Patents

Literature

99results about How to "Fast rust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid-wash additive for iron and steel

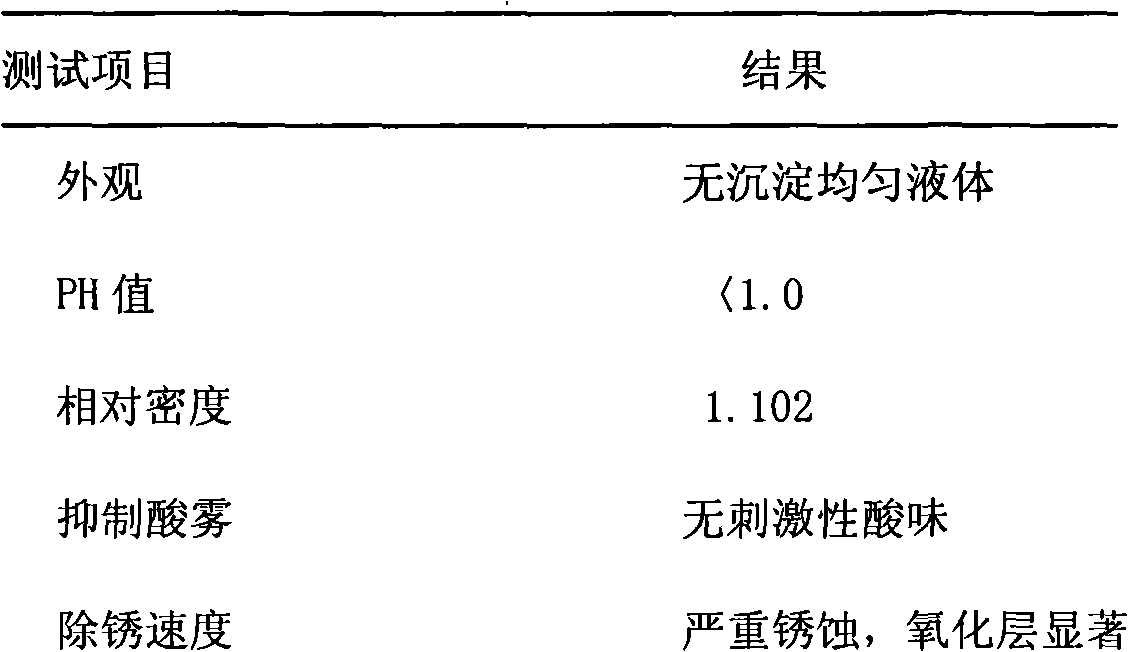

The invention discloses an acid-wash additive for iron and steel. Every 4000g of the acid-wash additive is prepared from 200-250g of accelerator-oxalic acid or citric acid, 900-1000g of phosphoric acid, 200-250g of anionic surfactant-sodium lauryl sulfate, 150-200g of corrosion inhibitor-urotropine, 150-200g of mist inhibitor-nonylphenol polyethenoxy ether and the balance of water. The acid-wash additive is prepared by the following steps: evenly mixing phosphoric acid, anionic surfactant and water, adding the rest of components, and dissolving by stirring. The FSD-7001 acid-wash additive can further increase the derusting speed of hydrochloric acid, prevent iron and steel workpieces from generating over etching, reduce the acid consumption, inhibit acid mist, and enable the acid liquor to have certain oil removal function.

Owner:CHONGQING NORMAL UNIVERSITY

Environmental-protection type multifunctional efficient acid washing mist inhibition corrosion inhibitor

The invention belongs to the technical field of metal surface cleaning treatment, and more particularly relates to an environmental-protection type multifunctional efficient acid washing acid inhibition corrosion inhibitor, which is formed by mainly compounding 2-6 parts of a surfactant, 8-15 parts of a corrosion inhibitor, 0.5-1 part of a penetrating agent, 2-4 parts of an acid washing accelerating agent, 74-87.5 parts of water, and other components, wherein the product achieves the optimal mist inhibition corrosion inhibition effect in the acid washing through the synergy effect of various components. The corrosion inhibitor of the present invention has the following beneficial effects that: (1) the rust removing is fast, the rust removing speed is significantly increased with the additions of the penetrating agent and the accelerating agent, and the rust can be completely removed within 5-30 min when the addition amount is 2%; (2) the mist inhibition property is good, and the good mist inhibition effects are provided for hydrofluoric acid, nitric acid, and the like; and (3) the corrosion inhibition is good .

