Patents

Literature

306 results about "Relative pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relative pressure (definition) Relative pressure is the atmospheric pressure corrected to sea-level conditions. To compare pressure conditions from one location to another, meteorologists correct the measured pressure (referred to as absolute pressure) to sea-level conditions.

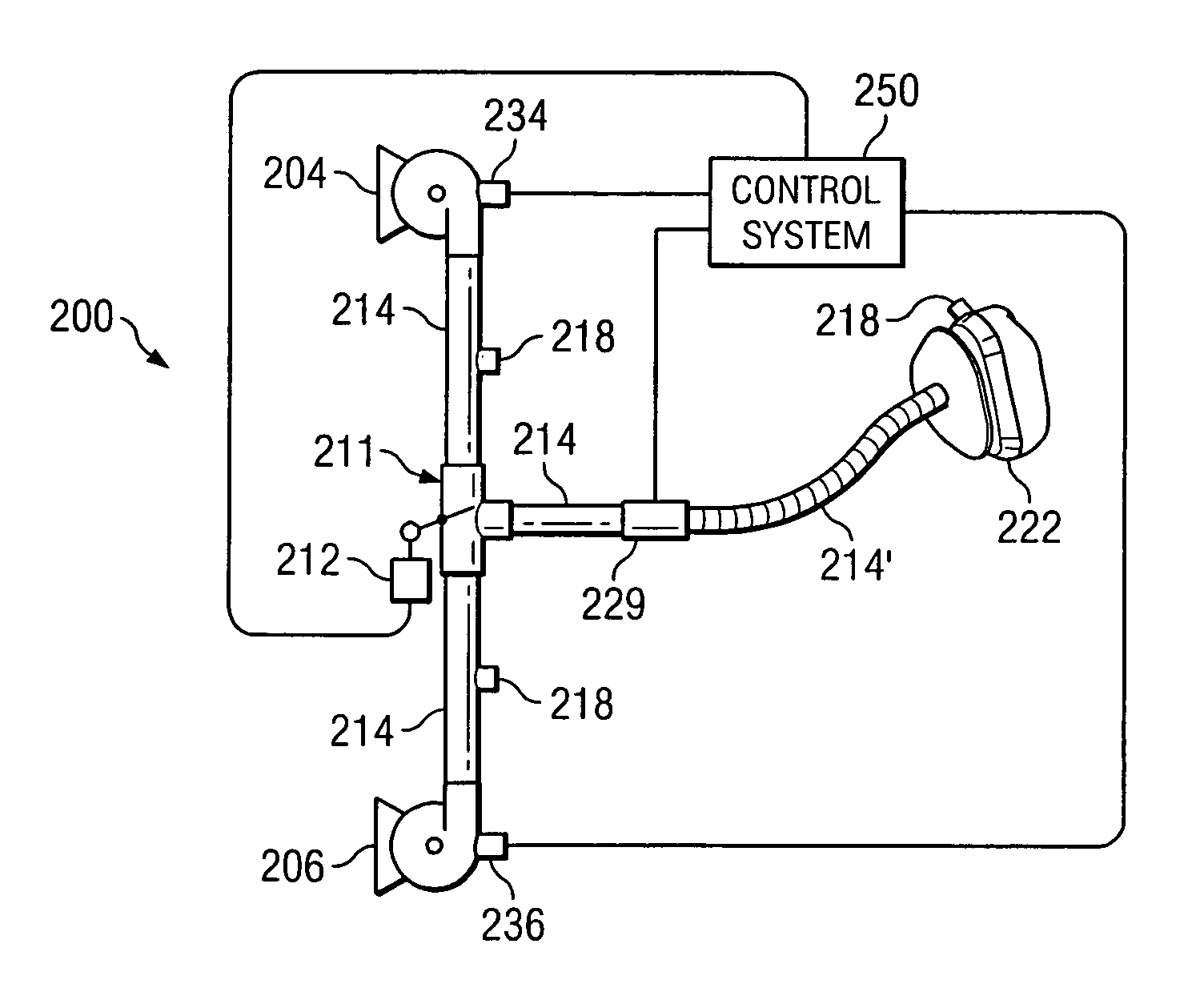

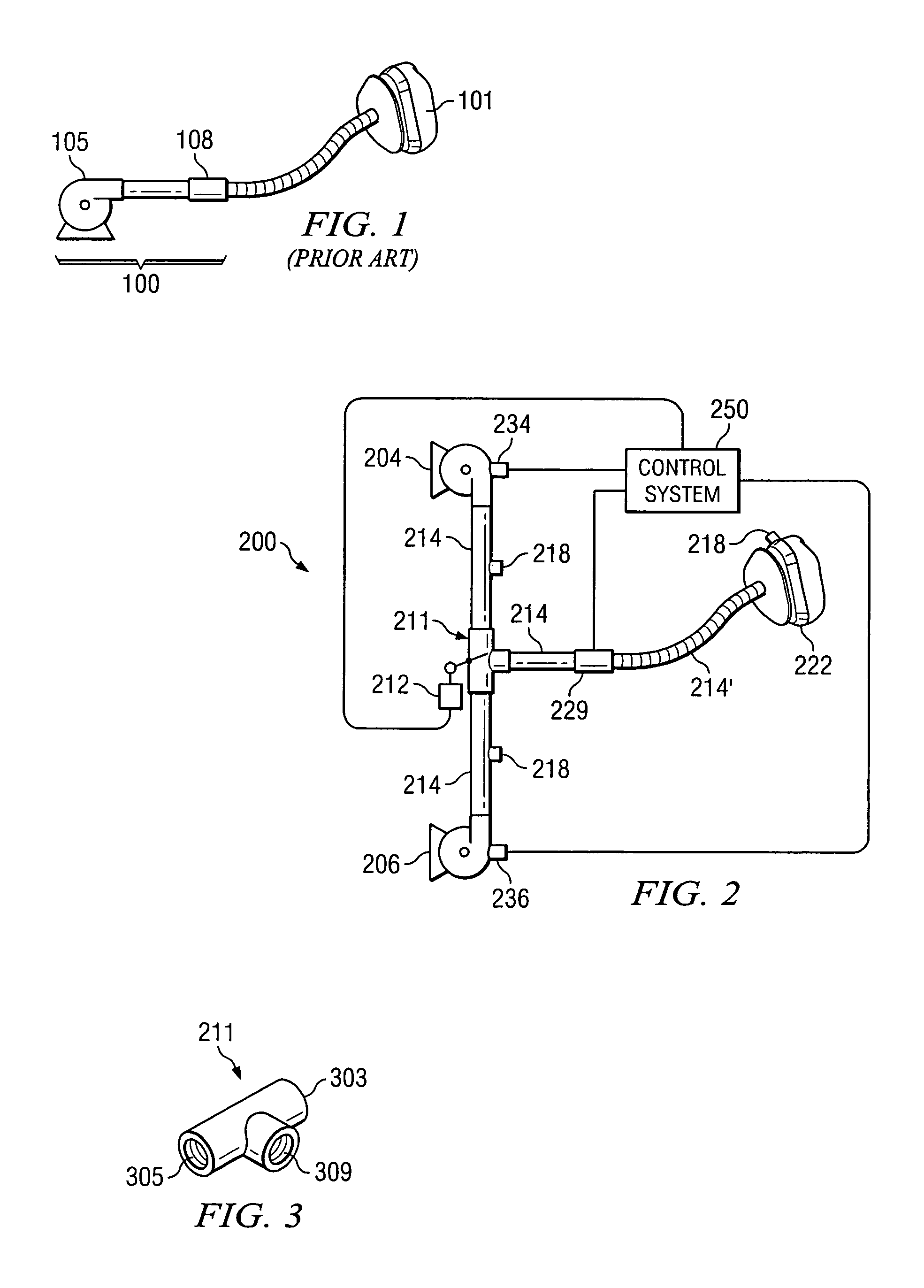

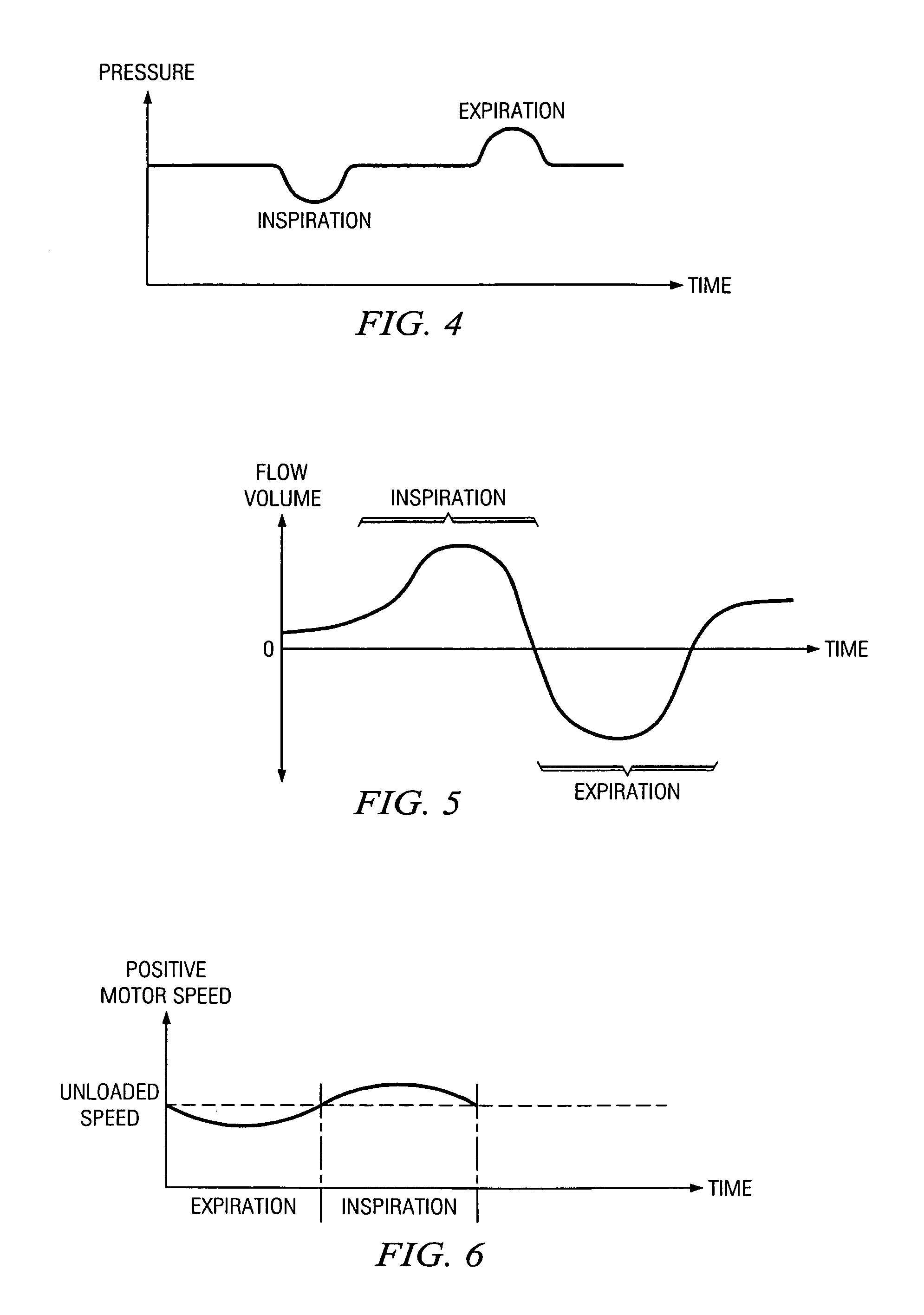

Ventilator with dual gas supply

InactiveUS7077131B2Minimize the differenceOperating means/releasing devices for valvesRespiratory masksRelative pressureValve actuator

A method of pressure regulation and a ventilator are provided. The ventilator includes a positive relative pressure gas supply, a negative relative pressure gas supply, and a diverter valve. The diverter valve includes a positive pressure port connected to the positive relative pressure gas supply, a negative pressure port connected to the negative relative pressure gas supply, and a gas supply port communicating with a gas delivery device. The ventilator preferably further includes a feedback sensor that detects a gas supply difference between a gas supply and a predetermined gas supply and generates a feedback signal that is substantially related to the gas supply difference. The ventilator preferably further includes a diverter valve actuator communicating with the diverter valve and operating the diverter valve to communicate the positive relative pressure gas supply and the negative relative pressure gas supply to the gas supply port of the diverter valve based upon the feedback signal.

