Patents

Literature

1140 results about "Current range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

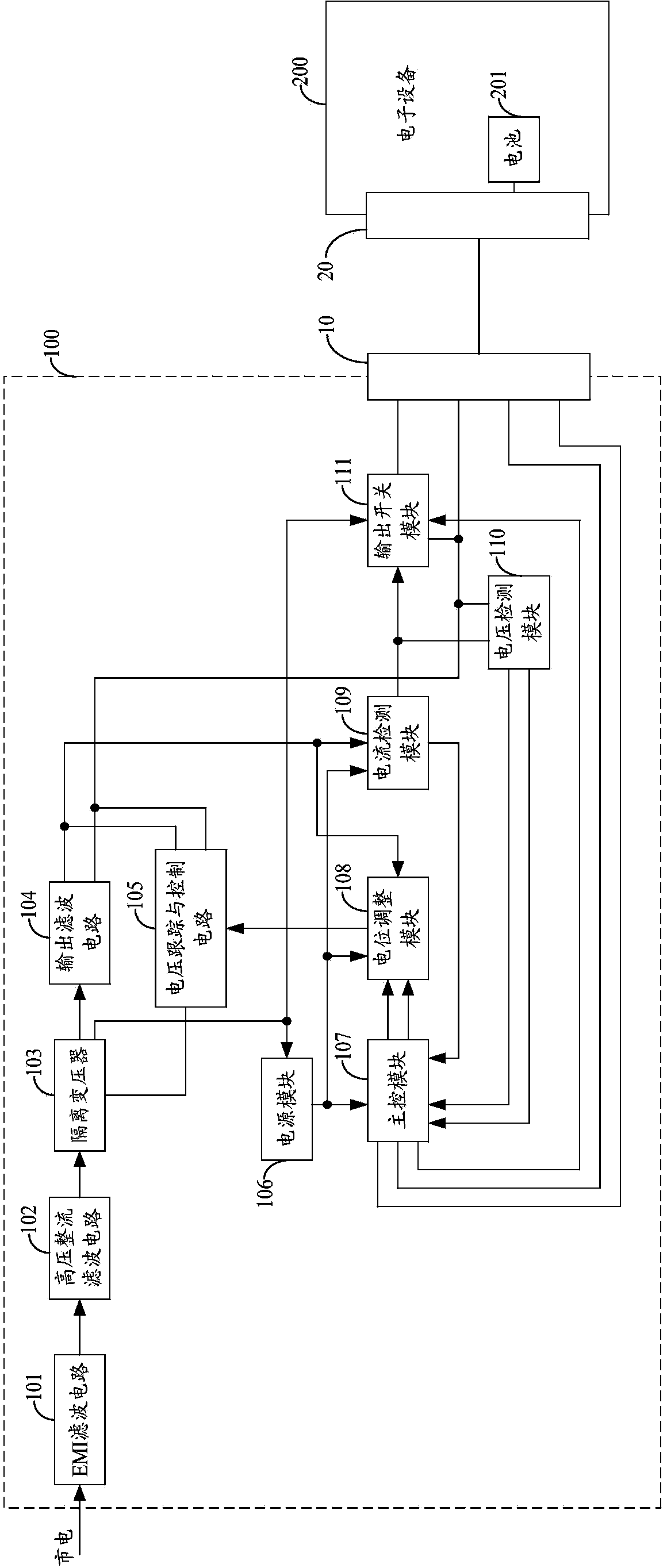

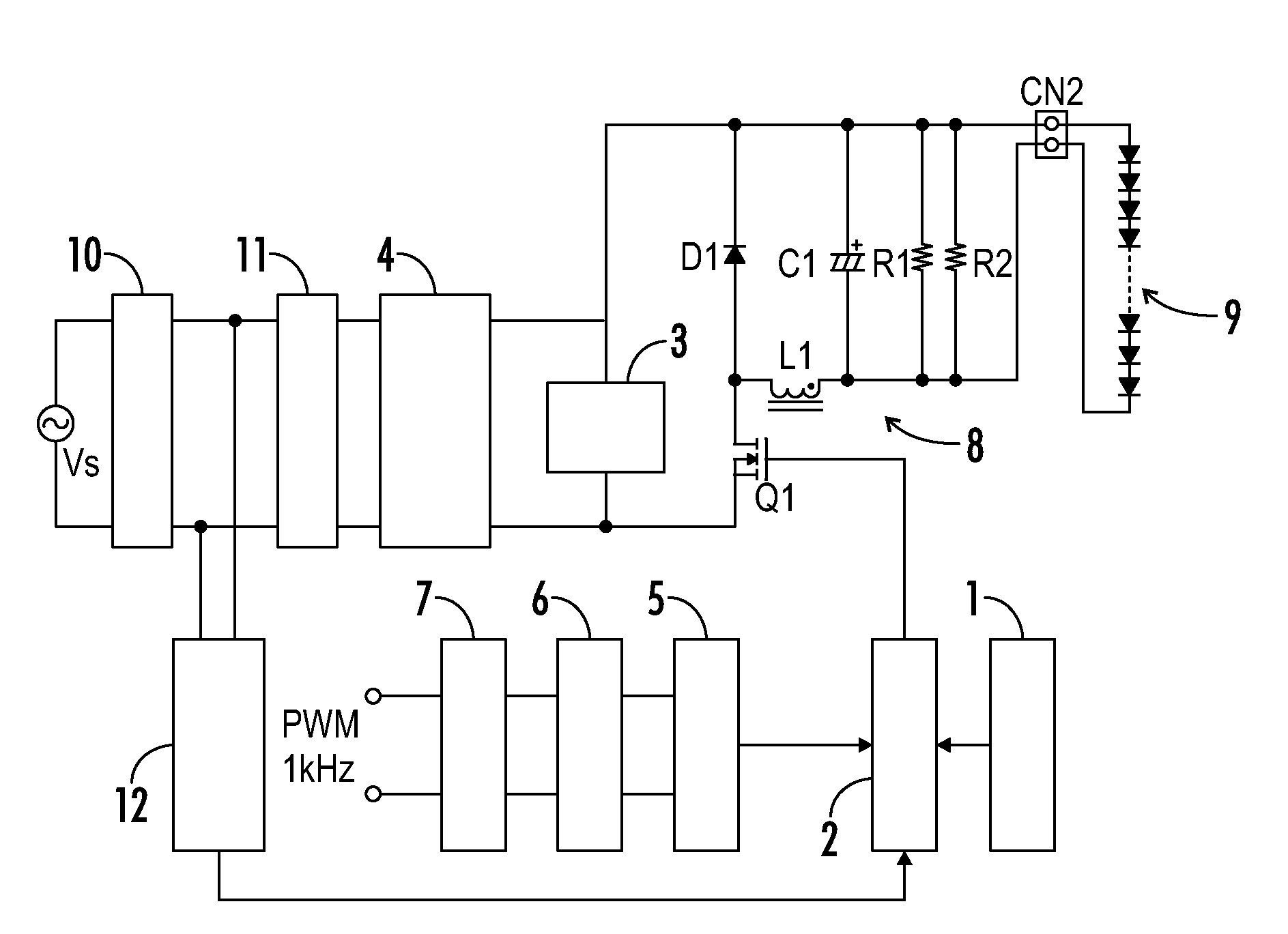

Charging device of electronic equipment and power adapter of charging device

ActiveCN103762702AShorten charging timeEmergency protective circuit arrangementsElectric powerElectricityElectrical battery

The invention belongs to the technical field of charging, and provides a charging device of electronic equipment and a power adapter of the charging device. In the process of charging a battery in a conventional charging mode after the power adapter is powered on or resets, when the output current value of the power adapter is within the conventional current range at a preset time interval, the power adapter is in quick charging inquiry communication with the electronic equipment; after the electronic equipment sends a quick charging instruction to the power adapter, the power adapter adjusts the output voltage according to the battery voltage information fed back by the electronic equipment, and when the output voltage meets the quick charging voltage condition preset by the electronic equipment, the power adapter adjusts the output current and the output voltage to charge the battery according to the quick charging mode, and therefore the purpose of quickly charging the battery to shorten the charging time is achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

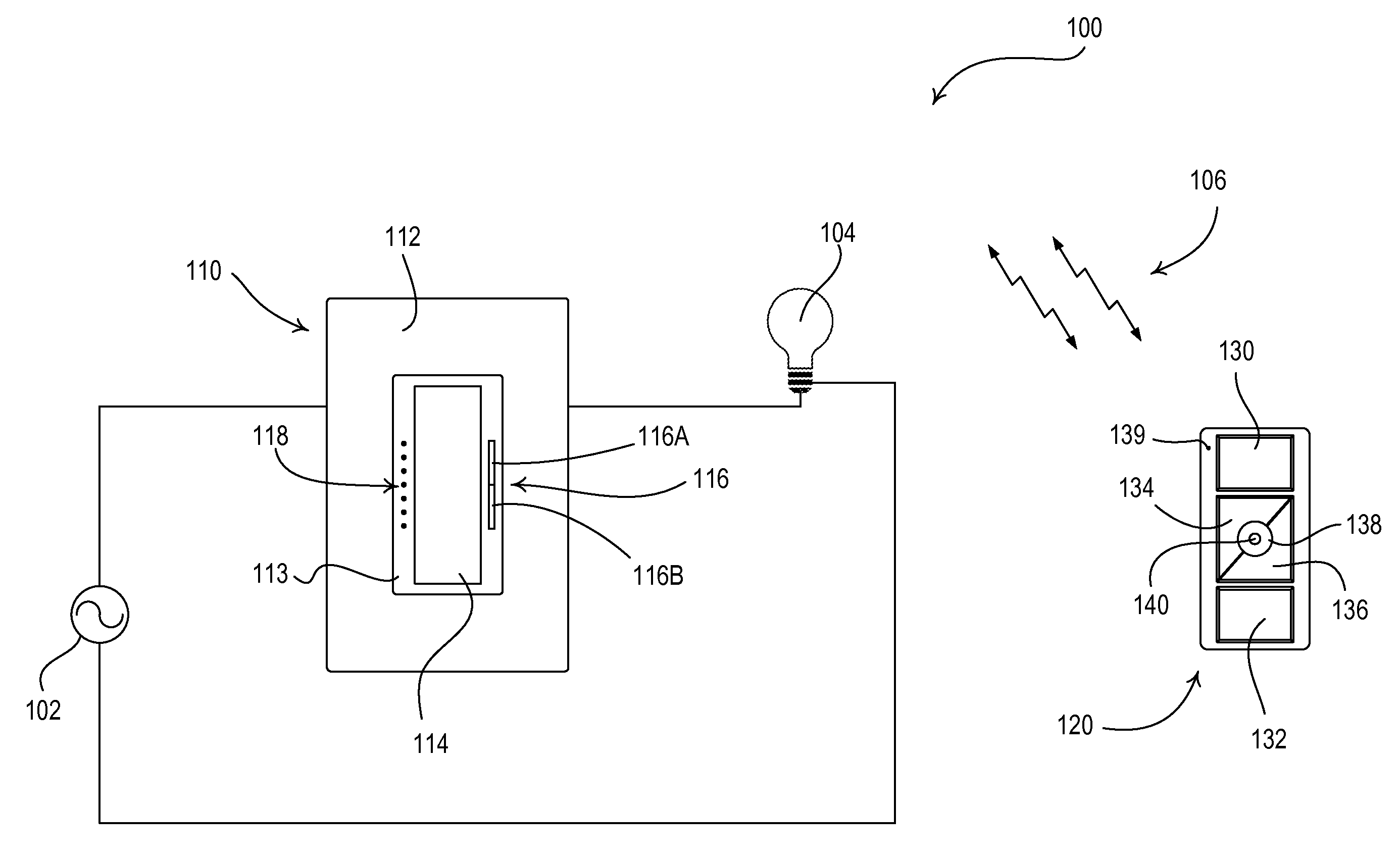

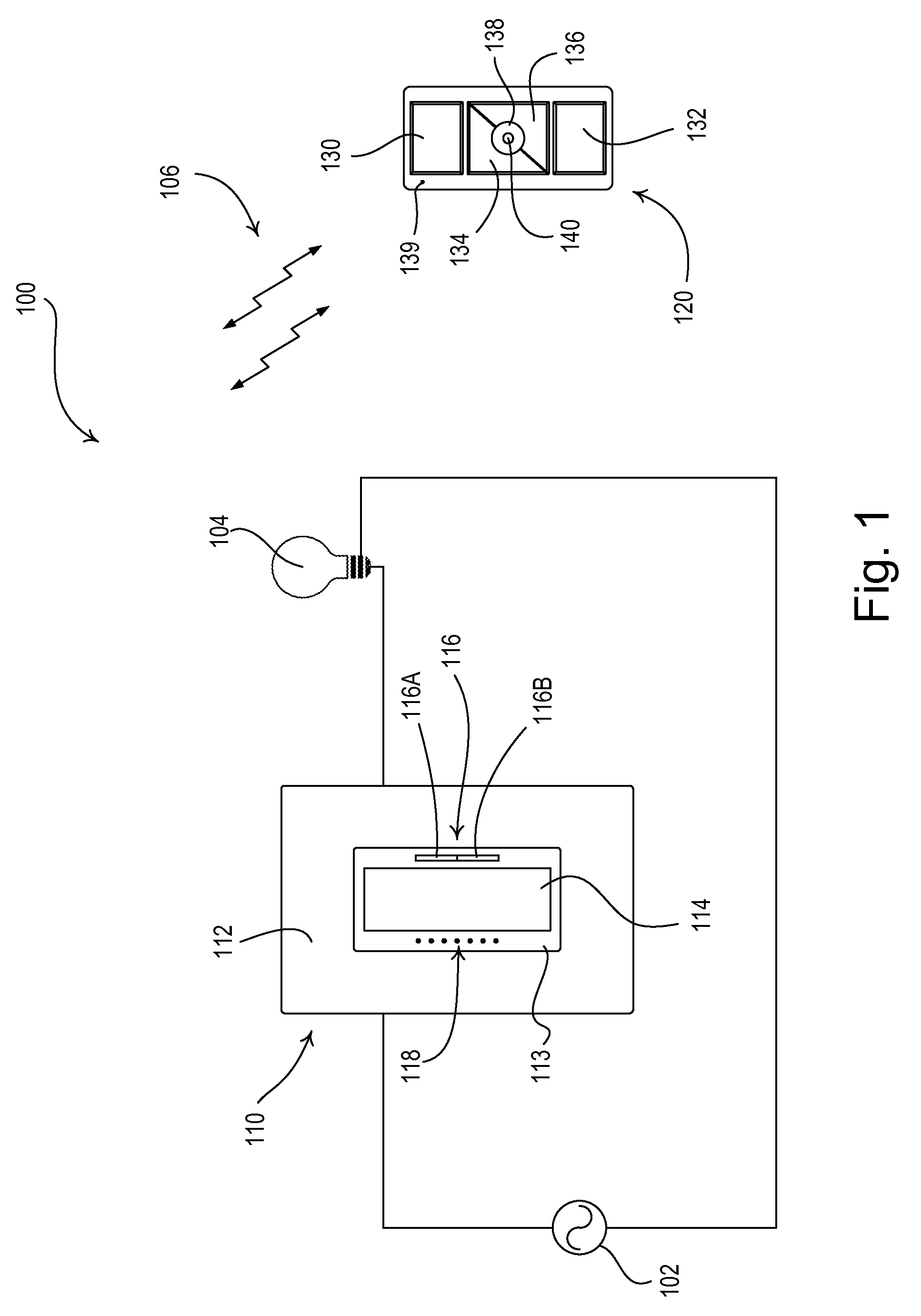

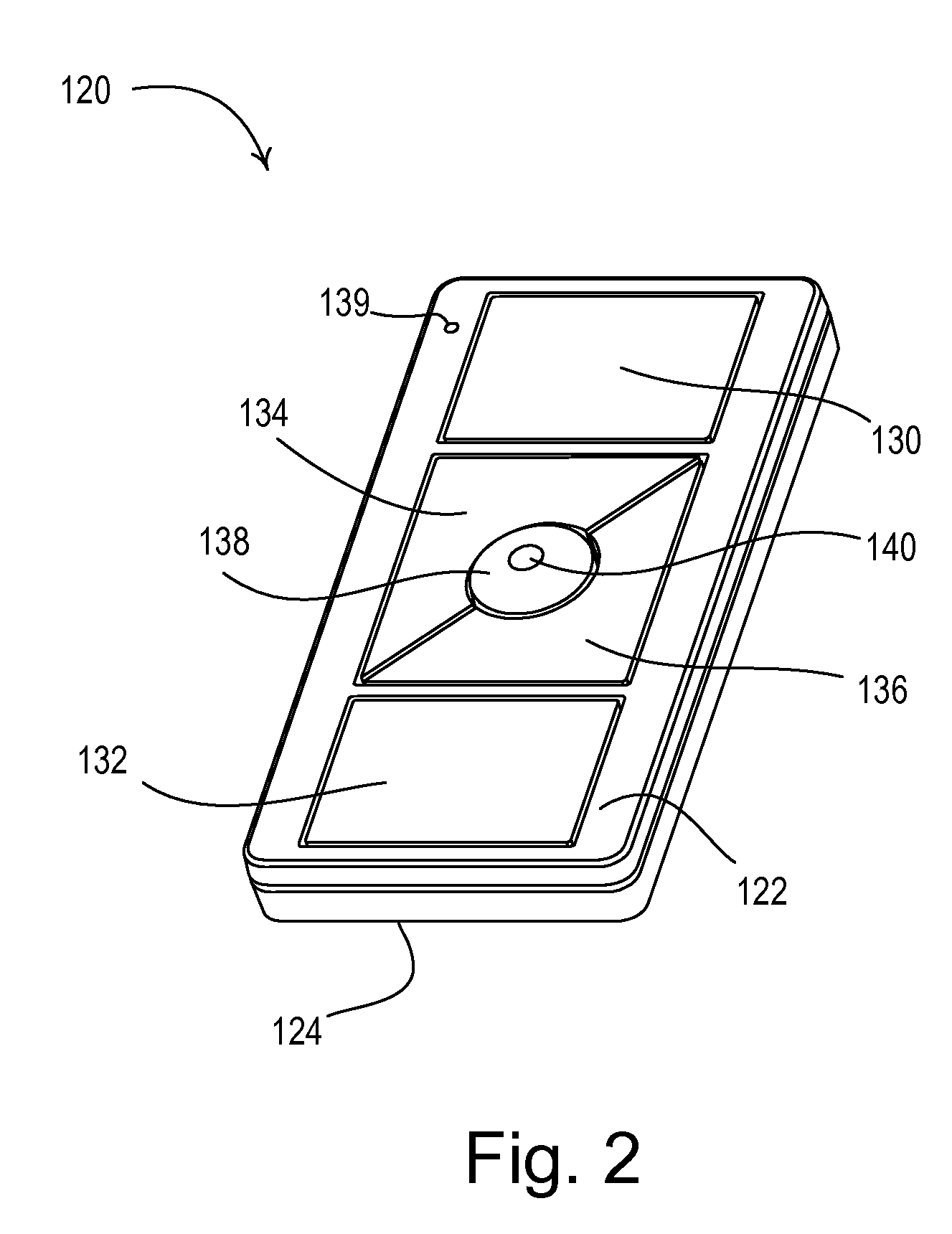

Control device having a night light

InactiveUS20120286940A1Easy to findGood off-angle viewingPoint-like light sourceElectric circuit arrangementsElectrical batteryCurrent range

A battery-powered remote control for radiating wireless signals to control a controlled device has a night light that glows whereby it is visible in a darkened room and the battery lasts at least about three years. It also includes a wireless transmitter, a controller, a battery and a control element. The control element generates a signal when activated to cause the controller to operate the wireless transmitter to transmit a wireless signal to control the controlled device. The night light comprises a light emitting diode and a light pipe having a textured front surface. A power supply circuit for the LED provides an LED current from the battery. The LED has a normal operating current range and the LED current is several orders of magnitude below the normal operating current range.

