Patents

Literature

137 results about "Toxic environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

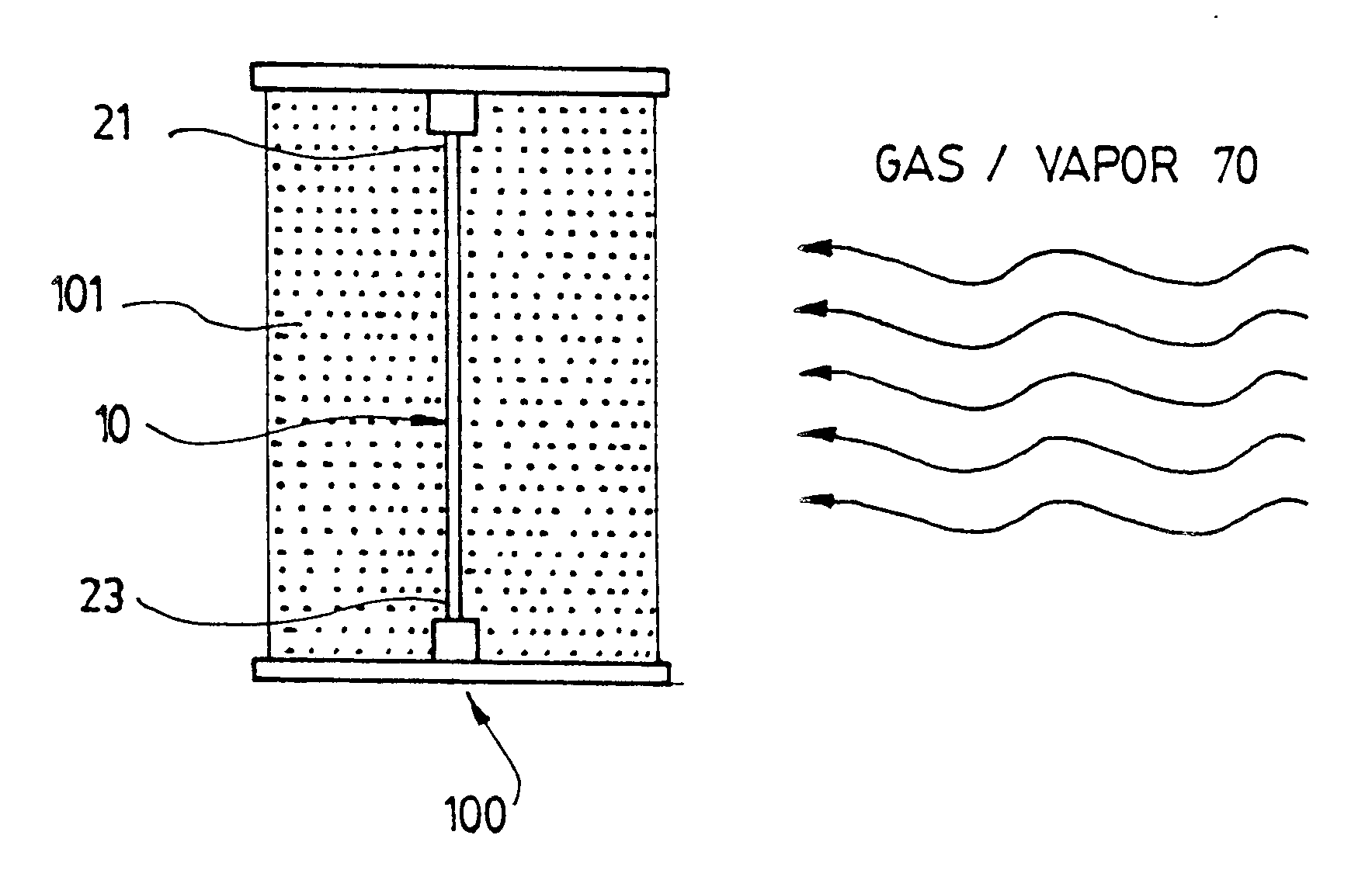

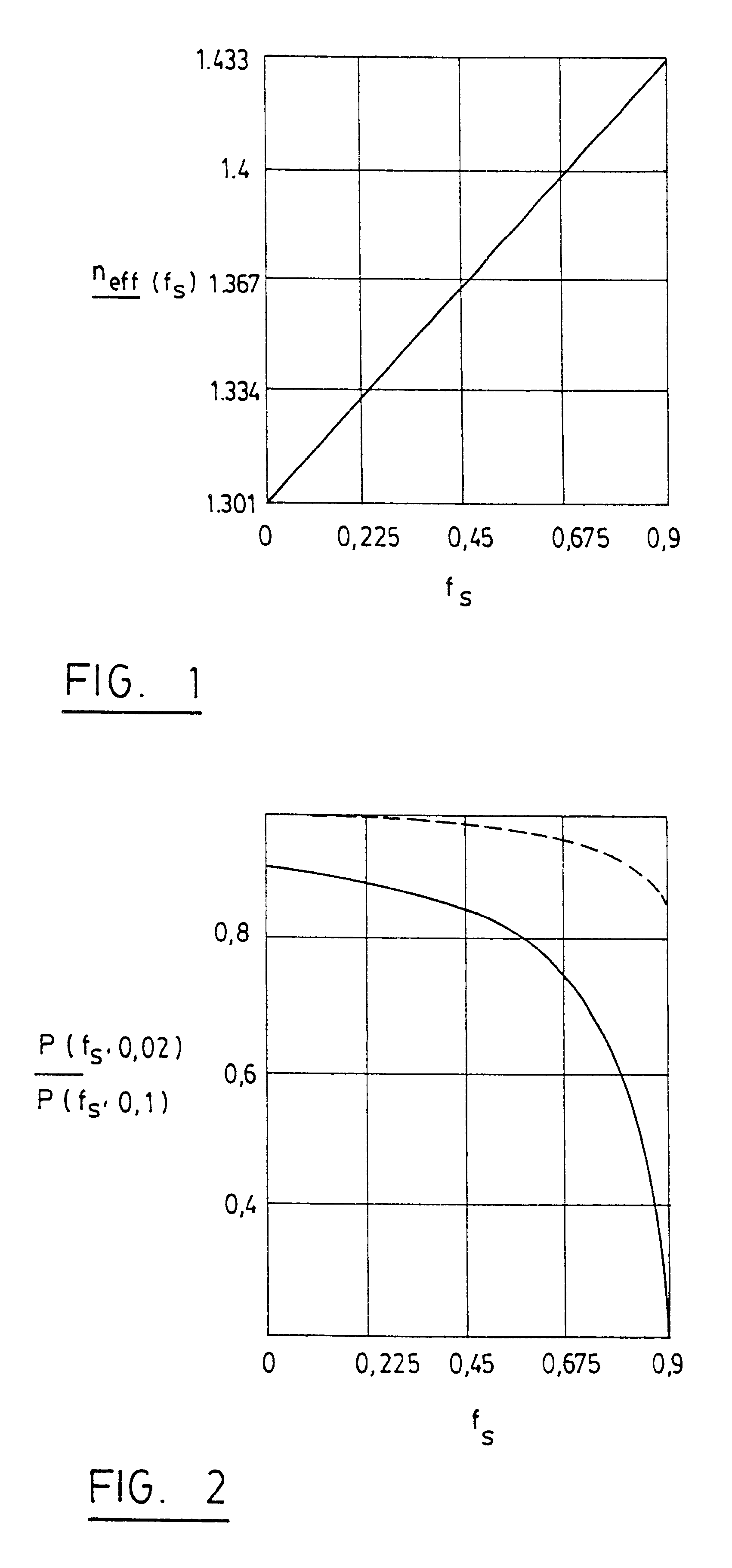

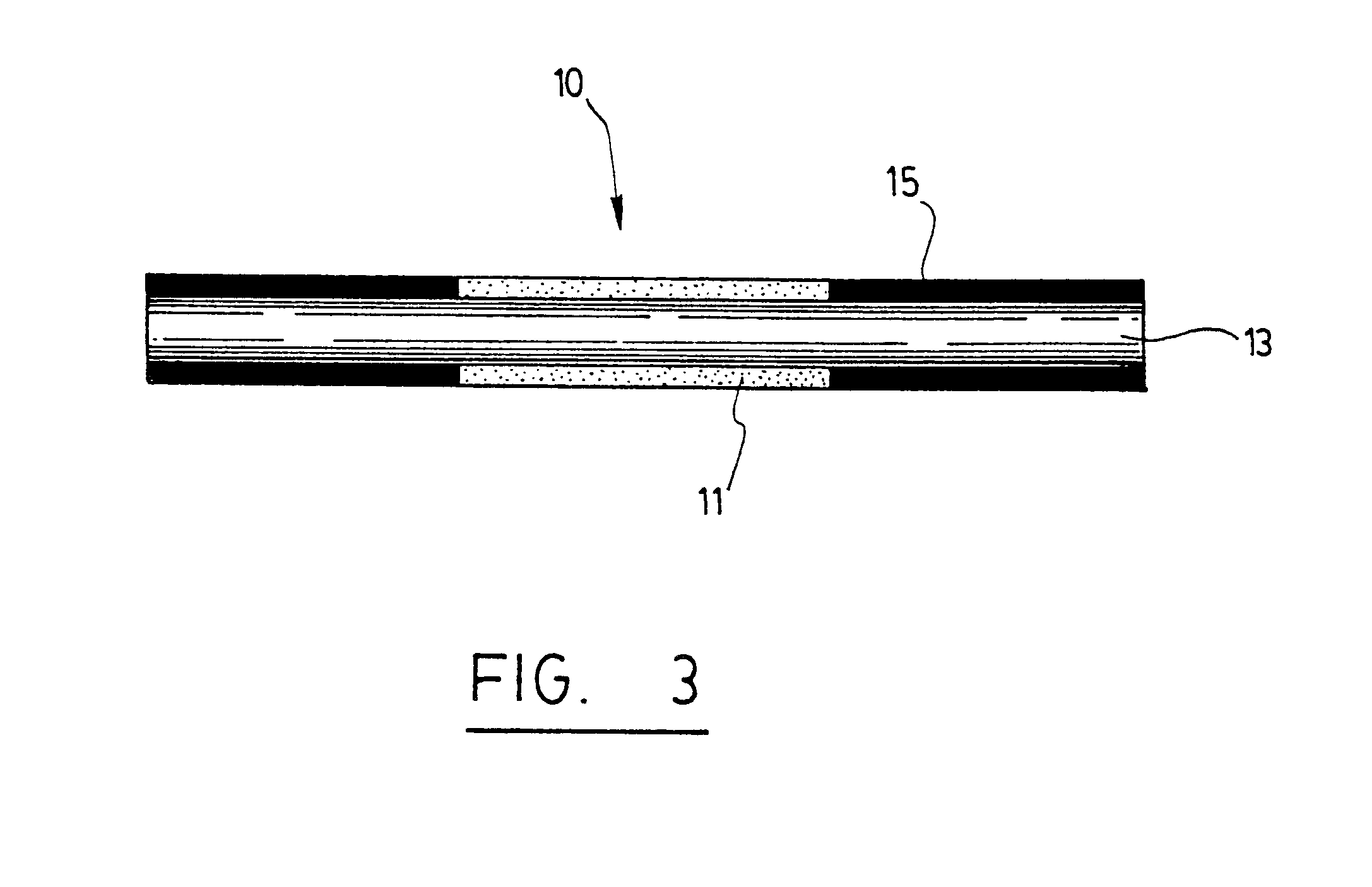

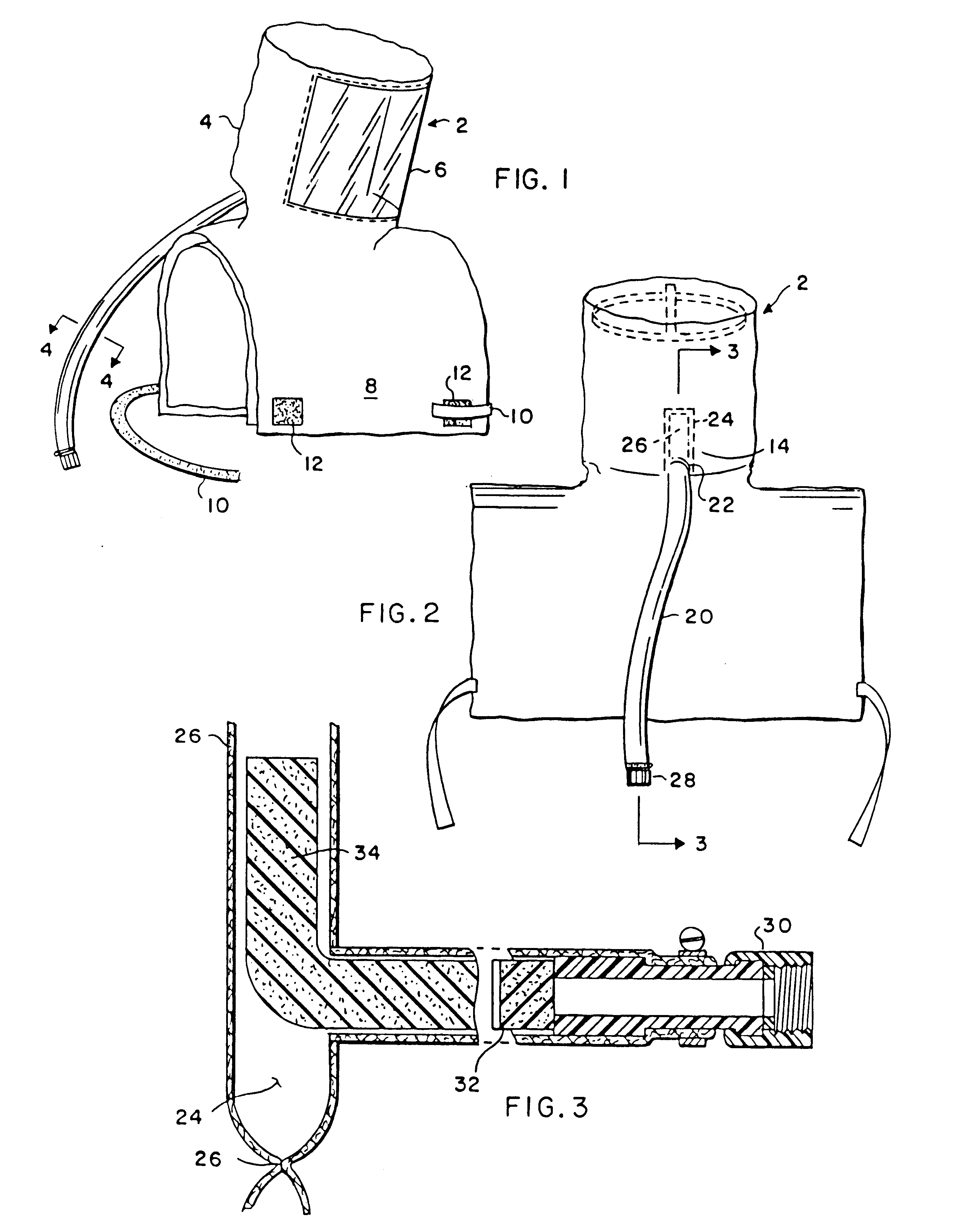

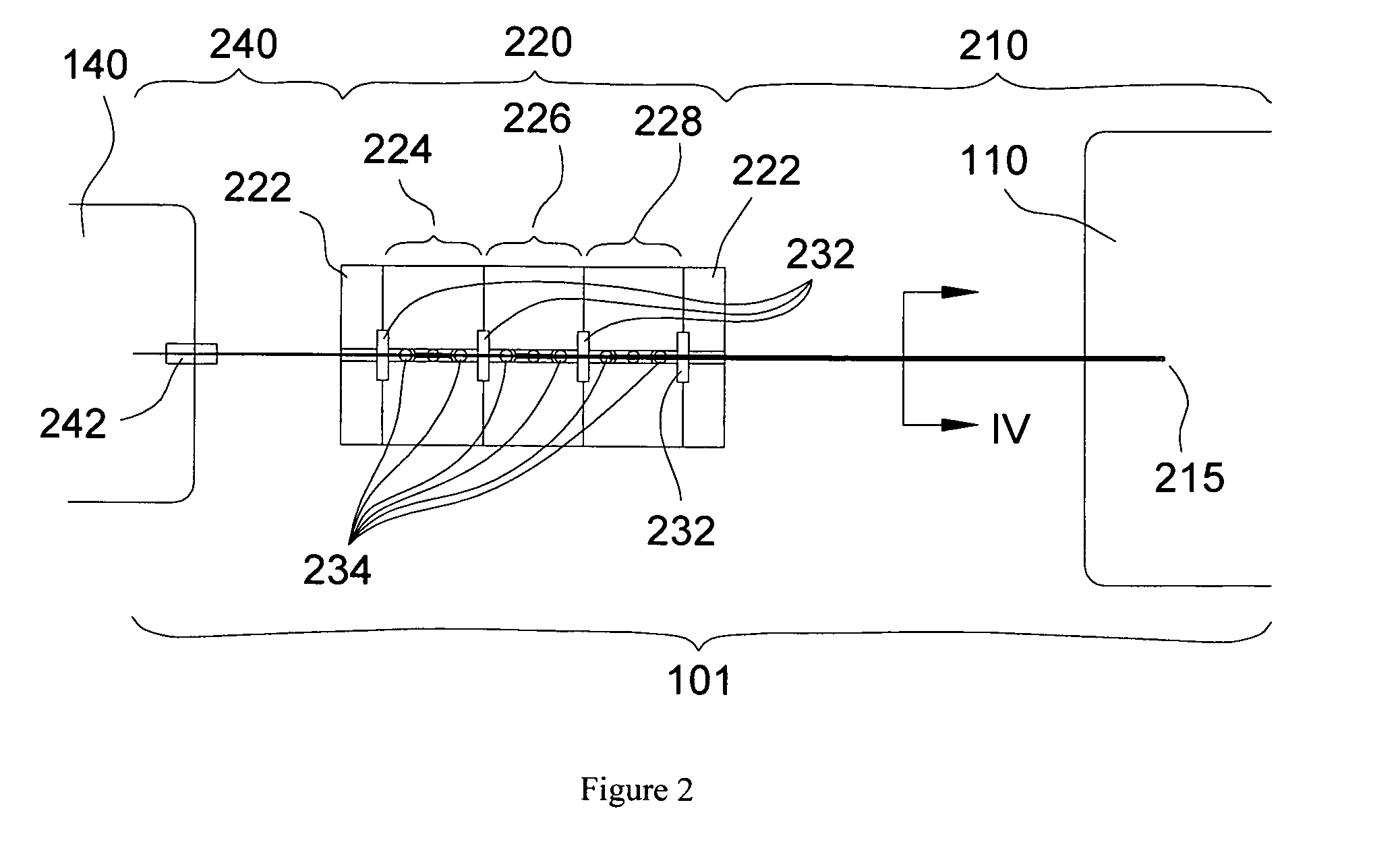

End-of-service indicator including a porous waveguide for respirator cartridge

An end-of-service indicator for use with a respirator cartridge, the end-of-service indicator having an optical waveguide having two extremities, one of the extremities being connected to a light source, the other of the extremities being connected to a detector which measures the intensity of light guided and transmitted by the fiber. An alarm is connected to the detector and is triggered when the intensity of light measured by the detector is below a predetermined level. An important aspect of the end-of-service indicator is that at least a portion of the optical fiber is porous. In use, the end-of-service indicator is placed inside a respirator cartridge having a gas / vapor sorbent, so that when the respirator cartridge is used in a toxic environment, the gas / vapor sorbent and the porous glass gradually become saturated. This porous glass will absorb the gas / vapor in the same fashion as the sorbent used in the respirator cartridge, thereby lowering the guiding and transmission properties of the optical fiber which loses the necessary conditions to guide light.

Owner:INSTITUT NATIONAL D'OPTIQUE +1

Production of pigments

InactiveUS6235104B1Low viscosityHigh flash pointFatty acid chemical modificationConductive materialVegetable oilLinseed oil

Metal pigment, especially aluminum pigment is produced in a non toxic environment by milling and / or blending in an inert medium comprising transesterified alkyl, especially methyl esters of vegetable oils selected from soybean oil, cotton seed oil and linseed oil. The metallic pigments produced are of improved quality and appearance. They have improved brightness and the non-leafing pigments produced have highly leafing characteristics.

