Patents

Literature

250 results about "Ferroniobium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferroniobium is an important iron niobium alloy, with a niobium content of 60-70%. It is the main source for niobium alloying of HSLA steel and covers more than 80% of the worldwide niobium production. The niobium is mined from pyrochlore deposits and is subsequently transformed into the niobium pentoxide Nb₂O₅. This oxide is mixed with iron oxide and aluminium and is reduced in an aluminothermic reaction to niobium and iron. The component metals can be purified in an electron beam furnace or the alloy can be used as it is. For alloying with steel the ferroniobium is added to molten steel before casting. The largest producers of ferroniobium are the same as for niobium and are located in Brazil and Canada.

High-carbon high-chromium high-niobium cast iron self-protecting flux-cored wire

InactiveCN101406994AHigh hardnessLow viscosityWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

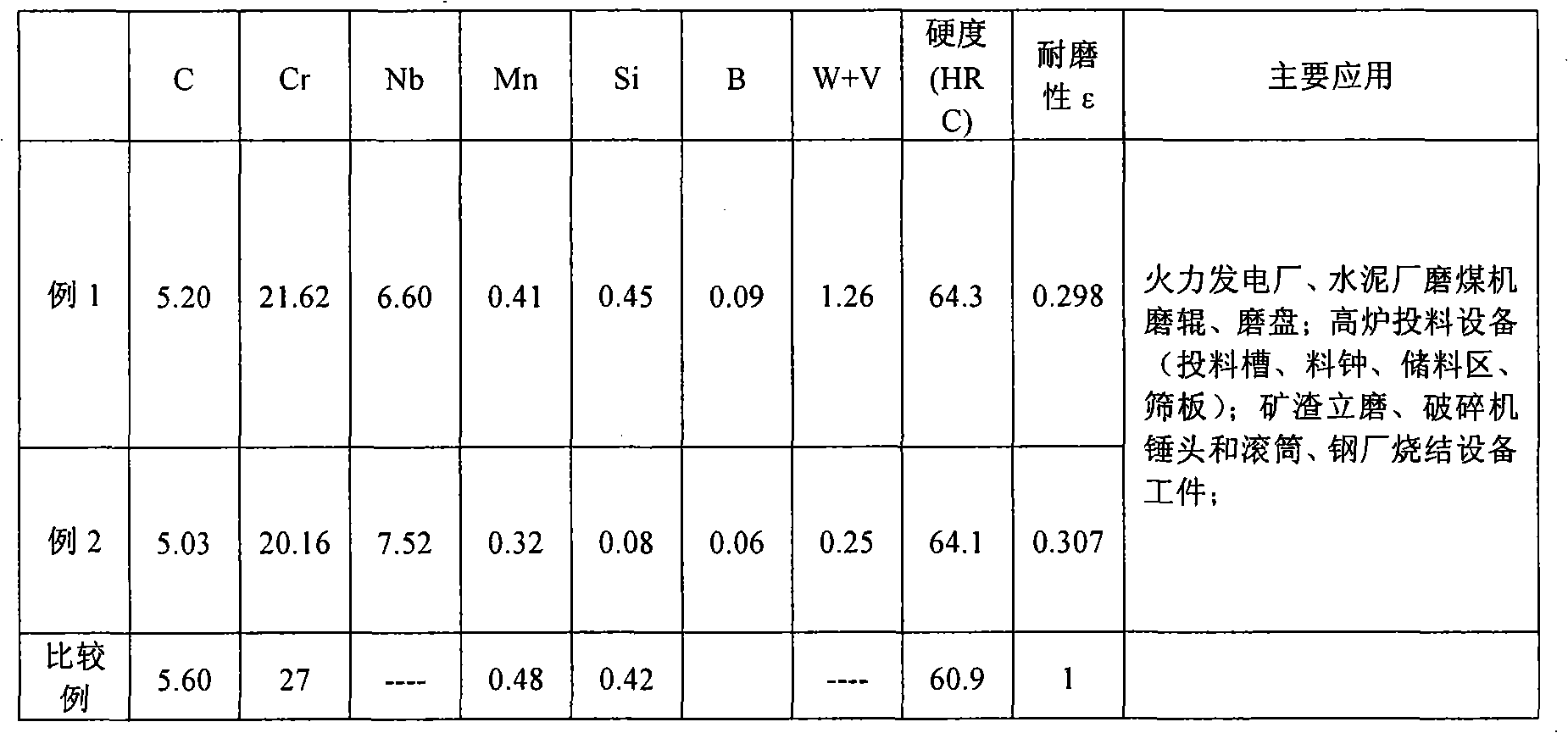

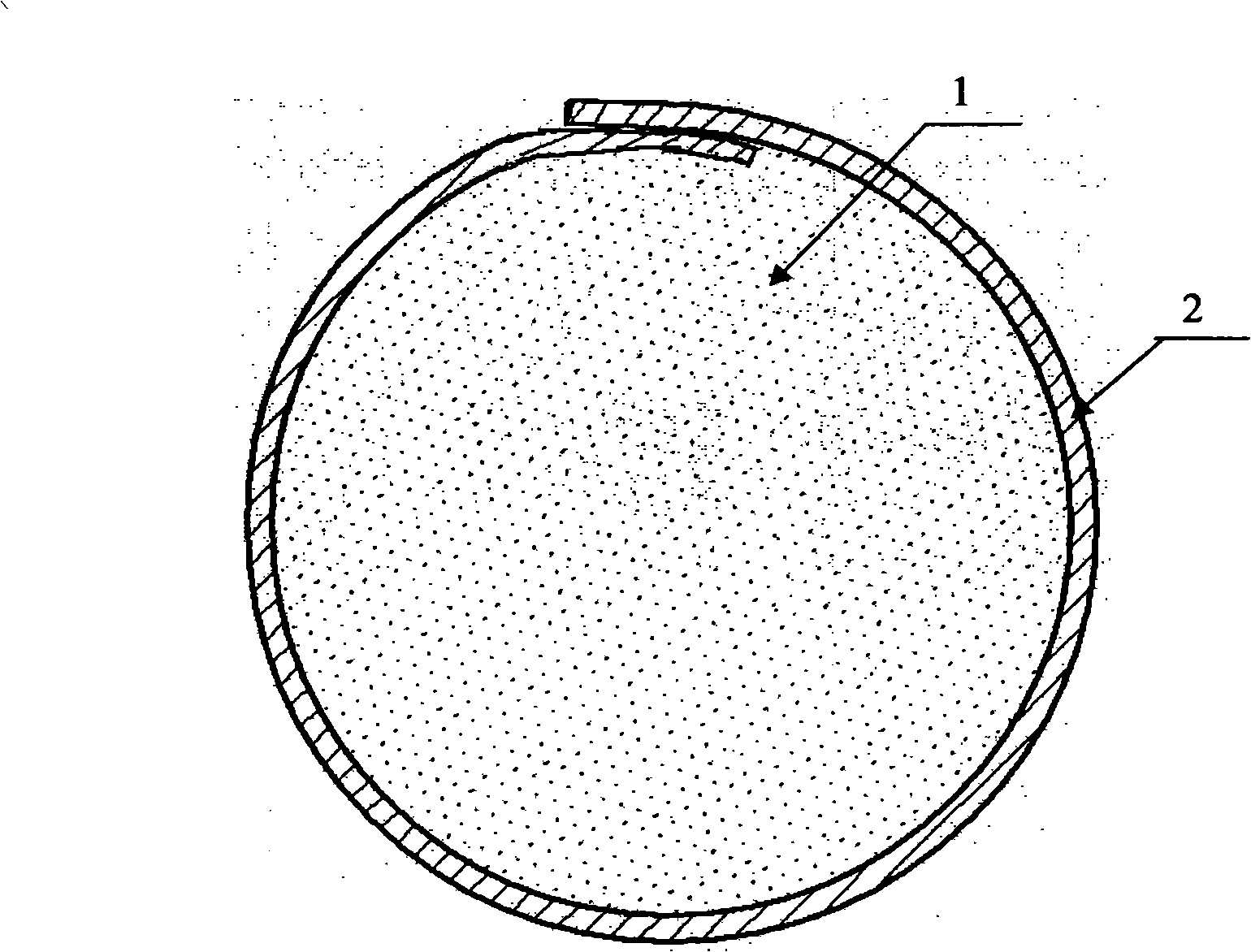

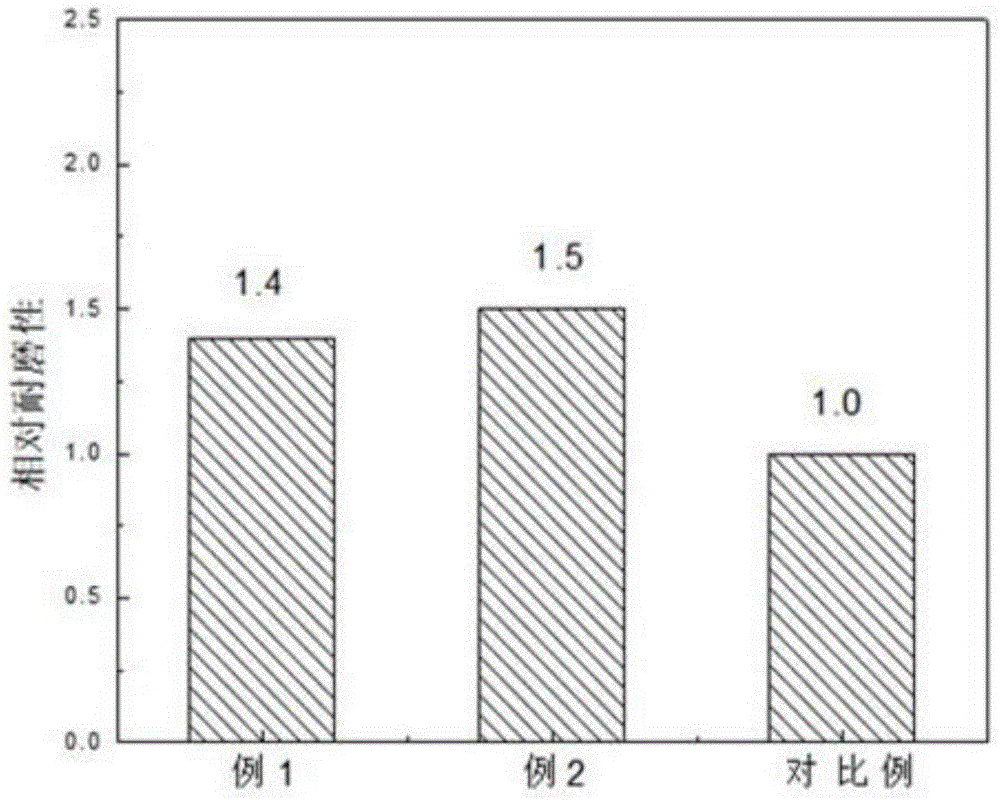

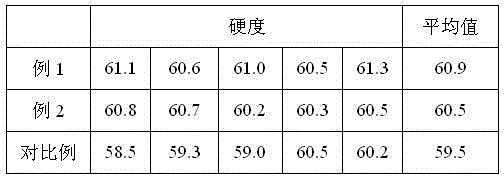

The invention provides a high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire. The flux-cored wire has a steel belt as an outer skin. The flux core comprises the following components in weight percentage: 10 to 30 percent of ferroniobium, 20 to 30 percent of high carbon ferrochrome, 0.1 to 3 percent of V, 0.2 to 3 percent of W, 0.6 to 0.8 percent of ferromanganese, 0.2 to 0.8 percent of 75 ferrosilicon, 20 to 30 percent of chromium carbide, 5 to 12 percent of graphite, 1 to 10 percent of aluminum-magnesium alloy, 1 to 5 percent of silicon carbide and 1 to 3 percent of ferroboron; and the percentage of a counter weight is between 46 and 54 percent. The high-carbon high-chromium high-niobium cast iron self-protection flux-cored wire has the advantages of high hardness, good wear resistance, good oxidation resistance and strong shock resistance, and is widely applied to grinding rolls and grinding disks of coal grinding machines in thermal power plants and cement plants, material charging equipment in blast furnaces(material charging slots, receiving cones, material storage areas and sieve plates), slag vertical mills, hammer heads and rollers of crushers and sintering equipment workpieces in steel plants.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

