Patents

Literature

88results about How to "Short degreasing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

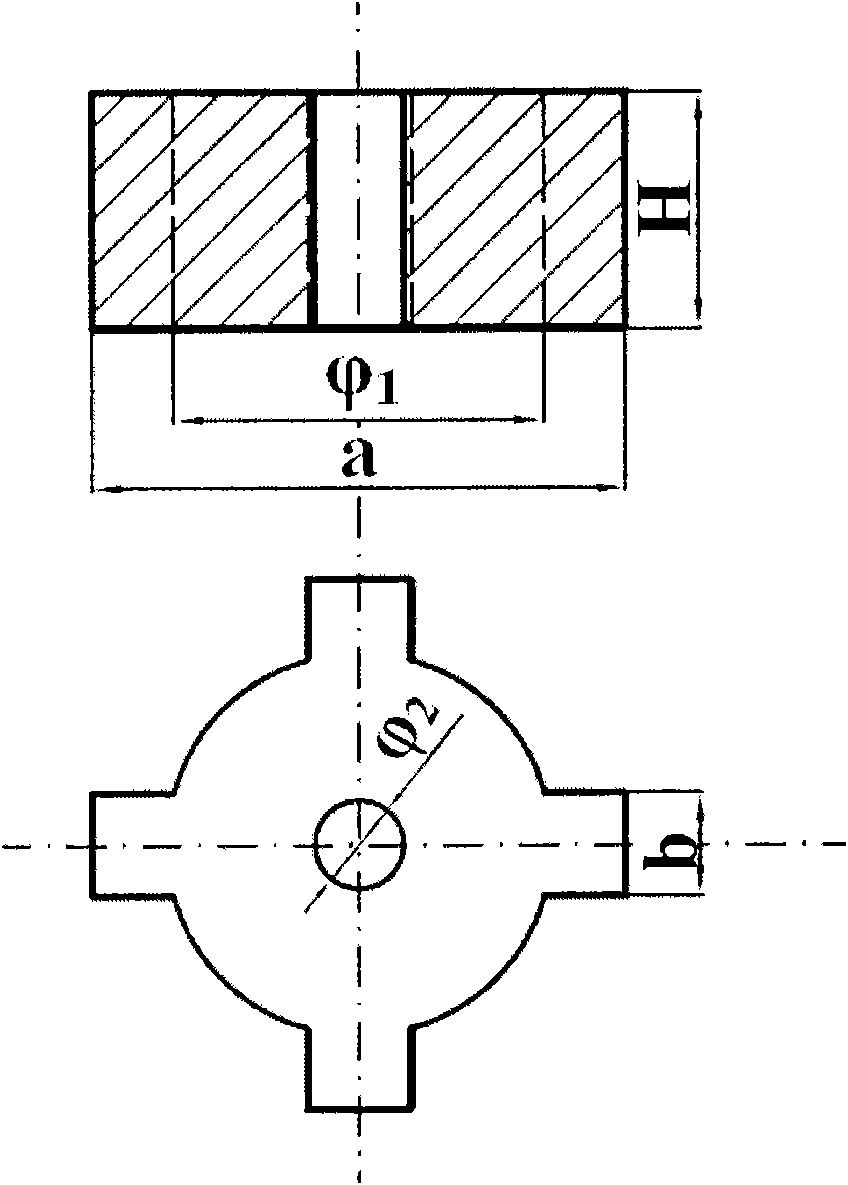

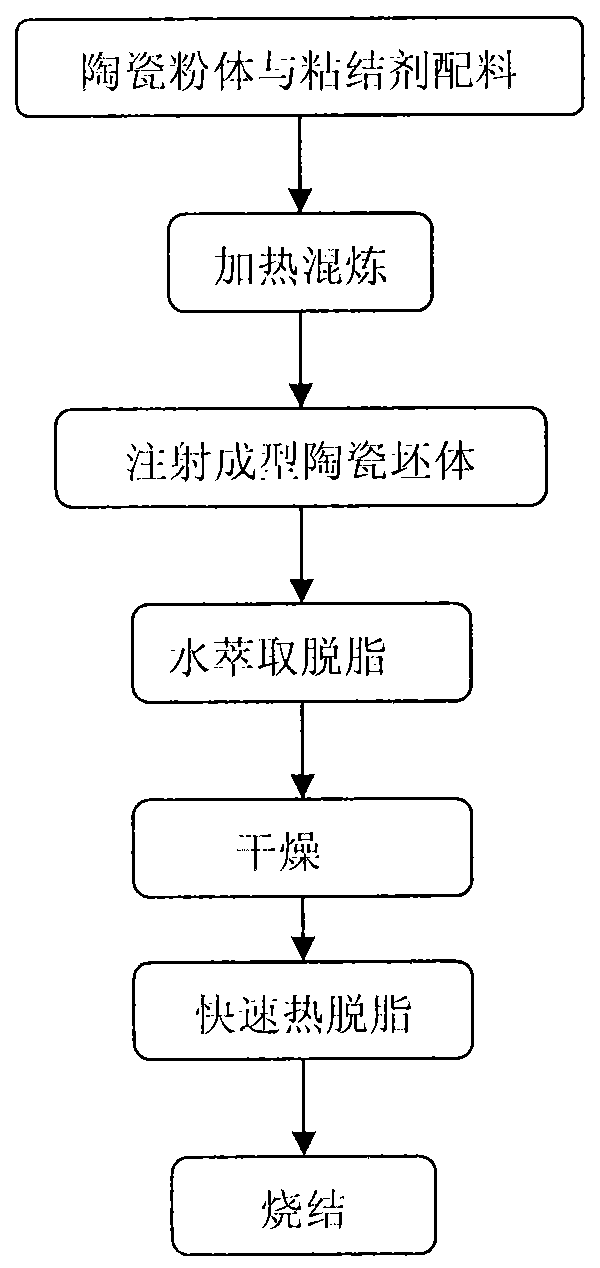

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

Preparation method of low-nickel high-nitrogen austenitic stainless steel product

InactiveCN103706793AShort degreasing timeIncrease productivityAustenitic stainless steelNitrogen gas

The invention provides a preparation method of a low-nickel high-nitrogen austenitic stainless steel product. The method comprises the steps of mixing 200-mesh iron powder, chromium powder, manganese powder and manganese powder as raw materials, with the purity of not less than 99.0%, and 200-mesh graphite powder according to the mass ratio of (66-72): (16-18): (10-12): (2.0-3.5): (0.1-0.3), grinding the above powder in a nitrogen environment, mixing with an adhesive, and then performing mixing and injection molding, catalytic debinding, residual adhesive desorption, sintering densification and sintering densification to obtain the low-nickel high-nitrogen austenitic stainless steel product. The low-nickel high-nitrogen austenitic stainless steel product provided by the invention has the characteristics of higher sintered density, nitrogen content and dimensional precision, excellent mechanical property and decay resistance and the like, thereby being suitable for large-scale industrial manufacturing.

Owner:WEIFANG UNIVERSITY

Method for preparing allograft acellular dermal matrixes

ActiveCN102580153AAvoid split skin graft swellingShort degreasing timeProsthesisAcellular DermisAnimal skin

The invention disclose a method for preparing allograft acellular dermal matrixes, comprising the following step of processing animal skins into the allograft acellular dermal matrixes by using processes of preparation of segmented skin, viral inactivation, degreasing, decellularization, freeze-drying, cutting, molding, packaging and irradiation disinfection. The method for the preparing allograft acellular dermal matrixes has the advantages of short degreasing time, high efficiency, complete decellularization and small damage to natural structures of dermal extracellular matrixes.