Owner:DAHLIA IRELAND

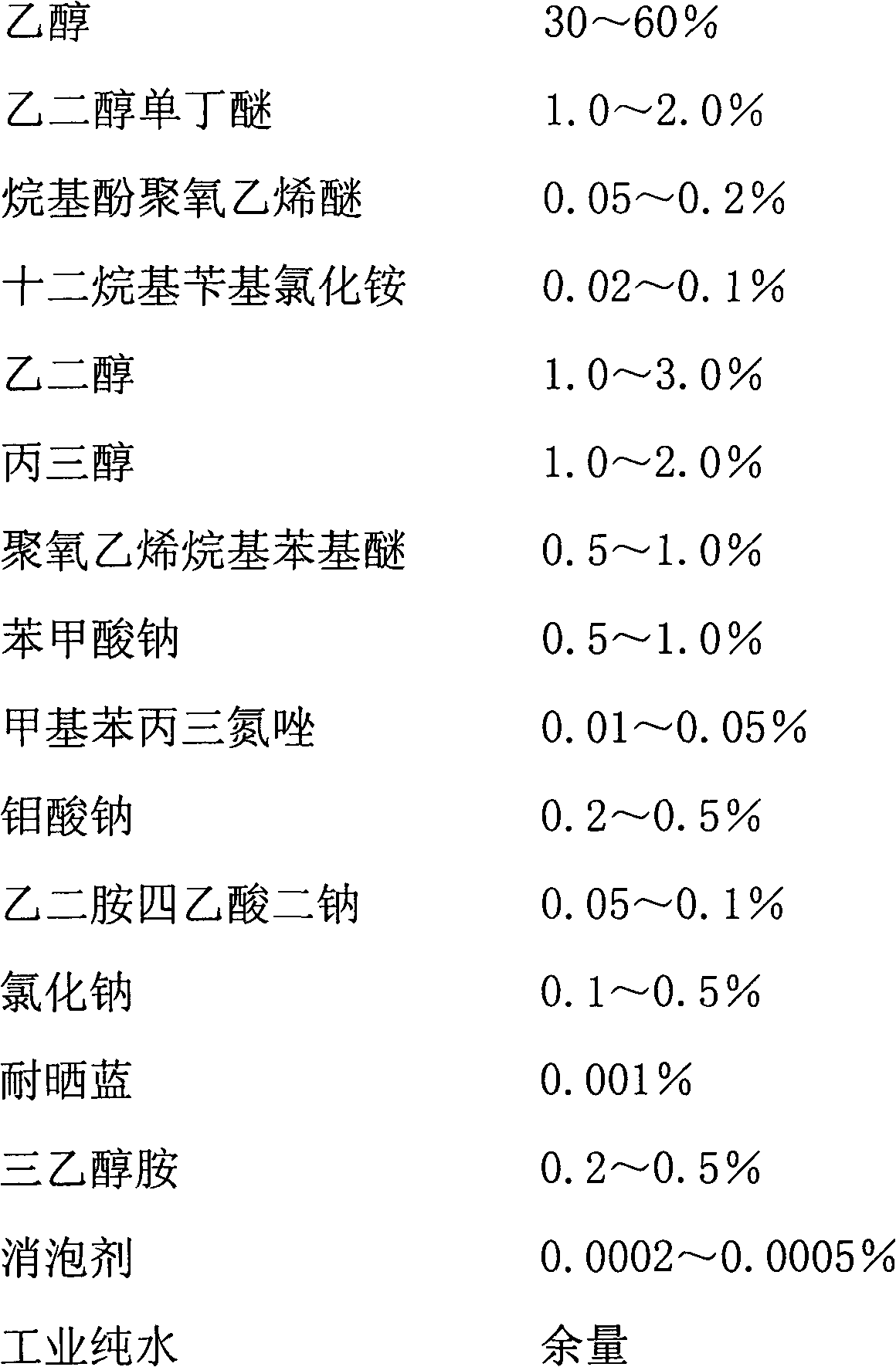

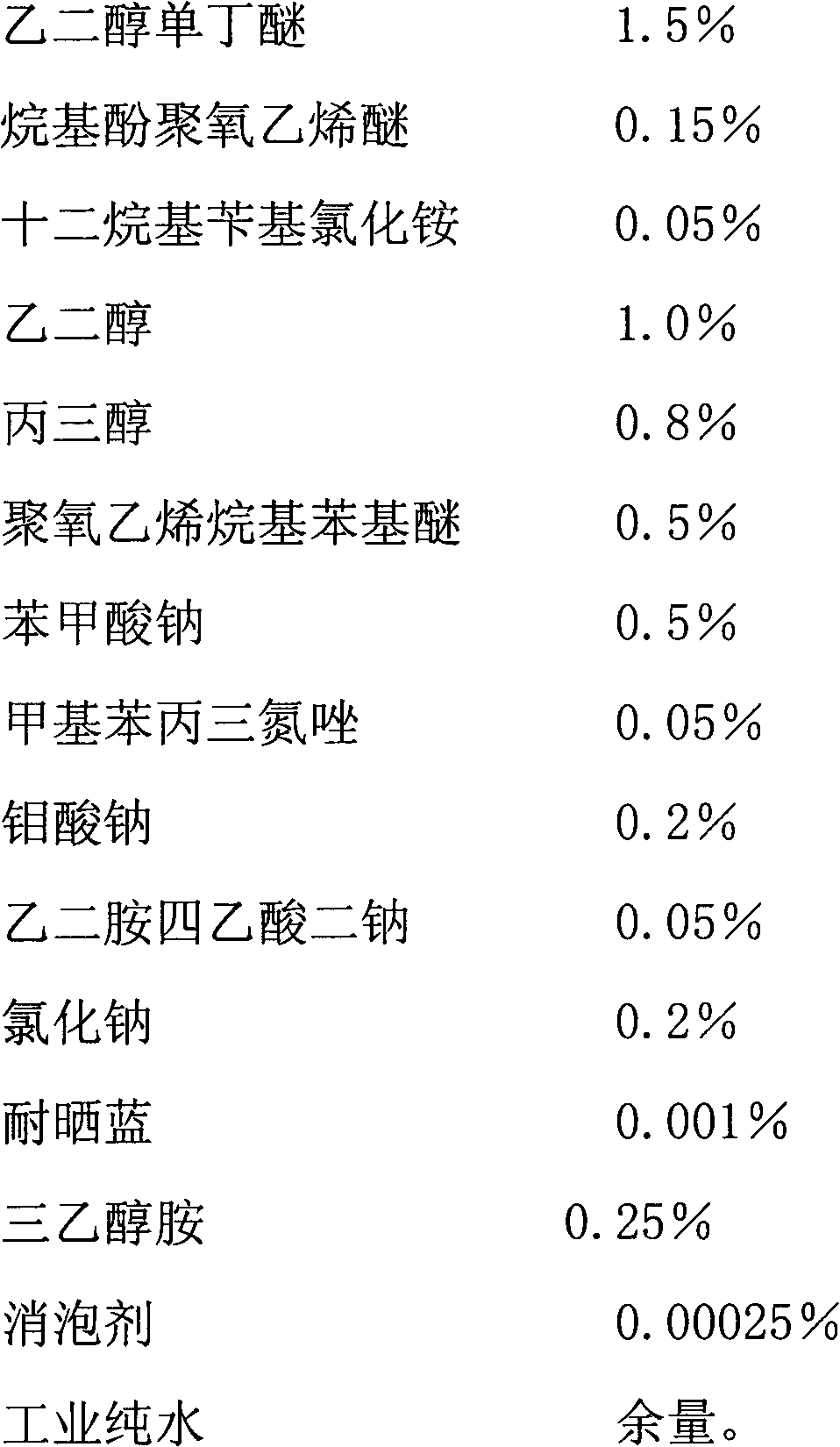

Long-acting environment-friendly automobile air window glass washing liquid

ActiveCN102492582ASolubilizeHigh speedSurface-active non-soap compounds and soap mixture detergentsPhenyl EthersGlycerol

The invention relates to a long-acting environment-friendly automobile air window glass washing liquid which is a non-toxic environment-friendly automobile air window glass washing liquid which can prevent freezing, prevent fog and remove ice and snow. The washing liquid is formed by stirring and reacting the following components by mass weight: ethanol, ethylene glycol monobutyl ether, alkylphenol polyoxyethylene ether, dodecyl benzyl ammonium chlorine, glycol, glycerol, polyoxyethylene alkyl phenyl ether, sodium benzoate, methyl benzotriazole, sodium molybdate, disodium ethylene diamine tetraacetate, sodium chloride, sunlight-resisting blue, triethanolamine, a defoaming agent and industrial pure water. By using the washing liquid, industrial methanol is prevented from being used as a solvent in the traditional formula; and simultaneously, the washing liquid and ethylene glycol monobutyl ether are matched and used, thereby greatly improving the dissolution effect of a single solvent on blots. The washing liquid disclosed by the invention is prepared by using non-toxic and easily biodegradable raw materials and is environment-friendly, can not pollute environment if being used for a long term, and prevents toxic gases from volatilization to harm a driver in the use process. The washing liquid has the characteristics of preventing fog, removing ice and snow, maintaining no icing on the surface of the glass for a long term, is not burnt and does not corrode.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

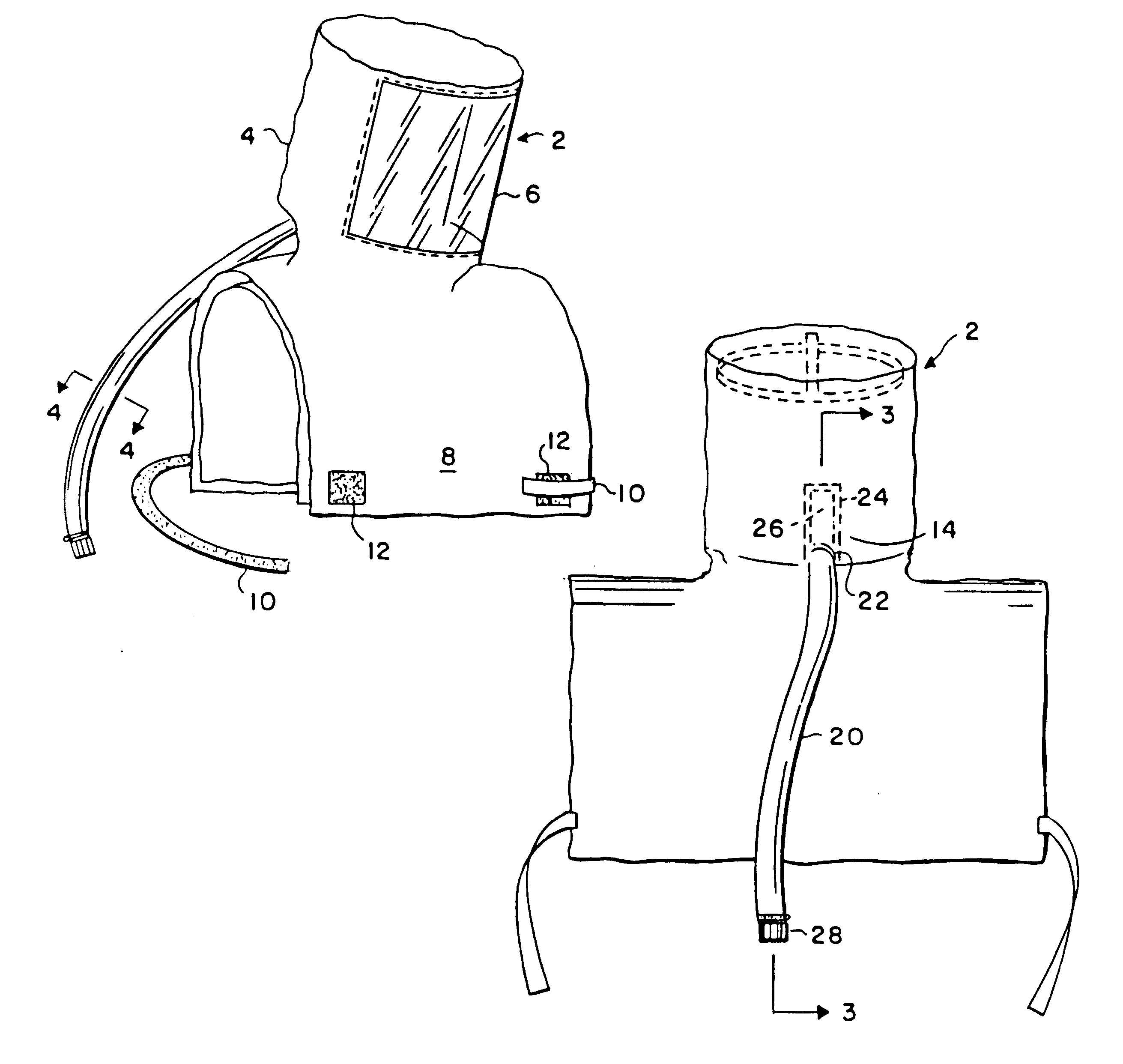

Disposable safety hood having unique air supply connector

InactiveUS6240567B1Improve dependabilityChemical protectionHeat protectionMechanical engineeringAtmosphere

Owner:NO FADE COATINGS

Preparation method of environment-friendly type precious metal beneficiation agent

ActiveCN103937986AAvoid pollutionEfficient leachingProcess efficiency improvementLead saltSodium cyanide

The invention relates to a preparation method of a low-toxic environment-friendly type novel precious metal beneficiation agent. Raw materials of the low-toxic environment-friendly type novel precious metal beneficiation agent comprise a cyanate, sodium hydroxide, sodium sulfate, sodium ferrocyanide, a bromide, and a lead salt. The preparation method comprises following steps: sodium cyanate, sodium hydroxide, sodium sulfate, and sodium ferrocyanide are mixed at a certain ratio; an obtained mixture is delivered into a smelting pot which is heated to be slightly red, and is heated to 650 to 750 DEG C so as to obtain a fused material, temperature is maintained to be 750 DEG C for 30 to 50min of reaction, and then an obtained product is collected and cooled; the obtained product is smashed, the bromide and the lead salt are added for stirring, and the environment-friendly type precious metal beneficiation agent is obtained via combination. The environment-friendly type precious metal beneficiation agent can be widely used for precious metal beneficiation metallurgy of nonferrous metals ores, contains no hypertoxic compounds, is safe for human and animal, and is friendly to the environment. Compared with other metal beneficiation agents, the environment-friendly type precious metal beneficiation agent is excellent in effects, stable in performance, and low in production cost; the preparation method is simple; and environmental protection can be realized.

Owner:广西河池鑫银环保科技有限公司

Non-toxic environment-friendly solvent type double-layer nanofiber skin dressing and preparation method thereof

InactiveCN110772661APromote healingImprove comfortAbsorbent padsNon-woven fabricsSpinningDermal dressing

The invention discloses a non-toxic environment-friendly solvent type double-layer nanofiber skin dressing and a preparation method thereof. The non-toxic environment-friendly solvent type double-layer nanofiber skin dressing comprises a drug-loaded hydrophilic repair natural polymer fiber layer and a waterproof and breathable synthetic polymer fiber layer, and is prepared by adopting a non-toxicenvironment-friendly solvent system through an electrostatic spinning technology layer by layer. The preparation method comprises the steps that a natural polymer and a drug are dissolved in a non-toxic environment-friendly solvent, and a cross-linking agent is added; a synthetic polymer is dissolved in the non-toxic environment-friendly solvent, and a water repellent agent is added; and a naturalpolymer solution and a synthetic polymer solution are placed in an injection syringe, and an electrostatic spinning device is adopted for spinning to prepare a double-layer fiber membrane. The double-layer nanofiber skin dressing prepared through the preparation method does not contain a toxic solvent, and does not generating toxic and side effects on open wounds when serving as the dressing; andthe double-layer nanofiber skin dressing has waterproof and breathable performance, is good in cytocompatibility, can promote wound healing of rats with skin damages, and has the huge application prospects in the field of skin dressings.

