Patents

Literature

328results about How to "Improve pickling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-field coupling efficient automatic salting device of preserved egg and salted egg and control method

InactiveCN102028249AReduce breakageReduce labor consumptionProgramme controlComputer controlSolenoid valveEngineering

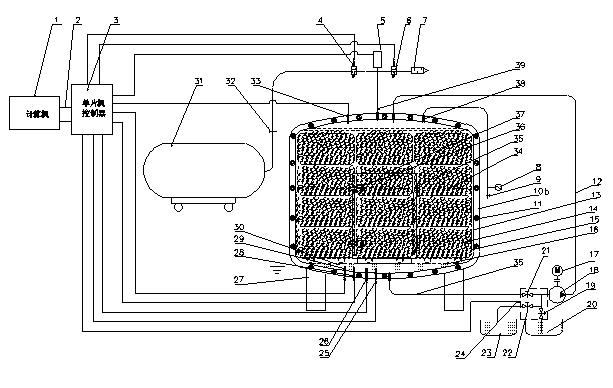

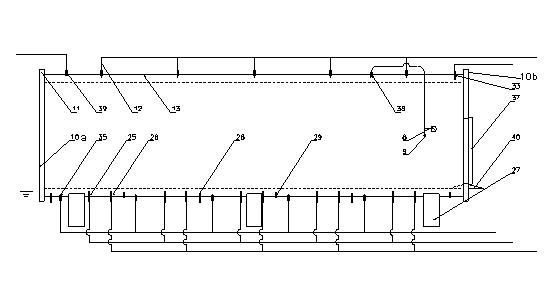

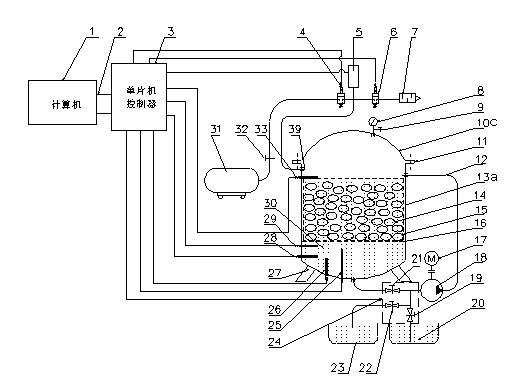

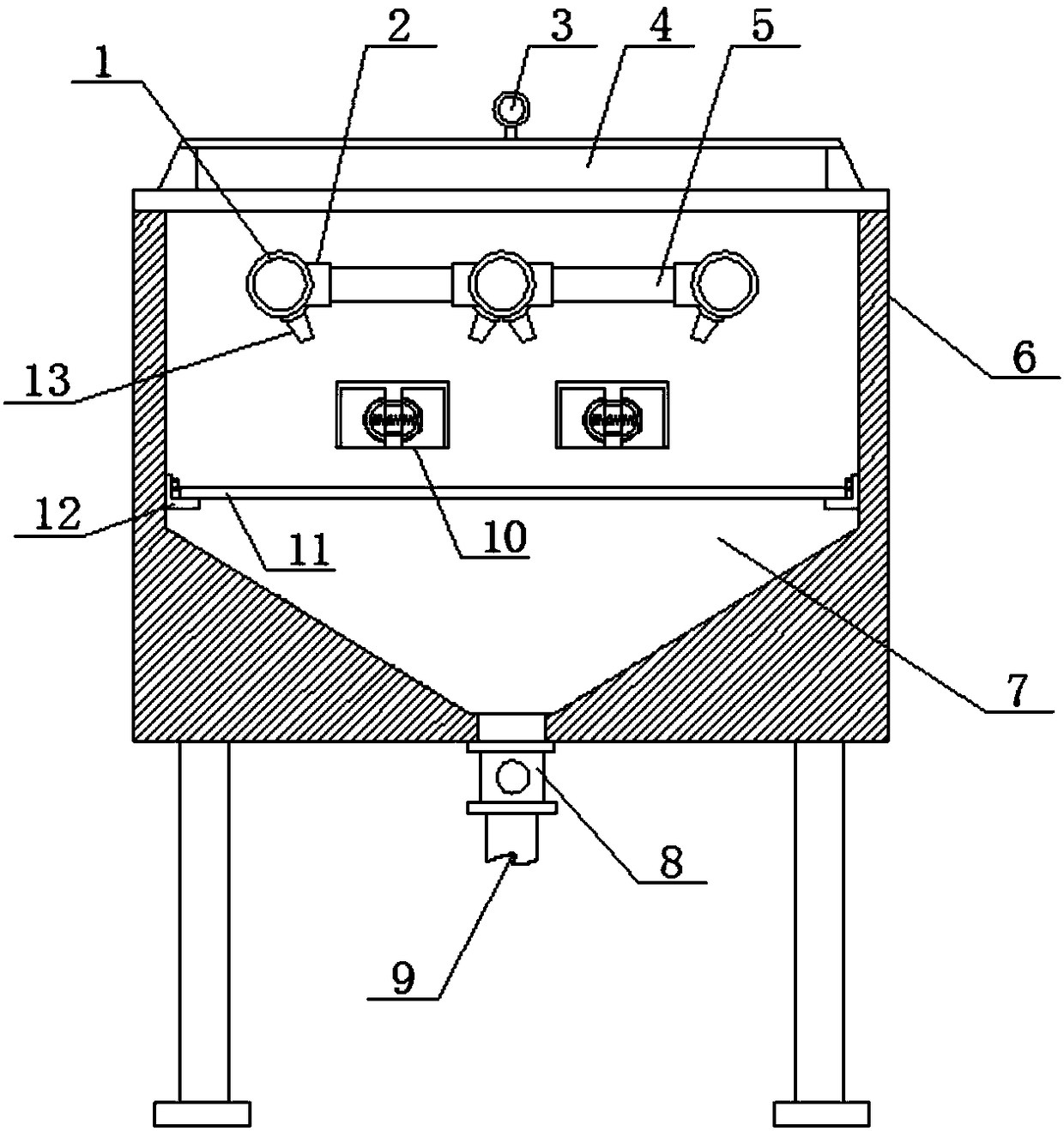

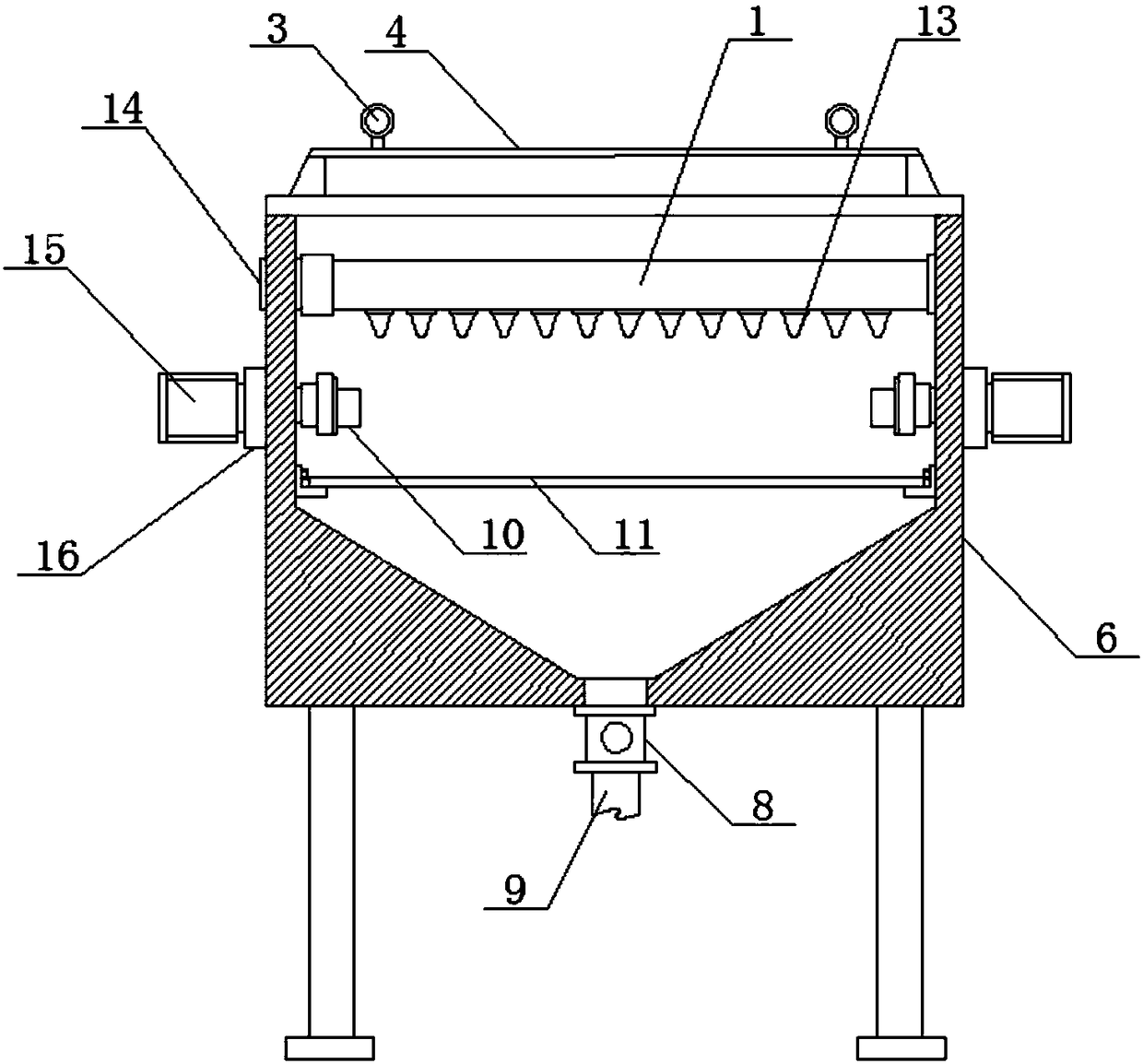

The invention discloses a multi-field coupling efficient automatic salting device of preserved eggs and salted eggs, comprising a tank body and a tank cover, wherein the tank body is a horizontal box body, the top of the tank body is provided with a safe overflow vent, and the bottom is connected with a self-circulation solenoid valve via a pipeline; each valve is connected with a singlechip controller; the top of the tank body is connected with a pressurized solenoid valve and a pressure-relief solenoid valve by an air tube; the pressurized solenoid valve is connected with an air compressor by the air tube; a heating pipe, a temperature sensor, an ultrasonic vibrator and a solution concentration sensor are arranged in an interlayer between the bottom of the tank body and a clapboard; the top of the tank body is provided with liquid level sensors, and each sensor is connected with the singlechip controller; and the on / off switches of the heating pipe and the ultrasonic vibrator are controlled by the singlechip controller. The invention also discloses a control method of a salting device, comprising five steps: starting the device; setting control parameters; controlling operation; and finishing control. The invention simultaneously utilizes four physical measures to improve salting efficiency.

Owner:HUAZHONG AGRI UNIV

Preparation method of highly pure quartz sands

The invention discloses a preparation method of highly pure quartz sands. The method comprises the following steps: 1, roughing: cleaning a raw material, and crushing the cleaned raw material; 2, carrying out calcining and water quenching: calcining the crushed raw material, taking out particles, and quenching the particles in an ice-water mixture; 3, carrying out electric separation and magnetic separation: milling the quenched particles, carrying out electric separation and magnetic separation twice, and carrying out pulse magnetic field treatment; 4, pickling: immersing a material obtained in step 3 in a hydrochloric acid solution, filtering the immersed material, dialyzing the obtained first filtrate to recover hydrochloric acid, preparing a first mixed acid by using the recovered hydrochloric acid and a sulfuric acid solution, immersing quartz sands in the first mixed acid, filtering the immersed quartz sands, dialyzing the obtained second filtrate to obtain recovered mixed acid, preparing a second mixed acid by using the recovered mixed acid and a nitric acid solution, immersing the quartz sands in the second mixed acid, adding the immersed quartz sands to a sodium carbonate solution, and flushing the quartz ands; 5, floating the flushed quartz sands; and 6, drying the floated quartz sands. The preparation method allows highly pure quartz sands with the SiO2 content to be not lower than 99.995% to be produced, and takes a greatly lower acid amount than traditional methods.

Owner:江苏凯达石英股份有限公司

Preparation method of Muslim low-temperature mutton ham

ActiveCN105581273AReduce dosageImprove durabilitySugar food ingredientsFood ingredient as flavour affecting agentFlavorRoom temperature

The invention discloses a preparation method of Muslim low-temperature mutton ham and belongs to the field of meat product processing. The preparation method of the Muslim low-temperature mutton ham comprises the steps that mutton is subjected to pretreatment, microwave-assisted vacuum rolling and kneading with specially-made curing liquid and ultrasonic wave composite variable pressure curing, then the mutton is filled and formed, and finally, after being sterilized in a composite mode at low temperature, the mutton is cooled to room temperature and stored at the temperature of 0 DEG C-4 DEG C. Hind quarters of sheep are used as raw materials of the prepared Muslim low-temperature mutton ham, and processed at low temperature, so that the loss of nutrient substances of mutton is reduced; moreover, original flavor of the mutton can be retained well, by means of ultrahigh pressure curing, tenderness of the mutton is improved, the color of the mutton is kept better, curing efficiency is improved, the processing period is shortened, novel products with high quality, high safety and long shelf life are produced, and a new thought is provided for deep processing in the mutton industry.

Owner:NINGXIA UNIVERSITY

Silicon material cleaning device

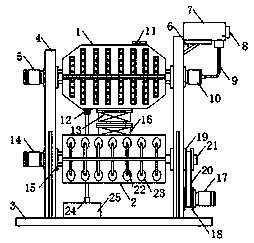

InactiveCN101357366AReduce labor intensityImprove pickling efficiencyDirt cleaningCleaning using liquidsEngineeringWater pipe

The present invention relates to a silicon material cleaning device, which belongs to the technical field of cleaning devices of material used in electronic and electric parts. The silicon material cleaning device comprises a pickling bath, the upside of which is equipped with a movable cover, and one side near the bottom of the pickling bath is provided with a drainpipe. A material containing roller is arranged in the pickling bath and is provided with a material door. A material containing roller driving mechanism is connected with the material containing roller. A high pickling solution storage vat is arranged above the pickling bath and is communicated with the pickling bath. A low pickling solution storage vat is arranged at one side of the pickling bath and is communicated with the pickling bath. A pickling solution lifting mechanism is communicated with the high pickling solution storage vat and the low pickling solution storage vat. A water inlet pipeline is connected with the upper part of the pickling bath and extends into the pickling bath. An air exchanging mechanism is communicated and connected with the pickling bath in a circular way. Harmful gas can not cause influence on operating workers. The silicon material cleaning device has low labor intensity and high pickling efficiency, so that the exhaust gas in the pickling bath can be replaced before the movable cover is opened, and the exhaust gas produced during the pickling process can be introduced to an exhaust gas treatment device to be disposed.

Owner:ZHEJIANG XINNENG PHOTOVOLTAIC TECH CO LTD

Diode pickling device

ActiveCN105390424AIncrease profitImprove pickling efficiencySemiconductor/solid-state device manufacturingEngineeringNet shape

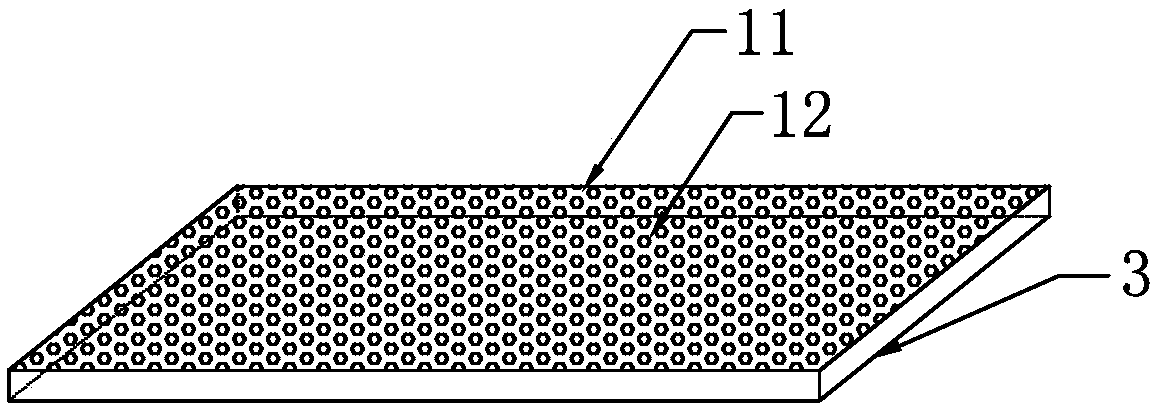

The invention discloses a diode pickling device belonging to the field of manufacturing of diodes. The diode pickling device comprises a pickling tank, a motor and a pickling box, wherein a pickling frame is arranged in the pickling tank; the side wall of the top end and the bottom surface of the pickling frame are in a net shape; a vibration frame is fixed at the top end of the pickling frame; the motor is located at one side of the pickling tank; a vibration device is fixed at an output end of the motor; the vibration frame is connected with the vibration device; the pickling box is located at one side, far away from the pickling tank, of the motor; the pickling box is connected with a liquid supply pipe; an outlet of the liquid supply pipe is located above the pickling tank; and a liquid supply valve is arranged at the outlet of the liquid supply pipe. According to the diode pickling device, the dosage of a pickling solution is controlled through the liquid supply valve; a diode fully contacts the pickling solution in the pickling process through the motor and the vibration device; pickling of the diode can be finished with only a little of pickling solution; the pickling solution is high in utilization rate and high in pickling efficiency; the surface of the diode is pickled evenly; and the pickling quality is good.