Owner:江苏优创生物医学科技有限公司

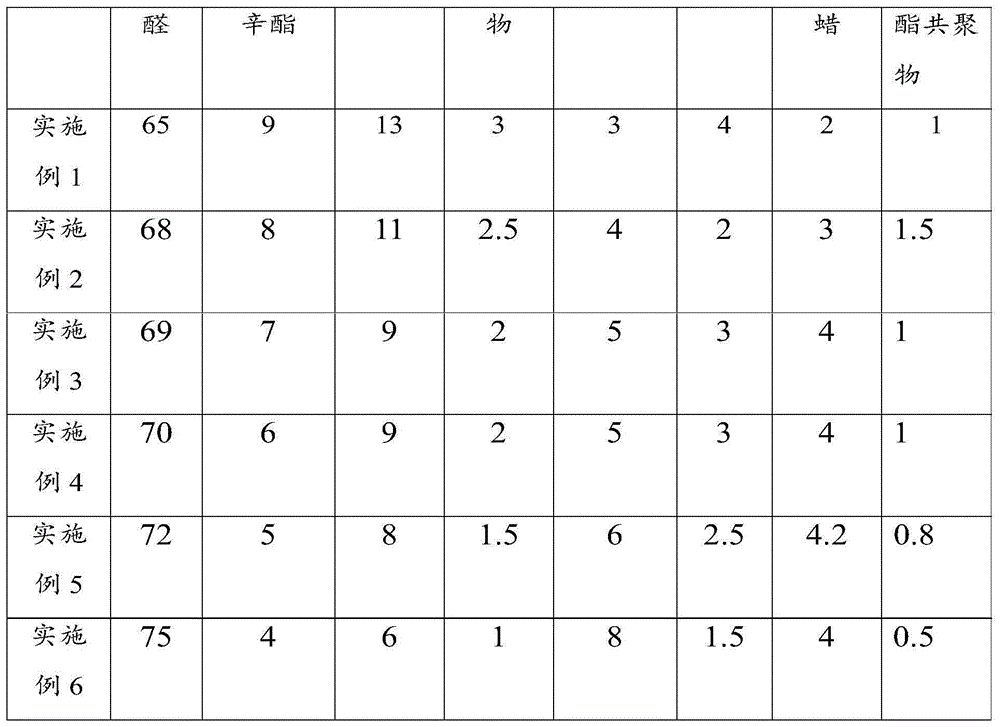

Binding agent for powder injection moulding, preparation method and application method of binding agent

The invention provides a binding agent for powder injection moulding, a preparation method of the binding agent and an application method of the binding agent. The binding agent is mainly prepared from the following components in percentage by mass: 65 to 75 percent of polyformaldehyde, 4 to 9 percent of dioctyl phthalate, 6 to 13 percent of polyethylene, 1 to 3 percent of acrylate copolymer, 3 to 8 percent of polyacrylamide, 1.5 to 4 percent of paraffin, 2 to 6 percent of microcrystalline wax and 0.5 to 2 percent of ethylene vinyl acetate copolymer. In the binding agent provided by the invention, multiple types of components are combined through scientific compatibility, so that the compatibility between metal powder or ceramic powder and the binding agent can be obviously improved, and meanwhile, the binding agent can be quickly removed in a degreasing process without causing the defects of bubbling and cracking of a green body, so as to guarantee the quality of the green body.

Owner:王有才

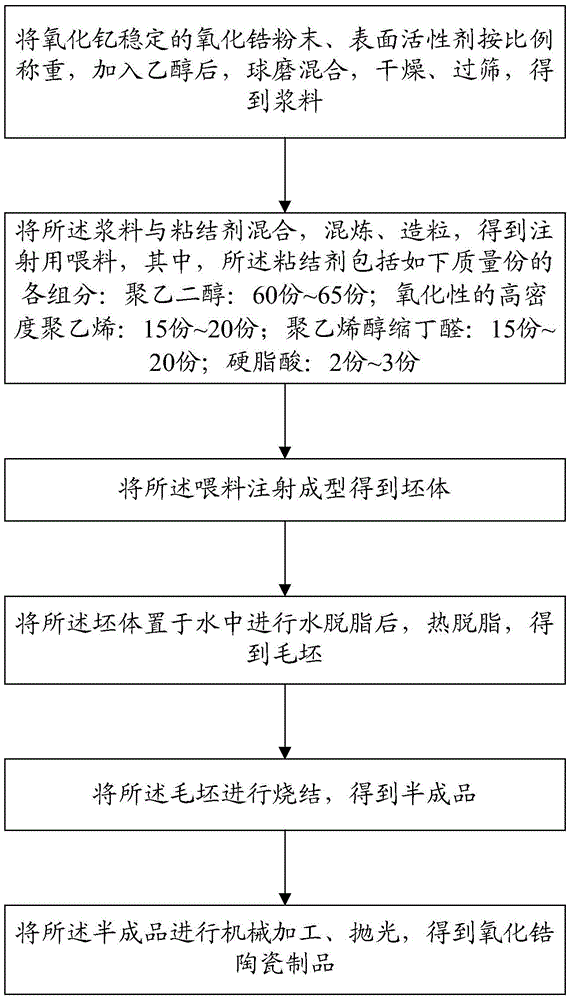

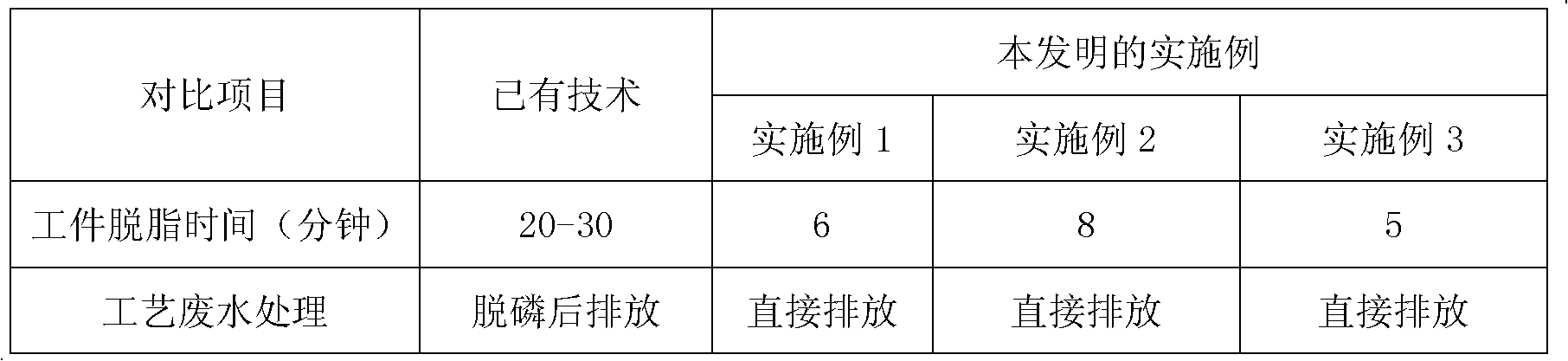

Forming method for zirconia ceramic products

The invention discloses a forming method for zirconia ceramic products. The forming method comprises the following steps: weighing yttria-stabilized zirconia powder and a surfactant in a ratio, adding ethanol, carrying out ball-milling mixing, drying, and sieving to obtain a slurry; mixing the slurry with a binder, mixing, and granulating to obtain a feedstock for injection, wherein the binder comprises the following components in parts by mass: 60-65 parts of polyethylene glycol, 15-20 parts of oxidizing high-density polyethylene, 15-20 parts of polyvinyl butyral, and 2-3 parts of stearic acid; carrying out injection forming on the feedstock to obtain green bodies; placing the green bodies in water and carrying out water debinding, and carrying out thermal debinding to obtain blanks; sintering the blanks to obtain semi-finished products; and machining and polishing the semi-finished products to obtain the zirconia ceramic products. The forming method for the zirconia ceramic products, which is disclosed by the invention, is capable of guaranteeing that the obtained ceramic products are high in strength, not liable to break, high in compactness, and uniform in porosity.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Method for preparing starch nanocrystal

The invention discloses a method for preparing starch nanocrystal, and belongs to the field of modified starch processing. The method is based on the principle that lipid layers in waxiness corn starch grains have resistance for acid, the starch is prompted to be crushed because of homogenization treatment under a certain pressure, the lipid is prompted to be digested through Soxhlet extraction by using an alcohol-water solution, a pore structure from outside to inside is formed, then the resistance to the acid is eliminated, and the penetration of the acid inside the starch is prompted under a negative pressure condition so as to accelerate hydrolysis of the starch grains in an amorphous area. The method specifically comprises the following steps: homogenously crushing the starch grains under a pressure of 50-150 MPa, degreasing the crushed starch by using a 70-90% methanol-water solution, and accelerating hydrogen ions in sulfuric acid to rapidly penetrate into the starch grains to be subjected to restrictive hydrolysis under a 0.06-0.1MPa negative pressure condition, so as to prepare the nanocrystal. Through the technical measures, the hydrolysis period of the starch is shortened to be 48-72 hours, the starch nanocrystal yield is greatly improved to be 19-25%, and the particle size distribution is 20-300nm.

