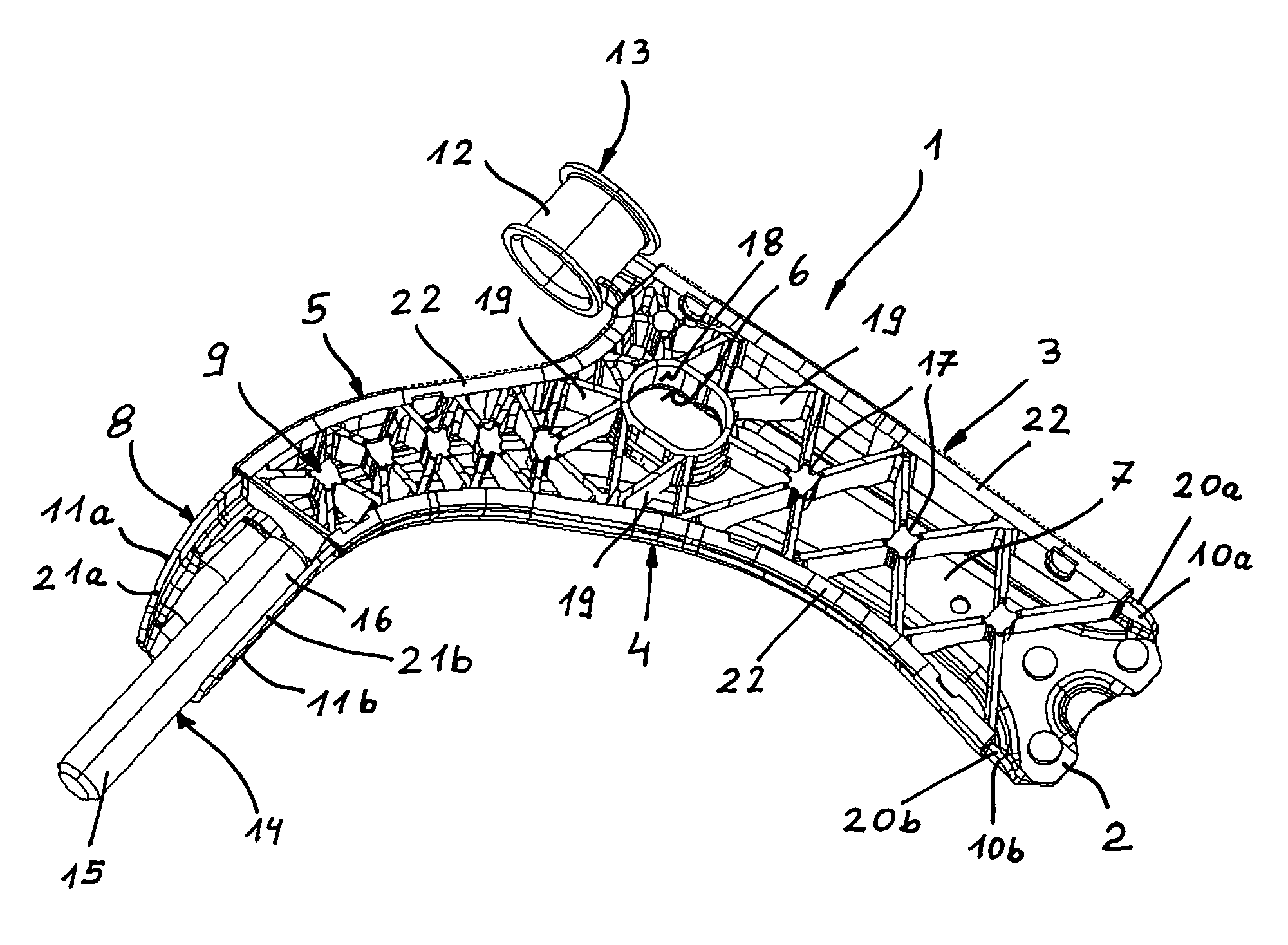

Control arm structure for wheel suspensions of motor vehicles, and method of making such a control arm structure

InactiveUS7556273B2Low ductility potentialHigh strengthBuilding roofsMetal-working apparatusMobile vehicleControl arm

In a method of making a control arm for a wheel suspension of a motor vehicle a blank of steel material having a tensile strength of at least 800 MPa is shaped, using a sheet metal forming process, into a shell body having a center web and plural flank portions extending from the center web in a same direction. The flank portions are connected by a latticed reinforcement made of plastic, without application of a heat treatment process.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

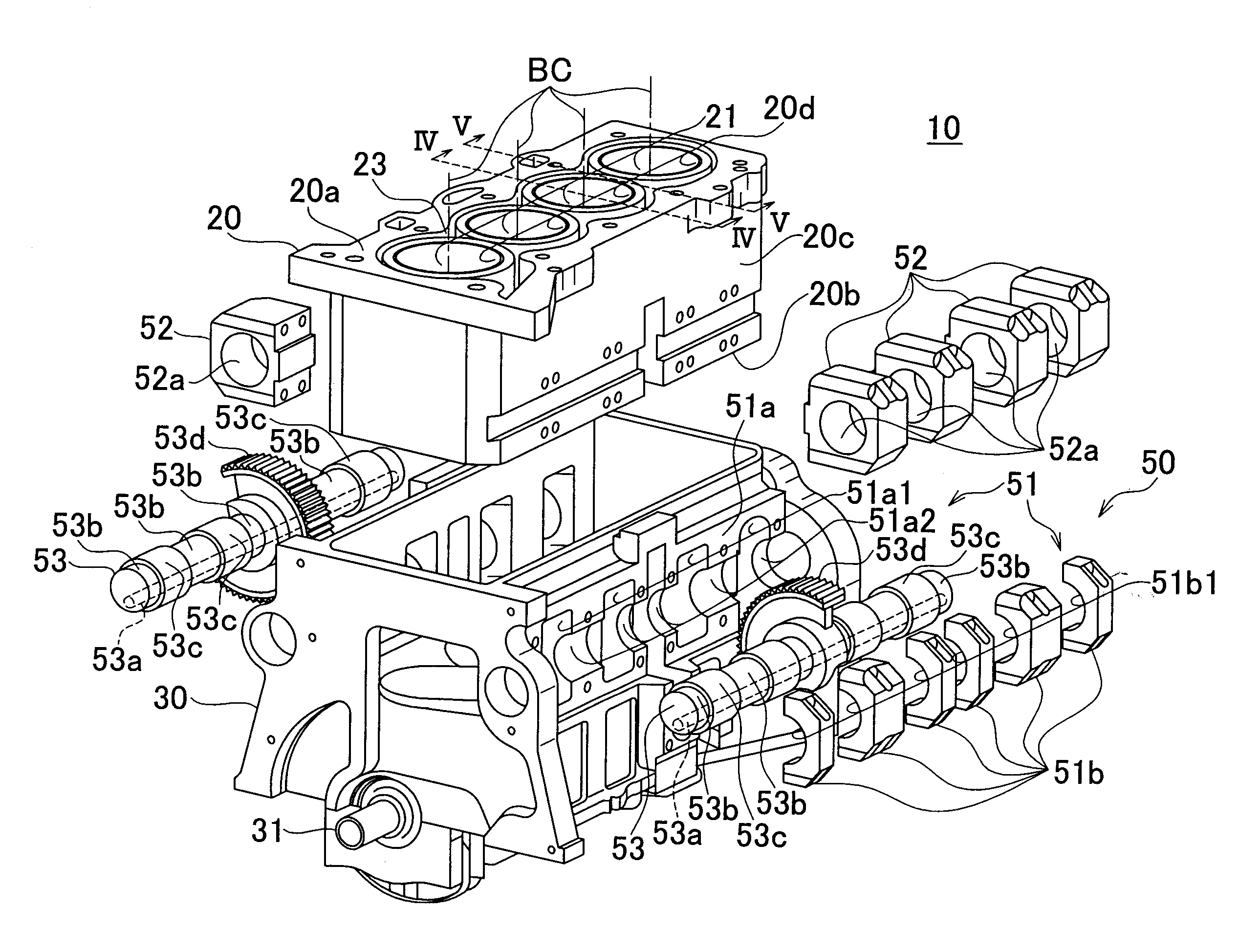

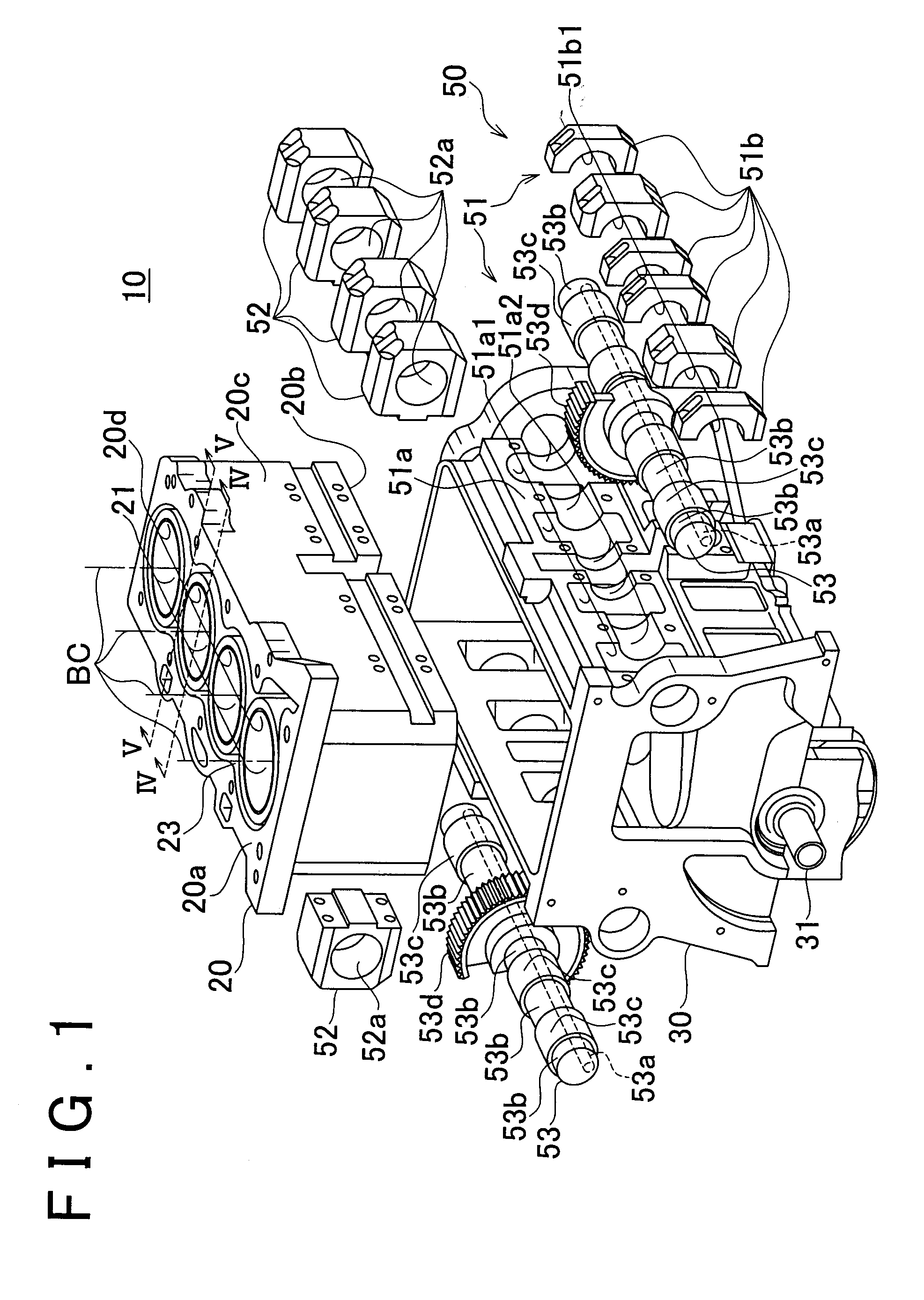

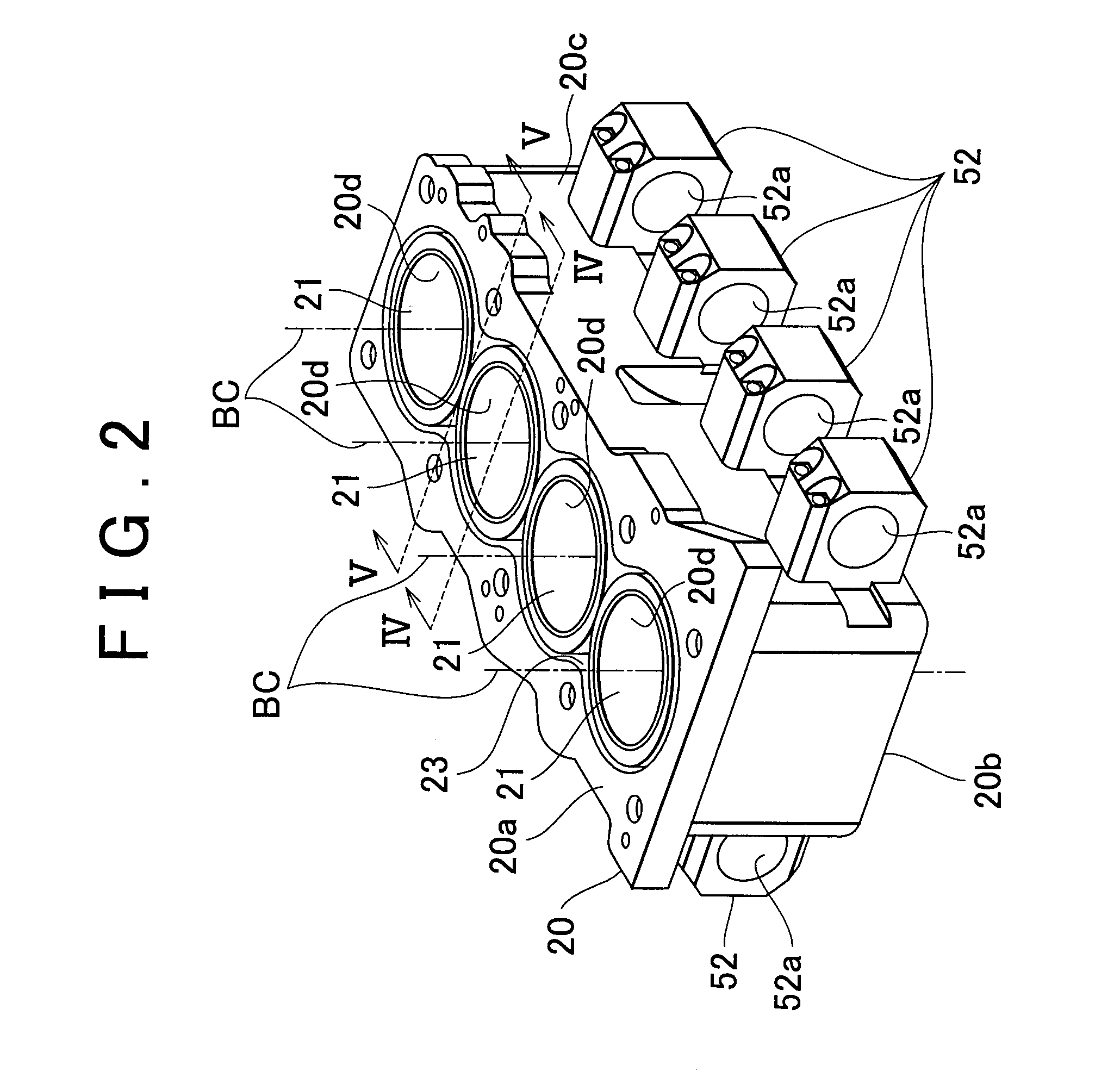

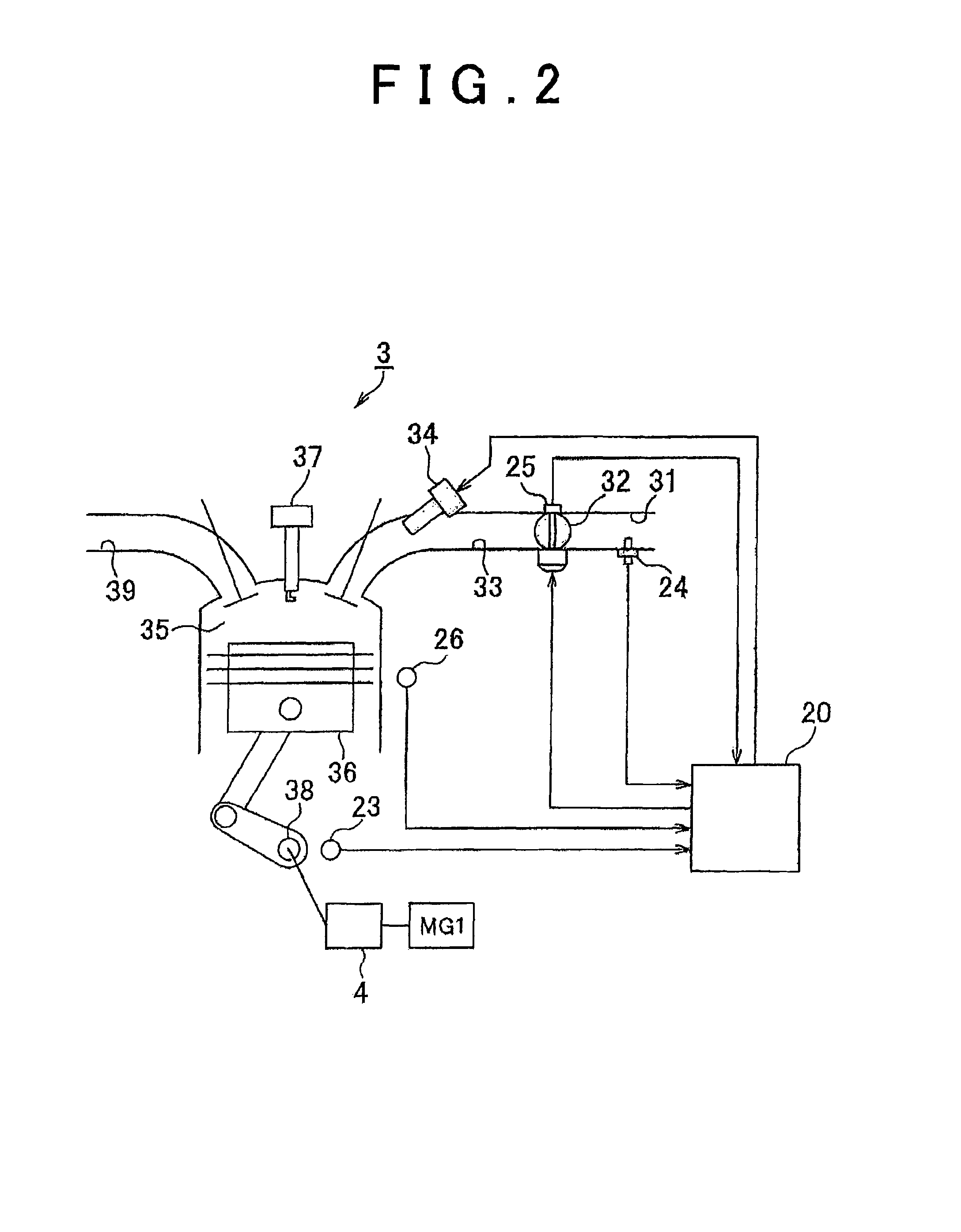

Variable compression ratio internal combustion engine

InactiveUS20080053420A1Avoid deformationDeterioration in fuel economy can be preventedCylinder headsCombustion enginesEngineeringCrankcase

An internal combustion engine includes a variable compression ratio mechanism made up of a case-side bearing-forming portion, a block-side bearing-forming portion, and a shaft-shaped drive portion. The case-side bearing-forming portion is formed in an upper portion of a crankcase. The block-side bearing-forming portion extends outward from a lower end portion of an outer wall surface of the cylinder block. The block-side bearing-forming portion is linked to the case-side bearing-forming portion by the shaft-shaped drive portion. Slit-shaped stress reduction groove portions each having an opening in a region between the block-side bearing-forming portion and cylinder bores are formed in a lower surface of the cylinder block. Therefore, even when the block-side bearing-forming portion presses the outer wall surface, the stress reduction groove portions reduce the stress, so that the deformation of the wall surface of each cylinder bore can be restrained.

Owner:TOYOTA JIDOSHA KK

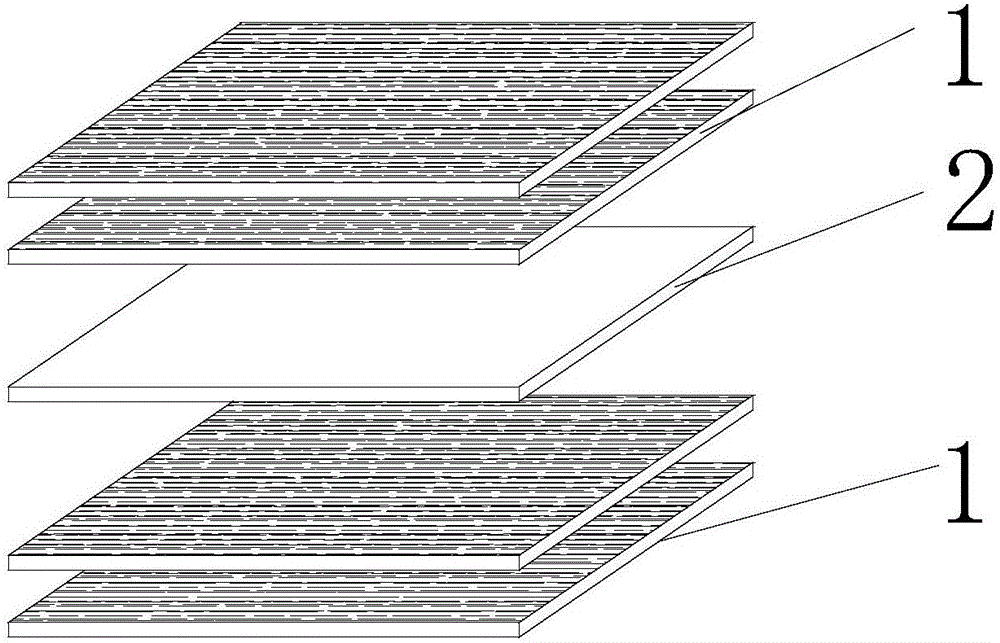

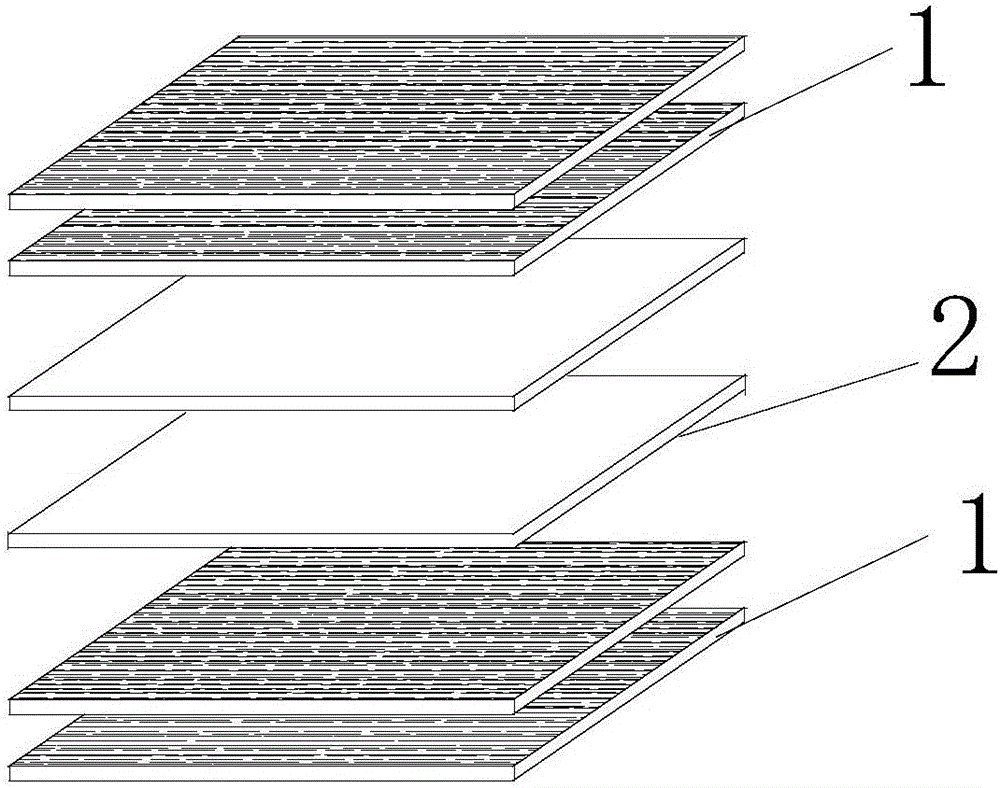

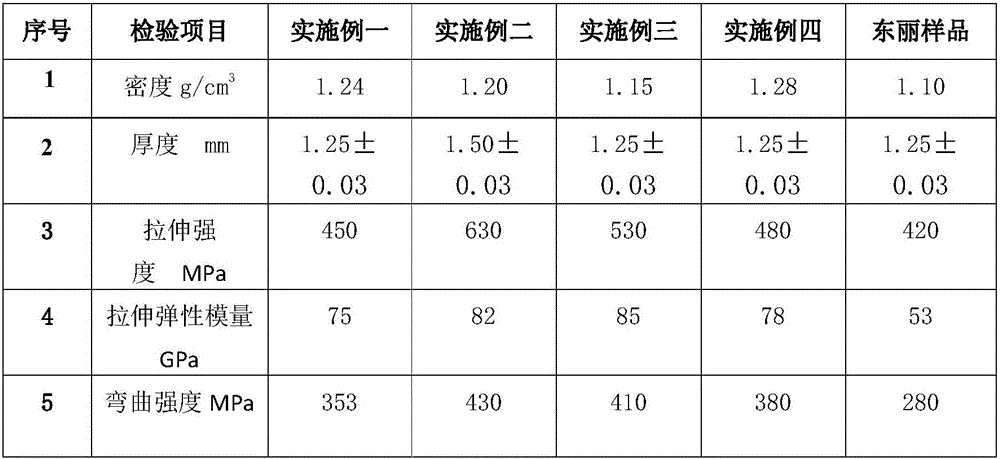

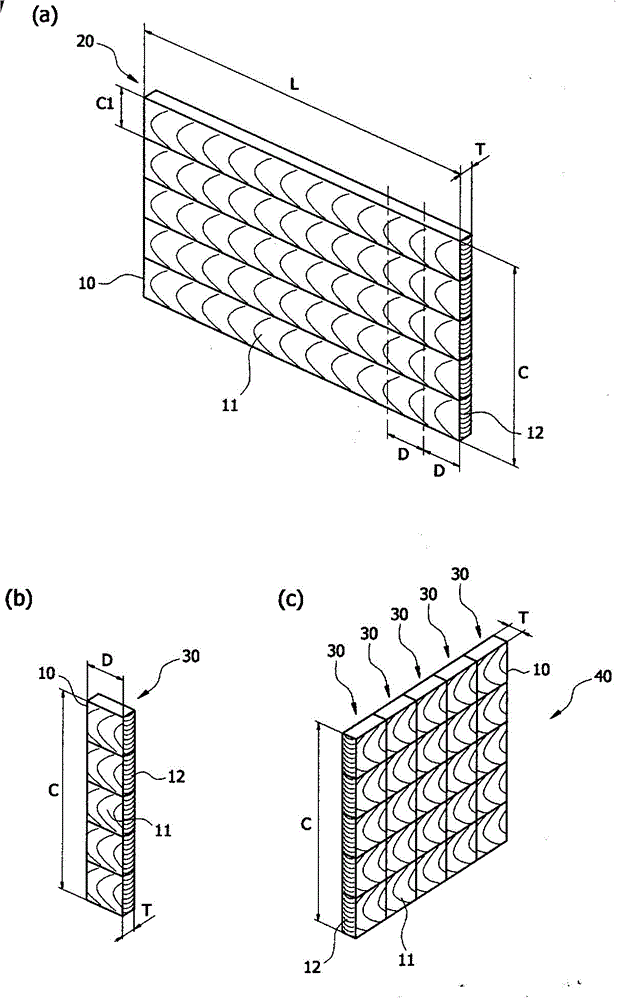

Carbon fiber sheet

InactiveCN106183135ASuitable for lightweight applicationsReduce weightSynthetic resin layered productsLaminationFiberPolymer science

