Patents

Literature

994results about How to "Solve temperature problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

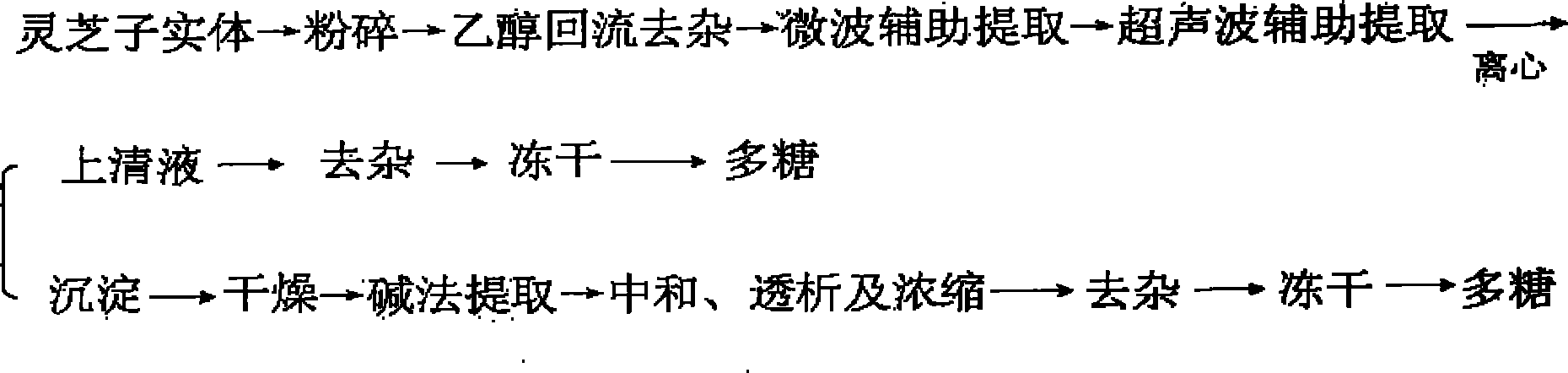

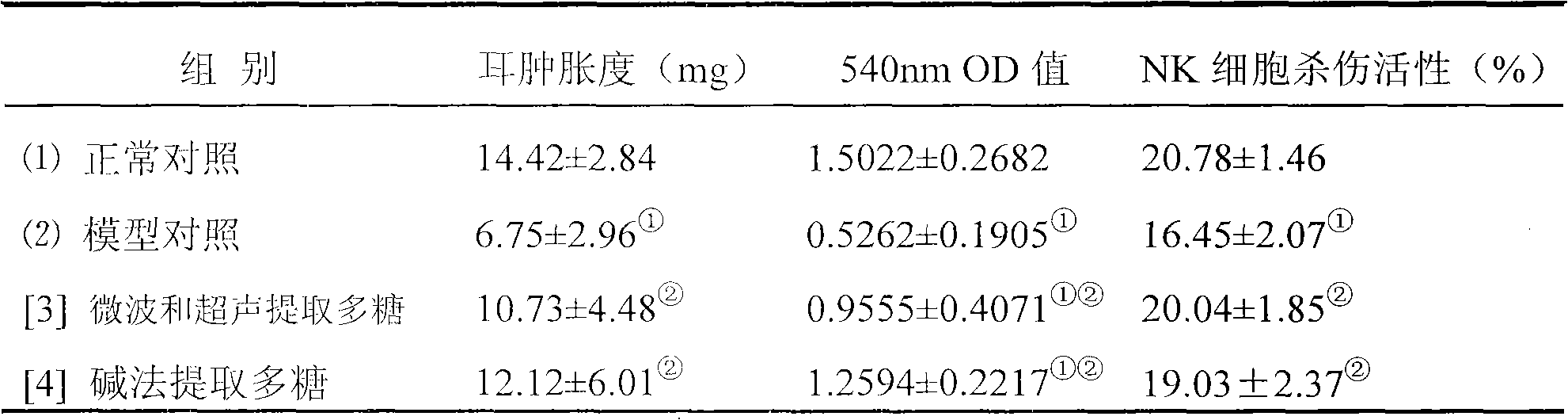

Preparation method of ganoderma lucidum polysaccharide with high yield

The invention discloses a preparation method of ganoderma lucidum polysaccharide with high yield, which comprises the following steps: firstly, crushing ganoderma lucidum fruiting bodies into ganoderma lucidum powder, then sequentially extracting the ganoderma lucidum powder by adopting a microwave-assisted hot water extraction method and an ultrasonic-assisted hot water extraction method, and carrying out concentration, impurity removal, concentration, alcohol precipitation and drying on the obtained extracting solution to obtain water-soluble ganoderma lucidum polysaccharide; and extracting the ganoderma lucidum residues by adopting an alkali extraction method, and carrying out neutralization, dialysis, concentration, impurity removal, alcohol precipitation and drying on the obtained extracting solution to obtain alkali-soluble ganoderma lucidum polysaccharide. The method is used for extracting the ganoderma lucidum polysaccharide by combining microwave heating action and ultrasonic cavitation and extracting the alkali-soluble polysaccharide in the ganoderma lucidum by utilizing the alkali extraction method, thereby reducing the loss of the ganoderma lucidum polysaccharide; and the prepared ganoderma lucidum polysaccharide has the characteristics of high production yield, strong immunological activity and the like.

Owner:INFINITUS (CHINA) CO LTD

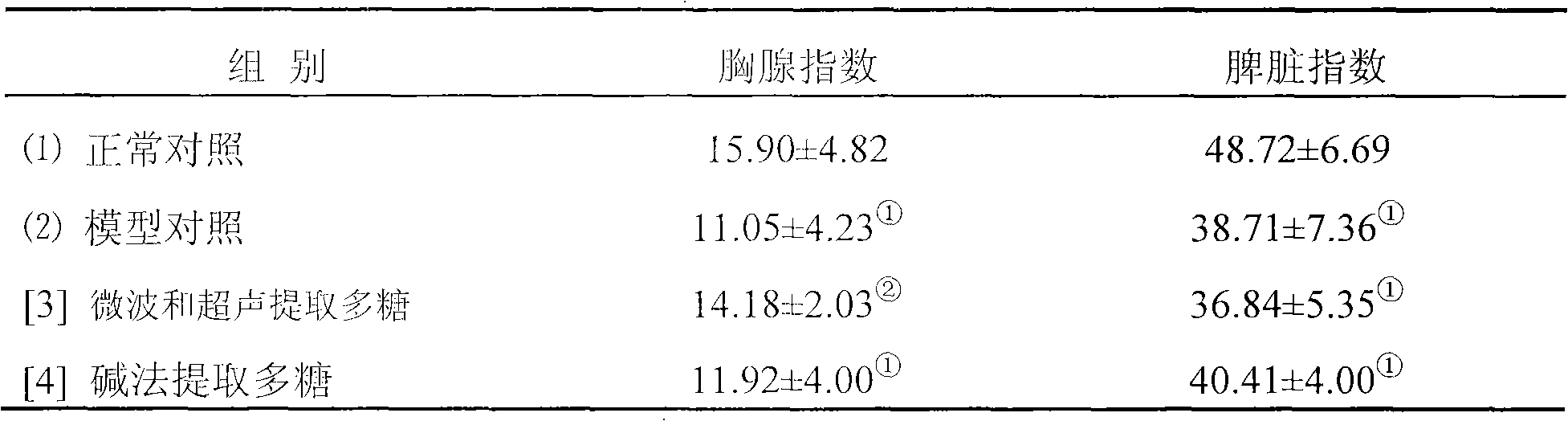

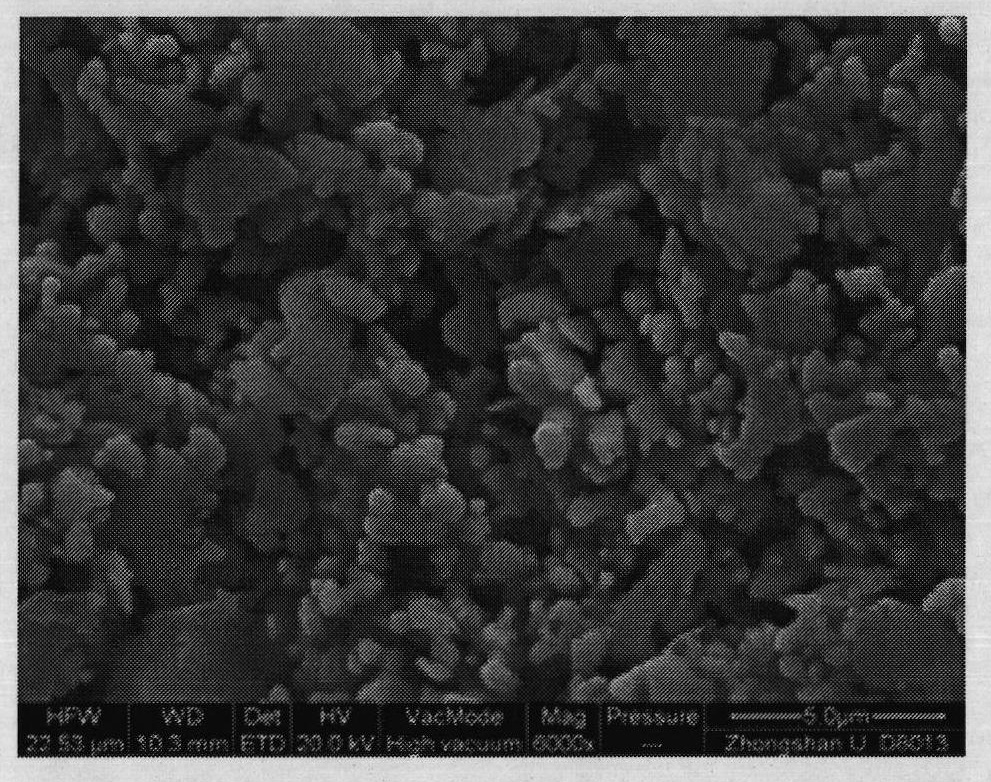

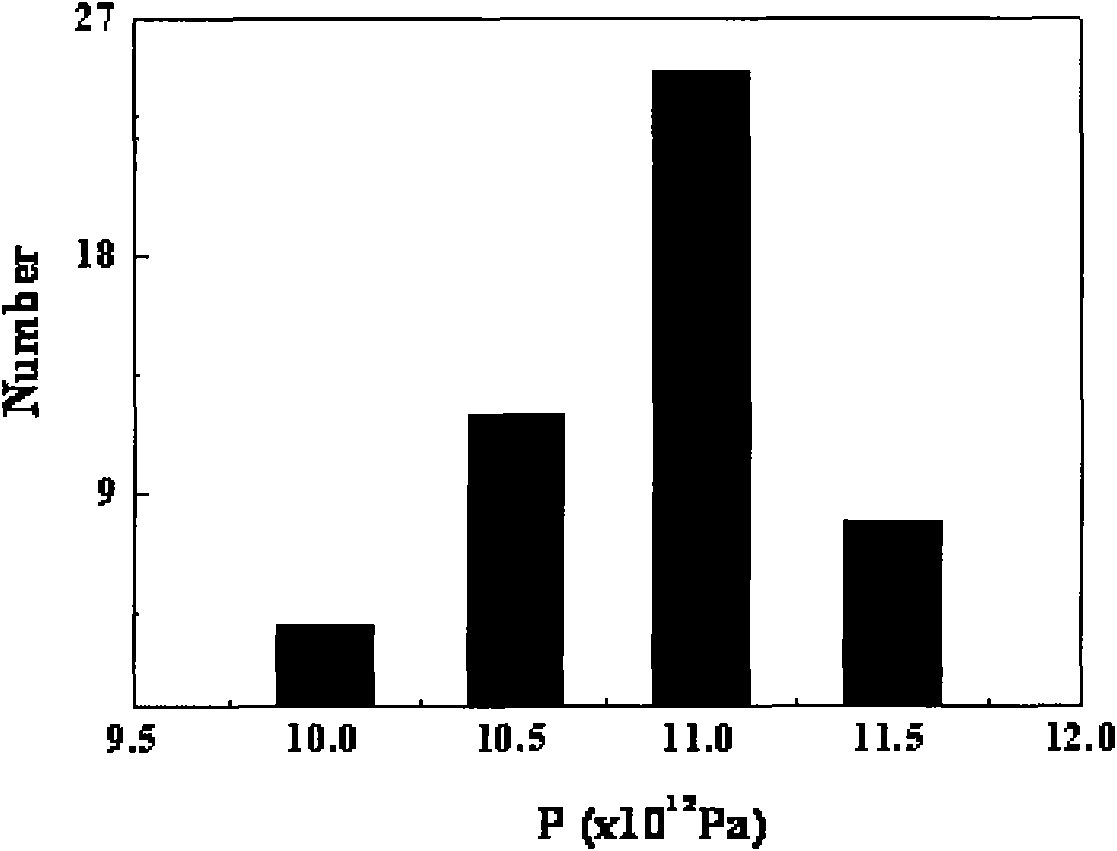

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

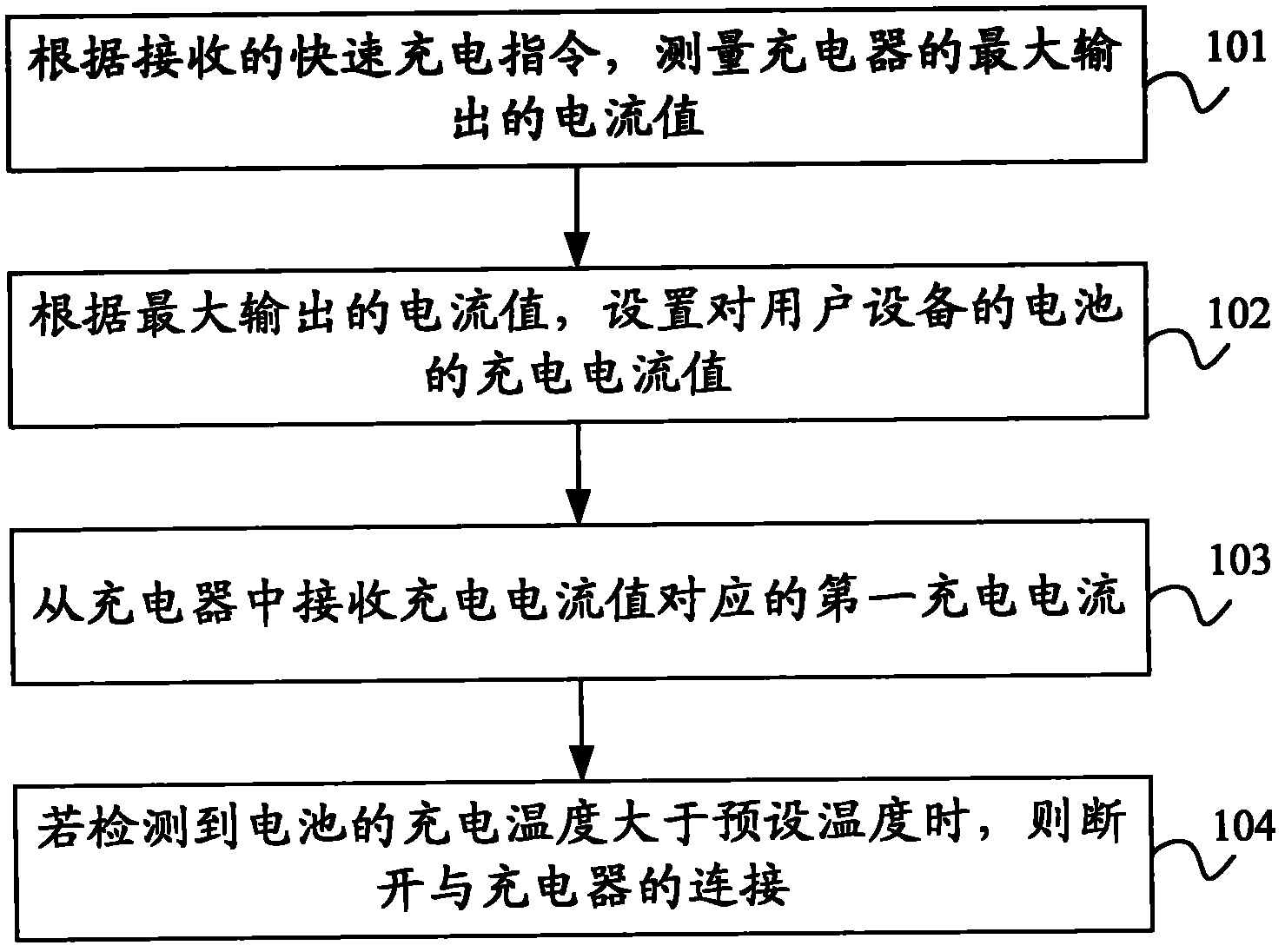

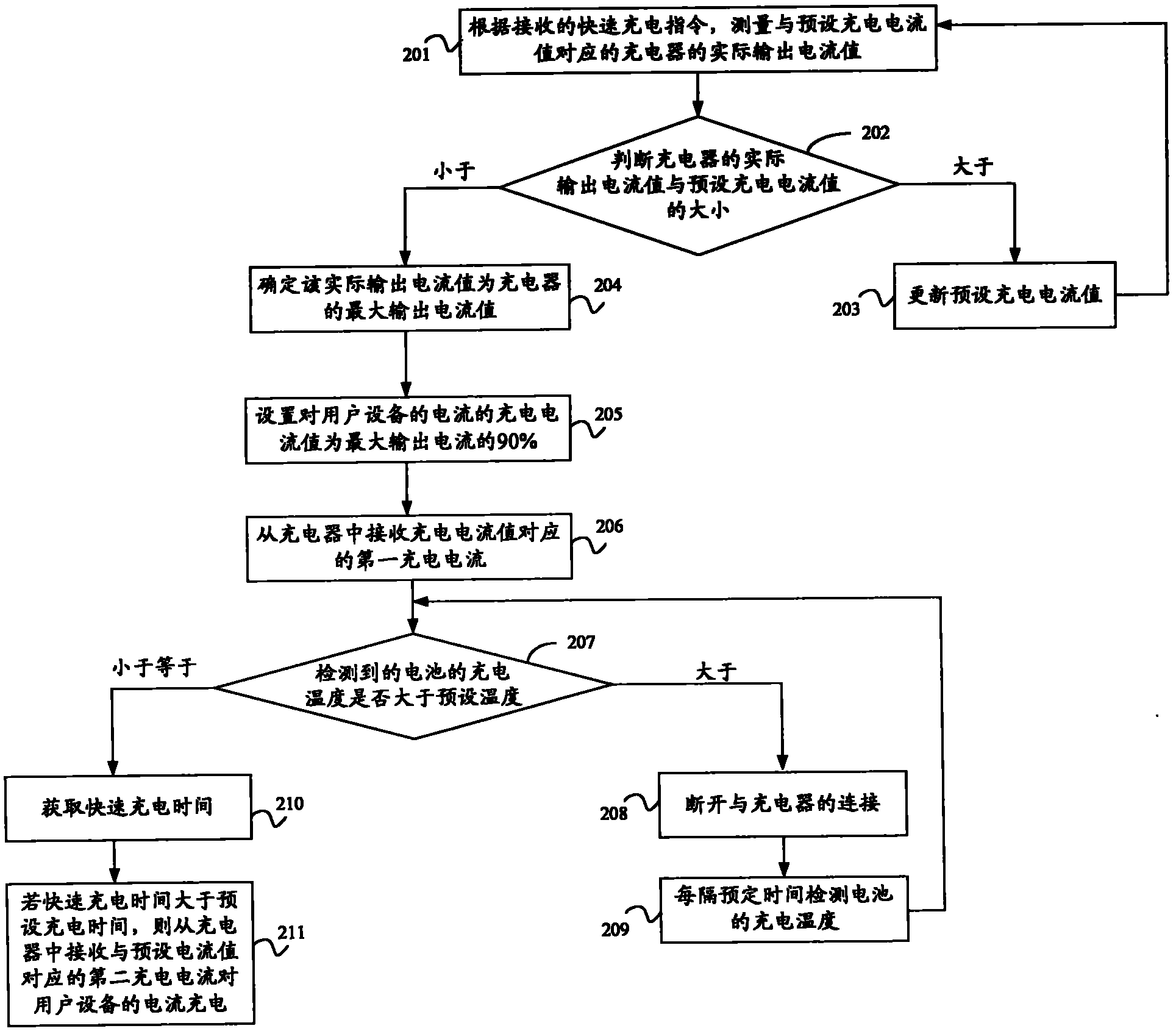

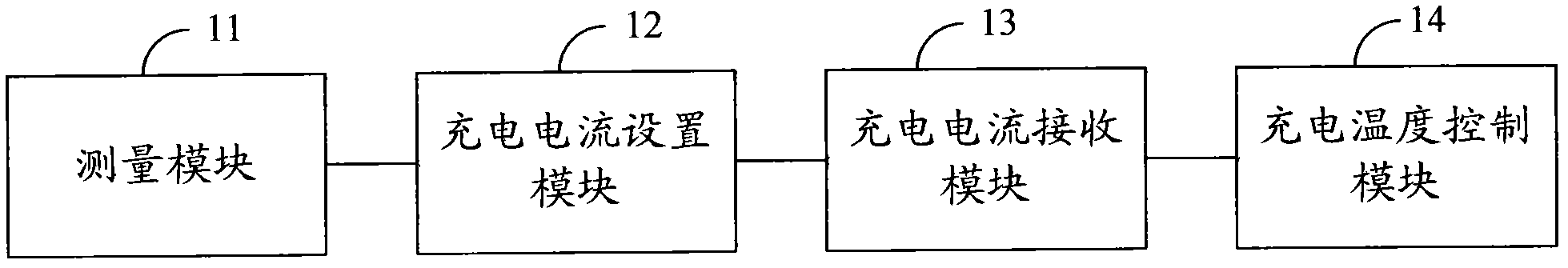

Charging method and user equipment

ActiveCN102122739ASolve temperature problemsSolve the problem of filling upSecondary cells charging/dischargingElectric powerCharge currentPower flow

The invention provides a charging method and a user equipment, and the charging method comprises the following steps: measuring the maximum output current value of a charger according to a received quick charge command; setting a charging current value for a battery of the user equipment according to the maximum output current value; receiving a first charging current corresponding to the charging current value from the charger; and disconnecting from the charger if the detected charging temperature of the battery is higher than a preset temperature. By adopting the charging method and the user equipment, the problems that the charger is damaged due to overload during emergency charge in the prior art and the charge explosion of the battery of the user equipment is caused due to too high charging temperature can be solved, and the safe and quick charge can be realized.