Owner:TYCO HEALTHCARE GRP LP

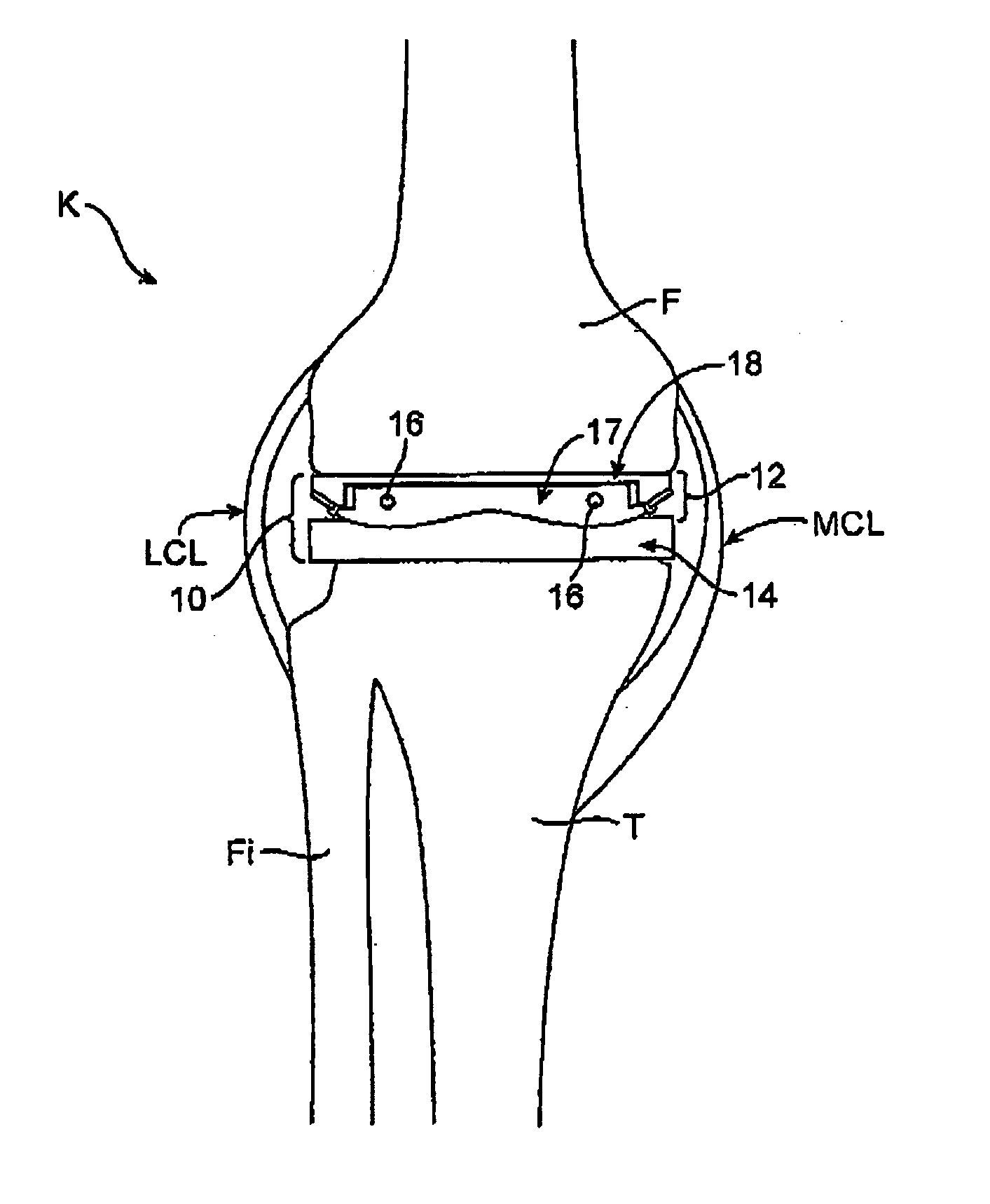

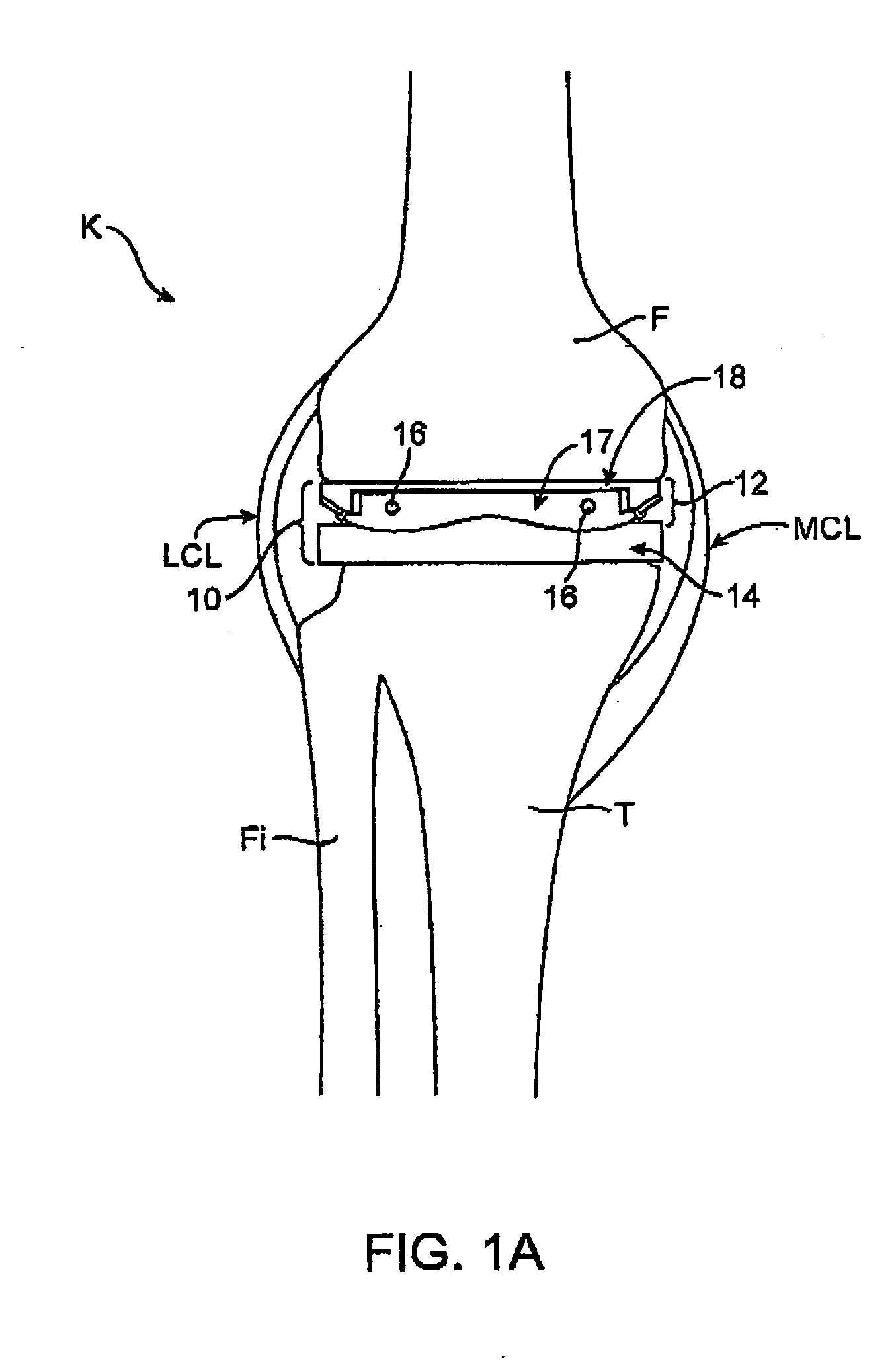

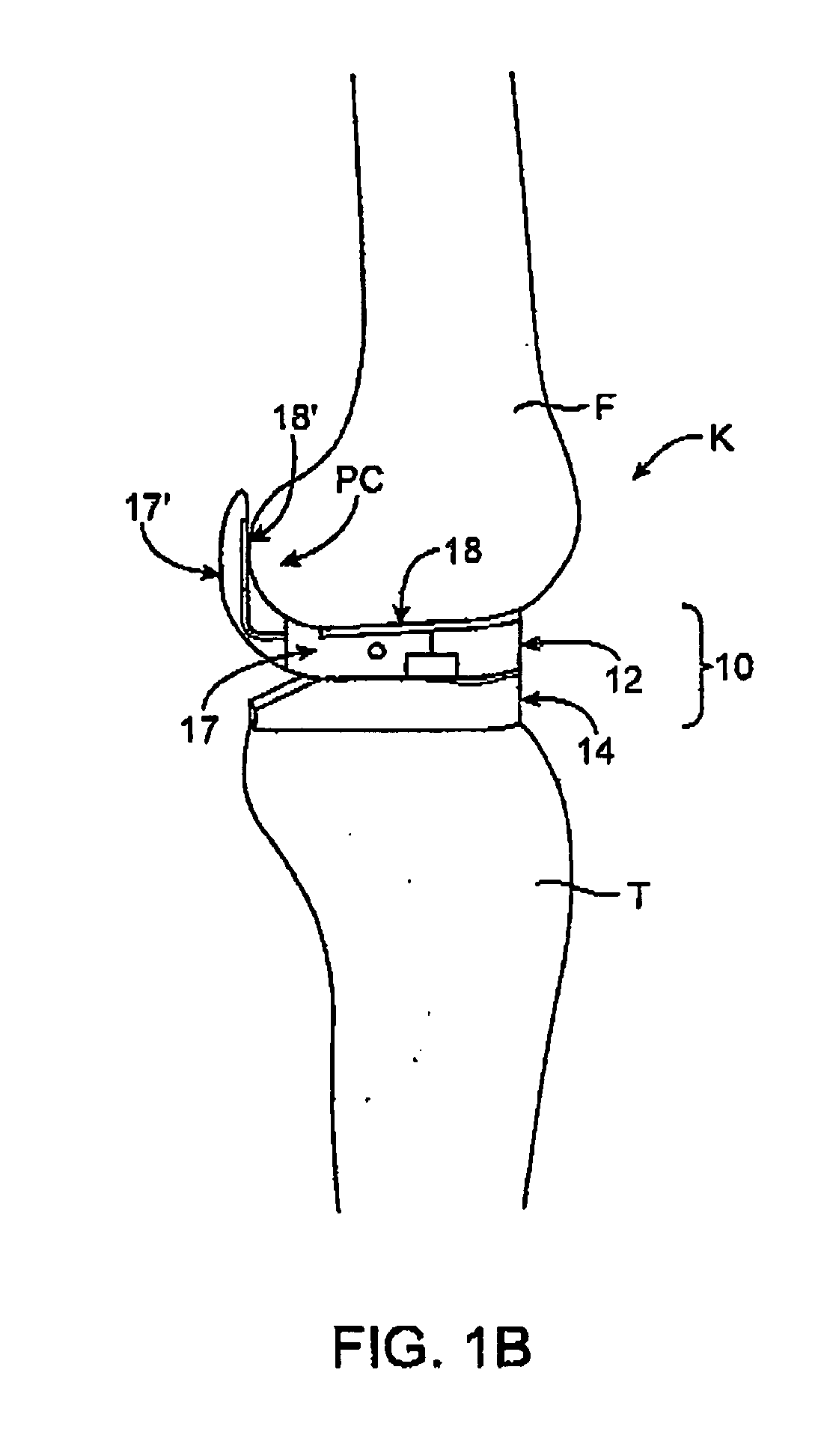

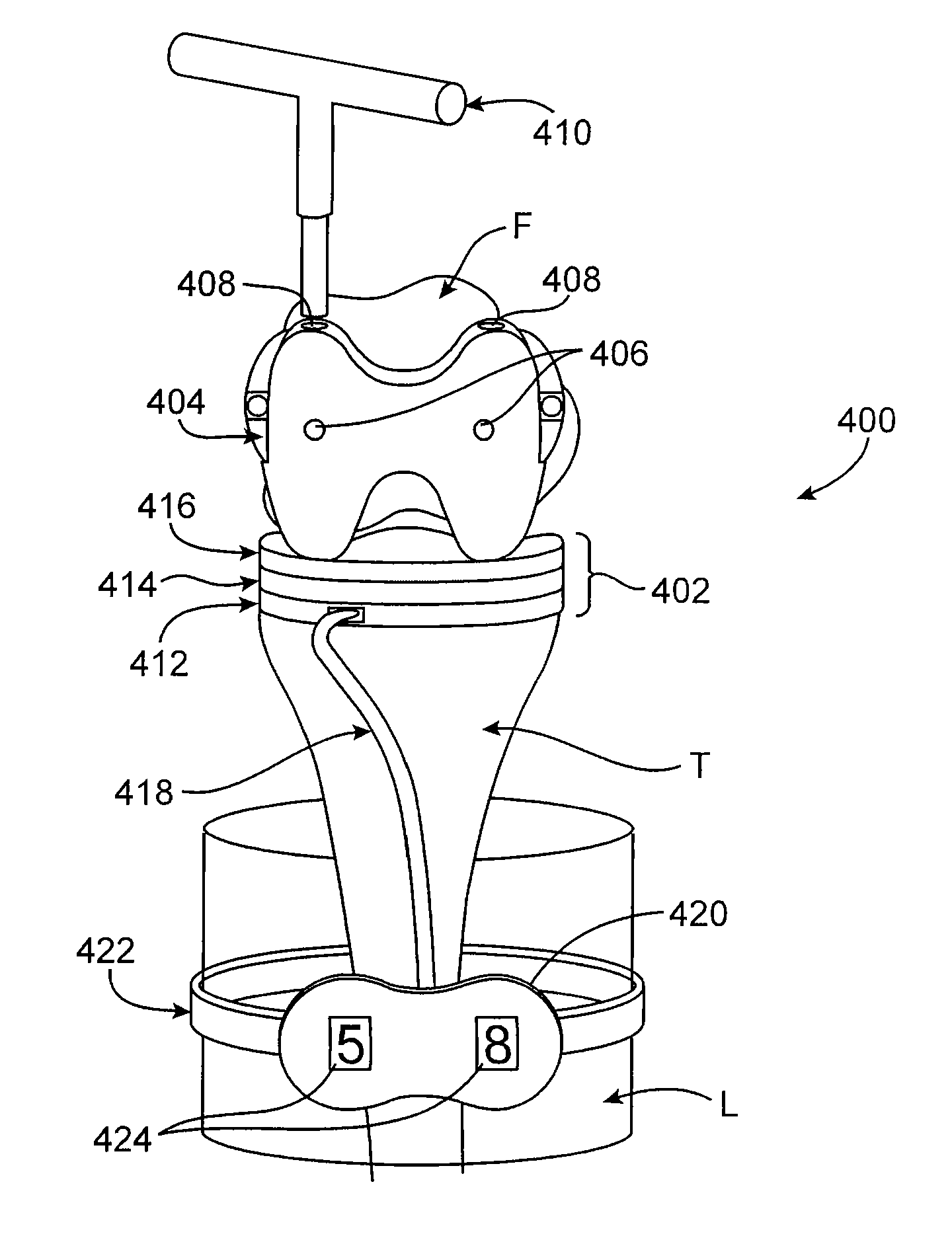

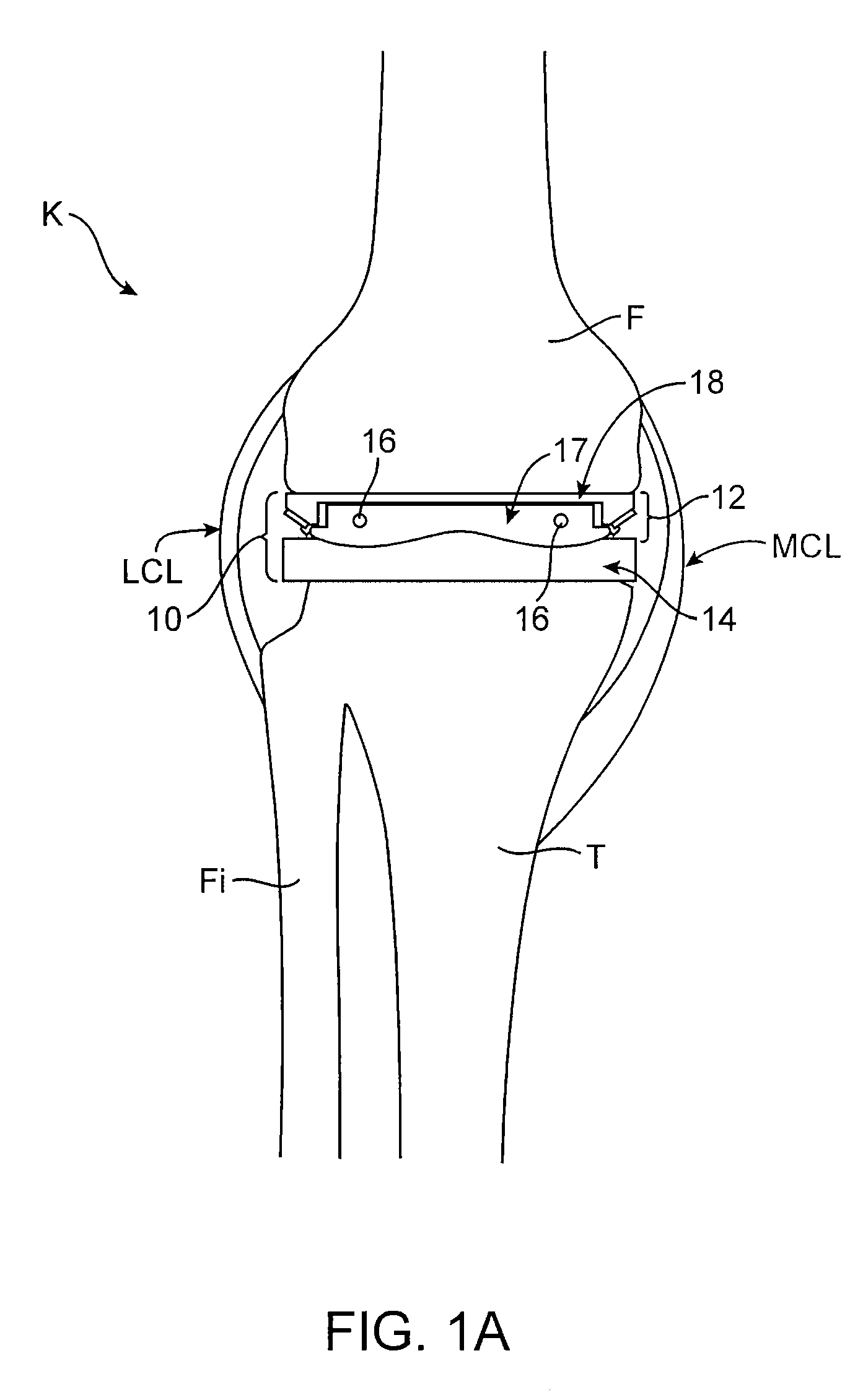

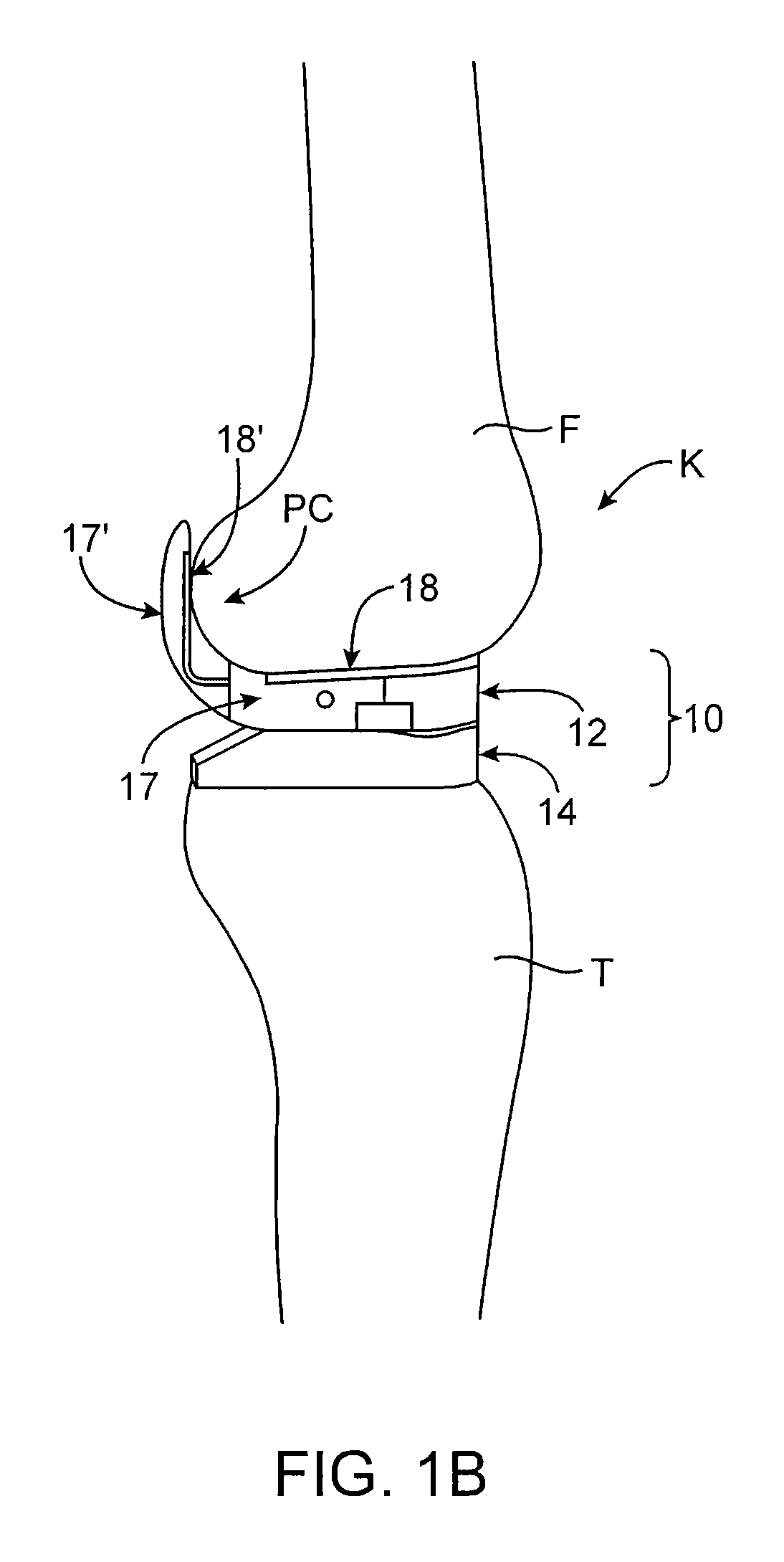

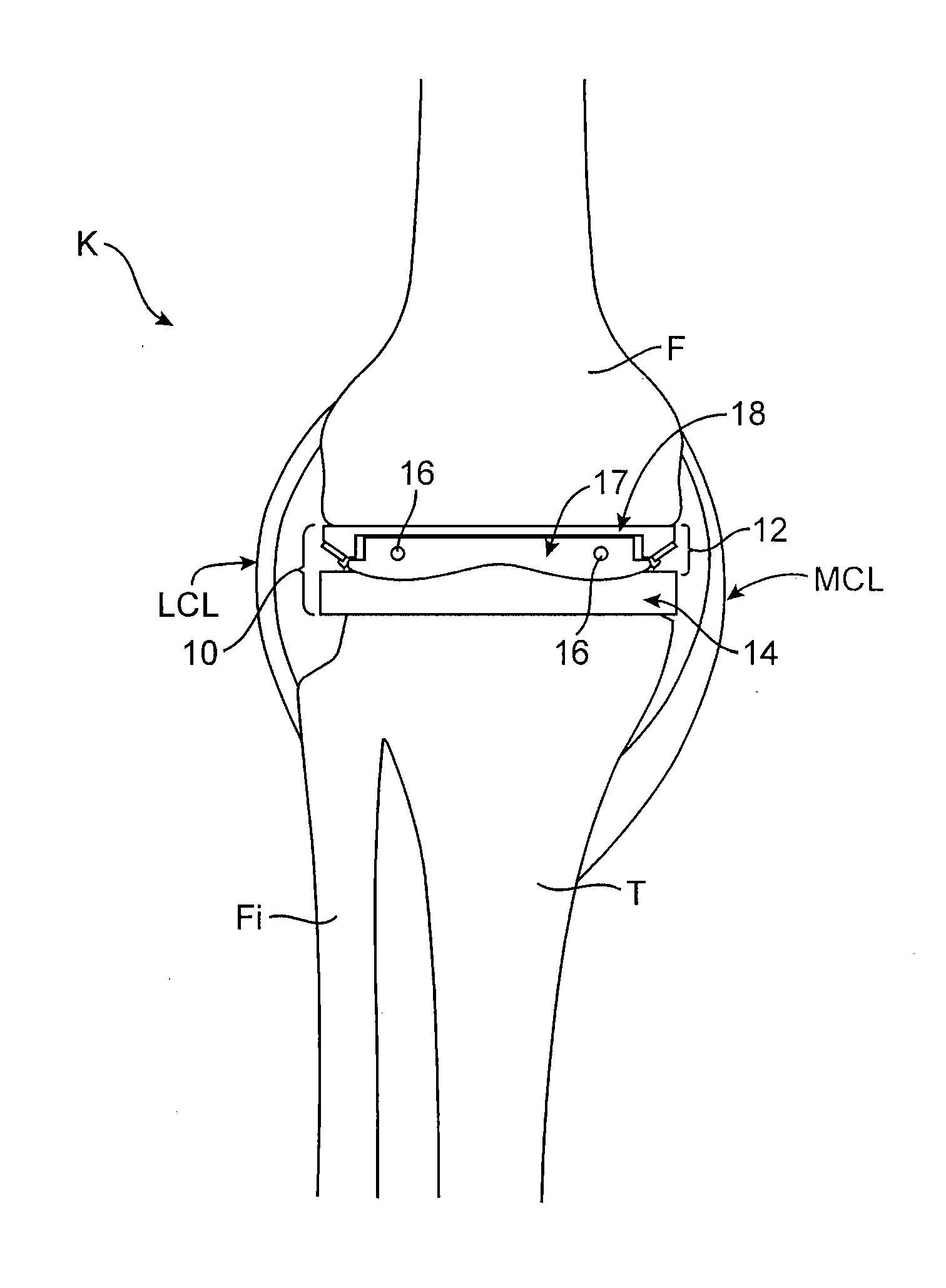

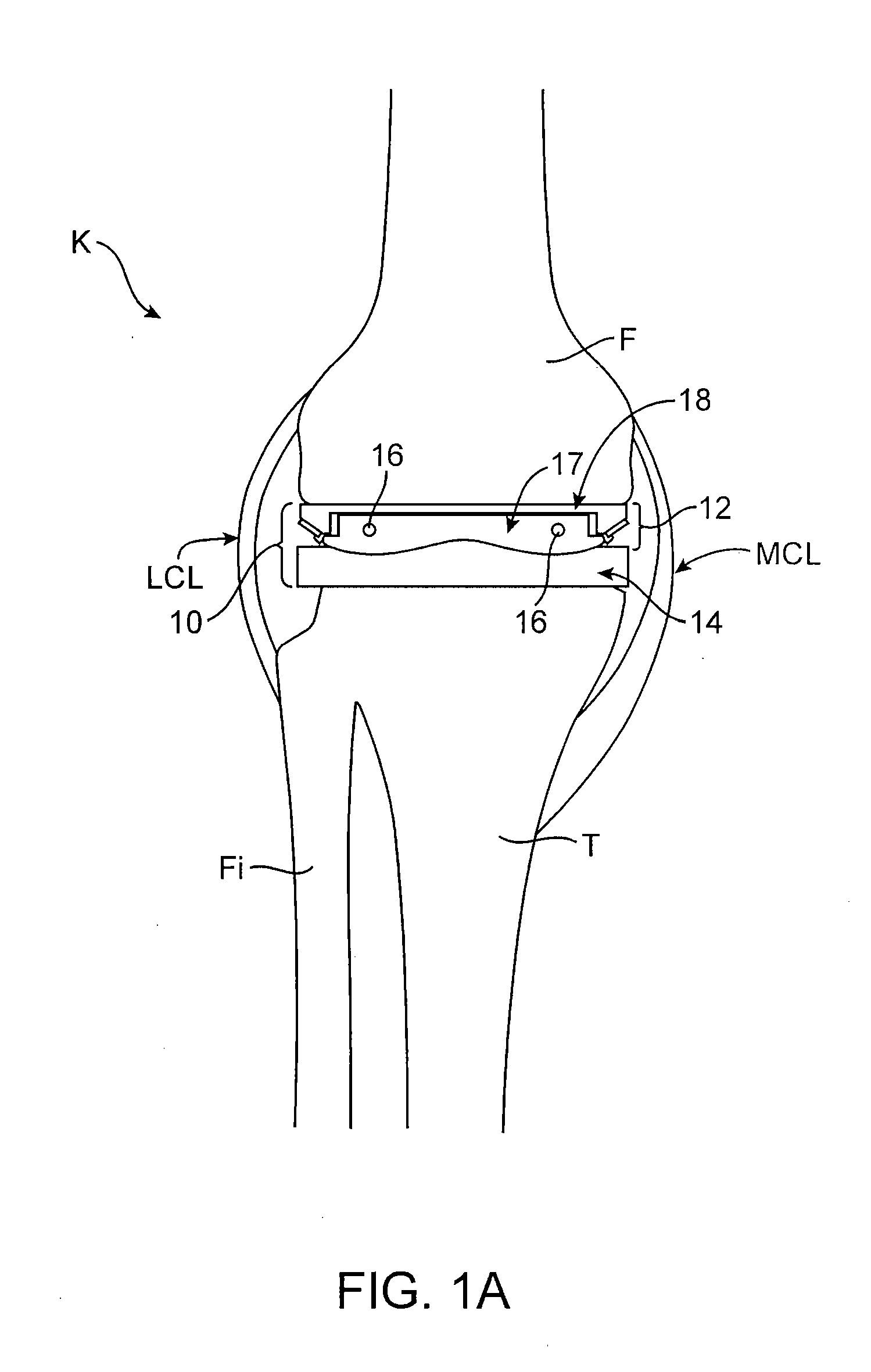

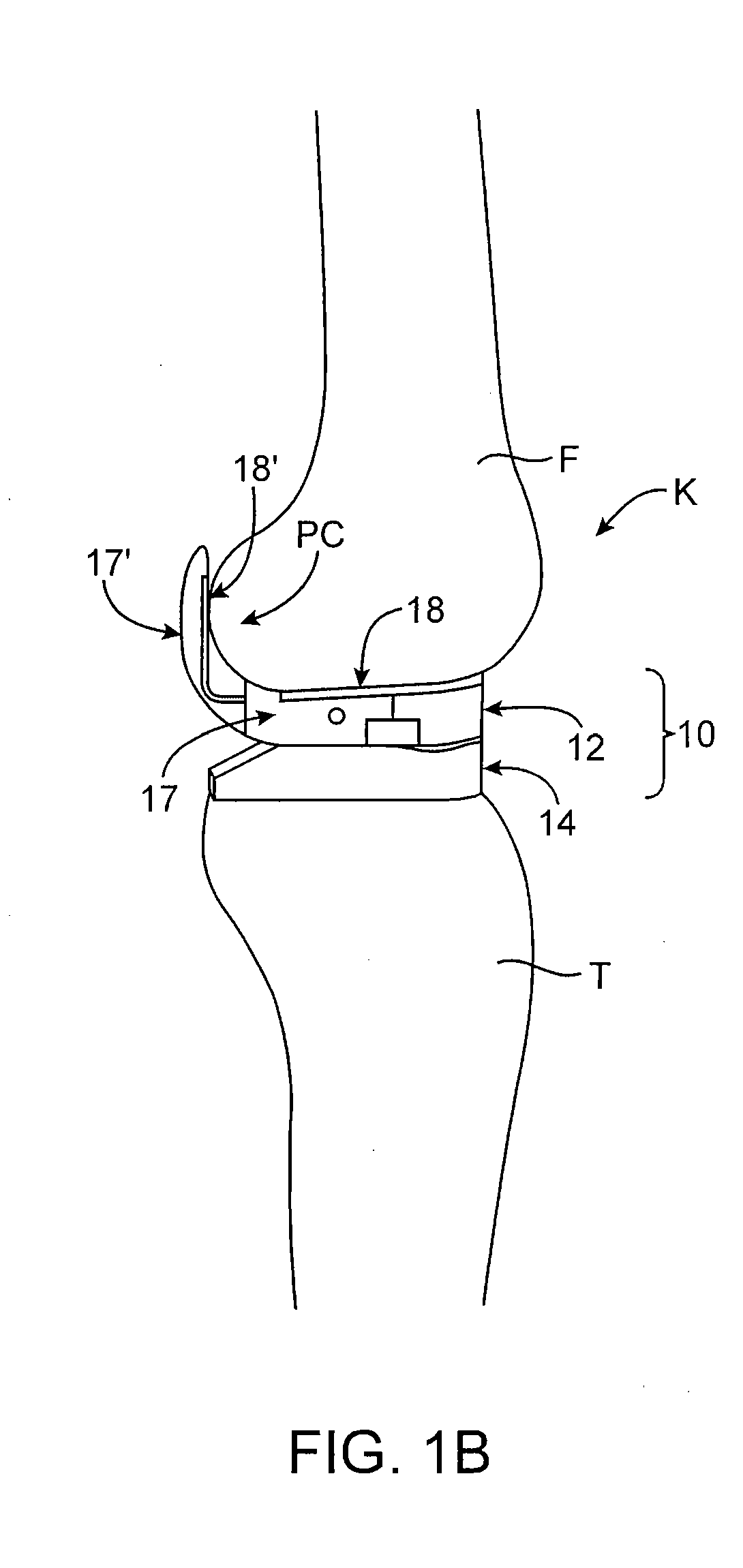

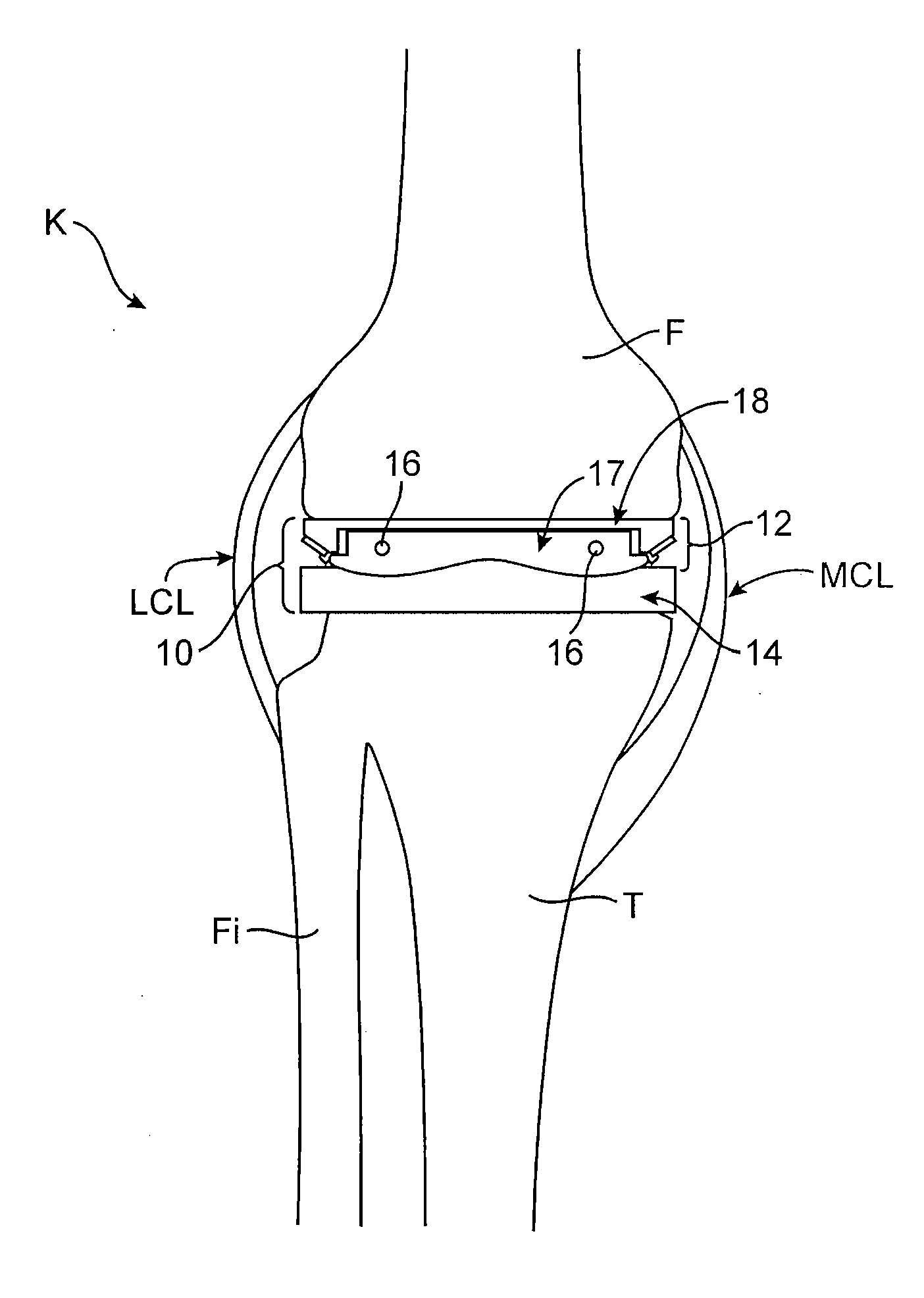

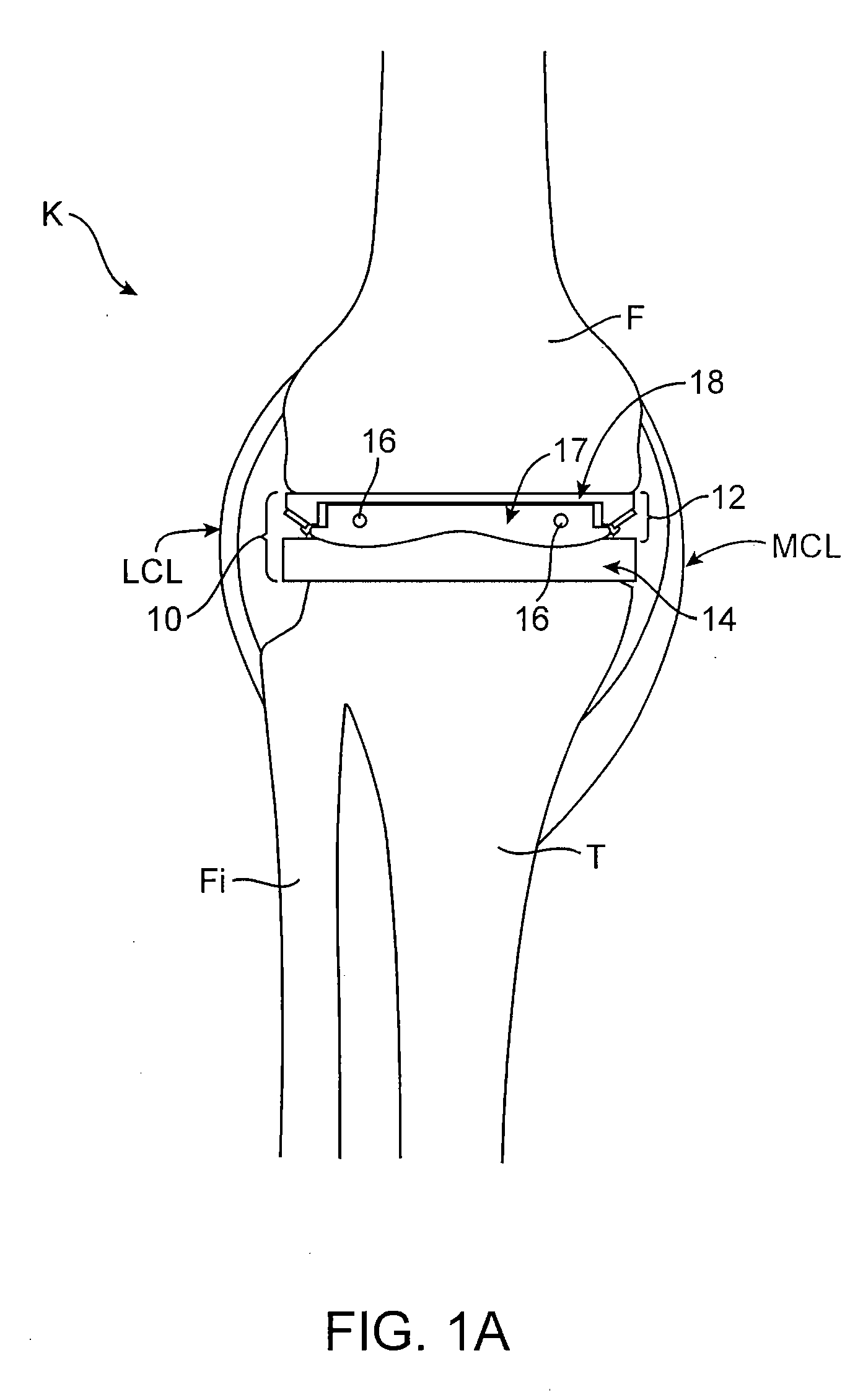

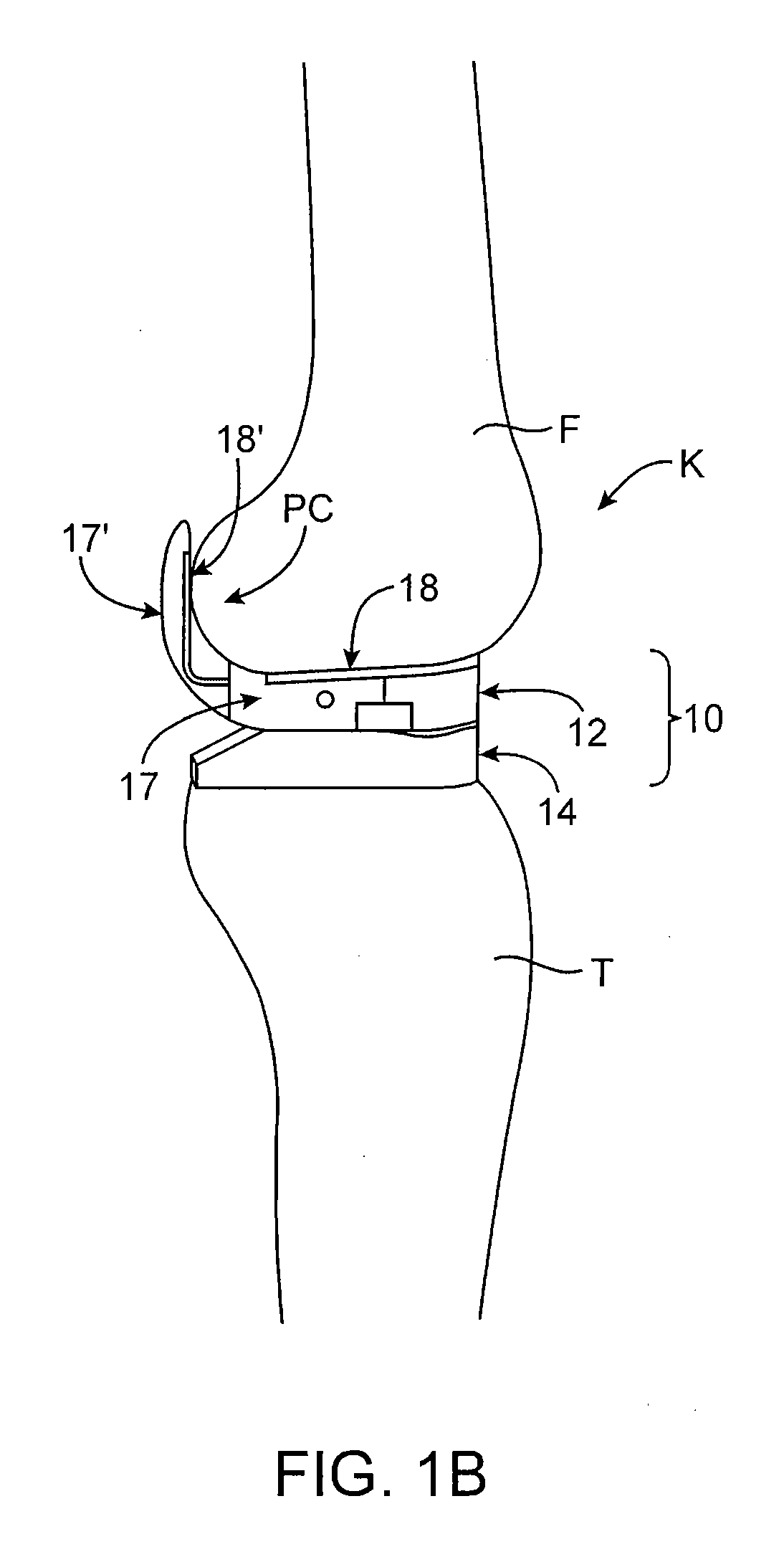

Dynamic knee balancer with pressure sensing

ActiveUS20050177170A1Enhancing knee surgery procedureAccelerated programPerson identificationJoint implantsTibiaRelative pressure

A device for performing a surgical procedure on a knee includes an adjustable femoral portion, a tibial portion and at least one sensor coupled with the femoral and / or tibial portions to sense pressure exerted by the femoral and tibial portions against one another. The femoral portion is adapted for removably coupling with a distal end of a femur to adjust tension in soft tissue adjacent the knee and has at least one positioning feature adapted to move relative to the distal end of the femur as the femoral portion is adjusted, thus helping position a femoral prosthetic on the distal end of the femur. The sensor(s) may be adapted to sense pressure at medial and lateral sides of the knee, and relative pressures may be displayed as data on a visual display. Adjustments to the femoral member may be made to balance pressure at flexion and extension of the knee.

