Acid pickling method for hot rolled 304 Austenitic stainless steel

A technology for pickling of austenitic stainless steel, which is applied in the field of pickling of hot-rolled 304 austenitic stainless steel, can solve the problems of affecting the quality of pickling, easily clogging acid pipes, affecting the circulation of acid solution, etc., so as to increase the efficiency of pickling , reduce emissions and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

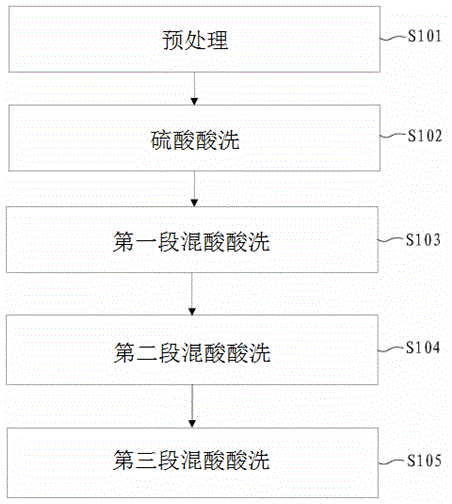

[0041] This embodiment provides a hot-rolled 304 austenitic stainless steel pickling method, comprising the following steps:

[0042] 1) The hot-rolled 304 austenitic stainless steel strip with a thickness of 2 mm is annealed and mechanically broken.

[0043] 2) Pre-pickling the steel strip after annealing and mechanical scaling treatment by immersing in sulfuric acid pickling solution. In the sulfuric acid pickling solution, H 2 SO 4 The concentration is 155g / L, and the metal ion concentration is 33 g / L; the temperature of the sulfuric acid pickling solution is 77°C; the pickling treatment time is 33s.

[0044] 3) After pickling with sulfuric acid, the steel strip is immersed in the first mixed acid solution for pickling. In the first mixed acid solution, HNO 3 Concentration is 77g / L, H 2 SiF 6 The concentration is 12 g / L, the metal ion concentration is 37 g / L, the temperature of the first mixed acid solution is 57° C., and the pickling treatment time is 33 s.

[0045]...

Embodiment 2

[0049] This embodiment provides a hot-rolled 304 austenitic stainless steel pickling method, comprising the following steps:

[0050] 1) The hot-rolled 304 austenitic stainless steel strip with a thickness of 2 mm is annealed and mechanically broken.

[0051] 2) Pre-pickling the steel strip after annealing and mechanical scaling treatment by immersing in sulfuric acid pickling solution. In the sulfuric acid pickling solution, H 2 SO 4 The concentration is 165g / L, and the metal ion concentration is 37 g / L; the temperature of the sulfuric acid pickling solution is 83°C; the pickling treatment time is 27s.

[0052] 3) After pickling with sulfuric acid, the steel strip is immersed in the first mixed acid solution for pickling. In the first mixed acid solution, HNO 3 Concentration is 83g / L, H 2 SiF 6 The concentration is 18 g / L, the metal ion concentration is 43 g / L, the temperature of the first mixed acid solution is 63°C; the pickling treatment time is 27s.

[0053] 4) Aft...

Embodiment 3

[0057] This embodiment provides a hot-rolled 304 austenitic stainless steel pickling method, comprising the following steps:

[0058] 1) The hot-rolled 304 austenitic stainless steel strip with a thickness of 2 mm is annealed and mechanically broken.

[0059] 2) Pre-pickling the steel strip after annealing and mechanical scaling treatment by immersing in sulfuric acid pickling solution. In the sulfuric acid pickling solution, H 2 SO 4 The concentration is 160g / L, and the metal ion concentration is 35 g / L; the temperature of the sulfuric acid pickling solution is 80°C; the pickling treatment time is 30s.

[0060] 3) After pickling with sulfuric acid, the steel strip is immersed in the first mixed acid solution for pickling. In the first mixed acid solution, HNO 3 Concentration is 80g / L, H 2 SiF 6 The concentration is 15 g / L, the metal ion concentration is 40 g / L, the temperature of the first mixed acid solution is 60° C., and the pickling treatment time is 30 s.

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com