Owner:JIANGNAN UNIV

Preparation method of acellular dermal matrix dressing

ActiveCN102580141AAchieve the inactivation effectInhibit swellingAbsorbent padsBandagesCell-Extracellular MatrixMedicine

The invention discloses a preparation method of an acellular dermal matrix dressing. The acellular dermal matrix is prepared from animal skin by segmented graft preparing, viruses inactivating, degreasing, decellularizing, iodizing, lyophilizing, packaging and radiation disinfecting. The method has the advantages of short degreasing time, high efficiency, complete decellurarization, light damage to natural structure of extracellular matrix of hypodermal cell, and antibacterial function.

Owner:江苏优创生物医学科技有限公司

Preparation method of special-shape ceramic

The invention provides a preparation method of an injection-moulded special-shape ceramic. The preparation method comprises the following ceramic green body degreasing steps: (1) immerging a ceramic green body into a solvent, sealing, maintaining at 40-70 DEG C and the pressure of 0.2-0.6 Mpa for 2-6 hours, and then taking out the ceramic green body; (2) airing the ceramic green body obtained from the step (1), then placing into embedding powder, drying at 180-200 DEG C, and naturally cooling; (3) heating the ceramic green body obtained from the step (2) to 300-400 DEG C, and maintaining at the pressure of 0.1-0.5 Mpa for 1-2.5 hours. The preparation method provided by the invention can be used for fast degreasing at low temperature by adopting an organic solvent without toxicity or hydrolytic oxidation, is simple in process operation, high in production efficiency and suitable for batched and automatic production, and can be used for improving the working environment and preventing the damage of toxic organic substance volatilization on the environment.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

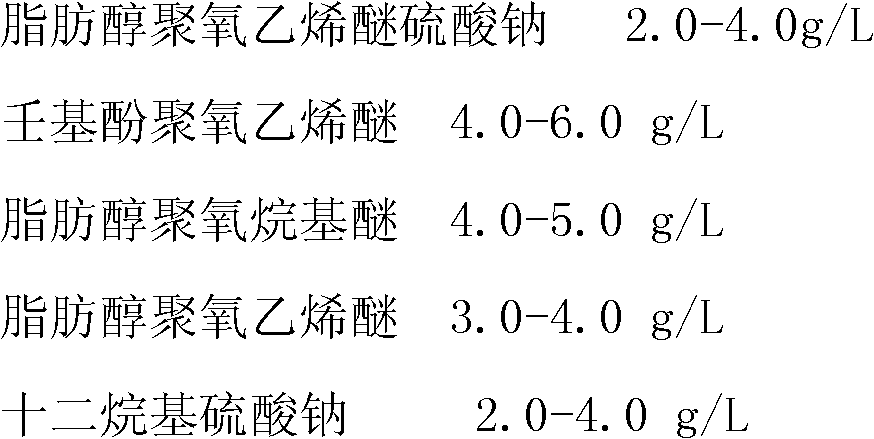

A kind of phosphorus-free degreasing agent and preparation method thereof

The invention discloses a non-phosphorus degreasing agent. The non-phosphorus degreasing agent is mixed solution prepared from the following components, wherein each liter of the mixed solution comprises the following components in part by weight: 2.0 to 4.0 grams of fatty alcohol-polyoxyethylene ether sodium sulfate, 4.0 to 6.0 grams of nonylphenol polyoxyethylene ether, 4.0 to 5.0 grams of fatty alcohol-polyoxy alkyl ether, 3.0 to 4.0 grams of fatty alcohol-polyoxyethylene ether, 2.0 to 4.0 grams of lauryl sodium sulfate, 2.0 to 3.5 grams of isopropanol, 0.1 to 0.12 gram of ethylene diaminetetraacetic acid, 1 to 2 grams of alkaline lipase and the balance of water. When the non-phosphorus degreasing agent is used for degreasing the metal, the non-phosphorus degreasing agent reduces the adsorbability of an active agent to the metal body, facilitates subsequent processing of the metal, has high degreasing speed, shortens degreasing time, improves working efficiency and is non-phosphorus and environment-friendly.

Owner:蚌埠市钰诚五金工贸有限公司

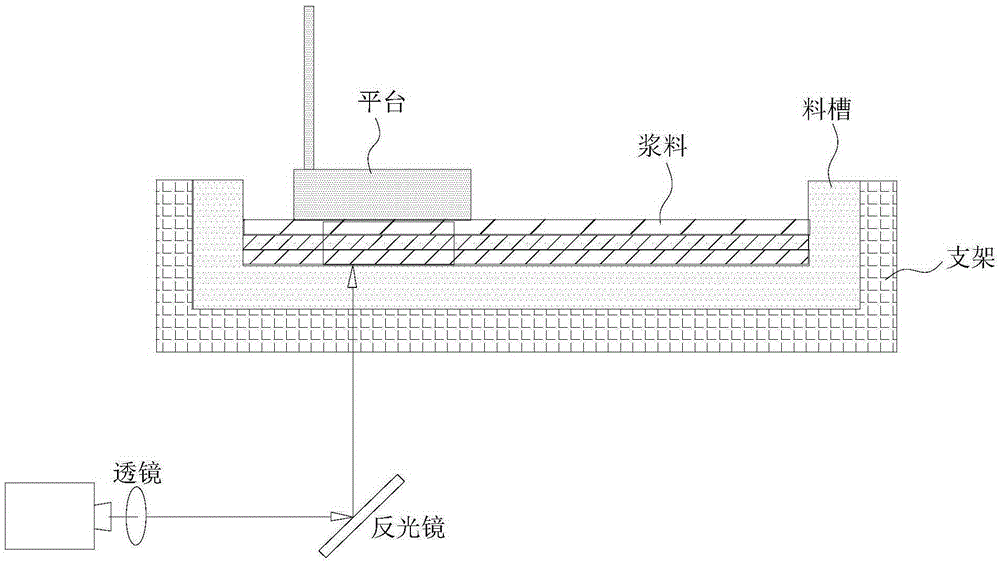

Manufacturing method of laminated ceramics

The invention relates to the technical field of ceramic manufacturing, in particular to a manufacturing method of laminated ceramics. Slurry can be applicable to a DLP photo-curing face forming method to manufacture laminated ceramic bodies by optimizing the composition and proportioning of the slurry, the forming efficiency is high, ceramic particles in the bodies can be dispersed evenly, and the shape and size accuracy of the bodies is high; then the bodies cannot deform and crack in the manufacturing process by controlling process parameters in degreasing and sintering steps, the laminated ceramics with micron-scale thickness can be manufactured and are uniform in compactness, good in surface smoothness, high in accuracy and excellent in performance, and manufactured ceramic products are high in reliability. The manufacturing method adopts a two-step degreasing method integrating vacuum / atmosphere protection degreasing and air degreasing, can remarkably improve the degreasing efficiency, enables the degreasing time to be shortened from 48-60 hours required by an existing method to 8-20 hours and can also decrease the defects including deformation, cracking, blistering and the like of the bodies due to the too high one-step degreasing and heating rate or the too high pyrolysis rate of organic matter in the bodies.