Owner:浏阳市三鹰新材料有限责任公司

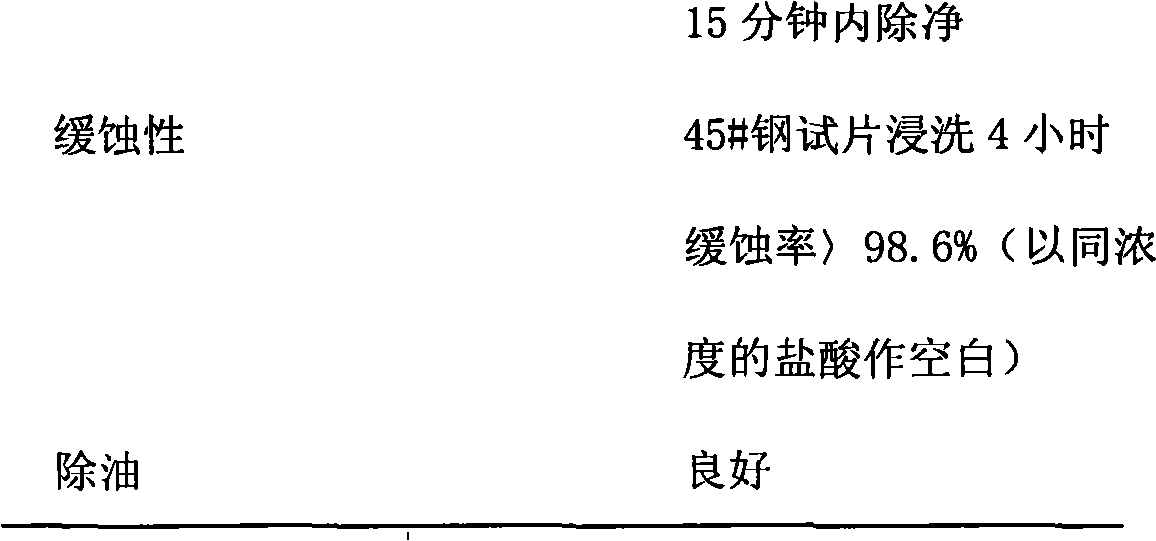

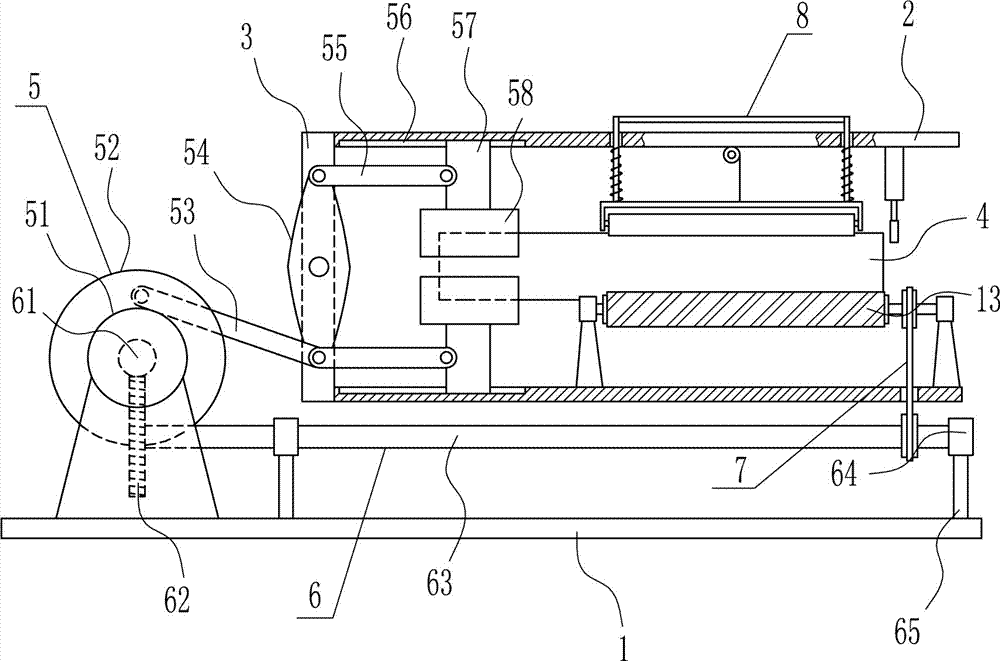

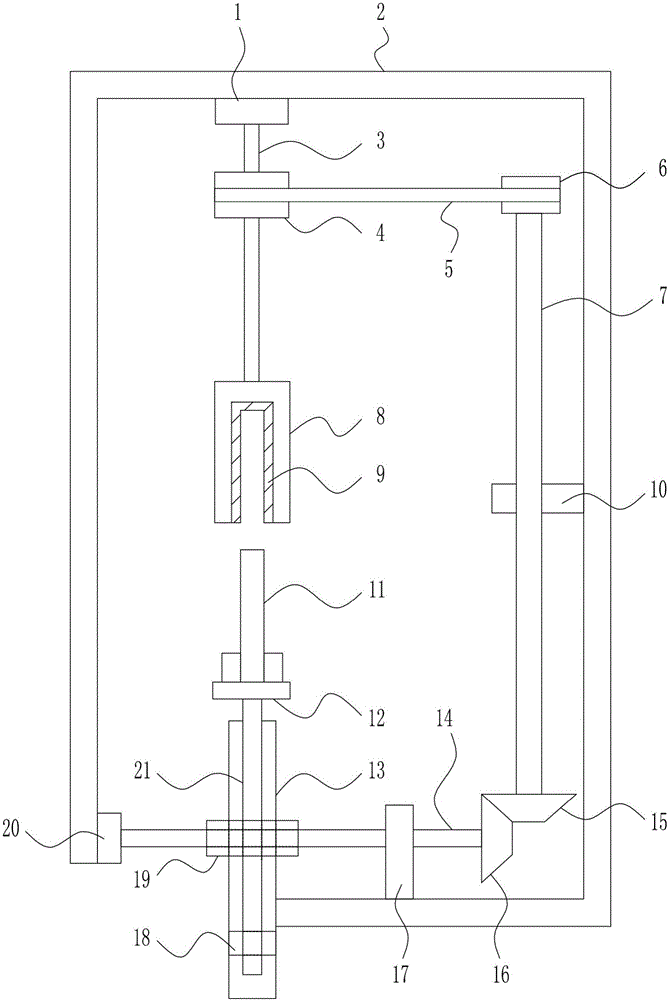

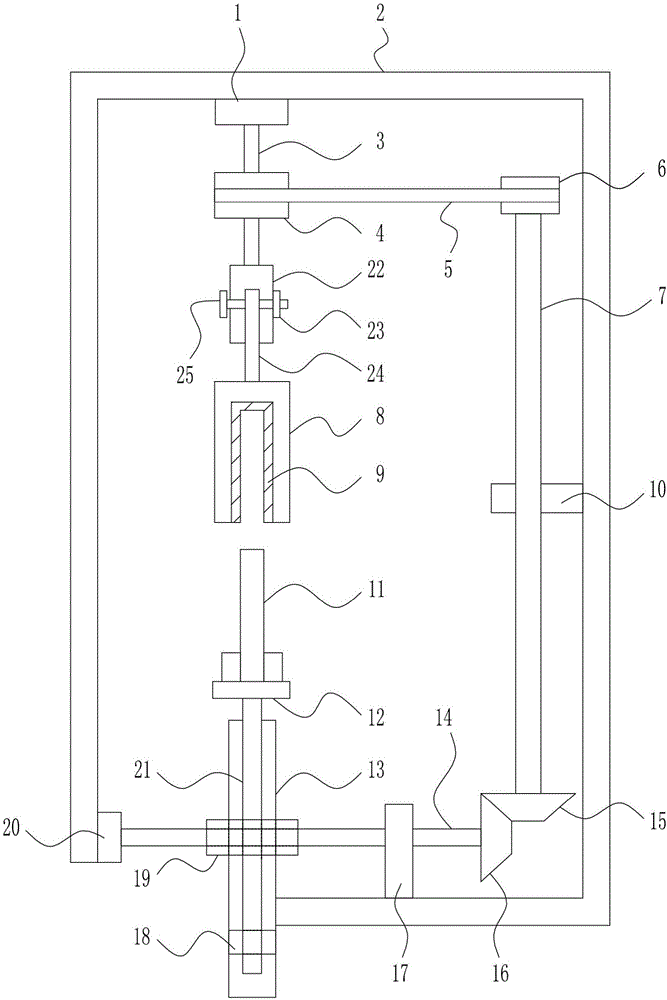

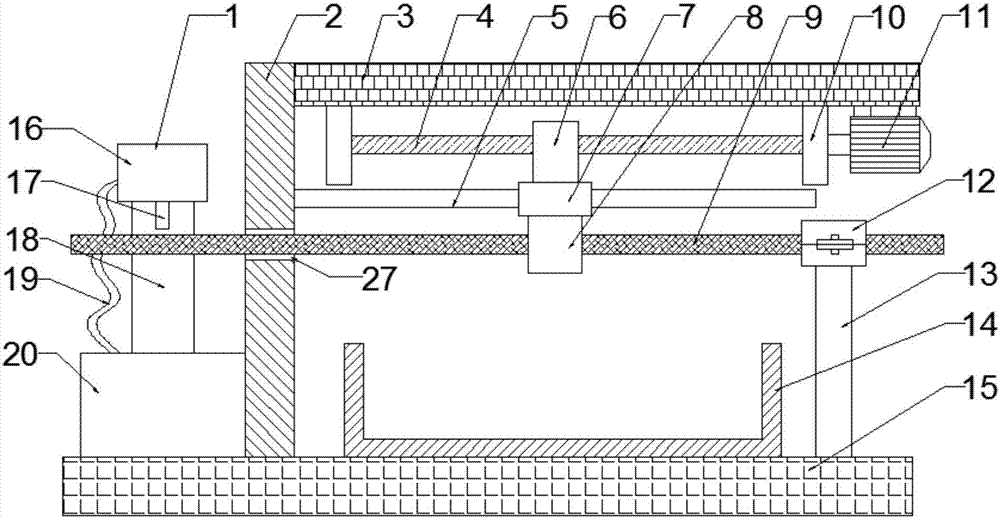

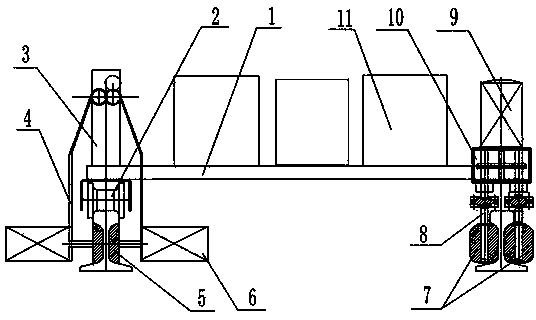

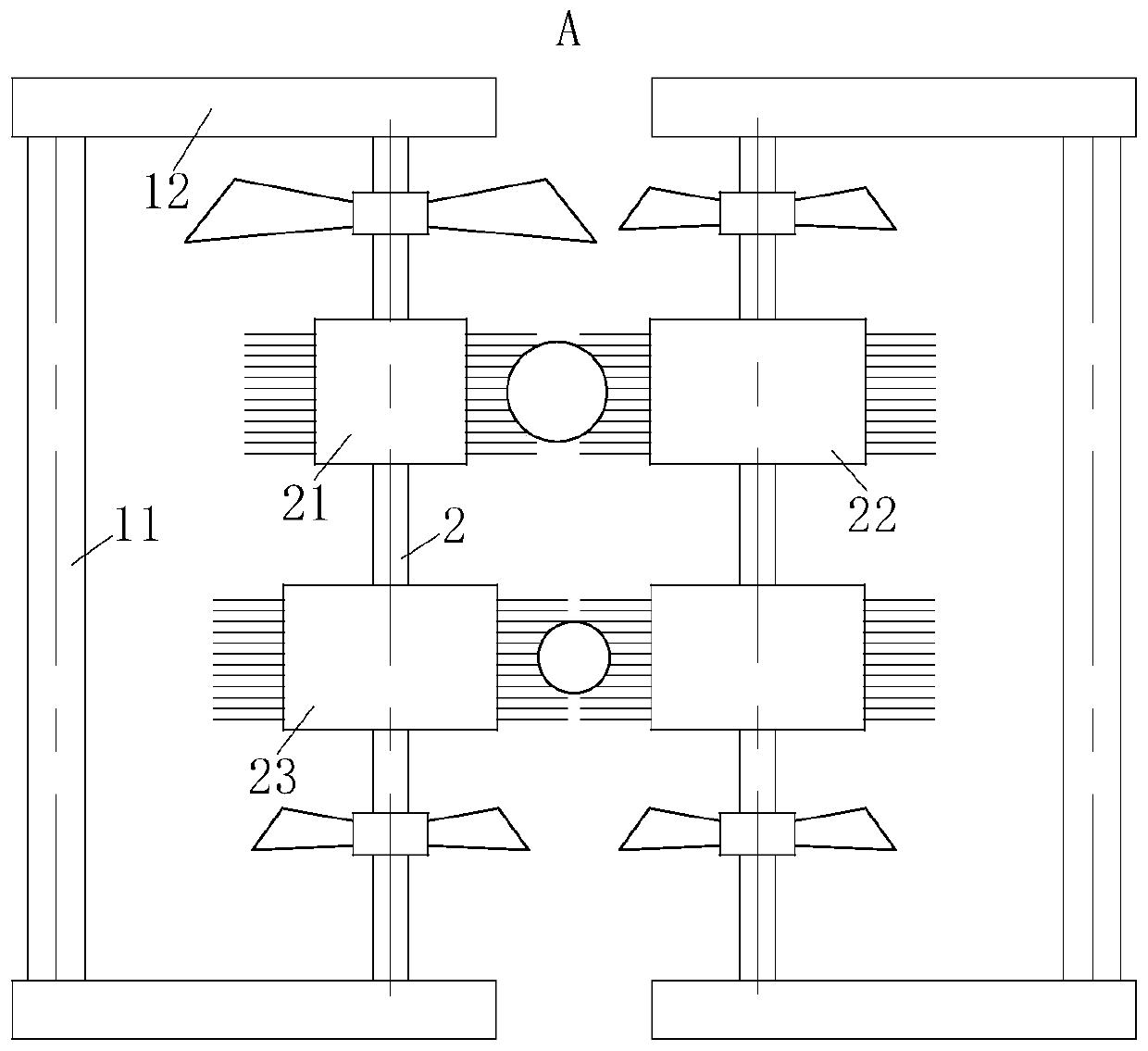

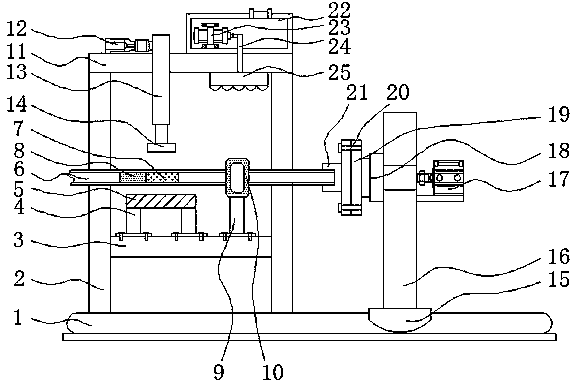

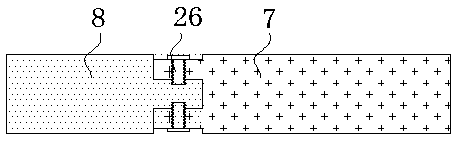

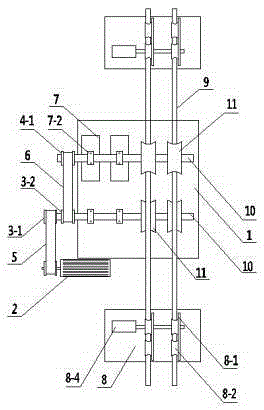

Quick rust removal device for iron rod

InactiveCN106112771AHigh degree of automationEasy to operateGrinding carriagesGrinding drivesEngineeringReagent

The invention relates to a quick rust removal device for an iron rod, in particular to a quick rust removal device for an iron rod, and aims to provide a quick rust removal device for the iron rod, which can completely remove rust and is high in rust removal speed and high in automation degree to solve the technical problem. To solve the technical problem, the quick rust removal device for the iron rod comprises a base plate, a first motor, a guide sleeve, a first supporting rod, a first rotating shaft, a gear, a rack, a reagent box, a stay wire, a right frame, a placement plate, a cleaning box, a fixed pulley, a first sliding rail, a first sliding block, an iron sand sleeve, a spring, a second supporting rod, a top plate, fixing rods, a second motor, a bearing pedestal, a second rotating shaft, an annular sliding rail, a second sliding block, a cylinder, a fixing device and a connection rod, wherein the first motor, the guide sleeve, the first supporting rod and the right frame are arranged at the top of the base plate from left to right; and the first rotating shaft is arranged at the top of the first motor. The quick rust removal device for the iron rod achieves the effects of clearing away the rust, being high in rust removal speed and high in automation degree.

