Method for improving electrical conductivity performance of lead electrolyte

A lead electrolyte and conductivity technology, applied in the metallurgical field, can solve the problems of high power consumption of the inert anode electrowinning method, aggravate equipment corrosion, and be unfavorable to the direct yield of lead refining, and achieve convenient operation, reduce cell voltage, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

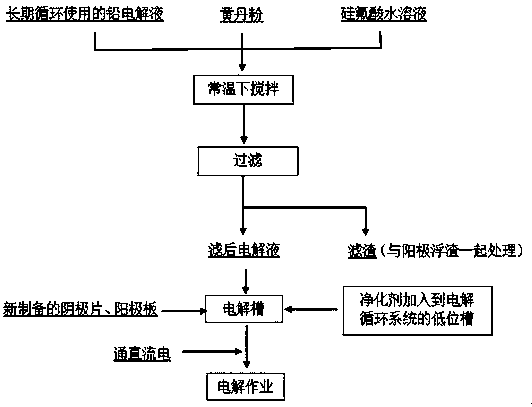

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the lead electrolyte (120.2g / L of lead ion, 75.6g / L of free fluorosilicic acid, 38.7g / L of aminoacetic acid, 38.7g / L of aminoacetic acid, which has been recycled for more than 2 years is used to measure the conductivity at 25°C as the reference temperature. 141mS / cm) as an example.

[0026] 1) Put 20m at room temperature 3 Lead electrolyte that has been recycled for more than 2 years, 5m 3 Fluorosilicic acid aqueous solution (free silicofluoric acid content is 18.1%) and 200kg industrial-grade yellow dandelion powder (PbO content 99%) are added to a stainless steel mixing tank and mixed in turn, and mechanically stirred for 3 hours to fully react to ensure that fluorosilicic acid and yellow dandelion Full response. Afterwards, the mixed solution is pumped into the filter press for pressure filtration while stirring, and the filtrate is recovered to the liquid storage tank for clarification for 12 hours and can be used as a newly prepared lead elect...

Embodiment 2

[0034] In this embodiment, the lead electrolyte (containing lead ion 135.2g / L, free silicofluoric acid 69.9g / L, aminoacetic acid 39.5g / L) which has been recycled for more than 2 years is used to measure the conductivity at 25°C as the reference temperature. 137mS / cm) as an example.

[0035] 1) Put 18m at room temperature 3 Lead electrolyte that has been recycled for more than 2 years, 6m 3 Fluorosilicic acid aqueous solution (free silicofluoric acid content is 18.1%) and 200kg industrial grade yellow lead powder (PbO content 99%) are added to the stainless steel mixing tank and mixed in turn, and mechanically stirred for 2.5h to fully react to ensure that the fluorosilicic acid and yellow Dan responded well. Afterwards, the mixed solution is pumped into the filter press for pressure filtration while stirring, and the filtrate is recovered to the liquid storage tank for clarification for 12 hours and can be used as a newly prepared lead electrolyte, and the filter residue is ...

Embodiment 3

[0043] In this embodiment, the lead electrolyte (144.7g / L of lead ion, 70.8g / L of free fluorosilicic acid, and 41.8g / L of aminoacetic acid) that has been recycled for more than 2 years is used to measure the conductivity at 25°C as the reference temperature. 134mS / cm) as an example.

[0044] 1) Put 17m at room temperature 3 Lead electrolyte that has been recycled for more than 2 years, 7m 3 Fluorosilicic acid aqueous solution (free silicofluoric acid content is 18.1%) and 250kg industrial grade yellow dan powder (PbO content 99%) are added to the stainless steel mixing tank and mixed in turn, and mechanically stirred for 3 hours to fully react to ensure that fluorosilicic acid and yellow dan Full response. Afterwards, the mixture is pumped into the filter press for pressure filtration while stirring, and the filtrate is recovered to the liquid storage tank for clarification 10h Finally, it can be used as a newly prepared lead electrolyte, and the filter residue is recovered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com