Automatic temperature control apparatus of pump laser for ASE broadband light source

An automatic control device, a technology for pumping lasers, applied in laser cooling devices, temperature control, laser parts, etc., can solve the problems of reduced work efficiency, drift of the center working wavelength of the pump laser, damage to the pump laser, etc. The effect of high cooling efficiency, simple and compact circuit design, and perfect protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

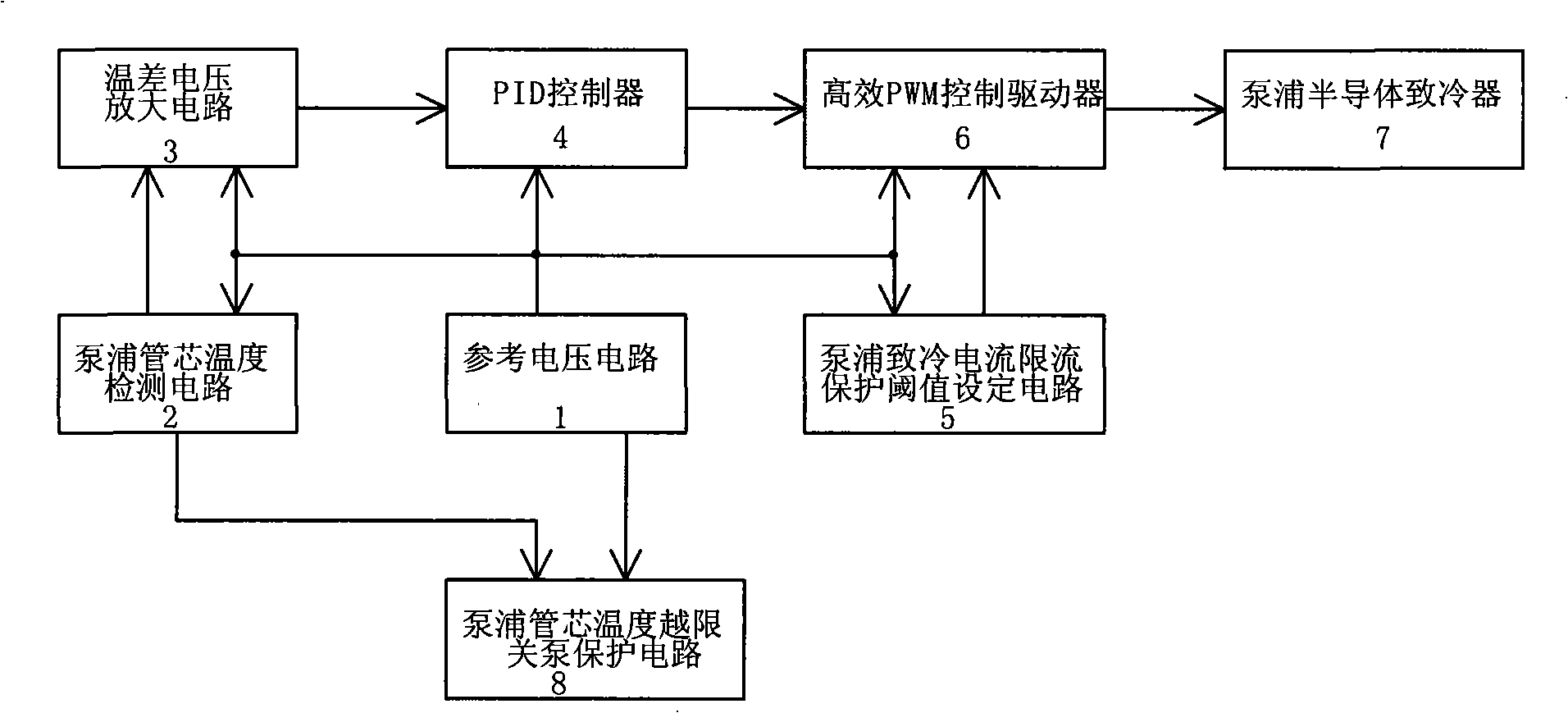

[0018] The principle block diagram of the pump laser temperature automatic control device for ASE broadband light source is as follows figure 1 shown.