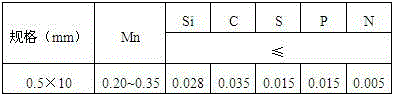

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Nickel-base welding rod

InactiveCN101745759AGood production technologyImprove yieldWelding/cutting media/materialsSoldering mediaSlagManganese

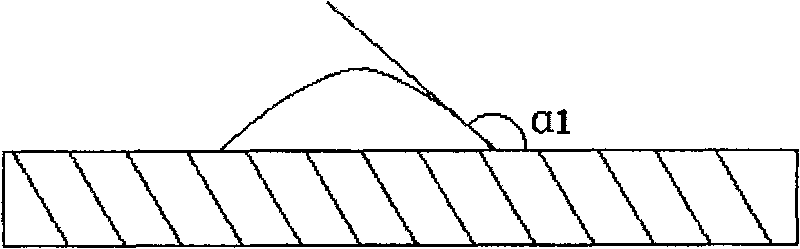

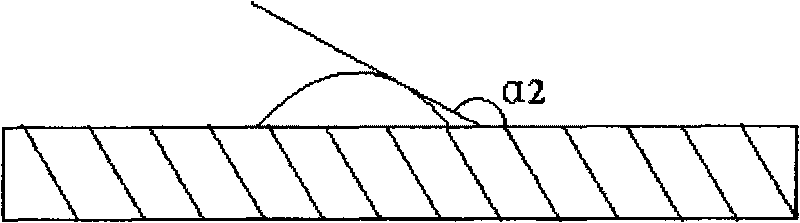

The invention relates to a welding material technology, in particular to a nickel-base welding rod. The welding rod uses a SNi6062 welding wire as a core wire. The electrode coating comprises the following solid ingredients in percentage by mass: 36-50% of rutile, 2-7% of titanium pigment, 20-30% of fluorite, 3-8% of cryolite, 2-4% of phlogopite, 2-4% of zircon sand, 0.5-1.5% of sodium carbonate, 5-10% of manganese metal, 2-4% of ferrotitanium containing 25-35% of Ti, and 2-4% of ferroniobium containing 50-60% of Nb. The nickel-base welding rod has the advantages of favorable performance of production technique, smooth welding rod surface, high yield, stable eccentricity; during welding, the nickel-base welding rod has the advantages of stable electric arc, basically no splash, favorable slag detachability and outstanding operating performance; and the appearance of the welding seam is beautiful, the height of a weld bead is moderate, the wetting angle of a welding seam is moderate, and the strength and plasticity of deposited metals are moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Ultra supercritical heat-resistant steel welding rod and production method thereof

InactiveCN103737199AGood workmanshipGood mechanicalWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses an ultra supercritical heat-resistant steel welding rod which is composed of an H08A core wire and coating wrapping the surface of the core wire, wherein contents of sulfur, phosphorus, arsenic, aluminum and the like in the H08A core wire are low, and the coating comprises components of 30%-39% of marbles, 22%-30% of fluorites, 6%-9% of rutiles, 7.5%-8.6% of ferromolybdenum, 29%-31% of chromium metal, 5%-9% of silica powder, 2%-5% of ferrosilicon, 1%-1.8% of ferrovanadium, 0.4%-0.8% of ferroniobium, 1.8%-2.8% of nickel powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxyl methyl cellulose (CMC), 0.2%-0.6% of amorphous graphite, 0.6%-1.5% of nitrogen-bearing ferrochromium, 1.6%-3% of electrolytic manganese, 3%-3.8% of cobalt powder and 4%-5% of ferroboron.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

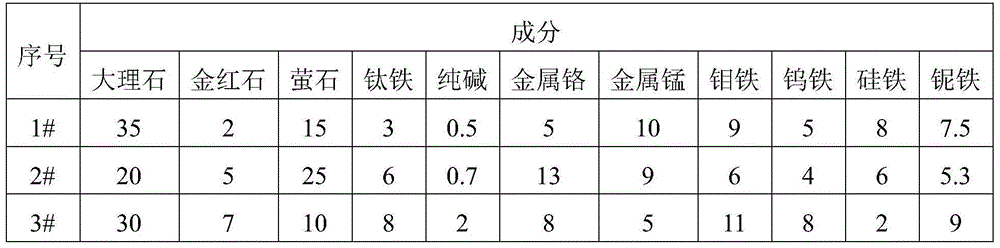

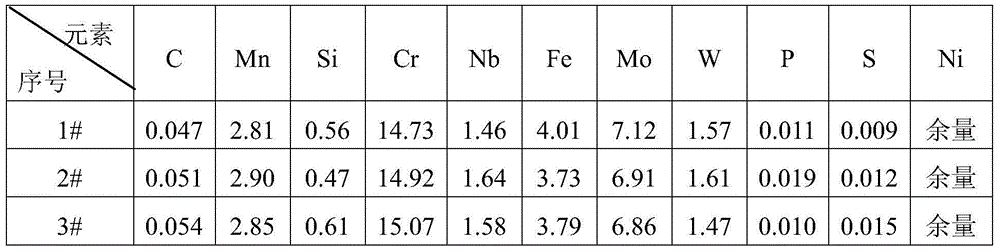

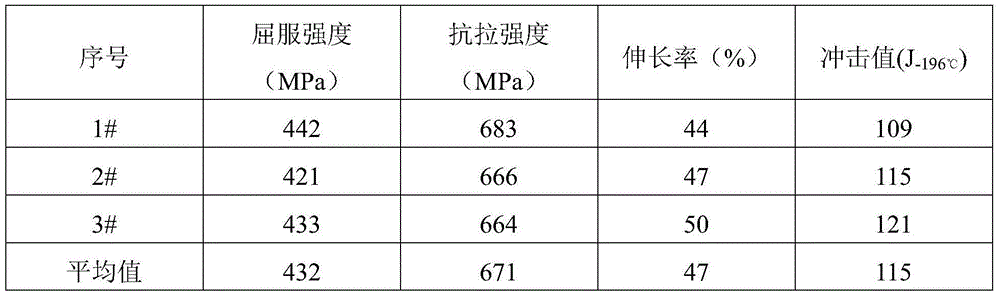

Nickel-based welding electrode matched with 9Ni steel

ActiveCN102500951AEasy to useExtend your lifeWelding/cutting media/materialsSoldering mediaNiobiumSlag

The invention belongs to a nickel-based welding electrode matched with 9Ni steel. A core wire comprises the following components in percentage by weight: more than or equal to 0.02 percent of C, 2.00 to 5.00 percent of Mn, 0.010 to 0.20 percent of Si, 55.0 to 70.0 percent of Ni, 2.50 to 10.00 percent of Fe, 0.05 to 0.30 percent of Cu, 14.00 to 19.00 percent of Cr, 7.00 to 10.00 percent of M, 1.00to 2.50 percent of Nb, 0.001 to 0.010 percent of Co, less than or equal to 0.010 percent of S, less than or equal to 0.020 percent of P and the balance of impurity; a coating comprises the following components 9.0 to 10.5 percent of marble, 7.0 to 8.5 percent of fluorite, 8.0 to 9.5 percent of barium carbonate, 8.0 to 8.5 percent of rutile, 4.0 to 5.0 percent of fluoride, 0.6 to 1.0 percent of ferroniobium powder, 1.2 to 1.5 percent of metal tungsten powder, 0.7 to 1.0 percent of soda ash, and 1.0 to 1.5 percent of electrolytic manganese based on the weight of the core wire; and binder is 20 percent based on the total weight of powder; the components are mixed, and wrapped on the core wire; and the coating and the core wire are baked at low and high temperature. The nickel-based welding electrode has the advantages that: during welding, an electric arc is stable, splashing is avoided basically, slag is detached well, the formed welding joint has an attractive appearance, and the nickel-based welding electrode is good in full-position welding performance; and the nickel-based welding electrode still has good comprehensive performance when used at the temperature of -196 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493AIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

