Patents

Literature

43 results about "Lead electrolyte" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overcharging with high charging voltages generates oxygen and hydrogen gas by electrolysis of water, which is lost to the cell. The design of some types of lead-acid battery allow the electrolyte level to be inspected and topped up with any water that has been lost.

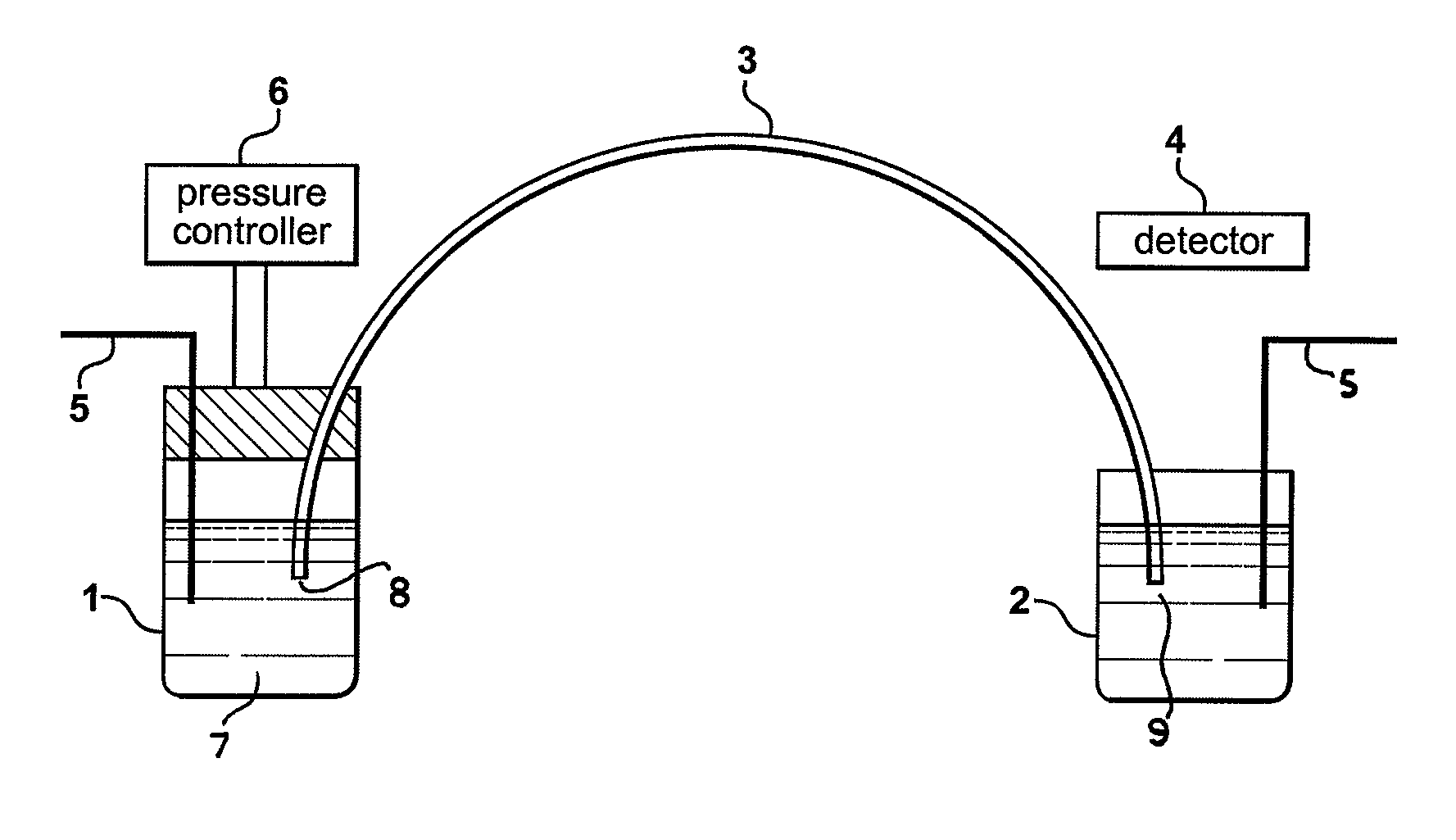

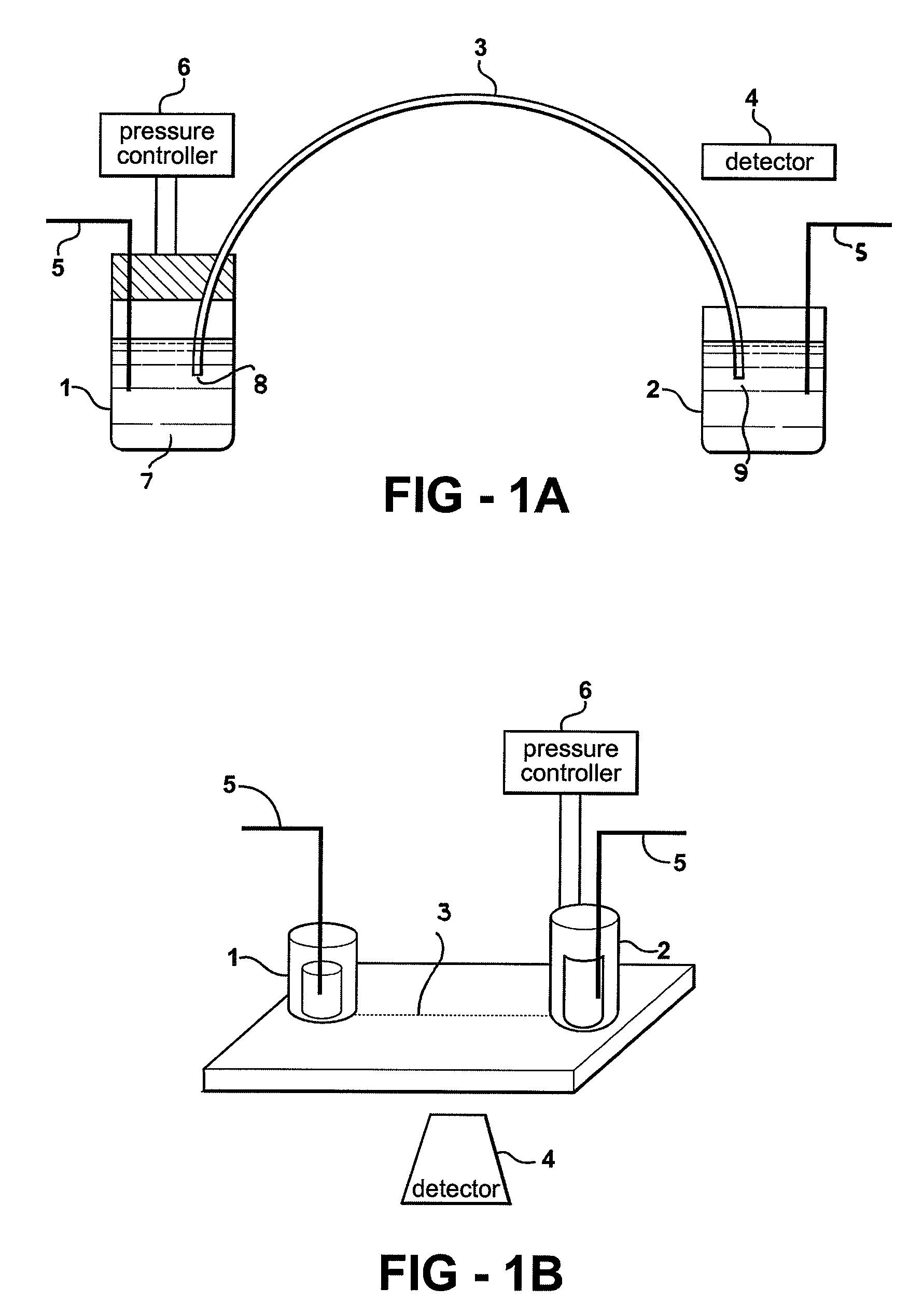

Analyte injection system

InactiveUS20050133370A1Increase in sizeShort amount of timeSludge treatmentVolume/mass flow measurementGlutaric acidAntibody conjugate

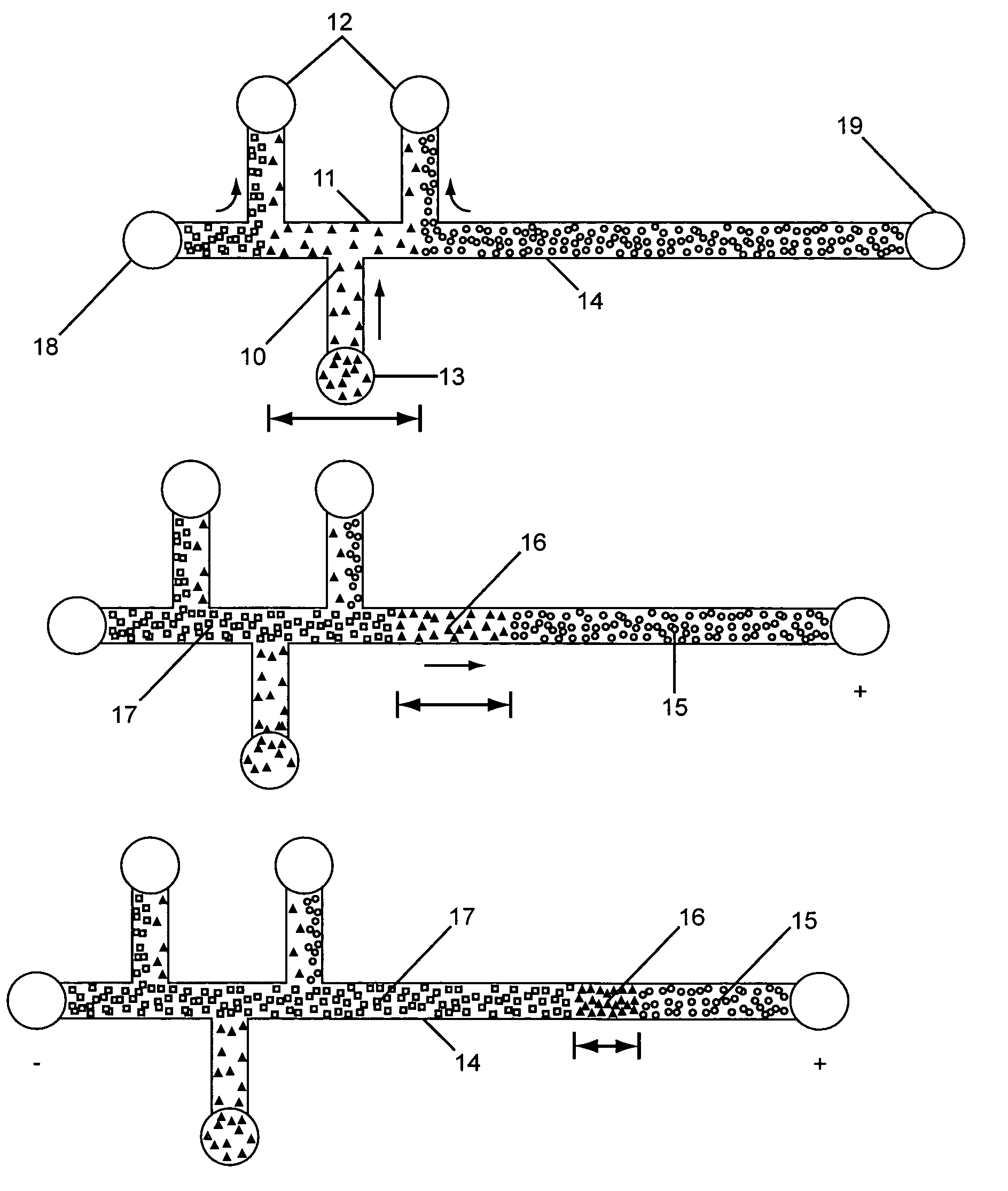

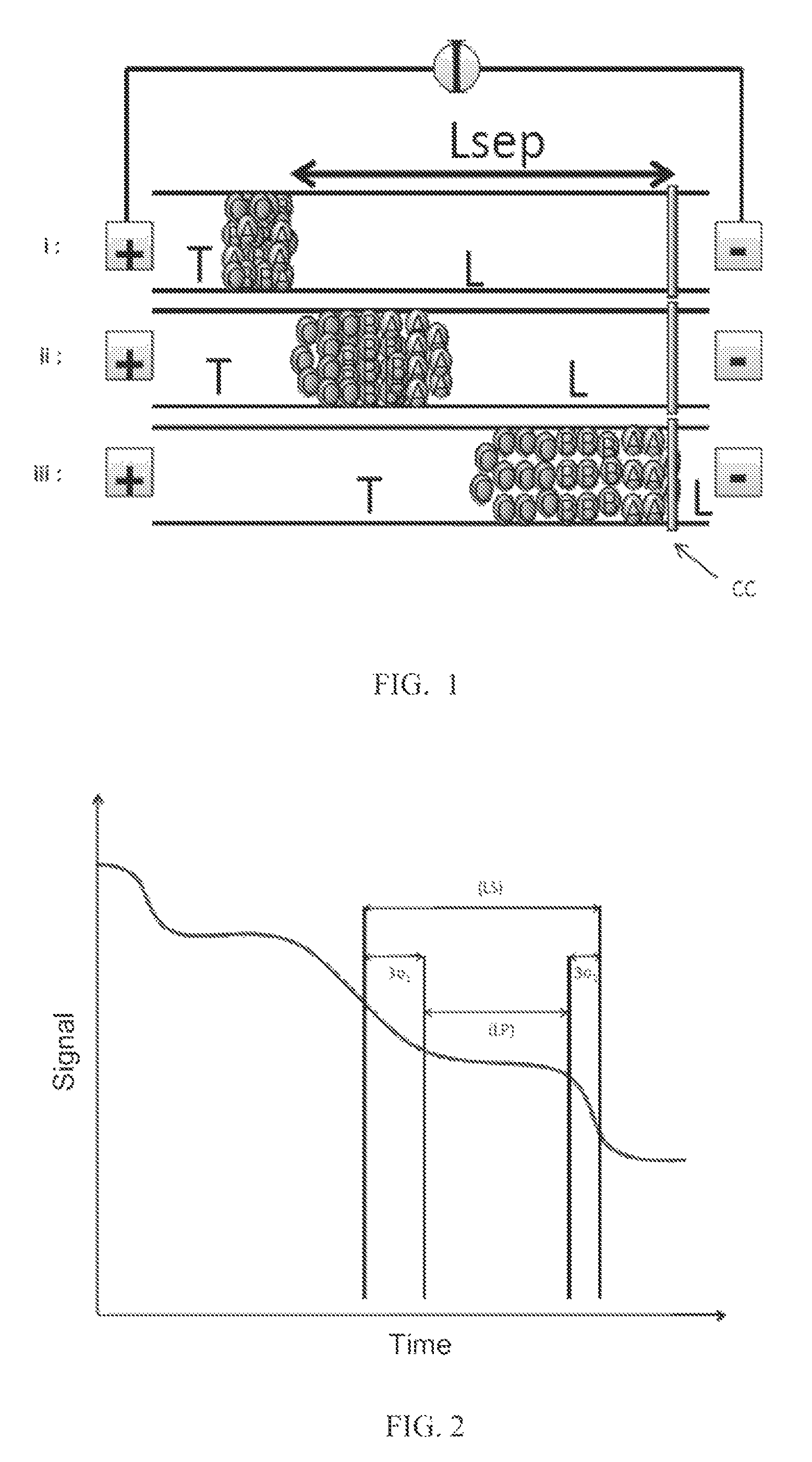

This invention provides methods and devices for spatially separating at least first and second components in a sample which in one exemplary embodiment comprises introducing the first and second components into a first microfluidic channel of a microfluidic device in a carrier fluid comprising a spacer electrolyte solution and stacking the first and second components by isotachophoresis between a leading electrolyte solution and a trailing electrolyte solution, wherein the spacer electrolyte solution comprises ions which have an intermediate mobility in an electric field between the mobility of the ions present in the leading and trailing electrolyte solutions and wherein the spacer electrolyte solution comprises at least one of the following spacer ions MOPS, MES, Nonanoic acid, D-Glucuronic acid, Acetylsalicyclic acid, 4-Ethoxybenzoic acid, Glutaric acid, 3-Phenylpropionic acid, Phenoxyacetic acid, Cysteine, hippuric acid, p-hydroxyphenylacetic acid, isopropylmalonic acid, itaconic acid, citraconic acid, 3,5-dimethylbenzoic acid, 2,3-dimethylbenzoic acid, p-hydroxycinnamic acid, and 5-br-2,4-dihydroxybenzoic acid, and wherein the first component comprises a DNA-antibody conjugate and the second component comprises a complex of the DNA-antibody conjugate and an analyte.

Owner:WAKO PURE CHEMICAL INDUSTRIES +1

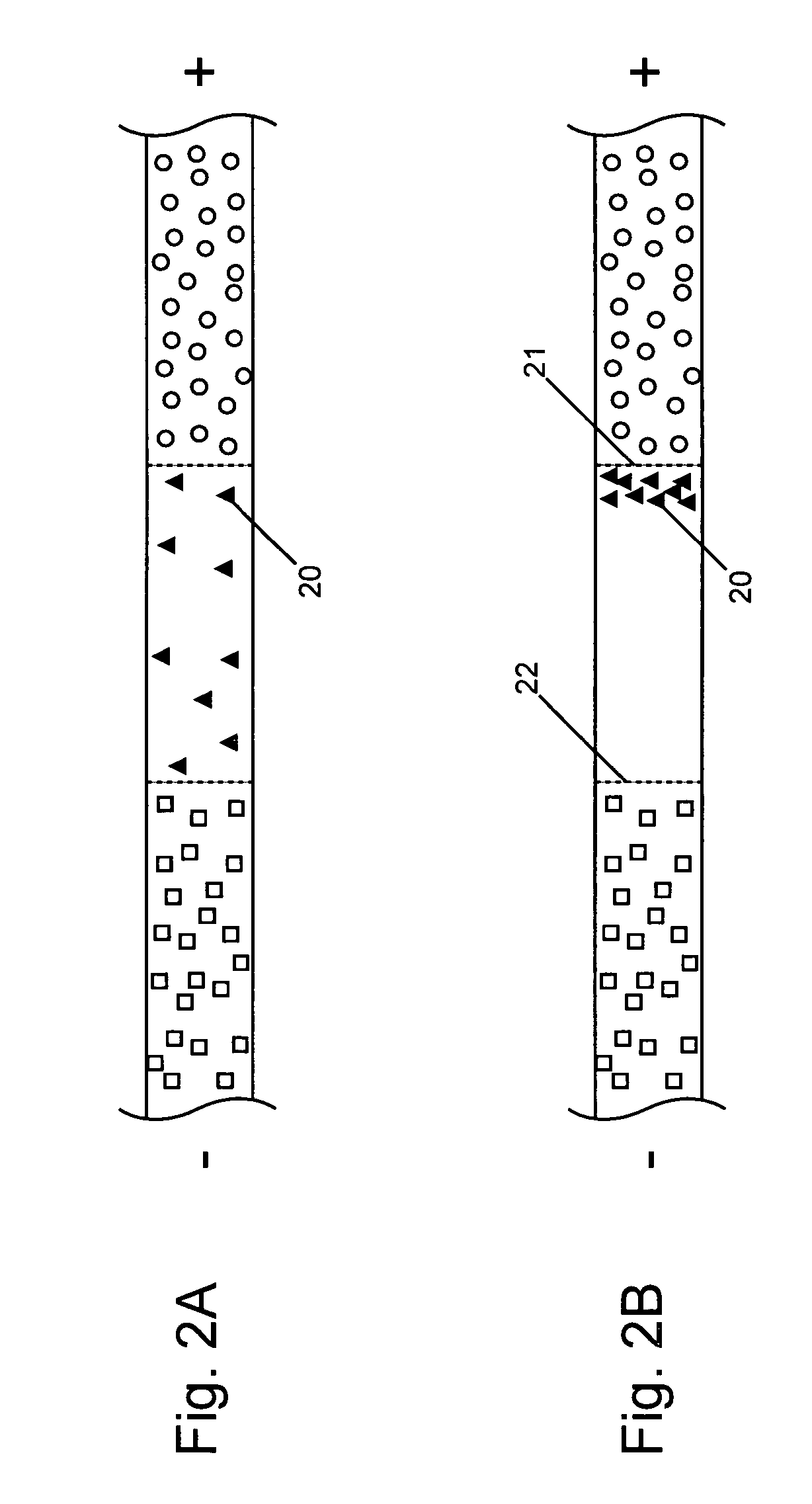

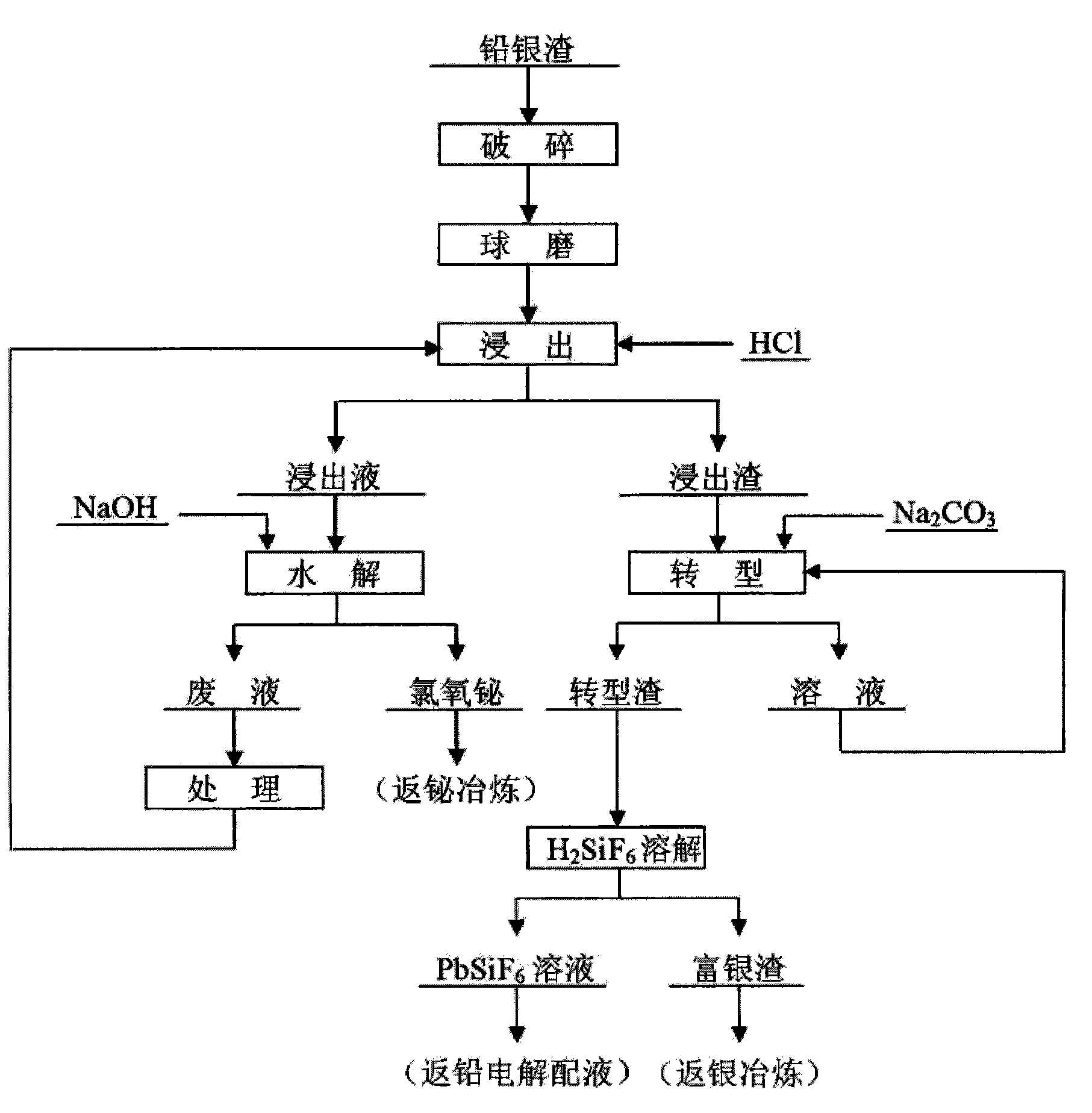

Wet process for lead-silver residues

ActiveCN102031383ANo pollution in the processSimple processProcess efficiency improvementElectrolysisBismuth oxychloride

