Patents

Literature

37results about How to "No effect on service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

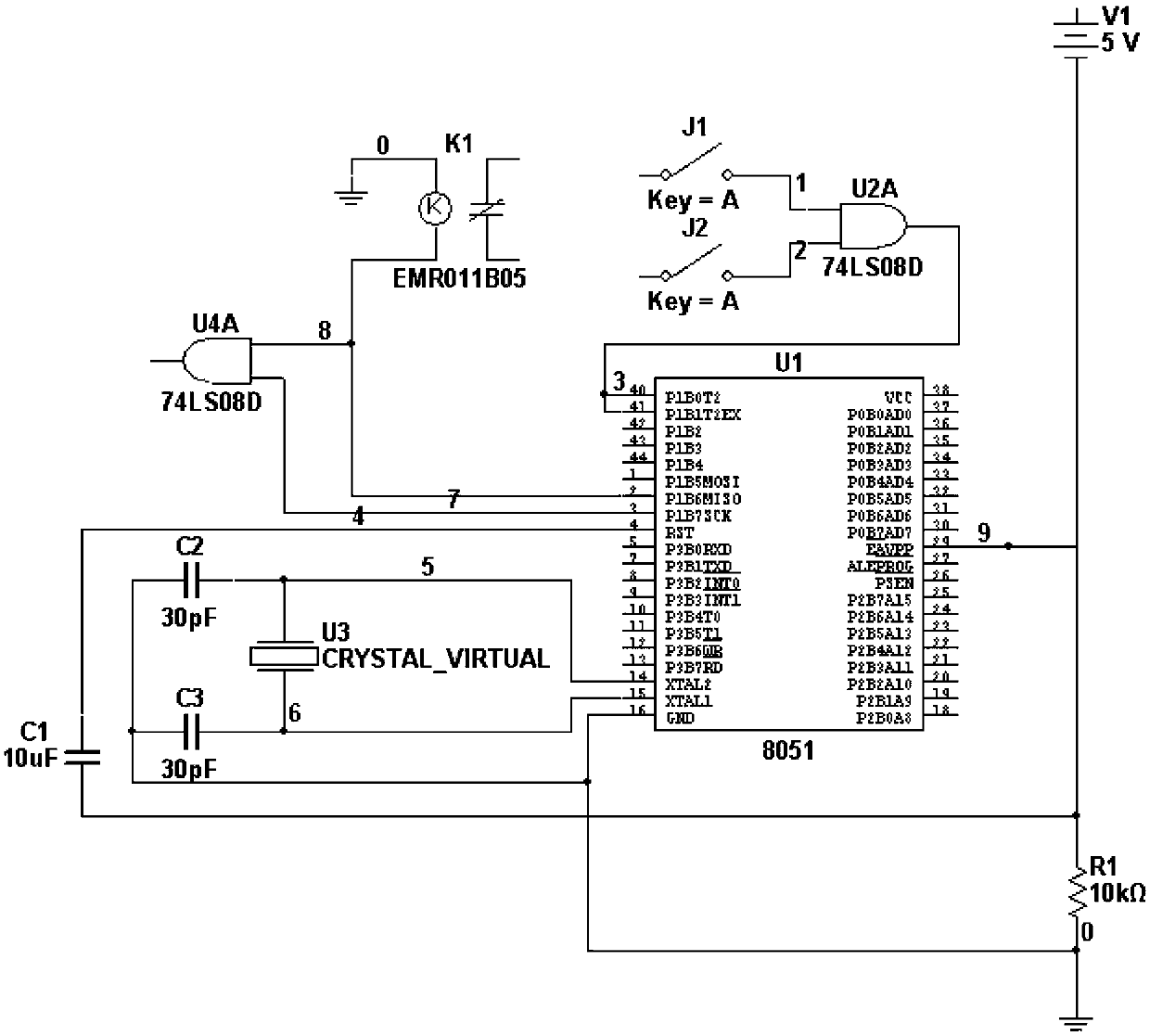

Low-temperature self-heating method for lithium ion battery

ActiveCN104064836ANo effect on service lifeReduced service lifeCell temperature controlInternal resistanceEngineering