Owner:TAIZHOU DEZHONG ELECTRON CO LTD

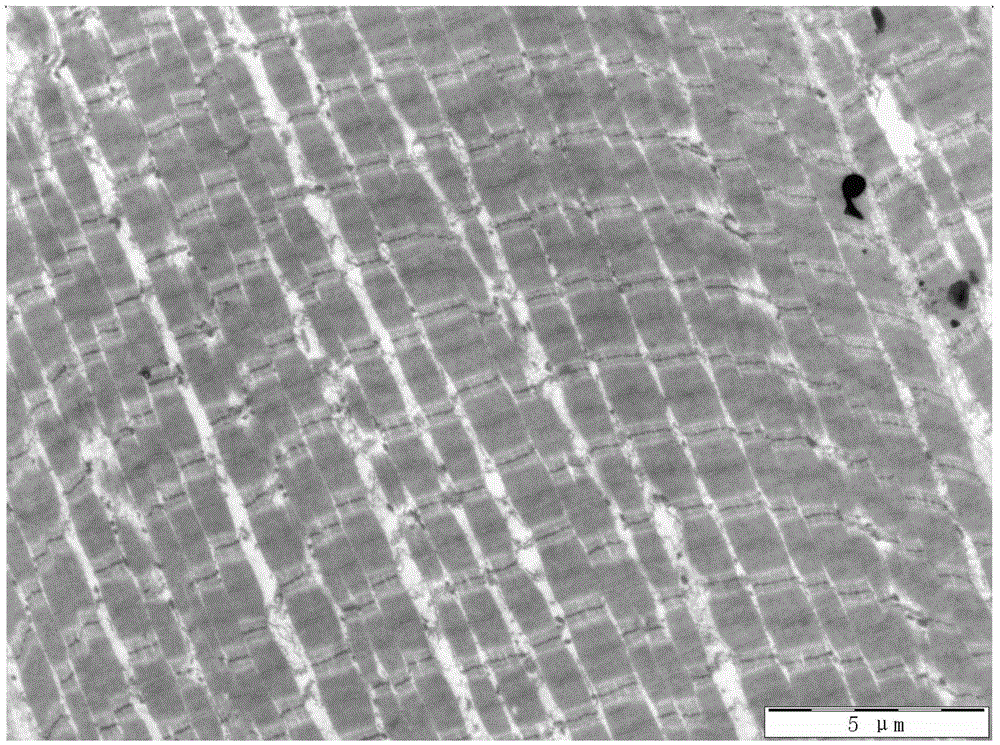

Method for making easy-to-pickle steel plate

InactiveCN102671992AIncreasing the thicknessImprove lateral uniformityRare end control deviceWork treatment devicesSheet steelStrip steel

The invention provides a method for making an easy-to-pickle steel plate and belongs to the technical field of metallurgy. The method comprises the following steps of: smelting molten steel, and making a plate blank by continuous casting; descaling by using high pressure water, performing rough rolling on the descaled plate blank, performing finish rolling, cooling to the temperature of 500 to 550 DEG C, cooling at the speed of 5 to 10 DEG C per minute to obtain the steel which is easy to pickle and in a hot rolling state and of which the content of FeO is over 25 percent; performing finish rolling, cooling to the temperature of 650 to 700 DEG C at the speed of 1 to 5 DEG C per minute to obtain the steel which is easy to pickle and in a cold rolling state and has a uniform structure and of which the content of iron oxide scale FeO is less than 10 percent. By adopting the method, the thickness of the iron oxide scale is reduced by 20 to 30 percent compared with the conventional process, the pickling speed of the strip steel is increased from 150 to 160 m per minute to 180 to 200 m per minute compared with the conventional process, not only the pickling quality of the steel plate is guaranteed, but also the pickling efficiency is effectively improved.

Owner:NORTHEASTERN UNIV +1

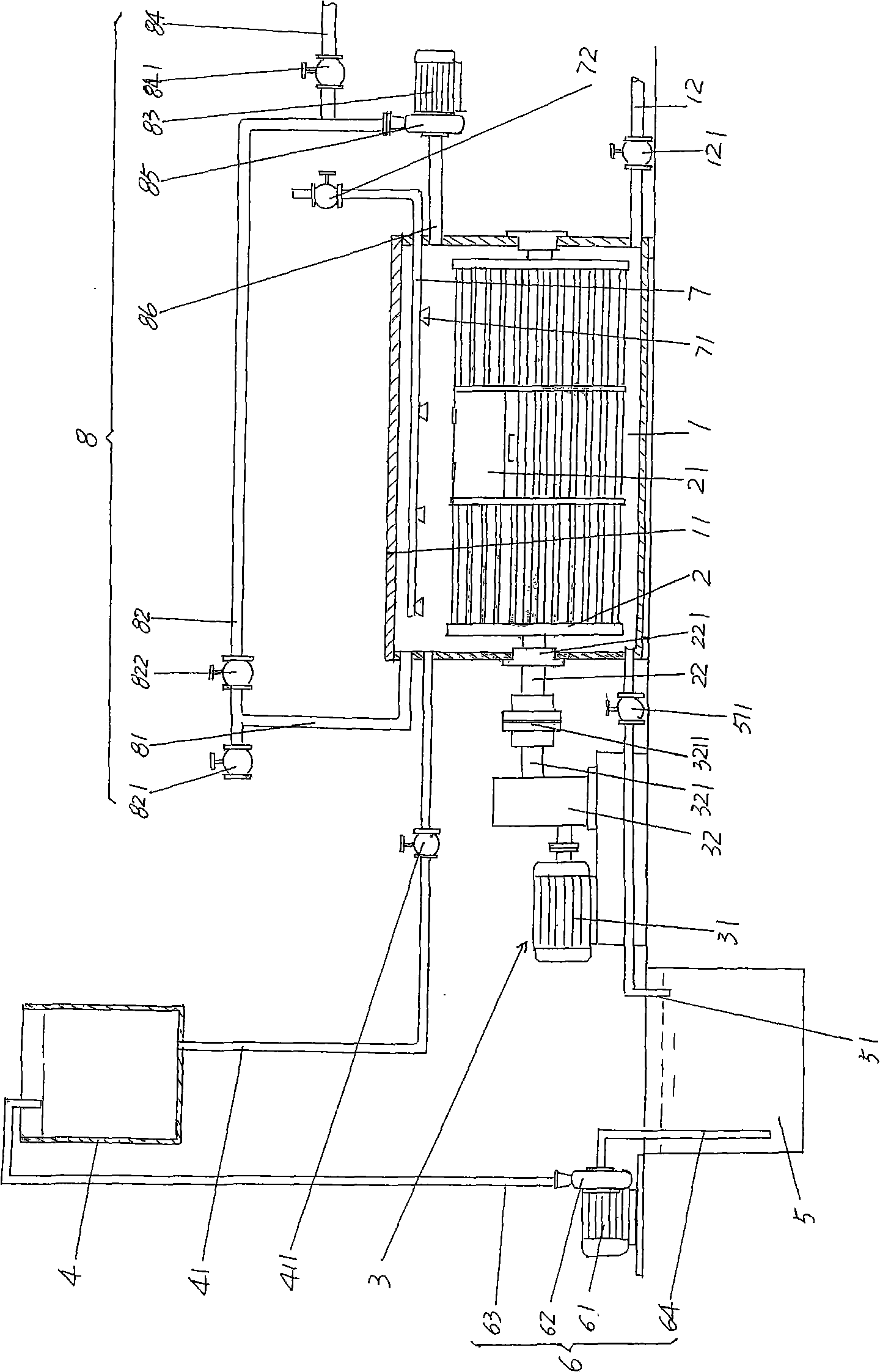

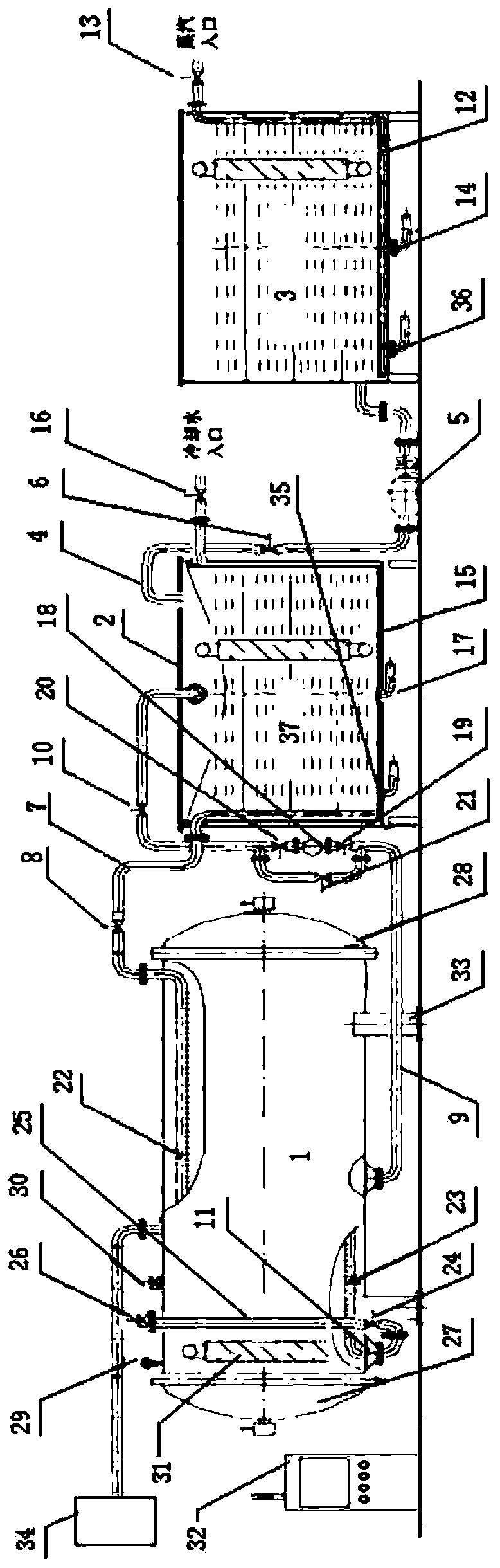

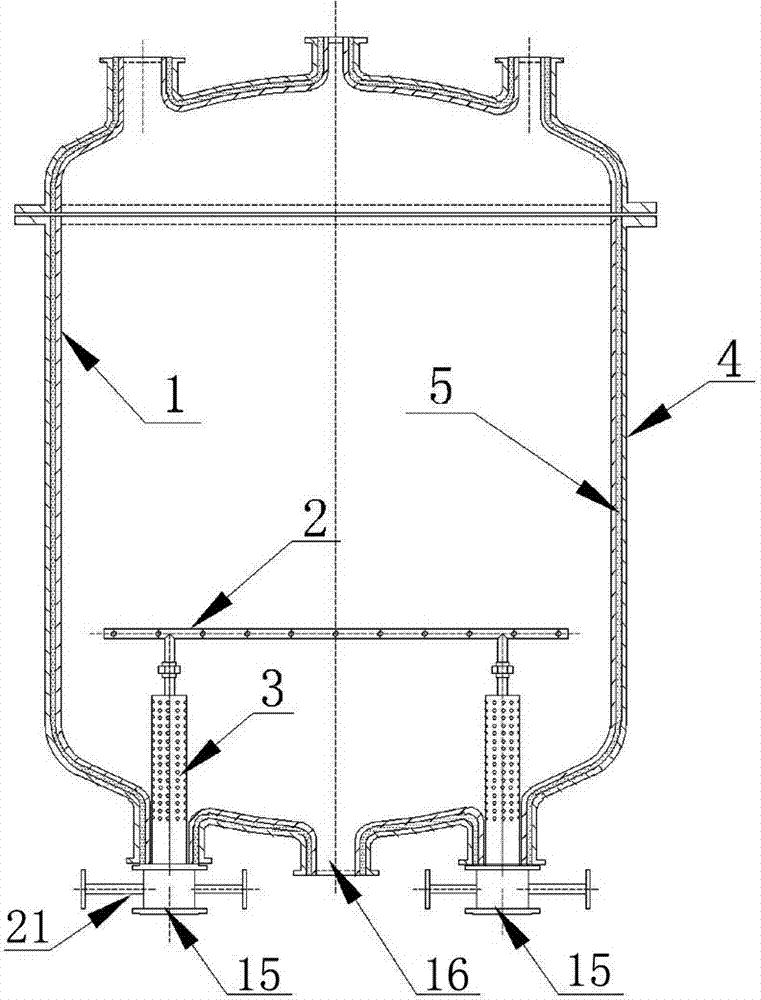

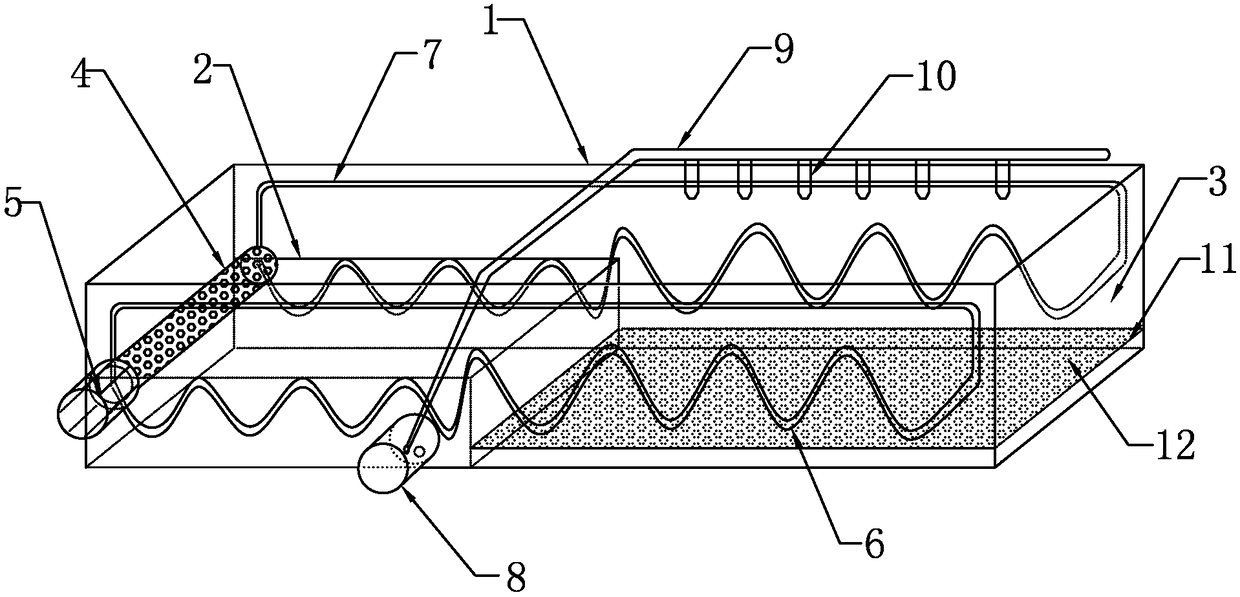

Method and device for fast and cyclically pickling salted eggs

ActiveCN102613603AImprove pickling efficiencyEase of industrial productionFood preparationPickling saltDissolution

The invention discloses a method for cyclically pickling salted eggs. The method comprises the following steps that: A, selecting fresh poultry eggs, cleanly washing the poultry eggs, and placing the eggs into a vacuum pickling tank; B, solution A and solution B for pickling are prepared, 1L of solution A comprises common salt and slaked lime, and 1L of solution B comprises white spirit, acid additives and natural spice; C, the solution A for pickling is filled into a sterilization device with a built-in liquid storage groove and is pumped into the tank containing the poultry eggs after beingsubjected to ultraviolet sterilization, the solution B is filled into an ultrasonic wave dissolution device provided with a built-in liquid storage groove and a stirring paddle, the stirring is carried out, the pump is started, and the solution B passes through a filtering device and the sterilization device and is then pulped into the tank; D, the pump is started, the flow rate is monitored through a flow rate counting meter so that the pickling solution circulates in a pickling device at the specified flow speed; and E, after the cyclic pickling fro a certain time, the eggs are taken out and are cleanly washed, and finished products are obtained. The salinity of the salted eggs is uniform, the flavor is very good, the pickling period is shortened, the shelf life can be prolonged, the utilization rate of the pickling solution is improved, meanwhile, the continuous production can also be realized, the factory building area is reduced, and the environment is protected.