[0019] It includes: reference voltage circuit 1, pump core temperature detection circuit 2, temperature difference voltage amplification circuit 3, proportional integral differential PID controller 4, pump cooling current limiting protection threshold setting circuit 5, high-efficiency PWM control driver 6 , the pump semiconductor refrigerator 7, and the pump core temperature exceeds the limit to turn off the pump protection circuit 8.

[0020] The connection relationship and working principle are as follows:

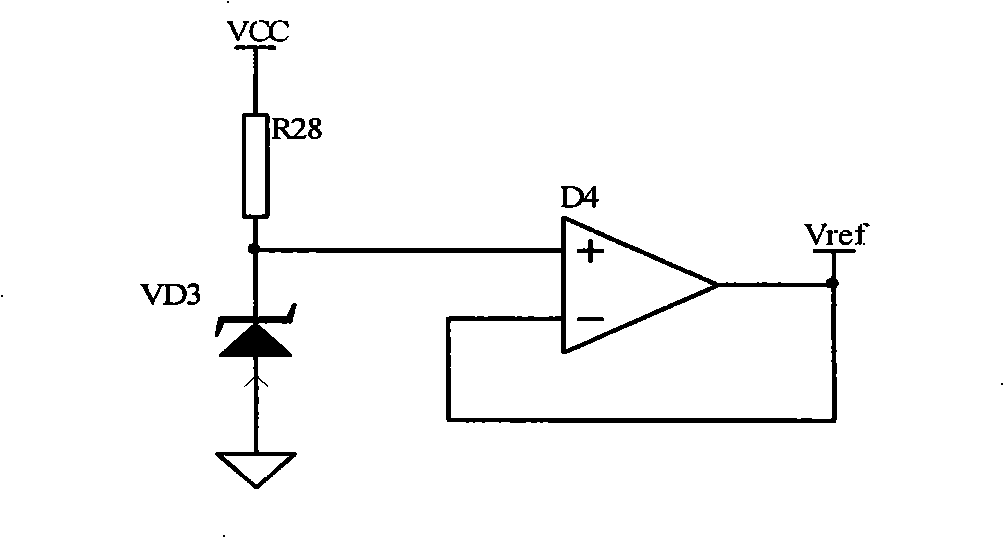

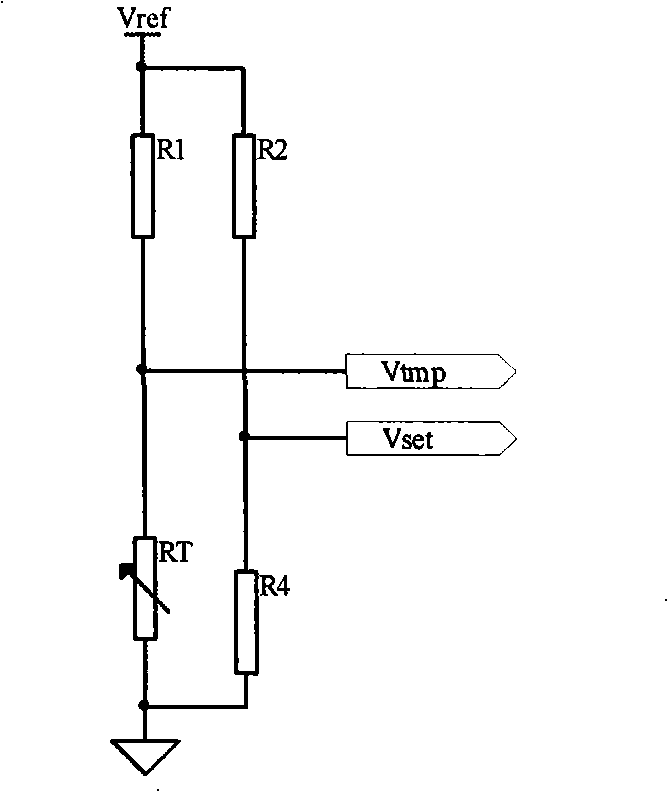

[0021] The reference voltage circuit 1 provides the working reference voltage of the entire pumping die temperature control circuit. It is output to all other functional circuits that need the reference voltage, these functional circuits include: pump core temperature detection circuit 2, temperature difference voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com