Patents

Literature

1769results about How to "Improve production environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

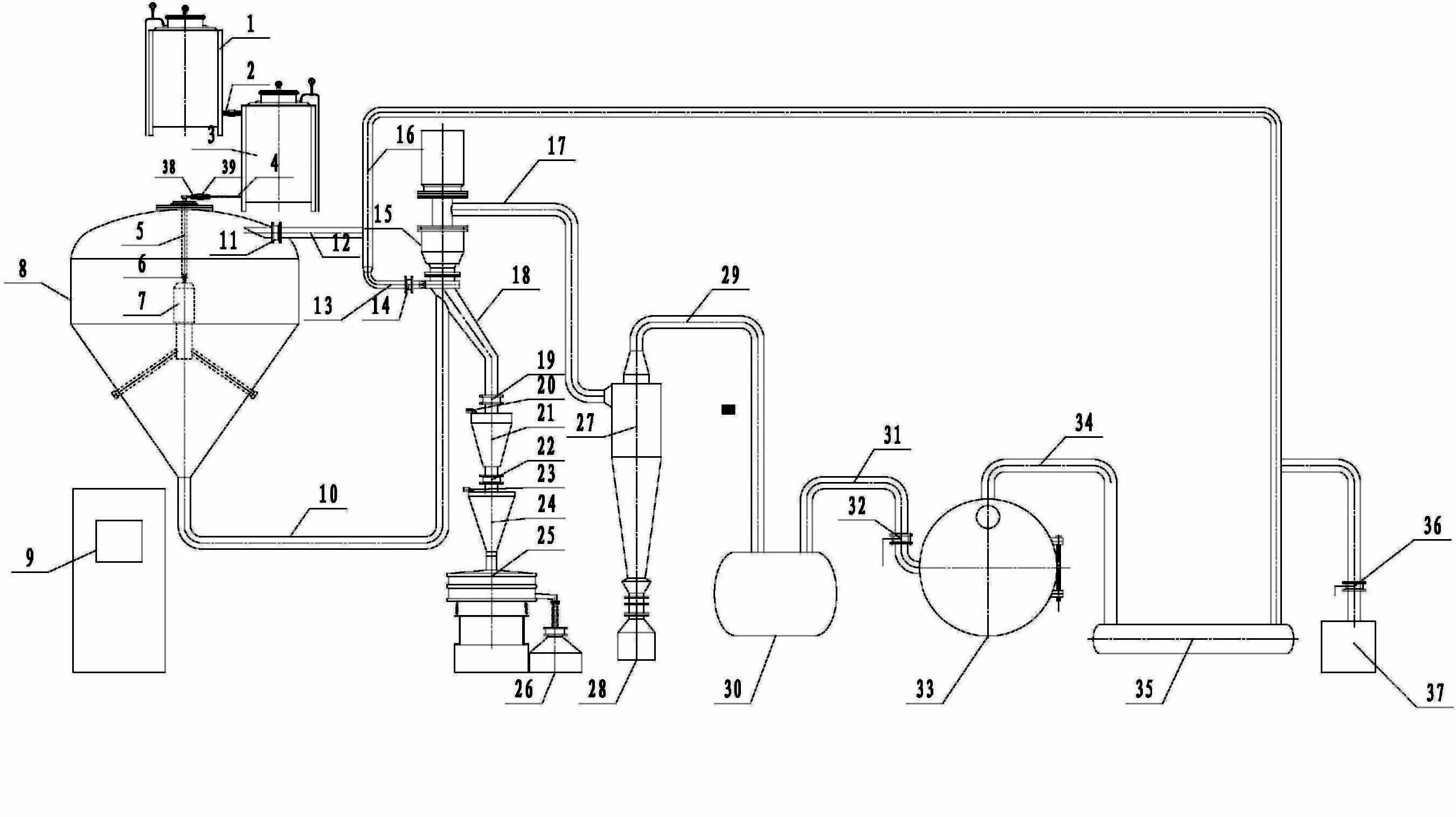

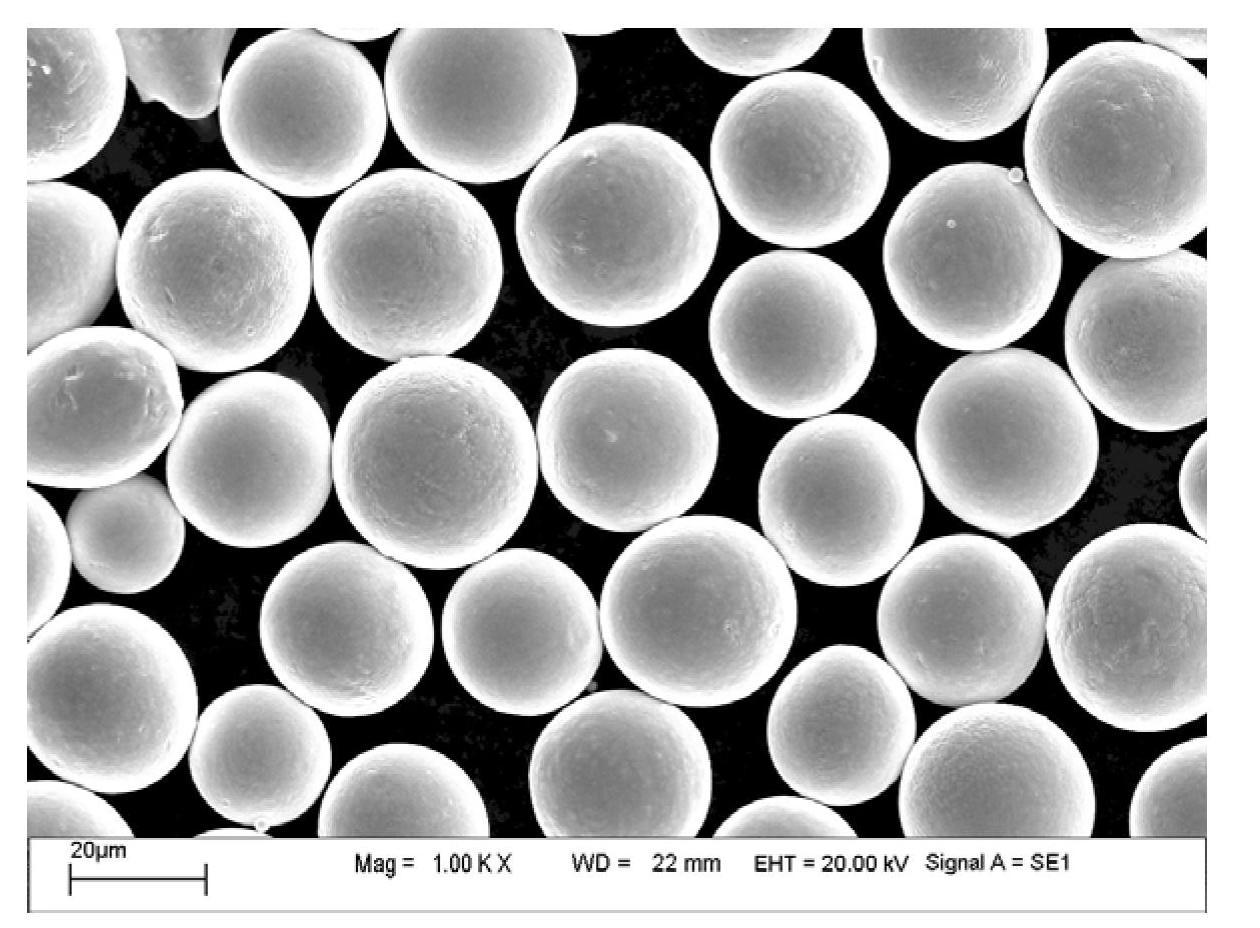

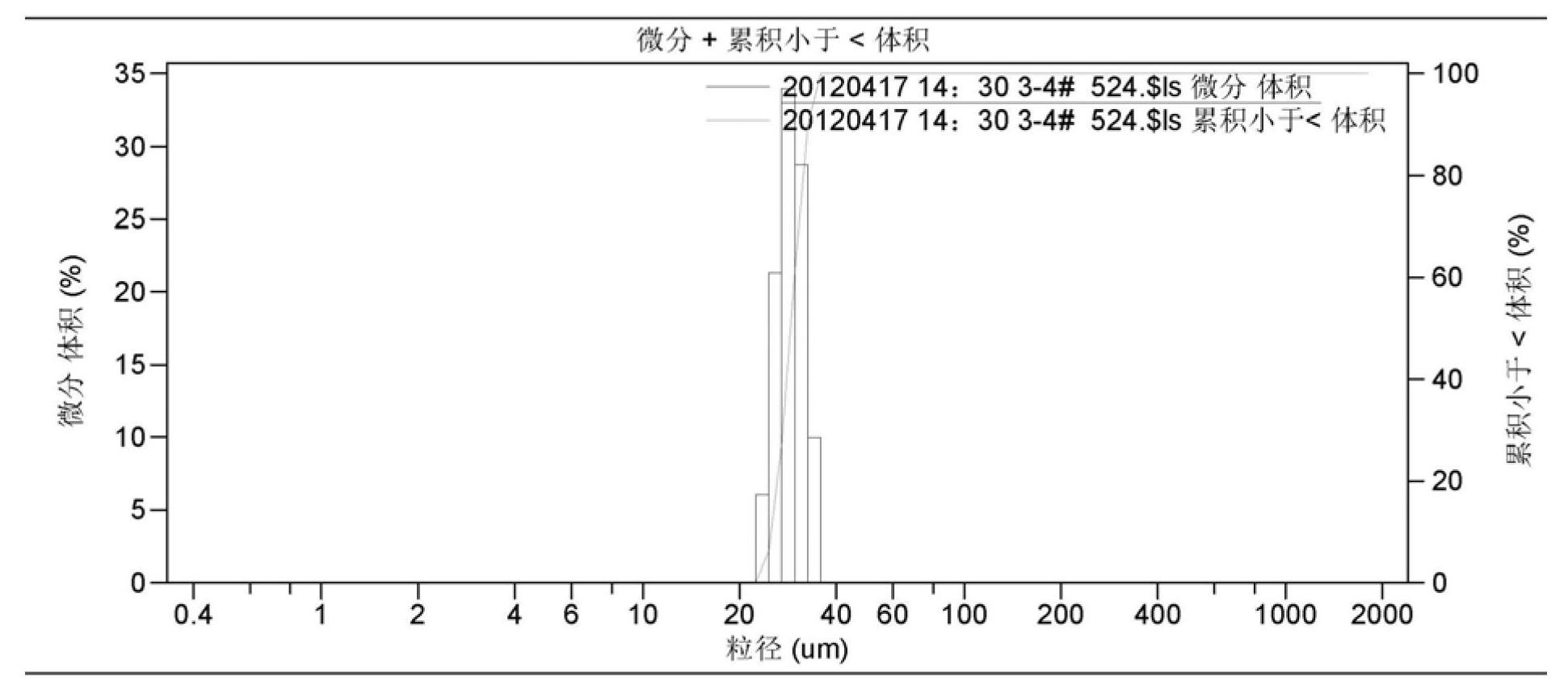

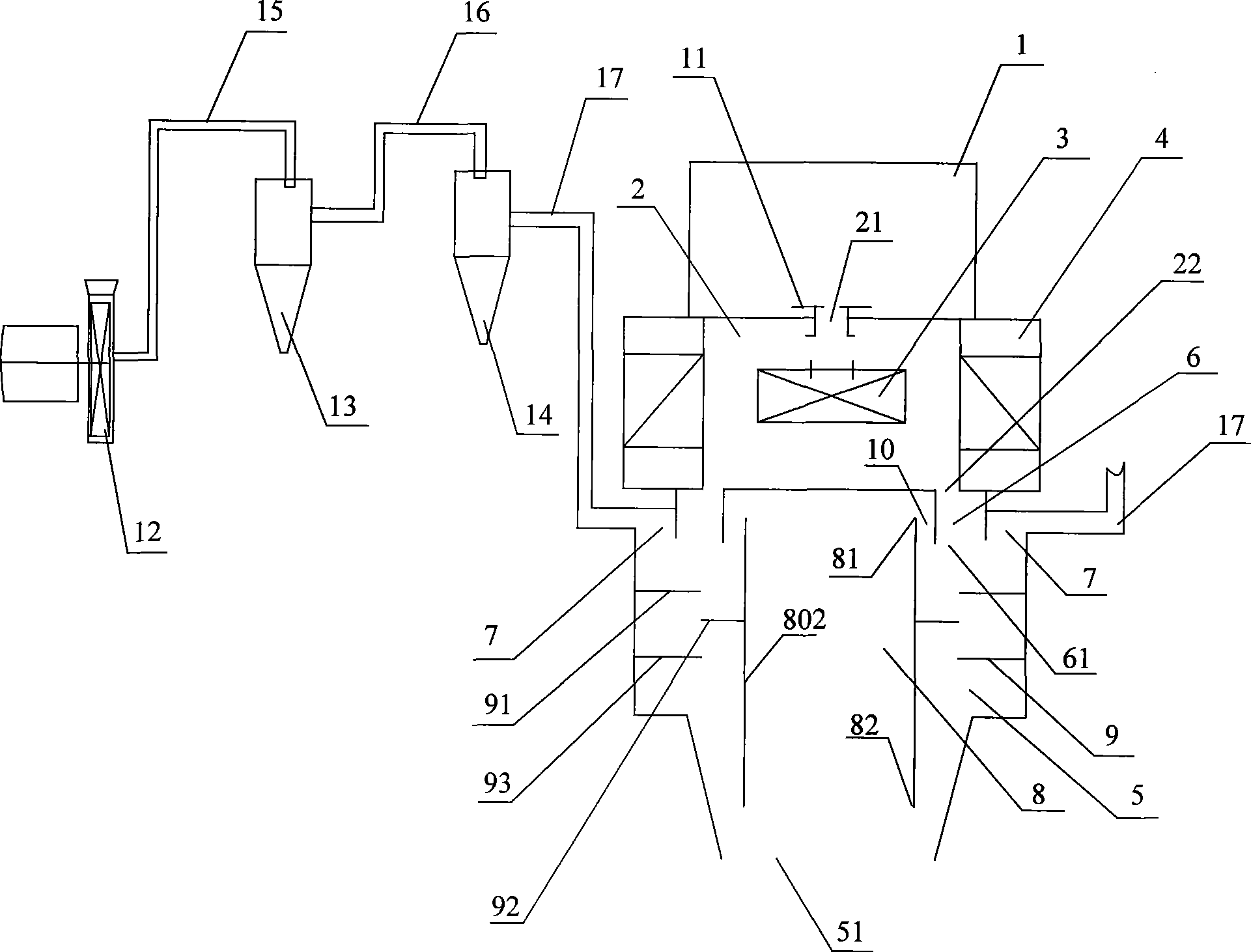

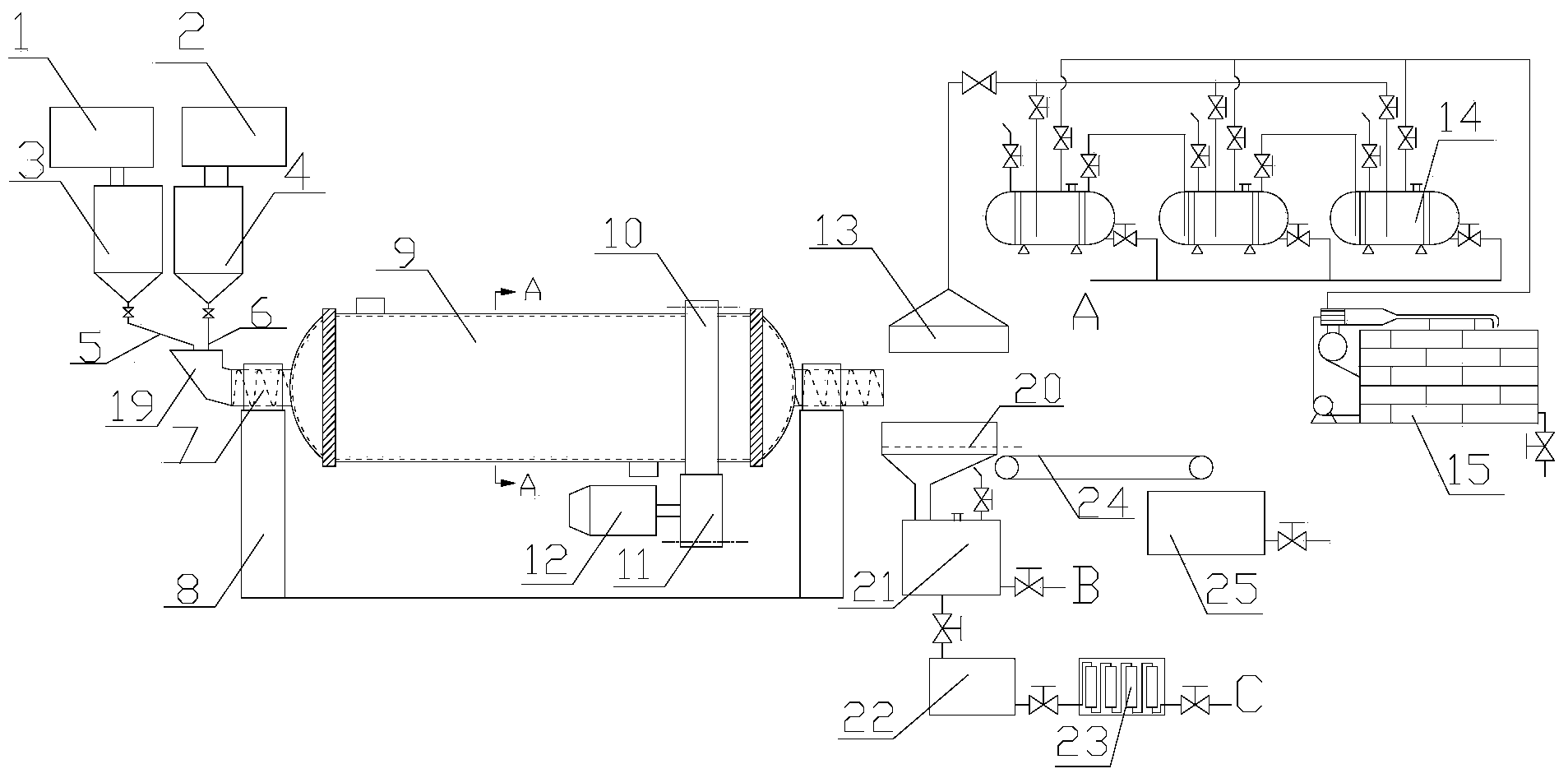

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

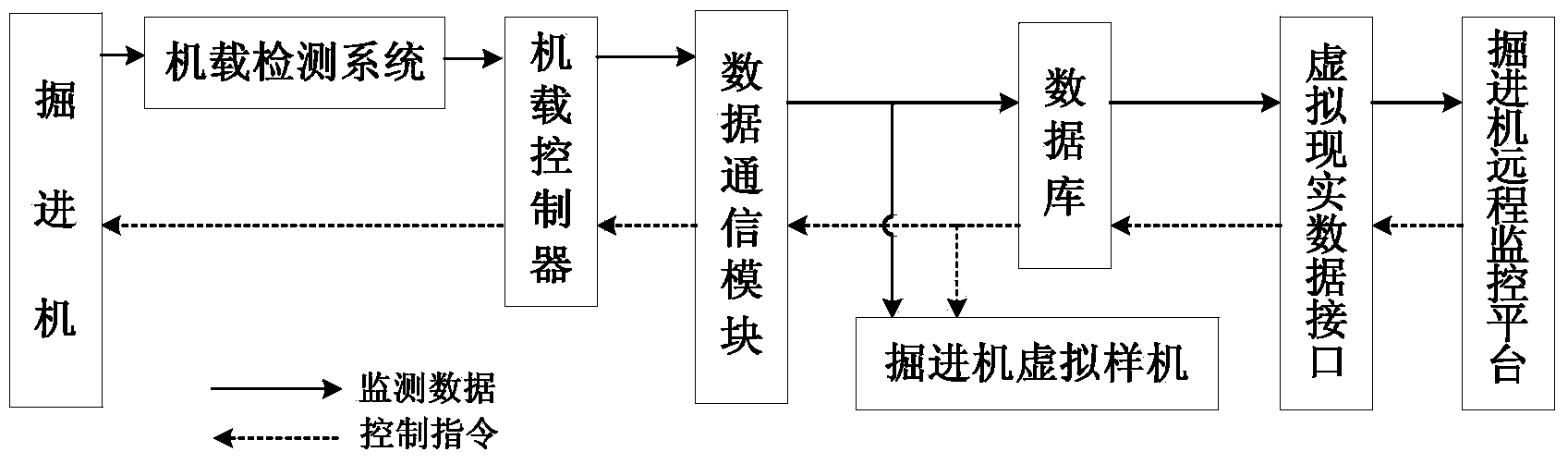

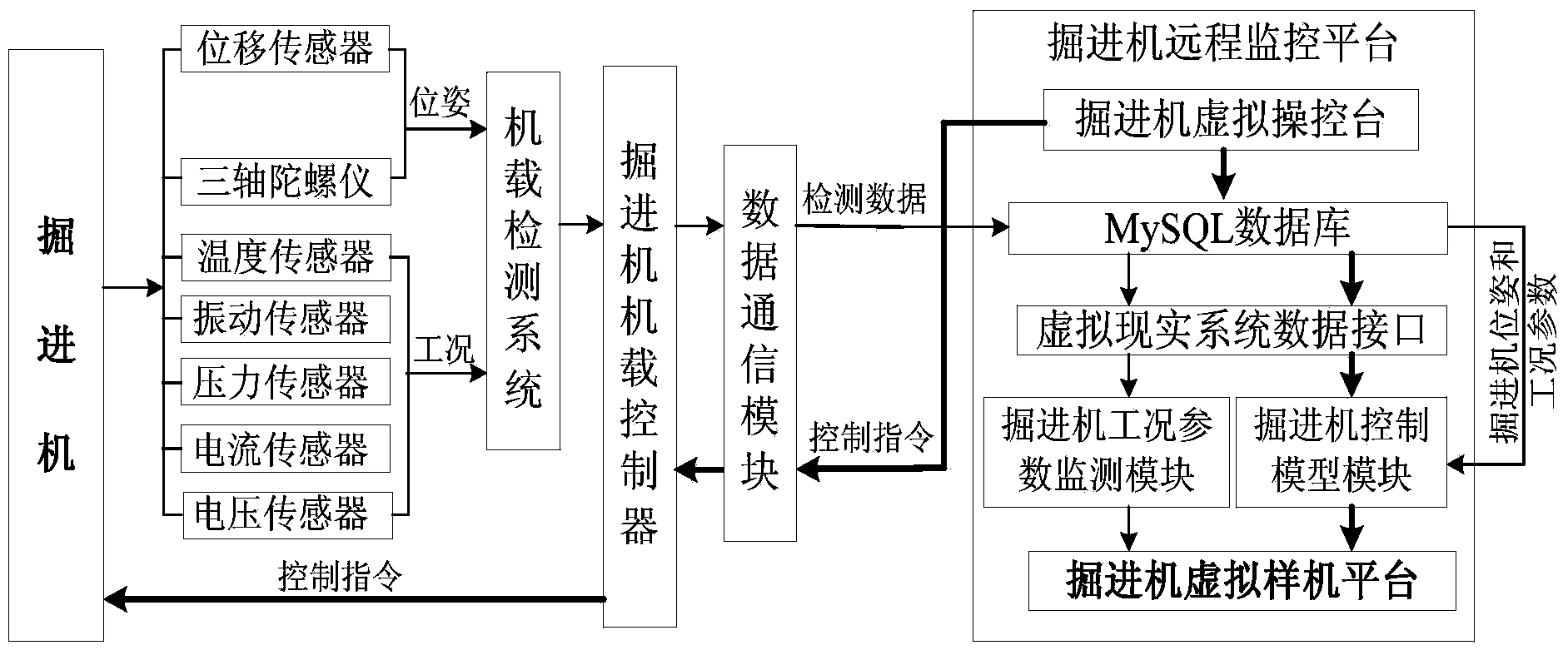

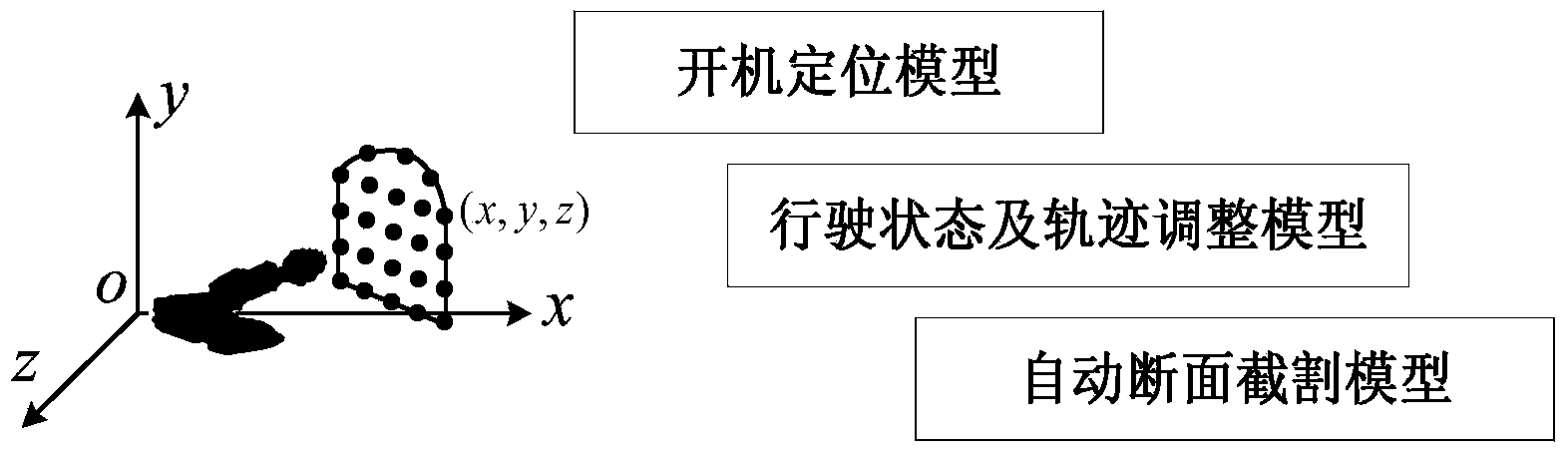

Remote control system and remote control method of heading machine

ActiveCN103867205AImplement the binding actionEnsure consistencySlitting machinesMachine controlRemote control

The invention discloses a remote control system and a remote control method of a heading machine. The remote control system comprises a sensor arranged on the heading machine, an onboard detection system, an onboard controller, a data communication module and a heading machine remote monitoring platform, wherein the heading machine remote monitoring platform comprises a heading machine virtual control table, a database, a virtual reality system data interface, a heading machine control model module, a heading machine working condition parameter monitoring module and a heading machine virtual prototype platform. The system and the method solve the problems that the working environment of the heading machine in underground coal mine has abundant dust and high noise, an operator has difficulty in mastering the specific situation of the heading cross section, and controls blindly due to lacking of working condition data and pose information of the heading machine, thereby promoting the roadway drifting quality and the drifting safety. The remote control system has good interaction, good reality sense, reasonable design, strong practicability and high popularization and application values.

