Patents

Literature

2388 results about "Self heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin Firming Anti-Aging Cosmetic Mask Compositions

InactiveUS20040161435A1Promote excess fat reductionPromote cellulite controlBiocideCosmetic preparationsAdditive ingredientPhase mask

I have discovered cosmetic mask compositions suitable for face, neck, chin or body applications. These compositions synergistically combine at least one skin beneficial cosmetic or drug composition with at least one composition to promote excess fat reduction, cellulite control, or muscle toning benefits. The mask composition also contains at least one binder composition that binds with other beneficial ingredients by electrostatic, atomic, or ionic charges to synergistically enhance their topical site-specific benefits. These mask compositions are suitable for a variety of delivery system methods that include peel-off mask, leave-in mask, moisturizing mask, exfoliating mask, prosthetic mask, soaking mask, depilatory mask, foaming mask, rinse-off mask, sloughing mask, rub-off mask, two-phase mask, dual-chamber mask, and self-heating (heat releasing) mask.

Owner:GUPTA SHYAM K

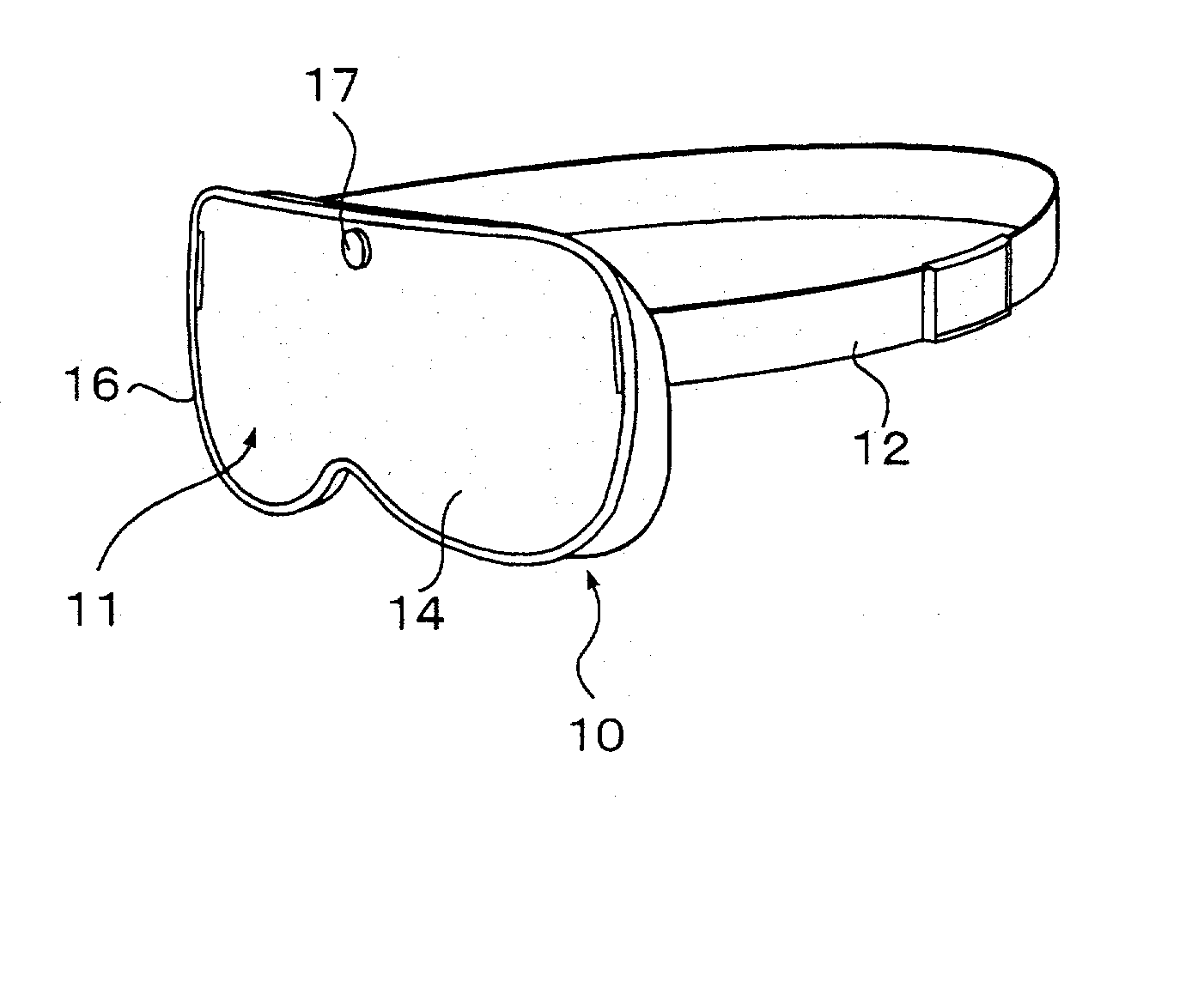

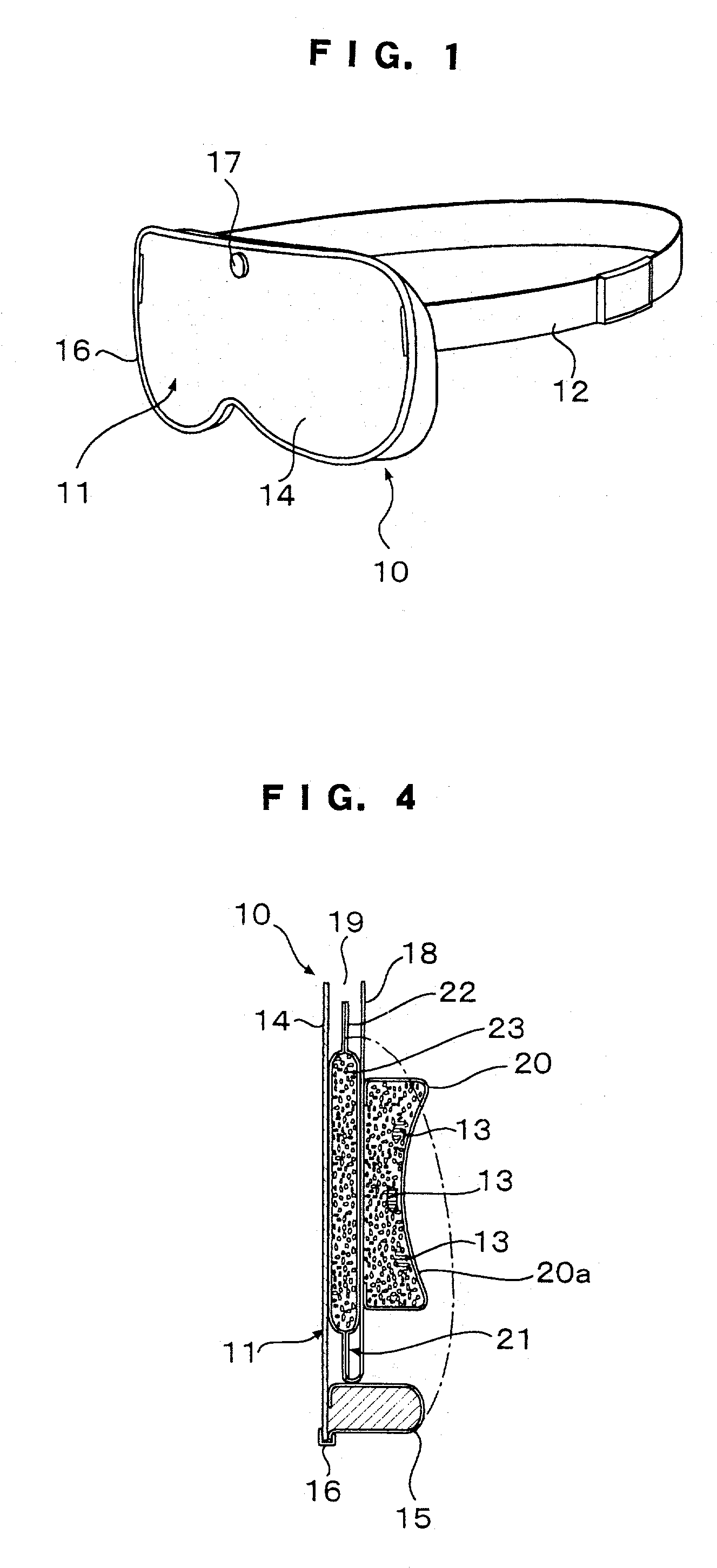

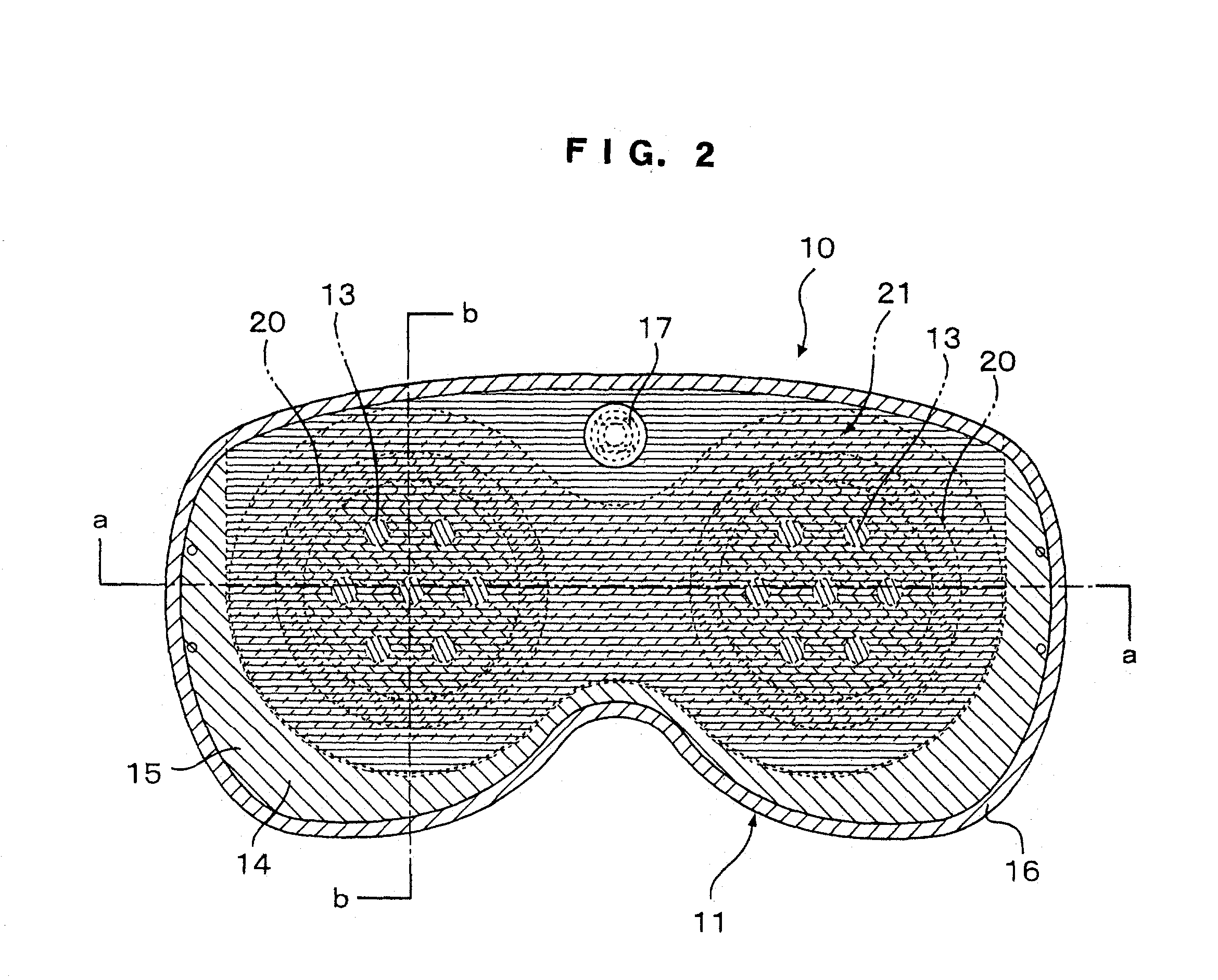

Eye mask

InactiveUS20030056281A1Recovering and restoringSimple structureElectrotherapyVibration massageDiseaseFarsightedness

An eye mask has magnetic bodies and self-heating warm members, which are inserted in eye pads on a mask member to be placed over eyeball parts. If required, vibrators and illumination bodies may be additionally placed in the eye pads. Thus, fatigue on the eyes and surroundings thereof can be relieved by the magnetic actions of the magnetic bodies and the warming effects of the warming member, in addition to expected effects of restoring ocular functions, recovering from various ocular diseases, and so on. Furthermore, the surface of each of the eye pads is gradually curved like the inner surface of a sphere. When the eye pads are press-contact to the eyeball parts at predetermined pressures for a long time, the cornea can be warmed by the warming members so that the shape of the cornea can be changed along the shape of the eye pad, resulting in the effects of recovering from eye sight disorder such as pseudo-myopia, moderate farsightedness, or moderate astigmatism.

