Environment-friendly urea resin for laminating plywoods from high water-content veneers and preparation and application thereof

An environmentally friendly urea-formaldehyde resin and formaldehyde technology, used in adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc. The effect of increased crosslink density, high bond strength and low formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

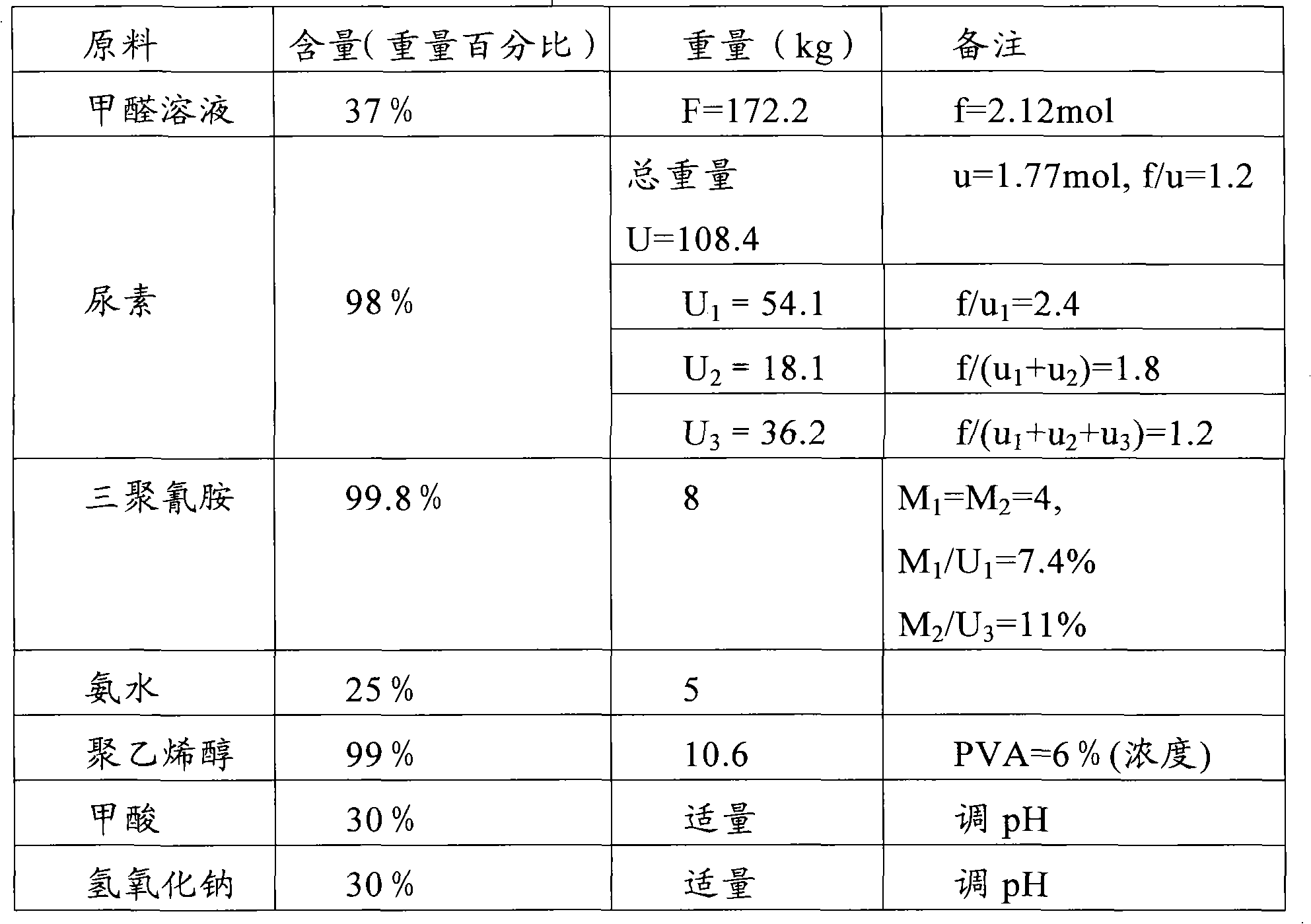

[0032] The raw material formula of table 1 embodiment one

[0033]

[0034] Note: F and U represent the weights of formaldehyde solution and urea added respectively, U 1 -U 3 respectively represent the weight of urea added in the first to third batches, f and u represent the moles of formaldehyde and urea respectively, u 1 -u 3 respectively represent the moles of urea added in the first to the third batch, and f / u represents the ratio of the moles of formaldehyde to the moles of urea.

[0035] Concrete reaction steps are as follows:

[0036] 1) Add 37% formaldehyde solution and PVA solution to the reaction kettle in sequence, turn on the steam to heat to 40-50°C, and turn off the steam;

[0037] 2) Use formic acid to adjust pH=4.0, and slowly add U 1 ,

[0038] 3) Then open the steam valve and turn off the steam when the temperature rises to 60-80°C, and raise the temperature to 90°C by the self-exothermic reaction. At 85°C, add M 1 and ammonia water, adjust the pH t...