Owner:XIAN UNIV OF SCI & TECH

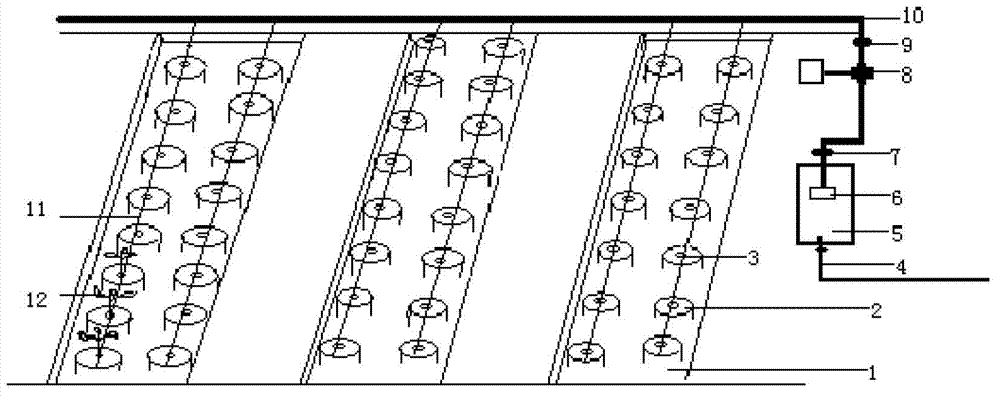

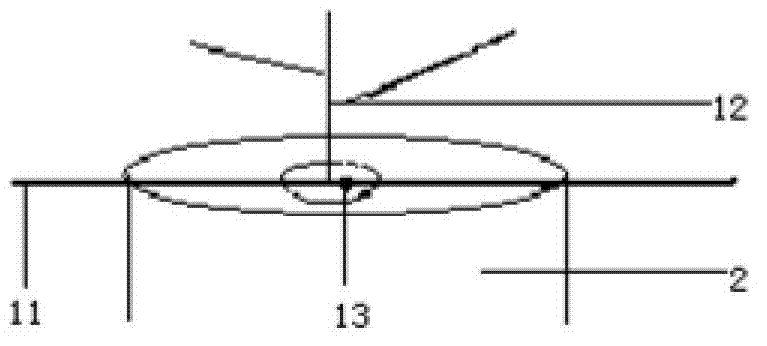

Bag culture system for large-scale production of solanaceous vegetables

InactiveCN102783402AIncrease productionImprove qualityAgriculture gas emission reductionCultivating equipmentsDiseaseDrip irrigation

A bag culture system for large-scale production of solanaceous vegetables comprises a plurality of culture troughs, a plurality of culture bags, a water inlet pipe, a reservoir, a water pump, a fertilizing device, a filter, a drip irrigation main pipe, a plurality of drip irrigation branch pipes and a plurality of emitters. The culture troughs are formed in parallel on the floor of a solar greenhouse by recessing. Two rows of upright culture bags are disposed in each culture trough. The reservoir is located inside the greenhouse. The water pump is disposed in the reservoir, and an outlet of the water pump is connected with a liquid inlet end of the drip irrigation main pipe. An outlet end of the fertilizing device is connected with a liquid inlet end of the drip irrigation main pipe. The filter is disposed on the drip irrigation main pipe. The rear of the drip irrigation main pipe is arranged above one ends of the culture troughs. One drip irrigation branch pipe is disposed above each row of culture bags, and one ends of the drip irrigation branch pipes are connected with the drip irrigation main pipe simultaneously. Each drip irrigation branch pipe is provided with the emitters, while each emitter is above a round hole of each culture bag. The bag culture system has the advantages that production environment can be improved, water and fertilizer can be economized, utilization rate of fertilizer is increased, spread of soil-borne diseases is avoided, and the like.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