Owner:周栋

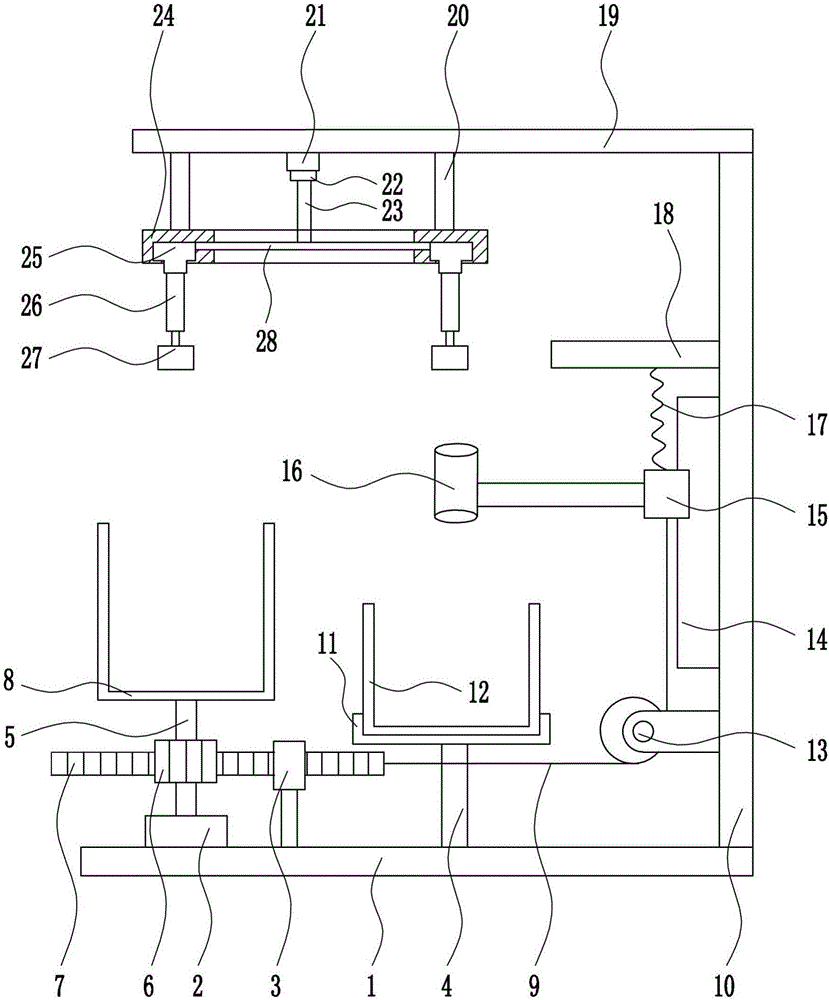

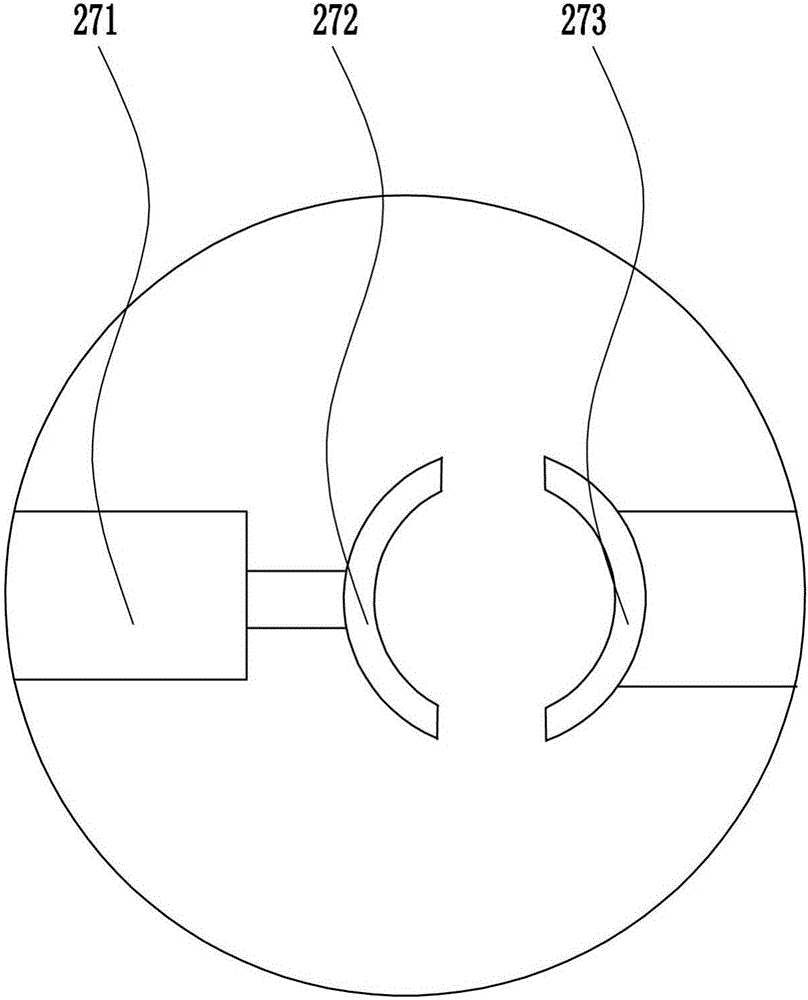

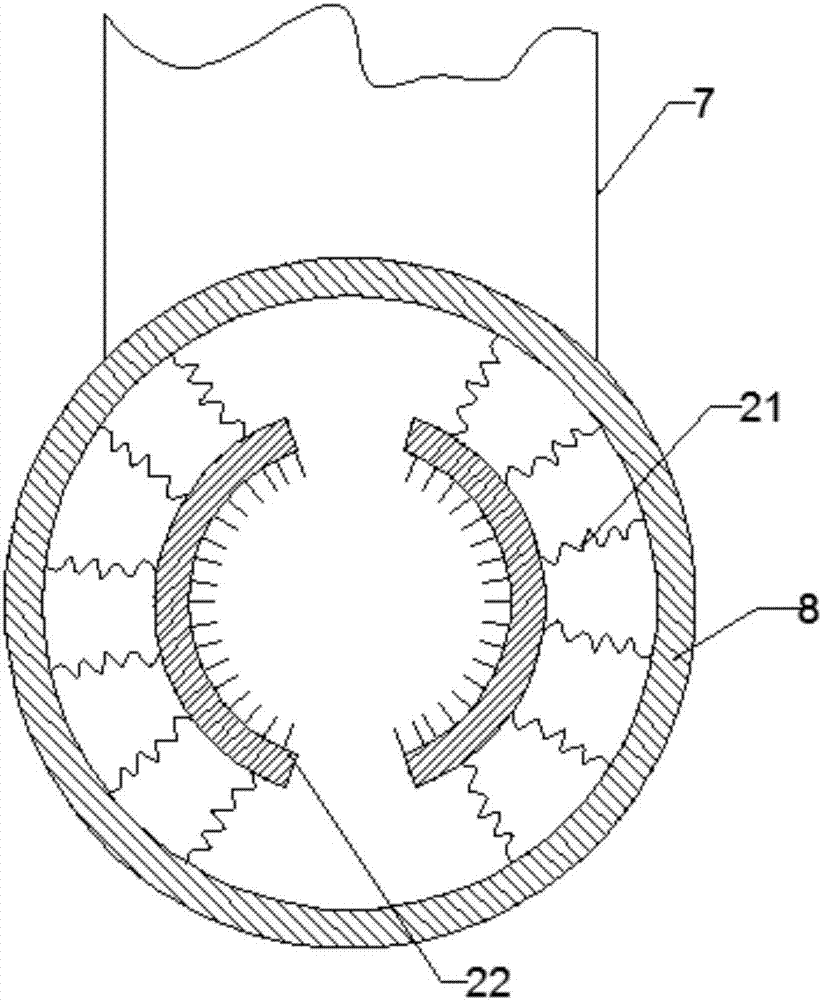

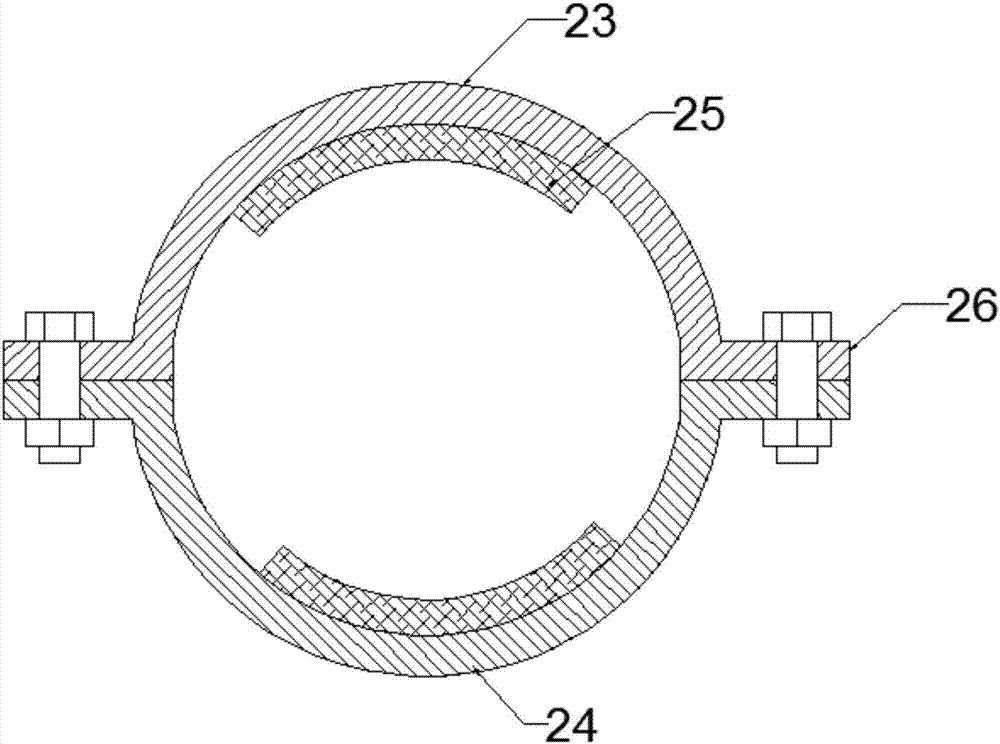

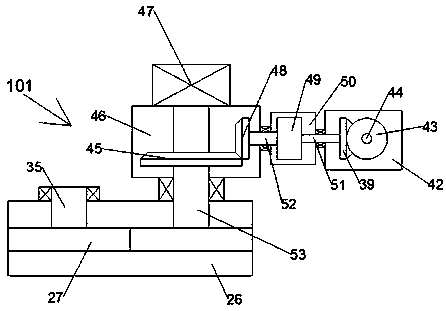

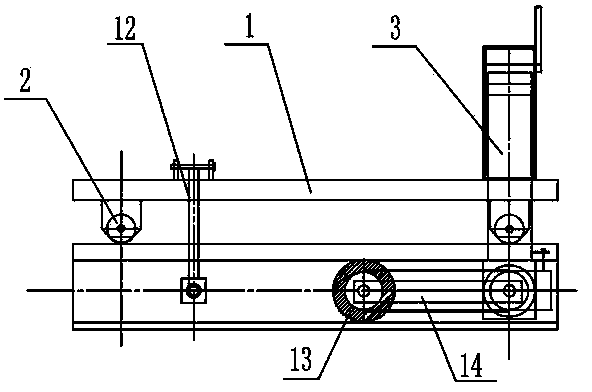

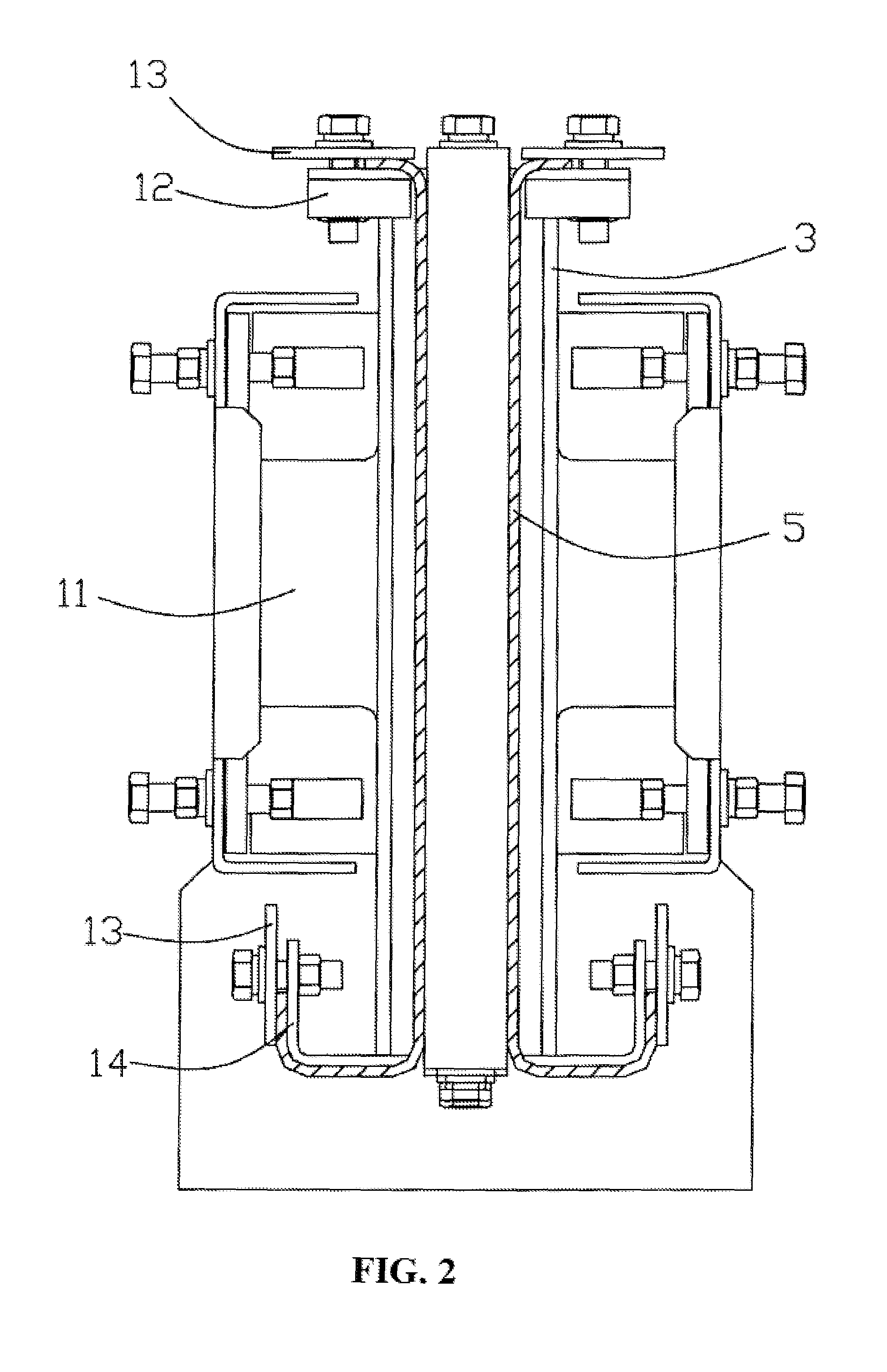

Diameter-variable steel wire rope derusting device

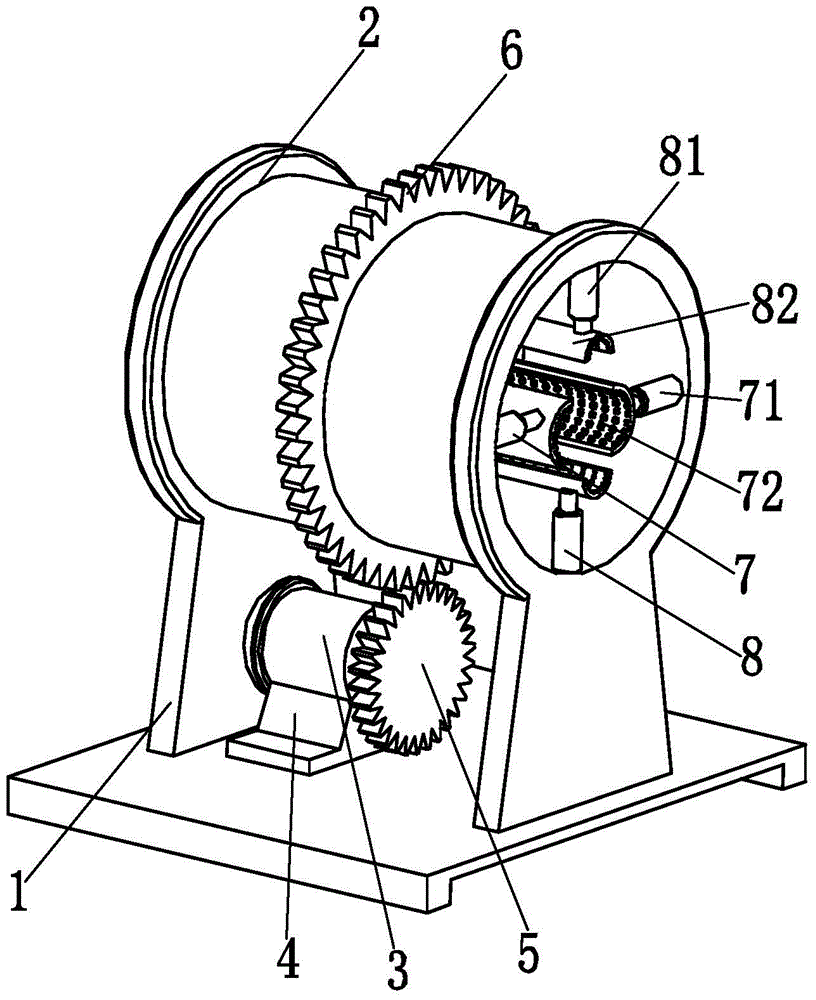

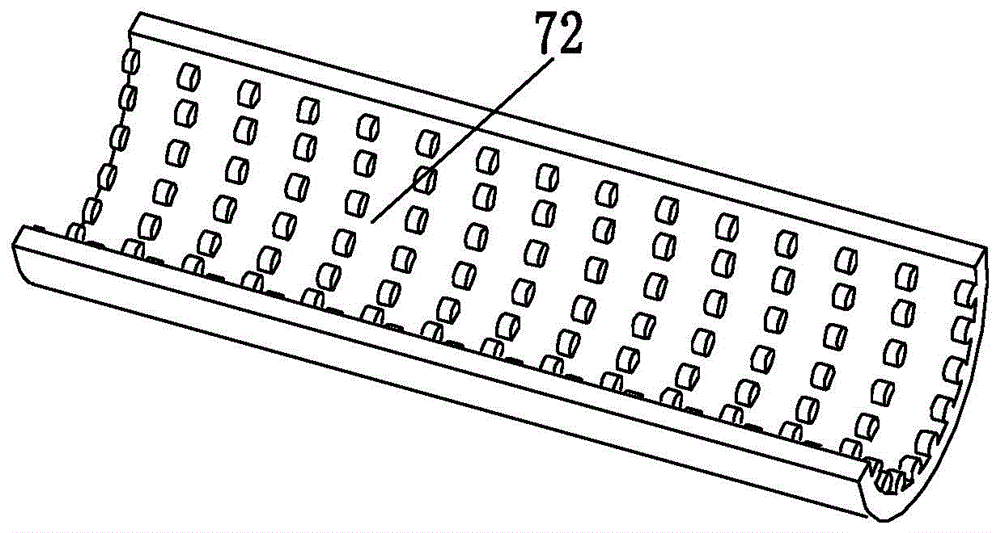

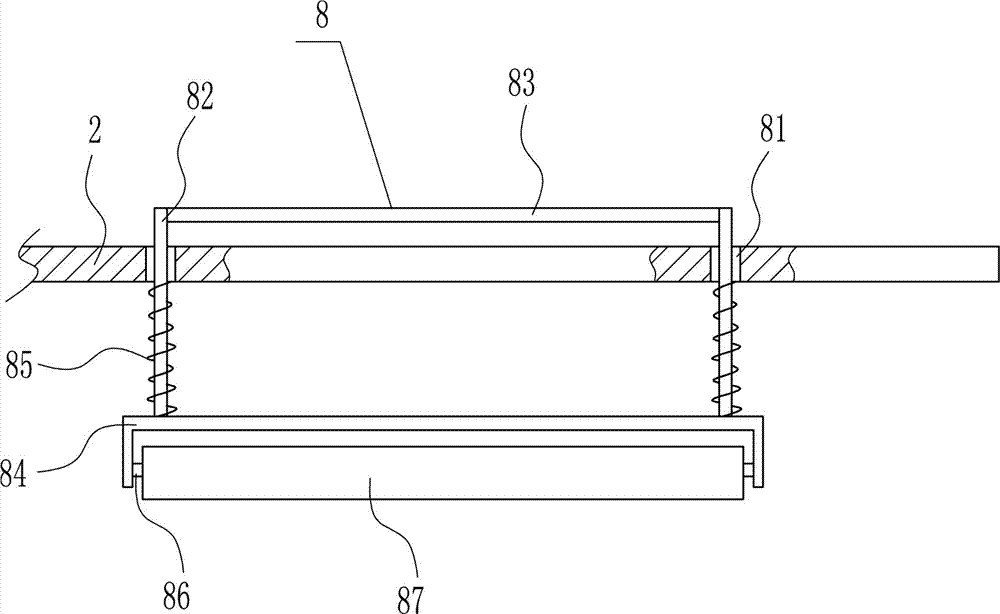

ActiveCN104907913ACompact structureEasy to operateGrinding machinesArchitectural engineeringAutomation

The invention relates to a diameter-variable steel wire rope derusting device which comprises two derusting supports, a derusting roller, a motor, a motor base, a driving gear, a driven gear, two large-diameter derusting mechanisms and two small-diameter derusting mechanisms. Rings are positioned at the upper ends of the derusting supports, the two ends of the derusting roller are installed in the rings at the upper ends of the two derusting supports respectively through bearings, the motor is located under the derusting roller, the driving gear is connected with a motor spindle through a key, the middle of the driven gear is provided with an installing sleeve ring, and the installing sleeve ring at the middle of the driven gear is fixed at the middle of the derusting roller. The driven gear is meshed with the driving gear; and the two large-diameter derusting mechanisms and the two small-diameter derusting mechanisms are located in the derusting roller. The diameter-variable steel wire rope derusting device can perform surface derusting treatment on steel wire ropes of different diameters, is quick in derusting speed, wide in applied range and high in mechanical automation degree and saves plenty of manpower.

Owner:江苏锐金钢丝绳索具有限公司

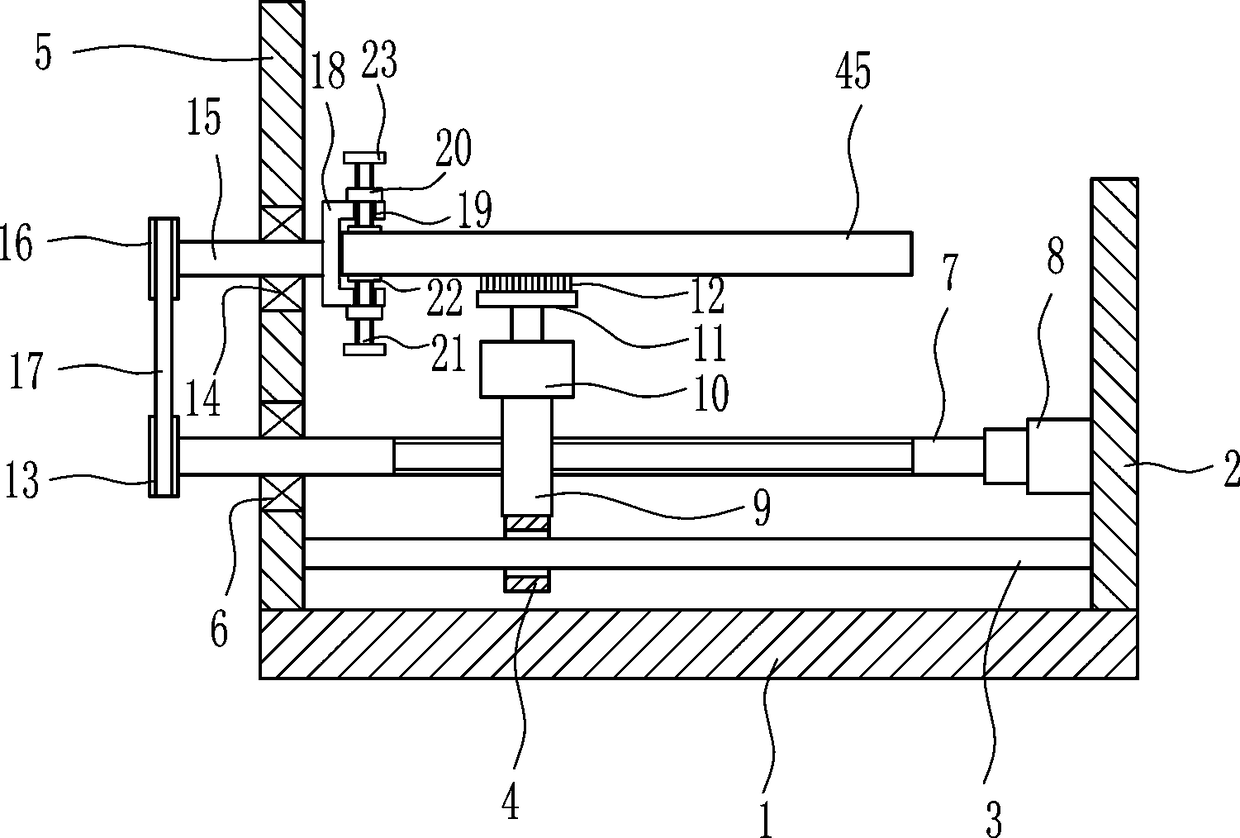

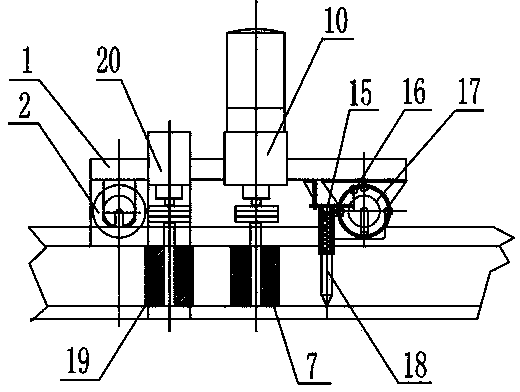

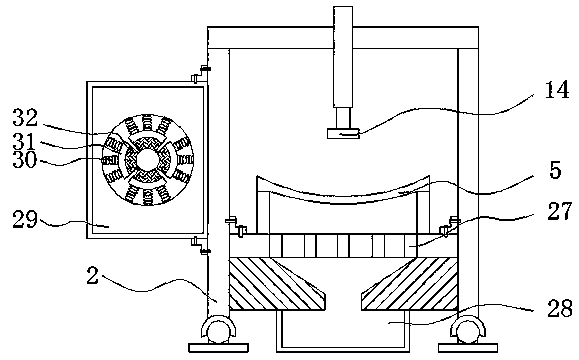

Iron pipe end dedusting and grinding device for mechanical machining

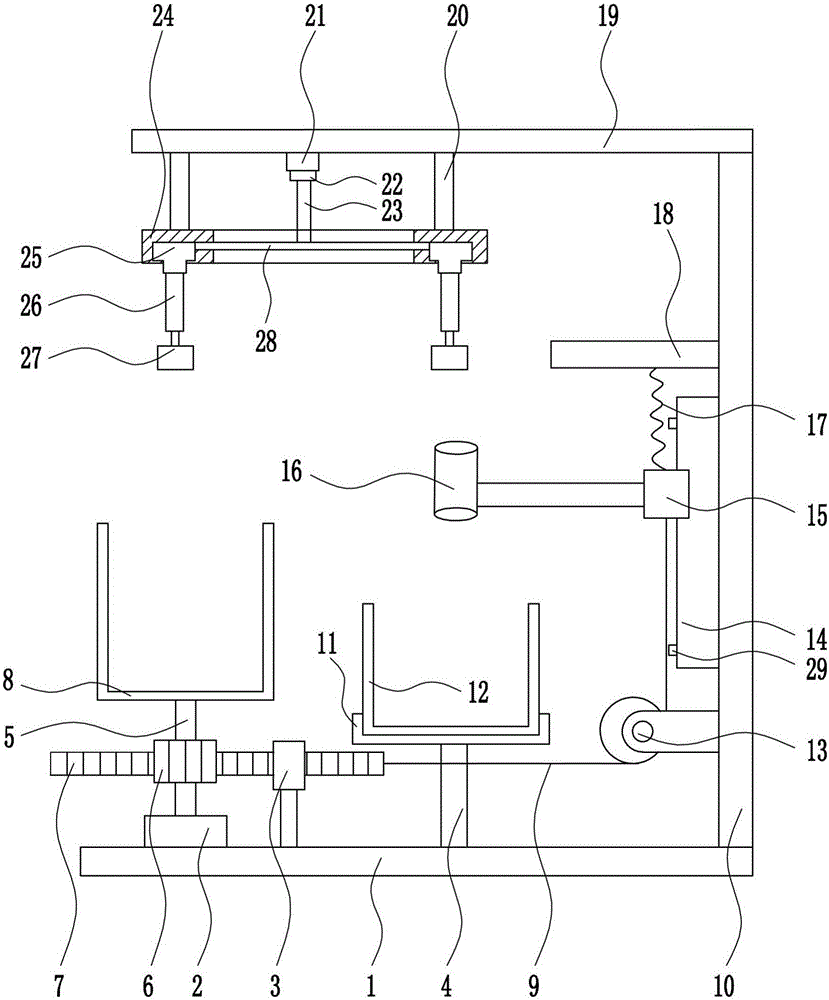

InactiveCN107984323AComprehensive rust removalSmooth rotationEdge grinding machinesGrinding carriagesMachining

The invention relates to a dedusting and grinding device, in particular to an iron pipe end dedusting and grinding device for mechanical machining. By means of the iron pipe end dedusting and grindingdevice for mechanical machining, time and labor are saved, the dedusting speed is high, and an iron pipe can be fixed and is not liable to roll in the dedusting process so that the dedusting effect cannot be affected. In order to achieve the technical purpose, the iron pipe end dedusting and grinding device for mechanical machining comprises a bottom board and the like, a transmission device is arranged on the top of the bottom board, two transverse boards are arranged above the transmission device, the transverse boards on the upper side and the lower side are arranged symmetrically, a rotating device is arranged on the right side of the top of the lower transverse board, and a drive component of the rotating device is connected with the transmission device. The iron pipe can be pressedby a pressing device so as not to fall off while rotating, and the effects that the time and labor are saved, the dedusting speed is high, and the iron pipe can be fixed and is not liable to roll in the dedusting process so that the dedusting effect cannot be affected are achieved.