The invention discloses a wet process for lead-silver residues, which comprises the following major steps: crushing lead-silver residues, carrying out ball milling, leaching with dilute hydrochloric acid, adding sodium hydroxide to the leached solution to hydrolyze so as to generate bismuth oxychloride as a precipitate, transferring the bismuth oxychloride to a bismuth smelting system, and treating the hydrolysis waste solution for cyclic use; and transforming the leached residues with sodium carbonate, then recycling the mother solution, dissolving the transformed residues in silicofluoric acid, filtering the residues to obtain silver-enriched residues, transferring the silver-enriched residues to a silver smelting system, and using the obtained lead silicofluoride solution for preparing a lead electrolyte. The invention has the advantages of simple flow and no environmental pollution; by preparing lead in lead-silver residues into lead silicofluoride used as the electrolyte, the input amount of yellow lead in the lead electrolysis system is reduced; by dissolving lead in silicofluoric acid, silver-enriched residues with a silver content up to more than 60% can be directly obtained, and the direct silver yield is high; the overall system realizes the cyclic use of the solution, and the comprehensive recycling degree is high; and the treatment time is short, and the comprehensive cost is low.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

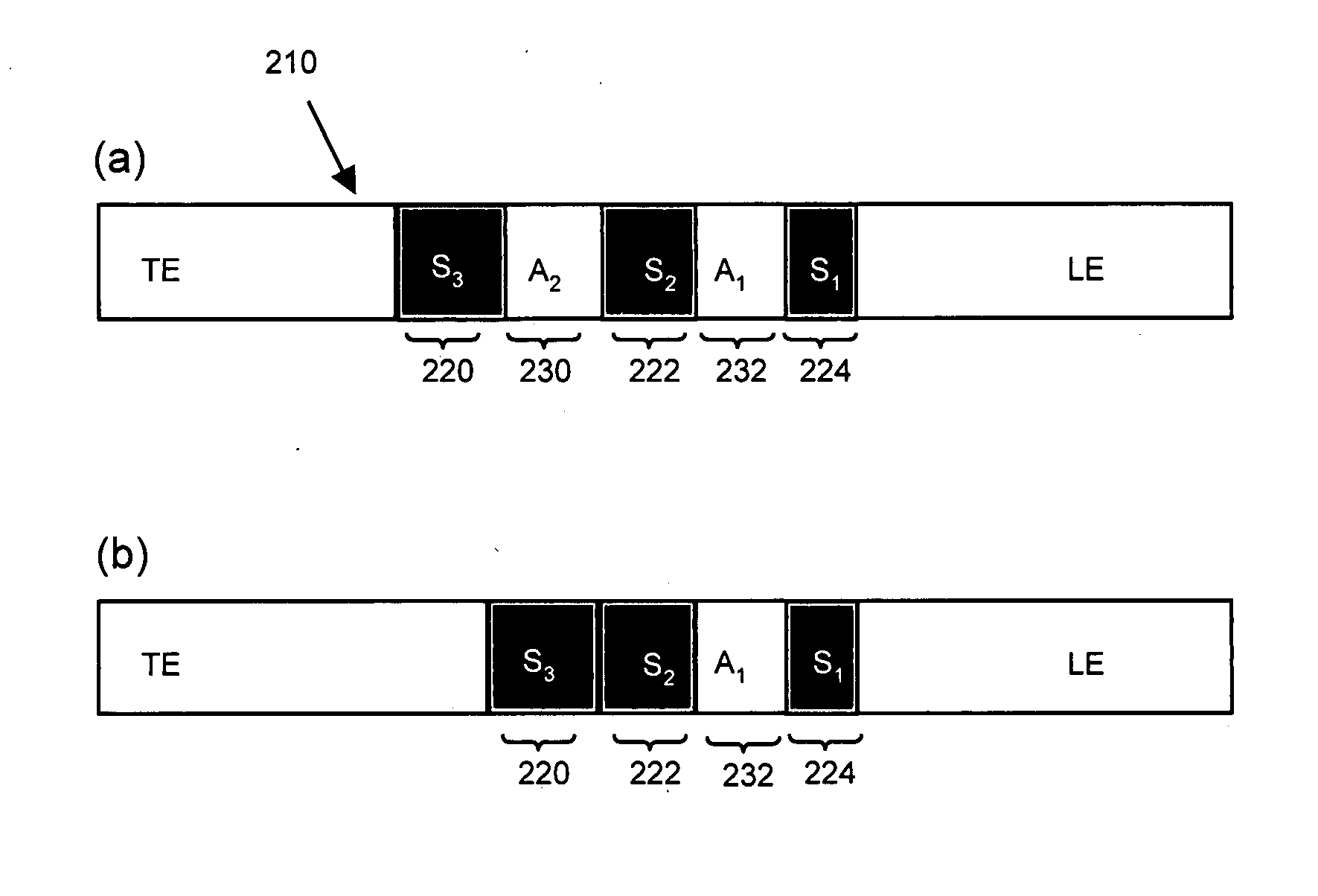

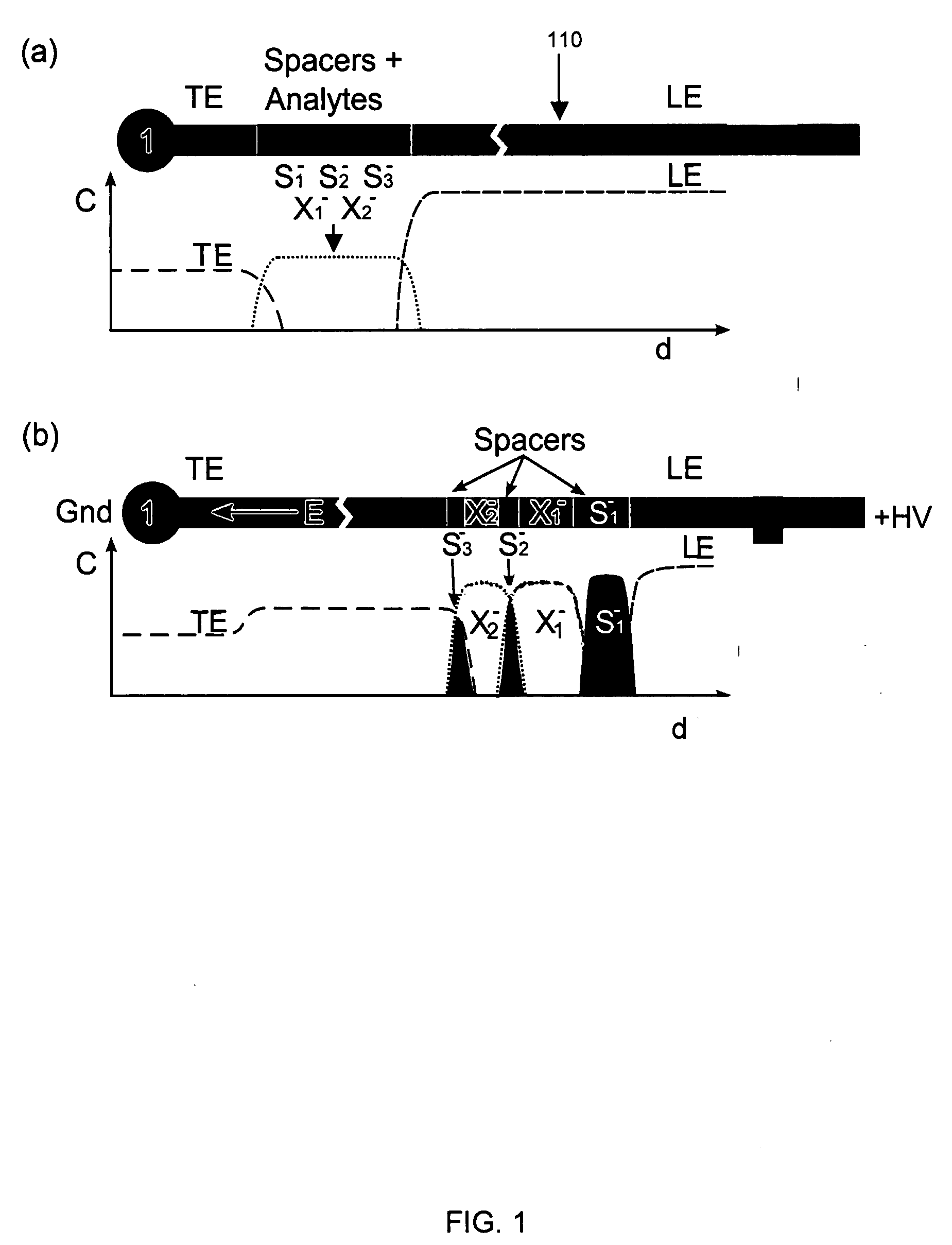

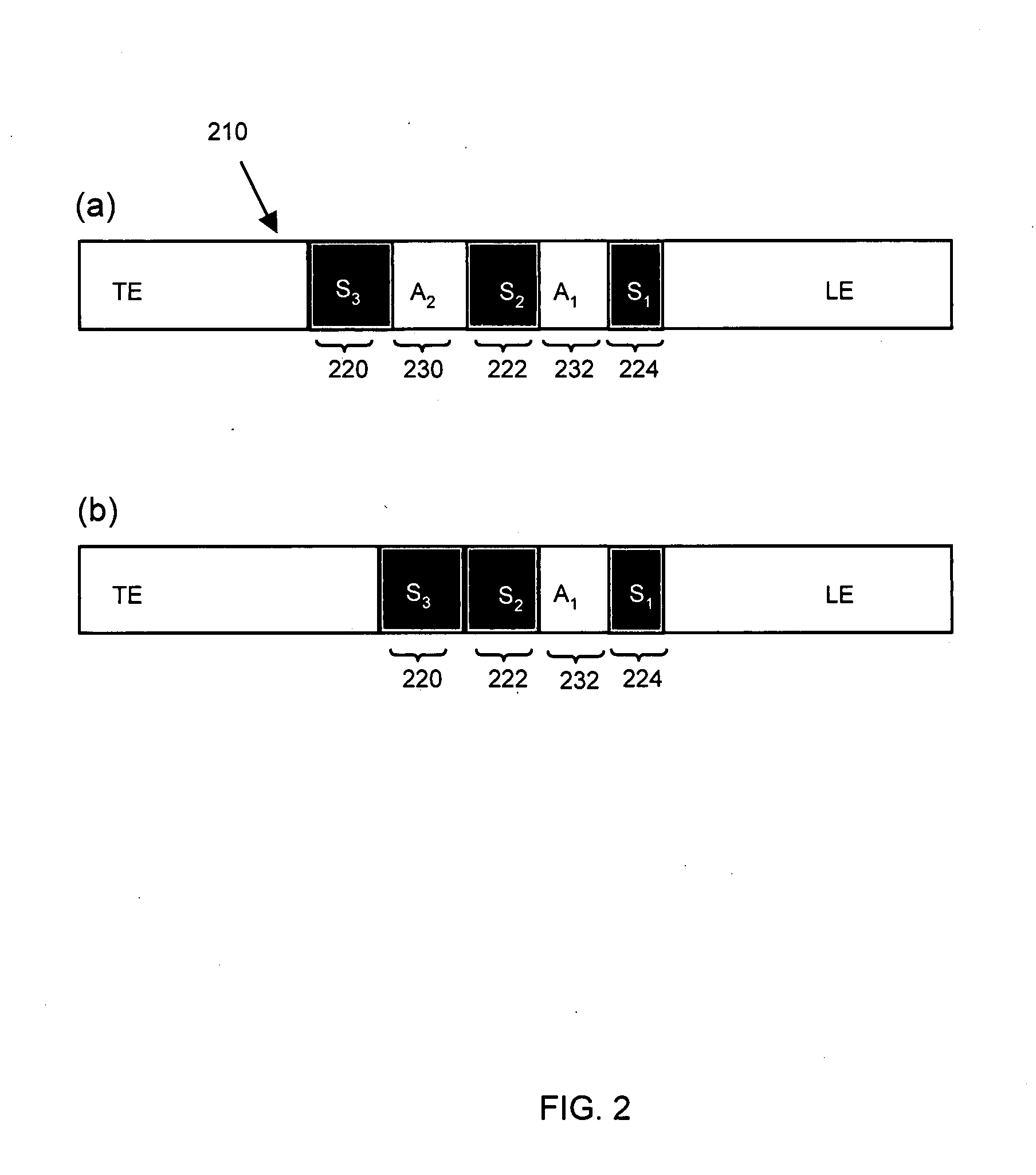

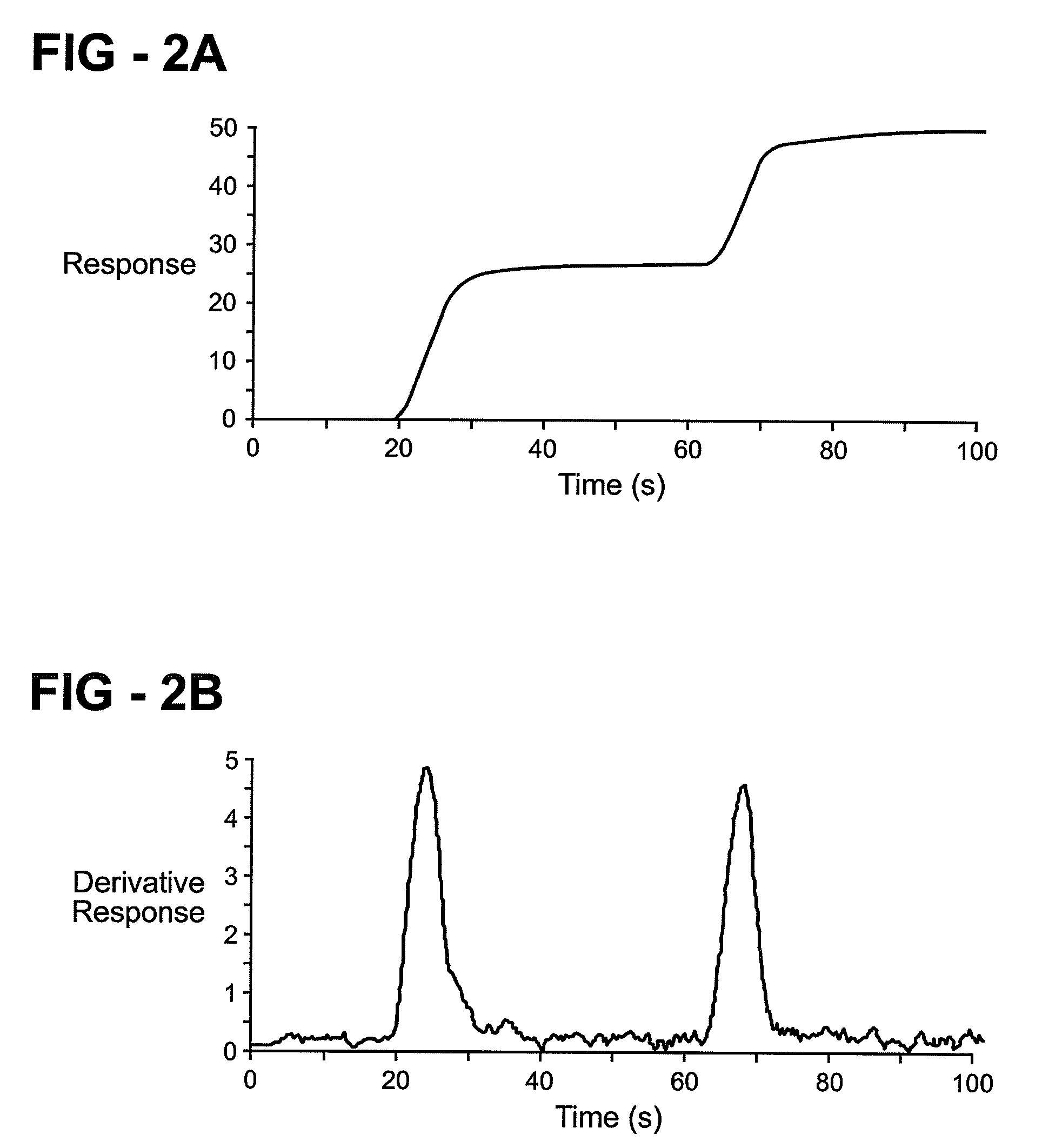

Method of detecting directly undetecable analytes using directly detectable spacer molecules