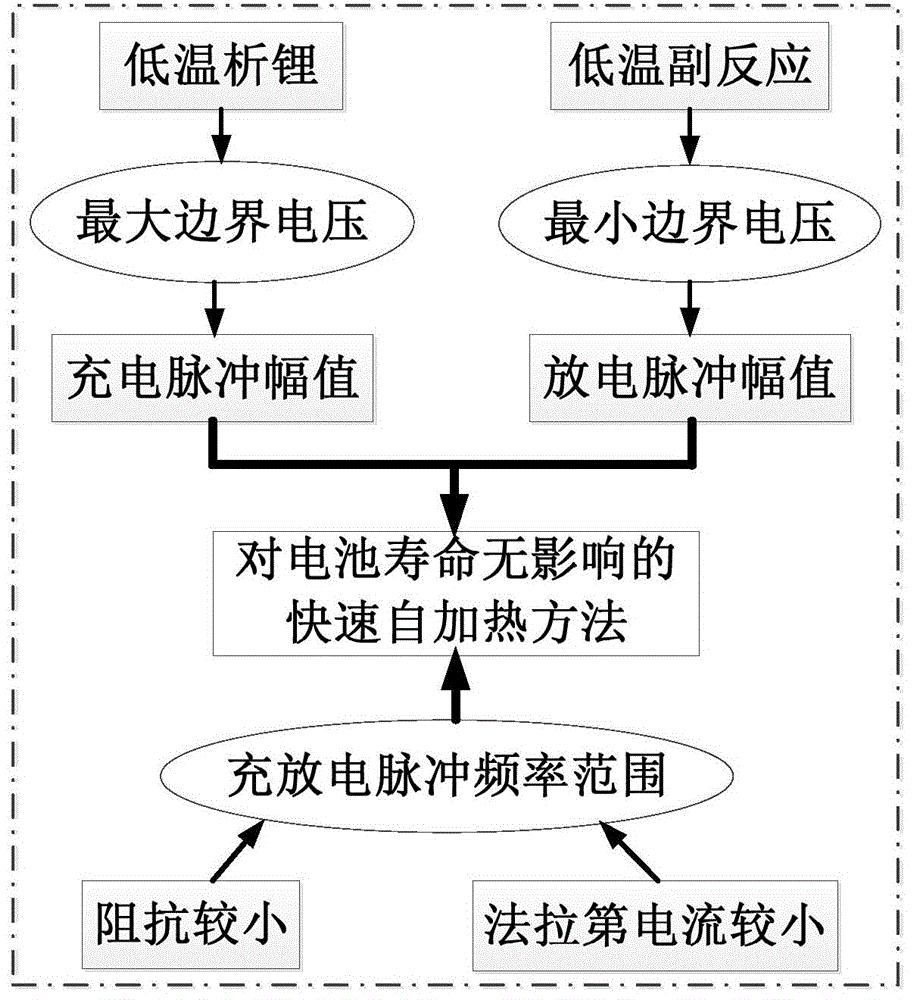

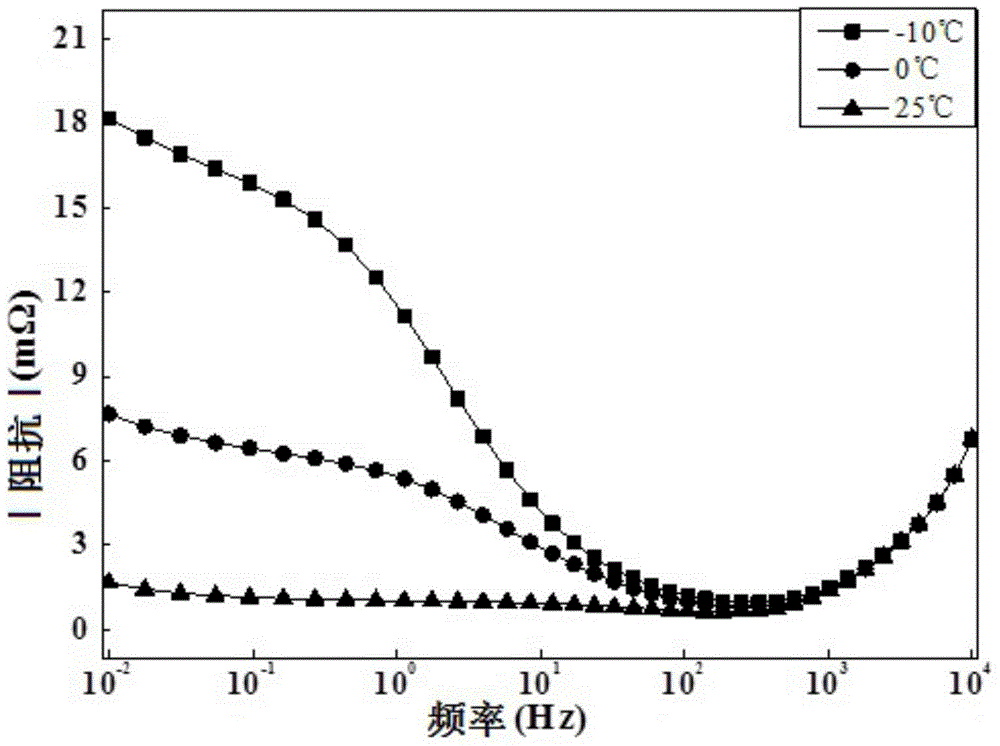

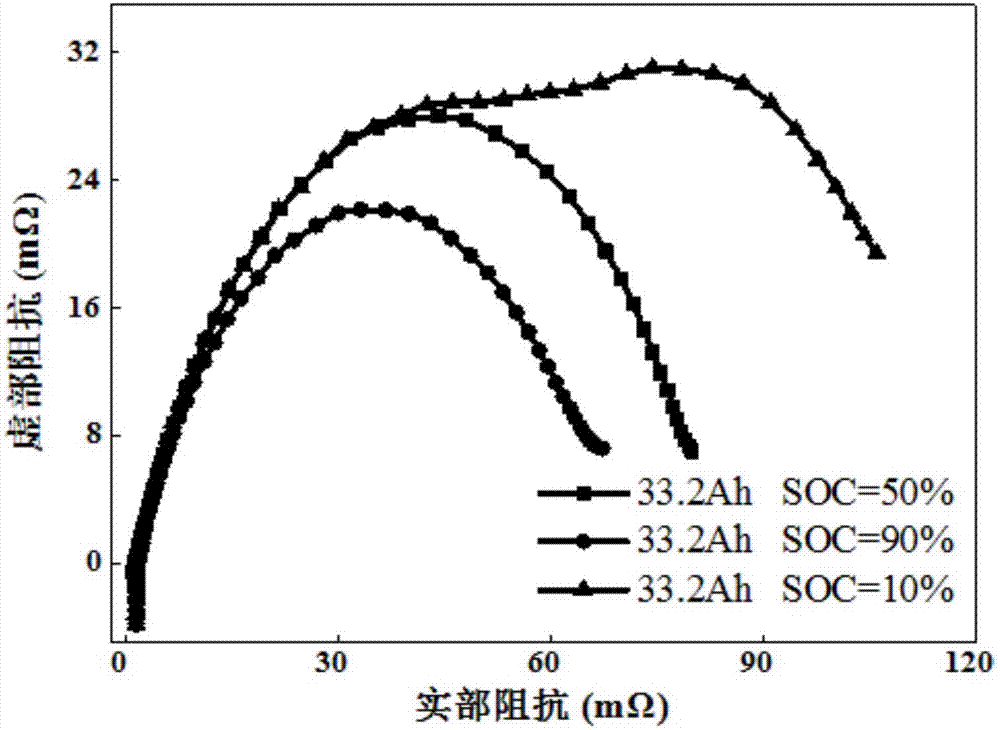

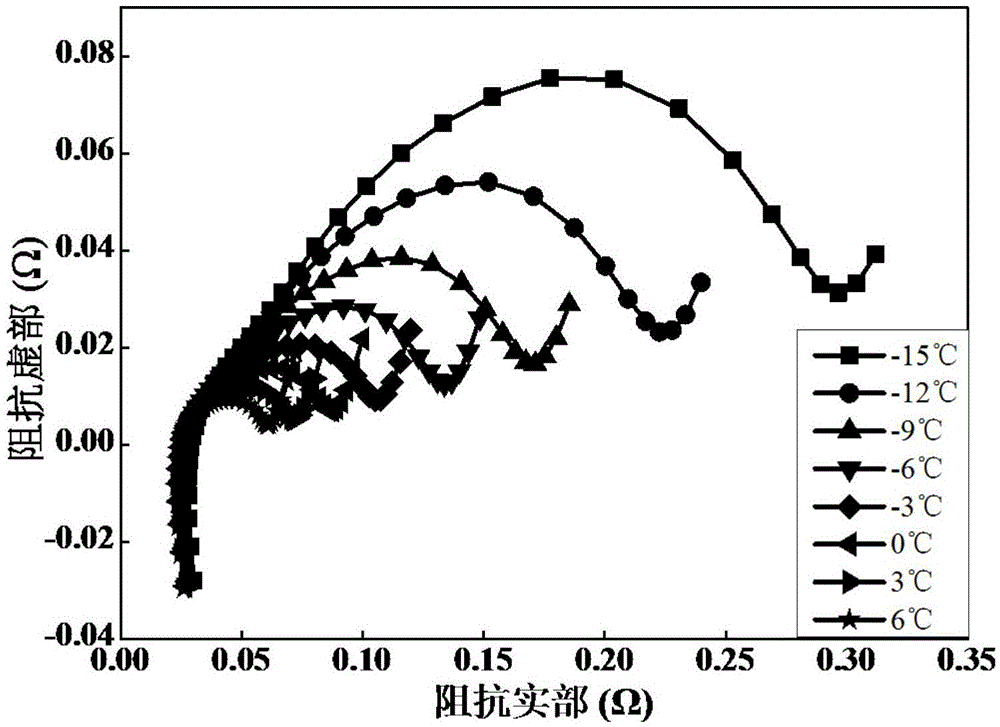

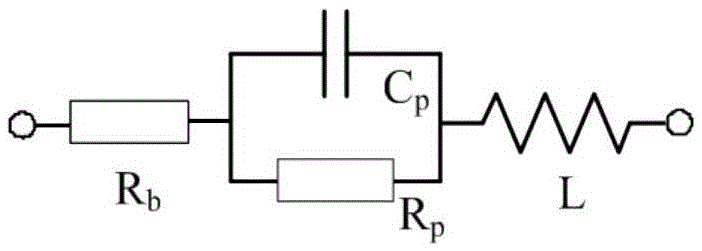

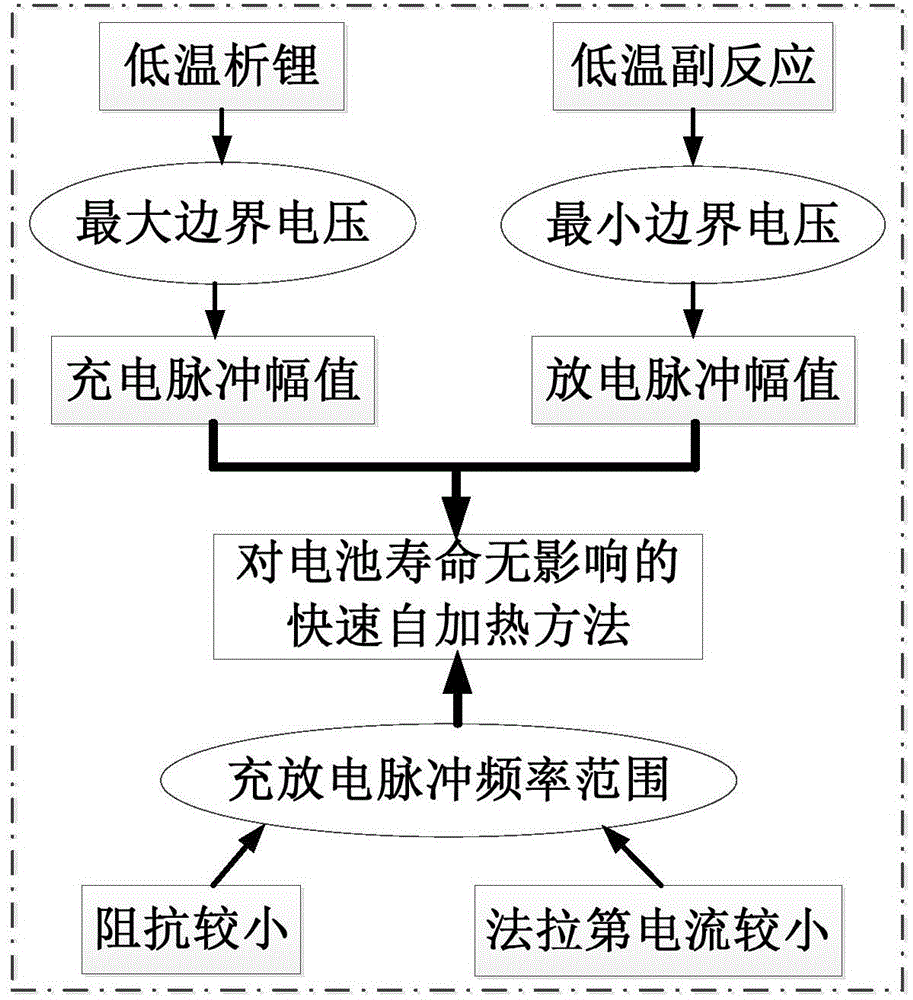

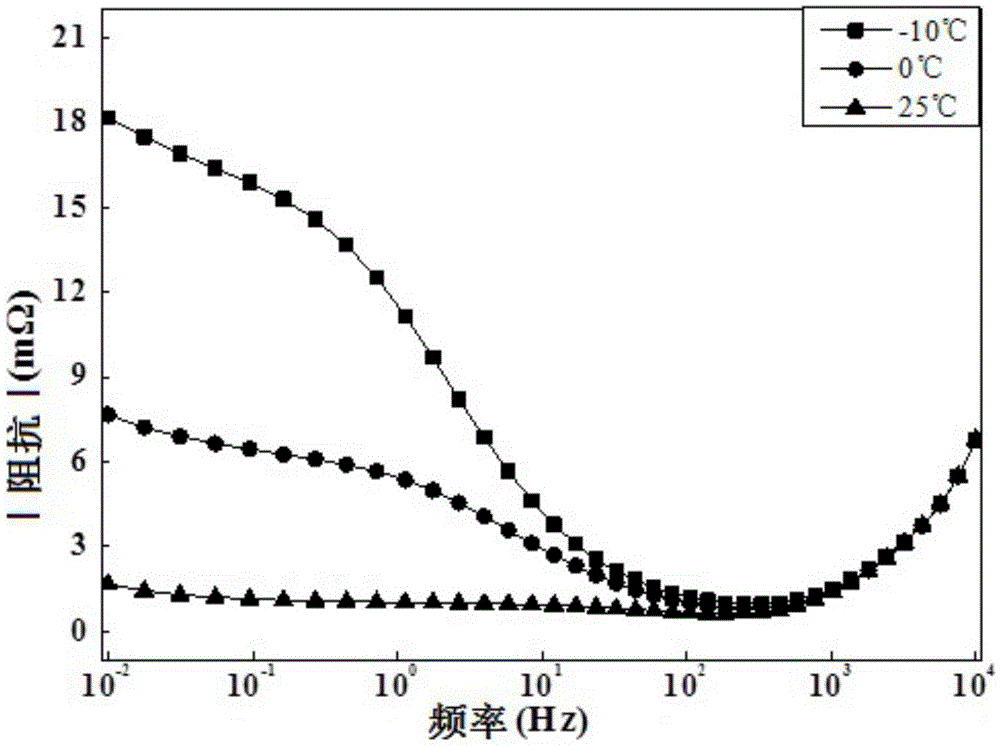

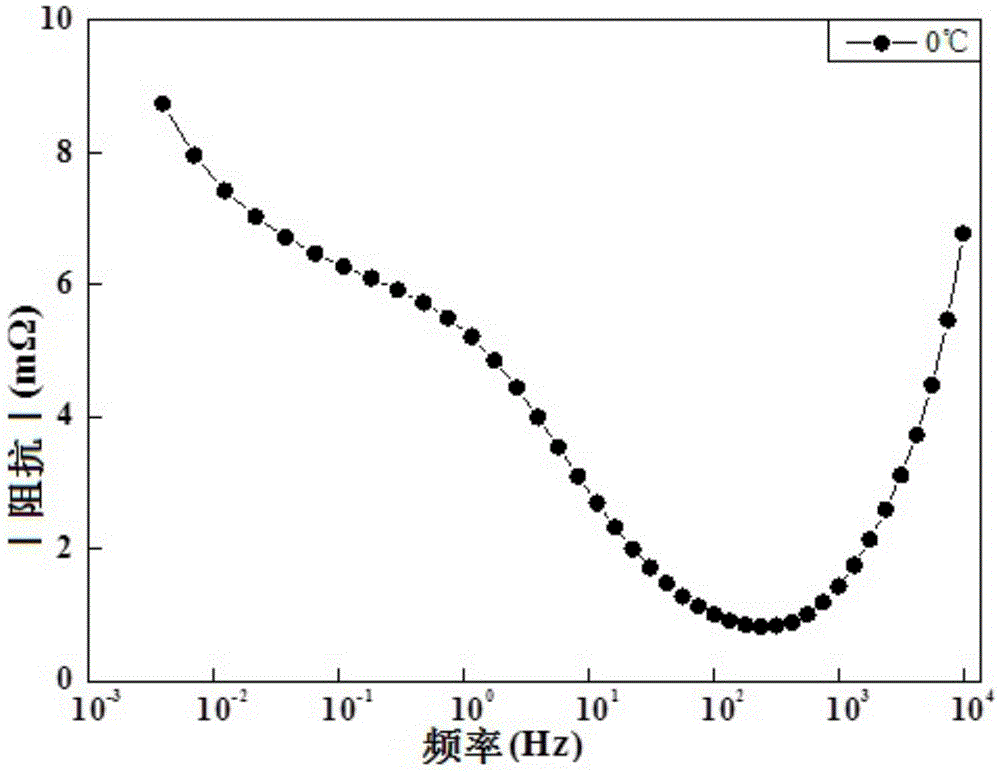

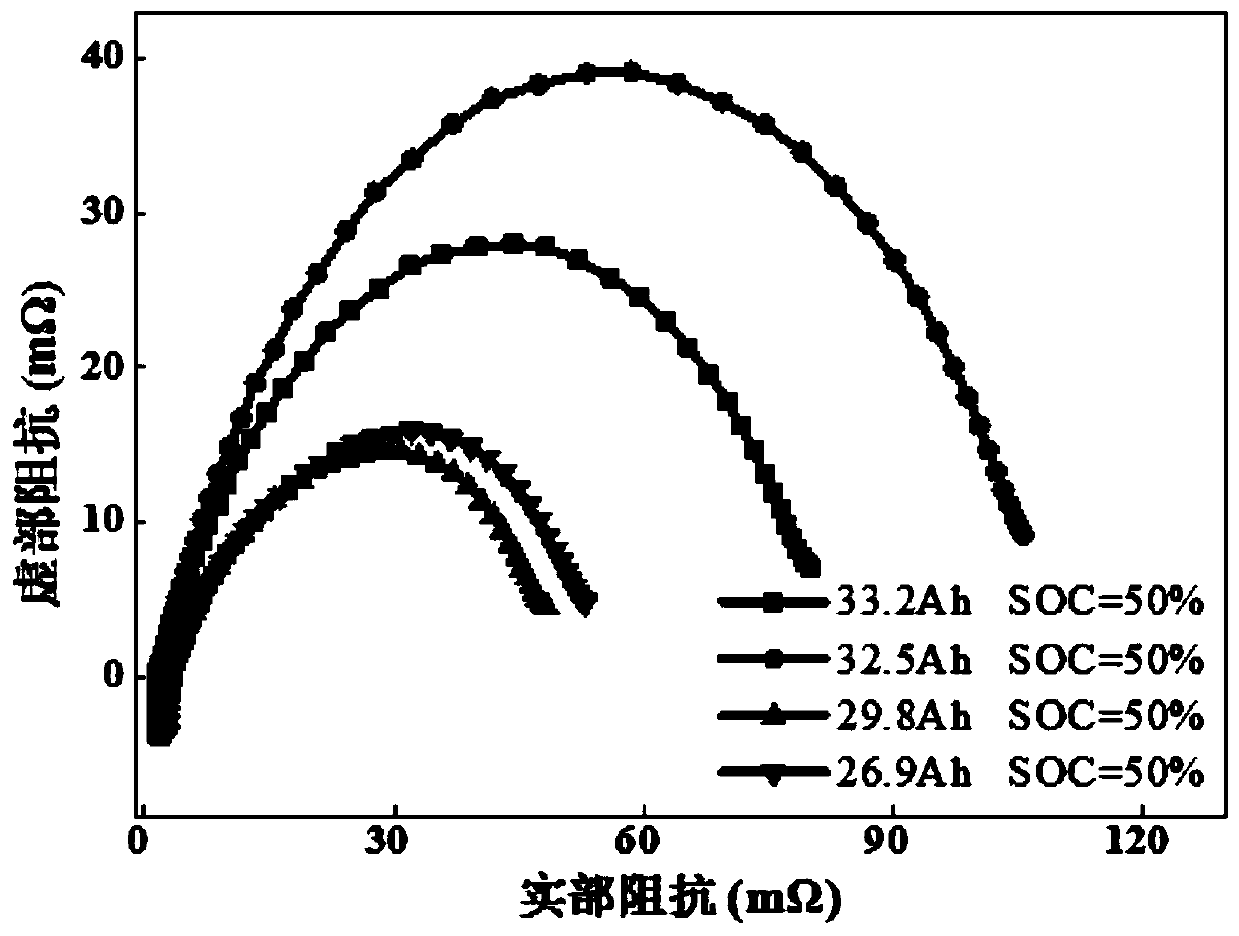

The invention discloses a low-temperature self-heating method for a lithium ion battery. The method comprises the steps of determining a frequency range in which the service life of the lithium ion battery cannot be affected, and selecting frequencies of charging and discharging pulses according to the range; setting a pulse current amplitude value selection basis under a selected charging and discharging mode, and calculating a charging current amplitude value Ic and a discharging current amplitude value Id; performing no-life-loss heating on the battery to be heated according to charging and discharging pulse signals of the determined frequencies and the amplitude values, wherein the inner resistance of the self-heated battery is greatly reduced, and the charging performance is greatly improved. According to the technical scheme, the low-temperature self-heating method has the effects of high self-heating speed, obvious low-temperature performance improvement and no influence on the service life of the battery.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

Low-temperature self-heating method of lithium ion battery pack

ActiveCN107039708AFast self-heating rateImprove low temperature performanceEfficient power electronics conversionSecondary cellsLithium electrodeHeating efficiency