Owner:HASEGAWA TOKUICHIRO

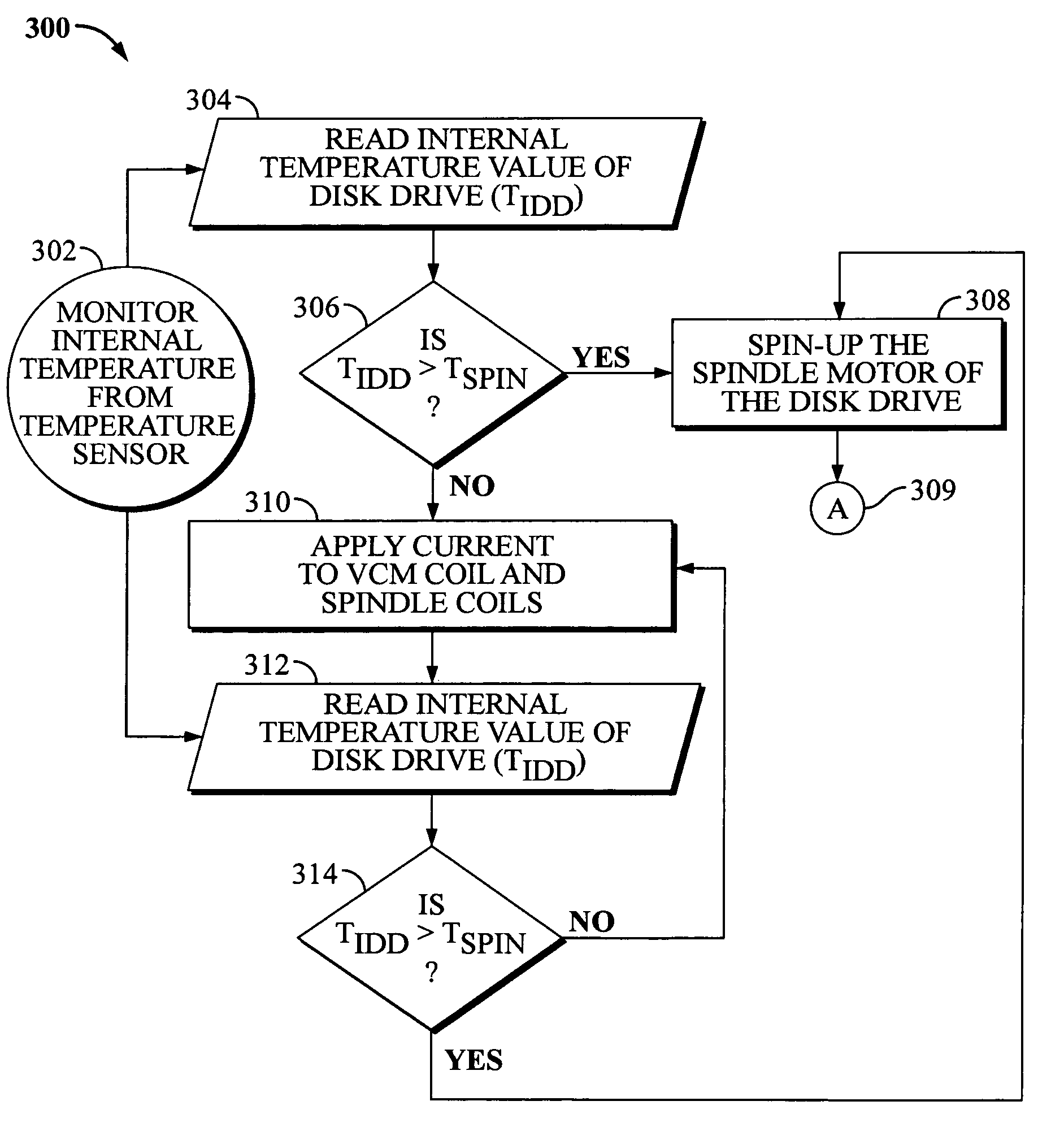

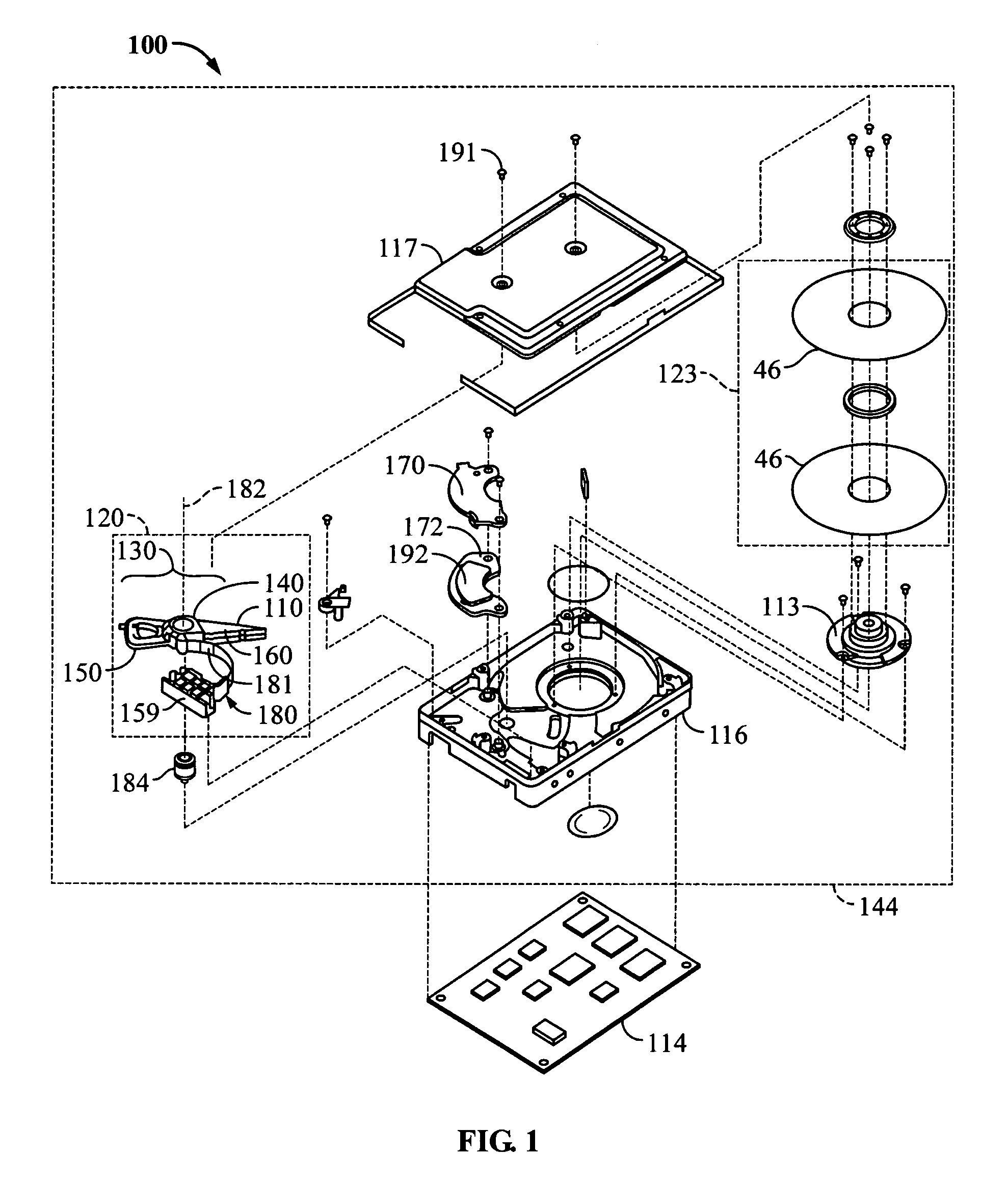

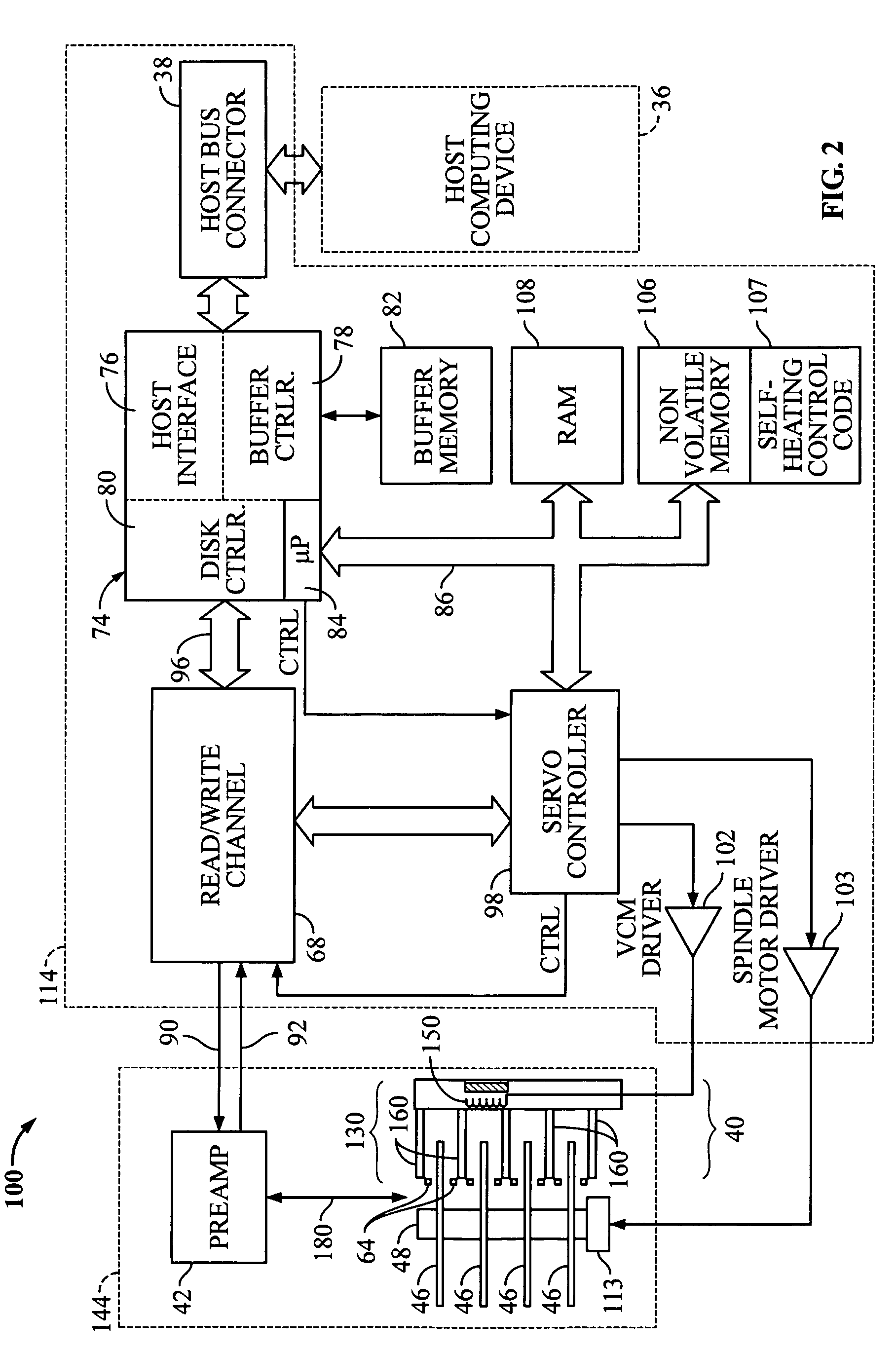

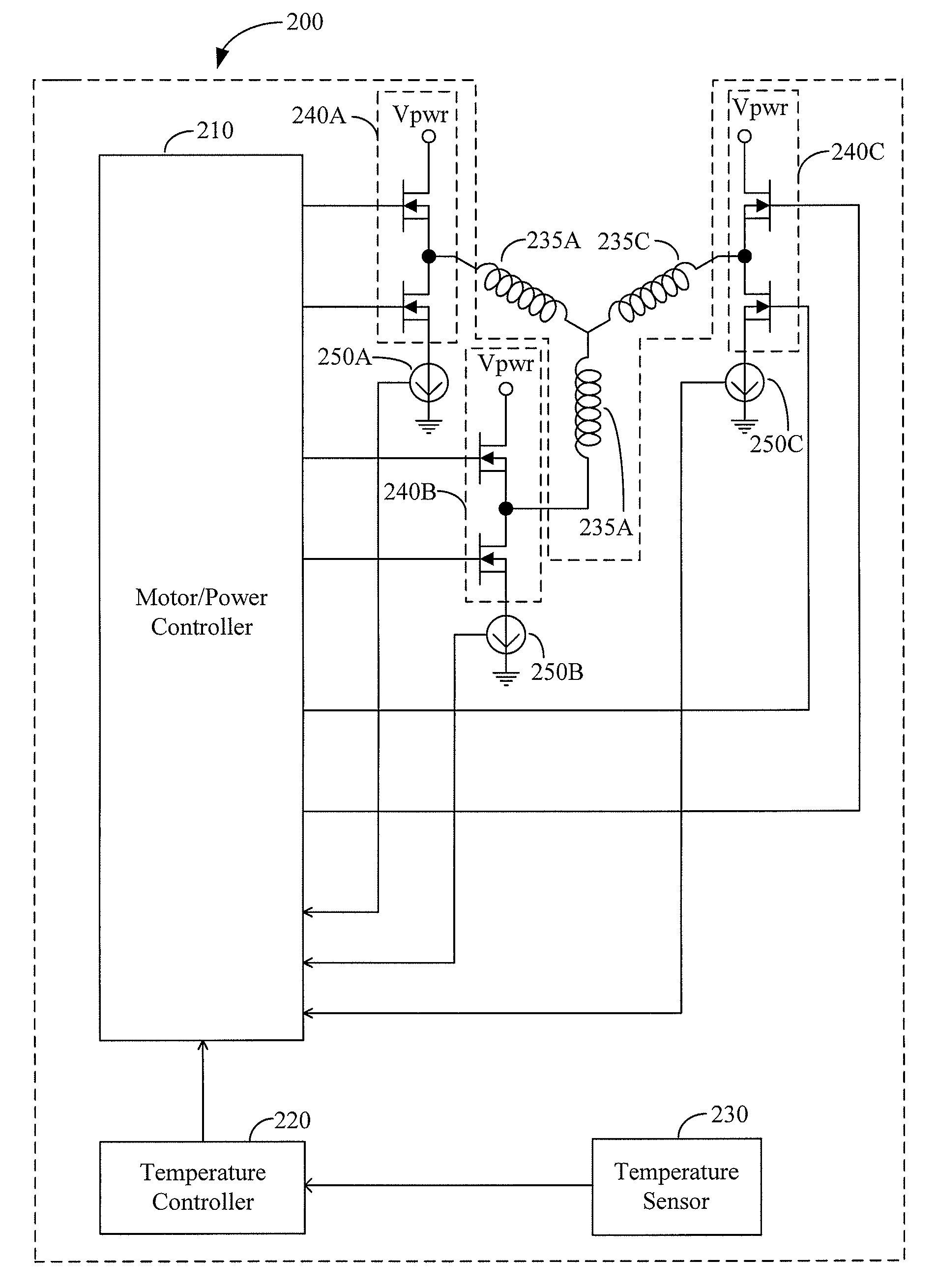

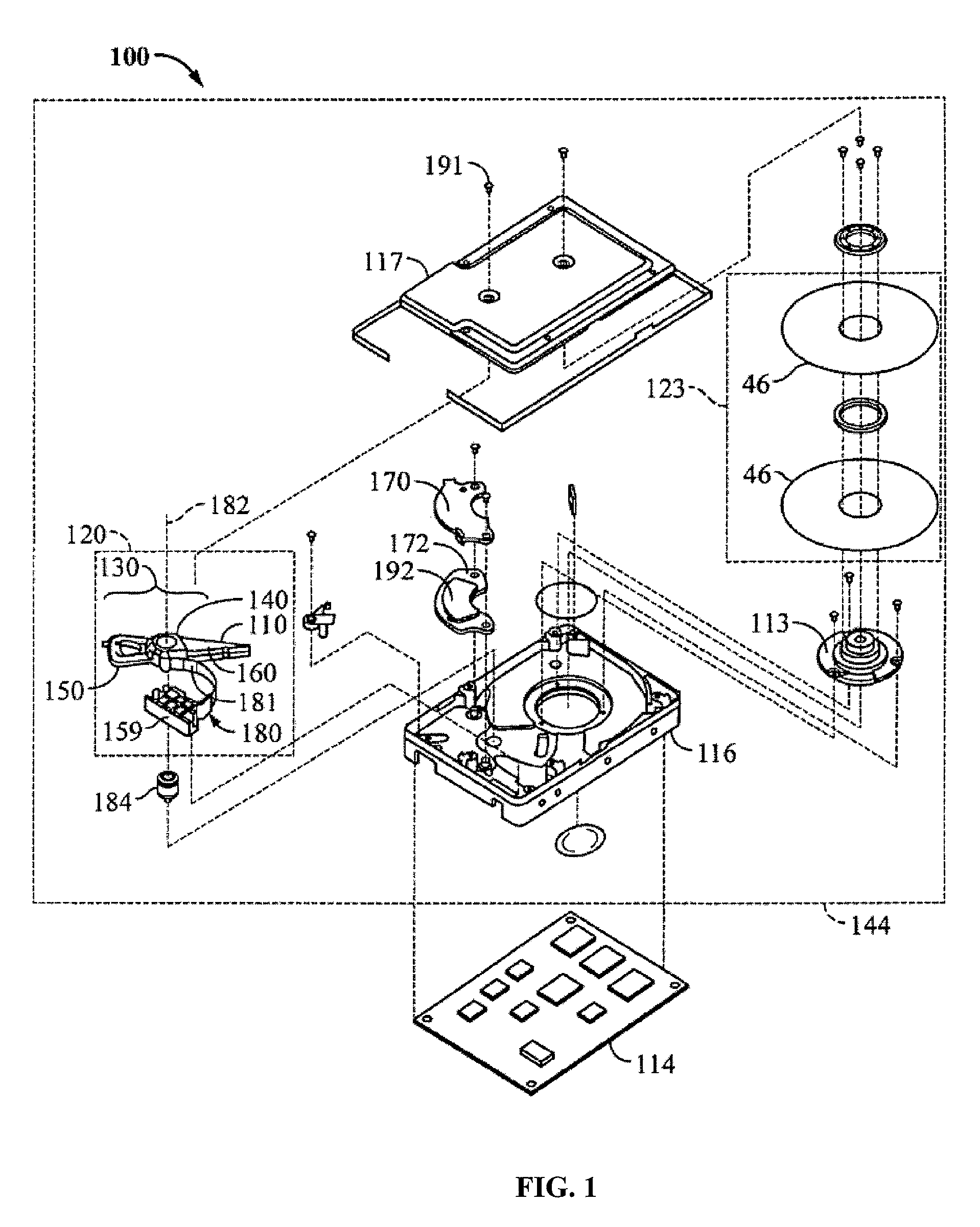

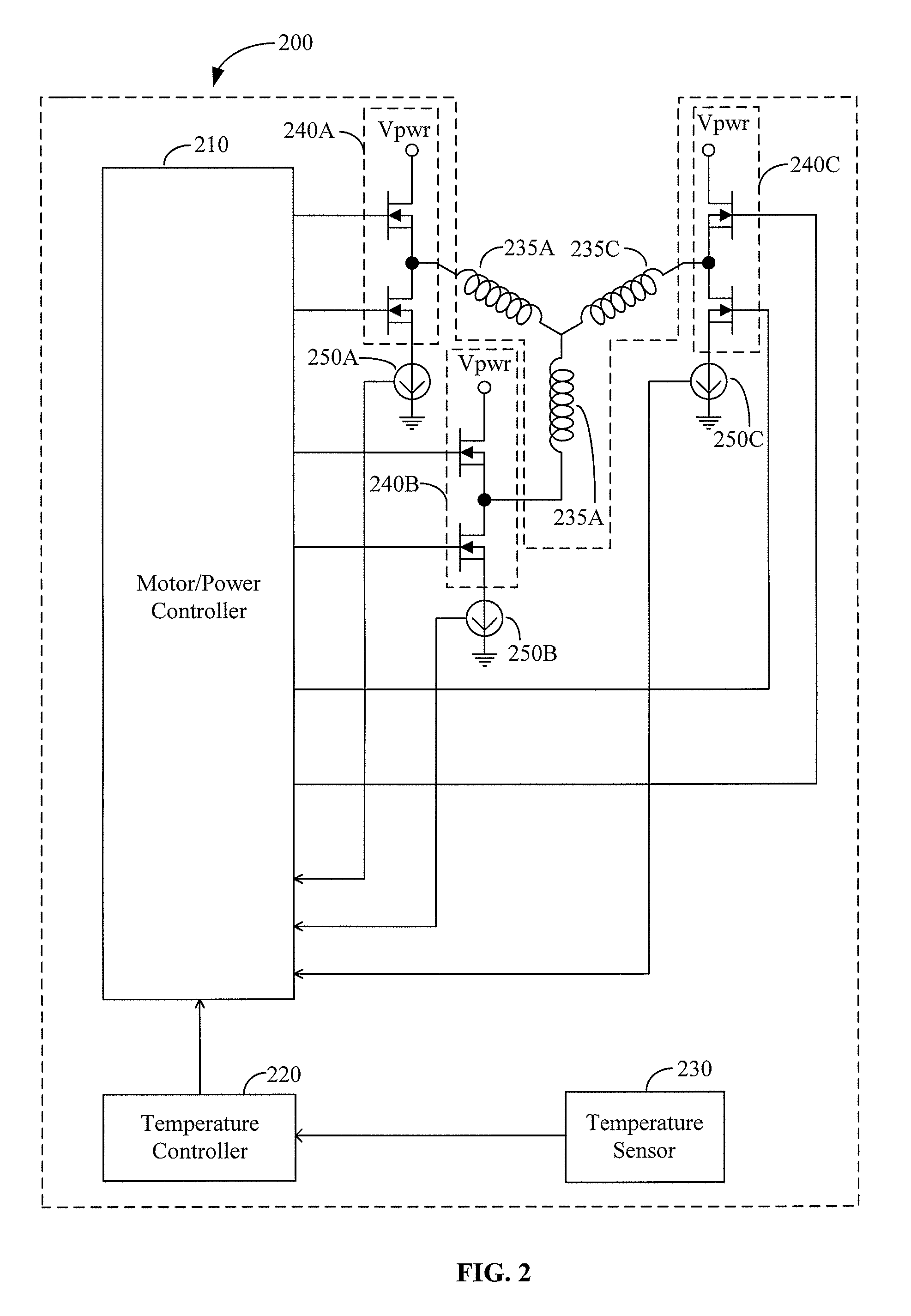

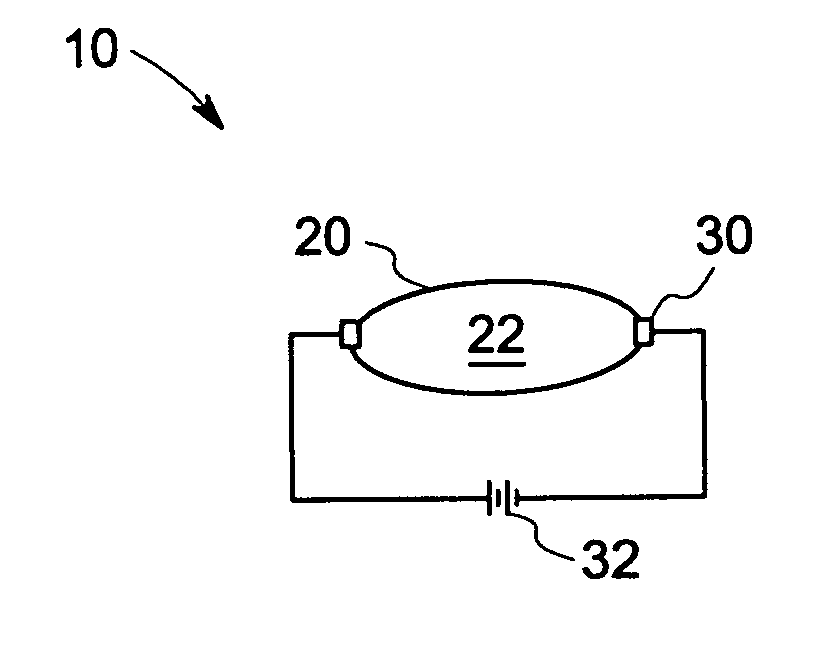

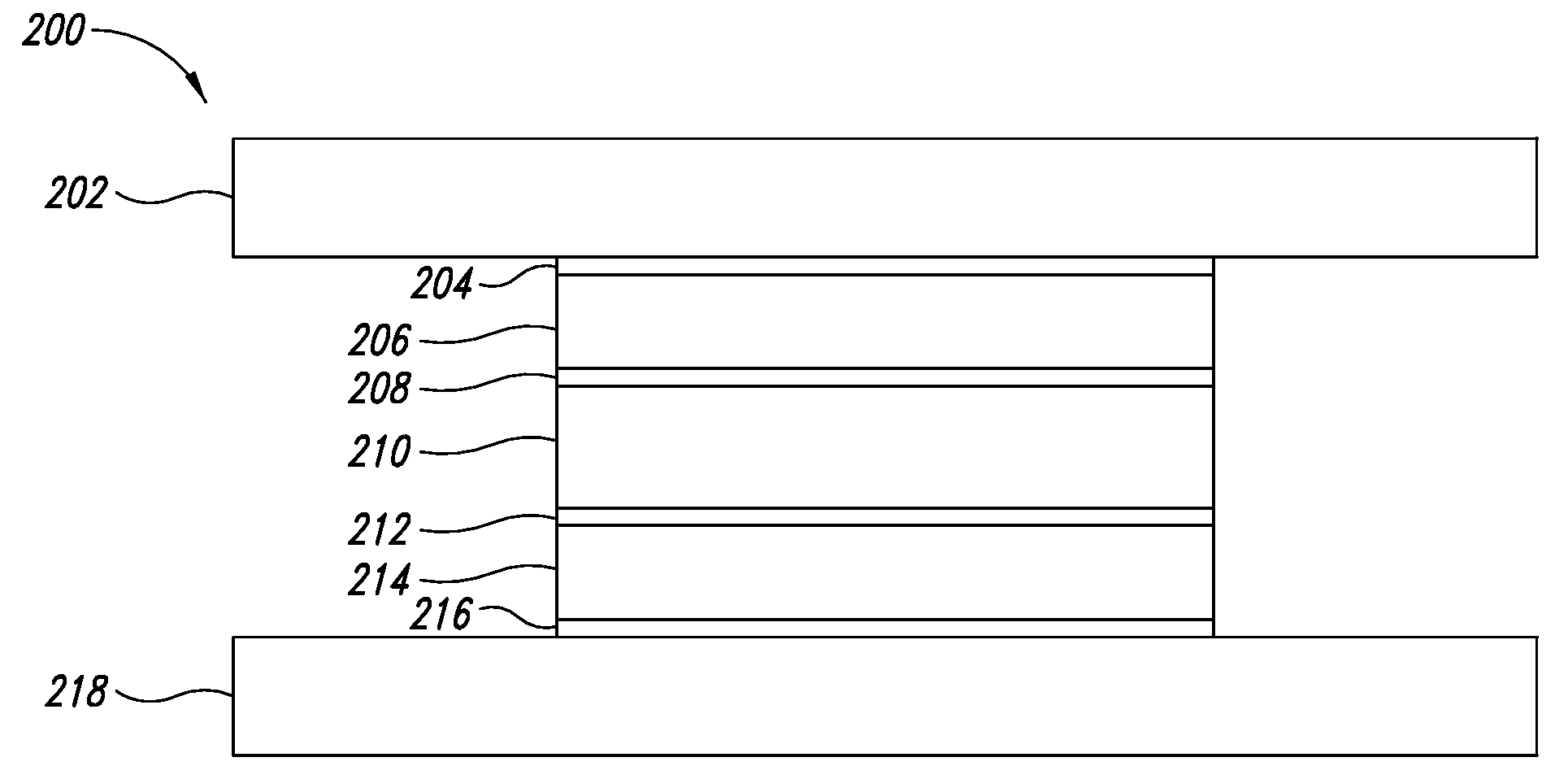

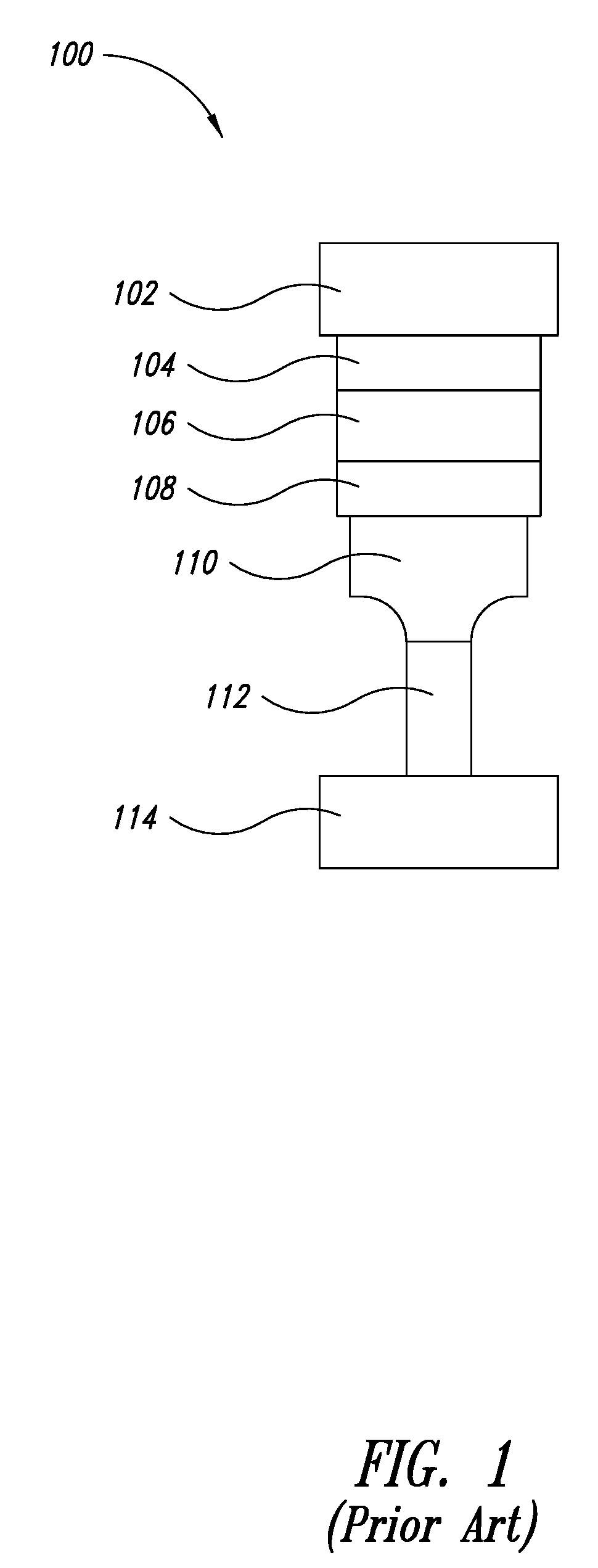

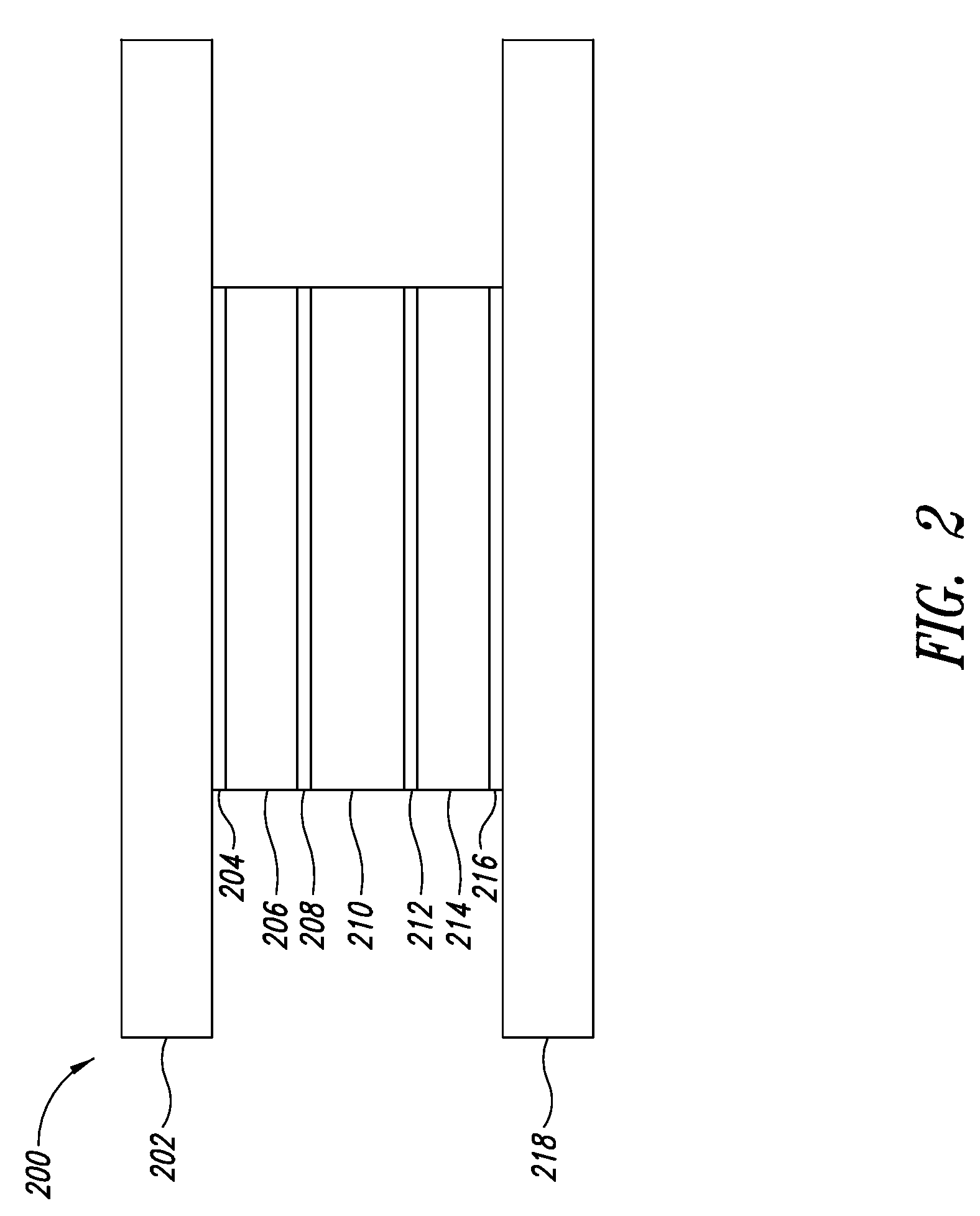

Self-heating disk drive

ActiveUS7203021B1Excessive heatingDriving/moving recording headsFilamentary/web record carriersElectric machineEngineering

Disclosed is a self-heating disk drive that comprises a voice coil motor (VCM), a spindle motor, and a temperature sensor. The VCM includes a VCM coil and the VCM is configured to move an actuator having a head attached to a distal end of the actuator. The spindle motor includes a plurality of spindle coils to spin a disk of the disk drive. The temperature sensor is used to read an internal temperature of the disk drive. Circuitry is configured to: command the application of current to the VCM coil without loading the head onto the disk and to the spindle coils of the spindle motor in a manner so as not to spin the disk; and, if the internal temperature reading reaches a pre-determined spindle temperature, the spindle motor is allowed to spin-up the disk.

Owner:WESTERN DIGITAL TECH INC

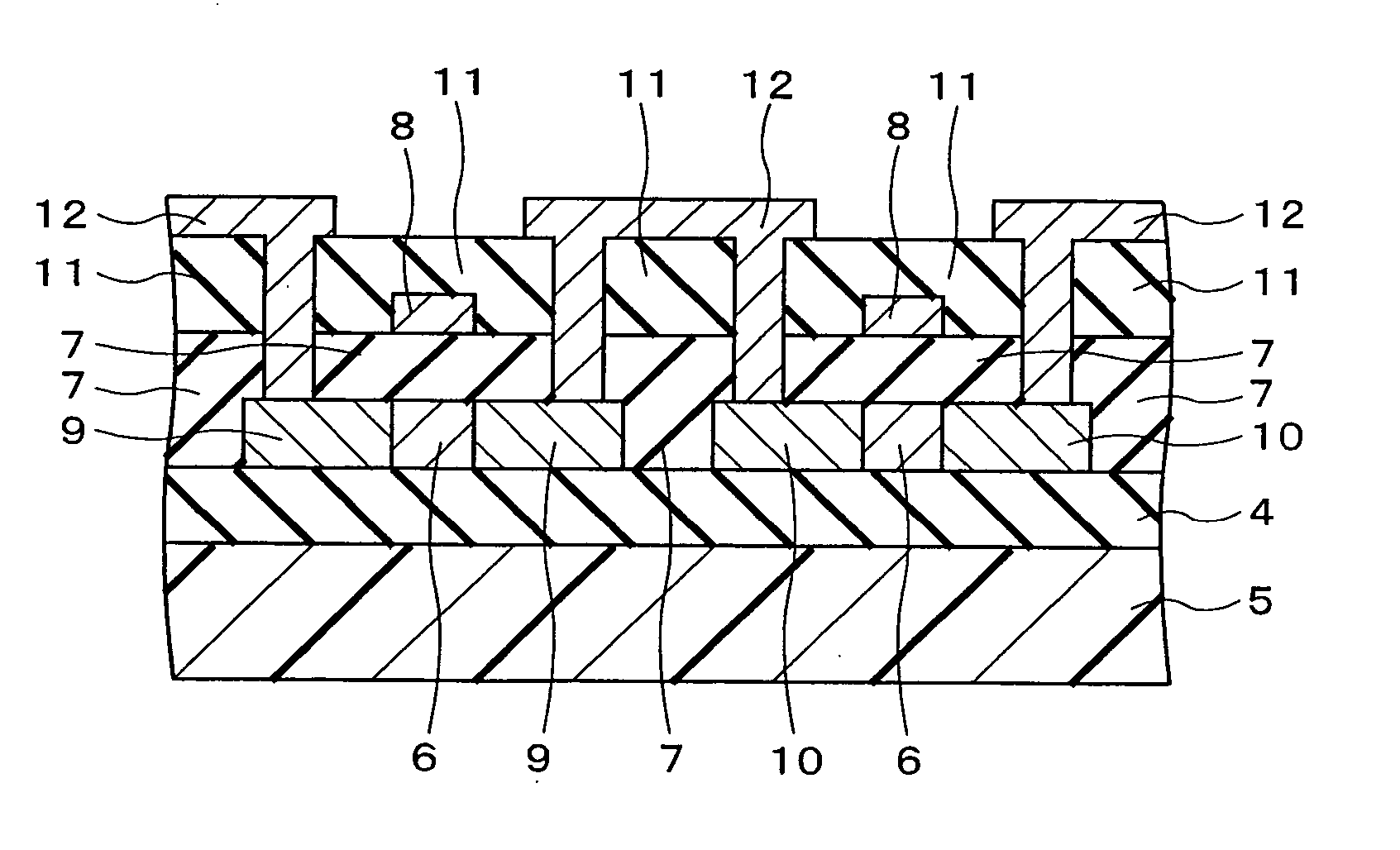

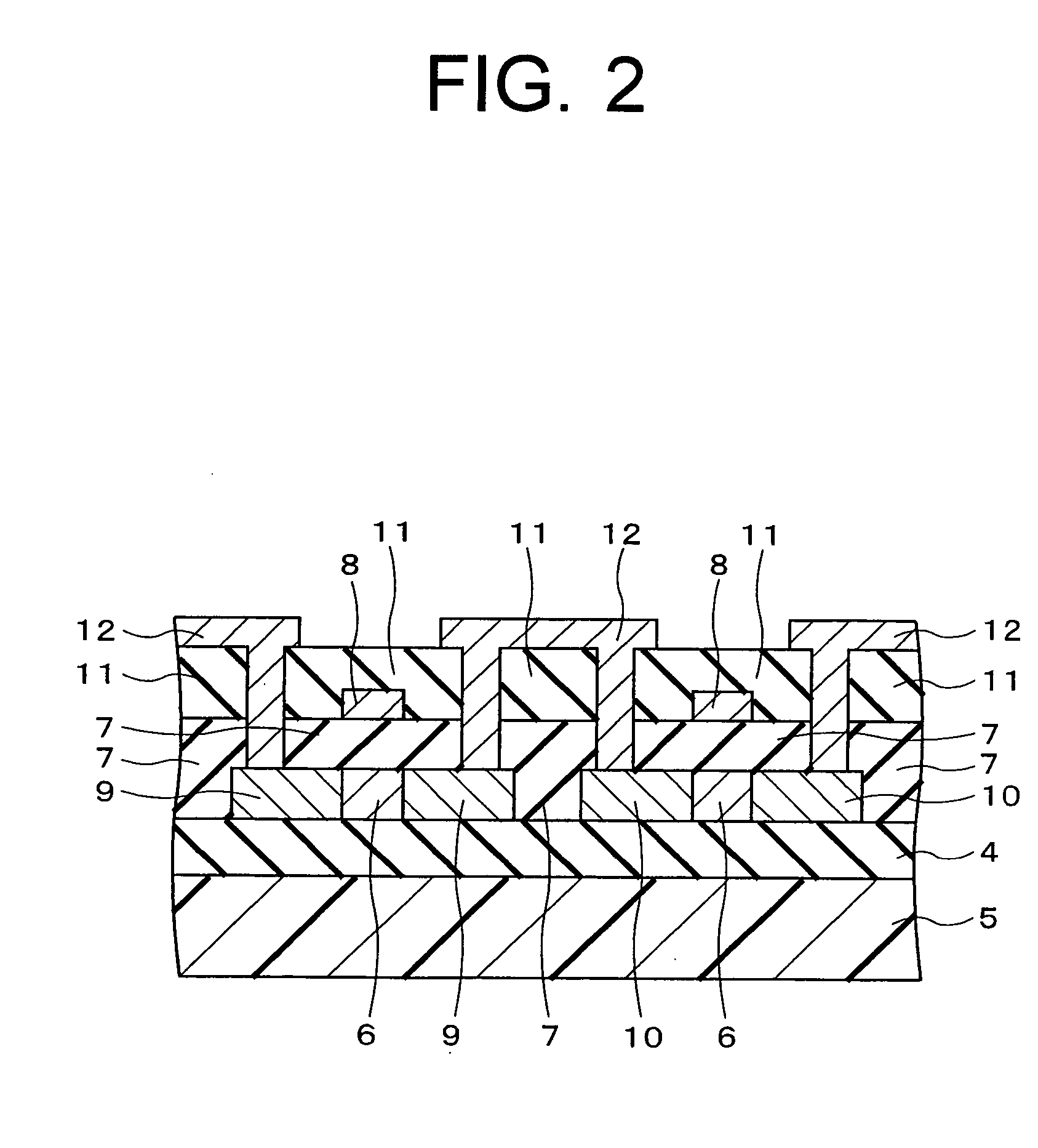

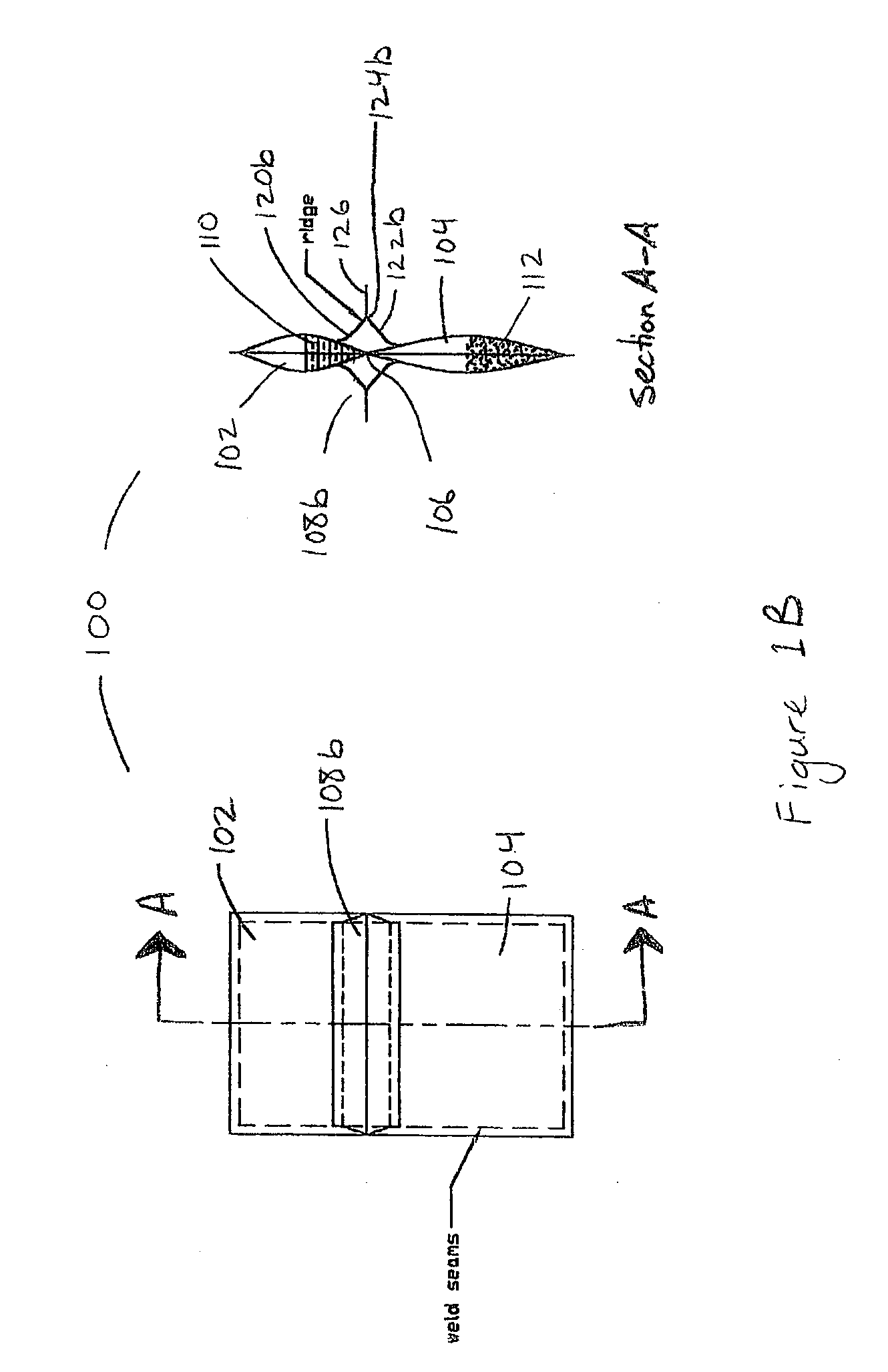

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

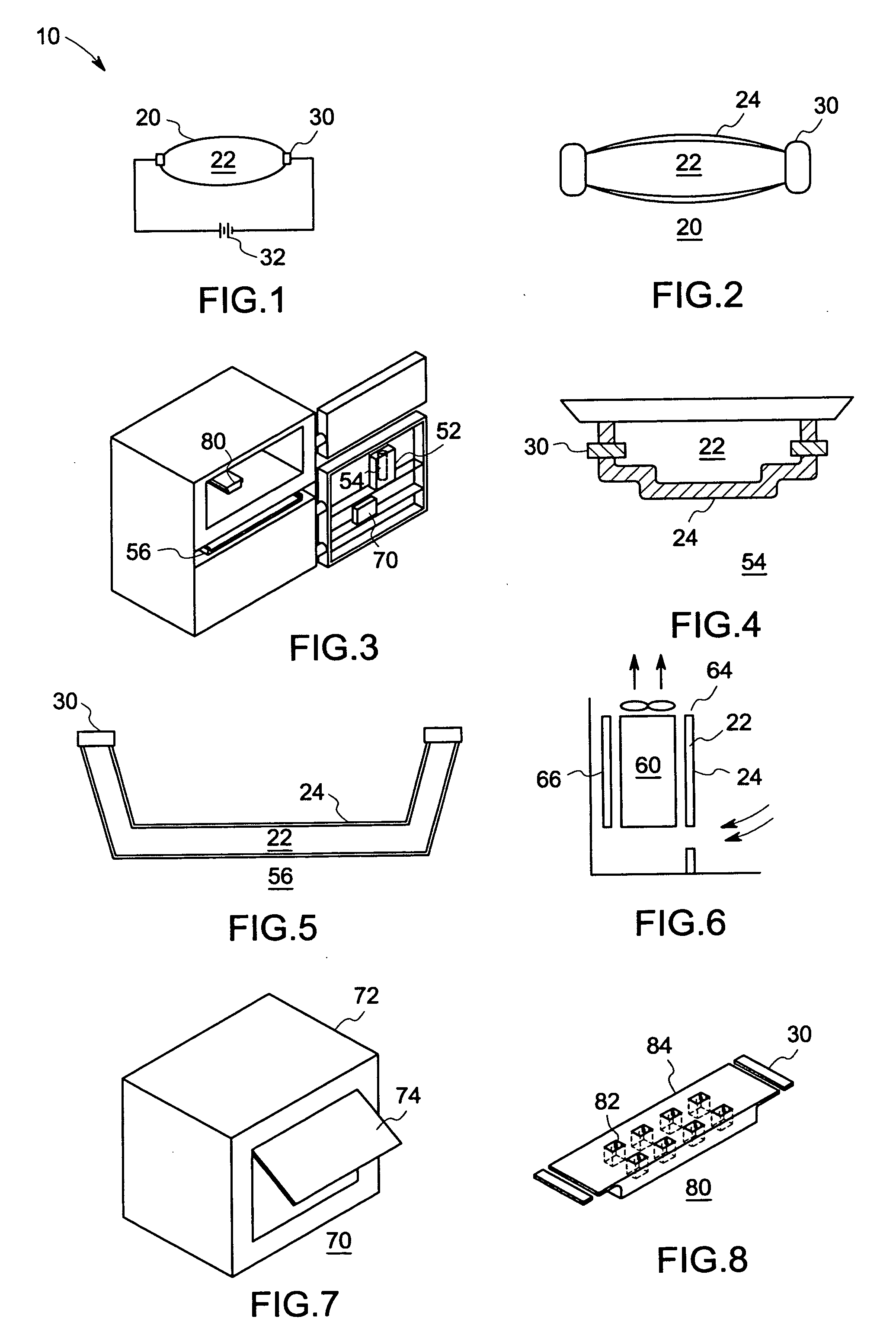

Self-heating integrated circuit

ActiveUS8358145B1Driving/moving recording headsSemiconductor/solid-state device detailsDriver circuitEngineering

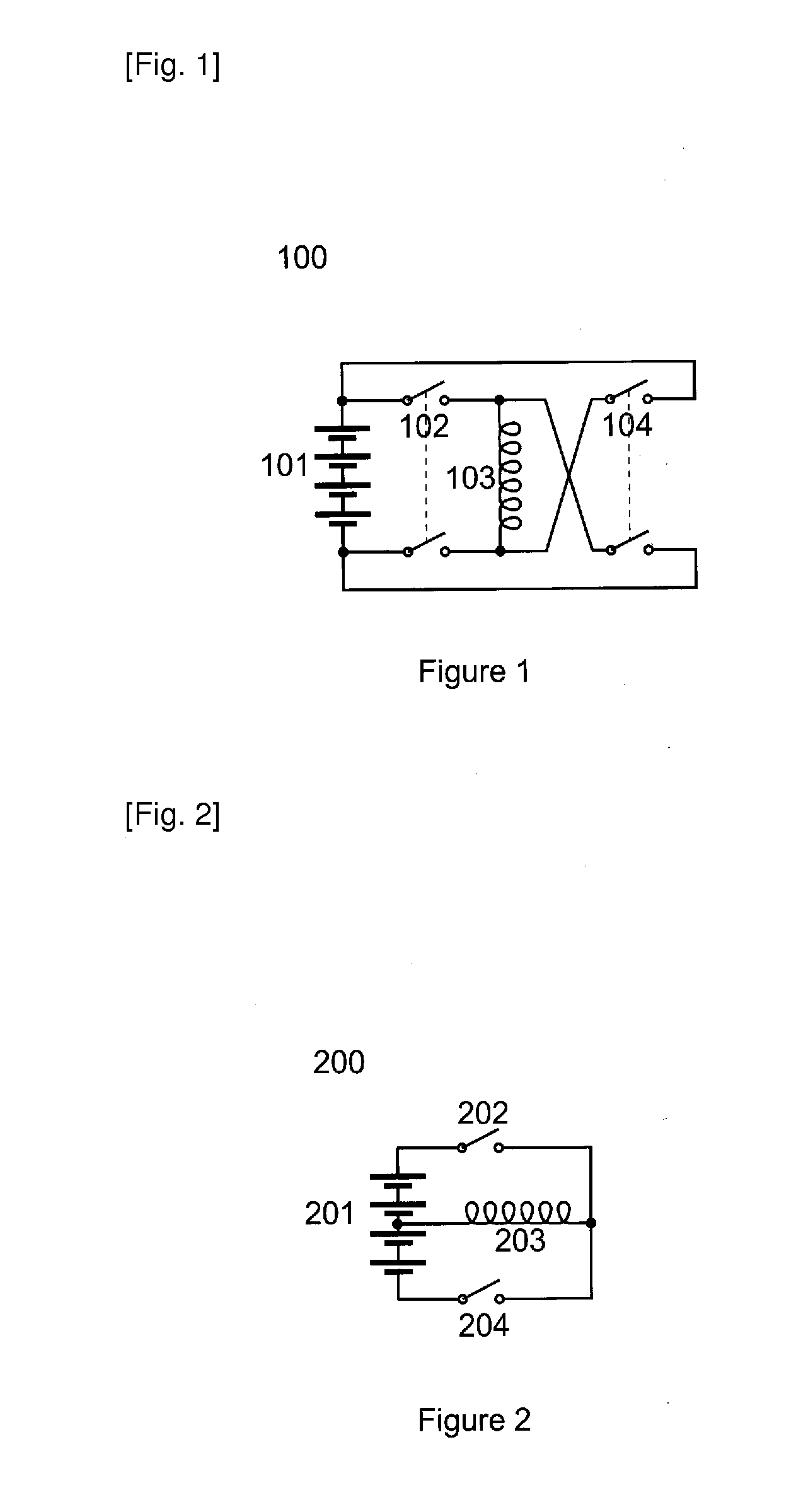

Self-heating integrated circuits are provided. In one embodiment, a self-heating integrated circuit comprises a drive circuit configured to drive a device and a controller configured to selectively operate the drive circuit in a first mode or a second mode. In the first mode, the controller is configured to operate the drive circuit to drive the device and, in the second mode, the controller is configured to operate the drive circuit to heat the integrated circuit to a target temperature.