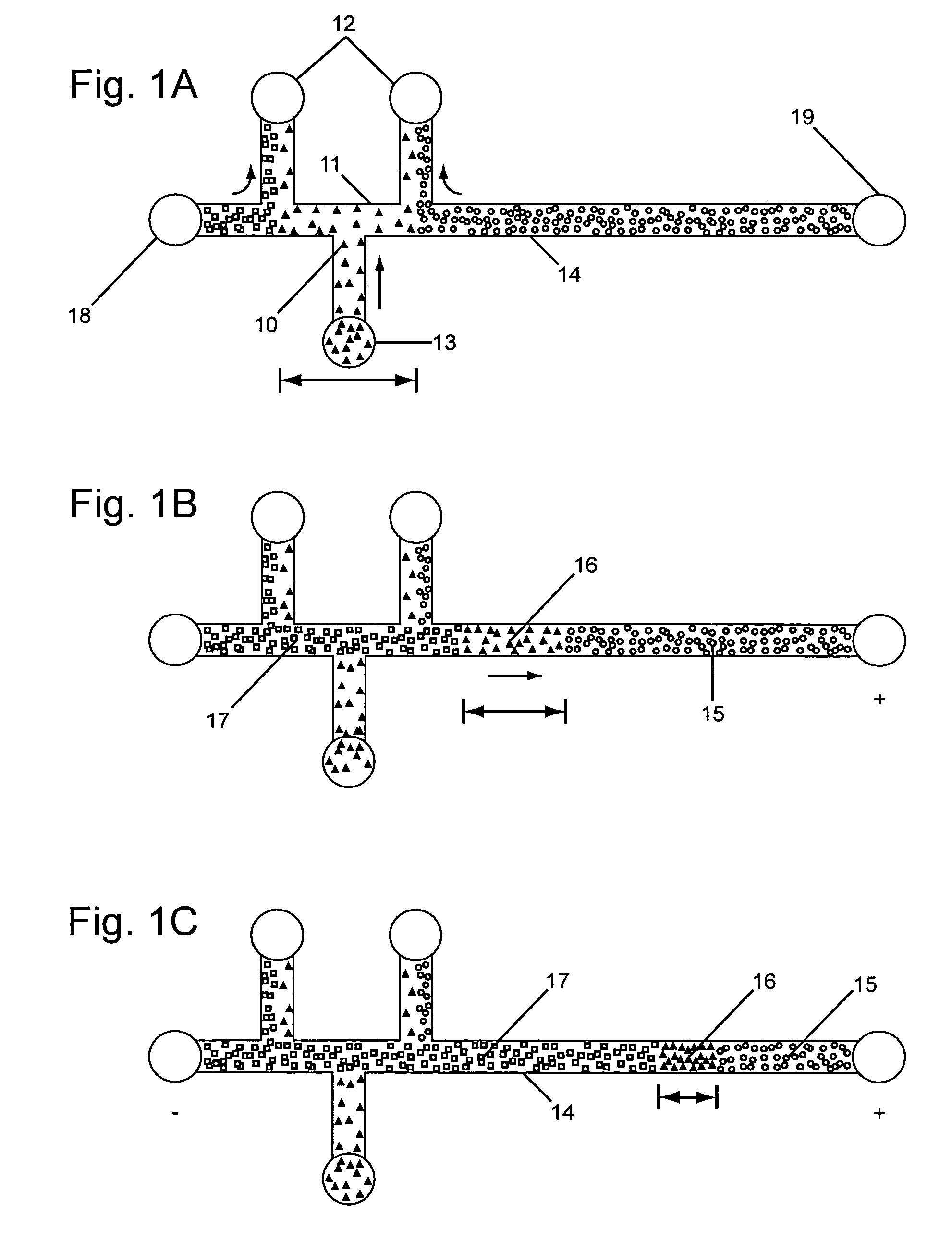

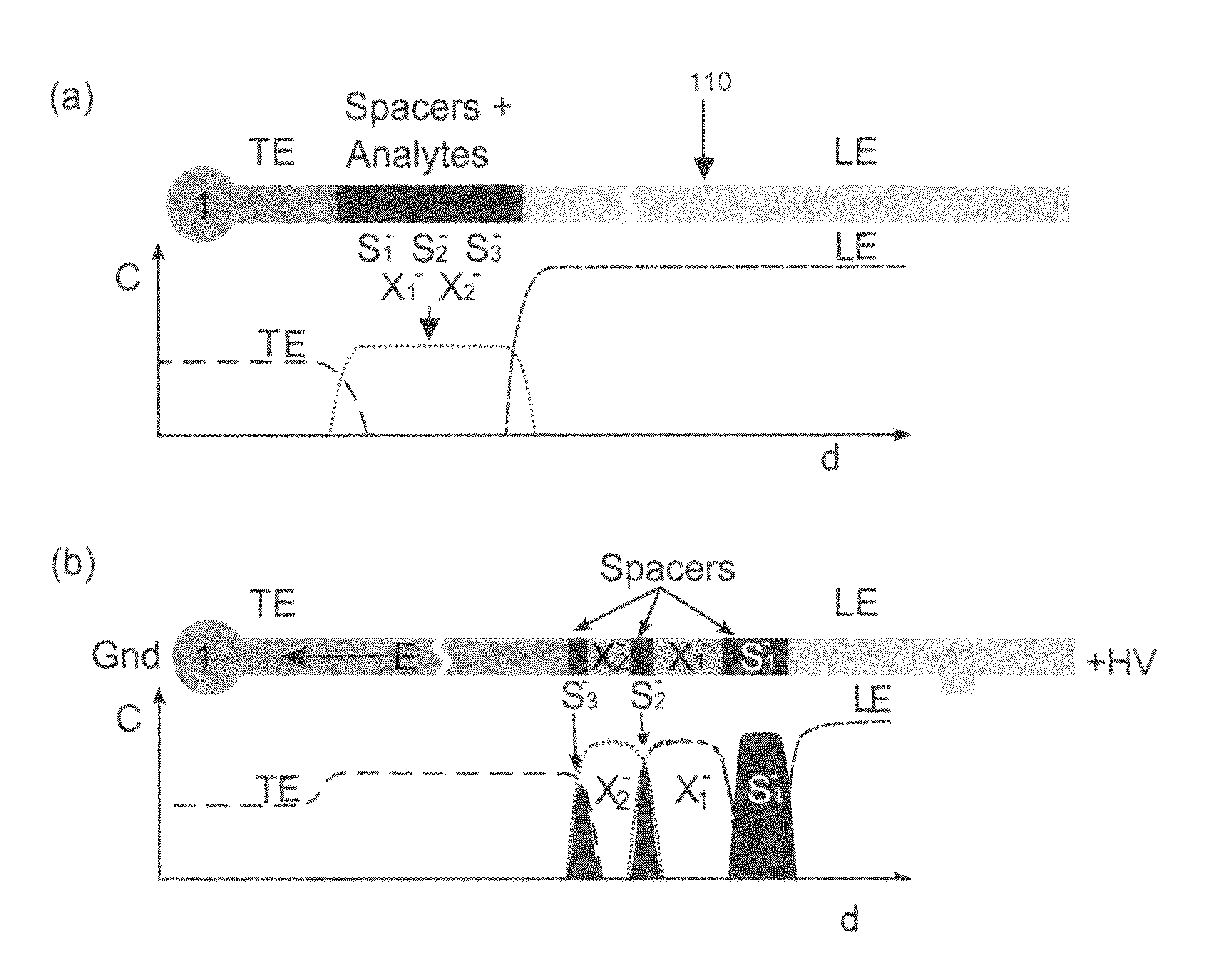

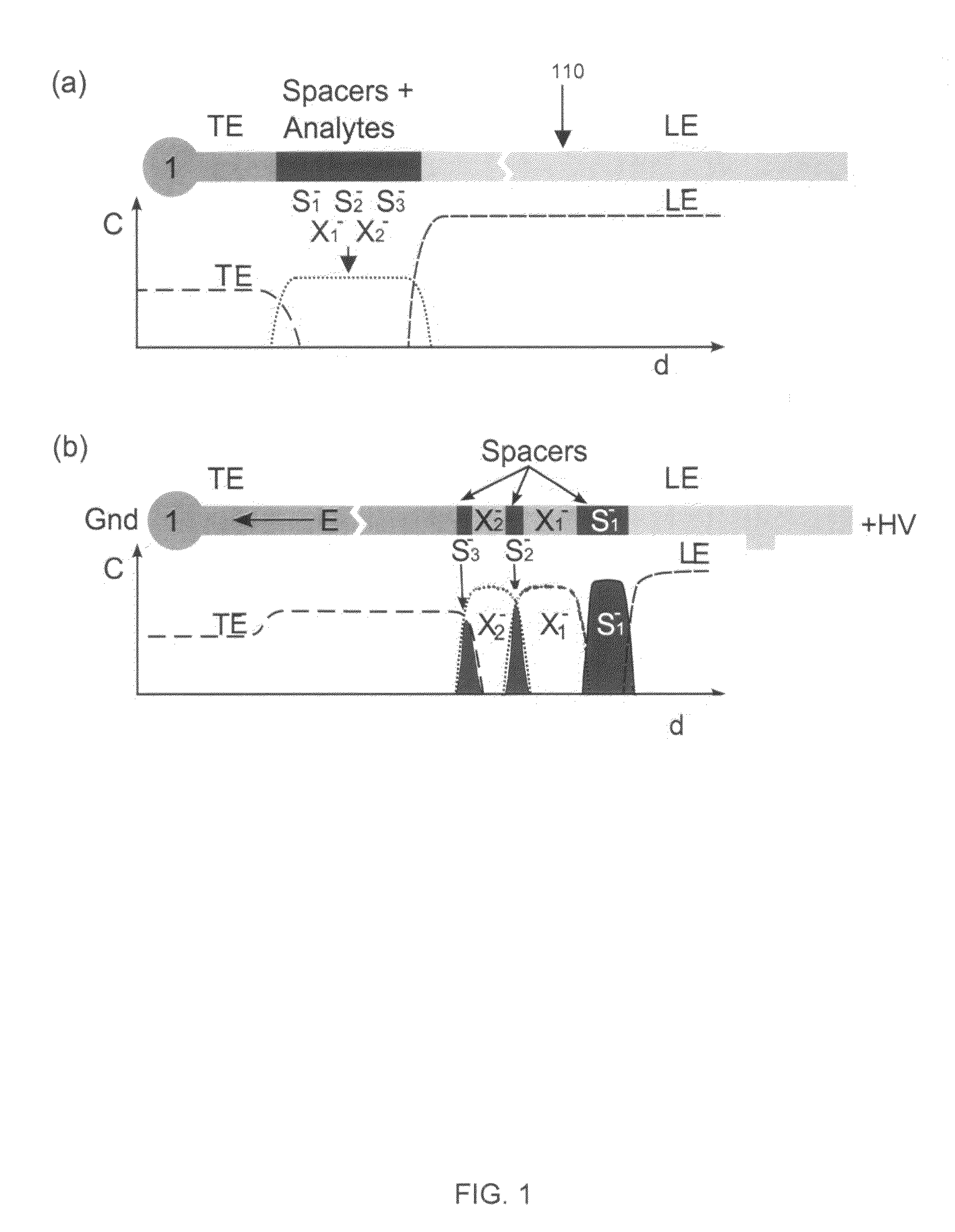

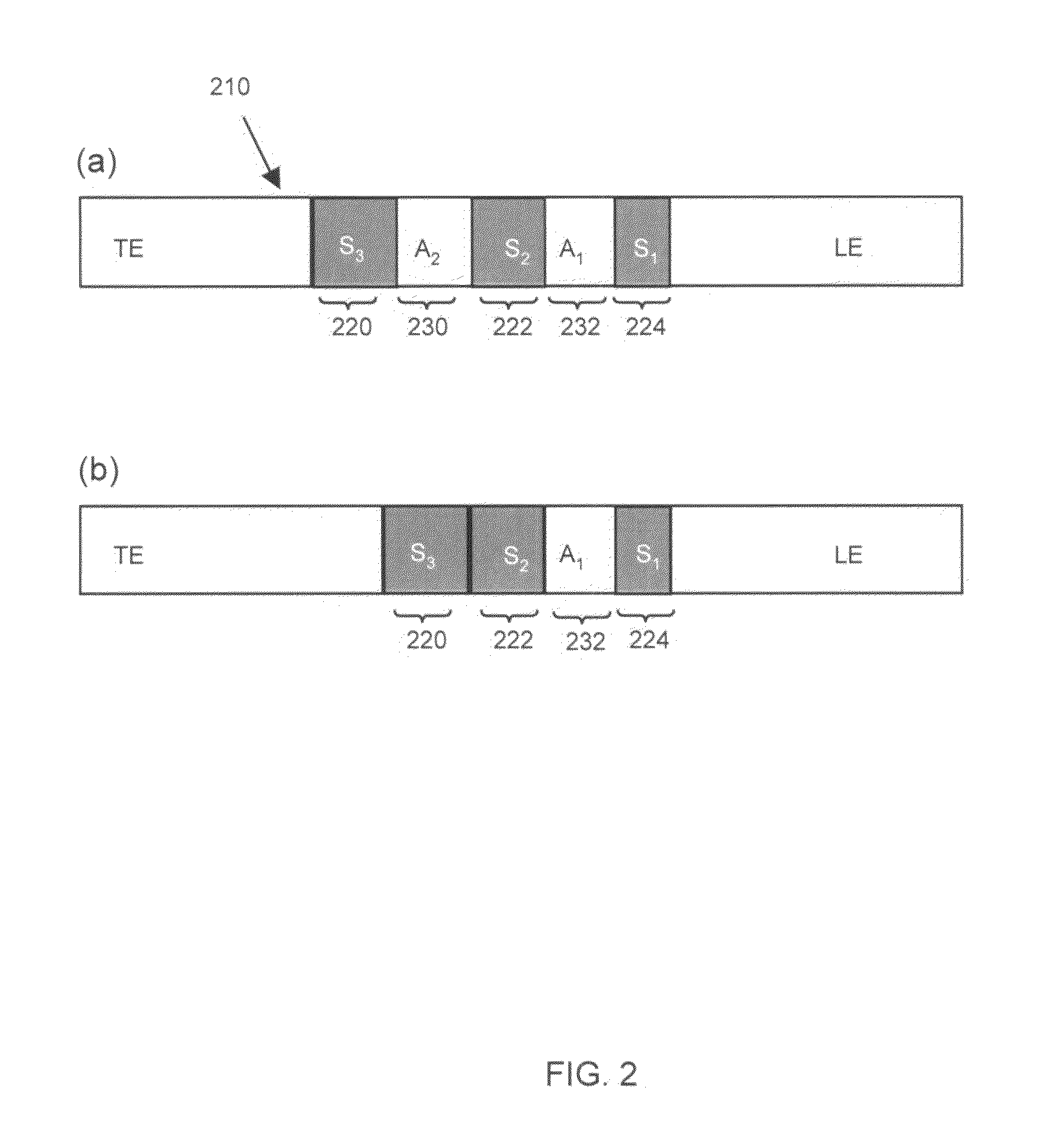

The present invention provides a method of indirectly detecting at least one directly undetectable analyte of interest. According to the method, a leading electrolyte and a trailing electrolyte are provided. In addition, a mixture of the at least one directly undetectable analyte and at least two directly detectable spacer molecules is provided. The directly detectable spacer molecules and the directly undetectable analyte are then concentrated and separated into zones using isotachophoresis. A displacement between the zones of directly detectable spacer molecules is then used to determine the presence of the directly undetectable analyte.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method of detecting directly undetectable analytes using directly detectable spacer molecules

The present invention provides a method of indirectly detecting at least one directly undetectable analyte of interest. According to the method, a leading electrolyte and a trailing electrolyte are provided. In addition, a mixture of the at least one directly undetectable analyte and at least two directly detectable spacer molecules is provided. The directly detectable spacer molecules and the directly undetectable analyte are then concentrated and separated into zones using isotachophoresis. A displacement between the zones of directly detectable spacer molecules is then used to determine the presence of the directly undetectable analyte.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Gradient elution electrophoresis

A method for performing electrophoretic separation of ionic compounds which involves varying a bulk fluid flow though a separation path into which ionic species are continuously introduced and separated. The method can also include the introduction of a leading electrolyte into the separation path to form an ionic interface with the sample and an optional terminating electrolyte to enrich ionic species for higher detection resolution.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF COMMERCE THE NAT INST OF STANDARDS & TEHCNOLOGY

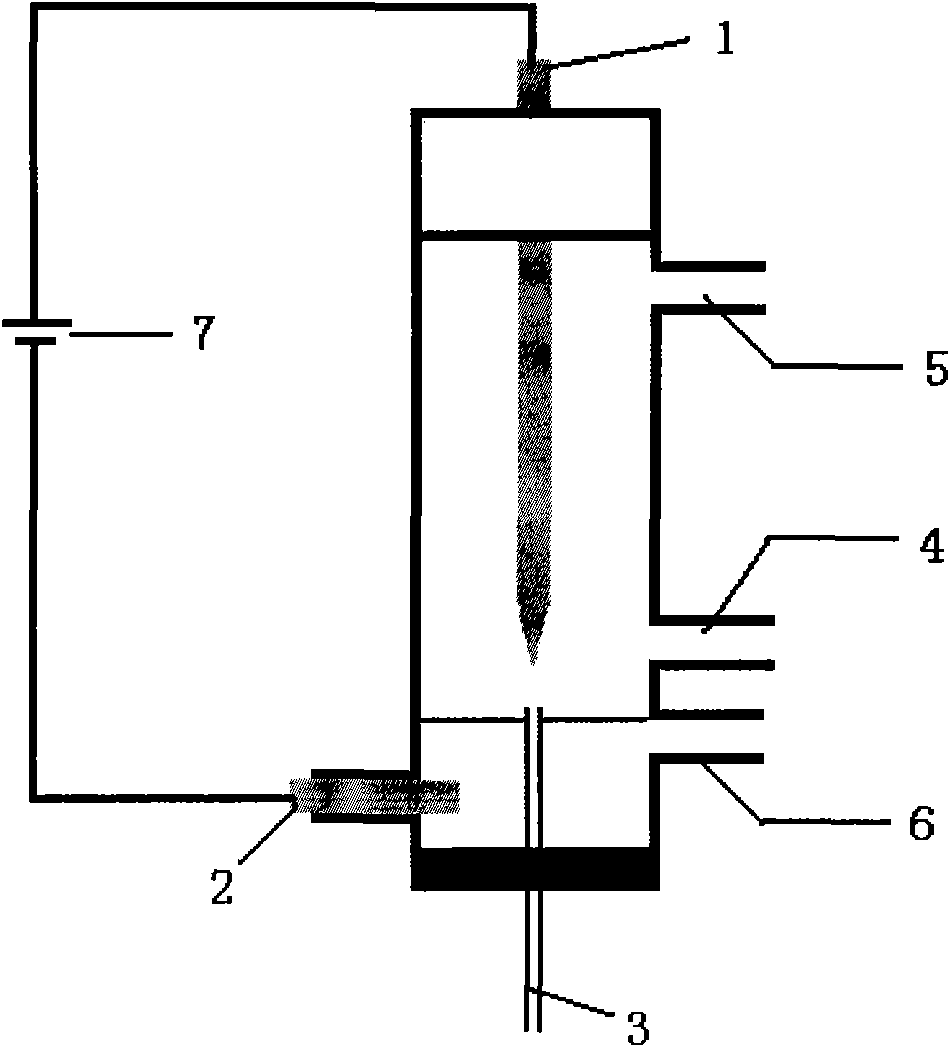

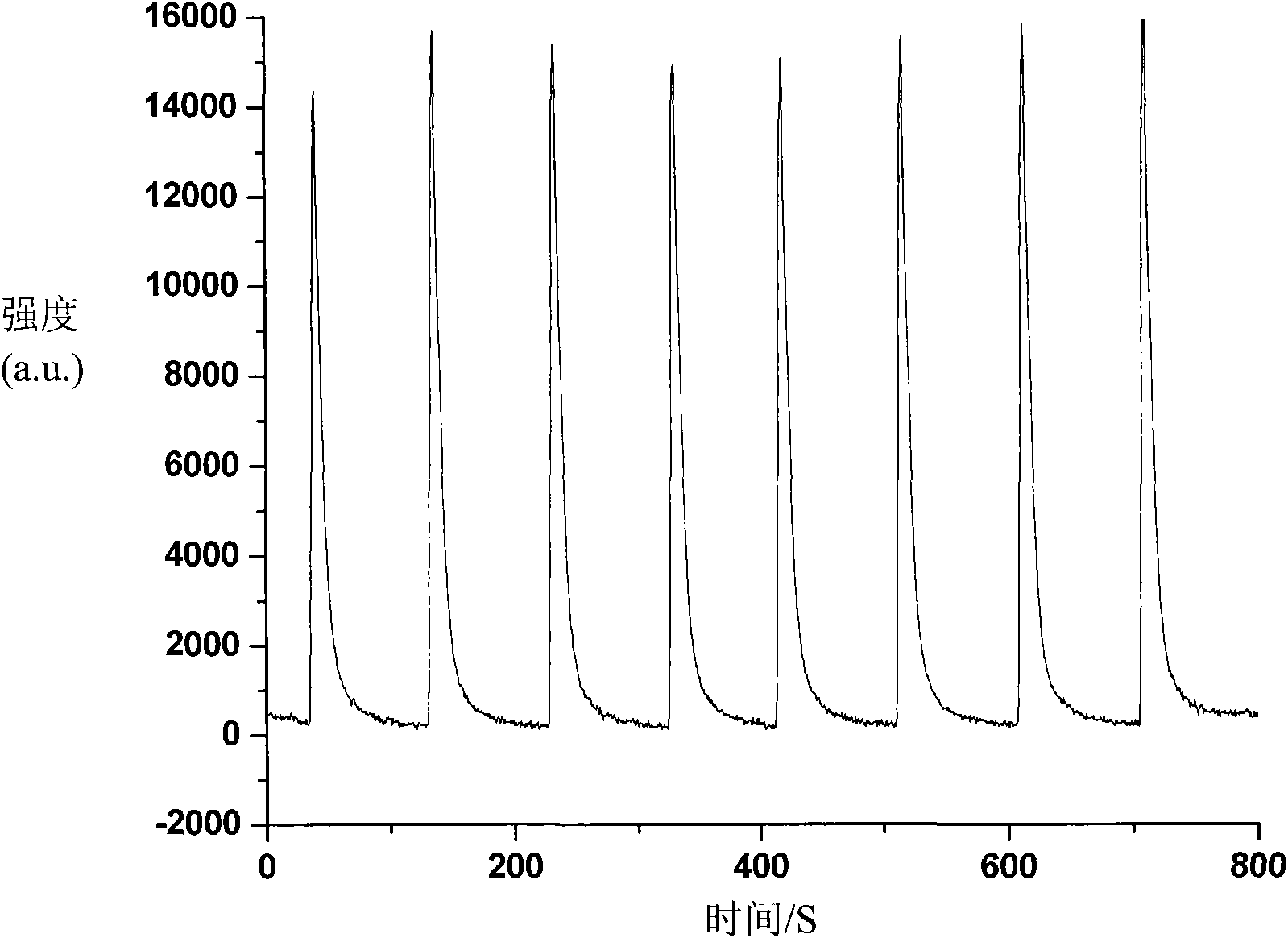

Mercury vapour generation method and device

InactiveCN101556246AReduce lossReduce riskAnalysis by electrical excitationMaterial analysis by electric/magnetic meansElectricityMercury vapour

The invention discloses a mercury vapour generation method and a device; the method realizes the generation of mercury in liquid sample in vapour form by the discharge of liquid cathode, comprising the following steps: first putting an anode and a cathode connected with two electrodes of a direct current power supply in a sealed discharging device, leading electrolyte solution of the sample containing mercury in the discharging device by a capillary, generating the discharging between the anode and the liquid sample on the sharp end of the capillary so as to generate the mercury vapour. The invention also provides a mercury vapour generation device, comprising the anode and the cathode connected with the two electrodes of the direct current power supply, wherein the anode and the cathode are placed in the discharging device; the discharging device is provided with the capillary with inner diameter of 01-5mm; the sample containing mercury is led in the discharging device by the capillary; the distance between the opening of the capillary and the anode is 1-4mm. The invention realizes the vapour generation of mercury by discharging without any reducing agent so as to reduce the reagent wastage and pollution danger.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