Owner:LUTRON TECH CO LLC

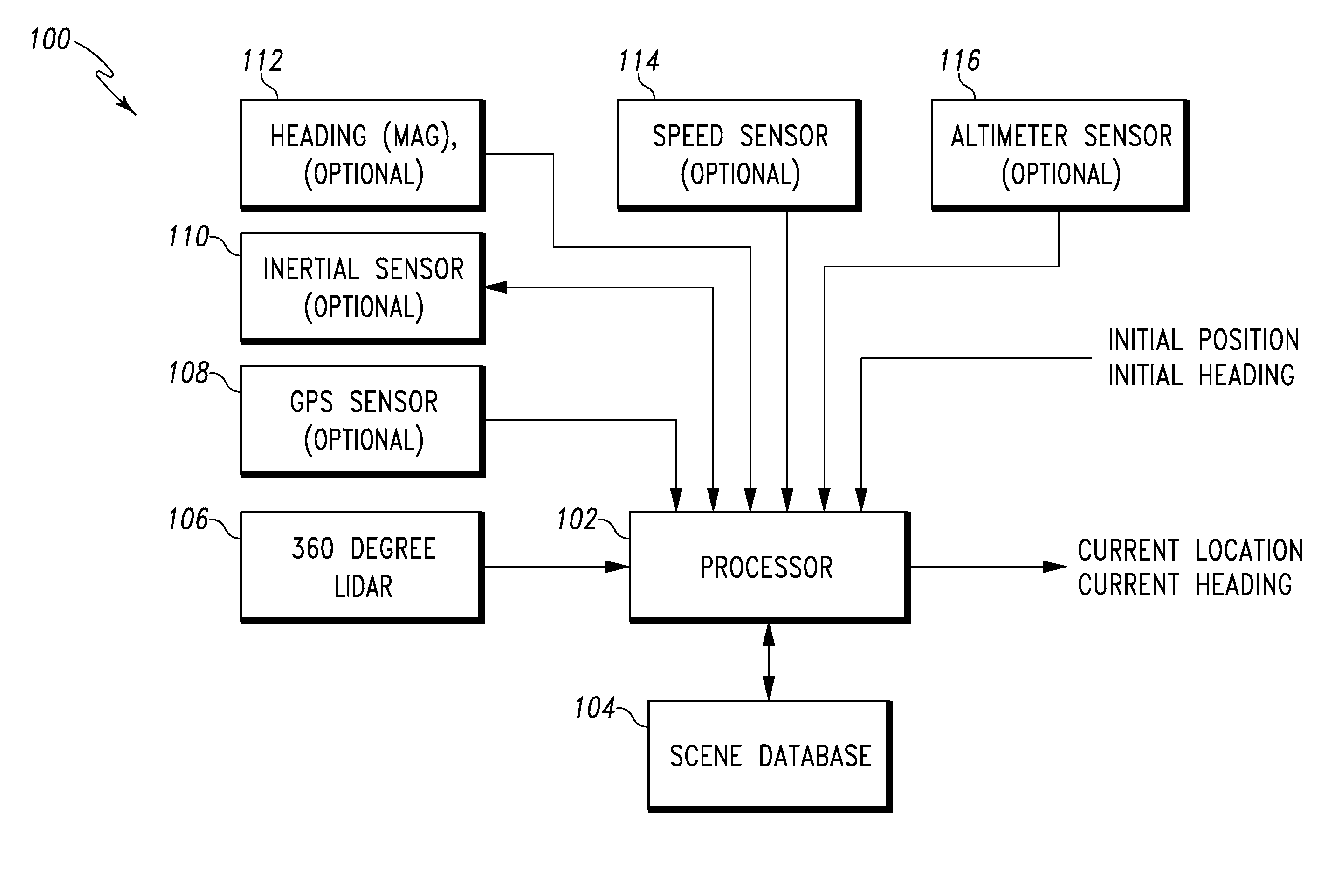

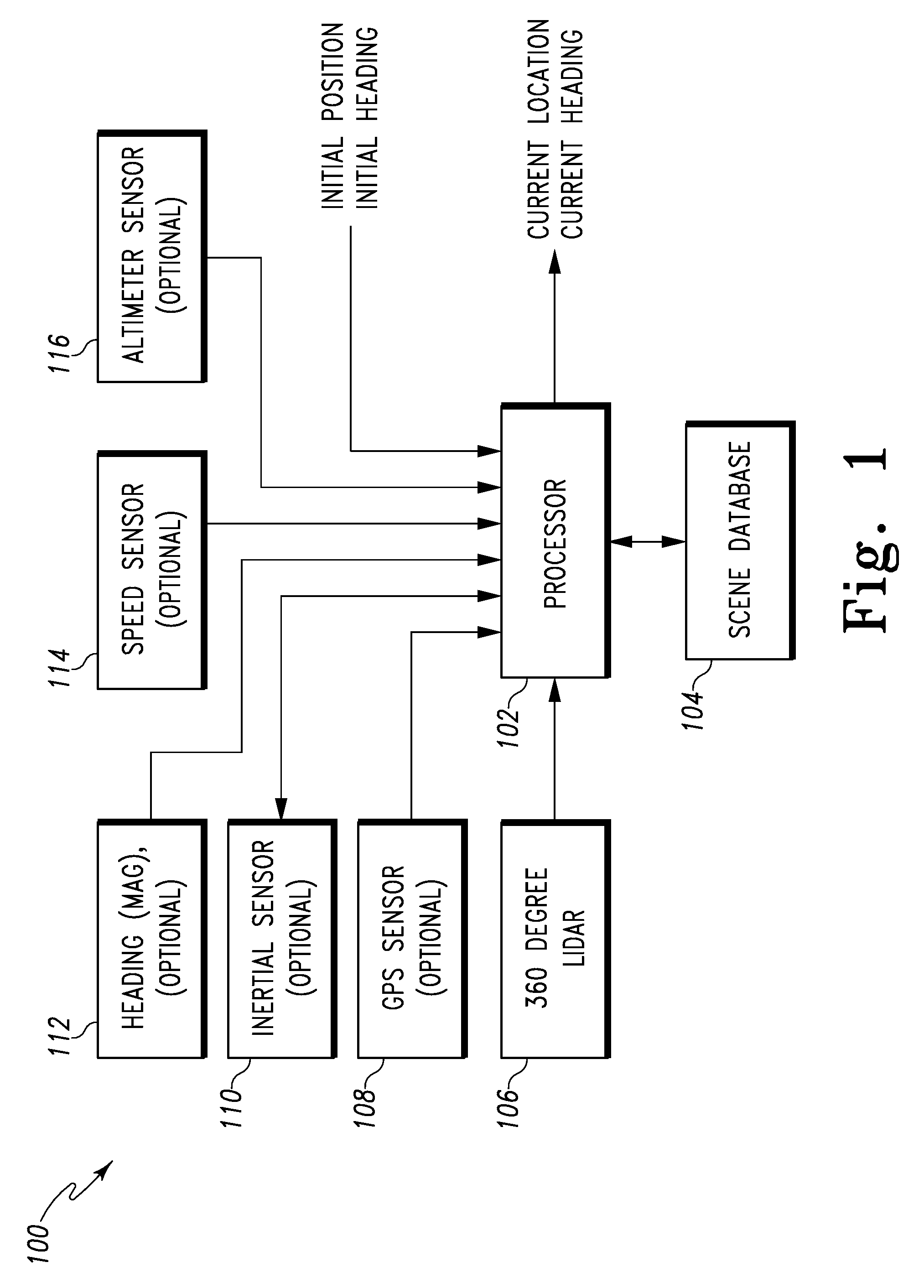

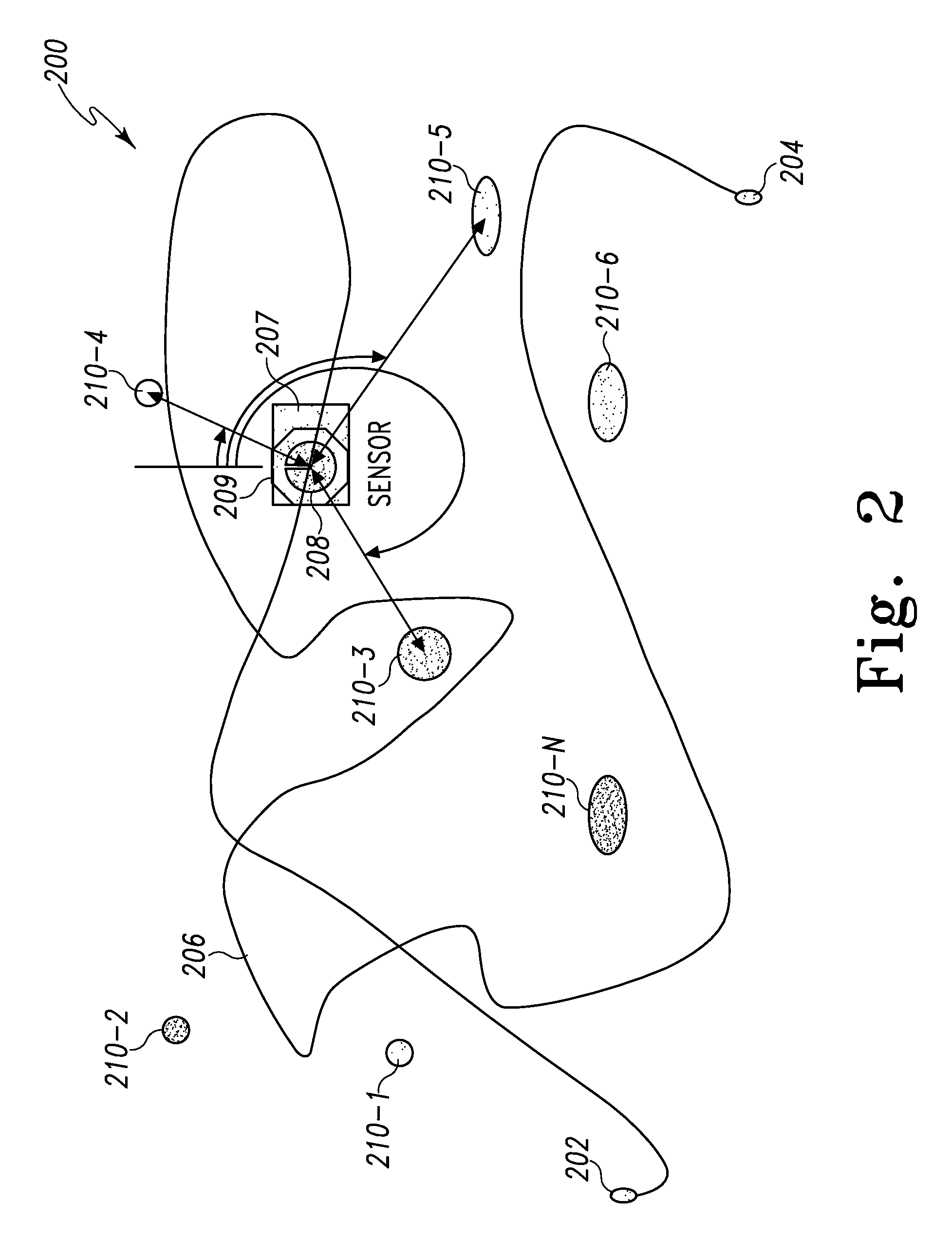

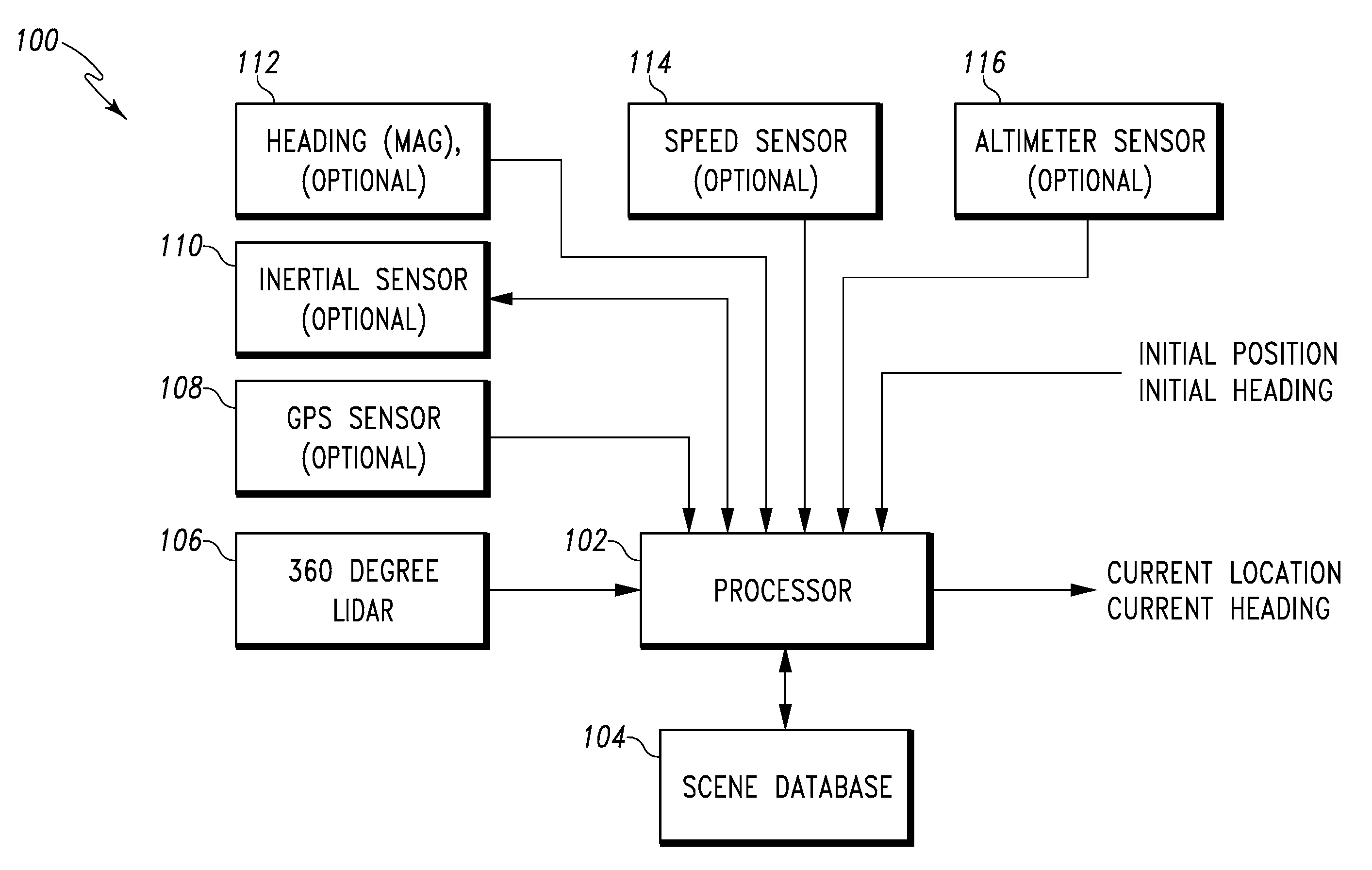

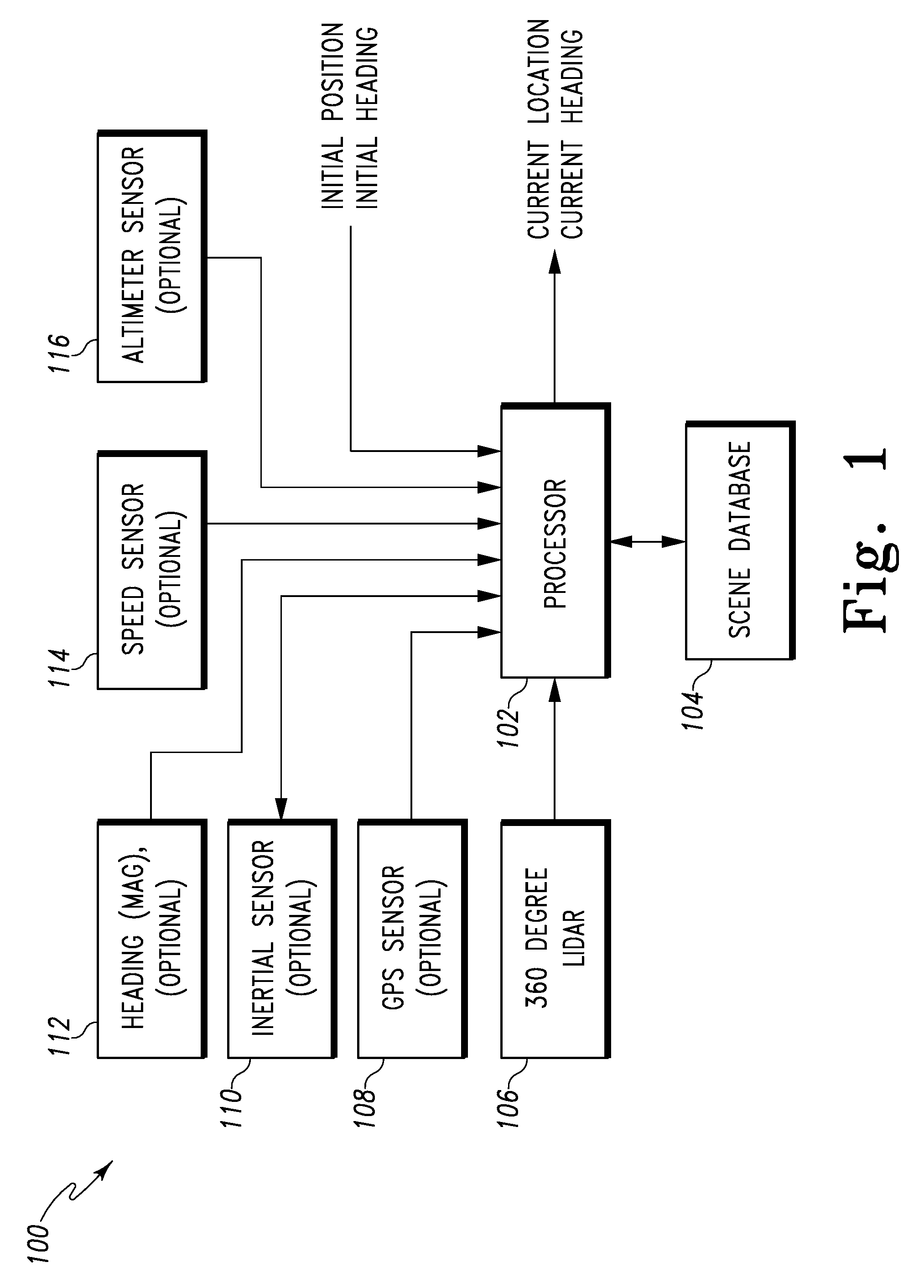

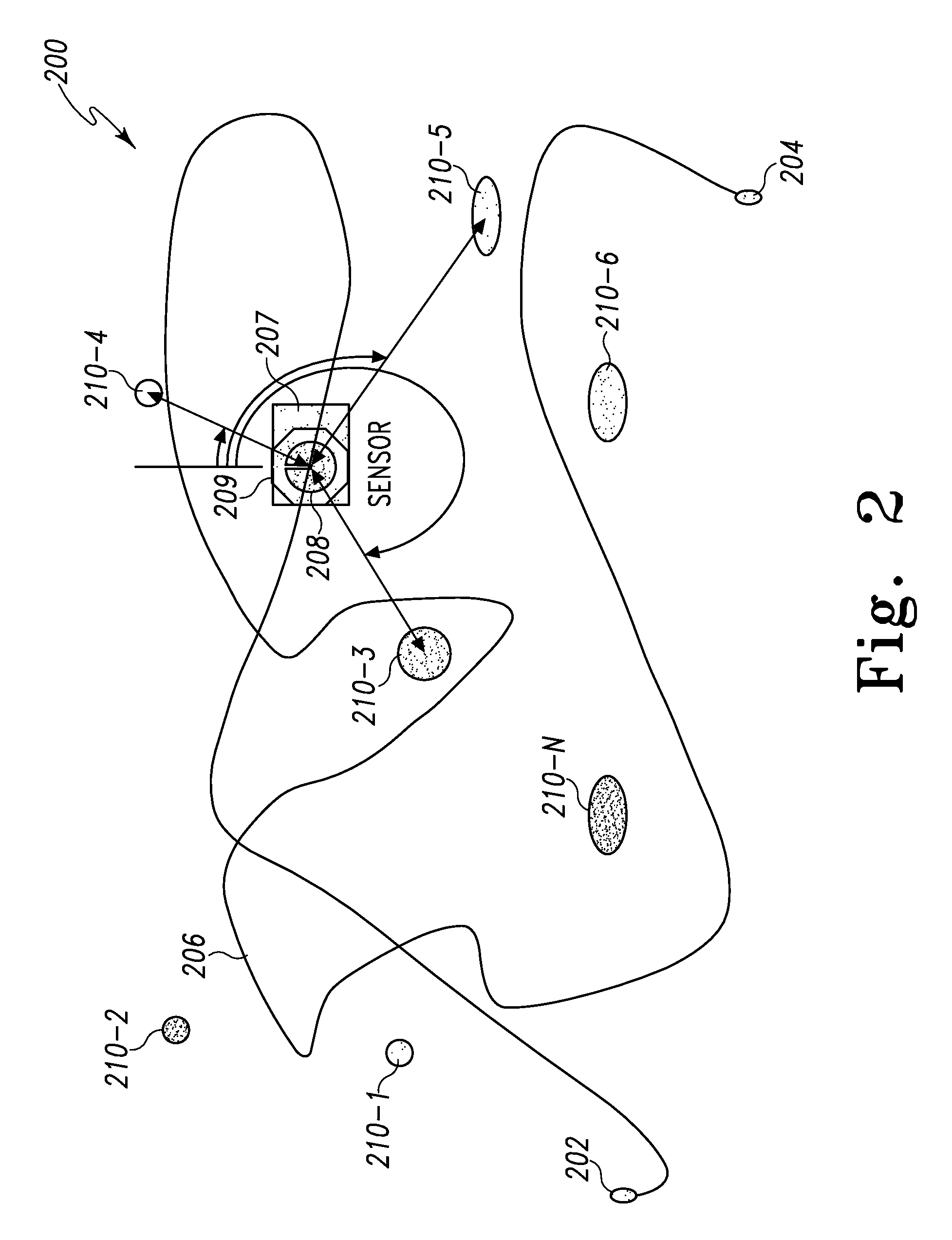

Correlation position determination

ActiveUS8554478B2Instruments for road network navigationRoad vehicles traffic controlAlgorithmCurrent range

Owner:HONEYWELL INT INC

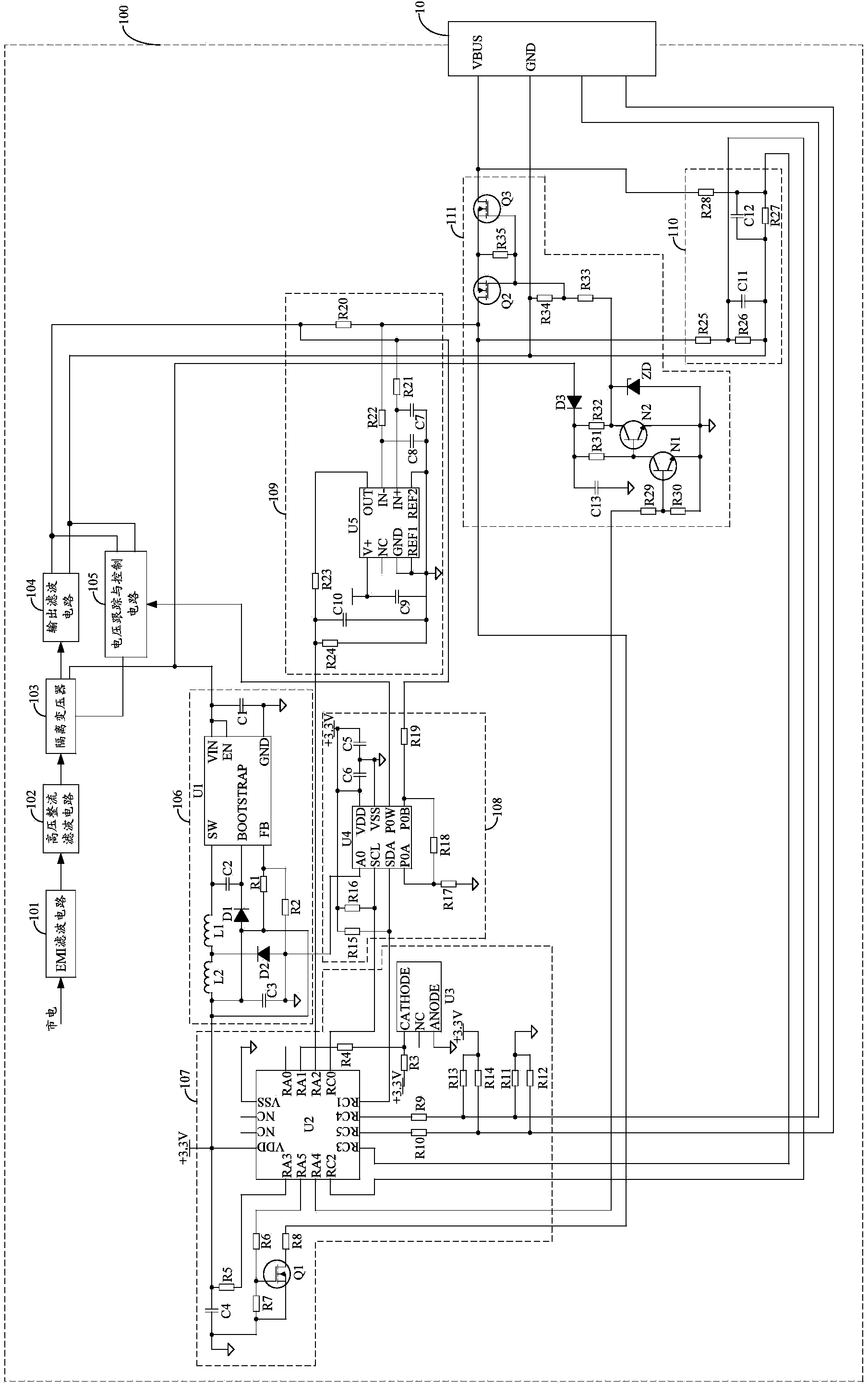

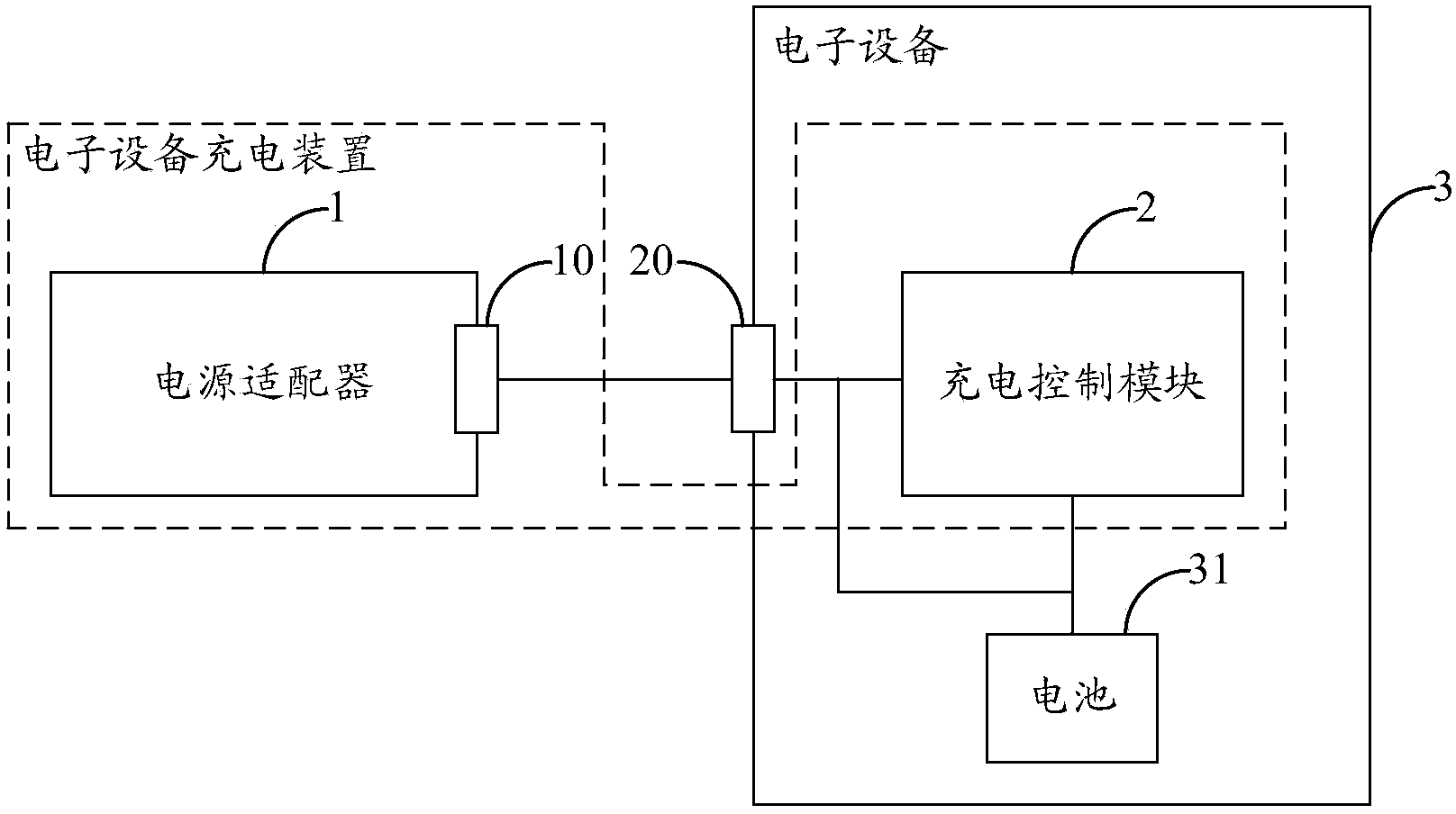

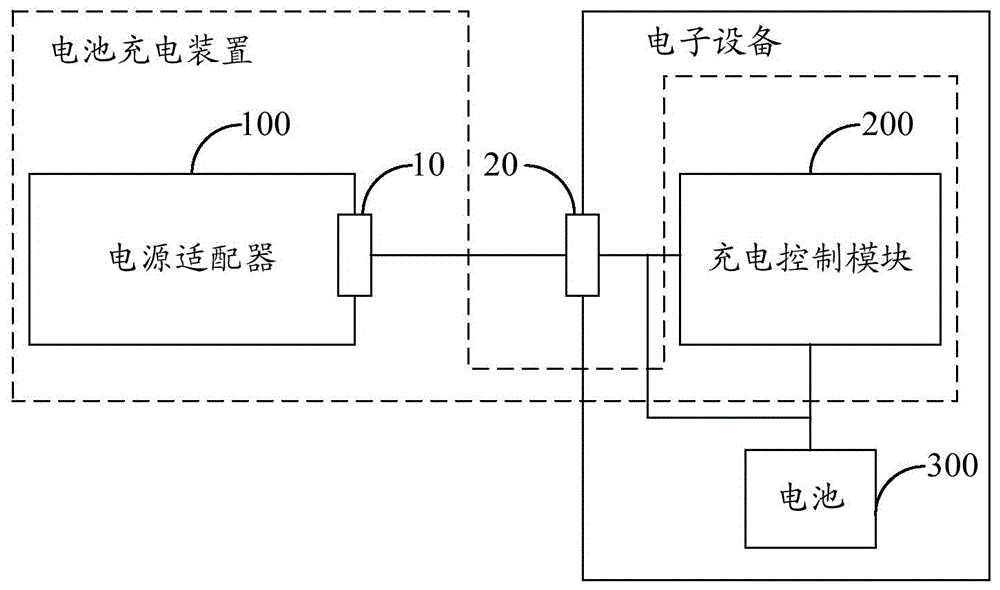

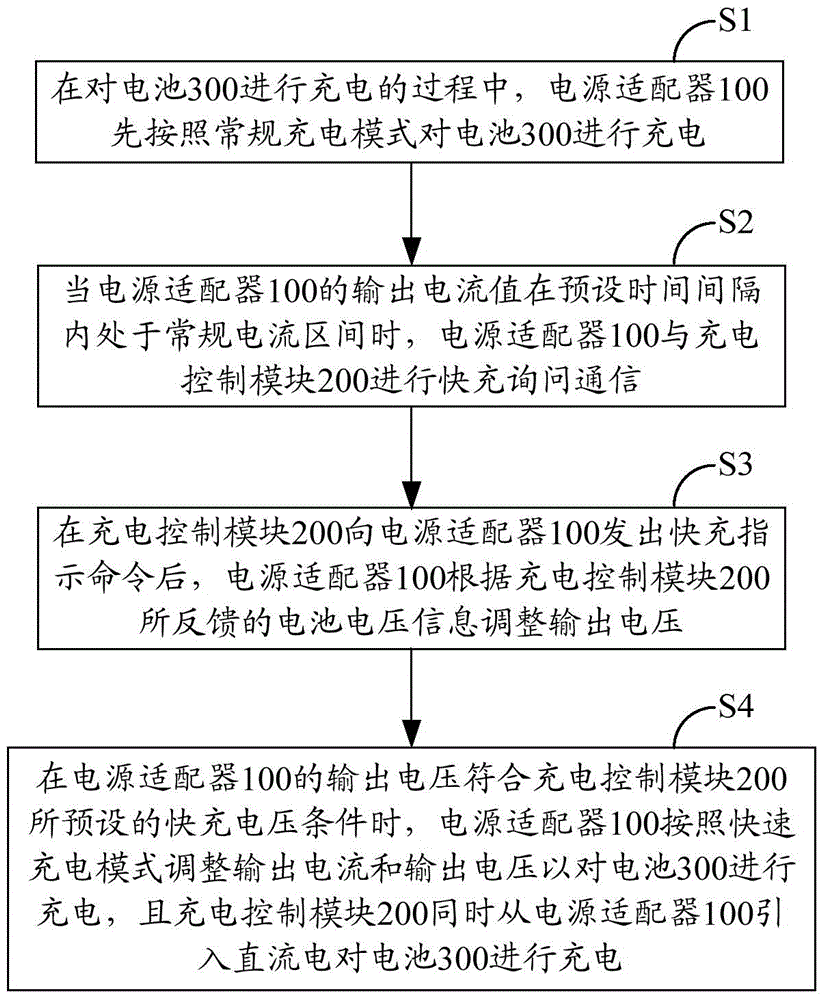

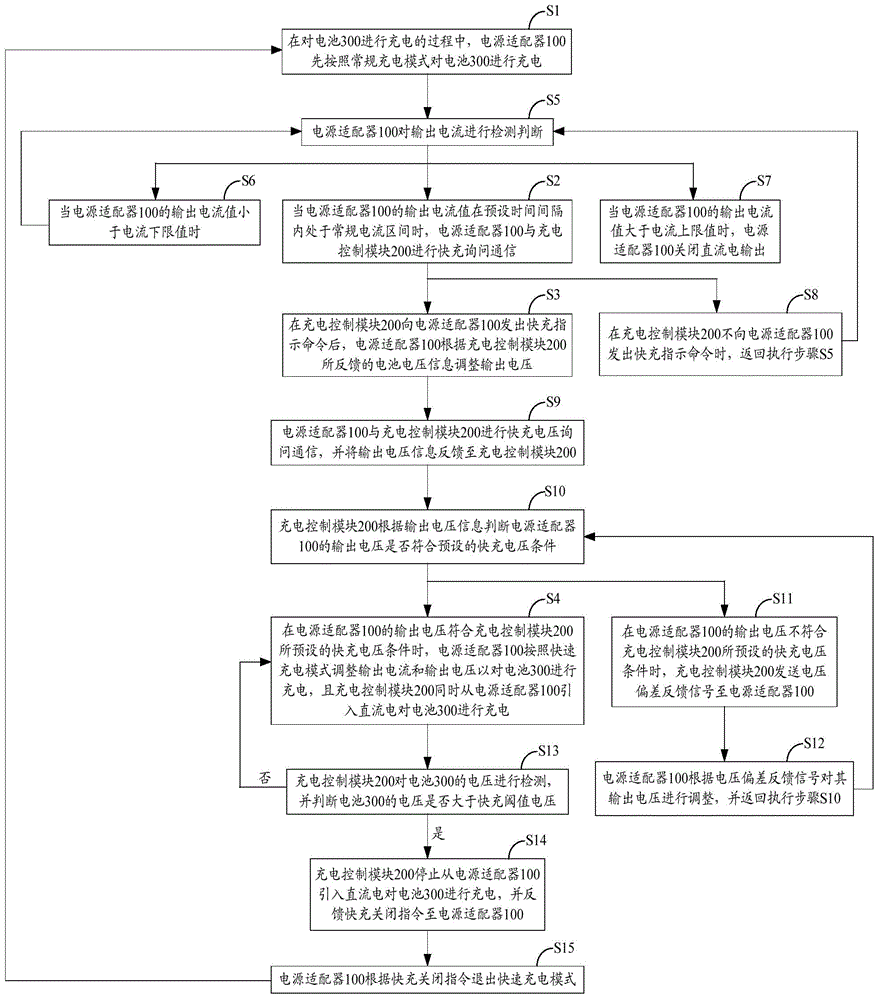

Cell charging device and method

ActiveCN104810877AShorten charging timeSecondary cells charging/dischargingElectric powerCurrent rangeCharge control

The invention belongs to the technical field of charging and provides a cell charging device and method. In the process of charging a cell by utilizing the cell charging device comprising a power adapter and a charging control module, the power adapter charges the cell in a conventional charging mode first; when the output current value of the power adapter is in a conventional current range in a preset time interval, the power adapter is in quick charge inquiry communication with the charging control module; after the charging control module sends a quick charge instruction command to the power adapter, the power adapter adjusts output voltage according to the cell voltage information fed back by the charging control module; when the output voltage accords with the preset quick charge voltage condition of the charging control module, the power adapter adjusts output current and output voltage according to the quick charge mode so as to charge the cell; and meanwhile, the charging control module introduces a direct current from the power adapter to charge the cell, and thus the purpose of reducing charging time by carrying out quick charge on the cell is realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

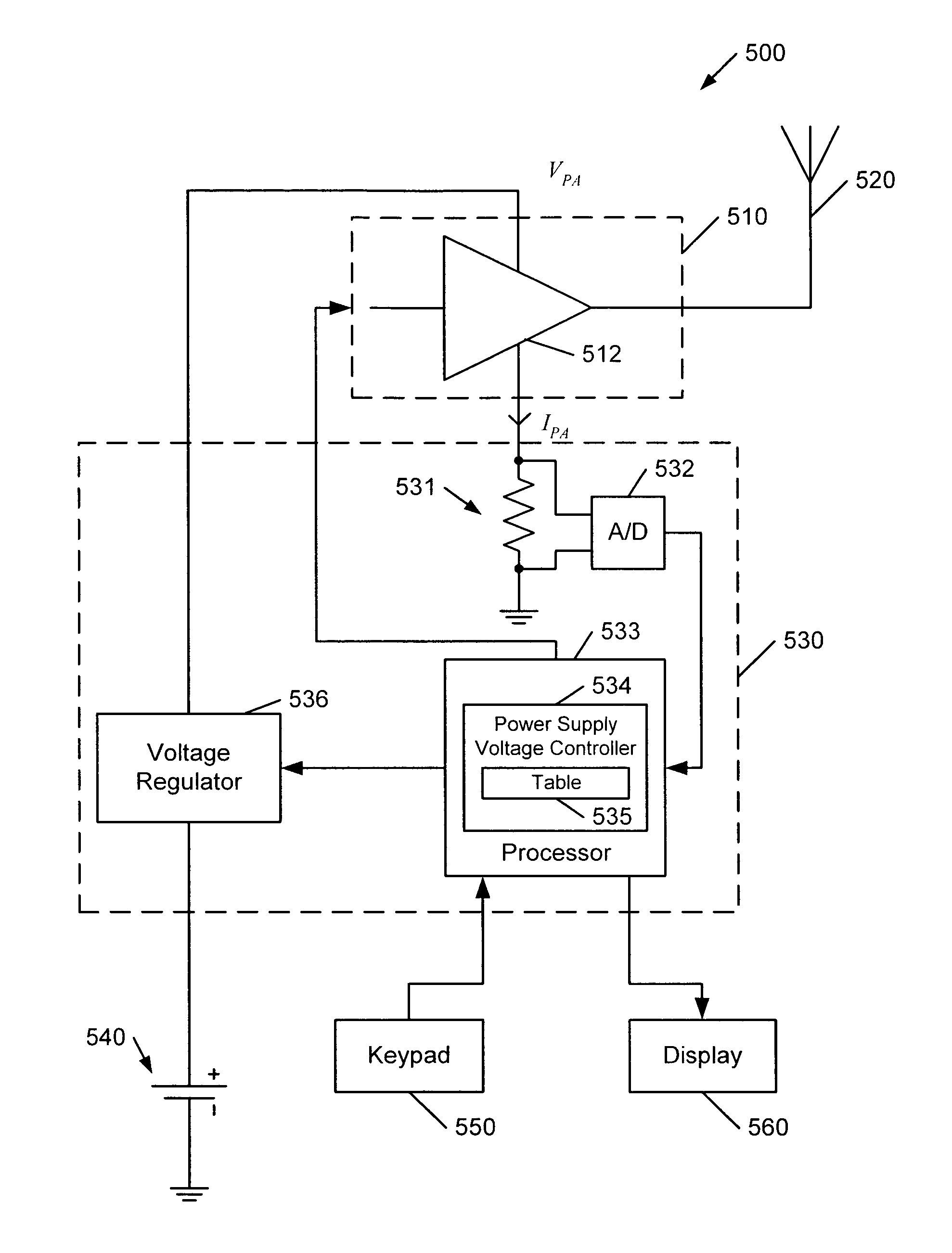

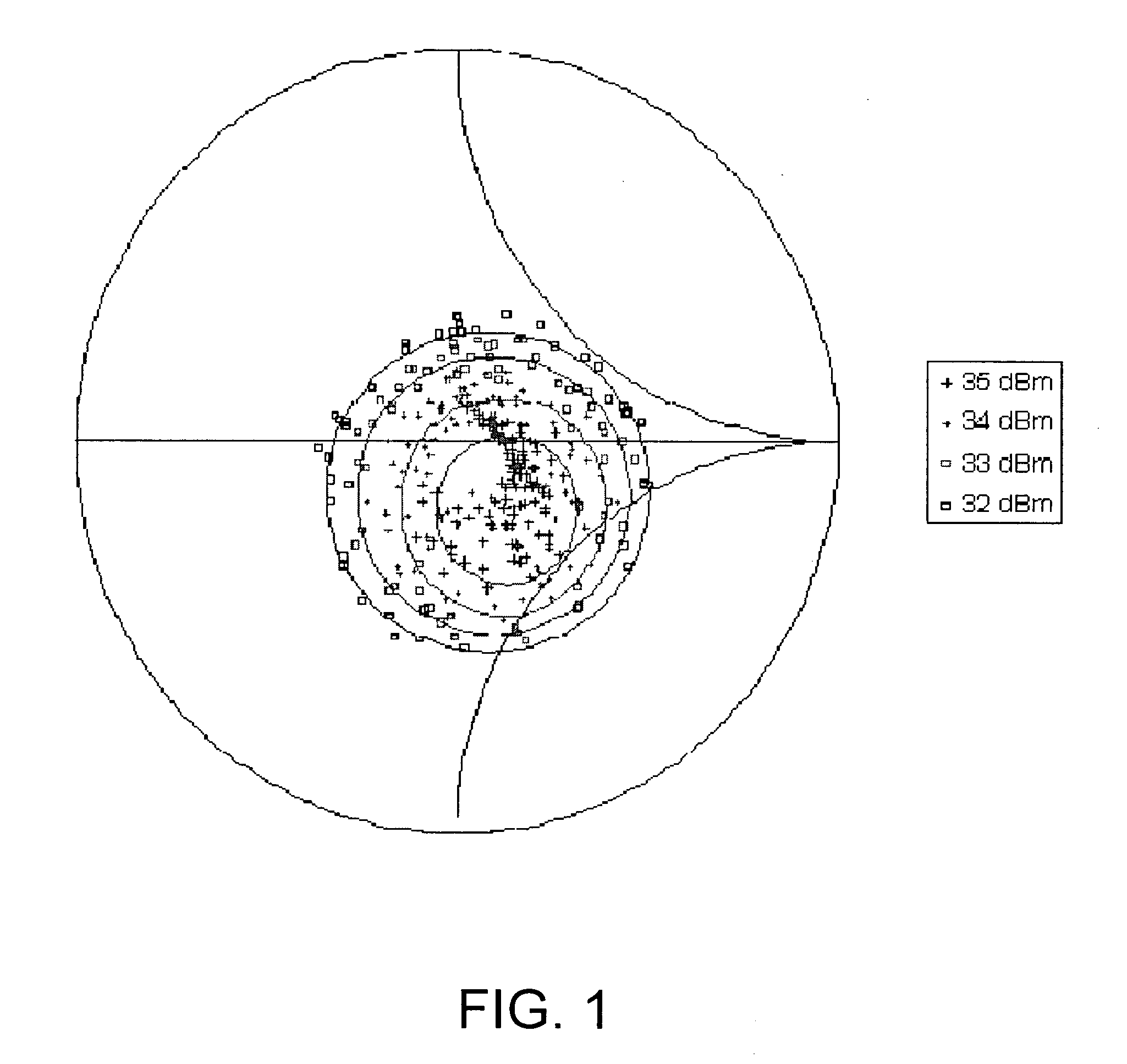

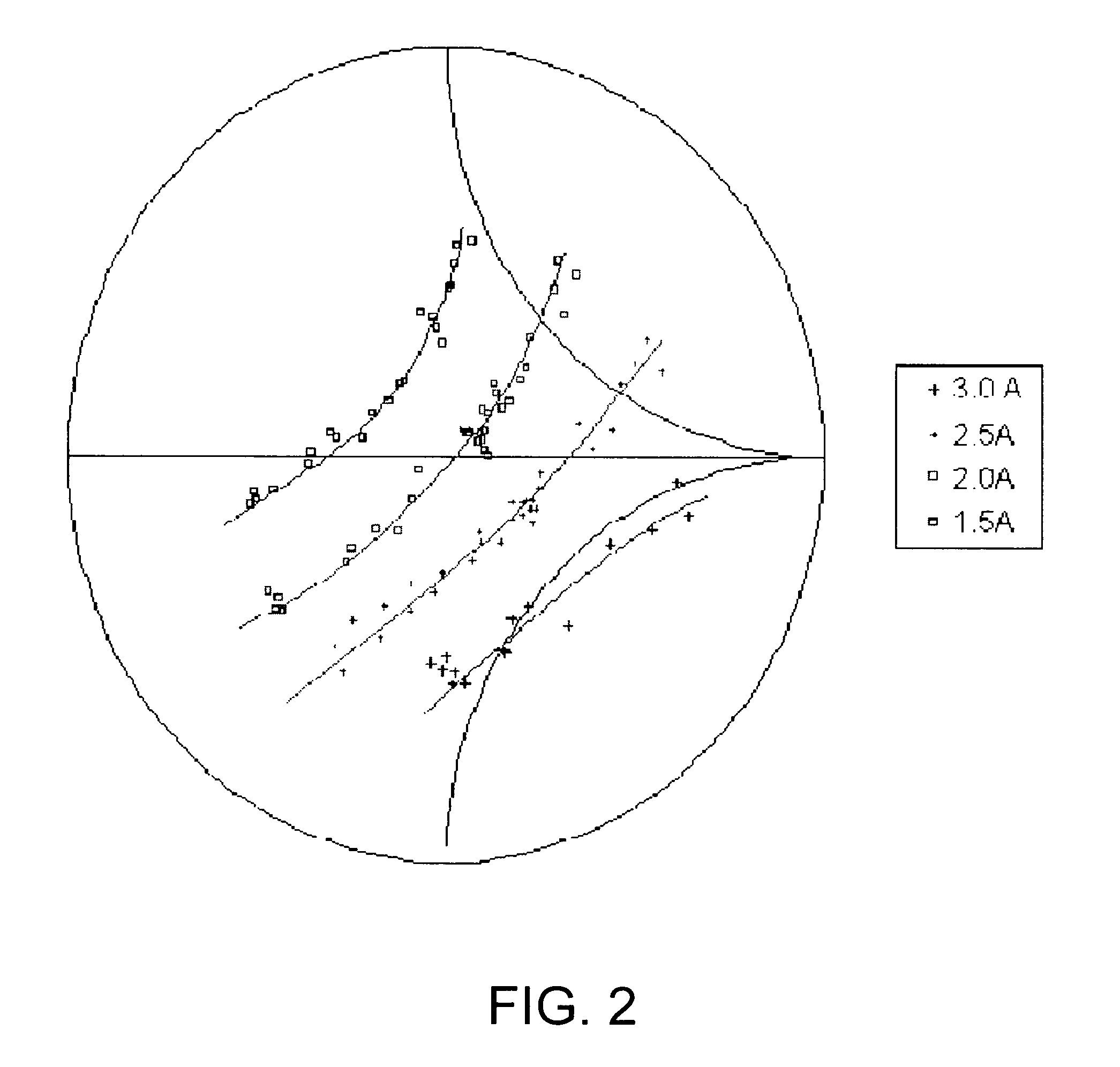

Wireless terminals, methods and computer program products with transmit power amplifier input power regulation

A transmit power amplifier of a wireless terminal is controlled by determining a power supply voltage applied to the transmit power amplifier, determining a power supply current provided to the transmit power amplifier, determining a relationship of the determined power supply current and the determined power supply voltage, and controlling the power supply voltage responsive to the determined relationship of the power supply current and the power supply voltage. For example, determining a relationship of the determined power supply current and the determined power supply voltage may include determining whether the power supply current meets a predetermined criterion, e.g., a predetermined current range, associated with the determined power supply voltage. The invention may be embodied as apparatus, methods, and computer program products.