Owner:WESTERN DIGITAL TECH INC

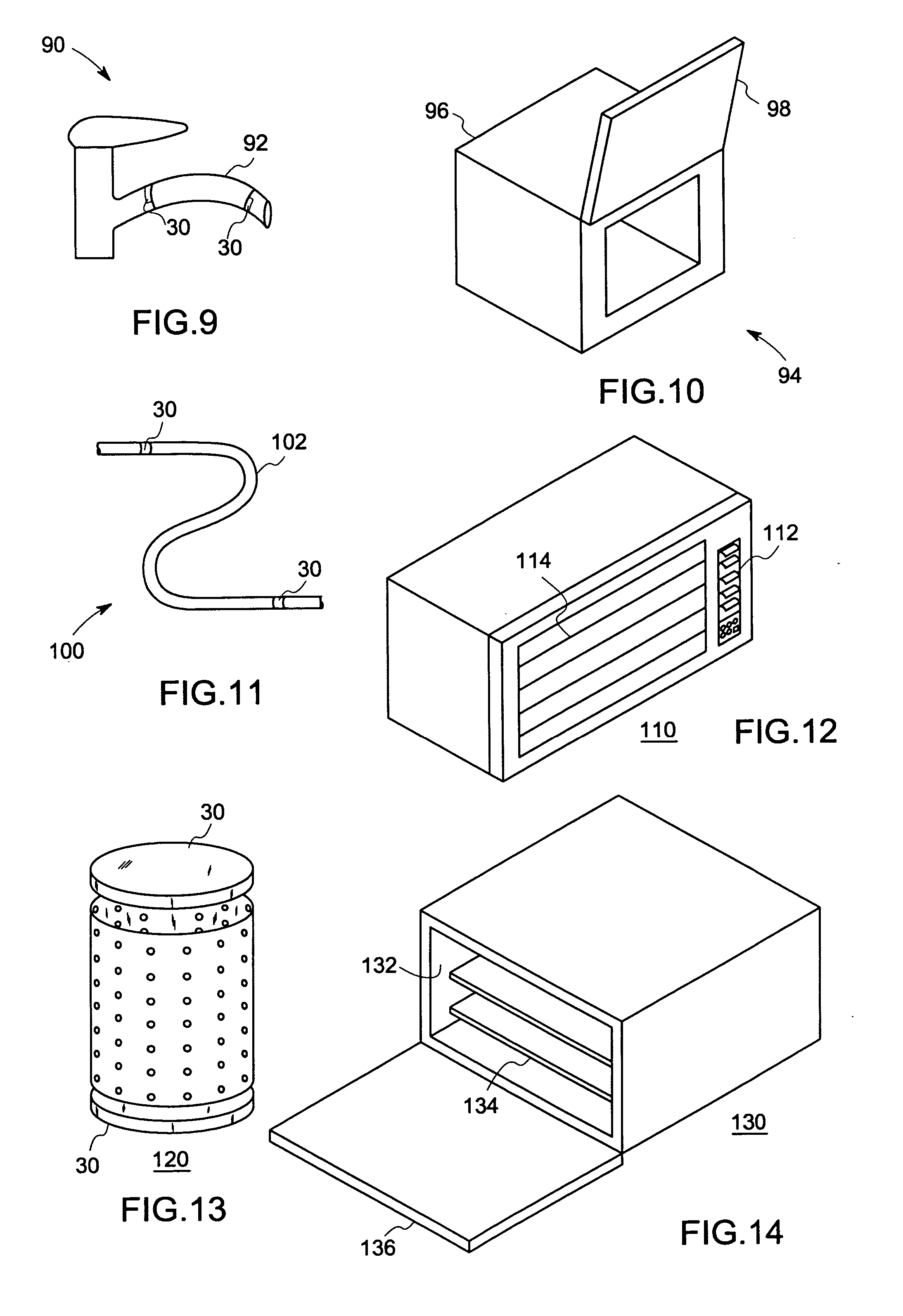

Self heating apparatus

InactiveUS20050067406A1Material nanotechnologyLighting and heating apparatusElectricityConductive composites

An apparatus with a self heating feature includes a conductive component of the apparatus having conductive composite. The conductive component is adapted to couple with a source of electricity, and the conductive component heats up on passage of electricity. According to another aspect, a domestic appliance that requires heating for its operation, includes at least one part comprising a conductive composite, which heats up on passage of electricity and the part is adapted to couple with a power supply. According to another aspect a method for providing heating in an apparatus includes heating at least one conductive component of the apparatus. The heating is done by passing an electric current through the conductive component, and the conductive component comprises a conductive composite.

Owner:GENERAL ELECTRIC CO

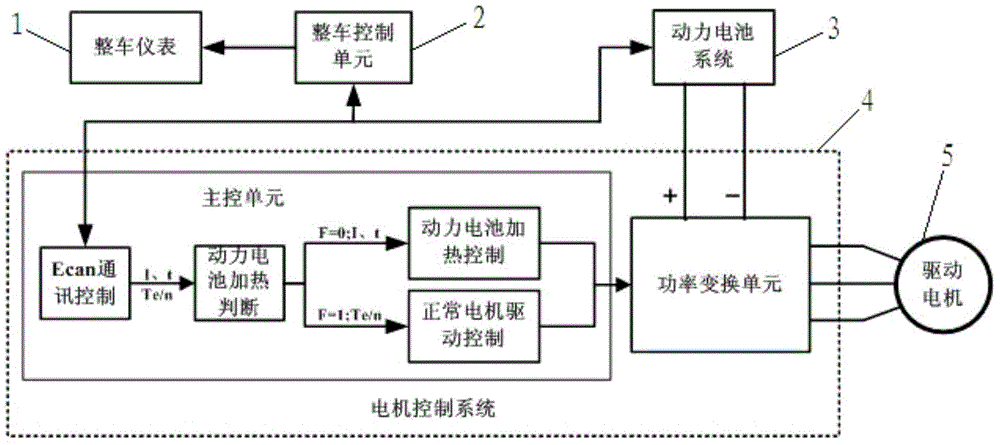

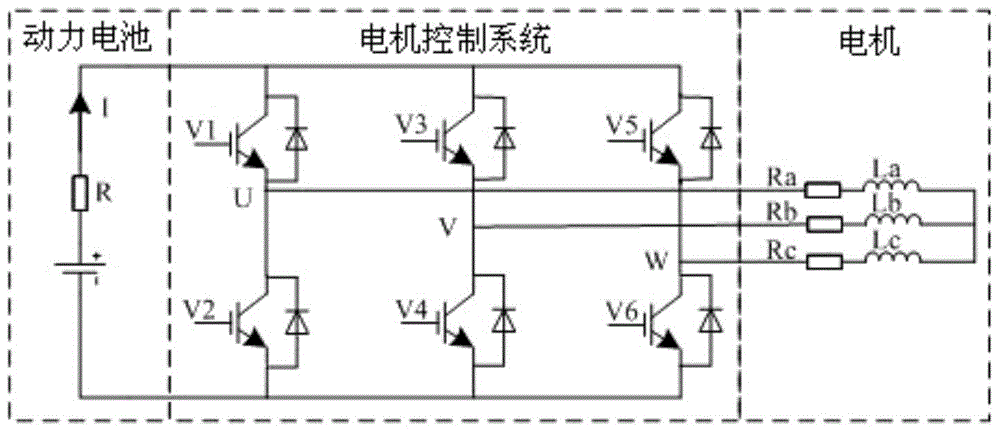

Heating control method of power battery pack of electric vehicle

ActiveCN103560304AIncrease temperatureControl heating rateCell temperature controlElectrical batteryEngineering

The invention belongs to the technical field of power batteries of vehicles, and particularly relates to a heating control method of a power battery pack of an electric vehicle. The heating control method is implemented by a whole vehicle instrument, a whole vehicle control unit, a power battery system, a motor control system and a driving motor, wherein the whole vehicle instrument is connected with the whole vehicle control unit, the whole vehicle control unit is connected with the power battery system and the motor control system respectively, and the motor control system is connected with the power battery system and the driving motor respectively. According to the method, power batteries are heated by virtue of an original electric drive system of the electric vehicle, the energy of the power batteries is mainly used for the self heating of the power batteries, so that the temperature of the power batteries can be rapidly raised without extra cost, and the heating efficiency is high.

Owner:DONGFENG MOTOR CORP HUBEI

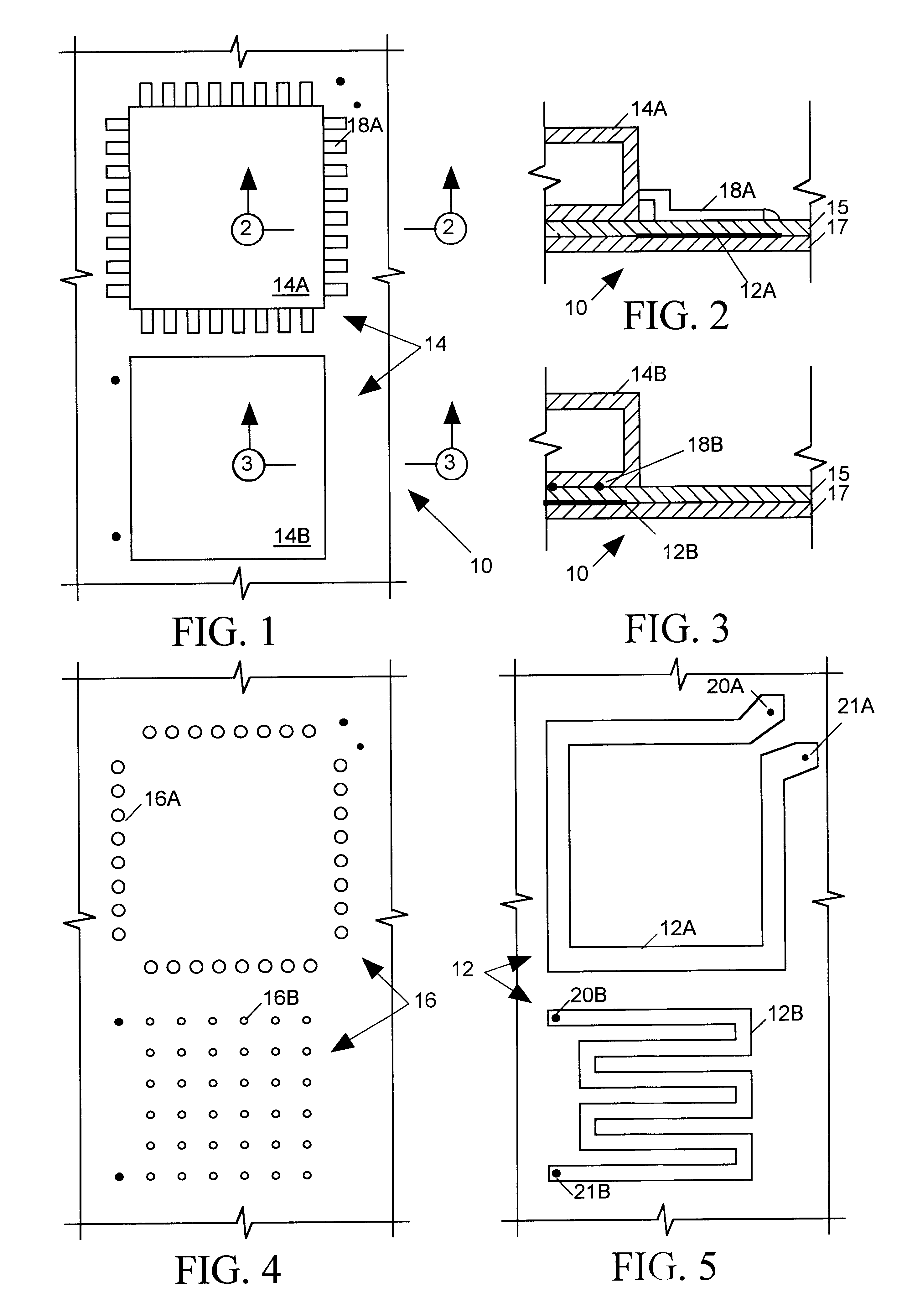

Self-heating circuit board

InactiveUS6396706B1Inexpensive and convenientSemiconductor/solid-state device detailsSolid-state devicesVoltage pulseAdhesive

Separate heating elements are embedded in a printed circuit board near integrated circuit (IC) packages or other parts mounted on the circuit board. Each heating element supplies heat to the part residing near it in response to an input voltage pulse. The heating elements are used to selectively melt solder or adhesives attaching the parts to the circuit board so that they can be easily removed or to temporarily melt solder or cure adhesive when the parts are mounted on the circuit board. The heating elements are also used to supply heat to IC packages for regulating their operating temperatures.

Owner:MA ZHONGXIN +1

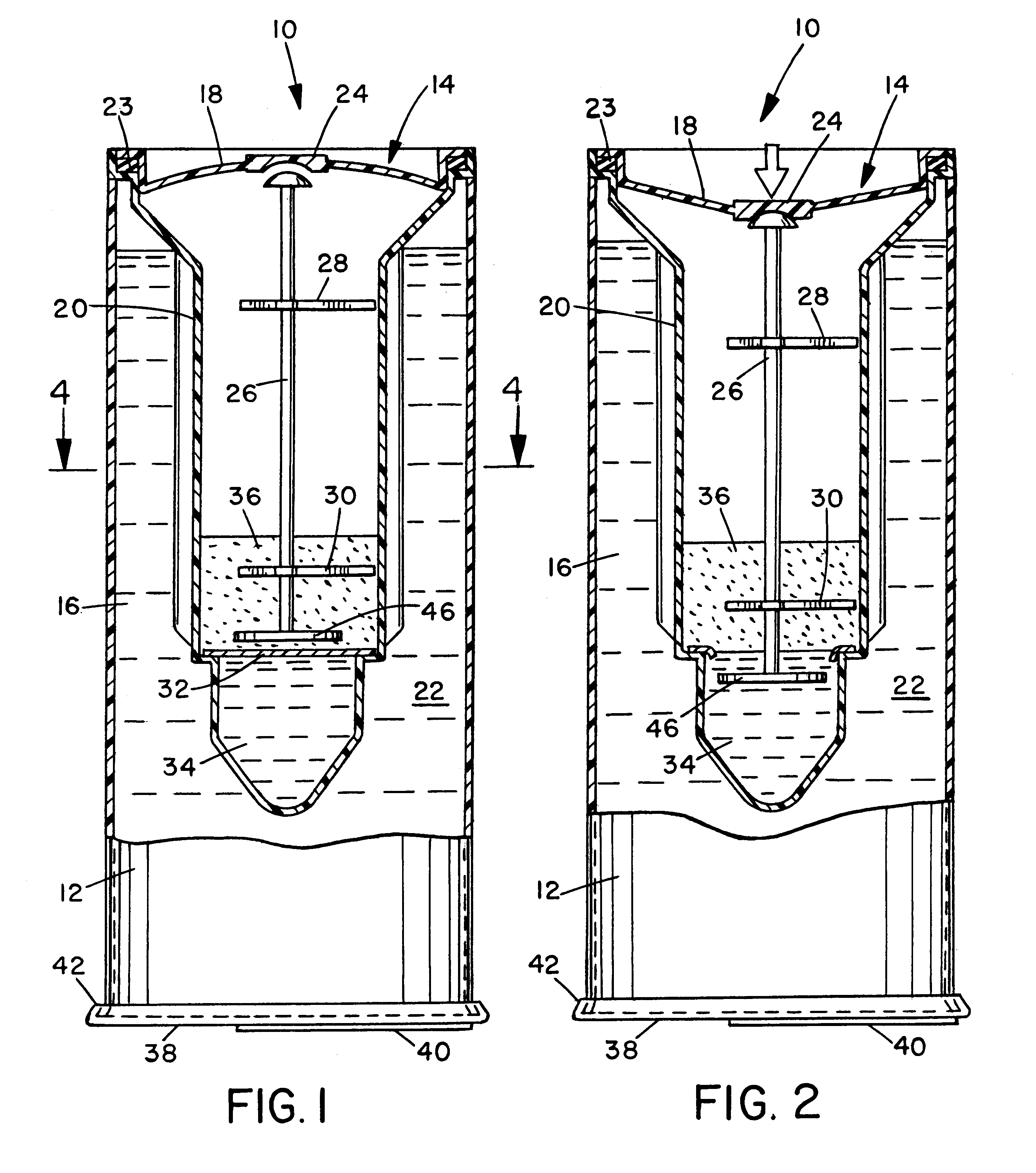

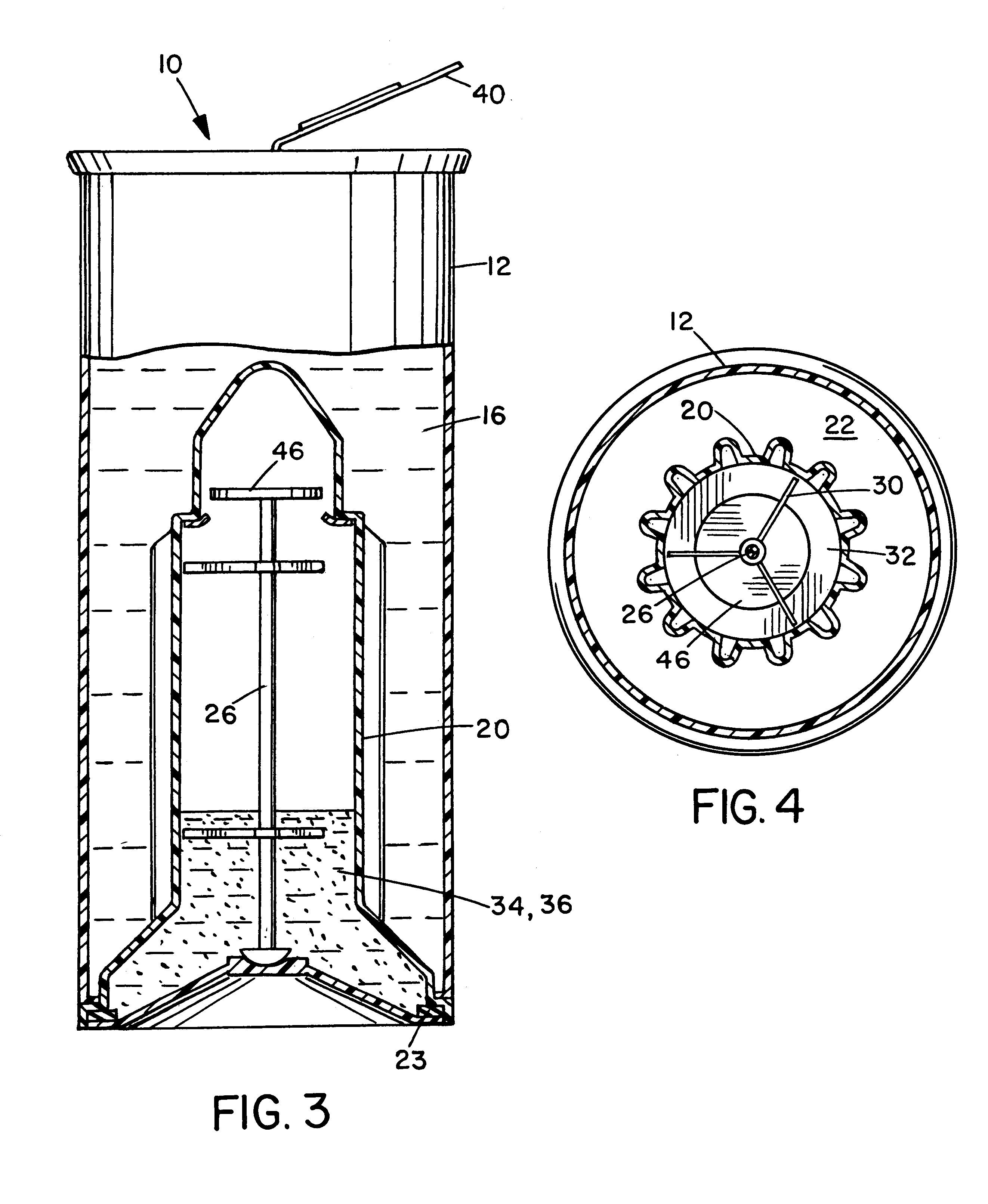

Container with self-heating module having liquid reactant and breakable reactant barrier at distal end of module

InactiveUS6178753B1Exothermal chemical reaction heat productionOther heat production devicesEngineeringActuator

A self-heating or self-cooling container has a container body, a closure at one end of the body through which the contents of the container can be consumed, and a thermic module at the other end of the body having an actuator portion and an elongated reaction chamber portion that extends distally into the container body and contains a liquid reactant relatively more distally from the actuator portion than a solid reactant separated from the liquid reactant by a breakable barrier. When a user actuates the thermic module, an elongated actuator member punctures the barrier. The user can then immediately invert the container, allowing the liquid reactant to drain through the puncture into the solid reactant in the reaction chamber. The reactants mix and produce a reaction that, depending upon the reactants, either heats or cools the container contents by conduction through the thermic module wall. An advantage is that the user does not need to wait to invert the container after actuating it. Rather, the user can actuate the container, immediately invert it, wait until the contents reach the desired temperature, and consume the contents through the closure.

Owner:ONTRO

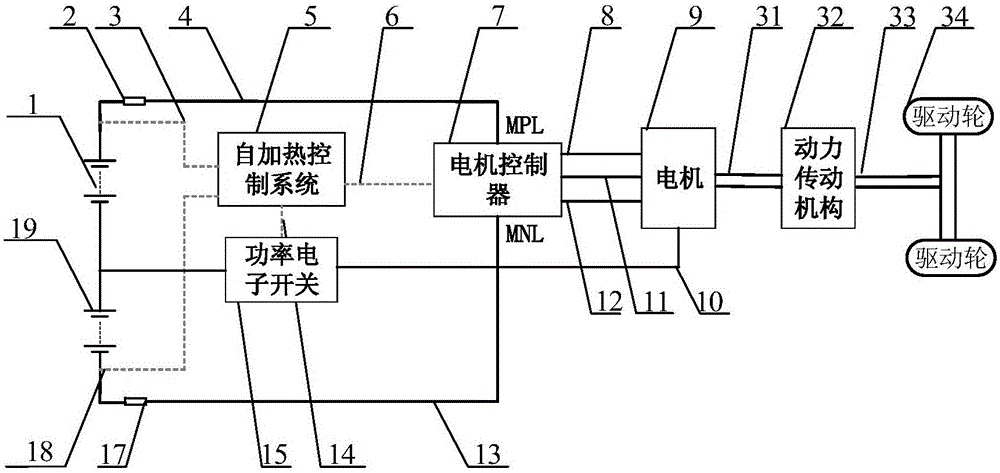

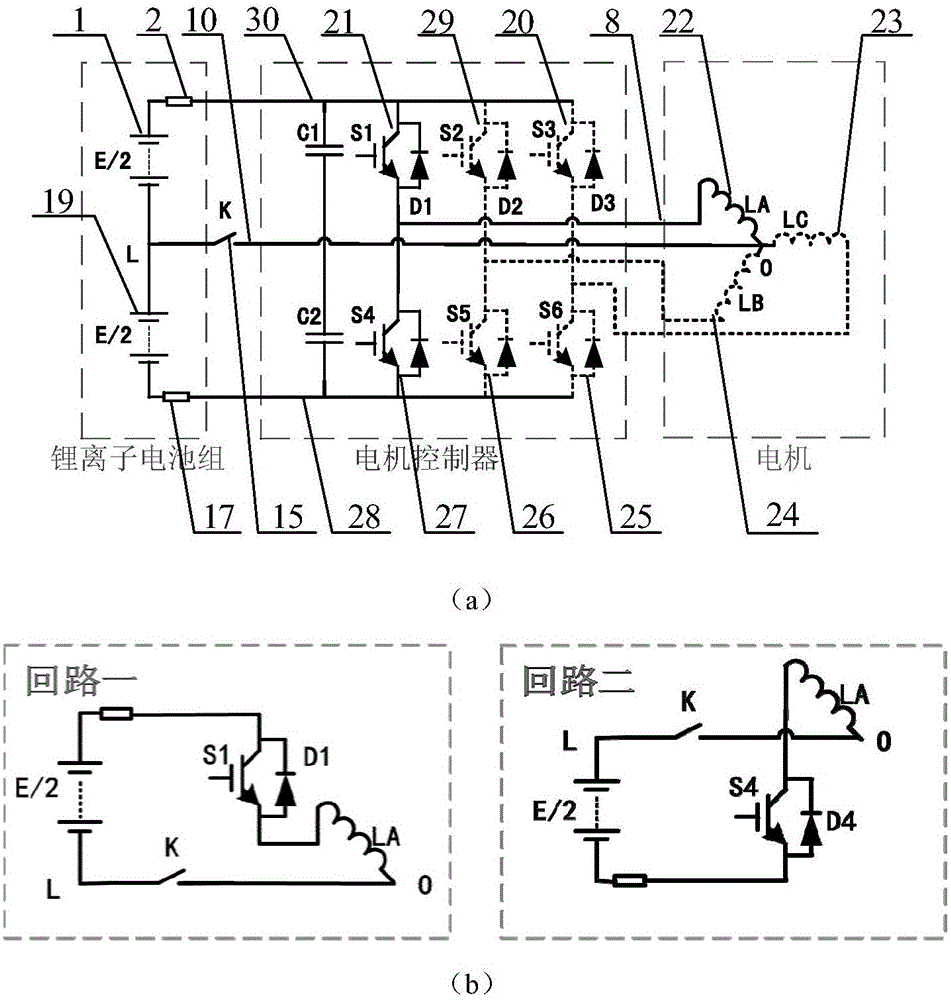

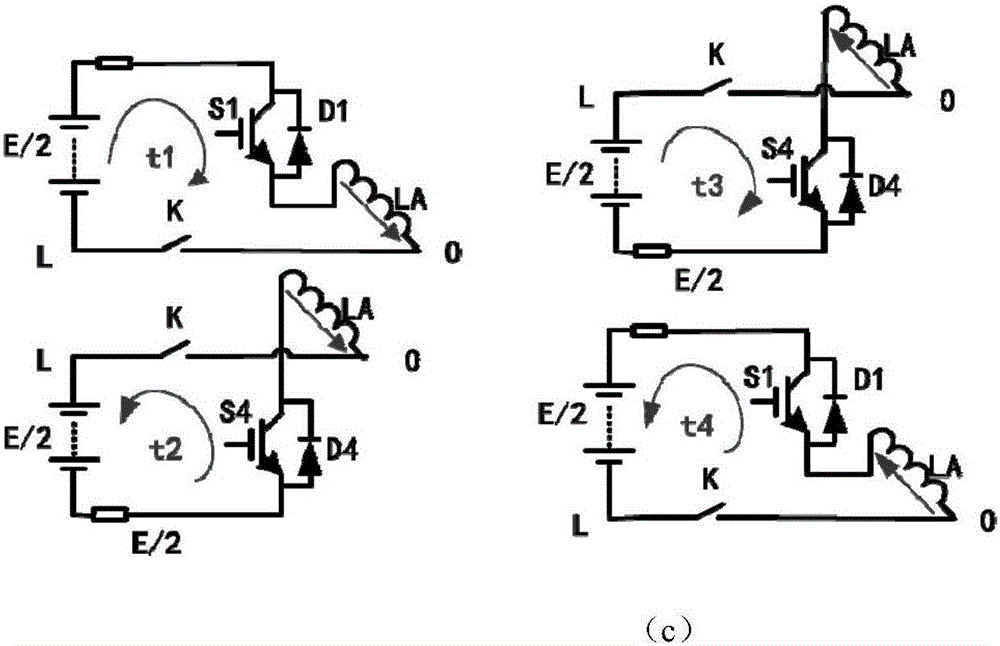

Power supply system with self-heating function and vehicle

ActiveCN105762434AActive and rapidly warming upLow costCell temperature controlPropulsion by batteries/cellsElectronic switchMotor controller

The invention relates to a power supply system with a self-heating function. An alternative-current self-heating loop consists of a first electrical storage device, a second electrical storage device, a power electronic switch, a motor controller and a motor, wherein a motor neutral point is electrically connected with an equipotential point between the first electrical storage device and the second electrical storage device through the power electronic switch; the power electronic switch is connected between the motor neutral point and the equipotential point in series. A power supply system device which is efficient and reliable, needs no external power supply device and has the self-heating function can be achieved, and moreover power supplied in the self-heating operation process is completely provided by a vehicle power supply system. The invention further relates to a vehicle.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

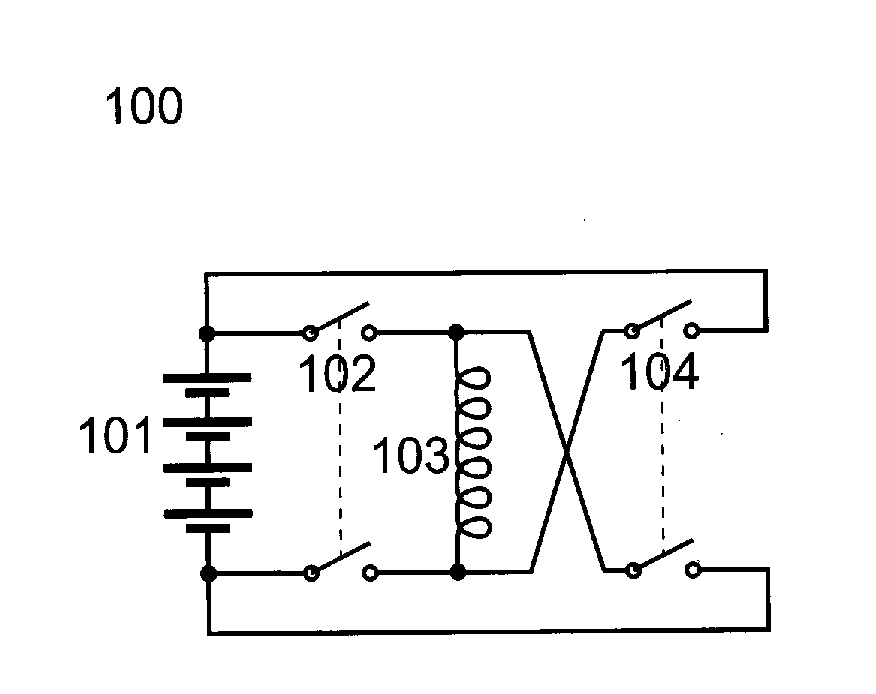

Self Heating Battery System

ActiveUS20120126753A1Supply will become excessiveHigh switching rateBatteries circuit arrangementsSecondary cellsCapacitanceCapacitive storage

A battery self heating system for batteries that experience battery impedance or internal battery resistance when temperature drops. The system comprises an energy storage element applied to the battery terminals to draw energy from the battery. The energy is stored in a magnetic or capacitive storage device. The system is self-resonant so that energy transfer from the storage device to the battery will occur at a frequency and load level that is compatible with the current state of the battery. Internal heating of the battery is accomplished by a cycle comprising the out flux and influx of energy through the impedance of the battery. Energy losses due to battery impedance are converted to heat thereby heating the battery internally.