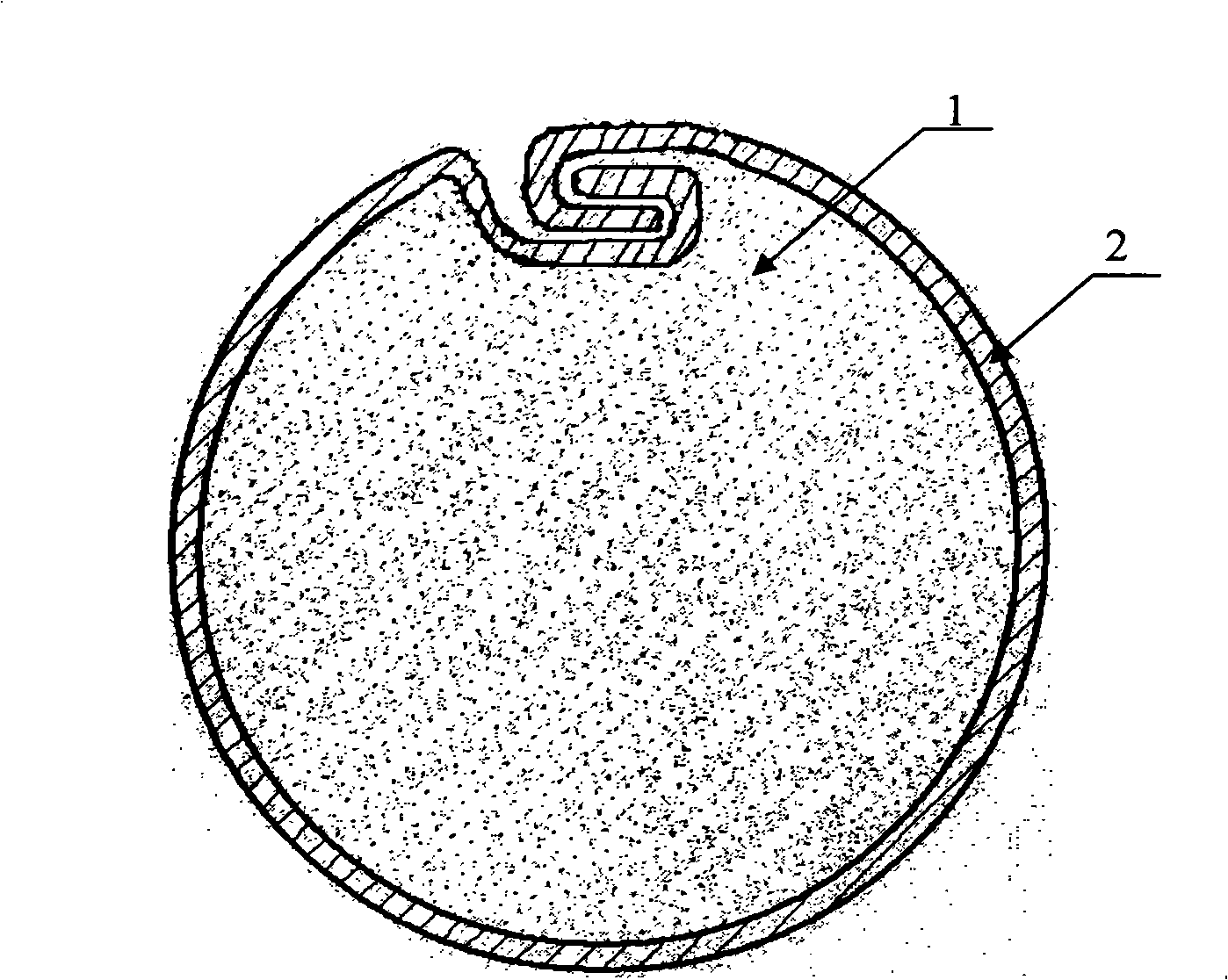

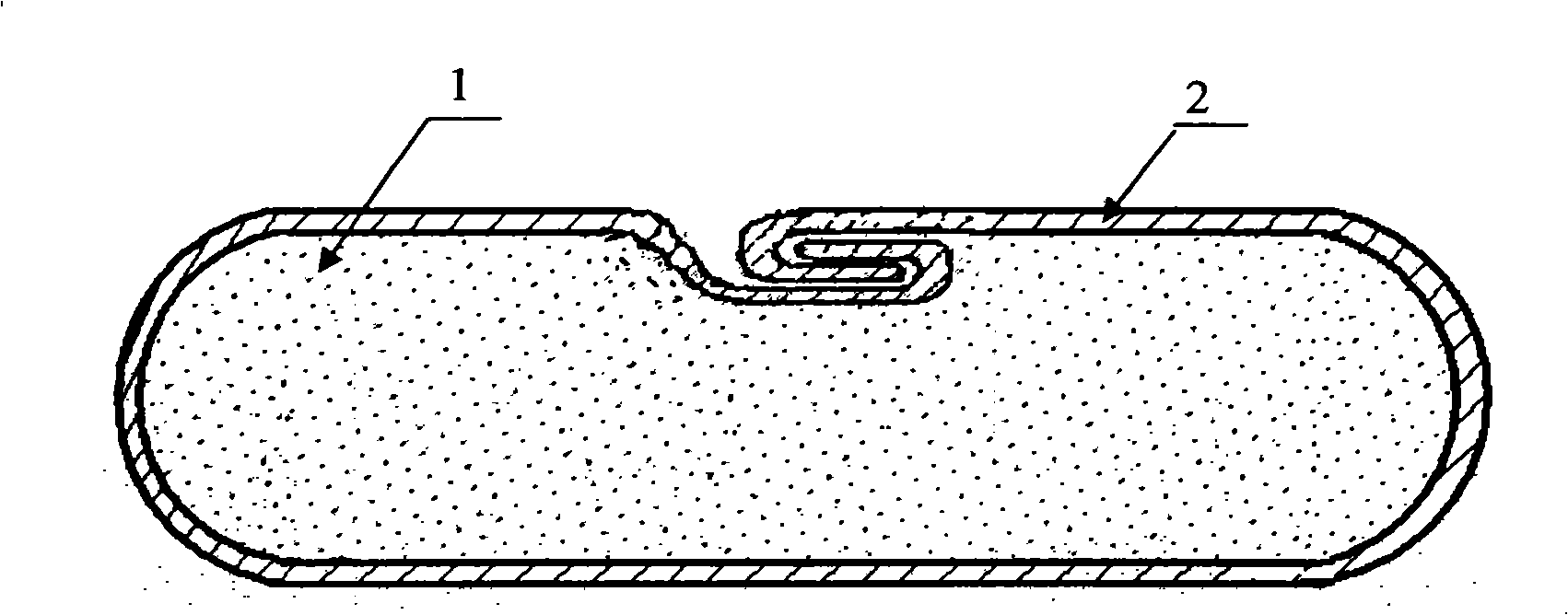

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can be coiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

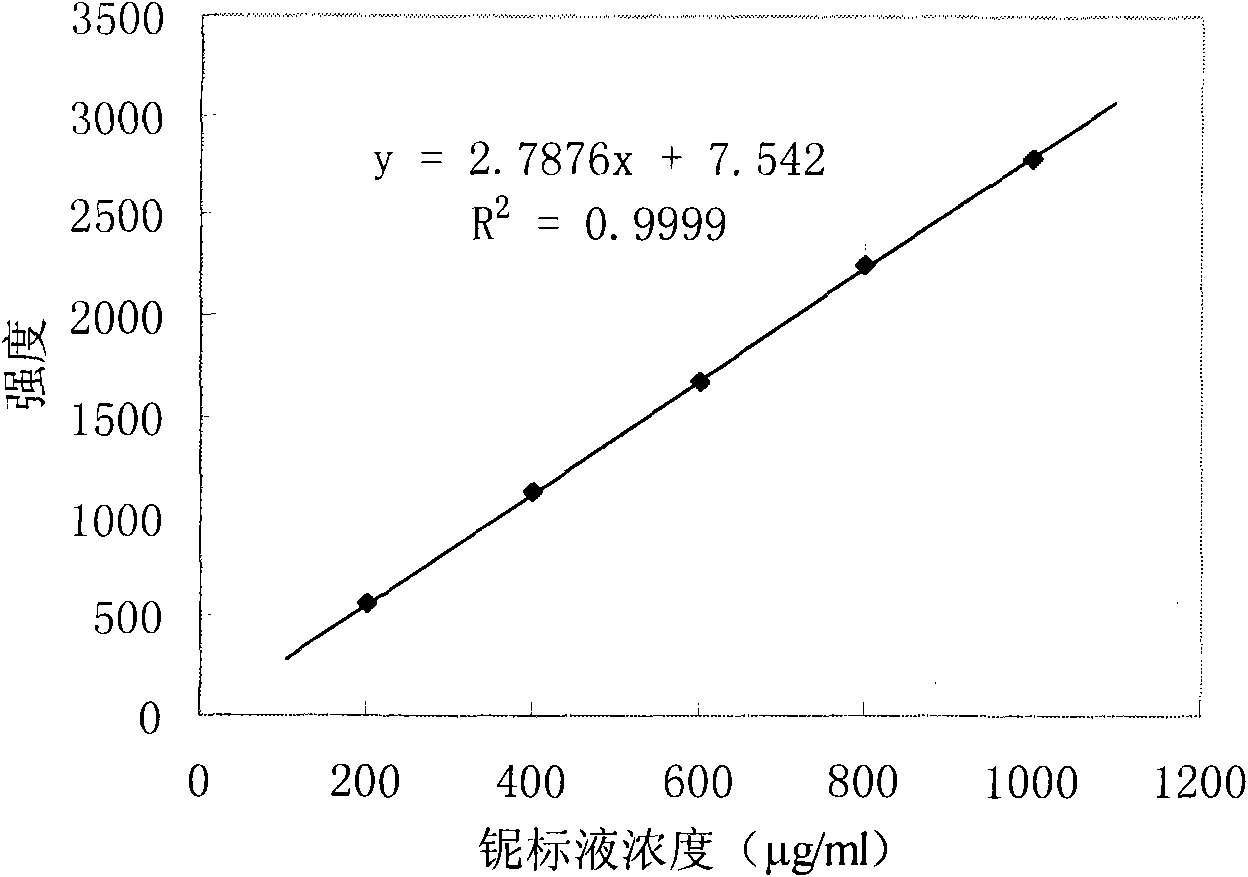

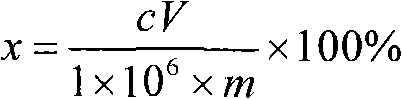

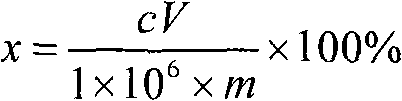

Method for determining niobium element content in ferroniobium

InactiveCN101609048AAvoid hydrolysisBreak down completelyAnalysis by thermal excitationPretreatment methodNiobium

The invention relates to a method for determining niobium element content in ferroniobium, which comprises the following steps: a sample is weighted and put in a polytetrafluoroethylene beaker and deionized water is added for humidifying the sample; hydrofluoric acid and nitric acid are added into the sample, and then are heated so that the sample is slowly dissolved; after the sample is completely dissolved, the breaker is taken down and cooled; after the sample is cooled to room temperature, the volume is metered; reagent blank without the sample is adopted, and then standard solution of niobium element with different volumes is added, and finally deionized water is added and the volume is metered; spectral line strength of niobium element in standard solution is determined under the working condition of a setting inductively coupled plasma atomic emission spectrometer and a working curve is drawn; the spectral line strength of niobium element in ferroniobium sample solution to be determined is determined, and then a computer automatically determines the concentration of niobium element in sample solution according to the working curve. The method mainly solves problems of long operational process, narrow measuring range and the like, determines appropriate sample processing methods and analytic conditions of instruments, and realizes effectively, rapidly and accurately measuring niobium element in ferroniobium.

Owner:武钢集团有限公司

High strength and toughness wear-resistant ductile iron rocking arm and production method thereof

ActiveCN104775065AReduce manufacturing costHigh strengthFoundry mouldsFoundry coresFerroniobiumNiobium

The invention discloses a high strength and toughness wear-resistant ductile iron rocking arm and a production method thereof, and belongs to the technical field of casting. The method comprises the following steps: carrying out mixing and heating fusion on common scrap steel, pig iron for nodular cast iron, a carburant, ferrosilicon, sheet copper and ferroniobium to obtain base molten iron, wherein the base molten iron comprises, by mass, 3.45-3.70% of C, 1.30-1.45% of Si, 0.20% or less of Mn, 0.15-0.25% of Cu, 0.03-0.06% of Nb, below 0.04% of S, below 0.04% of P, and the balance of Fe and inevitable impurity elements; and carrying out composite inoculation, spheroidization and multi-microalloying modification to obtain the ductile iron rocking arm. The obtained ductile iron rocking arm has the characteristics of fine graphite nodules, uniform distribution, good strength and toughness and good wear resistance, and has good use effects in automobile engines.

Owner:HANDAN LIANCHENG MACHINERY MFG CO LTD

Molten steel processing method of high-speed steel roller material

The invention relates to a molten steel processing method of a high-speed steel roller material, belonging to the technical field of metallurgy. The molten steel processing method comprises the following steps of: crushing the following materials containing metamorphic elements: rare earth magnesium-ferrosilicon alloy, ferrovanadium, ferrotitanium, ferroniobium, ferrozirconium, potassium oxide, silicon-calcium-barium alloy, nitrogenous ferrochrome, ferroboron and zinc into powder with a grain size of 60-100 meshes, and uniformly mixing the materials in percentage by mass; packaging the mixed materials by adopting a low-carbon steel strip with a thickness of 0.15-0.22 mm, and preparing a metal cored wire with a diameter phi of 5-8 mm by rolling; and adding the metal cored wire into molten steel for pouring high-speed steel rollers in a steel ladle by adopting a wire feeding method, wherein 8-10 kg of the metal cored wire is added into one ton of the molten steel. The molten steel processing method provided by the invention has the advantages of convenient and simple process, high yield of the metamorphic elements and stable metamorphism effect, so that the mechanical property and the operational performance of the high-speed steel roller are obviously improved; in addition, the molten steel processing method is easy to popularize and apply, and good in economic benefit.

Owner:BEIJING UNIV OF TECH +1

Self-shielded flux-cored wire for extrusion roller remanufacturing

InactiveCN104959746AImprove bindingImprove toughnessWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses a self-shielded flux-cored wire for extrusion roller remanufacturing. A mild-carbon steel strip is employed as the skin of the self-shielded flux-cored wire. The component of the flux comprises, by mass, 20%-40% of high carbon ferrochrome, 20%-40% of chromium carbide, 5%-20% of ferromolybdenum, 1%-10% of ferrovanadium, 1%-5% of ferroniobium, 1%-5% of graphite, 1%-5% of aluminum-magnesium, 1%-4% of electrolytic manganese, 1%-4% of ferrosilicon and 1%-4% of ferroboron, and the weight ratio is 44%-52%. The hardness of the surfacing alloy manufactured by the use of the self-shielded flux-cored wire can reach HRC60, and the surfacing alloy is fine and uniform in crack, is high in wear resistance, is high in shock resistance, and is suitable for being employed as a working layer in an extrusion roller remanufacturing process in a cement plant.