Owner:HUBEI SHUANGGANG AGRI SCI & TECH TRADE CO LTD

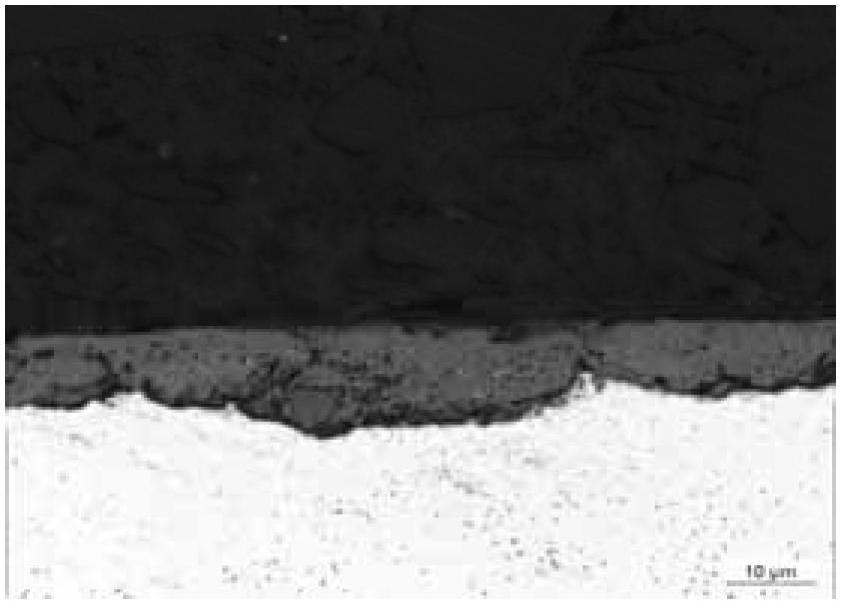

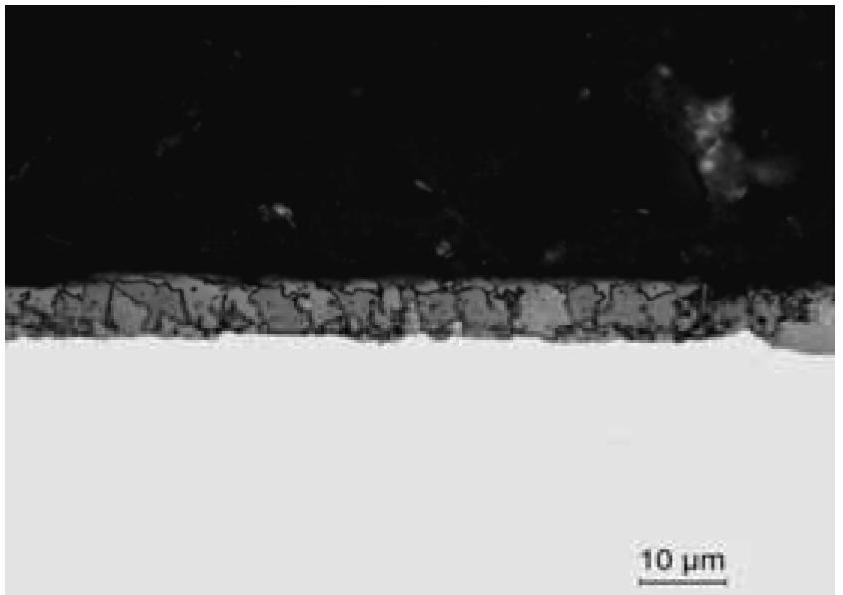

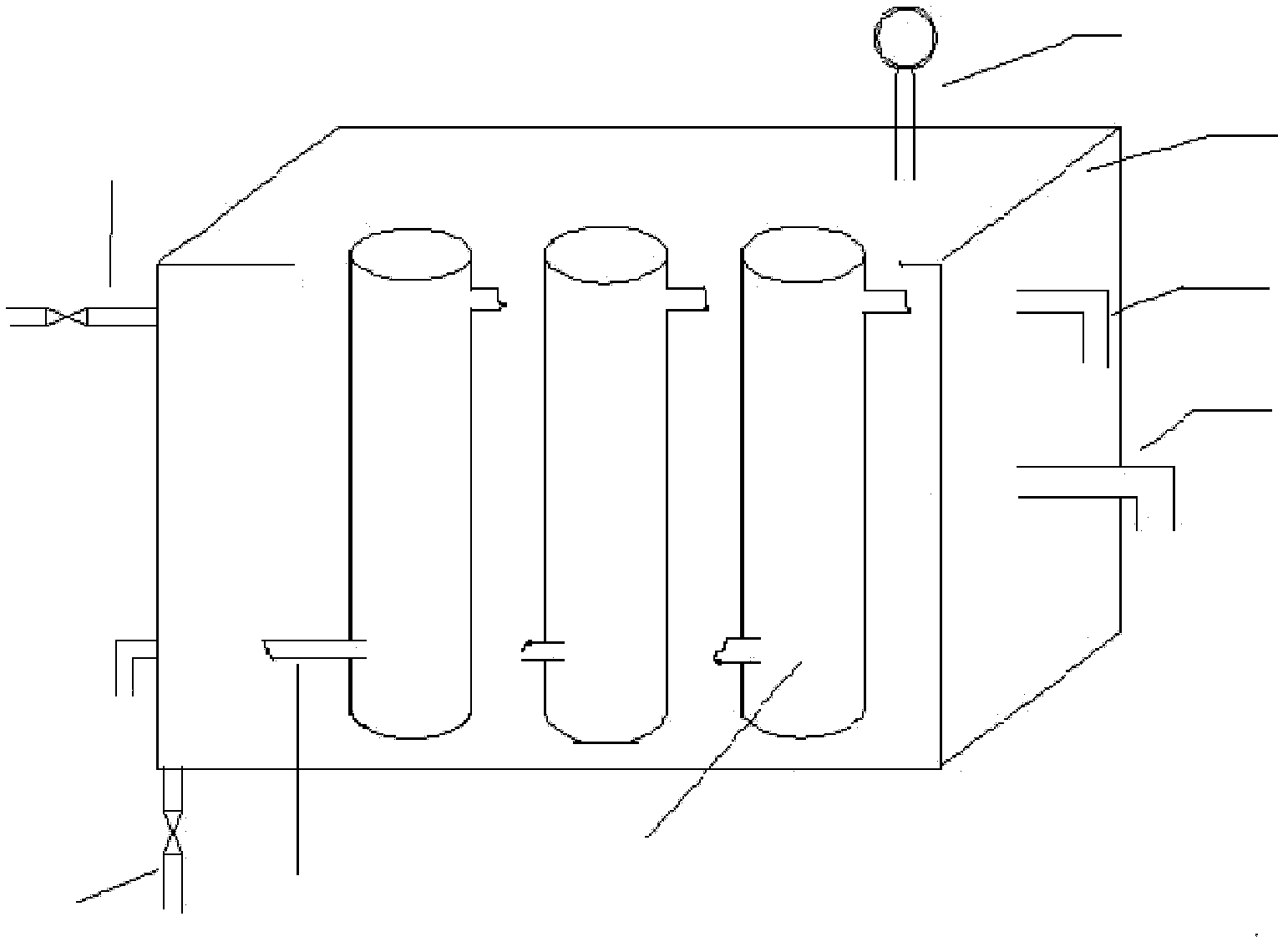

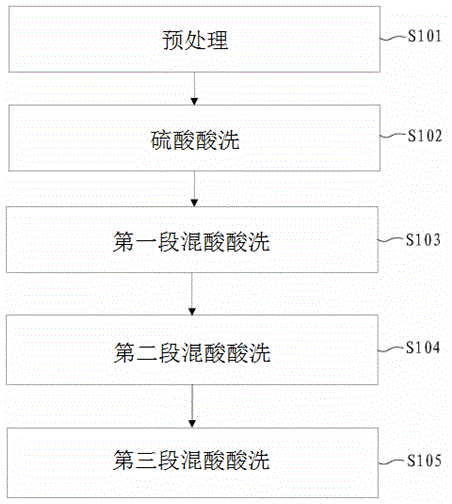

Acid pickling method for hot rolled 304 Austenitic stainless steel

The invention relates to an acid pickling method for hot rolled 304 Austenitic stainless steel. The acid pickling method comprises the steps of pretreatment, sulfuric acid pickling, mixed acid pickling for a first section, mixed acid pickling for a second section and mixed acid pickling for a third section. A mixed acid solution used in the steps of acid pickling for the three sections is formed by mixing nitric acid and fluorosilicic acid. According to the acid pickling method for the hot rolled 304 Austenitic stainless steel, the mixed acid solution formed by mixing nitric acid and fluorosilicic acid is adopted, H2SiF6 has a high ability to dissolve and corrode scale cinder and a metal matrix as HF, and therefore the acid pickling efficiency can be improved. In the acid pickling process, the activity of the acid solution is basically constant, and the service life of the acid solution is prolonged; in this way, the discharge amount of waste acid is reduced, and production cost and water treatment cost are reduced. In the mixed acid pickling process, fluoride sediment will not be generated, a pipeline will not be blocked, and the halt maintenance frequency is reduced.

Owner:WISDRI ENG & RES INC LTD

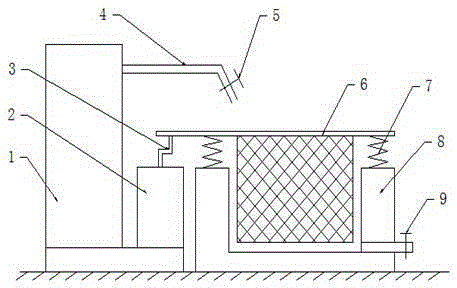

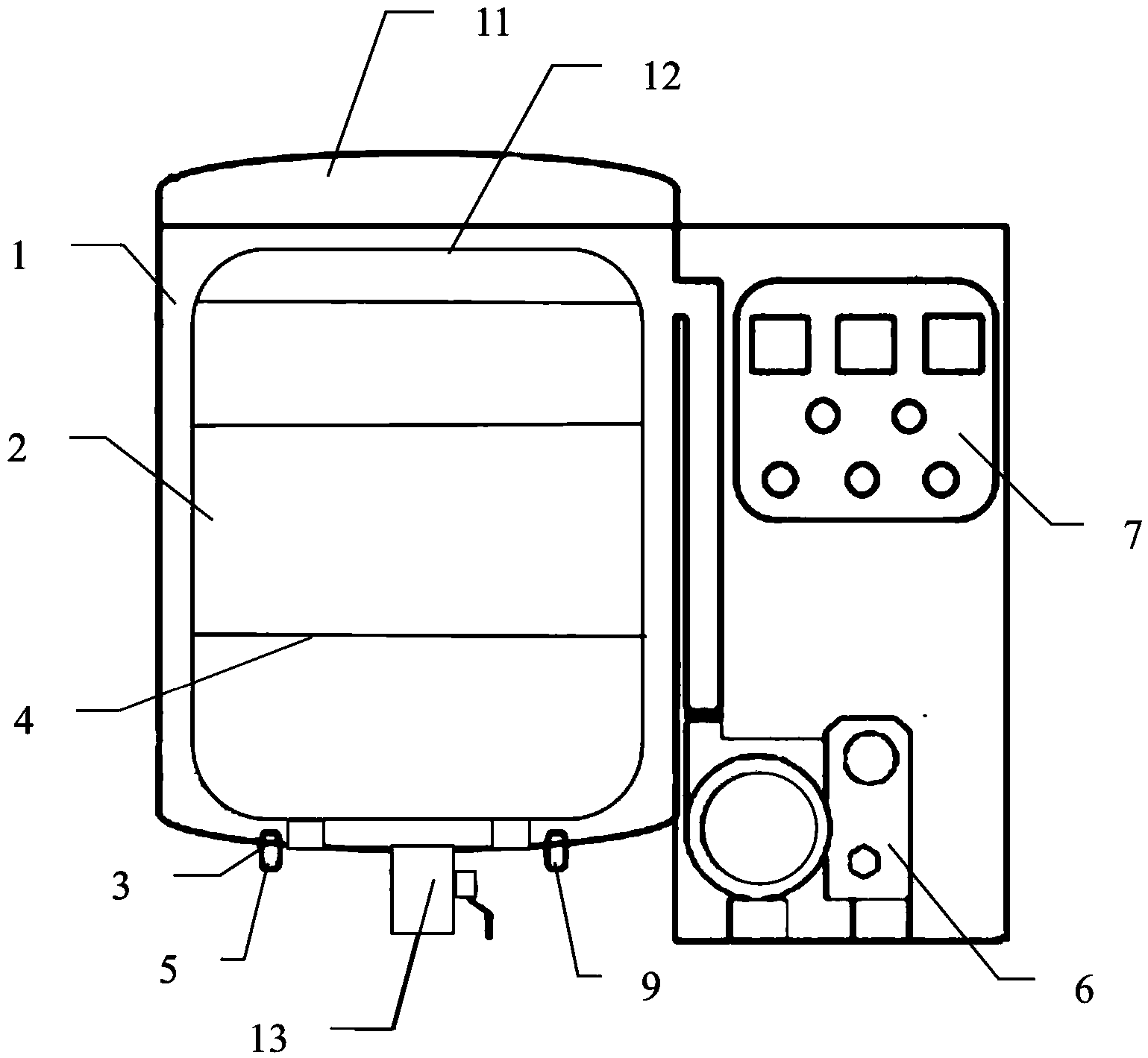

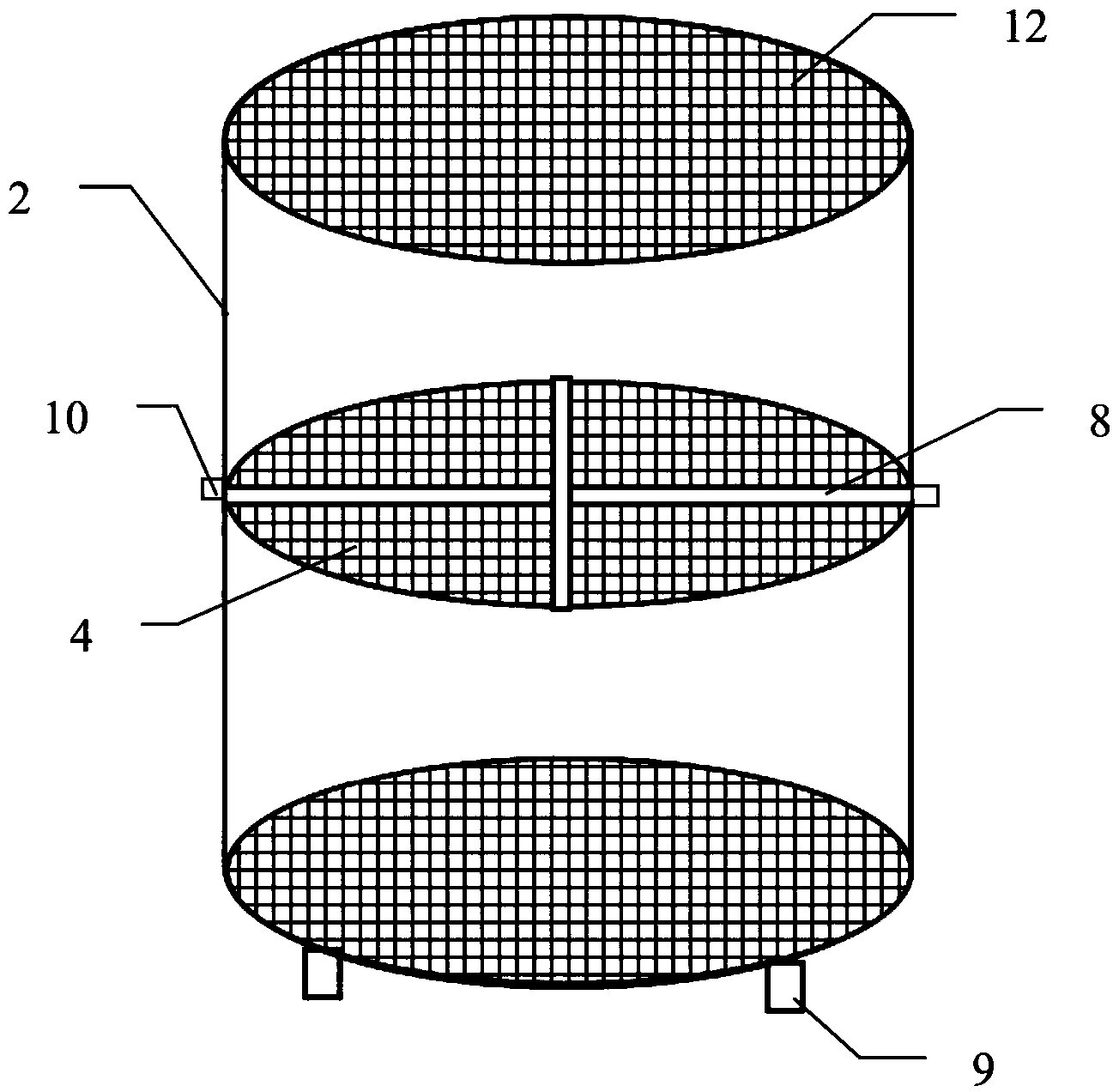

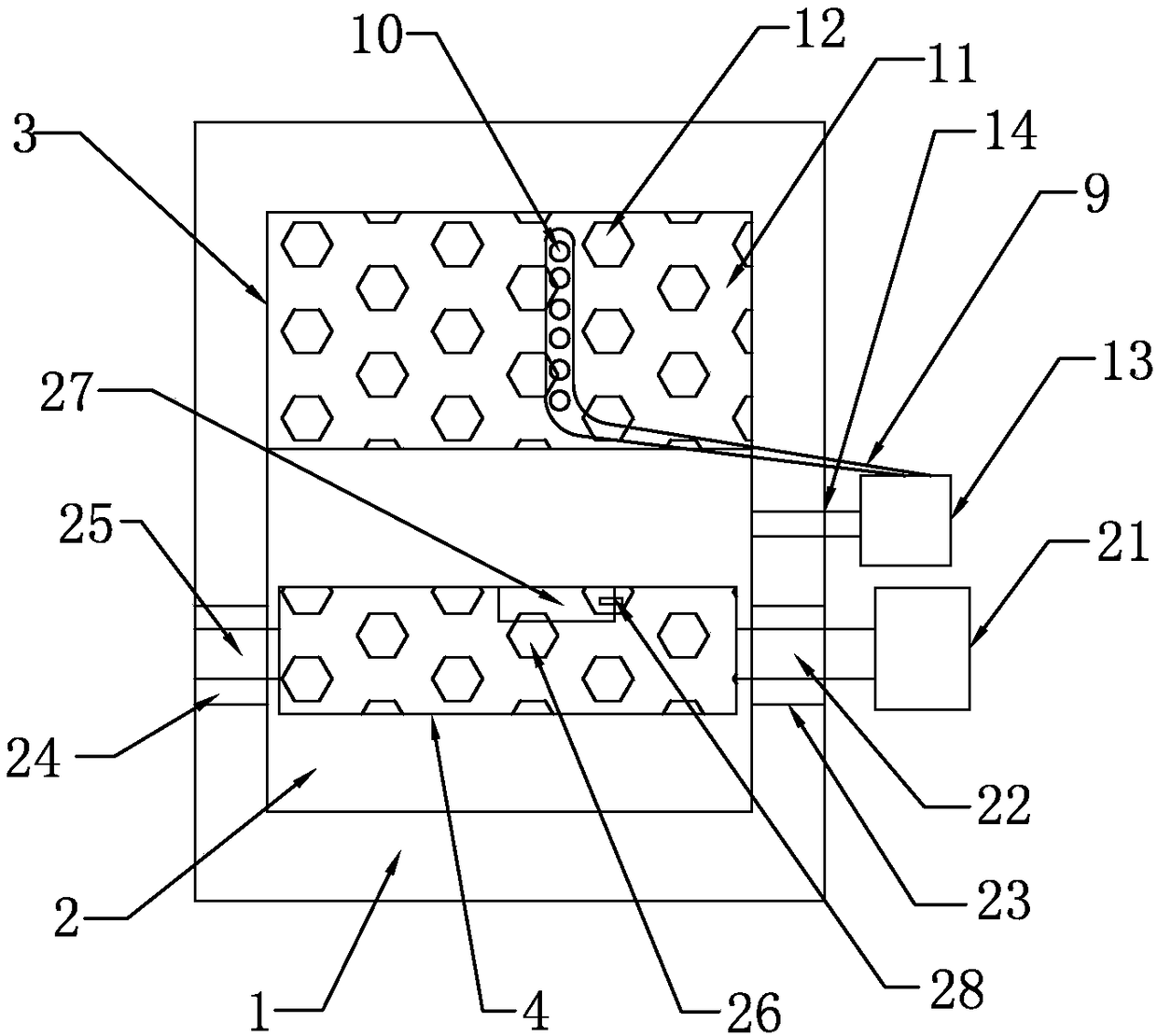

Transformation static curing equipment for foods and curing method thereof

ActiveCN104256848AIncrease impactAccelerate the speed of penetration into the tissue of the material to be marinatedFood preservationPositive pressureEngineering

