Patents

Literature

535 results about "Fluorosilicic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for the selective removal of silicon nitride

ActiveUS20100176082A1Increase etch rateHigh selectivitySolid-state devicesPhotomechanical apparatusSilicic acidSilicon oxide

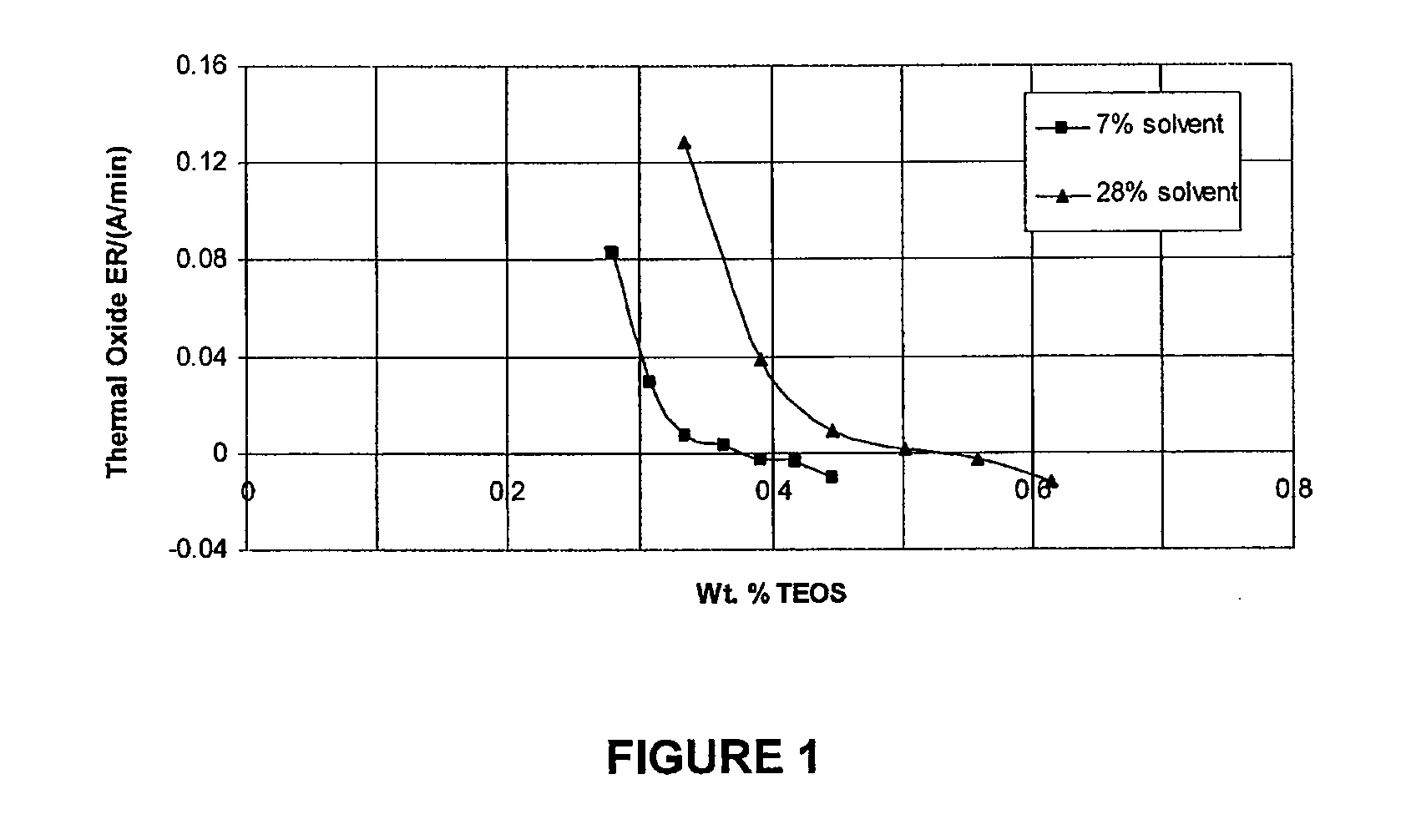

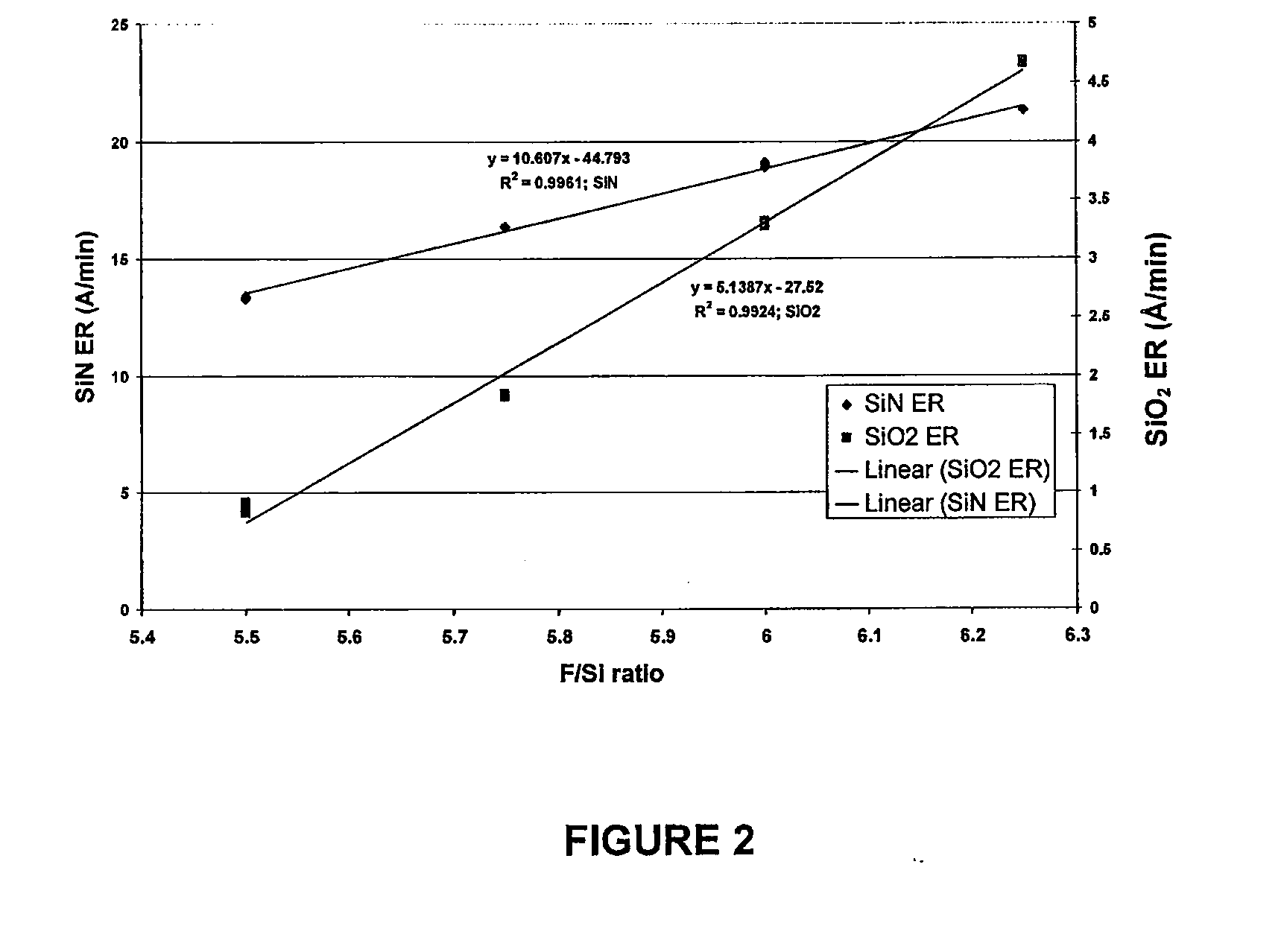

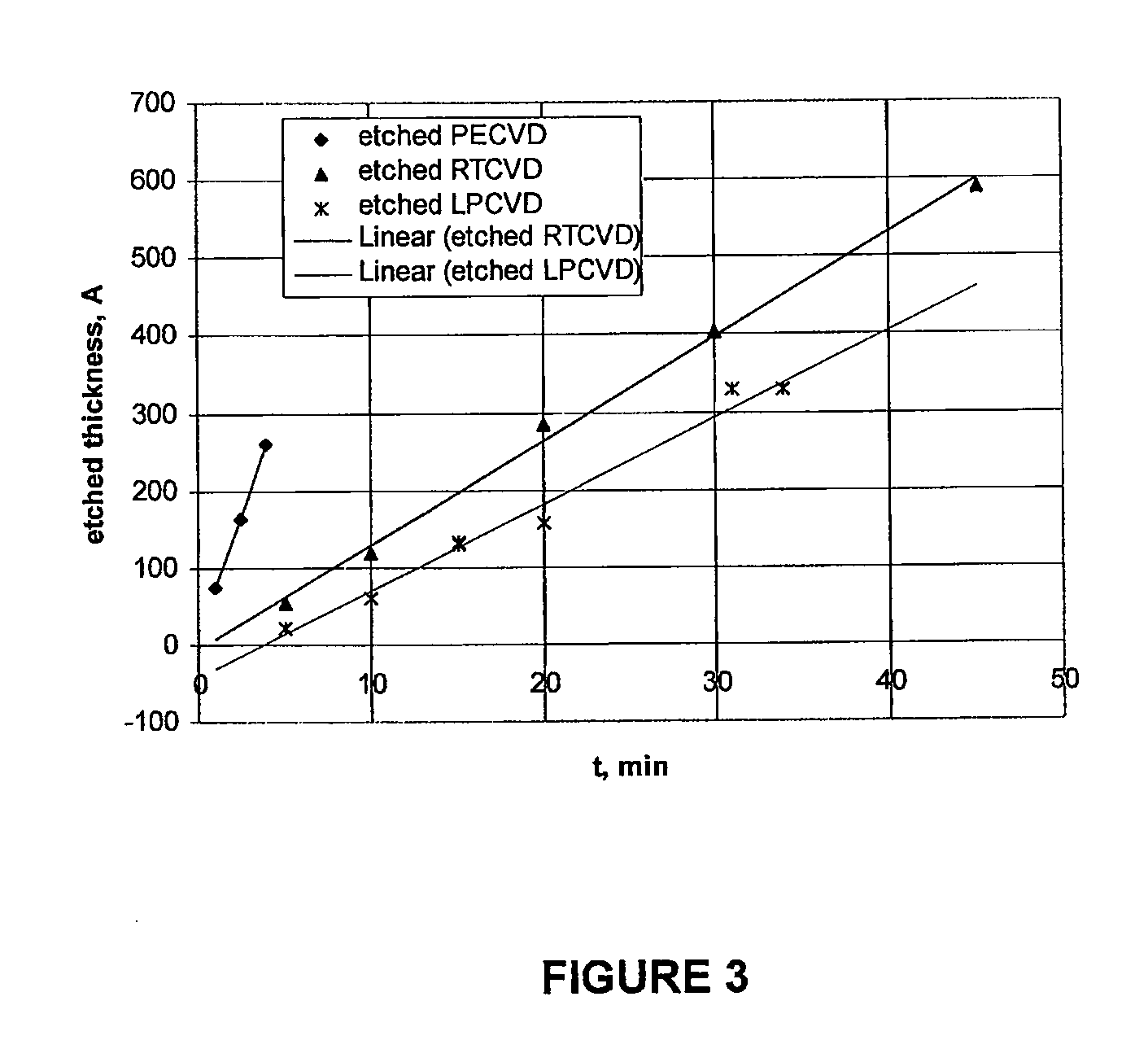

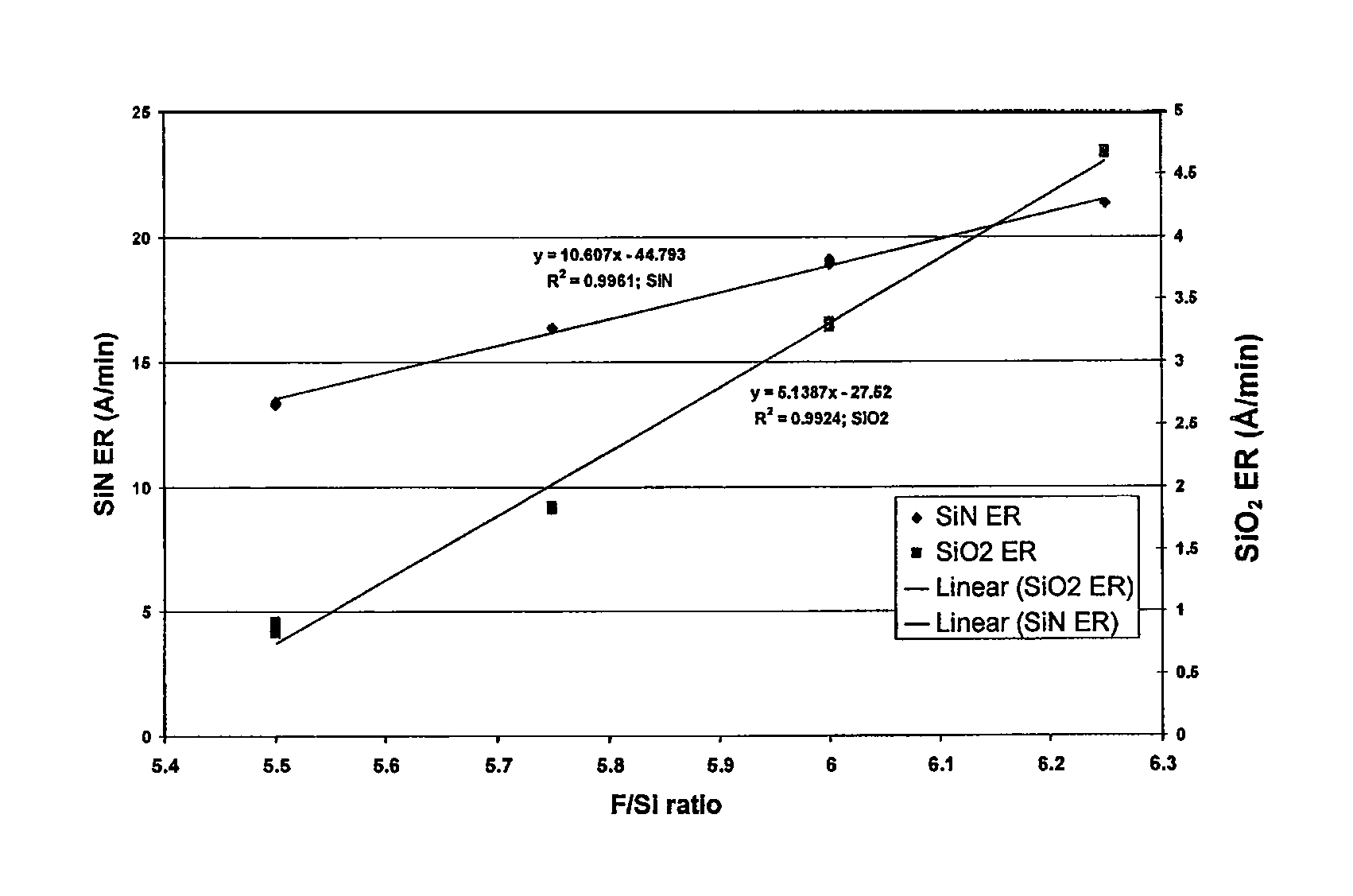

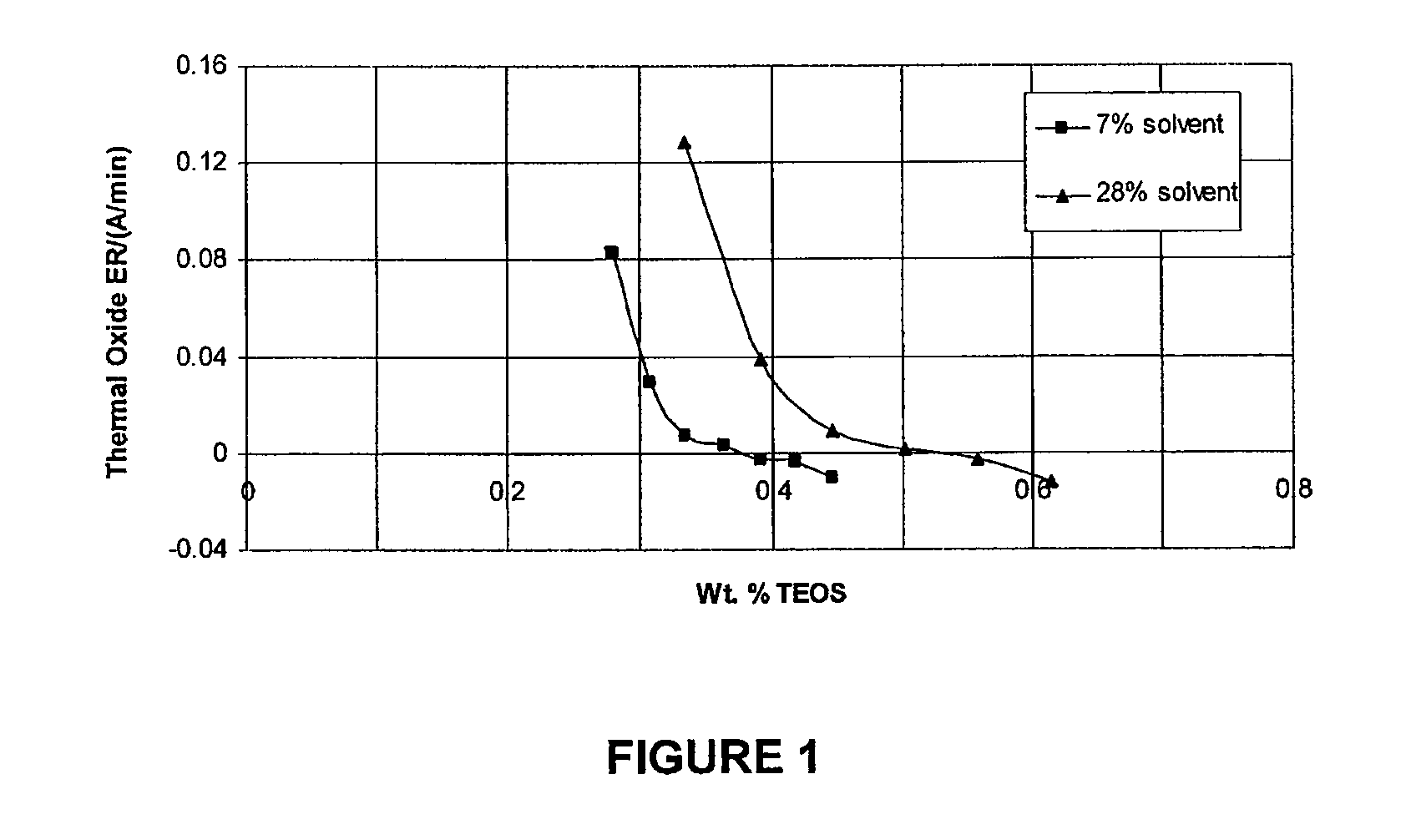

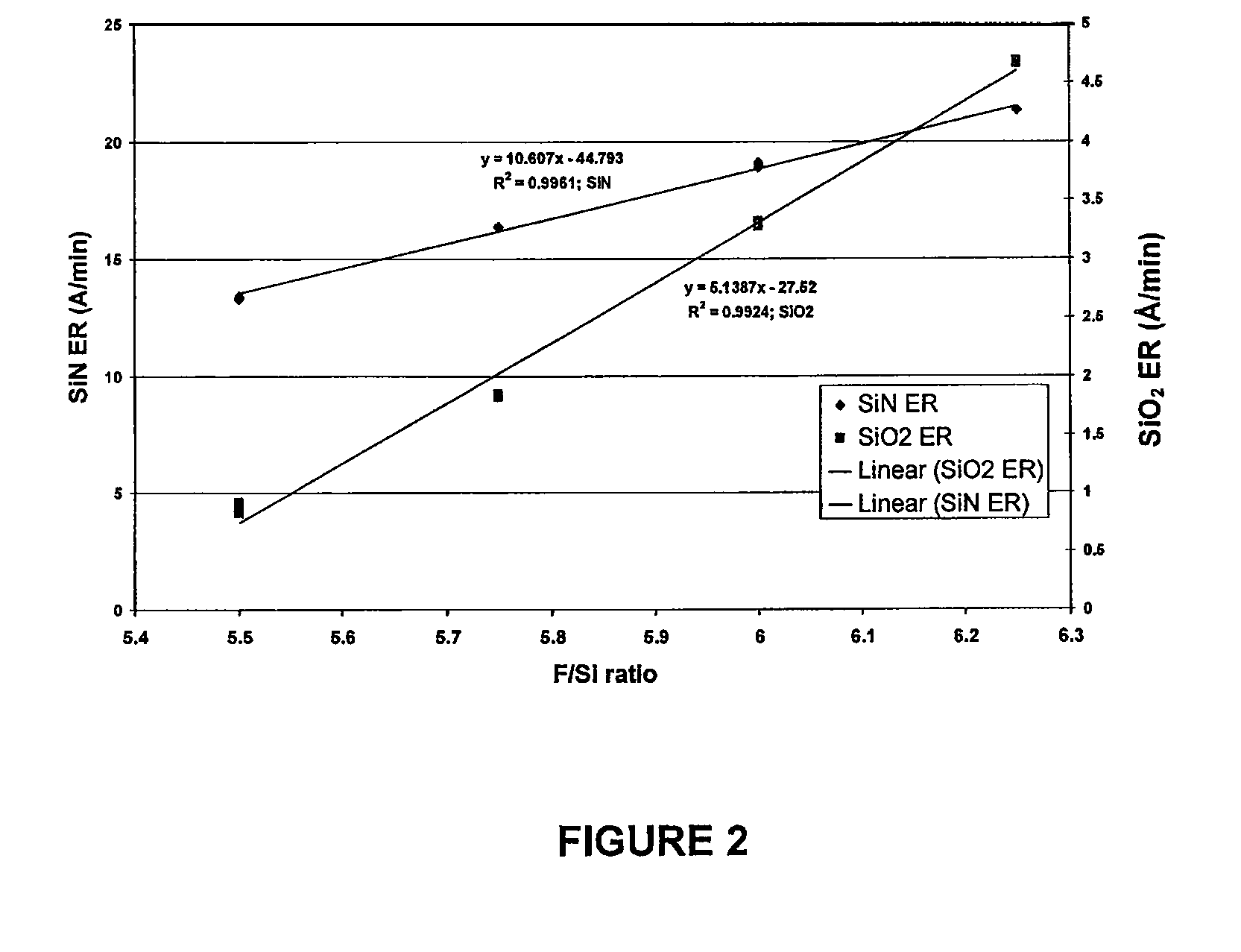

Compositions useful for the selective removal of silicon nitride materials relative to poly-silicon, silicon oxide materials and / or silicide materials from a microelectronic device having same thereon. The removal compositions include fluorosilicic acid, silicic acid, and at least one organic solvent. Typical process temperatures are less than about 100° C. and typical selectivity for nitride versus oxide etch is about 200:1 to about 2000:1. Under typical process conditions, nickel-based silicides as well as titanium and tantalum nitrides are largely unaffected, and polysilicon etch rates are less than about 1 Å min−1.