The invention discloses a carbon fiber sheet, comprising no more than six layers of carbon fiber prepreg and no more than two layers of glass bead-filled epoxy sheet laminate, the glass bead-filled epoxy sheet laminate It is arranged at the middle layer position of several carbon fiber prepregs, and a layer of carbon fiber woven cloth prepreg is added between the carbon fiber prepregs and carbon fiber prepregs, carbon fiber prepregs and glass bead-filled epoxy sheet laminates . The carbon fiber sheet prepared by the invention has flame retardancy, low degree of deformation, light weight, and is easy to produce in batches, and is especially suitable for light-weight application of electronic products.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

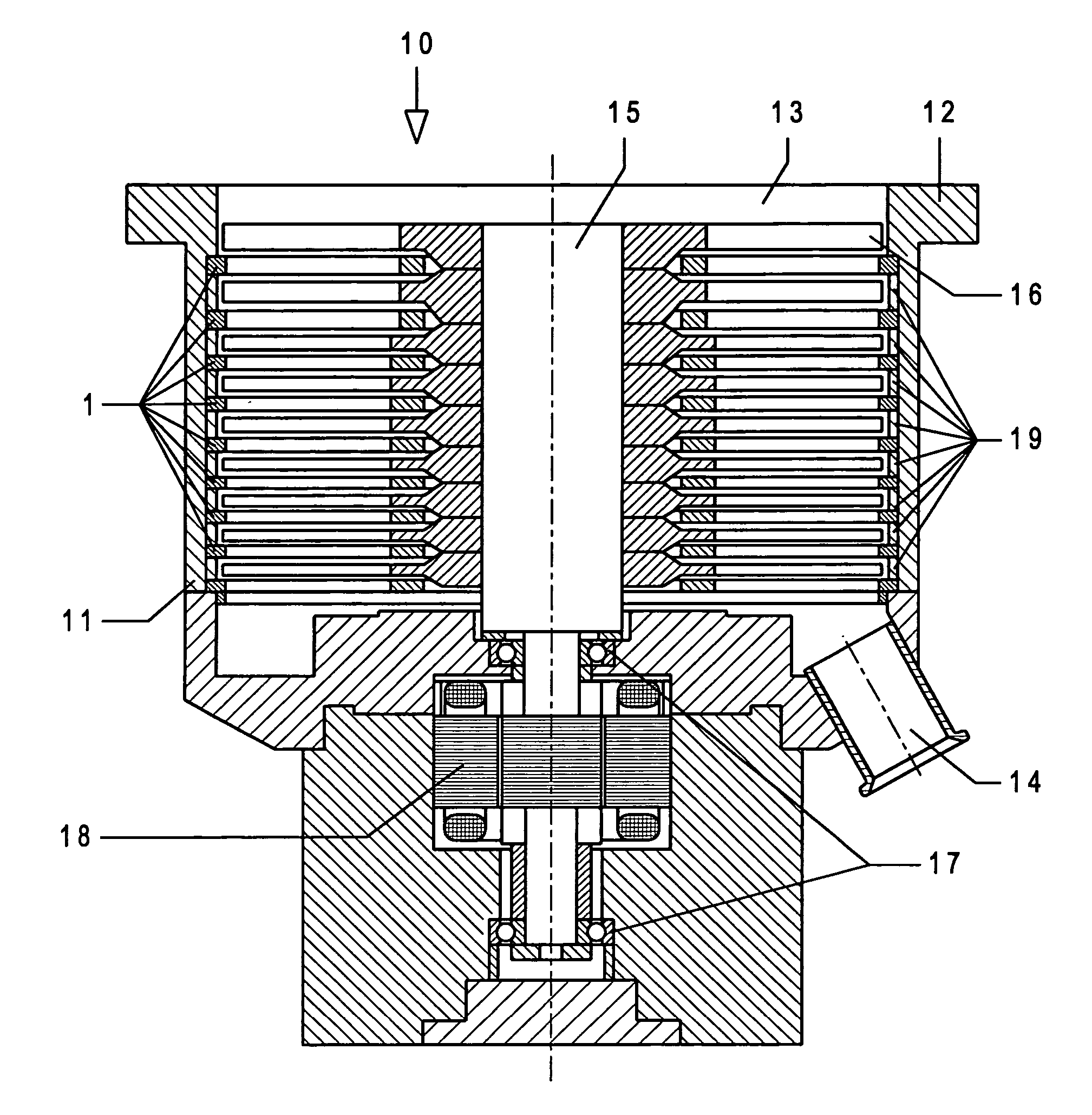

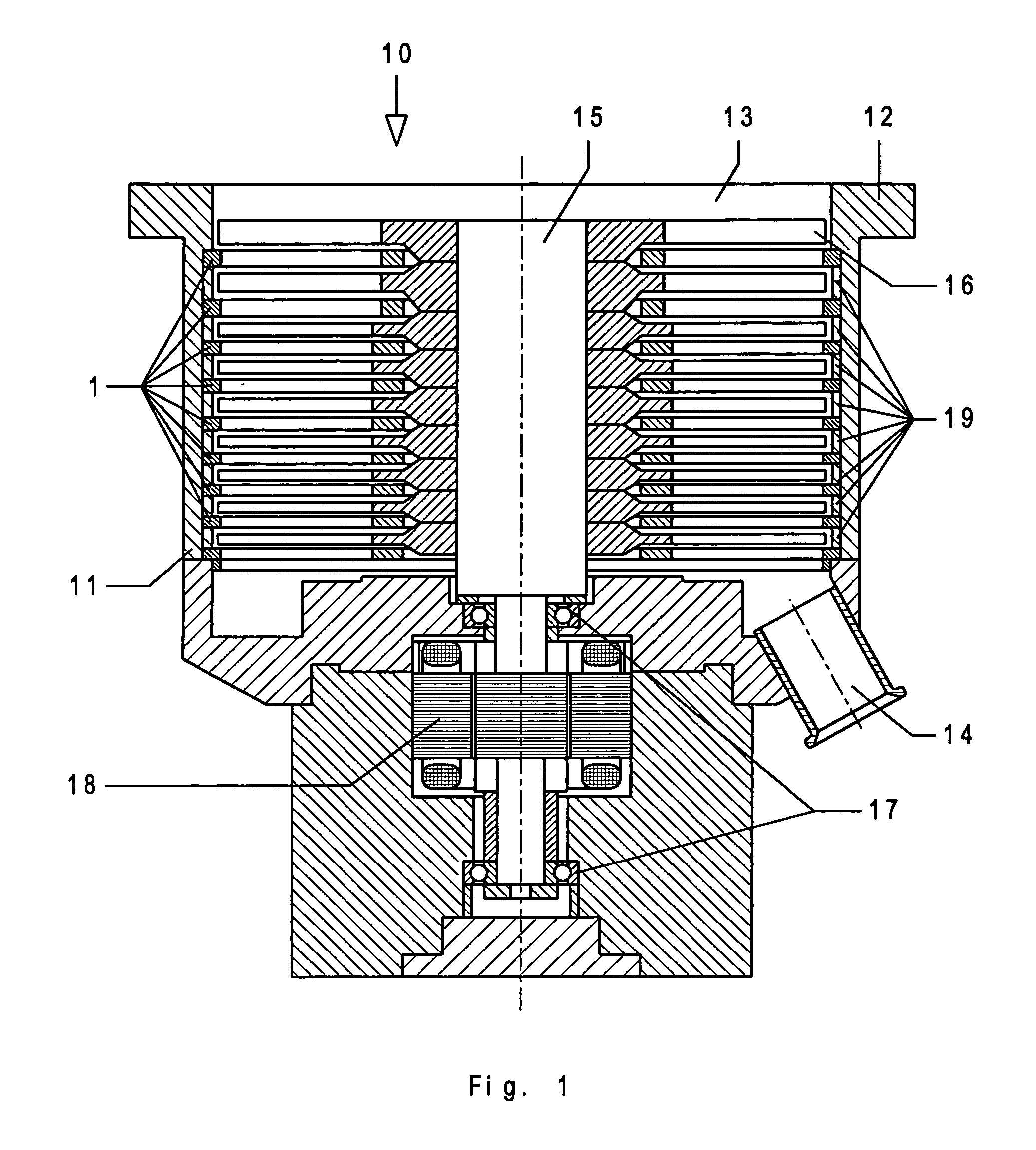

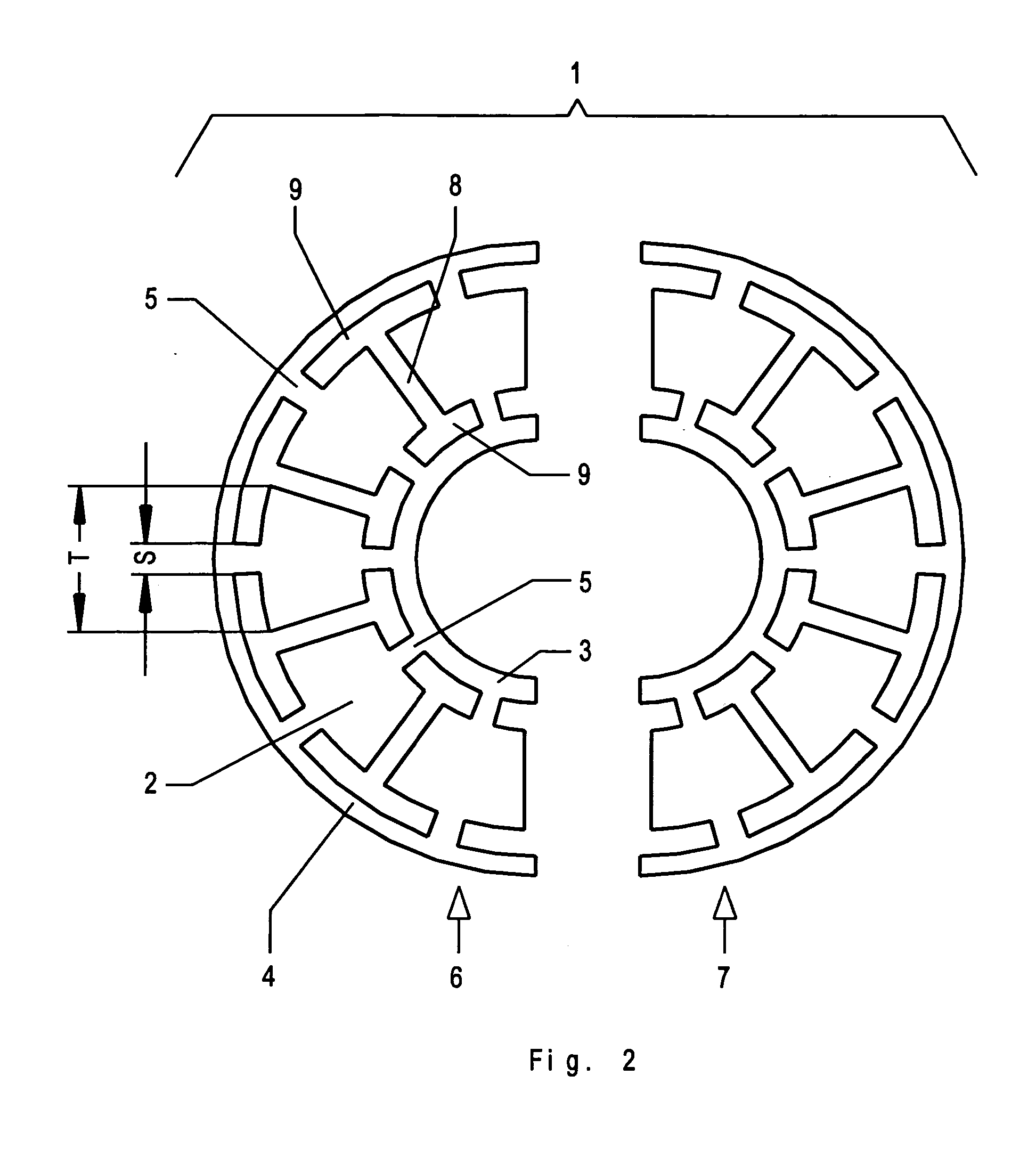

Stator disc for a turbomolecular pump

InactiveUS20060280595A1Eliminate high degree of deformationSmall regionEngine manufacturePump componentsCircular discEngineering

A stator disc for a turbomolecular pump has an inner ring (3), an outer ring (4), and a plurality of vanes (2) formed of a stator disc plane, extending between the inner and outer rings (3, 4), and having, in connection regions of the vanes with the inner and outer rings, respective radial webs (5) a circumferential width (S) of which is smaller than a vane width (T).

Owner:PFEIFFER VACUUM GMBH

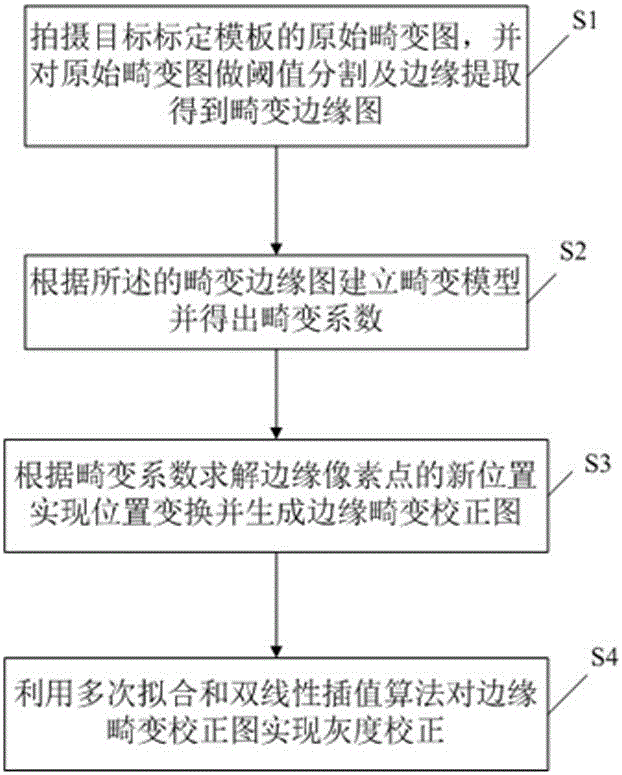

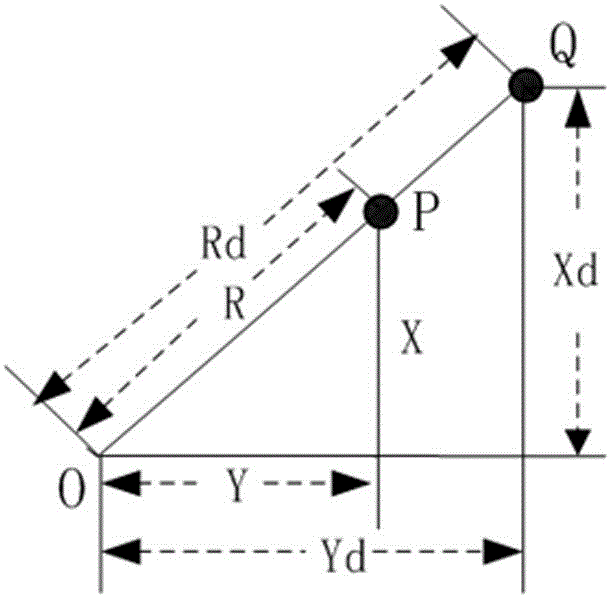

Wide-angle lens infrared image distortion correction method

ActiveCN105957041ASmall degree of deformationHigh precisionImage enhancementDistortion correctionComputer vision

The invention discloses a wide-angle lens infrared image distortion correction method. The method comprises steps that S1, an original distortion image of a target calibration template is shot, threshold segmentation and edge extraction of the original distortion image are carried out to acquire a distortion edge image; S2, a distortion model is established according to the distortion edge image, and a distortion coefficient is acquired; S3, the new position of an edge pixel point is solved according to the distortion coefficient, position transformation is realized, and an edge distortion correction image is generated; and S4, gray correction of the edge distortion correction image is realized by utilizing multiple times of fitting and a bilinear interpolation algorithm. The method can realized distortion correction of a wide-angle lens infrared image, an image distortion degree is reduced, and accuracy and reliability of measured parameters are improved.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