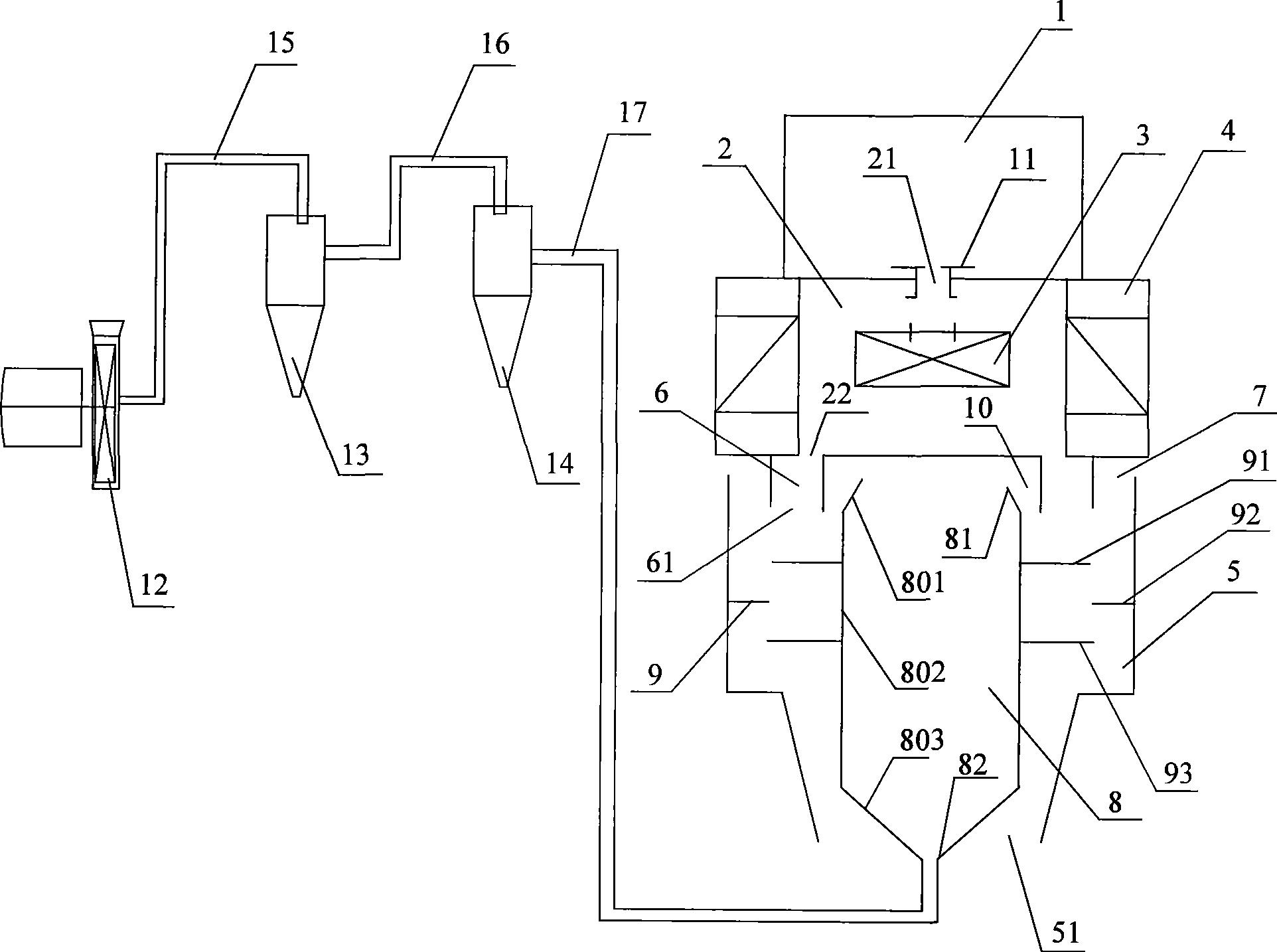

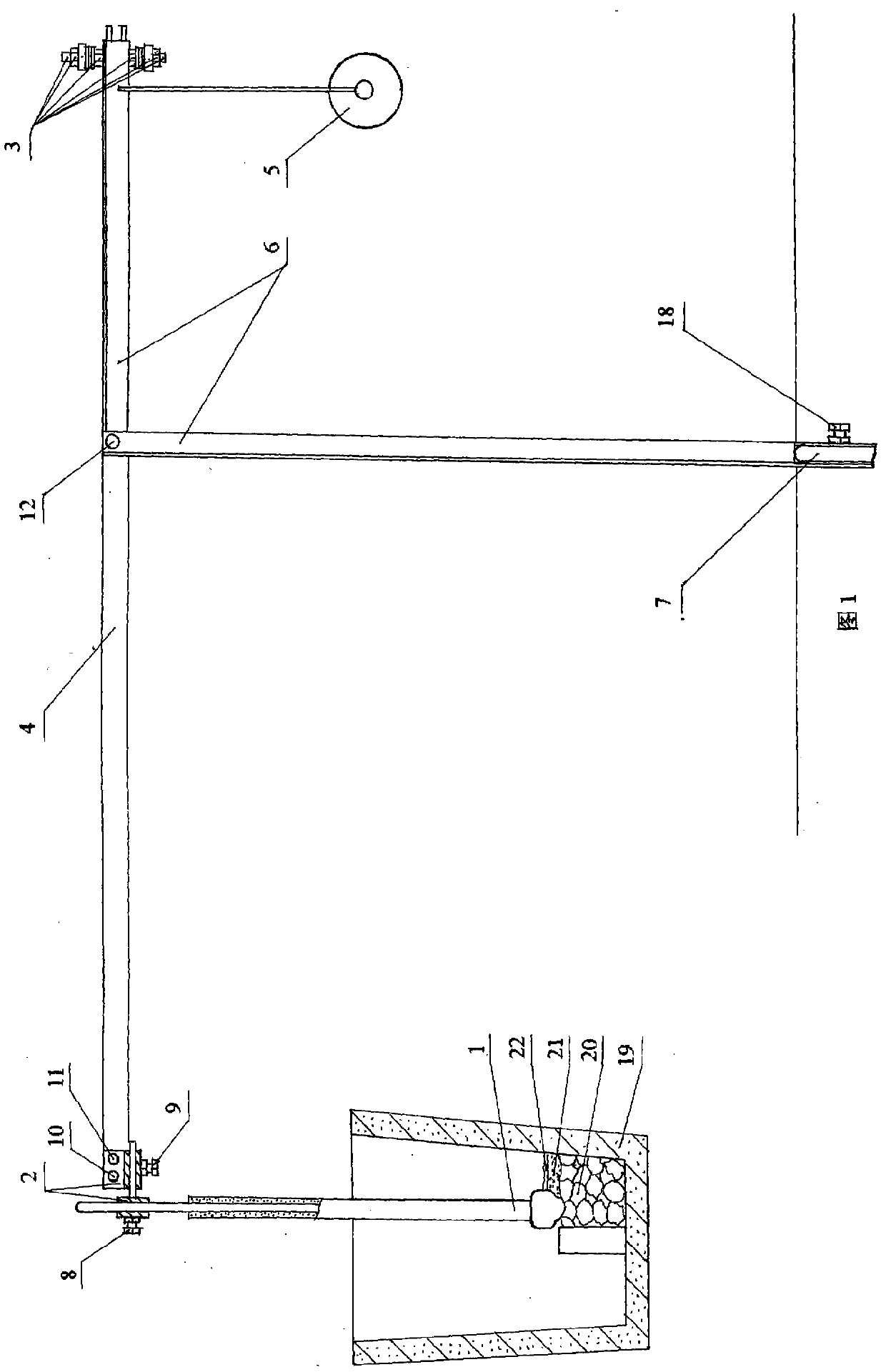

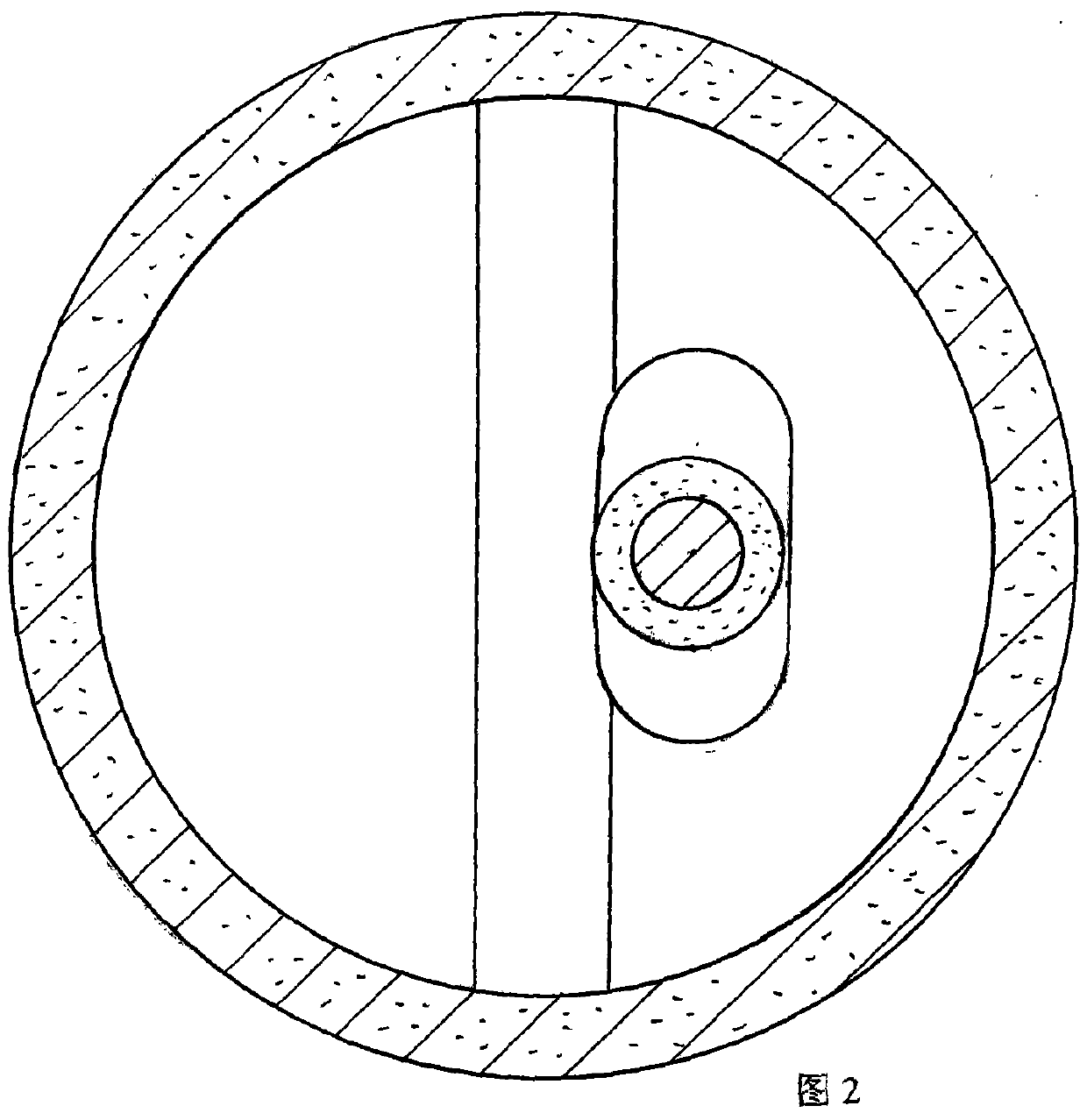

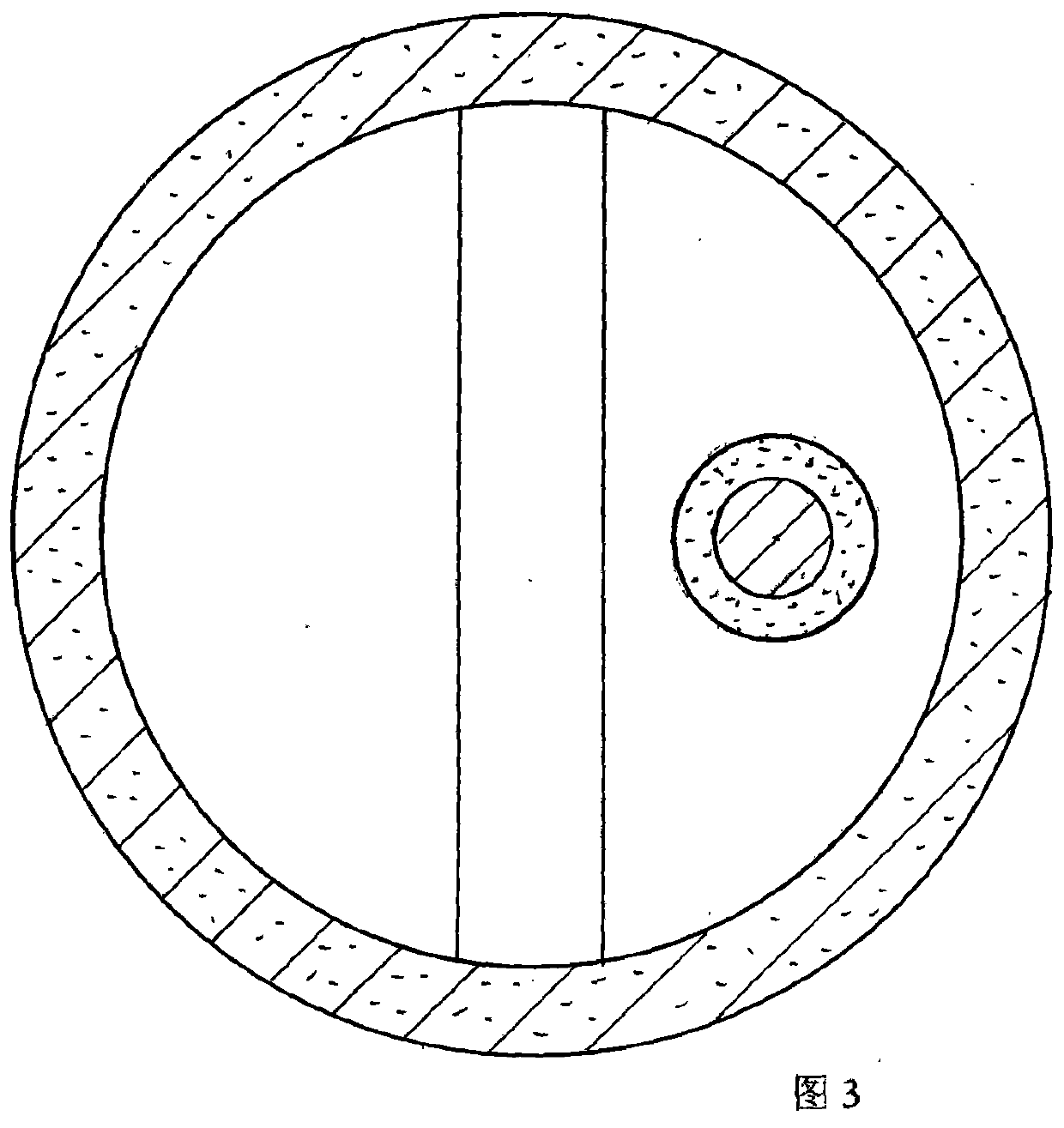

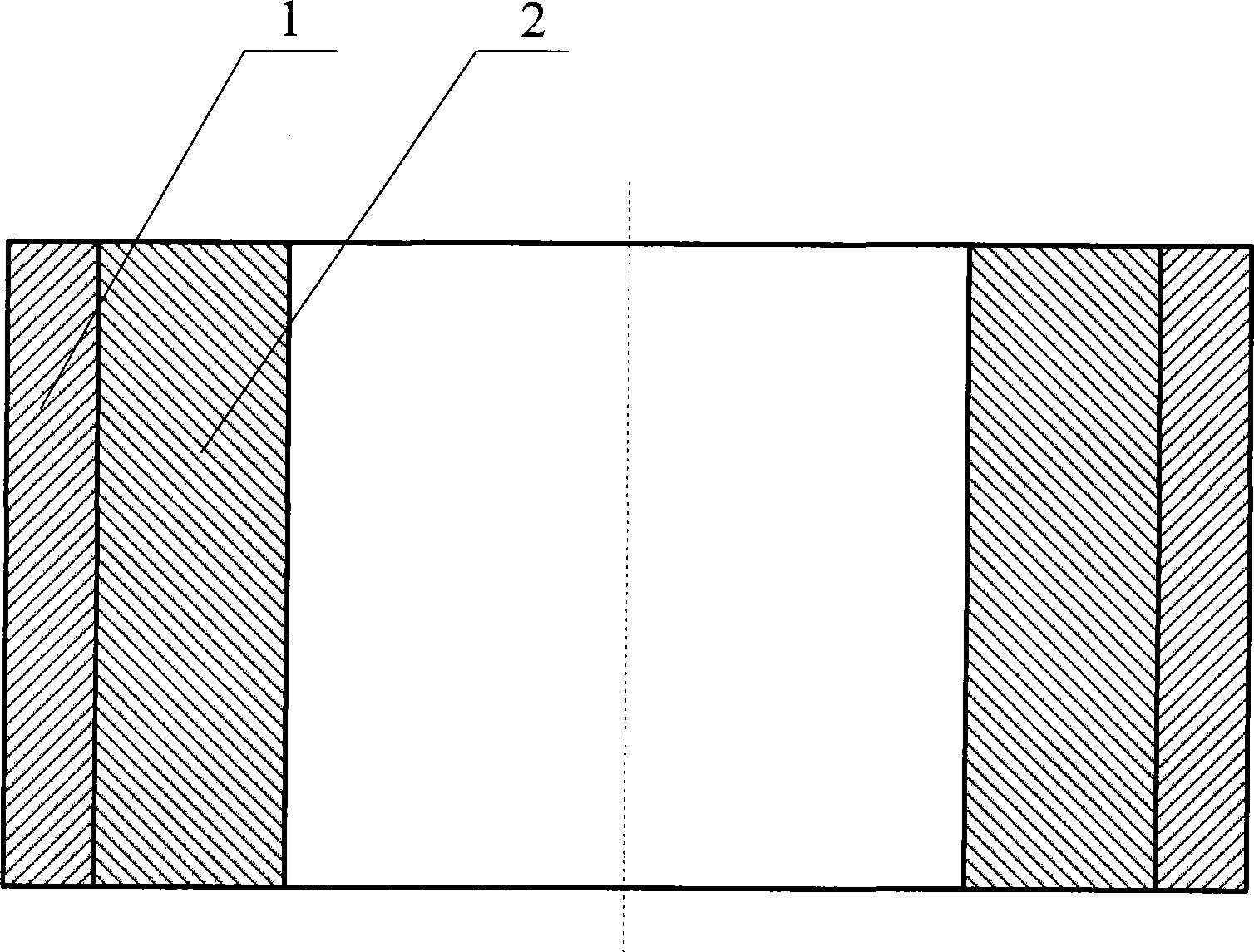

Dry-type sand making method and dry-type sand making machine thereof

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

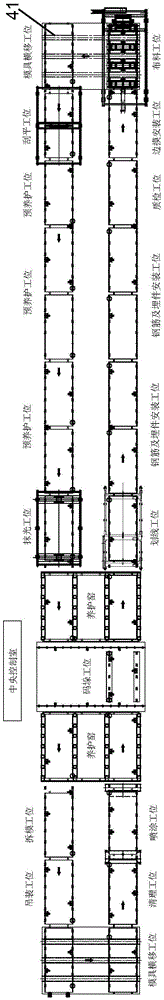

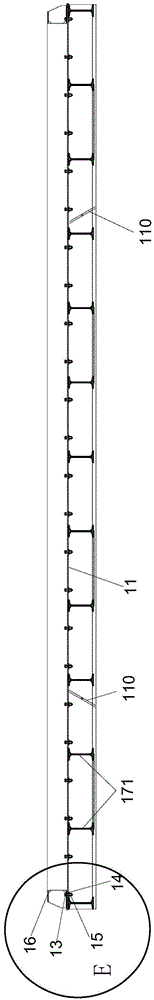

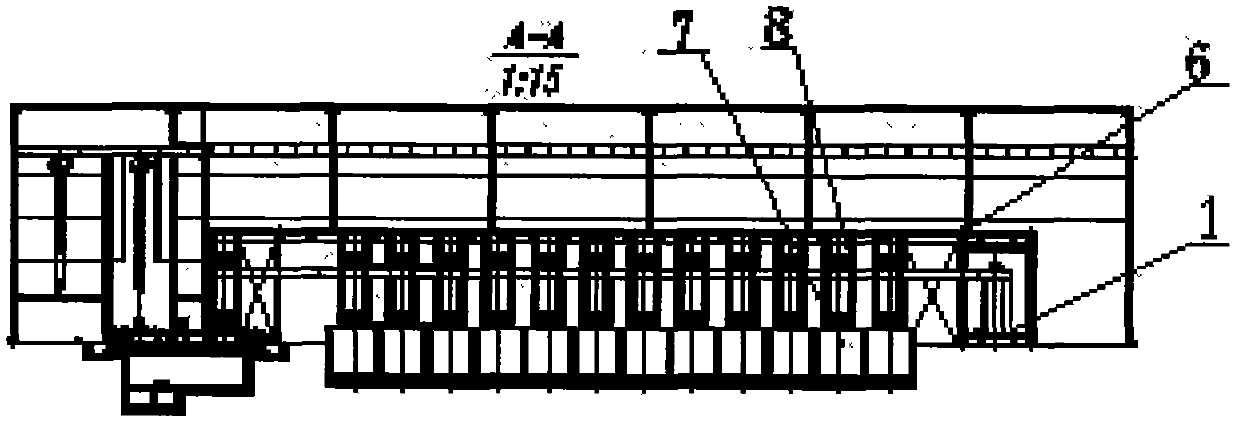

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

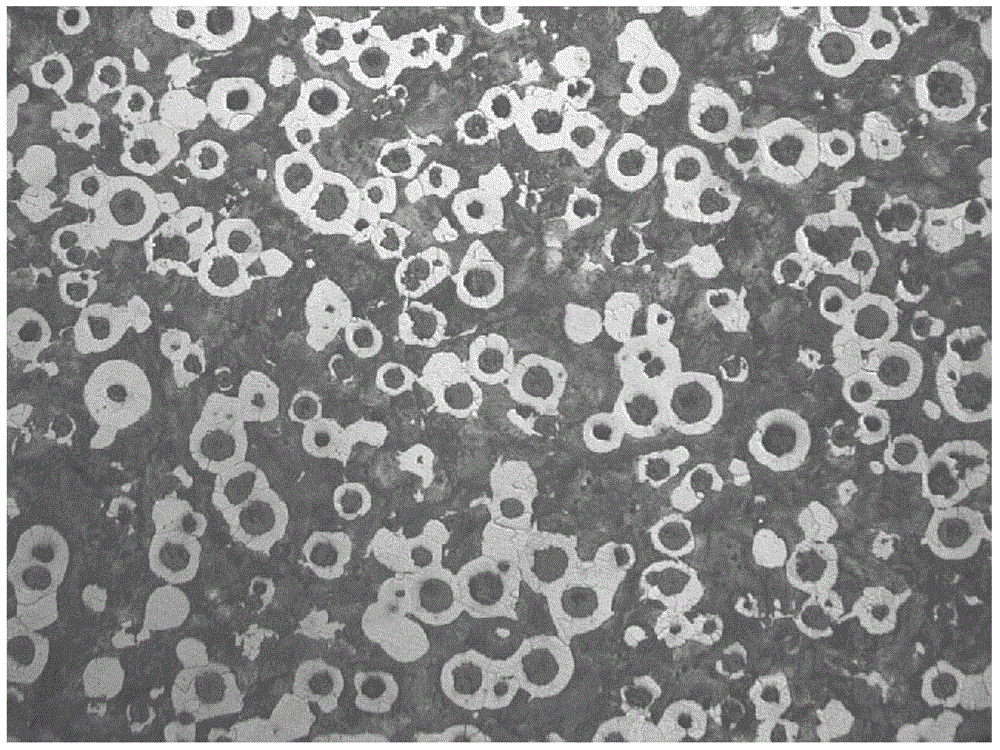

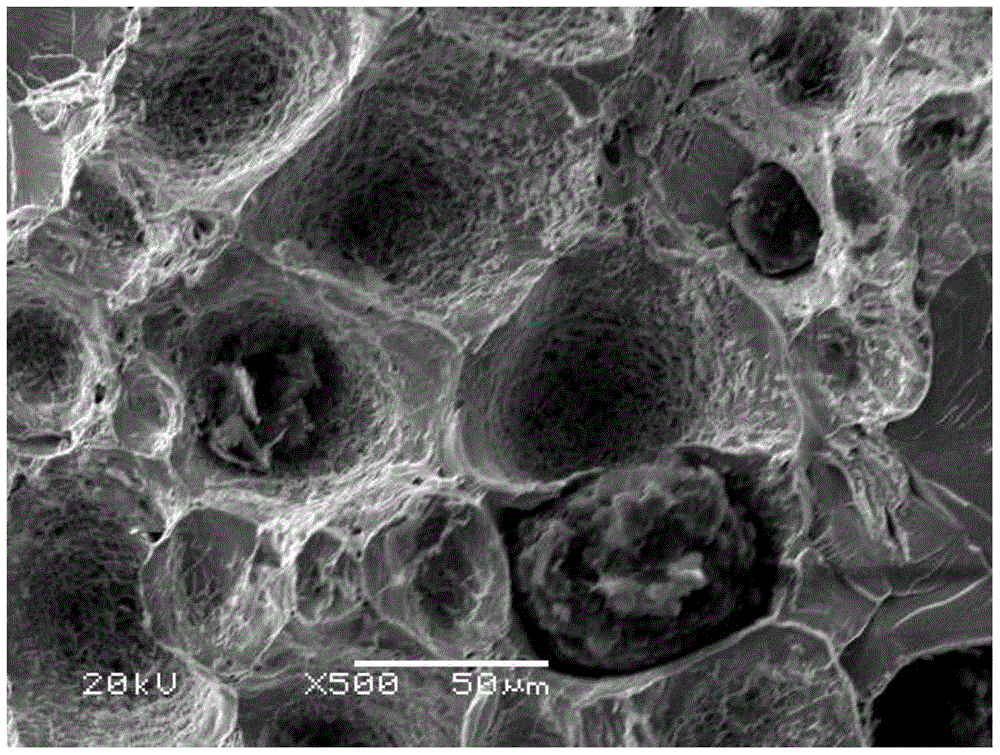

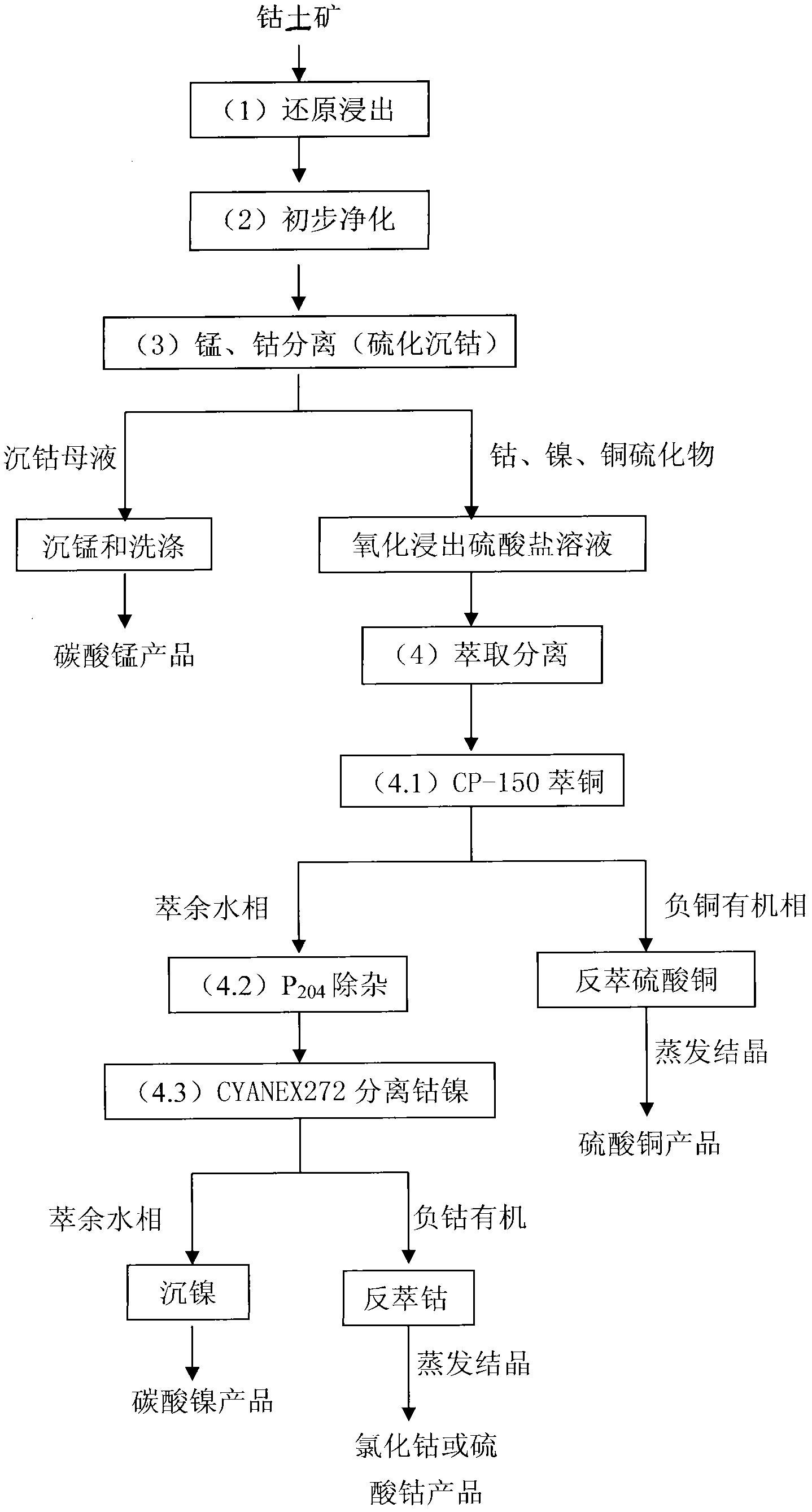

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

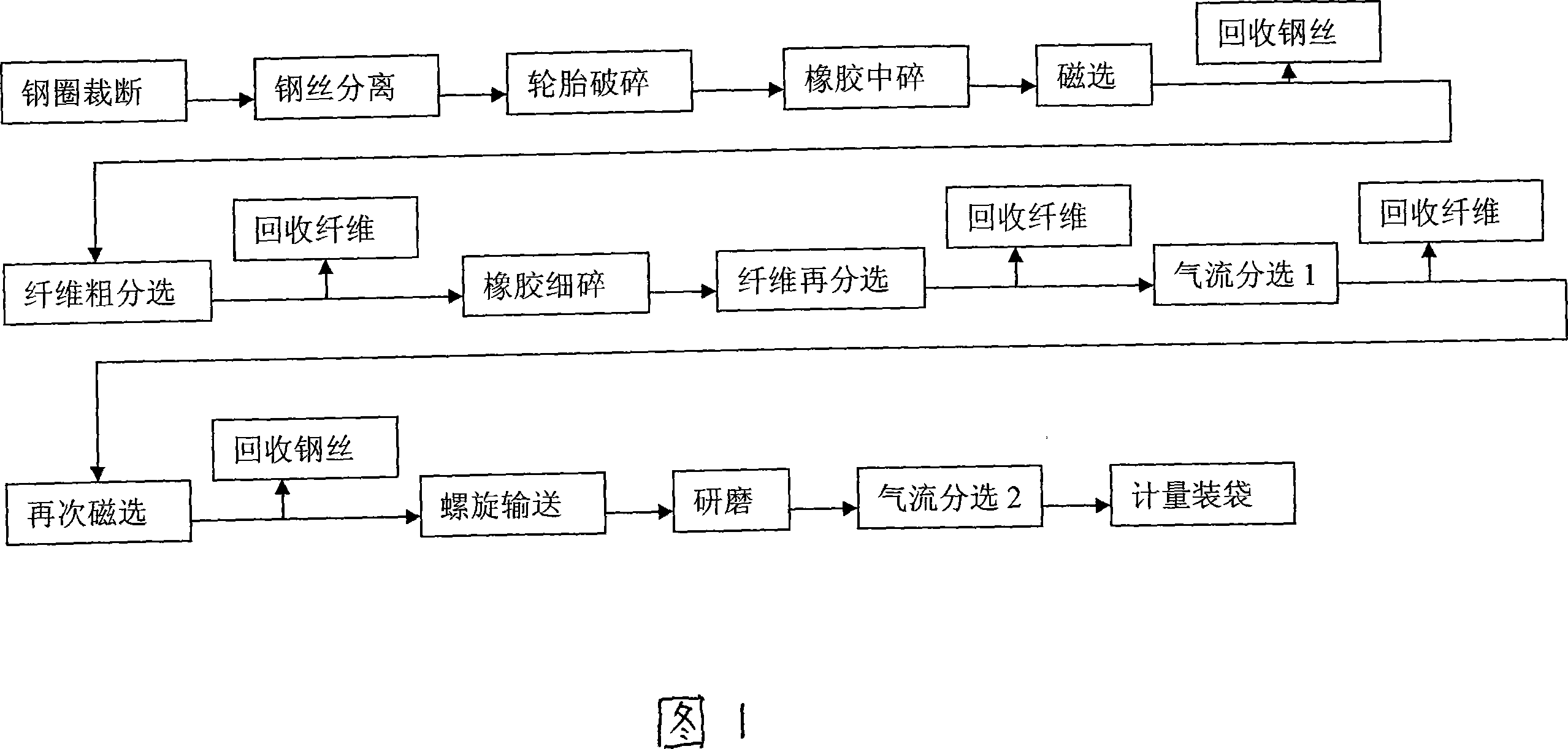

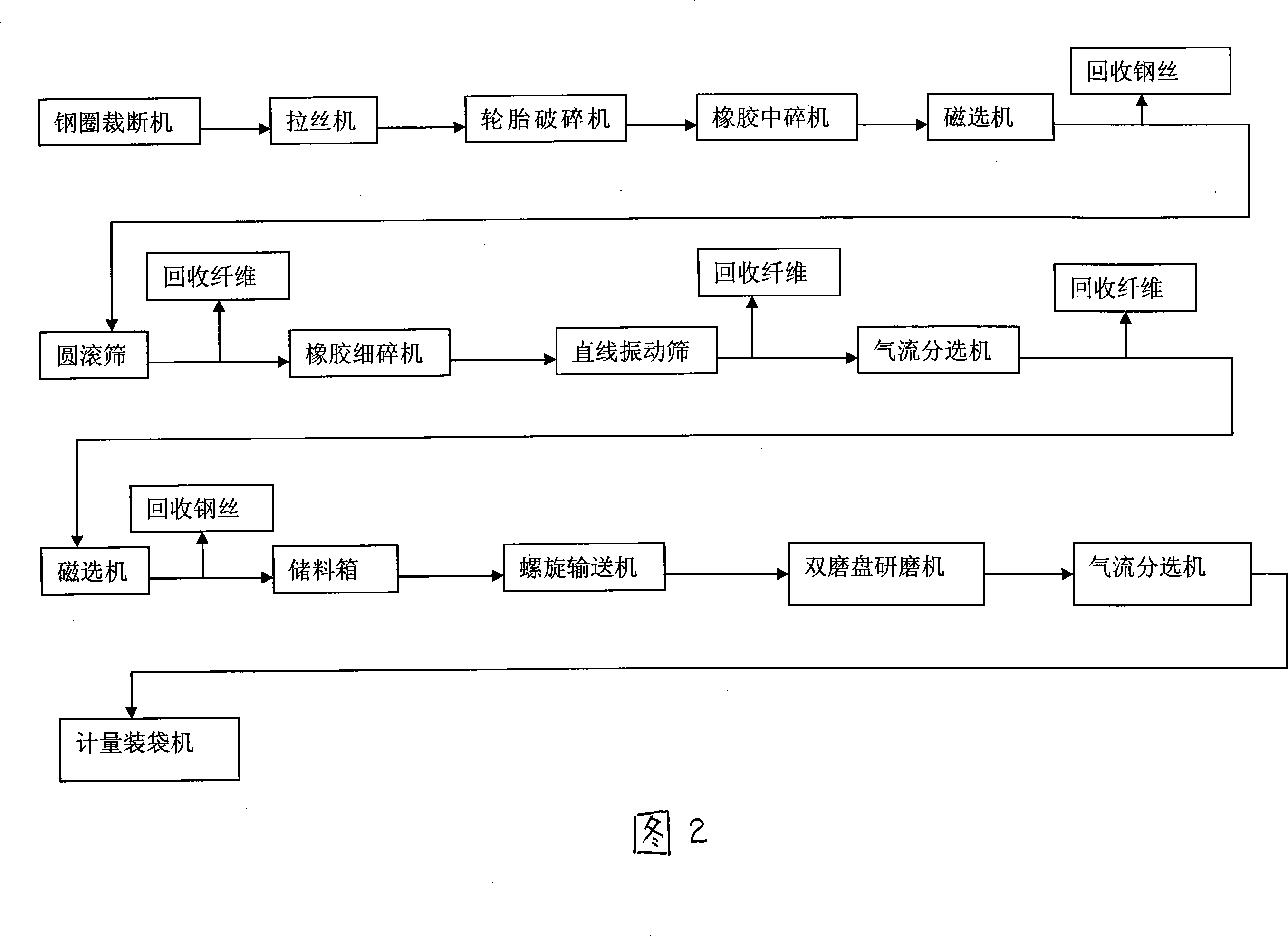

Method for crushing producing fineness rubber powder under normal temperature

InactiveCN101234517ACompact structureEasy to install and maintainSievingGas current separationProduction lineLow noise

The invention relates to a method for producing fine rubber powder by grinding under normal temperature, which adopts the following processes: trimming of steel rings, separation of steel wires, crushing of tires, grinding in the rubber, magnetic selection and separation, rough selection of fibers, finely grinding of the rubber, reselection of the fibers, magnetic reselection, spiral transportation, grinding and airflow selection. The industrial method initiates the precedent of the production of the fine rubber power in batch and the investment of equipment in a whole production line is a half investment of the traditional grinding method under the normal temperature while the investment of the equipment is one eighth of the investment of freezing grinding production line under low temperature. The industrial production line has the advantages of compact structure, convenient arrangement and maintenance of the equipment, long service, life, high rate of rubber output, low power consumption and low noise. Compared with rubber powder index of the freezing grinding production method under the low temperature, each technical index excels current the advanced technology for producing the rubber powder by expansion cooling of air turbines.

Owner:邓裕潮

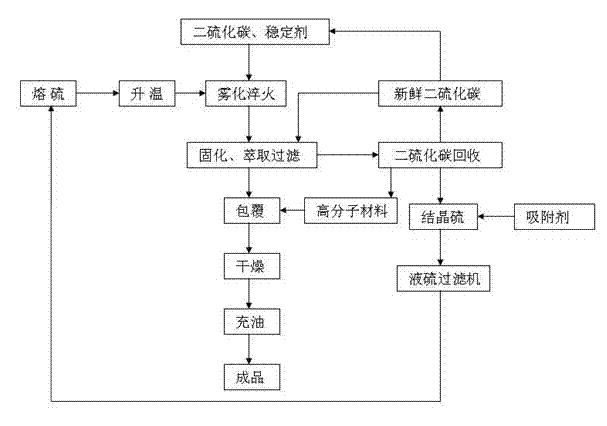

Production method of high-quality insoluble sulfur

ActiveCN102730648AFulfil requirementsHigh yieldSulfur preparation/purificationSulfurThermal stability

The invention provides a production method of high-quality insoluble sulfur, which comprises the following steps of : (1) melting sulfur and heating up; (2) performing spray quenching; (3) curing, and performing extraction separation; (4) cladding; (5) drying; and (6) charging oil to obtain the product finally. The production method provided by the invention is a continuous production method. Through this method, the product yield, high thermal stability and dispersion are greatly improved; and meanwhile, the product does not need to be smashed, thus shortening the production process and optimizing the production environment. The method achieves the recycling of the raw materials and reduces the production cost, which belongs to the green technology.