Owner:DONGHUA UNIV

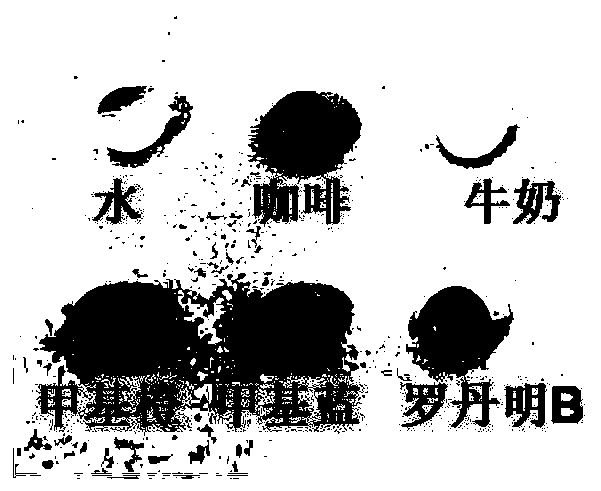

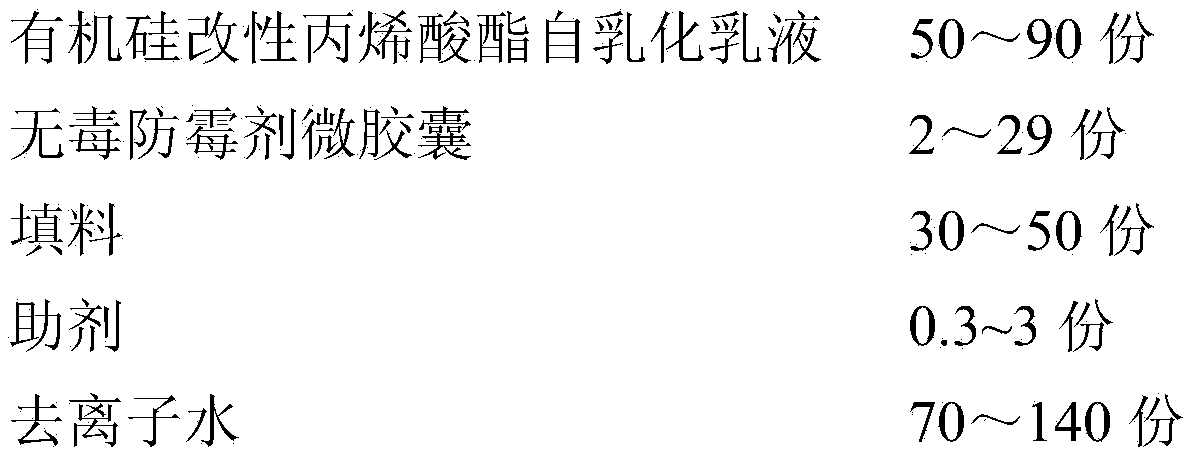

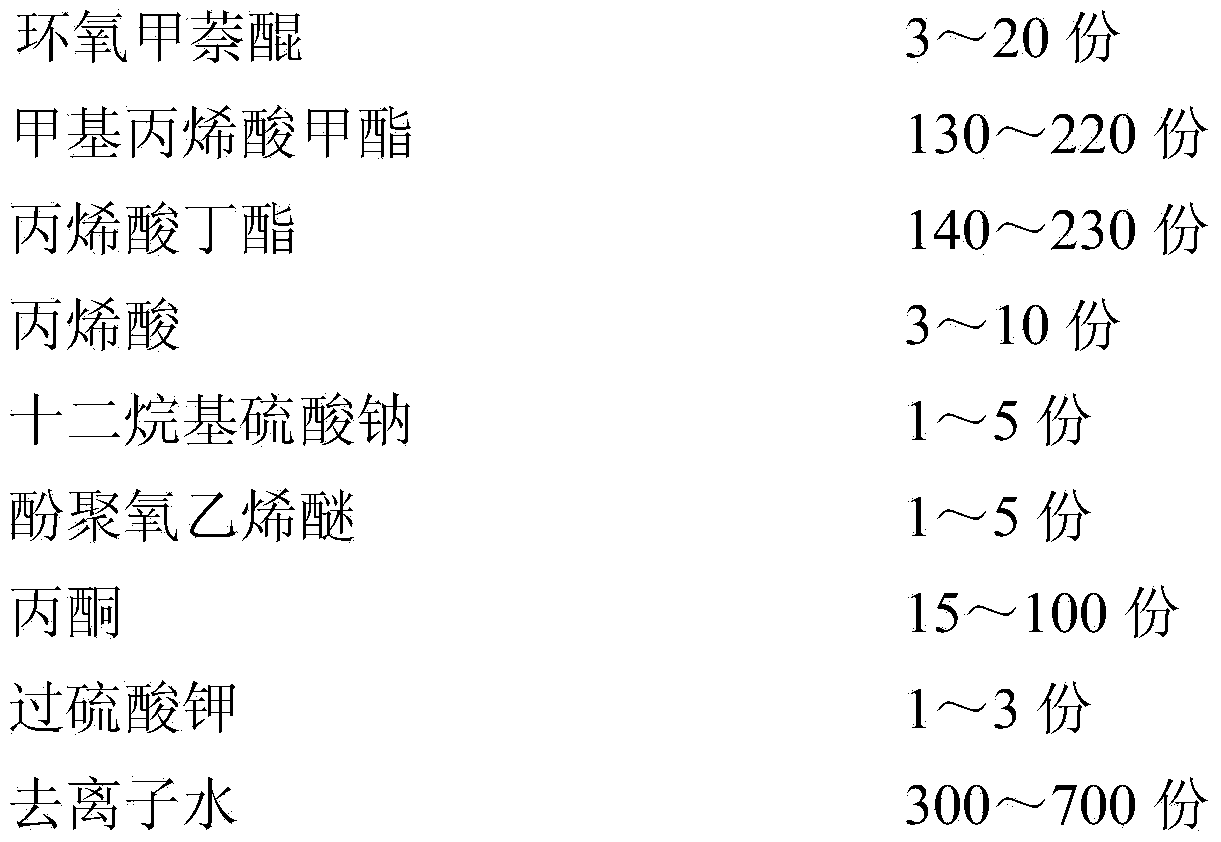

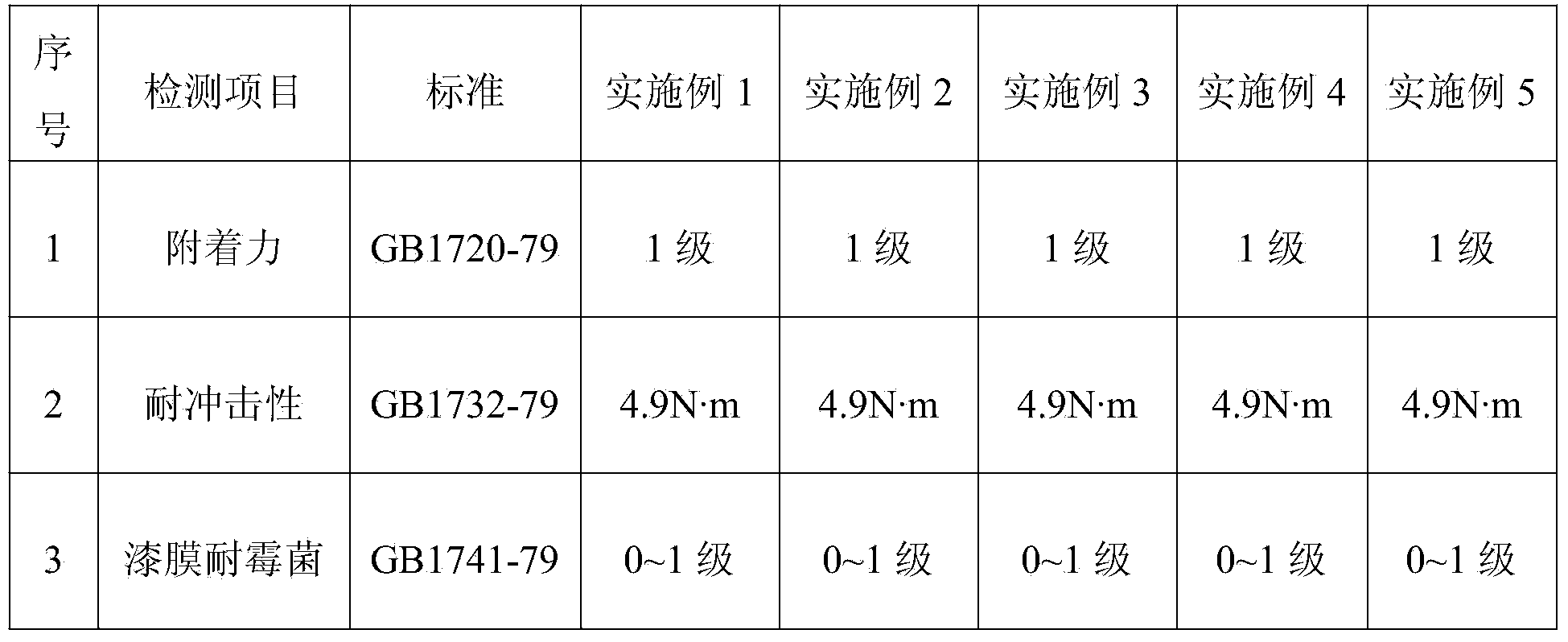

Non-toxic water-based microcapsule mold-proof heat insulation coating and preparation method thereof

ActiveCN104017453AGood antifoulingImprove mildew resistanceAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention provides a non-toxic water-based microcapsule mold-proof heat insulation coating and a preparation method thereof and relates to the field of mold-proof heat insulation coatings. The mold-proof heat insulation coating mainly consists of organosilicone modified acrylate self-emulsifying emulsion, non-toxic mildew preventive microcapsules, fillers, aids and deionized water, wherein in the non-toxic mildew preventive microcapsules, epoxy menadione and other oleophilic anti-fouling compositions are taken as capsule cores, and polyacrylate serves as a capsule wall; the mildew preventive uniformly and effectively diffuses for a long time. The water-based microcapsule mold-proof coating adopts a non-toxic environment-friendly mold-proof heat insulation material, is non-toxic, has obvious mold-proof heat insulation effects, has service life longer than that of a traditional mold-proof coating and has excellent physical performances such as high washing resistance, high adhesive force and high impact resistance.

Owner:DALIAN XINE TECH

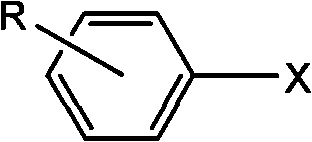

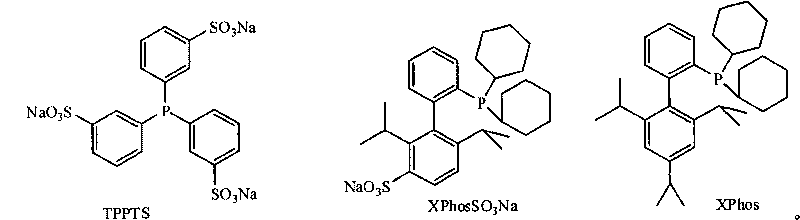

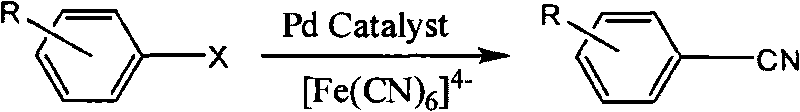

Synthetic method of aryl cyanide in water solution

InactiveCN101717350AEasy to separateReduce pollutionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by cyanide reactionSolubilityPalladium catalyst

The invention relates to a synthetic method of an aryl cyanide in a water solution, which comprises the following steps: adding an aryl compound, a ferrocyanide and a phase transfer agent into an alkaline water solution, or adding the aryl compound and the ferrocyanide into a mixed solution of alkaline water and an organic solution; controlling the reaction temperature at 30 DEG C-140 DEG C; and synthesizing the aryl cyanide by catalytic coupling of a metal palladium catalyst. In the invention, the non-toxic environment-friendly ferrocyanide is used as a cyanide source for synthesizing the aryl cyanide, and water is used as an environment-friendly solvent to substitute the virulent cyanide and the organic solvent in the prior art, thereby solving the problem of environment pollution in the process of synthesizing the aryl cyanide. In the invention, good solubility of the ferrocyanide in the water and the strong polarity of the ferrocyanide are used, thereby greatly promoting the generation of the aryl cyaniding reaction, the cyaniding reaction can be finished at lower temperature (30 DEG C-140 DEG C), the reaction yield is high, and the application range of the aryl cyaniding reaction is improved.

Owner:NANJING UNIV OF TECH

Non-toxic environment-friendly normal temperature steel nigrescence treating agent and preparation method thereof

InactiveCN102994996APromote environmental protectionQuality improvementMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a non-toxic environment-friendly normal temperature steel nigrescence treating agent, which consists of the following components by mass percent: 1-5% of blue copperas, 1-4% of zinc dihydrogen phosphate, 1-6% of zinc nitrate, 0.1-0.3% of citric acid, 1-2% of EDTA(ethylene diamine tetraacetic acid)-disodium, 1-6% of sodium thiosulfate, 1-4% of ammonium molybdate, 0.5-1.5% of nickel sulfate hexahydrate, 0.1-0.6% of hydroquinone, 0.5-1.5% of potassium dichromate and the balance of water. The steps of the preparation method is as follows in sequence: firstly adding water calculated and weighted into a reaction kettle, starting a stirrer, controlling the rotated speed within 60 turns per minute, then sequentially and slowly adding the blue copperas, nickel sulfate hexahydrate, citric acid, zinc dihydrogen phosphate, zinc nitrate, EDTA-disodium, sodium thiosulfate, ammonium molybdate, hydroquinone, and potassium dichromate that are calculated and weighted into the reaction kettle, wherein each raw material added into the reaction kettle needs to be stirred for complete dissolution so as to obtain yellowgreen white out uniform liquid finally.

Owner:DALIAN SANDAAOKE CHEM

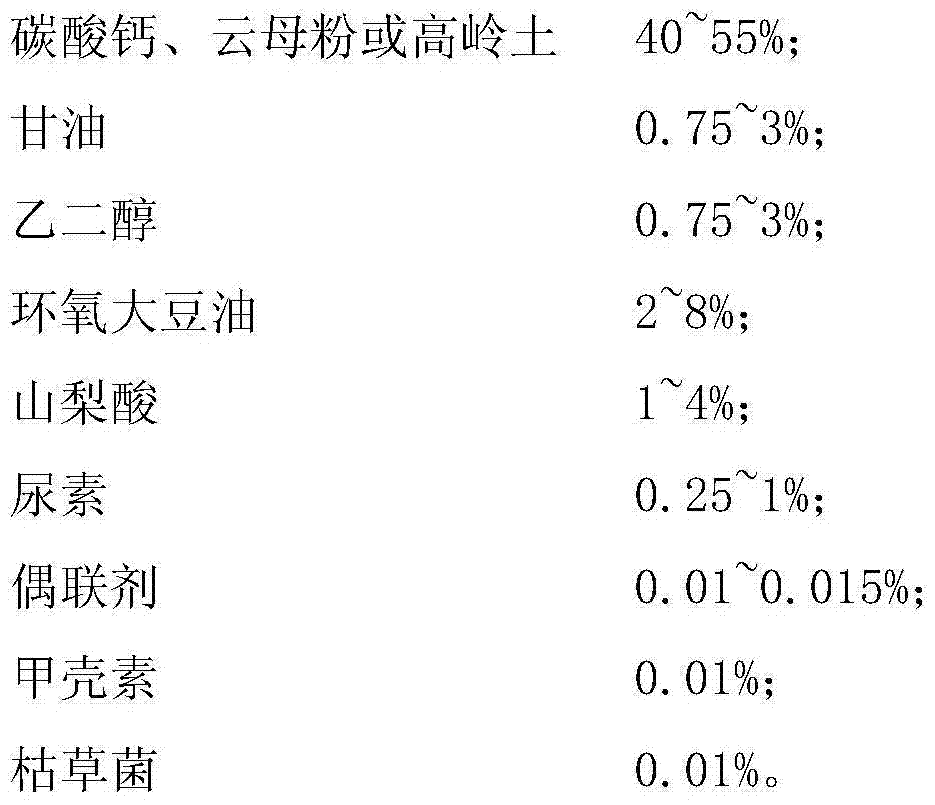

Noctilucent environment-friendly PVC (Polyvinyl Chloride) coated fabric

The invention discloses a noctilucent environment-friendly PVC (Polyvinyl Chloride) coated fabric. The noctilucent environment-friendly PVC coated fabric is composed of high-strength dacron cloth and a coating layer, wherein the coating layer is coated on the high-strength dacron cloth, and the coating layer and the high-strength dacron cloth are heated and dried to be formed. The coating layer comprises the following components in parts by weight: 70-90 parts of PCV paste resin, 100 parts of a packing material, 50-80 parts of a plasticizer, 0.5-1.5 parts of a mildew preventive, 0.5-1.5 parts of a stabilizer and 5-10 parts of a halogen-free frame retardant. The packing material comprises the following components in parts by weight: 20-50 of photoinduced energy storage noctilucent powder, 25-40 of white carbon black and 25-40 of aluminium hydroxide. According to the noctilucent environment-friendly PVC coated fabric, the photoinduced energy storage noctilucent powder is used as the component of the packing material, so that the coating layer can give out light at night or in dark and is safe and reliable, and energy sources are saved. The prepared product is green and environment-friendly due to the application of various non-toxic environment-friendly preparations, and the phenomenon that workers are poisoned is avoided.

Owner:GUANGDONG UPAL DISPLAY TECH CO LTD

Building stone surface curing agent and preparation method thereof

The invention relates to a stone surface curing agent, in particular to a building stone surface curing agent and a preparation method thereof. The building stone surface curing agent consists of the following components in percentage by weight: 50 to 80 percent of arene removed naphtha, 5 to 50 percent of fluoroalkyl acrylic copolymer, and 1 to 20 percent of one or combination of amino modified silicon oil, methyl hydrogen-containing silicon oil with hydrogen content of 0.2 to 1.6 percent and trialkoxysilane. Compared with the prior art, the organic fluorine material with extremely low surface energy and good hydrophobic, oleophobic and weather-resistant effects and the silicon material with good water-proof property are used, and a non-toxic environment-friendly solvent with good permeability is used, so the air permeability of stone is kept, the natural stone has good water-proof, oil-proof and weather-resistant attributes, the environment resisting capability of the stone is enhanced, the service life of the natural stone is effectively improved, natural textures of the stone can be kept for a long term, and the stone is prevented from being damaged by natural climates.

Owner:FUJIAN CHANGDE PLASTIC IND

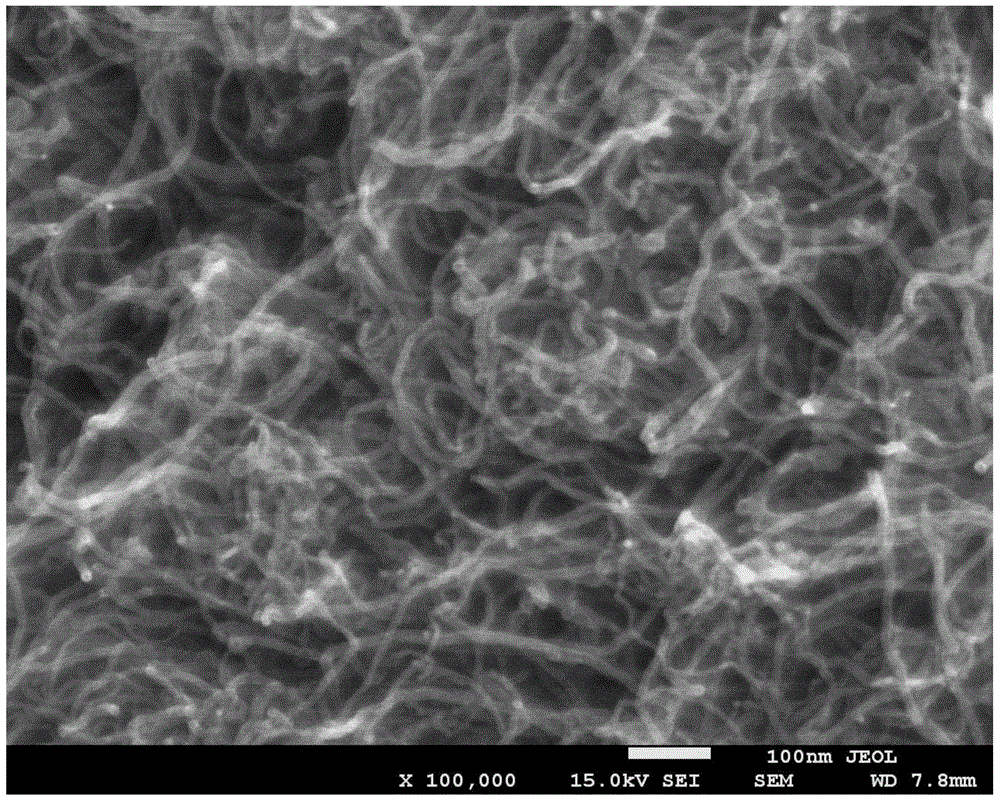

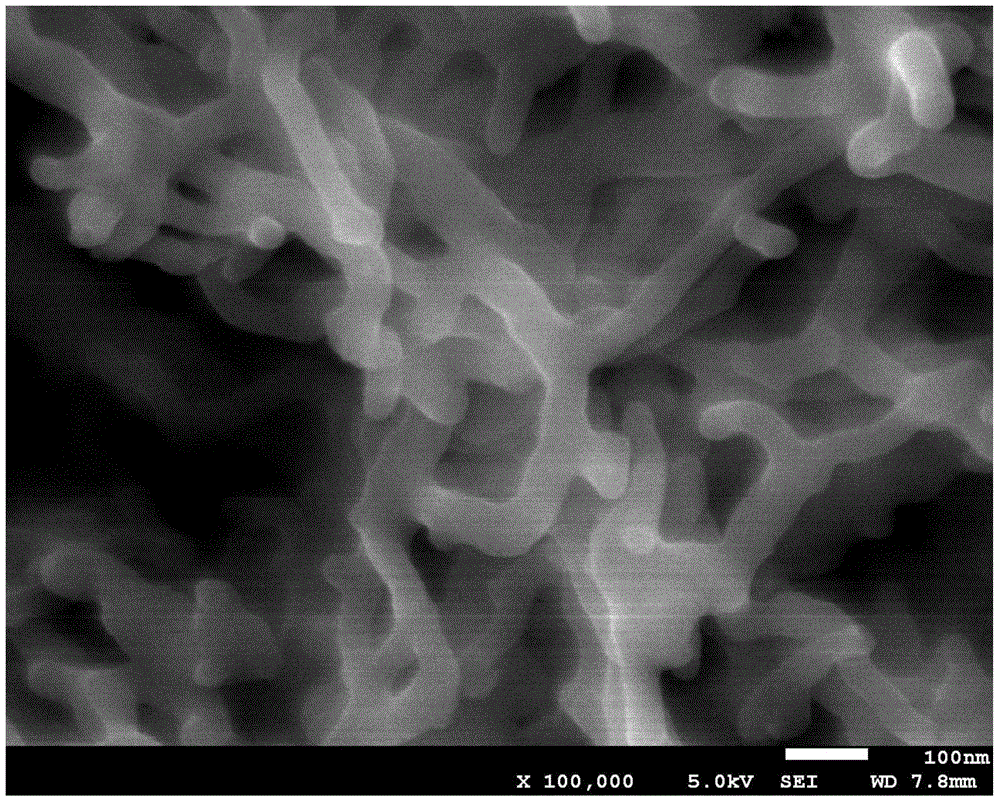

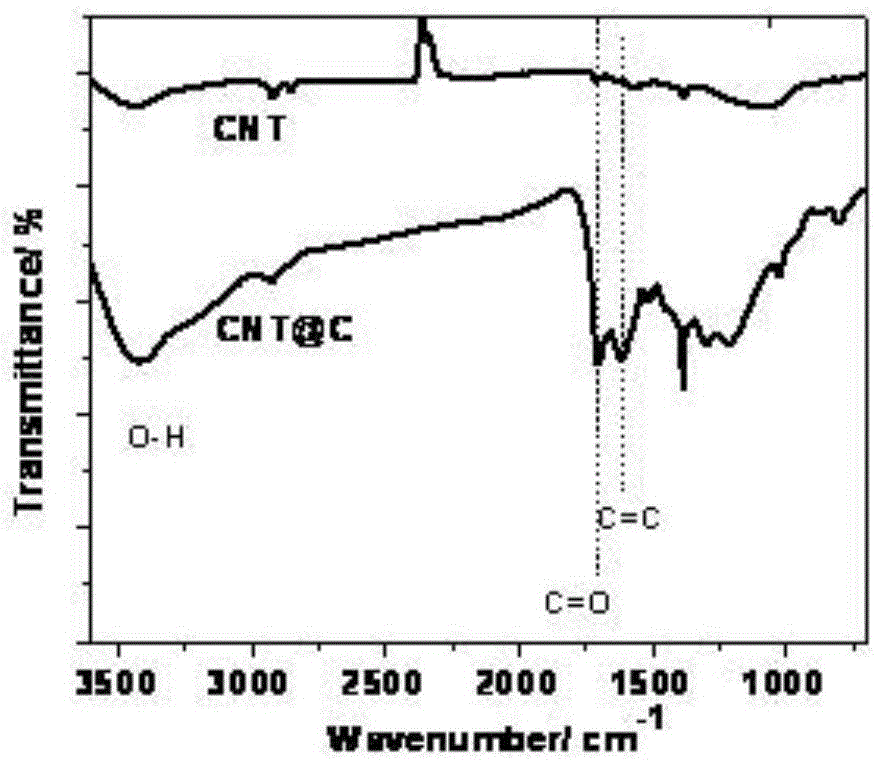

Method for surface modification of carbon material

The invention discloses a method for surface modification of a carbon material. By adopting a safe, low-cost, non-toxic environment-friendly structure-directing agent and a one-pot hydrothermal method, functionalized radicals are simply and efficiently introduced into surfaces of carbon nanotubes and graphene so that the surface of the carbon material is significantly modified, the structure stability of the carbon material is maintained to the greatest extent, the dispersion of the carbon material in a solution is improved, the carbon material has good dispersing effect in the process that a dispersion liquid is maintained for a long time and thus the carbon nanotubes and graphene can be uniformly dispersed and stably exist in different matrix materials and the mechanical property, electrical conductivity and the like of a composite material can be significantly improved. Compared with the prior art, the method disclosed by the invention has the advantages that environmental friendliness is achieved, large-scale production can also be achieved and no highly toxic waste is produced and the method is simple, efficient and safe and, thus being a very promising and efficient modification method of carbon material.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