Owner:STRYTEN ENERGY LLC

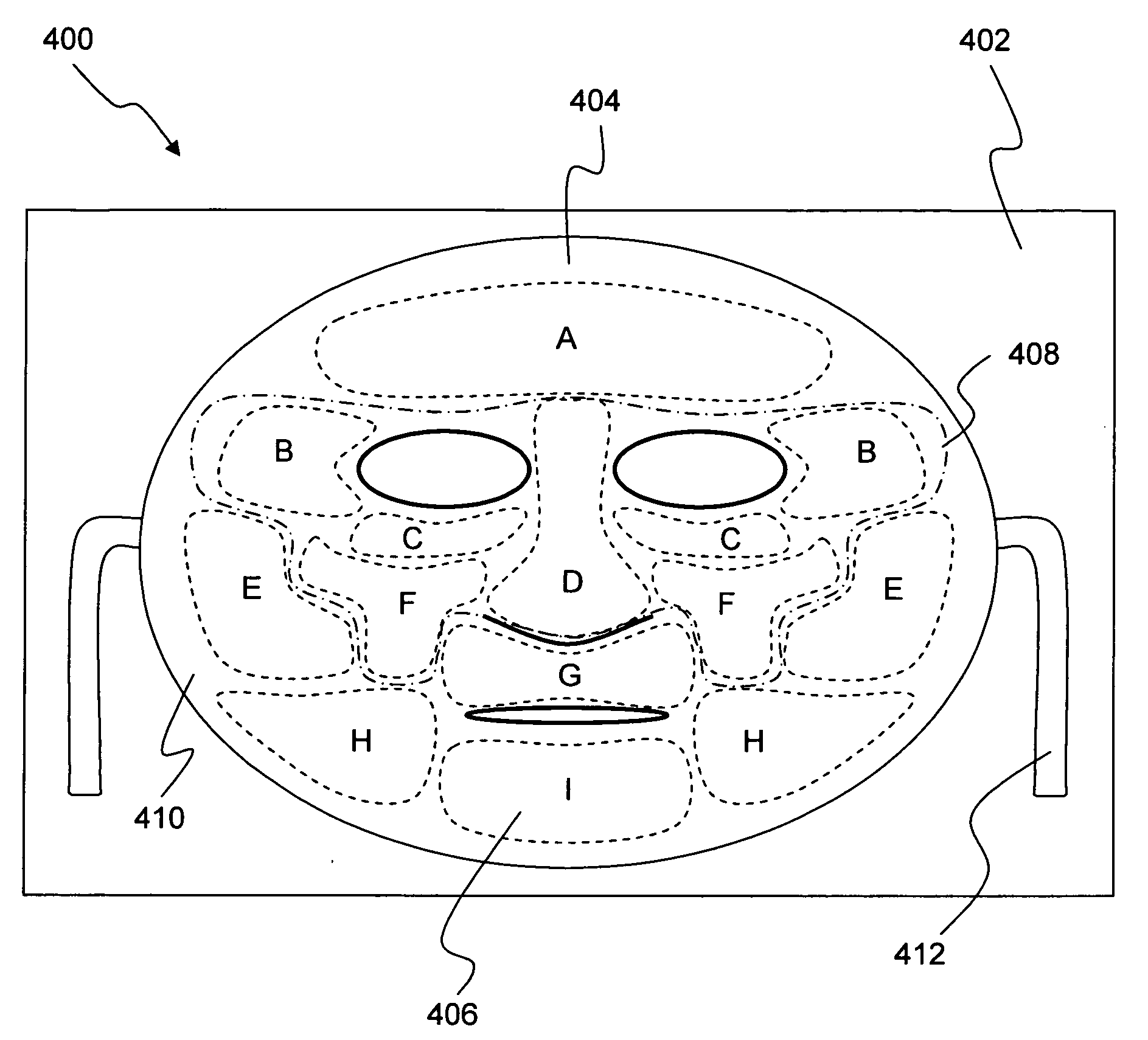

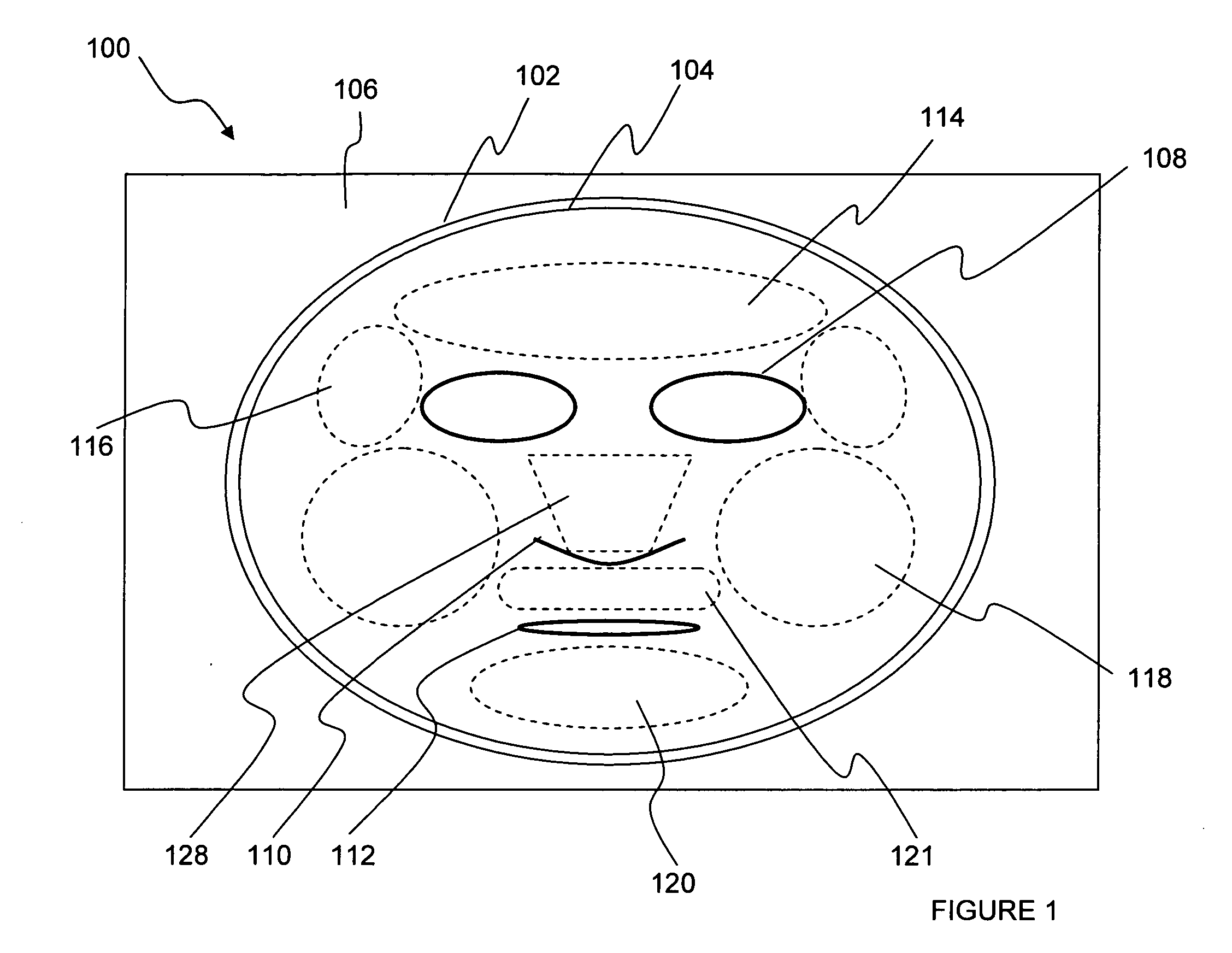

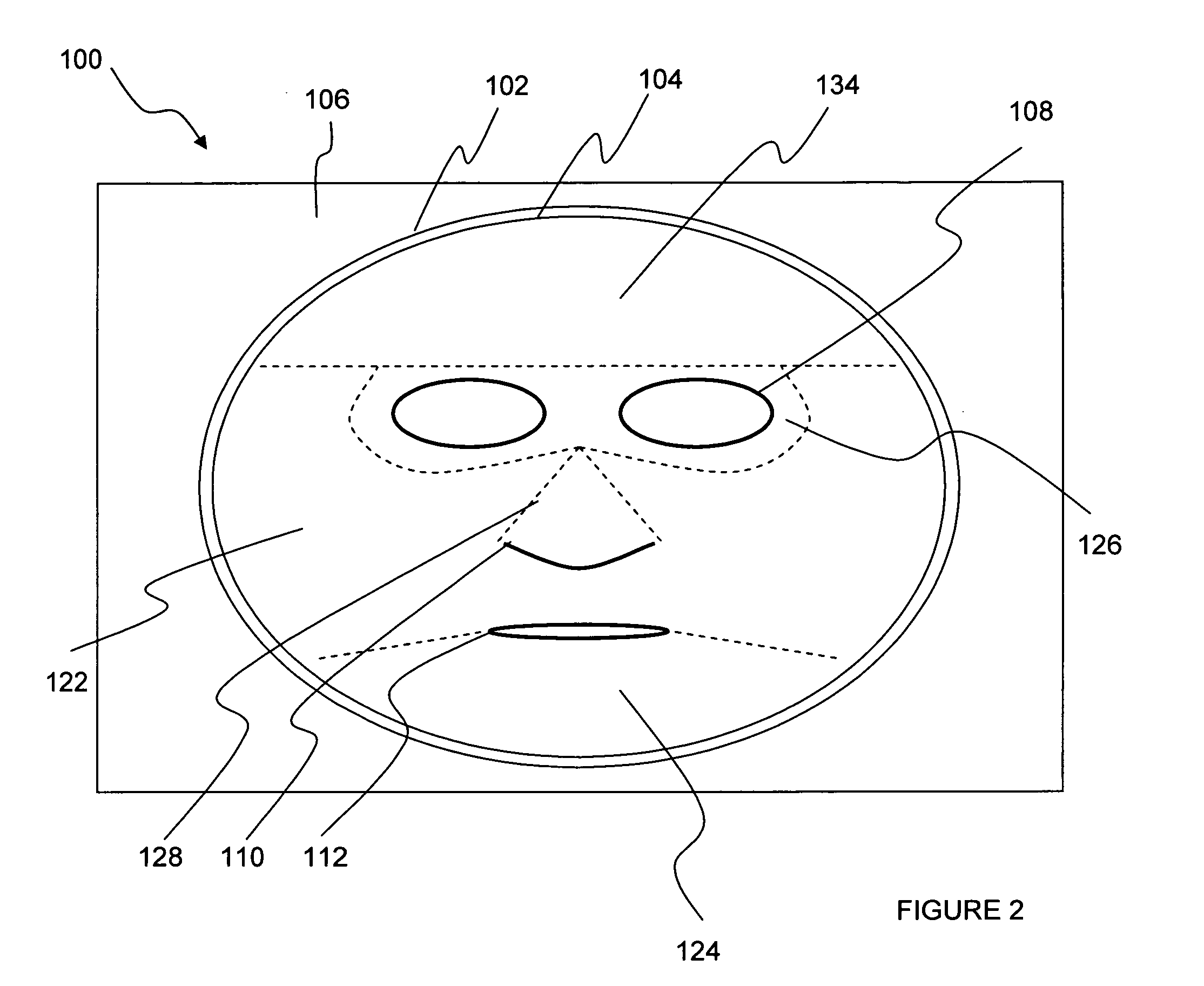

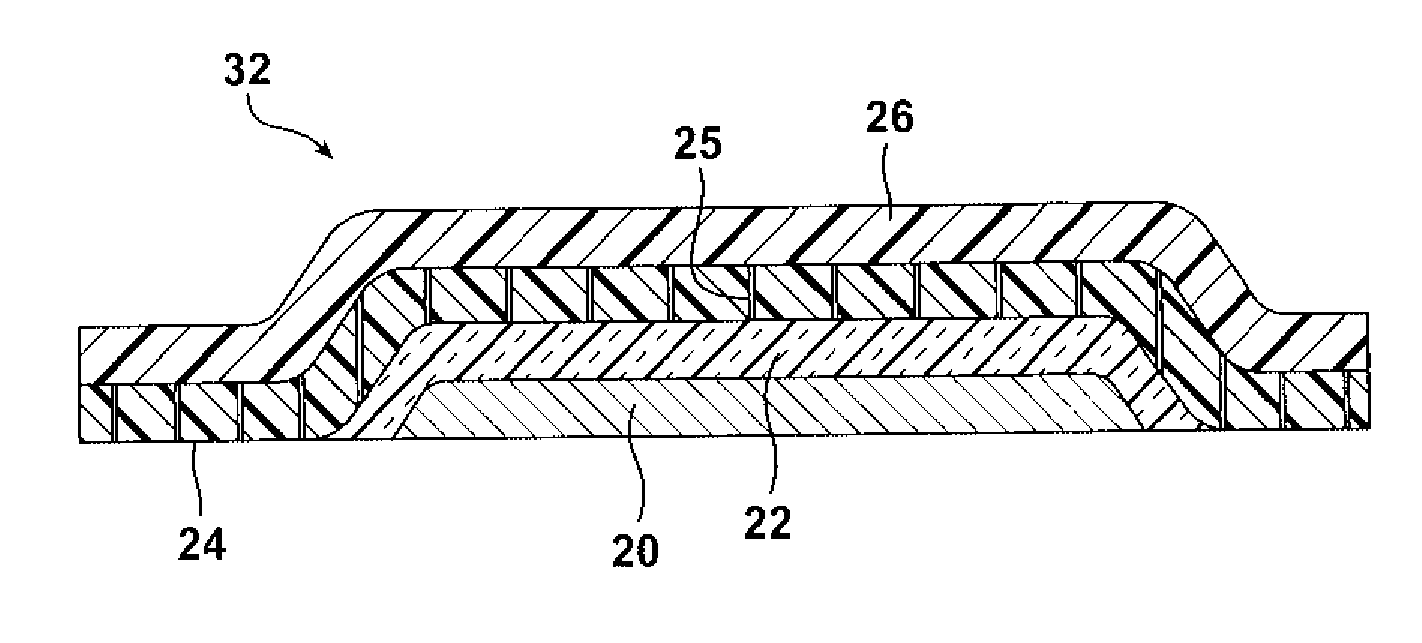

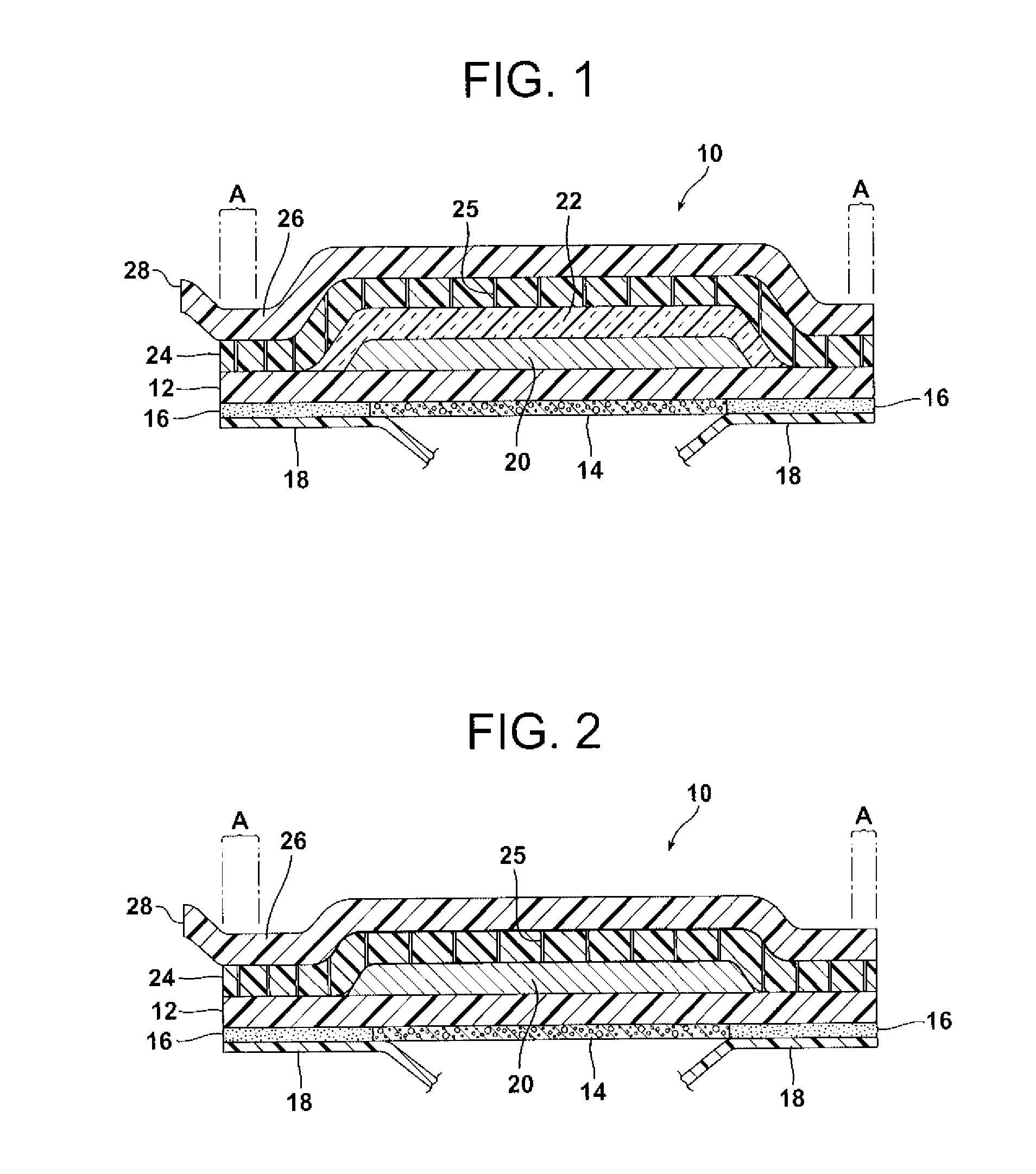

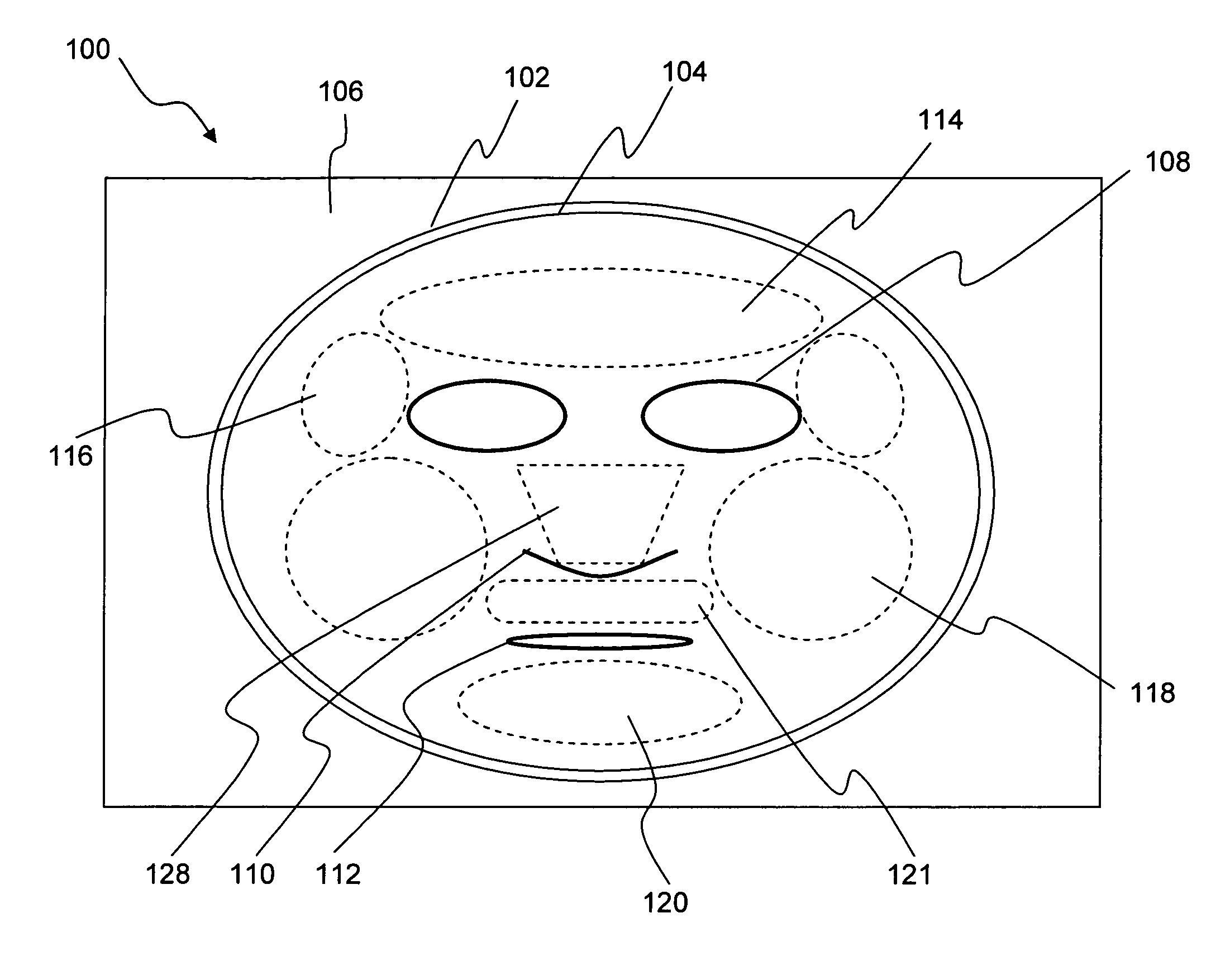

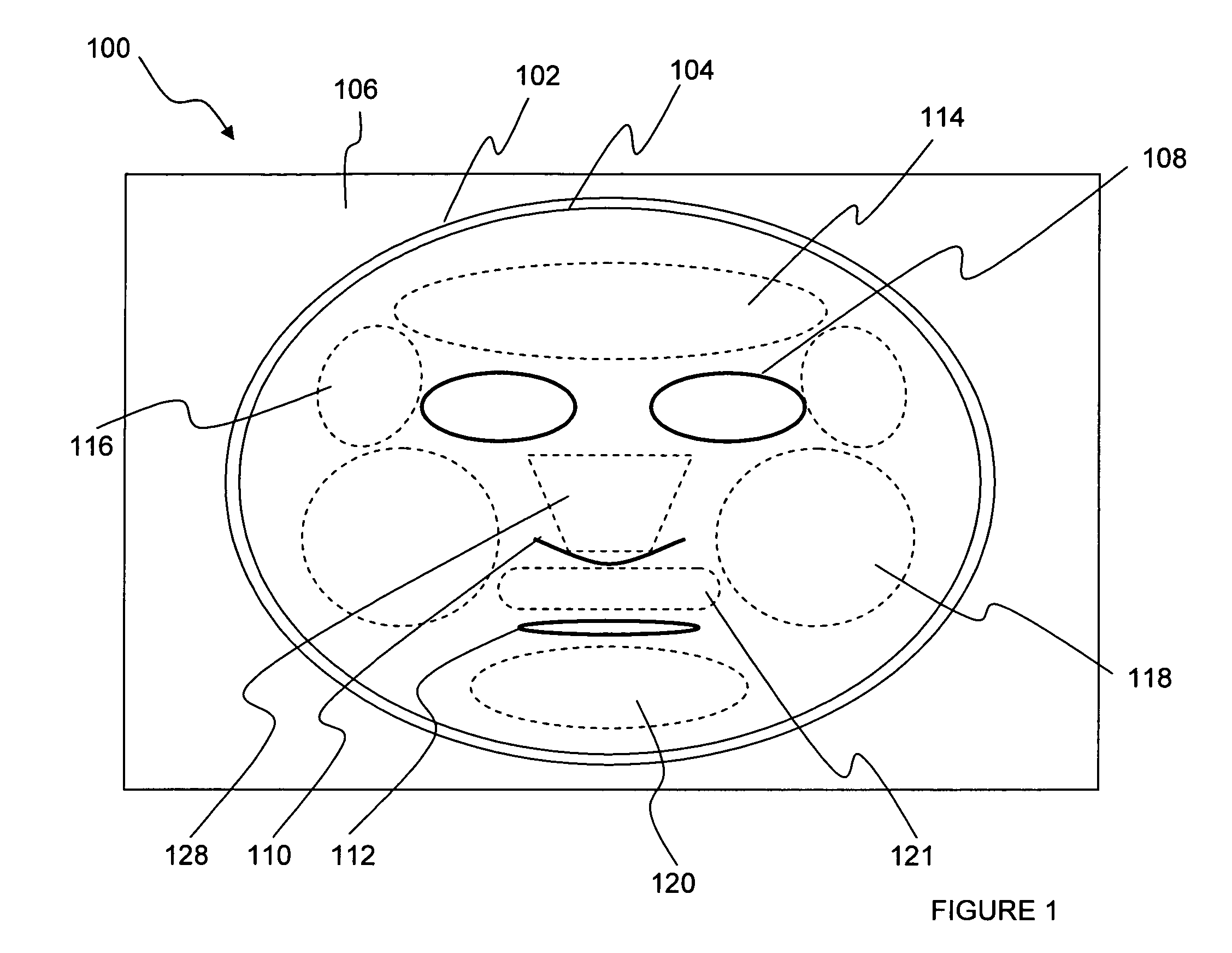

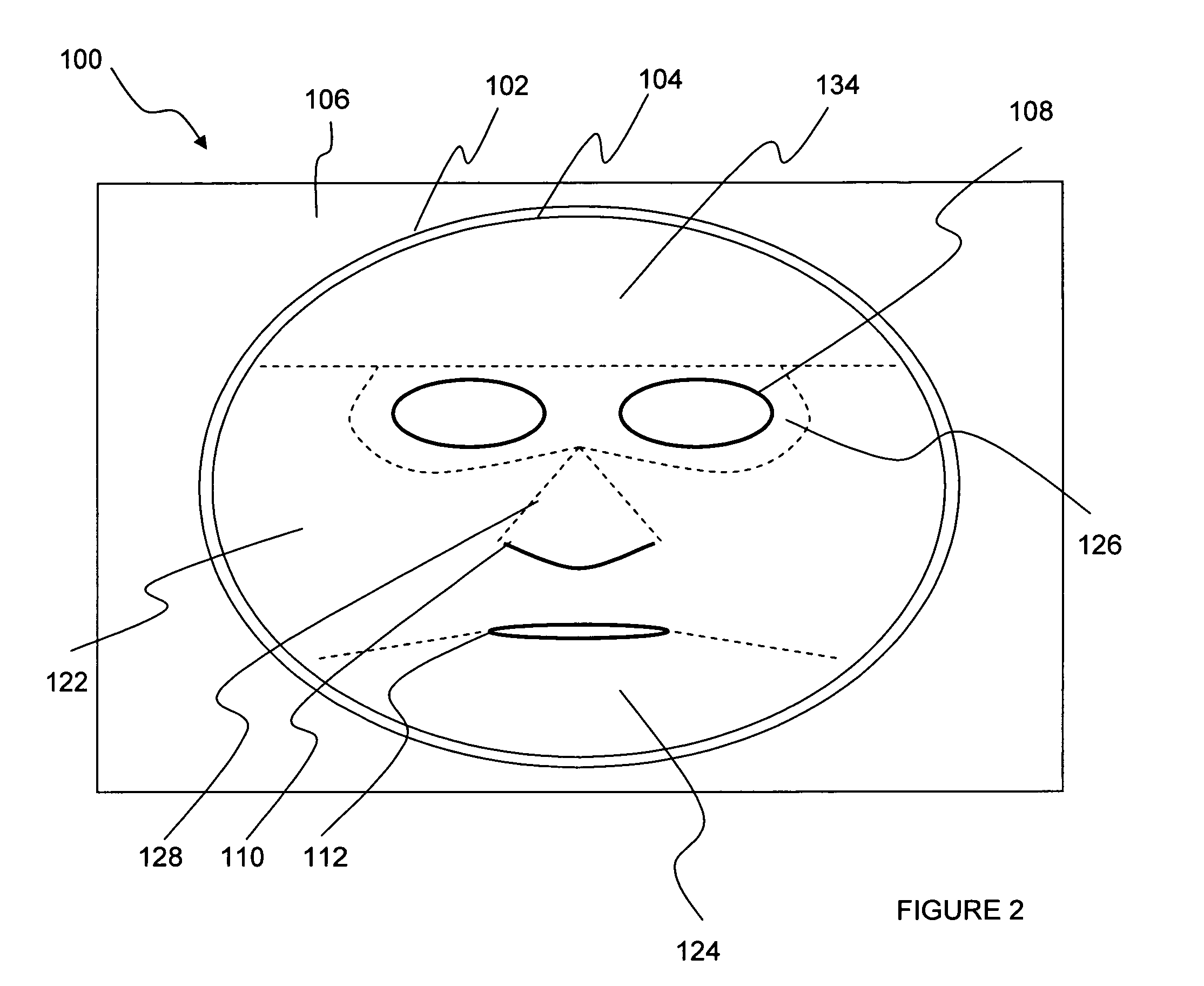

Temperature controlled facial mask with area-specific treatments

A temperature controlled cosmetic treatment facial mask with area-specific treatments of the present invention includes a substantially planar mask body which is formed with cut-outs for a person's eyes, nose, and mouth. The mask may include a number of large and small area treatment zones in combination with asymmetrical treatment zones suitable for treatment of specific and localized skin conditions. The treatments zones are coated with skin treatments, such as compounds, lotions, gels, and the like as are known in the facial treatment, cosmetics, spa and medical industry. The mask may include a self-heating or cooling substrate to provide temperature control to the face mask and each mask may include heating areas, cooling areas, or both. A system is also provided that includes an imaging device that feeds its output to a central computer system having an image analyzer, CPU, memory and Look Up Table, and face map for determining specific treatment requirements for the particular patient. An output from the central computer system is provided to a treatment deposition device which deposits various treatments onto an intermediate membrane layer to generate a custom temperature controlled facial mask with area-specific treatments for that particular patient.