Owner:ENTEGRIS INC

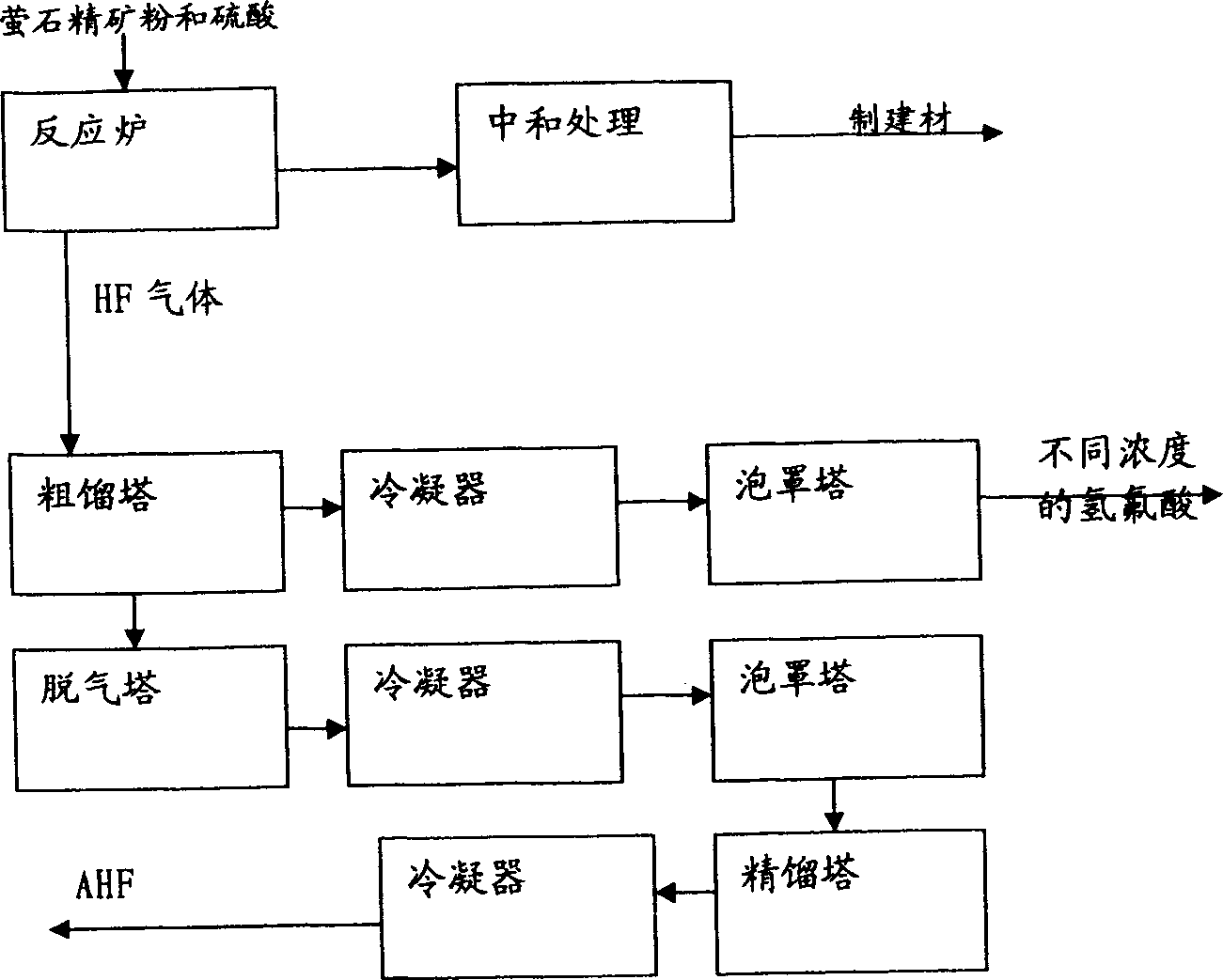

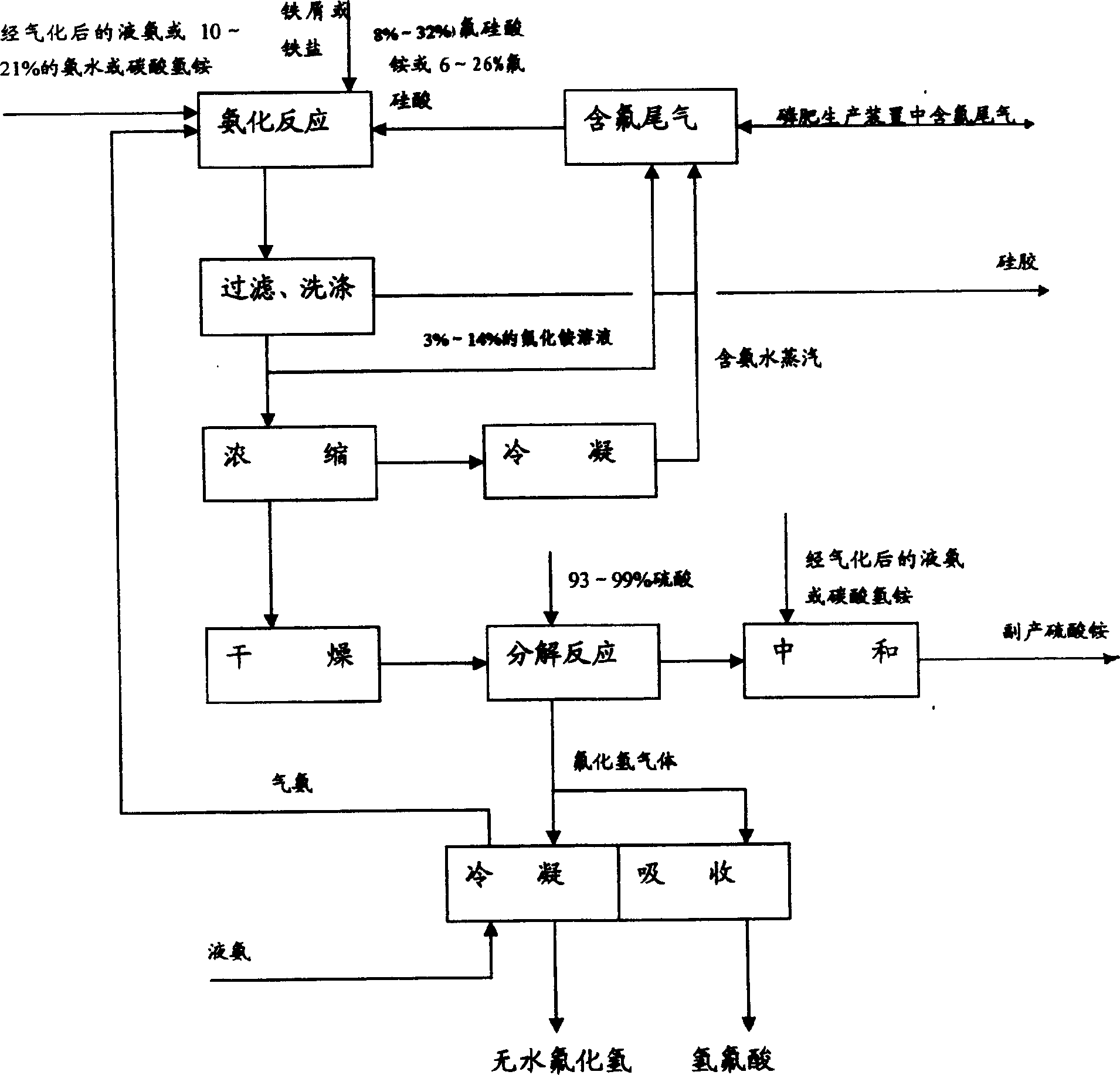

Method for comprehensively utilizing phosphate fertilizer by-product

InactiveCN1554570AReasonable designReduce material requirementsSolid waste disposalFluorine/hydrogen-fluorideIron saltsAmmonium fluorosilicate

The method of comprehensively utilizing phosphate fertilizer by-product includes utilizing ammonium fluoride solution of 3-14% concentration to absorb side product fluorine containing tail gas ammonium fluorosilicate solution; adding iron scrap or iron salt to fluorosilicic acid as one other by-product to eliminate phosphorus; adding liquid ammonia, ammonia water or ammonium bicarbonate; filtering, washing, and eliminating silica precipitate; returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying to obtain ammonium hydrogen fluoride; reacting solid ammonium hydrogen fluoride and sulfuric acid at high temperature to obtain HF gas, absorbing HF gas to obtain hydrofluoric acid, purification and condensation to obtain anhydrous HF; and mixing the mixture of ammonium sulfate and ammonium bisulfate with ammonium bicarbonate or ammonia in a mixer, curing and crushing to ammonium sulfate fertilizer.

Owner:云南三环化工有限公司 +1

Acid pickling and waste acid treatment process for improving purity of powdery quartz sand

The invention provides an acid pickling and waste acid treatment process for improving purity of powdery quartz sand. The process includes the steps: putting the powdery quartz sand in an acid pickling purification device, and using an acid pump for pumping acid pickling solution into the acid pickling purification device, wherein the acid pickling solution is composed of hydrofluoric acid, fluorosilicic acid, oxalic acid and water or composed of fluorosilicic acid, oxalic acid and water; removing the acid pickling solution after acid pickling, and collecting; delivering the powdery quartz sand to a washing device by clear water after acid pickling, washing to neutral, and dewatering to obtain a finished product of powdery quartz sand; transferring waste acid into a neutralization tank for neutralization, delivering into a sedimentation tank by the pump, and allowing calcium fluosilicate and calcium oxalate to precipitate; delivering the clear water into a regulation tank after precipitation to realize pH adjustment for precipitation of iron ions; using oxalic acid or fluorosilicic acid to adjust pH, precipitating calcium fluosilicate and calcium oxalate again, filtering to obtain clear water, and delivering the clear water to a workshop for recycling. The acid pickling and waste acid treatment process for improving purity of the powdery quartz sand has the advantages of remarkable purity improvement and impurity reduction and simplicity and convenience in subsequent treatment.

Owner:HUANGGANG NORMAL UNIV +1

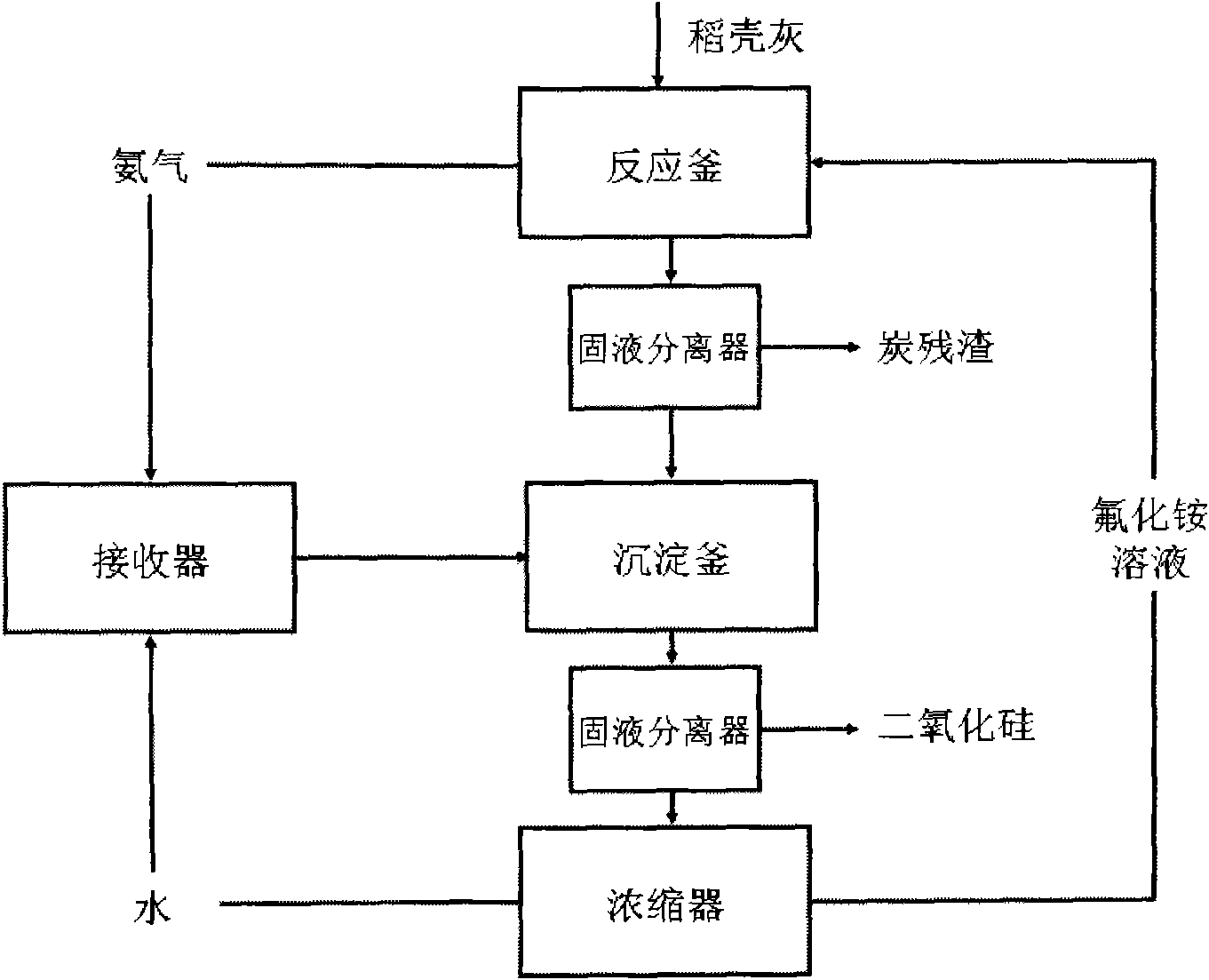

New method for preparing silicon dioxide by utilizing rice hull ash

The invention discloses a new method for preparing silicon dioxide by utilizing rice hull ash, comprising the following steps: neutralizing and dissolving the soluble impurities in the rice hull ash by utilizing a sulfuric acid solution; adding an ammonium fluoride solution in proportion; heating and dissolving to generate ammonium fluosilicate and discharge ammonia; modulating the concentration of the ammonia water to be 10-30wt% by the ammonia generated in the water recovering reaction; placing into a seal stillpot; regulating the temperature to be 50-90 DEG C; adding the ammonium fluosilicate solution into the ammonia water in proportion; separating out the sedimentation; ageing for 0.5-3h; filtering and performing solid-liquid separation; returning the filter liquor to a silicon dissolving procedure for recycling after the filter liquor concentration is adjusted; and washing and drying the filter cakes to obtain the silicon dioxide. The method of the invention takes the regenerated resource rice hull ash as a silicon source, and adopts constant-voltage low-temperature liquid phase dissolving silicon; and the reactant ammonium fluoride and the by-product ammonia can be recycled, which not only saves the energy consumption and lowers the cost, but also has no other by-product generation and no greenhouse gas emission, thus belonging to a low-carbon green new process.