Owner:鹿见安全科技(徐州)有限公司

Water-based metal cleaner

The invention provides a water-based metal cleaner, relating to a technology of pretreatment of processes of metal coating, electroplating, hot dipping coating and the like, in particular to a technology of cleaning the pretreatment surface of carbon steel. The water-based metal cleaner provided by the method comprises the following components of: 190 to 220 g / L of industrial hydrochloric acid, 1.7 to 8.5 g / L of phosphoric acid, 1 to 5 g / L of oxalic acid or 1 to 5 g / L of tartaric acid, 1 to 2.2 g / L of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES or 1.5 to 2 g / L of sodium dodecyl sulfate, 0.6 to 1.6 g / L of peregal 0-15, and 2 to 2.3 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The cleaner can fast, effectively and synchronously complete two processes of deoiling and derusting on the metal pretreatment surface, can effectively prevent acid mist from volatilizing, prolongs the service life of equipment and improves the working environment of labor workers.

Owner:BEIJING JJRS TECH DEV +1

Rust removal cleaning device special for screw rod

InactiveCN108273785ARealize the function of rust removalRealize the function of water spray cleaningCleaning using toolsCleaning using liquidsEngineeringWater spray

The invention relates to a special cleaning device, in particular to a rust removal cleaning device special for a screw rod. The rust removal cleaning device special for the screw rod aims at achieving the technical effects of being convenient to use and easy to operate. The rust removal cleaning device special for the screw rod comprises a base, a first support, a first sliding rod, a first sliding sleeve, a second support, a first bearing, a first screw rod, a first motor, a first nut and the like. The first support is fixedly connected with the right side of the top of the base, the first sliding rod is fixedly connected with the bottom of the left side of the first support, the first sliding sleeve is in sliding connection with the first sliding rod, and the second support is fixedly connected with the left side of the top of the base. The rust removal function is achieved for the screw rod, the function of rapidly removing rust on the screw rod is achieved, the function of cleaning the screw rod in a water spraying mode is also achieved, and the rust removal cleaning device special for the screw rod has the advantages of being convenient to use, safe to use, easy to operate, low in manufacturing cost and the like.

Owner:晋江盾研机械设计有限公司

Formula and production process for safe and quick derusting cleaning liquid

The invention provides a formula and a production process method for a derusting cleaning liquid used for surface treatment of metal. The formula comprises a first formula and a second formula, wherein the first formula comprises the following components in percentage by weight: 17 to 22 percent of 35-percent hydrochloric acid, 2 to 4 percent of 36-percent acetic acid, 1.5 to 3 percent of glyoxal,0.5 to 1 percent of sodium chloride, 10 to 20 percent of water; and the second formula comprises the following components in percentage by weight: 17 to 22 percent of 35-percent hydrochloric acid, 13to 18 percent of 60-percent formic acid, 1.5 to 3 percent of glyoxal, 0.5 to 1 percent of sodium chloride, 10 to 20 percent of water. The production process comprises the following steps of: adding the glyoxal and the sodium chloride into the acetic acid and the water (or the formic acid and the water) respectively, and evenly stirring the mixing solutions to obtain two types of mixing solutions;and adding the hydrochloric acid into the two types of mixing solutions respectively, and evenly stirring to obtain the finished productions of two types of products. The formula has the advantages of strong derusting ability, high derusting speed, uniform and quick removal of rust and concrete on steel and copper materials, safe and convenient production and use, and low cost.

Owner:BEIJING YUJIAMING TRI STATE ION RES INST

Iron product efficient rust removing device for hardware manufacturing

ActiveCN106181719AEasy to replaceAvoid pinchingGrinding machinesGrinding headsPinionIndustrial engineering

The invention relates to rust removing devices, in particular to an iron product efficient rust removing device for hardware manufacturing. The iron product efficient rust removing device for hardware manufacturing is good in rust removing effect. In order to solve the technical problem, the iron product efficient rust removing device for hardware manufacturing comprises a first bearing pedestal, a frame, a first rotating shaft, a big belt pulley, a flat belt, a small belt pulley, a second rotating shaft, a shell, a sanding device, a second bearing pedestal, a thumb cylinder, a sliding rail, a third rotating shaft, a first bevel gear, a second bevel gear, a third bearing pedestal, a sliding block, a pinion, a servo motor and a rack. The first bearing pedestal is arranged at the left side of the top inside the frame. The first rotating shaft is installed on the first bearing pedestal. The big belt pulley is arranged on the first rotating shaft. The lower end of the first rotating shaft is connected with the shell. The iron product efficient rust removing device has the effects that the rust removing effect is good and the rust removing speed is high.

Owner:山东安智电力设备有限公司

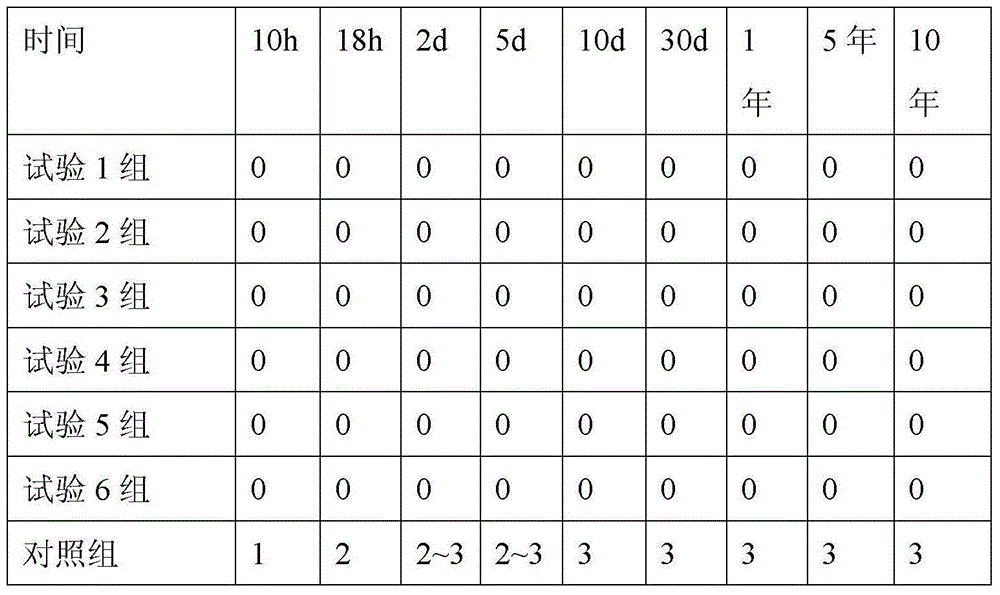

Environment-friendly steel rust remover and preparation method thereof

The invention belongs to the field of steel rust removers, and discloses an environment-friendly steel rust remover and a preparation method thereof. The environment-friendly steel rust remover and the preparation method thereof are used for solving the technical problems that an existing steel rust remover is prone to re-rusting, long in rust removal time and high in cost and pollutes the environment. The rust remover is composed of citric acid, oxalic acid, phosphoric acid, sodium alkyl benzene sulfonate, an emulsifier, a corrosion inhibitor and deionized water, or composed of citric acid, oxalic acid, phosphoric acid, sodium alkyl benzene sulfonate, an emulsifier, a corrosion inhibitor, an anti-freezing agent and deionized water. The preparation method includes the steps that 1 / 2 of water is added into a reaction still; the phosphoric acid, the citric acid, the oxalic acid, the sodium alkyl benzene sulfonate, the corrosion inhibitor and the emulsifier (or the phosphoric acid, the citric acid, the oxalic acid, the sodium alkyl benzene sulfonate, the corrosion inhibitor, the anti-freezing agent and the emulsifier) are sequentially added with stirring at the speed of 100-150 revolutions per minute; the remaining water is added; and the mixture is stirred at a constant speed till complete dissolution. The environment-friendly steel rust remover is applied to steel rust removal.

Owner:HARBIN JINSHIJIA TECH DEV CO LTD

Multifunctional phosphating solution, and preparation method and application thereof

InactiveCN103397324AHigh hardnessStrong impact resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention relates to a multifunctional phosphating solution and a preparation method and application thereof. The multifunctional phosphating solution comprises liquid A and liquid B and is characterized in that a ratio of the liquid A to the liquid B in the multifunctional phosphating solution is 1: 0.1-1. The liquid A comprises the following substances, by mass, 26 to 48 parts of diammonium phosphate, 0.9 to 12 parts of phosphoric acid with a concentration of 85%, 0.8 to 1.8 parts of metal powder, 0.6 to 1.4 parts of animal glue, 0.4 to 10 parts of calcined gypsum powder and 0.3 to 0.8 part of alum, with the balance being water. The liquid B comprises the following substances, by mass, 20 to 46 parts of zinc dihydrogen phosphate, 38 to 55 parts of zinc nitrate, 2 to 3.8 parts of sodium fluoride, 2 to 4 parts of zinc oxide and 2 to 6 parts of phosphoric acid with a concentration of 85%, with the balance being water. The multifunctional phosphating solution provided by the invention is composed of the liquid A and the liquid B, can realize removal of oil and rust at the same time and has the efficacy of rust protection, heat insulation, high temperature resistance, heat preservation, flame retardation, noise abatement, shock prevention, isolation, pollution cleaning and resistance to fire. The multifunctional phosphating solution has the following beneficial effects: a fast rust removal speed, great thickness of a formed film, long antirust time, etc.

Owner:李春清

Rust remover and preparation method thereof

The invention discloses a rust remover and a preparation method thereof. The rust remover is prepared from the following components in percentage by mass: 60 to 80 percent of organic acid, 19 to 39 percent of inorganic acid and 0.8 to 3 percent of corrosion inhibitor, wherein the organic acid is one or more than two kinds of tartaric acid, citric acid, oxalic acid and trichloroacetic acid; the inorganic acid is one or more than two kinds of sulfamic acid, phosphorous acid and ammonium acid fluoride; and the corrosion inhibitor is benzotrizaole or / and sodium dihydrogen phosphate. According to the rust remover disclosed by the invention, the use of hydrochloric acid or sulfuric acid is completely avoided; no acid mist during rust removal is generated, the corrosion to equipment in a workshop is avoided and the labor environment is improved; meanwhile, the corrosion inhibitor is weaker in acidity, the over corrosion to workpieces is avoided and the condition that the skin of an operator is severely corroded is prevented; in addition, after a certain amount of workpieces are treated, the rust removing efficiency is reduced; and by continuously adding the rust remover disclosed by the invention, the rust removing efficiency can be restored, i.e., a rust removing bath solution disclosed by the invention can be conveniently and repeatedly used.

Owner:ZHONGSHAN HUAGUANG CHEM

Chemical process for removing oxidizing layer of stainless steel

This invention discloses a chemical method for removing stainless steel oxide layer. The method comprises: soaking 2205 bi-phase stainless steel belt in an acid-washing pool filled with acid-washing solution. The acid-washing solution comprises: sulfuric acid 230-260 g / L, sodium sulfite 60-100 g / L, sodium chloride 40-60 g / L, sodium nitrate 15-30 g / L, sodium borofluoride 50-80 g / L, thiourea 4-8 g / L, oxalic acid 60-100 g / L, and water as balance. The temperature of the acid-washing solution is 50-70 deg.C. The soaking time of 2205 bi-phase stainless steel belt in the acid-washing pool is 40-60 min. The acid-washing solution is stirrer by aeration during the acid washing process. The method is especially suitable for acid-washing 2205 bi-phase stainless steel belt.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Building bar derusting device with good derusting effect

InactiveCN107962486AFast rust removalImprove rust removal effectGrinding machinesGrinding work supportsRebarDrive motor

The invention discloses a building bar derusting device with a good derusting effect, and belongs to the field of building equipment. The building bar derusting device comprises a bottom plate, wherein a liquid containing box is arranged just below a nozzle, the liquid containing box is fixed to the upper surface of the bottom plate, and the liquid containing box is connected with an input port ofa liquid pump through a liquid draining pipe; a left side plate is vertically arranged on the left side of a spray device, and the left side plate is fixedly connected with the bottom plate; two mounting plates are respectively arranged on the left and right sides of the lower end surface of a top plate; a driving motor is fixedly arranged on the right side of the lower end surface of the top plate by virtue of a bracket, and an output shaft of the driving motor is connected with a screw rod; and a screw rod sleeve is arranged on the screw rod and is movably connected with the screw rod. Thebuilding bar derusting device has the advantage of reasonable structural design; two steel wire brushes are symmetrically arranged in an annular block, so that bars can be derusted all round; and auxiliary derusting liquid is sprayed to the bars by the spray device before the bars enter the derusting device, so that the bar derusting speed is increased, and additionally, the bar derusting effect is increased.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

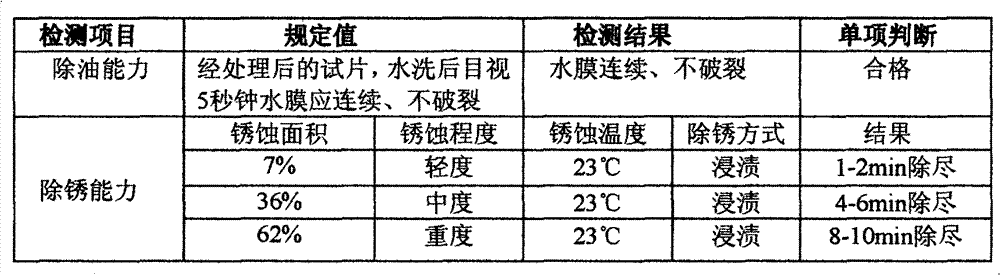

Highly-efficiently degreasing and rust-removal surface treating agent for metal

The invention discloses a highly-efficiently degreasing and rust-removal surface treating agent for metal. The agent is composed of the following components by weight percent: 20 to 40 % of phosphoric acid, 0.1 to 2 % of glucose, 0.1 to 2 % of 2,3-dihydroxysuccinic acid, 0.1 to 1 % of thiourea, 0.5 to 2.5 % of fatty alcohol polyoxyethylene ether and the balance being water. The degreasing and rust-removal surface treating agent for the metal integrates functions of degreasing and rust removal, wherein the main component phosphoric acid plays a role of rust removal, the glucose plays a role of osmosis, the 2,3-dihydroxysuccinic acid plays a role of rust removal and complexation, the thiourea plays a role of corrosion inhibition, and the fatty alcohol polyoxyethylene ether plays a role of degreasing. The above components are combined to be used, good in compatibility and superposed in efficacy, can well degrease and remove rust; and the agent has advantages of quick rust-removal speed, simple operation, saved investment and low cost, and can prolong service life of workpieces.