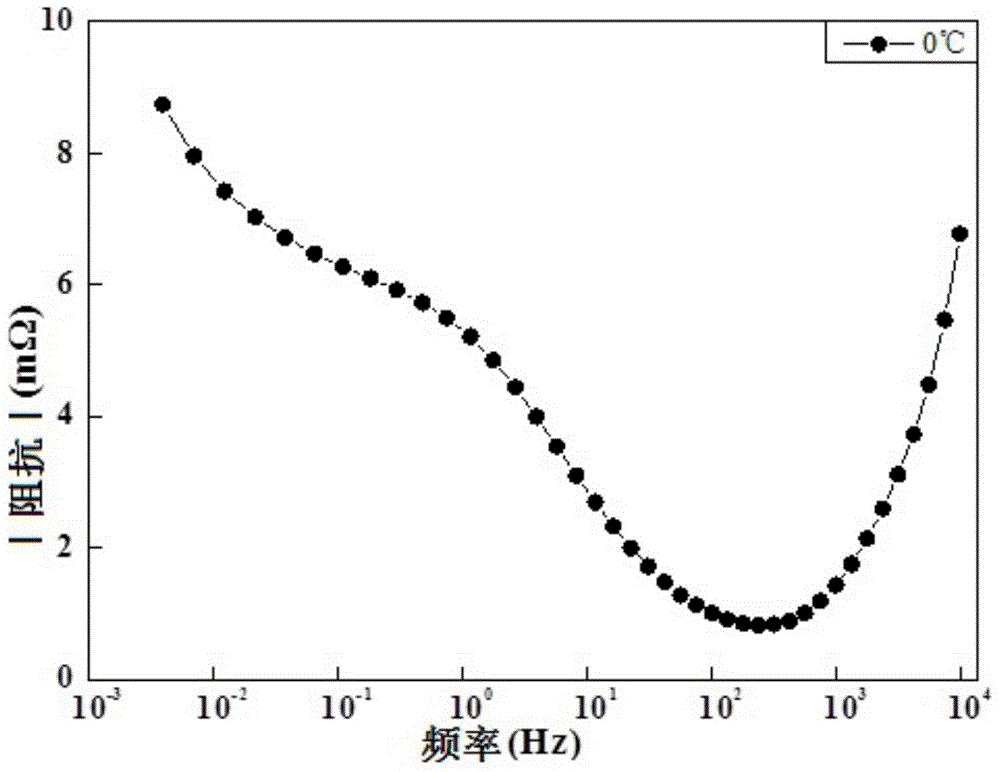

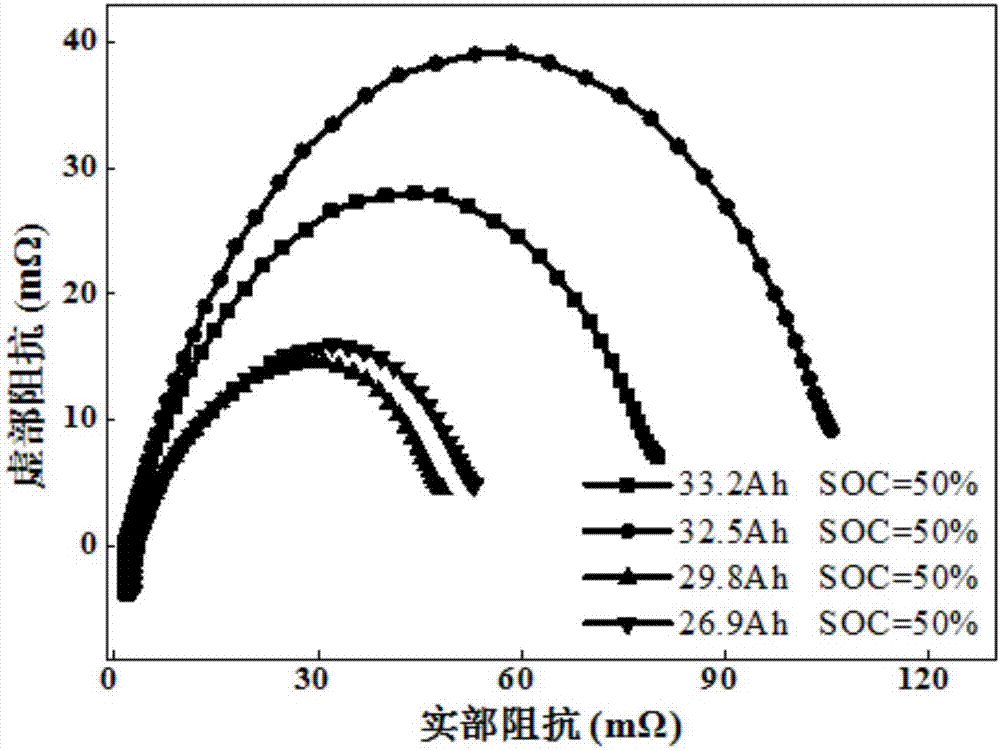

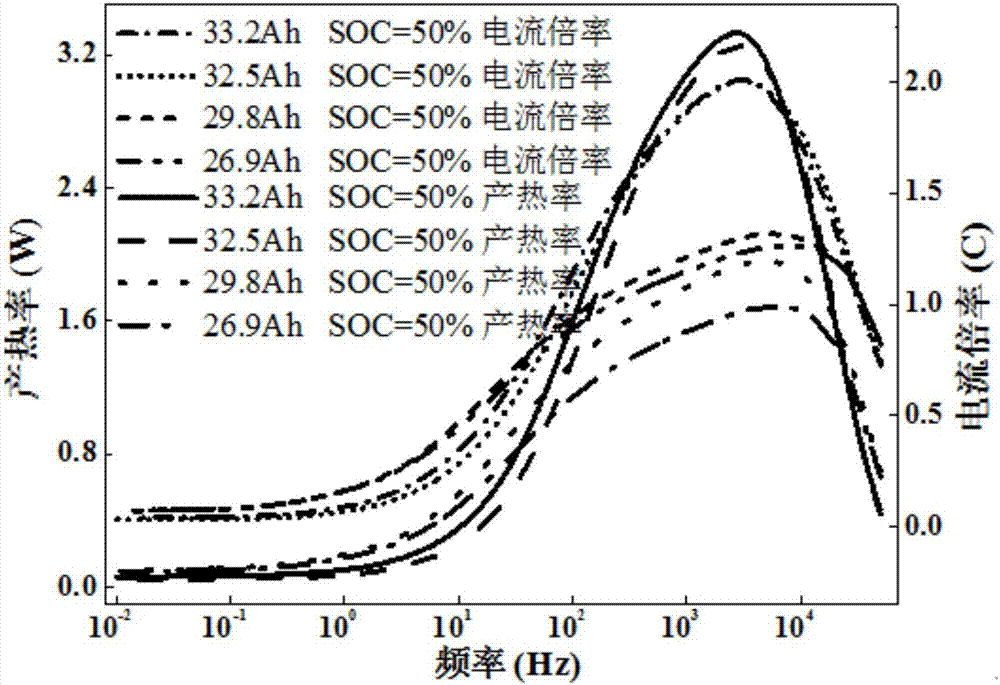

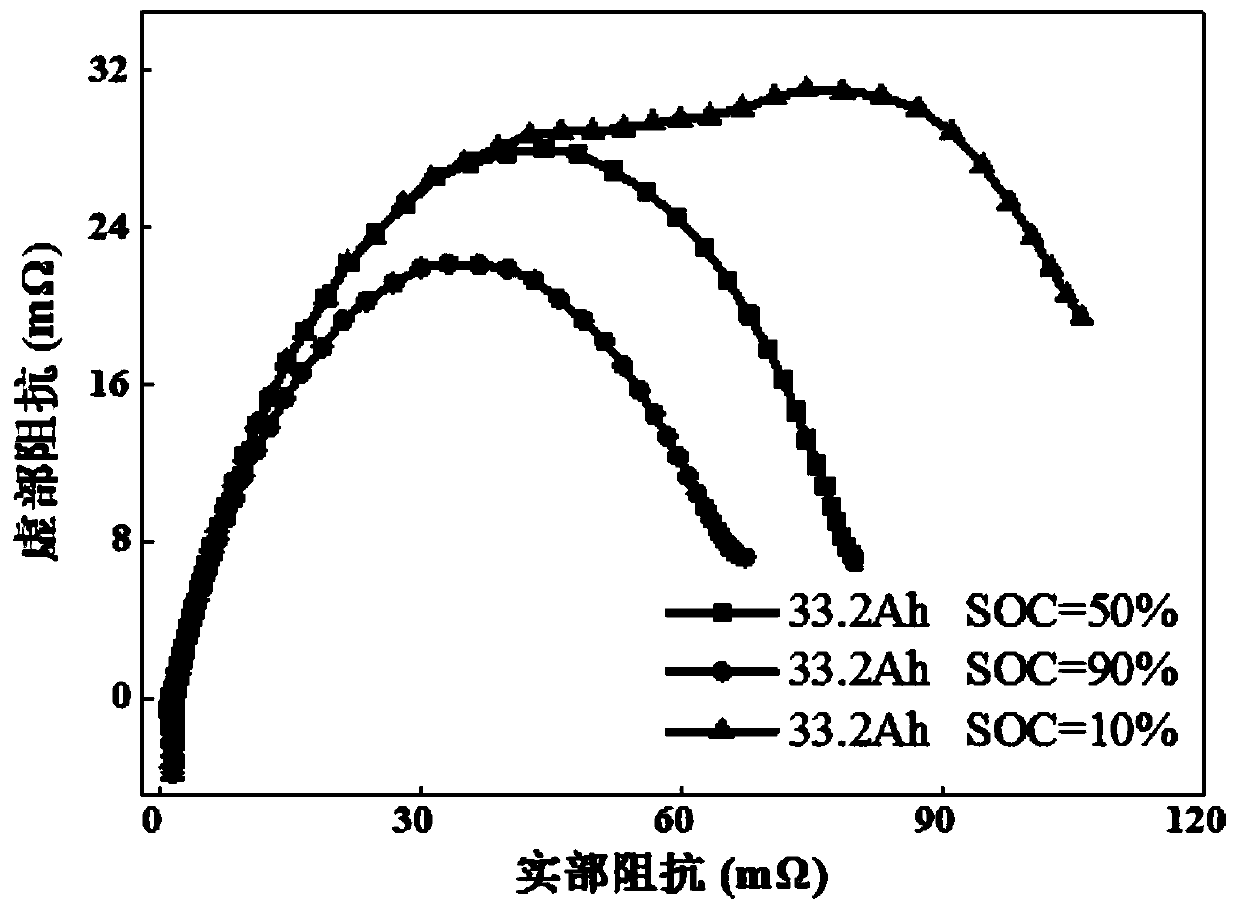

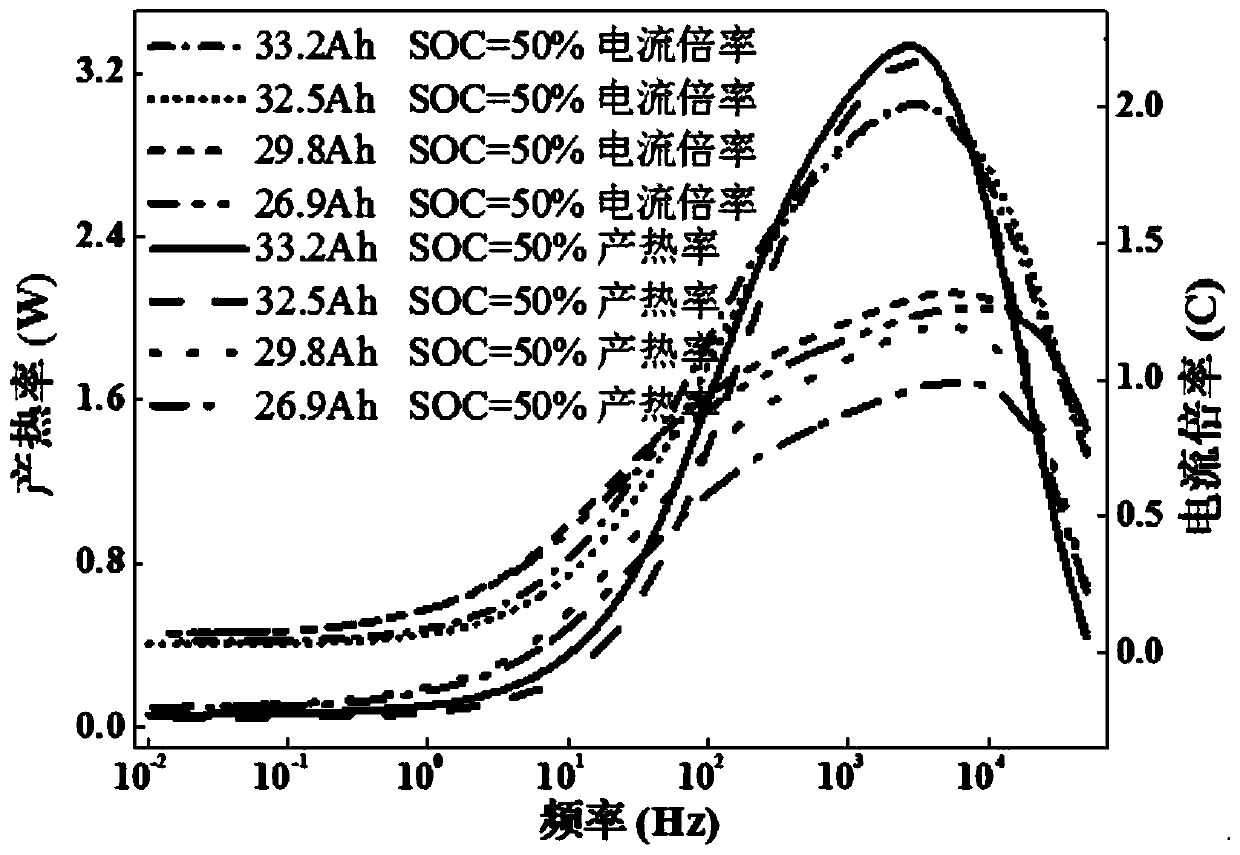

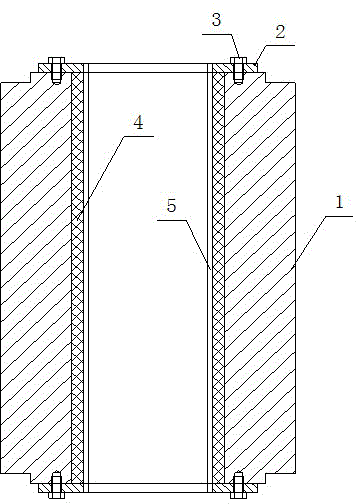

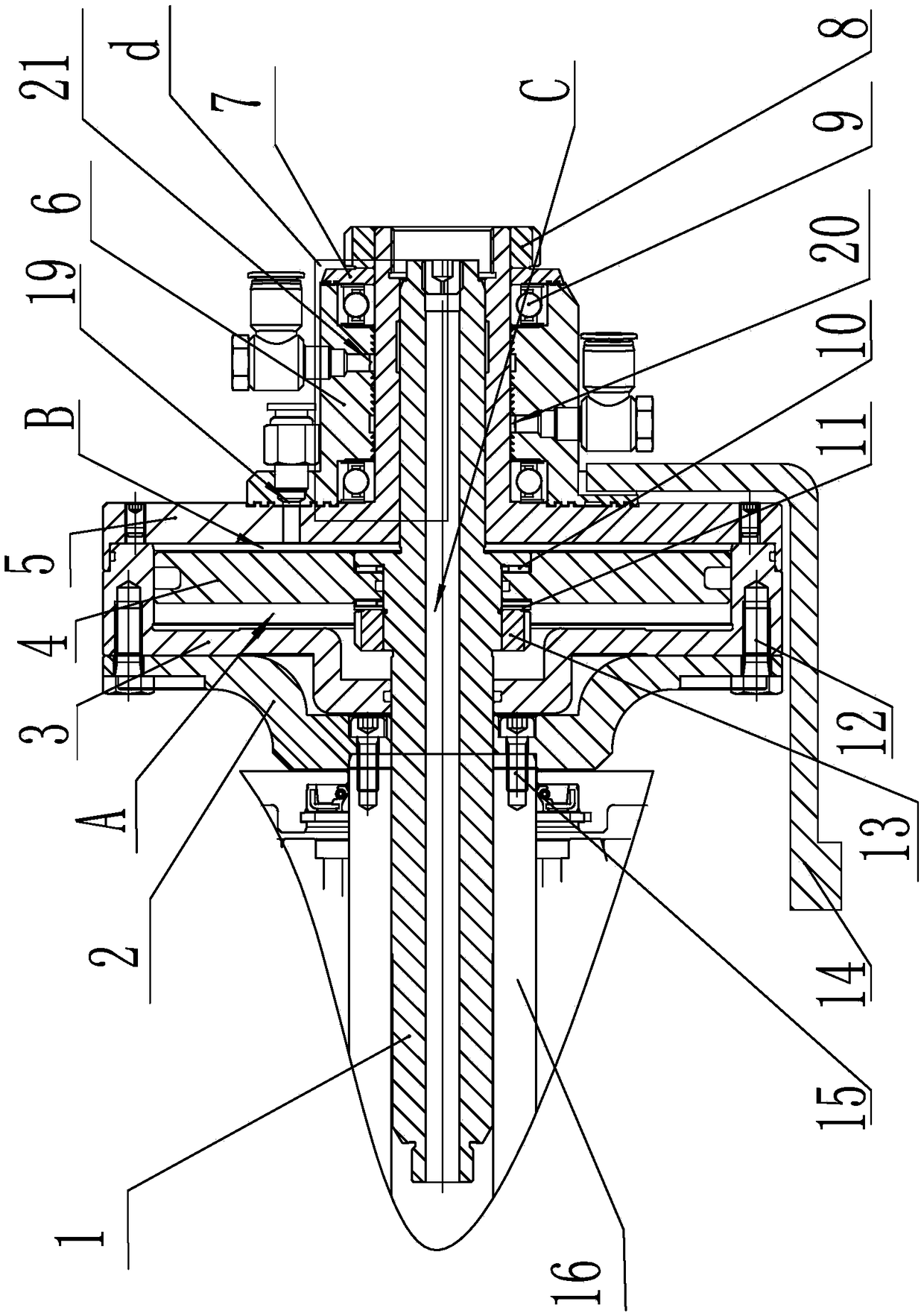

The invention discloses a low-temperature self-heating method of a lithium ion battery pack. The low-temperature self-heating method comprises the steps of determining an optimal heating frequency range compatible with a battery aging state and state-on-charge (SOC) according to a principle of minimum influence on lifetime of a battery; designing a series resonant inversion circuit, and exploring an optimal control strategy so that the inversion circuit outputs a sine AC current of a target frequency and target amplitude at a battery side; and performing low-temperature self-heating on the battery pack by the sine AC current output from the resonant inversion circuit, wherein the internal resistance of the battery is gradually reduced with the temperature rising of the battery, the output current amplitude of the resonant inversion circuit is adaptively increased, the heating rate of the battery pack is improved, and the battery pack is rapidly raised to a target temperature. The low-temperature self-heating method has the effects of fast self-heating rate on the lithium ion battery pack under a low temperature, obvious improvement on low-temperature performance, high self-heating efficiency, no influence on service lifetime of the lithium ion battery, good heating temperature uniformity and the like, and the promotion and the application of an electric vehicle in a cold place are facilitated.

Owner:BEIJING JIAOTONG UNIV +1

Low-temperature rapid self-heating method for lithium-ion battery

ActiveCN105680114ADetermining the Polarization Voltage Amplitude RangeNo effect on lifespanSecondary cellsVoltage amplitudeElectrical battery

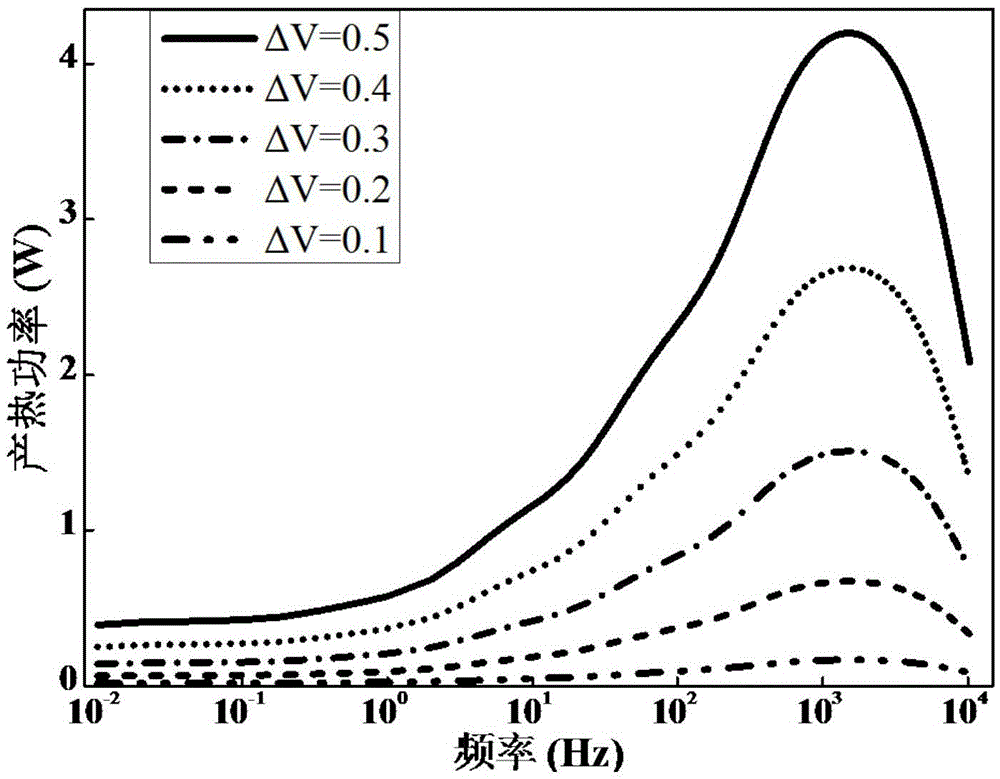

The invention relates to a low-temperature rapid self-heating method for a lithium-ion battery. The method comprises the following steps: (S1) determining a polarization voltage amplitude range which does not have influence on the service lifetime of the lithium-ion battery and is safely used, and selecting a sine AC voltage amplitude according to the range; (S2) calculating the relationship between heat production power and frequency and obtaining a frequency point, namely the optimal heat production frequency point, with the maximum heat production power according to the relationship between battery impedance and frequency under the selected sine AC voltage amplitude; and (S3) carrying out heating free of lifetime loss on the battery by a sine AC signal according to the amplitude determined in the step (S1) and the frequency determined in the step (S2). The low-temperature rapid self-heating method for the lithium-ion battery has the effects of being high in heating rate, obvious in low-temperature performance improvement, free of an influence on the service lifetime of the lithium-ion battery, good in heating temperature uniformity and the like; and the target of reducing the influence on the service lifetime of the lithium-ion battery to the maximal extent is achieved.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