Owner:盐城市成功机械制造有限公司

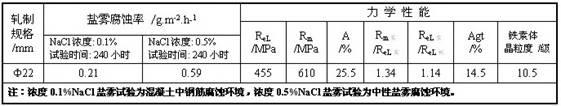

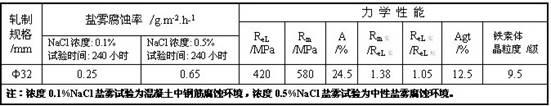

Technique for producing 500MPa level high-strength quake-proof reinforcing steel bar

The invention discloses a technique for producing 500MPa level high-strength quake-proof reinforcing steel bar. Nitrogen is blown into molten steel in a steel ladle by a microwave field in the process of steel taping, [N] in the molten steel ranges from 0.08% to 0.012%; reducible manganese oxide pellets are added in the metaphase of smelting; reducible vanadium oxide and niobium oxide pellets are added in the later stage of smelting; manganese family alloy, silicon family alloy and carburant are added in the process of steel taping, [Mn] in the molten steel ranges from 0.60% to 1.40%, [Si] in the molten steel ranges from 0.20% to 0.60%; ferrovanadium and ferroniobium are added in the process of steel taping to fine tunes vanadium and niobium in the steel, [V] in the steel ranges from 0.02% to 0.055%, [Nb] ranges from 0.02% to 0.055%; molten steel is cast into steel billets by a conticaster, the steel billets are heated by a heating furnace, heating temperature is between 1050 DEG C and 1250 DEG C, start rolling temperature is between 950 DEG C and 1150 DEG C, finishing temperature is between 950 DEG C and 1050 DEG C, and cooling speed after rolling is between 15 DEG C / s and 500 DEG C / s; Rel of the reinforcing steel bar produced by the method is between 530MPa and 560MPa, Rm is between 660MPa and 730MPa, A is between 18% and 25%, Rm / Rel is between 1.30 and 1.45, ageing lasts for three months, undulating quantity of Rel and Rm is less than 15MPa, welding performance is good, and popularization and application prospects are promising.

Owner:CENT SOUTH UNIV

Slag-free self-protection flux-cored wire for niobium-titanium compound reinforcement hardfacing

InactiveCN103785967AHigh hardnessImprove thermal stabilityArc welding apparatusWelding/cutting media/materialsSlagFerrotitanium

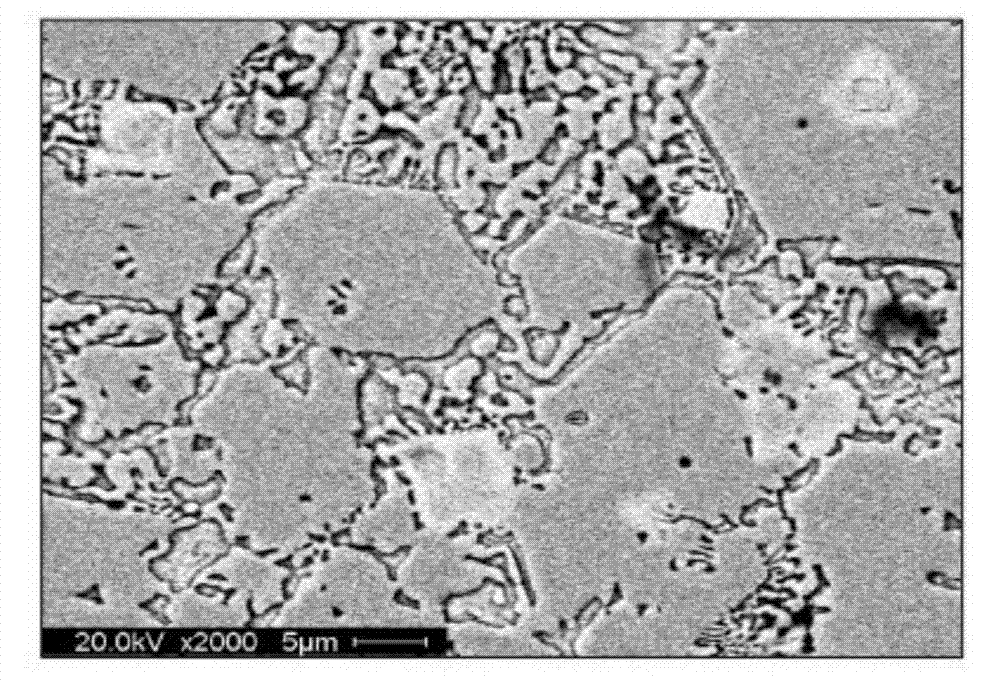

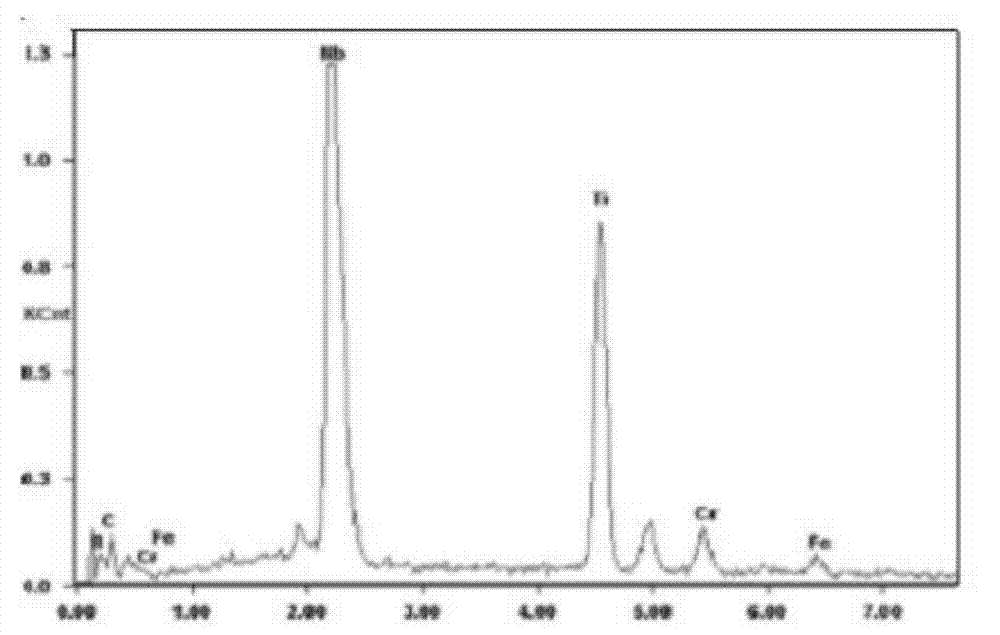

The invention discloses a slag-free self-protection flux-cored wire for niobium-titanium compound reinforcement hardfacing. The slag-free self-protection flux-cored wire for niobium-titanium compound reinforcement hardfacing comprises a mild-carbon steel strip and a flux core, and the steel strip is filled with the flux core. The flux core contains, by mass, 55-65 percent of high carbon ferro-chrome, four to eight percent of ferroniobium, four to eight percent of ferrotitanium, three to five percent of graphite, two to three percent of ferroboron, eight to fourteen percent of deoxidizing agent and the balance of iron powder, wherein the deoxidizing agent is a mixture of aluminum-magnesium alloy, manganese powder and silicon iron, the mass ratio of the aluminum-magnesium alloy, the manganese powder and the silicon iron is (2-3):(5-8):(1-4), the weight percent of the manganese powder is larger than or equal to the sum of the weight percent of the silicon iron and the weight percent of the aluminum-magnesium alloy, and the ratio of the weight of the flux core to the total weight of the flux-cored wire is between 49 percent and 56 percent. The flux-cored wire is low in cost; (Nb,Ti)C double carbide is dispersed and separated out in the welding process, and the flux-cored wire is low in cost, high and uniform in rigidity, good in abrasion resistance, free of slag clearing in multi-layer welding, low in pore sensitivity and good in welding processing property.

Owner:JIANGSU UNIV OF SCI & TECH

Flux-cored wire for titanium- or niobium-contained austenitic stainless steel welding

InactiveCN103418940AImprove slag removal rateImprove forming qualityWelding/cutting media/materialsSoldering mediaNiobiumManganese

A flux-cored wire for titanium- or niobium-contained austenitic stainless steel welding comprises welding flux powder and an external-use stainless steel band. A flux core accounts for 21.0-25.0% of the total weight of the flux-cored wire. The flux core comprises, by weight percentage, 15.0-18.0% of chromium powder, 9.5-11.0% of nickel powder, 4.0-5.0% of ferroniobium, 4.0-6.0% of electrolytic manganese, 1.0-3.0% of silicon-calcium alloy powder, 10.0-15.0% of rutile, 3.5-5.0% of quartz, 15.0-20.0% of zircon sand, 6.0-11.0% of feldspar, 1.5-2.5% of cryolite, 0.5-1.0% of lithium carbonate, 0.5-0.8% of bismuth oxide, and the balance of iron powder. In the flux core, the proportion of the content sum of titanium dioxide and zirconium dioxide to the content of silicon dioxide is 1.5-2.0; the proportion of the content of manganese powder to that of silicon-calcium alloy powder is 2.0-3.0. The external-use stainless steel band is austenitic stainless steel band 304L with carbon content lower than 0.02wt%. The diameter of the flux-cored wire is 0.9-1.2mm. By the flux-cored wire with good welding process property, all-position welding of titanium- or niobium-contained austenitic stainless steel can be achieved.

Owner:CHINA JINGYE ENG +1

Welding wire for welding FV520B martensitic stainless steel and manufacturing method thereof

InactiveCN103990918AGood soldering requirementsImprove self-protection performanceWelding/cutting media/materialsWelding/soldering/cutting articlesSlagMartensitic stainless steel

A welding wire for welding FV520B martensitic stainless steel comprises a powder core and an outer skin. The powder core is composed of, by mass, 15 percent to 35 percent of rutile, five percent to 15 percent of zircon sand, two percent to five percent of quartz, four percent to 10 percent of feldspar, two percent to five percent of sodium carbonate, two percent to five percent of aluminum oxide, six percent to 12 percent of aluminum magnesium alloy, five percent to 10 percent of electrolytic manganese metal, 18 percent to 25 percent of chromium powder, six percent to 10 percent of nickel powder, two percent to six percent of ferroniobium and one percent to 10 percent of molybdenum powder, and the sum of the mass percent of all the components is 100 percent. The welding wire is good in arcing and arc stabilizing performance, good in molten pool fluidity, fine in splashed particle and even in postwelding slag coverage, and enables deslagging to be easy, welding joint forming is meticulous and attractive, the welding wire is suitable for large linear energy welding, the organization and performance obtained through the prewelding preheating and postwelding heat treatment process can meet actual production needs, and the welding requirement for FV520B martensitic stainless steel is met.

Owner:XIAN UNIV OF TECH

Nickel-based welding rod for welding of ultralow-temperature container steel

InactiveCN106514049ASimple welding processImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaAlternating currentRutile

The invention discloses a nickel-based welding rod for welding of ultralow-temperature container steel and belongs to the technical field of nickel-based welding rods. The nickel-based welding rod comprises a welding core and a coating covering the surface of the welding core. The welding core comprises the chemical components of, by weight percentage, 0-0.1% of C, 0-0.6% of Si, 1.5%-4.5% of Mn, 0-0.012% of S, 0-0.015% of P, 0-17.0% of Cr, 4.5%-9.5% of Mo, 0.5%-2.0% of Nb, 0.5%-2.0% of W, and the balance Ni. The coating comprises the powdery materials of, by weight percentage, 20%-38% of marble, 5%-8% of strontium carbonate, 1%-4% of potassium feldspar, 3%-13% of fluorite, 2%-10% of magnesium fluoride, 3%-15% of cryolite, 10%-20% of rutile, 2%-7% of ferrotitanium, 2%-6% of ferro-aluminium, 0.5%-2% of aluminum magnesium powder, 4%-7% of ferro-molybdenum, 2%-5% of ferroniobium and 1%-3% of ferrotungsten, and the sum of all the components is 100%. The nickel-based welding rod has excellent welding manufacturability in horizontal, transverse, vertical, overhead and other welding positions when an alternating current power source is adopted for welding, and the nickel-based welding rod also has excellent low temperature toughness.