Owner:JILIN UNIV

Compositions and methods for the selective removal of silicon nitride

ActiveUS8778210B2Effectively and efficiently etching a layerIncrease etch rateSilicon halogen compoundsDecorative surface effectsSilicic acidSilicon oxide

Compositions useful for the selective removal of silicon nitride materials relative to poly-silicon, silicon oxide materials and / or silicide materials from a microelectronic device having same thereon. The removal compositions include fluorosilicic acid, silicic acid, and at least one organic solvent. Typical process temperatures are less than about 100° C. and typical selectivity for nitride versus oxide etch is about 200:1 to about 2000:1. Under typical process conditions, nickel-based silicides as well as titanium and tantalum nitrides are largely unaffected, and polysilicon etch rates are less than about 1 Å min−1.

Owner:ENTEGRIS INC

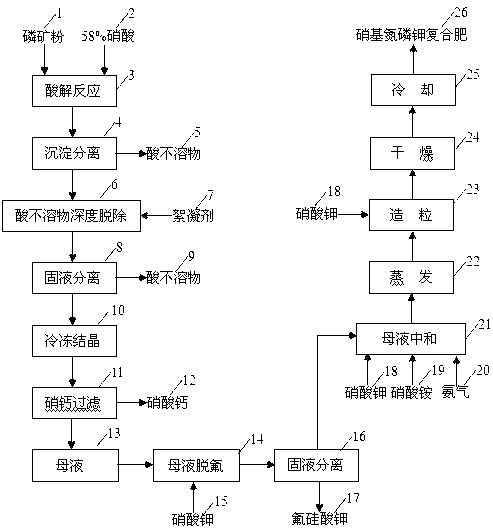

Production method for high-concentration defluorinate nitronitrogen phosphorus and potassium compound fertilizer

ActiveCN103073344AThe defluorination process method is simpleSimple technical transformationFertilizer mixturesPotassium nitrateSoil science

The invention discloses a production method for high-concentration defluorinate nitro nitrogen phosphorus and potassium compound fertilizer, which is based on the conventional process route of nitric acid phosphatic manure production, an acid-insoluble substance deep desorbing procedure is added in an acid-insoluble substance precipitation separation procedure so as to radically separate the acid-insoluble substance; a mother liquor defluorinating procedure is added between calcium nitrate filtration and mother liquor neutralization, by adding potassium nitrate into mother liquor, fluosilicic acid ions in mother liquor is reacted with potassium ion to generate potassium fluorosilicate product, after defluorinating reaction, potassium fluorosilicate is separated from slurry through filtering and separating, and ammonia neutralization, evaporation, pelletization, drying and cooling treatment are performed on defluorinated mother liquor by adding potassium nitrate and ammonium nitrate, namely, high-concentration nitro nitrogen phosphorus and potassium compound fertilizer is obtained. In the invention, mid low grade phosphate rock is used for preparing compound fertilizer, namely fluorine resource is recycled, and by-product potassium fluorosilicate is obtained, pollutions to the environment are reduced, the obtained product has an excellent performance, chlorine is not contained, the application range is broad, the probability of caking is low, and the market competitiveness is strong.

Owner:TIANJI COAL CHEM IND GROUP +1

Coating composition

InactiveUS7063735B2Improve corrosion resistanceAnti-corrosive paintsMetallic material coating processesHafniumFluoroboric acid

A coating composition comprising an aqueous mixture containing inorganic particles, a catechol compound, and one or more fluoroacids. The preferred fluoroacids are selected from fluorotitanic acid, fluorozirconic acid, fluorosilicic acid, fluoroboric acid, fluorostannic acid, fluorogermanic acid, fluorohafnic acid, fluoroaluminic acid or salts of each thereof. The invention is also directed to a coating on a metal substrate. The coating comprises silica particles attached to the metal substrate through a metal-oxide matrix. The metal-oxide matrix comprises a metal selected from titanium, zirconium, silicon, hafnium, boron, aluminum, germanium, or tin, and a catechol compound.

Owner:HENKEL KGAA

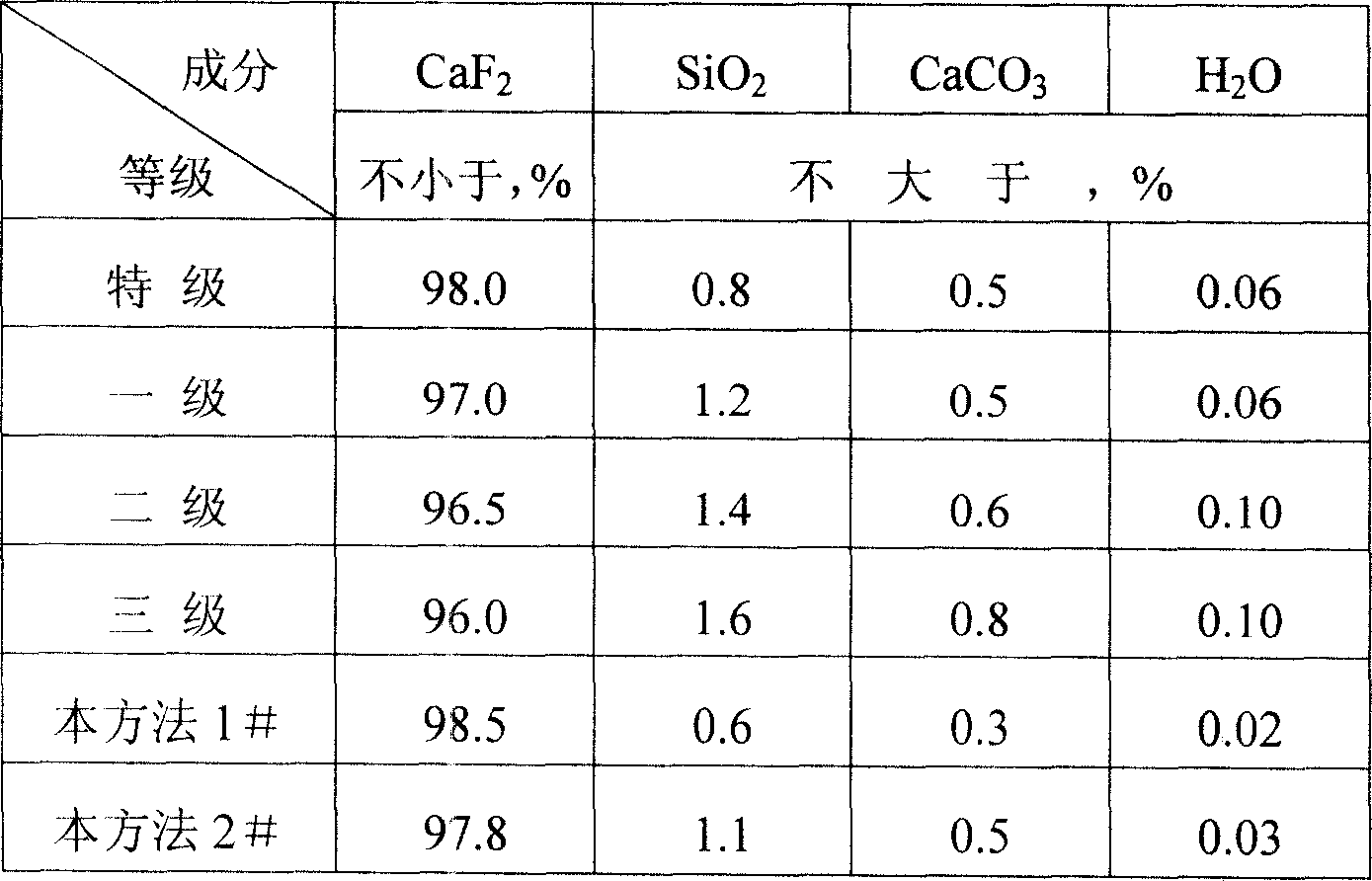

Producing method of calcium fluoride with white carbon black

ActiveCN103073040ALarge particle sizeFine particleSilicaCalcium/strontium/barium chloridesPhosphoric acidSlurry

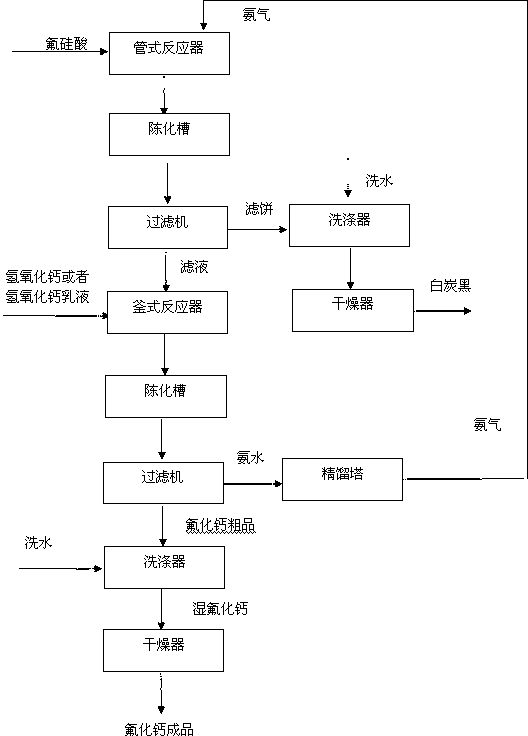

The invention discloses a producing method of calcium fluoride with white carbon black. The producing method comprises the steps of allowing fluorosilicic acid (a wet-process phosphoric acid by-product) and ammonia to react continuously in a tubular reactor, ageing and filtering generated slurry to obtain an ammonium fluoride filtrate and a white carbon black filter cake, and washing and drying the white carbon black filter cake to obtain the white carbon black. Produced ammonium fluoride is good in quality and high in purity; the white carbon black is high in content, small in particle size, large in specific surface area and excellent in reinforcement performance, can be used for completely substituting the existing industrial water glass precipitation-process white carbon black; the ammonium fluoride filtrate and calcium hydroxide react to form a crude product of calcium fluoride and ammonia water; the crude product of calcium fluoride is washed and dried to form calcium fluoride; and the ammonia water is distilled into ammonia to serve as a raw material for ammoniation of fluorosilicic acid.

Owner:KUNMING DAOERSEN TECH

Surface treating agent of recycled aggregate and preparation method thereof

InactiveCN102674730ALow water absorptionImprove water absorptionSolid waste managementCalcium silicateCalcium hydroxide

The invention discloses a surface treating agent of recycled aggregate. The surface treating agent is mainly prepared by the following raw materials by weight: 0.5-1.5% of polyvinyl alcohol, 4-10% of sodium silicate, 0.5-3% of urea, 0.2-1% of sodium fluosilicate and 88-93.8% of water. The surface treating agent has the advantages of being capable of improving surface state of the recycled aggregate and remarkably reducing water absorption rate of the recycled aggregate by utilizing the polyvinyl alcohol, sodium silicate and sodium fluosilicate which are good in film formation performance, utilizing sodium silicate and sodium fluosilicate solution to fill holes and micro cracks of the recycled aggregate and obviously improving strength of the recycled aggregate accordingly. In addition, when the recycled aggregate is processed and used for preparing concrete, the film-shaped sodium silicate and sodium fluosilicate on the surface of the recycled aggregate and cement are hydrated to be subjected to calcium hydroxide reaction to produce calcium silicate and calcium fluosilicate which are capable of remarkably improving strength of a concrete transition area and improving bounding performance between the aggregate and cement stone.

Owner:JIANGSU MINGHE GRP

Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

InactiveCN102502552AImprove use valueEffective way to usePhosphatesAlkali orthophosphate fertiliserO-Phosphoric AcidAgricultural engineering

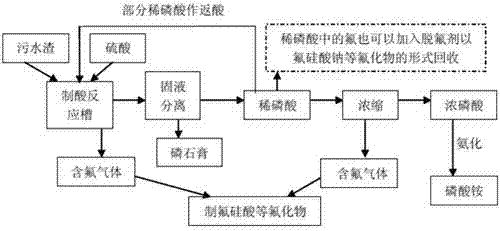

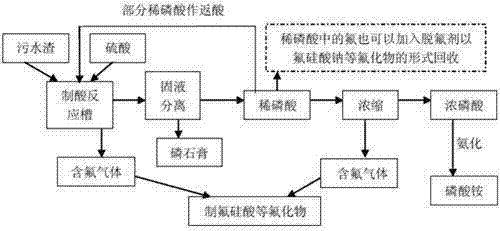

The invention discloses a method for recycling phosphorus and fluoride in the sewage residue of a phosphorus fertilizer plant. According to the method, the sewage residue is decomposed by using sulfuric acid, the phosphorus and the fluoride in the sewage residue are extracted, calcium sulfate dihydrate crystal or calcium sulfate hemihydrate crystal and diluted phosphoric acid solution are generated, diluted phosphoric acid and phosphogypsum which is the by-product are obtained through solid-liquid separation, the diluted phosphoric acid is concentrated into concentrated phosphoric acid, the escaped fluorine containing gas is recycled in the process of concentrating the phosphoric acid and making acid and produced into the fluoride such as the fluosilicic acid and the like, or defluorination agent is added into the diluted phosphoric acid to recycle fluoride resources in the form of the fluoride such as the sodium fluosilicate and the like, and the obtained concentrated phosphoric acid can be used to prepare other phosphate products such as the ammonium phosphate and the like by using the traditional method. The method can be used to effectively recycle the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant so that the waste materials can be changed into the valuable materials and the recycling value of the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant can be improved. The method has good economic benefit and environment protection significance.

