Patents

Literature

1979 results about "Hydroxybenzoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxybenzoic acid may refer to several related chemical compounds: 2-Hydroxybenzoic acid 3-Hydroxybenzoic acid 4-Hydroxybenzoic acid

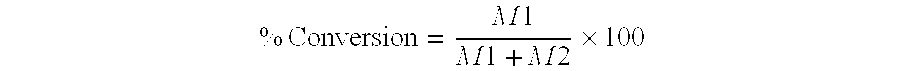

Analyte injection system

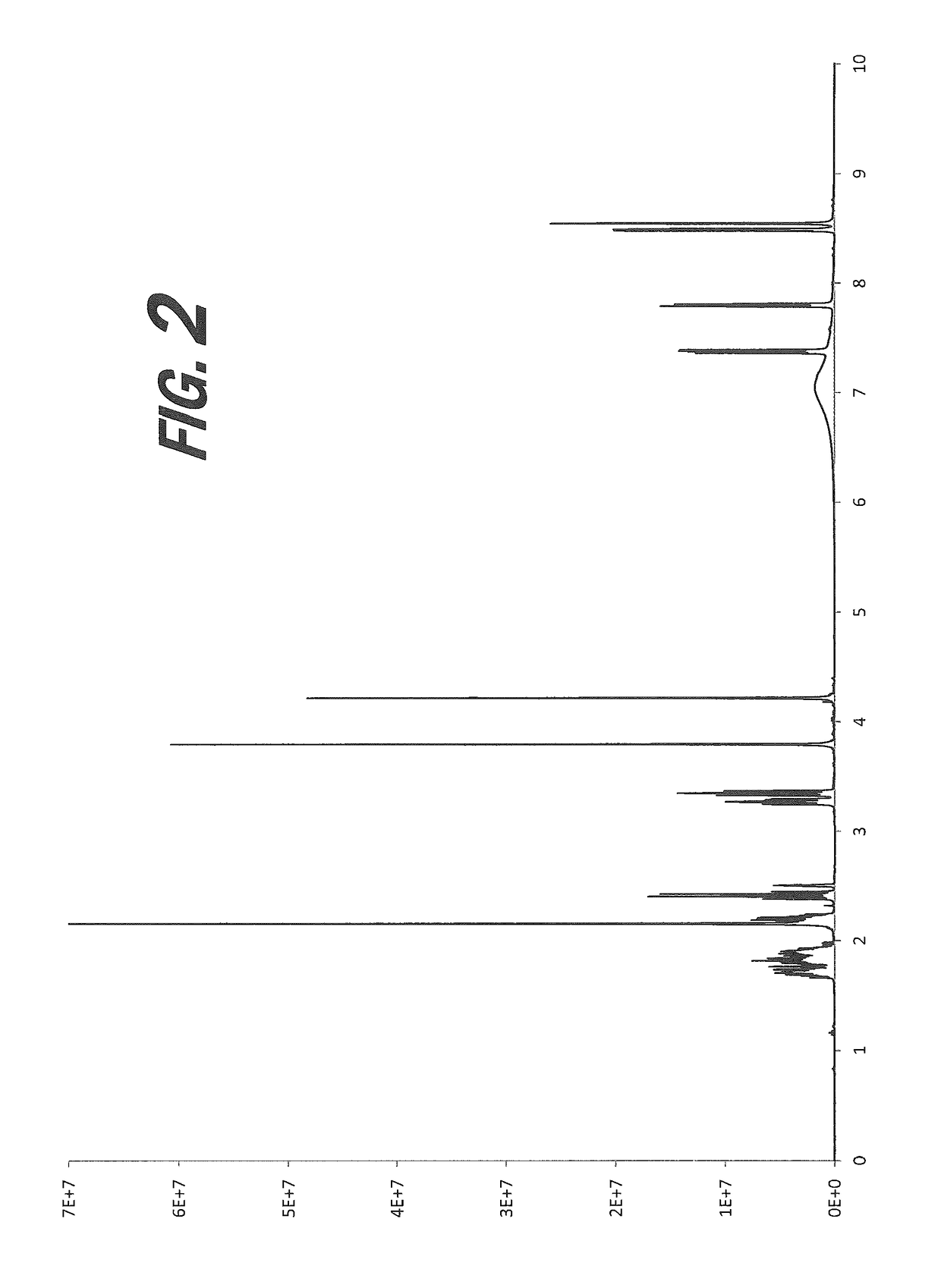

InactiveUS20050133370A1Increase in sizeShort amount of timeSludge treatmentVolume/mass flow measurementGlutaric acidAntibody conjugate

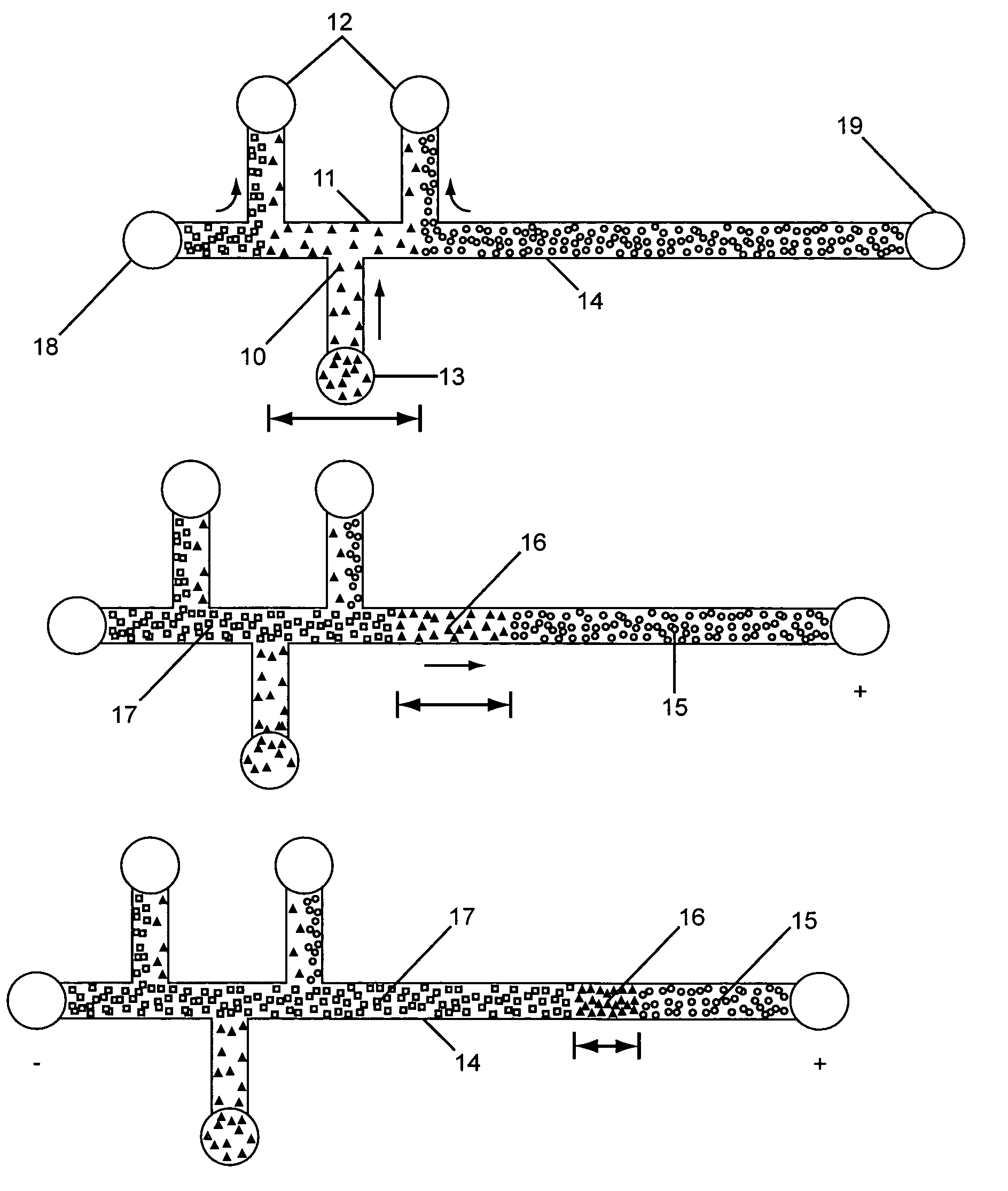

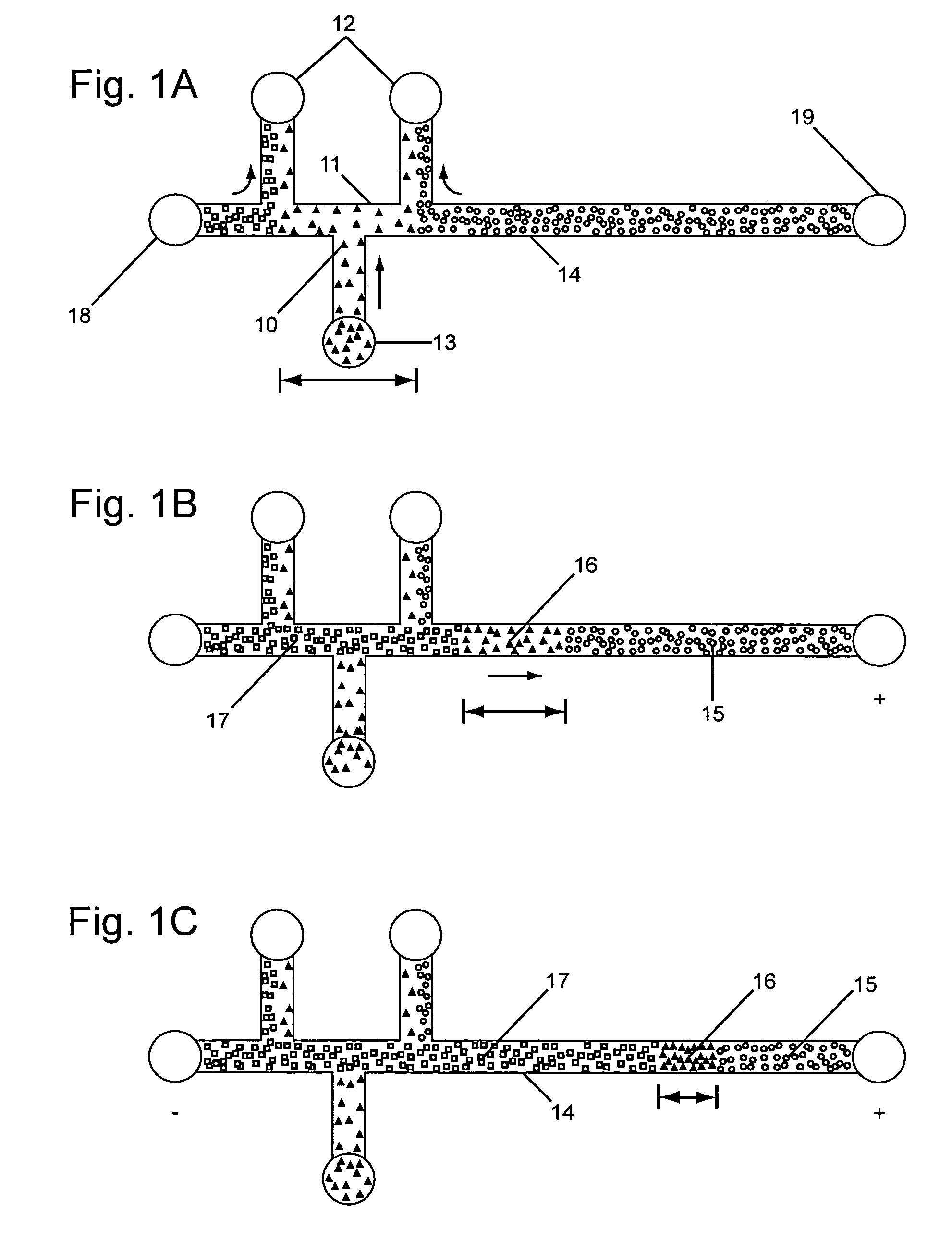

This invention provides methods and devices for spatially separating at least first and second components in a sample which in one exemplary embodiment comprises introducing the first and second components into a first microfluidic channel of a microfluidic device in a carrier fluid comprising a spacer electrolyte solution and stacking the first and second components by isotachophoresis between a leading electrolyte solution and a trailing electrolyte solution, wherein the spacer electrolyte solution comprises ions which have an intermediate mobility in an electric field between the mobility of the ions present in the leading and trailing electrolyte solutions and wherein the spacer electrolyte solution comprises at least one of the following spacer ions MOPS, MES, Nonanoic acid, D-Glucuronic acid, Acetylsalicyclic acid, 4-Ethoxybenzoic acid, Glutaric acid, 3-Phenylpropionic acid, Phenoxyacetic acid, Cysteine, hippuric acid, p-hydroxyphenylacetic acid, isopropylmalonic acid, itaconic acid, citraconic acid, 3,5-dimethylbenzoic acid, 2,3-dimethylbenzoic acid, p-hydroxycinnamic acid, and 5-br-2,4-dihydroxybenzoic acid, and wherein the first component comprises a DNA-antibody conjugate and the second component comprises a complex of the DNA-antibody conjugate and an analyte.

Owner:WAKO PURE CHEMICAL INDUSTRIES +1

Nicotine salts, co-crystals, and salt co-crystal complexes

Owner:R J REYNOLDS TOBACCO COMPANY

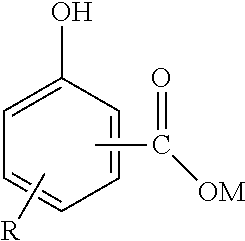

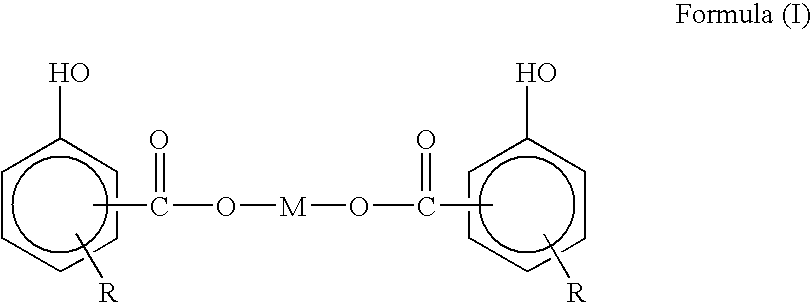

Marine engine lubrication

InactiveUS20120028522A1Easy to handlePropulsion power plantsOutboard propulsion unitsEngineeringFuel oil

Trunk piston marine engine lubrication, when the engine is fueled by heavy fuel oil, is effected by a composition comprising a major amount of an oil of lubricating viscosity containing at least 50 mass % of a basestock containing greater than or equal to 90% saturates and less than or equal to 0.03% sulphur or a mixture thereof, and respective minor amounts of an over-based metal hydrocarbyl-substituted hydroxybenzoate detergent other than such a detergent having a basicity index of less than two and a degree of carbonation of 80% or greater and at least 1 mass % of a hydrocarbyl-substituted carboxylic acid, anhydride, ester or amide thereof. Asphaltene precipitation in the lubricant, caused by the presence of contaminant heavy fuel oil, is prevented or inhibited.