Owner:SYNVASIVE TECH

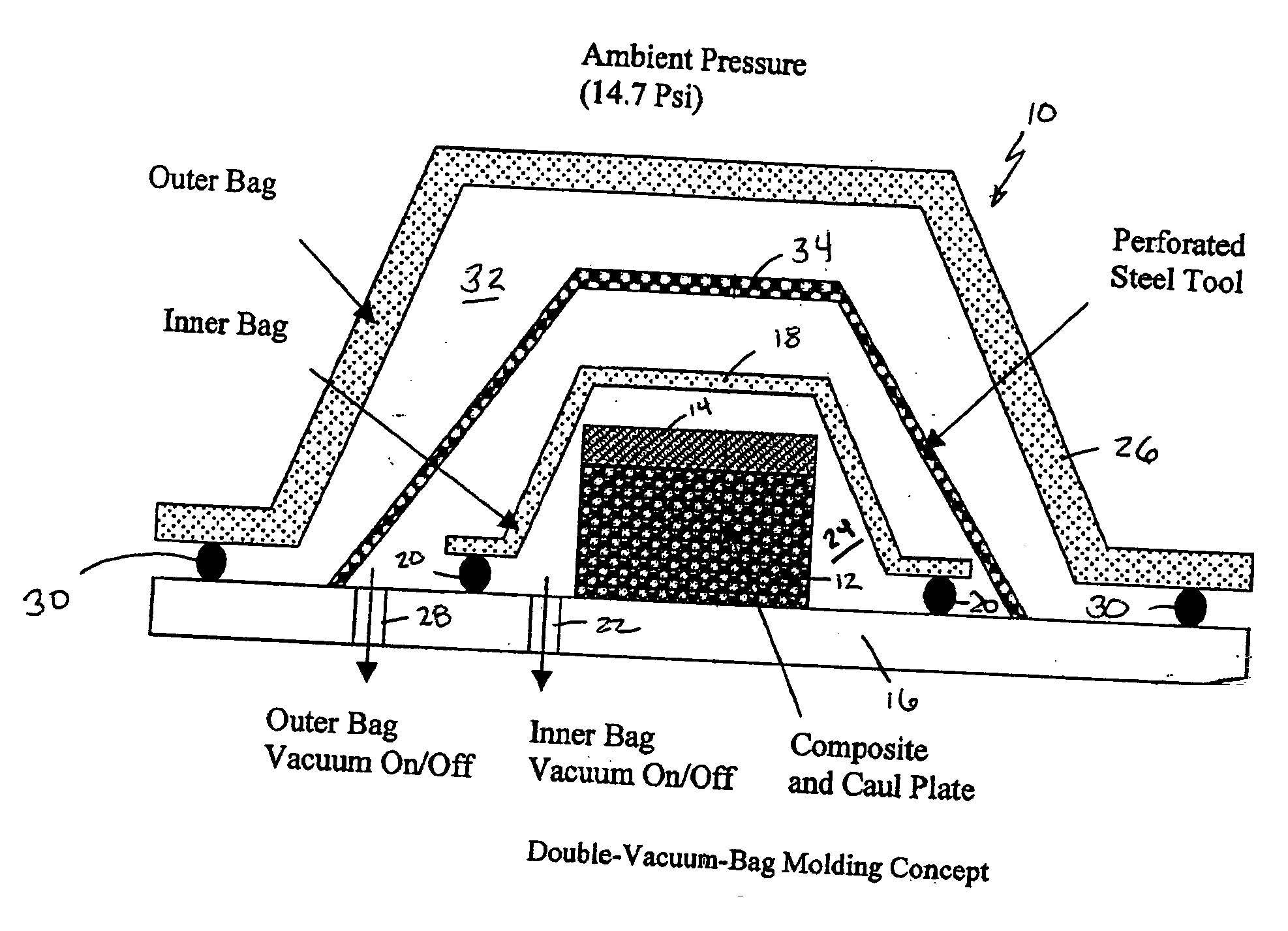

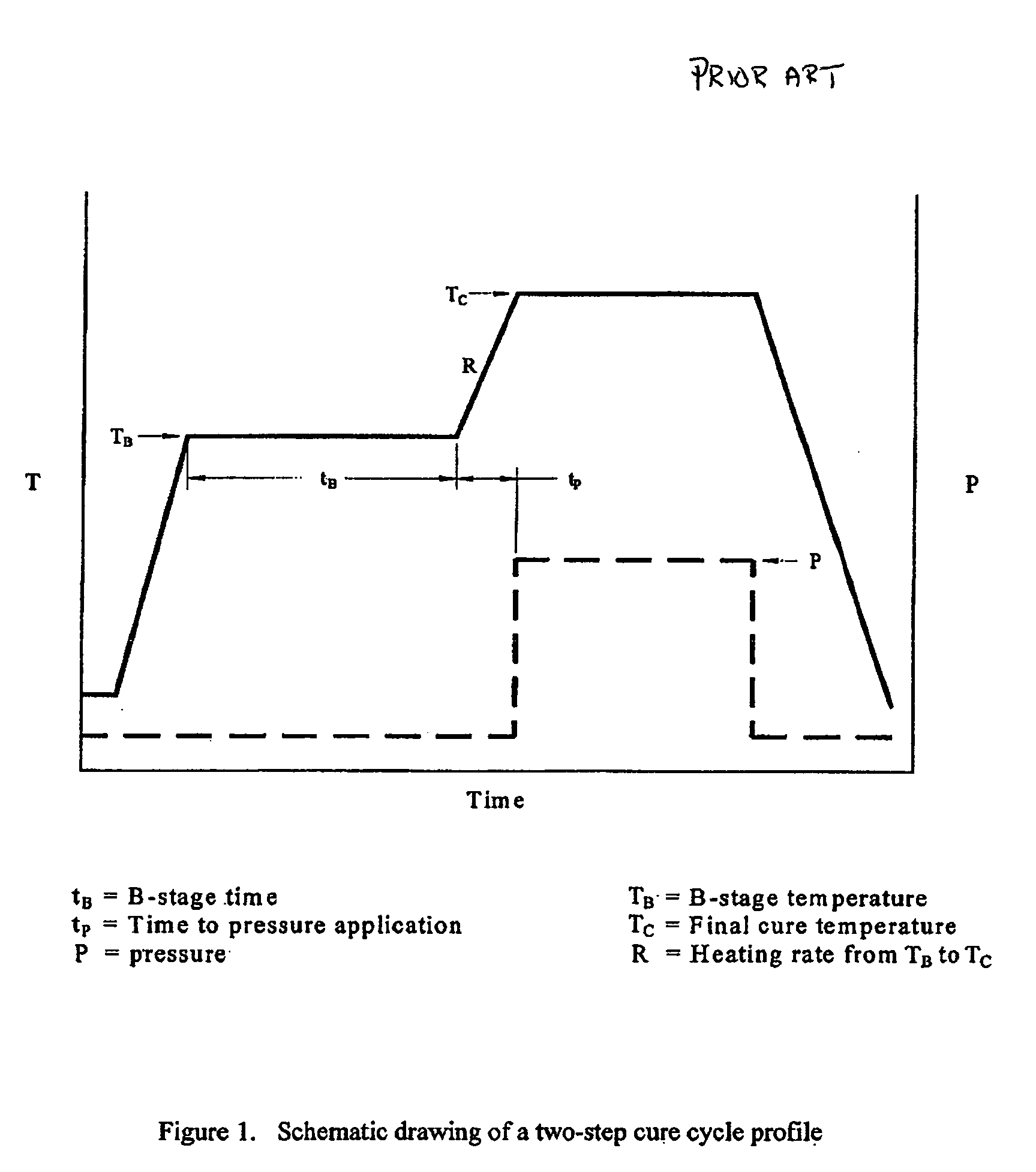

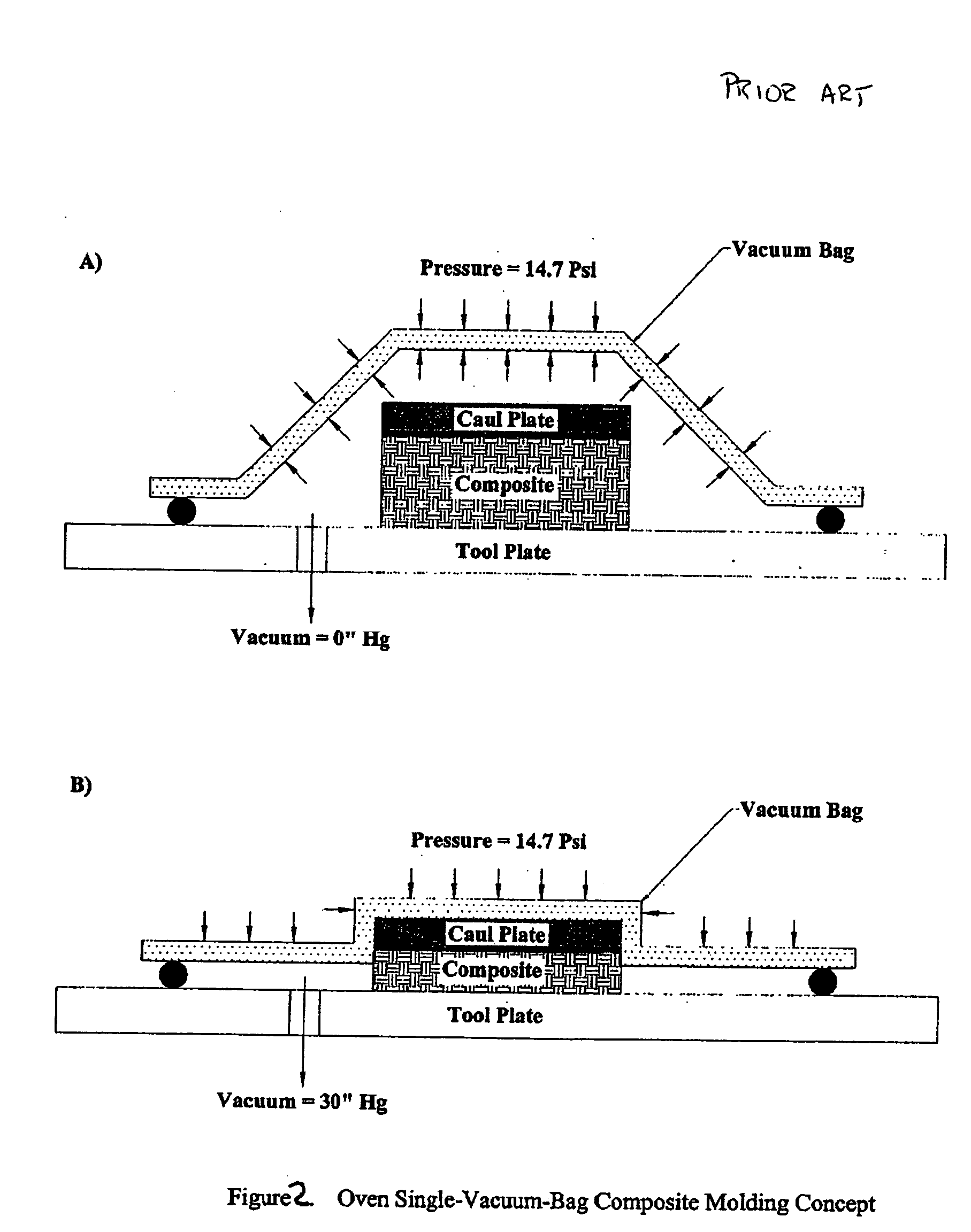

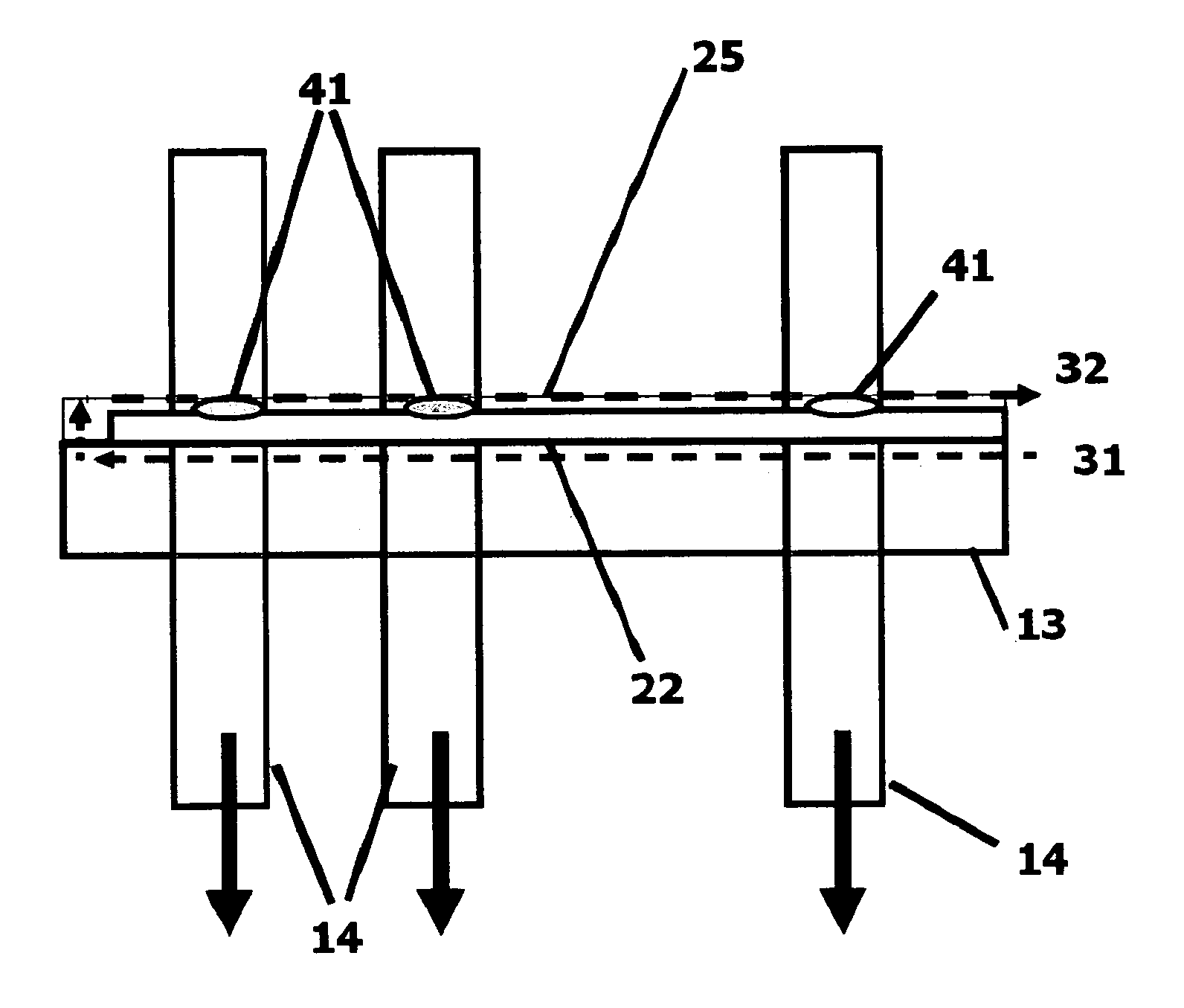

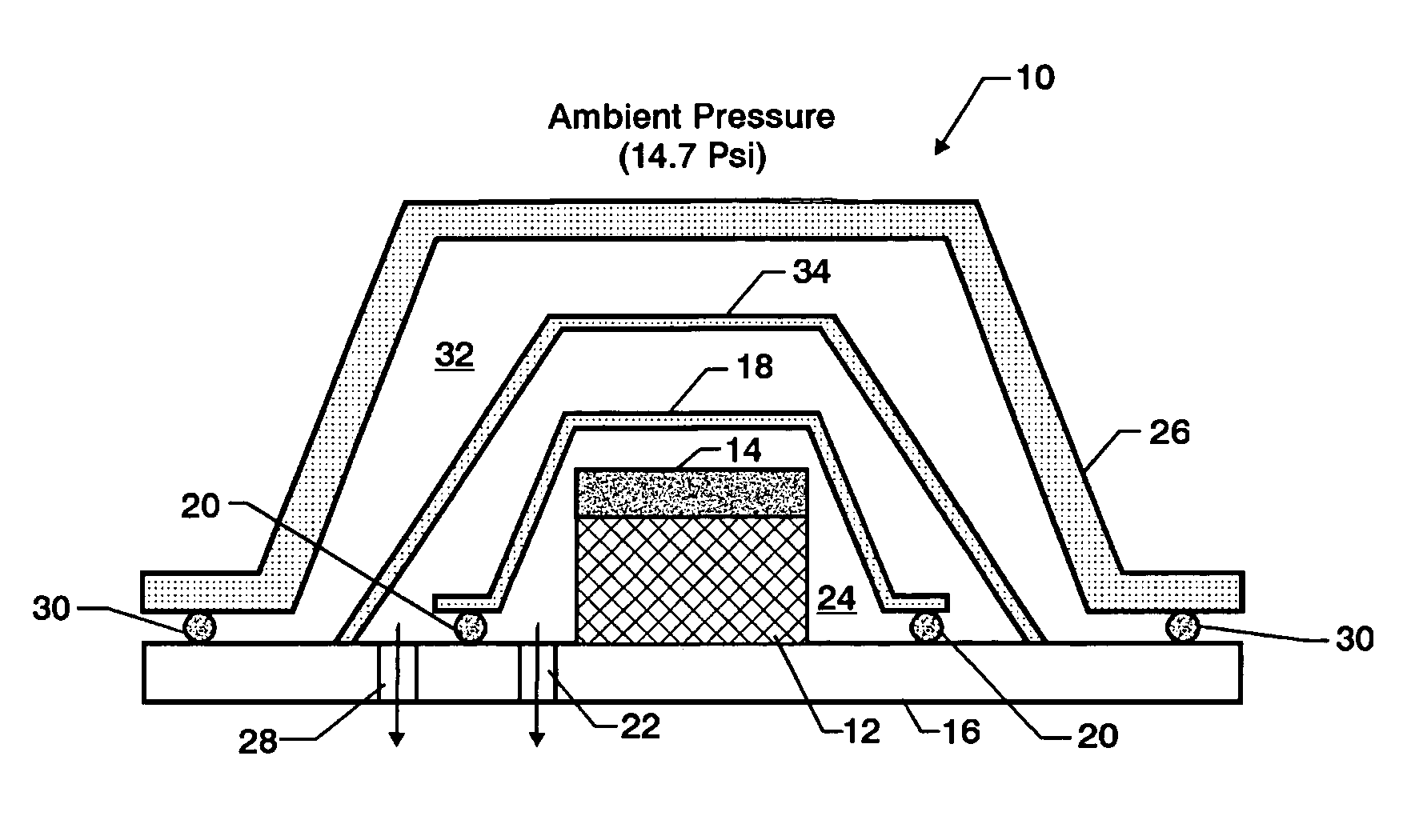

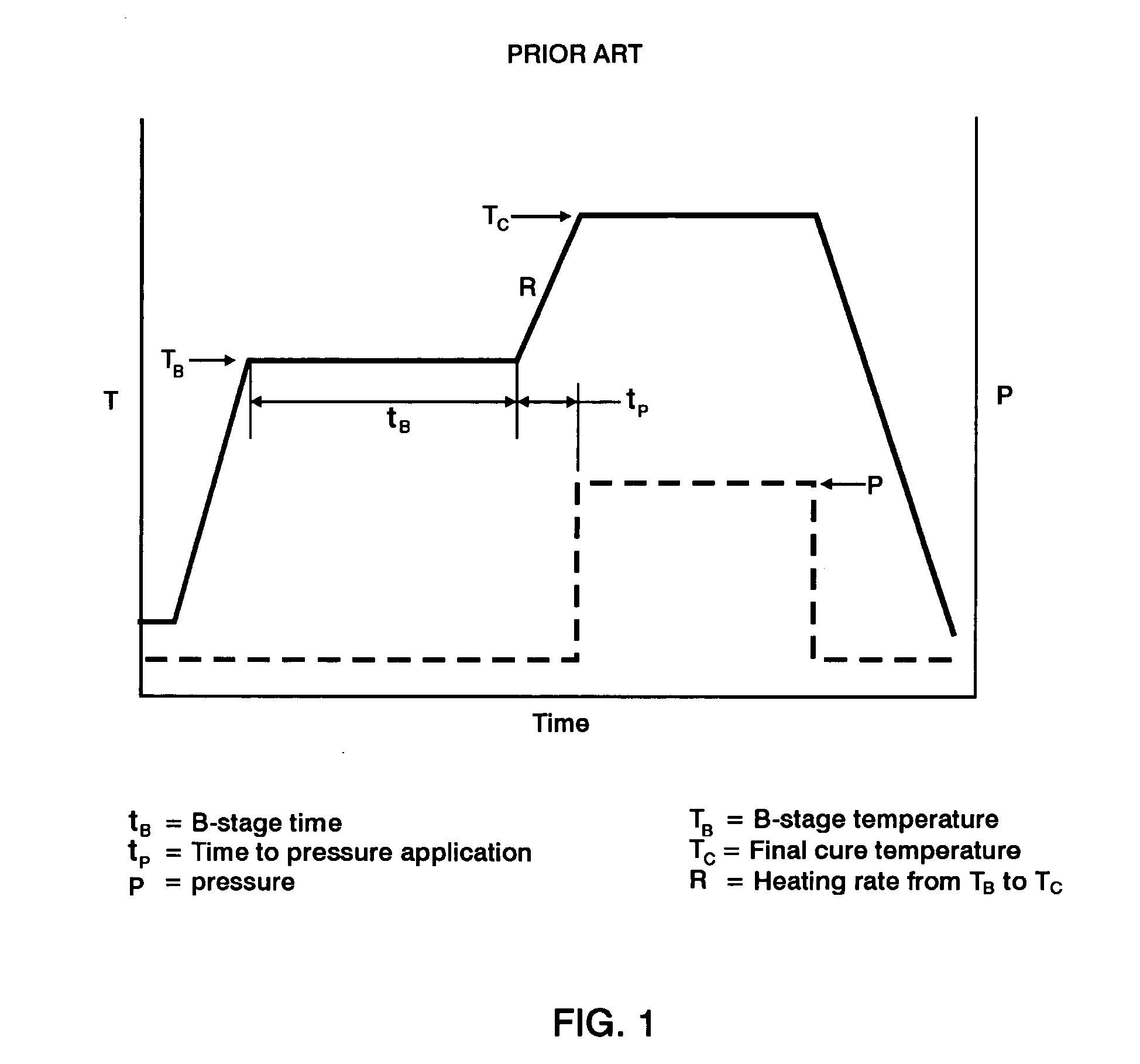

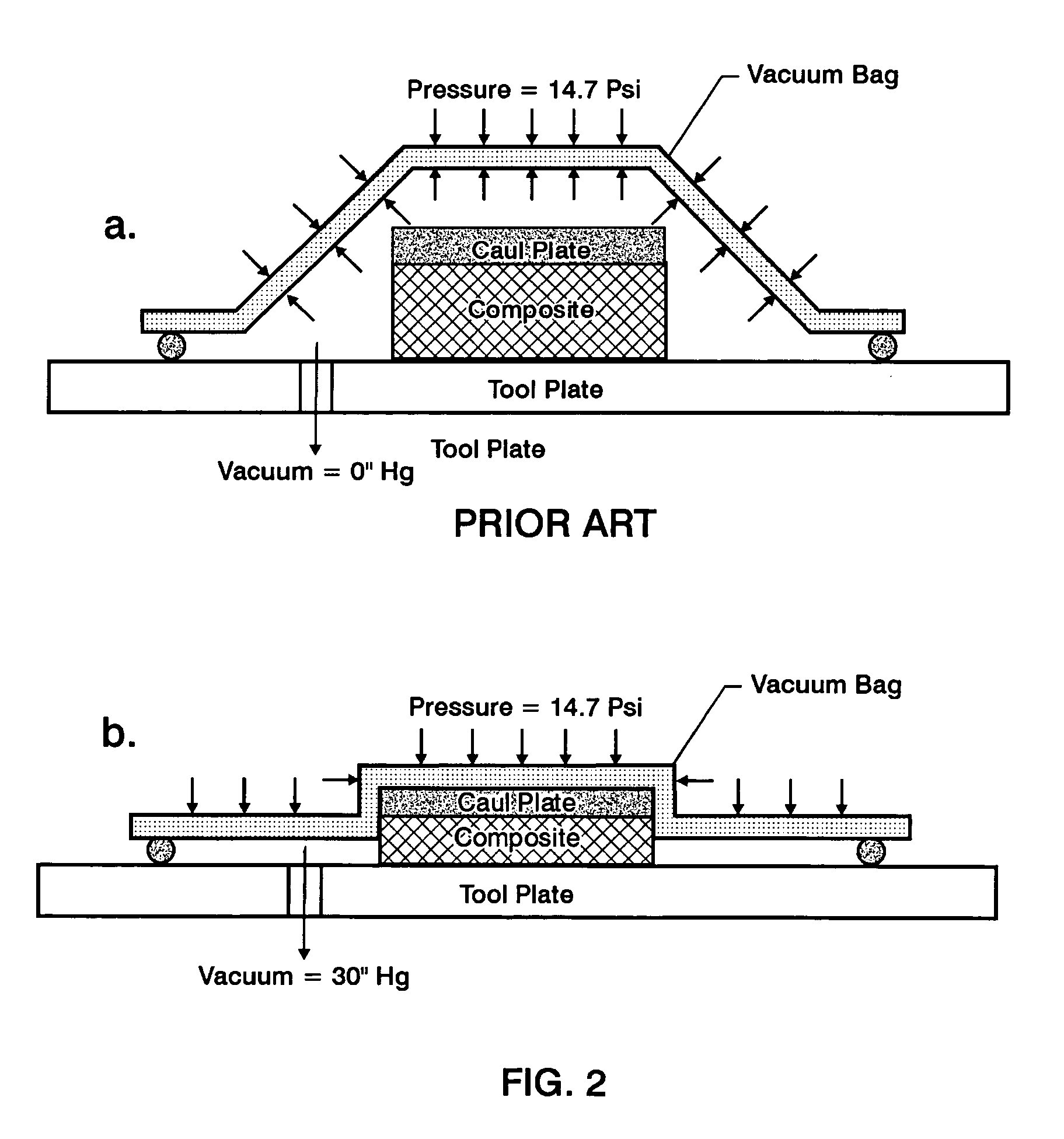

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

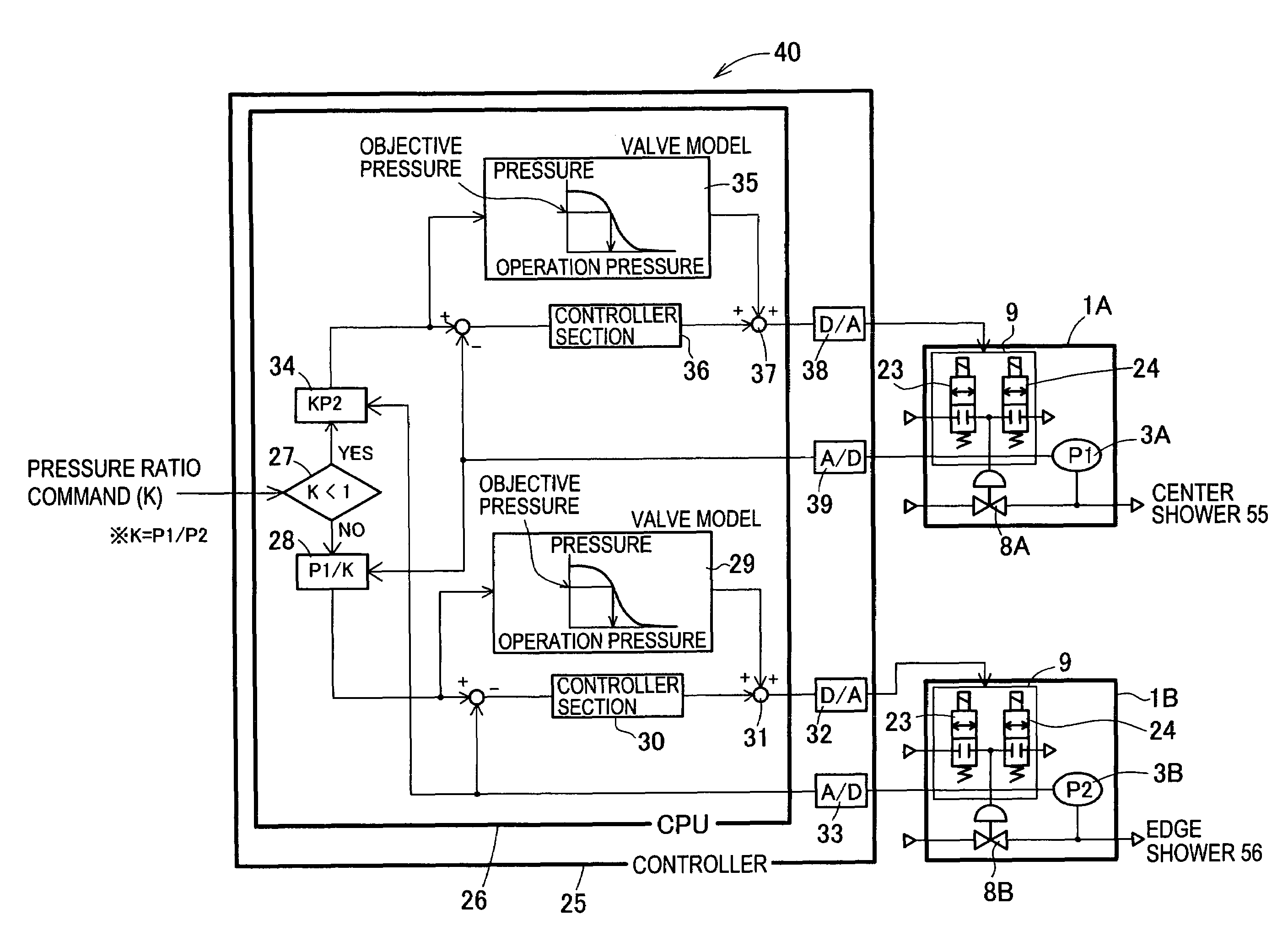

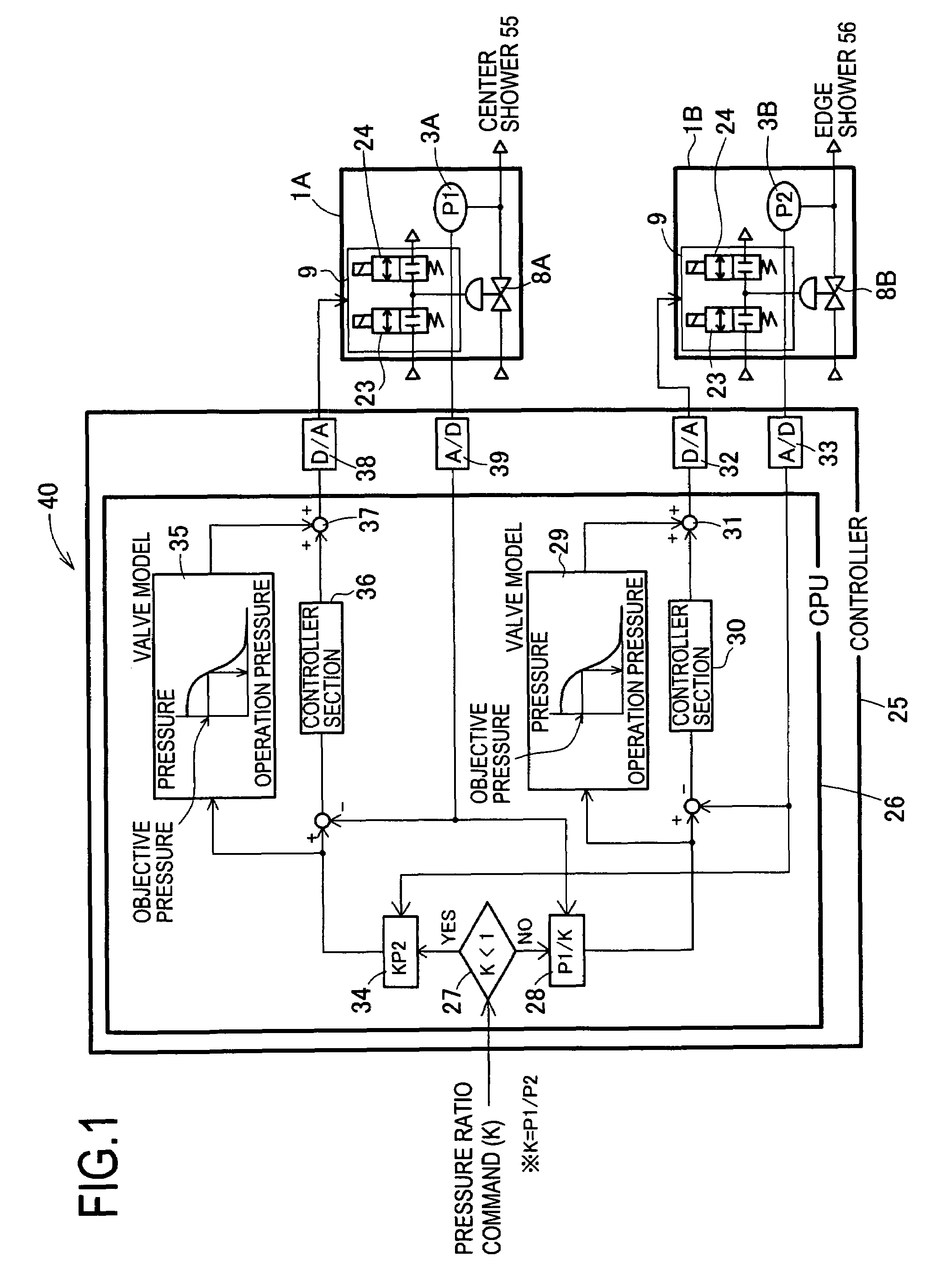

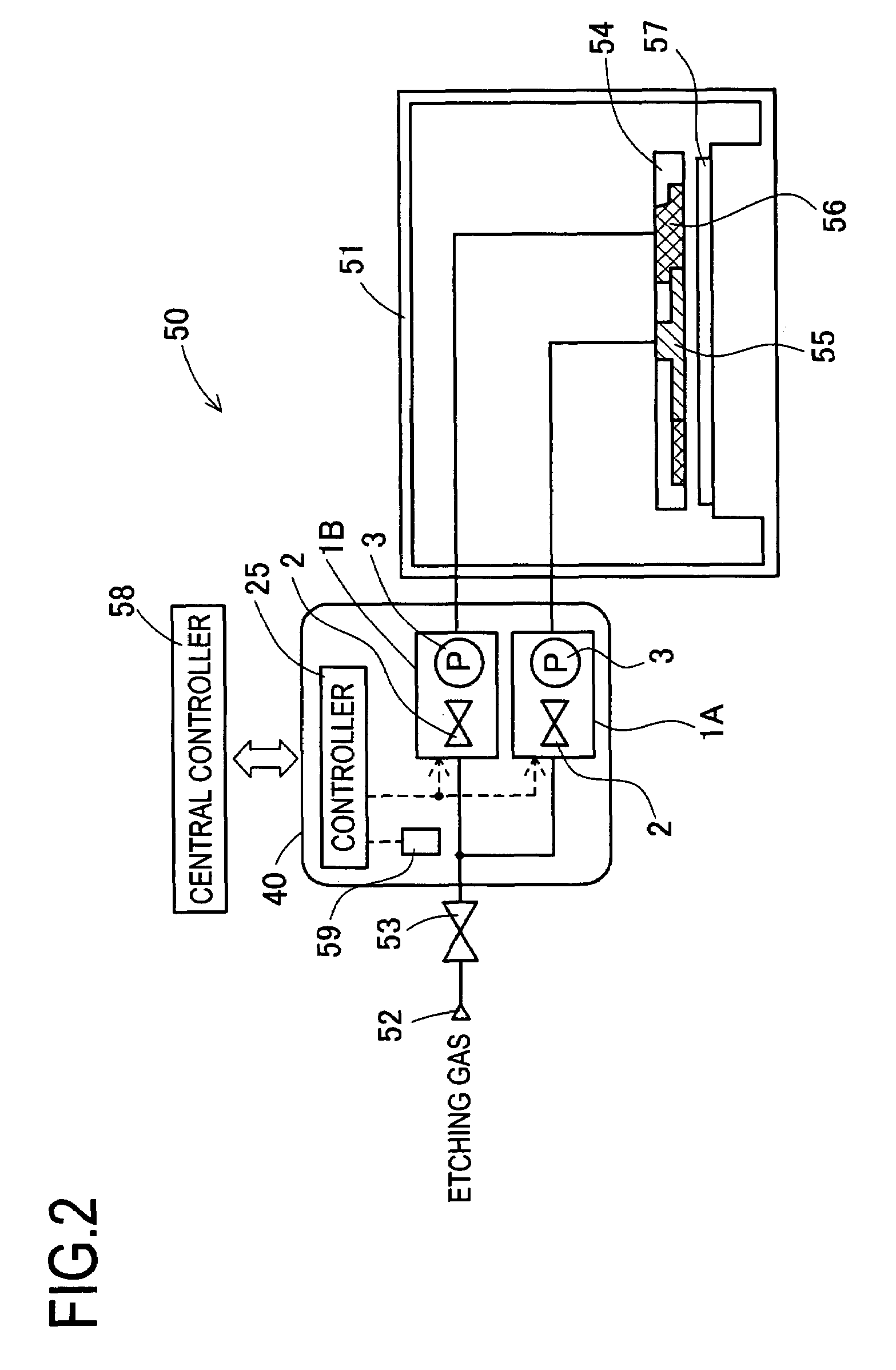

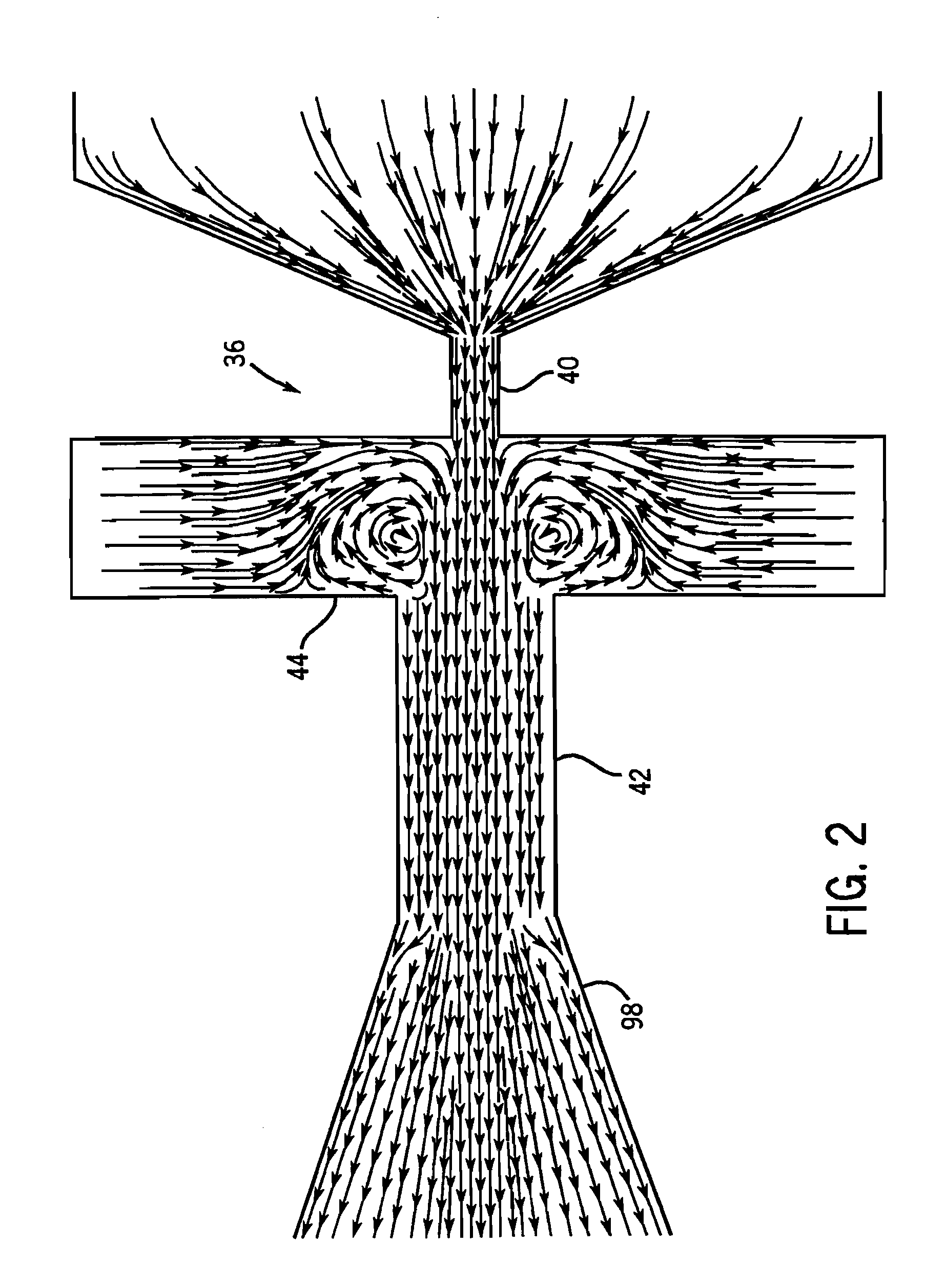

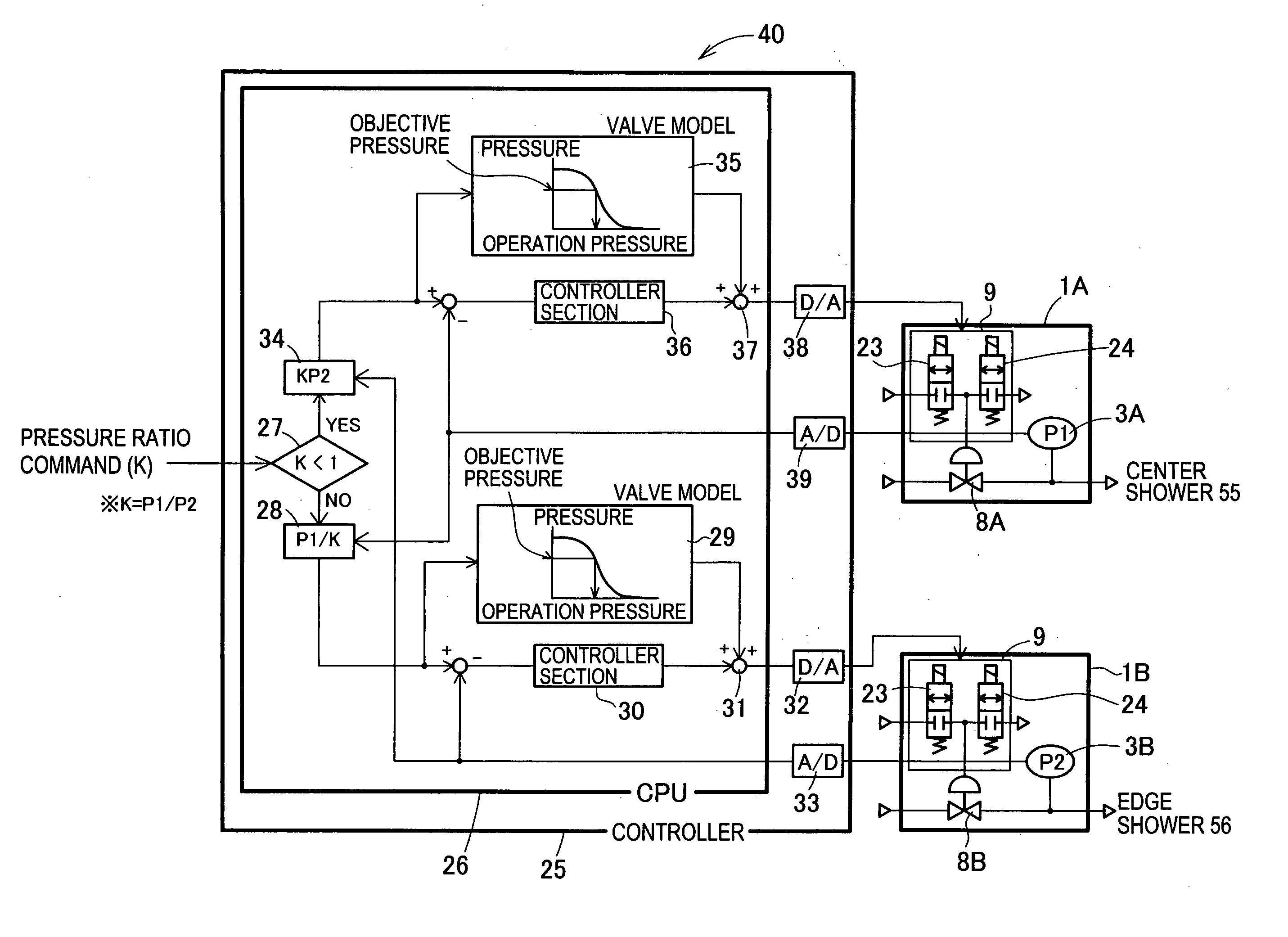

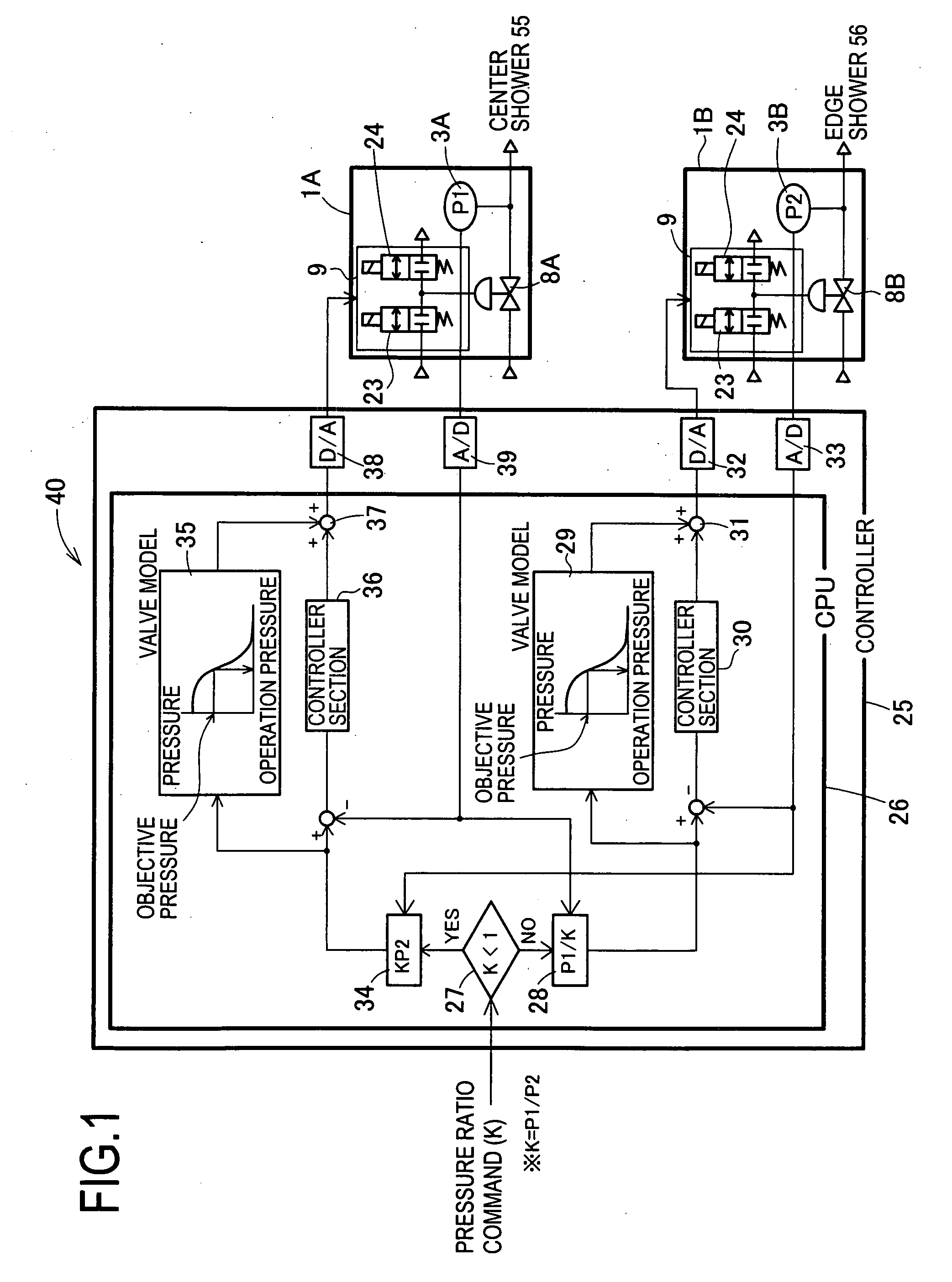

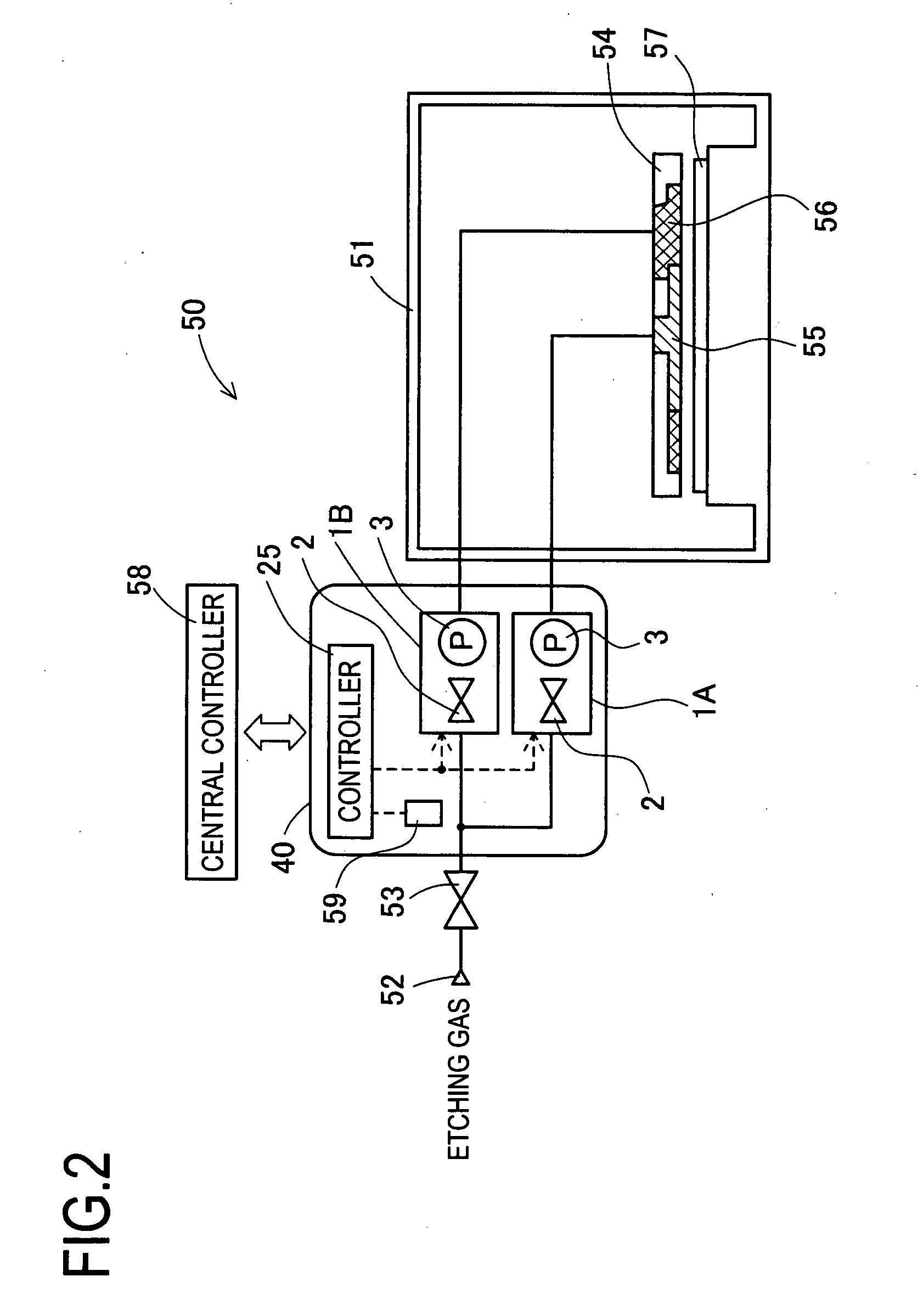

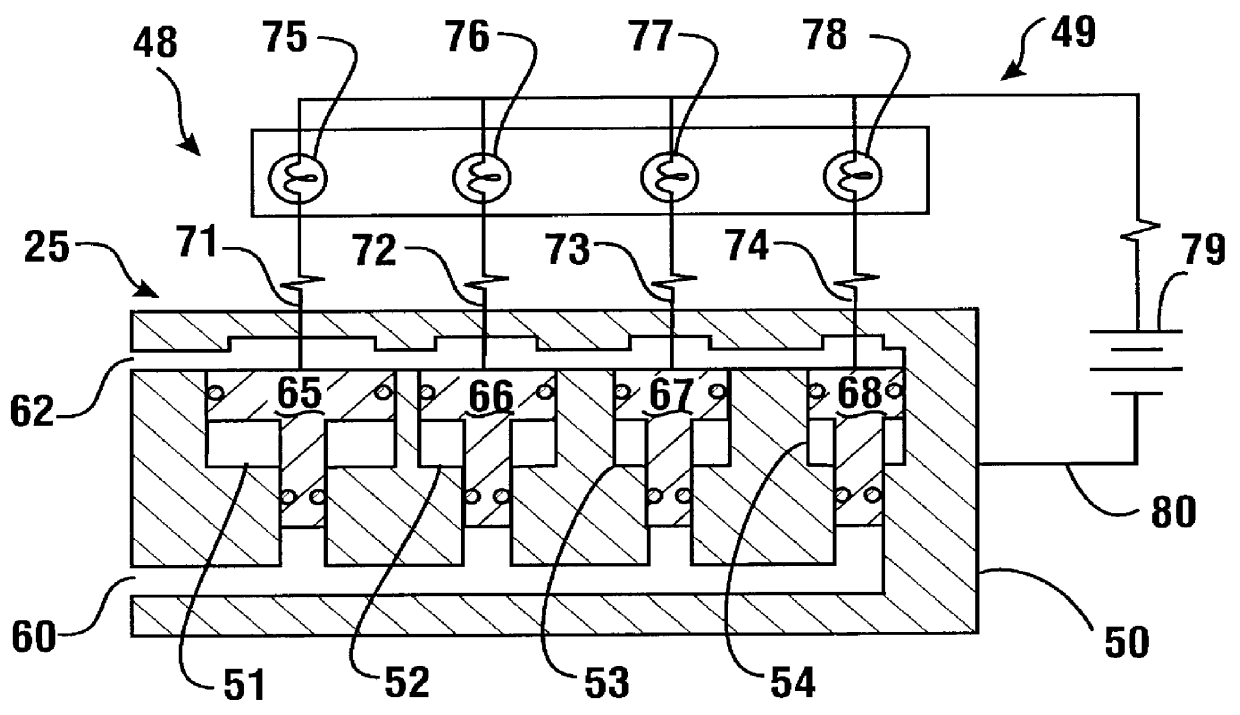

Relative pressure control system and relative flow control system

ActiveUS7353841B2Accurate supervisionReduce the amount of controlOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsRelative pressureSolenoid valve

Provided is a relative pressure control system has a simple configuration, but enables accurate regulation of a division ratio of an operation gas, and concurrently makes it possible to securely drain the operation gas from an operation gas pipeline in case of emergency. The system includes a plurality of air operated valves of a normally open type that are connected to an operation gas pipeline supplied with an operation gas; pressure sensors that are series connected to the respective air operated valves and that detect output pressures of the respective air operated valves; a controller that controls operation pressures of the respective air operated valves in accordance with the pressures detected by the pressure sensors; and a hard interlock solenoid valve that correlates the plurality of air operated valves to one another so that at least one of the plurality of air operated valves is normally opened. In the configuration, an opening of a specified one of the plurality of air operated valves is regulated, the operation gas is output at a predetermined division ratio.

Owner:CKD +1

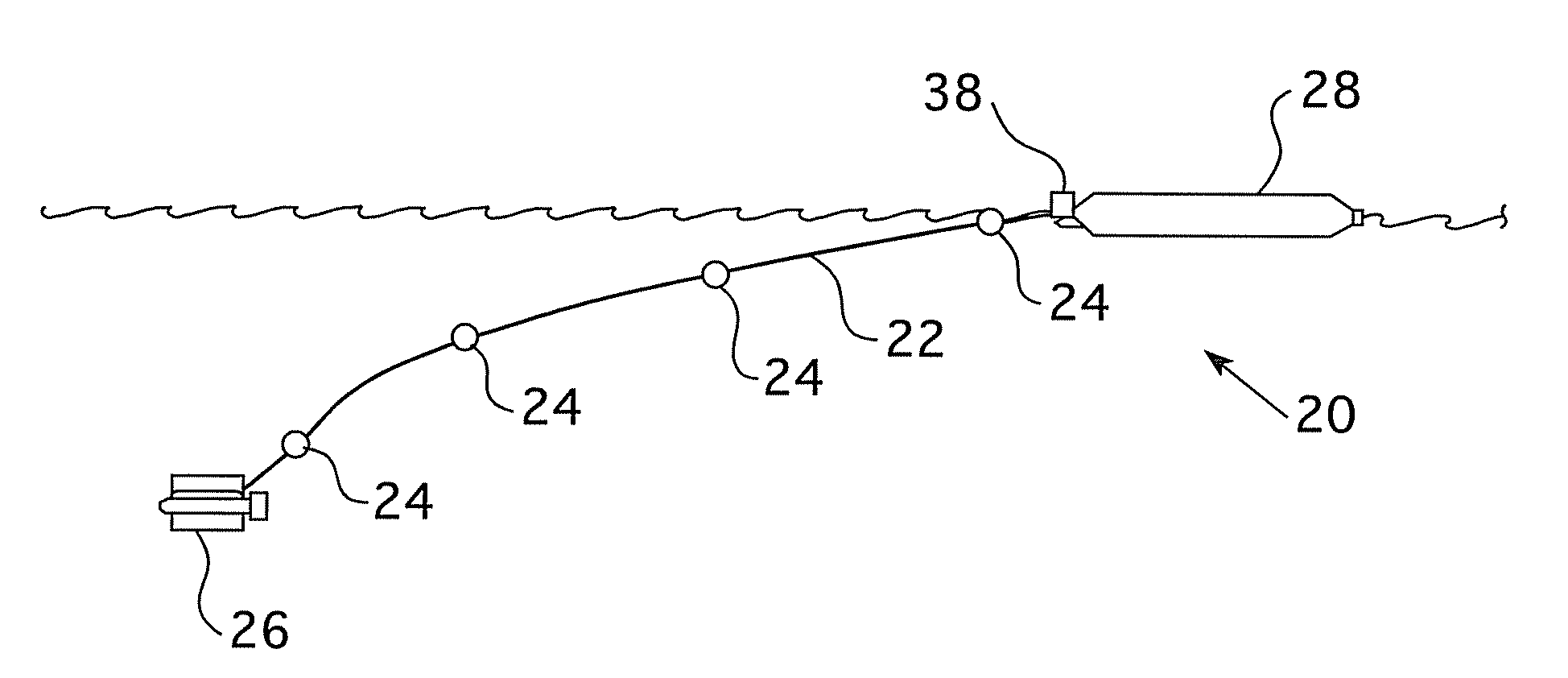

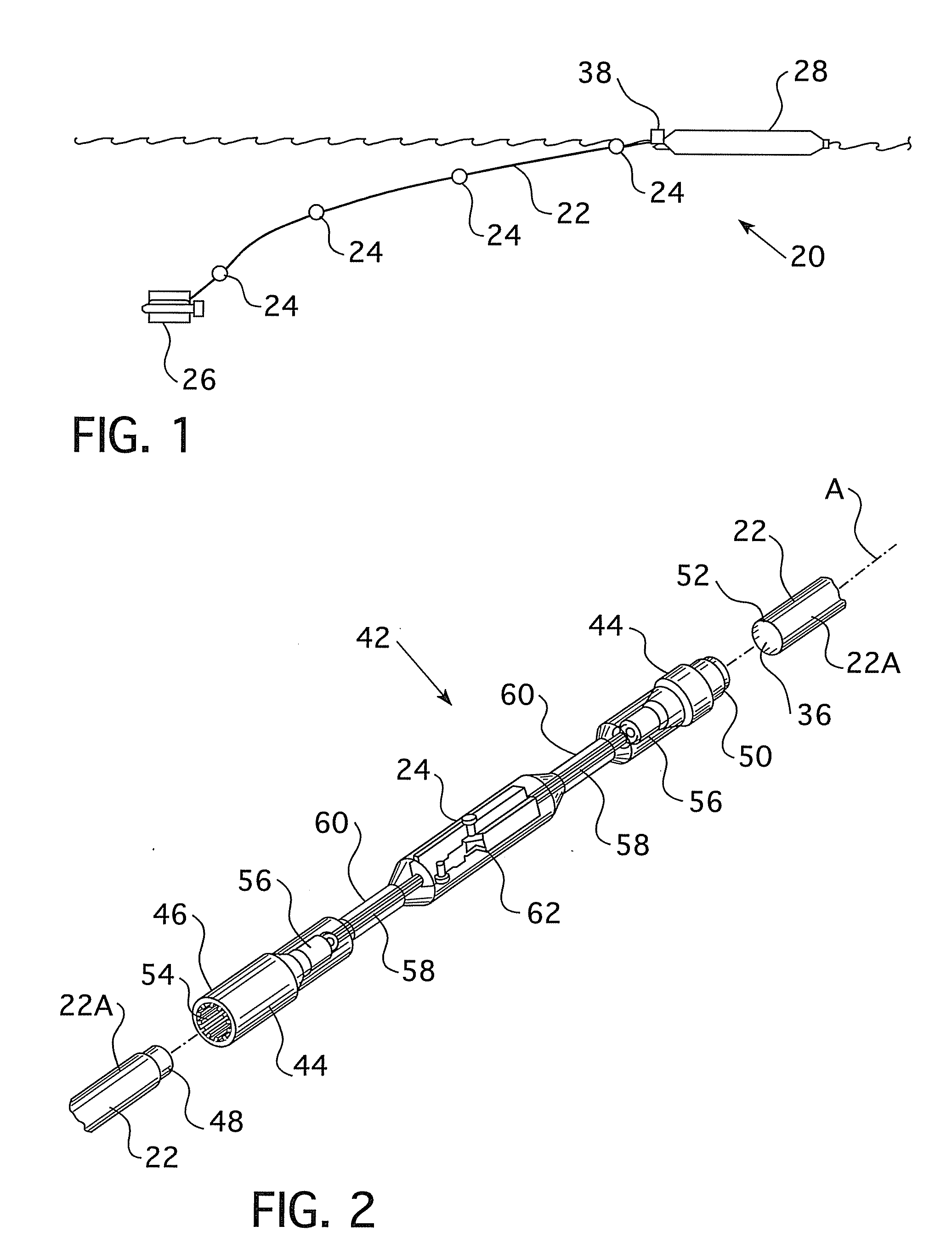

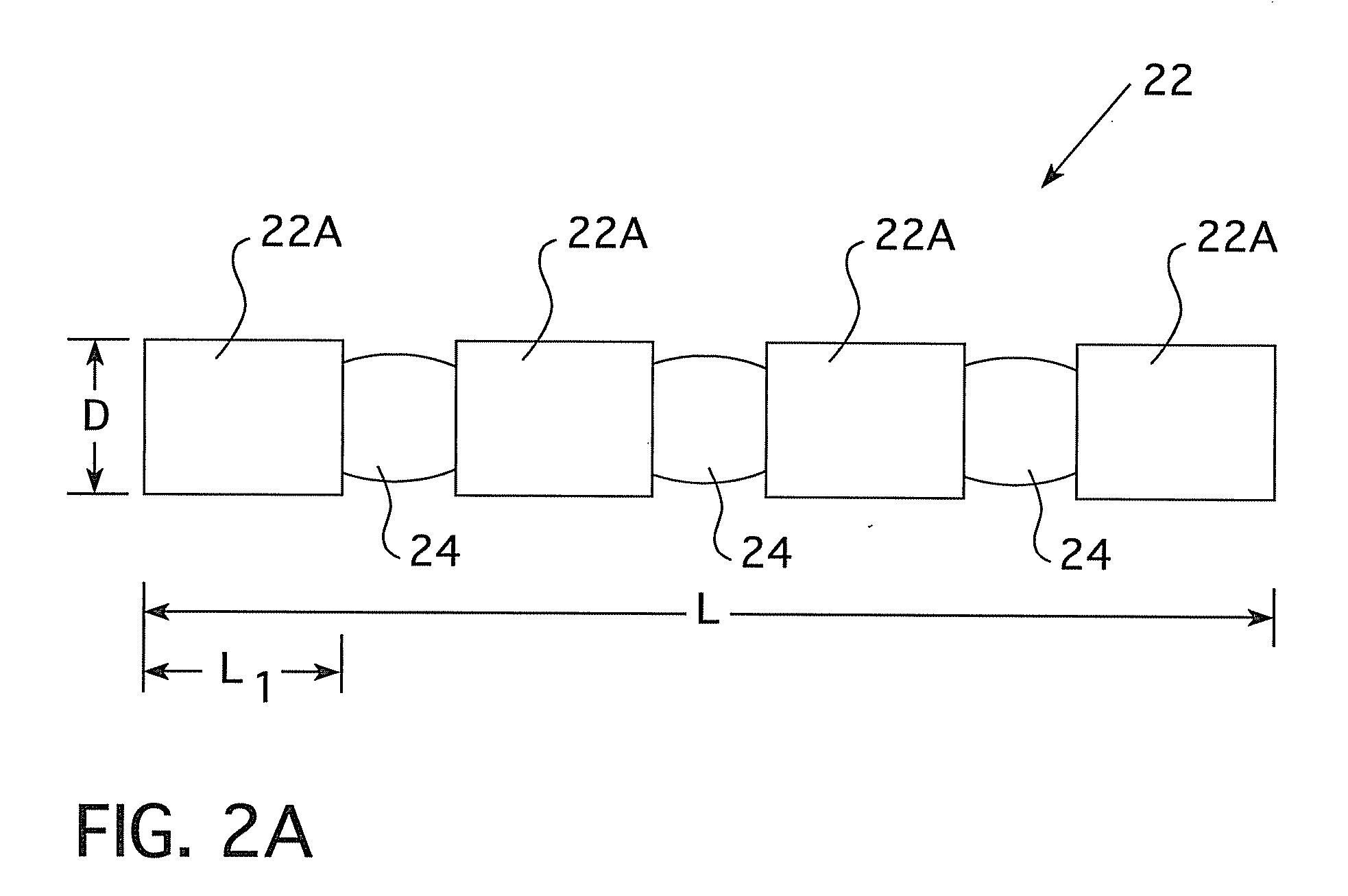

Smart tether system for underwater navigation and cable shape measurement

ActiveUS20080300821A1Digital computer detailsMechanical clearance measurementsRelative pressureUnderwater navigation

A position sensing system including a flexible tether and at least one sensor at least partially embedded within a portion of the flexible tether is disclosed. The sensor may be adapted to detect a sensor position factor. The system also includes a communication device adapted to transmit the sensor position factor from the sensor, and a signal processor adapted to receive the sensor position factor. The signal processor is also adapted to calculate at least one of the shape or orientation of the flexible tether from the sensor position factor. The sensor position factor may be relative orientation, relative depth, relative pressure, presence of a magnetic field, presence of an electric field, acceleration, or relative rate of rotation. The system may also include a probe connected to the flexible tether, and the signal processor may calculate the orientation of the probe from the sensor position factor.