Owner:广东金瓷三维技术有限公司

High entropy alloy feeding and preparation method and application thereof

InactiveCN107186208AImprove performanceHigh precision requirementsTransportation and packagingMetal-working apparatusHigh entropy alloysEconomic benefits

The invention relates to a high entropy alloy feeding and a preparation method and an application thereof. The high entropy alloy feeding comprises, by volume, 40%-70% of high entropy alloy powder, and 30%-60% of high molecular binder. The high entropy alloy feeding has the excellent properties of the high entropy alloy so that the high entropy alloy can be introduced in a metal injection molding technology, and application range of the high entropy alloy is expanded. According to the high entropy alloy feeding and the preparation method and the application thereof, the high entropy alloy feeding is applied to the metal injection molding technology, product stability during the injection molding process can be improved, the high entropy alloy product obtained has more than 97.5% of sintered density, production of high entropy alloy components and parts with complex production structures, excellent properties and high precision requirements is achieved beneficially. The high entropy alloy feeding has good economic benefit and application prospect.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

Method of preparing high size precision profiled molybdenum parts

InactiveCN1686642AUniform densityConsistent shrinkagePolyureas/polyurethane adhesivesParaffin waxHigh density

A process for preparing molybdenum part with high size precision and compactness includes preparing adhesive from paraffin wax, high-density polyethene, polypropene and stearic acid through proportionally mixing, mixing it with molybdenum powder, injection moulding, degreasing, presintering, sintering, holding the temp for 1-10 hr, and post treating.

Owner:UNIV OF SCI & TECH BEIJING

Light-yellow odourless degreasing silkworm pupa protein power and preparation method thereof

InactiveCN105124131ALow degreasing temperatureShort degreasing timeProtein composition from waste materialsProtein composition from vegetable materialsPROTEIN S HEERLENBiology

The invention relates to light-yellow odourless degreasing silkworm pupa protein power and a preparation method thereof. According to the technical scheme, silk reeling silkworm pupae of which the skin and the gland are removed are selected as the raw material, silkworm pupa pretreatment is conducted, and coarse silkworm pupa powder is obtained; the coarse silkworm pupa powder is evenly mixed in degreasing solvent, ultrasonic degreasing treatment is conducted, centrifugal separation is conducted, and degreasing fluid and degreasing coarse pupa protein are obtained; drying and smashing are conducted on the degreasing coarse pupa protein, and the degreasing coarse pupa protein power is obtained; the degreasing coarse pupa protein power is evenly mixed in a sodium hydroxide solution, a silkworm pupa protein extracting solution is obtained, ultrasonic extraction treatment is conducted, macroporous resin is added into the silkworm pupa protein extracting solution, adsorption treatment is conducted, solid-liquid separation is conducted, resin and protein fluid are obtained, the protein fluid pH is adjusted, protein precipitation is collected, and wet silkworm pupa protein is obtained; vacuum drying and smashing are conducted on the wet silkworm pupa protein, and the light-yellow odourless degreasing silkworm pupa protein power is obtained. The light-yellow odourless degreasing silkworm pupa protein power and the preparation method thereof have the advantages that the technology is simple, the degreasing efficiency is high, effects of deodorization and decolorization are good, the treatment is low in temperature and short in time, the cost is low, the green and environmental protection is achieved, and the light-yellow odourless degreasing silkworm pupa protein power and the preparation method thereof can be used for industrial production.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of acellular biomembrane dressing

ActiveCN102580140AAchieve the inactivation effectInhibit swellingAbsorbent padsBandagesPaleontologyBiological membrane

The invention discloses a preparation method of an acellular biomembrane dressing. The acellular biomembrane is prepared from an animal biomembrane by viruses inactivating, degreasing, decellularizing, silver adding, lyophilizing, packaging and radiation disinfecting. The method has the advantages of short degreasing time, high efficiency, strong protection effect of biomembrane tissue structure, complete decellurarization, light damage to natural structure of the biomembrane, and antibacterial function.