Owner:INFINEUM INT LTD

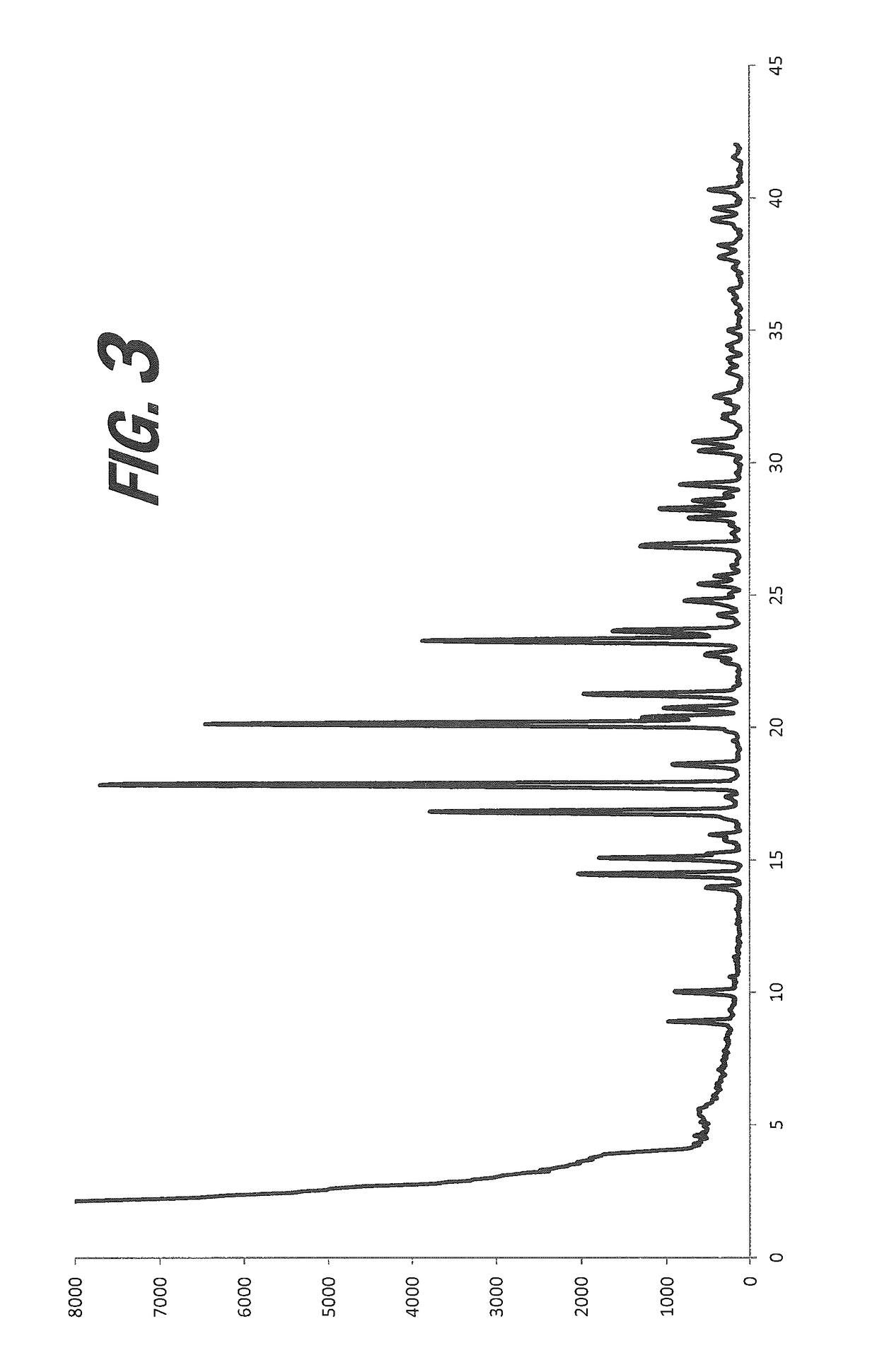

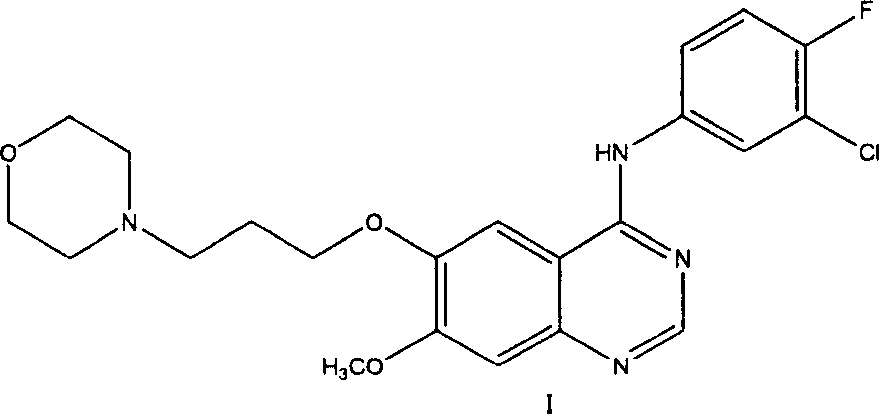

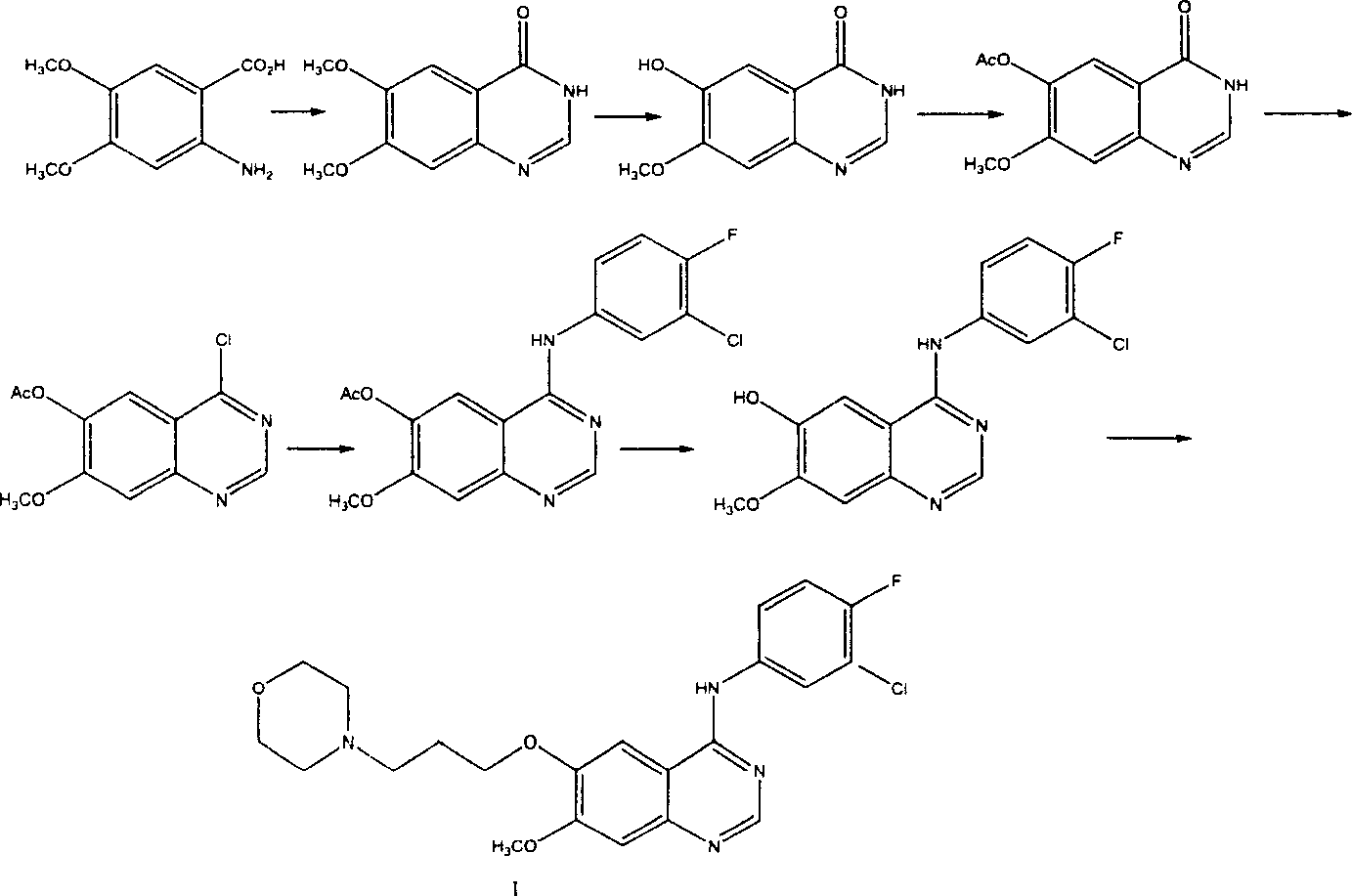

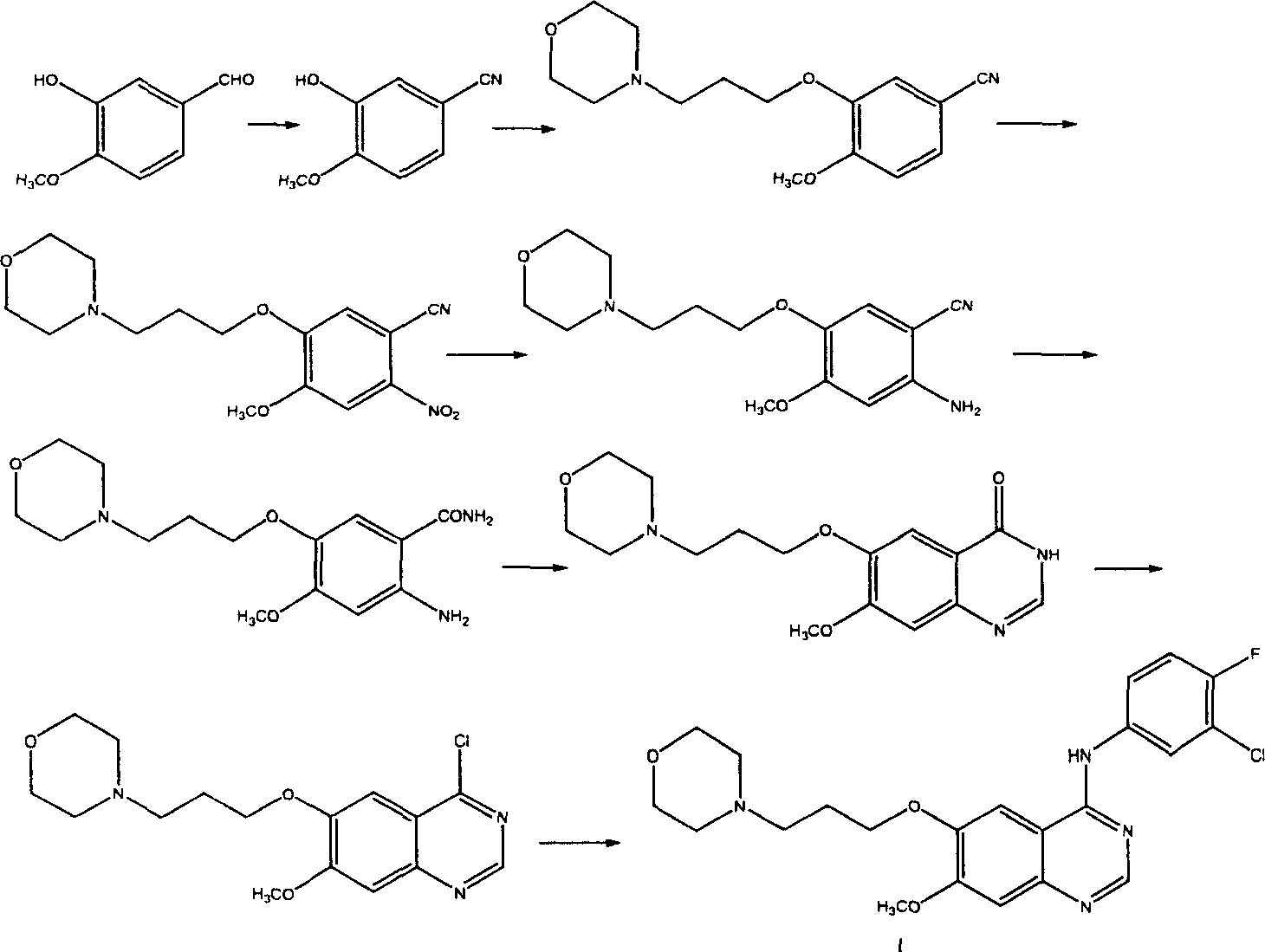

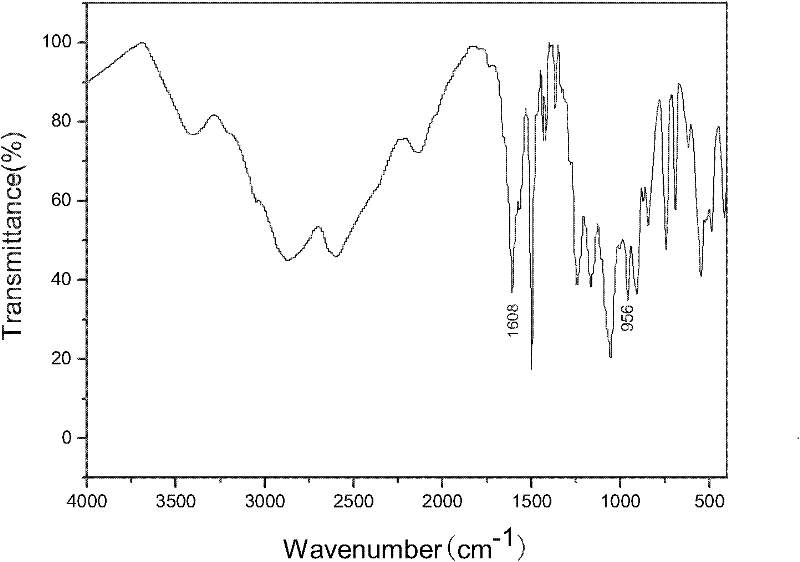

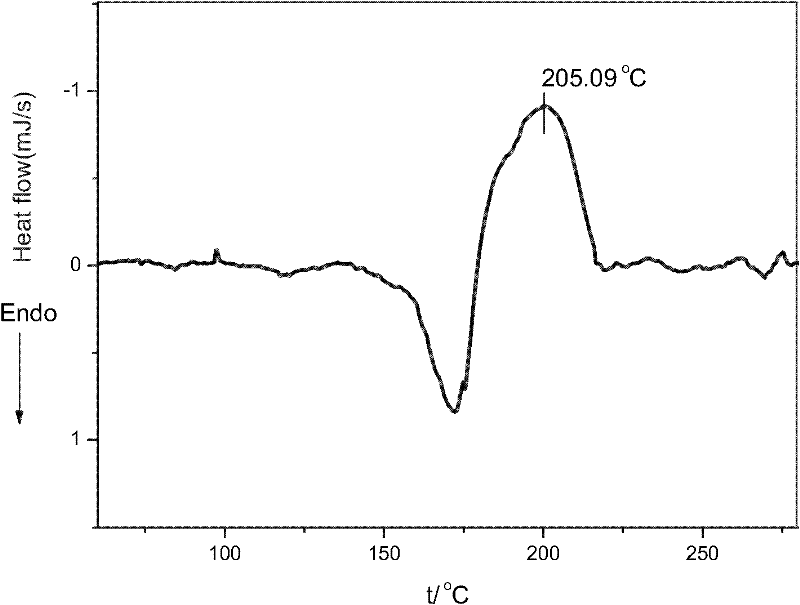

Preparation method of 4-(3-chlor-4-fluorobenzeneamidocyanogen)-7-methoxy-6-(3-morpholine oxypropyl)quinazoline

InactiveCN1733738AReduce pollutionReduce manufacturing costOrganic chemistryAntineoplastic agentsMorpholine3-chloro-4-fluoroaniline

The invention relates to a preparation method of 4-(3-chlor-4-fluorobenzeneamidocyanogen)-7-methoxy-6-(3-morpholine oxypropyl)quinazoline, which comprises using 3,4-dimethoxybenzoic acid (II) as raw material, synthesizing 2-amido-4-methoxy-5-hydroxybenzoic acid (V), cyclizing to obtain 6-hydroxy-7-methoxy-3,4-dihydroquinazolin-4-one (VI), directly chloridizing to obtain 4-chloro-hydroxy-7-methoxy-quinazoline (VII), reacting directly with 3-chloro-4-fluoroaniline, carrying out amination to obtain 4-(3-chloro-4-fluoroanilino)-6-hydroxy-7-methoxy-quinazoline (VIII), finally reacting with morpholinyl chloropropane to obtain Geftinat (I).

Owner:江苏吴中苏药医药开发有限责任公司

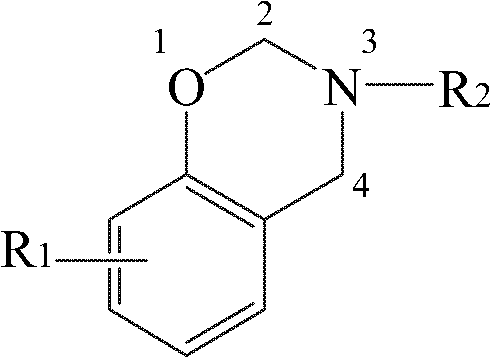

Dibenzoxazine containing oxazole ring and preparation method thereof

InactiveCN102250117ASimple preparation processLow equipment requirementsLiquid crystal compositionsOrganic chemistrySolventOrtho-aminophenol

The invention relates to a dibenzoxazine containing an oxazole ring and a preparation method thereof. The preparation method comprises the following two steps of: 1: mixing ortho-aminophenol hydrochloride and para-hydroxybenzoic acid, adding polyphosphoric acid as a solvent, reacting at 60-180 DEG C for 24-60 hours, and washing by using deionized water, filtering and drying to obtain diphenol containing an oxazole ring structure; and 2: mixing the diphenol containing the oxazole ring structure, phenylamine and paraformaldehyde, reacting at 80-110 DEG C for 40-80 minutes, then filtering and precipitating, washing 4-8 times by using alkali liquor, and then washing, filtering and drying to obtain the product. The dibenzoxazine disclosed by the invention has the advantages of very good mechanical property because the high temperature resistant oxazole ring structure is introduced to a benzoxazine molecule structure, dielectric constant of only 1.6-2.3, simple process, lower equipment requirement and suitability for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

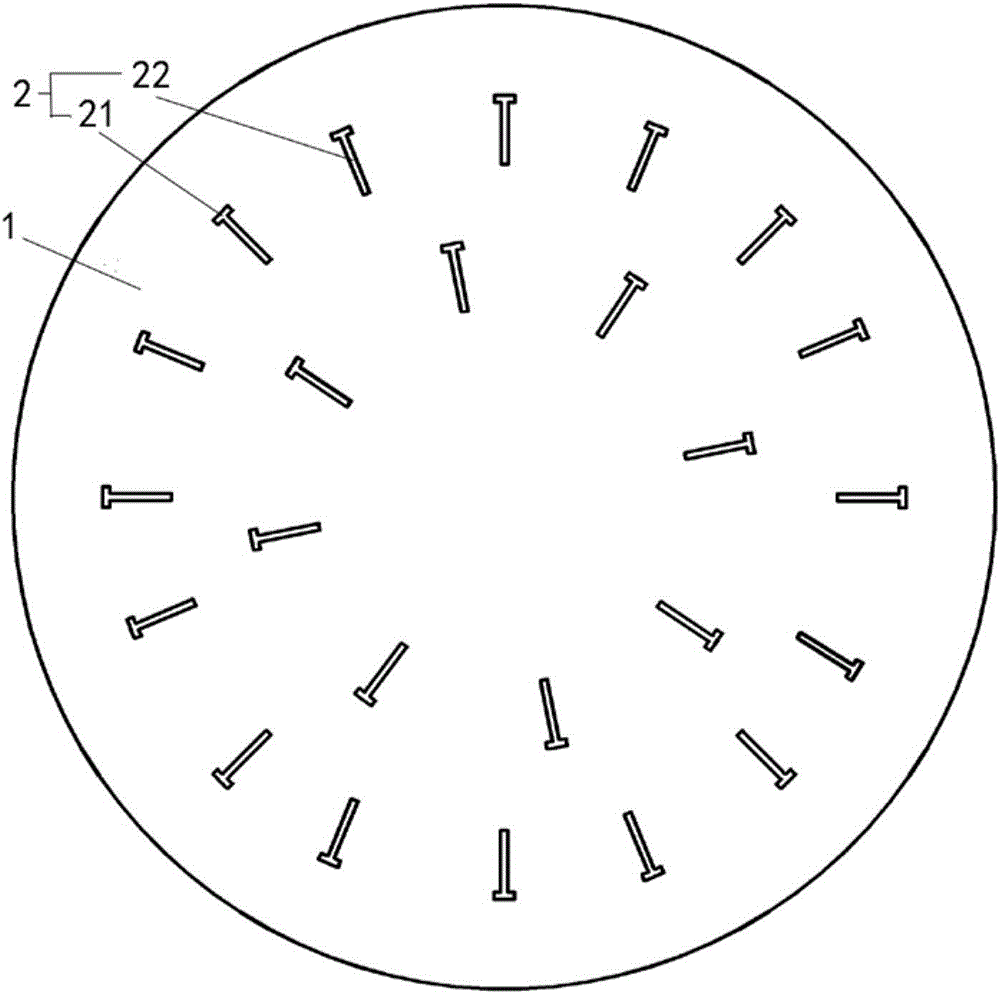

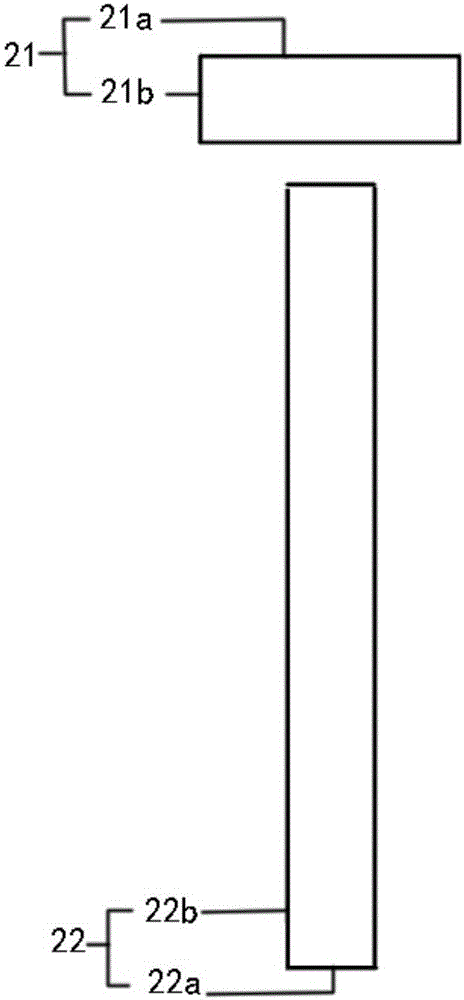

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

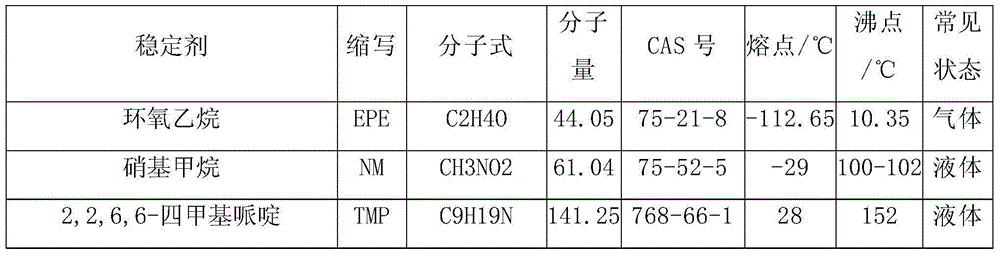

Composition containing HFC-161 and stabilizer

The invention discloses a composition containing HFC-161 and a stabilizer, wherein the stabilizer is selected from one or more of epoxy compound, nitro-compound, hindered amines, hindered phenols, secondary arylamines, beta-diketones, phosphite esters, salicylic acid esters, cinnamic acid esters, hydroxybenzophenones, hydroxybenzoic acids, hydroxylphenyl benzotriazoles, hydroxylphenyl triazines, oxanilides, formamidines, polyhydric alcohols, ortho-formates, organosulfur compounds, olefins, ethanol amines and fatty amines. The composition provided by the invention is capable of keeping a stable state in a long time under the coexistence of air or oxygen, and capable of being used as a heat transfer composition in the form of a liquid or a gas, a refrigerant, an aerosol propellant and the like.