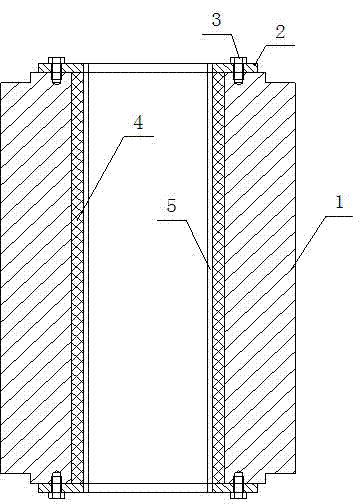

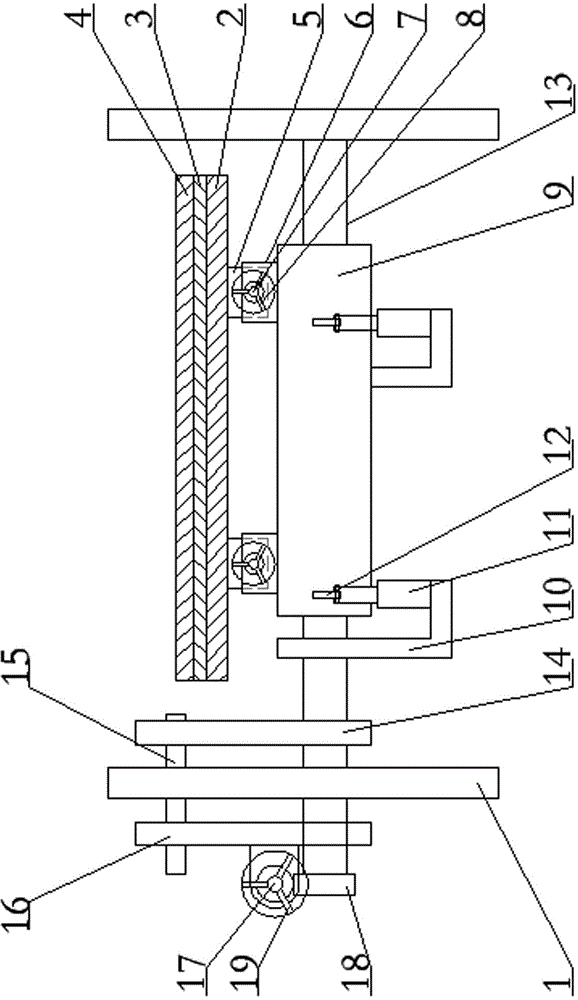

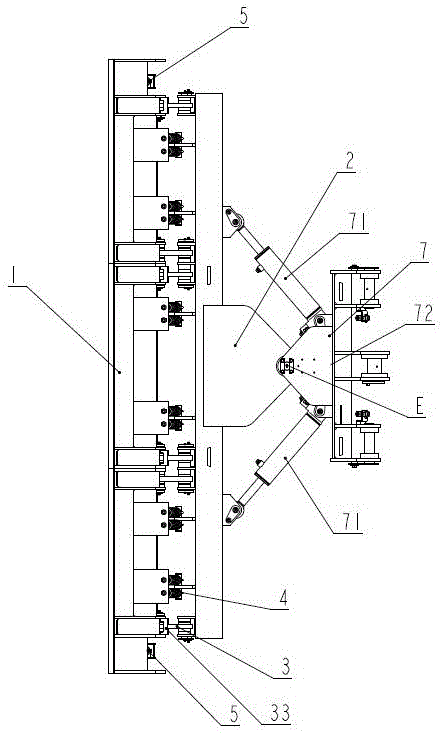

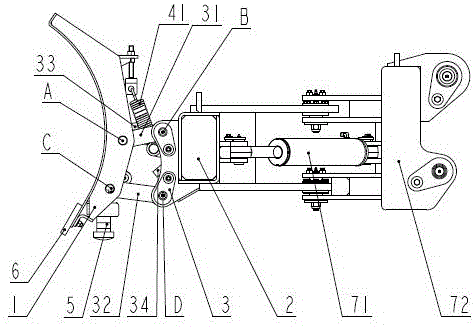

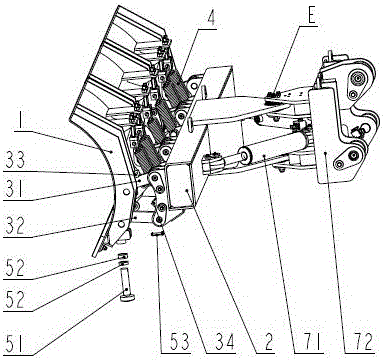

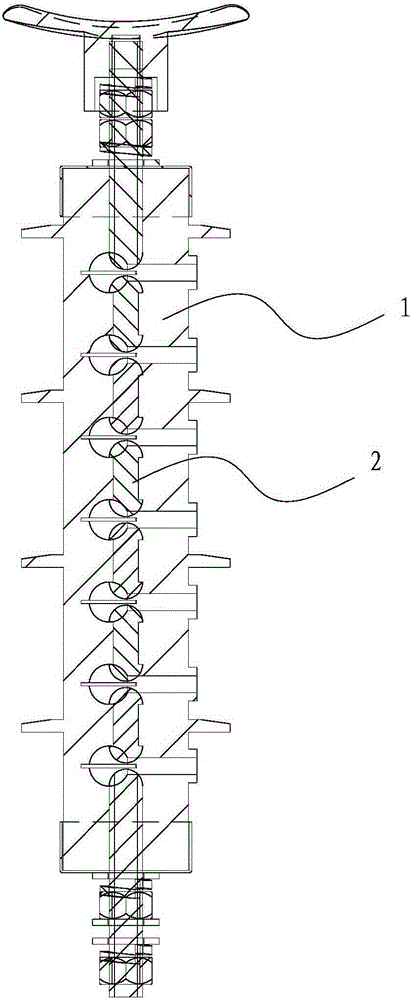

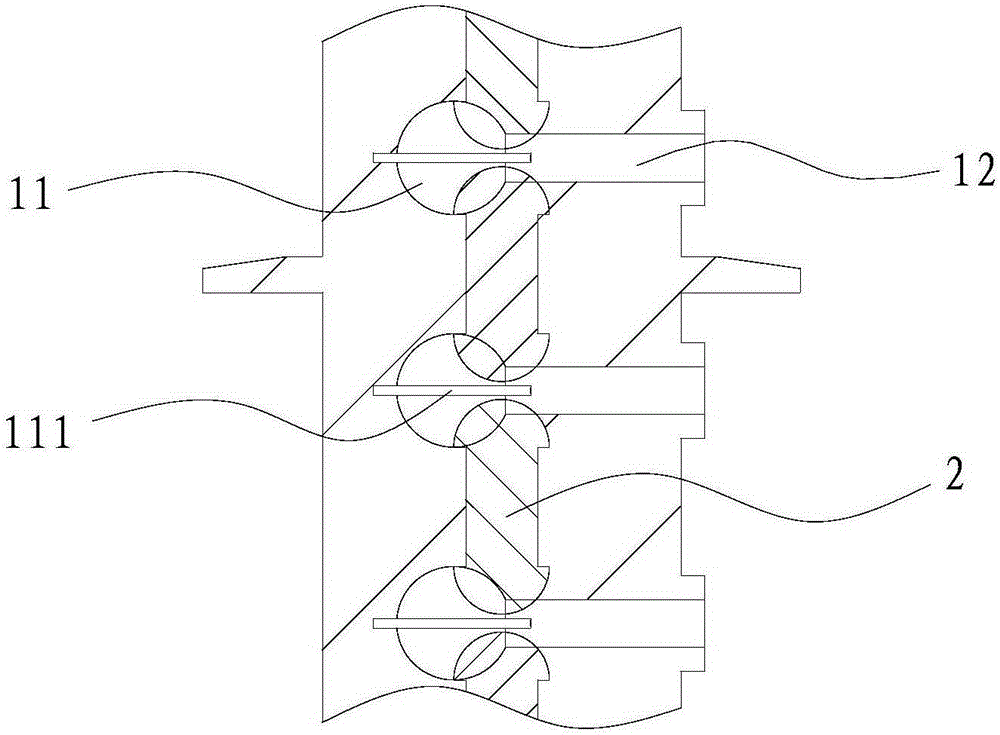

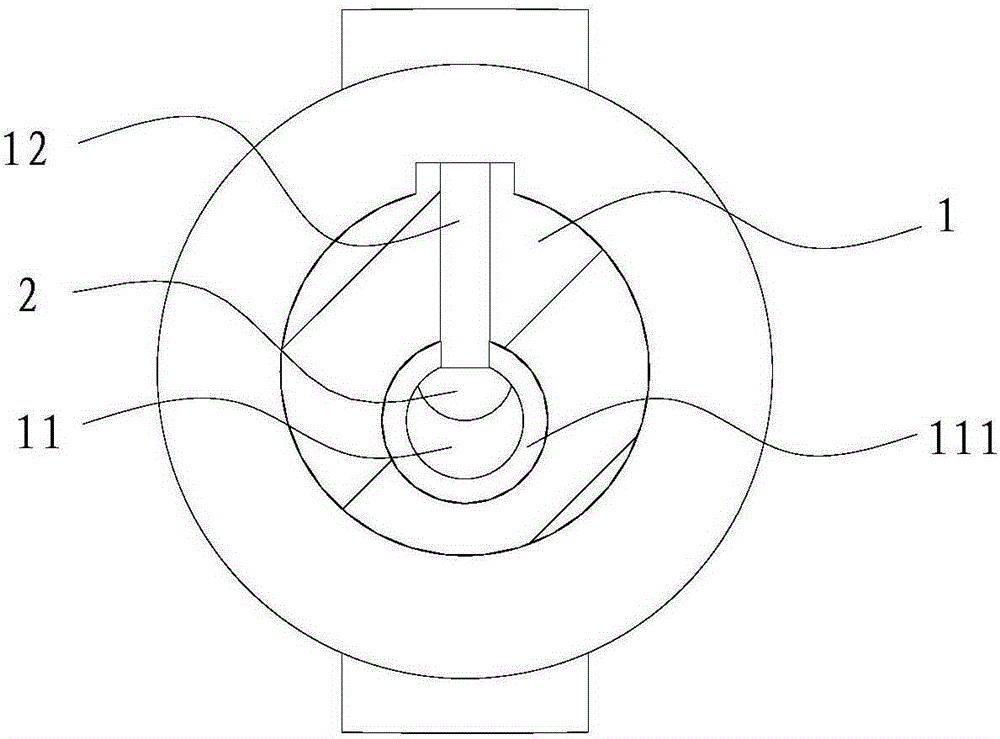

Coater scraper apparatus

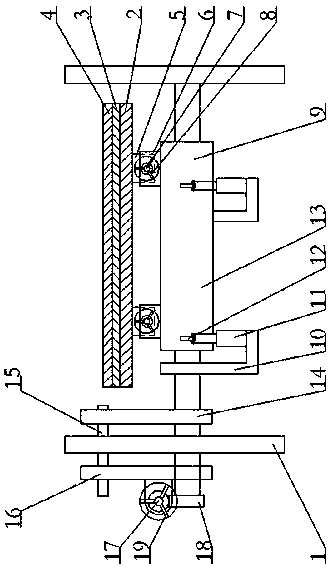

ActiveCN103350055AMake sure the thicknessEnsure flatnessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a coater scraper apparatus. The apparatus comprises a scraper rack connected to a coater frame, a scarper having a cutting edge corresponding the coating roller of a coater is press-fitted on the scraper rack through a scraper press plate, a scraper rack adjusting shaft paralleling to the scraper rack is movably arranged on the coater frame in a penetrating mode, the scraper rack is connected with the scraper rack adjusting shaft and rotate around the scraper rack adjusting shaft, an adjusting worm gear is fixedly connected with the scraper rack adjusting shaft in a penetrating mode, the coater frame supports an adjusting worm having a driving cooperation with the adjusting worm gear, and the adjusting worm is connected with a hand wheel. The coater scraper apparatus accurately controls the adjustment between the scraper and the coating roller by adopting the scraper rack rotatablely far from or close to the coating roller and combining the scraper adjusting seat and a trimming cylinder, so the apparatus has the advantages of simple and compact structure, convenient and accurate adjustment, and effective ensure of the thickness of a glue solution on the coating roller for the uniform adjustment, and is suitable for the use of various different specification coating rollers and coating thicknesses.

Owner:泰兴联创绝缘材料有限公司

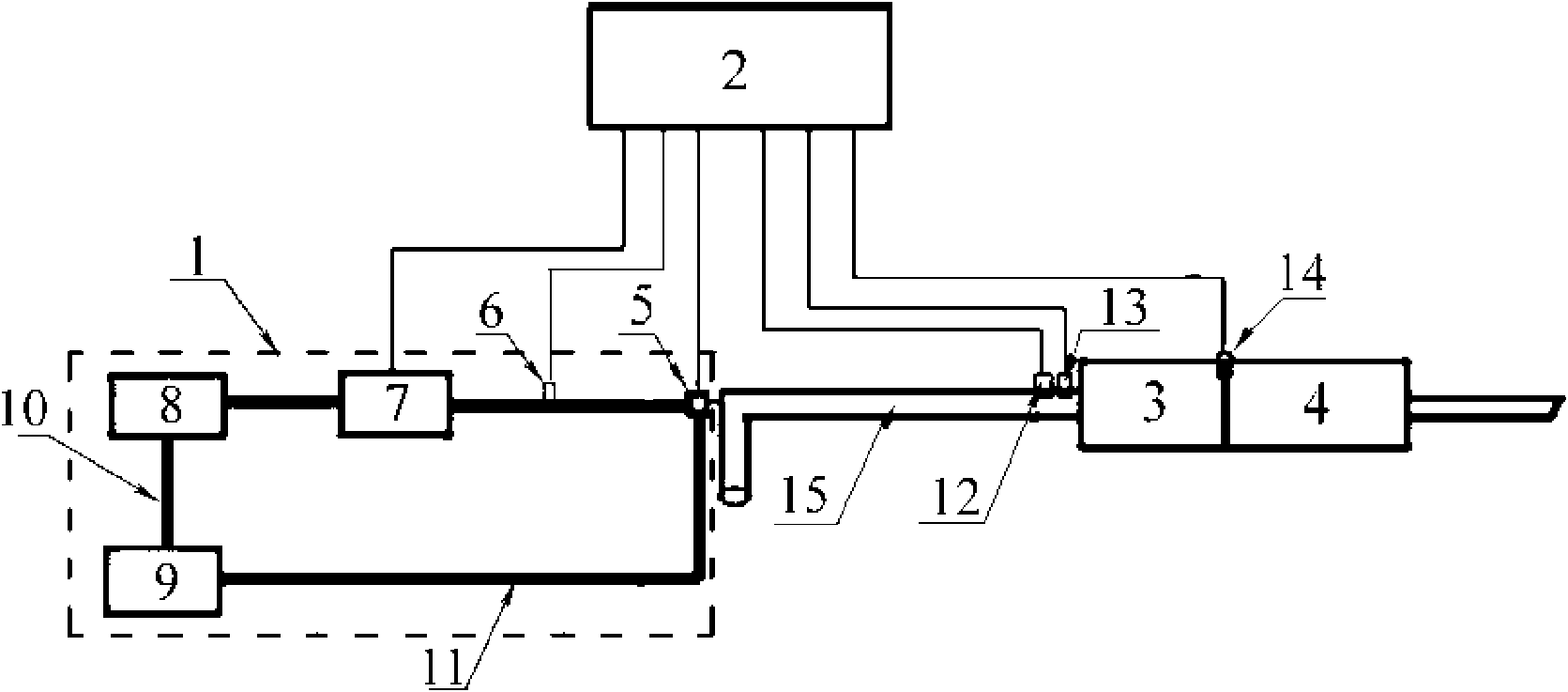

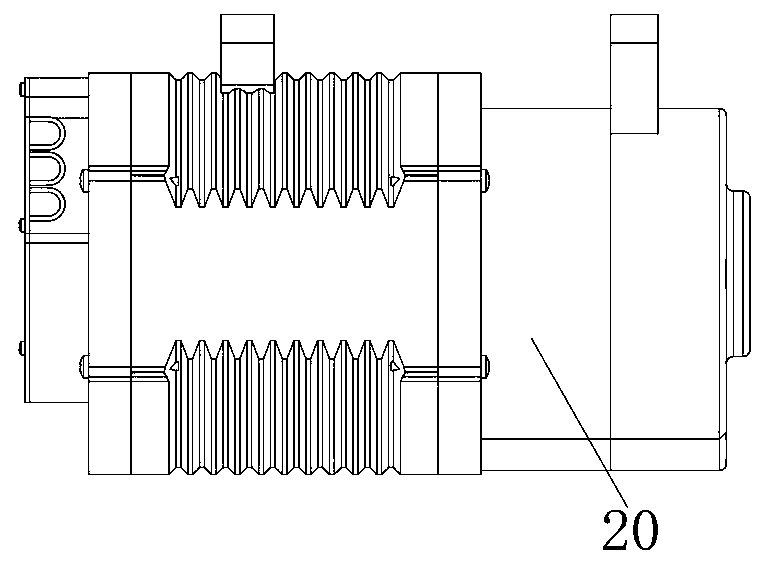

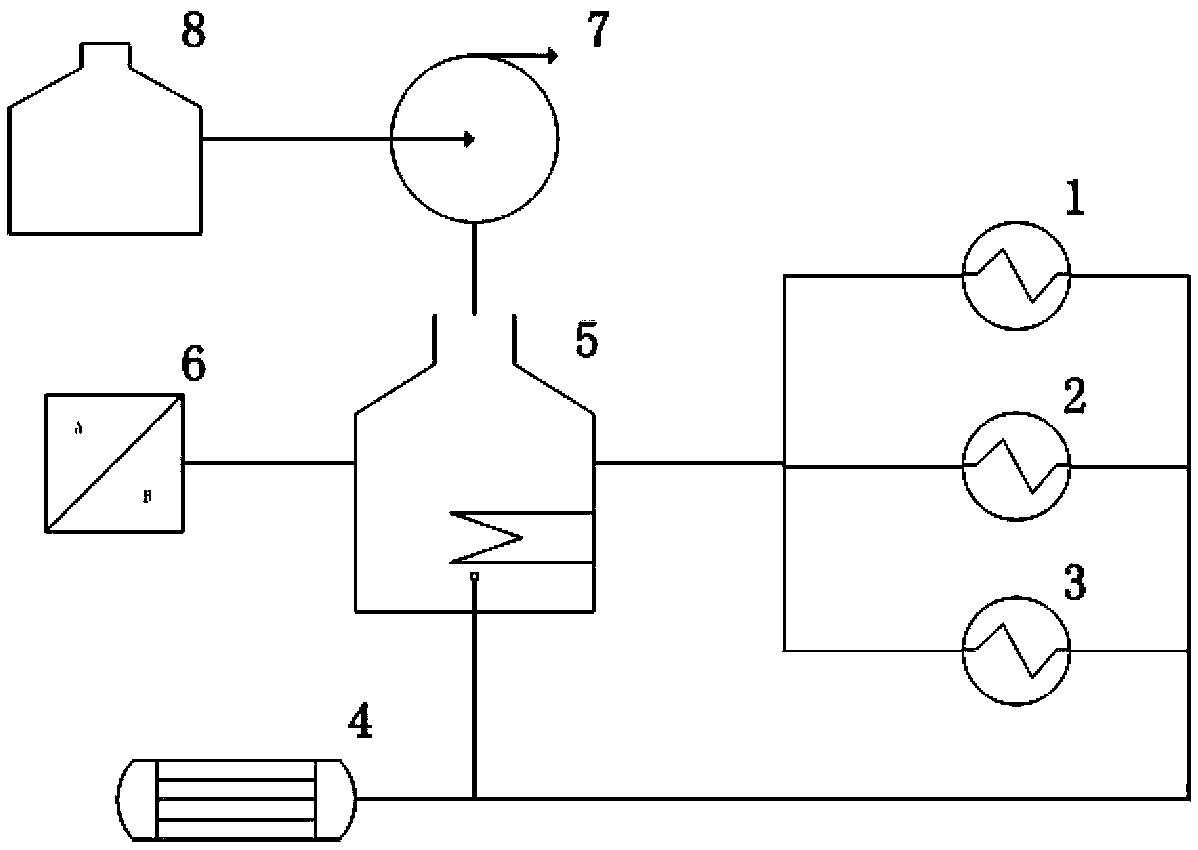

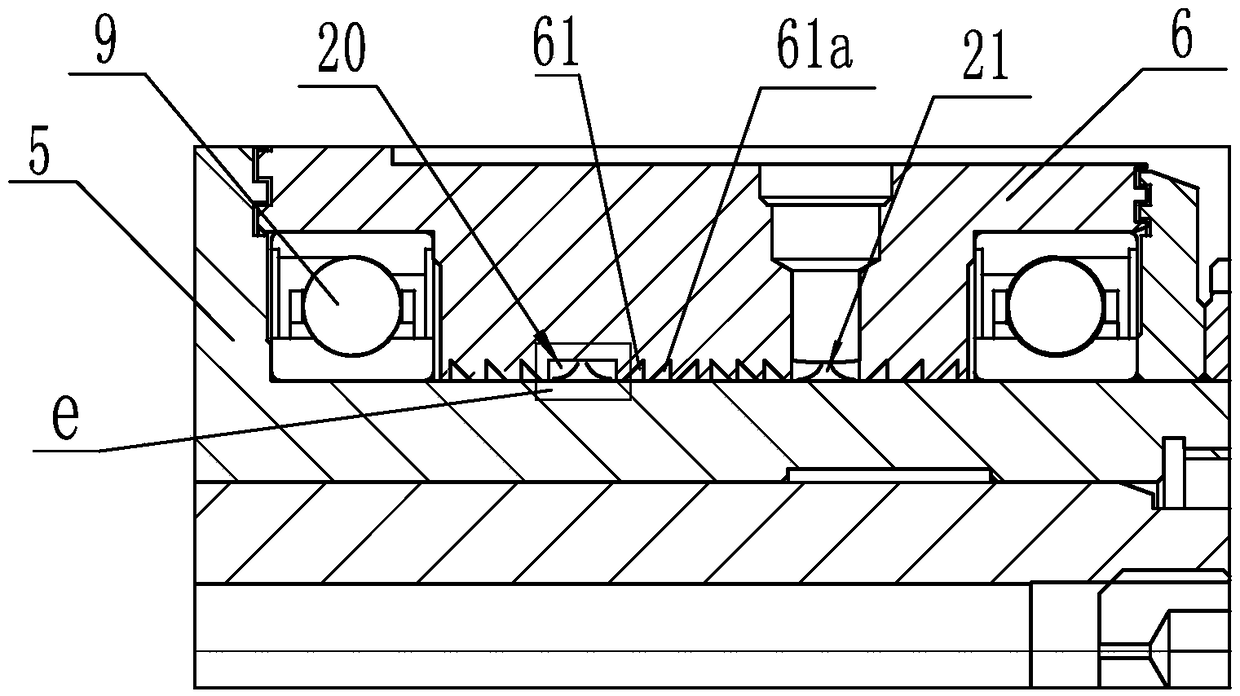

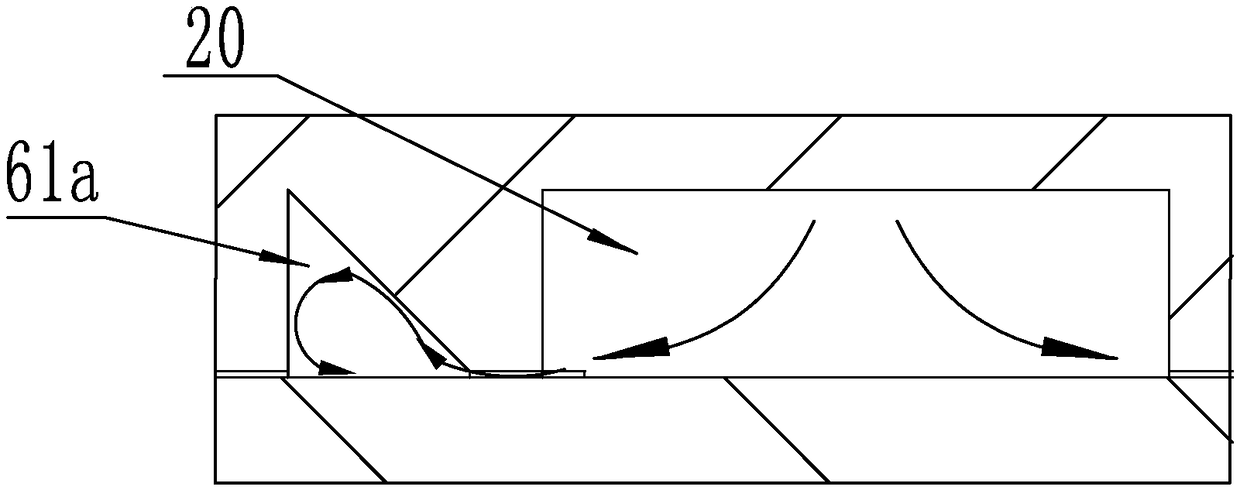

Oxidation type catalyst-assisting regeneration system for diesel particulate filter (DPF)