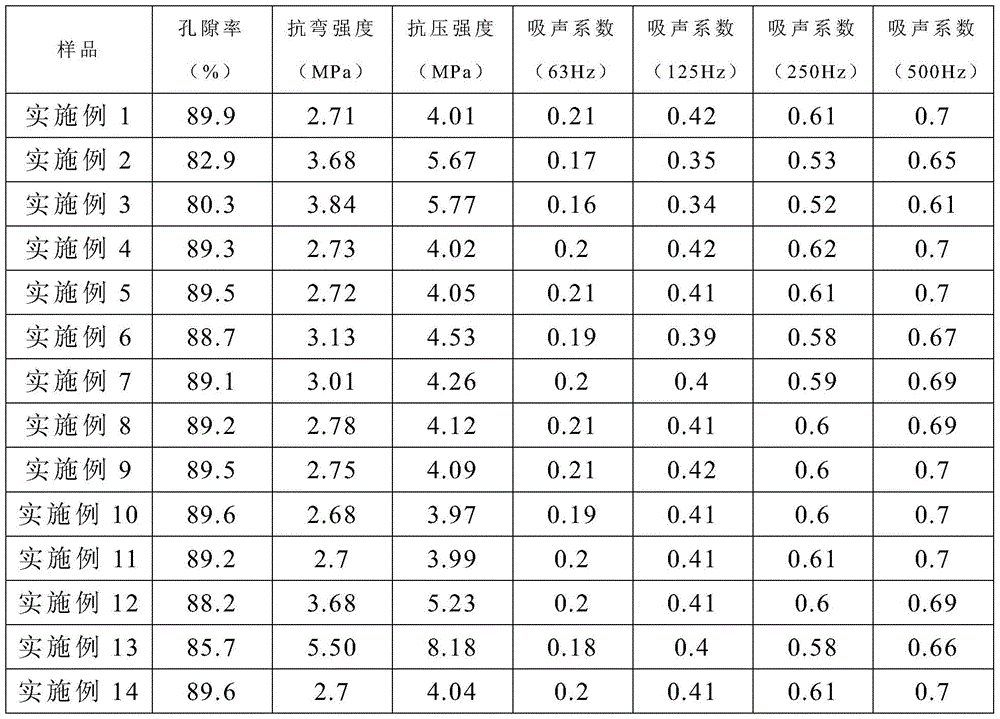

Preparation method of aluminum oxide porous foam ceramic sound absorption material

The invention discloses a preparation method of an aluminum oxide porous foam ceramic sound absorption material. The method comprises the following steps of 1, liquid preparation; 2, slurry forming; 3, shaping; 4 sintering. The non-toxic environment-friendly sepharose solution is used as gel; the aluminum oxide porous foam ceramic sound absorption material is prepared by a foam gel injection method; the prepared aluminum oxide porous foam ceramic sound absorption material has good sound absorption performance and mechanical intensity; the cost of equipment required by the preparation process is lower; the operation is convenient; the preparation period is shorter; the used raw materials are simple and can be easily obtained; the preparation method is suitable for industrial mass production.

Owner:STATE GRID CORP OF CHINA +2

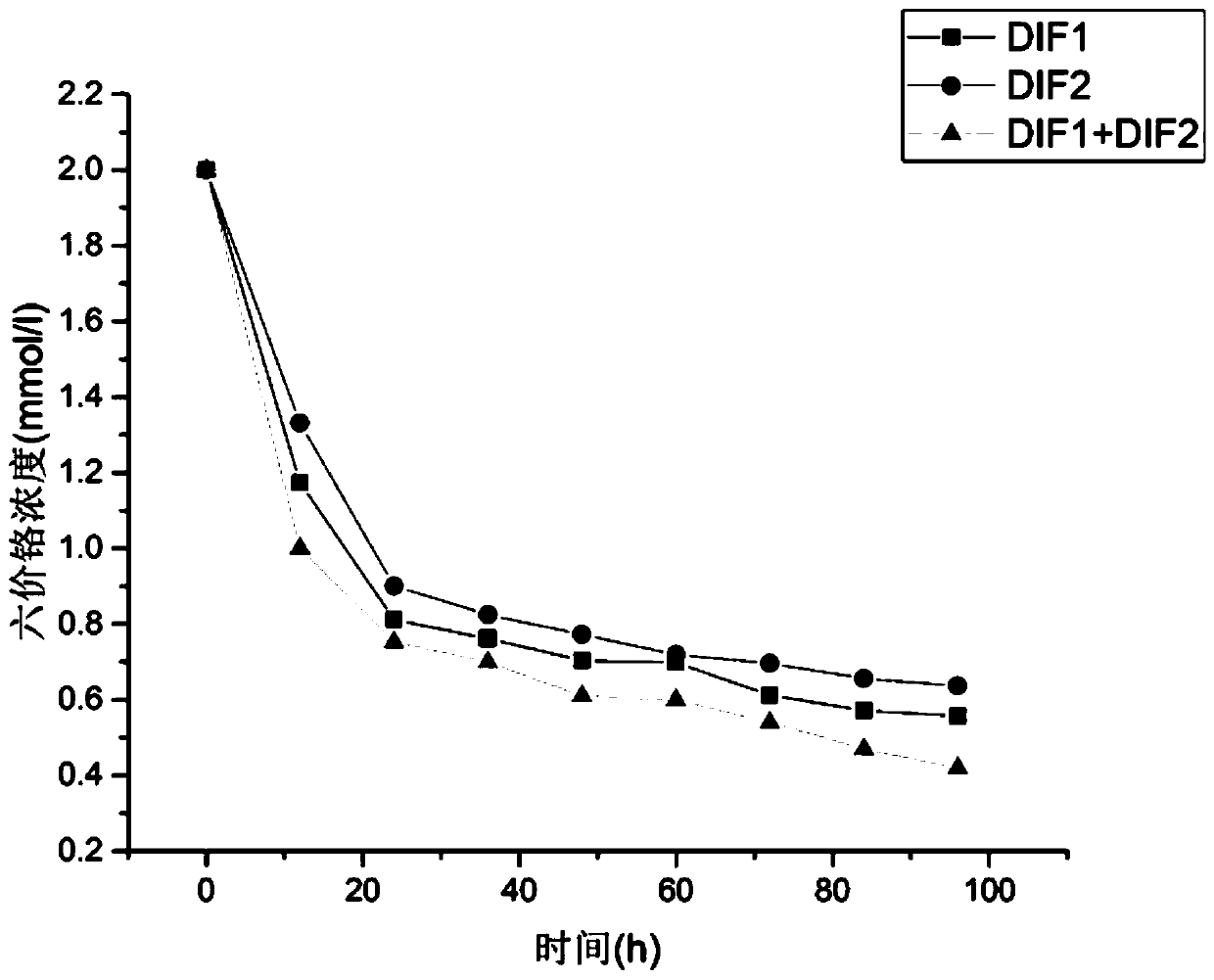

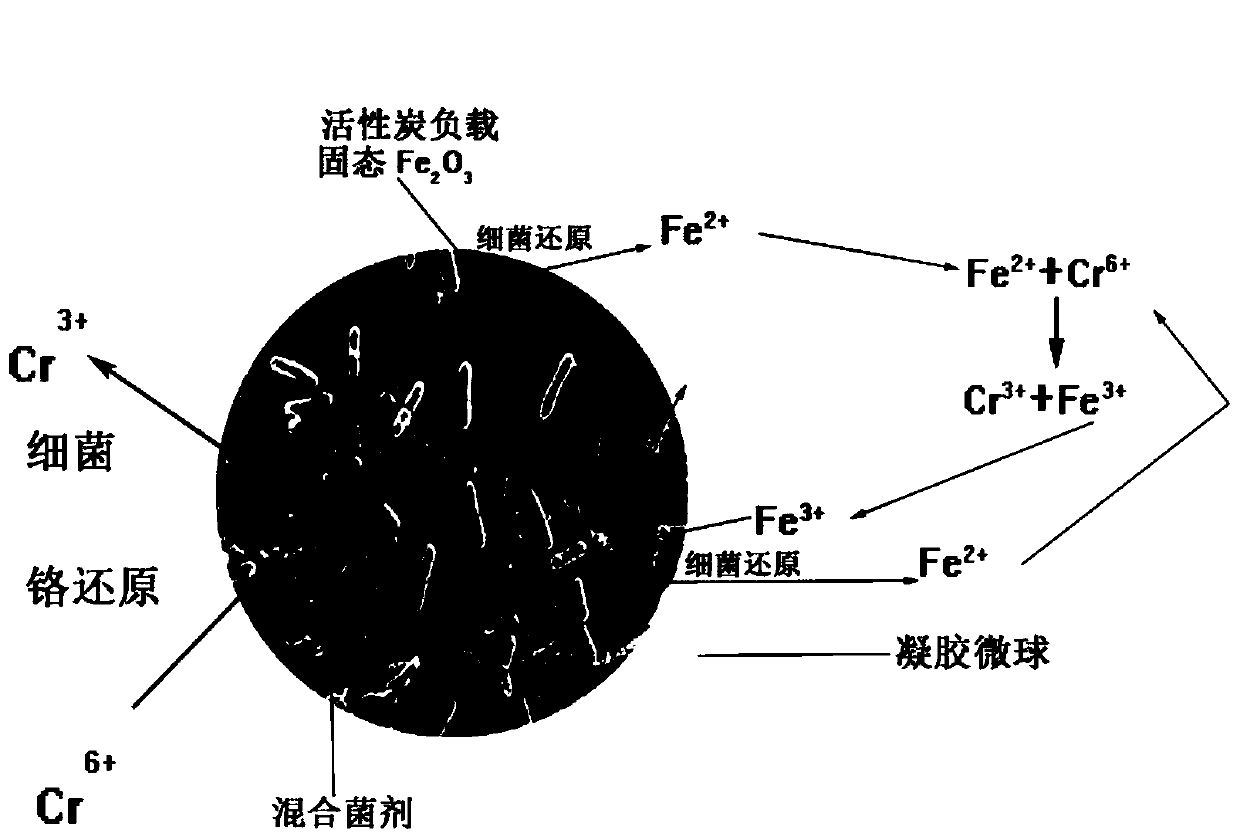

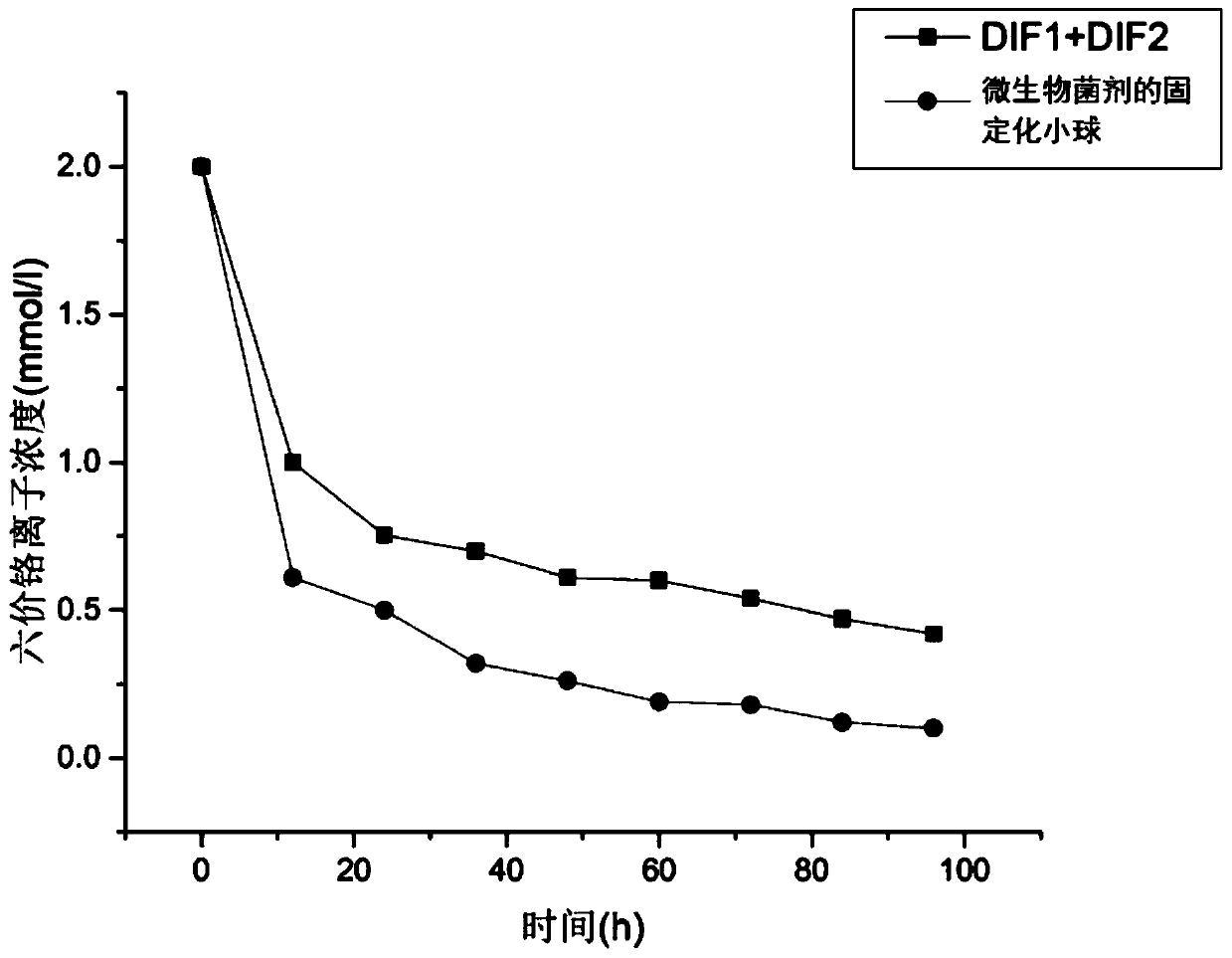

Method for reducing and adsorbing heavy metal chromium by immobilized microorganisms

ActiveCN110951642ANo secondary pollutionExtended use timeBacteriaWater contaminantsMicrobial agentPolyvinyl alcohol

The invention belongs to the technical field of environmental biology, and particularly relates to a method for reducing and adsorbing heavy metal chromium by immobilized microorganisms. According tothe method, a mixed microbial agent of bacillus cereus and rhodococcus ruber is immobilized by gel microspheres, and heavy metal chromium pollutants are reduced; and the mixed microbial agent can reduce ferric oxide into ferrous ions by using ferric oxide as an electron donor, so that reduction of hexavalent chromium is promoted. The invention further provides a method for immobilizing the mixed microbial agent. The method comprises the following steps: using activated carbon loaded ferric oxide as a carrier, adsorbing the mixed microbial agent and promoting the mixed microbial agent to grow by using the ferric oxide; and, embedding the carrier adsorbing the mixed microbial agent by using sodium alginate and polyvinyl alcohol as embedding agents, so as to prepare microbial agent immobilized microspheres. The microbial agent immobilized microspheres can provide a stable growth environment for the mixed microbial agent, adapt to a toxic environment, and efficiently reduce and adsorb heavy metal ions such as chromium.

Owner:SOUTHEAST UNIV

Non-toxic environment protective solvent type bridge floor water-proofing material and preparation thereof

InactiveCN101225289AHigh bonding strengthImprove waterproof performanceOther chemical processesBuilding insulationsEngineeringSolvent

The invention provides an innoxious environment-friendly solvent waterproof material of bridge floor, which can be painted on clean and dry cement bridge floors by a special painting spraying equipment in a certain of dosage and a layer of waterproof film with compact structure can be formed after nature solidification. The heat asphalt mix can be directly coated on the bridge floors and the work can be finished after rolling by a common road roller. The innoxious environment-friendly solvent waterproof material of bridge floor has the advantages of strong adhesiveness, good waterproof performance as well as good high temperature property and good low temperature property.

Owner:顾兴宇 +1

Method for manufacturing low toxic environment-protective common sponge

The invention relates to the foamed plastic technical field, in particular to a process for producing MDI common foamed plastic with low toxic and environmental-friendly, which adopts the hand foaming and continuous foaming method, uses 0-100% PPG (polyether polyatomic alcohol), 0-100% POP (graft polyether polyatomic alcohol), 0.01-4% H2O, 0.3-0.5 Silicon (silicon oil, interfacial active agent and ), 0.01-0.8% T-9 (metallic catalyst) and 0.01-0.8% A-1 or A-33 (tertiary amine catalyst), and alcohols whose low molecular weight is higher than OH value, stirs cross linking agent into pasty for backup, then adds with 0-100% liquefied MDI and or 0-100% MDI polymer and or 0-100% modified MDI, and obtains common foamed plastic of MDI through rapidly stirring. The production process of the invention has simple operation, and the foamed plastic which is produced has low toxic and meets the environmental-friendly requirements.

Owner:张正杰

Wax for micro-electronic product and method of producing the same

InactiveCN101367999AHigh purityImpurities are simpleWax adhesivesMicrocrystalline waxAutomatic control

The invention provides wax used for microelectronic products, and a preparation method thereof; the wax comprises the following components: Brazil wax, rosin, cera flava, Carnanba wax and microcrystal wax, wherein, the weight percent of Brazil wax is 30 percent to 40 percent, the weight percent of rosin is 10 percent to 15 percent, the weight percent of cera flava is 10 percent to 15 percent, the weight percent of Carnanba wax is 10 percent to 15 percent, and the rest is microcrystal wax; the wax is prepared with non-toxic environment protective raw materials, is good for maintaining the health of production operators and not inflammable, has good safety, and is convenient to be used and transported; during the production process, the automatic control and adjustment of temperature raising and stirring improves the product stability, consistency and reliability; the wax is produced in Class 1000 clean production environment, which prevents introducing foreign pollutants, dust, particles and the like during processing, effectively improves product purity and ensuring the surface polishing quality of the microelectronic products.