Owner:SONY ERICSSON MOBILE COMM AB

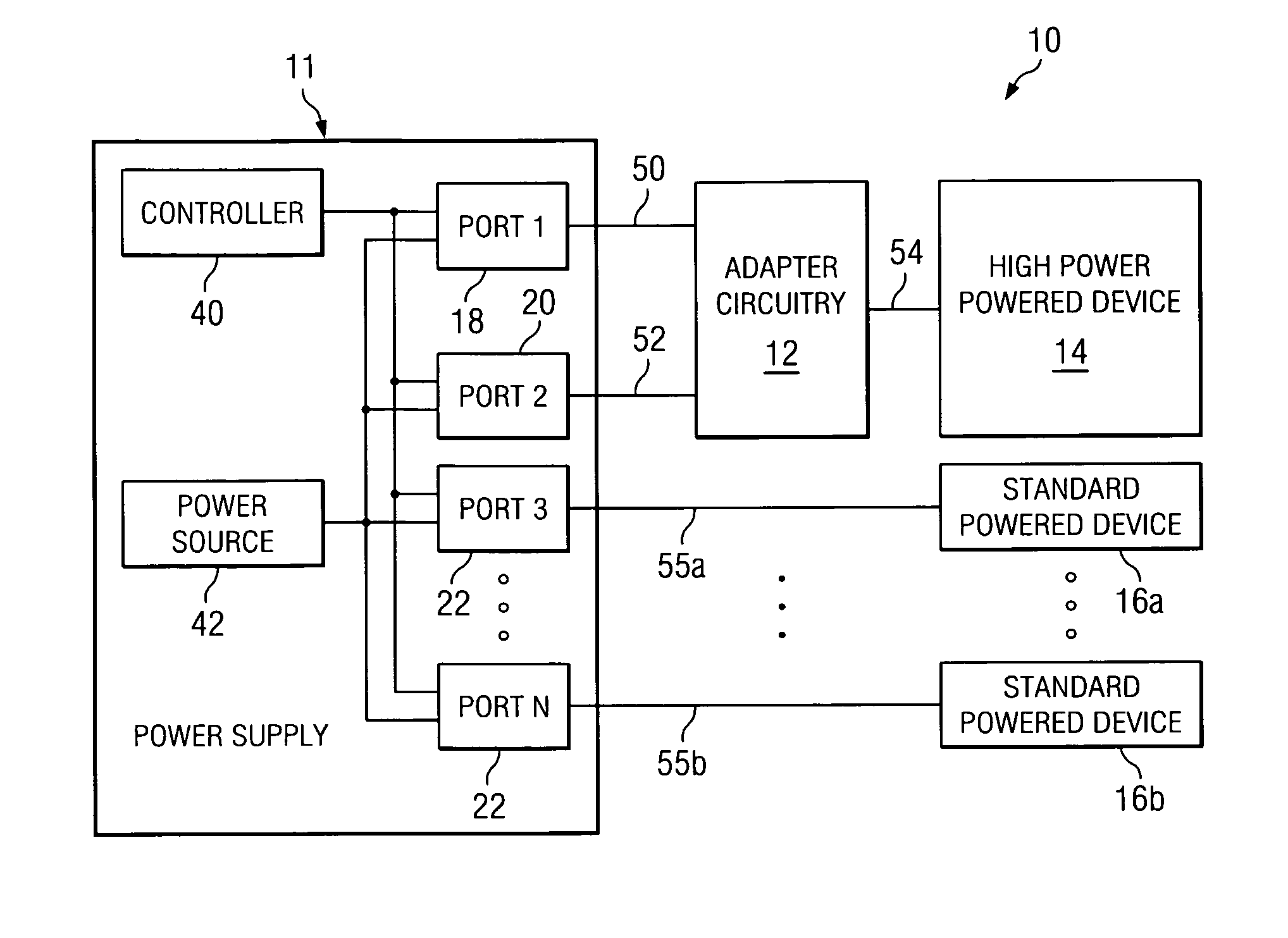

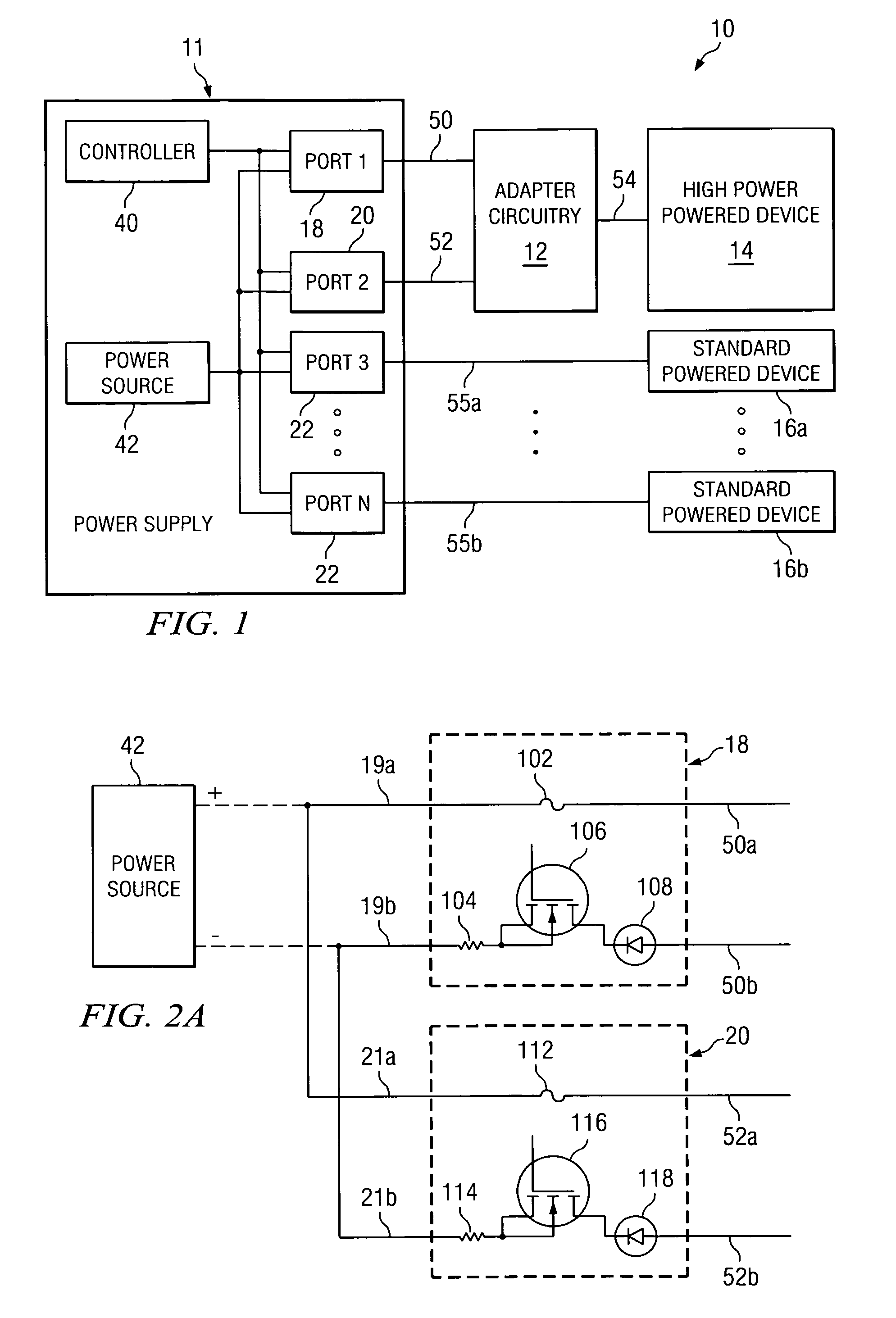

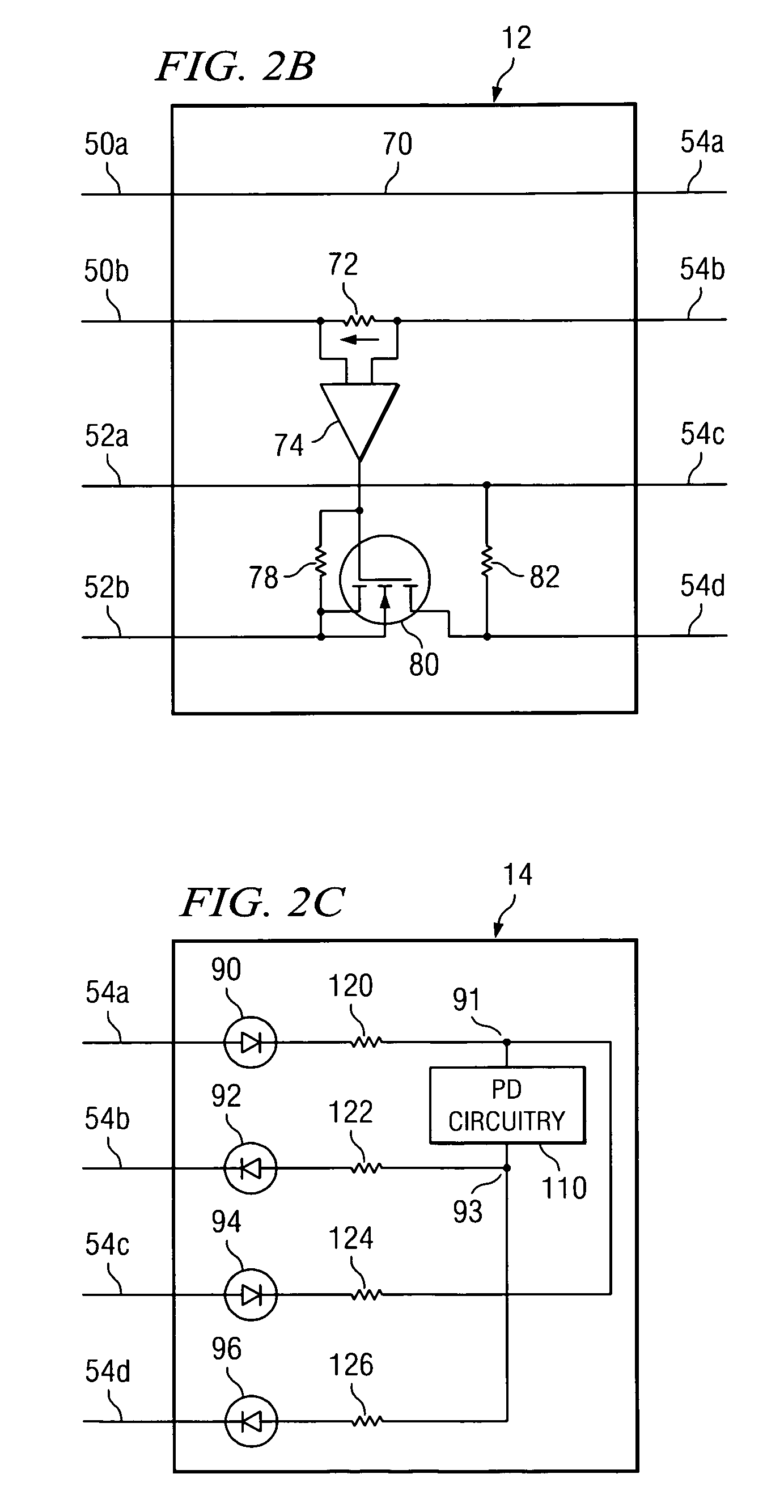

Increased power for power over Ethernet applications

ActiveUS7373528B2Volume/mass flow measurementPower supply for data processingCurrent rangeEngineering

According to one embodiment of the invention, a method for supplying power over Ethernet includes determining whether a first port of power sourcing equipment is supplying current to a power over Ethernet device in a predetermined current range. The method also includes logically connecting a second port of the power sourcing equipment to the power over Ethernet device in response to determining that a first port of the power sourcing equipment is supplying current to the power over Ethernet device. The method also includes supplying power from the second port to the power over Ethernet device.

Owner:CISCO TECH INC

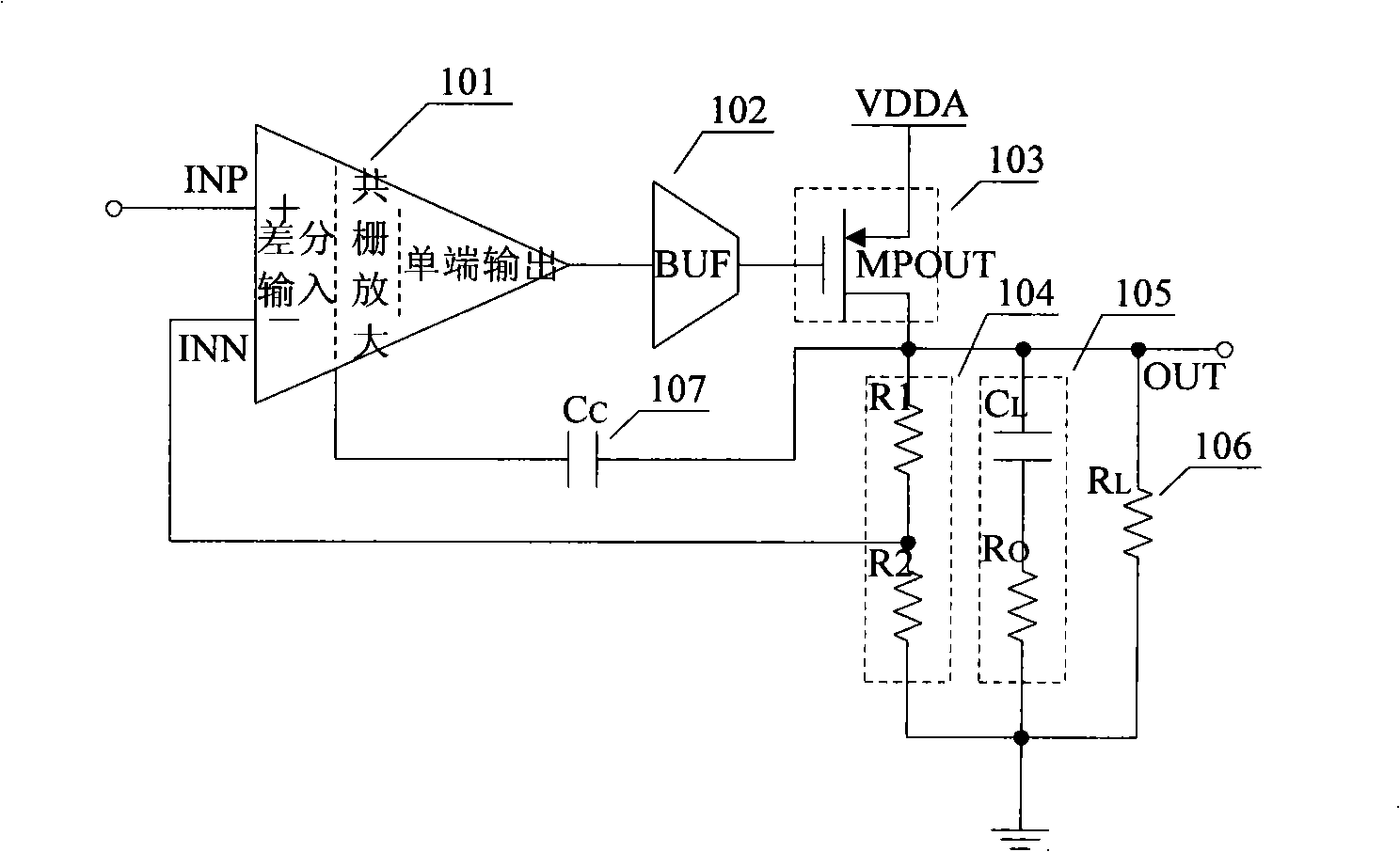

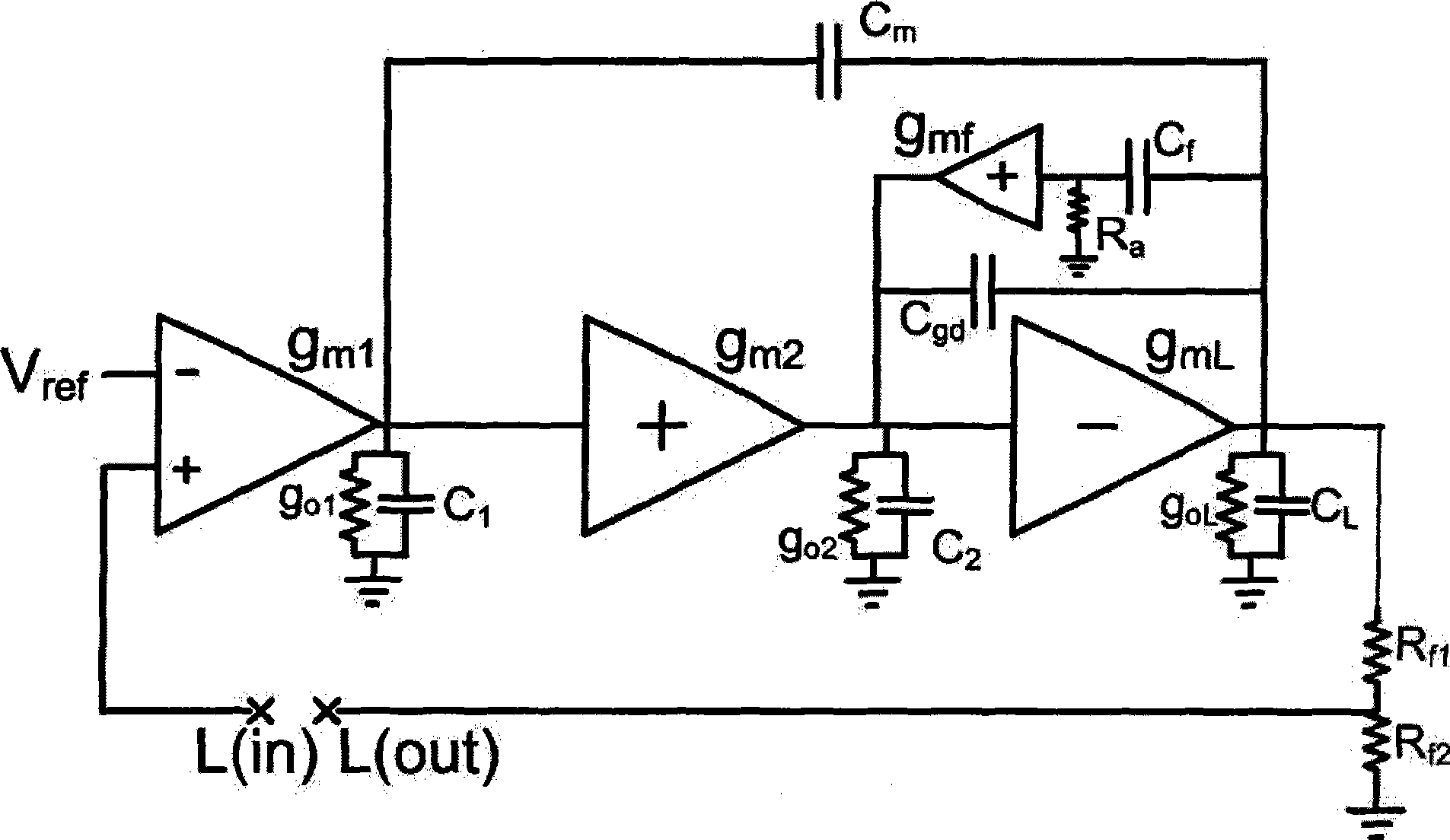

Broad output current scope low pressure difference linear manostat

InactiveCN101339443AIncreased unity-gain bandwidthImprove stabilityLogic circuits coupling/interface using field-effect transistorsDifferential amplifiersCapacitanceCurrent range

A low dropout linear voltage regulator with wide output current range and low pressure difference, comprises an error amplifier in the folding common source and common gate structure, a buffer circuit, a driving element, a feedback circuit, a load capacitance equivalent series resistance compensating circuit and a multistage Miller compensation circuit, wherein the buffer circuit changes the low frequency pole into a medium frequency pole and a high frequency pole; the large load capacitance of the load capacitance equivalent series resistance compensating circuit pushes the main pole to the low frequency, causing the gain crossover point to push inwards, and generating a medium frequency zero point for counteracting the medium frequency pole connected serially with the equivalent series resistance; the stride multilevel Miller compensation circuit generates a medium high frequency pole and a medium high frequency zero point slightly smaller than the medium high frequency pole for advancing the phase margin, thereby not only adding the unity gain bandwidth, but also saving considerable chip area. When the output current has a large change range, the structure provided by the invention generates wider unity gain bandwidth, provides the phase margin of greater than 85 degrees, ensures the stability of the system and advances the low pressure difference linear voltage stabilization performance.

Owner:WUHAN UNIV

Hybrid Power Control System

ActiveUS20120206064A1Efficient power controlMaximizing light emittedElectrical apparatusElectroluminescent light sourcesCurrent rangeLight emitting device

A hybrid power control system for providing dynamic power control to illumination systems in which a power source can supply any one of a range of AC or DC voltages. One or more switch mode power supplies incorporating one or more linear and switch mode regulator circuits combined to dynamically control current, voltage and power to the illumination system. A microprocessor or other integrated circuit device to receive and send control information in order to regulate the power to a light emitting device One or more output drive stage(s) capable of delivering a wide dynamic current range, channel bonding and protection circuitry compatible with standard or common anode illumination systems.

Owner:RADIANT RES

Non-contact electrical power transmission system having function of making load voltage constant

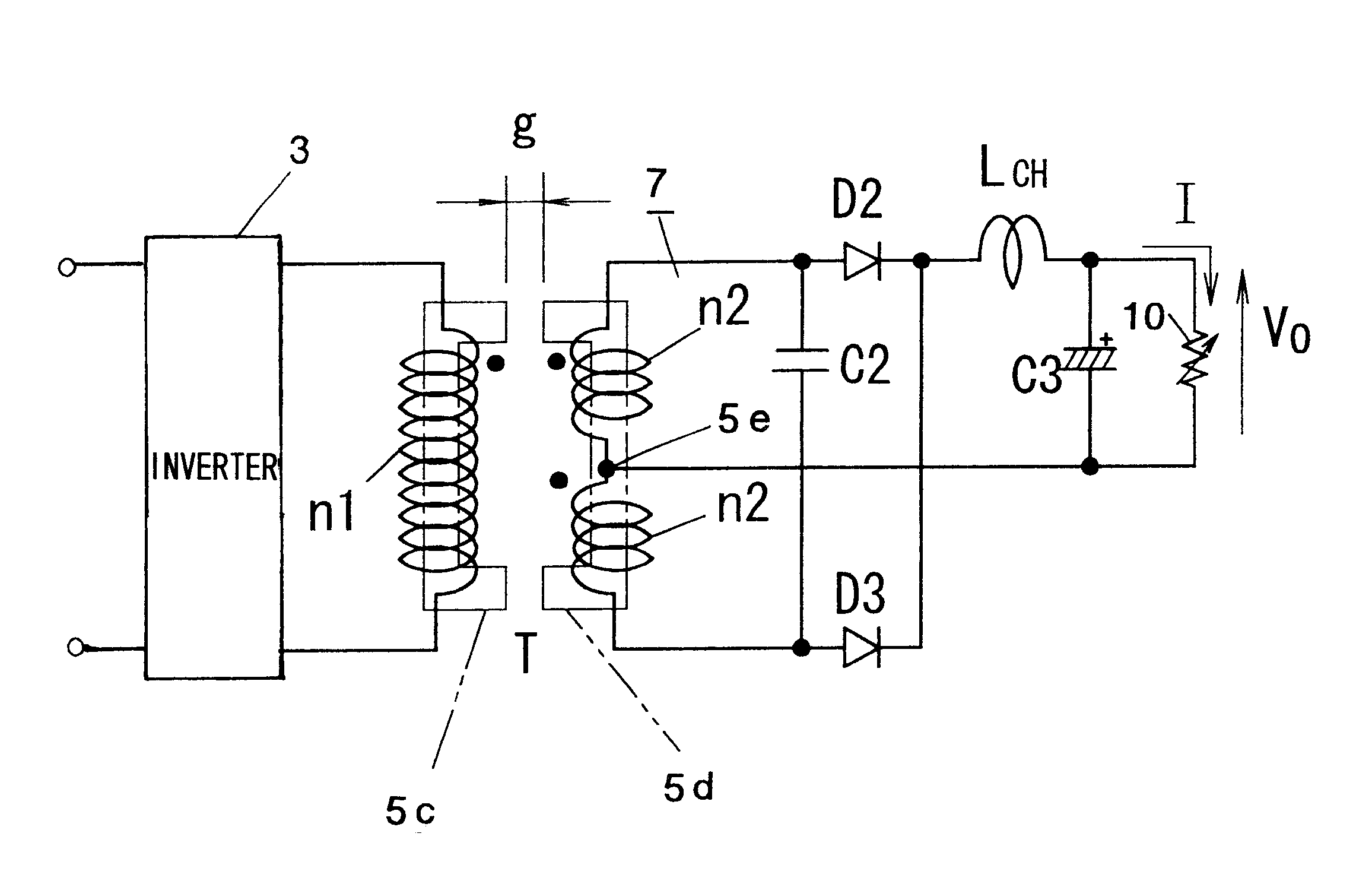

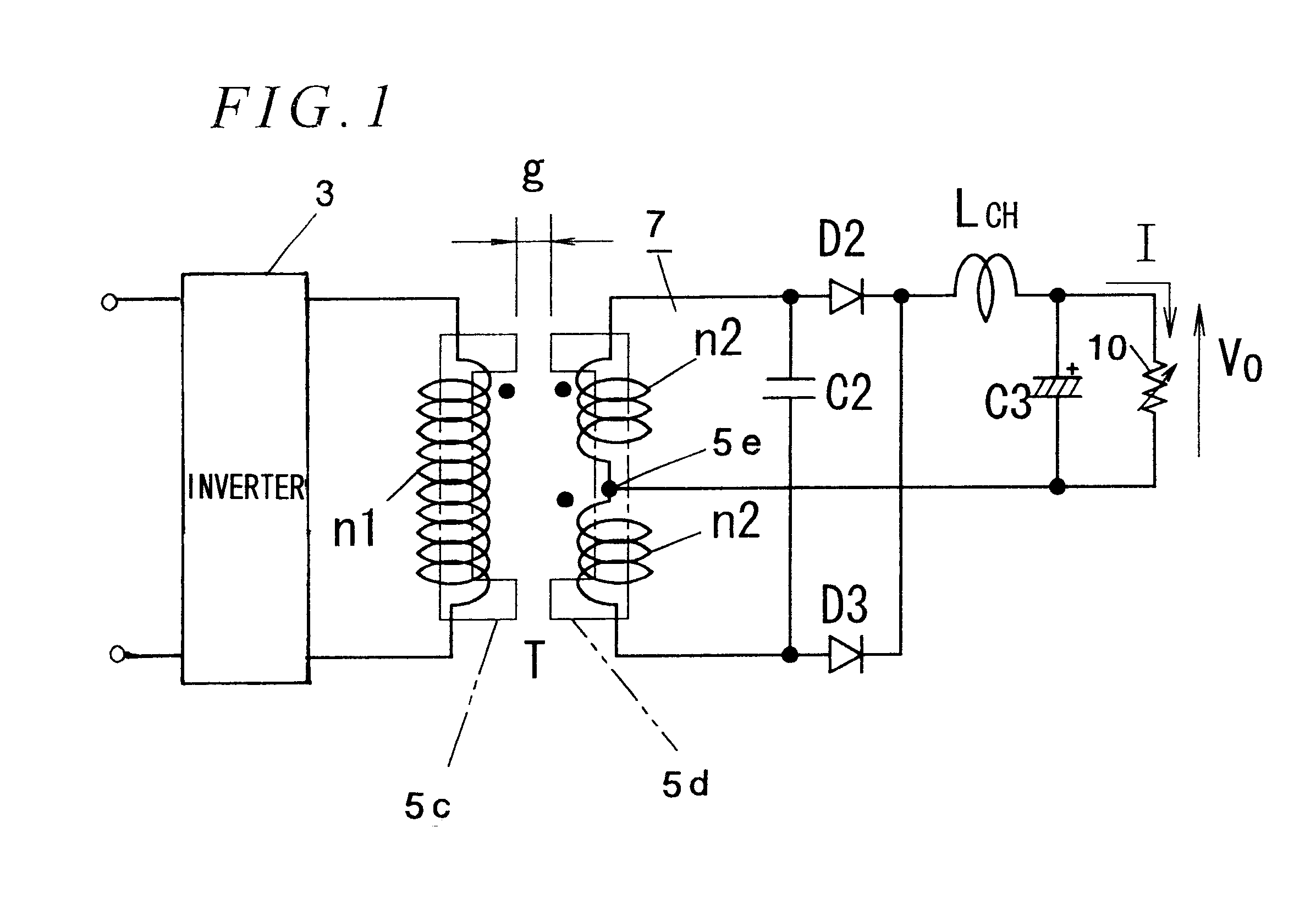

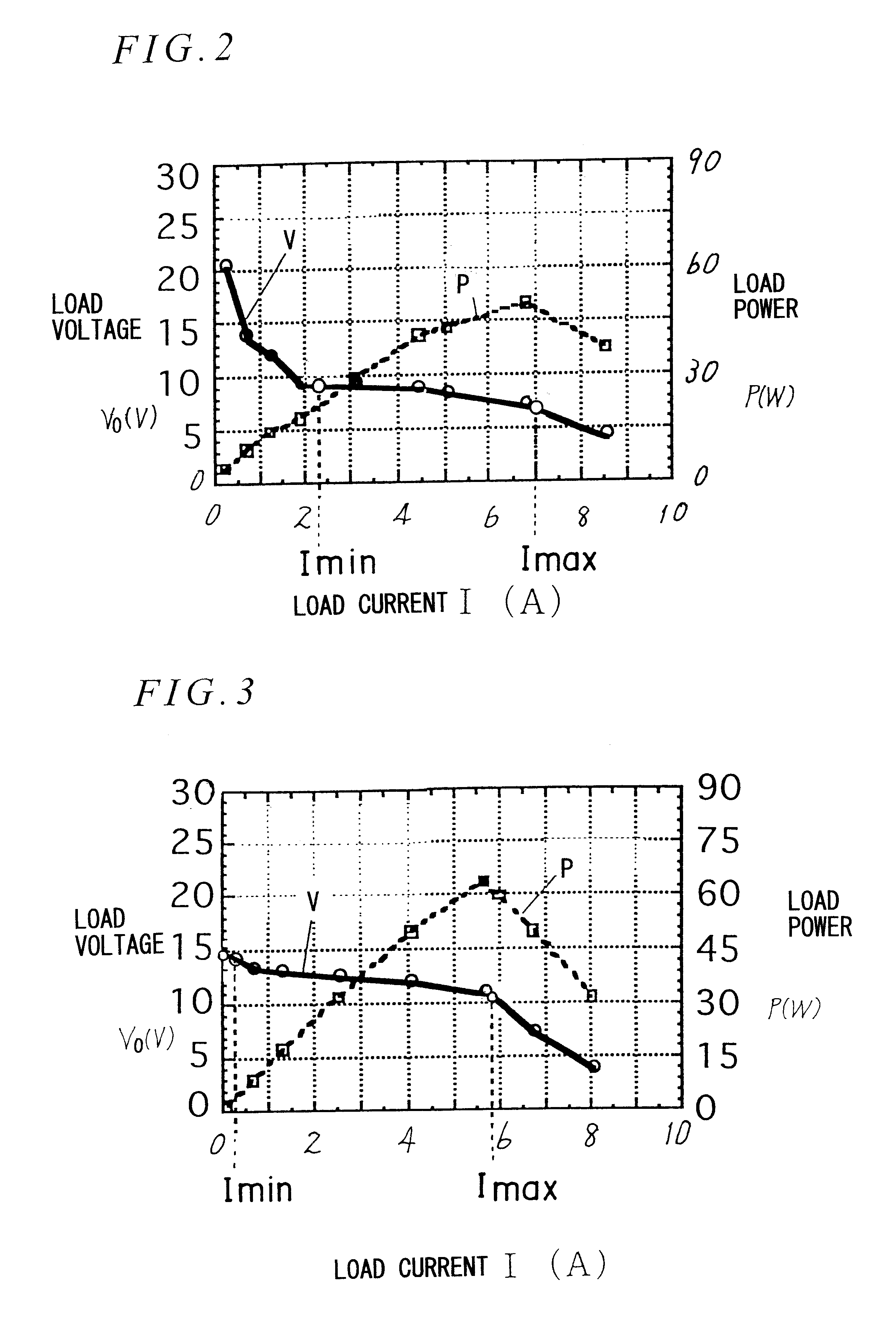

InactiveUS6504732B2Reduce lossSoft switchingDc network circuit arrangementsBatteries circuit arrangementsElectric power transmissionCapacitance

A transformer separable / detachable between a primary winding and a secondary winding, has a capacitor connected parallel to the secondary winding. A high-frequency AC voltage supplied to the primary winding of the transformer generates an induced voltage in the secondary winding. The secondary winding transmits electrical power to a load in non-contact manner. Either the output voltage remains constant as the output current varies, or vice versa. Taking as a first condition a fact that at the time of a maximum load, the time of the reversal of the voltage polarity of the primary winding substantially coincides with the time when an oscillating voltage of the capacitor reaches a maximum or minimum value. Taking as a second condition a fact that at the time of a minimum load, the time of the reversal of the voltage polarity of the above-mentioned primary winding substantially coincides with the time when the oscillating voltage of the above-mentioned capacitor completes one cycle. The capacitance of the capacitor is selected to satisfy simultaneously the first and second conditions. This allows the load voltage to remain constant in a load current range from a minimum to a maximum without requiring a feedback circuit.