Owner:HUAWEI DEVICE CO LTD

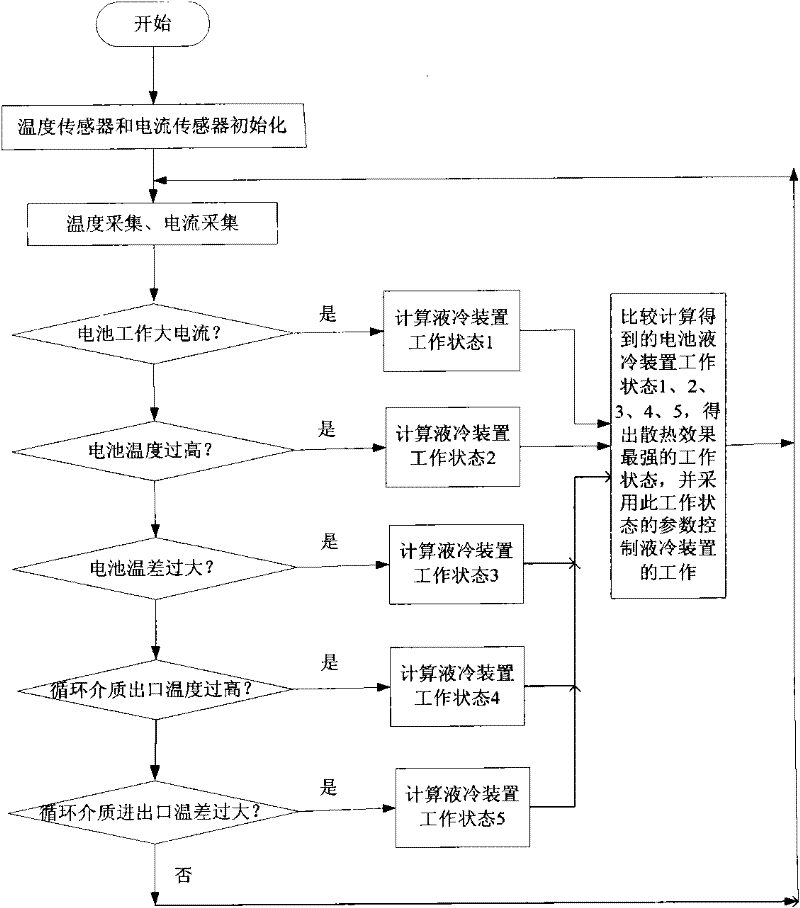

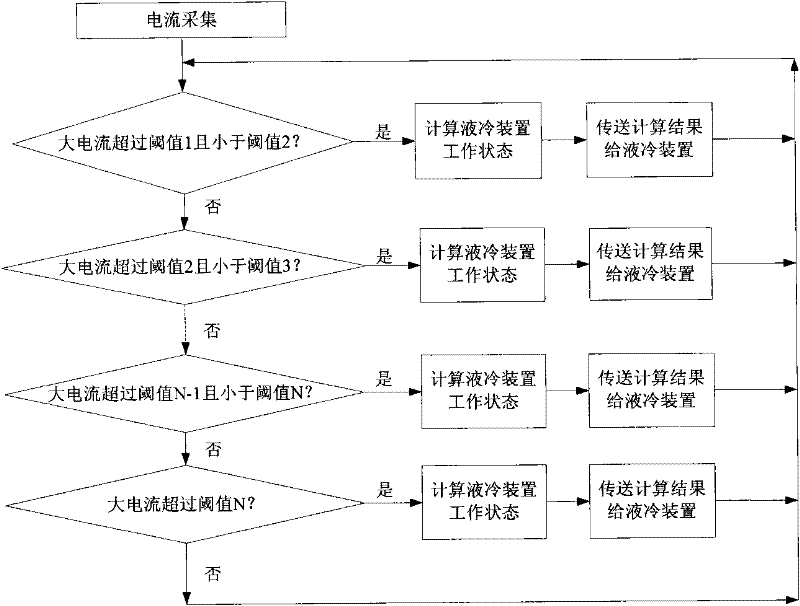

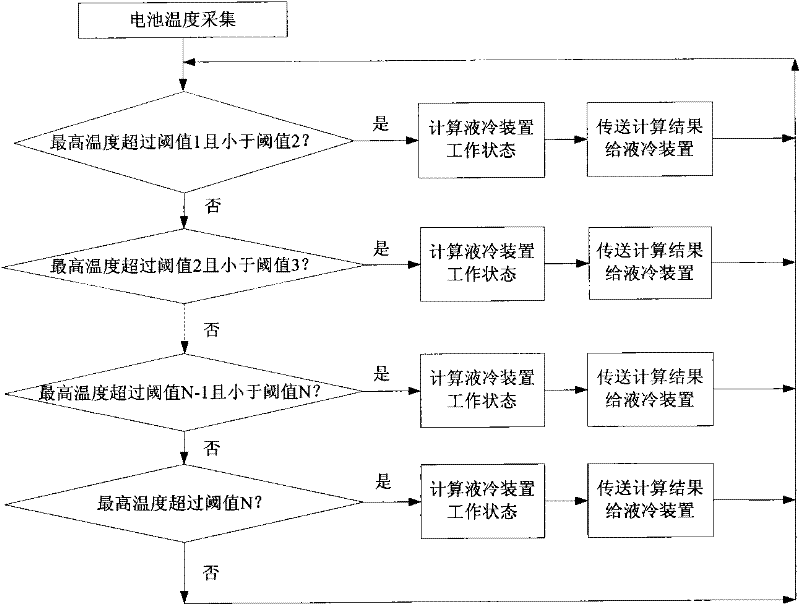

Liquid cooling temperature control and management method of power lithium ion battery

InactiveCN102544618AAvoid heat dissipationAvoid performance lossCell temperature controlTemperature controlPower flow

The invention discloses a liquid cooling temperature control and management method of a power lithium ion battery. The liquid cooling temperature control and management method comprises the steps of: 1) acquiring temperature and current; 2) obtaining a highest temperature value, a lowest temperature value, greatest temperature difference and liquid cooling system inlet and outlet temperature difference; 3) judging whether the current is large or not and computing a working state 1; 4) judging whether the temperature of the battery is high or not, computing a working state 2; 5) judging whether temperature difference of the battery is too great or not and computing a working state 3; 6) judging whether the outlet temperature of a battery pack is too high or not and computing a working state 4; 7) judging whether the temperature difference of circulating medium at the inlet and outlet of the battery pack is too great or not and computing a working state 5; and 8) comparing the computed working state 1, the working state 2, the working state 3, the working state 4 and the working state 5 to obtain a working state with the best heat dissipation effect for setting. The liquid cooling temperature control and management method of the power lithium ion battery solves the problems that the temperature of the battery is too high and the local temperature difference is too great, and has the beneficial effects that the performance of the battery is improved and the service life of battery is prolonged.

Owner:SHANGHAI AEROSPACE POWER TECH

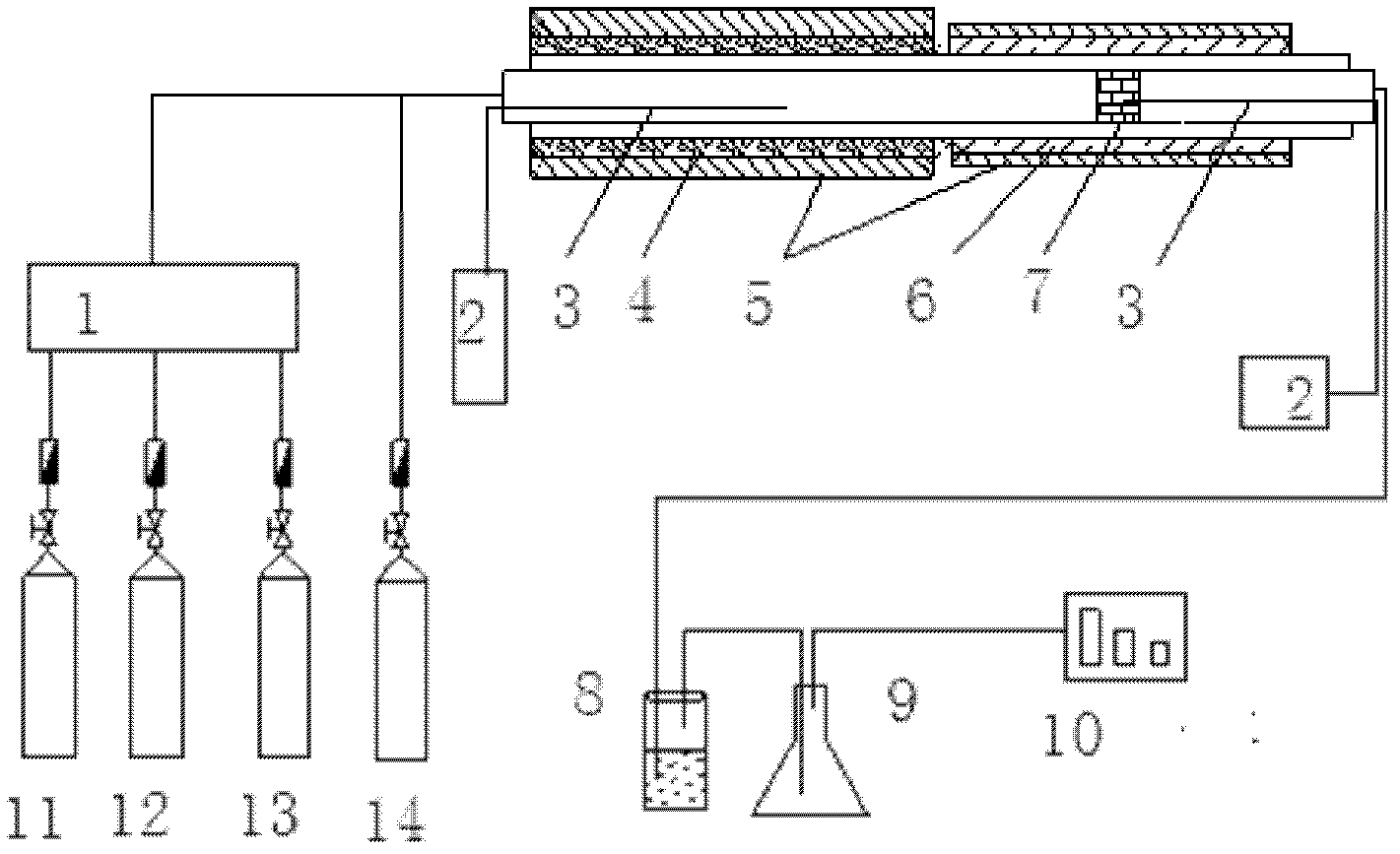

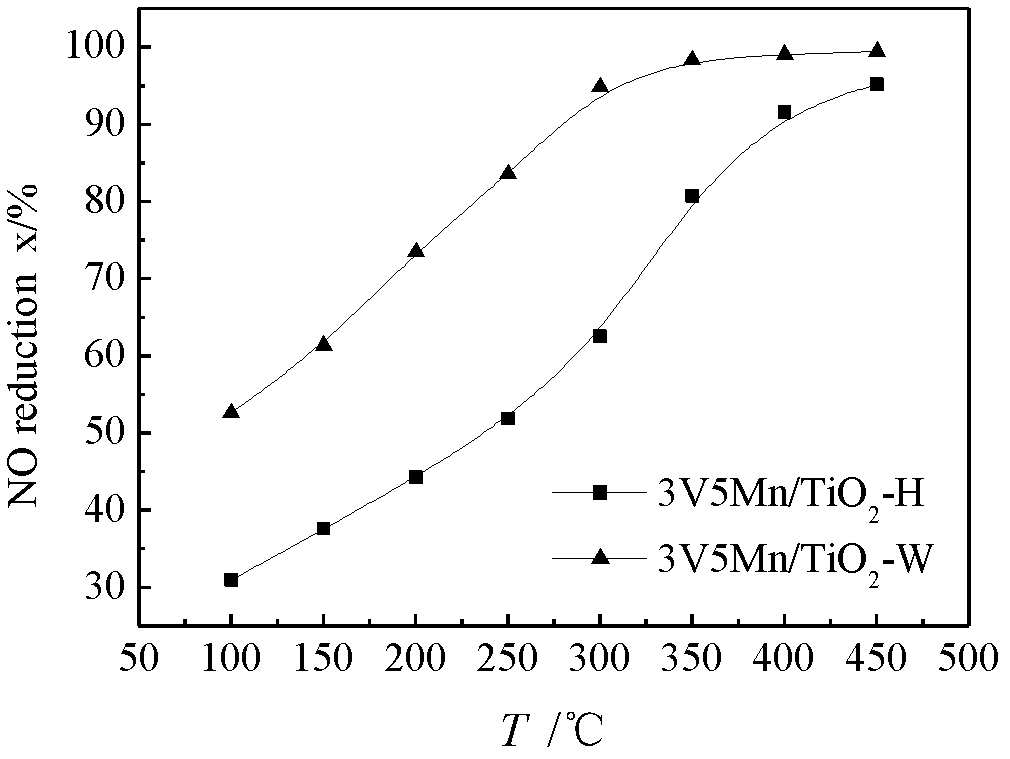

Method for preparing flue gas SCR (Selective Catalytic Reduction) denitration catalyst

InactiveCN102553574AShorten drying timeReduce energy consumptionDispersed particle separationCatalyst activation/preparationWater bathsAmmonium metavanadate

The invention relates to a method for preparing a flue gas SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: mixing ammonium metavanadate, oxalic acid, manganese salt and water for preparing a mixture solution, adding titanium dioxide powder into the mixture solution, heating in water bath and stirring, and obtaining mixed sol by standing at room temperature; putting the mixed sol into a microwave oven, heating and drying by utilizing microwave radiation; and putting dried solid into a muffle furnace for burning. According to the method disclosed by the invention, a temperature window of the SCR catalyst can be broadened to a low-temperature direction, the problems of low denitration efficiency at low temperature and narrow temperature window of a commercial catalyst are solved; compared with the traditional drying method, the microwave radiation heating and drying method has the advantages that low-temperature SCR denitration activity of the composite catalyst can be increased to a large extend, when the activity temperature is up to 250 DEG C, the denitration efficiency of the catalyst prepared by the traditional drying method is up to 51.9%, and the denitration efficiency of the catalyst can be increased by 31.7 percentage points and can be up to 83.6% by the microwave radiation heating and drying method.

Owner:SHANDONG UNIV

Optical fiber raster vibration sensor of tunable matching filtering demodulation

ActiveCN1752729ASolve wavelength demodulationSolve temperature problemsSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration amplitudeFrequency spectrum

The invented optical-fibre grating vibration sensor is characterized by that it utilizes a demodutation grating and a sensing grating and makes them be series-connected together, and respectively makes them be stuck on a main beam and an auxiliary beam, two beams are made of identical material and have identical heat expansion coefficient, so that their central wavelengths can be synchronously shifted with temperature, therefore they have automatic temperature compensation function so as to implement matching filter demodutation. Said invention utilizes the detection of light intensity change of sensing grating reflecting light to monitor the parameters of vibration frequency and vibration amplitude of monitored body, finally utilizes computer or single-chip computer to make analysis and processing of body vibration frequency spectrum.

Owner:WUHAN WUTOS

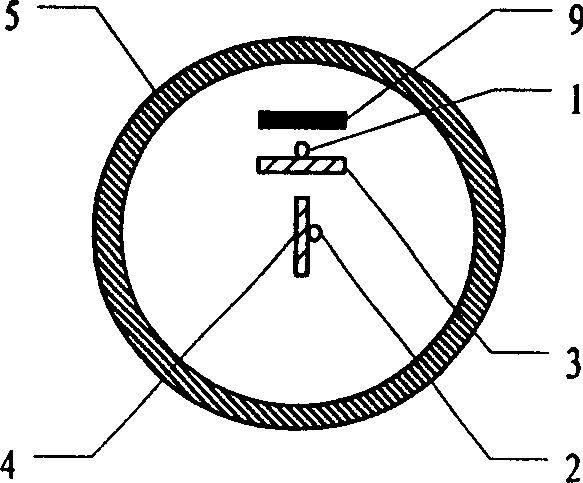

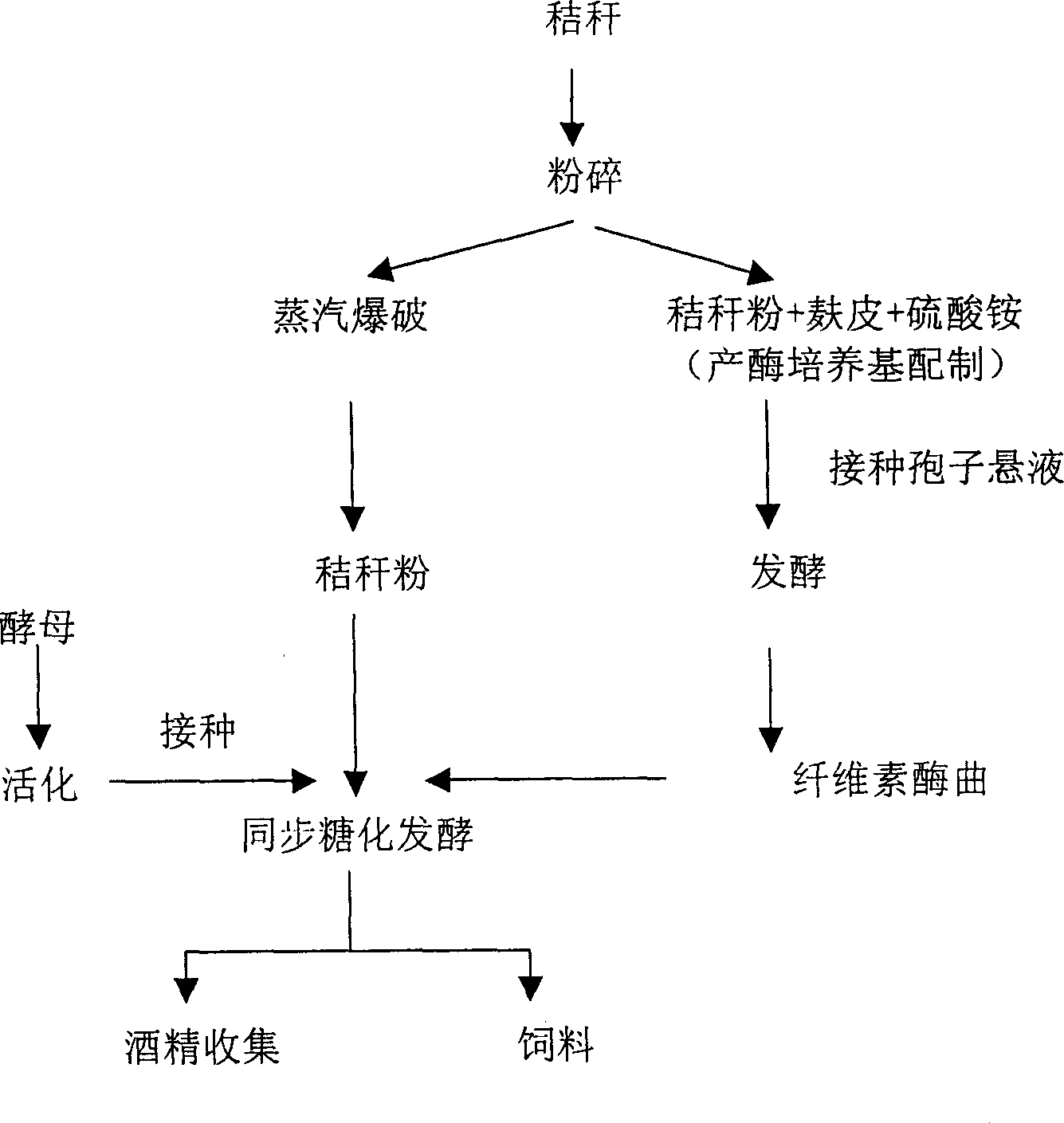

Method for producing alcohol by solid fermentation of stalks

InactiveCN1451755ARealize solid state simultaneous fermentationSolve temperature problemsFermentationYeastAlcohol

Owner:CHINA AGRI UNIV

Method for connection between composite type green low-melting solder glass and silicon carbide reinforced aluminum matrix composites

ActiveCN103894694AFirmly connectedSolve Wetting ProblemsWelding/cutting media/materialsWelding/soldering/cutting articlesWhiskersSoldering

The invention provides a method for connection between composite type green low-melting solder glass and silicon carbide reinforced aluminum matrix composites and relates to a method for connecting the silicon carbide reinforced aluminum matrix composites. The method aims at solving the problems that the silicon carbide reinforced aluminum matrix composites connected through an existing connection method are low in strength and the joint strength, and the surface of existing solder and the surface of the silicon carbide reinforced aluminum matrix composites are incompatible when the content of silicon carbide reinforced bodies in existing silicon carbide reinforced aluminum matrix composites is increased. The method includes the steps of classifying basis glass power, weighing, pretreating beta-SiC whiskers, preparing composite type lead-free low-temperature sealing glass powder, mixing, stirring, removing impurities, coating and assembling and welding test pieces. Through the method, the silicon carbide reinforced aluminum matrix composites can be connected in a low-temperature soldering mode.