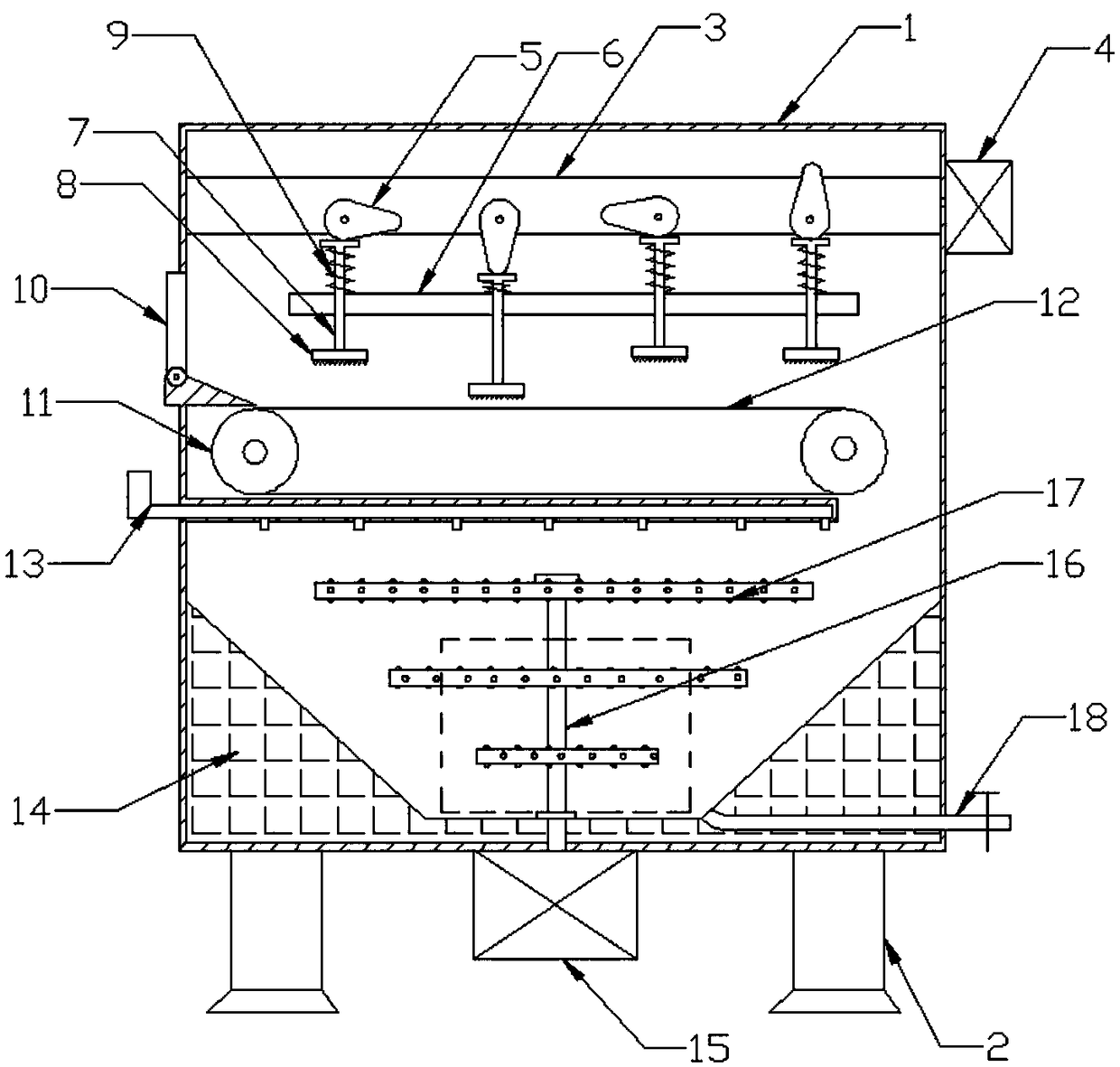

The invention discloses transformation static curing equipment for foods and a curing method thereof. A pressure regulation device which is capable of increasing or decreasing pressure in a curing pot is connected onto the curing pot; by utilizing pressure change in the curing pot, the materials to be cured are cured; particularly, when the curing pressure in the curing pot changes from negative pressure to positive pressure, the impact of the curing liquid entering into the materials to be cured is enlarged, so that the speed of the curing liquid permeating into the tissues of the materials to be cured is accelerated, the curing efficiency is improved and the requirements of the production process are satisfied. Moreover, the curing pot is designed into a double-layer structure of a latticed inner cylinder, and latticed separation plates are added in the inner cylinder to divide the inner cylinder into a plurality of communicated curing units, so that the structural strength of the curing pot is effectively improved, the extrusion between the materials to be cured can be decreased and the integrity of the cured materials is kept.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for preparing filler-level silicon micropowder by using waste quartz crucibles as raw materials

InactiveCN103613103AWide variety of sourcesMeet the requirements of filler useSilicaNatural resourceResource depletion

The invention relates to a method for preparing filler-level silicon micropowder by using waste quartz crucibles as raw materials. Aiming at the problems that the quartz crucible waste products have great stock at present and high-quality silicon natural resources are scarce increasingly, the invention provides a method for preparing silicon micropowder which is suitable for serving as fillers and has high purity, wide particle size distribution and low electric conductivity by using waste quartz crucibles as raw materials through the technical treatment of ultrasonic washing, crushing, levigating and acid washing, flotation, magnetic separation, flashing and drying, electric separation and the like. By adopting the method, the problem about resource exhaustion of high-purity quartz mine and the problem about comprehensive utilization of waste quartz crucibles of photovoltaic enterprises and crucible preparation enterprises are relieved to a certain degree.

Owner:南京工业大学东海先进硅基材料研究院 +1

Water-based metal cleaner

The invention provides a water-based metal cleaner, relating to a technology of pretreatment of processes of metal coating, electroplating, hot dipping coating and the like, in particular to a technology of cleaning the pretreatment surface of carbon steel. The water-based metal cleaner provided by the method comprises the following components of: 190 to 220 g / L of industrial hydrochloric acid, 1.7 to 8.5 g / L of phosphoric acid, 1 to 5 g / L of oxalic acid or 1 to 5 g / L of tartaric acid, 1 to 2.2 g / L of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES or 1.5 to 2 g / L of sodium dodecyl sulfate, 0.6 to 1.6 g / L of peregal 0-15, and 2 to 2.3 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The cleaner can fast, effectively and synchronously complete two processes of deoiling and derusting on the metal pretreatment surface, can effectively prevent acid mist from volatilizing, prolongs the service life of equipment and improves the working environment of labor workers.

Owner:BEIJING JJRS TECH DEV +1

Continuous pickling method for super austenitic stainless steel coil

The invention relates to a continuous pickling method for a super austenitic stainless steel coil. The method comprises the following successive steps: I, connecting the front end and the rear end of a hot-rolled and annealed super austenitic stainless steel coil to duplex stainless steel coils; II, carrying out shot blasting on the super austenitic stainless steel coil at a low rotating speed before pickling; III, allowing the coil to pass through a chemical pretreatment section, with a medium being H2SO4 and a pickling speed being 13 to 18 m / min; IV, allowing the coil to pass through a first chemical mixed pickling section, with a medium being HNO3 + HF and a pickling temperature being 50 to 65 DEG C; V, allowing the coil to pass through a second chemical mixed pickling section, with a medium being HNO3 + HF; VI, allowing the coil to pass through a first water tank; VII, allowing the coil to pass through a second water tank; and VIII, cutting off the duplex stainless steel at the front end and the rear end of the hot-rolled and annealed super austenitic stainless steel. The surface of the steel coil pickled by using the continuous pickling method provided by the invention meets requirements on No. 1 plates by GB 4237, and high pickling efficiency is obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

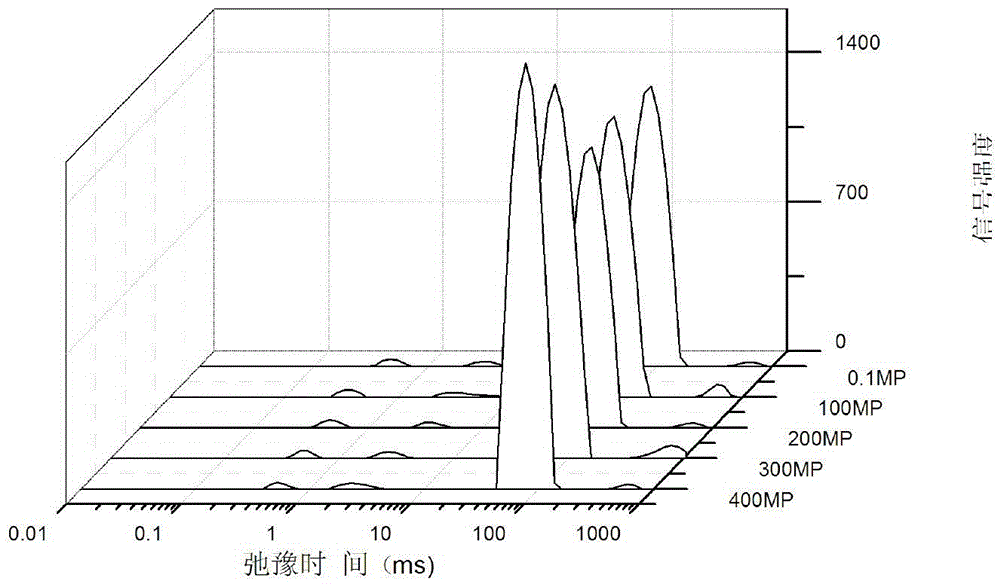

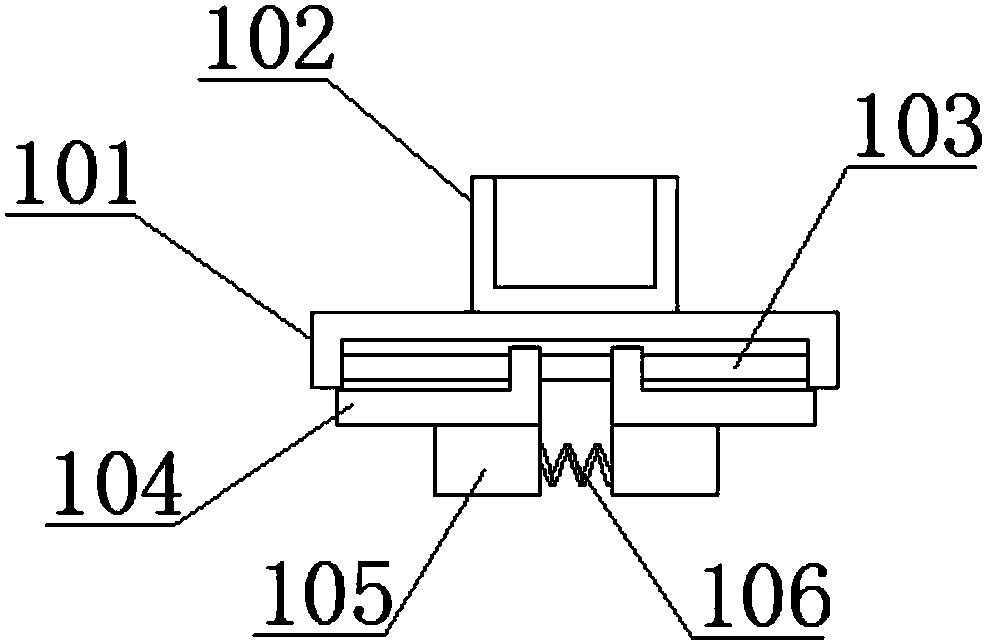

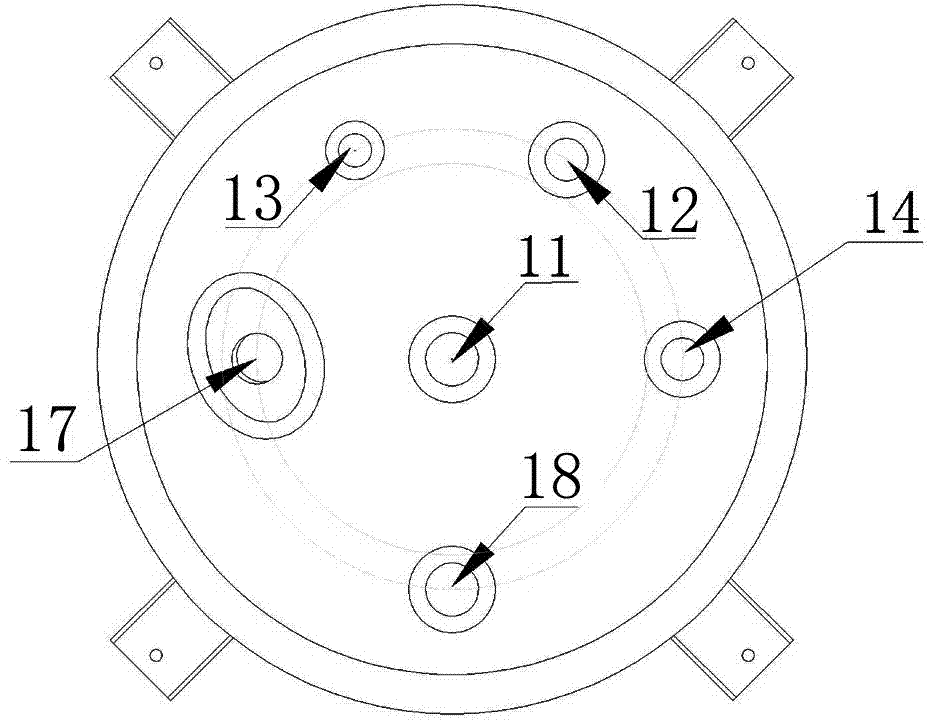

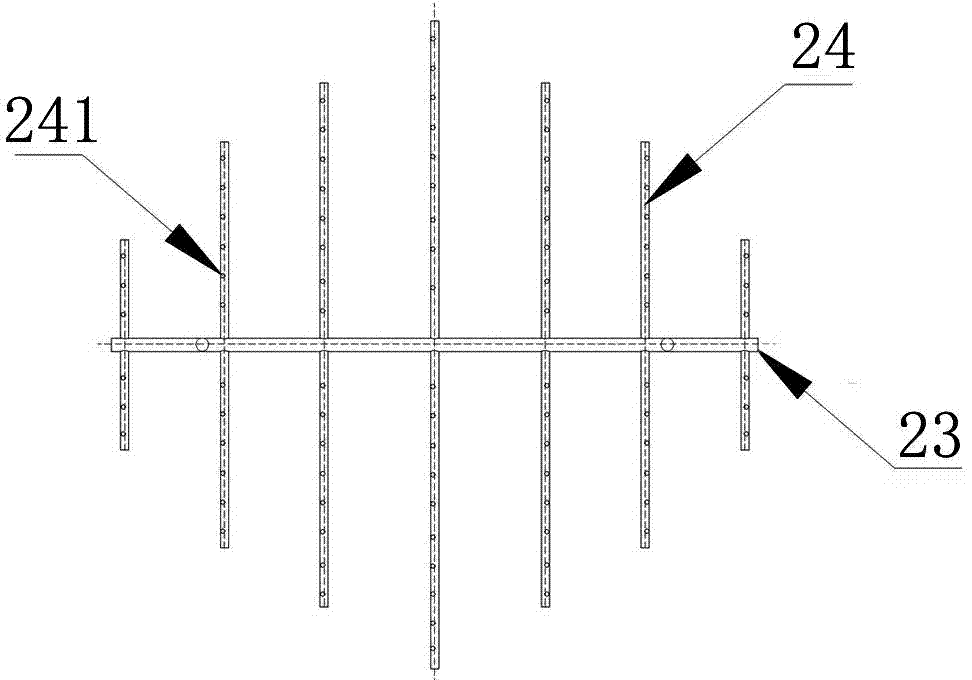

Static pressure-variable pickling system

The invention discloses a static pressure-variable pickling system. The static pressure-variable pickling system comprises a pickling tank, a pickling liquid stewing pool, a cooling storage pool and a control system, wherein the pickling liquid stewing pool, the cooling storage pool and the pickling tank are sequentially communicated with one another through liquid transmission pipelines, a pressure regulating device which conducts air exhaust and inflation on a tank body is arranged at the top end of the pickling tank, and the pressure regulating device is electrically connected with the control system. An air inlet hole is formed in the bottom of the pickling tank, a control valve which is electrically connected with the control system is arranged on the air inlet hole, and the control system controls the pressure regulating device and the first control valve so that the pressure state of the pickling tank can be switched among the negative pressure state, the normal pressure state and the positive pressure state by turns and in sequence. The static pressure-variable pickling system integrates stewing of pickling liquid and cooling of the pickling liquid and pickling conducted through the pickling tank, the operation of the whole system is controlled through the automatic control system, therefore, full automation is achieved, and the pickling efficiency is greatly improved due to the conversion of the pickling mode.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Duplex stainless steel cold rolling annealing and pickling process