Embodiment 2

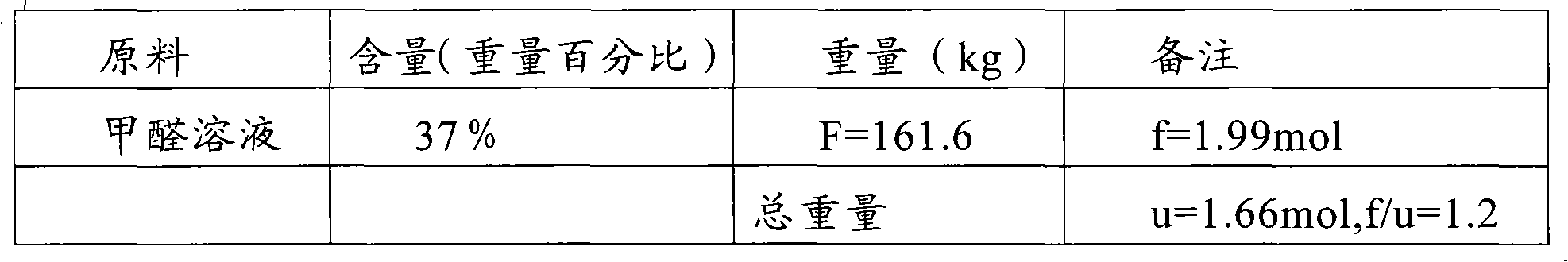

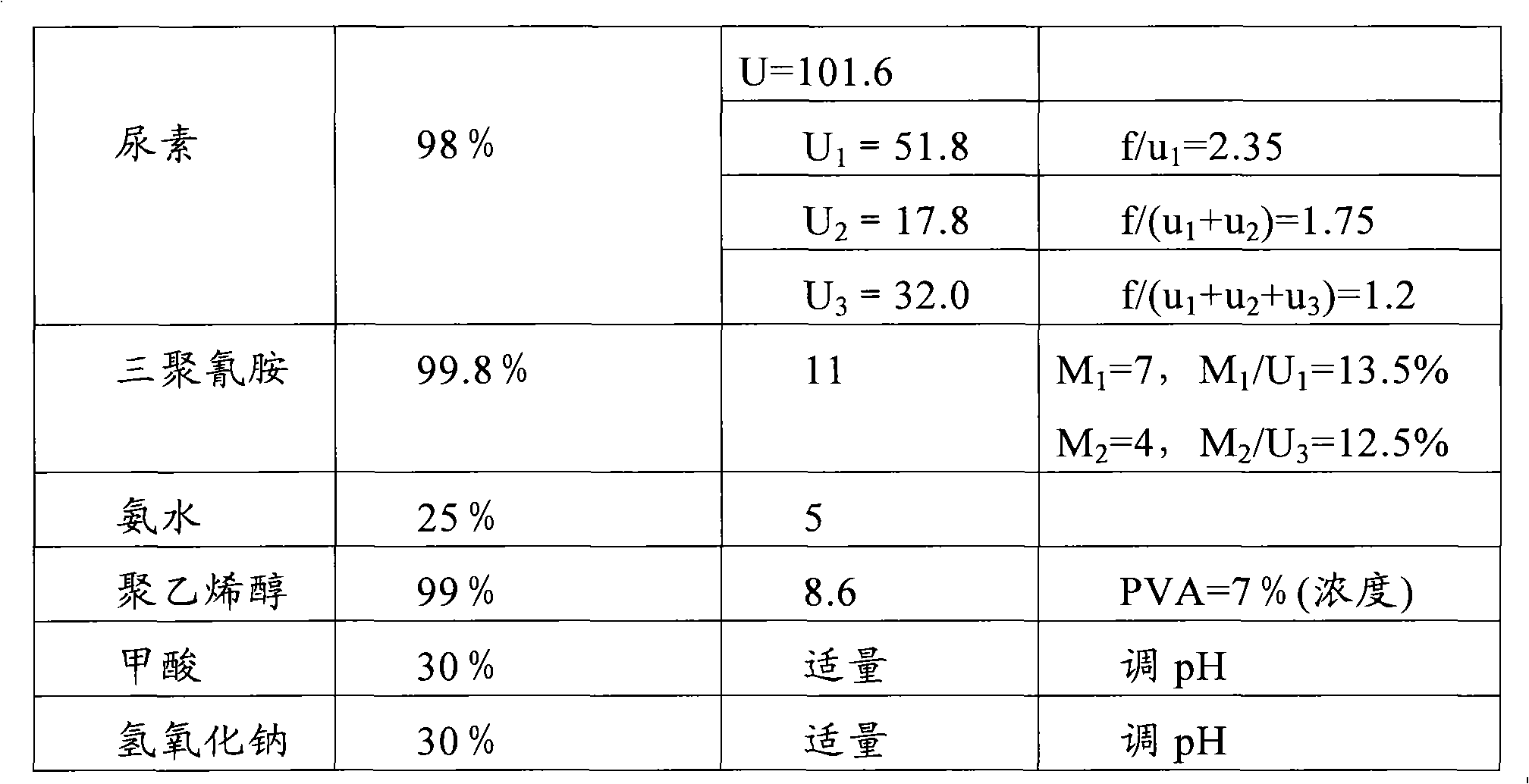

[0052] The raw material formula of table 2 embodiment two:

[0053]

[0054]

[0055] Note: F and U represent the weights of formaldehyde solution and urea added respectively, U 1 -U 3 respectively represent the weight of urea added in the first to third batches, f and u represent the moles of formaldehyde and urea respectively, u 1 -u 3 respectively represent the moles of urea added in the first to the third batch, and f / u represents the ratio of the moles of formaldehyde to the moles of urea.

[0056] Concrete reaction steps are as follows:

[0057] 1) Add 37% formaldehyde solution and PVA solution to the reaction kettle in sequence, turn on the steam to heat to 40-50°C, and turn off the steam;

[0058] 2) Use formic acid to adjust pH=4.2, and slowly add U 1 ,

[0059] 3) Then open the steam valve and turn off the steam when the temperature rises to 60-80°C, let it heat up to 90°C, and add M at 85°C 1 and ammonia water, adjust the pH to 8.5, and keep warm for 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com