Owner:HARBIN INST OF TECH

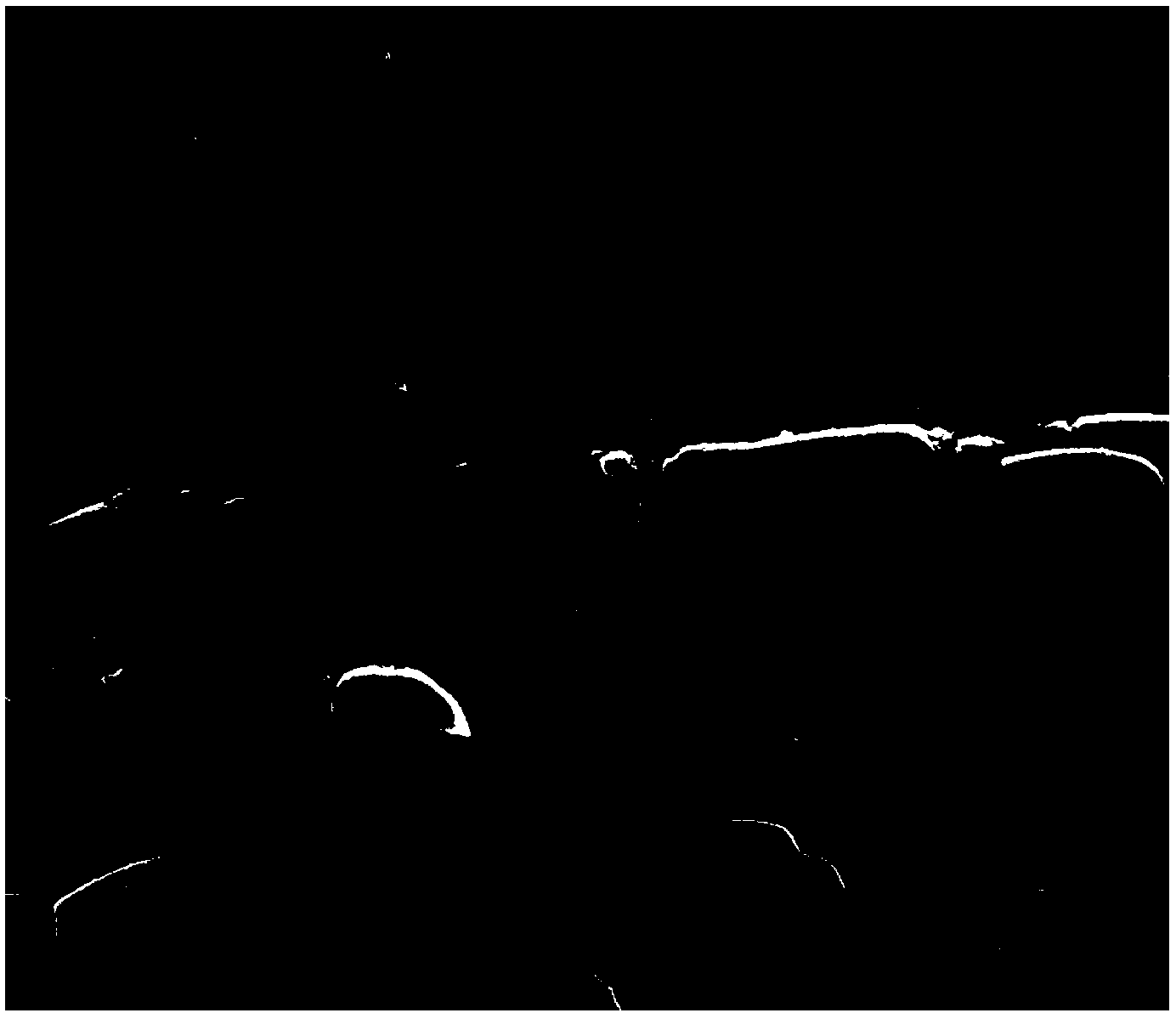

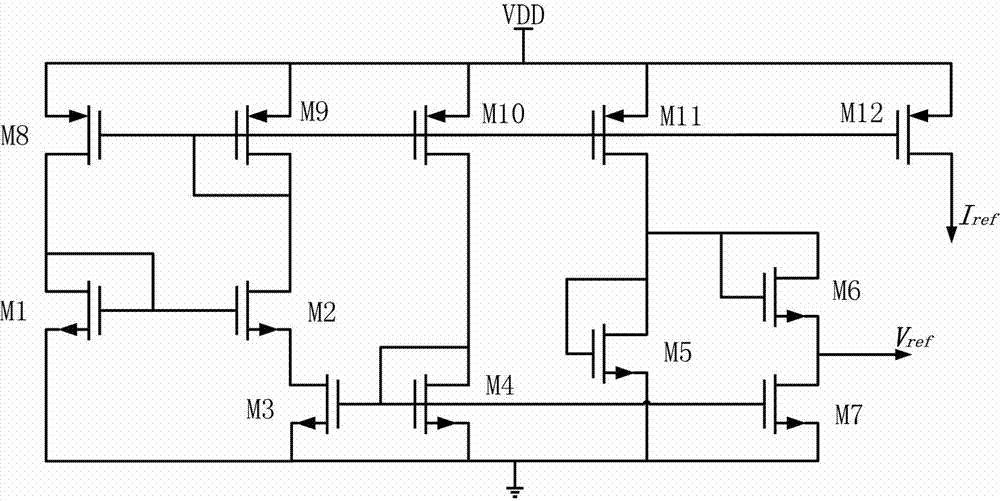

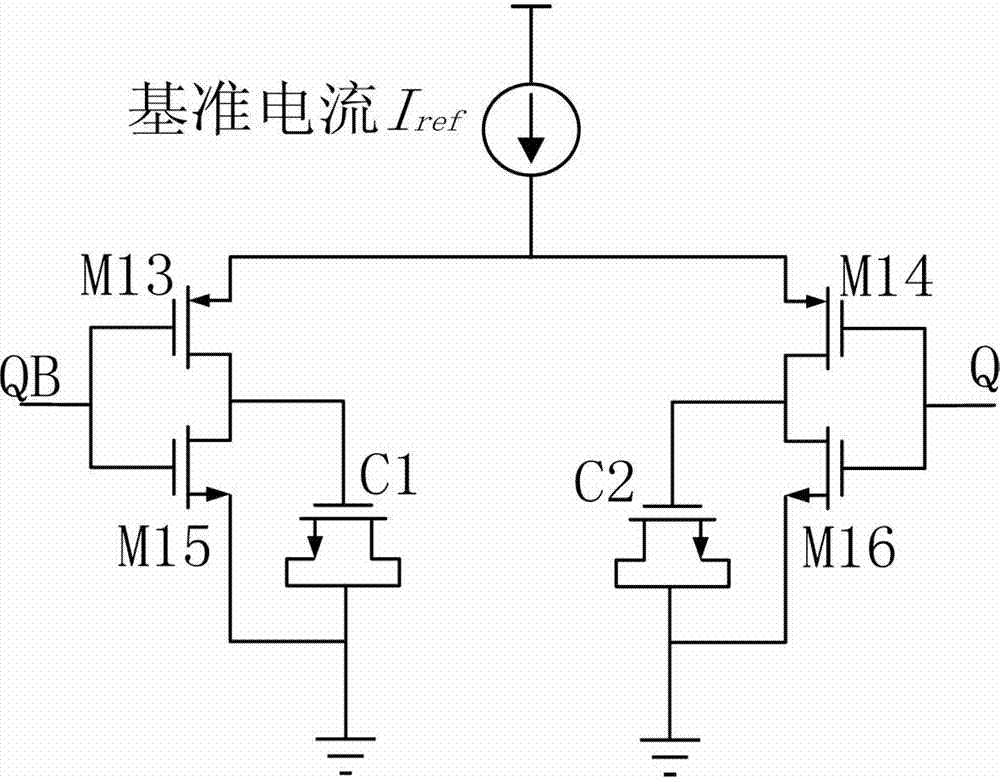

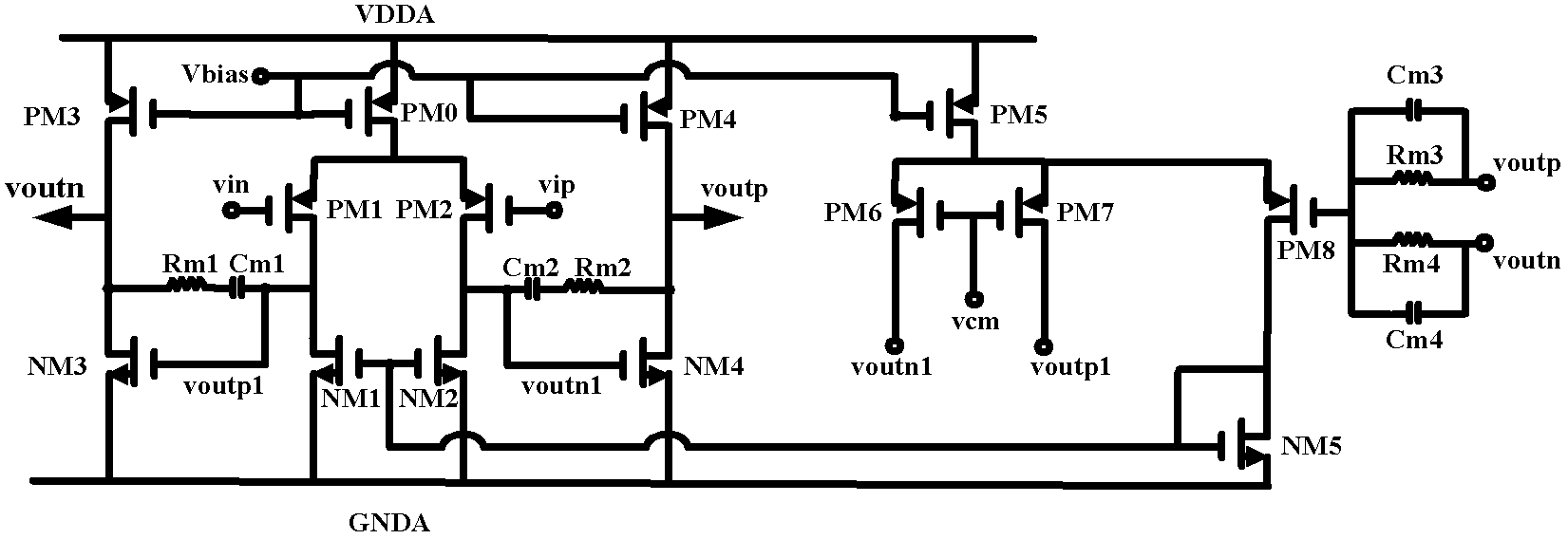

CMOS (complementary metal oxide semiconductor) relaxation oscillator with temperature and process self-compensating characteristics

ActiveCN103701411ASolve temperature problemsSolve process problemsOscillations generatorsCapacitanceProcess deviations

The invention discloses a CMOS (complementary metal oxide semiconductor) relaxation oscillator with temperature and process self-compensating characteristics. The CMOS relaxation oscillator comprises a reference source, a capacitor charge and discharge circuit, a first comparator, a second comparator and an SR (set reset) latch, wherein the reference current of the reference source is connected with the capacitor charge and discharge circuit, the reference voltage of the reference source is respectively connected with the same-phase input end of the first comparator and the same-phase input end of the second comparator, the reverse-phase input end of the first comparator and the reverse-phase input end of the second comparator are respectively connected with the capacitor charge and discharge circuit, the output end of the first comparator is connected with the R end of the SR latch, and the output end of the second comparator is connected with the S end of the SR latch. The CMOS relaxation oscillator with temperature and process self-compensating characteristics can overcome the defects of high cost, low reliability, great process deviation and the like in the prior art for realizing the advantages of low cost, high reliability and small process deviation.

Owner:四川电子科技大学教育发展基金会

High-performance conductive silver paste and preparation method thereof

ActiveCN101805575AEvenly dispersedUniform size distributionNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to a high-performance conductive silver paste, which is characterized by comprising the following raw materials in percentage by weight: 65-80% of micron-sized metal silver powder, 10-20% of epoxy resin, 1.4-3.5% of curing agent, 6-9% of solvent, 0.5-1.2% of accelerator, 0.05-0.1% of flexibilizer and 1-2% of additive. The invention also discloses a preparation method of the high-performance conductive silver paste. The conductive silver paste of the invention has high conductivity, very high thermal conductivity, high working temperature, strong viscosity and very high shear strength, and the performance indexes are apparently higher than the working performance of the conductive silver paste in the prior art, thereby solving the technical problems of poor shear performance, low working temperature, poorer thermal conductivity, long curing time, high curing temperature, poor viscosity, easy pollution of environment and the like in the field of the conductive silver paste in the prior art.

Owner:连云港市昭华光电科技有限公司

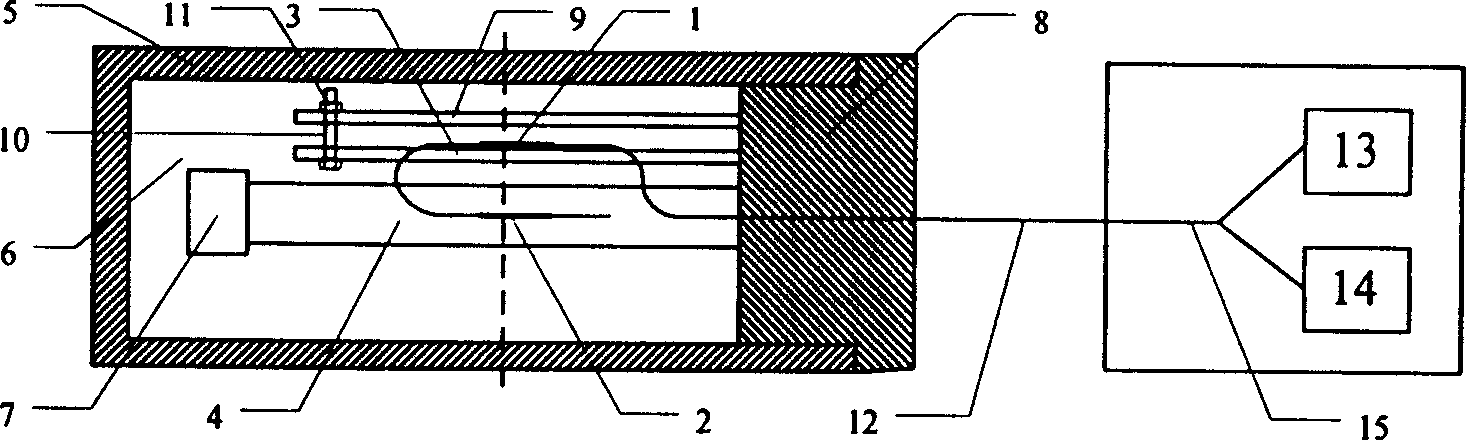

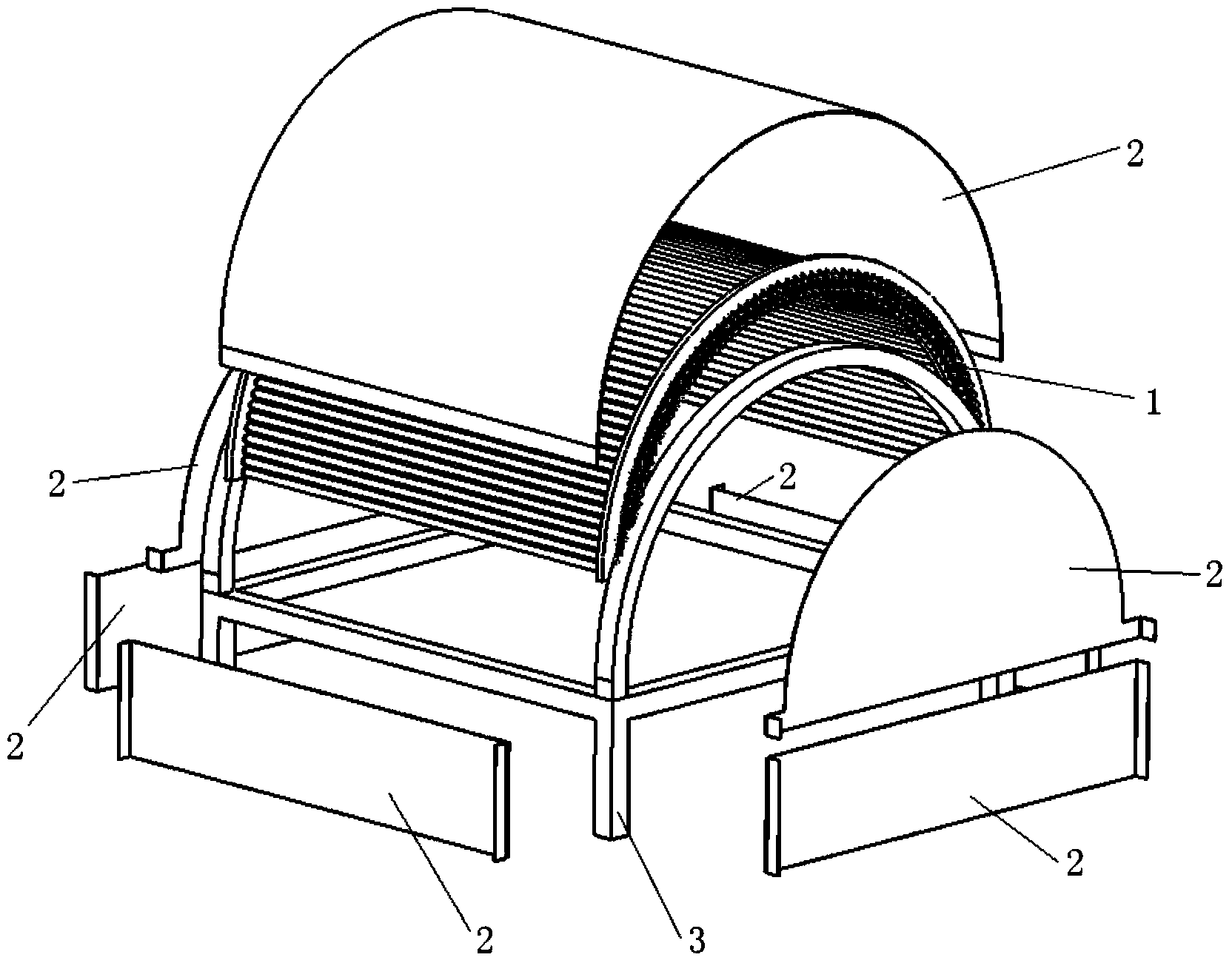

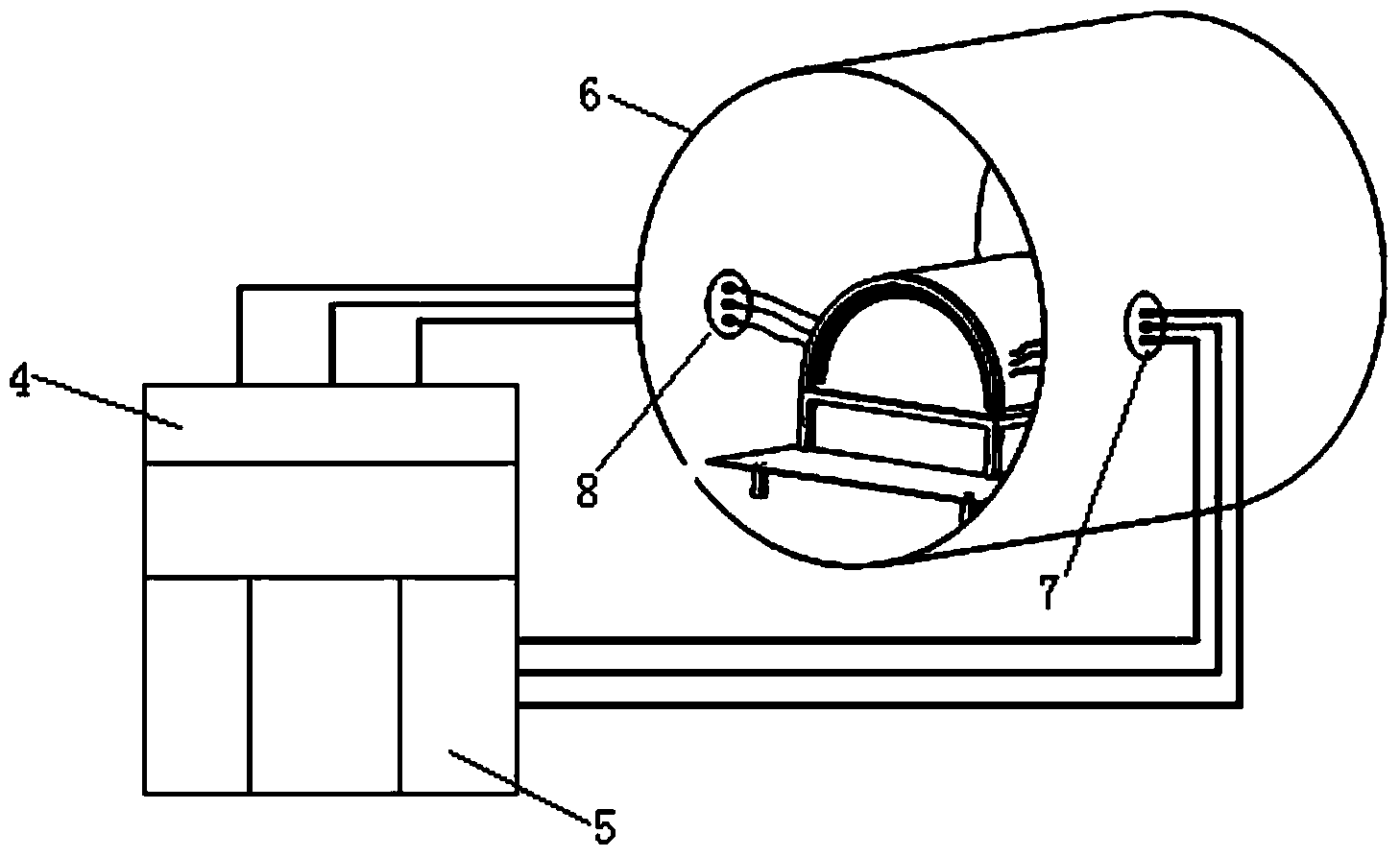

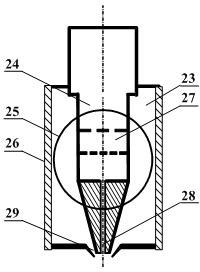

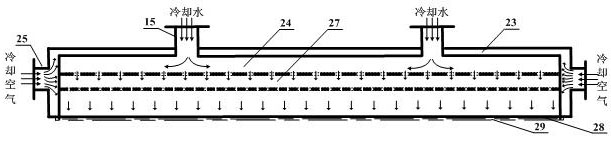

Ultrahigh-temperature thermal current simulation system used for spacecraft vacuum thermal test

InactiveCN104015942ASolve the technical problems of ultra-high temperature and extremely high heat flow simulationSolve temperature problemsCosmonautic condition simulationsThermal insulationHeater Rod

The invention discloses an ultrahigh-temperature thermal current simulation system used for a spacecraft vacuum thermal test in a vacuum container. The ultrahigh-temperature thermal current simulation system mainly comprises a semi-cylindrical graphite heating array, high-reflectivity high-temperature thermal insulation assembly units, a graphite heating array installing support, an ultrahigh temperature measuring unit and a power-regulator power control unit. A plurality of graphite heating rods are arranged and combined into the semi-cylindrical graphite heating array according to the requirements for the density and uniformity of thermal currents. Each graphite heating rod is composed of a graphite heating body and a graphite electrode, alternating-current electricity supply is adopted, and wiring electrode leads penetrate through a high-current cabin-penetrating electricity supply flange arranged on a container wall of the vacuum low-temperature environment simulation container and are electrically connected with the temperature measuring unit and the power-regulator power control unit respectively. Through the unique design of the graphite heating array, the high-reflectivity high-temperature thermal insulation assembly units and the ultrahigh temperature measuring unit, measurement of and control over temperatures over 1800 DEG C in the space environment simulation container are achieved, and the ultrahigh-temperature thermal current simulation system is also suitable for high-temperature and high-thermal-current environment simulation requirements in vacuum thermal tests of all types of spacecraft.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