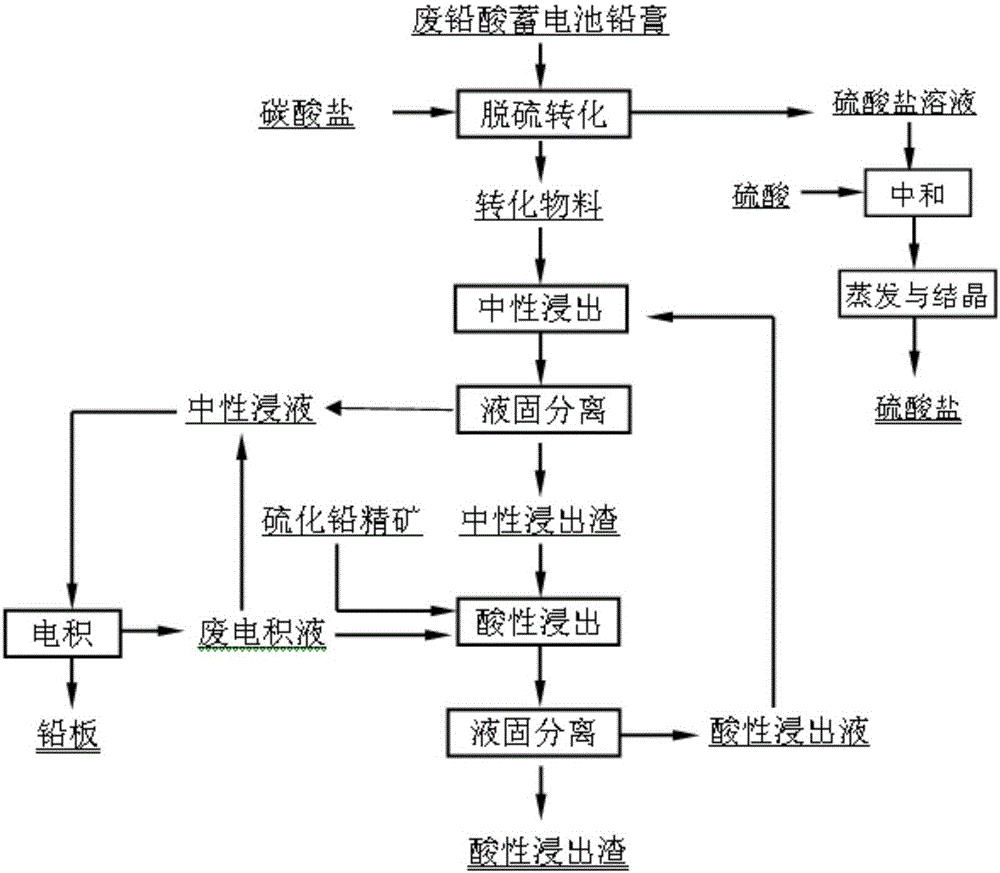

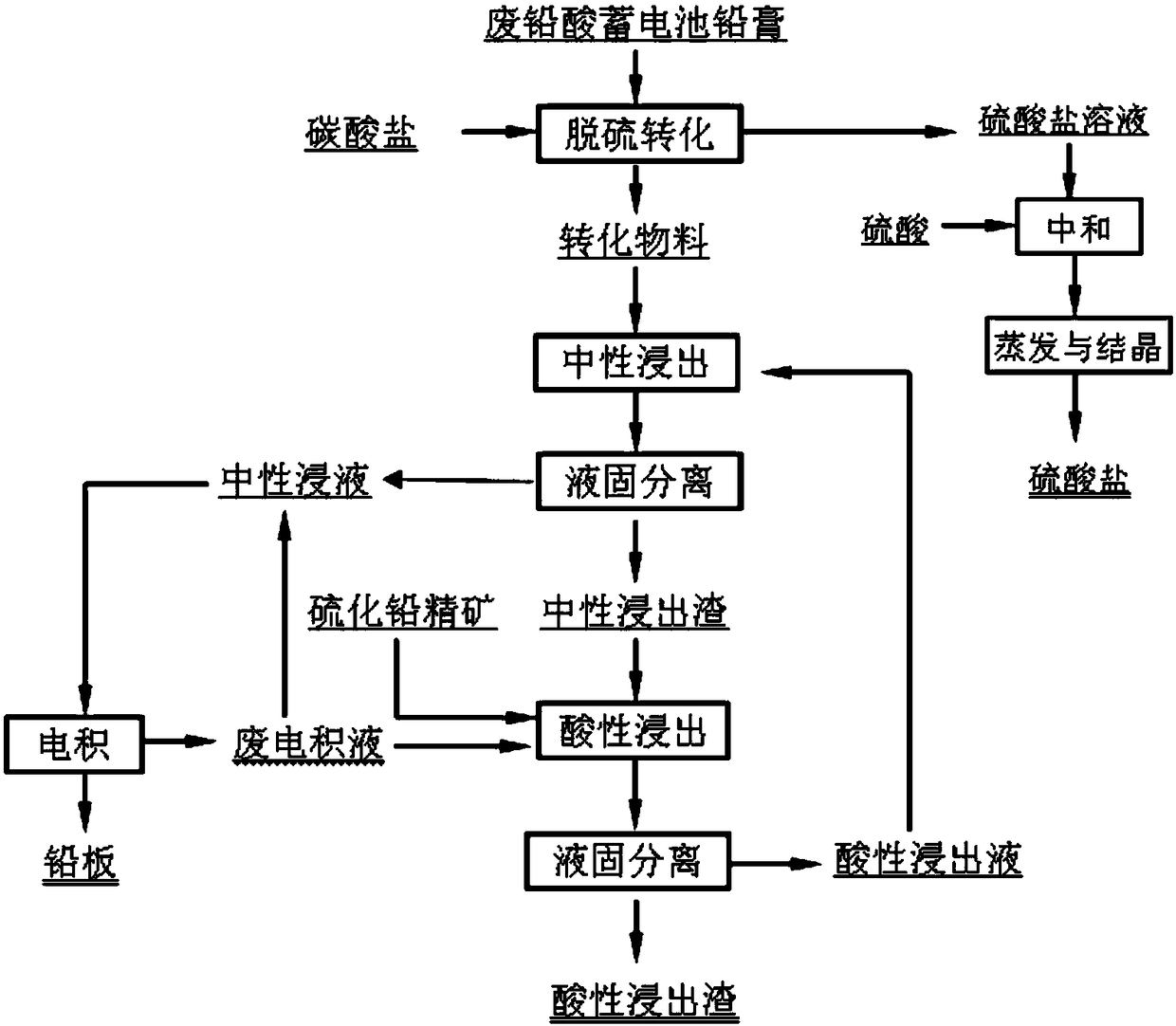

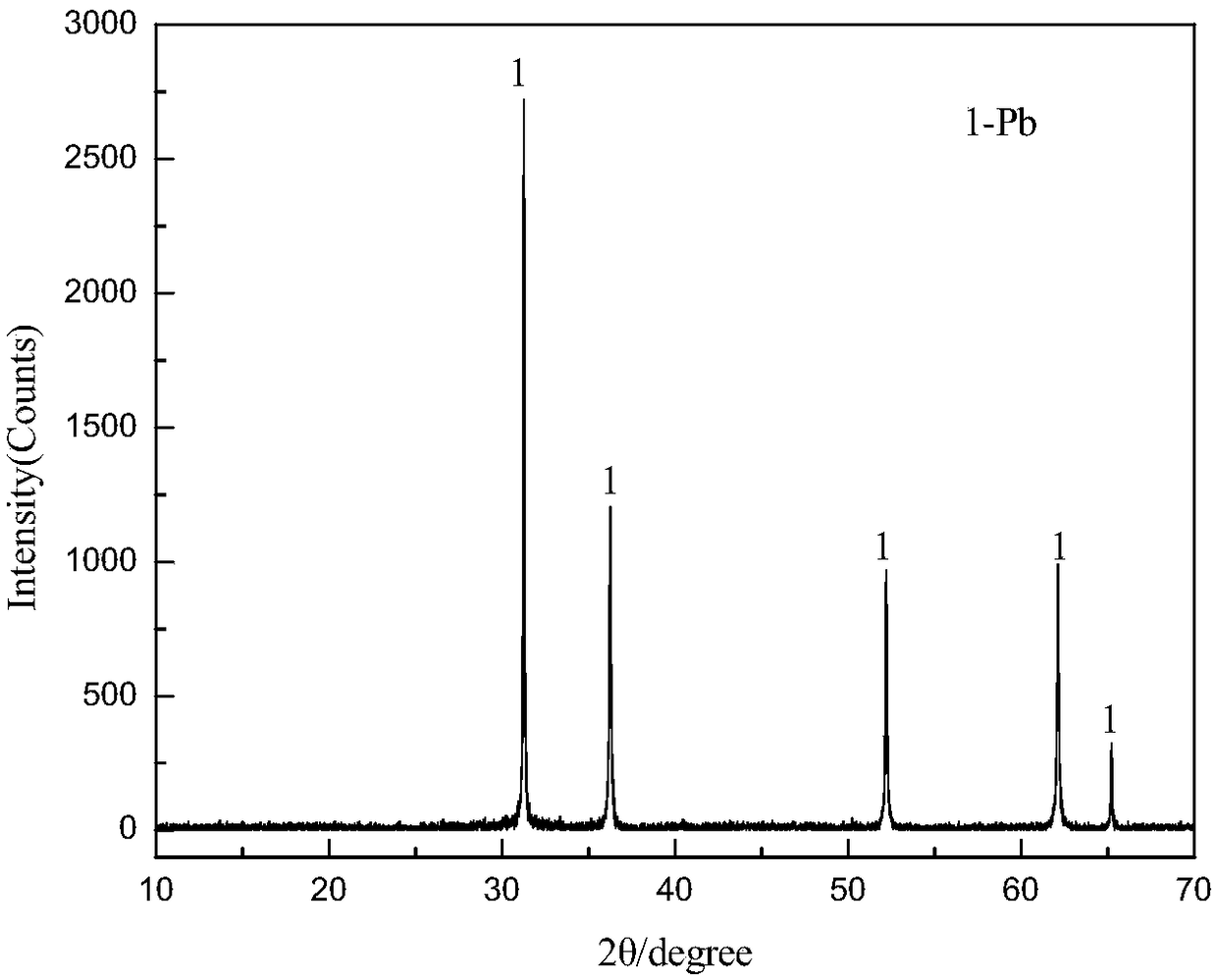

All-wet method for extracting lead from lead plaster and lead sulfide concentrate

ActiveCN106676270AHigh purityEfficient recyclingPhotography auxillary processesProcess efficiency improvementLiquid wasteLead sulfide

The invention discloses an all-wet method for extracting lead from lead plaster and lead sulfide concentrate. The method comprises the steps that the lead plaster of a waste lead acid accumulator and a carbonate solution are subjected to a desulfurization conversion reaction, solid-liquid separation is conducted, a sulfate solution and desulfurization conversion materials are obtained, the desulfurization conversion materials are subjected to neutral leaching by means of a methanesulfonic acid solution, and neutral leachate and neutral leaching residues are obtained through liquid-solid separation; the neutral leachate and waste sulfate electrolyte are blended for preparing sulfate electrolyte which is then subjected to lead electrodeposition, and a lead plate and waste lead electrolyte are obtained; and the neutral leaching residues serve as an oxidizing agent, the lead sulfide concentrate is subjected to acid leaching by means of the waste sulfate electrolyte, liquid-solid separation is conducted, acid leachate and acid leaching residues are obtained, and the acid leachate returns for application to neutral leaching next time. By adoption of the method, the lead is efficiently extracted, the leachate and the sulfate electrolyte are recycled, no waste liquid is generated, and the requirement for environment protection is met.

Owner:CENT SOUTH UNIV

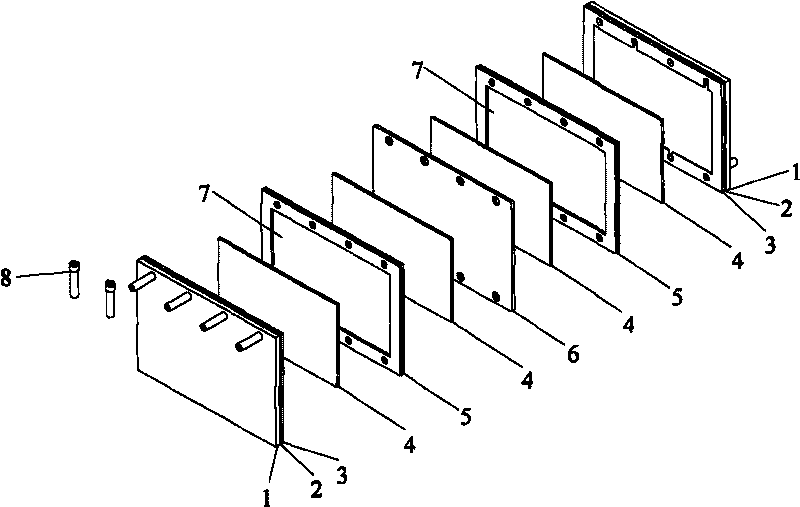

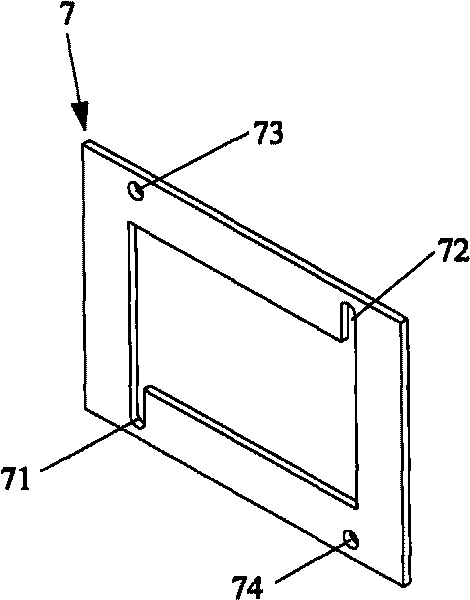

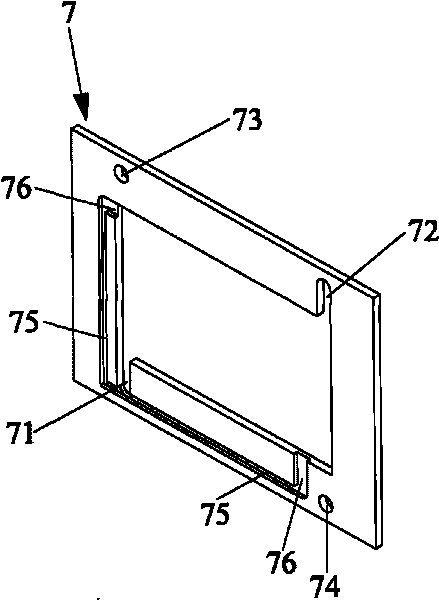

Redox flow cell stack

ActiveCN101702441APrevent leakageEasy to assembleFuel cells groupingFuel cell auxillariesFlow cellRedox

The invention provides a redox flow cell stack which comprises at least two redox flow frames (7) and flow collecting bodies (3) with the number corresponding to that of the redox flow frames. The redox flow cell stack is characterized in that the redox flow frames are provided with a liquid inlet hole (71) and a liquid outlet hole (72) which are respectively used for leading electrolyte onto the surface of the flow collecting bodies and out of the surface thereof. The design of the invention can avoid the phenomena of seepage and weeping since the liquid inlet hole and the liquid outlet hole of the flow collecting bodies (3) are scoured by the electrolyte in the flowing process; meanwhile, the liquid inlet hole, the liquid outlet hole and flow channels can be conveniently designed on the redox flow frames, so that the liquid flow inside a cell can be more balanced and smooth.

Owner:大力储能技术湖北有限责任公司

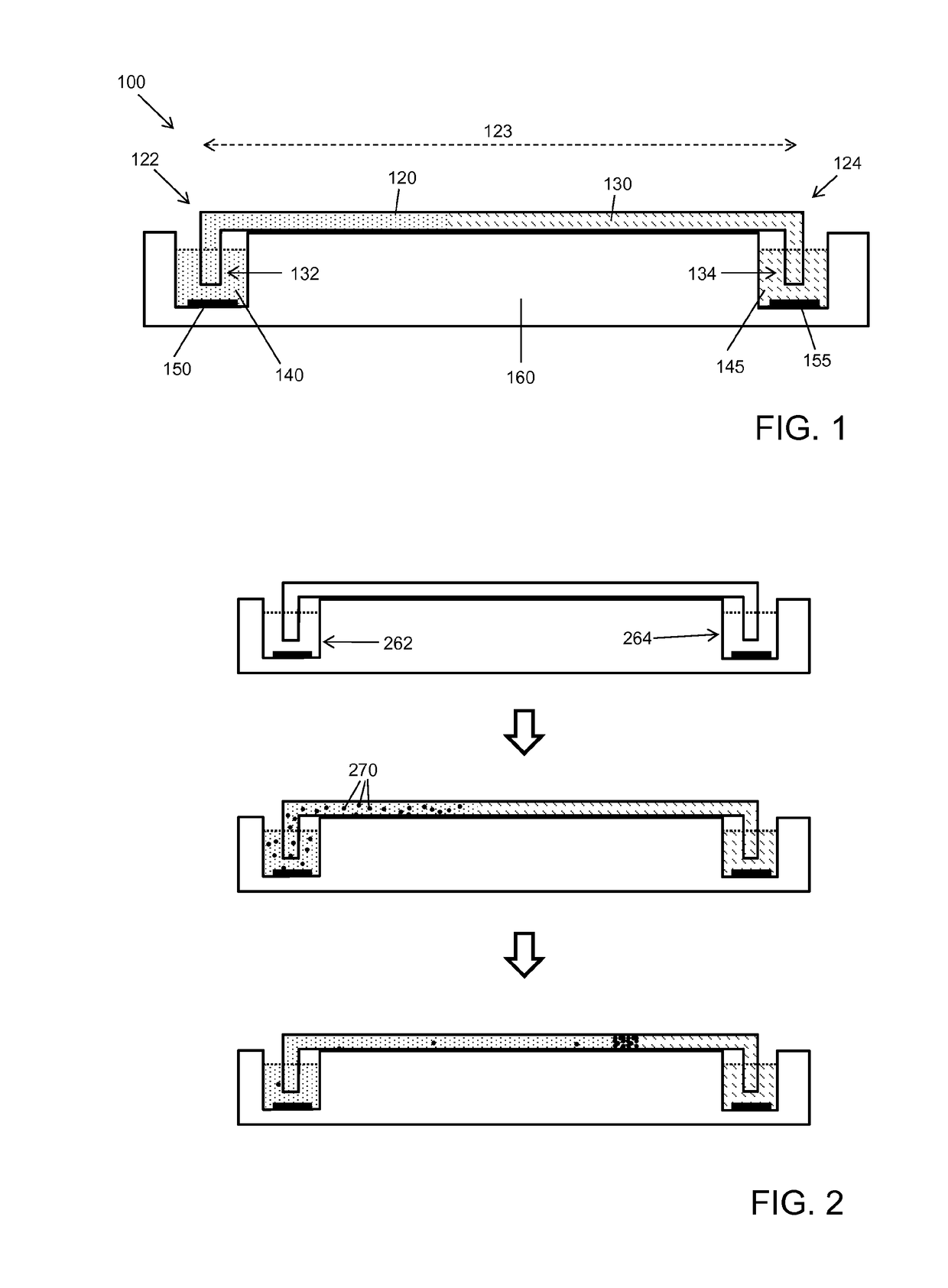

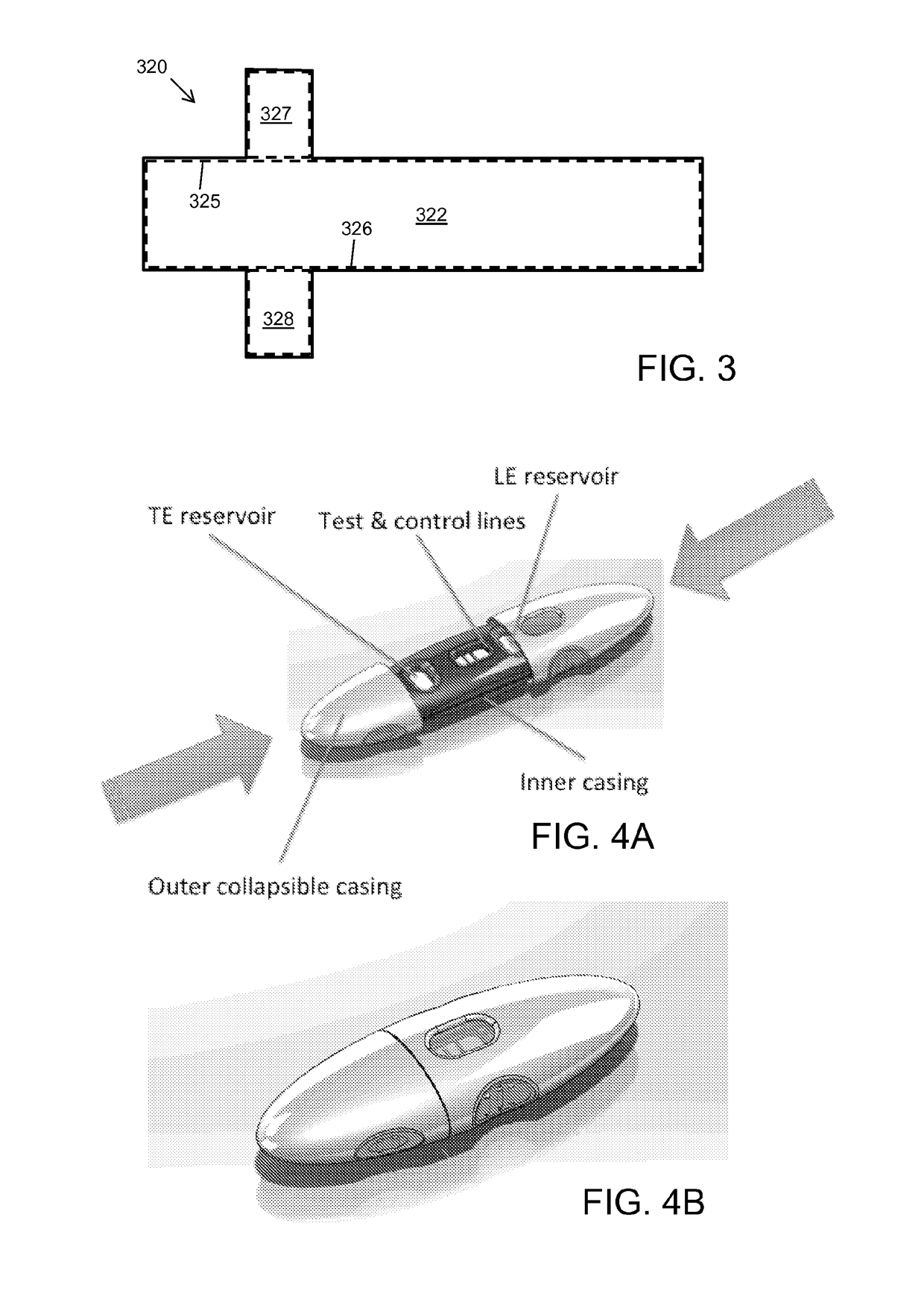

Isotachophoretic device and methods

InactiveUS20170184543A1Preparing sample for investigationMaterial analysis by electric/magnetic meansMetaboliteFirst pathway

The present disclosure relates to devices and methods for performing isotachophoretic concentration of analytes using a porous matrix, for example, for use in diagnostic assays such as lateral flow assays. For example, the disclosure provides a method of concentrating an analyte in a sample. The method includes providing a device comprising a porous matrix having a first fluid pathway having a first end and extending to a second end, a first electrode, and a second electrode; introducing to the first pathway a first fluid comprising a trailing electrolyte, a second fluid comprising a leading electrolyte and the analyte; and applying a voltage across the first electrode and the second electrode for a time sufficient to provide an ITP plug. As described herein, the devices and methods described herein can be used in conjunction with lateral flow assay techniques to detect and quantify a variety of biochemical and biological analytes, such as nucleic acids, proteins, cells and metabolites.