ActiveCN105586600AHigh glossSolve the problem of black bandsFurnace typesHeat treatment furnacesElectrolysisSS - Stainless steel

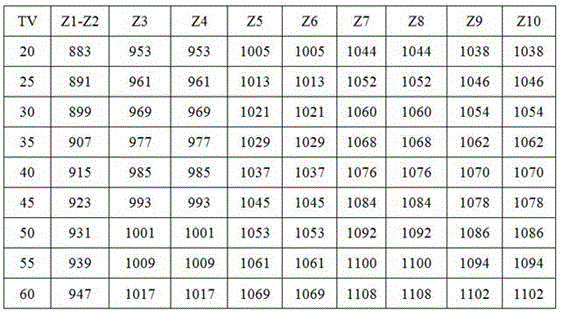

The invention discloses a duplex stainless steel cold rolling annealing and pickling process and belongs to the technical field of duplex stainless steel smelting. The process comprises the following steps: respectively connecting stainless steel rolls with annealing temperature approximating to the annealing temperature of duplex stainless steel to the front end and the rear end of the duplex stainless steel; setting process speed, calculating TV value according to the thickness and the process speed of the steel rolls, setting the hearth temperature of each region according to the TV value and carrying out annealing on the steel rolls; and then carrying out Na2SO4 electrolysis, HNO3 electrolysis, scrubbing, pickling with mixed acid and washing with desalted water on the stainless steel rolls after annealing, and finally cutting off the stainless steel rolls at the front end and the rear end of the duplex stainless steel roll, thus obtaining the duplex stainless steel roll finished products. According to the invention, by using proper annealing and pickling processes, the problems that black strips appear on the rear surface of the duplex stainless steel after pickling and width shrinking and thickness reduction are easy to cause are solved, an oxidation film on the surface of the duplex stainless steel is completely removed, the surface glossiness of the steel rolls is high, and the quality requirements of products can be met.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

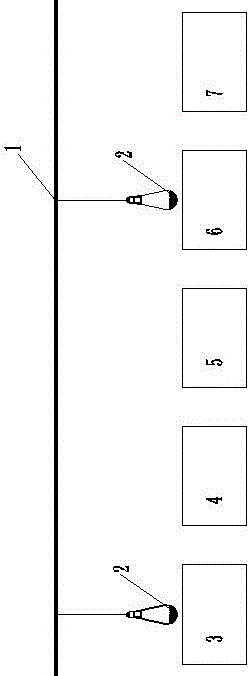

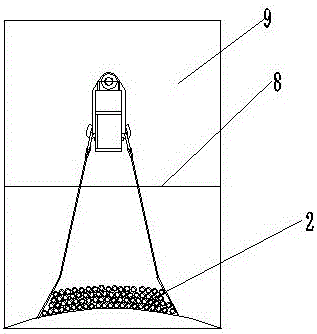

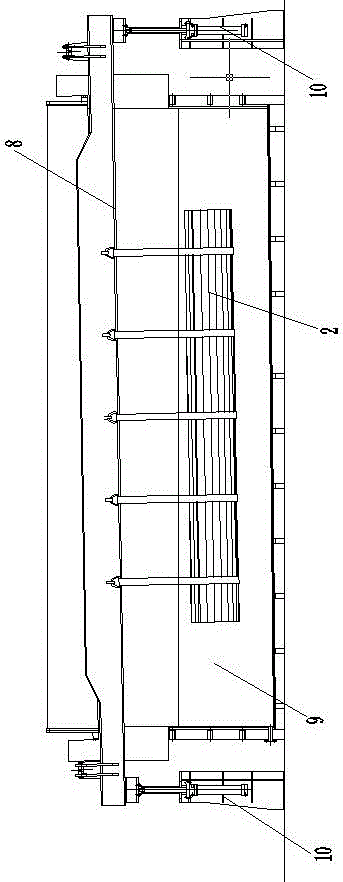

Closed-loop hot galvanizing production line and control method

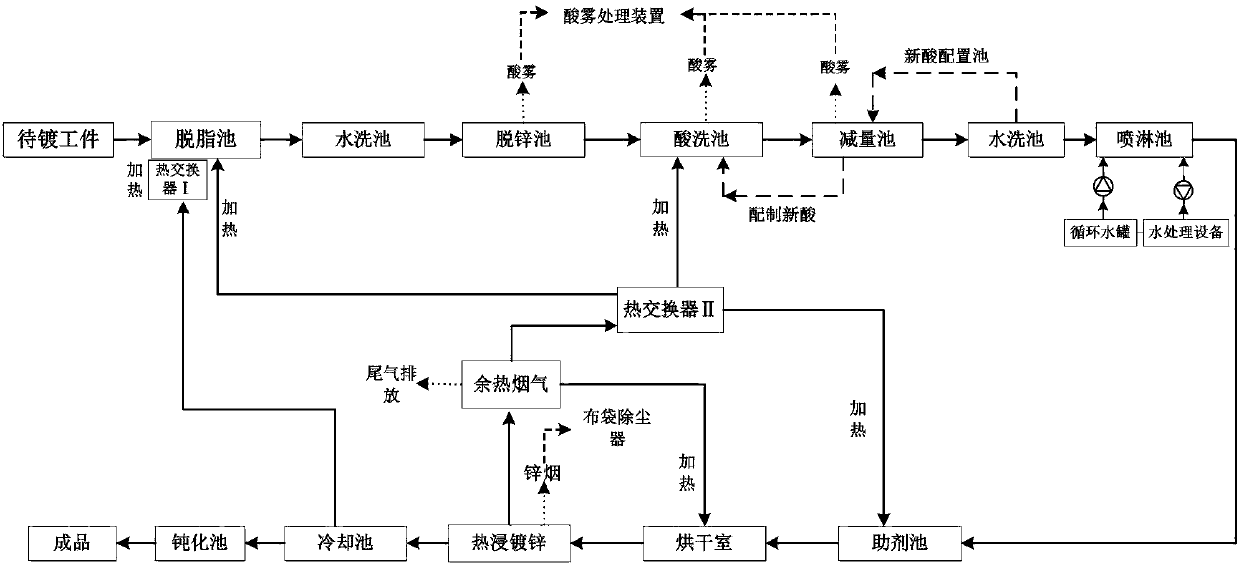

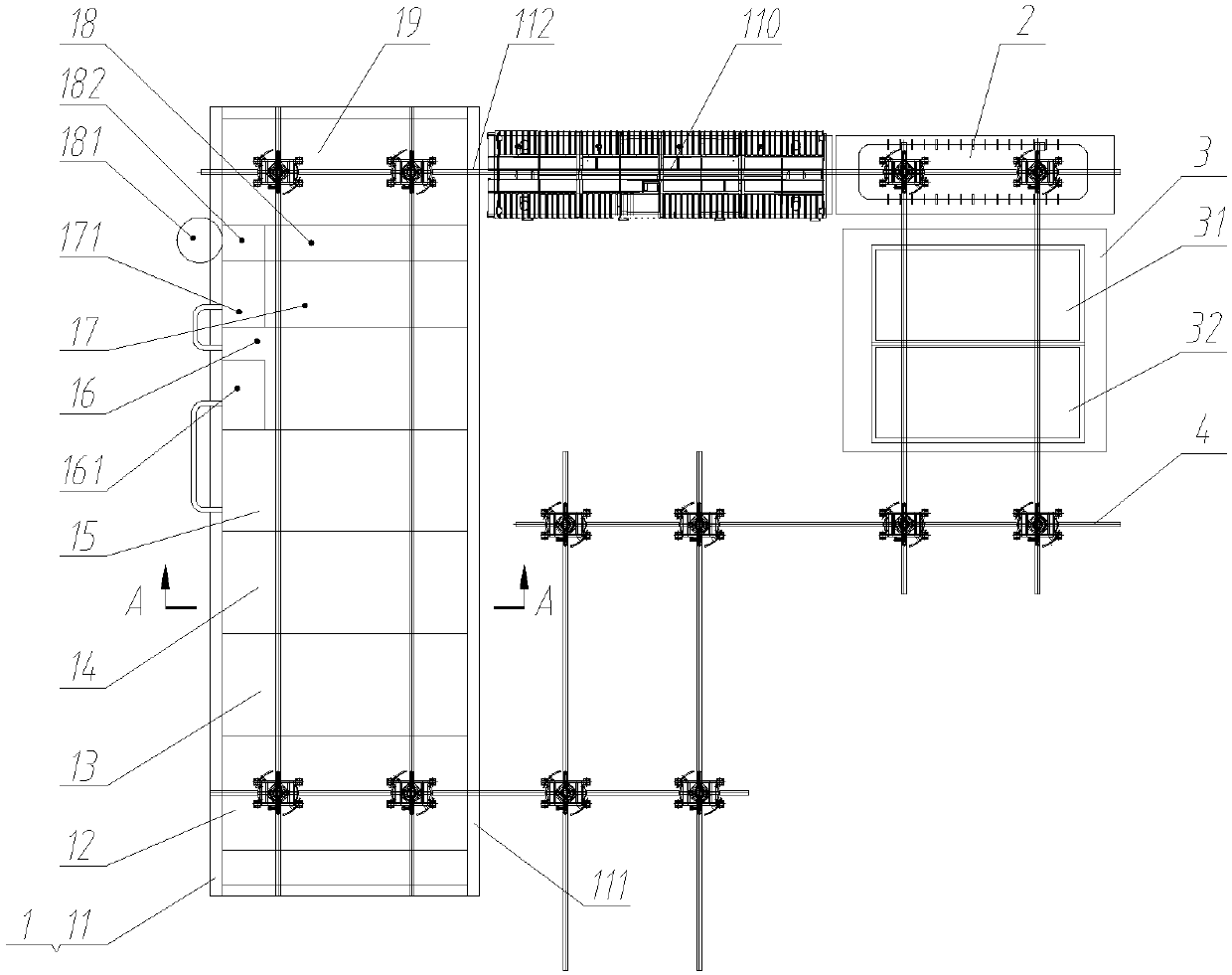

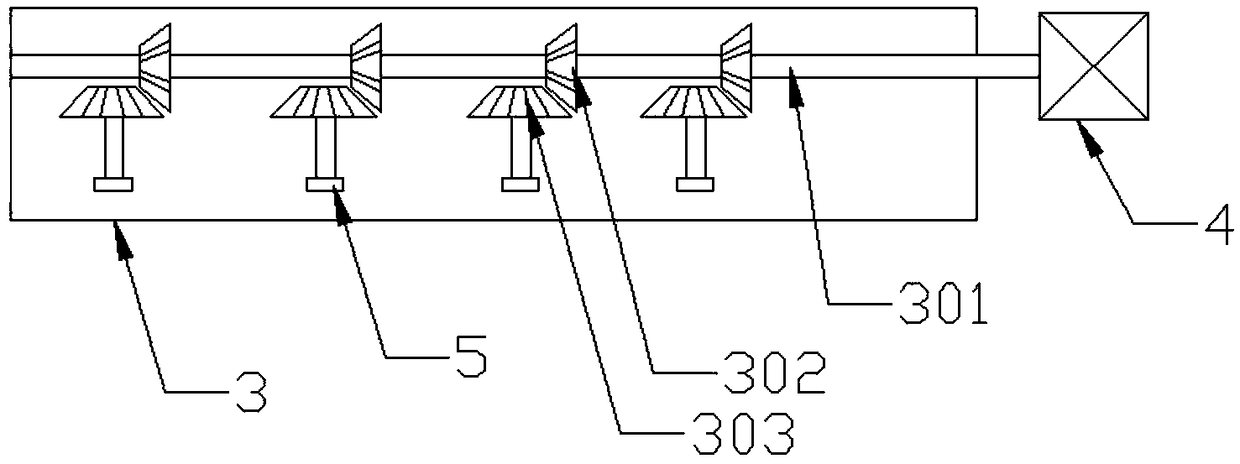

ActiveCN107557708ARealize secondary cleaningReduce surface quality defectsHot-dipping/immersion processesDirt cleaningProduction lineProcess engineering