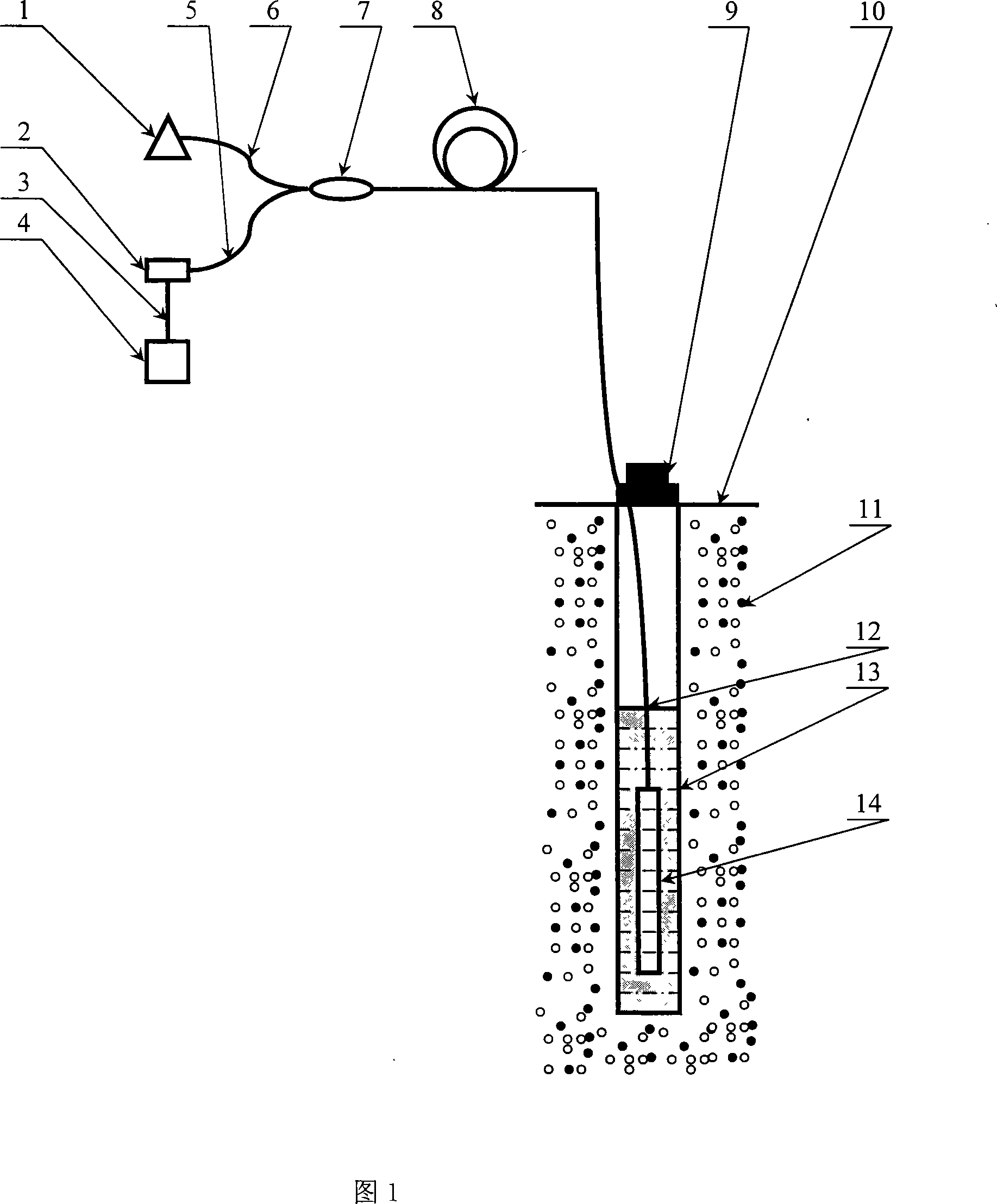

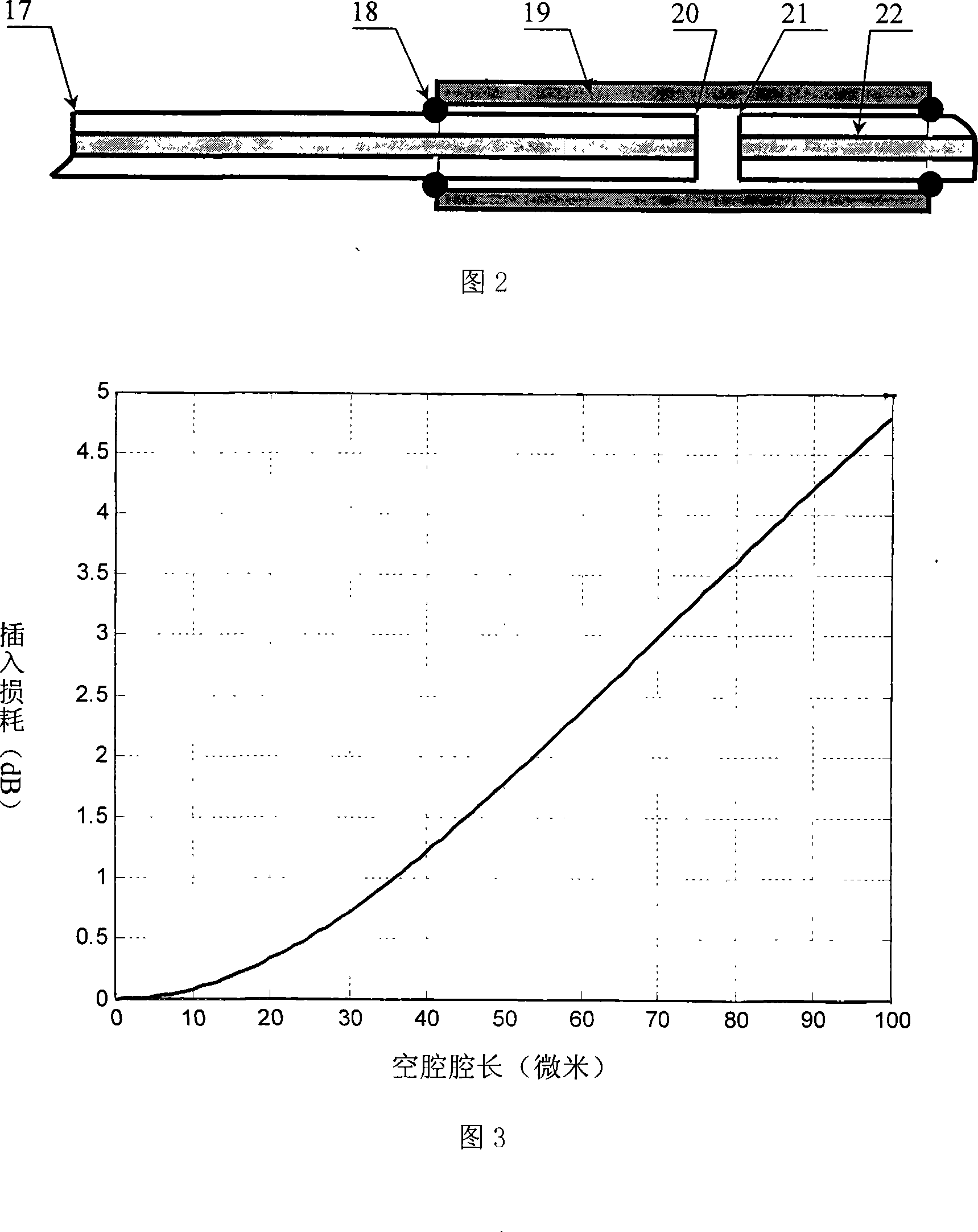

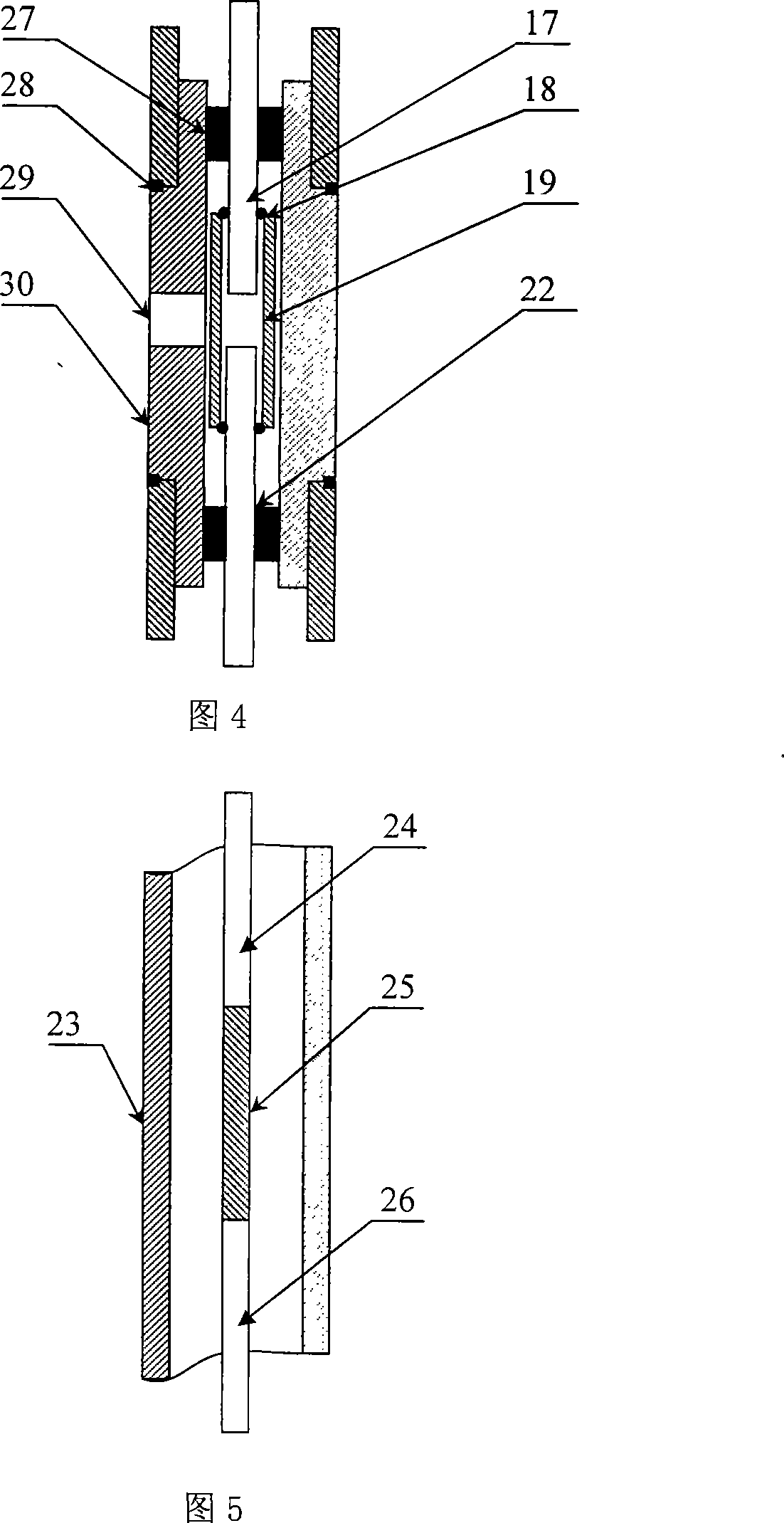

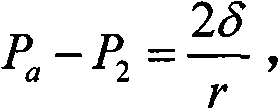

Optical fiber multi-point temperature and pressure measuring method for intelligent well and the device therefor

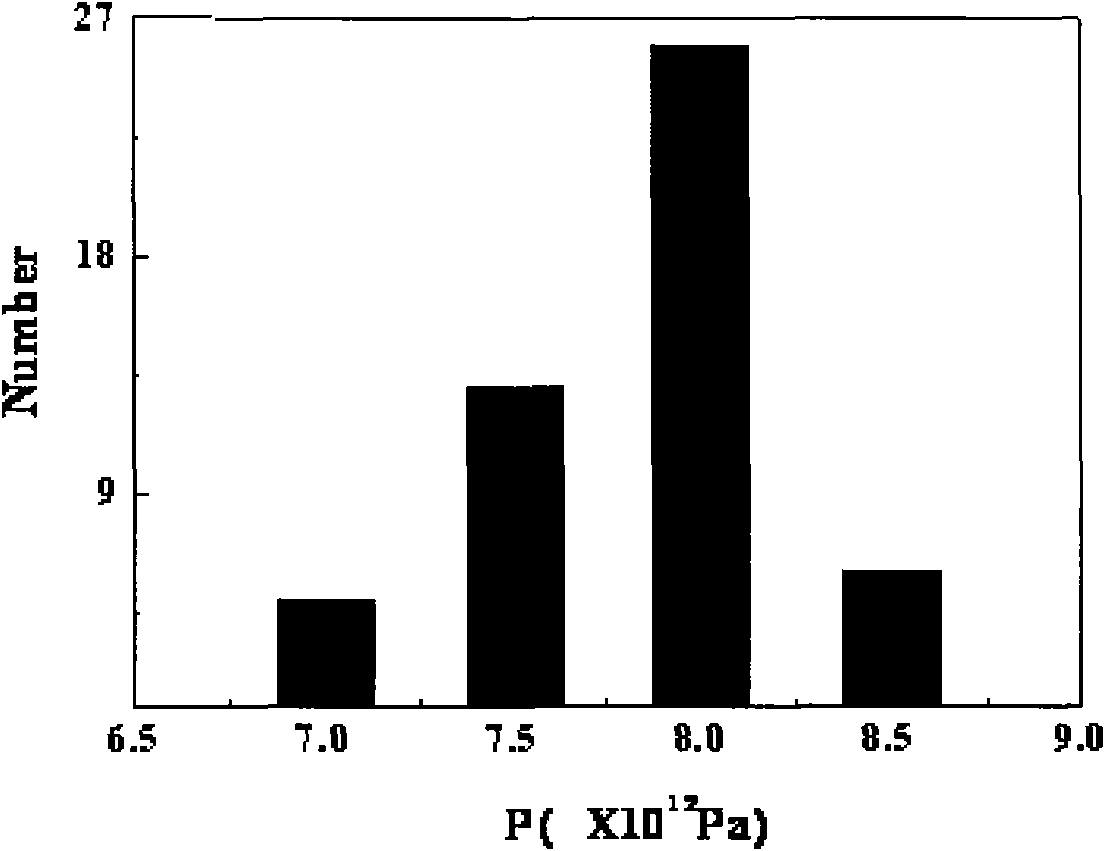

InactiveCN101187307ASolve stressSolve temperature problemsSurveyConstructionsGratingReflectance spectroscopy

The invention relates to a measuring method and a device for measuring optical fiber multipoint temperature and pressure of an intelligent well, belonging to the technical field of intelligent wells. The measuring method comprises that a plurality of optical fiber temperature sensors and optical fiber pressure sensors are arranged on an optical cable, wherein reversed lights which are reflected by the optical fiber temperature sensors and the optical fiber pressure sensors are respectively transformed into spectroscopic data which is transmitted to a processor, thereby respectively obtaining reflectance spectrums of all sensors, and a wave length value which is relative to the largest reflection rate is used as characteristic parameter of relative temperature sensors, the length of the cavity of each pressure sensor is calculated to be used as characteristic parameter of relative pressure sensors, and then the characteristic parameters of relative temperature and relative pressure sensors are compared with the characteristic parameter calibration curve to gain temperature reading or pressure reading of the optical fiber sensors. The device comprises a broad band light source, a modularized optical spectrometer, a data transmission line, a data processor, a first section optical fiber and a second section optical fiber, a optical fiber coupling, an optical cable, and a two-parameter sensor group of optical fiber temperature and optical fiber pressure. The invention solves the problems of pressure float and temperature crossfire when optical fiber grating technology is applied to a pressure sensor.

Owner:北京蔚蓝仕科技有限公司 +1

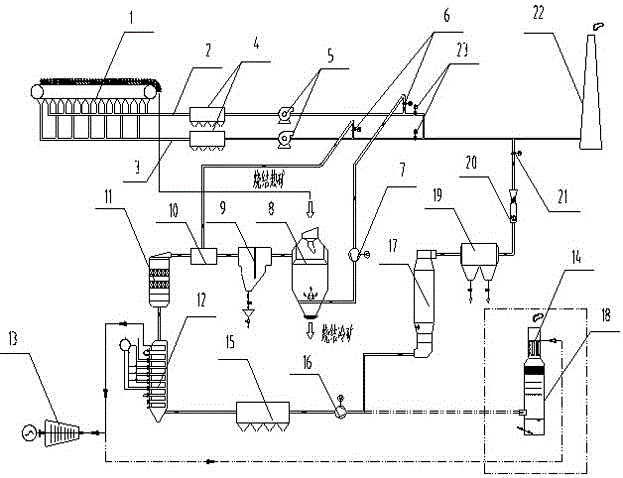

Sintering flue gas desulfurization and denitrification system and implementation method thereof

InactiveCN106215695ASolve temperature problemsRealize simultaneous desulfurization and destockingCombination devicesGas treatmentNitrogen oxidesMetallurgy

The invention relates to a sintering flue gas desulfurization and denitrification system and an implementation method thereof. According to the method, after two paths of sintering flue gas coming out of a sintering machine pass a dust collector, one path of sintering flue gas and high-temperature sintering ore coming out of the sintering machine are subjected to heat exchange and temperature rise, the sintering flue gas is mixed with the other path of sintering flue gas and enters an SCR (selective catalytic reduction) reactor after temperature rise, catalytic reduction reaction is performed in the SCR reactor, nitrogen oxide in the sintering flue gas is removed, the sintering flue gas without the nitrogen oxide enters a waste heat boiler, waste heat of the flue gas is recycled, the sintering flue gas subjected to heat exchange and cooling by the waste heat boiler enters a desulfurization device, sulfur dioxide is removed, and purified flue gas subjected to desulfurization and denitrification is discharged with standard level. The sintering flue gas is simultaneously subjected to desulfurization and denitrification, sensible heat of the sintering ore and the sintering flue gas is sufficiently recycled, and sintering energy conservation and emission reduction are realized in a real sense.

Owner:江苏垦乐节能环保科技有限公司

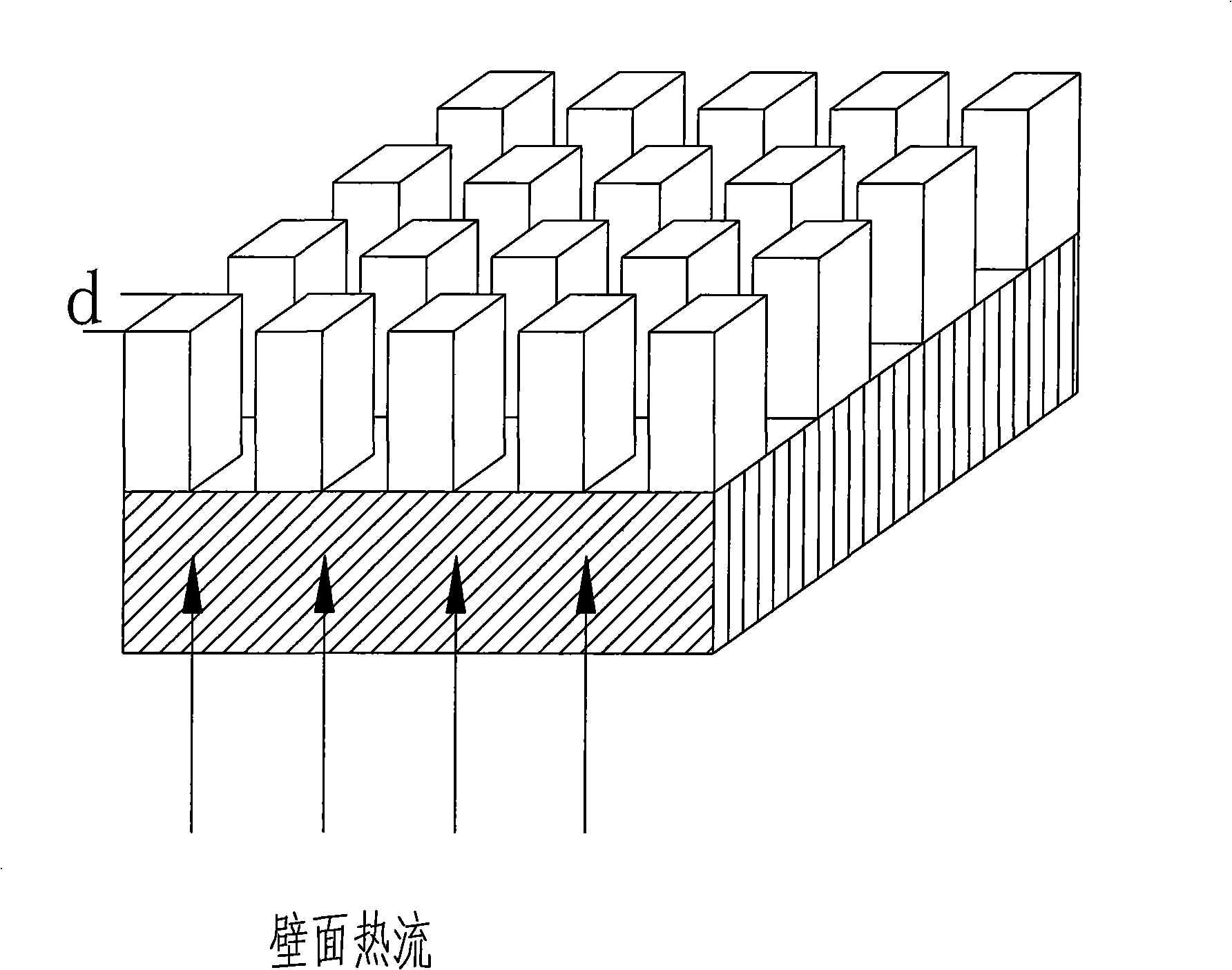

Boiling heat transfer device of electronic component

InactiveCN101541159AGood effectAvoid shockSemiconductor/solid-state device detailsSolid-state devicesElectronic componentBoiling heat transfer

The invention relates to the research field of boiling phase change heat transfer, in particular to a boiling heat transfer device of an electronic component. The boiling heat transfer device comprises a cooling plate fixed to the surface of the electronic component, a metal foam layer is sintered or welded on the upper surface of the cooling plate, the metal foam layer is provided with square column type microstructures with the width of 50 micron to 200 micron, and the interval between the square column type microstructures is 50 micron to 200 micron.

Owner:XI AN JIAOTONG UNIV

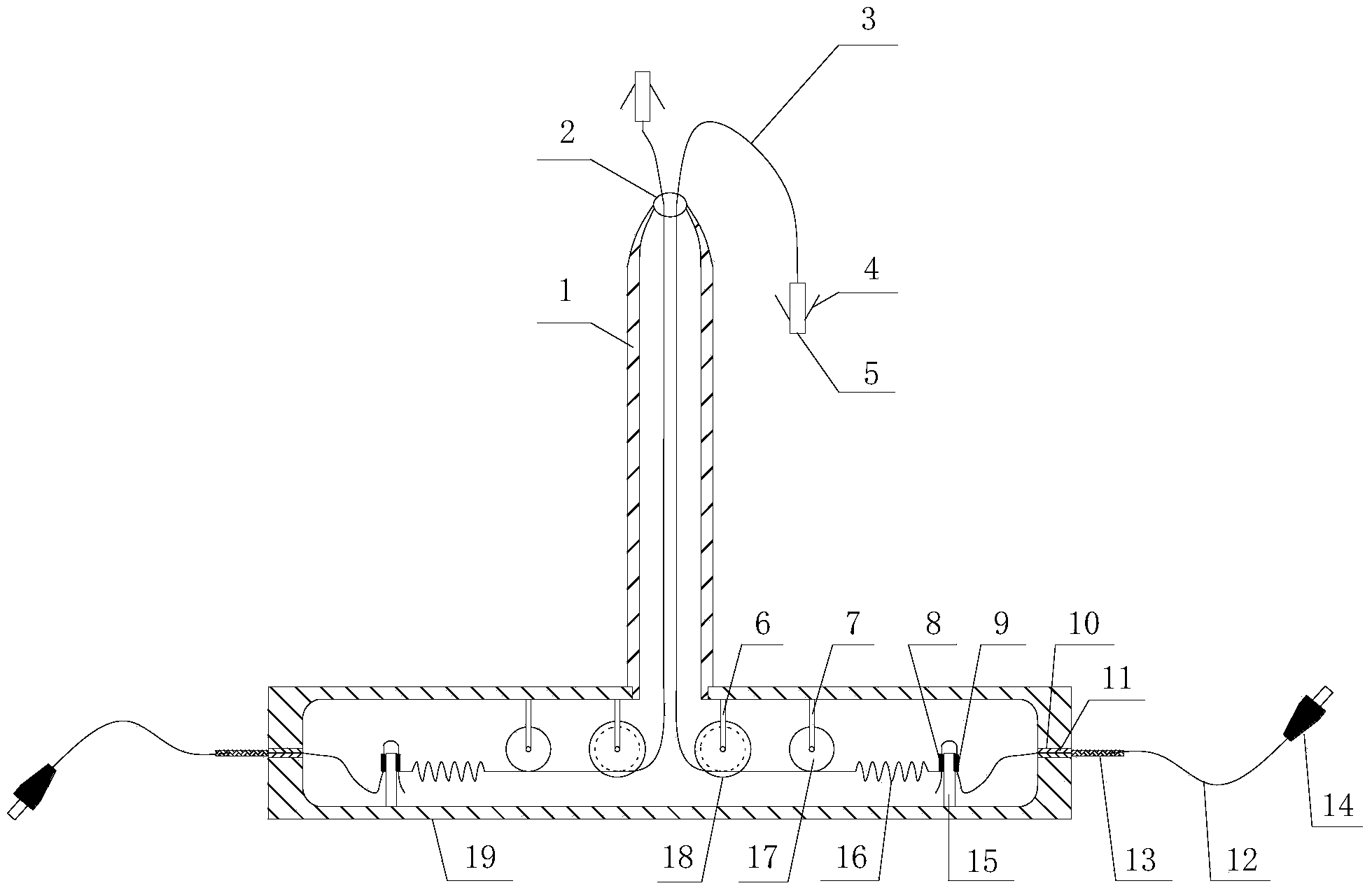

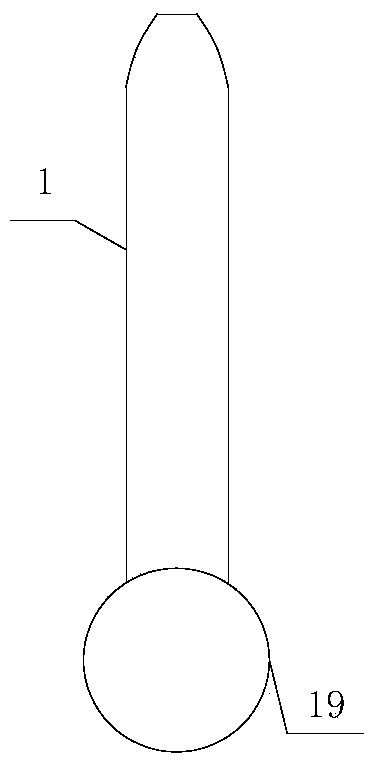

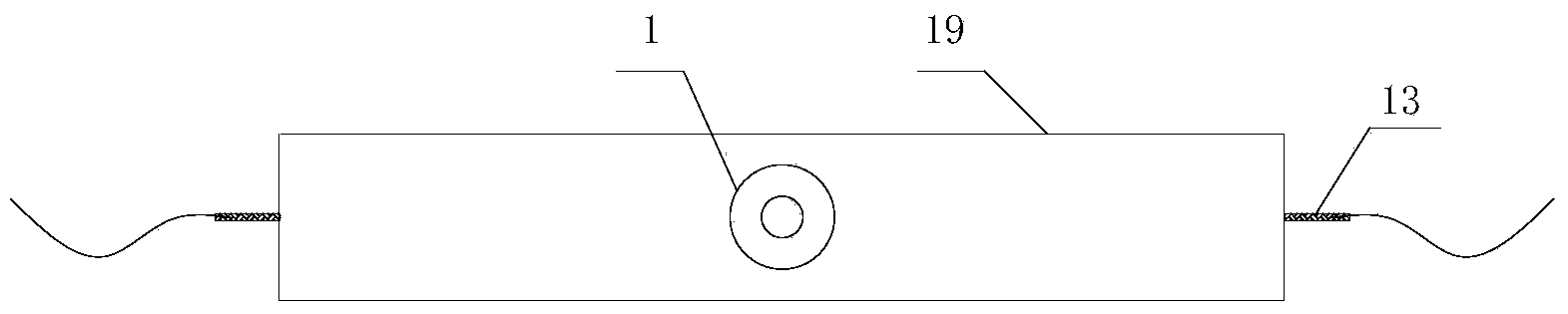

Monitoring device and monitoring method for mining FBG (fiber bragg grating) roof separation layer

ActiveCN103528530ARealize online measurementTimely warningMining devicesTesting machinesGratingBoundary values

The invention provides a monitoring device and a monitoring method for a mining FBG roof separation layer. The device comprises a vertical measurement barrel and a packaging casing, wherein fixed pulleys, tape pulleys and constant-strength cantilever beams are symmetrically arranged in the packaging casing; a steel wire rope penetrates through the tape pulleys and the fixed pulleys and penetrates out from a steel wire rope guide hole in the top part of the vertical measurement barrel; one end of the steel wire rope is connected with an anchor head; a shallow part measurement point and a deep part measurement point are distributed inside a drill hole; the anchor head is pushed to the measurement points in the drill hole; when the stress of the steel wire rope changes, the stress change is displayed through wavelength values of an FBG A and an FBG B; a wavelength demodulation device is used for demodulating the wavelength values into digital signals, the digital signals are sent to a computer for real-time processing, and a separation layer numerical value is combined for drawing a separation layer quantity changing curve and a set separation layer boundary value; whether the separation layer exists is judged; and the data change of the roof separation layer is monitored in real time. Temperature compensation is performed with a differential form, on-line measurement of the roof separation layer is realized, the reliability and the accuracy are high, an early warning signal can be issued, and roof fall accidents can be avoided.