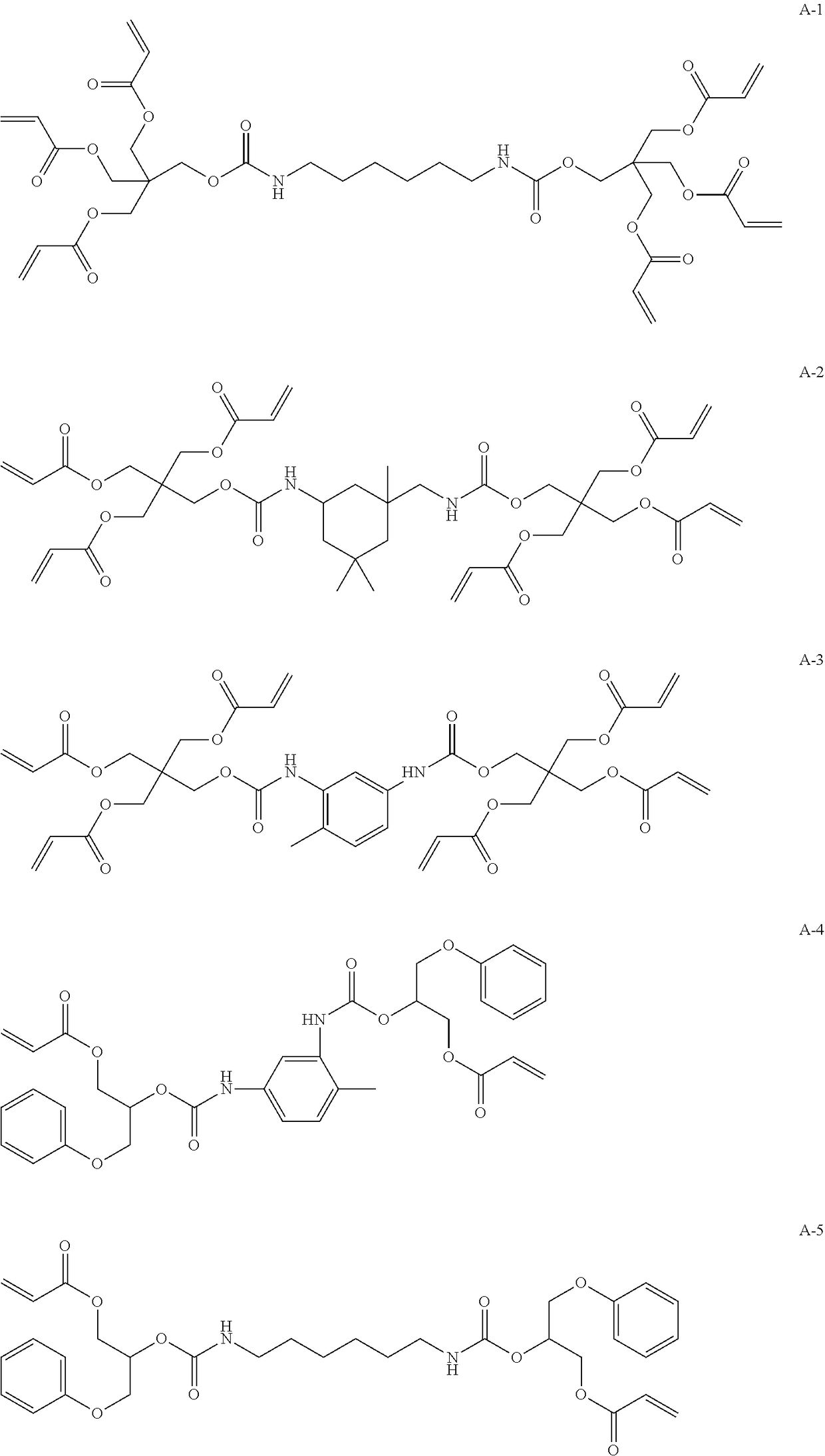

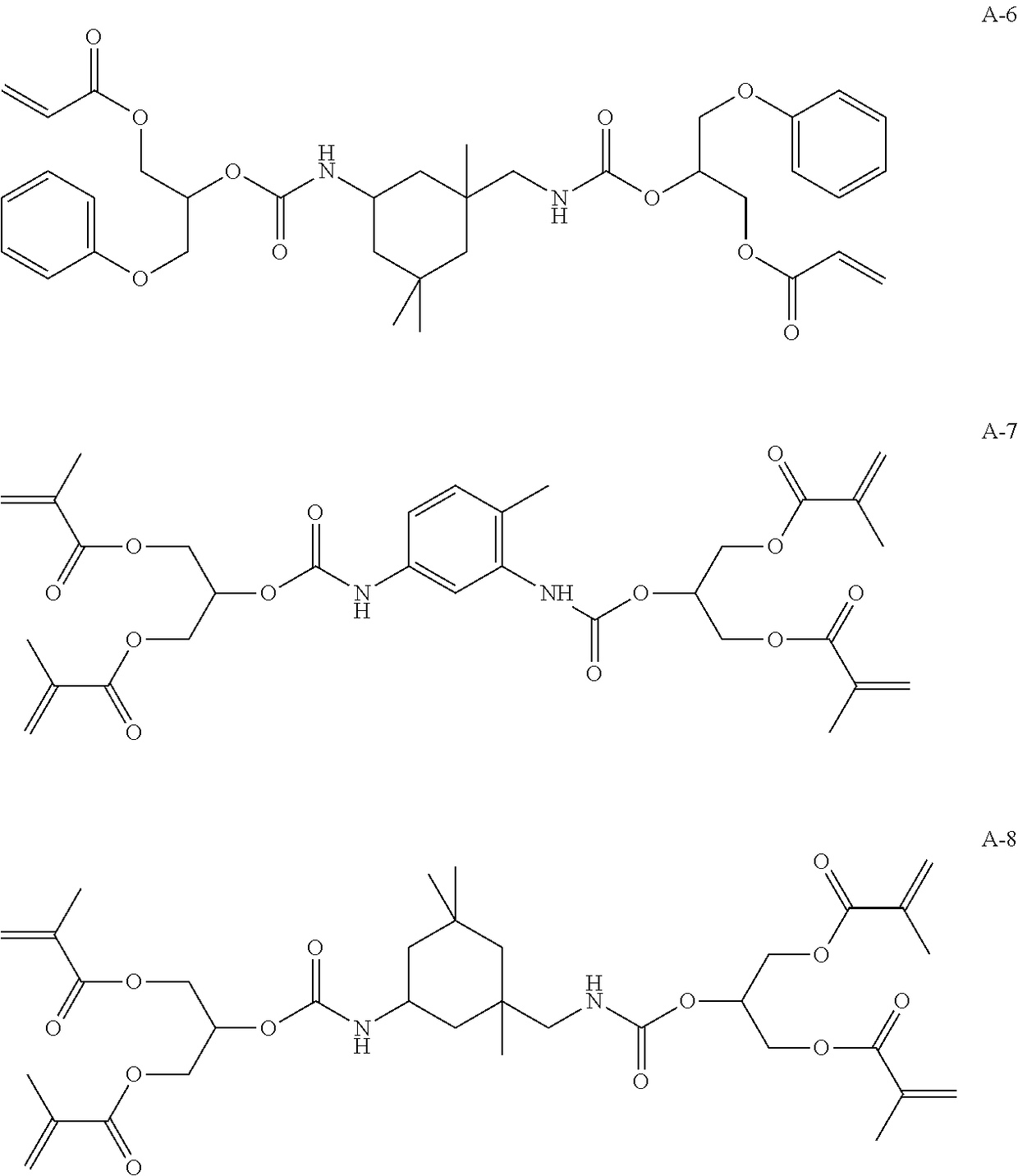

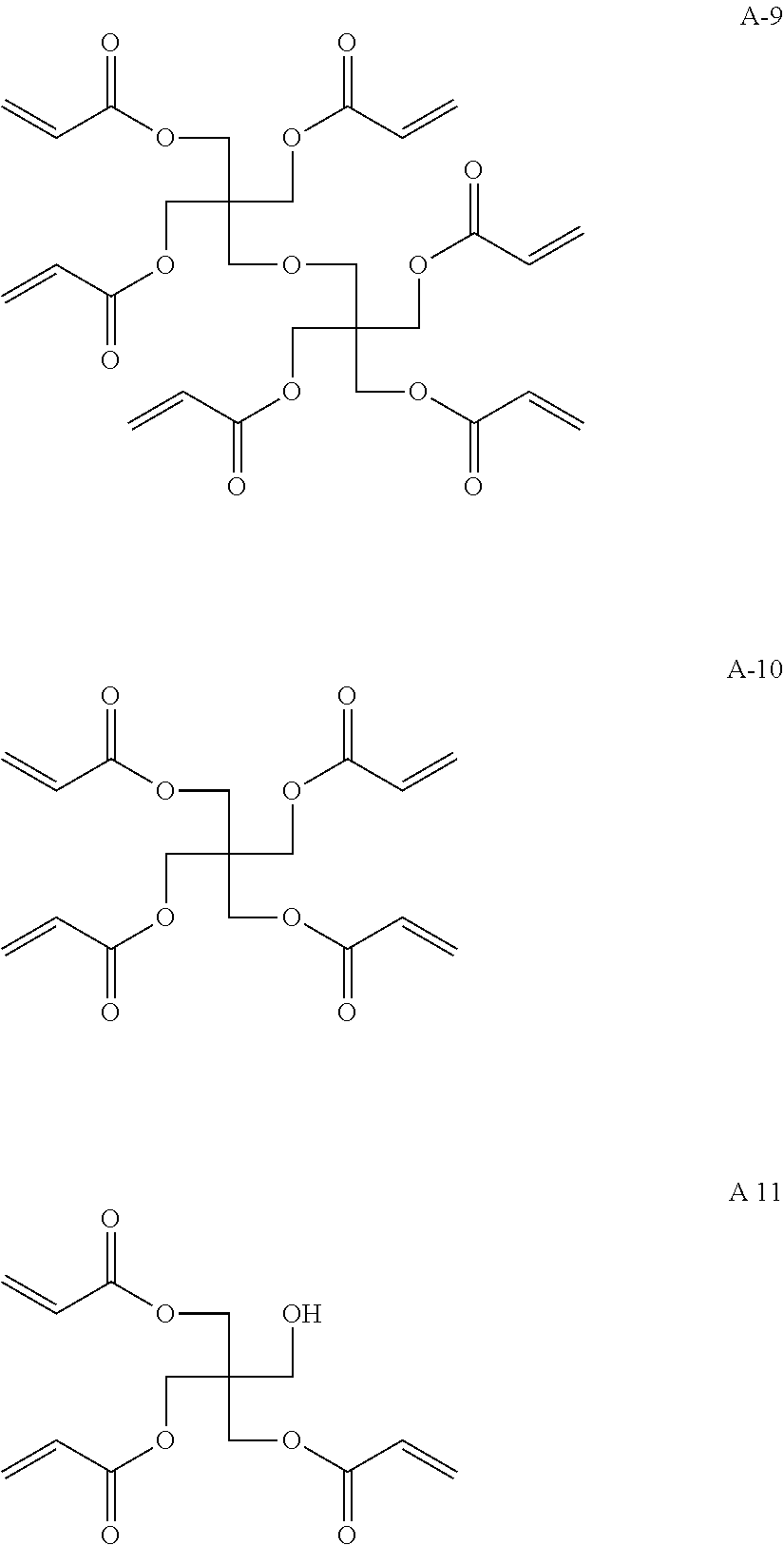

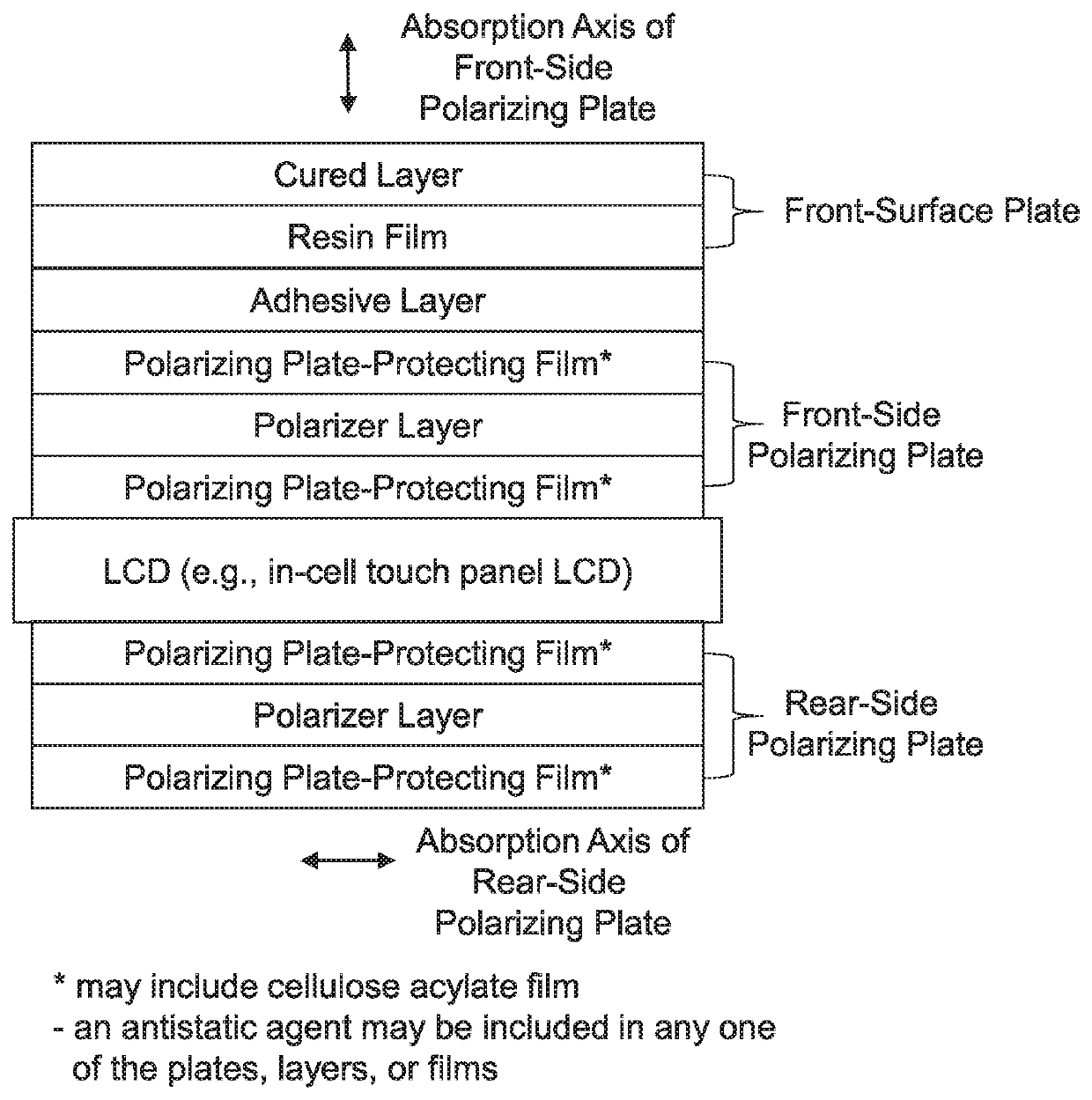

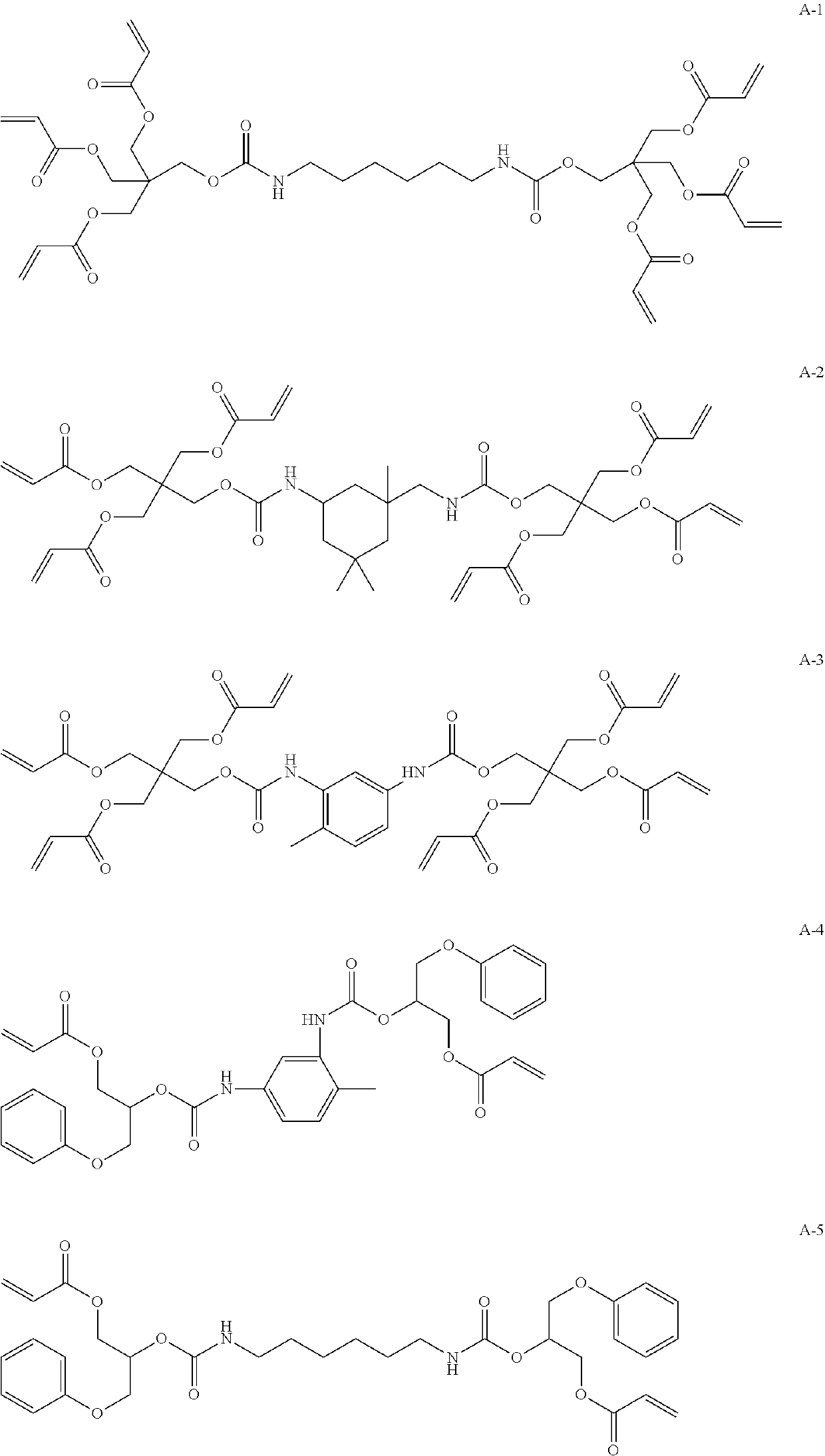

Liquid crystal panel and liquid crystal display device

ActiveUS20180157111A1Inhomogeneous suppressionImprove adhesionPolarising elementsNon-linear opticsLiquid-crystal displayStress relaxation

The liquid crystal panel has a front-surface plate, a front-side polarizing plate, a liquid crystal display element, and a rear-side polarizing plate in an integrally laminated state, in which the front-surface plate and the front-side polarizing plate are in the state of being laminated with each other via an adhesive layer having a thickness of 2 μm or more, and the liquid crystal panel satisfies Formula A-1: 2020>ECp×dCp×εCp×(100−P)+(Ef×df×εf)−(Er×dr×εr)>0 (ECp is the modulus of elasticity, dCp is the thickness, and εCp is the humidity dimensional change rate, of the front-surface plate, Ef is the modulus of elasticity, df is the thickness, and εf is the humidity dimensional change rate, of the front-side polarizing plate, Er is the modulus of elasticity, dr is the thickness, and εr is the humidity dimensional change rate, of the rear-side polarizing plate, P is the stress relaxation rate of the adhesive layer).

Owner:FUJIFILM CORP

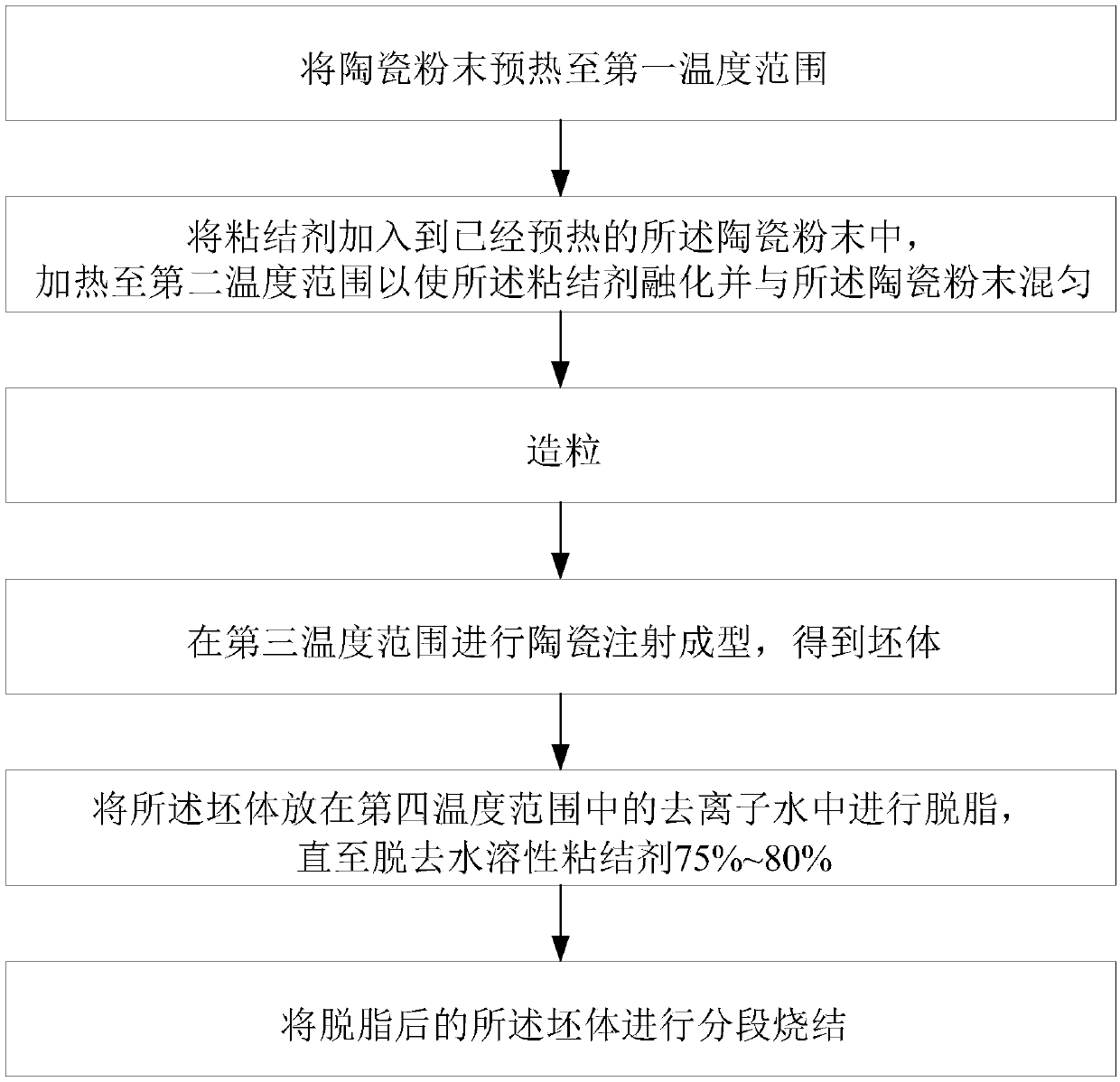

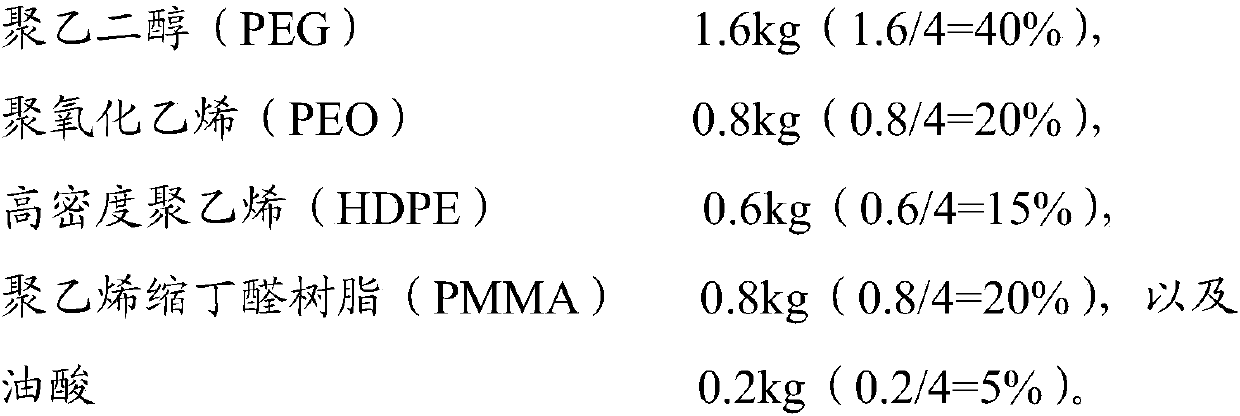

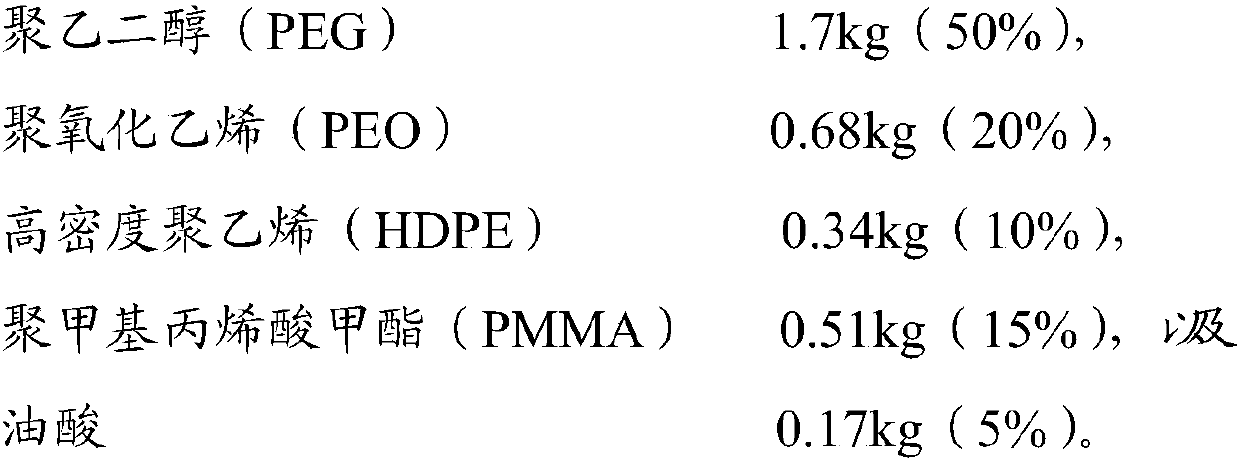

Ceramic, ceramic injection molding feeding material and preparation method thereof

InactiveCN107840666ALow costShort degreasing timeAuxillary shaping apparatusWater insolubleMass ratio

The invention relates to a ceramic, a ceramic injection molding feeding material and a preparation method thereof. The ceramic injection molding feeding material comprises, by mass, 80-83% of ceramicpowder and 17-20% of a binder. The binder comprises a water-soluble binder and a water-insoluble binder. A mass ratio of the water-soluble binder to the water-insoluble binder is (60-70): (23-35). TheCIM research process comprises researching binder selection, molding and discharge. The ceramic, ceramic injection molding feeding material and preparation method thereof have the advantages of low cost, short degreasing time, high efficiency, environmental pollution, no pollution and small product deformation.

Owner:DONGGUAN HUAJING POWDER METALLURGY

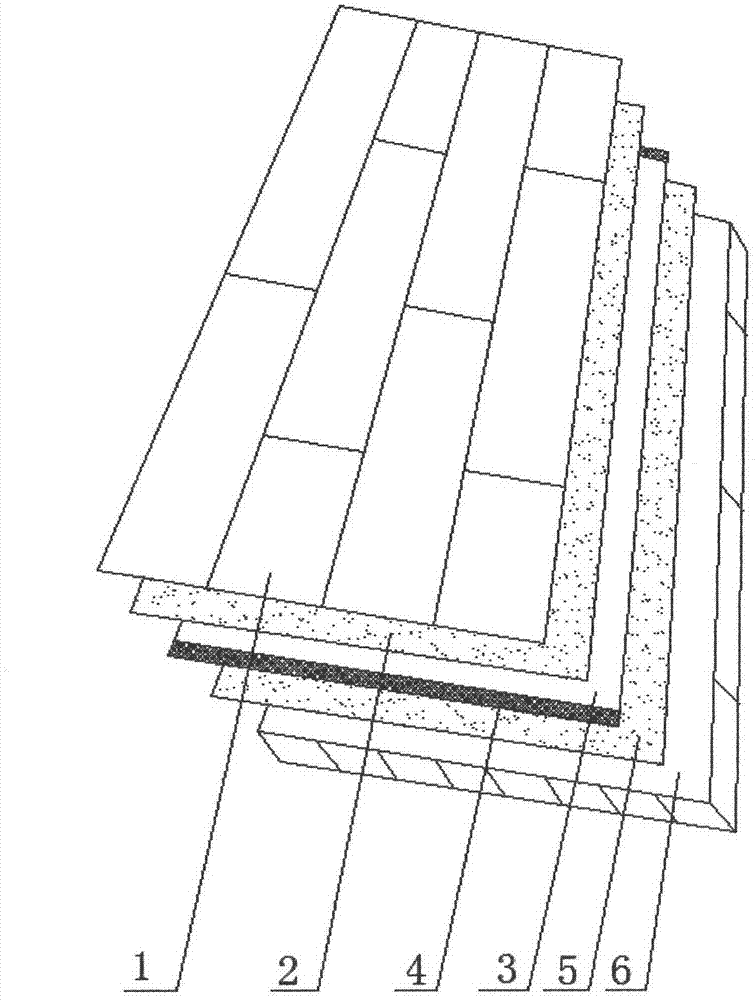

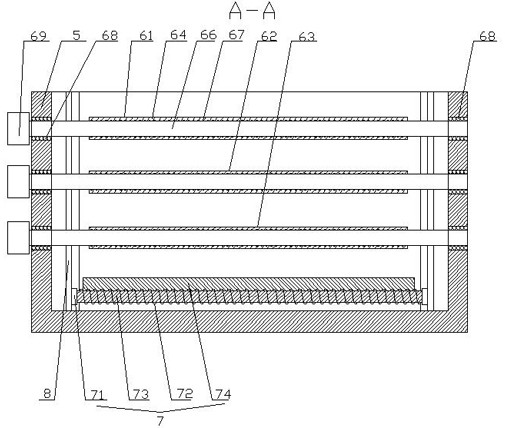

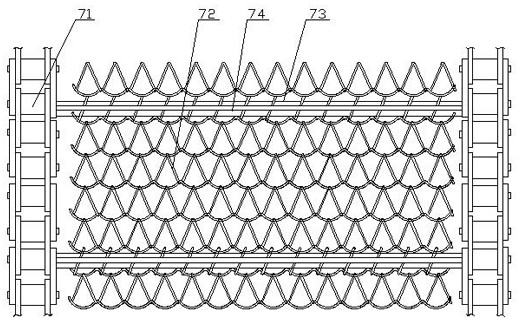

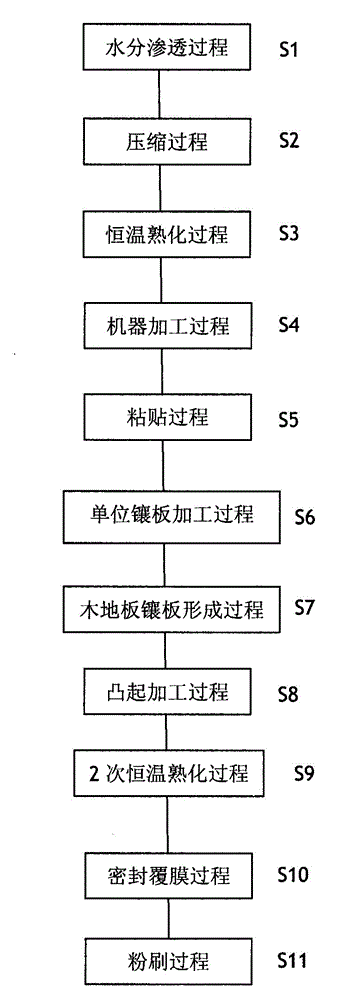

Three-layer solid wood composite electric heating floor and manufacturing method thereof

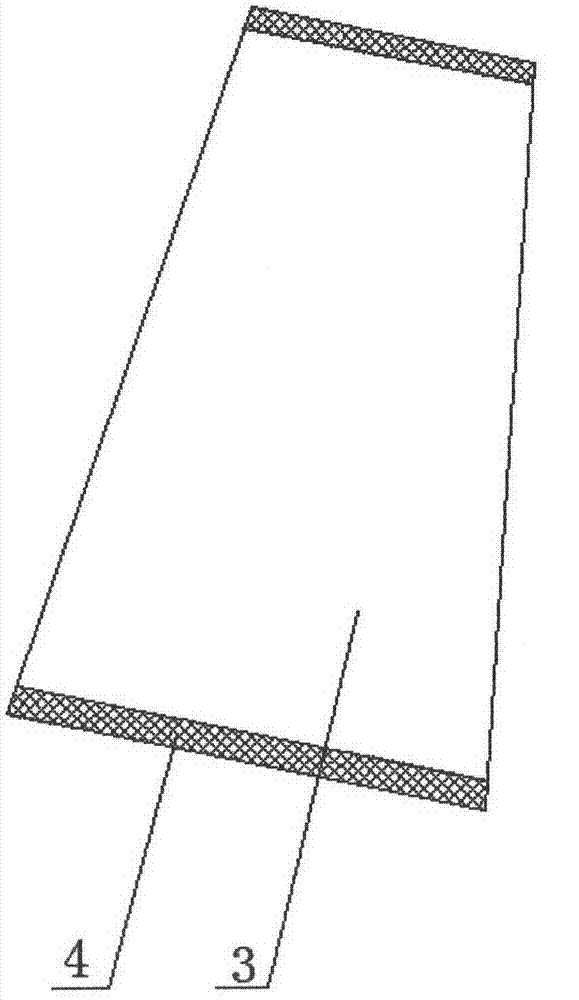

InactiveCN104712129AReduce the amount of glueSmall degree of deformationLighting and heating apparatusElectric heating systemSolid woodElectricity

The invention discloses a three-layer solid wood composite electric heating floor and a manufacturing method thereof. The three-layer solid wood composite electric heating floor comprises a decoration wood veneer, an upper insulation layer, an electric heating chip, a lower insulation layer and a three-layer solid wood base material layer. The three-layer solid wood base material layer is formed by laminating an upper wood veneer, a lower wood veneer and a solid wood batten base material layer clamped between the upper wood veneer and the lower wood veneer. The decoration wood veneer, the upper insulation layer, the electric heating chip, the lower insulation layer and the three-layer solid wood base material layer are sequentially overlapped and laid from top to bottom and laminated into the complete floor. The lower surface of the decoration wood veneer is coated with insulation resin glue to form the upper insulation layer and is attached to the upper surface of the electric heating chip. The upper surface of the three-layer solid wood base material layer is coated with insulation resin glue to form the lower insulation layer and is attached to the lower surface of the electric heating chip. The electric heating chip is formed by coating the surface of a copper strip used as a power plug with conductive hot melt glue and laying the copper strip on the surface of carbon fiber electric heating non-woven paper. According to the three-layer solid wood composite electric heating floor, the amount of adopted glue is small, the deformation degree is low, and the floor is more environmentally friendly. The electric heating chip and the copper strip are connected firmly, safety is good, and the service life is long.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

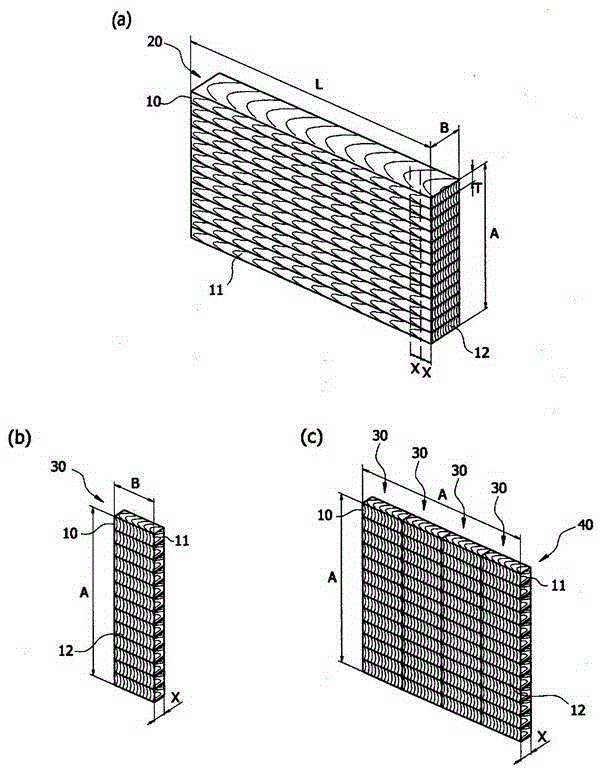

Veneer special for wood blade of classical ceiling fan and preparation method for plywood

ActiveCN102514052ASmall degree of deformationHigh strengthLaminationLamination apparatusCeiling fanPulp and paper industry

The invention discloses a veneer special for a wood blade of a classical ceiling fan and a preparation method for the plywood. The preparation method comprises the following steps of: preparing materials, wherein thickness difference between a eucalyptus core veneer and a eucalyptus long-center veneer is not more than 0.3mm; assembling; hot-pressing, namely performing hot-pressing on a three-layer blank veneer subjected to cold repair; hot stacking for 24 to 72 hours to cure glue water and eliminate stress; cutting an edge, supplying putty, sanding and veneering; hot-pressing the veneered 5-layer veneer; cooling, and hot staking for 2 to 3 days; cutting an edge; performing humidifying and formaldehyde pollution resistant posttreatment; eliminating secondary stress; and performing surface treatment and wood grain filling to obtain the veneer special for the wood blade of the classical ceiling fan. The veneer special for the wood blade of the classical ceiling fan has the advantages of small deformation, high integral strength, flat and smooth surface and no torn grains.