Owner:WENGFU (GRP) CO LTD

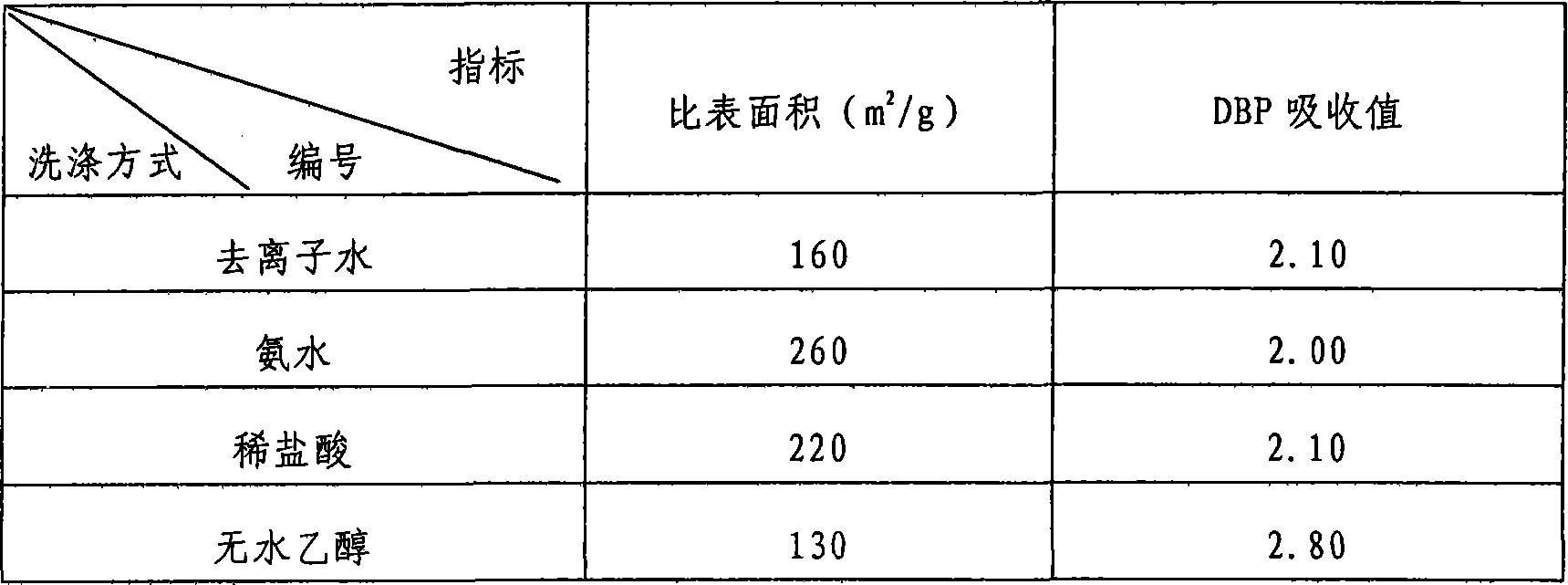

Method for linked producing potassium fluoride white carbon black

A process for preparing potassium fluoride and white carbon black simultaneously includes such steps as reaction between fluorosilicic acid (or potassium fluorsilicate) and potassium hydroxide to obtain the slurry of white carbon black and potassium fluoride solution, filtering, washing to obtain white carbon black paste and potassium fluoride solution, and respectively preparing white carbon black and potassium fluride from them.

Owner:DO FLUORIDE CHEM CO LTD

Stone crystal surface treatment composition and manufacturing method thereof

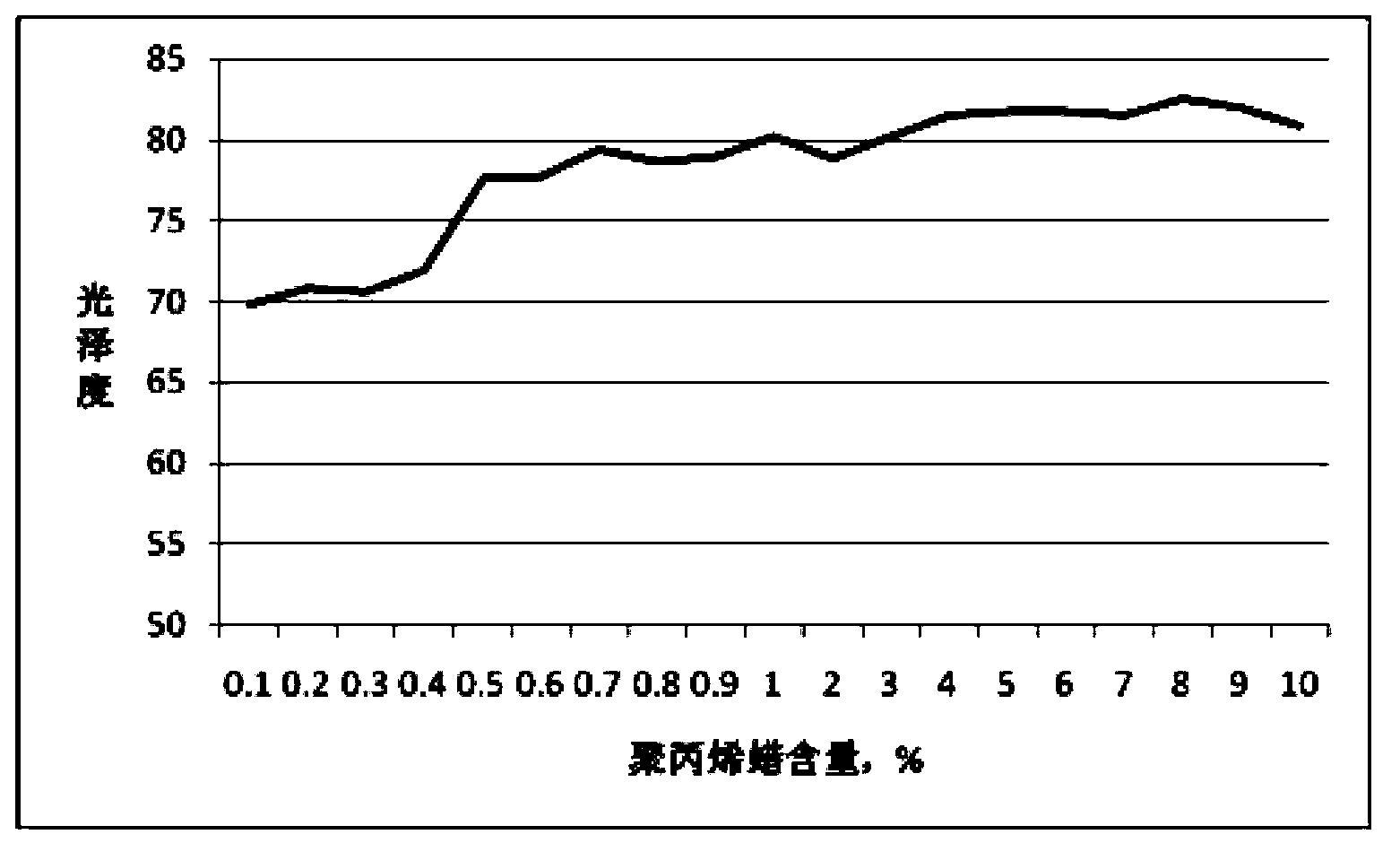

InactiveCN104119803AImprove mechanical propertiesNot easy to penetratePolishing compositionsHigh resistancePolyolefin

The invention discloses a stone surface treatment crystallizing agent comprising the following components in percentage by weight: 0.5-5% of polyolefin wax, 10-30% of fluorosilicic acid or fluorosilicate, 1-6% of acidity regulator, 0.5-5% of quick drying agent and the balance of water, wherein the polyolefin wax is added in an emulsion form, and the solid content of the polyolefin wax emulsion is kept within the range of 20-60%. The crystallizing agent disclosed by the invention can be used for crystallizing stones such as marble, waterstone or special granite and simultaneously hardening and brightening the surface of a stone floor so as to provide high glossiness and improved slip resistance for the crystal surface of the floor while protect the floor. Meanwhile, the treated stone surface has enhanced mechanical performance as well as higher wear resistance and chemical corrosion resistance, and water-soluble stains are not easy to permeate into the stone. The stone surface treated by using the crystallizing agent disclosed by the invention can be cleaned and treated by using water and is convenient and rapid in later-period maintenance and reduced in the maintaining cost as comparison with the stone surface treated by using a conventional waxing treatment method.