Owner:王爱民

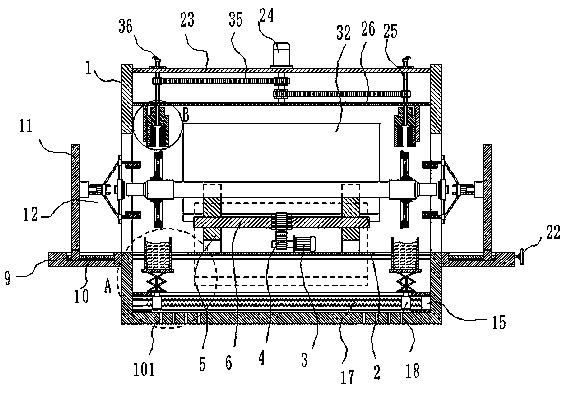

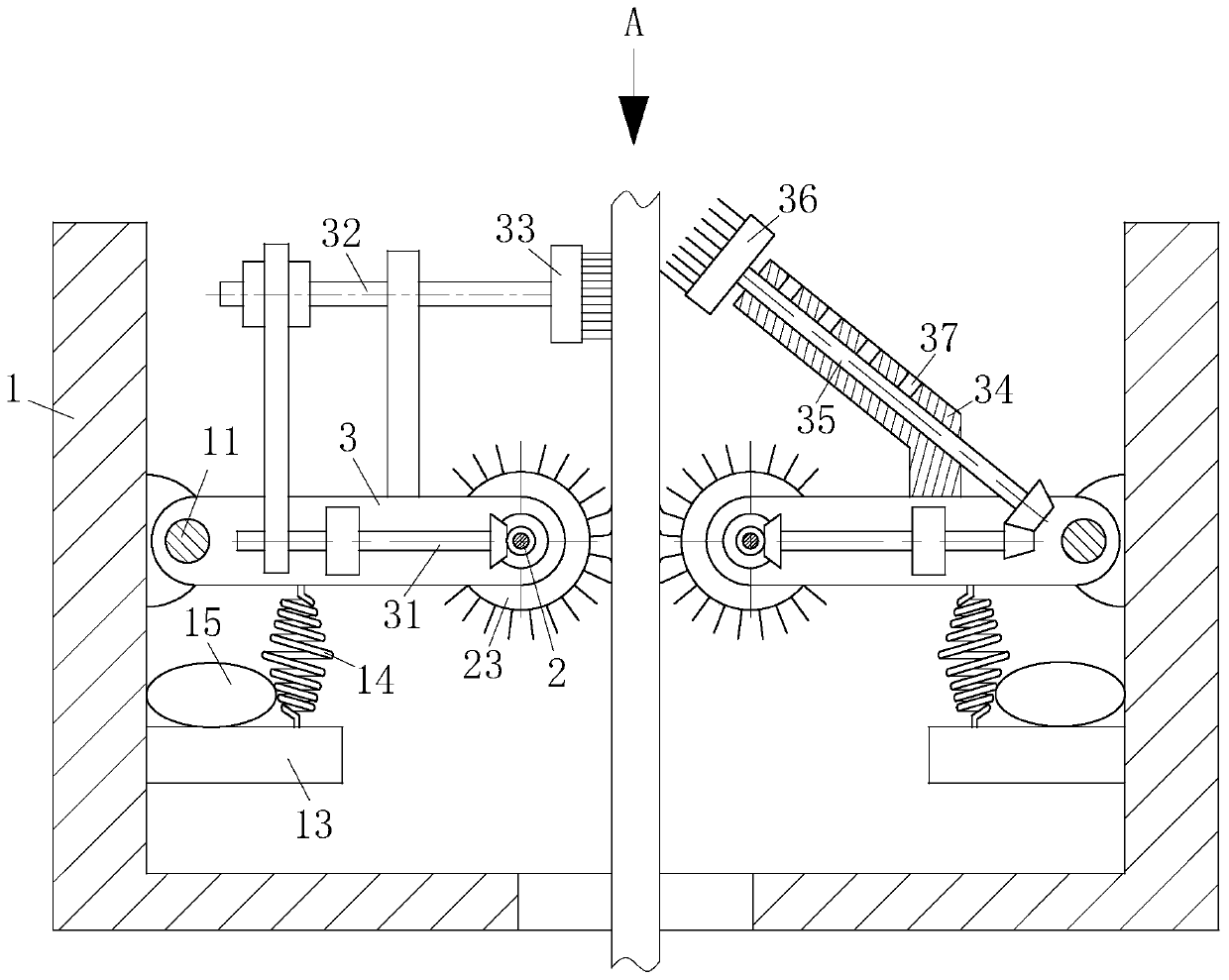

Lift type reinforcing steel bar rust removing device for bridge construction

InactiveCN110238742AMake sure the rust is completely removedFast rust removalGrinding drivesGrinding machinesArchitectural engineeringRebar

The invention discloses a lift type reinforcing steel bar rust removing device for bridge construction. The lift type reinforcing steel bar rust removing device for bridge construction comprises rust removal boxes which are symmetrical in the left-right direction. A reinforcing steel bar is arranged between the left rust removing box and the right rust removing box. By rotating rotary knobs, threaded rods are driven to rotate, threaded blocks move left and right, and steel wire brushes are driven to rotate by power mechanisms so as to remove rust on the reinforcing steel bar. When the steel wire brushes rotate, the power mechanisms provide power to enable moving blocks to move vertically, so that the steel wire brushes move vertically. Rotating blocks can rotate through rotating mechanisms, it can ensured that the steel wire brushes achieve complete rust removal on the reinforcing steel bar. Sprayers in spray mechanisms spray rust removing liquid, so that the speed of the steel wire brushes to remove the rust on the reinforcing steel bar is increased. By the adoption of the lift type reinforcing steel bar rust removing device for bridge construction, workers do not need to conduct rust removal by means of a lifting machine, so that potential safety hazards of manual rust removal are eliminated, and the rust removal efficiency is accelerated.

Owner:龙泉越来自动化技术有限公司

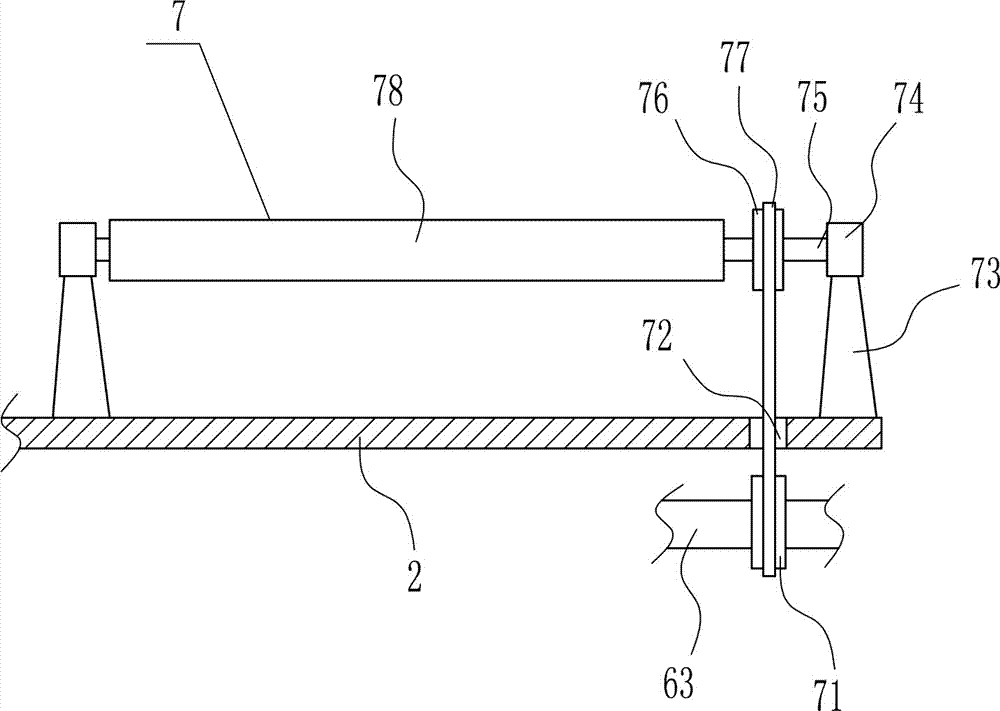

Rust removal oiler for steel rail

A rust removal oiler for a steel rail comprises a rack, travelling wheels, a generator, an oiling or oil spraying device and a dust exhaust device, wherein rolling pins are uniformly arranged on the outer side surface of a front travelling wheel of the rack; a chop rust cutter is mounted on the rack at the rear end of the front travelling wheel; the upper half part of the chop rust cutter is sleeved with a spring; the rolling pins on the front travelling wheel are contacted with the upper part of the chop rust cutter; rust removal machines are mounted on two sides of the rack and have two types, namely, a vertical type and a horizontal type; a vertical motor output shaft of the vertical type dust removal machine is connected with two vertical supporting shafts which are arranged symmetrically through gears; vertical steel wire rolls are mounted at end parts of the two vertical supporting shafts; two transverse motors of the horizontal type dust removal machine are symmetrically fixed on a supporting frame; transverse steel wire rolls are mounted at output shaft end parts of the two transverse motors; the oiling device or the oil spraying device are mounted on the rack between the rust removal machine and the rear travelling wheel; an oil roll is mounted on the oiling device; and a sprayer is mounted on the oil spraying device. The rust removal oiler for the steel rail has the characteristics of convenience in use, high rust removal speed, good effects and the like.

Owner:NANCHANG HENGFA MACHINERY MFG

Ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology

InactiveCN104313533AReduce concentrationReduce consumptionSolid state diffusion coatingThermal fatigueHeat resistance

The invention provides an ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology. The technology comprises the following steps: oil removing, acid pickling for rust removal, washing, surface activation, auxiliary infiltration, drying, and ultrasonic frequency induction heating technology based quick aluminizing. The technology has the following advantages: concentration and consumption of a pickling solution are reduced, and a rust removal speed is greatly increased; the hot-dipping aluminizing temperature is low, and the aluminizing process is short; compared with a heating method of a traditional resistance aluminizing furnace, the induction heating method adopted enables the utilization rate of electrical energy to be improved over 20%, and enables the annual output to be increased over one time; compared with traditional diffuse type aluminizing steel material, the new aluminizing steel material prepared with the technology retains a pure aluminium layer and an iron-aluminium alloy layer under a columnar eutectic state, and has the effects of corrosion resistance, heat resistance, abrasion resistance and photo-thermal reflectivity; a fragility area on the surface is eliminated; bending performance and punch forming performance are greatly improved; resistance to heat shocks and resistance to thermal fatigue are improved over 10%.

Owner:WUHAN TIANCONG CREATIVE TECH

High-efficiency derusting solution for steel derusting

The invention discloses a high-efficiency derusting solution for steel derusting, which is prepared from the following raw materials: 15-20 parts of phosphoric acid, 10-12 parts of acetic acid, 8-10 parts of carboxylic acid, 5-7 parts of fatty acid, 3-5 parts of citric acid, 3-6 parts of cupric hydroxide, 4-6 parts of calcium carbonate, 3-5 parts of ammonia water, 5-8 parts of tartaric acid, 3-6 parts of activated carbon, 4-5 parts of ethanol, 6-8 parts of toluene, 5-8 parts of potassium chloride, 5-10 parts of sodium bicarbonate, 2-5 parts of ferric hydroxide, 3-5 parts of dimethyl carbonate, 3-6 parts of fatty alcohol polyethenoxy ether, 6-8 parts of potassium silicate and 50-55 parts of deionized water. The high-efficiency derusting solution for steel derusting has the advantages of simple and accessible raw materials and low cost; and when being used for steel derusting, the high-efficiency derusting solution for steel derusting is convenient to use and has high derusting speed, the derusted steel does not have the phenomenon of over corrosion and has smooth surface, and the mechanical strength is not lowered due to hydrogen brittleness.