Owner:王佐生

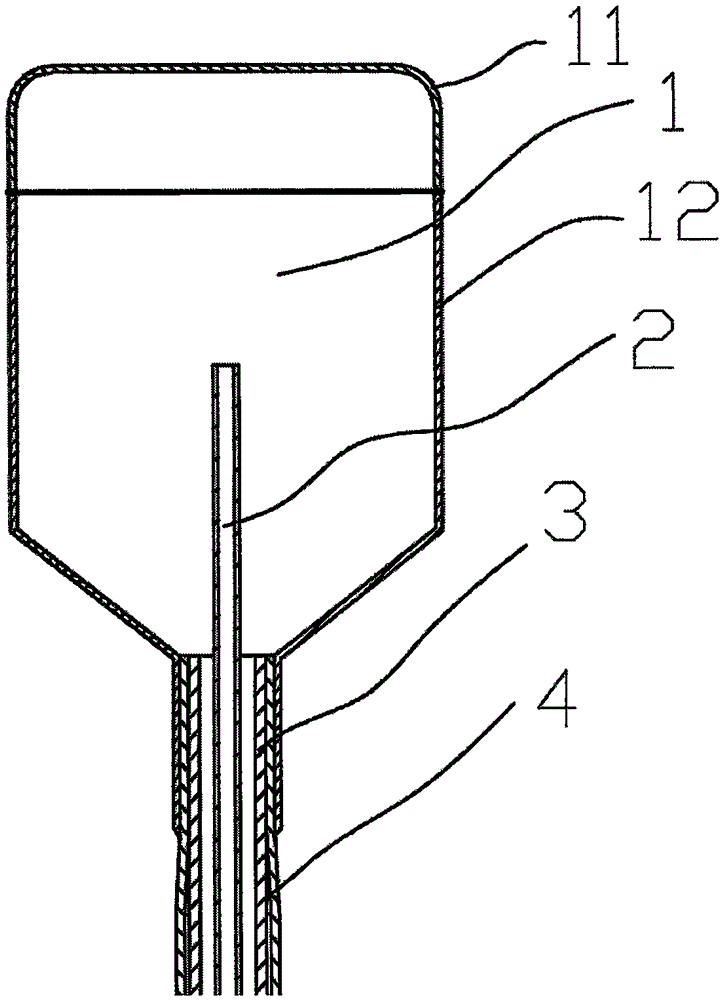

Novel tumor cryoablation catheter

ActiveCN105581838ALarge freezing contact areaExpand the scope ofCatheterSurgical instruments for coolingThermal insulationCold medium

The invention relates to a novel tumor cryoablation catheter. The novel tumor cryoablation catheter comprises a bag body and a pipe connected with the near end of the bag body, the pipe is externally wrapped with a thermal insulation layer and comprises an air inlet pipe and an air return pipe, the far end of the air inlet pipe extends into the bag body, the bag body comprises a far-end face located at the far end, in the ablation process, the air inlet pipe inputs a cold medium to strut the bag body, the far-end face is unfolded, a plane is formed at the far end of the bag body, the near-end part of the bag body bulges to be in a hemispherical shape, and the cold medium flows back through the air return pipe. According to the novel tumor cryoablation catheter, the air inlet pipe extends into the bag body, it is guaranteed that a cold source can be released sufficiently, heat exchange of the cold source is enhanced, and the freezing effect is improved; when the bag body is completely filled, the far end of the bag body is rarely quite little, it is guaranteed that the end face of the far end of the bag body is plane, point contact between a machine and tissues of the human body is avoided, the freezing range is enlarged, the freezing effect is improved, and a better effect is achieved for application of larger gross tumor volume.

Owner:NINGBO SHENGJIEKANG BIOTECH

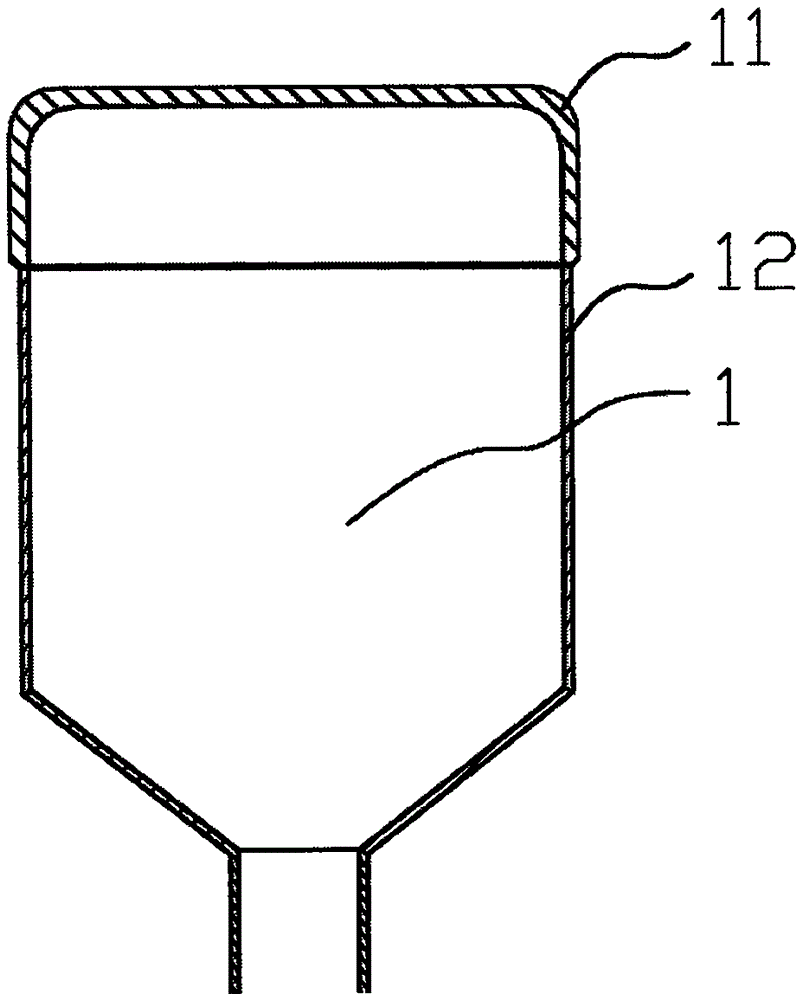

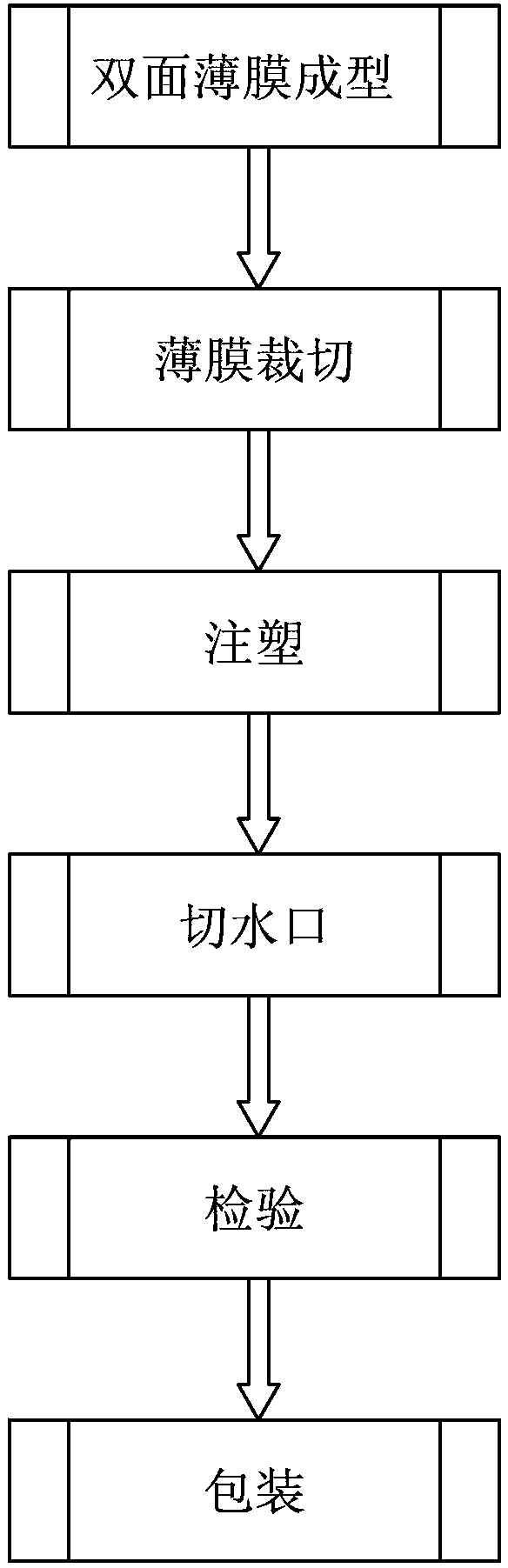

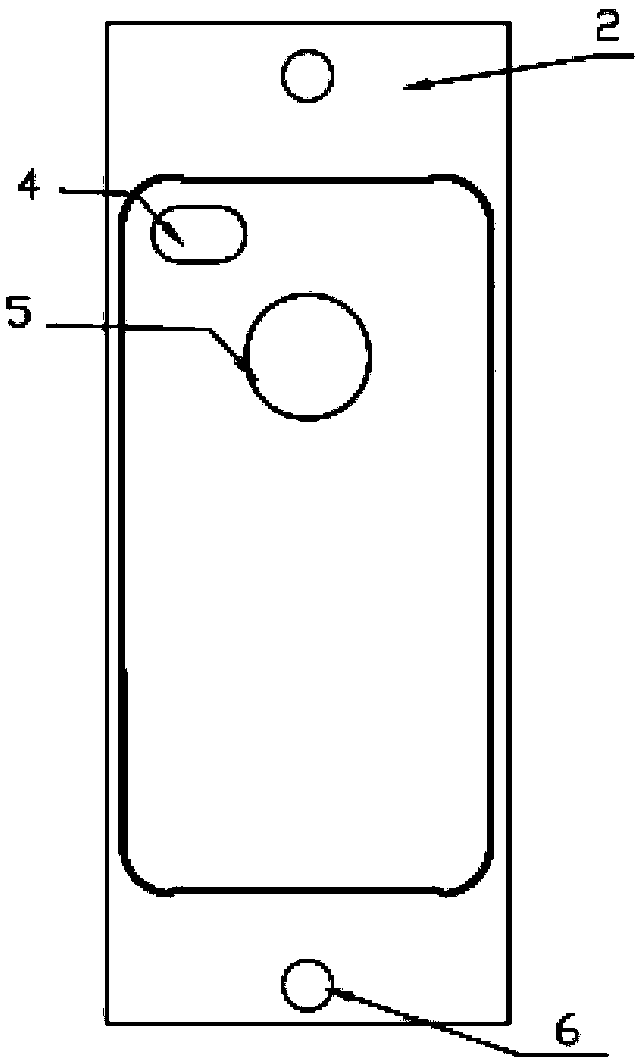

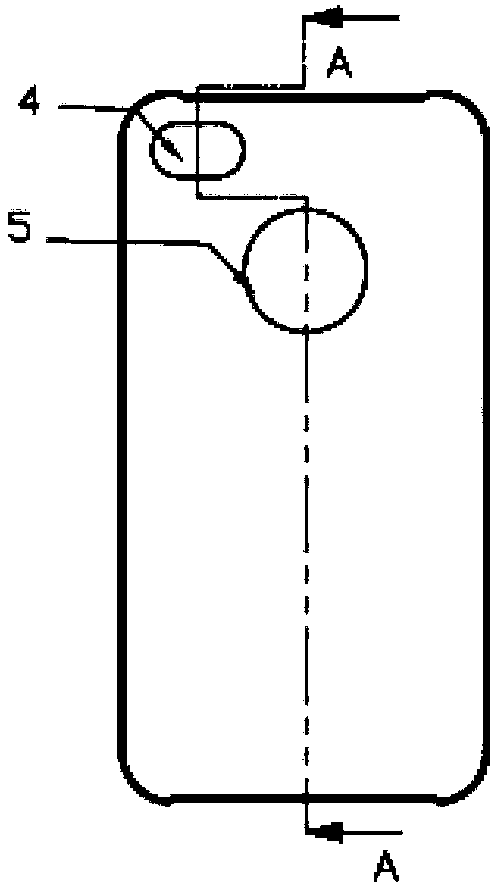

Double-surface die inner injection moulding product and production method thereof

ActiveCN104339600AReduce the difficulty of productionImprove yieldOther printing apparatusTelephone set constructionsColor printingEngineering plastic

The invention relates to a double-surface die inner injection moulding product and a production method thereof. The production method comprises the following steps: employing four-color printing to obtain a right side film (2) and employing Keshi color printing to obtain a back side film (3), forming a required shape through film moulding and cutting, respectively placing the right side film (2) and the back side film (3) in an injection moulding transparent engineering material (1) corresponding to an injection mould, performing nozzle cutting on an injection member after moulding, examining and packaging to obtain the right side film (2) and the back side film (3), and the transparent engineering plastics product capable of performing injection moulding of the right side film (2) and the back side film (3). The production method has the beneficial effect that pattern three-dimensional layering is stronger, no warping is generated on the products, the adhesive force between the film and the transparent plastic is large; product yield rate is increased by 20%, product deformation degree is decreased by 50%; and the production efficiency is increased.

Owner:QUNDA PLASTIC ELECTRONICS SHENZHEN

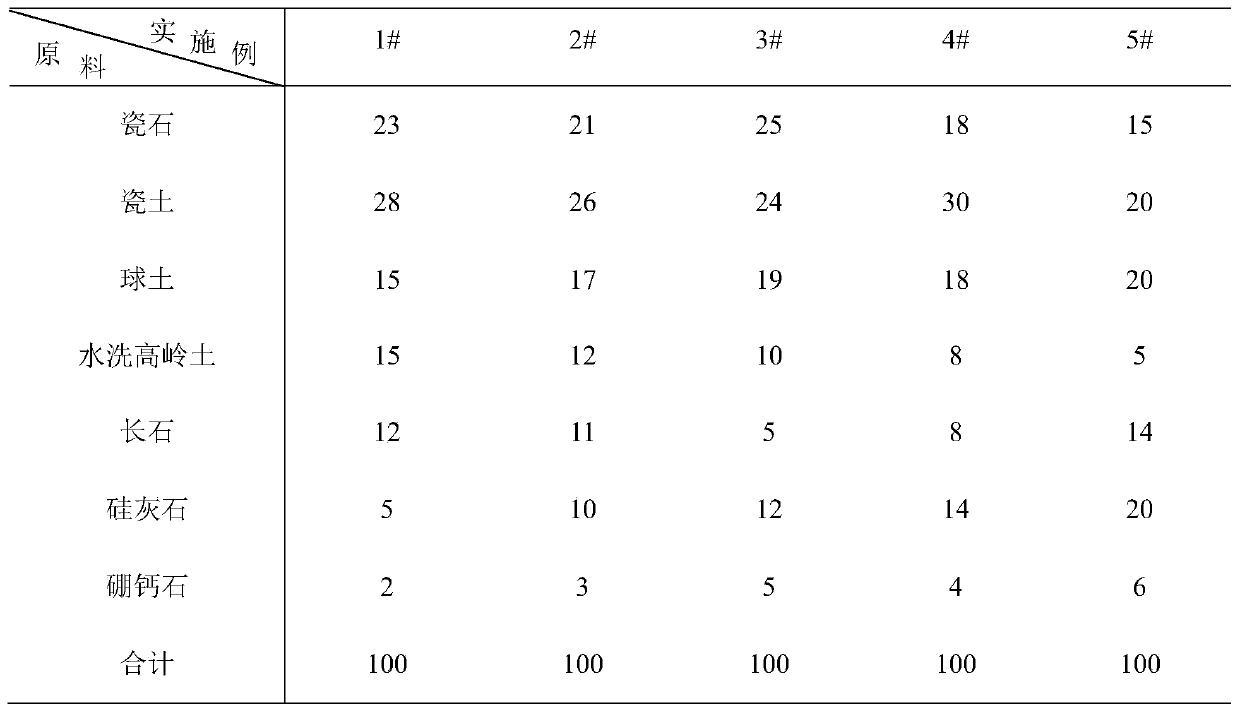

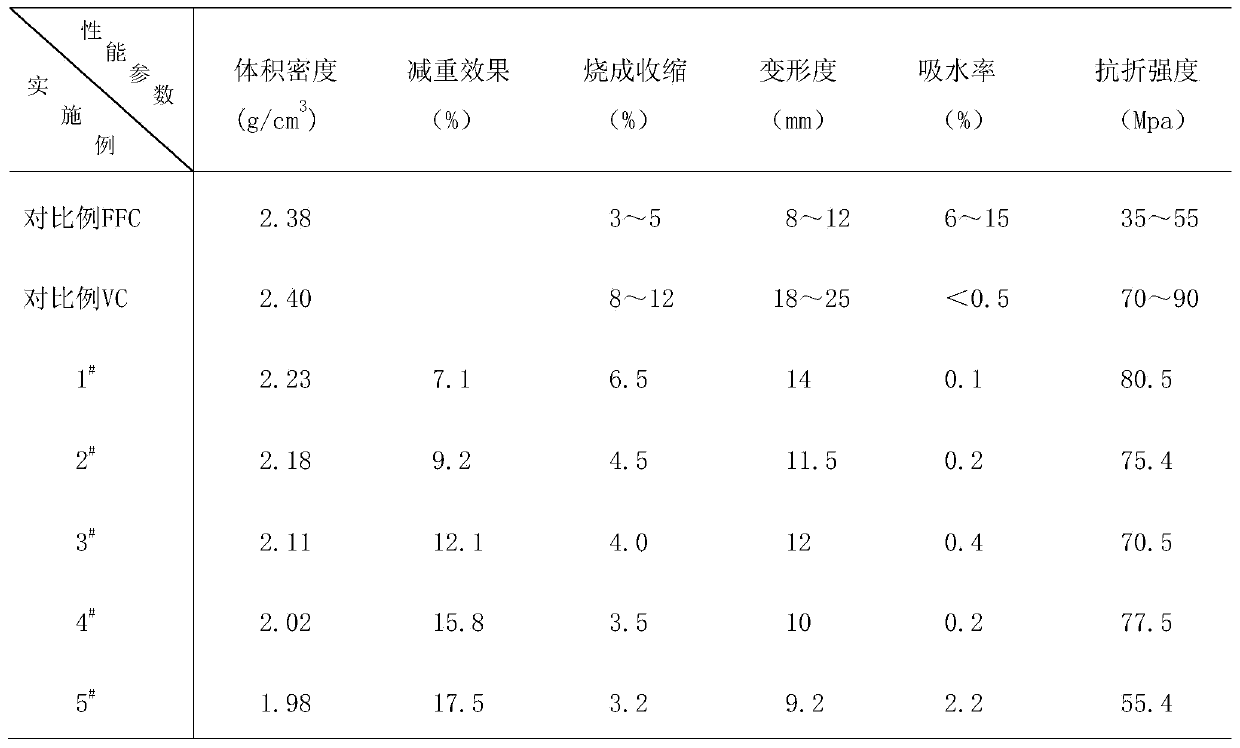

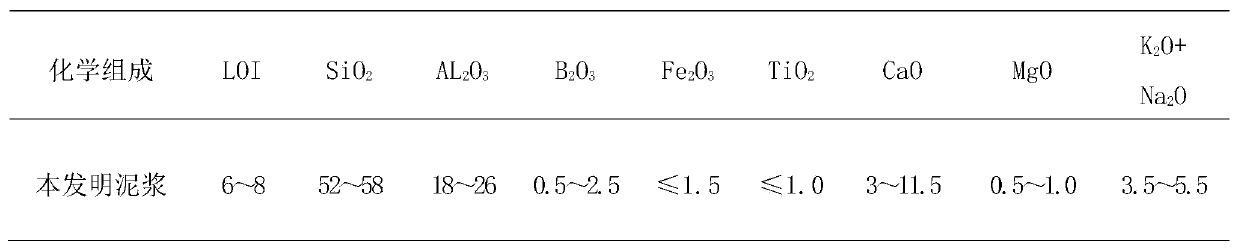

Sanitary ceramic formula and preparation method

ActiveCN111533530AHigh refractorinessSmall degree of deformationCeramic materials productionClaywaresChemical compositionMullite

The invention relates to the field of preparation processes of sanitary ceramics, in particular to a formula and a preparation method of sanitary ceramics, which improve the refractoriness of a greenbody and reduce the deformation degree of the green body by adjusting the raw material composition of the formula and optimizing the chemical composition. In the mineral composition of a common feldspar porcelain body, a proper amount of wollastonite raw material is introduced, the content of an anorthite crystalline phase is increased on the basis of original mullite and quartz crystalline phases, and a proper amount of closed independent pores are formed, so that the shrinkage rate and the volume density are reduced; by introducing a proper amount of the borocalcite flux, an (O = B-O-B = O)structure can be provided, the integrity and compactness of a network structure around the pores of the borocalcite flux are ensured, and the sizes of the independent pores are controlled within a certain range so as to avoid reduction of the firing strength.

Owner:HUIDA SANITARY WARE

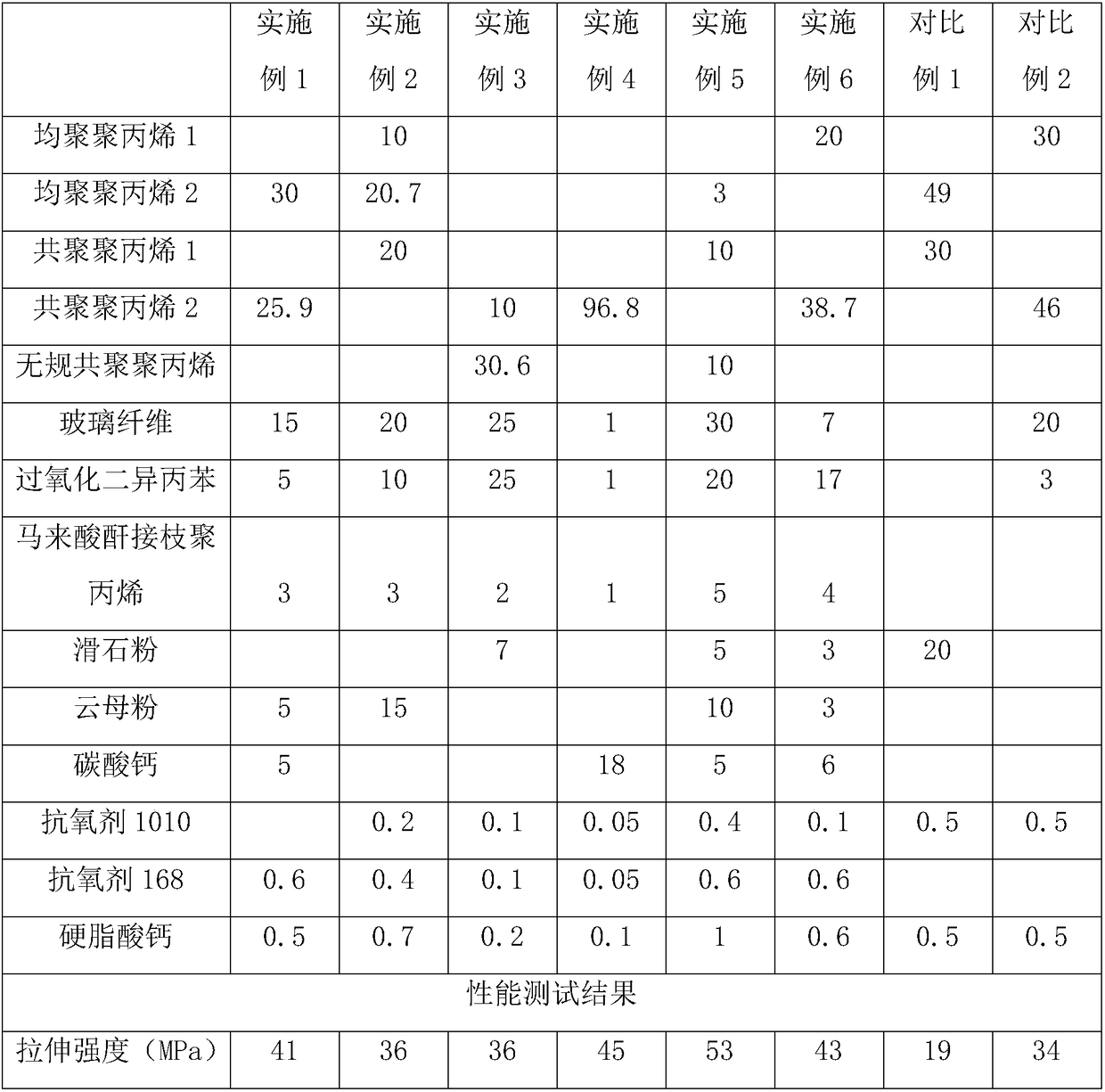

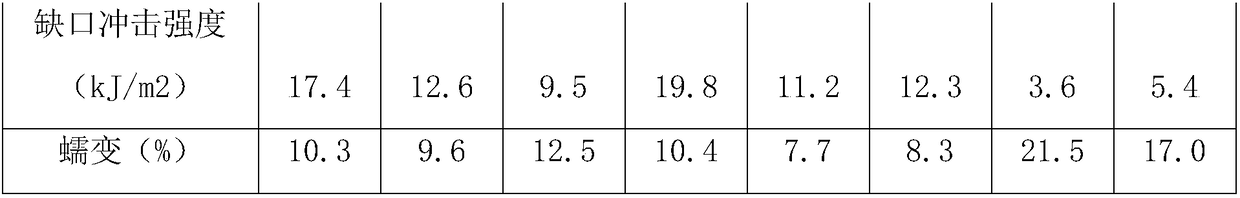

Creep-resistant polypropylene composite material

InactiveCN108929485AImprove rigidityHigh heat distortion temperaturePolypropylene compositesGlass fiber

The invention discloses a creep-resistant polypropylene composite material which is prepared from the following components in parts by weight: 23-96.8 parts of polypropylene, 1-30 parts of glass fibers, 1-20 parts of diisopropylbenzene peroxide, 1-5 parts of polypropylene grafted with maleic anhydride, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricant and 0-20 parts of a filler. With the addition of the glass fibers and the filler in the material, the rigidity of the material can be provided; with addition of diisopropylbenzene peroxide, the polypropylene material can be partially cross-linked, and the creep resistance of the polypropylene material is greatly improved. The material still maintains small deformation degree under long-term stress.