Owner:FOREVER YOUNG INT

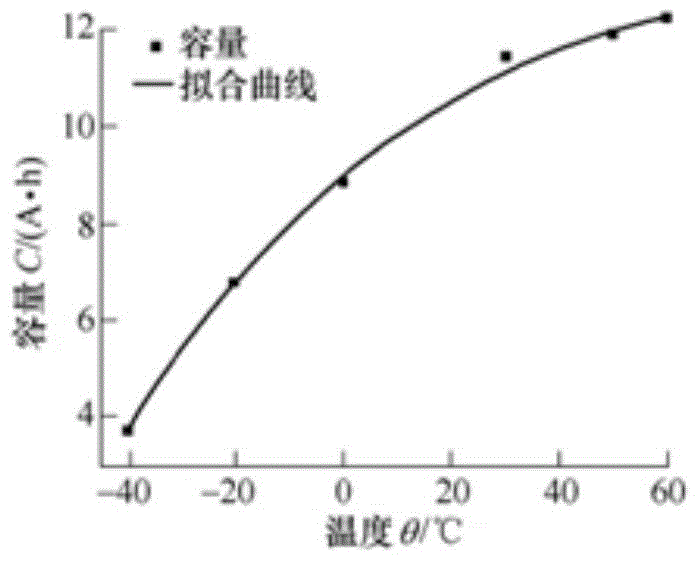

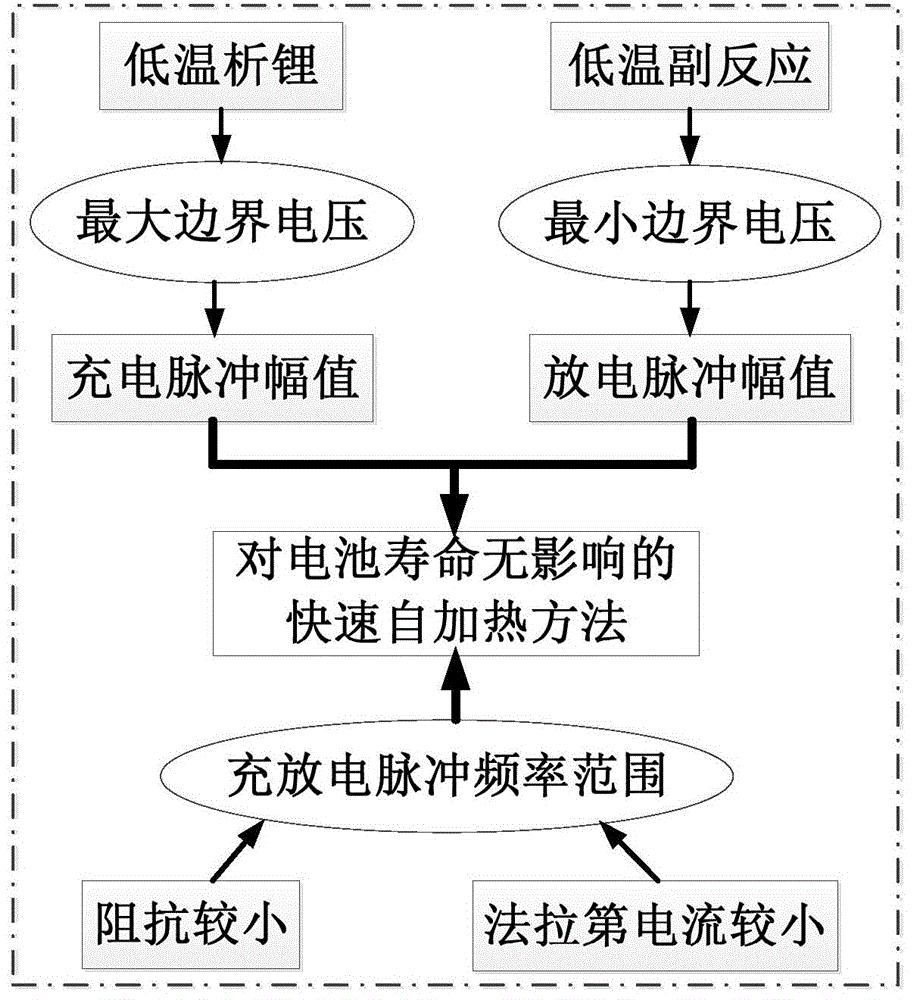

Low-temperature self-heating method for lithium ion battery

ActiveCN104064836ANo effect on service lifeReduced service lifeCell temperature controlInternal resistanceEngineering

The invention discloses a low-temperature self-heating method for a lithium ion battery. The method comprises the steps of determining a frequency range in which the service life of the lithium ion battery cannot be affected, and selecting frequencies of charging and discharging pulses according to the range; setting a pulse current amplitude value selection basis under a selected charging and discharging mode, and calculating a charging current amplitude value Ic and a discharging current amplitude value Id; performing no-life-loss heating on the battery to be heated according to charging and discharging pulse signals of the determined frequencies and the amplitude values, wherein the inner resistance of the self-heated battery is greatly reduced, and the charging performance is greatly improved. According to the technical scheme, the low-temperature self-heating method has the effects of high self-heating speed, obvious low-temperature performance improvement and no influence on the service life of the battery.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

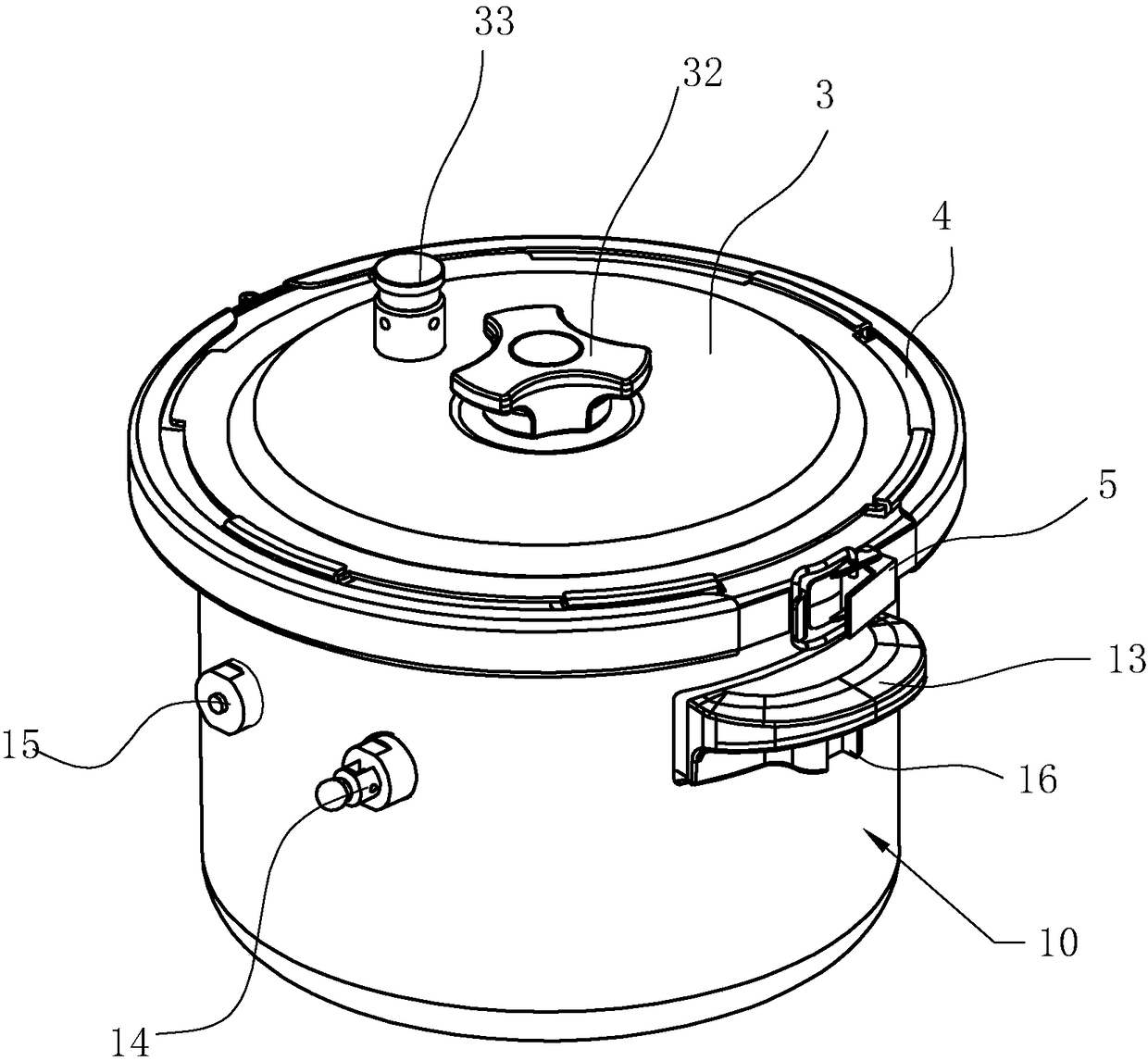

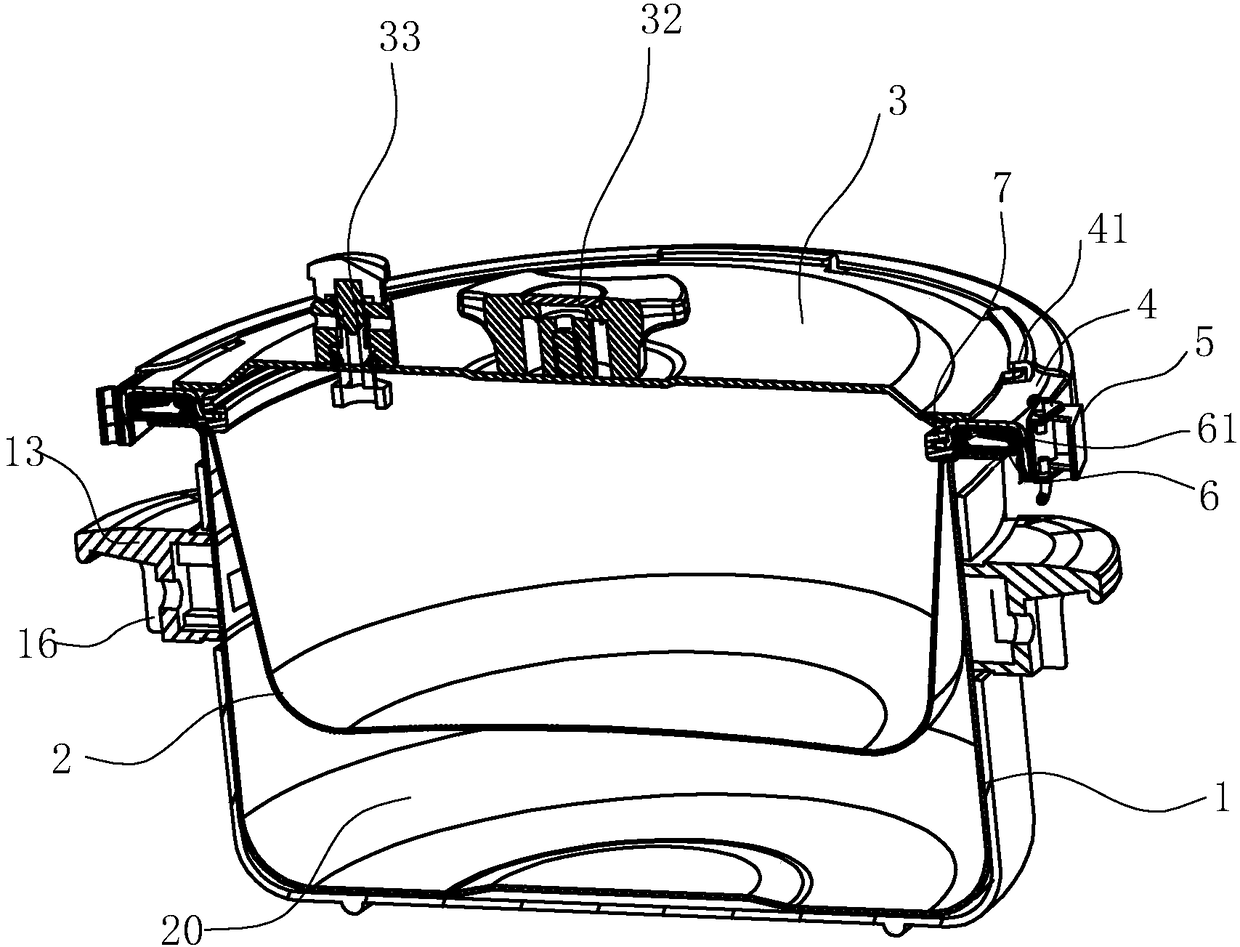

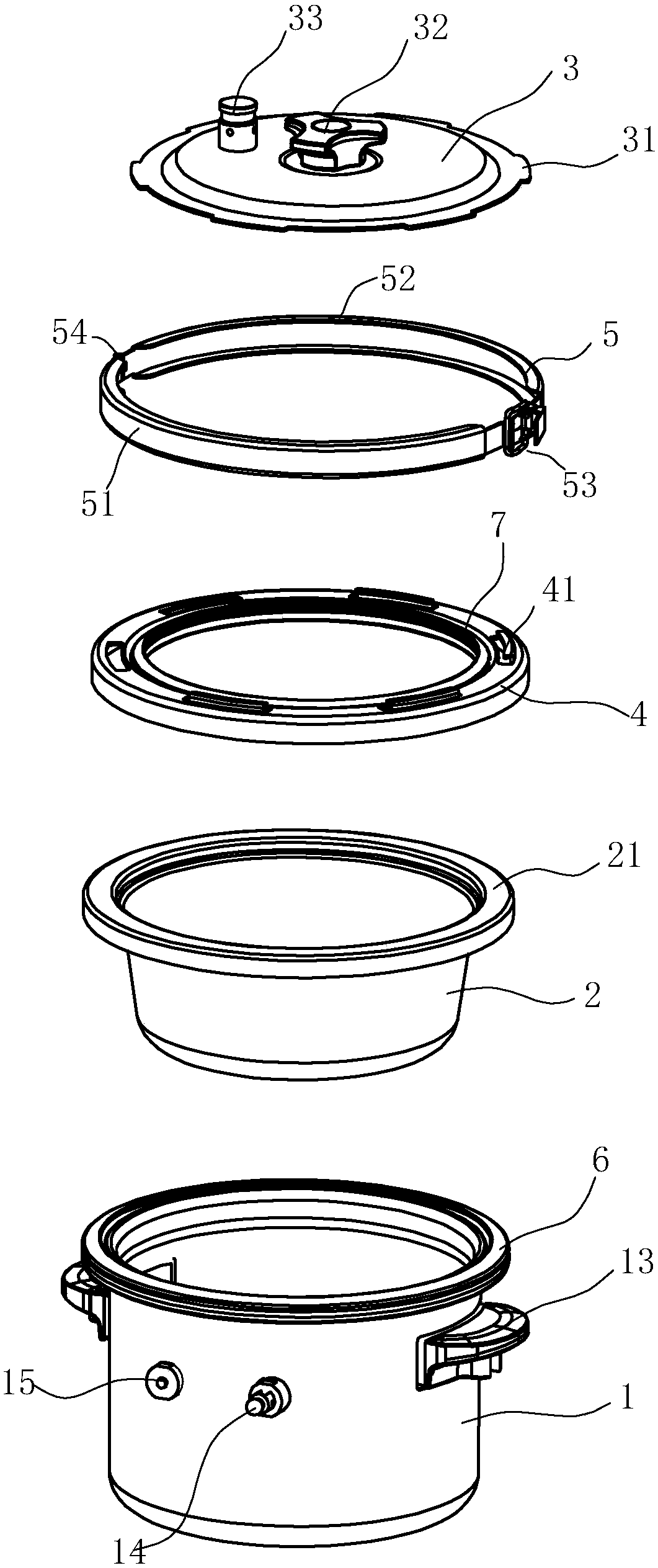

Portable pressure cooker

PendingCN108354444ADisassembly safetyEasy to assemble and disassemblePressure-cookersWarming devicesExhaust valveEngineering

The invention provides a portable pressure cooker. The pressure cooker comprises a cooker body and a cover. The pressure cooker is characterized in that the cooker body comprises an outer cooker bodyand an inner cooker body, the inner cooker body is sleeved with the outer cooker body and connected with the outer cooker body through a cover ring and a clamp ring, a cavity used for placing self-heating materials is formed in the part between the inner cooker body and the outer cooker body, and a pressure limiting valve and / or a safety valve communicated with the cavity is arranged on the side face of the cooker body. By arranging the inner and outer cooker bodies and placing the self-heating materials in the cavity formed in the part between the inner and outer cooker bodies, automatic heating can be conducted by adding in water to cook foods in the inner cooker body, so that the use of the cooker in an environment without heating sources in the field is convenient; by arranging the safety valve on the side of the outer cooker body and arranging an exhaust valve on the cover, the pressure cooker is safe and reliable to use; by fixing the inner cooker body and the outer cooker body through the clamp ring and the cover ring, the disassembly and assembly of the pressure cooker are convenient, and the sealing performance is good; the outer cooker body is divided into two layers, theouter layer is a heat preserving layer, heat does not disperse easily, the heat preserving performance is good, and cooking is faster. The pressure cooker has the advantages of being simple and reasonable in structure, convenient to dismantle and assemble and safe and reliable to use.

Owner:王国海

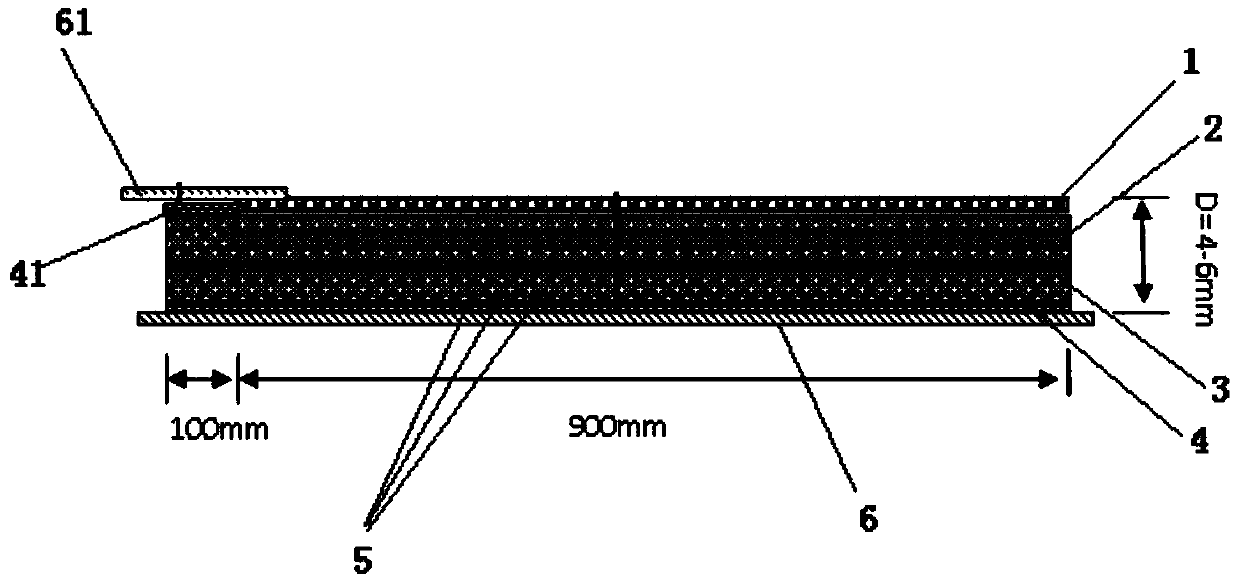

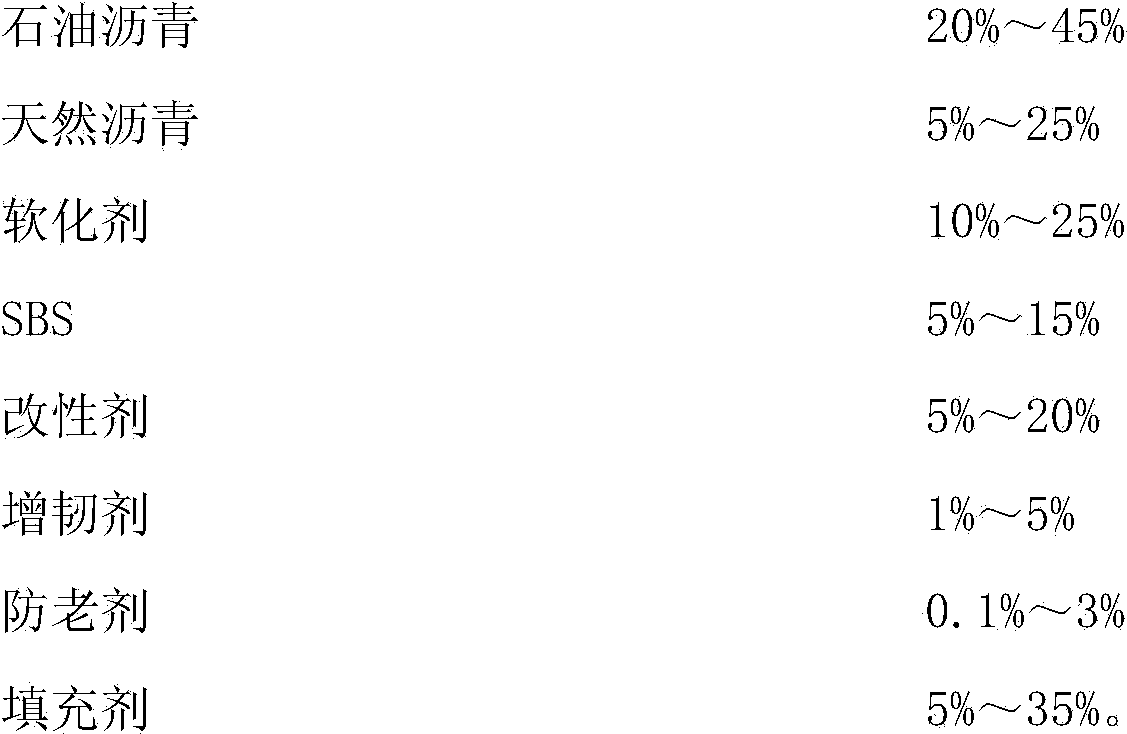

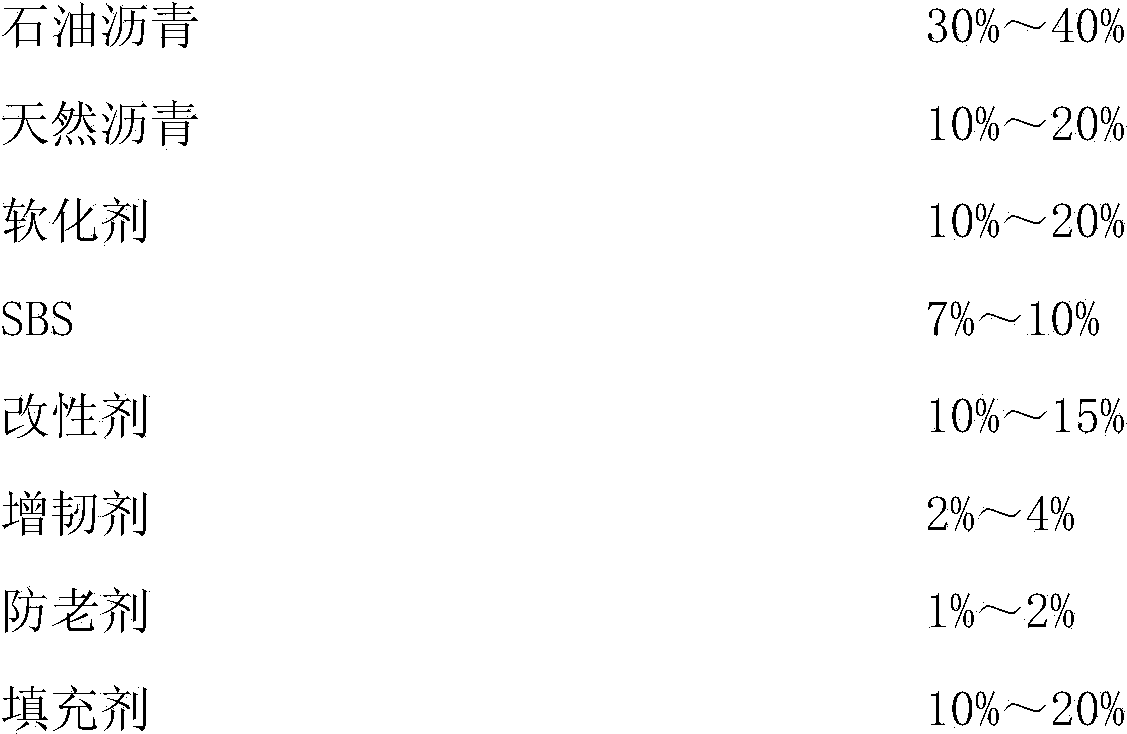

Modified asphalt waterproof sheet material

ActiveCN103802380AHigh tensile strengthGood dimensional stabilityNon-macromolecular adhesive additivesSynthetic resin layered productsElastomerPolyester

The invention discloses a modified asphalt waterproof sheet material. The modified asphalt waterproof sheet material is of a multilayer structure; the upper surface of the modified asphalt waterproof sheet material is a mineral granule layer; a fiberglass reinforcement basic layer and a polyester reinforcement basic layer are sequentially arranged in the middle part of the modified asphalt waterproof sheet material in sequence; a self-adhesion polymer modification asphalt sizing material layer is arranged in the bottom layer of the modified asphalt waterproof sheet material; adjacent layers are adhered through an elastomer polymer modification asphalt sizing material layer; an isolation film is adhered on the self-adhesion polymer modification asphalt sizing material layer. The structure of the modified asphalt waterproof sheet material provided by the invention can be applicable to small deformation of the basic layers, and has the advantages of higher size stability, convenience in construction, adhesion reliability and self-heating property. The invention provides a reliable and exposed modified asphalt waterproof sheet material, and is particularly applicable to monolayer roofs.

Owner:KUNMING FENGXING WATERPROOF MATERIAL +1

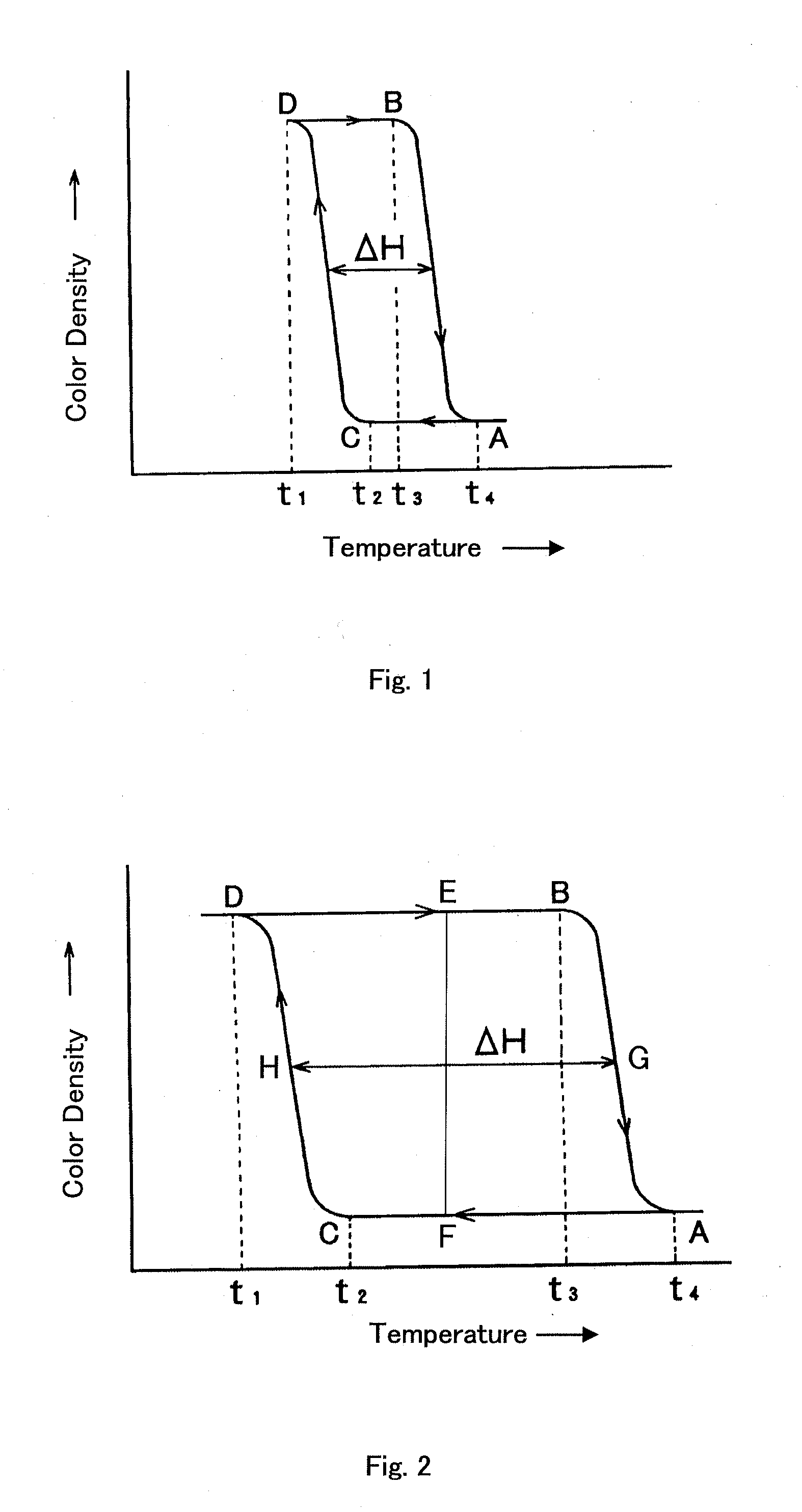

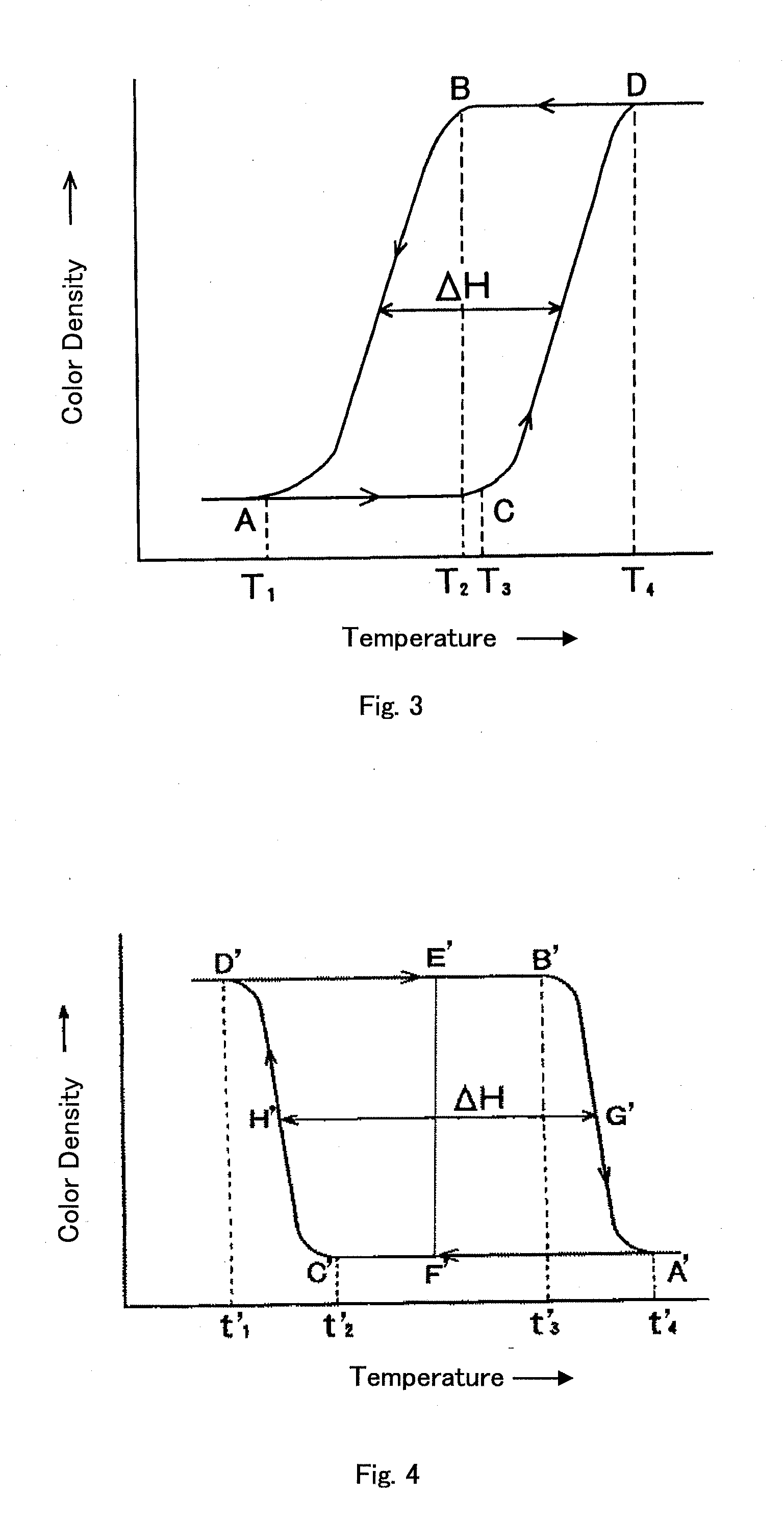

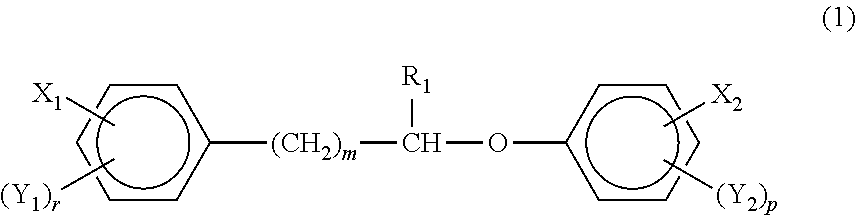

Reversibly thermochromic composition

InactiveUS20140291585A1Improve visibilityGood effectConductive materialPen repairingThermochromismHeat conducting

[Object] To provide a reversibly thermochromic composition free from accidental discoloration by heat conducting from the opposite side writing surface or by self-heating due to quick writing; and also to provide a solid writing material and a writing ink composition comprising that composition.[Means to solve the problem] A reversibly thermochromic composition comprising a combination of: (a) a reversibly thermochromic component capable of being discolored or decolored by heat and (b) a component for controlling heat conducting to the reversibly thermochromic component; and also a solid writing material and a writing ink composition comprising that composition.