Owner:UNIV OF WASHINGTON

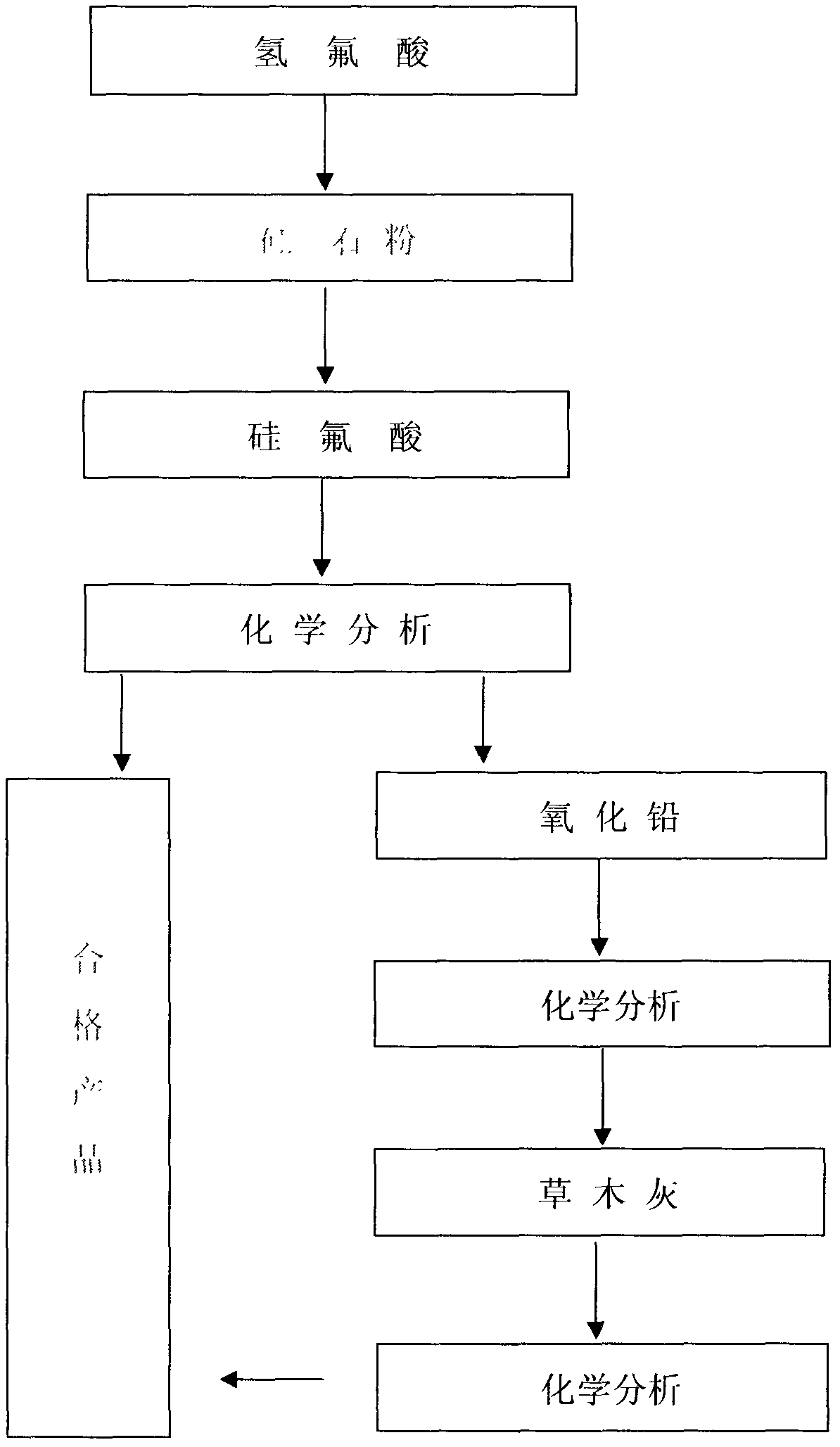

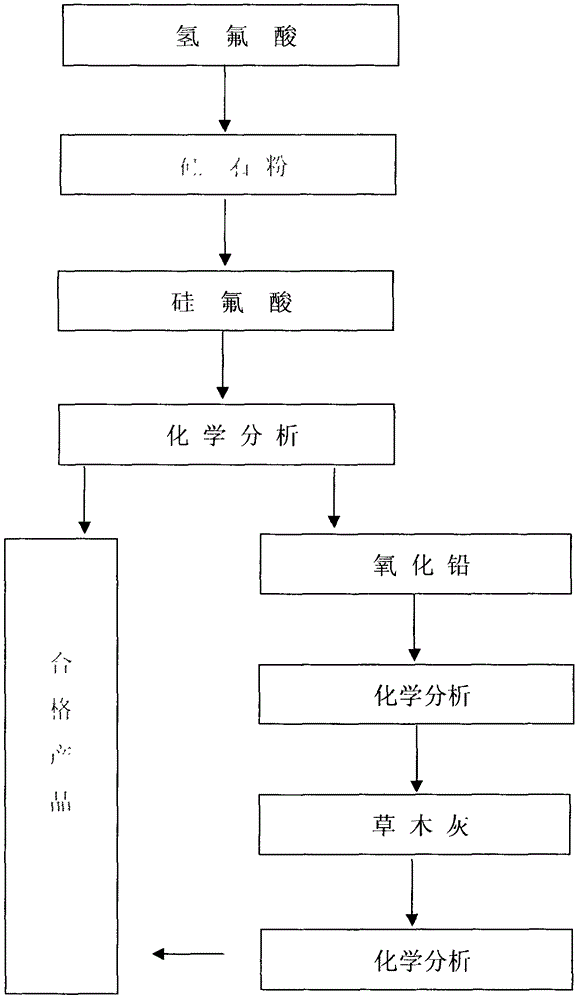

Method for preparing lead electrolyte by utilizing industrial waste liquids

InactiveCN103374728AEmission reductionReduce pollutionPhotography auxillary processesProcess efficiency improvementLiquid wasteHigh energy

The invention provides a method for preparing a lead electrolyte by utilizing industrial waste liquids and relates to the field of chemical technology. The method comprises the following operating steps. First, waste liquids generated from industrial production of high calcium fertilizer, phosphate fertilizer, anhydrous hydrofluoric acid and the like are employed as raw materials. Second, after the raw materials being sent into a factory, contents of various components of the raw materials are first tested, and water is added to dilute the raw materials according to the contents of hydrofluoric acid and silicofluoric acid in the raw materials. Third, according to the content of hydrofluoric acid in the raw materials, silicon powder is added, and stirred at a rotating speed of 50-100 r / min for about 24 hours. Fourth, according to the contents of harmful elements such as sulfur, phosphorus and the like, yellow lead powder is added and stirred for about 48 hours to remove sulfate and phosphate. Fifth, if hydrofluoric acid, sulfate, phosphate and the like which are not reacted completely are left in the solution, according to the contents, appropriate amounts of quicklime and plant ash are added to neutralize hydrofluoric acid, sulfate, phosphate and the like to remove hydrofluoric acid, sulfate, phosphate and the like completely, and a qualified lead electrolyte mother liquid is prepared finally. The method solves the problems of high production cost, high energy consumption, environmental pollution and the like in the prior art.

Owner:梁达保

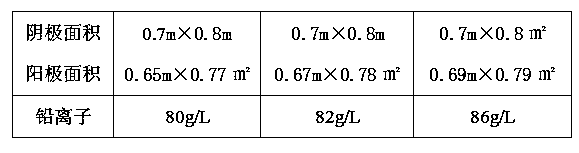

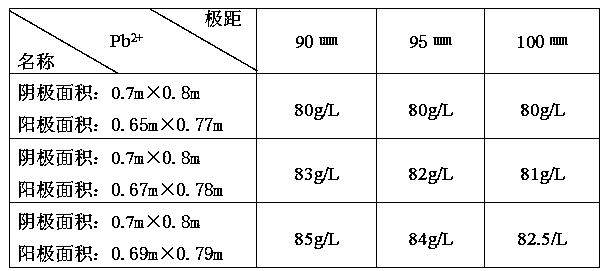

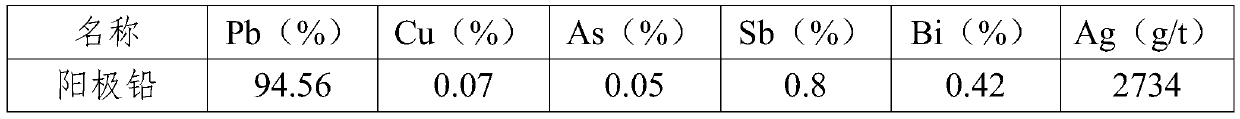

Method for resisting lead ion depletion of lead electrolyte

InactiveCN103695967AElectrolysis componentsPhotography auxillary processesElectrolysisVolumetric Mass Density

The invention discloses a method for resisting lead ion depletion of lead electrolyte. The method comprises the following steps: (1) preparing a lead anode plate by 88-92 percent of Pb, less than 4-5 percent of Sb, less than 4-6 percent of Bi, less than 0.06 percent of Cu, less than 0.035 percent of Sn and less than 1.5 percent of As; (2) controlling the temperature of the electrolyte at 45 DEG C, wherein the flowing speed of the electrolyte is 25 L / min, the electrolysis density is 200-210 A / m<2>, and an additive and the species are not changed. The method is characterized in that the change of lead ions is controlled by adjusting an immersion area of an anode and a cathode in an electrolytic tank and a polar distance between an anode plate and a cathode plate. Due to the method, the lead ions in the lead electrolyte can be stably controlled within a reasonable range, so that the depletion of the lead electrolyte is avoided.

Owner:湖南省桂阳银星有色冶炼有限公司

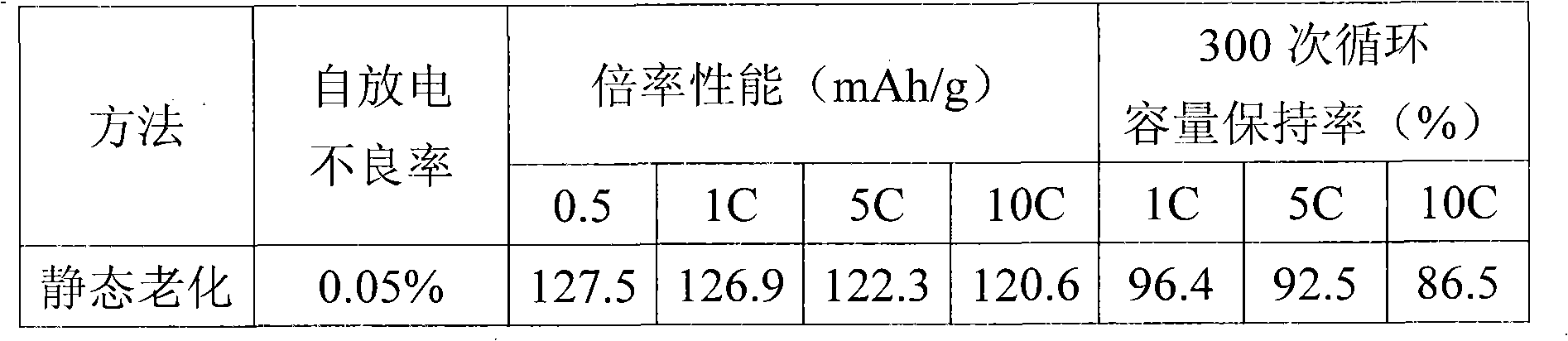

Ageing method of liquid electrolyte battery

InactiveCN101685888AImprove qualitySpread evenlyFinal product manufactureSecondary cellsAge methodEngineering

The invention discloses an ageing method of a liquid electrolyte battery; the battery is placed for aging, in the placing process, the battery is in a variable accelerated motion state; the dynamic aging process of the battery can lead electrolyte liquid to be fully diffused and permeated, thereby improving the battery quality and circulating performance, being helpful to selecting the batter which has poor self-charging performance completely and reducing the defect rate.

Owner:SHENZHEN BAK BATTERY CO LTD

Method for recycling lead from lead-containing waste material

ActiveCN110857454AConforming to the characteristics of an economic responseEliminate secondary pollutionPhotography auxillary processesProcess efficiency improvementElectrolytic agentLead salt

The invention discloses a method for recycling lead from a lead-containing waste material. The method comprises the following steps of: (1) making the lead-containing waste material and a complexing agent water solution react to make sure that lead oxide and / or lead sulfate in the lead-containing waste material are / is completely dissolved, and separating a lead-ion-containing liquid supernatant from the precipitates containing no lead salt after reaction is ended; (2) making the liquid supernatant and a precipitant react so that the lead ions in the liquid supernatant are completely precipitated, and separating the lead-salt-containing precipitates from a regenerated complexing water solution after reaction is ended; and (3) making the lead-salt-containing precipitates and an electrolyte Awater solution have dissolution reaction to make sure that the lead-salt-containing precipitates are completely dissolved and a lead-containing electrolyte B and a precipitant are generated after reaction is ended, recycling the precipitant, and making the lead-containing electrolyte B have electrolytic reaction to obtain metallic lead, oxygen and a regenerated electrolyte A. according to the method disclosed by the invention, the complexing agent, the precipitant and the electrolyte A used in a recycling process can be repeated recycled; the method satisfies the characteristics of atomic economic reaction, so the method realizes zero consumption and zero emission and lowers the production cost.

Owner:BEIJING UNIV OF CHEM TECH

Method for reducing concentration of lead ions in lead electrolyte

InactiveCN104264185AIncrease precipitation speedReduce the concentration of lead ionsElectrolysis componentsPhotography auxillary processesElectrolysisEnergy consumption

The invention discloses a method for reducing the concentration of lead ions in a lead electrolyte. The method is applied in an electrolytic refining process of lead and comprises the following steps: (1) casting by virtue of a vertical die to obtain anode plates of which sizes are 1210*810*27mm and preparing cathode starting sheets of which sizes are 1370*840*(0.85+ / -0.05) mm by virtue of a cathode sheet processing machine; (2) arranging pitches between the newly manufactured cathode starting sheets and the anode plates by virtue of an automatic pitch arranging machine, loading into a tank, switching the direct current on and electrolyzing for 3.5-4 days; and (3) taking the cathodes out, reloading the newly manufactured cathode starting sheets, continuously electrolyzing for 3.5-4 days and taking the cathodes and residual anodes out so that an electrolytic period is completed. The method disclosed by the invention has the characteristics that the effect of reducing the concentration of lead ions in a lead electrolyte is obvious and economic and technical indexes such as the current efficiency, the rate of residual anodes and energy consumption are significantly improved, and is economical, environmentally friendly and strong in operability.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

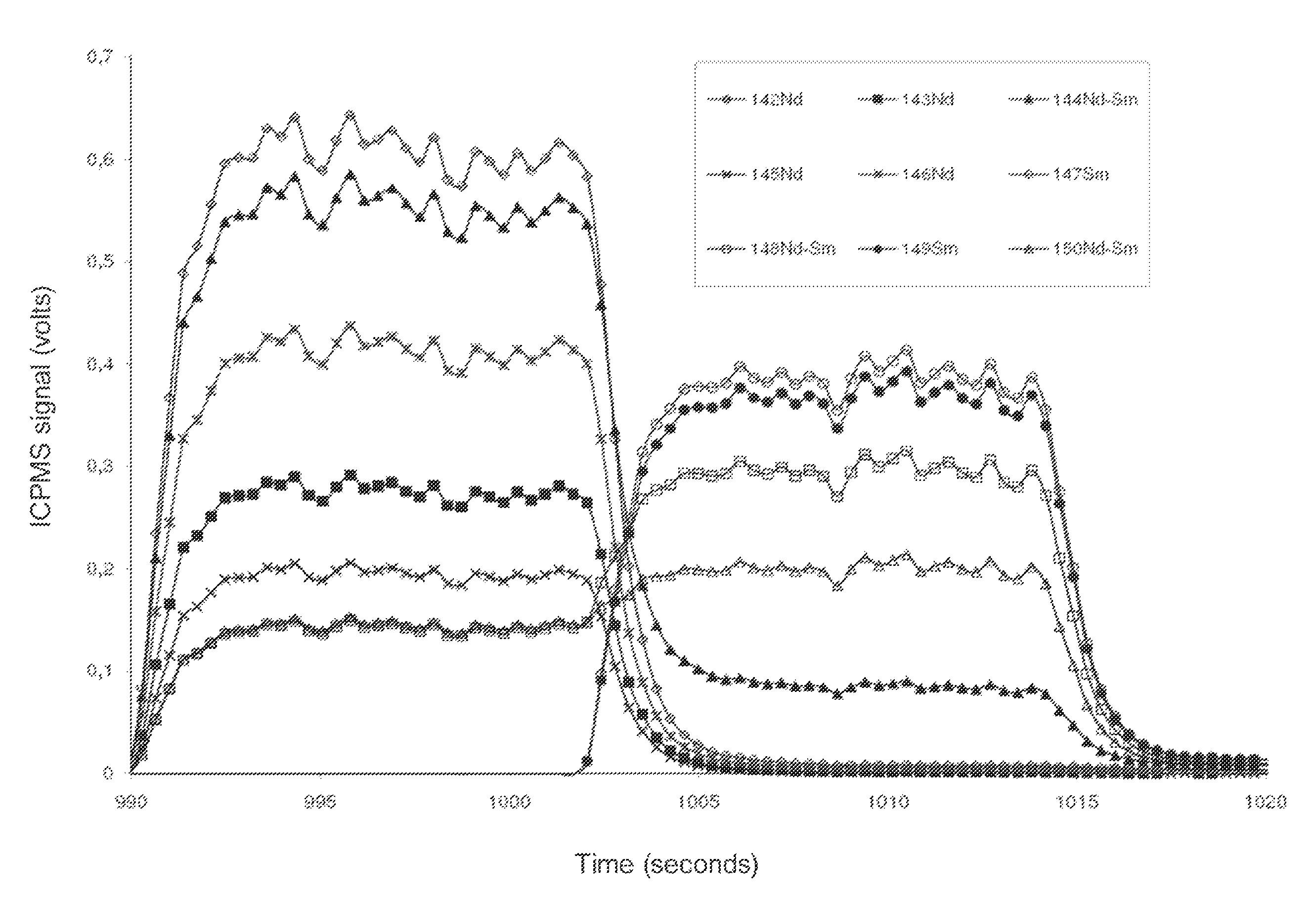

Method for isotopic measurement by ICPMS

ActiveUS9110016B2Less timeGood reproducibilityElectrolysis componentsComponent separationCapillary electrophoresisIsotachophoresis