Owner:ECOLAB USA INC

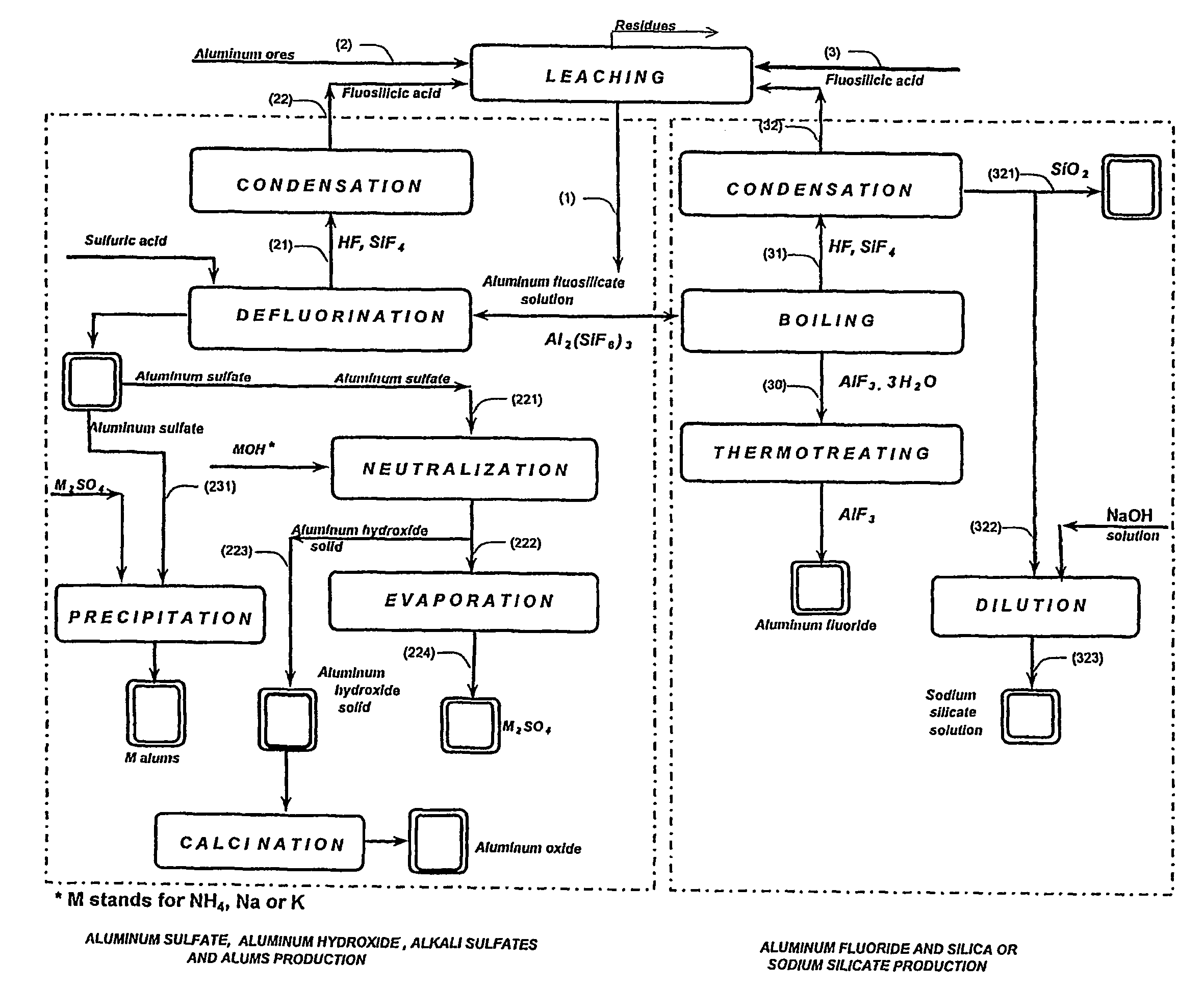

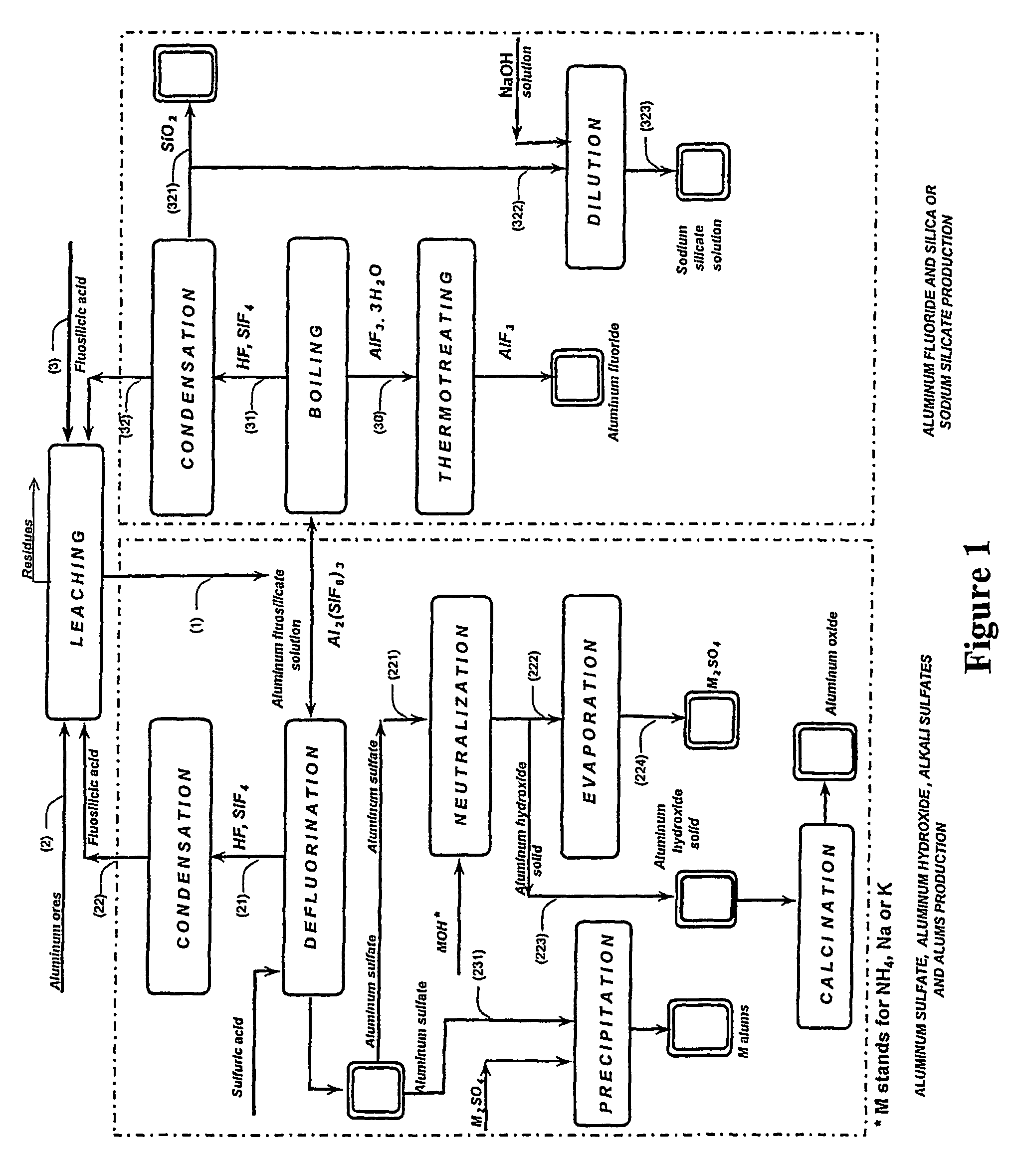

Production of aluminum compounds and silica from ores

A method for the production of inorganic aluminum substances and amorphous silica from aluminum oxide containing ores, comprising: (a) leaching of said ores with fluorosilicic acid to obtain aluminum fluosilicate solution; (b) filtering said leached solution from insoluble materials; and (c) washing said insoluble materials.

Owner:ATI ALUMINUM TECH ISRAEL

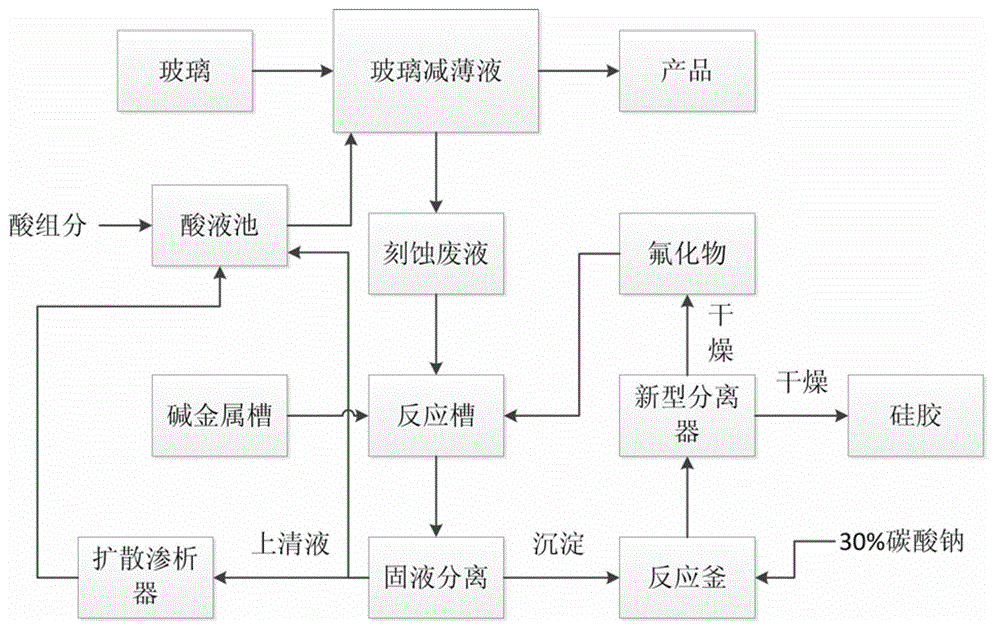

Method for treating and recycling glass thinning and etching waste liquor

InactiveCN102745837AImprove removal efficiencyLow costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentThinningSilica gel

The invention relates to a method for treating and recycling glass thinning and etching waste liquor. The method comprises the steps of: (1) mixing glass thinning and etching waste liquor with alkali metal salt, so as to generate fluosilicate precipitate in fluorosilicic acid in the glass thinning waste liquor to be separated out; (2) settling and filtering the fluosilicate precipitate to carry out solid-liquid separation; (3) introducing a filtrate to a diffusion dialysis device, removing redundant alkali metal ion in the filtrate to acquire acid liquor; (4) supplementing components to the acid liquor, so as to achieve the glass thinning and etching usage requirements and recycle; (5) reacting the fluosilicate precipitate acquired by filtering in the step (2) with soda ash solution to generate metal fluoride and silica gel precipitate; (6) separating the generated metal fluoride and the silica gel precipitate, wherein the metal fluoride is used for treating fluosilicic acid, and the silica gel is to be sold. Compared with the prior art, the method has the advantages that etching waste liquor can be recycled, the exhaustion of waste liquor and waste residue can eb reduced, the environment pollution risks are reduced, and the production cost is saved.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for producing calcium fluoride

InactiveCN101134595AReduce total usageSave resourcesCalcium/strontium/barium fluoridesCalcium silicateSilicon tetrafluoride

The process of producing calciumfluoride with fluorosilicic acid and calcium oxide as material includes the following steps: 1. reacting fluorosilicic acid solution and calcium oxide for 10-60 min, filtering to obtain solid calcium fluorosilicate; 2. decomposing calcium fluorosilicate at 200-600 deg.c for 1-5 hr to produce solid calcium fluoride product and silicon tetrafluoride gas; and 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white. The process utilizes fluorosilicic acid as one side product of phosphate fertilizer production as one main material, and has low cost and environment friendship.

Owner:DO FLUORIDE CHEM CO LTD

Method for linked producing ammonium fluoride and white carbon black

A process for preparing ammonium fluoride and white carbon black simultaneously includes such steps as fast reaction between fluorosilicic acid (or ammonium fluorosilicate) and ammonia water to obtain the crystal seeds of white carbon black, adding water, fluorosilicic acid (or ammonium fluorosilicate) and ammonia water, reacting while controlling pH=8-9 to obtain the slurry of white carbon black deposit and ammonium fluoride solution, filtering, washing to obtain white carbon black paste and ammonium fluoride solution, and respectively preparing white carbon black and ammonium fluoride from them.

Owner:DO FLUORIDE CHEM CO LTD

Integrated utilization method for phosphorus chemical industry byproduct fluorosilicic acid

The invention discloses a comprehensive utilization method of hydrofluosilicic acid which is by-product of phosphorus chemical engineering. The method is that hydrofluosilicic acid solution with concentration of 18%-35% is added to a container with intense agitation and rapid heat withdrawing under -5 DEG C to 30 DEG C, the agitation is started with an agitation speed of 500rmp-10000rmp, simultaneously ammonia with concentration of 13%-37% is added, or ammonia gas is added. Silica gel is obtained by filtration, after the silica gel is washed and dried, finished product of white carbon black with surface area of 160-350m2 / g is obtained. The filtering liquid is ammonium fluoride solution with concentration larger than 20%, and the ammonification recovery ratio can reach more than 98%. The invention is simple in technique, the hydrofluosilicic acid is made good use of, and the produced white carbon black has good quality.

Owner:YUNNAN CHEM RES INST

Phosphorus-free graphene-oxide-containing metal surface pretreatment solution and application method thereof

ActiveCN104962899ASolve pollutionReduce pollutionMetallic material coating processesSodium molybdatePhysical chemistry

The invention provides a phosphorus-free graphene-oxide-containing metal surface pretreatment solution and an application method thereof. The phosphorus-free graphene-oxide-containing metal surface pretreatment solution comprises the following components in percentage by weight: 1-2% of fluosilicic acid, 0.2-1% of sodium molybdate, 1-2% of sodium nitrate, 0.6-1.2% of metal surface oxidizer, 1-2% of disodium edetate, 0.8-1.5% of tartaric acid, 0.1-0.3% of graphene oxide and the balance of water, totaling 100%. The product has the advantages of stable and excellent properties and wide application range. The added graphene oxide can effectively enhance the paint film adhesion of the conversion coating.

Owner:QINGDAO GERUIXI METAL PROTECTION TECH CO LTD

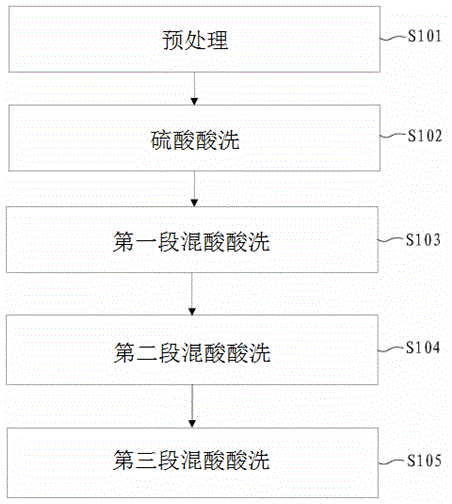

Acid pickling method for hot rolled 304 Austenitic stainless steel

The invention relates to an acid pickling method for hot rolled 304 Austenitic stainless steel. The acid pickling method comprises the steps of pretreatment, sulfuric acid pickling, mixed acid pickling for a first section, mixed acid pickling for a second section and mixed acid pickling for a third section. A mixed acid solution used in the steps of acid pickling for the three sections is formed by mixing nitric acid and fluorosilicic acid. According to the acid pickling method for the hot rolled 304 Austenitic stainless steel, the mixed acid solution formed by mixing nitric acid and fluorosilicic acid is adopted, H2SiF6 has a high ability to dissolve and corrode scale cinder and a metal matrix as HF, and therefore the acid pickling efficiency can be improved. In the acid pickling process, the activity of the acid solution is basically constant, and the service life of the acid solution is prolonged; in this way, the discharge amount of waste acid is reduced, and production cost and water treatment cost are reduced. In the mixed acid pickling process, fluoride sediment will not be generated, a pipeline will not be blocked, and the halt maintenance frequency is reduced.

Owner:WISDRI ENG & RES INC LTD

Method for preparing babbitt alloy from residue containing silver of copper anode slime

InactiveCN102312097AEasy to separateLow costProcess efficiency improvementElectrolytic agentAntimony potassium tartrate

The invention relates to a method for preparing a babbitt alloy from residue containing silver of copper anode slime. The method comprises the following steps:1, adding sodium carbonate, powdered carbon and borax according to the mass of the residue containing silver, and uniformly mixing; 2, melting to obtain a crude alloy containing lead; 3, preparing an electrolyte from fluosilicic acid, lead fluorosilicate, stannous oxide and potassium antimonyl tartrate, and adding with gelatin and ethyl naphthol; 4, treating the crude alloy as an anode and a stainless steel plate as a cathode, and taking the cathode plate (the stainless steel plate) and peeling cathode products each 12h; and 5, adding lead, antimony and copper or tin, antimony and copper to the cathode products, and melting to obtain the lead-based or tin-based babbitt alloy. The method which has the advantages of short flow, low cost, and strong practicality and allows the lead-based or tin-based babbitt alloy to be prepared from the residue containing silver of the copper anode slime is especially suitable for anode slime processing in electrolyzing electronic wastes with regenerated copper, and has the characteristics of simple and feasible operation, and high recovery rate of valuable metals.