Owner:MATSUSHITA ELECTRIC WORKS LTD

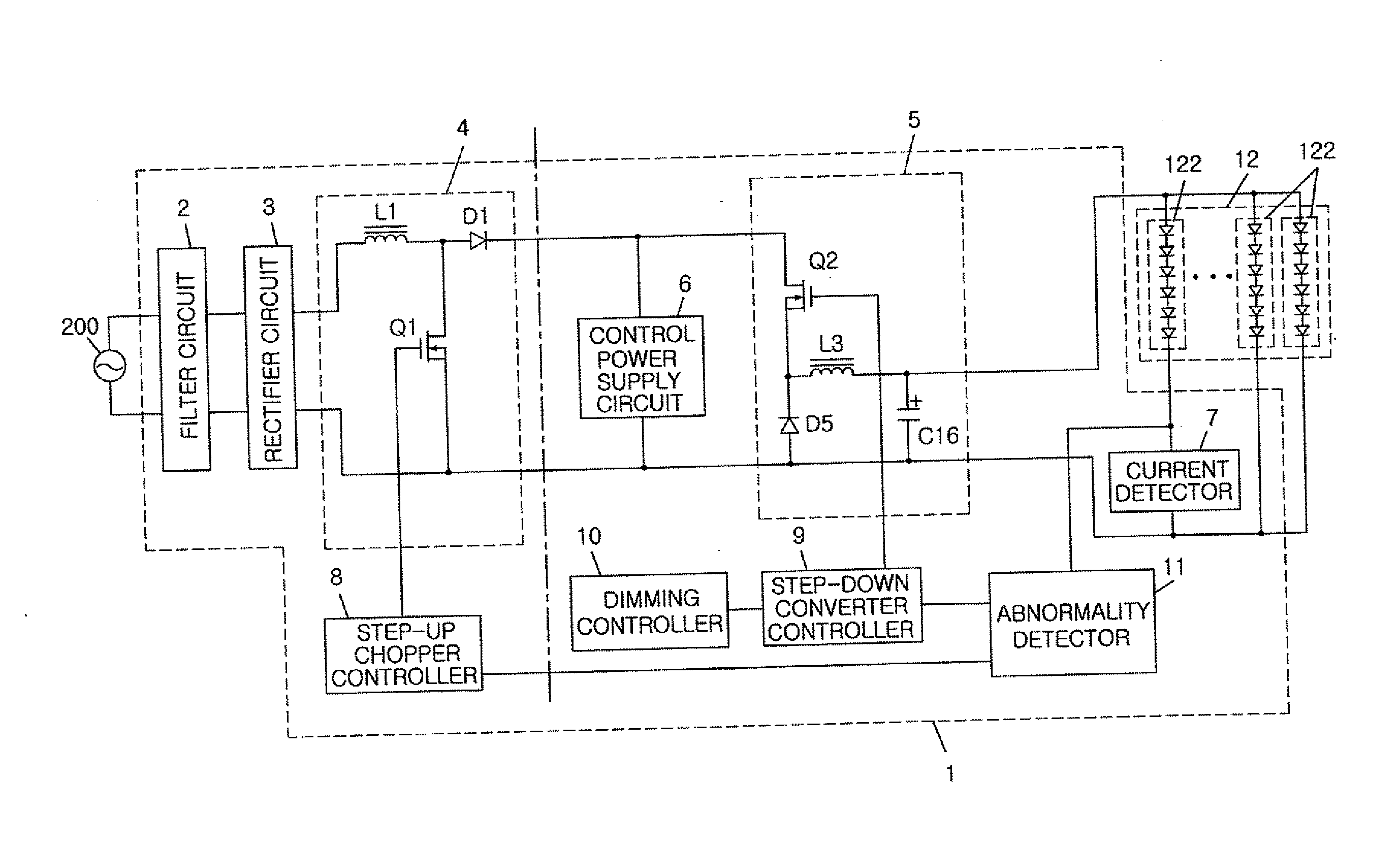

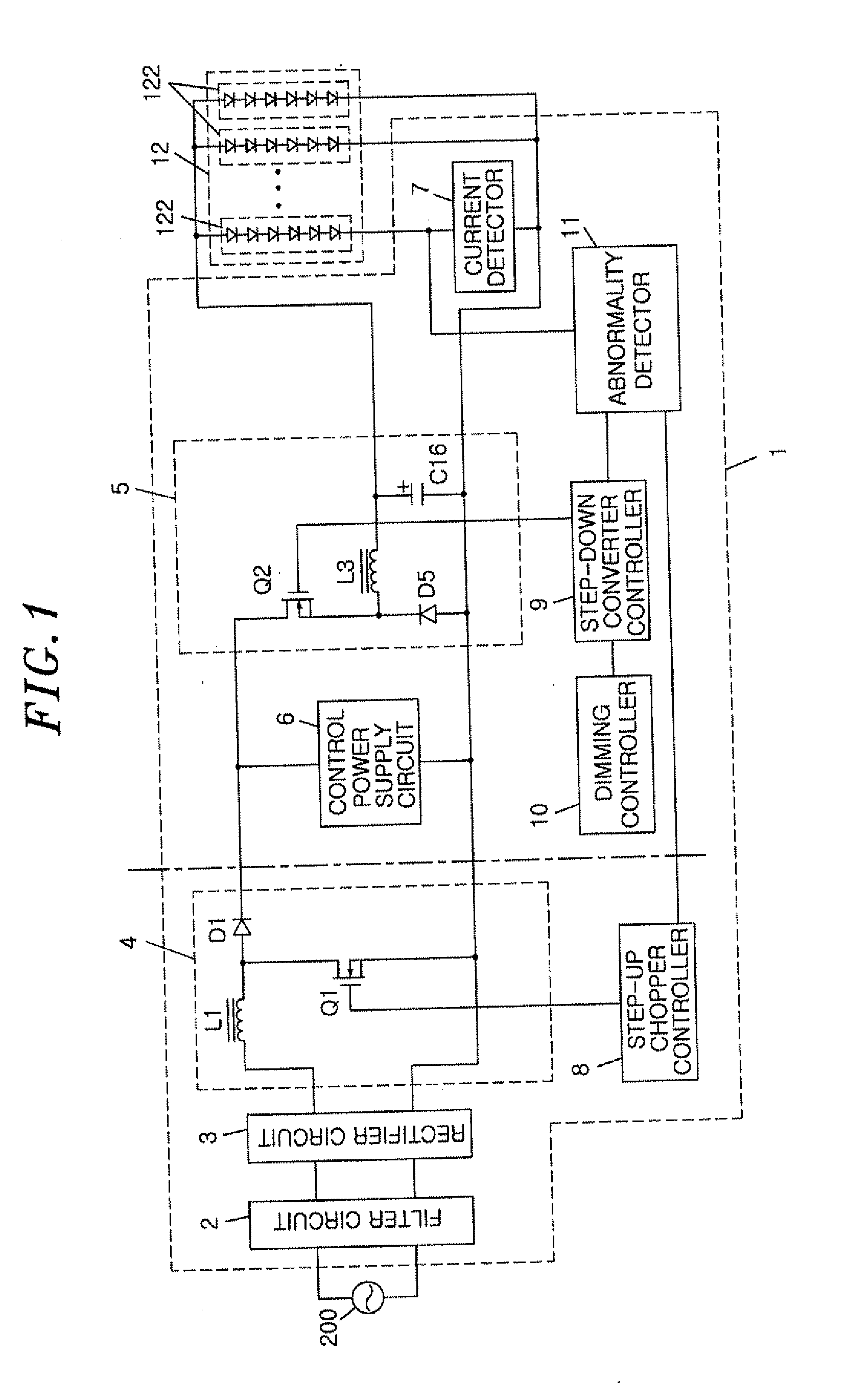

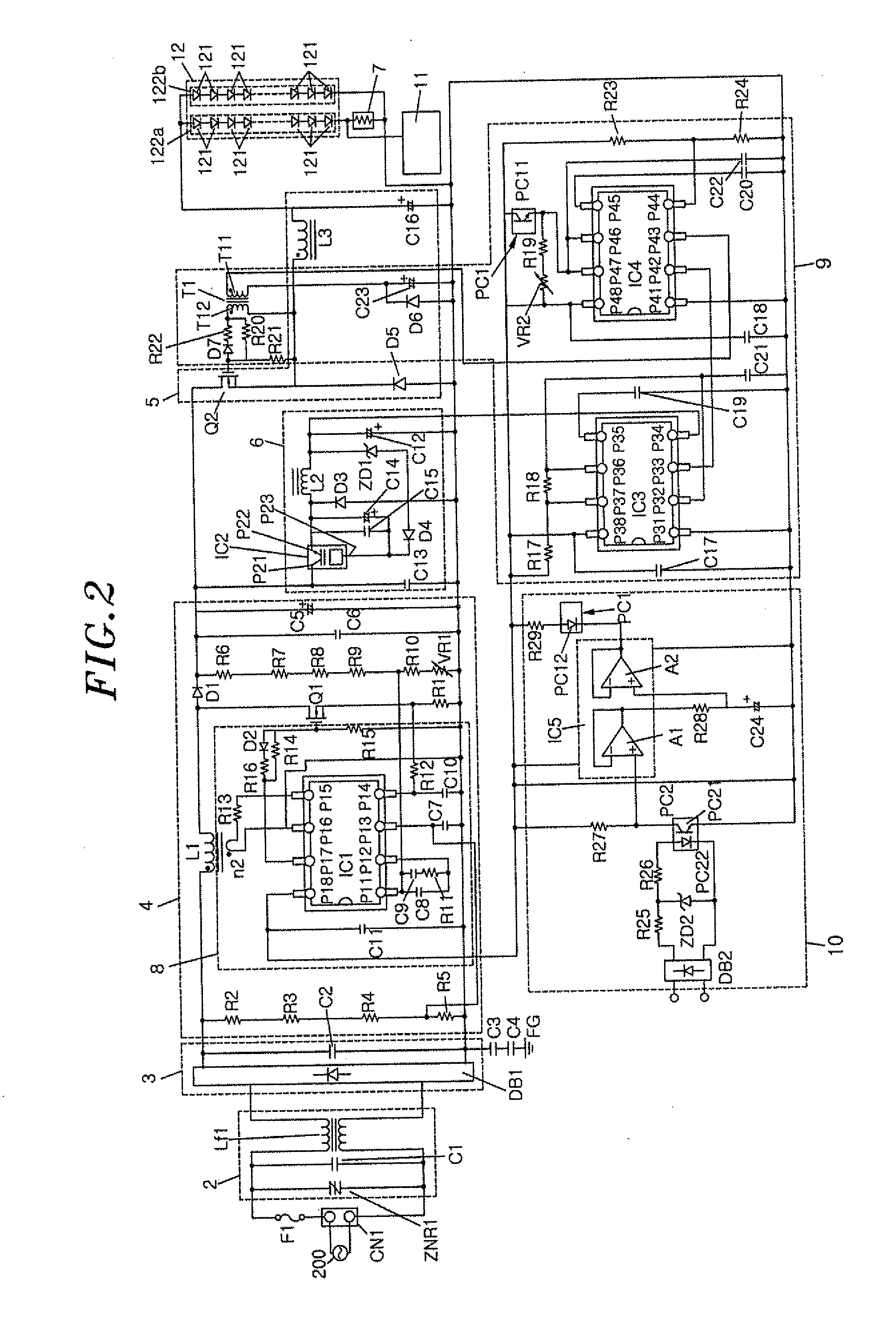

Lighting device and illumination apparatus including same

ActiveUS20120212143A1Reduce power lossSimple configurationElectrical apparatusElectroluminescent light sourcesLower limitLight equipment

A lighting device includes a lighting unit which controls a current being supplied to a load, in which light emitting modules, each having one or more semiconductor light emitting elements connected in series, are connected in parallel, to be a constant current; a current detector which detects a current flowing through one of the light emitting modules; and an abnormality detector which compares a detected value from the current detector with an upper limit and a lower limit of a predetermined current range to detect an abnormality in the load. The abnormality detector detects the abnormality in the load if the detected value from the current detector is larger than the upper limit or smaller than the lower limit, and if the abnormality in the load is detected, the lighting unit reduces the current being supplied to the load.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

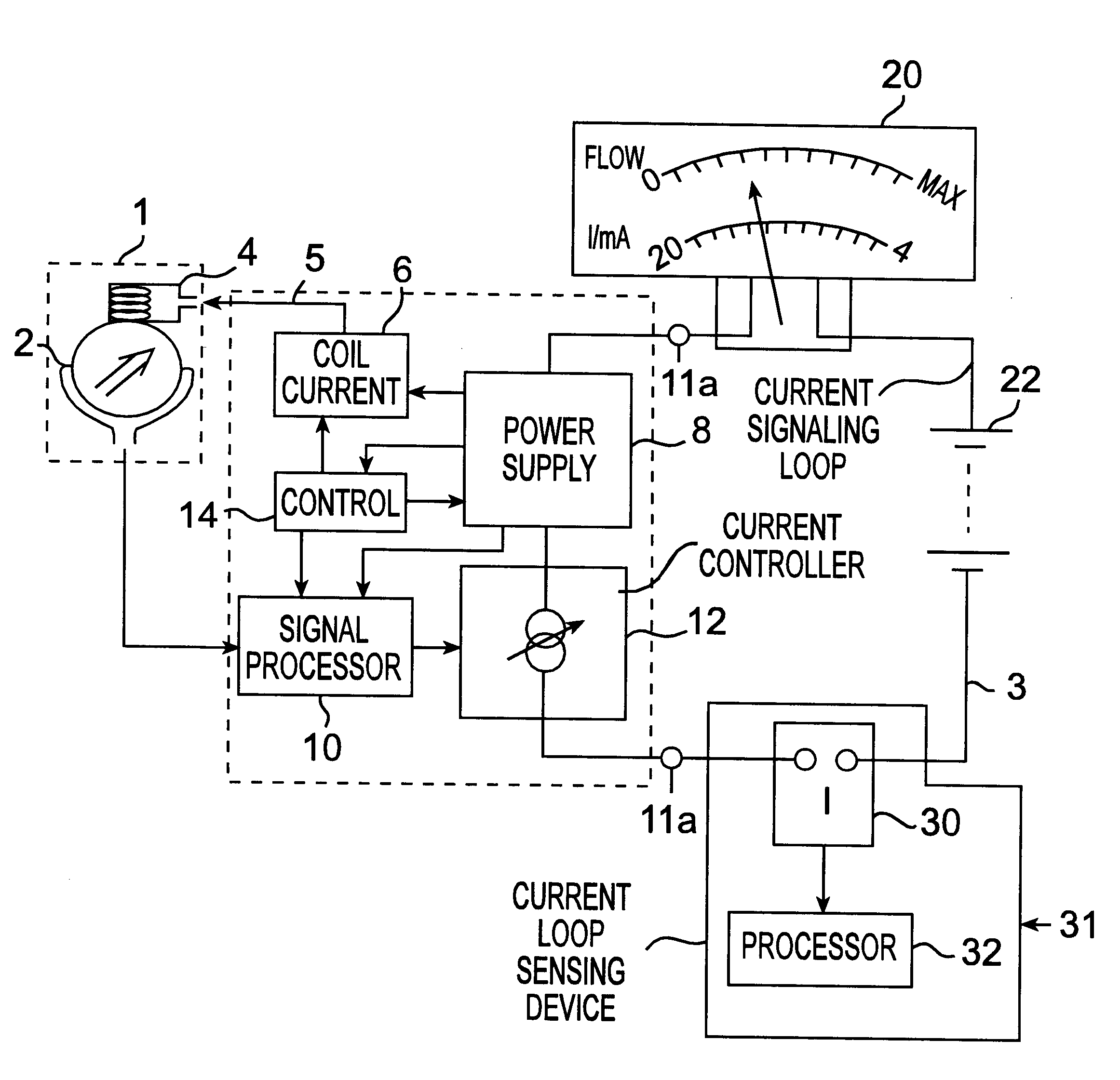

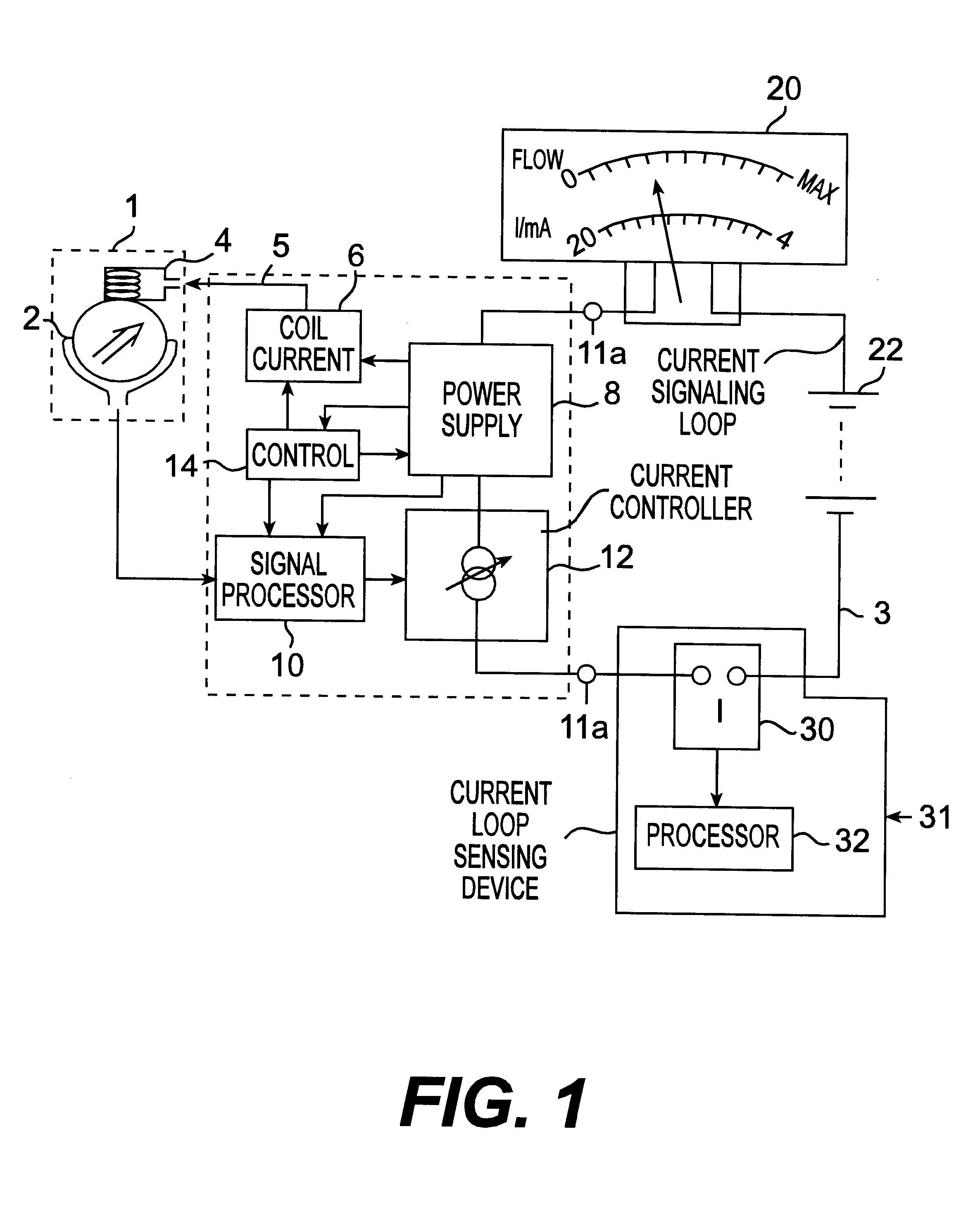

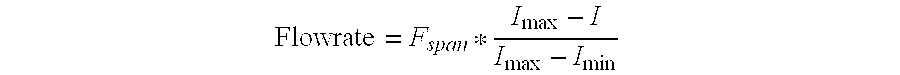

Electromagnetic flowmeter deriving power from signalling loop current

InactiveUS6269701B1Fluid speed measurementVolume/mass flow by electromagnetic flowmetersMaximum fluxCurrent range

An improvement over conventional electromagnetic flowmeters which signal a measure of flow rate by controlling the current in a current signalling loop (also known as a sensing loop) and in which power for the flowmeter is derived from the current in the signalling / sensing loop. Conventional electromagnetic flowmeters use a standard current range (typically 4-20 mA), in which zero flow is indicated by controlling the current in the loop to a minimum predeterimened value and maximum flow is indicated by controlling the current to a maximum predetermined value. In the improved flowmeter of the invention, minimum flow is signalled by maximum current in the signalling / sensing loop and maximum flow is signalled by minimum current. This has been found to enable improved accuracy to be obtained at low flow rates without requiring complex flowmeter circuitry.

Owner:ABB KENT TAYLOR

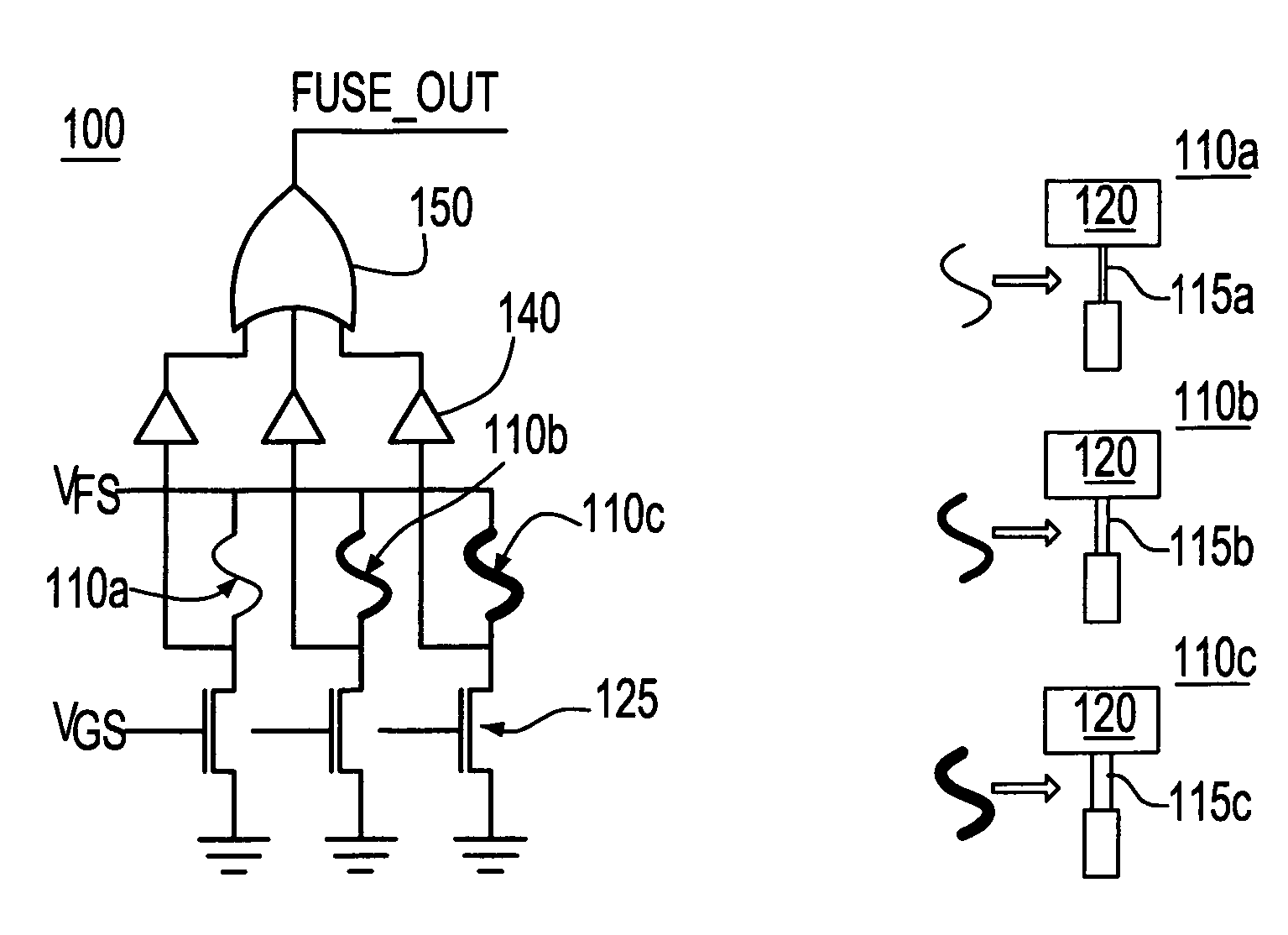

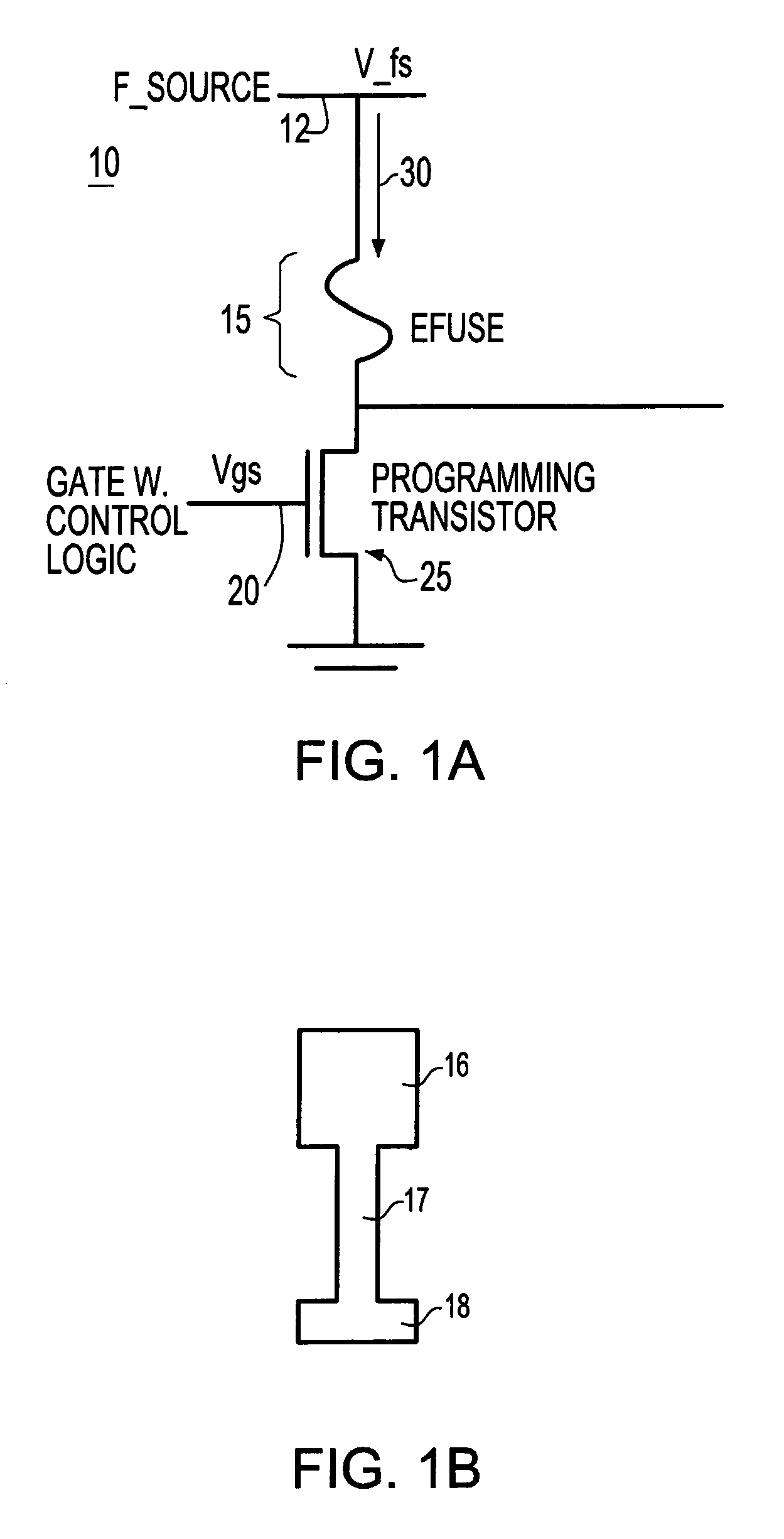

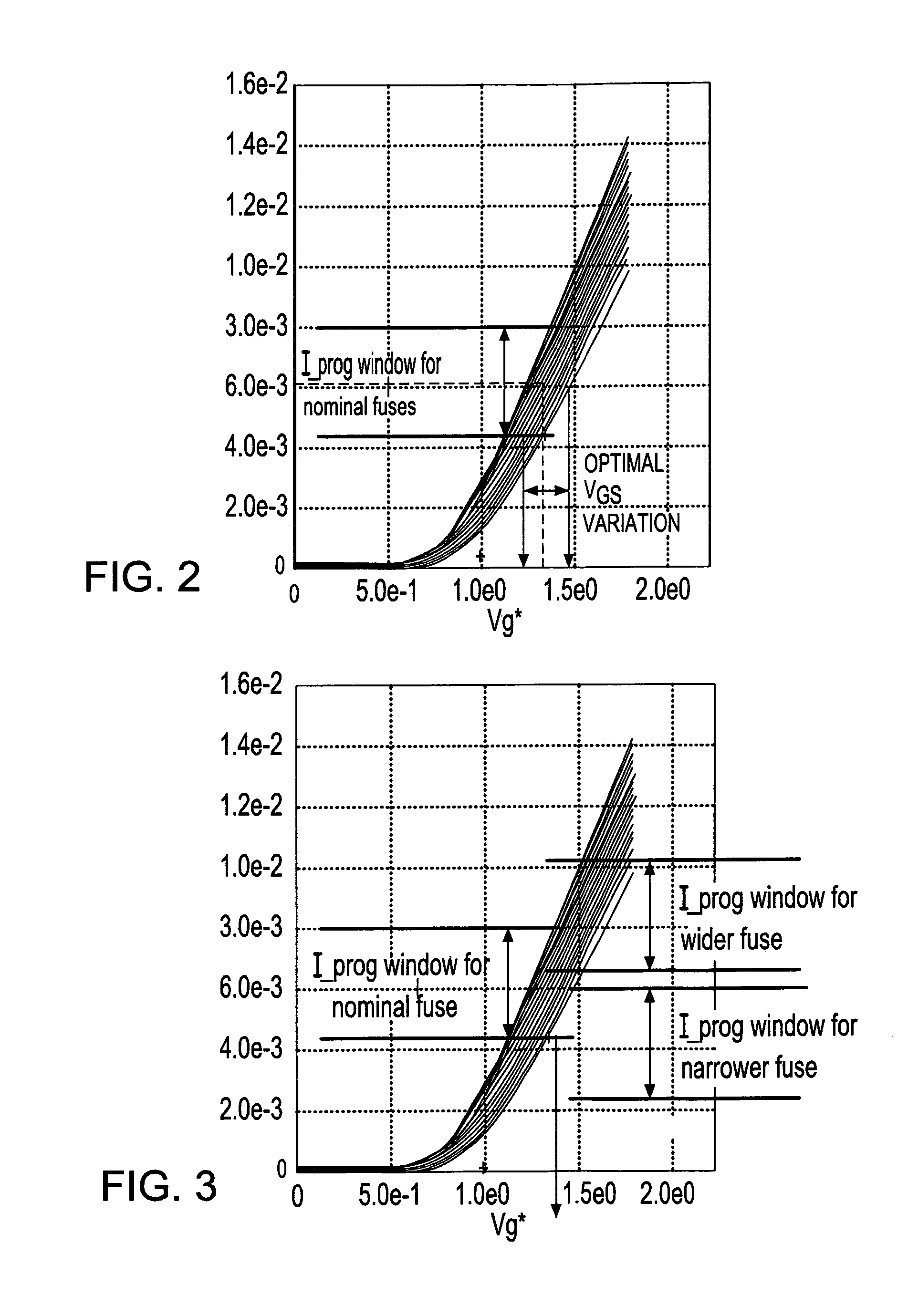

System and method for increasing reliability of electrical fuse programming

ActiveUS7254078B1Reliably programmedImprove programming reliabilityRead-only memoriesDigital storageElectricityCode redundancy

A system and method for achieving enhanced e-fuse programming reliability. By providing an e-fuse device with redundantly coded fuse structures each with a differing fuse size dimension, reliable encoding of a fuse with a programmed bit is enhanced. That is, for each e-fuse device, each of the multiple fuse structures and a corresponding programming devices associated with each fuse structure is dimensioned to achieve the coding redundancy such that one fuse structure of the multiple fuse structures provides for a current flow of sufficient current density to ensure programming reliability of the e-fuse device. In one embodiment, each the corresponding programming transistor device is of substantially identical size and, each fuse structure of the multiple fuse structures is of a different size. Alternately, each fuse structure is of substantially identical size and each programming transistor device is of a different size, thereby ensuring reliable coding over a programmed current range.