InactiveCN101975104ANo effect on service lifeDoes not affect fuel economyInternal combustion piston enginesExhaust apparatusControl systemDiesel particulate filter

The invention discloses an oxidation type catalyst-assisting regeneration system for a diesel particulate filter (DPF). The system consists of an oil injection system, a control system, an oxidation type catalyst, a diesel engine particles filter, an exhaust backpressure sensor and an exhaust temperature sensor. An atomization exhaust pipe composed of a section of straight pipe is connected between a nozzle and the oxidation type catalyst; the exhaust temperature sensor in front of the exhaust backpressure sensor and the oxidation type catalyst judges a regeneration time and an oil injection time; and when the regeneration time and the oil injection time both reach the pre-set fixed values and meet the oil injection and regeneration conditions, the control system starts an oil injection system so that an oil pump generates larger circulating pressure, the nozzle injects diesel oil into an upstream exhaust pipe of the oxidation type catalyst, and the injected diesel oil and the exhaust gas of an engine are sufficiently mixed and atomized in the straight pipe section. The oxidation type catalyst-assisting regeneration system for the DPF of the invention can solve the technical problems of the conventional diesel engine particles filter regeneration system that the service life of the engine is influenced, the economical efficiency of the diesel oil is low, the use cost of the technology is high, etc.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

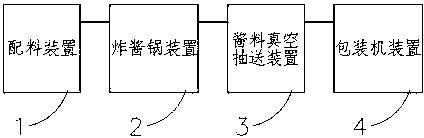

Vacuum discharge sauce production line

InactiveCN103798746ANo effect on service lifePrevent oxidative deteriorationFood preparationPulp and paper industryManufacturing line

The invention belongs to the field of food production, and particularly relates to a vacuum discharge sauce production line. The vacuum discharge sauce production line comprises a sauce frying pot device, a vacuum material pumping device and a packing machine device, and is characterized in that a control device, a batching apparatus, the sauce frying pot device, the vacuum material pumping device and the packing machine device are sequentially connected by totally closed pipelines, wherein the sauce frying pot device is provided with an upper discharge suction opening, materials are discharged from the upper discharge suction opening, the vacuum material pumping device is provided with a stirring storage tank and a vacuum device, and through the vacuum negative pressure of the stirring storage tank, sauce is pumped from the upper discharge suction opening of the sauce frying pot device into the stirring storage tank to be stored in vacuum. The vacuum discharge sauce production line has the advantages and beneficial effects that the upper discharge suction opening for discharging the materials has the advantage that a sauce frying pot does not need to be sealed in operation and is not affected in service life, the vacuum material pumping avoids problems of pollution caused by a material pumping manner of a sauce pump and blocking of pipelines, and the vacuum material storing prevents the sauce from oxidative deterioration.

Owner:NINGXIA NINGYANG HALAL FOOD

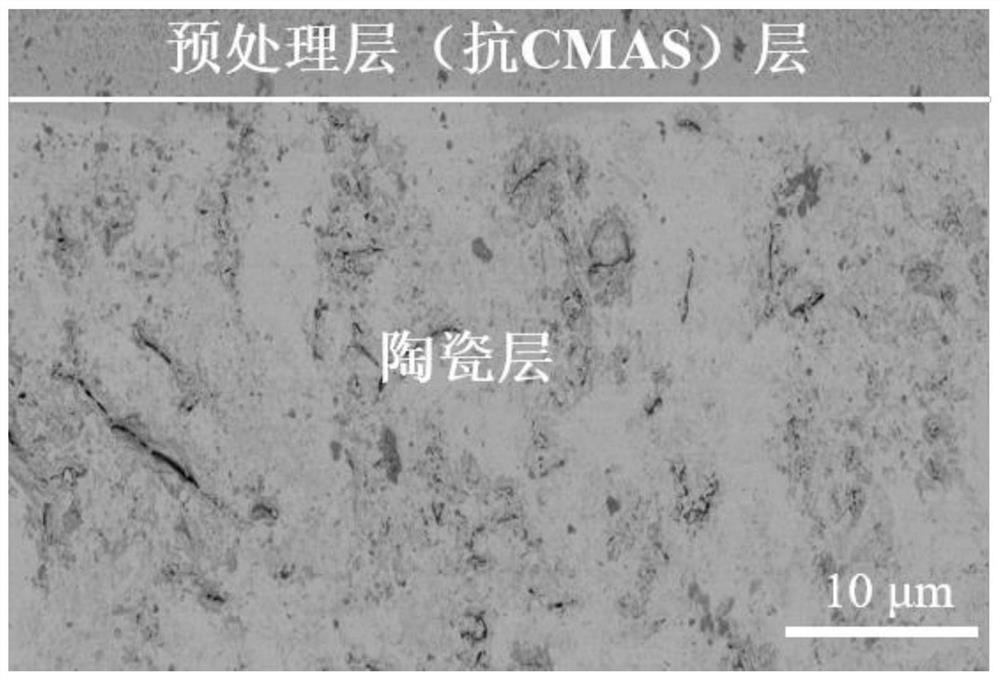

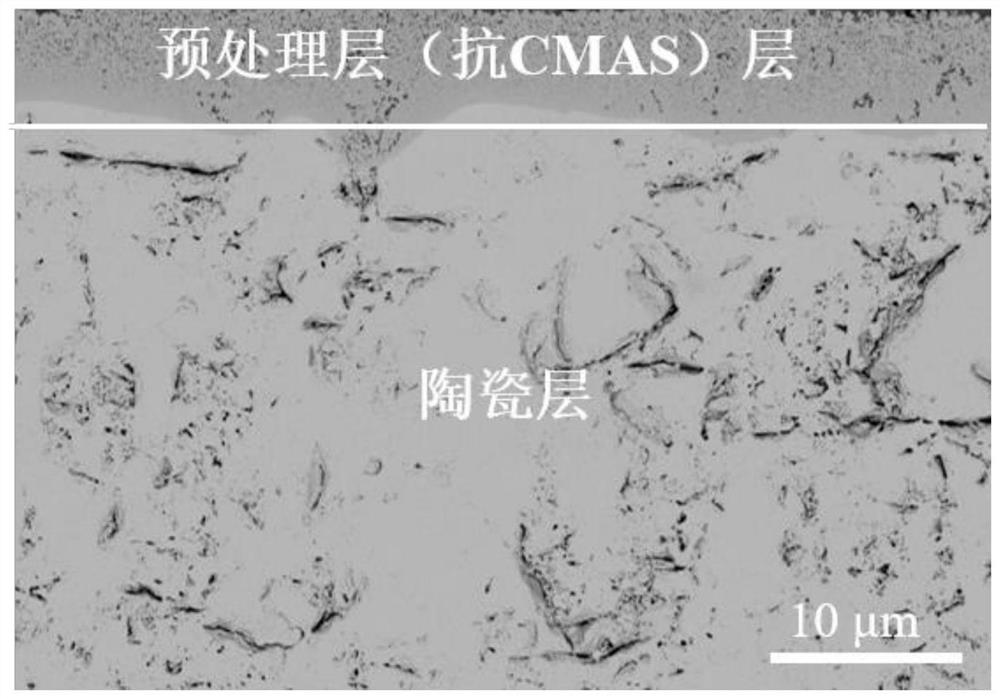

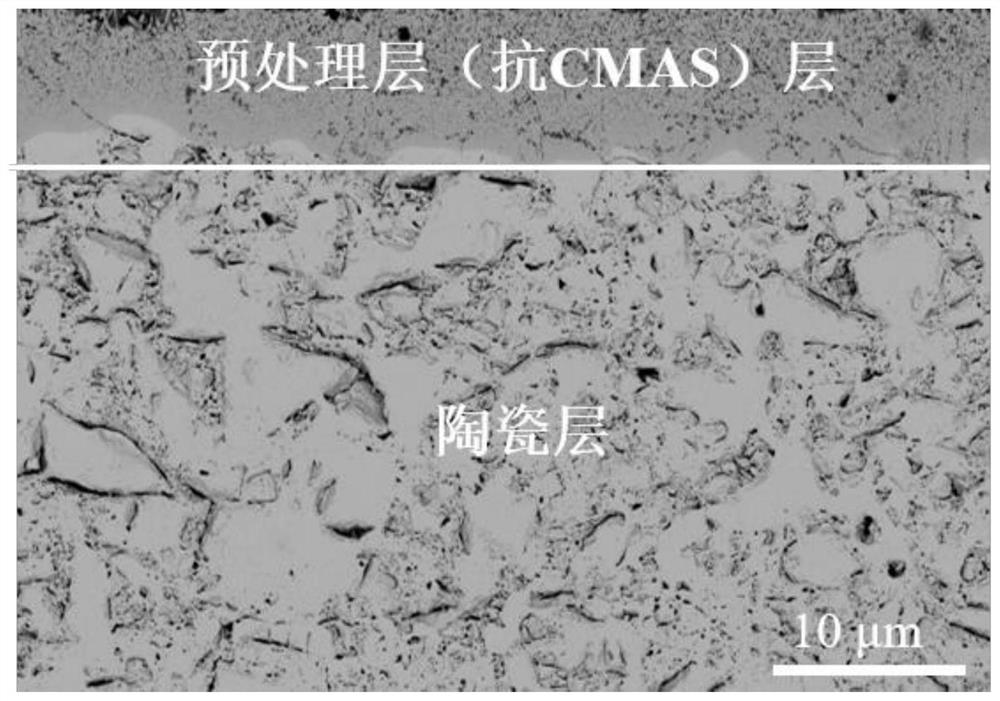

Thermal barrier coating layer resisting CMAS erosion and preparation method

ActiveCN111850454AImprove the ability to resist CMAS erosionHigh melting pointMolten spray coatingEfficient propulsion technologiesCrazingThermal barrier coating

The invention relates to the technical field of surface corrosion and protection of thermal barrier coating layers, specifically to a thermal barrier coating layer resisting CMAS erosion and a preparation method. In the technical solution of the invention, prefabricated CMAS suspension is uniformly coated on the surface of a thermal barrier coating layer; and then, the coating layer is sintered for a period of time in a high-temperature furnace to form a compact apatite phase barrier layer on the surface. The layer has the features of high melting point, high compactness, excellent phase stability and high bonding force, not only can fill inevitable holes and cracks in the surface spraying process of ceramic layers, but also can block CMAS diffusion channels in the ceramic layers, effectively improves the CMAS erosion resistance of the thermal barrier coating layer.

Owner:JIANGSU UNIV

Semi-conductive adhesive for repairing semi-conductive shield outside medium-voltage cross-linked cable

The invention provides a semi-conductive adhesive for repairing a semi-conductive shield outside a medium-voltage cross-linked cable, which comprises the following components: 30 to 50 grams of graphite powder, 20 to 30 grams of volatile solvent and 5 to 10 grams of plastic adhesive. Preferably, the semi-conductive adhesive comprises 30 grams of the graphite powder, 30 grams of the volatile solvent and 5 grams of the plastic adhesive, or 40 grams of the graphite powder, 25 grams of the volatile solvent and 8 grams of the plastic adhesive, or 50 grams of the graphite powder, 20 grams of the volatile solvent and 10 grams of the plastic adhesive, wherein the volatile solvent is ethanol or acetone, and the plastic adhesive is a 102 multi-purpose plastic adhesive. The semi-conductive adhesive also comprises 3 to 8 grams of colored conductive powder. The semi-conductive adhesive can well repair the semi-conductive shield outside the medium-voltage cross-linked cable, obtains good appearance quality after repairing, has no influence on the quality and the service life of the cable, reduces the using cost, saves resources, is simple and convenient to operate, is easy to be accepted by users, and is suitable for large-scale popularization and application.

Owner:上海德力西集团有限公司

Cold-type special molding sand for integral casting of large cast steel roller and manufacturing method of cold-type special molding sand

ActiveCN102886499AQuality improvementImprove casting qualityFoundry mouldsFoundry coresChemical compositionStrip mill

The invention discloses cold-type special molding sand for the integral casting of a large cast steel roller. The cold-type special molding sand is composed of the following compositions in parts by weight: 76% to 80% of quartz sand, 13% to 15% of clay, 1% to 2% of bentonite and the balance of water. When the special molding sand disclosed by the invention is used for the integral casting of a large cast steel roller having the diameter of Phi 900 to Phi 1400 and the amount of casting molten steel is 15 to 70 tons, the roller cold-type sanded thickness can be controlled within the range from 8mm to 9mm, thus improving the cold-type chilling capability of the roller body, enabling the columnar crystal thickness of the surface dense layer of the roller body to achieve about 150mm, reducing the chemical constitution aliquation of the outer layer, and enhancing the quality of the working layer of the roller body. The molding sand can prevent casting defects on roller surface excellently, such as sand adhesion and sand inclusion, results in smooth roller surface, improves the casting quality and the casting qualified rate of the large cast steel roller, and meets the demands on comprehensive application performances of the roller working layer of large section mills and strip mills, such as wear resistance, hot cracking resistance and accidence resistance.

