Brush electroplating repair experiment platform for oil cylinder barrel

An experimental platform, electric brush plating technology, applied in the electrolysis process, electrolysis components, cells and other directions, can solve the problems of high consumption of manpower, material and financial resources, high labor intensity, efficiency and poor surface quality of repair, etc., to improve labor Strong, damage-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

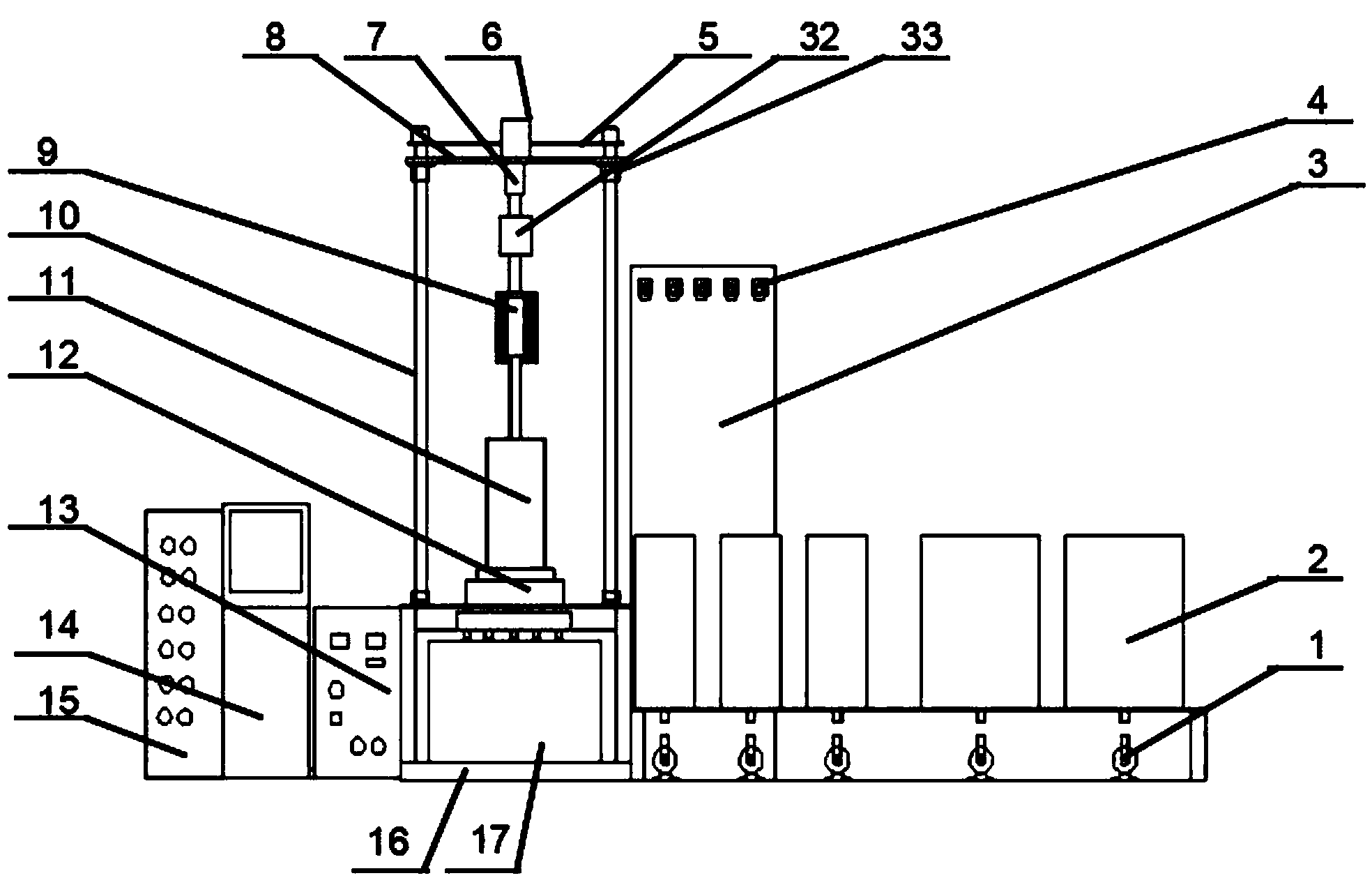

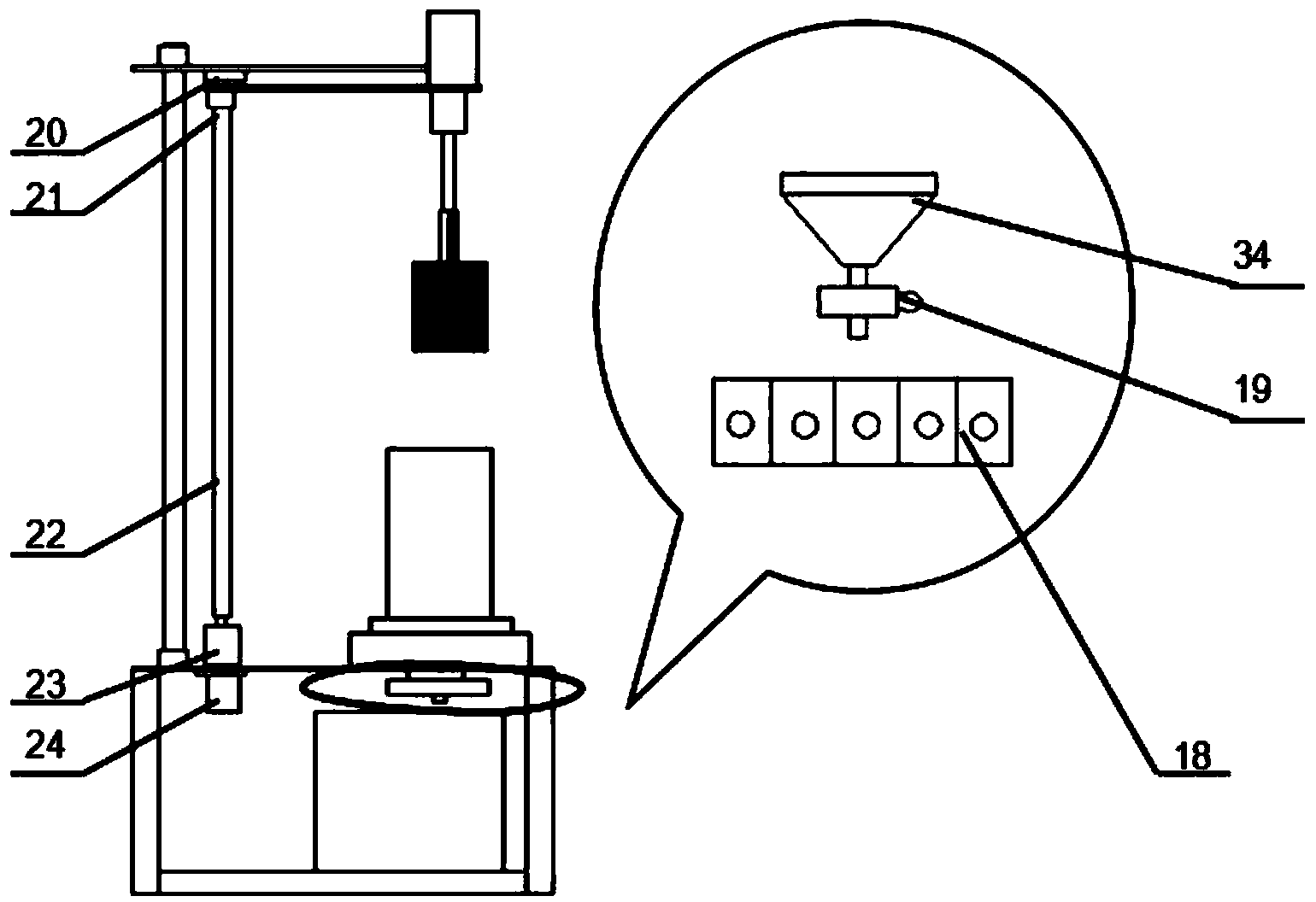