Owner:PILOT PEN CO LTD

Method of treating flammable catalyst

A method used for manufacturing a catalyst used for hydrogenation treating and / or hydrogenation cracking a hydrocarbon flow or exhaust treating a thionic gas flow comprises heating a prevulcanized composition to 200-500 DEG C in the presence of hydrogen gas to form a sulfide of a metal, wherein said prevulcanized composition contains a prevulcanized catalyst loaded at a porous carrier and at least part of the catalyst is coated and / or infused by at least a containing oxygen hydrocarbon having at least 16 carbon atoms and an iodine value of not less than 60, with a condition that when said hydrocarbon is glycerin trifatty acid ester, the catalyst is not coated and / or infused by said hydrocarbon when or before it is prevulcanized, and when there is no hydrogen added existing in the catalyst coated and / or infused, said catalyst has undergone a heating treatment at not lower than 175 DEG C, with reduced self-heating characteristics of said catalyst.

Owner:CRI INT

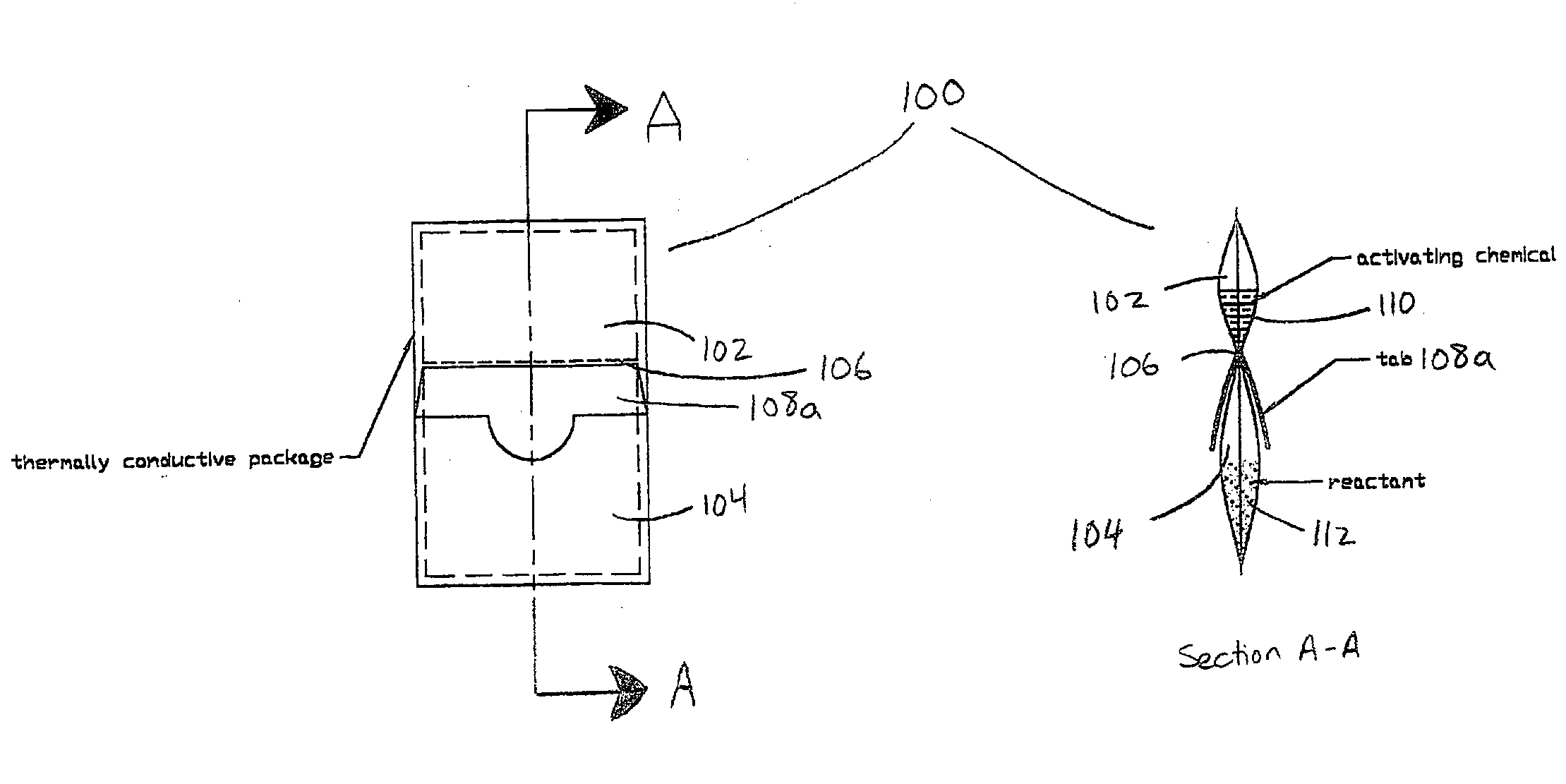

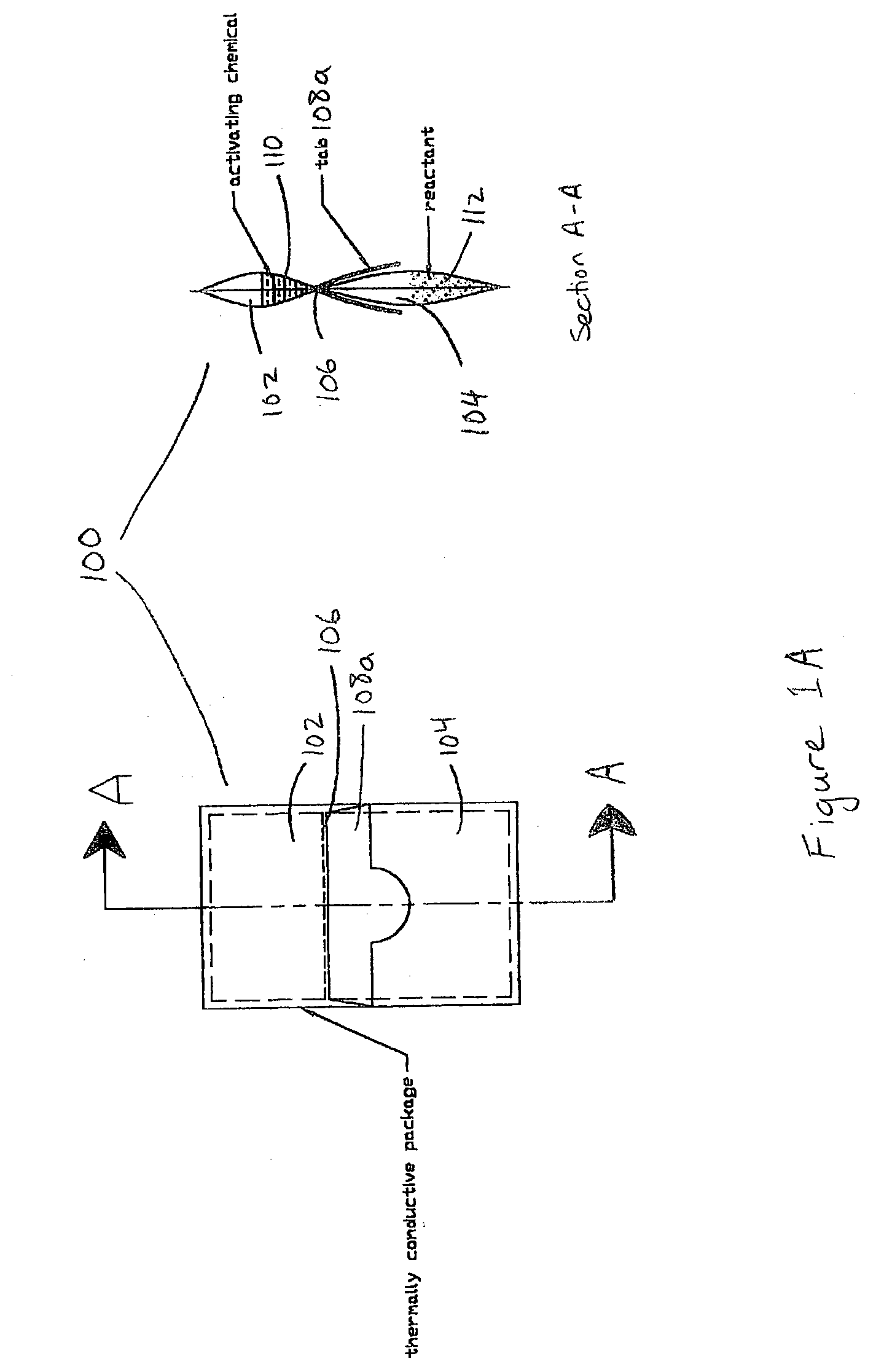

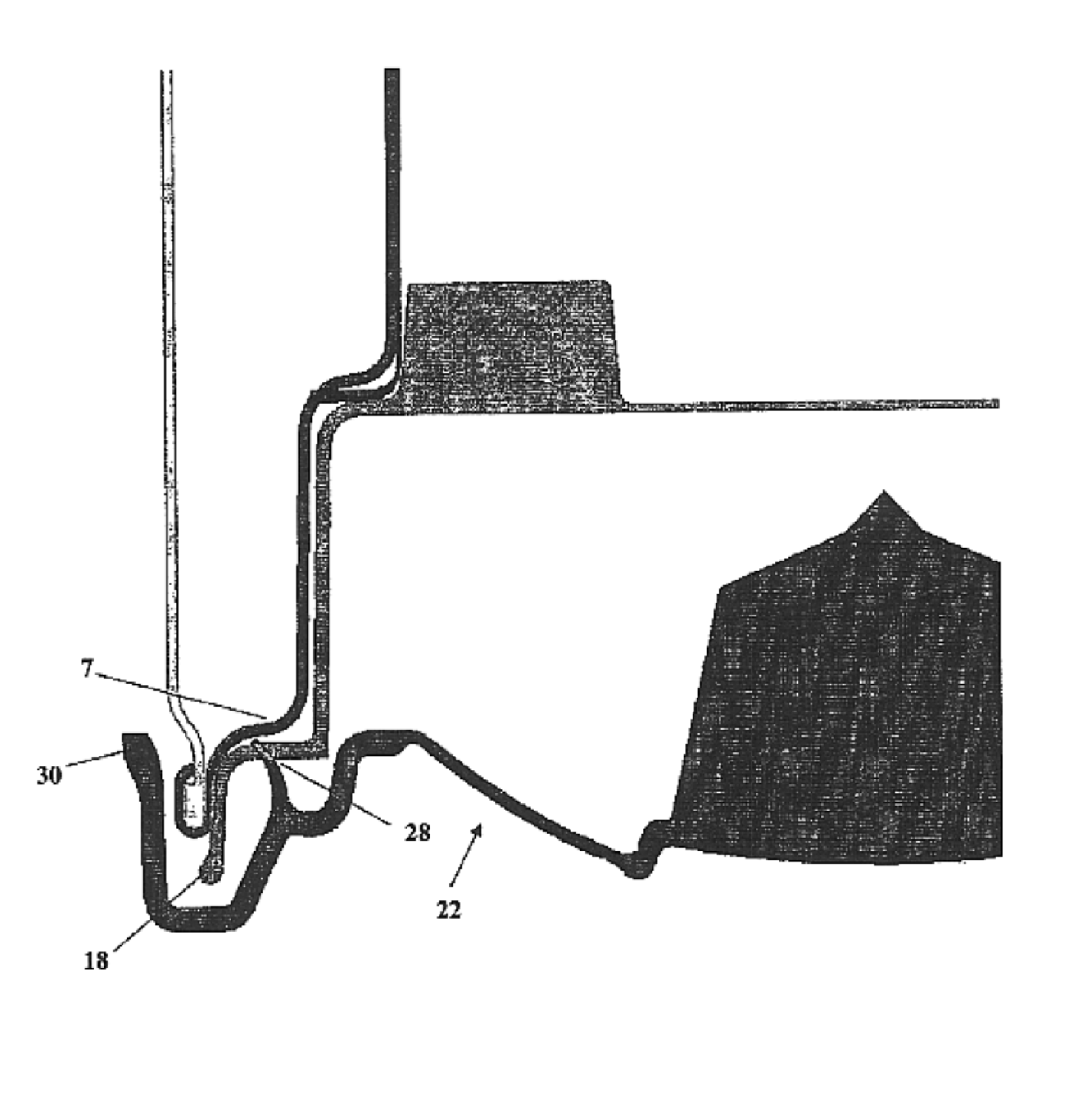

Trigger mechanism for self-heating/cooling packages or containers universally applied to both rigid and non-rigid packages and containers

InactiveUS20030116452A1Exothermal chemical reaction heat productionHeat storage plantsEngineeringMechanical engineering

A package is provided including a first sealable envelope containing a first agent, a second sealable envelope containing a second agent adjacent the first sealable envelope and a frangible seal separating the first sealable envelope from the second sealable envelope and a triggering mechanism located on an exterior of the package, the triggering mechanism having a first portion attached to the package at a first point adjacent the first sealable envelope and a second portion attached to the package at a second point adjacent the second sealable envelope such that, if the first portion and the second portion of the triggering mechanism are pulled, the frangible seal is stressed to rupture, allowing the first agent to communicate with the second agent.

Owner:SARIC JERKO +1

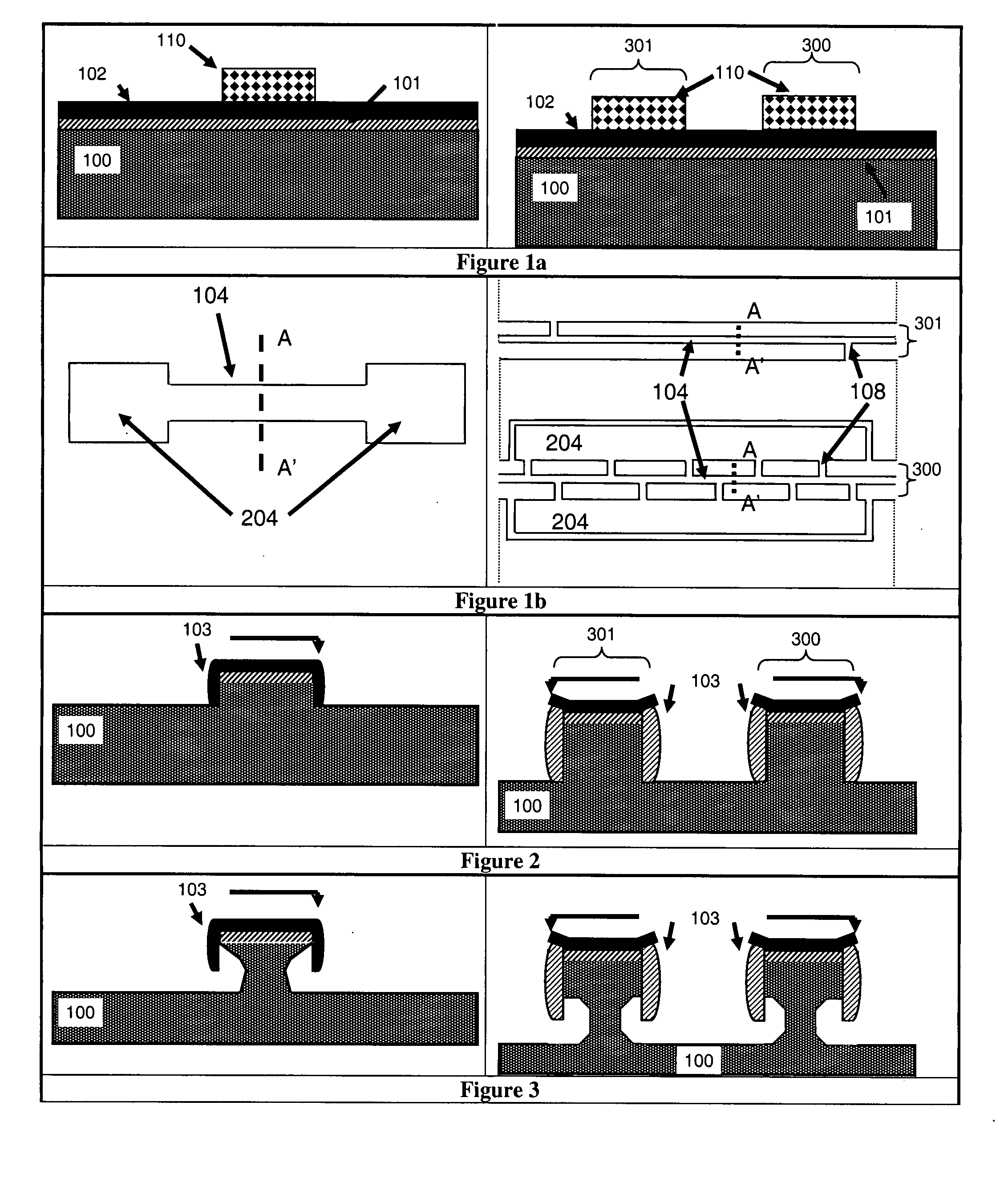

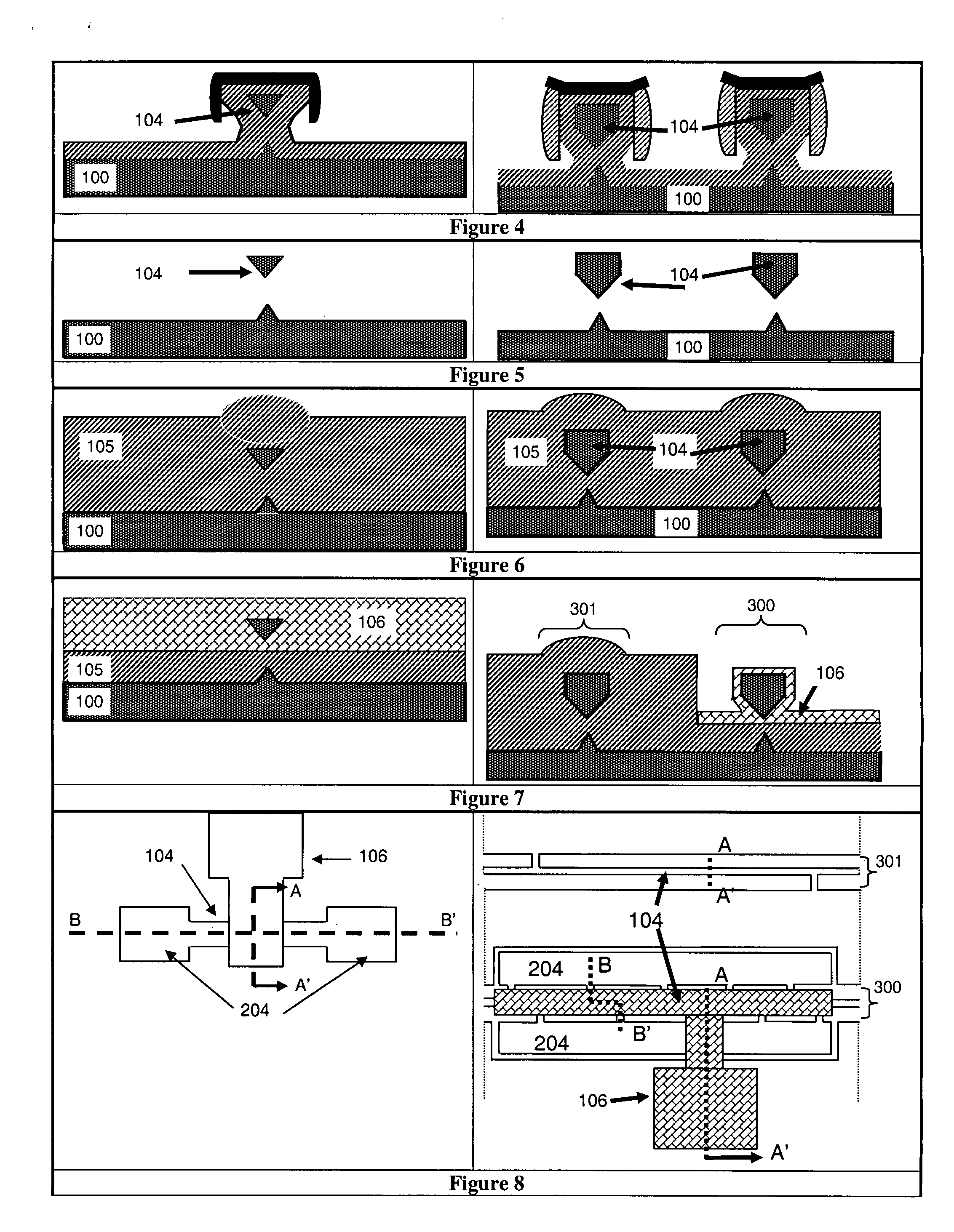

Fabrication of silicon nano wires and gate-all-around MOS devices

InactiveUS20070298551A1Quality improvementEnhance the quantum effectNanoinformaticsSemiconductor/solid-state device manufacturingMOSFETCapacitance

The invention relates to methods for manufacturing semiconductor devices. Processes are disclosed for implementing suspended single crystal silicon nano wires (NWs) using a combination of anisotropic and isotropic etches and spacer creation for sidewall protection. The core dimensions of the NWs are adjustable with the integration sequences: they can be triangular, rectangular, quasi-circular, or an alternative polygonal shape. Depending on the length of the NWs, going from the sub-micron to millimeter range, the NWs may utilize support from anchors to the side, during certain processing steps. By changing the lithographic dimensions of the anchors compared to the NWs, the anchors may be reduced or eliminated during processing. The method covers, among other things, the integration of Gate-All-Around NW (GAA-NW) MOSFETs on a bulk semiconductor. The GAA structure may consist of a silicon core fabricated as specified in the invention, surrounded by any usable gate dielectric, and finally by a gate material, such as polysilicon or metal. The source and drain of the GAA-NW may be connected to the bulk semiconductor to avoid self heating of the device over a wide range of operating conditions. The GAA-NW MOS capacitor can also be used for the integration of a Gate-All-Around optical phase modulator (GAA modulator). The working principle for the optical modulator is modulation of the refractive index by free carrier accumulation or inversion in a MOS capacitive structure, which changes the phase of the propagating light.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

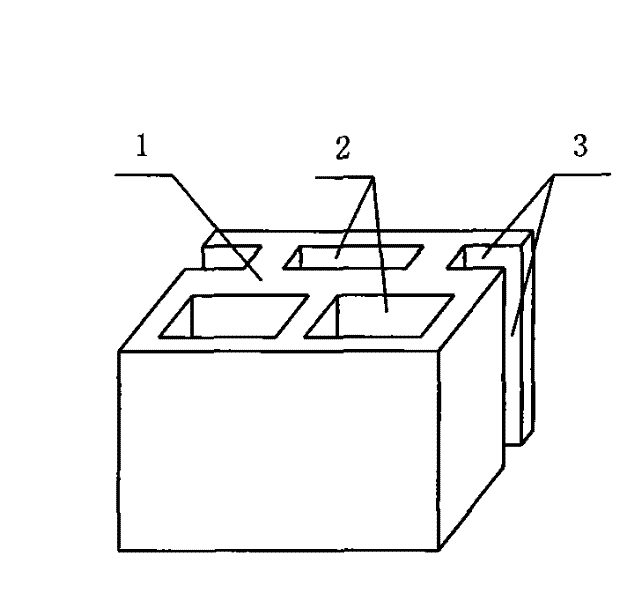

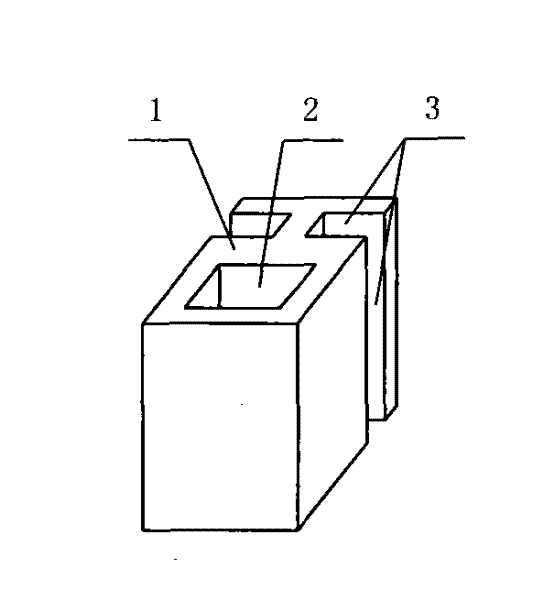

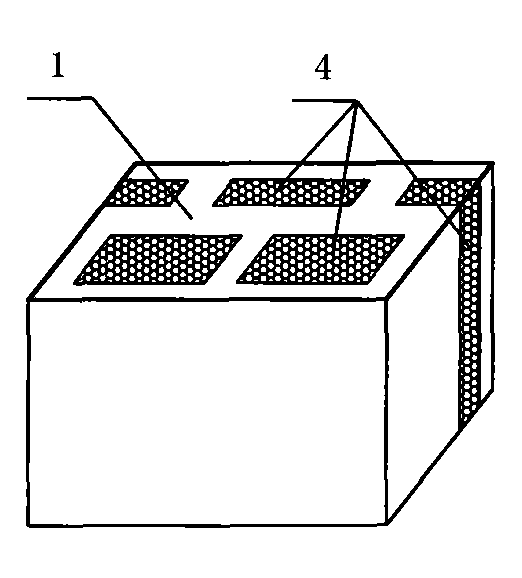

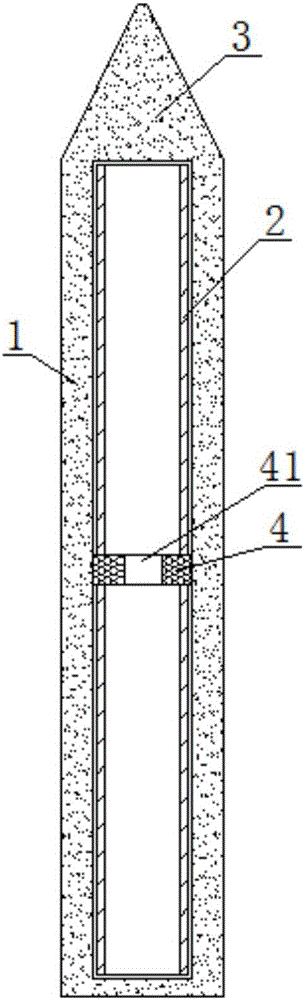

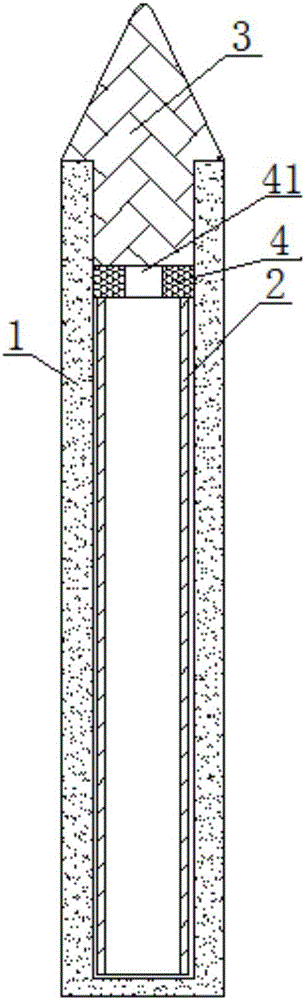

Self-heat-insulating concrete building block

InactiveCN102373763AEliminate cold bridgesGood energy saving effectConstruction materialSlurryMaterials science

The invention discloses a self-heat-insulating concrete building block, belonging to the field of building materials and used for masoning a heat-insulating wall body. The self-heat-insulating concrete building block is characterized in that heat-insulating through holes are distributed on a slurry paving surface, two ends of the self-heating-insulating concrete building block are respectively provided with one heat-insulating groove, heat-insulating materials are inserted into the heat-insulating through holes and the heat-insulating grooves, so that no cold bridges exist on the building block, and the energy saving effect of the masoned heat-insulating wall body can be obviously increased.

Owner:SHANDONG UNIV OF SCI & TECH

Self-heating container

InactiveUS20070125362A1Simple designEfficient preparationExothermal chemical reaction heat productionOther heat production devicesEngineeringMechanical engineering

Owner:HEAT WAVE TECH

Self-heating phase change memory cell architecture

ActiveUS20100163817A1Solid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryHeat sink

A method for manufacturing a phase change memory includes forming a phase change memory cell by forming a phase change layer between two switching layers. The phase change layer is separated from thermal heat sinks, such as the bitline or wordline, by the switching layers.