Owner:SHANDONG SUNSINE CHEM

Like-humic acid substance extracted from crop straw and preparation method of compound fertilizer thereof

InactiveCN103275333AImprove production environmentImprove stress resistanceOrganic chemistryFertilizer mixturesNutritionResource utilization

The invention relates to Like-humic acid substance extracted from crop straw and a preparation method of a compound fertilizer thereof. The resource utilization ratio is optimized by extracting humic acid and fulvic acid in rice straw; the pollution to the environment by rice straw is reduced indirectly; meanwhile, the crop production environment can be improved by utilizing the compound fertilizer prepared from the extracted humic acid-like substance; more nutrition is provided for the growth of crops; and the stress resistance of crops is intensified.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Novel continuous nitrification denitrating, abstraction, hydrogenation reduction production process for H acid

ActiveCN101367753ASmall footprintIncrease production capacityOrganic compound preparationSulfonic acid preparationNitro compoundReaction temperature

The present invention relates to a novel technology of continuous nitration and denitration, extraction, hydrogenation and reduction of H acid, and belongs to the technical field of H acid production. In the novel technology, H acid is prepared with liquid naphthalene through sulfonation, continuous nitration and denitration, extraction, hydrogenation and reduction, concentration, alkali fusion and separation of the H acid. The present invention not only solves the problems in the traditional technological process that the steps are more, the process is complex, the labor intensity of workers is high, the yield rate of the H acid is low and the pollution of wastewater is serious, but also eliminates the factors that the slightly inaccurate control over the reaction temperature and time of nitration and denitration can easily cause explosive polynitro compounds and thus hidden danger of security. The present invention has the advantages that the process is shortened, the byproducts are fewer, and the labor intensity is reduced. The continuous nitration and denitration has the advantages that the occupied area is small, the production capacity is high, the energy consumption is low, the yield rate is improved by 8 percent compared with the traditional process, about 1 ton of sulphuric acid is saves in production of one ton of the product, and the wastewater discharge is reduced. No iron ions are contained in the materials, the product quality of the H acid is improved, and the workshop production environment is obviously better.