Owner:MARVELL ASIA PTE LTD

Correlation position determination

Owner:HONEYWELL INT INC

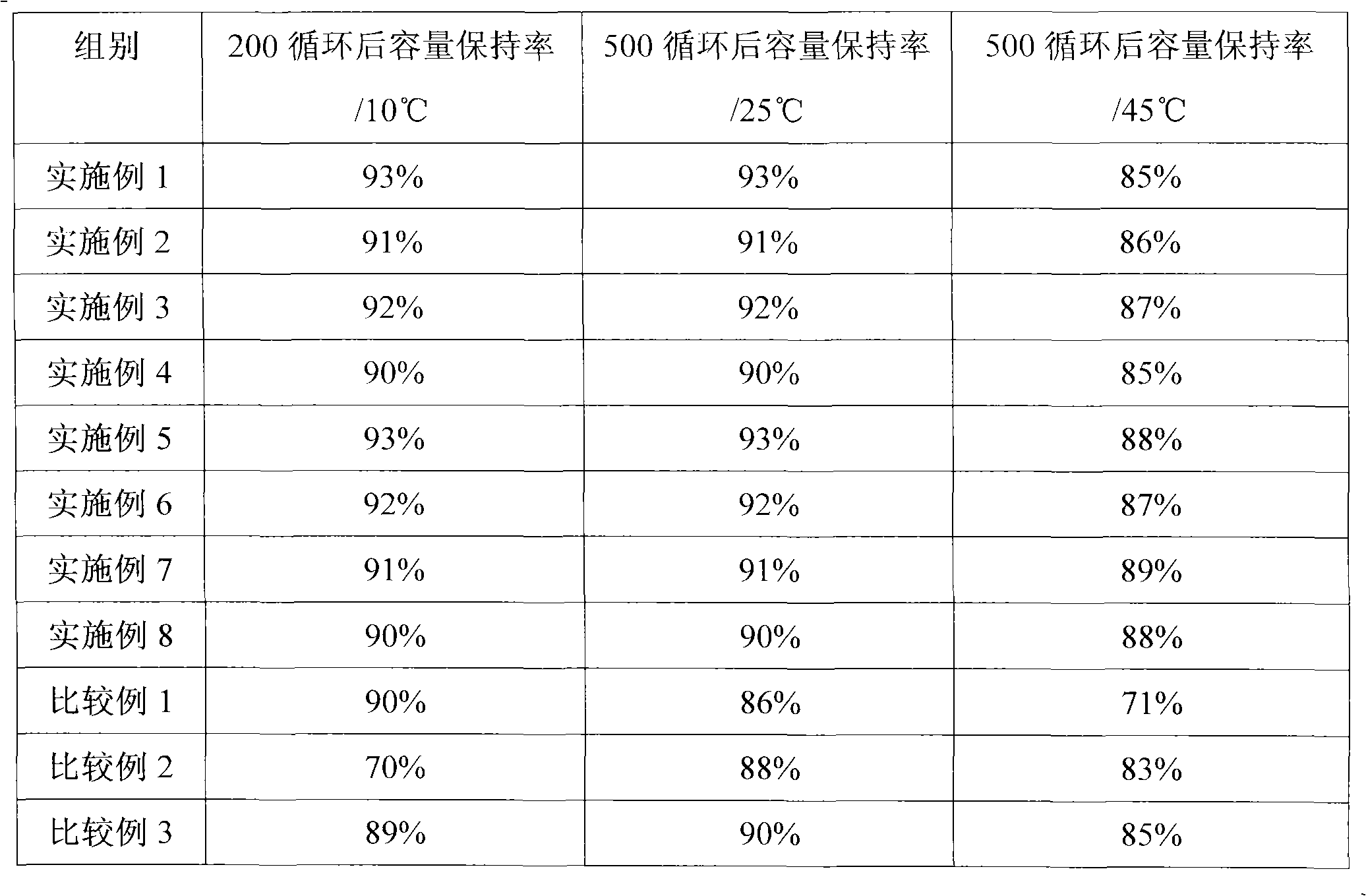

Formation method of lithium ion battery

InactiveCN102637903AOvercoming the Leakage ProblemAvoid influenceFinal product manufactureSecondary cells charging/dischargingPower flowCurrent range

The invention belongs to the technical field of lithium ion batteries and particularly relates to a formation method of a lithium ion battery. The formation method comprises the following steps of: vacuumizing a battery to be injected and performing first injection on the battery; performing opening formation on the battery subjected to the first injection, wherein a formation current ranges from 0.1C to 1.5C; and performing second injection and encapsulation on the battery subjected to the formation, wherein electrolyte for the second injection comprises high-temperature additives including at least one of trimethylene sulfite, ethylene sulfate, succinonitrile and adiponitrile. Compared with the prior art, the formation method disclosed by the invention avoids the electrolyte leakage caused by quick gas production during deformation with a large current by virtue of the way of twice injection, and avoids the influence on the components of an SEI (Solid Electrolyte Interface) membrane due to adding the electrolyte additives once, thereby improving the low temperature performance of a battery cell; and as the battery cell has high temperature performance by virtue of the additives injected after the formation, and the formation time is shortened greatly, the process efficiency is enhanced greatly, and the production cost is reduced.

Owner:NINGDE AMPEREX TECH +1

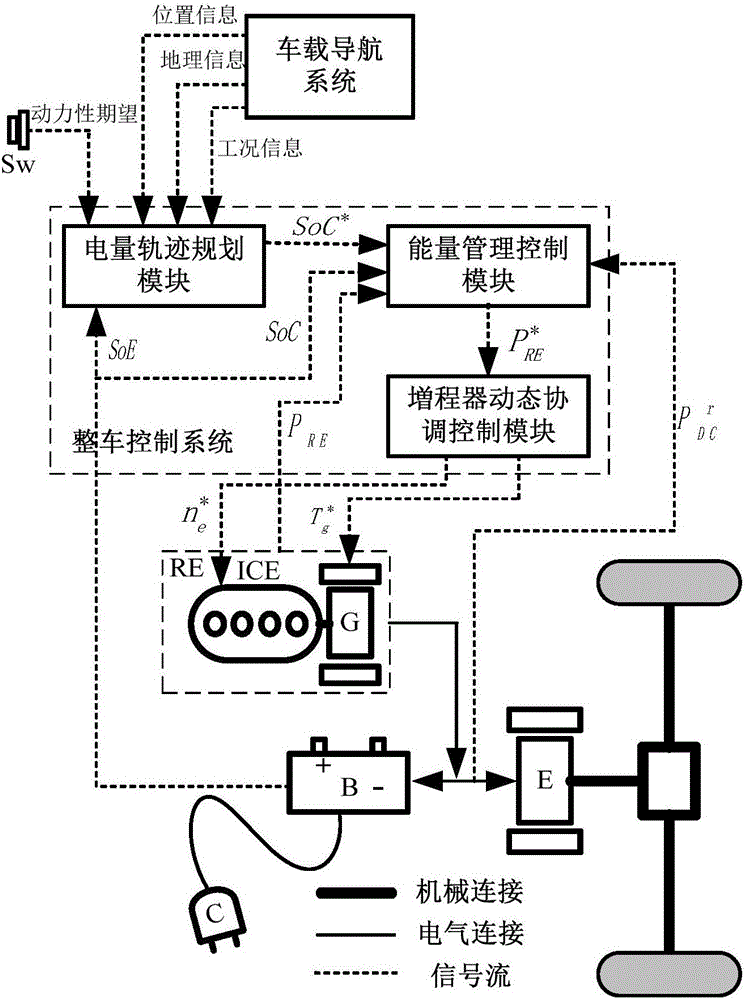

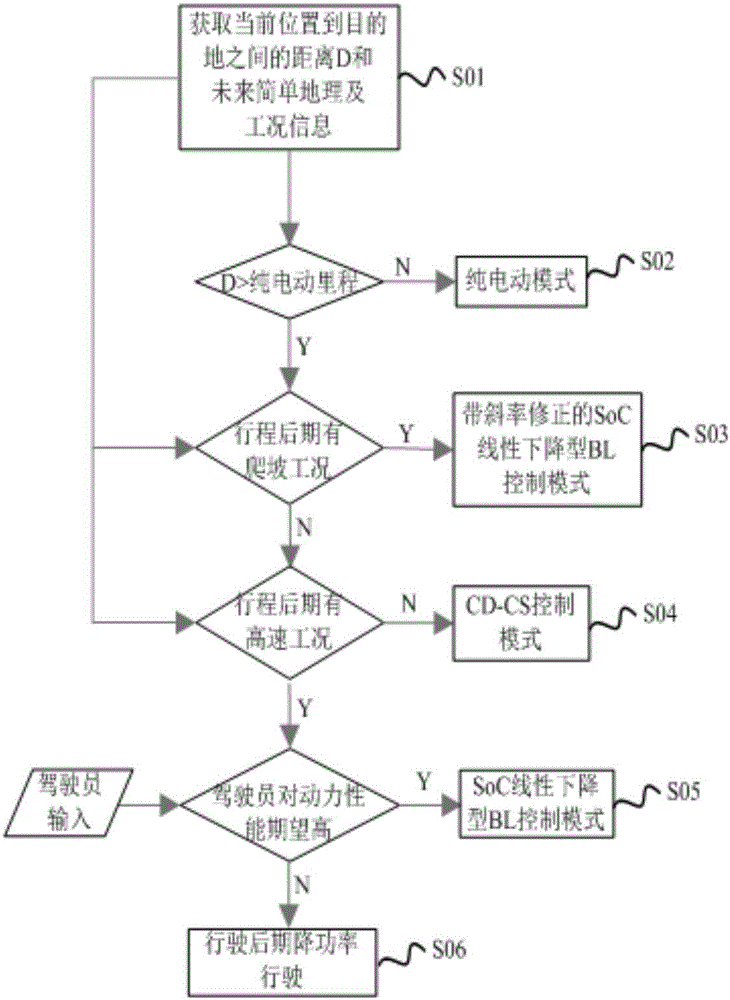

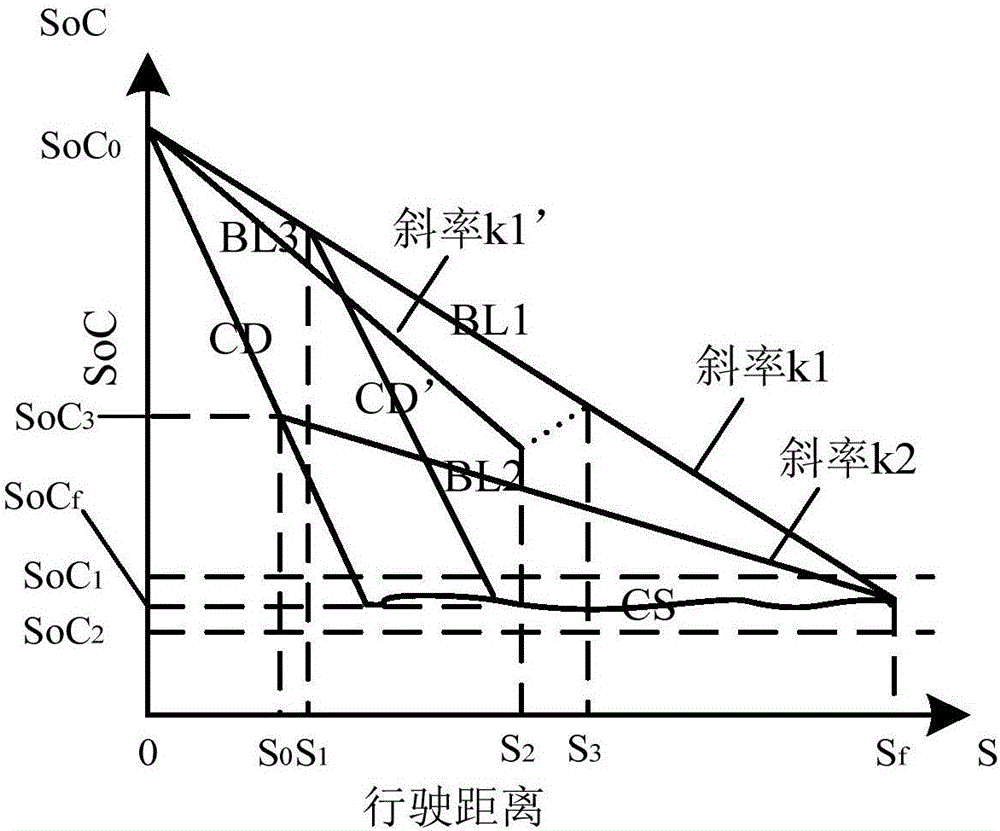

State of charge (SOC) trajectory planting system and control method of range extending type electric car

InactiveCN106476643AImprove energy efficiencyReduce fuel consumptionHybrid vehiclesOperating modesCurrent rangeElectric cars

The invention relates to an state of charge (SOC) trajectory planting system and control method of a range extending type electric car and aims to solve the problems that a current range extending type electric car in a low SOC state is insufficient in power performance during high-speed driving or slope climbing, and the driving experience of a driver is affected. The hardware of the system comprises a vehicular navigation system, a driver power performance expectation input button and a whole-car control system. The software of the system comprises a multi-mode SOC trajectory planning module, an energy management control module and a range extender dynamic coordination control module. The multimode SOC trajectory planning module automatically judges and switches the working modes of the electric car and plans the SOC trajectories under various modes according to the car power performance expectation input by a driver through the button and simple geographic and work condition information provided by the vehicular navigation system; the energy management control module controls the power distribution between a range extender and a power battery so as to allow the actual SOC of the power battery to accurately track the planned SOC, and efficient work of a hybrid power system is guaranteed.

Owner:HUNAN UNIV

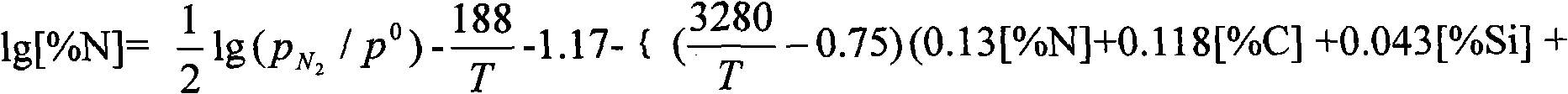

Method for smelting high-nitrogen steel by compression electroslag furnace

InactiveCN101260478ASolve the problem of uneven distribution of nitrogen contentAvoid secondary remeltingCurrent rangeSlag

The invention relates to a method for smelting the high-nitrogen steel by pressurizing an electroslag furnace. The method comprises the following steps that: the content and the weight percentage of each raw material of a self-consuming combined electrode parent metal are determined; the self-consuming electrode parent metal is smelted, an alloy pipe after charged with nitro-alloy particles and a deoxidizing agent is welded on the parent metal to produce the self-consuming combined electrode which is welded on a fake electrode and is clamped on the electrode; an arc starting agent is placed into a bottom water tank below the self-consuming electrode; the slag is dried for three to ten hours and is poured into a crystal device, a smelting chamber is sealed; under the condition of nitrogen, the slag is melted with a current ranging from 1000 to 2000A; afterwards, the pressure of the smelting chamber and the cooling water are increased to be 3 to 10 MPa, the smelting is performed with a current ranging from 2000 to 6000A; when the smelting current is reduced to 1000 A, the smelting is over. The method has the advantages that the solid state arc starting slagging way and the self-consuming combined electrode are adopted to perform the smelting in an over-normal pressure sealing smelting chamber, and the problem of the prior art of uneven distribution of nitrogen in the process of preparing high-nitrogen steel is solved, thereby avoiding the remelting and saving the production cost; moreover, the technique method is simple and the smelting effect is good.

Owner:NORTHEASTERN UNIV

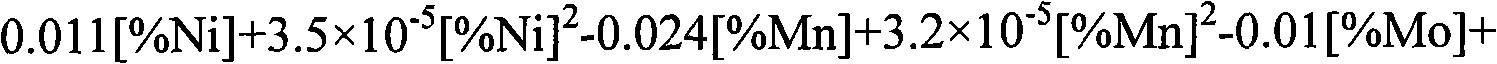

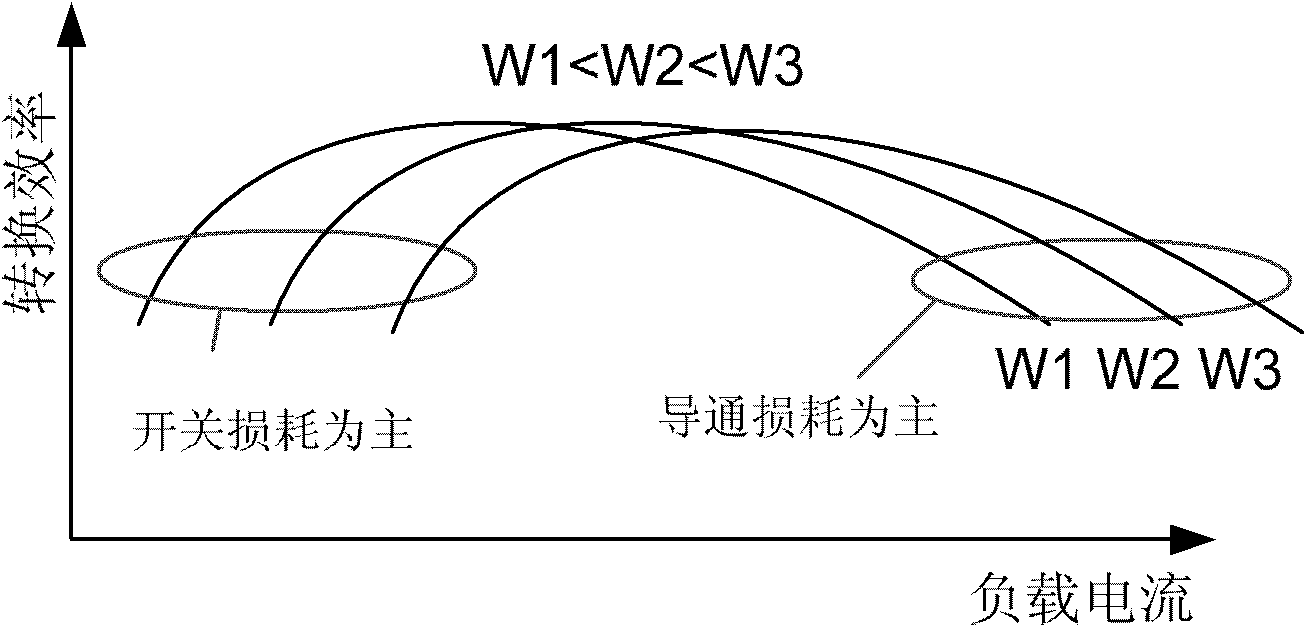

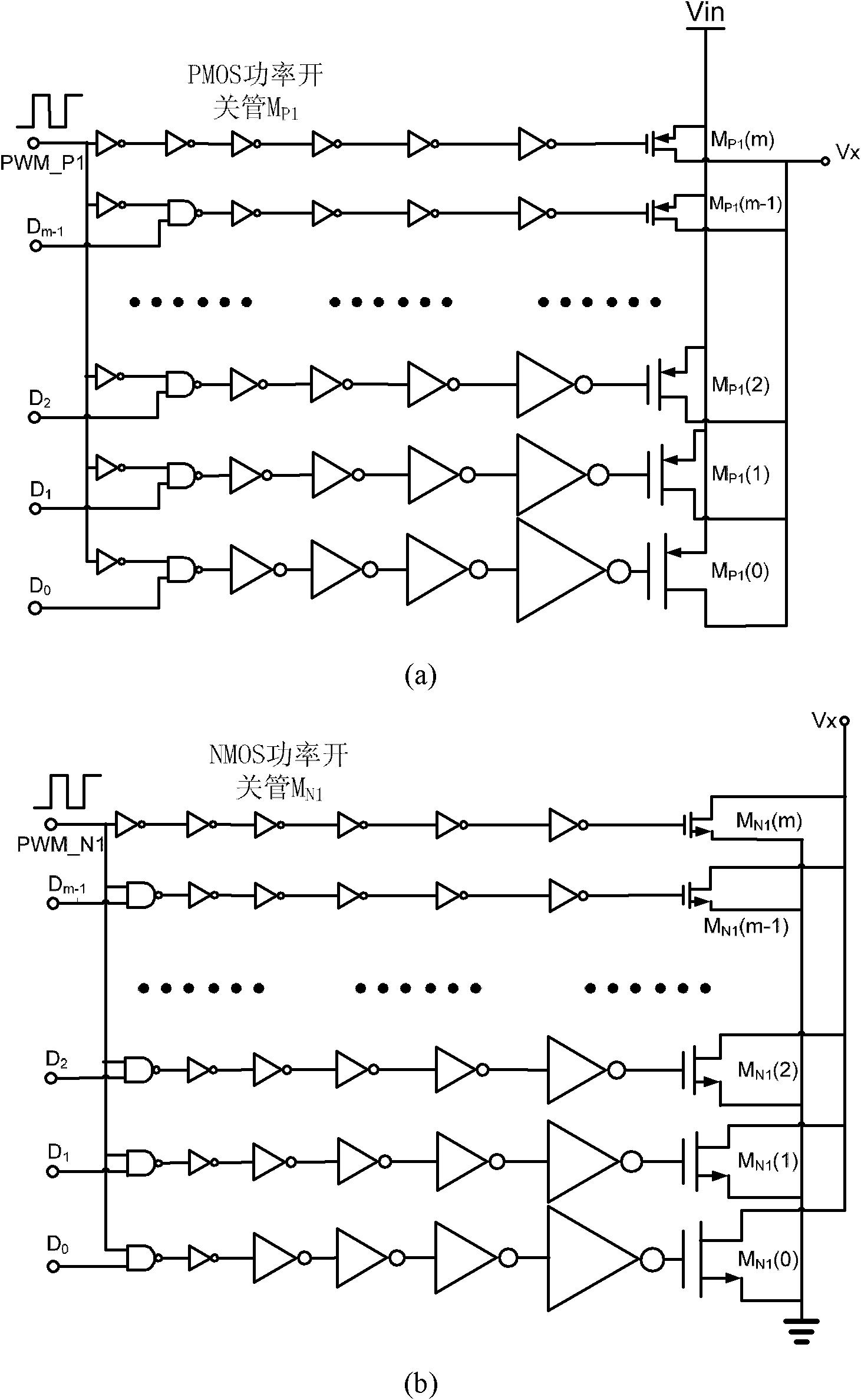

Method for enhancing non-uniform variation grid width of light load efficiency of integrated switch DC-DC converter

ActiveCN101931323ARealize full circuit integrationImprove light load efficiencyDc-dc conversionElectric variable regulationCapacitanceCurrent range

The invention discloses a method for enhancing the non-uniform variation grid width of the light load efficiency of an integrated switch DC-DC converter, a Buck-Boost converter in the invention adopts the design of a CSMC 0.5mu m CMOS process library, whole-circuit integration is realized except for a passive filter, the external filter inductance is 2.2mu H, and the filter capacitance is 1mu F. According to the requirements of input voltage and output voltage, the converter can work in three modes: Buck (voltage reducing), Buck-Boost (voltage reducing and boosting) and Boost (voltage boosting), the range of the input voltage is 2.5V-4.2V, the range of the output voltage is 1.5V-5V, and the working frequency is 5MHz. A non-uniform grid width modulation method is adopted in the whole load current range of 10mA-650mA. When the converter works at high frequency of 5MHz, the efficiencies of medium load and heavy load keep above 90 percent all the time, and the efficiency of light load (10mA) can reach above 80 percent. As the grid width of a switching tube is only changed and a control link of the working efficiency of an extra switching tube is not adopted, negative effects caused by frequency conversion control are eliminated fundamentally.

Owner:陕西北斗恒星科技发展有限公司

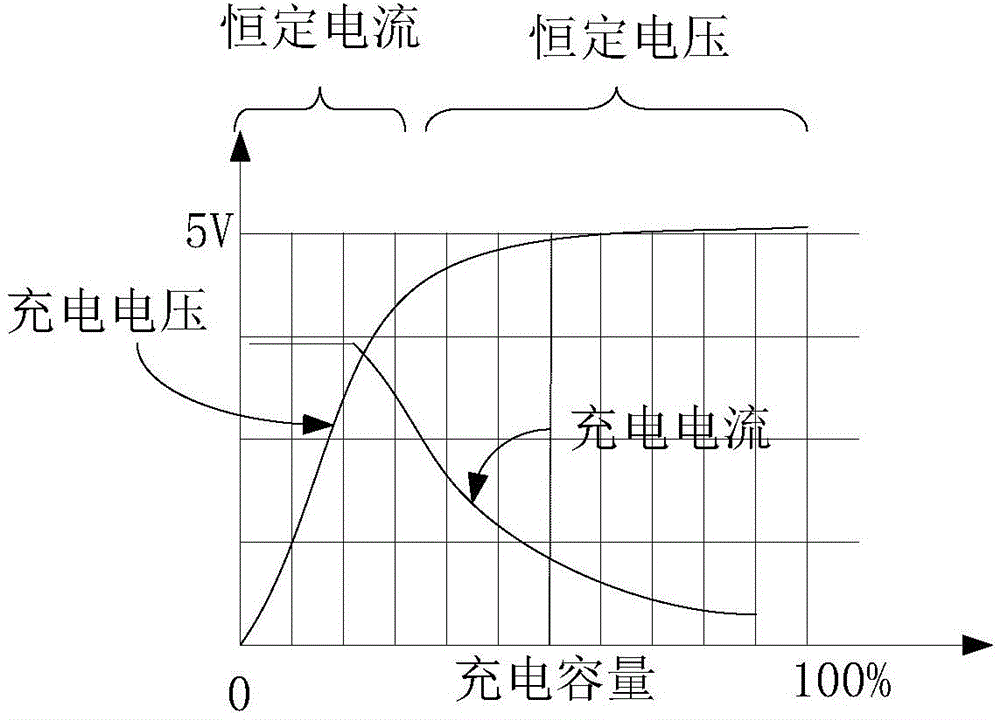

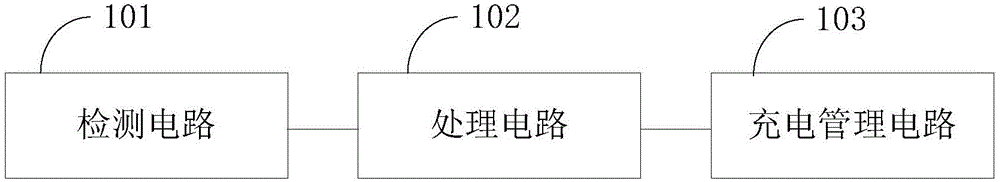

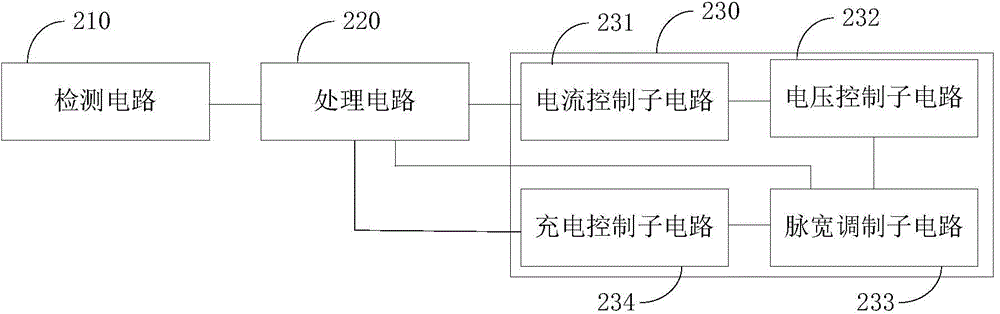

Quickly-charger mobile terminal, method and system

ActiveCN104600796AIncrease charging powerGuaranteed service lifeBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentPower flow

The invention discloses a quickly-charger mobile terminal and method and a charger. The quickly-charger mobile terminal comprises a detecting circuit, a processing circuit and a charging management circuit, wherein the detecting circuit is used for detecting the charging environment of the mobile terminal when the mobile terminal is connected with the charger for charging, and the charging environment includes the combination of one or more than two of room temperature, battery parameters and charger parameters; the processing circuit obtains an optimal quick charging curve according to the charging environment detected by the detecting circuit, selects relatively high current allowed by the battery parameters from a charging current range for charging, and / or selects relatively high current or voltage allowed under the room temperature from a charging current or voltage range for charging, and / or selects relatively high current or voltage allowed by the charger parameters from a charging current or voltage range for charging; the charging management circuit is used for charging the mobile terminal according to the optimal quick charging curve and the charging environment. The quickly-charger mobile terminal can ensure safety and the service life of the mobile terminal and achieve quick charging.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