Owner:KCF TECHNOLOGIES

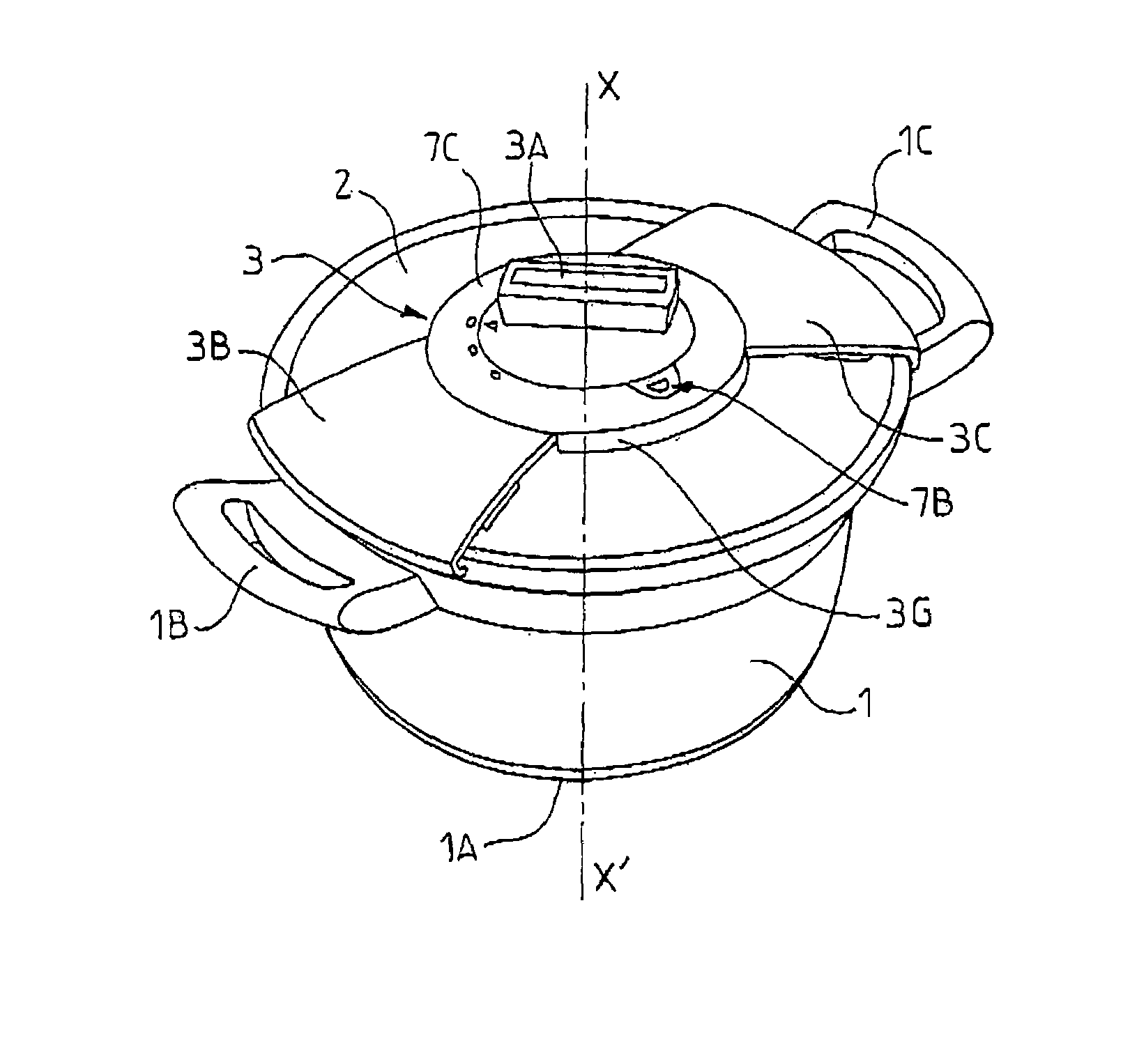

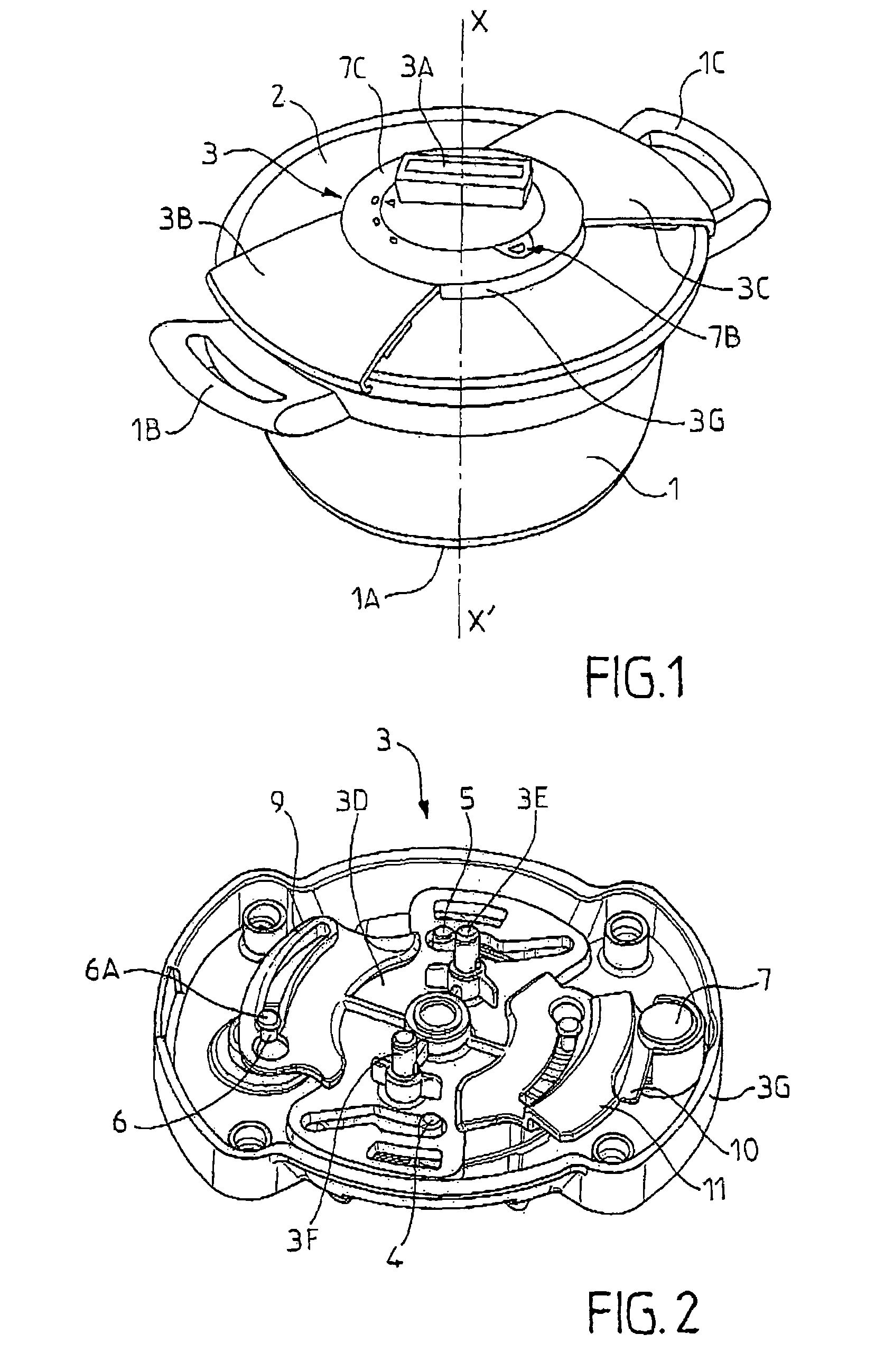

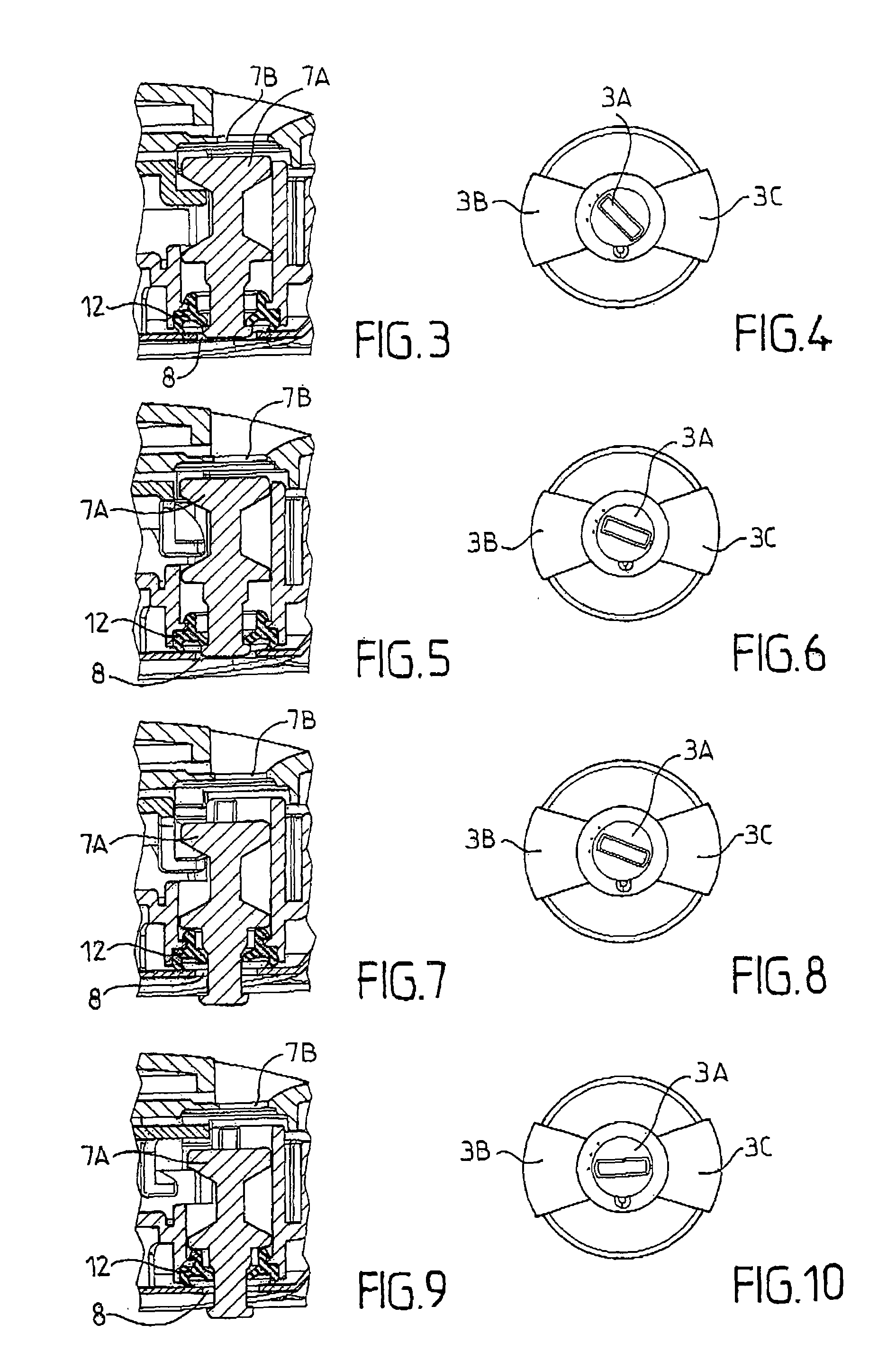

Appliance for cooking food under pressure

InactiveUS7322280B2Easy to openRaise security concernsPressure-cookersDeep fat fryersRelative pressureHome appliance

Owner:SEB SA

Dynamic knee balancer with pressure sensing

InactiveUS8758355B2Accelerated programDesired stability and range of motion and patellar trackingJoint implantsSurgical robotsTibiaRelative pressure

A device for performing a surgical procedure on a knee includes an adjustable femoral portion, a tibial portion and at least one sensor coupled with the femoral and / or tibial portions to sense pressure exerted by the a moral and tibial portions against one another. The femoral portion is adapted for removably coupling with a distal end of a femur to adjust tension in soft tissue adjacent the knee and has at least one positioning feature adapted to move relative to the distal end of the femur as the femoral portion is adjusted, thus helping position a femoral prosthetic on the distal end of the femur. The sensor(s) may be adapted to sense pressure at medial and lateral sides of the knee, and relative pressures may be displayed as data on a visual display. Adjustments to the femoral member may be made to balance pressure at flexion and extension of the knee.