Owner:CENT IRON & STEEL RES INST

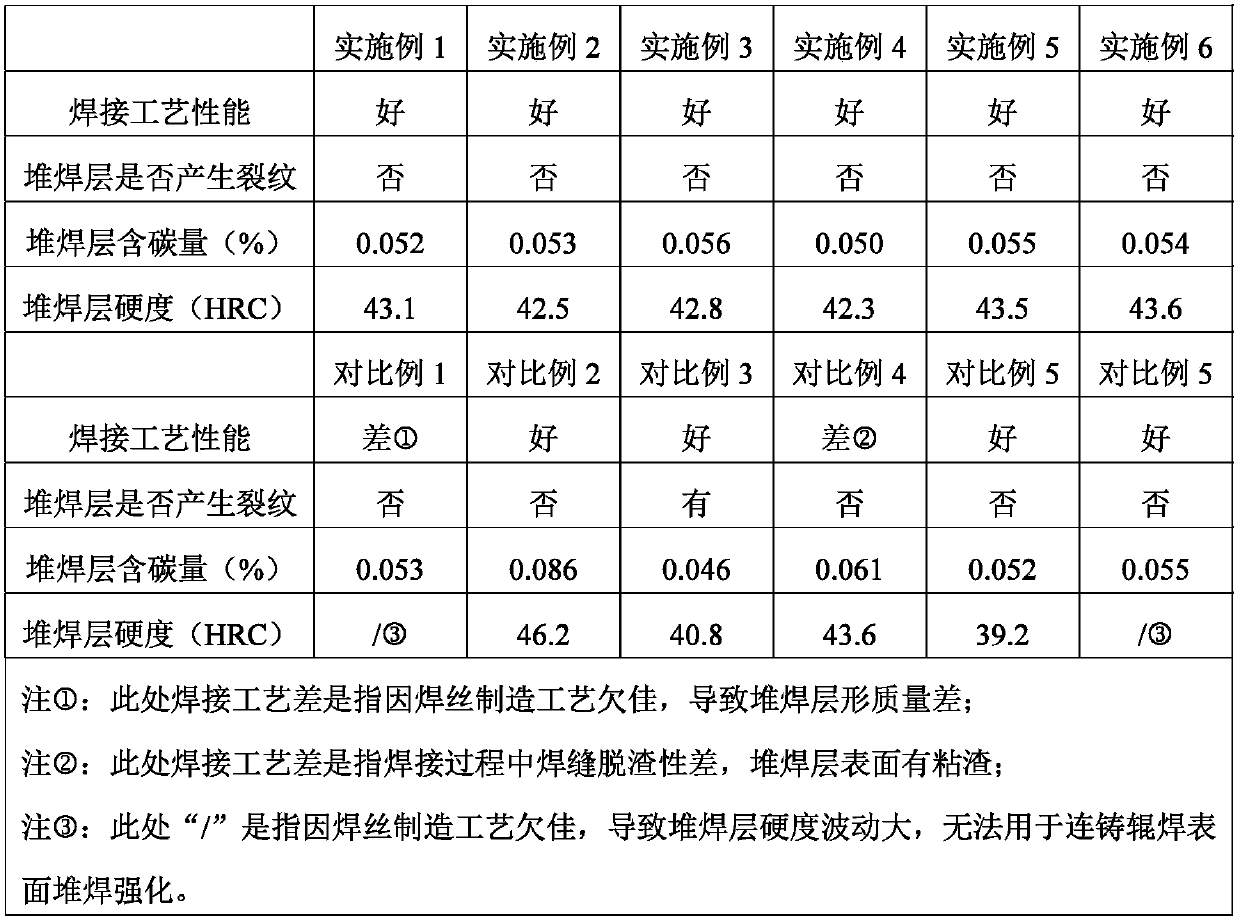

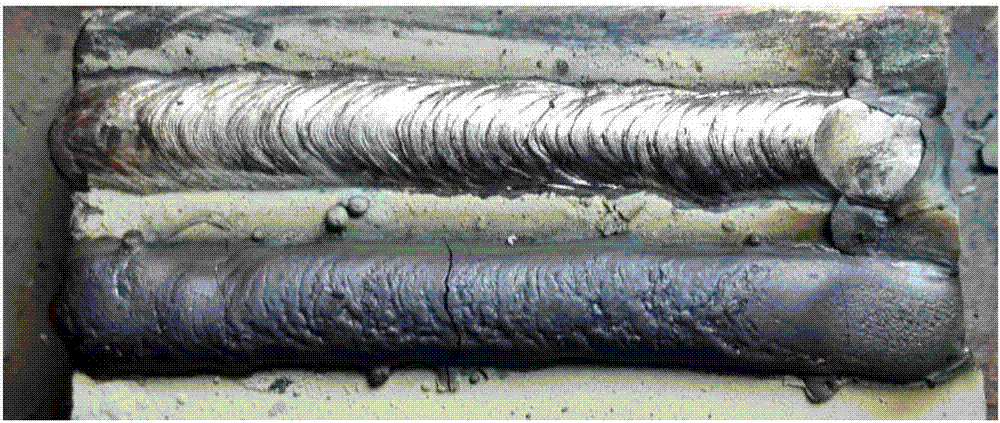

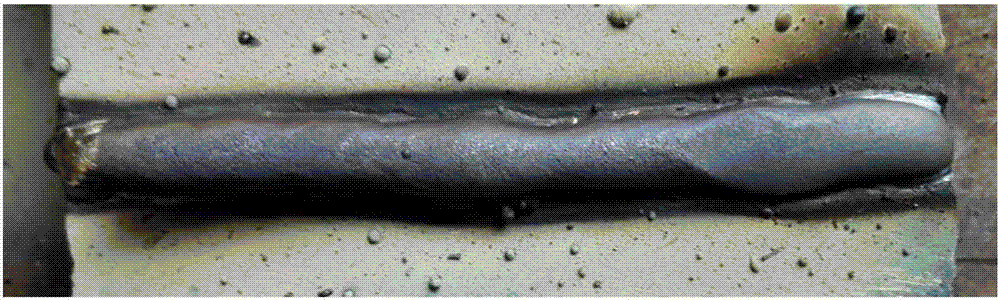

Precipitation hardening stainless steel flux-cored wire for continuous roller submerged arc overlaying and preparation method thereof

ActiveCN108015447AImprove performanceGood resistance to high temperature tempering softeningWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a precipitation hardening stainless steel flux-cored wire for continuous roller submerged arc overlaying and a preparation method thereof. The flux-cored wire consists of chemical powder and an external carbon steel strip; the chemical powder is 35.0-38.0% of the total weight of the wire; and the chemical powder comprises the following components in percentage by weight: 29.0-31.0% of metal chromium powder, 25.0-26.5% of low-carbon ferrochromium, 12.0-13.0% of metal nickel powder, 10.0-11.5% of metal copper powder, 0.8-1.2% of electrolytic metal manganese, 1.0-1.5% of ferroniobium, 0.1-0.8% of metal molybdenum powder, 0.3-0.6% of ferrotitanium, 2.0-2.5% of rare earth ferrosilicon, 0.3-0.6% of metal aluminum powder, 8.0-10.0% of barium fluoride, and the balance ironpowder. In the flux-cored wire, an overlaying layer achieves excellent wear resistance, corrosion resistance, cold and hot fatigue resistance and tempering softening resistance, so that the service life of continuous rollers can be prominently prolonged.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Corrosion-resistant welding rod and its preparing method

InactiveCN101148008AWill not cause short supplyAvoid corrosionLiquid surface applicatorsWelding/cutting media/materialsNiobiumBoron carbide

The present invention belongs to the field of welding material technology, and is especially one kind of anticorrosive welding rod. The welding rod includes one core wire and one welding rod coating comprising tungsten carbide 2-10 wt%, boron carbide or boron nitride 2-8 wt%, nickel powder 2-10 wt%, copper 0.30-0.85 wt%, RE elements 0.2-4.60 wt%, Mn-N alloy and / or V-N alloy in any ratio 0.20-2.80 wt%, ferromolybdenum 0.6-3.2 wt%, marble 25-38 wt%, titanium white powder 2-8 wt%, fluorite 1-6 wt%, low carbon ferromanganese 3-8 wt%, ferrovanadium 0.35-4 wt%, ferroniobium or ferrotitanium 0.35-4 wt%, and low carbon ferrochrome for the rest. The welding rod has high corrosion resistance, high wear resistance, good welding performance and other advantages.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3

ActiveCN106984918AArc blowing softStable arc blowing forceWelding/cutting media/materialsSoldering mediaManganeseRutile

The invention relates to an inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3 and a preparation method of the inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3. Specifically, the inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3 is prepared in the manner that powder materials of following ingredients are evenly mixed, potassium sodium water glass accounting for 20%-25% of the total weight of the mixed powder materials is then added, evenly stirring is conducted, a nickel-based alloy welding core is coated with the mixture in a pressing manner, and then the inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3 is obtained through drying; and the ingredients of the inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3 comprise 15-30 parts of marble, 5-30 parts of fluorite, 5-20 parts of cryolite, quartz, titanium dioxide, rutile, mica, potassium titanate, feldspar, sodium alginate, sodium carbonate, silicon iron, ferrotitanium, electrolytic manganese, ferroniobium and chromium metal. According to the provided nickel-based alloy welding core, the number of the parts, by weight, of fluorides is over one time that of the marble. During welding, the inversely-proportional alkaline low-hydrogen type coating nickel-based welding rod ENiCrMo-3 is flexible and stable in electric arc blow force, less in splashing and good in deslagging effect, complete molten slag coverage is achieved, a formed weld joint is smooth, and the large-current resistance of the coating is good.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Efficient nickel base welding rod special for ultralow temperature steel welding of LNG (liquefied natural gas) ship

InactiveCN103978322AArc stabilizationNo splashWelding/cutting media/materialsWelding/soldering/cutting articlesManganeseFerrosilicon

An efficient nickel base welding rod special for ultralow temperature steel welding of an LNG (liquefied natural gas) ship comprises a nickel alloy core wire and a medicine skin wrapping the surface of the core wire; the core wire is formed by the following chemical components in percentage by weight: less than or equal to 0.03% of C, less than or equal to 0.01% of S, less than or equal to 0.01% of P, 0.5-1.5% of Mn, 4-9% of Mo, 1.5-2.5% of Nb, less than or equal to 0.25% of Si, less than or equal to 1.0% of Fe, 12-18% of Cr and the balance of Ni, and the total quantity of all components is 100%. The medicine skin comprises the following components in percentage by weight: 20-35% of marble, 2-7% of rutile, 10-25% of fluorite, 5-13% of metal chromium, 5-10% of metal manganese, 6-11% of ferro-molybdenum, 4-8% of ferrotungsten, 3-8% of ferrotitanium, 2-8% of ferrosilicon, 5.3-9% of ferroniobium and 0.5-2% of sodium carbonate, and the total quantity of all components is 100%. The welding process is good, the arc is stable and small in splattering during the welding, the deslagging after the welding is good, the formed welding seams are attractive, full-position welding is realized, the deposited metal has well mechanical properties and especially has the well comprehensive mechanical properties at the temperature of minus 196 DEG C, and the welding demands of a storage tank of a 9Nisteel LNG ship are fully met.