Owner:HEFEI GENIUS NEW MATERIALS

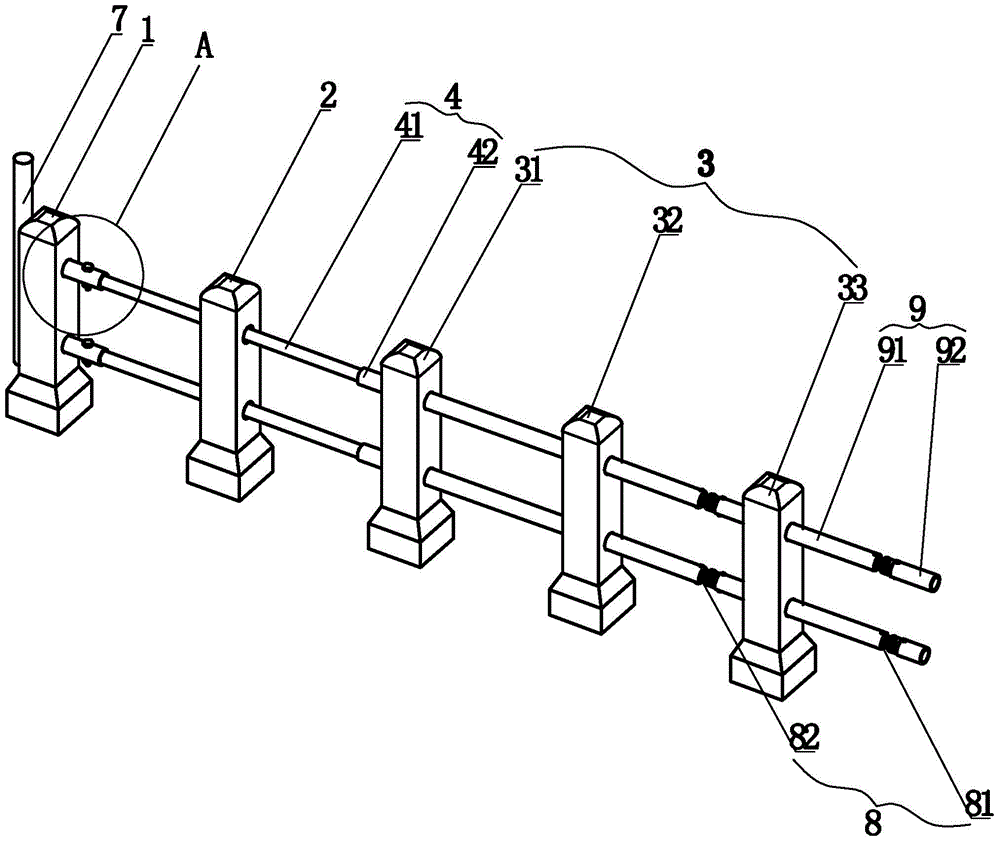

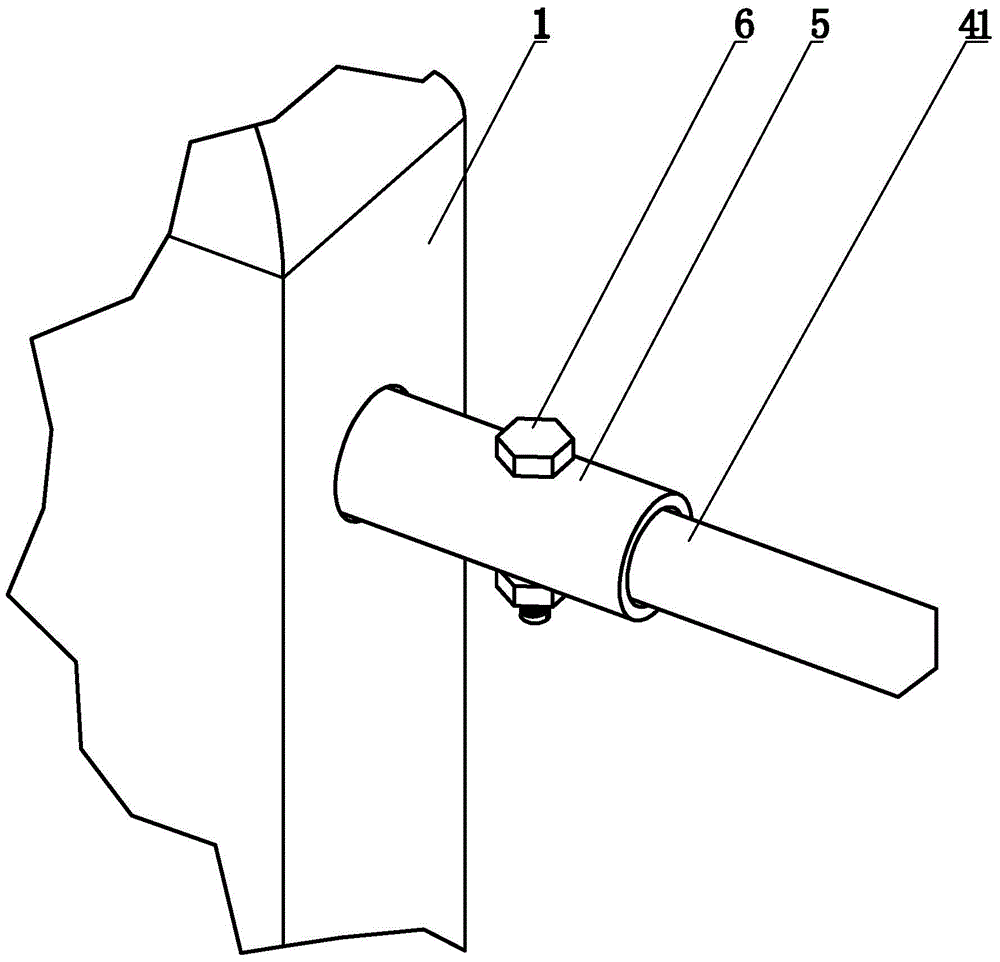

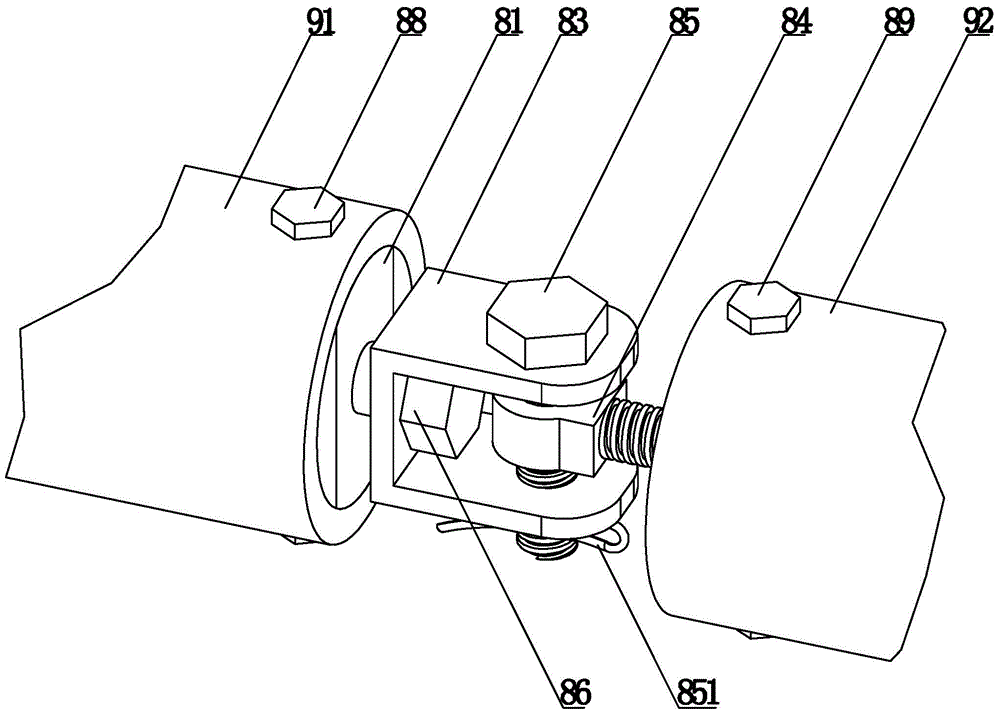

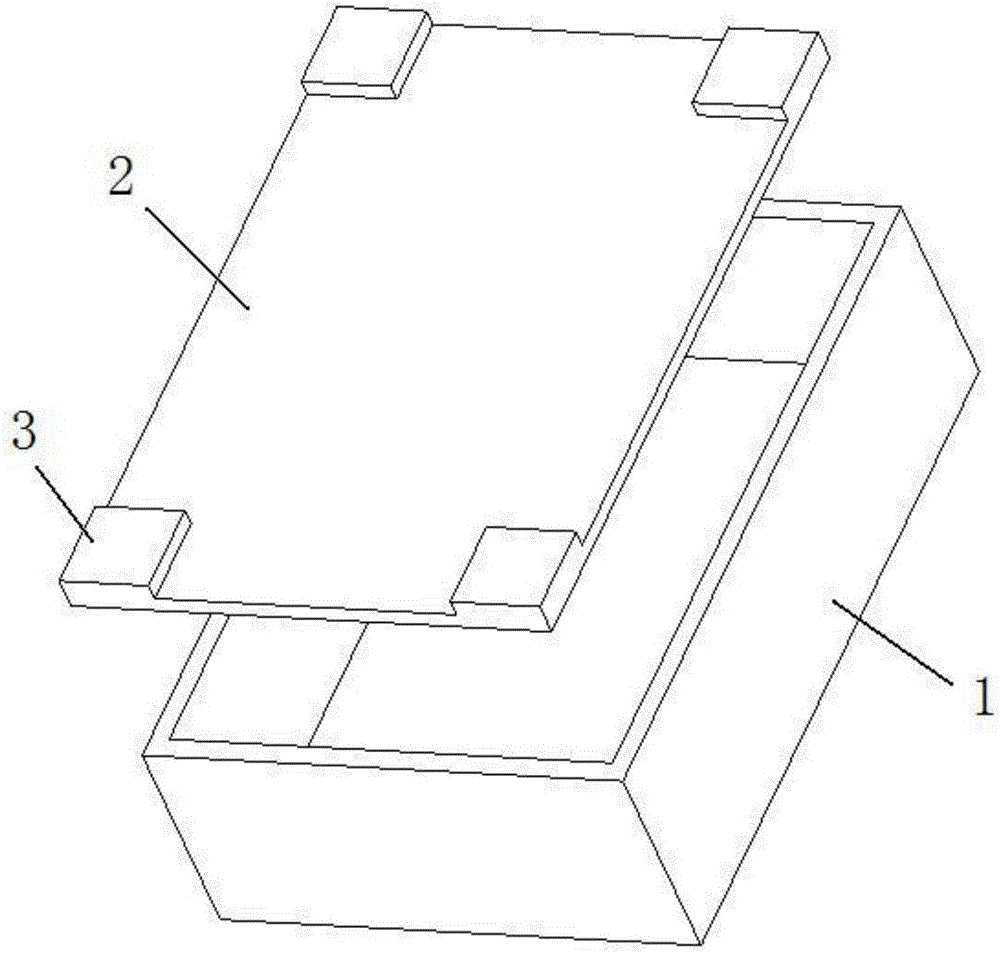

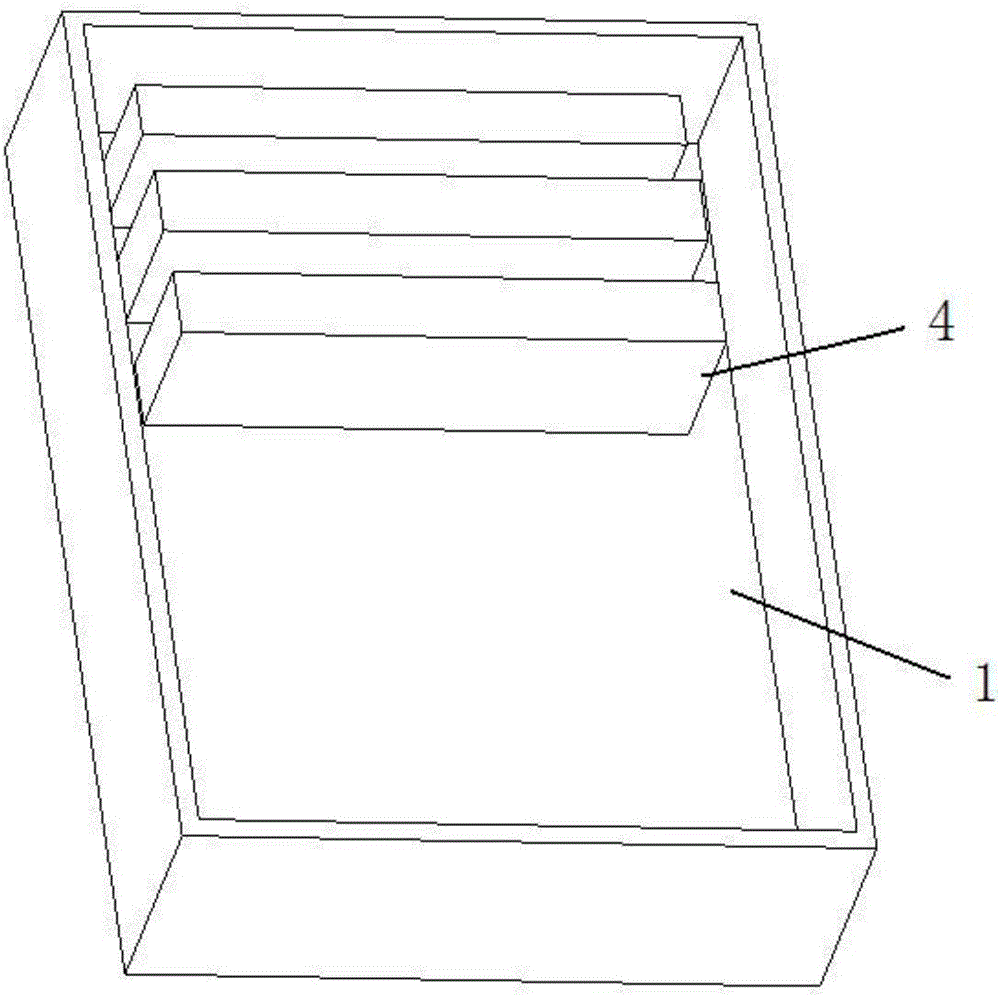

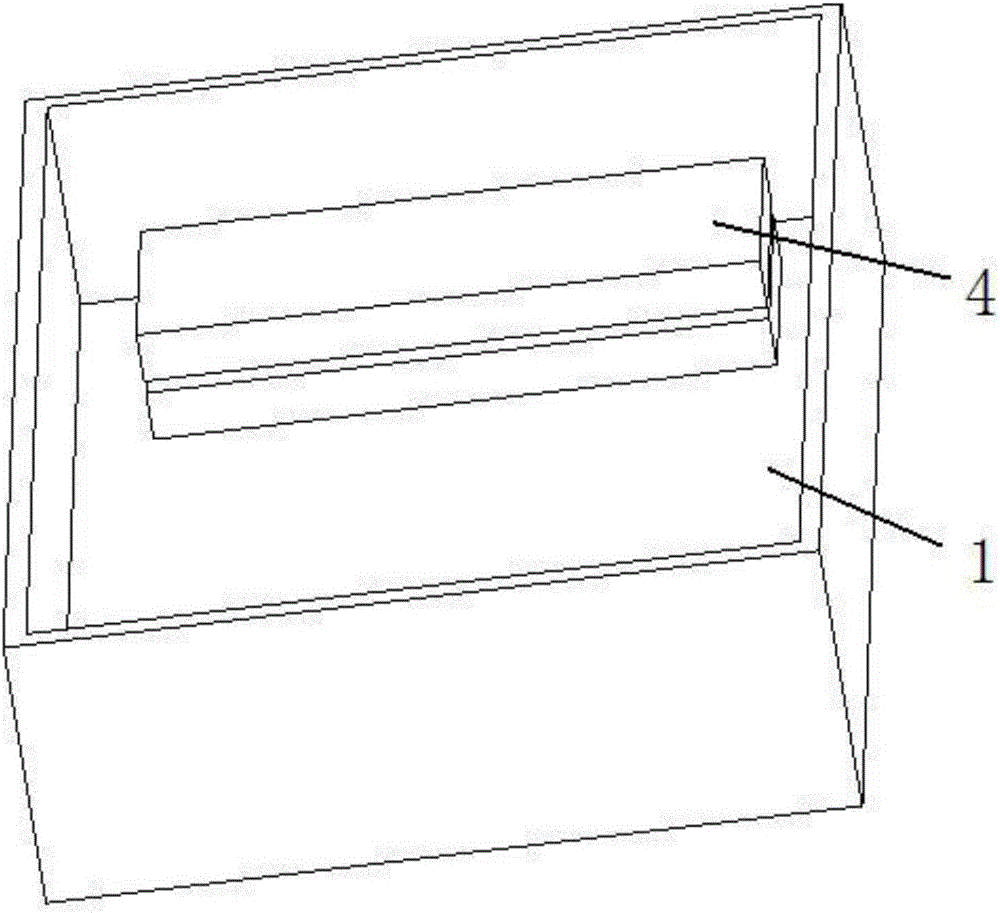

Safety telescopic guardrail

InactiveCN104831652ASmall degree of deformationFirmly connectedRoadway safety arrangementsCivil engineering

Owner:孟国华

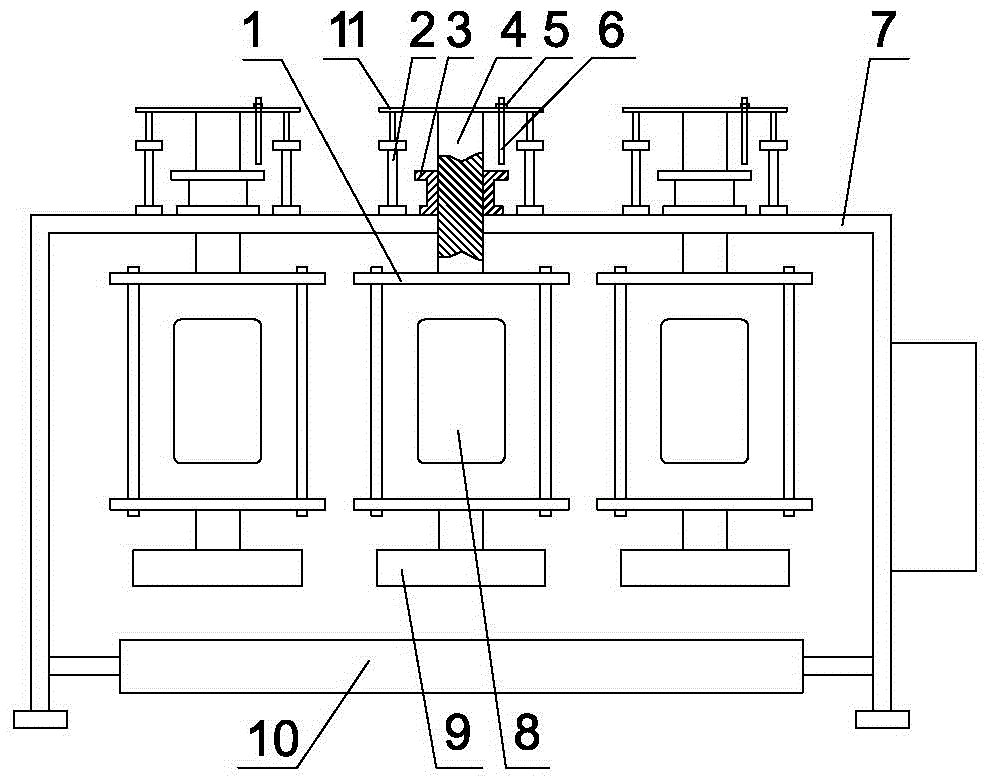

Sintering method and apparatus for rare earth neodymium-iron-boron magnet

ActiveCN105321701ASmall degree of deformationSolve the problem of difficult installation and burningInductances/transformers/magnets manufactureMagnetic materialsRare earthGraphite

The invention discloses a sintering method and apparatus for a rare earth neodymium-iron-boron magnet. The sintering method comprises the following steps specifically: (1) choosing a graphite box and a graphite cover plate with certain specifications; (2), drying the graphite box and the graphite box cover plate in a drying oven at the temperature of 60 DEG C for 8-24 hours for removing humidity; (3), uniformly paving a layer of high-temperature-resistant powder at the bottom of the graphite box; (4), putting the rare earth neodymium-iron-boron magnet products in the graphite box, and uniformly paving a layer of high-temperature-resistant powder in the contact surfaces of the products; (5), putting neodymium-iron-boron waste powder in the gaps of the graphite box; and (6), sintering the accommodated rare earth neodymium-iron-boron magnet products. The sintering method and the apparatus have the beneficial effects that the difficulties in sintering the rare earth neodymium-iron-boron magnet products with thinner thicknesses and cooling the graphite box are solved, the sintering amount of a single furnace is improved, the degree of deformation of products is effectively reduced, the material utilization is improved, the bonding of the products is prevented, the rate of finished products is improved, the oxidization of the products is reduced, and the consistence of the product performance is improved.

Owner:GANZHOU DMEGC RARE EARTH MAGNET CO LTD

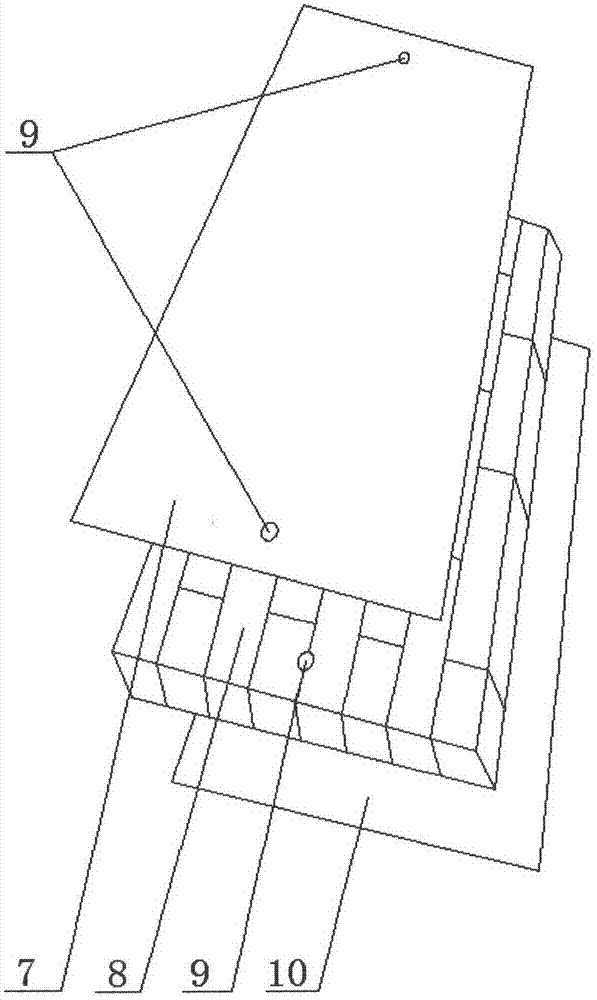

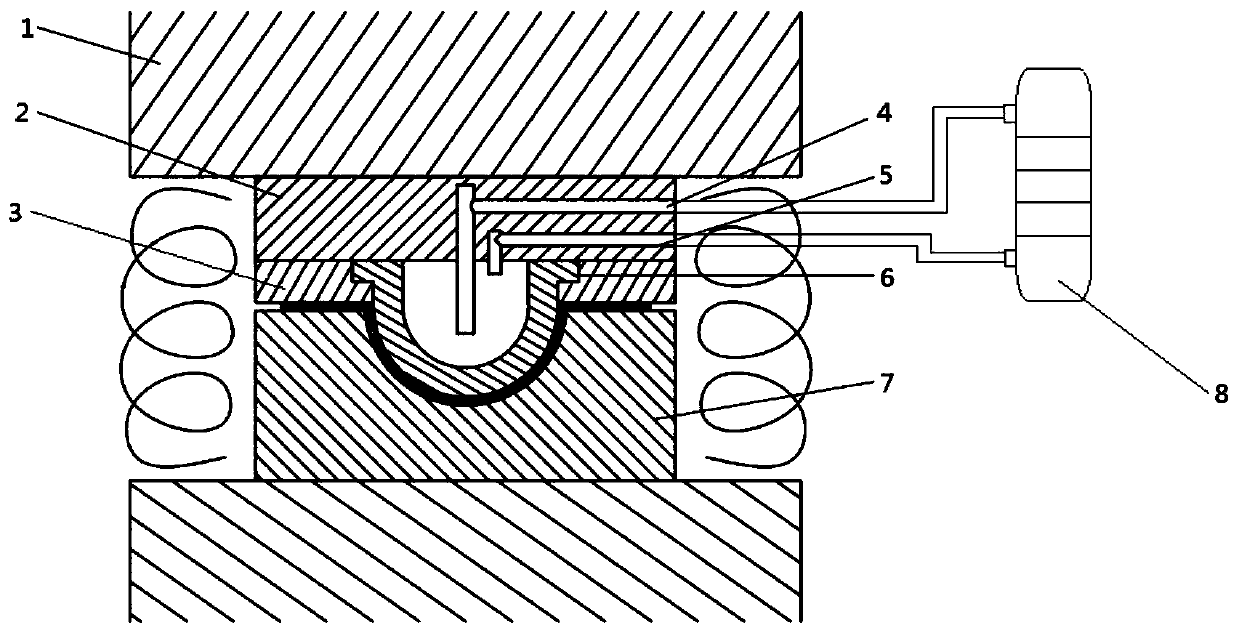

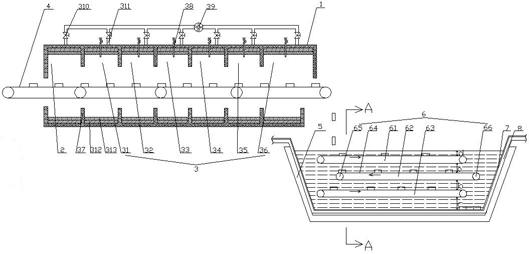

Equal-temperature hot drawing forming device and method for controlling wall thickness uniformity of component

The invention discloses an equal-temperature hot drawing forming device and method for controlling wall thickness uniformity of a component, and relates to the field of equal-temperature hot drawing forming devices and methods by controlling the wall thickness uniformity of the component, which solves the technical problem that in an existing hot drawing technology method, bottom part reduction issevere, and thus blank deformation is nonuniform. The equal-temperature hot drawing forming device includes a hot forming press machine, a die and a gas cooler, wherein the die includes a template, afixing plate, an air inlet pipe, an air outlet pipe, a male die and a female die. The method includes the steps that 1, the die is mounted on the hot forming press machine; 2, heating is conducted, sheet materials are put into, heat insulation is conducted, cooling gas is introduced, drawing forming is conducted, and pressure maintaining is conducted; and 3, the die is opened and is cooled to a room temperature, and inspection and acceptance are conducted. According to the equal-temperature hot drawing forming device and method, circulating helium is introduced into a male die hollow structural cavity through an air passage of an upper male die to lower the temperature of the upper die, the degree of deformation of the contact part of the sheet materials and the upper male die is reduced,the thicknesses of the arc positions of the bottom parts of the sheet materials are increased, and uniform deformation of a formed part is achieved. The equal-temperature hot drawing forming device and method are used for preparing sheet material parts.

Owner:HARBIN INST OF TECH

Preparation of cryogenic rubber-plastic thermal insulation material

InactiveCN112300479AImprove insulation effectHigh tensile strengthCoatingsPolymer scienceThermal insulation

The invention relates to the technical field of cryogenic rubber and plastic thermal insulation materials, in particular to preparation of a cryogenic rubber and plastic thermal insulation material. The thermal insulation material is prepared from the following raw materials in parts by weight: 4-8 parts of ethylene vinyl acetate copolymer (EVA), 8-12 parts of a foaming agent, 60-75 parts of a smoke suppressor, 20-25 parts of a plasticizer, 5-8 parts of carbon black, 1-2.5 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 1-2 parts of an anti-aging agent, 4-6 parts of an accelerant, 2-10 parts of ointment, 10-15 parts of argil, 2-5 parts of silicon dioxide and 1-3 parts of glycol. According to the invention, the ENB rubber improves the tensile strength and reduces the deformation degreeof the product; and the factice, the argil and the ethylene glycol further improve the freezing resistance and the stability of the product under the low-temperature condition, and the heat preservation performance of the material is greatly improved.