Owner:STMICROELECTRONICS SRL

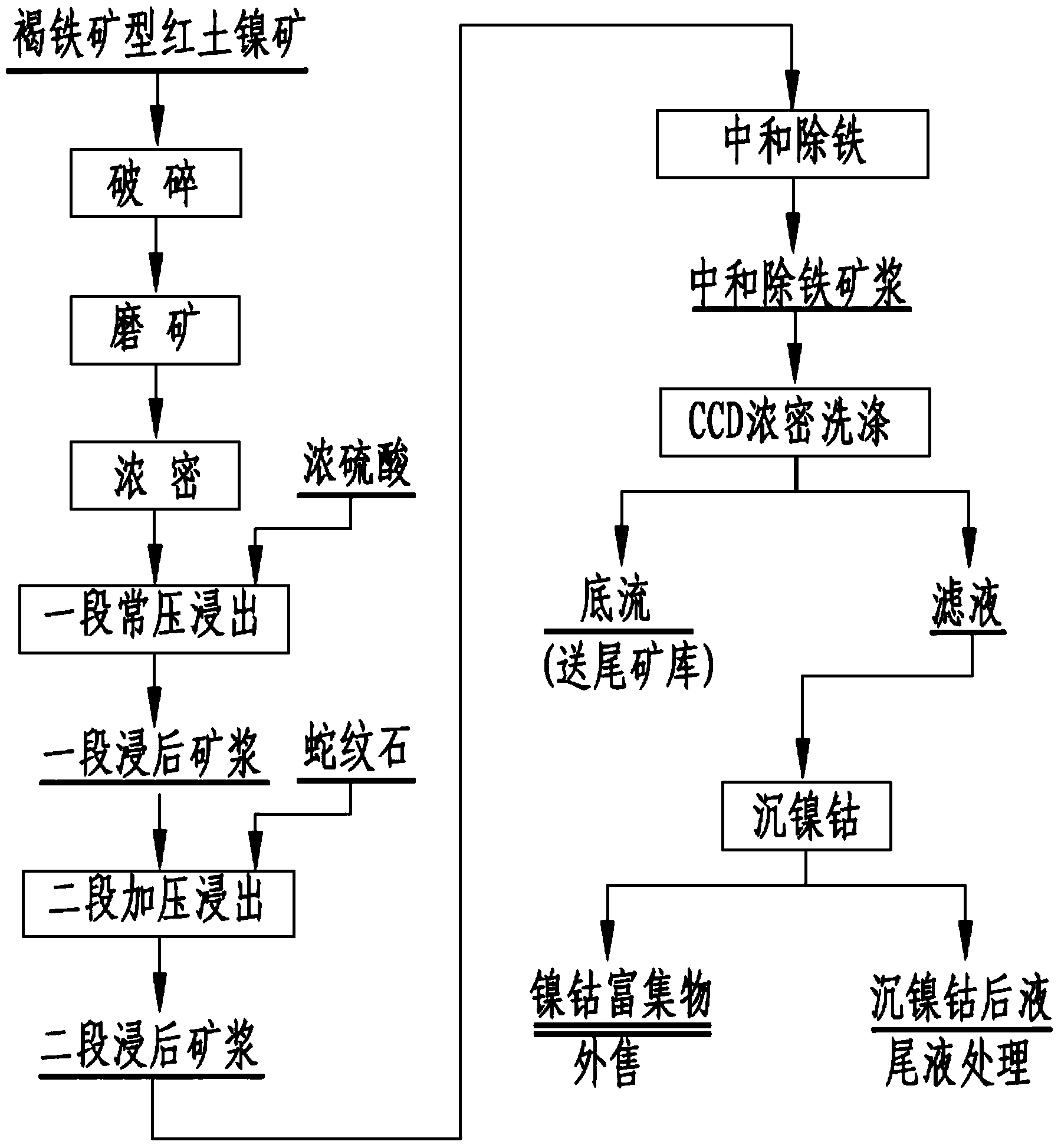

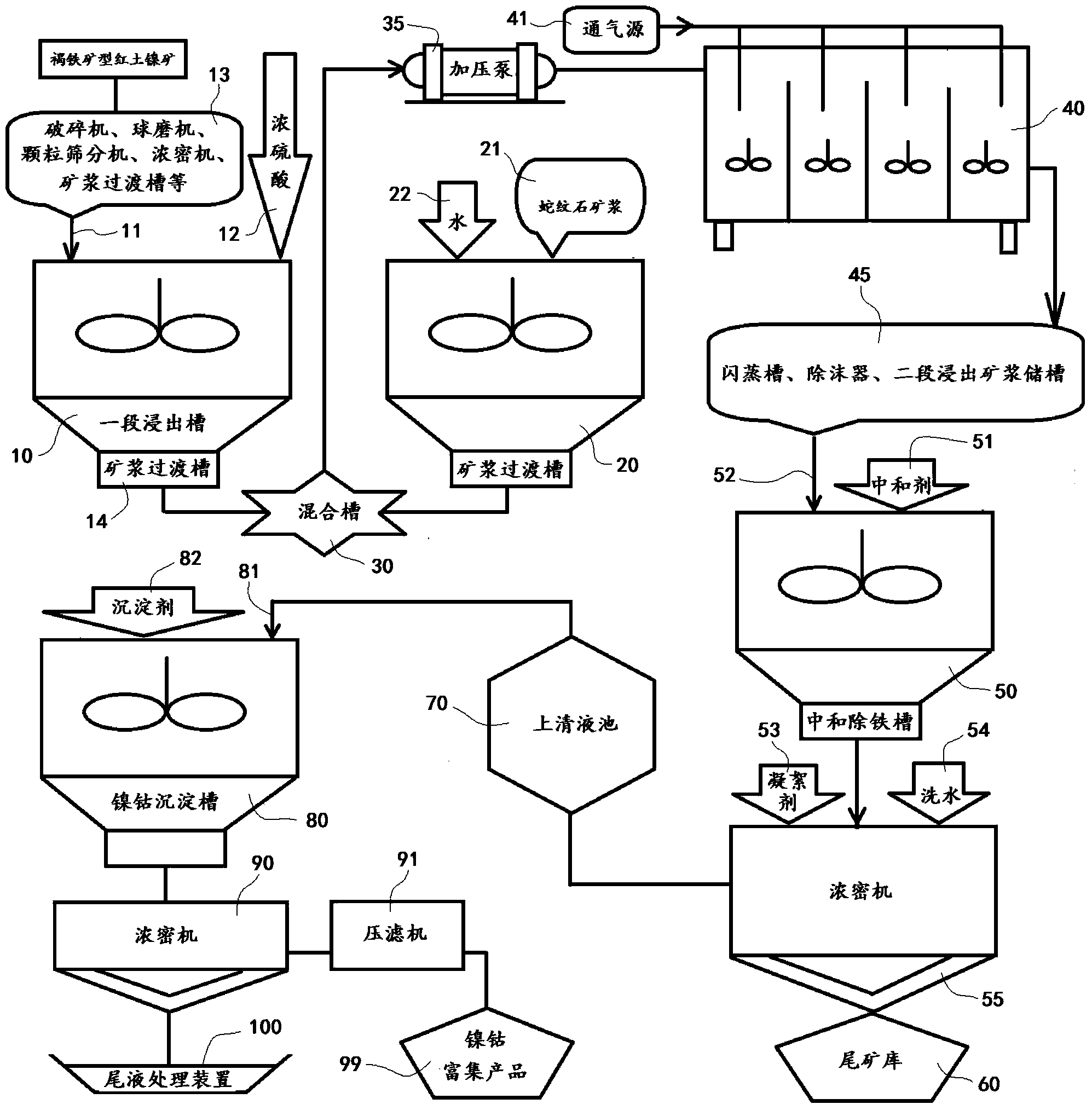

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

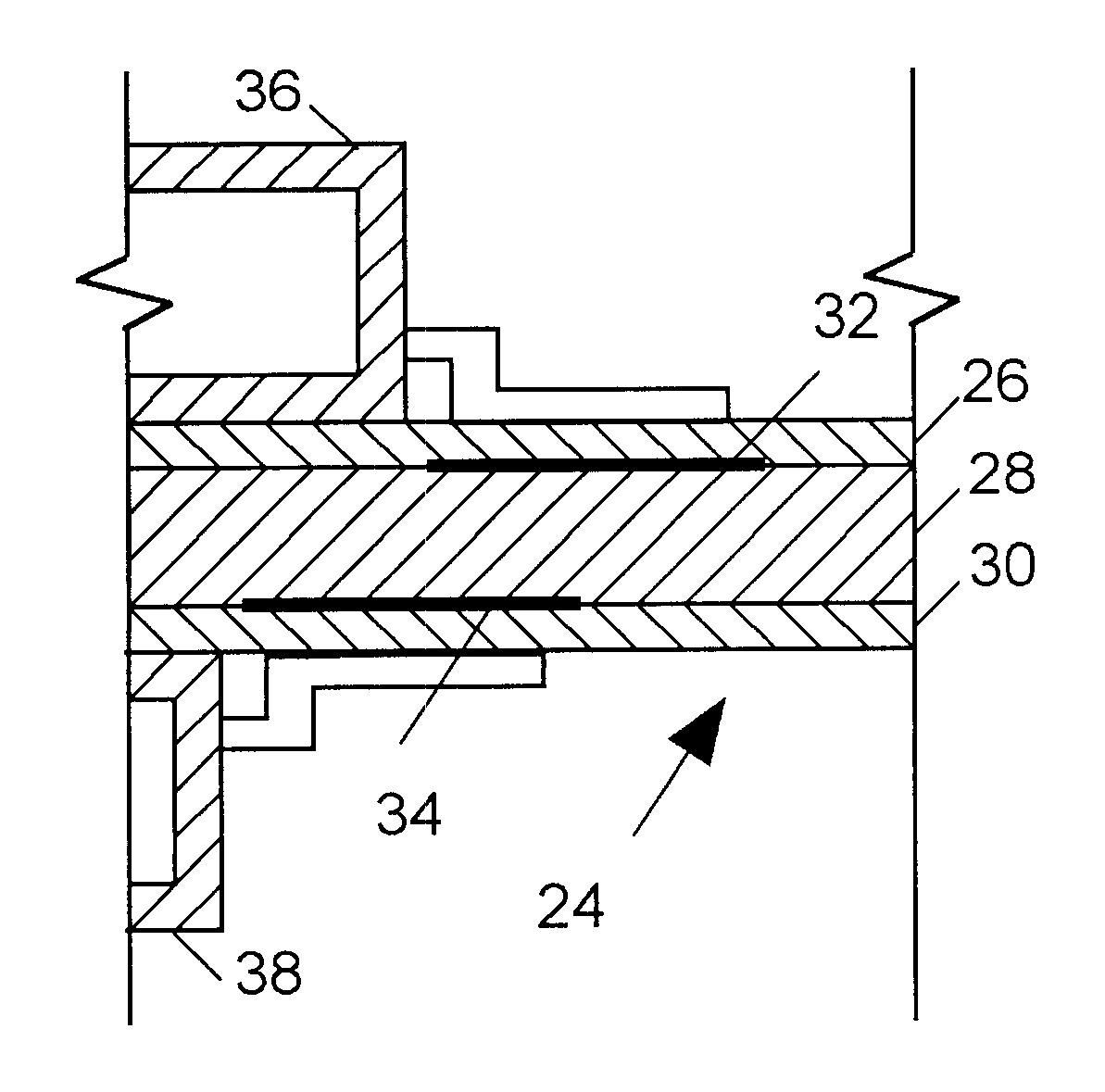

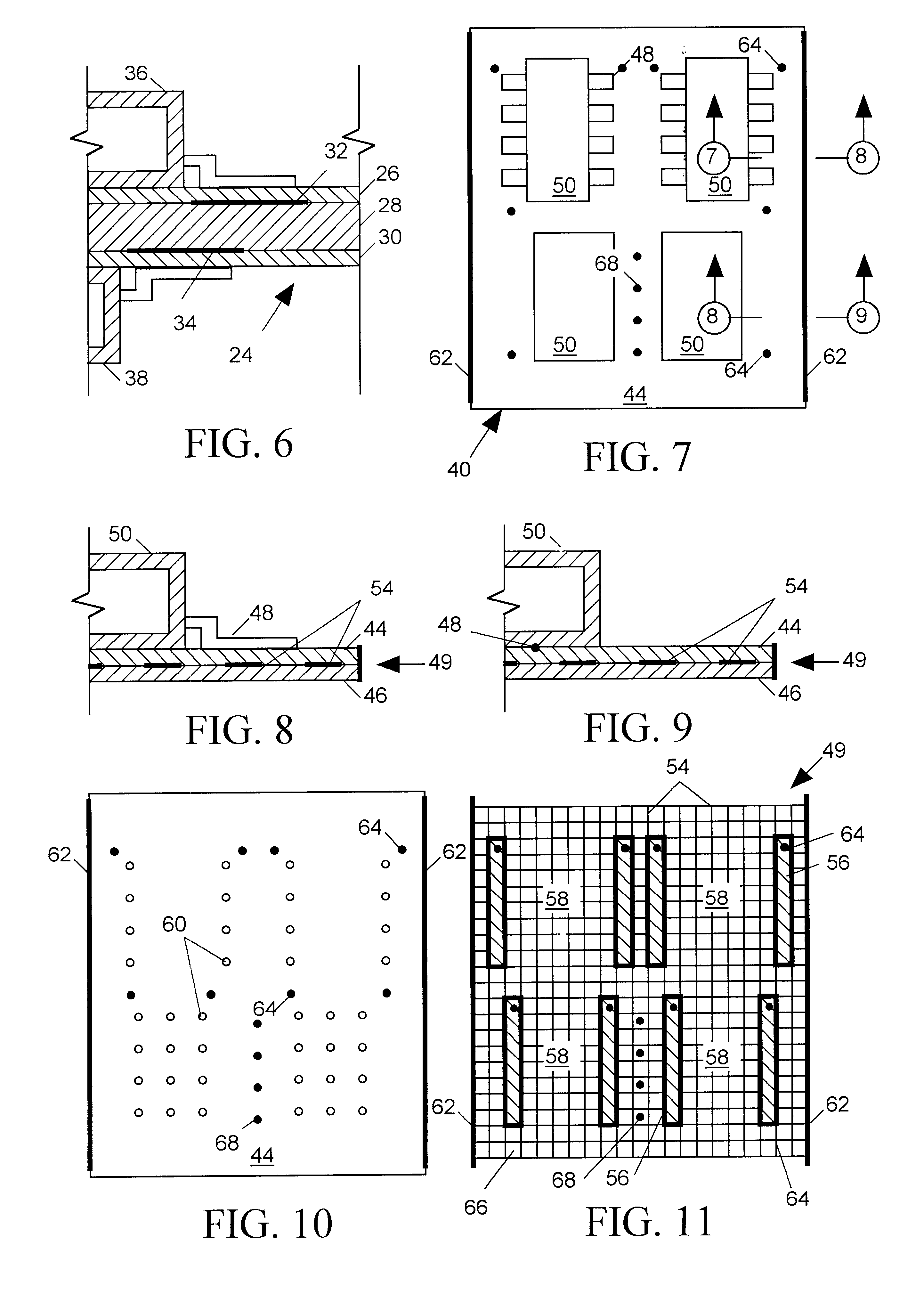

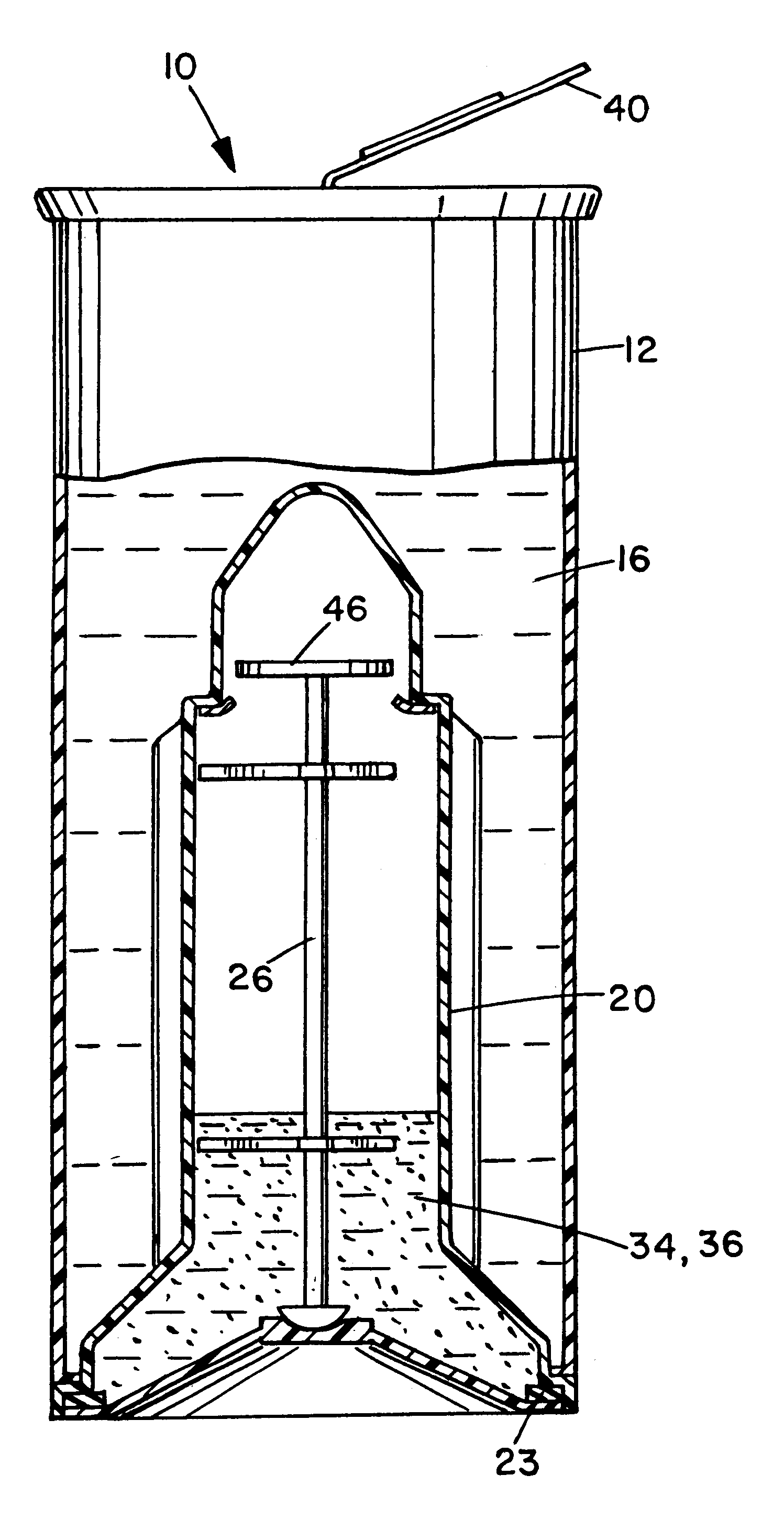

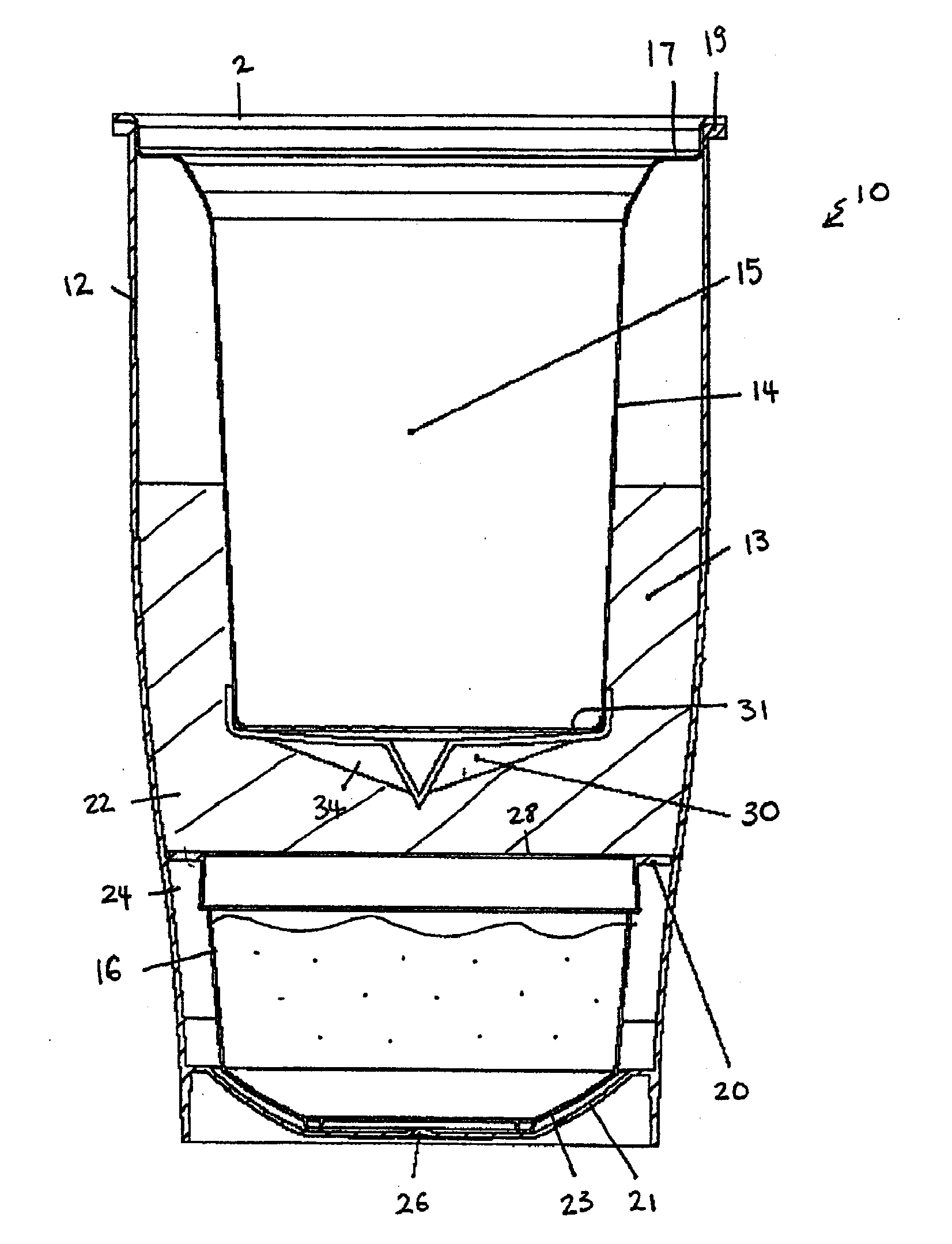

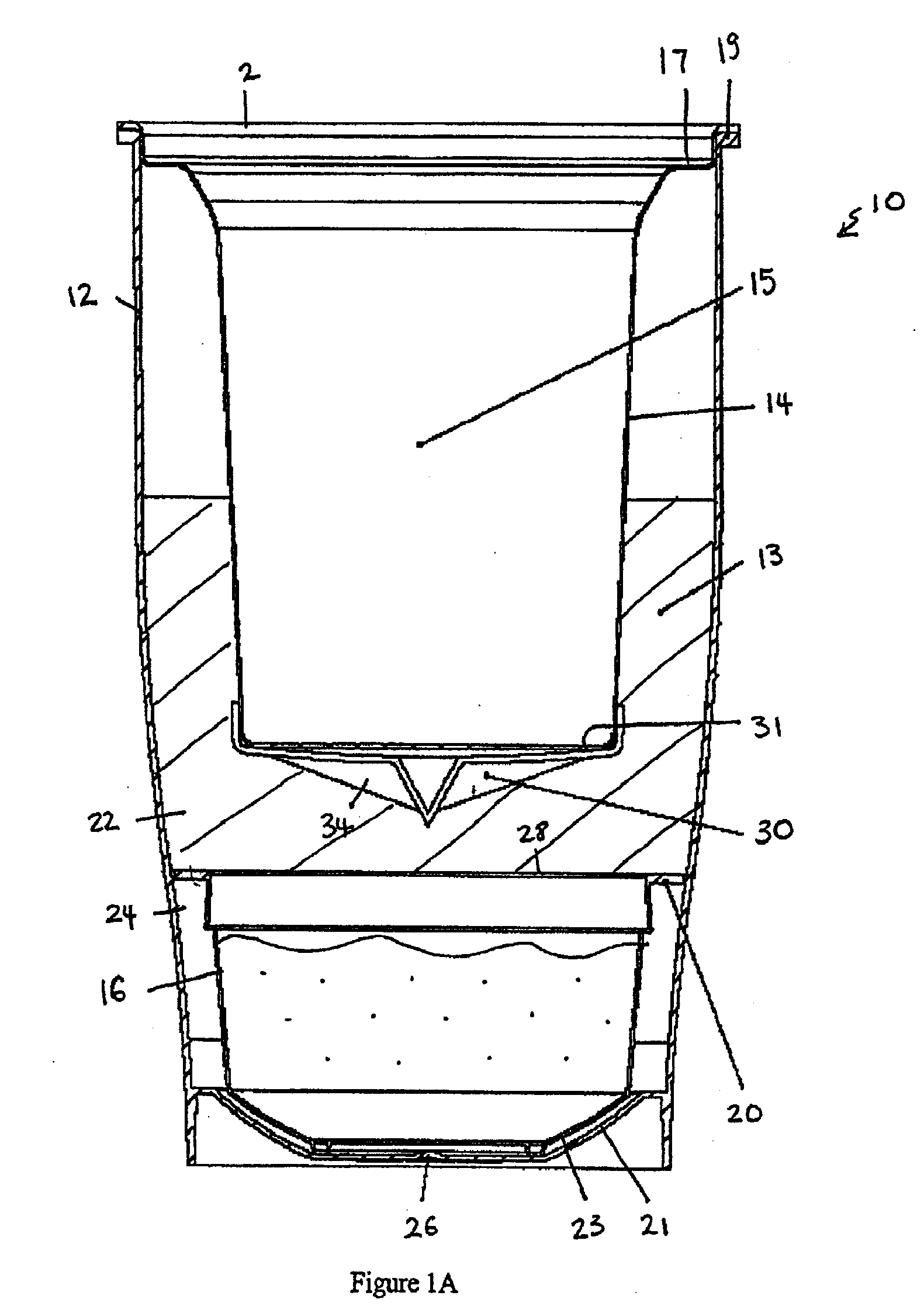

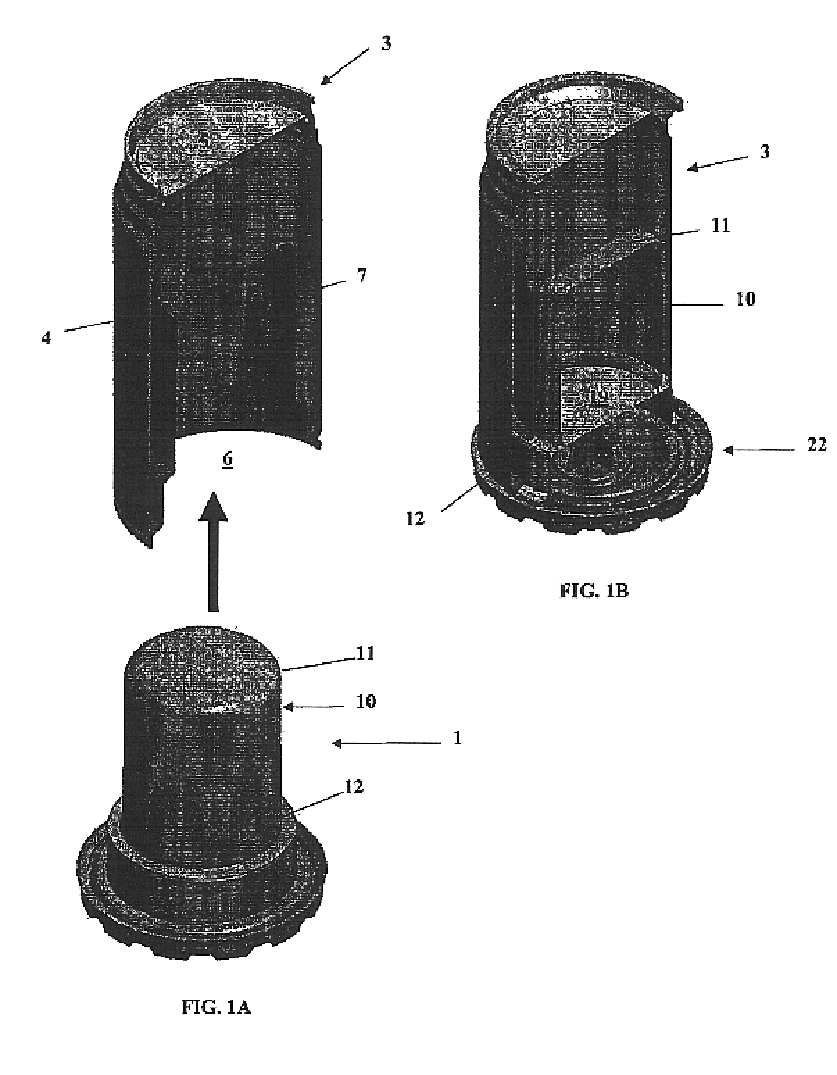

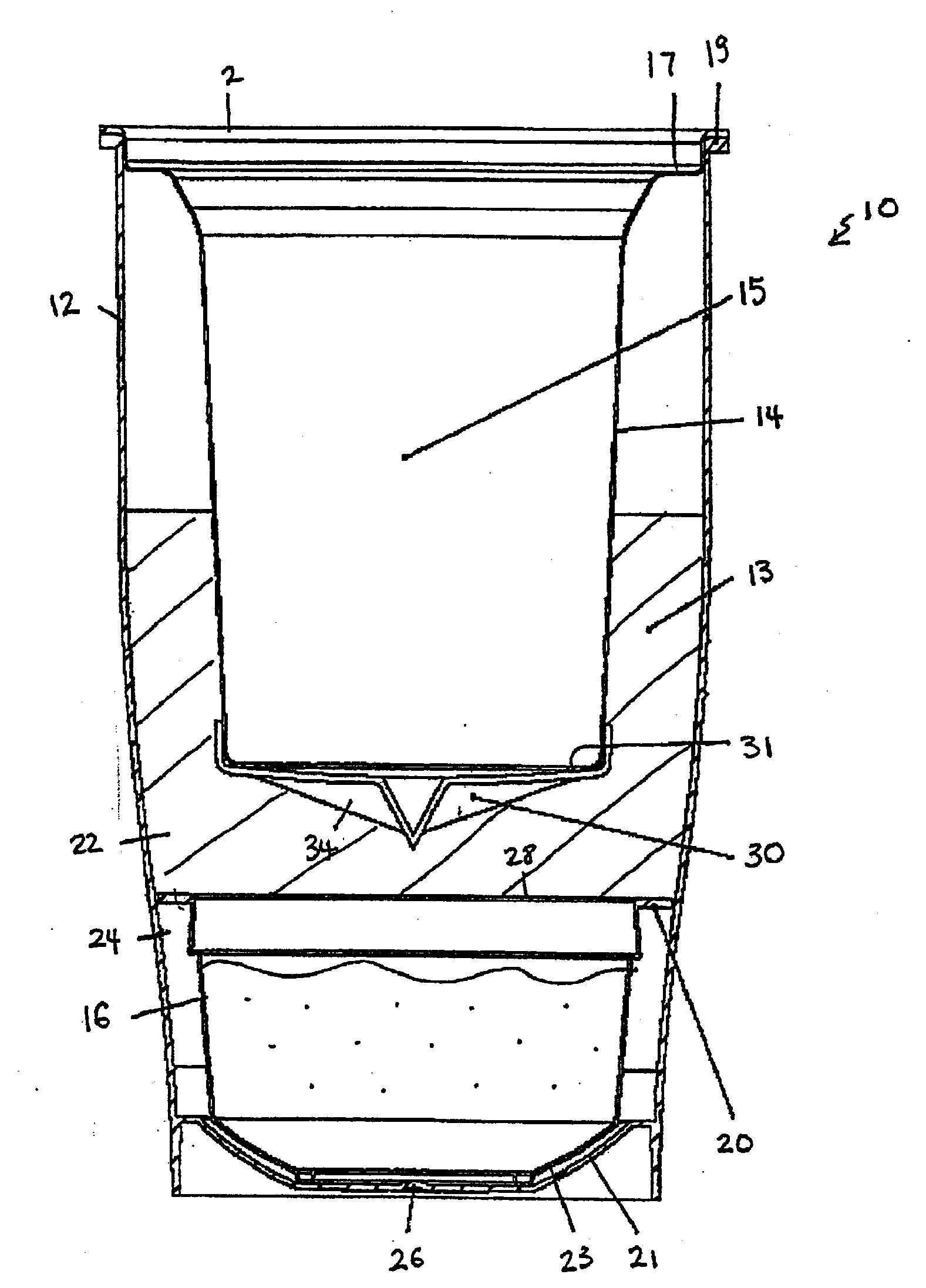

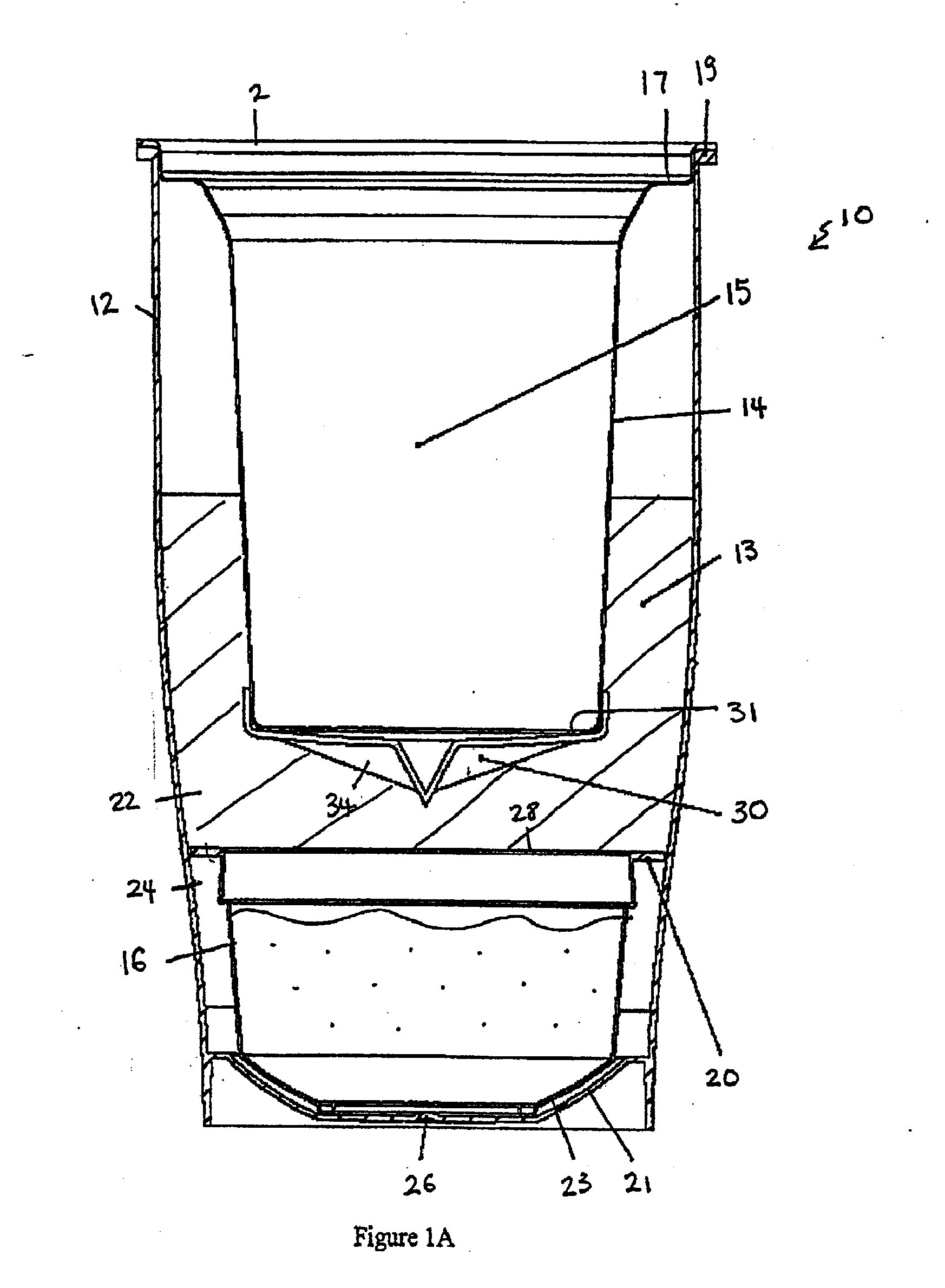

Insertable thermotic module for self-heating cans

InactiveUS7004161B2Exothermal chemical reaction heat productionDomestic cooling apparatusEngineeringSelf-heating can

A self-heating container which comprises a container body having an internal beverage section and a thermic cavity. A liquid reactant is positioned in a first section of the thermic cavity and a solid reactant positioned in a second section of the thermic cavity. The solid reactant includes at least 70% by weight CaO and at least 5% by weight of a carbonate from the group consisting of MgCO3, CaCO3, SrCO3, BaCO3, and RaCO3.