Owner:SYNVASIVE TECH

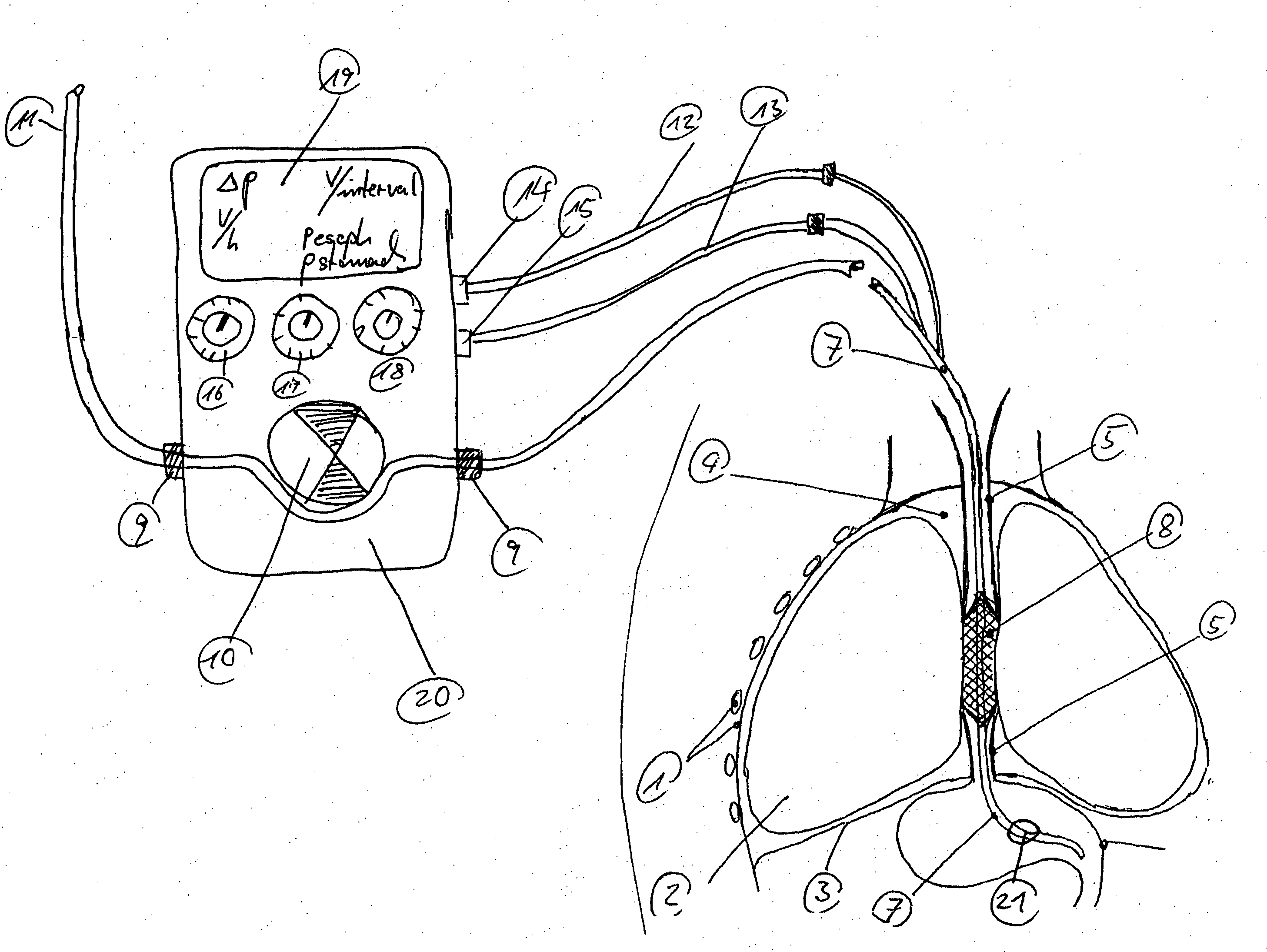

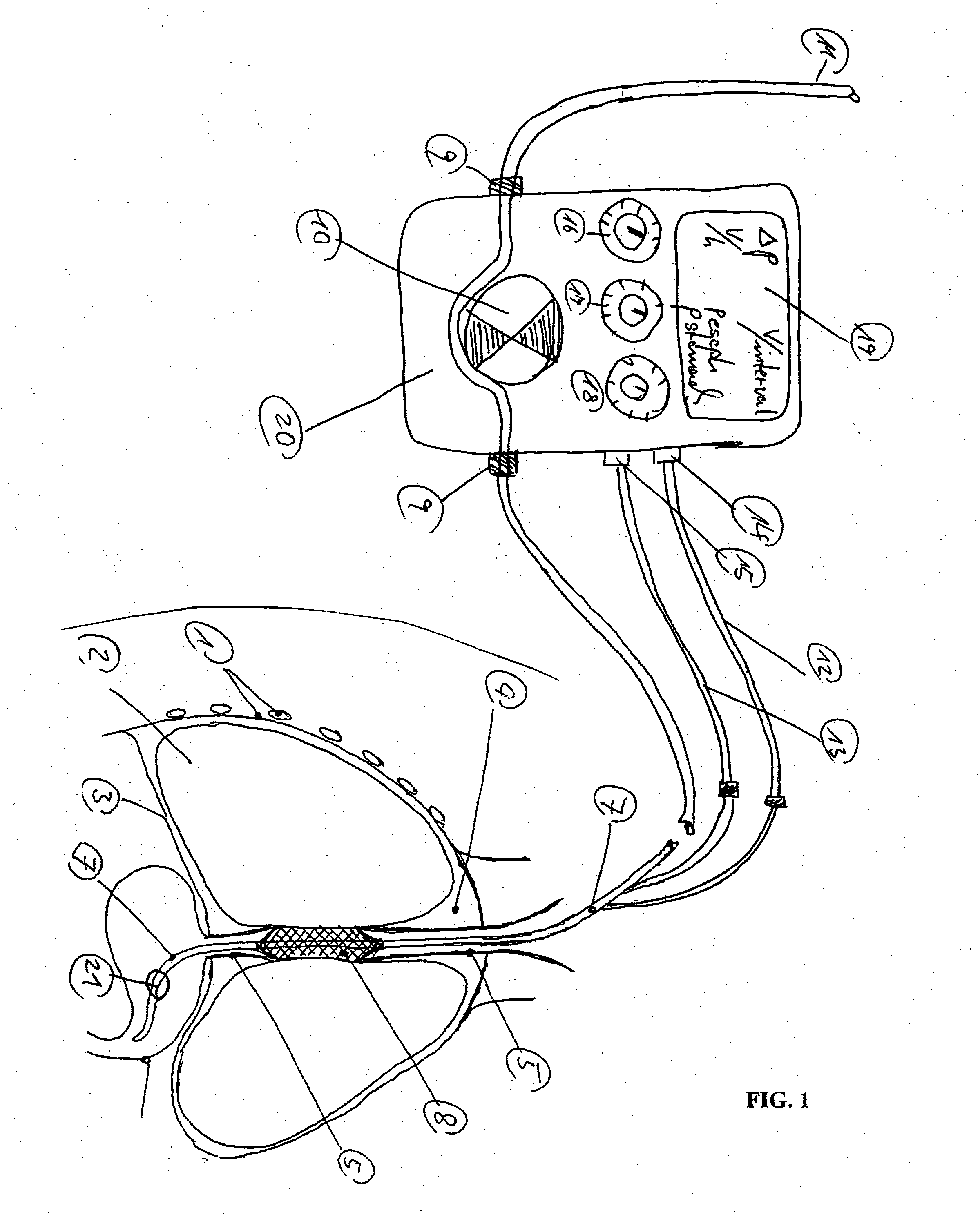

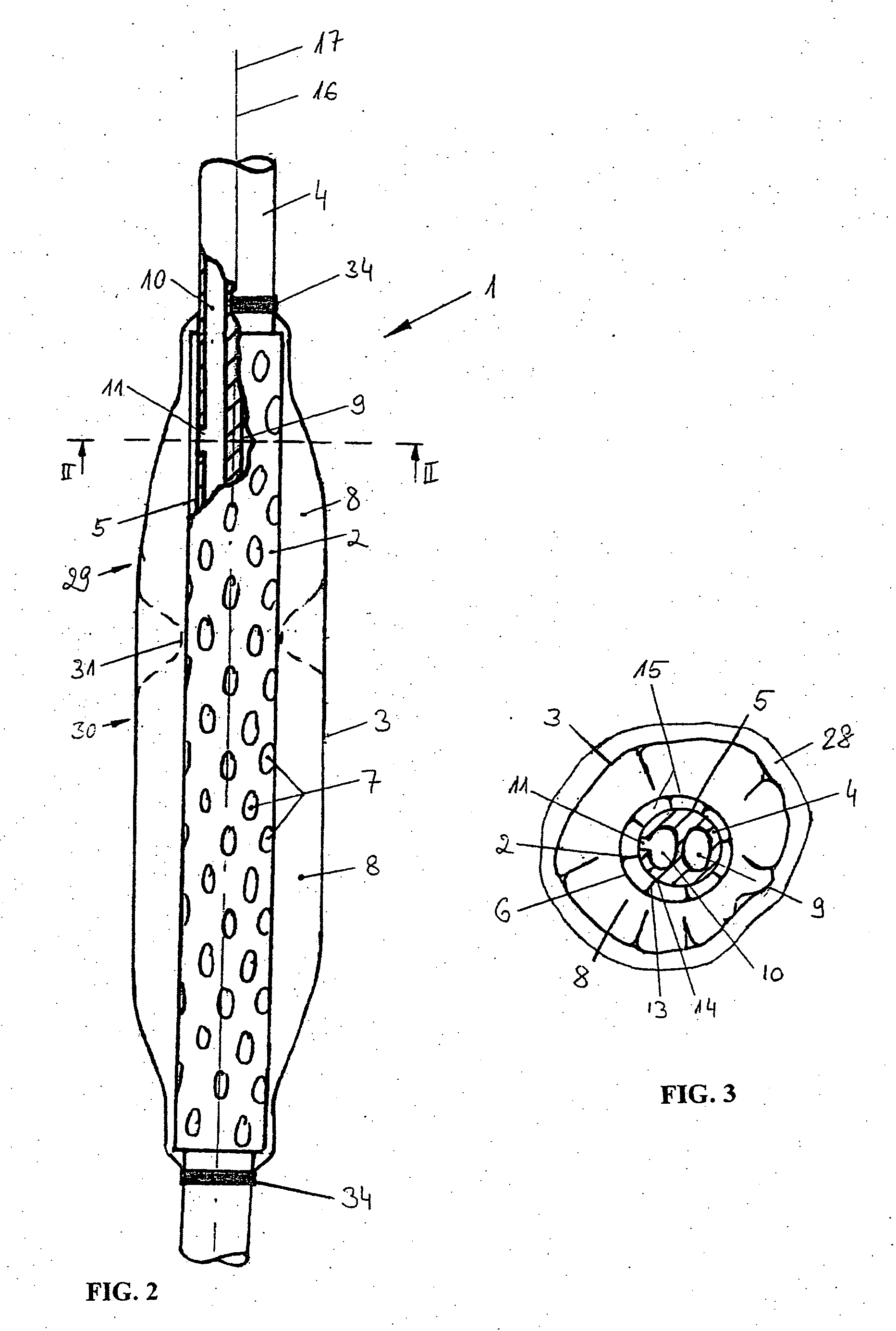

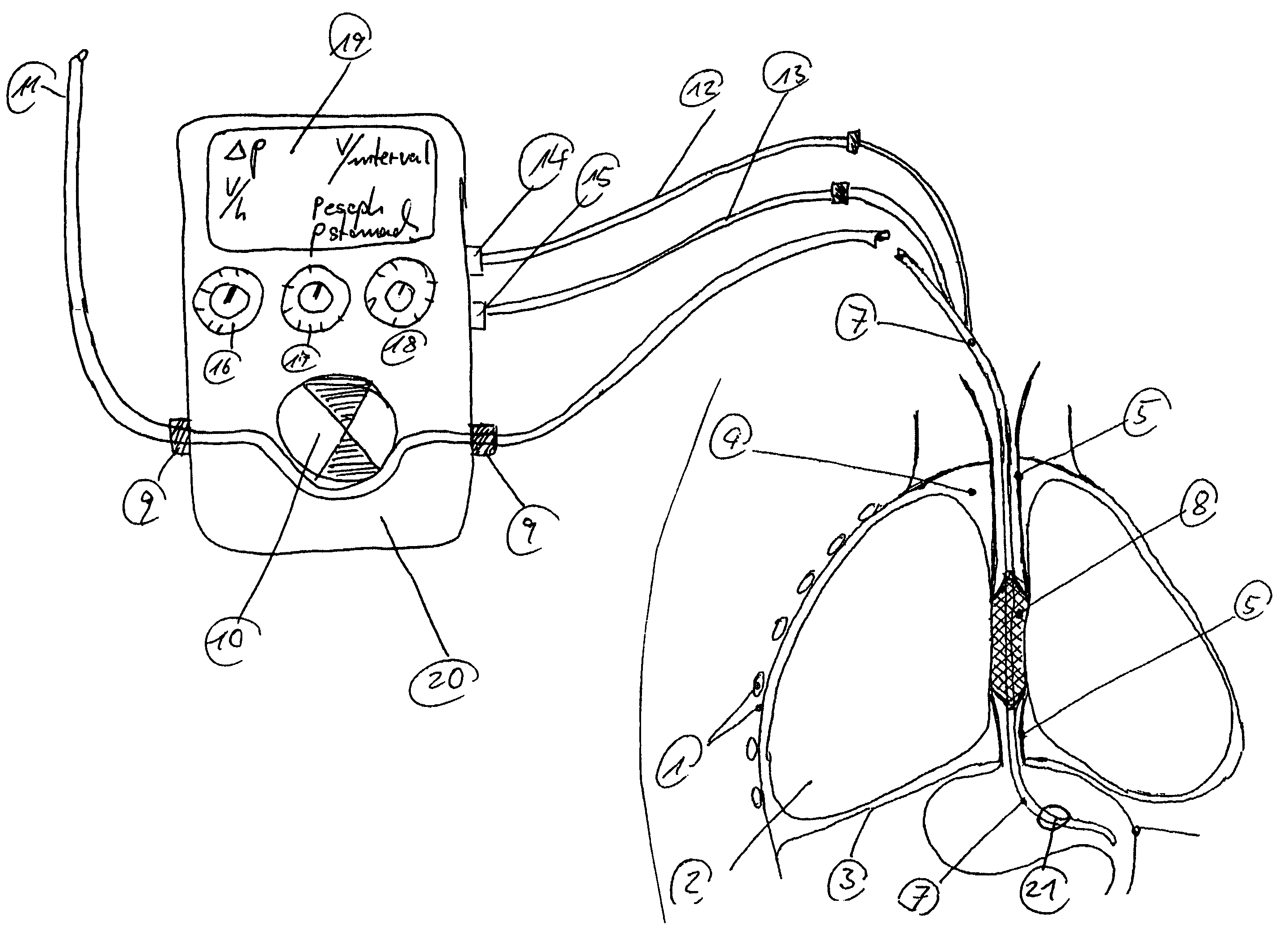

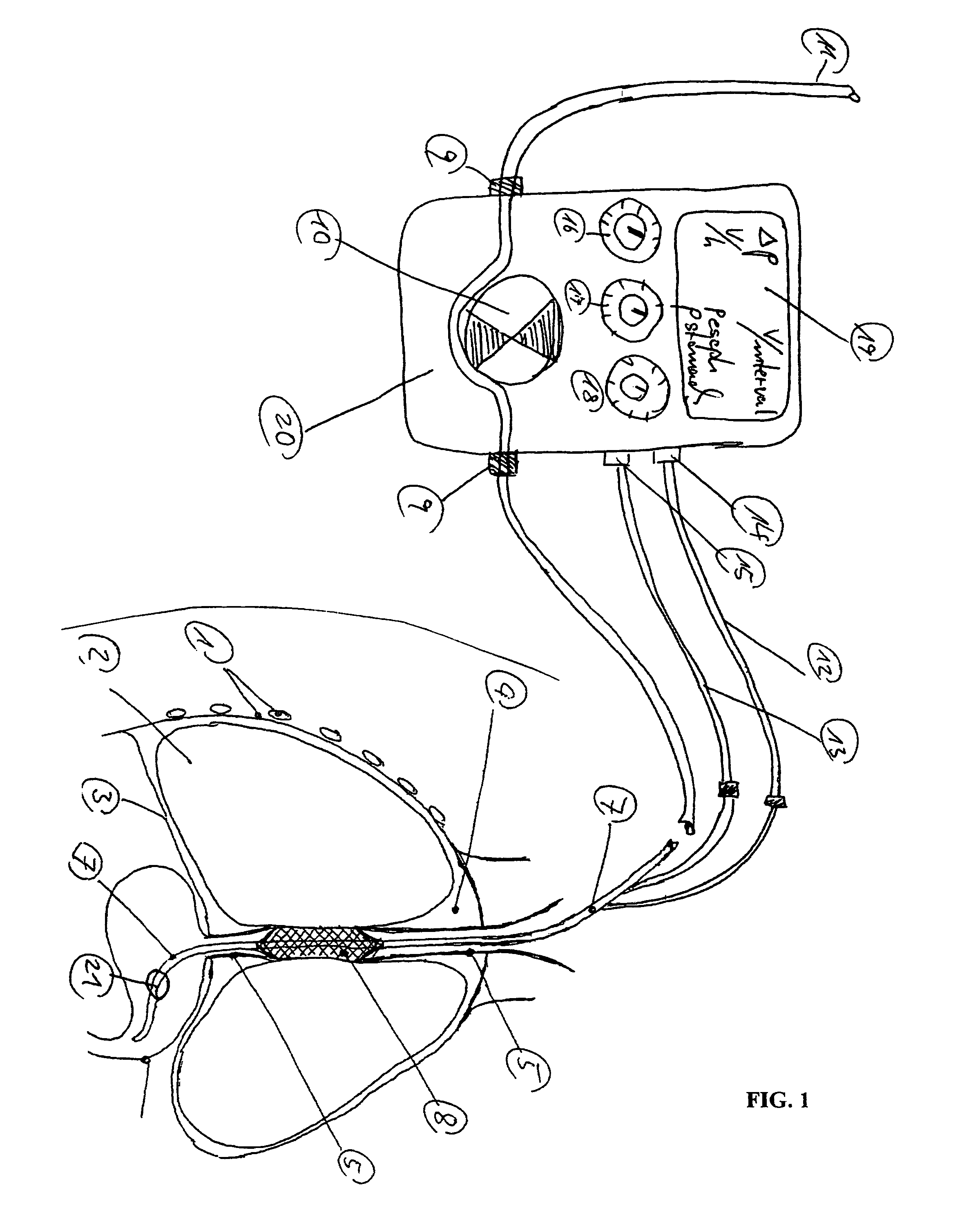

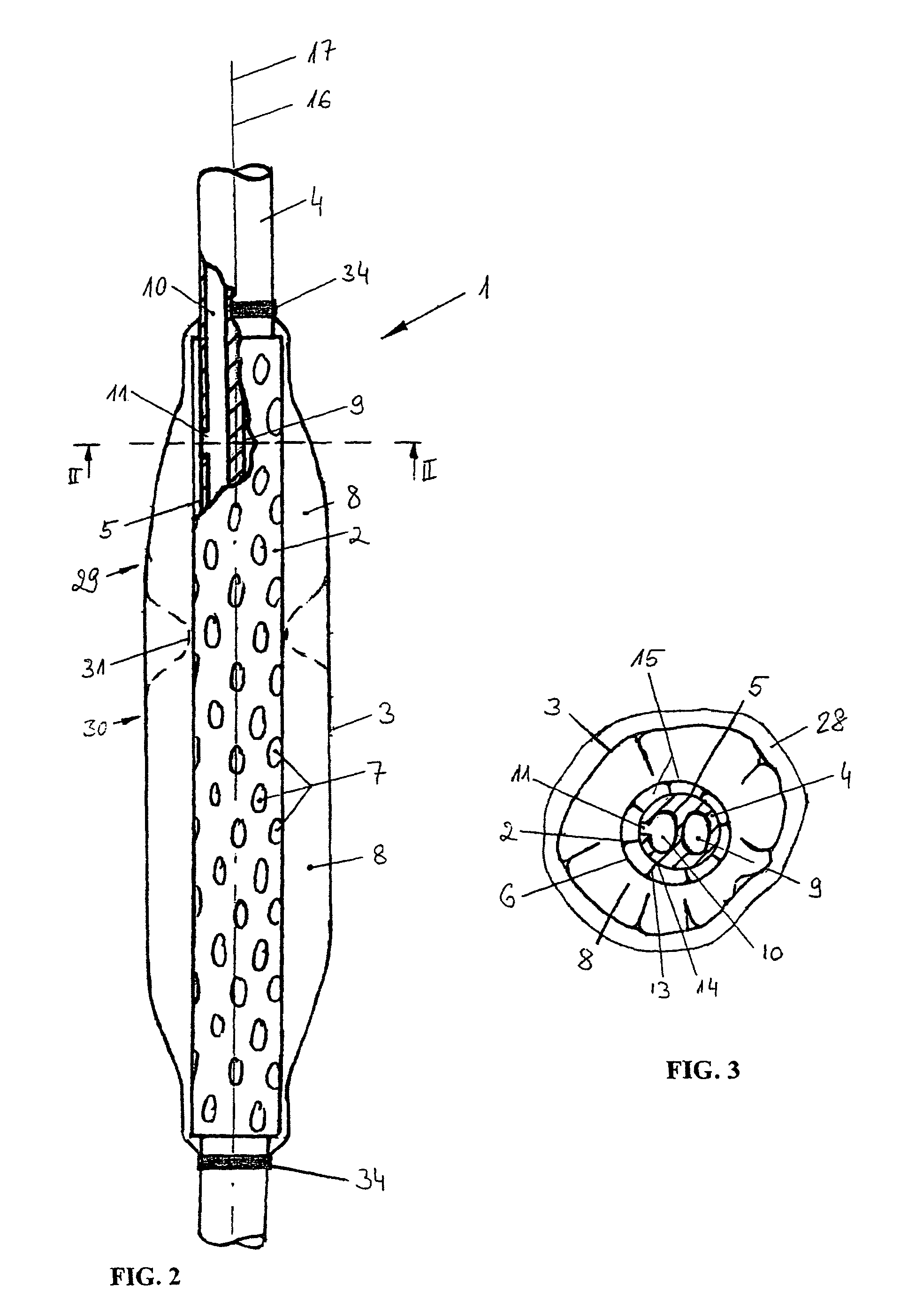

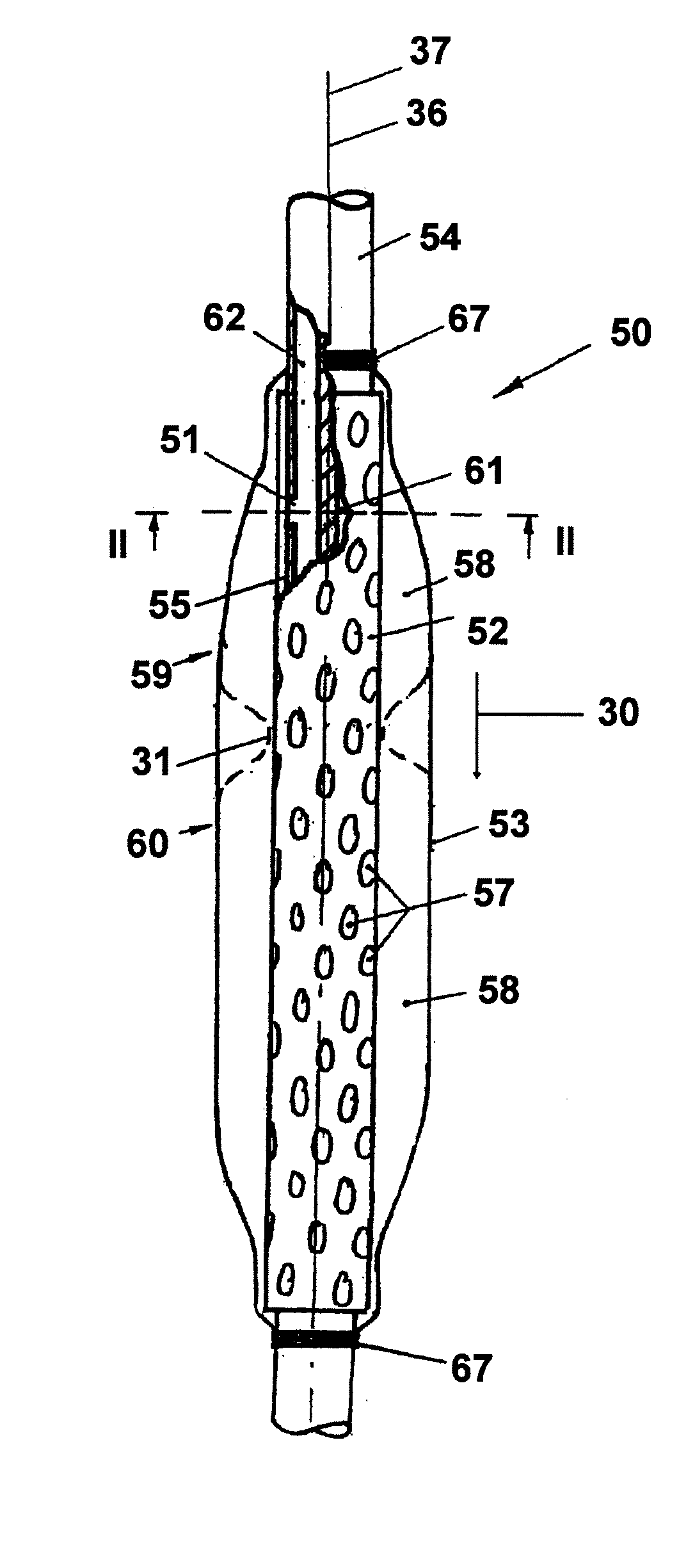

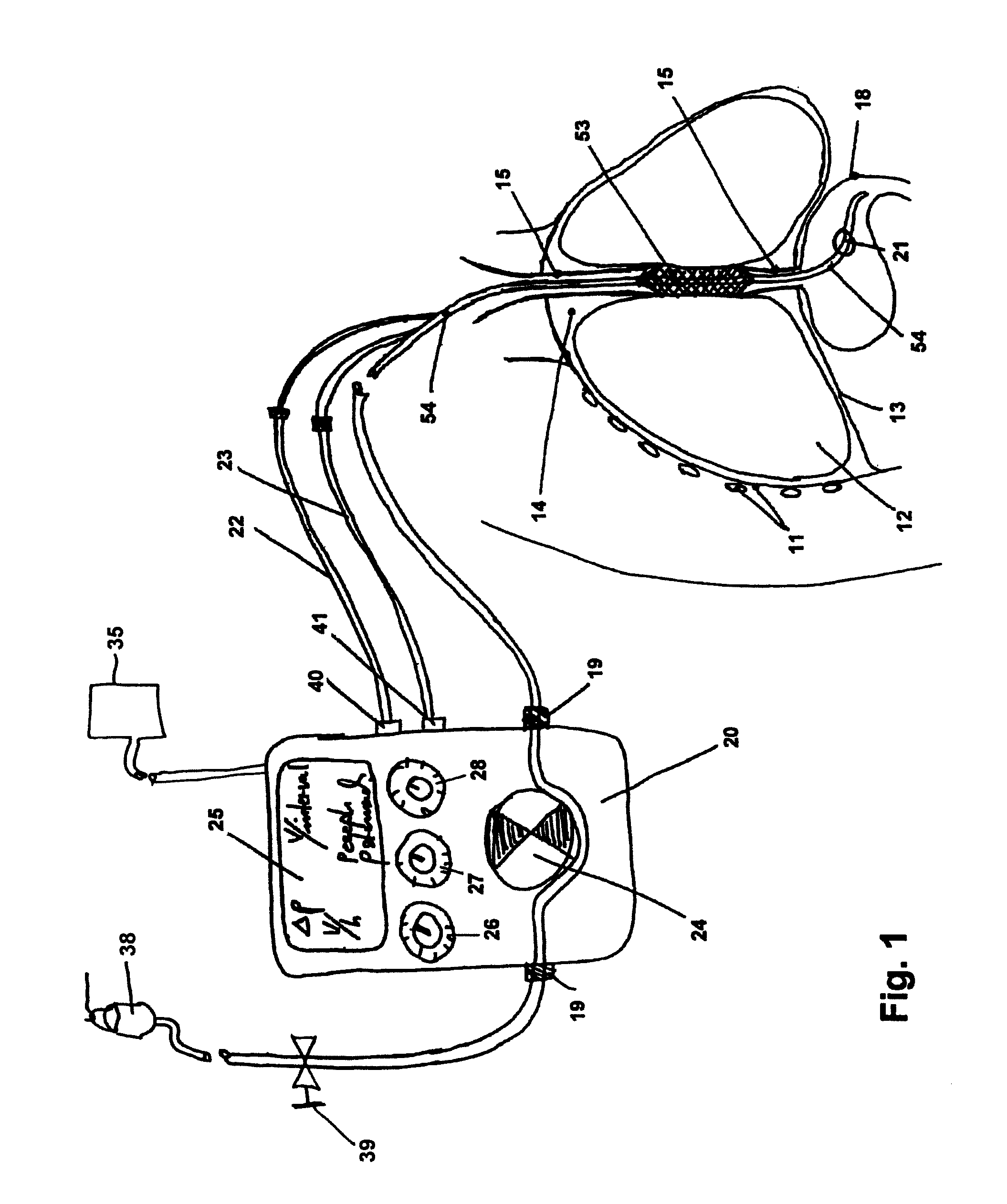

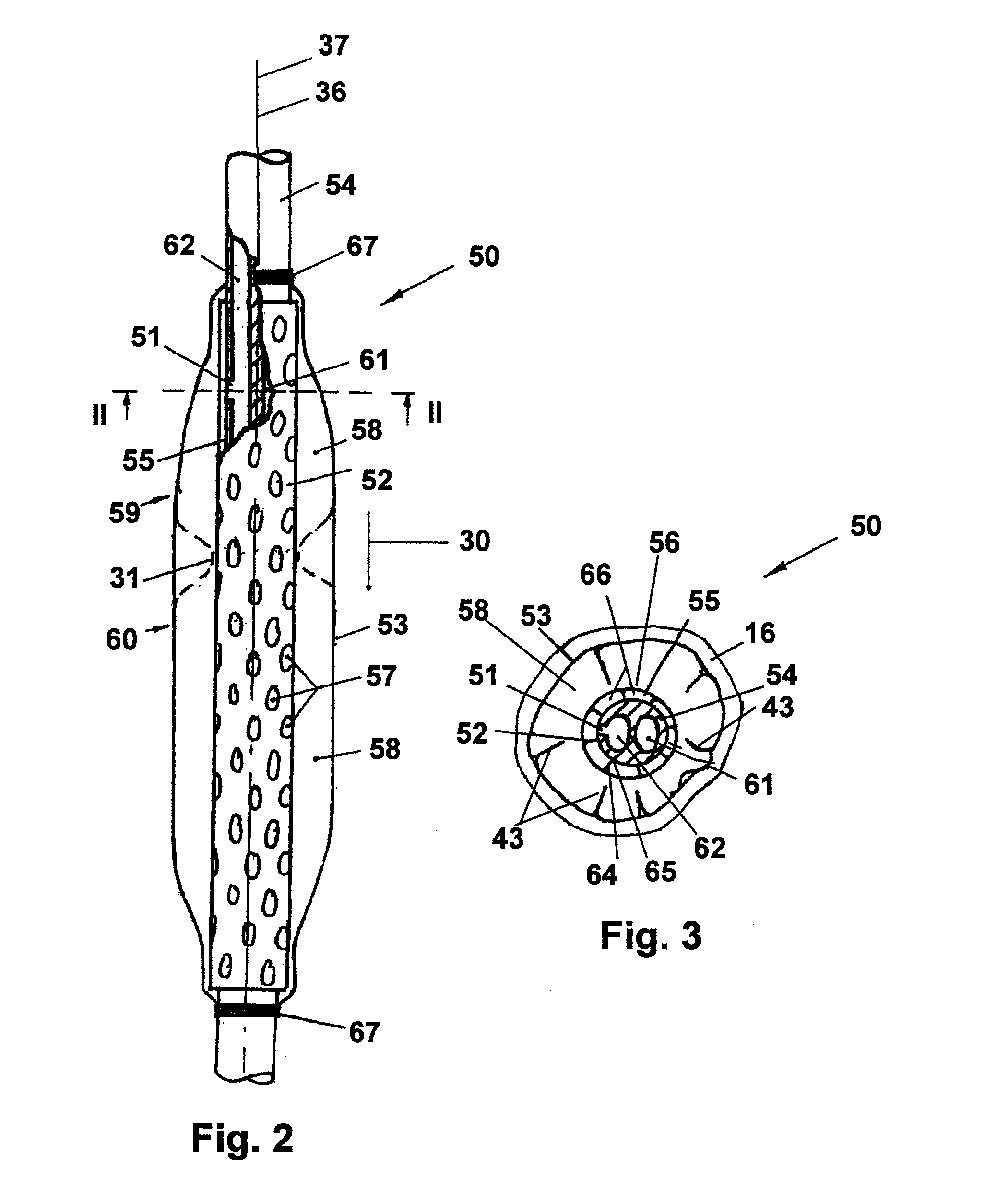

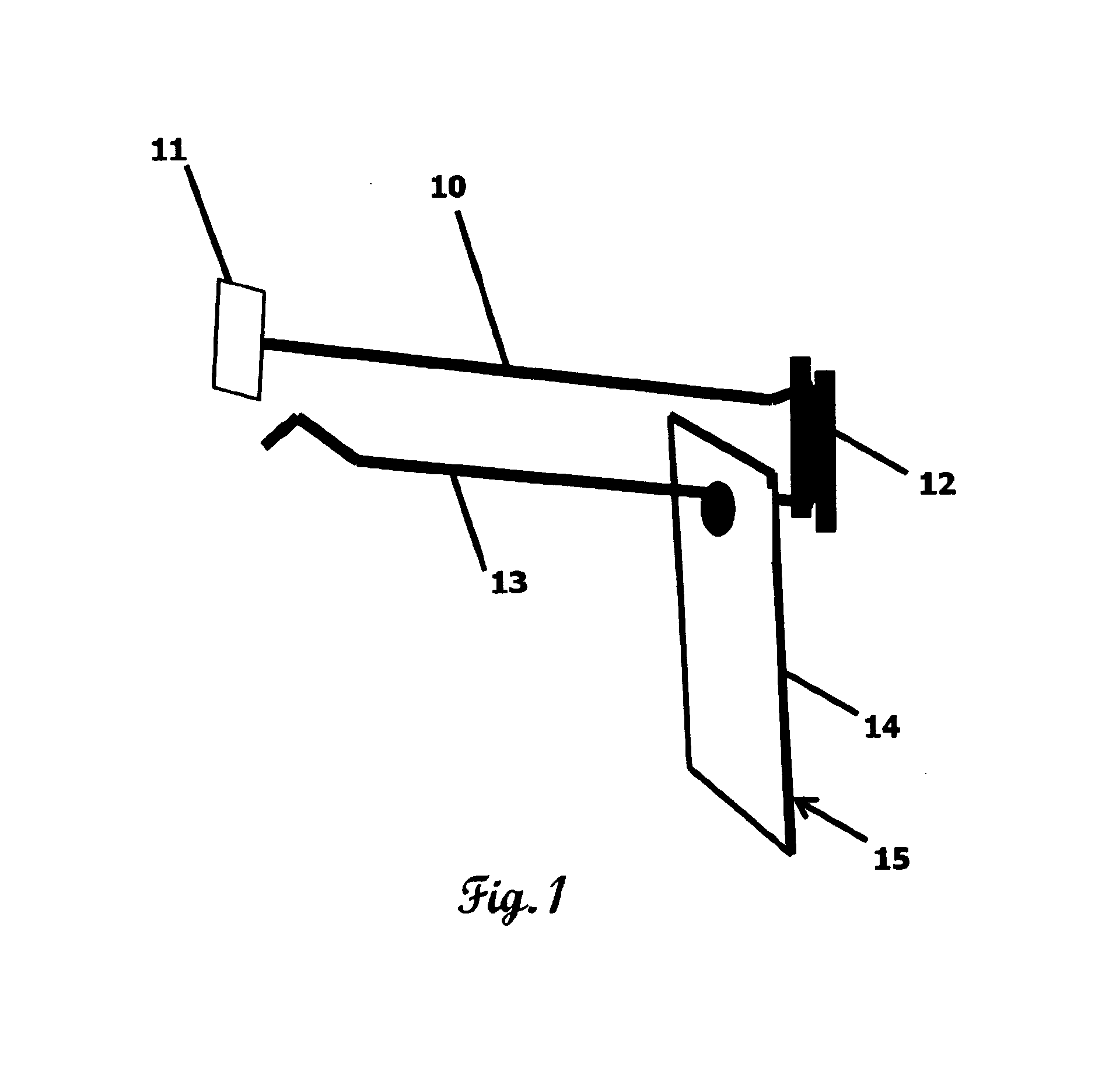

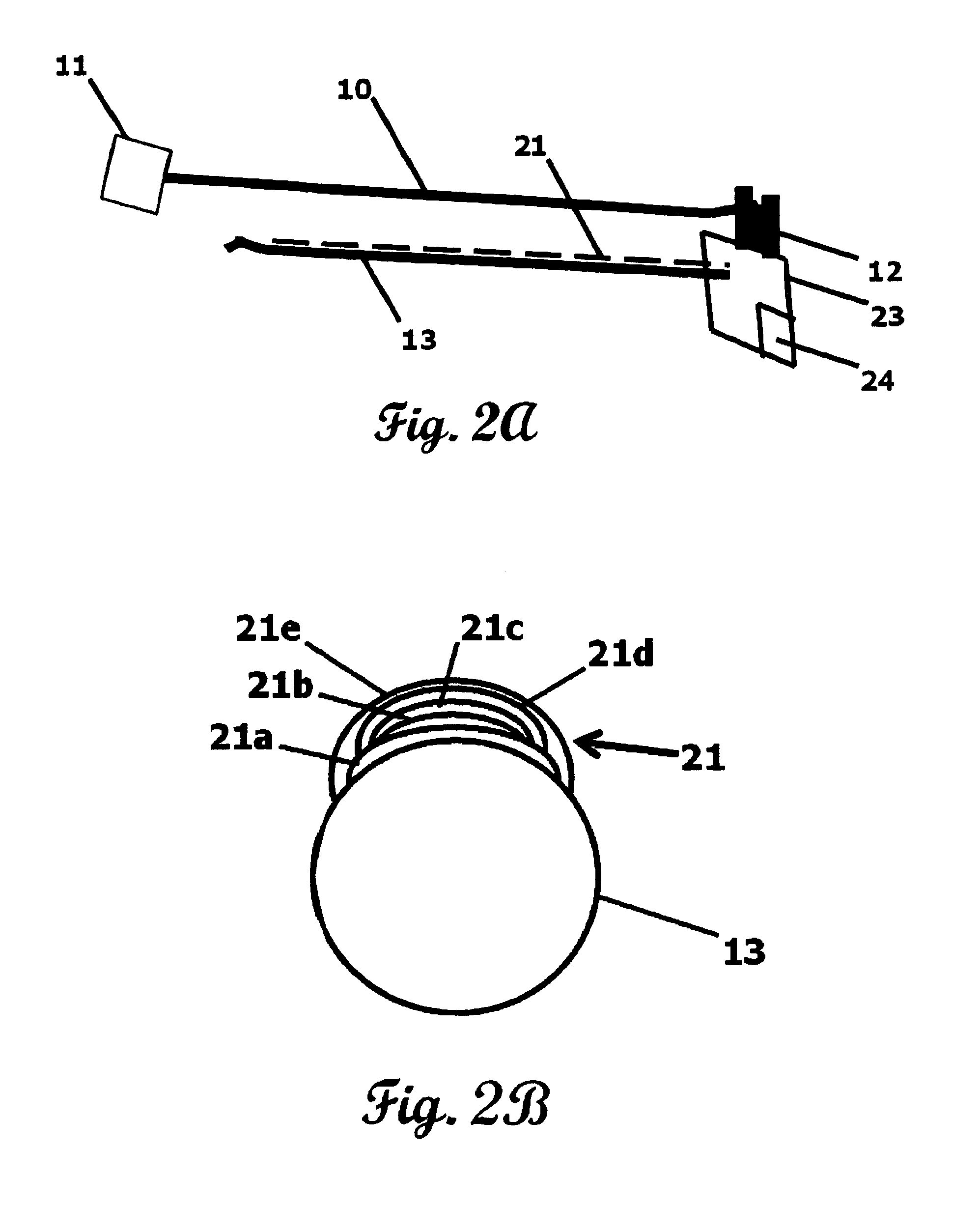

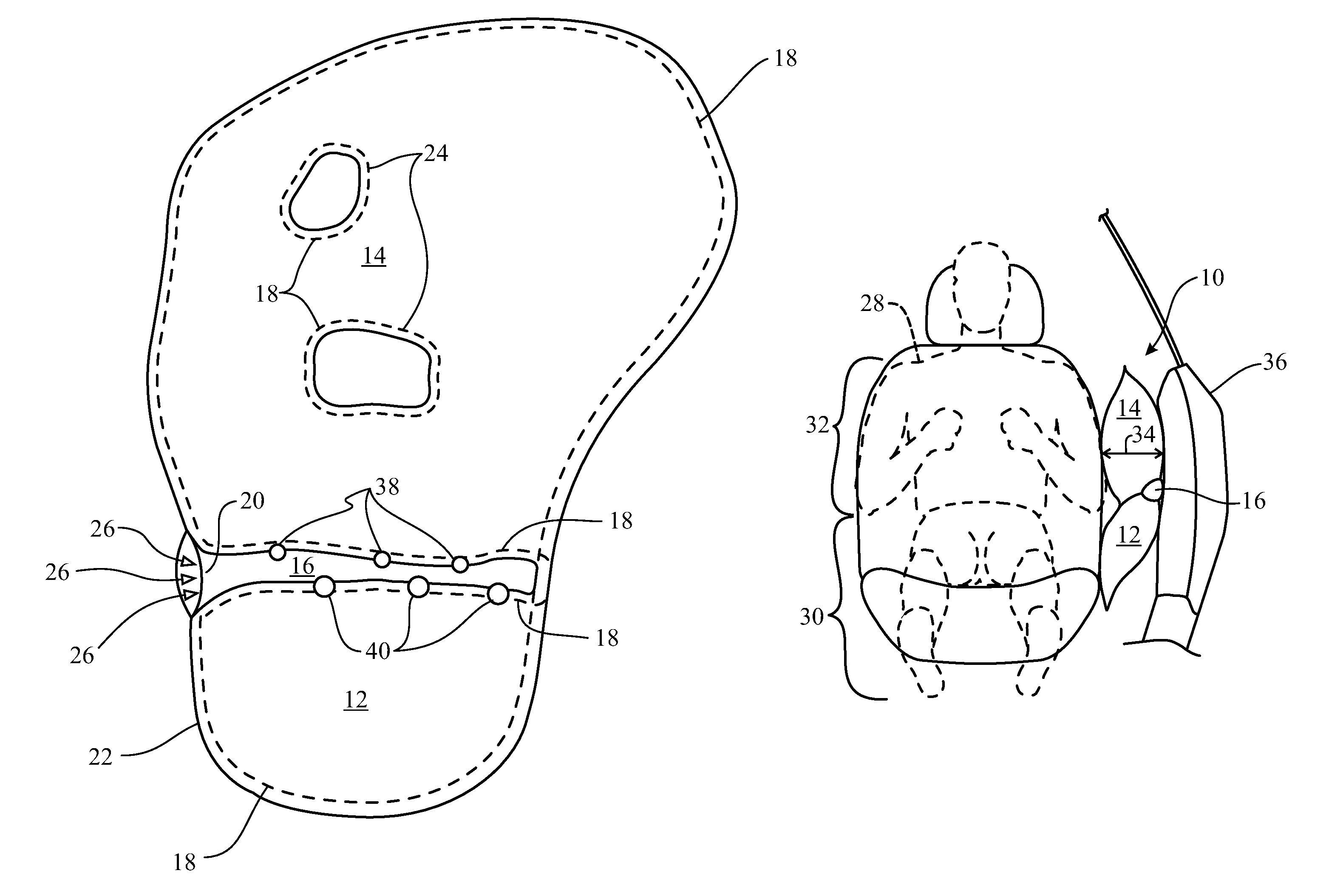

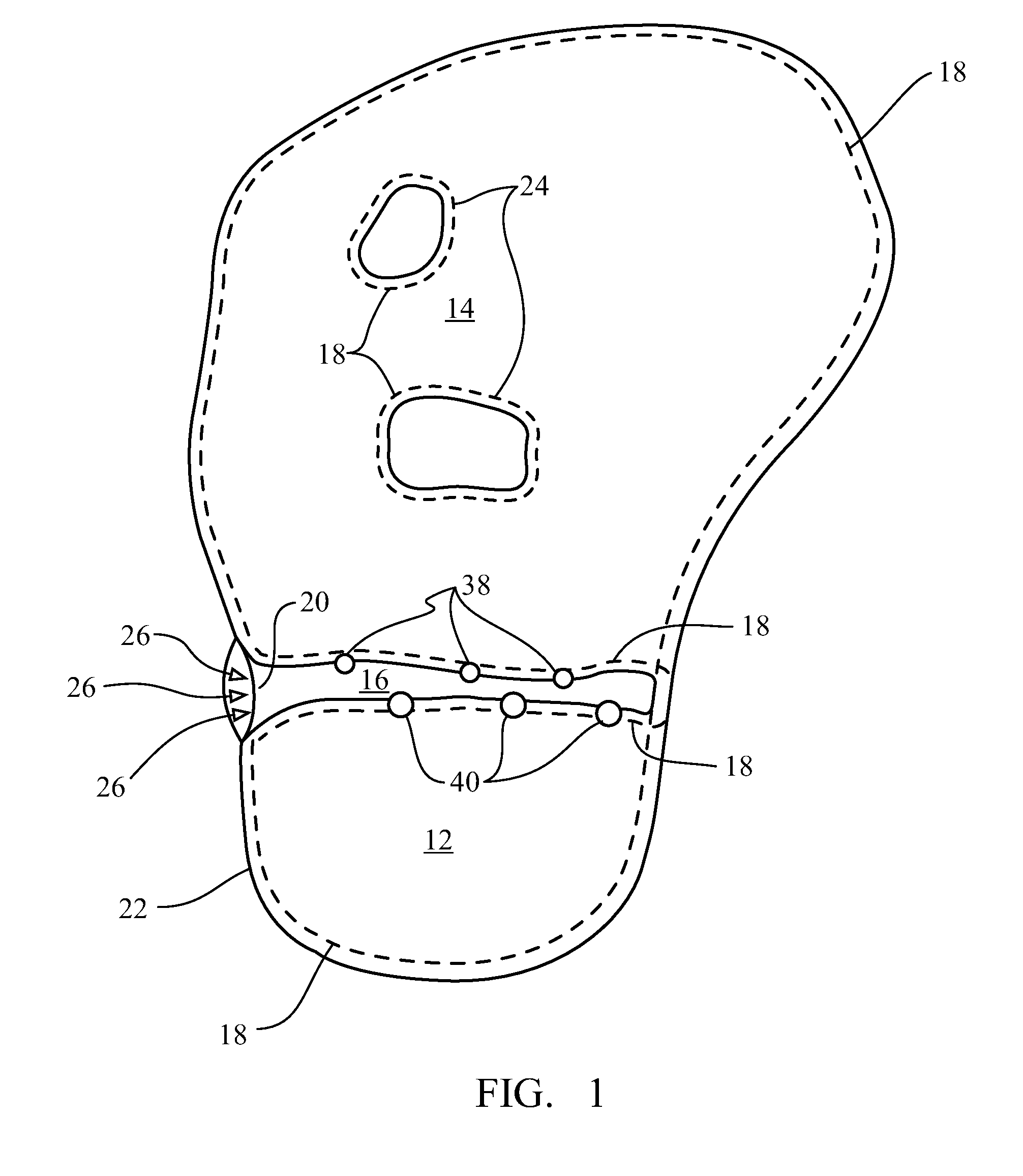

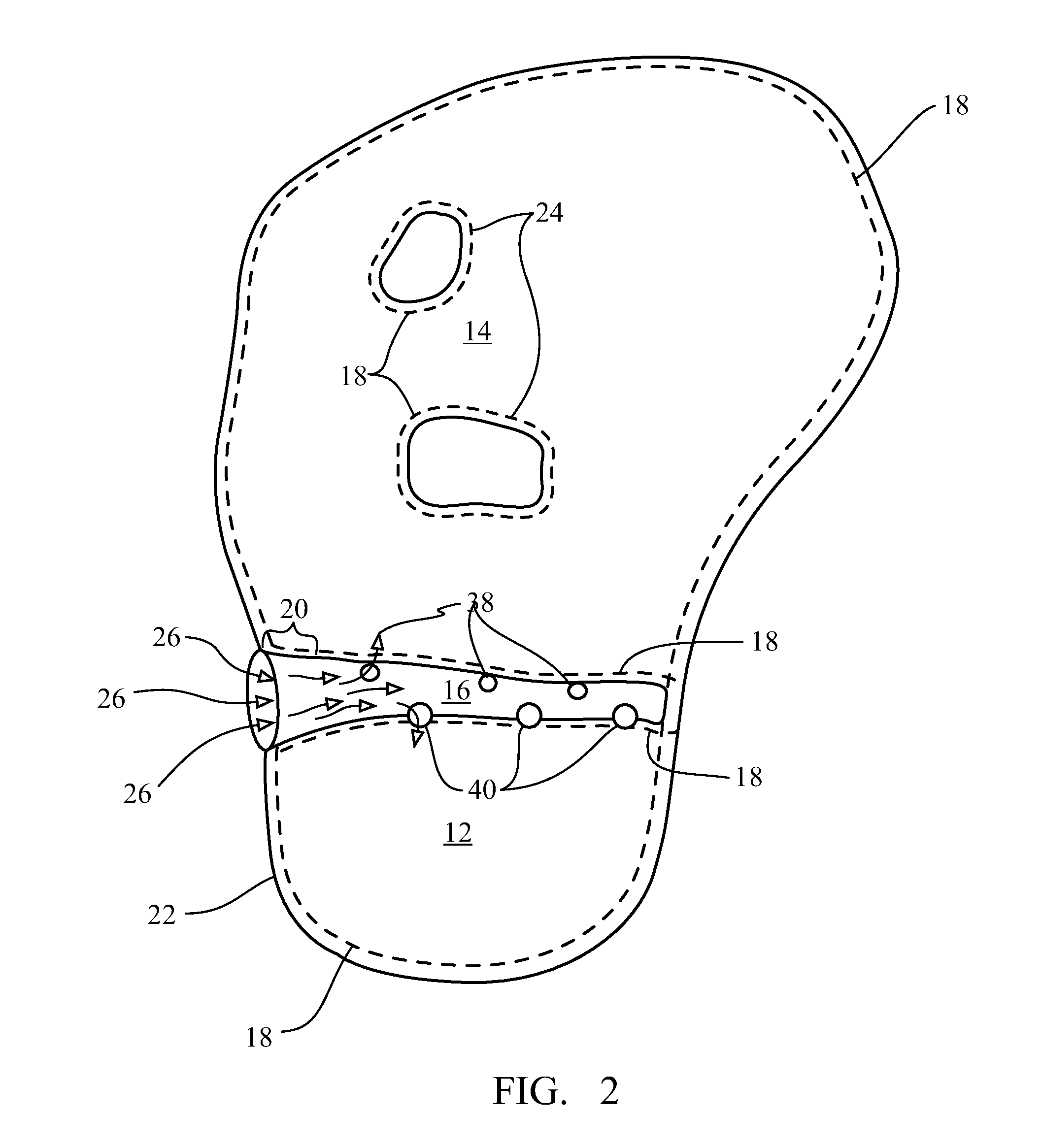

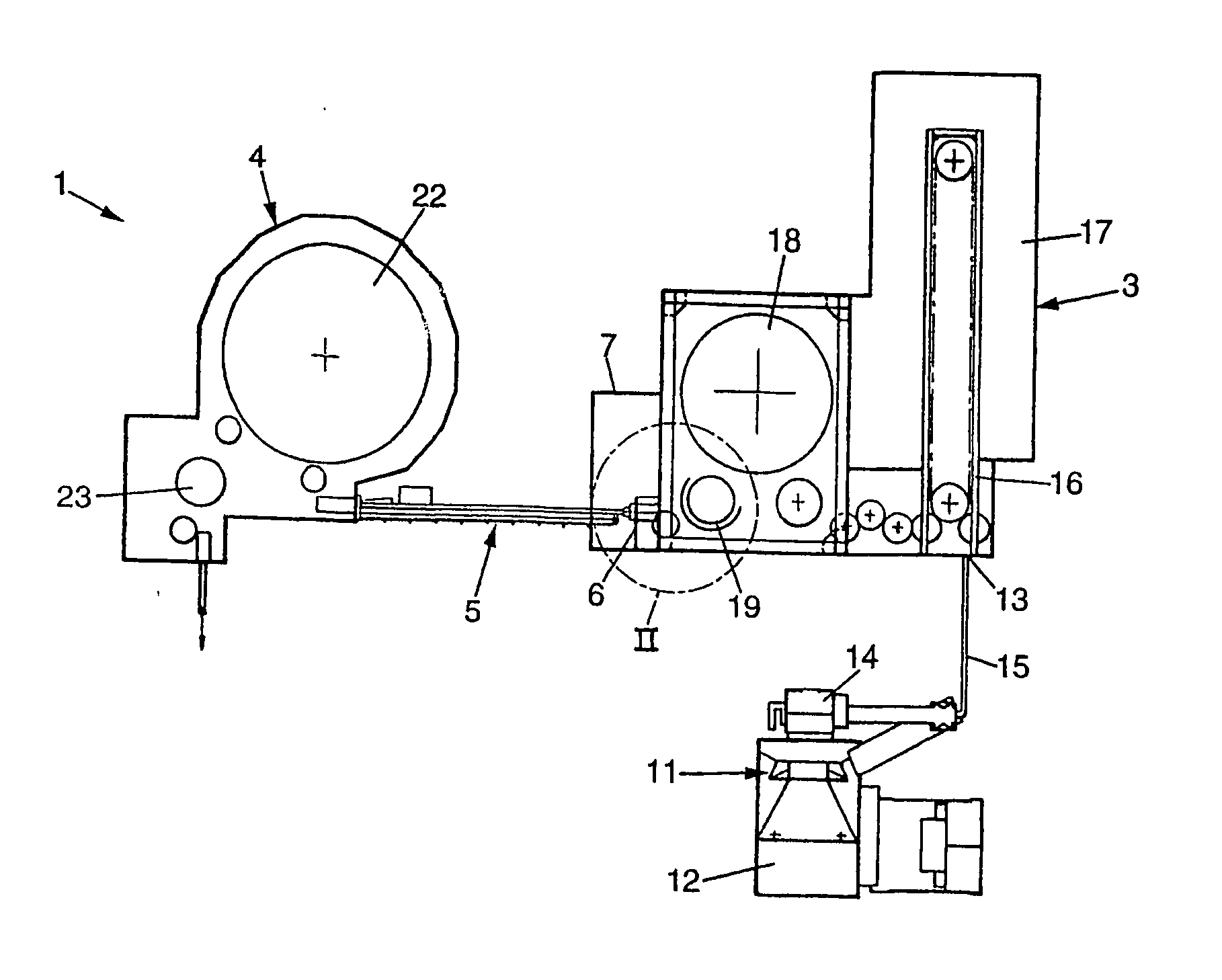

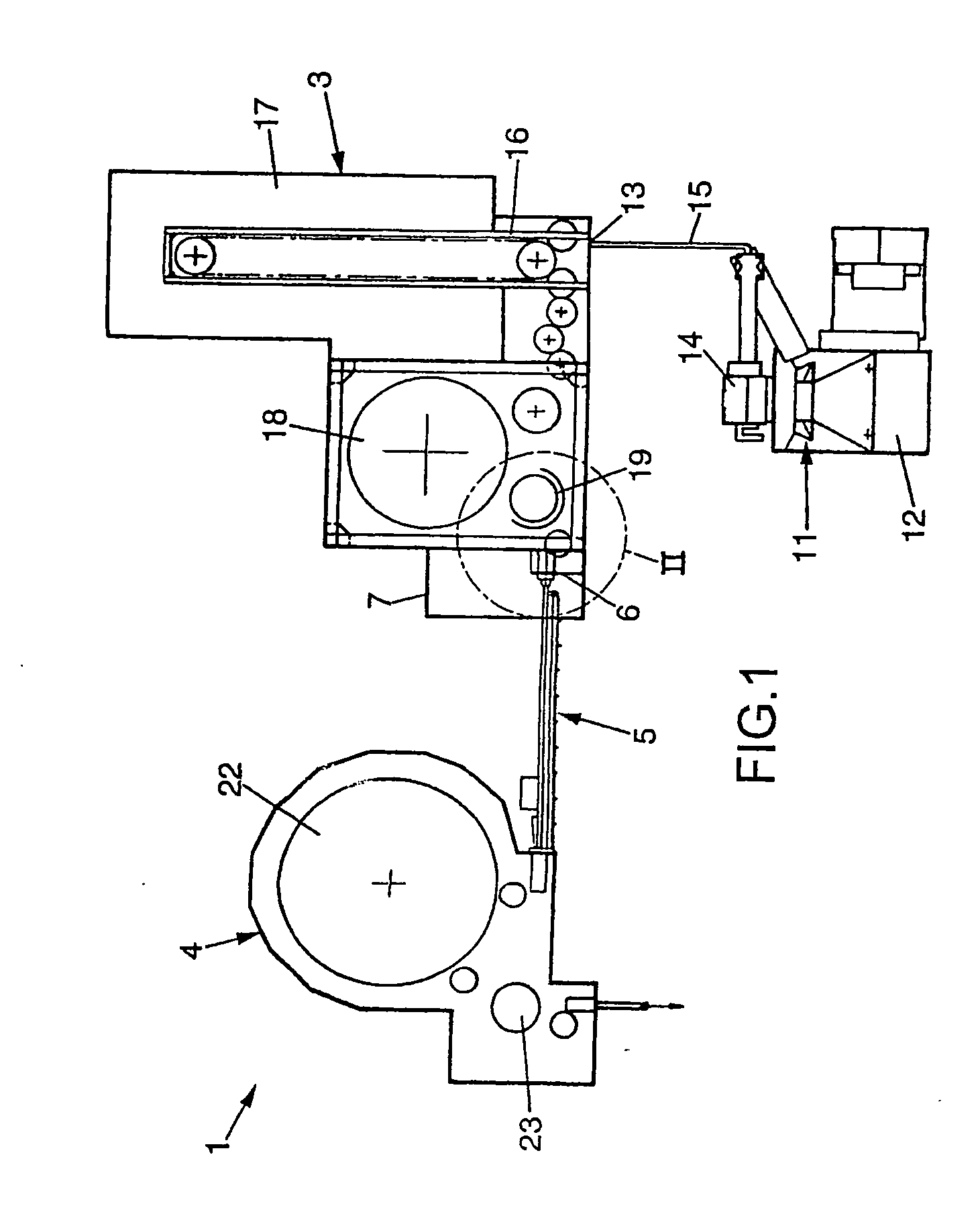

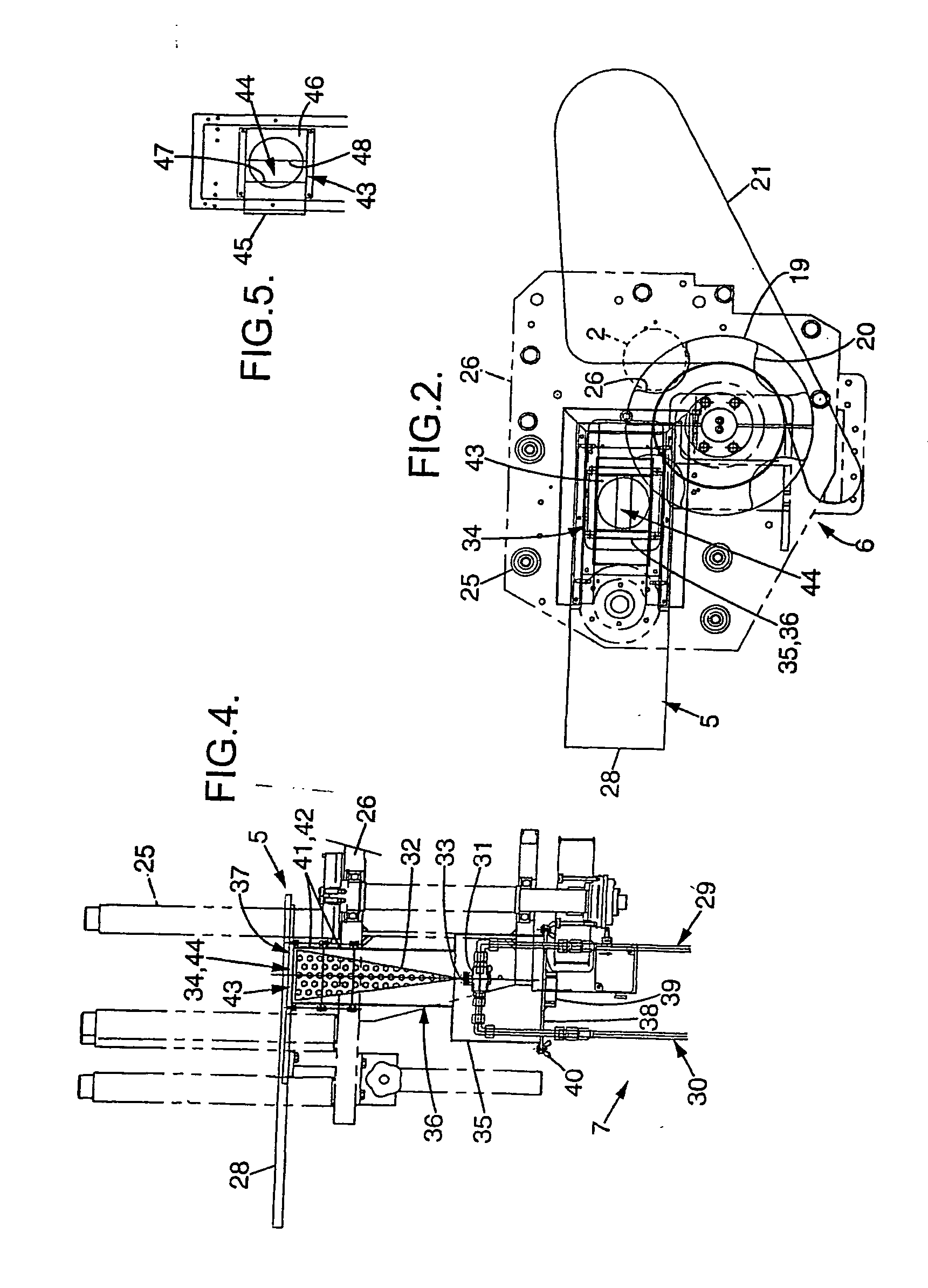

Gastro-esophageal reflux control system and pump

An enteral feeding unit or system that minimizes the occurrence of gastro-esophogeal-pharynegal reflux during feeding is described. The enteral feeding unit or device includes an automatable feeding pump with a feedback sensor for sensing a relative pressure in a patient's stomach and esophagus, and a regulator system for controlling or monitoring feeding rate to said patient as a function of said relative gastro-esophageal pressure. The system includes a stomach probe that has a fluid-tight closure of the esophagus. The stomach probe, according to the invention, is characterized by a tampon-bladder for watertight closure of the esophagus, in which the tampon-bladder forms from flexible and / or elastic material at least a closed inner cavity for the reception of a fluid medium, through a means (11) of establishing a prescribed pressure for the medium in the tampon-bladder (16) by an inner lumen forming the actual stomach probe, from which an outer hose-like lumen (18) extending to the tampon-bladder (16) is so arranged that between the outer lumen (18) and the inner lumen (17) a channel is formed connected to the inner cavity of the tampon-bladder (16) arranged on the outer lumen (18) by a number of openings (20), whereby the inner cavity of the tampon-bladder (16) is connected via the canal formed between the inner and outer lumina (17, 18) with the means of production of pressure in the tampon-bladder, that is, with a suitably graded reservoir or equalizing vessel (11) for the liquid medium situated above the tampon-bladder and outside the patient.

Owner:AVENT INC

Gastro-esophageal reflux control system and pump

An enteral feeding unit or system that minimizes the occurrence of gastro-esophogeal-pharynegal reflux during feeding is described. The enteral feeding unit or device includes an automatable feeding pump with a feedback sensor for sensing a relative pressure in a patient's stomach and esophagus, and a regulator system for controlling or monitoring feeding rate to said patient as a function of said relative gastro-esophageal pressure. The system includes a stomach probe that has a fluid-tight closure of the esophagus. The stomach probe, according to the invention, is characterized by a tampon-bladder for watertight closure of the esophagus, in which the tampon-bladder forms from flexible and / or elastic material at least a closed inner cavity for the reception of a fluid medium, through a means (11) of establishing a prescribed pressure for the medium in the tampon-bladder (16) by an inner lumen forming the actual stomach probe, from which an outer hose-like lumen (18) extending to the tampon-bladder (16) is so arranged that between the outer lumen (18) and the inner lumen (17) a channel is formed connected to the inner cavity of the tampon-bladder (16) arranged on the outer lumen (18) by a number of openings (20), whereby the inner cavity of the tampon-bladder (16) is connected via the canal formed between the inner and outer lumina (17, 18) with the means of production of pressure in the tampon-bladder, that is, with a suitably graded reservoir or equalizing vessel (11) for the liquid medium situated above the tampon-bladder and outside the patient.

Owner:AVENT INC

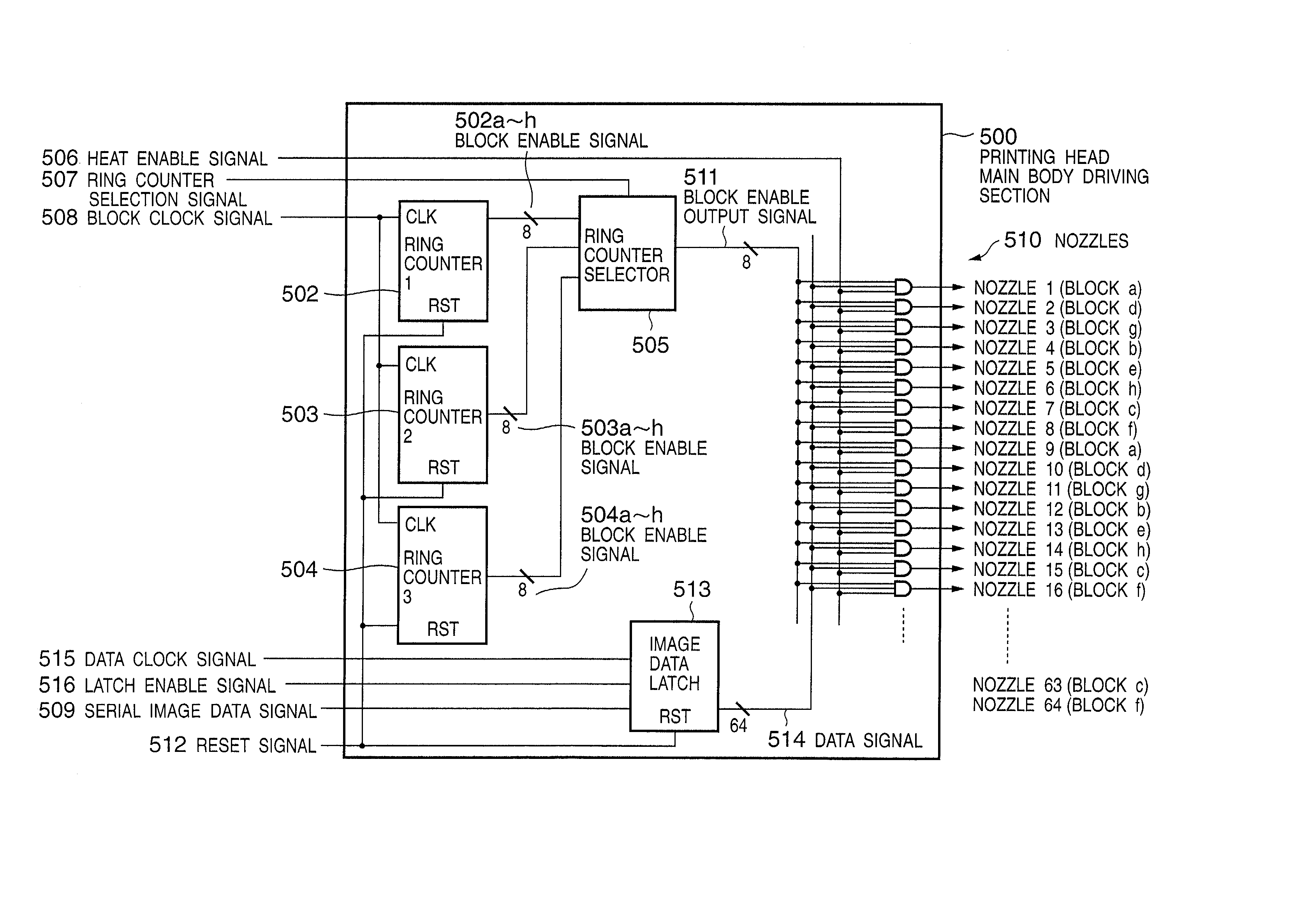

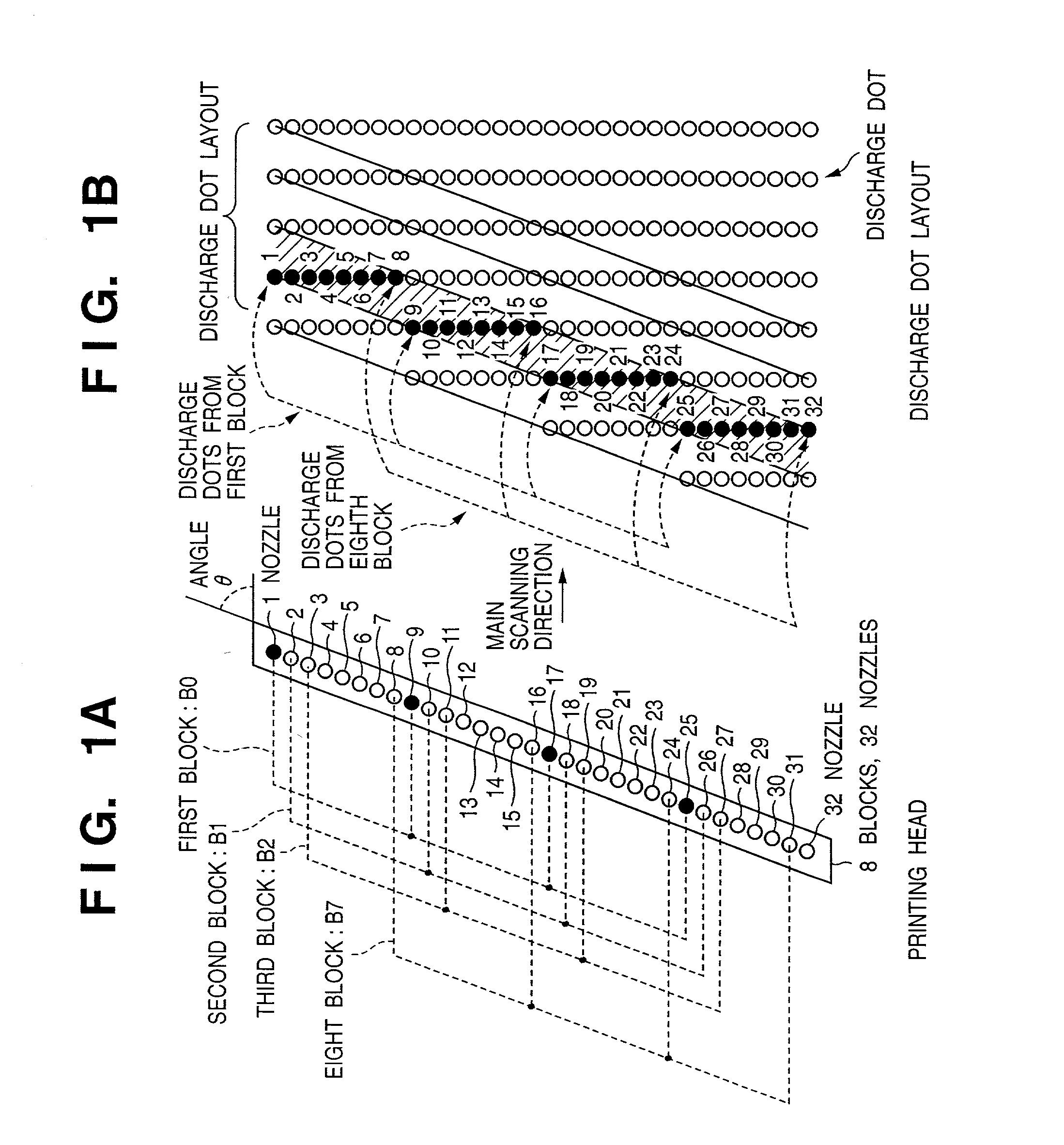

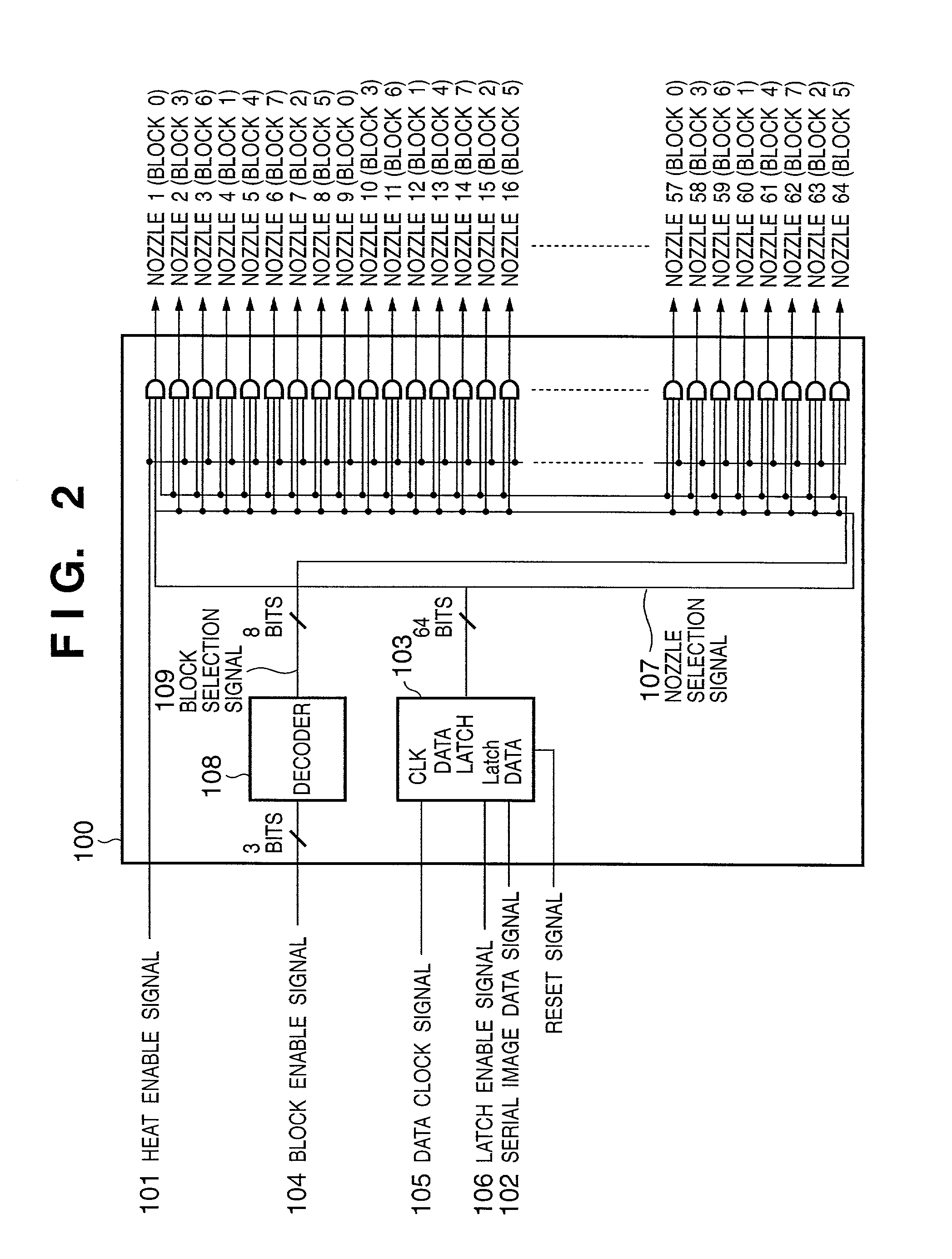

Printing head, image printing apparatus using the same, and control method therefor

InactiveUS20030142153A1Improve image qualityMinimize impactOther printing apparatusRing counterRelative pressure

This invention provides a printing head which can prevent an increase in the number of block enable signal lines, and can prevent changes in printing ink density caused by interference due to the relative pressures of nozzles generated in ink discharge, and an image printing apparatus using the printing head. For this purpose, an increase in the number of input signal lines along with an increase in the number of blocks is prevented using a block clock signal or the like instead of a block enable signal as an input signal to the printing head. Three ring counters generate signals having different nozzle driving orders. These signals are selectively used by a ring counter selection signal. Ink is not always discharged from the nozzles in the same output order. This can prevent changes in ink density caused by pressure interference.