Owner:SHANGHAI JIAO TONG UNIV

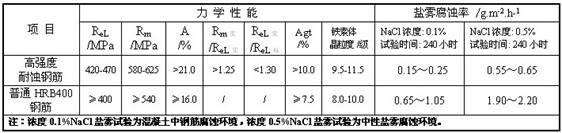

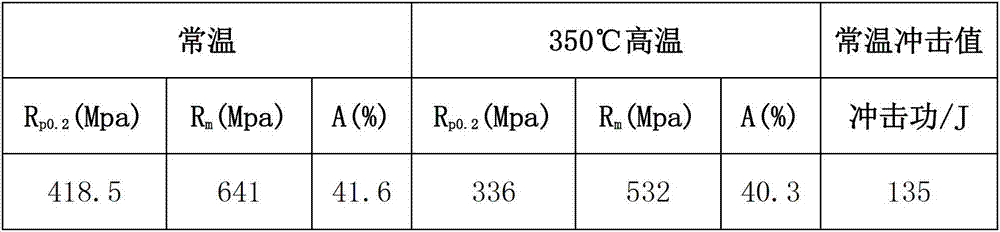

Corrosion resisting and shock resisting steel with high strength and preparation method thereof

ActiveCN102330026AImprove passivation corrosion resistanceEasy to weldTemperature control deviceManganeseFerrosilicon

The invention provides a corrosion resisting and shock resisting steel with high strength and a preparation method thereof. The method comprises the following steps of: after carrying out conventional composite top and bottom blowing, slagging and other smelting processes in a steel furnace, adding a compound deoxidizer, a silicon-manganese alloy, silicon iron, medium carbon ferrochromium, ferroniobium and a vanadium-nitrogen alloy to a steel ladle during tapping in sequence; carrying out deoxidation alloying treatment; after softly blowing argon to the molten steel for 4-5 minutes while the tapping is finished, casting the molten steel into a steel blank; after heating the steel blank at 1080-1120 DEG C, controlling open rolling temperature at 960-1010 DEG C to carry out rough rolling and medium rolling; controlling the cooling after the medium rolling is finished and before precision rolling is started; controlling the final rolling temperature at 870-960 DEG C to carry out final rolling; and then rapidly cooling the steel blank by water so that the steel is cooled to 640-680 DEG C; and naturally cooling the steel by air to room temperature so as to obtain the corrosion resisting and shock resisting steel with high strength. According to the invention, the corrosion resistance of the steel is obviously improved, the corrosion rate is only 1 / 5-1 / 4 of the corrosion rate of the400 MPa reinforcing steel bar produced by the traditional process, fine crystal particles, ferrite crystal particles at grade of 9.5-11.5 and excellent mechanical properties of the process are obtained; and the cost of the corrosion resisting and shock resisting steel with high strength is reduced by more than 20 yuan / t while being compared with the cost of the like products.

Owner:WUKUN STEEL

Lime-titania type nuclear power nickel base covered electrode coating and preparation method thereof

ActiveCN102773635ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaSolid componentNuclear power

The invention relates to a lime-titania type covered electrode coating in the welding technical field, in particular to a covered electrode coating used for a nickel base material Inconel 690 in nuclear power equipment. The covered electrode coating comprises solid components of, by mass, 12-20% of marble, 6-10% of fluorite, 35-42% of artificial rutile, 2-4% of titanium dioxide, 2-5% of feldspar, 8-15% of manganese metal, 3-6% of ferrotitanium, 0-1% of soda, 0-1% of CMC, 1-3% of nickel powder, 5-8% of chromium metal and 5-8% of ferroniobium, and the powder of the components are evenly mixed to produce the covered electrode coating. By aid of the technical scheme, the problem of poor welding technology of the covered electrode caused by low melting point, large metal viscosity and the like of the nuclear power nickel base material is solved completely, and deposited metal of the covered electrode is provided with good mechanical properties.

Owner:POWERCHINA SPEM CO LTD +1

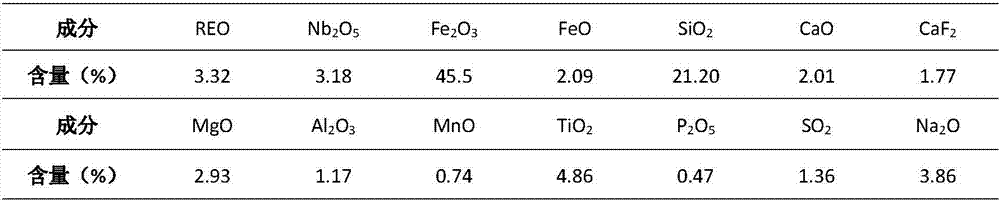

Preparation method for producing low-grade ferroniobium by using ferroniobium concentrate

The invention relates to the technical field of smelting ferroalloy, in particular to a production method of low-grade ferrocolumbium by using ferrocolumbium ore concentrate. The method is that ferrocolumbium ore concentrate is taken as primary raw material, which is characterized in that the power of ferrocolumbium ore concentrate, the coal power and a little of bond are blended, heated and pressed into block; after being preheated and selective solid-state deoxidated in high-temperature furnace, the block is loaded into an electric furnace and mixed with the molten iron to get rich niobium-bearing slag and phosphorous semi-steel, the rich niobium-bearing slag, mild-phosphor molten iron, reducer and agent of fusion are put into the electric furnace, and the rich niobium-bearing slag is deeply deoxidated to produce the low-grade ferrocolumbium alloy with high ration of Nb to phosphor. The invention has the advantages of saving energy, shortening the time of process flow and improving the recovery rate of Nb.

Owner:NORTHEASTERN UNIV

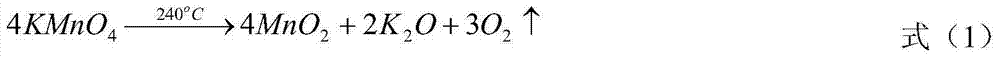

Method for preparing ferroniobium through aluminothermic reduction

The invention discloses a method for preparing ferroniobium through aluminothermic reduction. The method includes the following steps that firstly, a method in which multiple periods of smelting and gradient aluminum matching are combined is adopted for smelting, the multiple periods of smelting mean that Nb2O5 to be smelted and aluminum to be smelted are added into a tipping furnace in several batches to be smelted, after each batch is smelted, 55%-90% of lean slag is removed in a tipping manner, then the materials of the next batch are added repeatedly for continuous smelting, lean slag is removed in a tipping manner, gradient aluminum matching means that the aluminum matching proportions of all the batches are reduced in a gradient manner, the total aluminum matching amount is equivalent to 1.01-1.04 times, preferably 1.02 times, of the total reaction material proportion; and secondly, the smelted materials are poured into a die, and a ferroniobium alloy can be obtained after cooling. By means of the method, the content of niobium in the slag can be reduced while the aluminum consumption of a single furnace is reduced, and the ferroniobium smelting yield is increased.

Owner:CHENGDU TECHCAL UNIV

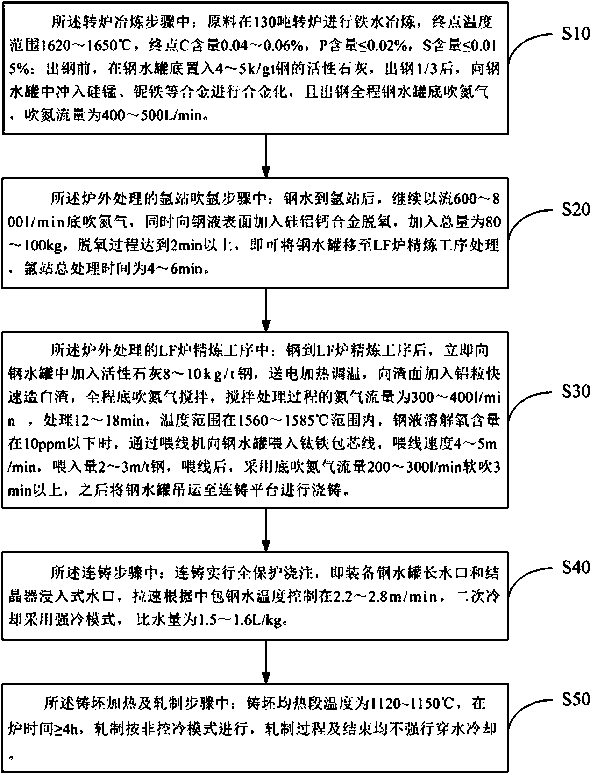

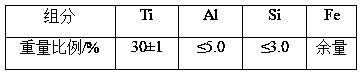

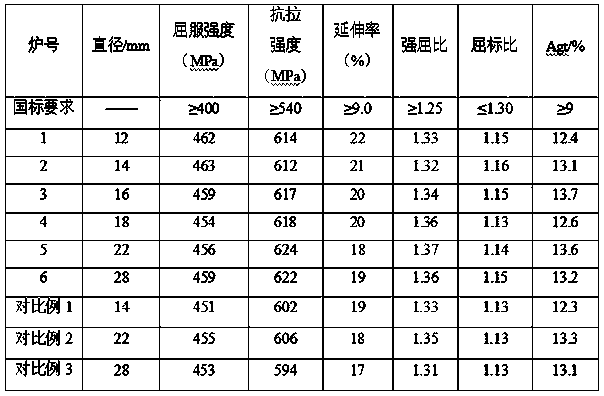

Niobium-titanium microalloying HRB400-scale screw-thread steel and manufacturing method thereof

The invention discloses a kind of niobium-titanium microalloying HRB400-scale screw-thread steel and a manufacturing method thereof. The screw-thread steel comprises C, Si, Mn, P, S, Nb, Ti, N and the balance Fe and impurities. The manufacturing method of the niobium-titanium microalloying HRB400-scale screw-thread steel comprises the following steps of smelting in a revolving furnace, treatment outside the furnace, continuous casting, casting blank heating and rolling. During smelting in the revolving furnace, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment. During treatment outside the furnace, argon is blown in an argon station, and refining is conducted in an LF furnace. In the process of refining in the LF furnace, a ferrotitanium core-spun yarn is fed for titanium microalloying treatment. According to the technical scheme, before tapping, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment, the ferrotitanium core-spun yarn is fed in the process of refining in the LF furnace for titanium microalloying treatment, after titanium is fused into molten steel, proper niobium-titanium microalloying treatment is conducted, the yield of the niobium-titanium alloy is increased, and stable, sustainable and low-cost production of the screw-thread steel is achieved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