Owner:上海优越生物医学科技有限公司

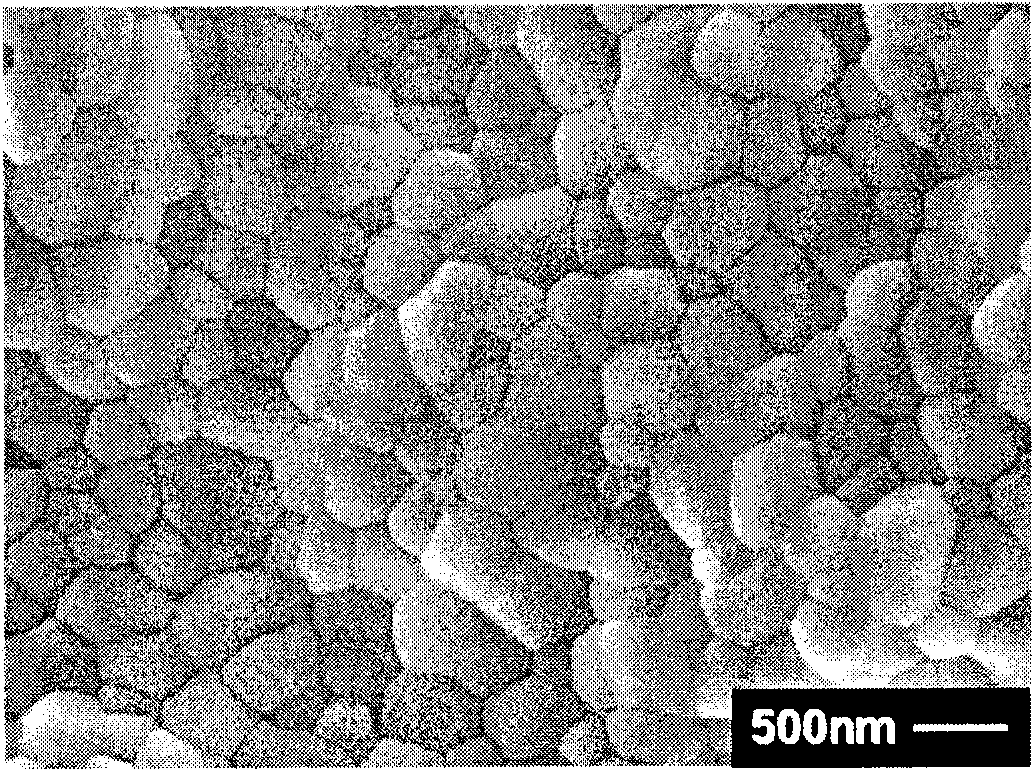

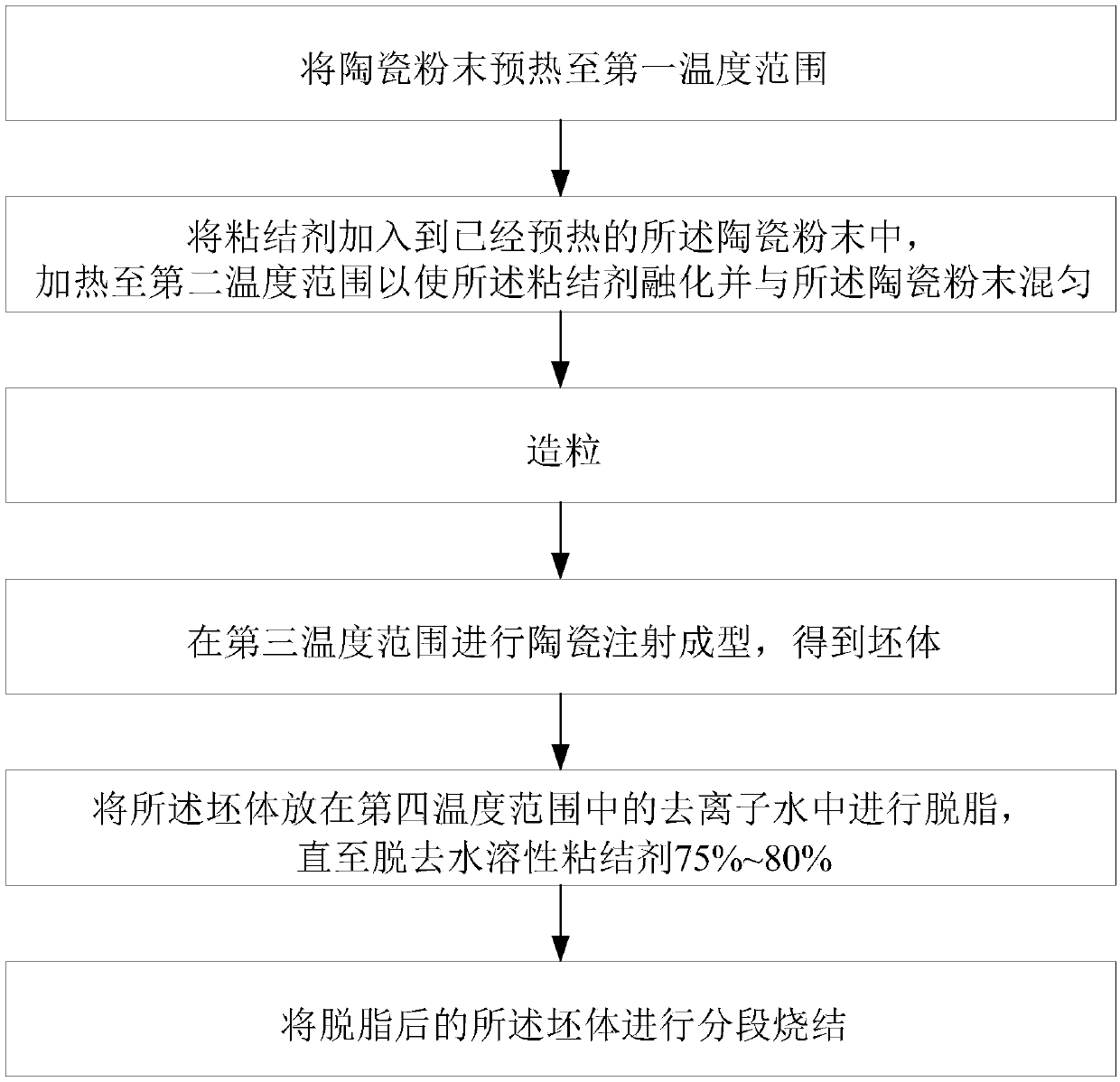

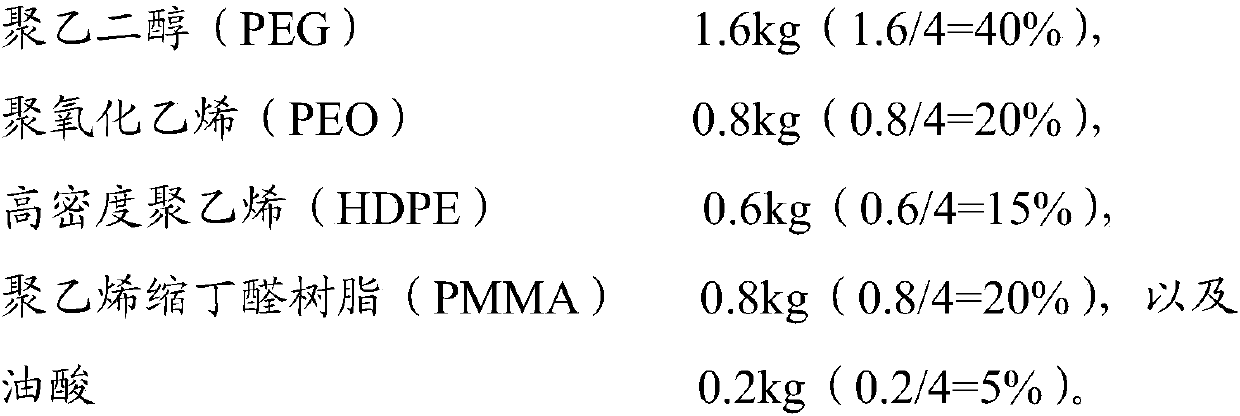

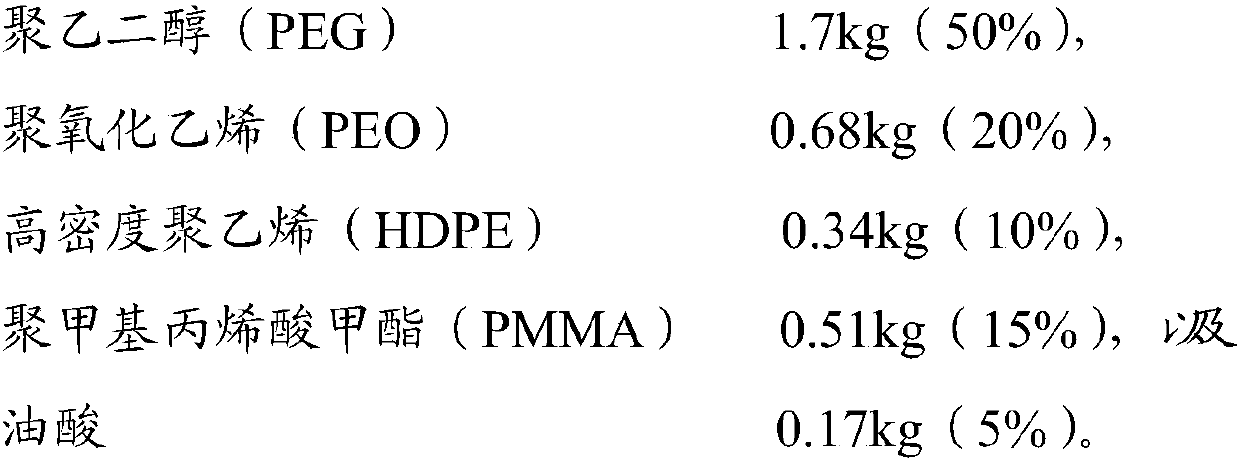

Ceramic, ceramic injection molding feeding material and preparation method thereof

InactiveCN107840666ALow costShort degreasing timeAuxillary shaping apparatusWater insolubleMass ratio

The invention relates to a ceramic, a ceramic injection molding feeding material and a preparation method thereof. The ceramic injection molding feeding material comprises, by mass, 80-83% of ceramicpowder and 17-20% of a binder. The binder comprises a water-soluble binder and a water-insoluble binder. A mass ratio of the water-soluble binder to the water-insoluble binder is (60-70): (23-35). TheCIM research process comprises researching binder selection, molding and discharge. The ceramic, ceramic injection molding feeding material and preparation method thereof have the advantages of low cost, short degreasing time, high efficiency, environmental pollution, no pollution and small product deformation.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Energy-saving and environment-friendly mink skin tanning method

ActiveCN102703619AUniform penetrationHomogeneous bindingTanning treatmentPre-tanning chemical treatmentPulp and paper industryEnvironmental engineering

The invention discloses an energy-saving and environment-friendly mink skin tanning method, which comprises the following working procedures of: A) carrying out a soaking working procedure in soaking solution with the solution formula of 25g / L of table salt and 1g / L of soaking enzyme100-c; B) carrying out a degreasing and re-soaking working procedure in degreasing and re-soaking solution with the solution formula of 1ml / L of degreasing agent (Supralan80), 1ml / L of wetter ethanoic acid (HAC) and 0.5ml / L of degreasing enzyme200; C) carrying out a softening and picking working procedure in softening and picking solution with the solution formula of 40g / L of table salt, 2-3ml / L of Super lotan A, 0.5ml / L of Sinxit and 6g / L of glycolic acid; and D) carrying out a tanning working procedure in tanning solution with the solution formula of 40g / L of table salt, 10g / L of aluminite powder (Novaltan Al) and 4-5g / L of Tanning assist B. The energy-saving and environment-friendly mink skin tanning method disclosed by the invention has the advantages of simpleness in manufacturing and processing the mink skin, small water consumption and pollution, and higher energy saving and environment protection effect.

Owner:故城县海青皮草有限公司

Chemic spent meal in use for processing surfaces of ferrous metal, and preparation method

This invention discloses a method for preparing chemical degreasing powder for surface treatment of ferrous metals. The degreasing powder is composed of: sodium carbonate 20-34 parts, sodium tripolyphosphate 14-30 parts, polyoxyethylene nonyl phenyl ether 1-6 parts, coconut oil diethanolamide 1-5 parts, sodium dodecyl sulfate 2-8 parts, and sodium hydroxide 25-45 parts. The method comprises: mixing sodium carbonate and sodium tripolyphosphate, stirring uniformly, adding polyoxyethylene nonyl phenyl ether and coconut oil diethanolamide, stirring uniformly, adding sodium dodecyl sulfate and sodium hydroxide, and stirring uniformly to obtain the final product. The degreasing powder has such advantages as good emulsification property, good cleaning effect, short degreasing time (shortened by 1-2 times), high cleaning rate (higher than 99.8%), low oxygen consumption, no toxicity and high biodegradability, and can be used repeatedly. Besides, the degreasing powder is environmentally friendly.