Owner:SINOCHEM LANTIAN +2

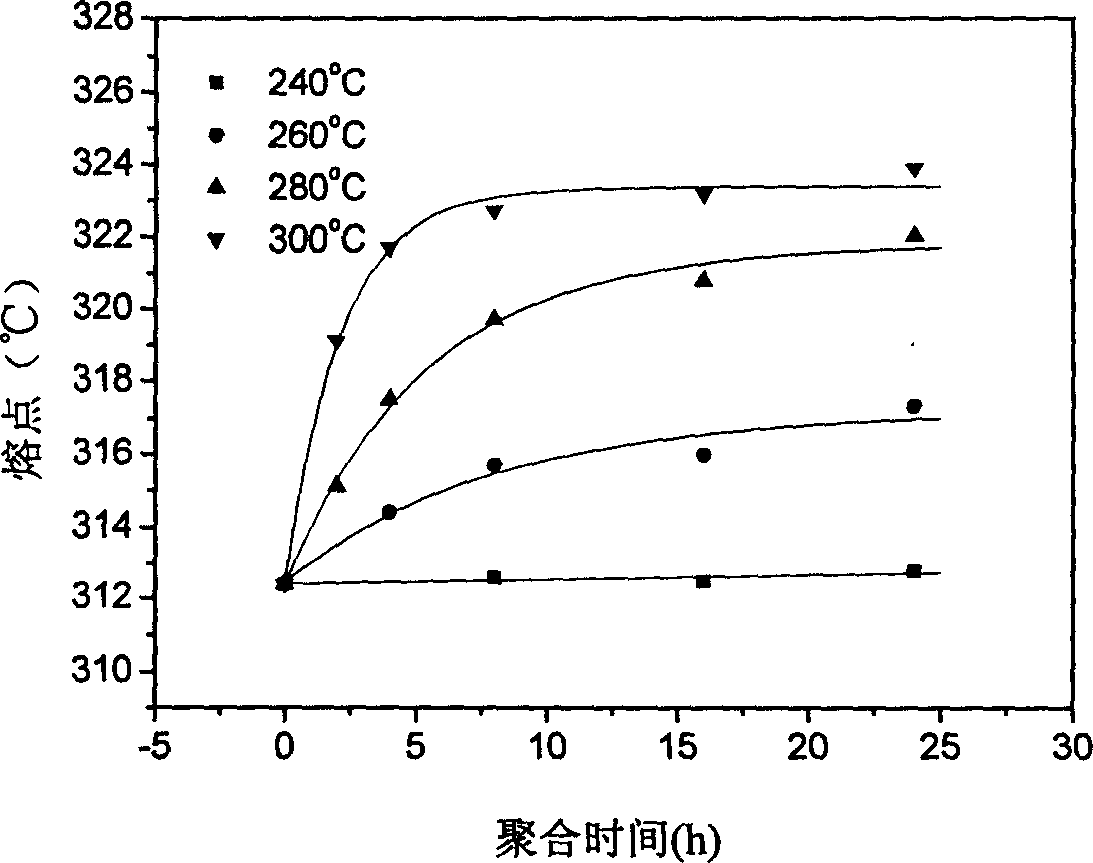

Solid state polymerization preparation method of liquid crystal copolyester

ActiveCN1597727ALower requirementLow costLiquid crystal compositionsBenzoic acidHydroquinone Compound

A process for preparing liquid crystal copolyester by solid polymerization includes such steps as heating the prepolymer poly(parahydroxy benzoic acid / 2,6-naphthalenediformic acid / terephthalic acid / hydroquinone) to a temp which is 10-60 deg.c lower than its fusion point, and solid polimerizing reaction under existance of inertial gas.

Owner:SHANGHAI PRET COMPOSITES +1

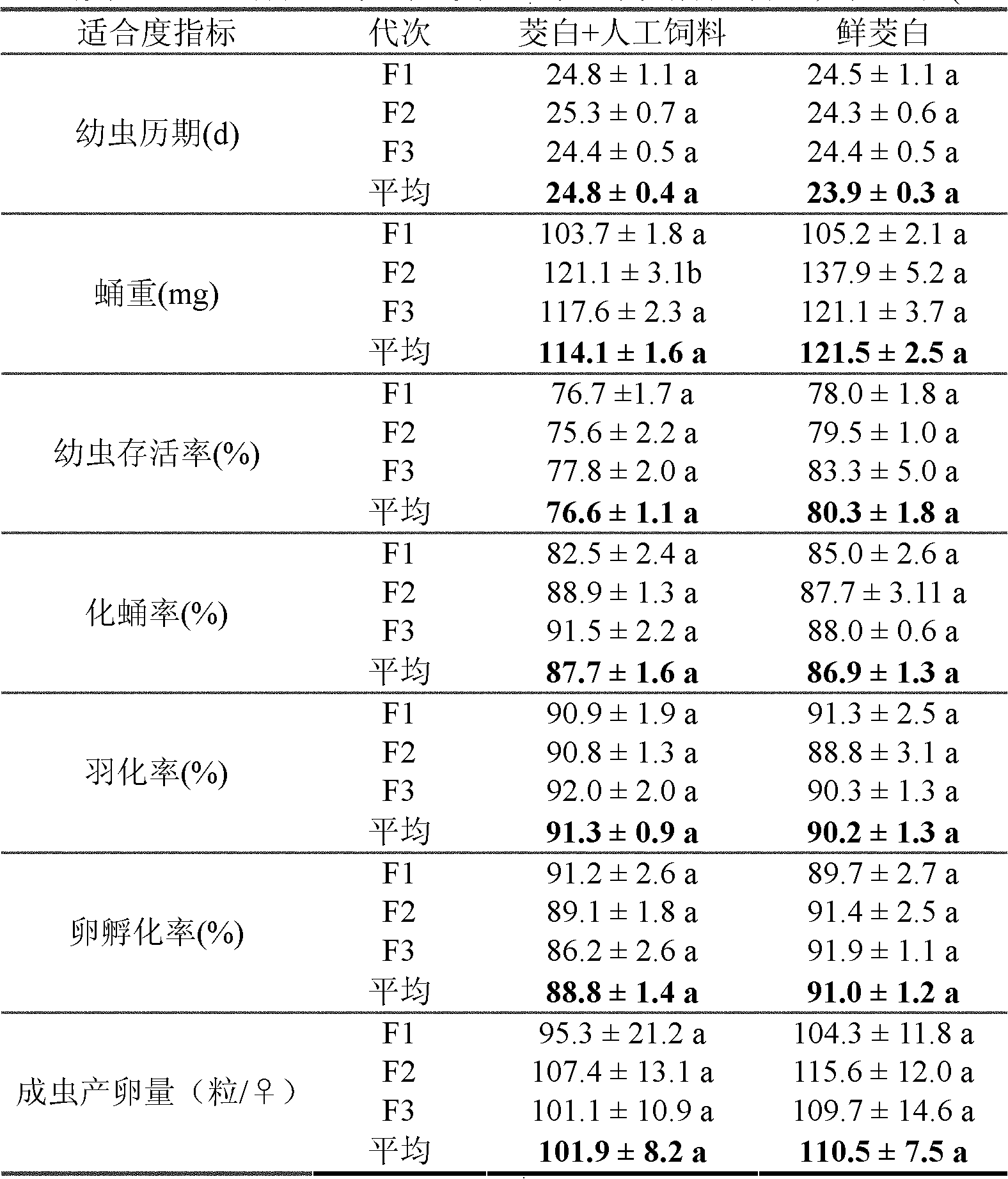

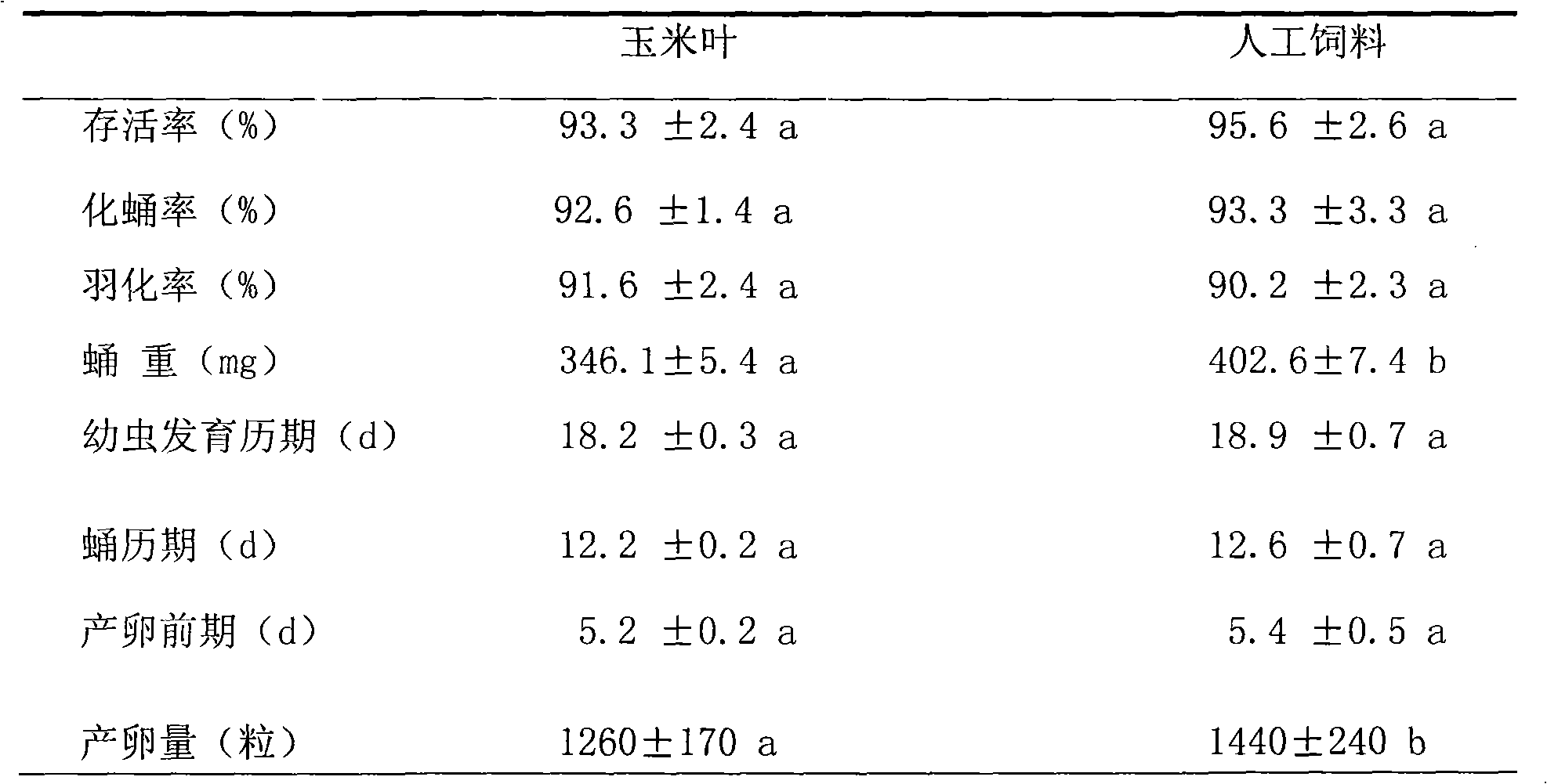

Artificial feed of sesamia inferens walker as well as preparation method and feeding method thereof

InactiveCN101971931ANormal growth and developmentGreat tasteAnimal feeding stuffAccessory food factorsShootCorn meal

The invention relates to an artificial feed of sesamia inferens walker as well as a preparation method and a feeding method thereof, belonging to the technical field of insect feeding. The artificial feed comprises soybean meal, corn meal, wheat germ, yeast powder, casein, cane sugar, honey, fresh wild rice shoots or fresh rice stems, ascorbic acid, cholesterol, choline chloride, Fiske salt, vitamin B complex, vitamin E, sorbic acid, methyl parahydroxybenzoats, 40 percent formaldehyde, 98.18 percent rice ketone, agal-agal and water. A long-term and successive feeding method of the sesamia inferens walker is carried out by adopting a wild rice shoots (young larva) and artificial feed (old larva until pupation). The fed larva of the sesamia inferens walker have development period of 24.8 days, larva survival rate of 76.6 percent, percentage of pupation of 87.7 percent, eclosion rate of 91.3 percent, egg laying amount of 101.9 for single adult and egg hatching rate of 88.8 percent. The invention has the advantages of low cost, practicability, simple preparation, and the like, and is suitable for massive, long-term and successive feeding of standard test sesamia inferens walkers.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