Owner:周彩球

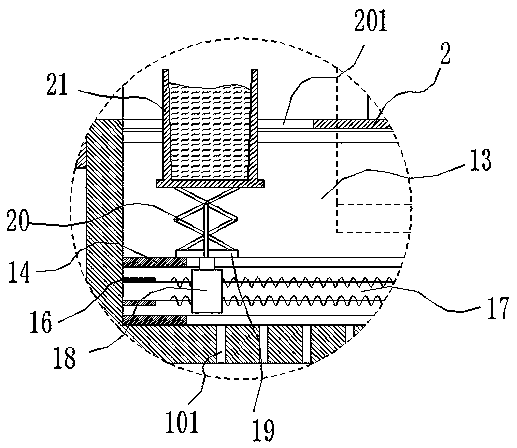

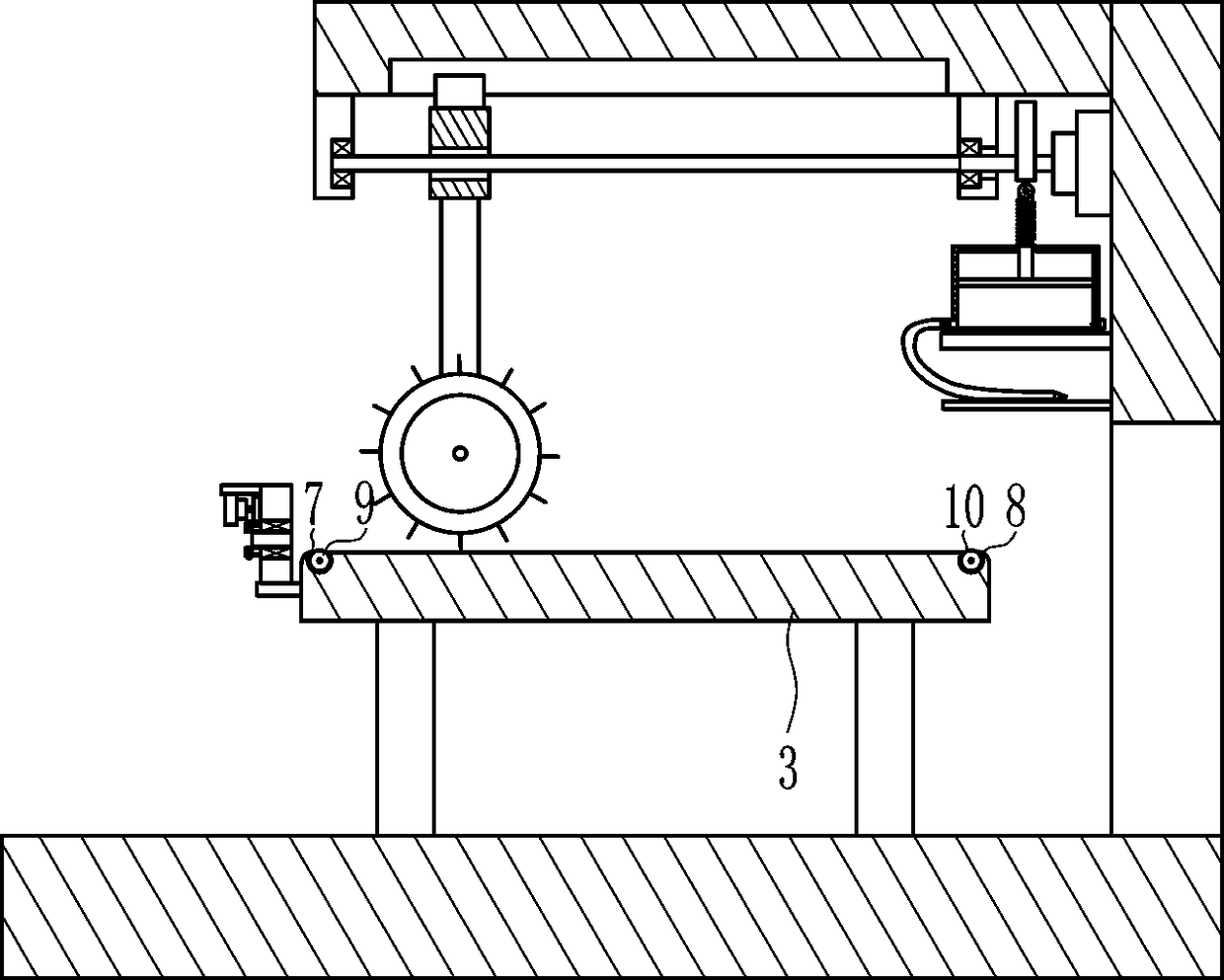

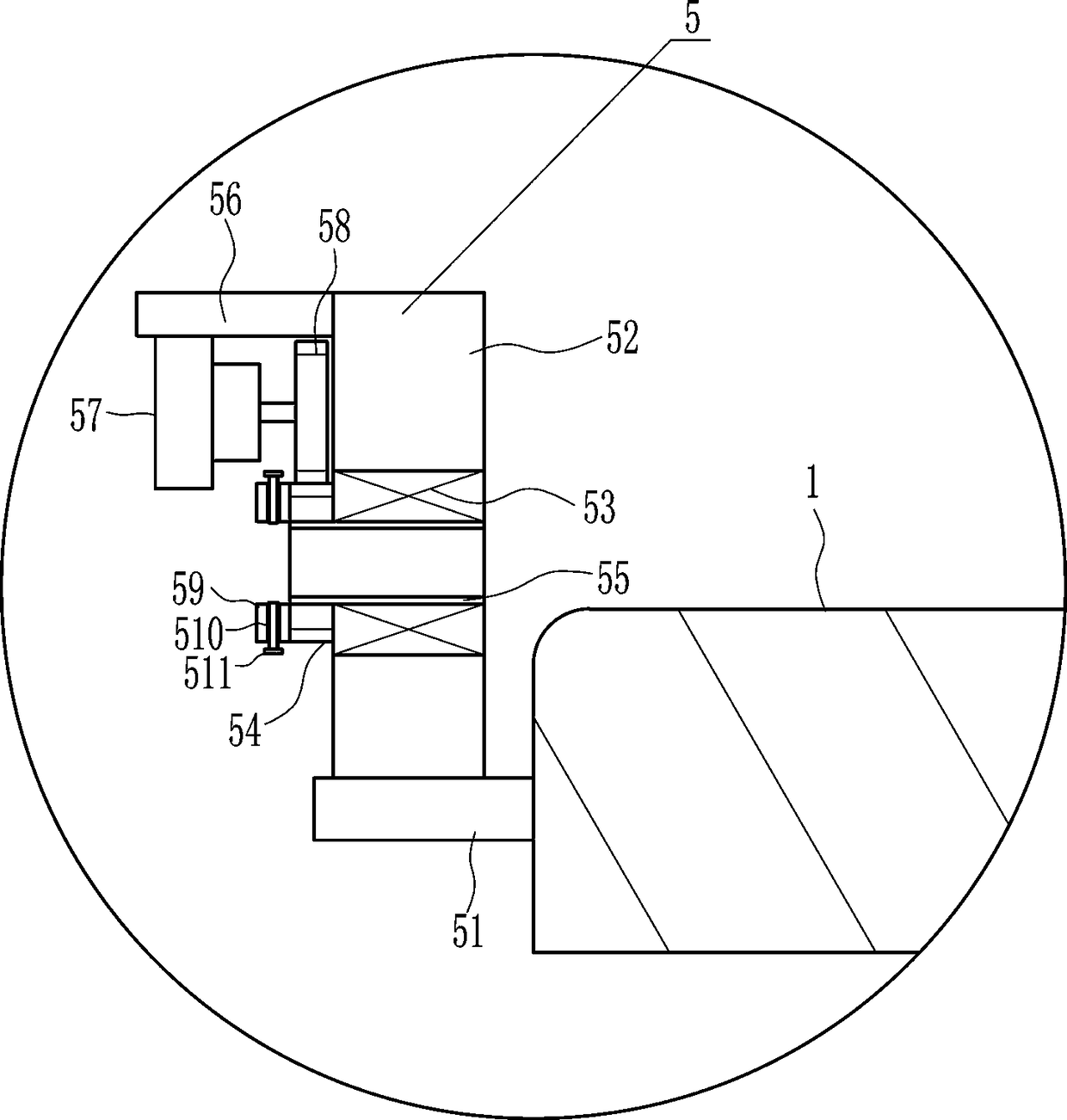

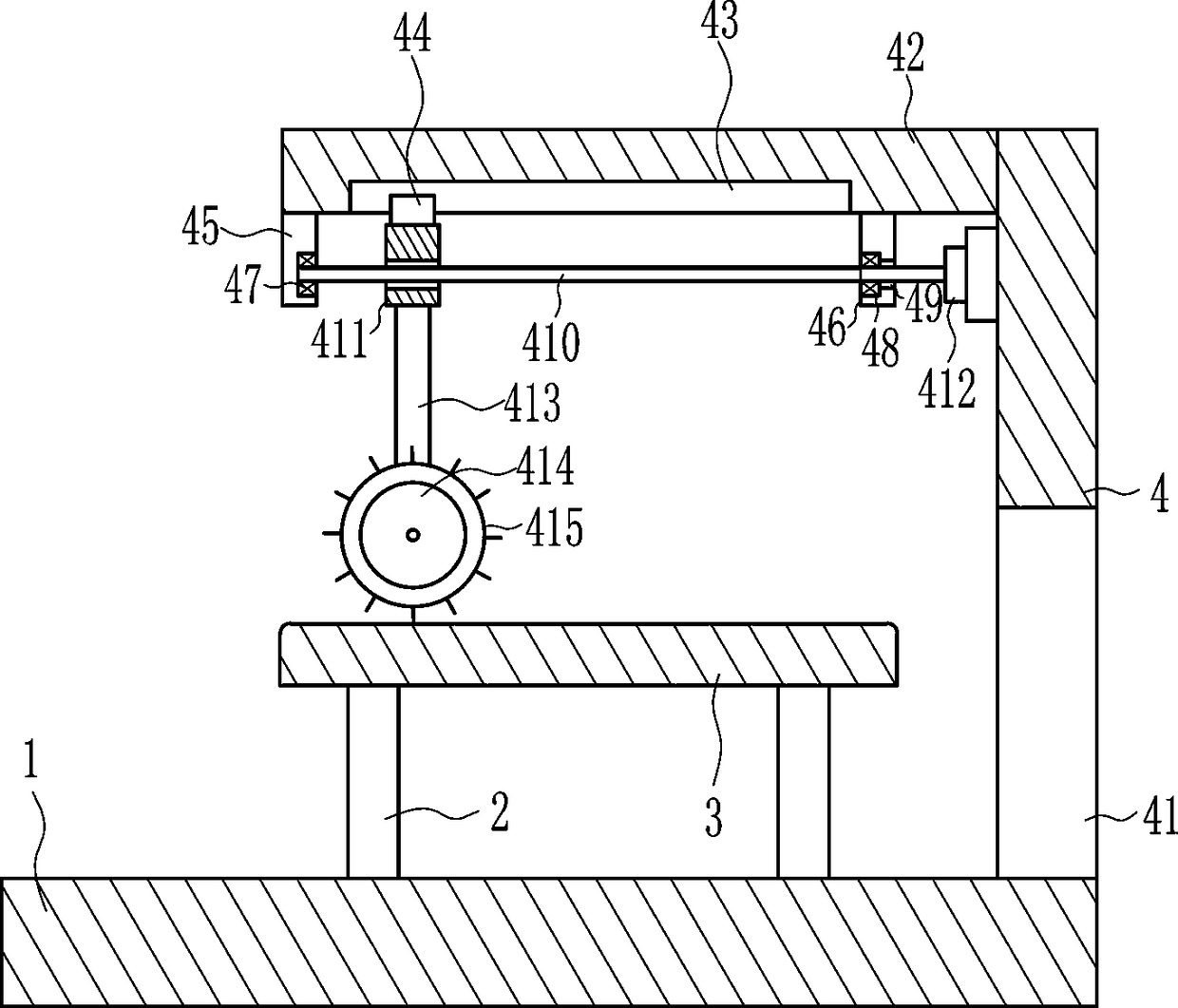

Wheel disk automatic derusting cleaning device

InactiveCN108754518APrevent intrusionFast rust removalCleaning using toolsCleaning using liquidsEngineeringDrive motor

The invention discloses a wheel disk automatic derusting cleaning device. The device comprises a rack. A mounting plate is arranged on the rack. Trays are arranged on the mounting plate and connectedwith a first servo motor through a drive belt I; and the mounting plate and the rack define an accommodating cavity, a slide frame is arranged in the accommodating cavity, a bearing pedestal and a drive motor are arranged on the slide frame, a second lead screw shaft is connected with the bearing pedestal and the drive motor, air cylinder seats are arranged on the second lead screw shaft, a lifting air cylinder is arranged on each air cylinder seat, a supporting plate and a scissor-fork type lifting frame are arranged on each lifting air cylinder, the scissor-fork type lifting frames are connected with liquid storage boxes correspondingly, and two openings allowing the liquid storage boxes to stretch out are formed in the positions, located at the lower end of a disk, of the mounting plate. For solving problems, the wheel disk automatic derusting cleaning device is provided, the device adopts a rust remover for performing semi-soaking type rotary derusting, rusty spots of the disk arebrushed during derusting, the derusting effect is good, meanwhile, disks of different models are derusted, and the automation degree is high.

Owner:DONGGUAN UNIV OF TECH

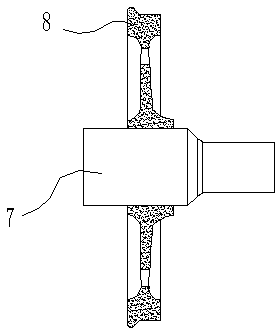

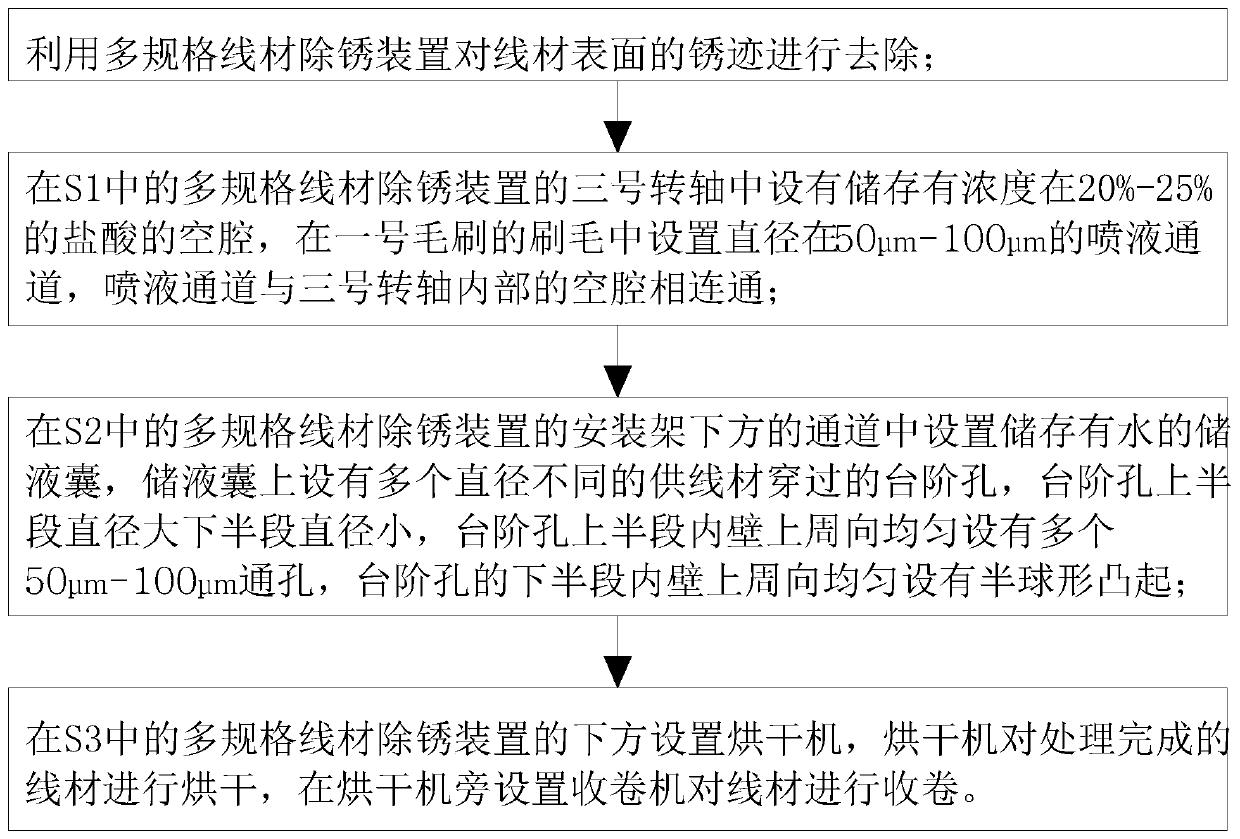

Wire rod rust removal process

ActiveCN109848246AFast rust removalRemove cleanCleaning using toolsCleaning using gasesWater storageWinding machine

