Iron-based overlaying flux-cored welding wire for abrasion-resistant belts of drill pipe joints

A technique for drill pipe joints and flux-cored wires, which is applied to welding media, welding equipment, welding equipment, etc., can solve problems such as insufficient crack resistance, and achieve the effects of less pollution, less spatter, and better surfacing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 1.5 kg of ferroboron, 0.06 kg of titanium powder, 0.85 kg of ferroniobium, 0.45 kg of nickel powder, 0.4 kg of electrolytic manganese powder, 0.4 kg of ferrosilicon, 0.25 kg of graphite, and 6.09 kg of reduced iron powder. Put the obtained flux core powder into the U-shaped steel belt groove, the filling rate is 20%, close the U-shaped groove to obtain the drill pipe wear-resistant band surfacing flux-cored wire with a diameter of 1.6mm, and prepare the surfacing according to the above process. The welding layer, the alloy composition in the obtained deposited metal is: C: 0.3wt.%; B: 0.5wt.%; Ti: 0.1wt.%; Nb: 1.0wt.%; Ni: 0.8wt.%; Mn: 0.6wt.%; Si: 0.3wt.%; Fe: balance.

Embodiment 2

[0036] Take 1.7 kg of ferroboron, 0.08 kg of titanium powder, 1.0 kg of ferroniobium, 0.5 kg of nickel powder, 0.45 kg of electrolytic manganese powder, 0.6 kg of ferrosilicon, 0.35 kg of graphite, and 5.32 kg of reduced iron powder. Put the obtained flux core powder into the U-shaped steel belt groove, the filling rate is 23%, close the U-shaped groove to obtain the drill pipe wear-resistant band surfacing flux-cored wire with a diameter of 1.6mm, and prepare the surfacing according to the above process. The welding layer, the alloy composition in the obtained deposited metal is: C: 0.5wt.%; B: 0.7wt.%; Ti: 0.2wt.%; Nb: 1.5wt.%; Ni: 0.85wt.%; Mn: 0.7wt.%; Si: 0.5wt.%; Fe: balance.