Owner:CANON KK

Gastro-esophageal reflux control system and pump

An enteral feeding unit that reduces the occurrence of gastro-esophogeal-pharynegal reflux during feeding includes an automatable feeding pump with a feedback sensor for sensing a relative pressure in a patient's stomach and esophagus, and a regulator system for controlling and monitoring feeding rate to the patient as a function of the relative gastro-esophageal pressure. The system includes a stomach probe that provides a fluid-tight closure of the esophagus. The stomach probe includes a tampon-bladder for watertight closure of the esophagus, in which the tampon-bladder is formed of flexible and / or elastic material. At least an inner cavity of the bladder is provided for the reception of a fluid medium. A prescribed pressure for the medium in the tampon-bladder (53) is maintained by an inner lumen forming the stomach probe, from which an outer hose-like lumen (62) extending to the tampon-bladder (53) is so arranged that between the outer lumen (62) and the inner lumen (61) a channel is formed connected to the inner cavity of the tampon-bladder (53) arranged on the outer lumen (62) by a number of openings (57). The inner cavity (58) of the tampon-bladder (53) is connected via a canal formed between the inner and outer lumina (62) with a suitably graded reservoir or equalizing vessel for the liquid medium situated above the tampon-bladder and outside the patient.

Owner:AVENT INC

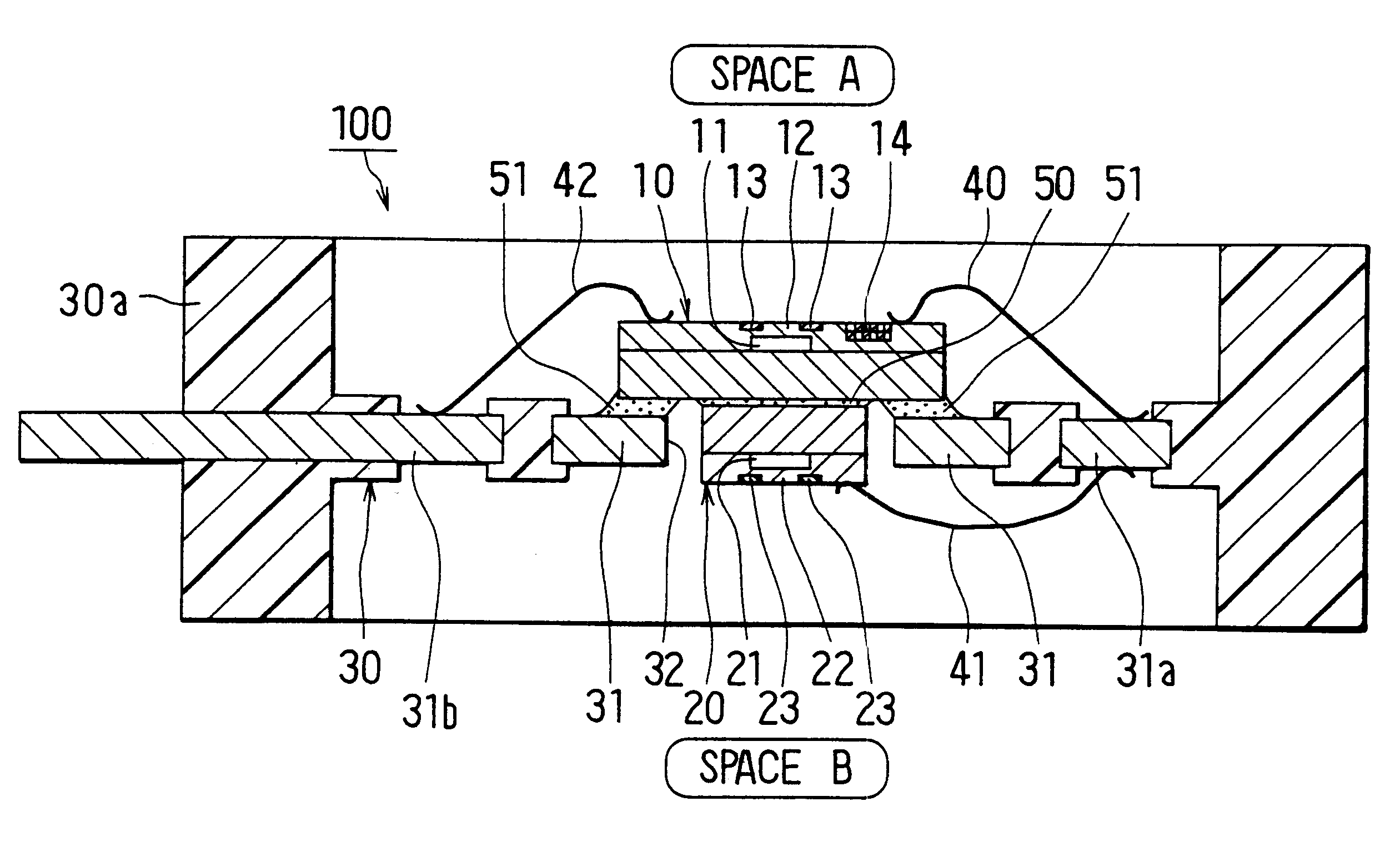

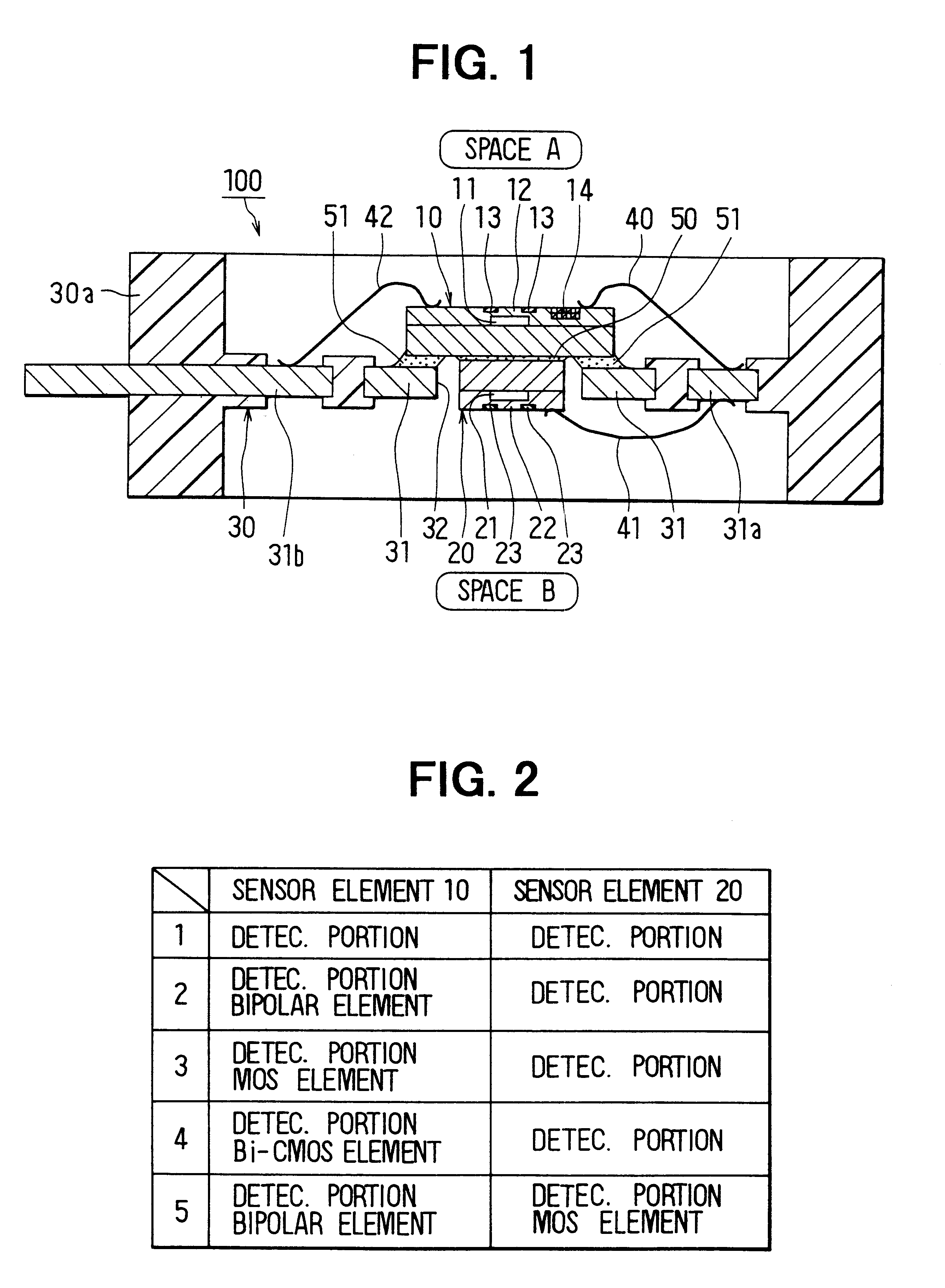

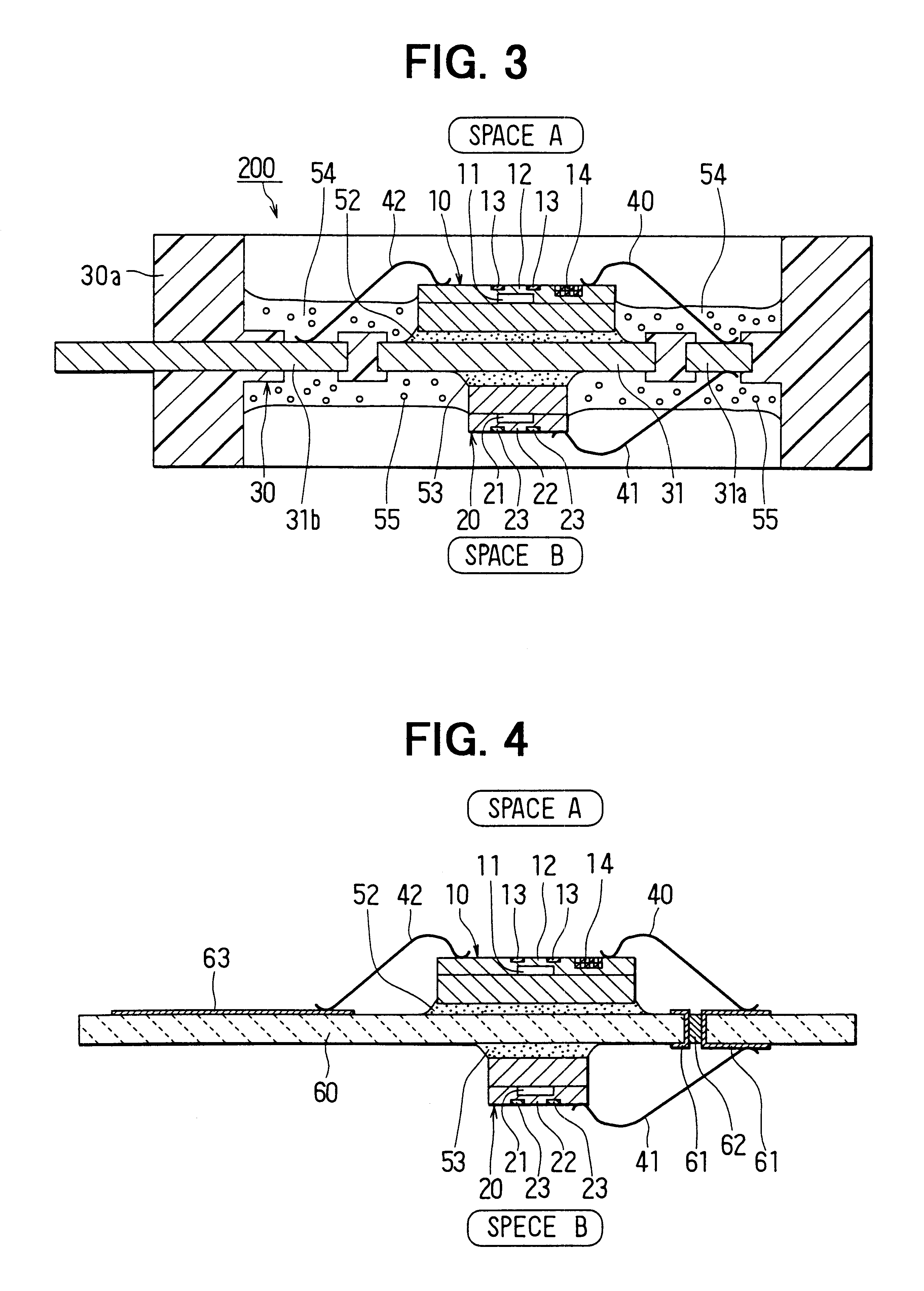

Pressure sensor for detecting differential pressure between two spaces

InactiveUS6550339B1Simple structureEasy to manufactureFluid pressure measurement by electric/magnetic elementsSolid-state devicesRelative pressureDifferential pressure

A pressure sensor has two sensor elements respectively disposed in different pressure spaces A and B. Each of the sensor elements has a semiconductor substrate having a pressure reference chamber therein, a diaphragm formed as a wall defining the pressure reference chamber, and gauges for converting deformation of the diaphragm into an electric signal. The two sensor elements overlap with each other at sides opposite to the respective diaphragms, and close a hole formed in a partition member partitioning the two pressure spaces A and B. A differential pressure between the pressure spaces A and B is detected as a relative pressure by a difference between outputs from the two sensor elements.

Owner:DENSO CORP

Dynamic knee balancer with force or pressure sensing

ActiveUS20130096567A1Accelerated programDesired stability and range of motion and patellar trackingJoint implantsSurgical robotsTibiaRelative pressure

A device for performing a surgical procedure on a knee includes an adjustable femoral portion, a tibial portion and at least one sensor coupled with the femoral and / or tibial portions to sense pressure exerted by the femoral and tibial portions against one another. The femoral portion is adapted for removably coupling with a distal end of a femur to adjust tension in soft tissue adjacent the knee and has at least one positioning feature adapted to move relative to the distal end of the femur as the femoral portion is adjusted, thus helping position a femoral prosthetic on the distal end of the femur. The sensor(s) may be adapted to sense pressure at medial and lateral sides of the knee, and relative pressures may be displayed as data on a visual display. Adjustments to the femoral member may be made to balance pressure at flexion and extension of the knee.

Owner:SYNVASIVE TECH

Dynamic knee balancer with pressure sensing

ActiveUS20130013076A1Accelerated programDesired stability and range of motion and patellar trackingJoint implantsSurgical robotsTibiaRelative pressure

A device for performing a surgical procedure on a knee includes an adjustable femoral portion, a tibial. portion and at least one sensor coupled with the femoral and / or tibial portions to sense pressure exerted by the a moral and tibial portions against one another. The femoral portion is adapted for removably coupling with a distal end of a Femur to adjust tension in soft tissue adjacent the knee and has at least one positioning feature adapted to move relative to the distal end of the femur as the femoral portion is adjusted, thus helping position a femoral prosthetic on the distal end of the femur. The sensor(s) may he adapted to sense pressure at medial and lateral sides of the knee, and relative pressures may he displayed as data on a visual display. Adjustments to the femoral member may be made to balance pressure at flexion and extension of the knee.

Owner:SYNVASIVE TECH

Item monitoring system and methods

An item monitoring system is provided which is operative at points of storage automatically to sense the presence, number of item(s) stored and relative location of items and to generate near real-time item and location data from storage locations so that time-related changes can be compared to detect item additions and subtractions, and to recognize and report events such as shrink / theft, low inventory conditions and misplaced items. Embodiments incorporate a surface sensing system comprised of one or more contiguous item sensor strips that measure the relative pressure of items in contact with a surface or a hanger support using pressure sensitive analog type conductive material. Item information can be collected from multiple hangers and / or storage surfaces and relayed to databases and application systems for varied uses. The system and method disclosed are cost effective and widely applicable to many categories of inventory application providing real-time updates without item packaging changes.

Owner:INTRINSIC MARKS INT

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS7186367B2Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

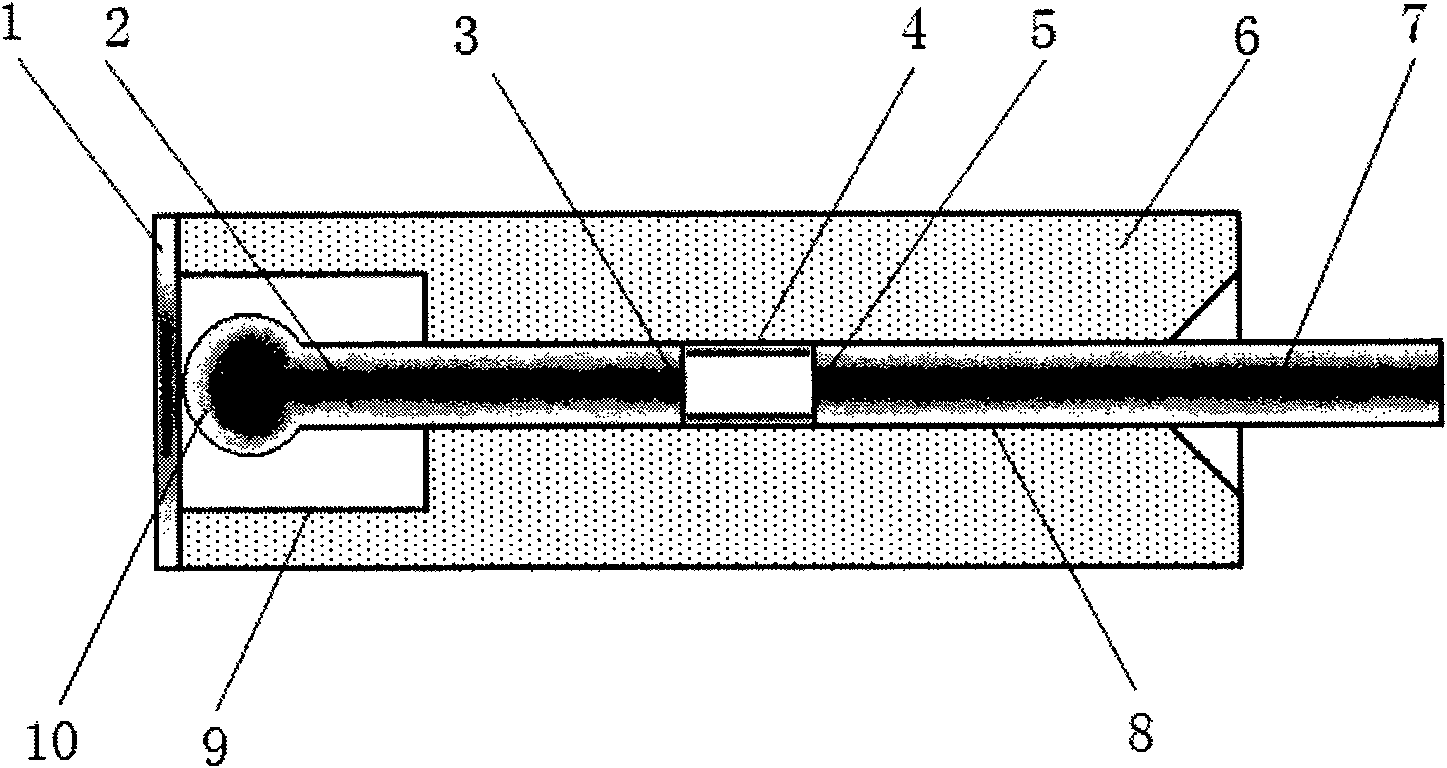

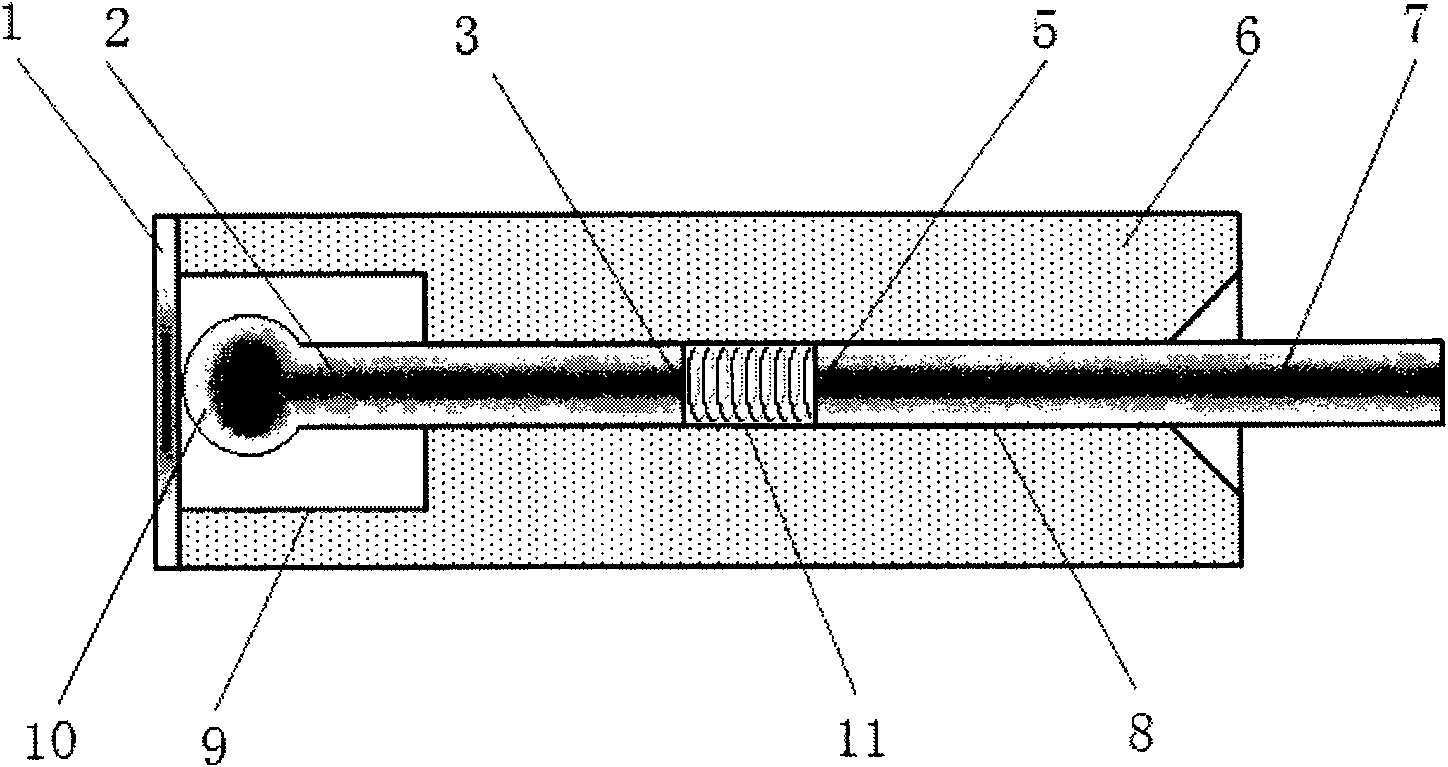

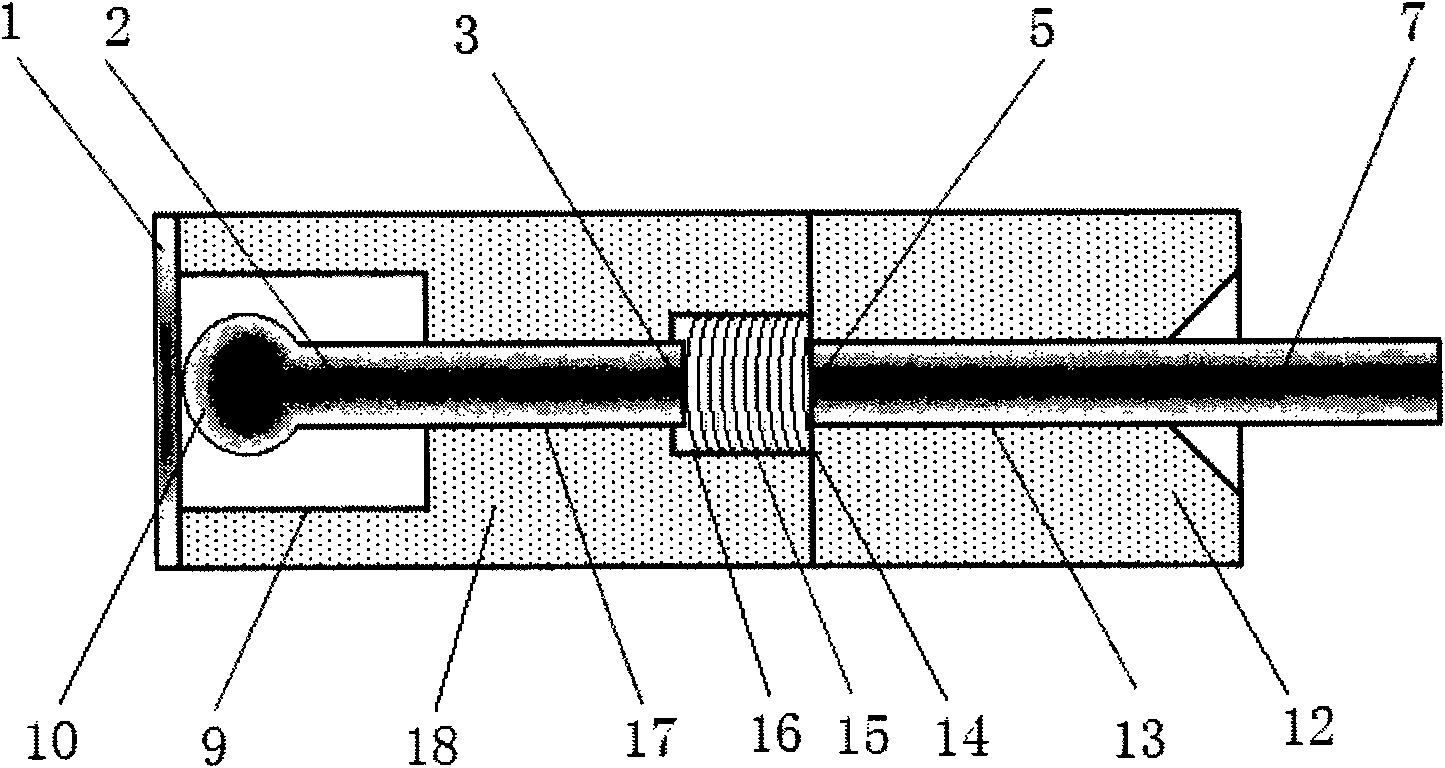

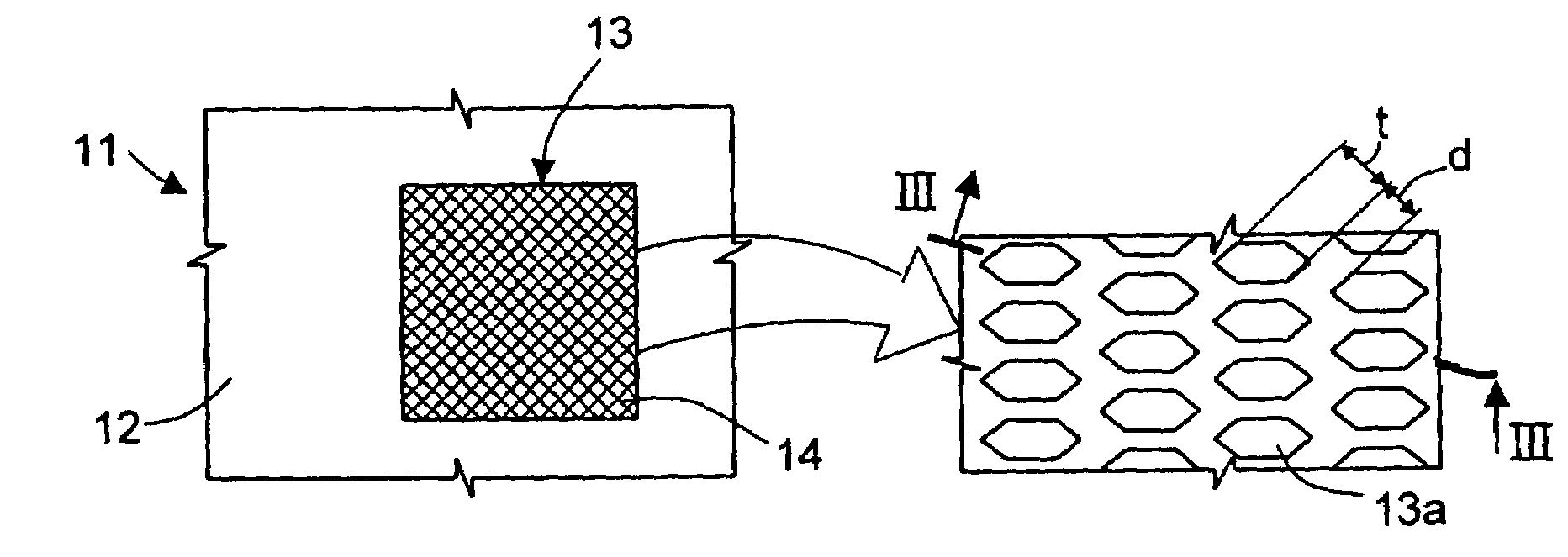

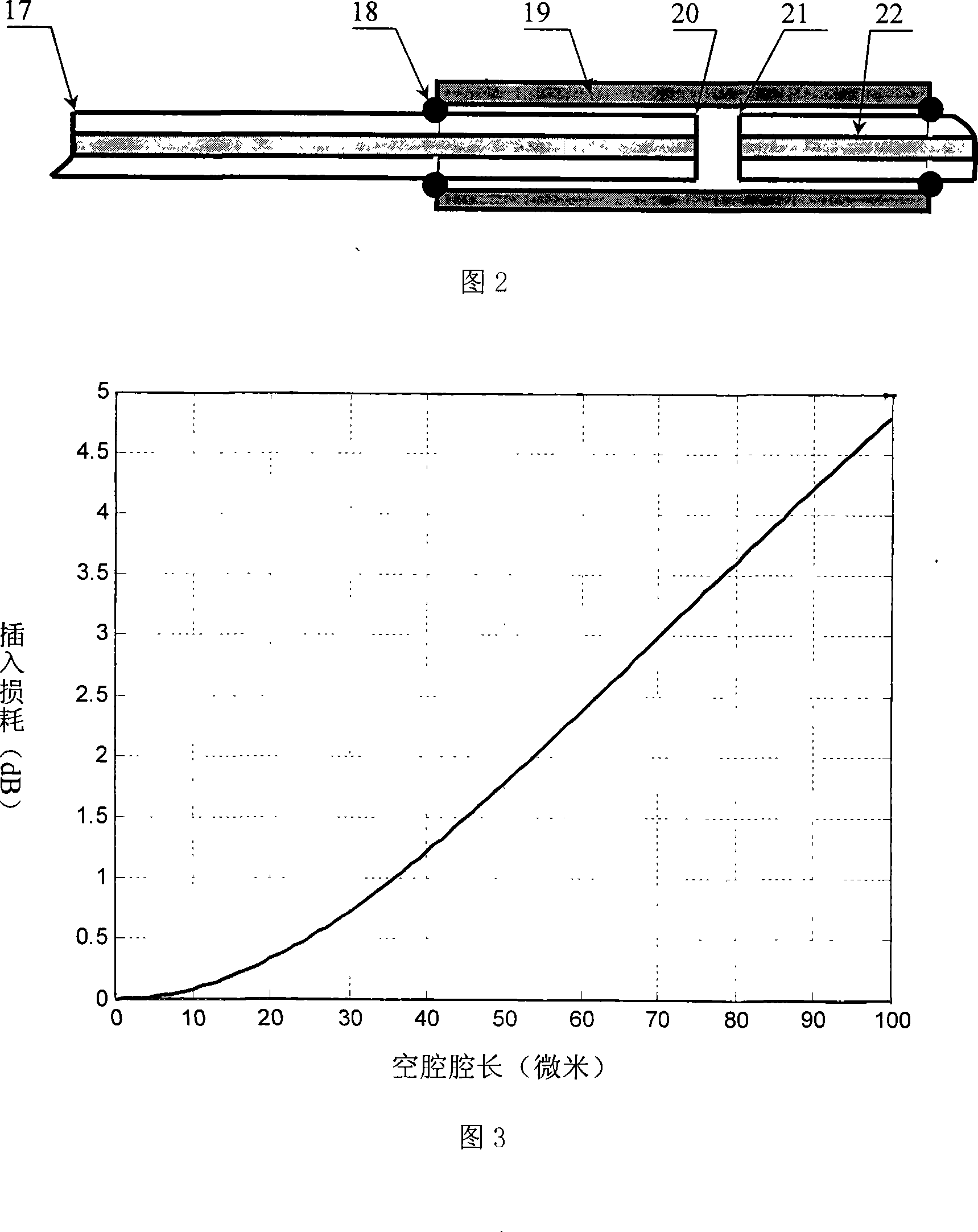

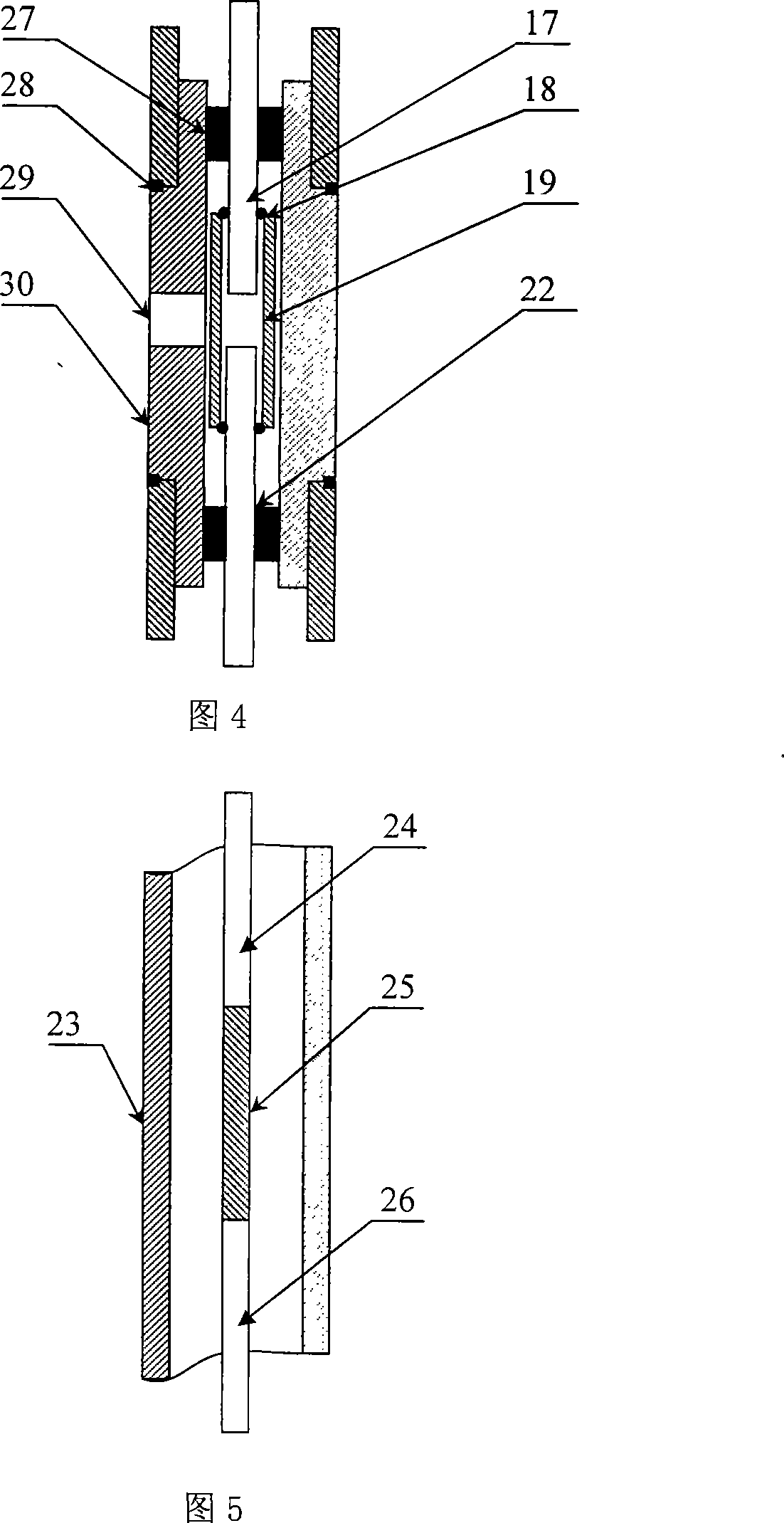

Optical fiber Fabry-Perot pressure sensor and fabrication method thereof

InactiveCN101858809AReduce measurement errorEnsure close contactCoupling light guidesFluid pressure measurement by optical meansEngineeringAlternative methods

The invention relates to a novel optical fiber Fabry-Perot pressure sensor and a fabrication method thereof. The optical fiber Fabry-Perot pressure sensor is used for detecting the relative pressure and absolute pressure of liquid and gas as well as sound wave signals, ultrasonic wave signals and the like. The structure of the optical fiber Fabry-Perot pressure sensor mainly comprises an optical fiber, an elastic diaphragm, a sensor body and a miniature spring. Two methods and an alternative method can be adopted to form a Fabry-Perot cavity and fabricate the sensor. The elastic diaphragm and the sensing optical fiber are tightly contacted in a plane-sphere point contact manner; when the outside pressure is changed to cause the deformation of the elastic diaphragm, the diaphragm can drive the optical fiber to axially move in the sensor body, so that the length of the Fabry-Perot cavity of the optical fiber is changed; after a broadband light source is connected, by scanning the spectrum of the light passing through the optical fiber Fabry-Perot pressure sensor or extracting low-coherence interference fringes, the change of the cavity length can be extracted, and thereby pressure information can be obtained. The structure can avoid the defect that the diaphragm of the conventional optical fiber Fabry-Perot pressure sensor cannot be over-deformed, and can obtain higher measurement precision.

Owner:TIANJIN UNIV

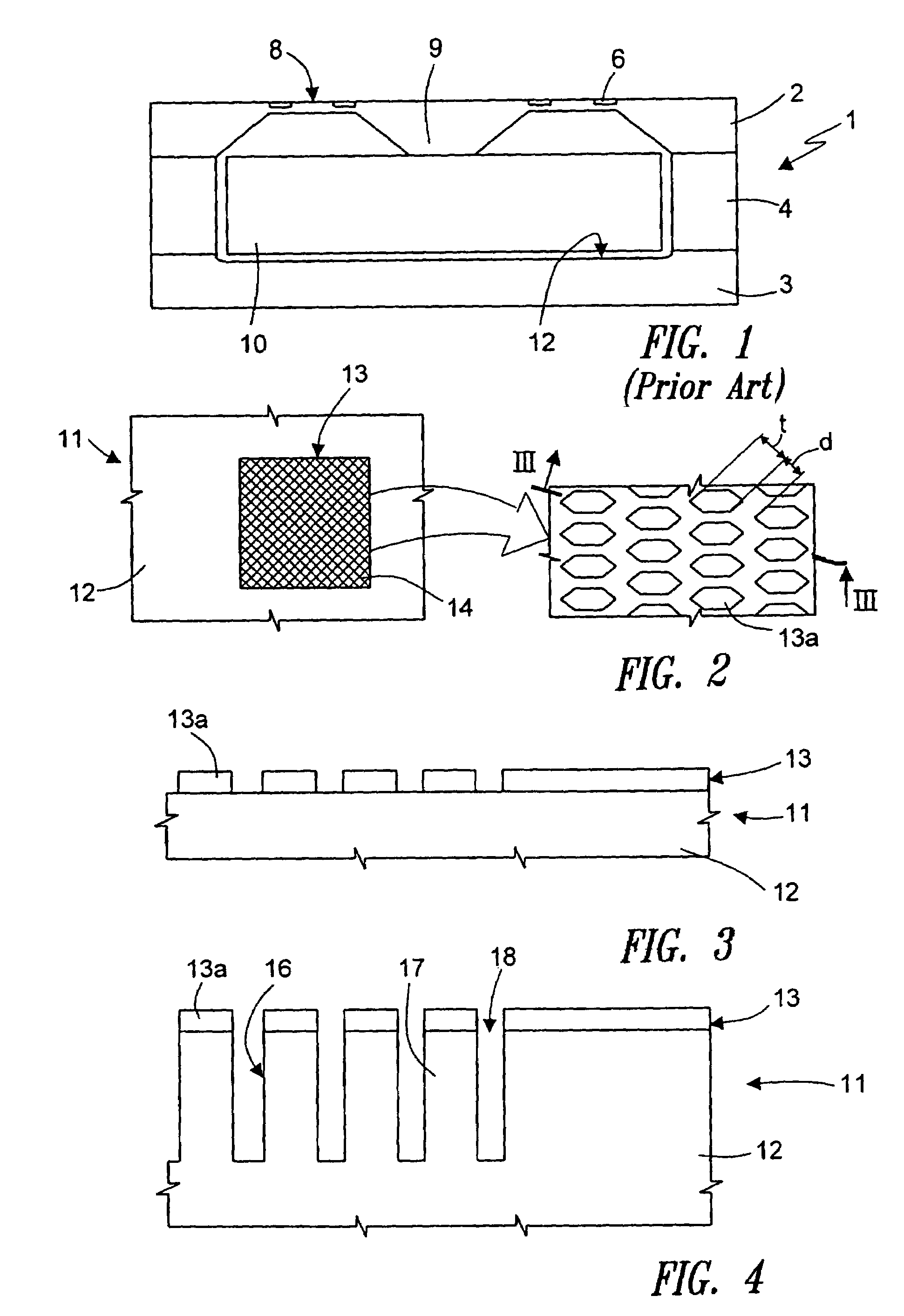

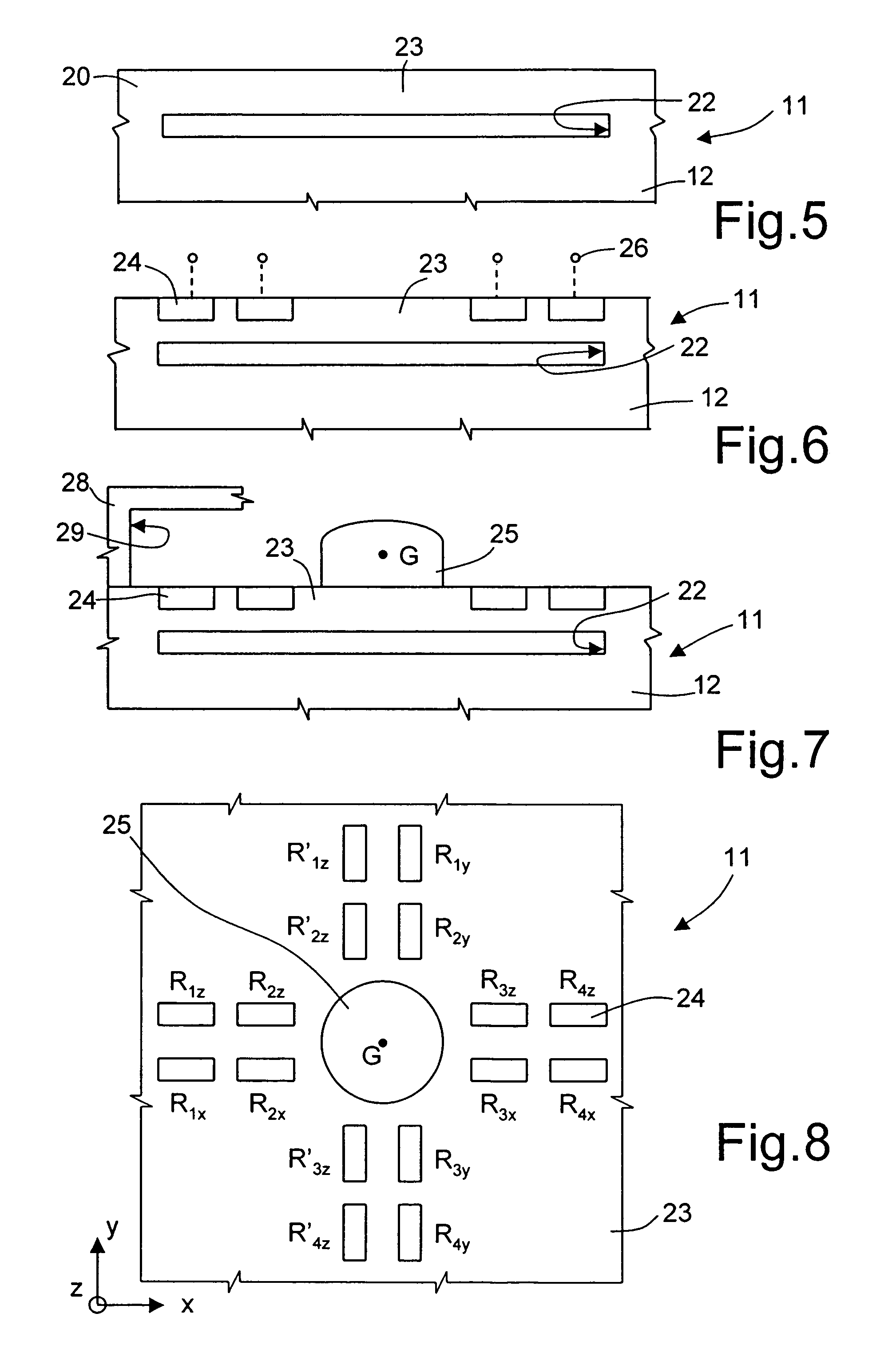

Process for manufacturing a triaxial piezoresistive accelerometer and relative pressure-monitoring device

ActiveUS7322236B2Simple and inexpensive to manufactureEasy to integrateAcceleration measurement using interia forcesNavigation instrumentsInertial massRelative pressure

A manufacturing process of a semiconductor piezoresistive accelerometer includes the steps of: providing a wafer of semiconductor material; providing a membrane in the wafer over a cavity; rigidly coupling an inertial mass to the membrane; and providing, in the wafer, piezoresistive transduction elements, that are sensitive to strains of the membrane and generate corresponding electrical signals. The step of coupling is carried out by forming the inertial mass on top of a surface of the membrane opposite to the cavity. The accelerometer is advantageously used in a device for monitoring the pressure of a tire of a vehicle.