Owner:成都三强轧辊股份有限公司

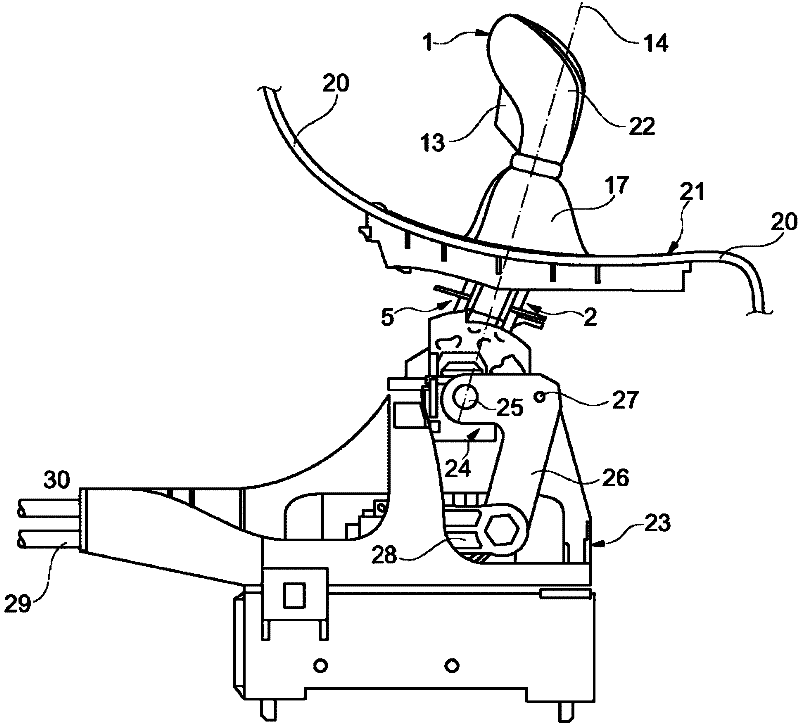

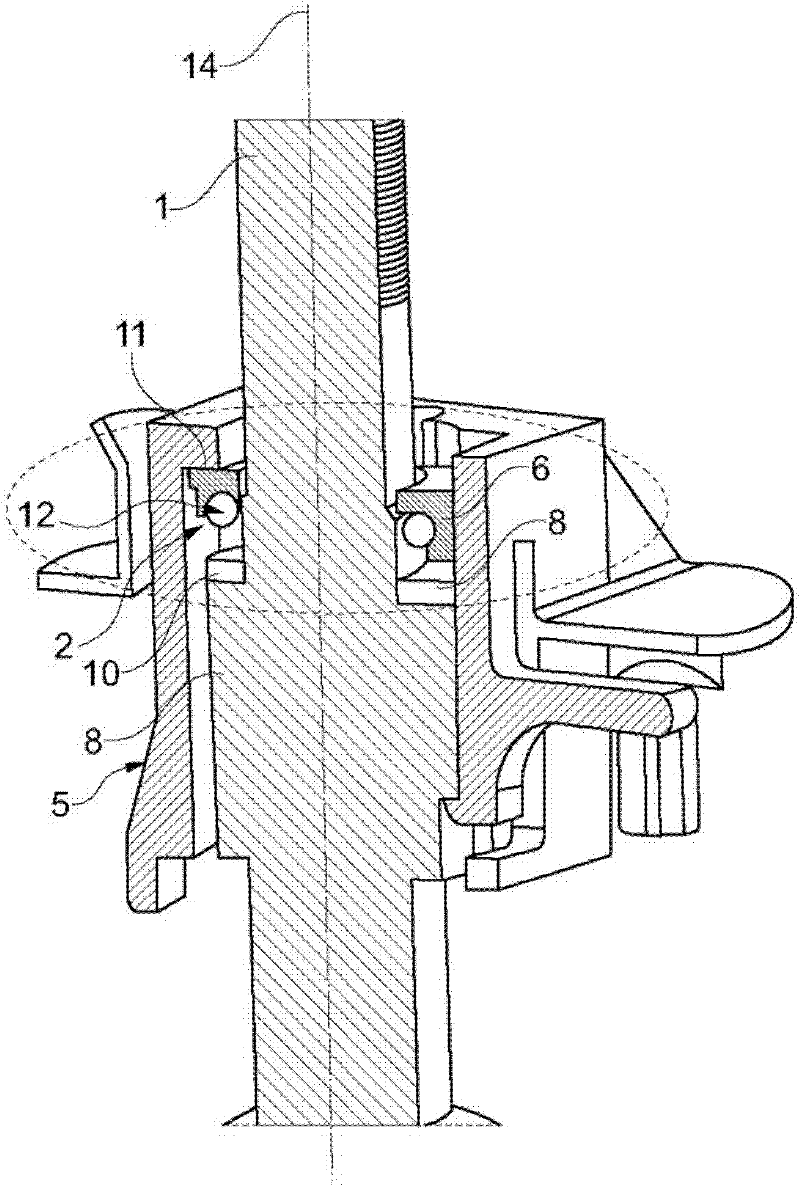

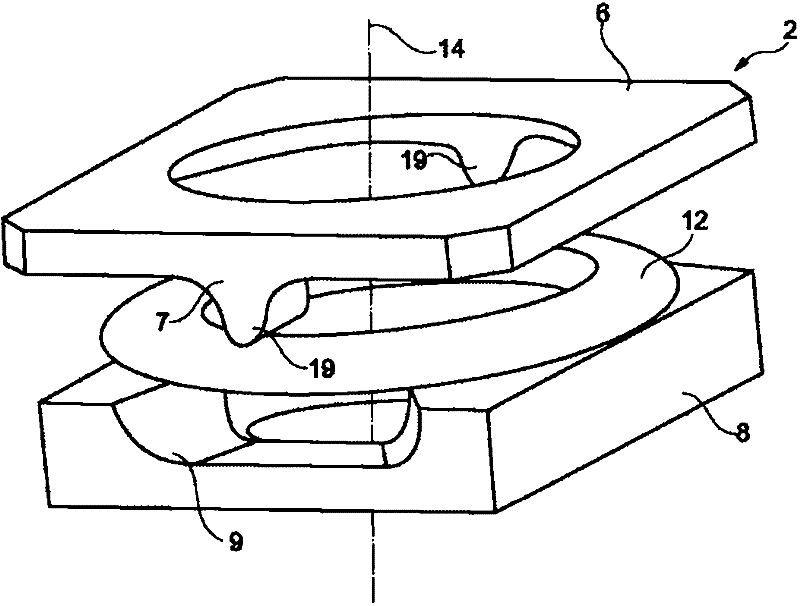

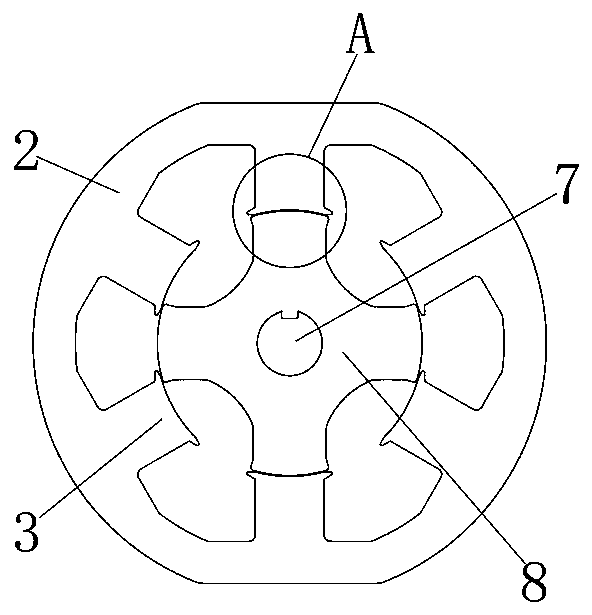

Car gear shifter with shock absorber

InactiveCN102261458ALow costReduced assembly effortNon-rotating vibration suppressionGearing controlRing elementEngineering

The invention relates to an automobile shift lever (1) with a shock absorbing device (2). The shock absorbing device plays a shock absorbing role when the reverse gear locking member (5) springs back to the locked position along the axial direction of the shift lever (1). For this purpose, the shock absorber (2) has a first rigid annular element (6) in the axial direction of the selector lever (1), which surrounds the selector lever (1) and has projections (7) distributed on the periphery in the axial direction . Furthermore, the damping device has a second rigid ring element (8) which has a recess in the area of the projection (7) of the first rigid ring element (6). Radial steps (10, 11) are provided on the reverse gear lock (5) and the shift lever (1), and the two rigid ring elements (6, 8) are axially supported on the steps (10, 11) superior. A rubber elastic ring (12) is arranged between the first and second rigid ring elements (6, 8), and when the reverse gear lock (5) rebounds, it can The rubber is elastically deformed between the lug (7) and the groove (9) of the second rigid ring element (8).

Owner:GM GLOBAL TECH OPERATIONS LLC

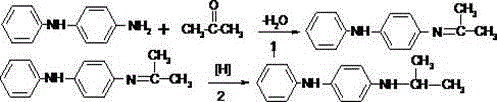

Method for preparing anti-aging agent 4010NA through modification-catalytic hydrogenation

InactiveCN104418757AHigh selectivityInhibit side effectsPreparation by reductive alkylationBulk chemical productionPtru catalystOrganic synthesis

The invention belongs to the technical field of organic synthesis and particularly relates to a method for preparing anti-aging agent 4010NA through modification-catalytic hydrogenation. The method is characterized by comprising following steps: (1) preparing a raw material solution with raw materials including 4-aminodiphenylamine, acetone and an ionic liquid; (2) filling a fixed bed reactor with a copper-based catalyst; and (3) feeding the raw material solution to the fixed bed reactor for preparing the high-purity anti-aging agent 4010NA through catalytic hydrogenation, wherein a ketone-alcohol ratio after the hydrogenation reaction is significantly increased. The method is simple in operation, is high in conversion rate, is good in selectivity and is high in yield. Side reactions, such as multi-alkyl reduction hydrocarbonylation and acetone hydrogenation with isopropanol generated, are significantly inhibited. The method is beneficial to industrial preparation of the high-purity anti-aging agent 4010NA and increase of the ketone-alcohol ratio after the hydrogenation reaction, can reduce consumption of acetone and significantly reduces a production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of low temperature self-heating method of lithium ion battery

ActiveCN104064836BNo effect on service lifeReduced service lifeCell temperature controlInternal resistanceEngineering

The invention discloses a low-temperature self-heating method for a lithium ion battery. The method comprises the steps of determining a frequency range in which the service life of the lithium ion battery cannot be affected, and selecting frequencies of charging and discharging pulses according to the range; setting a pulse current amplitude value selection basis under a selected charging and discharging mode, and calculating a charging current amplitude value Ic and a discharging current amplitude value Id; performing no-life-loss heating on the battery to be heated according to charging and discharging pulse signals of the determined frequencies and the amplitude values, wherein the inner resistance of the self-heated battery is greatly reduced, and the charging performance is greatly improved. According to the technical scheme, the low-temperature self-heating method has the effects of high self-heating speed, obvious low-temperature performance improvement and no influence on the service life of the battery.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

Coater scraper apparatus

ActiveCN103350055BEasy to replaceAccurate control precisionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a coater scraper apparatus. The apparatus comprises a scraper rack connected to a coater frame, a scarper having a cutting edge corresponding the coating roller of a coater is press-fitted on the scraper rack through a scraper press plate, a scraper rack adjusting shaft paralleling to the scraper rack is movably arranged on the coater frame in a penetrating mode, the scraper rack is connected with the scraper rack adjusting shaft and rotate around the scraper rack adjusting shaft, an adjusting worm gear is fixedly connected with the scraper rack adjusting shaft in a penetrating mode, the coater frame supports an adjusting worm having a driving cooperation with the adjusting worm gear, and the adjusting worm is connected with a hand wheel. The coater scraper apparatus accurately controls the adjustment between the scraper and the coating roller by adopting the scraper rack rotatablely far from or close to the coating roller and combining the scraper adjusting seat and a trimming cylinder, so the apparatus has the advantages of simple and compact structure, convenient and accurate adjustment, and effective ensure of the thickness of a glue solution on the coating roller for the uniform adjustment, and is suitable for the use of various different specification coating rollers and coating thicknesses.

Owner:泰兴联创绝缘材料有限公司

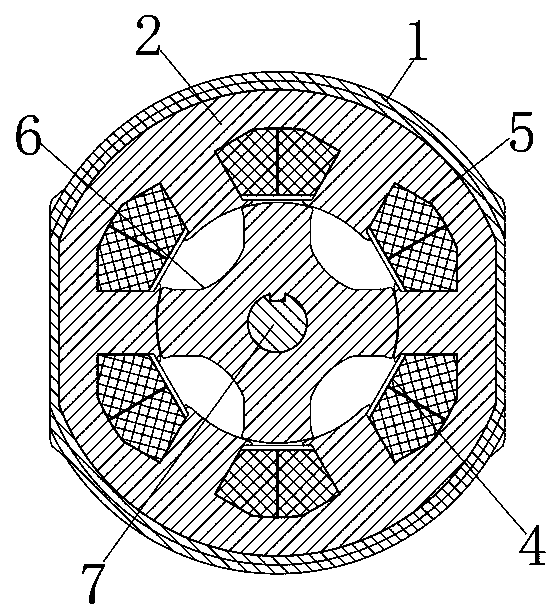

64-pole switch reluctance motor integrating CVT (continuously variable transmission)

PendingCN110474450AElimination of low frequency harmonics and high frequency harmonicsReduce vibrationMagnetic circuit stationary partsHigh frequencyContinuously variable transmission

The invention discloses a 64-pole switch reluctance motor integrating a CVT (continuously variable transmission). The 64-pole switch reluctance motor integrating the CVT (continuously variable transmission) comprises a non-magnetic-conduction outer shell and a switch reluctance motor position detection system; the switch reluctance motor position detection system is installed on a non-magnetic-conduction end cover; a stator iron core is arranged in the non-magnetic-conduction outer shell; six iron core protruding teeth are arranged on the inner wall of the stator iron core; excitation coils are wound on the outer sides of the six iron core protruding teeth respectively; the six excitation coils are connected into three sets of windings; and a rotor assembly is arranged in the stator iron core. According to the 64-pole switch reluctance motor integrating the CVT (continuously variable transmission), stator pole shoes are optimized, so that an auxiliary air gap is formed between a statorand a rotor; polar arc tail end structures are optimized, so that torque pulsation during the contact of the stator with the rotor and the disengagement of the stator from the rotor is effectively reduced; the low-frequency harmonic waves and high-frequency harmonic waves of part of torque are also eliminated, so that vibration is reduced. The structure of the product is simple; the influence ofelectric brush abrasion on the service life of the motor is avoided; the rotor is provided with no permanent magnets, so that the rotor is free of high-temperature demagnetization phenomena; cost is low; and high working temperature is allowed.

Owner:江蓝(深圳)新能源科技有限公司

Method for preparing semi-conductive adhesive for repairing semi-conductive shield outside medium-voltage cross-linked cable

InactiveCN101740159ANo impact on qualityNo effect on service lifeNon-conductive material with dispersed conductive materialApparatus for repairing insulation/armouring cablesCross-linkAdhesive

The invention provides a method for preparing a semi-conductive adhesive for repairing a semi-conductive shield outside a medium-voltage cross-linked cable, which prepares the semi-conductive adhesive by uniformly mixing 30 to 50 grams of graphite powder, 20 to 30 grams of volatile solvent and 5 to 10 grams of plastic adhesive, preferably, 30 grams of the graphite powder, 30 grams of the volatile solvent and 5 grams of the plastic adhesive, or 40 grams of the graphite powder, 25 grams of the volatile solvent and 8 grams of the plastic adhesive, or 50 grams of the graphite powder, 20 grams of the volatile solvent and 10 grams of the plastic adhesive, wherein the volatile solvent is ethanol or acetone, the plastic adhesive is a 102 multi-purpose plastic adhesive, and 3 to 8 grams of colored conductive powder is mixed in the semi-conductive adhesive. The semi-conductive adhesive prepared by the method can well repair the semi-conductive shield outside the medium-voltage cross-linked cable, obtains good appearance quality after repairing, has no influence on the quality and the service life of the cable, reduces the using cost, saves resources, is simple and convenient to operate, is easy to be accepted by users, and is suitable for large-scale popularization and application.

Owner:上海德力西集团有限公司

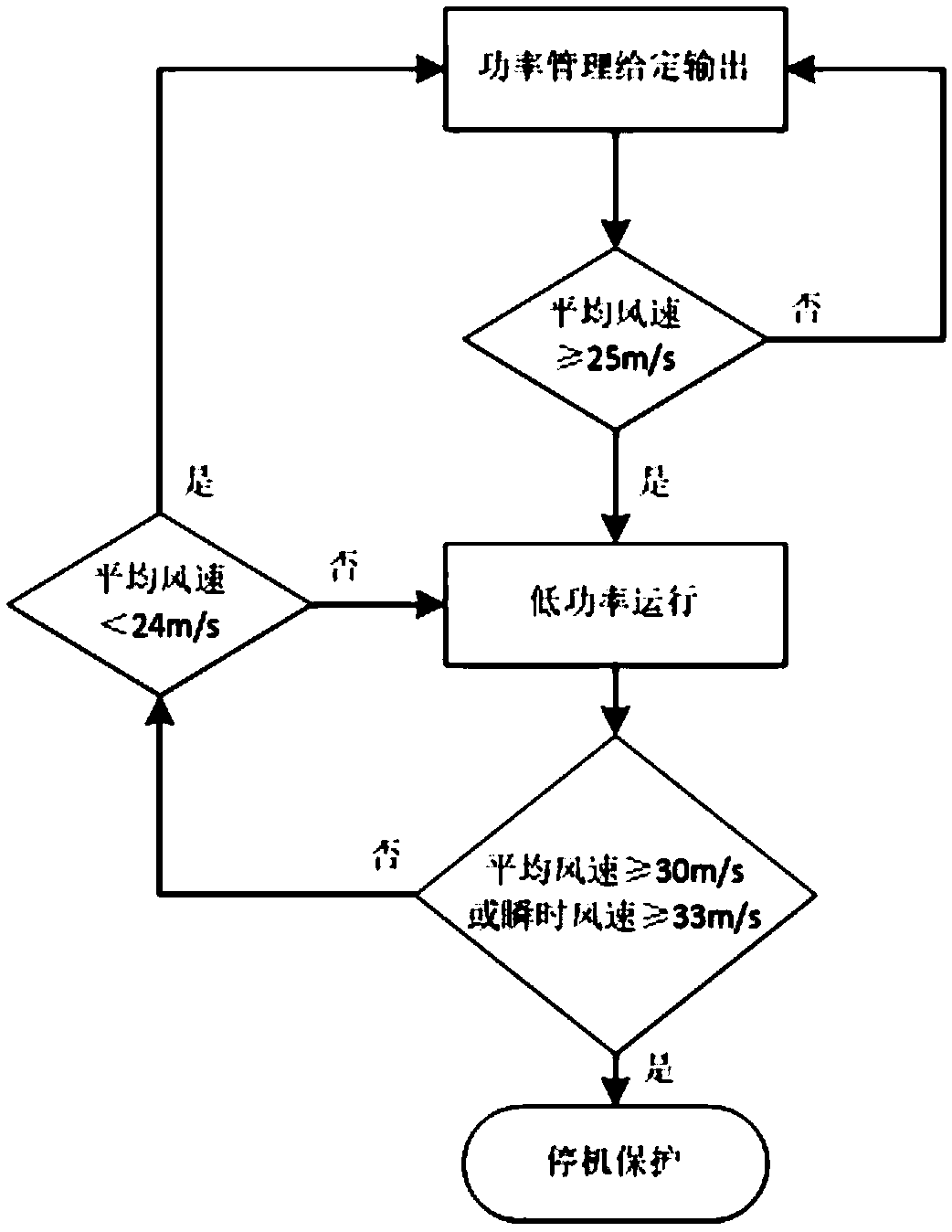

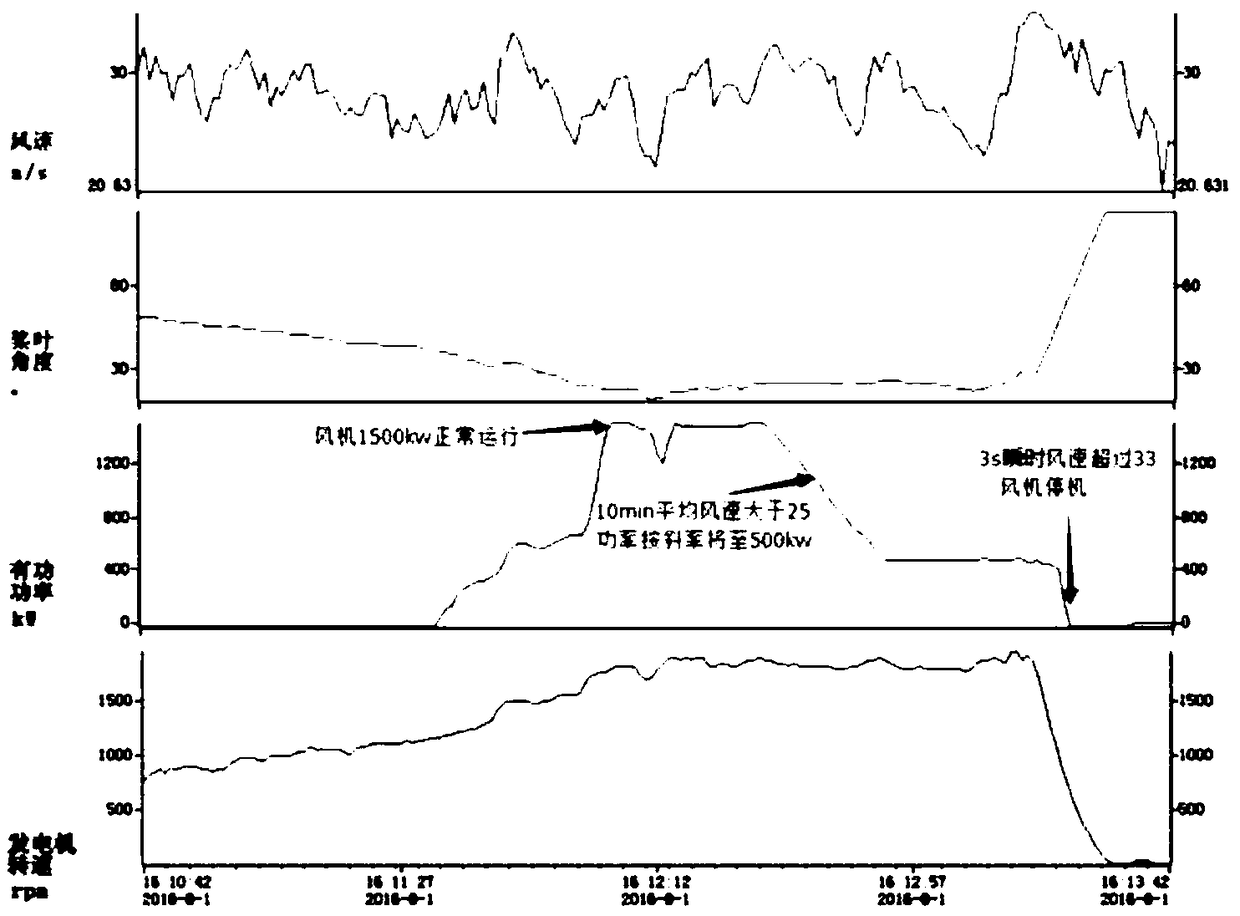

Controlling method for improving strong wind generating capacity of wind turbine

InactiveCN109404216AIncrease power generationImprove efficiencyWind motor controlMachines/enginesElectricityEngineering

The invention provides a controlling method for improving strong wind generating capacity of wind turbines. According to power management given output values, the wind turbines operate based on the following manners: when the measured average wind speed exceeds 25 meters per second, the given power is reduced at a fixed rate for running; when the wind speed is maintained at 25-30 meters per second, a fan operates at low power; when the average wind speed is greater than 30 meters per second, the fan is stopped for safety; and when the average wind speed is less than 24 meters per second, the given power begins to increase to the power output given power at a fixed rate. The number of available hours of the fan is increased and the amount of generating capacity is enhanced by means of the method.