Owner:CHUYUAN HIGH NEW TECH GRP

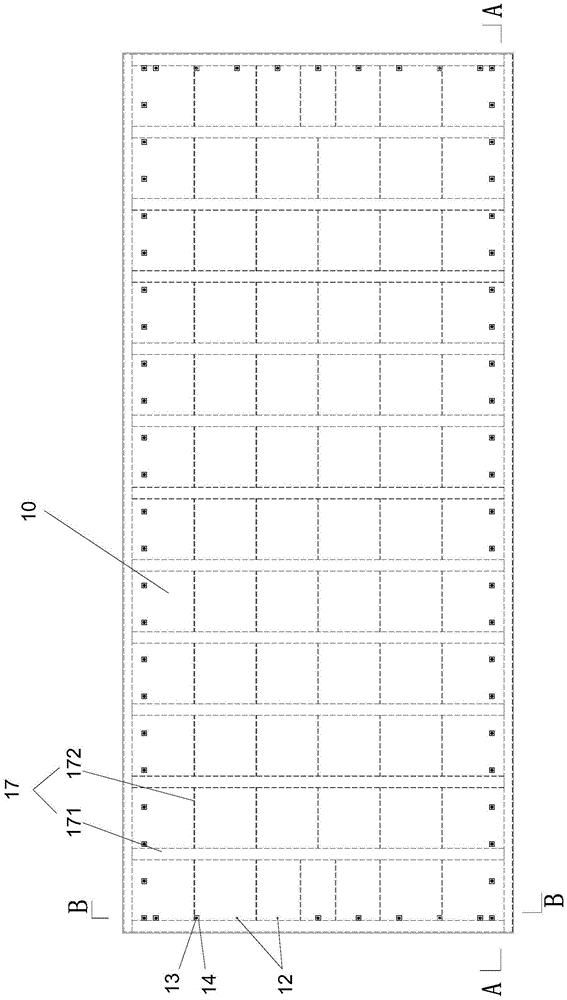

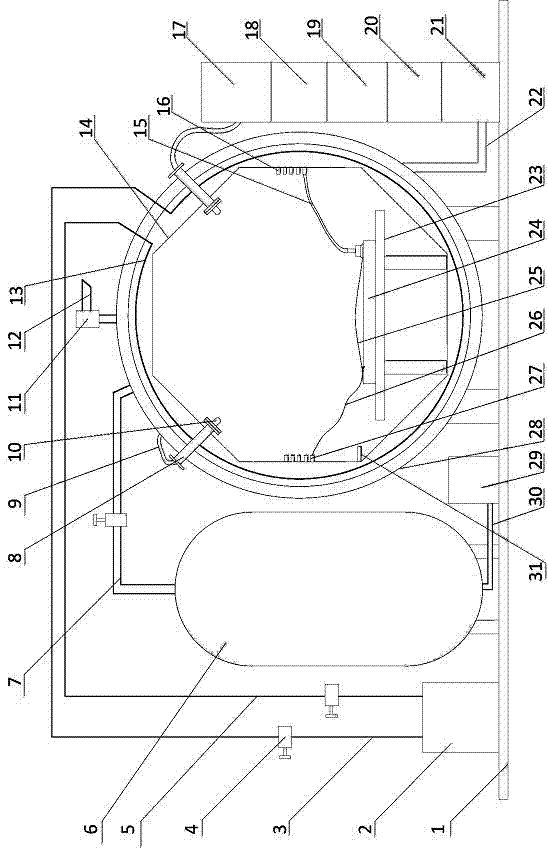

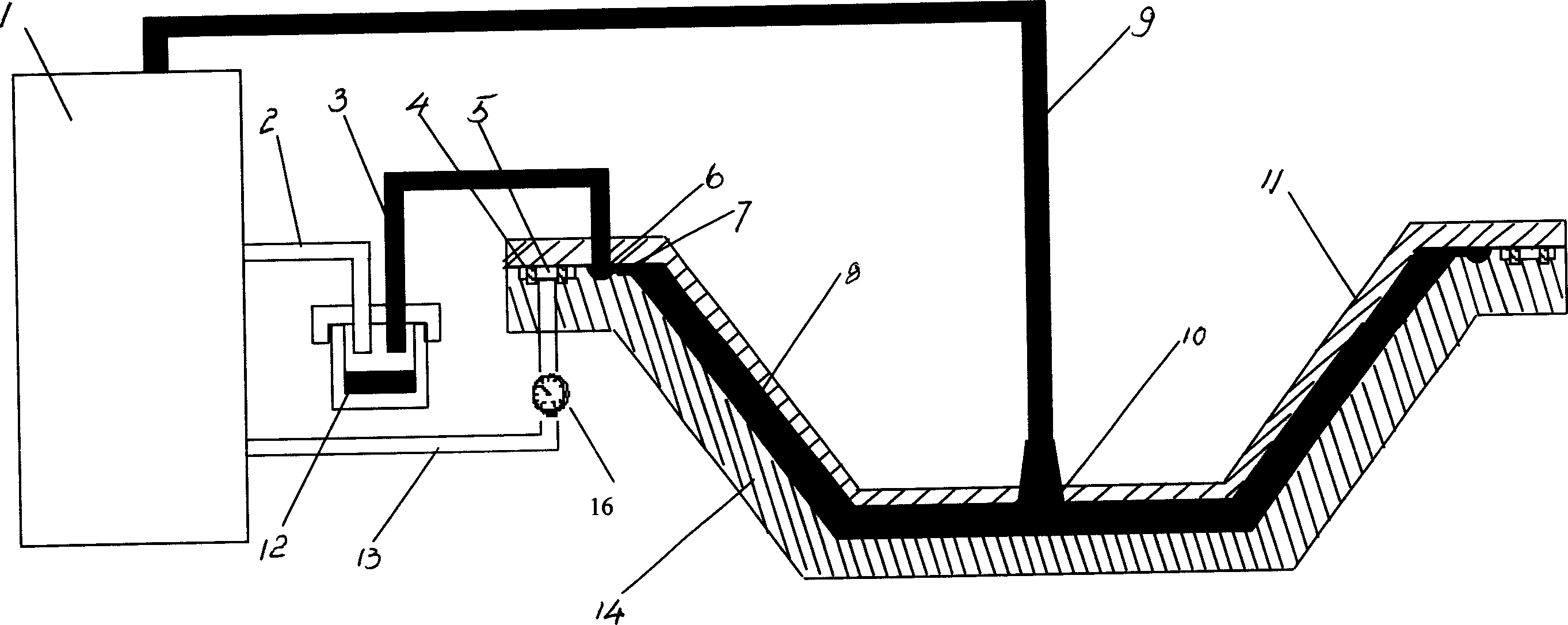

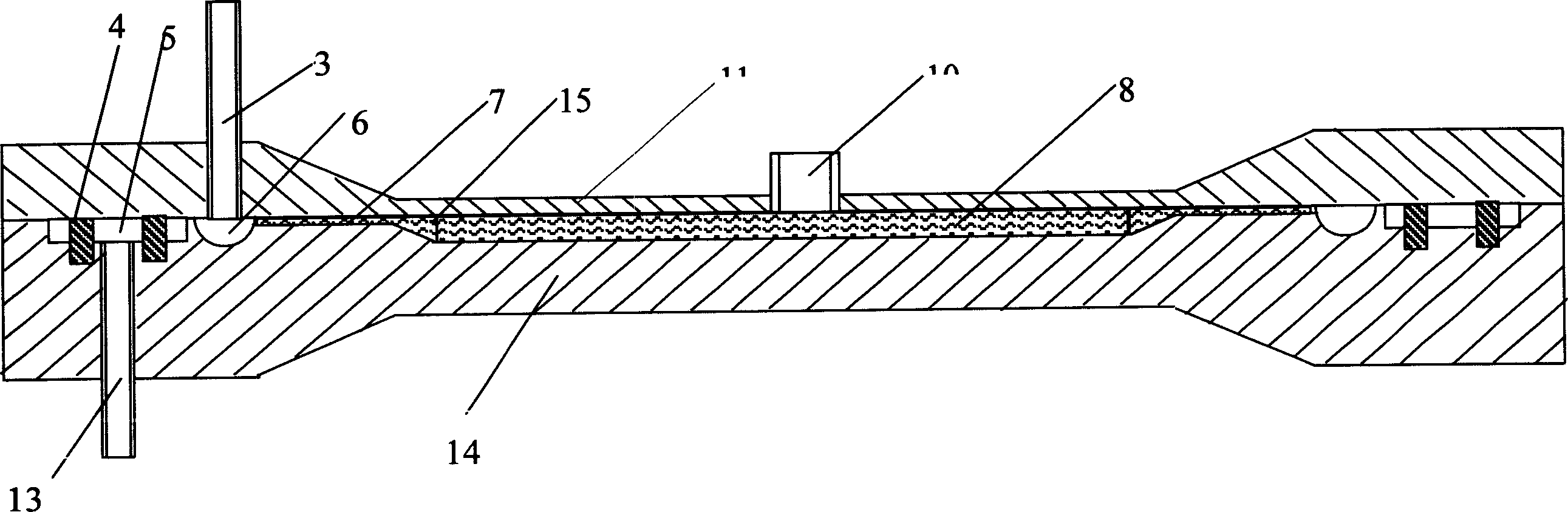

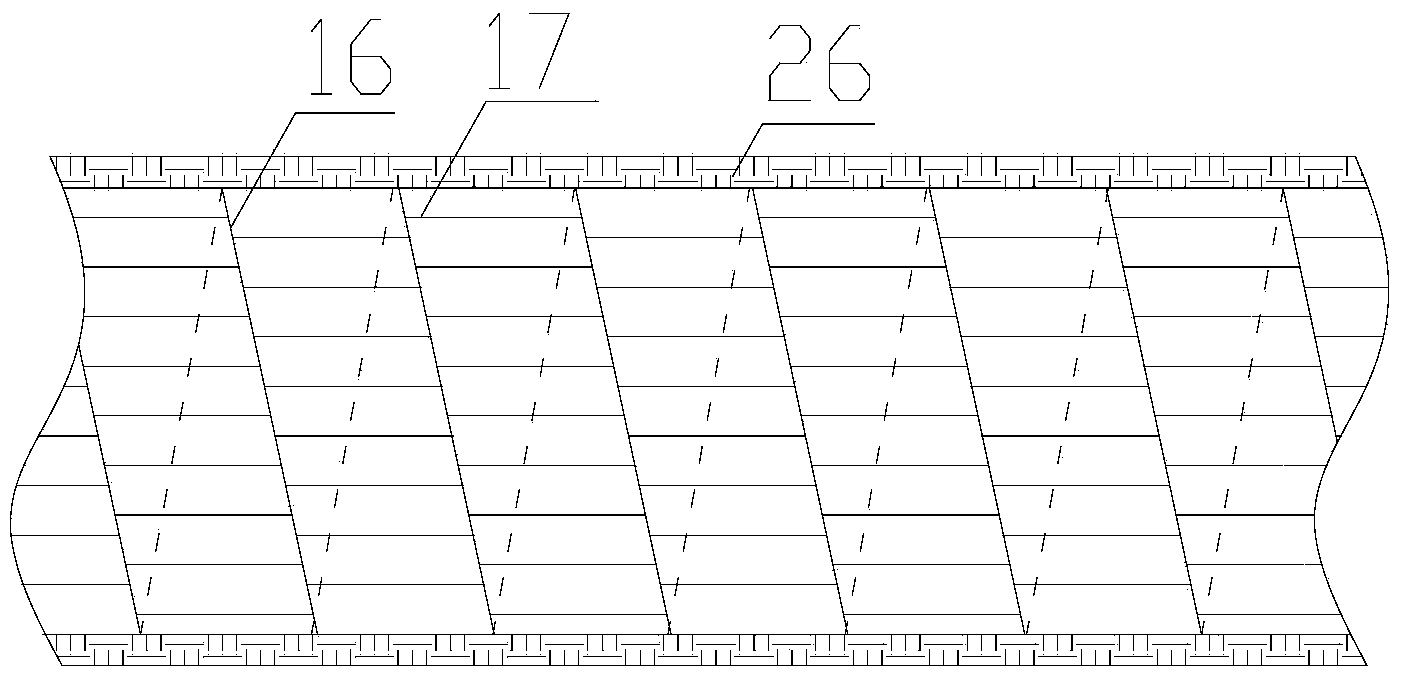

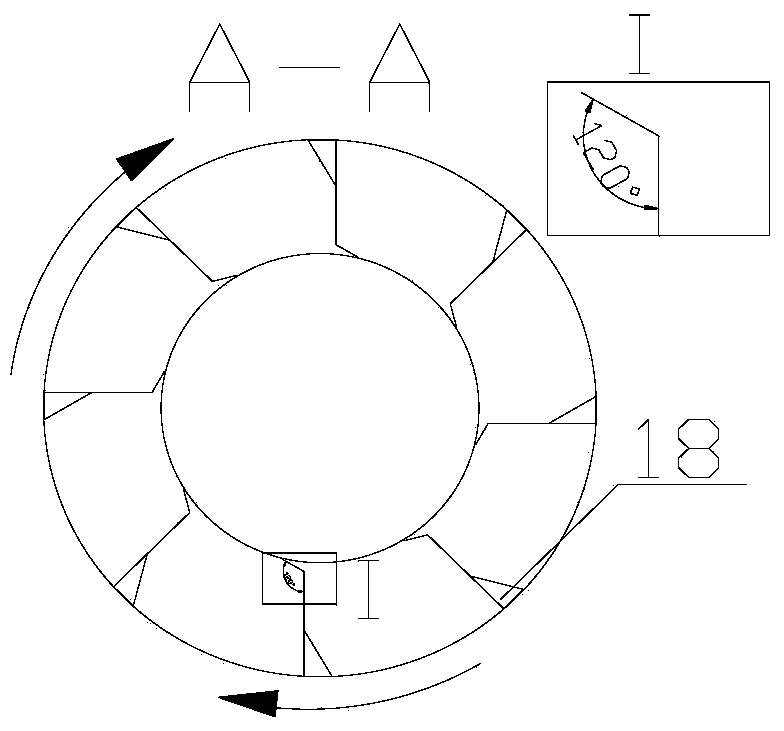

Method and device for forming high-performance composite material structural member through microwave-pressure tank

ActiveCN103587128AShorten the timeMicrowave heating and curing time is shortResonant cavityEngineering

The invention discloses a method and a device for forming a high-performance composite material structural member through a microwave-pressure tank. The device mainly comprises a cooling system (2), a gas storage tank (6), microwave transmission lines (9), microwave radiation antennas (10), a pressure safety valve (11), a polygonal multi-mode resonant cavity (14), a microwave generation and measurement module (17), a temperature measurement and control module (18), a vacuumizing and control module (19), a pressure measurement and control module (20), a power supply module (21), a material platform (23), a forming mold (24), a temperature sensor (26) and a tank body (28). The equipment is microwave forming equipment for the high-performance composite material structural member; a non-solidified composite material structural member is put into the equipment, and the high-performance composite material structural member can be quickly formed by technologies of vacuum bag vacuumizing, gas pressurization and microwave heating; the quality and the performance of the composite material structural member can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Halogen-free flame-retardant polypropylene master batch

The invention relates to a halogen-free flame-retardant polypropylene master batch. The halogen-free flame-retardant polypropylene master batch comprises the following components in percentage by weight: 20 to 40 percent of polypropylene pellets, 40 to 60 percent of ammonium polyphosphate, 0.5 to 3.0 percent of flame-retardant synergist, 6 to 25 percent of halogen-free charring agent, and 5 to 15 percent of compatibilizer. A method for preparing the halogen-free flame-retardant polypropylene master batch comprises the following steps of: weighing raw materials according to the weight proportion, drying, and extruding and granulating by a co-rotating or counter-rotating twin-screw extruder, wherein the rotating speed of a screw is 70 to 200rpm; and the temperature is 160 to 230 DEG C. The disadvantages that the atactic polypropylene (APP) is independently added, so flame-retardant efficiency is low, the mechanical properties of matrixes are greatly influenced, great inconvenience is brought to the drying treatment of the raw materials, dust pollution is caused and the like are overcome. The invention has the advantages that: the flame-retardant synergistic effect can be well realized among components of the master batch, mixing and drying processes of the raw materials in the production process are simplified, and the production efficiency is improved; the dust in the production process is reduced, and the production environment is improved; and a flame-retardant polypropylene material prepared from the master batch has a good flame-retardant effect and excellent mechanical properties.

Owner:YANGZHOU UNIV

Friction plate without asbestos and its preparation process

A non-asbestos friction disk for the brake of drilling machine, heavy machinery, etc is prepared from glass fibres, organic fibres, low-smelting-point metal powder and resin-rubber mixture. Its advantages are low hardness, high toughness, high friction coefficient, high mechanical strength, and low abrasion.