Owner:HUBEI DE MEI TECH

Preparation method of fish skin immunomodulatory peptides of Japanese croakers

The invention relates to the technical field of preparation of polypeptides of Japanese croakers and particularly relates to a preparation method of fish skin immunomodulatory peptides of Japanese croakers. The preparation method comprises the following steps: performing degreasing on fish skin by lipase combined with isopropanol to eliminate the bitter taste of immunomodulatory peptides; then, treating the fish skin through tartaric acid, a pulsed electric field and a reductive amination reagent to weaken the crosslinking degree among fish skin molecular proteins and enhance the swelling of the fish skin proteins; dissolving out the fish skin proteins in the fish skin as much as possible by virtue of the action of papain, chymotrypsin, trypsin, aspergillus serine protease or / and alkali protease and other protein extraction enzymes with weaker decomposition effect on the fish skin proteins at the temperature of 50-60 DEG C; and then, decomposing the fish skin proteins by virtue of thecombined action of neutral protease and neutral metal protease to obtain the fish skin immunomodulatory peptides. The utilization ratio of the fish skin proteins is high, the chain breaking decomposition uniformity is high, and the molecular weight of the obtained immunomodulatory peptides is 2000-3500Da.

Owner:ZHEJIANG OCEAN UNIV

Ceramic-base compound material and forming technique

The invention relates to a technology for shaping a ceramic-based composite material, which is integrated with principles of pressure injection, gel-casting and impregnating for preparing the ceramic-based composite material blank in complicated shape, even density of structure compositions and high strength so as to obtain a high-tenacity ceramic-based composite material product through sintering. The technology provided by the invention is a novel technology for shaping the ceramic-based composite material with high performance, complicated shape and fiber reinforcement, low cost and approximate net dimension. Compared with the prior art for shaping the fiber-reinforced ceramic-based composited material, the technology has the advantages of obvious superiority, short shaping time and high production efficiency.

Owner:肖青

Method for preparing acellular bone

ActiveCN102580152AAchieve the inactivation effectShort degreasing timeProsthesisCell-Extracellular MatrixBone tissue

The invention discloses a method for preparing acellular bone, comprising the following step of processing animal bones into acellular bones by using processes of preparation of bone pieces, viral inactivation, degreasing, decellularization, freeze-drying, cutting, molding, packaging and irradiation disinfection. The method for preparing acellular bone has the advantages of short degreasing time, high efficiency, strong protection effect on bone tissue structures, complete decellularization and small damage to natural structures of bone extracellular matrixes.

Owner:上海优越生物医学科技有限公司

Composite binder for powder injection moulding and preparation and application method

ActiveCN105860886AImprove liquidityGood liquidity lowNon-macromolecular adhesive additivesTransportation and packagingMicrocrystalline waxInjection moulding

The invention discloses composite binder for powder injection moulding and a preparation and application method. The composite binder for powder injection moulding comprises raw materials including furfuryl alcohol, trimethylolpropane, polypropylene, o-hydroxybenzoic acid, polyacrylamide, palm wax, microcrystalline wax and epoxidized soybean oil and further comprises boric acid and water. The composite binder combining thermoplasticity and a thermosetting system is adopted, advantages of thermoplasticity and the thermosetting system are utilized, on one hand, the problems that conventional binder is excessively long in thermal degreasing time and low in production efficiency are solved, and the degreasing rate can reach 90% or above within 6 hours; on the other hand, the yield rate of a powder injection moulding product is raised, and quality of a finished product is improved.

Owner:ANHUI SANLIAN UNIV

Injection forming feed for superfine hard alloy and preparation method thereof

ActiveCN109226742ANo defects such as swelling and bubblingShort degreasing timeTransportation and packagingMetal-working apparatusOXALIC ACID DIHYDRATEPolyethylene glycol

The invention discloses injection forming feed for superfine hard alloy and a preparation method thereof, and relates to the field of powder metallurgy. The feed is prepared from, by mass, 92-94.5% ofsuperfine hard alloy powder and 5.5-8% of a binding agent, wherein the binding agent is prepared from 59.0-69.0% of polyformaldehyde (POM), 23.0-35.0% of polyethylene glycol (PEG), 3.0-4.0% of high density polyethylene (HDPE), 2.0-2.5% of an ethylene-vinyl acetate copolymer (EVA) and 1.0-1.5% of stearic acid (SA). The PEG is added after the superfine hard alloy powder is preheated, after the PEDand the superfine hard alloy powder are mixed uniformly, the POM, HDPE, EVA and SA are added for mixing, and the preparation is completed. The feed adopts oxalic acid for catalyzing degreasing, so that the degreasing time can be reduced obviously, the production efficiency can be improved obviously, the use of acid catalysts and toxic solvents which are harmful to the environment is avoided, and the injection forming feed is economical and environmentally friendly and has a broad application prospect.

Owner:GUANGDONG INST OF NEW MATERIALS

Preparation method of dried salted large yellow croakers

InactiveCN108739968AIncrease contact surfaceFully infiltratedMeat/fish preservation by heatingFood ultrasonic treatmentUltrasonic assistedCold storage

The present invention provides a preparation method of dried salted large yellow croakers. The dried salted large yellow croakers are prepared by pre-treating, fish flesh perforating, ultrasonic assisted pickling, low-temperature dehydrating, quantifying, vacuum packaging and mild sterilizing. The prepared instant dried salted large yellow croakers can also be preserved for a long term; the quality of the product is improved; and the dried salted large yellow croakers have a shelf life of 30-60 days at a normal temperature and a shelf life of 300-360 days at a cold storage, and overcome problems that the processed dried salted large yellow croakers by using the prior art are high in oil content, need cold storage, are hard in texture, poor in mouthfeel, short in time, etc.

Owner:NINGDE CITY YUEHAI AQUATIC PROD

Method for simultaneously analyzing multiple aromatic hazardous substances in food

ActiveCN103439431AReduce consumptionReduce extraction timeComponent separationHazardous substancePollution

The invention aims at providing a method for simultaneously analyzing multiple aromatic hazardous substances in food, that is, a method for simultaneously extracting and preparing PAHs (Polycyclic Aromatic Hydrocarbons), phenolic compounds and aromatic amine in food. According to the method, sampling of only one time is needed, the sample consumption is reduced, the inspection time is shortened, the use amount of reagents is saved, secondary pollution is reduced at the same time, and the service life of a HPLC (High Performance Liquid Chromatography) chromatographic column is prolonged; as target detected substances are extracted by using an organic solvent ultrasonic extraction method, the extraction time of the target detected substance is greatly shortened; steps for extracting and preparing a sample liquid of PAHs in food are simplified, and organic solvent liquid-liquid extraction-reextraction degreasing is utilized in the PHAs detection process, so that the degreasing time is greatly shortened, and the experimental operation is simplified.

Owner:OCEAN UNIV OF CHINA

A kind of lipase degreasing agent and preparation method thereof

The invention discloses a lipase degreasing agent, which is a mixed liquid prepared from the following components. Phenol polyoxyethylene ether 4.0-6.0g, fatty alcohol polyoxyalkyl ether 4.0-5.0g, isopropanol 2.0-3.5g, disodium edetate 0.1-0.12g, alkaline lipase 1-2g, The remaining ingredients are water. When the lipase degreasing agent of the present invention degreases metal, it reduces the adsorption of the active agent and the metal body, facilitates the subsequent processing of the metal, and at the same time degreases quickly, shortens the degreasing time, and improves work efficiency.