Owner:WINCELL INSULATION CO LTD

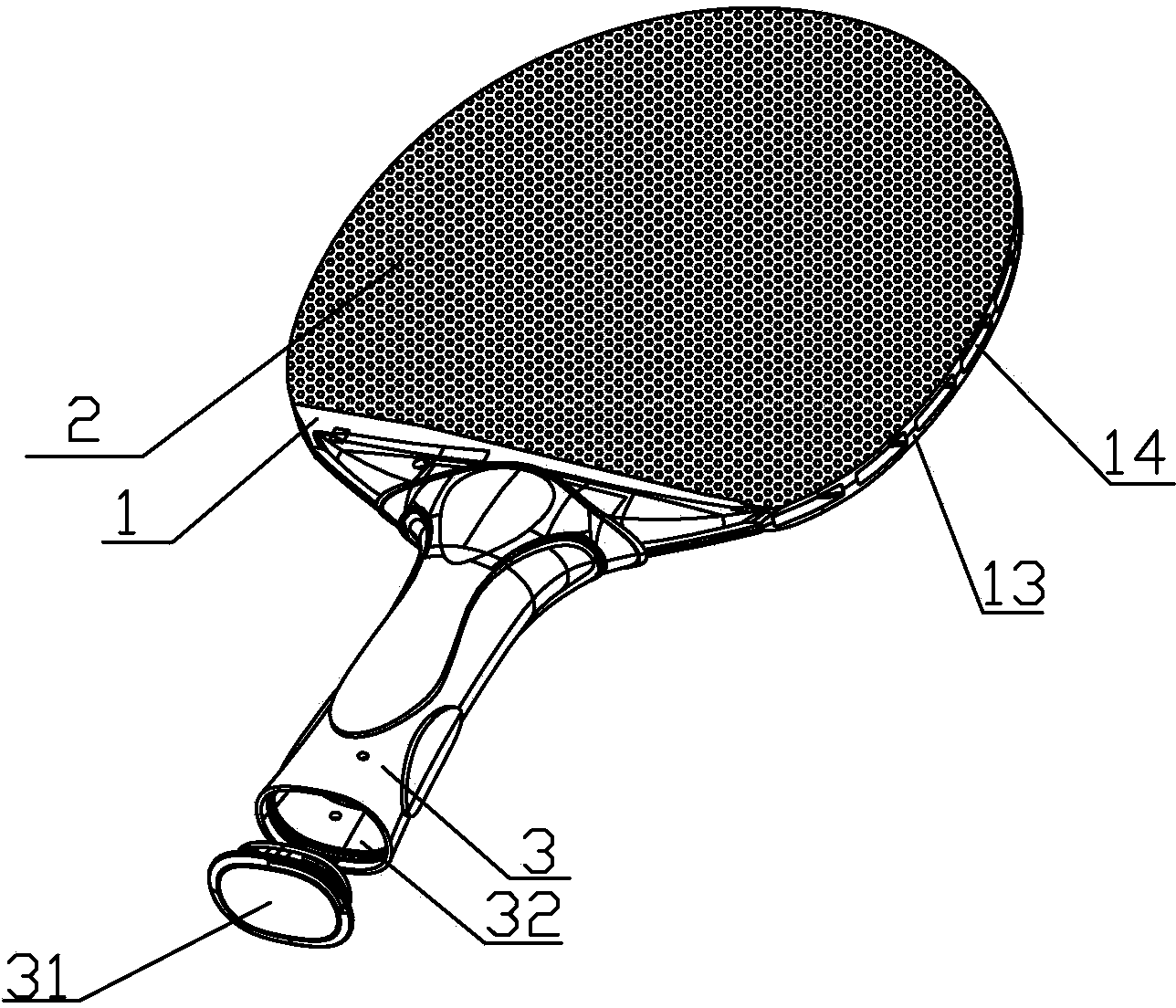

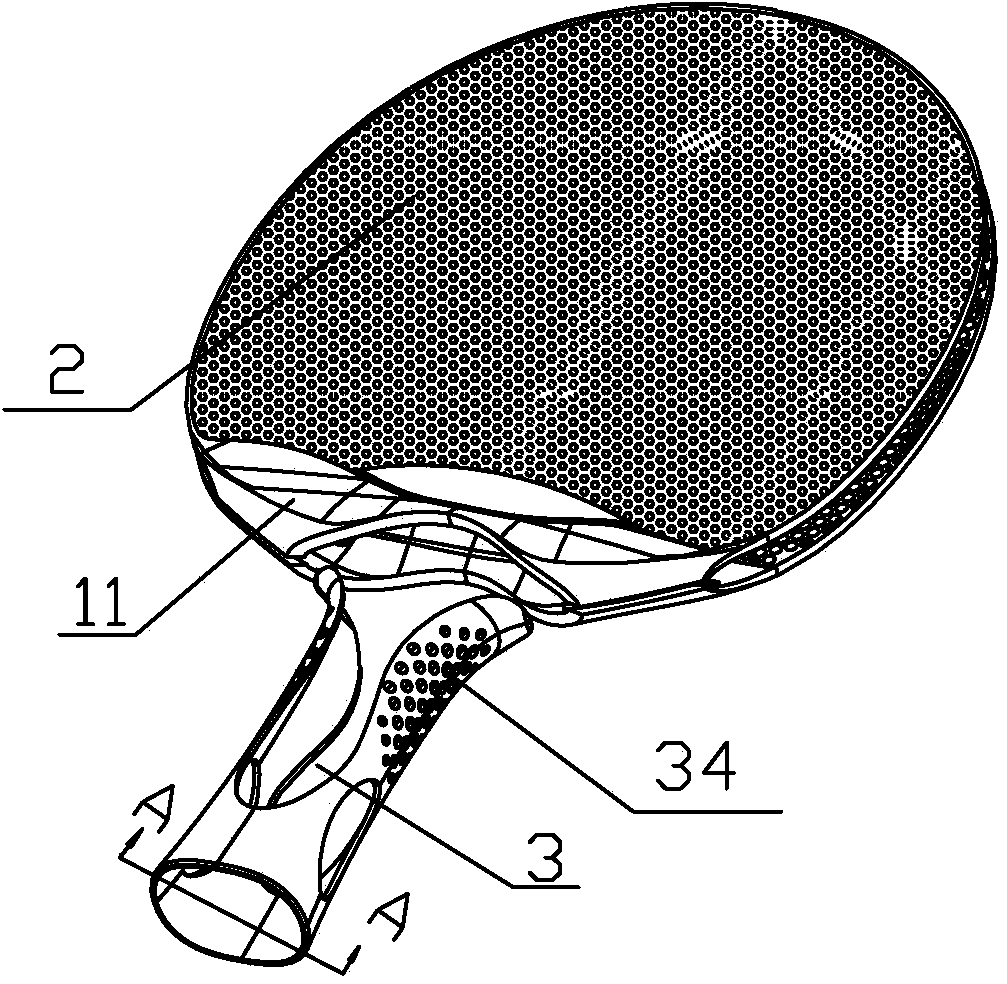

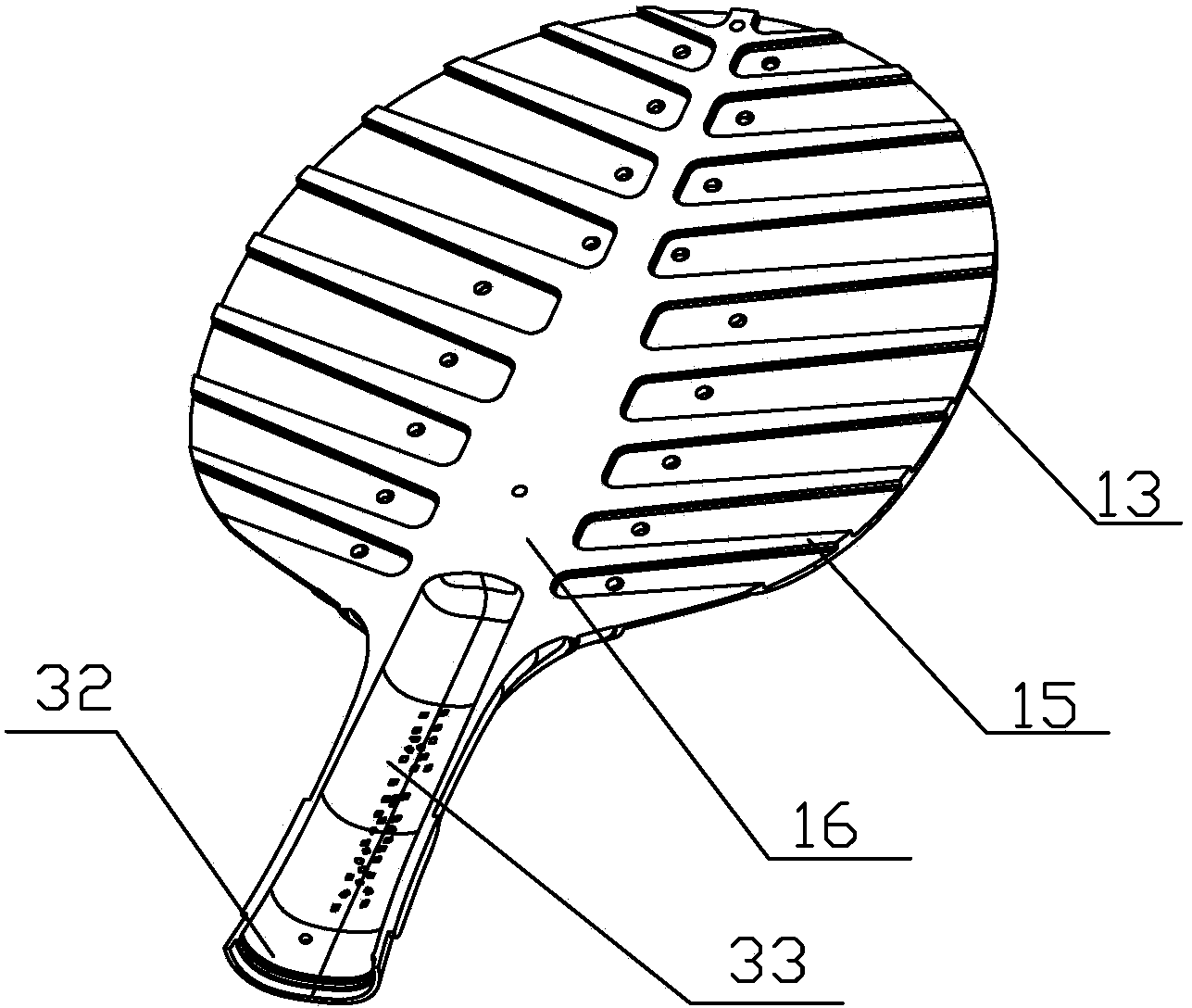

Bottom plate of improved table tennis bat and table tennis bat

The invention discloses a bottom plate of an improved table tennis bat and the table tennis bat. The bottom plate of the improved table tennis bat adopts a special material, so that the table tennis bat is impact-resistant, ageing-resistant and better in rigidity; the bottom plate of the improved table tennis bat adopts a fish bone structure to realize the partially hollow effect of the bat bottom plate, and the whole weight of the table tennis bat is reduced; a plurality of concave holes are uniformly distributed in an elastic bottom panel and the bottom plate of the table tennis bat, the contact surface between the table tennis bat and a table tennis is enlarged by the concave hole structure, and most important, the friction and the rotating speed which are produced by the bat to the table tennis when the table tennis is hit in the table tennis sport are improved.

Owner:GUANGZHOU DOUBLE FISH SPORTS GOODS GRP

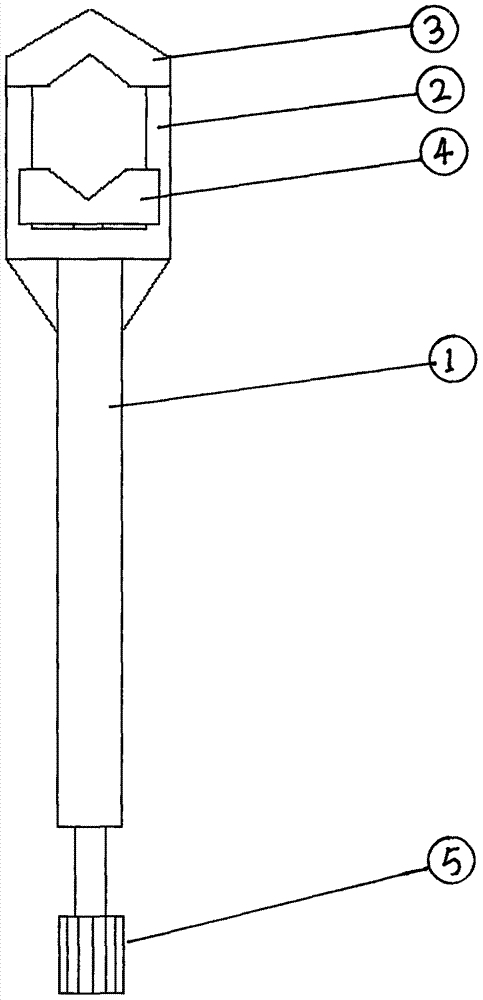

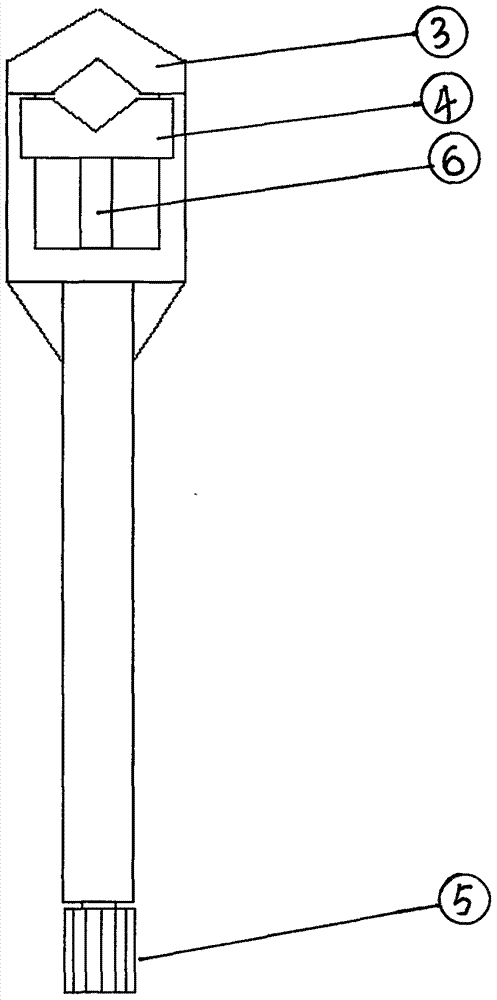

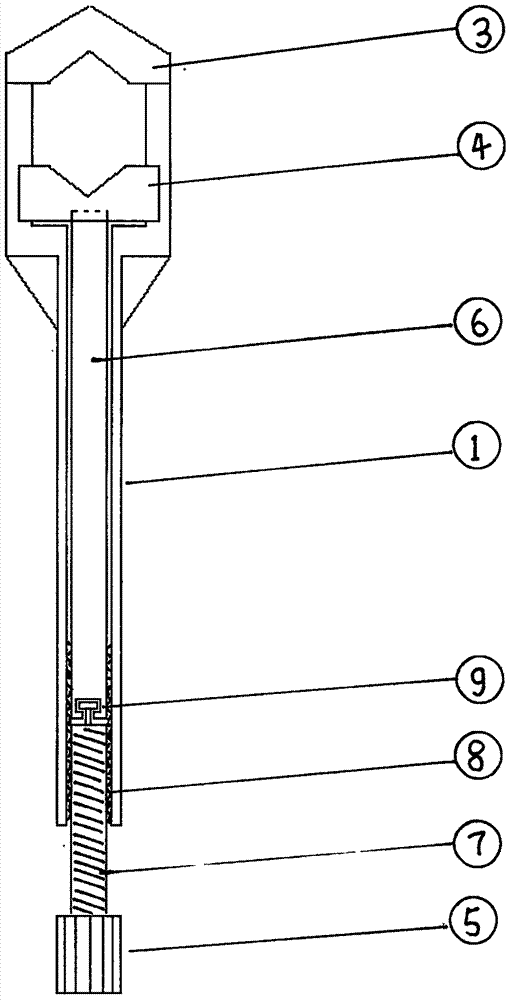

High-strength loosening prevention adjustable wrench

PendingCN107378838ASmall degree of deformationHigh precisionSpannersWrenchesHigh intensityEngineering

The invention relates to a bolt untightening tool, in particular to an adjustable wrench. The high-strength loosening prevention adjustable wrench comprises a fixed block, a sliding block, a handle, an adjusting cap and the like, wherein grooves are formed in the fixed block and the sliding block; when the wrench is combined to a bolt, the grooves are matched with the bolt angularly; a pushing rod is arranged in the handle and is connecting with the sliding block; the adjusting cap is arranged at the bottom of the handle; a bolt is arranged on the adjusting cap; threads are arranged on a surface, which is in contact with the bolt, of the handle; when the adjusting cap rotates clockwise, the pushing rod can be pushed to enable the sliding block to ascend; when the adjusting cap rotates anticlockwise, the pushing rod can be pushed to enable the sliding block to descend; when the adjustable wrench is used, the adjusting cap rotates to enable the sliding block to ascend, and then the sliding block is matched with a nut or a bolt which requires to be untightened or tightened; and then the wrench moves to operate. When the high-strength loosening prevention adjustable wrench is used, the grooves in the sliding block and the fixed block are matched with the nut angularly, therefore, the degree of deformation is quite small when the wrench is gripped with the nut, and slipping during stress can be prevented; and the fixed block and a support are formed integrally, so that the high-strength loosening prevention adjustable wrench can bear large working force.

Owner:王明中

Method for conducting flexibly-selective rough polishing on surface of polished tile and polished tile rough polishing machine

InactiveCN106271999AAvoid damageAchieve the effect of segmented polishingGrinding carriagesPolishing machinesHobbingEngineering

The invention discloses a method for conducting flexibly-selective rough polishing on the surface of a polished tile, and belongs to the field of polished tile processing. Rough polishing is conducted on the surface of the polished tile through grinding heads, and the grinding heads are located over a polished tile conveyer belt. The method is characterized in that multiple grinding heads are adopted and can vertically move, the grinding heads run in a mutually independent mode and are transversely arranged to be in a straight line, and the covering width of the transversely-arranged grinding heads is larger than or equal to the width of the polished tile; after the polished tile on the conveyer belt enters a space under the grinding heads, the grinding heads are flexibly selected according to the surface condition of the polished tile to conduct rough polishing on the surface of the polished tile. According to the method, motors can be flexibly selected to be started to conduct rough polishing on the surface of the polished tile according to the condition of a polished tile blank, and the segmented polishing effect is achieved. Compared with the prior art, the defect that the tile is damaged due to the fact that the polished tile is polished by integrally adopting one hobbing cutter is avoided, and damage to the grinding knifes is avoided.

Owner:山东狮王陶瓷有限公司

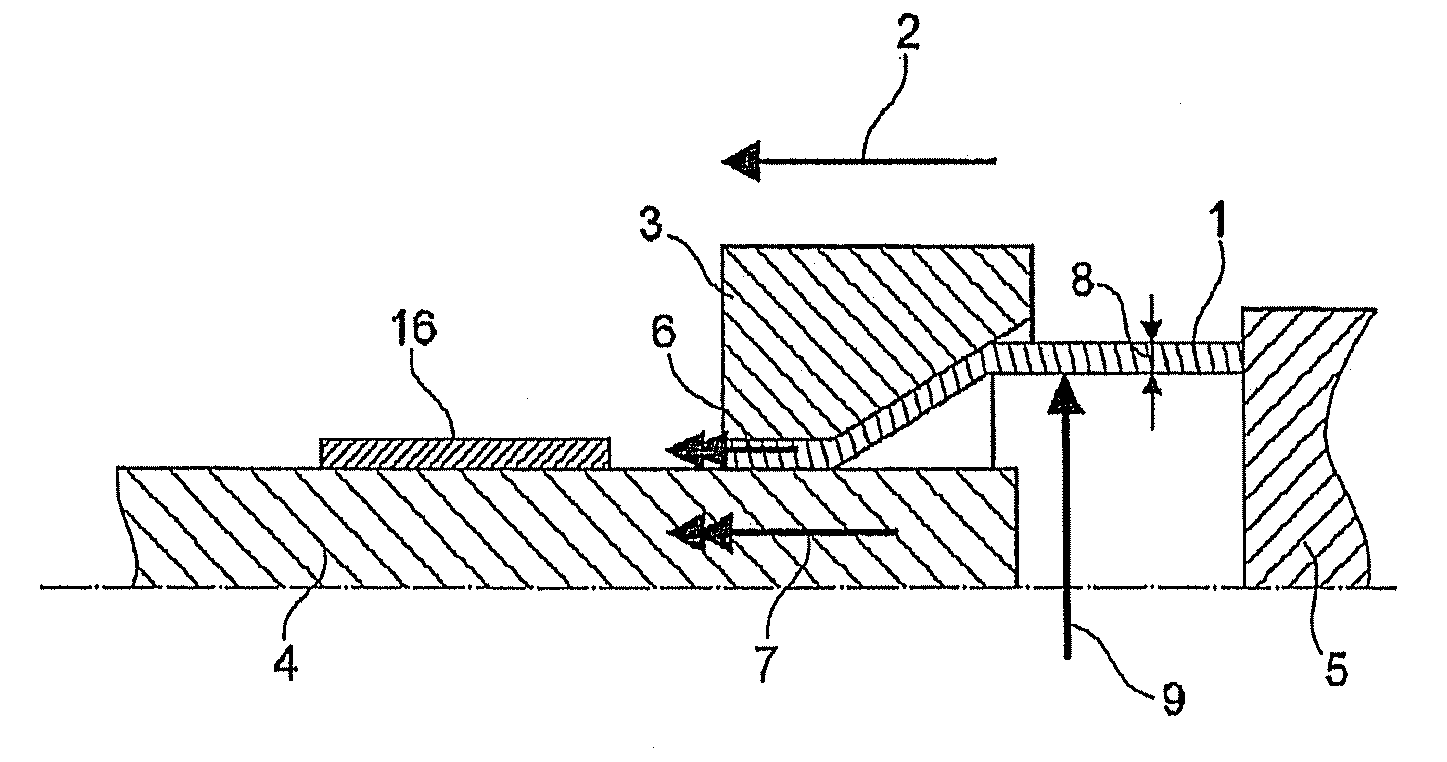

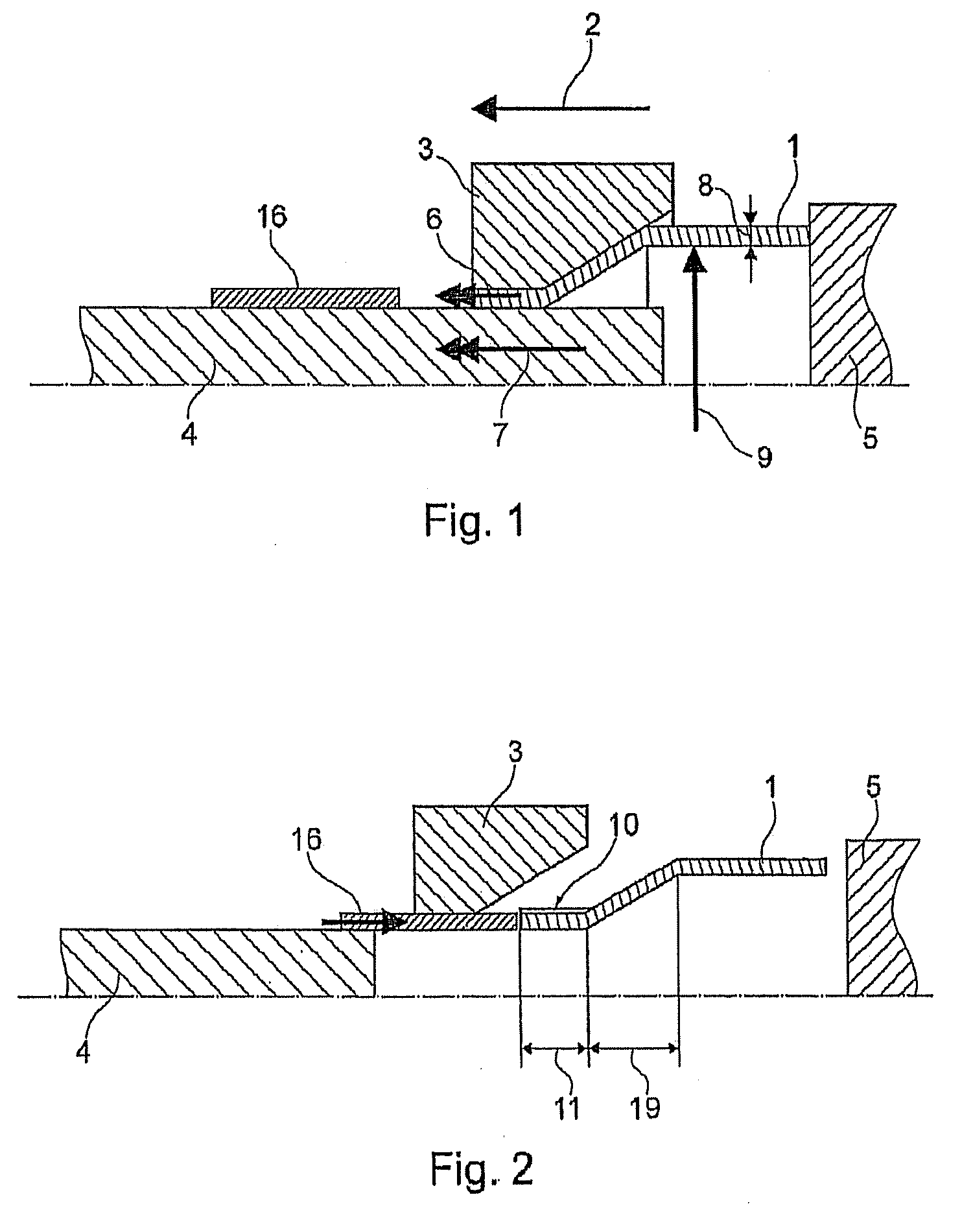

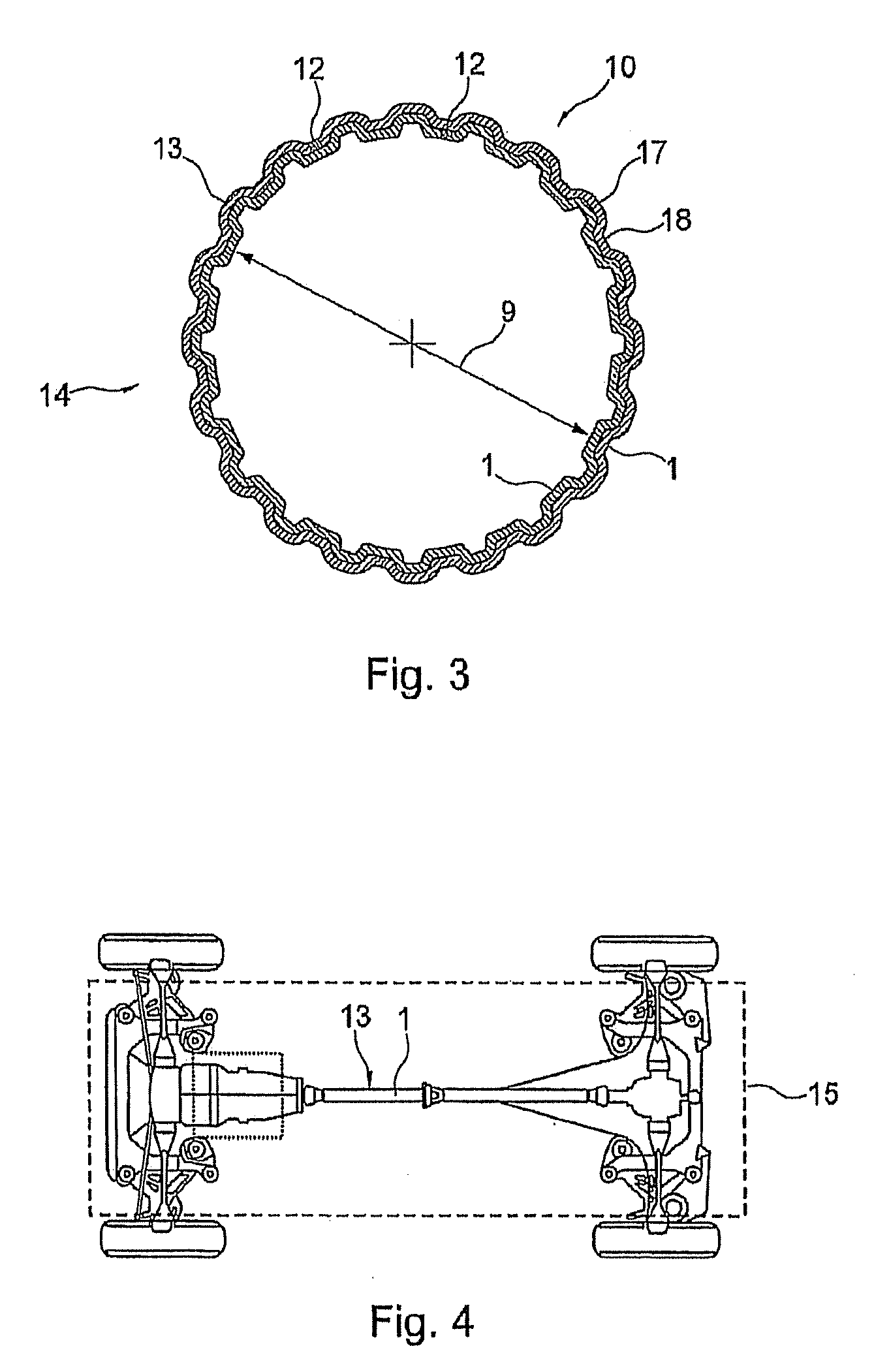

Method for forming hollow profiles

ActiveUS20090305797A1Improve performanceProduce cost-effectivelyDrawing mandrelsShaftsEngineeringMaterial flow

A method for forming hollow profiles is disclosed. In one exemplary method, a hollow profile is guided through a die in a processing direction and fixed by a mandrel such that at the die, the hollow profile has a material flow velocity in this processing direction (2), in which the method the mandrel has a drawing velocity in the processing direction that is greater than the material flow velocity.