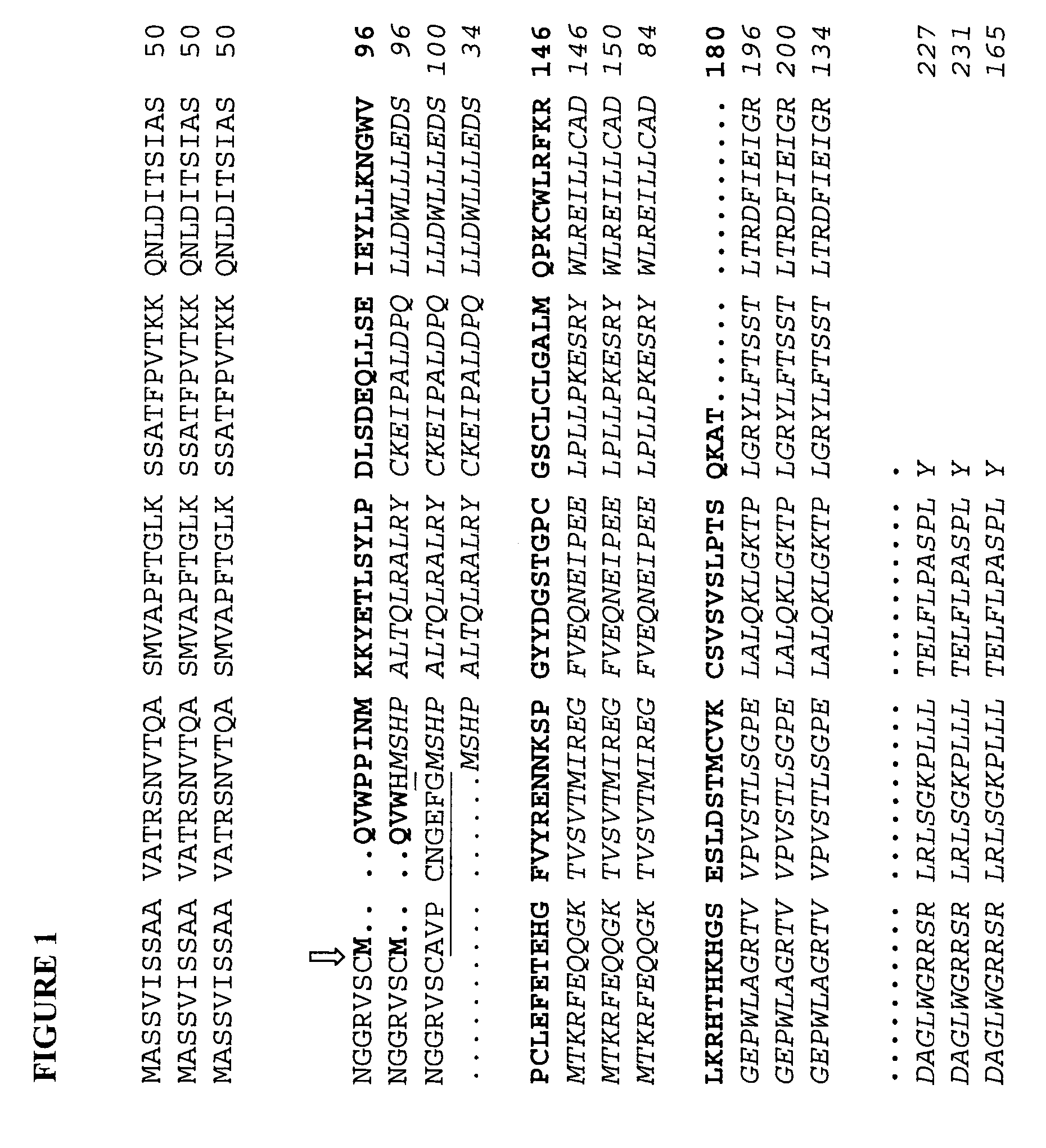

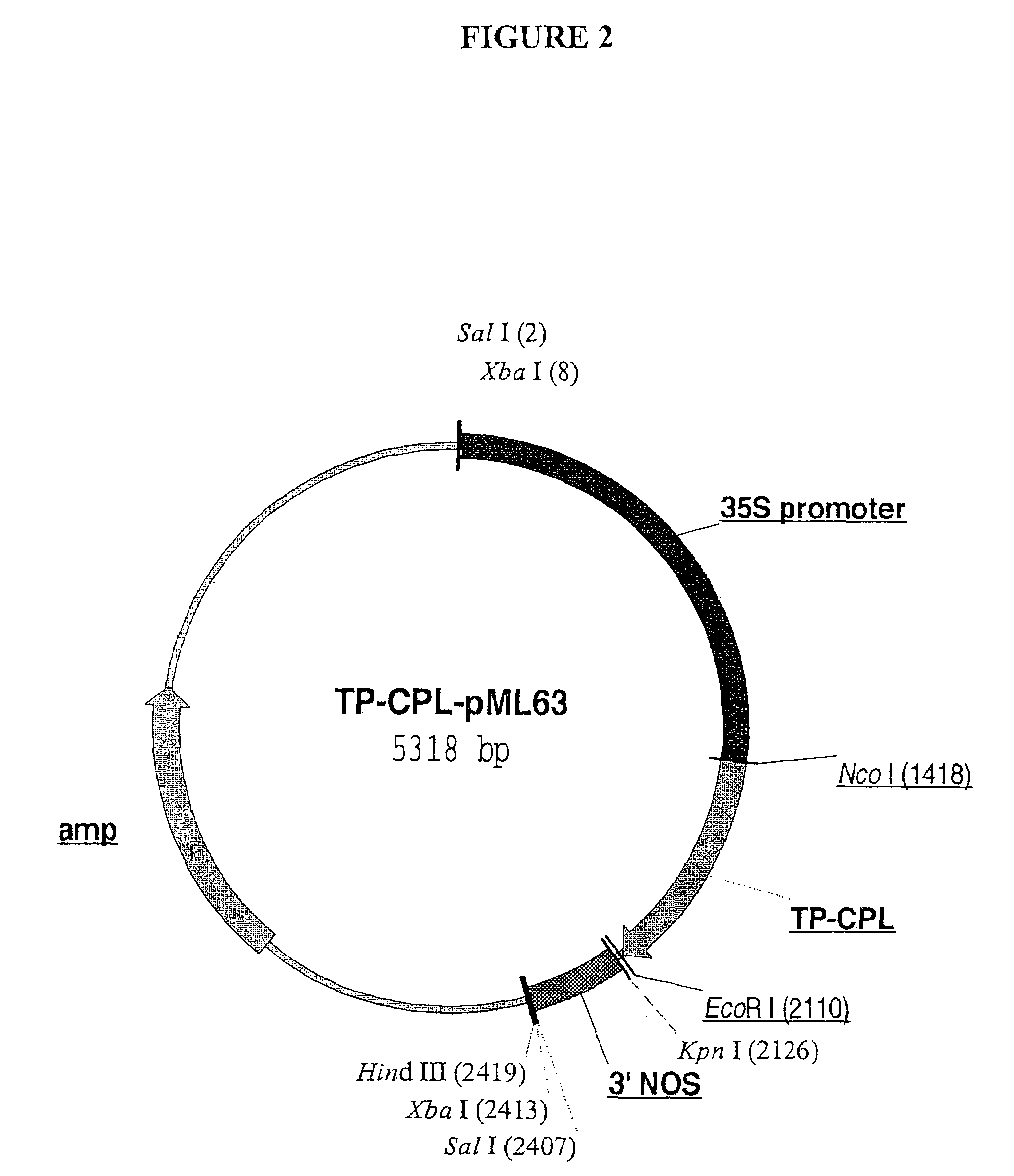

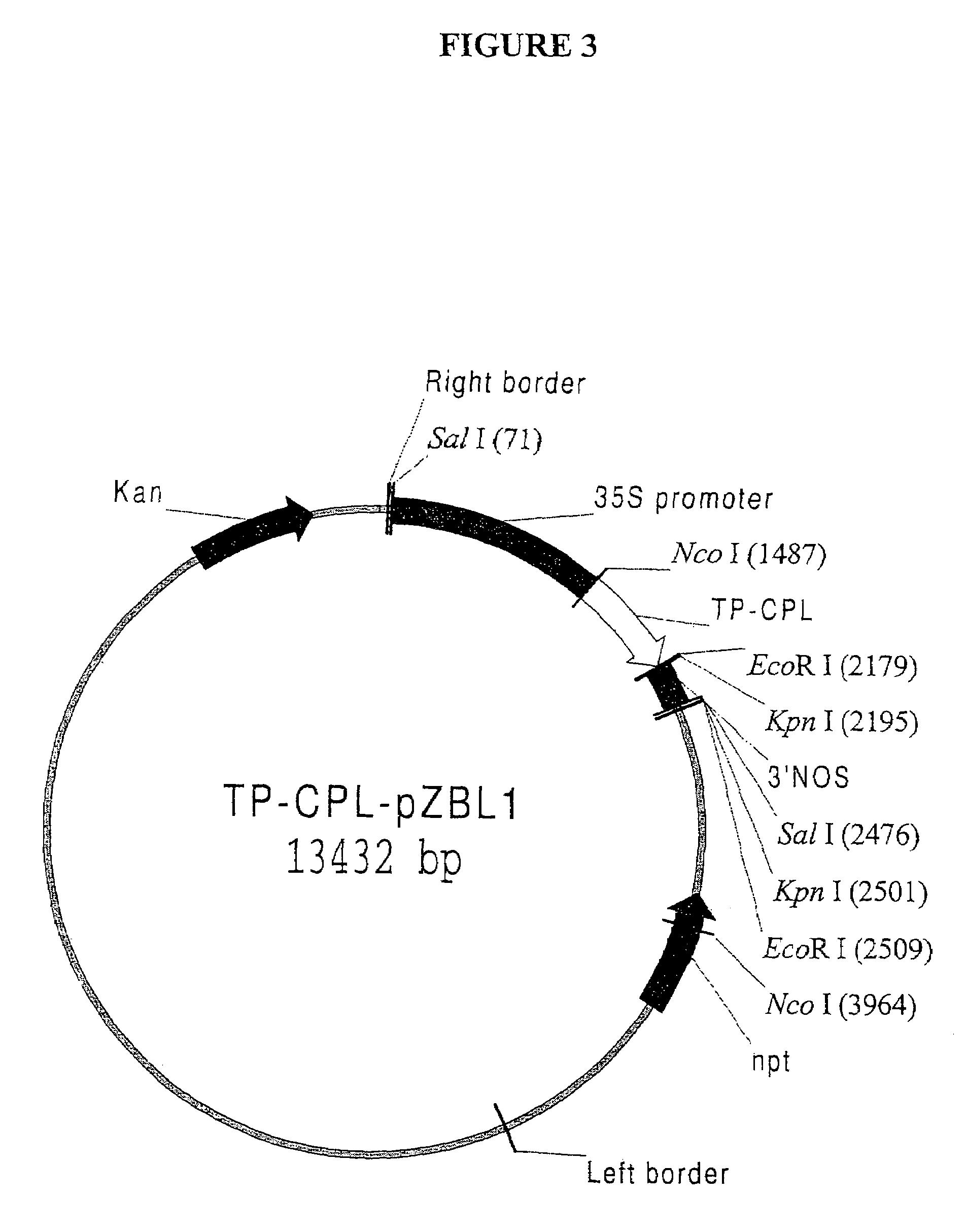

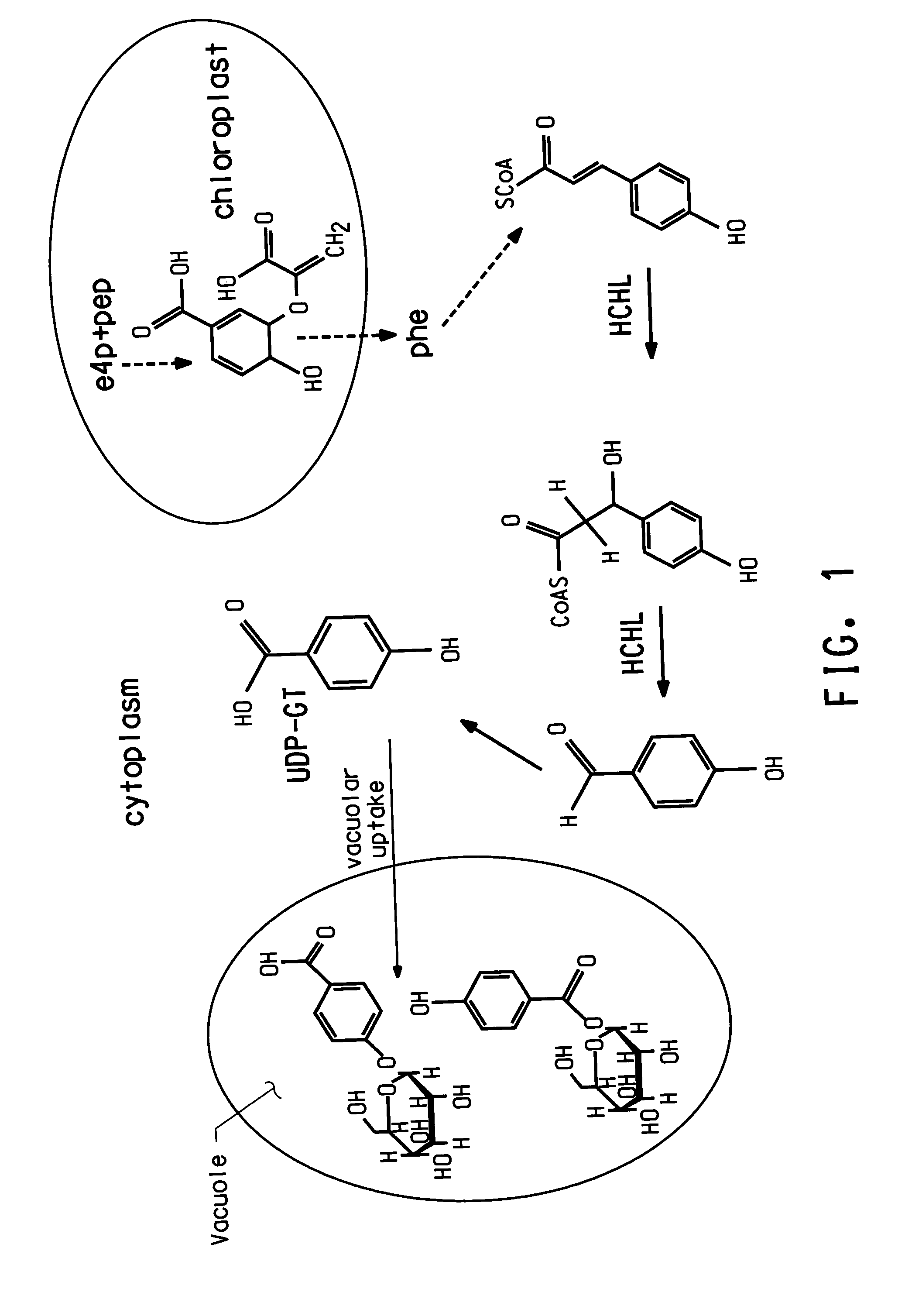

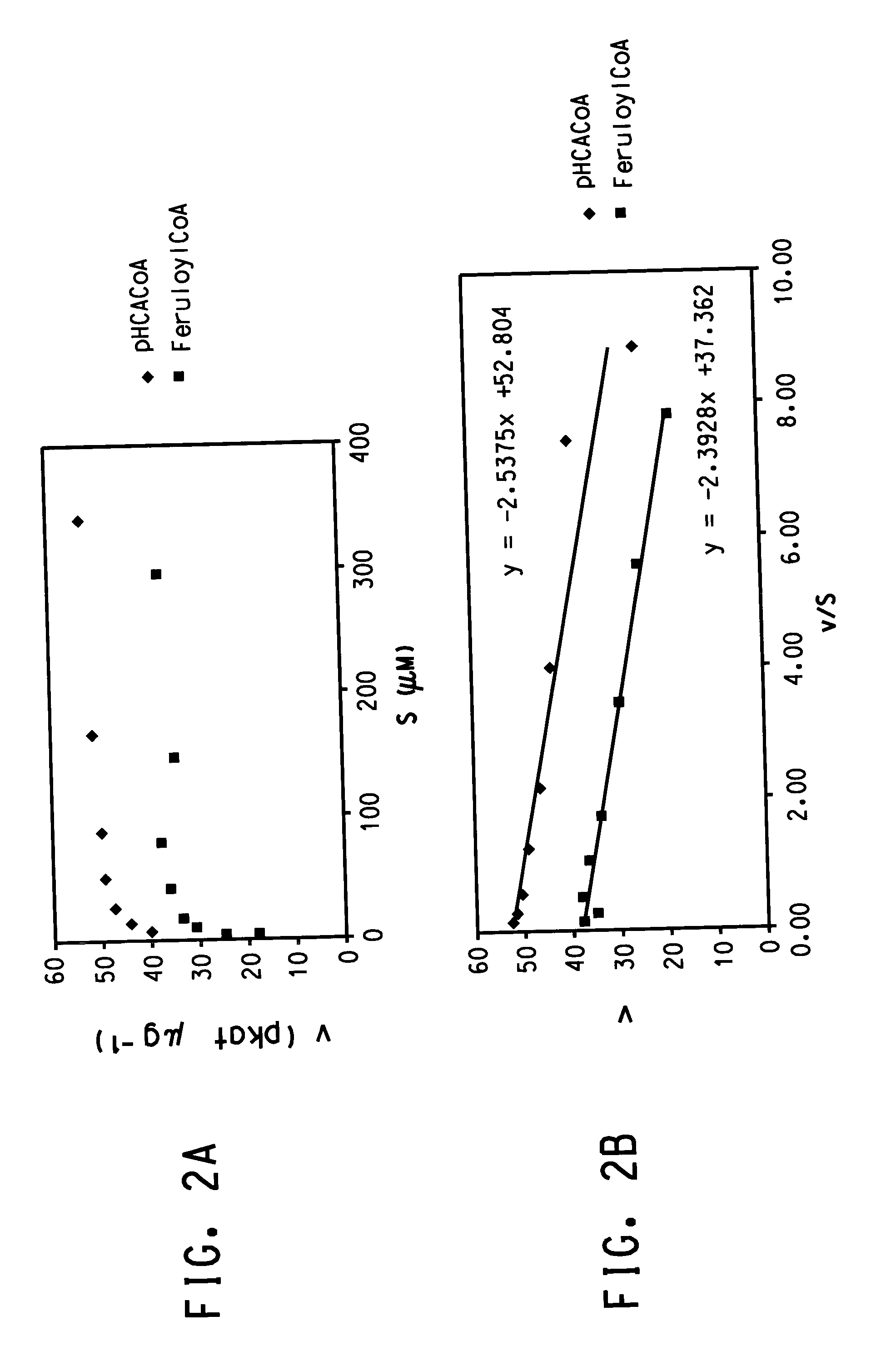

High level production of p-hydroxybenzoic acid in green plants

The invention relates to high-level production of pHBA in green plants using a unique expression cassette. The latter comprises a chorismate pyruvate lyase (CPL) coding sequence operably linked to a suitable promoter capable of driving protein expression in higher plants. Additionally, the CPL cassette comprises a sequence encoding a chloroplast transit peptide, its natural cleavage site, and a small portion of the transit peptide donor protein fused to the N-terminus of CPL. The chloroplast targeting sequence targets the foreign protein to the chloroplast compartment and aids in its uptake into the organelle. The cleavage site is unique to the transit peptide, and cleavage of the chimeric protein encoded by the cassette at this site releases a novel polypeptide that has full enzyme activity, comprising the mature CPL enzyme and a small portion of the transit peptide donor.

Owner:UNIVERSITY OF NORTH TEXAS

Underarm cosmetic method and compositions

InactiveUS20060115441A1Prevent skinDilute the colorCosmetic preparationsToilet preparationsGlycerolSalicylic acid

A method of inhibiting skin darkening whilst inhibiting perspiration in the underarm which comprises incorporating into a antiperspirant composition comprising an astringent salt comprising an aluminium and / or zirconium salt, a triglyceride oil and optionally an active acid comprising an aliphatic dicarboxylic acid, especially C6-C12 such as azelaic acid, an unsaturated C18 aliphatic carboxylic acid such as a linoleic acid or an hydroxybenzoic acid such as salicylic acid, at a ratio to said astringent salts, x:y, of 1:<4 in which x represents the weight concentration of said triglyceride oil plus 4 times the weight concentration of active carboxylic acid and y represents the weight concentration of said astringent salts. The composition can additionally comprise glycerol and / or a chelating agent for a transition metal.

Owner:CONOPCO INC D B A UNILEVER

Preparation method of thermotropic liquid crystal polyarylester fiber

InactiveCN104389045AEasy to operateReaction condition controlArtificial filament heat treatmentMonocomponent polyesters artificial filamentFiberAcetic anhydride

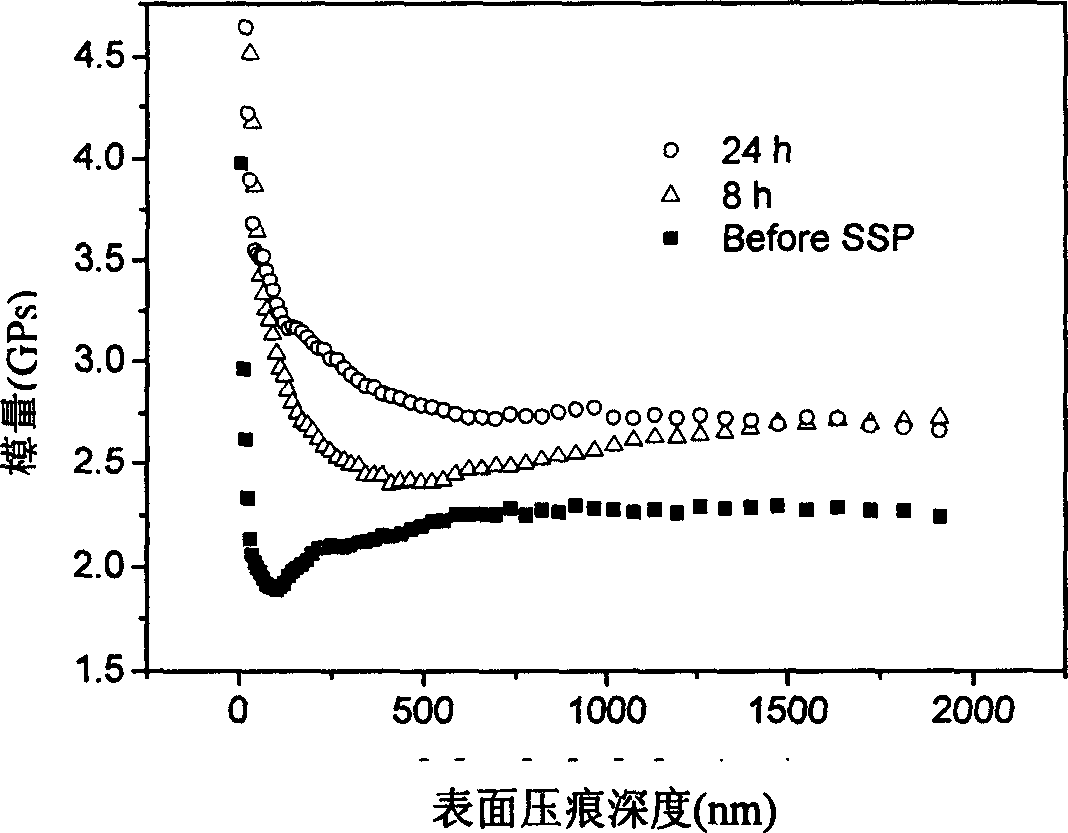

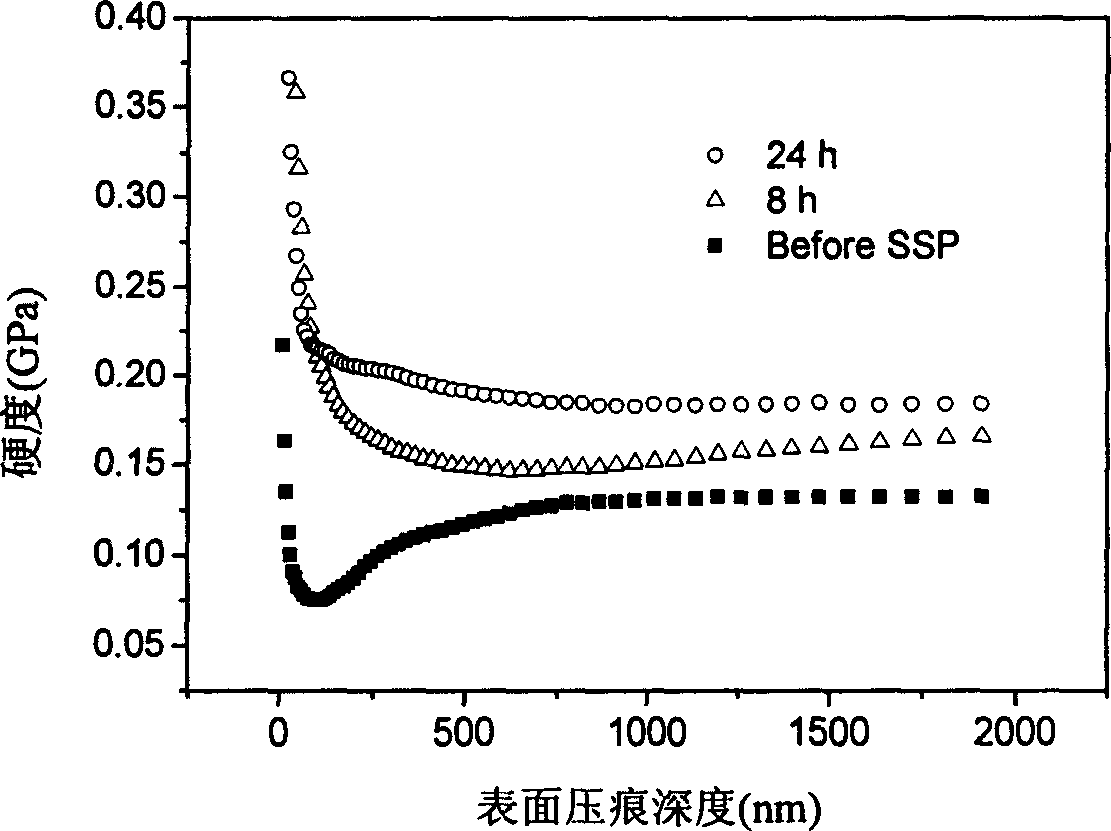

The invention discloses a preparation method of a thermotropic liquid crystal polyarylester fiber, relates to a preparation method of thermotropic liquid crystal polyarylester, and aims to solve the problems that the existing method for preparing the thermotropic liquid crystal polyarylester is complex and the polyarylester fiber is low in tensile strength. The preparation method of the thermotropic liquid crystal polyarylester fiber comprises the following steps: step one, adding p-hydroxybenzonic acid, 2-(4-hydroxyphenyl)-5-carboxylbenzimidazole, acetic anhydride, 4-diethylaminopyridine and an antioxidant into a polymerization kettle for carrying out melt condensation polymerization to prepare a pre-polymer of thermotropic liquid crystal polyarylester; step two, putting the pre-polymer in a rotary kiln under the condition with nitrogen protection for carrying out solid phase polycondensation reaction to obtain high-molecular-weight polymer powder; step three, mixing the high-molecular-weight polymer powder, then cooling and drawing to prepare primary polyarylester fiber; and step four, carrying out heat treatment on the primary polyarylester fiber. The preparation method of the thermotropic liquid crystal polyarylester fiber is simple to operate; the tensile strength of the polyarylester fiber which is finally obtained can reach 4.0-4.5GPa.