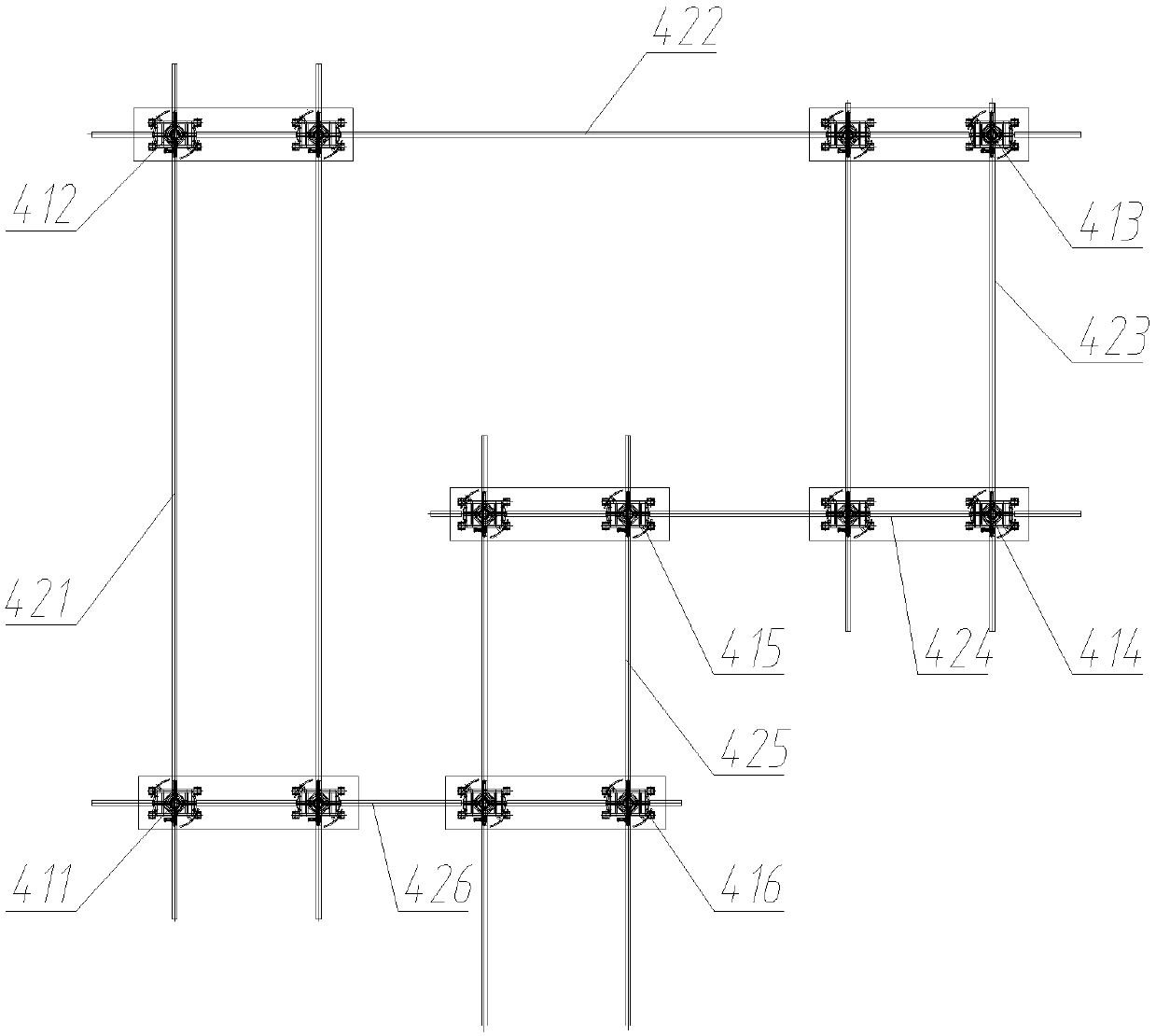

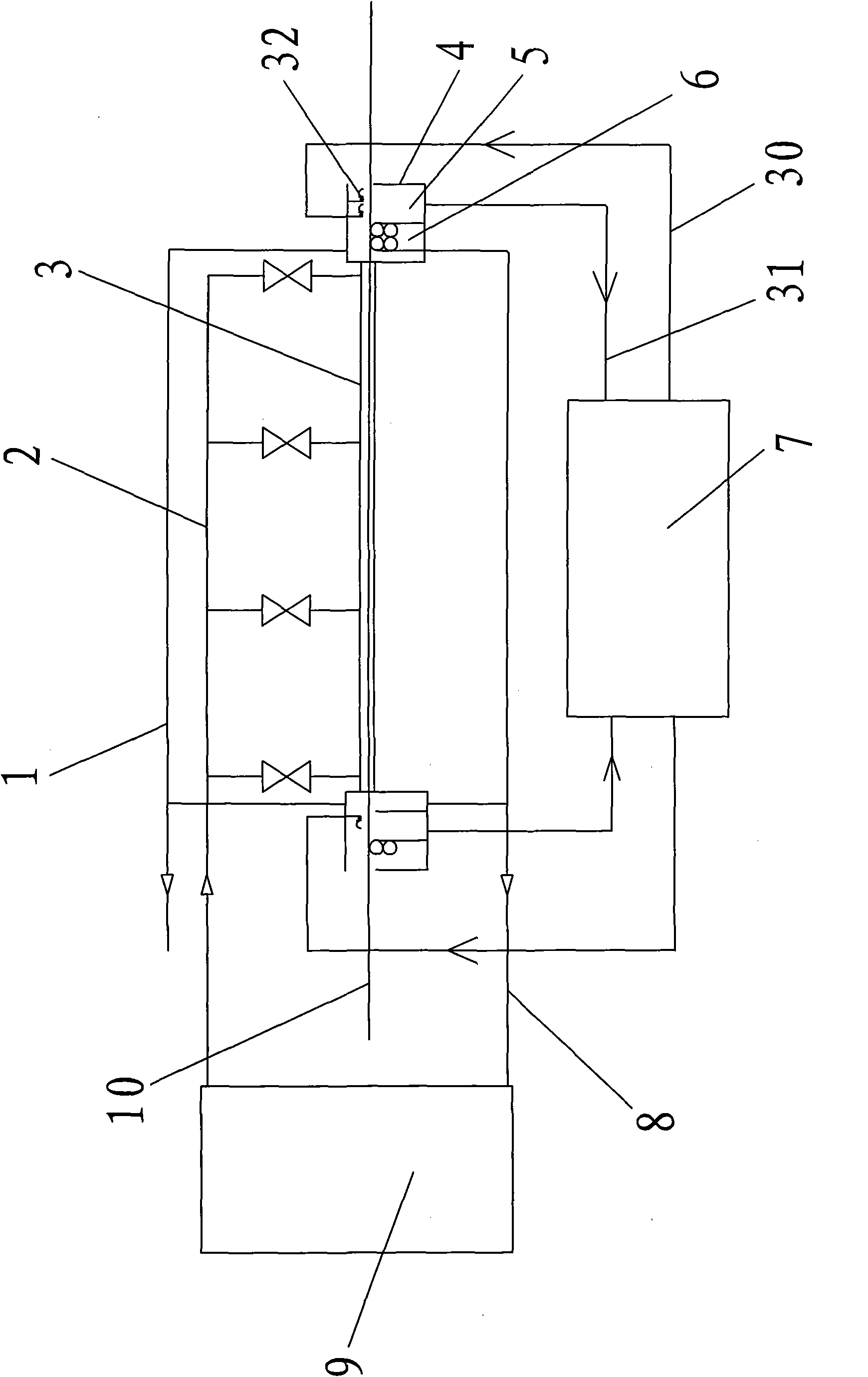

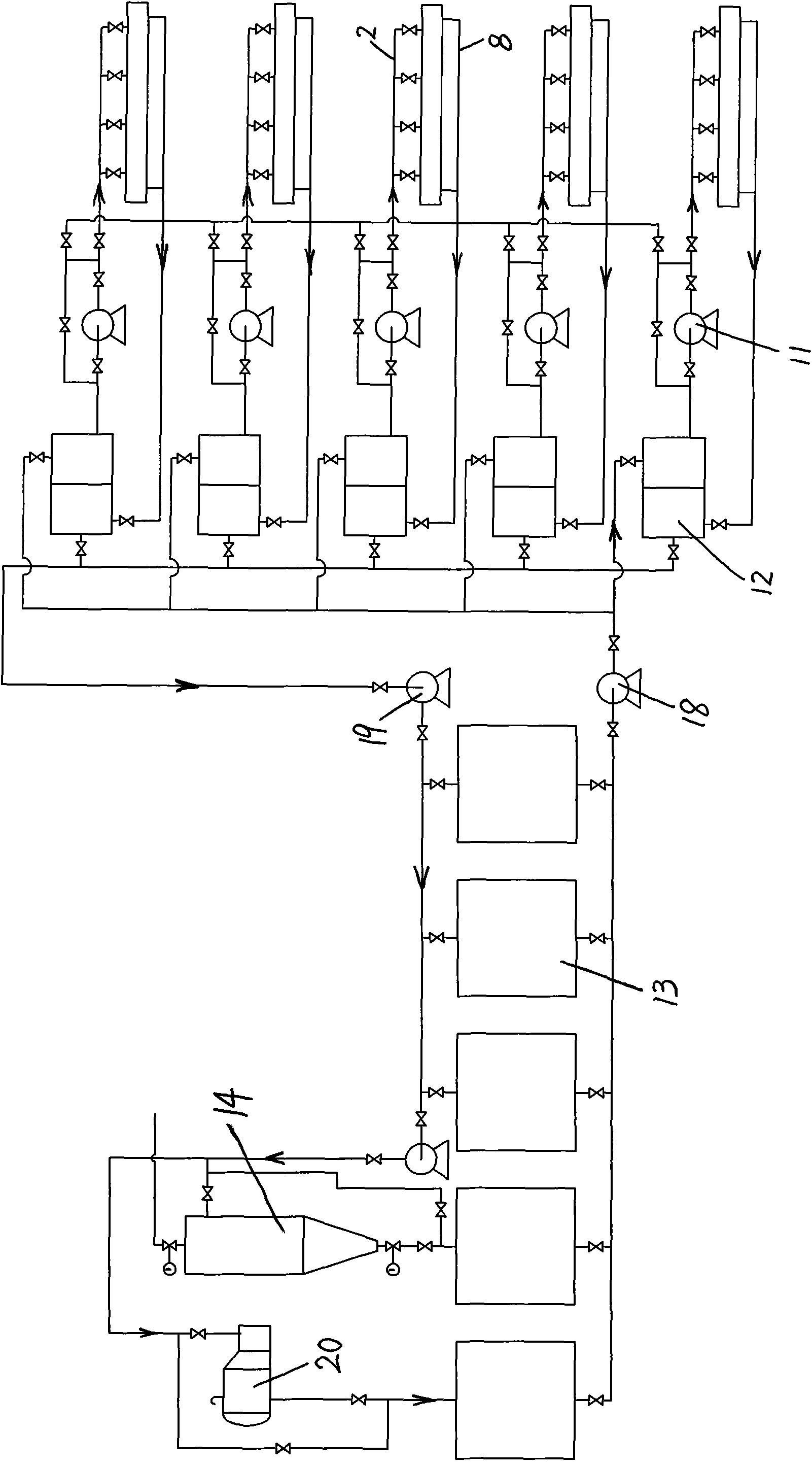

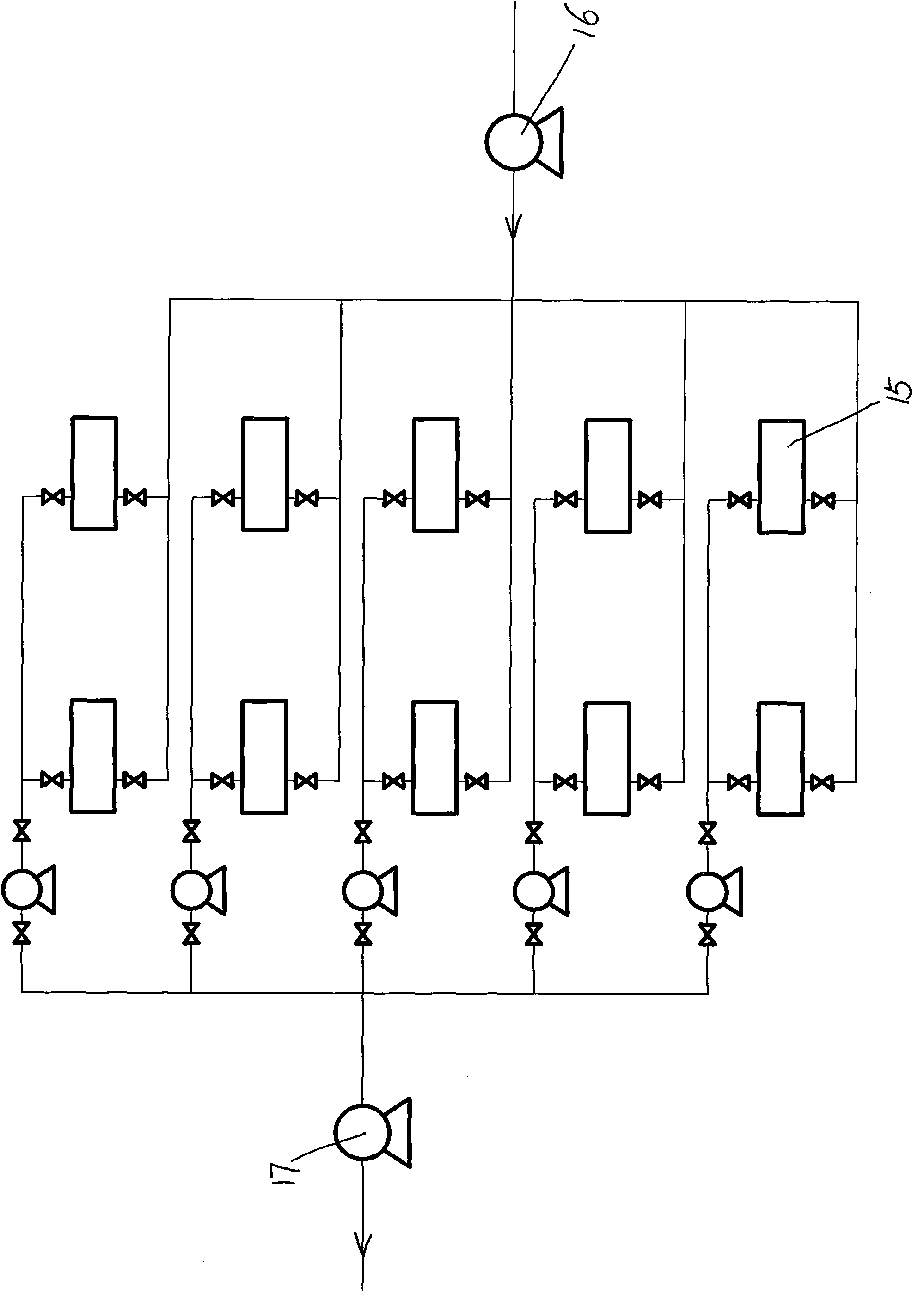

The invention discloses a closed-loop hot galvanizing production line and a control method. The closed-loop hot galvanizing production line comprises a preplating device (1), a galvanizing device (2),a postplating device (3), a travelling rail unit and an electronic control unit. The device (1) used before galvanizing comprises a degreasing pool (12), a water washing pool I (13), a zinc removal pool (14), an acid cleaning pool (15), a reduction pool (16), a water washing pool II (17), a spraying pool (18), an addition agent pool (19) and a drying chamber (110), wherein the degreasing pool (12), the water washing pool I (13), the zinc removal pool (14), the acid cleaning pool (15), the reduction pool (16), the water washing pool II (17), the spraying pool (18), the addition agent pool (19)and the drying chamber (110) are connected with the interior of a chamber (11) used before galvanizing in sequence. The postplating device (3) and the galvanizing device (2) are perpendicularly arranged. The travelling rail unit comprises a travelling rail device (4) and a travelling rail electronic control circuit, wherein the travelling rail device (4) is located above the preplating device (1), the galvanizing device (2) and the postplating device (3). By the adoption of the closed-loop hot galvanizing production line and the control method, the content of iron entering the hot galvanizingworking procedure can be effectively reduced, the waste of liquid zinc is reduced, the frequency of treatment of dangerous waste iron mud is reduced, the purpose that the surface quality of a galvanized part is better is achieved, and the production efficiency is improved.

Owner:徐州瑞马智能技术有限公司

Environment-friendly steel wire pickling bath

The invention discloses an environment-friendly steel wire pickling bath which comprises a water circulating device and an acid liquor circulating device. The pickling bath consists of a plurality of horizontally arranged pickling pipelines, and the pickling pipelines consist of PE (Polyethylene) pipes. A UHMV-PE (Ultra High Melt Viscosity-Polyethylene) layer is arranged on the inner wall of each pickling pipeline, acid adding pipes are uniformly connected at intervals on the top faces of the pickling pipelines, and the acid adding pipes are communicated with the acid liquor circulating device. Both ends of each pickling pipeline are respectively connected with a liquor collecting tank, a steel wire drawing device is arranged in the liquor collecting tank, and a steel wires pass through the pickling pipelines and the steel wire drawing devices in the two liquor collecting tanks. An acid return tank and a water return tank are also arranged in the liquor collecting tank, the acid return tank is communicated with both ends of the pickling pipeline, and the bottom face of the acid return tank is connected with the acid liquor circulating device through an acid return pipe. A water spray device for spraying water to the surfaces of the steel wires is arranged above the water return tank, the water spray device is connected with the water circulating device through a water inlet pipe, and the bottom face of the water return tank is connected with the water circulating device through a water return pipe. The top faces of the two liquor collecting tanks are respectively connected with air exhaust pipes.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Method for processing pickled seawater fish with grain and wine

ActiveCN104000237AImprove qualityImprove pickling efficiencyFood ingredient as antioxidantFood ultrasonic treatmentAlkaline waterPhenolic content in tea

The invention provides a method for processing pickled seawater fish with grain and wine. The method includes the following steps of pretreatment of seawater fish, cleaning, combination of alkaline water treatment and ultrasonic treatment for fishy smell elimination, pickling, dehydration, pickling with grain and wine, vacuum packaging and disinfection. The fishy smell and redundant fat of seawater fish are eliminated through alkaline water and ultrasonic waves, so that the product quality is improved, wherein the alkaline water is obtained through electrolysis. A vacuum pickling mode is adopted, so that pickling efficiency is greatly improved. The seawater fish is soaked and treated in a ClO2 solution, so that the good disinfection and preservative effect is achieved. The seawater fish is coated with natural antioxidant tea polyphenol, so that the good bacteriostat preservation effect is achieved.

Owner:福建坤兴海洋股份有限公司

Fast manufacturing method of cured old goose

InactiveCN103271372ASimple processIncrease nutritionClimate change adaptationFood preparationSaline waterPenetration enhancer

The invention provides a fast manufacturing method of a cured old goose. The fast manufacturing method comprises the following steps of: cleaning, namely after a fresh and live goose qualified by quarantine inspection is killed, discarding the intestines and the belly of the goose, soaking the goose for 0.5h-1h in 5%-10% saline water, and then cleaning; curing, namely performing ultrasonic curing on the cleaned live goose in curing liquid in an ultrasonic curing device; boiling, namely adding materials to be boiled in water 50-100 times the materials, adding the cured old goose, and continuously boiling the old goose for 0.5h-1.5h at the temperature of 90-100 DEG C; and draining and cooling, namely fishing out the old goose, and draining and cooling the goose to obtain the cured old goose. The fast manufacturing method provided by the invention has the advantages that the process is simple, and the cost is low; and by virtue of a natural penetration enhancer and an ultrasonic curing method, salt can permeate in goose meat in a quicker manner, the curing time is greatly shortened, the curing efficiency of the old goose is improved, and simultaneously, the taste of the cured old goose is good.

Owner:句容市天贵农副产品有限公司

Stainless steel pipes pickling spray device

The invention discloses a stainless steel pipe pickling spray device. The pickling spray device includes a pickling spray box. A sealing cover is arranged at the top of the pickling spray box, a lifting ring is installed on the sealing cover, and a pickling spray cavity is formed in the pickling spray box. A plurality of tee pipes are installed on the inner wall of the pickling spray cavity, the tee pipes are connected by diversion pipes, and spray pipes are nested into the tee pipes. The spray pipes are connected with a liquid inlet port through the tee pipes, and a row of spray nozzles are arranged below the spray pipes. The stainless steel pipe pickling spray device is internally provided with stainless steel pipe clamping mechanisms, motors drive the stainless steel pipe clamping mechanisms to rotate through rotating shafts, and then drive stainless steel pipes to rotate, so that the stainless steel pipes are in uniform contact with a pickling solution, no mark is produced on the surfaces of the stainless steel pipes after pickling, and the pickling efficiency is high; and the two stainless steel pipes can be fixed at the same time, the efficiency of pickling is improved, and residues produced from pickling are intercepted by a residue filtering plate to prevent from blocking a drain pipe.