Owner:CHINA UNIV OF MINING & TECH

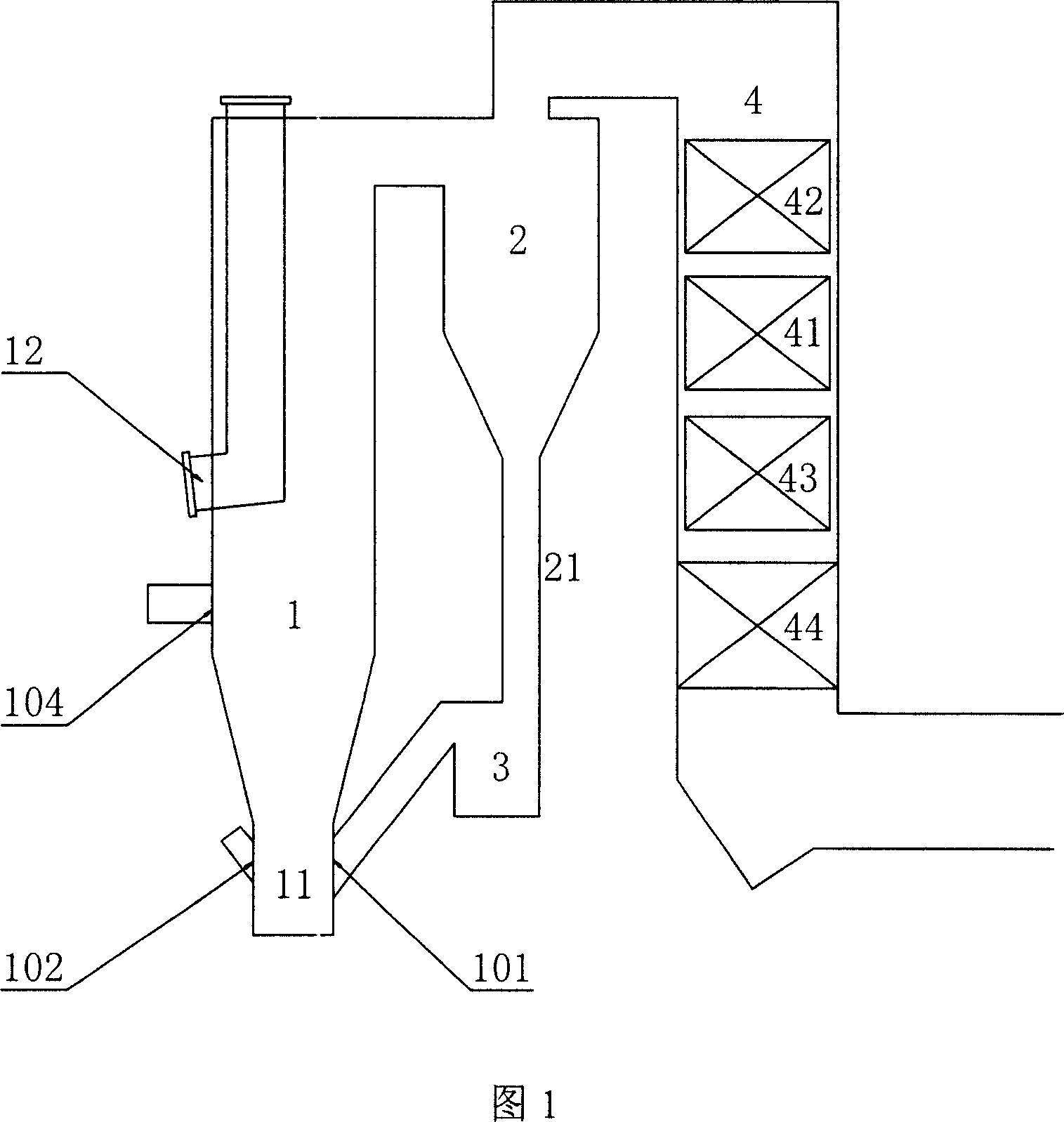

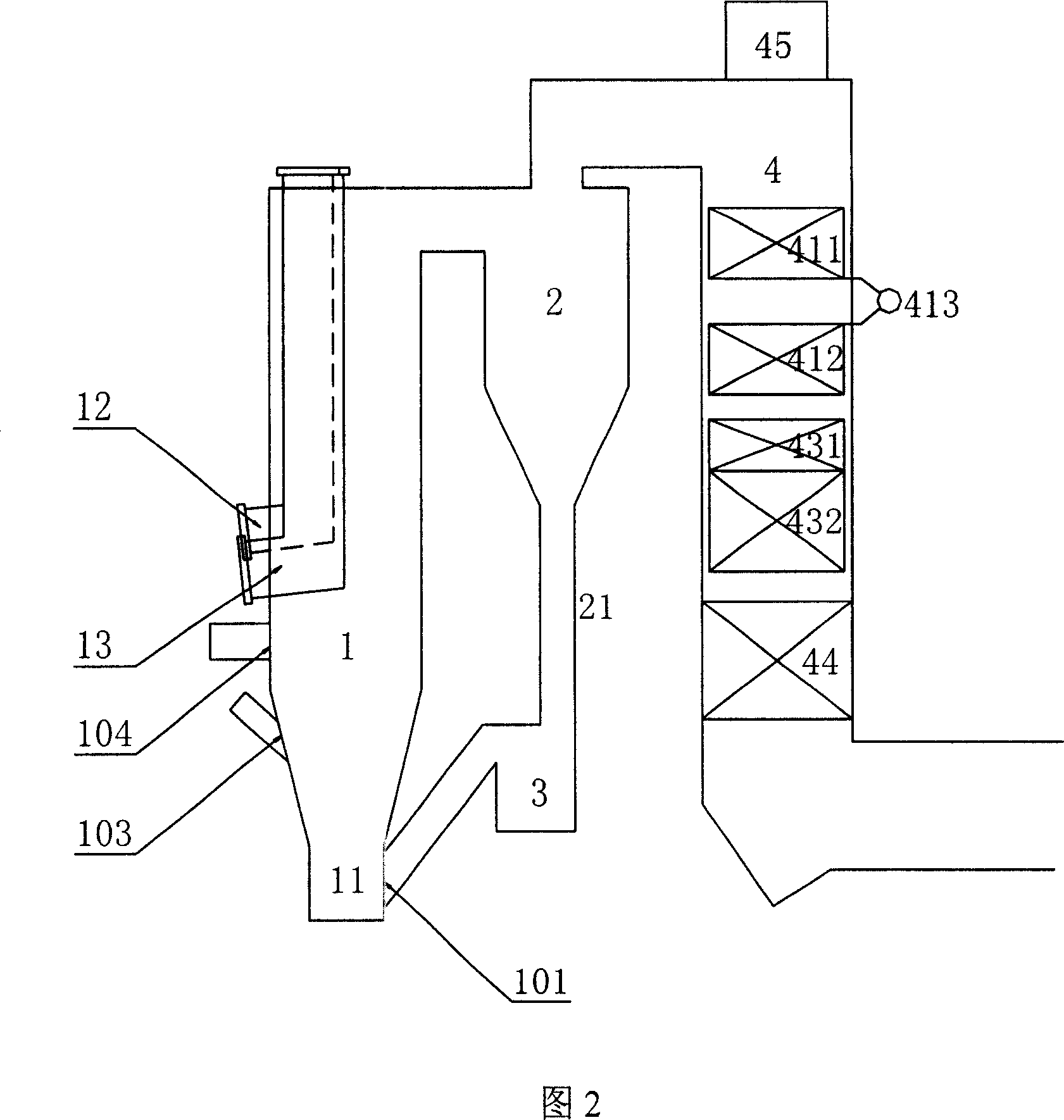

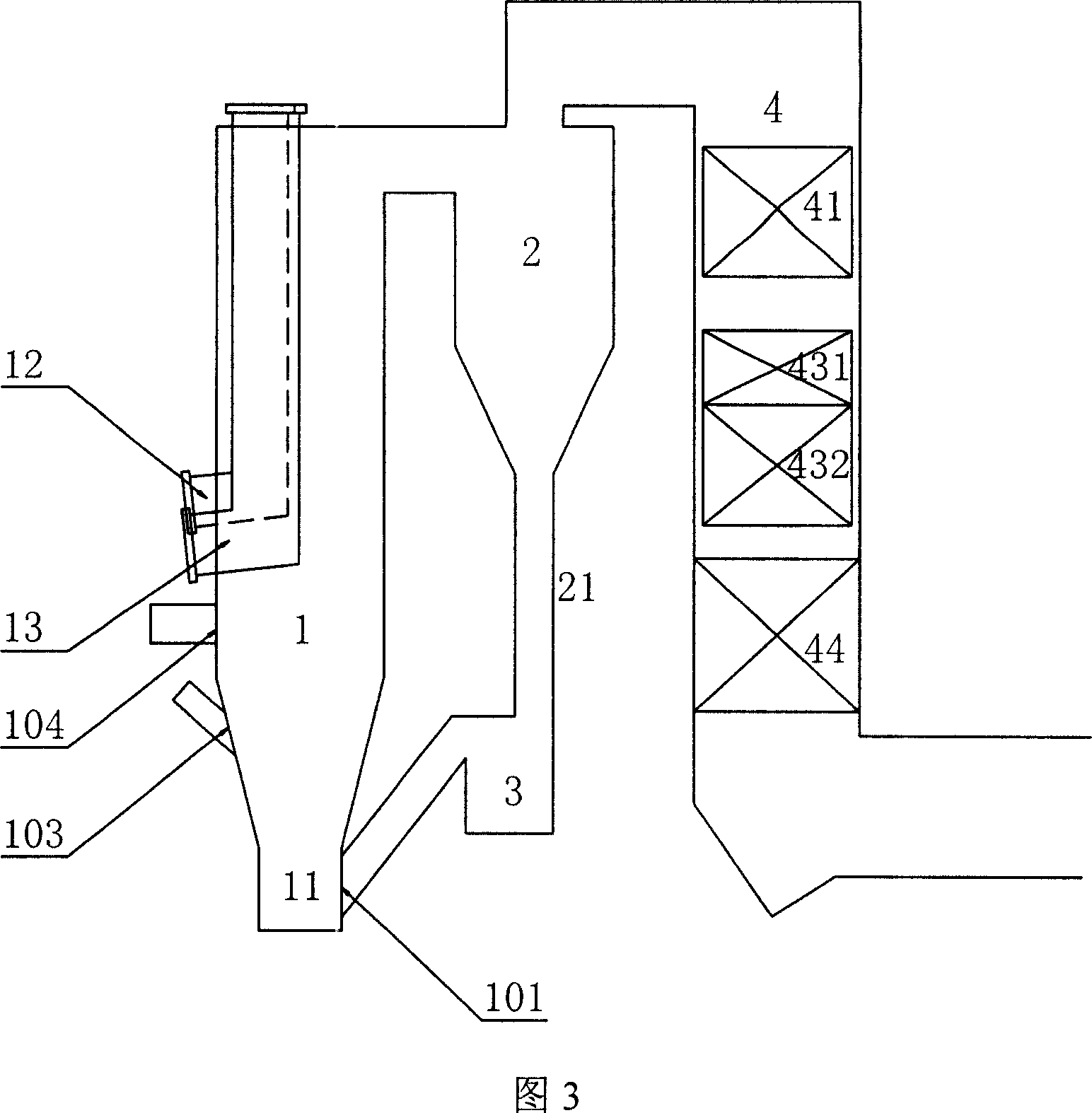

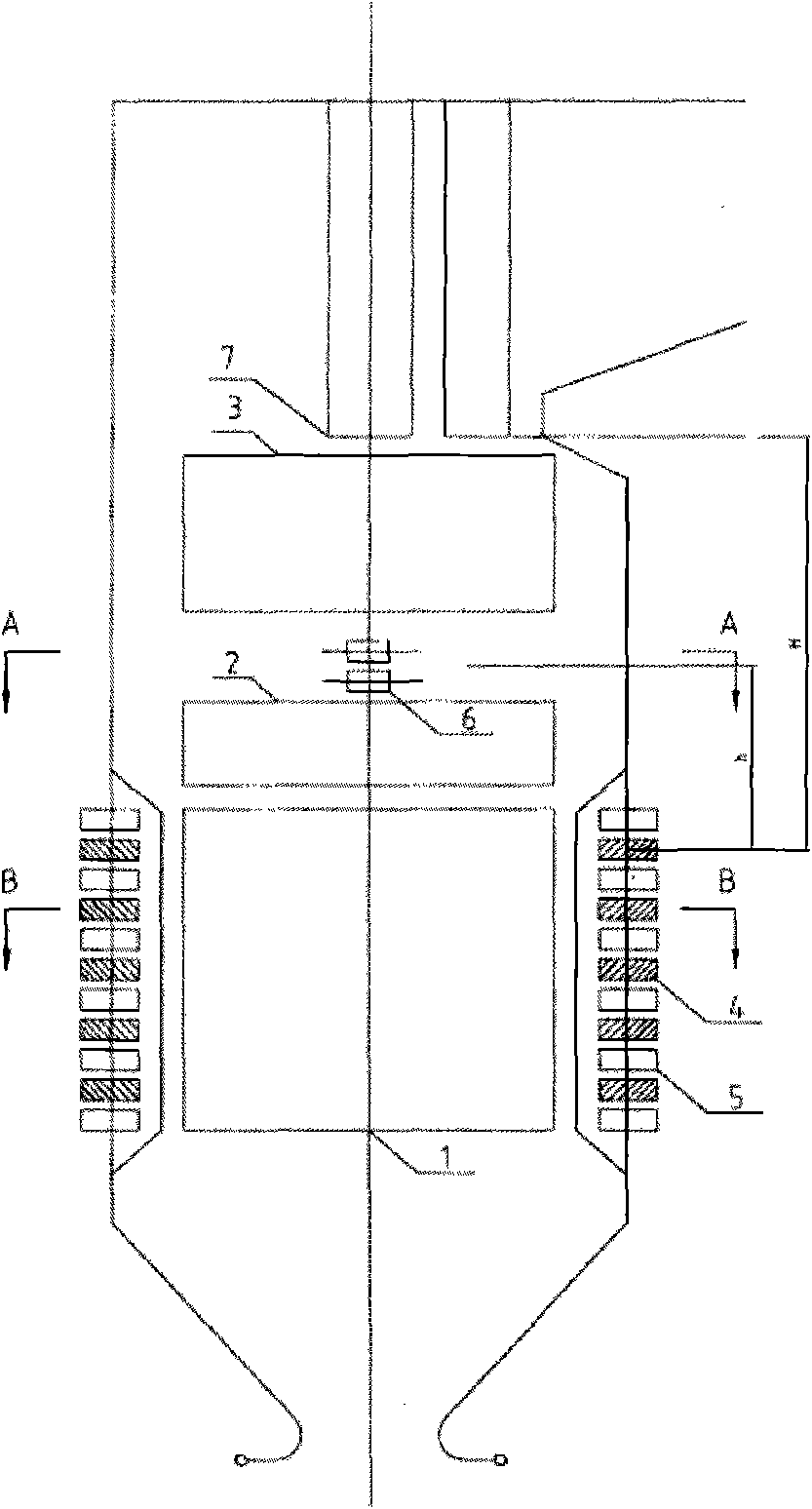

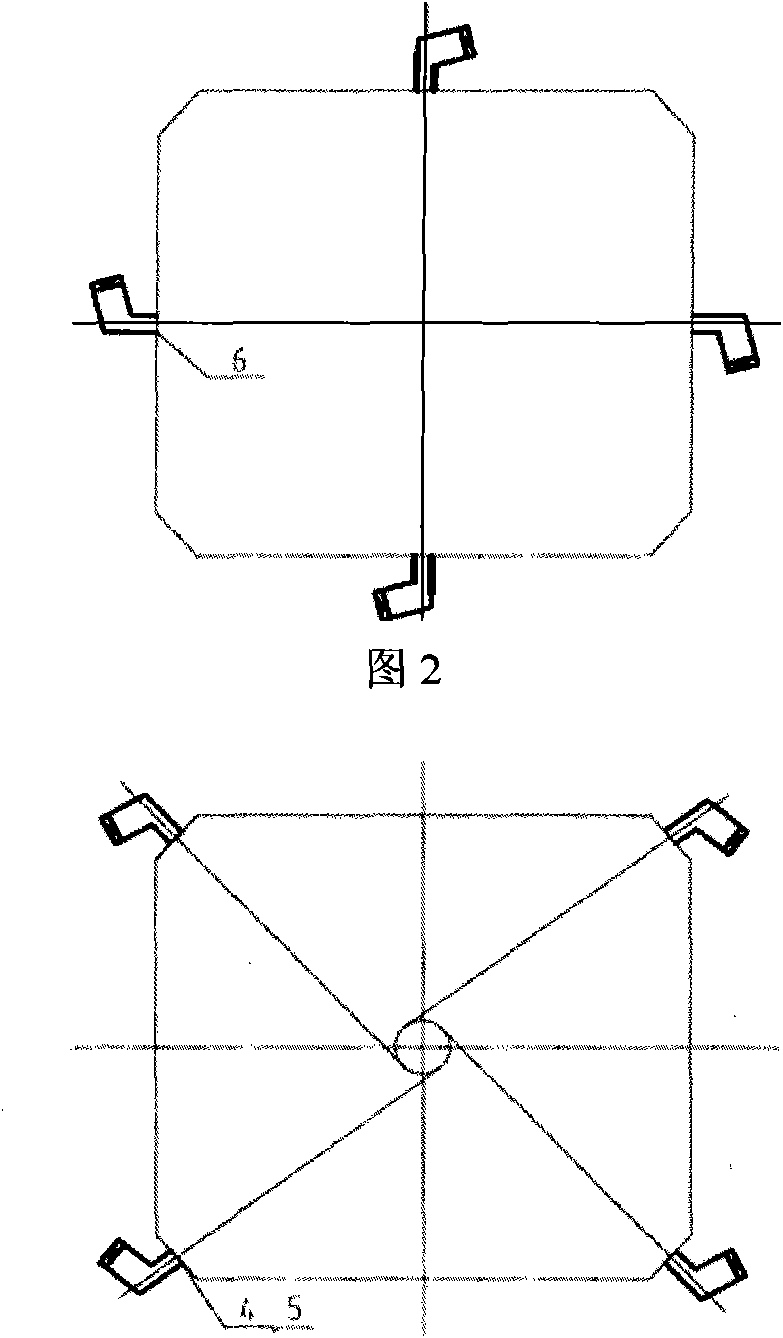

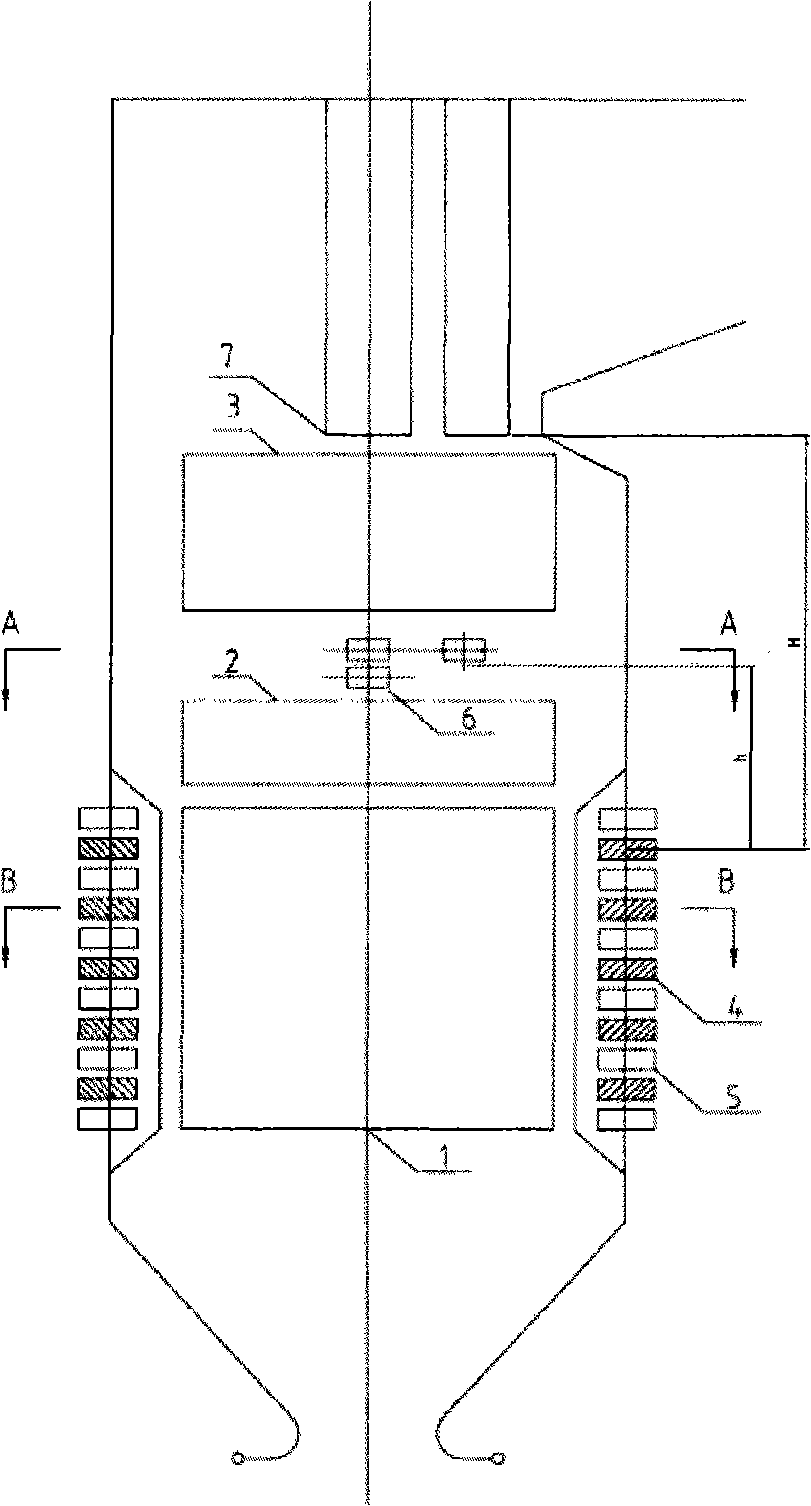

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816AReduce the temperatureImprove working environmentFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch, a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, and the material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption of biological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

High-copper alloy strip for heat sink of automobile

ActiveCN103088230ASolve conductivity problemsSolve temperature problemsHeat exchange apparatusMetallurgyCopper alloy

The invention relates to a high-copper alloy strip for a heat sink of an automobile. The high-copper alloy strip comprises the following components in percentage by weight: more than or equal to 99.6% of copper, 0.05-0.20% of silver, 0.01-0.02% of stibium, 0.01-0.02% of chromium, 0.005-0.01% of phosphorus, 0.01-0.05% of rare earth and less than 0.0005% of oxygen. A production process of the high-copper alloy strip comprises the following steps of: (1) upward continuous casting; (2) continuous extruding; (3) cold rolling; (4) intermediate annealing; (5) finish rolling; (6) washing and passivating; (7) slitting; and (8) packaging and warehousing. The high-copper alloy strip provided by the invention has the technical advantages that composition of a high-copper alloy strip for an ultrathin water tank strip of an automobile is reasonably optimized and the problems that comprehensive performances such as electrical conductivity, anti-softening temperature and tensile strength can not meet operating requirements as a strengthened red copper alloy is adopted for preparing the ultrathin water tank belt in the prior art are solved.

Owner:南通市电梯部件业商会

Preparation method of wall thickness controllable directional solidification casting mould

InactiveCN103231025ASolve the problem of precise control of temperature fieldImprove the quality of directional solidificationFoundry mouldsFoundry coresSuperalloyDirectional solidification

The invention discloses a preparation method of a wall thickness controllable directional solidification casting mould. The preparation method comprises the steps of: firstly, designing an initial casting mould in three-dimensional software; then, placing the initial casting mould into casting software to finish stress calculation, and determining the optimal casting mould wall thickness; next, placing a secondary casting mould into a directional crystal growth simulation environment to carry out radiative heat transfer calculation, analyzing a temperature field distribution rule and a thermal field change rule, changing the wall thickness and giving a wall thickness close to a directional solidification growth temperature gradient rule; repeating the radiative heat transfer calculation and stress check, and revising the design until the final three-dimensional design of the casting mould is determined; and manufacturing the casting mould based on a rapid manufacturing method for a rapidly-molded ceramic casting mould. The method is used for solving the problem that the casting mould affects the growth of a directional crystal in the direction solidification process of a complex high-temperature alloy structure, thus a directional crystal blade can be more easily obtained, higher-quality directional crystal products can be obtained, and problems such as crack and stress deformation caused by hot stress and other stresses are avoided to a certain extent.