Owner:李海 +4

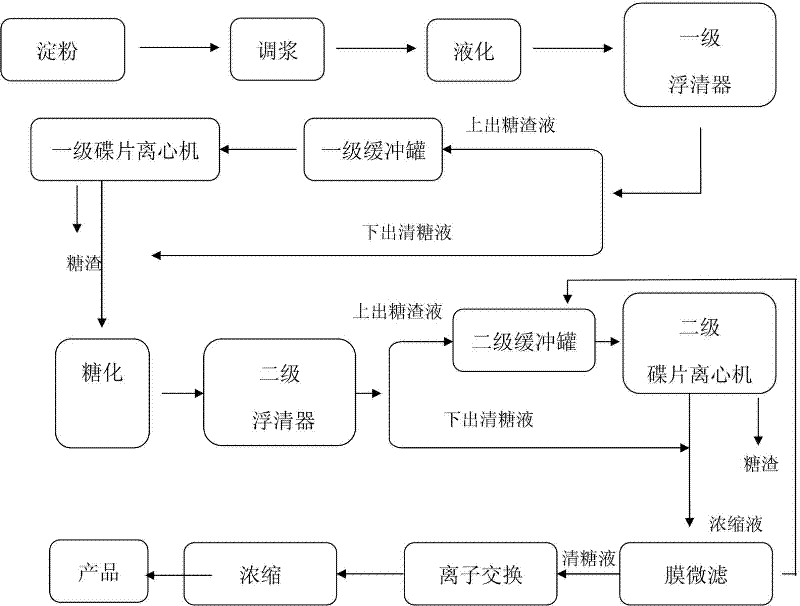

Process for producing starch sugar

ActiveCN102337316AQuality improvementImprove function and effectAnimal feeding stuffAccessory food factorsActivated carbonChaptalization

The invention discloses a process for producing starch sugar. The process comprises the following steps of: pulp-conditioning edible starch; liquefying; passing liquefied starch through a primary floating clarifier, guiding an upper floating sugar dreg liquid into a primary buffer tank, and then entering a primary disc-type centrifuge to be centrifugated and separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the primary disc-type centrifuge and a clear sugar liquid flowing out of the primary floating clarifier and flowing into a saccharifying tank to be saccharified into a saccharified liquid; passing the saccharified liquid through a secondary floating clarifier, guiding an upper floating sugar dreg liquid into a secondary buffer tank, and then enteringa secondary disc-type centrifuge to be separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the secondary disc-type centrifuge and a clear sugar liquid flowing out ofthe secondary floating scum clearing device and filtering by passing through a membrane micro-filtration system; and flowing a micro-filtered concentrated liquid containing dregs back to the secondary buffer tank, entering a micro-filtered clear sugar liquid into an ion exchange system to be decolorized and desalted, and then finally concentrating into a product. According to the process for producing the starch sugar disclosed by the invention, filter aids and activated carbon are not required in the clarification and the filtration processes, and high-purity sugar liquid can be obtained through the efficient operation of solid-liquid separation equipment; and meanwhile, sugar dregs without the filter aids and the activated carbon are extracted and can be used as a feedstuff raw materialfor animals, thereby changing waste into valuable, and no discharge of filtered solid wastes during the whole process exists.

Owner:双桥(厦门)有限公司

Ultraviolet curing anti-drag paint in steel pipes

ActiveCN102079937AGood adhesionGood mechanical properties and chemical resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPrepolymerSteel quality

The invention relates to an ultraviolet curing anti-drag paint in steel pipes. Epoxy acrylate and polyester acrylate are combinedly used as prepolymers, and phosphate-modified acrylate resin is used as an adhesion promotor, thereby greatly increasing the adhesion; a mixture of two or three of tripropylene glycol diacrylate, isobornyl acrylate and ethoxylated trimethylolpropane triacrylate is selected as an active monomer, and multiple functional group monomers are selectively added for compounding, thereby simultaneously satisfying curing speed, hardness, adhesion, flexibility and other requirements; multiple initiator compounding systems are adopted so as to simultaneously implement curing on the surface layer and deep layer; the paint provided by the invention has favorable mechanical properties and chemical resistance on a steel substrate; after coating, the surface is very smooth, has favorable anti-drag effect, can effectively enhance the salt fog resistance and corrosion resistance of the coating and the transmission efficiency of the pipeline, and can be widely used in anti-drag corrosion prevention in transmission pipelines in the fields of oil transmission, gas transmission, water supply and drainage, and the like.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

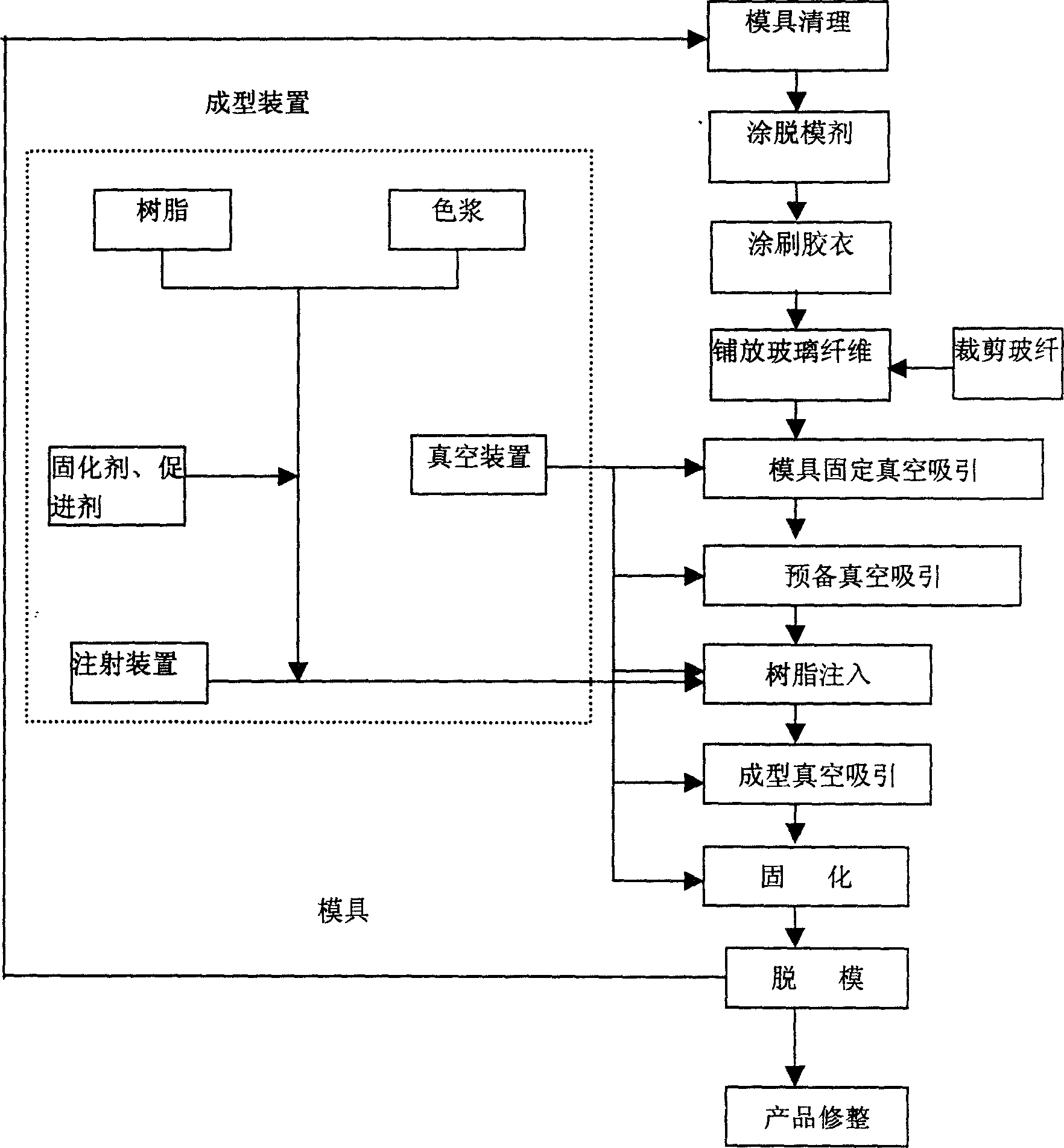

Vacuum auxiliary resin penetration process for composite material and mould therefor

The invention belongs to complex material shaping technics and the moulds. The technics includes that inject the resin through the injecting system into the soft mould to expand, close the injecting port after the determined resin is all injected and evacuate the mould cavity to let the resin fills the unfilled sections at the edge so to fill the whole cavity with resin. The mould includes upper mould which is ferroglass soft mould, lower mould which is ferroglass hard mould. Injecting and shaping evacuating ports are on the upper mould while equal flow canals and shaping vacuum circuit and fixing vacuum circuit are on the lower mould. Its advantages are that it is environmental, of low cost, and is able to shaping with products of large area and thin walls.

Owner:北京玻钢院复合材料有限公司

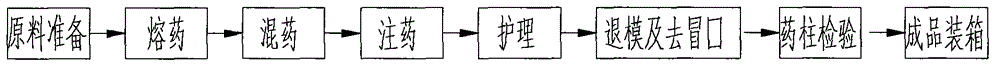

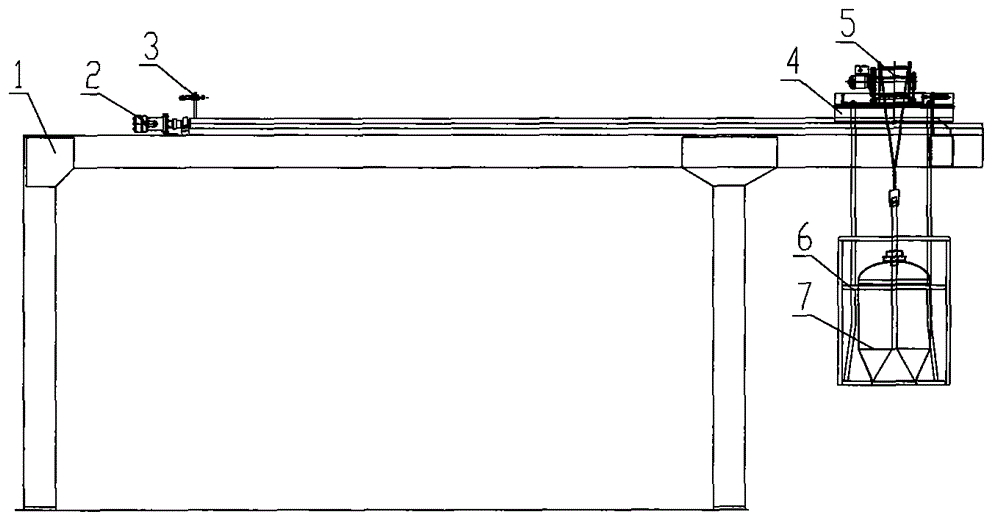

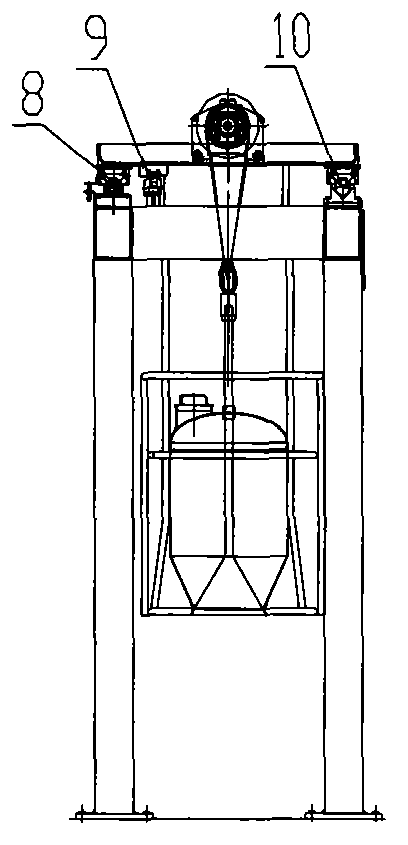

Detonating tool explosive casting automatic production technology and equipment

ActiveCN102944139ASolve technical bottlenecksIncrease production capacityBlasting cartridgesDetonatorSolid particle

The invention belongs to the technical field of production of detonators in civil explosion industry, and particularly relates to a detonating tool explosive casting automatic production technology and equipment. The technology comprises the following steps of removing impurities from raw materials, weighing the raw materials, putting the materials into a melting device by a lifting and delivery device to melt, putting the melted materials in a mixing tank, adding solid particles into the melted materials to mix, carrying out riser assembly on a riser and other assemblies, carrying out one-time multiple-mold quantitative casting in the explosive casting procedure after uniform mixing of the materials, delivering the cast grain to the treatment procedure by a delivery machine to carry out gradient cooling treatment, then delivering the cast grain to a stripping procedure to carry out integral stripping, removing the riser, separating the riser from the explosive, cleaning the riser for repetitive use, inspecting the grain, and directly packing the finished grain. The technology and the equipment have the advantages that the flow process is simple, safe and reliable; the one-time multiple-mold casting of the riser is adopted, so the automatic and continuous production is realized, the energy consumption is reduced, the labor and the material are saved, and the production efficiency and the product quality are improved.

Owner:CHINA WUZHOU ENG GRP +2

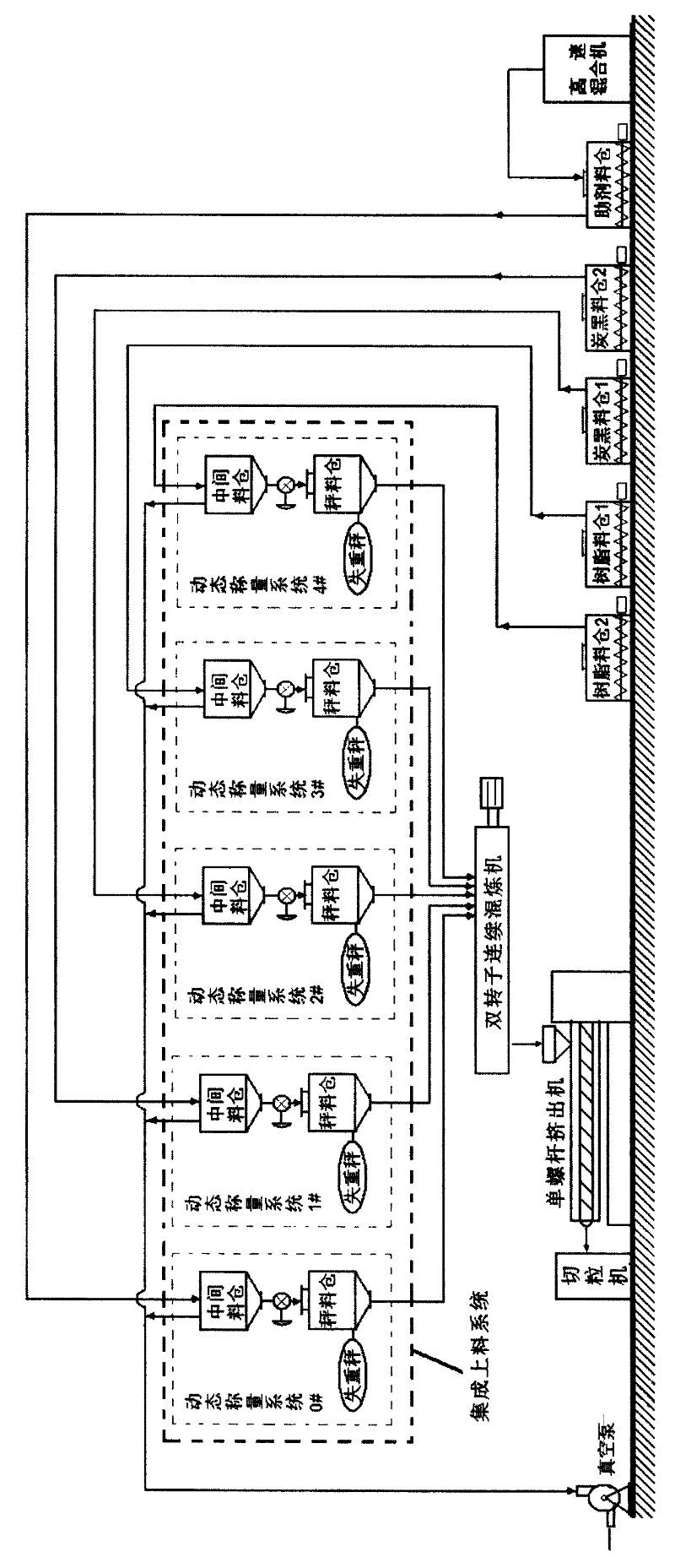

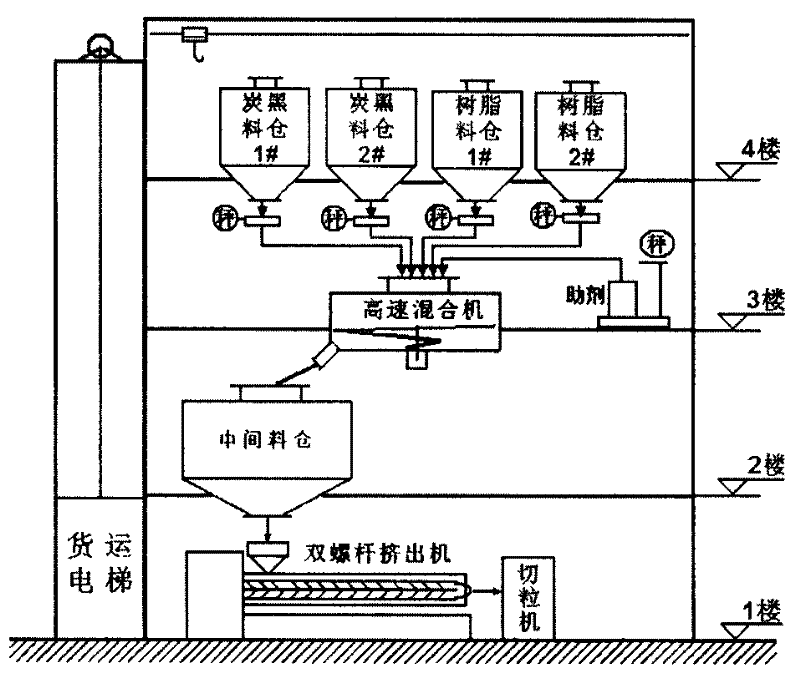

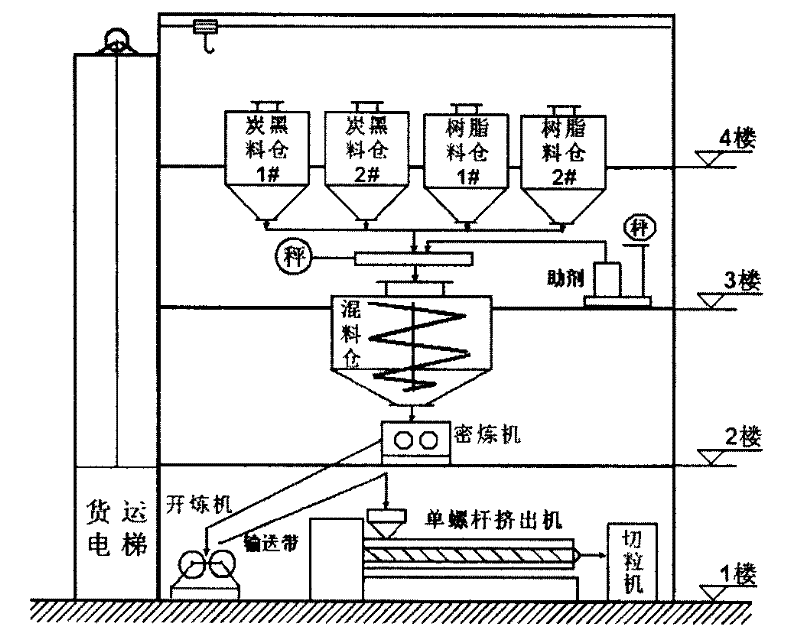

Black masterbatch with high performance, preparation system device and its preparation method

The invention discloses a black masterbatch with high performance, a preparation system device and its preparation method. The masterbatch can be taken as an ultraviolet shielding agent and a black coloring agent, which is widely applied to a polyolefin gas pipeline, a purified water delivering pipeline, conductive plastics, films and cable materials and the like. The characteristics of short production process, raw material negative pressure conveying, sealed type for formulating and feeding, continuously smelting and granulating system enable the raw materials to convey and produce in a sealed system without leakage and fly phenomenon of the carbon black, thereby the good production environment can be guaranteed. According to the invention, the black masterbatch with high performance isprepared by the following raw materials in weight proportion: 20 to 80 parts of polyolefin carrier resin, 20 to 55 parts of carbon black, 0.2 to 2 parts of dispersant, 0.1 to 0.5 parts of processing auxiliary agent and 0.1 to 1.0 parts of anti-oxidant.