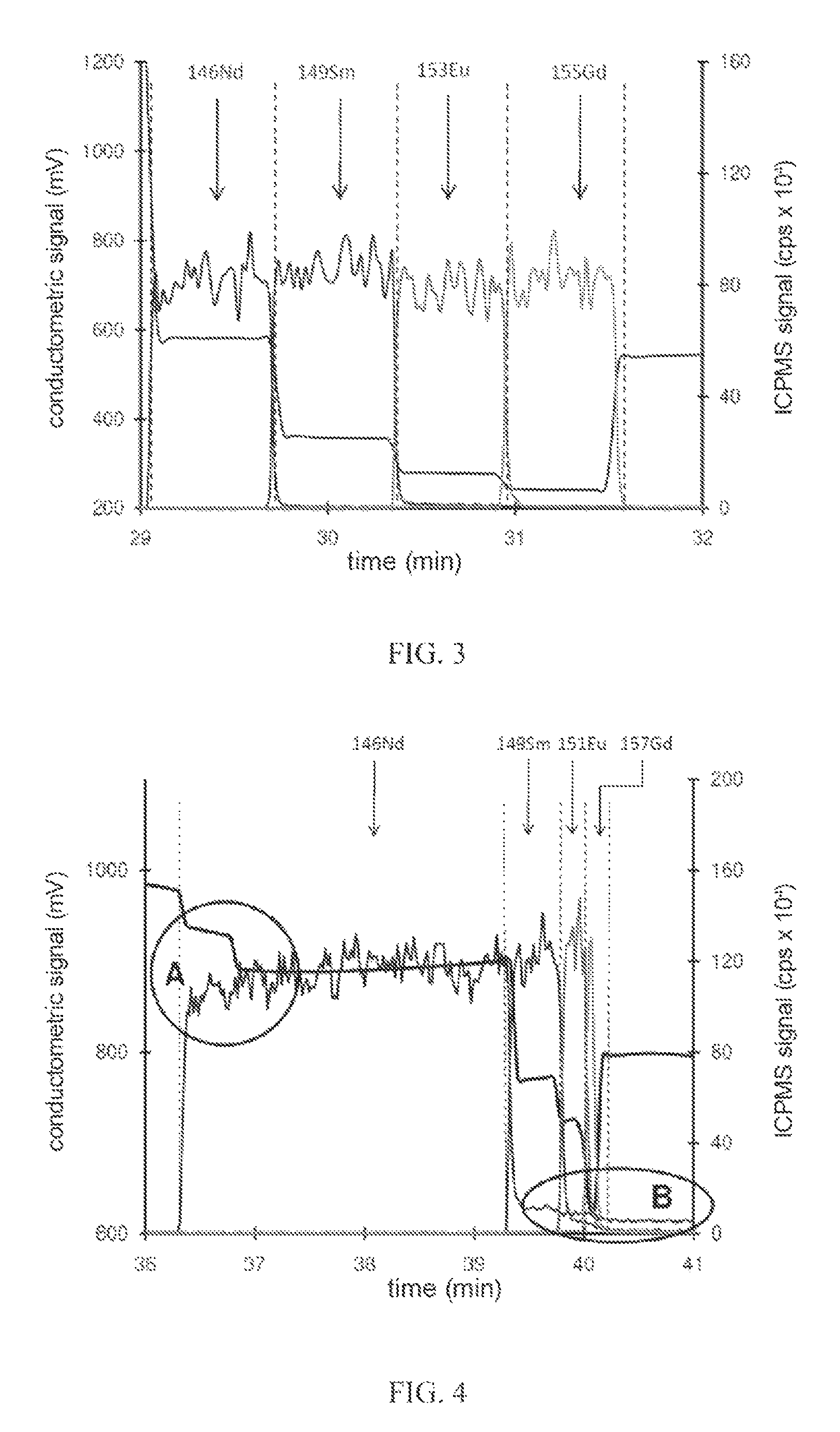

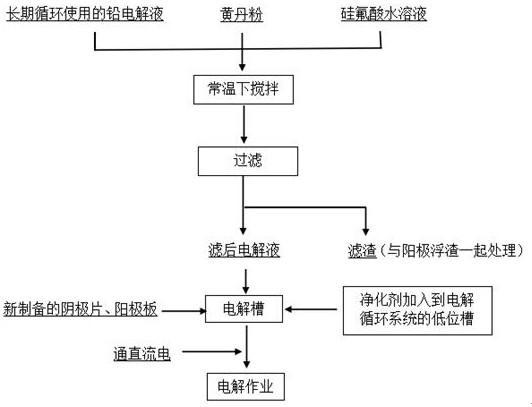

A method for isotope measurement of charged species contained in a solution to be analyzed, particularly charged species having an isobaric interference, has the following consecutive steps:a) in the capillary of a capillary electrophoresis device, the solution to be analyzed is inserted contiguously between a terminating electrolyte and a leading electrolyte that, respectively, are placed after the inlet and before the outlet of the capillary and contain ions of the same charge but with mobility inferior and superior to those of said species;b) separating the species by using the capillary electrophoresis device according to the isotachophoresis mode; thenc) in the continuity of the preceding step, performing an isotope measurement of the species detected in the form of a substantially constant amplitude signal by using an inductively coupled plasma mass spectrometer (ICPMS) connected by direct coupling with the capillary electrophoresis device.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

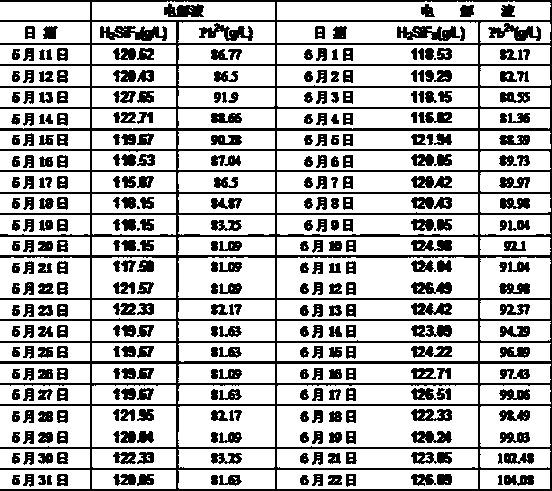

A method for improving the electrical conductivity of lead electrolyte

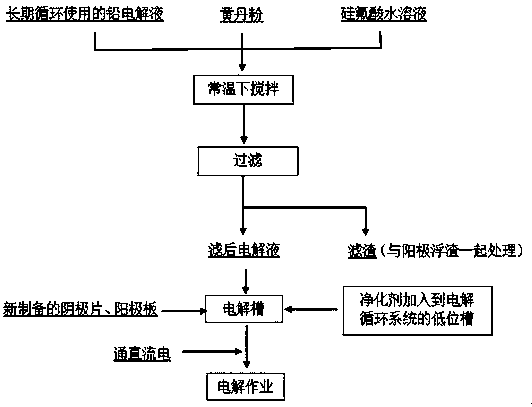

ActiveCN110219020BImprove conductivityIncrease productionElectrolysis componentsPhotography auxillary processesElectrolytic agentCleansing Agents

The invention relates to a method for improving the electrical conductivity performance of lead electrolyte and belongs to the technical field of metallurgy. The method specifically comprises the following steps of (1) rationally mixing a fluosilicic acid aqueous solution, industrial-grade yellow lead powder and the lead electrolyte with the poor electrical conductivity, filtering and clarifying the mixed solution and pumping the mixed solution into a lead electrolytic system; (2) spacing anode plates and cathode plates through an automatic spacing machine and mounting the anode plates and thecathode plates into an electrolytic cell; and (3) placing a filter device containing a compound electrolyte cleaning agent in a low tank in an electrolyte circulating system; regulating and controlling the circulating flow of electrolyte and the cell temperature in the electrolytic process, adding an appropriate amount of electrolytic additive every day, and taking cathode plates and anode scrapsafter electrolyzing for 7 days to complete an electrolytic cycle; and replacing the compound electrolyte cleaning agent once every two electrolytic cycles. The method is suitable for the lead electrolytic production process. The electrical conductivity of the electrolyte can be effectively improved. The cell voltage is reduced. The yield of electrolytic lead sheets is increased. The method has the advantages of being simple in process, convenient to operate, high in adaptability, friendly to environment and the like.

Owner:YUNNAN CHIHONG RESOURCE COMPREHENSIVE UTILIZATION CO LTD

Method for improving electrical conductivity performance of lead electrolyte

ActiveCN110219020AImprove conductivityIncrease productionPhotography auxillary processesElectrolysis componentsLead sheetCleansing Agents

The invention relates to a method for improving the electrical conductivity performance of lead electrolyte and belongs to the technical field of metallurgy. The method specifically comprises the following steps of (1) rationally mixing a fluosilicic acid aqueous solution, industrial-grade yellow lead powder and the lead electrolyte with the poor electrical conductivity, filtering and clarifying the mixed solution and pumping the mixed solution into a lead electrolytic system; (2) spacing anode plates and cathode plates through an automatic spacing machine and mounting the anode plates and thecathode plates into an electrolytic cell; and (3) placing a filter device containing a compound electrolyte cleaning agent in a low tank in an electrolyte circulating system; regulating and controlling the circulating flow of electrolyte and the cell temperature in the electrolytic process, adding an appropriate amount of electrolytic additive every day, and taking cathode plates and anode scrapsafter electrolyzing for 7 days to complete an electrolytic cycle; and replacing the compound electrolyte cleaning agent once every two electrolytic cycles. The method is suitable for the lead electrolytic production process. The electrical conductivity of the electrolyte can be effectively improved. The cell voltage is reduced. The yield of electrolytic lead sheets is increased. The method has the advantages of being simple in process, convenient to operate, high in adaptability, friendly to environment and the like.

Owner:YUNNAN HONGCHI RESOURCE INTEGRATION UTILIZATION CO LTD

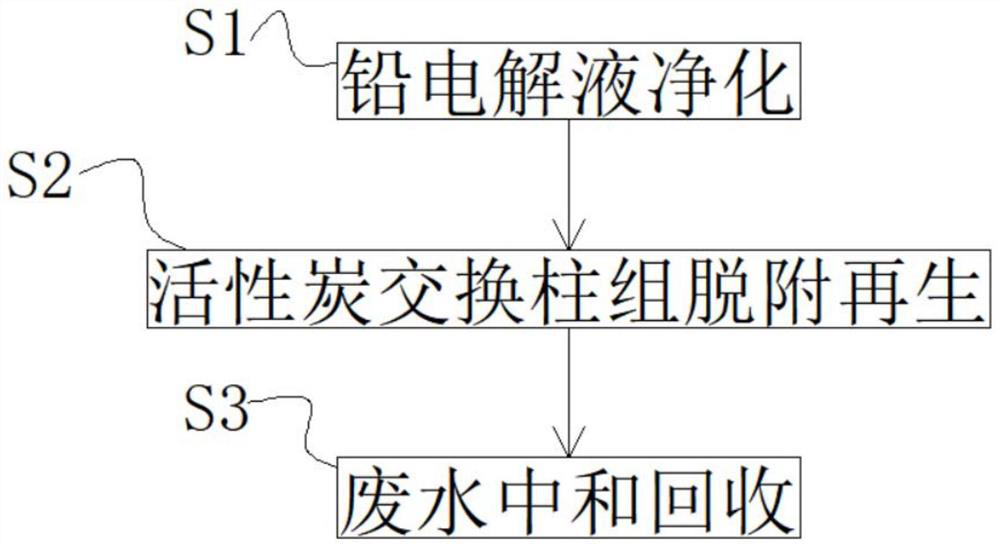

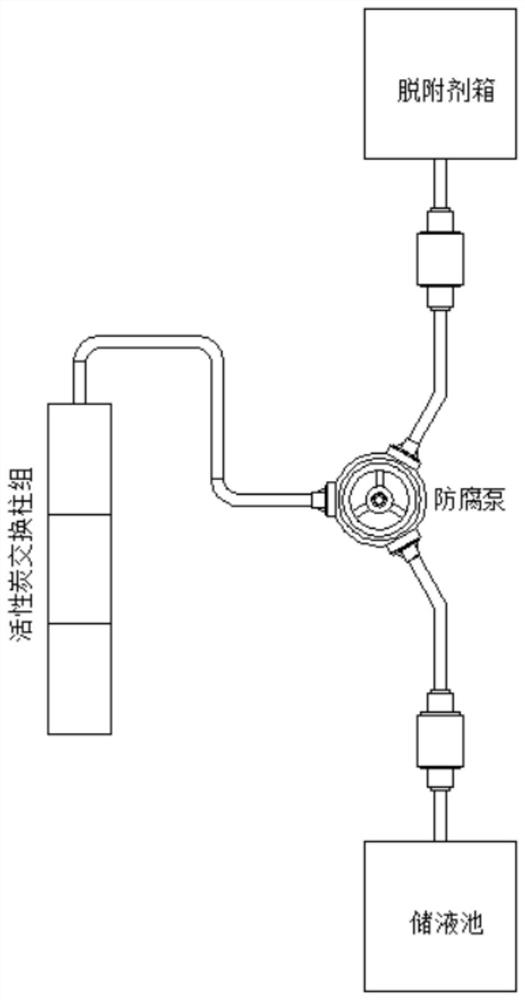

Method for purifying lead electrolyte by using columnar activated carbon

InactiveCN112403028AWill not change the principal componentsFriendly operating environmentIon-exchange process apparatusPhotography auxillary processesActivated carbonElectrolytic agent

The invention discloses a method for purifying a lead electrolyte by using columnar activated carbon, and relates to the technical field of purifying the lead electrolyte by using the activated carbon, in particular to the method for purifying the lead electrolyte by using the columnar activated carbon, which comprises the following steps: S1, purifying the lead electrolyte; S2, performing desorption and regeneration of the activated carbon exchange column group; and S3, neutralizing and recycling the wastewater. According to the method for purifying the lead electrolyte by using the columnaractivated carbon, the activated carbon adsorption exchange column group is adopted for purification, so that the operation is simple, other auxiliary reagents are not needed, and after the activated carbon adsorption exchange column group works for a period of time, desorption regeneration must be carried out generally for three months; substances in the to-be-separated solution can be adsorbed byusing activated carbon; calcium chloride is used as a desorbing agent for desorption and regeneration of the activated carbon; CaCl2 is selected as a desorption agent, so that the adsorption stability of activated carbon to adsorbate can be reduced, and the purpose of reducing desorption activation energy is achieved; and bismuth and antimony ions adsorbed in the activated carbon are eluted through desorption operation, and then the carbon column is washed with purified water to achieve the purpose of activated carbon regeneration.

Owner:郴州雄风环保科技有限公司

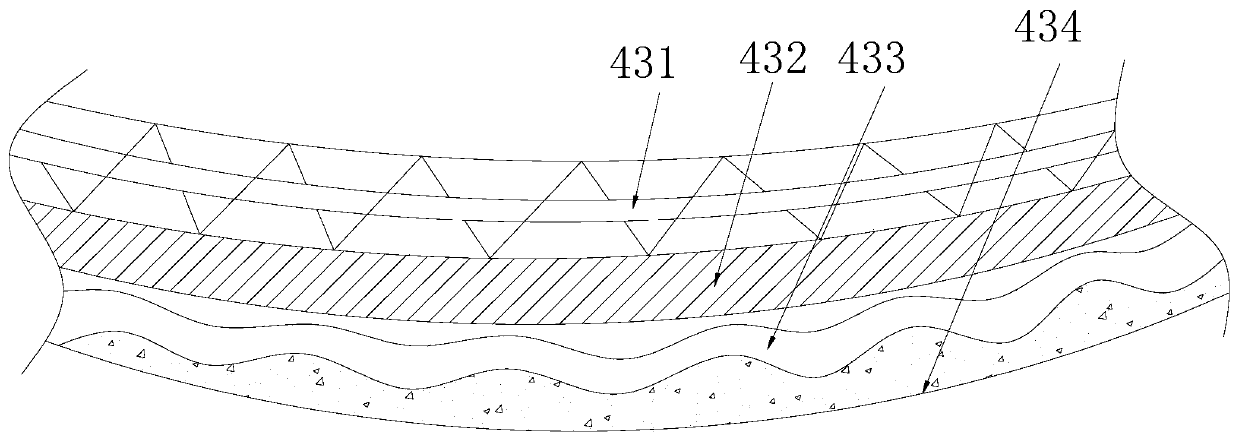

Fabrication device of sponge-shaped lead powder pillow cover for lead-acid storage battery sintered grid

PendingCN110048033AHigh dust and interference resistanceStrong sealing and isolation of static electricityFinal product manufactureSmall-sized cells cases/jacketsCapacitanceCold air

The invention discloses a fabrication device of a sponge-shaped lead powder pillow cover for a lead-acid storage battery sintered grid. The structure of the fabrication device comprises a substrate plate, a plastic shell cover, a negative electrode post end cover, a pillow cover rotation device, a positive electrode cover cap, a horizontal press plate, a truss handle and a sintered grid block. Thepillow cover rotation device is matched with the positive electrode cover cap, a hydrolysis gel block of a lead electrolyte is sealed by employing a pillow cover groove shell pillow structure, a positive electrode pin plate and a tail end of a lead powder sponge post plate are plugged and energized, an upper arc top and a lower arc top are expanded and contracted to match a cold air effect, a thermal expansion electrolyte overflows an energization capacitance groove to storage power so as to give the power to the negative electrode post end cover and the positive electrode cover cap, a cold contraction low-position fluid also can be contacted with the positive pin plate and is used for performing liquid sealing on a tail end of the lead powder sponge post plate, the continuous power supply is high, so that a pillow-shaped structure forms an ellipsoid-shaped inner ring electromagnetic field, a shielding net is erected, the effect that external environmental interference load is not absorbed is achieved, continuous static electricity is prevented, and the operation safety of a worker is also guaranteed.

Owner:泉州洛江旺利机械科技有限公司

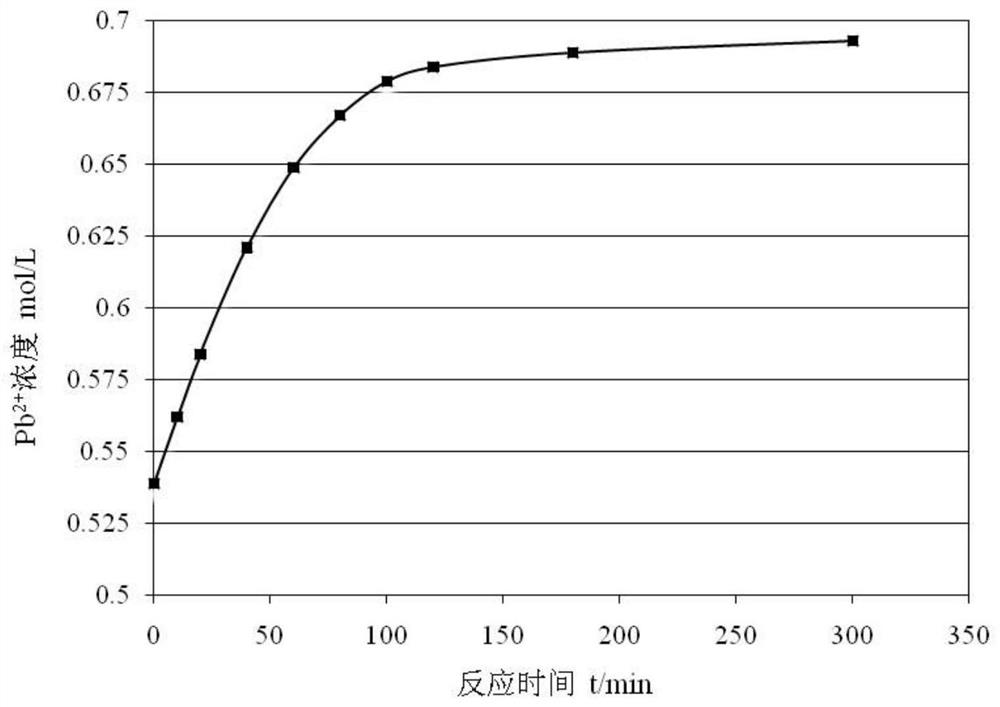

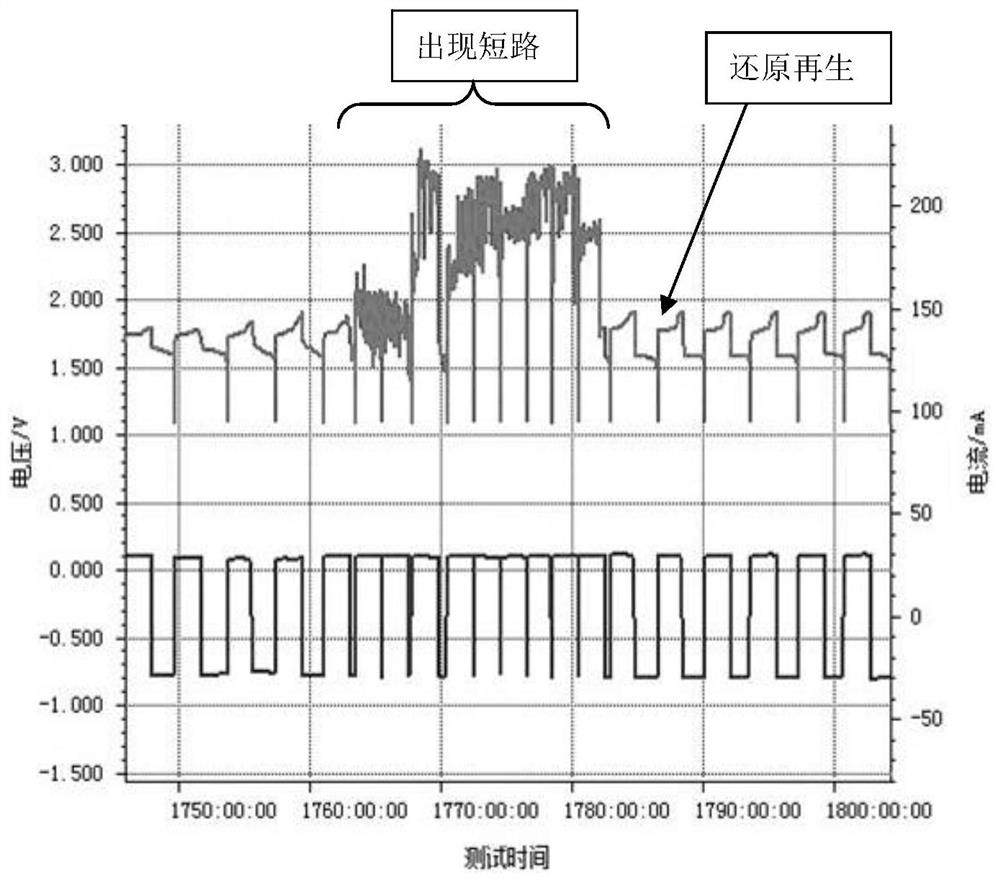

A kind of reduction regeneration agent of lead methanesulfonate electrolyte and the reduction regeneration method of lead methanesulfonate electrolyte

ActiveCN108417866BImprove cycle lifeImprove efficiencyElectrolyte stream managementRegenerative fuel cellsElectrolytic agentElectrical battery

The invention discloses a reduction regeneration agent for a lead methanesulfonate electrolyte and a method for carrying out reduction regeneration on the electrolyte of a lead methanesulfonate flow battery which is short-circuited or is relatively low in efficiency by using the reduction regeneration agent. The reduction regeneration agent is a water solution containing H2O2 and CH3SO3H; and thereduction regeneration method comprises the following steps of detecting the molar concentration of remaining active Pb<2+> in the electrolyte of the lead methanesulfonate flow battery which is short-circuited or is relatively low in efficiency; calculating the additive amount of the reduction regeneration agent according to the concentration of the remaining active Pb<2+>; and injecting the reduction regeneration agent into the electrolyte, controlling the injection rate and completing reduction regeneration of the electrolyte when no obvious bubble is generated at a reflux inlet of a liquidstorage tank. According to the reduction regeneration agent and the reduction regeneration method, the condition that the concentration of the Pb<2+> in the electrolyte of the battery which is short-circuited or is relatively low in efficiency is restored to be close to an initial state can be achieved, thereby achieving the targets of improving the charge-discharge cycle efficiency of the batteryand prolonging the cycle life of the battery.