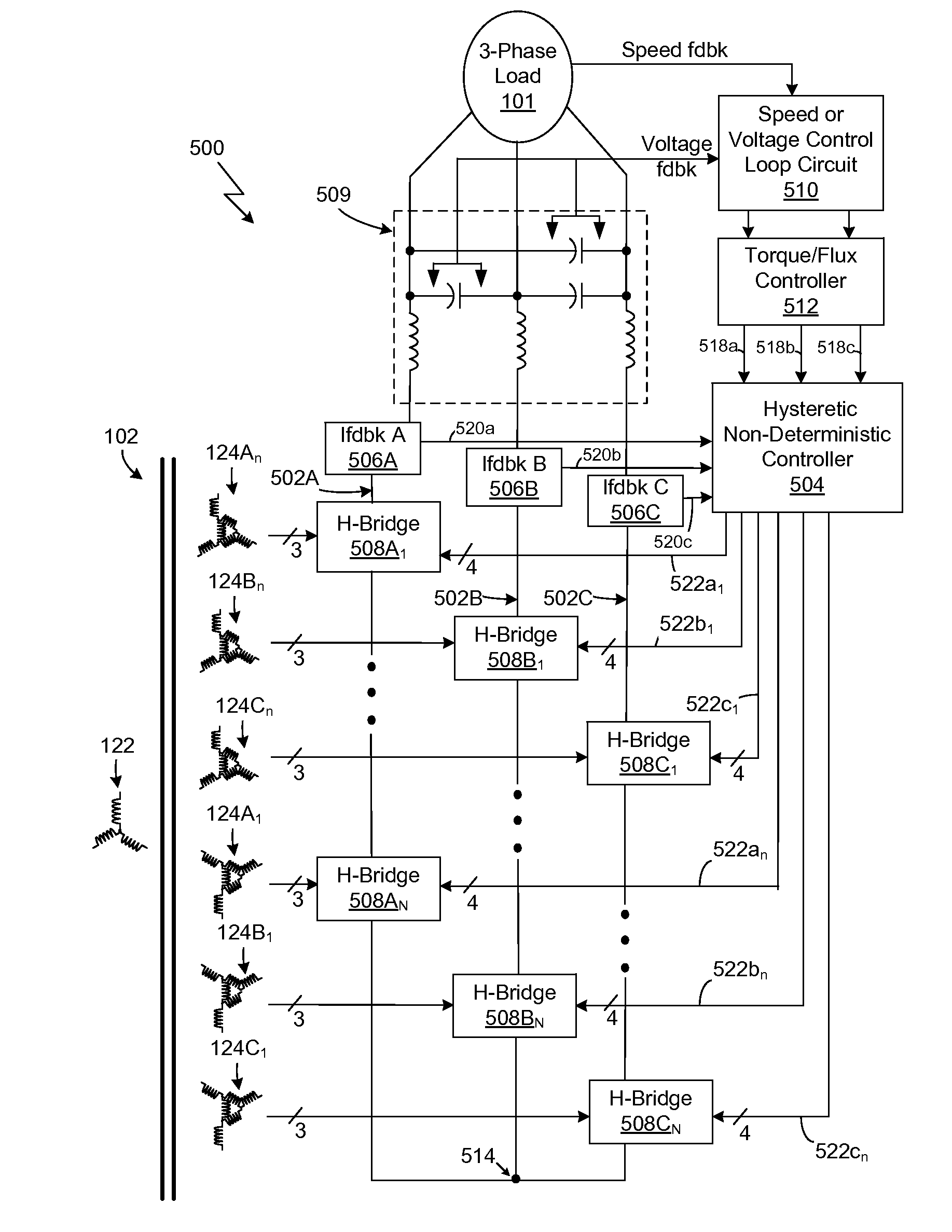

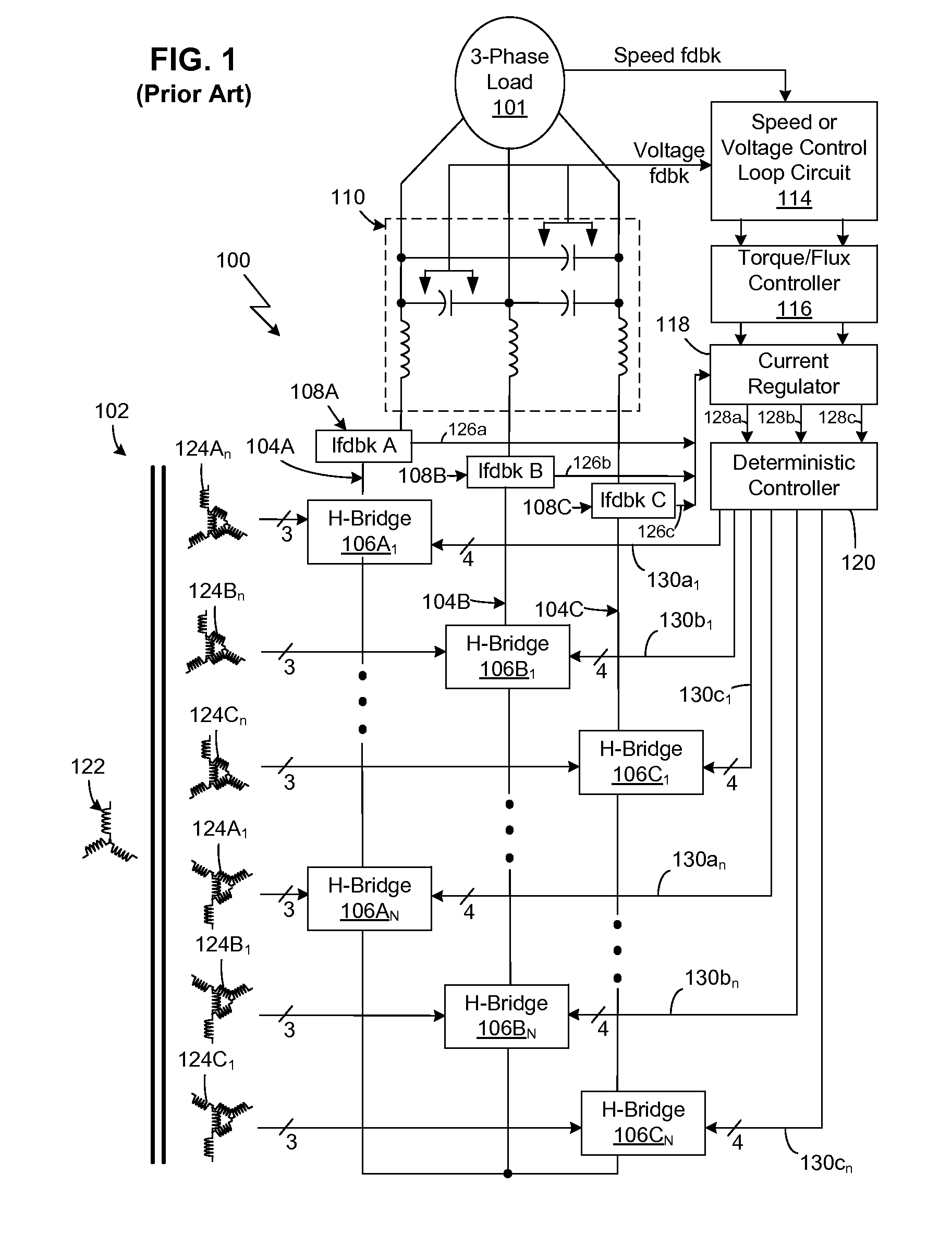

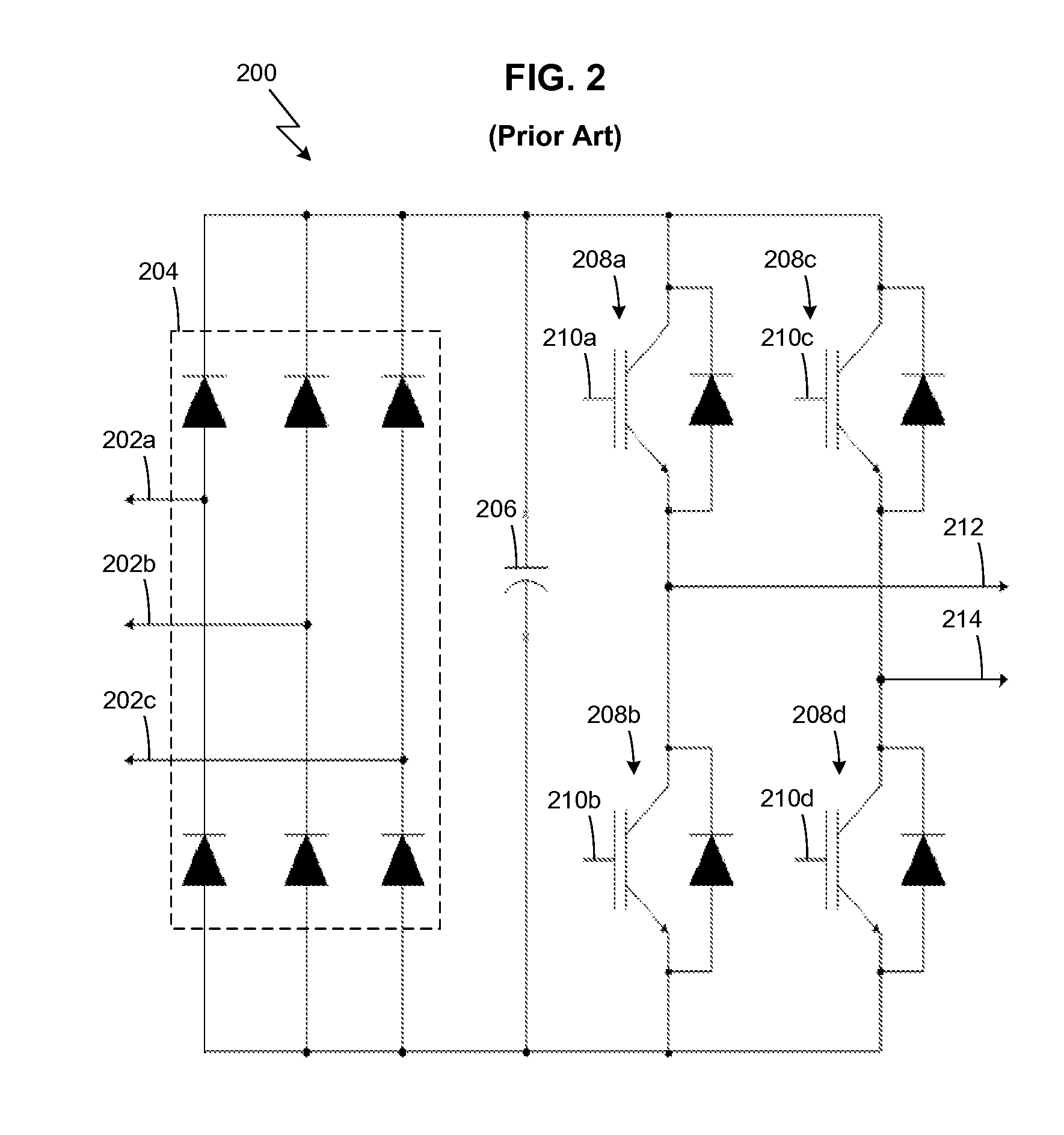

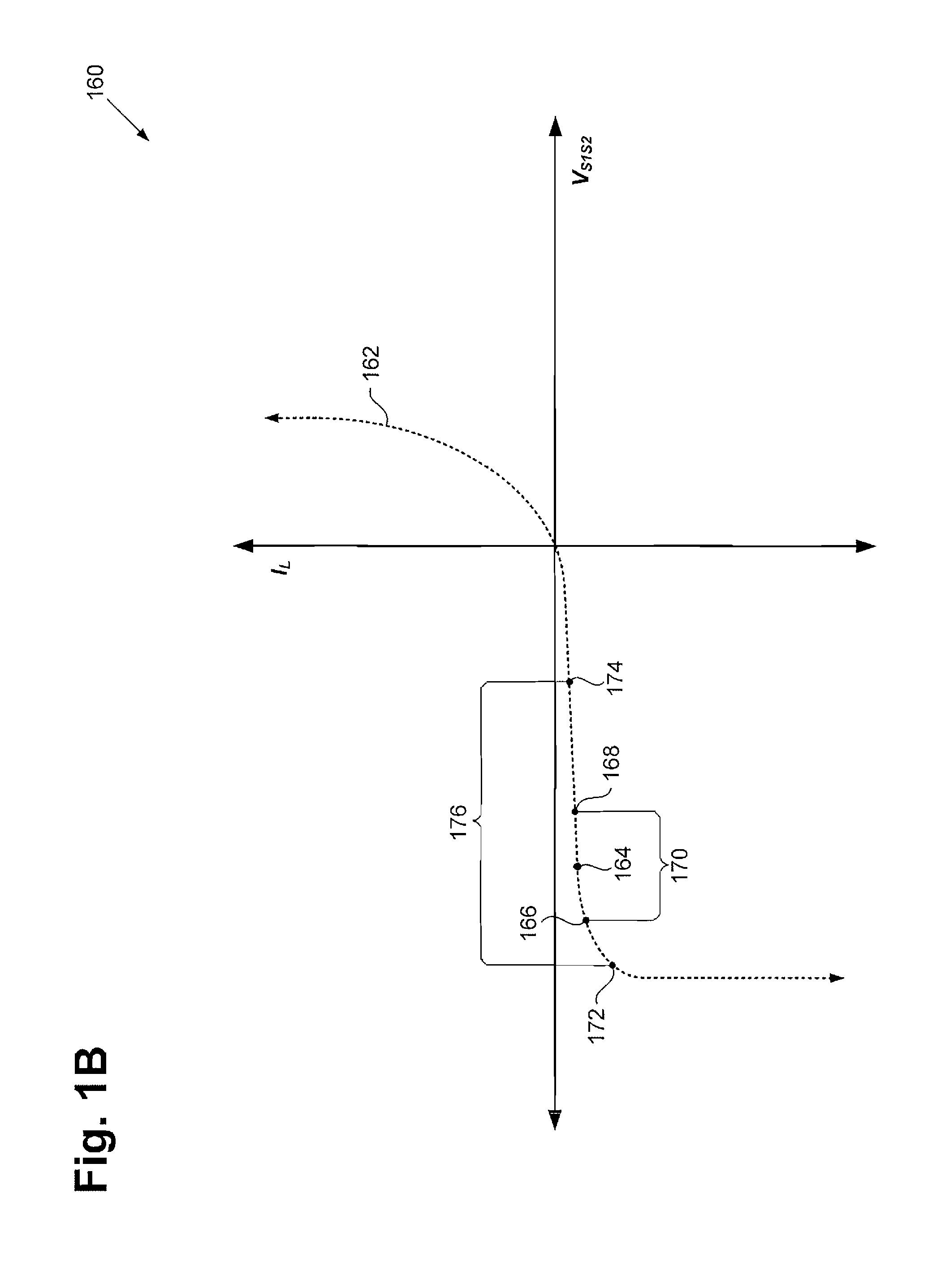

Voltage Drive System With Hysteretic Current Control And Method Of Operating The Same

ActiveUS20100085789A1Effectively causingConversion with intermediate conversion to dcDc-dc conversionPhase currentsTerminal voltage

A voltage drive system is provided having a plurality of modulators and a plurality of cascaded switching circuits which collectively generate a single-phase output signal to a load. Each modulator receives a phase current error and has an adder which generates a modulated phase current error based on the phase current error and based on a signal having a phase. For each respective modulator, the phase of the respective signal is different. Each respective modulator changes a respective gate input when the respective modulated phase current error changes from being within a predetermined current range to being outside of the predetermined current range. Each respective switching circuit receives the respective gate input and generates a respective output terminal voltage based on the respective gate input. The change in the respective gate input effectively causes a switching event of the respective switching circuit.

Owner:DRS NAVAL POWER SYST INC

LED lighting device with output impedance control

InactiveUS20120200230A1Stable lighting controlStable controlElectrical apparatusElectroluminescent light sourcesValue setCurrent range

An LED lighting device is provided with output impedance control to stabilize an optical output across a wide current range. A switching power supply generates the output current, with switching control circuitry to determine switching frequency and an ON period for an associated switch, and to turn on / off the switch according to the determined frequency and ON period. An impedance element is coupled across output terminals for the lighting device, with an impedance value set so that a load current is larger than a current flowing to the impedance element at maximum on-duty of the switch and a current flowing to the impedance element is larger than the load current at minimum on-duty. The impedance element may be a variable impedance element, wherein an impedance control circuit adjusts the variable impedance such that an impedance value for minimum on-duty of the switch is smaller than that for a maximum on-duty.

Owner:PANASONIC CORP

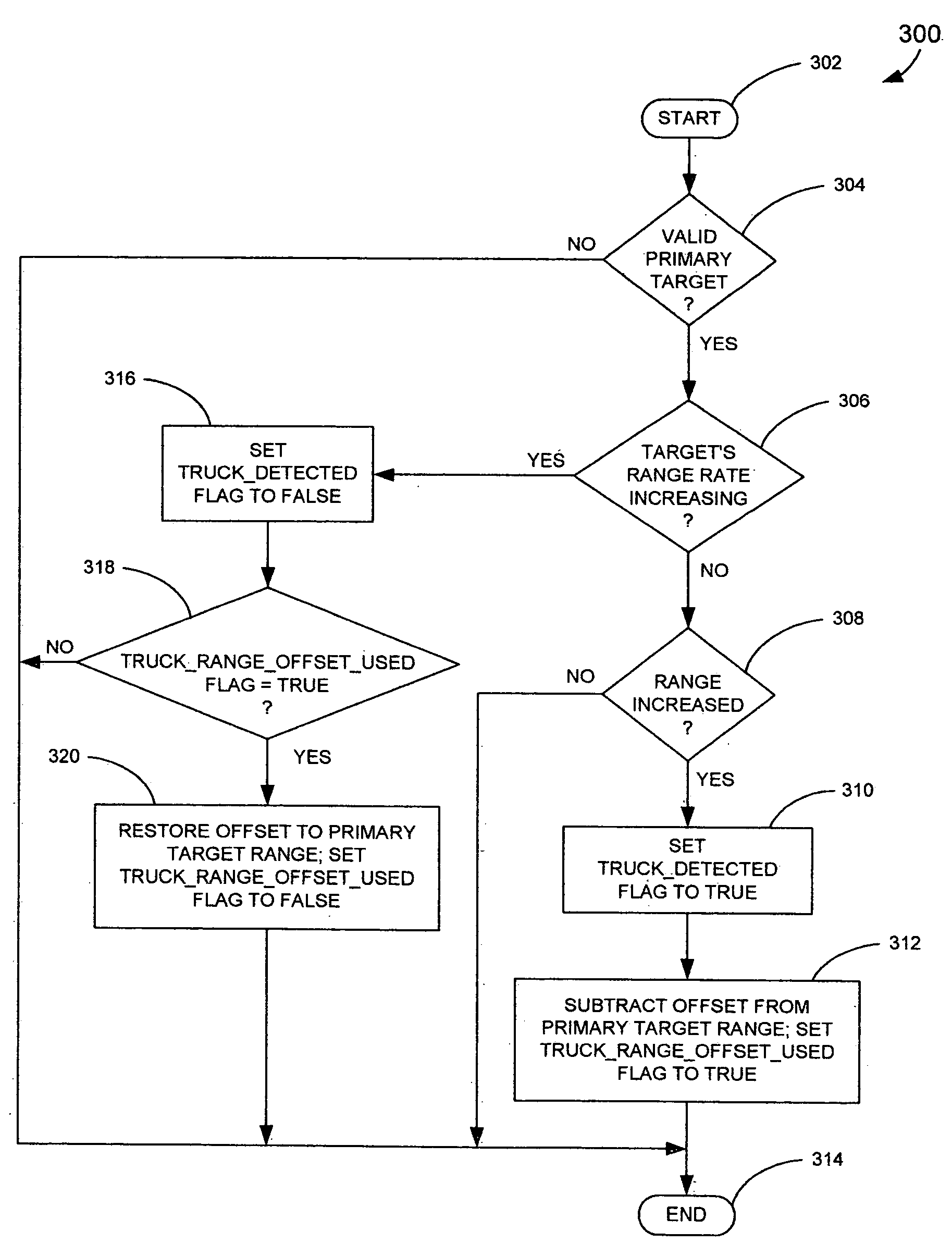

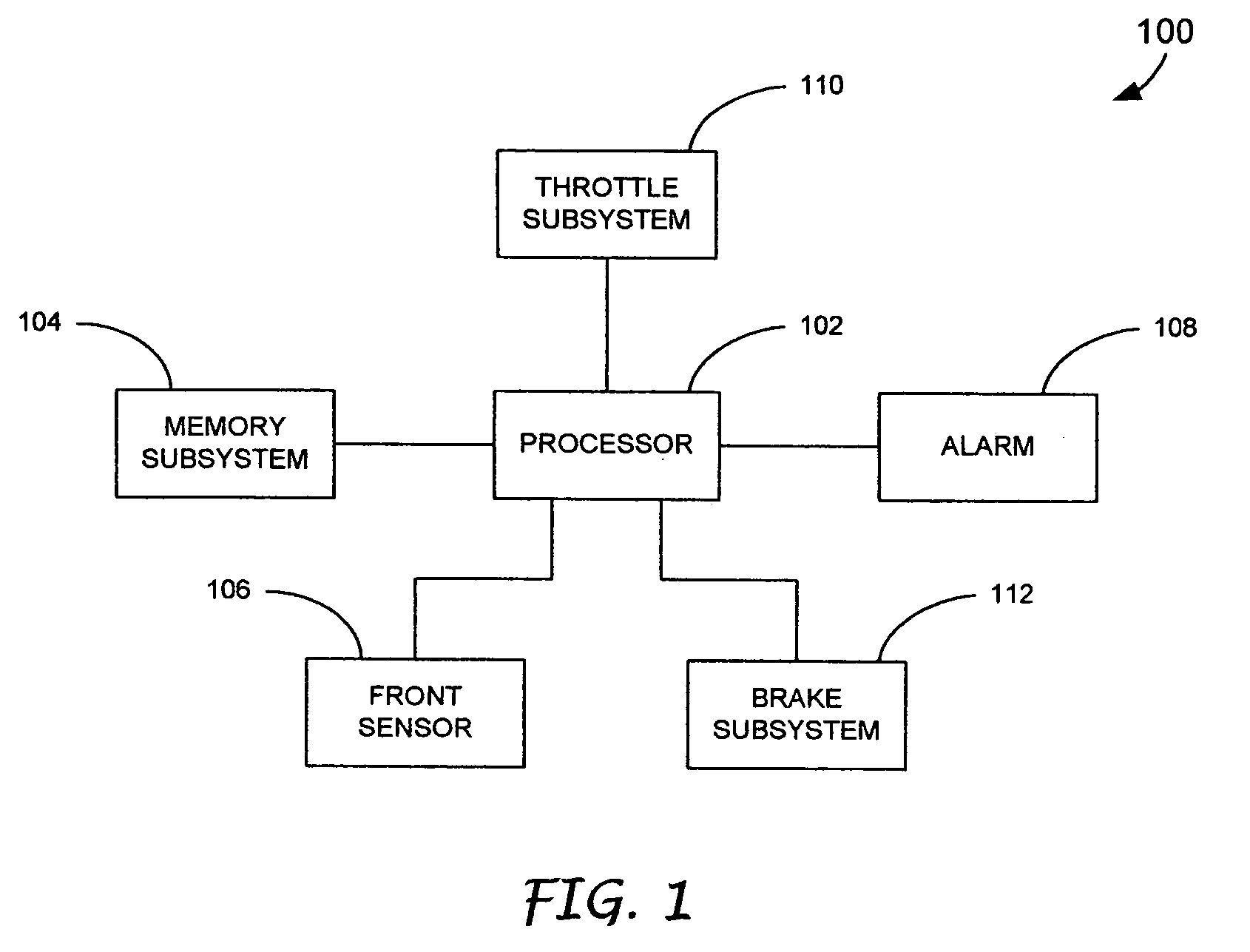

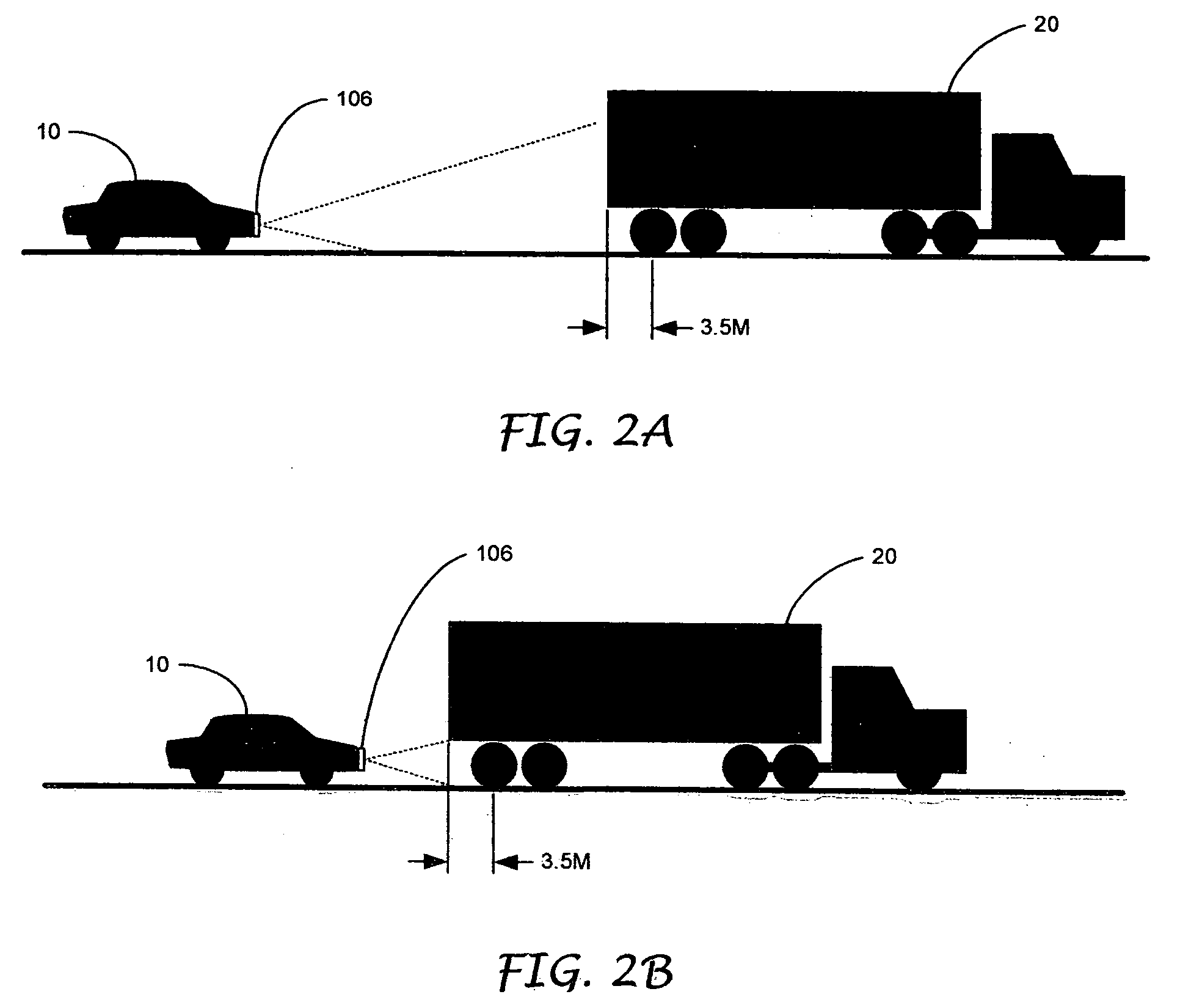

Technique for detecting truck trailer for stop and go adaptive cruise control

A technique for providing better detection of close range truck trailers for a motor vehicle with Stop and Go Adaptive Cruise Control determines if a range parameter to a target requires modification if such target is a truck trailer, for example. Truck trailer geometry is such that a standard adaptive cruise control system may have difficulty accurately determining the range to the rearmost position of the truck. The technique determines an initial range from the motor vehicle to a target. Then, the technique determines whether the range rate of the target is above a predetermined rate. When the range rate of the target is not above the predetermined rate, the technique determines whether the initial range to the target is less than a current range to the target. If so, the technique provides an adjusted range, which is then utilized in the control operation of the motor vehicle.

Owner:APTIV TECH LTD

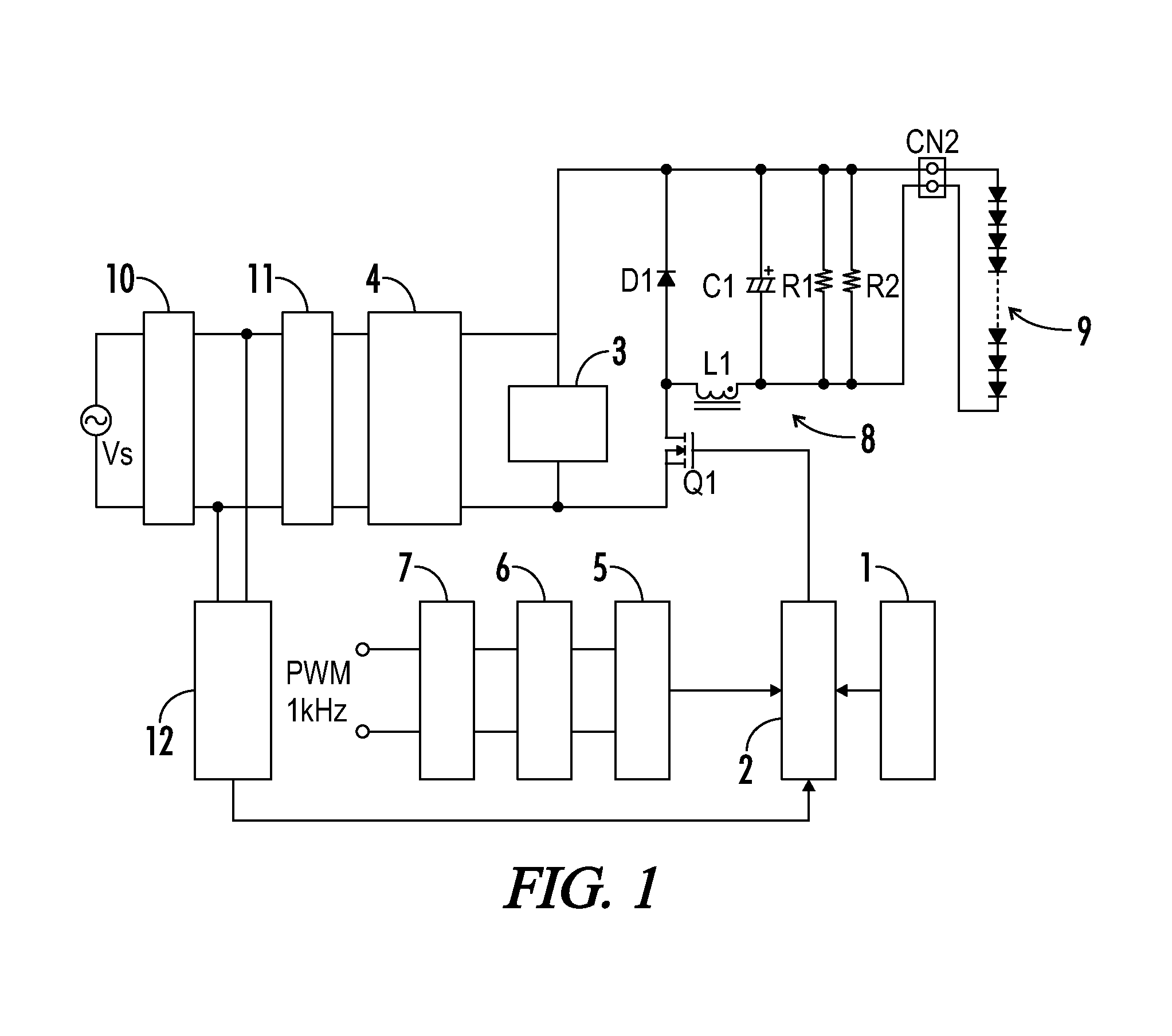

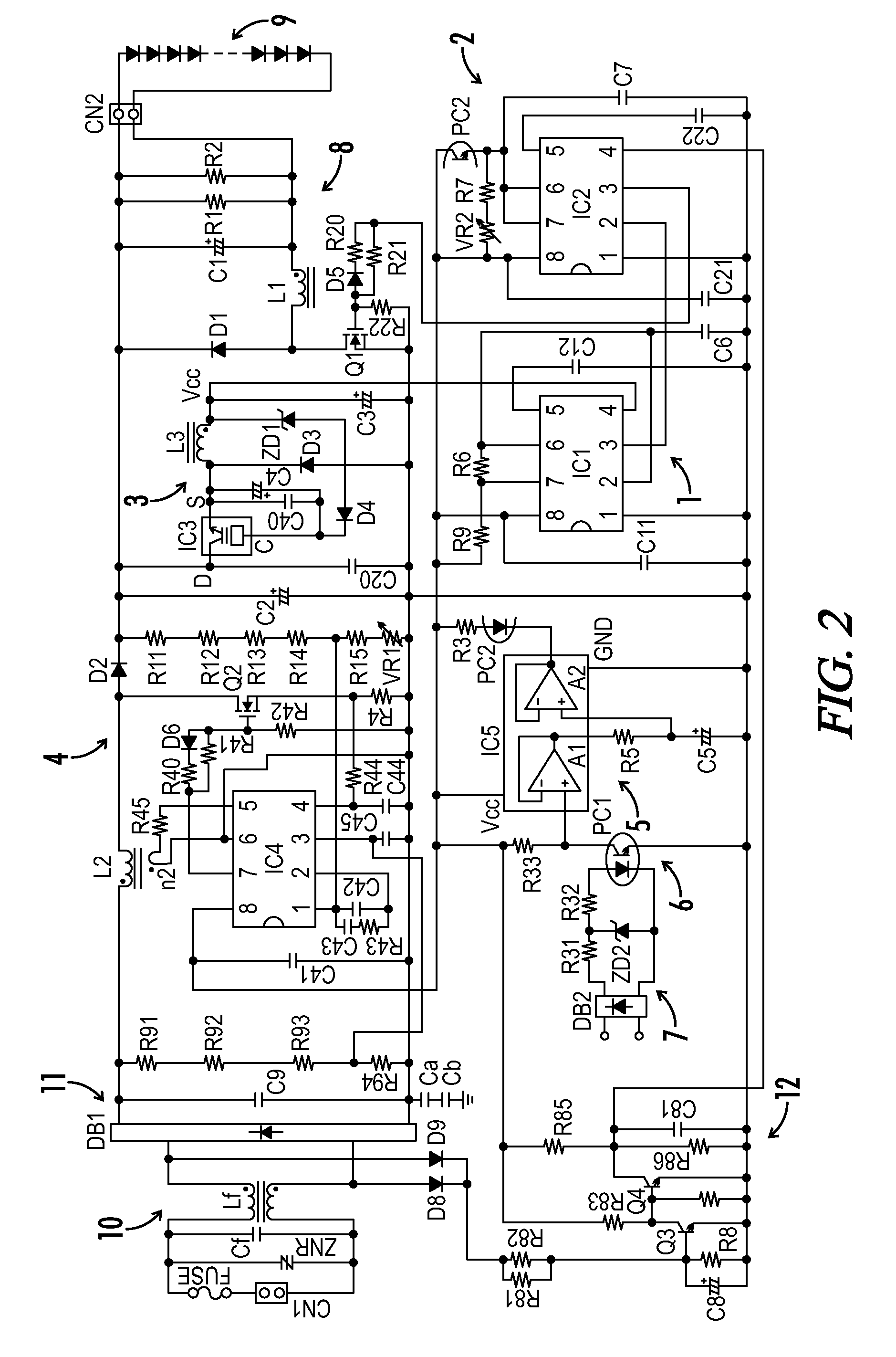

Hybrid power control system

ActiveUS8659237B2High protection levelEfficient powerElectrical apparatusElectroluminescent light sourcesCurrent rangeEngineering

A hybrid power control system for providing dynamic power control to illumination systems in which a power source can supply any one of a range of AC or DC voltages. One or more switch mode power supplies incorporating one or more linear and switch mode regulator circuits combined to dynamically control current, voltage and power to the illumination system. A microprocessor or other integrated circuit device to receive and send control information in order to regulate the power to a light emitting device One or more output drive stage(s) capable of delivering a wide dynamic current range, channel bonding and protection circuitry compatible with standard or common anode illumination systems.