Owner:JIANGSU HAIXUN IND GROUP SHARE

3D printing special engineering plastic support material and preparation method of wires of support material

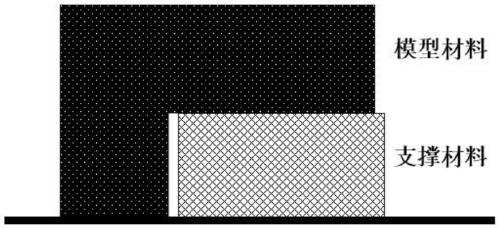

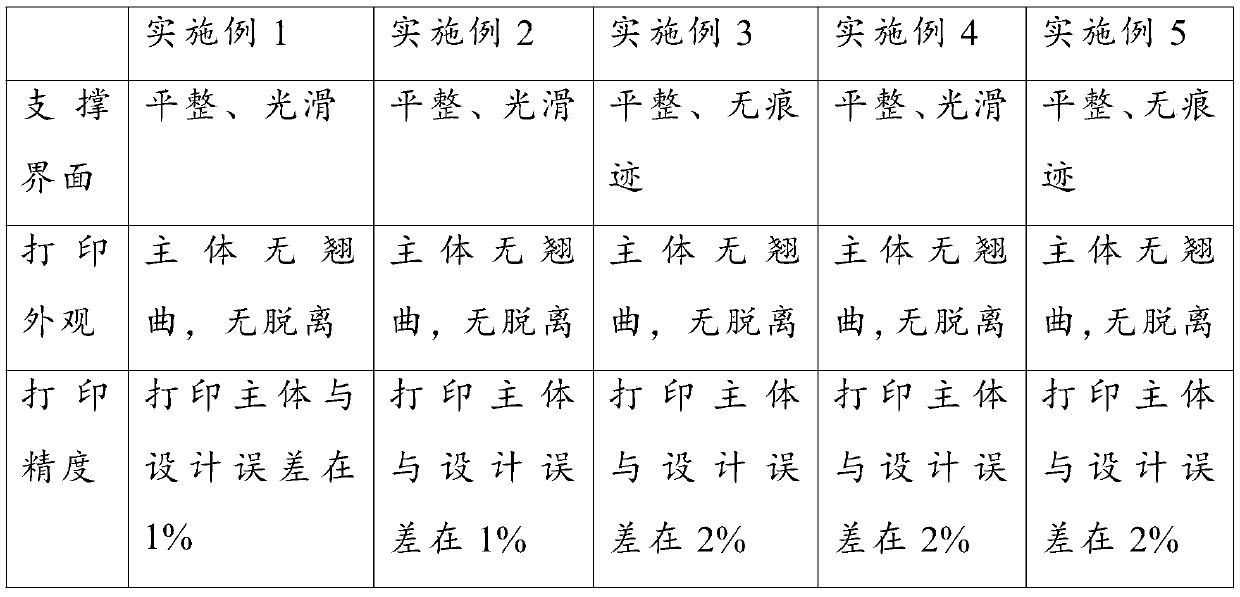

InactiveCN110437598ABuild stabilityImprove adhesionAdditive manufacturing apparatusPolyetherimideAntioxidant

The present invention discloses a 3D printing special engineering plastic support material and a preparation method of wires of the support material. The material is composed of the following components by weight percentage: 75-90 parts of polycarbonate resin; 5-15 parts of reinforcement material; 1-10 parts of compatibilizer; 2-5 parts of plasticizer; and 0.1-3 parts of antioxidant. The supporting wires prepared by the material ensures the stable establishment of a support portion in a 3D printing process of special engineering plastics under high temperature environment, is well bonded withthe special engineering plastics such as PEEK (polyetheretherketone), polyetherimide, PES (polyether sulfone), PEKK(polyetherketoneketone), PPS (polyphenylene sulfide), poly(phenylene sulfone),etc. atthe same time, products are put into a non-toxic environment-friendly solvent after printing is finished, and the support portion can be quickly removed by dissolution or swelling. The preparation method of the 3D printing support material of the invention has high chemical stability and a simple production process, an existing twin-screw extrusion mechanism can be used for preparation, and the 3D printing special engineering plastic support material is easy to prepare, suitable for industrial production and conducive to the market promotion of the 3D printing material.

Owner:INTAMSYS TECH CO LTD

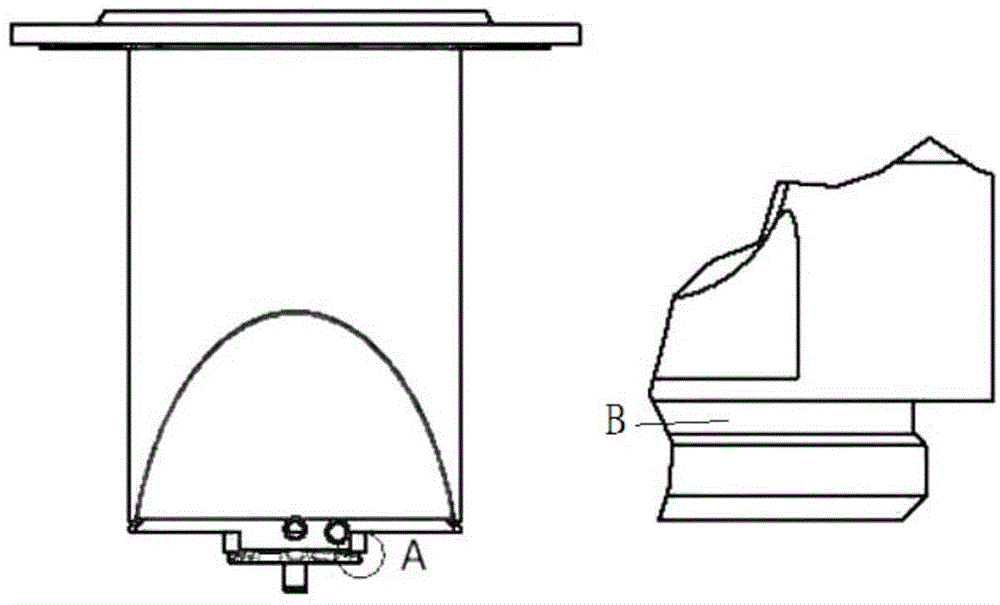

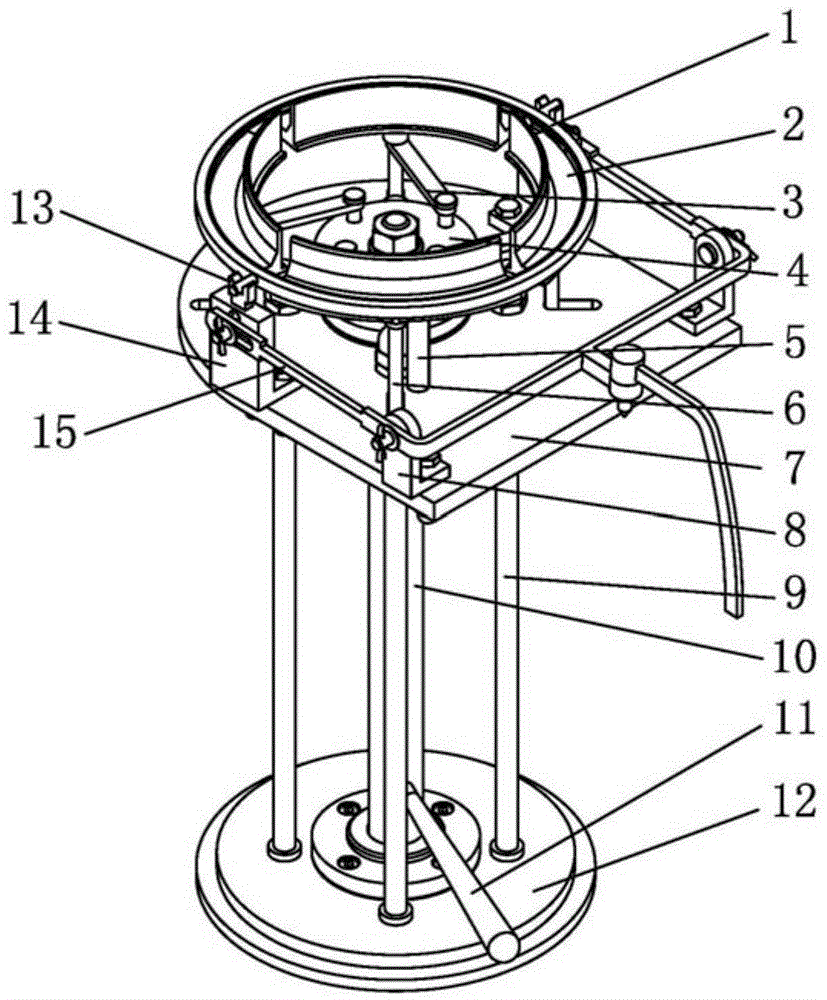

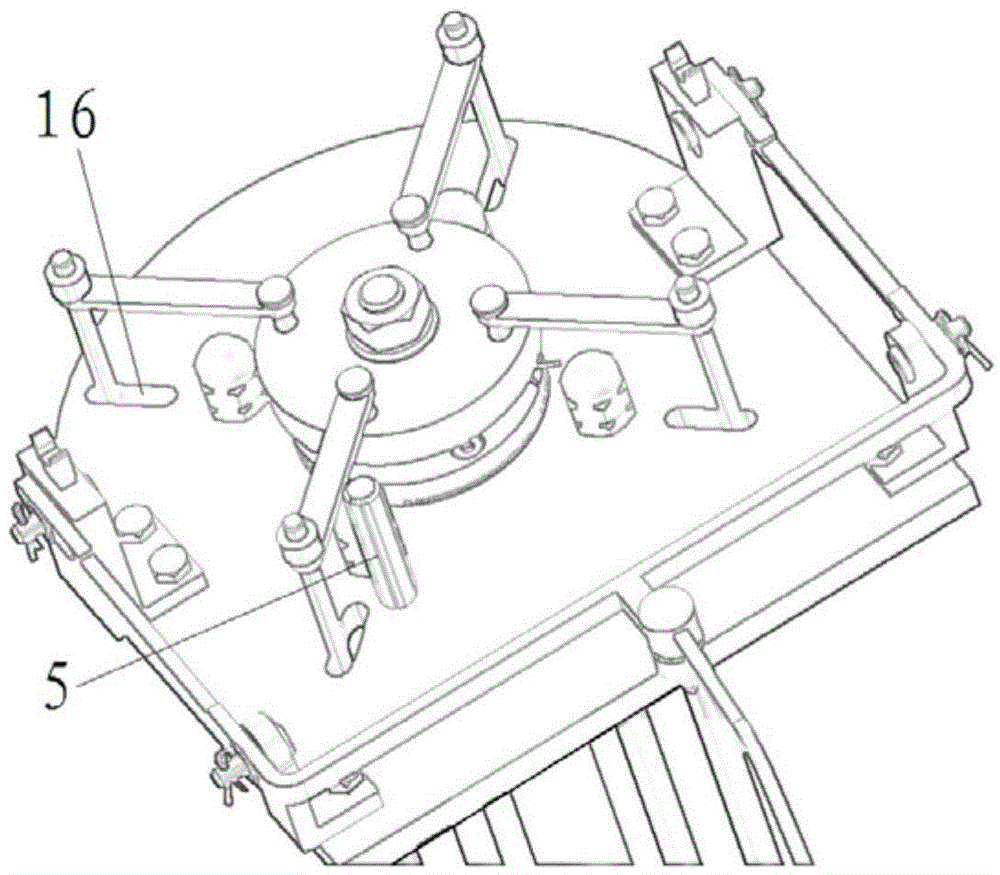

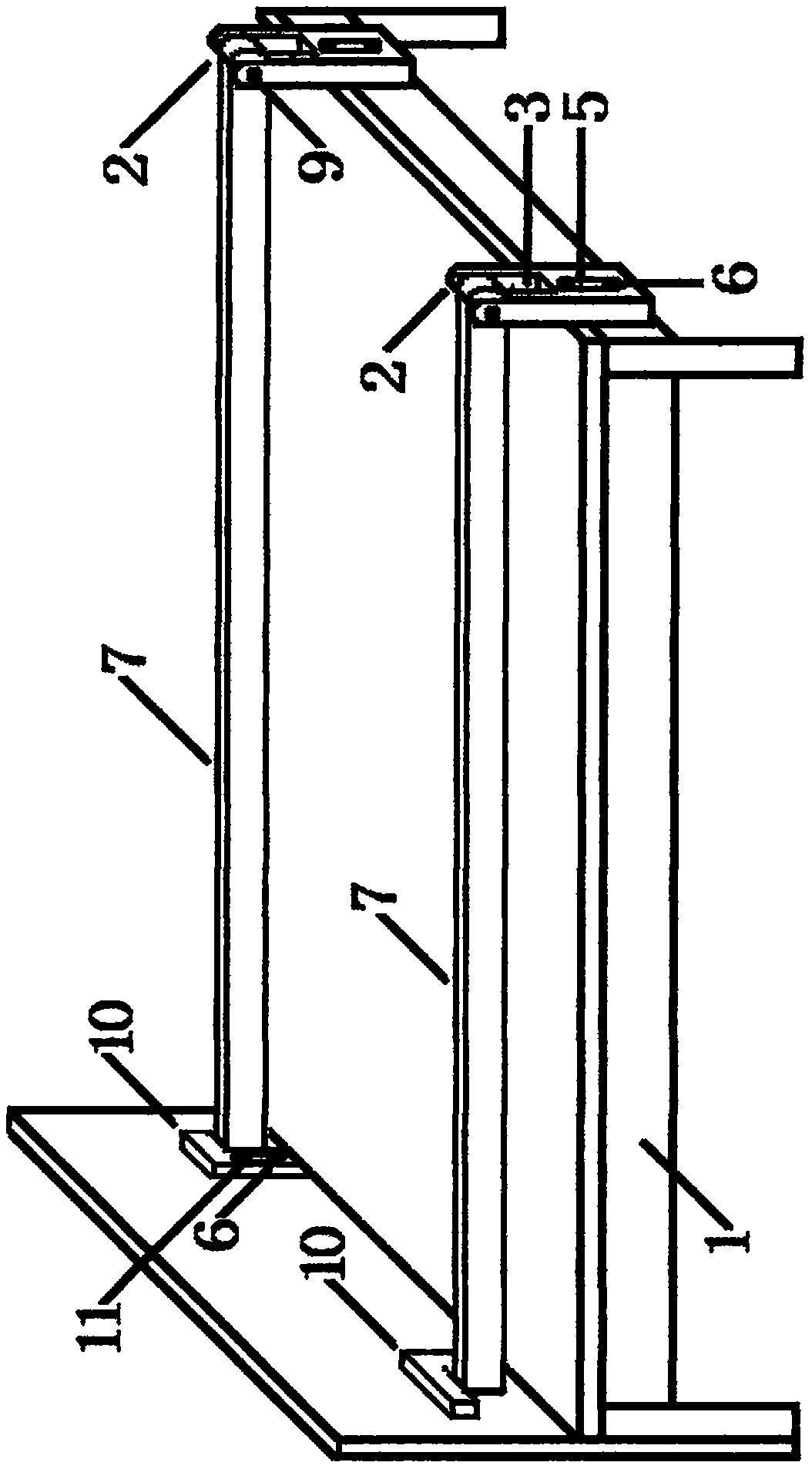

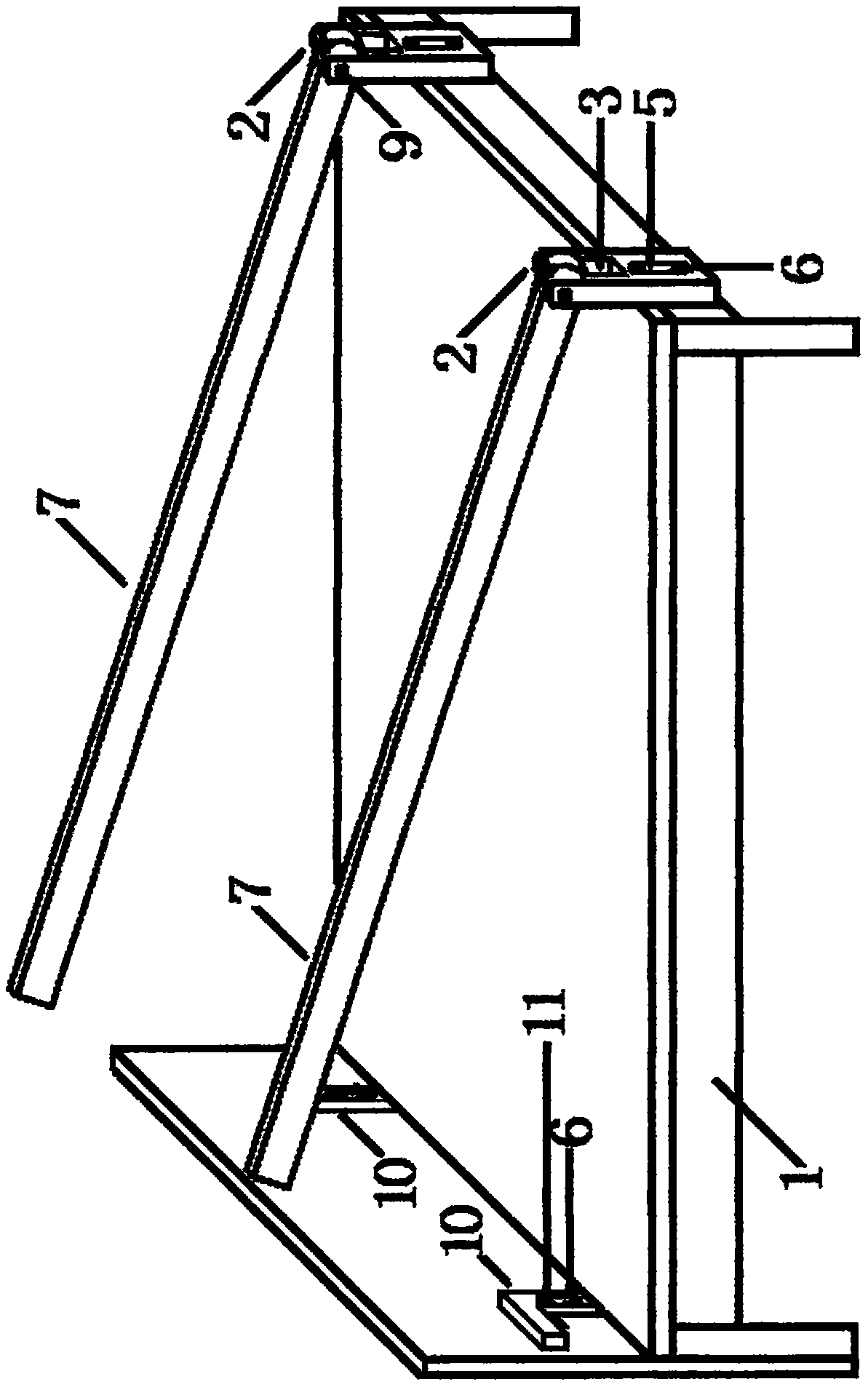

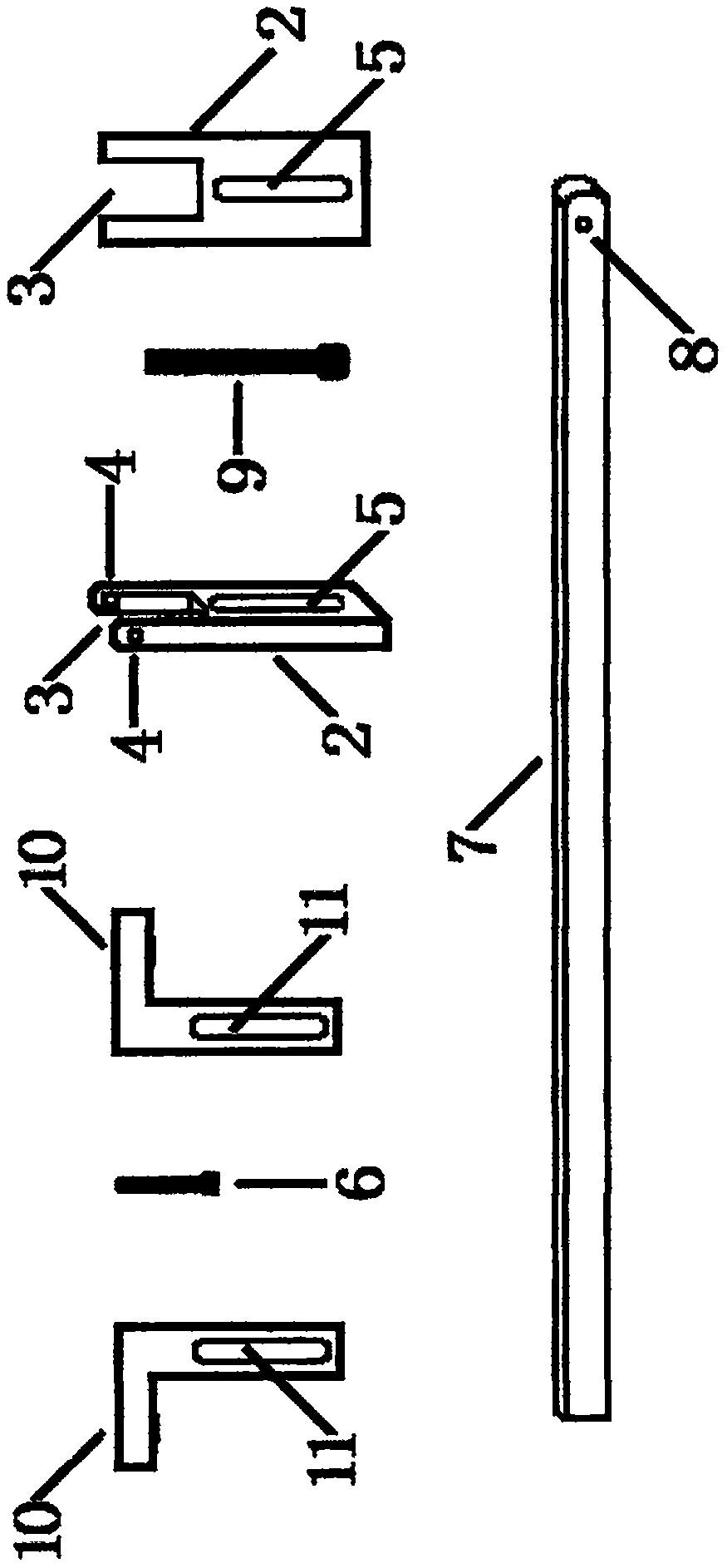

Remote replacement device for O-shaped ring

ActiveCN104149067AAchieve replacementAvoid contactMetal-working hand toolsEngineeringRemote operation