Owner:浙江剑麟金属制品有限公司

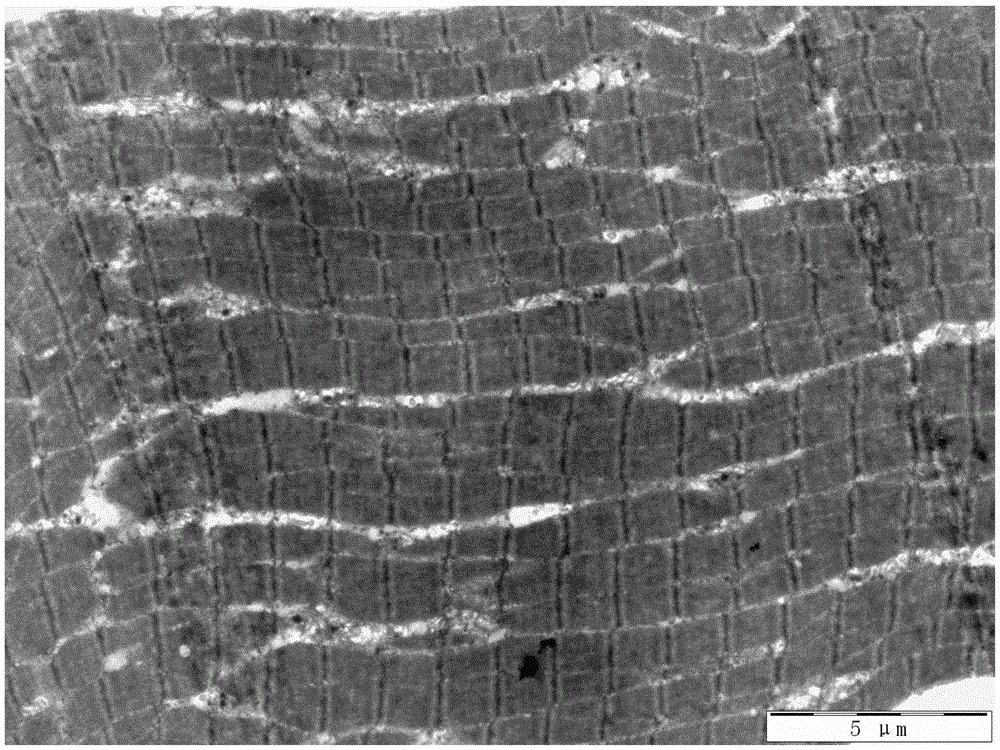

Titanium microalloyed hot rolled strip and manufacturing method thereof

ActiveCN101608284AImprove surface qualityImprove pickling efficiencyManufacturing convertersRoom temperatureReducing atmosphere

The invention provides a titanium composite microalloyed hot rolled strip and a manufacturing method thereof. The hot rolled strip comprises the following components by weight percentage: 0<C<=0.005, 0<N<=0.004, 0<Si<=0.03, Mn 0.10-0.20, 0<P<=0.018, 0<S<=0.015, Al 0.02-0.06, 0<Ti<=0.070, 0<O<=0.002, 0<Cr<=0.05, 0<Ni<=0.07, 0<Cu<=0.07 and 0<Mo<=0.020. The manufacturing method comprises the steps of preparing continuous castings according to the constituent requirement and processing the continuous castings into the hot rolled strip. The continuous castings are heated to the temperature more than 1200 DEG C during hot rolling, the holding time is longer than 2.5h and weakly reducing atmospheres are adopted for heating; the finishing temperature of the hot rolled strip is 880-930 DEG C; after finish rolling, the hot rolled strip is quickly water-cooled to the temperature of 680-750 DEG C to be reeled up; the telescoping of the coil is controlled to be less than or equal to 50mm and then the coil is cooled to the room temperature in the air. The surface quality of the strip prepared by the invention is good.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

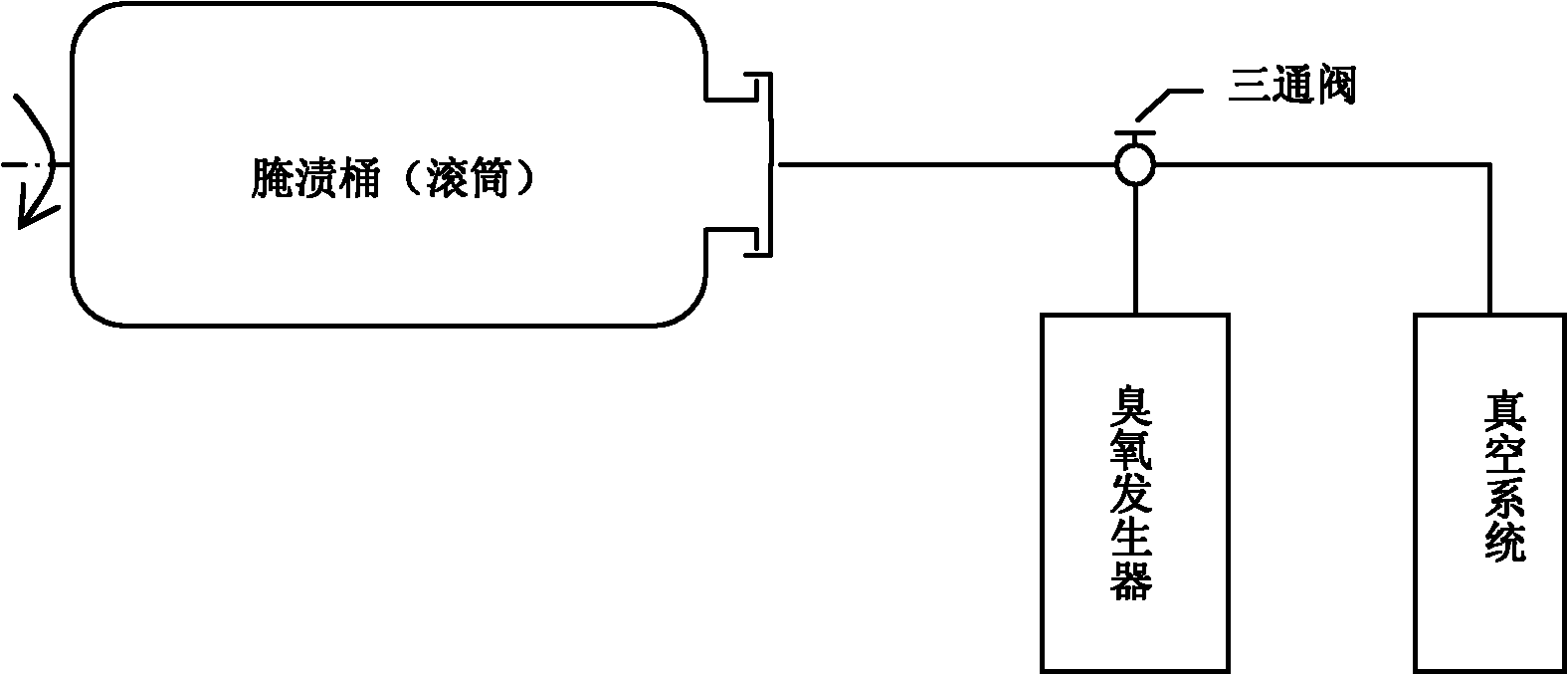

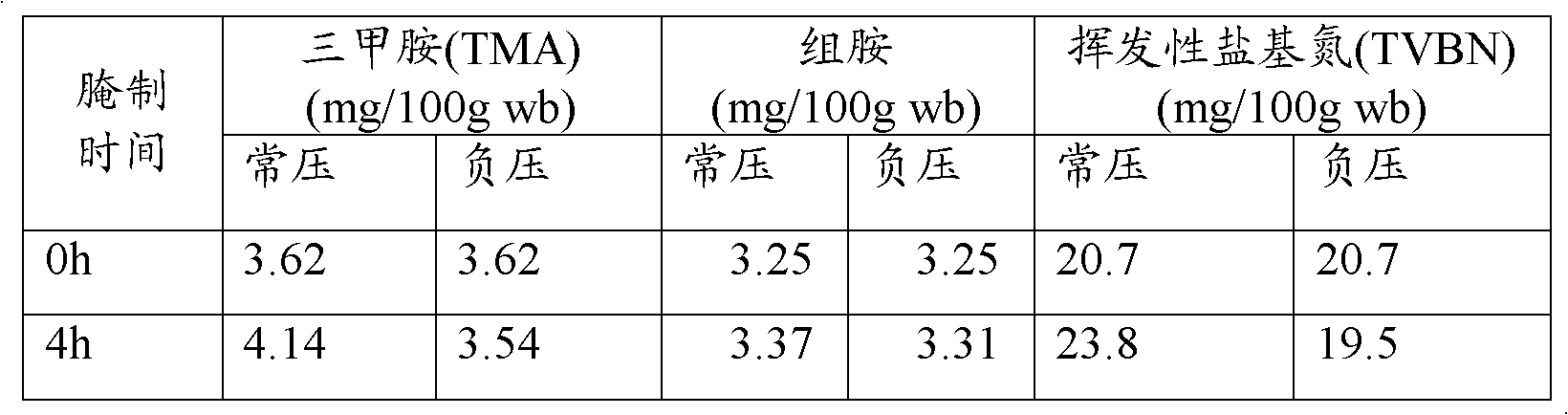

Method for curing fishes through negative pressure and ozone cold sterilization

ActiveCN102007958ALow in the food chainShort life cycleMeat/fish preservationMicroorganismPre treatment

The invention provides a method for curing fishes through negative pressure and ozone cold sterilization, in particular the method for curing red oil fishes through negative pressure cold sterilization. The method comprises the following steps of: putting preprocessed raw material fishes into a sealed container; adding salt in an amount which is 1 to 15 percent based on the mass of the fishes into the container; regulating the vacuum degree in the container to be 0.01 to 0.065MPa; rolling and kneading for 5 to 10 minutes at the rotating speed of 10 to 20 r / m; introducing ozone to ensure that the concentration of the ozone is 2.0 to 50ppm; rolling and kneading for 5 to 60 minutes at the rotating speed of 10 to 20 r / m; regulating the vacuum degree of the container to be 0.07 to 0.095MPa; and continuously curing for 4 to 24 hours to obtain the processed fish. The method has the advantages that the method has good effect of guaranteeing the quality by adopting negative pressure and ozone cold sterilization curing technology; compared with a product cured by a normal pressure curing method, the product cured by the process has lower content of volatile basic N, histamine and trimethylamine; and the method can obviously improve the organoleptic physical property and the edible safety of the product, also has the effect of effectively killing microorganisms in the raw material fishes and can improve the curing efficiency.

Owner:ZHEJIANG UNIV OF TECH

Activated carbon pickler

ActiveCN103480601AAchieving stirringPickling fullyCarbon compoundsCleaning using liquidsActivated carbonPulp and paper industry

The invention discloses an activated carbon pickler. The activated carbon pickler comprises a cylinder body, a steam heating pipe and a filter cylinder. A feeing port, an acid feeding port, a water inlet and an exhaust port are formed in the top of the cylinder body. A drainage port and a discharging port are formed in the bottom of the cylinder body. The steam heating pipe is located in the lower portion inside the cylinder body. The filter cylinder is arranged in the cylinder body and connected with the drainage port. A steam inlet of the steam heating pipe is led out via the inner space of the filter cylinder. By the adoption of the activated carbon pickler, a carbon bed layer in the cylinder body can be stirred, the damage, caused by manual stirring, to activated carbon is avoided, pickling of the activated carbon of the carbon bed layer can be thorough, and therefore the pickling efficiency and the pickling effect are improved. The activated carbon pickler has the advantages of being simple in structure, convenient to use, and low in degree of abrasion of the activated carbon. When the type of the activated carbon is changed, a user only needs to replace the filter cylinder and a filter screen.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Seamless steel pipe continuous pickling device and method

The invention relates to a seamless steel pipe continuous pickling device. An immersing tank and a spray-washing tank are arranged in a pickling tank, a first guide groove and a second guide groove which are closed are oppositely formed on the inner walls of two sides of the pickling tank, a pickling tank is arranged between the first guide groove and the second guide groove and used for putting apipe blank in for pickling, the pipe blank is added into the pickling tank which is immersed in the immersing tank, pickling liquid is arranged inside the immersing tank, the pickling tank is drivento rotate itself and move along the first guide groove and the second guide groove through a driving component connected on one side of the pickling tank, and the pickling tank is driven by the driving component to enter the spray-washing tank; a water extraction component is arranged on one side of the immersing tank, a water outgoing end of the water extraction component is connected with a liquid outgoing pipe, one end of the liquid outgoing pipe is arranged above the spray-washing tan, an atomizing nozzle is connected on the liquid outgoing pipe, and the pickling liquid is sprayed onto thepipe blank through the atomizing nozzle to flush and continuously pickle the pipe blank. The seamless steel pipe continuous pickling device is good in pickling effect and high in efficiency.

Owner:ZHEJIANG JINHANG STEEL PIPE TECH

Pickling device for processing of preserved meat

InactiveCN108771145ALoose fiberImprove pickling efficiencyBeating-based meat tenderisingFiberDrive motor

The invention discloses a pickling device for processing of preserved meat. The pickling device comprises a shell. The top of an inner cavity of the shell is provided with a driving box, and the rightside wall of the shell is connected with a driving motor. The front side wall of the driving box is connected with four groups of evenly distributed cams, below which a dead plate is arranged. A motion bar is inserted at the top of the dead plate. A pressure plate is connected at the bottom of the motion bar, the upper end of which is sleeved with a spring. A feed board is hinged to the left sidewall of the shell. Driving rollers are bilaterally symmetrically arranged in the inner cavity of the shell. An infusion tube is plugged in the left side wall of the shell. A stirring motor is connected at the central of the bottom of the shell. The structure of the pickling device is reasonable in design. With the cams pressing the motion bar intermittently, the pressure plate beats the preservedmeat to loosen fibers of the preserved meat, thus facilitating infiltration of seasoning during subsequent pickling. Through the stirring motor for driving a mixer shaft to rotate, a mixing rod stirsa seasoning solution and the preserved meat uniformly, thus facilitating rapid pickling of the preserved meat and greatly improving pickling efficiency of the preserved meat.

Owner:ANHUI HAOZAILAI FOOD

Pickling agent for stainless steel

The invention relates to a pickling agent for stainless steel. According to percentage by weight, the pickling agent consists of the following components: 23 to 30 percent of sulfuric acid; 4 to 6 percent of nitric acid; 7 to 14 percent of hydrochloric acid; 0.1 to 0.3 percent of corrosion inhibitor; 0.13 to 0.25 percent of additive; and the balance of water. The mass concentrations of the used acids are as follows: 95.0 to 98.0 percent of sulfuric acid; 65.0 to 68.0 percent of nitric acid; and 36.0 to 38.0 percent of hydrochloric acid. The components are uniformly mixed according to proportion. The corrosion inhibitor is hexamethylene tetramine, the additive is the mixture of sodium dodecyl sulfate and isooctyl phenol polyoxyethylene, the percentage by weight of the sodium dodecyl sulfate is 0.08 to 0.15 percent, the percentage by weight of the isooctyl phenol polyoxyethylene is 0.05 to 0.1 percent, and the effect is better when the temperature of each acid is 60 DEG C to 80 DEG C. The pickling efficiency of the pickling agent for stainless steel is increased by four to five times, the pickled surface is bright and clean, and the pickling agent for stainless steel is particularly suitable for pickling the surfaces of stainless steel with high Cr, Ni and Mo alloy contents to remove ferric oxide scales.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