Owner:RADIANT RES

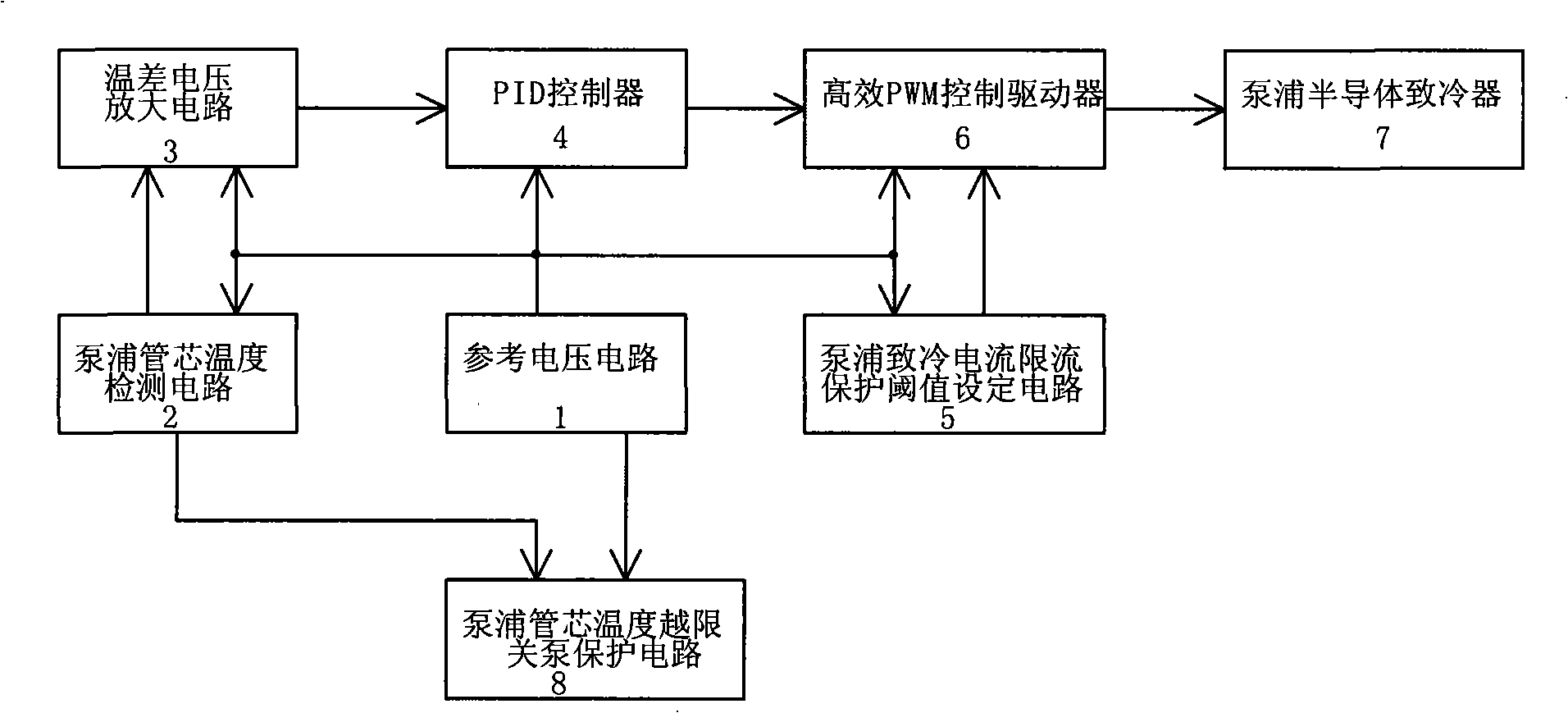

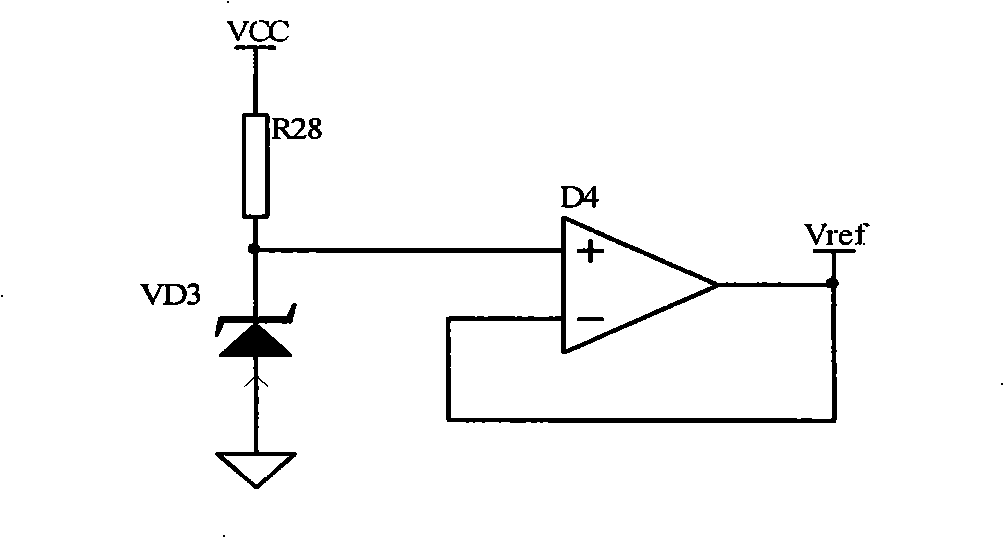

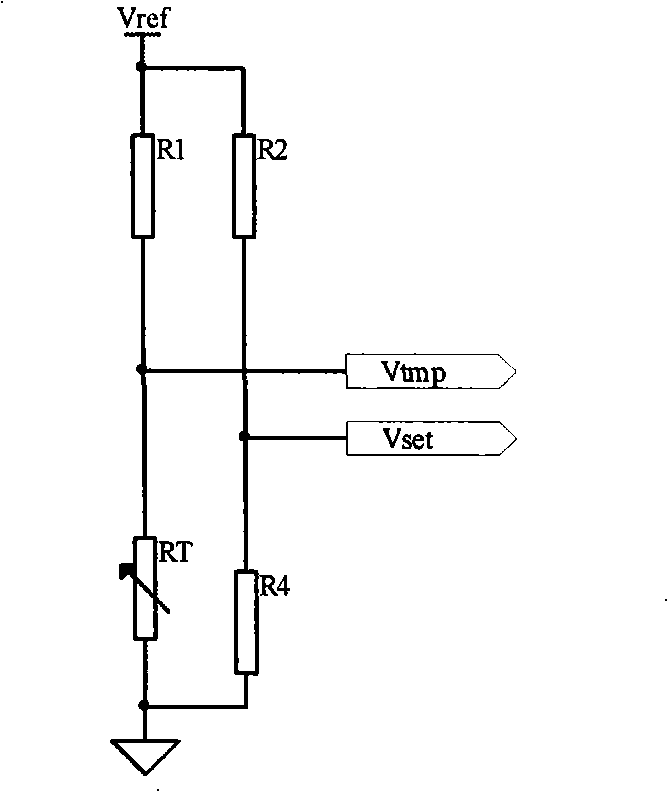

Automatic temperature control apparatus of pump laser for ASE broadband light source

ActiveCN101404376ACompact designImprove reliabilityTemperatue controlLaser cooling arrangementsAutomatic controlControl signal

The invention designs an automatic temperature control circuit which has exact control, reliable and stable performance and complete protective measures, and is used for executing effective real time control on the temperature of a tube core of a pump laser in ASE broadband light source. The control device adopts the design proposal of a temperature control system based on Proportion Integration Differentiation (PID) control and pulse-width modulation (PWM) braking mechanism and realizes the designs by adopting a pure hardware circuit; the control device comprises a reference voltage circuit, a pumping tube core temperature testing circuit, a thermoelectric voltage amplifier circuit, a PID controller, a pumping refrigeration current limiting protective threshold set circuit, an efficient PWM control driver, a pumping semiconductor refrigerator and a pumping tube core temperature out-of-limit close protective circuit. The whole circuit has simple and compact design, high reliability as well as heating and refrigerating efficiency, and little self heating, thereby greatly reducing the power consumption and volume of a pumping temperature controller; as the control device has the complete protective function, when the temperature of the pumping tube core exceeds the set range of operating temperature, the circuit sends out the gang control signal to automatically close a drive circuit of the pumping. The pumping refrigeration current limiting protective circuit limits the refrigeration current within the range of the preset maximum refrigeration current range to prevent the pumping from being damaged.

Owner:WUXI TACLINK OPTOELECTRONICS TECH CO LTD

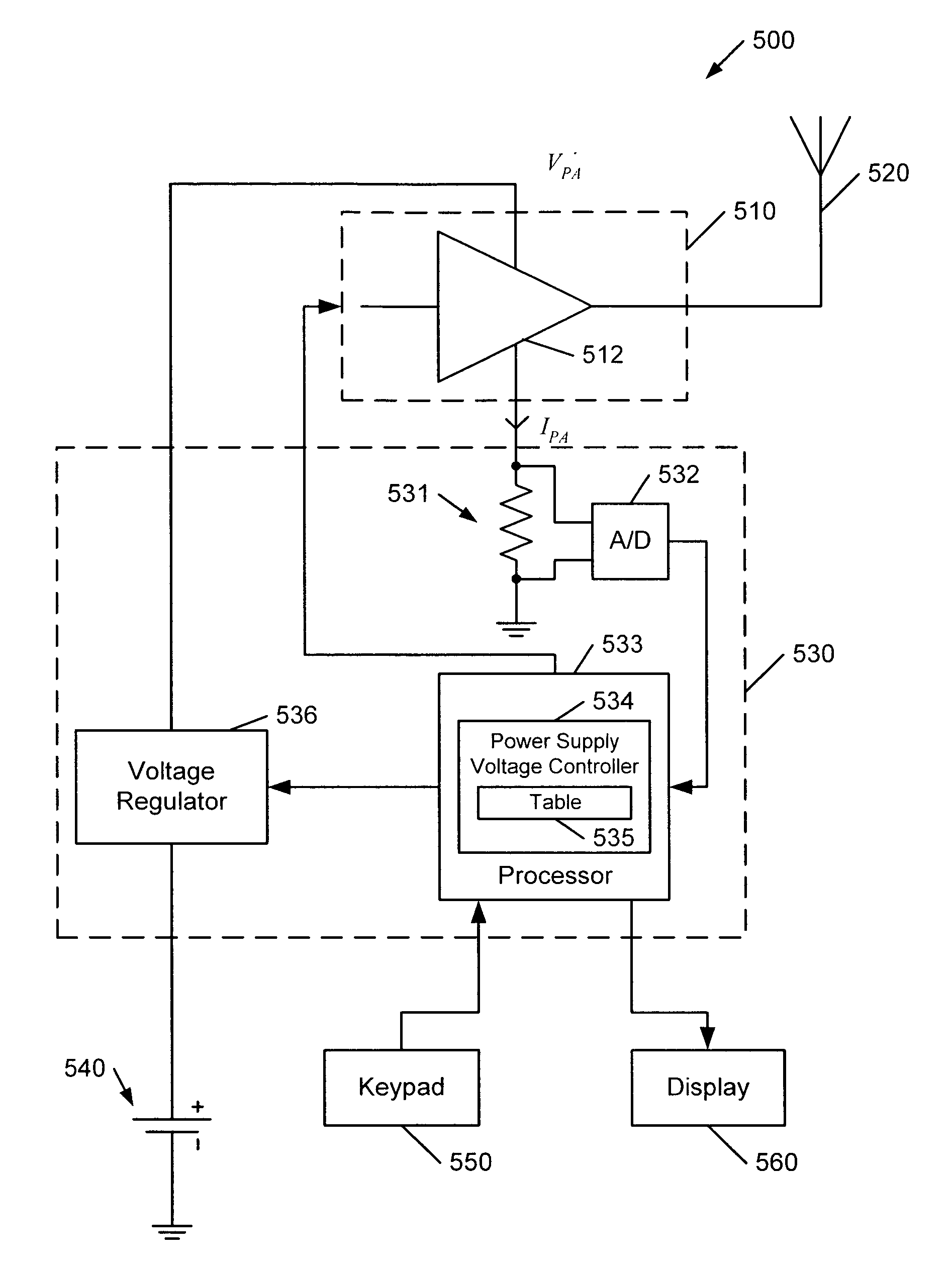

Wireless terminals, methods and computer program products with transmit power amplifier input power regulation

InactiveUS20050242882A1Power managementTransmission control/equalisingAudio power amplifierCurrent range

A transmit power amplifier of a wireless terminal is controlled by determining a power supply voltage applied to the transmit power amplifier, determining a power supply current provided to the transmit power amplifier, determining a relationship of the determined power supply current and the determined power supply voltage, and controlling the power supply voltage responsive to the determined relationship of the power supply current and the power supply voltage. For example, determining a relationship of the determined power supply current and the determined power supply voltage may include determining whether the power supply current meets a predetermined criterion, e.g., a predetermined current range, associated with the determined power supply voltage. The invention may be embodied as apparatus, methods, and computer program products.

Owner:SONY ERICSSON MOBILE COMM AB

High Voltage Rectifier and Switching Circuits

According to one exemplary embodiment, a rectifier circuit includes a diode. A first depletion-mode transistor is connected to a cathode of the diode. Also, at least one second depletion-mode transistor is in parallel with the first depletion-mode transistor and is configured to supply a pre-determined current range to a cathode of the diode. A pinch off voltage of the at least one second depletion-mode transistor can be more negative than a pinch off voltage of the first depletion-mode transistor and the at least one second depletion-mode transistor can be configured to supply the pre-determined current range while the first depletion-mode transistor is OFF. Also, the pre-determined current range can be greater than a leakage current of the first depletion-mode transistor.

Owner:INFINEON TECH AMERICAS CORP

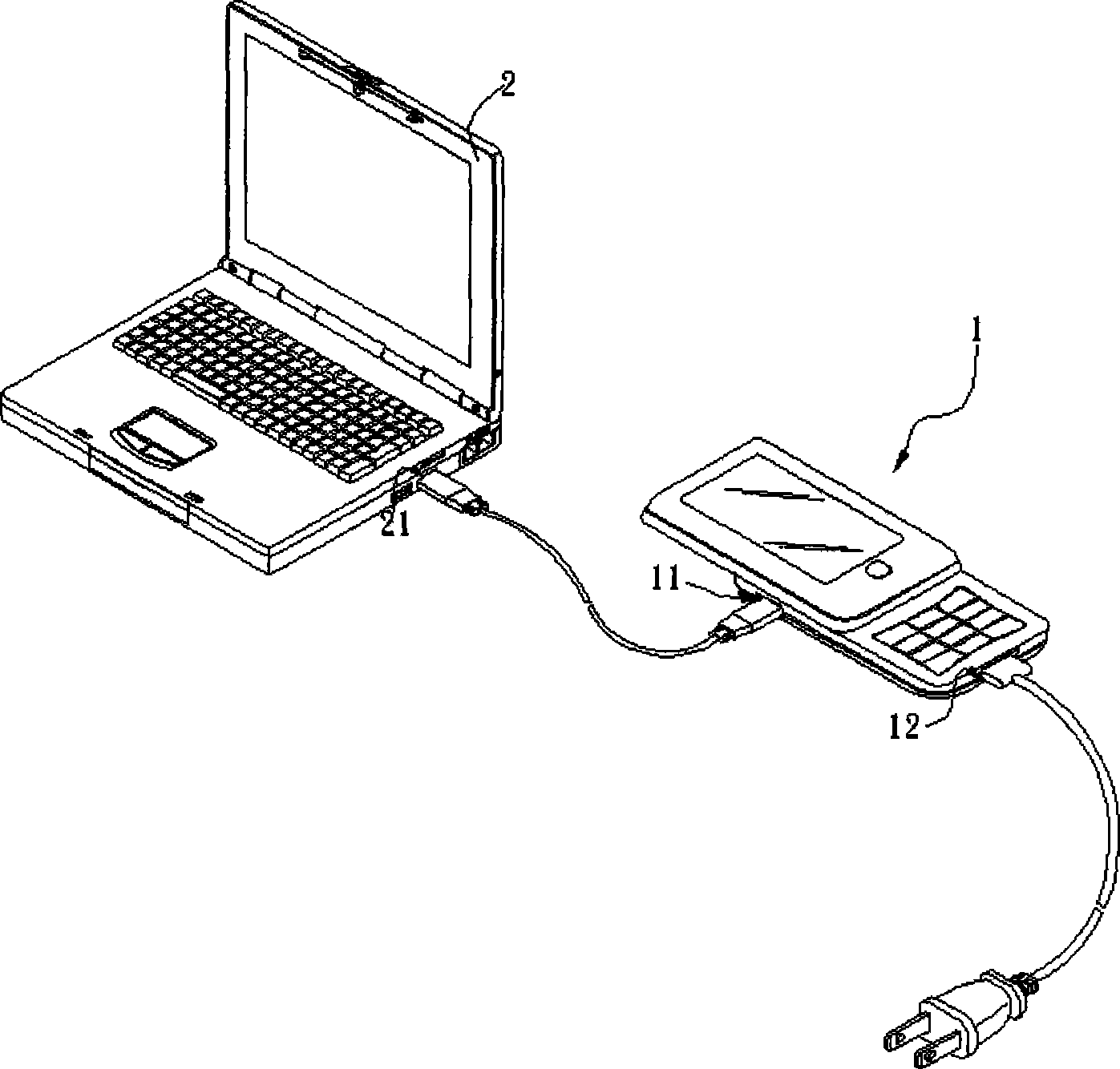

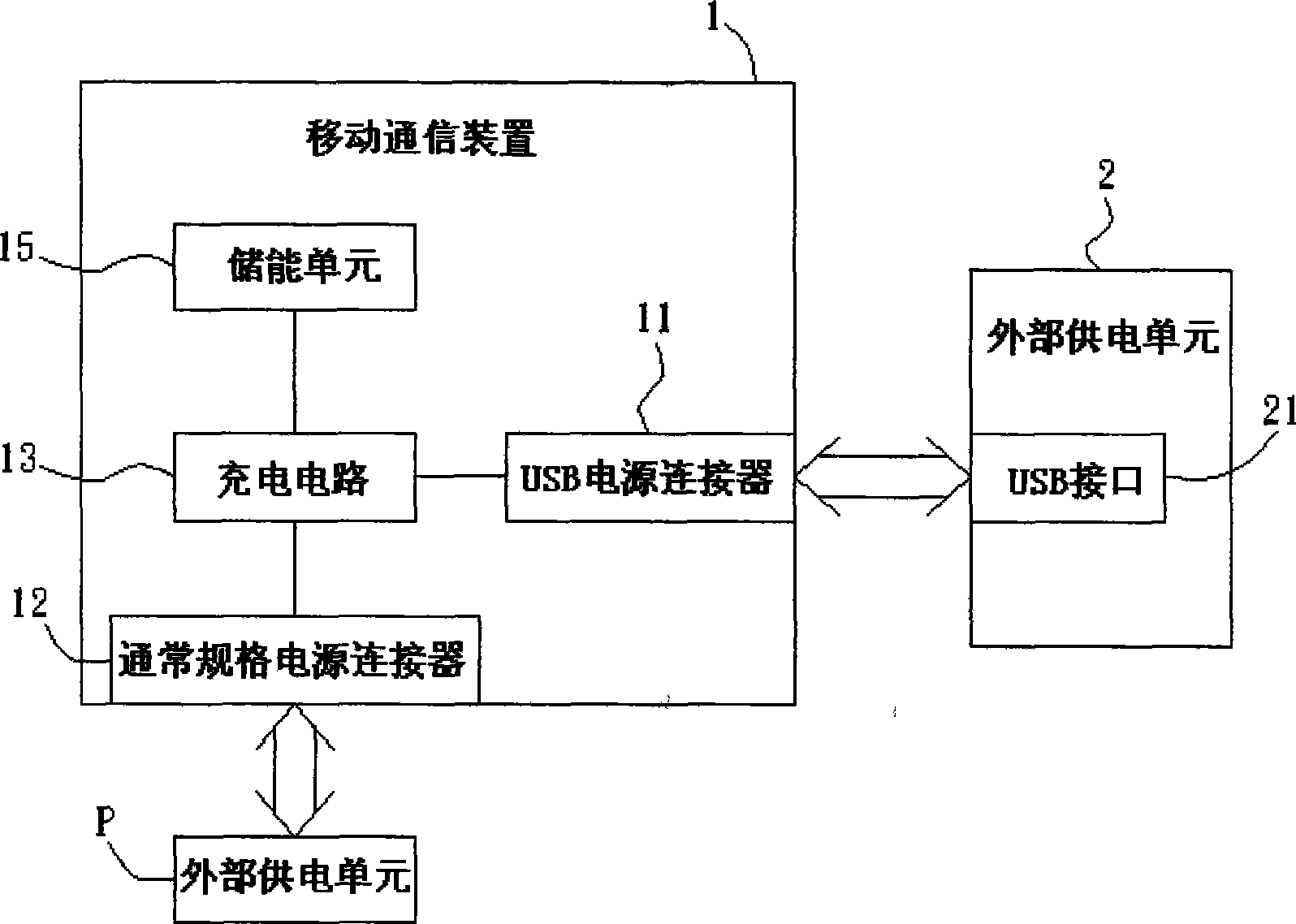

Mobile communication apparatus with current-limiting charge function

InactiveCN101414753AAvoid damageAvoid poor charging efficiencyBatteries circuit arrangementsSecondary cells charging/dischargingCurrent limitingCharge current

The present invention relates to a mobile communication device with current-limited charging function, which consists of an energy storage unit, a first power connector, a first charging circuit, a second power connector and a second charging circuit. The first charging circuit is electrically connected with the first power connector and the energy storage unit and the maximum current of the first charging circuit is not more than a set value; the second charging circuit is electrically connected with the second power connector and the energy storage unit and the maximum current of the second charging circuit is more than the set value. The mobile communication device with current-limited charging function adopts the structure; therefore, when the charging is carried out through different chargers, the mobile communication device can start the corresponding charging circuit according to the current range provided by the charger so as to prevent different charging currents from damaging the mobile communication device.

Owner:INVENTEC(NANJING) TECH CO LTD

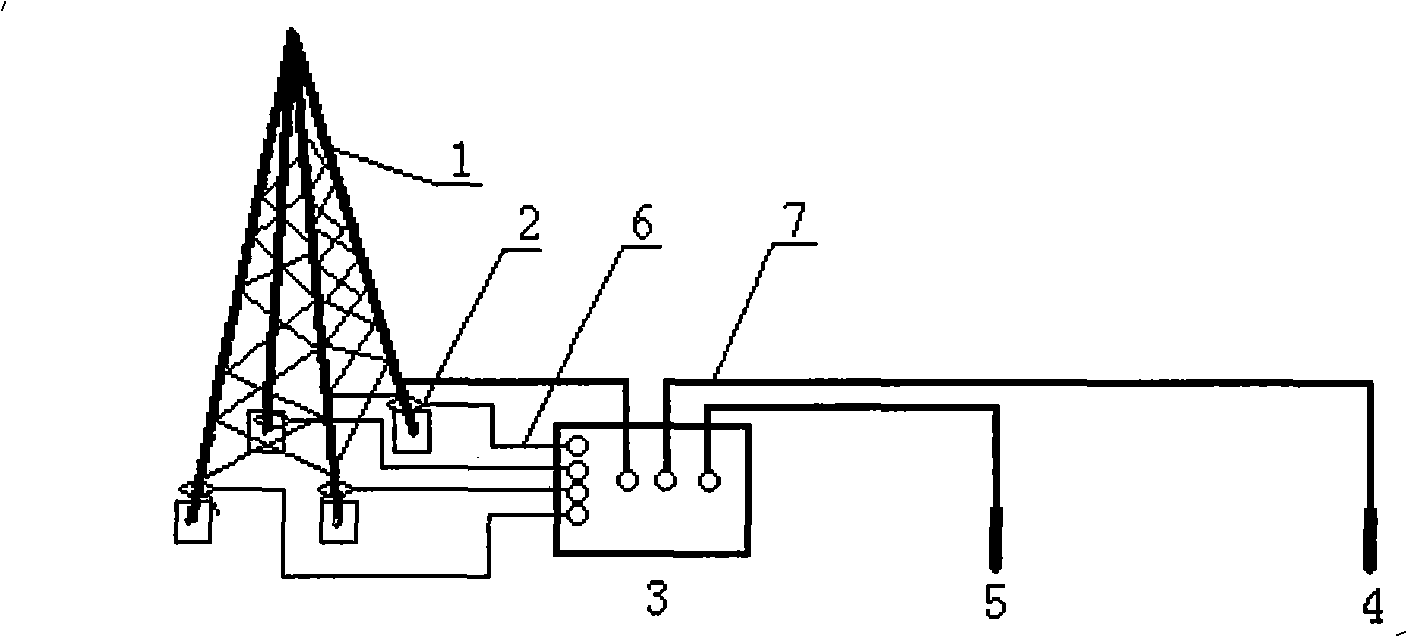

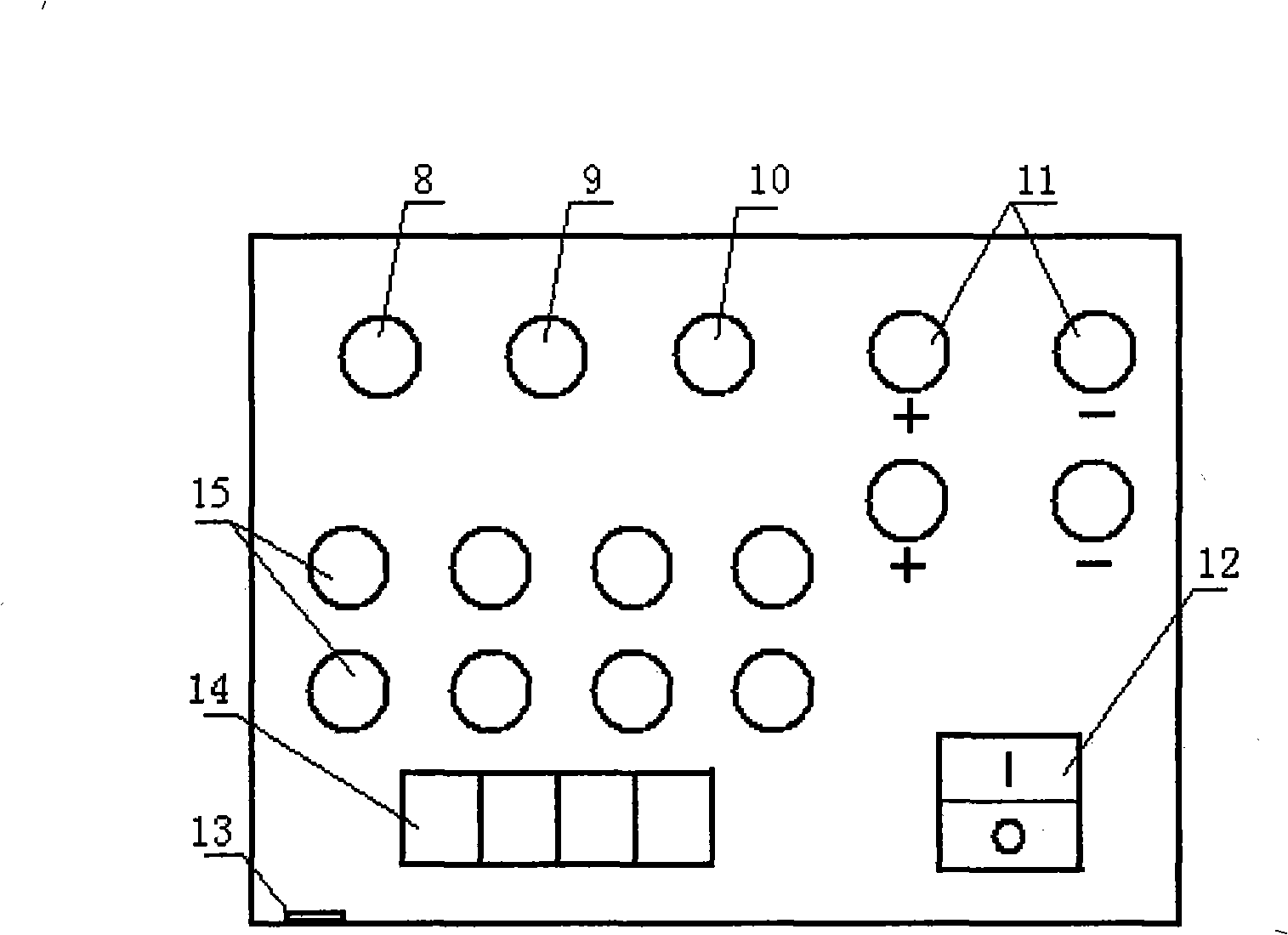

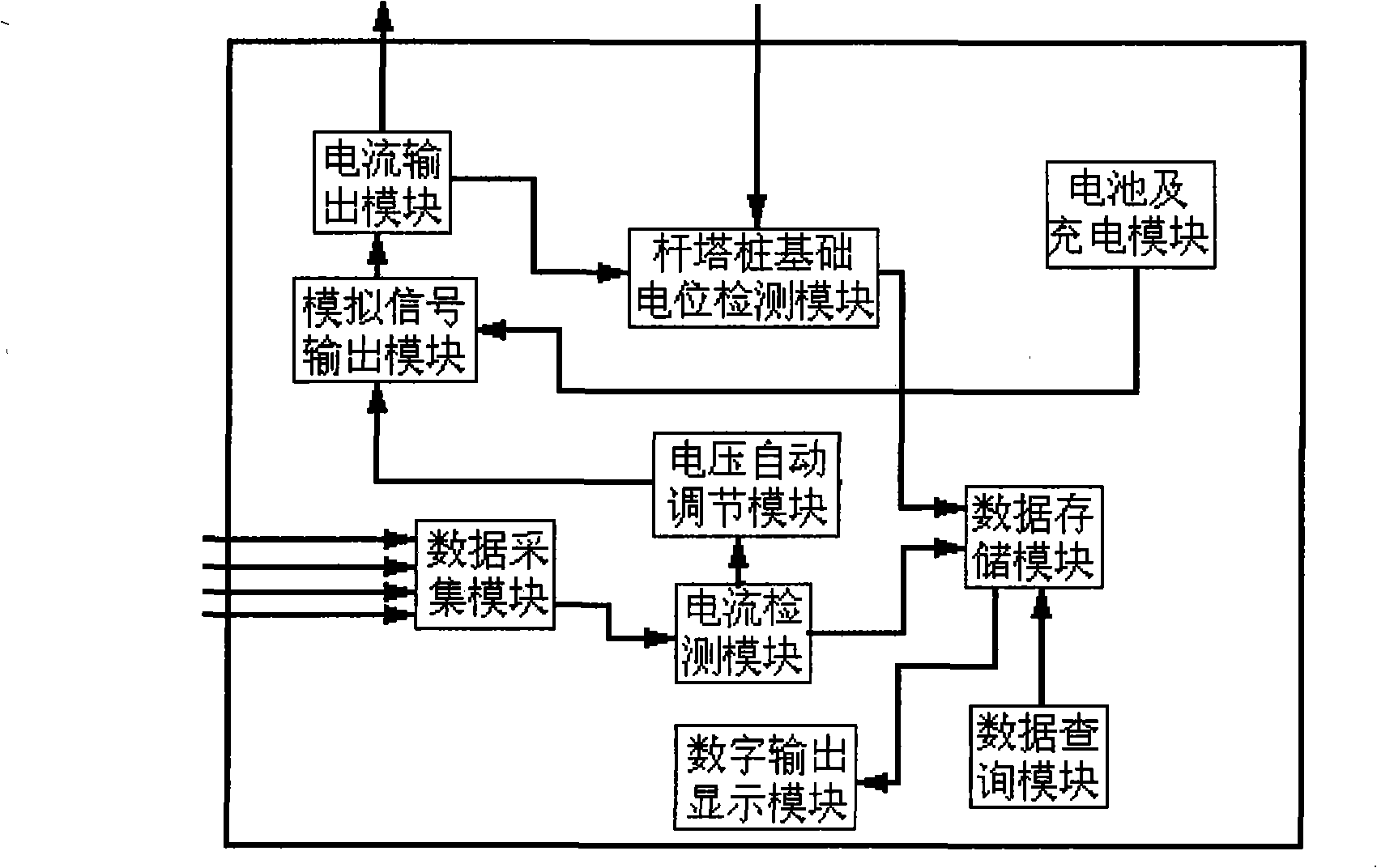

Pile foundation tower-footing impedance measuring apparatus and its method

InactiveCN101266270AAccurate measurementAccurate detectionEarth resistance measurementsCurrent rangeCurrent sensor

A pile foundation tower footing impedance measuring device and method thereof, relate to an overhead transmission line tower footing impedance measuring device and method thereof. The device comprises an auxiliary electrode, a high accuracy flexible Roche coil current sensor, a tower footing impedance measuring device or the like. The footing impedance of the pile foundation tower is measured by program. The invention has features: simple structure, low cost, easy operation, wide measuring current range, strong antijamming capability, high measuring accuracy and low measuring cost, therefore the invention can be widely used for measuring the overhead transmission line tower footing impedance, especially for measuring the tower footing impedance without down lead, incapable or inconvenient of unfastening the down lead, avoiding unfastening the down lead.