Owner:广东省资源综合利用研究所

Method for recycling hydrofluoric acid from wastewater containing fluorosilicic acid

InactiveCN106185817ARealize resource utilizationHigh recovery rateSilicaHydrogen fluorideSilicon dioxideFluorosilicic acid

The invention provides a method for recycling hydrofluoric acid from wastewater containing fluorosilicic acid. Ammonia or ammonium is added into the wastewater containing the fluorosilicic acid and the fluorosilicic acid is decomposed into sediments of ammonium fluoride and silicon dioxide; magnesium sulfate is added into a solution containing the ammonium fluoride and fluorine in the solution is precipitated and separated out in a magnesium fluoride form; the solution is filtered to obtain magnesium fluoride and a fluoride precipitation post-solution; then the magnesium fluoride is thermally decomposed by sulfuric acid; thermally decomposed steam is condensed and absorbed to obtain the hydrofluoric acid; residues of thermal decomposition are returned back to a fluoride precipitation and separation procedure and are circularly utilized. Lime is added into the fluoride precipitation post-solution, stirring and a mixed solution is evaporated to recycle the ammonia; the recycled ammonia is returned back to a fluorosilicic acid ammonolysis procedure for circular utilization; the method has the advantages of simple process, simplicity and convenience for operation, high fluorine recovery rate, low recovery cost, good working environment and the like.

Owner:CENT SOUTH UNIV

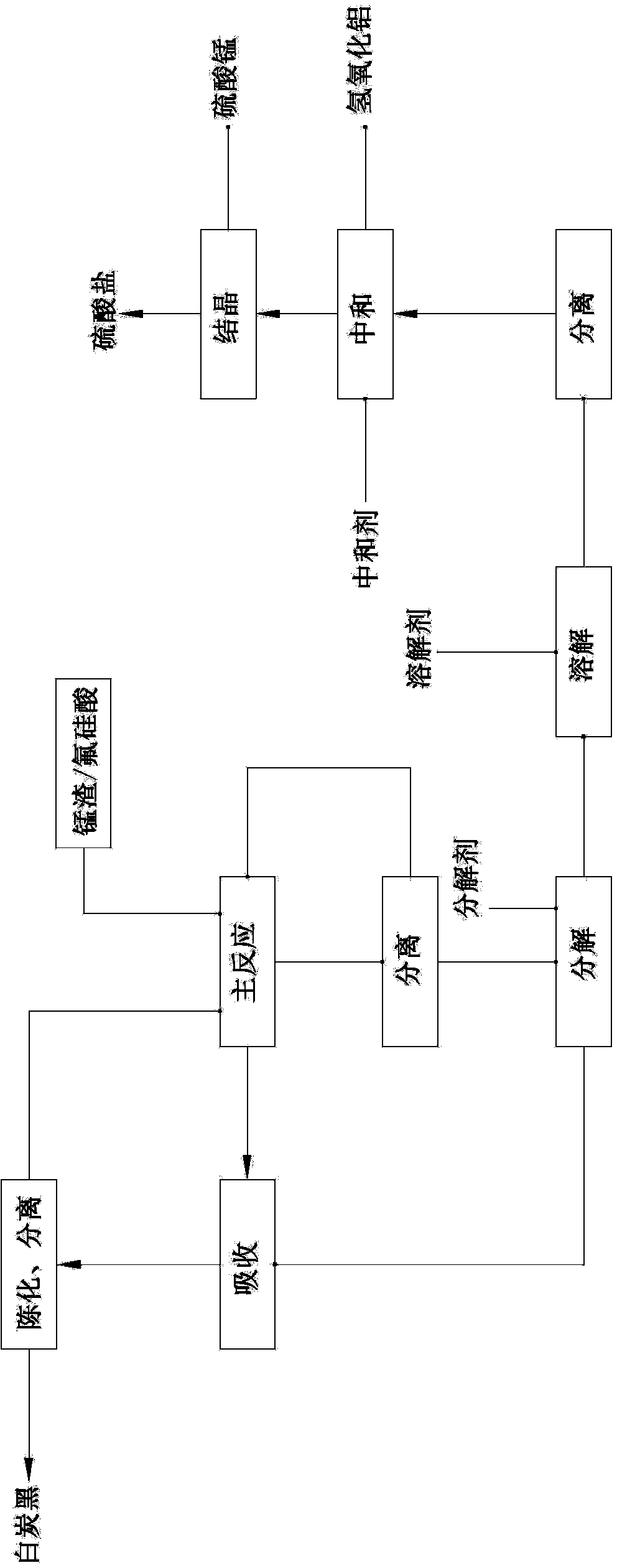

Comprehensive utilization method of manganese slag

ActiveCN104017998AHigh purityIncrease added valueProcess efficiency improvementManganese sulphateAluminium hydroxide

The invention relates to a comprehensive utilization method of industrial waste residues and particularly relates to a comprehensive utilization method of manganese slag. The method comprises the following steps: reaction, namely crushing the manganese slag, mixing the crushed manganese slag with a fluosilicic acid aqueous solution to react, and carrying out solid-liquid separation after reaction to obtain solid A and liquid A; decomposition, namely adding the solid A to a decomposing agent to undergo a decomposition reaction, adding a dissolving agent after the decomposition is finished, uniformly mixing and carrying out solid-liquid separation to obtain solid B and liquid B; absorption, namely enabling generated fluorine-containing gas to pass through an absorption tower to realize multistage circular absorption to obtain solid C and liquid C, and drying the solid C to obtain white carbon black; and neutralization, namely adding a neutralizing agent to the liquid B to obtain solid D and liquid D, carrying out high-temperature crystallization on the liquid D to obtain manganese sulfate and sulfate, and drying the solid D to obtain lightweight aluminium hydroxide. According to the comprehensive utilization method disclosed by the invention, useful elements in the manganese slag can be effectively extracted to produce basic chemical materials; in addition, the process is simple and no three-waste emission is caused; the effect of comprehensive utilization of manganese slag at high efficiency and low energy can be practically achieved.

Owner:崇左市富国新材料科技有限公司

Method for producing aluminun fluoride

The present invention relates to process of producing aluminum fluoride with fluorosilicic acid and aluminum hydroxide as material. The process includes the following steps: 1. reacting fluorosilicic acid solution and sodium sulfate for 10-60 min, filtering to obtain solid sodium fluorosilicate and waste sulfuric acid solution to be treated and drained; 2. decomposing aluminum fluorosilicate at 300-800 deg.c for 1-5 hr to produce solid sodium fluoride and silicon tetrafluoride gas; 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white; 4. reacting solid sodium fluoride and sulfuric acid, condensing, rectifying to obtain anhydrous hydrofluoric acid and solid sodium sulfate returned to the step 1; and 5. reacting anhydrous hydrofluoric acid and aluminum hydroxide to produce aluminum fluoride product. The process is environment friendly.

Owner:DO FLUORIDE CHEM CO LTD

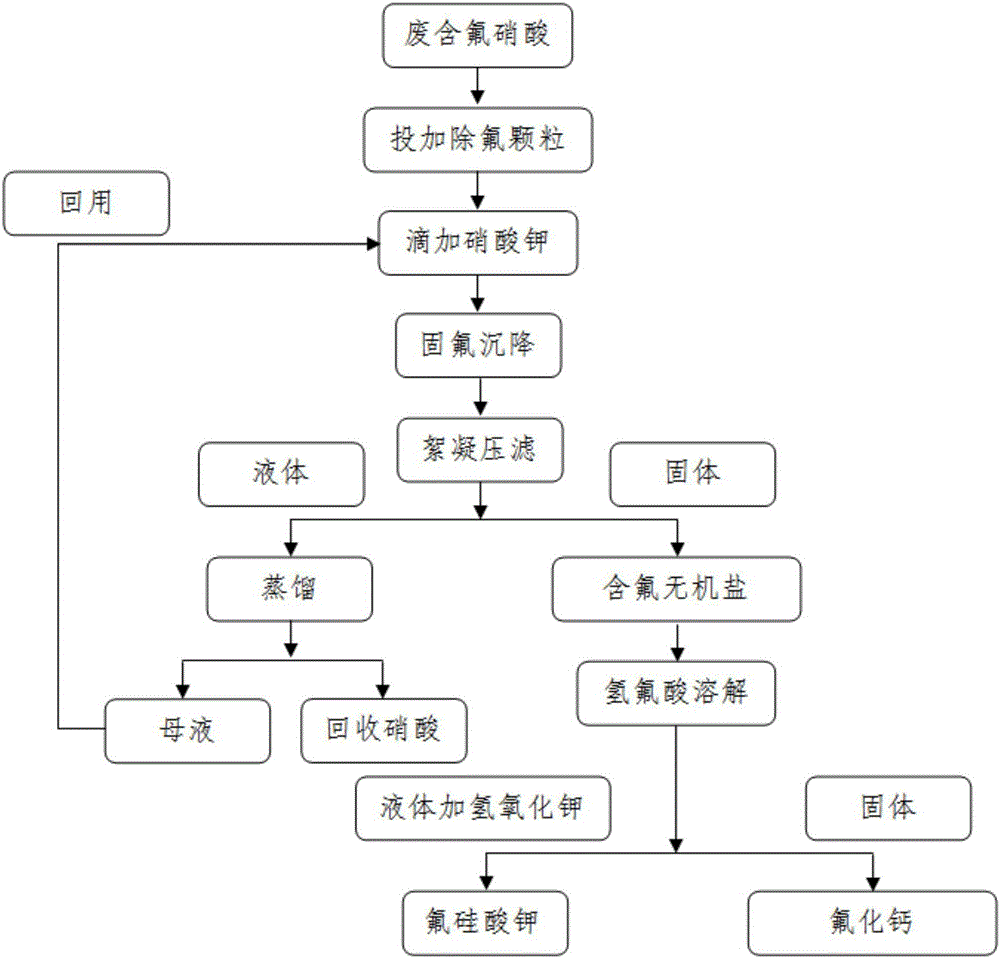

Method for preparing nitric acid, calcium fluoride and potassium fluosilicate through using waste fluorine-containing nitric acid

InactiveCN106379925ASimple processLow costCalcium/strontium/barium fluoridesFluosilicic acidDistillationFluoride calcium

The invention discloses a method for preparing nitric acid, calcium fluoride and potassium fluosilicate through using waste fluorine-containing nitric acid. The waste fluorine-containing nitric acid is subjected to fluorine retention sedimentation, flocculation press filtration separation, distillation, and crystallization, and nitric acid, calcium fluoride and potassium fluosilicate are extracted from waste fluorine-containing nitric acid. The method is relatively simple in process operation, the raw materials in the method can be recycled, and discharge of waste gas, waste water, and industrial residue is reduced. The method has preferable economic benefit.

Owner:盛隆资源再生(无锡)有限公司

Method for preparing white carbon black from silicon slags containing fluorine

The invention discloses a method for preparing white carbon black from silicon slag containing fluorine. The method comprises the steps of: adding silicon slag containing fluoride and measured alkaline solution according to the proportion into a reaction kettle provided with a stirrer and a heating device; heating the mixture to 40-80 DEG C under fully stirring condition for maintaining for 20-50 min, so that the fluosilicic acid in the silicon slag containing fluoride is reacted completely to prepare a mixed solution of silicon dioxide and fluoride salt; heating or cooling the prepared liquid-solid mixture of silicon dioxide and fluoride salt to 50 DEG C or less, then filtering or centrifuging the mixture for liquid-solid separation so as to prepare a wet cake of silica and a filtrate of fluoride salt; backwashing the prepared wet cake of silica for 4-6 times, merging the first washing solution with fluoride salt to prepare a fluoride salt solution for other uses, and putting the second to the sixth washing solution into the first to the fifth washing solution tank respectively for the next first to fifth washing; drying the wet filter cake of silica to obtain white carbon black products. The method has the advantages of simplicity in processing, less equipment, simplicity and convenience in operation, and low production cost, and is convenient to realize industrial production.

Owner:WENGFU (GRP) CO LTD +1

Method for producing potassium fluoride

The present invention relates to process of producing potassium fluoride with fluorosilicic acid and potassium chloride as material. The process includes the following steps: 1. reacting fluorosilicic acid solution and potassium chloride for 10-60 min, filtering to obtain solid potassium fluorosilicate and waste hydrochloric acid solution; 2. decomposing potassium fluorosilicate at 300-800 deg.c for 1-5 hr to produce solid potassium fluoride product and silicon tetrafluoride gas; and 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white. The process utilizes fluorosilicic acid as one side product of phosphate fertilizer production as one main material, and has low cost and environment friendship.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of sodium fluoride

The invention discloses a preparation method of sodium fluoride. Sodium fluosilicate or fluosilicic acid is taken as a raw material, and potassium chloride or potassium carbonate is taken as an intermediate reaction medium to react with sodium carbonate to prepare the sodium fluoride, and simultaneously, the potassium chloride or the potassium carbonate is recycled. The preparation method of the sodium fluoride of the invention is used, so that the generation of the sodium fluoride and the generation of the silicon dioxide are respectively in different reactions to radically solve the problemof difficult separation of the sodium fluoride and the silicon dioxide, thereby lowering the production cost of the sodium fluoride.