Owner:德清林缘金属制品有限公司

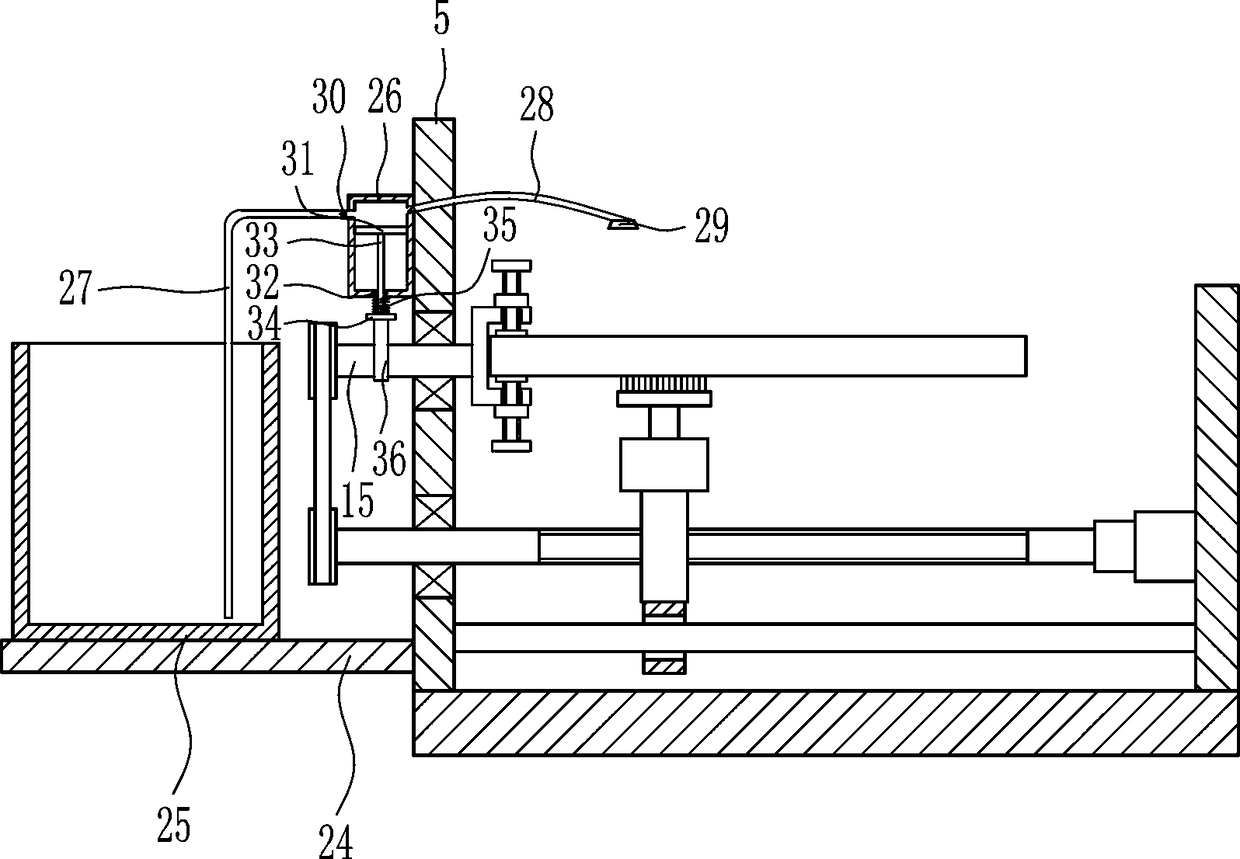

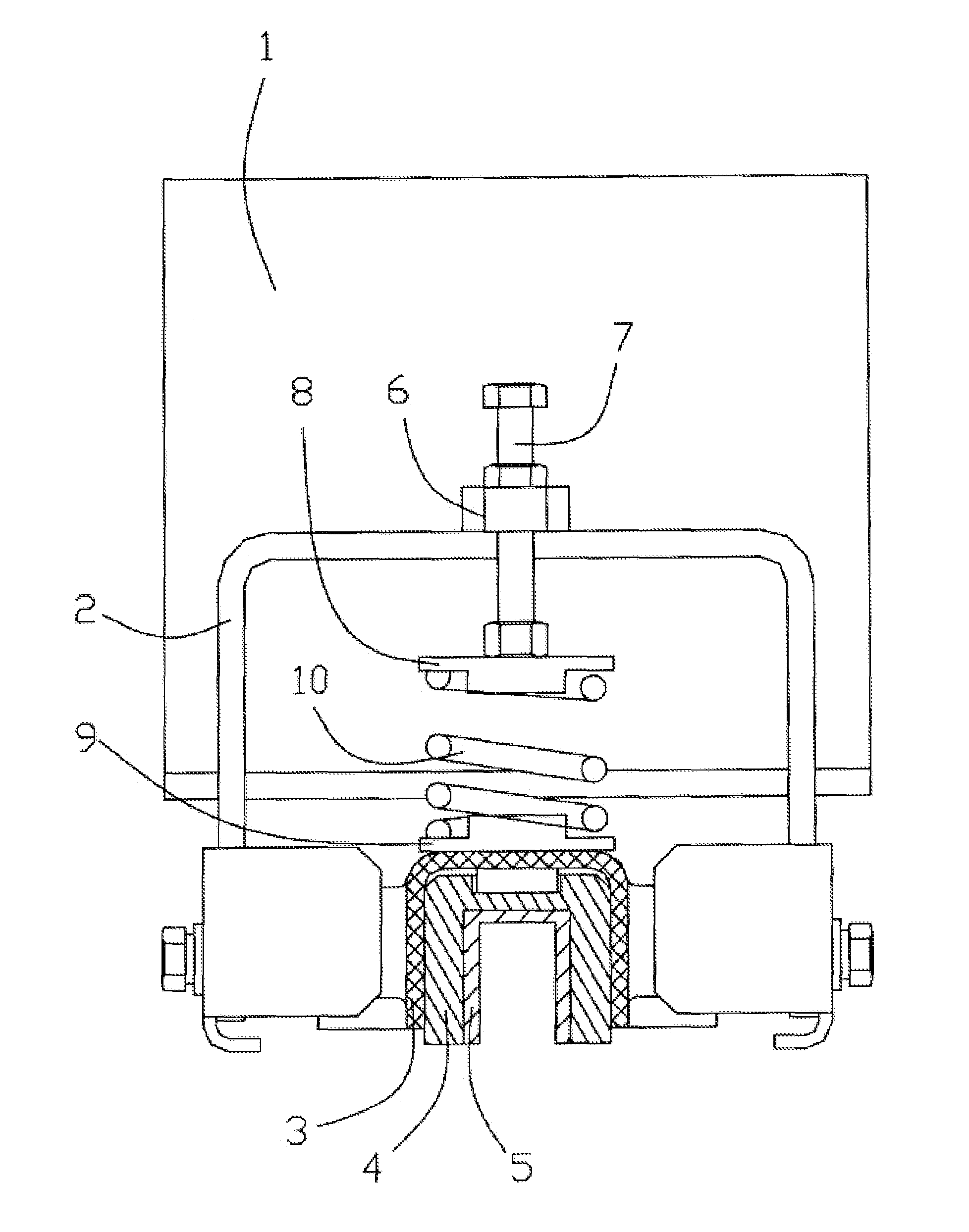

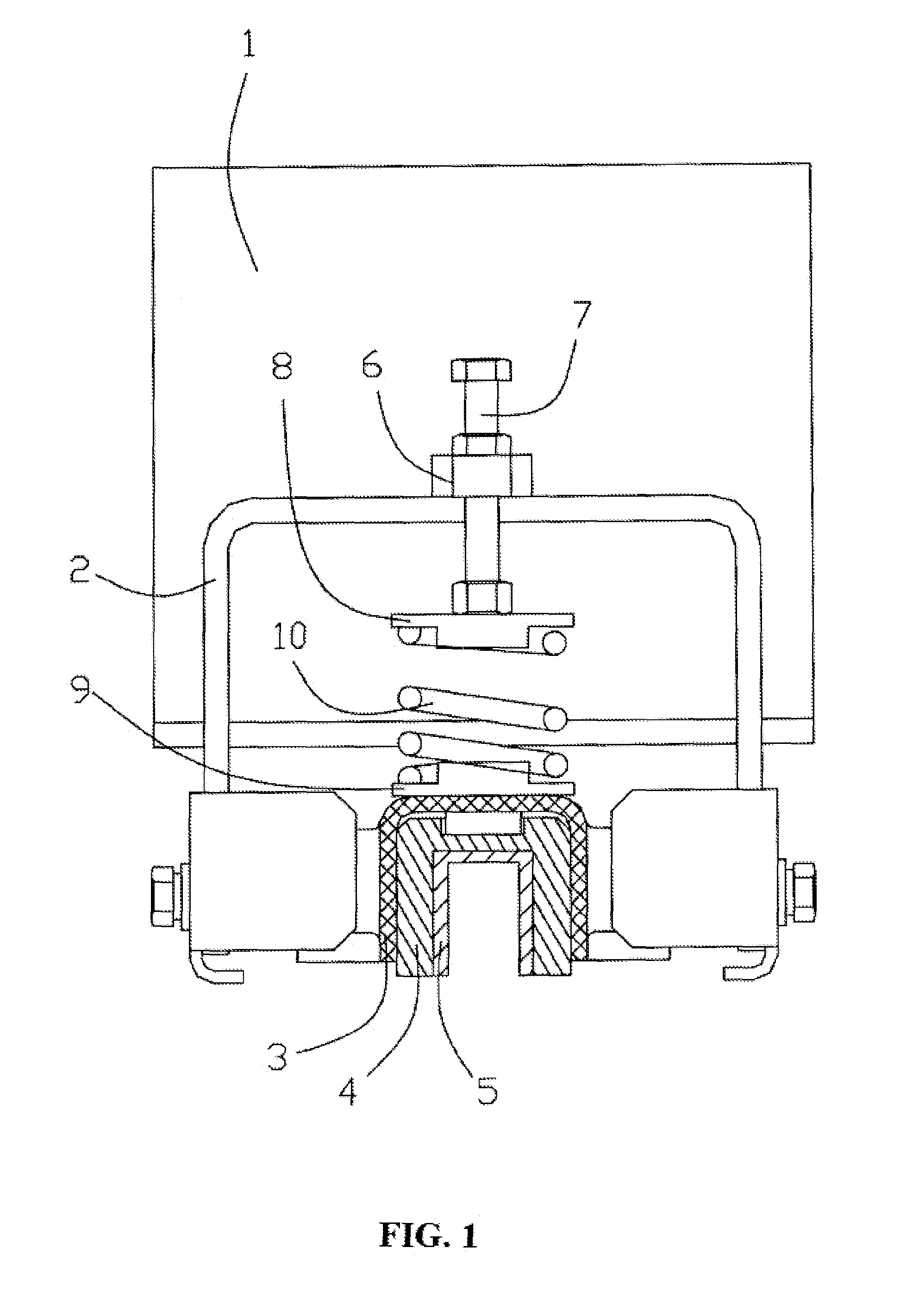

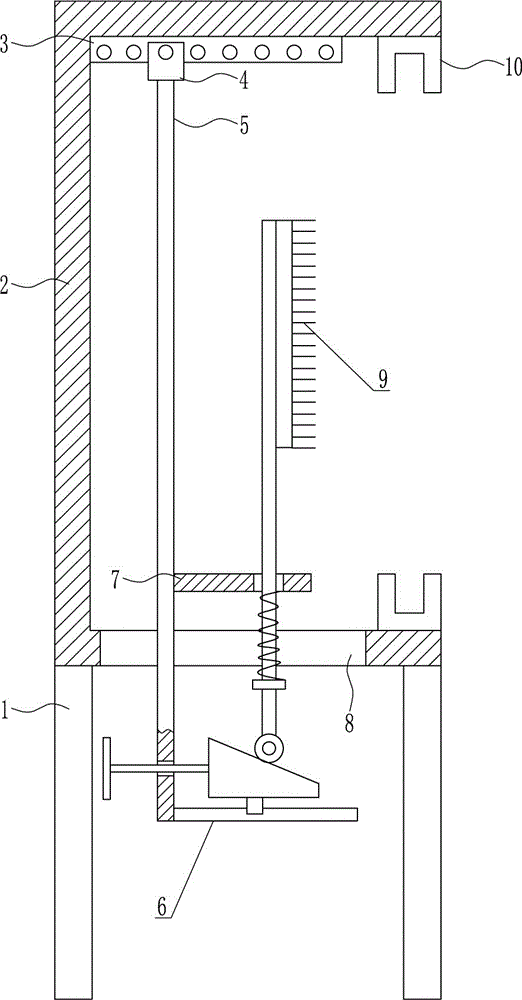

Rust removing device for elevator guide rail

The present invention relates to a rust removing device for an elevator guide rail and aims at solving a problem of great time and labor taken and insufficient rust removal due to that rust of existing guide rail is removed manually. The rust removing device comprises: a support; a rust removal rack, mounted on the support and covering guide rail; and a rust removal material, arranged on a U-shaped inner wall of the rust removal rack and fitted with a surface of the guide rail. The rust removing device of the present invention has advantages that the rust of the guide rail is removed automatically instead of being removed manually, featured by a high rust removing speed, energy saving, simple maintenance, and less influence on users due to long-time service stop because of rust removal.

Owner:XIZI OTIS ELEVATOR +1

Efficient metal rust remover

The invention relates to an efficient metal rust remover. The efficient metal rust remover is characterized by being composed of, by weight, 45-60 parts of hydrochloric acid, 4-5 parts of phosphoric acid, 0.4-0.6 part of hexamine, 0.4-0.6 part of lauryl sodium sulfate, 0.15-0.4 part of triethanolamine, 0.4-0.6 part of citric acid, 0.5-1.2 parts of oleic acid, 0.8-1.6 parts of oxalic acid, 3-6 parts of urotropin, 6-10 parts of fatty alcohol-polyoxyethylene ether, and 20-70 parts of water. The efficient metal rust remover is capable of removing rust efficiently and rapidly, does not burn or explode, is not volatile, and is low in substrate corrosion and price and convenient to use.

Owner:周仁勇

Rust removal device with maintenance function and for pipeline processing

ActiveCN109454536APromote repairAvoid repairsGrinding carriagesDrying solid materials without heatEngineeringRust

The invention relates to a rust removal device with a maintenance function and for pipeline processing. The rust removal device comprises a guiding rail and an ejecting rod, a supporting frame is arranged at the left side of the upper end of the guiding rail, a fixing rod is fixed at the lower end of the right side of the supporting frame, a first supporting rod is inlaid in the left side of the upper end of the fixing rod, a first magnet block is connected to the upper end of the first supporting rod, a pipeline is arranged above the first magnet block and a first magnet is arranged inside the pipeline. The rust removal device with the maintenance function and for pipeline processing has the beneficial effects that through the first magnet block, the pipeline can be supported when the sunken part of the pipeline is repaired, the first magnet can remain static when the pipeline moves through the magnetic attracting force between the first magnet and the first magnet block, the first magnet makes contact with the sunken part of the pipeline, when a hammer stone downwards hammers the pipeline, the first magnet can lift the sunken part to repair the pipeline well, and the fact that adevice before can only repair a raised part is avoided.

Owner:梁山亿隆冷弯型钢有限公司

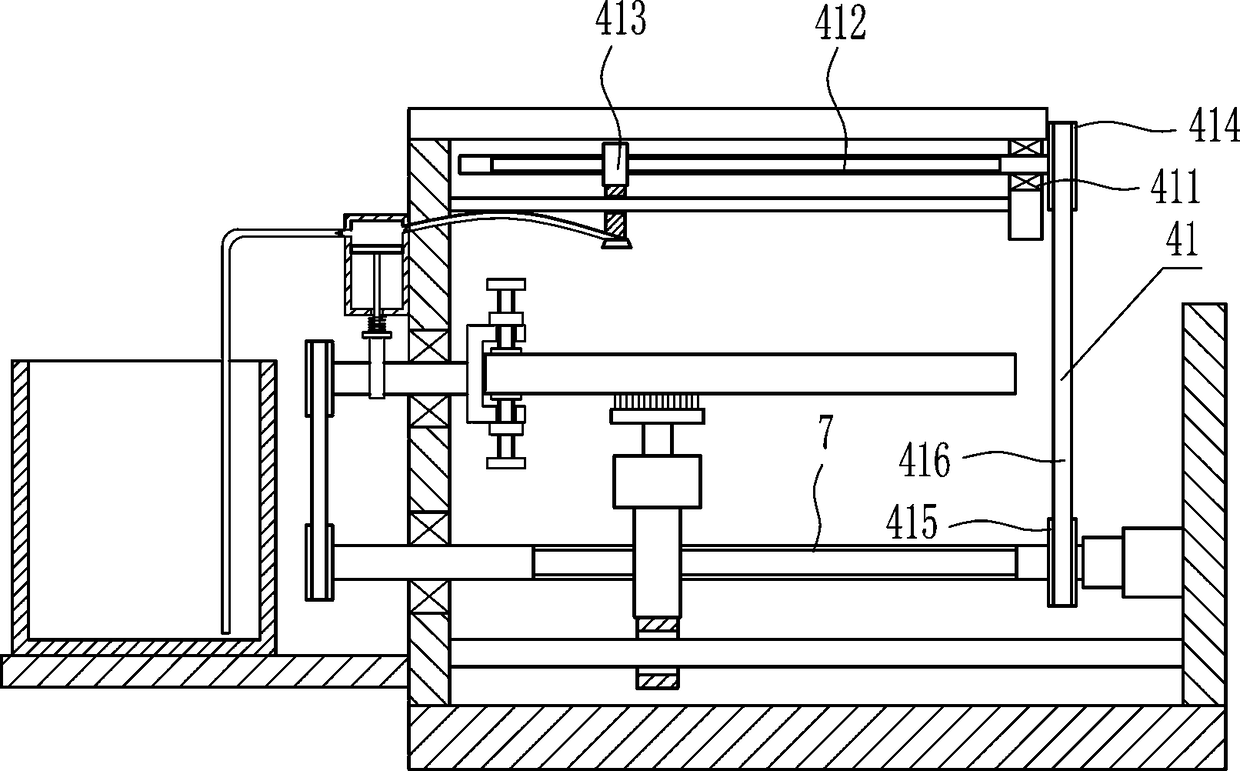

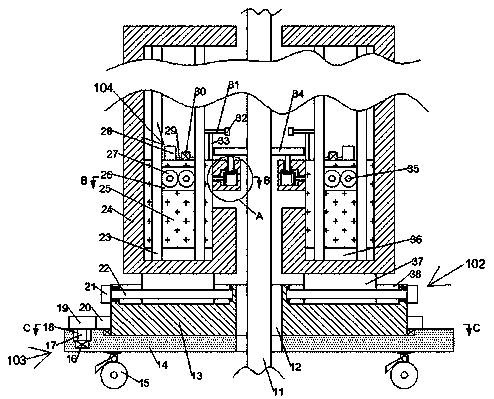

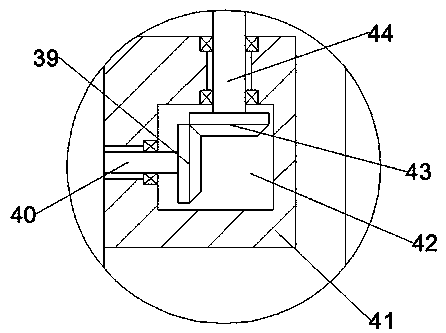

Steel bar derusting device used for municipal sewage treatment

InactiveCN107175570AEasy to fixShorten or increase distanceGrinding carriagesGrinding drivesMunicipal sewageEngineering

The invention belongs to the technical field of municipal sewage treatment, in particular to a steel bar derusting device for municipal sewage treatment. The technical problem to be solved by the present invention is to provide a steel bar derusting device for municipal sewage treatment that has low labor intensity, is not easy to injure hands during the derusting process, and has a fast derusting speed. In order to solve the above technical problems, the present invention provides such a steel bar derusting device for municipal sewage treatment, which includes a leg, a frame, a first slide rail, a first slider, a riser, a driving device, a guide plate, etc.; The top of the outrigger is connected to the frame by bolt connection, and the first slide rail is horizontally installed on the left side of the top of the frame by bolt connection. The first slide rail is slidably provided with a first slider. Bolt holes are provided on both the first slide block and the first slide block, and the bottom of the first slide block is connected with a riser by means of bolt connection. The invention achieves the effects of low labor intensity, less hand injury during the derusting process, and fast derusting speed.