Owner:NANJING UNIV OF TECH +1

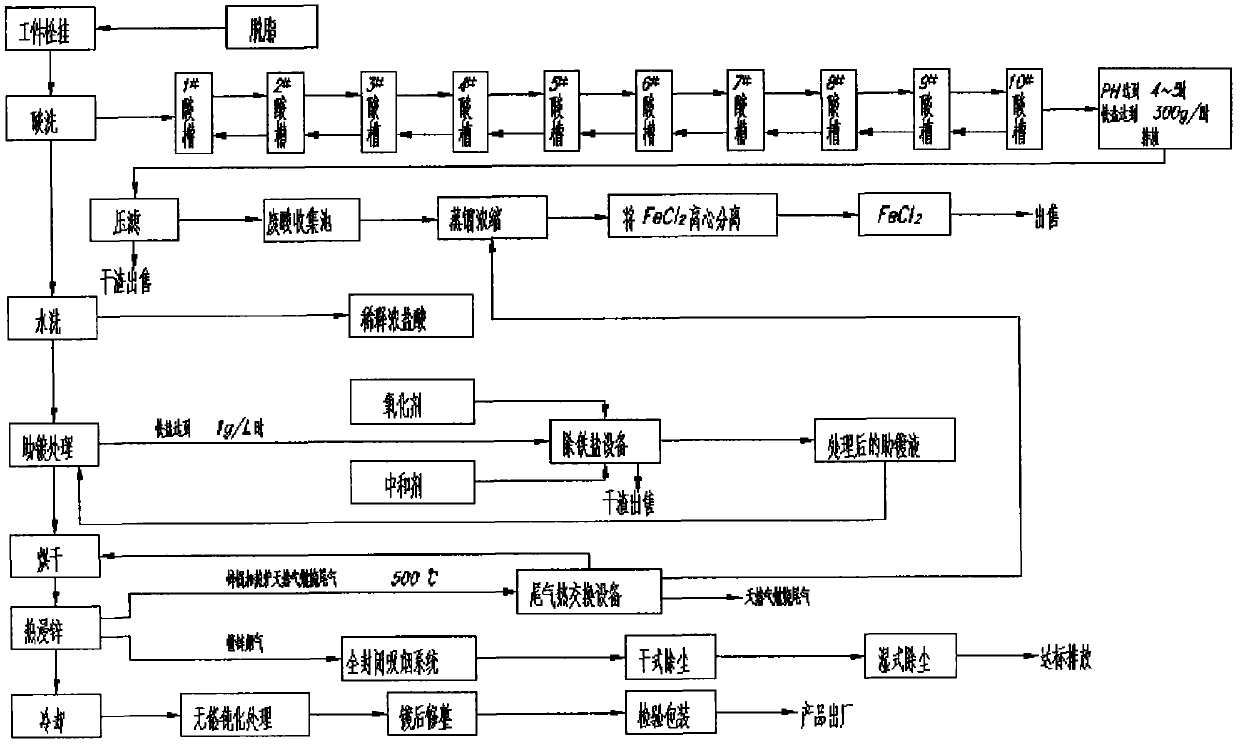

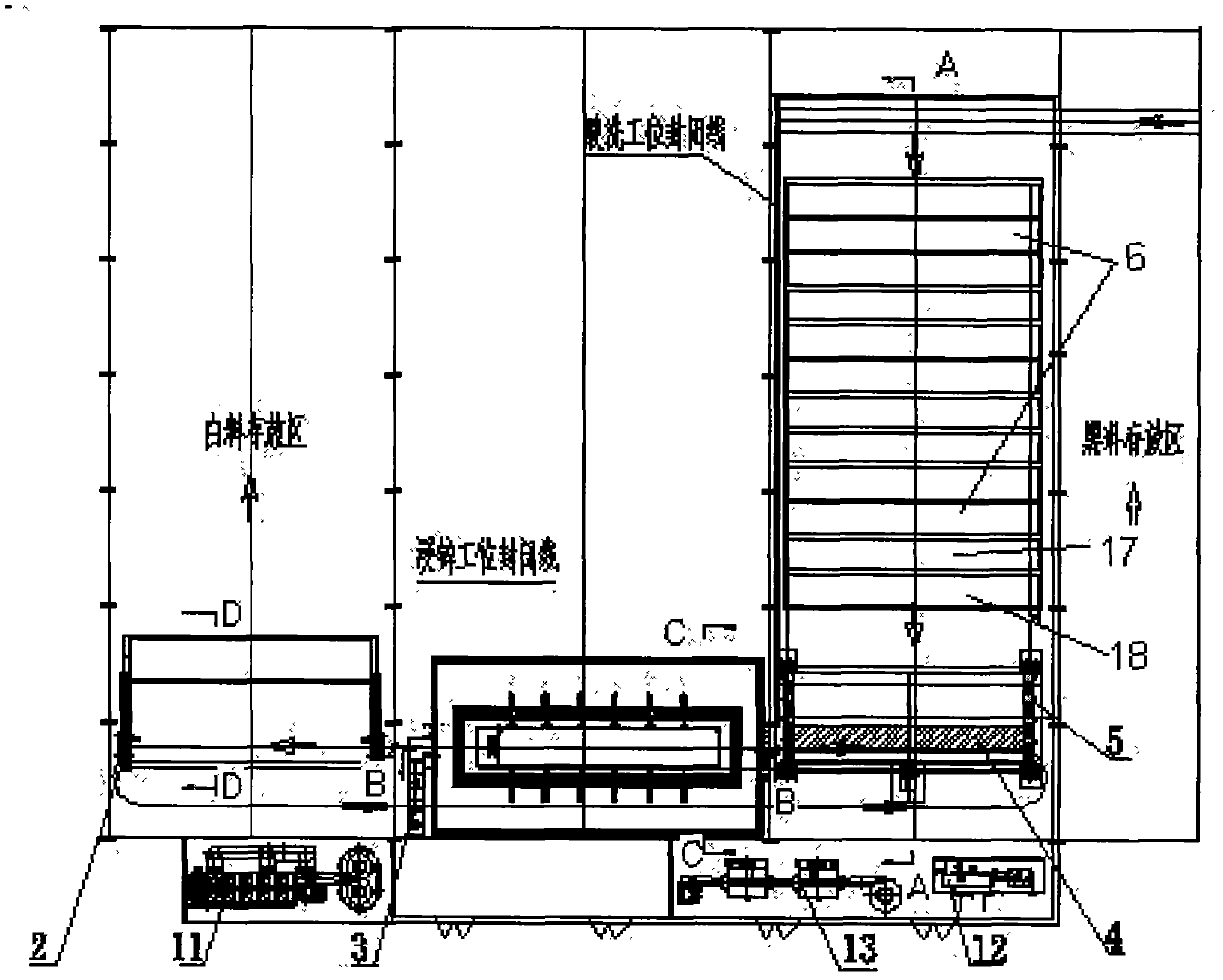

L-shaped full-closed environment-friendly hot galvanizing production equipment and method

InactiveCN102400075ADiffusion space is smallConvenient smokingHot-dipping/immersion processesAcid washingProcess engineering

The invention discloses an L-shaped full-closed environment-friendly hot galvanizing production method. The method is characterized in that: acid washing step-by-step automatic operation is implemented by adopting a mechanical hydraulic transmission manner, namely an acid washing workpiece automatic conveying system horizontally or vertically lifts to automatically convey workpieces to be galvanized to specified anti-collision acid washing tanks for acid washing and dust removing treatment step by step according to the multi-tank acid washing technological requirements, and the whole acid washing process is sequentially, progressively and automatically finished according to the technological requirements. The L-shaped full-closed environment-friendly hot galvanizing production method is pollution-free, environment-friendly, low in energy consumption, mechanical and automatic, and has the characteristics of full closure and integration of reclamation and treatment; and by the method, acid washing automation is realized, the labor intensity is furthest lightened, the production efficiency is improved, and the problem of pollution is solved.

Owner:张志红

Method and device for continuous acid pickling purification of quartz sand

ActiveCN104058413ARealized by continuous pickling and purificationImproving the effect of pickling and impurity removalSilicaQuartzSpiral line

The invention provides a method for continuous acid pickling purification of quartz sand. The method comprises the steps of heating, material loading, acid pickling, deacidifying, water washing, acid recovering and tail gas treatment. The invention also provides a device for implementing the method to perform continuous acid pickling purification on quartz sand; the device comprises a heating unit, a storage unit, a drum mixer, a water washing unit, an acid recovery unit and a water-jet vacuum unit; spiral line plates are arranged on the inner wall of a drum of the drum mixer, 20-60 lifting plates are mounted between two adjacent spiral line plates, two adjacent lifting plates and the spiral line plates on the two sides thereof are combined to form a lifting bucket, a driven gear is arranged on the outer wall of the drum of the drum mixer in a sleeved manner, a charging opening and a discharging opening are formed in the two ends of the drum, and spiral line plates are mounted on the inner walls of both of the charging opening and the discharging opening. The method and the device are capable of realizing sufficient acid pickling purification of the quartz sand by virtue of continuous automatic feeding, turning over and discharging of the quartz sand and acid liquor; as a result, the production efficiency and the quality of product are improved, and the acid is recycled and absorbed by use of alkaline so that the production cost is reduced, and meanwhile, the environmental pollution is reduced.

Owner:田辉明

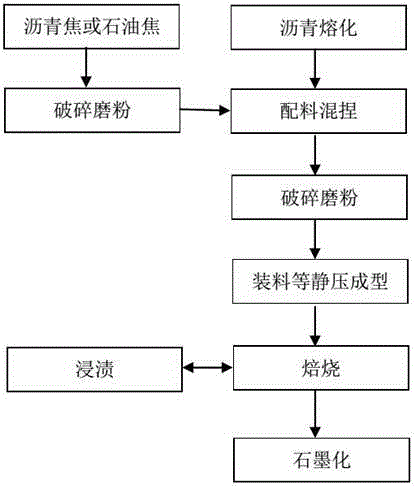

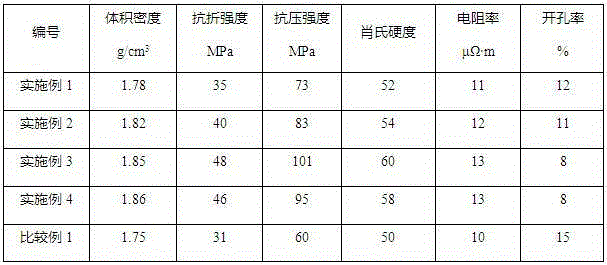

Preparation method of isostatic pressing formed graphite of ultra-thin structure

The invention discloses a preparation method of isostatic pressing formed graphite of an ultra-thin structure. The preparation method includes the steps that calcined petroleum coke or pitch coke is crushed to be smaller or equal to 1 mm, smashed to be within the range of 5 micrometers-10 micrometers and preheated to 100-150 DEG C, then brute-force mixing kneading, cooling, crushing and secondary powder grinding are performed on the calcined petroleum coke or pitch coke and liquid-state molten pitch, and heat treatment is performed on a green body obtained through isostatic pressing forming to obtain a carbon green body; immersion treatment is performed on the carbon green body through low-quinoline intermediate-temperature coat tar pitch, then the carbon green body is heated to 1000-1200 DEG C at 5-10 DEG C / h, and finally the isostatic pressing formed graphite of the ultra-thin structure is obtained through graphitization treatment. The prepared isostatic pressing formed graphite of the ultra-thin structure has the advantages of being compact in structure, good in evenness, high in mechanical strength and isotropy, low in production cost, short in production period and the like.

Owner:CHENGDU CARBON

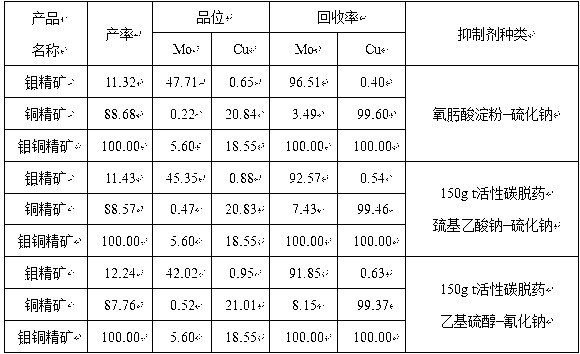

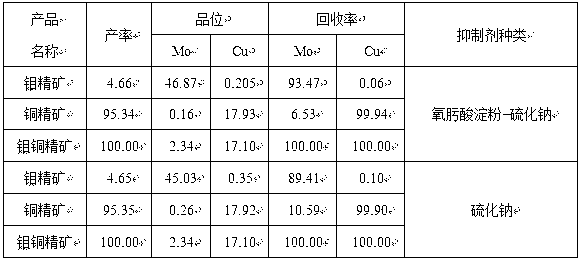

Method for flotation and separation of copper molybdenum sulphide bulk concentrates

The invention discloses a method for flotation and separation of copper molybdenum sulphide bulk concentrates and belongs to the technical field of mineral dressing. The method uses the copper molybdenum sulphide floated bulk concentrates as raw materials, adopts efficient environment-friendly copper ore inhibitor such as hydroxamic acid starch to inhibit copper sulphide ores, performs flotation of molybdenum sulphide ores and performs flotation and separation of copper and molybdenum. Oximido in the hydroxamic acid starch can be combined with active mass points Cu2+ on the surfaces of the copper sulphide ores to produce stable pentabasic chelate rings. Hydroxide radical and other polar radicals in a starch group at the other end of a chelate can be associated with water molecules through hydrogen bonds to enable the copper sulphide ores to be hydrophilic and inhibit the copper sulphide ores. In addition, the enormous hydrophilic water molecules of the hydroxamic acid starch can hide hydrophobic collecting agent molecules absorbed on the surfaces of copper ores, a collecting agent absorbed on the surfaces of the copper ores is not required to be removed, and the flotation and the separation of the copper molybdenum sulphide bulk concentrates do not need mechanical reagent removal or concentrated reagent removal. The hydroxamic acid starch serves as an inhibitor to inhibit the copper ores, sodium sulphide usage can be remarkably decreased, mechanical reagent removal or concentrated reagent removal is not needed, the chemical cost for the separation of the copper and the molybdenum is reduced, copper and molybdenum flotation and separation technological processes are simplified, good separation effect is obtained, and the method is environment-friendly and efficient.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Spheroidizing treater and process

InactiveCN101029367AIncrease Mg contentCancel the secondary smelting processDuctile ironUltimate tensile strength

A spheroidizing treater for producing spheroidal graphite cast iron is carried out by adjusting bearing rod head and dam seam and controlling iron-water and nodulizer contact. It adopts waste-heat one-step method and controls spheroidizing reactive time and strength; the spheroidizing agent consists of Mg<=20%, RE<=3% and Si<=65%. It's simple, cheap and can be used for large-scale continuous production.

Owner:河北贝广电力设备有限公司

Processing method of annular gear of thin-wall member

InactiveCN101844306ASave energyReduce consumptionOther manufacturing equipments/toolsThermal treatmentSteel tube

The invention relates to a processing method of an annular gear of a thin-wall member, comprising the following steps of: selecting a seamless steel tube as a raw material, blanking, sawing the seamless steel tube into a blank, carrying out thermal treatment, normalization process and isothermal annealing process, finely turning the blank, turning the thermal-treatment blank into the exterior geometric size of a product by using a lathe, processing internal teeth, and finally carrying out thermal treatment. The invention has the advantages of simple process, steel and electric energy saving, reduction of steel consumption and no forging, improves production environment, shortens manufacturing procedures, reduces manufacturing cost and improves the utilization rate of the materials.

Owner:ZHUZHOU GEAR CO LTD

Production of instant water-gas slurry

InactiveCN101029260AEasy to oxidizeNot easily oxidizedLiquid carbonaceous fuelsLump/pulverulent fuel preparationMixed materialsBall mill

Production of quick-dissolving powdered water gas slurry is carried out by mixing various additive solutions with raw material coal proportionally, delivering mixed materials into ball mill, and dry grinding to obtain the final product. It has better stability, shorter working time, less producer and consumption and higher efficiency.

Owner:陕西升基利科技有限公司

Clutch facing piece for automobile and production method thereof

InactiveCN101655128AHigh strengthHigh modulusMixing operation control apparatusCeramic shaping apparatusConductor CoilAntimony trisulfide

The invention discloses a clutch facing piece for an automobile and a production method thereof. The production method comprises the following steps: stirring 10-20% of water soluble phenolic resin, 0.5-1.5% of alumina, 4-8% of crystalline flake graphite, 0.6-1.2% of antimony trisulfide, 6-10% of ground calcium carbonate, 8-12% of chalcopyrite powder, 6-10% of magnetite powder, 3-8% of vermiculitepowder, 12-18% of barium sulfate, 6-15% of powder nitrile-butadiene rubber and water according to parts by weight of each component, preparing suspension, then dipping 15-25% of basalt fibre and obtaining a product by drying, winding, pressing, heat treatment and mechanical processing. By using the invention, the temperature resistance and the wear resistance of the clutch facing piece for the automobile are enhanced, a phenomenon of dust raising in the production and use process is reduced, and the product is more affinitive to the environment.