Owner:STMICROELECTRONICS SRL

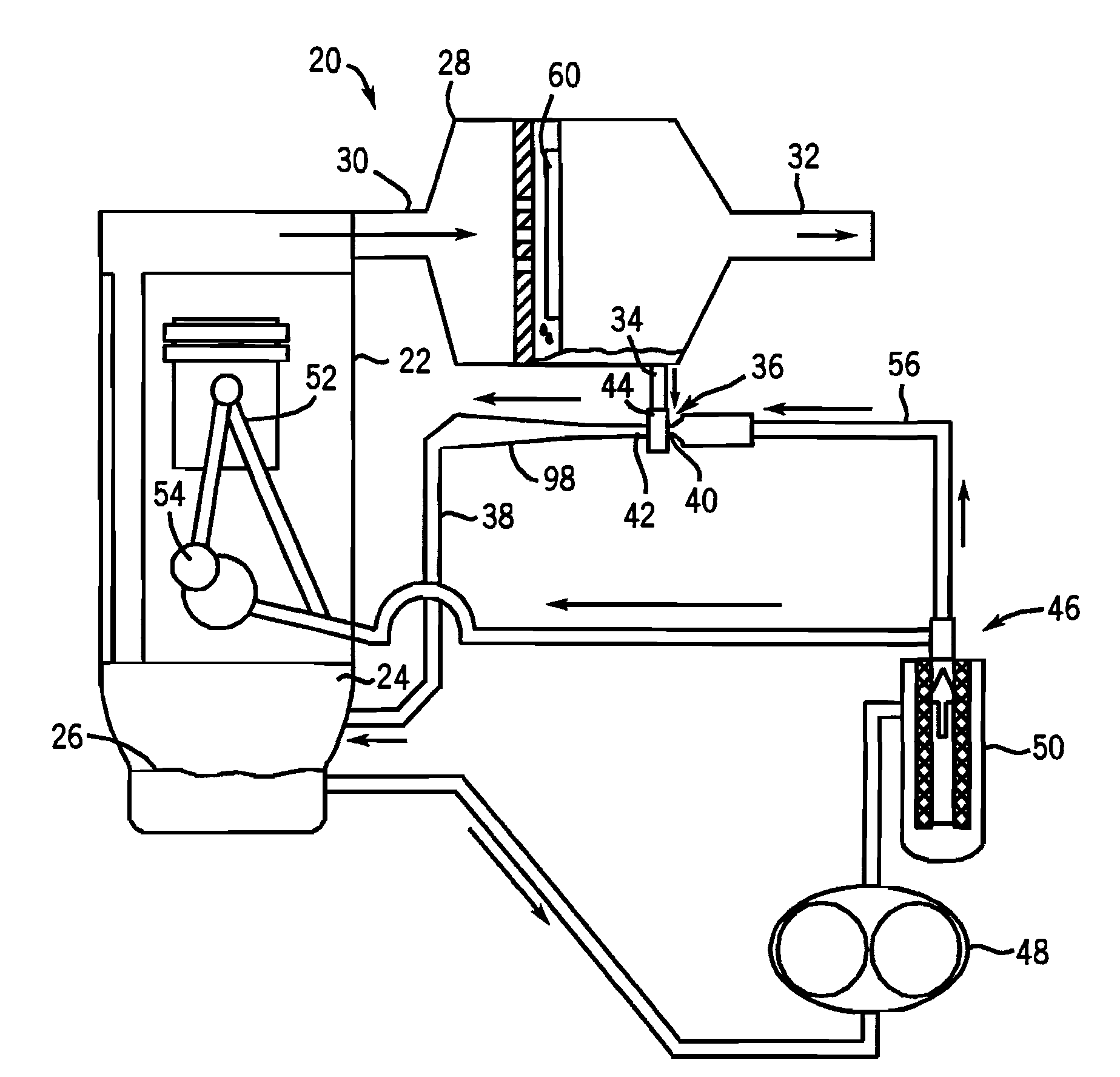

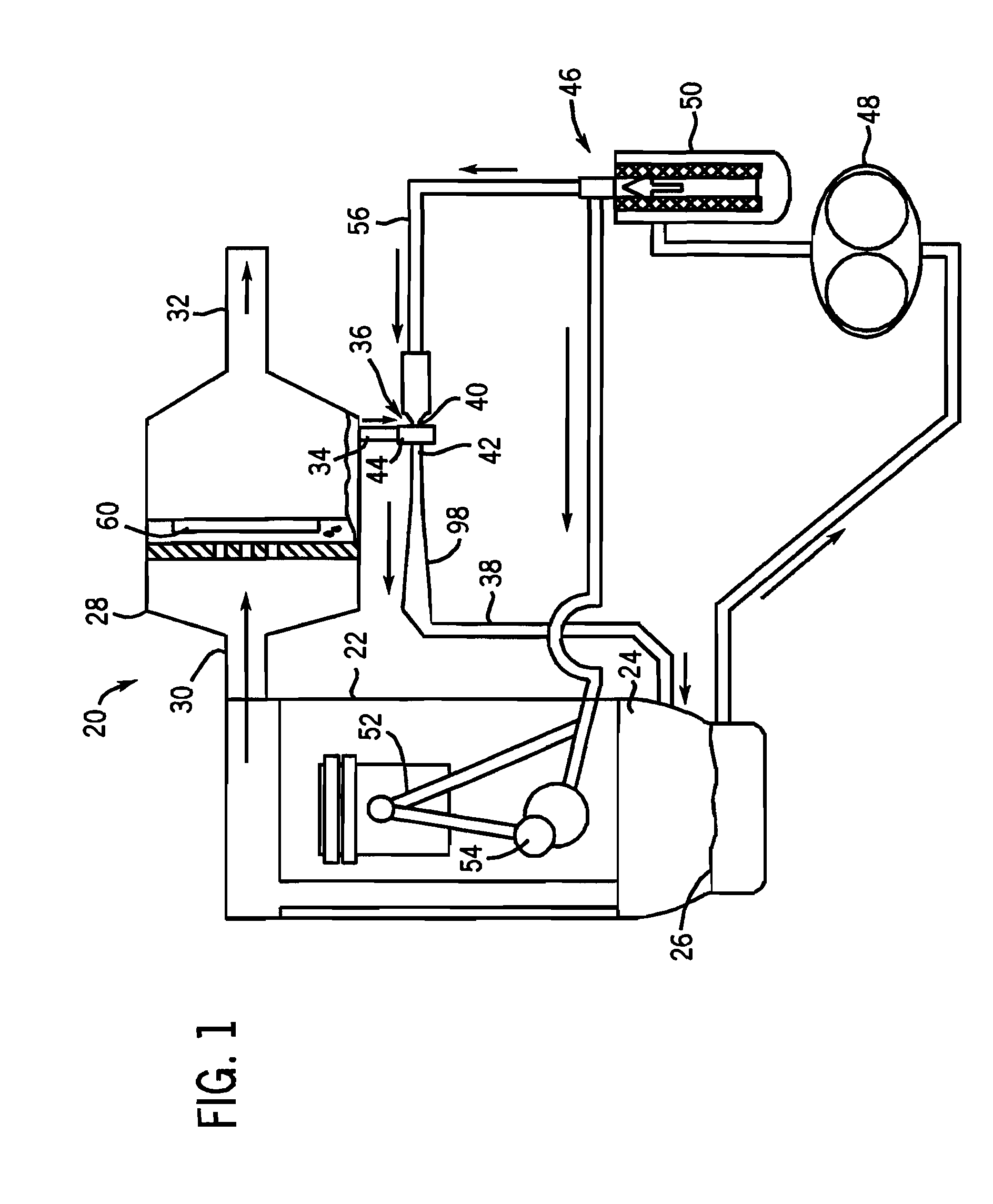

Crankcase Ventilation System with Engine Driven Pumped Scavenged Oil

InactiveUS20100043734A1The process is simple and effectiveSimple wayCombustion enginesCrankcase ventillationRelative pressureCrankcase ventilation system

A crankcase ventilation system for an internal combustion engine has an engine driven pump pumping scavenged separated oil from the oil outlet of an air-oil separator to the crankcase, preferably using engine generated pulsating oscillatory positive and negative relative pressure pulses.

Owner:CUMMINS FILTRATION IP INC

Relative pressure control system and relative flow control system

ActiveUS20060097644A1Accurate supervisionReduce the amount of controlOperating means/releasing devices for valvesElectric discharge tubesRelative pressureSolenoid valve

Provided is a relative pressure control system has a simple configuration, but enables accurate regulation of a division ratio of an operation gas, and concurrently makes it possible to securely drain the operation gas from an operation gas pipeline in case of emergency. The system includes a plurality of air operated valves of a normally open type that are connected to an operation gas pipeline supplied with an operation gas; pressure sensors that are series connected to the respective air operated valves and that detect output pressures of the respective air operated valves; a controller that controls operation pressures of the respective air operated valves in accordance with the pressures detected by the pressure sensors; and a hard-interlock solenoid valve that correlates the plurality of air operated valves to one another so that at least one of the plurality of air operated valves is normally opened. In the configuration, an opening of a specified one of the plurality of air operated valves is regulated, the operation gas is output at a predetermined division ratio.

Owner:CKD +1

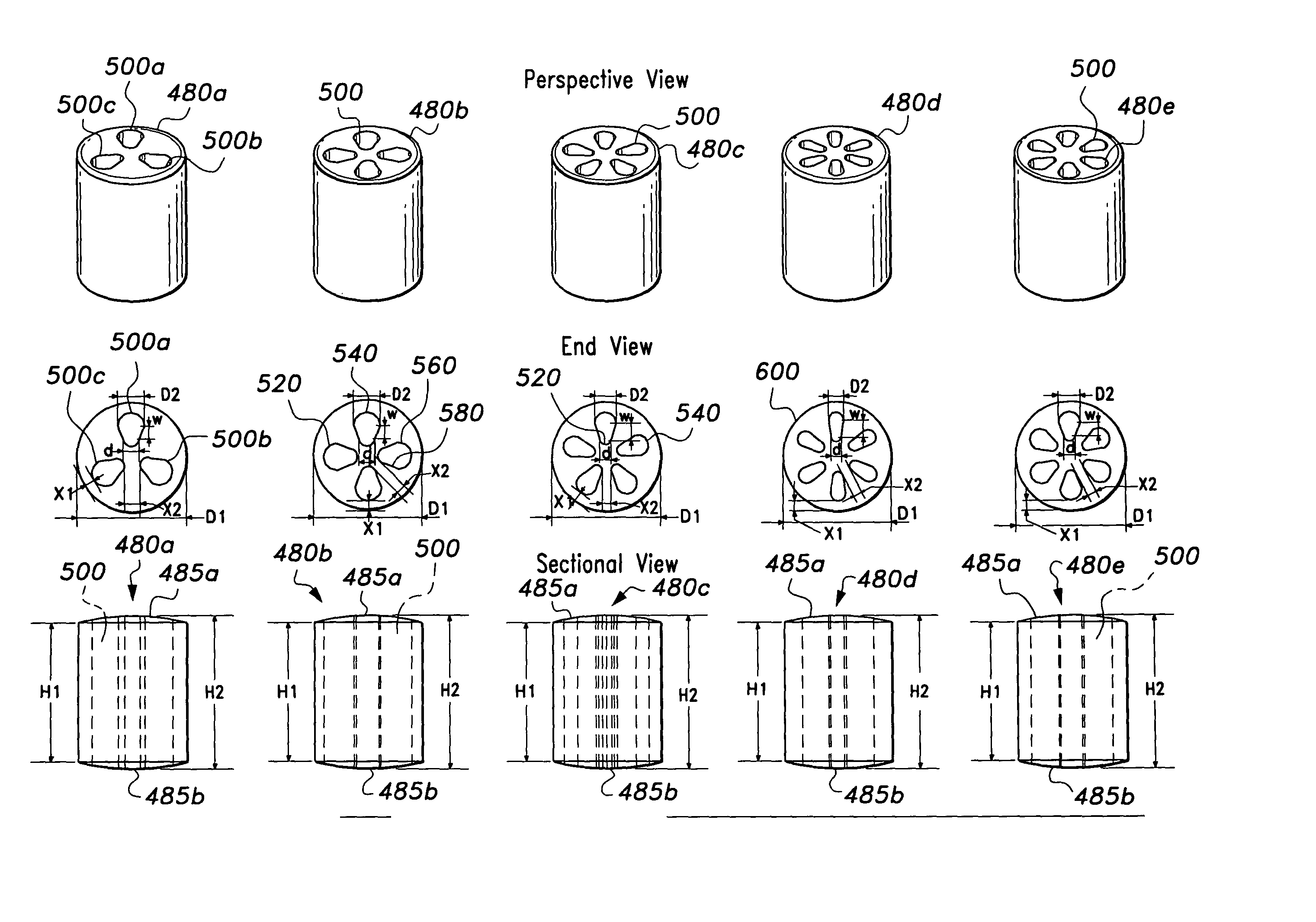

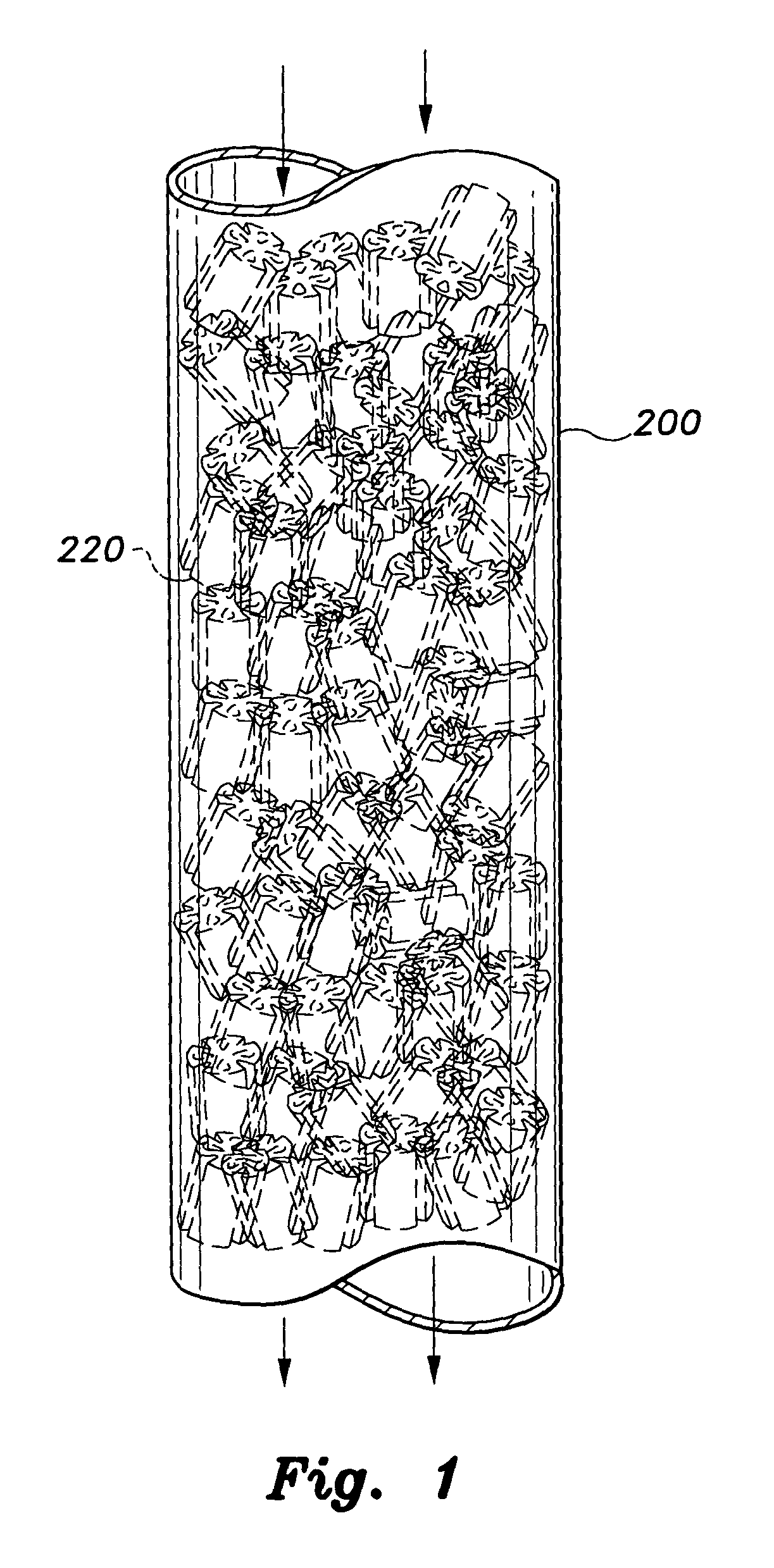

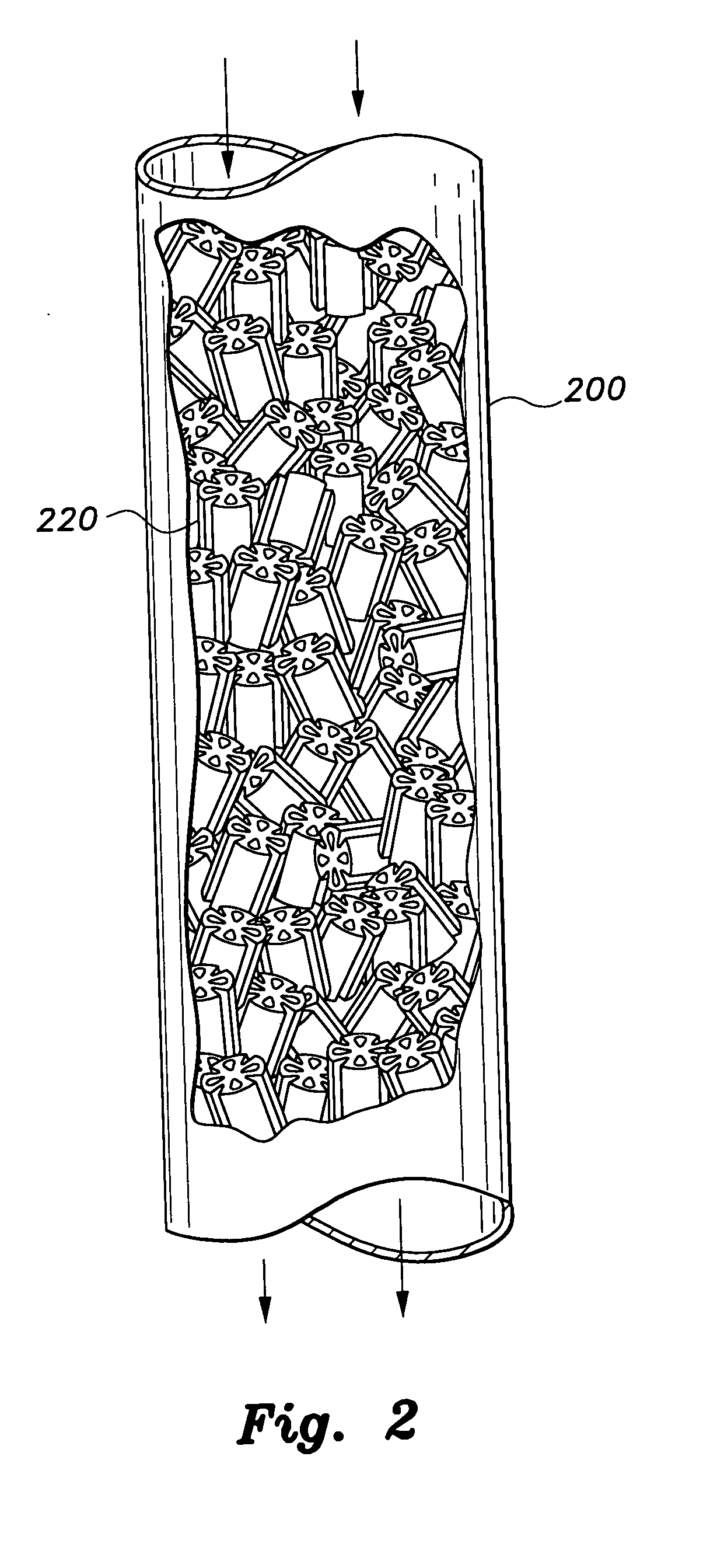

Heterogeneous gaseous chemical reactor catalyst

An improved heterogeneous catalyst for catalyzing the reaction of gaseous reactants, comprising a high performance catalyst particle with a diameter to height ratio in the range between about 0.5:1 to 1.0:1.0, the high performance catalyst particle has a Relative Particle Size Parameter (RPSP) and a Geometric Surface Area (GSA), wherein the high performance catalyst particle has a higher GSA for a particular RPSP than a prior art catalyst particle. In another embodiment the improved heterogeneous catalyst with a diameter to height ratio in the range between about 0.5:1 to 1.0:1.0 has a Relative Particle Size Parameter (RPSP), a Geometric Surface Area (GSA), and an associated Relative Pressure Drop (RPD), wherein the high performance catalyst particle has a higher GSA for a particular RPSP or alternately a lower RPD for a particular GSA than a prior art catalyst particle.

Owner:COMBS GLENN A

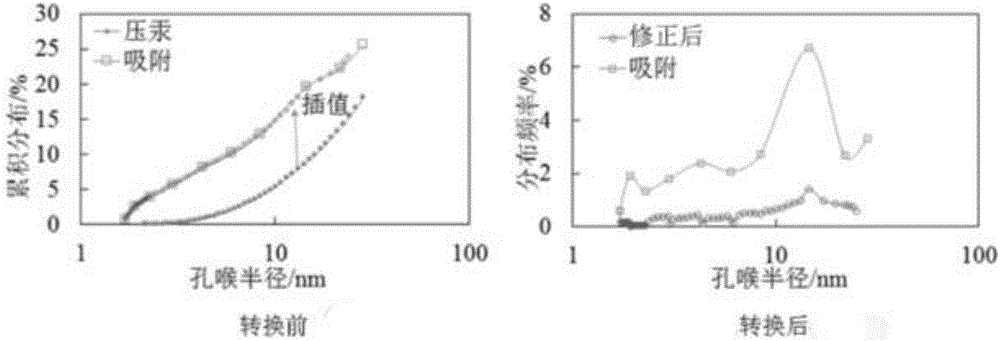

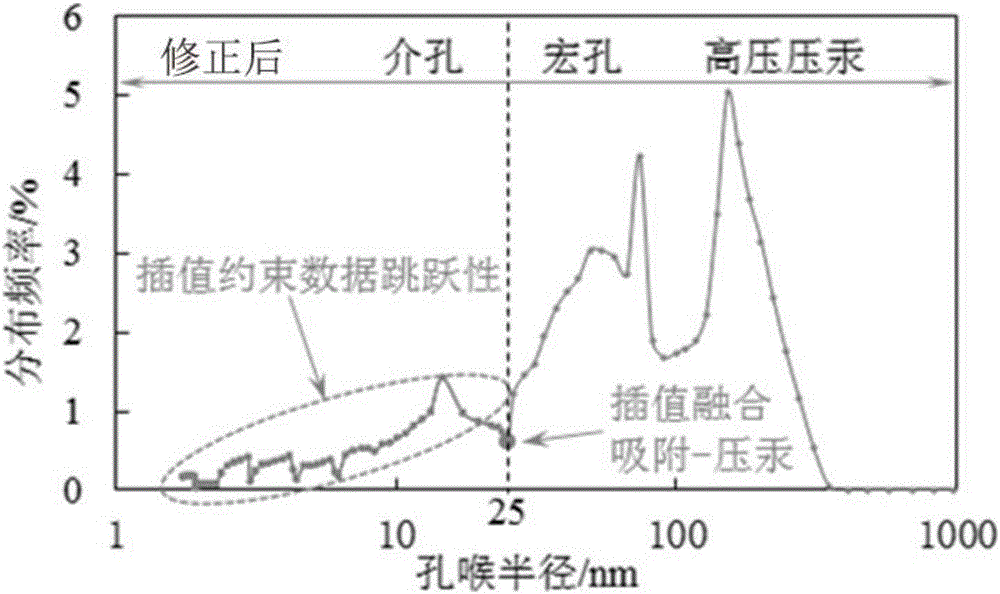

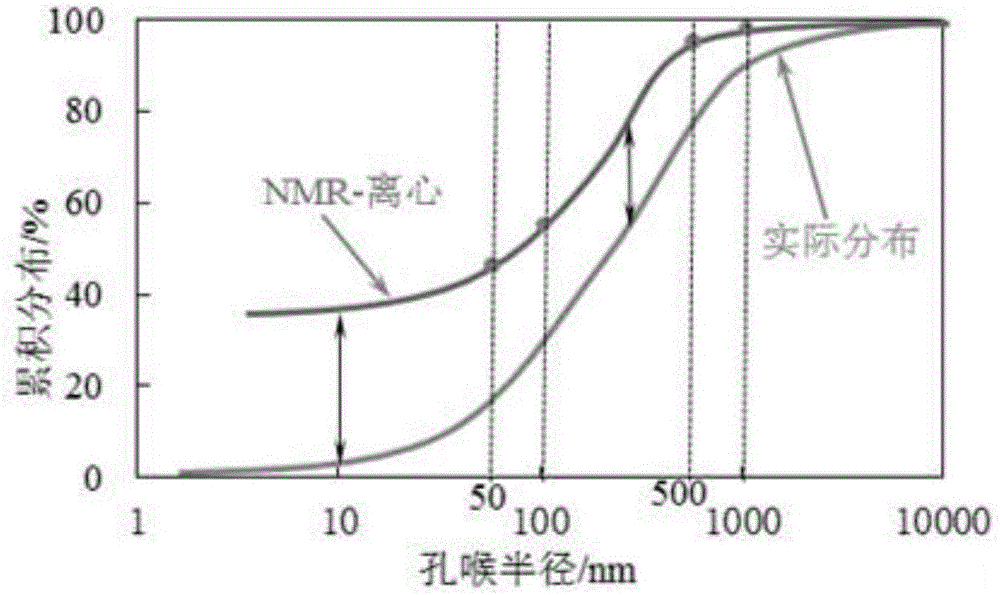

Method for full-dimension representation and analysis of dense reservoir pore throats

InactiveCN105974092AEfficient developmentReduce development costsEarth material testingNitrogen gasRock sample

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

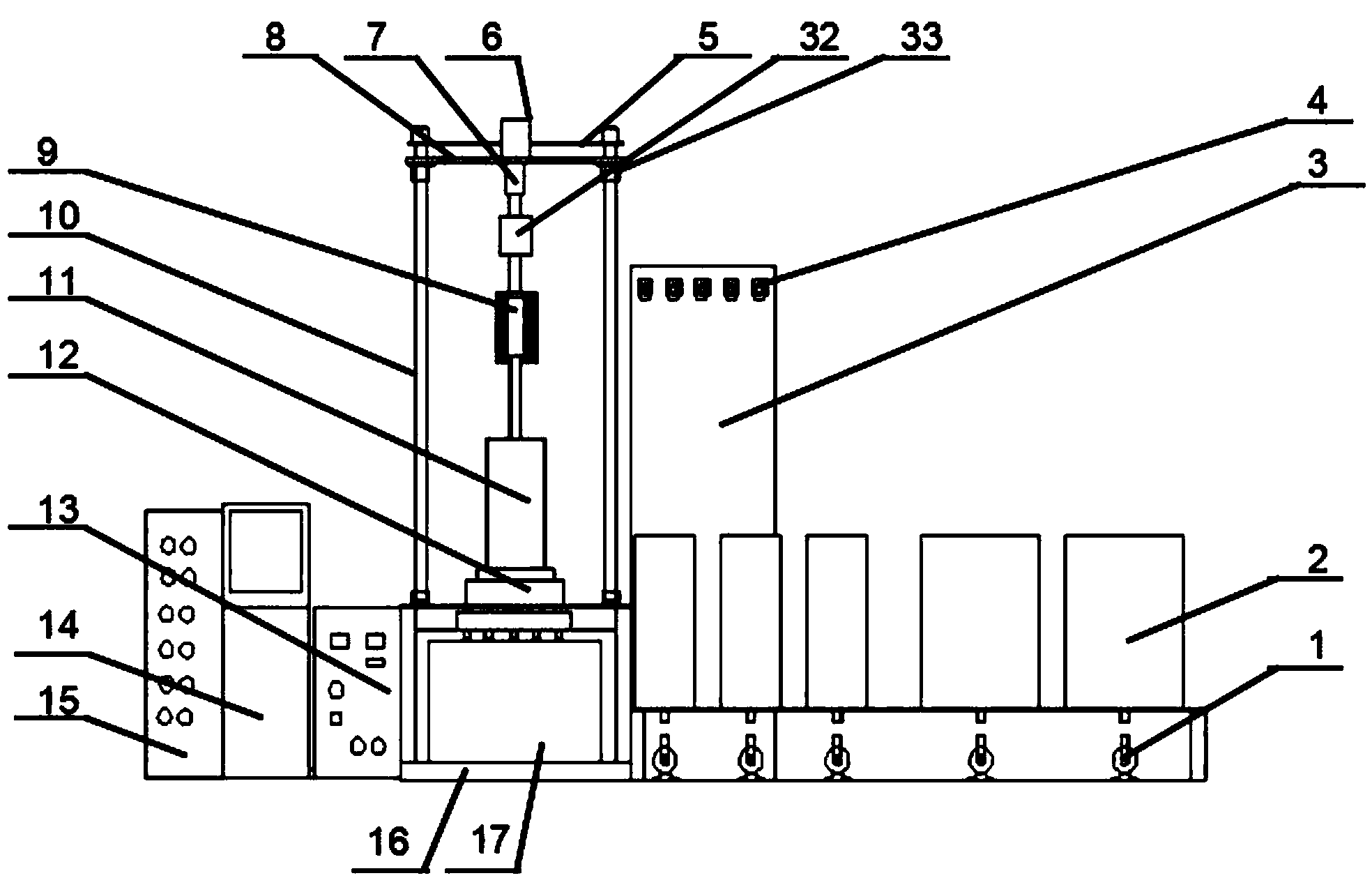

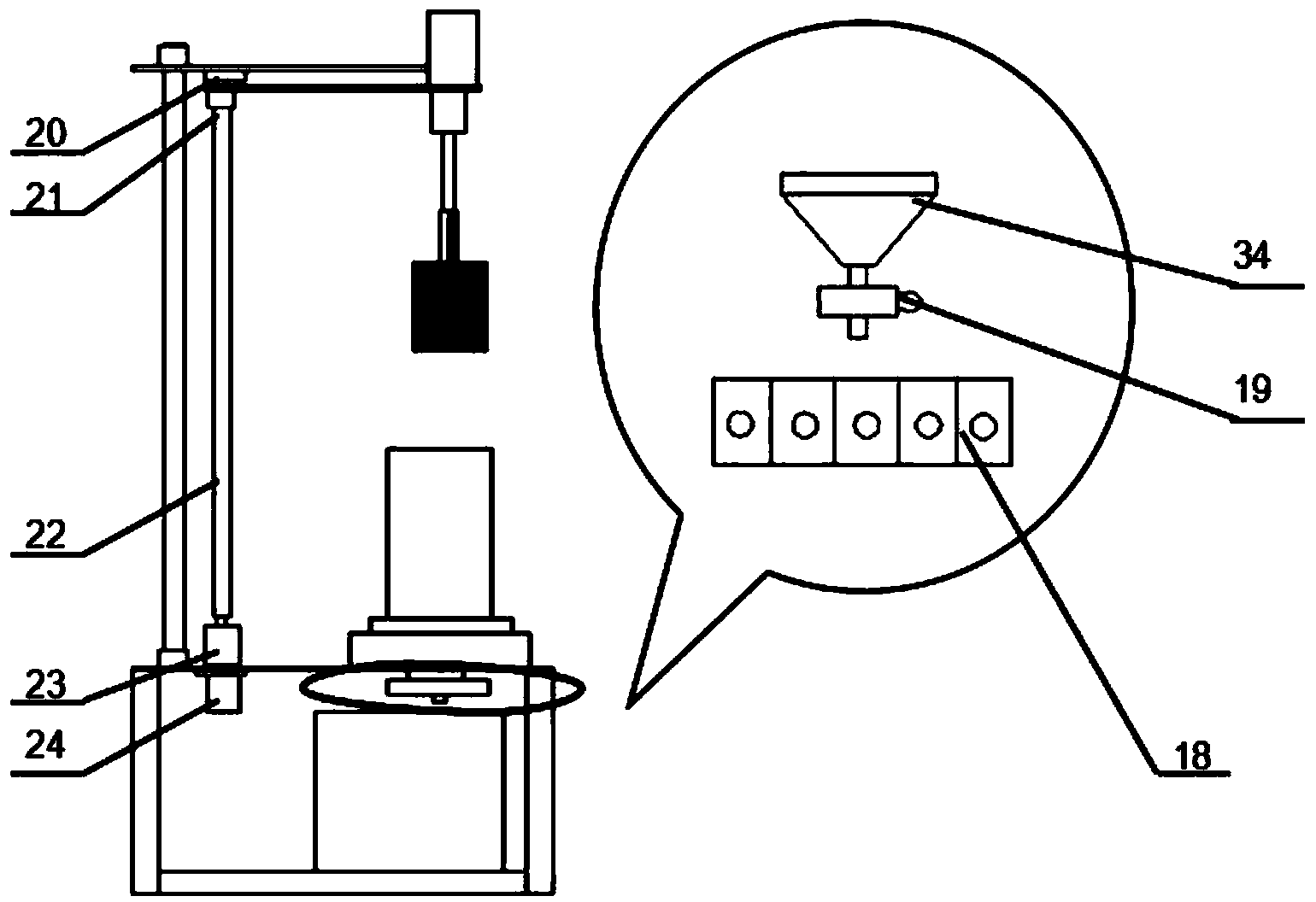

Brush electroplating repair experiment platform for oil cylinder barrel

InactiveCN103526243AIncrease labor intensityIncrease production capacityCellsRelative pressureProgrammable logic controller

The invention relates to a reproducing repair experiment platform and particularly relates to a brush electroplating repair experiment platform for an oil cylinder barrel. By adjusting four main parameters, which affect brush electroplating plating performances, such as brush electroplating voltage, relative movement speed of a workpiece and a plating pen, plating liquor flow rate, and relative pressure of the workpiece and the plating pen, optimal brush electroplating parameter value of the inner surface of the oil cylinder barrel can be obtained; the oil cylinder barrel is repaired through the obtained parameter value, so that dimension requirements and using performances can be satisfied well. According to the platform, a vertical structure is adopted, a plating brush adopts an inverter pulse power supply which is high in thickness measuring precision, and moreover, various parameters such as voltage are adjustable; the relative motion of the workpiece and the plating pen is decomposed into two major motions of linear feeding and rotation of the plating pen; each process step of the brush electroplating is automatically controlled by a PLC (Programmable Logic Controller); each of all different plating liquors has a respective specified plating liquor pump and a plating liquor box for realizing automatic applying and recycling. Besides, the brush electroplating repair experiment platform disclosed by the invention is simple and stable in structure, strong in practicability, high in automation degree, convenient to measure each parameter and capable of carrying out brush electroplating experiments, teaching and machining on the inner surface of a cylindrical workpiece.

Owner:GUANGXI UNIV

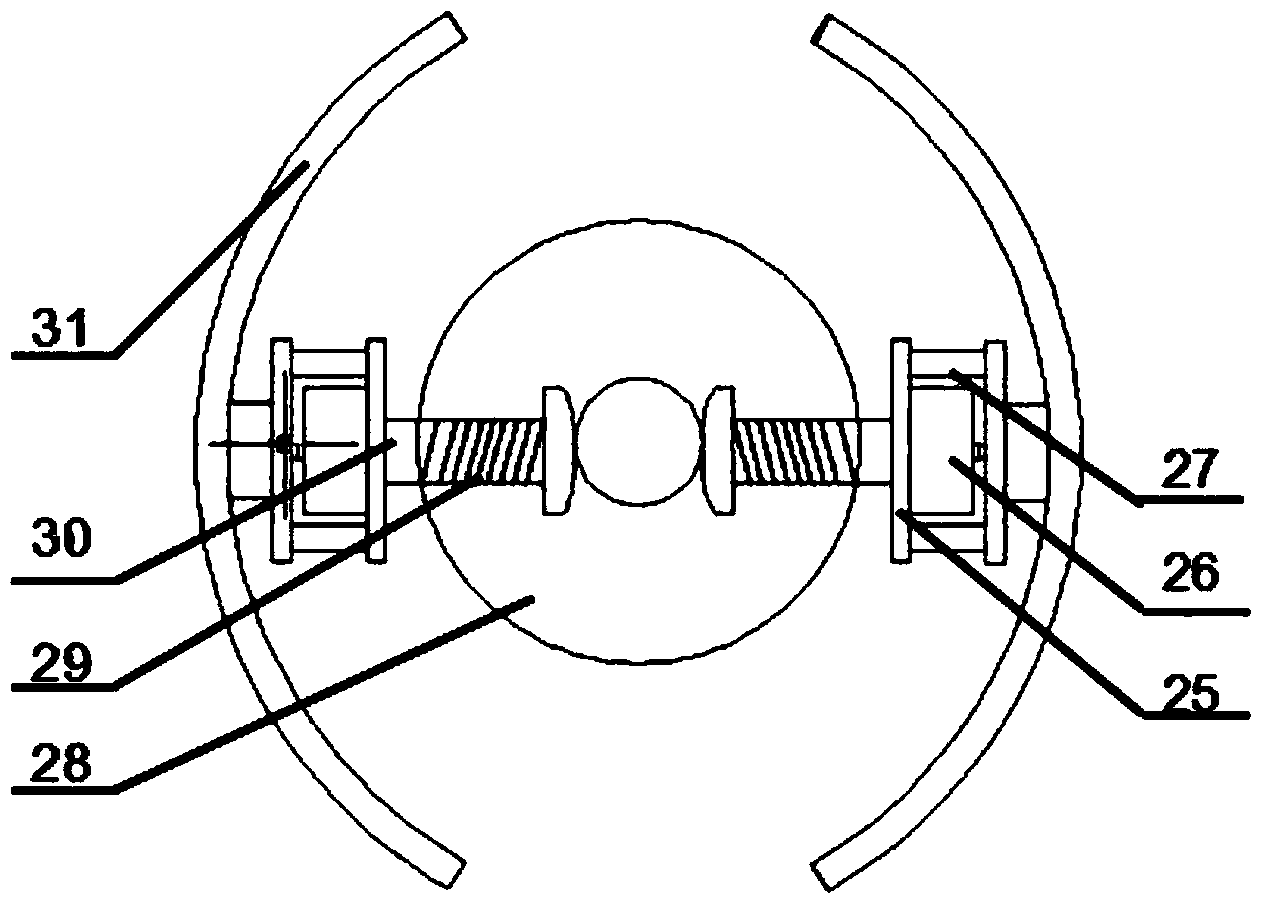

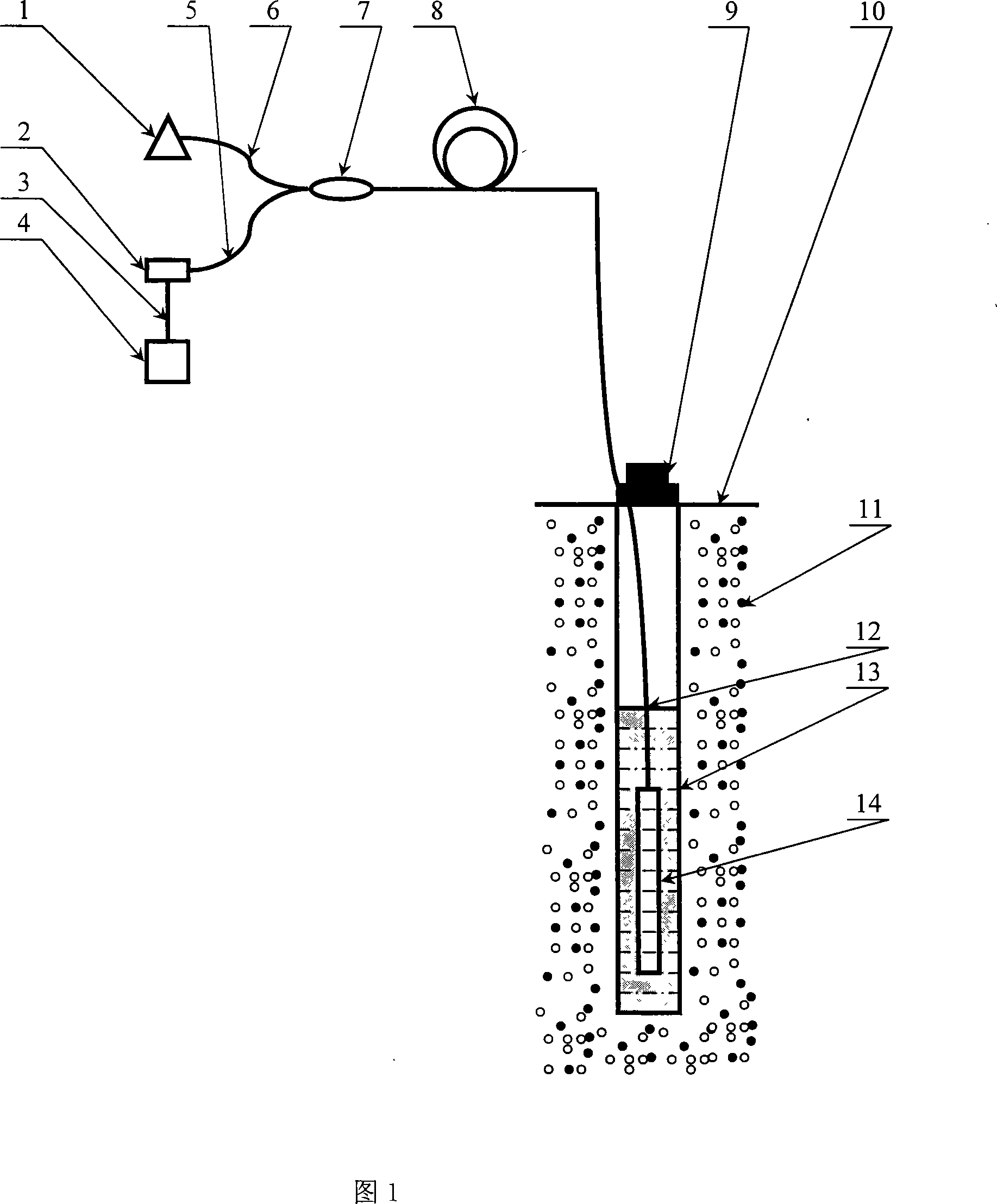

Optical fiber multi-point temperature and pressure measuring method for intelligent well and the device therefor

InactiveCN101187307ASolve stressSolve temperature problemsSurveyConstructionsGratingReflectance spectroscopy

The invention relates to a measuring method and a device for measuring optical fiber multipoint temperature and pressure of an intelligent well, belonging to the technical field of intelligent wells. The measuring method comprises that a plurality of optical fiber temperature sensors and optical fiber pressure sensors are arranged on an optical cable, wherein reversed lights which are reflected by the optical fiber temperature sensors and the optical fiber pressure sensors are respectively transformed into spectroscopic data which is transmitted to a processor, thereby respectively obtaining reflectance spectrums of all sensors, and a wave length value which is relative to the largest reflection rate is used as characteristic parameter of relative temperature sensors, the length of the cavity of each pressure sensor is calculated to be used as characteristic parameter of relative pressure sensors, and then the characteristic parameters of relative temperature and relative pressure sensors are compared with the characteristic parameter calibration curve to gain temperature reading or pressure reading of the optical fiber sensors. The device comprises a broad band light source, a modularized optical spectrometer, a data transmission line, a data processor, a first section optical fiber and a second section optical fiber, a optical fiber coupling, an optical cable, and a two-parameter sensor group of optical fiber temperature and optical fiber pressure. The invention solves the problems of pressure float and temperature crossfire when optical fiber grating technology is applied to a pressure sensor.