Owner:泉州市欣百亚智能科技有限公司

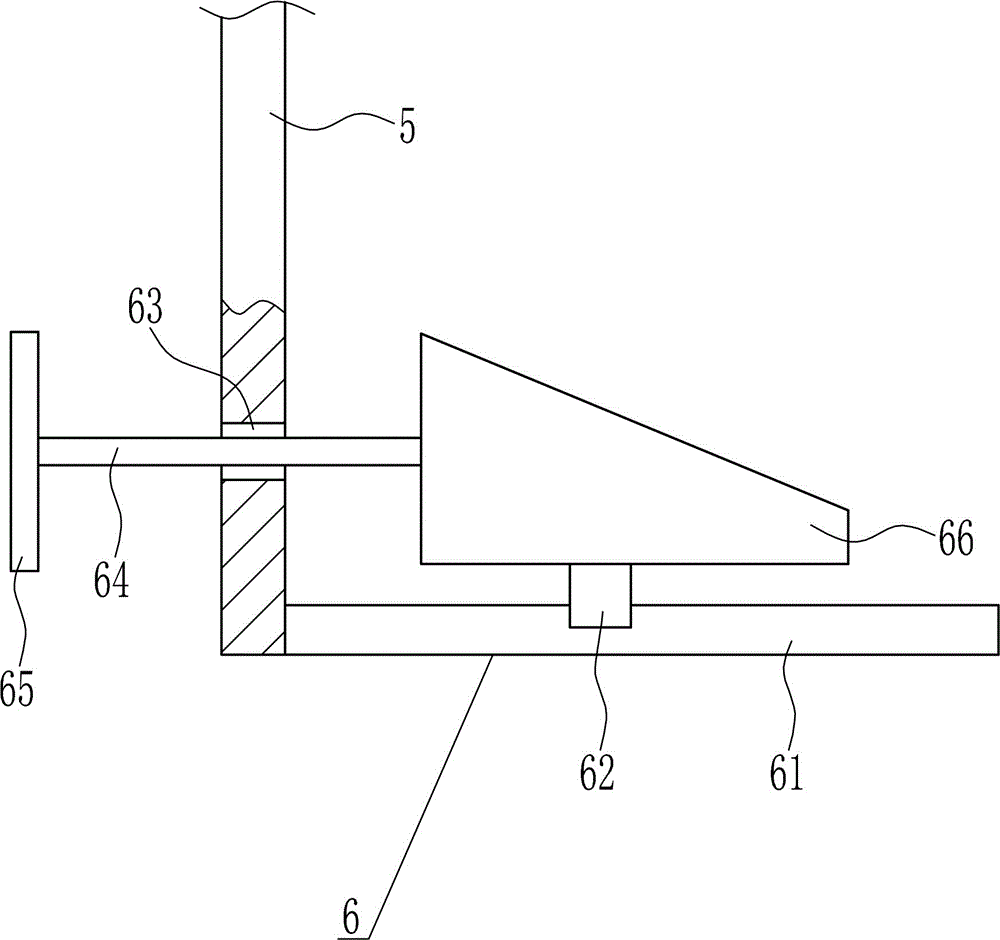

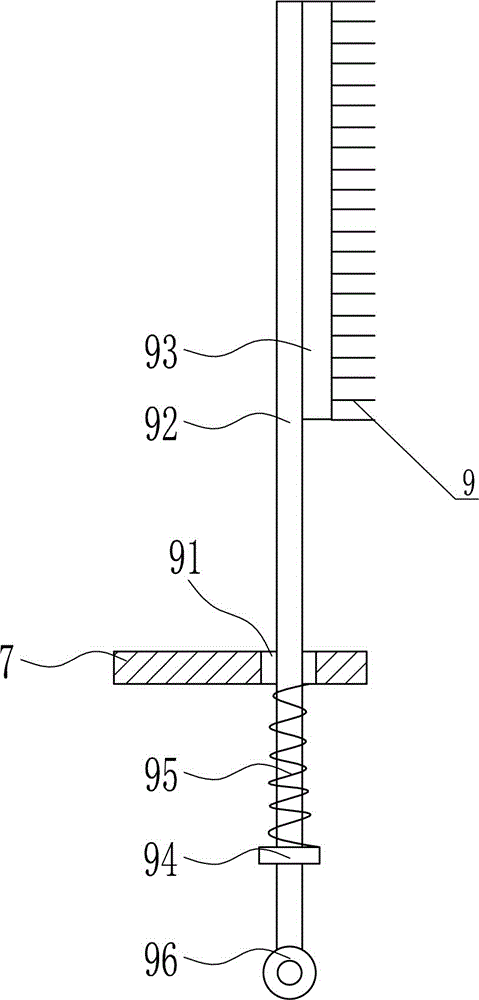

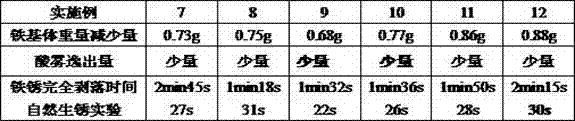

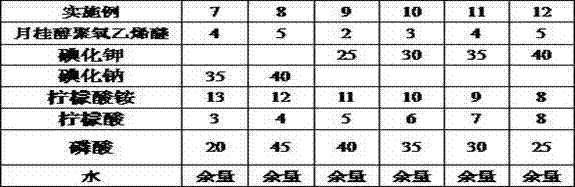

Multifunctional acid additive and preparation method thereof

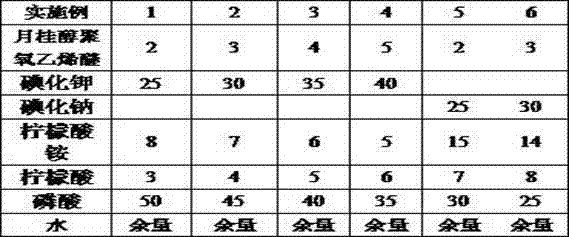

The invention provides a multifunctional acid additive and a preparation method thereof. In terms of 1 liter, the multifunctional acid additive is prepared from the following raw materials: 2-5g / L of polyoxyethylene ether surfactants, 25-40g / L of potassium iodide or sodium iodide, 5-15g / L of ammonium citrate, 3-8g / L of citric acid, 20-50g / L of phosphoric acid, and the balance of water. The multifunctional acid additive is used when a steel material is cleaned by hydrochloric acid, has the characteristics of oil removal, corrosion inhibition, mist inhibition, hydrogen brittleness inhibition, high rust removal speed and rust resistance after cleaning, is diluted by a large multiple during hydrochloric acid cleaning, and is relatively low in cleaning cost and economically competitive.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Spring rust cleaning liquid and rust cleaning process

InactiveCN104060282ANo corrosionAvoid harmMetallic material coating processesPhosphoric acidBinding force

The invention relates to rust cleaning liquid used for cleaning rust on the surface of a spring and a process adopting the dust cleaning liquid to clean rust for the spring. The spring rust cleaning liquid consists of the following components in percentage by weight: 25%-45% of phosphoric acid, 5%-10% of ethyoxyl alkyl sodium sulfate, 30%-50% of acetone, 8%-15% of catechol and the balance of deionized water. The spring rust cleaning liquid is utilized to carry out rust cleaning on the spring, so that greasy dirt and a rust layer on the surface of the spring can be removed at the same time, a phosphating film also can be generated on the spring surface, and therefore, the process is simplified; the process is free of environmental pollution, free of any harm on operation staff, low in cost, high in rust-cleaning speed, free of corrosion on spring, long in rust-preventing time, and capable of strengthening binding force between the metal surface and the paint.

Owner:ANHUI HONGQIAO METAL MFG

Environmental-friendly rust remover and preparation method thereof

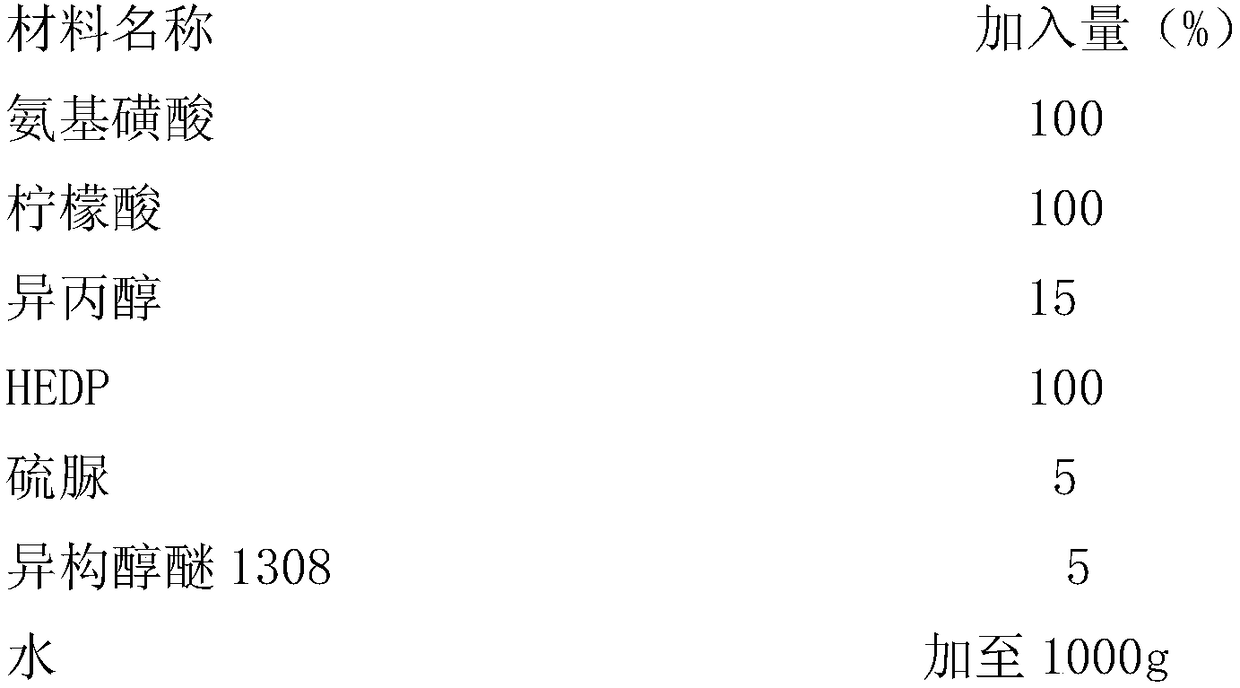

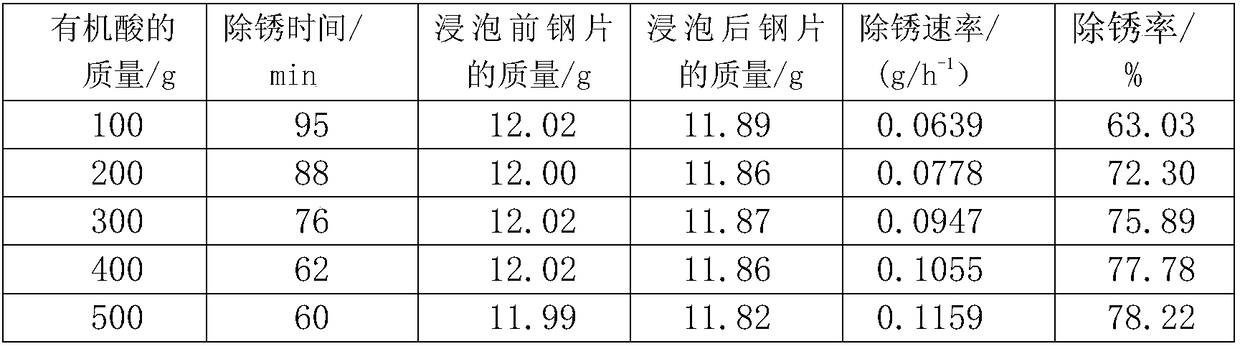

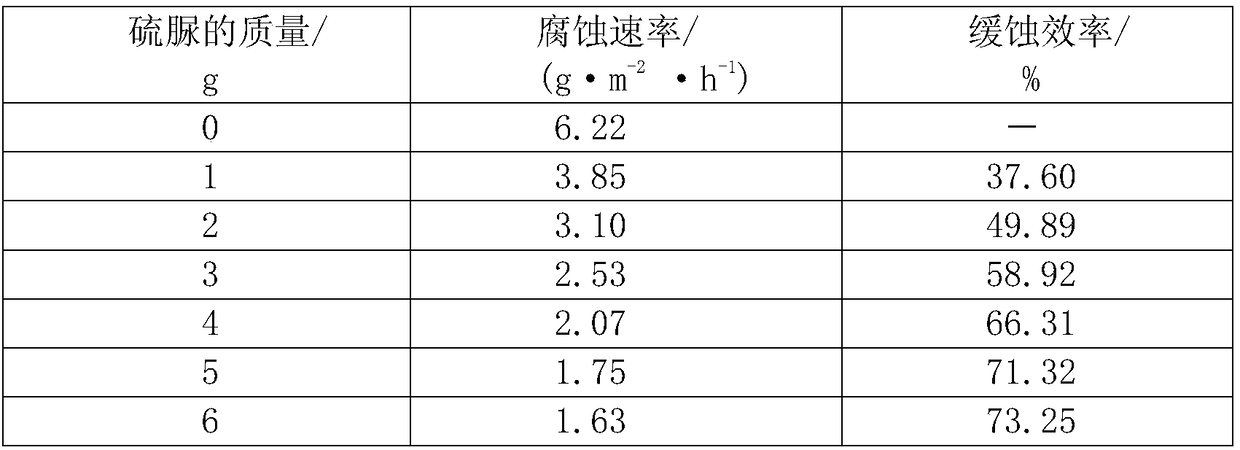

The invention discloses an environmental-friendly rust remover and a preparation method thereof. The environmental-friendly rust remover is prepared from the following ingredients in parts by weight:100g of sulfamic acid, 100g of citric acid, 15g of isopropanol, 100g of HEDP, 5g of thiourea, 1308 5g of heterogeneous alcohol ether 1308 and a proper amount of water to reach the total quantity of 1000g. The preparation method of the environmental-friendly rust remover comprises the following steps of weighing the materials according to the proportioning ratio; adding the materials during stirring; after sufficient dissolution, stirring the materials to a transparent state; preparing the materials into a 1000g rust removing solution. The invention aims at providing the environmental-friendlyrust remover and the preparation method of the environmental-friendly rust remover; the environmental-friendly rust remover can replace strong acid such as hydrochloric acid and sulfuric acid to remove rust, and has the advantages that no acid mist, no foreign smell and no toxicity exist; safety and environmental protection are realized; the work efficiency is effectively improved; the service life of the acid liquid is effectively prolonged; the treatment is simple; the production cost is reduced.

Owner:曾凡强

Round iron bar rust removal device

InactiveCN108312030AFast rust removalThorough rust removalGrinding carriagesGrinding drivesEngineeringRust

The invention relates to a rust removal device, in particular to a round iron bar rust removal device. According to the technical aim to be achieved, the round iron bar rust removal device is efficient. The round iron bar rust removal device comprises a bottom plate, supporting legs, a first containing plate, a support, a supporting plate, a sliding rail, a sliding block, a first mounting plate, asecond mounting plate and the like. The left side and the right side of the upper portion of the bottom plate are symmetrically and fixedly connected with the supporting legs, and the top ends of thetwo supporting legs are fixedly connected with the first containing plate. The right side of the upper portion of the bottom plate is fixedly connected with the support, and a first through hole is formed in the lower portion of the support. The upper portion of the left side of the support is fixedly connected with the supporting plate, and the sliding rail is arranged at the bottom of the supporting plate. The function that machines replace manpower to assist a round iron bar in rust removal is achieved, and the round iron bar rust removal device has the functions of being high in rust removal speed and thorough in rust removal and saving manpower resources, and meanwhile has the beneficial effects of being convenient to use, safe to use, easy to operate, low in manufacturing cost and the like.

Owner:伍振铭

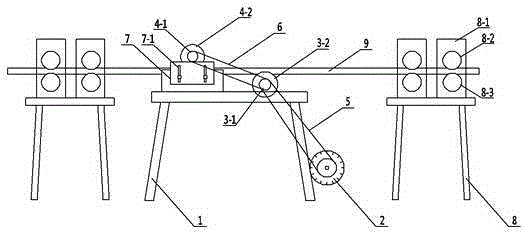

Steel pipe rust removal device

InactiveCN105382668AAutomatic rust removalFast rust removalGrinding machinesGrinding feedersWork periodEngineering

The invention discloses a steel pipe rust removal device which is used for removing rust from a rusty steel pipe. The steel pipe rust removal device comprises a support, a rust brushing motor arranged on the side face of the support, a rust brushing device I fixed to the support, a rust brushing device II connected to the support through an adjusting plate, and steel pipe conveying devices which are arranged on the front portion and the rear portion of the support respectively. The rust brushing motor is connected with the rust brushing device I through a transmission mechanism I. The rust brushing device I is connected with the rust brushing device II through a transmission mechanism II. By means of the steel pipe rust removal device, rust removal can be conducted on the steel pipe automatically, the rust removal speed is high, the working efficiency is improved, and the working time is shorted.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com