Owner:XI AN JIAOTONG UNIV +1

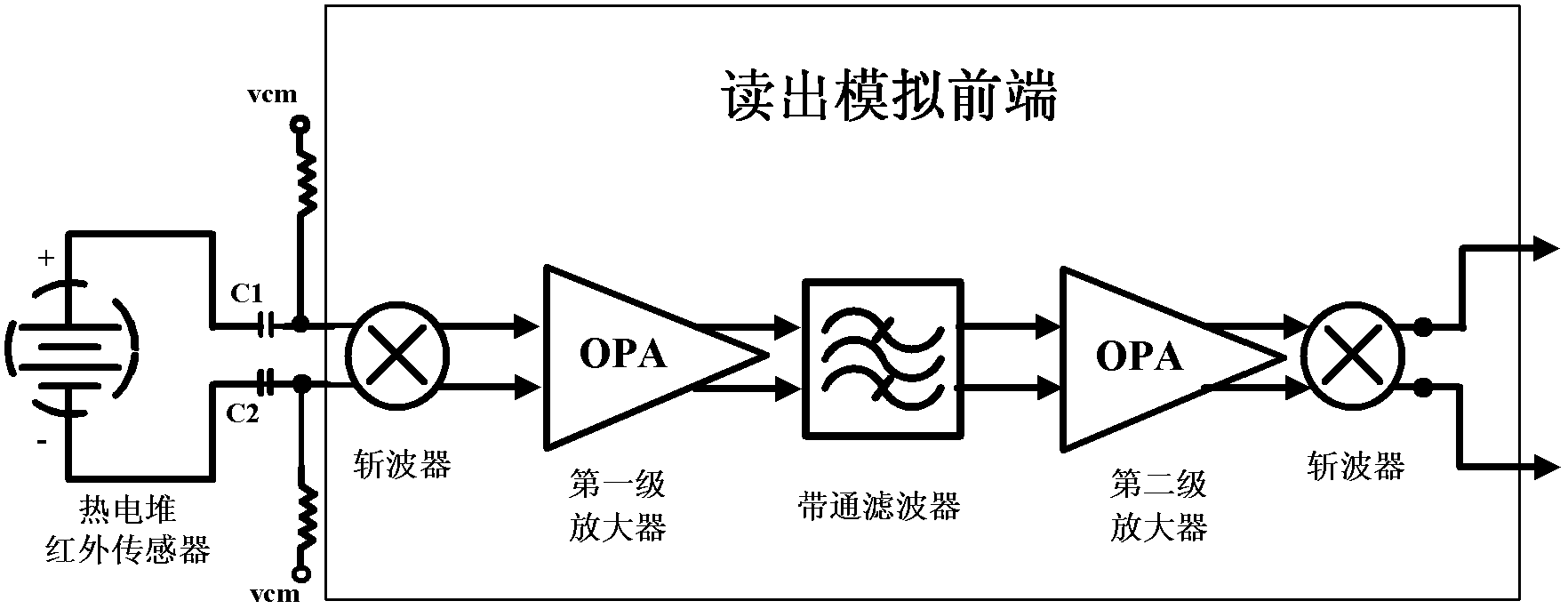

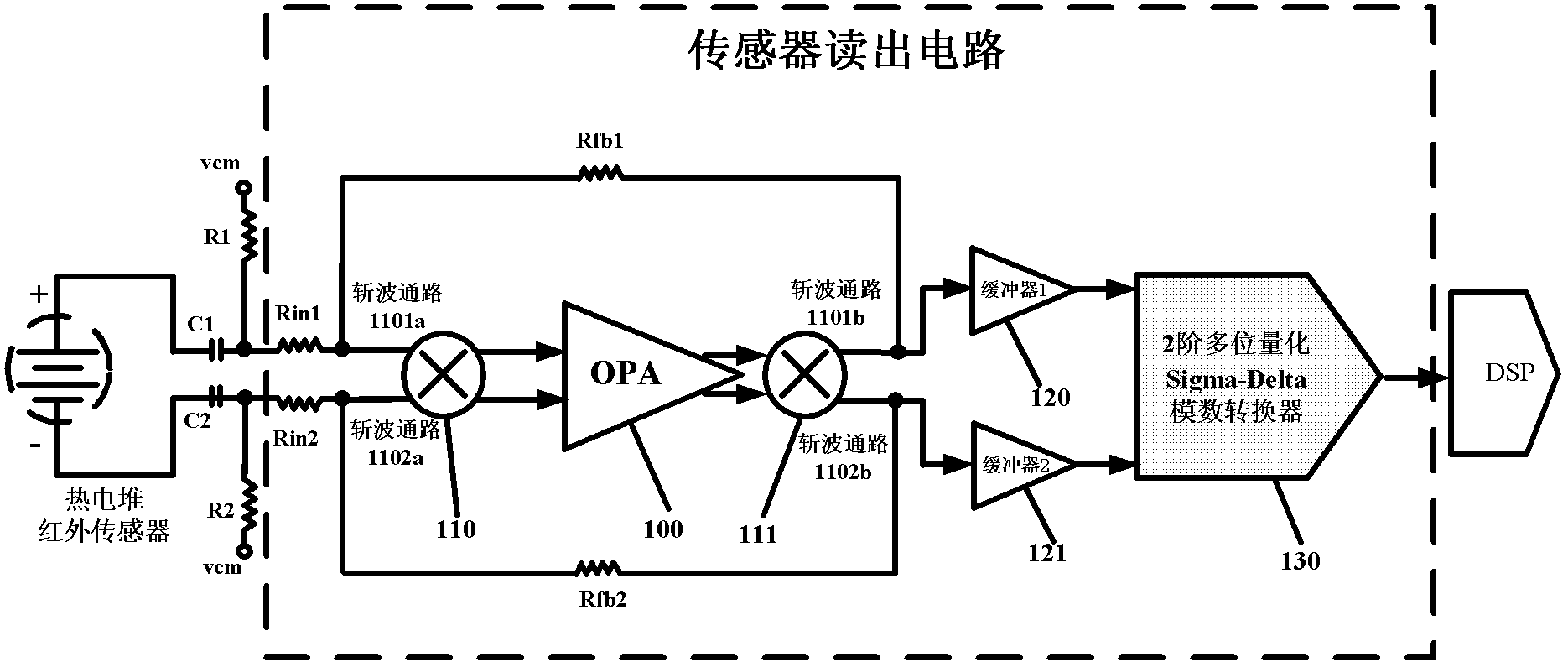

Reading circuit used for sensor

ActiveCN103308183AImprove detection accuracyHighly integratedPyrometry using electric radation detectorsEngineeringDigital converter

The invention relates to a reading circuit used for a sensor. The reading circuit comprises two levels of operational amplifiers, a chopper, a buffer and a 2-order 3-bit quantized Sigma-Delta analog / digital converter; the two levels of operational amplifiers amplify a weak voltage signal outputted from the sensor by a resistance ratio under a closed loop work state; the input / output chopper is used for reducing the direct current detuning voltage and low-frequency 1 / f noise of the operational amplifiers; the buffer performs isolation protection on the output signal of the operational amplifiers and provides a certain voltage driving capacity at the same time; and the 2-order 3-bit quantized Sigma-Delta analog / digital converter converts the amplified sensor voltage signal into a digital code and outputs to a DSP (digital signal processor) for processing.

Owner:中科芯未来微电子科技成都有限公司

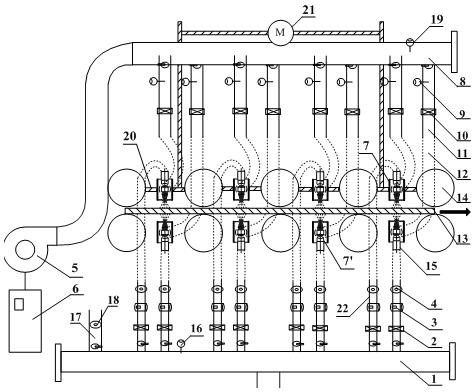

Vapor cooling system for use in offline heat treatment of thin medium and thick plates

ActiveCN102424902AGood atomization effectGood cooling uniformityQuenching devicesWater jetExperience management

The invention discloses a vapor cooling system for use in offline heat treatment of thin medium and thick plates, which comprises a water supply system, an air supply system, vapor spray nozzles and a control system, and is characterized in that: the vapor spray nozzles are symmetrically arranged above and below a rollway gap along the conveying rollway, the upper spray nozzle and an upper rollway are fixed on a movable upper frame, and the lower spray nozzle is fixed on a fixed frame; the water and air supply systems are led into the vapor spray nozzles by a shunt water collecting header anda shunt air collecting header respectively; a water supply pipe is provided with a valve, a flow meter and a regulating valve and is used for providing stable and reliable cooling water into an innerwater storage cavity in the spray nozzle from the side of the spray nozzle; and the control system consists of an experience management system and a PLC system, the experience management system makesa vapor cooling policy and cooling procedure and sends the cooling procedure to the PLC system to execute the cooling procedure, and the PLC system realizes the regulation of the intensity of coolingof the spray nozzle and the regulation of the state of water spraying. The vapor cooling system can solve the nonuniform cooling problem aroused by the high-pressure water jet cooling in the conventional thin medium and thick plate offline quenching.

Owner:NORTHEASTERN UNIV

Low-nitrogen oxide discharging coal powder tangential combustion device

ActiveCN101598333AEnhanced turbulent mixingGood for burnoutPulverulent fuel combustion burnersCombustion apparatusLow nitrogenHearth

The invention provides a low-nitrogen oxide discharging coal powder tangential combustion device, comprising a hearth; wherein the four corners of a main combustion area of the hearth are provided with primary air spray nozzles and secondary air spray nozzles which are arranged at intervals, and the axis of the primary air spray nozzles or the secondary air spray nozzles positioned on the same horizontal plane is tangential to a supposed tangential circle taking the center of the hearth as a circle center. The low-nitrogen oxide discharging coal powder tangential combustion device is characterized in that the four walls of the hearth above the primary air spray nozzles and the secondary air spray nozzles are provided with at least one burning-out air spray nozzle group; each burning-out air spray nozzle group comprises four burning-out air spray nozzles, one burning-out air spray nozzle is respectively arranged on one wall of the hearth, and the four burning-out air spray nozzles are positioned on the same horizontal plane; and the axis of the burning-out air spray nozzles in the same group are tangential to one supposed tangential circle taking the center of the hearth as a circle center. The invention can realize the low discharging of NOx, solves the problems of high content of fly ash combustible substances caused by a whole air classification technique in a furnace, high fume speed at a hearth outlet, large temperature deviation of the hearth outlet and the like, and increases the running regulation performance aiming at different coal species and load changes simultaneously.

Owner:SHANGHAI BOILER WORKS

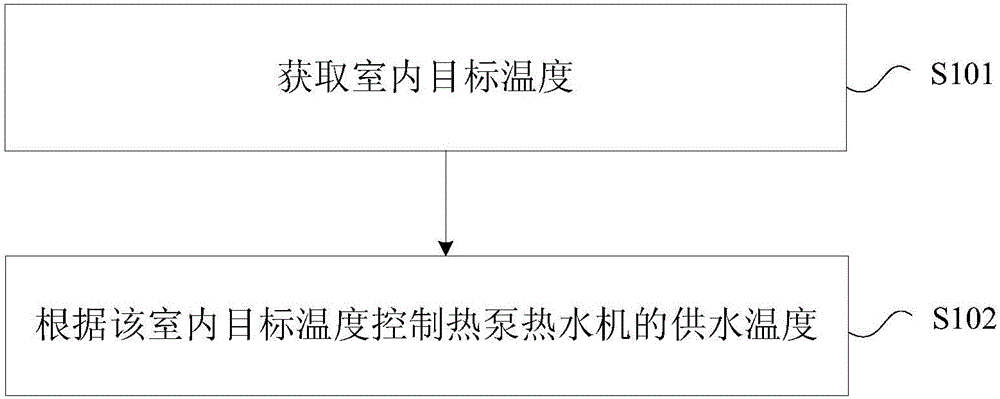

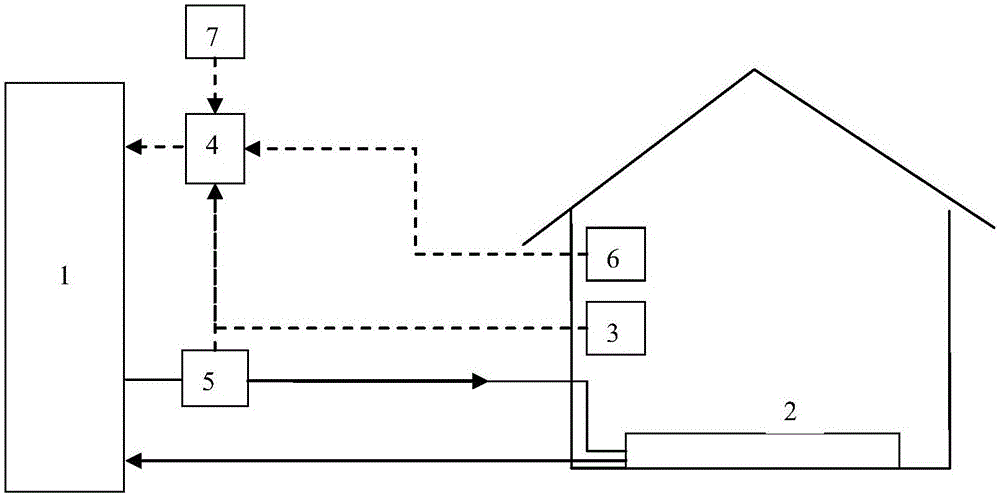

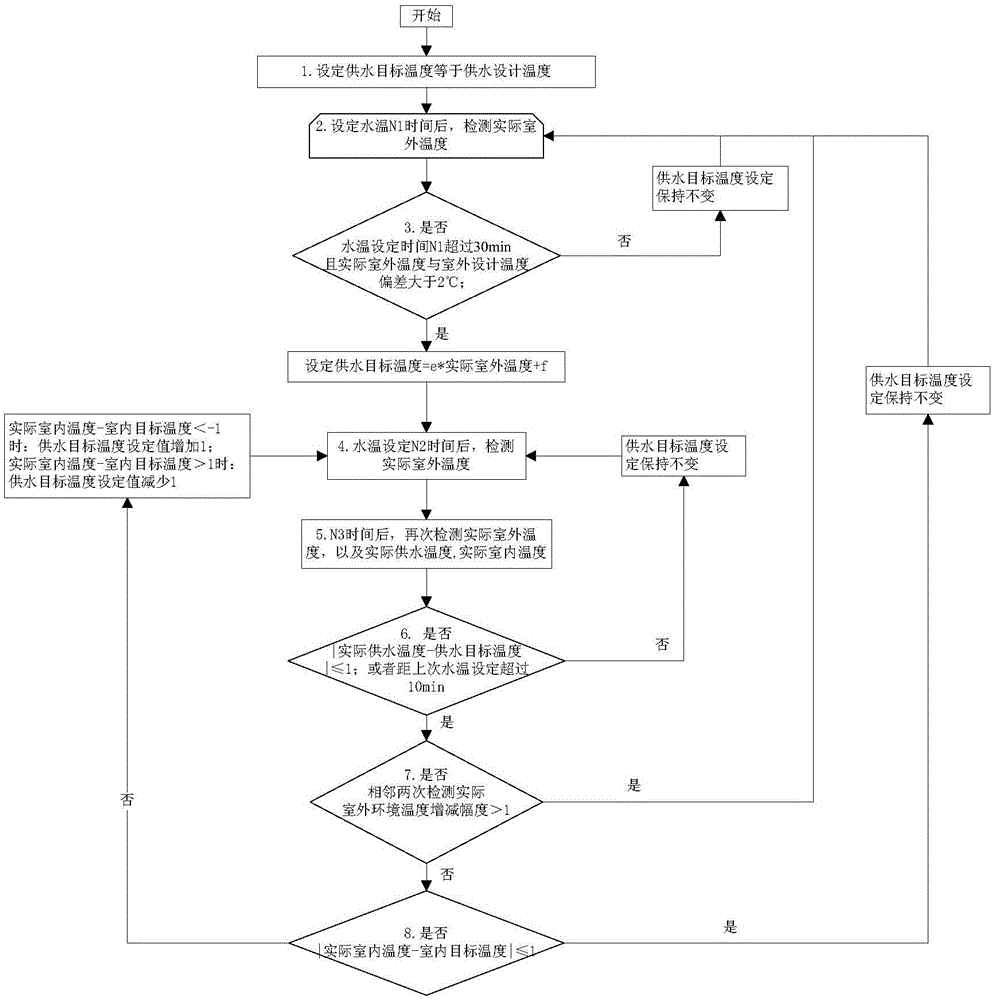

Water supply temperature regulating method and device of heat pump water heater

The invention provides a water supply temperature regulating method and device of a heat pump water heater. The method comprises: acquiring an indoor target temperature; and according to the indoor target temperature, controlling the water supply temperature of the heat pump water heater. Through the method and the device, the problem of energy wastes or large indoor temperature fluctuation caused by the manual setting of the water supply temperature of the heat pump water heater in the prior art is solved, the automatic control of the water supply temperature of the heat pump water heater is realized, and the indoor temperature can be continuously kept at the indoor target temperature. Energy wastes are reduced, and the comfort of users is improved.

Owner:GREE ELECTRIC APPLIANCES INC

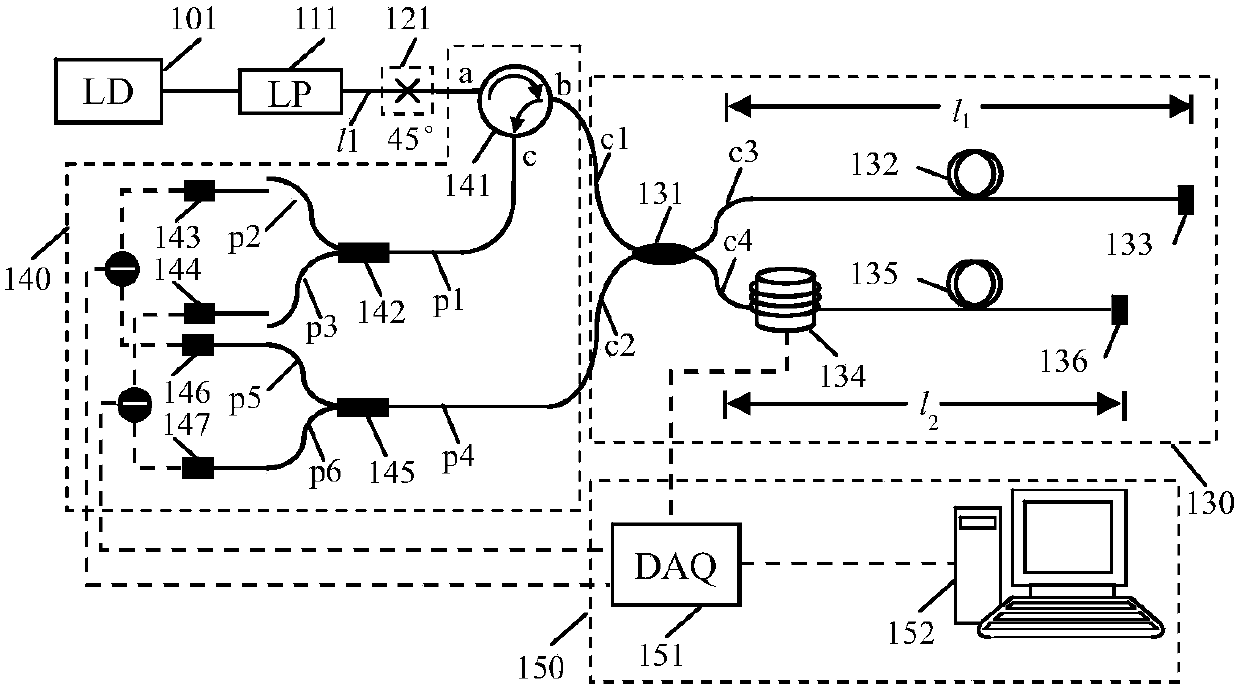

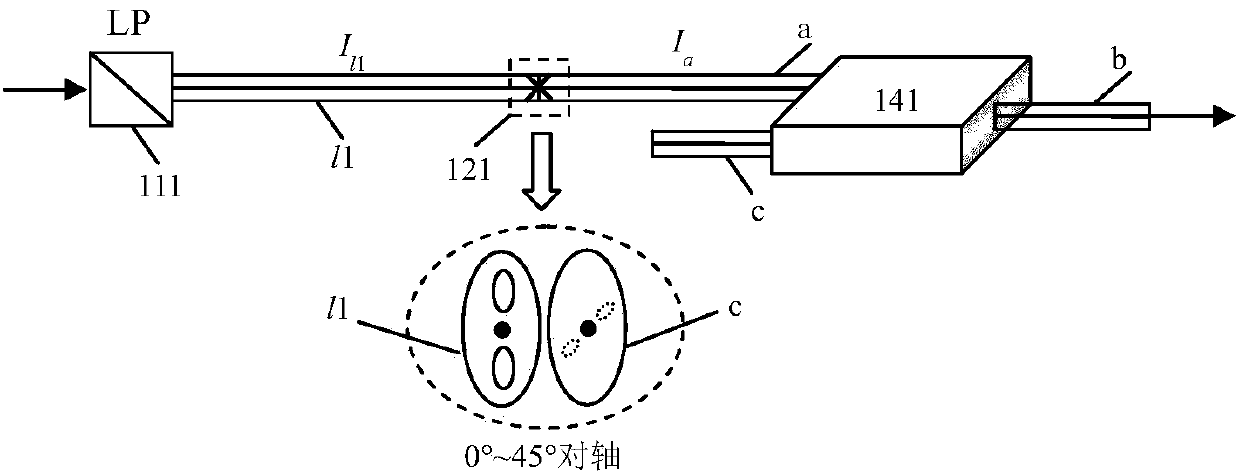

Unbalanced polarization maintaining fiber dual-interferometer temperature strain simultaneous measurement device and method

ActiveCN108168728ASolve temperature problemsGuaranteed accuracyThermometers using physical/chemical changesUsing optical meansFiber couplerTemperature response

The present invention provides an unbalanced polarization maintaining fiber dual-interferometer temperature strain simultaneous measurement device and method. A polarization-maintaining fiber coupler,a phase modulator, a polarization-maintaining fiber and a polarization-maintaining fiber reflector form an unbalanced polarization-maintaining fiber interferometer. A light source injects light intoa fast axis and a slow axis through a polarizer at the same time for transmission, coaxial transmission signal interference is achieved in the interferometer, interference signals are detected by a polarization beam splitting difference detection device formed by a polarization-maintaining circulator, a polarization beam splitter and a photoelectric detector, and finally, a signal collection and demodulation and record device processes the interference signals. Parameters of the fast axis and the slow axis of the polarization maintaining fiber are different to allow fast-axis signals and slow-axis signals to have different responses for the same temperature and the same strain, and an unbalanced interferometer structure is employed to construct an orthogonal response matrix and measure temperature response coefficients and strain response coefficients of two paths of interference signals to achieve simultaneous measurement of temperatures and strains. The unbalanced polarization maintaining fiber dual-interferometer temperature strain simultaneous measurement device and method solve the intersection sensitivity problem, the measurement result is accurate and stable, and the sensitivity is high.