Owner:CHONGQING UNIV +1

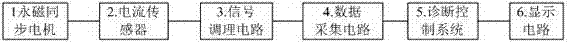

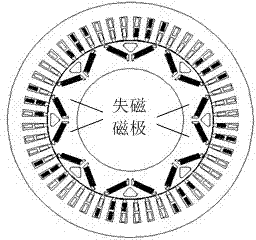

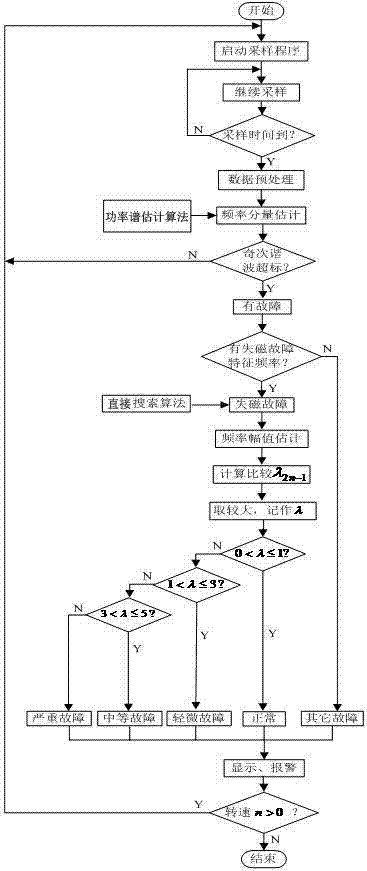

Field failure on-line diagnostic method and system for permanent magnet synchronous motor

InactiveCN103926533AEasy to installRunning does not affectDynamo-electric machine testingAnti jammingCurrent range

The invention discloses a field failure on-line diagnostic method and system for a permanent magnet synchronous motor. The field failure on-line diagnostic method comprises the steps of (1) sampling a stator three-phase current signal of the motor to be detected, (2) determining a field failure characteristic frequency according to the number of poles of the permanent magnet synchronous motor to be detected, using the field failure characteristic frequency as a field failure characteristic quantity, (3) estimating the frequencies of frequency components in the stator three-phase current signal to be detected, judging whether a field failure happens or not according to whether the field failure characteristic quantity appears or not, and (4) after estimating the amplitudes of the frequency components in the stator three-phase current signal to be detected, calculating the ratios of the amplitudes of the frequency components to the amplitudes of same-frequency components within a same-current range of a motor in the normal state so as to judge the degree of severity of a field failure. The field failure on-line diagnostic system comprises the permanent magnet synchronous motor, a Hall current sensor, a signal conditioning circuit, a data acquisition circuit, a diagnosis control circuit and a display circuit. The field failure on-line diagnostic system is short in sampling time and high in anti-jamming capability, can judge field failures at different rotating speeds and under different load conditions, and is applicable to dynamic on-line monitoring.

Owner:HOHAI UNIV

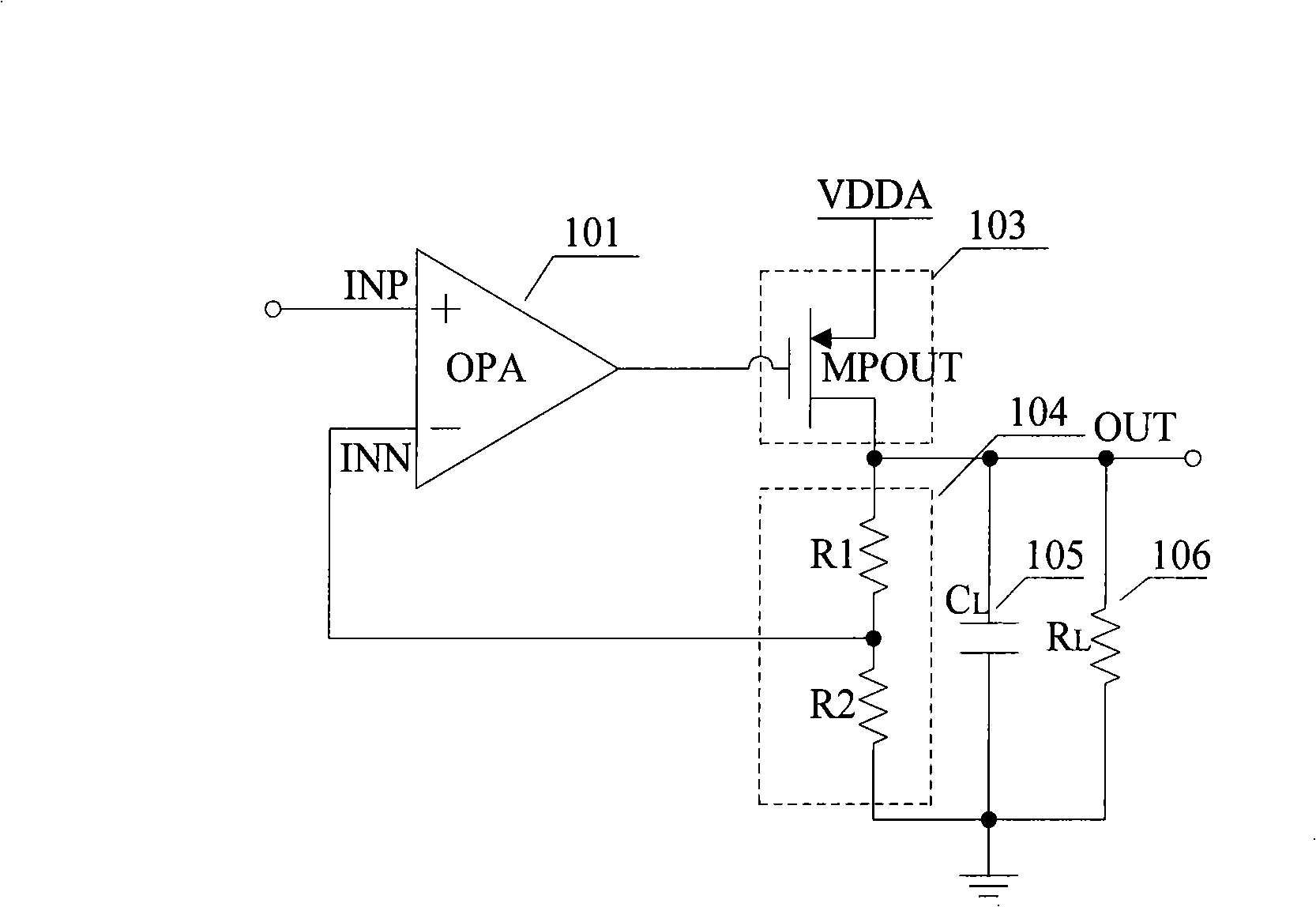

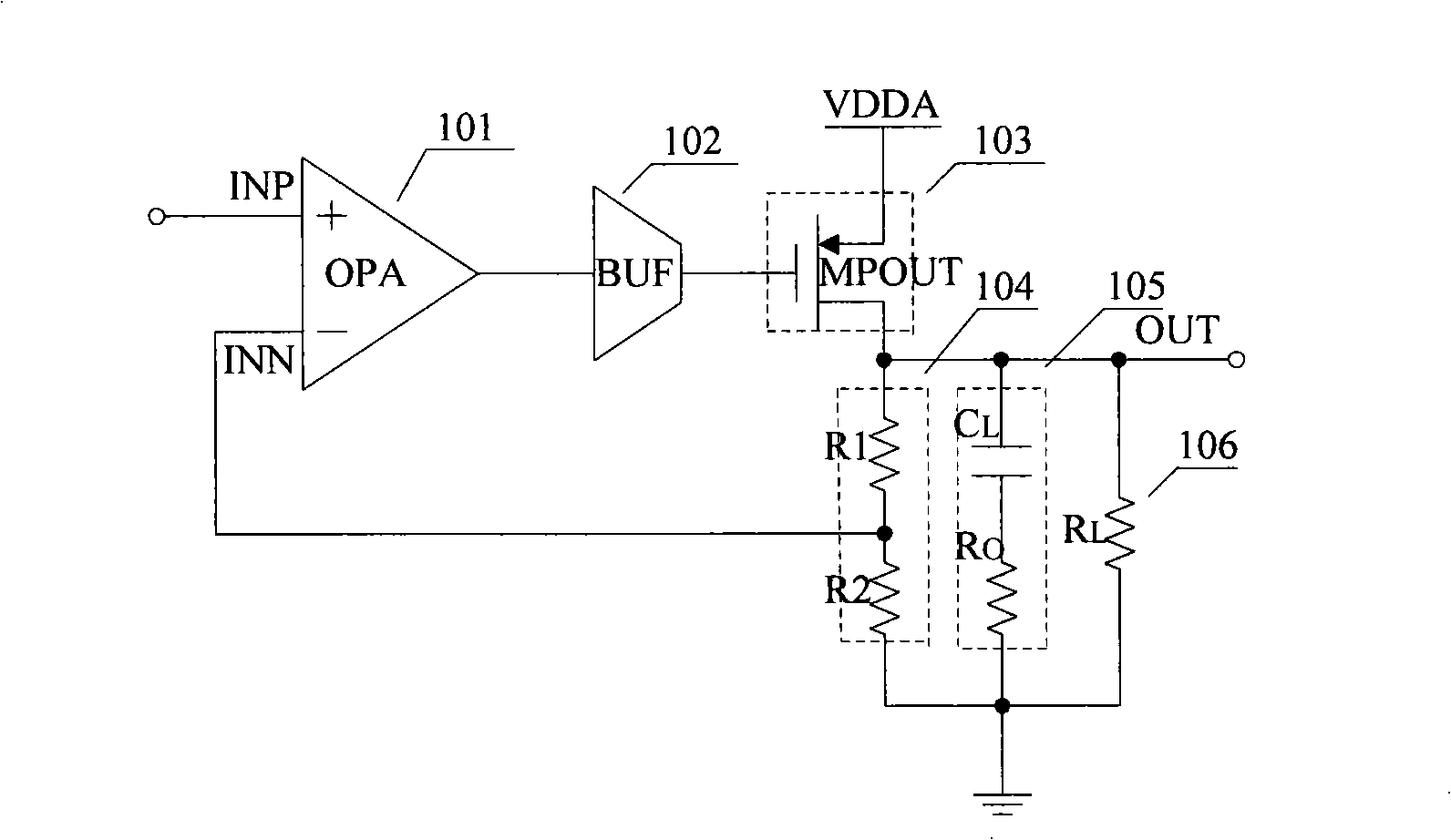

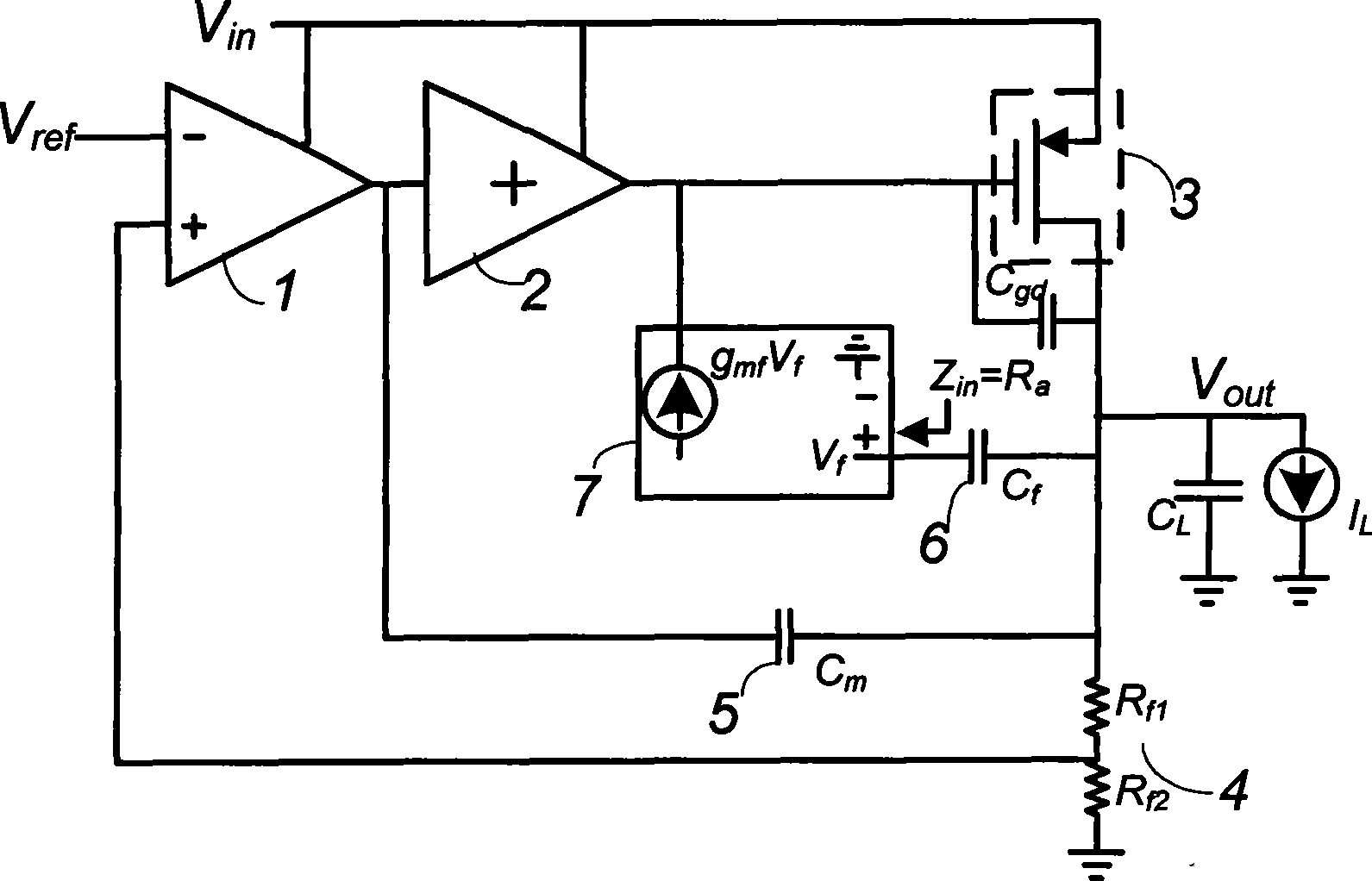

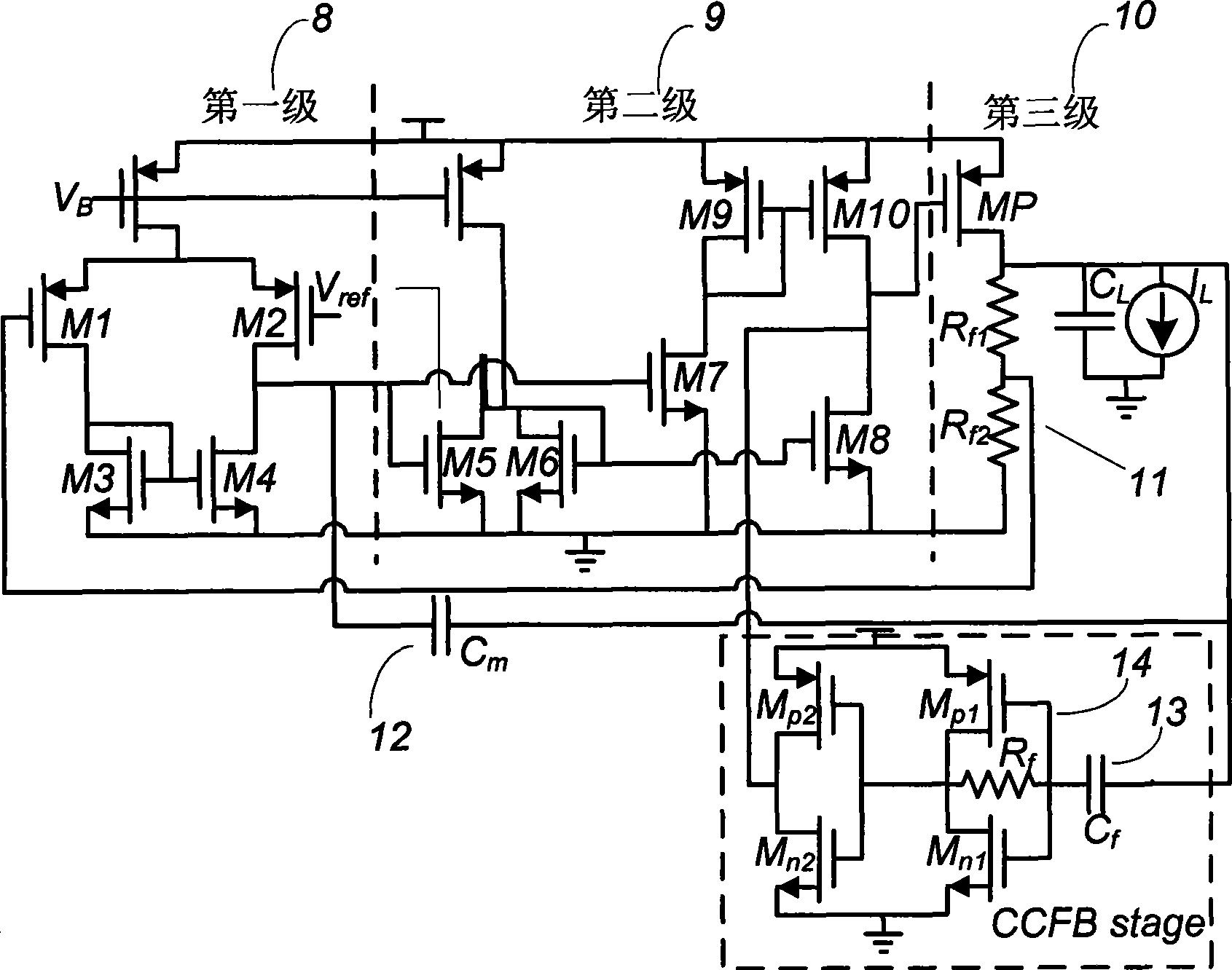

Low-voltage difference linear voltage stabilizer without off-chip compensation capacitor

InactiveCN101369161AMaintain stabilityHigh precisionElectric variable regulationLinear regulatorCapacitance

The invention provides a novel low dropout linear regulator without off-chip compensation capacitance, which is composed of a two-level error comparator, a power PMOS tube, two capacitors for frequency compensation and a first-level transconductance feedback circuit. The low dropout linear regulator can realize the stability in the full load current range by adopting the arrangement of frequency compensation network and the small-sized power tube; meanwhile, the linear regulator has extreme high precision due to the adoption of a two-level error amplifier; therefore, the linear regulator is quite suitable for being used under full system-on-chip (SoC) condition and has good applying prospect.

Owner:FUDAN UNIV

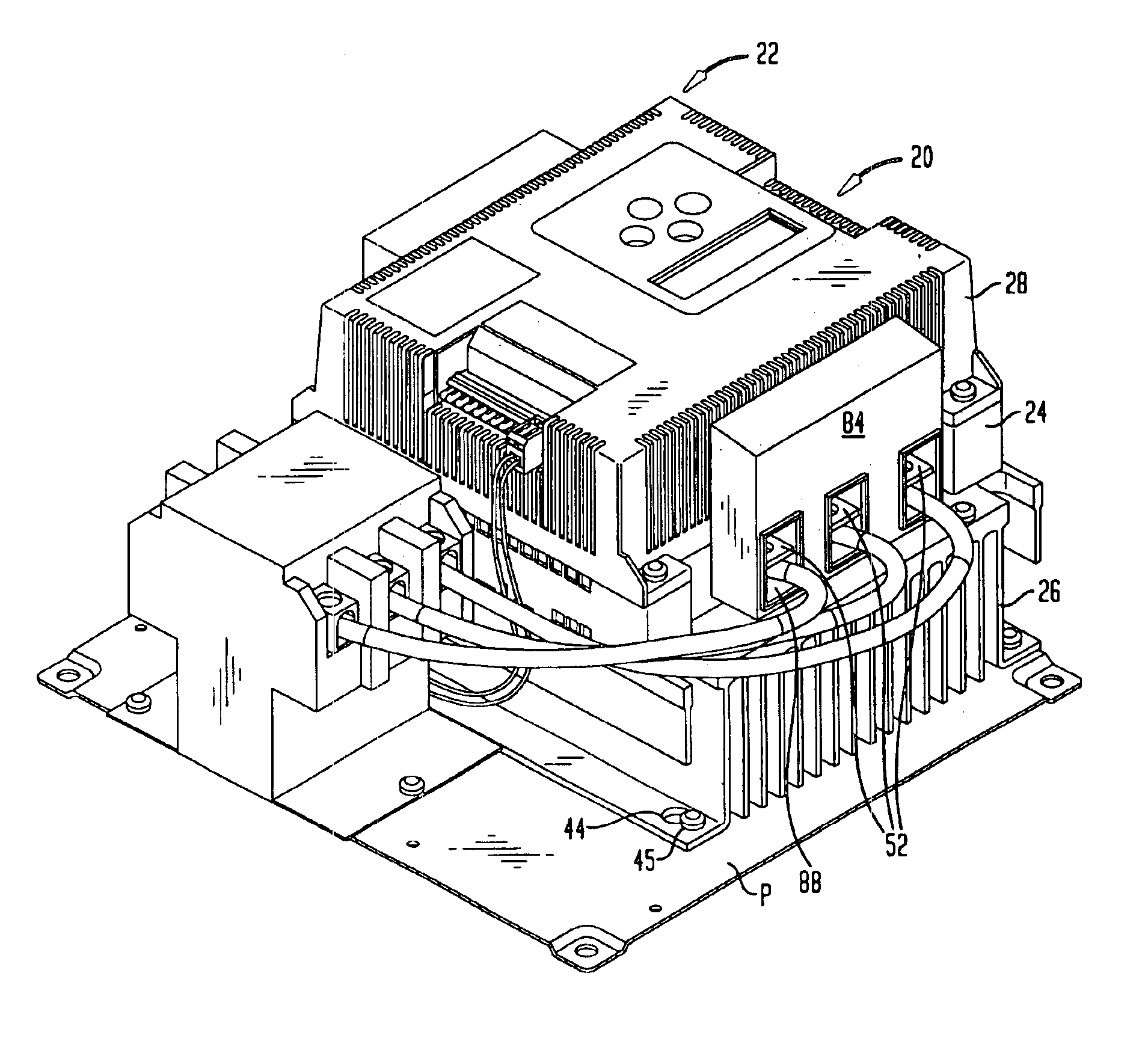

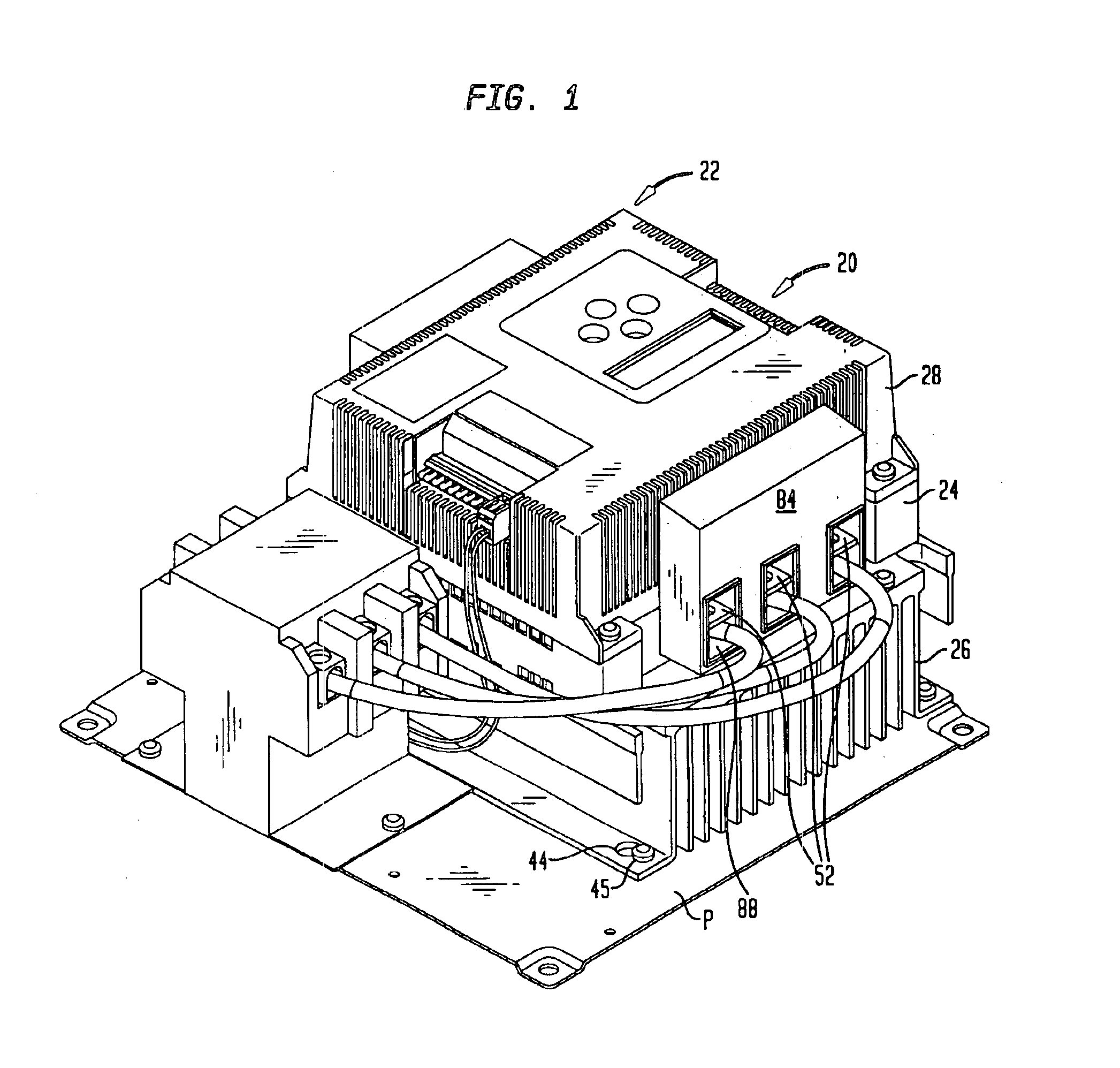

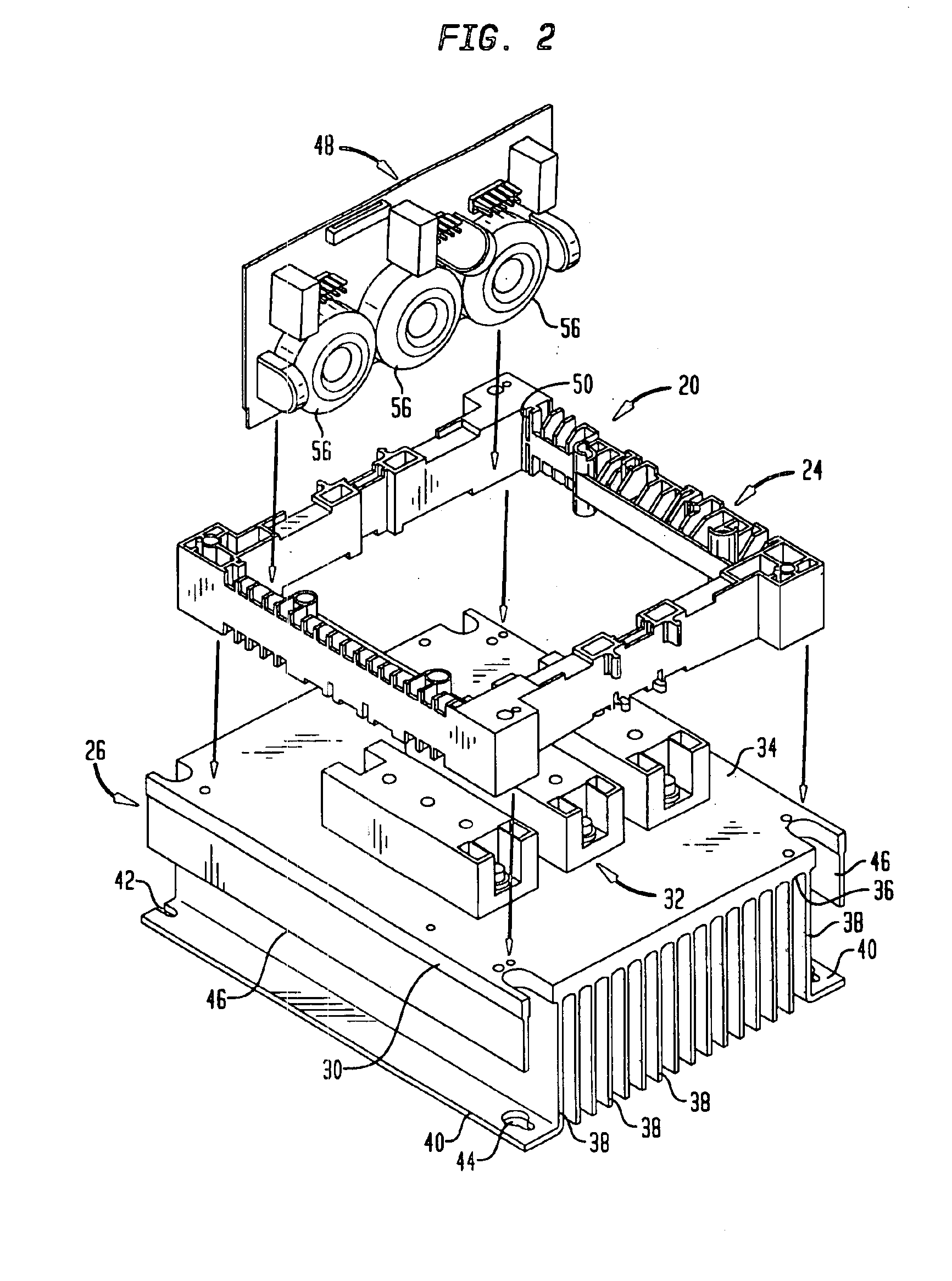

System and method for improved motor controller

InactiveUS6891725B2Reduce manufacturing costDecrease stockSingle-phase induction motor startersAC motor controlCurrent rangeModularity

Owner:SIEMENS ENERGY & AUTOMATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com