Owner:蚌埠市钰诚五金工贸有限公司

Degreasing agent and preparation method thereof

The invention discloses a degreasing agent, which is a mixed liquid prepared from the following components. The parts by weight of each component in each liter of the mixed liquid are: 2.0-4.0 g of sodium lauryl alcohol polyoxyethylene ether sulfate, nonylphenol polyoxyethylene Ether 4.0-6.0g, fatty alcohol polyoxyalkyl ether 4.0-5.0g, lauryl alcohol polyoxyethylene ether 3.0-4.0g, sodium lauryl sulfate 2.0-4.0g, ethanol 2.0-3.5g, ethylenediaminetetra Tetrasodium acetate 0.1-0.12g, alkaline lipase 1-2g, and the remaining ingredients are water. When the degreasing agent of the present invention degreases metal, it reduces the adsorption of the active agent and the metal body, facilitates the subsequent processing of the metal, and at the same time degreases quickly, shortens the degreasing time, and improves work efficiency.

Owner:蚌埠市钰诚五金工贸有限公司

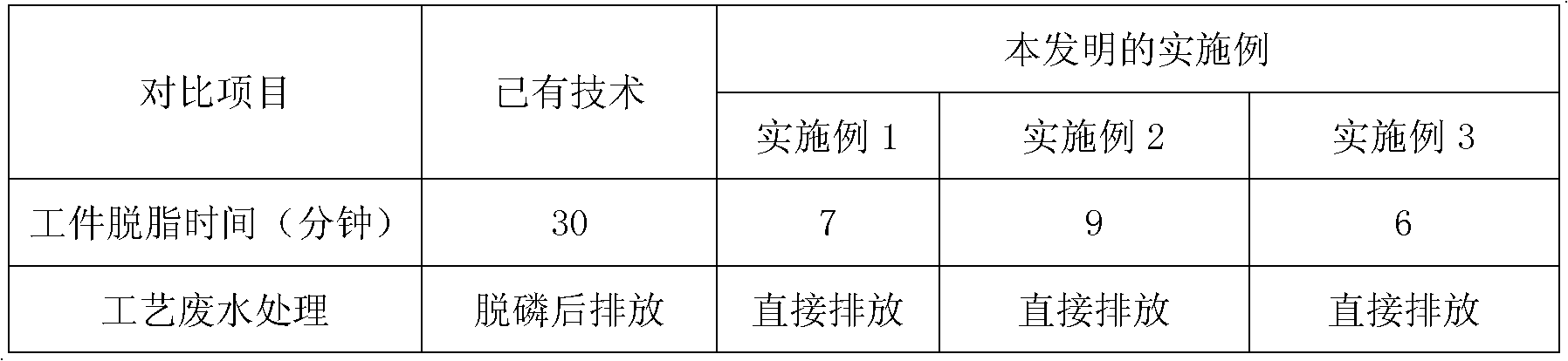

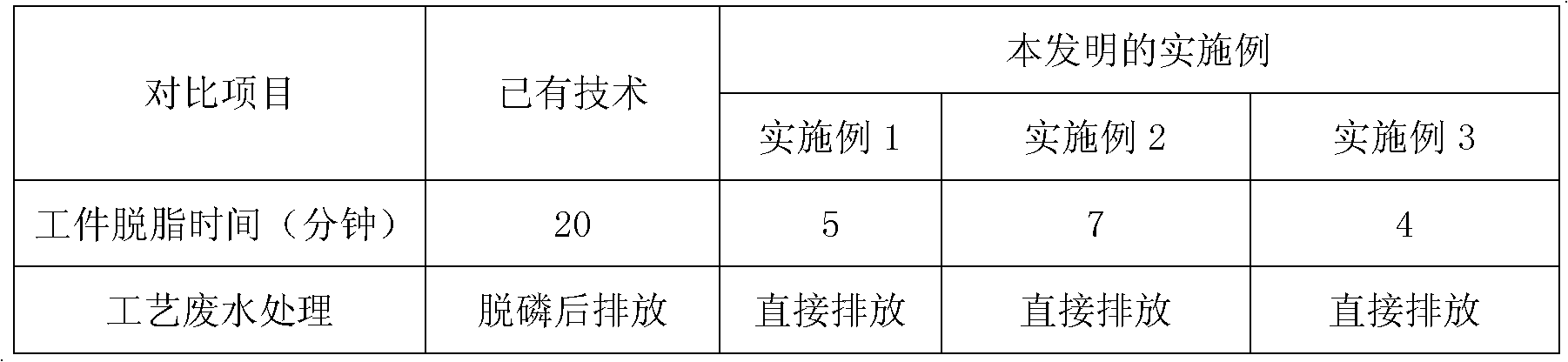

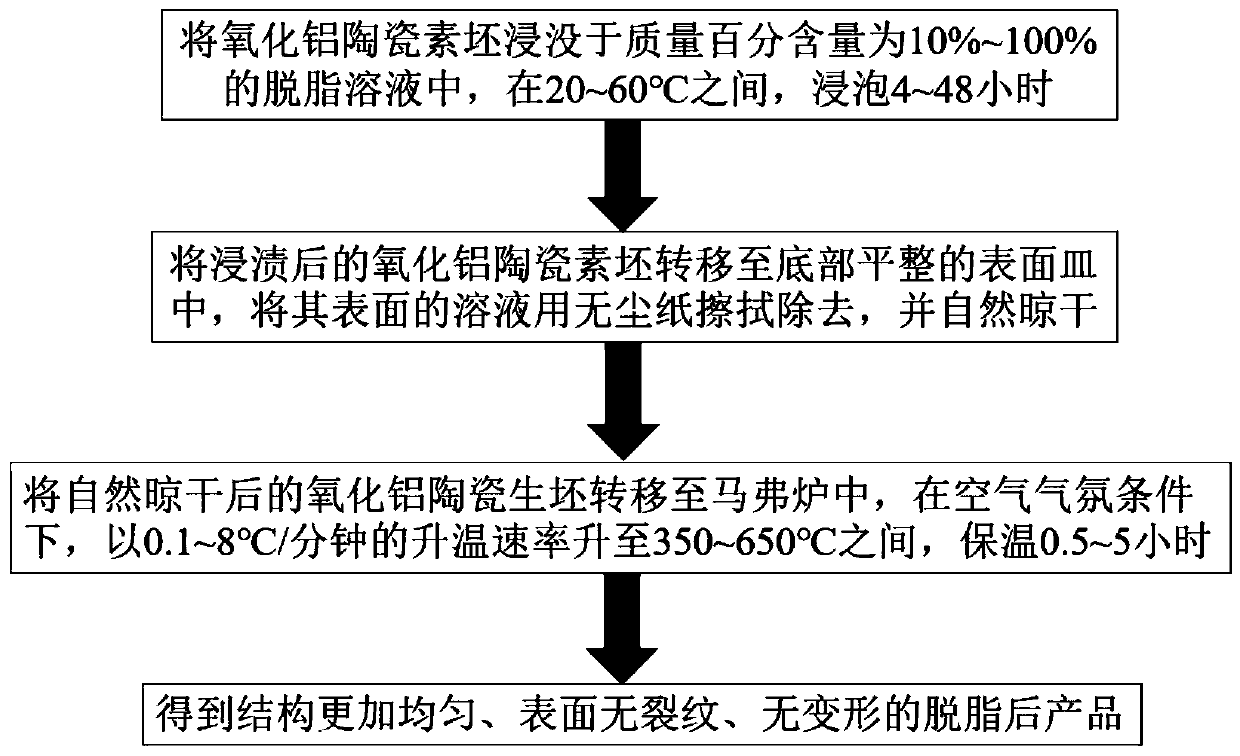

Cosolvent assisting degreasing method of light-cured 3D printed aluminum oxide ceramic biscuits