The invention discloses a remote replacement device for an O-shaped ring. The remote replacement device for the O-shaped ring comprises an O-shaped ring supporting mechanism and a lever mechanism used for controlling the O-shaped ring to ascend and descend. The supporting mechanism comprises a base and a supporting base, wherein the base and the supporting base are connected through a connecting rod. A center shaft is arranged between the base and the supporting base. The upper end of the center shaft penetrates through the supporting base to be connected with a rotary disk. A plurality of connecting rods are connected to the rotary disk in the circumferential direction. The sliding rods are connected with sliding shafts. The sliding shafts can slide in long straight grooves formed in the supporting base. The upper portions of the sliding shafts are connected with supporting rings. A bearing ring is arranged outside the supporting rings. The bearing ring is connected with the level mechanism. By the adoption of the remote replacement device for the O-shaped ring, the O-shaped ring can be replaced under the condition of remote operation. The remote replacement device for the O-shaped ring is particularly suitable for a radioactive environment or a toxic environment. Operators can be prevented from touching a radioactive medium or a toxic medium, the danger coefficient of an operator is greatly reduced, and the replacement safety is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

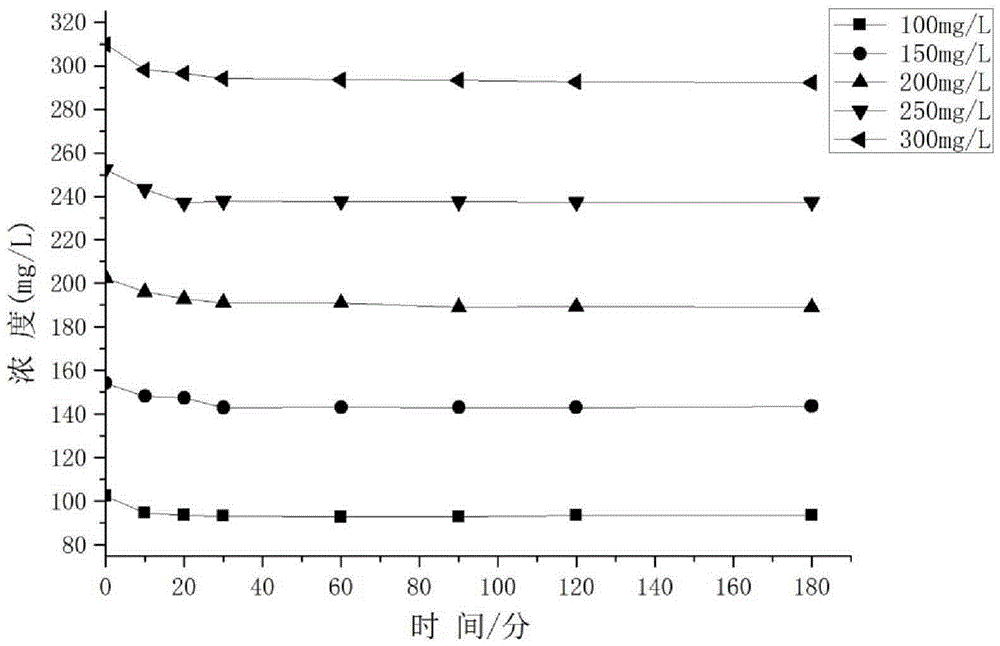

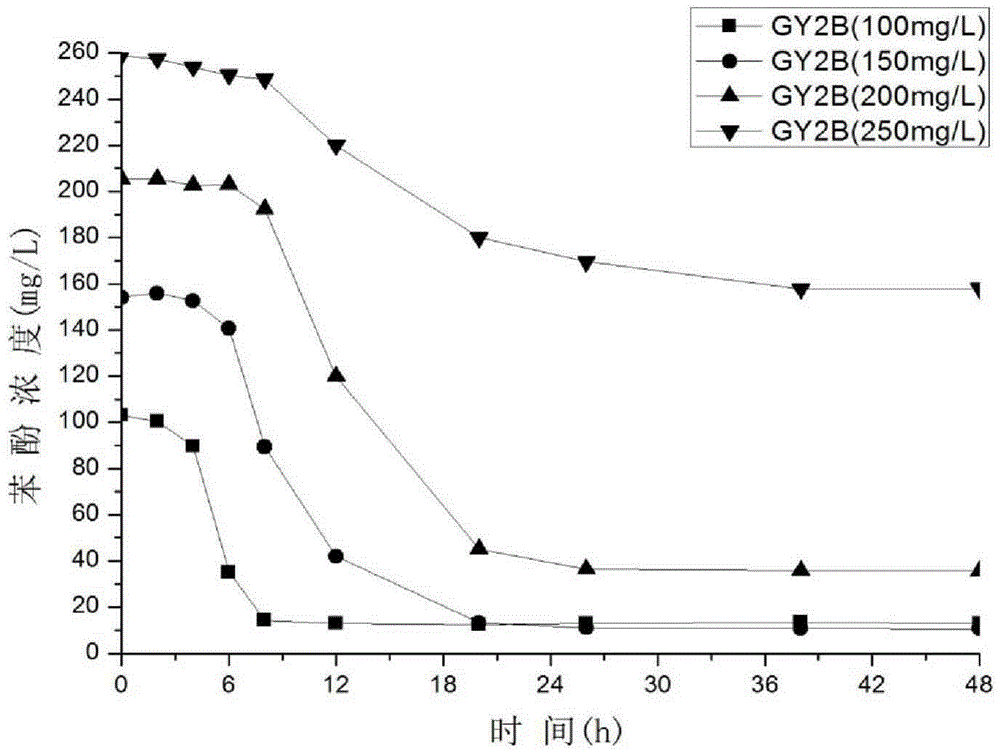

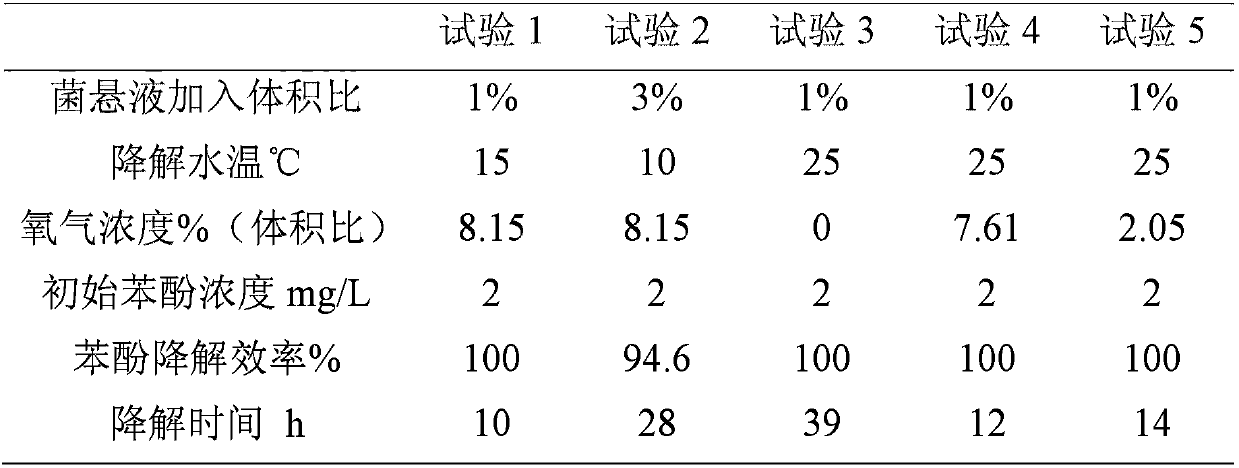

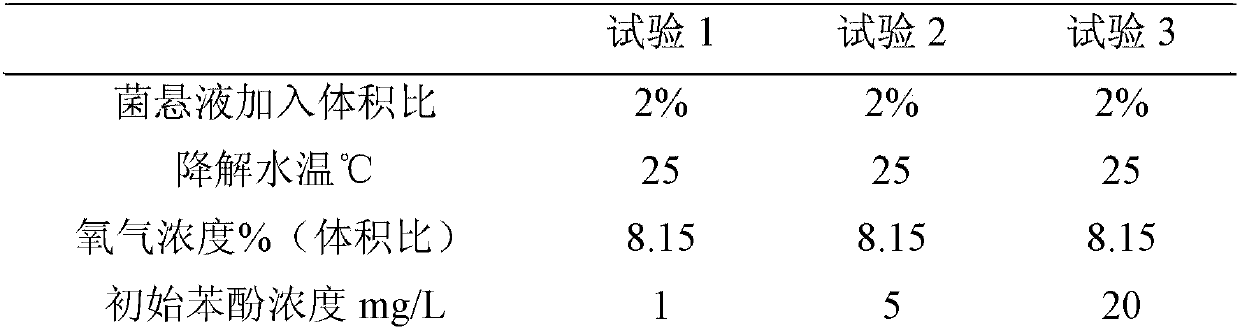

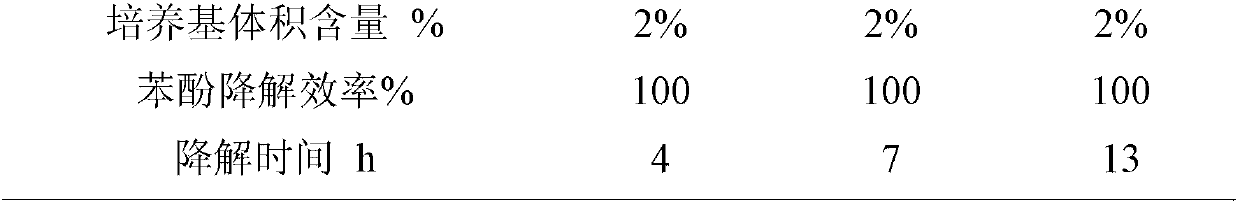

GY2B degrading bacteria immobilizing ball as well as preparation method and application thereof

ActiveCN104593349AImprove degradation efficiencyCompletely degradedWater contaminantsOn/in organic carrierPolyvinyl alcoholUltraviolet lights

The invention belongs to the technical field of microbial degradation of organic pollutants, and discloses a GY2B degrading bacteria immobilizing ball as well as a preparation method and application thereof. The GY2B degrading bacteria immobilizing ball is a gel ball formed by embedding GY2B degrading bacteria by taking a crosslinking polymerization product of polyvinyl alcohol, algin and kaolin as a carrier. The preparation method disclosed by the invention comprises the following steps: (1), sequentially adding polyvinyl alcohol and algin into water, heating, stirring and dissolving respectively, adding kaolin, and stirring and mixing uniformly so as to obtain a mixed solution; (2), cooling the mixed solution to room temperature under irradiation of ultraviolet light, adding a GY2B degrading bacteria suspension, and uniformly stirring to obtain a bacteria embedding solution; and (3), dropwise adding the bacteria embedding solution into a crosslinking solution, and crosslinking, solidifying and condensing to obtain the GY2B degrading bacteria immobilizing ball. The GY2B degrading bacteria immobilizing ball has more thorough, rapid and steady degrading effects to phenol; furthermore, a steady degrading environment can be provided; and the GY2B degrading bacteria immobilizing ball is adaptive to a toxic environment.

Owner:SOUTH CHINA UNIV OF TECH

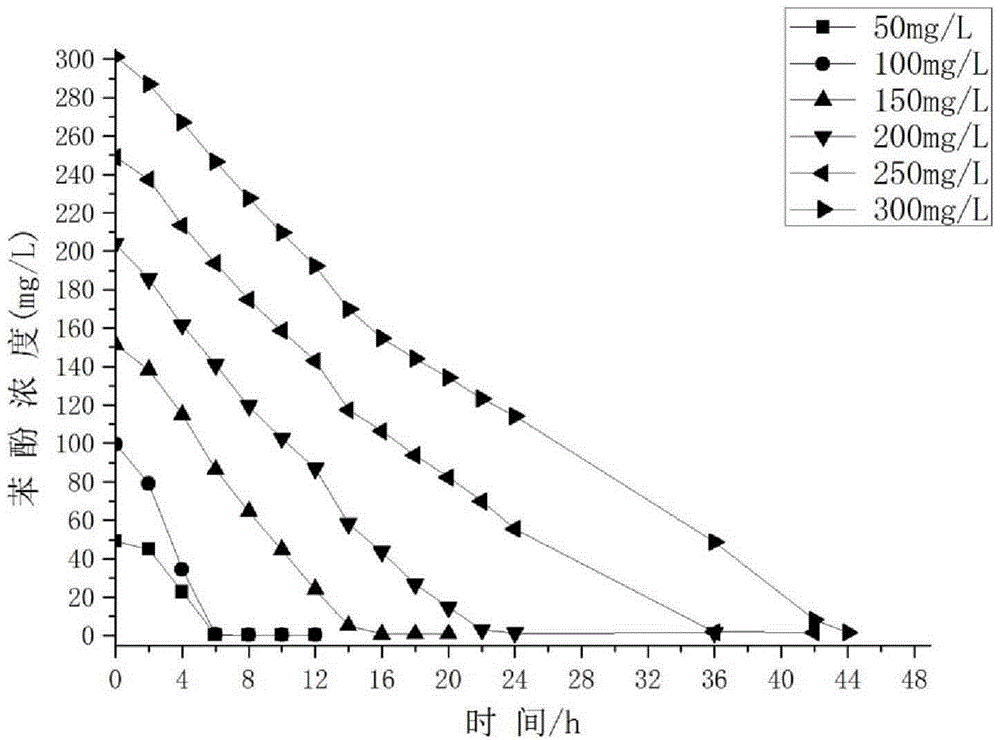

Phenol-degradation microbial agent, immobilized globules and preparation method

InactiveCN107653209ANo secondary pollutionExtended use timeBacteriaWater contaminantsHigh concentrationLiquid medium

The invention provides a phenol-degradation microbial agent, immobilized globules and a preparation method. Microorganisms in the phenol-degradation microbial agent are separated and extracted from surface filter materials of a biological manganese sand filter pool of a waterworks, and after the microorganisms are cultured and screened in a manganese-contained MSVP liquid medium and a manganese-contained MSVP solid medium and are activated in a TBS medium, the phenol-degradation microbial agent is prepared. The invention further provides the preparation method for preparing the phenol-degradation microbial agent into the immobilized globules. According to the preparation method, the gel globules are prepared by using cross-linking polymerization products of silicon dioxide or manganese dioxide and sodium alginate as carriers and embedding the phenol-degradation microbial agent. The phenol-degradation microbial agent can be applied to rapidly degrading phenol at low-temperature oxygen-free and neutral conditions of underground water. The phenol-degradation microbial agent immobilized globules can provide stable degradation environment, are more suitable for toxic environment, and are used for treating phenol pollution of the underground water with higher concentration.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

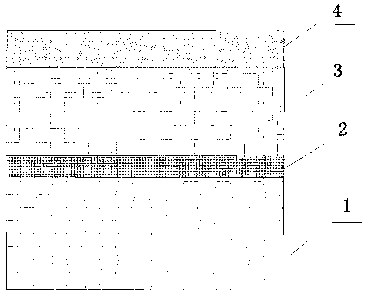

Environment-friendly flame-retarding full-plastic type plastic runway and construction method thereof

The invention provides an environment-friendly flame-retarding full-plastic type plastic runway. The environment-friendly flame-retarding full-plastic type plastic runway comprises a base layer, a bottom sealing layer, a shock absorption layer and a cover face protecting layer; the bottom sealing layer, the shock absorption layer and the cover face protecting layer are sequentially laid on the base layer, materials of the base layer are poured by adopting C30 commercial concrete, and the thickness of the base layer is 150 mm; the bottom sealing layer adopts materials of non-toxic environment-friendly single-component epoxy glue, black colloidal particles and silica sand, coating is conducted by adopting a coating machine, the thickness of the bottom sealing layer is 1.5 mm; the shock absorption layer adopts EPDM, SBR, CR, NR mixed rubber particles and the environment-friendly single-component epoxy glue materials, mechanical spreading is conducted, the laying thickness is 10 mm; and the cover face protecting layer adopts materials of polyurethane color paste, EPDM particles, the environment-friendly single-component epoxy glue, glass fiber, an antioxidant, a flame retardant and a fluorescent agent, mechanical coating is conducted, coating is conducted for three times in the forward direction, the reverse direction and the forward direction, the thickness of each time of coatingis 1 mm, and the thickness of the cover face protecting layer is 3 mm. The environment-friendly flame-retarding full-plastic type plastic runway has the advantages that non-toxic, odourless and environment-friendly effects are achieved, the runway is breathable, water does not accumulate on the surface of the runway, color is bright, and color fading is not likely to occur, and meanwhile, uvioresistant and strong light exposure resistance performance are achieved, bubbling and cracking are not likely to occur, the abrasion performance, compression resistance and durable performance are excellent, and the service life is long; and in addition, the runway is high in cost performance, low in input cost and good in weather-resistant performance and is suitable for using and popularizing in anational scale.

