Multifunctional acid additive and preparation method thereof

A pickling additive and multi-functional technology, applied in the field of metal surface treatment, can solve the problems of easy oxidation and corrosion of metal layers, slow rust removal, easy to rust again, etc. rust fast effect

Active Publication Date: 2015-04-08

HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] (1) Hydrochloric acid is highly volatile and easily produces more acid mist, which affects the operating environment and personnel health, and causes surface corrosion of equipment and workshops. This acid mist is caused by It is produced when the volatilized hydrogen chloride gas meets the water vapor in the air and condenses into small drops of hydrochloric acid;

[0004] (2) Hydrochloric acid is highly corrosive to the metal material matrix, that is, it will dissolve the material itself and cause metal waste;

[0005] (3) When hydrochloric acid erodes the base metal of the material, such as the reaction with metallic iron, hydrogen gas and atomic active hydrogen will be generated, and this active hydrogen will enter the metal material matrix , causing the problem of "hydrogen embrittlement", and the generated hydrogen will carry a lot of hydrogen chloride gas out, forming a more serious acid mist problem;

[0006] (4) The surface of the metal material after pickling is unprotected, and even in the process of draining and drying after rinsing, it is easy to rust again, which will affect the subsequent treatment ;

[0007] (5) The ability of hydrochloric acid to remove grease is very low, and the grease on the metal surface will obviously reduce the speed of pickling and rust removal, and even make the rust under the grease insoluble Cleaning, so the grease often needs to be cleaned separately before pickling

[0009] (1) The speed of rust removal is usually slow and the required cleaning time is also long;

[0010] (2) It is highly toxic and has safety problems during use;

[0011] (3) The corrosion inhibitor is basically washed away during cleaning, so the workpiece after cleaning does not have anti-rust ability, and the exposed surface metal layer is easily oxidized and corroded , thus affecting the subsequent processing

This kind of multifunctional hydrochloric acid pickling additive basically solves the above-mentioned technical problems, but because the unit price of the main ingredients in the formula is high and the concentration is very high, there is a problem of high cost. Diluted, cleaning costs remain high, economically uncompetitive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

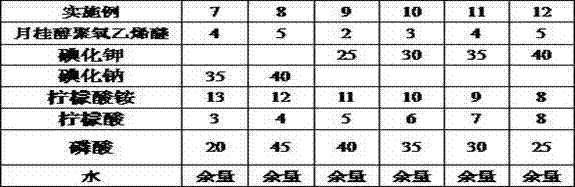

Embodiment 1-12

[0043] The composition of table 1 embodiment 1-6 multifunctional pickling additive

[0044]

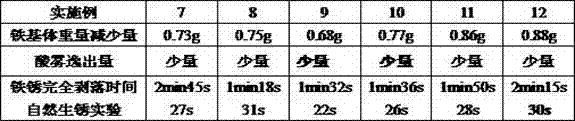

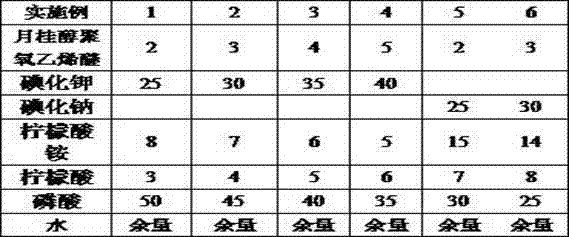

Embodiment 7-12

[0045] The composition of table 2 embodiment 7-12 multifunctional pickling additives

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a multifunctional acid additive and a preparation method thereof. In terms of 1 liter, the multifunctional acid additive is prepared from the following raw materials: 2-5g / L of polyoxyethylene ether surfactants, 25-40g / L of potassium iodide or sodium iodide, 5-15g / L of ammonium citrate, 3-8g / L of citric acid, 20-50g / L of phosphoric acid, and the balance of water. The multifunctional acid additive is used when a steel material is cleaned by hydrochloric acid, has the characteristics of oil removal, corrosion inhibition, mist inhibition, hydrogen brittleness inhibition, high rust removal speed and rust resistance after cleaning, is diluted by a large multiple during hydrochloric acid cleaning, and is relatively low in cleaning cost and economically competitive.

Description

technical field [0001] The invention relates to the technical field of metal surface treatment, in particular to a multifunctional pickling additive used when cleaning iron and steel materials with hydrochloric acid. Background technique [0002] Cleaning the rust on the surface of steel parts with hydrochloric acid is a common step in the processing of steel products or intermediate products. The advantage of hydrochloric acid is that it is cheap and easy to obtain, strong acidity, fast dissolution rate and large dissolving ability to the corrosion of steel surface, but there are also the following technical problems: [0003] (1) Hydrochloric acid is highly volatile, and it is easy to produce more acid mist, which affects the operating environment and the health of personnel, and causes surface corrosion of equipment and workshops. Produced by small drops of hydrochloric acid; [0004] (2) Hydrochloric acid is highly corrosive to the metal material matrix, that is, it w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23G1/08C23G1/06

CPCC23G1/06C23G1/08

Inventor 桂成方

Owner HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com