Owner:中国大唐集团新能源科学技术研究院有限公司

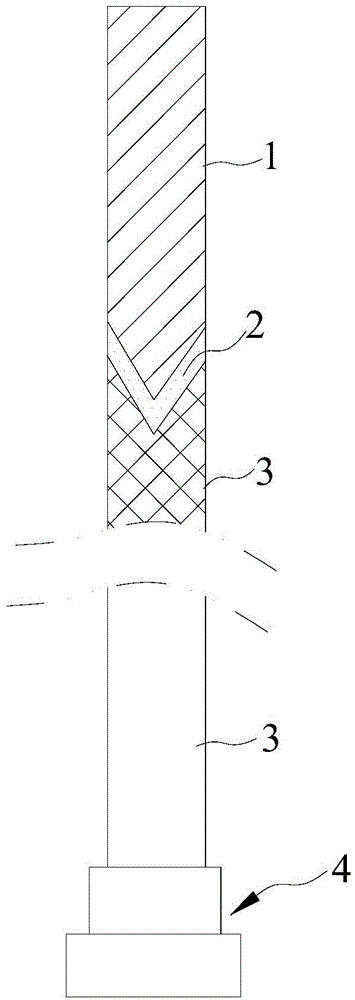

Welding process for mold tungsten steel core rod

InactiveCN104439736AGuaranteed firmnessLow costWelding/cutting media/materialsWelding/soldering/cutting articlesAfter treatmentCarbon steel

The invention relates to a welding process for a mold tungsten steel core rod. The welding process comprises the following steps that (1) preprocessing is carried out, a V-shaped groove is machined in a welded end of a carbon steel piece, and a V-shaped convex portion matched with the V-shaped groove is machined at the welded end of a tungsten steel core rod; (2) welding is carried out, the space between the V-shaped groove and the V-shaped convex portion is filled with welding materials, the welded end of the carbon steel piece is firstly heated to be of the tangerine color, then the welded end of the tungsten steel core rod is heated, heating is stopped when the welding materials completely become liquid, and the carbon steel piece and the tungsten steel core rod are welded together through the welding materials to form a welded piece; (3) after-treatment is carried out, and the mold tungsten steel core rod is obtained. The welding process for the mold tungsten steel core rod is simple in operation, and the obtained mold tungsten steel core rod is low in manufacturing cost and long in service life.

Owner:TAICANG JINLIDE POWDER METALLURGY

Snow pushing device

InactiveCN106400726AIncreased operating comfortNo effect on service lifeSnow cleaningLower limitEngineering

The invention discloses a snow pushing device comprising a snow pushing board and a supporting device. The snow pushing board is connected with the supporting device, and the other end of the supporting device is connected with a main engine in a hinged mode; the snow pushing board is connected with the supporting device through a connecting rod mechanism, and the connecting rod mechanism comprises an upper connecting rod, a lower connecting rod, an upper limiting position and a lower limiting position; one end of the upper connecting rod and the snow pushing board are hinged at a point A, and the other end of the upper connecting rod and the supporting device are hinged at a point B; one end of the lower connecting rod and the snow pushing board are hinged at a point C, and the other end of the lower connecting rod and the supporting device are hinged at a point D; the point A and the point B are both arranged above the point C and thepoint D; the movement range of the upper connecting rod is limited by the upper limiting position so that backward turning of the snow pushing board can be avoided; and the movement range of the lower connecting rod is limited by the lower limiting position so that forward turning of the snow pushing board can be avoided. The snow pushing device has the beneficial effects of being capable of quickly passing ground obstacles, and achieving large snow pushing quantity at a time and high reliability.

Owner:JIANGSU LIUGONG MACHINERY

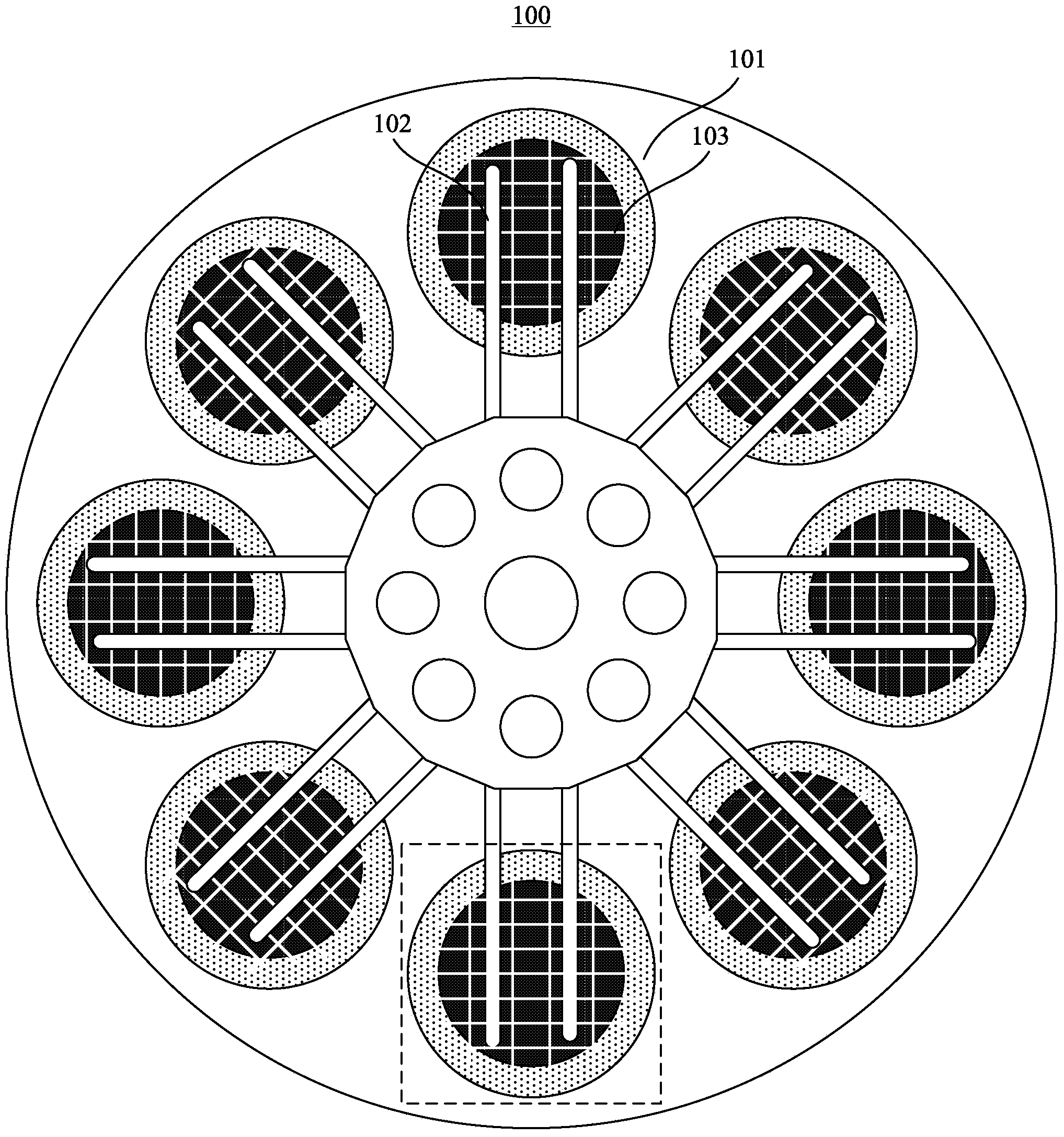

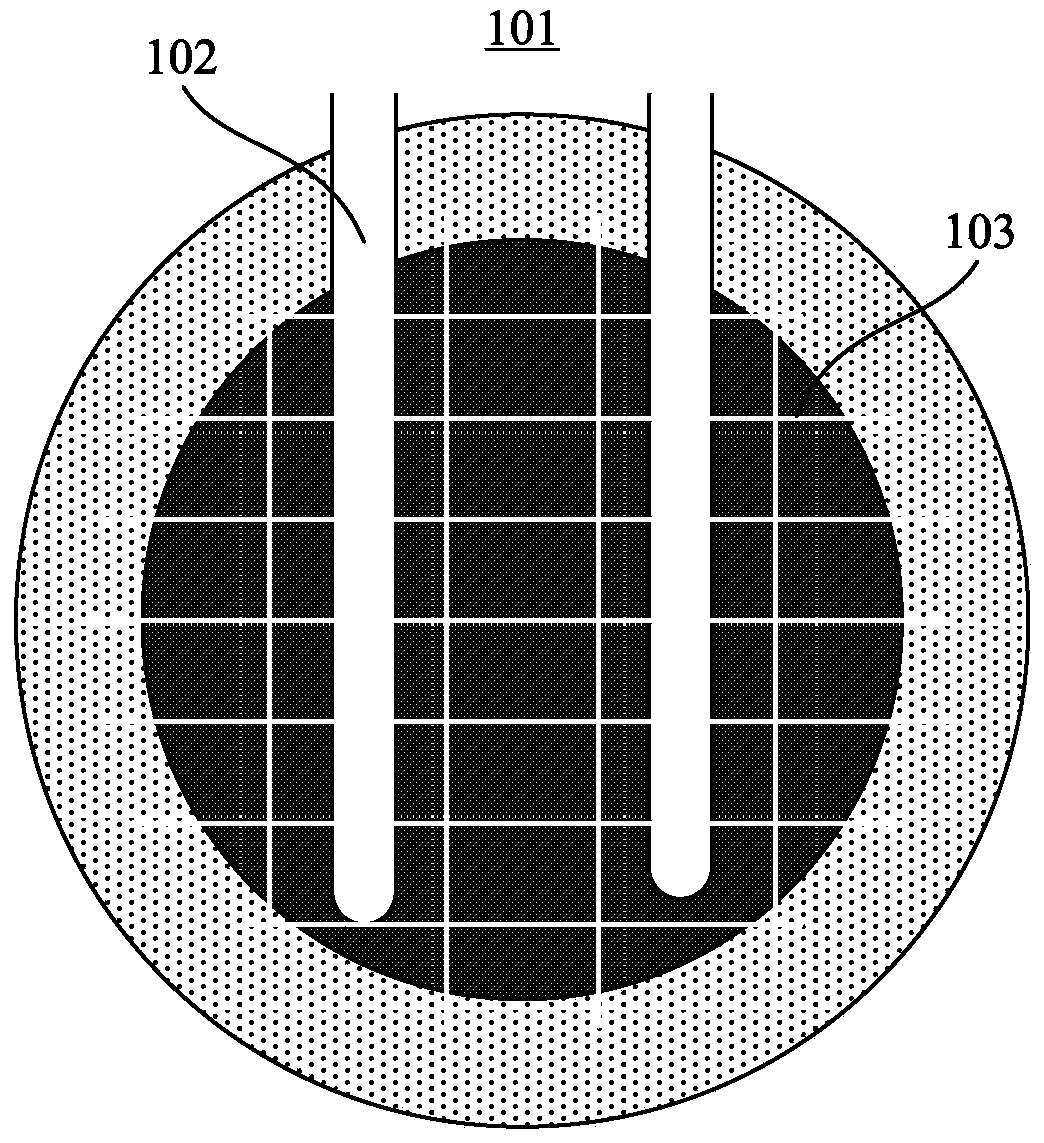

PECVD film deposition equipment and heating plate thereof

InactiveCN104064458AProcess parameters have no effectNo effect on service lifeElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringAir cushion

The invention provides PECVD film deposition equipment and a heating plate thereof. The heating plate is located in a process cavity of the equipment. Eight process positions are uniformly distributed on the heating plate. A wafer at each process position is passed to the next adjacent process position through rotation of an aluminum fork. A plurality of venting marks penetrating through a process area are distributed on each process position of the heating plate. According to the equipment and the heating plate, after the wafers are placed on the surface of the heating plate of the equipment, gas can be uniformly exhausted towards the periphery through the venting marks, and therefore slipping of the wafer due to the air cushion effect can be avoided.

Owner:ADVANCED SEMICON MFG CO LTD

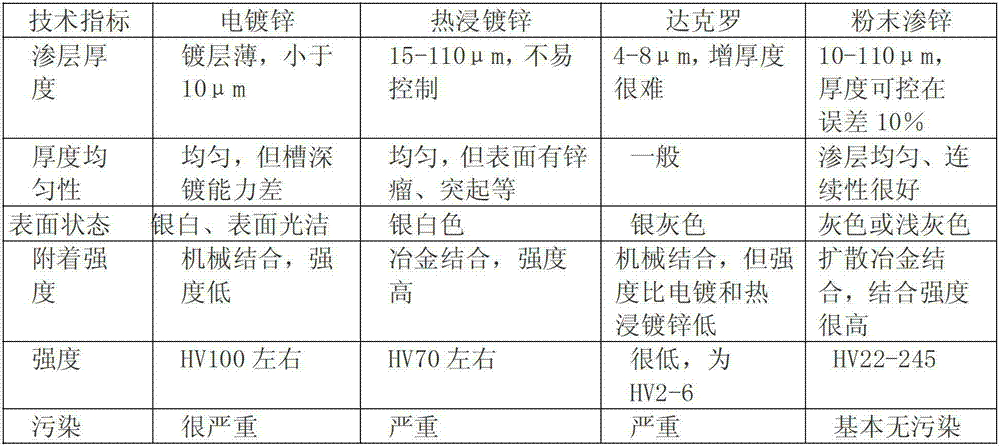

Application of zinc impregnation technology in rail suspension steel spring

InactiveCN103088284AImprove corrosion resistanceImprove adhesionSolid state diffusion coatingLow internal friction springsLower limitHigh humidity

The invention discloses application of zinc impregnation technology in a rail suspension steel spring. The zinc impregnation technology is applied to the rail suspension steel spring, and the spring manufacturing process is strictly controlled, namely the coverage rate of the shot-blasting surface treatment is strictly controlled to be 100 percent, and due to control of the spring temper temperature and zinc impregnation temperature, the upper limit of the zinc impregnation temperature is less than the lower limit of the temper temperature. The technology is applicable to anti-corrosion protection of the railway locomotive vehicle suspension steel spring, particularly springs operated in high-humidity or / and salt atmosphere special environmental areas. The zinc impregnation coating has high corrosion resistance and high adhesion force and impact resistance and does not influence the service life of the spring. The thickness of the powder zinc impregnation is controlled to be 10-110 mu m, and the error is 10 percent; the impregnation layer is uniform and good in continuity; the diffusion alloys are combined, and the bonding strength is high; and the technology has HV22-245 and is basically pollution-free.

Owner:TIANJIN JL RAILWAY TRANSPORT EQUIP

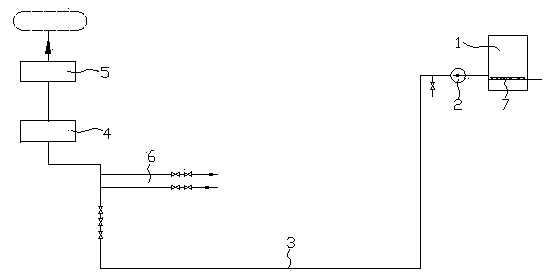

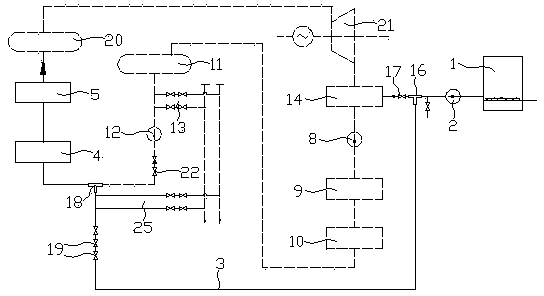

A pre-heating system for reducing cold-start emissions of motor vehicles

InactiveCN103452731BEmission reductionReduce wearMachines/enginesThermal treatment of fuelCombustorFuel supply

The invention discloses a preheating system for reducing cold start emission of a motor vehicle and belongs to the technical field related to automobile engines and accessories thereof. The system mainly comprises an automobile small-sized burner, a heat exchanger which has a heat exchange relationship with pipelines such as a cooling water pipeline, an engine oil pipeline and a fuel supply pipeline, a pipeline loop, air inlet and exhaust and fuel supply pipelines of the automobile small-sized burner, a controller and the like. The preheating system for reducing cold start emission of the motor vehicle has the advantages that after the system is additionally installed, the emission of the motor vehicle during cold start is reduced, the engine heating process is shortened, the emission of harmful gas produced at the stage is reduced and the low-temperature wear of the engine is relieved.