Owner:艺博建设集团有限公司

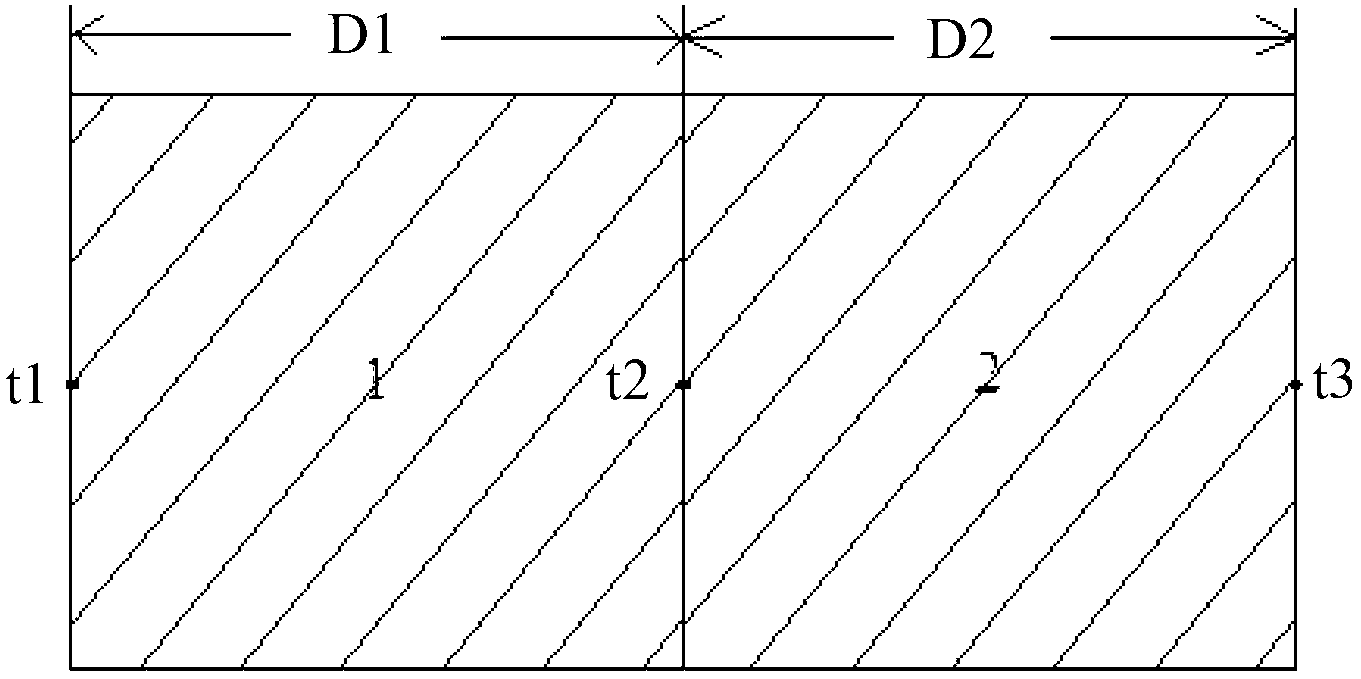

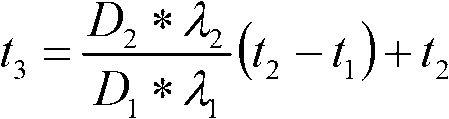

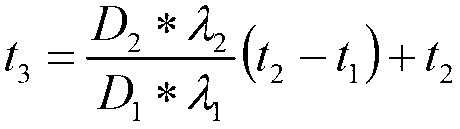

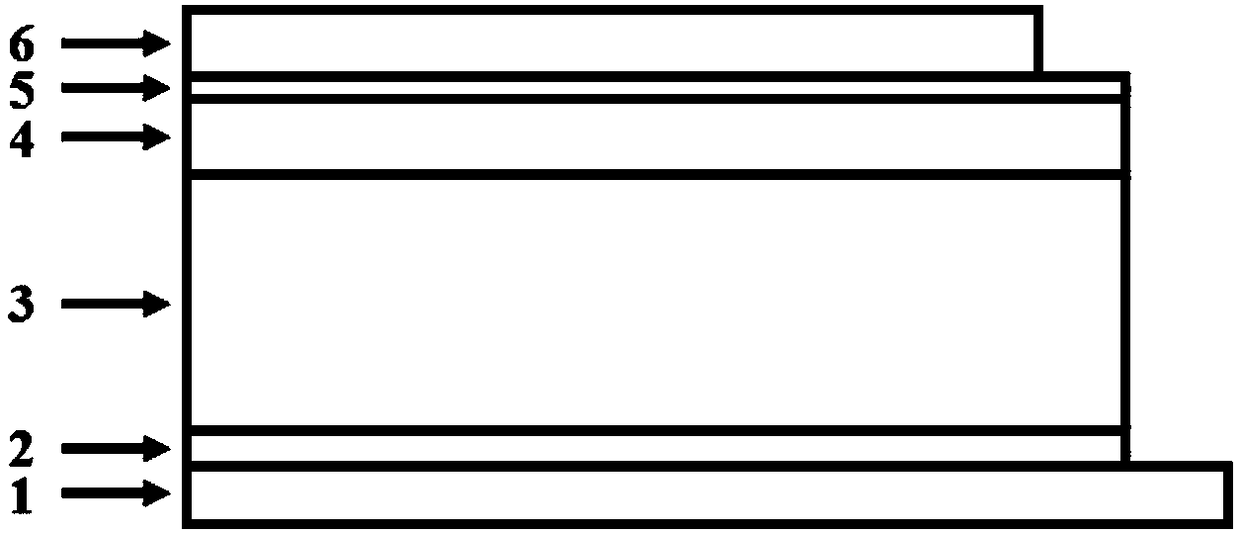

Temperature measuring method

InactiveCN102706465ALower requirementSolve temperature problemsThermometer detailsMeasurement deviceMeasuring instrument

The invention discloses a temperature measuring method, which comprises the following steps of: attaching a layer of measurement medium at the outside of a container for containing an object to be subjected to temperature measurement; arranging a first temperature sensor between the inner wall of the measurement medium and the outer wall of the container; arranging a second temperature sensor on the outer wall of the measurement medium; and combining with material of the container and the thermal diffusivity of the measurement medium to obtain the temperature of the object to be subjected to temperature measurement in the container according to the temperature measured by the first temperature sensor and the second temperature sensor. According to the invention, an indirect extrapolation method is adopted to solve the problems which can not be solved by the common temperature measuring method at the high-temperature, high-corrosion and toxic environment and to reduce the requirements on measurement devices; and the structure is simple, and the cost is saved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Inverted gradient bulk heterojunction perovskite solar cell on basis of gallium oxide protective layer and method for preparing inverted gradient bulk heterojunction perovskite solar cell

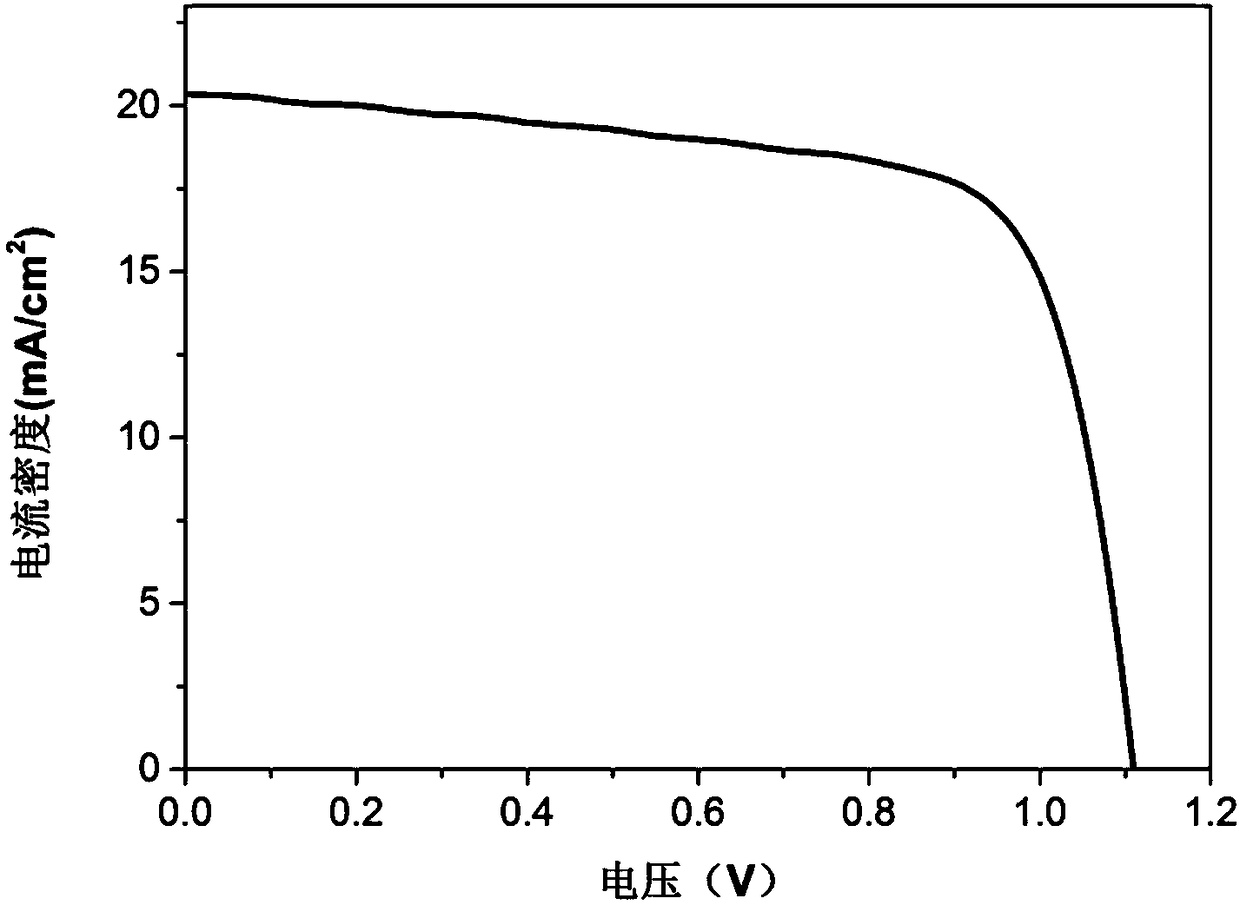

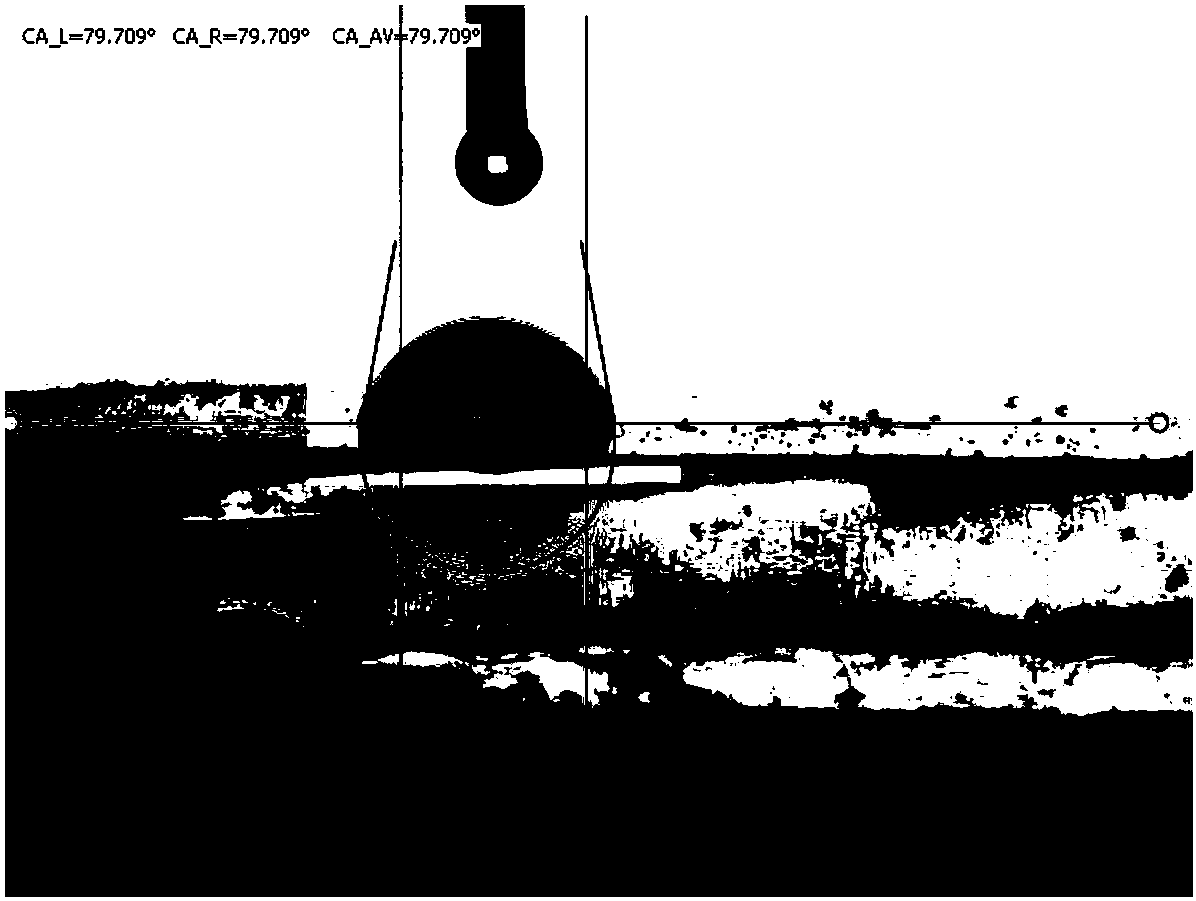

ActiveCN108281560AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionHeterojunction

The invention relates to an inverted gradient bulk heterojunction perovskite solar cell on the basis of a gallium oxide protective layer and a method for preparing the inverted gradient bulk heterojunction perovskite solar cell. The inverted gradient bulk heterojunction perovskite solar cell which is a perovskite cell comprises a transparent conductive substrate, a hole transport layer, a perovskite light absorption layer, an electron transport layer and metal electrodes. The inverted gradient bulk heterojunction perovskite solar cell and the method have the advantages that a high-quality gallium oxide thin film is prepared by the aid of low-temperature deposition atomic layer bottom sinking processes with simple technologies and is used as a cushion layer between the electron transport layer and the metal electrodes, and accordingly the photovoltaic performance of devices can be effectively improved; the gallium oxide thin film with inorganic and hydrophobic characteristics can be used as the protective layer, accordingly, cell erosion due to external environments can be effectively isolated, and the stability of the devices can be enhanced; non-fullerene materials IDIC are dissolved in a green and environment-friendly solvent ethyl acetate to prepare gradient heterojunction perovskite thin films, accordingly, defects of perovskite can be effectively passivated, the performance of the devices can be enhanced, and thin film preparation toxic environments can be relieved.

Owner:WUHAN UNIV

Crib pressing rod anti-quilt-kicking structure

The invention discloses a crib pressing rod anti-quilt-kicking structure. The structure is composed of a crib body, U-shaped fixing brackets, U-shaped grooves, bolt holes A, rectangular sliding grooves A, adjusting bolts, pressing rods, bolt holes B, bolts, F-shaped bayonets, rectangular sliding grooves B and the like; in the structure, the pressing rods are installed on a traditional crib or other beds, and the pressing rods movably press a quilt. The structure has the advantages that it is avoided that children or old people or patients kick off the quilt easily and get a cold, and the anti-quilt-kicking effect is quite good; the structure is made of non-toxic environment-friendly wood or plastic steel and thus is safe and reliable; besides, the structure is quite simple, the cost is quite low, the design is scientific and reasonable, and the structure is suitable for being installed and used on cribs or other beds and easy to widely promote.

Owner:傅银华

Degradable non-toxic environment-friendly toy material and preparation method thereof

The invention discloses a degradable non-toxic environment-friendly toy material and a preparation method thereof. The degradable non-toxic environment-friendly toy material comprises the following raw materials in parts by weight: 20-30 parts of rice husk, 18-26 parts of cellulose, 30-40 parts of natural resin, 10-16 parts of starch, 12-20 parts of sodium polyacrylate, 3-9 parts of polyvinyl alcohol, 1-2 parts of talcum powder, 0.3-0.8 part of an edible pigment, 20-26 parts of calcium carbonate, 20-26 parts of polyethylene and 0.4-0.8 part of a photodegradant. The degradable non-toxic environment-friendly toy material prepared according to a formula and the preparation method, which are provided by the invention, has the characteristics of nontoxicity and environment friendliness, can be biodegraded and photodegraded, can become an organic fertilizer and return to the nature after degradation, is moderate in hardness and density and free of discoloration, mildew, shrinkage, brittleness, crack and deformation, and is very applicable to toy production.

Owner:长荣玩具(东莞)有限公司

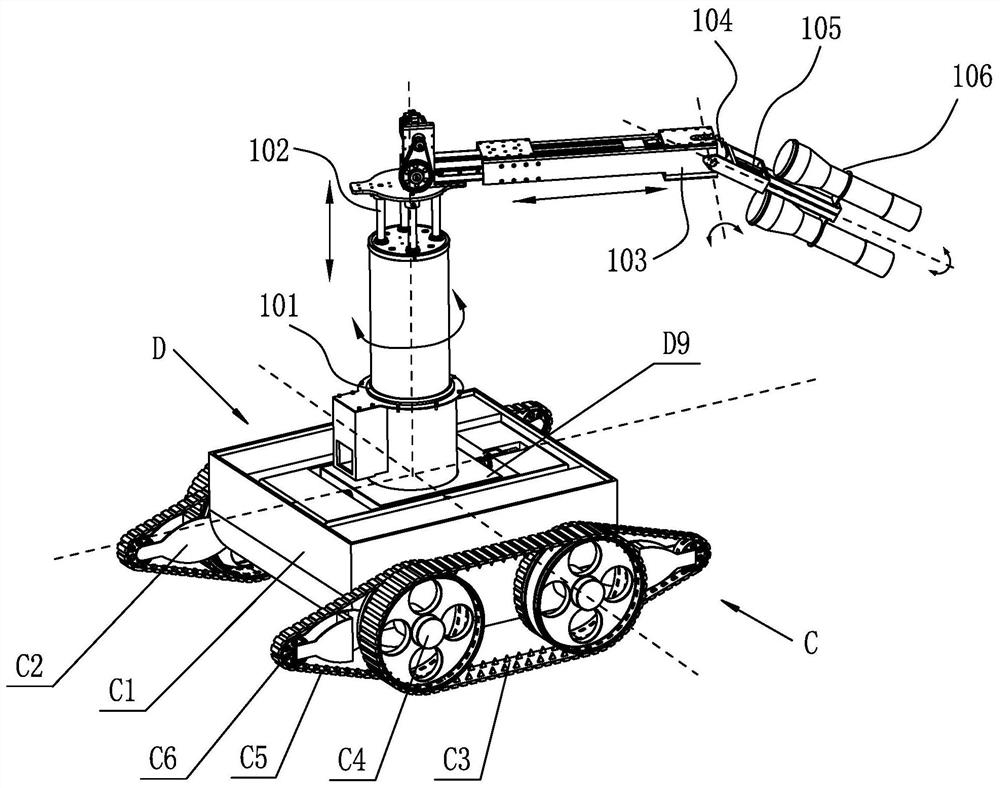

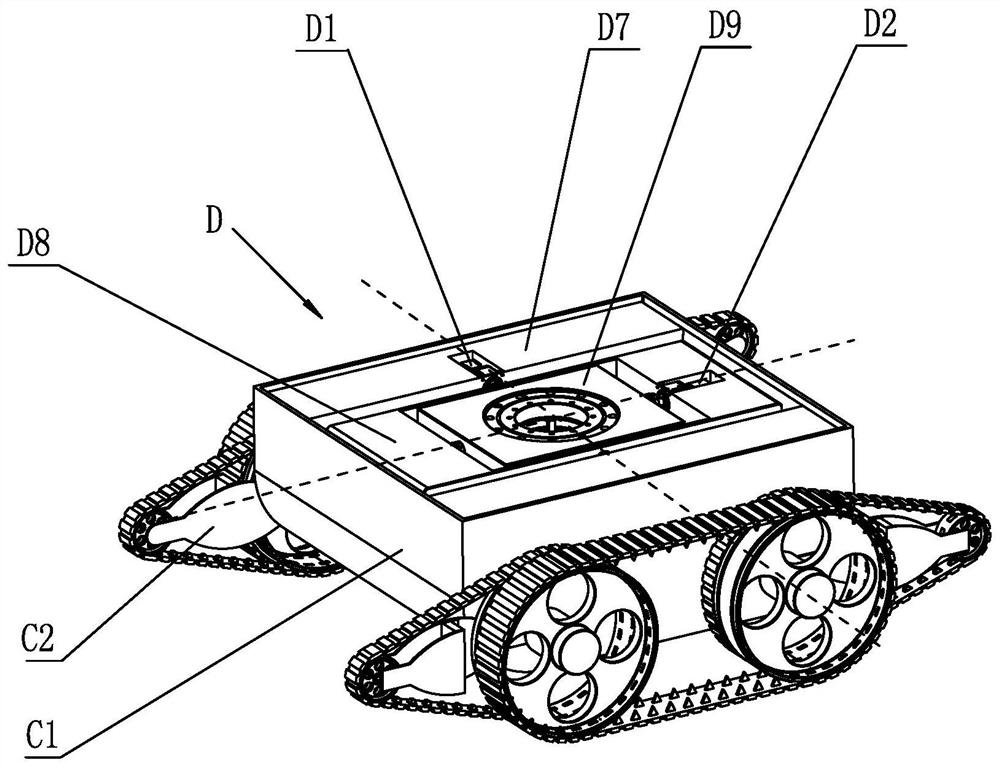

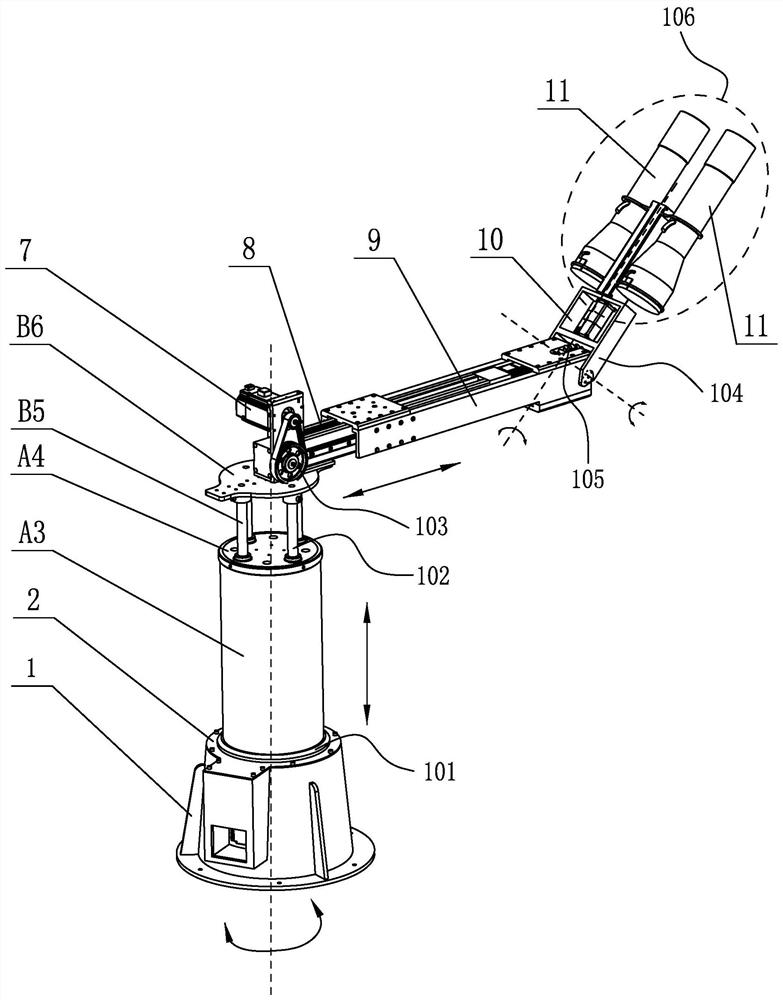

Outdoor environment disinfection robot based on two-degree-of-freedom balance holder

ActiveCN113478455AGood off-roadImprove anti-overturn performanceProgramme-controlled manipulatorGripping headsControl engineeringMachine

An outdoor environment disinfection robot based on a two-degree-of-freedom balance holder comprises a tracked robot with swing arm independent control, a five-degree-of-freedom disinfection mechanical arm and the actively-driven two-degree-of-freedom balance holder. The five-degree-of-freedom disinfection mechanical arm is arranged on the two-degree-of-freedom balance holder, and the two-degree-of-freedom balance holder is arranged on a bottom shell of the tracked robot and used for controlling the posture of the five-degree-of-freedom disinfection mechanical arm; and the five-degree-of-freedom disinfection mechanical arm is a disinfection mechanical arm based on a double-nozzle electric spray gun. According to the outdoor environment disinfection robot, the adaptability to a complex ground environment and a disinfection operation object environment can be improved, the working intensity of construction workers can be reduced, the workers are prevented from being in direct contact with a toxic environment, and a safety guarantee is provided.

