Abrasion-proof cast iron roll collar for straightening steel rail and preparation method thereof

A wear-resistant cast iron and roll ring technology, which is applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of easy cracks on the roll surface, high deformation resistance, high rail strength, etc., and achieve less processing, high hardness and wear resistance The effect of high reliability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

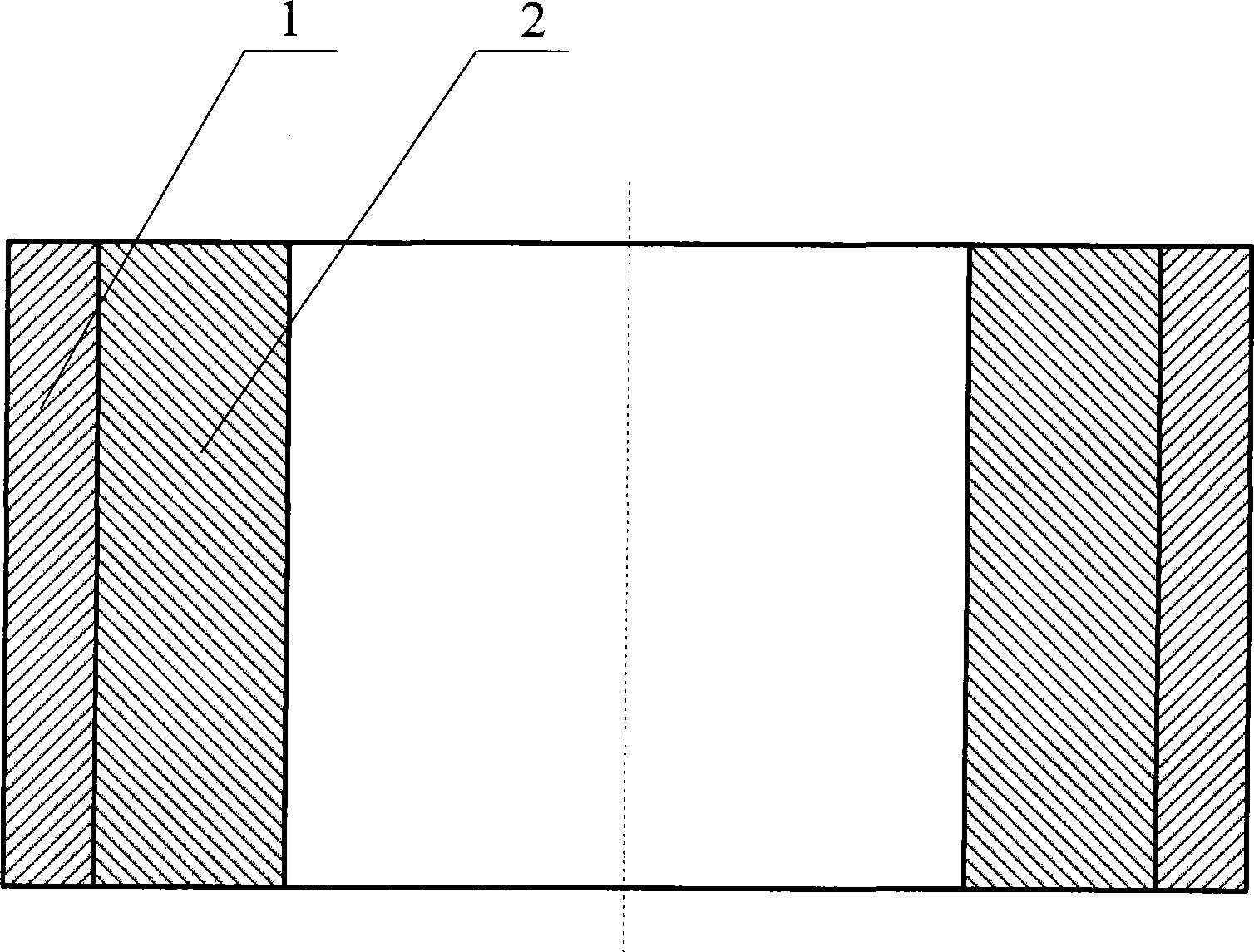

Image

Examples

Embodiment 1

[0034] ①Smelting outer layer cast iron: Firstly, ordinary steel scrap, graphite block, ferrochrome, ferrosilicon, ferromanganese, ferromolybdenum, ferroniobium, nickel plate and copper plate are mixed and heated and melted. After the molten iron is melted, ferrovanadium is added, and the composition is adjusted before the furnace. Finally, the temperature was raised to 1540°C, and then it was taken out of the furnace. In the process of taking out the outer layer of molten iron, 75Si-Fe and barium-containing Si-Fe (5-7% Ba, 65-70% Si, 0.8-1.5% Ca, 1.0-1.8 % Al, balance Fe) to inoculate the molten iron with flow, and use the rare earth magnesium alloy to carry out the spheroidization treatment by the flushing method. When the molten iron is 40-60% out of the furnace, the iron boron and the iron tellurium are broken to a particle size of 6-10mm. block, wrap it with paper and throw it directly into the molten iron ladle, and pour the molten iron after standing still and removing sl...

Embodiment 2

[0043] ①Smelting outer layer cast iron: Firstly, ordinary steel scrap, graphite block, ferrochrome, ferrosilicon, ferromanganese, ferromolybdenum, ferroniobium, nickel plate and copper plate are mixed and heated and melted. After the molten iron is melted, ferrovanadium is added, and the composition is adjusted before the furnace. After that, the temperature was raised to 1522°C, and then it was taken out of the furnace. In the process of taking out the outer layer of molten iron, 75Si-Fe and barium-containing Si-Fe (5-7% Ba, 65-70% Si, 0.8-1.5% Ca, 1.0-1.8 %A1, balance Fe) to inoculate the molten iron with flow, and use the rare earth magnesium alloy to carry out the spheroidization treatment by the flushing method. When the molten iron is 40-60% out of the furnace, the iron boron and the iron tellurium are broken to a particle size of 6-10mm. block, wrap it with paper and throw it directly into the molten iron ladle, and pour the molten iron after standing still and removing ...

Embodiment 3

[0052]①Smelting outer layer cast iron: Firstly, ordinary steel scrap, graphite block, ferrochromium, ferrosilicon, ferromanganese, ferromolybdenum, ferroniobium, nickel plate and copper plate are mixed and heated and melted. After the molten iron is melted, ferrovanadium is added, and the composition is adjusted before the furnace. Afterwards, the temperature was raised to 1549°C, and then it was taken out of the furnace. In the process of taking out the outer layer of molten iron, 75Si-Fe and barium-containing Si-Fe (5-7% Ba, 65-70% Si, 0.8-1.5% Ca, 1.0-1.8 %A1, balance Fe) to inoculate the molten iron with flow, and use the rare earth magnesium alloy to carry out the spheroidization treatment by the flushing method. When the molten iron is 40-60% out of the furnace, the iron boron and the iron tellurium are broken to a particle size of 6-10mm. block, wrap it in paper and throw it directly into the molten iron ladle, and pour the molten iron after standing still and removing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com