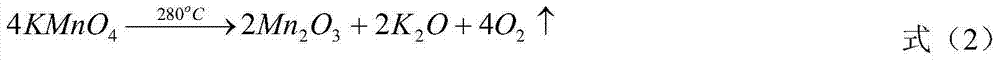

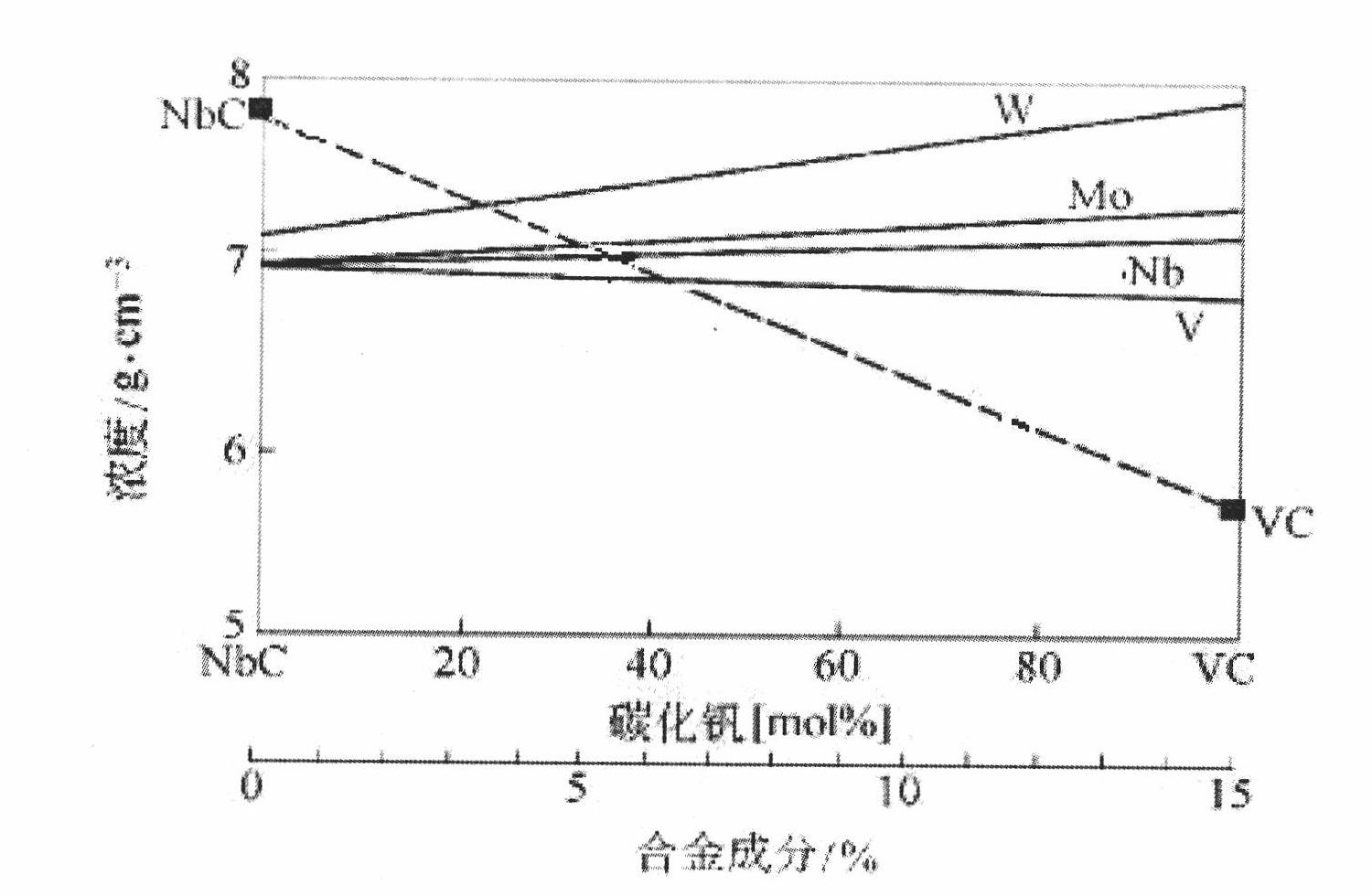

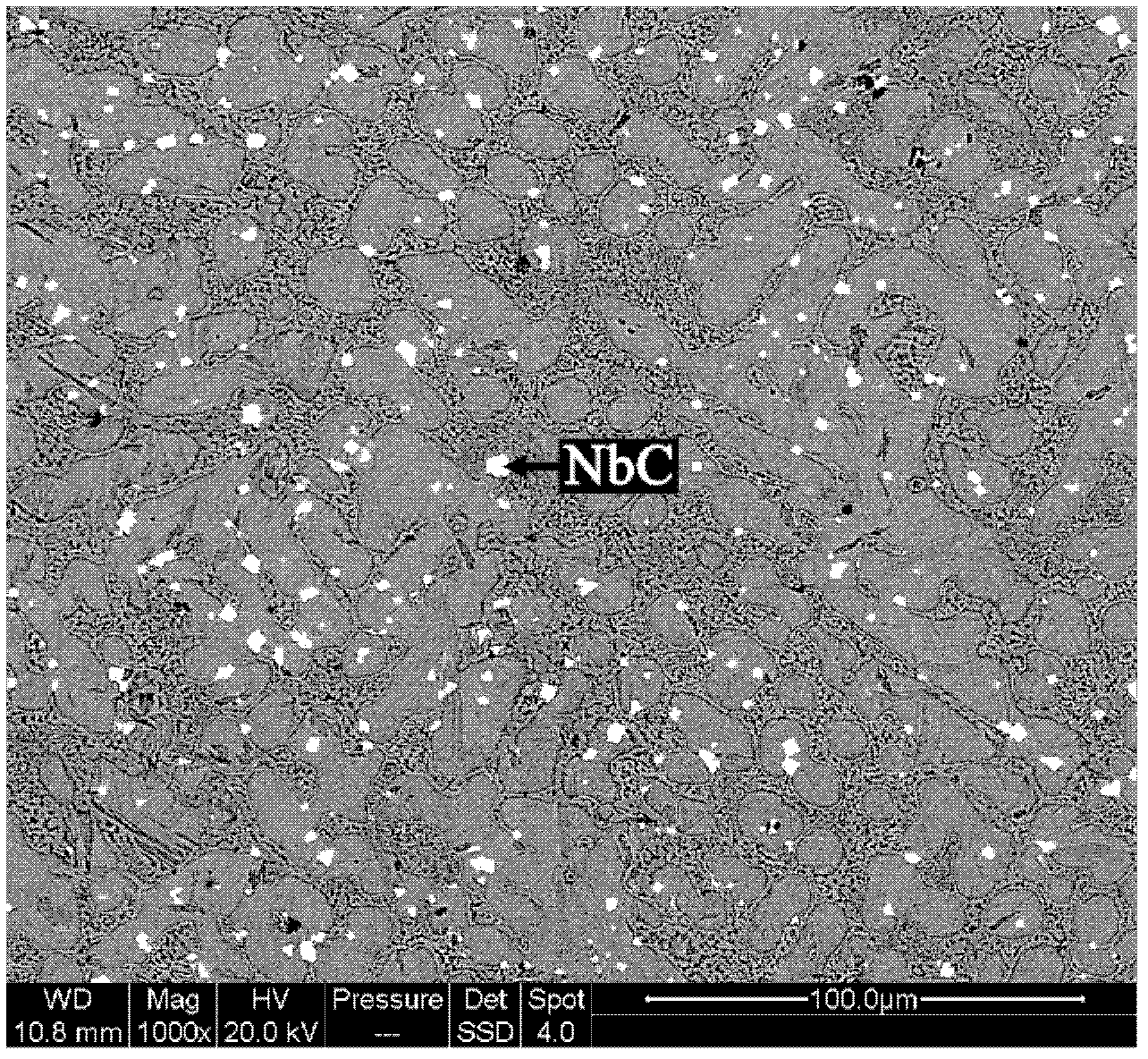

Preparation and application method of inoculant for tissue deterioration refinement of high-speed steel for roller

InactiveCN102031442AImprove mechanical propertiesEasy dispersive distributionMass ratioVolumetric Mass Density

The invention provides a preparation and application method of an inoculant for tissue deterioration refinement of high-speed steel for a roller, relating to a metal casting process. The inoculant is a thin strip obtained by mixing ferrovanadium, ferroniobium and pig iron under the condition that the mass ratio of Fe to V to Nb is (3.2-5.6):(1.9-4.3):(1.5-3.5) through the processes of smelting, solidifying and fast quenching. The inoculant is added in the process of smelting the high-speed steel for the roller to enable Nb and V to form a complex carbide (V, Nb)C in situ, and the density of the complex carbide is approximately identical to the density of the molten steel when the complex carbide is used as a primary crystal to be separated out. Thus, the inoculant is used as an inoculation deterioration nucleation core of matrix alloy liquid for integrally refining grains and tissues of a high-speed steel matrix for the roller, so that the comprehensive mechanical properties of the high-speed steel material for the roller are improved.

Owner:HEBEI UNIV OF TECH

Iron-based overlaying flux-cored welding wire for abrasion-resistant belts of drill pipe joints

InactiveCN102581515AReduce pollutionImprove wear resistanceArc welding apparatusWelding/cutting media/materialsCurrent rangeNiobium

An iron-based overlaying flux-cored welding wire for abrasion-resistant belts of drill pipe joints belongs to the field of welding materials for processing materials. Flux core powder is wrapped by a carbon steel strip, the filling rate of the flux-cored welding wire ranges from 20% to 35%, and the flux core powder comprises substances, by mass percentage, including from 15 to 27% of ferroboron, from 0.6 to 2.3% of titanium powder, from 8.5 to 18.5% of ferroniobium, from 4.5 to 7.5% of nickel powder, from 4 to 6% of electrolytic manganese powder, from 4 to 18% of ferrosilicon, from 2.5 to 7% of graphite and the balance iron powder. Overlaying technological parameters are set, voltage ranges from 26V to 29V, current ranges from 260A to 290A, wire feeding speed ranges from 430mm / min to 460mm / min, gas flow rate ranges from 18L / min to 23L / min, and the welding wire extends out of a contact tube by the length ranging from14mm to 28mm. The iron-based overlaying flux-cored welding wire does not contain chromium elements, is an environment-friendly welding material, has comprehensive performances of high abrasion resistant and high cracking resistance, and is fine in overlaying manufacturability, and weld joints are attractive in shape.

Owner:BEIJING UNIV OF TECH

Preparation method of TiC high-wear-resistant steel-bonded hard alloy

The invention relates to a preparation method of a TiC high-wear-resistant steel-bonded hard alloy. The preparation method is characterized by comprising the following steps: using titanium powder and graphite powder to prepare in-situ synthesized TiC powder according to the atomic ratio 0.7-1.1 of C to Ti; mixing ferrochromium powder, ferromolybdenum powder, ferrovanadium powder, ferrotungsten powder, ferroniobium powder, nickel powder, ferroboron powder, iron powder, colloidal graphite and a rare earth material according to the chemical component mass ratio of the bonding phase metals; filling the mixed powder in a steel ball mill; adding absolute ethyl alcohol as a medium and PVA (Polyvinyl Acetate) to the ball mill; after ball milling, drying the obtained slurry, pressing, molding and sintering the dried substance to obtain the steel-bonded hard alloy. The preparation method disclosed by the invention combines the in-situ reaction synthesis technology with the liquid-phase sintering technology to prepare the TiC high-wear-resistant steel bonded hard alloy. As TiC is prepared by in-situ synthesis inside the substrate through the reaction during the sintering process, the reinforced particle size is fine, the surface is free of sharp corners, the substrate interface bonding effect is good, and the interface is clean. The preparation method for the steel-bonded alloy can improve the comprehensive mechanical property of the alloy, and is low in price and simple and convenient in the technology.

