Environmental-friendly rust remover and preparation method thereof

A rust remover and environmental protection technology, applied in the field of environmental protection rust remover and its preparation, can solve the problems of large consumption of acid solution, affecting the health of operators, equipment and environment, and increasing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

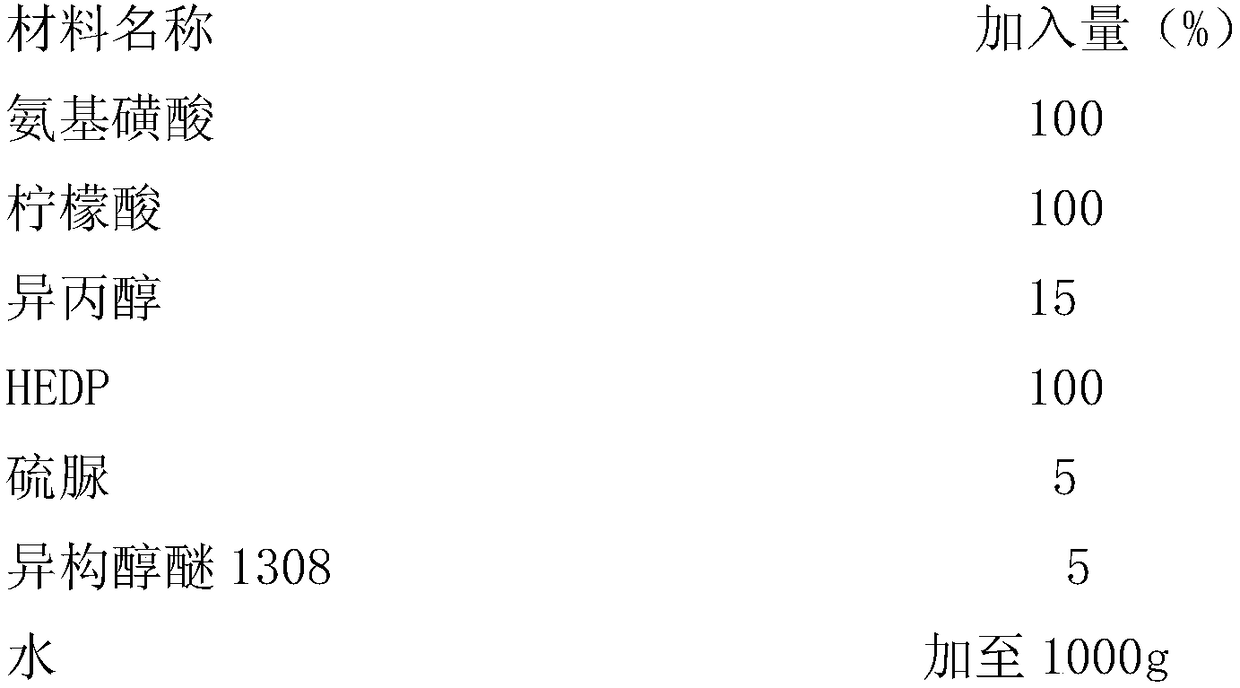

Method used

Image

Examples

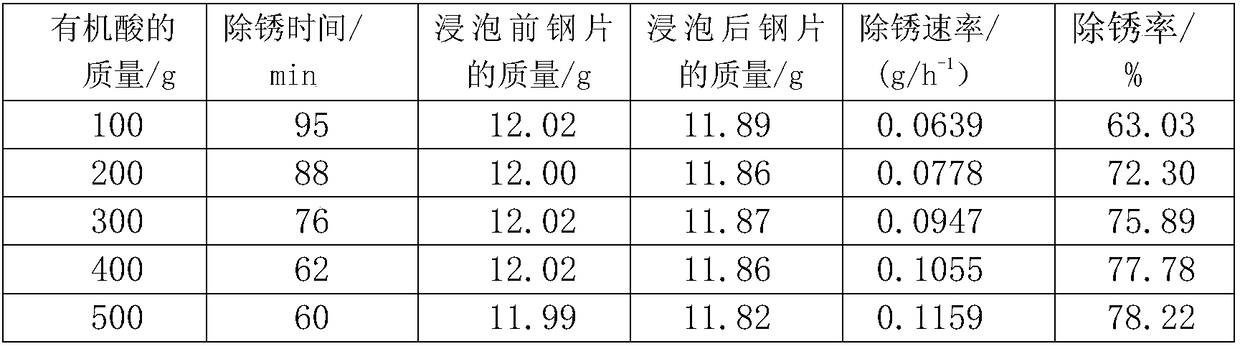

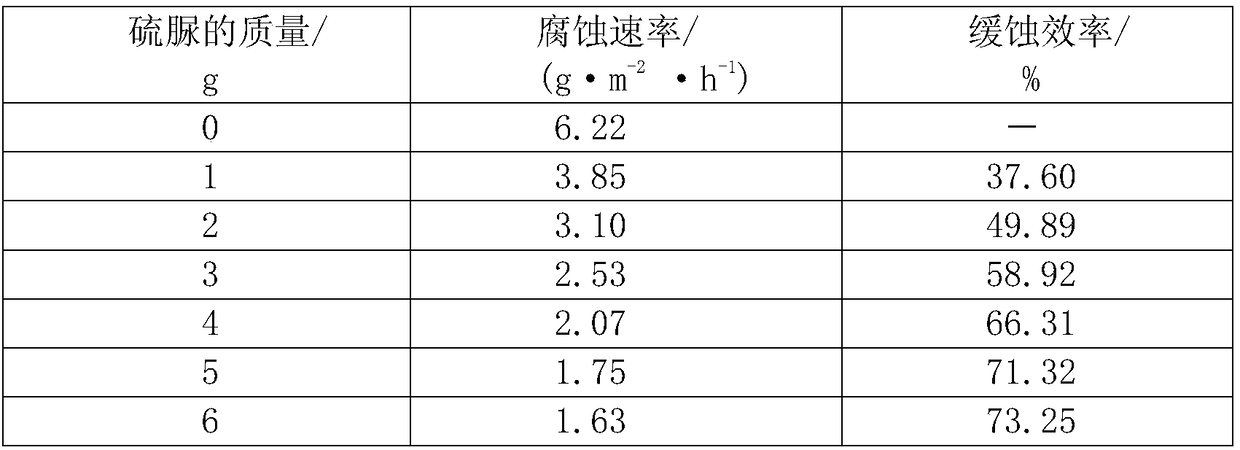

Embodiment Construction

[0011] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

[0012] 1 Rust removal principle

[0013] The rust (mFe2O3 · m1Fe2O3 · nFeO · nH2O) produced by corrosion on the surface of steel is loose and porous with a large surface area. The outermost layer of Fe2O3 is an intercalate structure, which is relatively dense. It has a certain protective effect, but it cannot prevent the penetration of water and oxygen. The structure of FeO in the inner layer is unstable, it can form with water

[0014] Fe(OH)2 can also react with oxygen to form Fe2O3 xH2O. The principle of removing rust is to use acid liquid to easily penetrate and diffuse into rust and quickly undergo a chemical reaction to dissolve it into iron salt and ferrous salt. Fe3+ and Fe2+ react with complexing agent to form stable complex and ions to achieve the purpose of complete elimination. Its main reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com