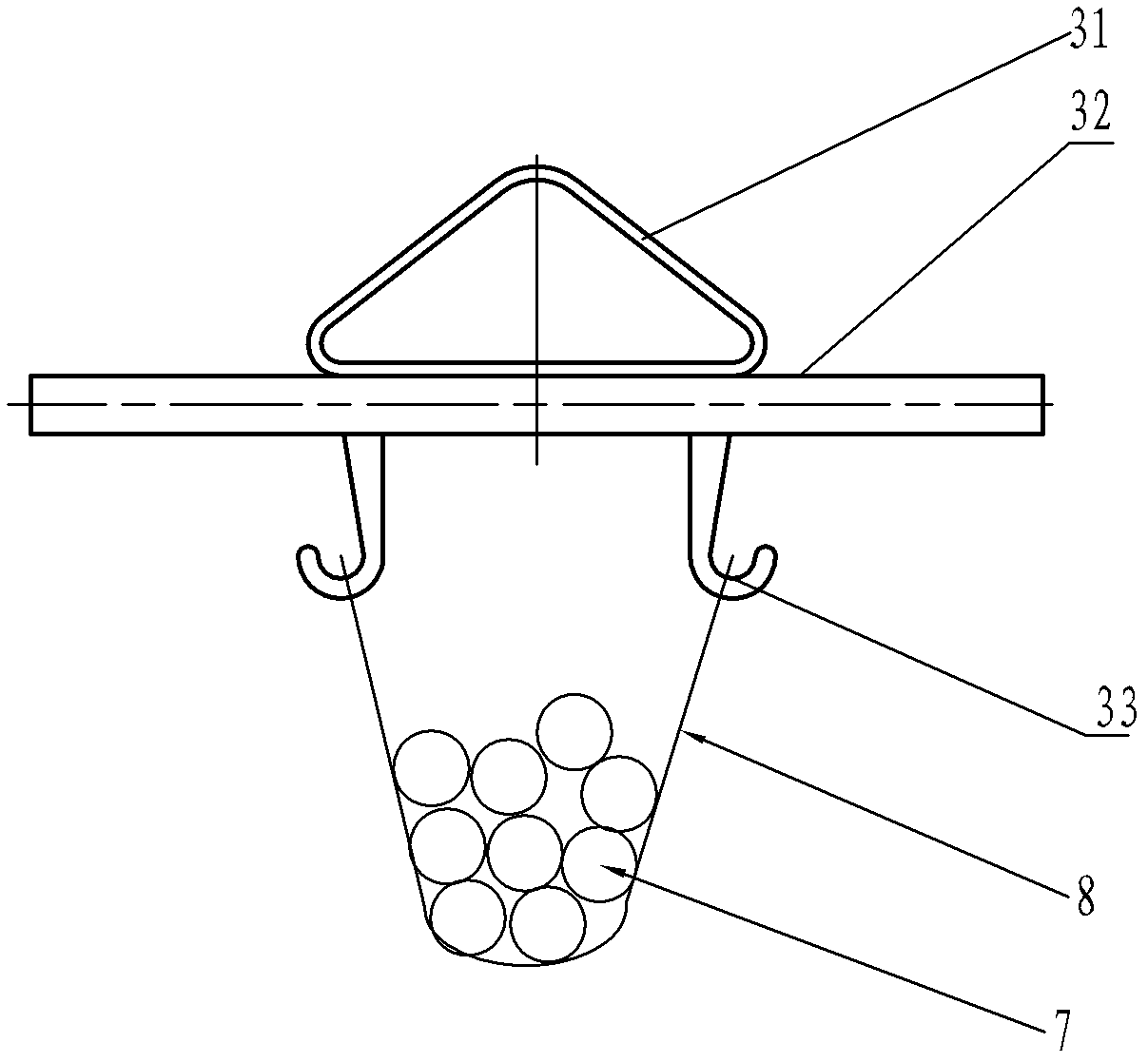

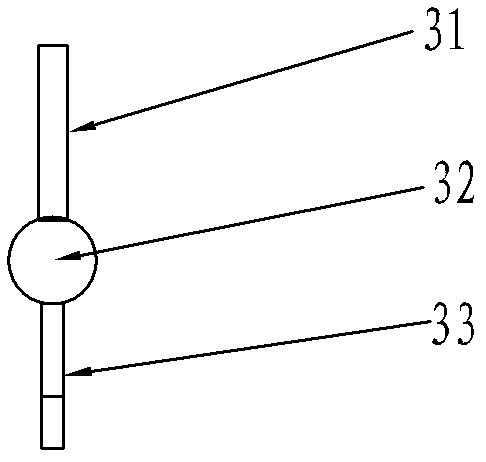

Overhead traveling crane lifting appliance for steel tube pickling

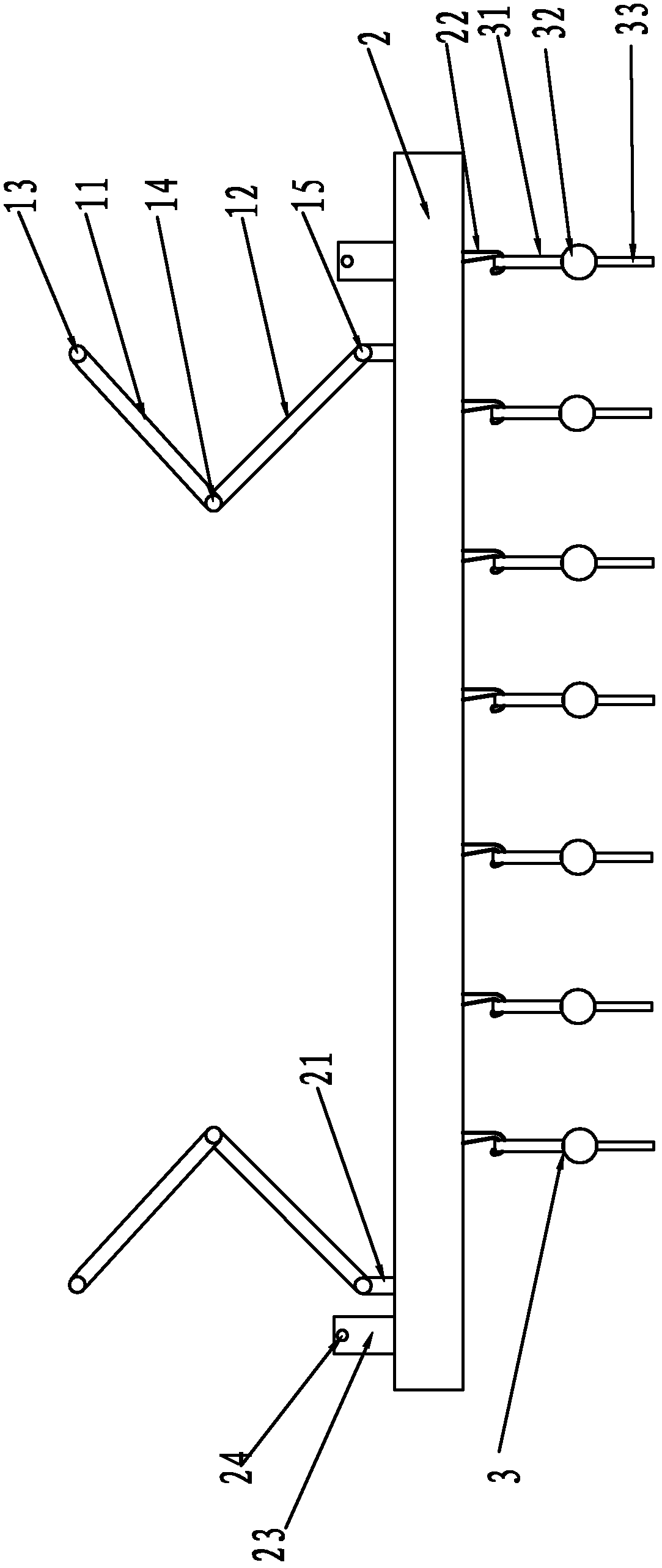

InactiveCN102358560AIncrease profitImprove pickling efficiencyLoad-engaging elementsSputteringEngineering

The invention discloses an overhead traveling crane lifting appliance for steel tube pickling. The overhead traveling crane lifting appliance comprises a balance device, a cross beam and a plurality of lifting hooks, wherein the balance device comprises two first balance plates and two second balance plates; a first rotating shaft is arranged at the upper end of each first balance plate; the lower end of each first balance plate is hinged with the upper end of the second balance plate through a second rotating shaft; angles are formed between the first balance plates and the second balance plates; the lower end of each second balance plate is hinged with the top of the cross beam through a third rotating shaft; a plurality of hooks are arranged at the bottom of the cross beam; and each hook hangs one lifting hook. The overhead traveling crane lifting appliance has a simple structure; by the overhead traveling crane lifting appliance, swinging of a steel tube and sputtering of acid liquor are avoided, and waste of the acid liquor and pollution to the environment are reduced; and furthermore, automatic unhooking and automatic hooking of the steel tube when the steel tube is fed intoa slot and discharged from the slot can be realized, so the utilization rate of an overhead traveling crane is increased and the steel tube pickling efficiency is improved. When the inclination degree of the cross beam is adjusted through a steel wire rope, the steel tube can be kept steady and made to be inclined.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

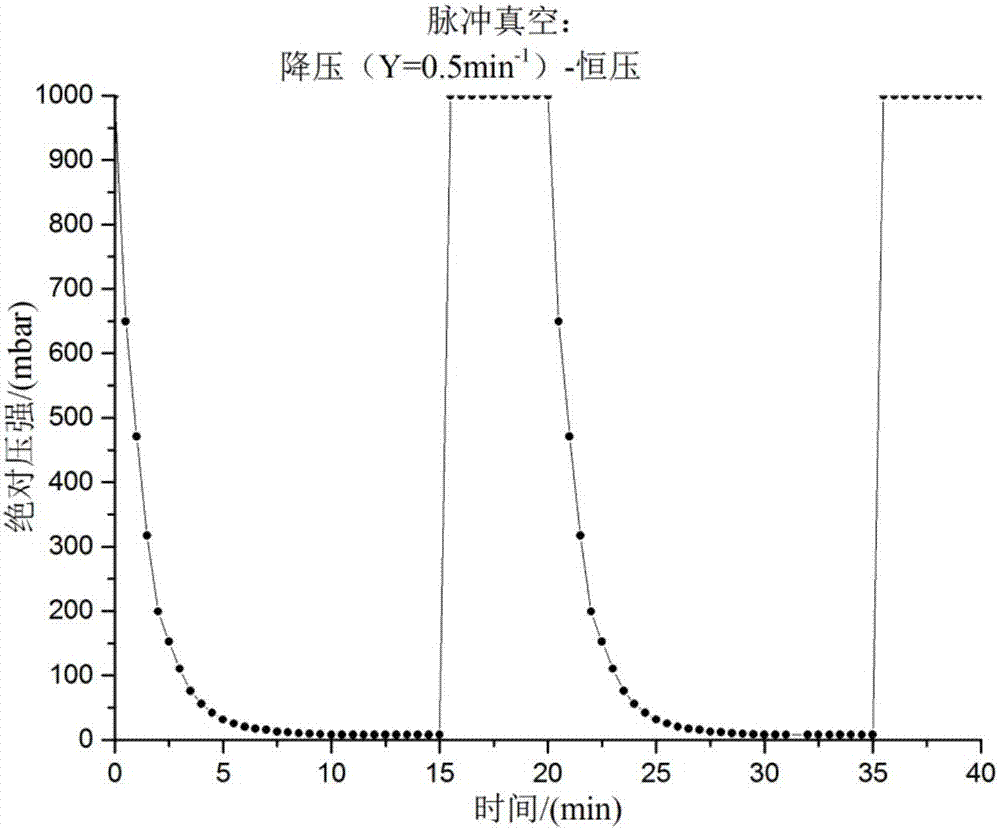

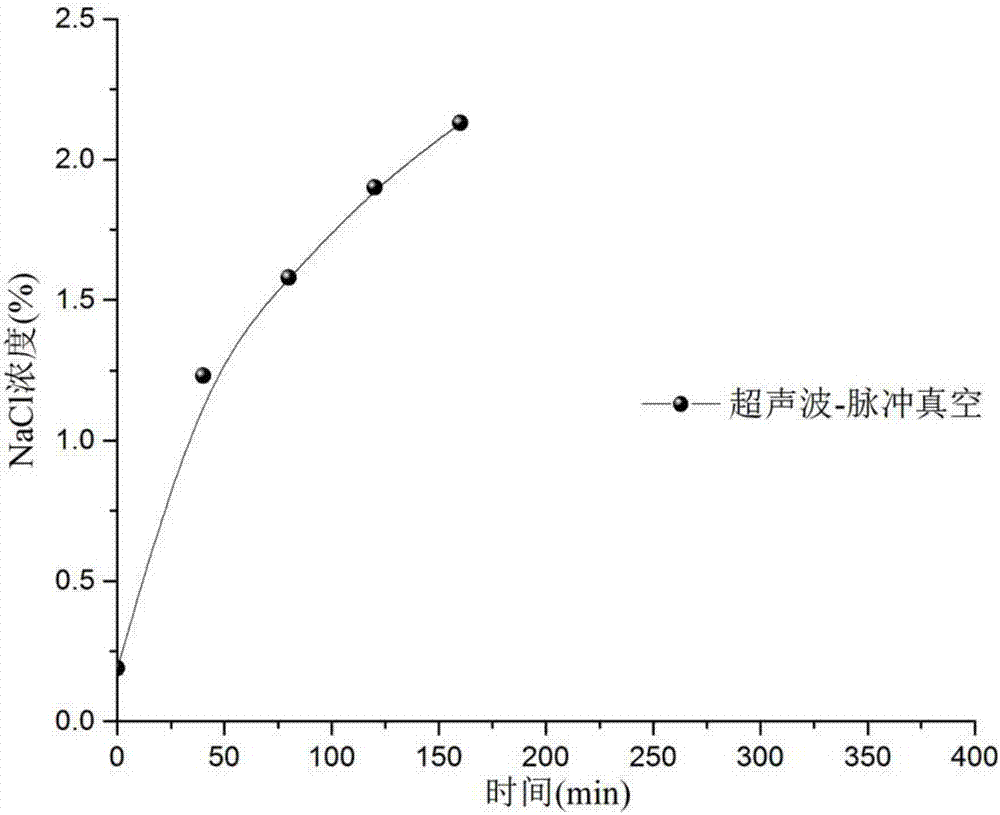

Ultrasonic wave-pulse vacuum synergistic fish meat salting method

ActiveCN106962826APrevent spoilageImprove mass transfer coefficientClimate change adaptationFood ultrasonic treatmentFisherySaline solutions

The invention relates to an ultrasonic wave-pulse vacuum synergistic fish meat salting method. The ultrasonic wave-pulse vacuum synergistic fish meat salting method includes the steps of S1, slaughtering live fish to remove scales and viscera, and cutting the slaughtered fish into fish blocks with a uniform thickness prior to cold storage; S2, putting the fish blocks subjected to cold storage into a low-temperature saline solution to make the temperatures of the fish blocks and the saline solution within 4+ / -1 DEG C, and subjecting the fish blocks and the saline solution to synchronous ultrasonic treatment and pulse vacuum treatment until salting is completed. Compared with the prior art, the ultrasonic wave-pulse vacuum synergistic fish meat salting method has the advantages that the ultrasonic wave-pulse vacuum synergistic fish meat salting method is higher in mass transfer coefficient and salting efficiency through ultrasonic wave-pulse vacuum synergistic assistance in salting.

Owner:SHAOGUAN COLLEGE

Energy-saving and high-efficiency device for pickling food

ActiveCN108685137AReduced tasteHit thoroughlyTransportation and packagingRotary stirring mixersSalt waterEngineering

The invention discloses an energy-saving and high-efficiency device for pickling food. The energy-saving and high-efficiency device comprises a pickling tank and a flavoring tank, wherein a main shaftis arranged in the pickling tank; a plurality of mixing paddles are mounted on the main shaft; a plurality of high-pressure through holes are formed in the mixing paddles; the flavoring tank is arranged between end plates below the pickling tank; a flipping shaft is arranged in the flavoring tank; one end of the flipping shaft extends to the outside of the flavoring tank and is fixedly connectedwith the output end of a second driving motor; and a plurality of flapping heads are mounted on the flipping shaft. The energy-saving and high-efficiency device has compact structure and convenient use; salt water with a regulated concentration enters the hollow main shaft under the effect of a booster pump, and then is ejected through the high-pressure through holes in the mixing paddles, so thesalt water can be well sprayed onto food while the mixing paddles overturn and stir the food, and the salt water is in more sufficient contact with the food; and the pickled food enters the flavoringtank, the flapping heads are driven by the flipping shaft to perform repeated beating on the food, so the preliminarily pickled food is more flavored.

Owner:佛山市新雨润食品有限公司

Large-specification free-cutting steel rolling method

ActiveCN105234170AImprove machinabilityExcellent rod surfaceTemperature control deviceMetal rolling arrangementsWire rodHigh pressure water

The invention discloses a large-specification free-cutting steel rolling method. The diameter of a steel wire rod of large-specification free-cutting steel is larger than or equal to 16 mm; the preheating segment temperature of a heating furnace ranges from 930 DEG C to 1000 DEG C; the temperature of a heating section ranges from 1010 DEG C to 1070 DEG C; the temperature of a soaking section ranges from 1110 DEG C to 1200 DEG C; the rolling temperature ranges from 1070 DEG C to 1130 DEG C; the high pressure water descaling water pressure is larger than or equal to 10 MPa; the shearing length of a second flying shear ranges from 250 mm to 350 mm, and the shearing length of a third flying shear ranges from 600 mm to 700 mm; the inlet temperature of a finishing mill ranges from 930 DEG C to 1000 DEG C; the reel collecting temperature ranges from 830 DEG C to 900 DEG C; and six draught fans on a stack cooling line are all started, the air amount is 100%, and the reel cooling speed ranges from 0.4 K / s to 3 K / s. The surface of the steel wire rod prepared with the method is excellent, defects of lug shapes, folding, scabbing and the like are avoided, and internal defects like shrinkage cavities in the centers of the cross sections of the steel wire rod are avoided.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for enhancing acid pickling efficiency of stainless steel tubes

The invention discloses a method for enhancing the acid pickling efficiency of stainless steel tubes. The method comprises the following steps of (1) acid pickling tank equipment modification, wherein the bottom of each acid pickling tank is arranged to be in an arc shape, and movable supporting devices are adopted on the two sides of an acid tank; and (2) an acid pickling process, wherein the procedures of carrying out feeding and acidification in sequence and carrying out acid discharge and uncovering in sequence are adopted, the acid mist discharge amount is greatly reduced, movement of the two ends of a crown block track is controlled in the acid pickling process, the two ends alternately move up and down, the process is repeated, acid liquor is disturbed by the steel tubes to form a turbulent flow state, the flow of an acid liquor circulation system is increased, the turbulent flow effect is enhanced, sludge accumulation in the acid tank is reduced, the acid liquor is cyclically heated through a heat exchanger, the temperature is automatically controlled, and the acid pickling efficiency is improved. According to the method, the acid pickling effect of the steel tubes is enhanced; the acid pickling efficiency is improved; and by means of an empty tank feeding and automatic acid discharge system, the acid mist discharge amount is greatly reduced, and environment benefits are enhanced.

Owner:TAIYUAN IRON & STEEL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com