Owner:HOT CAN INTPROP

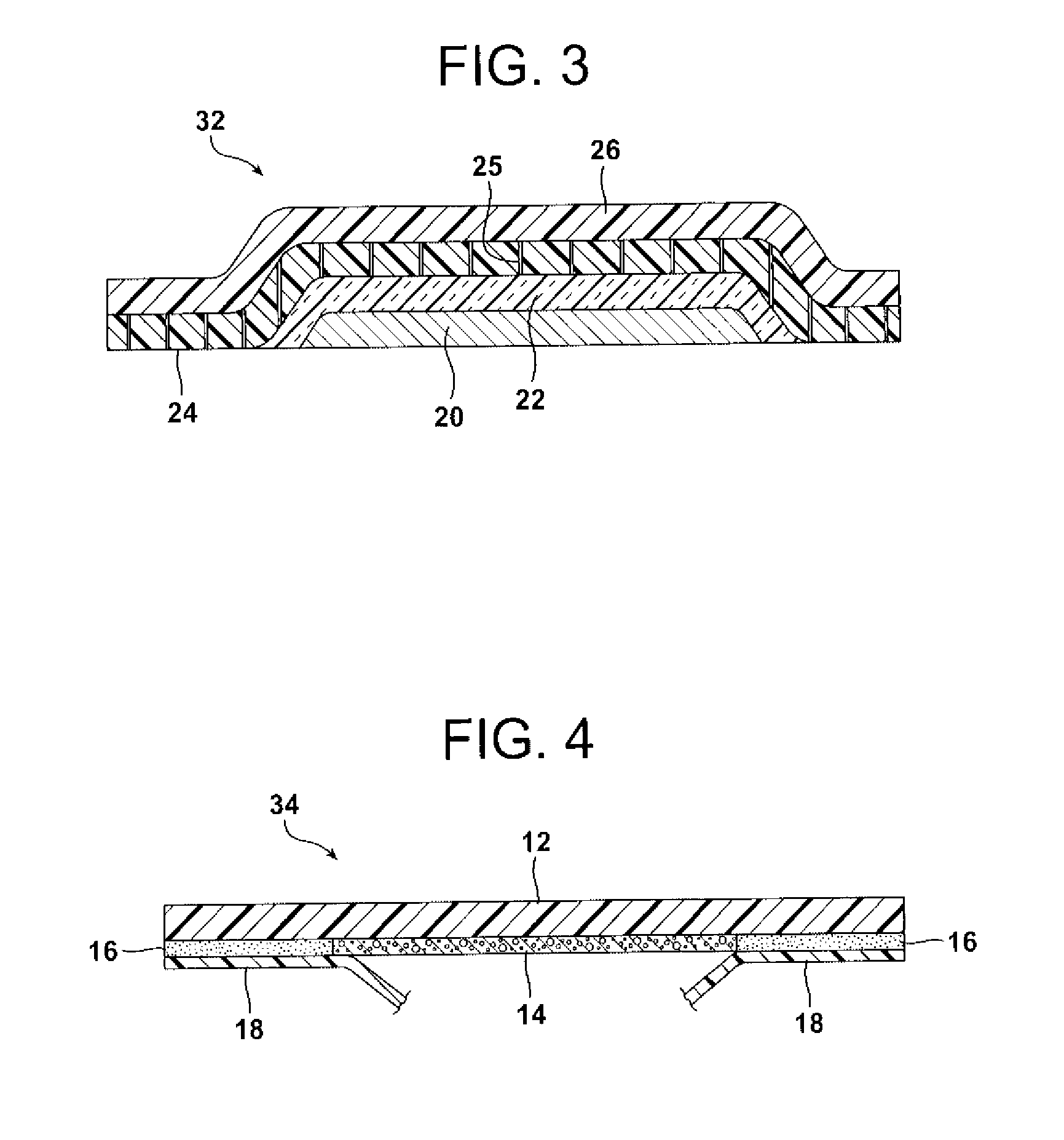

Self-Heating Patch

A self-heating patch includes a bottom barrier layer, an air-activated heat-generating layer, an air regulation layer, optionally a top barrier layer, and optionally a skin contact layer, wherein the air-activated heat-generating layer is encapsulated by the air regulation layer and bottom barrier layer, and / or the top and bottom barrier layers, and the temperature of the patch, when the air-activated heat-generating layer has been exposed to air, and when the top barrier layer if present is removed, is controlled at least in part by the air regulation layer; and a perimeter seal seals the air regulation layer to the bottom barrier layer around the perimeter of the patch. Optionally a temperature-responsive mechanism, such as a wax, can be used to reduce oxygen intake into the self-heating patch and thereby control the temperature of the self-heating patch during use. Optionally, a portion of the self-heating patch can be thermoformed.

Owner:SEALED AIR U S

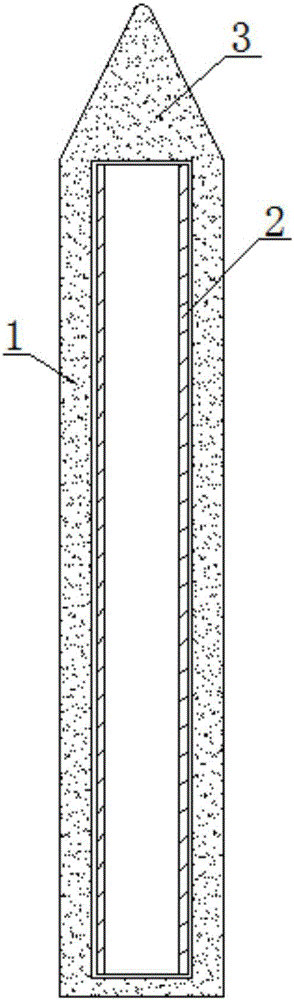

Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

PendingCN106617325AImprove yield rateAchieve atomizationTobacco devicesEngineeringAlternating current

The invention discloses a heating body and a curing object matched with the heating body, an electronic cigarette atomizer and an electronic cigarette. The heating body comprises a glass sleeve and multiple sections of metals which are embedded in the glass sleeve and are capable of generating magnetic induction intensity, a conical body in which the curing object is pierced is arranged at the front end of the glass sleeve; isolating layers for controlling various sections to generate heat independently are arranged between the adjacent metals; and pressure discharge holes are formed in the isolating layers. According to the invention, by conducting self-heating in a mode of electromagnetic induction heating and by generating high-frequency induction current for alternating current through DC conversion, the metals become heated to cure tobacco shreds, so that flavors and fragrances as well as fragrance compounds in the tobacco shreds are volatilized and atomized; by virtue of the glass sleeve, stuffing is prevented from getting oxidized or contaminated by the metals and staged heating is facilitated, so that a heating rate is uniform, curing is conducted fully, a heating rate is moderate and the cured tobacco shreds are pure in fragrance; and in addition, a sachet can be pierced to add relative aromatizing and atomizing aids.

Owner:湖南酷伯新晶电子科技有限公司

Self-heating apparatuses using solid chemical reactants

InactiveUS20090078711A1Exothermal chemical reaction heat productionDomestic cooling apparatusCompound (substance)Chloride

Owner:HEAT WAVE TECH

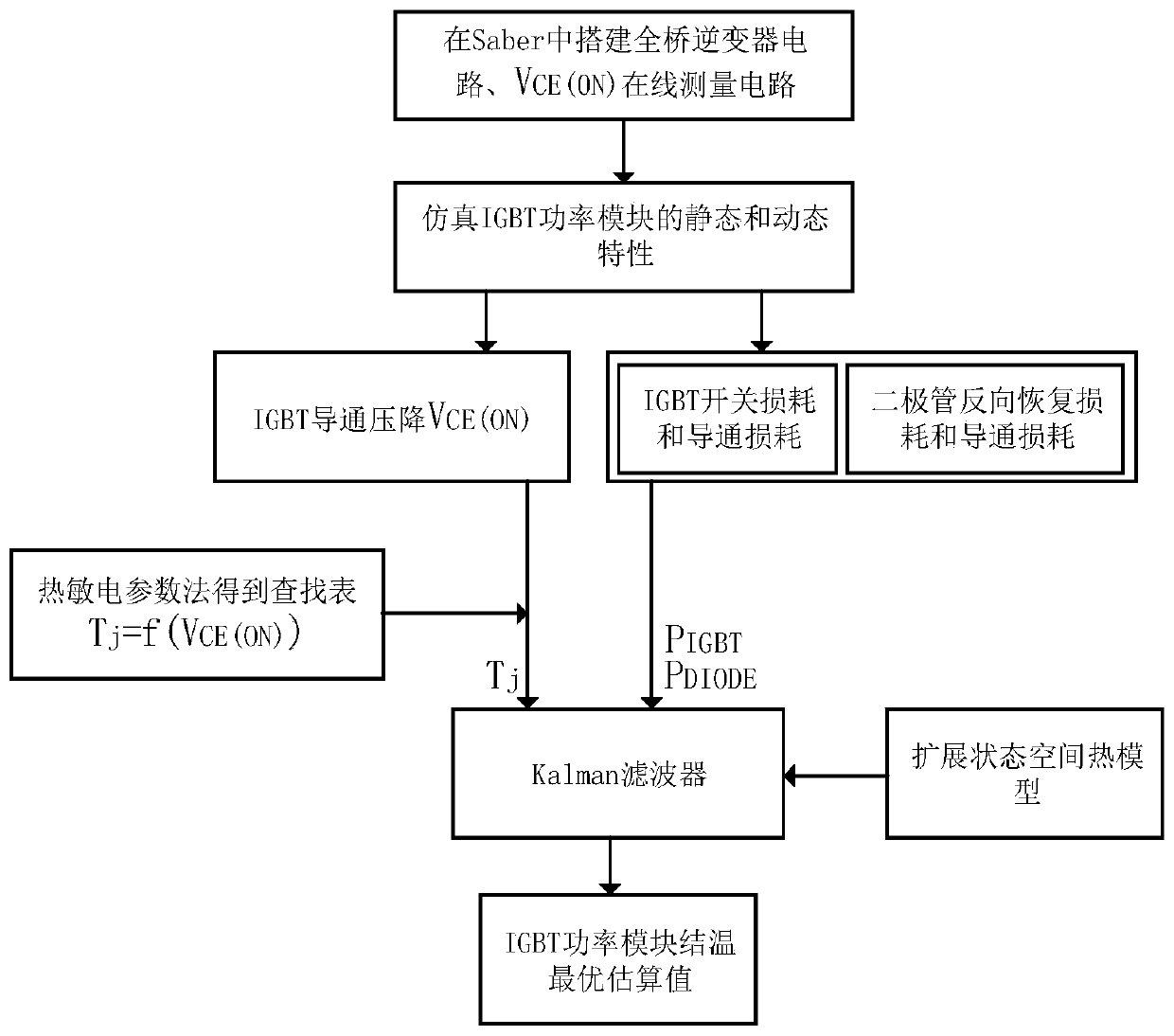

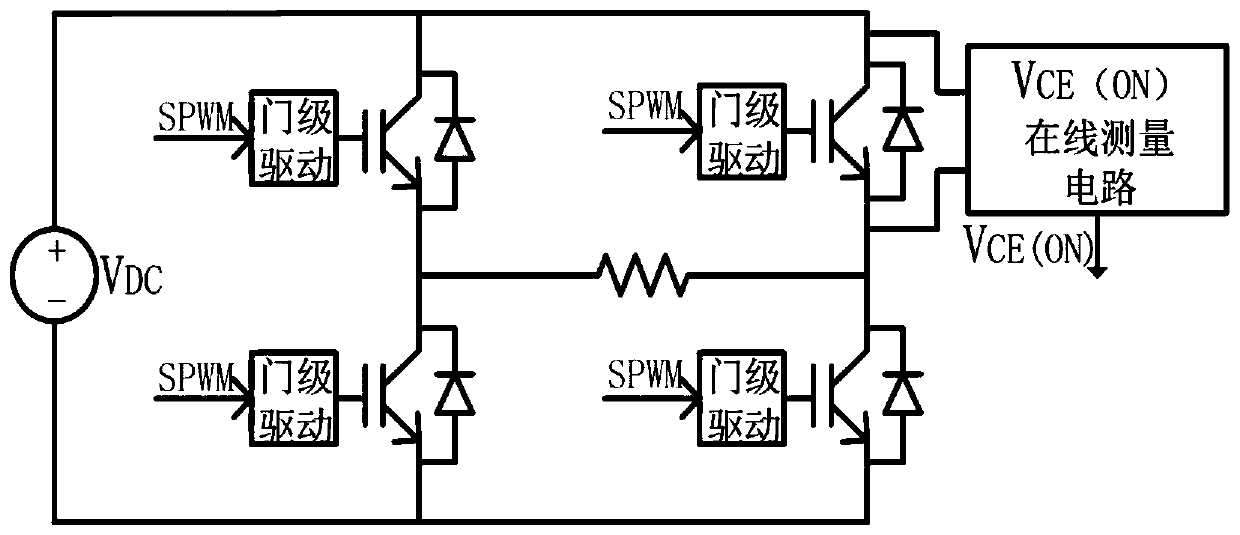

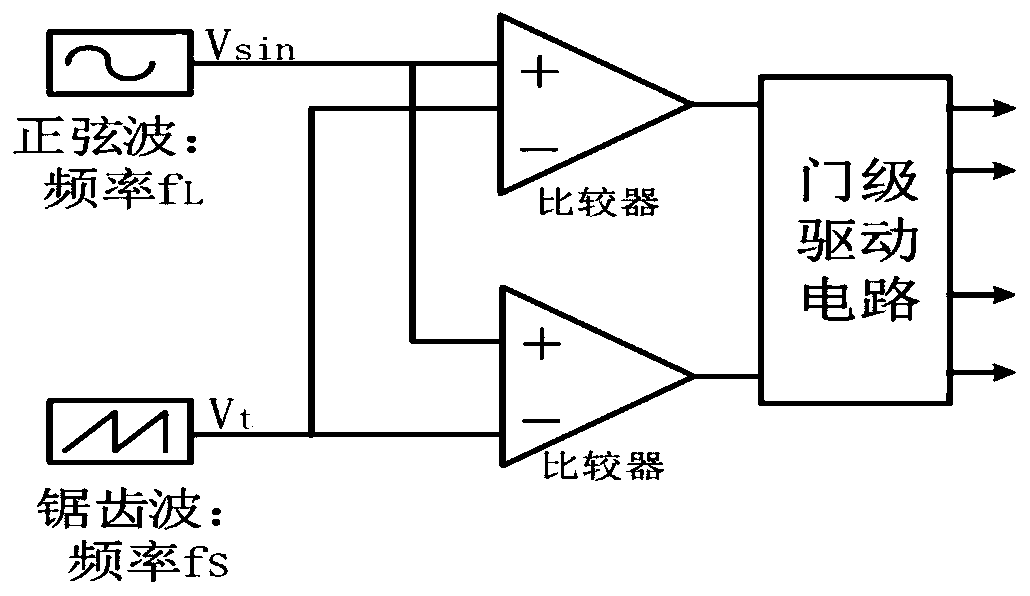

method for estimating the junction temperature of an IGBT power module on line

InactiveCN109871591AHigh measurement accuracyHigh simulationThermometers using electric/magnetic elementsUsing electrical meansJunction temperatureEngineering

The invention discloses a method for estimating junction temperature on line by an IGBT (Insulated Gate Bipolar Transistor) power module. The method comprises the following steps: estimating the junction temperature by using a thermo-sensitive electrical parameter method; establishing an extended state space thermal model; and applying a Kalman filter in junction temperature estimation. The thermosensitive electrical parameter method can estimate the junction temperature of an IGBT power module in real time, an IGBT conduction voltage drop VCE (ON) is selected as a thermosensitive electrical parameter, and a VCE (ON) online measurement circuit is provided. On the basis of a Foster thermal network model, the influence of diode coupling is considered, and an extended state space thermal model comprising self-heating and coupling heat is provided; And taking the power loss of the diode and the IGBT and the junction temperature estimation value obtained by using the thermosensitive electrical parameter method as the input of the Kalman filter, and considering the measurement noise and the process noise, thereby obtaining the optimal junction temperature estimation value. According to the method, electrical insulation is achieved, measurement is carried out without changing a control strategy of the power converter, noise is reduced, the intermittent influence of voltage measurementis eliminated, and the junction temperature measurement precision is improved.

Owner:WUHAN UNIV

Temperature controlled facial mask with area-specific treatments

A temperature controlled cosmetic treatment facial mask with area-specific treatments of the present invention includes a substantially planar mask body which is formed with cut-outs for a person's eyes, nose, and mouth. The mask may include a number of large and small area treatment zones in combination with asymmetrical treatment zones suitable for treatment of specific and localized skin conditions. The treatments zones are coated with skin treatments, such as compounds, lotions, gels, and the like as are known in the facial treatment, cosmetics, spa and medical industry. The mask may include a self-heating or cooling substrate to provide temperature control to the face mask and each mask may include heating areas, cooling areas, or both. A system is also provided that includes an imaging device that feeds its output to a central computer system having an image analyzer, CPU, memory and Look Up Table, and face map for determining specific treatment requirements for the particular patient. An output from the central computer system is provided to a treatment deposition device which deposits various treatments onto an intermediate membrane layer to generate a custom temperature controlled facial mask with area-specific treatments for that particular patient.

Owner:FOREVER YOUNG INT

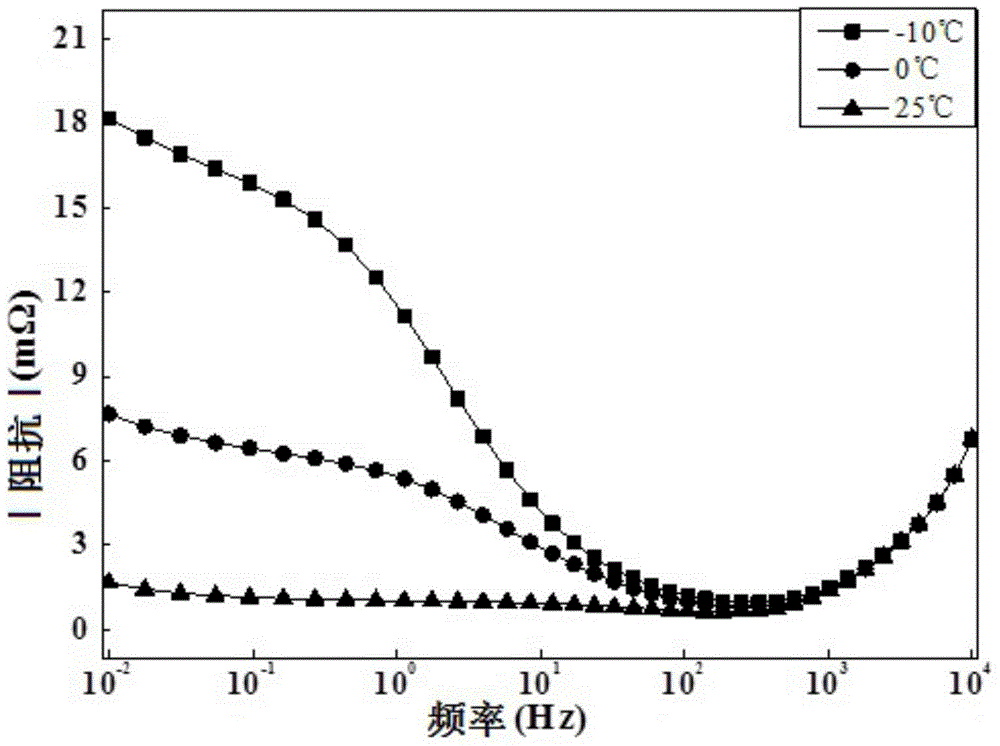

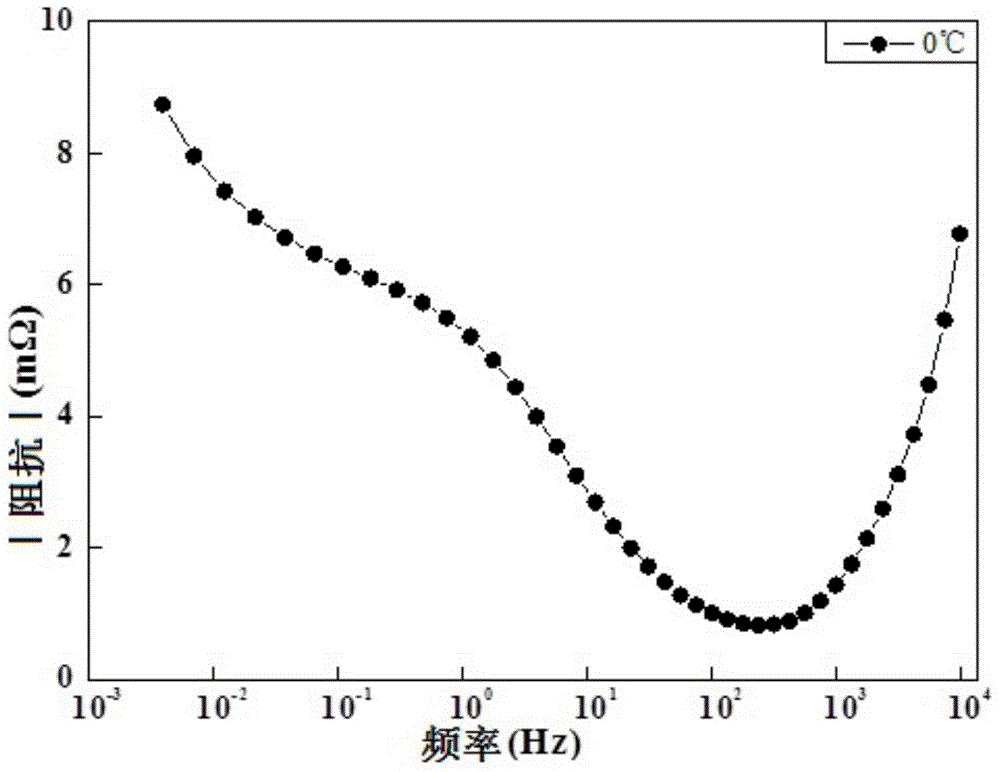

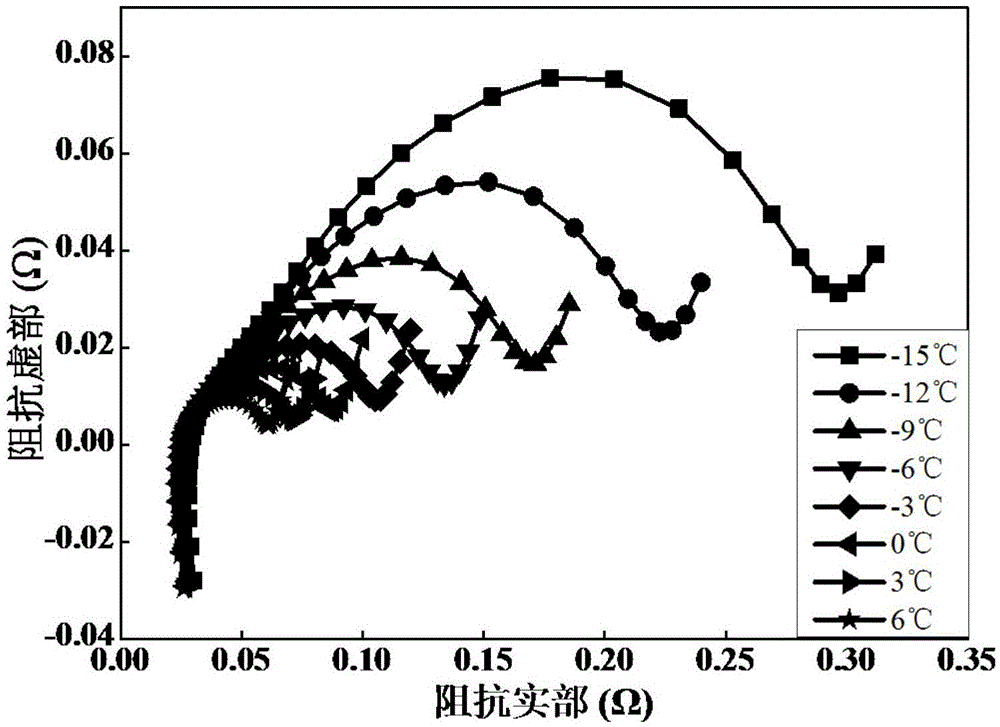

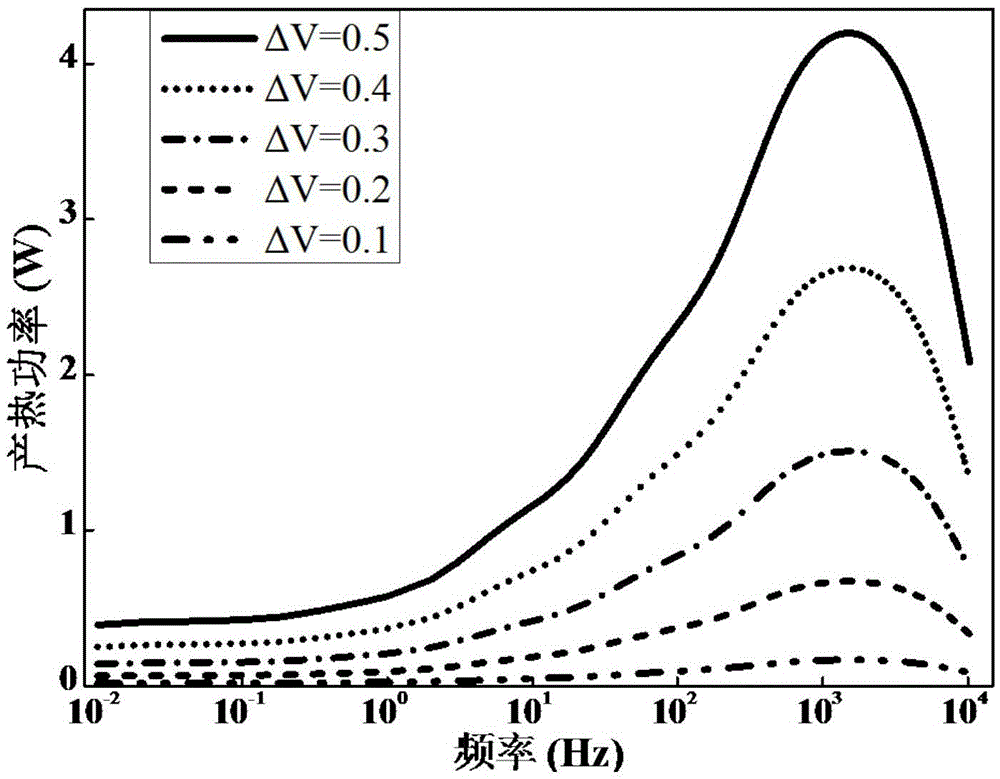

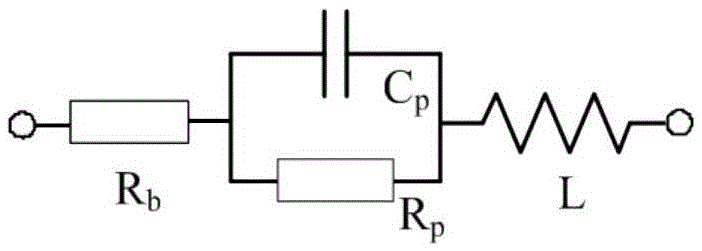

Low-temperature rapid self-heating method for lithium-ion battery

ActiveCN105680114ADetermining the Polarization Voltage Amplitude RangeNo effect on lifespanSecondary cellsVoltage amplitudeElectrical battery

The invention relates to a low-temperature rapid self-heating method for a lithium-ion battery. The method comprises the following steps: (S1) determining a polarization voltage amplitude range which does not have influence on the service lifetime of the lithium-ion battery and is safely used, and selecting a sine AC voltage amplitude according to the range; (S2) calculating the relationship between heat production power and frequency and obtaining a frequency point, namely the optimal heat production frequency point, with the maximum heat production power according to the relationship between battery impedance and frequency under the selected sine AC voltage amplitude; and (S3) carrying out heating free of lifetime loss on the battery by a sine AC signal according to the amplitude determined in the step (S1) and the frequency determined in the step (S2). The low-temperature rapid self-heating method for the lithium-ion battery has the effects of being high in heating rate, obvious in low-temperature performance improvement, free of an influence on the service lifetime of the lithium-ion battery, good in heating temperature uniformity and the like; and the target of reducing the influence on the service lifetime of the lithium-ion battery to the maximal extent is achieved.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com