Owner:BAIYIN ZHONGTIAN CHEM

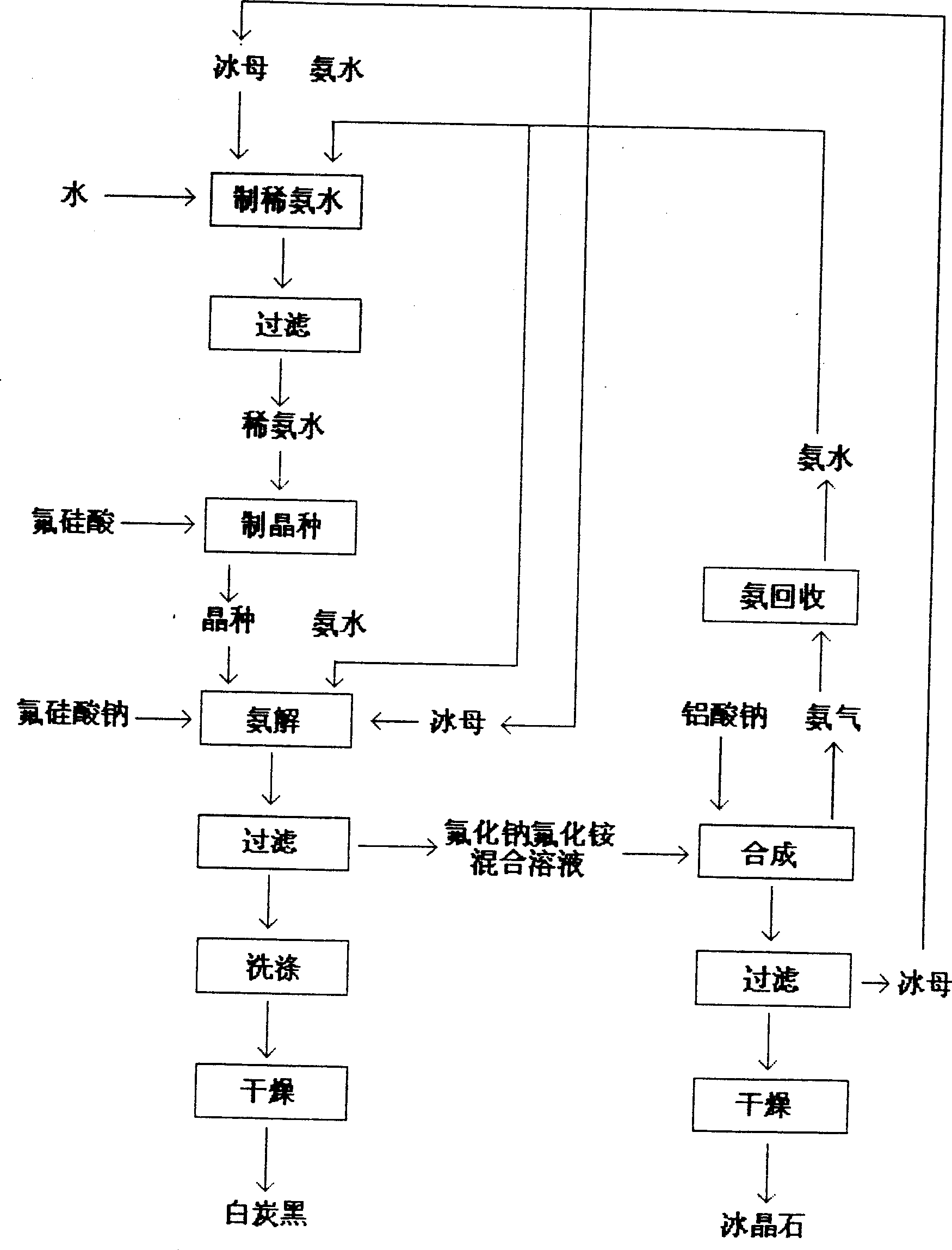

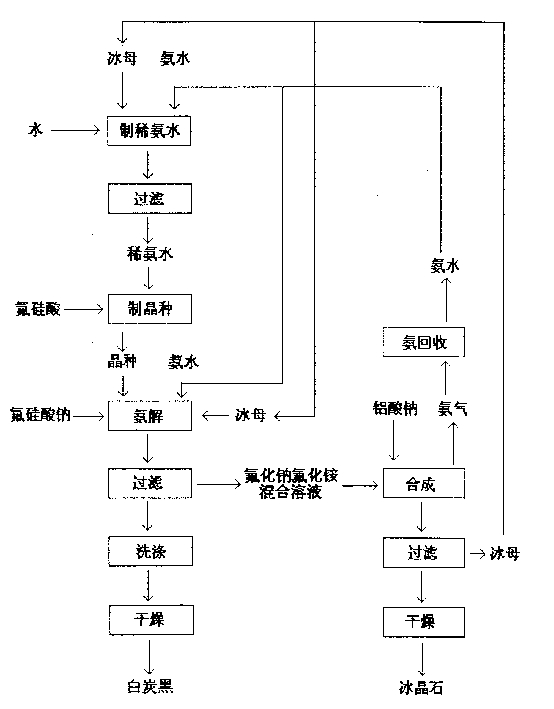

Method for simultaneously producing sodium aluminofluoride and silica white

InactiveCN1515493ALower molecular ratioHigh puritySilicon oxidesAluminium fluoridesReaction temperatureSodium aluminate

The method for producing ice spar and coproducing white carbon black includes the following steps: (1) adding ice mother and ammonia water in water to prepare dilute ammonia water, making fluorosilicic acid solution react with dilute ammonia water to obtain white carbon black crystal seed, controlling pH value of white carbon black in 6-8 and reaction temp. at 30-40 deg.C; (2). adding a certain quantity of white carbon black crystal seed into ammonolysis cell, in which the added quantity of crystal seed can be regulated according to the requirements, adding proper quantity of ice mother, in the presence of crystal seed making sodium fluorosilicate and ammonia water implement ammonolysis reaction at about 60 deg.C to obtain white carbon black slurry, filtering and washing to obtain white carbon black ointment, drying to obtain its finished product; (3). providing the steps for obtain ice spar product.

Owner:DO FLUORIDE CHEM CO LTD

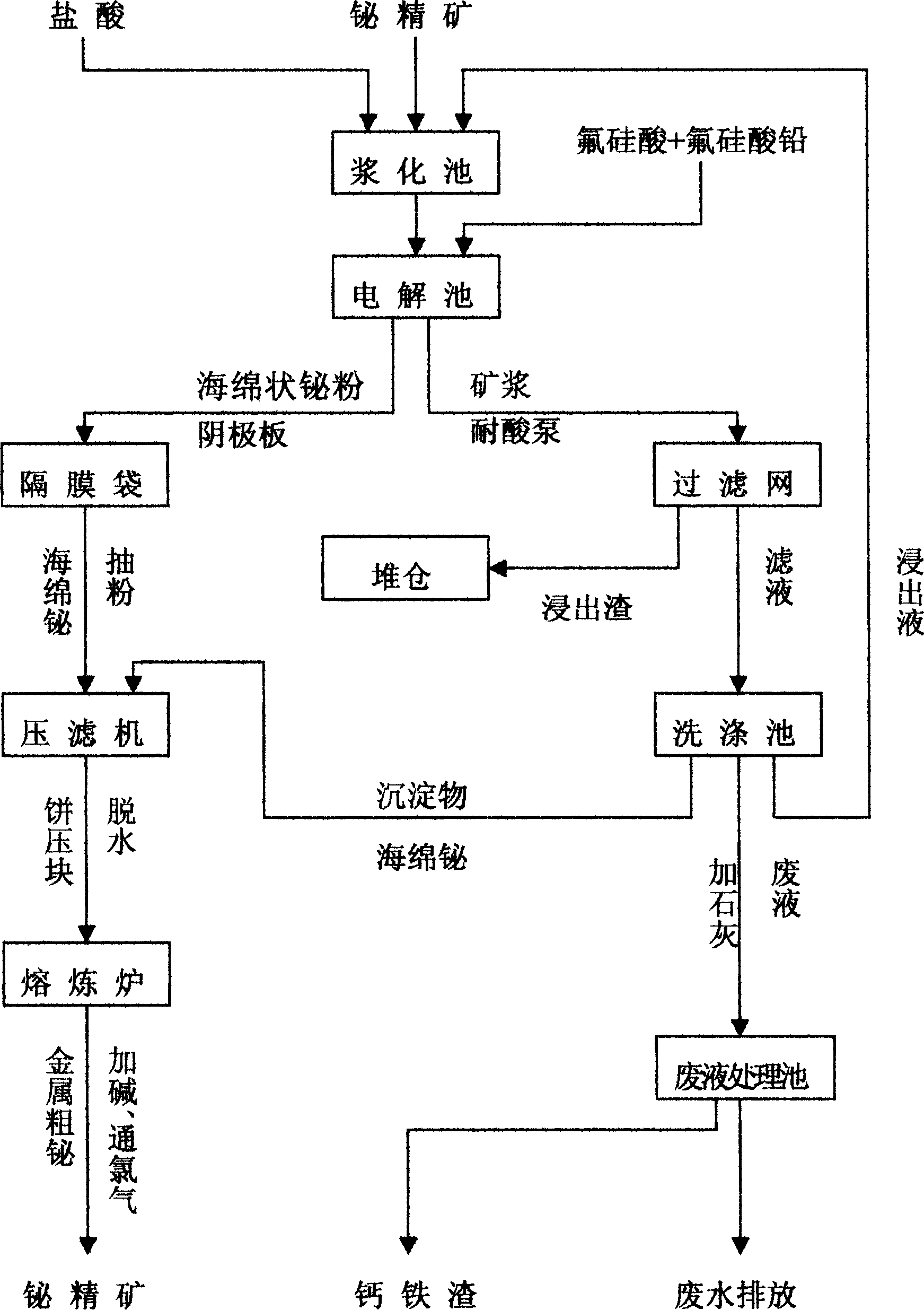

Technique for electrolyzing slurry of fluosilicic acid in bismuth mine

InactiveCN1415785AAddressing Adaptive IssuesTake advantage ofPhotography auxillary processesProcess efficiency improvementElectrolysisSludge

A process for electrolyzing the fluorosilicic acid sludge of bismuth ore concentrate to obtain high-purity (99.999%) bis muth includes such steps as preparing sludge, adding hydrochloric acid to regualte acidity, electrolyzing to educe out spongy bismuth from the cathode, pressure filter, smelting, and removing impurities by introducing chlorine gas and sodium hydroxide. Its advantages are low cost and energy consumption, and high quality of product.

Owner:HUNAN JINWANG BISMUTH

Production method of polishing powder for liquid crystal display device

InactiveCN101381586AHigh crystallinityAccelerated settlementPolishing compositionsNon-linear opticsComing outTunnel kiln

The invention relates to a method for producing polishing powder used for a liquid crystal display device. The method comprises the following steps: at the room temperature, 30 to 40 percent of fluorosilicic acid is added into rare earth chloride solution with REO of between 80 and 100 gram / litre and CeO2 / REO of more than or equal to 70 percent under the stirring; after five minutes, an additive A is added into the mixture, is heated to the temperature of between 70 and 80 DEG C, is kept at the temperature and is added with mixed precipitant solution till the reaction ends; the PH value of the mixture is 7; the mixture is stirred for 10 minutes, is kept stand for 3 to 5 hours and supernatant fluid of the mixture is removed through siphonage; under the stirring, cold water is added to nearly fill a groove fully; before the stirring is stopped, flocculant solution is added till appearing the flocculating effect; the mixture is kept stand, is deposited and the supernatant fluid of the mixture is removed through siphonage for three times; the mixture is washed, is heated up to 98 DEG C, is kept at the temperature for 10 minutes and is discharged to a stainless steel sieve with 120 meshes; the mixture is subjected to solid-liquid separation, vacuum extraction and filtering and dewatering by a centrifuge; a filter cake is transferred to a quartz material sagger; the charging thickness is less than or equal to 9 centimeters; the filter cake is transported to a muffle tunnel kiln at the temperature of 900 DEG C, is subjected to dehydration in a preheating section and decomposition and transformation at certain degree, is roasted for 3 to 4 hours at high temperature of 900 DEG C, is cooled to the temperature of less than 400 DEG C in a cooling section and comes out from the kiln; a roasted material is cooled to the room temperature and is subjected to stage treatment; and a quality part is the product.

Owner:SHANGHAI JIELONG RARE EARTCH FINE ABRASIVE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com