Owner:HARBIN ENG UNIV

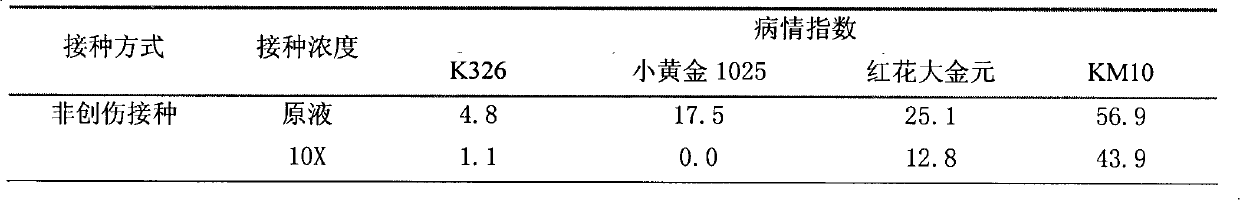

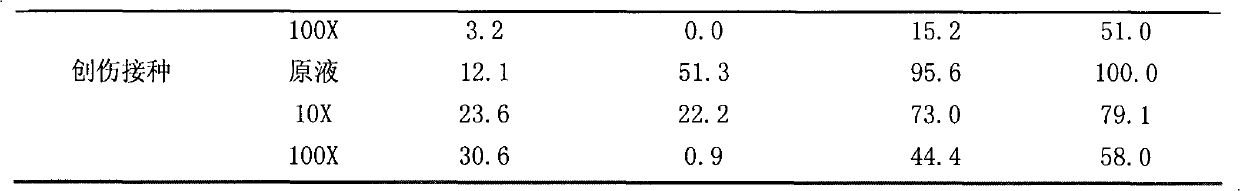

Thermostatic hydroponic identification method for resistance of tobacco black shank at seedling stage

ActiveCN101999287ALow costThe temperature is difficultFungiMicroorganism based processesNicotiana tabacumAgricultural engineering

The invention relates to a thermostatic hydroponic identification method for the resistance of tobacco black shank at a seedling stage. The method comprises the following steps of: establishing a water-insulating circulating floating pool; transplanting tobacco seedlings; preparing inoculum; and inoculating, investigating and grading illness states and estimating resistance. The invention has the advantages of rapid paroxysm, good and reliable result repetitiveness and no other disease interference, substitutes an identification result for a traditional land identification result at a seedling stage and can identify a great amount of materials in a small area for many times in a year, improve the result reliability, shorten the identification period and save the identification cost.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

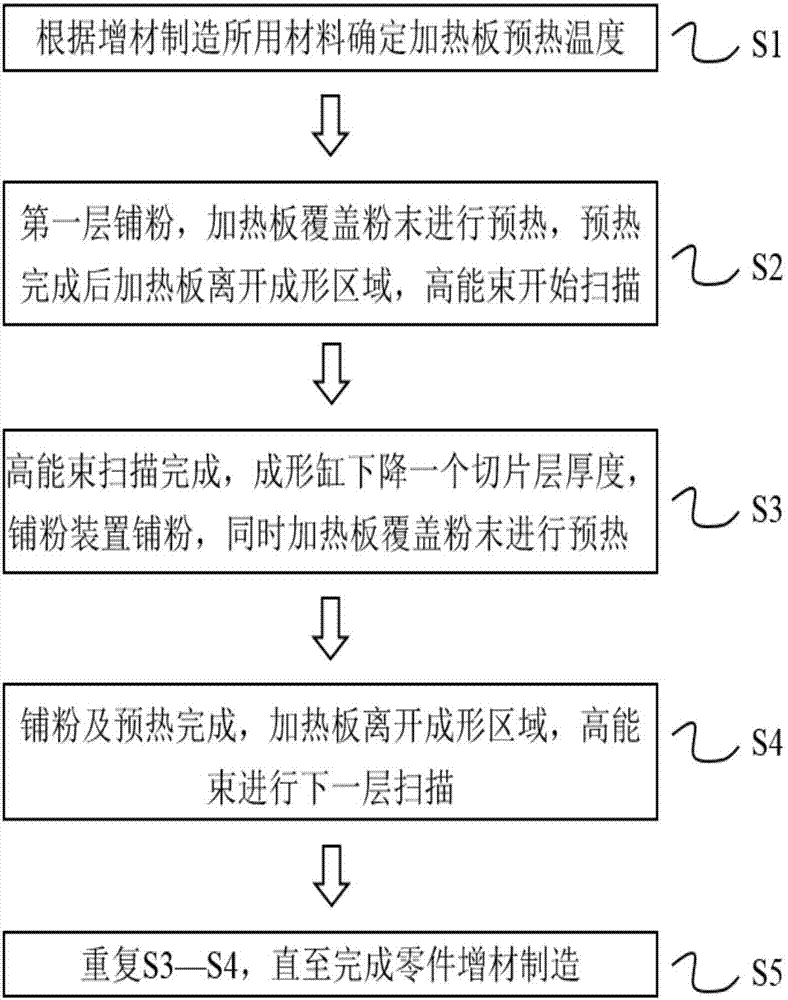

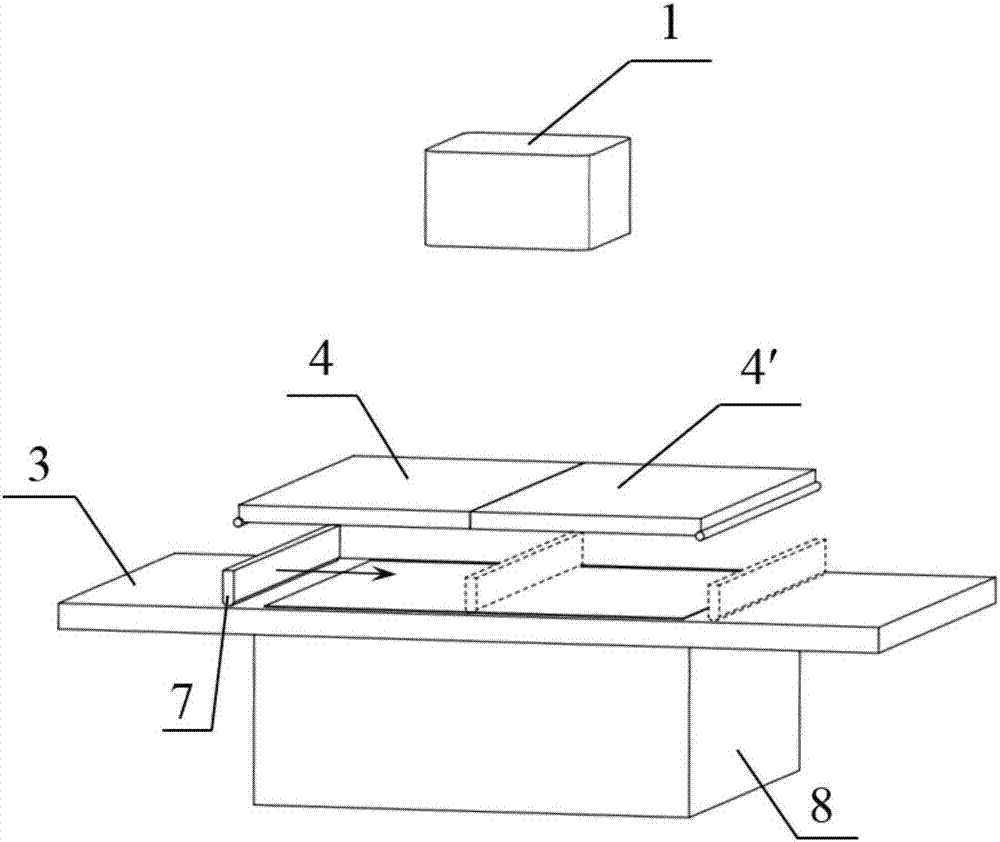

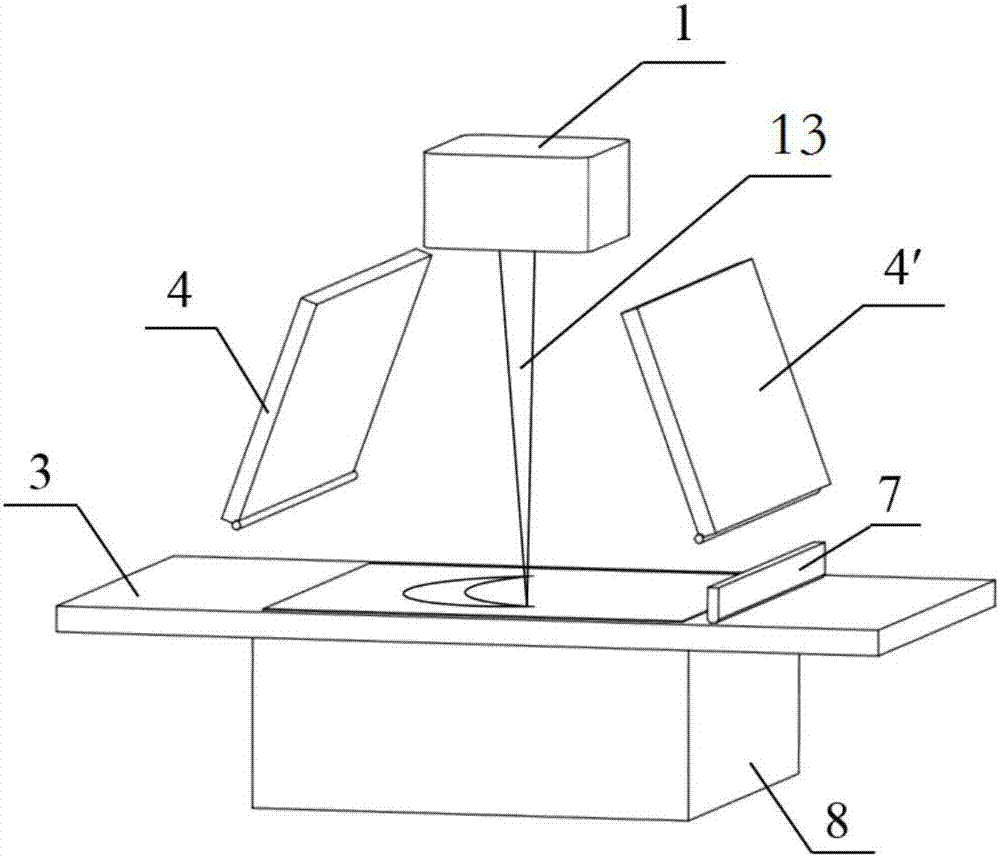

Preheating method and device suitable for powder laying type additive manufacturing

ActiveCN107379527AMonitor temperature in real timeHeating high temperatureManufacturing heating elementsIncreasing energy efficiencyControl systemMetallurgy

The invention provides a preheating method and device suitable for powder laying type additive manufacturing, and belongs to the technical field of additive manufacturing. A movable type plane heating plate capable of covering a whole powder bed is arranged over the powder bed, the mounting height of the plane heating plate is slightly larger than a powder laying device, in the powder laying process, the powder bed and parts are preheated, after powder laying is finished, a plane light source is closed and put away, and the phenomenon that in the machining process, the plane heating plate blocks a high-energy beam is avoided. In the heating process, a temperature measuring sensor is used for monitoring the temperature of the powder bed in real time, a control system is adopted to implement feedback control over preheating of the powder bed according to the temperature monitoring result, full-breadth covering type heating is adopted, and the powder bed and formed parts are subject to high-temperature, efficient and unifier preheating. The invention further provides the device achieving the above method. The method is wide in application material and high in expansibility and is particularly suitable for powder laying type additive manufacturing of multiple large-breadth high-energy beams.

Owner:HUAZHONG UNIV OF SCI & TECH

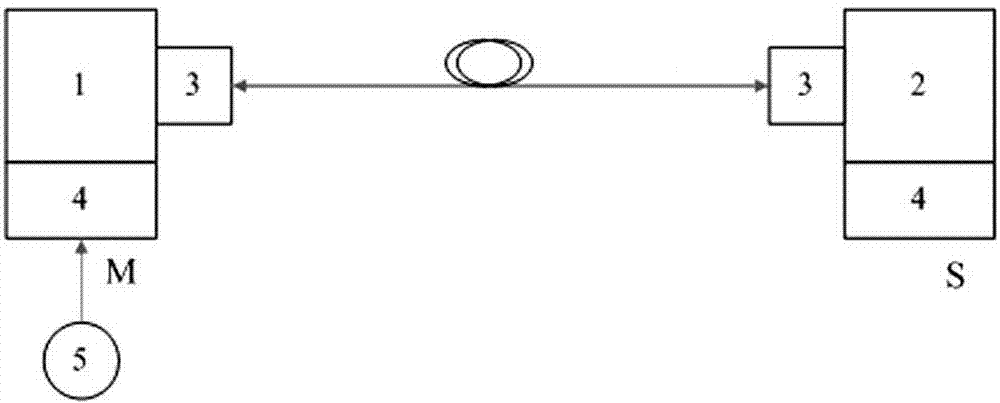

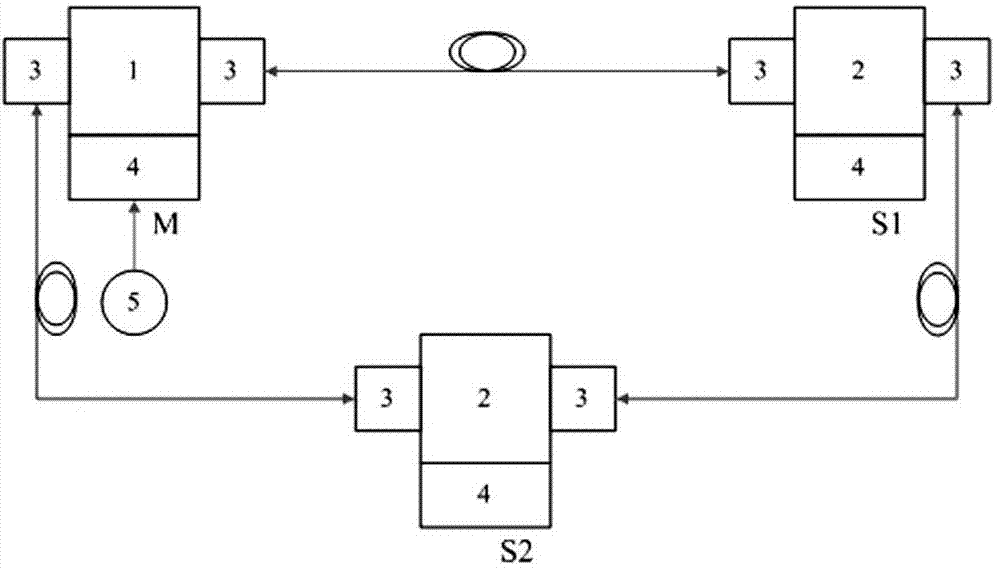

Single-fiber ultrahigh-precision time transmission method

The invention provides a single-fiber ultrahigh-precision time transmission method and aims to solve the problems that slow change in fiber transmission delay is uncontrollable and the extremely slow delay drift and drift accumulation cannot be solved in the existing fiber communication network time frequency synchronization technology. A single-fiber bidirectional optical transceiving module, a delay processing module and a master time synchronization device or slave time synchronization device are respectively connected to two ends of a same fiber. A cesium atomic clock is connected to the side of the master time synchronization device. Fiber delay between the master and slave time synchronization devices and a change value of the fiber delay are precisely measured and compensated. The method has the advantages that the problems that drift and drift accumulation caused by the extremely slow change in fiber transmission delay along with time, temperature, fiber ageing and the like cannot be eliminated in the prior art are solved; time synchronization precision is controlled in the range of + / -5 nanoseconds, networking can be in any form, and the method has promising market prospect and significant economic benefit.

Owner:四川泰富地面北斗科技股份有限公司

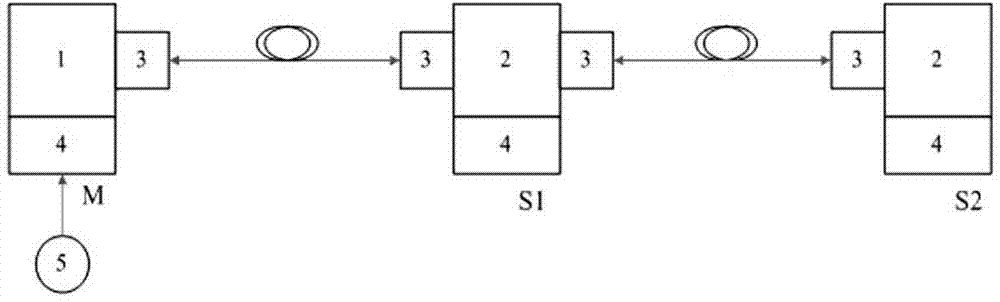

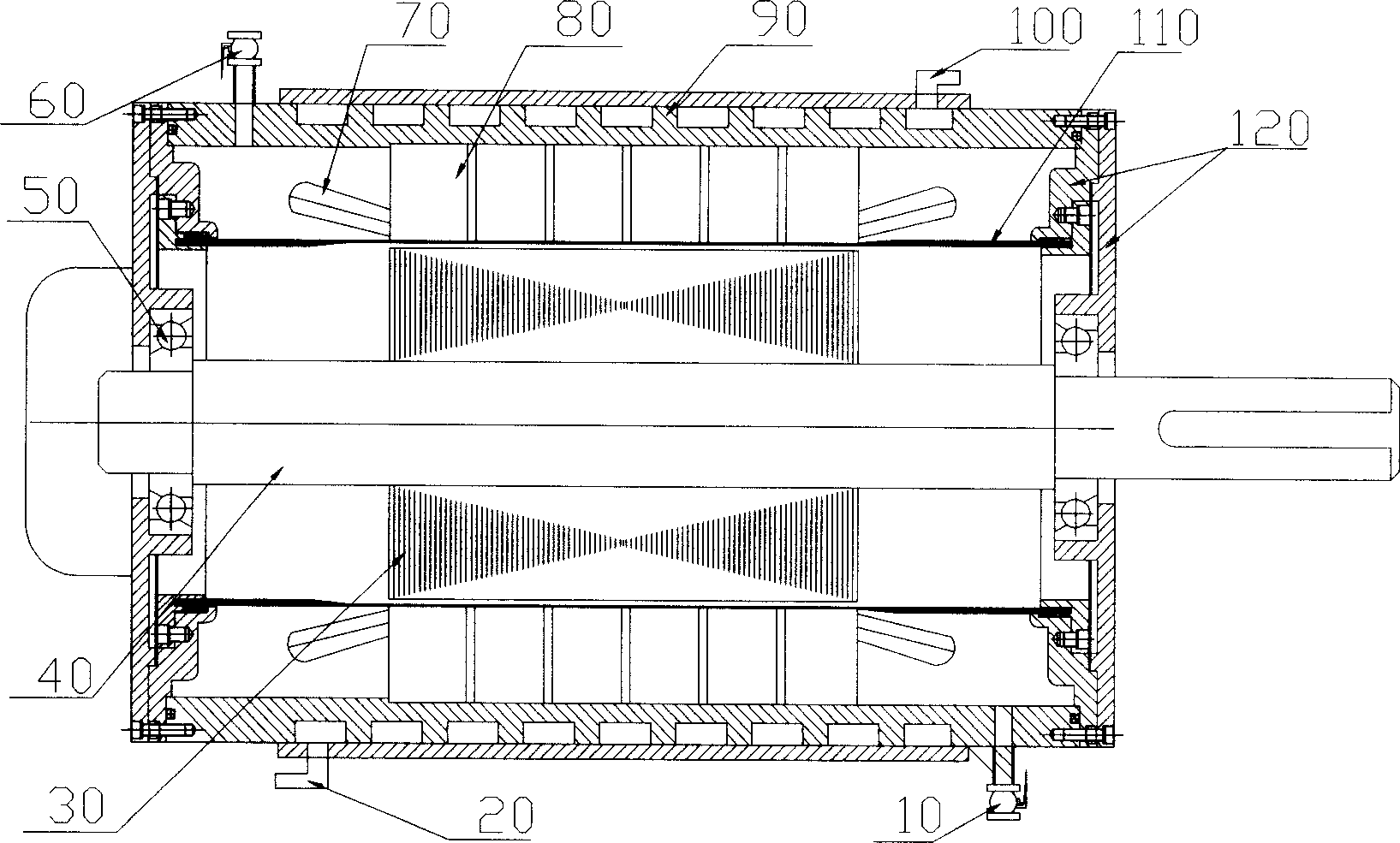

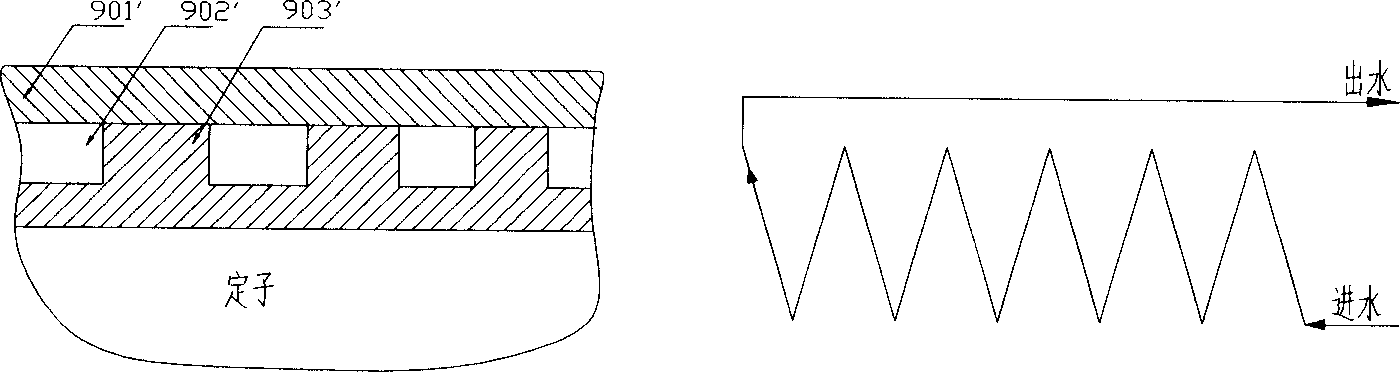

External water channel evaporative cooling horizontal motor

InactiveCN1889334ACompact structureUniform temperatureMagnetic circuit stationary partsManufacturing stator/rotor bodiesHeat sinkFree flow

A outside watercourse evaporative cooling horizontal motor features adopting sealing between stator housing and front rear endplate, inner sleeve two ends and front rear endplate, constituting inclosed stator cavity to seal whole stator in stator cavity, evaporative cooling media implanting in stator cavity. Evaporative cooling media free-flow in stator cavity and can penetrate into stator core interior. Stator winding and stator core etc heating part generated heat quantity is conducted evaporative cooling media, when evaporative cooling media main unit temperature rises to corresponding pressure saturation temperature, media bubble and generate phase transition heat sink and vapour. Vapour is condensed and liquefied by flowing in water jacket cylinder inner wall in stator cavity upper part, then flowing back in stator cavity bottom evaporative cooling media, forming non - external power stator evaporative cooling self -circulation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

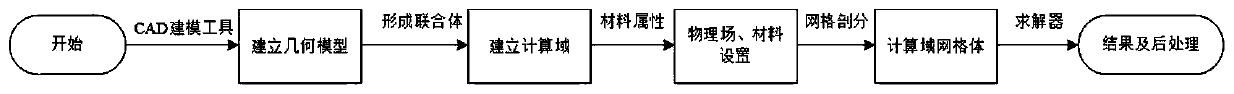

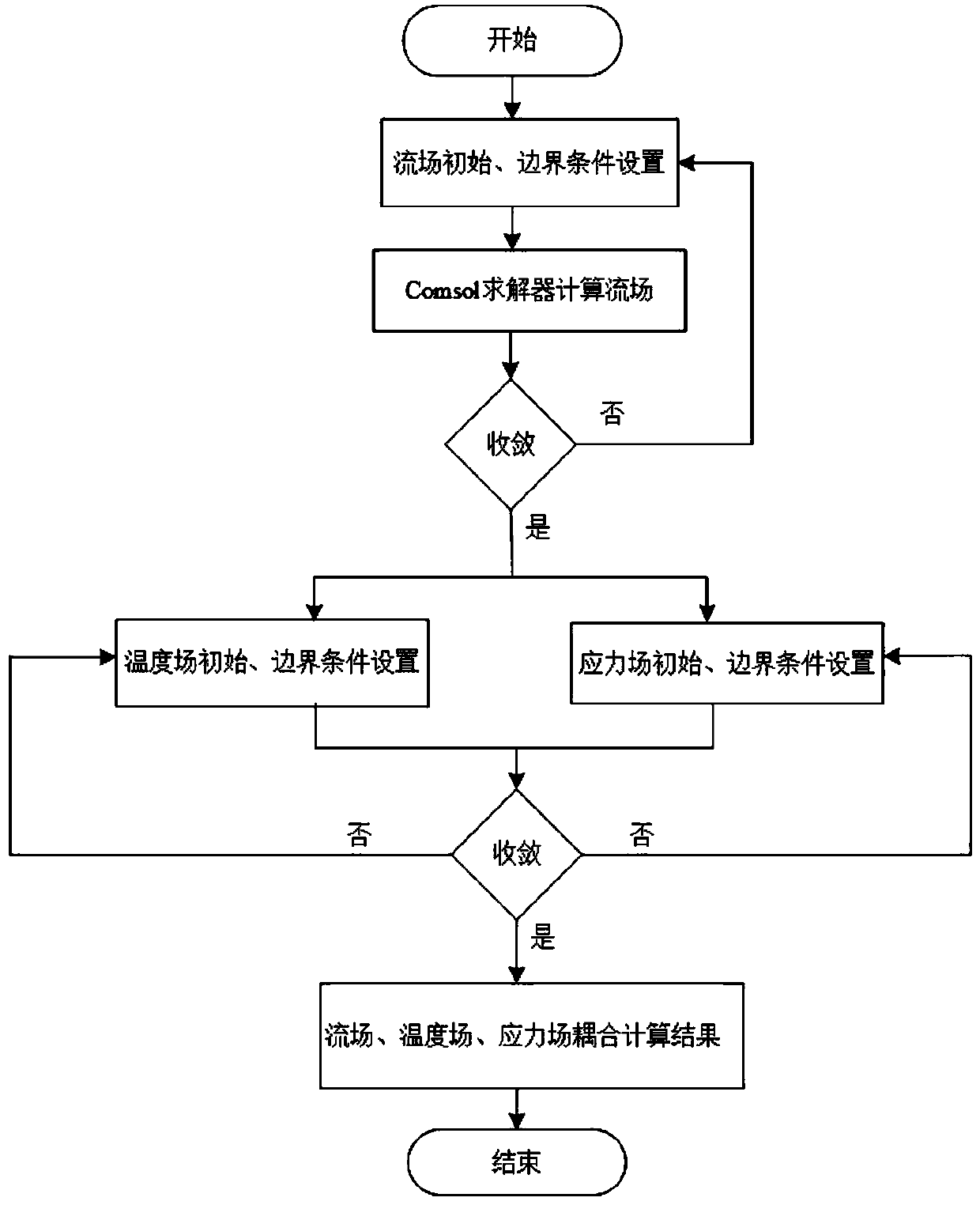

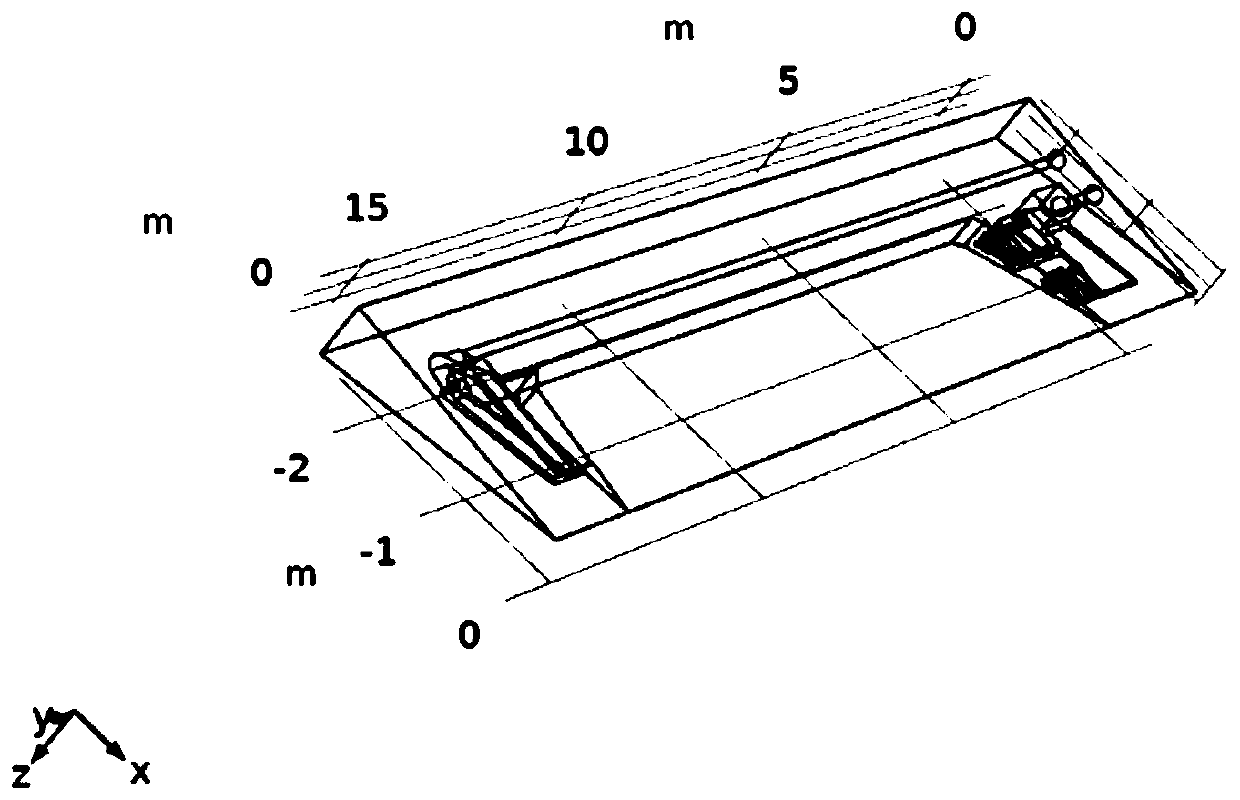

Reactor primary loop coolant flow field, temperature field and stress field coupling calculation method