Owner:北京蔚蓝仕科技有限公司 +1

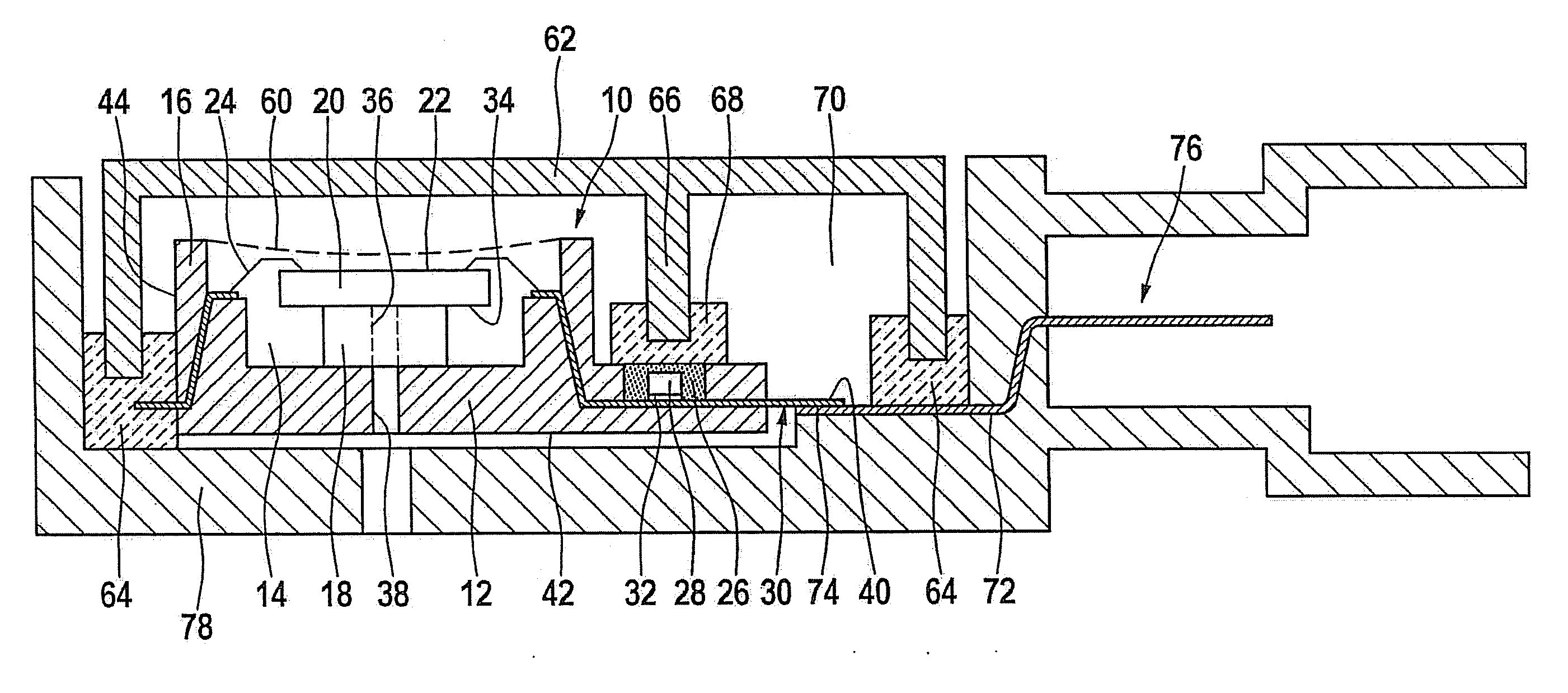

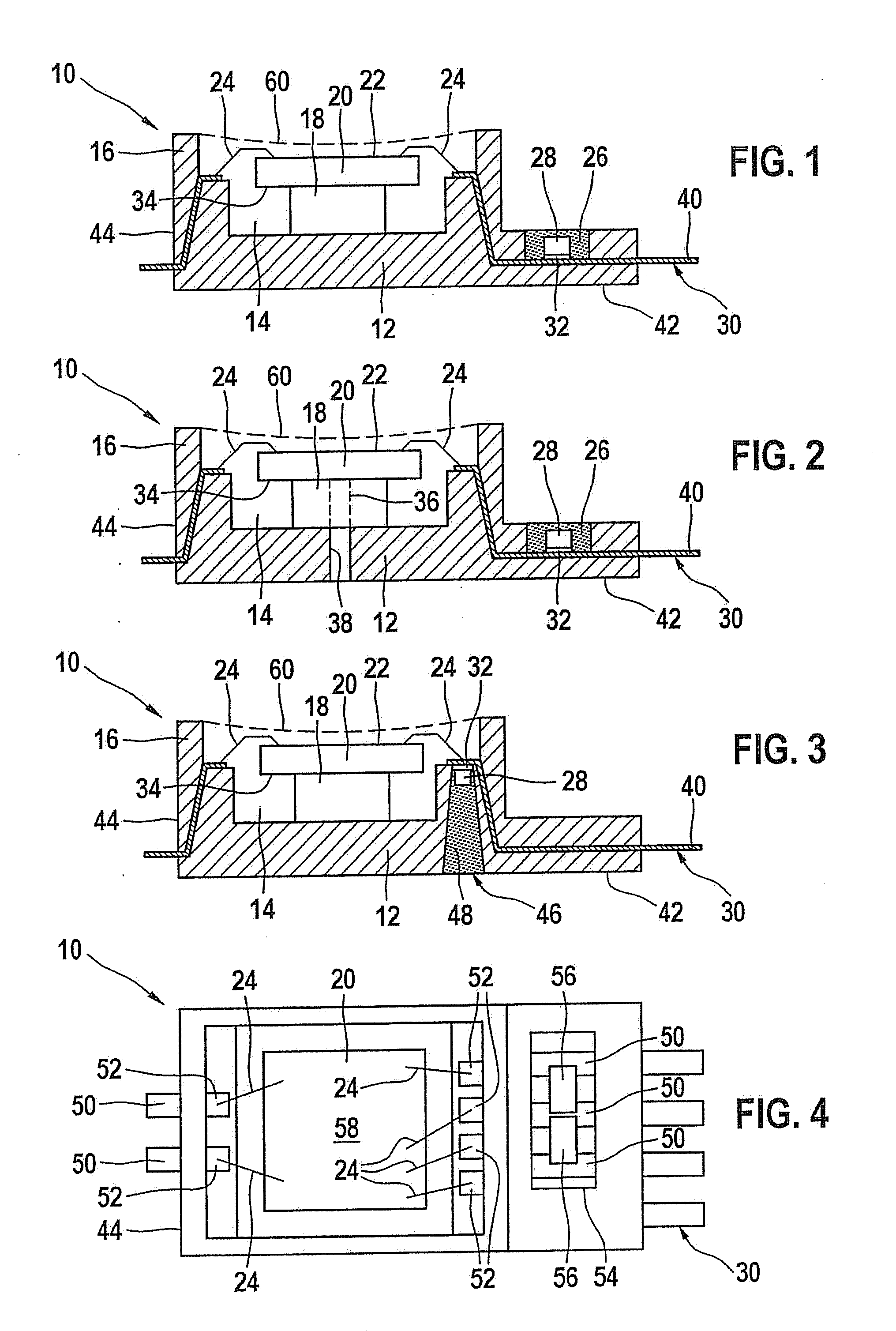

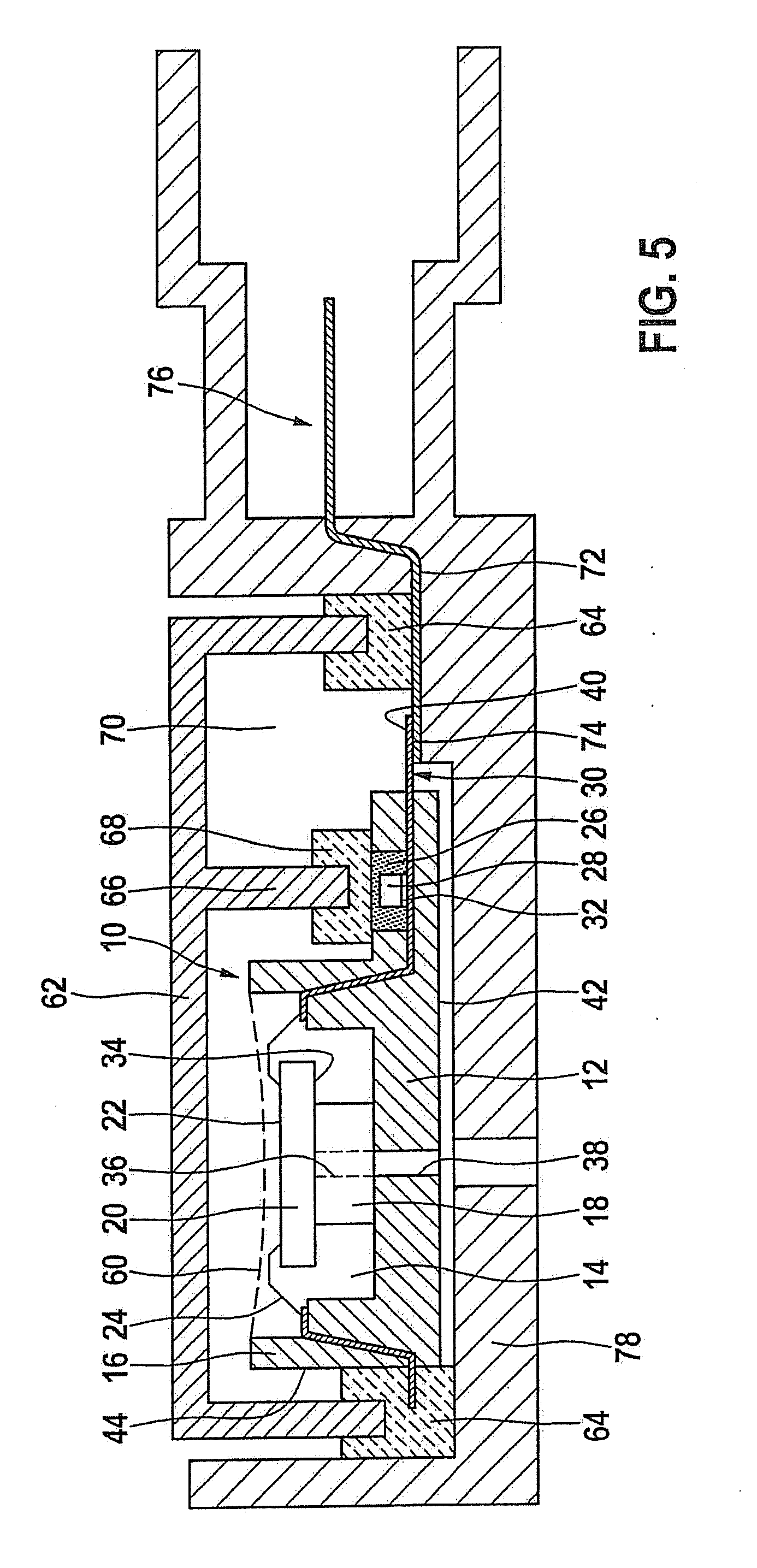

Pressure measurement module

ActiveUS20110016981A1Improve the immunitySimpler and flexibleFluid pressure measurement by electric/magnetic elementsPrinted circuit manufactureElectricityRelative pressure

A pressure measuring module for recording an absolute pressure or a relative pressure. Pressure measuring module includes a housing produced preferably as a premold, in which a pressure measuring chip is accommodated. The latter is contacted electrically either to a lead frame or to at least one printed circuit trace, at least one electronic component being provided, which is connected to a section of the lead frame or of the at least one printed circuit trace, exiting laterally from the housing that is produced as a premold, and is covered by a partition of a cover.

Owner:ROBERT BOSCH GMBH

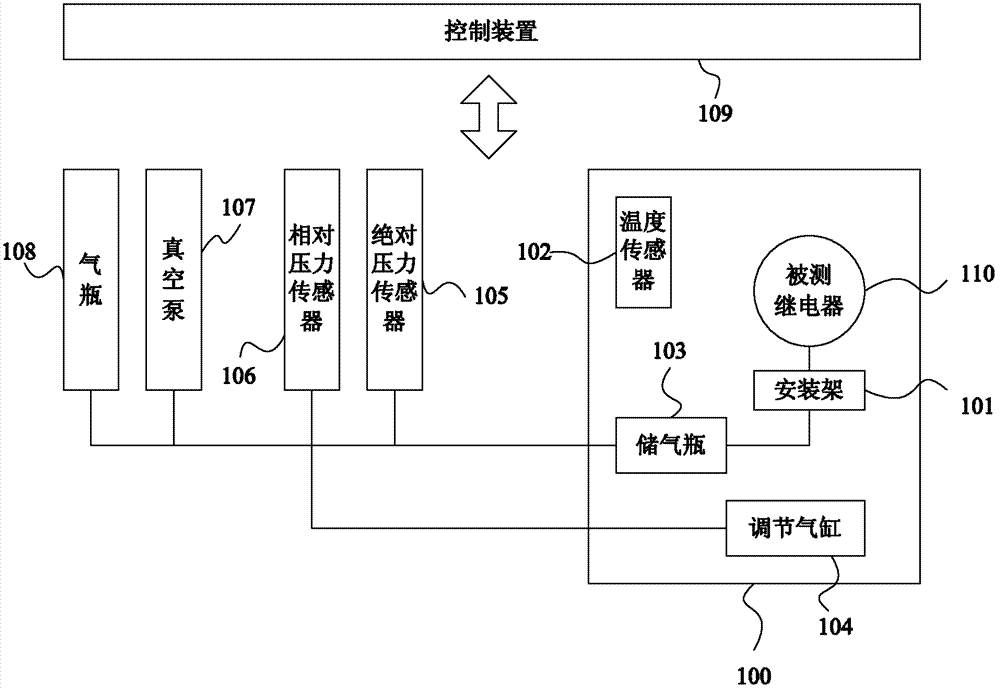

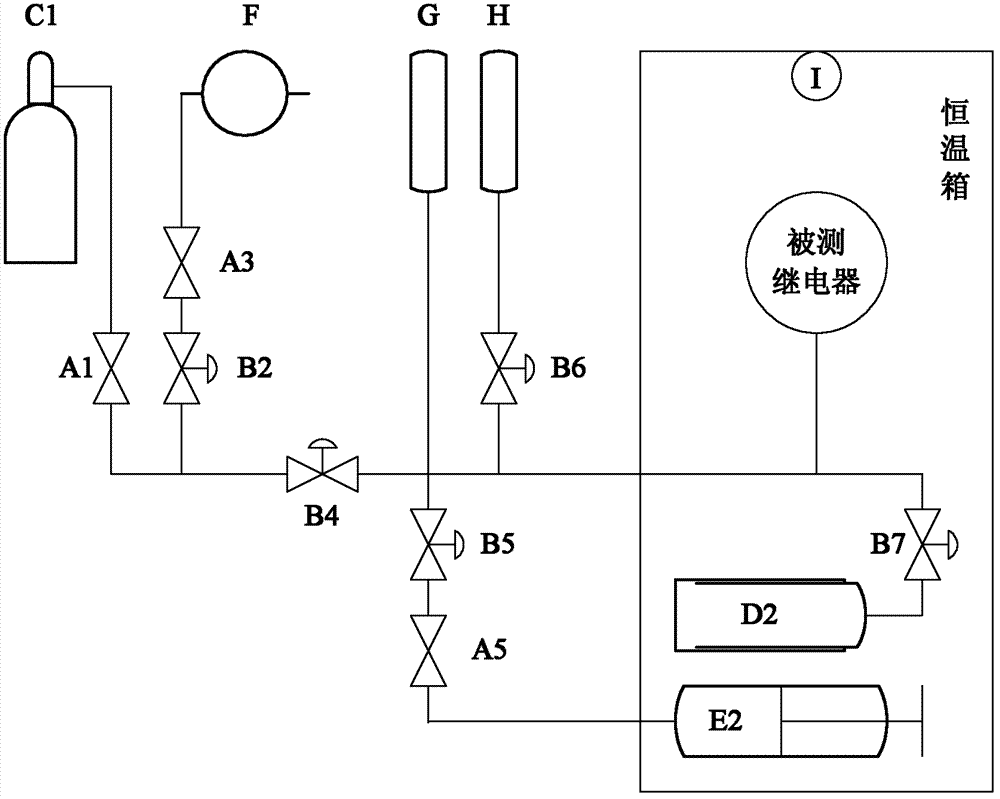

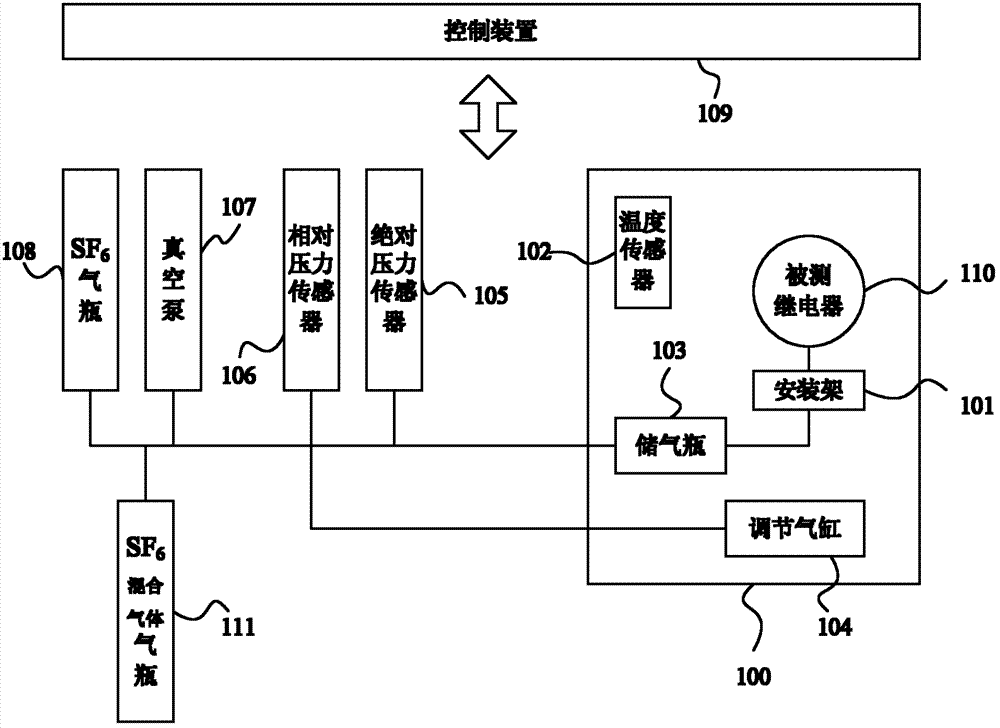

SF6 and SF6 mixed gas density relay verifying unit

ActiveCN103245908AAccurate CalibrationConvenient inflation systemCircuit interrupters testingSpecific gravity measurementData displayRelative pressure

The invention relates to a verifying unit which comprises a high-low temperature thermostat, and a to-be-tested relay mounting rack, a temperature sensor, an adjusting cylinder, and an SF6 and SF6 mixed gas cylinder which are arranged inside the high-low temperature thermostat, as well as an absolute pressure transducer, a relative pressure transducer, an SF6 gas cylinder, an N2 or CF4 gas cylinder, a vacuum pump and a control device which are arranged outside the high-low temperature thermostat, wherein the control device is respectively connected with the temperature sensor, a to-be-tested gas density replay, the absolute pressure transducer and the relative pressure transducer; and the control device is used for data processing, control command outputting, and verification result data display. The verifying unit is used for realizing the full-temperature accurate test to the SF6 gas density relay, and meanwhile realizes the full-temperature accurate test to the SF6 mixed gas density relay.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

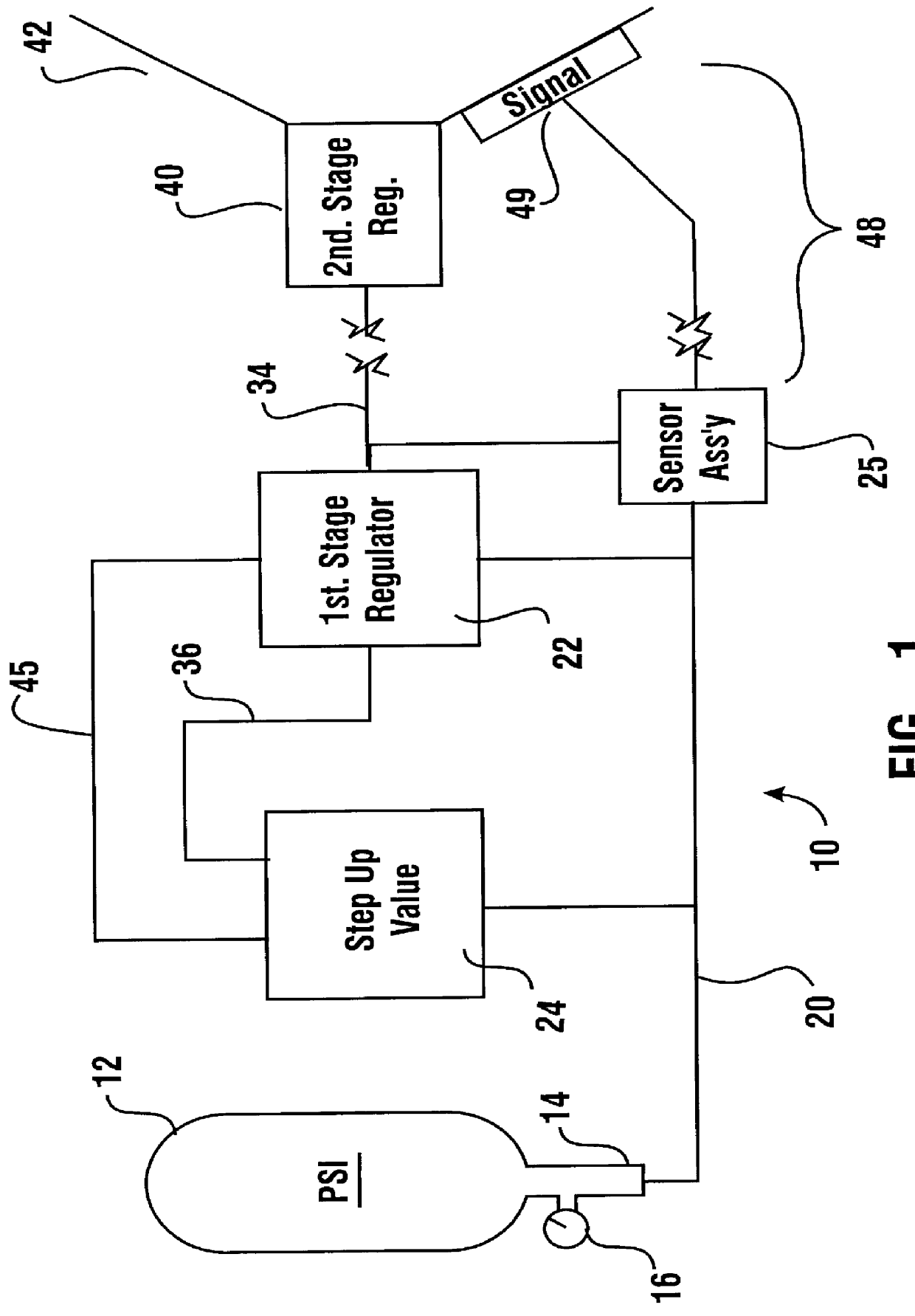

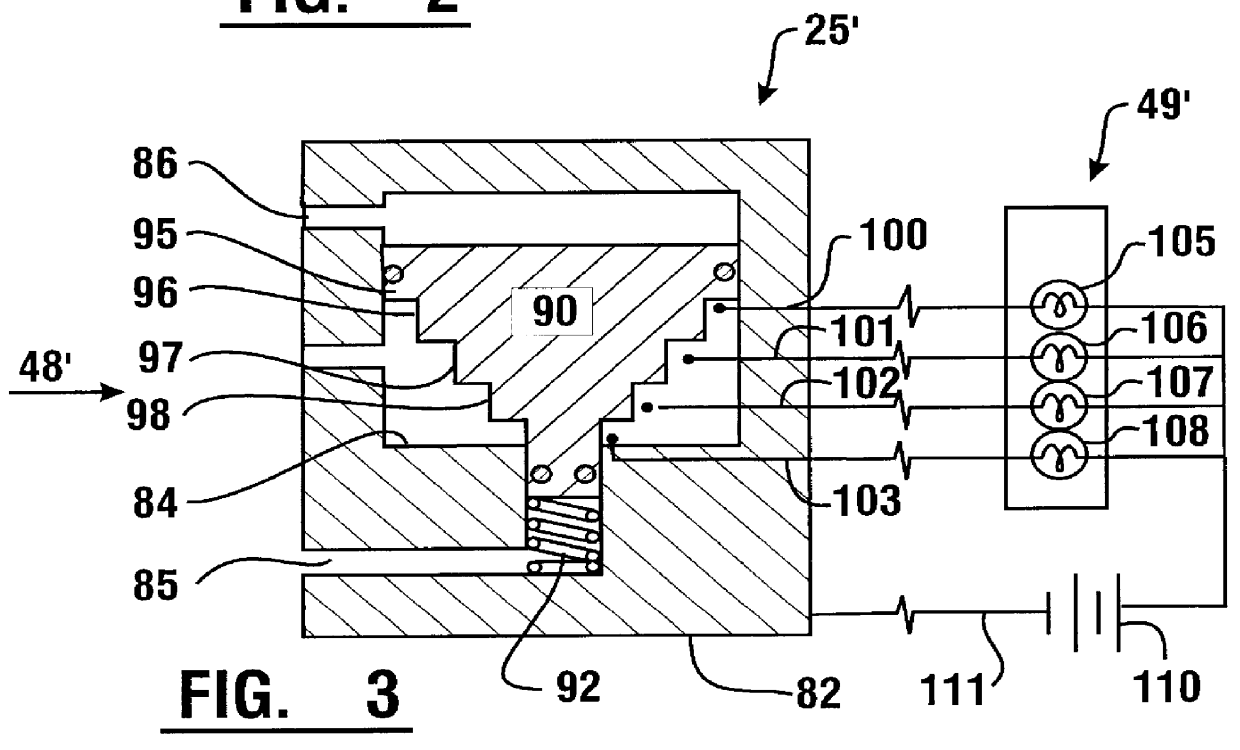

Progressive pressure indicator

InactiveUS6095142AAccurately indicateRespiratorsRespiratory device testingRelative pressureLED display

A pressure indicating device for self contained breathing apparatus includes a piston arrangement which is responsive to the relative pressures of the supply and the pressure at the outlet of the first stage regulator to assume several different positions in the containment housing. Piston position is recognized by electronic circuitry and an LED display is lighted accordingly to provide a series of unique signals to the user, of the remaining quantity of breathing fluid. In one embodiment of the invention, plural, graduated-size pistons provide a progressive indication of the air supply. In another embodiment, a single, stepped piston effects progressive electrical contact at various positions in the travel of the piston.

Owner:SCOTT TECH INC

Air bag with pressure-managed gas delivery inflatable duct

An inflatable side airbag has an inflatable duct for the delivery of inflation gas. The inflatable duct of the inflatable side airbag provides for rapid deployment of a multi-chamber air bag while controlling the rate of inflation and the relative pressure of the chambers. The inflatable duct allows a single inflator to inflate a high pressure pelvis chamber and a lower pressure thorax chamber while preventing fluid communication between the two chambers upon completion of inflation.

Owner:AUTOLIV ASP INC

Method and Installation for the Production of Containers

InactiveUS20070235906A1Improve cooling effectEconomical and simpleDomestic articlesHollow articlesThermoplasticRelative pressure

A method of producing containers, including a forming step in which thermoplastic performs are used to form containers including a body and a base; and, subsequently, a cooling step in which the formed containers are cooled by projecting a jet onto the containers in a localized manner on a target area including the base thereof, the jet consisting of a mixture of a gas and an atomized liquid which are both at a relative pressure of less than approximately 1 bar. The invention also relates to an installation for the production of containers, which is adapted for the aforementioned method.

Owner:SIDEL PARTICIPATIONS SAS

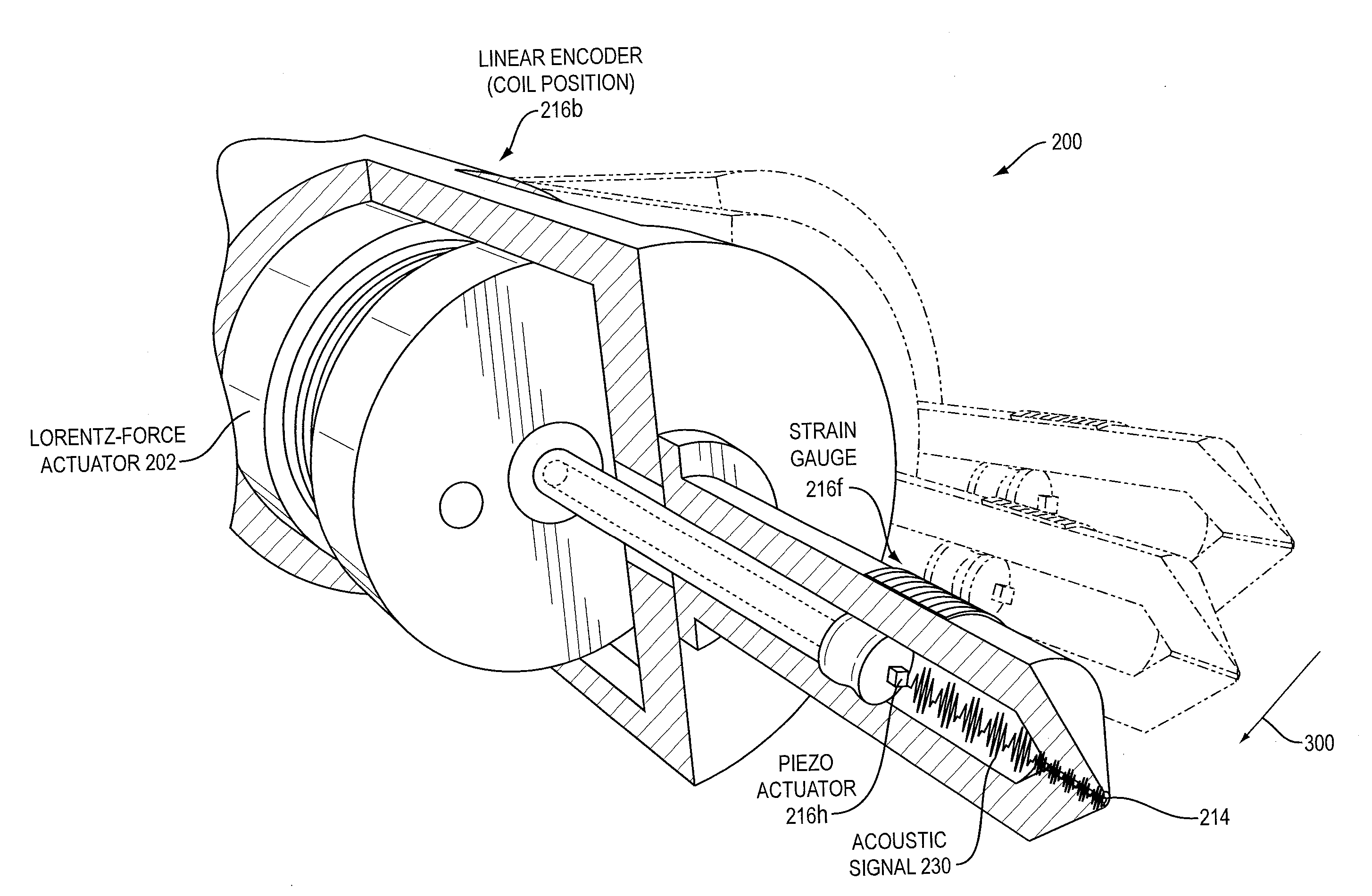

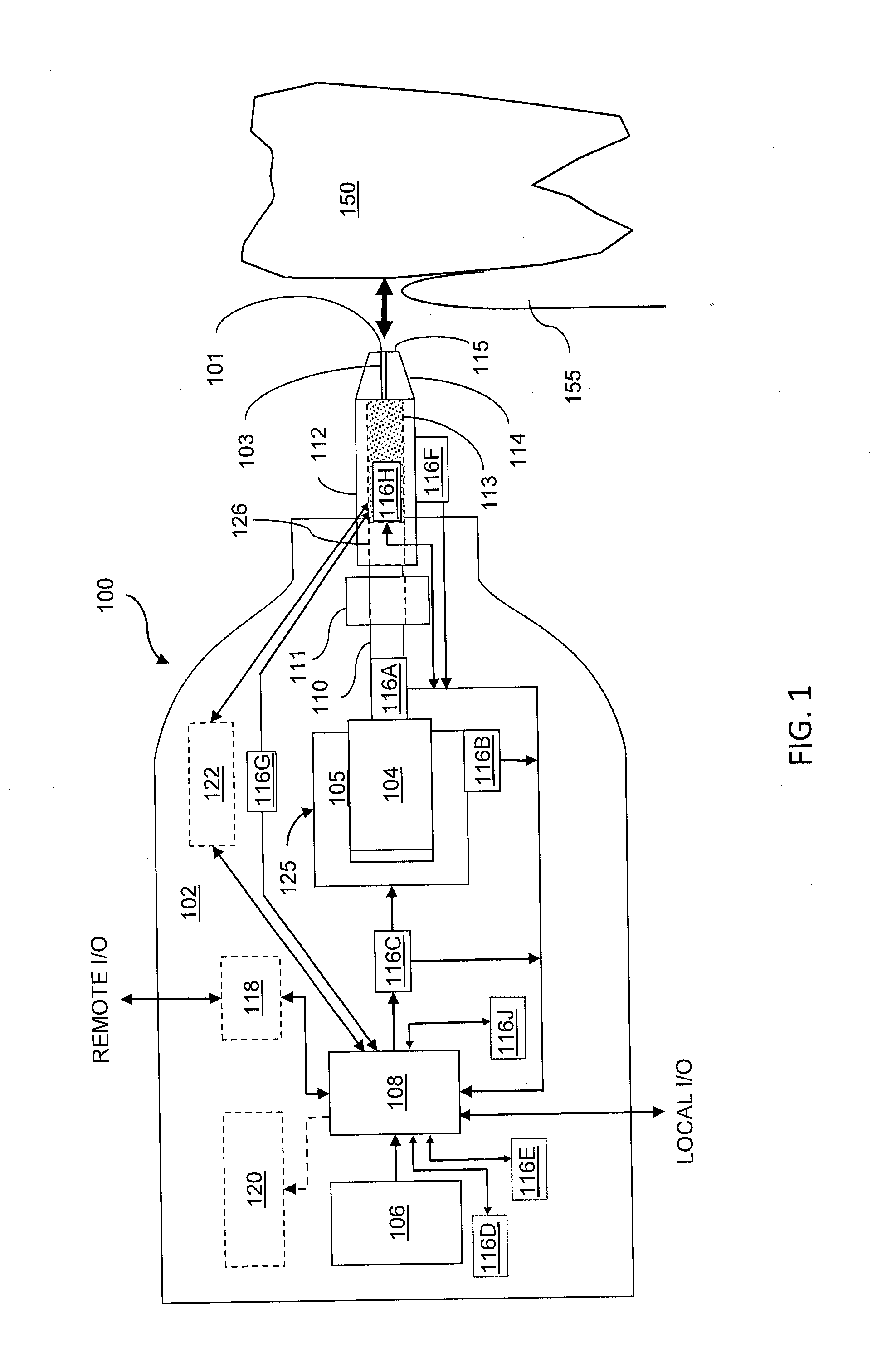

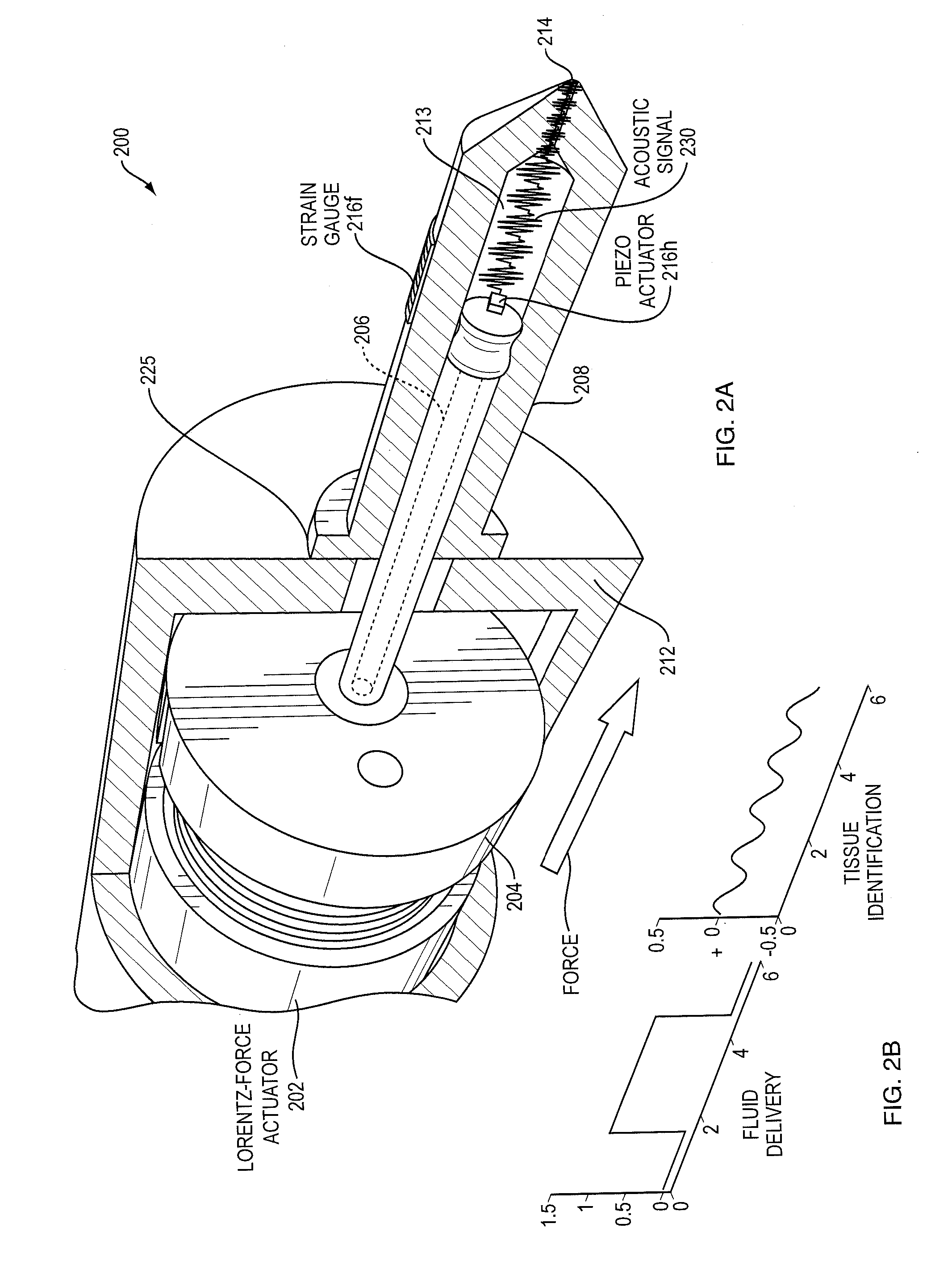

Plaque Removal and Differentiation of Tooth and Gum

A method of tooth treatment includes sensing a surface condition of tooth or gum and controlling ejection of a fluid jet against the tooth based on the sensed condition. The fluid may be a liquid and may be carried in a self-contained reservoir in a handle of a fluid ejection device. The liquid can be a cleansing solution and may contain cleaning particles. The ejection can be controlled to clean teeth at high pressure and to reduce pressure applied to gum, for example, to clean plaque. In some embodiments, the method may be used to remove soft tooth. The method may further include automatically scanning the fluid jet relative to a handle of an injection device. In an embodiment, the fluid is ejected by means of a fluid ejector comprising a stationary magnet assembly providing a magnetic field and a coil assembly, slidably disposed with respect to the magnet assembly, the coil assembly driving ejection of the fluid jet. Sensing the surface condition can include measuring a response of tissue to a mechanical perturbation and may include sensing an acoustic signal reflected from tissue. The mechanical perturbation can include applied force and the measured response can include deformation of the tissue. The method may further include mechanically disturbing the tissue with the fluid jet. A tooth treatment device includes a fluid ejector that ejects fluid against teeth and a servo controller controlling pressure of ejected fluid in response to a sensed surface condition. The fluid jet can have a diameter of less than 500 microns, a peak relative pressure of at least 1 kilopascal and velocity of at least 1 meter per second.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com