Owner:HEILONGJIANG JUXIANG TECH DEV CO LTD

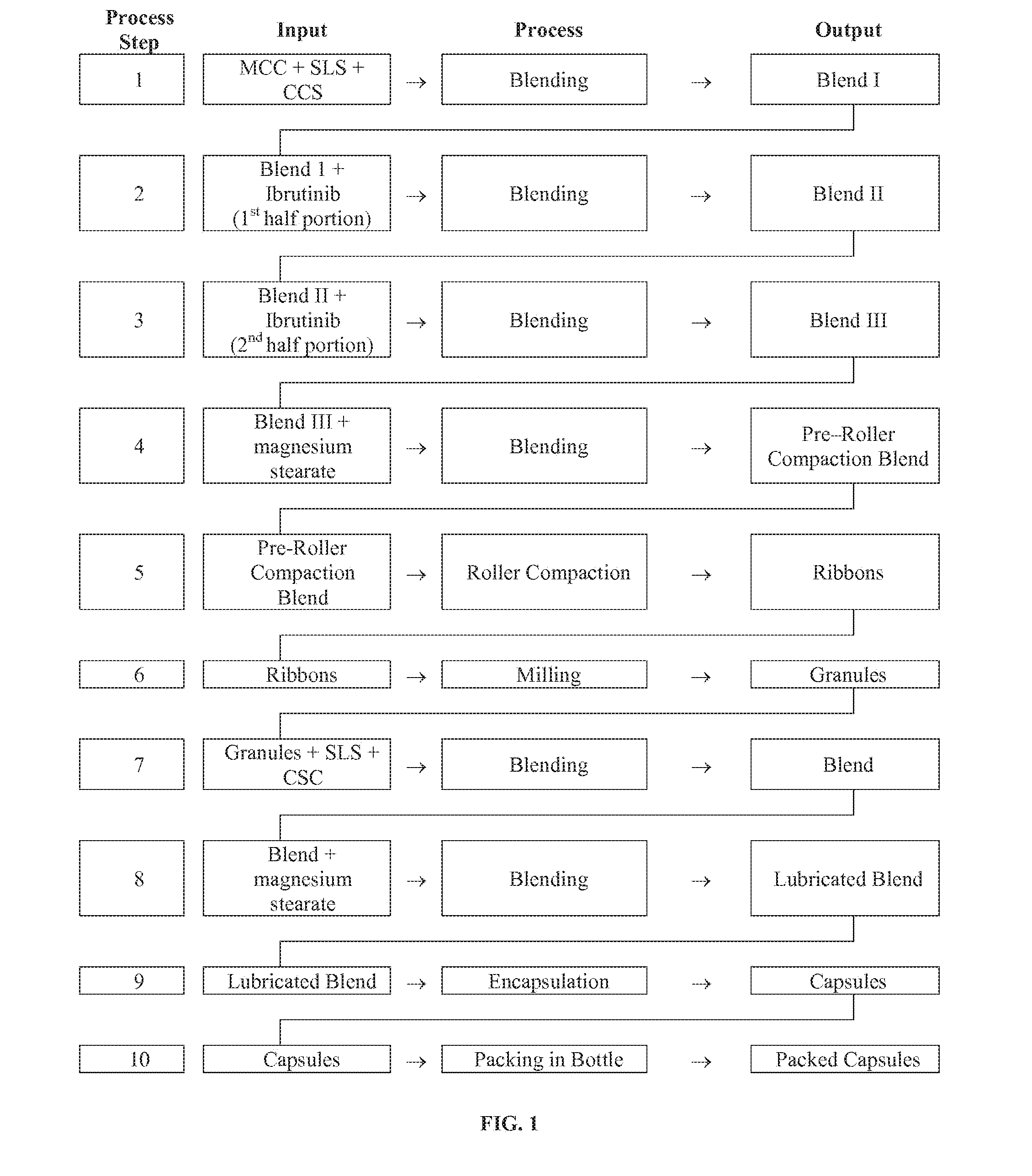

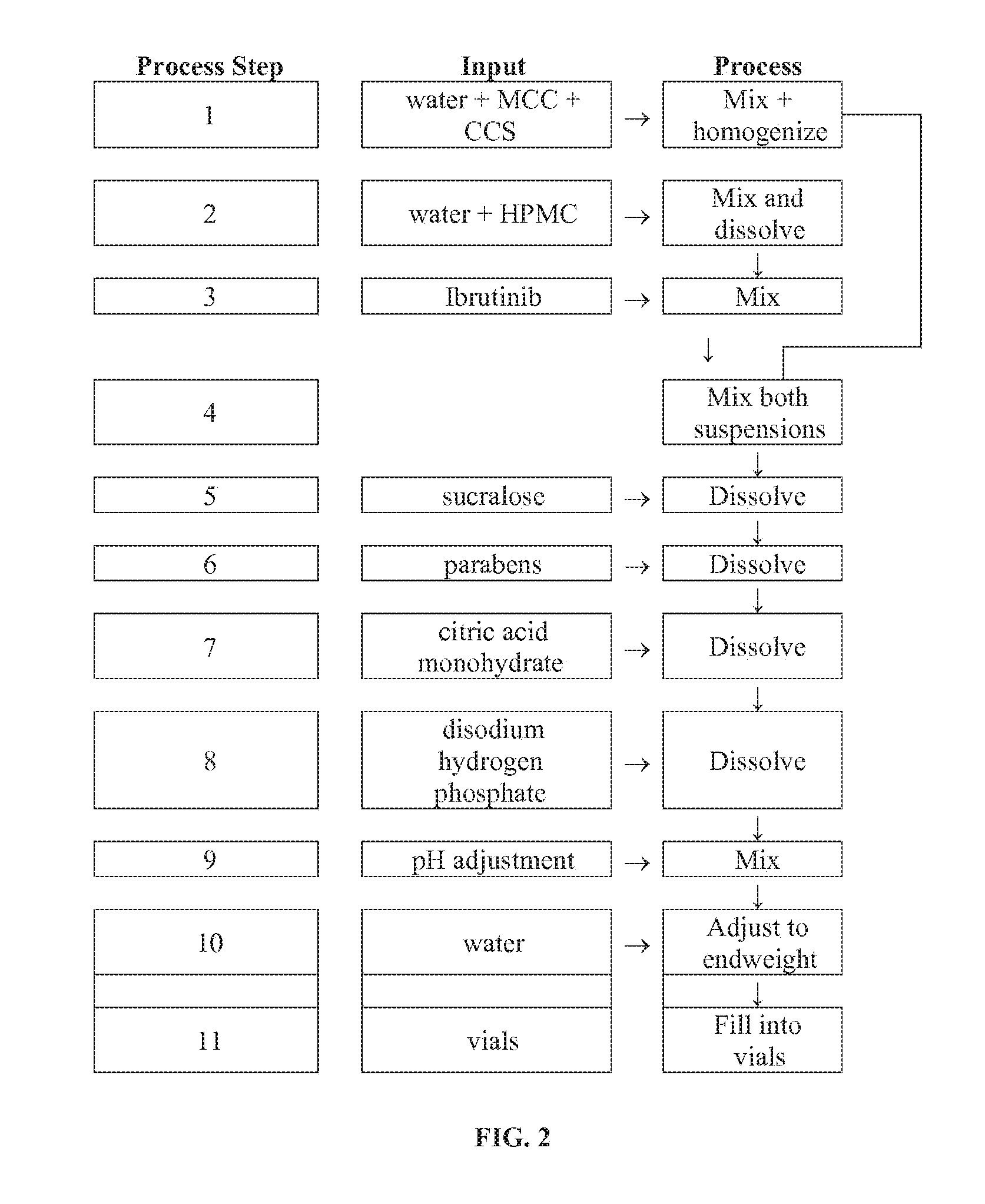

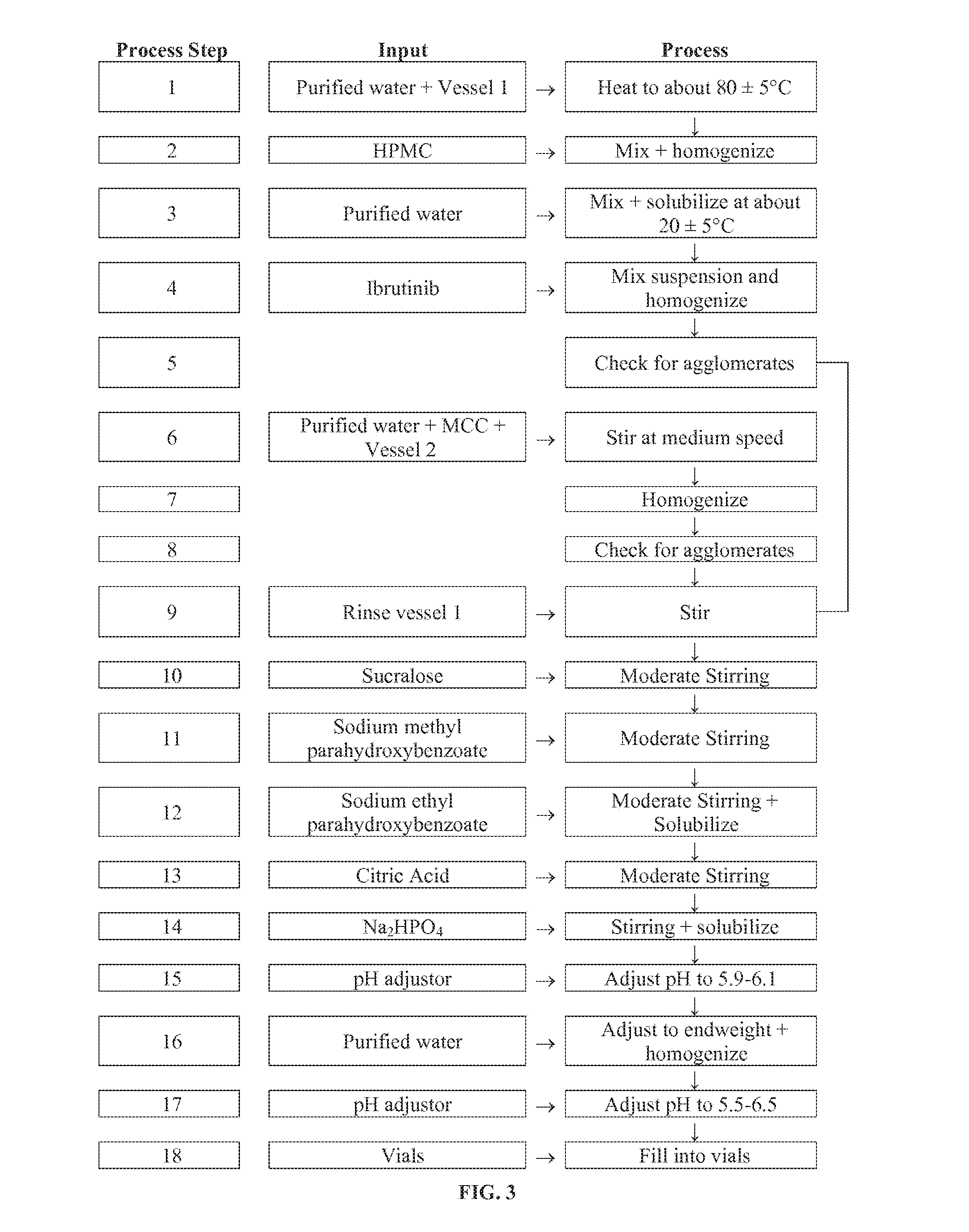

Compositions Containing Ibrutinib

InactiveUS20160287594A1Easy to sprinkleOrganic active ingredientsInorganic non-active ingredientsWaldenstrom macroglobulinemiaMetabolite

Discussed herein are pharmaceutical compositions containing Ibrutinib and processes for preparing them. The compositions may be utilized in the treatment of a variety of conditions including, without limitation, B-cell proliferative disorders such as non-Hodgkin lymphoma (diffuse large B cell lymphoma, follicular lymphoma, mantle cell lymphoma or burkitt lymphoma), Waldenstrom macroglobulinemia, plasma cell myeloma, chronic lymphocytic leukemia, lymphoma, or leukemia. These compositions are designed for oral ingestion. The compositions are contained within a capsule such as a standard or sprinkle or in a liquid formulation such as a suspension. In one embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, croscarmellose sodium, sodium lauryl sulfate, and magnesium stearate. In another embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, carboxymethylcellulose sodium, hydroxypropylmethylcellulose, citric acid monohydrate, disodium hydrogen phosphate, sucralose, sodium methyl parahydroxybenzoate, sodium ethyl parahydroxybenzoate, concentrated hydrochloric acid, sodium hydroxide, and water.

Owner:JANSSEN PHARMA NV

Organic anti-reflective coating compositions for advanced microlithography

InactiveUS6846612B2Radiation applicationsSemiconductor/solid-state device manufacturingEpoxyAnti-reflective coating

New polymers and new anti-reflective compositions containing such polymers are provided. The compositions comprise a polymer (e.g., epoxy cresol novolac resins) bonded with a chromophore (4-hydroxybenzoic acid, trimellitic anhydride). The inventive compositions can be applied to substrates (e.g., silicon wafers) to form anti-reflective coating layers having high etch rates which minimize or prevent reflection during subsequent photoresist exposure and developing.

Owner:BREWER SCI

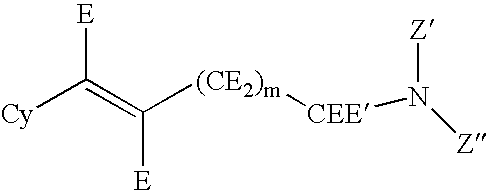

Hydroxybenzoate salts of metanicotine compounds

InactiveUS20060122237A1Prevent and suppress symptomsIncrease the number ofBiocideNervous disorderDouble bondMedicinal chemistry

Patients susceptible to or suffering from conditions and disorders, such as central nervous system disorders, are treated by administering to a patient in need thereof compositions that are hydroxybenzoate salts of E-metanicotine-type compounds. The formation of hydroxybenzoate salts of the E-metanicotine compounds is also useful in purifying the E-metanicotine compounds, as the hydroxybenzoate salts tend to crystallize out, leaving impurities such as Z-metanicotine compounds, and compounds where the double bond has migrated, in solution. If desired, the hydroxybenzoate salts can be converted to either the free base (the E-metanicotine) or to another pharmaceutically acceptable salt form.

Owner:TARGACEPT INC

Antimicrobial Composition and Method

InactiveUS20080249136A1Improve performanceImprove securityAntibacterial agentsBiocideSodium PyrithioneNitrostyrol

An antimicrobial composition containing a cationic polymer having limited antimicrobial activity (such as a hydrophobically-modified quaternary ammonium cellulose ether) and an antimicrobial compound (such as one or more compounds selected from the group consisting of diiodomethyl-para-tolylsulfone, ortho-phenylphenol, sodium pyrithione, zinc pyrithione, 3-iodo-2-propynylbutylcarbamate, 2-methyl-4-isothiazolin-3-one, 1,2-benzisothiazolin-3-one, 2-n-octyl-4-isothiazolin-3-one, 1-(3-chloroallyl)-3,5,7-triaza-1-azoniaadamantane chloride, 2-(4-thiazolyl)-benzimidazole, β-bromo-β-nitrostyrene, 2,4,4′-trichloro-2-hydroxyphenyl ether, chloroxylenol, chlorocresol, para-tert-amylphenol, N-(4-chlorophenyl)-N′-(3,4 dichlorophenyl)-urea, and para-hydroxybenzoic acid esters). The growth of microorganisms (such as Pseudomonas aeruginosa) can be inhibited by exposing the microorganism to such a composition.

Owner:DOW GLOBAL TECH LLC

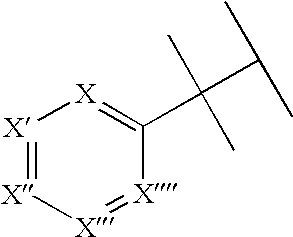

Overbased alkaline earth metal alkylhydroxybenzoates having low crude sediment

ActiveUS8030258B2Decrease in levelLow production costOrganic chemistryOrganic compound preparationAlkaline earth metalAliphatic hydrocarbon

A process for preparing an overbased alkaline earth metal alkylhydroxybenzoate, said process comprising overbasing an alkaline earth metal alkylhydroxybenzoate or a mixture of alkaline earth metal alkylhydroxybenzoate and up to 50 mole % of alkylphenol, based on the total mixture of alkylhydroxybenzoate and alkylphenol, with a molar excess of alkaline earth metal base and at least one acidic overbasing material in the presence of at least one carboxylic acid having from one to four carbon atoms and a solvent selected from the group consisting of aromatic hydrocarbons, aliphatic hydrocarbons, monoalcohols, and mixtures thereof.

Owner:CHEVRON ORONITE SA

Liquid crystalline polyester resin composition

Owner:POLYPLASTICS CO LTD

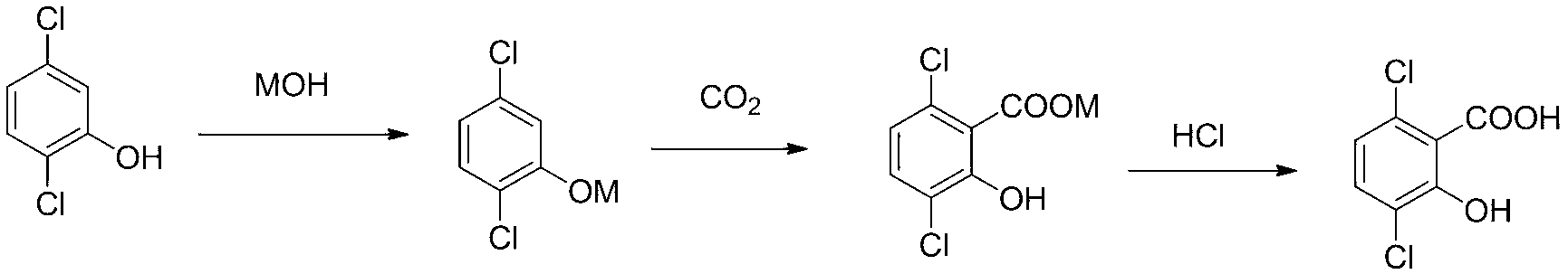

Preparation method of 3,6-dichloro-2-hydroxybenzoic acid

InactiveCN103012124AReduce manufacturing costOrganic compound preparationCarboxylic compound preparationFiltrationDistillation

The invention discloses a preparation method of 3,6-dichloro-2-hydroxybenzoic acid, which sequentially comprises the following steps: 1) salifying 2,5-dichlorophenol; 2) carboxylation: transferring the 2,5-dichlorophenate solution into a high-pressure reaction kettle, adding a cocatalyst, and introducing CO2 to carry out high-pressure carboxylation reaction to obtain the reaction product containing 3,6-dichloro-2-hydroxybenzoate, wherein the cocatalyst is composed of potassium carbonate and activated carbon; 3) refinement: after cooling the reaction product containing 3,6-dichloro-2-hydroxybenzoate obtained in the step 2) to room temperature, adding an alkali solution, regulating the pH value to 11-13, uniformly stirring, filtering to recover activated carbon, stratifying the filtrate, and taking the water phase; and adding an acid solution into the water phase, regulating the pH value to 1-3, carrying out vapor distillation to recover the 2,5-dichlorophenol, cooling to crystallize, carrying out vacuum filtration, and drying to obtain the 3,6-dichloro-2-hydroxybenzoic acid.