Owner:GKN DRIVELINE INT GMBH

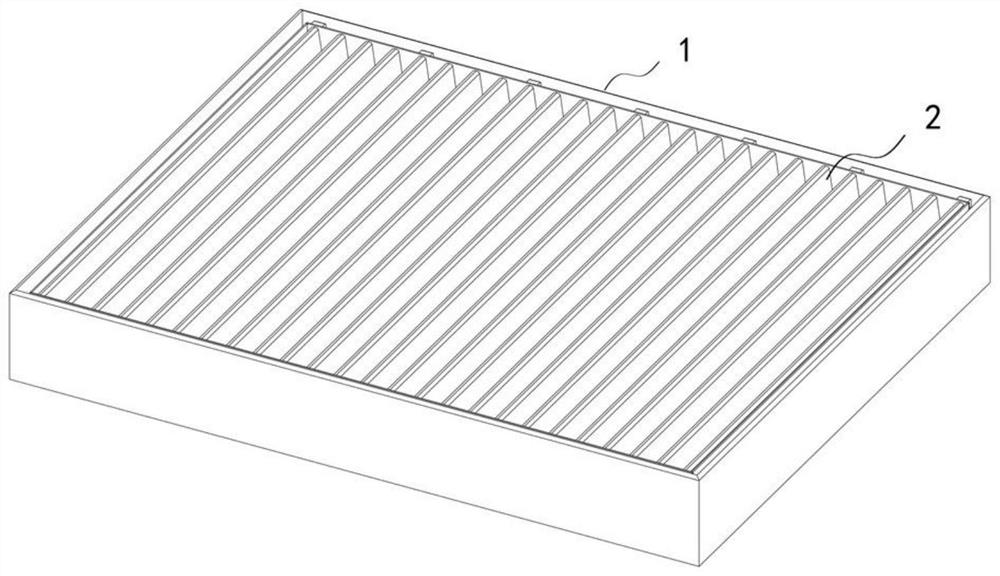

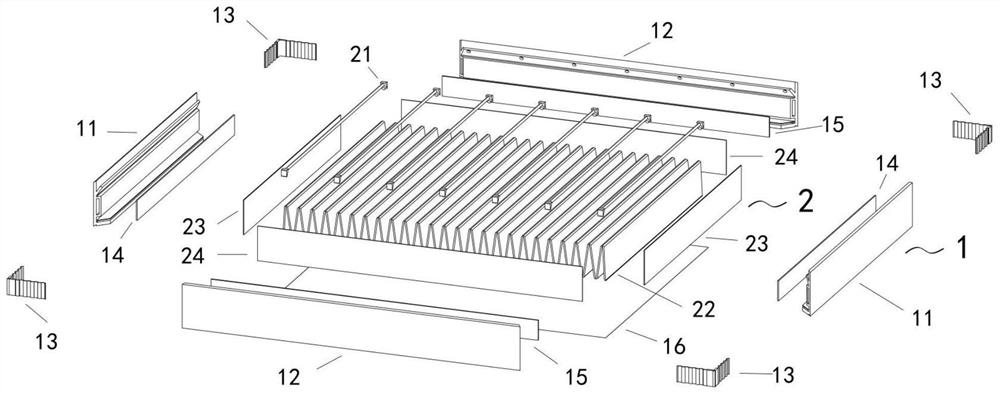

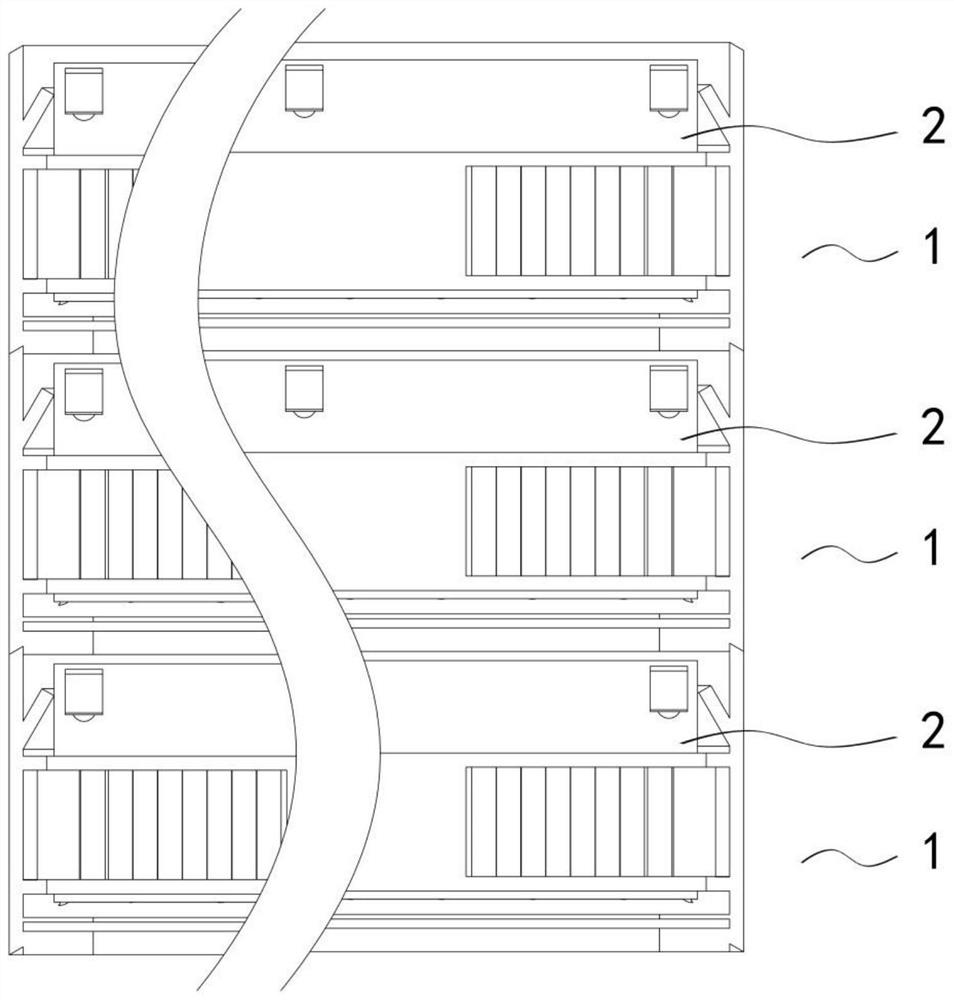

Telescopic filter element, and filter with replaceable filter element

ActiveCN113856367ASave manpower and material resourcesReduce hazardous wasteDispersed particle filtrationStructural engineeringControl theory

The invention discloses a telescopic filter element, and a filter with a replaceable filter element. The telescopic filter element comprises a wave-shaped filter part, first edge sealing strips and second edge sealing strips are arranged on the periphery of the wave-shaped filter part, the first edge sealing strips are arranged on the two sides of the folded edge of the filter part, the second edge sealing strips are arranged on the two sides of the multi-folded edge of the filter part, and fixing pieces are further arranged on the two sides of the multi-folded edge; and the filter with the replaceable filter element comprises the filter element and a frame, the frame is formed by splicing a first frame piece and a second frame piece, the whole frame piece is of an L-shaped structure, the upper edge of the top end of the long side of the frame piece is arranged to be an inclined face, an inclined protruding strip, a hollow reinforcing rib and a protective net baffle are sequentially arranged on the inner side of the long side from top to bottom, a surface protecting net is installed between the protective net baffle and the L-shaped short edge, and the filter element is installed in the upper space of the surface protecting net. The frame body and the filter element can be separated, the frame can be reused, the filter element can be replaced regularly, and energy conservation and consumption reduction are achieved; and the filter element is telescopic and is convenient to transport and store after being compressed.

Owner:MAYAIR TECH (CHINA) CO LTD

Quenching process of high-carbon chromium bearing

ActiveCN111893290AGuaranteed hardnessSmall degree of deformationFurnace typesHeat treatment furnacesTemperingOil temperature

The invention relates to a quenching process of a high-carbon chromium bearing. The quenching process comprises the following specific steps of S1, positioning a quenching furnace device; S2, preheating the high-carbon chromium bearing; S3, heating the high-carbon chromium bearing; S4, cooling and quenching; and S5, cleaning and tempering. The quenching process has the following advantages that preheating is conducted firstly, then uniform heating is conducted, the deformation degree is reduced while the hardness of the high-carbon-chromium bearing is guaranteed, oil flowing in a quenching oiltank is accelerated through the arrangement of a circulating conveying assembly, the uniformity of the oil temperature in all directions in the quenching oil tank is achieved, deformation of the high-carbon-chromium bearing is reduced, meanwhile, direct impact with a baffle on a conveying mesh belt is avoided, the hardness of the high-carbon chromium bearing is guaranteed, and the high-carbon chromium bearing is overturned up and down multiple times through the circulating conveying assembly, so that the quenching cooling uniformity is further improved, and the deformation degree is reduced.

Owner:RUGAO NONSTANDARD BEARING

Compression and compression integrated floor by floor

InactiveCN102873735AHigh strengthHigh densityWood compressionWood dampingLongitudinal planePulp and paper industry

The invention relates to a compression floor and a producing method of the compression integrated floor. According to the properties of the wood, the processed wood is cut; after the paste in the outer layer coated layer to prevent the external show of wooden floor, to prevent deformation, can be use for a long time, and keep good quality. Each wood floor blocks combined with other wood block of cross-sectional or longitudinal plane way, multiple wood blocks on the deformation of the steel together play the role of complement each other, therefore, increases the stiffness, especially in wood cutting surface is not connected, but independent existence, so, no direction for deformation, can reduce the overall degree of deformation of wooden floor, and can form a variety of compressed wood texture style and integrating compression wood floor production method.

Owner:金奇豪

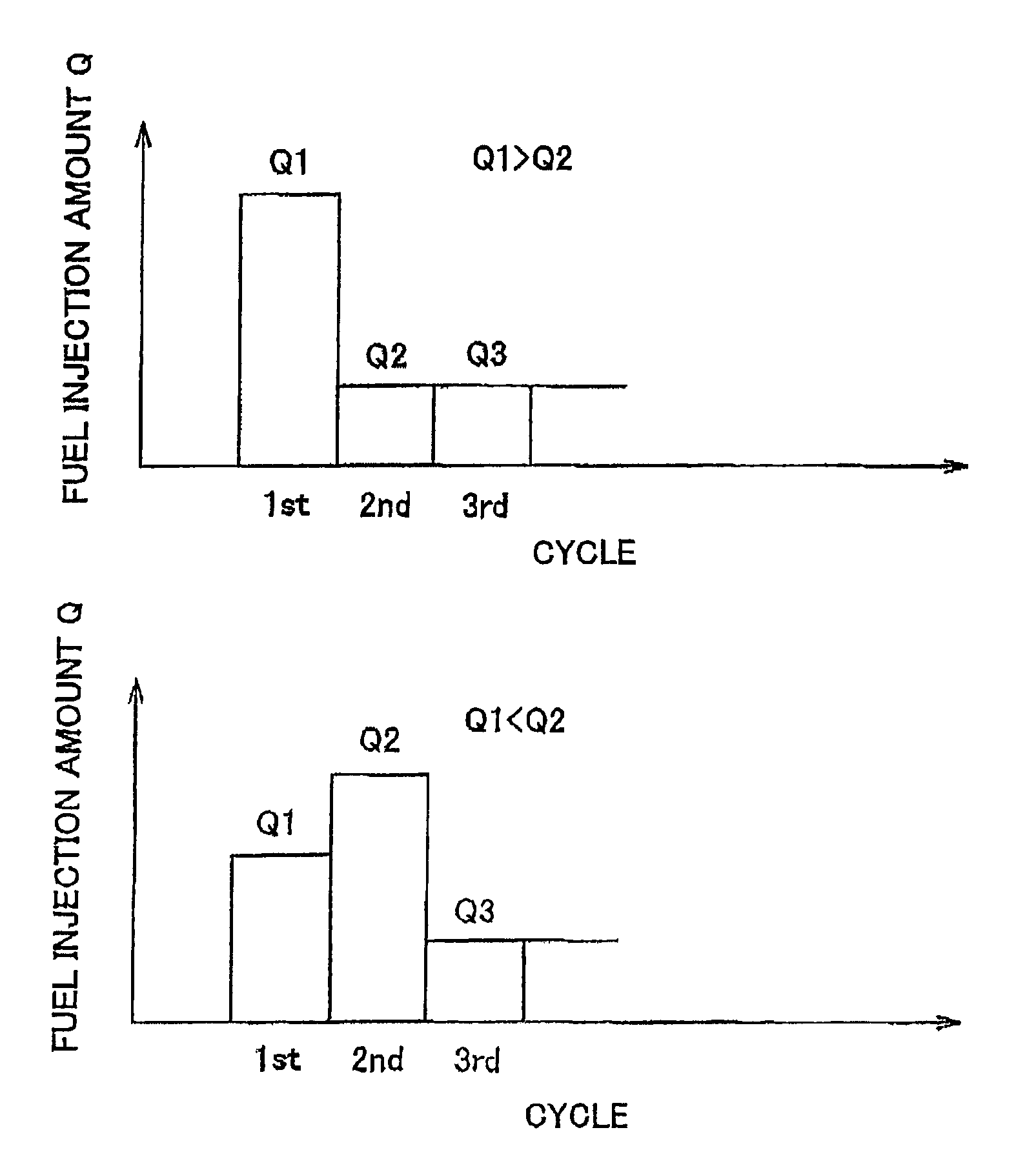

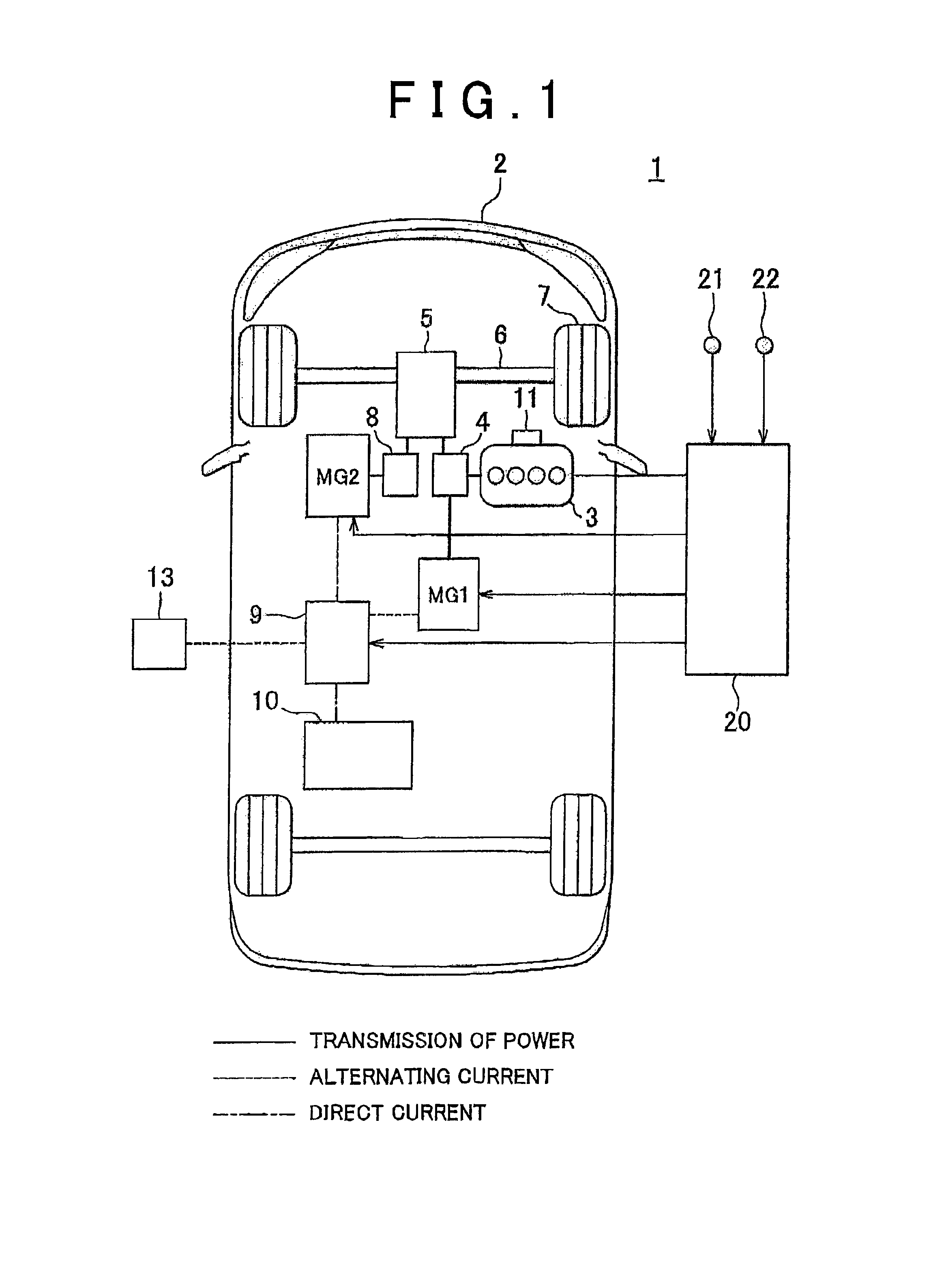

In-vehicle internal combustion engine control device, and control method for internal combustion engine

ActiveUS9026344B2Less discomfortReduce transmissionHybrid vehiclesAnalogue computers for vehiclesIn vehicleVehicle driving

At the time of an engine start while the vehicle is driving, when a required vehicle driving force (TRQ) is smaller than or equal to a predetermined value (TRQth), an electronic control unit (20) estimates that the degree of deformation of a mount (11) is smaller than or equal to a predetermined degree and sets a second-cycle fuel injection amount (Q2) so as to be larger than a first-cycle fuel injection amount (Q1) at the time of the engine start. On the other hand, when the required vehicle driving force (TRQ) is larger than the predetermined value (TRQth), the electronic control unit (20) estimates that the degree of deformation of the mount (11) is larger than the predetermined degree and sets the first-cycle fuel injection amount (Q1) so as to be larger than the second-cycle fuel injection amount (Q2) at the time of the engine start.

Owner:TOYOTA JIDOSHA KK +1

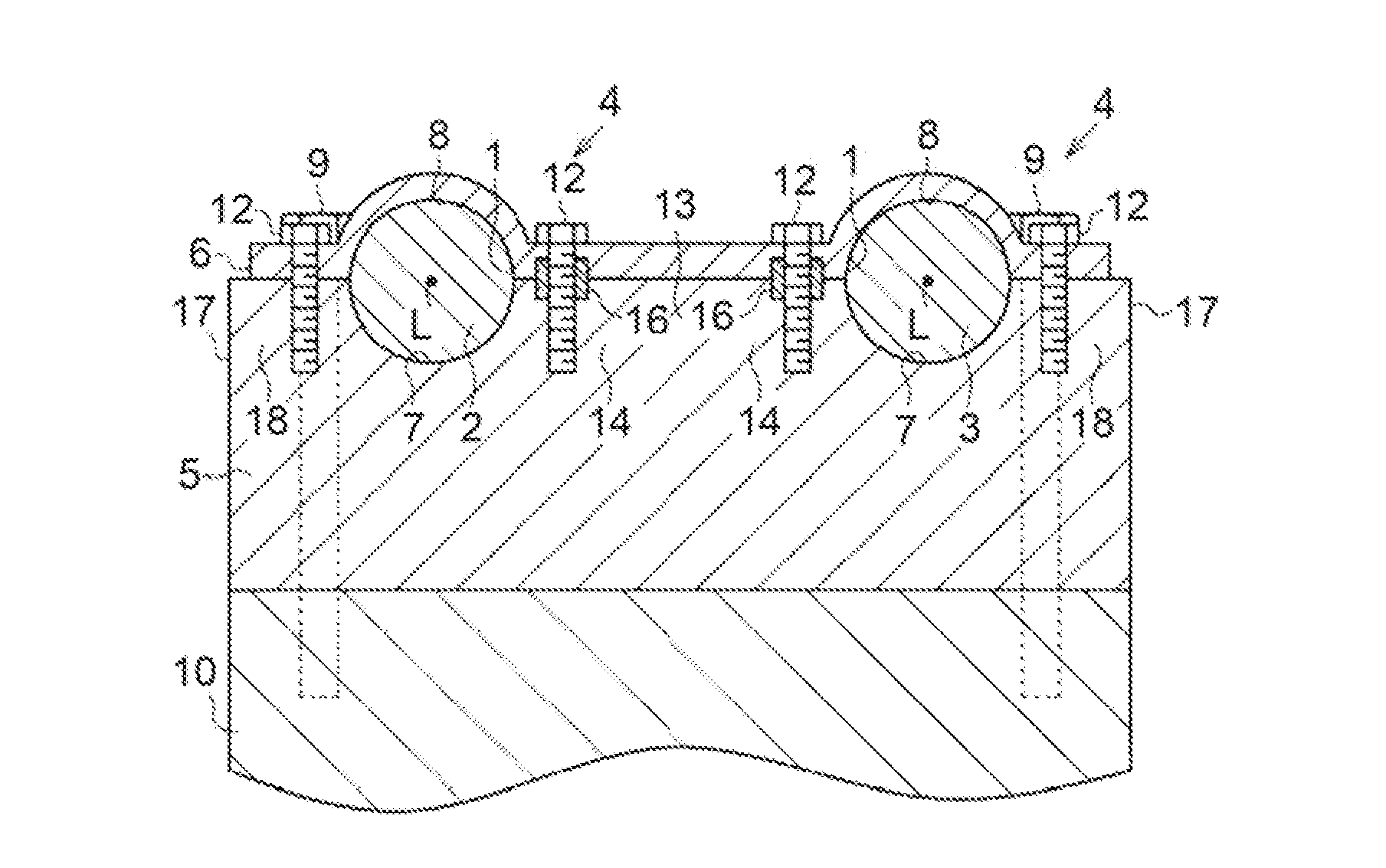

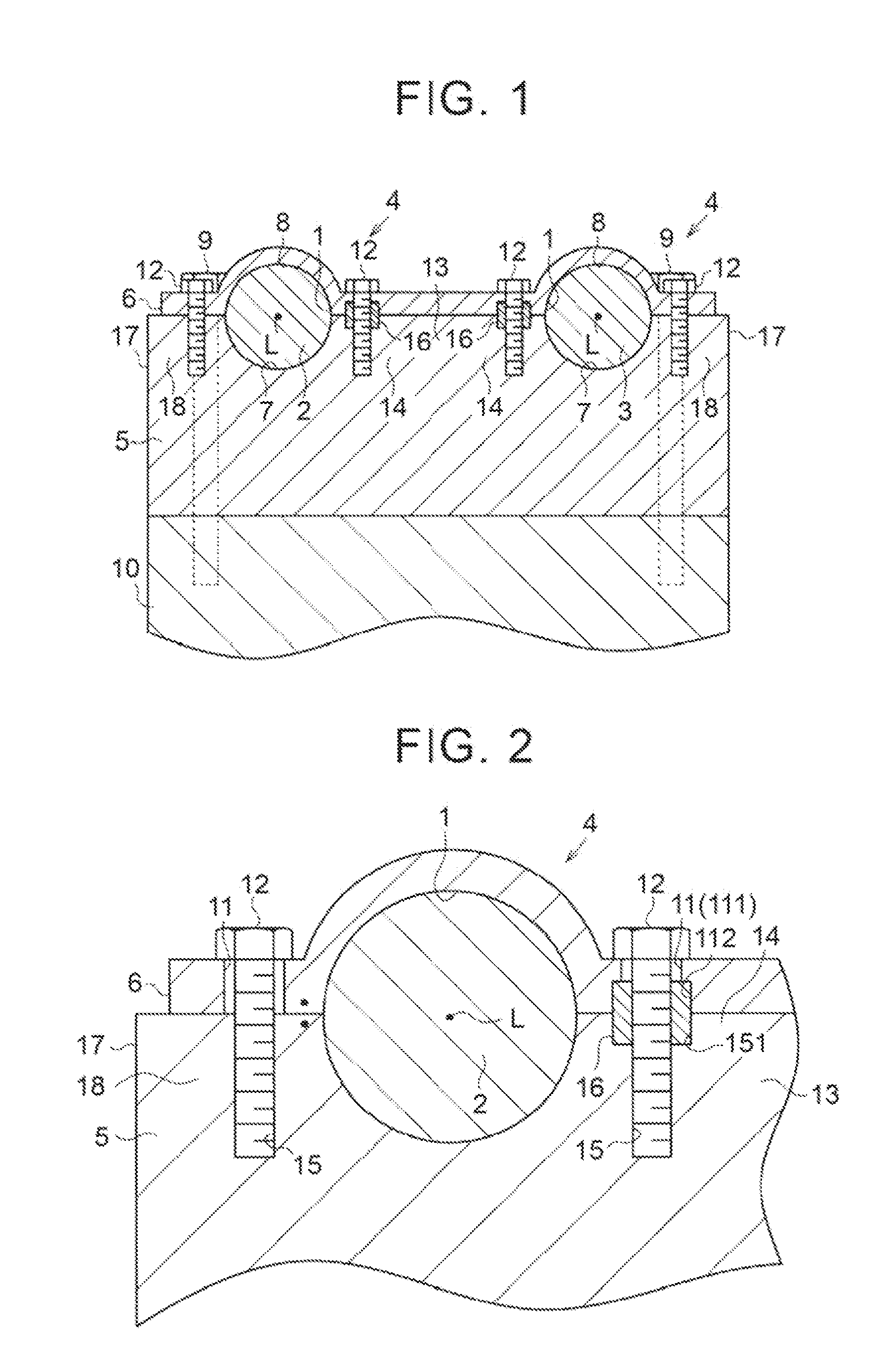

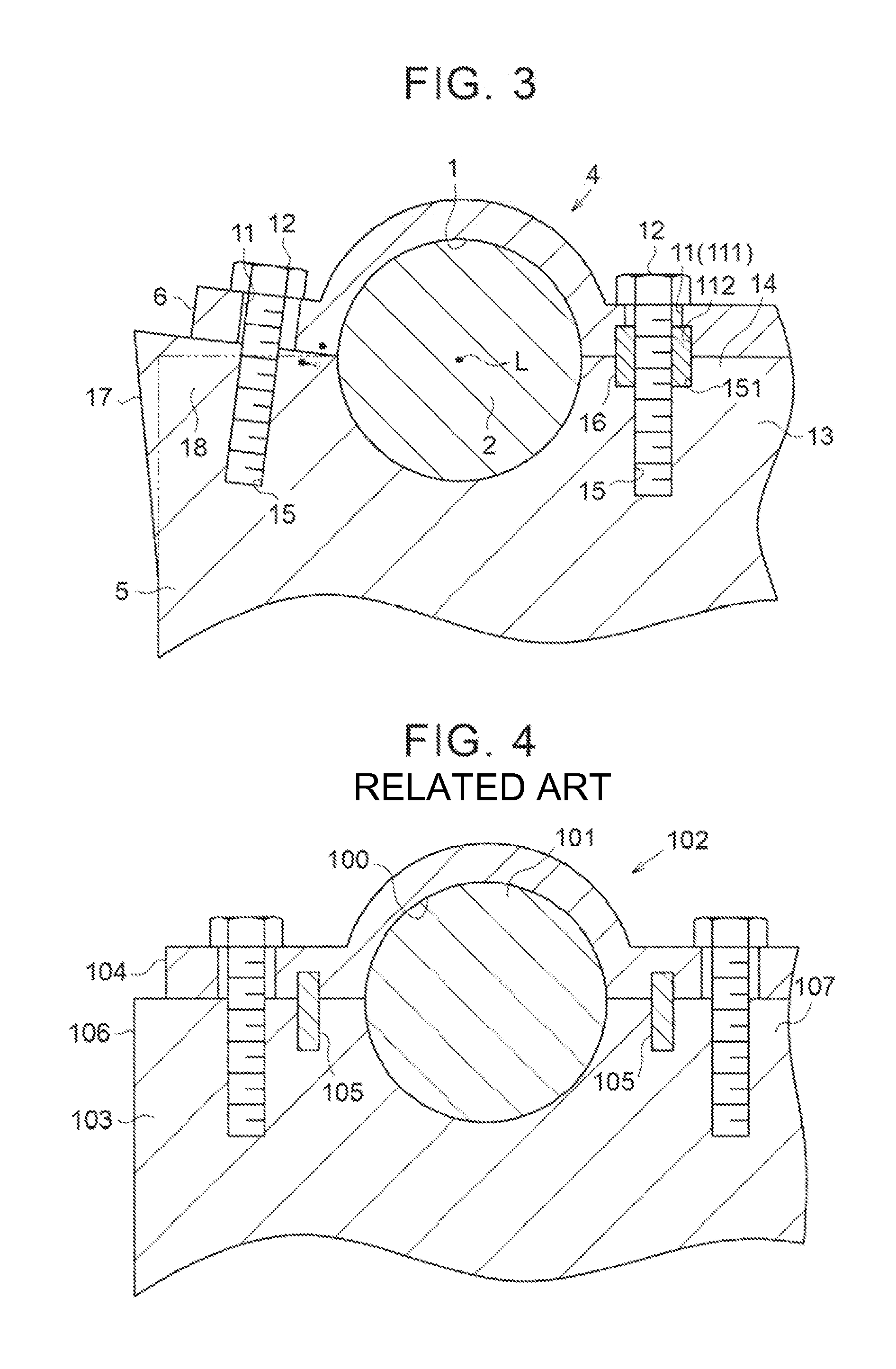

Camshaft bearing structure

InactiveUS20150377088A1Small degree of deformationLarge degree of thermal deformationValve arrangementsCylinder headsCylinder headEngineering

A bearing structure for a camshaft includes a bearing part that includes a cylinder head, a cam cap, and a positioning member. The cam cap is assembled to an upper part of the cylinder head. The cylinder head and the cam cap define a journal hole. The cylinder head and the cam cap rotatably support the camshaft in the journal hole. The positioning member determines the position where the cylinder head and the cam cap are assembled to each other. The positioning member is press-fitted into the cylinder head and the cam cap. In the bearing part for the camshaft, the positioning member is provided only in an inner part, which is a part of the bearing part between an axis of the camshaft and a center of an upper part of the cylinder head.

