Optical fiber multi-point temperature and pressure measuring method for intelligent well and the device therefor

A technology of optical fiber temperature and multi-point temperature, which is applied in the field of smart wells, can solve problems such as large insertion loss, spectral interference, and temperature crosstalk, and achieve the effects of long service life, good stability, and use without ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The optical fiber multi-point temperature and pressure measurement method and device for smart wells proposed by the present invention are described in detail in conjunction with the accompanying drawings and embodiments as follows:

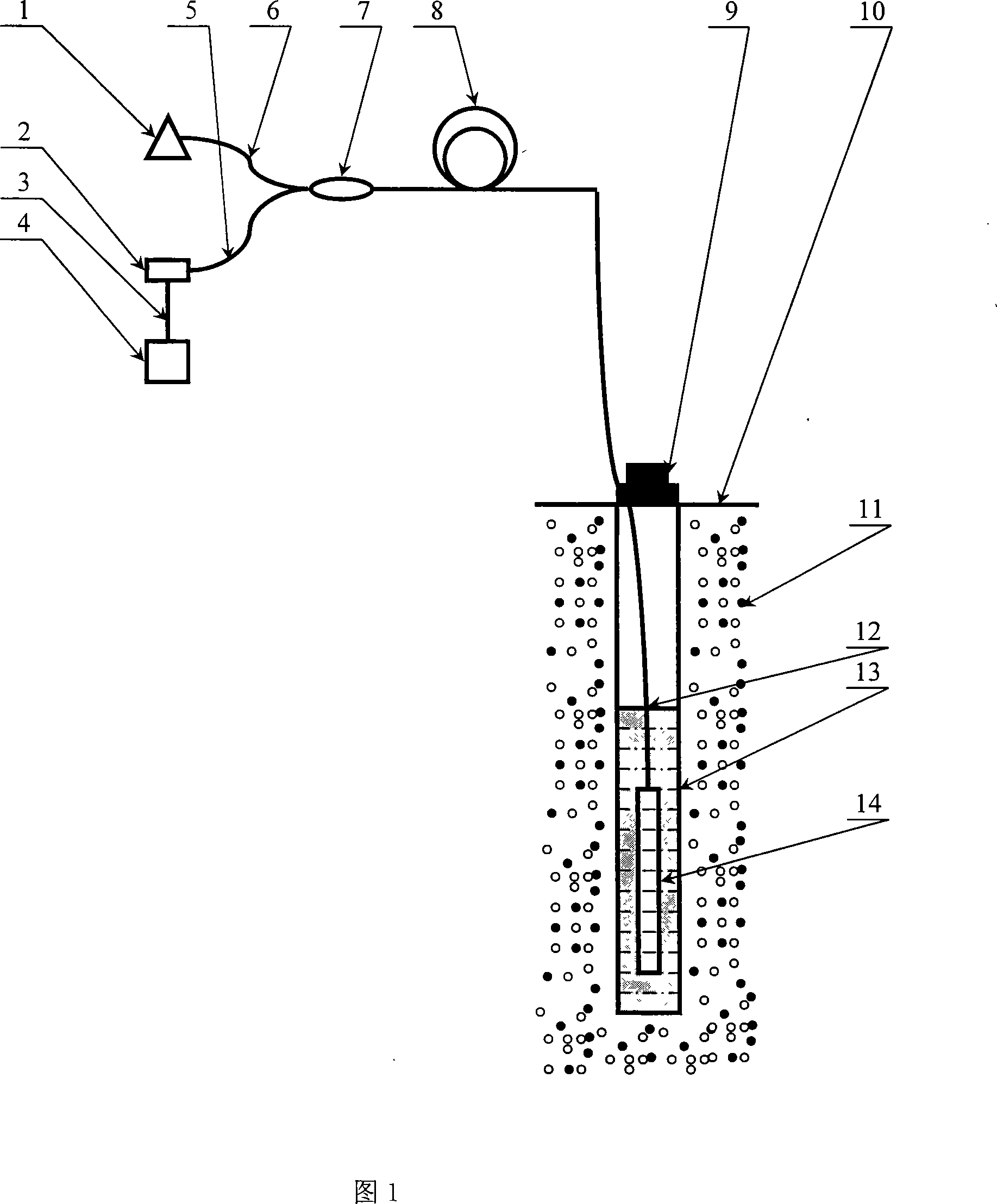

[0030] Measuring method of the present invention is described as follows in conjunction with Fig. 1:

[0031] The light emitted from the broadband light source 1 is coupled and injected into the optical fiber 6, and injected into the optical cable 8 composed of optical fibers through the optical fiber coupler 7; the optical fiber temperature sensor and the optical fiber pressure sensor group 14 are distributed on the optical fiber cable 8, and the optical fiber temperature sensor and the optical fiber pressure sensor group 14 Under the action of external temperature and pressure, the reflected spectra are respectively modulated, and then pass through the optical cable 8 again in the reverse direction, and then inject into the modular spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com