Owner:HAOFA ENVIRONMENTAL PROTECTION TECH SHENZHEN CO LTD

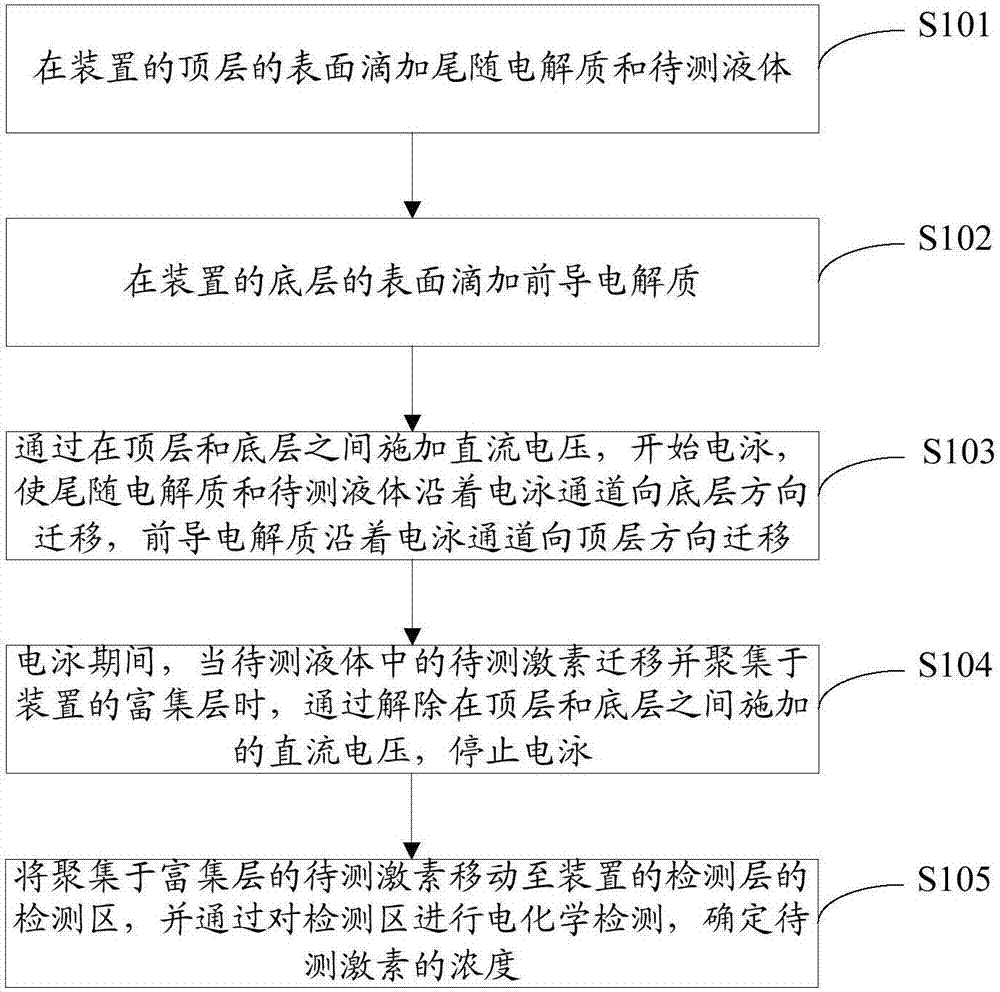

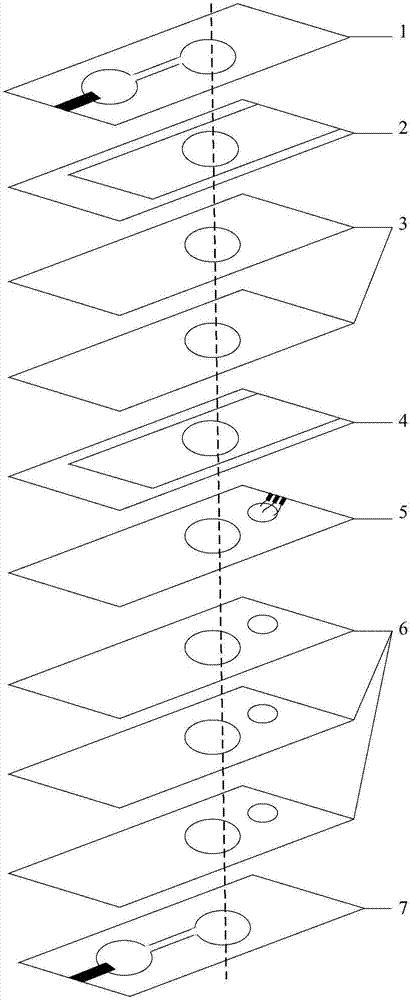

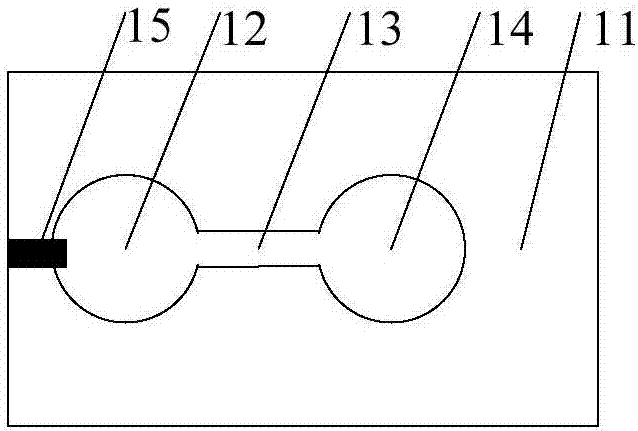

A low-abundance hormone detection method and device

ActiveCN106199013BQuick checkSensitive detectionMaterial analysis by electric/magnetic meansBiological testingElectrophoresisHormones regulation

The invention discloses a low abundance hormone detection method and device. A device for executing detection is provided with a multi-layer structure. Electrophoresis through hole regions of each layer structure are communicated to form an electrophoresis channel. The method comprises the steps that a trailing electrolyte and to-be-detected liquid are dropped on the surface of a top layer of the device; a leading electrolyte is dropped on the surface of a bottom layer of the device; electrophoresis is started by applying direct current voltage between the top layer and the bottom layer, so that the trailing electrolyte and the to-be-detected liquid are migrated in the direction of the bottom layer along the electrophoresis channel, and the leading electrolyte is migrated in the direction of the top layer along the electrophoresis channel; during electrophoresis, when to-be-detected hormone in the to-be-detected liquid is migrated and gathered on an enrichment layer of the device, and electrophoresis is stopped by removing the direct current voltage applied between the top layer and the bottom layer; the to-be-detected hormone gathered on the enrichment layer is moved to a detection region of a detection layer of the device, and electrochemical detection is performed on the detection region, and the concentration of the to-be-detected hormone is determined.

Owner:PEKING UNIV FIRST HOSPITAL +1

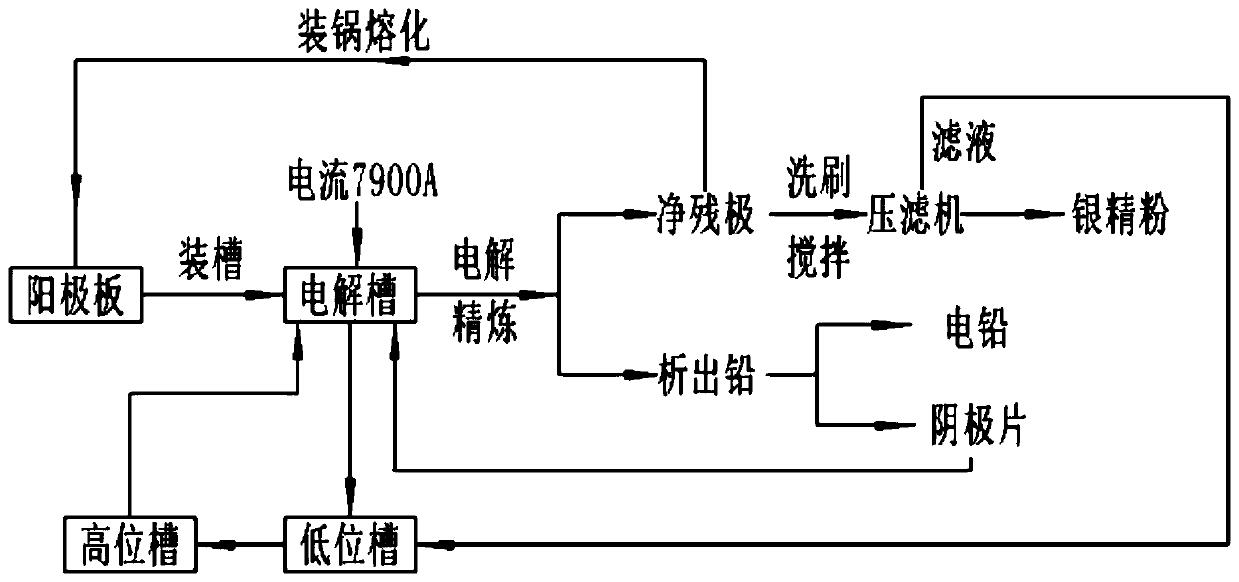

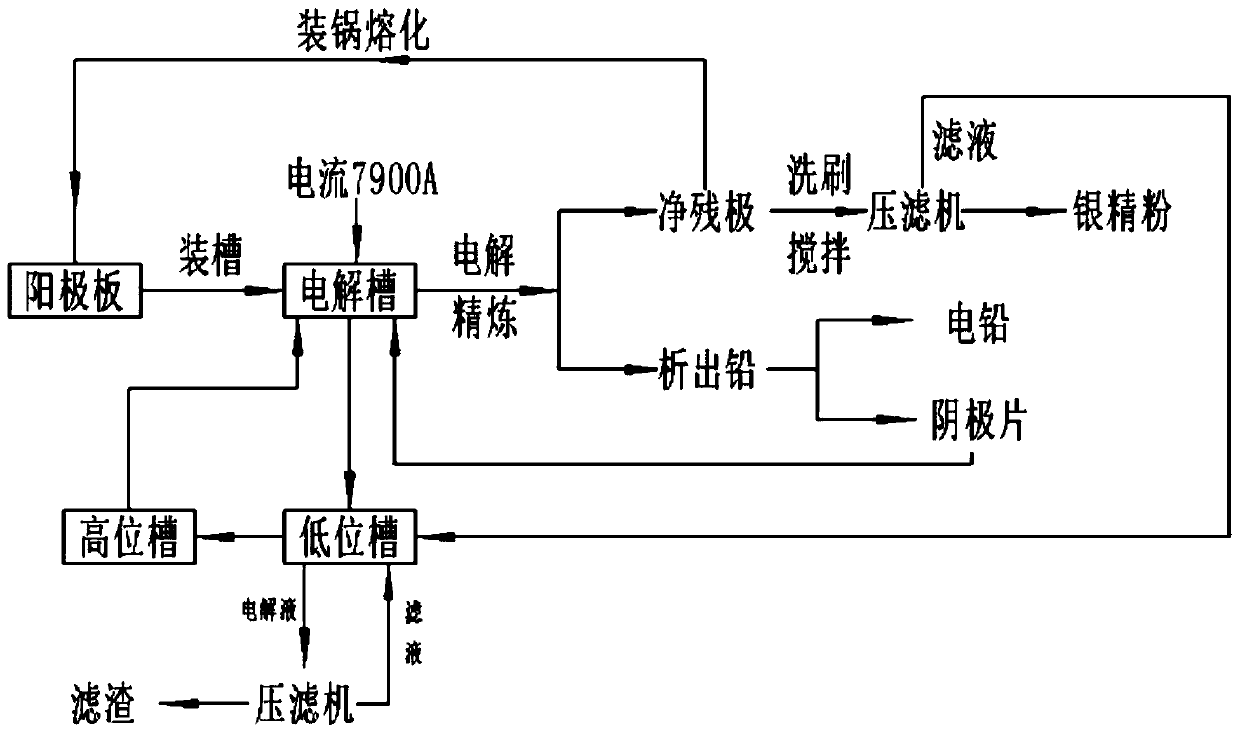

Lead electrolyte purification process

InactiveCN111519214AEfficient separationImprove purification effectPhotography auxillary processesElectrolysis componentsElectrolytic agentDC - Direct current

An embodiment of the invention discloses a lead electrolyte purification process, and belongs to the technical field of lead electrolytic refining. According to the lead electrolyte purification process, a filter press provided with acid-proof filter cloth is used for filtering and removing impurities of an electrolyte, and after impurity metal ions of the electrolyte reach the standard, the electrolyte is electrified for normal production. An adsorbent adopted by an existing purification process is changed into the filter press provided with the acid-proof filter cloth. The filter press cooperates with a filter press pump and a circulating pump in use to filter and remove impurities from the electrolyte, so that the particulate impurities contained in the electrolyte can be effectively separated, and the lead electrolyte purification process has the advantages of good purification effect and high purification efficiency. After purification, the current efficiency is improved to 94-95%from the original 90-92%, the unit consumption of direct current is reduced to 110-130 kwh from the original 130-150 kwh, the quality of electric lead (pb) reaches 99.997% or above, and the application prospect is wide.

Owner:内蒙古兴安银铅冶炼有限公司

Method for reducing impurity bismuth ions in lead electrolyte

PendingCN112981460AStable productionPhotography auxillary processesLead electrolyteElectrolytic agent

The invention discloses a method for reducing impurity bismuth ions in a lead electrolyte. The technical problem to be solved is that potential hazards are brought to the quality of electrolytic lead due to continuous accumulation of bismuth ions in the electrolysis process of high-bismuth lead bullion or the bismuth content of the electrolytic lead is suddenly increased due to accidental factors; and for the adverse consequences brought by two common treatment methods, under the conditions that production is not stopped for a long time and a large amount of unqualified precipitated lead is not produced, long-time normal and stable production of the high-bismuth lead bullion is realized or the problem of unqualified electrolytic lead caused by the accidental factors is quickly solved.

Owner:湖南省桂阳银星有色冶炼有限公司

Lead electrolyte and purification method of impurity metal ions in anode slime washing water

ActiveCN103938228BHigh degree of automationIncrease productivityElectrolytic agentPurification methods

A purifying method for removing impurities metal ions in lead electrolyte and anode slime washing water comprises the following steps: for removing impurities metal ions in the lead electrolyte, installing an anode plate and a cathode plate in an electrolytic cell, controlling the electrolyte circulation speed in the electrolytic cell at 8-10 L / min, sampling and detecting once every 6-12 h until the impurities metal ions in the electrolyte reach the standard, and then conducting electricity to perform normal production; and for removing impurities metal ions in anode slime washing water, conveying anode slime washing water to a washing water purifying tank, installing a lead plate in the tank, controlling the ratio of the lead plate superficial area to the anode slime washing water volume, reacting and clarifying for 24-48 h, after the impurities metal ions in the anode slime washing water reach the standard, mixing with an electrolyte. The purification method helps to solve the technical problem that unqualified precipitated lead is produced in a high-impurity crude lead electrolytic refining process or a lead electrolysis recovery production preliminary stage because impurities metal ions in electrolytes exceed standard; the precipitated lead produced by employing the purification method has qualified quality; and the purification method has the advantages of simple operation, high production efficiency and high valuable metal recovery rate, and the economic benefit is substantial.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