Owner:JIANGSU HUICHENG MACHINERY MFG

Surfacing welding flux-cored wire

ActiveCN102974956AReduce oxygen contentHigh hardnessWelding/cutting media/materialsSoldering mediaFerrosiliconFerrochrome

The invention discloses a surfacing welding flux-cored wire. The surfacing welding flux-cored wire comprises carbon steel outer skin and medicinal powder which is filled in the carbon steel outer skin, wherein the medicinal powder comprises the following components in percentage by mass: 1.0%-4.5% of rutile, 0.20%-0.50% of feldspar, 2.0%-4.5% of one or two of NaF and fluorite, 1.0%-4.5% of silicon iron, 0.3%-1.5% of Mg, 6.0%-10.0% of mid-carbon ferromanganese, 23.0%-35.0% of high-carbon ferrochrome, 40.0%-60.0% of tungsten carbide, 0.5%-4.0% of graphite, 1.0%-3.5% of ferroniobium, 0%-1.5% of ferrovanadium and 0.5%-1.0% of rare earth oxide. The surfacing welding flux-cored wire disclosed by the invention is in spray transfer as the surfacing welding flux-cored wire is in fine molten drops during the welding, the splashing is small, a welding joint is essentially free from slag, continuous multi-pass welding can be carried out without removing the slag, and the surfacing welding flux-cored wire simultaneously has the characteristics that the gas protection welding and the self-protection welding are adopted.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Wear-resistant roll and manufacture method thereof

ActiveCN107034411AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesWear resistantFerrosilicon

The invention discloses a wear-resistant roll and a manufacture method thereof, belonging to the field of wear-resistant material manufacture. An induction electric furnace is adopted for smelting; waste steel, pig iron, ferrochromium, a nickel plate, ferrotungsten, ferroniobium, ferrosilicon, ferromanganese and aluminum are adopted for material preparation; firstly, the ferrotungsten, the ferroniobium, the waste steel, the pig iron and the nickel plate are mixed, heated and melted in the furnace; after the above materials are completely melted, the ferrochromium, the ferrosilicon, the ferromanganese and aluminum are added; then molten iron is subjected to compound modification in a ladle, and is poured into a mould at 1437-1470 DEG C to obtain the roll product; after stress relief treatment of heat preservation for 10-15 hours at 375-425 DEG C, the roll has the characteristics of high hardness and good abrasion-resistance; and the wear-resistant roll is suitable for promotion and application and has good use effect.

Owner:JIANGSU GANGBAO ROLLER

Method for enriching niobium from titanium-containing ferrocolumbium concentrate through dressing-metallurgy combination

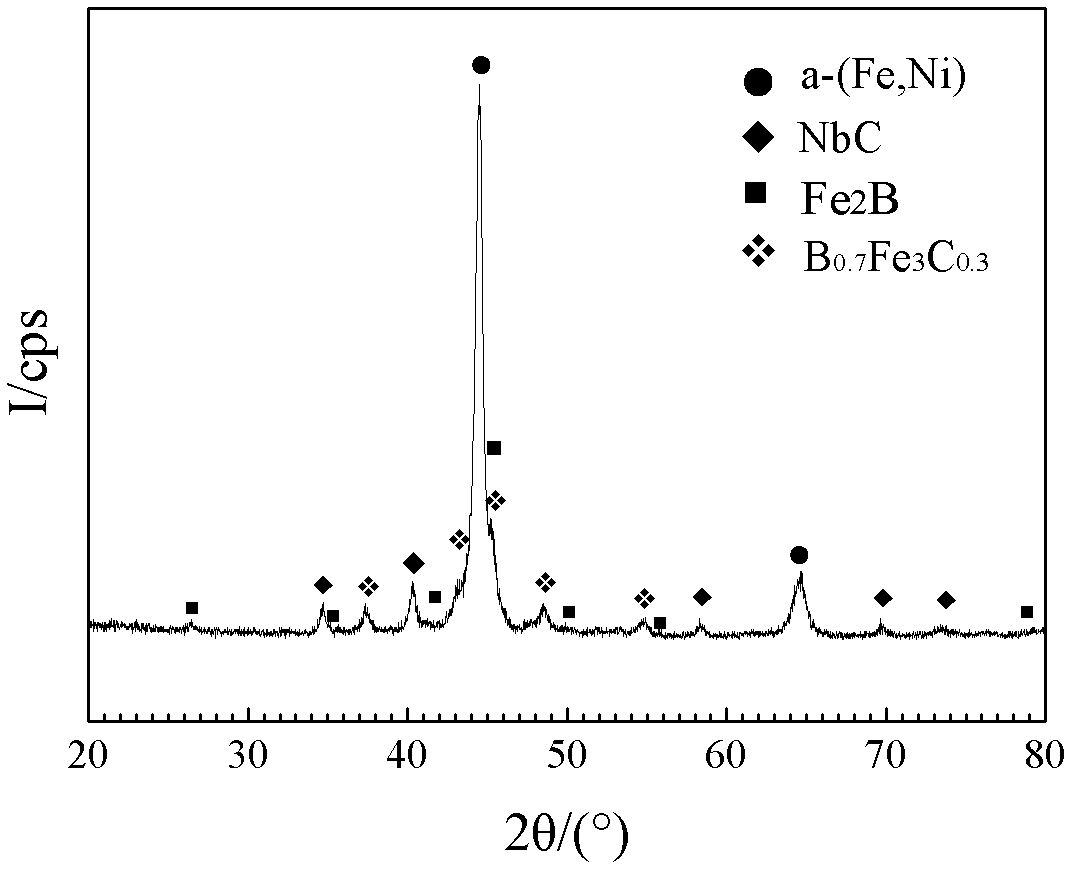

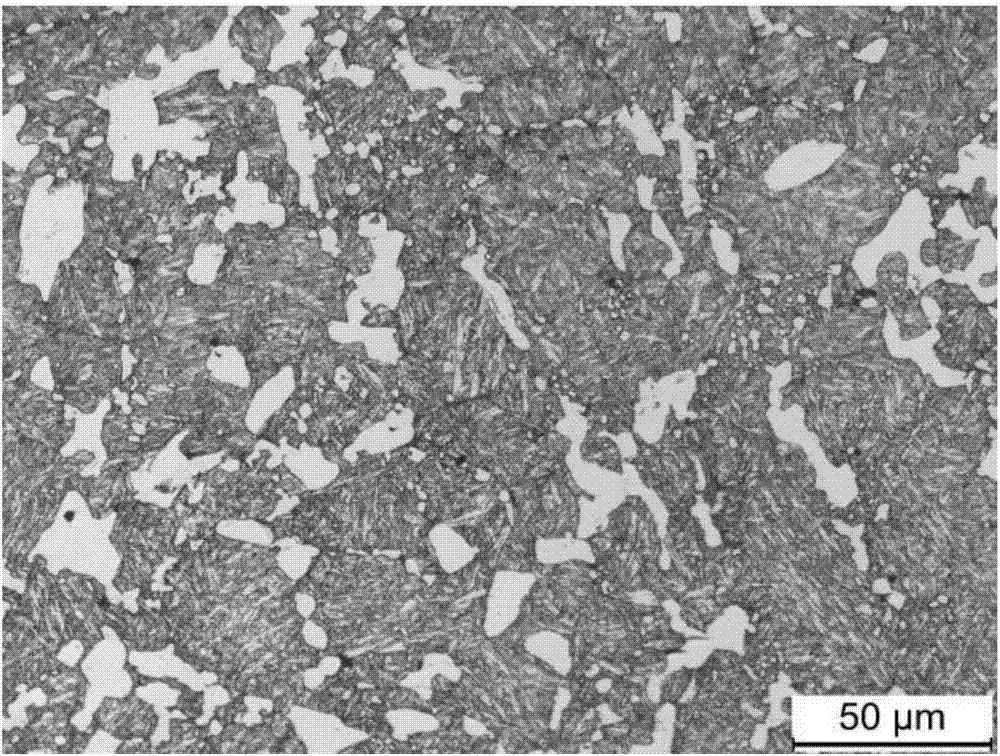

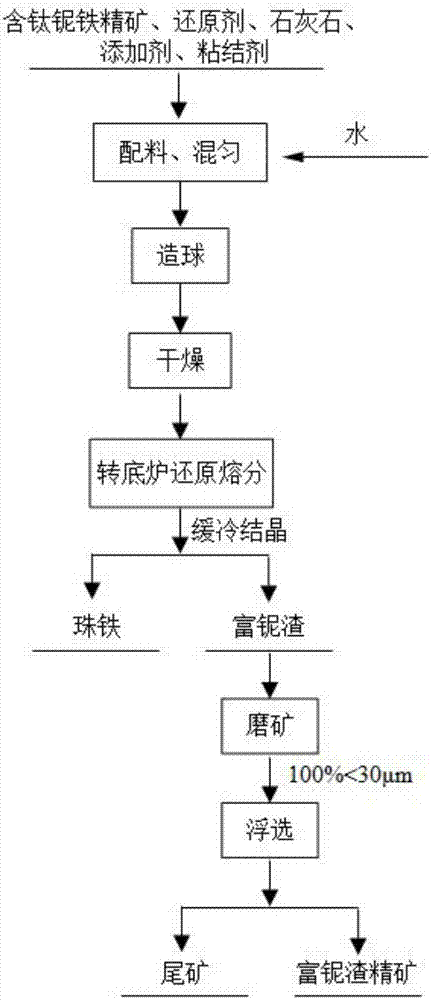

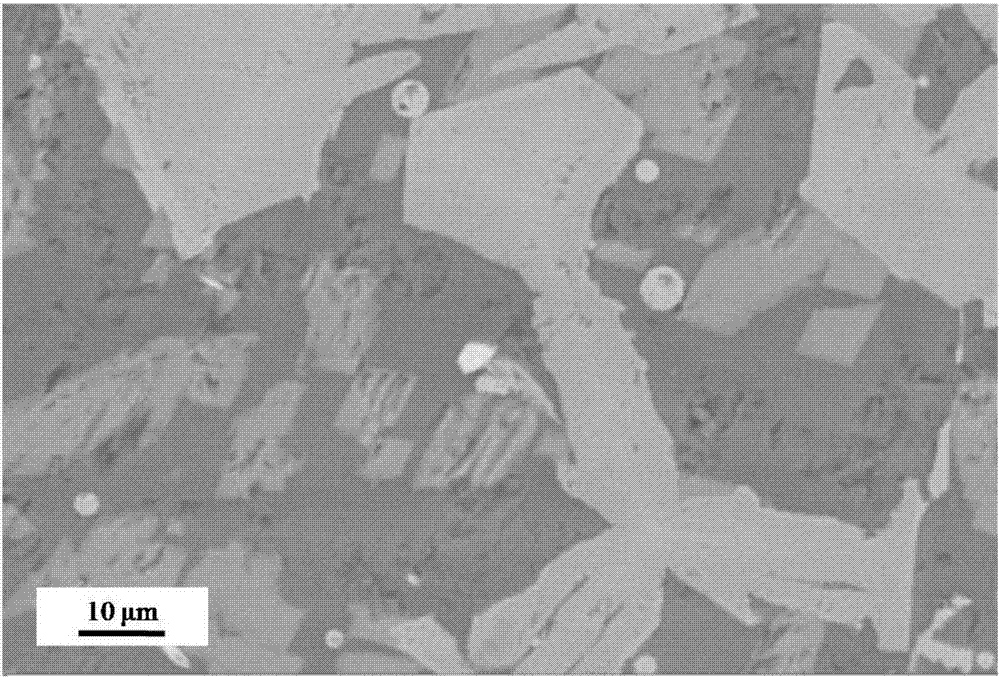

The invention discloses a method for enriching niobium from titanium-containing ferrocolumbium concentrate through dressing-metallurgy combination, and belongs to the field of mining industry, metallurgy and resource comprehensive utilization. The method is characterized in that titanium-containing ferrocolumbium concentrate mineral powder, a carbonaceous reducing agent, CaCO3, an additive and a binder are taken as raw materials; ferrocolumbium separation is realized through processes such as batching, uniform mixing, agglomerating and reduction melting to prepare raw iron and niobium-rich slag with Nb2O5 content of 5-12%, wherein raw iron can be used as a steelmaking raw material, aggregation and growth of niobium minerals are realized by performing slag-phase tempering and slow-cooling crystallizing on the niobium-rich slag, and the dimension of the niobium minerals can be 20-50 [mu]m; and the element niobium is further enriched by fine-grinding and flotation, so that niobium-rich slag concentrate with Nb2O5 content of 15-40% is obtained, and a recovery rate of niobium is 70-85%. The obtained niobium-rich slag concentrate can replace high-grade niobium minerals to produce high-grade ferrocolumbium, so that the low-grade niobium resources of China can be sufficiently utilized, and efficient utilization of the niobium resources is realized. The method is simple in process, is short in flow, is high in efficiency, and has relatively good social and economic benefits.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com