Embodiment 3

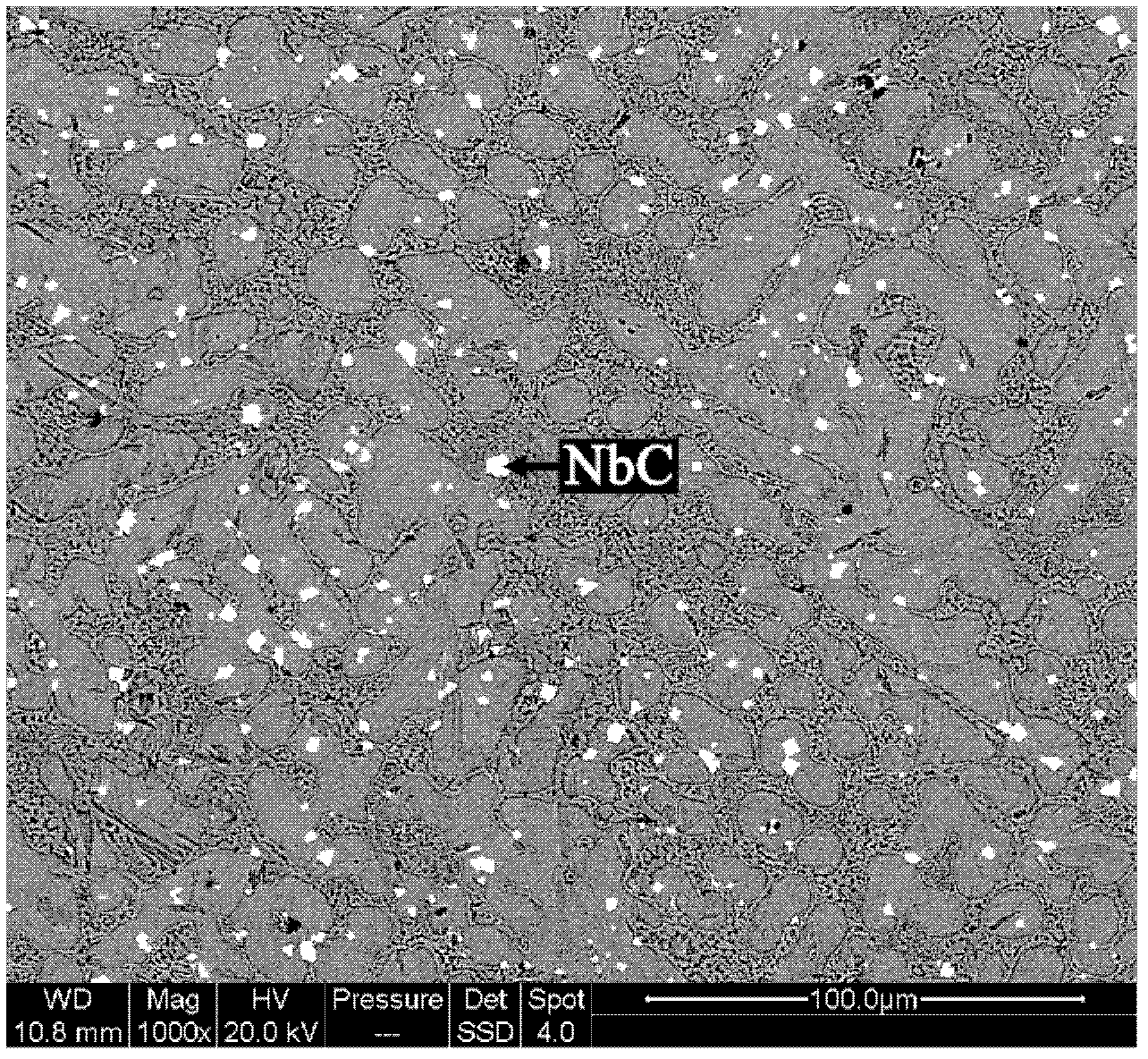

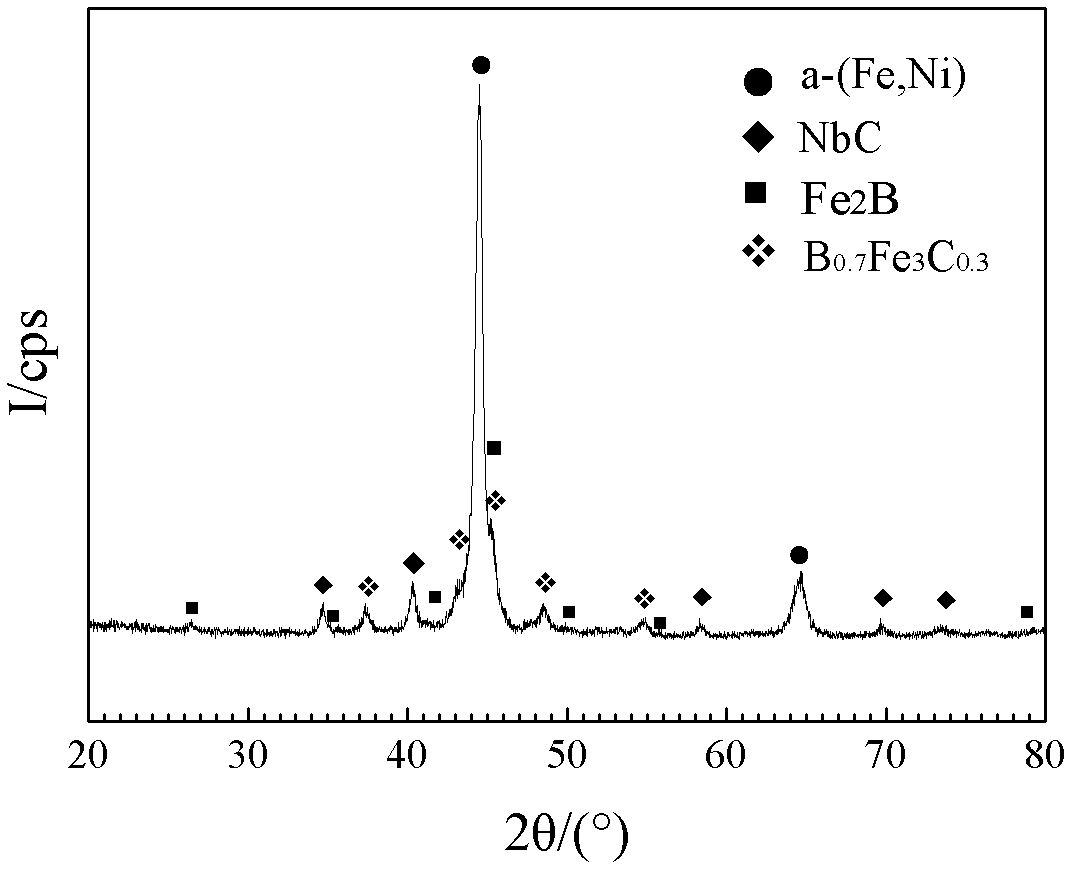

[0038]Take 1.75 kg of ferroboron, 0.085 kg of titanium powder, 1.2 kg of ferroniobium, 0.55 kg of nickel powder, 0.48 kg of electrolytic manganese powder, 0.7 kg of ferrosilicon, 0.4 kg of graphite, and 4.835 kg of reduced iron powder. Put the obtained flux core powder into the U-shaped steel belt groove, and the filling rate is 25%. Close the U-shaped groove to obtain a drill pipe wear-resistant band surfacing flux-cored wire with a diameter of 1.6mm, and prepare the surfacing according to the above process. The welding layer, the alloy composition in the obtained deposited metal is: C: 0.54wt.%; B: 0.75wt.%; Ti: 0.25wt.%; Nb: 1.55wt.%; Ni: 0.9wt.%; Mn: 0.8wt.%; Si: 0.6wt.%; Fe: balance. The EBSD diagram of the obtained surfacing deposited metal is shown in figure 2 , XRD diagram see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com