Owner:TOYOTA JIDOSHA KK

Production method of activated aluminum oxide micropowder

The invention discloses a production method of activated aluminum oxide micropowder and relates to the field of materials. In the production method, a tunnel kiln sintering method is adopted to produce alpha-aluminum oxide micropowder; a green brick is uniform in drying and small in deformation degree; in addition, green brick movement links are relatively small, the broken brick rate is low, andthe conditions are beneficial to keeping good working condition of a tunnel kiln and also ensuring good calcining quality; and the prepared activated aluminum oxide micropowder can be used for a lighttransmitting aluminum oxide sintered body, a carrier for a phosphor, a single crystal material, a high-grade porcelain, an artificial bone, a semiconductor, an integrated circuit substrate, an audiotape filler, a catalyst and a carrier thereof, an abrasive material, a laser material, a cutting tool and the like and particularly plays an important role in development of microelectronics and material industry. The production method has the advantages of simpleness in operation, obvious effect and the like and is suitable for large-scale popularization and application.

Owner:洛阳利尔功能材料有限公司

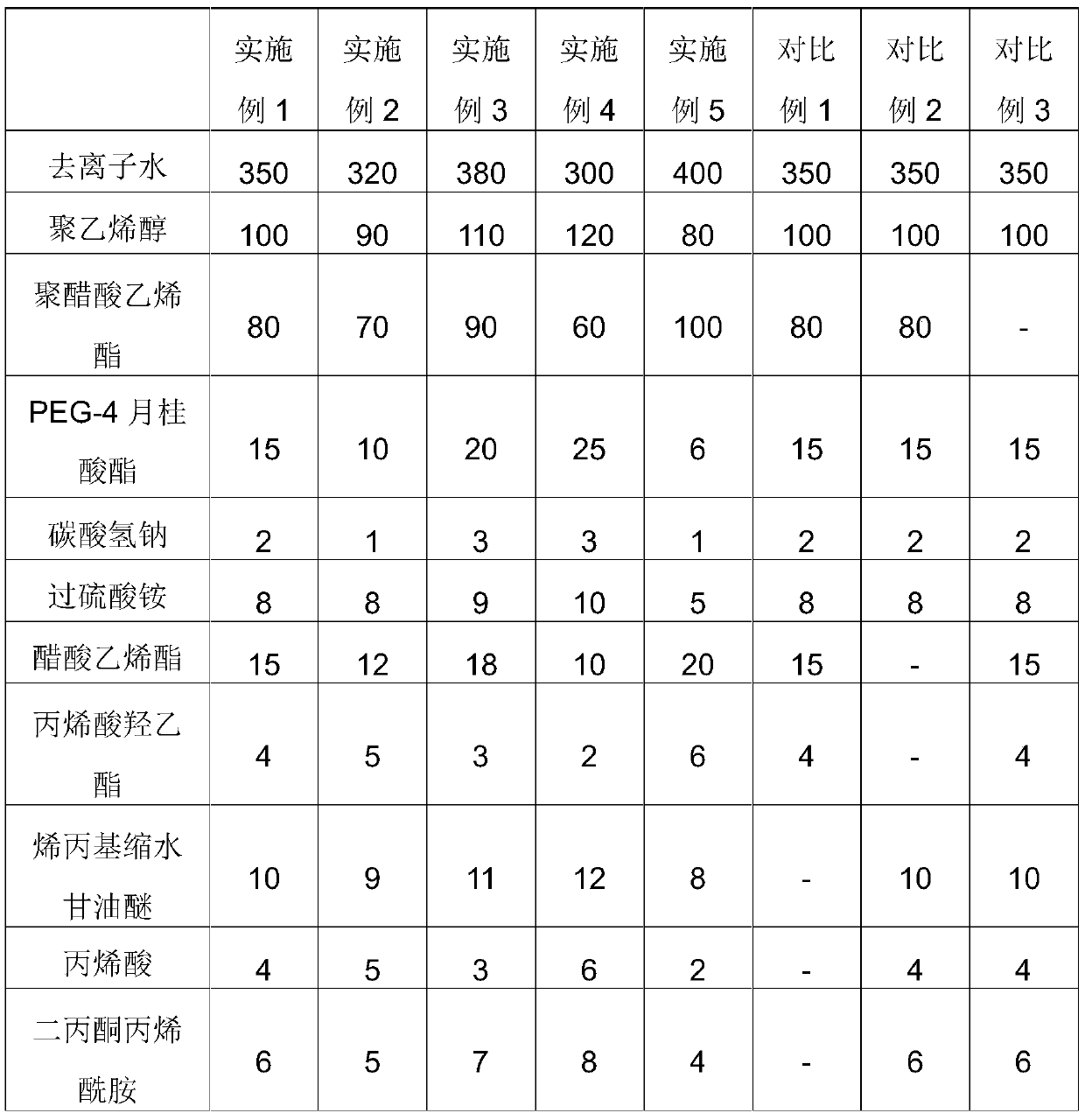

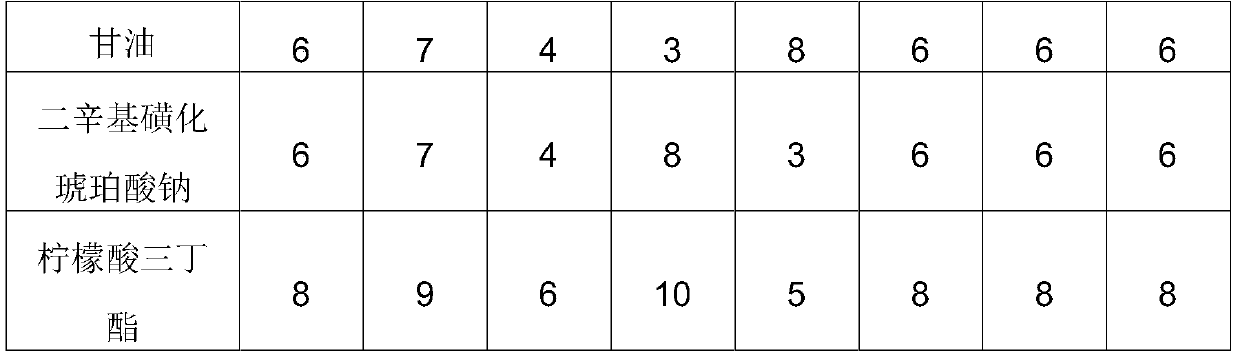

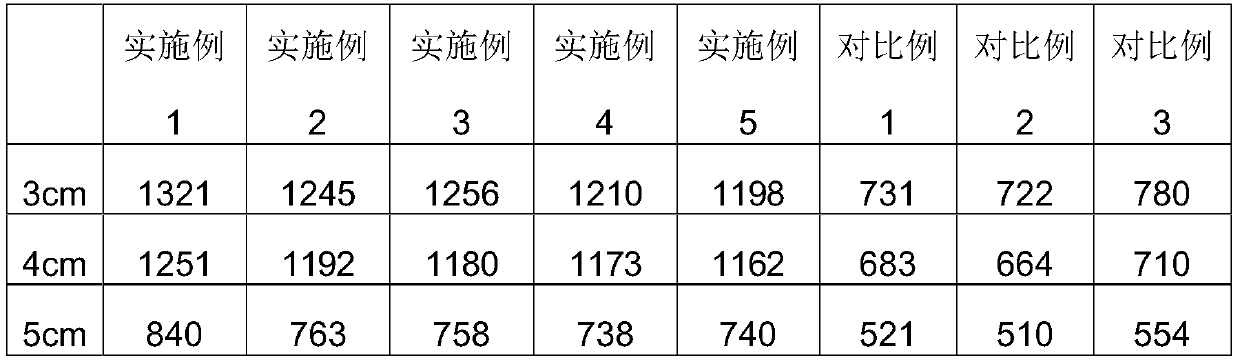

Quick-drying environment-friendly glue applicable to toy book mounting process and preparation method thereof

ActiveCN110964463AGood for mountingNot easy to fall offMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium bicarbonatePolyvinyl alcohol

The invention provides rapid-drying environment-friendly glue suitable for a toy book mounting process. The rapid-drying environment-friendly glue is prepared from the following components: deionizedwater, polyvinyl alcohol 2699, PEG-4 laurate, sodium bicarbonate, ammonium persulfate, vinyl acetate, hydroxyethyl acrylate, allyl glycidyl ether, acrylic acid, diacetone acrylamide, glycerol, dioctylsodium sulfosuccinate and tributyl citrate. The rapid-drying environment-friendly glue is small in expansion and contraction along with the change of temperature and humidity, so that the rapid-drying environment-friendly glue is good in mounting effect, flat, free of warping, easy to dry, not easy to fall off, excellent in temperature resistance, moisture resistance and heat resistance, high insolid content and small in deformation degree, does not contain aldehyde compounds, and is environment-friendly and pollution-free. Various non-environment-friendly substances forbidden to be used inthe ROHS instruction of the European Union are not used, and the rapid-drying environment-friendly glue is suitable for the toy book mounting process.

Owner:HUNAN DIMENSION INTELLIGENT TECH CO LTD

Liquid crystal panel and liquid crystal display device

ActiveUS10578914B2Improve adhesionReduce generationPolarising elementsNon-linear opticsLiquid-crystal displayPolarizer

Owner:FUJIFILM CORP

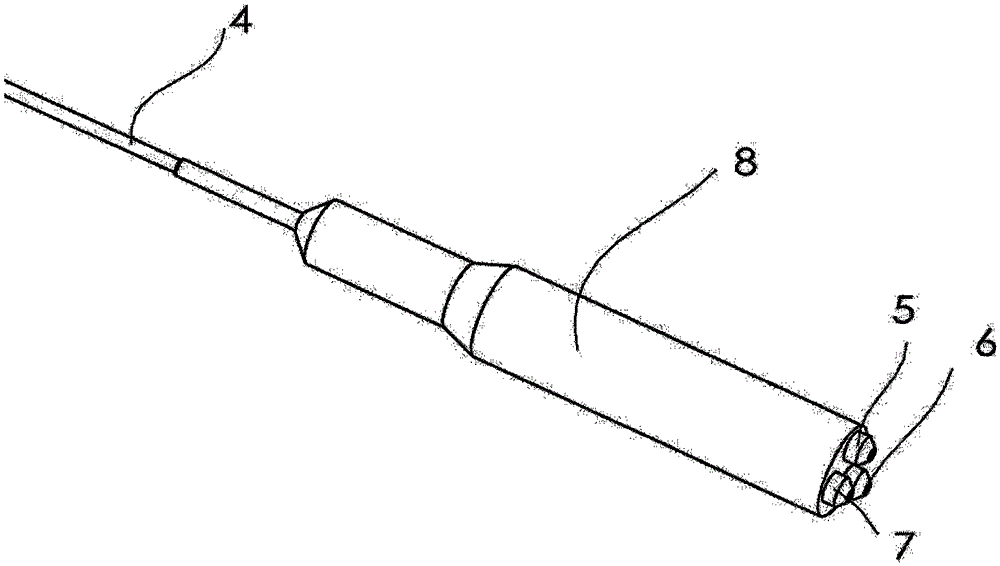

Linear actuator

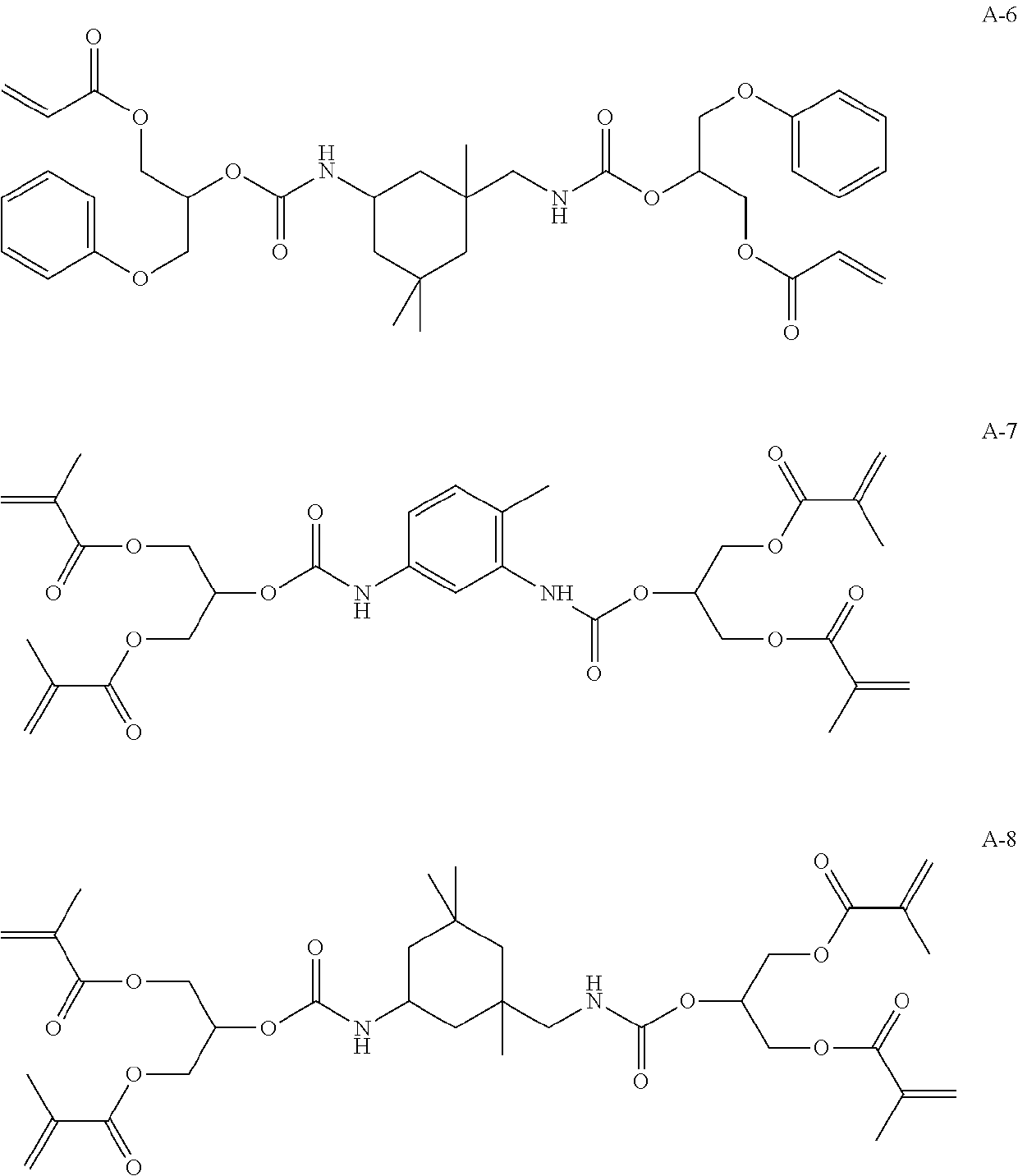

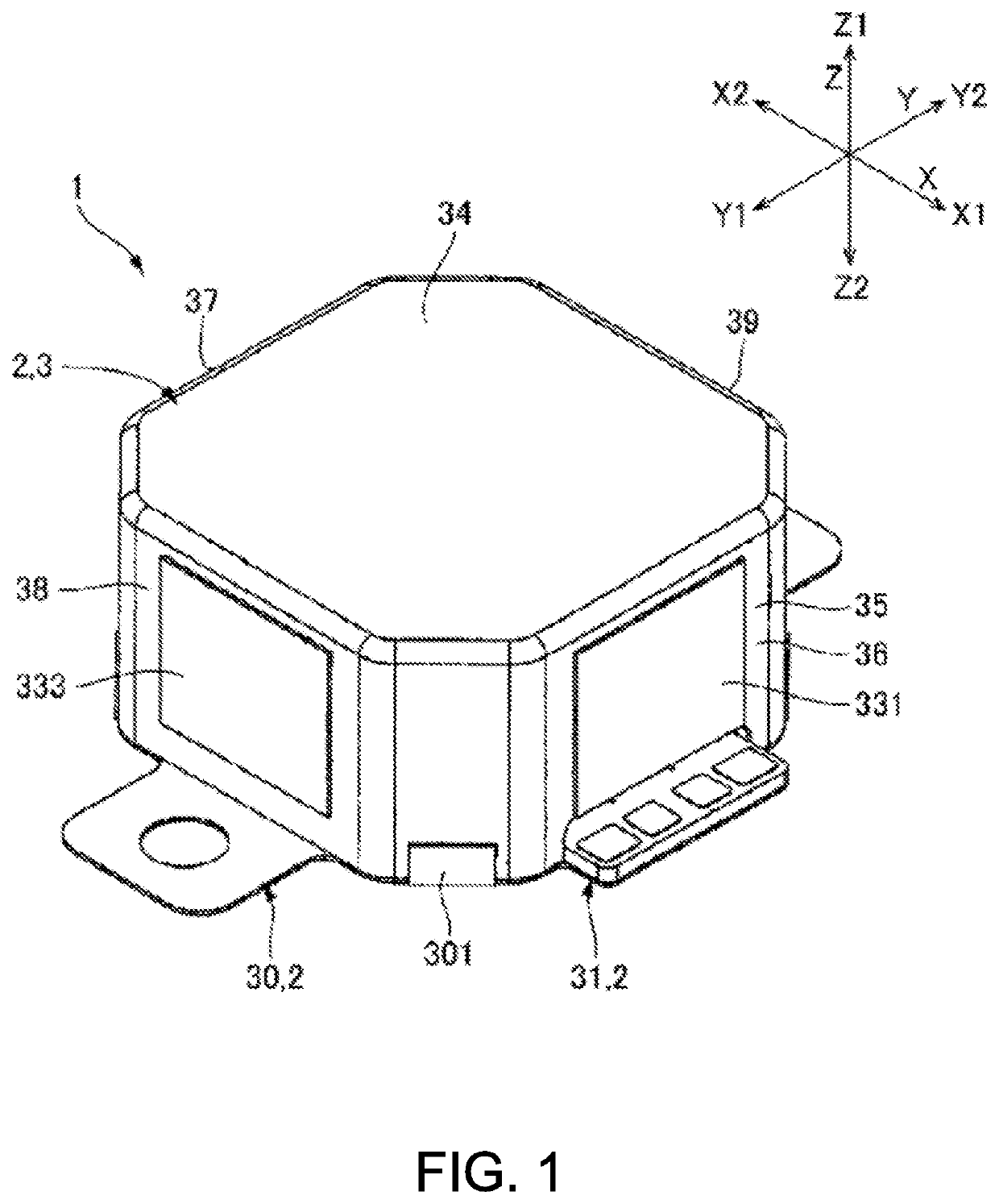

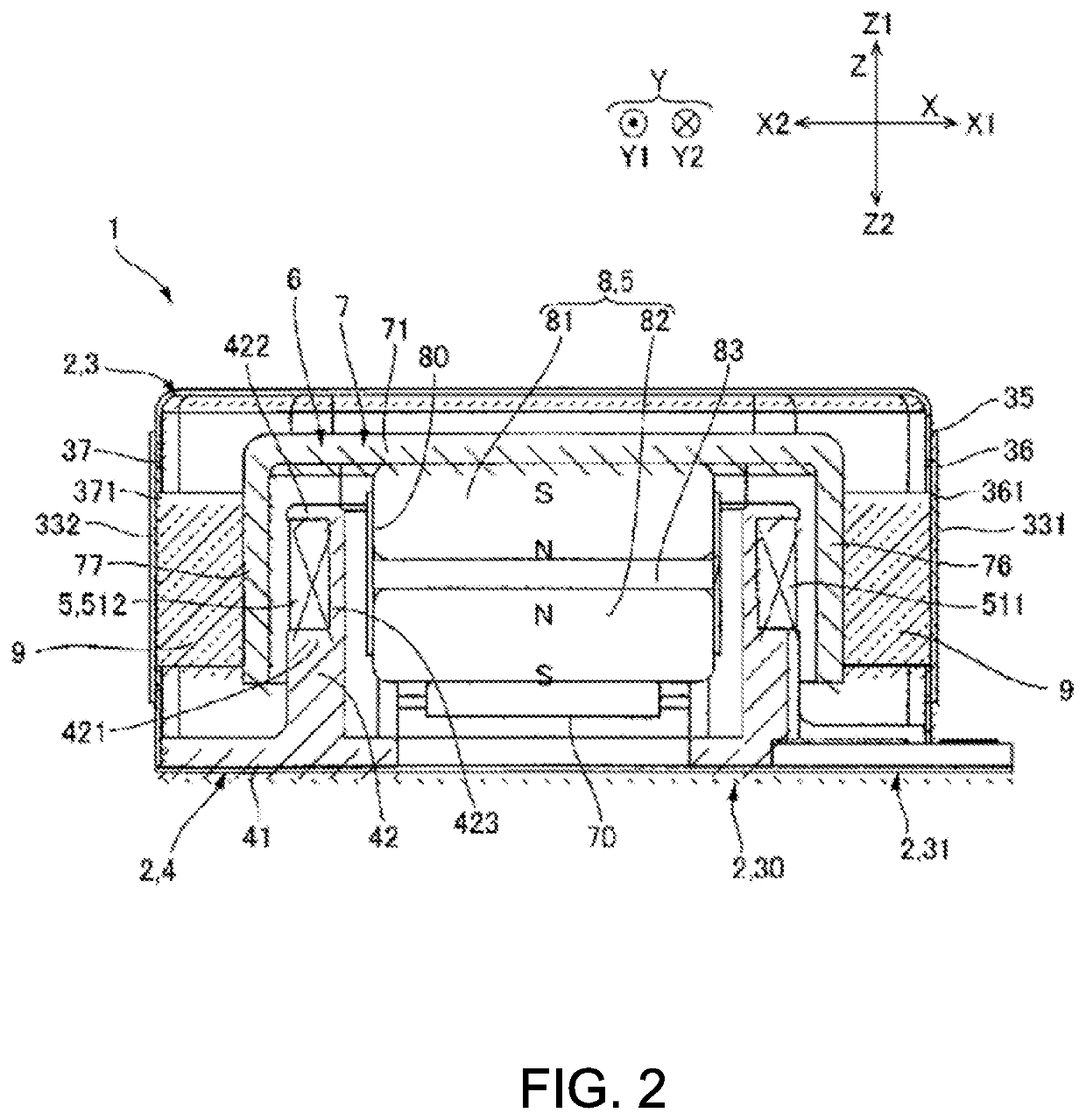

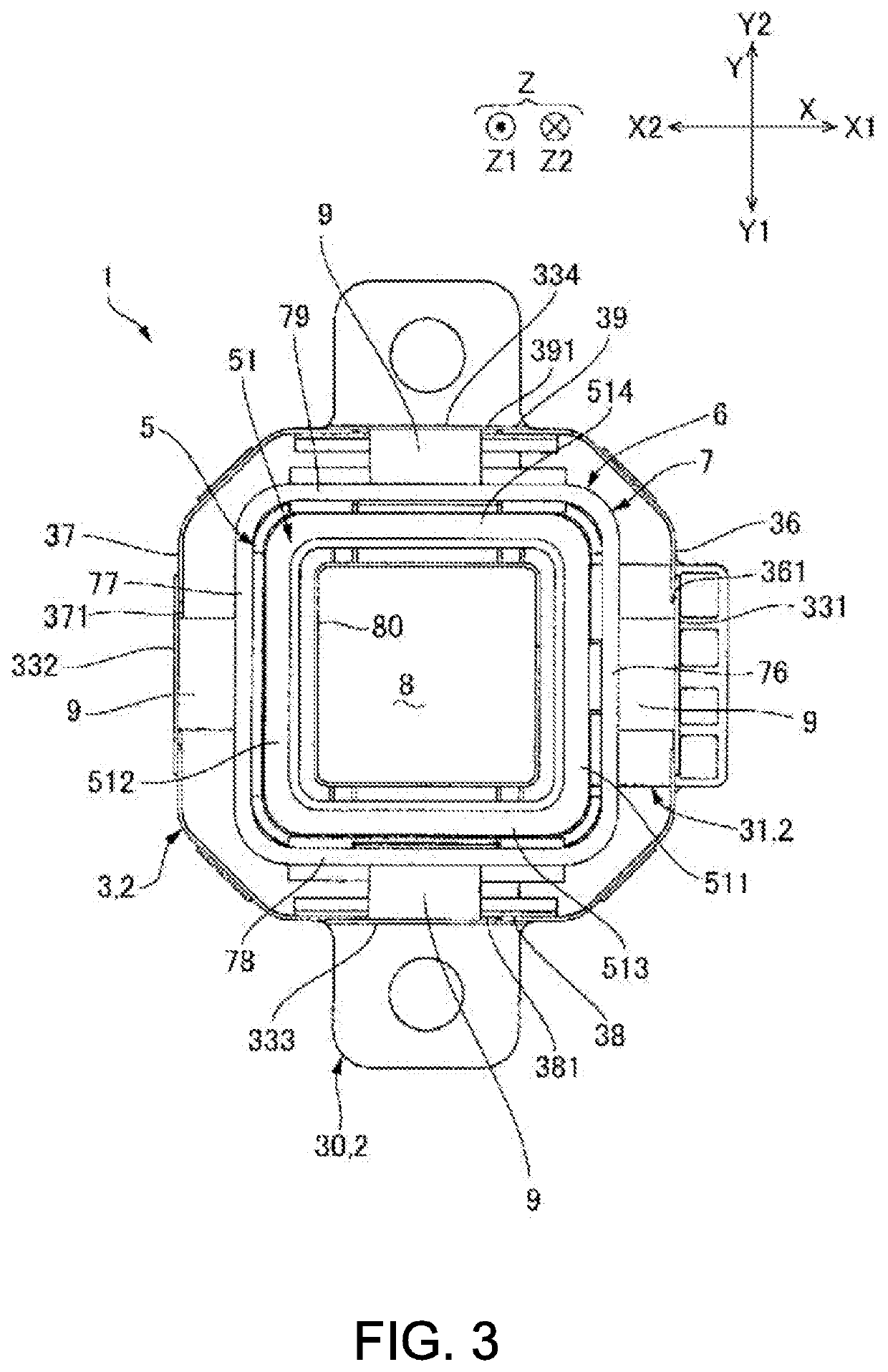

InactiveUS20200044541A1Stable characteristicsSmall degree of deformationMechanical vibrations separationDynamo-electric machinesPhysicsShearing deformation

A linear actuator can properly drive a movable body even if a viscoelastic body is provided between the movable body and a fixed body. For example, a linear actuator 1 includes a fixed body 2, a movable body 6, a magnetic drive mechanism 5 configured to linearly drive the movable body 6 with respect to the fixed body 2, and a viscoelastic body 9 made of a silicone gel or the like where the viscoelastic body 9 is arranged between the fixed body 2 and the movable body 6. In a case 3 of the fixed body 2 and a first yoke 7 of the movable body 6, the viscoelastic body 9 is arranged between a fixed body side flat surface unit (such as a first fixed plate 331 and a second fixed plate 332) facing parallel to a first direction and a second direction Y orthogonal to a drive direction Z by the magnetic drive mechanism 5 and a movable body side flat surface unit (such as a first side plate unit 76 and a second side plate unit 77). Therefore, when the movable body 6 is driven, the movable body 6 undergoes shear deformation.

Owner:NIDEC SANKYO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com