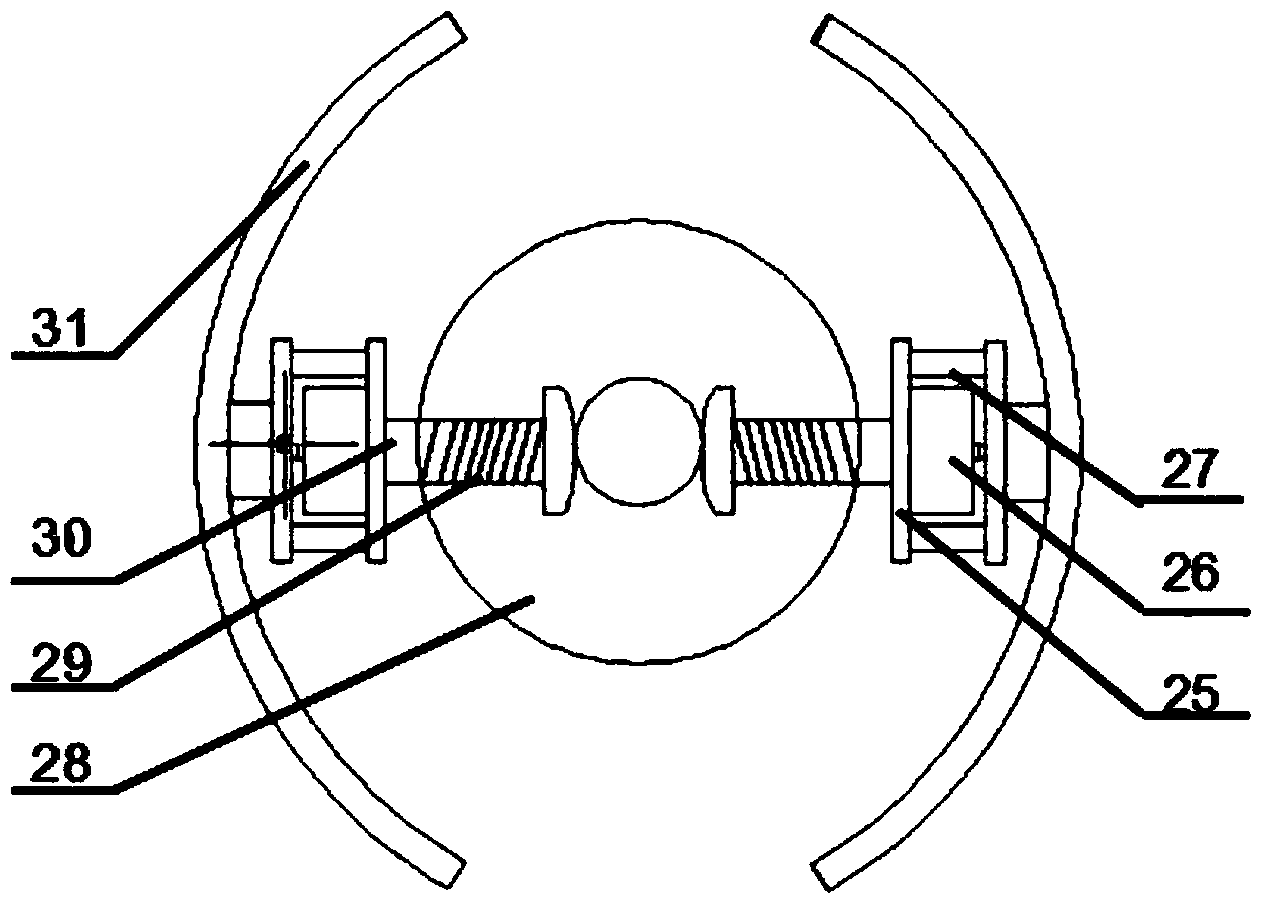

[0019] Now in conjunction with the accompanying drawings, the specific embodiment, shape, structural features and performance of the present invention will be described in detail as follows.

[0020] like Figure 1-3 As shown, the whole experimental platform is supported by a supporting platform 16, and a stepper motor 24 is installed at the bottom end of one side of the supporting platform 16 and fixed on the supporting platform 16. The stepper motor 24 is connected with the ball screw 22 through a shaft coupling 23 , and the other end of the ball screw 22 is supported by a screw support base 20 , and the support base 20 is fixed on the top fixing plate 5 . The ball screw nut 21 is fixed with the moving plate 8, and the other end of the moving plate 8 is connected with the linear bearings 33 connected to the two optical axes 10 in the front section. The upper end of the moving plate 8 fixes the rotary motor 6 and fixes the plating pen force applying device through the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com