Owner:十堰法雷诺动力科技有限公司

Abrasion-proof cast iron roll collar for straightening steel rail and preparation method thereof

InactiveCN101412050AEliminate high temperature heat treatmentShorten the production cycleRollsProcess efficiency improvementCompound aWear resistant

The invention provides a wear resistant cast iron roll collar used for aligning a steel rail and a preparation method, which belong to the technical field of steel rail processing. The prior wear resistant cast iron roll collar used for aligning the steel rail has the defects of easy occurrence of cracks, complicated manufacture process and the like in quenching process. The method is to compound a wear resistant outer layer with a magnesium iron inner layer into an integral roll collar by centrifuge casting, wherein the wear resistant outer layer comprises the following ingredients in weight percentage: 3.0 to 3.4 percent of C, 1.5 to 2.0 percent of Si, 1.2 to 1.6 percent of Mn, 0.2 to 0.4 percent of Nb, 0.03 to 0.06 percent of RE, 0.03 to 0.06 percent of Mg, 2.5 to 3.0 percent of Ni, 0.4 to 0.6 percent of Mo, 0.8 to 1.2 percent of Cu, 1.5 to 1.8 percent of Cr, 1.0 to 1.4 percent of V, 0.03 to 0.08 percent of B, 0.002 to 0.005 percent of Te, 0.01 to 0.03 percent of Ba, less than or equal to 0.06 percent of P, less than 0.03 percent of S, and the balancing being Fe. The invention has the advantages of high hardness of the roll collar, good wear resistance, simple production process and low production cost.

Owner:BEIJING UNIV OF TECH

Continuous colloid mixer and its application

ActiveCN1986064ASolve the problem that continuous production cannot be realizedIncrease productivityRotary stirring mixersCocoaDrive shaftEngineering

The continuous colloid mixer includes the following members: solid feeding pipe, liquid feeding pipe, stator, rotor, pedestal, discharge port, rotating shaft and driving shaft. The continuous colloid mixer can mix solid powder and liquid to prepare colloid continuously in high production efficiency, and is used in the continuous production of cracking catalyst. Compared with available intermittent mixer, the present invention has lowered manufacture cost, continuous and stable production and improved product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

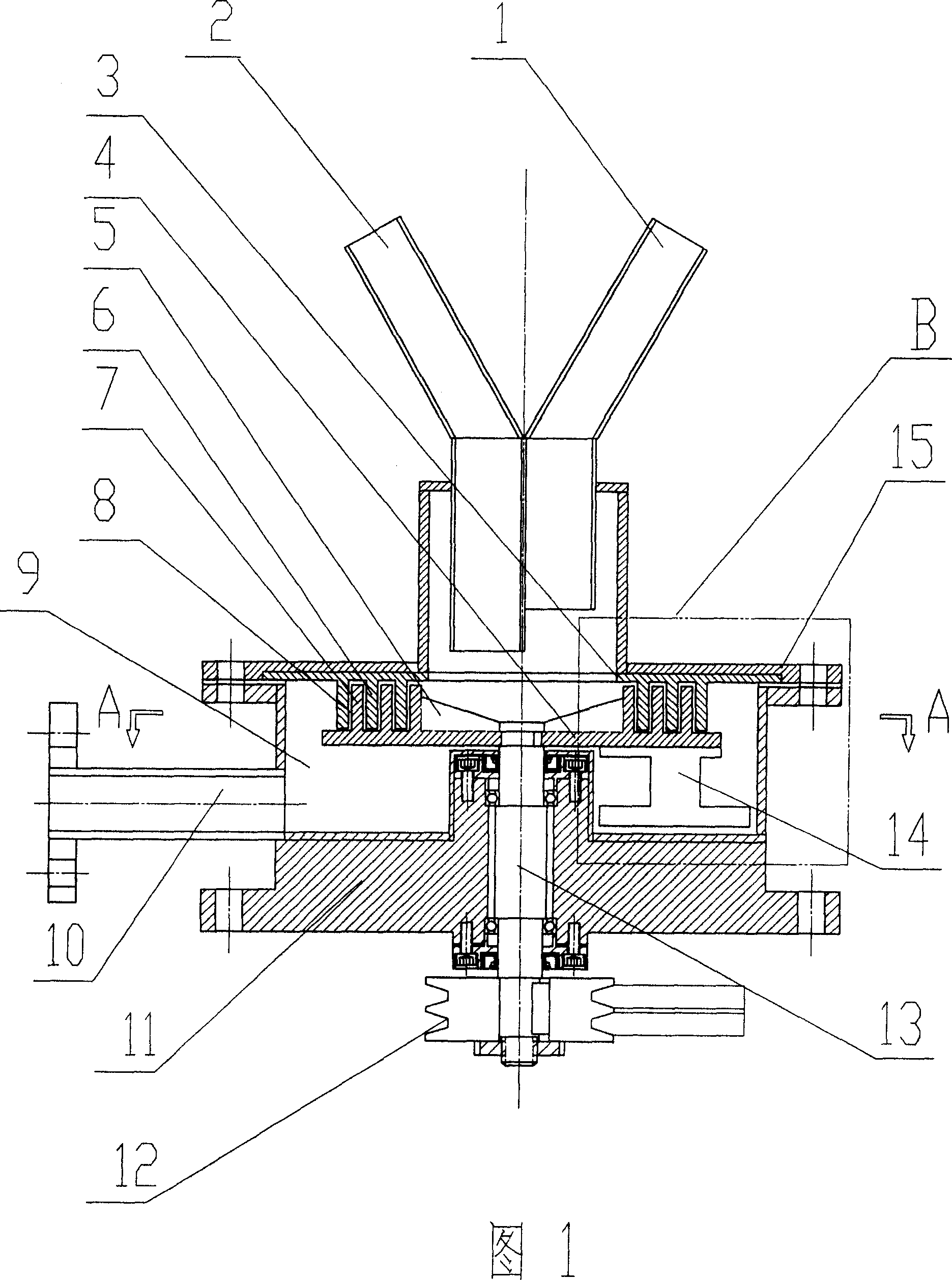

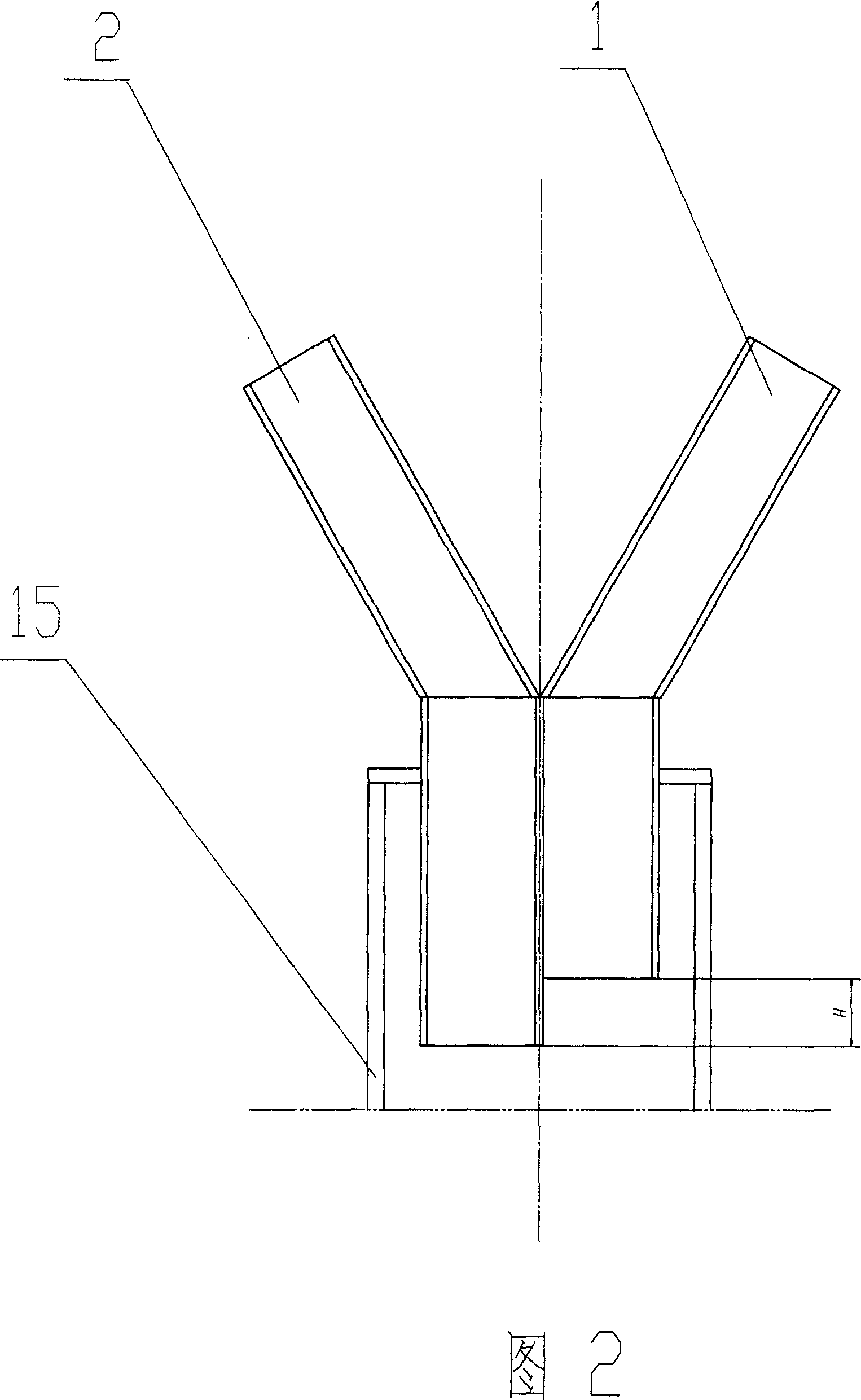

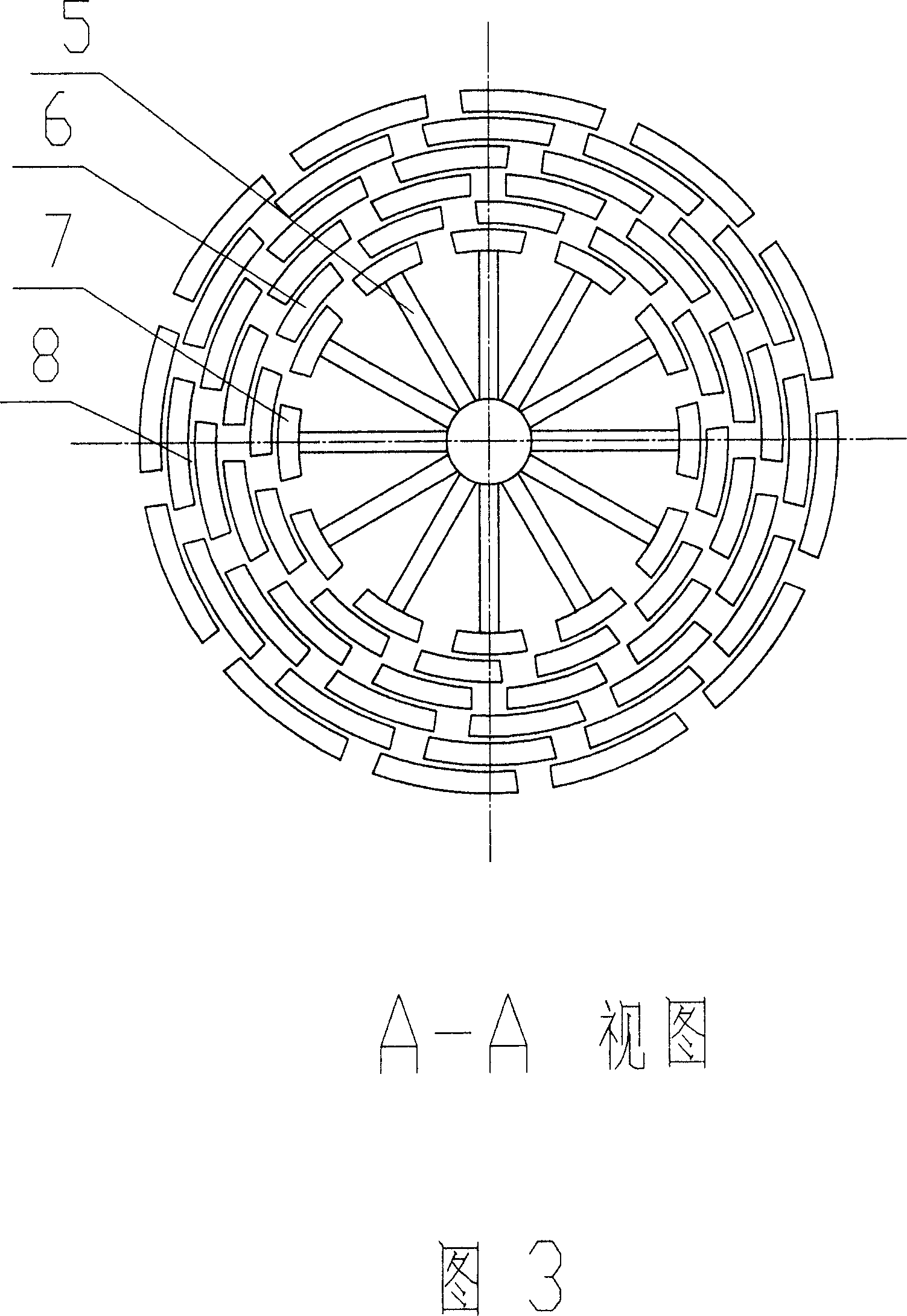

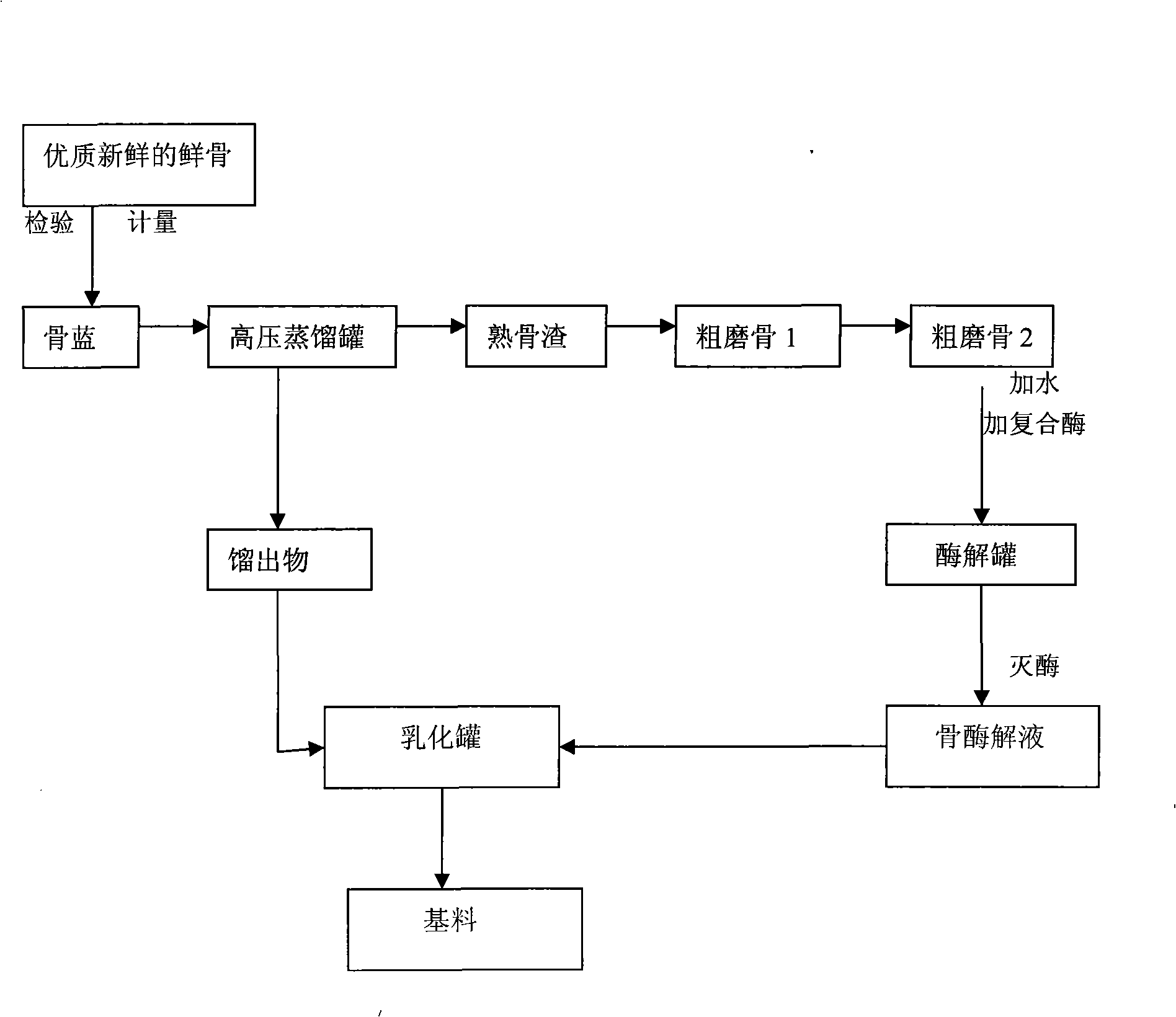

Processing method for fresh bone with combination of heavy pressure extraction and biological enzymolysis

The invention relates to a fresh bone processing method with high-pressure extraction combined with biological enzymolysis, which effectively solves the problems of high energy consumption, easy pollution and low resource utilization during the fresh bone processing so as to meet the demand on fresh bone products by people. The invention has the technical proposal for solution that the heating, extraction and enzymolysis are combined to process the fresh bones which are classified into different grades for fine grinding and treated with enzymolysis, heat reaction, emulsification, enzyme deactivation and sterilization to obtain fresh bone extracts. The processing method of the invention is simple without crushing the fresh bones and can ensure a bone resource utilization rate of 100 percent and optimize the production environment; in addition, the produced products have high concentration, obvious flavor property, mellow taste and natural nutrition, so the fresh bone processing method is a great creation in the fresh bone processing and has great economic and social benefits.

Owner:河南京华食品科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com