ActiveCN111261232ASafe and stable operationSolve coupled numerical simulation calculation problemsNuclear energy generationChemical processes analysis/designAnalogue computationCoolant flow

The invention discloses a reactor primary loop coolant flow field, temperature field and stress field coupling calculation method. The method comprises the following steps: 1) constructing a high-temperature gas cooled reactor core model and a steam generator model with the same size as actual equipment; 2) establishing a computational domain 1, a computational domain 2 and a computational domain3; 3) setting equipment materials and fluid domains in the computational domain 1, the computational domain 2 and the computational domain 3; 4) setting areas and boundary layers of a flow field, a temperature field and a stress field; 5) meshing the flow field, the temperature field and the stress field; 6) adopting a k-epsilon turbulence model in the computational domain 1 and the computationaldomain 3, and adopting a porous medium model in the computational domain 2; 7) obtaining flow field, temperature field and stress field distribution results of the computational domain 1, the computational domain 2 and the computational domain 3, and 8) obtaining optimal operation parameter configuration of the high-temperature gas cooled reactor at different power levels. The method can realize coupling numerical simulation calculation of the coolant flow field, the temperature field and the stress field of a reactor primary loop.

Owner:XIAN THERMAL POWER RES INST CO LTD

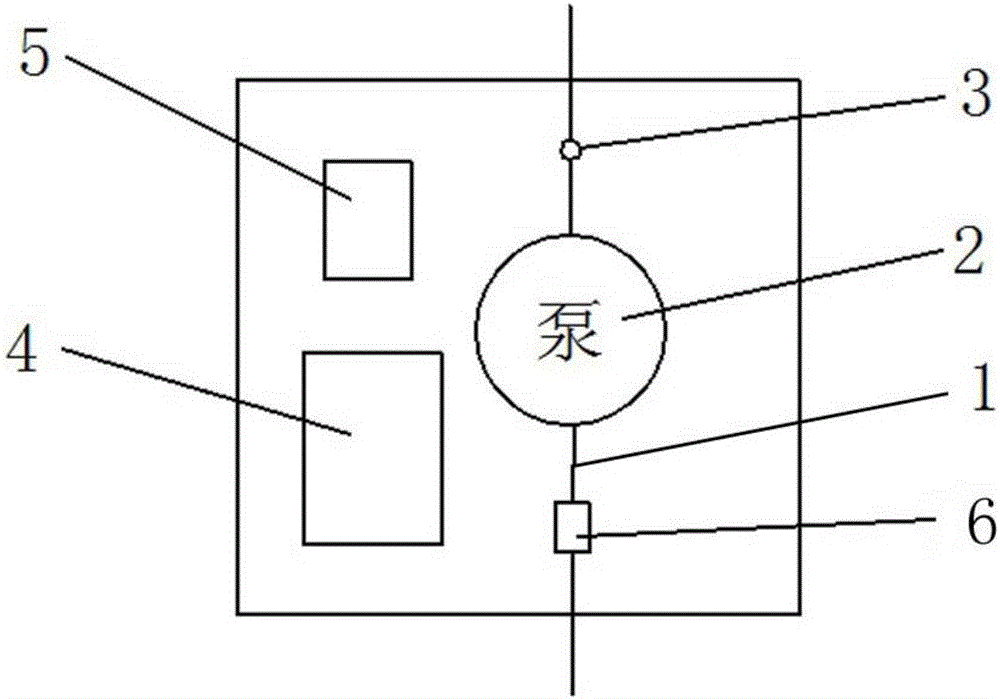

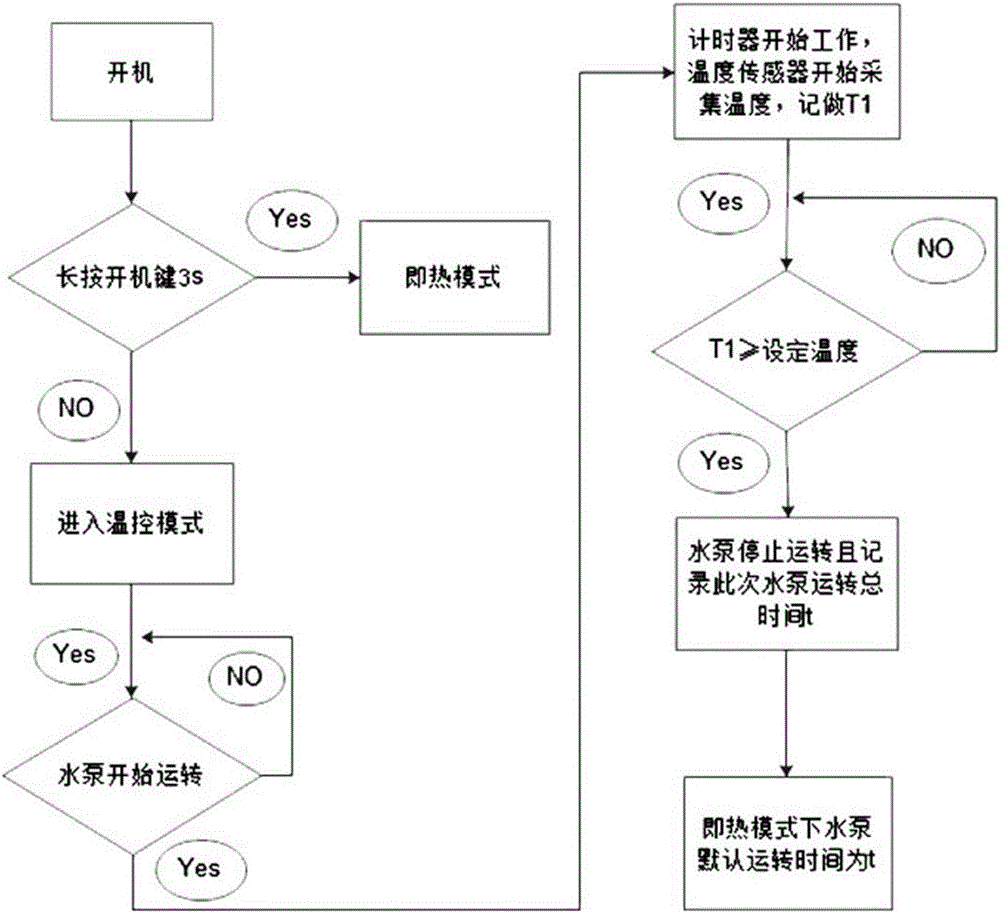

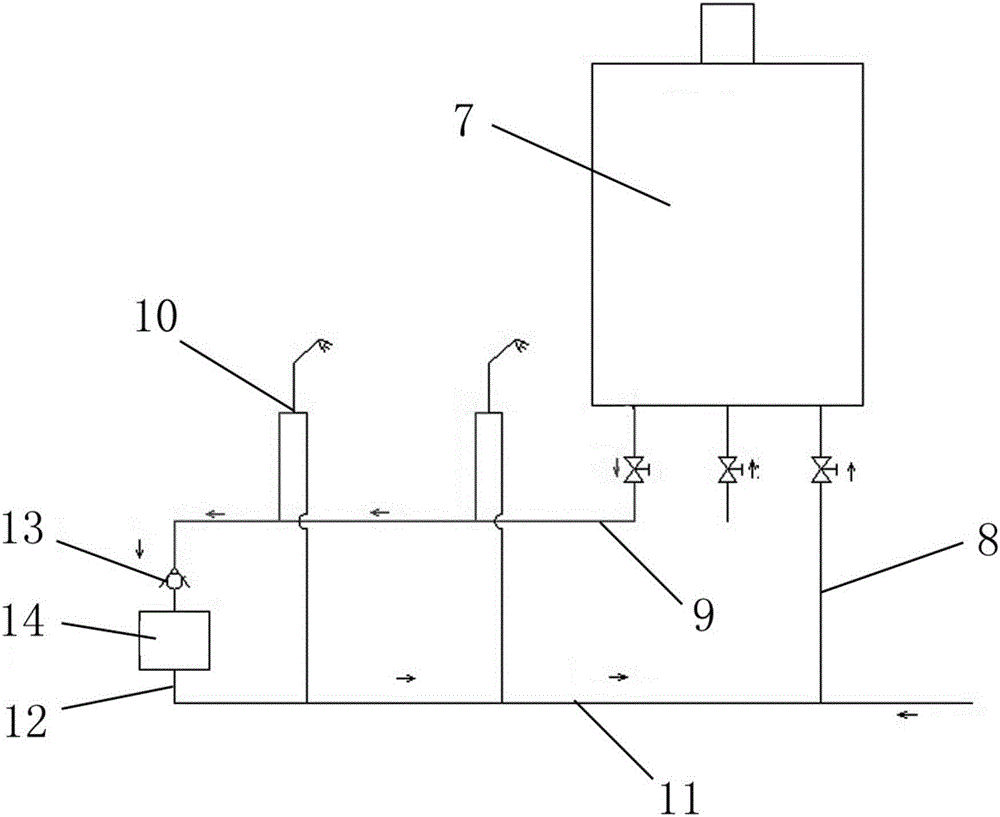

Hot water circulation device, hot water circulation control method and water heater

InactiveCN106091399AEasy to learn automaticallyReduce wasteFluid heatersMechanical apparatusWater useElectricity

The invention discloses a hot water circulation device. The hot water circulation device is characterized by comprising a circulating pipeline, a circulating water pump installed on the circulating pipeline, a temperature sensor, a controller connected with the circulating water pump and the temperature sensor, and an operation display device connected with the controller. The hot water circulation device is convenient for automatic learning of speedy heating time and enables a user to set the time by himself / herself under a speedy heating function by the operation display device, thus immediately obtaining hot water while opening at a bath water using time point, and reducing unnecessary waste of water, gas and electricity. The invention also provides a hot water circulation control method and a water heater.

Owner:GUANGDONG MACRO GAS APPLIANCE

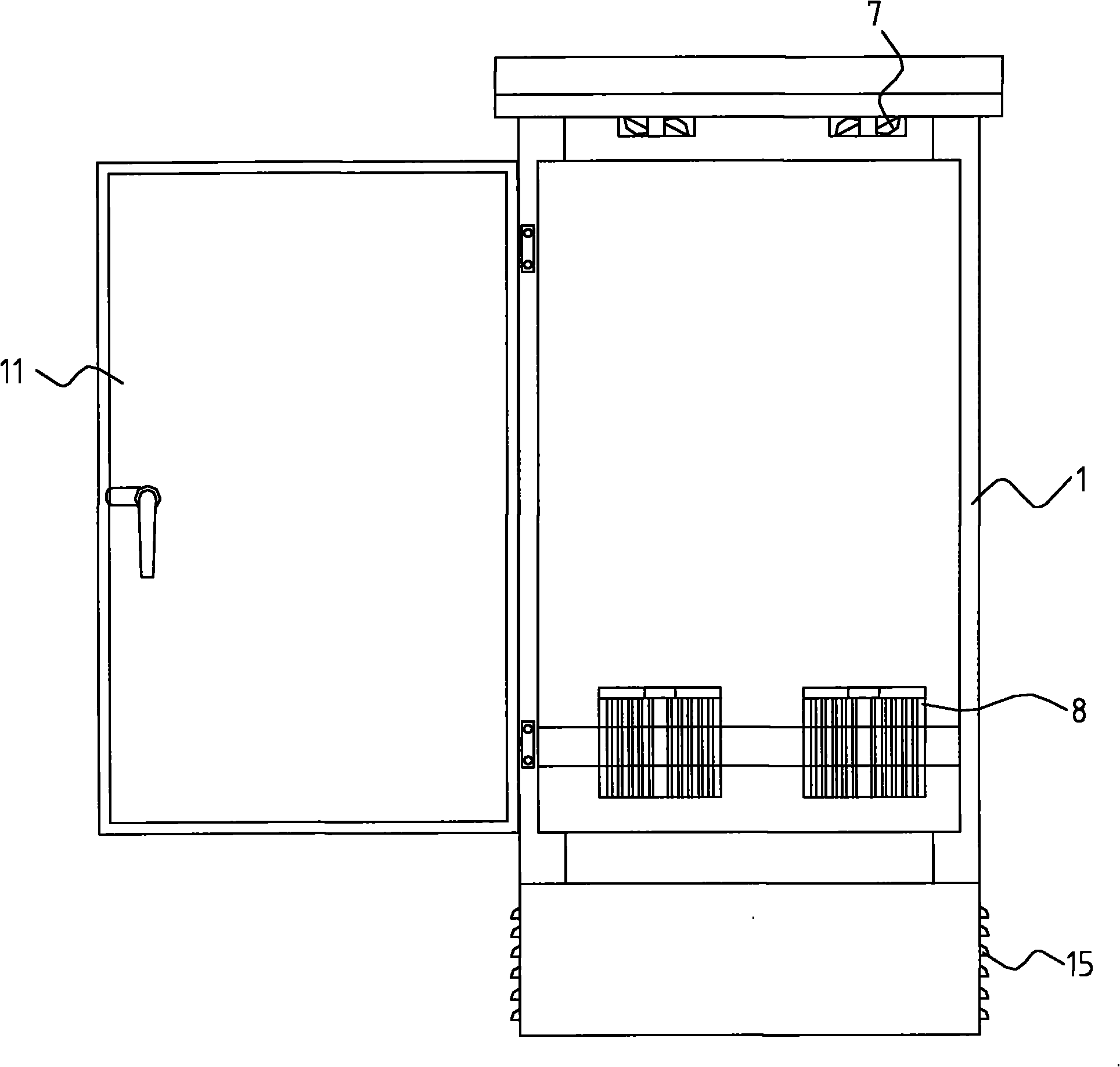

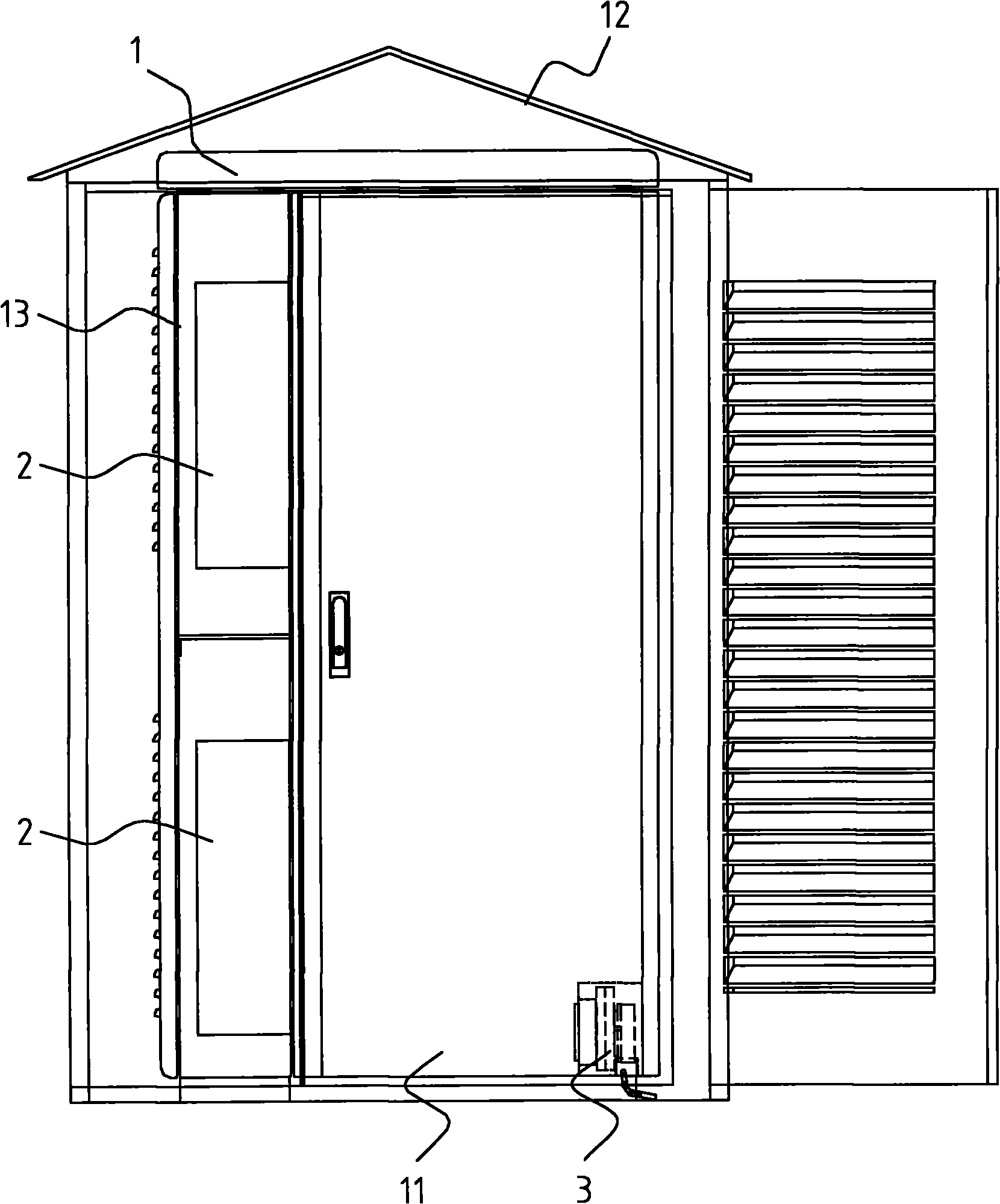

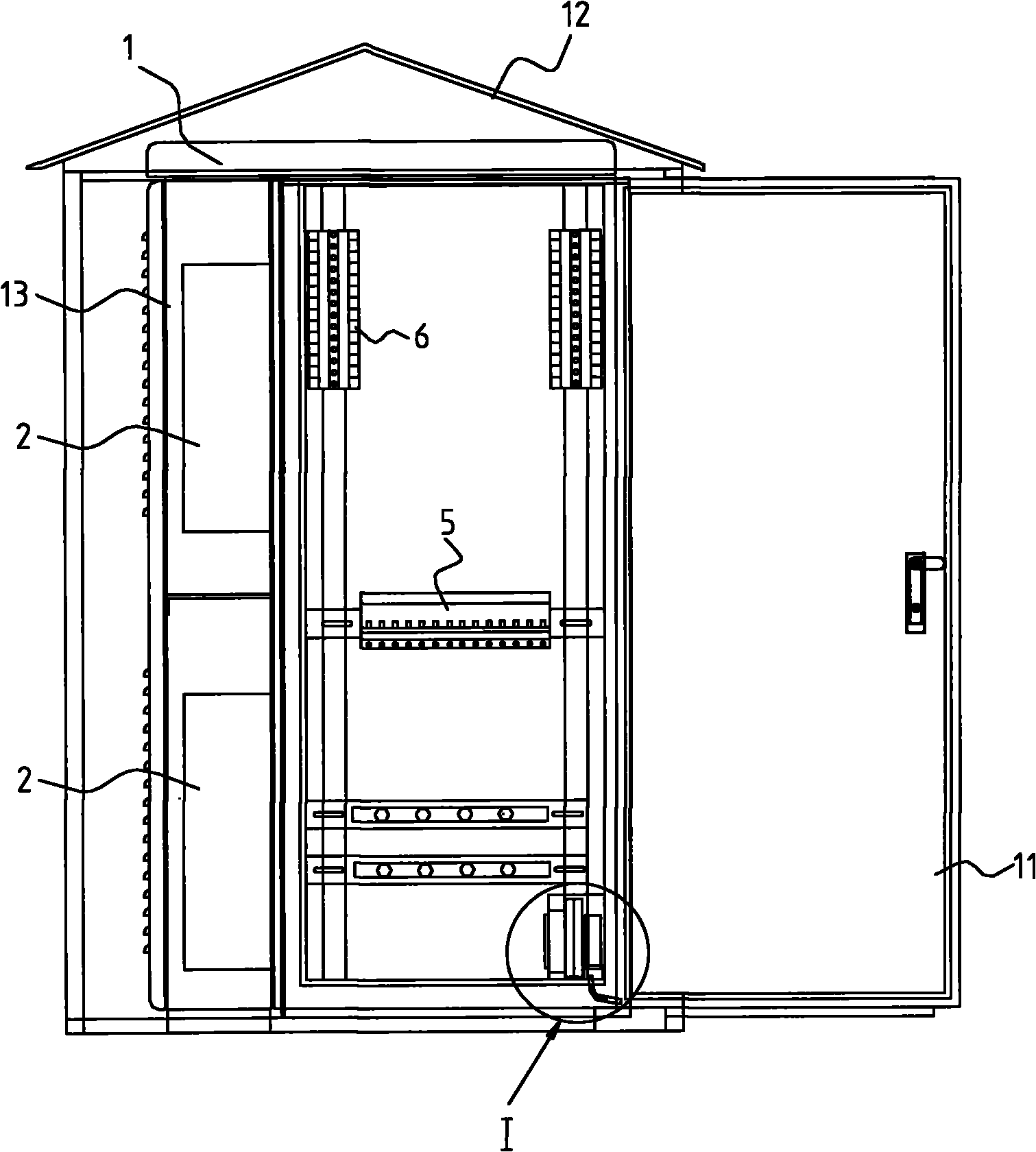

Terminal box

InactiveCN101916968ASolve temperature problemsSolve Humidity ProblemsHumidity controlTemperature control using electric meansEngineeringMoisture sensor

The invention discloses a terminal box which comprises a box body and a temperature and humidity control device, wherein the box body is in an enclosed structure; the temperature and humidity control device comprises a controller, an air conditioner, a dehumidifier, a temperature sensor and a humidity sensor. The temperature sensor and the humidity sensor are respectively used for collecting temperature and humidity signals in the box body and transmitting the temperature and humidity signals to the controller. The controller is used for respectively comparing the temperature and the humidity in the box body with set operating temperature and set operating humidity. Moreover, when the temperature in the box body is higher than the maximum operating temperature or is lower than the minimum operating temperature, the controller switches on the air conditioner. When the humidity in the box body is higher than the maximum operating humidity, the controller switches on the dehumidifier. According to the invention, the temperature and the humidity in the box body are adjusted by using the air conditioner and the dehumidifier respectively and the operating requirements on precision electrical elements in the box body are better met by controlling the operation of the air conditioner and the dehumidifier through the controller.

Owner:GUANGZHOU ELECTRIC POWER DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com