The invention relates to a cosolvent assisting degreasing method of light-cured 3D printed aluminum oxide ceramic biscuits. The cosolvent assisting degreasing method of light-cured 3D printed aluminum oxide ceramic biscuits comprises following steps: 1, aluminum oxide ceramic biscuits are immersed in a degreasing solution; 2, after immersion, the aluminum oxide ceramic biscuits are introduced into watch glasses with flat bottoms, the surface solution is removed using dust-free paper, and natural air drying is carried out; 3, after natural air drying, the aluminum oxide ceramic biscuits are introduced into a muffle furnace, are heated to 350 to 650 DEG C at a heating rate of 0.1 to 8 DEG C / min in air atmosphere, and then thermal insulation treatment is carried out for 0.5 to 5h. According to the method, cosolvent assisting degreasing is adopted, so that aluminum oxide ceramic biscuit degreasing time is shortened, aluminum oxide ceramic biscuit internal stress generated in heating process is reduced, the product structure after degreasing is more uniform, no surface crack is caused, and no deformation is caused. The cosolvent assisting degreasing method of light-cured 3D printed aluminum oxide ceramic biscuits is capable of shortening degreasing time, increasing degreasing efficiency and production efficiency, and can be used in the field of aluminum oxide ceramic production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

White-smoke-free promotion flux for steel fastener hot dip galvanizing and application process of white-smoke-free promotion flux

PendingCN108193154AReduce pollutionImprove working environmentHot-dipping/immersion processesHexamethylenetetramineChloride

The invention relates to the technical field of steel fastener hot dip galvanizing, in particular to white-smoke-free promotion flux for steel fastener hot dip galvanizing and an application process of the white-smoke-free promotion flux. The white-smoke-free promotion flux for steel fastener hot dip galvanizing comprises the following components: 100-200g / L of zinc chloride, 10-40g / L of magnesiumchloride, 8.0-13g / L of nickel chloride, 6.0-12g / L of hydrochloric acid, 2.0-3.5g / L of hexamethylenetetramine, 2.0-10g / L of a flux additive, and the balance of water. The application process of the white-smoke-free promotion flux comprises steps of degreasing, water cleaning, rust-removing, secondary water cleaning, promotion flux adhering, drying, galvanizing and the like. The white-smoke-free promotion flux for steel fastener hot dip galvanizing disclosed by the invention does not contain ammonium chloride which generates white smoke while encountering molten metal zinc, and can greatly reduce generation of soot during hot-dip galvanizing of the steel fastener; and a hot-dip galvanizing process which uses the promotion flux is more optimized, and has the advantages of being low in production cost, stable in plating assistance quality, capable of producing steel fasteners for hot dip galvanizing on a large scale, and the like.

Owner:WENZHOU XINDE ELECTRIC FITTINGS +2

Method for making transparent parusvenustulus skeleton specimen

InactiveCN105145544AAvoid deformationAvoid sex changeDead animal preservationGlycerolPotassium hydroxide

The invention relates to a method for making a transparent parusvenustulus skeleton specimen. Compared with the prior art, the dehydration gradient is increased, the gradient difference is reduced, dehydration is soft in intensity and thorough, and deformation or denaturation of the specimen can be prevented in the dehydration process. According to the method, sodium hydroxide and xylene are combined for degreasing, the degreasing effect is better and more thorough, degreasing time is short, specimen making time is shortened to a certain degree, and making efficiency is improved; a method that two kinds of transparency agents including potassium hydroxide and glycerin are used in cooperation is adopted, transparency is carried out for two days through a low-concentration potassium hydroxide solution and is soft, the specimen is not damaged, then the specimen is transferred into glycerin potassium hydroxide transparency liquid, and transparent treatment is carried out for 5 days; due to glycerin, corrosion of the specimen by potassium hydroxide is reduced, the concentration of the potassium hydroxide can be increased to be higher than 3.5%, and the transparency effect can be improved; as alcian blue dye liquor is used, cartilage is dyed into a blue color, and the transparent skeleton specimen is bright in color and more attractive.

Owner:HENAN UNIV OF SCI & TECH

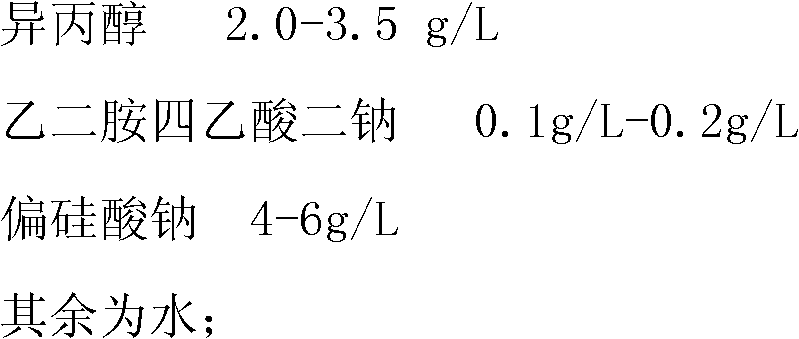

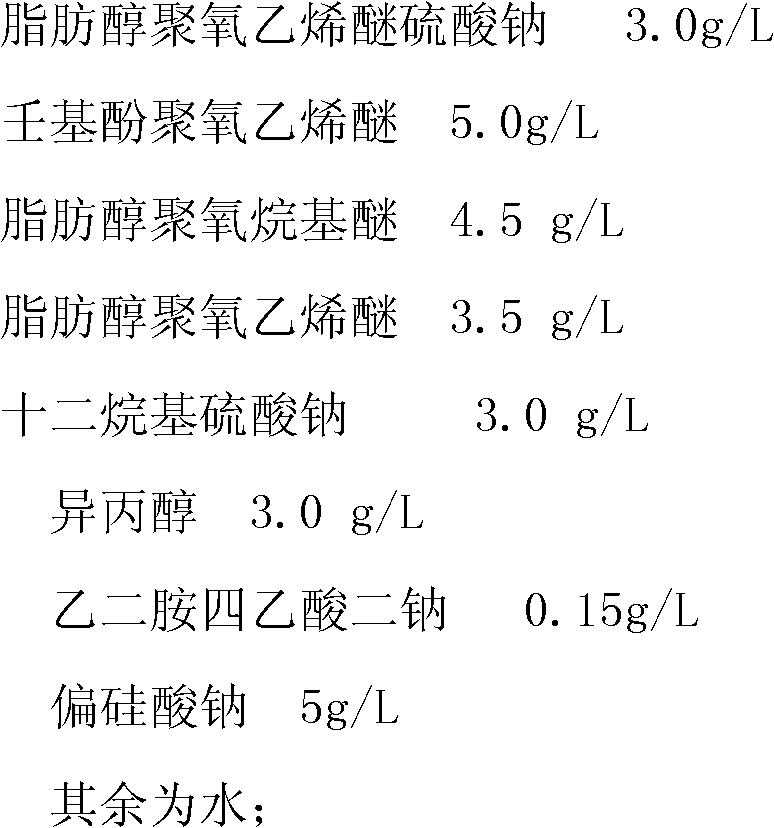

Environment-friendly microbial degreasing agent and preparation method thereof

The invention discloses an environment-friendly type microbial degreasing agent. The environment-friendly type microbial degreasing agent comprises two components A and B, wherein one liter of the component A comprises the following raw materials: 2.0 to 4.0 grams of fatty alcohol-polyoxyethylene ether sodium sulfate, 4.0 to 6.0 grams of nonylphenol polyoxyethylene ether, 4.0 to 5.0 grams of fatty alcohol polyoxy alkyl ether, 3.0 to 4.0 grams of fatty alcohol-polyoxyethylene ether, 2.0 to 4.0 grams of lauryl sodium sulfate, 2.0 to 3.5 grams of isopropanol, 0.1 to 0.2 gram of ethylene diamine tetraacetic acid, 4 to 6 grams of sodium metasilicate and the balance of water; and one liter of the component B comprises the following raw materials: 3 to 5 grams of soluble starch, 2 to 4 grams of glucose, 0.5 to 1.0 gram of peptone, 0.2 to 0.5 gram of calcium carbonate, 0.5 to 0.8 gram of magnesium sulfate, 1 to 2 milligrams of vitamin E, 5 billion units of bacillus and the balance of water. When the environment-friendly type microbial degreasing agent is used for degreasing the metal, the adsorbability of an active agent to the metal body is reduced; and the bacillus can degrade grease, so the service life of bath solution is prolonged, degreasing time is shortened, working efficiency is improved, and degreasing cost is reduced.

Owner:蚌埠市钰诚五金工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com