Owner:BEIJING UNIV OF TECH

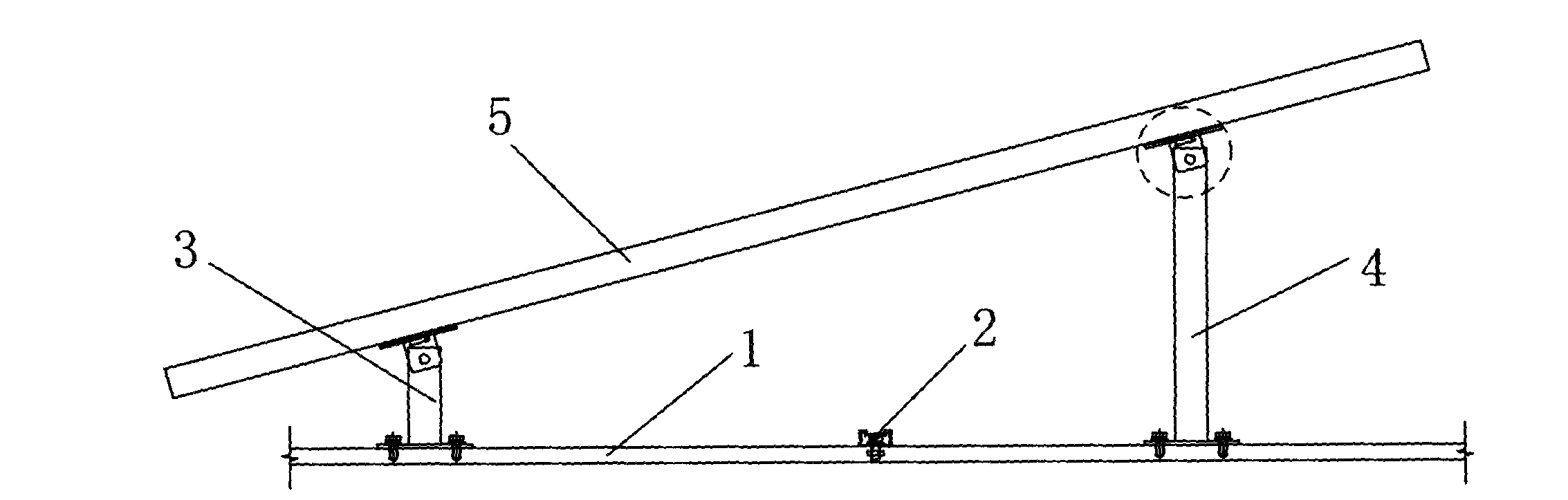

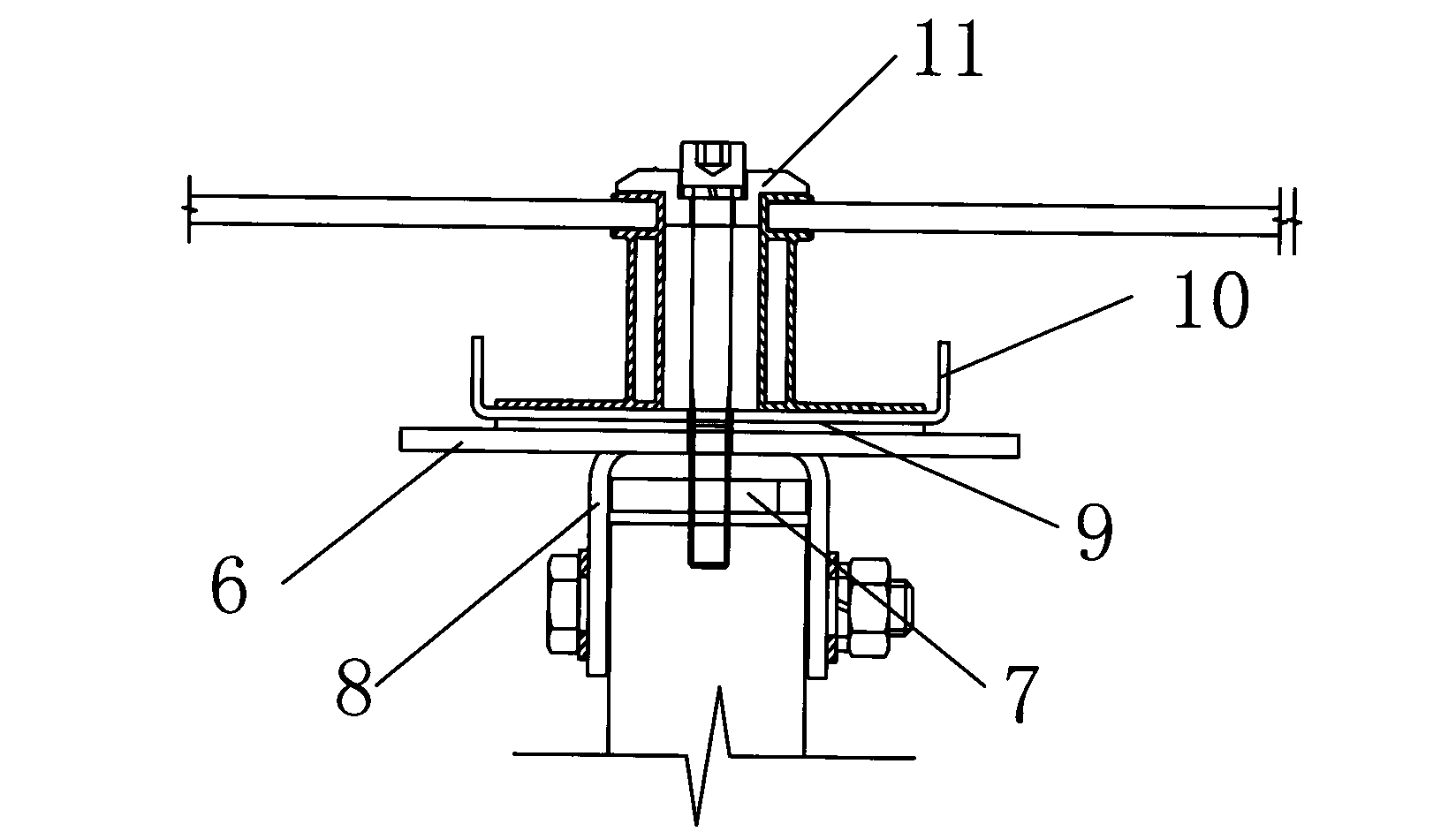

Photovoltaic bracket for double-T plate plant roof

ActiveCN103015645ADoes not damage waterproofReduce weight bearing riskPhotovoltaic supportsRoof covering using slabs/sheetsMechanical engineeringBuilding construction

The invention relates to a photovoltaic bracket for a double-T plate plant roof. The photovoltaic bracket comprises a longitudinal ground net, wherein horizontal ground nets are distributed on the longitudinal ground net in a crossed form; the photovoltaic bracket is characterized in that a front support is distributed on one side of the longitudinal ground net; a rear support is distributed on the other side of the longitudinal ground net; and meanwhile, pressing block components are arranged at the tops of the front support and the rear support; and inclined load-bearing plates are connected with the pressing block components through bolts. Thus, a '#' shaped net is formed by the front support, the rear support and the horizontal ground nets in the crossed form; the wind load overturn resistance is high; the longitudinal ground net is paved in advance, so that the roof waterproof material is not damaged; the service life of the plant is not influenced; a connector is adopted, so that the mounting of each component is more firm and safe; the photovoltaic bracket is material-saving and is light in unit weight; the load-bearing risk of the roof is reduced; furthermore, the whole construction is simple; the assembling maneuverability is strong and is not limited by a foundation; and the popularization is benefited.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

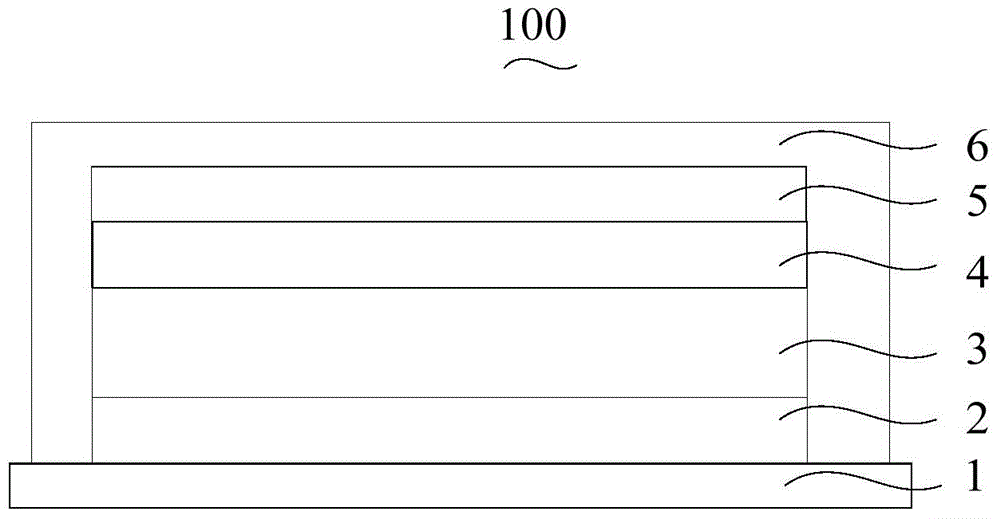

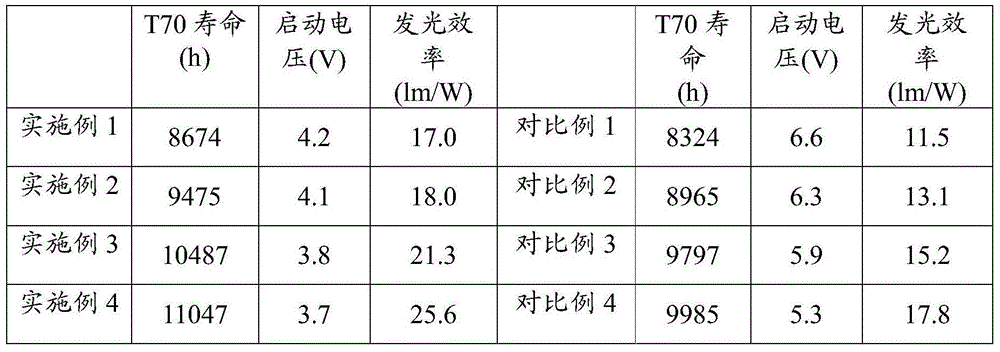

Organic electroluminescent device and preparation method thereof

InactiveCN104979488AReduce diffuseReduce quenchingSolid-state devicesSemiconductor/solid-state device manufacturingPhenanthrolineMixed materials

The invention discloses an organic electroluminescent device and a preparation method thereof. The organic electroluminescent device comprises an conductive anode, a hole transport layer, a light emitting layer, an electron transport layer and a cathode layer; wherein the conductive anode, the hole transport layer, the light emitting layer, the electron transport layer and the cathode layer are successively laminated. The electron transport layer is made of a mixed material which is composed of organic lithium, a metal element and an organic electron transport material. The organic lithium is 4-hydroxyl phenanthridine lithium, 2-(5-phenyl-1,3,4-oxadiazole)-phenol lithium, 2,3-diphenyl-5-hydroxyquionline lithium, lithium tetra(8-hydroxyquinolinato)boron, tert-butylcyclopentadienyl lithium or lithium acetylacetonate. The metal element and the cathode layer are made of same materials, namely silver or aluminum. The organic electrode transport material is 8-hydroxyquinoline aluminum, 4,7-diphenyl-phenanthroline, 1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl)benzene or 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline. The organic electroluminescent device has long service life and relatively high light emitting efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Lightning protection device

ActiveCN104332827BNo effect on service lifeAchieve automatic arc extinguishing effectOvervoltage arrestors using spark gapsElectricityHigh pressure

The invention relates to a lightning protection device which comprises a shell and electrodes. Arc extinguishing chambers and at least two electrode chambers are formed in the shell, the inner-wall surface of each arc extinguishing chamber is round and smooth, the arc extinguishing chambers and the electrode chambers are arranged in a staggered manner, each arc extinguishing chamber is provided with two openings which are communicated with the two adjacent electrode chambers respectively, and each arc extinguishing chamber is communicated with the outside through an arc blowing passage; a lightning receiving face is arranged at each of two ends of each electrode, the electrodes are placed in the electrode chambers, the lightning receiving faces at the two ends of the electrodes are exposed in the arc extinguishing chambers on two sides of the electrode chambers at the same time to communicate the arc extinguishing chambers on the two sides, and a flashover gap is reserved between the two lightning receiving faces in each arc extinguishing chamber. The lightning protection device is free of charge accumulation effect, less prone to being broken down under identical gap voltage and capable of improving line insulation level; especially when being on a high-voltage power distribution line network, influence on power distribution quality caused by voltage fluctuation of the power distribution network due to great lowering of voltage of the power distribution network because of frequent misoperation discharging of the lightning protection device can be avoided.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

A kind of low-temperature self-heating method of lithium-ion battery pack

ActiveCN107039708BFast self-heating rateSignificant improvement in low temperature performanceEfficient power electronics conversionSecondary cellsResonant inverterElectrical battery

The invention discloses a low-temperature self-heating method for a lithium-ion battery pack. Based on the principle of minimum impact on battery life, the optimal heating frequency range is determined taking into account both the aging state of the battery and the SOC; a series resonant inverter circuit is designed to explore the optimal control The strategy makes the inverter circuit output the sinusoidal AC current with target frequency and target amplitude on the battery side; the sinusoidal AC current output by the resonant inverter circuit is used to self-heat the battery pack at low temperature. As the battery temperature increases, the internal resistance of the battery gradually increases. The resonant inverter circuit adaptively increases the output current amplitude, increases the heating rate of the battery pack, and quickly raises the battery pack to the target temperature. The invention has the effects of fast self-heating rate of lithium-ion battery packs at low temperatures, obvious improvement in low-temperature performance, high self-heating efficiency, no influence on the service life of lithium-ion batteries, and good heating temperature uniformity, and will promote the use of electric vehicles in cold regions. Promote apps.

Owner:BEIJING JIAOTONG UNIV +1

Cold-type special molding sand for integral casting of large cast steel roller and manufacturing method of cold-type special molding sand

ActiveCN102886499BQuality improvementImprove casting qualityFoundry mouldsFoundry coresChemical compositionStrip mill

The invention discloses cold-type special molding sand for the integral casting of a large cast steel roller. The cold-type special molding sand is composed of the following compositions in parts by weight: 76% to 80% of quartz sand, 13% to 15% of clay, 1% to 2% of bentonite and the balance of water. When the special molding sand disclosed by the invention is used for the integral casting of a large cast steel roller having the diameter of Phi 900 to Phi 1400 and the amount of casting molten steel is 15 to 70 tons, the roller cold-type sanded thickness can be controlled within the range from 8mm to 9mm, thus improving the cold-type chilling capability of the roller body, enabling the columnar crystal thickness of the surface dense layer of the roller body to achieve about 150mm, reducing the chemical constitution aliquation of the outer layer, and enhancing the quality of the working layer of the roller body. The molding sand can prevent casting defects on roller surface excellently, such as sand adhesion and sand inclusion, results in smooth roller surface, improves the casting quality and the casting qualified rate of the large cast steel roller, and meets the demands on comprehensive application performances of the roller working layer of large section mills and strip mills, such as wear resistance, hot cracking resistance and accidence resistance.

Owner:成都三强轧辊股份有限公司

Broaching tool mechanism capable of rotating at high speed

InactiveCN108747611ALighten the loadReduce starting torqueOther manufacturing equipments/toolsGrinding feedersEngineeringContact type

The invention discloses a broaching tool mechanism capable of rotating at high speed. Non-contact type seal is adopted to replace the traditional Glyd ring seal manner. A supporting sleeve is rotatably connected to a bearing pedestal through two angular contact bearings arranged on two ends of the bearing pedestal, the distance between the outer wall of the cylindrical segment of the supporting sleeve and the inner wall of the bearing pedestal and the distance between the right side wall of the supporting sleeve and the left side wall of the bearing pedestal are each 0.02 to 0.05 mm, three airsource joints are formed in a body of the bearing pedestal, air seal parts are arranged at the positions, on two sides of the three air source joints, of the inner wall and the side wall of the bearing pedestal, and the air seal parts are composed of multiple annular air seal grooves formed in the inner wall and the side wall of the bearing pedestal in parallel. Air enters the seal structure through the air source joints, vortex is generated in air in the air seal grooves, and air overflowing is prevented; high-speed functions are achieved, the mechanism has the rotating speed being 3000 rpmin the application of a five-axis tool grinding machine, and compared with 500 rpm in the prior art, the speed is improved by multiple times.

Owner:KEDE NUMERICAL CONTROL CO LTD

Method for treating dinitro-diazophenol (DDNP) primary explosive production wastewater

ActiveCN102003715BHandling safety and environmental protectionZero emissionGeneral water supply conservationEnergy based wastewater treatmentHigh concentrationSolid fuel

Owner:山东圣世达化工有限责任公司

Water filling device and method for subcritical and above pressure boiler

The invention discloses a water filling device and method for a subcritical and above pressure boiler. The water filling device is sequentially connected with a demineralized water supplement tank, a condensed water supplement pump, a water filling pipeline, a three-stage high-pressure heater and a coal economizer, wherein a medicine feeding device used for sampling and feeding a treatment medicine to the demineralized water in the pipeline is arranged on the water filling pipeline. The method comprises the following steps: firstly placing the demineralized water into the demineralized water supplement tank, and pumping the demineralized water in the demineralized water supplement tank by the condensed water supplement pump into the subcritical and above pressure boiler via the filling pipeline, the three-stage high-pressure heater and the coal economizer that are sequentially connected; then during the process of filling water into the subcritical and above pressure boiler, adjusting the water quality parameters of the demineralized water in the pipeline by adopting the method of sampling and feeding the treatment medicine by the medicine feeding device. The device and the method are simple, the water pump motor is a normal motor with low voltage of 380V and low power of 90KW, the use of a high pressure electric water feed pump is avoided, the operation is simplified, the electric consumption is less, the impact to the system is small, and the service life of high pressure large power equipment is not affected.

Owner:LIAONING DIAOBINGSHAN COAL GANGUE POWER GENERATION CO LTD

All-vanadium redox flow battery electrolyte stabilizer and preparation method thereof

ActiveCN106654333BImprove stabilityPrevent or inhibit self-polymerizationRegenerative fuel cellsOrganic electrolytesVanadium redox batteryRedox

The invention provides an electrolyte stabilizing agent for an all-vanadium redox flow battery and a preparation method for the electrolyte stabilizing agent. The stabilizing agent comprises a carboxyl functional group and an amino functional group. The preparation method comprises the following steps of mixing maleic anhydride, acrylamide, glycerine and distilling water to obtain a mixed solution; taking out a part of the mixed solution for use; and stirring and heating the residual mixed solution, dropwise adding hydrogen peroxide and the mixed solution for use, and cooling to obtain the electrolyte stabilizing agent for the all-vanadium redox flow battery. The stabilizing agent can supply the carboxyl functional group which can generate chelating with pentavalent vanadium ions and the amino functional group which has an adsorption effect on the pentavalent vanadium ions, so that self polymerization of the pentavalent vanadium ions can be effectively prevented or restrained, generation of sediments can be prevented, and the stability of the electrolyte can be effectively improved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com