Owner:DONGGUAN UNIV OF TECH

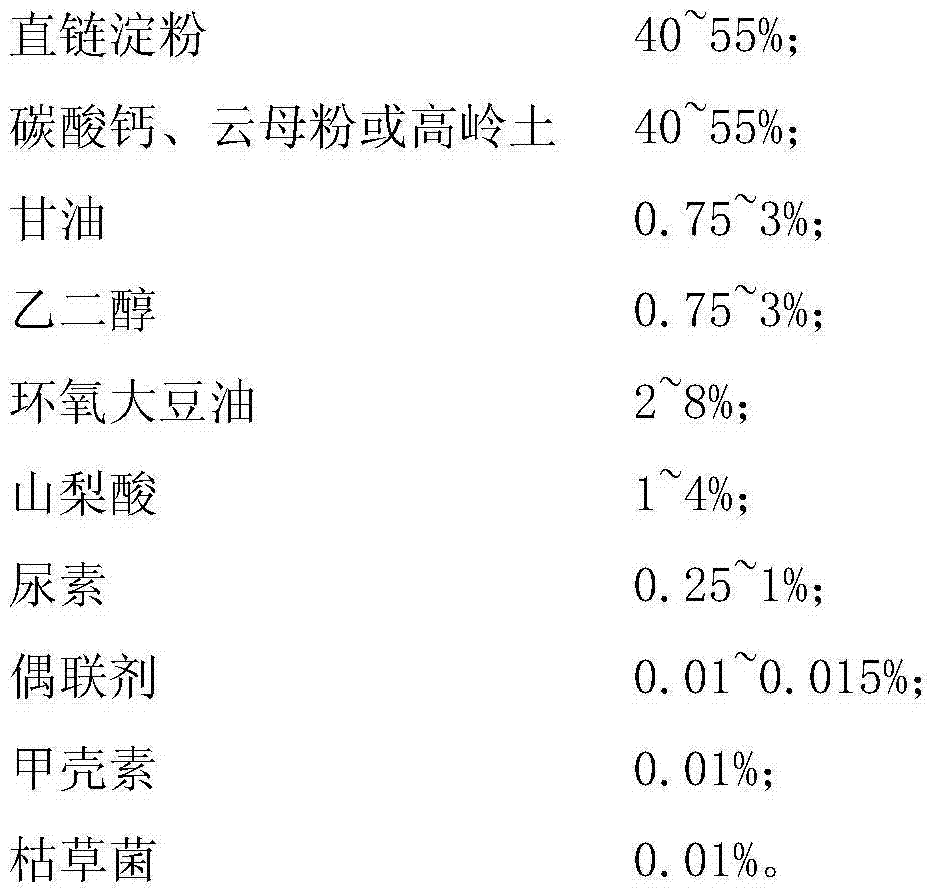

Starch environment-friendly paper and preparation method thereof

ActiveCN103588995AReduce specific gravityLow densityNon-fibrous pulp additionSpecial paperPetroleumPolylactic acid polymer

The invention discloses a starch environment-friendly paper, comprising a three-layer composite structure formed by an upper layer of polylactic acid polymer material, a middle layer of papermaking masterbatch and a lower layer of polylactic acid polymer material, wherein the ratio of the three layers is 1:8:1 in thickness; the papermaking masterbatch comprises the following components by mass percent: 30% of starch material, 20% of polylactic acid polymer material and 50% of calcium carbonate material. The invention provides the starch environment-friendly paper and the preparation method thereof, wherein the starch environment-friendly paper is prepared from plant materials which can be reproduced year after year, and constant calcium carbonate and natural assistants by special production equipment after polymerization under the conditions of not cutting the trees down, not using petroleum chemicals, not producing air pollution or not producing sewage. The starch environment-friendly paper produced by the method is a natural and non-toxic environment-friendly material, which is free of heavy metal or plasticizer and can be completely biodegraded. The starch environment-friendly paper can be supplied to all walks of life. Thus, the purposes of protecting the environment and not wasting resources are achieved.

Owner:郑文彬 +1

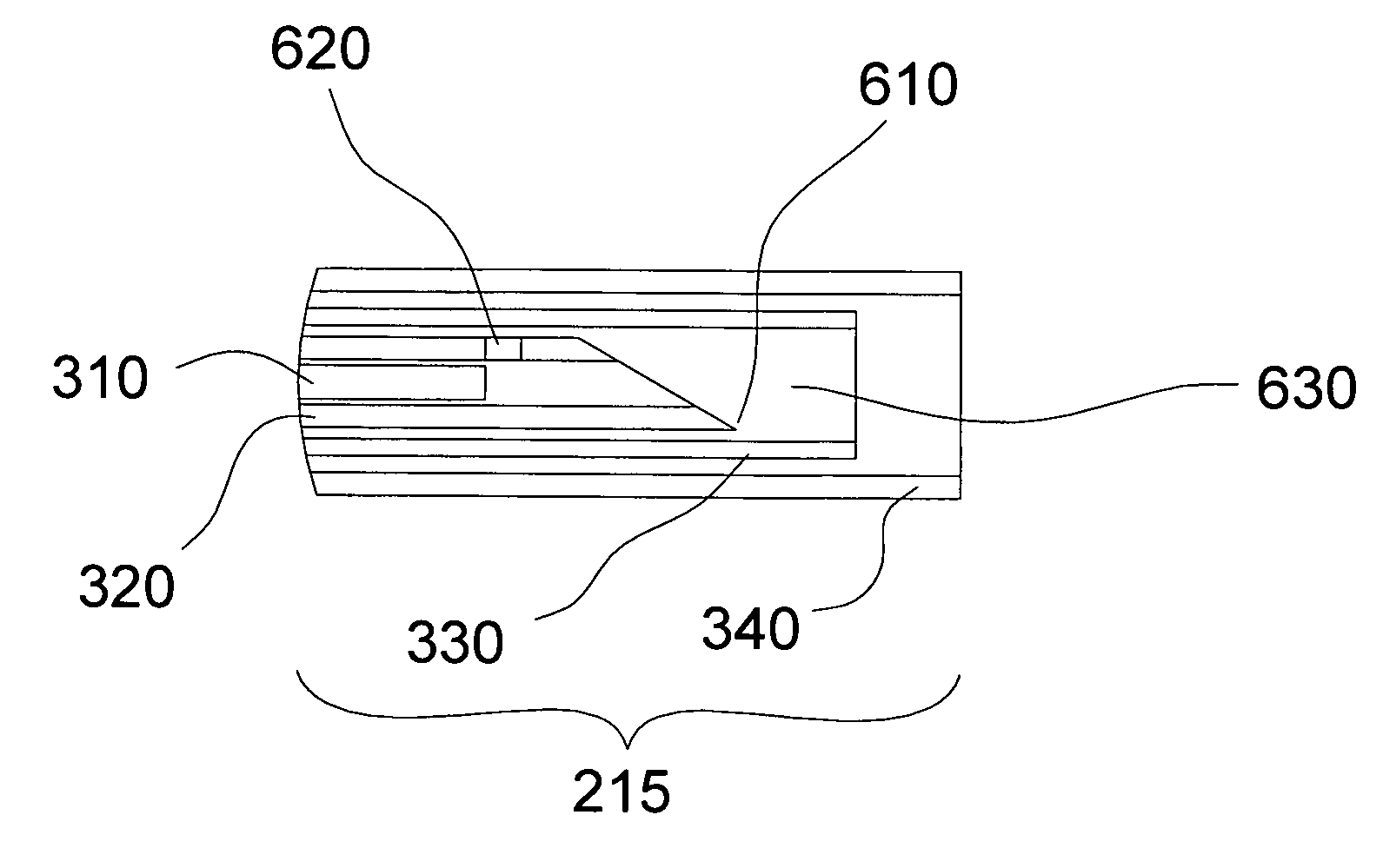

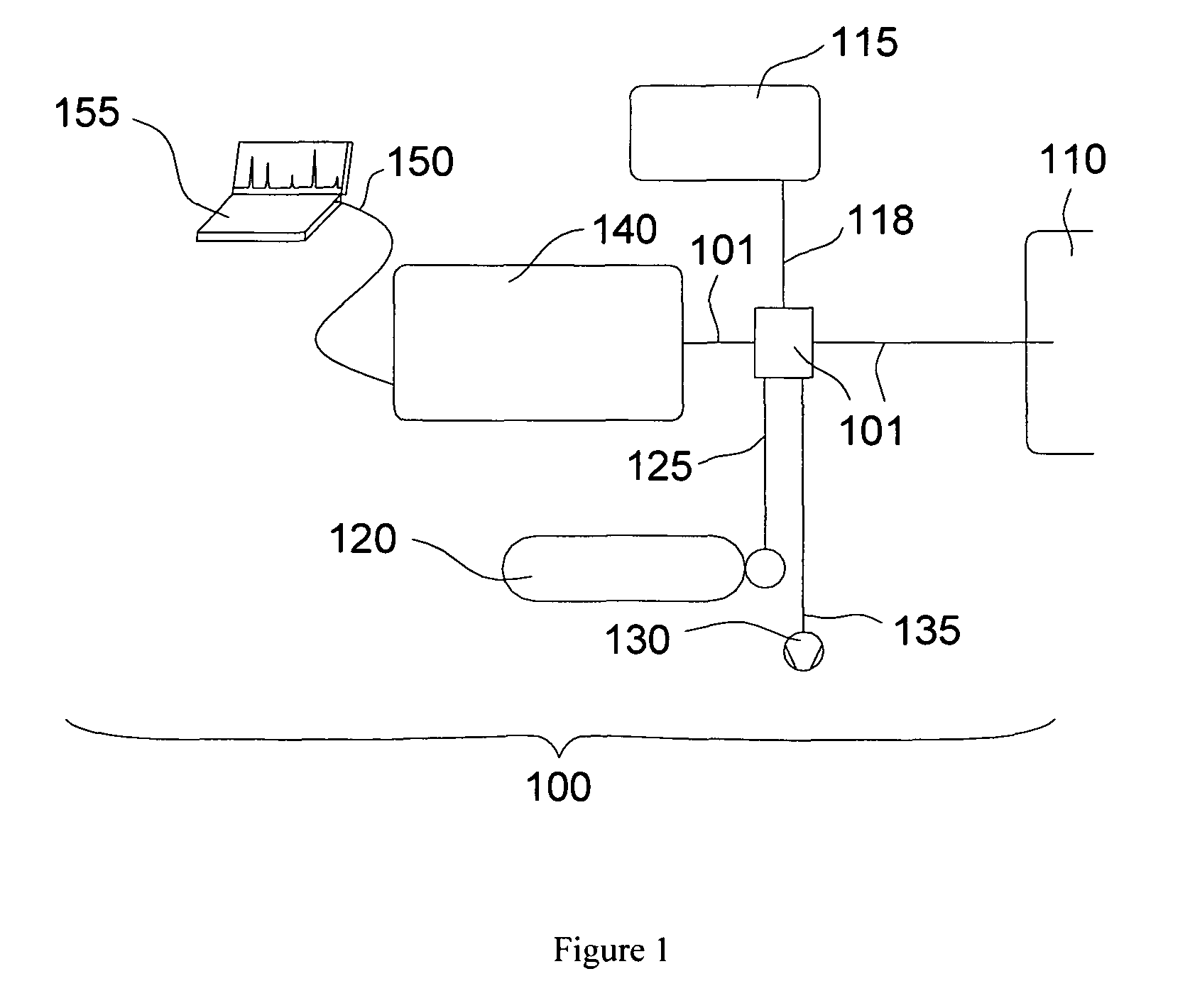

Axial-geometry micro-discharge detector

A detection device capable of giving atomic and molecular compositions of gases made of concentric tubes and a fiber optic. The body of the detector holds these constituents in their relative positions. A micro-discharge is created between two of the concentric tubes at the tip of the device. The small size of the tubes allows a stable discharge to be achieved. The light from this discharge is delivered from the discharge area to an optical sensing device through the fiber optic. The optical sensing device, along with a computer, analyzes the light to determine the composition of the gas in the discharge. Gas and vacuum are applied through the tubes as needed to aid operation. The detector can be battery powered and used in both hot and toxic environments. Alternatively, a voltmeter can be used to measure impedance across the discharge thus providing another means to determine relative changes in gas composition.

Owner:HERRING CYRUS M

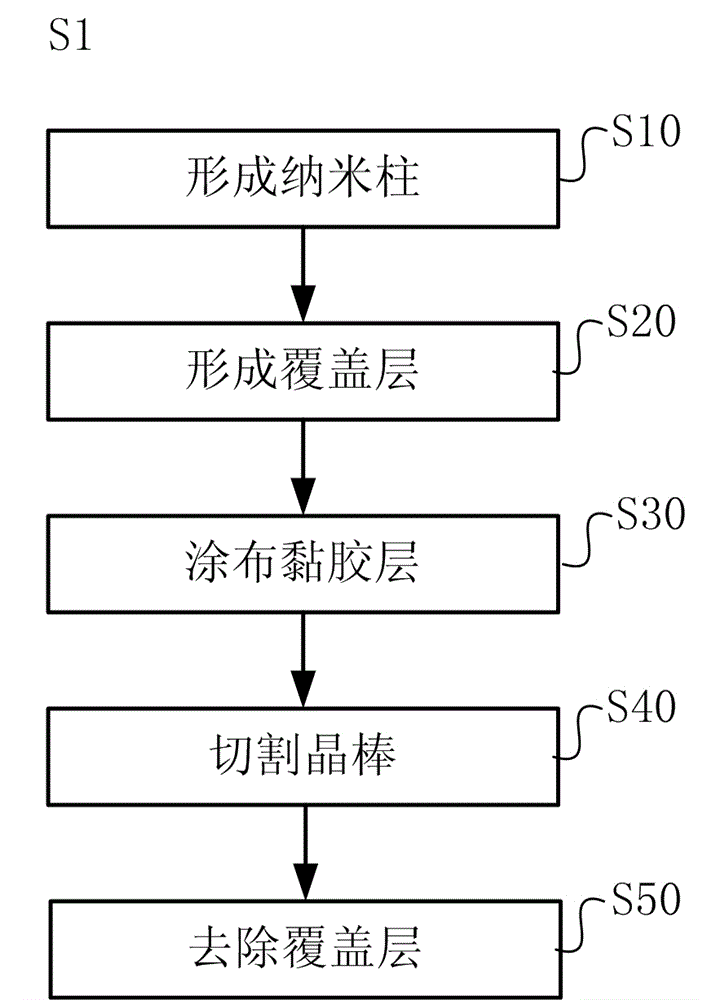

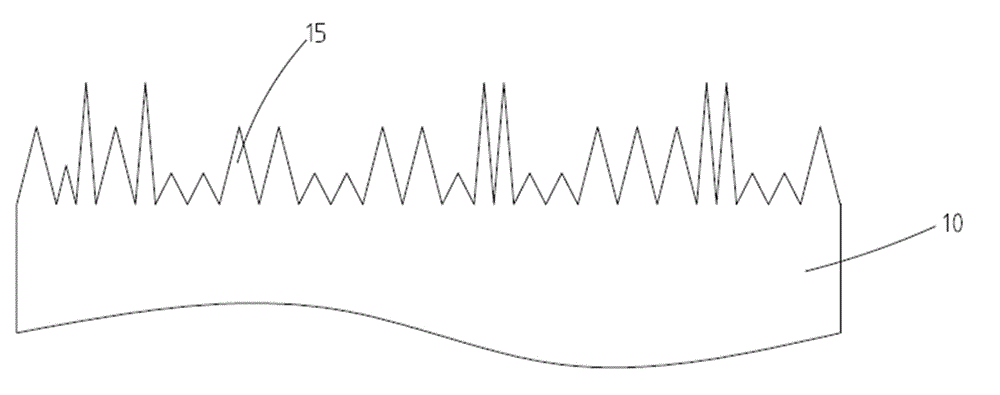

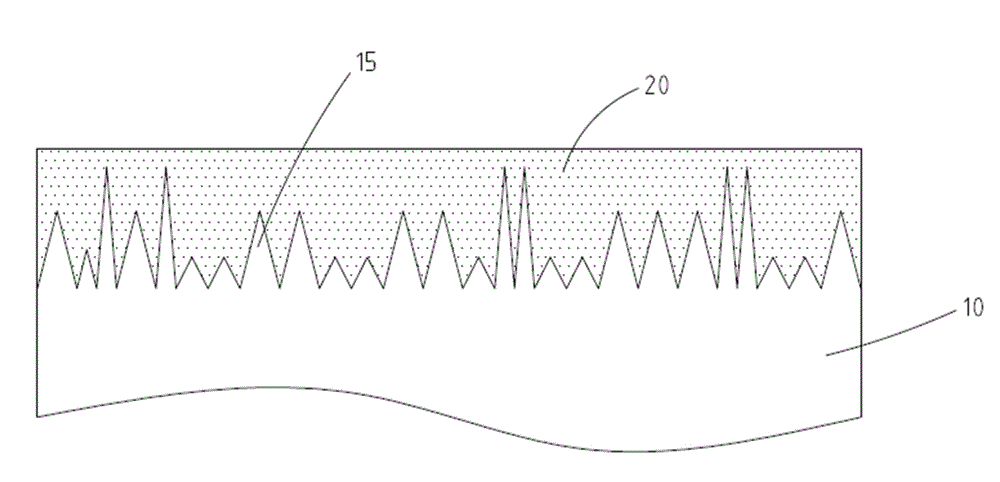

Method of manufacturing wafer

InactiveCN106206250AAvoid breakingReduce spreadPolycrystalline material growthAfter-treatment detailsChemical reactionNanopillar

The invention provides a method of manufacturing a wafer. A method of manufacturing a wafer includes a step for forming nanorods on the surface of an ingot, a step for forming a coating layer covering the nanorods on the surface of the ingot, a step for forming an adhesive layer on the surface of the coating layer, a step for cutting the ingot as a plurality of wafers, and a step for removing the coating layer and adhesive layer on the wafer simultaneously, with a solvent causing chemical action on the coating layer, but not causing chemical action on the wafer. Since the nanorods are covered by forming a coating layer, and the coating layer can be removed by chemical reaction, problem of residual adhesive can be solved. Furthermore, since the method can be operated under low temperature environment, the problem of exposure to a toxic environment in the operation flow is solved, while reducing diffusion phenomenon of metal elements.

Owner:KUNSHAN ZHONGCHEN SILICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com