Owner:ZHEJIANG UNIV

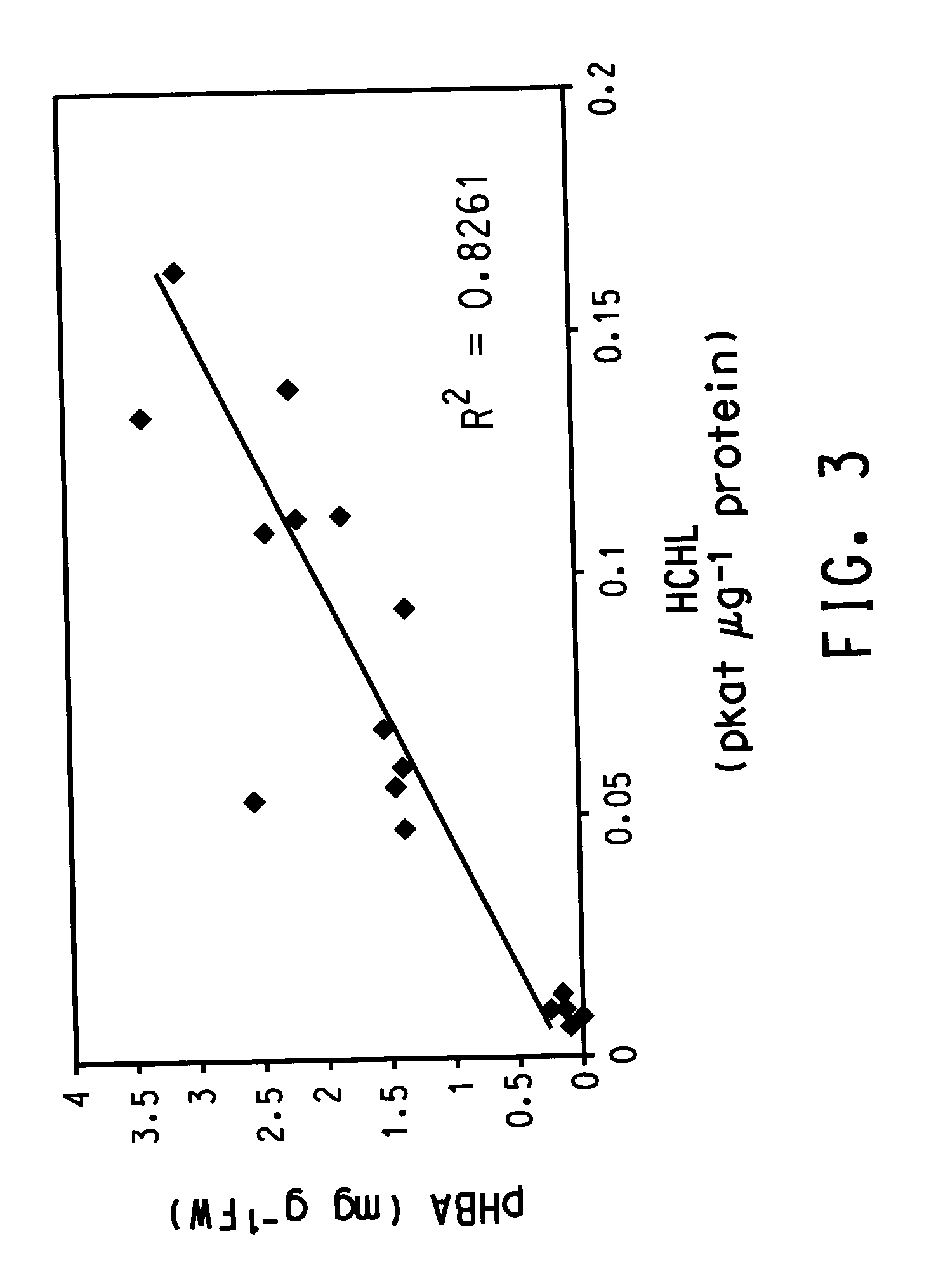

Method to produce para-hydroxybenzoic acid in the stem tissue of green plants by using a tissue-specific promoter

This invention relates to methods and materials to produce para-hydroxybenzoic acid in the stem tissue of transgenic green plants using a cellulose synthase promoter to operably express a gene encoding HCHL.

Owner:UNIVERSITY OF NORTH TEXAS

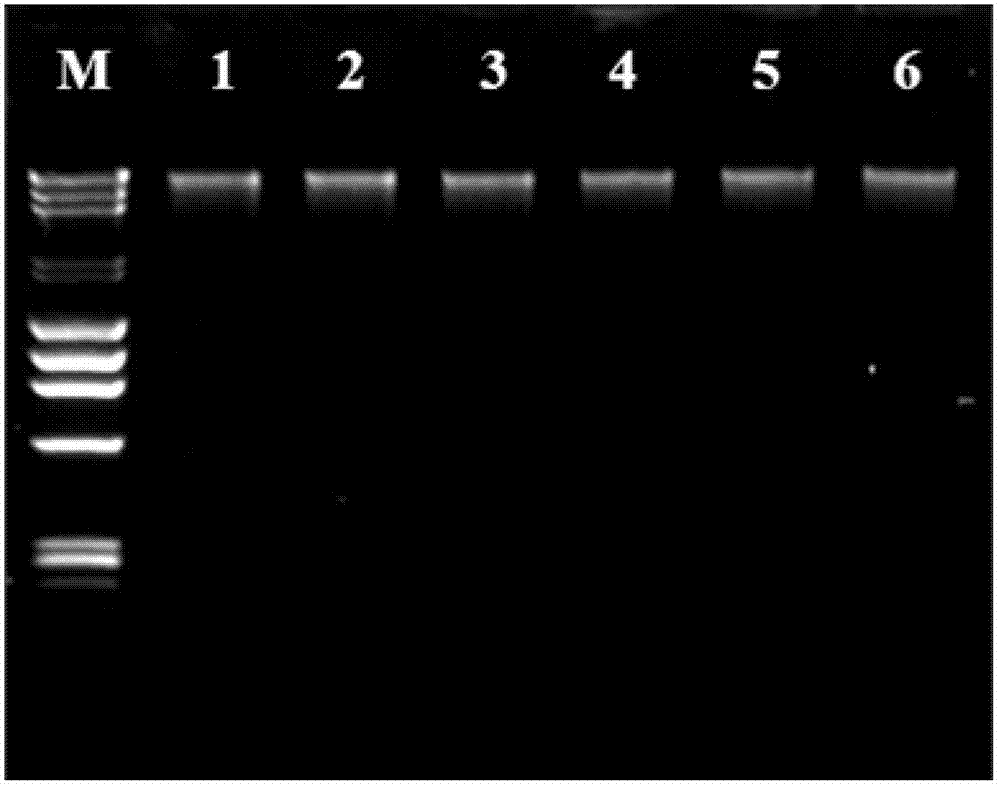

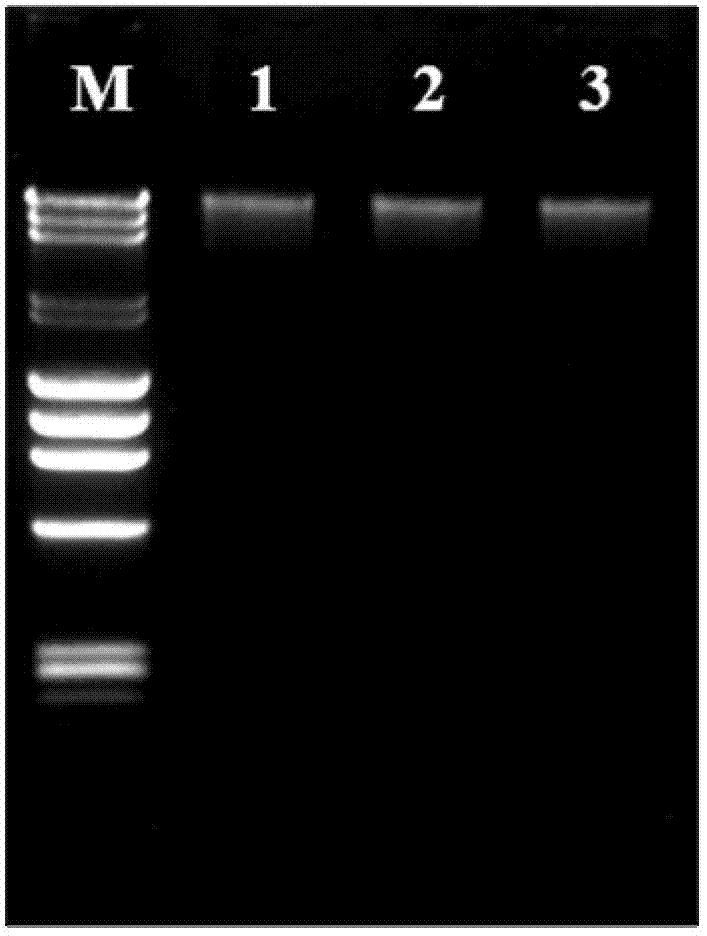

Composite for preservation of human saliva and preparation method there of

InactiveCN102919218APollution suppressionAvoid pollutionDead animal preservationN-Acetyl-5-methoxytryptamineGenomic DNA

The invention relates to a composite for preservation of human saliva and a preparation method of the composite. The composite comprises the following components: Tris-HCl with pH being 6-8.5 (5-20mmol / L), EDTA (Ethylene Diamine Tetraacetic Acid) (0.5-2mmol / L), NaOAc (2.5-3.5mol / L), cane sugar (0.1-0.4mol / L), N-acetyl-5-methoxytryptamine (1-3mmol / L), propylparaben (1-4mg / mL), diazonium imidazolidinyl urea (1-3mg / mL), protease K(10mu g / mL) and a system with pH being 7.5-8.5. When used for preservation of human saliva, the composite is capable of inhibiting nuclease activity and preventing nuclease from being contaminated by external microbes or being oxidized by itself, thereby guaranteeing the integrality and the purity of genomic DNA (deoxyribonucleic acid). The composite is long in preservation period, wide in preservation temperature range and applicable to gene detection and related scientific researches.

Owner:湖北维达健基因技术有限公司

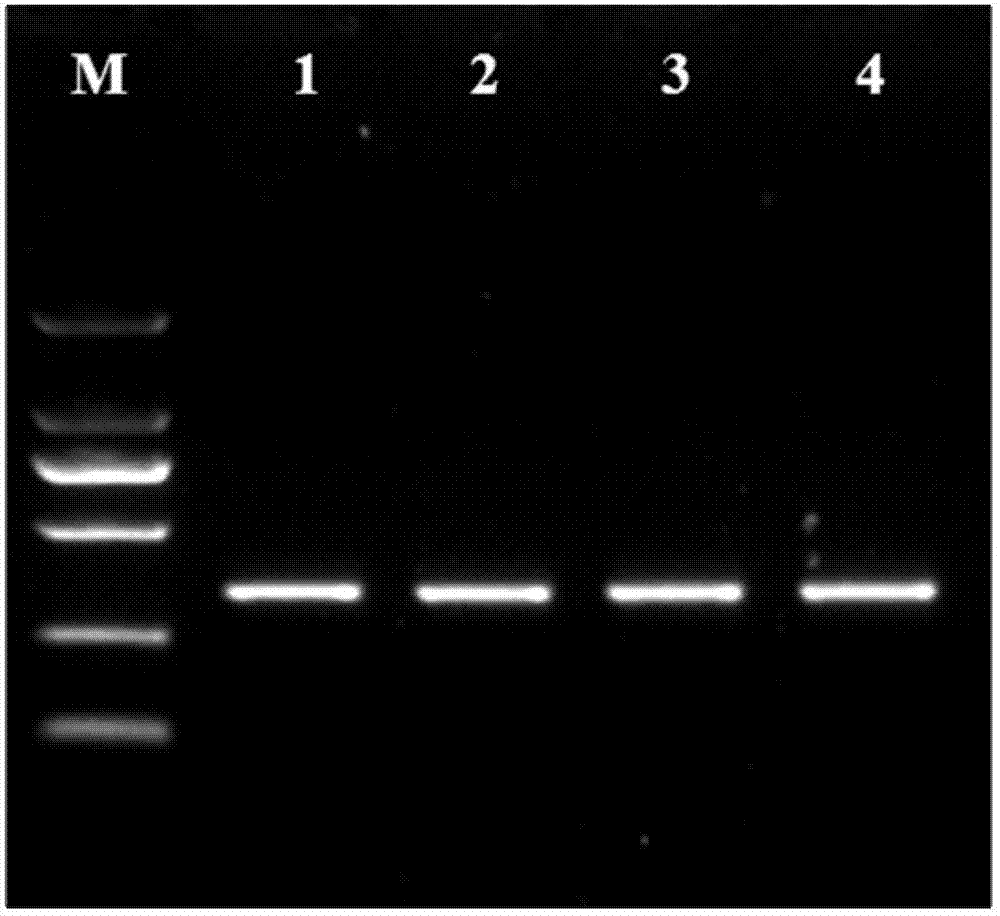

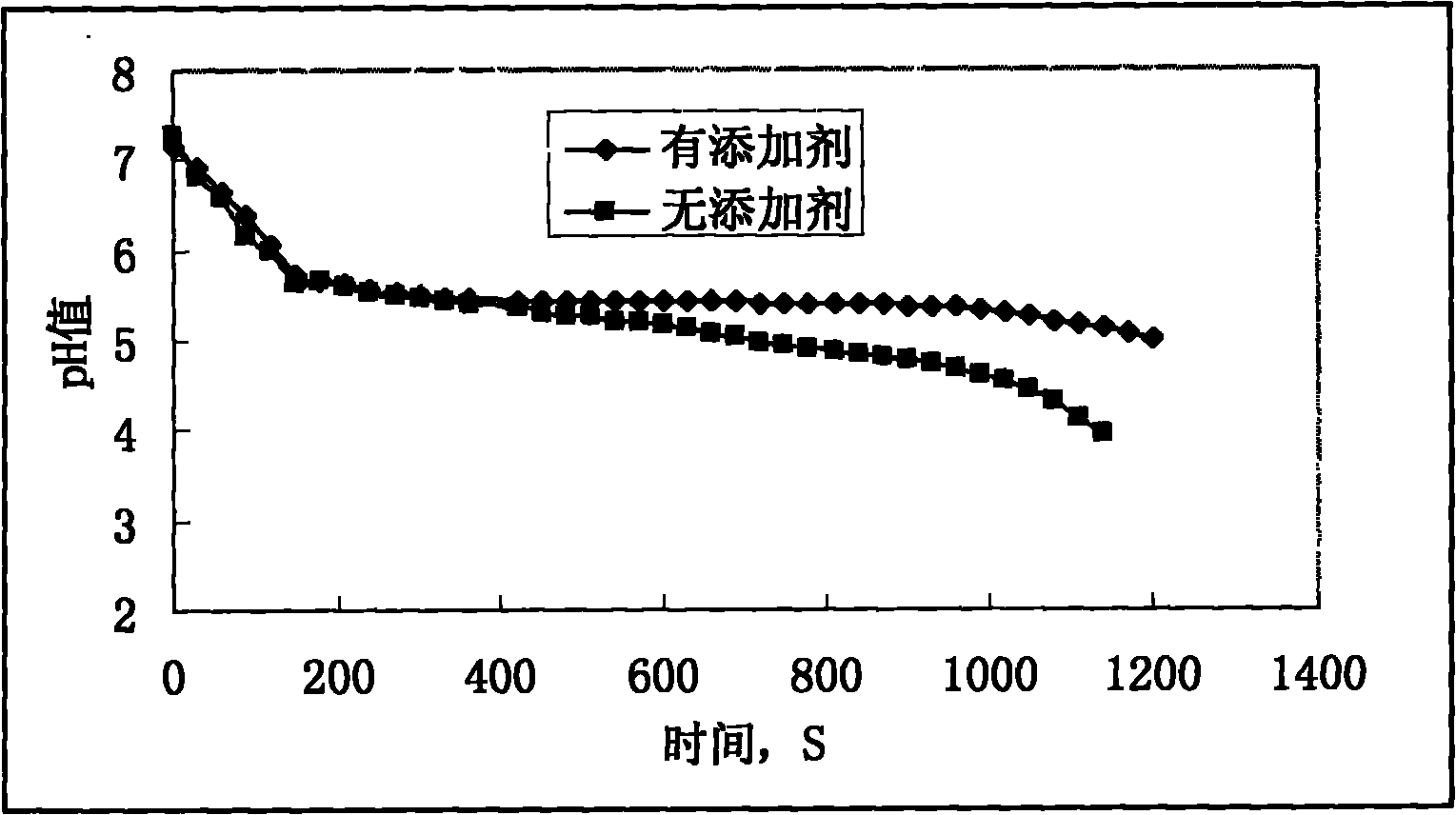

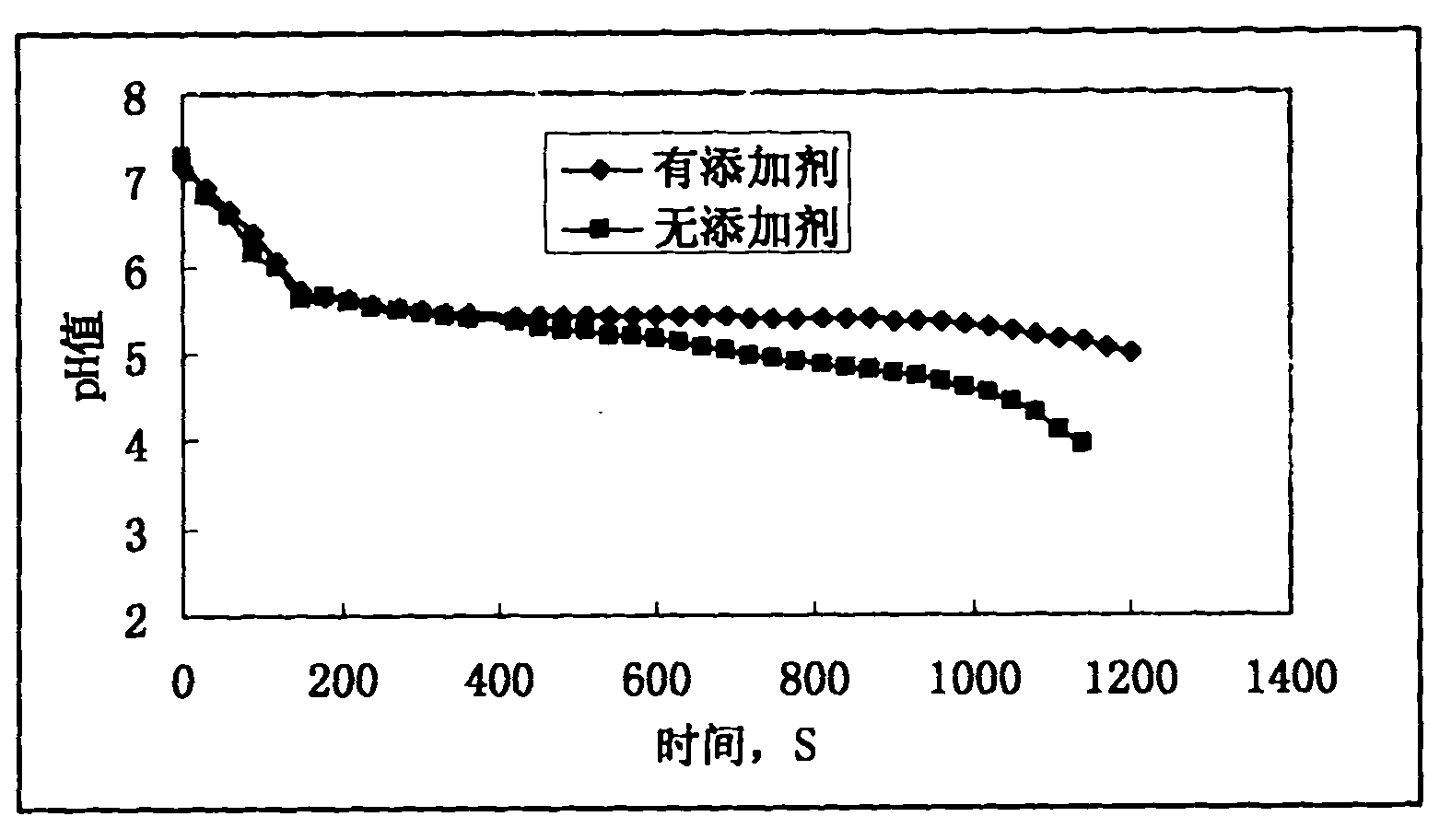

Multifunctional composite additive for wet-method flue gas desulfuration process and using method thereof