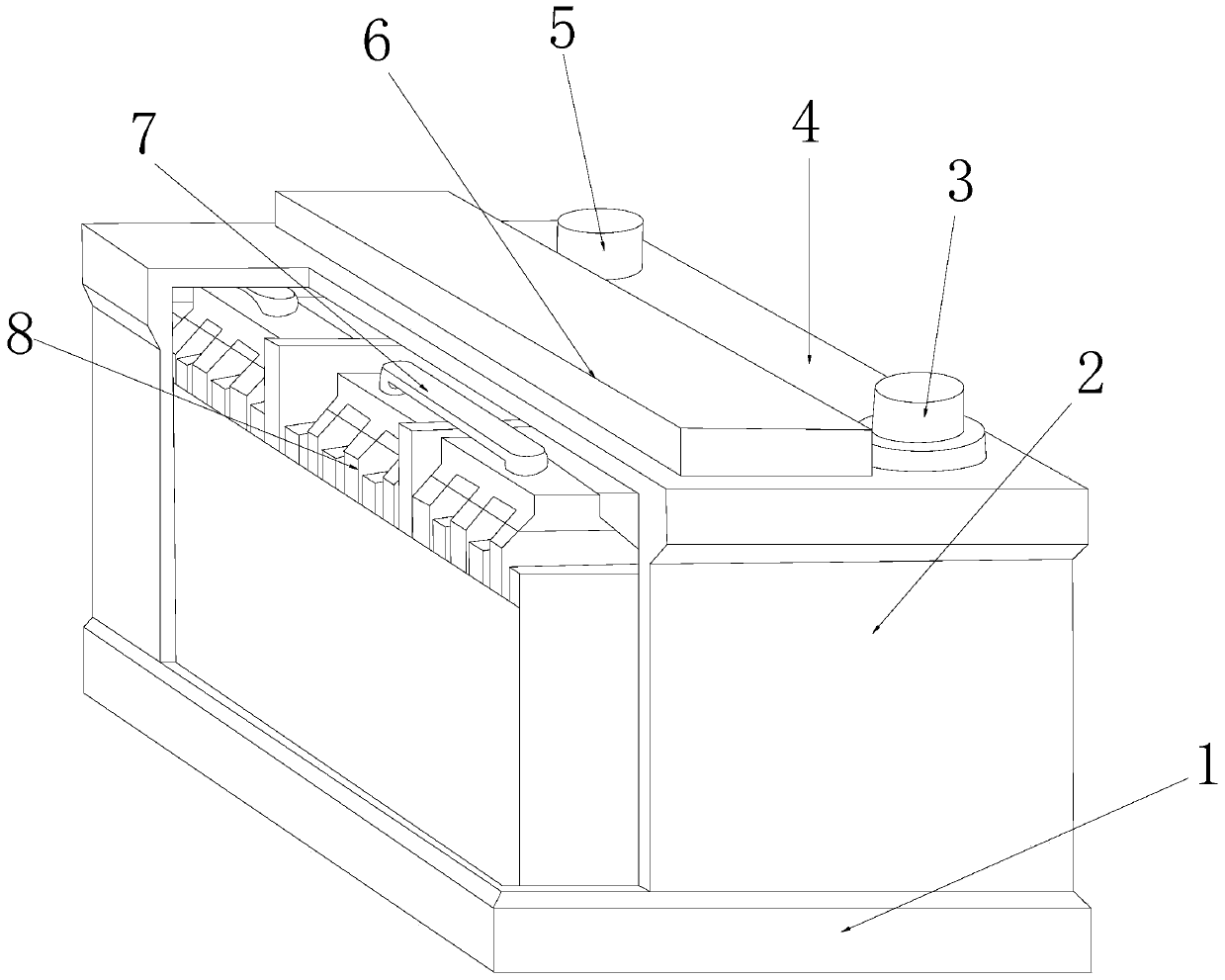

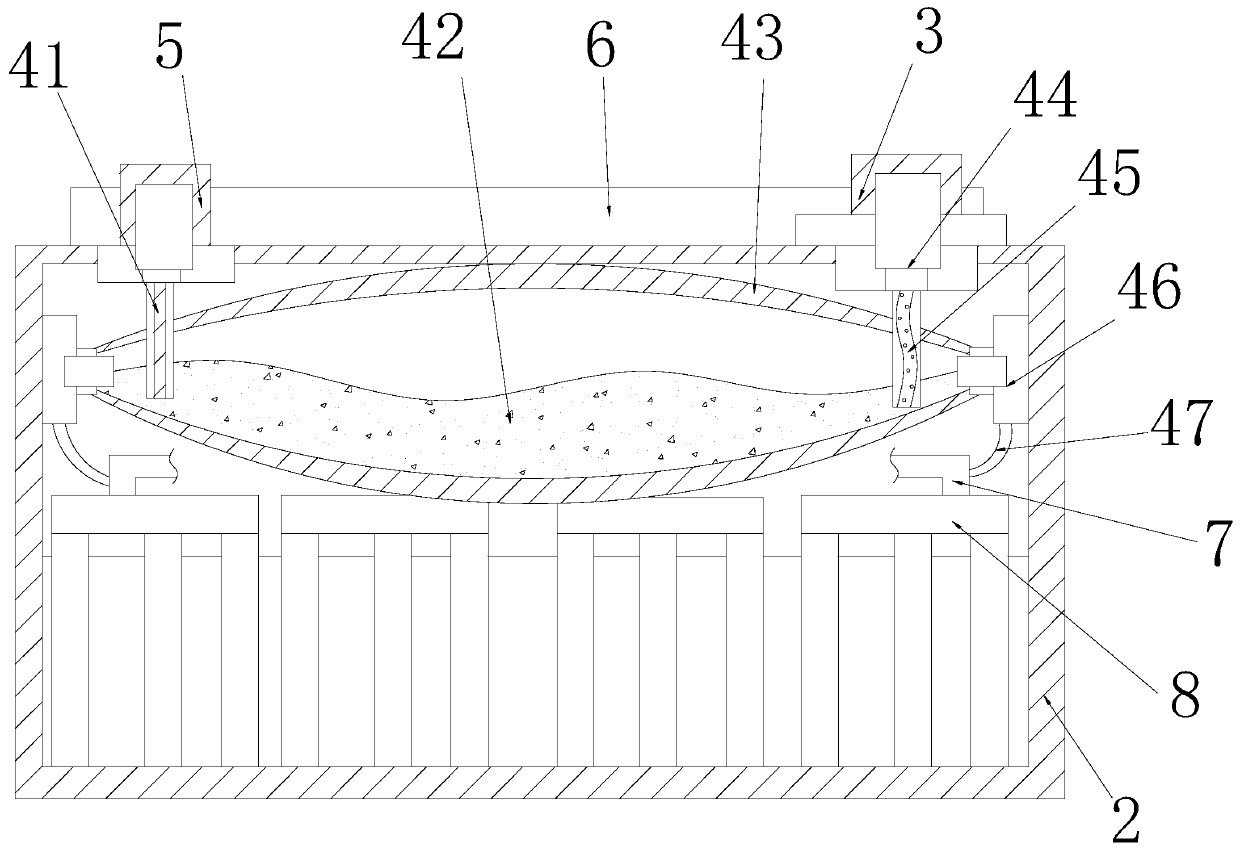

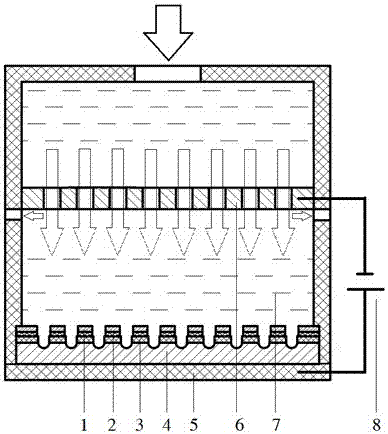

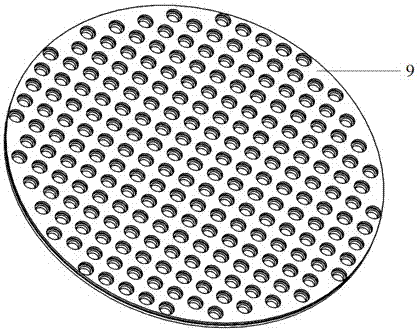

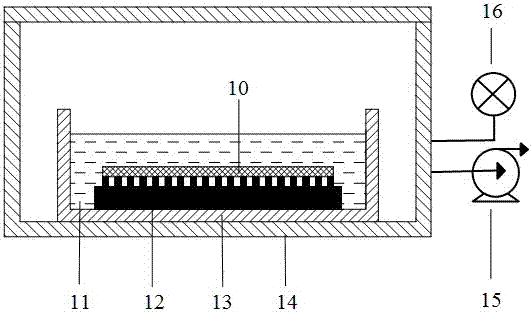

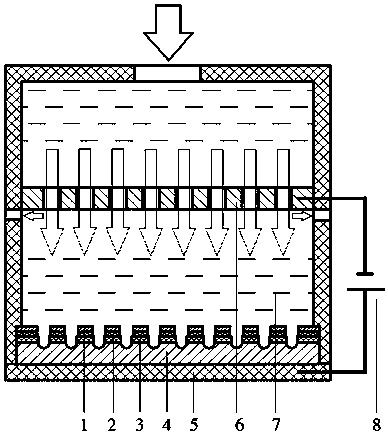

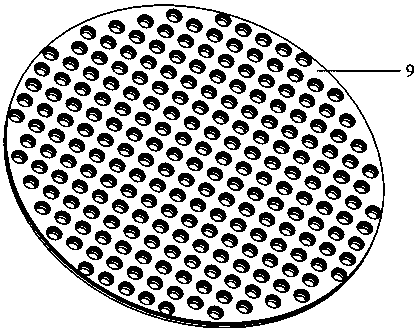

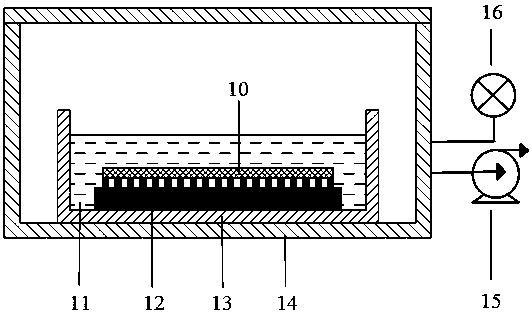

Micro-pit array electrolysis system and method based on dual-layer mold plate and mold plate preparing method

ActiveCN107199379ASolve problems such as poor bonding and serious stray corrosionImprove machining accuracyDomestic articlesElectrochemical machining apparatusEpoxyElectrolysis

The invention relates to a micro-pit array electrolysis system and method based on a dual-layer mold plate and a mold plate preparing method, and belongs to the field of minuteness electrolytic machining. The method comprises the steps of a, manufacturing a cathode tool (6) and a clamp (5); b, manufacturing a dual-layer mold plate (9) with a through hole array; c, attaching the dual-layer mold plate (9) to the upper surface of an anode workpiece (4), and using the clamp (5) to enable the cathode tool (6), the anode workpiece (4) and the dual-layer mold plate (9) to be clamped together; d, enabling the anode workpiece (4) and the cathode tool (6) to be connected with a positive electrode and a negative electrode of a power source (8) correspondingly; e, leading electrolytes (7) to the clamp (5), wherein the pressure intensity of the electrolytes is larger than 0.4 MPa; f, switching on the power source (8), and performing electrolyte machining. The method is adopted for carrying out electrolyte machining, rigidity of the epoxy resin mold plate is used, machining stability of a micro-pit array is improved, flexibility of a PDMS mold plate is used for promoting the PDMS mold plate to be tightly attached to the surface of an anode workpiece, and machining precision is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

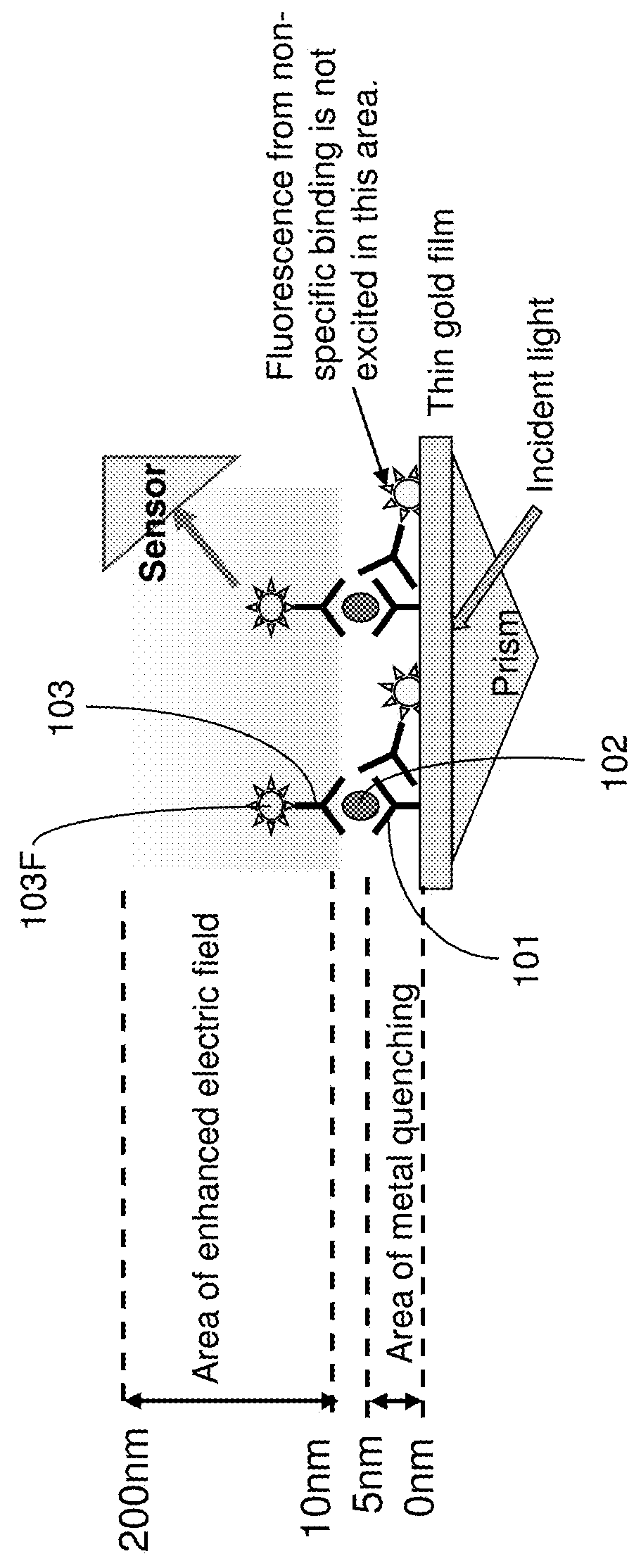

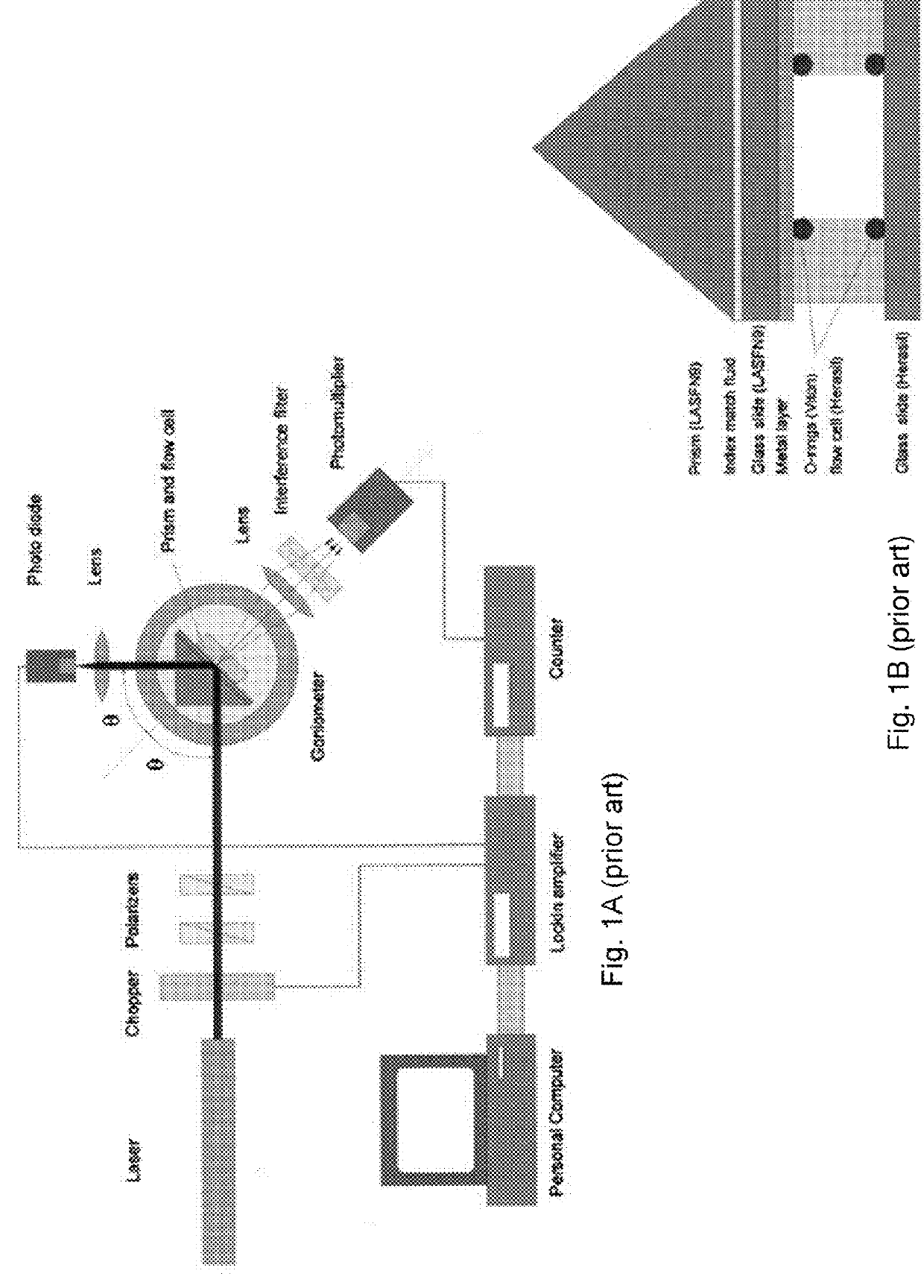

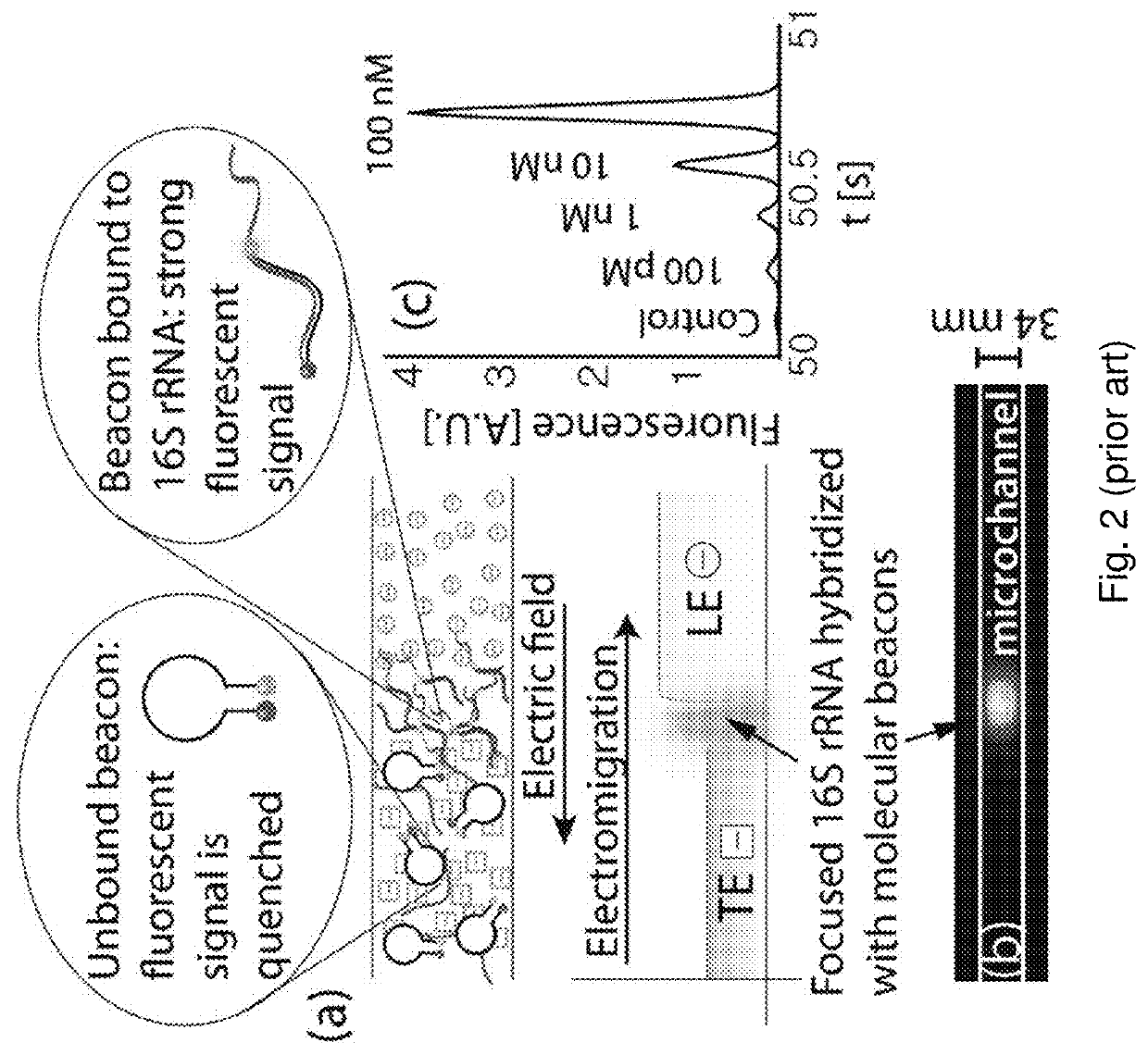

Detection of biological molecules using surface plasmon field enhanced fluorescence spectroscopy (SPFS) combined with isotachophoresis (ITP)

ActiveUS20180095080A1Material analysis by electric/magnetic meansLaboratory glasswaresIsotachophoresisLow mobility

A combination of surface plasmon field enhanced fluorescence spectroscopy (SPFS) and isotachophoresis (ITP) technologies for detecting biomolecules is disclosed. It uses ITP to preconcentrate the reactants and accelerate the reaction, and then delivers the reacted sample to an SPFS sensor for detection. A microfluidic device with a T-junction is provided, which has two reservoirs respectively containing a low-mobility trailing electrolyte buffer and a high-mobility leading electrolyte buffer, and a main fluid channel between the two reservoirs, where the SPFS sensor is located on a side channel joined to the main channel. A two-step technique is employed, including a step of sample loading and ITP extraction, and a step of delivery of concentrated sample to the detector chamber by pressure-driven flow. In another embodiment, the SPFS sensor is located on the main fluid channel between the two reservoirs. In a particular example, the technique is used in a DNAzyme assay.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Method for adding carbonate to treat hydrofluoric acid in lead electrolyte

ActiveCN103779617BReduce usageLow costSecondary cells servicing/maintenanceLead-acid accumulators constructionHydrofluoric acidLead oxide

The invention relates to a method for adding carbonate into lead electrolyte to treat hydrofluoric acid. The lead electrolyte is lead silicofluoride obtained through reaction between industrial silicofluoric acid and lead oxide. The method comprises the following steps of (1) adding silica powder into the industrial silicofluoric acid, wherein the silica powder reacts with hydrofluoric acid to generate silicofluoride, so as to remove a part of the hydrofluoric acid; (2) adding a certain amount of carbonate, and adding the lead oxide after the hydrofluoric acid is removed. The method has the beneficial effects that the using amount of the lead oxide is reduced; the added carbonate is low in cost, so that the cost can be effectively lowered.

Owner:梁达保

Method for producing lead electrolyte by utilizing industrial waste liquid

InactiveCN103374728BEmission reductionReduce pollutionPhotography auxillary processesProcess efficiency improvementLiquid wasteHigh energy

The invention provides a method for preparing a lead electrolyte by utilizing industrial waste liquids and relates to the field of chemical technology. The method comprises the following operating steps. First, waste liquids generated from industrial production of high calcium fertilizer, phosphate fertilizer, anhydrous hydrofluoric acid and the like are employed as raw materials. Second, after the raw materials being sent into a factory, contents of various components of the raw materials are first tested, and water is added to dilute the raw materials according to the contents of hydrofluoric acid and silicofluoric acid in the raw materials. Third, according to the content of hydrofluoric acid in the raw materials, silicon powder is added, and stirred at a rotating speed of 50-100 r / min for about 24 hours. Fourth, according to the contents of harmful elements such as sulfur, phosphorus and the like, yellow lead powder is added and stirred for about 48 hours to remove sulfate and phosphate. Fifth, if hydrofluoric acid, sulfate, phosphate and the like which are not reacted completely are left in the solution, according to the contents, appropriate amounts of quicklime and plant ash are added to neutralize hydrofluoric acid, sulfate, phosphate and the like to remove hydrofluoric acid, sulfate, phosphate and the like completely, and a qualified lead electrolyte mother liquid is prepared finally. The method solves the problems of high production cost, high energy consumption, environmental pollution and the like in the prior art.

Owner:梁达保

A method for extracting lead from lead plaster and lead sulfide concentrate by wet method

ActiveCN106676270BHigh purityEfficient recyclingPhotography auxillary processesProcess efficiency improvementLiquid wasteLead sulfide

The invention discloses an all-wet method for extracting lead from lead plaster and lead sulfide concentrate. The method comprises the steps that the lead plaster of a waste lead acid accumulator and a carbonate solution are subjected to a desulfurization conversion reaction, solid-liquid separation is conducted, a sulfate solution and desulfurization conversion materials are obtained, the desulfurization conversion materials are subjected to neutral leaching by means of a methanesulfonic acid solution, and neutral leachate and neutral leaching residues are obtained through liquid-solid separation; the neutral leachate and waste sulfate electrolyte are blended for preparing sulfate electrolyte which is then subjected to lead electrodeposition, and a lead plate and waste lead electrolyte are obtained; and the neutral leaching residues serve as an oxidizing agent, the lead sulfide concentrate is subjected to acid leaching by means of the waste sulfate electrolyte, liquid-solid separation is conducted, acid leachate and acid leaching residues are obtained, and the acid leachate returns for application to neutral leaching next time. By adoption of the method, the lead is efficiently extracted, the leachate and the sulfate electrolyte are recycled, no waste liquid is generated, and the requirement for environment protection is met.

Owner:CENT SOUTH UNIV

Micropit array electrolysis system and method based on double-layer template and template preparation method

ActiveCN107199379BImprove machining accuracyDomestic articlesElectrochemical machining apparatusEpoxyElectrolysis

The invention relates to a micro-pit array electrolysis system and method based on a dual-layer mold plate and a mold plate preparing method, and belongs to the field of minuteness electrolytic machining. The method comprises the steps of a, manufacturing a cathode tool (6) and a clamp (5); b, manufacturing a dual-layer mold plate (9) with a through hole array; c, attaching the dual-layer mold plate (9) to the upper surface of an anode workpiece (4), and using the clamp (5) to enable the cathode tool (6), the anode workpiece (4) and the dual-layer mold plate (9) to be clamped together; d, enabling the anode workpiece (4) and the cathode tool (6) to be connected with a positive electrode and a negative electrode of a power source (8) correspondingly; e, leading electrolytes (7) to the clamp (5), wherein the pressure intensity of the electrolytes is larger than 0.4 MPa; f, switching on the power source (8), and performing electrolyte machining. The method is adopted for carrying out electrolyte machining, rigidity of the epoxy resin mold plate is used, machining stability of a micro-pit array is improved, flexibility of a PDMS mold plate is used for promoting the PDMS mold plate to be tightly attached to the surface of an anode workpiece, and machining precision is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com