InactiveCN102019138AImprove solubilityFacilitate absorption reactionDispersed particle separationDissolutionSlurry

The invention belongs to the technical field of a limestone-gypsum wet-method flue gas desulfuration process and relates to a multifunctional composite additive for a wet-method flue gas desulfuration process and a using method thereof. The composite additive comprises the following components in percentage by mass: 31 to 45 percent of nylon acid, 31 to 45 percent of sodium humate, 6 to 9 percentof organic silicon defoaming agent, 2 to 5 percent of potassium formate, 2 to 5 percent of manganese sulfate and 2 to 5 percent of p-hydroxybenzoic acid. The composite additive can promote the dissolution of the limestone and reduce the using amount of the limestone, has an enhancement factor for improving an absorption reaction of sulfur dioxide (SO2), accelerates the migration speed of SO2 gas liquid, promotes the adsorption reaction of the SO2 in a liquid membrane, inhibits the soft scales of calcium sulfate (CaSO3) from generating, improves the pH value buffer capacity of limestone slurry, slows down the reducing speed of the pH value in the process of absorbing the SO2 by the desulfuration slurry continuously, and achieves the effect of avoiding bubbling and overflow of the desulfuration slurry.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

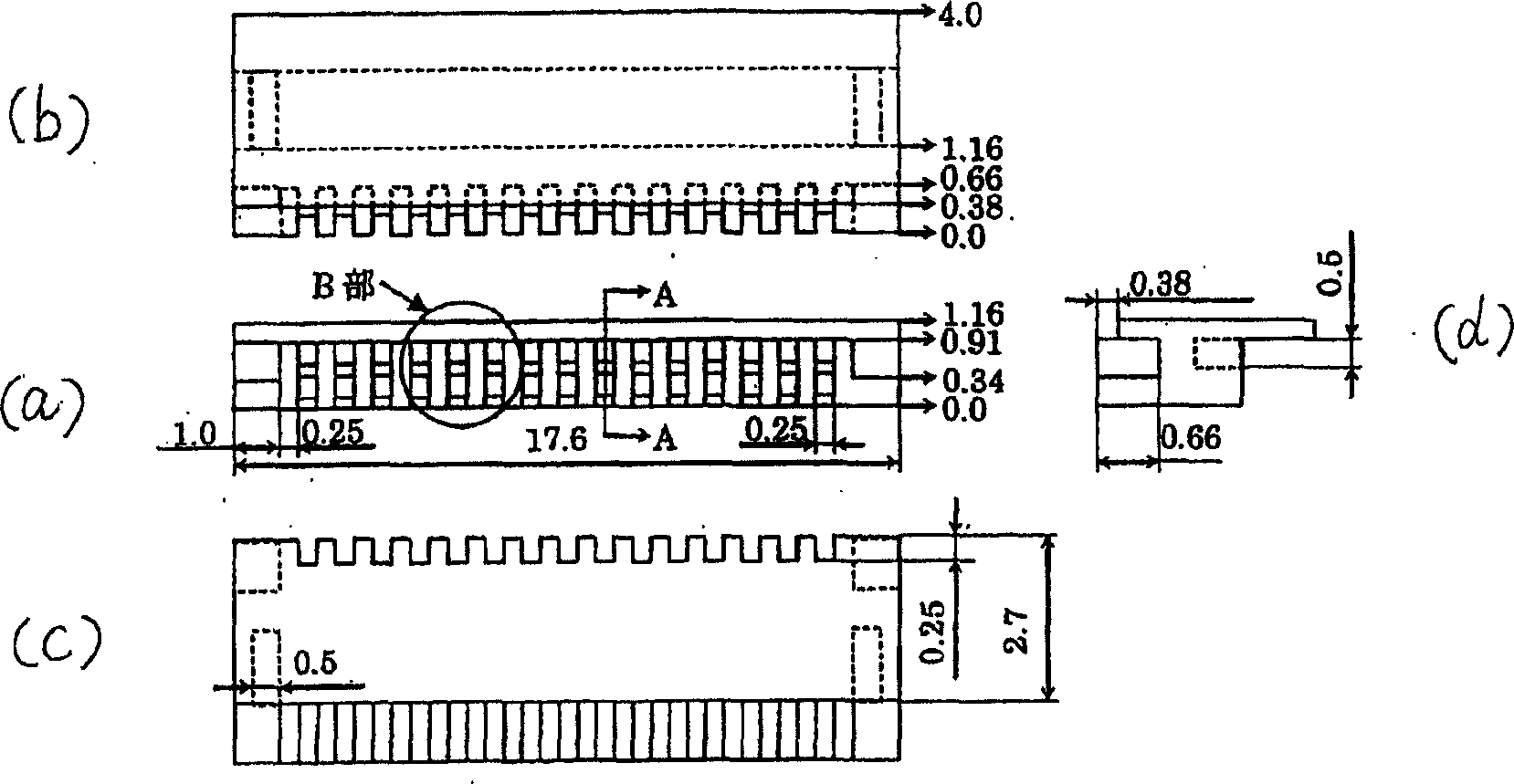

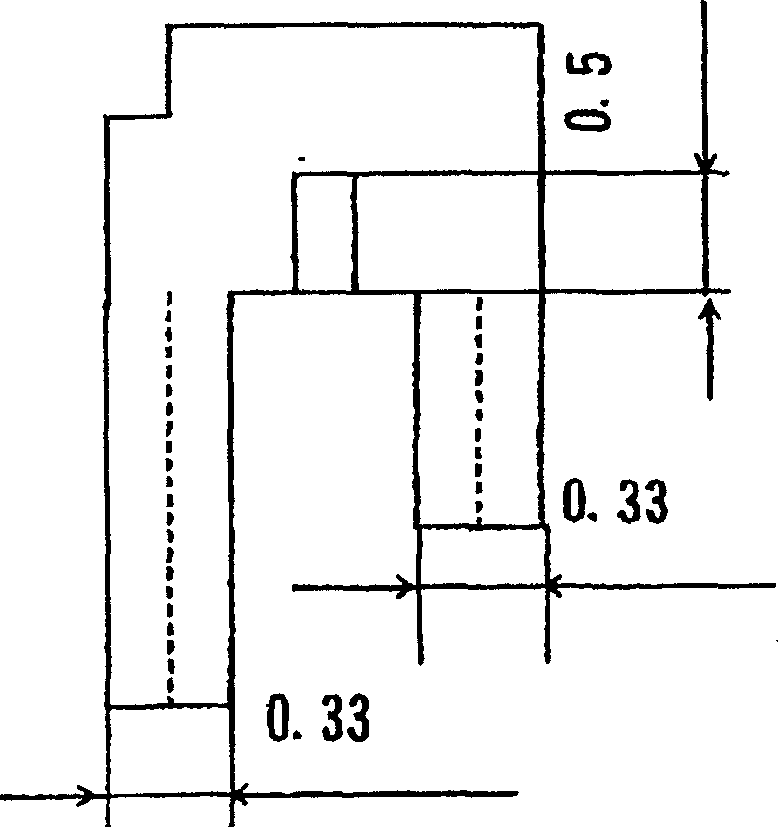

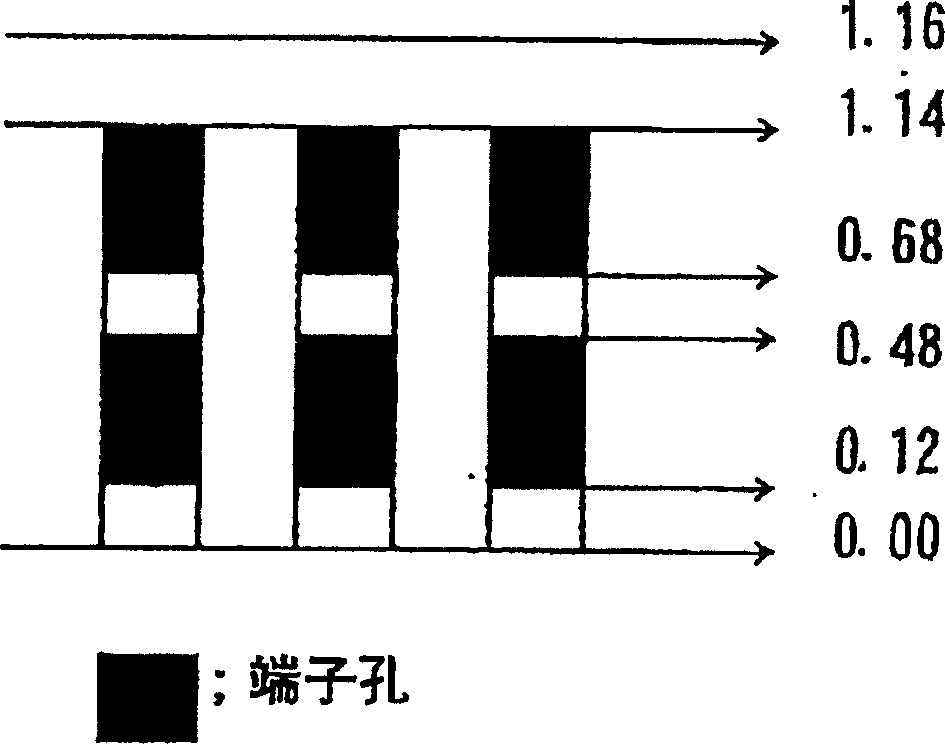

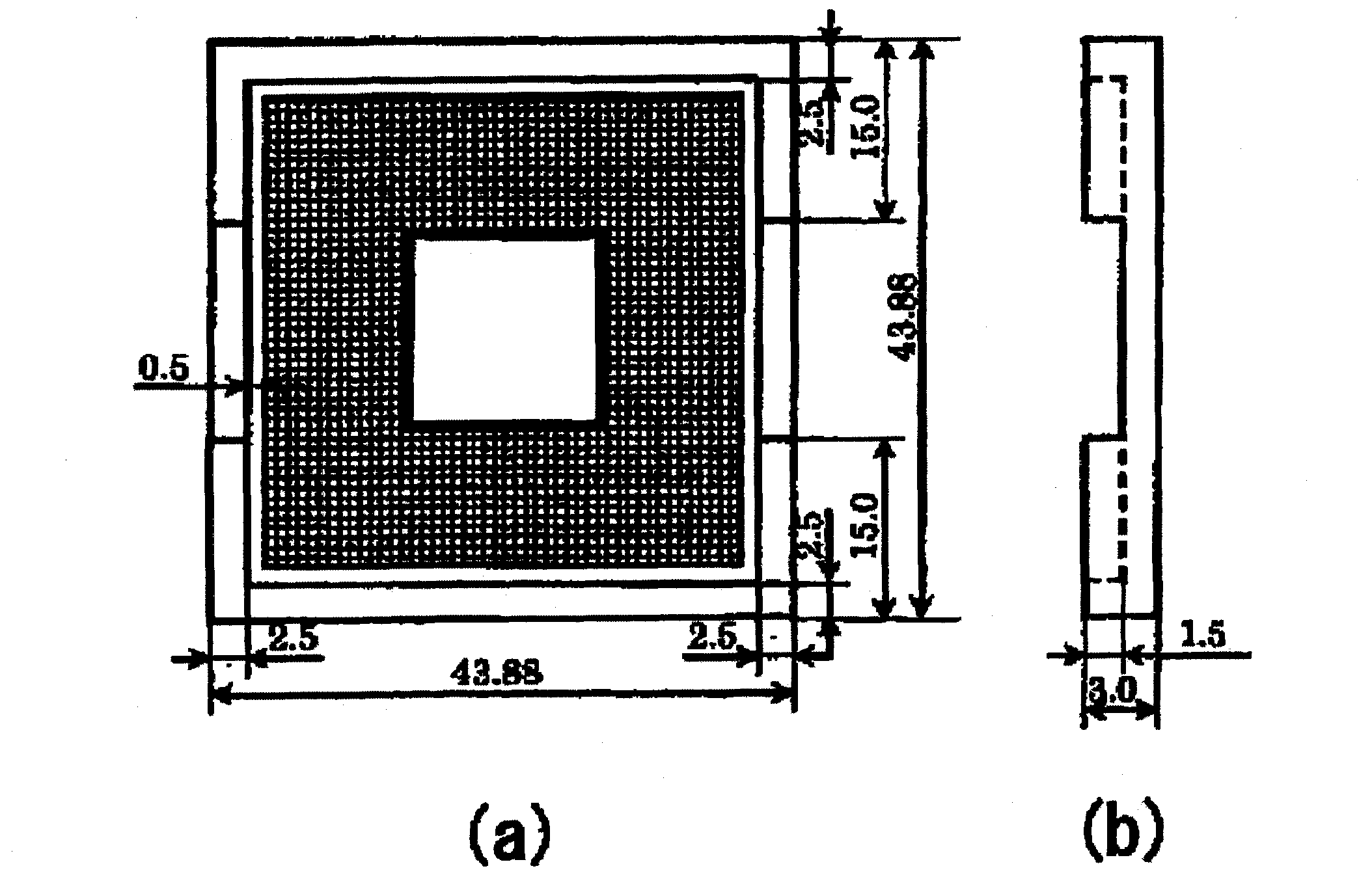

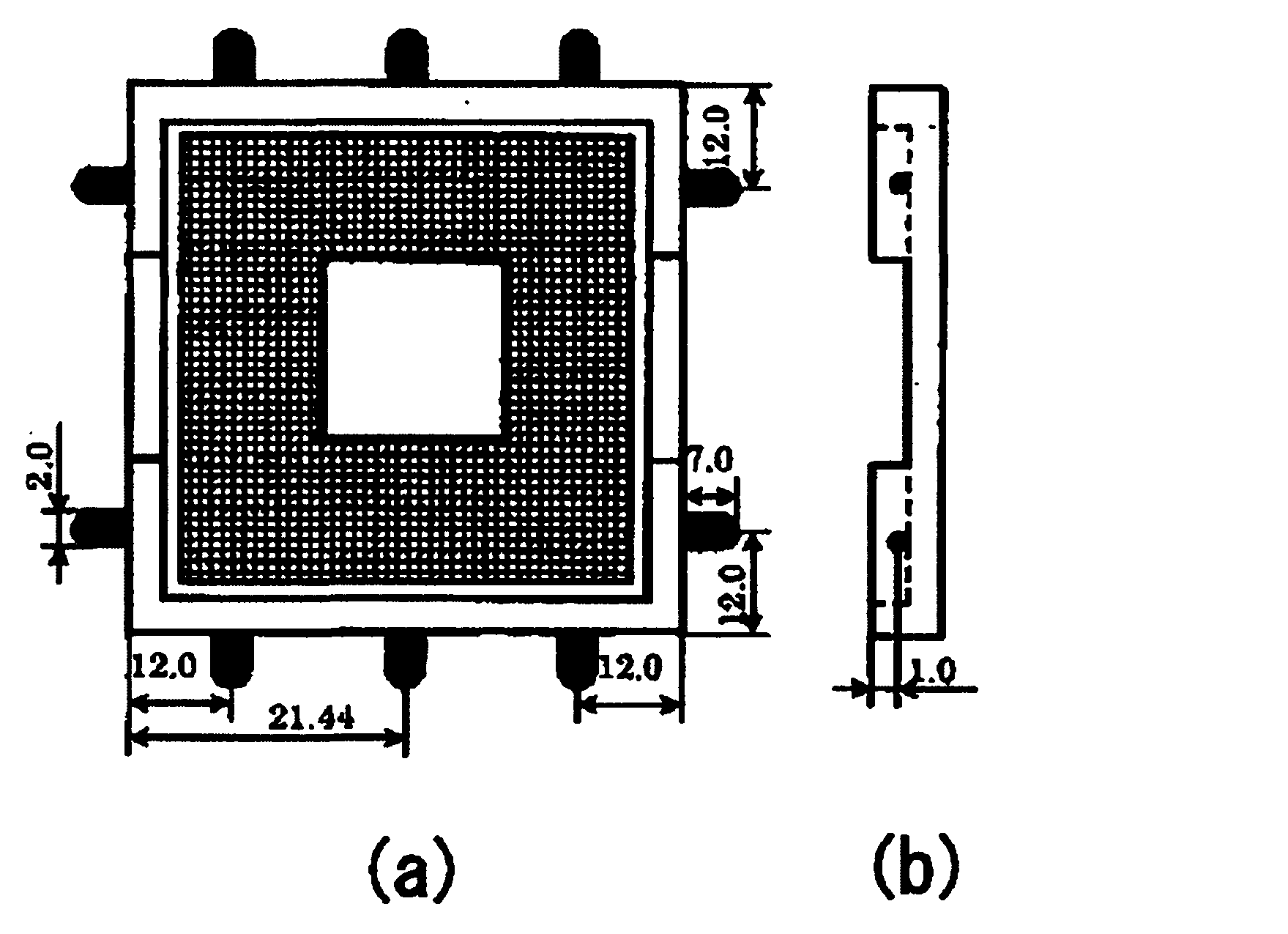

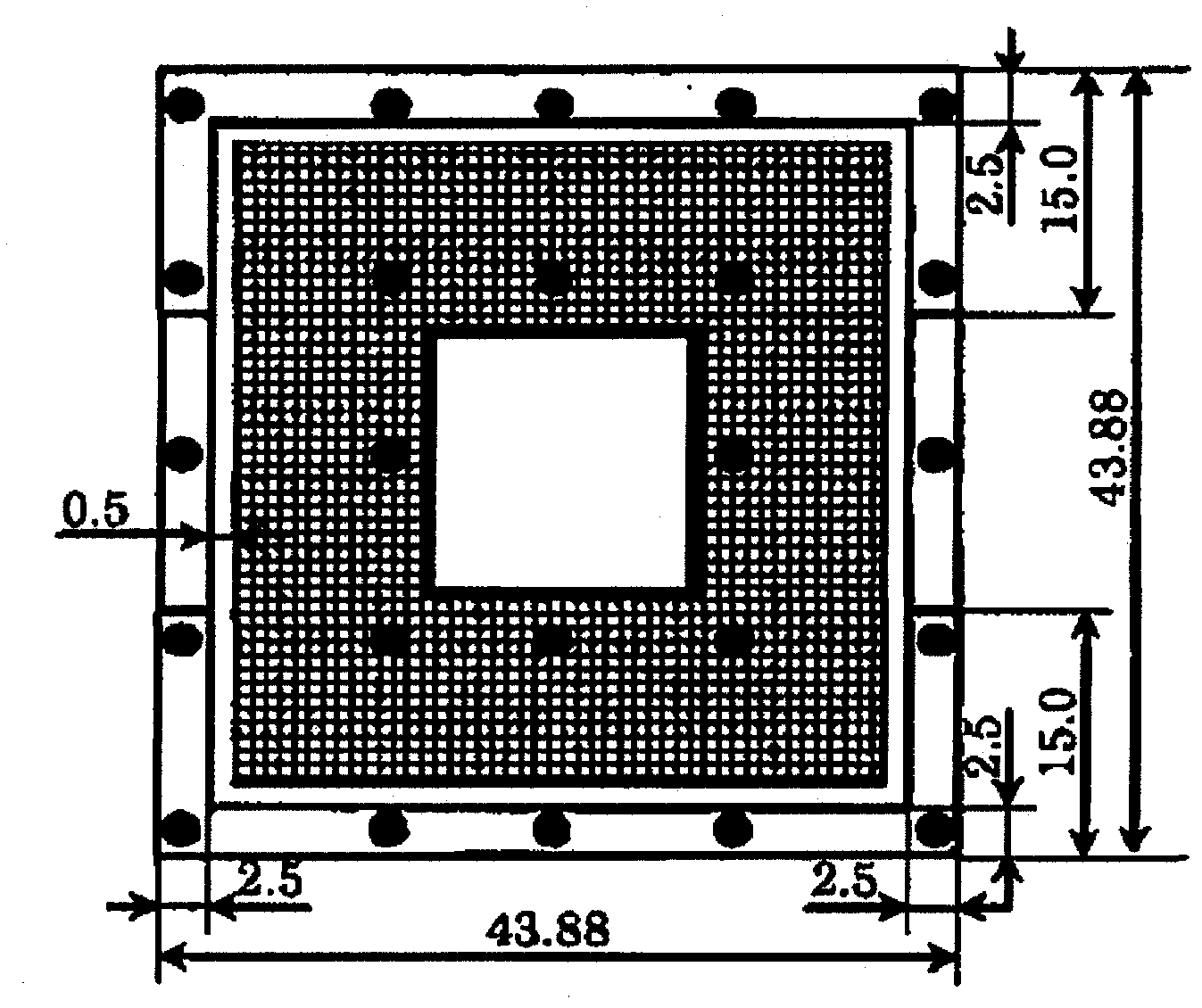

Planar connector

Disclosed is a planar connector that can cope with even a change in shape of recent planar connectors and is excellent, for example, in all of flatness, warpage deformation, and heat resistance properties. Specifically, the planar connector is characterized in that the planar connector is formed of a composite resin composition comprising (A) a liquid crystalline polymer having a p-hydroxy benzoic acid residue content of not more than 55% by mole and having a melting point of 330 DEG C or above, (B) a plate-like inorganic filler, and (C) a fibrous filler having a weight average fiber length of 250 to 600 [mu]m, the content of the component (B), the content of the component (C), and the total content of the components (B) and (C) being 25 to 35% by weight, 10 to 25% by weight, and 40 to 50% by weight, respectively, based on the whole composition, and the planar connector has such a structure that the inside of an outer frame has a lattice structure, the inside of the lattice structure has an opening part, the pitch interval of the lattice part is not more than 1.5 mm, and the ratio between the thickness of the outer frame part and the thickness of the lattice part is not more than 0.8.

Owner:POLYPLASTICS CO LTD

Microbicidal composition

A microbicidal composition of 1,2-benzisothiazolin-3-one; and at least one of benzalkonium chloride, benzethonium chloride, benzyl alcohol, caprylyl glycol, chlorphenesin, diazolidinyl urea, ethylparaben, imidazolidinyl urea, methylparaben, phenoxyethanol, linoleamidopropyl PG-dimonium chloride phosphate, cocamidopropyl PG-dimonium chloride phosphate, propylparaben, cis-1-(3-chloroallyl)-3,5,7-triaza-1-azoniaadamantane chloride, dehydroacetic acid or its salts, benzoic acid or its salts, and sodium hydroxymethylglycinate.

Owner:DDP SPECIALTY ELECTRONICS MATERIALS US 8 LLC

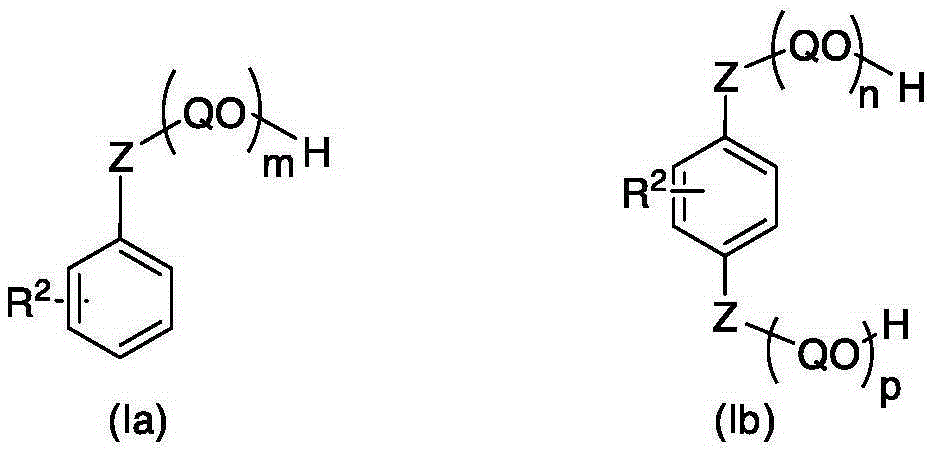

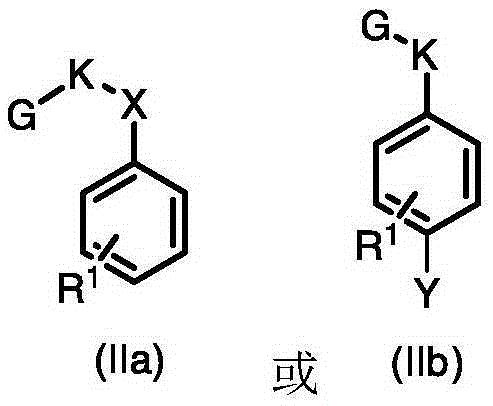

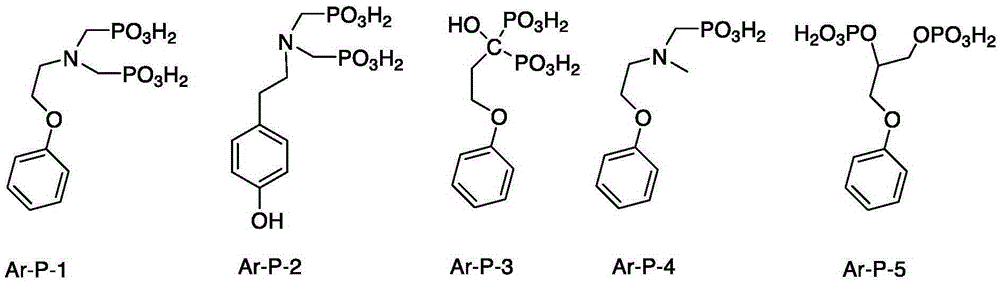

Preparation method and application of anti-soil polymer

The invention provides a preparation method and application of an anti-soil polymer. The prepared polymer is used as a dispersant for a hydraulic cementing agent and / or an aqueous dispersion for potential hydraulic cementing agent and has good anti-soil performance. The preparation method the anti-soil polymer comprises a step of subjecting polyether macromonomer A with a special structure, monomer B containing a phosphoric acid or phosphorous acid group, optional monomer D and aldehyde C to condensation polymerization so as to prepare the anti-soil polymer, wherein the monomer D is selected from the group consisting of phenol, aniline, p- / o-aminobezene solfonic acid, p- / o-hydroxybenzoic acid, p- / o-aminobenzoic acid, p- / o-hydroxyezene solfonic acid, p- / o-toluidine and p- / o-methylphenol, a mol ratio of the polyether macromonomer A to the monomer B to the monomer D is 1: (0.5-12): (0-8.0), and a mol ratio of the polyether macromonomer A to the monomer B and the monomer D is 1: (0.5-12.0).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Artificial feed for armyworm, preparation method thereof, and feeding method

InactiveCN101856085AEasy accessImprove anti-corrosion performanceAnimal feeding stuffBiotechnologySucrose

The invention relates to an artificial feed for armyworm, a preparation method thereof, and a feeding method, and belongs to the technical field of insect feeding. The artificial feed for the armyworm is mainly prepared from the following components: soybean meal, yeast powder, casein, dry corn leaf meal, cholesterol, sucrose, ascorbic acid, sorbic acid, agal-agal, hydroxybenzoate methyl paraben, vitamin solution and distilled water. The feed has strong adaptivity and is a favorite food for the armyworm, so the armyworm has normal growth and development and the nutrition requirement of the armyworm of the whole generation and the followed generation can be met. The feed and the feeding method are used for feeding the armyworm, the problem that the successive generation feeding of the armyworm throughout the year cannot be carried out caused by season change, particularly insufficient natural feed in winter and early spring seasons is solved, and the massive, annual and successive generation feeding of standard worm sources is realized.

Owner:罗礼智 +1

Antidaudruff hair conditioning composition

Disclosed is hair conditioning compositions comprising antidandruff agent wherein the hair conditioning composition is substantially free of the group selected from a chelating agent, methylchloroisothiazolinone, and methylisothiazolinone. The compositions comprise by weight: (a) from about 0.1 % to about 15 % of a high melting point fatty compound; (b) compounds selected of; (b1a) from about 0.1 % to about 10 % of an amidoamine having the following general formula: R<1> CONH (CH2)m N(R<2>)2 wherein R<1> is a residue of C11 to C24 fatty acids, R<2> is a C1 to C4 alkyl, and m is an integer from 1 to 4; (b1b) an acid selected from the group consisting of 1 glutamic acid, lactic acid, hydrochloric acid, malic acid, acetic acid, fumaric acid, 1 glutamic acid hydrochloride, tartaric acid, and mixtures thereof, at a level such that the mole ratio of amidoamine to acid is from about 1:0.3 to about 1:1; or (b2) the combination of; (b2a) from about 0.1% to about 10% of a cationic conditioning agent; and (b2b) from about 0.1% to about 10% of a low melting point oil having a melting point of less than 25 DEG C; (c) a safe and effective amount of an antidandruff agent; (e) a preservative system comprising, by weight of the entire composition, from about 0.1% to about 1.0% of benzyl alcohol, from about 0.1 % to about 1.0 % of phenoxy ethanol, from about 0.05 % to about 1.0 % of methyl paraben, and from about 0.05 % to about 1.0 % of mettryl paraben, and from about 0.01 % to about 1.0 % of propyl paraben; and (f) an aqueous carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Skin whitening, moisturizing and nourishing gel and method for preparing same

InactiveCN101700218AMoisturizingAnti agingCosmetic preparationsToilet preparationsBletilla striataMedicine

The invention discloses skin whitening, moisturizing and nourishing gel. Each 160 grams of the skin whitening, moisturizing and nourishing gel comprises the following materials by weight: 0.1-1.5 g of carbomer, 0.05-0.1 g of triethanolamine, 2-8 g of glycerol, 3-7 g of olive oil, 1-4 ml of 70% sorbitol,0.5-3.5 g of honey, 2-5 g of bletilla striata extract, 13-20 g of cucumber extract, 0.1-1 g of tween-80, 0.1-0.5 g of ethyl p-hydroxybenzoate, 1-3 ml of 95% ethanol, 0.05-0.25 ml of essence and 90-150 ml of distilled water. Compared with the prior art, the skin whitening, moisturizing and nourishing gel is glittering and translucent, has suitable viscosity and consistency, good stability and fragrant smell, can make the skin feel better and can be absorbed quickly.

Owner:北京维斯卡特生物技术有限公司

After shave treatment preparation

InactiveUS6277362B1Reduce skin irritationPrevention and treatmentCosmetic preparationsHair removalAdditive ingredientIrritation

Non-steroidal anti-infammatory after shave preparations to aid in the prevention and treatment of Pseudofolliculitis Barbae and a method of delivering the ingredients of the preparation to affected areas of the skin. Formula I comprises ethanol, salicylic acid, propylene glycol, glycerine, fragrance, at least one compound for reducing skin irritation and at least one non-steroidal anti-inflammatory agent wherein said non-steroidal anti-inflammatory agent is an NSAID drug, a naturally occurring herbal compound containing an anti-inflammatory component or combinations thereof. Formula 11 comprises water, hydrolyzed oat flour, sorbitol, methylparaben, petrolatum, lanolin, cetyl alcohol, sunflower seed oil, stearic acid, propylparaben, triethanoloamine, a preservative, and at least one non-steroidal anti-inflammatory agent wherein said non-steroidal anti-inflammatory agent is an NSAID drug, a naturally occurring herbal compound containing an anti-inflammatory component or combinations thereof. The formulas have sufficient viscosity to allow the after shave preparation to remain on an affected area of the skin for a sufficient period of time to optimize the skin irritation reduction and anti inflammatory effects on the affected area thus providing local relief from irritation due to PFB.

Owner:PC & K HLDG +1

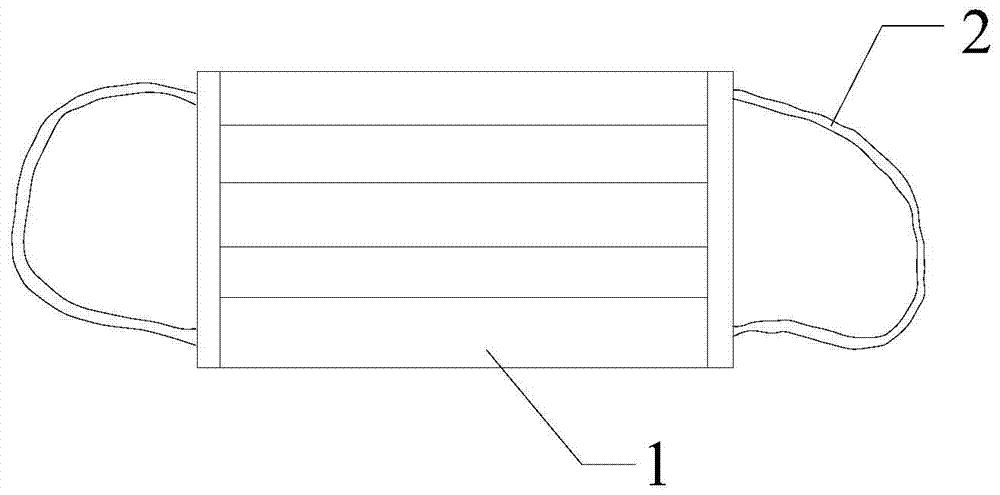

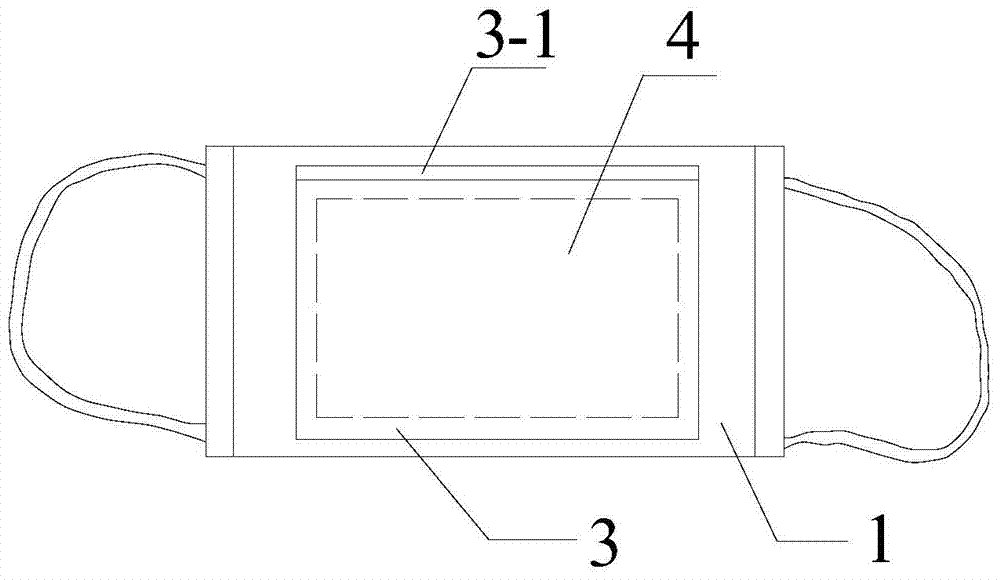

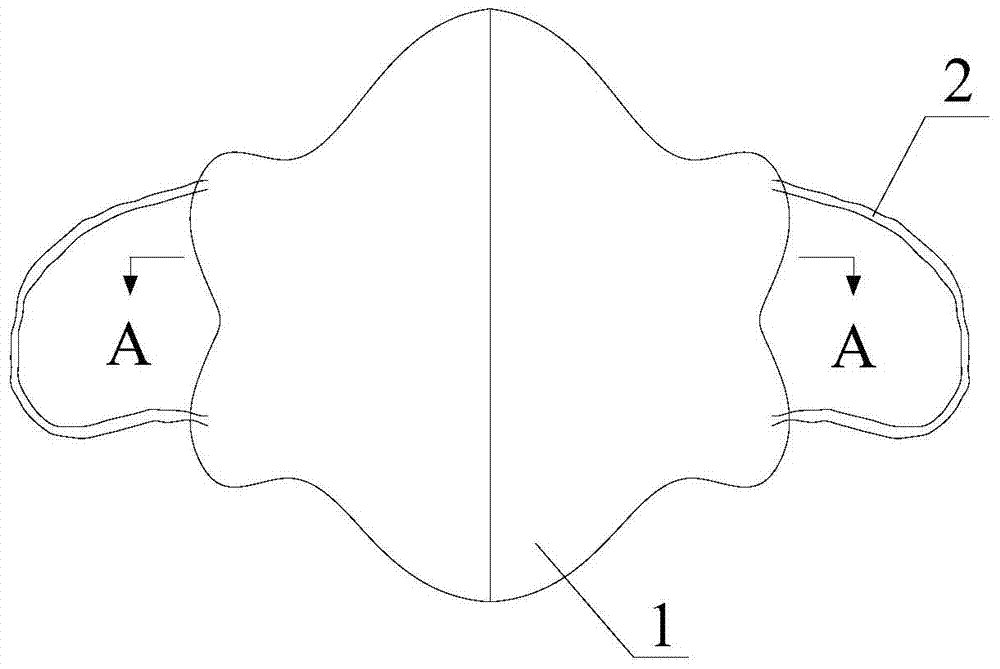

Humidifying piece and humidifying mask with same

InactiveCN104510031AImprove the physiological environmentPrevent drynessProtective garmentNasal cavityEngineering

The invention discloses a humidifying piece and a humidifying mask with the same. The humidifying piece comprises moisturizing components, wherein the moisturizing components include one or multiple components of hyaluronic acid, hydroxyethyl cellulose, trimethyl glycine and ethyl p-hydroxybenzoate. Medical components can be selectively added into the humidifying piece and include mint, eucalyptus oil or natural borneol. The humidifying piece comprising the moisturizing components is placed in an interlayer of a mask body to provide moisture needed by nasal cavities of a human body, the humidity of the nasal cavities and an oral cavity is kept, medicines are continuously fed, nasal mucosa drying is avoided, and the humidifying mask is suitable for wearing in dry air environments or after various rhinitis or nasal operations.

Owner:王彤 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com